Page 1

1 - 1

BD Home Theater System

HTB7250D_HTB7255D/12

Service

Service Manual

under license.

TABLE OF CONTENTS

Location of PCB Boards ............................................ 1-2

Versions Variation ...................................................... 1-2

Specifications ............................................................ 1-3

Measurement Setup .................................................. 1-6

Service Aids .............................................................. 1-7

ESD & Safety Instruction .......................................... 1-8

Lead-free Soldering Information ................................ 1-9

Setting Procedure & Repair Instructions ...................... 2

Disassembly Instructions & Service Positions .............. 3

Block & Wiring Diagram ................................................ 4

MAIN+VFD+SUB+USB+MP3+SENSOR+BT Board .... 5

BD Board........................................................................ 6

Touch Board .................................................................. 7

Power Board(Subwoofer) ............................................ 8

Mechanical Exploded View............................................ 9

Revision List ................................................................ 10

Chapter

©

Copyright 2013Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Published by SL_HF1305 Service Audio Printed in The Netherlands Subject to modification

Version 1.1

GB

3141 785 39441

Page 2

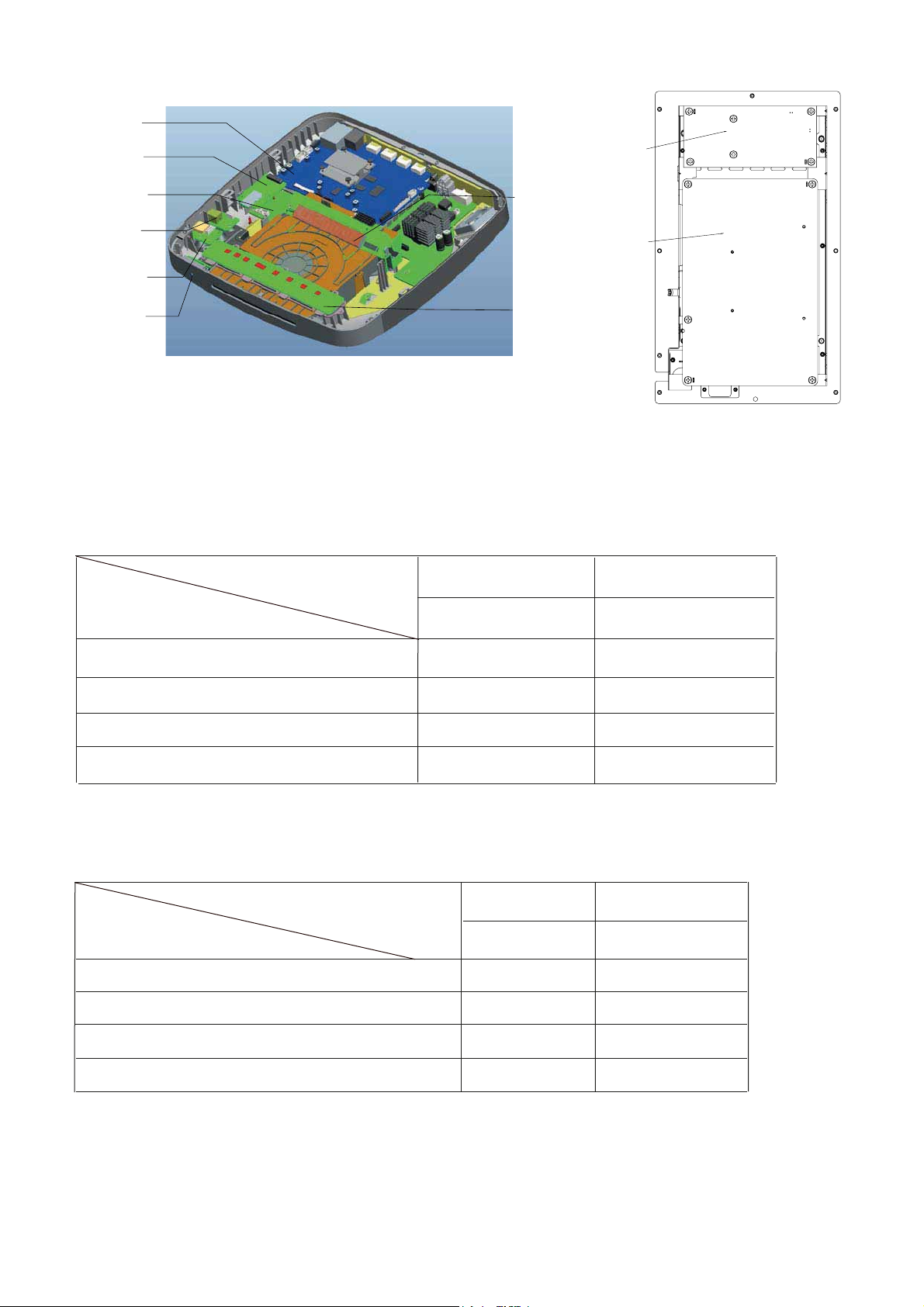

LOCATION OF PCB BOARDS

BD PCB

1 - 2

BT PCB

MAIN PCB

MP3 PCB

USB PCB

SENSOR PCB

Main Unit

VERSION VARIATION:

Type/Versions

VFD PCB

TOUCH PCB

HTB7250D

SUB PCB(AMPPCB)

SUB _POWR CPB

Subwoofer

HTB7255D

Features

Output Power - 500W

Voltage (220~240V)

Bluetooth

Subwoofer

SERVICE SCENARIO MATRIX:

Type/Versions

Board in used

MAIN+VFD+SUB+USB+MP3+SENSOR+BT Board

Power Board(subwoofer)

BD Board

Touch Board

/12

x

x

x

x

HTD7250D

/12

C

C

Bd

Bd

/12

x

x

x

x

HTD7255D

/12

C

C

Bd

Bd

*Bd= Board Level Replacement

*C = Component Level Repair

Page 3

SPECIFICATIONS

1 - 3

Region codes

The type plate on the back or bottom of the

home theater shows which regions it supports.

Country

Europe,

United Kingdom

Asia Pacific, Taiwan,

Korea

Latin America

Australia,

New Zealand

Russia, India

DVD BD

AA

AA

CC

China

CC

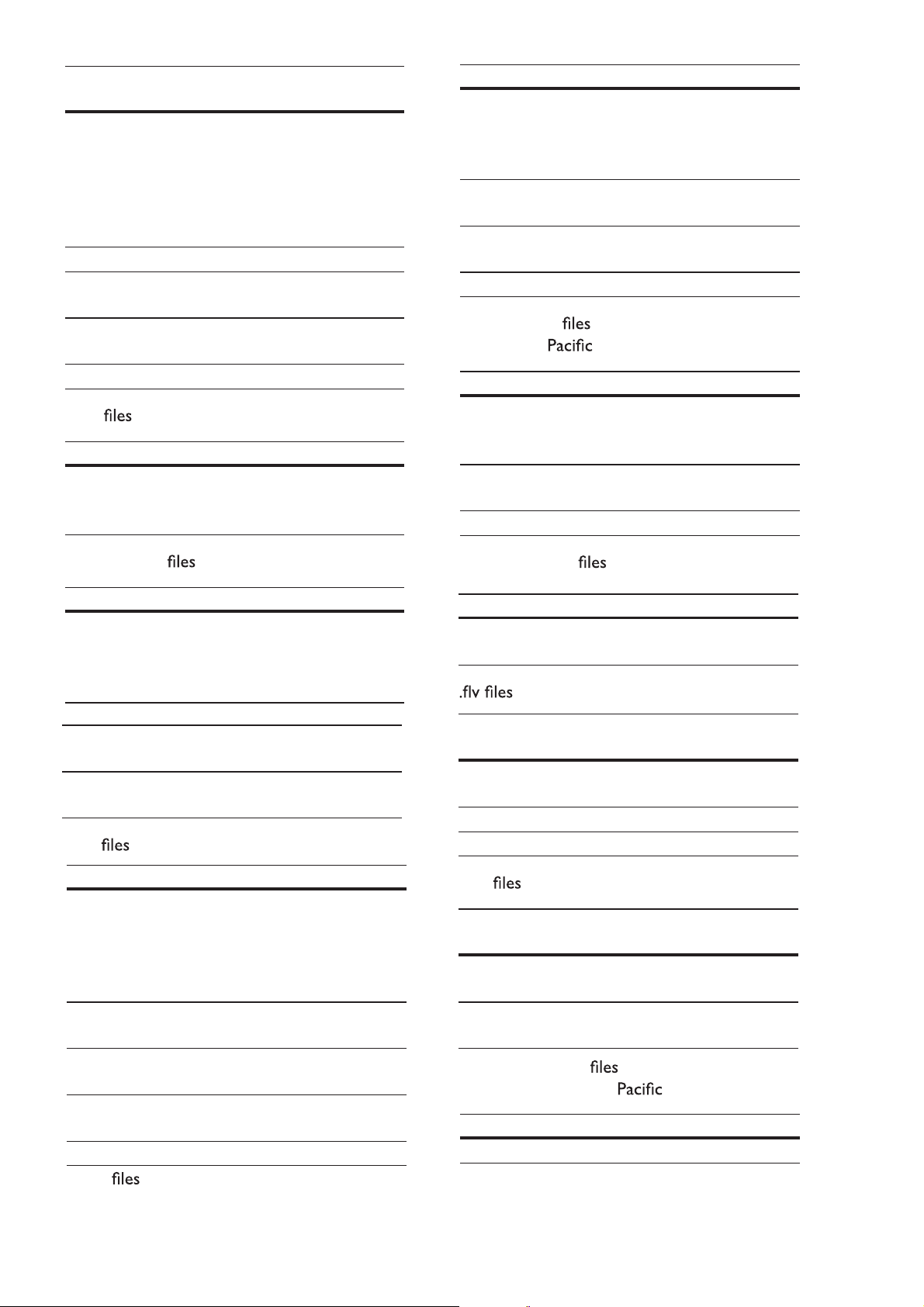

Media formats

• AVCHD, BD, BD-R/ BD-RE, BD-Video,

DVD-Video, DVD+R/+RW, DVD-R/-RW,

DVD+R/-R DL, CD-R/CD-RW, Audio CD,

Extension Con-

tainer

.mp3 MP3 MP3 Upto 320 kbps

.wma ASF WMA Upto 192 kbps

.aac AAC AAC, HE-

.wav WAV PCM 27.648 Mbps

.m4a MKV AAC 192 kbps

.mka MKA PCM 27.648 Mbps

.ra RM AAC, HE-

FLAC FLAC Upto 24 bps

.ogg OGG Vorbis Variable bit rate,

Audio

codec

WMA Pro Upto 768 kbps

AAC

Dolby

Digital

DTS core 1.54 Mbps

MPEG 912 kbps

MP3 Upto 320 kbps

WMA Upto 192 kbps

WMA Pro Upto 768 kbps

AAC, HE-

AAC

AAC

Cook 96469 bps

Bit rate

Upto 192 kbps

640 kbps

Upto 192 kbps

Upto 192 kbps

maximum block

size 4096

WMA media, DivX Plus HD media, USB

storage device

File formats

• Audio:

• .aac, .mka, .mp3, .wma, .wav, .mp4, .m4a,

•

China)

• Video:

• .avi, .divx, .mp4, .m4v, .mkv, .m2ts, .mpg,

• .asf, .wmv, .rmvb, .rm, .rv (Available only

•

Audio formats

Your home theater suppor ts the following

Extension Con-

tainer

Video formats

theater allows you to play your:

•

1080 pixels (except DivX, which has a

resolution of 77220 x 576) and frame rate

of 6 ~ 30 frames per second.

