Page 1

Register your product and get support at

www.philips.com/welcome

OPERATING INSTRUCTIONS

02

English

Type HD8838

SUP 037DRJ

EN

02

READ THESE INSTRUCTIONS CAREFULLY BEFORE USING THE MACHINE.

Page 2

IMPORTANT SAFEGUARDS

When using electrical appliances, basic safety precautions should always be

followed, including the following:

1. Read all instructions.

2. Do not touch hot surfaces. Use handles or knobs.

3. To protect against fire, electric shock and injury to persons do not immerse

cord, plugs, or appliance in water or other liquid.

4. Close supervision is necessary when the appliance is used by or near

children.

5. Unplug from outlet when not in use and before cleaning. Allow to cool

before putting on or taking off parts, and before cleaning the appliance.

6. Do not operate any appliance with a damaged cord or plug or after the

appliance malfunctions, or has been damaged in any manner. Return

appliance to the nearest authorized service facility for examination, repair

or adjustment.

7. The use of accessory attachments not recommended by the appliance

manufacturer may result in fire, electric shock or injury to persons.

8. Do not use outdoors.

9. Do not let cord hang over edge of table or counter, or touch hot surfaces.

10. Do not place on or near a hot gas or electric burner, or in a heated oven.

11. Always attach plug to appliance first, then plug cord into wall outlet. To

disconnect, turn any control to “off”, then remove plug from wall outlet.

12. Do not use appliance for other than intended use.

13. Save these instructions.

SAVE THESE INSTRUCTIONS

• IV •

Page 3

CAUTION

This appliance is for household use only. Any servicing, other than cleaning and

user maintenance, should be performed by an authorized service center. Do not

immerse machine in water. To reduce the risk of fire or electric shock, do not

disassemble the machine. There are no parts inside the machine serviceable by

the user. Repair should be done by authorized service personnel only.

1. Check voltage to be sure that the voltage indicated on the nameplate

corresponds with your voltage.

2. Never use warm or hot water to fill the water tank. Use cold water only.

3. Keep your hands and the cord away from hot parts of the appliance during

operation.

4. Never clean with scrubbing powders or harsh cleaners. Simply use a soft

cloth dampened with water.

5. For optimal taste of your coffee, use purified or bottled water. Periodic

descaling is still recommended every 2-3 months.

6. Do not use caramelized or flavored coffee beans.

INSTRUCTIONS FOR THE POWER

SUPPLY CORD

A. A short power-supply cord (or detachable power-supply cord) is to be

provided to reduce risks resulting from becoming entangled in or tripping

over a longer cord.

B. Longer detachable power-supply cords or extension cords are available

and may used if care is exercised in their use.

C. If a long detachable power-supply cord or extension cord is used,

1. The marked electrical rating of the detachable power-supply cord or

extension cord should be at least as great as the electrical rating of the

appliance

2. If the appliance is of the grounded type, the extension cord should be a

grounding-type 3-wire cord, and

3. The longer cord should be arranged so that it will not drape over the

counter top or table top where it can be pulled on by children or tripped

over.

• V •

Page 4

GENERAL INFORMATION

The co ee machine is suitable for preparing espresso co ees using co ee beans; it is equipped

with a device to dispense steam and hot water. The structure of the machine with its elegant

housing has been designed for domestic use only and is not suitable for continuous professional-type operation.

Keep these operating instructions in a safe place and make them available to anyone

who may use the co ee machine.

For further information or in case of problems that are not included or not completely explained

in these instructions, please contact the authorised service centres.

Warning. No liability is held for damage caused by:

• Incorrect use not in accordance with the intended purposes;

• Repairs not carried out by authorised service centres;

• Tampering with the power cord;

• Tampering with any parts of the machine;

• Storage or use of the machine at a temperature outside the operating temperature

range (+15°C / +45°C);

• The use of non-original spare parts and accessories.

In these cases, the warranty is not valid.

SAFETY REGULATIONS

Never allow water to come into contact with any of the electrical parts of the

machine: Danger of short circuit! Steam and hot water may cause scalding!

Do not direct the steam or hot water jet towards body parts. Carefully handle the

steam/hot water spout by its grip: Danger of scalding!

• 2 •

Intended use

The co ee machine is intended for domestic use only. Do not make any technical changes or use

the machine for unauthorised purposes since this would create serious hazards! The appliance is

not to be used by persons (including children) with reduced physical, mental or sensory abilities

or with scarce experience and/or expertise, unless they are supervised by a person responsible

for their safety, or they are instructed by this person on how to properly use the machine.

Power Supply - Power Cord

Only connect the co ee machine to a suitable socket.

The voltage must correspond to that indicated on the machine label located on the inside of

the service door.

Never use the co ee machine if the power cord is defective or damaged.

If damaged, the power cord must be replaced by the manufacturer or an authorised service

centre. Do not pass the power cord around corners, over sharp edges or over hot objects and

keep it away from oil. Do not use the power cord to carry or pull the co ee machine.

Do not pull out the plug by the power cord or touch it with wet hands. Do not let the power cord

hang freely from tables or shelves.

For the safety of others

Prevent children from playing with the machine.

Children are not aware of the risks related to electric household appliances.

Do not leave the machine packaging materials within the reach of children.

Page 5

Danger of burns

Never direct the jet of hot steam and/or hot water towards yourself or others: Danger of

scalding! Always use the handles or knobs provided.

Milk Container

At rst use or after a long period of inactivity wash all components of the milk container to

guarantee good operation and to avoid proliferation of bacteria, harmful to health.

The milk in the carafe may be stored inside the carafe using the instructions and precautions on

the original package. Do not use milk after its expiration date indicated on the package.

If milk is left in the carafe, make sure it is still suitable for food consumption before using it.

At least once a week the carafe must be removed for thorough cleaning.

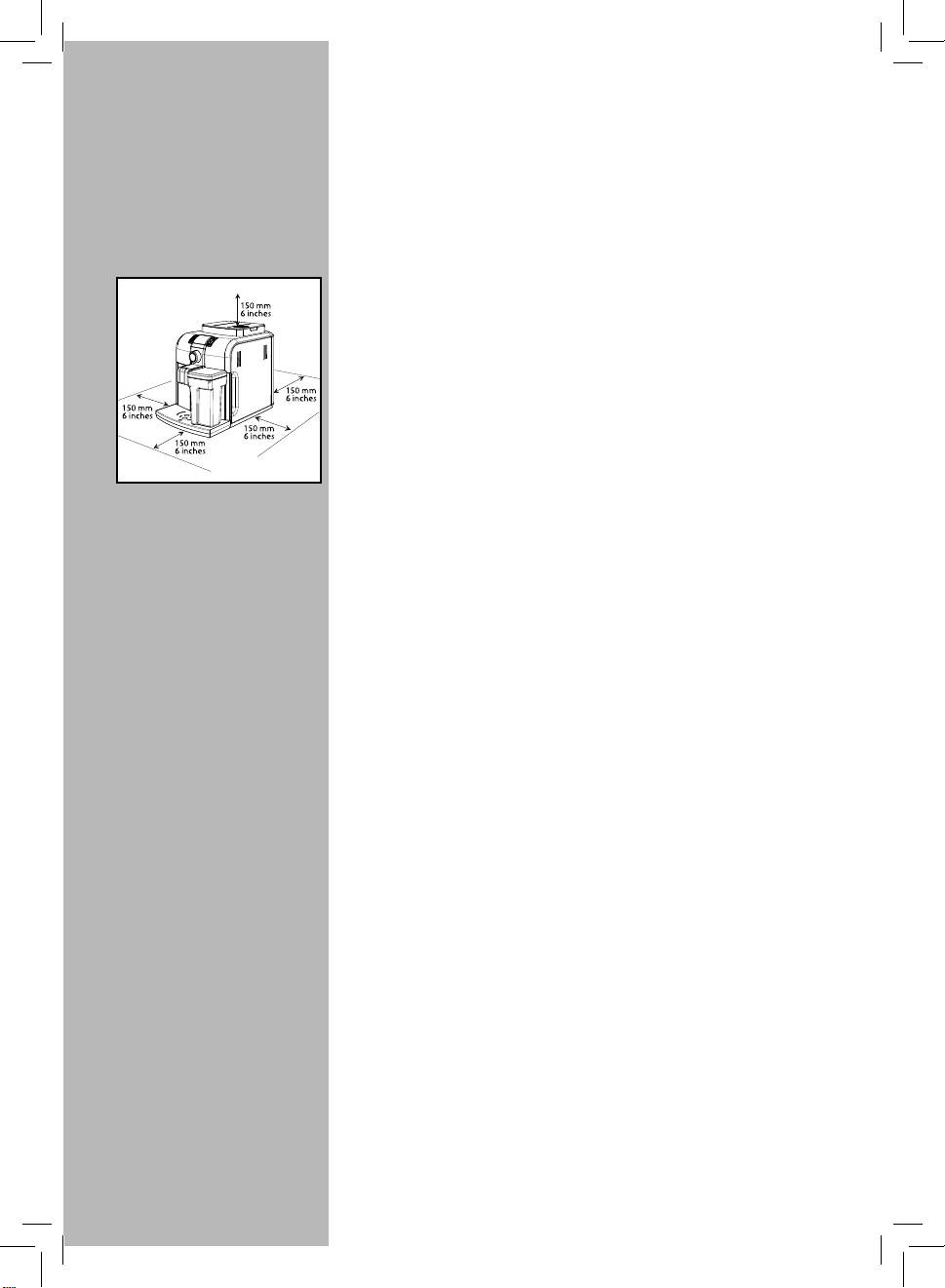

Machine Location - Suitable Location for Operation and Maintenance

For best use, it is recommended to:

• Choose a safe, level surface, where there will be no danger of overturning it or being in-

jured.

