Philips HeartStart XL Service manual (2)

HEARTSTART XL

Service Manual

M4735A

Service Manual

M4735A HeartStart XL

Defibrillator/Monitor

Notice

About This Edition

Edition 2

Printed in the USA

Publication number M4735-90900

The information in this manual applies

to the M4735A HeartStart XL Release

Main 15 and earlier This information is

subject to change without notice.

Philips Medical Systems shall not be

liable for errors contained herein or for

incidental or consequential damages in

connection with the furnishing,

performance, or use of this material.

Edition History

Edition 1, October 1, 2000

Edition 2, February 2003

Copyright

Copyright © 2003

Philips Electronics North America

Corporation

3000 Minuteman Road

Andover, MA 01810-1099 USA

(978) 687-1501

All rights are reserved. Reproduction in

whole or in part is prohibited without

the prior written consent of the copyright holder.

WARNING

Radio Frequency (RF) interference

from nearby transmitting devices may

seriously degrade performance of the

M4735A. Electromagnetic

compatibility with surrounding devices

should be assessed prior to using the

defibrillator.

CAUTION

Use of supplies or accessories other

than those recommended by Philips

Medical Systems may compromise

product performance.

THIS PRODUCT IS NOT INTENDED

FOR HOME USE.

IN THE U.S., FEDERAL LAW

RESTRICTS THIS DEVICE TO SALE

ON OR BY THE ORDER OF A

PHYSICIAN.

Medical Device Directive

The M4735A Defibrillator/Monitor

complies with the requirements of the

Medical Device Directive 93/42/EEC

and carries the

ingly.

Authorized EU-representative:

Philips Medizinsysteme Böblingen

GmbH

Hewlett Packard Str. 2

71034 Böbingen

Germany

Canada EMC:ICES-001

mark accord-

0123

ii

Conventions

This manual uses the following text conventions:

Printed and On-Line

WARNING W arning statements describe conditions or actions that can result in personal injury

or loss of life.

CAUTION Caution statements describe conditions or actions that can result in damage to

the equipment or loss of data.

NO TE Notes contain additional information on servicing this product.

TIP:

Tips provide hands-on insight into servicing this product.

Tex t represents messages that appear on the display

Softkey

represents softkey labels that appear on the display

above or below the button to which they correspond

On-Line Only

Hypertext

represents hypertext links, which will display as blue;

click on the link to go to that destination, then click on

the destination to return.

iii

Contents

Text Conventions

Printed and On-Line .....................................................................................................iii

On-Line Only ...............................................................................................................iii

Hypertext ...........................................................................................................................iii

Introduction

Overview ....................................................................................................................1-1

Web-Based Training ....................................................................................................... 1-1

Defibrillator/Monitor ...................................................................................................... 1-1

Batteries .......................................................................................................................... 1-2

Installation ...................................................................................................................... 1-2

Upgrades ......................................................................................................................... 1-2

Preventive Maintenance .................................................................................................. 1-2

Repair Philosophy ........................................................................................................... 1-3

Performance Verification and Safety Tests

Overview ......................................................................................................................... 2-1

Chapter Contents ............................................................................................................. 2-1

Required Testing Levels .............................................................................................2-2

External Repairs/No Trouble Found ............................................................................... 2-2

Printer .............................................................................................................................. 2-3

Internal Repairs ...............................................................................................................2-3

Test and Inspection Matrix .........................................................................................2-4

Test Equipment ....................................................................................................... ..2-10

Configuration and Diagnostic Modes ......................................................................2-11

Configuration Mode ...................................................................................................... 2-11

Diagnostic Mode ........................................................................................................... 2-12

The Language Support Tool .....................................................................................2-13

Using the Language Support Tool ................................................................................ 2-13

Performance Verification Tests ................................................................................2-15

Visual Inspection ........................................................................................................... 2-16

Functional Checks ......................................................................................................... 2-18

Diagnostic Tests ............................................................................................................ 2-22

Safety Tests ...................................................................................................................2-43

Battery Capacity Test .................................................................................................... 2-47

v

Contents

Troubleshooting

Overview ....................................................................................................................3-1

Chapter Contents ............................................................................................................. 3-1

Repair Philosophy ........................................................................................................... 3-1

Equipment Required ....................................................................................................... 3-1

Troubleshooting and Repair Methodology ................................................................3-2

Methodology Overview ..................................................................................................3-2

Evaluate ......................................................................................................................3-3

Troubleshoot ...............................................................................................................3-5

System Errors ..................................................................................................................3-5

Repair .........................................................................................................................3-6

Check the repair .............................................................................................................. 3-6

Verify ..........................................................................................................................3-7

Troubleshooting Tables ..............................................................................................3-8

Using the Tables ............................................................................................................. 3-8

General Problems .......................................................................................................3-9

Unit Unresponsive ...........................................................................................................3-9

Error Codes ................................................................................................................... 3-10

System Messages .......................................................................................................... 3-12

Momentary Messages ................................................................................................... 3-15

Audio Tones ................................................................................................................ 3-17

Extended Self Test Failures .......................................................................................... 3-18

Operational Problems ...............................................................................................3-19

ECG Monitoring ......................................................................................................... 3-19

SpO2 Monitoring ..........................................................................................................3-22

Defibrillation and Cardioversion .................................................................................. 3-23

Pacing ............................................................................................................................3-25

Printer ............................................................................................................................ 3-26

Display .......................................................................................................................... 3-27

Audio ............................................................................................................................ 3-28

Controls ......................................................................................................................... 3-29

Battery and Charging Circuits ......................................................................................3-30

Data Card ......................................................................................................................3-31

Calling for Service ...................................................................................................3-32

United States of America .............................................................................................. 3-32

Latin America ............................................................................................................... 3-32

Canada .......................................................................................................................... 3-32

Other International Areas .............................................................................................. 3-33

Equipment Information ................................................................................................. 3-34

vi

Contents

Removal and Replacement

Overview ....................................................................................................................4-1

Chapter Contents ............................................................................................................. 4-1

Servicing Notes ..........................................................................................................4-1

Key Components ............................................................................................................. 4-1

Removal, Handling, and Replacement ........................................................................... 4-2

Tool Requirements .......................................................................................................... 4-3

Disposal .......................................................................................................................... 4-3

External Assemblies ...................................................................................................4-4

User Replaceable Parts and Accessories ......................................................................... 4-5

User Maintenance ........................................................................................................... 4-5

Printer Assembly ............................................................................................................. 4-6

Battery Cover ................................................................................................................ 4-10

Main Fuse ..................................................................................................................... 4-12

Battery Eject Assembly ................................................................................................ 4-14

Data Card Door ............................................................................................................. 4-16

Energy Select Knob .................................................................................................... 4-17

Paddle Holders .............................................................................................................. 4-18

Labels ............................................................................................................................ 4-20

Label Descriptions ........................................................................................................ 4-20

Removing and Replacing Labels .................................................................................. 4-23

Opening the Case .....................................................................................................4-24

Discharge the Power Supply Capacitors ....................................................................... 4-24

Separate the Case ........................................................................................................ 4-26

Discharge the Defibrillator Capacitor ........................................................................... 4-30

Identifying Internal Subassemblies ............................................................................... 4-32

Internal Assemblies - Top Case ................................................................................4-33

Lithium Backup Battery ................................................................................................ 4-34

Control PCA ................................................................................................................. 4-36

Shield Plate ...................................................................................................................4-40

Keyscan PCA ................................................................................................................ 4-42

Bezel Assembly .......................................................................................................... 4-48

Energy Select Switch .................................................................................................... 4-52

Display Assembly ......................................................................................................... 4-54

Parameter PCA .............................................................................................................. 4-56

SpO2 PCA .................................................................................................................. 4-58

ECG Connector ............................................................................................................. 4-60

SpO2 Connector ............................................................................................................ 4-62

Speaker ....................................................................................................................... 4-64

AC Mains Connector ....................................................................................................4-66

ECG Out (Sync) Connector .......................................................................................... 4-69

Pacer Keypad ................................................................................................................4-70

Replacement Top Case ..................................................................................................4-75

vii

Contents

Internal Assemblies - Bottom Case ..........................................................................4-79

Battery PCA .................................................................................................................. 4-80

Defibrillator Capacitor .................................................................................................. 4-84

Power PCA .................................................................................................................... 4-86

Power Supply ................................................................................................................ 4-90

Patient Connector .......................................................................................................... 4-94

Replacement Bottom Case ............................................................................................4-97

Closing the Case .......................................................................................................4-99

Replacement Parts

Overview ......................................................................................................................... 5-1

Chapter Contents ............................................................................................................. 5-1

Ordering Replacement Parts ...........................................................................................5-1

