Page 1

Micro Audio Jukebox HDD084/HDD085/HDD082/HDD086

A

All Versions

Service Manual

©Copyright 2005 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

ll rights reserved. No part of this publication may by reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronics,

mechanical, photocopying, or otherwise without the prior permission of Philips

TABLE OF CONTENTS

Chapter

Technical Specification and Service hints.…………………1

Safety Instructions………………………………………………2

Instructions for Use……………………………………………. 3

Mechanical Instructions………………………………………. 4

Exploded view and Service parts list…………………...….. 5

Factory Service Mode testing………………………………… 6

Overall Block diagram…………………………………………. 7

Overall Electrical diagram……………………………………. 8

Component layout……………………………………………… 9

Revision list………………………………………………………10

3141 785 30487

Version 1.7

Page 2

1.0 TECHNICAL SPECIFICATION and SERVICE HINTS

General

Dimensions (WxLx H) : 53 x 86 x 16.7 mm (2.1 x 3.4 x

Weight : 78 g (2.8 oz)

Output power : 2 x 5 mW

Frequency response : 20-20 000 Hz

Equalizer : 5 band DSP controlled

Hard disk : 1,0” micro HDD

Capacity : 3GB

Display : Black/White

Backlight : White Led

Battery : 640 mAh Li-ion internal

Battery life time: >9hr

File transfer rate using

USB :

Battery charging current 320 -420mA

Maximum charging time : 4hrs

0.7 inches)

(16 ohm)

: 96 x 64 pixels

rechargeable battery

800kbyte/s

Battery cutoff voltage: 3.4V

Connections: Stereo headphone

Mini USB (B-type)

DC charger input

Battery level detection

Detection Level Typ.

4-step to 3-step voltage 3.95V

3-step to 2-step voltage 3,8V

2-step to 1-step voltage 3,7V

Force Power Off voltage 3,4V

Current consumption

DC-IN SUPPLY (3.8V)

Battery Charging Current 370mA typ.

BATT. SUPPLY (3.4V)

Power Off <15uA

Idle with LCD Backlight on 55mA

Playback without HDD reading 45mA

Playback with HDD reading 350mA

File transfer using USB1.1 350mA

Headphone out (headphone output load 2x16 ohm)

Maximum output power : 1mW

Frequency response : 20Hz - 20kHz

SNR (A-wght) :

THD (1kHz) : 0,5% - 1.0%

Left-Right Channel

Separation :

Left-Right Channel

Balance :

>75 dB

40dB typ.

0,5dB

Supported playback format

MP3 :

8 - 320 Kbps and VBR

WMA : 32 - 192 Kbps

Sample rates : 8, 11.025, 16, 22.050

32, 44.1, 48

ID3-tag support : Yes

PC Connectivity : USB

File Transfer

For HDD084

via Windows Media Player 9 or 10 for music playback

or Windows Explorer for general data (music playback

disabled)

For HDD082/HDD085/HDD086

via Windows Media Player 10 for music playback or

Windows Explorer for general data (music playback

disabled)

Firmware and software upgrades

For HDD084

1. Download the latest version of the Device

Manager application from

http://www.philips.com/support. You may need to

enter your language preference and the model

number e.g.hdd084, to access the Device

Manager application upgrade file.

2. Double click the downloaded execution file to start

the installation of the Device Manager.

3. Once the installation is completed, connect the

GoGear to the power supply with the AC/DC

adapter.

4. Launch the Device Manager at Start->Programs-

>Philips GoGear HDD->Philips GoGear HDD on

your PC

5. A dialogue box will pop up; click Upgrade to start

the upgrading of the firmware. (Please do not

disconnect the jukebox during the upgrading

process as this interruption may damage the

firmware!)

6. Follow all screen instructions to complete the

firmware upgrade.

7. The Device Manag er will close automatically once

the success message is displayed. Close all

opened application and then safely remove your

GoGear micro jukebox by clicking on the

in your task tray bar. When prompted, “The USB

Mass Storage Device can now be safely removed

from the system”, click OK and unplug your micro

jukebox.

icon

Page 3

1.0 TECHNICAL SPECIFICATION and SERVICE HINTS

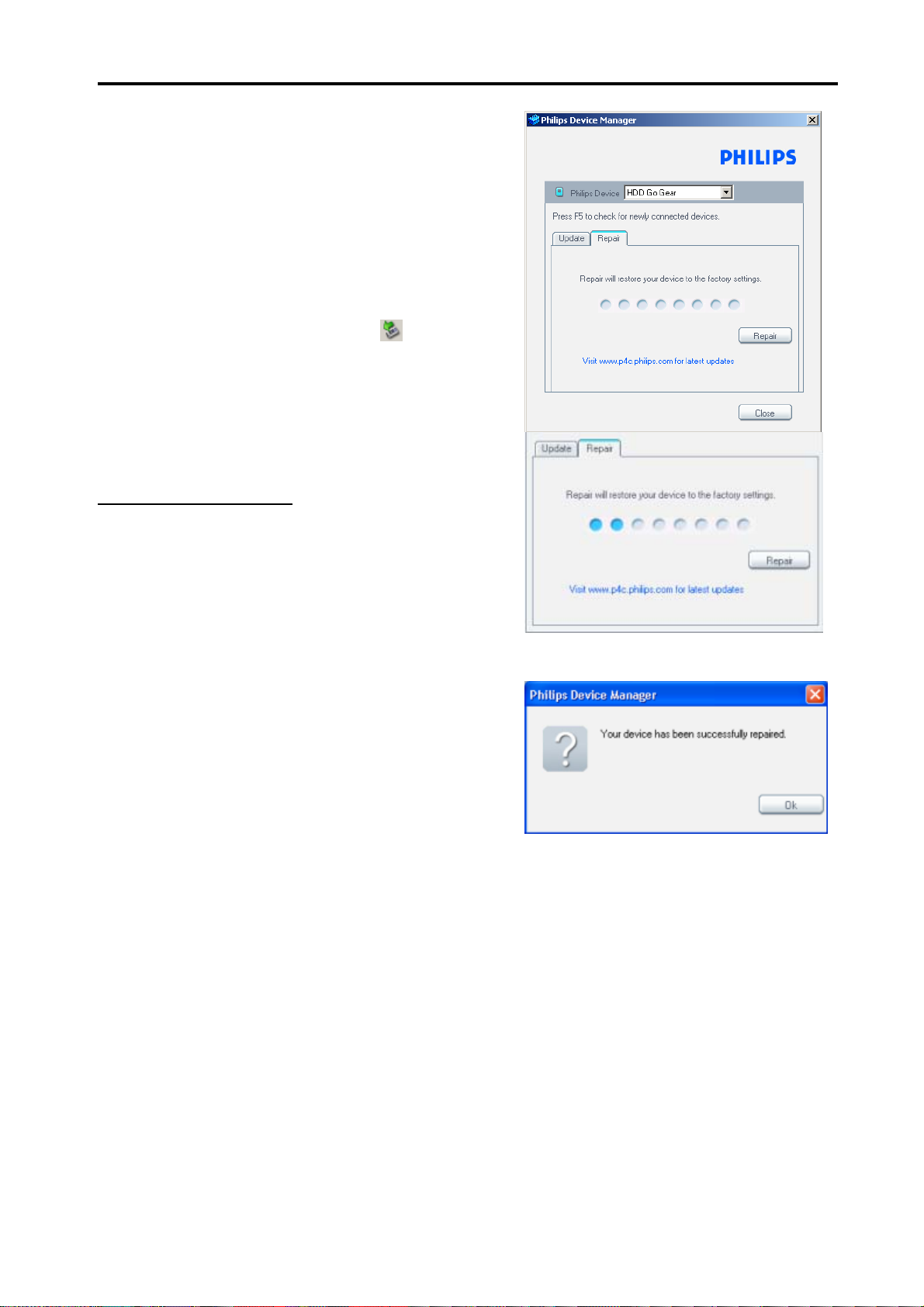

8. Once the GoGear micro jukebox is disc onnected

from the computer, the display will show “Firmware

Upgrading” for a couple of seconds and then start

up as usual. If the message does not disappear

after 2 minutes, do a soft reset by pressing and

holding the key and the volume + key for a

couple of seconds.

For HDD085/HDD082

1. Download the latest version of the Device

Manager application from

http://www.philips.com/support. You may need to

enter your language preference and the model

number e.g. hdd085, to access the Device

Manager application upgrade file.

2. Double click the downloaded execution file to start

the installation of the Device Manager.

3. Connect the GoGear to the power supply with the

AC/DC adapter and to the computer with the

provided USB cable. Make sure that Windows

Media Player along with any other applications are

closed.

4. Launch the Philips Device Manager by double

clicking the Device Manager icon at the task bar

on your computer.

