Philips HTS5110, HTS5110/12, HTS5110/51, HTS5110/98 Service Manual

Published by KC-LQ 1004 AVM Printed in he Netherlands

HTS5110/12/51/98

Subject to modification EN 3139 785 35230

Home Theater System

Contents

Page

Contents

Page

©

Copyright 2010 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Version 1.0

2 Importand Safety Precautions ......................... 2-1 to 2-2

3 Safety Check After Servicing ..................................... 3-1

4 Safety Information Genard Notes & Lead Free

5 Standard Notes For Servicing ................................... 5-1

6 Special Information of BGA IC & Flat

7 Direction of USE ............................................. 7-1 to 7-5

1 Technical Specification and Connection Facilities

8 Cabinet Disassembly Instructions ................... 8-1 to 8-3

9 Troubleshooting ......................................................... 9-1

10 Software Upgrading Procedure ............................. 10-1

11 Software Version Check Procedure ...................... 10-2

12 Block Diagram ....................................................... 11-1

13 Wiring Diagram ..................................................... 12-1

14 Main Unit--Touch Board Diagram

Circuit Diagram ............................................13-1

Layout Diagram ...........................................13-1

15 Main Unit--VFD Display Board Diagram

Circuit Diagram ............................................14-1

PT6311 IC Specification ..............................14-2

Layout Diagram ...........................................14-3

16 Main Unit--Decoder Board Diagram

Circuit Diagram ...............................15-1 to 15-3

Circuit Diagram ...............................15-6 to 15-9

EN29LV320A IC Specification ....................15-5

UDA1355H IC Specification .....................15-10

Layout Diagram ........................................15-11

M12L64164A IC Specification ....................15-4

17 Main Unit--Radio Transmit Board Diagram

Circuit Diagram ................................16-1 to 16-3

Layout Diagram ...........................................16-4

20 Main Unit Exploded View ...................................... 19-1

18 Subwoofer--Radio Receiver Board Diagram

Circuit Diagram ................................17-1 to 17-3

Layout Diagram ...........................................17-4

19 Subwoofer--Power Board Diagram

Circuit Diagram ................................18-1 to 18-2

Layout Diagram ...........................................18-3

21 Subwoofer Exploded View .................................... 19-2

22 Revision List .......................................................... 20-1

Features

RDS

Voltage Selector

ECO Standby

DTS

Feature

Different

/12

/51 /98

Pack-IC.................................... 6-1 to 6-3

Requirement ....................................... 4-1

................................................ 1-1 to 1-2

Technical Specifications and Connection Facilities

1. Technical Specifications and Connection Facilities

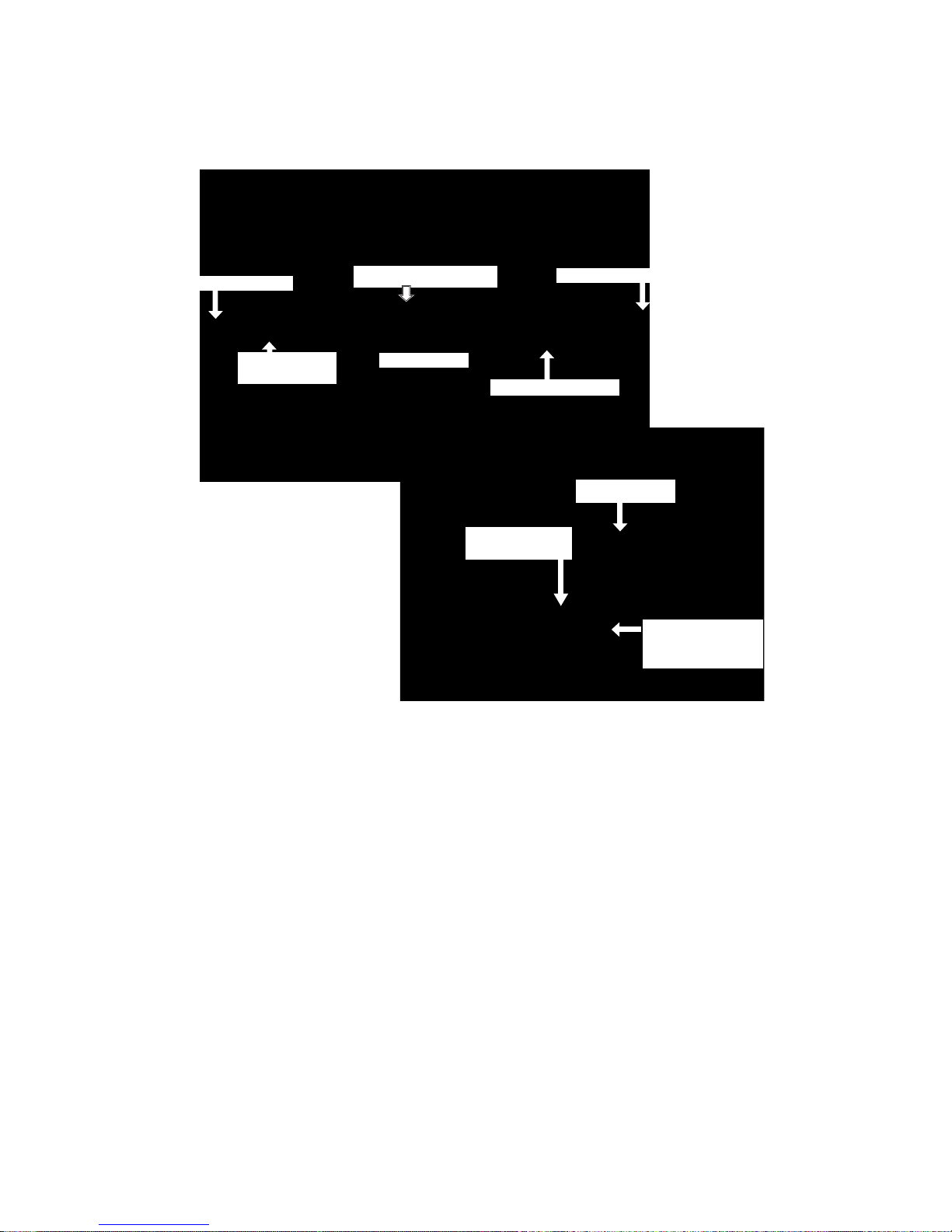

1.1 PCB Locations

Main Unit

Subwoofer

1.2 General:

Power supply : 100-240V, ~50 Hz

Power consumption : 35 W

Standby power consumption : < 1 W

1.4 Analog Inputs/Outputs

1.4.1 MP3 LINK IN of Cinch connector to be used for

measurements(direct input from Front end)

MP3 LINK Performance:

Frequency Response : -1 ± 3dB (150 to 20KHz)

Input and output voltages : 500 mV / 20 kOhm

1.3 Radio

Tuning Frequency Range : 87.5 MHz – 108 MHz

Antenna Level for 40dB luminance

S/N (video unweighted) at 75Ω : ≤ 71dBμV (High End)

≤ 50dBμV (Low End)

Automatic Search Tuning:

Scanning time auto search without

RF Signal : < 2.5 min.

