Page 1

Service

Service

DVD Receiver

Service Manual

Service

Service

Service

HTS3410

D/55

©

Copyright 2005 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Published by KC-ET0409 Service Audio Printed in The Netherlands Subject to modification.

Version 1.0

TABLE OF CONTENTS

Page

Location of PC Boards................................................1-2

Versions Variation

Specifications..............................................................1-3

Measurement Setup ................................................... 1-4

Service Aids ................................................................1-5

ESD & Safety Instruction ............................................1-6

Information about lead-free soldering .........................1-7

Setting Procedure & Repair Instructions ....................... 2

Disassembly Instructions & Service positions .............. 3

Block & Wiring Diagram ................................................ 4

Control / Power Switch / Volume Board ........................ 5

Tuner Board ................................................................... 6

DVD loader .................................................................... 7

Main Board .................................................................... 8

Power Board .................................................................. 9

Exploded View ............................................................. 10

......................................................1-2

CLASS 1

LASER PRODUCT

GB

3139 785 31390

Page 2

2-1

2-1

System, Region code, Tuner, etc. setting procedure

1) System Reset

a) Press "SYSTEM" button on R/C. TV show "SETUP"

b) Select the menu using the "

c) Go feature setup page to do system reset

2) Region Code Change

After replacement / repair of the MPEG board, the customer

setting and the region code may lost. Changing the Region

code will put the player back in the state which it has left the

factory.

Region Code

1 USA

2EU

3AP

4 Australia, NZ, Latam

5 RUSSIA, INDIA

6 CHINA

TV System

1 NTSC

2PAL

3 AUTO

Menu/ Audio Subtitle (AS) Language

1 English

2 English

3 English

4 English

AFS

001 LX3000D/LX3500D /MRD200

002 MX3600D/MX3800

003 LX3700D/LX3750W

005 MRD210

006 MX3660D

008 FW-D550

010 MRD120/MX6050/HTS3400

" and " " button on R/C

Hence in total, reprograming will be done by way of the

remote control. It should run as below :-

a) Put the player in stop mode. No disc loaded.

b) Press the following key on remote control:

For HTS3400 /37 (US) :

<PLAY> <159> <111> <010> <08> <PLAY>

∗∗

∗ After the Region Code is changed it is necessary to reset

∗∗

the system so that the new Region Code will be fully

effective. All customer setting will be lost.

∗∗

∗ On top of the maximum number of times allowed for

∗∗

changing the region code is changed to 25.

∗∗

∗ When the counter reach 25, you will not be able to further

∗∗

change the code until you reset the timer by the Region

Code timer reset procedure

CAUTION !

This information is confidencial and may not

be distributed. Only a qualified service

person should reprogram the Region Code.

3) Region code change timer reset

Press below key to reset the timer :

a) In DISC source, stop mode and no disc in tray.

b) Press R/C "Play -159-PLAY" to reset timer to 25

4) Tuner area change

a) Press the "OPEN/CLOSE" button to open the set's door

b) Press "1" "5" "9" button by using R/C.

c) TV Show "TUNER AREA"

d) Select the tuner area you want by using the "

" " button on R/C, then press "OK" to confirm. TV show

" TUNER AREA CHANGED"

If you didn't press it in five seconds, the system will remain

original status.

AREA BAND FREQUENCY (Hz) STEP(Hz)

FM

87.5M 108M 50K

USA (37)

Note :Please refer to the above different tuner area.

531K 1602K 9K

AM

530K 1710K 10K

" and

5. Video Out Change

a) Press "SYSTEM" on R/C button

b) Select the menu using the " " and " " button on R/C

c) Go picture setup page select Video out item.

6. Password Change

a) Press "SYSTEM" on R/C button

b) Select the menu using the " " and " " button on R/C

c) Go feature setup page select "PASSWORD". TV show

"ENTER CODE".Press 4 times of "STOP" button on R/C.

d) Select "PARENTAL" "8 ADULT" on TV.

e) Enter PASSWORD to "1234".

∗∗

∗

"1234" is a default password supplied.

∗∗

7. Checking on the Software version

a) Open the CD door.

b) Press "123" and "OK" on the remote control.

c) TV will show the version on screen.

8. Upgrading new software

a) Open the door, then insert the CD-R program disc.

b) Close the door.

c) TV will show:-

.

"disc loading"

.

"bank30.rom"

.

"writing" about 6 seconds.

.

"Done"

oem derivative

08

.

region code = 1 digit

.

tv system = 1 digit

.

"as/menu lang" = 1 digit

.

"AFS" = "architechture Feature Set" = 3 digits

This field is used to define the architecture / features sets for

each product.

.

"oem derivative" = 2 digit

This field is use to define the OEM set. This will affect the

background display.

Page 3

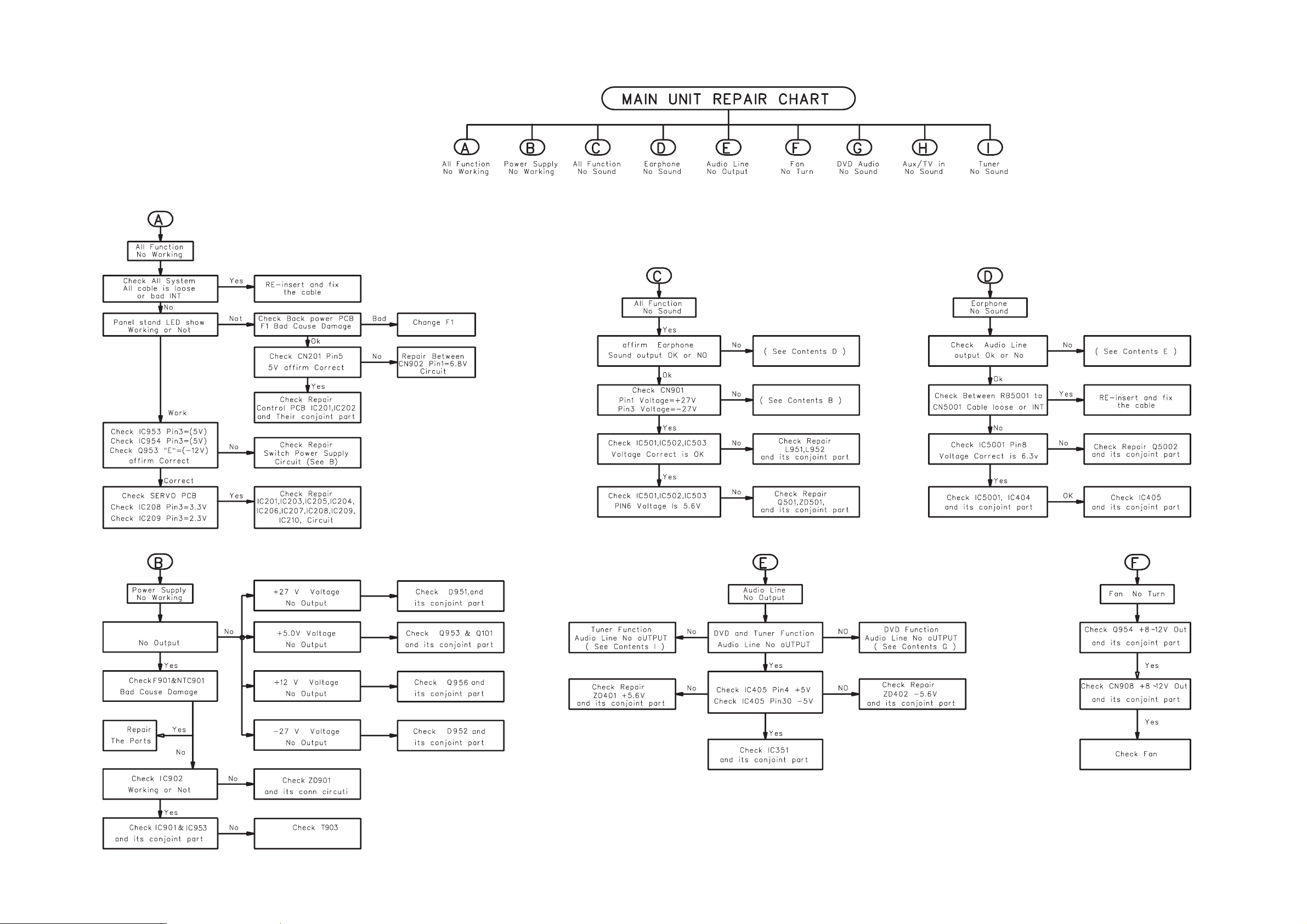

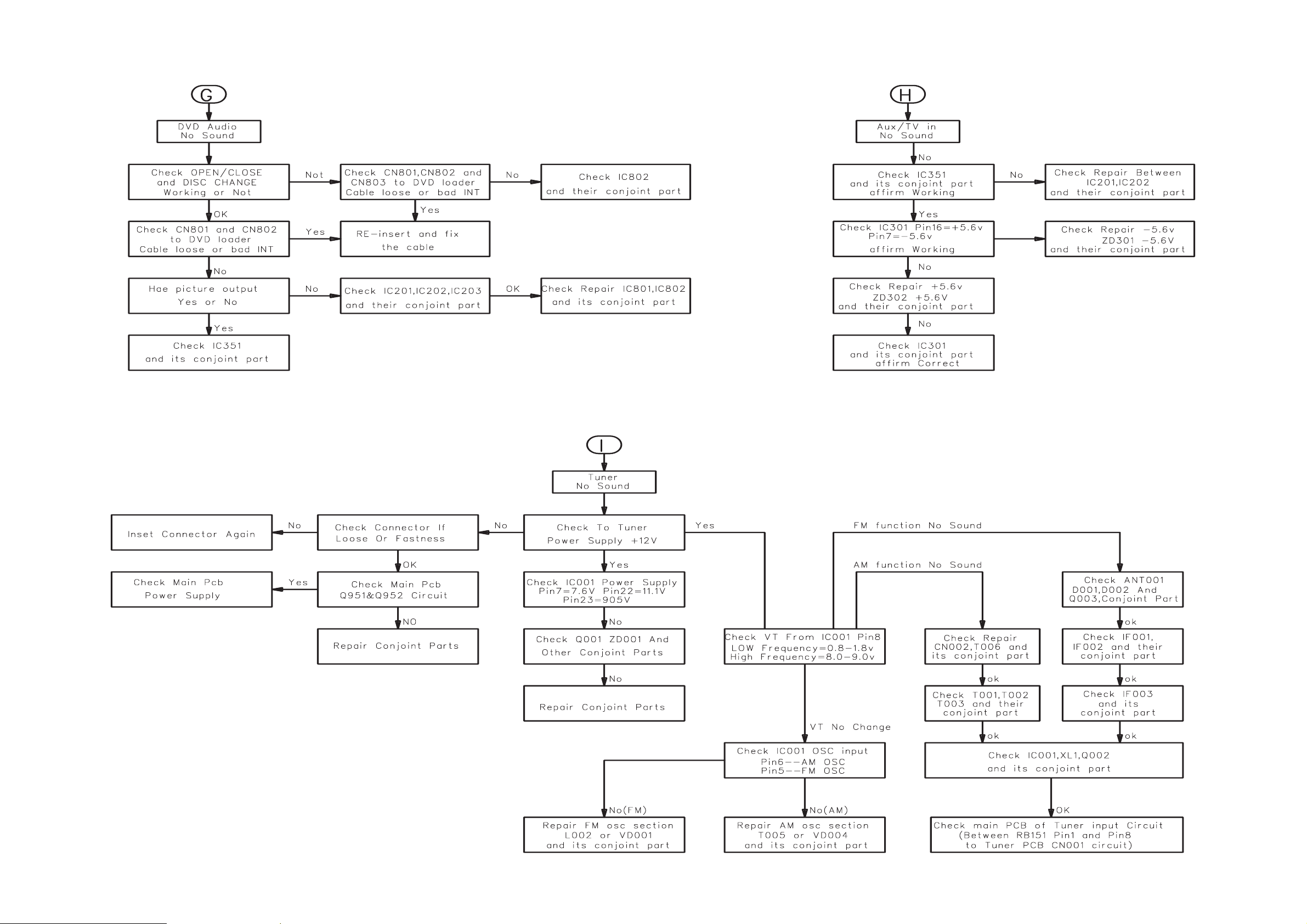

REPAIR INSTRUCTIONS (1 of 2)

