Page 1

1 - 1

BD Home Theater System

HTS3231/12

Service

Service Manual

TABLE OF CONTENTS

Location of PCB Boards ............................................ 1-2

Versions Variation ...................................................... 1-2

Specifications ............................................................ 1-3

Measurement Setup .................................................. 1-4

Service Aids .............................................................. 1-5

ESD & Safety Instruction .......................................... 1-6

Lead-free soldering Information ................................ 1-7

Setting procedure & Repair Instructions........................ 2

Disassembly Instructions & Service positions ..............3

Block & Wiring Diagram ................................................4

Quick Start Guide ..........................................................5

VFD+VOL+USB+MP3 PCB .......................................... 6

MAIN PCB......................................................................7

POWER PCB ................................................................ 8

BD PCB.......................................................................... 9

TOUCH PCB ................................................................ 10

Mechanical Exploded view .......................................... 11

Revision List ................................................................ 12

©

Copyright 2010 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Published by RY_HY 110

2 Service Audio Printed in The Netherlands Subject to modification

Chapter

3139 785 35570

GB

Version 1.0

Page 2

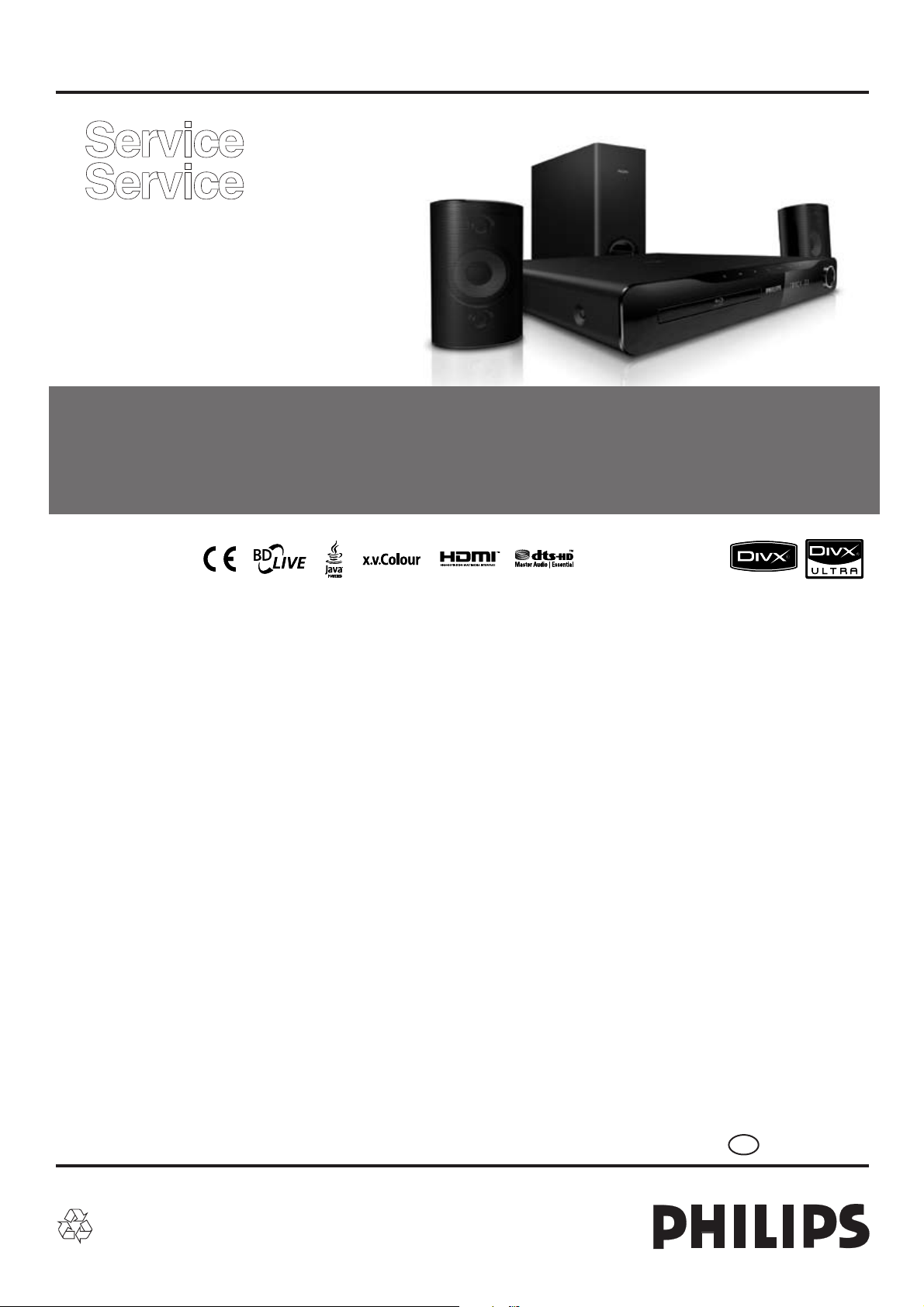

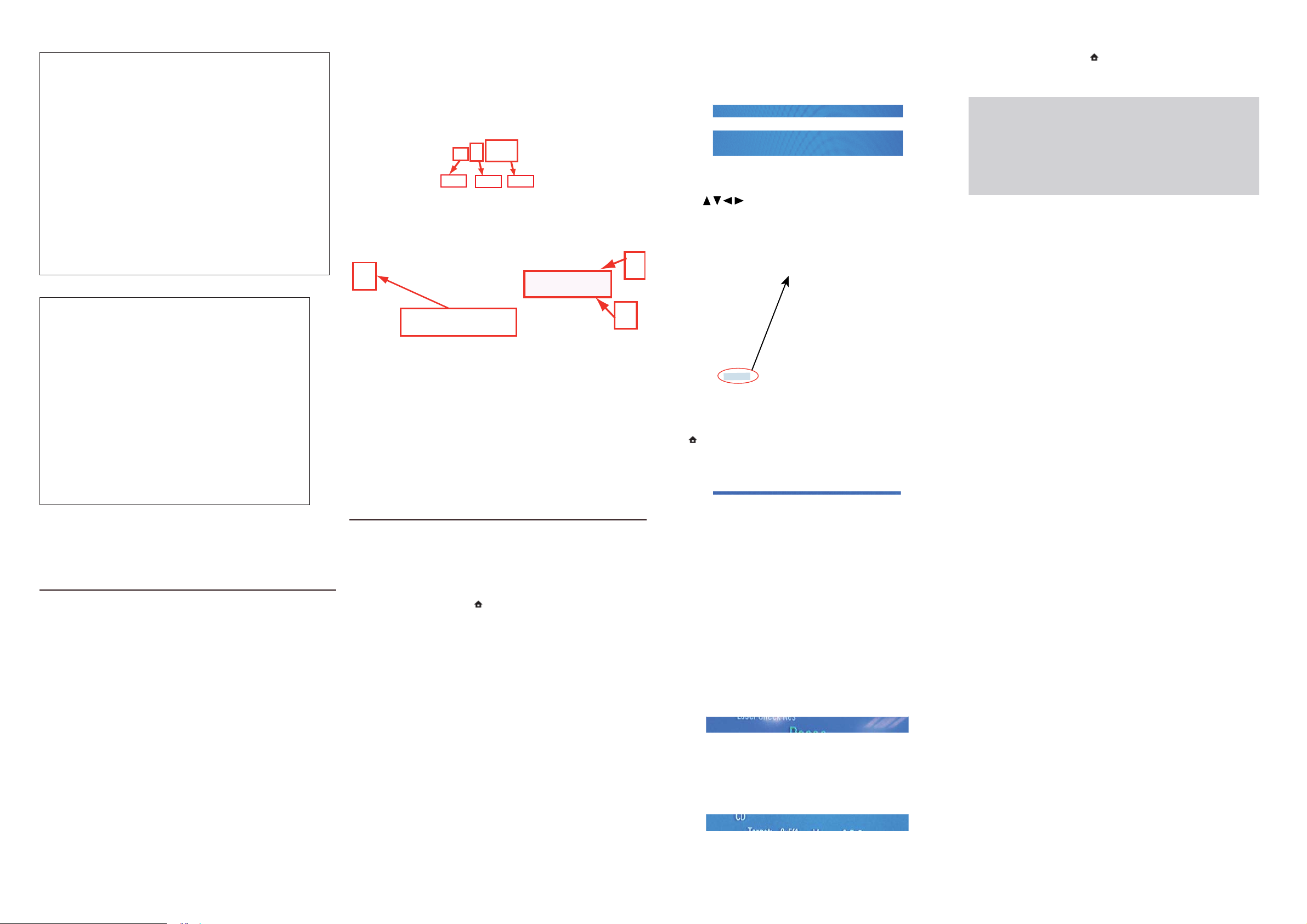

LOCATION OF PCB BOARDS

TOUCH PCB

VFD PCB

1 - 2

BD PCB

MAIN PCB

POWER PCB

Vol+USB+MP3 PCBB

VERSION VARIATION:

Type/Versions

Features

Output Power - 300W

Voltage (220~240V)

AUX/MP3

SERVICE SCNARIO MATRIX:

Type/Versions

Board in used

Main Board

HTS3231

/12

x

x

x

HTS3231

/12

C

Power Board

VFD+VOL+USB+MP3 Board

BD Board

Touch Board

*C = Component Level Repair

*Bd = Board Level Replacement

C

C

Bd

C

Page 3

SPECIFICATIONS

1 - 3

Playback media

BD-Video, DVD-Video, DVD+R/+RW,DVD-R/-RW, DVD+R/R DL, CD-R/CDRW,Audio CD, Video CD/SVCD, PictureCD,

MP3-CD, WMA-CD, DivX (Ultra)-CD, USB ash drive.

File Format

Audio ........................................................................mp3, .wma

Video ...................................................... .avi, .divx, .mkv, .wmv

Picture ...................................................................jpg, .gif, .png

Amplifier

Total output power

Frequency response .................................. 20 Hz-20 kHz /±3dB

Signal-to-noise ratio... ................. > 65 dB (CCIR) /(A-weighted)

Input sensitivity:

AUX .............................................................................. 1000 mV

MP3 LINK ...................................................................... 500 mV

Video

Signal system

HDMI output .............480i/576i, 480p/576p,720p, 1080i, 1080p

Audio

Sampling frequency:

MP3 .................................................. 32 kHz, 44.1 kHz, 48 kHz

WMA ............................................................... 44.1 kHz, 48 kHz

Constant bit rate:

MP3 ...........................................................112 kbps - 320 kbps

WMA ............................................................ 48 kbps - 192 kbps

................................ 300 W RMS (30%THD)

........................................................ PAL / NTSC

Subwoofer

Impedance ....................................................................... 4 ohm

Speaker drivers .......................................165 mm (6.5”) woofer

Frequency response ............................................ 40 Hz-150 Hz

Dimensions (WxHxD) ..............................123 x 309 x 369(mm)

Weight ............................................................................3.56 kg

Cable length ........................................................................ 4 m

Laser specification

Laser Type (Diode)

...................................................InGaAIP (DVD), A IGaAs (CD)

Wave length ..............................................405 +5nm/-5nm (BD)

............................................................ 650+13nm/-10nm (DVD)

...............................................................790 +15nm/-15nm(CD)

Output power (Max. ratings) ......... 20mW(BD), 7mW (DVD/CD)

Speci cations subject to change without prior notice.

......................................InGaN/AIGaN (BD)

Radio

Tuning range ..................................FM 87.5-108 MHz (50 kHz)

Signal-to-noise ratio ....................................................FM 55 dB

Frequency response ....................... FM 180 Hz-12.5 kHz/ ±3dB

USB

Compatibility ...............................................Hi-Speed USB (2.0)

Class support ......................... UMS (USB Mass Storage Class)

File system ............................................. FAT16, FAT32, NTFS

Maximum memory support .......................................... < 160GB

Main Unit

Power supply

Power consumption ............................................................ 55W

Standby power consumption ........................................ ≤ 0.9 W

Dimensions (WxHxD) ................................ 360 x 58 x 351(mm)

Weight ............................................................................ 3.1 kg

Speakers

Speaker impedance ......................................................... 8 ohm

Speaker drivers .......................................1 x 3”woofer+1”twitter

Frequency response ...........................................150 Hz-20 kHz

Dimensions (WxHxD): ............................... 95 x161x 87 (mm)

Weight: .......................................................................... 0.56 kg

Cable length: .......................................................................3 m

................................................ 220-240V; ~50 Hz

Page 4

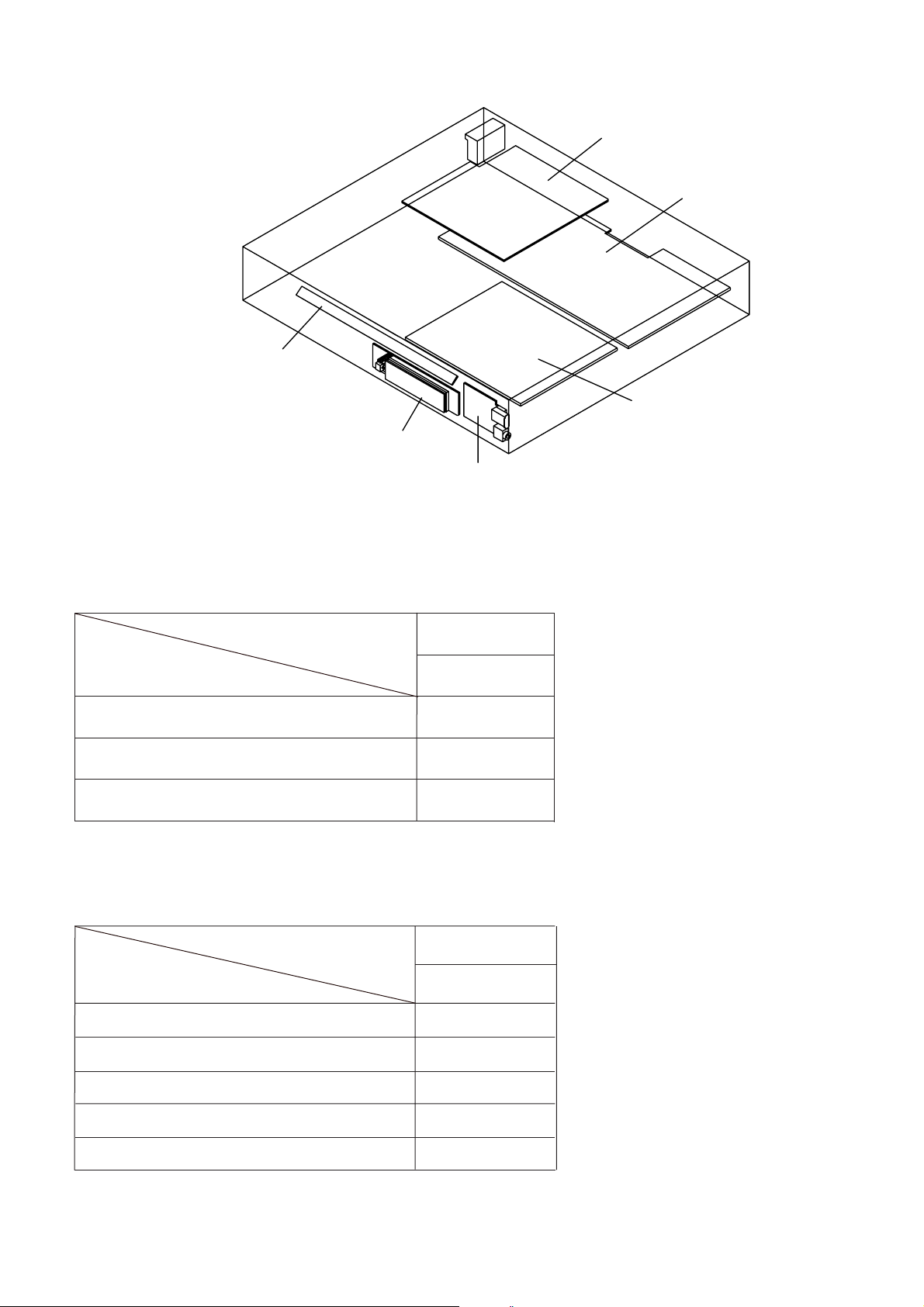

MEASUREMENT SETUP

Tuner FM

1 - 4

Bandpass

LF Voltmeter

e.g. PM2534

RF Generator

e.g. PM5326

DUT

250Hz-15kHz

e.g. 7122 707 48001

Ri=50

S/N and distortion meter

e.g. Sound Technology ST1700B

Use a bandpass filter to eliminate hum (50Hz, 100Hz) and disturbance from the pilottone (19kHz, 38kHz).