(Typical 3 minutes)

Stop level (vision carrier) : ≥ 31dBμV

Maximum tuning error during

operation (drift) : ≤ 50kHz

Maximum tuning error of a recalled

program : ± 22.5 kHz

Tuning Principles:

Automatic system recognition

Decoder Board

VFD Display Board

USB Board

Touch Board-2

Touch Board-1

Radio Transmit

Board

1-1

Power Board

Power Control

Switch 110/220V

(for 55/98version)

Radio Receiver

Board

1.4.2 Video Rear output Connector

CVBS output:

DC Level : 0V+1V

Amplitude output: : 1.04V

Technical Specifications and Connection Facilities

1-2

1.6 Dimension and Weight

1.5 (AUDIO OUT) Coaxial Digital

LPCM : according IEC 60958

MPEG 1, MPEG 2, AC3 : according IEC 61937

DTS : according IEC 61937 +

addendum

1.5.1 USB

Compatibility : USB 2.0

Type of connector : Series A Connector

1.5.2 HDMI Output

Set Dimension W x H x D : 790.6 x 100.3 x 50mm

Net Weight : 1.5kg

Subwoofer Dimension W x H x D : 182 x 365 x 306mm

Net Weight : 6kg

Compatibility : HDMI version 1.3

Type of connector : Type A connector

(19 pins)

1.7 Video Performance

1.7.1 SNR

PAL

RGB CVBS Y/C

≥ 55 dB Lumincance: ≥ 55 dB

Chroma: ≥ 55 dB (AM)

≥ 52 dB (PM)

Y: ≥ 57 dB

C: ≥ 57 dB (AM)

≥ 54 dB (PM)

NTSC

Y Pb Pr CVBS Y/C

≥ 55 dB Lumincance: ≥ 55 dB

Chroma: ≥ 54 dB (AM)

≥ 54 dB (PM)

Y: ≥ 55 dB

C: ≥ 54 dB (AM)

≥ 54 dB (PM)

1.7.2 Bandwidth

PAL

RGB CVBS Y/C

0.5 to 4 MHz:+1dB/

-2dB

0.5 to 4 MHz:+1dB/

-2dB

Y:4.8MHz-3dB

4.8 MHz:-3dB 4.8 MHz:-3dB C:700 kHz

5.8 MHz:-6dB 5.8 MHz:-6dB

NTSC

YPbPr CVBS Y/C

4.2 MHz:-3dB 4.2 MHz:-3dB Y:4.2MHz-3dB

5.8 MHz:-6dB 5.8 MHz:-6dB C:≥ 700 kHz

With Pscan:

8.4MHz -3dB

Electronics N.V. bears no responsibility

for improper wall mounting that results in

accident, injury or damage.

For speakers with stands, use only the

supplied stands. Secure the stands to

the speakers tightly. Place the assembled

stands on flat, level surfaces that can

support the combined weight of the

speaker and stand.

Never place the product or any objects

on power cords or on other electrical

equipment.

If the product is transported in

temperatures below 5°C, unpack the

product and wait until its temperature

matches room temperature before

connecting it to the power outlet.

Visible and invisible laser radiation when

open. Avoid exposure to beam.

Do not touch the disc optical lens inside

the disc compartment.

Risk of overheating!

Never install this product in a confined

space. Always leave a space of at least

four inches around the product for

ventilation. Ensure curtains or other

objects never cover the ventilation slots

on the product.

Risk of contamination!

Do not mix batteries (old and new or

carbon and alkaline, etc.).

Remove batteries if they are exhausted

or if the remote control is not to be used

for a long time.

Batteries contain chemical substances,

they should be disposed of properly.

Product care

Do not insert any objects other than discs

into the disc compartment.

Do not insert warped or cracked discs

into the disc compartment.

Remove discs from the disc compartment

if you are not using the product for an

extended period of time.

•

•

•

•

•

•

•

•

•

•

•

•

Only use microfiber cloth to clean the

product.

•

Important

Important Safety Precautions

Read and understand all instructions before you use

your home theater. If damage is caused by failure to

follow instructions, the warranty does not apply.

Safety

Risk of electric shock or fire!

Never expose the product and

accessories to rain or water. Never place

liquid containers, such as vases, near the

product. If liquids are spilt on or into the

product, disconnect it from the power

outlet immediately. Contact Philips

Consumer Care to have the product

checked before use.

Never place the product and accessories

near naked flames or other heat sources,

including direct sunlight.

Never insert objects into the ventilation

slots or other openings on the product.

Where the mains plug or an appliance

coupler is used as the disconnect device,

the disconnect device shall remain readily

operable.

Disconnect the product from the power

outlet before lightning storms.

When you disconnect the power cord,

always pull the plug, never the cable.

Risk of short circuit or fire!

Before you connect the product to the

power outlet, ensure that the power

voltage matches the value printed on the

back or bottom of the product. Never

connect the product to the power outlet

if the voltage is different.

Risk of injury or damage to the home theater!

For wall-mountable products, use only

the supplied wall mount bracket. Secure

the wall mount to a wall that can support

the combined weight of the product

and the wall mount. Koninklijke Philips

•

•

•

•

•

•

•

•

2-1

Disposal of your old product and

batteries

Your product is designed and manufactured

with high quality materials and components,

which can be recycled and reused.

When this crossed-out wheeled bin symbol

is attached to a product it means that the

product is covered by the European Directive

2002/96/EC. Please inform yourself about the

local separate collection system for electrical

and electronic products.

Please act according to your local rules and

do not dispose of your old products with your

normal household waste.

Correct disposal of your old product helps to

prevent potential negative consequences for

the environment and human health.

Your product contains batteries covered by

the European Directive 2006/66/EC, which

cannot be disposed with normal household

waste.

Please inform yourself about the local rules

on separate collection of batteries because

correct disposal helps to prevent negative

consequences for the environmental and

human health.

Important Safety Precautions

2-2

3-1

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts, and

wires have been returned to their original positions. Afterwards, do the following tests and confirm the specified

values to verify compliance with safety standards.