•

.avi in AVI container

Audio

codec

FLAC Upto 24 bps

OGGPCM No limit

MP3 Upto 320 kbps

Bit rate

Page 4

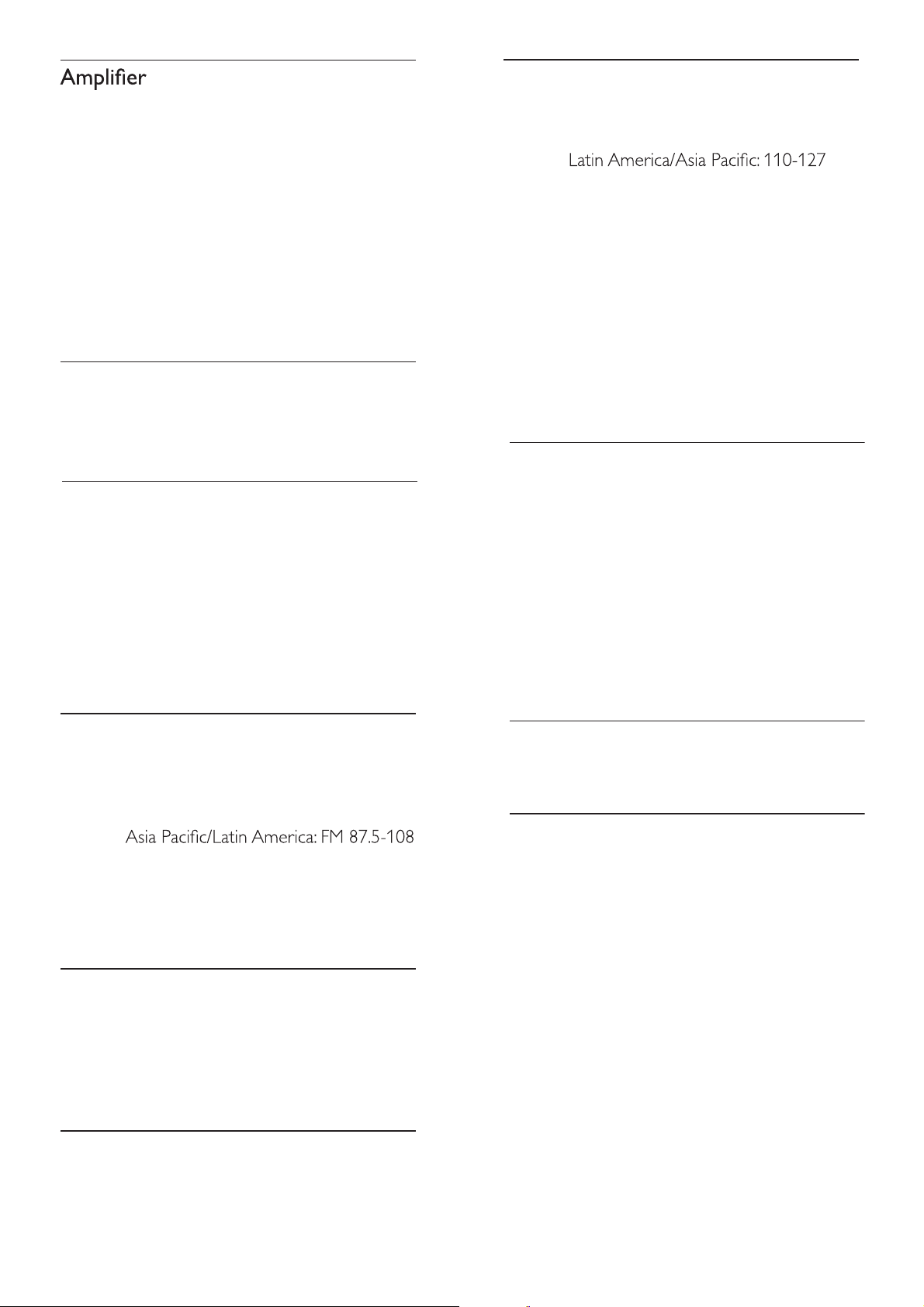

1 - 4

Audio

codec

PCM,

Dolby

Video codec Bit rate

DivX 3.11, DivX 4.x,

DivX 5.x, DivX 6.x

10 Mbps

max

Digital,

DTS core,

MP3,

WMA

MPEG 1, MPEG 2 40 Mbps

MPEG 4 SP / ASP 38.4

Mbps

H.264/AVC upto

25 Mbps

HiP@5.1

WMV9 45 Mbps

.divx

Audio codec Video codec Bit rate

PCM, Dolby

Digital, MP3,

WMA

in AVI container

DivX 3.11,

DivX 4.x, DivX 5.x,

DivX 6.x

10

Mbps

max

Audio codec Video codec Bit rate

PCM, Dolby Digital,

DTS core, MPEG,

MPEG 1,

MPEG 2

40 Mbps

MP3, WMA, AAC,

HE-AAC, DD+

MPEG 4 ASP 38.4

Mbps

H.264/AVC

25 Mbps

HiP@5.1

WMV9 45 Mbps

.asf and .wmv

only in Asia

Audio codec Video codec Bit rate

Dolby Digital,

in ASF container (Available

and China)

MPEG 4 ASP 38.4 Mbps

MP3, WMA,

DD+

H.264/AVC

25 Mbps

HiP@5.1

WMV9 45 Mbps

.mp4 or .m4v

Audio codec Video codec Bit rate

Dolby Digital,

MPEG, MP3,

in MP4 container

MPEG 1,

MPEG 2

40 Mbps

AAC, HE-AAC,

DD+

MPEG 4 ASP 38.4

Mbps

H.264/AVC

25 Mbps

HiP@5.1

.mkv

Audio codec Video codec Bit rate

PCM, Dolby

in MKV container

DivX Plus HD 30 Mbps

Digital, DTS core,

MPEG, MP3,

WMA, AAC, HEAAC, DD+

MPEG 1, MPEG 240 Mbps

MPEG 4 ASP 38.4

Mbps

H.264/AVC

25 Mbps

HiP@5.1

WMV9 45 Mbps

.m2ts

in MKV container

.mpg and .mpeg

Audio codec Video codec Bit rate

PCM, DTS core,

MPEG, MP3

in PS container

MPEG 1,

MPEG 2

40

Mbps

in FLV container

Audio

codec

MP3,

AAC

Video codec Bit rate

H.264/AVC upto

25 Mbps

HiP@5.1

H.263 38.4 Mbps

On2 VP6 40 Mbps

.3gp in 3GP container

Audio

codec

AAC, HE-

Video codec Bit rate

MPEG 4 ASP 38.4 Mbps

AAC

H.264/AVC upto

HiP@5.1

.rm, .rv, and .rmvb

in RM container

(Available only in Asia

Audio codec Video codec Bit rate

25 Mbps

max

and China)

AAC, COOK RV30, RV40 40 Mbps

Page 5

1 - 5

Subwoofer

• Total output power: 500W RMS (+/- 0.5

dB, 30% THD) / 400W RMS (+/- 0.5 dB,

10% THD)

• Frequency response: 20 Hz-20 kHz / ±3

dB

• Signal-to-noise ratio: > 65 dB (CCIR) /

(A-weighted)

• Input sensitivity:

• AUX: 650 mV

• AUDIO-IN: 300 mV

Video

• Signal system: PAL / NTSC

• HDMI output: 480i/576i, 480p/576p, 720p,

1080i, 1080p, 1080p24

Audio

• S/PDIF Digital audio input:

• Optical: TOSLINK

• Sampling frequency:

• MP3: 32 kHz, 44.1 kHz, 48 kHz

• WMA: 44.1 kHz, 48 kHz

• Constant bit rate:

• MP3: 32 kbps - 320 kbps

• WMA: 48 kbps - 192 kbps

• Power supply:

• Europe/China: 220-240 V~, 50 Hz

•

V/220-240 V~, 50/60 Hz

• Russia/India: 220-240 V~, 50 Hz

• Power consumption: 110 W

• Standby power consumption: ≤ 0.5 W

• Impedance: 3 ohm

• Speaker drivers: 165 mm (6.5") woofer

• Frequency response: 20 Hz-150 Hz

• Dimensions (WxHxD): 204 x 394 x 345

mm

• Weight: 6.1 kg

Speakers

• Output power: 2 x 135W RMS (30%

THD)

• Speaker impedance: 5 ohm

• Speaker drivers: 2 x 76.2 mm (3") woofer

+ 1 x 25.4 mm (1") tweeter

• Frequency response: 150 Hz-20 kHz

• Dimensions (WxHxD): 97 x 301 x 120

mm

• Weight: 1.45 kg/each

Radio

• Tuning range:

• Europe/Russia/China: FM 87.5-108

MHz (50 kHz)

•

MHz (50/100 kHz)

• Signal-to-noise ratio: FM 50 dB

• Frequency response: FM 180 Hz-12.5 kHz

/ ±3 dB

USB

• Compatibility: Hi-Speed USB (2.0)

• Class support: USB Mass Storage Class

(MSC)

• File system: FAT16, FAT32, NTFS

Main unit

Remote control batteries

• 2 x AAA-R03-1.5 V

Laser

• Laser Type (Diode): InGaN/AIGaN (BD),

AIGaInP (DVD/CD)

• Wave length: 405 +7 nm/-7 nm (BD), 655

+10 nm/-10 nm (DVD), 790 +10 nm/-20

nm (CD)

• Output power (Max. ratings): 20 mW

(BD), 6 mW (DVD), 7 mW (CD)

Speci cations subject to change without

prior notice.

• Dimensions (WxHxD): 304.4 x 68.8 x

307.2 mm

• Weight: 2.4 kg

Page 6

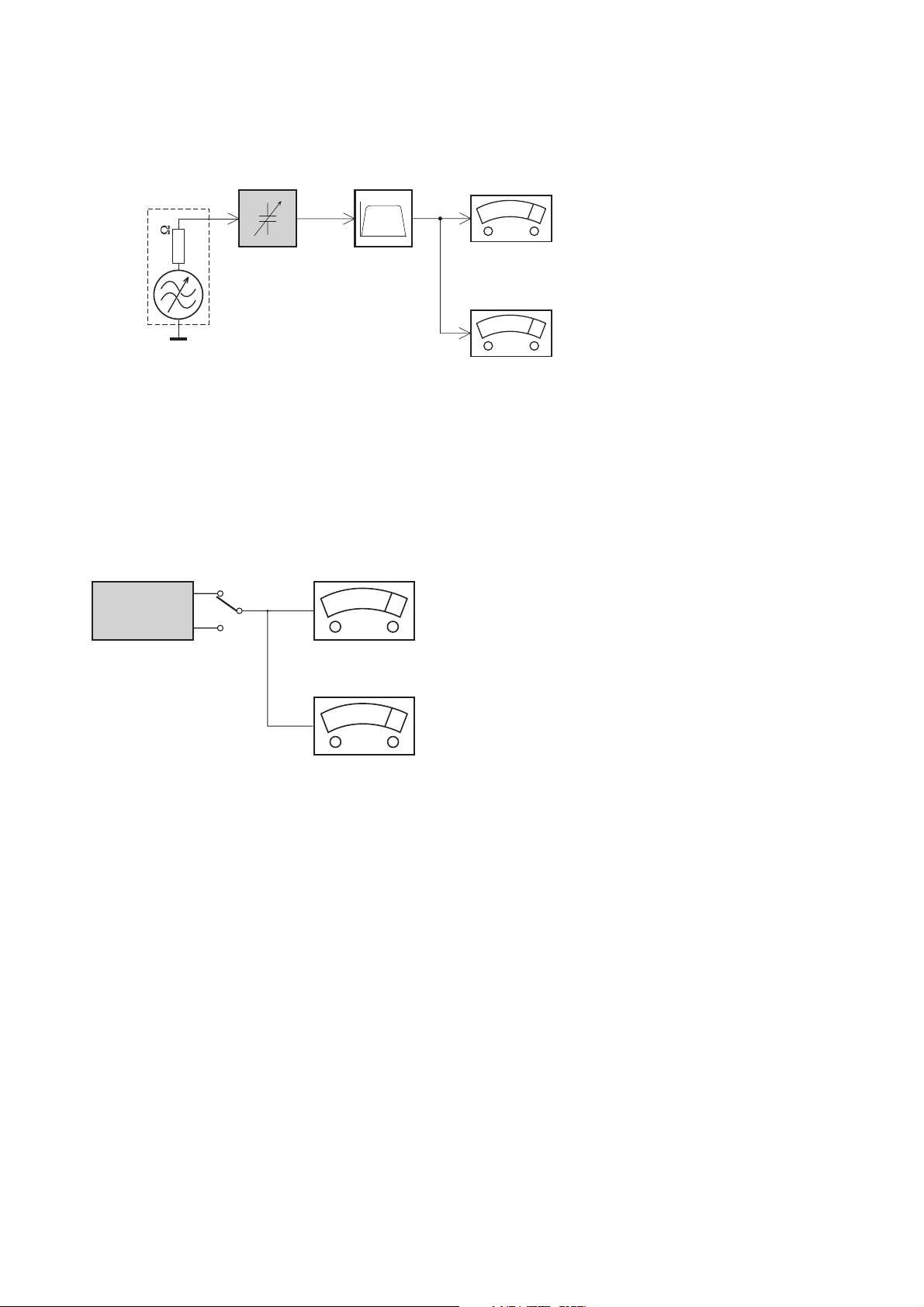

MEASUREMENT SETUP

Tuner FM

1 - 6

Bandpass

LF Voltmeter

e.g. PM2534

RF Generator

e.g. PM5326

DUT

250Hz-15kHz

e.g. 7122 707 48001

Ri=50

S/N and distortion meter

e.g. Sound Technology ST1700B

Use a bandpass filter to eliminate hum (50Hz, 100Hz) and disturbance from the pilottone (19kHz, 38kHz).

