Page 1

PSSG

PHILIPS SERVICE SOLUTIONS GROUP

PHILIPS TECHNICAL

TRAINING

PHILIPS

TECH

VIDEOTAPES

MANUALS

COLOR TV

CHASSIS

Philips Technical Training (USA)

401 E. Old Andrew Johnson hwy

PO box 555

Jefferson City, TN 37760

PH: 865-475-0397

FAX: 865-475-0221

TRAINING

EMAIL: Technical.Training@Philips.com

G7

Page 2

TABLE OF CONTENTS

CUSTOMER SERVICE MODE 13

EAST WEST CORRECTION CIRCUIT 11

HORIZONTAL OUTPUT CIRCUIT 9

INTRODUCTION 1

MICROPROCESSOR CIRCUIT 11

POWER SUPPLY BLOCK 5

POWER SUPPLY 8

SERVICE ALIGNMENT MODE 13

SERVICE DEFAULT MODE 11

SIGNAL FLOW 1

TROUBLESHOOTING FLOW 15

Page 3

G7 COLOR TV CHASSIS

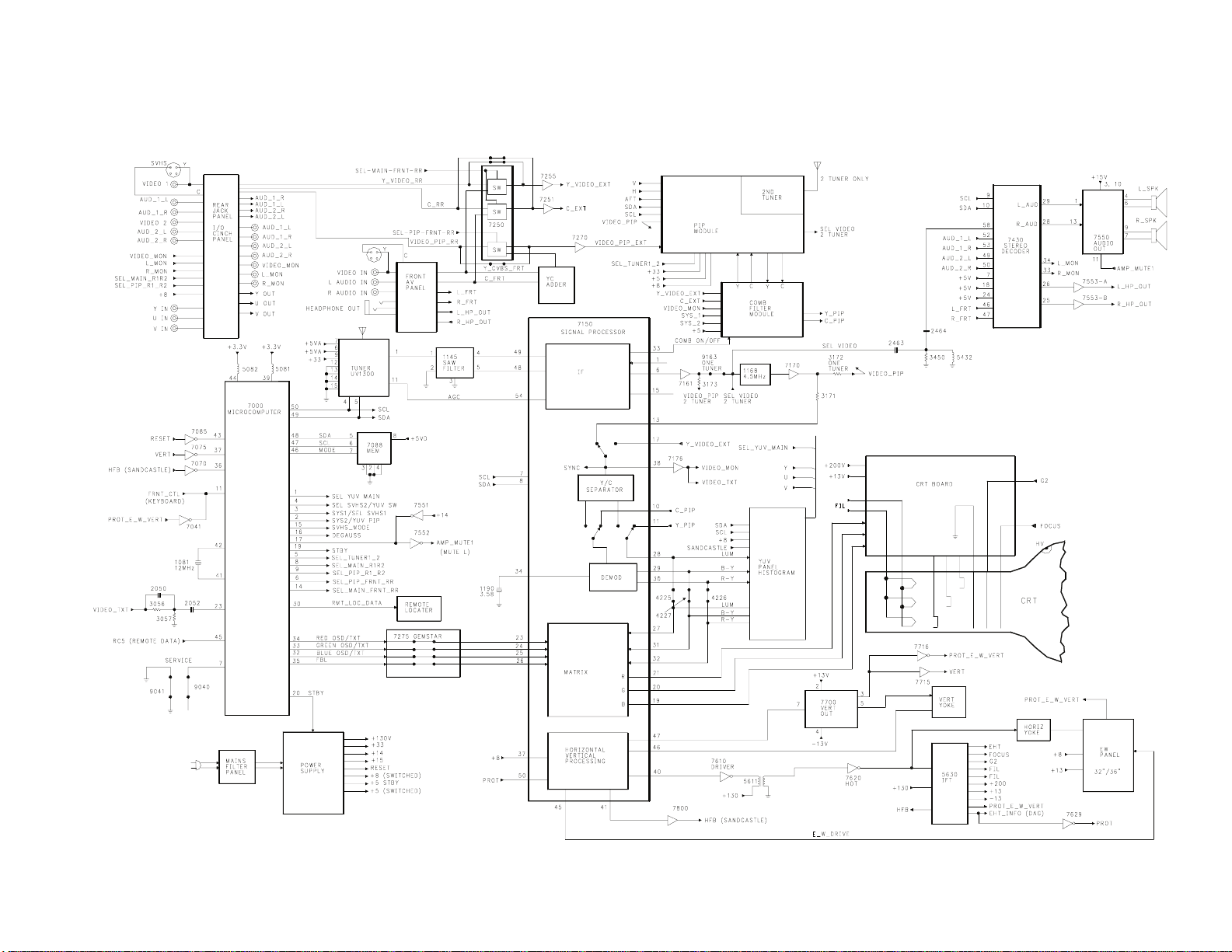

INTRODUCTION (Figure 1)

The G7 chassis is a high end TV

chassis produced by Philips

Consumer Electronics Company for

the 1999-2000 model year. The G7

chassis is used in TV sets with

27, 32, and 36 inch screen sizes.

The G7 Tuning System features 181

channel tuning with On-Screen

display. In the two tuner

version, the second Tuner and IF

circuits are located on the PIP

module. The Tuning System uses

two ICs mounted on the main

chassis, which include a

microcomputer IC and a memory IC.

The microcomputer communicates

with the Memory IC, the Customer

Keyboard, the Remote Receiver, the

U/V Tuner, the Signal Processor,

the Stereo Decoder, the PIP

module, the Side Jack Panel

(optional), the Comb Filter module

and the Power On/Off circuitry.

The Memory IC retains the settings

for favorite station, customer

control settings, and Factory

Setup data.

The chassis features a Very Large

Scale Integration (VLSI) IC for TV

signal processing. This IC

performs video IF, AFT/AGC

control, horizontal/vertical

synchronization, Chrominance/

luminance processing, and video

switching between internal and

external inputs in versions