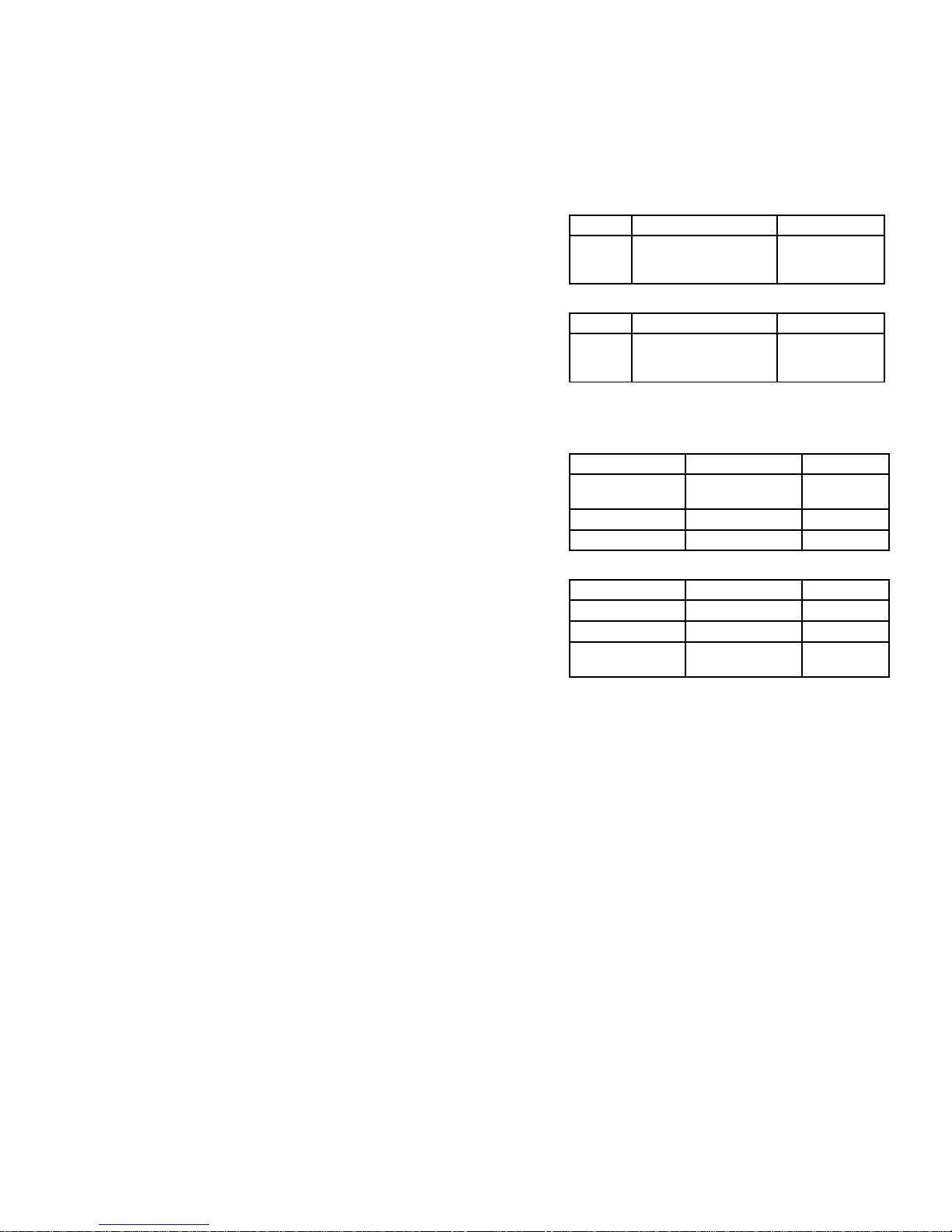

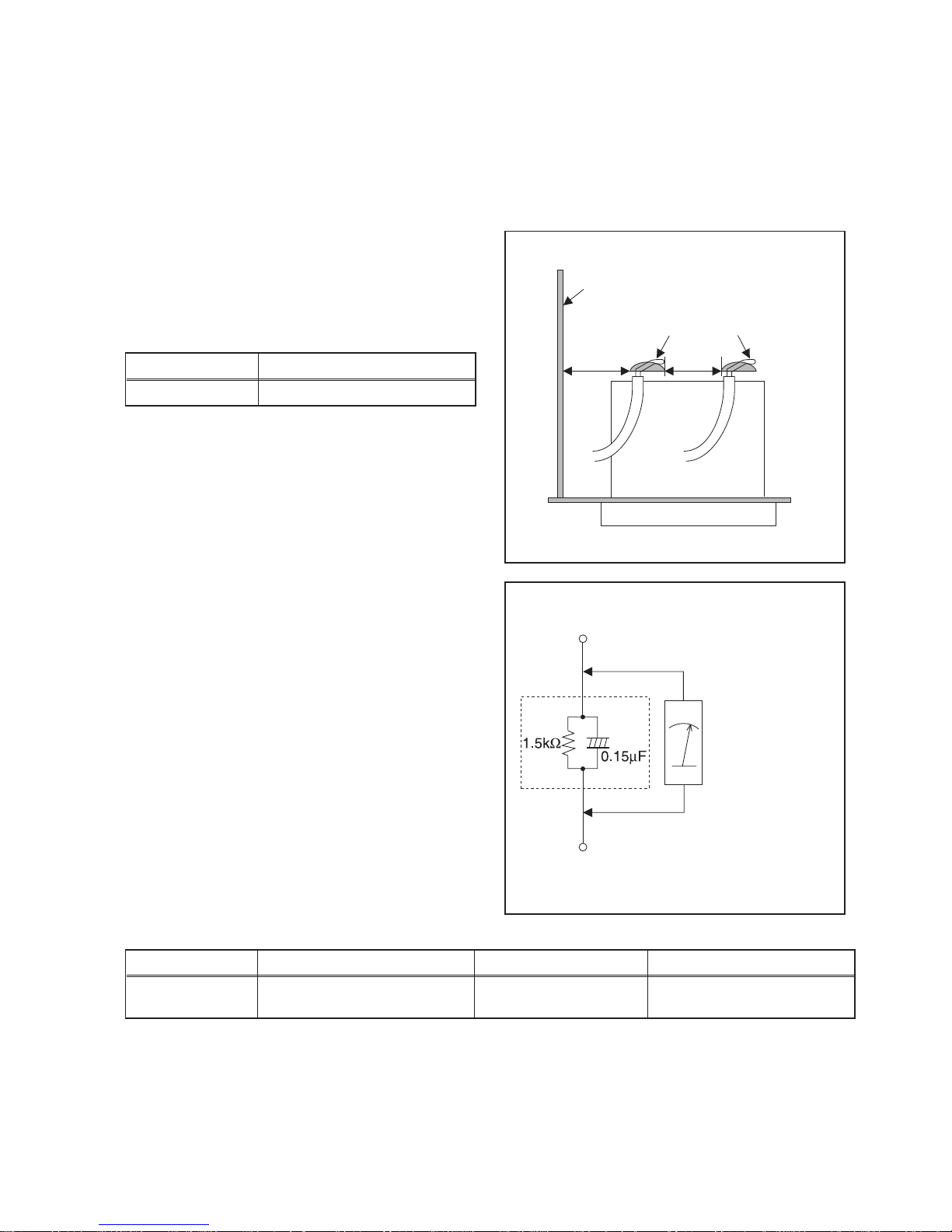

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method (Power ON):

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across the terminals of load Z.

See Fig. 2 and the following table.

Table 2: Leakage current ratings for selected areas

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

AC Line Voltage Clearance Distance (d), (d’)

110V~220V ≥ 3.2 mm (0.126 inches)

AC Line Voltage Load Z Leakage Current (i) Earth Ground (B) to:

110V~220V

0.15 µF CAP. & 1.5 kΩ RES.

Connected in parallel

i ≤ 0.5 mA Peak Exposed accessible parts

Chassis or Secondary Conductor

Primary Circuit

Fig. 1

d' d

AC Voltmeter

(High Impedance)

Exposed Accessible Part

B

Earth Ground

Power Cord Plug Prongs

Z

Fig. 2

1 Safety Instructions

1.1 General Safety

Safety regulations require that during a repair:

• Connect the unit to the mains via an isolation transformer.

