Page 1

HEARTSTART XLT

Service Manual

M3500B/

M5500B

Page 2

Page 3

Service Manual

M3500B HeartStart XLT/

M5500B Heartstart 4000

Defibrillator/Monitor

Page 4

Notice

About This Edition

Edition 2

Printed in the USA

Publication number M3500-90900

The information in this manual applies

to the M3500B HeartStart XLT Release

Main 34 and earlier, and to the

Heartstart 4000 Release Main 34 and

earlier. This information is subject to

change without notice.

Philips Medical Systems shall not be

liable for errors contained herein or for

incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

Edition History

Edition 1.1, March 28, 2000

Edition 2, February 2003

Copyright

Copyright © 2003

Philips Electronics North America

Corporation

3000 Minuteman Road

Andover, MA 01810-1099 USA

(978) 687-1501

All rights are reserved. Reproduction in

whole or in part is prohibited without

the prior written consent of the copyright holder.

WARNING

Radio Frequency (RF) interference

from nearby transmitting devices may

seriously degrade performance of the

M3500B/M5500B defibrillator/monitor. Electromagnetic compatibility with

surrounding devices should be assessed

prior to using the defibrillator.

CAUTION

Use of supplies or accessories other

than those recommended by Philips

Medical Systems may compromise

product performance.

THIS PRODUCT IS NOT INTENDED

FOR HOME USE.

IN THE U.S., FEDERAL LAW

RESTRICTS THIS DEVICE TO SALE

ON OR BY THE ORDER OF A PHYSICIAN.

Medical Device Directive

The M3500B/M5500B Defibrillator/

Monitor complies with the requirements

of the Medical Device Directive 93/42/

EEC and carries the

accordingly.

Authorized EU-representative:

Philips Medizinsysteme Böblingen

GmbH

Hewlett Packard Str. 2

71034 Böbingen

Germany

Canada EMC:ICES-001

0123

mark

ii

Page 5

Conventions

This manual uses the following text conventions:

NO TE Notes contain additional information on servicing this product.

CAUTION Caution statements describe conditions or actions that can result in damage to

the equipment or loss of data.

WARNING W arning statements describe conditions or actions that can result in personal injury

or loss of life.

Text represents messages that appear on the display

Softkey

represents softkey labels that appear on the display

above or below the button to which they correspond

iii

Page 6

Page 7

Contents

Introduction

Overview ............................................................................................................................... 1-1

Defibrillator/Monitor ...................................................................................................... 1-1

Batteries, Power Modules, Battery Charger Adapter ..................................................... 1-2

Installation ...................................................................................................................... 1-2

Upgrades ......................................................................................................................... 1-2

Preventive Maintenance .................................................................................................. 1-2

Repair Philosophy ...........................................................................................................1-3

Defibrillator/Monitor ................................................................................................ 1-3

Batteries, Power Modules, Battery Charger Adapter ............................................... 1-3

Performance Verification and Safety Tests

Overview ............................................................................................................................... 2-1

Mandatory Testing ................................................................................................................ 2-1

External Repairs/No Trouble Found ...............................................................................2-1

Printer .............................................................................................................................. 2-2

Internal Repairs ...............................................................................................................2-2

Test and Inspection Matrix ................................................................................................... 2-3

Test Equipment ..................................................................................................................... 2-8

Configuration and Diagnostic Modes ................................................................................. 2-10

Configuration Mode ...................................................................................................... 2-10

Diagnostic Mode ........................................................................................................... 2-11

Performance Verification .................................................................................................... 2-12

Visual Inspection .......................................................................................................... 2-12

Functional Checks ......................................................................................................... 2-13

ECG Functional Checks .......................................................................................... 2-13

Shock Advisory Functional Check ......................................................................... 2-14

Synchronized Cardioversion Functional Check ..................................................... 2-14

Functional Check ........................................................................................... 2-15

Sp0

2

Diagnostic Tests .................................................................................................................. 2-16

The System Log ............................................................................................................ 2-16

Extended Self Test ........................................................................................................ 2-17

User Interface Tests ...................................................................................................... 2-19

To check the Controls (keys): ................................................................................. 2-19

To check the display: .............................................................................................. 2-20

To check the audio output: ...................................................................................... 2-20

To check the printer: ............................................................................................... 2-21

ECG Tests ..................................................................................................................... 2-22

ECG Status messages .............................................................................................. 2-23

DC Offset ................................................................................................................ 2-23

ECG amplifier tests ................................................................................................. 2-23

PCI function ............................................................................................................ 2-24

v

Page 8

Contents

Pacing Test ....................................................................................................................2-25

Defibrillator Test (AC Power At 200 J) ........................................................................ 2-27

Defibrillator Test (Battery Power At 200 J) ................................................................. 2-28

Defibrillator Disarm Test ..............................................................................................2-29

Safety Tests ...................................................................................................................2-30

Earth Leakage ......................................................................................................... 2-30

Patient Lead Leakage ..............................................................................................2-30

Battery Capacity Test ..........................................................................................................2-31

Troubleshooting

Overview ............................................................................................................................... 3-1

Repair Philosophy ...........................................................................................................3-1

Equipment Required ....................................................................................................... 3-1

Troubleshooting and Repair Methodology ........................................................................... 3-2

Interview the User ..................................................................................................... 3-2

Identify the Problem ................................................................................................. 3-2

Perform the Repair ....................................................................................................3-2

Test the Unit .............................................................................................................. 3-2

Initial Assessment ................................................................................................................. 3-3

Attempt Power Up .................................................................................................... 3-3

Evaluate the Response .............................................................................................. 3-3

Diagnosing External Failures ................................................................................................ 3-4

Capture the Configuration Data ................................................................................ 3-4

Print the System Log ................................................................................................. 3-4

Rule out external components and improper use ...................................................... 3-4

Diagnosing Internal Failures ................................................................................................. 3-5

Run Self Tests ........................................................................................................... 3-5

Use the Troubleshooting Tables ............................................................................... 3-5

Configuration and Diagnostic Modes ............................................................................. 3-5

Accessing Configuration Mode ...................................................................................... 3-5

Accessing Diagnostic Mode ........................................................................................... 3-6

Printing the System Log ........................................................................................... 3-6

Troubleshooting Tables ........................................................................................................ 3-8

Using the Tables ............................................................................................................. 3-8

Unit Unresponsive ................................................................................................................ 3-9

Error Codes ......................................................................................................................... 3-11

System Messages ................................................................................................................3-13

Momentary Messages ......................................................................................................... 3-16

Audio Tones .................................................................................................................. 3-17

Extended Self Test Failures .......................................................................................... 3-18

vi

Page 9

Contents

Operational Problems ......................................................................................................... 3-19

ECG Monitoring ........................................................................................................... 3-19

SpO2 Monitoring ........................................................................................................... 3-21

Defibrillation and Cardioversion .................................................................................. 3-22

Pacing ............................................................................................................................ 3-24

Printer ............................................................................................................................ 3-25

Display .......................................................................................................................... 3-26

Audio ............................................................................................................................ 3-27

Keys .............................................................................................................................. 3-28

Battery and Power Modules .......................................................................................... 3-29

Data Card ......................................................................................................................3-31

Calling for Service - Philips HeartStart XLT ..................................................................... 3-32

United States of America .............................................................................................. 3-32