without a PIP module. On-Screen

Graphics generation and Closed

Caption decoding are done within

the Microcomputer with signals

being sent to the TV signal

processor. The On-Screen Graphics

information is placed on the main

signal within the TV Signal

Processor. Automatic Volume Level

(AVL) control from the

microcomputer is sent to the

Stereo Decoder IC via the I2C bus.

The G7 chassis features a

Switching Mode Power Supply for

the voltage source. A "HOT"

ground reference is used in the

primary side of the power supply.

"COLD" (signal) ground is used

from the secondary of the power

supply throughout the rest of the

chassis. AN ISOLATION TRANSFORMER

IS REQUIRED WHEN DOING SERVICE ON

ANY VERSION OF THE NEW CHASSIS.

SIGNAL FLOW

The incoming RF signal is applied

to the U/V Tuner via the Antenna

and RF input. The 45.75MHz IF

signal is developed within the U/V

Tuner, then amplified by an IF

Preamplifier located inside the

Tuner. The amplified IF signal is

sent from Pin 1 of the U/V Tuner

to Pin 1 of the SAW filter 1145.

The SAW filter produces bandpass

shaping for the IF signal before

it is applied to the TV Signal

Processing Integrated Circuit 7150

Pins 48 and 49 for Processing.

AGC voltage is developed within

7150 and sent to the Tuner for RF

Amplifier gain control. The AFT

(to the Microcomputer) signal is

developed within IC 7150 and sent

to the Microcomputer via the I2C

bus for Tuner Oscillator frequency

correction.

Video switching by the Rear Jack

panel is accomplished by the

Microcomputer via SEL_MAIN_R1R2

and SEL_PIP_R1_R2. The Rear Jack

panel selects between Video1 or

page 1

Page 4

FIGURE 1 - OVERALL BLOCK DIAGRAM

page 2

Page 5

Video2 as the signal source for

the outputs Y_Video_RR or

Video_PIP_RR. The SVHS input is

connected to the Video1 input.