• Replace safety components, indicated by the symbol

,

only by components identical to the original ones. Any

other component substitution (other than original type)

may increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

• Route the wires/cables correctly, and fix them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the electrical DC resistance between the mains

plug and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the ‘on’ position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains

plug and the front panel, controls, and chassis

bottom.

4. Repair or correct unit when the resistance

measurement is less than 1 MΩ.

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

2 Warnings

2.1 General

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD,

). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are at the same potential as the mass

of the set by a wristband with resistance. Keep

components and tools at this same potential.

Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable)

4822 310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the live voltage

section. The primary side of the power supply, including

the heatsink, carries live mains voltage when you

connect the player to the mains (even when the

player is ‘off’!). It is possible to touch copper tracks and/

or components in this unshielded primary area, when

you service the player. Service personnel must take

precautions to prevent touching this area or components

in this area. A ‘lightning stroke’ and a stripe-marked

printing on the printed wiring board, indicate the primary

side of the power supply.

• Never replace modules, or components, while the unit is

‘on’.

Safety Information, General Notes & Lead Free Requirements

4-1

5-1

Standard Notes for Servicing

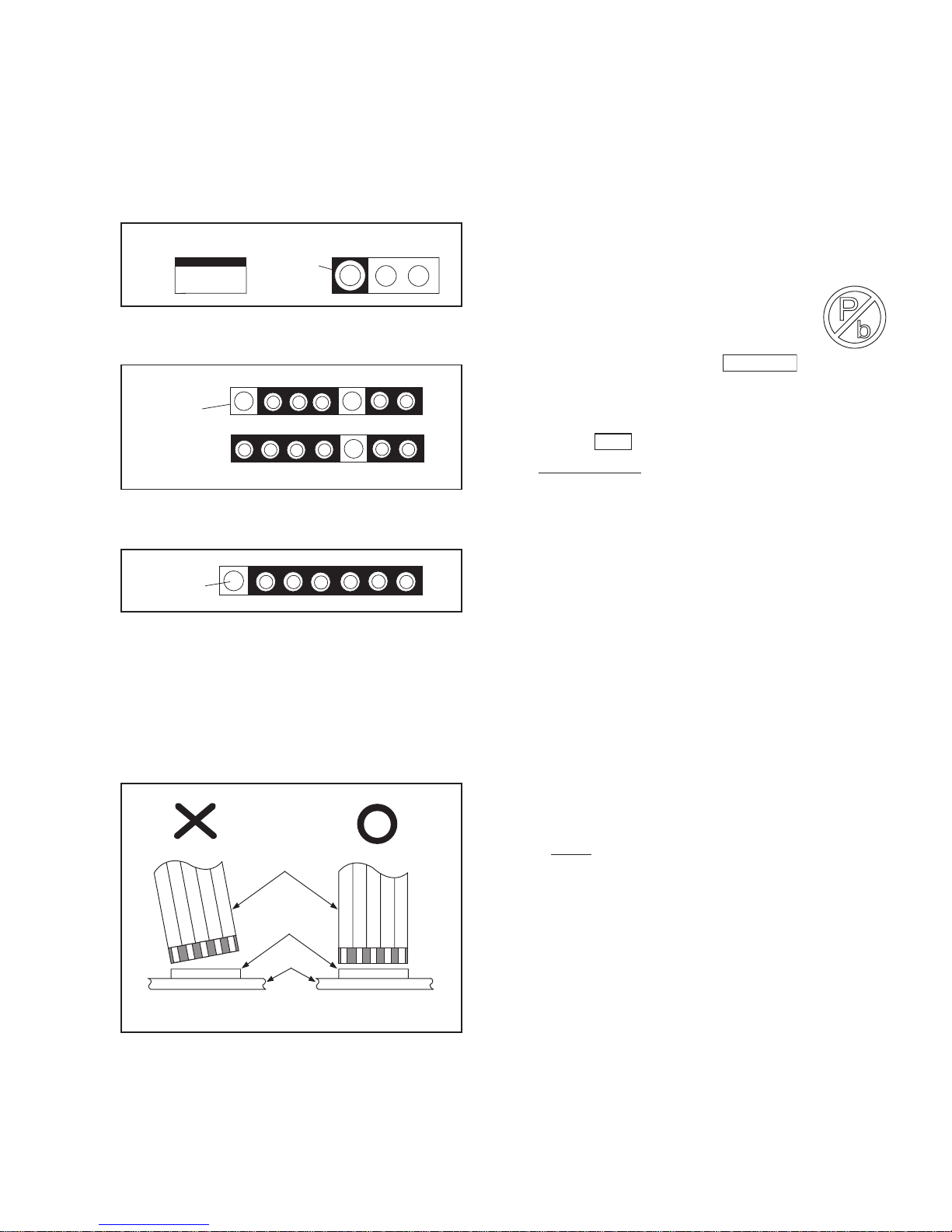

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

3. The 1st pin of every male connector is indicated as

shown.

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

Information about lead-free soldering

Philips CE is producing lead-free sets from 1.1.2005

onwards.

IDENTIFICATION

Regardless of special logo (not always

indicated)

One must treat all sets from

onwards, according to the next rule:

Serial Number gives a 14-digit. Digit 5&6 shows the

YEAR, and digit 7&8 shows the WEEK.

So from onwards=from 1 Jan 2005 onwards

Important note : In fact also products of year 2004

must be treated in this way as long as you avoid

mixing solder-alloys (leaded/ lead-free). So best to

always use SAC305 and the higher temperatures

belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solderpaste is required, please contact the manufacturer

of your solder-equipment. In general use of solderpaste within workshops should be avoided because

paste is not easy to store and to handle.

• Use only adequate solder tools applicable for leadfree solder alloy. The solder tool must be able

• To reach at least a solder-temperature of 400°C,

• To stabilize the adjusted temperature at the solder-

tip

• To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around

360°C

- 380°C is reached and stabilized at the

solder joint. Heating-time of the solder-joint should

not exceed ~ 4 sec. Avoid temperatures above

400°C otherwise wear-out of tips will rise drastically

and flux-fluid will be destroyed. To avoid wear-out of

tips switch off un-used equipment, or reduce heat.

• Mix of lead-free solder alloy / parts with leaded

solder alloy / parts is possible but PHILIPS

recommends strongly to avoid mixed solder alloy

types (leaded and lead-free).

If one cannot avoid or does not know whether

product is lead-free, clean carefully the solder-joint

from old solder alloy and re-solder with new solder

alloy (SAC305).

• Use only original spare-parts listed in the ServiceManuals. Not listed standard-material (commodities)

has to be purchased at external companies.

Top View

Out

In

Bottom View

Input

5

10

Pin 1

Pin 1

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

1 Jan 2005

0501

6-1

•

Special information for BGA-ICs:

- always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for desoldering always use the lead-free temperature

profile, in case of doubt)

- lead free BGA-ICs will be delivered in so-called

'dry-packaging' (sealed pack including a silica gel

pack) to protect the IC against moisture. After

opening, dependent of MSL-level seen on indicatorlabel in the bag, the BGA-IC possibly still has to be

baked dry. (MSL=Moisture Sensitivity Level). This

will be communicated via AYS-website.

