Page 1

1 - 1

Service

Service

DVD Home Theater System

HTS5200/12/98/51

Tfswjdf

Tfswjdf

Service

Service Manual

TABLE OF CONTENTS

Location of PCB Boards ............................................ 1-2

Versions Variation ...................................................... 1-2

Specifications ............................................................ 1-3

Measurement Setup .................................................. 1-4

Service Aids .............................................................. 1-5

ESD & Safety Instruction .......................................... 1-6

Lead-free soldering Information ................................ 1-7

Setting procedure & Repair Instructions........................ 2

Disassembly Instructions & Service positions .............. 3

Block & Wiring Diagram ................................................ 4

VFD+USB+AUX Board .................................................. 5

Main+LED Board............................................................ 6

Power Board .................................................................. 7

AMP Board .................................................................... 8

Touch Board .................................................................. 9

Mechanical Exploded view .......................................... 10

Revision List ................................................................ 11

Chapter

©

Copyright 2010 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Published by RY1014 Service Audio Printed in The Netherlands Subject to modification

Version 1.1

3139 785 35301

GB

Page 2

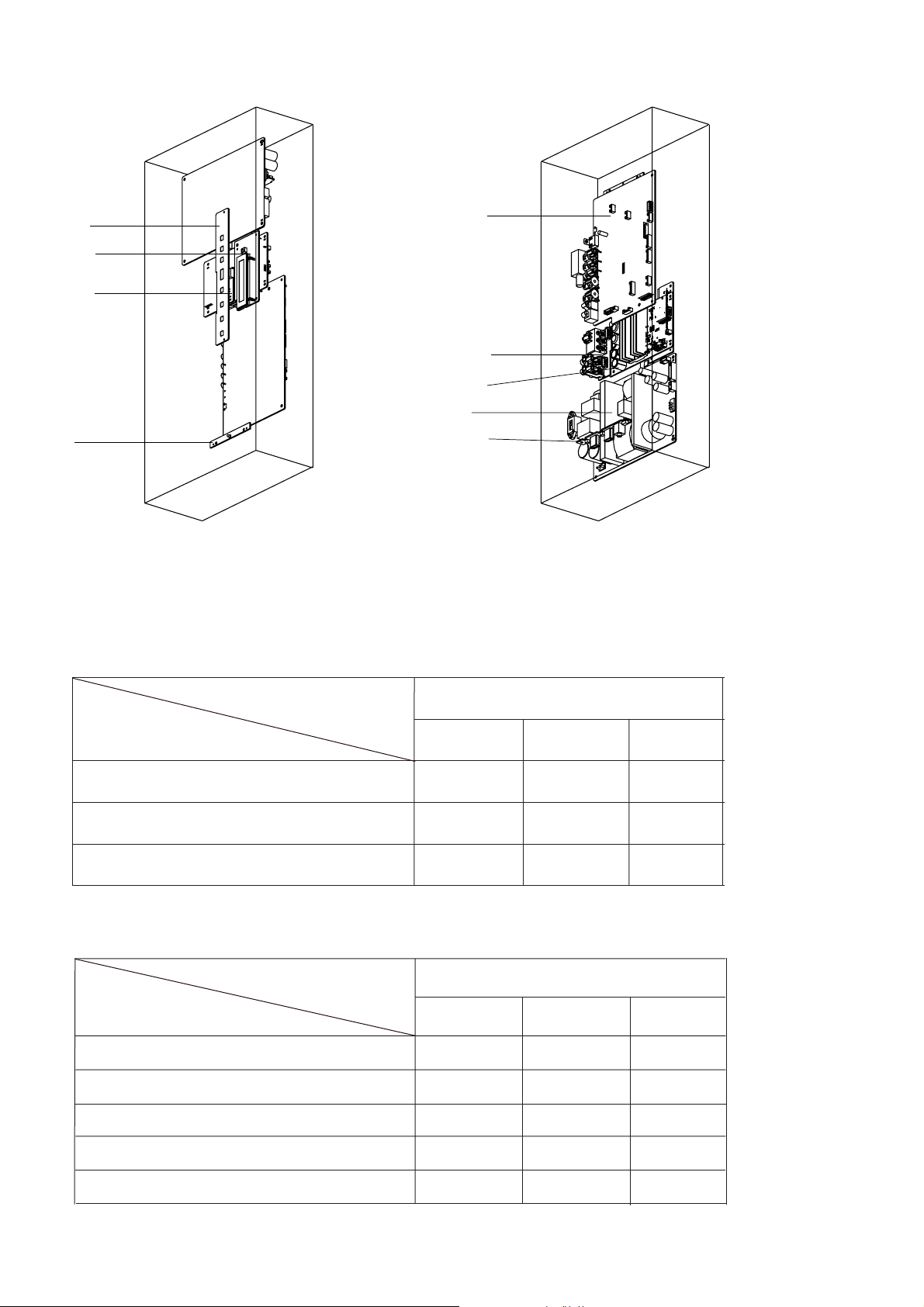

LOCATION OF PCB BOARDS

POWER PCB

TOUCH PCB

VFD PCB

LED PCB

1 - 2

MAIN PCB

AUX PCB

MAIN PCB

DOOR LED PCB

TOP VIEW BOTTOM VIEW

VERSION VARIATION:

Type/Versions

Features

Output Power - 400W

Voltage (110~127V)

POWER PCB

/12

x

AMP PCB

USB PCB

HTS5200

/98

x

x

/51

x

Voltage (220~240V)

REPAIR SCENARIO MATRIX:

Type/Versions

Board in used

Main+Led Board

Power Board

VFD+USB+UAX Board

AMP Board

Touch Board

*C = Component Level Repair

x

/12

C

C

C

C

C

x

HTS5200

/98

C

C

C

C

C

x

/51

C

C

C

C

C

Page 3

SPECIFICATIONS

1 - 3

Playback media

DVD-Video, DVD+R/+RW, DVD-R/-RW, DVD+R DL,CD-R/CDRW, Audio CD, Video CD/SVCD, Picture CD, MP3-CD, WMACD, DivX-CD, USB storage device (for /12/98)

AVCHD, BD-RE, BD-Video, DVD-Video, DVD+R/+RW, DVDR/-RW, DVD+R/-RDL, CD-R/CD-RW, Audio CD, Video CD/

SVCD, Picture CD, MP3-CD, WMA-CD, DivX (Ultra)-CD, USB

storage device (for /51)

File Format

Audio ................................................... .mp3, .wma (for /12/98)

Audio ................................................. .mp3, .wma.wav (for /51)

Video ....... .divx, .divx ultra, .mpeg, .mpg, .wmv (simple pro le)

..................................................................................(for /12/98)

Video .................... .avi, .divx, .mp4, .mkv, .mov, .wmv (for /51)

Picture .................................................... .jpeg, .jpg (for /12/98)

Picture ................................................... .jpg, .gif, .png (for /51)

Amplifier

Total output power .............................. 400 W RMS (for /12/98)

Total output power ............... 1000 W RMS (30%THD) (for /51)

Frequency response ................................ 20 Hz-20 kHz / ±3dB

Signal-to-noise ratio .................. > 65 dB (CCIR) / (A-weighted)

Input sensitivity ..........................................................................

AUX ....................................................... 1000 mV (for /12/98)

AUX .............................................................. 900 mV (for /51)

MP3 LINK ................................................ 550 mV (for /12/98)

MP3 LINK ..................................................... 500 mV (for /51)

Video

Signal system ........................................................ PAL / NTSC

Component video output ...........................................................

............................... 480i/576i, 480p/576p, 720p, 1080i (for /51)

HDMI output ..............................................................................

.............. 480i/576i, 480p/576p, 720p, 1080i, 1080p (for /12/98)

HDMI output ..............................................................................

.... 480i/576i, 480p/576p, 720p,1080i, 1080p, 1080p24 (for /51)

Audio

S/PDIF Digital audio input .........................................................

Coaxial ................................................................ IEC 60958-3

Sampling frequency ...................................................................

MP3 ................................................ 32 kHz, 44.1 kHz, 48 kHz

WMA ............................................................ 44.1 kHz, 48 kHz

Constant bit rate ........................................................................

MP3 ........................................................ 112 kbps - 320 kbps

WMA ......................................................... 48 kbps - 192 kbps

Radio

Tuning range ................... FM 87.5-108 MHz (50 kHz) (for /12)

Tuning range ....... FM 87.5-108 MHz (50/100 kHz) (for /98/51)

Signal-to-noise ratio ................................................... FM 50 dB

Frequency respose ..................... FM 180 Hz~12.5 kHz / ±3dB

USB

Compatibility .............................................. Hi-Speed USB (2.0)

Class support ........................ UMS (USB Mass Storage Class)

File system ........................................................ FAT16, FAT32

Maximum memory support ........................................ < 160GB.

Main Unit

Power supply .............................................................................

Russia/China/India .................................... 220-240V; ~50 Hz

Asia Paci c/Latin America .......................................................

................................110-127V/220-240V; ~50-60Hz switchable

Power consumption ..................................... 100 W (for /12/98)

Power consumption .......................................... 135 W (for /51)

Standby power consumption ..................... ≤ 0.3 W (for /12/98)

Standby power consumption .......................... < 0.9 W (for /51)

Dimensions (WxHxD) .......... 434 x 253 x 129 (mm) (for /12/98)

Dimensions (WxHxD) ................. 435 x 58 x 358 (mm) (for /51)

Weight .......................................................... 3.6 kg (for /12/98)

Weight ............................................................. 3.87 kg (for /51)

Speakers

System .......................................................... full range satellite

Speaker impedance ...................................... 6 ohm (for /12/98)

Speaker impedance ...................................................................

..............................3 ohm (center), 5 ohm (Front/Rear) (for /51)

Speaker drivers ........... 1 x 3” full range + 1” twitter (for /12/98)

Speaker drivers .................................. 2 x 3” full range (for /51)

Frequency response .......................................... 150 Hz-20 kHz

Dimension (WxHxD) ..................................................................

..............................................114 x 316 x 114 (mm) (for /12/98)

Center ..........................................280 x 95 x 92 (mm) (for /51)

Speaker ...................................100 x 280 x 115 (mm) (for /51)

Tall speaker ........................... 260 x 1101 x 260 (mm) (for /51)

Weight .......................................................................................

.................................................................... 1.03 kg (for /12/98)

Center ............................................................ 1.40 kg (for /51)

Speaker ....................................... 0.98~1.05 kg/each (for /51)

Tall speaker ................................. 3.73~3.81 kg/each (for /51)

Cable length ..............................................................................

.......................................................................... 2 m (for /12/98)

Center .................................................................. 3 m (for /51)

Front .................................................................... 4 m (for /51)

Rear ................................................................... 10 m (for /51)

Subwoofer

Impedance ...................................................................... 3 ohm

Speaker drivers ................... 165 mm (6.5”) woofer (for /12/98)

Speaker drivers ........................... 203 mm (8”) woofer (for /51)

Frequency response ........................................... 40 Hz-150 Hz

Dimensions (WxHxD) ............................ 196 x 395 x 342 (mm)

Weight .......................................................... 4.7 kg (for /12/98)

Weight ............................................................. 5.37 kg

Cable length ....................................................................... 4 m

Laser specification

Type ................. Semiconductor laser GaAIAs (CD) (for /12/98)

Laser Type (Diode) ....................................................................

.....InGaN/AIGaN (BD), InGaAIP (DVD), A IGaAs (CD) (for /51)

Wave length ...............................................................................

.................650 - 660 nm (DVD), 784 - 796 nm (CD) (for /12/98)

Wave length ...............................................................................

....................... 405 +5nm/-5nm (BD), 650+13nm/-10nm (DVD),

................................................ 790 +15nm/-15nm (CD) (for /51)

Output power ......... 6 mW (DVD), 7 mW (VCD/CD) (for /12/98)

Output power (Max. ratings) ......................................................

....................................... 20mW (BD), 7mW (DVD/CD) (for /51)

Beam divergence ................................. 60 degrees. (for /12/98)

(for /51)

Speci cations subject to change without prior notice.