• Choose a location that is su ciently well-lit, clean and near an easily reachable socket;

• Provide for a minimum distance from the sides of the machine as shown in the illustra-

tion

;

• During machine turning on/o , it is recommended to place an empty glass under the dis-

pensing spout.

Do not keep the machine at temperatures below 0°C. Frost may damage the machine.

Do not use the co ee machine outdoors.

In order to prevent its housing from melting or being damaged, do not place the machine on

very hot surfaces and close to open ames.

Storing the Machine - Cleaning

Before cleaning the machine, turn it o by pressing the ON/OFF button, and then by switching

the power button to “0”. Finally, remove the plug from the socket. Wait for the machine to cool

down.

Never immerse the machine in water!

It is strictly forbidden to tamper with the internal parts of the machine.

Water left in the tank for several days should not be consumed. Wash the tank and ll it with

fresh drinking water.

If the machine is not to be used for a long time, dispense water from the dispensing spout, then

turn o the machine and unplug it from the socket.

Store it in a dry place, out of the reach of children.

Keep it protected from dust and dirt.

Repairs / Maintenance

In case of failure, problems or a suspected fault resulting from the falling of the machine, immediately remove the plug from the socket. Never attempt to operate a faulty machine.

Servicing and repairs may only be carried out by authorised service centres.

All liability for damages resulting from work not carried out by professionals is declined.

Fire Safety Precautions

In case of re, use carbon dioxide (CO2) extinguishers. Do not use water or dry powder extinguishers.

• 3 •

Page 6

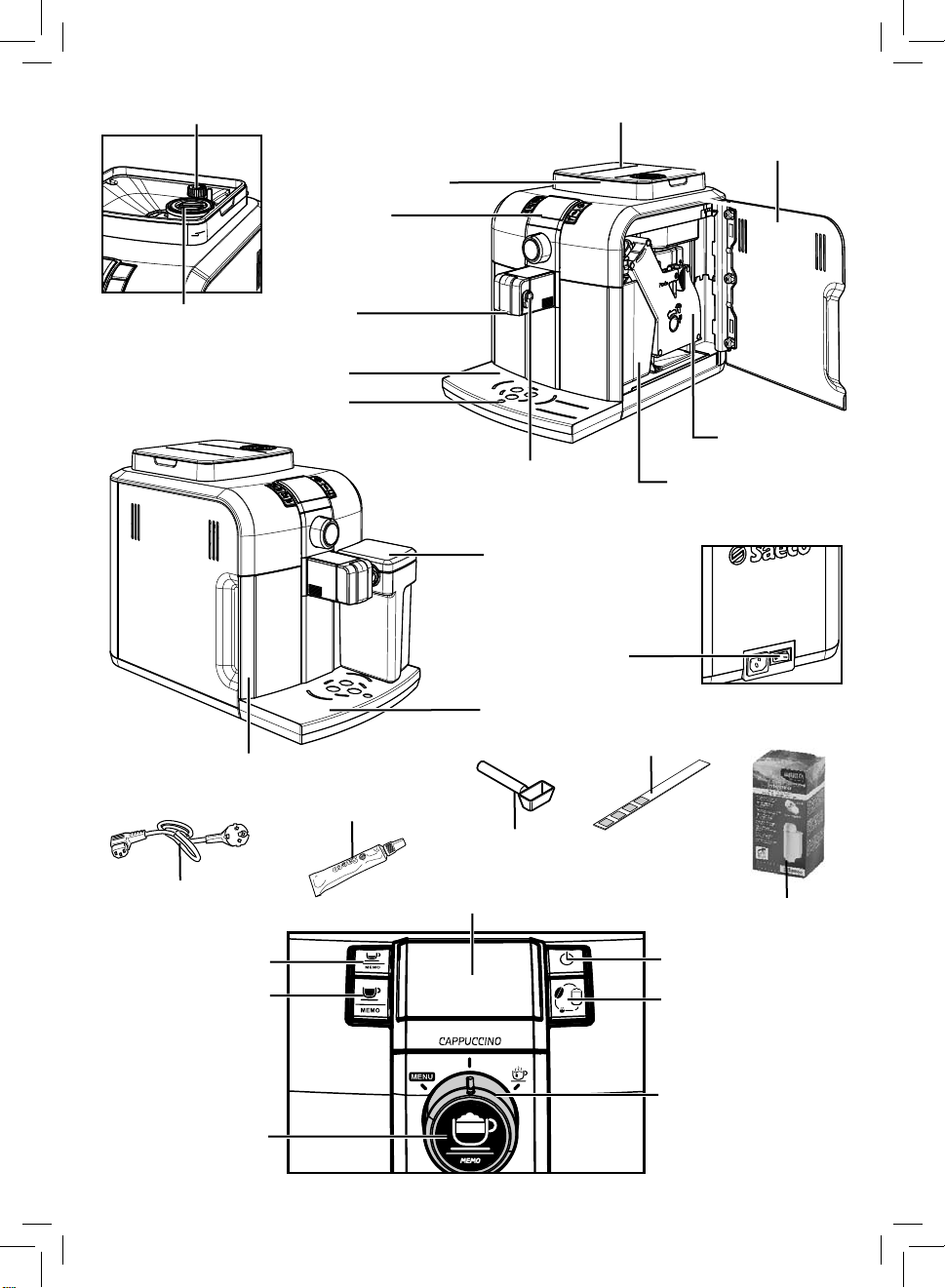

Grinder

adjustment knob

Co ee bean hopper cover

Service door

Co ee bean hopper

Control Panel

Pre-ground co ee

compartment

Power cord

Water tank

Co ee / hot water /

Cappuccino dispensing spout

Cup holder grill

Full drip tray indicator

Grease for the Brew Group

Milk container

Milk Container

Drip tray

Pre-ground

co ee doser

LCD Display

coupling

Power button

Water hardness test

Brew Group

Co ee grounds drawer

Intenza water lter

Strong co ee brew button

Long co ee brew button

Cappuccino / hot milk

brew button

• 4 •

ON/OFF button

“Aroma” - Pre-ground co ee /

hot milk selector switch

Co ee / hot water /

PROGRAMMING MENU selector

switch

Page 7

TABLE OF CONTENTS INSTALLATION

GENERAL INFORMATION• ......................................... 2

SAFETY REGULATIONS• ............................................ 2

INSTALLATION• ........................................................ 5

Machine Packaging .............................................................. 5

Preliminary Operations ........................................................5

RINSE/SELFCLEANING CYCLE• ................................. 6

USING THE MACHINE FOR THE FIRST TIME OR •

AFTER A LONG PERIOD OF INACTIVITY. .................... 7

“INTENZA” WATER FILTER.• ...................................... 8

WATER HARDNESS MEASUREMENT• ......................... 9

MILK CONTAINER• ................................................... 9

COFFEE BREWING• ................................................. 10

Dispensing Spout Adjustment ............................................10

'Aroma' Adjustment ...........................................................10

Using Co ee Beans .............................................................10

Using Pre-ground Co ee ....................................................11

CAPPUCCINO • ....................................................... 12

HOT MILK BREWING• ............................................. 12

CLEANING OF THE MILK BREWING SYSTEM• ........... 14

Automatic cleaning functions ............................................14

Fast cleaning ...................................................................... 14

Periodic cleaning ................................................................15

HOT WATER DISPENSING• ...................................... 18

ADJUSTMENTS• ..................................................... 19

Saeco Adapting System ......................................................19

Co ee Grinder Adjustment .................................................19

Adjusting the Co ee Length ...............................................19

Cappuccino Adjustment .....................................................20

Adjusting the amount of frothed milk ................................21

Stand-by ............................................................................21

PROGRAMMING• ................................................... 22

Enter the “menu” ................................................................22

Programming controls .......................................................22

Exit Programming Mode ....................................................22

Functions ...........................................................................22

Programming Example ......................................................23

CLEANING AND MAINTENANCE• ............................. 24

General Cleaning ................................................................24

Brew Group ........................................................................24

DESCALING• .......................................................... 26

CONTROL PANEL DISPLAY• ..................................... 28

Ready Signals .....................................................................28

Alarm Signals ..................................................................... 29

Warning Signals .................................................................30

TECHNICAL SPECIFICATIONS• ................................. 30

TROUBLESHOOTING• ............................................. 31

For your safety and the safety of others, carefully follow the instructions

provided in the "Safety Regulations"

section.