CD

Use Audio Signal Disc

(replaces test disc 3)

DUT

SBC429 4822 397 30184

L

R

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

Page 7

SERVICE AIDS

Service Tools:

Universal Torx driver holder .................................4822 395 91019

Torx bit T10 150mm ...........................................4822 395 50456

Torx driver set T6-T20 .........................................4822 395 50145

Torx driver T10 extended .....................................4822 395 50423

Compact Disc:

SBC426/426A Test disc 5 + 5A ...........................4822 397 30096

SBC442 Audio Burn-in test disc 1kHz .................4822 397 30155

SBC429 Audio Signals disc .................................4822 397 30184

Dolby Pro-logic Test Disc ....................................4822 395 10216

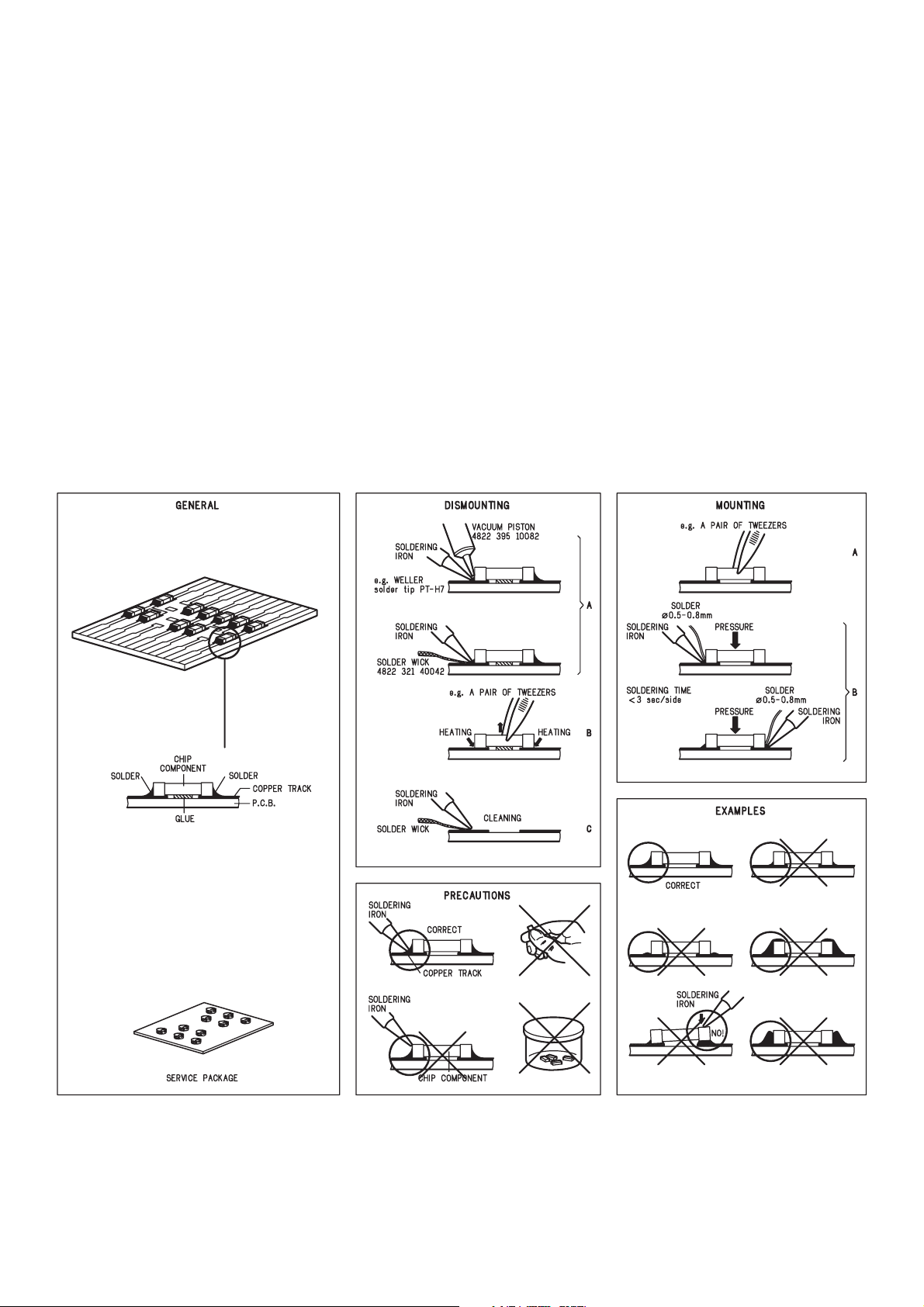

HANDLING CHIP COMPONENTS

1 - 7

Page 8

GB

A

WARNING

1 - 8

ESD

WAARSCHUWING

NL

ll ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

F

ATTENTION

Tous les IC et beaucoup d’autres

semi-conducteurs sont sensibles aux

décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est

prise à leur manipulation.

Lors de réparations, s’assurer de bien être relié

au même potentiel que la masse de l’appareil et

enfiler le bracelet serti d’une résistance de

sécurité.

Veiller à ce que les composants ainsi que les

outils que l’on utilise soient également à ce

potentiel.

GB

Complete Kit ESD3 (small tablemat, wristband,

connection box, estention cable and earth cable ....... 4822 310 10671

Wristband tester ................................................................. 4822 344 13999

D

WARNUNG

Alle ICs und viele andere Halbleiter sind

empfindlich gegenüber elektrostatischen

Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kan

die Lebensdauer drastisch reduzieren.

Veranlassen Sie, dass Sie im Reparaturfall über

ein Pulsarmband mit Widerstand verbunden

sind mit dem gleichen Potential wie die Masse

des Gerätes.

Bauteile und Hilfsmittel auch auf dieses gleiche

Potential halten.

ESD PROTECTION EQUIPMENT

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor electrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie kan

de levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

I

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevità potrebbe essere fortemente

ridatta in caso di non osservazione della più

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto

a resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo

potenziale.

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used.

Safety components are marked by the symbol

!

.

CLASS 1

LASER PRODUCT

NL

Veiligheidsbepalingen vereisen, dat het apparaat bij reparatie in

zijn oorspronkelijke toestand wordt teruggebracht en dat onderdelen,

identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbol

!

.

3122 110 03420

F

Les normes de sécurité exigent que l’appareil soit remis à l’état

d’origine et que soient utiliséés les piéces de rechange identiques

à celles spécifiées.

Less composants de sécurité sont marqués

!

.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu

beachten. Der Original zustand des Geräts darf nicht verändert werden;

für Reparaturen sind Original-Ersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol

!

markiert.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso

nelle condizioni originali e che siano utilizzati i pezzi di ricambio

identici a quelli specificati.

Componenty di sicurezza sono marcati con

!

.

GB

After servicing and before returning set to customer perform a leakage

current measurement test from all exposed metal parts to earth ground

to assure no shock hazard exist, The leakage current must not

exceed 0.5mA.

GB

Warning !

Invisible laser radiation when open.

Avoid direct exposure to beam.

S

Varning !

Osynlig laserstrålning när apparaten är öppnad och spärren

är urkopplad. Betrakta ej strålen.

Varoitus !

SF

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen!

DK Advarse !

Usynlig laserstråling ved åbning når sikkerhedsafbrydere er

ude af funktion. Undgå udsaettelse for stråling.

F

"Pour votre sécurité, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

Page 9

Pb(Lead) Free Solder

When soldering , be sure to use the pb free solder.

INDENTIFICATION:

Regardless of special logo (not always indicated)

onemust treatall setsfrom 1 Jan 2005 onwards,according

next rules:

Important note: In fact also products of year 2004 must

be treated in this way as long as you avoid mixing solderalloys (leaded/ lead-free). So best to always use SAC305

and the higher temperatures belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solder-paste

is required, please contact the manufacturer of your

solder-equipment. In general use of solder-paste

within workshops should be avoided because paste is

not easy to store and to handle.

• Use only adequate solder tools applicable for lead-

free solder alloy. The solder tool must be able

– To reach at least a solder-temperature of 400@C,

– To stabilize the adjusted temperature at the solder-

tip

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around

360@C – 380@C is reached and stabilized at the solder

joint. Heating-time of the solder-joint should not exceed

~ 4 sec. Avoid temperatures above 400@C otherwise

wear-out of tips will rise drastically and flux-fluid will

be destroyed. To avoid wear-out of tips switch off unused equipment, or reduce heat.

• Mix of lead-free solder alloy / parts with leaded solder

alloy / parts is possible but PHILIPS recommends

strongly to avoid mixed solder alloy types (leaded and

lead-free).

If one cannot avoid or does not know whether product

is lead-free, clean carefully the solder-joint from old

solder alloy and re-solder with new solder alloy

(SAC305).

• Use only original spare-parts listed in the Service-

Manuals. Not listed standard-material (commodities)

has to be purchased at external companies.

• Special information for BGA-ICs:

– Always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for desoldering always use the lead-free temperature profile,

in case of doubt)

– Lead free BGA-ICs will be delivered in so-called ‘dry-

packaging’ (sealed pack including a silica gel pack) to

protect the IC against moisture. After opening,

1 - 9

dependent of MSL-level seen on indicator-label in the

bag, the BGA-IC possibly still has to be baked dry.

(MSL=Moisture Sensitivity Level). This will be

communicated via AYS-website.

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products

of 2004), containing leaded solder-alloy and

components, all needed spare-parts will be available

till the end of the service-period. For repair of such

sets nothing changes.

• On our website www.atyourservice.ce.Philips.com

you find more information to:

• BGA-de-/soldering (+ baking instructions)

• Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical information

within the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

Page 10

2 - 12 - 1

Software upgrade & Procedure to restore product setting

1)Restore factory setting

a) Press “ ” <Home> button on R/C.

b) Select <SETUP>, then press “OK” button on R/C.

c) Select <Advanced>.

d) Select <Restore default settings>,then press <OK> to confirm.

2)Password change

a) Press “

” <Home> button on R/C.

b) Select <SETUP>, then press “OK” button on R/C.

c) Select <preference>.

d) Select <Change Password> <Confirm>, then press <OK> button

on R/C.

“0000” is default password supplied.

3)Trade mode

a) In open model,press “

” <Home> button on R/C.

b) Press “2” “5” “9” on R/C,VFD will display “TRA ON” or “TRA

OFF”.

4)Check software version

a) Press “

” <Home> button on R/C

b) Select <Setup>, then press <OK> button on R/C.

c) Select <Advanced Setup> <Version information>,then press

<OK> button on R/C.

d) TV will show message as follow:

Model:HTB7250D/12

Versions

System SW:X.XX.XXX

Subsystem SW:XX-XX-XX-XX

Wireless(Wi-Fi):XX:XX:XX:XX:XX:XX

Extended unique Identifier(EUI64):0025d1fffeof3c15

PRODUCT ID:A5UDJSCREQVGSCG5

For information,frequently asked questions and

software updates,please visit

www.philips.com/support

Close

e) press <OK> button to exit .

5) Upgrading new software

Method 1: Update software from a USB storage device

a) Create a folder named “UPG” in your USB storage device, and

Copy the latest upgrading software into the folder.

b) Connect the USB storage device to the home theater.

c) Press “

” <Home> button on R/C, and select <Setup>.

d) Select <Advanced> <Software Update> <USB>.

e)Follow the onscreen instructions to confirm the update.

»» Update process takes about 5 minutes to complete.

»» Once complete, the home theater automatically switches off and

restarts.If it does not, disconnect the powercord for a few seconds

and then reconnect it.

Method 2: Update software from the internet

Note: To check for new updates, compare the current software

version of your home theater with the latest software version (if

available) on the Philips web site, and for BD-Live application and

software update, make sure that the network router has access to

the Internet and the firewall is disabled.

a) The “LAN” jack at the back panel of the set must be connect to

the network router via network cable and the set connect to TV,

Prepare the connection as shown follow:

/NI IMDH

CRA IMDH

b) Press “

” <Home> button on R/C, and select <Setup>.

c) Select <Advanced> <Software Update> <Network>.

»» If an upgrade media is detected, you are prompted to start or

cancel the update.

»» Downloading of the upgrading file maytake long, depending on

your home network condition.

5 Follow the onscreen instructions to confirm the update.

»» Update process takes about 5 minutes to complete.

»» Once complete, the home theater automatically switches off and

restarts.If it does not, disconnect the powercord for a few seconds

and then reconnect it.