CD

Use Audio Signal Disc

(replaces test disc 3)

DUT

SBC429 4822 397 30184

L

R

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

Page 5

SERVICE AIDS

Service Tools:

Universal Torx driver holder .................................4822 395 91019

Torx bit T10 150mm ...........................................4822 395 50456

Torx driver set T6-T20 .........................................4822 395 50145

Torx driver T10 extended .....................................4822 395 50423

Compact Disc:

SBC426/426A Test disc 5 + 5A ...........................4822 397 30096

SBC442 Audio Burn-in test disc 1kHz .................4822 397 30155

SBC429 Audio Signals disc .................................4822 397 30184

Dolby Pro-logic Test Disc ....................................4822 395 10216

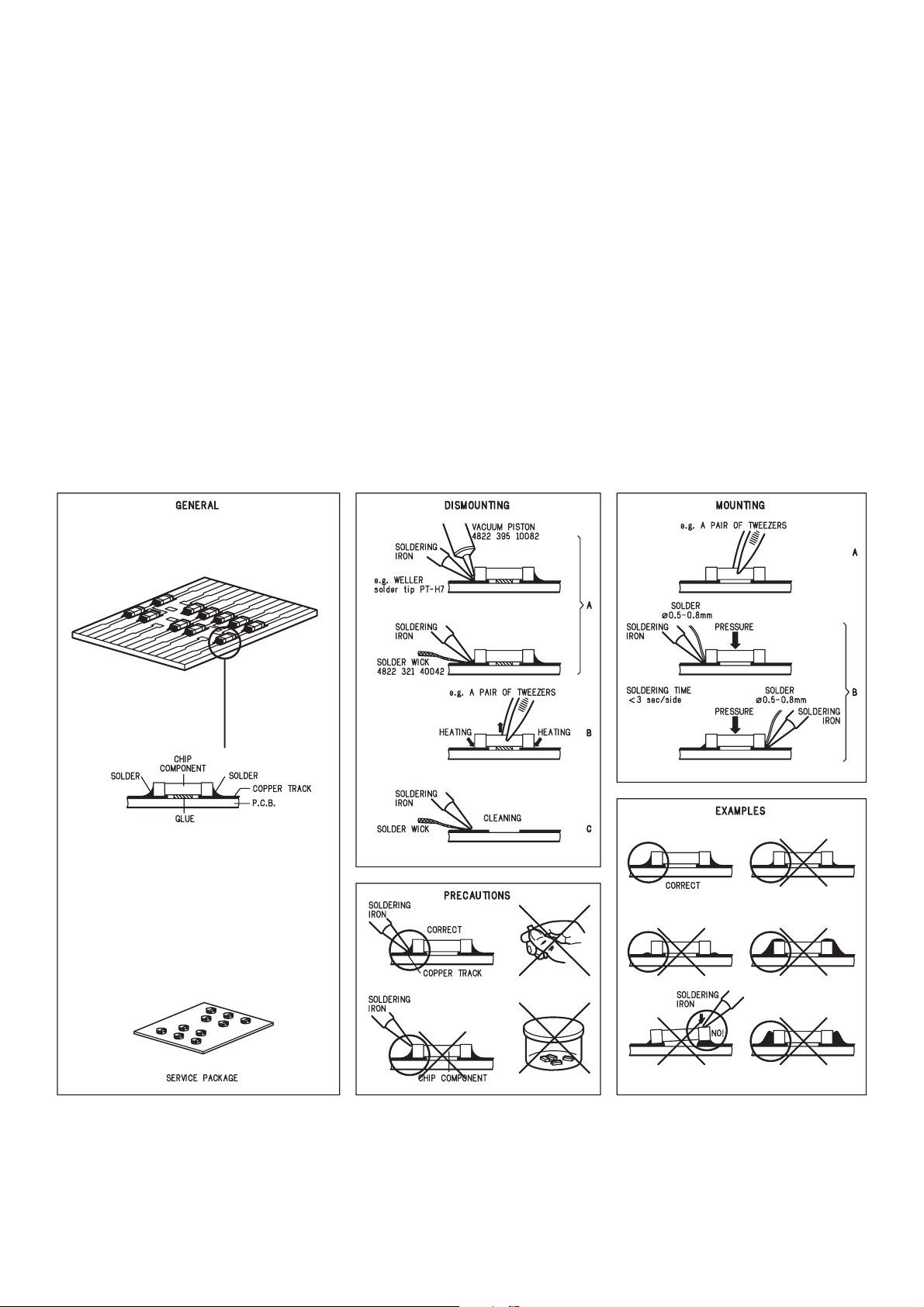

HANDLING CHIP COMPONENTS

1 - 5

Page 6

GB

A

WARNING

1 - 6

ESD

WAARSCHUWING

NL

ll ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

F

ATTENTION

Tous les IC et beaucoup d’autres

semi-conducteurs sont sensibles aux

décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est

prise à leur manipulation.

Lors de réparations, s’assurer de bien être relié

au même potentiel que la masse de l’appareil et

enfiler le bracelet serti d’une résistance de

sécurité.

Veiller à ce que les composants ainsi que les

outils que l’on utilise soient également à ce

potentiel.

GB

Complete Kit ESD3 (small tablemat, wristband,

connection box, estention cable and earth cable .......4822 310 10671

Wristband tester .................................................................4822 344 13999

D

WARNUNG

Alle ICs und viele andere Halbleiter sind

empfindlich gegenüber elektrostatischen

Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kan

die Lebensdauer drastisch reduzieren.

Veranlassen Sie, dass Sie im Reparaturfall über

ein Pulsarmband mit Widerstand verbunden

sind mit dem gleichen Potential wie die Masse

des Gerätes.

Bauteile und Hilfsmittel auch auf dieses gleiche

Potential halten.

ESD PROTECTION EQUIPMENT

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor electrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie kan

de levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

I

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevità potrebbe essere fortemente

ridatta in caso di non osservazione della più

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto

a resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo

potenziale.

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used.

Safety components are marked by the symbol

!

.

CLASS 1

LASER PRODUCT

NL

Veiligheidsbepalingen vereisen, dat het apparaat bij reparatie in

zijn oorspronkelijke toestand wordt teruggebracht en dat onderdelen,

identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbol

!

.

3122 110 03420

F

Les normes de sécurité exigent que l’appareil soit remis à l’état

d’origine et que soient utiliséés les piéces de rechange identiques

à celles spécifiées.

Less composants de sécurité sont marqués

!

.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu

beachten. Der Original zustand des Geräts darf nicht verändert werden;

für Reparaturen sind Original-Ersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol

!

markiert.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso

nelle condizioni originali e che siano utilizzati i pezzi di ricambio

identici a quelli specificati.

Componenty di sicurezza sono marcati con

!

.

GB

After servicing and before returning set to customer perform a leakage

current measurement test from all exposed metal parts to earth ground

to assure no shock hazard exist, The leakage current must not

exceed 0.5mA.

GB

Warning !

Invisible laser radiation when open.

Avoid direct exposure to beam.

S

Varning !

Osynlig laserstrålning när apparaten är öppnad och spärren

är urkopplad. Betrakta ej strålen.

Varoitus !

SF

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen!

DK Advarse !

Usynlig laserstråling ved åbning når sikkerhedsafbrydere er

ude af funktion. Undgå udsaettelse for stråling.

F

"Pour votre sécurité, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

Page 7

Pb(Lead) Free Solder

When soldering , be sure to use the pb free solder.

INDENTIFICATION:

Regardless of special logo (not always indicated)

onemusttreatallsetsfrom1 Jan2005onwards,according

next rules:

Important note: In fact also products of year 2004 must

be treatedin this way as long as youavoid mixing solderalloys(leaded/ lead-free). So best to always use SAC305

and the higher temperatures belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with

ordercode 0622149 00106. Iflead-free solder-paste

is required, please contact the manufacturer of your

solder-equipment. In general use of solder-paste

withinworkshops shouldbeavoidedbecausepaste is

not easy to store and to handle.

• Use only adequate solder tools applicable for lead-

free solder alloy. The solder tool must be able

– To reach at least a solder-temperature of 400@C,

– T o stabilize theadjustedtemperature atthesolder-

tip

– T o exchange solder-tips fordifferent applications.

• Adjust your solder tool so that a temperature around

360@C – 380@C is reachedand stabilized at thesolder

joint.Heating-timeofthesolder-jointshould notexceed

~ 4 sec. A void temperaturesabove 400@C otherwise

wear-out of tips will rise drastically and flux-fluid will

be destroyed. To avoid wear-out of tips switch off unused equipment, or reduce heat.

• Mix of lead-free solderalloy / parts with leadedsolder

alloy / parts is possible but PHILIPS recommends

strongly to avoidmixed solderalloy types (leadedand

lead-free).

Ifonecannot avoid or does not knowwhetherproduct

is lead-free, clean carefully the solder-joint from old

solder alloy and re-solder with new solder alloy

(SAC305).

• Use only original spare-parts listed in the Service-

Manuals. Not listed standard-material (commodities)

has to be purchased at external companies.

• Special information for BGA-ICs:

– Always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for desolderingalwaysuse thelead-free temperatureprofile,

in case of doubt)

– Lead free BGA-ICs will be deliveredin so-called ‘dry-

packaging’(sealedpack including a silica gelpack) to

protect the IC against moisture. After opening,

1 - 7

dependent of MSL-level seenonindicator-label in the

bag, the BGA-IC possibly still has to be baked dry.

(MSL=Moisture Sensitivity Level). This will be

communicated via AYS-website.

Do not re-use BGAs at all.

• Forsets produced before 1.1.2005 (except products

of 2004), containing leaded solder-alloy and

components,all neededspare-parts willbe available

till the end of the service-period. For repair of such

sets nothing changes.

• On our websitewww.atyourservice.ce.Philips.com

you find more information to:

• BGA-de-/soldering (+ baking instructions)

• Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical information

within the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

Page 8

Setting procedure & Repair instruction

1)Restore factory setting

a) Press “ ” <Home> button on R/C.

b) Select <SETUP>, then press “OK” button on R/C.

c) Select <Advanced setup> ,then press < OK > button on R/C.

d) Select <Restore default settings>,then press <OK> to confirm.

2)Password change

a) Press “

b) Select <SETUP>, then press “OK” button on R/C.

c) Select <preference setup>, then press <OK> button on R/C.

d) Select <Change Password> <Confirm>, then press <OK> button

on R/C.

“0000” is default password supplied.

3)Trade mode

” <Home> button on R/C.

5) Upgrading new software

Method 1: Update software from a USB storage device or CD-R

a) Create a folder named “UPG” in your CD-R or USB storage

device, and Copy the latest upgrading software into the folder.

b) Insert the CD-R program disc or connect the USB storage device

to the home theater.

c) Press “

” <Home> button on R/C, and select <Setup>.

d) Select <Advance Setup> <Software Update> <USB>.

e) TV will show message as follow:

Now searching for upgrade software!

Please wait...!

Software upgrade will take 5 minutes

Do not switch off!

Package version: 000029.0

Software BE Completed

Software FE Completed

Software MCU1: Not started

Software Dock: 2%

Software MCU3: Not started

Software upgrade will take 5 minutes

Do not switch off!

2 - 12 - 1

b) Press “

” <Home> button on R/C, and select <Setup>.

c) Select <Advance Setup> <Software Update> <Network>.

d) TV will show message as follow:

Now searching for upgrade software!

Please wait...!

Software updates for this player have been found. Do you want to

upgrade?

a) In open model,press “

” <Home> button on R/C.

b) Press “2” “5” “9” on R/C,VFD will display “TRA ON” or “TRA

OFF”.

4)Check software version

a) Press “

” <Home> button on R/C

b) Select <Setup>, then press <OK> button on R/C.

c) Select <Advanced Setup> <Version Info.>,then press <OK>

button on R/C.

d) TV will show message as follow:

Model:HTS3231/12

!

Version:

System SW:29.00

Subsystem SW:28-00-00-00

Ethernet MAC:00-25-D1-02-25-D4

http://www.philips.com/support

Close

e) Select <Close> on the version display screen and press <OK>

button to exit .

Software updates for this player have been found. Do you want to

upgrade?

Cancel

Start

f) Select <Start>, press <OK> button on R/C.

Software upgrade will take 5 minutes

Do not switch off!

Package version: 000029.0

Package version: 000029.0

Software BE Completed

Software FE Completed

Software MCU1: 1%

Software Dock: Failed

Software MCU3:

g)The set will shut down automatically when the software upgrade

is completed.