2-2

2-2

Page 4

REPAIR INSTRUCTIONS (2 of 2)

2-3

2-3

Page 5

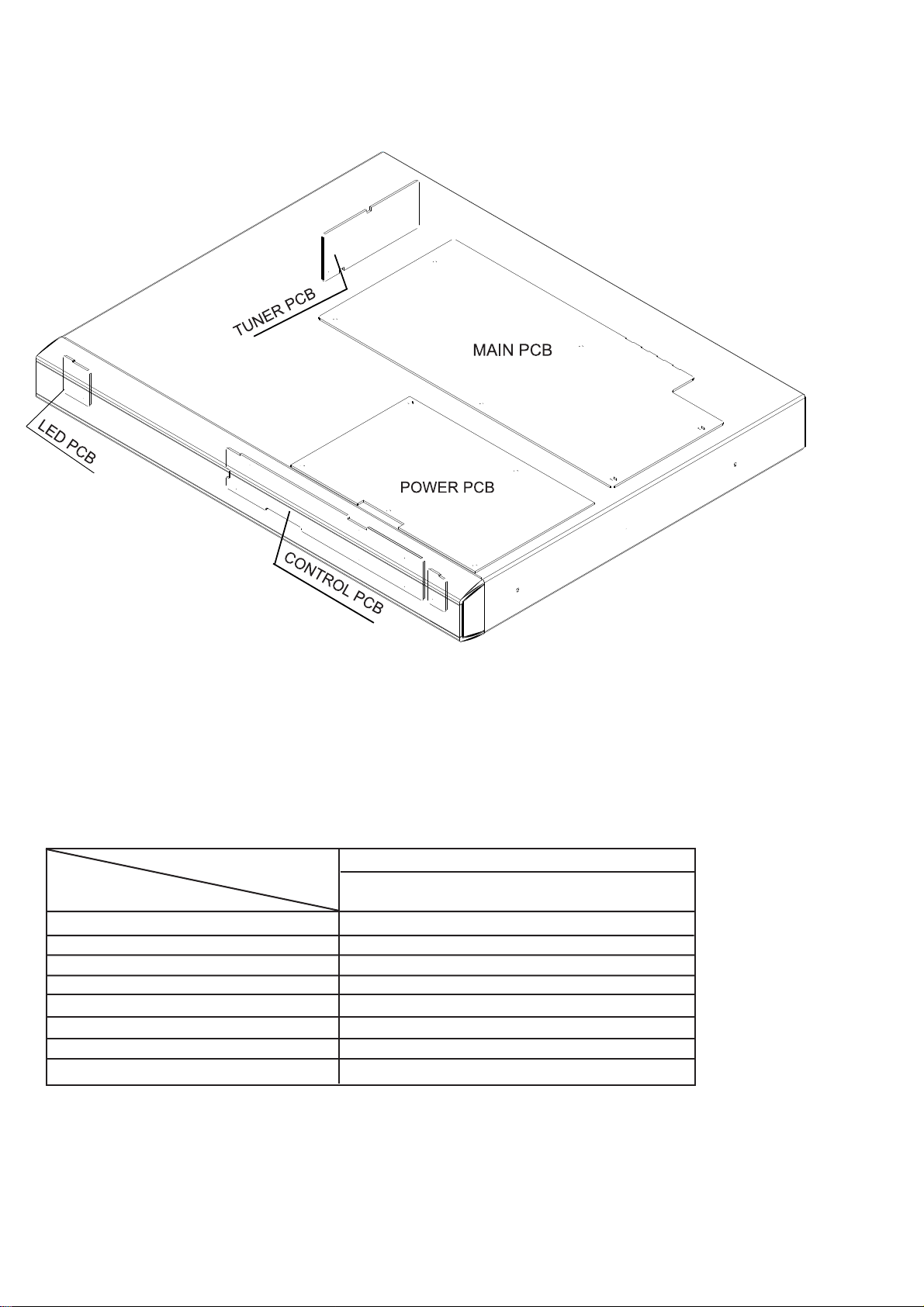

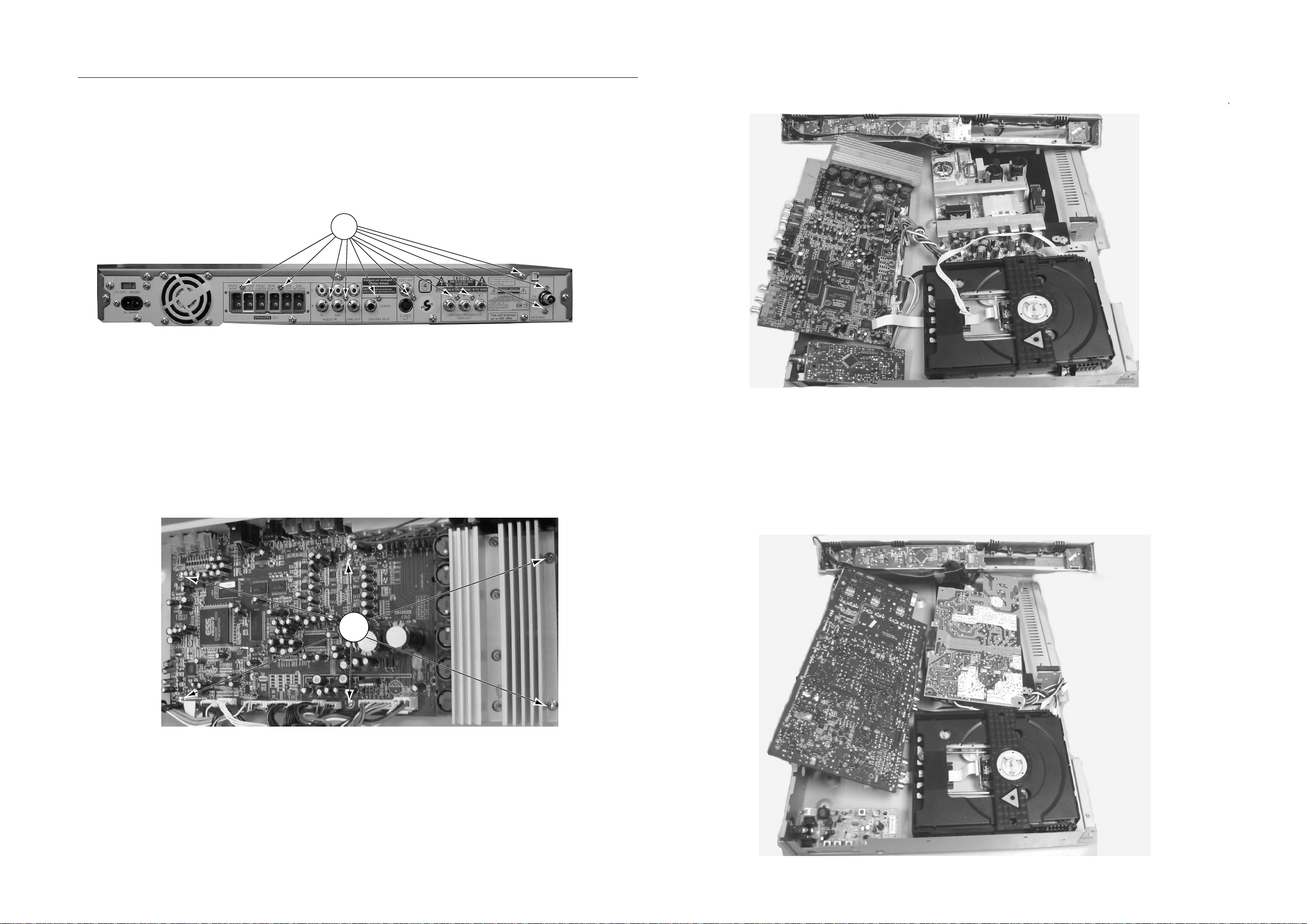

LOCATION OF PC BOARDS

1-2

VOL.

PCB

VERSION VARIATION:

Type /Versions: HTS3410D

Features &

Board in used:

RDS

Rotary Encoder (volume control) x

Aux Input x

Digital Output x

Line Output x

Progressive scan x

Power supply (110-127/220-240V) x

/ 55

Page 6

SPECIFICATIONS

1-3

AMPLIFIER SECTION

PMPO Power ..........................................................5000 W

Total output power

Home Theater Mode .................................................. 700W

1% THD .................................................................... 330 W

- Front ................................................................. 50 W1 x 2

- Rear ..................................................................50 W1 x 2

- Center .....................................................................50 W

- Subwoofer .............................................................. 80 W

Frequency Response .................. 180 Hz - 14 kHz / ±3 dB

Signal-to-Noise Ratio........................ > 60 dB (A-weighted)

Input Sensitivity

AUX/TV In ............................................................... 400 mV

1 3 ohm, 140 Hz- 20 KHz, 1% THD

2 3 ohm, 40Hz- 2 KHz, 1% THD

TUNER SECTION

Tuning Range ..... FM 87.5 – 108 MHz (50/100 kHz steps)

................................... AM 530 – 1710 kHz (10 kHz steps)

.......................................... AM 531 –1602kHz(9kHz steps)

26 dB Quieting Sensitivity ................................. FM 22 dBf

26 dB Quieting Sensitivity .......................... AM 5000 µV/m

IF Rejection Ratio ............................................... FM 60 dB

............................................................................ AM 24 dB

Signal-to-Noise Ratio.......................................... FM 55 dB

............................................................................ AM 40 dB

AM Suppression Ratio ........................................ FM 30 dB

Harmonic Distortion ......................................FM Mono 3 %

.................................................................... FM Stereo 3 %

............................................................................... AM 5 %

Frequency Response ............ FM180 Hz – 10 kHz / ±6 dB

Stereo Separation ................................... FM 26 dB (1 kHz)

Stereo Threshold ............................................. FM 23.5 dB

MAIN UNIT

Power Supply Rating .....................110 - 127V / 220-240 V

50 - 60 Hz Switchable

Power Consumption .................................................. 180W

Dimensions (w × h × d) ...................... 435× 53 × 365 (mm)

Weight .................................................................... 4.25 kg

1

2

SPEAKERS

Front/Rear speakers

System .....................................................................2-ways

Impedance .................................................................... 3 Ω

Speaker drivers ........................... 3" full-range woofer, 1"

conical dome tweeter

Frequency response ................................ 140 Hz – 20 kHz

Dimensions (w × h × d) ....................... 93 × 169 × 65 (mm)

Weight ........................................... 0.73 kg (Front speaker)

0.77 kg (Rear speaker)

(Front speakers are magnetically shielded)

CENTER SPEAKERS

System ................................ 2-way, maganetically sheided

Impedance .................................................................... 3 Ω

speaker drivers ............................ 2 x 3" full-range woofer,

1" conical dome tweeter

Frequency response ................................ 140 Hz – 20 kHz

Dimensions (w × h × d) ....................... 245 × 93 × 70 (mm)

Weight ..................................................................... 1.37 kg

PASSIVE SUBWOOFER

Impedance .................................................................... 3 Ω

speaker drivers ............................................. 6 1/2" woofer

Frequency response .................................... 40 Hz – 2 kHz

Dimensions (w × h × d) ................... 156 × 360 × 350 (mm)

Weight ....................................................................... 4.3 kg

DISC SECTION

Laser Type .................................................. Semiconductor

Disc Diameter .................................................. 12cm / 8cm

Video Decoding ................................... MPEG-2 / MPEG-1

Video DAC ............................................................... 10 Bits

Signal System .................................................. PAL / NTSC

Video Format ....................................................... 4:3 / 16:9

Video S/N ................................................ 56 dB (minimum)

Composite Video Output ............................ 1.0 Vp-p, 75 Ω

S-Video Output ...................................... Y - 1.0 Vp-p, 75 Ω

.......................................................... C - 0.286 Vp-p, 75 Ω

Audio DAC .................................................24 Bits / 96 kHz

Frequency Response .................. 4 Hz - 20 kHz (44.1kHz)

........................................................ 4 Hz - 22 kHz (48kHz)

....................................................... 4 Hz - 44 KHz (96KHz)

Digital Output ......................................................................