Ordering Supplies and Accessories ................................................................................ 5-1

Key Components ........................................................................................................... 5-2

Calling for Service .....................................................................................................5-3

United States of America ................................................................................................ 5-3

Latin America ................................................................................................................. 5-3

Canada ............................................................................................................................ 5-3

Other International Areas ................................................................................................ 5-4

Special Tools ..............................................................................................................5-5

M4735A Unit Exchange Program ..............................................................................5-6

Replacement Parts Tables ...........................................................................................5-7

Electrical Assemblies .................................................................................................5-8

Control PCA ................................................................................................................... 5-8

Other Replacement PCAs ............................................................................................. 5-10

Other Electrical Assemblies .......................................................................................... 5-10

Individual Electrical Parts ............................................................................................. 5-11

Mechanical Assemblies ............................................................................................5-12

Bezel Assembly ............................................................................................................ 5-12

Pacer Keypad Assembly ...............................................................................................5-13

Other Mechanical Assemblies ...................................................................................... 5-14

Connector Assemblies .................................................................................................. 5-14

Individual Mechanical Parts ..........................................................................................5-15

Labels .......................................................................................................................5-16

Instruction Label Sets ................................................................................................... 5-16

Case Label Sets ............................................................................................................. 5-18

Paddle Labels ................................................................................................................ 5-20

Other Labels .................................................................................................................. 5-20

Supplies & Accessories ............................................................................................5-21

Key Components ......................................................................................................5-25

viii

Contents

Theory of Operation

Overview ....................................................................................................................6-1

PCA Descriptions .......................................................................................................6-2

Control PCA ................................................................................................................... 6-2

Power PCA ..................................................................................................................... 6-3

Parameter PCA ............................................................................................................... 6-3

Keyscan PCA .................................................................................................................. 6-3

SpO2 PCA .......................................................................................................................6-4

Battery PCA ....................................................................................................................6-4

Battery ............................................................................................................................. 6-4

Power Supply .................................................................................................................. 6-4

Printer .............................................................................................................................. 6-4

System Level Interconnections ..................................................................................6-5

System Functional Descriptions .................................................................................6-6

Signal and Data Flow ...................................................................................................... 6-6

ECG Monitoring Functions ............................................................................................ 6-7

Patient impedance functions ........................................................................................... 6-7

SpO2 Monitoring Functions ........................................................................................... 6-8

Defibrillation Functions .................................................................................................. 6-9

Pacing Functions ........................................................................................................... 6-11

Audio Functions ............................................................................................................ 6-11

Display Functions ......................................................................................................... 6-11

Indicator Functions ....................................................................................................... 6-11

Key Functions ............................................................................................................... 6-11

Energy Select Switch .................................................................................................... 6-12

Printing Functions ......................................................................................................... 6-12

Battery/Power Functions ............................................................................................... 6-12

Lithium Backup Battery ................................................................................................ 6-16

Data Card ......................................................................................................................6-16

Specifications

Overview ......................................................................................................................... 7-1

Specifications .............................................................................................................7-1

Defibrillator .................................................................................................................... 7-1

ECG Monitoring ............................................................................................................. 7-3

Display ............................................................................................................................ 7-4

Battery ............................................................................................................................. 7-4

Thermal Array Printer ..................................................................................................... 7-5

Noninvasive Pacing ........................................................................................................ 7-6

SpO2/Pulse Oximetry ..................................................................................................... 7-6

Event Storage ..................................................................................................................7-6

General ............................................................................................................................ 7-7

Environmental ................................................................................................................. 7-7

ix

Contents

Waveforms - 150J ......................................................................................................7-8

150J, 25 ohms .............................................................................................................. 7-8

150J, 50 ohms .............................................................................................................. 7-8

Waveforms -150J (continued) ....................................................................................7-9

150J, 75 ohms ............................................................................................................... 7-9

150J, 100 ohms ............................................................................................................ 7-9

Waveforms -150J (continued) ..................................................................................7-10

150J, 125 ohms (2ms/div) ........................................................................................ 7-10

150J, 125 ohms (5 ms/div) .......................................................................................... 7-10

Waveforms - 200J .................................................................................................7-11

Waveforms - 200J (continued) .................................................................................7-12

Waveforms - 200J (continued) ............................................................................7-13

Symbol Definitions ..................................................................................................7-14

Safety Considerations ...............................................................................................7-16

Electromagnetic Compatibility ................................................................................7-19

Reducing Electromagnetic Interference ........................................................................ 7-19

Restrictions for Use ...................................................................................................... 7-20

Immunity Level ............................................................................................................. 7-20

x

1Introduction

This Service Manual provides the information needed to successfully service the

M4735A HeartStart XL Defibrillator/Monitor. The intended users of this manual are

technical personnel who have been trained in the safe and proper servicing of the

M4735A. 1

Overview

In this chapter, you’ll find general information that you should become

familiar with before servicing the M4735A. Detailed information regarding

controls, operation, and capabilities of the instrument can be found in the

Instructions for Use (M4735-91900) that was shipped with the product. We

recommend you review the Instructions for Use before servicing this device.

This Service Manual assumes you are familiar with the controls and with

basic operations.

Web-Based Training

Web-based service training for the M4735A HeartStart XL

Defibrillator/Monitor is available. You can access the training through the

Biomed On-Line web site at http://bol.medical.philips.com.

Defibrillator/Monitor

1

The M4735A is a biphasic, semi-automated external defibrillator. This

portable, lightweight device offers two modes of operation for defibrillation:

z Semi-Automatic External Defibrillation (AED) Mode

z Manual Mode

In AED Mode, the M4735A analyzes the patient’s ECG and advises the

clinician whether or not to deliver a shock. Defibrillation is performed

through multifunction defib electrode pads.

In Manual Mode, the M4735A turns control of the defibrillation process over

to the clinician. The clinician analyzes the patient’s ECG, decides if

defibrillation is advised, and determines the energy setting for defibrillation.

Defibrillation is performed either through multifunction defib electrode pads

or through paddles.

Manual Mode also allows the clinician to perform synchronized cardioversion

and offers optional noninvasive pacing (using a monophasic waveform).

ECG monitoring can be accomplished in either mode using one of 3 methods:

z ECG from the defib pads.

z 3-lead ECG using separate monitoring electrodes.

z Optional 5-lead ECG using separate monitoring electrodes.

1-1

Overview

Optional pulse oximetry (SpO2) monitoring is available in both modes, as

well.

The M4735A automatically stores critical events, such as shocks and alarm

violations, in its internal memory. An Event Summary may be printed at any

time. The M4735A also enables you to store data and events on an optional

M3510A Data Card for downloading to the Event Review Data Management

System.

Batteries

The M4735A is powered by a rechargeable Sealed Lead Acid (SLA) battery

(M3516A). Proper care of these batteries will ensure that they have the energy

required to operate the M4735A and deliver the appropriate therapy. For more

details see the “Battery Maintenance” section in the Instructions for Use, and

the Battery Maintenance Application Note.

NO TE The defibrillator will take longer to charge when powered by AC without a

battery installed. To ensure optimal performance, always have a fully charged

battery in the defibrillator, even when using AC power.

Installation

The M4735A does not require installation. The Instructions for Use describes

the setup required before placing the device into service, as well as configuration options.

Upgrades

Upgrades are available to add specific functionality to units in the field.

These upgrades are:

z M4738A Pacing Upgrade (adds pacing).

z M4739A SpO

upgrade. (adds SpO2).

2

Consult your sales representative or dealer or distributor for the latest details.

Preventive Maintenance

Preventive maintenance and periodic operational checks are intended to be

performed by the user. Both topics are covered in the Maintenance chapter of

the Instructions for Use.

1-2 Introduction

Overview

Repair Philosophy

Defibrillator/Monitor

The repair philosophy of the M4735A is subassembly replacement. Examples

of subassemblies are the printer, the Control Printed Circuit Assembly (PCA),

and selected connectors and other items. Repairs that involve replacing components on a PCA are not supported.

CAUTION Individual component replacement should not be attempted outside of a fac-

tory authorized repair facility. Component level repair is extremely difficult

due to the extensive use of surface mount technology and the high parts-density on the circuit boards. Unauthorized component replacement can impair

performance of the M4735A.

Batteries

The repair philosophy for the SLA battery (M3516A) is unit replacement. If a

battery fails, it is replaced, not repaired.

For information on ordering replacements, see "Supplies & Accessories" on

page 5-21.

1

M4735A Service Manual 1-3

2 Performance Verification and Safety Tests

Overview

This chapter describes the tests and inspections required to verify

performance of the M4735A Portable Defibrillator/Monitor.