Machine Packaging

The original packaging has been designed

and constructed to protect the machine

during transport. We recommend keeping the packaging material for possible

future transport.

Preliminary Operations

• Remove the co ee bean hopper cover,

the drip tray with grill and the milk

container from the packaging.

• Remove the co ee machine from the

packaging and position it in a place

that meets the requirements described

in the safety regulations.

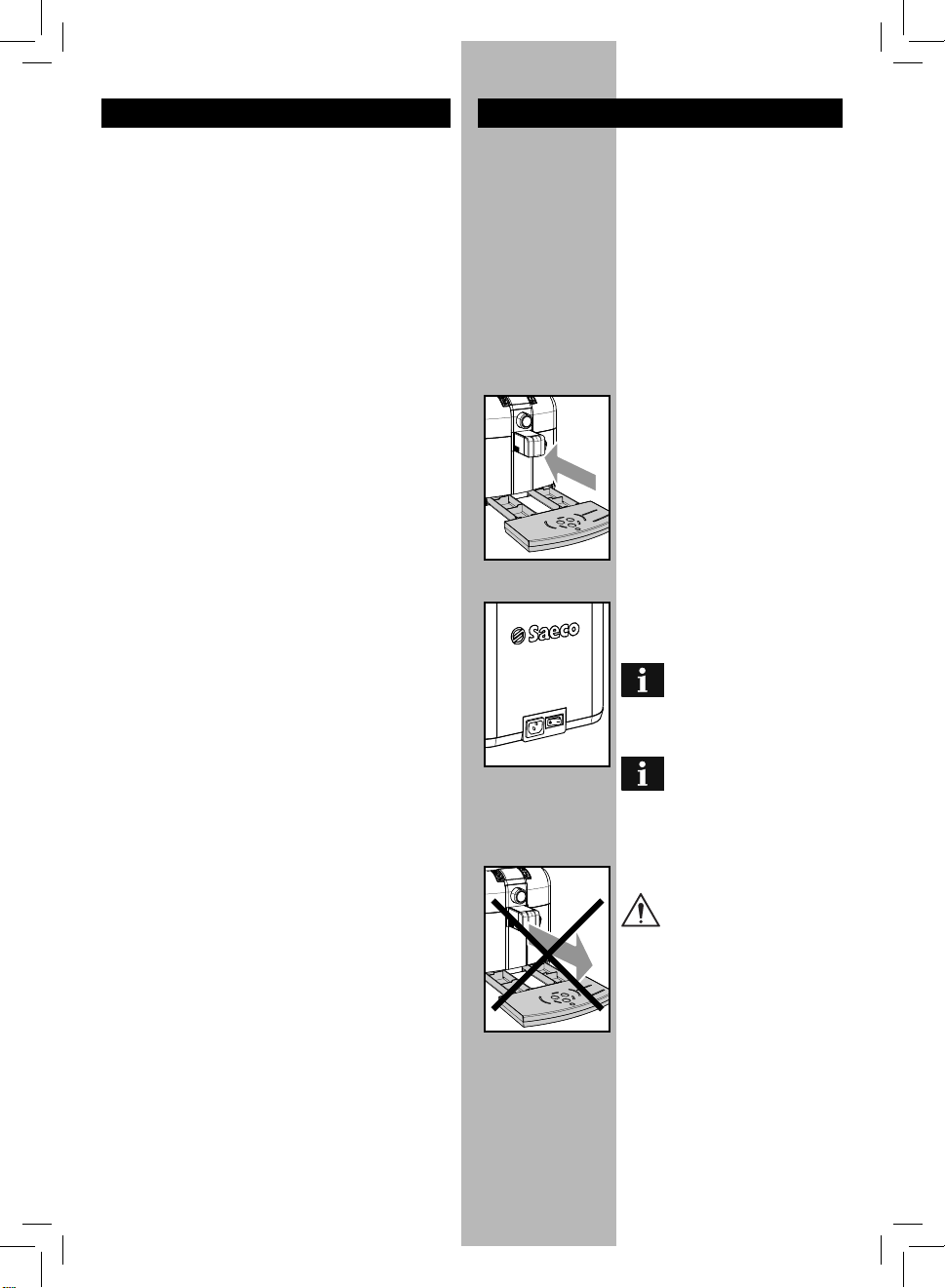

• Place the drip tray with grill into its

appropriate seat on the machine. Make

sure it is fully inserted to its limit stop.

• Insert the co ee bean hopper cover.

Note: Insert the plug into the

socket only when indicated

and check that the general switch is

in "0" position.

Important note: Carefully

read the explanations of all

the warnings the machine displays

to the user on the control panel

LCD display (section "LCD Display

Warnings").

NEVER remove the drip tray

when the machine is turned

on. Wait a couple of minutes after

turning on/o , as the machine will be

carrying out a rinse/self-cleaning cycle (see section "Rinse/Self-cleaning

Cycle").

• 5 •

Page 8

• Remove the water tank from its place.

• Rinse and ll it with fresh water making sure that it is not lled exceeding

the (MAX) level indicated in the tank.

Put the tank back in its place.

Fill the tank only with fresh,

non-sparkling water. Hot water or any other liquid may damage

the tank and/or the machine. Do not

operate the machine if water is not

present: Make sure there is enough

water in the tank.

• The display shows the ON/OFF icon.

Black

• Make sure the selector switch is on “

” position; if necessary, turn it to the

indicated position.

• To turn the machine on simply press the

ON/OFF button.

• Remove the co ee bean hopper cover.

Note: The hopper may be pro-

vided with different safety

features according to the regulations of the country of use of the

machine.

• Slowly pour the co ee beans into the

hopper.

Only coffee beans must be

put into the co ee bean hopper. Ground co ee, instant co ee or

any other object may damage the

machine.

• Replace the co ee bean hopper cover.

• Insert the plug into the socket on the

back of the machine.

• Insert the plug of the other end of the

cable into a wall socket with suitable

power voltage.

• Switch the power button to “I” to turn

the machine on.

• The display indicates that the machine

is priming the circuit.

Orange

Note: In some cases you may

be requested to manually

prime the circuit. For this operation

see section “Control Panel Display”.

RINSE/SELFCLEANING CYCLE

This cycle allows rinsing the co ee circuits

with fresh water.

The cycle is carried out:

• At machine start (with cold boiler)

• After priming the circuit (with cold

boiler)

• During the Stand-by preparation phase

(if a co ee product has been brewed)

• During the turning off phase after

pressing the ON/OFF button (if a coffee product has been brewed).

A small amount of water will be dispensed to rinse and heat all the machine

components; in this phase this icon is

displayed.

Wait for the cycle to nish automatically.

Orange

You can stop dispensing by pressing

either the co ee button and/or the

ON/OFF button.

• 6 •• 6 •

Page 9

USING THE MACHINE FOR THE FIRST TIME OR AFTER A LONG PERIOD OF INACTIVITY

8 Turn the selector switch clockwise and

set it to the “

The following icon will be displayed.

Press button “

hot water.

9 Dispense water until the no water

signal appears, then rotate the selector switch counter-clockwise until it is

back into the “

10 At the end, fill the water tank again.

Then the products can be brewed as

described in the following sections.

” position.

“ to start dispensing

” position.

Green

These simple operations will make it possible to always brew excellent co ee.

1 Place a large container under the

dispensing spout.

2 Before starting the procedure, check

that the following icon is displayed.

3 Select the pre-ground co ee brewing

function by pressing the “

one or more times.

Do not add pre-ground co ee

to the compartment.

The icon will appear on the display.

” button

Green

Red

Green

4 Press the button to brew a long cof-

fee.

5 Wait until brewing is completed and

empty the water container.

6 Repeat the operations from step 1 to

step 5 for 3 times; then continue with

step 7.

7 Empty the container and replace it

under the dispensing spout.

• 7 •

Page 10

“INTENZA” WATER FILTER

To improve the quality of the used water,

it is advisable to install the water lter.

Press the “

page is displayed.

” button until the following

Remove the water lter from its packaging, immerse it vertically (with the opening positioned upwards) in cold water

and delicately press the sides so as to let

the air bubbles out.