................... SPDIF (Sony Philips digital interface) Coaxial

- PCM ................................................................. IEC 60958

- Dolby Digital ................................. IEC 60958, IEC 61937

Page 7

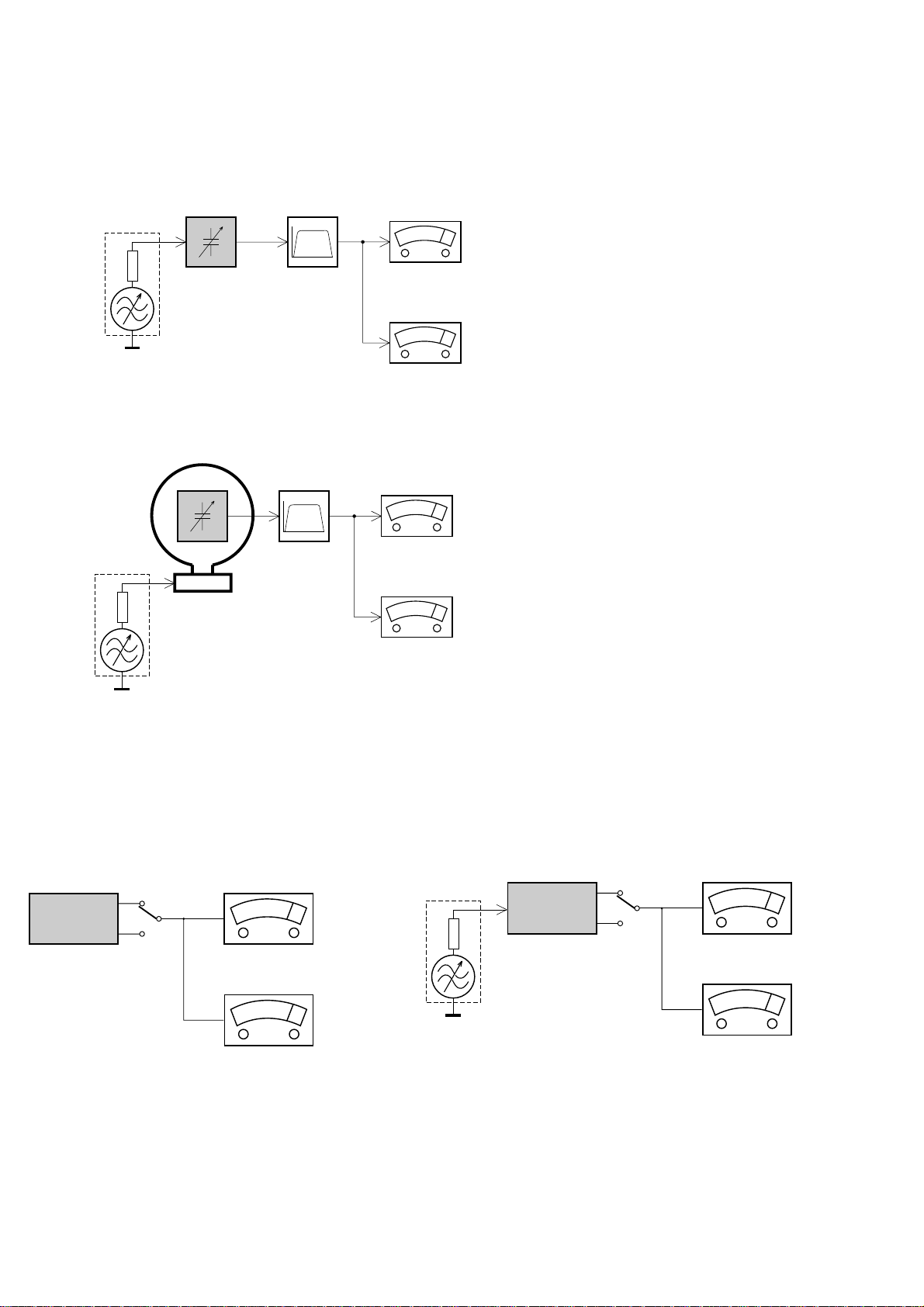

MEASUREMENT SETUP

Tuner FM

1-4

Bandpass

LF Voltmeter

e.g. PM2534

RF Generator

e.g. PM5326

DUT

250Hz-15kHz

e.g. 7122 707 48001

Ri=50Ω

S/N and distortion meter

e.g. Sound Technology ST1700B

Use a bandpass filter to eliminate hum (50Hz, 100Hz) and disturbance from the pilottone (19kHz, 38kHz).

Tuner AM (MW,LW)

RF Generator

e.g. PM5326

Ri=50Ω

DUT

Frame aerial

e.g. 7122 707 89001

Bandpass

250Hz-15kHz

e.g. 7122 707 48001

LF Voltmeter

e.g. PM2534

S/N and distortion meter

e.g. Sound Technology ST1700B

To avoid atmospheric interference all AM-measurements have to be carried out in a Faraday´s cage.

Use a bandpass filter (or at least a high pass filter with 250Hz) to eliminate hum (50Hz, 100Hz).

CD

Use Audio Signal Disc

(replaces test disc 3)

SBC429 4822 397 30184

Recorder

Use Universal Test Cassette CrO2 SBC419 4822 397 30069

or Universal Test Cassette

DUT

L

R

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

LF Generator

e.g. PM5110

Fe SBC420 4822 397 30071

DUT

L

R

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

Page 8

SERVICE AIDS

Service Tools:

Universal Torx driver holder .................................4822 395 91019

Torx bit T10 150mm ...........................................4822 395 50456

Torx driver set T6-T20 .........................................4822 395 50145

Torx driver T10 extended .....................................4822 395 50423

Compact Disc:

SBC426/426A Test disc 5 + 5A ...........................4822 397 30096

SBC442 Audio Burn-in test disc 1kHz .................4822 397 30155

SBC429 Audio Signals disc .................................4822 397 30184

Dolby Pro-logic Test Disc ....................................4822 395 10216

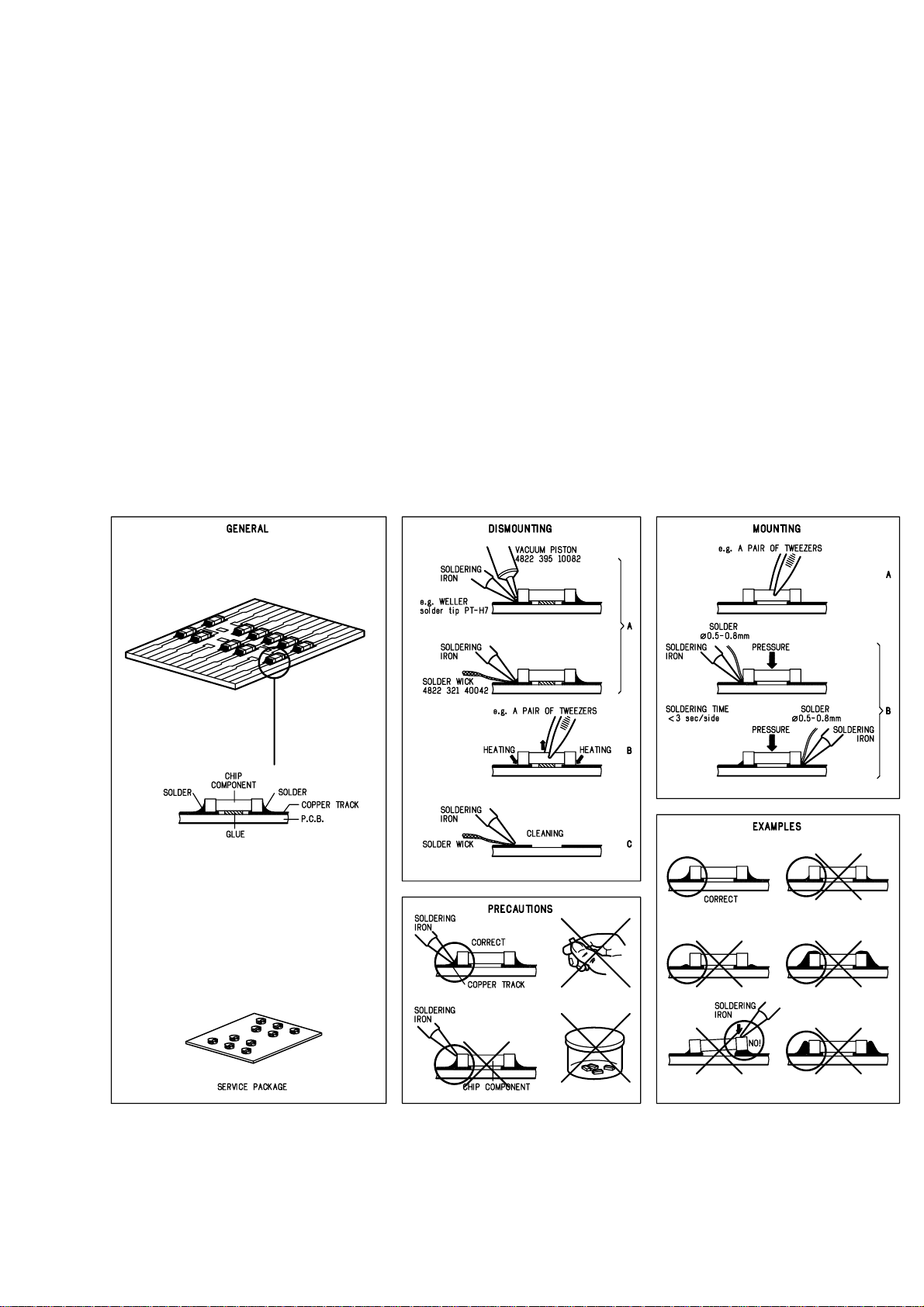

HANDLING CHIP COMPONENTS

1-5

Page 9

1-6

WARNING

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

F

ATTENTION

D

WARNUNG

Tous les IC et beaucoup d’autres

semi-conducteurs sont sensibles aux

décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est

prise à leur manipulation.