Chapter Contents

The major sections of this chapter are as follows:

Section Page

Required Testing Levels 2-2

Test and Inspection Matrix 2-4

Test Equipment 2-10

Configuration and Diagnostic Modes 2-11

The Language Support Tool 2-13

Performance Verification Tests 2-15

2

2-1

Required Testing Levels

Required Testing Levels

The Performance Verification Tests in this chapter are intended to verify

proper operation of the M4735A following repair. The level of testing

required corresponds to the type of repair performed, and is divided into 3

categories:

z External Repairs/No Trouble Found.

z Printer Replacement.

z Internal Repairs.

External Repairs/No Trouble Found

External Repairs are those involving the repair or replacement of one or

more of the items below. No Trouble Found applies when no malfunction

can be found, or when the problem appears to be due to improper use. In

either situation, the key point is that the case has not been opened.

z External paddles

z Internal paddles and/or adapter cable

z Paddle holders

z Pads adapter cable

z ECG cable

z SpO

z Battery

z Labels

z AC Power cord

z Consumables (ECG monitoring electrodes, multifunction defibrilla-

cable or sensor

2

tion pads, printer paper)

z Main fuse (on Battery PCA)

z Data Card Door Assembly

z Battery Eject Assembly

The following testing is required after an External Repair or when the

outcome of the service is No Trouble Found (when the case has not been

opened):

z Perform the Visual Inspection (page 2-16).

z Run the Extended Self Test (page 2-25).

z Print and Verify the System Log (page 2-23).

2-2 Performance Verification and Safety Tests

Required Testing Levels

Printer

If the printer was replaced, and the case was not opened, the following tests

are required:

z Perform the Visual Inspection (page 2-16).

z Run the Extended Self Test (page 2-25).

z Run the Printer Test (page 2-30).

z Print and Verify the System Log (page 2-23).

Internal Repairs

If the case was opened (regardless of what the repair involved), all of the

Performance Verification Tests must be performed, beginning with "Visual

Inspection" on page 2-16.

2

M4735A Service Manual 2-3

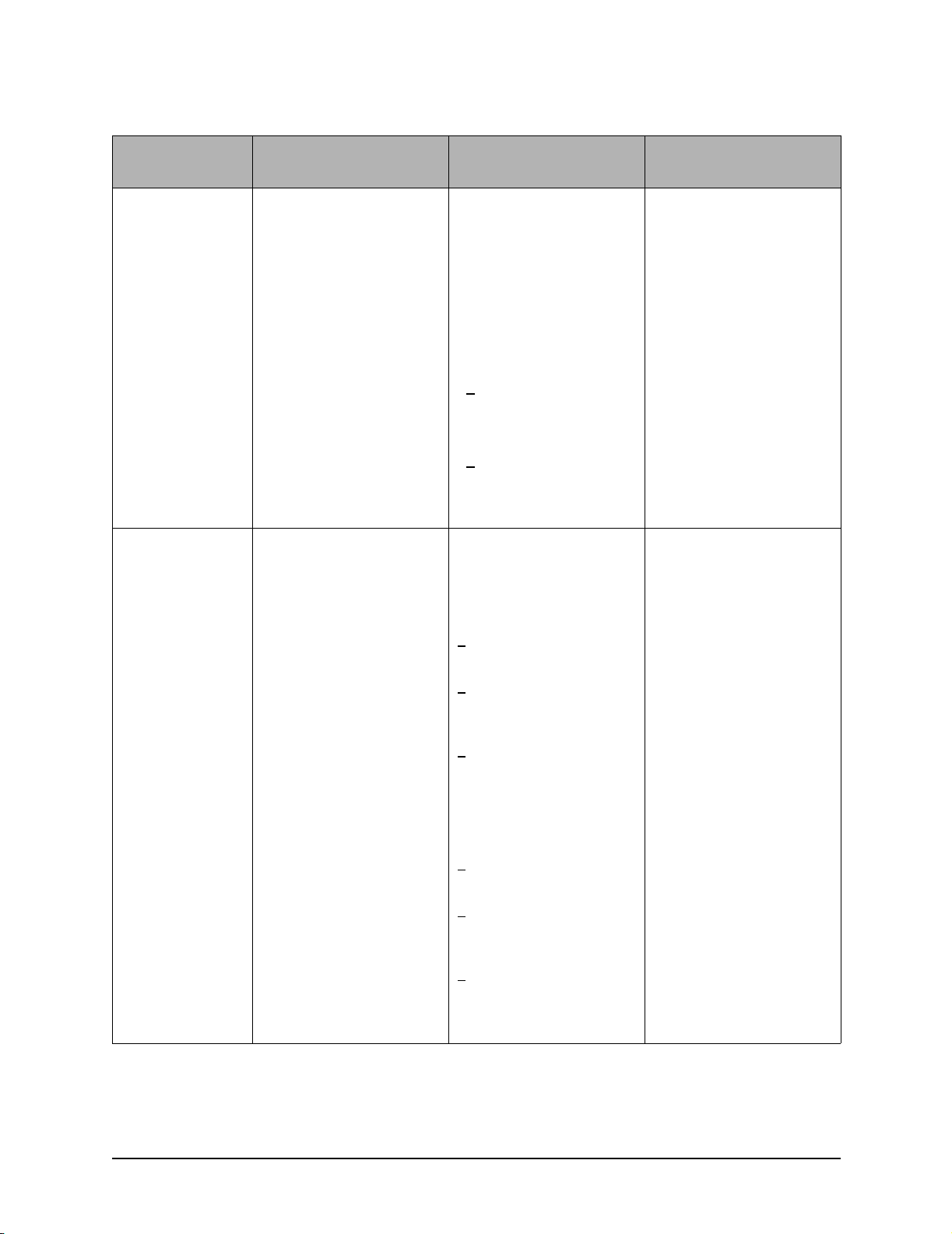

Test and Inspection Matrix

Test and Inspection Matrix

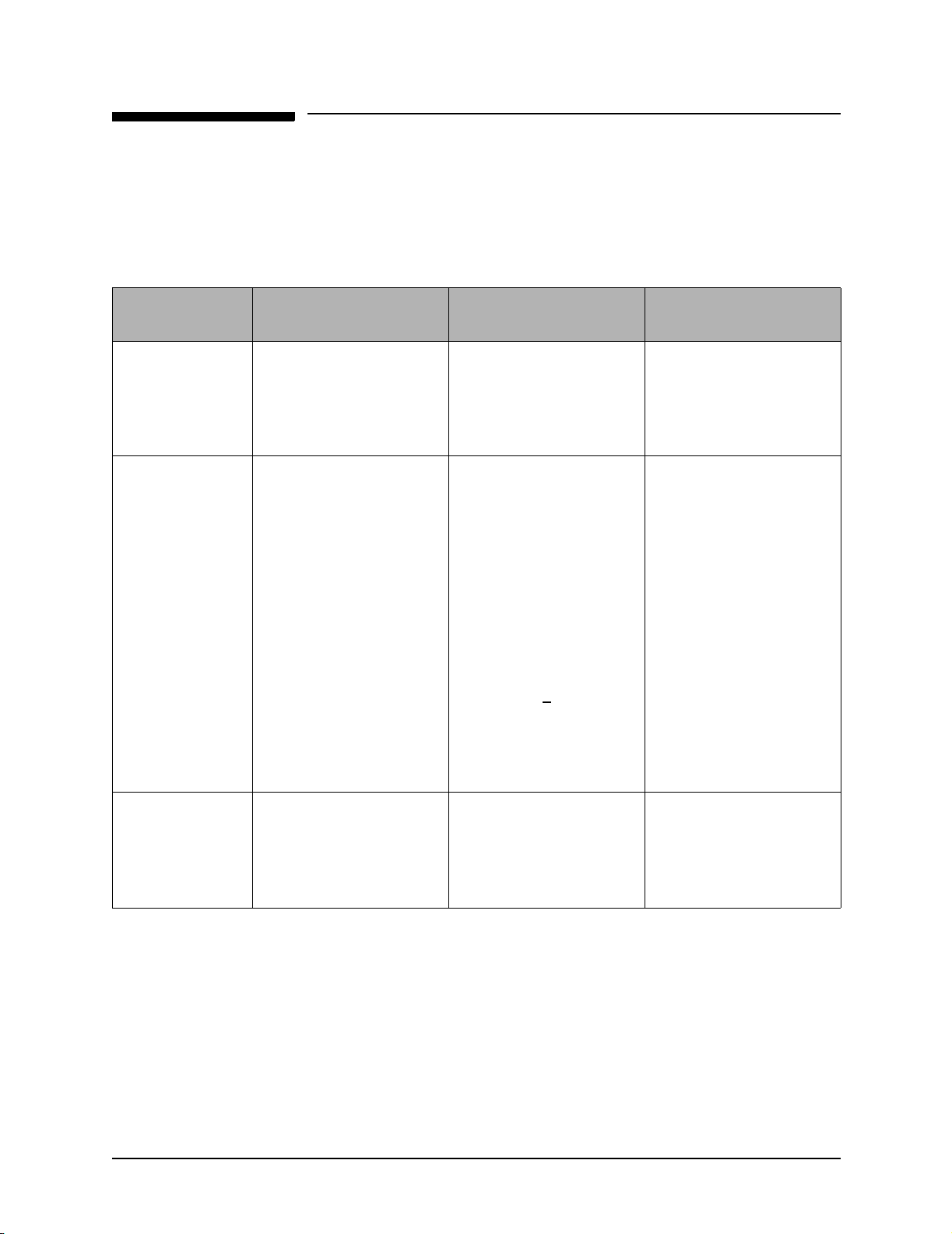

Table 2-1 summarizes performance verification tests and inspections for the

M4735A; including test name, test or inspection to perform, expected test

results, and data to record.