Remove the small white filter from the

tank and store it in a dry place sheltered

from dust.

Set the Intenza Aroma System as speci ed

on the box.

A = Soft water

B = Hard water (standard)

C = Very hard water

Insert the lter into the empty tank. Press

it until its limit stop.

Fill the tank with fresh drinking water and

reinsert it into the machine.

Orange

Orange

Orange

Orange

Press the “

press the “

In this way, the machine has been programmed to inform the user of the need

to replace the lter.

one, the function must be reset. Replace the lter as previously shown.

After that, enter the programming

menu until the indicated window

is displayed and select the “RESET”

option. Then press the “

This way, the machine is programmed

to manage a new lter.

remove - but not replace - it, select

the “OFF” option and then press the

“

” button to select “ON” and

” button to con rm.

Note: When an “Intenza” lter

must be replaced with a new

” button.

Note: If the lter is already

installed and you want to

” button.

• 8 •• 8 •

Dispense the water in the tank by using

the hot water function (see section "Hot

water dispensing”).

Fill the water tank again.

Turn the selector switch counter-clockwise and set it to the “

Condition for rst use of the machine.

” position.

To exit, turn the selector switch clockwise

and set it to the “

ously-removed small white lter into

the water tank.

” position.

Note: If there is no Intenza

water lter, insert the previ-

Page 11

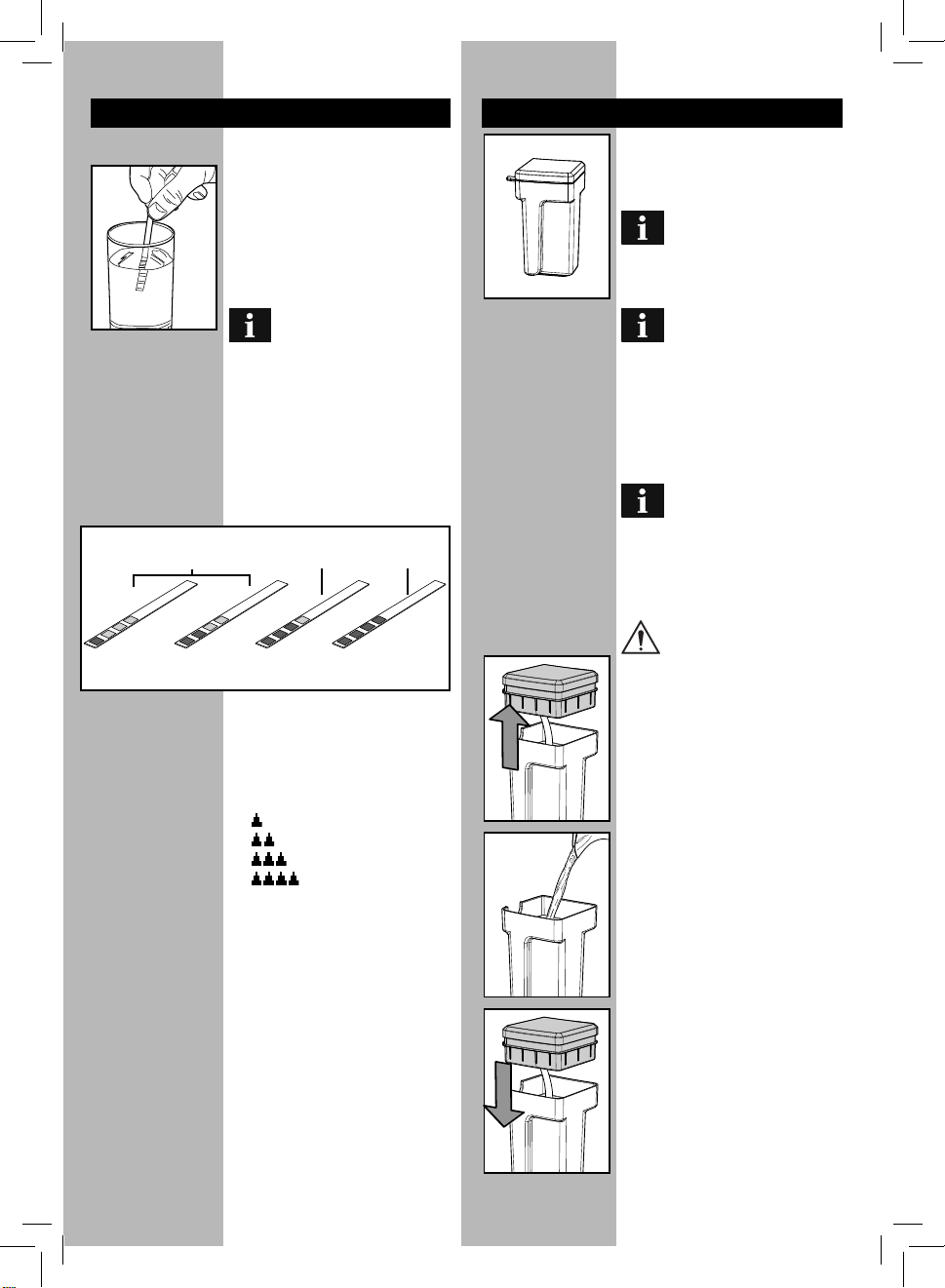

WATER HARDNESS MEASUREMENT

The water hardness measurement is very

important in order to correctly manage

the “Intenza” lter and the frequency with

which the machine must be descaled.

Immerse the water hardness test strip

provided with the machine in water for

1 second.

MILK CONTAINER

This section explains how to use a milk

container for the preparation of cappuccino or hot milk.

Note: Before using the milk

container, clean it thoroughly

as described in section "Cleaning and

Maintenance".

Note: The test strip is only

valid for one measurement.

Check how many squares change colour

and refer to the table.

The letters correspond to the references

that are located in the base of the Intenza

lter. The lter must be adjusted based on

this measurement.

Intenza Aroma System

A

1

23 4

Machine water hardness setting

The numbers correspond to the settings

that are found for the water hardness adjustment that is shown in the programming section.

More precisely:

1 =

2 =

3 =

4 =

B

(very soft water)

(soft water)

(hard water)

(very hard water)

C

Note: The milk must be

stored in the refrigerator

and poured into the container only

when preparing a cappuccino. After

use, put the container back in the

refrigerator.

DO NOT store milk out of the refrigerator for longer than 15 minutes.

Note: In order to ll the milk

container, remove it from

the machine.

The milk container must be filled

with whole milk at refrigerator

temperature.

Warning! It is forbidden to use

the container for any other

liquids other than drinking water.

To properly use the container, proceed as

follows:

1 Remove the top cover paying attention

to the suction pipe.

2 Fill the container with milk: Do not

exceed the MAX level indicated on the

container.

Once this value is known, set the water

hardness value as specified in the programming section.

3 Replace the suction pipe inside the

container and close the cover by pressing it to the end.

After that, the container may be used to

brew the desired beverages.

• 9 •

Page 12

COFFEE BREWING

the water tank contains water.

make sure the water tank and co ee

bean hopper are full.

Note: Should the machine not

brew co ee, make sure that

Before brewing co ee check

the lights on the display and

• Two cups/mugs can be placed under

the dispensing spout for brewing two

co ees at the same time.

Green

Leave the selector switch on

the co ee position “

the brewing phase.

Before brewing the cof-

fee, adjust the height of the

dispensing spout according to your

needs and select the aroma or preground co ee.

” during

Dispensing Spout Adjustment

Most cups on the market can be used with

this co ee machine.

The height of the dispensing spout may

be adjusted to better t the dimensions

of the cups that you wish to use.

Manually move the dispensing spout up

or down to adjust its height by placing

your ngers as shown in the gure.

The recommended positions are:

For the use of small cups;

Green

Green

'Aroma' Adjustment

The machine is set-up for adjusting the

amount of co ee to be ground.

Four choices are possible by pressing and

releasing the “

or strong aroma, and ground co ee.

Selection can be made when the beans

appear on the display. Each time the “

” button is pressed and released, the

aroma changes by one degree:

Selection must be made prior to selecting

the co ee. The system sets the aroma according to the personal taste of the user.

After selecting "Strong aroma", the function for brewing co ee with pre-ground

co ee is displayed.

This selection is displayed by the icon on

the side.

Refer to the relevant section to use this

function.

” button: mild, medium

= Mild aroma

= Medium aroma

= Strong aroma

• 10 •• 10 •

For the use of large cups.

Green

Note: A subsequent pressure

allows access to the page on

the side. This function allows brewing

hot milk.

Refer to the relevant section to use this

function.

Page 13

Green

Green

Using Coff ee Beans

• To brew co ee, press and release:

the “

the “

the “

• Then, the brewing cycle starts.

machine manages the brewing cycle

automatically.