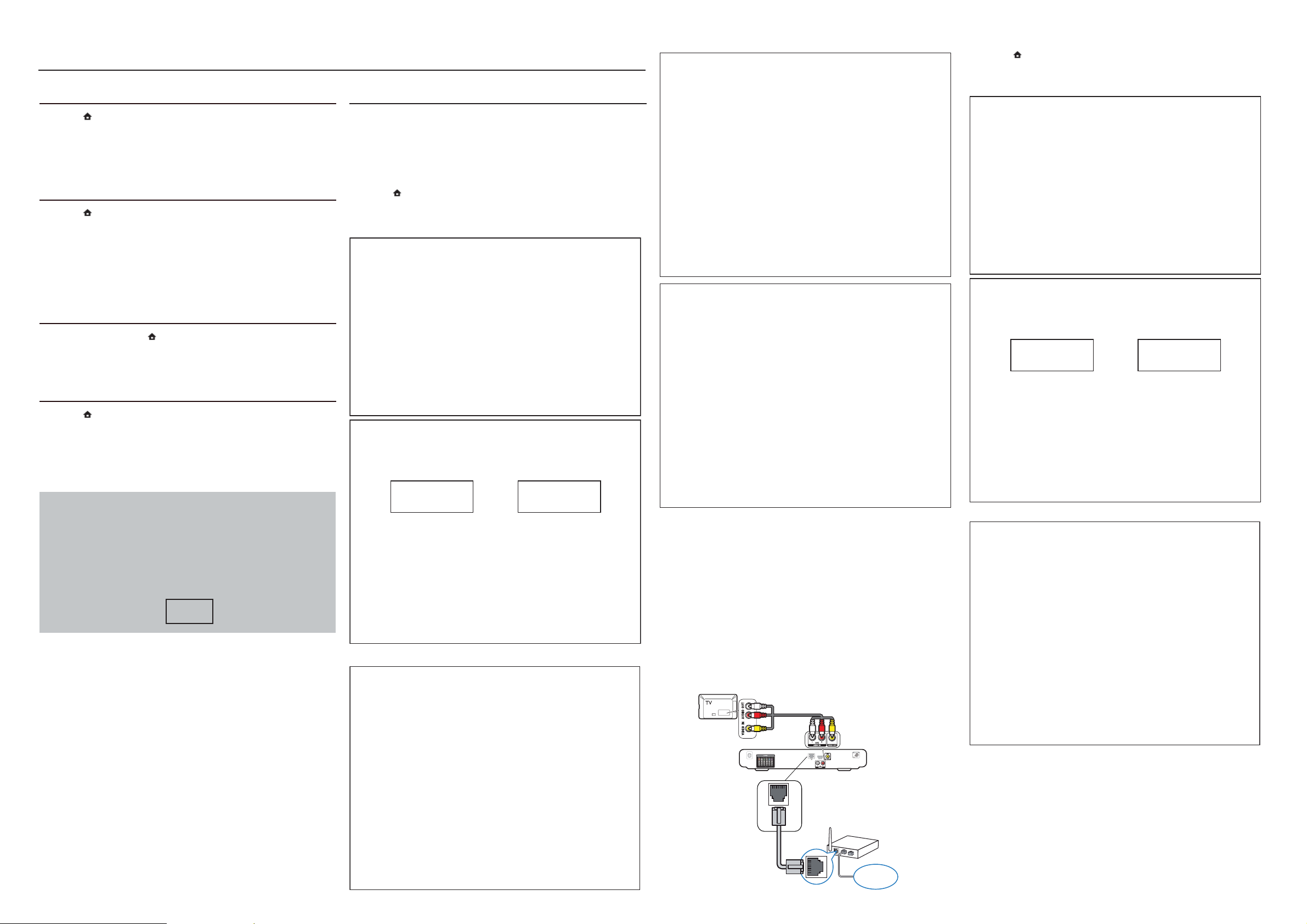

Method 2: Update software from the network

Note: To check for new updates, compare the current software

version of your home theater with the latest software version (if

available) on the Philips web site, and for BD-Live application and

software update, make sure that the network router has access to

the Internet and the firewall is disabled.

a) The “LAN” jack at the back panel of the set must be connect to

the network router via network cable and the set connect to TV,

Prepare the connection as shown follow:

Cancel

e) Select <Start>, press <OK> button on R/C.

Software upgrade will take 5 minutes

Do not switch off!

Package version: 000029.0

Software BE 80%

Software FE Completed

Software MCU1:

Software Dock:

Software MCU3:

Start

Software BE 80%

Software FE Completed

Software MCU1:

Software Dock:

Software MCU3:

LAN

www

Page 9

Software upgrade will take 5 minutes

Do not switch off!

c) Assembly Blu-ray Loader to “J802”,”J900”,”J906” on the top of

BD Board as shown below.

e) Insert empty USB device of MSC type and press <OK> button

with R/C as shown follow:

2 - 22 - 2

j) If laser check fails press “

matching procedure.

” <Home> button and repeat OPU

Package version: 000029.0

Software BE Completed

Software FE Completed

Software MCU1: Not started

Software Dock: 2%

Software MCU3: Not started

Software upgrade will take 5 minutes

Do not switch of

Package version: 000029.0

Software BE Completed

Software FE Completed

Software MCU1: 1%

Software Dock: Failed

Software MCU3:

f!

J906

J900

J802

d) Remove soldered joint on the ESD protection points.

The ESD protection points

on the bottom of board.

The ESD protection points

on the top of board.

Top side view of OPU

Bottom side view of OPU

Note: The 2 ESD protection points on any one side must be

soldered if

o the Blu-ray Loader is OK and needs to be disconnected

from connector J802, J900 and J906 of the BD Board.

o the defective Blu-ray Loader is needed to be send back to

supplier for failure analysis and to support backcharging evidence.

“

f) Using

” buttons on R/C input the 6-digits OPU data

given on the 1D barcode (see label on the Loader) with the on-

screen selection and press <OK> button to save each digit entered

as shown follow:

1 2 3 4 1 2

g) Press <Back> followed by <OK> button to finish OPU matching

and “

”<Home> button to exit.

h) Repeat step c) and select item [6] ,then press <OK> button on

R/C as shown follow:

CAUTION!

This information is confi dential and may not be

distributed.Only a qualifi ed service person should

reprogram the Region Code.

f) The set will shut down automatically when the software upgrade

is completed.

6)How to replace the defective Blu-ray Loader

a) Remove the defective Blu-ray Loader.

b) Remove the shield cover at the top of Blu-ray Loader as shown

below.

7)BD board and Blu-ray Loader OPU matching procedure

Note: This procedure must be performed whenever the defective

Blu-ray Loader or BD Board has been replaced .

a) Assembly Blu-ray Loader to BD Board.

b) Remove soldered joint on the ESD protection points.

c) Power on the set , press “

” <Home> button and input “5” “1”

“7” “7” on R/C.

d) Go into OSD Select mode and select item [5] ,then press <OK>

button on R/C as shown follow:

Wait laser check to complete,press <stop> button to exit as

i)

shown follow:

Page 10

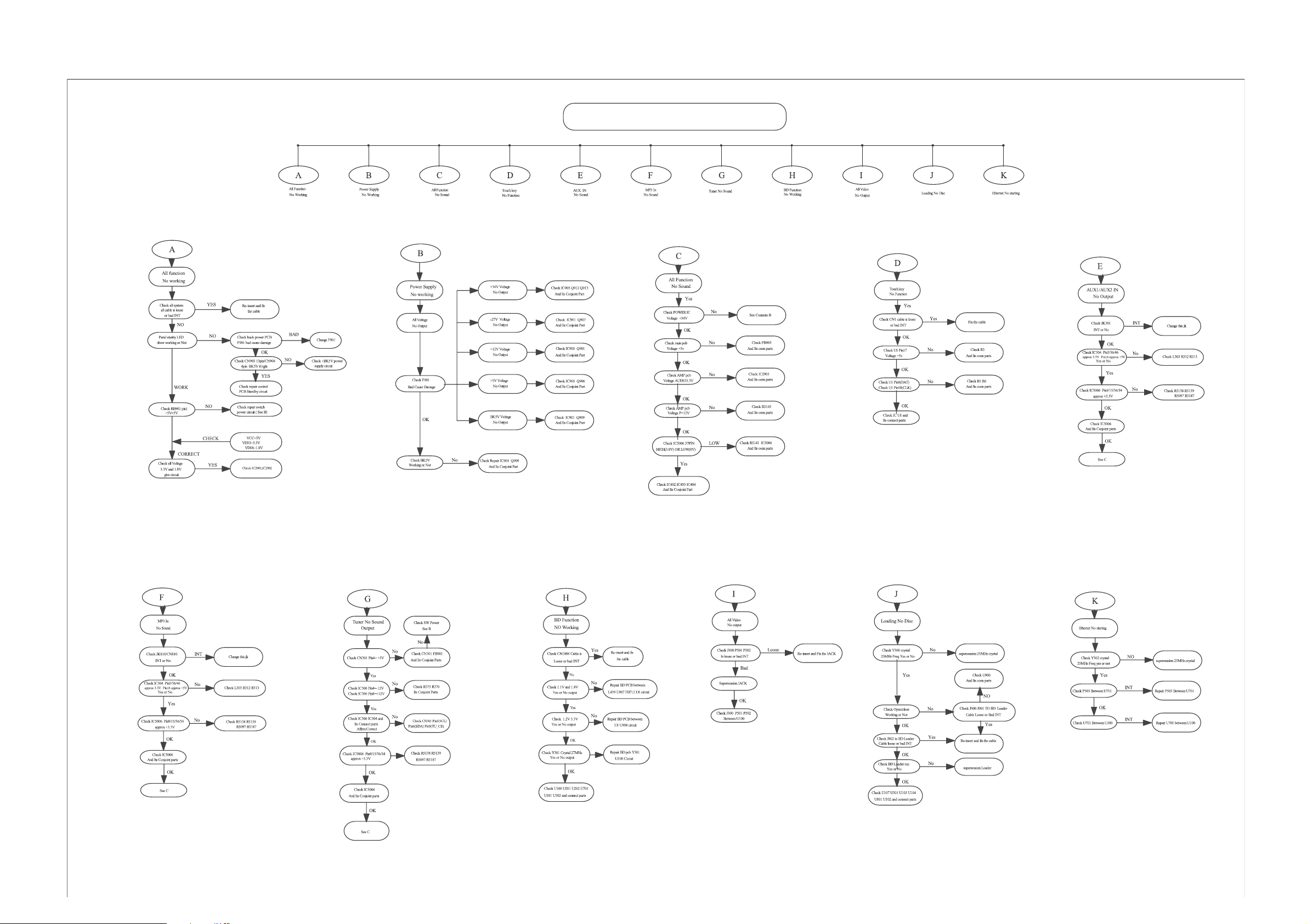

REPAIR INSTRUCTIONS

2 - 32 - 3

MAIN UNIT REPAIR CHART

Page 11

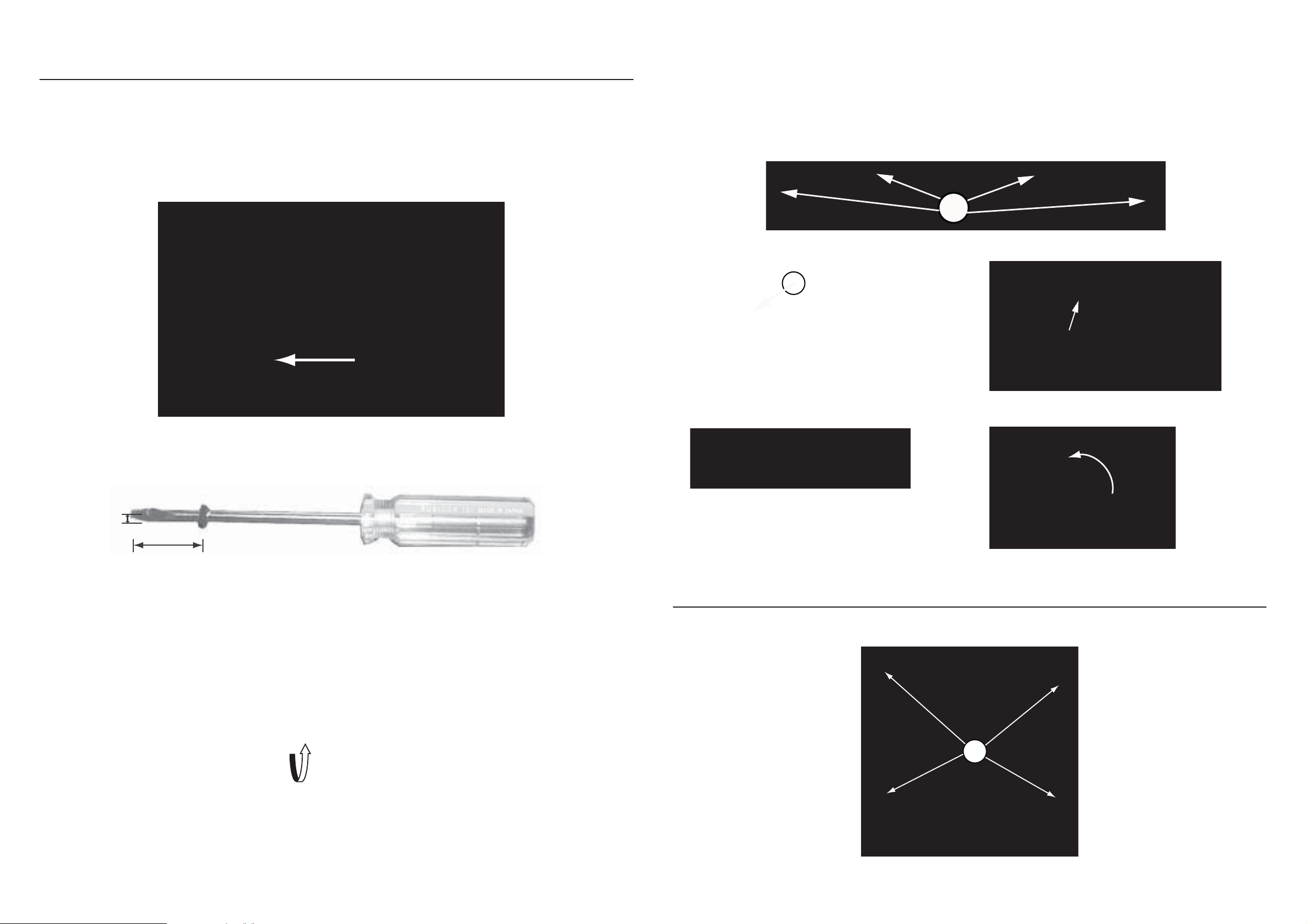

DISASSEMBLY INSTRUCTIONS

3 - 1 3 - 1

Dismantling of theTop & Front Panel Assemble

1) Open the BD Tray by using the Open/Close Button while the Set is ON and disconnect the mains supply after removing the Tray

Cover.

Note: If this is not possible, the BD Tray has to be open manually.

Take a mini screw driver about 2mm diameter and make a marking 24mm from the tip as shown in gure 2 . Place the set on its

side, insert the mini screw driver till the marking and slide it towards the left as shown in gure 1 until the Tray moves out of the Front

Panel.

2) Return the set to its upright position and remove the Tray Cover as shown in Figure 3 and close the tray manually by pushing it back

in.