The Y_Video_RR output of the Rear

Jack can either be composite video

from Video1 or Video 2. If the

selected Video1 input is from the

SVHS Jack, this is a luminance

signal. The Y_Video_RR is fed to

switching IC 7250, which selects

between Y_Video_RR or Y-CVBS_FRT

from the Side Jack panel. If the

input to the Side Jack panel is

from an SVHS source and this

source is selected by the user as

the PIP window, the YC is fed to

a YC adder. IC 7250 then selects

between the output of the YC adder

or the Video_PIP_RR source from

the Rear Jack panel. This

Composite signal is then buffered

by transistor 7270 and becomes

Video_PIP_EXT. This Composite

video is fed to the PIP module

where it is used as the source for

the PIP window. Selected

Composite video for the main

picture from 7250 is buffered by

transistor 7255. It becomes

Y_Video_ext and is then fed to the

Comb Filter panel and Pin 17 of IC

7150 Signal Processor. Chroma

C_RR from the Rear Jack panel's

SVHS jack is fed to 7250, which

selects between C_RR and C_FRT.

This signal is then buffered by

transistor 7255 becoming C_ext

before being fed to the Comb

Filter module. Video_PIP_RR from

the Rear Jack panel is also fed to

7250, which selects between

Video_PIP_RR or the output of the

YC adder. This signal is then

buffered by transistor 7270 and

becomes Video_PIP_ext and is fed

to the PIP module.

Composite video from 7150 Pin 6 is

buffer by transistor 7161. In the

one Tuner PIP or in the non-PIP

version, the video signal is

passed through jumper 9163. In

the two Tuner version, video is

passed through resistor 3173 to

the Video PIP input of the PIP

module. The PIP module selects

either the Video from IC 7150, or

from the second Tuner located on

the PIP module. The second Tuner

on the PIP module has its own IF

circuit. The SEL_Video in the

two-tuner version is then fed back

to the input of the 4.5 MHz trap

1167. SEL_Video is fed to the

Stereo decoding circuit for audio

processing. The signal is

buffered again by transistor 7170

before being passed to Pin 13 of

7150. In the single tuner

version, video is passed through

resistor 3172 to the Video_ PIP

input of the PIP module if this

source is selected for the PIP

window. The switch inside 7150

selects between the output of 7170

or Y_Video_ext for either the

single or two tuner versions. The

Internal/External switch of IC

7150 is controlled by the

Microcomputer via the I2C bus.

Selected video from IC 7150 on Pin

38 is buffered by transistor 7176

where it is sent to the

Input/Output (I/O) panel, the Comb

filter, and the Video Text input

of the Microcomputer. The I/O

panel has an external jack for

video output. The Comb filter

separates the video into Y

(Luminance) and C (Chroma)

signals. If the SVHS input is

selected the Y signal is fed to

the Comb filter via the

Y_Video_ext line and the C signal

is fed to the Comb filter on the

C_EXT line. The Comb On/Off line

page 3

Page 6

from Pin 33 of 7150 switches the

Comb Filter between VIDEO_MON and

the SVHS input. In the PIP

versions, the Y and C signals are

sent to the PIP module. The PIP

circuit selects as the main

picture the YC signals from the

Comb filter. The YC signals from

the PIP module are then looped

through the Comb filter module to

Pins 11 and 10 of IC 7150. In

the non-PIP version, the Y and C

signals are sent to pins 11 and 10

of IC 7150 from the Comb filter.

The Chroma signal on Pin 10 is fed

to an internal Demodulator inside

7150. B-Y and R-Y signals

developed by the Demodulator and

output on Pins 29 and 30. The Y

or Luminance signal on Pin 11 is

looped through 7150 to Pin 28. In

sets with the YUV panel, Y, B-Y,

and R-Y are fed to the YUV panel.

The YUV panel then selects between

the output of 7150 or the YUV

signal from the Rear Jack panel.

The Y, B-Y, and R-Y signals from

the YUV panel are fed to Pins 27,

31, and 32 of IC 7150. The YUV

panel is a Histogram circuit,

which processes the Luminance to

set the black bias level. In sets

without the YUV panel, the Y, R-Y,

and B-Y signals are fed through

jumpers 4225, 4226, and 4227.