• Coffee brewing stops automatically

” button to select the desired

Aroma.

” button for an espresso cof-

fee;

” button for a long co ee.

To brew 2 cups of co ee, press

the desired button twice. The

when the pre-programmed level is

reached; however, it is possible to interrupt co ee brewing by pressing the

button initially pressed.

Using Pre-ground Coff ee

This function allows using

pre-ground and decaffein-

ated co ee.

Note:

• If no pre-ground co ee is poured

into the compartment, only water

will be dispensed;

• If the dose is excessive and 2 or

more measuring scoops of co ee

are used, the machine will not

brew the product. Also in this case,

the machine will run an empty

cycle and discharge any ground

coffee into the coffee grounds

drawer.

• Add only 1 scoop of pre-ground co ee

to the compartment. Use the measuring scoop supplied with the machine to

perform this operation. Then, close the

cover.

Warning: Only add pre-ground

coffee to the compartment.

Only use ground co ee for espresso

machines and never co ee beans or

instant co ee. Other substances and

objects may cause severe damages to

the machine. Such damages will not

be covered by warranty.

Press and release:

the “

the “

• Then, the brewing cycle starts.

• Coffee brewing stops automatically

After brewing the product, the co ee

” button for an espresso cof-

fee;

” button for a long co ee.

when the pre-programmed level is

reached; however, it is possible to interrupt co ee brewing by pressing the

button initially pressed.

beans con guration of the machine is

restored.

Repeat the steps described

above to brew other co ees.

Green

To brew co ee:

• Press and release the “

select the pre-ground co ee function.

• Lift the pre-ground coffee compartment cover.

” button to

• 11 •

Page 14

CAPPUCCINO

Danger of scalding! Brewing

may be preceded by small jets

of hot water.

Important note: Immediately

after using the machine to

brew a cappuccino, clean all components as described in the "Cleaning of

the Milk Brewing System" section.

After lling the milk container, place it in

the machine. Insert the container pin in

its seat.

Make sure the container is inserted up to

its limit.

Green

Place the cup you use every day to enjoy

your cappuccino.

Before brewing co ee check

the lights on the display and

make sure the water tank and co ee

bean hopper are full.

It is possible to prepare a

cappuccino with pre-ground

co ee. Select the function with the

“

” button and pour the co ee in

the compartment as described in the

proper section.

HOT MILK BREWING

Danger of scalding! Brewing

may be preceded by small jets

of hot water.

After lling the milk container, place it in

the machine. Insert the container pin in

its seat.

Make sure the container is inserted up to

its limit.

Place the cup you use every day to enjoy

your hot milk.

• 12 •• 12 •

Green

Press the “

page is displayed.

Press the “

hot milk.

” button until the following

” button to start brewing

Page 15

Press the “ “ button.

Each brewing phase is programmed, but can be inter-

rupted in advance by pressing the “

” button.

• Once milk has been brewed, the ma-

chine brews the co ee.

• The following icon is displayed during

Green

the preheating time required by the

machine:

Orange

In this phase the machine

starts grinding co ee and/or

gets ready to brew co ee.

• When the following icon is displayed,

the machine brews frothed milk directly

Orange

in the cup.

Green

The icon on the side is displayed during

the short warm-up phase required by the

machine.

Orange Orange

Once the ideal temperature is reached, the

machine begins brewing the programmed

amount of hot milk.

Important note: Immediately

after using the machine to

brew a cappuccino, clean all components as described in the "Cleaning of

the Milk Brewing System" section.

Important note: Immediately

after using the machine to

brew a hot milk, clean all components

as described in the "Cleaning of the

Milk Brewing System" section.

Green

Brewing will stop automatically.

If you wish to interrupt hot milk brewing,

press the “

” button.

• 13 •

Page 16

Milk, even UHT milk, goes bad easily at room temperature; therefore, it is recommended to DO

NOT keep it at room temperature for long periods. Furthermore, the milk carafe has always to be

put back in the fridge when it is not needed.

It is also advisable to keep the parts in contact with the milk cleaned following the directions and

recommendations described in these instructions.

AUTOMATIC CLEANING FUNCTIONS

Before entering the Stand-by mode, the machine automatically performs a short cleaning cycle in the milk brewing area.

Moreover, after brewing any kind of milk-based beverage, the

machine reminds the user to clean the parts that have been

in contact with the milk.

This warning does not block any function of the machine

and can be deleted by pressing the right lower button every

time it appears.

However, it is advisable to regularly clean the parts

of the machine in contact with the milk following

the instructions described in the "CLEANING OF THE

MILK BREWING SYSTEM" section of the manual.

FAST CLEANING

(It is recommended to perform it after each milk brewing)

Before performing this operation remove the milk carafe from the machine.

Orange

• 14 •

Orange

Page 17

After having brewed milk for some times, turn the main knob to the right as for hot water dispensing: the image "CLEAN+” will appear.

Place a container under the dispensing spout and push the upper link button to start the cleaning operation. Then, bring the knob back

to the central position to allow other brewing programmes.

PERIODIC CLEANING

(It is recommended to perform this cleaning every time the milk carafe is removed, when the milk

system does not work properly or has milk deposits on it).

It is recommended to regularly clean the parts for brewing and frothing milk by dismounting both the parts

installed on the machine and those installed on the carafe.

Dismount the parts installed on the machine according to the instructions showed in the following gures:

• 15 •

C

L

E

A

N

I

N

G

O

F

T

H

E

M

I

L

K

B

R

E

W

I

N

G

S

Y

S

T

E

M

Page 18

PERIODIC CLEANING

Proceed as follows for the parts installed on the carafe.

• Remove the carafe from the machine.

• Lift the cover and pay attention that the wand does not splash the remaining milk.

• Remove the wand from the cover.

• Remove the pin:

- Rotate it counter-clockwise.

- Take o the pin from the cover.

• Wash the cover and the carafe with lukewarm water.

• Wash the wand and the pin of the machine by running lukewarm water inside the duct.

• 16 •

• After rinsing and drying all components, assemble the pin on the cover:

- Place the pin into the cover.

- Turn it clockwise until it is locked.

Insert the wand in the cover FROM THE STRAIGHT-CUT END and place the cover over the

milk container.

These parts can also be washed in the dishwasher placing them in the cutlery

basket so that they do not get lost.

Otherwise, the best way to clean the above-mentioned components is to leave

the dismounted parts for 30 min in a basinful of lukewarm water with the

speci c detergent Saeco Cleaning Powder. (Rinse the parts with running water

before reassembling them on the machine).

Page 19

Green

Proceed as follows to complete the cleaning process:

1 Remove the top cover paying attention to the suction pipe.

2 Fill the container with lukewarm water: Do not exceed the MAX level indicated on the

container.

3 Replace the suction pipe inside the container and close the cover by pressing it to the

end.

Place the cup you use every day to enjoy your hot milk.

Press the “

Press the “

Dispensing will stop automatically.

If you wish to interrupt water dispensing, press the “

” button until the following page is displayed.

” button to start dispensing water.

” button.

• 17 •

C

L

E

A

N

I

N

G

O

F

T

H

E

M

I

L

K

B

R

E

W

I

N

G

S

Y

S

T

E

M

Page 20

HOT WATER DISPENSING

Warning: At the beginning,

short spurts of hot water may

come out. Danger of scalding.

• Before dispensing hot water, check

that the following icon is displayed:

To reset the machine to normal opera-

tion turn the selector switch counterclockwise until it is set to the “

tion.

” posi-

Green

Green

When the machine is ready, proceed as

follows:

• Place a container under the dispensing

spout.

• Turn the selector switch clockwise and

set it to the “

• The following icon will be displayed.

Press the “ ” button to start dis-

pensing hot water.

position.

Orange

Orange

It may happen that, even

though the selector switch

has been turned, hot water does not

come out and the following icon is displayed. Wait for the warm-up phase

to end in order to obtain a ow of hot

water from the dispensing spout.

If the following icon is dis-

played, clean the dispensing

spout. After placing an empty container press the “

wait until the dispensing is nished.

Then, hot water may be dispensed.

” button and

• 18 •• 18 •

Green

• Pour the desired amount of hot water. To stop the hot water dispensing

press the “

” button.

Page 21

ADJUSTMENTS

The machine that you have bought allows

for certain adjustments that will permit

you to use it to its full potential.

Saeco Adapting System

Coffee is a natural product and its characteristics may change according to its

origin, blend and roast. The Saeco co ee

machine is equipped with a self-adjusting

system that allows the use of all types of

co ee beans available on the market (non

caramelised).