Latin America ............................................................................................................... 3-32

Canada .......................................................................................................................... 3-32

Other International Areas .............................................................................................. 3-33

Calling for Service - Laerdal Heartstart 4000 .....................................................................3-34

United States of America ......................................................................................... 3-34

International Customers ................................................................................................ 3-34

Removal and Replacement

Overview ............................................................................................................................... 4-1

Servicing Notes ..................................................................................................................... 4-1

Key Components ............................................................................................................. 4-1

Removal, Handling, and Replacement ........................................................................... 4-1

Flex Circuit Connections .......................................................................................... 4-1

Flex Circuit Handling ............................................................................................... 4-2

Internal Connections ................................................................................................. 4-2

Cable and Assembly Placement ................................................................................ 4-2

Instrument Reassembly ............................................................................................. 4-2

Tool Requirements ................................................................................................................ 4-3

User-replaceable Parts and Accessories ................................................................................4-4

Manual Door ................................................................................................................... 4-4

Removal .................................................................................................................... 4-4

Replacement ..............................................................................................................4-4

Carrying Case ................................................................................................................ 4-7

Removal .................................................................................................................... 4-7

Replacement ..............................................................................................................4-8

User Maintenance ................................................................................................................. 4-9

Cleaning the Printer Printhead ........................................................................................ 4-9

vii

Page 10

Contents

External Assemblies ........................................................................................................... 4-10

Printer Assembly ........................................................................................................... 4-11

Removal .................................................................................................................. 4-11

Replacement ............................................................................................................4-12

Printer Sliding Door ...................................................................................................... 4-13

Removal .................................................................................................................. 4-13

Replacement ............................................................................................................4-13

Printer Platen .................................................................................................................4-14

Removal .................................................................................................................. 4-14

Replacement ............................................................................................................4-14

Battery Cover ................................................................................................................ 4-15

Removal .................................................................................................................. 4-15

Replacement ............................................................................................................4-16

Main Fuse ..................................................................................................................... 4-17

Removal .................................................................................................................. 4-17

Replacement ............................................................................................................4-17

Battery Eject Assembly ................................................................................................ 4-17

Removal .................................................................................................................. 4-17

Replacement ............................................................................................................4-18

Data Card Door ............................................................................................................. 4-18

Removal .................................................................................................................. 4-18

Replacement ............................................................................................................4-18

Labels .................................................................................................................................. 4-19

Label Descriptions ........................................................................................................ 4-19

Case Label Set ........................................................................................................ 4-19

Branding Label Set ................................................................................................. 4-21

Ambient Light Sensor Label ...................................................................................4-21

Speaker Label Set ................................................................................................... 4-22

Removing and Replacing Labels .................................................................................. 4-22

Removal .................................................................................................................. 4-22

Replacement ............................................................................................................4-22

Opening the Sealed Case .................................................................................................... 4-23

Discharging the Power Supply Capacitors ................................................................... 4-23

Primary Method ......................................................................................................4-23

Secondary Method: ................................................................................................. 4-23

Separating the Case ..................................................................................................... 4-25

Discharging the Defibrillator Capacitor ....................................................................... 4-27

Primary Method ......................................................................................................4-27

Secondary Method .................................................................................................. 4-28

Identifying Internal Subassemblies ..................................................................................... 4-29

viii

Page 11

Contents

Top Case Assemblies .......................................................................................................... 4-30

Lithium Backup Battery ................................................................................................ 4-30

Removal .................................................................................................................. 4-30

Cleaning .................................................................................................................. 4-30

Replacement ............................................................................................................4-30

Disconnecting the Control PCA ................................................................................... 4-31

From the Rest of the Unit ....................................................................................... 4-31

From the Display .................................................................................................... 4-31

Reconnecting the Control PCA ..................................................................................... 4-31

To the Display ......................................................................................................... 4-31

To the Rest of the Unit ............................................................................................ 4-32

Control Stack ................................................................................................................ 4-33

Removal .................................................................................................................. 4-33

Replacement ............................................................................................................4-33

Control PCA ................................................................................................................. 4-34

Removal .................................................................................................................. 4-34

Replacement ............................................................................................................4-35

LCD Display Assembly ................................................................................................ 4-37

Removal .................................................................................................................. 4-37

Replacement ............................................................................................................4-37

SpO2 PCA ..................................................................................................................... 4-38

Removal .................................................................................................................. 4-38

Replacement ............................................................................................................4-39

ECG Connector .............................................................................................................4-40

Removal .................................................................................................................. 4-40

Replacement ............................................................................................................4-41

SpO2 Connector ............................................................................................................ 4-42

Removal .................................................................................................................. 4-42

Replacement ............................................................................................................4-43

Manual Keypad Assembly ............................................................................................ 4-44

Removal .................................................................................................................. 4-44

Replacement ..................................................................................................................4-47

Interface PCA ............................................................................................................... 4-50

Removal .................................................................................................................. 4-50

Replacement ............................................................................................................4-52

Speaker .......................................................................................................................... 4-55

Removal .................................................................................................................. 4-55

Replacement ............................................................................................................4-55

Top Case Assembly ............................................................................................................ 4-56

Description ..............................................................................................................4-56

Removal and replacement ....................................................................................... 4-56

ix

Page 12

Contents

Bottom Case Assemblies .................................................................................................... 4-58

Battery PCA .................................................................................................................. 4-58

Removal .................................................................................................................. 4-58

Replacement ............................................................................................................4-59

Defibrillator Capacitor .................................................................................................. 4-60

Removal .................................................................................................................. 4-60

Replacement ............................................................................................................4-61

Power PCA ................................................................................................................... 4-62

Removal .................................................................................................................. 4-62

Replacement ............................................................................................................4-63

Power Connector ........................................................................................................... 4-64

Removal .................................................................................................................. 4-64

Replacement ............................................................................................................4-64

Patient Connector .......................................................................................................... 4-65

Removal .................................................................................................................. 4-65

Replacement ............................................................................................................4-65

Bottom Case Assembly ....................................................................................................... 4-66

The Language Support Tool ............................................................................................... 4-67

Using the Support Tool ................................................................................................. 4-67

Closing the case .................................................................................................................. 4-69

Disposing of the M3500B/M5500B ................................................................................... 4-70

Disposing of the SLA Battery ....................................................................................... 4-70

Replacement Parts

Overview ............................................................................................................................... 5-1

Ordering Replacement Parts ........................................................................................... 5-1

Ordering Supplies and Accessories ................................................................................ 5-1

Key Components ................................................................................................................... 5-1

Calling for Service - Philips HeartStart XLT ....................................................................... 5-2

United States of America ................................................................................................ 5-2

Latin America ................................................................................................................. 5-2

Canada ............................................................................................................................ 5-2

Other International Areas ................................................................................................ 5-3

Calling for Service - Laerdal Heartstart 4000 .......................................................................5-4

United States of America ........................................................................................... 5-4

International Customers .................................................................................................. 5-4

Special Tools ......................................................................................................................... 5-4

M3500B Unit Exchange Program ......................................................................................... 5-5

Logistics .................................................................................................................... 5-5

Replacement Parts Tables ..................................................................................................... 5-6

Electrical Assemblies ............................................................................................................ 5-7

Control PCA ................................................................................................................... 5-7

Other Replacement PCAs ............................................................................................... 5-8