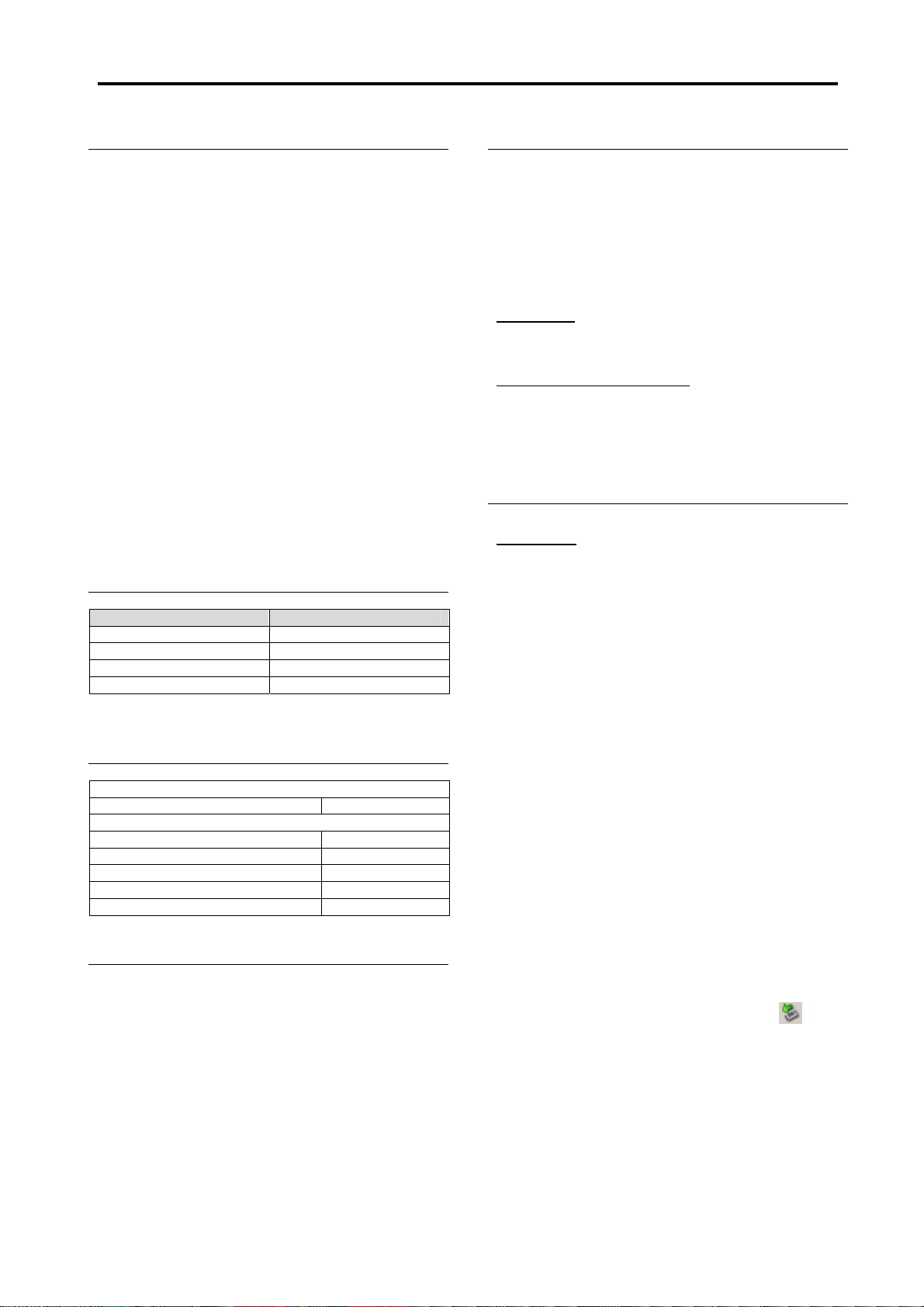

5. The Philips Device Manager will detect the

connection of your GoGear and the application will

automatically check on the server to see if an

update is available and prompt user to download

the updated firmware. Click YES to start the

downloading.

7. The application will show the status of updating

and at the end you need to click OK to complete

the update. (Please do not disconnect the jukebox

during the upgrading process as this interruption

may damage the firmware!)

6. A status bar will show the downloading pro gress of

the firmware. Once the downloading is complete

the application will prompt you to install the update

onto your GoGear. Click YES to confirm

8. Once the success message is displayed. Close

Device Manager and all opened application and

unplug your GoGear.

Service Hints

Rebuild database & firmware after

replacement of hard disk drive

IMPORTANT: All devices having the hard disk

replaced must have the firmware image & database

rebuilt before returning to customers.

After the replacement of hard disk the database and

firmware image must be rebuilt in the device with

device manager by following the procedure below.

For HDD084

1. Connect the GoGear to the po wer supply with the

Page 4

1.0 TECHNICAL SPECIFICATION and SERVICE HINTS

AC/DC adapter and to the computer with the

provided USB cable.

2. Launch the Device Manager at Start->Programs-

>Philips GoGear HDD->Philips GoGear HDD on

your PC

A dialogue box will pop up; click Restore and OK

to confirm and start restoring the unit to its factory

setting.

3. Follow all screen instructions to complete the

restoration.

4. The Device Manag er will close automatically once

the success message is displayed. Close all

opened application and then safely remove your

GoGear micro jukebox by clicking on the

in your task tray bar. When prompted, “The USB

Mass Storage Device can now be safely removed

from the system”, click OK and unplug your micro

jukebox.

5. Once the GoGear micro jukebox is disc onnected

from the computer, the display will show “Firmware

Upgrading” for a couple of seconds and then start

up as usual.

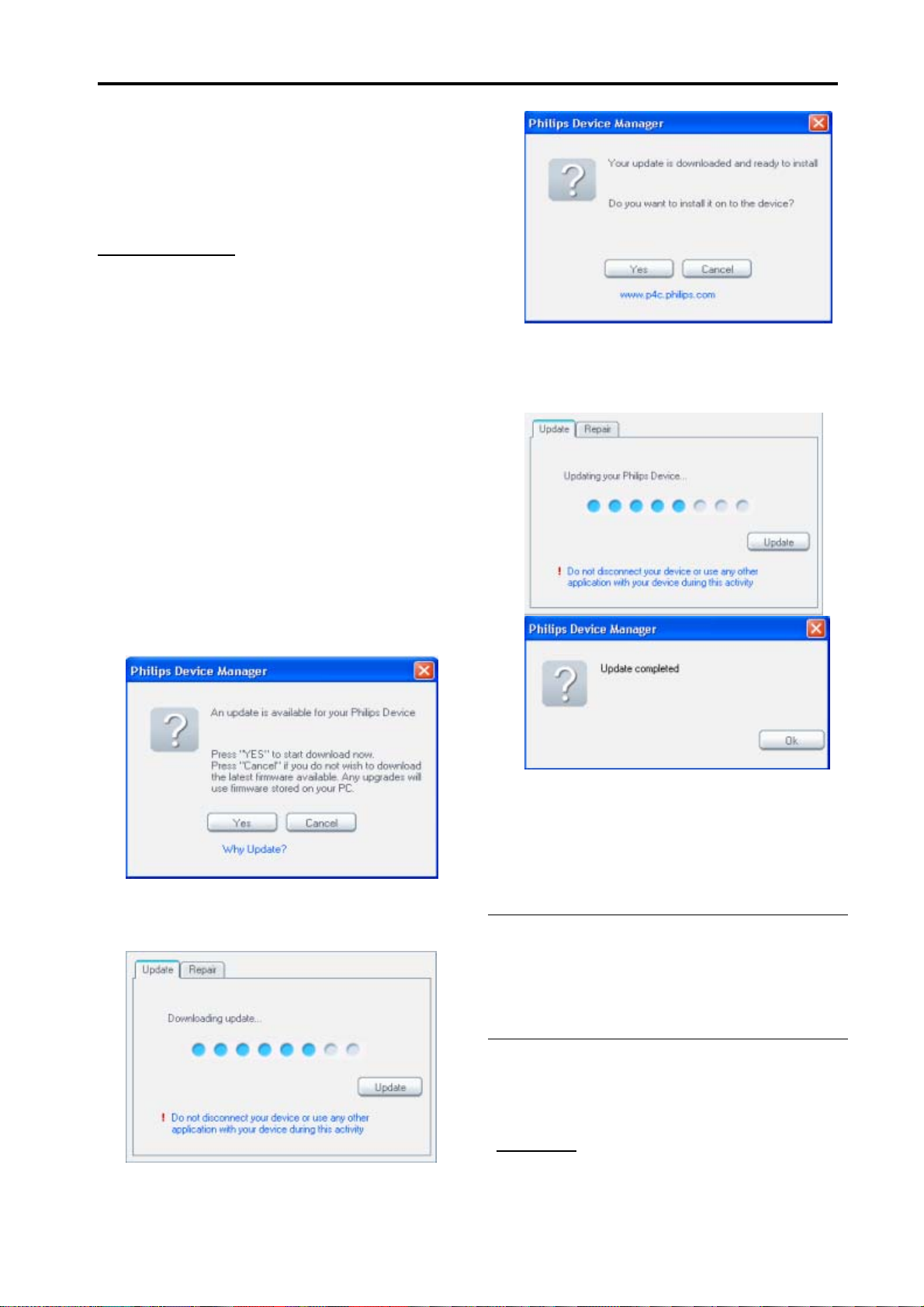

For HDD086/HDD085/HDD082

1. Download the latest version of the Device

Manager application from

http://www.philips.com/support. You may need to

enter your language preference and the model

number e.g.hdd085, to access the Device

Manager application upgrade file.

2. Double click the downloaded execution file to start

the installation of the Device Manager.

3. Connect the GoGear to the po wer supply with the

AC/DC adapter and to the computer with the

provided USB cable. Make sure that Windows

Media Player along with any other applications are

closed.

4. Launch the Philips Device Manag er by double

clicking the Device Manager icon at the task bar

on your computer.

5. Select the REPAIR tab on the dialogue box and

then click Repair to start repairing.

IMPORTANT: All music & content of your micro

jukebox will be erased once the GoGear is

repaired.

icon

6. Once the repair is complete a dialogue b ox will

pop up; click OK and unplug the GoGear from the

computer.

Page 5

1.0 TECHNICAL SPECIFICATION and SERVICE HINTS

Capture the log file from device

1. Switch on the device in FSM mode b y pr essing

and holding the Rec key and then the power

key together.

2. Device will s witch on an d FSM main menu will

be displayed

3. Scroll Down using the key to item 14 HDDinit

4. Press the key, HDD will be initialized, wait till

HDD is initialized, you will get HDD INIT OK

message once initialization is complete

5. Press to display main menu

6. Scroll down using the key to Item 19 Log to

File, press thekey.

7. Wait till writing is completed you will get a

message, writing done

8. Connect USB to device, you will se e a file

LOGINFO.TXT in the root, this is device log

file, size will be around 3KB, copy the file

9. You will also see the pcloginfo.bin in the audio

folder this is the PC log file.

10. Copy both of the above files to PC for future

analysis by the Business if needed.

If the HDD failed the HDDInit test then the device

log may only be read off the LCD display with the

Log to LCD option by following the steps below:

1.

In the FSM main menu scroll down and

select Log to LCD.

2.

Press the key and then when prompted

to “Press RIGHT KEY” message on

display, press the key again you will see

5 parameters at a time on the display and

then press again to see the next 5

parameters.