LAN

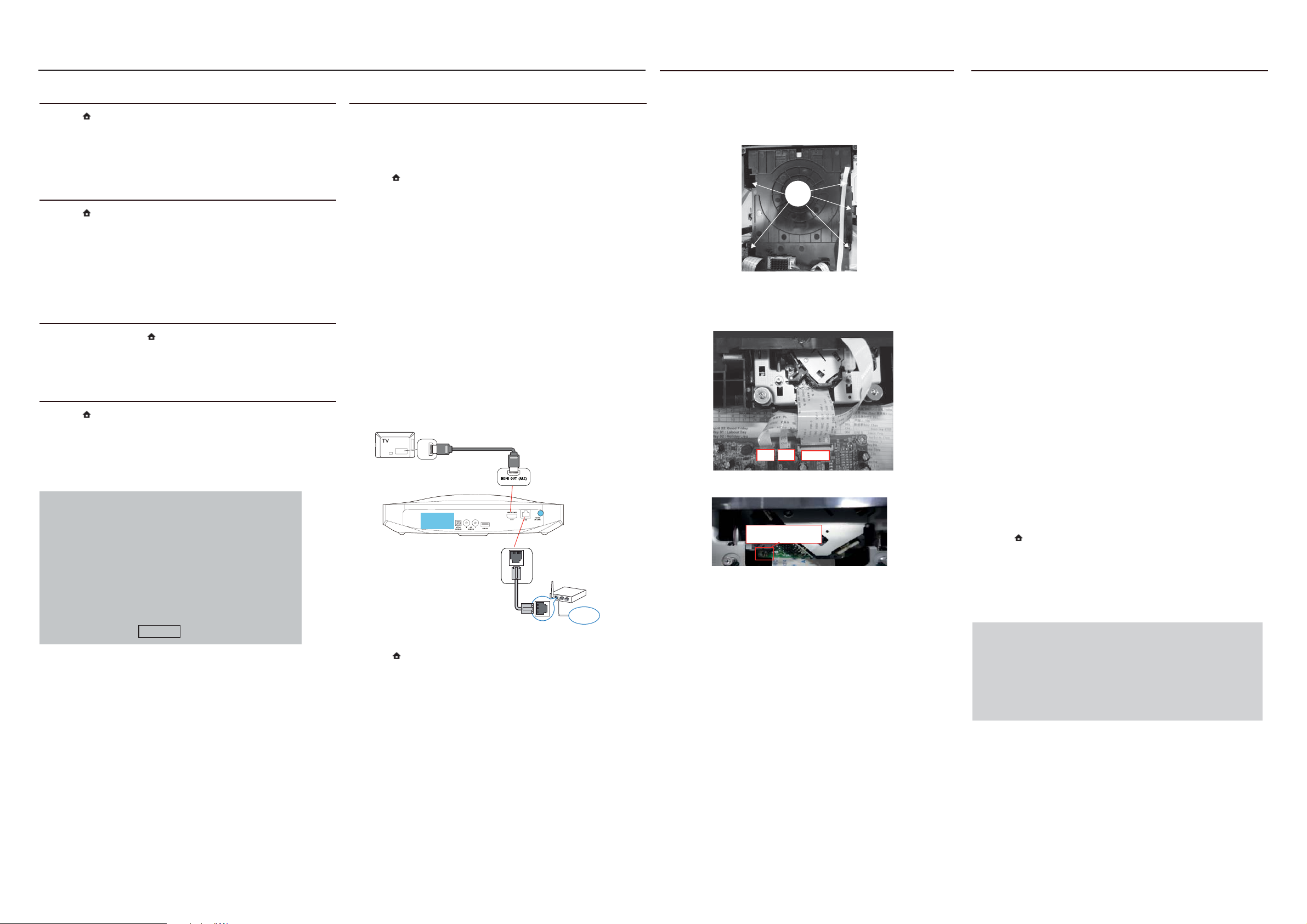

6)How to replace the defective Blu-ray Loader

a) Remove the defective Blu-ray Loader.

b) Remove the shield cover at the top of Blu-ray Loader as shown

7) Update the onscreen help

If the current version of the onscreen help is lower than the latest

version available on www.philips.com/support, download and install

below:

i) Loosen 5 screws on the top of Blu-ray Loader as shown in

figure1

the latest onscreen help.

* A USB flash drive that is FAT or NTFS formatted, with at least

35MB of memory. Do not use a USB hard drive.

* A computer with internet access.

A

* An archive utility that supports the ZIP file format

a) Connect a USB flash drive to your computer.

b) In your web browser, go to www.philips.com/support.

c) At the philips support website, find your product and click on User

Figure 1

c) Assembly Blu-ray Loader to “J800”,”J900”,”J901” on the top of BD

Board as shown below.

manuals, and then locate the User Manual Upgrade Software. (The

help update is available as a zip file).

d) Save the zip file in the root directory of your USB flash drive.

e) Use the archive utility to extract the help update file in the root

directory. (A file named “HTSXXXXeDFU.zip” is extracted under the

UPG folder of your USB flash drive, “xxxx” being the model number

of your home theater.)

f) Disconnect the USB flash drive from your computer.

Caution: Do not switch off the home theater or remove the USB

J900

J901

J800

d) Remove soldered joint on the ESD protection points.

flash dirve during the update.

g) Connect the USB flash drive containing the downloaded file to

your home theater. (Make sure that no disc is loaded inside the disc

compartment)

The ESD Protection points

on the top of board

h) Press “

” <Home> button on R/C.

i) Enter 338 on the remote control.

Bottom side view of OPU

Note: The ESD protection points must be soldered if

www

o the Blu-ray Loader is OK and needs to be disconnected from

connector J800, J900 and J901 of the BD Board.

o the defective Blu-ray Loader is needed to be send back to

supplier for failure analysis and to support backcharging evidence.

j) Follow the onscreen instructions to confirm the update.

k) Disconnect the USB flash drive from the home theater.

CAUTION!

This information is confi dential and may not be

distributed.Only a qualifi ed service person should

reprogram the Region Code.

Page 11

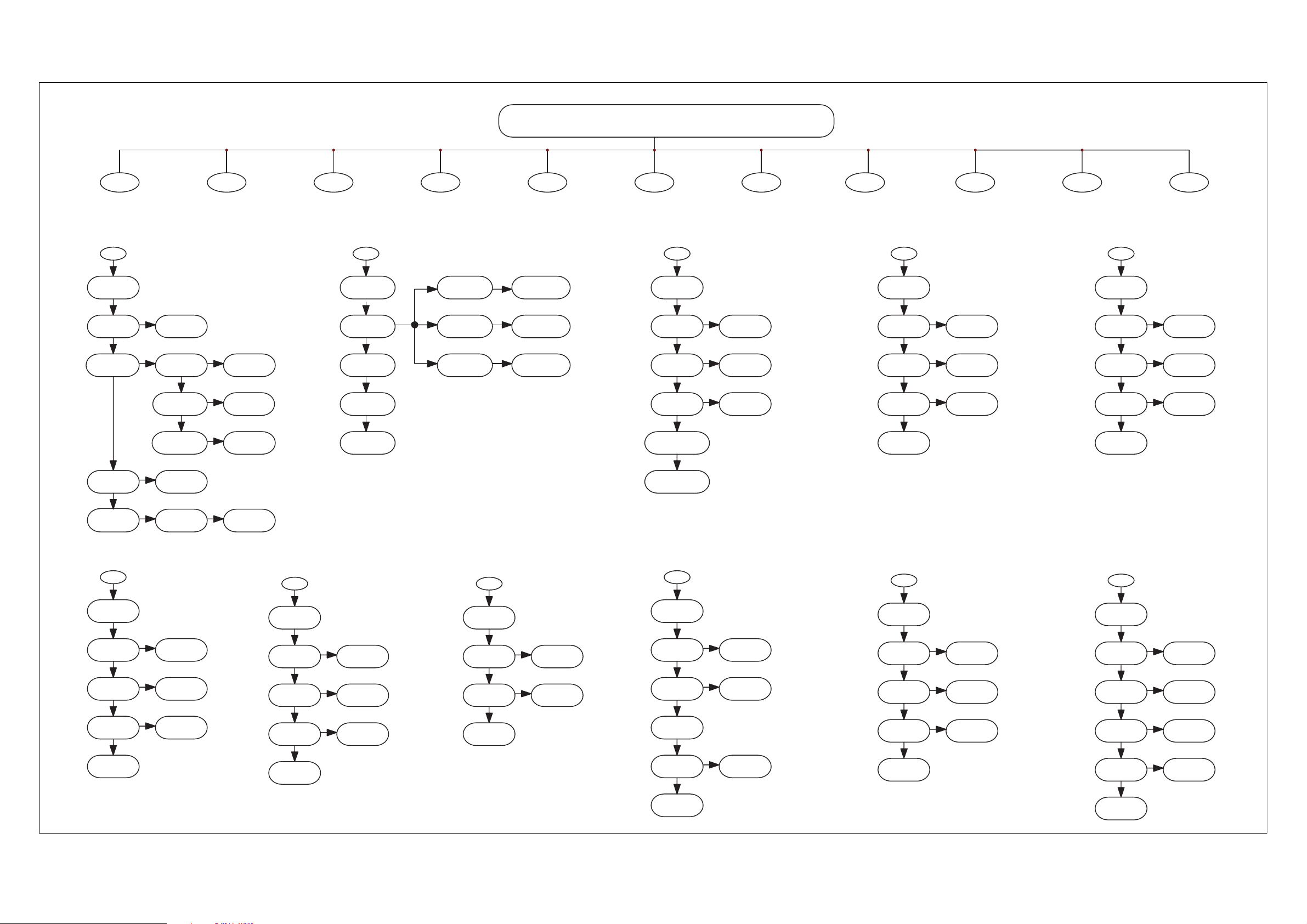

REPAIR INSTRUCTIONS(main unit)

2 - 22 - 2

HTB7225/9225 REPAIR CHART

A

All Functio n

No Working

A

All functi on

No working

Check all system

all cable is loose

or bad INT

NO

Panel stanby LED

show working or Not

WORK

Check All DC TO DC IC

OUT Voltage approx

+5V +12V -12V -24V

CORRECT

Check IC721 IC162

OUT Voltage 3.3V

YES

Re-insert and fix

the cable

NO

Check back power PCB

F901 bad cause damage

Check CN903 JK401

And Its Conjoint parts

Check IC162

And Its Conjoint parts

NO

Check repair

And Its Conjoint parts

YES YES

Check IC101 Pin12 pin13

OSC frequency 8MHz

OK

YES

BAD

NO

OK

B

Power Supply

No Working

Change F901

Check 3m cable

REPAIR ok

Check repair t ouch

PCB Standby circuit

Repair main pcb between

IC201 Q202

And Its Conjoint parts

C

All Functio n

No Sound

Check Repair IC901 IC903

Q901 IC904 D921 And Its

D

Key board

No Functi on

E

VFD bo ard

No Funct ion

No Sound

B C

Power Supply

No working

All Voltage

No Output

YES

Check F901

Bad Cause Damage

No

Check BKVCC

Working or Not

No

CONN CIRCUIT

+32V Voltage

No Output

No

+14V Voltage

No Output

BKVCC Voltage

No Output

Check Q902 Q903 IC905

D923 And Its Conjoint Part

Check D921 Q901

And Its Conjoint Part

Check R919 D921 Q904

And Its Conjoint Part

F

AUX IN

All Functi on

No Sound

Check POWER IC

Voltage +18V ~ +33V

Check Power Ic

Pin 1,2,22

Voltage 12V

Check IC 4103 Pin9/14

Pin35/50 Voltage +3.3v

Check CN201 Pin

And Its Conjoint Part

Check BD Board

See C onte nts BD Boar d

G

MP3 In

No Sound

H

BT In

No Sound

D

Key board

No Function

I

Optica l In

No Sound

J

Tuner No Sound

E

VFD board

No Function

K

Subwoofer No Sound

Yes

No

See C onte nts B

Check the cable connect

CN207 CN600 loose or bad INT

OK

YES

Check IC131

And Its Conjoint Part

OK

No

Check IC721 FB721

And Its Conjoint Par t

Check IC1 Pin12

Voltage approx +3.3 V

Check I C1 Pin7(DAT)

Check IC1 Pin6(CL K)

OK

Check IC1

And Their Conjoint Parts

YES

Re-insert and f ix

the cable

Check the cable connect

CN207 CN600 loose or bad INT

OK

No

And Its Conjoint parts

Check R125

Check IC600 Pin14/33/45

Voltage approx +5V

Check IC600 Pin34

Voltage approx -24 V

OK

No

Check CN601.CN1 And

Their Conjoint Parts

Check IC600 Pin6( DAT)

Check IC600 Pin8(CLK)

Check IC600 Pin9(CE)