Table 2-1 Performance Verification and Safety Tests

Test Group Name

Visual Inspection

(V)

Functional

Checks (F)

Test or Inspection to

Perform

Inspect the unit, accessories, cables, etc.for signs

of wear, damage, corrosion, or missing items, as

described on page 2-16.

In normal Operating Mode,

perform the following functional checks:

• ECG (page 2-18). • Waveform clear on dis-

• Shock Advisory (page 2-

19).

• Synchronized Cardiover-

sion (page 2-20).

• SpO

(page 2-21). • 95% -100%

2

Expected Test Results

If no unusual damage, no

corrosion, no missing items:

x=p.

then Visual Inspection

passes

If all functions respond as

expected: x=p

play; HR correct on display;

HR alarm works. Leads off,

pads off indicators as

expected.

• Shock Advised only when

appropriate

• Shock delivered with cor-

rect timing (<

60msec)

Data to Record

x = p (pass) or f(fail)

V:x

Example V:p

F:x

Example F:p

then Functional Check

passes

Extended Self

Test (X)

In Diagnostic Mode, run

the Extended Self Test

(page 2-25). Includes Data

Card T est and time/date

check.

If “Pass” reported on all tests

applicable to the device configuration and options: x=p.

then Extended Self test

passes

X:x

Example X:p

2-4 Performance Verification and Safety Tests

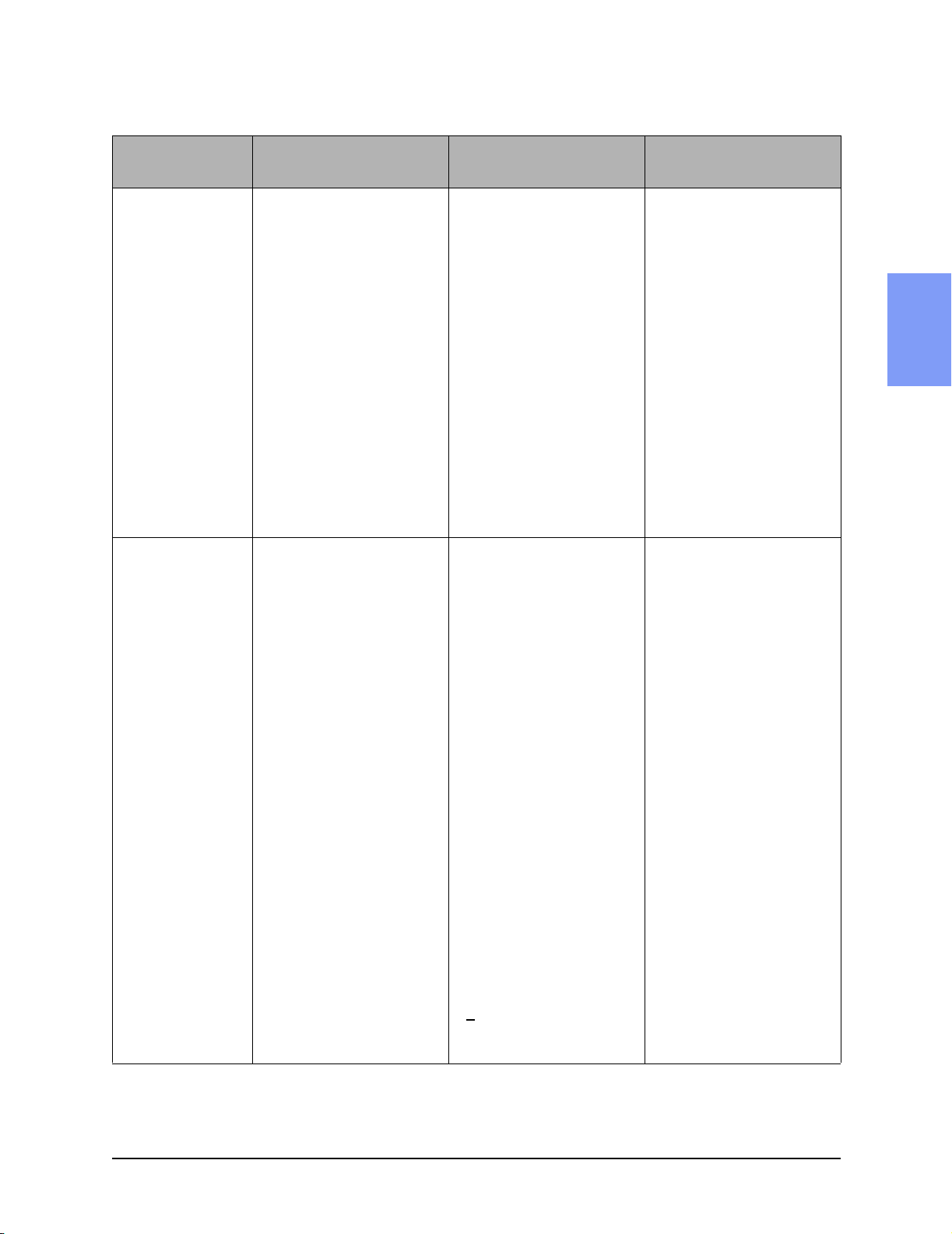

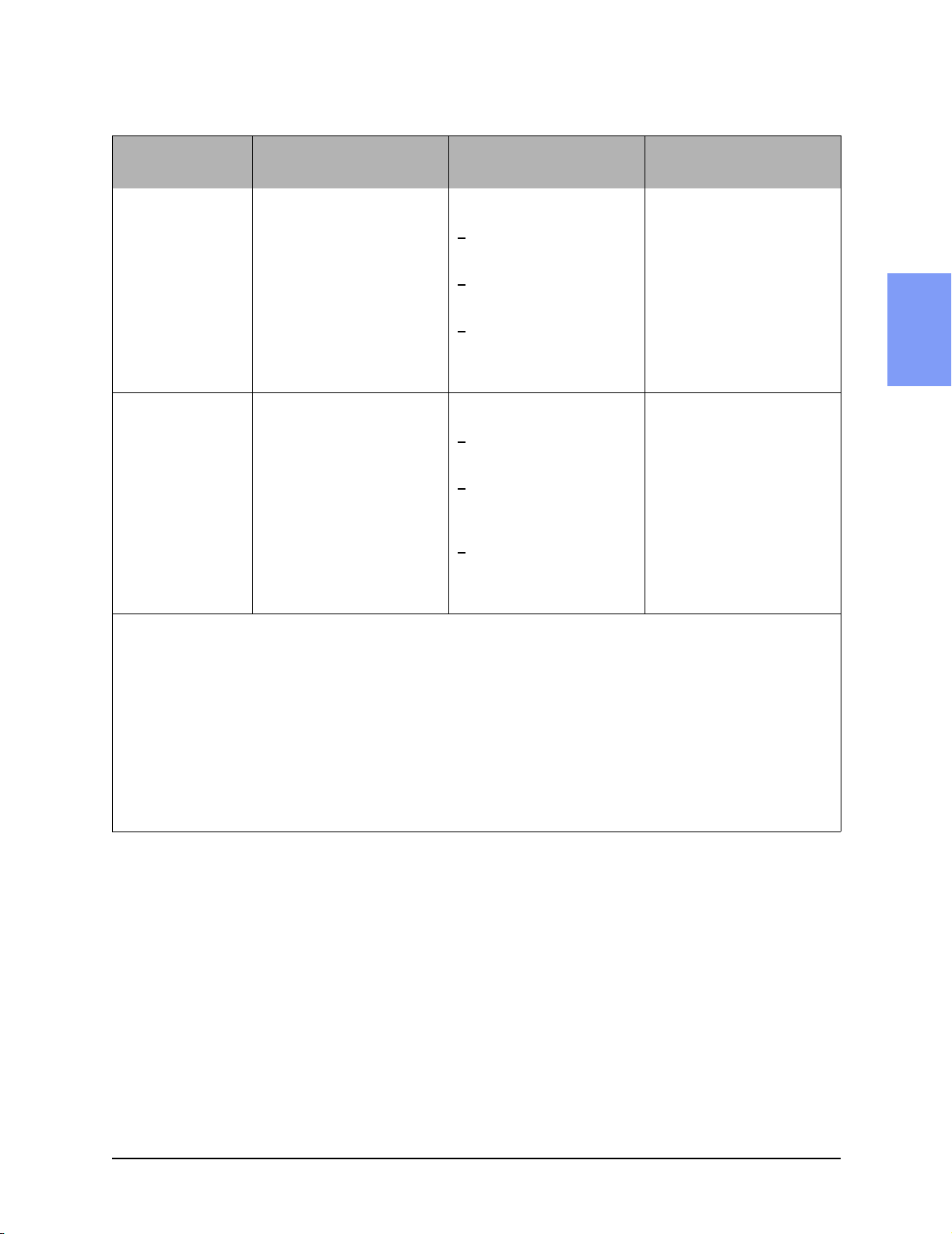

Table 2-1 Performance Verification and Safety Tests (Continued)

Test and Inspection Matrix

Test Group Name

User Interface

Tests (U)

ECG Tests (E) In Diagnostic Mode, run

Test or Inspection to

Perform

• In Diagnostic Mode, run

the following tests (page

2-28):

• Controls Test • All keys respond as

• Display Test • Visual Pass assessment by

• Audio Test • Alerts, alarms, and tones

• Printer Test • Print quality is adequate;