Lors de réparations, s’assurer de bien être relié

au même potentiel que la masse de l’appareil et

enfiler le bracelet serti d’une résistance de

sécurité.

Veiller à ce que les composants ainsi que les

outils que l’on utilise soient également à ce

potentiel.

GB

Complete Kit ESD3 (small tablemat, wristband,

connection box, estention cable and earth cable ....... 4822 310 10671

Wristband tester ................................................................. 4822 344 13999

Alle ICs und viele andere Halbleiter sind

empfindlich gegenüber elektrostatischen

Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kan

die Lebensdauer drastisch reduzieren.

Veranlassen Sie, dass Sie im Reparaturfall über

ein Pulsarmband mit Widerstand verbunden

sind mit dem gleichen Potential wie die Masse

des Gerätes.

Bauteile und Hilfsmittel auch auf dieses gleiche

Potential halten.

ESD PROTECTION EQUIPMENT

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used.

Safety components are marked by the symbol

!

.

NL

Veiligheidsbepalingen vereisen, dat het apparaat bij reparatie in

zijn oorspronkelijke toestand wordt teruggebracht en dat onderdelen,

identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbol

!

.

ESD

WAARSCHUWING

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor electrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie kan

de levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

I

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevità potrebbe essere fortemente

ridatta in caso di non osservazione della più

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto

a resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo

potenziale.

CLASS 1

LASER PRODUCT

3122 110 03420

F

Les normes de sécurité exigent que l’appareil soit remis à l’état

d’origine et que soient utiliséés les piéces de rechange identiques

à celles spécifiées.

Less composants de sécurité sont marqués

!

.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu

beachten. Der Original zustand des Geräts darf nicht verändert werden;

für Reparaturen sind Original-Ersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol

!

markiert.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso

nelle condizioni originali e che siano utilizzati i pezzi di ricambio

identici a quelli specificati.

Componenty di sicurezza sono marcati con

!

.

GB

After servicing and before returning set to customer perform a leakage

current measurement test from all exposed metal parts to earth ground

to assure no shock hazard exist, The leakage current must not

exceed 0.5mA.

GB

Invisible laser radiation when open.

Avoid direct exposure to beam.

Osynlig laserstrålning när apparaten är öppnad och spärren

är urkopplad. Betrakta ej strålen.

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen!

DK Advarse !

Usynlig laserstråling ved åbning når sikkerhedsafbrydere er

ude af funktion. Undgå udsaettelse for stråling.

S

SF

Warning !

Varning !

Varoitus !

F

"Pour votre sécurité, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

Page 10

1-7

Pb(Lead) Free Solder

When soldering , be sure to use the pb free solder.

INDENTIFICATION:

Regardless of special logo (not always indicated)

one must treat all sets from 1 Jan 2005 onwards, according

next rules:

Important note: In fact also products of year 2004 must

be treated in this way as long as you avoid mixing solderalloys (leaded/ lead-free). So best to always use SAC305

and the higher temperatures belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solder-paste

is required, please contact the manufacturer of your

solder-equipment. In general use of solder-paste

within workshops should be avoided because paste is

not easy to store and to handle.

• Use only adequate solder tools applicable for lead-

free solder alloy. The solder tool must be able

–To reach at least a solder-temperature of 400°C,

–To stabilize the adjusted temperature at the solder-

tip

–To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around

360°C – 380°C is reached and stabilized at the solder

joint. Heating-time of the solder-joint should not exceed

~ 4 sec. Avoid temperatures above 400°C otherwise

wear-out of tips will rise drastically and flux-fluid will

be destroyed. To avoid wear-out of tips switch off un-

used equipment, or reduce heat.

• Mix of lead-free solder alloy / parts with leaded solder

alloy / parts is possible but PHILIPS recommends

strongly to avoid mixed solder alloy types (leaded and

lead-free).

If one cannot avoid or does not know whether product

is lead-free, clean carefully the solder-joint from old

solder alloy and re-solder with new solder alloy

(SAC305).

• Use only original spare-parts listed in the Service-

Manuals. Not listed standard-material (commodities)

has to be purchased at external companies.

• Special information for BGA-ICs:

– Always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for de-

soldering always use the lead-free temperature profile,

in case of doubt)

– Lead free BGA-ICs will be delivered in so-called ‘dry-

packaging’ (sealed pack including a silica gel pack) to

protect the IC against moisture. After opening,

dependent of MSL-level seen on indicator-label in the

bag, the BGA-IC possibly still has to be baked dry.

(MSL=Moisture Sensitivity Level). This will be

communicated via AYS-website.

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products

of 2004), containing leaded solder-alloy and

components, all needed spare-parts will be available

till the end of the service-period. For repair of such

sets nothing changes.

• On our website www.atyourservice.ce.Philips.com

you find more information to:

• BGA-de-/soldering (+ baking instructions)

• Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical information

within the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

Page 11

3-1

24mm

2mm

Repeat

Marking just outside the

slot on the rear cabinet

C

A

B

3-1

DISASSEMBLY INSTRUCTIONS

Dismantling of the Front Panel Assembly

1) Open the DVD Tray by using the Open/Close Button

while the Set is ON and disconnect the mains supply after

removing the Tray Cover.

Note: If this is not possible, the DVD Tray has to be open

manually.

Take a mini screw driver about 2mm diameter and make

a marking 24mm from the tip as shown in figure 2. place

the set on its side, insert the mini screw driver till the

marking and slide it towards the right as shown in figure

1 until the Tray moves out of the Front Panel.

Dismantling of the DVD Module

1) Loosen 4 screws "A" to remove the DVD Module as shown in figure 4.

2) Return the set to its upright position and remove the Tray

Cover as shown in Figure 3 and close the tray manually

by pushing it back in.

3) Loosen 9 screws and remove the Top Cover by lifting the

rear portion upwards before sliding it out towards the rear.

-5 screws on the back

-2 screws each on the left & right side

4) Loosen 7 screws & lift up the top edge of Front Panel

assembly to free some catches before sliding it out

towards the front.

-4 screws on the bottom

-1 screw "E" on the inside as indicated in Figure 8.

-1 screw each on the left & right side

Figure 1

Figure 2

Figure 4

Dismantling of the Power Board

1) Loosen 2 screws "B" on the bottom cover as shown in

figure 5.

2) Loosen 4 screws "C" at the top of the Power Board as

shown in figure 6.

Figure 3

Figure 5

Figure 6

Page 12

3-2

E

D

3-2

Dismantling of the Main PCB

1) Loosen 10 screw " D " at the back panel as shown in figure

7 .

2) Loosen 6 screw " E " on the top of main board as shown in

figure 8.

SERVICE POSITIONS

Service position A

Figure 7

Note: In some service positions the components or copper patterns of one board may risk touching its neighbouring pc

boards or metallic parts. To prevent such short-circuit use a piece of hard paper or other insulating material between them.

Service position B

Figure 9

Page 13

BLOCK DIAGRAM

4-1

4-1

Page 14

WIRING DIAGRAM

4-2

4-2

Page 15

5-1

5-1

FTD DISPLAY PIN ASSIGNMENT

1G 2G3G4G5G6G7G8G9G10G 1G

CONTROL/POWER SWITCH

/VOLUME

TABLE OF CONTENTS

FTD Display Pin Assignment........................................... 5-1

Pin Connection ................................................................ 5-1

Circuit Diagram ................................................................5-2

PCB Layout Top View ...................................................... 5-3

PCB Layout Bottom View ................................................5-3

Electrical Parts List & Voltages ....................................... 5-4

BOARD

P1

P2

P3

P4

P5

P6

P7

P8

P9

P10

P11

P12

P13

P14

P15

P16

P17

P18

a

b

f

h

j

k

m

s

g

c

e

r

p

n

d

Dp

Dp

a

b

f

h

j

k

m

s

g

c

e

r

p

n

d

Col

a

b

f

h

j

k

m

s

g

c

e

r

p

n

d

a

f

e

10G 9G 8G 7G 6G 5G 4G 3G 2G 1G

a

b

h

k

m

s

g

c

e

p

n

d

a

b

f

f

h

j

j

k

m

s

g

c

e

r

r

p

n

d

a

b

h

k

m

s

g

c

e

p

n

d

a

b

f

f

h

j

j

k

m

s

g

c

e

r

r

p

n

d

a

b

f

h

j

k

m

s

g

c

e

r

p

n

d

h

g

r

j

k

m

s

p

n

d

(2G - 10G)

a

b

f

h

j

k

m

s

g

c

e

r

p

n

d

b

c

Col

PIN CONNECTION

CONNECTION

PIN NO.

F2 NP

## Note ##

1. Fn: Filament pin

2. NP : No Pin

3. NX : No Extended Pin

4. nG : Grid Pin

5. PN : Anode Pin

NP 10G

36373839404142434445

31~2332333435

NX9G8G7G6G5G4G3G2G1GF2

P10P11P13 P12P14P15P16P17P18

P1P2P3P4P5P6P7P8P9

12345678910111213141516171819202122

F1

F1NPNP

Page 16

CIRCUIT DIAGRAM - KEY BOARD

5-2

5-2

C

D

A

B

E

C2201 E1

123456

104

C2224

RB202

123456

C2202 E1

C2204 E1

C2206 D2

C2207 D2

C2208 C4

C2209 C4

C2212 D6

C2213 C5

C2214 A6

C2215 A6

C2216 A1

A

C2217 A1

C2218 B1

C2219 B2

C2220 B2

C2221 A4

C2222 A5

C2223 A3

C2224 B2

C22051 D1

D2201 C2

D2202 C3

DP2201 A4

IC2201 E2

IC2202 A2

B

LD2201 E6

Q2201 D2

Q2202 D3

Q2203 C4

Q2204 D5

Q2205 E5

R2201 D3

R2202 D3

R2203 D3

R2204 D3

R2205 D3

R2207 D3

C

R2208 D3

R2209 B5

R2210 D2

R2211 D2

R2212 D2

R2213 D2

R2214 E1

R2215 D1

R2217 D2

R2218 D4

R2219 C4

R2221 D5

R2222 C5

R2223 D6

D

R2224 D5

R2226 B5

R2227 B6

R2228 D5

R2231 D2

R2232 D2

R2233 D3

R2234 D3

R2235 D4

R2236 D3

R2237 D1

R2238 D1

R2239 D1

E

R2240 A2

R2241 A2

R2242 D1

R2243 D1

R2244 D1

R2245 A1

R2246 B1

R2247 B1

R2248 B1

R2249 B2

R2250 B2

R2251 B2

R2252 B2

R2253 E4

R2254 E5

R2255 E5

RB201 B6

RB202 C6

RB202A E5

RB202B E5

RB203A A6

RB203B A6

SN2201 C6

TA2201 D2

TA2202 C2

TA2203 C2

TA2204 C2

TA2205 C2

TA2206 D3

TA2207 D3

TA2208 E6

VR2201 A6

XL2201 E1

ZD2201 D3

ZD2202 D6

ZD2203 D6

Page 17

PCB LAYOUT - KEY BOARD (TOP)