Other Electrical Assemblies ............................................................................................ 5-8

Individual Electrical Parts ............................................................................................... 5-8

x

Page 13

Contents

Mechanical Assemblies ........................................................................................................ 5-9

Manual Door ................................................................................................................... 5-9

Manual Keypad Assembly ............................................................................................ 5-10

Other Mechanical Assemblies ...................................................................................... 5-12

Connectors .................................................................................................................... 5-12

Individual Mechanical Parts ......................................................................................... 5-13

Labels .................................................................................................................................. 5-14

Case Label Sets ............................................................................................................. 5-14

Other Labels .................................................................................................................. 5-15

Supplies & Accessories ...................................................................................................... 5-16

Key Components .................................................................................................................5-20

Theory of Operation

Overview ............................................................................................................................... 6-1

PCA Descriptions ................................................................................................................. 6-2

Control PCA ................................................................................................................... 6-2

Interface PCA ................................................................................................................. 6-3

Power PCA ..................................................................................................................... 6-3

SpO2 PCA .......................................................................................................................6-3

Battery PCA ....................................................................................................................6-4

Battery ............................................................................................................................. 6-4

Printer .............................................................................................................................. 6-4

System Level Interconnections ............................................................................................. 6-5

System Functional Descriptions ........................................................................................... 6-6

Signal and Data Flow ...................................................................................................... 6-6

ECG Monitoring Functions ............................................................................................ 6-7

ECG - Pads ................................................................................................................ 6-7

ECG - 3/5-lead cable ................................................................................................. 6-7

Patient impedance functions ..................................................................................... 6-8

SpO2 Monitoring Functions ........................................................................................... 6-8

Defibrillation Functions .................................................................................................. 6-9

Charging .................................................................................................................... 6-9

Delivering a shock .................................................................................................... 6-9

Delivering synchronized cardioversion .................................................................. 6-10

Pacing Functions ...........................................................................................................6-11

Audio Functions ............................................................................................................ 6-12

Display Functions ......................................................................................................... 6-12

Contrast - manual control ....................................................................................... 6-12

Contrast - automatic control ................................................................................... 6-12

Backlight ................................................................................................................. 6-12

Indicator Functions ....................................................................................................... 6-13

Key Functions ............................................................................................................... 6-14

Main Keys ...............................................................................................................6-14

Other Keys ..............................................................................................................6-14

xi

Page 14

Contents

Printing Functions ......................................................................................................... 6-15

Contrast ................................................................................................................... 6-15

Out of paper/door open ........................................................................................... 6-15

Battery/Power Functions ............................................................................................... 6-16

Contacts/Battery Type ............................................................................................ 6-16

Charging .................................................................................................................. 6-16

Lithium Backup Battery ................................................................................................ 6-18

Data Card ......................................................................................................................6-18

Specifications

Overview ............................................................................................................................... 7-1

Specifications ........................................................................................................................ 7-1

Defibrillator .................................................................................................................... 7-1

Manual Mode ............................................................................................................ 7-2

AED Mode ................................................................................................................ 7-3

ECG Monitoring ............................................................................................................. 7-3

Frequency Response: ................................................................................................ 7-4

Patient Isolation: ....................................................................................................... 7-4

Display ............................................................................................................................ 7-4

Thermal Array Printer ..................................................................................................... 7-4

Continuous Real Time Strip: .................................................................................... 7-4

Battery and Battery Power Modules ............................................................................... 7-5

Noninvasive Pacing ........................................................................................................ 7-6

SpO2/Pulse Oximetry ...................................................................................................... 7-6

Accuracy with: .......................................................................................................... 7-6

Event Storage ..................................................................................................................7-6

Internal Event Summary: .......................................................................................... 7-6

Data Card Event Summary: ...................................................................................... 7-6

General ............................................................................................................................ 7-7

Environmental ................................................................................................................. 7-7

Waveforms - 150J ................................................................................................................. 7-8

150J, 25 ohms .............................................................................................................. 7-8

150J, 50 ohms .............................................................................................................. 7-8

Waveforms -150J (continued) .............................................................................................. 7-9

150J, 75 ohms ............................................................................................................... 7-9

150J, 100 ohms ............................................................................................................ 7-9

Waveforms -150J (continued) ............................................................................................ 7-10

150J, 125 ohms (2ms/div) ........................................................................................ 7-10

150J, 125 ohms (5 ms/div) .......................................................................................... 7-10

xii

Page 15

Contents

Waveforms - 200J ............................................................................................................7-11

Waveforms - 200J (continued) ........................................................................................... 7-12

Waveforms - 200J (continued) ...................................................................................... 7-13

Symbol Definitions .............................................................................................................7-14

Safety Considerations ......................................................................................................... 7-16

Electromagnetic Compatibility ........................................................................................... 7-18

Reducing Electromagnetic Interference ........................................................................ 7-18

Restrictions for Use ...................................................................................................... 7-18

Immunity Level ............................................................................................................. 7-19

xiii

Page 16

Page 17

1Introduction

This Service Manual provides the information needed to successfully service

the Philips M3500B HeartStart XLT and the Laerdal M5500B Heartstart 4000

Defibrillator/Monitors. The intended users of this manual are technical personnel who have been trained in the safe and proper servicing of the M3500B/

M5500B.

Overview

In this chapter, you’ll find general information that you should become familiar with before servicing the M3500B/M5500B. Detailed information regarding controls, operation, and capabilities of the instrument can be found in the

Instructions for Use that was shipped with the product. We recommend you

review the Instructions for Use before servicing this device. This Service

Manual assumes you are familiar with the controls and with basic operations.

1

Defibrillator/Monitor

The M3500B/M5500B is a biphasic, semi-automatic external defibrillator.

This portable, lightweight device offers two modes of operation for defibrillation:

z Semi-Automatic External Defibrillation (AED) Mode

z Manual Mode

In AED Mode, the M3500B/M5500B analyzes the patient’s ECG and advises

the clinician whether or not to deliver a shock. In Manual Mode, the M3500B/

M5500B turns control of the defibrillation process over to the clinician. The

clinician analyzes the patient’s ECG, decides if defibrillation is advised, and

determines the energy setting for defibrillation. Manual Mode also allows the

clinician to perform synchronized cardioversion and offers optional noninvasive pacing (using a monophasic waveform).

Defibrillation is performed through multifunction defib electrode pads. In

addition, both AED and Manual Mode offer monitoring through pads, 3-lead

ECG monitoring electrodes, or optional 5-lead ECG monitoring electrodes.

Optional pulse oximetry (SpO

well.

) monitoring is available in both modes, as

2

1-1

Page 18

Overview

The M3500B/M5500B automatically stores critical events, such as shocks

and alarm violations, in its internal memory. An Event Summary may be

printed at any time. The M3500B/M5500B also enables you to store data and

events on an M3510A/M5510A Data Card for downloading to the Event

Review Data Management System.

Batteries, Power Modules, Battery Charger Adapter

The M3500B/M5500B is powered by a rechargeable Sealed Lead Acid (SLA)

battery (M3516A/M5516A). Proper care of these batteries will ensure that

they have the energy required to operate the M3500B/M5500B and deliver the

appropriate therapy (See "Battery Maintenance" section in Instructions for

Use).

Batteries may be charged either in the defibrillator or in the Battery Charger

Adapter (M3506A/M5506A). In either case, power for charging can be provided by the AC Power Module (M3517A/M5517A), or by the DC Power

Module (M3518A/M5518A).