Page 4

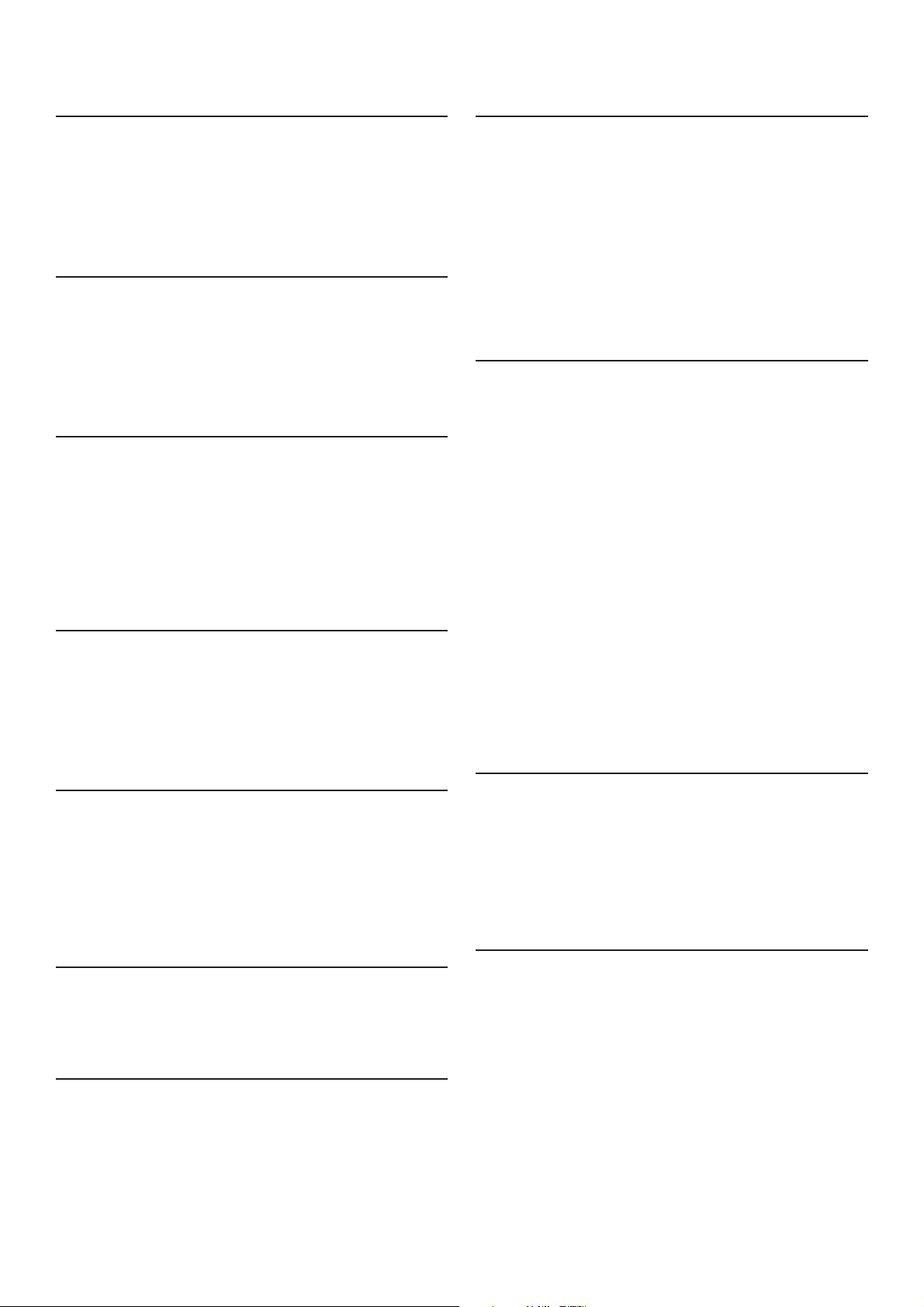

MEASUREMENT SETUP

Tuner FM

1 - 4

Bandpass

LF Voltmeter

e.g. PM2534

RF Generator

e.g. PM5326

DUT

250Hz-15kHz

e.g. 7122 707 48001

Ri=50

S/N and distortion meter

e.g. Sound Technology ST1700B

Use a bandpass filter to eliminate hum (50Hz, 100Hz) and disturbance from the pilottone (19kHz, 38kHz).

CD

Use Audio Signal Disc

(replaces test disc 3)

DUT

SBC429 4822 397 30184

L

R

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

Page 5

SERVICE AIDS

Service Tools:

Universal Torx driver holder .................................4822 395 91019

Torx bit T10 150mm ...........................................4822 395 50456

Torx driver set T6-T20 .........................................4822 395 50145

Torx driver T10 extended .....................................4822 395 50423

Compact Disc:

SBC426/426A Test disc 5 + 5A ...........................4822 397 30096

SBC442 Audio Burn-in test disc 1kHz .................4822 397 30155

SBC429 Audio Signals disc .................................4822 397 30184

Dolby Pro-logic Test Disc ....................................4822 395 10216

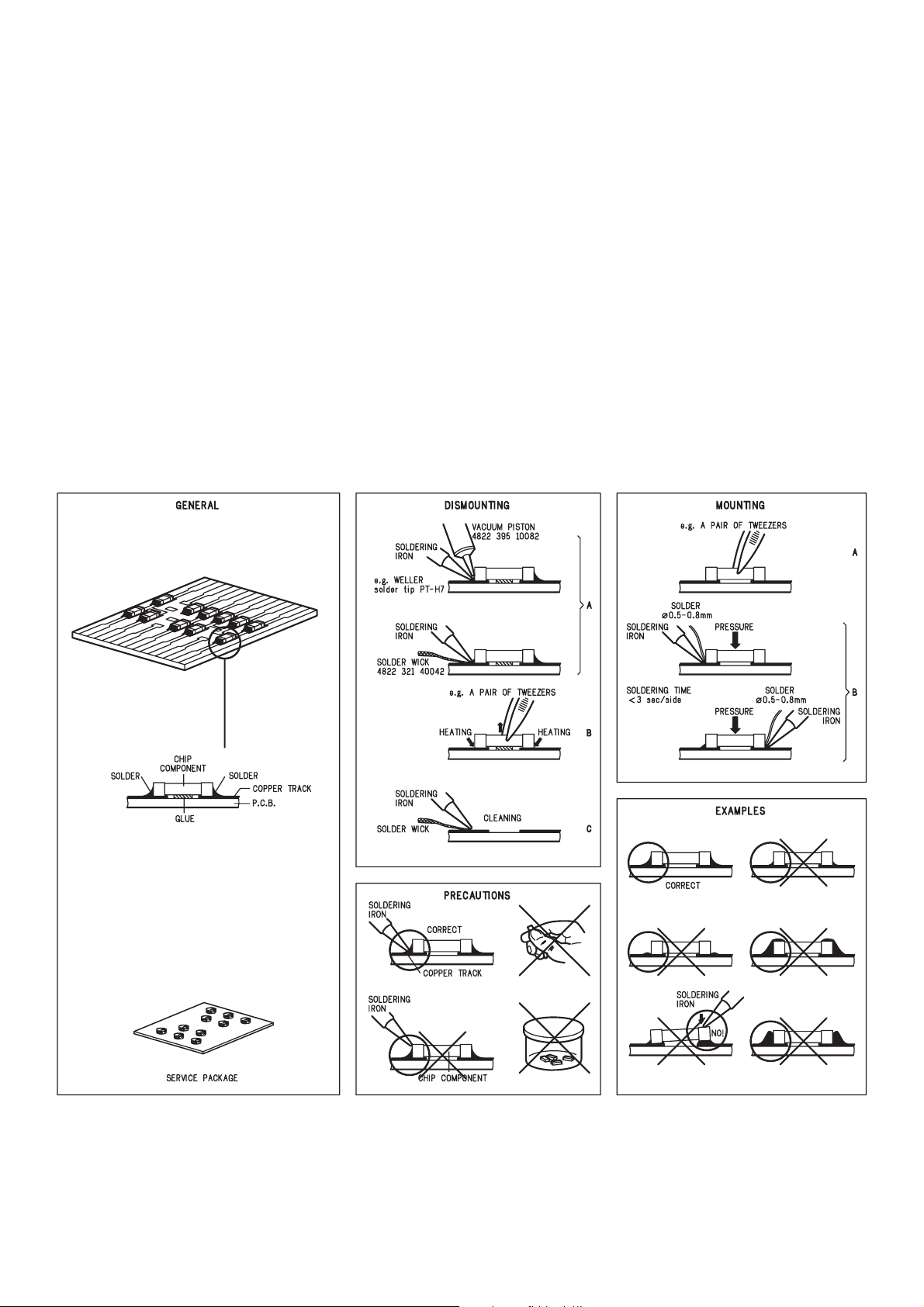

HANDLING CHIP COMPONENTS

1 - 5

Page 6

GB

A

WARNING

1 - 6

ESD

WAARSCHUWING

NL

ll ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

F

ATTENTION

Tous les IC et beaucoup d’autres

semi-conducteurs sont sensibles aux

décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est

prise à leur manipulation.

Lors de réparations, s’assurer de bien être relié

au même potentiel que la masse de l’appareil et

enfiler le bracelet serti d’une résistance de

sécurité.

Veiller à ce que les composants ainsi que les

outils que l’on utilise soient également à ce

potentiel.

GB

Complete Kit ESD3 (small tablemat, wristband,

connection box, estention cable and earth cable ....... 4822 310 10671

Wristband tester ................................................................. 4822 344 13999

D

WARNUNG

Alle ICs und viele andere Halbleiter sind

empfindlich gegenüber elektrostatischen

Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kan

die Lebensdauer drastisch reduzieren.

Veranlassen Sie, dass Sie im Reparaturfall über

ein Pulsarmband mit Widerstand verbunden

sind mit dem gleichen Potential wie die Masse

des Gerätes.

Bauteile und Hilfsmittel auch auf dieses gleiche

Potential halten.

ESD PROTECTION EQUIPMENT

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor electrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie kan

de levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

I

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevità potrebbe essere fortemente

ridatta in caso di non osservazione della più

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto

a resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo

potenziale.

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used.

Safety components are marked by the symbol

!

.

CLASS 1

LASER PRODUCT

NL

Veiligheidsbepalingen vereisen, dat het apparaat bij reparatie in

zijn oorspronkelijke toestand wordt teruggebracht en dat onderdelen,

identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbol

!

.

3122 110 03420

F

Les normes de sécurité exigent que l’appareil soit remis à l’état

d’origine et que soient utiliséés les piéces de rechange identiques

à celles spécifiées.

Less composants de sécurité sont marqués

!

.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu

beachten. Der Original zustand des Geräts darf nicht verändert werden;

für Reparaturen sind Original-Ersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol

!

markiert.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso

nelle condizioni originali e che siano utilizzati i pezzi di ricambio

identici a quelli specificati.

Componenty di sicurezza sono marcati con

!

.

GB

After servicing and before returning set to customer perform a leakage

current measurement test from all exposed metal parts to earth ground

to assure no shock hazard exist, The leakage current must not

exceed 0.5mA.

GB

Warning !

Invisible laser radiation when open.

Avoid direct exposure to beam.

S

Varning !

Osynlig laserstrålning när apparaten är öppnad och spärren

är urkopplad. Betrakta ej strålen.

Varoitus !

SF

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen!

DK Advarse !

Usynlig laserstråling ved åbning når sikkerhedsafbrydere er

ude af funktion. Undgå udsaettelse for stråling.

F

"Pour votre sécurité, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

Page 7

Pb(Lead) Free Solder

When soldering , be sure to use the pb free solder.

INDENTIFICATION:

Regardless of special logo (not always indicated)

onemusttreatallsetsfrom1 Jan 2005 onwards,according

next rules:

Important note: In fact also products of year 2004 must

be treated in this way as long as you avoid mixing solderalloys (leaded/ lead-free). So best to always use SAC305

and the higher temperatures belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solder-paste

is required, please contact the manufacturer of your

solder-equipment. In general use of solder-paste

within workshops should be avoided because paste is

not easy to store and to handle.