5-3 5-3

C2204 A2

C2207 B1

C2208 B4

C2213 A3

C2217 B3

C2223 A3

D2201 A4

D2202 A4

DP2201 B3

LD2201 B1

R2228 B2

RB201 B2

RB202 B2

RB202A A1

RB202B A1

RB203A A5

RB203B A5

SN2201 A4

TA2201 B4

TA2202 A5

TA2203 B4

TA2204 B4

TA2205 A4

TA2206 B1

TA2207 B5

TA2208 B1

VR2201 B5

XL2201 A2

ZD2201 B2

A1 B1

A2 B2

A3 A4

1234 5

A

B

A

B

12345

PCB LAYOUT - KEY BOARD (BOTTOM)

C2201 A4

C2202 A4

C2206 B4

C2209 A2

C2212 A2

C2214 A1

C2215 A1

C2216 B3

C2218 B3

A

C2219 B3

C2220 B3

C2221 A4

C2222 A3

C2224 A3

C22051 B4

IC2201 B4

IC2202 B3

Q2201 A2

Q2202 B1

Q2203 B1

Q2204 B2

Q2205 A5

R2201 B4

R2202 B5

R2203 B5

R2204 B5

R2205 B5

12345

R2207 A5

R2208 A4

R2209 B4

R2210 B4

R2211 A4

R2212 A4

R2213 A4

R2214 A4

SR2215 A4

R2216 A4

R2217 A4

R2218 A4

R2219 A2

R2221 B2

R2222 A2

R2223 A2

R2224 B2

R2226 A1

R2227 A1

R2231 B2

R2232 A2

R2233 B1

R2234 A1

R2235 B1

R2236 B1

R2237 A4

R2238 B4

R2239 B4

R2240 B4

R2241 B3

R2242 B4

R2243 A4

R2244 A4

R2245 A3

R2246 A3

R2247 B3

R2248 B3

R2249 B2

R2250 B1

R2251 A1

R2252 B1

R2253 A5

R2254 A5

R2255 A5

R2256 B2

ZD2202 A2

ZD2203 A2

A

B

B

12345

Page 18

5-4 5-4

00

0 0 3.8 3.8

03.83.70000

0

19.7

-22.2

-22

-11.2-19.9 -17.8

-21 -15.6 -13.4

-20 -13.4 -20

-22.4 -18 -20.3 -13.6

-15.8 -11.4 -4.6

-22.6 -20.4

00

4.6

5.1

0

-20.4 -20.4 -20.4

-20.4 -20.4

-20.4-20.4

-20.4-20.5

4.6

4.64.6

4.64.6

5.1

5.1 5.1

0

5.1

00

4.9 4.9 5.2

00

0000

PIN 123456789

10 11 1

21314

15 16 1

718

19 20

VOLTAGE

PIN

21 22

23 24

25 26 27

28 29

30 31 32 33

34 35 36

37 38 39 40

VOLTAGE

PIN

41 42

43 44 45

46 47 48 49

50 51 52

VOLTAGE

PIN 123456789

10 11 1

21314151

6

VOLTAGE

17 18

IC2202 (TP6311)

IC2201 (HT480051)

PIN

123

VOLTAGE

Q2201 (2SA733)

5

50

5

5

0

PIN

1

23

VOLTAGE

Q2204 (2SC1623)

5

5

0

5

50

PIN

123

VOLTAGE

Q2202 (2SA733)

PIN

12

3

VOLTAGE

Q2203 (2SA733)

4.6

4.2

4.2

PIN

12

3

VOLTAGE

Q2205 (2SA733)

ELECTRICAL PARTLIST - KEY (CONTROL , VOLUME , PWR ) PCBA

MISCELLANOUS

IC2201 9965 000 23592 IC 18PIN HT48R05A-1 SOP HOLTEK

LD2201 9965 000 26953 LED 3 DIA RED ROUND HP

TA2201 9965 000 26950 AI TACT SW SKHVBE3520 ALPS

TA2202 9965 000 26950 AI TACT SW SKHVBE3520 ALPS

TA2203 9965 000 26950 AI TACT SW SKHVBE3520 ALPS

TA2204 9965 000 26950 AI TACT SW SKHVBE3520 ALPS

TA2205 9965 000 26950 AI TACT SW SKHVBE3520 ALPS

TA2206 9965 000 26950 AI TACT SW SKHVBE3520 ALPS

TA2207 9965 000 26950 AI TACT SW SKHVBE3520 ALPS

TA2208 9965 000 26952 TACT SW H5.0MM 2PIN 160GF

VR2201 9965 000 29233 ENCODER L20 A=12 WITHO CC

XL2201 9965 000 23590 CRYSTAL 4MHZ HC-49US

DIODES

D2201 9965 000 26949 DIODE SW 1N4148

D2202 9965 000 26949 DIODE SW 1N4148

DP2201 9965 000 26957 VFD 100X25MM PIN LENGHT=10MM

TRANSISTORS & INTREGATED CIRCUITS

IC2202 9940 000 00907 IC 52 PIN TP6311QH

Q2201 9940 000 00921 XISTR PNP 2SA812 HFE:200-400

Q2202 9940 000 00921 XISTR PNP 2SA812 HFE:200-400

Q2203 9940 000 00921 XISTR PNP 2SA812 HFE:200-400

Q2204 9940 000 00915 XISTR NPN 2SC1623

Q2205 9940 000 00921 XISTR PNP 2SA812 HFE:200-400

SN2201 9965 000 26956 IRT RECEIVER IRM-2638F4

ZD2201 9965 000 26942 DIODE ZENR 5.0-5.2V 0.5W

ZD2202 9965 000 26930 CHIP ZENER 5.6V 0.05 0.5W

ZD2203 9965 000 26930 CHIP ZENER 5.6V 0.05 0.5W

Note : Only the parts mentioned in this list are normal

service spare parts.

Page 19

6-1

6-1

TUNER BOARD

TUNER ADJUSTMENT TABLE

Waverange Input frequency Input Tuned to Adjust Output Scope/Voltmeter

VARICAP ALIGNMENT

FM

87.5 - 108MHz

(50kHz grid)

AM

530-1710kHz

(10kHz grid)

( 21L / 21L / 37S )

FM - IF

FM

10.7MHz, 50mV

continuous wave

108MHz

87.5MHz check

1602KHz

531KHz

1700KHz

530KHz

IC001

23

short circuit

to block AFC

200P

check

check

T005

check

T005

No need

to adjust

6.5V ±1.2V

1.0V ±0.5V

7.8V ±0.2V

1.1V ±0.5V

8.0V 1HV

1.1V 0.2V

fo

±

±

Max

Symmetric

TABLE OF CONTENTS

Tuner adjustment table................................................................... 6-1

Circuit Diagram ...............................................................................6-2

PCB Layout View (Top) .................................................................. 6-3

PCB Layout View (Bottom) ............................................................ 6-4

Electrical Parts List & Voltage List .................................................6-5

FM - RF

FM

AM IF

AM

AM AFC

MW

AM RF

108MHz

87.5MHz

450kHz

Connect pin 29 of

IC001 (AM Osc.)

mod=1kHz

∆f= ±22.5kHz

∆f = ±15kHz

V

= 3mV

RF

106MHz

90.1MHz

IC001

24

R220

100nF

VC001

L001

T001

T002

MAX

MAX

MAX

f

o

symmetric

max.

with short wire to

ground (pin 6)

3)

1404kHz VC001

∆

V=mV

1404kHz

612kHz576kHz

T003

T006

MW

1400kHz

610kHz

Use Service Testprogram. By selecting the TUNER TEST test frequencies will be stored as preset frequencies automatically.

1)

If sensitivity of frequency counter is too low adjust to max. channel separation

(input signal: stereo left 90% + 9%, adjust output on right channel to minimum)

3)

For AM RF adjustments the original frame antenna has to be used!

∆f = ±30kHz

as low as

V

RF

possible

1400kHz

610kHz

VC002

T006

2)

RC network serves for damping the IF-filter while

adjusting the other one.

MAX

symmetric

max.

f

o

Page 20

CIRCUIT DIAGRAM - TUNER BOARD

6-2

6-2

A

B

C

12

12

34

34

ANT001 A1

C002 A1

C005 A1

C007 A2

C006 B2

C008 B2

C009 B2

C01 C4

C02 C3

C03 A2

C010 B1

C011 C1

C012 B2

A

C013 C2

C014 C1

C015 C1

C016 C1

C019 A2

C020 B3

C021 C2

C022 C2

C023 C2

C024 C2

C025 C2

C026 C2

C029 C3

C030 C3

C031 C2

C032 A3

C033 B3

B

C034 C3

C035 B2

C036 B4

C037 B3

C038 B4

C039 C4

C040 B3

C041 B3

C042 B4

C043 B4

C044 B3

C047 A1

C048 B1

C0501 A2

CN001 C4

CN002 B1

D001 A1

D002 A1

D003 A4

D004 C3

C

D005 B1

IC001 B3

IF001 A3

IF002 A3

IF003 C3

L02 B1

L001 A2

Q001 B3

Q002 B4

Q003 A2

R001 A1

R002 B1

R004 A2

R005 B2

R006 A1

R010 C1

R011 C1

R015 B2

R016 B4

R017 C2

R018 B3

R019 C3

R020 B4

R021 C4

R023 B4

R024 B2

R025 C3

R026 C3

R027 B3

R028 B4

R029 B4

R030 B4

R032 B3

R033 A2

T001 A2

T002 A4

T003 A4

T005 C1

T006 B1

VC001 A2

VC002 B1

VD001 B1

VD002 A1

VD003 B1

VD004 C1

VR001 B2

XL1 B3

Page 21

PCB LAYOUT - TUNER BOARD (TOP)

6-3

6-3

A

ANT001 B1

C005 A1

C006 A2

C007 B1

C009 A2

C019 B1

C024 B2

C025 B2

C030 B3

C035 A2

C047 A1

CN001 B3

CN002 A1

D001 A1

D002 A1

D003 B2

D004 B3

D005 A1

IC001 B2

IF001 B1

IF002 B2

IF003 A2

JWP2 B1

JWP3 A3

JWP4 A3

JWP5 B2

JWP6 B3

JWP7 B2

JWP8 A3

JWP9 B3

L02 A2

L001 B1

Q001 A3

Q002 B2

R018 B3

T001 B1

T002 B2

T003 B2

T005 A2

T006 A1

VC001 A1

VC002 A1

VD001 A2

VD002 A1

VD003 A1

VD004 A2

VR001 A3

XL1 B2

123

W

A

W

B

W

W

B

W

W

W

W

123

Page 22

6-4

PCB LAYOUT - TUNER BOARD (BOTTOM)

6-4

A

C01 A3

C03 B3

C001 A3

C002 B3

C008 B3

C010 A3

C011 A2

C012 A2

C013 A3

C014 A3

C015 A2

C016 A3

C020 B2

C021 A3

C022 A3

C023 A3

C023 A3

C026 A3

C029 A2

C031 A3

C032 A2

C033 B2

C034 B2

C036 A3

C037 A2

C038 B3

C039 A3

C040 B2

C041 B2

C042 B3

C043 B2

C044 B3

C048 A2

C050 A3

C052 A2

IC001 A2

Q003 B3

R001 A3

R002 A3

R004 B3

R005 A2

R006 A3

R007 B3

R010 A2

R011 A2

R015 A2

R016 B3

R017 A3

R019 B3

R020 A3

R021 A3

R023 B2

R024 A2

R025 A3

R026 A3

R027 B2

R028 B3

R029 B3

R030 B2

R031 B3

R032 B3

R033 B3

R034 B3

321

A

B

B

321

Page 23

ELECTRICAL PARTLIST - TUNER PCB

(

)

)

(

)

)

(

)

)

6-5 6-5

MISCELLANOUS

ANT001 9965 000 24668 RF JACK MALE TYPE 75 OHM

CN002 9965 000 25150 CONNECTOR S2B-XH-A 2 PIN

CO47 9965 000 27096 COND DISC 100PF 50V 5% NPO

IC001 9965 000 27003 IC 44 PIN TEA5757H QFP44 PHILIPS

IF001 9965 000 24093 CERFILTER 3P 10.7MHZ LT10.7MA5

IF002 9965 000 24670 CER FILTER 10.7 MHZ

L001 9965 000 23587 MOULDED COIL 2.5T 57-89NH

L02 9965 000 23586 SPRING COIL 0.8X4.5DX(1-2)2.5T

T001 9965 000 24672 AM IFT 450KHZ 180PF Q=80MIN

T002 9965 000 24673 AM IFT 450KHZ 180PF Q=80MIN

T003 9965 000 24673 AM IFT 450KHZ 180PF Q=80MIN

T005 9965 000 24674 OSC COIL AM 120UH (796KHZ)

T006 9965 000 26964 ANT OSC AM 4-6:10T 1-3:86T

XL1 9965 000 23588 CRYSTAL 75KHZ +/-15 PPMCOLUMN

TRANSISTORS & INTREGATED CIRCUITS

Q001 4822 130 41198 2SC945P

Q002 4822 130 41198 2SC945P

Q003 9940 000 00921 XISTR PNP 2SA812 HFE:200-400

Q003 9965 000 27004 XISTR PNP BF550 SOT23 PHILIPS

Note : Only the parts mentioned in this list are normal

service spare parts.