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products

of 2004), containing leaded solder-alloy and

components, all needed spare-parts will be available

till the end of the service-period. For repair of such

sets nothing changes.

• On our website

www.atyourservice.ce.Philips.com

you find more

information to:

• BGA-de-/soldering (+ baking instructions)

• Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical information within

the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

How to Remove / Install Flat Pack-IC

Special Information of BGA IC & Flat Pack-IC

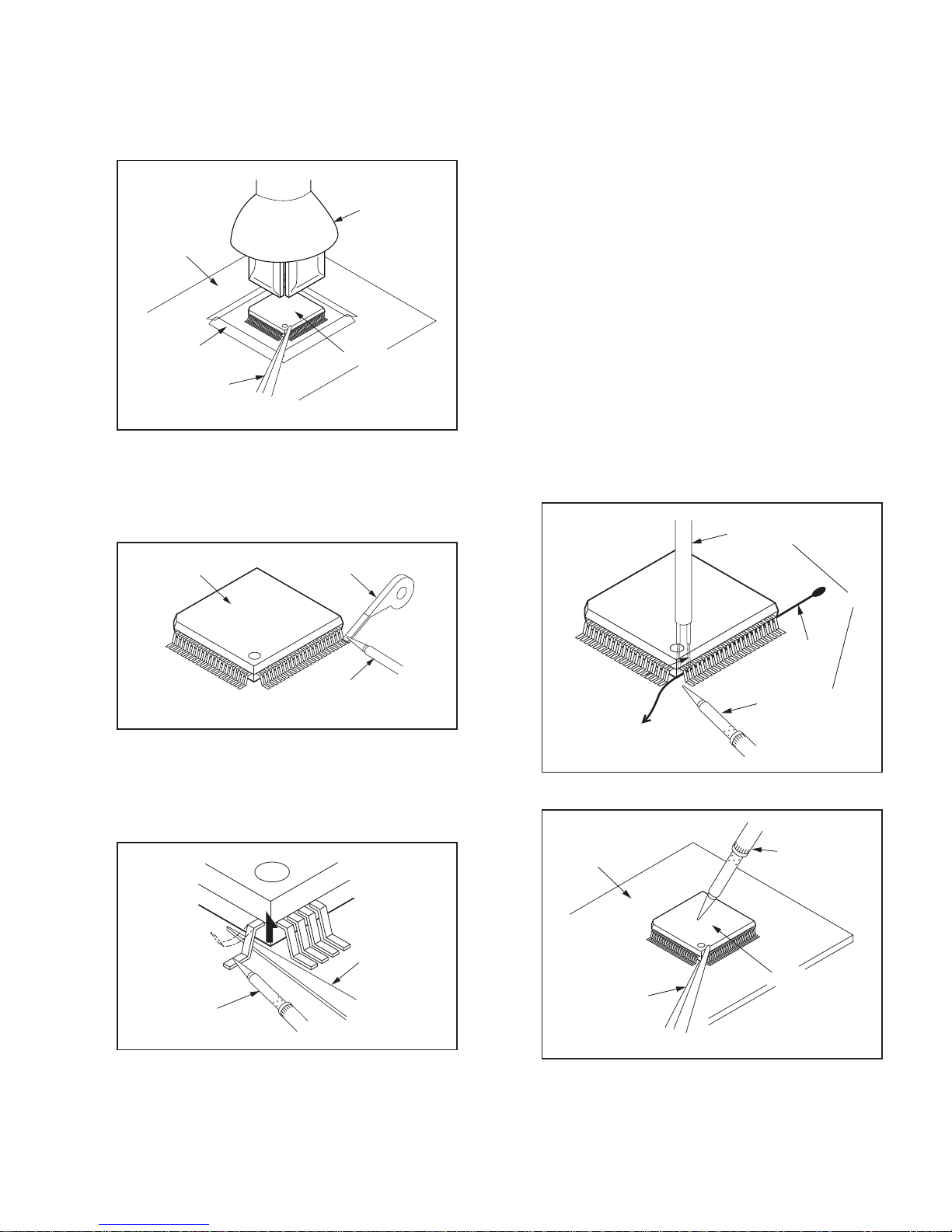

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

Fig. S-1-1

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

Hot-air

Flat Pack-IC

Desoldering

Machine

CBA

Flat Pack-IC

Tweezers

Masking

Tape

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

Fine Tip

Soldering Iron

Sharp

Pin

Fig. S-1-4

To Solid

Mounting Point

Soldering Iron

Iron Wire

or

Hot Air Blower

Fig. S-1-5

Fine Tip

Soldering Iron

CBA

Flat Pack-IC

Tweezers

Fig. S-1-6

6-2

6-3

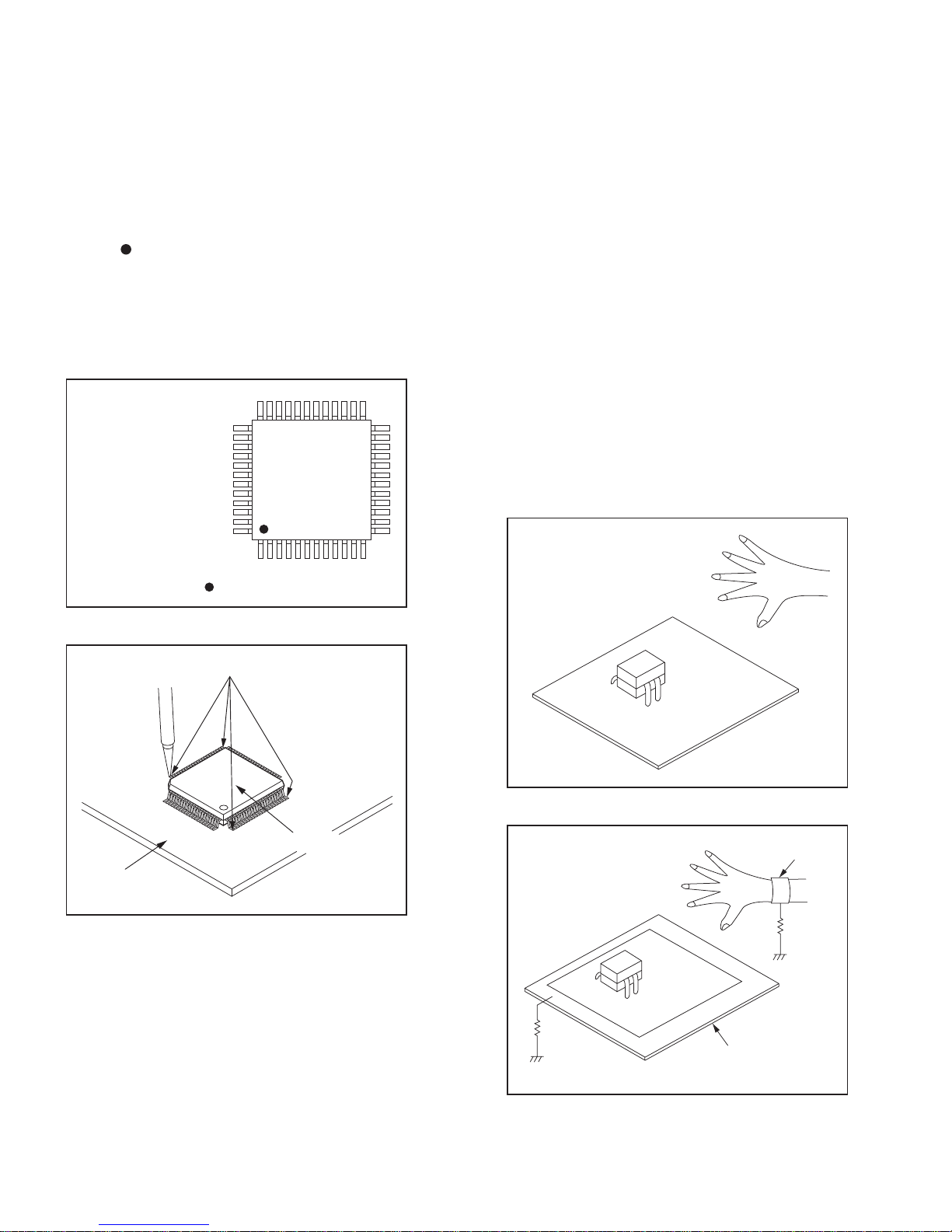

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “

” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

presolder the four corners of the flat pack-IC. (See

Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Instructions for Handling Semi-

Special Information BGA IC & Flat Pack-IC

conductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

Presolder

CBA

Flat Pack-IC

Fig. S-1-8

<Incorrect>

CBA

Grounding Band

Conductive Sheet or

Copper Plate

1MΩ

1MΩ

<Correct>

CBA