Red, Green, and Blue On-Screen

display signals from the

Microcomputer IC 7000 Pins 34, 33,

and 32 are fed to the Signal

Processor 7150 Pins 23, 24, and

25. Fast blanking from IC 7000

Pin 35 is fed to IC 7150, Pin 26.

The On-Screen signals are applied

to the Red, Blue, and Green

signals developed in the signal

processor matrix. Brightness,

Picture, Sharpness, Color, and

Tint control voltages are

developed within IC 7150 from the

Tuning System Microcomputer, IC

7000, via the I2C bus. The Red,

Green, and Blue signals developed

by the signal processor 7150 from

Pins 21, 20, and 19 are applied to

the CRT board. On the CRT board,

these signals are amplified before

being applied to the CRT.

The Drive and Cutoff controls for

the CRT set-up are controlled

within IC 7150 and are set by the

Microcomputer IC 7000 via the I2C

bus. Adjustments are performed

with the set in the Service Test

Mode. Always use the procedures

given in the Service Manual for

setting up the CRT circuits (White

Balance). The Drive controls are

adjusted for proper mixing of the

Luminance and Chrominance signals.

The Cutoff Controls provide

adjustment of the bias level for

the CRT cutoff values.

Horizontal and Vertical signals

are developed within IC 7150.

Adjustments for Horizontal

Centering, Vertical Centering,

AFT, and Vertical Height are done

with the Remote Transmitter via

the Service Test Mode. There is

no adjustment for the Horizontal

Oscillator. The Horizontal

circuit is a count down type of

system that gets its base

frequency from the 3.58MHz

circuit.

When the set is turned On, a High

is output from IC 7000 Pin 20 to

turn On the switched +8 volt

supply. The +8 volt supply

provides voltage to Pin 37 of IC

7150 to the Horizontal oscillator.

The Horizontal drive on Pin 40

page 4

Page 7

drives transistor 7610.

Horizontal drive from transistor

7610 coupled through the Driver

Transformer 5611 to drive the

Horizontal Output transistor 7620.

The Horizontal Output transistor

7620 drives the IFT and Horizontal

Yoke. The IFT develops the high

voltage, focus voltage, and

filament voltage for the picture

tube. Scan derived voltages

provided by the IFT for use by the

chassis are the G2, +200, +13, and

-13 volt.

The Vertical signal output from IC

7150, Pin 47, is applied to the

vertical output IC 7700. The

vertical signal output from IC

7700 is applied to the Vertical

Yoke. Feedback from the vertical

circuit is fed to IC 7150, Pin 46.

Vertical output on Pin 3 of 7700

is buffered by transistor 7715 to

provide Vertical sync to the

Microcomputer to synchronize the

On-Screen Display and Closed

Caption.

The Stereo decoder IC 7430

performs audio selection and Sound

processing in the G7 chassis.

SEL_Video is fed to 7430 which has

built in Sound IF and decoding

circuits. IC 7430 selects between

internally decoded audio or from

AUD_1, AUD_2, or FRT. Left and

Right monitor audio is output on

Pins 34 and 33. This signal is

fed to the Rear Jack panel. Main

Audio is output on Pins 28 and 29

and fed to the Audio amplifier

7550 before being applied to the

speakers. Headphone audio is

output on pins 25 and 26 and is

amplified by 7553 before being

applied to the Headphone jack.

The PROT_E_W_VERT line monitors

three points to shut down the set

in case of a problem. Transistor

7716 monitors the Vertical output

circuit for failure. The IFT

circuit is monitored for

overvoltage. A circuit on the EW

panel monitors for a failure of

horizontal sweep. A failure at

any one of the three points will

place a High on the PROT_E_W_VERT

line turning On transistor 7041

causing Pin 11 of Microcomputer

7000 to go Low, turning the set

Off. In the case of an

Overcurrent condition in the IFT

circuit, the PROT line which

monitors the EHT_INFO (DAG) line

will go High. This voltage is

applied to Pin 50 of the Signal

Processor 7150. If this voltage

goes above 3.9 volts, 7150 will

detect the increase. This

information will be communicated

to the Microcomputer IC 7000

through the I2C bus. The

Microcomputer will then shut the

set Off.