• Use only adequate solder tools applicable for lead-

free solder alloy. The solder tool must be able

– To reach at least a solder-temperature of 400@C,

– To stabilize the adjusted temperature at the solder-

tip

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around

360@C – 380@C is reached and stabilized at the solder

joint. Heating-time of the solder-joint should not exceed

~ 4 sec. Avoid temperatures above 400@C otherwise

wear-out of tips will rise drastically and flux-fluid will

be destroyed. To avoid wear-out of tips switch off unused equipment, or reduce heat.

• Mix of lead-free solder alloy / parts with leaded solder

alloy / parts is possible but PHILIPS recommends

strongly to avoid mixed solder alloy types (leaded and

lead-free).

If one cannot avoid or does not know whether product

is lead-free, clean carefully the solder-joint from old

solder alloy and re-solder with new solder alloy

(SAC305).

• Use only original spare-parts listed in the Service-

Manuals. Not listed standard-material (commodities)

has to be purchased at external companies.

• Special information for BGA-ICs:

– Always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for desoldering always use the lead-free temperature profile,

in case of doubt)

– Lead free BGA-ICs will be delivered in so-called ‘dry-

packaging’ (sealed pack including a silica gel pack) to

protect the IC against moisture. After opening,

1 - 7

dependent of MSL-level seen on indicator-label in the

bag, the BGA-IC possibly still has to be baked dry.

(MSL=Moisture Sensitivity Level). This will be

communicated via AYS-website.

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products

of 2004), containing leaded solder-alloy and

components, all needed spare-parts will be available

till the end of the service-period. For repair of such

sets nothing changes.

• On our website www.atyourservice.ce.Philips.com

you find more information to:

• BGA-de-/soldering (+ baking instructions)

• Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical information

within the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

Page 8

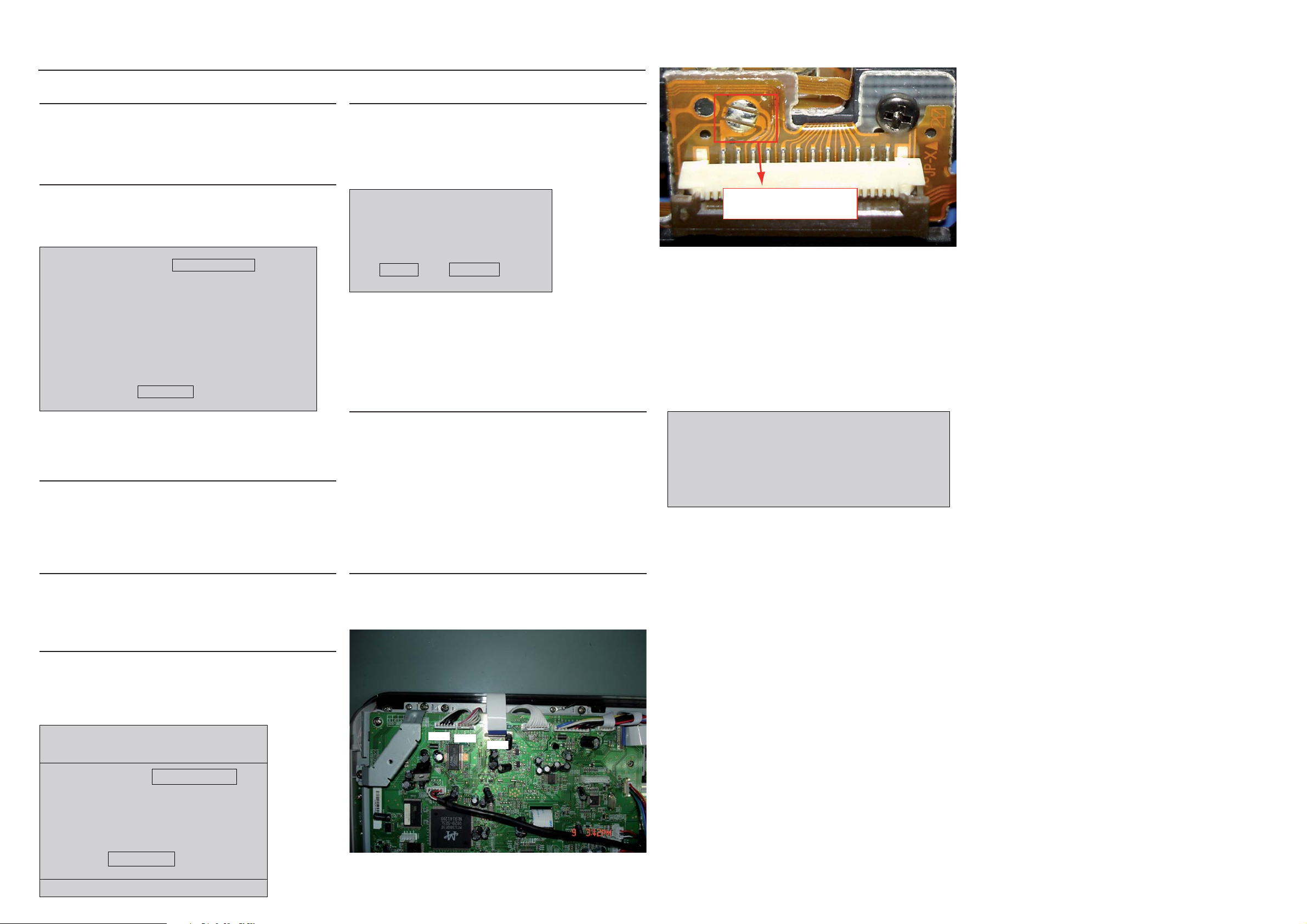

System , Region Code , etc. Setting Produre

2 - 12 - 1

c) Remove solder joint on the ESD protection point.

1)Restore factory setting

a) Press <SETUP> button on R/C

b) Select <preference setup> ,then press < OK >

c) Select <default>,then press <OK> to con rm

2)Region code change

a) Open the Door,then,press “1” “5” “9” on RC

b) Press <OK> button on RC

c) TV will show message as follow:

Current model: 5200-12/98/51

Version:00.08.00_1 Release:2009.12.16

Region: 2 Servo:D1.72.01.00

8032: 05.00.04.06 Risc: BB.00.00.00

MCU: 06.01 Touch: 0044 Dock: Error

if current model doesnot match your set,

use down arrow key on the remote to change

OK

d) If current model doesnot match your set, use down arrow key on

the remote to change.

3)Password change

a) Press <SETUP> button on R/C

b) Select <preference setup> ,then press <OK>

c) Select <password> <change>,then press <OK> to con rm

“0000” is default password supplied.

6) Upgrading new software

a) Copy the latest upgrading software onto a CD-R or USB storage

device

b) Insert the CD-R program disc or connect the USB storage device

to the home theater

c) TV will show message as follow

Upgrade fi le detected

Do you wish to continue with

the software upgrade?

OK Cancel

d) Select <OK>,the home theater will start to upgrading

automatically

Note: when upgrade in progress, please do not unplug or switch off

the device.

when the updated is complete ,the home theater automatically

switch to standby.

7) Produce to change Tuner grid (for /98)

Only applicable for certain regions, in some countries, the

frequency step between adjancent channels in the FM hand is

50KHZ(100KHZ in some areas)

a) Press<radio> on R/C to select “FM”

b) In “FM” playbak mode,press & hold< play/pause> button until

“grid 9” or “grid 10” appears

Note: repeaing the same action will toggle back to it previous

tunning grid setting.

* “grid 10” is default for /55/98 version.

The ESD protection point

on the top side view of OPU

Note: The ESD protection point on any one side must be soldered if

- the DVD Loader is OK and needs to be disconnected from

connector CN802, CN803 and CN801 of the main board.

- the defective DVD Loader is needed to be send back to supplier

for failure analysis and to support back charging evidence.

The Top side view of OPU

CAUTION!

This information is confi dential and may not be

distributed.Only a qualifi ed service person should

reprogram the Region Code.

4)Trade model

a) Press <Open/Close>button on R/C

b) Press “2” “5” “9” on R/C,VFD will display “TRA ON “ or “TRA

OFF“

5)Check on software version

a) Press <SETUP> button on R/C

b) Select <preference setup> ,then press <OK>

c) Select <version info>,then press <OK>

d) TV will show message as follow:

Preference setup

Version Info.

Current model: 5200-12/98/51

Version :00.08.00_1 Release: 2009.12.16

Region: 2 Servo: D1 .72.01.00

8032:05.00.04.06 Resc: BB.00.00.00

MCU: 06.01 Touch: 0044

OK

Press SETUP to exit menu

8)How to replace the defective DVD Loader

a) Remove the defective DVD Loader (see chapter 3).

b) Accordingly connect DVD Loader and “CN802”, “CN803”,

“CN801” on the top of main board as shown below:

CN802

CN803

CN801

Page 9

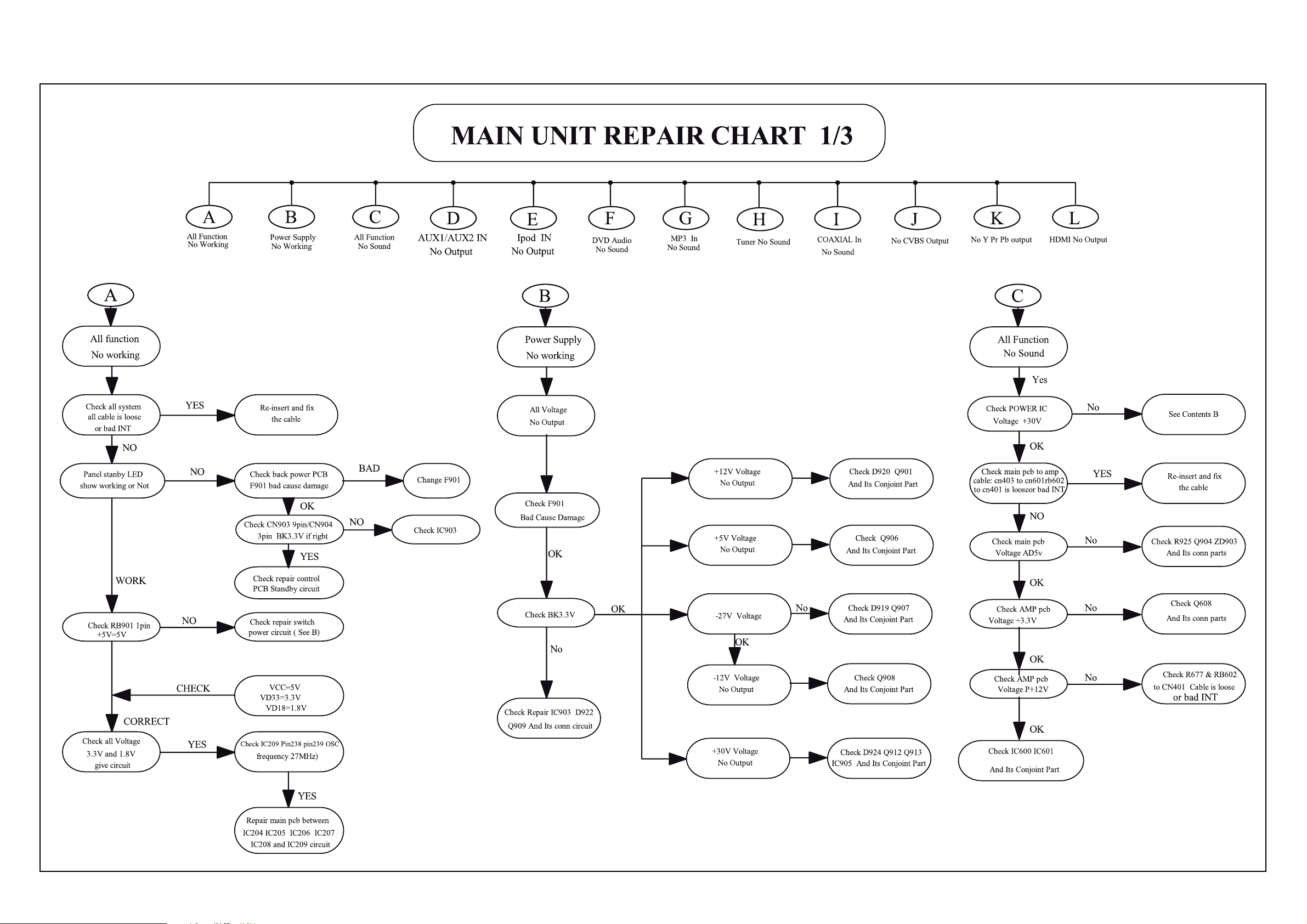

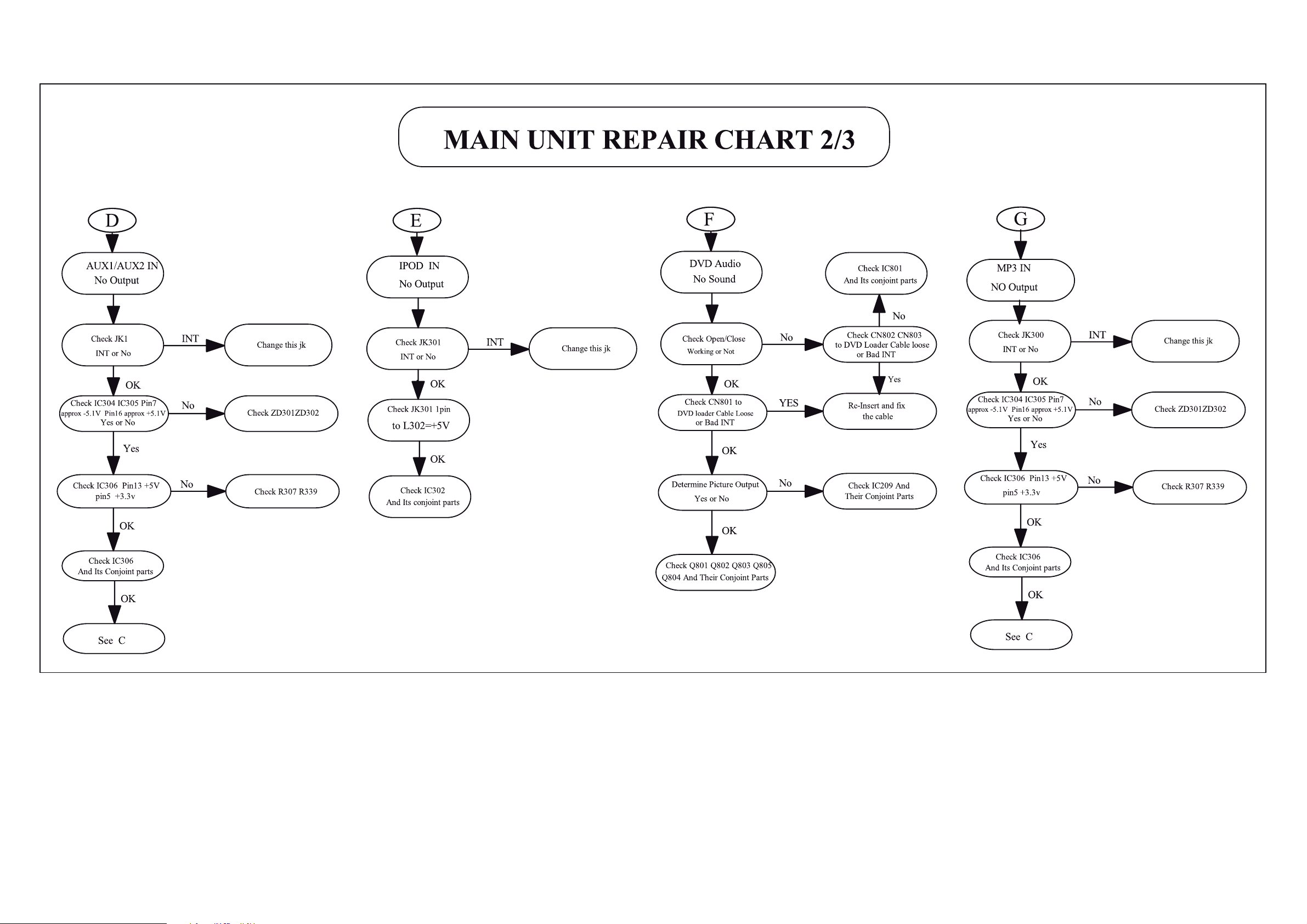

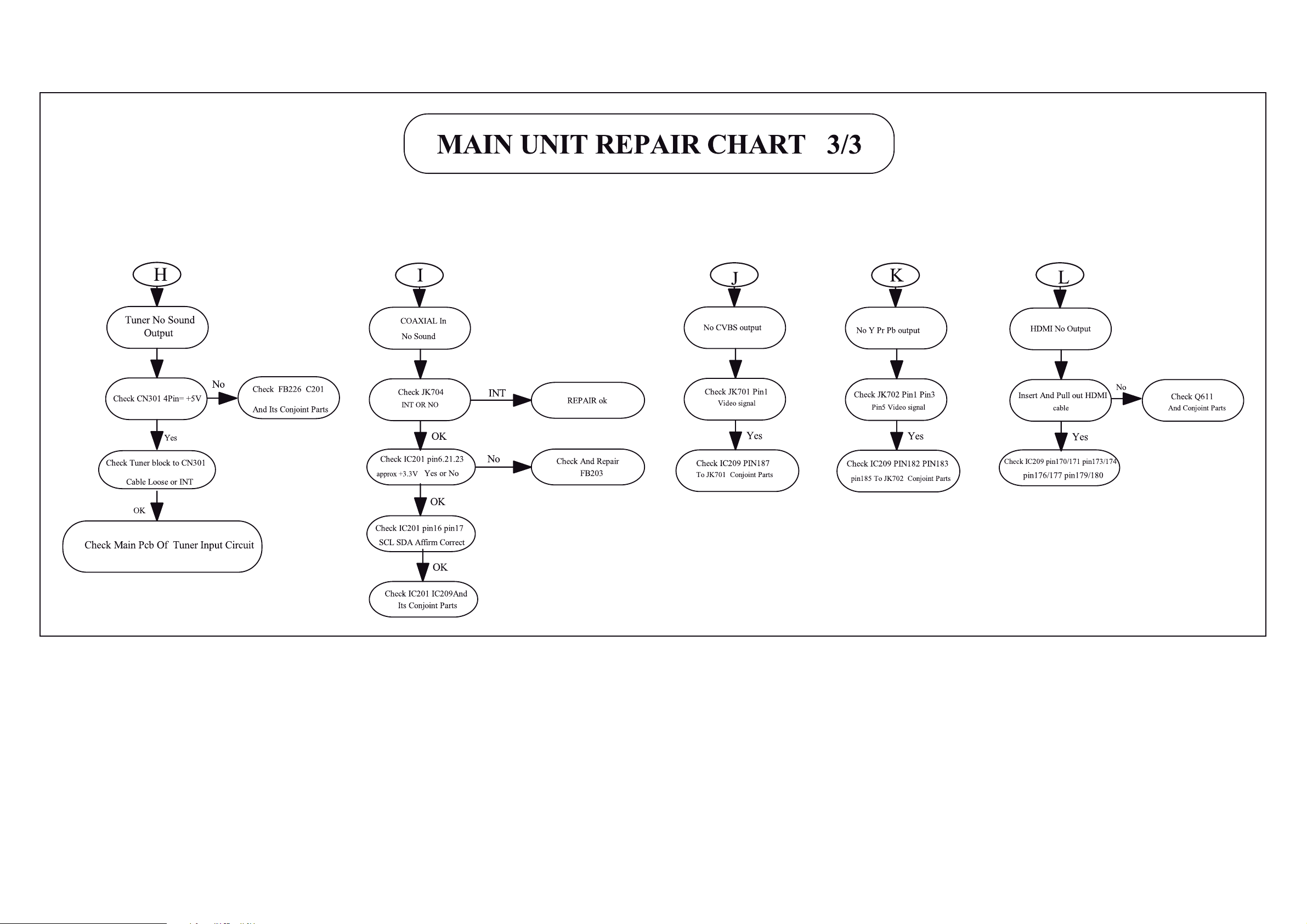

REPAIR INSTRUCTIONS (One)

2 - 22 - 2

Page 10

REPAIR INSTRUCTIONS (Two)

2 - 32 - 3

Page 11

REPAIR INSTRUCTIONS (Three)

2 - 42 - 4

Page 12

DISASSEMBLY INSTRUCTIONS

3 - 1 3 - 1

Dismantling of Rear Panel

1) Using hands to push the cable door to remove it as shown in gure 1.

2) Loosen 2 screws “A” to remove footstand ass’y as shown in gure 2.

3) Loosen 9 screws “B” to remove rear panel as shown in gure 3.

PUSH

Dismantling of the Main PCB

1) Loosen 8 screws “C” to remove main PCB bracket as shown in gure 4.

2) Loosen 3 screws “D” and loosen 7 screws “E” at the main PCB bracket as shown in gure 5&6 to remove main PCB.

C

Figure 1

A

Figure 2

Figure 4

D

Figure 5

B

Figure 3

E

Figure 6

Page 13

3 - 2 3 - 2

Dismantling of the USB+AUX PCB

1) Loosen 2 screws “F” at the main PCB bracket to remove AUX PCB as shown in gure 7.

2) Loosen 9 screws “G” to remove DVD fan bracket&fan&USB bracket as shown in gure 8.

3) Loosen 2 screws “H” on the USB PCB to remove it as shown in gure 9.

F

Figure 7

Figure 8

H

Figure 9

Dismantling of the Power PCB

1) Loosen 6 screws “I” at the power PCB bracket as shown in gure 10.

2) Loosen 4 screws “J” on the power PCB bottom to remove power PCB as shown in gure 11.

J

G

Figure 11

Dismantling of the AMP PCB

1) Loosen 4 screws “K” on the AMP PCB bottom to remove AMP PCB as shown in gure 12.

Figure 10

I

K

Figure 12

Page 14

Dismantling of the DVD Module

3 - 3 3 - 3

1) Loosen 3 screws “L” at the power PCB bracket bottom to remove DVD module as shown in gure 13.

L

Figure 13

SERVICE POSITIONS

Dismantling of the VFD+LED+DVD LED PCB

1) Loosen 3 screws “M” on the VFD PCB to remove it as shown in gure 14.

2) Loosen 2 screws “N” on the LED PCB to remove it as shown in gure 15.

3) Loosen 2 screws “O” on the door LED PCB to remove it as shown in gure 16.

4) Loosen 2 screws “P” at the DVD door lens ass’y to remove it as shown in gure 17.

5) Loosen 4 screws “Q” at the touch PCB bracket as shown in gure 18

M

Figure 14

O

N

Figure 15

Note:In some service positions the components or copper patterns of one board may risk touching its neighbouring pc boards or

metallic parts. To prevent such short-circuit use a piece of hard paper or other insulating material between them.