Qvti

3) Loosen 6 screws and remove the Top Cover by lifting the rear portion upwards before sliding it out towards the rear.

- 4 screws “A” at the back panel as shown in gure 4.

- 1 screw “B” each on the left & right side as shown in gure 5.

4) Remove Volume KNOB as shown in gure 6 and using sleeve to lossen screw as shown in gure 7 & 8 to remove the front panel.

A

Figure 4

B

Push

Figure 5

mm2

24mm

Figure 6

Figure 1

Figure 7

Figure 8

Figure 2

Dismantling of the BD Module

1) Loosen 4 screws “ C “ at the BD Module as shown in gure 9.

Figure 3

C

Figure 9

Page 12

3 - 2 3 - 2

Dismantling of the VFD+VOL+USB+MP3 Board

1) Loosen 6 screws “D” on the top of VFD+VOL+USB+MP3 Board as shown in gure 10.

D

Figure 10

Dismantling of the TOUCH Board

1) Loosen 4 screws “ E ” on the top of touch Board bracket as shown in gure 11.

Dismantling of the MAIN Board

1) Loosen 3 screws “ H ” on the top of MAIN Board as shown in gure 14.

2) Loosen 3 screws “ I ” at the back panel as shown in gure 15.

H

E

Figure 11

Dismantling of the BD Board

1) Loosen 4 screws “ F ” on the top of BD Board as shown in gure 12

2) At the back panel, loosen 2 screws “G” as shown in gure 13

F

Figure 14

I

Figure 15

Dismantling of the POWER Board

1) Loosen 5 screws “J ” on the top of Power Board as shown in gure 16.

k

Figure 12

G

Figure 13

J

Figure 16

Page 13

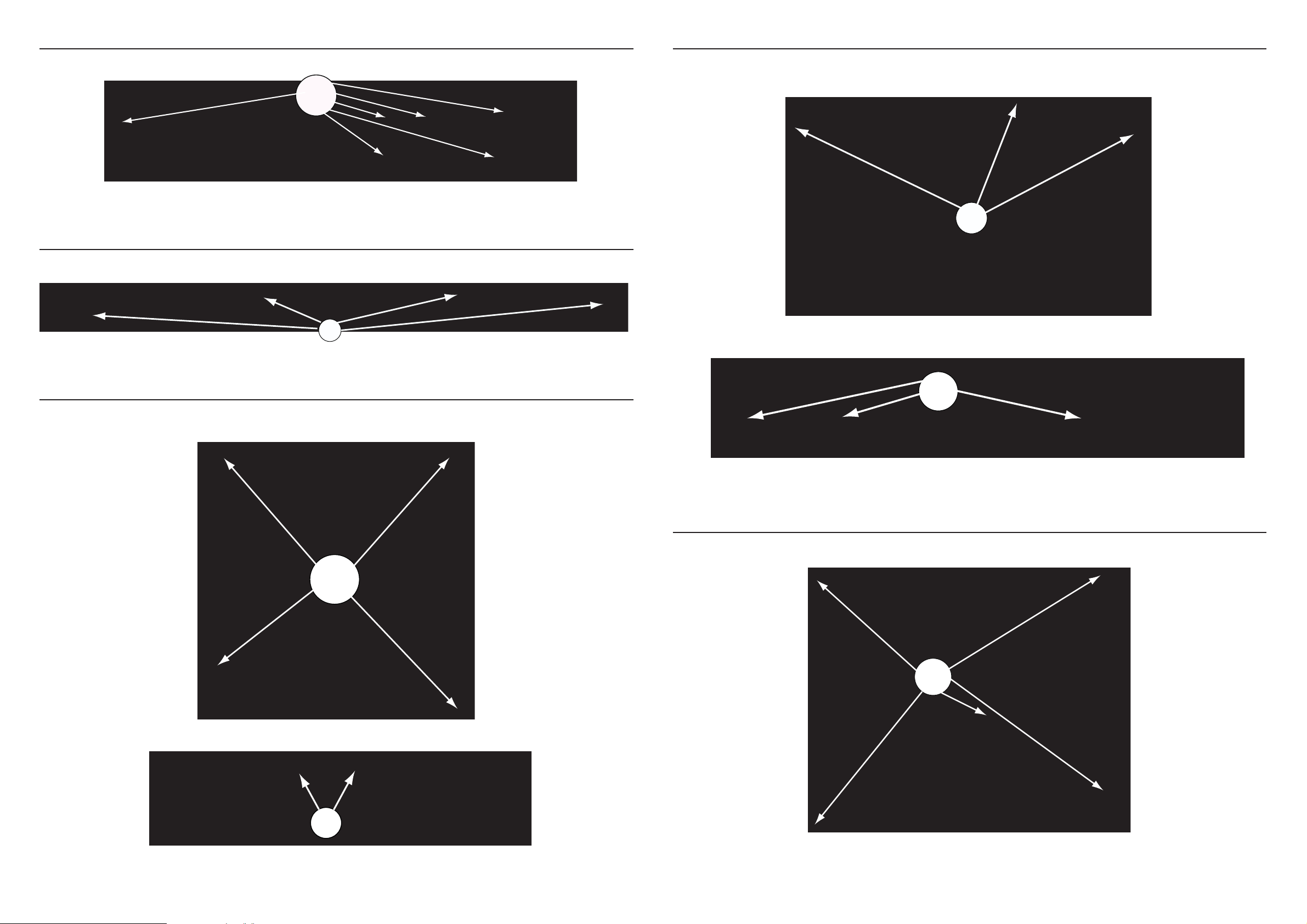

SERVICE POSITIONS

3 - 3 3 - 3

Note:In some service positions the components or copper patterns of one board may risk touching its neighbouring pc boards or

metallic parts. To prevent such short-circuit use a piece of hard paper or other insulating material between them.