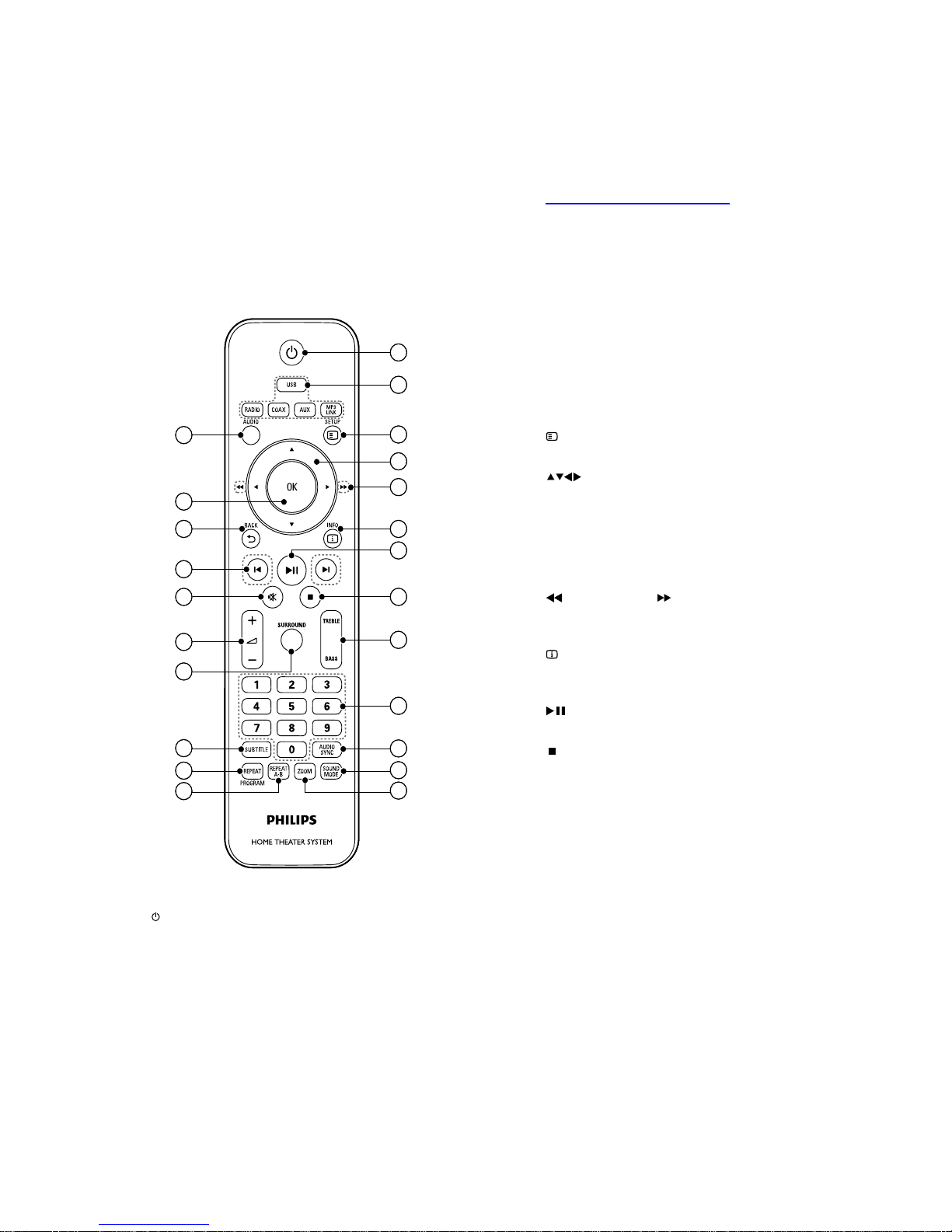

RADIO: Switches to FM radio.

COAX: Switches to coaxial digital

input source.

AUX: Switches to auxiliary input

source.

MP3 LINK: Switches to MP3 Link

input source.

c

SETUP

Accesses or exits the setup menu.

d

(Navigation buttons)

Navigate menus.

In video mode, press left or right to

fast backward or fast forward.

In radio mode, press left or right to

search a radio station; press up or

down to fine tune a radio frequency.

e

(Fast Backward) (Fast Forward)

Fast backwards or fast forwards. Press

repeatedly to change the search speed.

f

INFO

Displays information about what is

playing.

g

(Play/Pause)

Starts, pauses or resumes playback.

h

(Stop)

Stops playback.

In radio mode, erases the current

preset radio station.

i TREBLE / BASS

Changes treble or bass. Use with +/-.

j Numeric buttons

Selects an item to play.

k AUDIO SYNC

Press and hold to access the setting for

audio sync, then press +/- to set the

audio delay time.

l SOUND MODE

Selects a predefined sound effect.

m ZOOM

Zooms into a video scene or picture.

n REPEAT A-B

•

•

•

•

•

•

•

•

•

a

(Standby-On)

Switches the home theater on or to

standby.

When EasyLink is enabled, press

and hold for at least three seconds

to switch all connected HDMI CEC

compliant devices to standby.

b Audio Source

USB: Switches to USB storage

device.

•

•

•

19

18

17

16

15

1

2

3

5

4

7

6

9

8

12

11

10

14

13

22

21

20

23

19

18

17

16

15

1

2

3

5

4

7

6

9

8

12

11

10

14

13

22

21

20

23

Direction of Use

*The following excerpt of the DFU/QSG serves as an introduction to the set.