OK

Check DP600

And Their Conjoint Parts

YES

Re-insert and f ix

the cable

OK

No

Check IC600

And Its Conjoint part s

OK

No

Check R604/603/602

And Their Conjoint Parts

OK

Yes

F

AUX IN

No Output

Check JK301

INT or No

OK

Check IC304 Pin5/14/36

approx +5V Pin46 approx

+3.3V Yes or No

Yes

Check CN201

Loose or bad INT

OK

Check BD Board

See Contents BD Board

INT

No

Check R312 R313 R377

And Its Conjoint Parts

Yes

Re-insert and fix

Change this jk

the cable

G

MP3 In

No Sound

Check JK831 CN805

RB303 INT or No

OK

Check IC304 Pin5/14/36

approx +5V Pin46 approx

+3.3V Yes or No

Yes

Check CN201

Loose or bad INT

OK

Check BD Board

See Contents BD Board

INT

Change this jk

Check R312 R313 R377

And Its Conjoint Parts

Yes

Re-insert and f ix

the cable

H

BT In

No Sound

Check CN881 CN883

RB303 INT or No

OK

Check BT881 Pin18

+3.3V Yes or No

Yes

Check BT881 Q881 Q882

And Its Conjoint Part

INT

OP

And Its Conjoint Parts

Change this jk

Check L300

I

Optical

No Sound

Check JK303

INT OR NO

OK

Check JK303 pin1

Yes or No

approx +3.3V

OK

Check IC305Pin11/12

f=24.576MHz

OK

Check IC305 Pin3 /19/22

approx +3.3V

OK

Check BD Board

See C onte nts BD Boar d

INT

No

Check And Repair

No

Check R314 R358 R375

REPAIR ok

R343

J

Tuner No Sound

Output

Check Check TUNER PACK

Pin5 approx +3.3V

Yes

Check IC304 Pin5/14/36

approx +5V Pin46 approx

+3.3V Yes or No

Yes

Check CN201

Loose or bad INT

OK

Check BD Board

See C onte nts BD Boar d

No

Check CN3 CN301

And Its Conjoint Par ts

No

Check R312 R313 R377

And Its Conjoint Parts

Yes

Re-insert and f ix

the cable

K

Subwoofer

No Sound

Yes

Check POWER IC

Voltage +18V ~ +33V

OK

Check Power Ic

Pin 1,21,22,23,44

Voltage 12V

OK

Check IC 5202 Pin9/14

Approx Voltage +3.6v

OK

Check CN903 JK401

And Its Conjoint Part

Yes

Check IC4013

See C onte nts C

No

YES

No

INT

Check CN904 RB5201

INT or No

Check R5226

And Its Conjoint Par t

Check IC721 ZD5201

And Its Conjoint Par t

REPAIR ok

Page 12

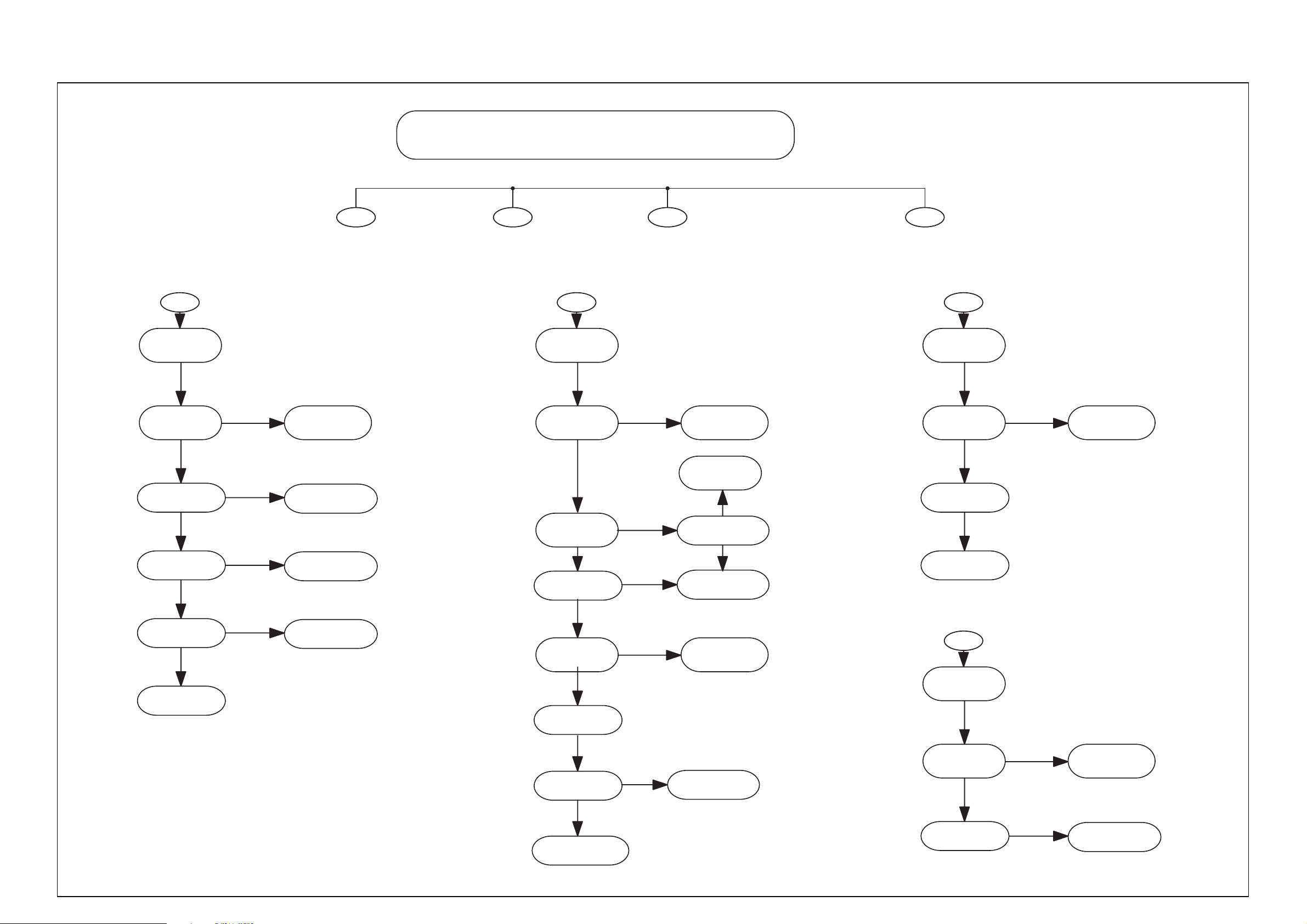

REPAIR INSTRUCTIONS(BD Board)

2 - 32 - 3

A

BD function

No working

Check CN4 cable is loose

or bad INT

YES

BD Function

No Working

Re-insert and fix

the cable

A

BD Board

B

Loading

No DISC

Check Y300 crystal

27MHz Freq Yes or NO

REPAIR CHART

C

All Video

No OUTPUT

B

Loading

No Disc

NO

supersession 27MHz crystal

D

HDMI_RX no output

All Video

No OUTPUT

Check JK805 is

loose or bad

C

loose

Re-insert and fix

the JACK

NO

Check 1.1V 1.5V

Yes or No output

YES

Check 3.3V

Yes or No output

YES

Check Y300 Crystal 27MHz

Yes or No output

YES

Check U100 U201 U101

U102 and connect part

NO

NO

NO

Repair BD pcb between

L1 U1 L3 U905 circuit

Repair BD pcb between

U901 L2 FB19 circuit

Repair BD pcb between

Y300 U100 Circuit

YES

Check Open/Close

Working or Not

OK

Check J800 to

BD loader Cable Loose

ps!Cbe!JOU

OK

Check BD Loader run

Yes or NO

YES

Check U101 U102 U201

and connect part

OK

Determine Picture Output

Zft!ps!Op

OK

Check U10 u408

Boe!Uifjs!Dpokpjou!Qbsut

YES

NO

No

No

Check U10

And Its conjoint parts

No

Check J900 J901

up!CE!Mpbefs!Dbcmf!mpptf

ps!Cbe!JOU

Zft

Re-Insert and fix

the cable

supersession Loader

Check U100 And

Their Conjoint Parts

Bad

supersession JACK

PL

Check JK805

between U100

D

Ethernet No starting

Check P401 loose

or bad INT

NO

Check P401 between U100

YES

INT

supersession P401

Repair P401 between U100

Page 13

3 - 1 3 - 1

DISASSEMBLY INSTRUCTIONS-MAIN UNIT

Note:In some service positions the components or copper patterns of one board may risk touching its

neighbouring pc boards or metallic parts. To prevent such short-circuit use a piece of hard paper or

other insulating material between them.

Dismantling of the VFD Board

1) Loosen 1 screws “D” on the top of VFD Board as shown in gure 4.

Dismantling of the Top Cover

1) Loosen 1 screw “A” at the back panel to remove the top cover as shown in gure 1.

A

Figure 1

Dismantling of the BT Board

1) Loosen 2 screws “B” on the top of BT board as shown in gure 2.

D

Figure 4

Dismantling of the DVD Module

1) Loosen 5 screws “E” at the DVD Module as shown in gure 5.

E

B

Figure 2

Dismantling of the TOUCH Board

1) Loosen 3 screws “C” at the bracket of Touch Board as shown in gure.

C

Figure 5

Dismantling of the MP3 &USB &SENSOR Board

1) Loosen 3 screws “F” on the top of MP3&USB Board as shown in gure 6.

2) Loosen 2 screws “G” on the top of SENSOR Board as shown in gure 7.

G

F

Figure 3

Figure 7

Figure 6

Page 14

Dismantling of the BD Board

1) Loosen 4 screws “H” on the top of BD Board as shown in gure 8.

2) Loosen 1screw “I” at the back panel as shown in gure 9.

H

Figure 8

3 - 2 3 - 2

K

Figure 11

SERVICE POSITIONS (MAIN UNIT)

Service Position A - MAIN&BD Board

Figure 9

Dismantling of the MAIN Board

1) Loosen 6 screws “J” on the top of main board as shown in gure 10.

2) Loosen 2 screws “K” at the back panel as shown in gure 11

J

I

Service Position E - All Boards

Figure 10

Page 15

3 - 3 3 - 3

DISASSEMBLY INSTRUCTIONS-SUBWOOFER

Dismantling of the Subwoofer Rear Panel

1) Loosen 9 screws “Q” at the subwoofer rear panel as shown in gure 17.

Q

Dismantling of the Subwoofer AMP Board

1) Loosen 4 screws “S” on the top of subwoofer AMP board as shown in gure 19.

S

Figure 19

Figure 17

Dismantling of the Power Board

1) Loosen 5 screws “R” on the top of power board as shown in gure 18.

SERVICE POSITIONS (SUBWOOFER)

R

Figure 18

Page 16

3 - 1 3 - 1

DISASSEMBLY INSTRUCTIONS-MAIN UNIT

Note:In some service positions the components or copper patterns of one board may risk touching its

neighbouring pc boards or metallic parts. To prevent such short-circuit use a piece of hard paper or

other insulating material between them.

Dismantling of the VFD Board

1) Loosen 1 screws “D” on the top of VFD Board as shown in gure 4.

Dismantling of the Top Cover

1) Loosen 1 screw “A” at the back panel to remove the top cover as shown in gure 1.

A

Figure 1

Dismantling of the BT Board

1) Loosen 2 screws “B” on the top of BT board as shown in gure 2.

D

Figure 4

Dismantling of the DVD Module

1) Loosen 5 screws “E” at the DVD Module as shown in gure 5.

E

B

Figure 2

Dismantling of the TOUCH Board

1) Loosen 3 screws “C” at the bracket of Touch Board as shown in gure.

C

Figure 5

Dismantling of the MP3 &USB &SENSOR Board

1) Loosen 3 screws “F” on the top of MP3&USB Board as shown in gure 6.

2) Loosen 2 screws “G” on the top of SENSOR Board as shown in gure 7.

G

F

Figure 3

Figure 7

Figure 6

Page 17

Dismantling of the BD Board

1) Loosen 4 screws “H” on the top of BD Board as shown in gure 8.

2) Loosen 1screw “I” at the back panel as shown in gure 9.

H

Figure 8

3 - 2 3 - 2

K

Figure 11

SERVICE POSITIONS (MAIN UNIT)

Service Position A - MAIN&BD Board

Figure 9

Dismantling of the MAIN Board

1) Loosen 6 screws “J” on the top of main board as shown in gure 10.

2) Loosen 2 screws “K” at the back panel as shown in gure 11

J

I

Service Position E - All Boards

Figure 10

Page 18

3 - 3 3 - 3

DISASSEMBLY INSTRUCTIONS-SUBWOOFER

Dismantling of the Subwoofer Rear Panel

1) Loosen 9 screws “Q” at the subwoofer rear panel as shown in gure 17.

Q

Dismantling of the Subwoofer AMP Board

1) Loosen 4 screws “S” on the top of subwoofer AMP board as shown in gure 19.