the ECG Tests (page 2-33):

• Status messages (lead,

pad, DSP)

Expected Test Results

If all data within limits, all

checks pass: x=p

expected

service personnel

are clearly heard

no stray marks or lines.

• Print speed: 25 mm

(1.25mm)

then User Interface test

passes

If all data within limits, all

checks pass: x=p

• “Good” displayed for all

three status messages

± 5%

Data to Record

x = p (pass) or f(fail)

U:x

Example: U:p

2

E: x

Example: E:p

• DC offset • Ignore DC Offset - used

only in factory manufacturing.

Amplifier gain

• Pads Peak to Peak (Moni-

tor)

• Leads Peak to Peak (Diag-

nostic)

Amplifier noise

• Leads Peak to Peak (Diag-

nostic) - cc

• Pads Peak to Peak (Moni-

tor) - dd

PCI measurement

• PCI - Paddles in Pockets • 50 ± 30 Ω

• PCI - Paddles open • >

• 1000uV

• 1000uV

• 0

• 0

then ECG Test passes

±10%

±10%

± 30uV

± 30uV

1250 Ω

M4735A Service Manual 2-5

Test and Inspection Matrix

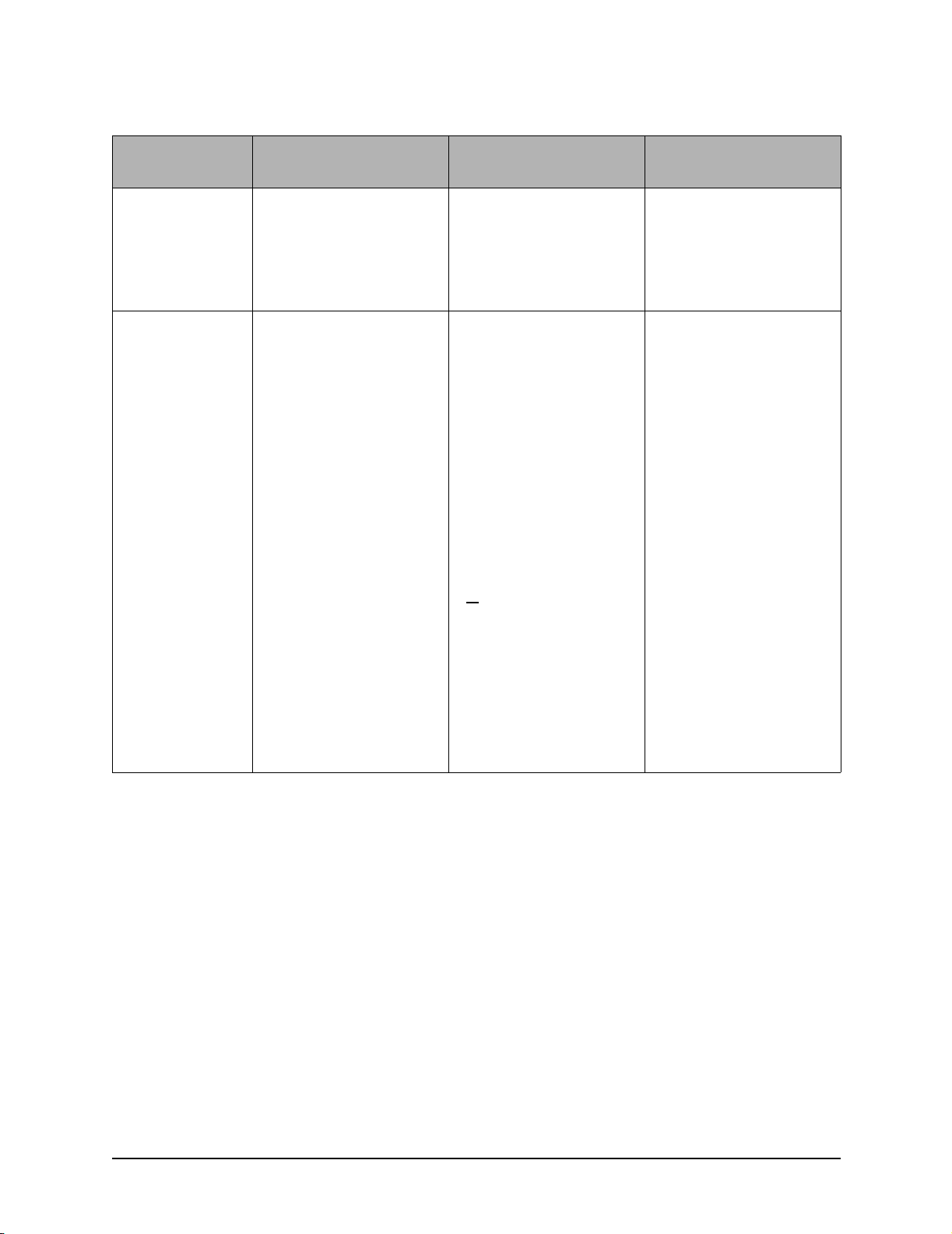

Table 2-1 Performance Verification and Safety Tests (Continued)

Test Group Name

Pacing Test (P) In Diagnostic Mode, run

Defibrillator Test AC Power (DA)

(if AC Power used

in normal operation)

Test or Inspection to

Perform

the Pacing Test (page 2-

38):

• (70 ppm) 30 mA • 30 mA ± 5 mA

• (180 ppm) 200mA • 200mA± 20 mA

Using only AC power,

enter Diagnostic Mode

and run the Defibrillator

Test (AC Power at

200Joules) (page 2-40):

Measured by

Defibrillator Analyzer:

• Delivered energy

Displayed by

M4735A:

• Available Energy after

Shock

• Msec to charge • <

Expected Test Results

All data within limits, all

checks pass: x=p

All data within limits, all

checks pass: x=p. If the

measurements are as follows:

± 30J

• 200

• 0

15000 msec

Data to Record

x = p (pass) or f(fail)