NO TE The defibrillator will take longer to charge when powered with either power

module without a battery installed. The recommended practice is to use a battery in conjunction with the power module to ensure optimal performance.

For information on either the power modules or the adapter, see the documentation supplied with the power module or adapter.

Installation

The M3500B/M5500B does not require installation. The Instructions for Use

describes the setup required before placing the device into service, as well as

configuration options.

Upgrades

Upgrades are available to add specific functionality to units in the field. As of

the publication of this manual, these upgrades are:

z M3514A Pacing Upgrade (adds pacing)

z M3515A SpO2 upgrade.

Consult your sales representative or dealer or distributor for the latest details.

Preventive Maintenance

Preventive maintenance and periodic operational checks are intended to be

performed by the user. Both topics are covered in the Maintenance chapter of

the Instructions for Use.

1-2 Introduction

Page 19

Overview

Repair Philosophy

Defibrillator/Monitor

The repair philosophy of the M3500B/M5500B is subassembly replacement.

Examples of subassemblies are the printer, the Control Printed Circuit Assembly (PCA), and selected connectors and other items. Repairs that involve

replacing components on a PCA are not supported.

CAUTION Individual component replacement should not be attempted outside of a fac-

tory authorized repair facility. Component level repair is extremely difficult

due to the extensive use of surface mount technology and the high parts-density on the circuit boards. Unauthorized component replacement can impair

performance of the M3500B/M5500B.

Batteries, Power Modules, Battery Char ger Adapter

The repair philosophy for the SLA battery (M3516A/M5516A), AC Power

Module (M3517A/M5517A), DC Power Module (M3518A/M5518A), and

the Battery Charger Adapter (M3506A/M5506A) is unit replacement. These

accessories are not repaired in the field.

1

For information on ordering replacements, see "Supplies & Accessories" on

page 5-16.

M3500B/M5500B Service Manual 1-3

Page 20

Page 21

2 Performance Verification and Safety Tests

Overview

This chapter describes the tests and inspections required to verify performance of the M3500B/M5500B Defibrillator/Monitor.

The information is presented in the following sequence:

Test Matrix A list of the tests required to verify per-

formance of the M3500B/M5500B,

along with expected test results.

Test Equipment A list of commercially available test, cal-

ibration and simulation devices needed

to perform performance verification

tests.

Performance Verification Step-by-step instructions for performing

each of the Performance Verification

Tests.

Mandatory Testing

The Performance Verification Tests in this chapter are intended to verify

proper operation of the M3500B/M5500B following repair. The level of testing required corresponds to the type of repair performed, and is divided into 3

categories:

2

z External/No Trouble Found

z Printer

z Internal

External Repairs/No Trouble Found

External Repairs are those involving the repair or replacement of one or

more of the items below. No Trouble Found applies when no malfunction

can be found, or when the problem appears to be due to improper use. In

either situation, the key point is that the case has not been opened.

z ECG cable

z SpO

z Battery

cable or sensor

2

2-1

Page 22

Mandatory Testing

z Labels

z AC or DC Power module

z Consumables (ECG monitoring electrodes, multifunction defibrilla-

tion pads, printer paper)

z Main fuse (on Battery PCA)

z Manual Door Assembly

z Data Card Door Assembly

z Battery Eject Assembly

The following testing is required after an External Repair or when the outcome of the service is No Trouble Found (when the case has not been

opened):

z Perform the Visual Inspection (page 2-12).

z Run the Extended Self Test (page 2-17).

z Print and Verify the System Log (page 2-16).

Printer

If the printer was replaced, and the case was not opened, the following tests

are required:

z Perform the Visual Inspection (page 2-12).

z Run the Extended Self Test (page 2-17).

z Run the Printer Test (page 2-21).

z Print and Verify the System Log (page 2-16).

Internal Repairs

If the case was opened (regardless of what the repair involved), all of the Performance Verification Tests must be performed, beginning with "Visual

Inspection" on page 2-12.

2-2 Performance Verification and Safety Tests

Page 23

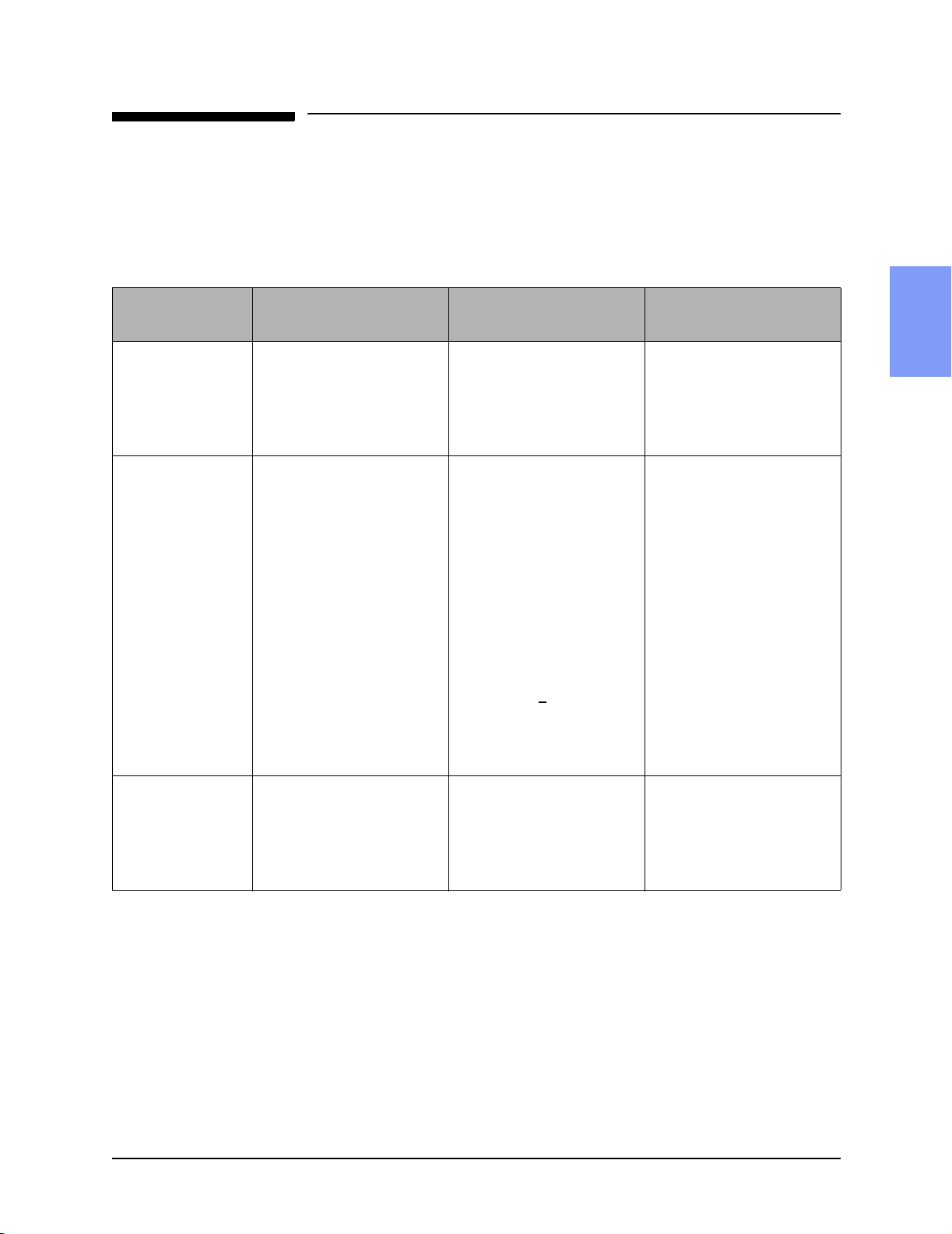

Test and Inspection Matrix

The matrix in Table 2-1 summarizes performance verification tests and

inspections for the M3500B/M5500B; including test name, test or inspection

to perform, expected test results, and data to record.