S

Figure 19

Figure 17

Dismantling of the Power Board

1) Loosen 5 screws “R” on the top of power board as shown in gure 18.

SERVICE POSITIONS (SUBWOOFER)

R

Figure 18

Page 19

BLOCK DIAGRAM

4 - 1 4 - 1

BD OPU Sanyo TRV-415H09

Walleywood loader Loader

RJ-45

Ethernet

BRAND: ALPHA

WiFi Module

Model Number: WUS-N18M

(Ralink RT3370)

USB 2.0

Audio/Karaoke DAO

slot Loader

TPIC2050

Motor driver

Build in(integrated)

USB cable

+5V/1.0A

+5V/1.0A

USB1 Front

RF

Connector

USB2

Current pr otect

TPS2553

Current protect

TPS2553

Audio/Karaoke DAO

CEC

HDMI

HDMI IN + MPEG BOARD

SERVO

BD HDMI1

EP94M3 CTL I2C

DDR3

128MB 2pcs

DDR3

256MB 1pcs

NADN Flash

256MB

BD Backend

MT8580BDAG

H_I2S

BD-MCLK

BD I2S

SPF-MCLK

I2C

Audio I2S

MCLK

IR

INT

I2C

UART

HDMI Out

Write

EDID AT24C02

Serial EEP ROM

Read

iPOD

Implementation

MFI337S3959

ESD Protect

x 2pcs

BK5V

BK5V

+12V

+5V

CEM8311/AO4813

(7.0A MOSFET SW IC)

HDMI1 Out

LDO Reg.

LM1117-33

LDO Reg.

LM1117-33

H/L Power SW control

DC TO DC

TPS54418RE

DC TO DC

G5627F11U

WB1542

DC/DC

LM1117-3.3V

LDO

HD1V8

HD3V3

Motor driver

+12V (1.3A)

+5V

Motor driv er

1.2V

(3.5A)

1.5V

(2.0A)

USB/WiFI

3.3V(1.0A)

3.3V(0.3A)

UART

LM1117-ADJ

LM1117-1.2V

LM1117-1.8V

Debug1

Debug2

Debug3

Debug4

Debug5

GND

+3.3V

For MCU Debug

+3.3V

TX

RX

SW-Upgrade

LDO

LDO

LDO

CEC

9V

TO OPU

1.2V

(0.3A)

1.8V

To video ADC

0R Jump

(Simple)

Powre down

0R Jump

(Advance)

PWR/STBY

UART1

AT24C02

EEPROM

UART2

DE-PWR

EP94M3 CTL I2C

IR

IR

Transistor

PWM port

8 - Char Only THB72XX

LCD Display Only THB9245

13-Char Only THB92XX

AC(to VFD)

VFD DRIVER

STM32F100VC

256K FLASH,16K SRAM

UI-User Input ( Key/IR)

VFD display

D-AMP control

CEC Player

CEC Audio System

Tuner/RDS control

VFD Display

PT6311

7 KEY

LED x 1 only STB for HTB72XX

LED x 7 for HTB92XX

Touch PAD IC

eKT4701

I2C

Tuner Pack

MP3/Mic Delect

DC port

Diode

and R.C

PWM pin

Transistor

FAN Control

CTL IO BT

Display Unit Part

White LED

Only THB92XX

Tuner Audio

From spk output

Fan

HDMI3 IN

EDID AT24C02

Serial EEP ROM

EDID AT24C02

Serial EEP ROM

For HTB72xx

MAIN BOARD

COAXIAL

OPTICAL

Blutooth module

BM84

Audio/Karaoke DAO

Tuner Audio

AUX-IN

MP3/Mic Detect

MP3/Mic

ESD Protect

For HTB92xx

CTL IO BT

BT Audio

AUX in

IC 4558

MP3 in

x 2pcs

MIC in

I2C

CS8422

SPDIF Rx

CS5346

MUX+ADC

Switch

EP94M3

HDMI SPDIF IN(ARC)

BD-MCLK

SPF-MCLK

I2C

SCLK

LRCK

MCLK

3.3V

LDO Reg.

LM1117-33

5V

LDO Reg.

LM1117-33

Mic Mono Jack

Provision Mic for 93/98 version

BD-MCLK

I2C

Mic

SPF-MCLK

BD I2S

1.8V

3.3V

I2C

Audio I2S

H_I2S

MCLK

+32.5V

GND

+15V

GND

BK9V

Reset

S-PWM

S-GND

DE-PWR

STBY

3M 14pin cable

10pin connector

HDMI SPDIF IN(ARC)

H-I2S

+32.5V

(wire #24)

+32.5V

(wire #24)

GND

(wire #24)

GND

(wire #24)

+15V

(wire #24)

+15V

(wire #24)

GND

(wire #24)

GND

(wire #24)

(wire #24)

BK9V

Reset

(wire #28)

S-PWM

(wire #28)

S-GND

(wire #28)

(wire #28)

DE-PWR

(wire #28)

STBY

I2C

PWM IN

+15V

Transistor

MCLK

Buffer

74HC04

+12V

Subwoofer Unit Part

TAS5538

D-AMP PWM

TAS5612

AMP

Fan

VOLUME

FAN CTRL

SUB SPK

180W(10%)

230W(30%)

I2C

TAS5612A

PWR AMP

+-

EP94M3 I2C

DDCTX-I2C

EP94M3-RST

TXHPD To MT8580 HDMI IN

DDCTX-I2C To MT8580 HDMI IN

SRR/SRL

RR/RL

FL

FL

FR/FL

135W

OUTPUT 30% 270W

C/SUB

RR/RL

5

FR/FL

SPK (ohm)

3

SUB

RX5V(H1/2/3)

TO-EP94M3

Subwoofer PSU

Power consumption < 0.5W

PSU

EP94M3-INT

RXHPD(H1/2/3)

STBY

DE-PWR

+33V

+33V

+12V

+12V

BK5V

For HTB92xx

For HTB72xx

Page 20

WIRING DIAGRAM

4 - 2 4 - 2

AC SOCKET

CN901

SV1

SV2

V2

V10

V5

V3

V4

V1

Page 21

5 - 1 5 - 1

IC304 INTERNAL IC DIAGRAM - CS5346 CQZ

MAIN+VFD+SUB+USB+MP3+SENSOR+BT BOARD

TABLE OF CONTENTS

Internal IC Diagram ...........................................................................5-1

Circuit Diagram .................................................................................. 5-3

PCB Layout Top View ........................................................................ 5-4

PCB Layout Bottom View ................................................................... 5-5

3.3 V 5 V

Internal Voltage

Reference

Low-Latency

Anti-Alias Filter

Low-Latency

Anti-Alias Filter

Multibit

Oversampling

ADC

Multibit

Oversampling

ADC

PGA

PGA

®

I²C

™

/SPI

Control Data

Interrupt

Overflow

Reset

Serial

Audio

Output

3.3 V to 5 V

rotalsnarT leveL

rotalsnarT

leveL

ec

a

fretnI

l

a

ir

eS

M

CP

Register Configuration

High Pass

Filter

High Pass

Filter

IC201 INTERNAL IC DIAGRAM - STM32F100VBT6BATR

MUX

+32 dB

+32 dB

Left PGA Output

Right PGA Output

Stereo Input 1

Stereo Input 2

Stereo Input 3

Stereo Input 4 /

Mic Input 1 & 2

Stereo Input 5

Stereo Input 6

Page 22

5 - 2 5 - 2

A

A

IC4103 INTERNAL IC DIAGRAM - TAS5538 DGG

AVSS_PLL

VDD_REF

VRA_PLL

VBGAP

VRD_PLL

DVDD

DVSS

AVD D

AVS S

VDD_PLL

VR_PLL

CM

KL

7

0

auqiB

sd

teD

LP

L

TM

L

F_

TP

LF_LLP

KL

CS

CRL

KL

1NIDS

NIDS

2

DS

3NI

4NIDS

2

I

ADS

LCS

TESER

NDP

M

ETU

LES_PH

E_DNKB

RR

C

reS

lai

lortno

C

I/F

veD

eci

o

C

rtno

l

DAP Control

0

7

teD

auqiB

sd

0

8

8

7

teD

auqiB

sd

0

7

teD

auqiB

sd

0

7

auqiB

teD

sd

0

7

auqiB

teD

sd

0

7

teD

auqiB

sd

0

7

teD

auqiB

sd

8

9

Loud

tfoS

oS

tf

T

eno

oS

tf

T

eno

oS

tf

T

eno

oS

tf

T

eno

tfoS

eno

T

oS

tf

eno

T

oS

tf

T

eno

oS

tf

eno

T

4

e

loV

mu

rtnoC

lo

D

V

V

V

V

V

V

V

V

CR

lo

pmo

C

Loud

tfoS

D

CR

C

lo

pmo

tfoS

Loud

D

CR

lo

C

pmo

tfoS

Loud

C

lo

pmo

Loud

tfoS

C

pmo

lo

Loud

tfoS

C

pmo

lo

Loud

tfoS

C

pmo

lo

tfoS

Loud

C

lo

pmo

8

8

D

CR

RD

C

D

CR

D

CR

RD

C

2

2

D

C

eD

hpmE

kcolB

eD

D

C

hpmE

kcolB

eD

D

C

kcolB

D

C

kcolB

D

C

kcolB

D

C

kcolB

D

C

kcolB

D

C

kcolB

retnI

hpmE

eD

hpmE

eD

etnI

hpmE

eD

E

hpm

eD

hpmE

eD

hpmE

IC305 INTERNAL IC DIAGRAM - CS8422-CNZR QFN

CRS

pretnI

etalo

CRSM

pretnI

etalo

SMWPS

talop

CR

e

SMWPS

CR

talopretnI

e

C

S

R

talopr

e

CRSMWP

pretnI

etalo

CRSMWP

pretnI

etalo

CRSMWP

pretnI

etalo

8

MWPSN

SN

P

W

N

N

N

MWPS

SN

SN

SN

8

CVSP

PA

WP

M

dna

8MA

efoowbuS

r

LA

DI

V

CVSP

Page 23

CIRCUIT DIAGRAM

CN202

FB201

C221

104

C223

104

R291 33

VBSU`UY2`NUL

VBSU`SY2`NUL

R292 33

R293 33

R295 33

R296 33

R297 33

R298 33

R299 33

VTC`N

VTC`N

6

USB606

6

2

2

3

3

4

4

5

5

7

USB2.0

7

C3000

4.7u

Q3002

2SA733

R341 open

INDV`TEB

100

C222

220U/10V

FB202

C224

220U/10V

NJD`TEPVU

CE0JO`ETE3

CE0JO`ETE2

CE0JO`ETE1

CE0JO`TDML

CE0JO`MSDML

CE`NDML

C`NDML

J3D`TEB2` NUL

J3D`DML2`NUL

CE`NVUF

DFD

J3D`JOU` NDV`UP`NUL

CE`JS

SYEBUB1

9533`CDML

NU9691BVEJP!JO!NDML

9533`MSDL

INDV`TDM

IC606

2

J0P2

3

HOE

4

CAB066

HOE

VTC`N

VTC`Q

CE`WDD

Q3001

2SC945

5/8L

R3024

Q3006

2SA733

NJD`TXJUDI2

R3026 1K

Q3007

2SC945

C3018

100U/10V

NQ4!!M0NJD

NQ4!!S

C344 100PC343 102

C342 102

UVO.M

UVO.S

UVOFS`STU

,23/1W

,CE6W

100

CL4/4W

CL4/4W

DFD

TQEJG`JSR

TQEJG`SFTFU

BED`STU

,4/4WE

TQEJG`BSD

J3D`DML2`NUL

J3D`TEB2`NUL

CE`NDML

CE0JO`MSDML

CE0JO`TDML

NJD`TEPVU

9533`HQP4

VTC`Q

7

J0P5

C696

CE`WDD

6

WDD

215

VTC`Q

J0P45J0P3

RB606

5

2

RB4/20

TO BD BOARD

R3003

93L

C3002 150P

R3002

C3001

4.7u

1K

R3001

R3000

3L3

3K3

R3023

2K2

C3017

104

R3025

2K2

600

FB302

600

FB303

R342 open

C345 100P

R308

18K

R309

18K

D306

R303 33K

D307

C3005

IC301A

4

,

4.7u

2

C.

3

JRC4558

.