G7 CHASSIS POWER SUPPLY BLOCK

(Figure 2)

When the 120Vac source is connected to the G7 chassis, approximately 160Vdc is developed by the

bridge rectifier circuit. The 160

volts dc goes through transformer

5912 to the Switch Regulator

Driver IC 3917. The Start voltage

for the switching mode power

supply is taken from the neutral

leg of the input ac.

The power supply includes a single

integrated circuit, operating as a

free-running switching mode power

supply. There is no separate

power supply for standby. The

page 5

Page 8

FIGURE 2 - POWER SUPPLY BLOCK

power supply turns On when ac is

applied to the set. The switching

regulator IC 7902 starts switching

when the initial voltage is

applied through the Start circuit.

The switch inside IC 7902 turns On

and Off to allow current to flow

through the primary of the

transformer 5912. Energy stored

in the primary during the On-time

is delivered to the secondaries

during the Off-time. Positive

voltage from the hot secondary on

Pin 8 is rectified to provide

operating voltage for the

switching regulator. The

secondary 130 volt supply is the

reference voltage for the supply.

This voltage is sampled by the

Voltage Control Feedback IC 7904.

This drives the Opto-isolator

7950, which provides feedback to

IC 7902. The feedback controls

the On time of the switch inside

IC 7902.

The voltages needed to operate the

television are developed from the

secondaries of transformer 5912.

When the set is turned On, the Low

on the Standby (STBY) line turns

Off transistor 7909 to switch the

8 volt regulator switch IC 7908 On

to provide the +8 volt supply to

the set. The regulator switch IC

7907 provides Reset to the

Microcomputer, a +5 volt standby,

and a switched +5 volt supply when

the scan derived +13 volts is

applied to the IC.

page 6

Page 9

FIGURE 3 - G7 POWER SUPPLY

page 7

Page 10

G7 SWITCH MODE POWER SUPPLY

(Figure 3)

Startup voltage for 7902 is taken

from the neutral side of the ac

line and fed to Pin 4 through

resistor 3917. When Capacitor

2912 charges to 14.5 volts, the

oscillator inside 7902 turns On

switching the FET inside the IC

On. Voltage from Pin 8 of

transformer 5912 is rectified by

6908 to develop the operating

voltage for the IC. The 130 volt

supply is the reference supply for

the IC. The 130 volt supply drives

the feedback IC 7904 which drives

the feedback optoisolator 7950.

This causes changes in the

reference voltage on Pin 1 of 7902

to regulate the 130 volt supply.

The Power supply produces a 130

volt, 33 volt, 14 volt, and 5 volt

standby voltage when power is

applied to the set. When the set

is turned On, the On/Standby line

goes Low turning transistor 7909

Off, turning 7908 On to produce

the 8 volt source. The Low will

also turn 7955 Off. The 5V_STBY

voltage is then applied to Pin 3

of 7907 through resistors 3951 and

3980. The 5 volt regulator inside

7907 will then be switched On to

output the 5 volt source on Pin 6.

G7 HORIZONTAL OUTPUT BLOCK

(Figure 4)

The +8 volt source turns the

Horizontal Oscillator section

inside 7150 On to produce horizontal drive on Pin 40. Vertical

drive on Pin 47 drives the

Vertical output IC 7700. The

output of the Vertical Output IC

on Pin 3 drives is buffered by

FIGURE 4 - HORIZONTAL AND VERTICAL BLOCK

page 8

Page 11

transistor 7715. This signal is

fed to the Microprocessor to synchronize the On Screen Display.

Vertical drive also keeps

transistor 7716 turned On to keep

the PROT_E_W_VERT line low. If

Vertical drive is lost, this turns

transistor 7716 Off, causing the

PROT_E_W_VERT line to go High

which will turn the set Off.

G7 HORIZONTAL OUTPUT CIRCUIT

(Figure 5)

Horizontal drive is fed to

transistor 7610 which drives the

Horizontal Output transistor 7620.