Page 6

1.0 TECHNICAL SPECIFICATION and SERVICE HINTS

Recovery procedure for flash

corrupt problem

If the device cannot be powered on but it can be

detected by DFU program (device firmware upgrade

application), it can be recovered by following the

procedure below.

Note: Close all applications e.g. Philips Device

Manager before launch the DFU program. Run this

program by Window XP only.

For HDD084 only (MSC mode device)

1. Connect the DFU USB cable to the device first

and then connect to your PC.

2. Launch the DFU program by unzip the

Symphony.rar file and then double click the

DFUAPP.exe file from Symphony folder.

3. Observe the dialogue box to ensure “DEVICE

IS IN DFU MODE”.

4. Select Download and then click Browse to get

the FWImage.ebn file from your PC.

5. Click Start Download to download the firmware

to the device.

6. The program will stop once the successful

message is display.

7. Disconnect DFU USB cabl e from the device.

8. Connect the device to the PC by normal USB

cable and launch the Philips Device Manager to

repair the device. (Download the latest version

of the Device Manager application from Philips

support website http://www.philips.com/support)

Page 7

1.0 TECHNICAL SPECIFICATION and SERVICE HINTS

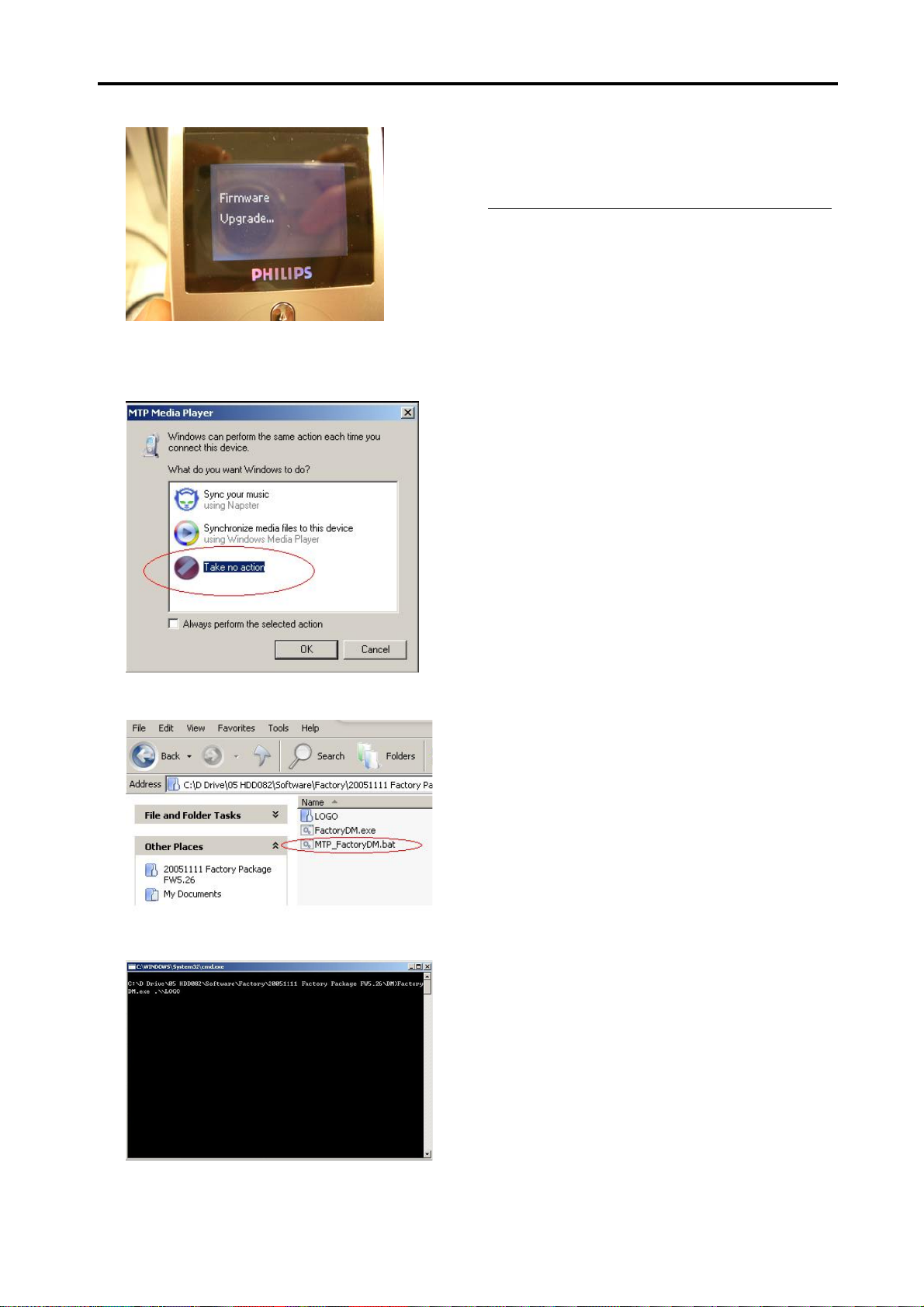

For HDD086/HDD085/HDD082 (MTP mode device)

1. Unzip the Factory.rar file to your PC. You

should find three folder name “Bootloader”,

“DM” & “Drive_I”.

2. Unzip the Setting.rar file and choose the right

deviceinfo.sec file according to the device

model. Then copy this file into

\Drive_I\UnzipToRoot folder to rewrite the

original deviceinfo.sec file.

8. Disconnect DFU USB cabl e from the device.

9. Open the device, displace will show “BOOT

LOADER APPLICATION Version 4.0”.

10. Connect the device with your PC by normal

USB cable.

3. Connect the DFU USB cable to the device first

and then connect to your PC.

4. Launch the DFU program.

5. Observe the dialogue box to ensure “DEVICE

IS IN DFU MODE”.

6. Select Download and then click Browse to get

bootLoader_HDDXXX.ebn file from

Bootloader folder.

11. Run the install_HDD08x.bat file from Drive_I

folder.

12. Follow all screen instructions to complete the

installation.

7. Click Start Download to download the firmware

to the device. The program will stop once the

successful message is display.

13. Safely remove the device from PC by clicking

on the

device is disconnected from the PC, the display

will show “Firmware Upgrade” for a couple of

icon in your task tray bar. Once the

Page 8

1.0 TECHNICAL SPECIFICATION and SERVICE HINTS

seconds and then start up as usual.

14. Connect the device with PC by normal USB

cable again for MTP connection. Select “Take

no action” once the device is detected by the

PC.

MTP mode installation procedure

after replaced the mainboard

Note: Applicable for HDD085/HDD082 only

Repeat the recovery procedure for flash corrupt

problem from step 9 to 16.

15. Run the MTP_FactoryDM.bat from DM folder to

copy all necessary files into the device.

16. Once the installation is completed, below

dialogue box will auto close.

Page 9

WARNING

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

F

ATTENTION

Tous les IC et beaucoup d’autres

semi-conducteurs sont sensibles aux

décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est

prise à leur manipulation.

Lors de réparations, s’assurer de bien être relié

au même potentiel que la masse de l’appareil et

enfiler le bracelet serti d’une résistance de

sécurité.

Veiller à ce que les composants ainsi que les

outils que l’on utilise soient également à ce

potentiel.

2.0 SAFTETY INSTRUCTIONS

ESD

D

WARNUNG

Alle ICs und viele andere Halbleiter sind

empfindlich gegenüber elektrostatischen

Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kan

die Lebensdauer drastisch reduzieren.

Veranlassen Sie, dass Sie im Reparaturfall über

ein Pulsarmband mit Widerstand verbunden

sind mit dem gleichen Potential wie die Masse

des Gerätes.

Bauteile und Hilfsmittel auch auf dieses gleiche

Potential halten.

WAARSCHUWING

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor electrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie kan

de levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

I

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevità potrebbe essere fortemente

ridatta in caso di non osservazione della più

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto

a resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo

potenziale.

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat bij reparatie in

zijn oorspronkelijke toestand wordt teruggebracht en dat onderdelen,

identiek aan de gespecificeerde, worden toegepast.

F

Les normes de sécurité exigent que l’appareil soit remis à l’état

d’origine et que soient utiliséés les piéces de rechange identiques

à celles spécifiées.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu

beachten. Der Original zustand des Geräts darf nicht verändert werden;

für Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso

nelle condizioni originali e che siano utilizzati i pezzi di ricambio

identici a quelli specificati.

“Pour votre sécurité, ces documents

doivent être utilisés par des spécialistes agréés, seuls habilités à réparer

votre appareil en panne”.

CLASS 1

LASER PRODUCT

GB

Warning !

Invisible laser radiation when open.

Avoid direct exposure to beam.

S

Varning !

Osynlig laserstrålning när apparaten är öppnad och spärren

är urkopplad. Betrakta ej strålen.

Varoitus !

SF

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen!

3122 110 03420

"After servicing and before returning set to customer perform a

leakage current measurement test from all exposed metal parts to

earth ground to assure no shock hazard exist. The leakage current

must not exceed 0.5mA."

DK Advarse !

Usynlig laserstråling ved åbning når sikkerhedsafbrydere er

ude af funktion. Undgå udsaettelse for stråling.

Page 10

Overview of controls and connections

3.0 Instructions for use

1 USB cable connector

2 p Headphones jack

3 5V DC Charging socket

4 HOLD slider To disable key press

5 LCD display Dynamically displays menu, options and track information

6 VIEW To switch between root menu, library and now playing screens

7 3 / 4 Scroll; SuperScroll; 3 / 4

J( / § Rewind / Fast forward; Up / Down to 1 level / Skip to previous / next

y 2; Power on / off and Play / Pause; confirms a menu setting

8 Neckstrap eyelet

9 Volume + / - Volume control

0 REC Start or Stop Voice recording

! PLAYLIST Add the current track to My Playlist

@ MIC Microphone

3

Page 11

4.0 MECHANICAL INTRUCTIONS

Set Disassembly

1. Remove the Cosmetic screw with an Allen key

2. Use a s crewdriver to carefully lift up the back cover of

the device.

3. Gently open up the back cover.

4. Remove 4 x screws. See arrows

Page 12

4.0 MECHANICAL INTRUCTIONS

5. Open up and remove the bottom part.

6. Remove the battery pack and then the hard disk

7. Take out the 2 screws on the PCB assembly to replace

it from the casing.