Figure 16

P

Figure 17

Q

Figure 18

Page 15

BLOCK DIAGRAM

4 - 1 4 - 1

Page 16

WIRING DIAGRAM

4 - 2 4 - 2

V1

V2

V3

V4

Page 17

5 - 1 5 - 1

VFD+USB+AUX BOARD

FTD DISPLAY PIN ASSIGNMENT

TABLE OF CONTENTS

FTD Display Pin Assignment ............................................................. 5-1

Circuit Diagram ................................................................................. 5-2

PCB Layout Top & Bottom View ........................................................ 5-3

PIN CONNECTION

Page 18

CIRCUIT DIAGRAM

5 - 2 5 - 2

C300 A1

C302 A1

C303 A1

C500 B1

C501 B1

C502 B1

C503 B1

C504 B1

C505 B1

C506 B1

C507 B1

C508 B1

C509 B1

C510 B1

C512 B1

C513 B2

C514 C2

C515 C1

C516 C1

C517 C1

C518 C1

C519 C1

C520 C2

C521 C2

C522 C2

C523 A2

C524 A2

C525 A2

C526 A2

C527 A1

A

C528 A1

CN2 A1

D500 C2

D501 C2

DP500 B1

FB300 A1

FB301 A1

IC500 B1

IC500 B1

JK2 A2

JK300 A1

LD502 B2

Q501 C2

Q502 C2

Q503 C2

Q504 C2

R500 B1

R501 B1

R502 B1

R503 B2

R504 B1

R505 B1

R506 B1

R507 B1

R509 C2

R510 C2

R511 C1

R512 C1

R513 C1

R514 C1

R515 C1

R516 C1

R518 C2

R519 C2

R520 C1

R521 C1

R522 C1

R523 C1

R524 C1

R525 C1

R526 C2

R527 C2

R528 C2

R529 C2

R530 C2

R533 B2

R534 C1

R536 A1

RB3 A2

RB300 A1

RB301 A1

RB503 B2

RB506 C1

RB507 C1

SN500 B1

12

A

USB300 A1

ZD500 B1

ZD501 C1

B

C

B

C

12

Page 19

PCB LAYOUT - TOP VIEW

5 - 3 5 - 3

C502 A1

C503 A1

C504 A2

C519 A2

C520 A2

C521 A2

DP500 A2

J500 A1

J501 A2

J502 A1

A

B

J503 A1

J504 B1

J505 A2

J506 A2

JK1 A1

JK2 B1

JK300 B2

LD502 B2

Q501 A2

Q503 A2

R507 B2

R510 B1

R534 B1

RB3 A1

RB300 B2

RB301 B2

RB503 B1

RB506 A1

RB507 A1

SN500 A1

1 2

A

B

USB300 B2

PCB LAYOUT - BOTTOM VIEW

C300 B2

C302 B2

C303 B2

C500 A1

C501 A1

C505 A1

C506 B2

C507 A2

C508 A1

C509 A2

C510 A2

C512 A2

C513 A1

C514 A2

C515 B1

C516 B1

C517 A2

C518 A2

C522 A1

C523 A1

C524 A1

A

C525 A1

C526 A1

C527 A1

C528 A1

CN2 A1

D500 B2

1 2

D501 B2

FB300 B2

FB301 B2

IC500 A2

IC500 A2

Q502 A1

Q504 B2

R500 A1

R501 A1

R502 A2

R503 A1

R504 B1

R505 B1

R506 B1

R509 B2

R511 A1

R512 A2

R513 A2

R514 A2

R515 A2

R516 A2

R518 B2

R519 B2

R520 A2

R521 A2

R522 A2

R523 A2

R524 A2

R525 A2

R526 A2

R527 A2

R528 A2

R529 A1

12

A

R530 A1

R533 B2

R536 B2

ZD500 A1

ZD501 A2

B

B

12

Page 20

6 - 1 6 - 1

INTERNAL IC DIAGRAM - MT1389FEX/SN

DVB-T

MAIN+LED BOARD

TABLE OF CONTENTS

Internal IC Diagram ...........................................................................6-1

Circuit Diagram(part one) .................................................................. 6-2

Circuit Diagram(part two) ................................................................... 6-3

PCB Layout Top View .......................................................................6-4

PCB Layout Bottom View .................................................................. 6-5