Page 14

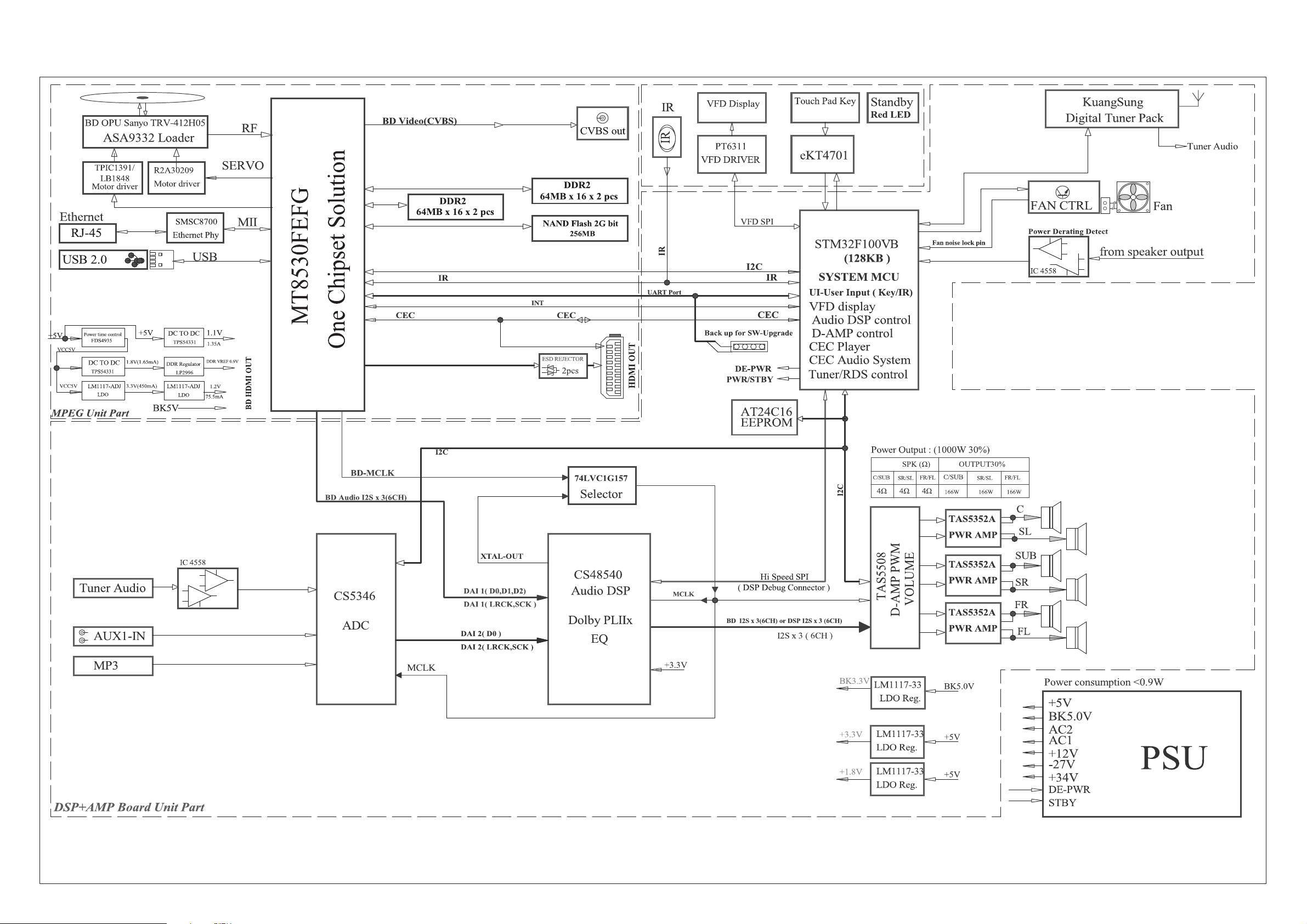

BLOCK DIAGRAM

4 - 1 4 - 1

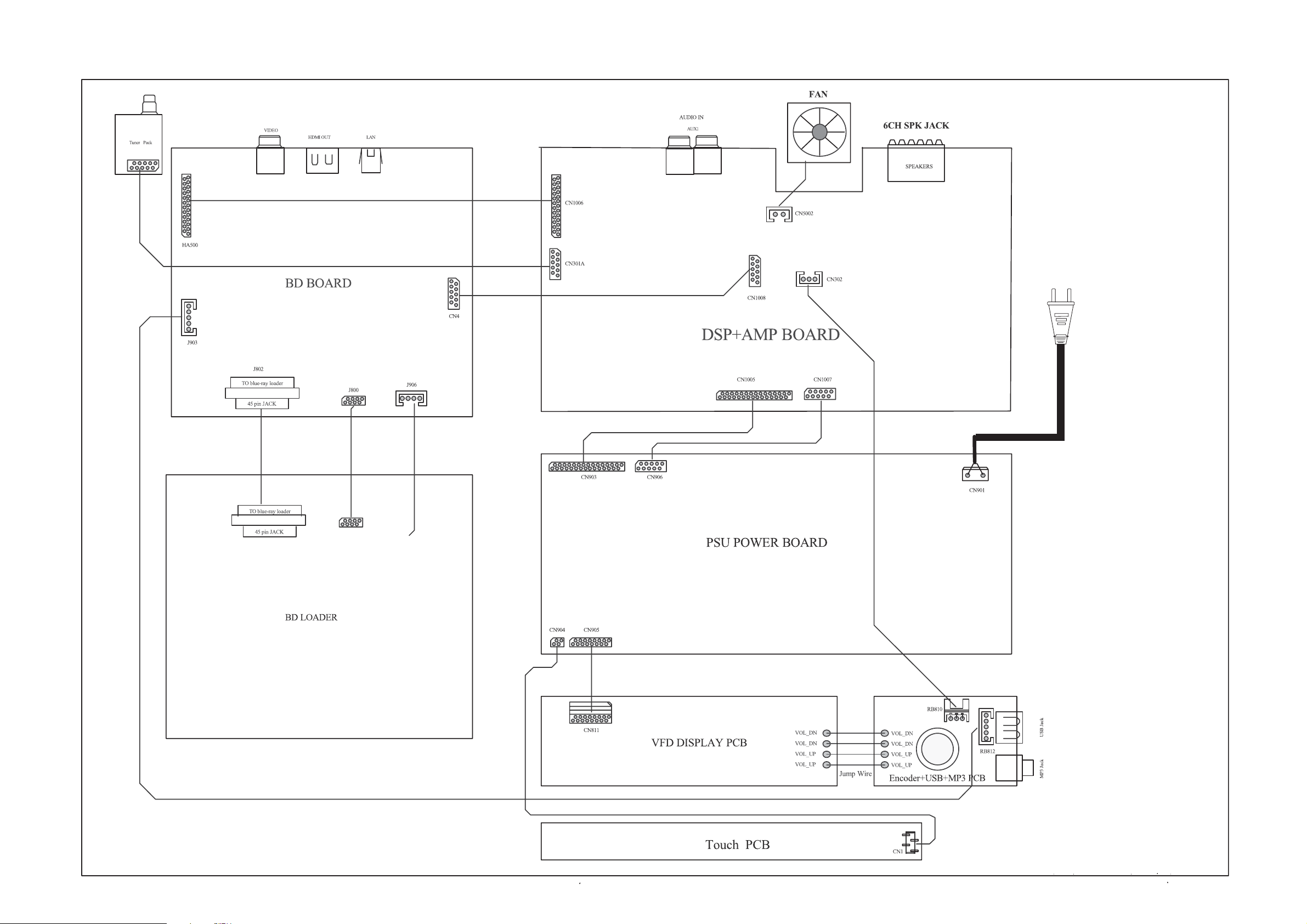

Page 15

WIRING DIAGRAM

4 - 2 4 - 2

V3

V7

V4

V8

V5

V2

V1

V6

Page 16

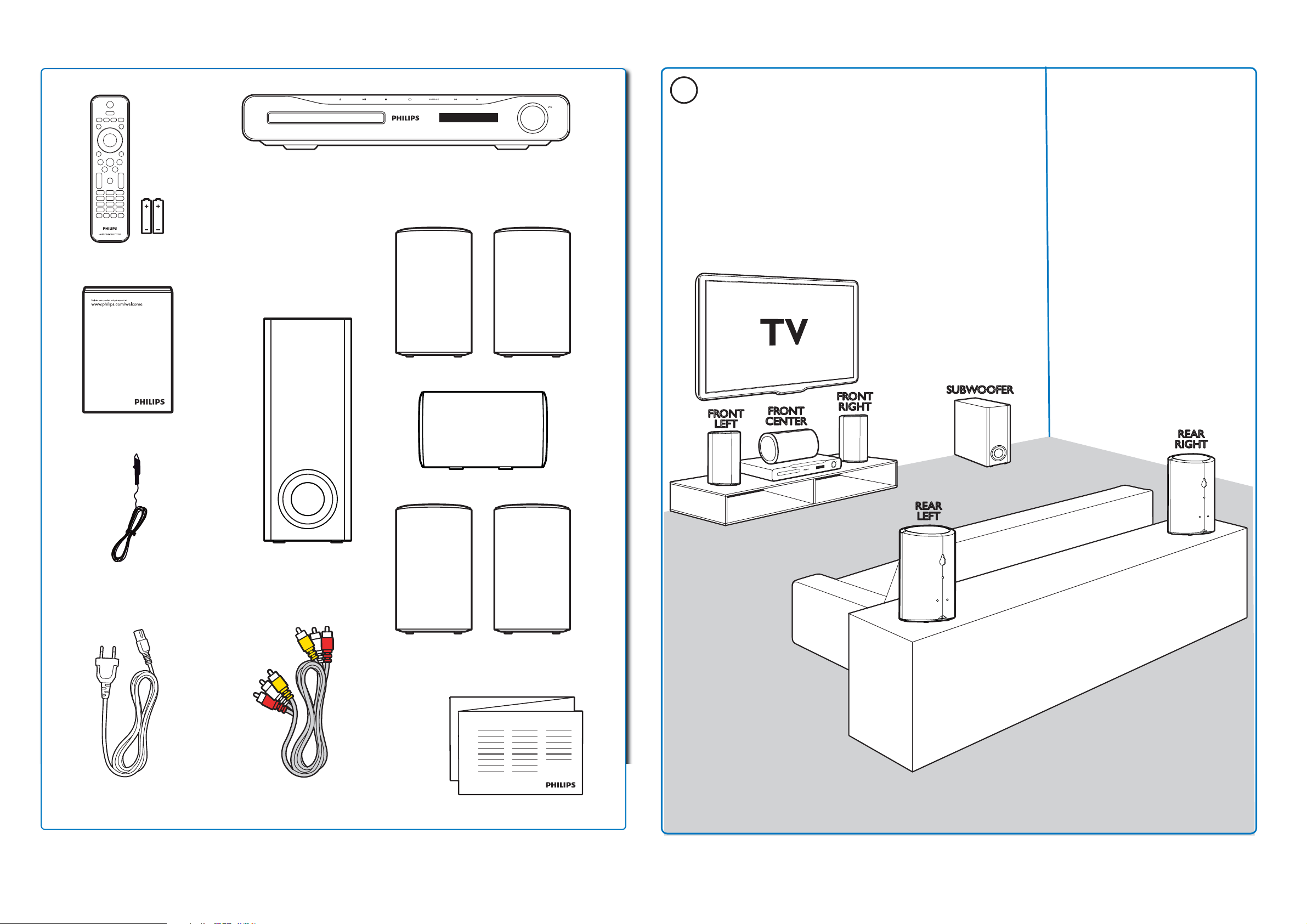

QUICK START GUIDE

SUBWOOFERSUBWOOFER

REAR

LEFT

REAR

LEFT

REAR

RIGHT

REAR

RIGHT

FRONT

CENTER

FRONT

CENTER

FRONT

LEFT

FRONT

LEFT

FRONT

RIGHT

FRONT

RIGHT

User Manual

5 - 1 5 - 1

1

FM Antenna

Power cord

Audio/Video

Page 17

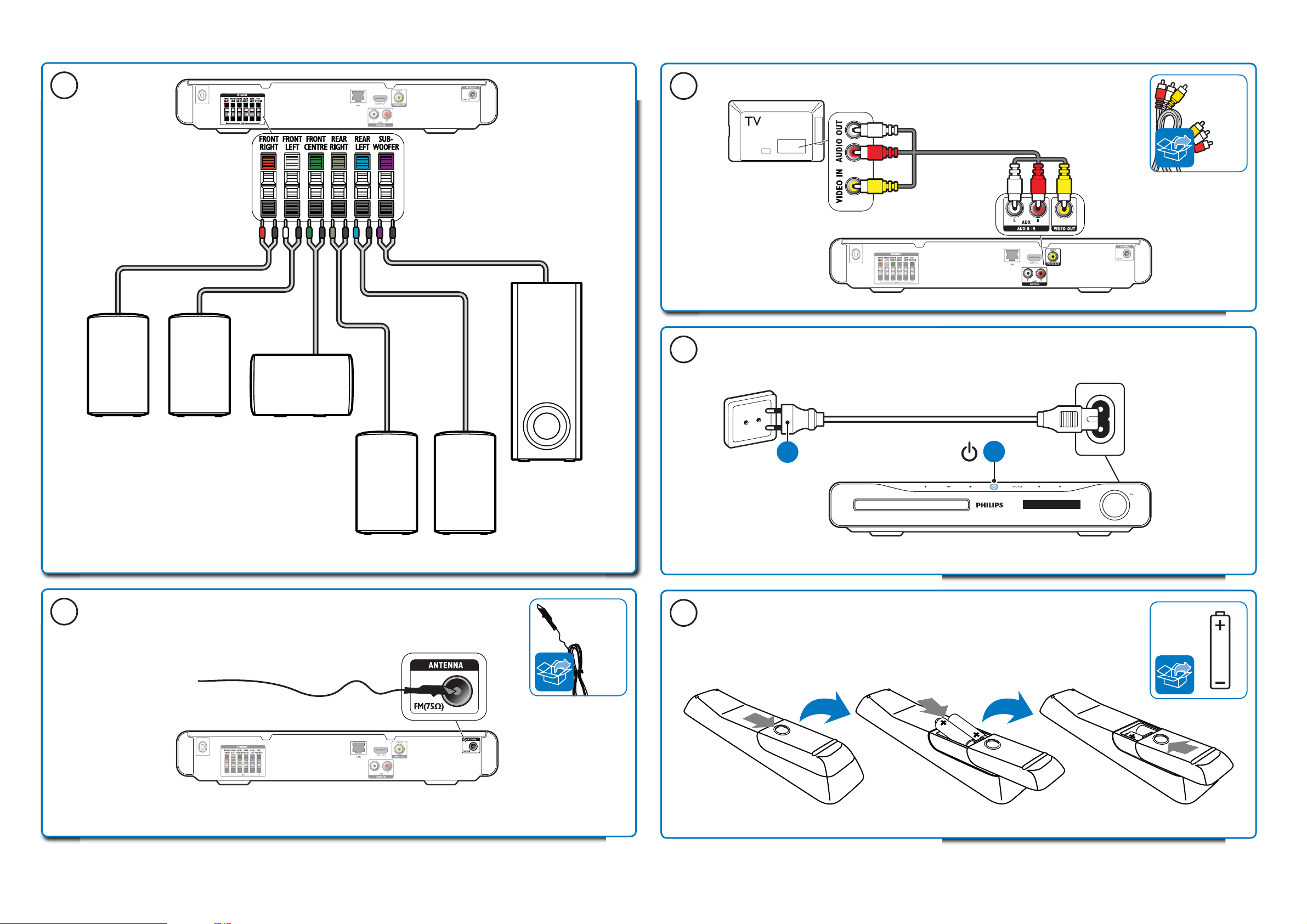

5 - 2 5 - 2

SUBWOOFER

REAR

LEFT

REAR

RIGHT

FRONT

RIGHT

FRONT

LEFT

FRONT

CENTER

2

4

5

Audio/

Video

Cable

3

FM

Antenna

6

1

2

AAA

x 2

Page 18

5 - 3 5 - 3

USB

Settings

TV

AV

Wjefp!Tfuvq

Bvejp!Tfuvq

FbtzMjol!Tfuvq

Bvejp

Ejtd!Nfov

Qbsfoubm!Dpouspm

Tdsffo!Tbwfs

Bvup!Tvcujumf!Tijgu

Tvcujumf

Dibohf!Qbttxpse

Nfov!Mbohvbhf

Ofuxpsl!Tfuvq

Fohmjti

Qsfgfsfodf!Tfuvq

Bewbodfe!Tfuvq

Nfov!Mbohvbhf

Bvejp

Ejtd!Nfov

Qbsfoubm!Dpouspm

Tdsffo!Tbwfs

Bvup!Tvcujumf!Tijgu

Tvcujumf

Dibohf!Qbttxpse

Fohmjti

Gsbèbjt

Jubmjbop

Ftqbòpm

Ofefsmboet

Twfotlb

Efvutdi

Qpsuvhvët

HOME THEATER

HOME THEATER

HOME THEATER

1

1

3

2

2

3

4

5

6

7

8

1

2

3

Page 19

MP3 Link

User Manual

w

Cable

5 - 4 5 - 4

2

1

1

2

3

3

ww.philips.com/support

Speci? cations are subject to change without notice

Trademarks are the property of Koninklijke Philips Electronics N.V.

or their respective owners

2010 © Koninklijke Philips Electronics N.V. All rights reserved.

sgsna_1052/12_v1

Page 20

6 - 1 6 - 1

VFD+VOL+USB+MP3 BOARD

FTD DISPLAY PIN ASSIGNMENT

TABLE OF CONTENTS

FTD Display Pin Assignment ............................................................. 6-1

Circuit Diagram ................................................................................. 6-2

PCB Layout Top & Bottom View ........................................................ 6-3

PIN CONNECTION

Page 21

CIRCUIT DIAGRAM

6 - 2 6 - 2

C810 A1

C811 B1

C812 B1

A

C813 B2

C814 B1

C815 B2

C816 B2

C817 B2

C818 A3

C819 A3

C820 B2

C821 B2

C822 B2

C823 C1

C824 C1

CN810 B1

CN811 A1

CN812 B1

DP810 A2

FB810 B1

FB812 B1

IC810 B2

IC810 B2

JK810 B1

R811 B1

R812 B1

R813 B1

R814 B1

R815 B2

R816 B2

R817 A2

R818 A3

R819 B1

R820 B1

R821 B2

R822 B2

R823 B2

SN810 B1

USB810 B1

VR810 C1

VR810 C1

ZD810 B1

ZD811 B2

123

A

B

C

CN810

B

CN812

C

123

Page 22

PCB LAYOUT - TOP VIEW

6 - 3 6 - 3

C810 A1

C815 A1

C816 A1

A

C817 A1

CN810 A3

CN811 A1

CN812 A3

DP810 A1

JK810 A3

JP810 A1

JP811 A1

JP812 A1

JP813 A2

JP814 A2

JP815 A1

JP816 A3

JP817 A1

JP818 A1

JP819 A2

JP820 A2

JP821 A2

JP822 A2

JP823 A2

SN810 A1

USB810 A3

VR810 A3

123

CN810

CN812

A

PCB LAYOUT - BOTTOM VIEW

C811 A1

C812 A1

C813 A1

C814 A3

C818 A1

C819 A1

C820 A1

C821 A2

C822 A1

C823 A3

C824 A3

FB810 A3

123

FB812 A3

IC810 A2

R811 A1

R812 A1

R813 A1

R814 A1

R815 A1

R816 A2

R817 A1

R818 A1

R819 A3

R820 A3

R821 A1

R822 A1

R823 A1

R824 A1

R825 A1

ZD810 A1

ZD811 A1

321

A

A

321

Page 23

7- 1 7 - 1

MAIN BOARD

TABLE OF CONTENTS

Internal IC Diagram ........................................................................... 7-1

Circuit Diagram . . . . . . . . . . . . . . .................................................................... 7-2

PCB Layout Top View ....................................................................... 7-3

PCB Layout Bottom View .... .. .. .. .. .. ....................................................7-4