Overview of the disassembly parts

Bottom

parts

Back cover

Mainboard /

LCD

module

Top

assembly /

Key set

Hard

Disk

Battery

Page 13

5.0 EXPLODED VIEW & SERVICE PARTS LIST

111

110

108

109

100

105,106

107

103

102

112

101

MECHANICAL PARTS

100 314017750142 FRONT CAB. ASSY HDD084 SILVER

101 314017750591 COVER-REAR LAQ ASSY HDD084 SIL

102 314017750132 REAR CABINET ASSY HDD084

103 314017870131 BATTERY PACK 610MA H LI POLYMER

105 314017900191

314017900231

314017900261

106 314017900121

314017900121

314017800261

107 314017800131

108 282206200083

282206200083

310420052301

282 206200108 HDD086 – HDD 1.0” 4GB

109 314017400331

314017400651

110 314017750321

111 314017750181

112 314017040031

314017320171

PCBA KIT ASSY HDD084/00/05

PCBA KIT ASSY HDD085/00/05

PCBA KIT ASSY HDD086/00/05

PCBA KIT ASSY HDD084/17

HDD082 serial nr. (NW01_ _ _ _ _ _ _ _) PCBA KIT ASSY*

HDD082 serial nr. (NW00_ _ _ _ _ _ _ _) PCBA KIT ASSY*

PCBA KIT ASSY HDD084/97

HDD084/HDD085 - HDD 1.0"3GB 000936-02(CORN)Y

HDD082 serial nr. (NW01_ _ _ _ _ _ _ _) - HDD 1" 3GB*

HDD082 serial nr. (NW00_ _ _ _ _ _ _ _) - HDD 1” 2GB*

DAMPER HDD084

DAMPER HDD082/HDD086

KEYSET-FRONT-ASSY HDD084

LENS-PRI ASSY HDD084

SCREW HEXAGON HDD084

PLATE-PROTECTION

IMPORTANT:

* Please note that there are 2 different execution of HDD082/17 in the market, that

can be distinguished by the serial number with the change code “00” & “01”

please refer to the above table for different applicable PCBA & HDD

MISCELLENEOUS

908210004736 Headphone SHE775BI/00 (for HDD084/HDD085/HDD082)

908210008773 Headphone SHE2550BI/00 (for HDD086)

314017310091 Neck Strap (not for HDD086)

314017400511 Rubber Sleeve (not for HDD086)

272201200608 MOD SUPP AC-DC /00

272201200609 MOD SUPP AC-DC /05

314017830111 AY4108/17 AC/DC Adaptor /17

242207600755 USB CABLE ASSY

314017870361 CD-ROM HDD086

SERVICE TOOL

824041001931 DFU CABLE

Page 14

6.0 FACTORY SERVICE MODE TESTING

Programming the device using for stand-alone FSM

The following is the description for programming the device in stand-alone

mode.

1. Press & hold “ Rec” and then Press together

2. The FSM/DV T application will start and you will see the following

screen.

3. Navigate to the required test.

Using the FSM integrated with UI

Press UP/DOWN key to browse through available tests. Please note that

this action does not activate the test. Press RIGHT key to activate the test

[which is displayed on the screen]. Within a given test LEFT key always

exits from the test back to the test browse screen [Exceptions are Keypad

test, Remote Keypad Test, where test can be exited by 2 short left key

presses].

The following diagram describes the test flow.

<HDD 084>

<FSM/DVT X.X>

<Week XXX>

DOWN

3

5-Key Remote

Test

DOWN

4

SDRAM Read/

Write Test

DOWN

5

SDRAM Self

Refresh Test

DOWN

UP

UP

UP

6

2

LCD and Back

Light Test

LEFT

UP

RIGHT

RIGHT

HDD Test

RIGHT

Perform LCD and

Back Light Test

Perform 5-Key

Remote T e st

LEFT

RIGHT

Perform SDRAM

LEFT

RIGHT

Perform SDRM Self

refresh Test

LEFT

Perform HDD Test

LEFT

DOWN

UP

DOWN

R/W Test

Device Keypad

LEFT short

press (2 Times)

Perform Audio Test

RIGHT

1

Test

Perform Device

KeyPad Test

LEFT

RIGHT

Perform FM Tuner

Test

RIGHT

Device K e y T e s t

LCD B a ck ligh t T e st

5-key Re mote Key Test

SDRAM Read/W rite Test

SDRAM Self-refresh T e s t

HDD T e st

Audio Te s t

FM Tuner Test

Battery L ev e l T e s t

Battery C h a rg ing T e s t

MIC R ec o rd in g T e s t

Real Tim e C lo ck T e s t

. EEPR OM Test

RIGHT

Perform

EEPROMTest

Perform RTC Test

Perform MIC

RecordingTest

Perform Battery

Charging Test

Perform Battery

Level Test

LEFT

LEFT

RIGHT

RIGHT

LEFT

LEFT

RIGHT

RIGHT

DOWN

EEPROM Test

RTC Test

MIC Recording

DOWN

Charging

LEFT

Battery Level

DOWN

Battery

test

UP

13

UP

DOWN

12

UP

11

UP

10

DOWN

UP

9

7

UP

Audio Test

UP

DOWN

FM Tuner Test

8

Page 15

6.0 FACTORY SERVICE MODE TESTING

Test USAGE Description

Power ON screen

Test Browse Screen

Pressing UP/DOWN keys will display names of test cases that can be

selected following are the test cases that are displayed. The current test

that will be selected by pressing RIGHT key will be as shown below.

Note: scroll bar to indicate the test selected can be used provided the

UI+FSM/DVT FW does not exceed 1 MB.

LCD Backlight

> Device Key

5-key Remote Key

LCD Remote Key

<HDD 084>

<FSM/DVT X.X>

<Week XXX>

1. FSM

2. LCD Test

3. Device Keypad Test

4. 5-key Remote Key

5. SDRAM Read/Write

6. HDD Test

7. Audio Test

8. FM Tuner

9. Battery Level

10. Battery Charging

11. Internal MIC Checking

12. RealTime Clock RTC

13. EEPROM Checking

14. Harddisk HDD Initialization

15. Firmware Upgrade

16. Read Device Information

17. Write Device Information

18. Log to file

19. Log to LCD

20. Write to RTC

1.1.3 LCD Back Light Test

Steps

• Scroll to “LCD Test” using UP / Down Key

• Press RIGHT to enter the test. “ LCD Test” is displayed on the LCD.

• Press RIGHT to see the first bitmap

• To view the next bitmap press RIGHT again.

• 4 bitmaps (TBD) are thus displayed and once all the bitmaps are

displayed, it return to the test browser screen, where a next test can

be selected.

• The LCD test can be exited in between the testing process by

pressing LEFT key.

• Pressing “PLAY/PAUSE” Key will turn ON/OFF the Back Light.

• Pressing UP/DOWN Key The contrast level can be changed in steps

of 1 while displaying the test patterns.

Page 16

6.0 FACTORY SERVICE MODE TESTING

• The Test patterns which will be displayed will be as shown

LCD pattern 1: White screen

LCD pattern 2: Black screen with a white square at right upper corner

LCD pattern 3: Checkerboard pattern

LCD pattern 4: Black background

Page 17

6.0 FACTORY SERVICE MODE TESTING

NOTE: The LCD patterns will changed after the new test patterns are

received because the LCD that will be used with HDD084 is black and

white LCD and cannot display greyscale.

Device Key Test

Steps

• Scroll to “Device KEYPAD Test” using UP / Down Key.

• Press RIGHT to enter the test. “ Keypad Test” is displayed on the LCD.

• Press all keys one by one. Every time a key is pressed, the

corresponding key number is displayed as “KEY x DOWN”.

• After releasing the key, KEY x UP is displayed.

• NOTE THAT 2 SHORT LEFT KEY PRESSES CAN EXIT THIS TEST.

• Note: The ADC value will not be displayed on the LCD.

• Once all keys are pressed the test success screen is displayed.

• The Result is indicated as shown

.

<HDD084 Key Test >

< >

<PLAY/PAUSE Up>

< >

<HDD084 Key Test >

< >

<PLAY/PAUSE Down>

< >

<HDD084 Key Test >

< >

<Test S

uccess >

< >

5-Key Remote Control Keys Test

Steps

• Scroll to “ 5-Key REMOTE Key Test” using UP / Down Key

• Press RIGHT to enter the test. “Remote Key Test” is displayed on the

LCD.

• Press all keys one by one. Every time a key is pressed, the

corresponding key number is displayed as “KEY x DOWN”.

• After releasing the key, KEY x UP is displayed.

• Once all the keys are pressed, the test is exited after a brief delay and

the test browse screen will be entered, where next test can be

selected.

• NOTE THAT LEFT KEY PRESSES CAN EXIT THIS TEST.

• Once all keys are pressed the test success screen is displayed.

• The result is as shown

<HDD084 RemoteKey test >

< >

<RC PLAY Up >

< >

<HDD084 Remote Key Test >

< >

<RC PLAY Down >

< >

<HDD084 Remote Key Test >

< >

<Test S

uccess >

< >

Page 18

6.0 FACTORY SERVICE MODE TESTING

SDRAM Read/Write Test

Steps

• Scroll to “SDRAM Read/Write Test” using UP / Down Key

• Press RIGHT to enter the test.

• The test status and results will be shown on LCD. If the test is

successful, “SDRAM R/W TEST OK” is displayed on the LCD and if

the test fails “SDRAM TEST FAIL” will be displayed on the LCD.

• This test can be exited in between the testing process by pressing

LEFT key.

Verification of SDRAM Read Write Functionality

To Verify SDRAM Read Write Functionality Write a pattern 0x55aa55aa to

a specific location and read back the data to verify the data Integrity.

Verification of SDRAM Self-Refresh Functionality

• To verify the SDRAM self-Refresh functionality, we write a string

of characters to the SDRAM and put the SDRAM in self-refresh

mode for 5 Seconds and Check the data integrity before entering

and after leaving Self-refresh mode without any write action on

SDRAM.