The Complete Direction for Use can be download in different languages from

the internet site of Philips Customer care Center: www.p4c.philips.com

Remote Control

7-1

Marks two points within a chapter or

track for repeat play, or turns off repeat

mode.

o REPEAT / PROGRAM

Selects a repeat or shuffle mode.

In radio mode, programs radio

stations.

p SUBTITLE

Selects a subtitle language for video.

q SURROUND

Selects Dolby Virtual Speaker surround

sound.

r

+/-

Increases or decreases volume.

s

(Mute)

Mutes or restores volume.

t

/ (Previous/Next)

Skips to the previous or next track,

chapter or file.

u

BACK

Returns to a previous menu screen.

v OK

Confirms an entry or selection.

w AUDIO

Selects an audio language or channel.

•

•

Direction of Use

Remote Control

7-2

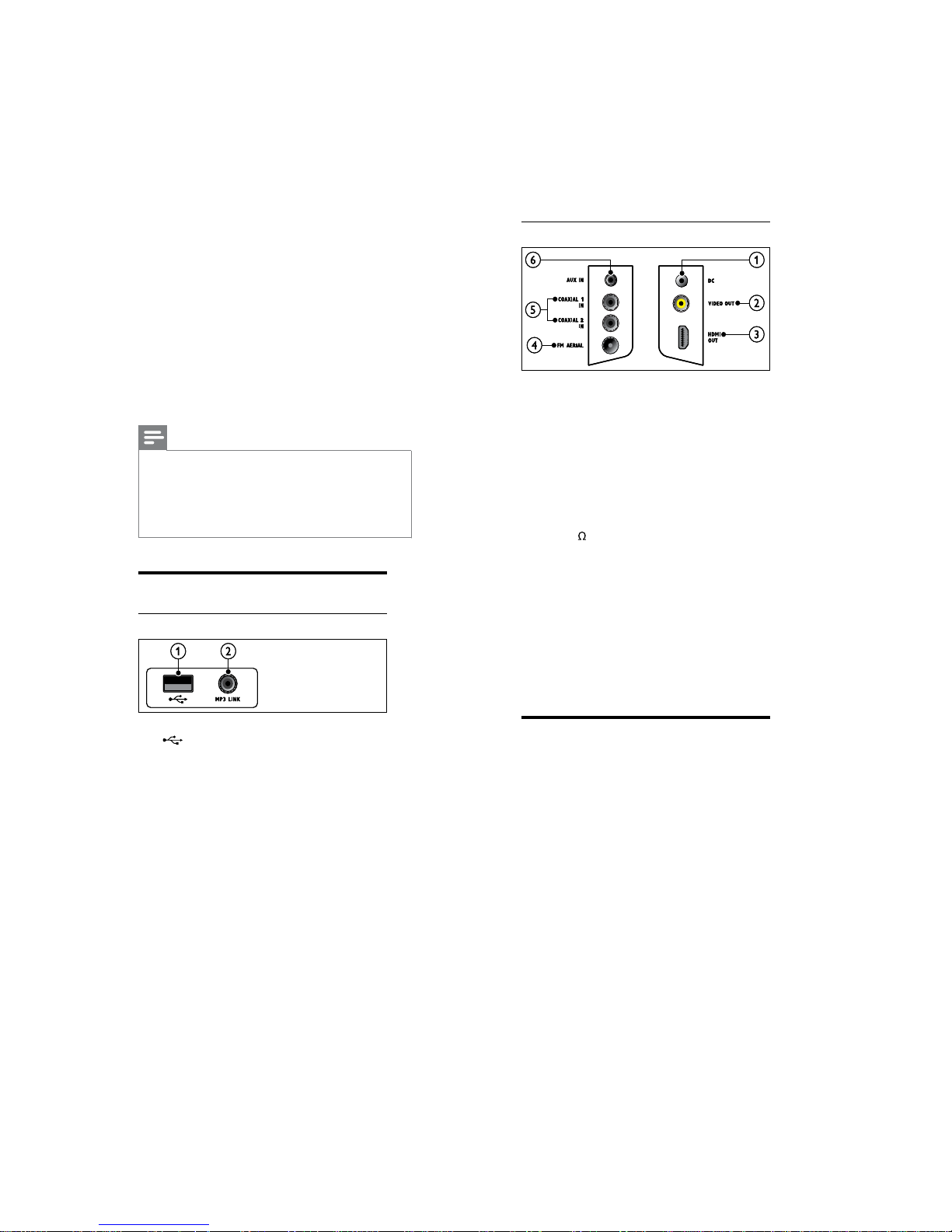

Back connectors

a DC IN

Connects to the AC-DC adapter.

b VIDEO OUT (CVBS)

Connects to the composite video input

on the TV.

c HDMI OUT

Connects to the HDMI input on the TV.

d FM75

Connects the FM antenna for radio

reception.

e DIGITAL IN-COAXIAL

Connects to the coaxial audio output on

the TV or a digital device.

f AUX IN

Connects to the analog audio output on the

TV or an analog device.