P:x

Example: P:p

DA:x

Example: DA:p

• Delivered energy • Actual delivered energy

±7%

• Impedance • 42 to 57 Ω

• Defib errors • None (0)

then the Defibrillator test

(AC Power) passes

2-6 Performance Verification and Safety Tests

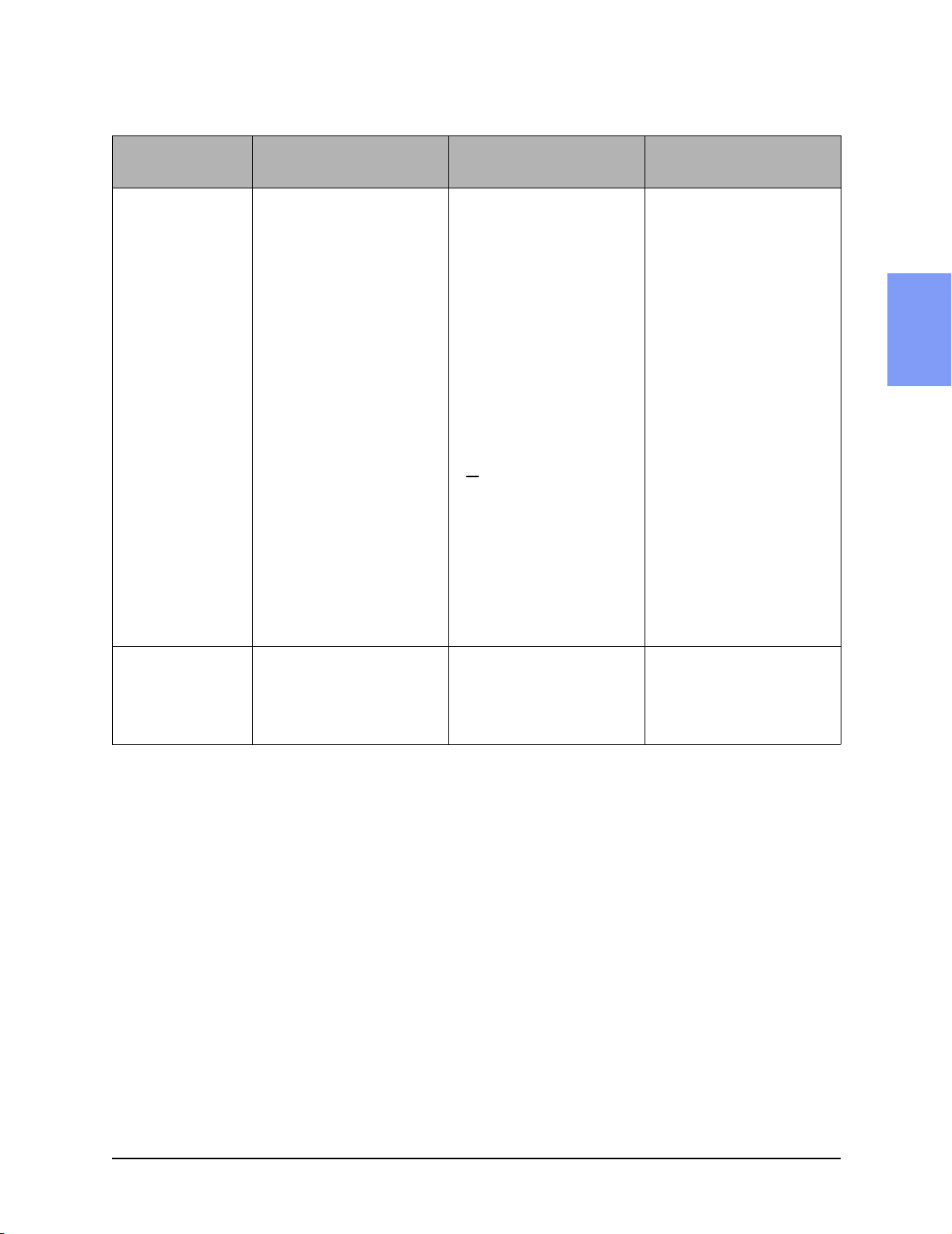

Table 2-1 Performance Verification and Safety Tests (Continued)

Test and Inspection Matrix

Test Group Name

Defibrillator Test Battery Power

(DB)

Test or Inspection to

Perform

Using only battery power,

enter Diagnostic Mode

and run the Defibrillator

Test (at 200Joules) (page

2-41).

Measured by

Defibrillator Analyzer

• Delivered energy • 200 ± 30 J

Displayed by

M4735A

• Available Energy after

Shock

• Msec to charge • <

• Delivered energy • Actual delivered energy

Expected Test Results

All data within limits, all

checks pass: x=p

If the measurements are:

• 0

3000 msec

±7%

• Impedance • 42 to 57 Ω

• Defib errors • None (0)

Data to Record

x = p (pass) or f(fail)

DB:x

Example: DB:p

2

Defibrillator

Disarm Test (D)

Enter Diagnostic Mode

and run the Defibrillator

Disarm Test (page 2-42)

then the Defibrillator test

(Battery Power) passes

All readings as expected:

x=p. No errors reported.

then the Defibrillator Disarm

test passes

D:x

Example: D:p

M4735A Service Manual 2-7

Test and Inspection Matrix

Table 2-1 Performance Verification and Safety Tests (Continued)

Test Group Name

Test or Inspection to

Perform

Safety Tests Indicate test results as

follows:

Earth Leakage

Current (S1)

Earth Leakage Current

NC (Normal Condition) - aaa

Earth Leakage Current

SF (Single Fault -open neutral) - bbbb

Patient Lead

ECG Patient Cable If readings are as expected: S3:P/aa/bb/cc/dd/ee/ff/ggg/

Leakage (S3)

Expected Test Results

Note: All leakage current

tests include both Normal

and Reverse Polarity Conditions.

Report worst case values.

All values within limits: x=p

If Normal Condition Maximum leakage current

• < 300 uA (UL, 120 VAC)

500 uA (IEC, 240 VAC)

• <

If Single Fault Maximum

leakage current

1000 uA

• <

then Earth Leakage Safety

test passes

Data to Record

x = p (pass) or f(fail)

S1:P/aaa/bbbb

Example:

S1:P/125/800

hhh/iii/jj/kk/lll

Example:

S3:P/9/49/49/10/50/50/100/

499/4750/9/49/83

• Source

(Normal Condition) - aa

• Source (Single Fault

condition - open earth,

open neutral) - bb

• With Mains on applied part

(Single Fault condition) - cc

SPO

2

• Source

(Normal Condition) - dd

• Source (Single Fault

Condition - open earth,

open neutral) - ee

• With Mains on applied part

(Single Fault condition) - ff

< 10 uA

<

50 uA

<

50 uA

then Patient Lead Leakage

Safety test passes

If readings are as expected:

<

10 uA

<

50 uA

50 uA

<

then Patient SPO

Leakage

2

Safety test passes

2-8 Performance Verification and Safety Tests

Table 2-1 Performance Verification and Safety Tests (Continued)

Test and Inspection Matrix

Test Group Name

Test or Inspection to

Perform

External Paddles/Pads If readings are as expected:

• Source

(Normal Condition) - ggg

• Source (Single Fault

Condition) - hhh

• With Mains on applied part

(Single Fault Condition) - iii

Internal Paddles If readings are as expected:

• Source

(Normal Condition) - jj

• Source

(Single Fault Condition) kk

• With Mains on applied part

(Single Fault Condition) - lll

Expected Test Results

<

100 uA

<

500 uA

<

5000 uA

then External Paddles/Pads

Safety test passes

<

10 uA

<

50 uA

<

100 uA

then Internal Paddles/Pads

Safety test passes

Data to Record

x = p (pass) or f(fail)

2

Note: When recording test results, separate results within a test by slashes; separate tests by a semicolon (;); and

use no empty spaces. For example:

V:x;F:x;X:x;U:x;E:x;P:x;

DA:x;DB:x;D:x;

S1:P/aaa/bbbb;S3:P/aa/bb/cc/dd/ee/ff/ggg/hhh/iii/jj/kk/lll

V:p;F:p;X:p;U:p;E:p;P:p;

DA:p;DB:p;D:p;