<HDD084 SDRAM >

< Self Refresh Test >

<SDRAM Under Test >

< >

HDD084 SDRAM >

< Self Refresh Test >

<SDRAM Self refresh FAIL >

< >

<HDD084 SDRAM R/W Test >

< >

<SDRAM Under Test >

< >

<HDD084 SDRAM R/W Test >

< >

<SDRAM R/W OK >

< >

SDRAM Self-Refresh Test

Steps

• Scroll to “SDRAM Self Refresh Test” using UP / Down Key

• Press RIGHT to enter the test.

• The test status and results will be shown on LCD. If the test is

successful, “SDRAM self refresh TEST OK” is displayed on the LCD

and if the test fails “SDRAM self refresh FAIL” will be displayed on the

LCD.

• This test can be exited in between the testing process by pressing

LEFT key.

Page 19

6.0 FACTORY SERVICE MODE TESTING

HDD Test

Preconditions

• Connect the device to the PC.

Steps

• Scroll to “HDD Test” using UP / Down Key

• Press RIGHT to enter the test.

• The test status and results will be shown on LCD. If the test is

successful, “HDD TEST OK” is displayed on the LCD and if the test

fails “HDD TEST FAIL” will be displayed on the LCD.

• This test can be exited in between the testing process by pressing

LEFT key.

Verification of HDD Functionality

• After connecting it to the PC.

• Create a file “HDD084.txt”.

• Write a predefined sting of characters such as “A-Z”, ”a-z” and “0-

9”.

• Close the file.

• Open it back and read and verify the contents.

• If the contents are same the test has passed else the test is failed.

<HDD084 HDD >

< >

<HDD Under Test >

< >

<HDD084 HDD >

< >

<HDD Test OK >

< >

FM Tuner Test

Precondition

• Ensure that headphones are connected.

Steps

• Scroll to “Tuner Test” using UP / Down Key

• Press RIGHT to enter the test.

• Initialization of the tuner will be done when test is entered.

• Press UP now to search UP in steps of 50kHz.

• Press DOWN to search DOWN in steps of 50kHz.

• Use FUNC1 Key to select manual or auto search mode.

• Whenever a station is found, the frequency and Signal strength are

displayed on the LCD.

• Press PLAY/PAUSE Key to set Stereo Mode. (TBC)

• Press PLAY/PAUSE key to set Mono Mode. (TBC)

• FM recording Test can be performed along with the tuner test as

mentioned in 4.1.14.

• Press LEFT to exit the test, tuner will be disabled and the test browse

screen will be entered where a next test can be selected.

<HDD084 FM TUNER TEST>

< F106.50 S3 >

<MODE STEREO/MONO >

< >

Page 20

6.0 FACTORY SERVICE MODE TESTING

Battery Level Test

Steps

• Scroll to “Battery Test” using UP / Down Key

• Press RIGHT to enter the test.

• Battery level is displayed on the screen in Volts

• Battery Level will be refreshed regularly every 1 sec.

• If the battery level is lesser than 2.8 V a “LOW BATTERY” warning

will be flashed on the LCD for 10 seconds and the device goes to

shutdown mode (TBD).

• Press LEFT key to exit the test.

• Note this test should be done without initialising the HDD.

<HDD084 BATTERY LEVEL TEST>

< X.XXXV >

<CAL.STATUS >

< >

Battery Charging Test

Steps

• Scroll to “Battery Charging test” using UP / Down Key

• Press RIGHT to enter the test

• Press LEFT to exit the test

• The charging current is updated every 1 seconds

• If charging current is less than 20mA, battery is not in the charging

status.

• The following tale indicates the charge current for different states

CHG_STATUS

(GPA4)

CHG_CURRENT INDICATION ON

THE LCD

H X Charge Up

L <20mA Charge Up

L > = 20mA Charging

• The Following information is displayed on the LCD.

NON-USB CHARGING MODE

<HDD084 BATTERY CHARGING TEST>

< X.XXXV YYY.YmA >

<CHG.STATUS >

< Adaptor STATUS >

>

USB CHARGING MODE

If the USB connection is made the system will startup in the low power

mode (trickle charging – <100mA include system current) and after the

enumeration process, SW can decide whether high power mode can be

switched on for a fast charging - <500mA include system current.

<HDD084 BATTERY CHARGING TEST>

< X.XXXV YYY.YmA >

<CHG.STATUS >

< USB STATUS >

>

Page 21

6.0 FACTORY SERVICE MODE TESTING

• The battery level will be refreshed regularly every 1 second.

MIC Recording Test

• The recoded file can be verified in “AUDIO TEST CASE” (4.1.9)

• Press LEFT to exit the test.

Steps

• Connect a microphone.

• Scroll to “MIC Recording Test” using UP / Down Key

• Press RIGHT to enter the test.

• Press REC key to start the recording .The recorded file will be

“MICREC.MP3”.

• The recoded file can be verified in “AUDIO TEST CASE” (4.1.9)

• Press LEFT to exit the test

FM Recording Test

Steps

• This test will be done during the tuner test and is not a separate test

• Initialise the Tuner.

• Search the desired station using UP/DOWN Key.

• Press REC key to start the recording .The recorded file will be

<HDD084 MIC RECORDING >

< >

<REC ON >

< >

case .

“FMREC.MP3”.

<HDD084 FM RECORDING >

< F106.50 S3 >

<STEREO >

< REC ON >

Real Time Clock Test

Steps

• Scroll to “Real Time Clock Test” using UP / Down Key

• Press RIGHT to enter the test. “

• If the test is successful “RTC TEST OK” is shown on LCD, if the Test

fails “RTC TEST FAIL” is shown on the LCD.

• Press LEFT to exit the test.

.

Verification of RTC

• When user selected the RTC test, Software will write a pre-defined

register value to the RTC.

• After 1 second, Software will read back the RTC register value

and check if the RTC date is correct and clock is incremented by 1

second.

• If the test is successful, “RTC TEST OK” is shown on the LCD

display, if test fails “RTC FAIL” is shown on the LCD display.

.

Page 22

6.0 FACTORY SERVICE MODE TESTING

<HDD084 EXTERNAL RTC >

< >

<RTC under Test >

< >

EEPROM Test

Steps

• Scroll to “EEPROM test “using UP / Down Key

• Press RIGHT to enter the test. “

• If the test is successful “EEPROM TEST OK” is shown on LCD, if the

test fails “EEPROM TEST FAIL” is shown on the LCD.

• Press LEFT to exit the test.

Verification of EEPROM Functionality

To Verify EEPROM Functionality Write a pattern 0x55aa55aa to a specific

location and read back the data to verify the data Integrity, repeat the

write/read test by pattern 0xaa55aa55.

<HDD084 EXTERNAL RTC >

< >

<RTC Test Ok >

< >

Steps

Powering Off

• Pressing play key for longer than 2 seconds causes system power off.

• Release the PLAY key once “OFF” is displayed in the LCD. Note that

system is shutdown only after release of PLAY key.

• System can be powered off while any test case is being executed.

• System can again be powered on by pressing play key and holding for

2 seconds

< HDD084 >

< >

< POWER OFF >

< >

Appendix I

Firmware Upgrade

Steps

<HDD084 EEPROM TEST >

< >

<EEPROM under Test

>

< >

<HDD084 EEPROM TEST >

< >

<EEPROM Test Ok

>

< >

• Select the test and press right key to enter the test

• Firmware upgrade can be done by copying a hdd084_FSM.ebn

file from a specified directory I.e. “_system” on HDD

• The device copies the firmware image into the device

NOTE: this test should be done after initializing the HDD

Page 23

6.0 FACTORY SERVICE MODE TESTING

HDD initialisation

Steps

• Select the test and press right key to enter the test

• Initialize the HDD

Page 24

7.0 OVERALL BLOCK DIAGRAM

Cornice

3GB Hard Disk

HDD Connector

Cornice

TIC

HDD084 BLOCK DIAGRAM

(V1.2)

(2005-05-09)

Analog keys

on the 5-key Remote

SDRAM

Analog Keys on the

Device

USB Mini-B Socket

USB_SUSPEND

USB_HIGH_PWR

CHG_STATUS

BATT_LOW_N

Power On

PWR_ACK

logic

PMU

LTC3455

AC/DC Input Jack

Reverse +

Overvoltage

protection

Constant

Current

Source

1 Cell Li-polymer

Battery

Battery Connector

MultiICE connector

+ mode selection

switches

Symphony

UART

JTAG

GPIO

LCD_BL_CTRL

LCD Interface

LCD Connector

LCM

96x64

B/W

12MHz

sysclock

EEPROM

M24C08

RTC

32KHz

RTCclock

Memory Bus GPA

Symphony

PNX0102

interface

RTC_OUT

I2C

LNA

MIC

amplifier

MIC

FM tuner

Line In

Line Out

FM_ANT

USB2.0

Headphone

Out

Headphone

connector

High

Speed

GPIO

GPA

Reset

1V8 3V1

BAT_LEVEL

CHG_CURRENT

Reset

logic

VBacklight

LDO

3V0_A

EXTERNAL DEVICES

HDD084 Only, not for

3V0_RF

LEGEND

BOARD

COMPONENTS

CONNECTORS

PSA610

LDO

Page 25

1 2415

8.0 ELECTRICAL DIAGRAM

2 3

4

5 23

6

7

8 9

10

11 19

12 16

13

14

17

20

2118

22

25 28

26

27

A

1300 F2

1400 J5

1401 F6

B

1402 D6

1403 D11

1404 I8

1405 K1

1406 J20

C

D

A

E

B

F

C

G

D

H

I

E

J

F

K

G

L

H

M

N

I

O

J

P

is prohibited without the written consent of the copyright

All rights reserved. Reproduction in whole or in parts

owner.