DVD

PUH

Module

MT1389S

FLASH

Front-panel

Remote

DRAM

INTERNAL IC DIAGRAM - A641604L

USB2.0/3 in 1 card

reader

HDMI1.2Tx

RGB video

CVBS

8ch Audio

SPDIF

Page 21

CIRCUIT DIAGRAM - part one

C0201 C2

C0202 A2

C0203 A2

C0204 D1

C0205 A2

C0206 A2

C0207 A3

C0208 A3

C0209 A2

C0210 B4

C0211 A2

C0212 C2

C0213 C4

C0214 C4

C0215 C2

C0216 D1

C0217 D1

C0218 D1

C0219 D1

C0220 D1

C0221 D1

C0222 D1

C0226 D1

C0227 C2

C0228 D1

C0229 D1

C0230 D1

C0235 D2

C0237 D4

C0238 D4

C0239 D4

C0240 D4

C0241 D4

C0242 D4

C0243 D4

C0244 A2

C0245 A2

C0246 A2

C0247 A2

C0248 B4

C0249 A2

C0251 C4

C0252 C4

C0253 B4

C0254 A2

C0601 C4

C0602 C4

C0603 C4

C0604 C4

C0606 C4

C201 A2

C202 B4

C203 A2

C204 B2

C205 C4

C206 D1

C207 D3

C208 A2

C209 B3

C210 C2

C211 D4

C212 A2

C214 C2

C215 A2

C217 A2

C218 B4

C219 A3

C220 A3

C221 B4

C223 D1

C224 D1

C226 C2

C227 C2

C228 C2

C230 D2

C231 D2

C233 D1

C237 B3

C238 B3

C239 D4

C242 B2

C243 D2

C250 D1

C254 D3

C256 D1

C257 D1

C260 D1

C261 D1

C319 A4

C600 C4

6 - 2 6 - 2

C601 C4

C602 C4

C703 A3

C704 A3

C705 A3

C706 A3

C707 A3

C708 A3

C709 A3

C713 A3

C716 B3

C717 A3

C718 B3

C719 A3

C720 B3

C721 A3

C722 A3

C723 B3

C731 A2

C732 A2

C735 C2

C736 A3

C737 A3

C738 C2

C801 A1

C802 A2

C803 B1

C804 A2

C805 B1

C806 B1

C807 B1

C808 B2

C809 B2

C810 A2

C811 A2

C812 A2

C813 B2

C816 B2

C817 B2

C818 A2

C819 B1

C820 B2

C821 B2

C822 B2

C823 B2

C824 B2

C825 B2

C826 B2

C827 B2

C828 B2

C829 B2

C830 B2

C831 B2

C832 B2

C833 B3

C834 B1

C835 A1

C836 A2

C837 A2

C838 B2

C839 B2

C840 B2

C841 B2

C843 B1

C844 B2

C846 C2

C849 B2

C851 C1

C852 C1

C853 C1

C854 C1

C855 C2

C856 C1

C857 C1

C858 C1

C859 C1

C860 C1

C861 A2

C862 C1

C864 D3

CE201 D1

CE202 D1

CE203 D1

CE204 D1

CE206 D1

CE208 A4

CE212 A4

CE215 C2

CE216 C2

CE217 C2

CE218 C2

CE219 C2

CE220 C2

CE801 D1

CE802 D1

CE803 D1

CE804 D1

CE805 D1

CE806 D1

CE807 D1

CE808 D1

CE809 D1

CN201 B4

CN206 B4

CN305 A4

CN306 A4

CN801 A1

CN802 B1

CN803 B1

D201 A3

D202 D1

D204 A3

D205 D3

D600 D1

F201 B4

FB1007 C3

FB201 A2

FB202 A2

FB203 A2

FB204 A2

FB205 C4

FB206 C4

FB207 D4

FB208 D4

FB216 C2

FB217 A2

FB224 D4

FB225 D4

FB226 A2

FB301 C1

FB302 A4

FB303 A4

FB304 A4

FB305 A4

FB307 A4

FB308 A4

FB309 A4

FB317 C1

FB601 A3

FB602 C4

FB603 C4

FB703 A3

FB704 A3

FB705 A3

FB706 A3

FB707 C2

FB708 C2

FB715 A2

FB801 A1

FB802 A1

FB803 B1

FB804 A4

IC201 C1

IC202 C4

IC203 D3

IC204 D2

IC206 D4

IC207 D3

IC208 D2

IC209 B4

IC210 A3

IC301 A2

IC302 B2

IC801 B1

JK601 B4

JK701 A3

JK702 A3

JK704 A3

L201 A2

L202 A2

L203 A2

L204 D4

L205 B4

L206 B3

L207 B4

L208 A2

L701 B3

L702 B3

L703 B3

L704 B3

L707 A3

L801 A2

L802 A2

L803 B2

Q201 D4

Q204 A3

Q205 D1

Q206 D1

Q300 D3

Q307 A4

Q308 A4

Q309 D2

Q602 A3

Q705 A3

Q706 A3

Q707 A3

Q708 A3

Q713 B3

Q714 B4

Q715 B4

Q716 B3

Q718 A3

Q719 A3

Q720 A3

Q721 A3

Q801 A1

Q802 A1

Q803 A1

Q804 A2

Q805 A1

R201 C4

R202 B4

R203 D1

R204 D1

R205 D1

R206 D1

R207 A3

R208 D2

R209 B4

R210 C4

R211 C4

R212 C4

R213 D2

R215 D2

R218 D2

R219 A3

R220 C4

R221 C4

R222 D3

R223 D3

R224 D3

R225 B4

R227 D2

R228 D1

R233 D2

R235 B2

R236 B2

R238 D4

R239 D3

R242 D1

R250 D3

R254 D4

R256 D1

R257 D1

R258 D1

R259 D2

R260 D2

R261 D2

R262 D3

R263 D2

R264 D2

R267 D2

R268 D2

R269 D1

R270 D2

R272 D2

R276 D2

R277 D2

R278 D2

R280 B3

R281 D3

R285 D2

R286 D2

R287 D2

R288 D2

R289 D1

R290 B1

R291 B1

R292 D3

R293 D2

R294 B2

R295 D1

R296 D1

R297 D1

R298 D4

R299 D4

R3024 D1

R3026 D1

R337 D2

R338 D2

R339 D2

R404 A4

R405 A4

R406 A4

R407 A4

R408 A4

R410 A4

R411 A4

R601 D1

R603 C4

R604 B4

R605 B4

R701 A3

R702 A3

R703 A3

R704 A3

R705 A3

R706 A3

R731 B3

R732 B3

R733 B3

R734 B3

R737 A3

R738 C2

R748 A3

R802 A1

R803 A1

R804 B1

R805 B1

R806 C2

R807 C2

R808 A1

R812 A1

R813 A1

R814 A2

R815 A2

R816 A1

R817 B2

R820 A1

R822 A2

R823 A2

R824 A2

R826 B1

R827 B1

R829 B1

R830 B2

R831 B2

R833 B2

R834 B2

R835 B2

1234

R836 B1

R838 B2

R839 B2

R840 B2

R841 B2

R842 B2

R845 C2

R846 C1

R847 C1

R848 C1

R849 C1

R850 C1

R851 C1

R852 C1

R853 C1

R854 C1

R855 C1

R856 C1

R857 C1

R858 C1

R869 C1

R870 C2

RA201 C2

RA202 C4

RA203 C2

XL201 B3

XL202 D1

ZD209 B4

A

B

C

A

B

C

D

D

1234

Page 22

CIRCUIT DIAGRAM - part two

C303 A2

C304 A2

C305 A2

C306 A2

C307 B2

C308 A2

C309 A2

C311 A2

C313 A2

C315 A2

C316 A2

C317 C3

C320 B3

C321 B3

C322 B3

C324 B3

C327 A2

C328 A2

C331 A3

C332 A2

C333 A2

C334 B3

C340 A3

C341 B2

A

B

C

C342 A2

C343 A2

C345 A1

C346 B3

C348 A1

C349 B3

C350 B3

C351 A3

+5V

+5V

+12V

+12V

UAR T R X

UA RT RX

UAR T TX

UA R T TX

TU_C K

TU_CK

TU_DA

TU_DA

TU_C E

TU_CE

ST _L ED

ST_ LED

FM_ DET

FM_DET

SCL

SCL

SDA

SDA

P_MU TE

P_MUTE

308_TSD 0

308_TSD0

308_TSD 1

308_TSD1

308_TSD 2

308_TSD2

POWE R_ C

POWER_ C_1

PSU_POWER

PSU_POWER

RESE T

RE SE T

ABCK

ABCK

AL RC K

AL RCK

A_MCLK

A_MC LK

IPOD_C VB S

FAN

FAN

MP3L

MP3L

MP3R

MP3R

WL K

WL K

WDA

WDA

74F244 SW

74F244 SW

PDAT A

PDAT A

PDAT A1

PDAT A1

LI NO UT _L

LI NO UT _L

LI NO UT _R

LI NO UT _R

5508_RES ET

5508_RES ET

PSU on/o

PSU on/off

-12V_B IN_-12V

+12V

C352 B1

C353 B1

C354 B1

C355 B1

C356 B1

C357 B1

C362 B3

C363 B3

R928

56

C918

100U/16V

R929

56

C919

100U/16V

PUS ON/O FF

+12.5V/1.2A

TO P OWER BOAR D

IN_+12V

C366 A1

C367 A1

C381 C2

C382 C2

C384 C3

C389 B3

C393 C1

C394 C1

RB 901

BK 3.3V

-12V

GN D

+5V/2A

+5V/2A

GN D

GN D

CN9 /25

C931

100U/16V

6 - 3 6 - 3

C395 C2

C396 B2

C518 B3

C519 B3

C521 B3

C739 A2

C740 A2

C741 A2

C742 A2

C743 A2

C744 A2

C745 A2

C746 A2

C901 C1

C902 C1

C903 C1

C904 C1

C905 C1

C908 C2

C911 C2

C912 C2

C918 C1

C919 C1

C920 C1

C921 C1

C924 C1

C929 C1

C931 C1

C935 C2

C936 B3

CE301 C1

CE304 C1

CE305 C1

CE306 C1

CE307 C1

CE308 C1

CE314 C1

CE315 C2

CE316 C2

CE320 C2

CE321 C2

CE322 C2

CE324 C2

CE325 C2

CE326 C2

CE327 C2

CE328 C2

CE329 C2

CE345 A1

CE346 A1

CE347 A1

CE348 A1

CE901 C2

CE903 C1

CE904 C1

CN301 A1

CN303 B1

CN401 B3

CN403 C3

CN504 C3

FB310 A3

FB312 B1

FB313 B1

FB314 A1

FB315 B3

FB316 B3

FB901 C2

FB905 B1

FE301 C2

FE302 C2

FE303 C2

FE306 C2

FE307 C2

FE308 C2

FE309 C2

FE310 C2

FE311 C2

FE312 C2

IC304 A2

IC305 A2

IC306 B3

IC307 C2

JK301 A1

L302 A1

LD501 C3

Q507 A1

Q508 A1

R3019 A2

R3020 B2

R3021 A1

R3022 A1

R3023 A1

R303 A1

R304 B2

R305 C2

R308 C2

R311 A2

R312 A2

R315 A2

R316 A2

R317 A2

R318 A2

R319 A2

R320 B2

R323 A2

R324 A2

R327 A2

R328 B2

R329 A2

R330 A2

R331 A2

R332 B2

R334 A3

R335 A3

R336 B3

R343 A2

R344 A2

R348 B1

R349 B1

R350 B1

R351 B1

R352 B1

R353 B1

R354 B2

R355 B2

R356 B2

R357 B2

R358 B2

R359 B2

R360 A3

R361 B3

R368 B1

R369 B1

R385 A1

R386 A1

R387 A1

R389 B3

R390 B3

R532 C3

R546 A2

R558 C3

R560 C3

R708 A1

R710 A1

R711 A1

R712 A2

R713 A2

R714 A2

R715 A2

R716 A2

R717 A2

R718 A2

R719 A2

R720 A2

R721 A2

R722 A2

R723 A2

R903 B2

R928 C1

R929 C1

123

R719

TP901

BK 3.3V

PSU on/off

TP902

TP903

TP904

104

C901

R714

1K

R712

TUN_ L

2K2

R711

RX

UARTR X

CE345 100P

CE346 100P

100

R3023

33

C348

C345

R3021

10K

102

C356

FB312 600

FB313 600

1K2

R368

R910

105

TUN_ R

CE347 100P

UAR T T XTX

105

47U/16V

C922

2.2K

++5V

R710

2.2K

TX

UARTTX

Ipod_mute

OPEN

CE348 100P

CE 351

+5V

UAR T R X

R3022

10K

R348

R349

R350

R351

102

C357

R352

R353

OPEN

Q9012SC945

104

C906

CN301

CN125

1

2

3

4

TU_C K

5

TU_DA

6

7

R707 OPEN

TU NE R

8

TU_C E

9

10

R708

10K

Ipod_mute

UAR TTX

UAR TR X

OPEN

Q724

Q507

Q508

5V

C366104

5V

C36747U/10V

L302

1

10K

2

R385

3

4

R387

1K

5

RX

6

600

7

FB 314

8

1K

9

R369

1K2

R386

TP320

TP321

TP322

TP323

102

102

C354

C352

100P

100P

C355

C353

++5V+5V

104

470U/16V

470U/10V

C921

C920

C905

DIJK

JK301

CN303

TV_L

TV_R

AUX_ L

AUX_ R

TO AUX IN JACK

CN6/20_L

MP3L

MP3R

+5

-12V

FB905

100

FB 301

104

C904

10uH

104

C902

OPEN

R901

104

C924

104

C903

104

CE903

-12V_B

100U/16V

C929

104

CE904

R716

8K2

C740

R715

1K

R713

2K2

R717

8K2

TX

Q306

UART RX

L_ CH

R303

R311

4.7K

10K

102

C304

102

C303

R913

330

ZD904

5V1

R_ CH

12K

12K

12K

12K

3.3K

3.3K

R924

2.2 1/4W

R354

47K

4.7K

R312

R355

47K

T12V

600

FB901

104

104

C908

CE901

10K

R304

2.2K

C741

272

6

5

332

2

3

R316

6

5

C308

R315

2

3

C307

R356

47K

R358

47K

470U/16V

C935

R718

C327

+12V

C739

R546

C328

C742

332

C305

R357

47K

R359

47K

104

104

104

TV _L

TV _R

AUX _ L

AUX _ R

MP3_L

MP3_R

470U/16V

C912

8

4

8

4

B+

B-

VD33

B+

272

B-

C306

24K

47P

JRC4558

R319

24K

47P

IC302A

JRC4558

R320

R317

2.2K

IC301A

JRC4558

R318

104

4K7

IC302B

7

IC301B

JRC4558

1

56

VD33

7

56

1

56

C744

R720

1.5K

4.7U

C745

R723

3K

180P

56

Siri us_L

TU-L

4051_A

4051_B

4051_C

4051_A

4051_B

4051_C

AUX _ L

TV _L

MP3_L

KA RA OKE_L

P_LOUT

R3019

104

C309

Siri us_R

TU-R

AUX _ R

TV _R

MP3_R

KA RA OKE_R

P_ROUT

R3020

104

C311

104

C313

C332

4.7U

C333

4.7U

R721

1.5K

R722

3K

C743

4.7U

C746

180P

Q301

RX

R324

3k9

1K81K8

R327R328

R323

3k9

R903

0

OPEN

104

C923

C911

AUX /TUNER /DOC K

IC304

13

0

14

15

12

1

5

2

4

0

11

10

9

6

13

14

15

12

1

5

2

4

11

10

9

6

X0

X1

X2

X3

X4

X5

X6

X7

A

B

C

INH

VSS8VE E

IC_TC 4051

5V6

ZD301

IC305

X0

X1

X2

X3

X4

X5

X6

X7

A

B

C

INH

VSS8VE E

IC_TC 4051

3

X

R329

VD

16

VDD

VE

7

R330

47U/16V

104

47U/16V

5V6

ZD302

C343

C315

C342

R344

3

X

680

R332

100K

16

VDD

VD

VE

7

AD_ DOU T

PDAT A PDAT A1

C381

1

2

C382

IC307

10P

10P

330

-12V_B

330

104

C316

4052_ROUT

AD R IN

C341

470P

R381

open

I1

S

GN D

VC C

I03Y

IC_74L VC 1G157

S4 (OUT)

HL1 ( I 1)

3 ( I 0)