• The machine automatically adjusts

• The optimisation process is a learning

• Attention should be given to special

Coff ee Grinder Adjustment

bean hopper, must be turned only

when the grinder is working. Do not

pour ground and/or instant coffee

into the co ee bean hopper.

itself in order to optimise the extraction of the coffee, ensuring perfect

compression of the tablet to obtain a

creamy espresso co ee that will release

all the aromas, regardless of the type of

co ee used.

process that requires the brewing of a

certain number of co ees to allow the

machine to adjust the compactness of

the ground co ee.

blends, which require grinder adjustments in order to optimise the extraction of the co ee - (see section Co ee

Grinder Adjustment).

Warning! The grinder adjustment knob, inside the co ee

any type of operation inside the coffee bean hopper. Do not pour co ee

beans when the coffee grinder is

working.

The machine allows slight adjustments to

the co ee grinder to adapt it to the kind

of co ee used.

To make any adjustment, press and turn

the knob inside the co ee bean hopper.

Press and turn the knob by one notch at

a time and brew 2-3 cups of coffee; this

is the only way to notice differences in

grind.

The reference marks inside the coffee

bean hopper indicate the grind setting.

There are 5 different grind settings to

choose from with the following references:

Large Mark - Coarse Grind

Small Mark - Fine Grind.

Adjusting the Coff ee Length

The machine allows you to adjust the

amount of brewed coffee according to

your taste and/or the size of your cups.

Each time the “

pressed and released, the machine brews

a pre-set amount of co ee. This amount

may be reprogrammed to your taste. Each

button may be individually programmed

for a speci c brew setting.

As an example, the following procedure

describes the programming of the “

button, which is normally associated with

espresso co ee.

” or “ ” button is

”

Do not insert any material

other than co ee beans into

the hopper. The grinder contains

moving parts that may be dangerous.

Therefore, do not insert ngers and/

or other objects. The grind setting

may only be adjusted using the knob.

Turn o the machine and unplug it

from the socket before carrying out

• Place a cup under the dispensing

spout.

• 19 •

Page 22

ADJUSTMENTS

Green

Green

• Press and hold the “ ” button until

the (MEMO) icon is displayed. At this

point, the machine is programming it.

• The machine begins the brewing

phase. The “ ” icon will be displayed

to show which button is being programmed.

• From now on, press the button with

the “

” icon each time the desired

amount of coffee is reached in the

cup.

At this point, the “

grammed; each time it is pressed and

released, the machine will brew the same

amount of co ee that has just been programmed.

” button is pro-

Cappuccino Adjustment

The machine allows you to adjust the

amount of dispensed milk and co ee, in

order to obtain a cappuccino according to

your taste and/or the size of your cups.

Each time the “

and released, it is possible to brew a

programmed cappuccino according to

several pre-set parameters. The amount

of milk and co ee may be reprogrammed

to your taste.

” button is pressed

Orange

Green

Green

Green

Green

When the icon on the side appears, release the “

warming up for the preparation of milk.

In this phase the machine grinds the desired amount of co ee.

Once the machine is warmed up, the

brewing of hot milk starts.

The “

From now on, press the “

each time the desired amount of milk is

reached in the cup.

Once milk has been prepared, the machine starts brewing the co ee.

The “ ” icon will appear on the display.

From now on, press the “

each time the desired amount of co ee is

reached in the cup.

At this point, the “

grammed; each time it is pressed and

released, the machine will brew the same

amount of cappuccino that has just been

programmed.

” button. The machine is

” icon will appear on the display.

” button

” button

” button is pro-

• 20 •• 20 •

After lling the milk container, place it in

the machine. Insert the container pin in

its seat.

Make sure the container is inserted up to

its limit.

Place the cup you use every day to enjoy

your cappuccino.

Press and hold the “ ” button.

Orange

Note: After programming, the

following page appears. See

the "Cleaning of the Milk Brewing

System" section.

Page 23

Adjusting the amount of

frothed milk

The machine allows you to adjust the

amount of dispensed milk according to

your taste and/or the size of your cups.

Whenever you wish, it is possible to brew

a programmed amount of frothed milk in

your favourite cup. This amount may be

reprogrammed to your taste.

After lling the milk container, place it in

the machine. Insert the container pin in

its seat.

Make sure the container is inserted up to

its limit.

Place the cup you use every day to enjoy

your hot milk.

Press the “ ” button until the following

page is displayed.

Green

Orange

The “

” icon will appear on the display.

From now on, press the “

each time the desired amount of milk is

reached in the cup.

At this point, the “

grammed; each time it is pressed and

released, the machine will brew the same

amount of hot milk that has just been

programmed.

Note: After programming, the

following page appears. See

the "Cleaning of the Milk Brewing

System" section.

” button

” button is pro-

Green

Orange

Green

Press and hold the “

When the icon on the side appears, release the “

warming up for the preparation of milk.

Once the machine is warmed up, the

brewing of hot milk starts.

” button.

” button. The machine is

Black

Stand-by

The machine is designed for energy saving.

The machine automatically turns o after

60 minutes of inactivity.

Note: During the turning o

phase, the machine performs

a rinse cycle, if a co ee product has

been brewed.

To turn the machine on again, simply

press the ON/OFF button (if the power

button is set to “I”). In this case the machine will go through the rinse cycle only

if the boiler is cold.

• 21 •

Page 24

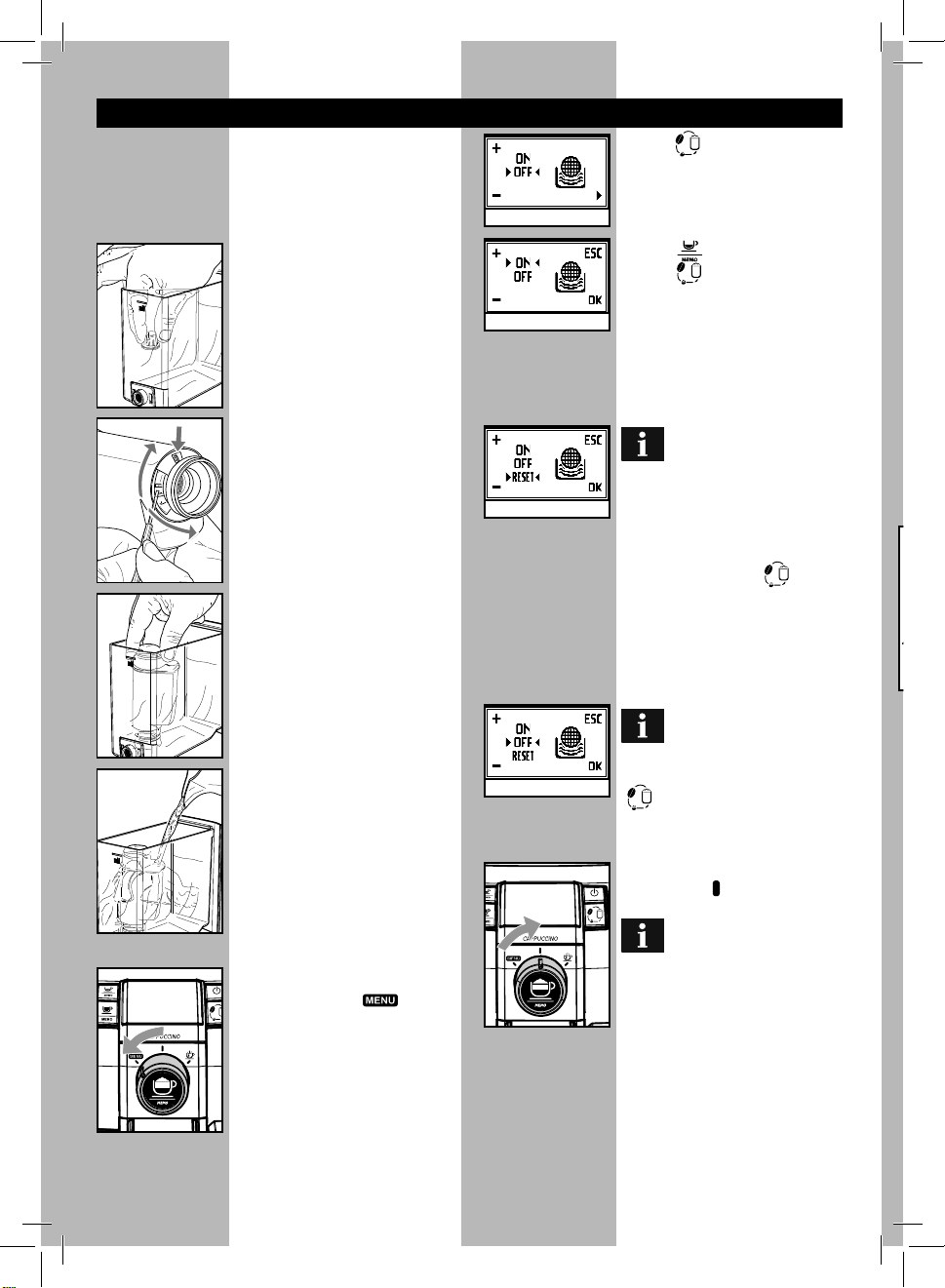

PROGRAMMING

The user can change some of the machine operating parameters to suit his/

her needs.