K

Q

L

1407 J18

1408 C4

1409 A4

1411 C5

1412 D6

1413 E3

1414 E4

1415 E4

KEY_UP

KEY_PLAY

FM_ANT

RXD

RTC_INT

IIC_SCL

IIC_SDA

1416 E5

1417 C4

1419 A14

2300 F6

2301 G6

2302 G3

2303 G4

2304 G5

2305 G6

2306 G4

2307 G3

2308 G4

2400 L6

2401 B8

2402 C7

2403 E7

2404 D11

2405 D11

2406 E8

2407 F9

2408 F9

2409 F8

2410 F8

2412 C12

2413 E11

2414 B12

2415 B12

2416 B13

2418 B13

2419 B13

2420 B14

2421 B14

2422 B14

2423 B14

2424 G7

2425 G7

2426 G9

2427 G9

2428 H7

2429 H8

2430 G8

2431 H8

2432 J3

2433 J1

2434 K1

2435 B18

2436 B18

2437 B18

2438 B18

2439 B19

2440 B19

2441 B19

2442 J15

2443 H20

2444 K15

2446 F11

2447 K15

2451 C4

2452 C4

2456 L7

2457 C5

2459 C5

2461 C6

2470 L7

2471 L6

2472 L7

2473 L6

2474 L7

2475 L6

2476 A13

2477 A15

2478 A15

2479 A16

2480 A17

2481 K6

2482 K6

2483 L6

2484 K17

2486 C7

2493 E3

2494 D4

2495 D4

2496 D5

2497 D6

2498 D7

2499 L6

3300 F5

3301 G5

3302 G6

3303 G6

3304 F4

3305 F5

3306 G5

3401 B7

3402 D7

3403 H14

3404 E9

3405 F8

3406 C12

3407 G7

3408 I17

3410 F7

3411 F7

3412 H1

3413 H1

3414 H2

3415 H2

3416 I2

3417 I10

3418 J9

3419 K10

3420 K11

3421 J2

3422 H3

3423 I3

3424 H5

3425 G14

3426 G14

3427 I5

3428 H16

3429 H16

3430 H16

3431 H14

3432 H15

3433 I14

3434 K14

3436 J15

3437 J16

3447 J6

3448 J4

3449 K2

3450 K1

3451 I12

3452 A3

3453 A7

3454 A7

3455 C1

3456 B5

3457 B5

3458 B6

3459 B7

3460 B4

3461 D4

3462 D4

3463 D5

3464 D7

3465 E7

3466 D6

3467 I20

3468 I20

3469 I7

3470 I7

3471 I15

3472 I15

3473 I12

3474 I12

3475 I12

3476 I12

3477 F16

3478 H14

3479 H17

3480 H14

3481 H15

3482 J16

3483 K15

3486 F14

3491 A14

3492 A15

3493 C7

3494 C7

3495 E6

3496 I19

3498 I16

3499 A10

4400 H7

4401 I7

4402 J5

4403 J5

4405 G12

4406 C13

4407 D11

4408 E12

4409 E8

4410 F15

4411 F15

4412 F15

4413 F15

5300 F3

5301 G3

5302 F4

5303 G4

5304 G2

5305 F3

5400 J17

5403 J6

5404 A17

6103 E2

6400 K18

6401 K19

6402 K19

6403 B2

6404 B3

6405 D2

6406 D3

6407 C3

6408 H3

6409 G1

6411 I5

7401 J2

7402 I20

7410 A6

7411 E18

7412-1 E6

7412-2 E5

7413 A16

7414 A10

7415 D12

7417-1 C7

7417-2 C6

7418-1 H2

7418-2 H2

7419 H4

7420 I4

7421 H5

7422 H5

F001 K8

F002 K9

F003 K9

F004 K10

F005 K10

F006 K10

F401 J4

F402 K2

F403 I4

F404 F15

F405 F15

F409 J11

F410 J11

F411 E3

F412 E4

F413 E5

F414 E6

F415 G14

F416 E6

F417 A11

F420 H17

F421 H17

F422 A3

F423 E2

F424 B9

F425 B9

F426 D8

F430 G14

F432 H16

F433 C4

F434 C5

F435 C5

F436 C6

F437 C6

F480 G2

F481 G2

F482 G2

F483 I8

F484 I8

F485 I8

F486 I8

F487 J8

F488 J8

F489 J8

F490 J8

F491 A15

F492 E8

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

KEY_VOL_UP

VREF_KEY

10K

3455

KEY_INT

KEY_PLAY_RST

PGB

6409

150V

RF_GND

3412

47K

2433

12p

2434

12p

1405

3450

100R

BAT54 COL

V3V0_A

3413

F402

BAT54 COL

F423

TC38-360-33-TR

3414

100K

32K768

3449

100R

6405

6403

1300

18K

7418-1

BC847BPN

2

V3V3_D

3421

BAT54C

1

2

4

3

BC847BPN

100K

1

2 OSCO

3 INT_

6 SCL

6103

F480

F481

F482

5304

RF_GND

7418-2

4

5

6

1

6K8

3416

7401

PCF8563TS

OSCI

SDA5

BAT54 COL

BAT54 COL

HP_OUTR

HP_OUTL

1u0

3

32.768kHz

VOLTAGE

DETECTOR

MONITOR

INTERFACE

VSS

4

3415

OSC

OSC

I2C

KEY_HOLD

6404

6406

6408

BAS316

1K0

VBAT

8

VDD

BUS

6407

BAT54 COL

2n2

2493

5305

5300

5301

2432

100n

CLKO

DIVIDER

CONTROL

LOGIC

POR

ADDRESS

REGISTER

VREF_KEY

3452

100K

4

6

1408

2n2

1%22K

1414

SKQY

2306

2308 330p

RF_GND

LCD_RST_N

RSTIN_N

2K2

F401

5

7

F412

3304

1K0

4n7

2303

F422

1413

2302

RF_GND

7

SKQY

3

2

1

2451

3461

2n2

F411 F413

330p2307

4n7

RF_GND

3422

330R

7419

BC817-40W

3423

330R

7420

BC817-40W

V3V3_D

3448

CONTROL/STATUS1

CONTROL/STATUS2

SECONS/VL

MINUTES

HOURS

DAYS

WEEKDAYS

MONTHS/CENTURY

YEARS

MINUTE ALARM

HOURS ALARM

DAY ALARM

WEEKDAY ALARM

CLKOUT CONTROL

TIMER CONTROL

TIMER

F433

SKRE

1409

SSSS8

3462

24952494

2n2

4n7

F403

RTC_OUT

3460

22K

1%

2452

2n2

5302

5303

1%10K

1415

F434

1417

SKRE

3463

6K8

2496

2n2

SKQY

KEY_REMOTE_IN

3305

8R2

3306

8R2

4402

4403

1400

27FX-RSM1-S-TB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

2829

3456

10K

1%

2457

3424

330R

1%

7421

BC817-40W

3427

330R

F435

1411

7412-2

BC847BS

7422

BC817-40W

6411

BAT54 COL

2459

SKRE

1416

3300

8R2

3301

8R2

2n22n2

SKQY

KEY_REMOTE_IN

3457

6K8

1%

3

4

F414

4n7

2304

V3V3_D

3458

3K3

1%

2461

3

2n2 2n2

4

7417-2

BC847BS

F436

1412

SKRE

3466

1%

3K3

2497

2n2

3495

5

470K

7412-1

BC847BS

1401

4n7

3302

V3V3_D

10K

5403

10K

2305

3447

5

6

1

SKQY

3303

VIN_R

VIN_L

7410

BC847B

6

BC847BS

1

1402

2

F416

2300

6.3V220u

2301

6.3V220u

10K

1u02481

2482 1u0

1u02483

100n

2471

100n2473

VREF_KEY

7417-1

F437

SKRE

3464

2498

2n2

2470 100n

2472 100n

2474 100n

2

3459

2486

3453

1K0

1%

2

1

1%1K0

3465

470K

4400

4401

10K

3

3493

470K

3494

470K

2424

VREF_KEY

V3V0_A V3V0_A

3410

100K

V3V0_A

10u

2425

100n

1M0

3469

3470

LCD_RW_WR

LCD_E_RD

LCD_D(0)

LCD_D(1)

LCD_D(2)

LCD_D(3)

LCD_D(4)

LCD_D(5)

LCD_D(6)

LCD_D(7)

10R

2428

LCD_CS

LCD_RS

VREF_KEY

1%

10K

3454

F426

VREF_KEY

F492

3405

150R

V1V8_D

2430

1404

9

8

7

6

5

4

3

2

1

2n2

2401

KEY_INPUT_LINE1

2406

1u0

2409

100n

2410

22u 6.3V

V3V0_A

2431

F483

F484

F485

F486

F487

F488

F489

F490

100n

100n

VREF_KEY

1%

10K

3401

2n2

2402

VREF_KEY

1%

10K

3402

2n2

2403

V3V0_A

4409

V3V0_A

3411

100K

3407

10u

100n

2429

{LCD_RW_WR,LCD_E_RD,LCD_D(0:7),LCD_CS,LCD_RS}

1M0

10FMN-BMT-A-TFT

10

F001

F425

V3V0_A

GPIO_2

1V8_PROG

2426

F424

10u

F002

2427

3404

10R

100n

3418

2407

100K

F003

NCP305LSQ28

2

RST-OUTPVIN

EXTERNAL_5KEY_RC

KEY_INPUT_LINE2

10u

2408

100n

LCD_RW_WR

LCD_E_RD

LCD_D(0)

LCD_D(1)

LCD_D(2)

LCD_D(3)

LCD_D(4)

LCD_D(5)

LCD_D(6)

LCD_D(7)

LCD_CS

LCD_RS

IIC_SCL

IIC_SDA

RSTIN_N

F004

7414

GND

4NC3

BAT_LEVEL

CHG_CURRENT

V3V3_D

3417

100K

V3V3_D

F005

VREF_KEY

3492

1K0

V3V0_A

F491

2478

10u

2479

100n

4

7413

NCP500SN30

ENABLE

VOUTNCVIN

GND

2

3

15

1u0

2480

1

10K

3499

F417

RTC_OUT

RC_INT

4407

56K

V1V8_D

3406

2R2

V1V8_D

2412

2414

100n

PNX0102AET

100n

7415

2415

2416

100n

V1V8_D

H1

V11

VDDI

100n

4406

V16

MIC_IN

V3V3_D

V3V3_D

E1

V5

2476

1u0

2418

V14

VDDE

KUF4523

100n

J18

A16

1419

2419

A7

2

100n

+

2420

1

100n

2421

100n

2422

3491

2K2

100n

2423

100n

2477

47u 6.3V

5404

V3V3_D

V3V3_D

2435

100n

2436

100n

2437

100n

2438

100n

2439

100n

2440

100n

2441

100n

MPMC_D_(0:15)