5

10

R3005

104

100U/16V

D3002

R30043/3L

1N4148

C3003

C3004

,23W

0

R3021

470

R3022

R30191K

Q3004

2SC945

Q3003

2SC945

R3020

270K

47U/16V

C307 475

21L

R346

C308 475

R345

21L

R349 33K

R348 33K

C305 475

BVY.M

C306 475

BVY.S

180P

180P

C312

R304 33K

C313

R373

C301 475

0

C309

open

R310 openR311 open

R374

C302 475

0

C310

open

DDO2361:1.1323

CN201

GPS!!CE!!QDC

NQ4!JO0NJD!JO

BVY!JO

58

57

JK301A

TUNER

CN8/20

RB303

RB4/20

CN301

12

11

10

9

8

7

6

5

UP!CE!CPBSE

4

3

2

1

56

55

54

53

52

51

4:

49

48

47

46

45

44

43

42

J3DJSR

41

3:

39

38

37

36

35

34

33

32

31

2:

29

28

27

26

SY`TEB

25

SY`TDM

24

SY`IQE

23

SY6W`JO3

22

SYIQE`DUM3C

21

SY6W`JO2

:

SYIQE`DUM2C

9

SY6W`JO1

8

SYIQE`DUM1C

7

FQ:5N4`STUC

6

FQ:5N4`JOUC

5

4

3

2

2

NJD`EFUFDU

NQ4!!S

5

NQ4!!M0NJD

AUX-L

AUX-R

2

3

4

5

6

J3D`TEB4 `UVOFS0FQSPN

7

J3D`TD M4`UVOFS0FQSPN

8

9

RCI024004-0005

IC202

2

T1

3

T2

4

T3

5

HOE

R281

R282

R283

R284

UVOFS`STU

CL4/4W

CL4/4W

TO 5538 17PIN

R209

C`NDML

C218 10P

ASW100010-0007

R3006

1

.23W

D3003

1N4148

D3004

1N4148

C3015

C311 180P

XL201

D3005

R203

J3D`JOU`NDV`UP`NUL

JK303A

24C16B

C201

10P

C203

R2034

4.7K

J3D`TDM3`UJ6649

PVU

HOE

WDD

C3014

10U/50V

C314 180P

R204

30K

R2033

4.7K

C3006

WDD

XD

TDM

TEB

4.7K

4.7K

10K

10K

8MHz

C202

10P

1N4148

R2032

4.7K

J3D`TEB3`UJ6649

4

3

2

4.7u

R3007 10K

1N4148

R3018 4K7

BVY`M

BVY`S

UVO`M

UVO`S

9

8

7

R279 33

6

R280 33

UPVDI`QBOFM` SFTFU

100K

104

4.7K

GBO`MFWFM`EFUFU

BNQ`MFWFM`EFUFU

BJSQMBZ.SFTU

CE`MFE

IQ`DPOUSPM

D202

R210

3.3M

C1029

R343 10

C320

104

R3008 4.7K

R3028 3/3L

Q3005

2SC945

NQ4`M

NQ4`S

R278

C214

C215

C216

C217

R2029

4.7K

J3D`TEB6`DT645709533

OPEN

R3009

C3007 270P

R3017

100K

C339

100U

6

7

104

C3008

104

C213

100P

100P

100P

100P

MCU RST

BVEJP44W

,

.

R3016

1K

33

J3D`TDM4`UVOFS0FQSPN

J3D`TEB4`UVOFS0FQSPN

R208

D201 1N4148

R211 2 2K

Q201

KTC3875

R2027

4.7K

UPVDI`QBOFM`SFTFU

R344 10

38L

C,

9

R3010

C3009

100U/16V

R3015

100K

R3014

3k3

5 - 3 5 - 3

DP601

VFD_32P

211Q

D111

SR34

9

8

6

7

C115 562

220U/10V

BD2

C606106

10K

10K

10K

211Q

C854

CN883

CN17/10H

C114 68

L111

6.8UH

R600

2R2

102

C603

C600

C602

100U/10V

104

R605 56K

63

62

PTD

HOE

2

T2

3

T3

4

T4

5

T5

6

EPVU

7

EJO

8

OD

9

DML

:

TUC

21

L2

22

L3

23

L4

24

L5

DEE25TH20LT226TH30LT327TH40LT428TH50LT529TH60LT62:TH70LT731TH80LT832TH90LT933TH:0LT:34TH210LT2135TH2236TH23

,6WE

.38/W

C601 104

NQ4!!M`N

HOE`N2

NQ4!!S` N

NJD`EFU

BVEJP44 W

28

27

C`GM`B

26

25

C`GS`B

24

VBSU6`SY

23

VBSU6`UY

22

21

OFYU

:

QMBZ0QBVTF/

9

QSWF

8

7

1113

6

CU`PO0PG G

5

NVUF`EFU/

4

3

1112

2

C111

C112

C113

104

10UF

220U

R113

510

FB722

600

220U/10V

C722 104

C723

DP600

VFD_45P

1

23456789:

R660

open

R659

open

MFE261MFE35:MFE459MFE558MFE6

6.8V

ZD601

C611

C607

470

22U/50V

22UF/5 0V MIN

RB805

CN4/20

M014

R111

12K

C169

R11512K

R112

2K7

100U/16V

BVEJP44W

C724

104

23456789:

2122232425262728292:3132333435363738393:414243

2122232425262728292:3132333435363738393:4142434445464748494:5154555652

R661 0

R662 0

R663 0

51

57

56

IC600

HS255HS354HS453HS552HS6

WEE

4:

HS7

49

HS8

48

HS9

47

TH310HS:

46

TH2:0HS21

45

.38/W

WFF

,6WE

44

WDD

43

TH290HS22

42

TH280HS23

41

TH270HS24

3:

TH260HS25

39

TH25

38

TH24

IC_PT63 11

37

HOE

C605

102

R618

,23WE

330R

+

C614

10UF/3 5V MIN

SBO119161.2113

+

C613

22UF/3 5V MIN

SBQ119661.1112

Q600

2SC8050

Q602

2SC8550

HOE

VTC0 NQ40 QDC

6

USB701

6

2

2

3

VTCN

3

VTCQ

4

4

5

VTC6W

5

7

USB2.0

7

R617

R616

R615

470R

470R

10K

C612

+

CL4/4W

,23/1W

QXN`QTV`WDD`dpouspm3

,TVC

.TVC

FB400

60

QTV`PO0PGG

EF`QXS

FB401

60

C420

15P

C404

220U/25V

C147

R143

FB145

,24W

80

7

C145

C146

104

100U

R144

CL23W

C160

10U/16V

,CE6W

C110

104

,24W

,24W

22U35V

L145

8

9

2

0.22

3

JT

TD

ED

TF

Wdd

100UH

4

UD

D114

FM140

HOE5DJo

R145

C144

6

100P

56K

3K

AP34063

IC141

JD273

JD.BQ3315

2

JO

4

DF

10K

C167

R165

104

R163

10K

C168

104

FB121

80

IC121

3

WJO

4

FO

5

R124

TT

200K

R137

104

C130

68K

C128

C127

100U

104 change 103

C136

104

FB108

R135

200K

80

104

68K

100U/25V

C140

R136

C138

R620

3.9K

C705

104

C4008 220U/10V

TPS54331

2

3

4

5

C137

104 change103

R631 0

C402

15P

C403

104

D113

FM140

R632 0

3

C124

104

2

CPPU

HOE

WTFO

DPNQ

CPPU

WJO

FO

TT

R633 0

R634 0

R619

330R

HOE

C4007 104

R404

1K

R405

100K

R407 0

R406 0

,44/6W

C407

1uF

C119

104

PVU

BEK

HOE

D121

SR34

9

QI

8

6

7

C126 562

IC131

HOE

DPNQ

WTFO

IC_TPS54331

R636 0

R635 0

SDO119161.2112

,4/4WE

C401

15P

C406

104

.38W

6

5

R166

9K1

L121

6.8UH

C125 68

9

QI

8

7

6

HTB7251D

HTB9225D

45

53

open

R657

102

R601

R658

2R2

open

C604

BD3

R637 0

R638 0

R639 0

R640 0

R641 0

R642 0

R622

33R

C615

105

R621

Q601

2SC8050

1K

RB703

2

6

RB5/20

M007

M013

FB723

600

D206

1N4148

Q401

C408

2SC945

105

WBMJE3

HOE

CL23W

EF`QXS`E

QPXFS`PO0PGG`D

HOE

,24W

R401

3.3

C405

103

D112

FB107

100MHZ

IN4148

C142

104

C141

47U/35V

15K

R167

C165

R168

10U/16V

150K

C121

C122

C123

104

10UF

220U

R122

R123

2K2

510

R116

C132

L131

C133

10UF/10V

6.8UH

10UF/10V

D131

SR34

C134

C135

562

68

R134

510

R648 open

R647 open

R646 open

R645 open

R644 open

R643 open

R653 open

R654 open

R655 open

R656 open

R649 open

R650 open

R651 open

R652 open

CN601

CL4/41W

QXNQXN

,4/4W

C4130 104

C4155 104

C4154 220U/10V

R403

EF`QXS

4k7

R402

2K4

C409

JK401

15P

2

3

4

5

6

7

8

9

:

21

.23W

C143

100U

CL4/4W

C166

104

FB109

80

FB105

R121

100MHZ

12K

C139

104

C199

100U/16V

33

,23/1W

1K

R131

104

100U/16V

R132

20K

C131

C198

R133

1K5

2

U6W

3

4

U`EB

5

U`DML

6

7

CN6/P1.0H

TVCXPPGFS!BNQ

T,23W

C5716

R571310

333

104

55

54

CTU`B

HWEE`B

HWEE`C2PUX3TE6QXN`B7SFTFU`BC8QXN`C9PD`BEK:HOE21BKOE22WSFH23N424N325N226QXN`D27SFTFU`DE28QXN`E29WEE32HWEE`D

TP1

TP504

R5701

C5701

104

10

T,23W

UXFO

R594

10K

D585 1N4148

R597

BNQ`MFWFM`EFUFU

1K

ZD585

R598 47K

C5991 104

RCZ005004-1020

,CE6W

,6W

C5723 102 C5722

X`TVC,

R5715

3.3

103

C5721

C5719

104

C5717 C474/63V

L570210UH/10A

,WDD`B

C5715

53

52

OD

OD4OD

5

R57030

C5745

104

D586

1N4148

C599 47U/25V

,WDD`B

104

C5714

C5713

104

C5712

333

49

45

47

4:

46

51

PVU`C

PVU`B

HOE`C48HOE`B

QWEE`C

QWEE`B

QWEE`B

IC_TAS5342ADDV

R570727K

R57081

R5705

R570433

R5718 33

.TVC

33

R5728

IC5702G

,TVC

10K

WBMJE3`X

74HC04

8

25

21 22

.TVC

IC5702E

IC5702D

74HC04

74HC04

3 2

IC5702A

IC5702F

74HC04

74HC04

7 6

IC5702C

IC5702B

74HC04

74HC04

C597

R591

1K

4.7uF

C598

D587

1N4148

150K

R596

Q,23W

WBMJE2

R595 10K

,GM

.GM

,GS

.GS

CLOE`FSS

Q,23W

D588

1N4148

R5301

C5301 104

C5302 10U/16V

C5303 104

R5302 24K

R5303 33

R5304 33

R5305 33

R5306 33

R5307 33

R5308 33

R5309 OPEN

R5310 33

C5307 104

R5311

4.7uF

C5304 104

C5305 1uF

C5306 1uF

R592

1K

3.3

3.3

C5720 103 R5 714 3 .3

,WDD`B

R5712

C5709

C5708

C5711

333

42

43

CTU`D44CTU`C

QWEE`D

C5702

104

L5703

2.4UH

C5734

104

R5734

open

9

:

23

24

5 4

GM,

GS,

2

HWEE`BC

3

WEE

4

PD!BEK

5

0SFTFU

6

JOQVU`B

7

JOQVU`C

8

D`TUBSU

9

EWEE

:

HOE

21

HOE

22

HOE

23

HOE

24

BWEE

25

JOQVU`D

26

JOQVU`E

27

0GBVMU

28

0PUX

29

0DMJQ

2:

N2

31

N3

32

N4

33

HWEE`DE

TQFBLFS!KBDL

3.3

41

TP503

R5725

100K

A01/HU011075L

C5710

C5707 104

HOE`E3:HOE`D

UBT6263!EJHJUBM!QPXFS

TP

R5729 3K3

C5742

,4/4WE

QXN`GBO`DPOUSPM

IC5301

X`TVC.

103

39

PVU`E

UBT64YY!

C5746

104

C5727

104

104

GBO`MFWFM`EFUFU

CN5701

CN2/396

2

3

X`TVC,

X`TVC.