Enter the “menu”

The programming menu can be accessed

at any time when the machine is turned

on and ready to be used.

Programming controls

Changes can be made on each page:

Orange

Green

Orange

Orange

Orange

To access the programming menu, turn

the selector switch counter-clockwise and

set it to the “

The rst page that is displayed is shown

here.

pages and the selector switch is turned

counter-clockwise to be set to the

“

” position, the machine immediately displays the main menu to

complete the requested procedure.

This operation facilitates maintenance.

All menu items can still be viewed

and edited with the appropriate

controls.

” position.

Important note. When the machine displays the following

Orange

- The “ ” and “ ” buttons allow

changing the value of the function,

among those present on the page.

- The “

is changed; when the displayed

value is changed, the “OK” message

appears.

- The “ON/OFF” button allows you to exit

” button allows you to scroll

the functions and store the performed

changes.

Note: Changes can be stored

only after the displayed value

the change mode.

Exit Programming Mode

To exit the programming mode, turn the

selector switch back to the “

” position.

• 22 •• 22 •

Note: changes that were not

stored with the “

will be ignored.

” button

Page 25

Orange

Orange

Orange

Orange

Functions

COFFEE TEMPERATURE

This function allows you to adjust the coffee brewing temperature.

TIMER STANDBY

This function allows you to adjust the

time the machine will go into stand-by

mode after the last brewing.

CONTRAST

This function allows you to adjust the

contrast of the display to better view the

messages.

WATER HARDNESS

This function allows you to adjust the

water hardness in order to better manage

machine maintenance:

= very soft water

= soft water

= hard water

= very hard water

Orange

Orange

Programming Example

In this example, we want to explain how

to programme the display contrast. Proceed in a similar manner to change the

other functions.

With the machine turned on, access the

programming menu, turn the selector

switch counter-clockwise and set it to the

“

” position.

The rst page is displayed.

Press the “

TRAST" function is displayed.

Press the “ ” button once to increase

the contrast.

” button until the "CON-

Orange

Orange

Orange

For details, see the "Water

Hardness Measurement" sec-

tion.

"INTENZA" WATER FILTER

This function allows you to manage the

“Intenza” water lter.

For more details, see the section related

to lter handling.

DESCALING

This function allows you to manage the

machine's descaling cycle.

For more details, see the section related

to descaling.

FACTORY SETTINGS

This function allows you to reset all factory values.

Orange

Orange

Press the “

” button to con rm.

To exit the programming mode, turn the

selector switch back to the “

” position.

At this point, the function is programmed

and will be active immediately.

• 23 •

Page 26

CLEANING AND MAINTENANCE

General Cleaning

• Empty and clean the coffee grounds

drawer daily, with the machine turned

on.

• Maintenance and cleaning operations

can only be carried out when the machine is cold and disconnected from the

power supply.

• Do not immerse the machine in water.

• Do not wash any of its parts in the

dishwasher.

• Do not use sharp objects or harsh

chemical products (solvents) for cleaning.

• Use a soft, dampened cloth to clean the

machine.

• Do not dry the machine and/or its

components using a microwave and/

or standard oven.

• It is recommended to clean the water

tank daily:

- Remove the small white lter in the

water tank and wash it under running

drinking water.

- Reposition the small white lter in

its housing by gently pressing and

turning it at the same time.

- Fill the tank with fresh drinking

water.

• Empty and clean the drip tray daily.

Perform this operation also when the

oat is raised.

Brew Group

• The Brew Group should be cleaned

every time the co ee bean hopper is

lled or at least once a week.

• Turn o the machine by pressing the

ON/OFF button and remove the plug

from the socket.

• Remove the coffee grounds drawer.

Open the service door.

• To remove the Brew Group, pull it by

the handle and press the «PUSH» button. The Brew Group must be washed

only with lukewarm water with no

detergent/soap.

• Wash the Brew Group with lukewarm

water and carefully clean the upper

lter.

• Thoroughly wash and dry all the parts

of the Brew Group.

• Thoroughly clean the inside of the

machine.

• Make sure that the two reference signs

match up.

• 24 •• 24 •

• Also clean the seat of the tray every

week through the openings on the

bottom of the machine.

• Make sure that the lever is in contact

with the Brew Group. Press the "PUSH"

button to make sure that the Brew

Group is in the correct position.

Page 27

Lubricate the Brew Group af-

ter approximately 500 brewing cycles. The grease to lubricate

the Brew Group may be purchased at

authorised service centres.

• Lubricate the brew group guides using

the supplied grease only.

• Apply the grease evenly on both side

guides.

• Inser t the Brew Group in its seat until it

locks into place WITHOUT pressing the

"PUSH" button.

• Inser t the co ee grounds drawer. Close

the service door.

• 25 •

Page 28

DESCALING

Limescale normally builds up with the use

of the appliance.

• Then, the page appears on the display

to start descaling.

Orange

The display informs you when descaling

is necessary:

In case of conflict, prior-

ity must be given to what

is indicated in the operation and

maintenance manual over the instructions provided on separately

sold accessories and materials.

Empty the drip tray before

performing the descaling

cycle.

Use the Saeco descaling prod-

uct only. Its formula has been

designed to ensure better machine

performance and operation for its

whole operating life. If correctly used,

it also avoids alterations in the brewed

product.

Warning! Never drink the des-

caling solution or any products dispensed until the cycle has

been carried out to the end. Never use

vinegar as a descaling solution.

• Turn the machine on by pressing the

ON/OFF button. Wait for the machine

to finish its rinse and warm-up

process.

Warning! Remove the "In-

tenza" lter before adding the

descaling solution.

Remove the milk group before performing the descaling

cycle.

• Turn the selector switch counter-

clockwise and set it to the “

position.

Orange

Red

”

Red

• Press the “

descaling menu.

button to quit.

the descaling cycle.

• Pour the entire content of the Saeco

concentrated descaling solution into

the water tank, and then ll the tank

with fresh drinking water up to the

MAX level. Place the tank back into the

machine.

• Place a container under the dispensing

spout.

have a container of this capacity, pause the cycle by pressing the espresso

co ee button, empty the container,

place it under the dispensing spout

and restart the cycle by pressing the

same button again.

• Only after adding the descaling solution

in the tank, press the “

start the descaling cycle.

• At this point the machine will start

dispensing, at regular intervals, the

descaling solution (the bar shows the

cycle progress).

“ button to enter the

If you press the “ ” button

by mistake, use the same

If you press the “ ” button,

it is necessary to complete

Use a container of at least 1

litre capacity. If you do not

” button to

• 26 •• 26 •

Page 29

Red

Red

Note: The descaling cycle may

be paused by pressing the

“

“ button. To resume the cycle,

press the button again. This allows you

to empty the container or to go away

for a short period of time.

• When the solution in the tank is

nished, the icon on the side is displayed.

• The icon indicates that the tank must

be rinsed and lled.

Rinse the water tank thoroughly and

re ll it with fresh drinking water.

• Empt y the container used to collect the

liquid dispensed by the machine and

place it under the dispensing spout.

• When inserting the tank filled with

water the icon on the side is displayed.

The rinse cycle of the machine starts.

Red

Orange

• When inserting the water tank again

into the machine, the icon on the side

is displayed. Press the “

” button to

quit the descaling cycle.

• The machine now carries out the

warm-up and rinse cycle to prepare for

product brewing.

• The main page of the programming

menu is displayed.

• Then, turn the selector switch back to

the “

” position.

• The descaling cycle is complete.

Red

Red

Red

Red

Red

Note: The rinse cycle may be

paused by pressing the “

button. To resume the cycle, press the

button again. This allows you to empty

the container or to go away for a short

period of time.

• When the water in the tank is nished,

the icon on the side is displayed to

indicate that the tank must be rinsed

and lled with fresh drinking water to

nish the cycle.

• Empt y the container used to collect the

liquid dispensed by the machine and

place it under the dispensing spout.

• When inserting the tank lled with wa-

ter the icon on the side is displayed. The

rinse cycle of the machine continues.

• At the end, ll the tank again with fresh

drinking water, and empty the container

placed under the dispensing spout.

“

be disposed of according

to the manufacturer’s instructions

and/or regulations in force in the

country of use.

After completing the descal-

ing cycle, wash the brew

group as described in the “Brew

Group” section in the “Cleaning and

Maintenance” section.

When the descaling cycle is

complete, we recommend

emptying the drip tray.