VOLTAGES

IC101 (TEA5757H)

PIN 123456789

VOLTAGE

VOLTAGE(AM

VOLTAGE

VOLTAGE(AM

VOLTAGE

VOLTAGE(AM

FM

PIN 21 22 23 24

FM

PIN 41 42 43 44

FM

Q003 (BF550)

PIN

VOLTAGE(FM)

VOLTAGE(AM)

10 11 12 13 14 15 16 17 18 19 20

2.1 0.01 0.01 0.01 0.01 0.01 7.21

2.1 0.01 0.01 0.01 0.01 0.01 7.45

4.49 1 0.7 1.24 0.83 0.77 0.63

1.12 1.36 0.58 1.24 0.18 0.77 0.63

25 26 27 28 29 30 31

1.94 10.9 9.13 1.26 1.92 0.01 0.19 0.52 0.2 0.01

1.94 10.9 9.13 1.2 1.88 0.01 0.19

1.35 0.01 0.75 0.15

1.35 0.01 0.75 0.43

0.52 0.2 0.01 0.01 1.43 1.44 1.47

Q001 (2SC945)

123 PIN

0.01 0.66 0.01

0.01 0.66 0.01

VOLTAGE(FM)

VOLTAGE(AM)

1 2 3 PIN

0.07 -0.03 1.3

0.08 0.01 1.24

0.64 1.01 0.01

0.64 1.01 0.01

32 33 34 35 36 37 38 39 40

1.43 0.62 1.35 1.02 1.34

0.01 1.43 0.75 1.43

0.7

1.42 1.47 1.32 1.35 1.41 1.37

Q002 (2SC945)

123

VOLTAGE(FM)

VOLTAGE(AM)

11.8

2

10.1

10.1711.81

0 1.15 1.15

0 1.15 1.15

10.77

10.82

DIODES

D001 9965 000 26949 DIODE SW 1N4148 PB<1000PPM

D002 9965 000 26949 DIODE SW 1N4148 PB<1000PPM

D003 9965 000 26949 DIODE SW 1N4148 PB<1000PPM

D004 9965 000 26940 DIODE ZENR 11.9-12.4V 0.5W

D005 9965 000 26949 DIODE SW 1N4148 PB<1000PPM

VC001 9965 000 24676 CONDTRIM 3-10PF NP0

VC002 9965 000 24676 CONDTRIM 3-10PF NP0

VD001 9965 000 27006 DIODE TUNG FM TOSHIBA 1SV101

VD002 9965 000 27006 DIODE TUNG FM TOSHIBA 1SV101

VD003 9965 000 26965 DIODE TUNG AM TOSHIBA 1SV149B

VD004 9965 000 26965 DIODE TUNG AM TOSHIBA 1SV149B

VR001 9965 000 27005 CNTL TRIMR 30 K OHM

Page 24

7-1

DVD LOADER

It is not recommended for component repair on this Module

but to replace the major assembly when it becomes defective.

Therefore limited service parts list are published in this

chapter.

TABLE OF CONTENTS

Explorer View (DVD Loader) ........................................... 7-2

Page 25

Explorer view

7-2

19

13

18

14

4

8

23

2

9

10

11

1

15

17

16

21

22

7

21

5

6

3

12

20

Page 26

8-1

ES6629F INTERNAL IC DIAGRAM

DVD/CD

Mot o r

OP U

Motor Dr i v er

8-1

MAIN BOARD

TABLE OF CONTENTS

Internal IC Diagram ......................................................... 8-1

Voltages List .................................................................... 8-2

Circuit Diagram(1) ........................................................... 8-3

Circuit Diagram(2) ........................................................... 8-4

PCB Layout Top View ...................................................... 8-5

PCB Layout Bottom View ................................................ 8-6

Electrical Parts list ........................................................... 8-7

ES6 603

RF Amp

SDRA M

8/16-MB

E S 6629

EE PROM

RO M / F l a s h

V i bratto-II

AM5868S INTERNAL IC DIAGRAM

MUTE

28

MUTE

Thermal

Shut down

+

1

VINPC OP2N+

BIAS

27

-

+

25K

-

10K

2 3 4 5 6 7

VINTK

26

OP2N-

OP1N+

25 24

10K

25K

-

+

VINSL+

10K

OP2OUT

OP1N-

VINLD

23

GND

-

+

FWD REV VCCL

GND

22

10K

V i deo

Au dio DAC

Au dio ADC

S/ P D I F

VFD Dr i v er

T

V Di splay

Spe akers

M i c r o phon e I

A/ V Re ce iv er

VFD Pan el

n

I R R e m o te

VCTL OP1OUT

21

GND

+

25K

Pre-DRV

PGND

Vcc1

8

VCC2

20 19 18 16 15

Vcc2

15K

-

+

TRY

DRIVER

9 10 11 12 13

VOTR-

VOTR+ VOSL+

VOLD-

Spindle

Driver(4X)

Sled

Driver(4X)

VOLD+

17

VOSL-

VOTK-

Actiator

Driver(6X)

Actiator

Driver(6X)

VOFC+

VOTK+

14

VOFC-

Vcc2

Vcc2

Vcc1

TDA8920BTH INTERNAL IC DIAGRAM

handbook, full pagewidth

SGND1

MODE

SGND2

IN1

IN1+

OSC

IN2+

IN2

V

9 (3)

8 (2)

11 (5)

7 (1)

6 (23)

2 (19)

5 (22)

4 (21)

V

DDA2

MODE

SSA2

3 (20)

INPUT

STAGE

mute

mute

INPUT

STAGE

1 (18)

V

DDA1

10 (4)

OSCILLATOR

12 (6)

V

SSA1

PWM

MODULATOR

STABI

MANAGER

PWM

MODULATOR

PROTSTABI

RELEASE1

SWITCH1

ENABLE1

TEMPERATURE SENSOR

CURRENT PROTECTION

ENABLE2

SWITCH2

RELEASE2

19 (-)24 (17)

V

SSD

n.c.

CONTROL

AND

HANDSHAKE

CONTROL

AND

HANDSHAKE

DRIVER

HIGH

DRIVER

LOW

TDA8920BTH

TDA8920TH

DRIVER

HIGH

DRIVER

LOW

V

DDP2

23 (16)13 (7)18 (12) 14 (8)

17

V

SSP1

V

V

V

V

DDP1

15 (9)

16 (10)

SSP1

DDP2

22(15)

21 (14)

20 (13)

SSP2

BOOT1

OUT1

BOOT2

OUT2

MBL461

Page 27

VOLTAGES

8-2

8-2

IC201 (ES6629F)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

3.3 1.77 1.77 1.77 3.3 3.3 3.3 1.5 0 3.3 1.4 1.5 1.5 1.5 1 0 0 0 3.3 0.1

Voltage

PIN NO 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

Voltage 3.3 2.8 3.1 3 0.2 0 2 0.2 3.3 3 1.3 1.3 1.4 0 3.3 1.4 1.3 1.3 1.2 1.3

PIN NO 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

Voltage

1.4 1.4 0 3.3 1.5 1.1 1.2 1.2 1.2 1.3 1.6 0 3.3 0.1 3.3 0 0 0 0 0

PIN NO 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

0 3.3 1.3 1.6 2.6 1.8 1.2 2.5 0.7 0 2 2 1.1 1.7 2 2.6 2 0 3.3 2

Voltage

PIN NO 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

Voltage

223.3 3.3 3.3 0 2 0 3.3 0 0.7 0.9 1.7 1.4 0 3.3 1.7 1.8 1.6 1

PIN NO 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120

1.2 1.6 1.6 3.3 0 1.3 2.1 1.3 3.3 0.6 3.3 0 1 0.8 0.7 1.6 1 0 0 0

Voltage

PIN NO 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140

Voltage

0 1.5 1.6 1.6 1.2 3.3 0 3.3 3 3.6 3.6 3.6 0.2 3.3 3.3 3.3 0 2 1.3 0

PIN NO 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160

Voltage

2 1.6 0 1.6 1.5 0 3.3 2.1 0.9 1.5 1.3 3.3 1.5 1.5 1.5 1.5 0 0 1.5 1.5

PIN NO 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180

Voltage

1.5 3.3 0.6 2.19 1.5 1.5 0 1.5 3 3.3 2.1 1.5 1.7 1.5 1.6 1.7 2.5 2.5 0 2.4

PIN NO 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200

Voltage

3.3 0 3.3 3.3 3.3 0 0 2.4 0 2.4 0 0.7 3.3 3.3 3.3 0 0 2.1 5 5

PIN NO 201 202 203 204 205 206 207 208

Voltage

-0.4 -0.4 -0.4 4 4 3.3 3.1 0

IC202 (MX26LV800BTC)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

0 1.2 1.7 2.6 2 1.2 2.5 0.7 0 0 0 3.2 0 0 1.3 0 0 2.1 1.7

Voltage

2.5

PIN NO 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

Voltage

2 1.9

2.1 2.1 2.1 0 0 0 1.8 1.2 1.9 1.7 1.2 1.3 1.2 3.3 1.5 1.2

1.2 2

PIN NO 41 42 43 44 45 46 47 48

Voltage

1.7 1.2 1.5 2

0000

IC203 (EDS6416AHTA-6B-E)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Voltage