The Horizontal output circuit

produces High Voltage, Focus

NOTES:

Voltage, 200 volts, and G1 Voltage

to drive the CRT. A +13 volt and

a -13 volt supply is developed to

drive the Vertical output circuit.

The DAG voltage from Pin 10 of the

IFT is fed to the signal processor

to make changes in the Picture

level. This maintains the CRT at

a constant brightness level to

compensate for changes in Beam

Current. Transistor 7629 monitors

the DAG voltage to shut the set

down in the case of excessive Beam

Current. Excessive Beam current

would cause the DAG voltage to

become negative turning 7629 On.

This would cause the High Beam

Protect line to go High.

page 9

Page 12

FIGURE 5 - HORIZONTAL OUTPUT CIRCUIT

page 10

Page 13

G7 EAST - WEST CORRECTION CIRCUIT

(Figure 6)

East West Drive is fed to the gate

of 7680 on the East-West

correction panel to perform

linearity correction. The negative

horizontal pulses on the source

leg of 7680 keeps transistor 7658

turned Off. Transistor 7659 turns

On through resistor 3658. If the

Horizontal Output circuit should

fail, a dc voltage will develop on

the source of 7680. This will

turn transistor 7658 On, turning

transistor 7659 Off. The

PROT_E_W-VERT line will then go

High, which will shut the

Horizontal drive Off.

FIGURE 6 - EAST WEST CORRECTION CIRCUIT

G7 MICROPROCESSOR CIRCUIT (Figure

7)

The Microprocessor communicates

with the set via the control lines

and the SDA and SCL lines.

Vertical and Horizontal sync is

fed to the IC on Pins 37 and 36.

A High on the PROT_W_W_VERT line

will cause transistor 7041 to turn

On. This will cause Pin 11 of

the IC to go Low turning the set

Off.

Service Default Mode (SDM)

The Service Default Mode is used

to display Errors that have been

detected by the Microprocessor

during the operation of the set.

This is useful to the service

technician to determine what

circuit areas an intermittent

problem may have occurred. To

enter the Service Default Mode,

enter 0-6-2-5-9-6-Menu on the

remote control. To display the

Error Codes, press the Status

button on the remote. The Error

Codes will be hidden if the Status

button is pressed again. Up to

six Error Codes will be displayed.

The List of Error Codes is shown

on page 18 of the service manual.

Some of them are listed below:

0 =No Error

1 =X-ray protection, E/W

page 11

Page 14

FIGURE 7 - MICROPROCESSOR CIRCUIT

page 12

Page 15

protection, and/or Vertical

protection active

2 =High beam current protection

active

3 =Reserved

4 =+5V protection active

5 =Signal Processor (IC 7150)

register corrupted

To perform customer adjustments

while in this mode, press the Menu

button. The text "SDM" will

continue to be displayed in the

upper right hand corner of the

screen while adjustments are made.

To exit the Service Default Mode

and erase the Error Codes, turn

the unit Off using the power

button on the remote control.

Customer Service Mode

The Customer Service Mode (CSM)

allows the customer to retrieve

Error Data from a set that has a

working display. The customer is

instructed by phone to enter CSM

and read off the display that

appears. During this mode,

Parental lockout mode is defeated.

To enter the Customer Service

Mode, press and hold the Mute

button on the remote and the

Channel Up button on the set for

four seconds. To exit this mode,

press the power button on the

Remote or the front of the set.

Service Alignment Mode (SAM)

been On in hexadecimal format.

The next set of characters

(A80US1-2.1) displays the software

identification, country, and

software version. The characters

in the upper right hand corner of

the screen "SAM" shows that the

set is in the Service Alignment

Mode. The next line displays any

errors which may have occurred in

the set. The "SDM" mode is used

to erase the error codes. The

next line displays the OPT codes

which are the Feature Bits for the

chassis version being used. The

Feature Bits are changed in the

Options selection of the menu.