R343

680

R331

100K

C334

4.7U

6

R305

5

R308

4

C317 C384

104 10P

4052_LOUT

10K

33

R360

4K7

R361

4K7

C340

470P

600

C351

470P

C350

470

74F244 SW

C331

4.7U

100U/16V

C346

R335

10k

R336

10k

104

C320

DVC C

FB316

10uH

AD L IN

20

19

18

17

16

15

14

13

12

11

10U/16V

C363

M/S

AI NL

AI NO PL

COM

AI NR

AI NO PR

AGND

AVDD

VR EF P

VR EF GND

104

C322

R334

3K3

IC_W M8781

IC306

+5V

220U/10V

C936

MCLK

DOUT

LRCL K

DGND

DVDD

FSA MPE N

FORM AT

VM ID

A

FB310

1

100

2

ADOUT

3

4

5

6

BCL K

7

IWL

8

9

10

104

10U/16V

C321

C362

R558

TSDA

R560

TSCL

R389

33

R390

33

AD3 .3 I< 5mA

104

100U/16V

C324

C349

00WDA

A_M C L K

AD_DOU T

ALRCK

ABCK

ZD303 OPEN

WL K

FB315

10uH

R333 OP EN

+5V

VD33AD33V+5V

C518

104

C519

104

104

C521

+12V

TI3. 3V

+5V

-12V

1

P_MU TE

2

LINO UT _L

3

LINO UT _R

4

5

6

PSU_POWER

7

8

POWER_ C

9

FAN_ CONT

10

FAN

11

12

308_TSD2

13

308_TSD1

14

308_TSD0

15

AL RCK

16

17

ABCK

18

19

5508_RESET

20

TSDA

21

TSCL

22

A_MC LK

23

24

-12V

+5V

+12V

CN401

CN5/20

CN403

B

TO AMP BOAR D

TO TAS 5508

C

RB901 B1

ZD301 A2

ZD302 A2

M1MBM2

MB

CE301 104

CE304 104

CE305 104

CE306 104

EMC A dd part 104p GND TO GND Ol ny

600

600

600

600

600

600

600

600

600

600

CE307 104

CE308 104

CE314 104

CE315 104

CE316 104

CE320 104

CE321 104

CE322 104

CE324 104

CE325 104

CE326 104

CE327 104

CE328 104

CE329 104

FE301

FE302

FE303

FE306

FE307

FE308

FE309

FE310

FE311

FE312

123

Page 23

PCB LAYOUT - TOP VIEW

C0202 A3

C0207 B3

C0208 C3

C0211 B1

C0213 B3

C0235 A3

C0247 A2

C201 C2

C202 B2

C203 B2

C204 C3

C205 A3

C207 B3

C208 B2

C210 B3

C211 A3

C212 B1

C214 B3

C215 B2

C217 A2

C218 A2

C219 C3

C220 C3

C221 A2

C230 A3

C231 A3

C237 B2

C238 A2

C239 A3

C242 B2

C243 A3

C254 A3

C257 B1

C260 B1

C261 B1

C303 A1

C304 A1

C315 B1

C316 A1

C317 B1

C319 C1

C320 C2

C321 C1

C322 C2

C327 A1

C328 A1

C331 B1

C332 A1

C333 A1

C334 B2

C340 B1

C341 B2

C342 B1

C343 A1

C345 A1

C346 C2

C348 A1

C349 C2

C350 B2

C351 B2

C352 B1

C353 A1

C354 A1

C355 A1

C356 A1

C357 A1

C362 C1

C363 C2

C367 A1

C381 B1

C382 B1

C384 B1

C389 C1

C601 A3

C602 A3

C703 A2

C704 A2

C705 A2

C706 A2

C707 A2

C708 A2

C709 A2

C713 A2

C716 A2

C717 A2

C718 A2

C719 A2

C720 A2

C721 A2

C722 A2

C723 A2

C731 A2

C732 A2

C736 A2

C737 A1

C739 A1

C740 A1

C741 A1

C742 A2

C743 A1

C744 A1

C745 A1

C746 A1

C801 C2

C803 C2

C805 C3

C806 C3

C809 B2

C810 C2

C811 C2

C812 C2

C813 B2

C816 C2

C817 C2

C818 C2

C819 C3

C820 C2

C821 C3

C822 C2

6 - 4 6 - 4

C823 B3

C824 B3

C825 B2

C827 B2

C829 C2

C830 C2

C831 B2

C832 C2

C833 C2

C834 C2

C835 C2

C838 B2

C839 B2

C840 B2

C841 B2

C843 C3

C844 C3

C849 B2

C851 A2

C852 A2

C853 A2

C854 B2

C855 B2

C856 A2

C857 A2

C858 A2

C859 A2

C903 C1

C908 C1

C912 A1

C918 A1

C919 A1

C920 B3

C921 B2

C924 A1

C929 A1

C931 A1

C935 C1

C936 C1

CE215 A2

CE218 B2

CE219 B2

CE220 B2

CE345 B1

CE348 B1

CE803 C2

CE901 C2

CE903 A3

CE904 A3

CN201 B3

CN206 B1

CN301 B2

CN303 A1

CN305 C1

CN306 C2

CN401 C1

CN403 C1

CN504 B1

CN801 C2

CN802 C3

CN803 C2

D201 C3

D202 B1

D204 C3

D205 A3

D600 B1

F201 B3

FB1007 B1

FB201 B3

FB202 A2

FB203 A2

FB205 B3

FB206 B3

FB207 A3

FB208 A3

FB217 B2

FB224 A3

FB225 A3

FB226 C2

FB301 A1

FB302 C2

FB303 C2

FB304 C2

FB305 C2

FB307 C1

FB308 B1

FB309 C2

FB310 B1

FB312 A1

FB313 A1

FB314 B1

FB315 C2

FB316 C2

FB317 A2

FB601 A3

FB603 A3

FB703 A2

FB704 A2

FB705 A2

FB706 A2

FB708 B3

FB715 A2

FB801 C2

FB802 C2

FB803 C3

FB804 C2

FB901 C2

FB905 C1

FE312 A2

IC201 A2

IC202 B3

IC203 A3

IC204 A3

IC206 A3

IC207 B3

IC208 B1

IC209 A3

IC210 C3

IC301 A1

IC302 A1

IC304 B1

IC305 B1

IC306 B1

IC307 B1

IC801 C3

JK301 A1

JK601 A2

JK701 A1

JK702 A2

JK704 A1

L201 B2

L202 C2

L203 B2

L204 A3

L205 A2

L206 B2

L207 B2

L208 B1

L302 A1

L701 A2

L702 A2

L703 A2

L704 A2

L707 A2

L801 C2

L802 C2

L803 C2

LD501 A1

Q201 A3

Q204 C3

Q205 B1

Q206 C1

Q300 A3

Q307 C1

Q308 C1

Q309 C1

Q507 A1

Q508 A1

Q602 A3

Q706 A2

Q707 A2

Q708 A2

Q718 A2

Q719 A2

Q720 A2

Q721 A2

Q801 C2

Q802 B2

Q803 C2

Q804 C2

Q805 B2

R201 B3

R202 B3

R203 B3

R205 B1

R206 C1

R207 C3

R208 B1

R209 B3

R210 B3

R211 A3

R212 A3

R213 B1

R215 C1

R218 C1

R219 C3

R220 A3

R221 A3

R222 B3

R223 A3

R224 A3

R225 A2

R227 B1

R228 B1

R233 A3

R235 C3

R236 C3

R239 A3

R242 B1

R250 C2

R254 A3

R256 C1

R257 C1

R258 B1

R259 B1

R260 B1

R261 B1

R263 B1

R267 C1

R268 B1

R269 B1

R270 B1

R272 B1

R276 B1

R277 B1

R278 B1

R280 A2

R281 A3

R285 B1

R286 A3

R287 A3

R288 B1

R289 C1

R290 C2

R291 C2

R293 B1

R294 A2

R295 C1

R296 C1

R297 C1

R298 A3

R299 A3

R3019 B1

R3020 B1

R3021 B1

R3022 B1

R3023 B1

R3024 C1

R3026 C1

R303 A1

R304 A1

R305 B1

R308 B1

R311 A1

R312 A1

R315 A1

R316 A1

R317 A1

R318 A1

R319 A1

R320 A1

R323 A1

R324 A1

R327 A1

R328 A1

R329 A1

R330 B1

R331 B1

R332 B2

R334 C1

R335 B2

R336 C2

R337 C1

R338 C1

R339 C1

R343 B1

R344 B2

R348 B1

R349 A1

R350 B1

R351 A1

R352 A1

123

R353 A1

R354 B1

R355 A1

R356 B1

R357 A1

R358 B1

R359 B1

R360 B1

R361 B2

R368 A1

R369 A1

R385 B1

R386 B1

R387 B1

R389 B1

R390 B1

R404 C2

R405 C2

R406 C2

R407 C1

R408 C2

R410 C2

R411 C1

R532 A1

R546 B1

R558 C1

R560 C1

R601 B1

R603 A3

R604 A3

R605 A3

R701 A2

R702 A2

R703 A2

R704 A2

R705 A2

R706 A2

R710 A2

R711 A1

R712 A1

R713 A2

R714 A1

R715 A2

R716 A1

R717 A1

R718 A2

R719 A1

R720 A1

R721 A2

R722 A2

R723 A1

R731 A2

R732 A2

R733 A2

R734 A2

R737 A2

R738 B3

R748 A2

R802 C2

R803 C2

R804 B3

R805 C3

R806 C2

R807 C2

R808 B2

R812 C2

R813 C2

R814 C2

R815 C2

R816 C2

R817 B2

R820 C2

R822 C2

R823 C2

R824 C2

R826 C2

R827 C2

R829 C3

R830 C3

R831 C3

R833 C3

R834 C2

R835 C3

R836 C3

R838 C3

R839 C3

R840 B2

R841 B3

R842 C2

R845 C3

R846 A2

R847 A2

R848 A2

R849 B2

R850 B2

R851 A2

R852 A2

R853 A2

R854 A2

R855 A2

R856 A2

R857 B2

R858 B2

R869 B2

R870 B2

R903 C1

R928 A1

R929 A1

RA201 B2

RA202 A3

RB901 C1

XL201 B2

XL202 B1

ZD209 B3

ZD301 B1

ZD302 B1

A

B

A

B

C

C

123

Page 24

PCB LAYOUT - BOTTOM VIEW

C0201 B3

C0203 B2

C0204 B2

C0205 C2

C0206 B2

C0209 B2

C0210 A2

C0212 B3

C0214 B3

C0215 B3

C0216 A3

C0217 A2

C0218 B3

C0219 A3

C0220 A3

C0221 B3

C0222 A3

C0226 B3

C0227 B3

C0228 A3

C0229 B3

C0230 A3

C0237 A3

C0238 A3

C0239 A3

C0240 A3

C0241 A3

C0242 A3

C0243 A3

C0244 B2

C0245 B2

C0246 A2

C0248 B2

C0249 B2

C0251 A3

C0252 A3

6 - 5 6 - 5

C0253 A2

C0254 B1

C0601 A3

C0602 A3

C0603 A3

C0604 A2

C0606 A3

C206 B2

C209 B2

C223 B1

C224 B1

C226 B2

C227 B2

C228 B2

C233 B1

C250 B1

C256 B1

C305 A1

C306 A1

C307 A1

C308 A1

C309 A1

C311 A1

C313 A1

C324 B1

C366 A1

C393 A1

C394 A1

C395 A1

C396 A1

C518 C1

C519 C1

C521 C1

C600 A3

C735 B3

C738 B3

C802 C2

C804 B3

C807 C3

C808 B3

C826 B3

C828 B2

C836 B2

C837 B2

C846 B3

C860 B1

C861 A2

C862 A2

C864 A3

C901 C1

C902 C1

C904 C1

C905 B2

C911 C1

CE201 C2

CE202 C2

CE203 C2

CE204 C2

CE206 C2

CE208 B1

CE212 B1

CE216 A2

CE217 A2

CE301 A1

CE304 A2

CE305 A2

CE306 A1

CE307 B1

CE308 B2

CE314 B1

CE315 A2

CE316 A1

CE320 B2

CE321 A1

CE322 B2

CE324 A2

CE325 B2

CE326 A2

CE327 A3

CE328 A1

CE329 B1

CE346 A1

CE347 A1

CE801 C2

CE802 C2

CE804 C2

CE805 C3

CE806 C3

CE807 C3

CE808 C3

123

CE809 C3

FB204 B2

FB216 B3

FB602 A3

FB707 B3

FE301 A3

FE302 A3

FE303 A2

FE306 A3

FE307 A2

FE308 A2

FE309 A3

FE310 A2

FE311 A3

Q705 A2

Q713 A2

Q714 A2

Q715 A2

Q716 A2

R204 B1

R238 B3

R262 B3

R264 B1

R292 A3

R708 B2

RA203 B2

A

B

A

B

C

C

123

Page 25

7 - 1 7 - 1

+

-

POWER BOARD

INTERNAL IC DIAGRAM - AZ431

CATHODE

REF

REF

V

TABLE OF CONTENTS

Internal IC Diagram ...........................................................................7-1

Circuit Diagram .................................................................................. 7-2

PCB Layout Top View .......................................................................7-3

PCB Layout Bottom View .................................................................. 7-4

ANODE

INTERNAL IC DIAGRAM - AZ7500BP

6

RT

CT

DTC

1IN +

1IN -

2IN +

2IN -

FEEDBACK

5

4

0.12V

1

2

16

15

3

Dead-Time Control

+

Error Amplifier 1

+

Error Amplifier 2

+

Oscillator

Comparator

+

PWM

Comparator

0.7mA

Pulse-Steering

Flip-Flop

D

CK

Reference

Regulator

OUTPUT CTRL

13

Q1

Q2

11

12

14

10

8

C1

9

E1

C2

E2

V

CC

REF

7

GND

Page 26

CIRCUIT DIAGRAM

BD901 A1

C901 C1

C902 C1

C903 C1

C904 A1

C905 A1

C913 C3

C915 B1

C917 B1

C918 B1

C919 B1

C920 A1

C921 A1

C922 C1

C923 C2

C924 C2

C925 C2

C926 C2

C927 B2

C928 B2

C929 B2

C930 A3

C931 C2

C936 B2

C938 C1

C939 C3

C940 B1

C941 C2

C943 B2

C944 A2

C946 A2

C947 C2

C948 B2

C949 A2

C950 A2

C951 A2

C952 A1

C953 C3

C954 C3

C955 B2

C956 C2

C957 A3

C958 A2

C960 B2

C961 B2

C962 B2

C963 B2

C964 B3

C965 C2

C966 B3

7 - 2 7 - 2

C967 B2

C968 A3

C969 A2

C970 A2

C971 A2

C972 A2

C973 A2

C974 B3

C975 B3

C976 C2

C977 B1

C978 B2

C979 C3

C980 B3

C981 B3

C982 C1

C984 C2

C990 A1

C991 B3

C992 B3

C993 B3

C994 A1

CN901 C1

CN902 A1

CN903 B3

CN904 C3

CN905 A3

CN907 B3

D902 B3

D903 C2

D904 B2

D905 B1

D906 A1

D907 A2

D908 B2

D909 A2

D910 A2

D912 A3

D913 A3

D914 A3

D915 A3

D916 A3

D918 B1

D919 C2

D920 B2

D922 B2

D924 A2

D925 B3

D930 A1

D931 B1

F901 C1

GT902 B1

GT903 C2

IC901 C1

IC902 C2

IC903 C2

IC904 C2

IC905 B3

L901 B1

L902 A1

L904 B2

L905 B2

L906 C2

L907 A2

L908 A2

NTC901 C1

Q901 B3

Q902 C3

Q903 B3

Q904 C3

Q906 B3

Q907 C3

Q908 C3

Q909 C2

Q910 B2

Q911 A2

Q912 A1

Q913 A1

Q914 B3

Q915 B3

Q917 C3

Q918 C2

Q919 B3

R901 B1

R902 B1

R903 B1

R904 B1

R905 B1

R906 B1

R907 A1

R908 A1

R909 A1

R910 A1

R911 B3

R912 B1

R915 C1

R916 A3

R917 A3

R918 A3

R919 A3

R920 C2

R921 A2

R922 C2

R923 C3

R924 C2

R925 C2

R926 A3

R927 C2

R928 C2

R929 C2

R930 C2

R932 A1

R933 C1

R935 C1

R936 C2

R937 B2

R938 B2

R939 B2

R940 B1

R941 B1

R942 B1

R943 B2

R944 A2

R945 A2

R947 C2

R948 C3

R949 A1

R950 C3

R953 A3

R954 C2

R955 C2

R956 B2

R957 B3

R958 B3

R959 B3

R960 A3

R961 B3

R962 C2

R963 B2

R964 B3

R965 B2

R966 B2

R967 A2

R968 A3

R969 A3

R970 A3

R971 A2

R972 A2

R973 A2

R974 A3

R975 A3

R976 A3

R977 B3

R979 B3

R980 B3

R981 C2

R982 C3

R983 C3

R984 C3

R985 C3

R986 C3

R987 C2

R988 C2

R989 C2

R990 C3

R991 C2

R992 C3

R993 B3

R994 C3

R995 B3

R996 C3

R997 B3

R998 B3

R999 B3

T901 B2

T902 A2

T903 A2

TVR901 B1

TVR902 A1

TVR903 A1

ZD902 C2

ZD903 B1

ZD904 A1

ZD905 A3

ZD907 A3

ZD908 A3

ZD909 A3

ZD910 A3

ZD913 A3

ZD915 C3

123

A

B

C

220V

SW-110/220V

SW1A

!