S1:P/125/800; S3:P/9/49/49/10/50/50/100/499/4750/9/49/83

M4735A Service Manual 2-9

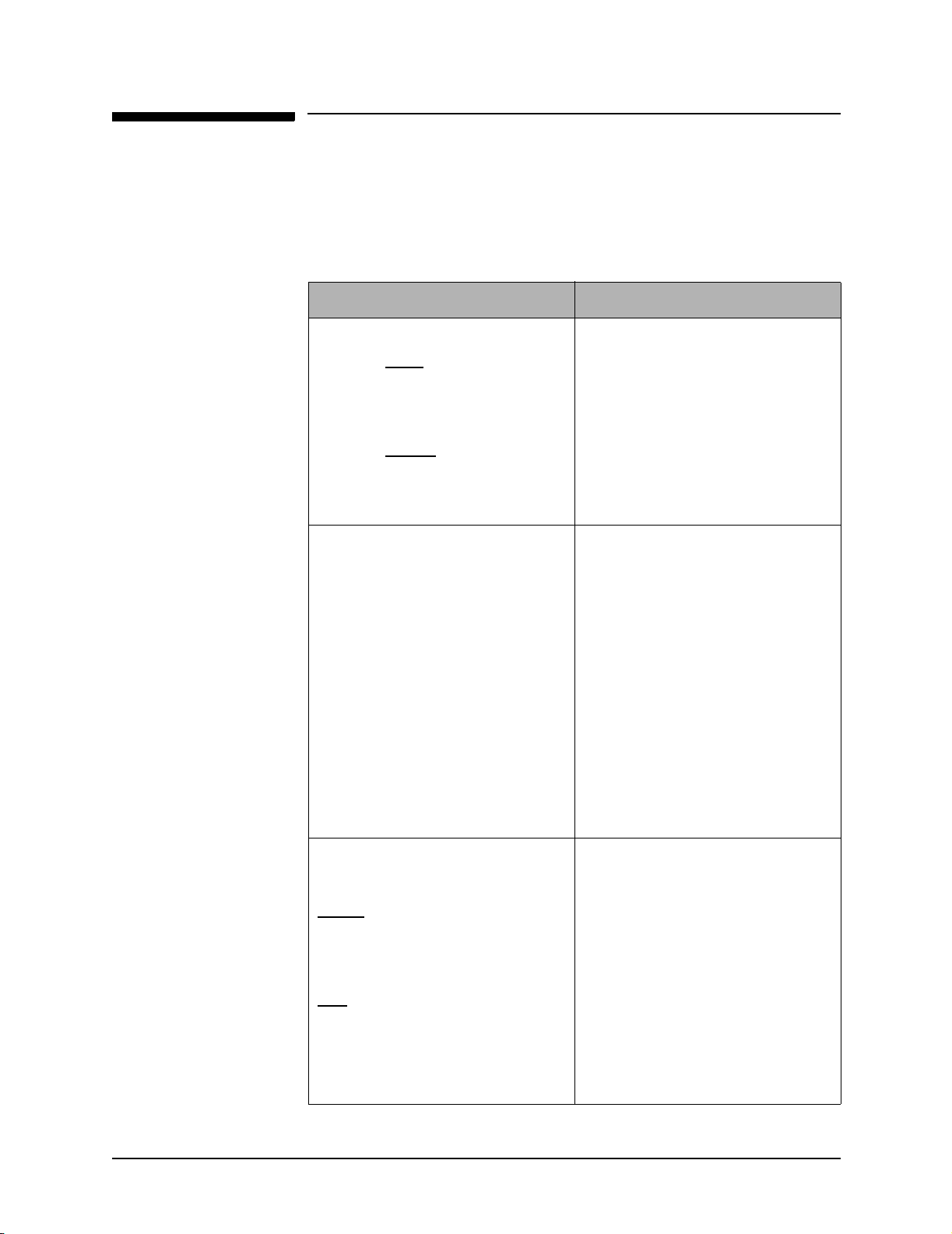

Test Equipment

Test Equipment

Table 2-2 lists the equipment needed to perform the Performance Verification

tests, and provides specifications for commercially available analyzers and

simulators. Test equipment is called out within each test procedure when

needed. In addition, A 50 ohm test load is available (M1781A or M3725A).

Table 2-2 Equipment List

Equipment/Test Specifications

ECG Simulator

Calibrated Leads

• Amplitude accuracy ±2%

• Rate accuracy ±2%

Calibrated Paddles

• Amplitude accuracy ±2%

• Rate accuracy ±2%

Defibrillator Analyzer

Waveform compatibility Meets all specs below using biphasic

Load resistance: 50 Ω ±1% (non-inductive)

Maximum energy: ≥ 200 joules

Maximum voltage: ≥ 2500 V

Maximum current: ≥50 A

Measurement accuracy:

• ≥ 20 joules: ≤ ±2% of reading

• < 20 joules: ≤ ±0.4 joules

ECG simulator

ECG simulator

truncated exponential waveform.

Cardioversion measurement range: –150 to +150 ms

Pacer tester

Load impedance: ≤400 Ω

Current

measurement accuracy

• 10 mA–50 mA: <±2 mA

• 50 mA–200 mA: <±4%

Rate

measurement accuracy

• 30–180 ppm: <±0.5%

Waveform duration accuracy:

• 30–180 ppm: ±1ms

2-10 Performance Verification and Safety Tests

Configuration and Diagnostic Modes

Configuration and Diagnostic Modes

The instructions below describe how to enter Configuration Mode and

Diagnostic Mode.

Configuration Mode

These instructions describe briefly how to use Configuration Mode. See the

Instructions for Use for details on configuration settings and what effect they

have.

CAUTION Inserting or removing the Data Card while the unit is on can corrupt the Data

Card and prevent the unit from powering on again. If this occurs, see Chapter

3, Troubleshooting.

1. Power off.

Make sure the unit’s power is off.

2. Insert a Data Card (if applicable).

If you intend to save the configuration to a Data Card (or load the

configuration from a Data Card), insert the Data Card now. To avoid

possible confusion, designate one Data Card as the “Configuration Card”

and label it clearly. Keep this card physically separate from cards used by

the clinical staff for data storage.

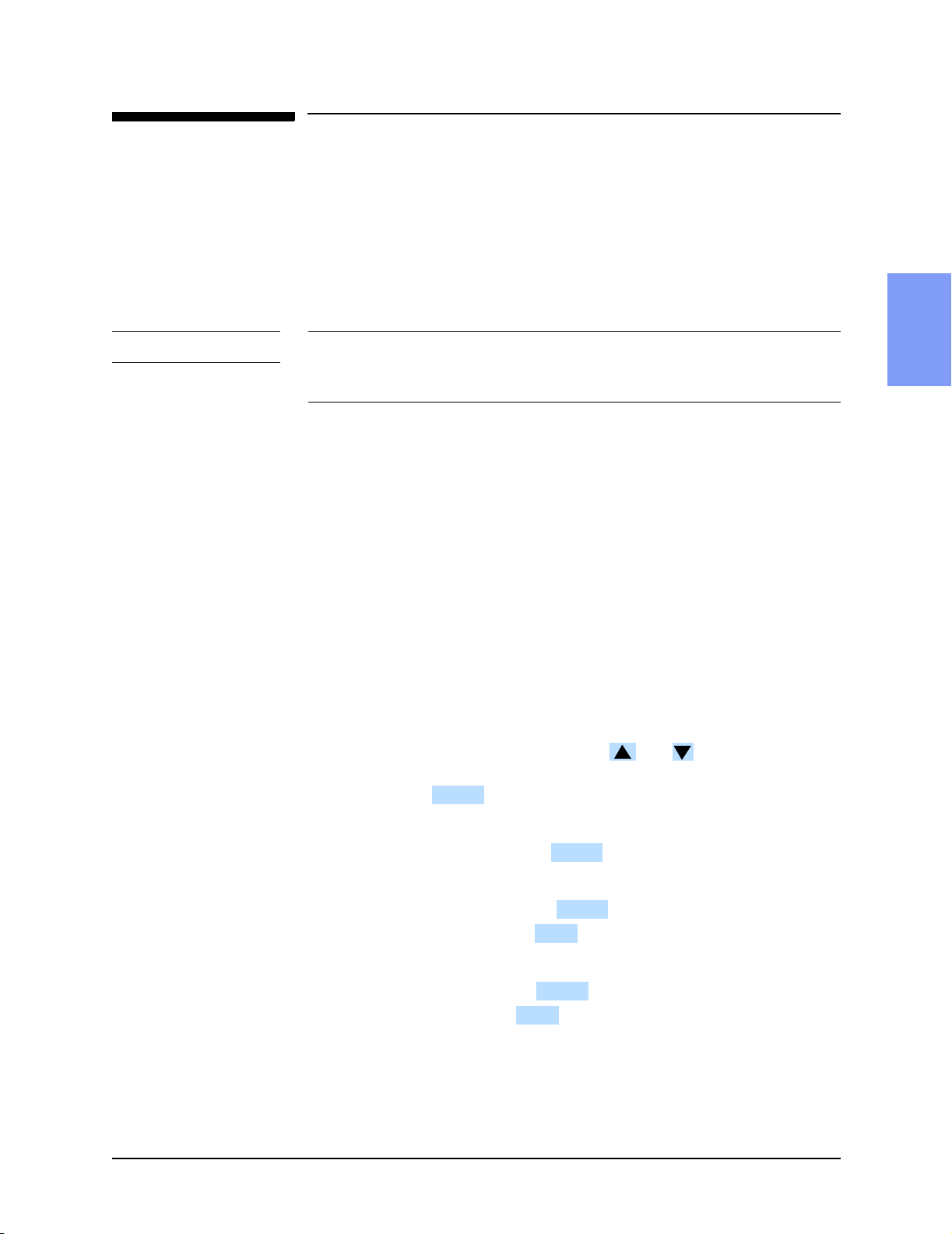

3. Enter Configuration Mode.

Press softkeys 4 and 5 at the same time, and hold them down while

turning the power on. See Figure 2-1 for softkey numbering.