MPMC_A_(0:14)

{SD_CLK,SD_CKE,SD_DQM1,SD_DQM0,SD_RAS,SD_CAS,SD_CS,SD_WE}

Φ

SOLID STATE

IN

OUT

VDDA18

VSSA

IN

OUT

VDDA18

VSSA

IN

VDDA33

GNDA

0

1

2

GPA

3

4

VDDA33

GNDA

R

VOUT

L

VDDA33

P

VREF

N

R

OUT

L

A

OUTC

B

VDDA33A

VDDA33B

GNDAA

GNDAB

MIC_LNA

VCOM

P

REF

N

VDDA18

VDDA33

GNDA

VREF

VINR

VINL

MIC

RW_WR

E_RD

0

1

2

3

DB LCD

4

5

6

7

CSB

RS

0

1

DAT

2

3

CLK

CMD

BCK

WS

DATA

CLK

BCK

WS

DATA

TRST

TCK

TMS

TDI

TDO

SEL_ARM

SCL

SDA

RSTIN

FLASH_VDD_HV

AUDIO

XTALH

XTALL

SPDIF

ADC10B

DAC

HP

ADC

MCI

DAI

DAO

JTAG

IIC

VSSI VSSE

G1

V12

V17

MPMC

UART

DCDC

USB

VDDA33_DRV

F1

V6

D

A

STCS

DYCS

CLKOUT

CKE

WE

RAS

CAS

DQM

OE

BLOUT

RPOUT

TXD

RXD

CTS

RTS

GPIO

PLAY

STOP

LX1

LX2

VUSB

VBAT

VOUT33A

VOUT33B

VOUT18

VSS1

VSS2

GND

CLEAN

RPU

DP

DM

VBUS

RREF

GNDA

VSSA_REF

VSSA_TERM

VDDA18_PLL

VDDA18_BG

VDDA13

A6

A15

V13

H18

A1

0

A2

1

B2

2

A3

3

A4

4

B4

5

A5

6

B5

7

C4

8

C5

9

C6

10

B6

11

C7

12

B7

13

C8

14

B8

15

E16

0

E17

1

E18

2

D16

3

D17

4

D18

5

A18

6

B18

7

C18

8

B17

9

C17

10

B16

11

C16

12

B15

13

C15

14

A14

15

B14

16

C14

17

A13

18

B13

19

C13

20

C9

0

A8

1

B11

2

B9

A10

B10

C11

A9

C10

C12

0

A11

1

A17

A12

0

B12

1

B1

L3

K3

K2

K1

K16

0

K17

1

K18

2

J16

3

L17

L18

P17

N17

T18

M17

R18

M16

N18

P18

N16

L16

M18

T15

U17

T17

U14

P16

R17

R16

T16

U15

U16

U18

V18

F430

MPMC_D_(0)

MPMC_D_(1)

MPMC_D_(2)

MPMC_D_(3)

MPMC_D_(4)

MPMC_D_(5)

MPMC_D_(6)

MPMC_D_(7)

MPMC_D_(8)

MPMC_D_(9)

MPMC_D_(10)

MPMC_D_(11)

MPMC_D_(12)

MPMC_D_(13)

MPMC_D_(14)

MPMC_D_(15)

3486

3426 1K0

F415

1K03403

1K03478

3431

3480

3433 1K5 1%

3434

MPMC_A_(0)

MPMC_A_(1)

MPMC_A_(2)

MPMC_A_(3)

MPMC_A_(4)

MPMC_A_(5)

MPMC_A_(6)

MPMC_A_(7)

MPMC_A_(8)

MPMC_A_(9)

MPMC_A_(10)

MPMC_A_(11)

MPMC_A_(12)

MPMC_A_(13)

MPMC_A_(14)

1K0

1K03425

1K0

1%

12K

F404

F405

BATT_RD_EN

CHG_STATUS

1K0

3432

3481 1K0

3471

2447

MPMC_A_(13)

MPMC_A_(14)

4412

4413

ATA_DMARQ

BATT_LOW_N

HD_PWR_N

1K0

3472

100K

2442

100n

1u0

2444

100n

4410

4411

SD_CS

SD_CLK

SD_CKE

SD_WE

SD_RAS

SD_CAS

SD_DQM0

SD_DQM1

RC_INT

USB_HIGH_PWR

LCD_RST_N

USB_SUSPEND

LCD_BL_CTRL

100K

3436

2R2

3483

2R2

V3V3_D

V1V8_D

3477

1K0

ATA_CS0

ATA_CS1

ATA_INTRQ

V3V3_D

10K

3428

3430 100R

V3V3_D

3498

3437

RXD

F432

1M0

100K

100R3429

3482

56K

SD_CLK

SD_CKE

SD_CS

SD_RAS

SD_CAS

SD_WE

F420

F421

3479 1K0

3408

56K

MPMC_A_(0)

MPMC_A_(1)

MPMC_A_(2)

MPMC_A_(3)

MPMC_A_(4)

MPMC_A_(5)

MPMC_A_(6)

MPMC_A_(7)

MPMC_A_(8)

MPMC_A_(9)

MPMC_A_(10)

MPMC_A_(11)

MPMC_A_(12)

MPMC_A_(13)

MPMC_A_(14)

VUSB

2484

MT48LC16M16A2

UART_TXD

UART_RXD

GPIO_2

PWR_ACK

1V8_PROG

5400

100n

7411

23

0

24

1

25

2

26

3

29

4

30

5

31

6

32

7

33

8

34

9

22

10

35

11

36

12

20

0

BA

21

1

38

CLK

37

CKE

19

CS

18

RAS

17

CAS

16

WE

MMBZ15VALT1

14

1

VDD

0

A

4M-1

VSS

28

41

6400

V3V3_D

27

3

9

VDDQ

Φ

DRAM

4M X 16 X 4

VSSQ

6

54

12

1407

DLW31S

43

49

40

NC

2

0

1

2

3

4

5

6

7

D

8

9

10

11

12

13

14

15

H

DQM

L

46

52

V3V3_D

10K

3496

1

2

3

43

12

6401

MPMC_D_(0)

4

MPMC_D_(1)

5

MPMC_D_(2)

7

MPMC_D_(3)

8

MPMC_D_(4)

10

MPMC_D_(5)

11

MPMC_D_(6)

13

MPMC_D_(7)

42

MPMC_D_(8)

44

MPMC_D_(9)

45

MPMC_D_(10)

47

MPMC_D_(11)

48

MPMC_D_(12)

50

MPMC_D_(13)

51

MPMC_D_(14)

53

MPMC_D_(15)

39

15

(1Kx8)

EEPROM

NC1

NC2

E2 SDA

ADR

PGB

6402

150V

SD_DQM1

SD_DQM0

V3V3_D

M24C08-WDW6TP

84

Φ

PGB

150V

2443

WC

SCL

100n

7402

7

6

5

1406

TCX0101-110177

1

2

3

4

5

6 7

8 9

3467 100R

100R

3468

3419

F006

1403

22p

2404

2K7

2K7

3420

hole-pth-0150

12M

2405

MIC_IN

ATA_IORDY

ATA_RESET

BURST_DIS

V1V8_D

22p

2413

V3V0_A

2446

ATA_IOWR

ATA_IORD

KEY_HOLD

TIC_CLK

RTC_INT

KEY_INT

TIC_OFF

EXT_DC

F409

F410

100n

100n

3451 1K0

3473 1K0

3474

3476 1K0

4408

V1V8_D

4405

1K03475

100K

1K0

T10

V9

U9

T9

V7

T8

U8

V8

T12

U11

T11

U7

T7

U6

T6

U5

V10

U10

M3

M2

L1

L2

M1

P3

N3

N2

N1

R1

R2

P2

P1

T2

T3

U2

V1

V3

U3

V2

U1

T1

T4

R3

G2

F2

C2

C1

C3

D2

D1

D3

E2

E3

B3

F3

H3

J2

J1

J3

G3

H2

H17

G17

G16

F16

G18

F18

F17

T13

V4

U12

T5

U13

U4

H16

J17

T14

V15

IIC_SCL

IIC_SDA

A

B

C

D

E

F

G

H

J

K

L

A

B

C

D

E

F

G

H

I

J

K

L

M

I

N

O

P

Q

R

toestemming van de auteursrechthebbende.

gedeeltelijk, is niet toegestaan dan met schriftelijke

Alle rechten voorbehouden. Verveelvuldiging, geheel of

S

T

1

2499

470p

2400

100n

2475

1u0

2456

1u0

R

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

S

HDDSETNAMECHN

CLASS_NO

3PC330

1

2004-12-10

2005-04-12

NAME

RAYMOND CHOI

2

3

4

5 16

6

7 8

9

10

11 12

13 15

14

17

18 22

19

20

21

2

3

23

PBAS HDD084

HDD084

SUPERS.

2004-06-11

DATECHECK

24

25

3140 178 0012

130

4

C

KONINKLIJKE PHILIPS ELECTRONICS N.V. 2004

1

26

1

1

1

1

1

2005-04-12

2005-03-24

2005-03-07

2004-12-10

2004-09-23

2827

T

A1

Page 26

1

8.0 ELECTRICAL DIAGRAM

3

5

6

7

84

9

10

112

12

13

14

15

16

17

18

19

20

1410 E13

1418 E4

A

2137 I13

B

A

C

D

B

E

C

F

D

G

H

E

I

F

J

K

is prohibited without the written consent of the copyright

owner.