Table 2-1 Performance Verification and Safety Tests

Test and Inspection Matrix

Test Group Name

Visual Inspection

(VI)

Functional

Checks (F)

Test or Inspection to

Perform

Inspect unit, accessories,

cables, etc. as described on

page 2-12.

In normal Operating Mode,

perform the following functional checks:

• ECG (page 2-13). • Waveform clear on dis-

• Shock Advisory (page 2-

14).

• Synchronized Cardiover-

sion (page 2-14).

• SpO

(page 2-15). • 95% -100%

2

Expected Test Results

• If no unusual damage, no

corrosion, no missing

items,

then Visual Inspection

passes

• If all functions respond as

expected:

play; HR correct on display;

HR alarm works. Leads off,

pads off indicators as

expected.

• Shock Advised only when

appropriate

• Shock delivered with cor-

rect timing (<

60msec)

Data to Record

P (pass) or F (fail)

Example VI:p

Example F:p

2

then Functional test passes

Extended Self

Test (X)

In Diagnostic Mode, run the

Extended Self Test (page 2-

17). Includes Data Card Test

and time/date check.

If "Pass" reported on all

tests applicable to the device

configuration and options,

then Extended Self test

passes

Example X:p

M3500B/M5500B Service Manual 2-3

Page 24

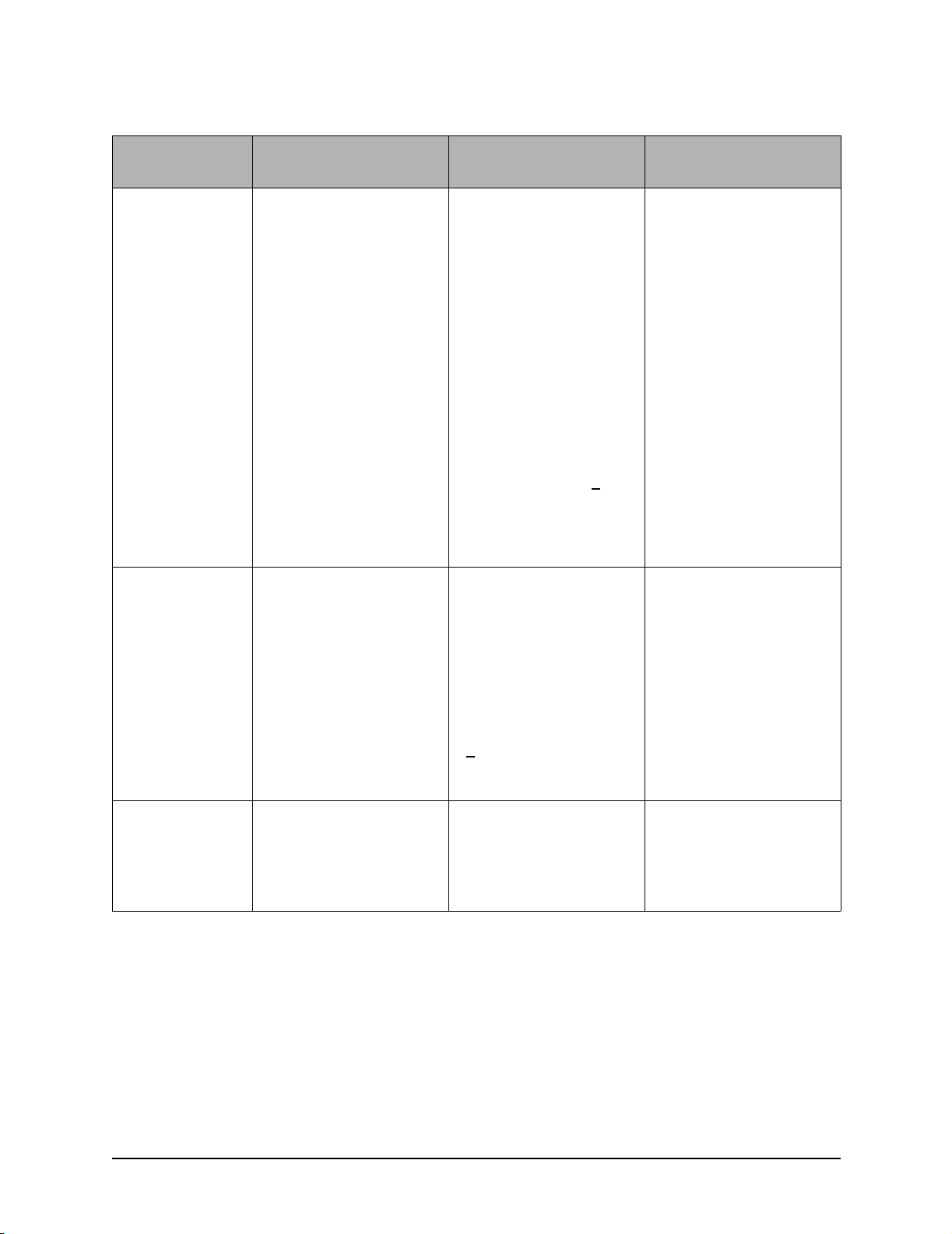

Test and Inspection Matrix

Table 2-1 Performance Verification and Safety Tests (Continued)

Test Group Name

User Interface

Tests (U)

ECG Tests (E) In Diagnostic Mode, run the

Test or Inspection to

Perform

• In Diagnostic Mode, run

the following tests

(page 2-19):

• Controls Test • All keys respond as

• Display Test • Display goes dark, then

• Audio Test • Alerts, alarms, and tones

• Printer Test • Print quality is adequate;

ECG Tests (page 2-22):

Expected Test Results

If all responses as expected: Example: U:p

expected

light. Black vertical bar

scrolls across the screen

from left to right.

are clearly heard

no stray marks or lines

• Print speed: 25 mm +

(1.25mm)

then User Interface test

passes

If all data within limits, all

checks pass:

5%

Data to Record

P (pass) or F (fail)

Example:E:p

• Status messages (lead,

pad, DSP)

PCI measurement If all PCI measurements are

• PCI - Test Load attached • 50 ± 30 Ω

• PCI - Pads open • >

Pacing Test (P) In Diagnostic Mode, run the

Pacing Test (page 2-25):

• 200 mA • 200 mA± 20 mA

• "Good" displayed for all

three status messages

within the following ranges:

2000 Ω

then ECG test passes

If measurement is within the

following limit:

then Pacing test passes

Example: P:p

2-4 Performance Verification and Safety Tests

Page 25

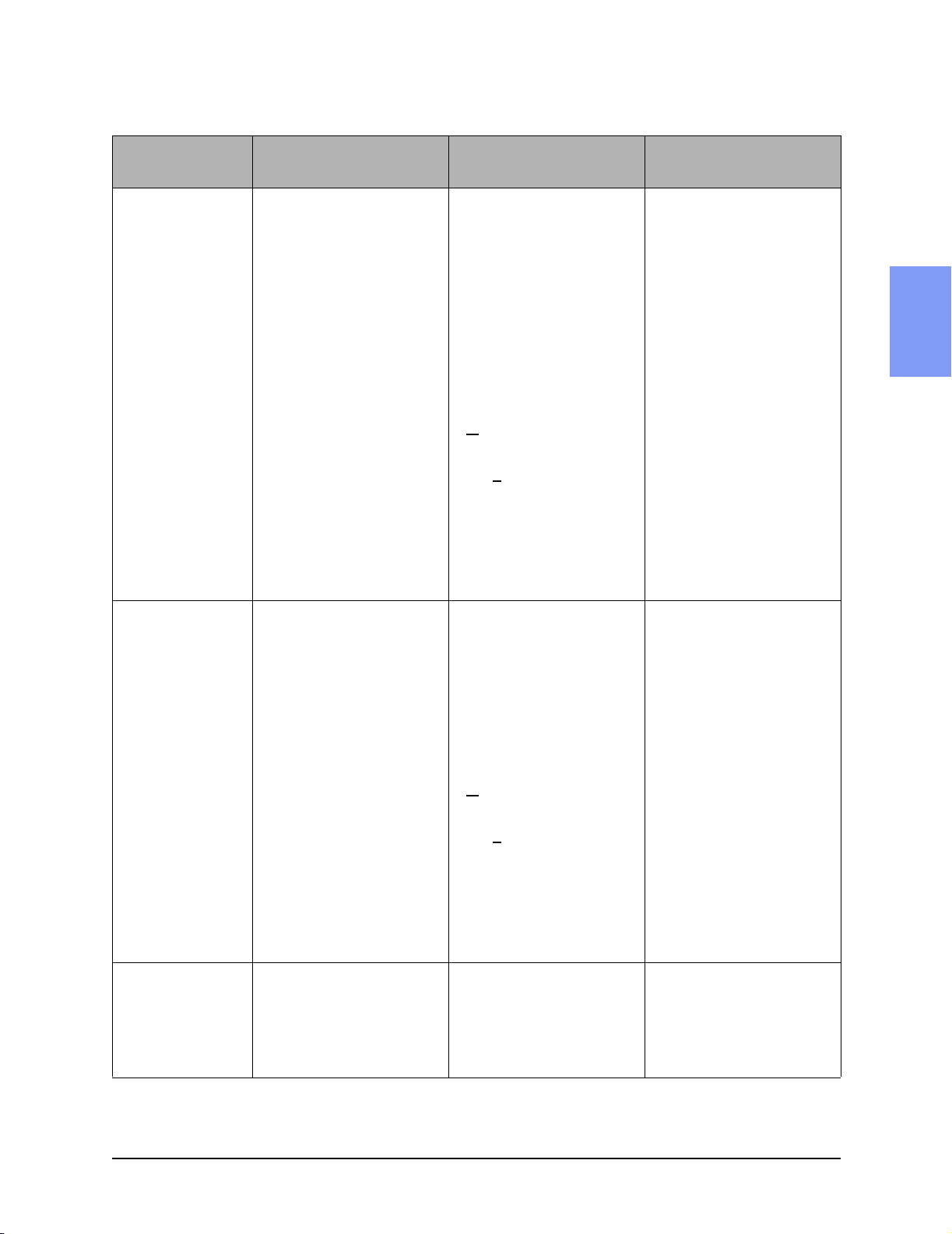

Table 2-1 Performance Verification and Safety Tests (Continued)

Test and Inspection Matrix

Test Group Name

Defibrillator Test AC or DC P ower

Module (DM)

(Required only

when AC or DC

power module

used.)

Test or Inspection to

Perform

Using only the AC or DC

power module, enter Diagnostic Mode and run the

Defibrillator Test (at

200Joules) (page 2-27):

Displayed by

M3500B/M5500B:

• Available Energy after

Shock

• Msec to charge • <

• Delivered energy • Actual delivered energy

• Impedance • 42 to 57 Ω

• Defib errors • None (0)

Expected Test Results

If the measurements are as

follows:

• 0

15000 msec

200 +

7%

then the Defibrillator test

(Power Module) passes

Data to Record

P (pass) or F (fail)

Example: DM:p

2

Defibrillator Test Battery Power

(DB)

Defibrillator

Disarm Test (D)

Using only battery power,

enter Diagnostic Mode and

run the Defibrillator Test (at

200Joules) (page 2-28).

Displayed by

M3500B/M5500B

• Available Energy after

Shock

• Msec to charge • <

• Delivered energy • Actual delivered energy

• Impedance • 42 to 57 Ω

• Defib errors • None (0)

Enter Diagnostic Mode and

run the Defibrillator Disarm

Test (page 2-29)

If the measurements are as

follows:

• 0

3000 msec

200 +

7%

then the Defibrillator test

(Battery Power) passes

If all readings as expected

Available energy - failure >0

No errors reported

then the Defibrillator Disarm

test passes

Example: DB:p

Example: D:p

M3500B/M5500B Service Manual 2-5

Page 26

Test and Inspection Matrix

Table 2-1 Performance Verification and Safety Tests (Continued)

Test Group Name

Safety Tests Indicate test results as

Earth Leakage

Current (S1)

(Required only

when AC Power

module is used.)

Patient Lead

Leakage (S3)

(Required only

when AC Power

module is used.)

Test or Inspection to

Perform

follows:

Earth Leakage Current NC

(Normal Condition)

Earth Leakage SF

(Single Fault - open neutral)

ECG Patient Cable If readings are as expected:

• Source

(Normal Condition) - aa

Expected Test Results

Note: All Safety tests include

both Normal and Reverse

Polarity conditions.

If NC maximum leakage

current:

300 uA (UL), <500 uA

<

and

If SF maximum leakage

current:

< 1000 uA

then S1 test passes

• <

10 uA

Data to Record

P (pass) or F (fail)

Example: S1:p/200/300

S3:p/aa/bb/cc/dd/ee/ff/ggg/

hhh/iii

Example: S3:p/9/49/49/10/

50/50/100/499/750

• Source (Single Fault

Condition - open earth,

open neutral) - bb

• With Mains on applied part

(Single Fault condition) - cc

SPO

2

• Source

(Normal Condition) - dd

• Source (Single Fault

Condition - open earth,

open neutral) - ee

With Mains on applied part

(Single Fault condition) - ff

• <

50 uA

• <

50 uA

then Safety Patient Lead

Leakage test passes

If readings are as expected:

• <

10 uA

• <

50 uA

• <

50 uA

then Safety Patient SPO2

Leakage test passes.