3.3 1.3 3.3 1.2 1.4 0 1.4 1.3 3.3 1.1 1.1 0 1.4 3.3 0.1 3 3.1 3 2.8 0.2

PIN NO 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

Voltage

0.2

0.1

0 0.5 1.5 3.3 0 1.4 1.5 1.5 1.5 1 0 0.1 1.6 3.3 1.6 0.1 0

0

PIN NO 41 42 43 44 45 46 47 48 49 50 51 52 53 54

Voltage

0 1.2 3.3

1.2

0 1.1 1.1 3.3 1.4 1.5 0 1.4 0

1.2

IC206 (74F374D)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Voltage

0 3.8 1.2 1.7 3.8 4.3 1.4 0.8 0.1 0 5 4 0.1 1.5 4 0 1.9 1.2 3.5 3.3

PIN NO 21 22

4.5 0

Voltage

IC207 (74F374D)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Voltage

0 3.8 1.2 1.7 3.8 4.3 1.4 0.8 0.1 0 5 4 0.1 1.5 4 0 1.9 1.2 3.5 3.3

PIN NO 21 22

4.5 0

Voltage

IC209 (AP1117E18LA)

PIN NO 1 2 3

Voltage

3.3 2.2 1.0

IC210 (AP1117E33LA)

PIN NO 1 2 3

Voltage

5 3.3 0

IC301 (CD4052BM)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

0000005.603.8 3.8 0 0.1 0 0 0 5.8

Voltage

IC351 (WM8772SEDS)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Voltage

0 1.7 1.7 3.3 0 0 0 0 0 0 0 0 0 5 5 0 5 5 0 0

PIN NO 21 22 23 24 25 26 27 28

Voltage

00

000005

IC401 (RC4558D)

PIN NO 1 2 3 4 5 6 7 8

Voltage

00 0 -12 0 0 0 12

IC402 (RC4558D)

PIN NO 1 2 3 4 5 6 7 8

Voltage

00 0-12 0 0 0 12

IC403 (RC4558D)

PIN NO 1 2 3 4 5 6 7 8

Voltage

00 0-12 0 0 0 12

IC404 (RC4558D)

PIN NO 1 2 3 45678

Voltage

00 0-12 0 0 0 12

IC405 (M62446AFP)

PIN NO 1234567891011121314151617181920

Voltage

00005.60000 00000000 000

PIN NO 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

Voltage

4.5 0

0000000-6000000 000.10.1

PIN NO 41 42

4.6 4.9

Voltage

IC406 (RC4558D)

PIN NO 1 2 3 45678

Voltage

00 0-12 0 0 0 12

IC407 (RC4558D)

PIN NO 1 2 3 45678

Voltage

00 0-12 0 0 0 12

IC408 (RC4558D)

PIN NO 1 2 3 45678

Voltage

00 0-12 0 0 0 12

IC409 (RC4558D)

PIN NO 1 2 3 45678

Voltage

00 0-12 0 0 0 12

IC501 (TDA8920BTH)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Voltage

1.5 0.7 2 1.5 4.6 0 0 4.5 0 0 2.1 2.2 2.2 1.8 2.1 2.1 1.1 3.1 4.5 0.1

PIN NO 21 22

1.2 1.1

Voltage

IC5001 (APA3541-TRL)

PIN NO 1 2 3 45678

Voltage

2.7 0 2.7 0 2.7 2.7 2.7 5.7

IC502 (TDA8920BTH)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Voltage

1.5 0.7 2 1.5 4.6 0 0 4.5 0 0 2.1 2.2 2.2 1.8 2.1 2.1 1.1 3.1 4.5 0.1

PIN NO 21 22

1.2 1.1

Voltage

IC503 (TDA8920BTH)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Voltage

1.5 0.7 2 1.5 4.6 0 0 4.5 0 0 2.1 2.2 2.2 1.8 2.1 2.1 1.1 3.1 4.5 0.1

PIN NO 21 22

1.2 1.1

Voltage

IC504 ( 74HCU04D)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14

Voltage

4.1 0 2.6 3 2.5 2.6 0 0 5.7 2.6 3 5.7 0 5.7

IC801 (ES6603S)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Voltage 3.5 3.5 2.6 2.6 2.6 2.6 3.8 3.8 2.7 2.6 2.7 2.7 2.6 2.6 2.7 2.7 2.6 2.6 5.1 2.6

PIN NO 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

Voltage 3.9 5.1 0.2 0.2 0 3.3 0 2.6 0 0 0 1.5 2.4 0 3.9 1.6 3.3 2 1.5 1.6

PIN NO 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

Voltage 1.6 2 4.2 4.2 3.3 3.3 2.7 0 1.5 0 0 2.5 2.5 3.5 3.5 2.5 2.4 5.1 4.3 4.3

PIN NO 61 62 63 64

Voltage 3.2 3.1 0.8 3

IC802 (AM5868S)

PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Voltage

1.5 0.7 2 1.5 4.6 0 0 4.5 0 0 2.1 2.2 2.2 1.8 2.1 2.1 1.1 3.1 4.5 0.1

PIN NO 21 22 23 24 25 26 27 28 29 30

00

Voltage

Q301 (2SC1623)

Pin No. 1 2 3

Voltage 0.6 0 0

Q5001 (2SC1623)

Pin No. 1 2 3

Voltage

0.6 0 0

Q5042 (2SA812)

Pin No. 1 2 3

Voltage 0.6 0 0

Q803 (2SC2812N)

Pin No. 1 2 3

Voltage

Q811 ( 2SA812)

Pin No. 1 2 3

Voltage

0.1

1.2 1.1 1.2 1.5 1.5 2 0 0

Q401 (KTC3875-Y)

Pin No. 1 2 3

Voltage

Q5002 (2SC2001L)

Pin No. 1 2 3

Voltage

Q501 (2SC1623)

Pin No. 1 2 3

Voltage 0.6 0 0

Q804 (2SC2812N)

Pin No. 1 2 3

0 2.3 0

Voltage

Q951A (2SA952)

Pin No. 1 2 3

0.8

0

Voltage

0.6

0

5.6

14.4 6.2

0.6 0 0

14 14

Q402 (KTC3875-Y)

Pin No. 1 2 3

0

Voltage 0.6 0 0

Q5003 (2SC1623)

Pin No. 1 2 3

Voltage 0 0

Q801 (2SK3018)

1.9

Pin No. 1 2 3

Voltage 0 0 0

Q805(2SB1132RT100)

Pin No. 1 2 3

Voltage

4.8

4.8

0

Q952A (2SC1623)

Pin No. 1 2 3

Voltage

0.6 0 0

Q403 (2SA812)

Pin No. 1 2 3

Voltage

Q5041 (2SC1623)

0.1

0.7

0.7

Pin No. 1 2 3

Voltage 0.6 0 0

Q802 ( 2SK3018)

Pin No. 1 2 3

Voltage 2.3

Q806(2SB1132RT100)

00

Pin No. 1 2 3

Voltage

3.8

Q953A (TIP42C)