All rights reserved. Reproduction in whole or in parts

G

L

H

M

I

N

2139 G12

2140 G12

2411 E12

ATA_DMAACK

2448 E4

2449 D11

2450 E12

2453 I12

2454 I12

2455 I12

2458 I13

2460 I13

2462 I13

2463 I14

2464 D3

2465 D5

2466 D10

2467 D9

2468 E3

2469 B2

2487 G5

2488 E13

2489 G12

2490 G3

2491 D5

2492 D10

3438 A6

3439 B3

3440 C5

3441 E4

3442 D5

3443 E4

3444 C3

3484 B3

3485 F3

3487 C4

3488 C4

3489 C8

3490 B5

4404 D9

5401 E12

7403-1 H9

7403-2 A7

1 2 3 4 5 6 7 8

V3V3_D

V3V3_D

J12

B12

A13

A12

B11

A

CS

DMA

NC

CLK

B2

M8

7403-2

TIC-001829-01

Φ

HOST

REVERSE

CF-PF="0"

D

DASP

PDIAG

INTRQ

PG

A5

0

B5

1

B4

2

J13

3

H12

4

G12

5

E13

6

C12

7

A4

8

A3

9

A2

10

11

G13

12

F13

13

D13

14

C13

15

E12

F12

A9

N13

CLOCK &

CONTROL

H2

0

EMU

H1

1

JTAG

{SE_NRZD(0:7),SE_NRZDC,SE_SG,SE_RG-WG,SE_DATA,SE_CLOCK,SE_SSM-ERR}

SE_NRZD(0) SE_NRZD(1)

SE_NRZD(1)

SE_NRZD(2)

SE_NRZD(3)

SE_NRZD(4)

SE_NRZD(5)

SE_NRZD(6)

SE_NRZD(7)

V3V3_D

2469

100n

4

7416

74AHC1G32GW

F440

1

2

3 5

HD_PWR_N

V3V3_D

3439

3484

TIC_CLK

100K

100K

ATA_IORD

ATA_IOWR

3444

10K

2468

3485

33R

2464

100n

2

18p

V3V3_D

NC

1

3441

1418

2490

C11

C5

D4

D3

C3

C4

L7

L6

L5

L4

L3

L11

K3

K11

J3

J11

H3

H11

G11

F2

E11

E3

1M0

7409

BC857B

5

1

12M

5p6

NC

ATA_DMARQ

ATA_RESET

ATA_IORDY

74LVC1GU04

4

3

3443

2448

TIC-001829-01

7406

1K0

18p

7403-5

Φ

DSP

3488

3487

100K

TIC_OFF

7405

74LVC1G14GW

15VCC

L10

M11

NCNC

M12

K10

D10

D11

C10

V3V3_D

M6

M5

M4

M3

M7

L9

L8

C6

C9

3490

100K

NC

A2

GND

3

100K

F460

Y 4

MPMC_A_(10)

MPMC_A_(11)

MPMC_A_(12)

ATA_CS0

ATA_CS1

V3V3_D

3440

2465

100n

3442

33R

SE_SSM-ERR

SE_CLOCK

SE_DATA

SE_RG-WG

SE_SG

SE_NRZDC

F459

100K

V3V3_D

2487

10K

3438

5p6

2491

F441

7403-3

TIC-001829-01

Φ

SE

NORMAL

SE-PINFLIP="1"

F11

SE-PINFLIP

M1

SSM-ERR

N1

CLOCK

N2

DATA

N3

RG-WG

N4

SG

M13

NRZDC 7

100n

7403-4

TIC-001829-01

C2

D2

D1

E2

E1

F1

L12

F493

L13

GPIO-7

K12

GPIO-8

K13

M9 C7

L2

M2

NC

NC

NC

GPIO

TEST

Φ

C8

CF-PF

B6

0

B7

1

B8

2

D12

0

B13

1

A7 H13

ACK

A6

RQ

B9

RESET

A10

RD

B10

WR

A8

RDY

B3

CS16

G1

1

G2

2

F3

SEL

C1

IN

B1

RST

M10

TICOFF

A1

INH-PG

L1

TMS

K2

TRST

K1

TDI

J2

TDO

J1

TCK

N5

0

N6

1

N7

2

N8

3

NRZD

4

5

6

NC

GPIO-C

NC

GPIO-E

NC

NC

N10

N11

N12

N9

MPMC_D_(0)

MPMC_D_(1)

MPMC_D_(2)

MPMC_D_(3)

MPMC_D_(4)

MPMC_D_(5)

MPMC_D_(6)

MPMC_D_(7)

MPMC_D_(8)

MPMC_D_(9)

MPMC_D_(10)

MPMC_D_(11)

MPMC_D_(12)

MPMC_D_(13)

MPMC_D_(14)

MPMC_D_(15)

3489

V3V3_D

7403-3 F6

7403-4 H6

7403-5 H4

100K

PWR_ACK

A11

D7

E4

G4

H10

K5

K6

G3

K7

G10

D8

7405 D5

7406 D4

7408 C11

ATA_INTRQ

TIC-001829-01

SUPPLY

VDDSHV

VDDSHVREG

7409 C4

7416 C2

9 10

MPMC_D_(0:15)

VBAT

4404

1u0

2466

2467

7403-1

Φ

VSS

E10

F10

J10

D5

D6

D9

F4

H4

J4

K4

K8

K9

F441 E6

F442 E12

F443 F12

10n

2492

8

3

5

100p

F444 G13

F445 F11

F446 F11

TPS73633DRBR

IN

NR

FB

EN

7408

Φ

4

SE_NRZDC

SE_NRZD(7)

SE_NRZD(6)

SE_NRZD(5)

SE_NRZD(4)

SE_NRZD(3)

SE_NRZD(2)

SE_NRZD(0)

SE_SG

SE_RG-WG

SE_DATA

SE_CLOCK

SE_SSM-ERR

F447 F11

F448 F11

F449 F11

F450 F11

F451 F11

F452 F11

F453 F11

F454 F11

F455 F11

F456 G11

F457 G11

F458 G11

F459 B5

F460 C5

F493 H5F440 B2

A

11 12 13 14

B

A

C

B

D

E

C

1

OUT

2

6

NC

7

HS_GNDGND

9

2449

10u

D

F

G

V3V3_HDD

5401

F442

H

E

6.3V220u

2140

F443

6.3V220u

2411

22u 6.3V

20FLH-SM1-TB(LF)(SN)

F444

2489

100n

1410

21 22

100n

2488

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

F

G

I

J

K

F445

F446

F447

F448

F449

F450

F451

F452

F453

F454

F455

F456

F457

F458

2450

100n

2139

L

V3V3_D

H

M

2453

100n

2454

2455

100n

2458

100n

2460

100n

2137

100n

2462

100n

2463

100n

100n

I

N

gedeeltelijk, is niet toegestaan dan met schriftelijke

Alle rechten voorbehouden. Verveelvuldiging, geheel of

toestemming van de auteursrechthebbende.

O

P

1

1 2 3 4 5 6 7 8 9 10

3

4

5

6

9872

10

11 12

13

14

11

CHN SETNAME HDD

CLASS_NO

3PC330

2004-12-10

2005-04-1223

NAME

RAYMOND CHOI

1

CHECK DATE

PBAS HDD084

15

12 13

HDD084

SUPERS.

2004-06-11

16

17

14

O

1

2005-04-12

1

2005-03-24

1

3140 178 0012

4

C

KONINKLIJKE PHILIPS ELECTRONICS N.V. 2004

18

130

19

2

1

1

20

2005-03-07

2004-12-10

2004-09-23

A2

P

Page 27

9.0 COMPONENT LAYOUT

Page 28

9.0 COMPONENT LAYOUT

Page 29

9.0 COMPONENT LAYOUT

Page 30

10.0 REVISION LIST

Version 1.0 (3141 785 30480)

• Initial release HDD084/00/05/17

Version 1.1 (3141 785 30481)

• Chapter 4 Photo added to the disassemble instructions for the removal of screws on the PCB Assembly.

Version 1.2 (3141 785 30482)

• Include content on HDD082/17

• Chapter 5 Changes in the service 12NC on the following parts

o FRONT CAB. ASSY HDD084 SILVER (314017750142)

o COVER-REAR LAQ ASSY HDD084 SIL (314017750172)

o REAR CABINET ASSY HDD084 (314017750132)

• Chapter 5 Adding of the following new service parts

o HDD 1" 2GB+SW CONFIG HDD082/17 (314017050361)

o USB CABLE ASSY (314011769601)

Version 1.3 (3141 785 30483)

• Chapter 5 New PCBA kits with different resistor value are used.

o PCBA KIT ASSY HDD084/00 (314017900191)

o PCBA KIT ASSY HDD084/05 (314017900111)

o PCBA KIT ASSY HDD084/17 (314017830111)

o PCBA KIT ASSY HDD082/17 (314017900181)

• Chapter 5 Changes in the service 12NC on the following parts

o AY4108/00 AC/DC Adaptor (312017830122)

o AY4108/05 AC/DC Adaptor (314017830132)

Version 1.4 (3141 785 30484)

• Chapter 1 Added procedure on rebuilding the firmware image & database after the replacement of hard disk.

Chapter 1 Added procedure on how to capture the device log file & the pc log file from the device.

• Chapter 2 Clarified on the PCBA and HDD used on HDD082/17 with different cha nge code in the serial number

• Chapter 5 Changes in the service 12NC on the following part

o PCBA KIT ASSY HDD082/17 (314017800261)

Version 1.5 (3141 785 30485)

• Chapter 1 Added firmware upgrade and firmware rebuilding re-building procedure for HDD082/HDD085

• Chapter 5 New service parts added with the 12NC below

o PCBA KIT ASSY HDD085/00 (314017900231)

o PCBA KIT ASSY HDD085/05 (314017900231)

o MOD SUPP AC-DC HDD085/00 (272201200608)

o MOD SUPP AC-DC HDD085/05 (272201200609)

Page 31

10.0 REVISION LIST

Version 1.6 (3141 785 30486)

• Chapter 1 Added recovery procedure for flash corrupt problem for HDD084/HDD085/HDD02 and MTP mode installation procedure after replaced the

mainboard for HDD085/HDD082.

• Chapter 5 Added new service 12NC on the following part

o DFU CABLE (824041001931)

Version 1.7 (3141 785 30487)

• Include content on HDD086/00/05/17

• Chapter 5 Added new service 12NC on the following part

o HDD 1.0” 4GB (2822 0620 0108)

o PCBA KIT ASSY HDD086/00/05 (3140 1790 0261)

o CD ROM HDD086 (3140 1787 0361)

o Headphone SHE2550BI/00 (9082 1000 8773)

Loading...

Loading...