2-6 Performance Verification and Safety Tests

Page 27

Table 2-1 Performance Verification and Safety Tests (Continued)

Test and Inspection Matrix

Test Group Name

Note: When recording test results, separate results within a test by slashes; separate tests by a semicolon (;); and

do not use empty spaces. For example:

VI:p;F:p;X:p;U:p;E:p;P:p;DM:p;DB:p;D:p;S1:p/200/300;S3:p/9/49/49/10/50/50/100/499/750

Test or Inspection to

Perform

Pads If readings are as expected:

• Source

(Normal Condition) - ggg

• Source (Single Fault

Condition) - hhh

• With Mains on applied part

(Single Fault condition) - iii

Expected Test Results

<

100 uA

<

500 uA

<

5000 uA

then Safety Pads Test

passes

Data to Record

P (pass) or F (fail)

2

M3500B/M5500B Service Manual 2-7

Page 28

Test Equipment

Test Equipment

Table 2-2 lists the equipment needed to perform the Performance Verification

tests, and provides specifications for commercially available analyzers and

simulators. Test equipment is called out within each test procedure when

needed. In addition, a digital voltmeter is also useful.

A 50 ohm test load is available from Philips Medical Systems (M1781A).

Table 2-2 Equipment List

Equipment/Test Specifications

ECG Simulator

Calibrated Leads

• Amplitude accuracy ±2%

• Rate accuracy ±2%

Calibrated Paddles

• Amplitude accuracy ±2%

• Rate accuracy ±2%

Defibrillator Analyzer

Waveform compatibility Meets all specs below using biphasic

Load resistance: 50 Ω ±1% (non-inductive)

Maximum energy: ≥ 200 joules

Maximum voltage: ≥ 2500 V

Maximum current: ≥50 A

Measurement accuracy:

• ≥ 20 joules: ≤ ±2% of reading

• < 20 joules: ≤ ±0.4 joules

ECG simulator

ECG simulator

truncated exponential waveform.

Cardioversion measurement range: –150 to +150 ms

2-8 Performance Verification and Safety Tests

Page 29

Table 2-2 Equipment List

Equipment/Test Specifications

Pacer tester

Load impedance: ≤400 Ω

Test Equipment

Current

• 10 mA–50 mA: <±2 mA

• 50 mA–200 mA: <±4%

Rate

• 30–180 ppm: <±0.5%

Waveform duration accuracy:

• 30–180 ppm: ±1ms

measurement accuracy

measurement accuracy

2

M3500B/M5500B Service Manual 2-9

Page 30

Configuration and Diagnostic Modes

Configuration and Diagnostic Modes

The instructions below describe how to enter Configuration Mode and Diagnostic Mode.

Configuration Mode

These instructions describe briefly how to enter Configuration Mode. See the

Instructions for Use for details on configuration settings and what effect they

have.

CAUTION Inserting or removing the Data Card while the unit is on can corrupt the Data

Card and prevent the unit from powering on again. If this occurs, see Chapter

3, Troubleshooting.

1. Power off.

Make sure the unit’s power is off.

2. Insert the Data Card.

If you intend to save the configuration to a Data Card (or load the configuration from a Data Card), insert the Data Card now. To avoid possible

confusion, designate one Data Card as the "Configuration Card" and label

it clearly. Keep this card physically separate from cards used by the clinical staff for data storage.

3. Enter Configuration Mode.

Press softkeys 4 and 5 at the same time, and hold them down while turning the power on. See Figure 2-1 for softkey numbering.

4. Select and manage Configuration choices.

z To select a configuration, press the and softkeys to move up

or down the list until the desired Settings item is highlighted. Then

press the softkey to access those settings.

z To print out a strip with all the current configuration choices, select

Print All Settings and press .

z To store the configuration settings on a data card, select Save Settings

to Data Card and press . When prompted with Save Settings to

Data Card? press .

z To load configuration settings from a Data Card, select Load Settings

from Data Card and press . When prompted with Load Settings

from Data Card? press .

ENTER

ENTER

ENTER

SAVE

ENTER

LOAD

5. Exit Configuration Mode.

z To exit Configuration Mode, turn the unit off.

z Wait 2 seconds. Remove the Data Card by pressing the black eject

button and pulling the Data Card from the compartment.

2-10 Performance Verification and Safety Tests

Page 31

Figure 2-1 Softkey Numbers

Configuration and Diagnostic Modes

Contrast

ECG Size

Volume

Diagnostic Mode

These instructions describe how to enter Diagnostic Mode. Once in Diagnostic Mode, you can:

z Print the System Log (see "Printing the System Log" on page 3-6).

z Run the Extended Self Test (see "Diagnostic Tests" on page 2-16).

z Run other Diagnostic Tests (see "Diagnostic Tests" on page 2-16).

1. Power off.

Make sure the power is off.

2. Enter Diagnostic Mode.

Press softkeys 4 and 6 at the same time, and hold them down while turning the power on. See Figure 2-1.

3. Wait for the Diagnostic software to initialize.

This will take several seconds. The unit is ready to proceed when the

screen cursor responds to softkey inputs.

2

4. Select the desired test or function.

z To select a test, press the and softkeys to move up or down

the list until the desired test is highlighted. Then press the

ENTER

softkey to start that test.

5. Exit Diagnostic Mode.

To exit Diagnostic Mode, turn the unit off.

M3500B/M5500B Service Manual 2-11

Page 32

Performance Verification

Performance Verification

This section gives instructions for running Performance Verification tests on

the M3500B/M5500B. The tests are sequenced to check more basic functions

first, and then build on that to check more complex functions. We recommend

you perform these tests in this sequence. If desired, you can make copies of

the Test Results Matrix (page 2-3) and use it to record results.

The Performance Verification is divided into four sections:

Visual Inspection Items that should be inspected each

time the defib is serviced.

Functional Checks A series of checks in normal operating

mode to assess general performance.

Diagnostic Tests A series of tests using the built-in Diag-

nostic Test menu. Describes how to

access Diagnostic Mode, and how to

run each of the Diagnostic Tests.

Safety Tests Tests of safety related parameters such

as leakage current.

Visual Inspection

1. Inspect the entire unit, especially power cords, printer, battery, cables, and

sensors for signs of the following.

z Wear or damage to patient cables and associated strain reliefs.

z Mechanical damage to case, membrane switches, speaker cover,

ambient light sensor cover, display window.

z Loose or missing hardware.

z Evidence of liquid spill. Check inside the printer bucket and clean out

any accumulation using gloves and an approved cleaner.

z Residue on the thermal printhead.

z Printer roller wear.

z Wear or damage to power cord and associated strain relief.

z Corrosion on connector pins, printer parts, or battery contacts.

Pass: Only normal wear, no damage serious enough to inhibit

performance. No corrosion visible.

2. Check ECG electrodes and defibrillator pads for freshness (data code or

expiration date) and condition.

Pass: Electrodes and pads are within their expiration date and

appear usable. Packaging is unopened and shows no tears or punctures.

No corrosion visible on connector sockets, electrodes, or pads.

2-12 Performance Verification and Safety Tests

Page 33

Performance Verification

Functional Checks

The following functional checks exercise the basic functions of the defibrillator/monitor. They are intended as a broad check of the unit’s performance, and

are designed to complement (not replace) the Diagnostic Tests described later.

If all elements of a test pass, record that test as a PASS and return to the main

diagnostic menu by pressing . If there is any failure, begin troubleshooting and repairing the unit as needed. See "Troubleshooting"

on page 3-1.

MAIN

ECG Functional Checks

This section describes how to check the operation of the ECG functions. Each

of the ECG checks assumes the unit and the simulator are still set up as they

were at the end of the previous ECG check.