2.0

0

Pin No. 1 2 3

Voltage -12 -24 -13

Page 28

CIRCUIT DIAGRAM (1)- MAIN BOARD

8-3 8-3

D4

C267

D3

C862

D3

C2001

D4

C268

D2

C2002

D4

C2003

C2004

C2005

C2006

C2007

C2008

C2009

C201

1

2

3

4

5

6

A

B

C

D

1

2

345

6

C2010

C2011

C2012

C2013

C2015

C2016

C2017

C2018

C2019

C202

C2020

C2021

C2022

A

C2023

C2024

C2025

C2026

C2027

C2028

C2029

C203

C2030

C2031

C2032

C2033

C2034

C2035

C2036

C2037

C2038

C2039

C204

C2040

C2041

C205

C206

B

C207

C208

C209

C210

C211

C212

C213

C214

C215

C216

C217

C218

C219

C220

C221

C222

C223

C224

C225

C226

C227

C228

C229

C

C230

C231

C232

C233

C234

C235

C236

C237

C238

C239

C240

C241

C242

C243

C244

C245

C246

C247

C248

C249

C250

D

C251

C252

C253

C254

C255

C256

C257

C257

C258

C258

C259

C260

C261

C262

C263

C264

C265

C266

C269

D4

C270

D4

C271

D4

C272

D4

C273

D4

C274

D4

C275

B4

C276

D4

C277

D4

C278

D4

C279

D4

C280

D3

C281

D3

C282

D3

C283

D3

C284

D4

C285

B4

C286

D4

C287

C288

D5

C289

D5

C290

D5

C291

D5

C32

D3

C33

D4

C34

D4

C35

D4

C351

D4

C352

B4

C353

D4

C354

D4

C355

D4

C356

D4

C357

D4

C358

D4

C359

D4

C36

D4

C360

D4

C361

D4

C362

B4

C363

D4

C364

D5

C365

B4

C366

B4

C367

B4

C37

B4

C38

B4

C801

B4

C802

B4

C803

B4

C804

B4

C805

B4

C806

B4

C807

B4

C808

B4

C809

B4

C810

B4

C811

B4

C812

B4

C813

B4

C814

B3

C815

B4

C816

B4

C817

C4

C818

C3

C819

C3

C820

C3

C821

C3

C822

C3

C823

C4

C824

C3

C825

C3

C826

C3

C827

C3

C828

C3

C829

D3

C830

D3

C831

D3

C832

D3

C833

D3

C834

D3

C835

D4

C837

D3

C838

D4

C839

D4

C840

D4

C841

D6

C842

D6

C844

D6

C845

D6

C846

D6

C847

D6

C848

B5

C849

B5

C850

A4

C851

B5

C852

A4

C853

B5

C854

C3

C855

C3

C856

C2

C857

C2

C858

C2

C859

C2

C860

C2

C861

C3

C863

C1

C864

C1

C865

C1

C866

C1

C867

C1

C868

C1

C869

C2

C870

C2

C871

C2

CN801

D1

CN802

D1

CN803

D1

CN804

D1

D801

D1

D802

D1

D803

D1

FB201

D2

FB801

D2

FB802

D2

IC201

D2

IC202

B5

IC202

B5

IC203

D5

IC204

D5

IC205

D5

IC206

D5

IC207

D3

IC208

B6

IC209

B6

IC210

B6

IC351

B6

IC801

B6

IC802

B6

IC803-A

B6

IC803-B

B6

IC803-C

B6

IC803-D

D3

IC803-E

B6

IC803-F

B6

JK801

B6

JK802-A

B6

JK802-B

B6

JK803

B6

JK804

B6

JK805

B6

L187

D3

L201

D5

L202

A1

L203

A1

L204

A2

L205

A1

L206

A2

L207

A2

L208

A2

L351

A2

L352

A3

L801

A3

L802

A3

L803

A3

L804

A3

L805

A3

L806

A3

L807

A3

L808

A3

L809

A3

L810

A3

L811

A3

L812

A3

L813

A3

L814

A3

L815

A3

L816

A4

L817

A4

L818

A4

L819

A3

L820

B3

L821

B3

L822

B3

L824

B4

L825

B2

Q201

B2

Q801

B2

Q802

D1

Q803

D1

Q804

D1

Q805

D1

Q806

D1

Q806

D1

Q809

A6

Q810

A6

Q811

A6

R10

A6

R11

A6

R12

A6

R13

A6

R14

A6

R201

A6

R202

A6

R203

A6

R204

A6

R205

A6

R206

A6

R207

A6

R208

A6

R209

D2

R210

D2

R211

R212

D3

R213

D3

R214

D3

R215

D3

R216

D3

R217

A3

R218

A3

R219

A6

R220

D2

R221

A1

R223

B1

R224

B1

R225

A6

R226

A2

R227

A2

R228

B2

R230

D5

R231

A6

R232

A6

R233

C5

R234

C6

R235

C6

R236

D6

R237

D4

R240

C3

R241

C3

R242

C3

R243

C1

R244

C1

R245

D1

R246

B6

R247

A3

R249

B2

R25

A4

R250

A4

R251

A5

R252

A5

R253

A5

R254

A5

R255

A6

R256

A6

R257

A6

R258

D3

R259

D1

R262

D1

R263

D2

R264

D4

R34

B5

R35

D1

R351

C2

R352

D2

R353

A6

R354

D6

R355

B5

R356

B6

R357

B6

R358

A2

R359

A2

R36

B2

R360

A6

R363

A6

R37

A6

R38

A6

R39

A6

R40

A6

R41

A6

R42

A6

R43

A6

R44

A6

R45

A6

R46

D2

R47

D2

R48

D3

R49

D3

R5

D3

R50

D3

R51

D3

R52

D3

R53

A6

R54

A5

R6

C1

R63

A1

R7

A2

R8

A1

R801

A2

R802

A2

R803

A2

R803

A2

R803

D2

R804

D2

R805

C3

R805

C2

R807

C2

R808

C2

R810

C2

R811

C2

R812

B5

R813

B5

R814

B4

R815

B4

R816

B4

R817

B4

R818

B4

R819

B3

R820

B4

R821

B4

R822

B4

R823

R824

B4

C4

C4

C4

C4

C4

C4

C4

C4

C4

C4

C4

C4

C3

C3

C3

D4

D4

D4

D5

D6

D6

D6

D6

C6

B6

B6

B5

B5

B5

B5

B5

C2

B6

C2

C2

C1

C1

C1

C1

C2

D1

D1

D1

C1

C1

C6

D5

D5

B6

D5

D5

D5

D5

D5

D5

D5

D5

D3

D5

D5

D3

D4

D4

D4

D4

D4

D5

D5

D5

D5

D5

D5

D5

C2

D5

D5

D5

D5

D5

C2

D4

C2

C2

A1

A1

A2

B3

B1

A2

A2

A3

A5

A2

B2

B1

B1

B2

B2

B2

B2

B2

B2

B2

B3

B2

B3

B2

R825

R826

R827

R828

R829

R830

R831

R832

R833

R834

R835

R836

R837

R838

R840

R842

R845

R846

R847

R848

R849

R850

R851

R852

R853

R854

R855

R856

R857

R859

R860

R861

R862

R863

R864

R865

R866

R867

R868

R869

R870

R881

R882

R883

R884

R9

RA351

RA352

RN201

RN202

RN203

RN204

RN205

RN206

RN207

RN208

RN209

RN210

RN211

SW803

SW804

XL201

ZD201

ZD801

ZD802

ZD803

ZD804

ZD805

ZD806

ZD807

ZD808

ZD809

ZD810

B3

B2

B3

B3

B3

B3

B2

B2

B2

B3

B2

B3

D1

D1

D1

D1

D1

A5

A5

A5

A5

A5

A5

A5

A5

A5

A5

A5

D2

D2

D2

D2

D2

D2

D3

D3

A5

A6

A6

A6

A6

B3

A2

A2

A2

A2

C2

B6

B6

C4

C4

C4

C4

D4

D4

D5

D6

B5

B5

C2

B1

C1

D4

C1

A5

A5

A5

A5

A5

A5

A5

A5

A5

A5

Page 29

8-4 8-4

CIRCUIT DIAGRAM (2)- MAIN BOARD

1

A

B

C

D

E

F

2

21

C1

C10

C11

C12

C15

C16

C17

C18

A

B

C

D

E

F

C2

C21

C22

C23

C24

C25

C26

C27

C28

C29

C30

C301

C302

C303

C304

C31

C311

C312

C313

C314

C315

C316

C39

C39

C4

C40

C4007

C4008

C4009

C401

C4010

C4011

C402

C403

C404

C405

C406

C407

C408

C409

C410

C411

C412

C413

C414

C415

C416

C417

C418

C419

C420

C421

C422

C423

C424

C425

C426

C427

C428

C429

C430

C431

C432

C433

C434

C435

C436

C437

C438

C439

C440

C441

C442

C443

C444

C445

C446

C447

C448

C449

C450

C451

C452

C453

C454

C455

C456

C457

C458

C461

C462

C462

C463

C464

C464

C465

C466

C467

C468

C469

C471

C472

C473

C474

3

3

4

4

5

5

6

6 7

7

C475

C476

C477

C478

C479

C480

C481

C482

C483

C484

C485

C486

C487

C488

C490

C491

C492

C494

C495

C496

C5

C5001

C5002

C5003

C5004

C5005

C5006

C5007

C5008

C5009

C501

C5010

C5010

C5011

C5012

C502

C503

C504

C5041

C5042

C5043

C5044

C5045

C5046

C5047

C5048

C5049

C505

C5050

C5050

C5051

C5052

C5053

C5054

C5055

C5057

C5058

C5059

C506

C5060

C5061

C5062

C5063

C5064

C5065

C5066

C507

C5071

C5072

C5073

C5074

C5075

C5076

C5077

C5078

C5079

C508

C5080

C5081

C5082

C5083

C5084

C5085

C5086

C5087

C5088

C5089

C509

C5090

C5091

C5092

C5093

C5094

C5095

C5096

C5097

C5098

C5099

C510

C5100

C5101

C5102

C5103

C5104

C5105

C5106

C5107

C5108

C5109

C511

C5110

C5111

C4

C4

C4

C3

C4

B4

C4

B4

C4

B4

C4

B4

B4

B4

B4

B4

B4

B4

B4

F5

B6

E5

D5

E5

E5

E5

E5

E5

E5

E5

D4

E5

E5

E5

E5

D4

D4

D4

D1

D1

D1

D1

E1

E1

E1

E1

E1

D4

D3

E1

F1

F1

D3

D3

D3

D2

D2

F1

D4

D1

F4

F4

F3

F3

F2

F2

D4

D3

D3

D2

D2

D2

D2

D2

D2

D2

E4

D2

D2

D2

D2

D1

D1

D1

D1

D1

D1

E4

D1

F4

F4

F3

F3

F2

F2

D1

D1

D1

E4

C2

C2

C2

C2

C2

C2

C2

C2

C2

C1

E4

C1

C1

F6

E5

C6

C6

C6

C6

C6

B6

F7

A6

A6

A6

A6

A6

A6

A6

A6

A6

E5

A7

A7

A7

A7

E5

B6

B6

C6

C6

B6

B6

A3

A3

B6

D4

C4

C4

C4

D7

B4

B4

D7

E7

E7

E7

D7

D7

E7

E7

E7

D6

D6

E7

E6

E6

D6

D6

E6

E6

E6

D6

D6

E6

E6

E6

C7

D7

C6

C6

D6

B1

B1

C1

B2

B1

C2

D5

C5

C5

C5

C5

D5

D5

D5

D5

D5

D5

D5

D5

C5

C5

C5

B5

B5

B5

B5

C5

C5

F7

B4

F7

F7

F7

F3

E6

E6

F6

F6

B4

C5

C5

C4

C4

C5112

C5113

C5114

C5115

C5116

C5117

C5118

C5119

C5120

C5125

C5126

C5126

C5127

C5128

C513

C514

C515

C516

C517

C517

C518

C519

C520

C521

C523

C524

C525

C526

C527

C528

C529

C530

C531

C532

C533

C534

C535

C536

C537

C538

C539

C54

C541

C542

C543

C544

C545

C546

C547

C548

C549

C55

C56

C560

C561

C562

C563

C565

C566

C566

C567

C569

C57

C570

C571

C572

C573

C574

C575

C576

C577

C578

C579

C58

C580

C581

C582

C583

C584

C585

C586

C587

C588

C589

C590

C591

C592

C593

C594

C595

C596

C597

C598

C599

C6

C65

C66

C7

C8

C9

C951

C952

C955

C956

C957

C958

C959

C960

C961

C962

C963

C965

C1

C1

C1

C1

C1

C1

C1

E5

F5

E5

D5

E4

E5

E5

E4

E4

D4

D4

E4

F4

E4

E4

E4

F4

F4

F4

F4

F4

F4

F4

F4

F4

D3

D3

D3

D3

D3

D3

E3

E3

E3

B2

E3

E3

E3

E3

D3

D3

E3

E3

E3

A6

A6

E3

F3

F3

F3

F3

F3

F3

F3

F3

A6

F3

D2

D2

D2

D2

D2

D2

E2

E2

E2

A6

E2

E2

E2

E2

D2

D2

E2

E2

E2

E2

F2

F2

F2

F2

F2

F2

F2

F2

F2

F2

A6

A6

A6

A6

D7

E5

A2

A2

A2

A2

A2

A2

A2

A2

B3

B3

B3

B3

C966

C967

C968

C969

C970

C971

C972

C973

C974

C975

C976

C977

C978

C979

C980

C981

C982

C983

C984

C985

CF5041

CF5042

CN201

CN202

CN401

CN5001

CN901A

CN902A

CN903A

CN908A

D1

D2

D301

D302

D303

D304

D305

D306

D307

D308

D309

D310

D311

D312

D313

D314

D315

D316

D317

D5001

D5002

D501

D502

D503

D504

D505

D506

D951

D954

FB301

FB302

FB303

FB5003

IC1-A

IC1-B

IC301

IC401-A

IC401-B

IC402-A

IC402-B

IC403-A

IC403-B

IC404-A

IC404-B

IC405

IC406-A

IC406-B

IC407-A

IC407-B

IC408-A

IC408-B

IC409-A

IC409-B

IC5001

IC501

IC502

IC503

IC504-A

IC504-B

IC504-C

IC504-D

IC504-E

IC504-F

IC505-A

IC505-B

IC953A

IC954A

JK401-A

JK401-B

JK401-C

JK5001

JK501

L5001

L5002

L501

L502

L503

L504

L5041

L505

L506

L951

L952

C3

L955

B3

L957

B3

L958

A2

Q1

A2

Q2

A2

Q3

A2

Q301

B3

Q401

B3

Q402

B3

Q403

B3

Q404

B2

Q405

B2

Q407

B2

Q408

B2

Q410

B2

Q411

C2

Q5001

C2

Q5002

A4

Q5003

A3

Q501

E1

Q5041

E1

Q5042

A5

Q951

A4

Q952A

F5

Q953A

F5

Q954A

A2

Q955A

A3

Q956

A4

QR960

C1

R1

D4

R15

A3

R16

B6

R17

B6

R18

B6

R19

B5

R2

B5

R20

B5

R21

B5

R22

B5

R23

B5

R24

B5

R260

B5

R261

B5

R3

B5

R301

B5

R302

B4

R303

B6

R304

B6

R305

D5

R306

D5

R307

F4

R308

F4

R309

F3

R310

F3

R311

F2

R312

F2

R315

B3

R316

C3

R319

A5

R32

A5

R320

A5

R321

E5

R322

A6

R323

A6

R324

B7

R33

E7

R4

E7

R4001

E6

R4002

E6

R4003

E6

R4004

C6

R4005

B1

R401

B1

R402

C5

R4021

F7

R4022

F6

R4023

C4

R4024

C4

R403

B4

R404

B4

R405

C4

R406

B4

R407

E5

R408

E4

R409

E3

R410

E2

R411

E1

R412

E1

R413

E1

R414

F1

R415

F1

R416

F1

R417

F1

R418

F1

R419

B3

R420

B2

R421

A7

R422

A7

R423

F7

R424

F5

R425

F3

R426

E5

R427

E5

R428

F4

R429

F4

R430

F3

R431

F3

R432

D1

R433

F2

R434

F2

R435

A2

R436

A2

R437

B3

R438

B3

R439

B3