INTERNAL IC DIAGRAM - STM32F100VBT6ATR

INTERNAL IC DIAGRAM - CS5346-CQZR

3.3 V to 5 V

Low-Latency

Anti-Alias Filter

Internal Voltage

Reference

Multibit

Oversampling

ADC

Multibit

Oversampling

ADC

Low-Latency

Anti-Alias Filter

High Pass

Filter

High Pass

Filter

Stereo Input 1

Serial

Audio

Output

3.3 V 5 V

MUX

ec

a

fretnI

l

a

ir

eS

M

CP

Register Configuration

leveL

rotalsnarT

Stereo Input 2

Stereo Input 3

Stereo Input 4 /

Mic Input 1 & 2

Stereo Input 5

Stereo Input 6

PGA

+32 dB

+32 dB

rotalsnarT leveL

Reset

I²C/SPI

Control Data

Interrupt

Overflow

Left PGA Output

Right PGA Output

PGA

Page 24

7 - 2 7 - 2

CIRCUIT DIAGRAM

1 2 3 4

1 2 3 4

A

B

C

D

A

B

C

D

C1005 C2

C1008 D2

C1009 D2

C101 A2

C1010 D2

C1011 D2

C1012 D2

C1013 D2

C1014 D2

C1015 D2

C1016 D2

C1018 B2

C1019 C2

C102 A2

C1020 C2

C1021 C2

C1022 D2

C1023 D2

C1024 D2

C1026 B2

C1027 C2

C103 A3

C1037 A2

C1038 A2

C1039 A2

C104 A3

C1040 A2

C1041 D2

C1042 D3

C1047 D1

C1048 A2

C1049 A2

C105 A3

C106 A3

C107 A3

C108 A2

C109 D1

C110 A2

C111 A2

C112 A2

C113 A2

C114 D1

C115 D1

C116 D1

C117 D1

C119 D1

C120 D1

C143 D1

C144 D1

C145 A3

C146 A3

C147 A3

C148 A3

C149 A3

C150 A2

C241 A1

C242 A1

C243 A1

C244 A1

C245 A1

C251 A1

C252 A1

C253 A1

C254 A1

C255 A1

C256 A1

C257 A1

C258 A1

C2901 C2

C2902 C2

C2903 C2

C2904 C2

C2905 C2

C301 C1

C302 C1

C305 B1

C306 B1

C307 B1

C308 B1

C309 C1

C310 C1

C311 B1

C312 B1

C313 B1

C314 B1

C317 B1

C318 B2

C319 B1

C323 C1

C324 C2

C325 C2

C332 B1

C334 C2

C342 B1

C343 B1

C344 B1

C345 B1

C347 B2

C348 B2

C350 C1

C351 C1

C352 C1

C353 C1

C354 C1

C355 C1

C356 C1

C357 C1

C4000 C4

C4001 C4

C4002 C4

C4003 C4

C4006 C4

C4007 B3

C4008 B3

C4009 B3

C4010 C3

C4011 C4

C4012 C4

C4013 B4

C4014 B4

C4015 B4

C4018 B4

C4019 C4

C4020 B4

C4021 B4

C4022 B4

C4023 B4

C4024 B4

C4025 C4

C4026 C4

C4029 B4

C4030 B4

C4031 B4

C4032 B4

C4035 B4

C4036 B4

C4037 B4

C4038 B4

C4039 B4

C4040 B4

C4041 B4

C4042 B4

C4045 B4

C4080 B4

C4081 C4

C4082 D4

C4083 D4

C431 D3

C432 D3

C433 D3

C434 D3

C435 D4

C436 D4

C437 D4

C438 D4

C439 D4

C443 D4

C444 D4

C445 D4

C446 D4

C447 D4

C448 D4

C449 D4

C450 D4

C453 D4

C454 D4

C455 D4

C456 D4

C457 D4

C458 C2

C460 D4

C461 D4

C462 D4

C463 D4

C464 D4

C465 D4

C466 D4

C467 D4

C470 C3

C471 C3

C472 C3

C473 C3

C474 C4

C475 C4

C476 C4

C477 C4

C478 C4

C482 C4

C483 C4

C484 C4

C485 C4

C486 C4

C487 C4

C490 C4

C491 C4

C492 C4

C493 C4

C496 C4

C497 C4

C498 C4

C499 C4

C5011 B3

C5017 C2

C502 A1

C503 A2

C5031 C3

C5032 C4

C5033 C4

C5034 D4

C5035 D4

C5036 B3

C5045 C2

C5047 C3

C5048 C3

C5049 C3

C5051 C3

C506 A1

C5064 C3

C5065 D3

C5066 D3

C5067 D3

C507 A1

C508 A1

C509 A1

C510 A1

C511 A1

C512 A1

C513 A1

C514 A1

C5149 C3

C515 A1

C5150 C3

C5151 C3

C5152 D3

C5153 D3

C5154 D3

C5155 D3

C5156 D3

C5157 D3

C5158 D3

C5159 D3

C516 A1

C5160 D3

C5161 D3

C5163 B3

C5164 C2

C5165 C2

C5166 C3

C5167 C3

C5168 D3

C5169 C3

C517 A1

C5170 D3

C5171 C3

C5172 B3

C5174 C3

C5175 C3

C5176 B3

C5178 B3

C5179 D3

C5180 D3

C5181 D3

C5217 C2

C5223 D3

C589 C4

C590 C4

C701 C1

C702 D1

C703 C1

C704 D1

C801 C1

C802 C2

C803 C1

C804 C1

C805 C1

C806 C1

C807 C1

C808 C1

C809 C2

CN101 A2

CN202 A1

CN1004 A2

CN1005 C1

CN1006 A1

CN1007 C2

CN1008 C1

CN101 A2

CN202 A1

CN301A C1

CN302 B1

CN5002 B3

D1001 C2

D1002 B2

D1004 C1

D1005 A3

D1006 D2

D201 D1

D202 B3

D203 B2

D5005 B3

D5007 C3

D5008 C3

D5015 B3

D5017 B3

D5018 B3

D5019 B3

FB203 D1

FB204 D1

FB210 D1

FB211 D1

FB212 D1

FB214 D1

FB302 B1

FB303 B1

FB5002 C4

FB5003 C4

FB5004 D4

FB5005 D4

FB5006 D1

FB5007 C1

FB901 C1

FB903 C1

FB904 C1

IC1001 A2

IC101 A3

IC103 A3

IC404 B4

IC2901 C1

IC2902 C2

IC2903 C1

IC304 B2

IC306 C1

IC402 D4

IC403 C4

IC404 B4

IC5006 C3

IC5007 C2

IC501 A2

JK301 B1

JK401 C4

L303 C2

L306 A2

L401 D4

L402 D4

L403 D4

L404 D4

L405 C4

L406 C4

L407 C4

L408 C4

L409 C4

L410 B4

L411 B4

L412 B4

L501 A1

L502 A1

L503 A1

L606 C4

L607 C4

Q1005 D2

Q1005 D2

Q1007 C2

Q101 B2

Q105 D1

Q106 B3

Q107 B1

Q5001 D2

Q5002 D3

Q5007 B3

Q5008 B3

Q5009 B3

R1001 A1

R1002 A1

R1004 B2

R1005 A1

R1006 A1

R1007 A1

R1009 B1

R101 A2

R1010 B1

R1011 B1

R1012 B1

R1014 A1

R102 A3

R1022 A2

R1023 A2

R1026 A3

R1027 A3

R1028 B3

R1029 A3

R103 B3

R1038 D2

R104 A3

R1040 A3

R1041 A3

R1045 D2

R1046 D2

R105 A3

R1052 A3

R1056 C2

R106 A3

R1065 D3

R1066 D3

R1067 B3

R107 D1

R1070 A3

R1071 C2

R1072 C2

R1073 B2

R1074 B2

R1075 B2

R1076 B2

R1077 A2

R1078 B2

R1079 C2

R108 D1

R1080 C2

R109 D1

R1091 A1

R1092 A1

R1093 A1

R1096 A2

R1097 D2

R1098 D3

R1099 D3

R110 B2

R1112 D1

R125 B2

R127 A3

R128 A3

R129 A3

R130 D1

R134 B3

R135 B3

R136 D1

R137 D1

R138 D1

R139 D1

R140 A3

R144 A2

R145 A2

R146 A2

R147 A2

R148 A2

R149 B3

R150 A2

R151 B3

R152 B3

R153 B3

R154 A3

R156 A3

R157 A3

R158 A3

R159 A3

R160 A3

R161 A3

R162 A3

R163 A3

R164 A3

R165 A3

R166 B3

R167 B3

R168 B3

R169 B3

R170 A2

R171 A3

R172 A3

R173 B3

R174 A3

R175 B3

R178 B3

R179 B3

R180 A3

R181 A3

R182 A3

R183 B3

R184 B3

R185 B3

R186 B3

R189 B3

R190 A3

R191 A3

R192 A3

R193 A3

R194 B3

R195 B3

R196 B3

R198 A3

R199 A2

R200 B2

R206 A3

R207 B3

R208 B3

R209 A3

R215 B3

R260 A2

R282 D3

R283 D3

R284 D3

R301 C1

R302 C1

R303 C1

R308 B1

R309 B1

R310 C1

R311 C1

R312 B1

R313 B2

R316 B1

R317 B1

R318 B3

R319 B3

R320 B1

R321 B1

R322 B1

R323 B2

R324 B2

R325 B2

R326 B2

R327 B1

R328 B1

R329 B1

R345 B1

R346 B1

R348 B1

R349 B1

R351 B1

R352 B1

R354 B1

R355 C1

R356 B1

R358 C1

R359 C1

R360 C1

R367 C1

R368 C1

R369 C1

R370 C1

R371 C1

R372 C1

R373 C1

R374 C1

R375 C1

R376 C1

R429 D3

R431 D3

R432 D3

R433 D3

R434 D3

R435 D3

R436 D3

R437 D3

R438 D3

R439 D4

R440 D4

R441 D4

R442 D4

R445 D4

R446 D4

R449 D4

R450 C3

R452 C3

R453 C3

R454 C3

R455 C3

R456 C3

R457 C3

R458 C3

R459 C3

R460 C4

R461 C4

R462 C4

R463 C4

R466 C4

R467 C4

R470 C4

R471 C4

R472 B3

R474 B3

R475 B3

R476 B3

R477 B3

R478 B3

R479 B3

R480 C3

R481 C3

R482 C4

R483 D4

R484 C4

R485 C4

R488 B4

R489 B4

R492 B4

R493 B4

R501 A1

R5017 C2

R502 A1

R503 A1

R5032 C3

R503A A1

R504 A1

R5040 C3

R5042 B3

R5043 B3

R5044 B3

R5045 B3

R5046 B3

R5049 B3

R505 A1

R5050 B3

R506 A1

R5064 C2

R5065 B2

R507 A1

R5079 C3

R5082 C3

R5083 D3

R5084 D3

R5085 A2

R5086 A2

R5087 A1

R5088 A1

R509 A2

R5097 D3

R510 A2

R5110 C3

R5111 D3

R5113 D3

R5114 D3

R5115 D3

R5116 D3

R5117 D3

R5118 D3

R512 A2

R513 A2

R5130 C2

R5131 C3

R5133 C3

R5134 B3

R5135 B3

R5138 C3

R5139 D3

R5140 D3

R5144 C3

R5144A C3

R5145 C3

R5148 C3

R5148A C3

R5149 C3

R515 A1

R5151 C3

R5152 B2

R5153 B2

R5155 B2

R5156 C3

R5158 B3

R5159 C2

R5162 C2

R5163 C2

R5165 D3

R518 A1

R5183 C3

R5184 C3

R5185 C3

R5187 C3

R519 A1

R520 B2

R521 B2

R522 B2

R523 A1

R524 A1

R525 A2

R526 A2

R527 A1

R5281 B3

R5282 C3

R5284 C3

R535 B2

R537 A2

R543 C3

R547 C3

R552 A2

R553 A2

R554 A2

R556 A2

R557 A2

R558 A2

R801 C1

R802 C1

XL101 A2

XL5001 D3

XL501 A1

ZD801 C1

ZD802 C1

Page 25

7- 3 7 - 3

PCB LAYOUT - TOP VIEW

1 2 3 41 2 3 4

1

2 3 4

A

B

C

A

B

C

C1005 C3

C101 C1

C1018 B3

C1019 B3

C102 C1

C1020 A2

C1021 B2

C1026 B3

C1027 B2

C1037 B2

C1038 B2

C1039 B2

C1040 A1

C1041 C2

C1042 C3

C1047 C2

C1048 B2

C1049 B2

C109 C2

C114 C2

C115 C2

C116 C2

C117 C2

C119 C2

C120 C2

C143 C1

C144 C1

C146 C1

C150 B1

C251 A1

C252 A1

C253 A1

C254 A1

C255 A1

C256 A1

C257 A1

C258 A1

C2901 C1

C2902 B1

C2903 C2

C2904 C1

C2905 C1

C301 B1

C302 B1

C305 A1

C306 A1

C307 A1

C308 A1

C309 B1

C310 B1

C311 A1

C312 A1

C313 A1

C314 A1

C318 B1

C323 B2

C325 B1

C332 B1

C334 B1

C342 A1

C343 A2

C344 A1

C345 A1

C347 B1

C348 B1

C350 B1

C351 B1

C352 B1

C353 B1

C354 B1

C355 B1

C356 B1

C357 B1

C4006 B3

C4007 B3

C4008 B3

C4009 B3

C4010 B3

C4011 B3

C4012 B3

C4013 B3

C4014 B3

C4015 B3

C4018 B4

C4019 B3

C4020 A4

C4029 B3

C4030 B3

C4031 B3

C4032 B3

C4035 B3

C4036 A3

C4045 A3

C4080 B3

C4081 C3

C4082 C4

C4083 C3

C431 C3

C432 C3

C433 C3

C434 C3

C435 C3

C436 C3

C437 C3

C438 C3

C439 C3

C443 C3

C444 A4

C453 C3

C454 C3

C455 C3

C456 C3

C457 C3

C458 B1

C460 C3

C461 C4

C470 B3

C471 B3

C472 C3

C473 C3

C474 C3

C475 C3

C476 B3

C477 B3

C478 B3

C482 C3

C483 A4

C490 B3

C491 B3

C492 B3

C493 B3

C496 B3

C497 A4

C5011 A2

C5017 B3

C5031 A3

C5032 B4

C5033 C4

C5034 C4

C5035 C4

C5036 A3

C5045 B3

C5047 B3

C5048 B3

C5049 B3

C5064 B3

C5066 C3

C5067 C3

C509 C2

C510 C2

C5149 B3

C515 C2

C5150 B3

C5151 B3

C516 C2

C5163 A3

C5164 C3

C5165 B3

C5166 A3

C5167 B3

C5169 B3

C517 B2

C5170 B2

C5171 B3

C5172 A3

C5174 B3

C5175 A3

C5176 A3

C5178 A2

C5179 C3

C5180 C3

C5181 B2

C5217 B3

C701 C2

C702 C2

C704 C2

C705 B2

C801 A2

C802 B2

C803 B2

C804 B1

C805 C2

C807 A2

C808 B2

C809 B2

CN101 A2

CN202 A1

CN1004 B1

CN1005 C2

CN1006 A1

CN1007 C3

CN1008 B2

CN101 B1

CN202 B1

CN301A B1

CN302 B2

CN5002 A2

D1001 C2

D1002 C1

D1004 C2

D1005 B1

D1006 C3

D201 C2

D202 C1

D203 C1

D5005 A3

D5007 A3

D5008 A3

D5015 A3

D5017 A3

D5018 A3

D5019 A3

FB203 C2

FB204 C2

FB210 C2

FB211 C2

FB212 C2

FB214 C2

FB302 A1

FB303 A1

FB5002 B4

FB5003 C4

FB5004 C4

FB5005 C4

FB5006 B2

FB5007 B2

FB901 B1

FB903 B1

FB904 C2

IC1001 B2

IC101 B1

IC103 C1

IC404 B4

IC2901 C2

IC2902 C2

IC2903 C1

IC304 B1

IC306 B1

IC402 C3

IC403 C3

IC404 B3

IC5006 C3

IC5007 B3

IC501 B2

JK301 A1

JK401 A4

JP503 B4

L303 B2

L306 B2

L401 C4

L402 C4

L403 C4

L404 C4

L405 C4

L406 B4

L407 B4

L408 B4

L409 A4

L410 B4

L411 B4

L412 A4

L501 C2

L502 C2

L606 C4

L607 B4

Q1005 B3

Q1005 B3

Q1007 C3

Q105 C2

Q105 C2

Q106 C1

Q106 C1

Q107 C2

Q107 C2

Q5001 C2

Q5002 C3

Q5002 C3

Q5007 A3

Q5008 A3

Q5009 B2

R1001 A1

R1002 A1

R1004 C2

R1005 A1

R1006 A1

R1007 A1

R1009 A1

R101 C1

R1010 A1

R1011 B1

R1012 B1

R1014 A1

R102 B2

R1022 C1

R1023 C1

R1026 C1

R1028 B1

R1029 B1

R103 C1

R1038 B2

R104 C1

R1040 C1

R1041 B1

R1045 B3

R1046 B2

R105 C1

R1052 C1

R1056 C3

R106 C1

R1067 B1

R107 C2

R1070 B1