There are four selections in this

menu which are Reload Default,

Erase Buffer, Options, and

Alignments. Use the cursor up and

down buttons on the remote to

highlight the selection. Use the

cursor right button to select the

highlighted selection. Pressing

the Menu button on the Remote will

allow customer settings to be

made. The "SAM" will continue to

be displayed in the upper right

hand corner of the screen. Press

the Menu button again to return to

the alignment menu.

The "OPTIONS" selection in the

menu will allow changes to be made

in the Option Bits or Bytes. Refer

to the service manual for correct

Options of the chassis being

serviced.

Service alignments are performed

in the Service Alignment Mode. To

enter the Service Alignment Mode,

press 0-6-2-5-9-6-Status on the

Remote Control. The first set of

characters (00E6 for example) is a

Run Timer. The Run Timer displays

the number of hours the set has

The Alignment selection in the

Menu has a sub menu with four

selections. They are GEOMETRY,

WHITE TONE, TUNER, and BTSC SND.

White Tone settings are used to

set the white balance and CRT

drives. The Tuner settings are

used to set the AFT and AGC.

page 13

Page 16

The Geometry selection in the menu

has eleven selections in its sub

menu. Use the cursor up-down keys

on the Remote to highlight the

desired selection. Use the cursor

right-left keys to change the

value of the selection.

NOTES:

To save the changes, turn the set

Off using the power button on the

Remote Control. To ensure that

the new settings will be read by

the Microcomputer, remove ac power

from the set for a few seconds.

page 14

Page 17

START

DOES THE SET

TURN ON

DOES THE SET

SHUT DOWN

AFTER TURN ON

IS A PICTURE

PRESENT

IS COLOR

PRESENT

IS AUDIO

PRESENT

YES NO YES YES

IS 130 VOLTS

PRESENT ON 6913

CATHODE

MEASURE THE

RESISTANCE OF THE

130 VOLT LINE TO

GROUND

IS THE

RESISTANCE >4K

NO

CHECK FOR SHORTED

7620

NO

IS APPROX 140-160

VOLTS PRESENT ON

PIN 3 OF 7902

YES

CHECK FUSE 1900

AND BRIDGE 6903

NO

IS THE DRIVE ON PIN 3

OF 7902 PULSING ON

AND OFF

YES

CHECK DIODE 6908

AND RESISTOR 3959

YES

IS PIN 4 OF 7902 >

16 VOLTS

CHECK RESISTOR

3917 AND BRIDGE

6903

NO

NO YES

REPLACE 7902

DOES THE BASE OF 7909

GO LOW WHEN THE

POWER BUTTON IS

PRESSED

DOES PIN 2 OF

7908 GO TO 8V

IS PIN 1 OF 7904 >

10V

REPLACE 7908

IC7000 AND RELATED

COMPONENTS

REPLACE 7909

YES NO

YES

YES

NO

NO

YES

IS HORIZ DRIVE

PRESENT ON THE

BASE OF 7620

IS HORIZ DRIVE

PRESENT ON THE

COLLECTOR OF 7620

REPLACE 7150

TRANSISTOR 7610 OR

TRANSFORMER 5611

TRANSISTOR 7620

SET IS TURNING ON

TRY ANOTHER

SYMPTOM

YES

NO

NO

YES

NO

YES

IS HORIZONTAL

DRIVE PRESENT ON

PIN 40 OF 7150

A

YES

IC 7150 OR XTAL 1190

NO

YOUR PROBLEM IS

BEYOND THE SCOPE OF

THIS FLOWCHART

TRY CALLING FOR

TECHNICAL ASSISTANCE

YES

INSERT AUX AUDIO INTO THE

JACK PANEL AND SELECT THE

CORRECT INPUT IN THE MENU

NO

IS AUDIO

PRESENT AT THE

SPEAKERS

IC 7430

NO

IS AUDIO

PRESENT ON PINS

28&29 OF 7430

IC 7430

IS AUDIO

PRESENT ON PINS

4,6,9, AND 7 OF

7550

CHECK SPEAKERS

IS PIN 11 OF 7550

HIGH (14V) OR

LOW (0.7V)