• 27 •

The descaling solution must

Page 30

CONTROL PANEL DISPLAY

Ready Signals

• The machine is ready for brewing co ee and

cappuccino with co ee beans.

• The machine is brewing a cappuccino with

ground co ee.

Green

Green

Green

Green

Green

Green

• The machine is ready for brewing co ee and

cappuccino with pre-ground co ee.

• The machine is ready for hot milk brewing.

• The machine is ready for hot water dispens-

ing.

• The machine is brewing 1 cup of espresso

co ee.

• The machine is brewing 1 cup of long cof-

fee.

• The machine is brewing 2 cups of espresso

co ee.

Green

• The machine is programming the amount of

co ee to be brewed.

Green

• The machine is programming the amount of

hot milk to be brewed.

Green

• The machine is programming the amount of

cappuccino to be brewed.

Green

• 28 •• 28 •

Green

• The machine is brewing 2 cups of long cof-

fee.

Green

• The machine is brewing a cappuccino with

co ee beans.

Green

Page 31

Alarm Signals

• Close the service door.

• Start screen for descaling cycle activation.

Press “ESC” to quit.

Red

Red

Red

Red

Red

Red

• No co ee beans in the co ee bean hopper.

After re lling the hopper, the cycle can be

restarted.

• Turn the machine o . After 30 seconds, turn

it back on. Try this 2 or 3 times.

If the machine does NOT start, contact an

authorised service centre.

• The Brew Group must be inserted into the

machine.

• Insert the co ee grounds drawer.

• Empty the co ee grounds drawer and the

liquid recovery tray.

• Fill the water tank.

Red

• Descaling cycle in progress.

Red

• Descaling cycle PAUSED.

Red

• Rinse cycle of descaling cycle in progress.

Red

• Rinse cycle of descaling cycle PAUSED.

Red

• Descaling cycle ended. Press the “ ”

button to quit the descaling cycle.

Red

• Fill the water tank.

Red

Red

• Insert the drip tray

Red

• 29 •

Page 32

CONTROL PANEL DISPLAY

Warning Signals

• The machine is warming up to brew co ee

and dispense hot water and steam.

Orange

• The machine is performing the rinse cycle.

Wait until the machine stops the opera-

tion.

Orange

• The machine needs a descaling cycle.

Orange

• The Intenza lter must be replaced with a

new one.

This message will only be dis-

Orange

played if the function is activated

in the programming mode.

Orange

Orange

Orange

• The machine needs the milk system to be

cleaned. Refer to section “CLEANING OF THE

MILK BREWING SYSTEM”.

After washing the milk group, press the

“ ” button to cancel the warning.

• The Brew Group is being reset due to ma-

chine reset.

• Re ll the co ee bean hopper with co ee

beans and restart the co ee brewing cycle.

• Problems with the water circuit. Press the “

” button to start the manual priming

cycle of the water circuit.

The alarm is deactivated only if it is "RESET" in the programming mode.

Orange

Orange

TECHNICAL SPECIFICATIONS

The manufacturer reserves the right to make changes to the technical speci cations of the product.

Nominal Voltage - Power Rating - Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See label on the inside of the ser vice door

Housing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Thermoplastic Material/Metal

Size (w x h x d) (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256 x 315 x 415

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 kg

Power Cord Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.2 m

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Front side

Water tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.2 litres – Removable

Co ee Bean Hopper Capacity (g). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Co ee Grounds Drawer Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pump pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 bar

Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Stainless steel type

Safety Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Thermal fuse

• 30 •• 30 •

Page 33

TROUBLESHOOTING

Machine Actions Causes Solutions

The machine does not turn on. The machine is not connected to the electric net-

work.

The co ee is not hot enough The cups are cold. Preheat the cups with hot water.

No hot water or cappuccino comes out. The milk group is clogged. Clean the milk group.

The co ee has not enough crema.

(See note)

The machine takes a long time to warm up

or the amount of water dispensed from the

wand is too little.

The brew group cannot be removed. The brew group is out of place. Turn on the machine. Close the service door. The brew

The machine grinds the co ee beans but

no co ee comes out.

(See note)

The co ee is too weak.

(See note)

Co ee is brewed slowly.

(See note)

Co ee leaks out of the dispensing spout. The dispensing spout is clogged. Clean the dispensing spout and its holes.

The coffee blend is unsuitable, the coffee is not

freshly roasted or the grind is too coarse.

The machine circuit is clogged by limescale. Descale the machine.

The co ee grounds drawer is inserted. Remove the coffee grounds drawer before removing

There is no water. Fill the water tank and prime the circuit (section "Using

The brew group is dirty. Clean the brew group (section "Brew Group").

The circuit is not primed. Prime the circuit (section "Using the Machine for the

Rare event that occurs when the machine is automatically adjusting the dose.

The dispensing spout is dirty. Clean the dispensing spout.

Rare event that occurs when the machine is automatically adjusting the dose.

The co ee grind is too ne. Change co ee blend or adjust the grind as explained in

The circuit is not primed. Prime the circuit (section "Using the Machine for the

The brew group is dirty. Clean the brew group ("Brew Group" section).

Connect the machine to the electric network.

Make sure that the machine is turned o and has

cooled before performing this operation.

Change co ee blend or adjust the grind as explained in

section "Co ee Grinder Adjustment".

group automatically returns to the correct position.

the brew group.

the Machine for the First Time").

First Time").

Brew a few coffees as described in section “Saeco

Adapting System”.

Brew a few coffees as described in section “Saeco

Adapting System”.

section "Co ee Grinder Adjustment".

First Time").

Note: These problems can be considered normal if the co ee blend has been changed or the machine is being installed for

the rst time. In this case wait until the machine performs a self-adjusting operation as described in section "Saeco Adapting System".

Please contact customer service for any problems not covered in the above table or when the suggested solutions do not

solve the problem.

• 31 •

Page 34

• 32 •

Page 35

• 33 •

Page 36

02

EC DECLARATION OF CONFORMITY

YEAR 09

EC 2006/95, EC 2004/108,

SAECO INTERNATIONAL GROUP S.P.A.

Via Torretta, 240 - 40041 Gaggio Montano (BO) - Italy

we declare under our sole responsibility that the following product:

AUTOMATIC COFFEE MACHINE

SUP 037DRJ

to which this declaration relates is compliant with the following directives:

• Speci cation for safety of household and similar electrical appliances - General

requirements

EN 60335-1 (2002) + A1(2004) + A2(2006) + A11(2004) + A12 (2006) +A13 (2008)

• Speci cation for safety of household and similar electrical appliances - Part 2-15

Particular requirements for appliances for heating liquids

EN 60335-2-15 (2002) + A1(2005) + A2 (2008)

• Safety of household and similar appliances. Electromagnetic elds

Methods for evaluation and measurement - EN 62233 (2008)

• Speci cation for safety of household and similar electrical appliances - Part 2-14

Particular requirements for pulverisers and co ee grinders

EN 60335-2-14 (2006) + A1 (2008).

• Limits and methods of measurement of radio interference characteristics of

electric motor operated and thermal household appliances, portable tools and

similar electrical apparatus - EN 55014-1 (2006).

• Electromagnetic compatibility (EMC) Part 3 Limits - Section 2:

Limits for harmonic current emissions (equipment input current ≤ 16A per

phase) - EN 61000-3-2 (2006)

• Electromagnetic compatibility (EMC) Part 3 Limits - Section 3:

Limitation of voltage uctuations and icker in low-voltage supply systems for

equipment with rated current ≤ 16A.

EN 61000-3-3 (1995) + current (1997) + A1(2001) + A2 (2005).

• Immunity requirements for household appliances, tools and similar apparatus.

Product family standard EN 55014-2 (1997) + A1 (2001)

according to the provisions of the directives: EC 2006/95 , EC 2004/108.

MACHINE DISPOSAL

- The packing materials can be recycled.

- Appliance: Unplug the appliance and cut the power cord.

- Deliver the appliance and power cord to a service center or public

waste disposal facility.

This product complies with eu directive 2002/96/ec.

The symbol

this product may not be treated as household waste. Instead it shall

be handed over to the applicable collection point for the recycling of

electrical and electronic equipment.

By ensuring this product is disposed of correctly, you will help prevent potential negative consequences for the environment and

human health, which could otherwise be caused by inappropriate

waste handling of this product. For more detailed information about

recycling of this product, please contact your local city o ce, your

household waste disposal service or the shop where you purchased

the product.

on the product or on its packaging indicates that

Gaggio Montano

28.04.2009

R & D Manager

Eng. Andrea Castellani

The manuf a ct ur e r re se rves the ri ght t o ma ke c ha ng es w i th o ut p r io r no t ic e.

www.philips.com/saeco

EN

Rev.03 del 15-07-10

02

Loading...

Loading...