R1071 C3

R1072 C3

R1073 B3

R1074 B3

R1075 B3

R1076 B3

R1077 B3

R1078 B3

R1079 B3

R108 C2

R1080 B3

R109 C2

R1091 A1

R1092 A1

R1093 A1

R1096 B2

R1097 C2

R1098 C2

R1099 C2

R110 C1

R1112 C2

R125 C1

R127 B1

R128 B1

R129 B1

R130 C2

R134 C1

R135 B1

R136 C2

R137 C2

R138 C2

R139 C2

R140 B1

R144 B1

R145 B1

R146 B1

R147 B1

R148 B1

R149 C1

R152 C1

R156 C1

R157 C1

R158 C1

R159 C1

R162 B1

R165 B1

R166 B1

R167 C1

R168 C1

R169 C1

R170 B1

R172 B1

R173 B1

R179 C1

R180 B1

R181 B1

R182 B1

R183 C2

R184 C2

R185 B1

R186 B1

R189 C1

R190 C1

R191 C1

R192 C2

R193 C2

R194 C1

R195 B1

R196 B1

R198 C1

R199 C1

R200 C1

R206 C1

R207 C1

R208 C1

R209 B1

R215 B1

R260 B2

R301 B1

R302 B1

R303 B1

R308 A1

R309 A2

R310 B1

R311 B1

R312 B2

R313 B1

R316 B1

R317 B1

R320 B2

R321 B1

R322 B1

R323 B1

R324 B1

R325 B1

R326 B1

R345 A1

R346 A1

R348 A1

R349 A1

R351 A1

R352 A2

R354 B2

R355 B1

R356 B2

R358 B1

R359 B1

R360 B1

R367 B1

R368 B1

R369 B1

R370 B1

R371 B1

R372 B1

R373 B1

R374 B1

R375 B1

R376 B1

R429 C3

R431 C3

R432 C3

R433 C3

R434 C3

R435 C3

R436 C3

R437 C3

R438 C3

R439 C3

R440 C3

R449 C4

R450 B3

R452 B3

R453 B3

R454 B3

R455 B3

R456 B3

R457 B3

R458 C3

R459 C3

R460 C3

R461 C4

R470 B3

R471 B3

R472 B3

R474 B3

R475 B3

R476 B3

R477 B3

R478 B3

R479 B3

R480 B3

R481 B3

R482 B3

R483 C3

R492 B3

R493 A3

R501 B2

R5017 B3

R502 B2

R5032 C3

R503A B2

R504 B2

R5040 A3

R5042 B3

R5043 A3

R5044 A3

R5045 A3

R5046 B3

R5049 A2

R505 C2

R5050 B3

R506 C2

R5064 A2

R5065 B2

R507 C2

R5079 B3

R5082 B3

R5085 B2

R5086 B2

R5087 B2

R5088 B2

R509 C2

R5097 C3

R5110 B3

R5111 C3

R5113 C3

R5114 C3

R5115 C3

R5116 C3

R5117 C3

R5118 C3

R512 C2

R513 C2

R5130 B3

R5131 B3

R5134 A2

R5138 B3

R5139 B3

R515 C2

R5151 A3

R5152 B3

R5153 B3

R5155 B3

R5156 A3

R5158 A3

R5159 B3

R5162 A2

R5163 A2

R5165 C3

R518 C2

R5183 C3

R5184 C3

R5185 B3

R5187 B3

R519 C2

R520 C2

R521 C2

R522 C2

R523 B2

R525 B2

R526 B2

R527 B2

R537 C2

R543 B3

R547 B3

R554 B2

R556 B2

R557 B2

R558 B2

R801 C2

R802 B2

XL101 C1

XL5001 B3

XL501 B2

ZD801 B3

ZD802 B2

Page 26

7 - 4 7 - 4

PCB LAYOUT - BOTTOM VIEW

4

3 2

1

4

3 2

1

A

B

C

A

B

C

C1008 A2

C1009 C3

C1010 B1

C1011 A2

C1012 A2

C1013 A2

C1014 B1

C1015 C3

C1016 C3

C1022 A2

C1023 A2

C1024 B1

C103 C1

C104 C1

C105 C1

C106 B1

C107 C1

C108 B1

C110 B1

C111 B1

C112 B1

C113 B1

C145 C1

C147 C1

C148 C1

C149 B1

C241 B1

C242 B1

C243 C1

C244 C1

C245 C1

C317 B1

C319 B1

C324 B1

C4000 B4

C4001 A4

C4002 A4

C4003 A4

C4021 A4

C4022 B4

C4023 A4

C4024 B4

C4025 A4

C4026 A4

C4037 A4

C4038 A3

C4039 A4

C4040 A3

C4041 A3

C4042 A3

C445 C4

C446 C4

C447 C4

C448 C4

C449 A4

C450 A4

C462 C4

C463 C4

C464 C4

C465 C4

C466 A4

C467 A4

C484 C4

C485 B4

C486 A4

C487 A4

C498 B4

C499 A4

C502 B2

C503 B2

C5051 B3

C506 B2

C5065 B3

C507 B2

C508 C2

C511 C2

C512 B2

C513 B2

C514 B2

C5152 B3

C5153 B3

C5154 C2

C5155 C3

C5156 C2

C5157 C3

C5158 C2

C5159 C2

C5160 C3

C5161 C3

C5168 B3

C5223 B3

C589 C4

C590 B4

C703 C2

C806 B1

L503 B2

Q101 C1

R1027 B1

R1065 C3

R1066 C3

R150 C1

R151 C1

R153 C1

R154 B1

R160 C1

R161 C1

R163 C1

R164 B1

R171 B1

R174 B1

R175 C1

R178 C1

R282 C3

R283 C2

R284 C3

R318 C1

R319 C1

R327 B2

R328 B2

R329 B2

R441 A4

R442 A4

R445 A4

R446 A4

R462 A4

R463 A4

R466 A4

R467 A4

R484 A4

R485 A4

R488 A3

R489 A3

R503 B2

R5065 B3

R5083 C3

R5084 C3

R510 B2

R5133 B3

R5140 B3

R5144 A4

R5144A A4

R5145 A4

R5148 A4

R5148A A4

R5149 A3

R524 B2

R5281 A4

R5282 A4

R5284 A4

R535 C2

R552 B2

R553 B2

Page 27

8 - 1 8 - 1

POWER BOARD

TABLE OF CONTENTS

Internal IC Diagram ........................................................................... 8-1

Circuit Diagram . . . . . . . . . . . . . . .................................................................... 8-2

PCB Layout Top View ....................................................................... 8-3

PCB Layout Bottom View .... .. .. .. .. .. ....................................................8-4

INTERNAL IC DIAGRAM - SSC620S SOP

INTERNAL IC DIAGRAM - AZ7500BP

Oscillator

0.12V

5

6

CT

RT

4

DTC

1IN +

1IN -

2IN +

2IN -

1

2

16

15

Error Amplifier 1

Error Amplifier 2

Dead-Time Control

Comparator

D

CK

3

FEEDBACK

PWM

Comparator

Pulse-Steering

Flip-Flop

OUTPUT CTRL

13

Reference

Regulator

Q1

Q2

12

10

11

9

8

C1

E1

C2

E2

V

CC

REF

GND

14

7

0.7mA

+

+

+

+

Page 28

8 - 2 8 - 2

CIRCUIT DIAGRAM

1 2 3 4

1 2 3

4

A

B

C

A

B

C

BD901 A1

C901 C1

C902 C1

C904 A1

C905 A1

C912 C1

C913 C3

C915 B1

C917 B1

C918 B1

C919 B1

C920 A1

C921 A1

C922 C2

C923 C2

C924 C2

C925 C2

C926 C2

C927 B3

C928 B3

C929 B3

C930 A4

C931 C3

C935 C2

C936 B2

C938 C1

C940 B1

C941 C2

C943 A2

C944 A2

C946 A2

C947 C2

C948 B2

C949 A2

C950 A2

C951 A2

C952 A2

C953 B4

C954 C3

C955 B3

C956 C2

C957 A3

C958 A3

C959 A4

C960 B3

C961 B3

C962 B3

C963 B3

C964 B3

C965 C3

C966 B3

C967 B3

C968 A3

C969 A3

C970 A3

C971 A3

C972 A3

C973 C3

C974 B4

C975 B4

C976 C3

C977 B2

C978 B2

C979 C2

C980 B3

C981 B3

C982 C1

C983 C3

C984 C4

C991 B3

C992 B4

C993 B4

C994 A1

C998 C4

CN901 C1

CN903 B4

CN904 C4

CN905 C4

CN906 A4

D903 C2

D904 B2

D905 B2

D906 A2

D907 A2

D908 B2

D909 A3

D910 A3

D912 A3

D917 A3

D918 B1

D919 C2

D920 C2

D921 B2

D922 B2

D924 A3

D926 A3

D927 A3

D929 A3

D930 A1

D931 B1

D932 B4

D933 B4

D935 C4

F901 C1

GT902 B1

GT903 C2

GT904 B2

GT905 A2

IC901 C1

IC902 C2

IC904 C2

IC905 B3

L901 B1

L902 B1

L904 B3

L905 B3

L906 C3

L907 A2

L908 A3

NTC901 C1

Q901 B3

Q902 C3

Q903 B4

Q904 C3

Q906 B3

Q907 C3

Q909 C2

Q910 B2

Q911 A2

Q912 A2

Q913 A2

Q914 B3

Q915 B3

Q917 C3

Q918 C3

Q919 B4

Q919 B4

Q920 C4

R901 B1

R902 B1

R903 B1

R904 B1

R905 B1

R906 B1

R907 A1

R908 A1

R909 A1

R910 A1

R911 B3

R912 B1

R915 C2

R916 A4

R917 A4

R918 A4

R919 A4

R920 C2

R921 C2

R923 C3

R925 C3

R926 A3

R927 C2

R928 C2

R929 C2

R930 C2

R932 A2

R933 C2

R935 C2

R936 C2

R937 B2

R938 B2

R940 B1

R941 B1

R942 B2

R943 B2

R944 A2

R945 A2

R946 B4

R947 C3

R948 C3

R949 A1

R950 C3

R952 B3

R953 A3

R954 C2

R955 C2

R956 B3

R957 B3

R958 B3

R959 B3

R960 A4

R961 B3

R962 C2

R963 B3

R964 B3

R965 B3

R966 B3

R967 A3

R968 A3

R969 A3

R970 A4

R971 A3

R972 A3

R973 A3

R975 A3

R976 A3

R977 B4

R978 B4

R979 C4

R980 C4

R981 B3

R982 C4

R983 C4

R984 C3

R985 C3

R989 C3

R990 C3

R991 C3

R992 C3

R993 C3

R994 C3

R995 B4

R996 C3

R997 B4

R998 B4

R999 B4

T901 B2

T902 B2

T903 A2

TVR901 B1

TVR902 A1

TVR903 A1

ZD902 C2

ZD903 B2

ZD904 A2

ZD905 A3

ZD907 A4

ZD908 A3

ZD909 A3

ZD910 A3

ZD913 A3

ZD920 C4

ZD927 B4

Page 29

8 - 3 8 - 3

PCB LAYOUT - TOP VIEW

1 2 3 4

1 2 3 4

A

B

C

A

B

C

BD901 B4

C901 A2

C902 A3

C915 A4

C917 B4

C918 B4

C919 B4

C921 C4

C922 C3

C923 C2

C926 C2

C938 C3

C940 C3

C952 B3

C960 C2

C961 C1

C962 C1

C963 C1

C965 C2

C966 B1

C968 B2

C969 B2

C970 A2

C971 A1

C973 C1

C974 C1

C976 C2

C978 C3

C979 C2

C982 C2

C983 A1

C984 B1

CN901 A4

CN903 A1

CN904 C 1

CN905 C 1

CN906 A2

D904 C3

D918 C3

D919 C2

D920 C2

D921 C2

D922 B2

D924 B2

D926 B2

D930 B3

D931 B3

D932 B1

F901 A3

GT902 A4

GT903 C3

GT904 B3

GT905 B3

IC904 C2

IC904 C2

IC905 B2

J903 B3

J904 B3

J905 B4

J906 B3

J907 B3

J908 C3

J909 C3

J910 B1

J911 B1

J912 B1

J913 C1

J914 C1

J915 C1

J916 C1

J917 C2

J918 C2

J919 B1

J920 B1

J921 B1

J923 C2

J924 C2

J925 C2

J926 C1

J927 B1

J928 B1

J929 B1

J930 A1

L901 B4

L902 B4

L904 C1

L905 C1

L906 C2

L907 B2

L908 A1

NTC901 A4

Q903 B1

Q907 C1

Q909 C3

Q910 B2

Q911 B2

Q912 B3

Q913 B3

R912 B4

R929 C2

R930 C3

R935 C3

R940 C3

R941 B3

R943 B3

R944 B3

R945 A2

R949 B3

R958 C1

R977 A1

R978 B1

R981 C1

R985 C2

R989 C1

R991 C1

R993 C1

T901 C3

T902 B2

T903 A2

TVR901 A4

TVR902 C4

TVR903 C4

Page 30

8 - 4 8 - 4

PCB LAYOUT - BOTTOM VIEW

4 3 2 1

4 3 2 1

A

B

C

A

B

C

C904 C4

C905 C4

C912 C3

C913 C2

C924 C2

C925 C2

C927 B1

C928 B1

C929 C1

C930 B1

C931 C2

C935 C2

C936 B2

C941 B2

C943 B3

C944 B3

C946 A2

C947 B2

C948 C2

C949 A1

C950 A2

C951 A2

C953 A2

C954 A1

C955 C1

C956 C2

C957 A1

C958 A1

C959 A2

C964 B2

C967 B2

C972 A1

C975 B1

C977 C3

C980 B1

C981 B1

C982 A1

C991 A1

C992 C1

C993 A1

C994 B3

C997 C1

C998 C1

D903 C3

D905 B3

D906 B3

D907 B2

D908 B2

D909 B2

D910 B2

D912 B2

D917 B2

D927 B4

D929 B1

D933 A1

D935 A1

IC901 C3

IC902 C3

J922 C2

Q901 C1

Q902 C2

Q904 C1

Q906 B1

Q914 C1

Q915 C1

Q917 C1

Q918 A1

Q919 B1

Q920 B1

R901 A4

R902 A4

R903 A4

R904 A4

R905 A4

R906 A4

R907 C4

R908 C4

R909 C4

R910 C4

R911 B1

R915 C3

R916 A2

R917 A2

R918 A2

R919 A2

R920 C3

R921 C2

R922 B1

R923 C1

R924 C1

R925 B1

R926 B2

R927 C2

R928 C2

R932 B3

R933 C3

R936 C3

R937 C3

R938 C2

R942 B3

R946 B1

R947 C1

R948 B1

R950 C1

R952 C1

R953 B1

R954 C2

R955 C2

R956 C1

R957 C1

R959 C1

R960 B2

R961 B1

R962 C2

R963 B2

R964 B1

R965 B2

R966 B2

R967 B2

R968 B1

R969 B2

R970 B2

R971 B2

R972 B2

R973 B2

R975 A1

R976 A1

R979 B1

R980 A1

R982 A1

R983 A1

R984 C1

R990 C1

R992 C1

R994 C1

R995 B1

R996 C1

R997 B1

R998 B1

R999 B1

ZD902 C3

ZD903 B3

ZD904 B3

ZD905 B2

ZD907 B2

ZD908 B2

ZD909 B2

ZD910 B2

ZD913 B2

ZD920 B1

ZD927 C1

Page 31

9 - 1 9 - 1

BD BOARD

TABLE OF CONTENTS

Circuit Diagram (one) ........................................................................9-2

Circuit Diagram (two) ........................................................................ 9-3

Circuit Diagram (three) .....................................................................9-4

Circuit Diagram (four) .......................................................................9-5

Circuit Diagram ( ve) ........................................................................ 9-6

Circuit Diagram (six) .........................................................................9-7

Circuit Diagram (seven) .................................................................... 9-8

Circuit Diagram (eight) ...................................................................... 9-9