4. Select and manage Configuration choices.

z To select a configuration, press the and softkeys to move up

or down the list until the desired Settings item is highlighted. Then

press the softkey to access those settings.

ENTER

2

z To print out a strip with all the current configuration choices, select

Print All Settings and press .

z To store the configuration settings on a Data Card, select Save Set-

tings to Data Card and press . When prompted with Save Settings to Data Card? press .

z To load configuration settings from a Data Card, select Load Settings

from Data Card and press . When prompted with Load Settings

from Data Card? press .

M4735A Service Manual 2-11

ENTER

ENTER

SAVE

ENTER

LOAD

Configuration and Diagnostic Modes

5. Exit Configuration Mode.

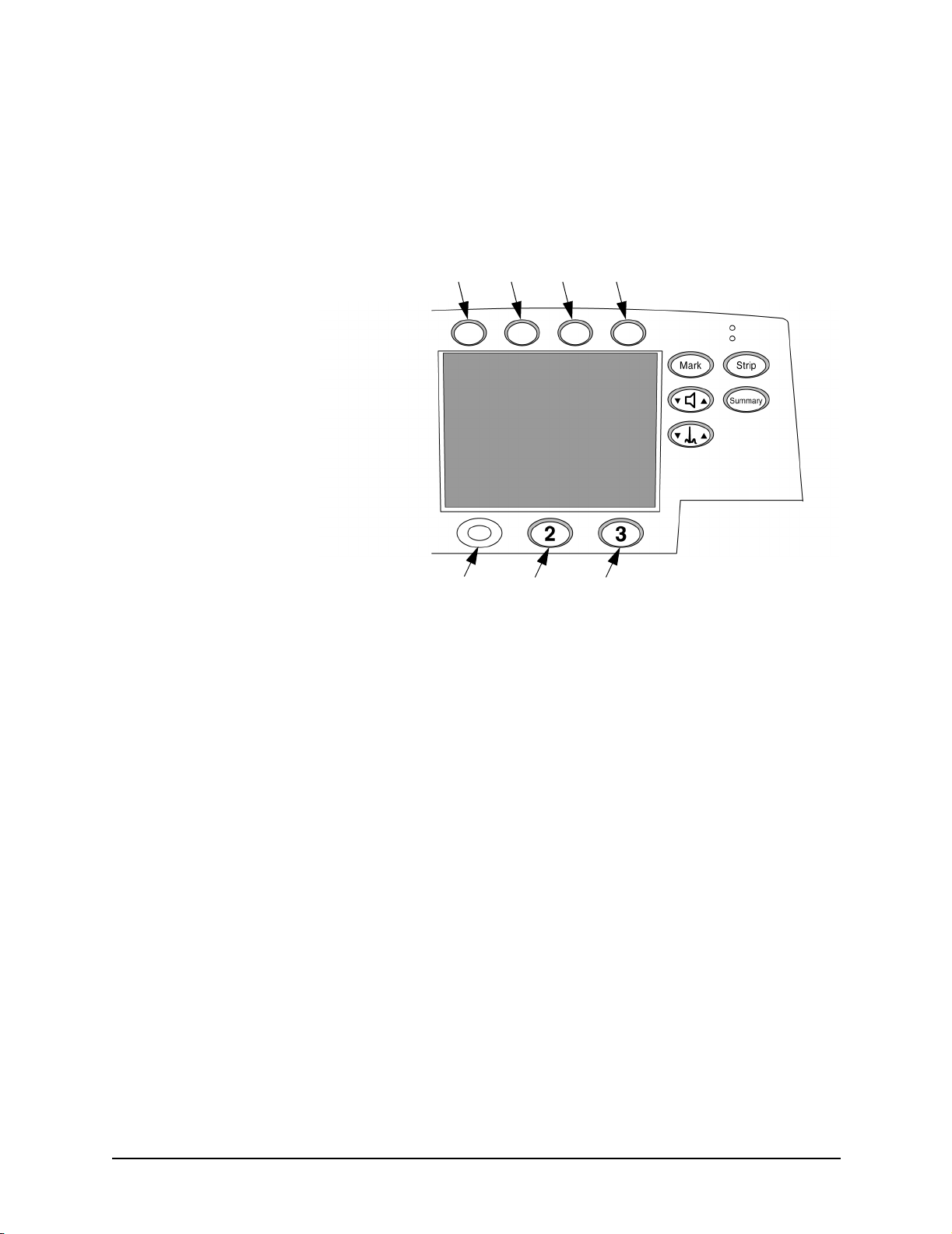

Figure 2-1 Softkey Numbers

z To exit Configuration Mode, turn the unit off.

z Wait 2 seconds. Remove the Data Card by pressing the black eject

button and pulling the Data Card from the compartment.

4567

123

Diagnostic Mode

These instructions describe how to enter Diagnostic Mode. Once in

Diagnostic Mode, you can do the following:

z Print the System Log. See "System Log" on page 2-23.

z Run the Extended Self Test. See "Extended Self Test" on page 2-25.

z Run other Diagnostic Tests. See "Diagnostic Tests" on page 2-22.

1. Power off.

Make sure the unit’s power is off.

2. Enter Diagnostic Mode.

Press softkeys 4 and 6 at the same time, and hold them down while

turning the Energy Select Switch to Manual On. (See Figure 2-1 for

softkey numbering.)

3. Wait for the unit to initialize.

This may take several seconds. The unit is ready to proceed when the

screen cursor responds to softkey inputs.

2-12 Performance Verification and Safety Tests

The Language Support Tool

4. Select the desired test or function.

To select a test, press the and softkeys to move up or down the

list until the desired test is highlighted. Then press the softkey to

ENTER

start that test.

5. Exit Diagnostic Mode.

To exit Diagnostic Mode, turn the unit off.

The Language Support Tool

The Language Support Tool allows field service personnel to perform several

tasks:1) to set the language of the Control PCA of the defibrillator; 2) to

enable the SpO

to be performed under the following circumstances:

z The Control PCA has been replaced.

The Control PCA contains all the operating software, configured

for the installed hardware. It also contains the unit’s serial number,

which was assigned and programmed during manufacturing.

The new Control PCA must be programmed to recognize the

hardware installed in this unit, to contain that unit’s

serial number, and to set the language of the unit.

z The unit has received an upgrade adding the SpO

The added hardware will not be automatically recognized. The

Control PCA must be programmed to recognize the new hardware

installed.

z The unit’s software is being updated.

Software upgrades are periodically released to resolve customer

issues. The Language Support tool enables you to load new software

onto the unit.

option; 3) to program in the serial number. These tasks need

2

capability.

2

2

Using the Language Support Tool

1. Save the configuration to a Data Card.

a. Make sure the unit is powered off, and have either a fresh battery

installed or the AC power cord plugged in.

b. Follow the instructions in "Configuration Mode" on page 2-11 to save

the configuration to a Data Card.

M4735A Service Manual 2-13

The Language Support Tool

2. Activate the Language Support Tool

a. Insert the Language Support Tool data card into the unit.

b. Press softkey 7 and Mark at the same time, and hold them down while

turning the Energy Select Switch to Manual On. (See Figure 2-1 for

softkey numbering.)

3. Follow the screen prompts.

a. Press YES to continue.

The message "Upgrade software found Proceed to Program?" is displayed.

b. Press Yes to set the unit’s language. Do not press any keys or touch

the unit until the process is complete.

c. Select whether SpO

d. Program in the unit’s serial number.

z If this is an SpO

hardware is installed or not as appropriate.

2

upgrade, the serial number should already be

2

present. In this case, verify it against the factory-applied label on

the bottom of the case.

z If this is a Control PCA replacement, program in the serial num-

ber found on the factory-applied label on the bottom of the case

using the softkeys as instructed on the screen. Be sure to program

it in accurately, as the serial number is used for all repair history

tracking.

e. Check all the displayed information carefully before proceeding.

z If the displayed information is correct, follow the screen prompts

to save the configuration.

z If any of the information is incorrect, follow the prompts to NOT

save the configuration, then start over by powering the unit off,

then back on.

4. Turn off the power. Wait 2 seconds. Remove the Data Card by press-

ing the black eject button and pulling the card from the compartment.

5. Check the customer configuration.

a. Turn the unit back on and enter Configuration Mode (see

"Configuration Mode" on page 2-11).

b. Print the configuration and check it against the printout from before

the servicing began. Reset the configuration (or load it from a Data

Card) as needed.

6. Verify performance.

Perform Performance Verification Testing as described in "Performance

Verification and Safety Tests" starting on page 2-1.

2-14 Performance Verification and Safety Tests

Loading...

Loading...