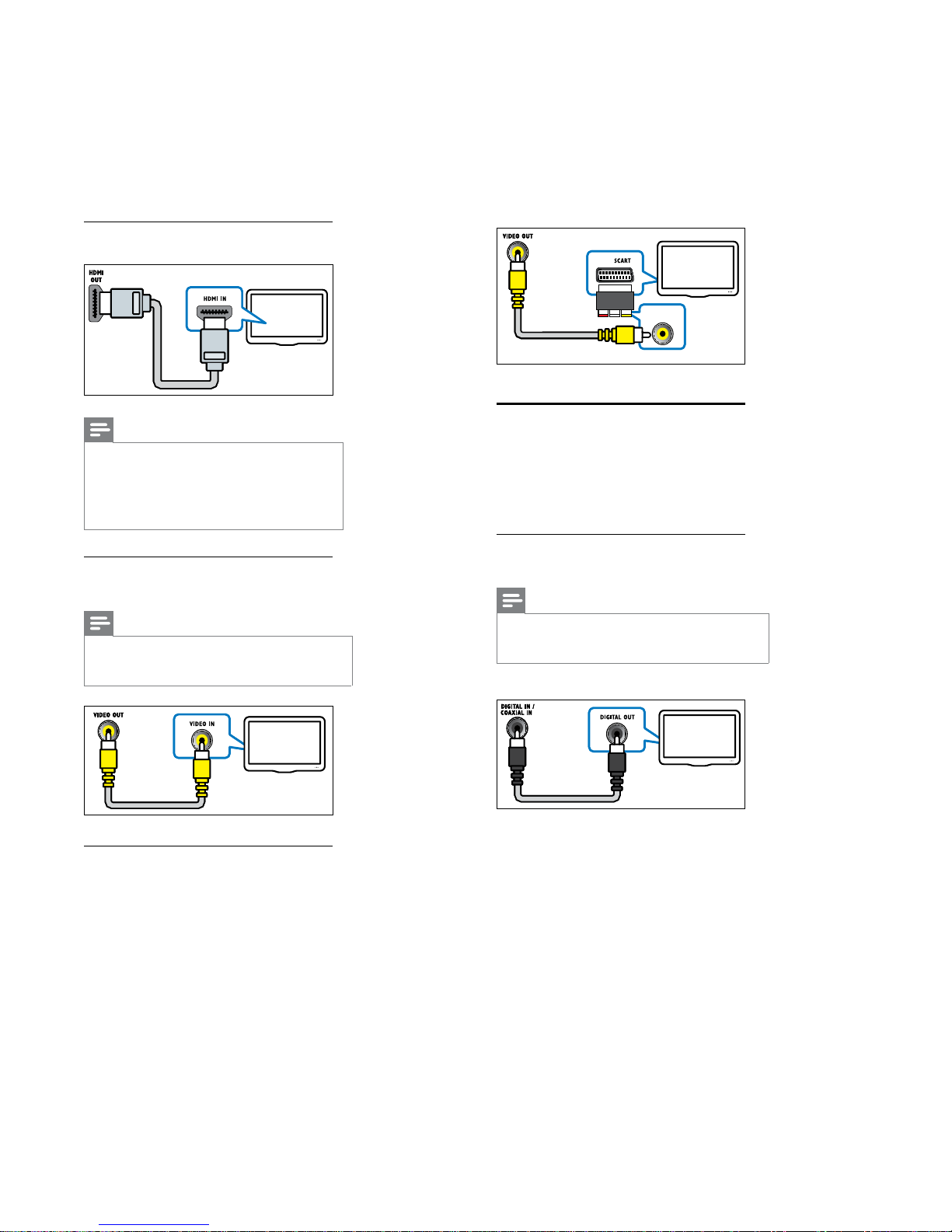

Connect to the TV

Connect your home theater directly to a TV

through one of the following connectors (from

highest to basic quality video):

a HDMI

b Composite video

c SCART

Connect your

Direction of Use

home theater

This section helps you connect your home

theater to a TV and other devices. The basic

connections of the home theater with its

accessories are provided in the Quick Start. For

a comprehensive interactive guide, see www.

connectivityguide.philips.com.

Note

Refer to the type plate at the back or bottom

of the product for identification and supply

ratings.

Before you make or change any connections,

ensure that all devices are disconnected from

the power outlet.

•

•

Connectors

Front connectors

a (USB)

Audio, video or picture input from a USB

storage device.

b MP3 LINK

Audio input from an MP3 player.

7-3

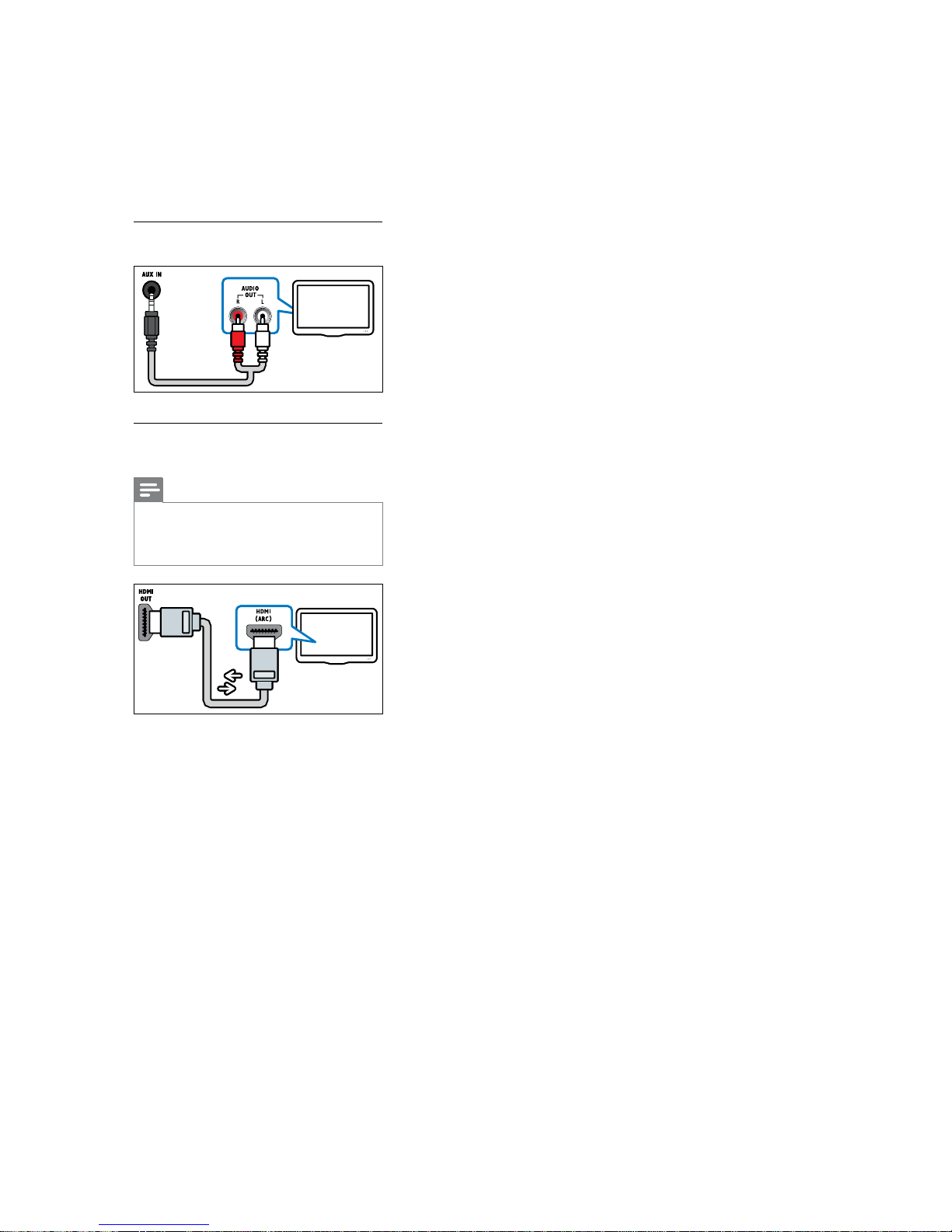

Connect audio from TV or

other devices

Use your home theater to play audio from

the TV or other devices such as a cable box.

Choose from the following connectors.

Option 1: Connect audio through a

digital coaxial cable

Note

The digital coaxial cable or connector might be

labeled COAXIAL DIGITAL OUT or SPDIF

OUT.

•

(Cable not supplied)

Option 1: Connect to the TV through

HDMI

Note

If the HDTV has a DVI connector, connect

using an HDMI/DVI adaptor.

If the TV supports EasyLink HDMI CEC,

control the home theater and TV with one

remote control (see ‘Use Philips EasyLink’ on

page 17).

•

•

Option 2: Connect to the TV through

composite video (CVBS)

Note

The composite video cable or connector might

be labeled AV IN,VIDEO IN,COMPOSITE or

BASEBAND.

•

Option 3: Connect to the TV through

SCART

Use the supplied scart adapter.

Direction of Use

7-4

Option 2: Connect audio through

analog audio cables

Option 3: Connect audio through an

HDMI cable

Note

The HDMI connector on the TV might be

labeled HDMI 1 or HDMI ARC.This feature

works with Audio Return Channel (ARC)

compatible devices only.

•

Direction of Use

7-5

Loading...

Loading...