,23W/

T,23W

,WDD`B

R5711

C5705104

C5706

333

10

36

34

35

37

38

OD

CTU`E

QWEE`E

QWEE`E

HWEE`E

IC5701

OD2:OD

33

31

0

C5703

C5704

R5710

R57091

10

104

R5706

104

T,23WT,23W

,23W`B

R5727

1K5

C5726

ZD5701

4V7

100U/16V

15P

C5741

,TVC`X

R501

10k

CTU`B

CTU`C

HOE

HOE

PVU`B

PVU`B

QWEE`BC

QWEE`BC

QWEE`BC

PVU`C

HOE

HOE

PVU`D

QWEE`DE

QWEE`DE

QWEE`DE

PVU`E

TAS5612LA DIGITAL POWER

PVU`E

HOE

HOE

CTU`D

CTU`E

3K9

R506

R502

1K

55

C5331C333

54

53

52

51

4:

49

48

47

46

45

44

43

42

41

3:

39

38

37

36

35

34

C5308

C5332C

333

R5731

100K

,23W

2SC945

100K

R503

L5303 10UH/10A

C5309333

333

C5743

R5732

R504

560

Q501

10UH/10A

C5321 104

C5320 104

C5319 104

10UH/10A

10UH/10A

104

3K3

R507

10K

D501

1N4148

QWEE

L5304

C5341 104

C5322

470U/50V

R5113

3.3

R5118

3.3

L5302

104

C5310

C5311

470U/50V

L5301

24W

R5226

,WDD`B

T,23W

M021 M023M022

.TVC`X

C5744

15P

Q502 KTC8050

R505

100

C501

10U/50V

C5325

104

C5323

474

C5326

104

C5114

103

C5132

103

C5313

104

C5312

474

C5314

104

Q5201

Q_2SC8050SMT

,23W/

R5227

2K2

C5238100U/25V

C5239

C5241100U/16V

R5228

C5240

C520

0

R5229

104

2R2

C5236

220U/16V

FB5701

100

FB5702

100

R5700

C5724220U/16V

C5725

104

D502

1N4148

C502 104

FB5101

R5315

3.3

C5327

103

C5328

103

R5314

3.3

R5313

3.3

C5315

103

C5316

103

R5312

3.3

FB5102

104

20K

33U/16V

FB5203

100

,WDD`B

Q,23/1W

104

C5237

2R2

C5732

104

C503

220U/16V

100

,WDD

FB5204

100

RB5700

,WDD

3.3

R5717

C5730 104

C5729

Q5702

KTC8050

,23W`B

2

d3f

c

C5736100U/16V

R5721

4

R5722

C5737

R5723

20K

33U/16V

M024

M025 M026

CN2/25

CN501

2

3

2

103

3

C5731

4

1uF

5

WBMJE3`X

6

,TVC`X

7

8

9

.TVC`X

,24W`B

1K5

0

TO PSU

:

RB9/25

C5738

C5739100U/16V

104

.TVC`X.TVC

NC

R5733

,TVC`X,TVC

NC

R5724

GBO2

,44/6W

C5343 104

C5329

102

L5305

GM,

42

GM.

5

3

OPEN

C5330

102

C5317

102

L5306

2

3 5

OPEN

C5318

102

100

,44/6W

GM!TQL!)6*

219!X!)UIE21&*

246X!)UIE41&*

JK5301

TS!TQL!)6

*

219X!)UIE21&*

TQFBLFS!KBDL

246X!)UIE41&*

GS,

4

GS.

102

C5718

104

470U/50V

104

PVU`D

C5342 104

CN203

2

CL4/4W

VBSU6`SY

VBSU6`UY

10K

,4/4WE

CL4/4W

R277 10K

J3D!TDM7!UPVDI

J3D!TEB7!UPVDI

UVOFS`STU

R201

33

R202

33

CL4/4W

R205

33

R206

R207

33

33

0

DFD`JO

DFD`PVU

R202410K

R202510K

R2026

R2023

R2022

R2021

4.7K

4.7K

10K

10K

ETQ`EFCVH

NJD`EFUFDU

NJD`TXJUDI2

J3D`TEB2`NUL

J3D`DML2`NUL

NJD`TX`3

R1084

OPEN

R3011

120

IC301B

8

JRC4558

10

,23W

C3016

100U/16V

C3010

4.7u

,23W

R3012 2.2K

C3012 105

R276 4.7K

R288 4.7K

2

QF3

3

QF4

4

QF5

5

QF6

6

QF7

7

WCBU

8

QD24.UBNQFS.SUD

9

QD25.PTD43`JO

:

QD26.PTD43`PVU

21

WTT`6

22

WEE`6

23

PTD`JO

24

PTD`PVU

25

OSTU

26

QD1

27

QD2

28

QD3

29

QD4

2:

WTTB

31

WSFG.

32

WSFG,

33

WEEB

34

QB1.XLVQ

35

QB2

36

QB3

CL4/4W

R212

4K7

D203

1N4001

D204

1N4148

4K7

R215

4K7

R213

CE`JS

,4/4WE

104

C322

C3011 10U/16V

R3013 7/9L

C3013 105

R273

INDV`TEB

INDV`TDM

QXN`WGE`BD

QXN`GBO`DPOUS PM

QXN`QTV`WDD`dpouspm3

SY`TEB

CL4/4W

R27533

R28633

R274 10K

R272 33

R271 33

CPPU1

::

:4

:9

211

:5

QC9:6QC::7QF1:8QF2

WTT`4

WEE`4

CPPU1

STM32F100VC

RCI321006-0000

QB437WTT`538WEE`539QB53:QB641QB742QB843QD544QD645QC146QC247QC30CPPU2

33

JS

R218 33

R219 33

R220 33

CL4/4W

R216 33

R217 33

R221

TDQ`DML

TDQ`NPTJ

ETQ`JSR

TDQ`NJTP0TEB

NJD`EFUFDU

NJD`TXJUDI2

UP!!5:6424!5Qjo!

UP!5:6424!237Qjo

UP!5:6424!!235Qjo

UP!5:6424!!234Qjo

R1057 open

BVEJP44W

R375

4.7

BVEJP44W

PQUJDBM`T QEJG

TQEJG`BSD

C329 10 4

C1032

103

C328 10 4

C330 104

9533`JOU2

FQ:5N4`STUC

SY`TDM

UP!!DO@!2Qjo!

UP!!DO@!3Qjo!

efcvh5

efcvh6

R268 33

R270 33

98

QE899QC49:QC5:1QC6:2QC7:3QC8

256 K

IC201

QF849QF94:QF:51QF2152QF2253QF2354QF2455QF2556QF2657QC2158QC22

48

10K

10K

33

33

R223

R285

R222

R2044

1112

1113

TL`B

MFE!`TX

TQEJG`SFTFU

6457`STU

9533`HQP4

R319 4K7

R318 4K7

R1095 4K7

DPBYJBM`TQEJG

C337 10U/16V

R3320

BVEJP44W

WE

SYIQE`DUM1C

SYIQE`DUM2C

SYIQE`DUM3C

R266 33

R267 33

33

WGE`DL

WGE`DF

TQEJG`SFTFU

C1036 OPEN

C375 15 P

R3330

R377 4.7

C317 104

6457.TEB

6457.TDM

WMD

R320

6457`STU

BED`STU

NQ4`M

0

NQ4`S

C`GM`B

C`GS`B

BVY`M

BVY`S

WMD

R312 10

,6W

C319 104

R265 33

R22633R22433R225

WGE`EB

9533`CDML

2

3

4

5

6

7

8

9

R334 33

J3D`DML2`NUL

J3D`TDM4`UVOFS0FQSPN

R264 33

R228 33

NDML`TXJUDI

9533`MSDL

C376 15 P

SY10SYQ1

SY20SYO1

WB

BHOE

SY30SYQ2

SY40SYO2

BE10DT

BE20DEJO

R335 33

J3D`TEB2`NUL

C332

2

TEB0DEPVU

3

TDM0DDML

4

BE10DT

5

BE20DEJO

6

WMD

7

STU

8

BJO4B

9

BJO4C

:

BJO3B

21

BJO3C

22

BJO2B

23

BJO2C

,6W

J3D`TEB4` UVOFS0FQSPN

VBSU6`SY

33

33

R26233R263 33

R261

91

QE192QE293QE394QE495QE596QE697QE7

0

R229

R230 33

XJSMFTT`SFTFU

J3D`DML2`NUL

TQEJG`SFTFU

NU9691BVEJP!JO!NDML

R32733

R3570

C377 15 P

43

STU

TDM0DDML:TEB0DEPVU21YUJ22YUP23JMSDL24JTDML25TEJO26HQP1

XL305

24.576MHZ

C3051 15P

10U/16V

10U/16V

C333

C323 104

VBSU6`UY

R25933R260

59

33

R231

J3D`TEB2`NUL

NU9691BVEJP!JO!NDML

9533`HQP4

R328

33

41

42

SNDL

IC305

CS8422

R321 open

CL4/4W

UP!@

UP!@!

C212 104

efcvh3

efcvh4

QB2587QB2688QD2189QD228:QD23

86

WEE`3

85

WTT`3

84

OD

83

QB24

82

QB23

81

QB22

7:

QB21

79

QB:

78

QB9

77

QD:

76

QD9

75

QD8

74

QD7

73

QE26

72

QE25

71

QE24

6:

QE23

69

QE22

68

QE21

67

QE:

66

QE9

65

QC26

64

QC25

63

QC24

62

QC23

WTT`25:WEE`2

61

R232

10k

CL4/4W

9533`MSDL

9533`CDML

SYEBUB1

R32933

R33033

R33133

37

3:

39

HQP4

UEN`JO

TEPVU238PTDML2

PMSDL2

R336 33

R337 33

R338 33

C3052 15P

R322 open

6457.PW

6457.JOU

6457.NDML

56

58

59

55

57

WE

JOU

PWGM

EHOE

IC304

CS5346

BHOE24WB25BGJMUB26BGJMUC27WR28UTUP29GJMU,2:UTUJ31BJO5B0NJDJO232BJO5C0NJDJO333BJO6B34BJO6C

222

C348 222

C347

C334 10U/16V

ETQ`EFCVH

efcvh6

104

104

104

efcvh5

efcvh4

efcvh3

C207 104

C206 104

C211

C210

C208

C209 104

efcvh2

R252

10K

efcvh2

UP@

OFYU

33

R898

QSWF

33

R897

VBSU`SY2`NUL

R249 3 3

VBSU`UY2`NUL

33

R248

J3D`JOU`NDV`UP`NUL

R247 33

SY`IQE

R246 3 3

FQ:5N4`JOUC

33

R245

QMBZ0QBVTF/

33

R896

CU`PO0PG G

33

R895

SY6W`JO3

R244 3 3

SY6W`JO2

R243 33

SY6W`JO1

R287 33

NVUF`EFU/

R241 33

UJ6649`SFTFU

R240 33

R239 33

J3D`TDM3`UJ6649

R238

J3D`TEB3`UJ6649

33

1K

R233

CL4/4W QTV`PO0PGG

Q202

QXN`QPXFS

2SC945

R361

10k

C219

104

QXN`QTV`WDD `dpouspm3

BVEJP44W

C353 100U/10V

R358 4.7

104

C326

36

10U/16V

C335

C1035

PMSDL3

35

PTDML3

103

34

TEPVU3

33

WM

32

EHOE

31

WE`GJMU

R314 4.7

2:

W`SFH

0

29

HPQ3

28

HQP2

R340 33

44

HOE

R359 OPEN

27

103

C327 10 4

C331 10 4

C338 10U/16V

C1034 103

C1033

6457.TDM

R317 33

6457.TEB

R316 33

R323 0

R324 33

R325 33

6457.TDML

6457.TEPVU

R326

33

6457.MSDL

54

52

53

48

51

OD49OD4:OD

UTUJ

TDML

MSDL

NDML

TEPVU

WMT

UTUP

BHOE

BHOE

QHBPVUC

QHBPVUB

BJO7C

BJO7B

NJDCJBT

35

47U/16V

C324 10 4

C349

C325 104

UVO`M

UVO`S

LBSBPLF`M

LBSBPLF`S

5

CN4/20

2

3

C204

104

R242 47K

D205

4K7

R2038

WGE`DF

CN204

2

33

3

33

4

5

CN205

6

7

33

8

CN7/20

CL4/4W

C205

47U/10V

NVUF

NVUF

FM140-M

UJ6649`SFTFU

J3D`TDM3`UJ6649

J3D`TEB3`UJ6649

,4/4WE

10K

10K

10K

10K

R2040

R2043

R2039

R2045

VBSU6`UY

VBSU6`SY

VBSU`SY2`NUL

VBSU`UY2`NUL

R258 33

R257

R256

R255 33

R254 33

R253

Q`NVUF

RCD100140-0020

4K7

4K7

R2037

R2036

UJ6649`SFTFU

WGE`EB

WGE`DL

C354 104

WM

BVEJP44W

HOE

R339

TQEJG`JSR

C336 10U/16V

J3D`DML2`NUL

J3D`TEB2`NUL

FB207

CE`NDML

600

CE0JO`MSDML

CE0JO`TDML

NJD`TEPVU

R313