To check ECG display and Heart Rate (HR) functions:

1. Connect the ECG simulator to both the Pads input and the 3- or

5-lead ECG cable. Set the simulator for normal sinus rhythm (NSR), 1mV

amplitude, at some nominal rate (e.g., 60 bpm).

2. Set the M3500B/M5500B to Manual operating mode (not Diagnostic

Mode).

3. Using the softkey, verify that the display shows a normal

ECG with a clean baseline for both Pads and Lead II.

4. Verify the Heart Rate (HR) displayed is correct.

5. Disconnect the ECG simulator from the pads cable and verify that the display shows a dashed line in place of the waveform and that the unit both

alarms and gives the Pads Off message.

6. If using a 5-lead ECG cable, set the defibrillator to monitor from the V

lead.

7. Disconnect each of the ECG leads from the simulator one at a time, and

verify that the display shows a dashed line in place of the waveform and

that the unit both alarms and gives the Leads Off message.

LEAD SELECT

2

To check ECG printing functions:

1. Reconnect the simulator.

2. Print a strip and verify that the strip shows a normal ECG with a clean

baseline.

3. Verify that the date, time, and configuration information printed at the top

of the strip is correct.

M3500B/M5500B Service Manual 2-13

Page 34

Performance Verification

Shock Advisory Functional Check

This section describes how to check the Shock Advisory function.

1. Connect the ECG simulator to the pads cable. Set the simulator for normal sinus rhythm (NSR), 1mV amplitude, at some nominal rate (e.g., 60

bpm).

2. Set the M3500B/M5500B to AED Mode and press .

ANALYZE

3. Verify that the defibrillator responds with No Shock Advised.

4. Set the simulator to Asystole (or turn the simulator off) and press

ANALYZE

. Verify that the defibrillator still responds with No Shock

Advised.

5. Set the simulator to VF (Ventricular Fibrillation) and press .

ANALYZE

Verify that the defibrillator responds with Shock A dvised and charges up to

150J. If the unit is configured to do so, verify that it automatically prints a

strip of the event.

WARNING Do not discharge the stored energy unless you are certain the simulator contains a

50 ohm test load.

6. If the simulator contains a 50 ohm test load, discharge the stored energy

into the test load. If it does not, or you are not sure, wait until the defibril-

lator reports Shock cancelled before proceeding with other tests.

Synchronized Cardioversion Functional Check

This section describes how to check the operation of the synchronized cardioversion function.

1. Connect the ECG simulator to the ECG cable. Connect the defibrillator

analyzer to the pads cable.

2. Set the simulator for normal sinus rhythm (NSR), 1mV amplitude, at

some nominal rate (e.g., 60 bpm).

3. Set the defibrillator to Manual Mode, and press SYNC.

4. Verify that sync markers appear on the display, at the peak or on the falling side of the QRS complex. Adjust the size of the displayed ECG as

needed to view it more clearly.

5. Select an energy of 5 J. Press then press and hold until

CHARGE SHOCK

the shock is delivered (at next QRS).

6. Verify on the defibrillator analyzer that the shock was delivered, and was

5J +

2J.

7. If the unit is configured to do so, verify that it prints a strip with the correct information on it (waveform, text).

8. Verify on the defibrillator analyzer that the delay between the peak of the

QRS and the delivered shock was <

2-14 Performance Verification and Safety Tests

60 msec.

Page 35

Performance Verification

Sp02 Functional Check

This check only needs to be performed if SpO2 is installed.

1. Attach the SpO

2. Activate Manual Mode and press the SpO

3. The SpO

is less than 95%, check that your finger is fully inserted into the sensor

and properly positioned.

2

transducer to your finger.

2

softkey to turn SpO2 on.

2

value displayed should be in the range of 95-100%. If the value

2

M3500B/M5500B Service Manual 2-15

Page 36

Diagnostic Tests

Diagnostic Tests

The M3500B/M5500B includes an extensive set of diagnostic tests, which

test the major hardware components of the defibrillator.

The System Log

These instructions describe how to print the system log, which includes the

unit’s serial number, hardware configuration, and a listing of error codes. The

System Log should be printed each time a Performance Verification Test is

run.

1. Enter Diagnostic Mode as described in "Diagnostic Mode" on page 2-11.

2. Select Print Log and press .

ENTER

3. The printer will print the System Log strip.

4. Check the printout to verify the printed results are consistent with the

hardware in place. Check options installed (SpO

serial number (on the bottom of the case). If the printout is not correct,

investigate and resolve the source of the mismatch. Then reset the hardware options and serial number as needed using the Support Software

Tool. See "The Language Support Tool" on page 4-67.

5. If there are errors reported in the System Log:

a. Check the time and date stamps to see if they are recent errors or not.

Consult Table 3-2 "Error Codes" on page 3-11 to identify the errors.

Then begin troubleshooting as needed (see the "Troubleshooting"

chapter.)

b. Check that the time and date are correct. If they are not correct, access

Configuration Mode and reset them.(If there are no errors, the time

and date are not displayed.) See "Configuration Mode" on page 2-10.

Figure 2-2 Sample System Log Printout

SYSTEM LOG

Firmware Versions Error Codes

Main: 34 90007 18:33 19 Jan 2000

DSP: 02

196: 57.00

Key: 06

SpO2: 02.42 01.04

, pacing) and the unit’s

2

Language: English

Serial Number: US01000241

Options: Pacer SpO2

Shocks: 2

2-16 Performance Verification and Safety Tests

Page 37

Diagnostic Tests

Extended Self Test

The Extended Self Test checks that all internal processors are operating and

communicating with each other. The instructions below describe how to run

the Extended Self Test.

If all results are as described, the unit passes this test. Return to the main

Diagnostic Test menu by pressing .

If there is any failure, begin troubleshooting and repairing the unit as needed.

See "Troubleshooting" on page 3-1, and Table 3-6 "Extended Self Test Failures" on page 3-18.

NO TE Make sure that no one touches the unit during the self test as that can generate

an erroneous Not Tested or Fail message.

1. Connect the test load to the pads cable.

2. Access the Diagnostic Test menu as described in "Diagnostic Mode"

above.

MAIN

2

3. Select Extended Self Test and press . The printout should appear

ENTER

similar to Figure 2-3.

Figure 2-3 Sample Extended Self Test Printout

EXTENDED SELF TEST 18:48 1/19/2000

ROM: Pass

RAM: Pass

System: Pass

Data Card: Not Tested

CODEC: Pass

IRDA: Not Tested

Timebase: Pass

Defib: Pass

FE: Pass

SpO2: Pass

Pacer: Pass

4. Check the printout to verify that the time and date are correct. If they are

not, reset them using the Configuration Mode. See "Configuration Mode"

on page 2-10.

5. The results of the following tests will appear on the display and on the

printout:

z ROM

Tests the Read Only Memory (ROM).

z RAM

Tests the Random Access Memory (RAM).

M3500B/M5500B Service Manual 2-17

Page 38

Diagnostic Tests

z SYSTEM

Tests the integrity of the core processing system and checks

the Lithium backup battery.

z Data Card

The Data Card test writes a small file to the data card, reads it back

and checks it, then erases that file. If no Data Card is present, the

test result will be Not Tested.

z CODEC

The processor turns on the CODEC (coding/decoding) chip (used

for voice prompts), and gets an acknowledgement that it’s ready to