R02-220

1

2

3

R913

YP-501M

!

GT901

!

HEAT 1

103P-1KV

CN2P-396-1

CN902

C919

102P-400V

R906

R901

C911

102 250V

C903A

C903

102P-1KV

102P-1KV

C912

102P-1KV

ALL RES. ARE 1/6W EXCEPT SPECICAL EXPLAIN WITH NOTES

ALL EC.CAP. ARE 50V EXCEPT SPECICAL EXPLAIN WITH NOTES

1

2

OPEN

BD901

!

41

43

!

!

C917

43

!

R905 1M

1M

1M R9031M

R902 1M

50A/560V

!

RNT-6A

NTC901

!!

1

CN901

ECO POWER <0.3W

C902

C914

C982

C906

C901

J901

K8U808

12

L902

L-7MH

C224P-275V

12

L901

L-7MH

C915C224P-275V

2

102/250V

561 400V

561 400V

C994

102

32

C918

102P-400V

R9041M

TVR901

!

CN2P-396-2

102 250V

J902

TVR10241KS

!

YP-501M

TVR10241KS

TVR903

!

TVR902

GT902

F901

!

!

T6.3AL 250V

R969

ZD909ZD908

D912

C993

C992

R985

R996

ON/OFF

13

OUT/C

R911

C913

C980C981

12

P908

P907

VC C

ZD910

R960

D914

R970

IC_12V

11

C2

IC905

R979

R983

ZD915

J912

AM P_VC C

C959

J917

J916

J915

9E210

E1

8

CE

C975

R980

J911J910

CE

Q908

B

C939

R986

C979

R918R916 R917 R919

Q903

B

C953

ZD907

C930

C974

D925

R931

R995

R997

J913

R982

CN905

1

30V

2

3

4

HEAT 2

CN907

1

2

Q919

B

R999

EC

R977

+12V

SG ND

SG ND

+5V

+5V

SG ND

J914

-12V

ON/OFF

BK 3.3V

C973

C954

+12V

SG ND

BK 3.3V

-27V

SG ND

TO CO NT ROL

R998

1

2

3

4

5

6

7

8

9

1

2

3

4

5

AM P_VC C

D902

CN903

CN904

A

B

TO MAIN BOAR D

C

J904

J903

C952

7

C905

R910

1M

330U

C921

C920

330U

R912

R02-220

R909

1M

R908

C904

1M

R907

1M

C990

R949

R941

D931 D930

!

Q913

G

D906

R932

ZD904

!

Q912

G

D905

R942

ZD903

C944

DS

R944

DS

R943

C943

R951

C945

R921

R939

!

C938

J905

R940

C940

J909

3

NC

D918

C977

4

IC901

2

Vc c

Dri ve

R935

5

ST AR TUP

7

FM

GN D

8

J906

J907

J908

6

OC P

PB OL P

1

R915

C922

R936

R933

C978

D903

IC902_4

HV

G

R920

ZD902

C942

D904

GT 903

DS

!

Q909

R930

!

4

3

IC902

!

T903

10

11

6

C946

2

4

3

5

4

T902

5

1

2

8

9

C950

12

13

6

10

C908

C936

C907

!

!

R937

C934

1

2

6

5

4

2

1

T901

R928

C926

3

R924

R927

C923

12V

12

C932

11

10

C933

8

9

5V

13

-27

C935

14

R929

2

IC904

R922

C949

D924

1

3

R945

L907

6

3

C951

D907

5

1

4

B

Q911

CE

CE

Q910

B

D908

D921

C963

D920

R938

C948

923

D

1

3

C947

C941

D919 L906

R962

C924

1

2

C925

R 981

C960

D922

C956

R955

R954

Q918

EC

C972

B

2

D910

R991

R963

R965

C955

C927

C965

D909

L905

L904

R987

C962

R989

C984

R 988

C969

C961

C976

L908

R971

R966

1

3

R967

IC903

C970

C931

IN

CE

ON /OFF

43

C971

12

C958

R973

R972

C967

Q901

C929

R956

C928

Q906

DS

R925

EC

R947

Q904

B

OU T

NC

GN D

2

R976

R974

C968

R926

CE

G

G

R992

5

4

P906

P905

C957

R975

R953

ZD913

ZD905

D916

R968

C966

R964

DS

Q915

Q914

CE

B

R957

B

R948

CE

Q907

B

R950

CE

BK 3.3V

C983

Pin4

Pin4

C991

R984

B

Q917

R990

D913

D901

D915

1

14

15

EA(-)

EA(+ )

EA(+ )

VE RF

EA(-)2COM/IN3D/C4C-T5R- T6GN D7C1

16

R961

C964

B

R959

R958

R923

Q902

A

EC

R993

R994

123

Page 27

PCB LAYOUT - TOP VIEW

BD901 B1

C901 B2

C902 B2

C915 A1

C917 A1

C918 A1

C919 A1

C920 B1

C921 B1

C922 A2

C923 A2

C926 A3

C938 A2

C940 A2

C952 B1

C960 A3

C961 A3

C962 A3

C963 A3

C965 A3

C966 A3

C968 B3

C969 B3

C970 B3

C971 B3

7 - 3 7 - 3

C973 A3

C974 A3

C976 A3

C978 A2

C979 A3

C982 A2

C990 A2

CN901 A1

CN902 B1

CN903 A3

CN904 A3

CN905 B3

CN907 A3

D902 B3

D904 A2

D907 B2

D908 A2

D918 A2

D919 A3

D920 A3

D922 A3

D924 B3

D925 A3

D930 A2

D931 A2

F901 A1

GT902 A1

GT903 A2

IC904 A2

IC905 B3

J902 A1

J903 B1

J904 B1

J905 A1

J906 A2

J907 A2

J908 A2

J909 A2

J910 A3

J911 A3

J912 A3

J913 A3

J914 A3

J915 B3

J916 A2

J917 B3

J918 A3

J919 B3

L901 A1

L902 B1

L904 A3

L905 A3

L906 A3

L907 B3

L908 B3

NTC901 A1

Q903 A3

Q907 A3

Q908 A3

Q909 A2

Q910 A2

Q911 B2

Q912 A2

Q913 B2

R902 B2

R912 B1

R921 B2

R929 A3

R930 A2

R939 A2

R940 A2

R941 A2

R943 A2

R944 B2

R945 B2

R949 B2

R966 A2

R967 B2

R973 B3

R980 A3

R981 A3

R983 A3

R991 A3

T901 A2

T902 B2

T903 B2

TVR901 A1

TVR902 B1

TVR903 B1

123

A

A

B

B

123

Page 28

PCB LAYOUT - BOTTOM VIEW

C903 A1

C904 B1

C905 B1

C913 A3

C924 A2

C925 A3

C927 A3

C928 A3

C929 A3

C930 A3

C931 A3

C936 B2

C939 A3

C941 A3

C943 A2

C944 B2

C946 B2

C947 A3

C948 A3

C949 B3

C950 B2

C951 B2

C953 A3

C954 A3

C955 A3

C956 A3

C957 B3

C958 B3

C964 B3

C967 B3

C972 B3

C975 B3

C977 A2

C980 A3

C981 A3

C984 A3

7 - 4 7 - 4

C991 A3

C992 A3

C993 A3

C994 B1

D903 A1

D905 A2

D906 B2

D909 B3

D910 B3

D912 B3

D913 A3

D914 B3

D915 A3

D916 B3

IC901 A2

IC902 A2

IC903 A3

Q901 A3

Q902 A3

Q904 A3

Q906 A3

Q914 A3

Q915 A3

Q917 A3

Q918 A3

Q919 A3

R901 A1

R902 A1

R903 A1

R904 A1

R905 A1

R906 A1

R907 B1

R908 B1

R909 B1

R910 B1

R911 A3

R915 A2

R916 B3

R917 B3

R918 B3

R919 B3

R920 A2

R922 A2

R923 A3

R924 A2

R925 A3

R926 B3

R927 A2

R928 A2

R932 B2

R933 A2

R935 A2

R936 A2

R937 A2

R938 A3

R942 A2

R947 A3

R948 A3

R950 A3

R953 B3

R954 A3

R955 A3

R956 A3

R957 A3

R958 A3

R959 A3

R960 B3

R961 B3

R962 A3

R963 B2

R964 A3

R965 A2

R968 B3

R969 B3

R970 B3

R971 B3

R972 B3

123

R974 B3

R975 A3

R976 B3

R977 A3

R979 B3

R982 A3

R984 A3

R985 A3

R986 A3

R987 A3

R988 A3

R989 A3

R990 A3

R992 A3

R993 A3

R994 A3

R995 A3

R996 A3

R997 A3

R998 A3

R999 A3

ZD902 A2

ZD903 A2

ZD904 B2

ZD905 B3

ZD907 A3

ZD908 B3

ZD909 B3

ZD910 B3

ZD913 B3

ZD915 A3

A

A

B

B

123

Page 29

8 - 1 8 - 1

AMP BOARD

INTERNAL IC DIAGRAM - TA5508APAG

WS`QMM

BWEE`QMM

BWTT`QMM

BWEE`SFG

WCHBQ

WSB`QMM

WSE`QMM

EWEE

EWTT

BWEE

BWTT

Qpxfs!Tvqqmz

!!Ejhjubm!Bvejp!Qspdfttps

1

Tpgu

!!!!!!8

Efu

Cjrvbet

1

!!!!!!8

Efu

Cjrvbet

1

!!!!!!8

Cjrvbet

Efu

1

!!!!!!8

Cjrvbet

Efu

1

!!!!!!8

Efu

Cjrvbet

1

!!!!!!8

Efu

Cjrvbet

9!y!9!Dspttcbs!Njyfs

1

!!!!!!8

Efu

Cjrvbet

1

!!!!!!8

Efu

Cjrvbet

:

Upo f

Tpgu

Upo f

Tpgu

Upo f

Tpgu

Upo f

Tpgu

Upo f

Tpgu

Upo f

Tpgu

Upo f

Tpgu

Upo f

99 5

Wpmvnf

Dpouspm

Tpgu

Wpm

Tpgu

Wpm

Tpgu

Wpm

Tpgu

Wpm

Tpgu

Wpm

Tpgu

Wpm

Tpgu

Wpm

Tpgu

Wpm

9

Mpve

Dpnq

Mpve

Dpnq

Mpve

Dpnq

Mpve

Dpnq

Mpve

Dpnq

Mpve

Dpnq

Mpve

Dpnq

Mpve

Dpnq

ESD

ESD

ESD

ESD

ESD

ESD

ESD

ESD

3

3

YUM`!PVU

!YUM`!JO

QMM`GMUN

QMM`GMUQ

PTD!DBQ

MSDML

IQ`TFM

CLOE`FSS

NDML

TDML