Circuit Diagram (nine) ....................................................................... 9-10

Circuit Diagram (ten) ........................................................................9-11

Circuit Diagram (eleven) ................................................................... 9-12

Circuit Diagram (twelve) ...................................................................9-13

PCB Layout Top View .......................................................................9-14

PCB Layout Bottom View ..................................................................9-15

Page 32

CIRCUIT DIAGRAM (one)

9 - 2 9 - 2

C1 A3

C15 B1

C16 B1

C19 A3

C2 A3

C20 B3

C23 B1

C27 B1

C3 C1

C30 B1

C31 C1

C32 C2

C33 C2

C4 C2

C5 C1

A

C6 C1

C960 A2

C961 A2

C962 A2

C965 B3

C966 B2

C971 B2

C975 C2

CB10 A2

CB11 A2

CB12 A3

CB13 A1

CB14 C3

CE1 A3

CE18 A2

CE19 A2

CE2 A3

CE20 A2

CE21 A2

CE22 A1

CE23 B2

CE24 B3

CE26 C2

CE6 C2

CE8 B3

CE9 C3

CN4 A1

D201 C2

D202 B1

D456 A2

FB705 A1

FB710 B1

FB712 B2

FB717 B3

FB718 B3

FB719 B3

FB722 B3

FB723 B3

FB733 A2

FB734 A2

FB738 B2

FB742 A1

FB743 A1

L3 C2

L459 A2

Q518 B2

Q519 B2

Q6 A3

Q7 A3

Q8 B1

Q9 B1

R24 A3

R26 A3

R27 A3

R28 A3

R29 A3

R30 B1

R31 B1

R32 B1

R35 B1

R40 B1

R41 C2

R42 C2

R43 C2

R471 A2

R472 A2

R473 A2

R474 A2

R475 A2

R476 B2

R477 B2

R478 B2

R479 B2

R6 C2

R672 C2

U1 A3

U3 A1

U5 B1

U6 C2

U907 A2

U908 B2

123

A

B

C

B

C

123

Page 33

CIRCUIT DIAGRAM (two)

9 - 3 9 - 3

C100 A1

C101 A2

C102 A2

C103 A2

A

C104 A2

C105 A2

C106 A2

C107 A2

C108 A1

C109 A1

C110 A2

C111 A2

C112 A2

C113 A2

C114 A2

C115 A2

C116 A2

C117 A1

C118 A1

C119 A1

C120 A1

C121 A2

C122 A2

C123 A2

C124 A2

C125 A2

C126 A2

C127 A2

C128 A2

C129 A1

C130 A1

C131 A1

C132 A1

C133 B2

C134 B2

C135 B2

C136 B2

C137 B2

C138 B3

C139 B3

C140 B3

C141 B3

C142 B3

C143 B3

C144 B3

C145 C3

C146 C3

C147 C3

C148 C3

C149 B2

C150 B2

C151 C2

C152 C2

C153 C2

C155 C1

C156 C2

C970 C2

CE25 C2

FB100 C1

R100 B3

R101 B3

R102 B3

R103 B3

R104 B3

R105 B3

R106 C2

R108 C2

R109 C2

RN100 B3

RN101 B3

RN102 B3

RN103 B3

RN104 C3

RN105 C3

U100 C1

U101 A3

U102 A3

U103 C2

123

A

B

C

B

C

123

Page 34

CIRCUIT DIAGRAM (three)

9 - 4 9 - 4

C200 C2

C201 A1

C202 A1

C203 A2

C204 A2

C205 A2

C206 A2

C207 A1

C208 A1

A

C209 A2

C210 A2

C211 A2

C212 A2

C213 A1

C214 A1

C215 A2

C216 A2

C217 A2

C218 A2

C219 A2

C220 A2

C221 B3

C222 B3

C223 B3

C224 B2

C225 B3

C226 B3

C227 B3

C228 B3

C229 B3

C230 B3

C231 B3

C232 B3

C233 B3

C234 B2

C235 B2

C236 B3

C237 C3

C238 C2

C239 C1

R200 B2

R201 B2

R202 B2

R203 B2

R204 B2

R205 B2

R206 C1

RN200 B3

RN201 B3

RN202 B3

RN203 B3

RN204 B3

RN205 B3

U201 A2

U202 A3

123

A

B

C

B

C

123

Page 35

CIRCUIT DIAGRAM (four)

9 - 5 9 - 5

C300 B2

C302 A1

C304 A1

C306 A1

C308 A1

C309 A3

C310 A3

C312 A1

A

C313 A2

C315 B1

C316 B2

C317 B3

C318 B3

C319 B1

C321 B1

C322 B1

C325 B1

C326 B1

C328 B1

C329 B2

C330 B2

C332 B1

C334 C1

C335 C1

C336 C3

C906 C2

C907 C2

C908 C2

C909 C2

C910 C2

C911 C2

C967 C2

CB1 B3

CB2 B3

FB300 A1

FB301 A1

FB302 A1

FB303 A1

FB304 A1

FB305 A1

FB306 B3

FB307 B3

FB308 B1

FB309 B1

FB310 B1

FB311 B1

FB312 C1

J300 A3

Q300 B3

Q301 C3

Q517 C3

R300 B2

R302 A2

R303 B3

R304 B1

R305 B1

R306 B3

R308 B3

R309 B3

R310 B3

R312 B2

R313 B3

R314 B2

R315 B3

R316 B3

R317 C2

R319 C2

R320 C1

R321 C3

R322 C3

R323 C3

R330 C2

R331 C2

R332 C2

R333 C2

R334 C2

R335 C2

R336 C2

R482 B3

R483 B3

R484 B3

R485 B2

R673 B3

U300 B3

Y300 B1

Y301 C1

123

A

B

C

B

C

123

Page 36

CIRCUIT DIAGRAM ( ve)

9 - 6 9 - 6

C350 B3

C351 A2

C353 A1

C354 A1

C355 A3

C356 A1

C357 A1

C358 A3

C359 A1

C361 A2

C363 A2

C364 B2

A

C366 B3

C367 B3

C368 B2

C370 B3

C374 B3

C375 B3

C376 B3

C377 B3

CB3 B2

CB4 C2

CB8 B2

CB9 B2

CE10 B2

CE11 C2

FB350 A1

FB351 A1

FB352 A1

FB353 A1

FB354 A2

FB355 A2

FB356 A2

FB357 B2

FB724 B2

FB725 C2

J351 C2

J903 C2

Q401 C1

Q402 C2

R326 B2

R350 A2

R351 A2

R352 A3

R354 A3

R355 A3

R358 B1

R359 B1

R360 B1

R363 C1

R365 C1

R367 B1

R368 B1

R369 B1

R370 B1

R373 C3

R375 C3

R376 C3

R377 C3

R378 B1

R381 C3

R415 C1

R416 C2

R417 C1

R418 C2

R427 A1

R486 B2

R487 B2

R488 B2

R489 C2

RN350 B1

U351 A3

U905 B2

ZD2 C2

123

A

B

C

B

C

123

Page 37

CIRCUIT DIAGRAM (six)

9 - 7 9 - 7

C386 B1

C388 B1

C389 B3

C956 C3

FB358 A1

FB359 A1

A

FB360 B3

HA501 C2

J355 B3

Q901 C4

R393 A2

R394 A3

R397 A1

R398 A3

R399 A3

R400 A2

R401 B2

R402 B2

R404 B3

R405 B3

R407 B2

R412 C2

R419 B2

R423 C1

R424 C1

R495 C2

R496 C2

R497 C2

R677 C2

123

A

B

C

B

C

123

Page 38

CIRCUIT DIAGRAM (seven)

9 - 8 9 - 8

C390 B1

C391 B2

C392 B2

C393 B2

C394 B2

C395 B1

C396 B1

C397 B1

C398 B1

C399 B1

C400 B2

C401 C1

C402 C1

C403 C1

A

C404 C1

C405 C1

C406 C2

C407 C1

C408 C1

C409 C1

C410 C1

C411 C1

C412 C2

C413 C1

C414 C1

C415 C1

C416 C1

C417 C1

C418 C1

C419 C1

C420 C1

C421 C1

12

A

C422 C1

C423 C1

C424 C1

FB361 A1

R425 A2

R426 B1

B

C

B

C

12

Page 39

CIRCUIT DIAGRAM (eight)

9 - 9 9 - 9

C455 B1

C456 B1

A

C459 A1

C460 A1

C463 A1

C464 A1

C465 B1

C466 B1

123

C501 B3

CB5 A3

CN203 A3

D450 A2

D451 B2

D454 A2

D455 A2

FB501 B3

L450 A1

L451 B1

L453 A1

L455 A1

P501 B3

P502 B3

Q511 A2

Q512 A2

Q513 A2

Q514 B2

R455 B1

R461 A1

R467 A1

R470 A1

R559 B3

A

B

C

B

C

123

Page 40

CIRCUIT DIAGRAM (nine)

HA500 A3

9 - 10 9 - 10

123

A

123

Page 41

CIRCUIT DIAGRAM (ten)

9 - 11 9 - 11

C700 B1

C701 A1

C702 A1

C703 A1

A

C704 A2

C705 A2

C706 A2

C707 A2

C708 A2

C709 A2

C711 A1

C712 A1

C713 B2

C714 B2

C715 B1

C716 B1

C905 B2

FB700 A2

FB701 A1

P503 A3

R498 A3

R499 A3

R500 A2

R501 A2

R502 A2

R503 A2

R504 A3

R505 A1

R506 A1

R507 A1

R508 A1

R509 A1

R510 A1

R511 A1

R512 A1

R513 A1

R514 A3

R515 A3

R516 A1

R517 A3

R518 A1

R519 A1

R520 A1

R521 A3

R522 A1

R523 A2

R524 A1

R525 B1

R526 B2

R531 B1

R534 B3

R535 B3

R536 B3

R537 B1

R538 B3

R542 B2

R544 B3

R547 B3

RN351 B3

U701 A1

Y302 B1

123

A

B

B

123

Page 42

CIRCUIT DIAGRAM (eleven)

9 - 12 9 - 12

C801 A2

C802 A3

C803 A2

C804 A2

C805 A3

C807 A2

C808 A3

C809 A1

C810 B3

C811 B1

C813 B1

C814 B1

A

C815 B1

C816 B1

C817 B1

C818 B1

C819 B1

C820 B1

C822 B1

C826 B1

C827 B1

C830 B3

C831 B3

C832 B3

C833 B3

C834 B3

C835 B3

C836 B3

C837 B3

C838 B3

C842 B3

C901 A1

C902 A2

C903 A2

C916 A2

C917 A2

C918 A2

C923 A2

C924 A2

C927 B1

C928 B1

C929 C2

C930 C1

C931 C2

C932 C3

C933 C3

C934 C1

J800 A3

J802 B1

L456 C2

L457 C4

L458 C3

Q503 C2

Q504 C3

Q505 C2

Q506 C4

Q507 C3

Q508 C3

Q509 C2

Q510 C2

R550 A1

R555 A1

R556 A3

R557 A3

R558 A3

R560 A1

R561 A3

R565 B3

R566 B3

R567 B1

R568 B1

R572 B3

R573 B3

R575 B3

R576 B3

R577 B2

R578 B3

R579 B3

R580 B3

R581 B3

R582 B3

R583 B3

R584 B3

R588 B1

R589 B1

R590 B1

R591 C1

R592 C1

R593 C1

R594 C1

R595 C1

R596 C1

R597 C2

R598 C3

R599 C1

R600 C1

R601 C3

R602 C3

R603 C1

R604 C2

R605 C2

R606 C3

R607 C3

R608 C4

R609 C4

R610 C3

R611 C2

R612 C2

R613 C2

R614 C3

R615 C2

R616 C1

R617 C1

R618 C3

R619 C2

R620 C2

1234

A

B

C

B

C

1234

Page 43

CIRCUIT DIAGRAM (twelve)

9 - 13 9 - 13

C935 A1

C936 A2

C937 A1

C938 A3

A

C939 A3

C940 A3

C941 A3

C942 A2

C943 B2

C944 B3

C945 B3

C946 B3

C947 B2

C948 B3

C950 B1

C951 C1

C952 C2

C953 C1

C955 B1

CB6 A1

CB7 C1

CE12 A2

CE13 A1

CE14 A1

CE15 B2

CE16 C1

CE17 B1

FB728 A1

FB729 A1

FB730 A1

FB731 C1

J900 A3

J906 A3

R621 A1

R622 A1

R623 A2

R624 A3

R625 A1

R626 A2

R627 A2

R628 A2

R630 C2

R634 A1

R639 B1

R640 B2

R641 B2

R642 B2

R643 C2

R645 C2

R646 C1

R648 C2

R650 C2

R651 C1

R654 C2

R655 C2

R656 C2

R657 C1

R658 C2

R659 C2

R660 C1

R661 C2

R662 C2

R664 C2

R671 B2

R674 C2

R675 C2

R683 A1

R684 A1

U900 A2

U902 C1

U906 C2

123

A

B

C

B

C

123

Page 44

PCB LAYOUT - TOP VIEW

9 - 14 9 - 14

C831 A1

C1 A3

C129 C1

C138 B1

C139 B1

C140 C1

C141 C1

C142 C1

C143 C1

C144 C1

C145 C1

C146 C1

C147 C1

C148 C1

C149 B1

C156 C1

C16 C3

C19 D1

C2 B3

C221 D2

C222 D2

C223 D2

C228 D2

C229 D2

C230 D2

C231 D2

C232 D2

C233 D2

C236 D2

C237 D2

C3 C3

C31 C3

C312 C2

C319 B1

C32 D1

C322 B1

C326 B2

C33 D1

C334 C3

C335 C3

C350 B2

C366 B2

C367 B2

C370 B2

C374 B1

C375 B1

C376 B1

C377 B1

C455 C3

C456 B3

C459 A3

C460 A3

C463 B3

C464 B3

C465 B3

C466 B3

C501 C3

C700 D4

C705 C3

C706 C3

C707 C3

C708 C2

C709 C2

C711 C3

C712 C3

C715 D4

C716 C3

C808 B3

C818 B2

C834 A2

C838 A2

C906 B3

C927 B2

C928 B1

C932 B1

C933 B1

C934 B1

C936 A1

C937 A1

C938 C1

C939 C1

C940 C1

C941 C1

C942 A2

C943 A1

C944 C1

C945 C1

C946 C1

C947 A2

C950 A2

C951 D1

A

C952 A1

C953 D1

C955 A1

C956 A3

C960 D1

C961 D1

C962 D2

C965 A3

C967 A3

CB1 D4

CB12 D1

CB13 D2

CB14 C1

CB2 D3

CB5 C3

CB7 C1

CE1 A3

CE10 A2

CE11 A2

CE12 A1

CE13 C1

CE14 A1

CE15 A1

CE16 D1

CE17 A1

CE18 D1

CE19 D1

CE2 B3