IS 15 VOLTS

PRESENT ON PIN 3

OF 7550

IC 7550

DIODE 6918 IN THE

POWER SUPPLY

CHECK TRANSISTORS

7552 AND 7551 OR MICRO

7000

YES

NO

YES

YES

NO

LOW

HIGHNO

YES

NO

B

NO

G7

TROUBLESHOOTING

FLOW CHART

page 15

Page 18

A

DOES THE SCREEN

GO BRIGHT BEFORE

THE SET SHUTS

DOWN

IS THE VOLTAGE >

3.9 VOLTS

DOES PIN 11 OF 7000 GO

LOW AFTER THE POWER

BUTTON HAS BEEN

RELEASED

NO

CHECK I2C BUS ON

PINS 49 AND 50 OF

7000

IS THE VOLTAGE ON THE

CATHODE OF 6627 > 45

VOLTS WHEN THE SET IS

TURNED ON

IS HORIZ DRIVE

PRESENT ON PIN

36 OF 7000

IS VERTICAL DRIVE

PRESENT ON PIN 37 OF

7000

IS VERTICAL DRIVE

PRESENT ON PIN 3 OF

7700

NO

YES

NOYESNO

CHECK 200 VOLT

SOURCE

RESISTOR 3643 AND

DIODE 6641

TRANSISTOR 7629,

DIODE 3628, IFT, AND

RELATED

COMPONENTS

EW CORRECTION

CIRCUIT

IC 7150

TRANSISTOR 7610 OR

7620

IFT, TUNING

CAPACITORS

YES

NO

YES

YESYES

CHECK THE DC

VOLTAGE ON PIN 50

OF 7150 WHILE

TURNING THE SET ON

NO

TRANSISTORS 7715

AND 7075

CHECK PLUS AND

MINUS 13 VOLT

SUPPLIES

7700 VERTICAL OUT

7150 SIG PROC

NO

YES

B

IS OSD (ON

SCREEN DISPLAY)

PRESENT

INSERT A COMPOSITE

VIDEO SIGNAL INTO

THE REAR JACK

PANEL AND SELECT

THAT INPUT IN THE

MENU

IS THE PICTURE

PRESENT

YES

IS > 2V p-p DRIVE

PRESENT ON PINS

19,20, AND 21 ON 7150

NO

CHECK CRT BOARD

REPLACE 7150

YES NO

C

NO

WITH THE TUNER

SELECTED, IS VIDEO

PRESENT ON PIN 6

OF 7150

YES

D

NO

IS VIDEO PRESENT

ON PIN 13 OF 7150

TRANSISTORS 7161

OR 7170

FILTER 1168

PIP MODULE IF 2

TUNER VERSION

REPLACE 7150

NO

YES

YES

page 16

Page 19

D

IS 33 VOLTS

PRESENT ON PIN

12 OF THE TUNER

CHECK RESISTOR

3994 AND DIODE 6955

IS 5 VOLTS

PRESENT ON PIN 6

OF THE TUNER

SUB IF ON PIN 1 OF

1145, SAW FILTER

DOES VIDEO

APPEAR ON THE

SCREEN

SUB IF ON PIN 49 OF

7150

DOES VIDEO

APPEAR ON THE

SCREEN

REPLACE SAW FILTER

1145

REPLACE 7150

IS 5 VOLTS

PRESENT ON PIN 3

OF 7907

REPLACE 7907

CHECK 7955 AND

RELATED

COMPONENTS

NO

YES

YES

NO

NO

YES

NO

YES

NO

REPLACE TUNER

YES

C

IS VIDEO PRESENT ON THE

VIDEO_MON INPUT ON THE

COMB FILTER

IS VIDEO PRESENT

ON PIN 38 OF 7150

IS VIDEO PRESET

ON PIN 17 OF 7150

TRANSISTOR 7176

IC 7150

REAR JACK PANEL

IF Y-C PRESENT

GOING TO THE PIP

MODULE

IF PIN 33 OF 7150

APPROX 3 VOLTS

DC

NO

YES

NO

YES

NO

YES

NO

IC 7150

COMB FILTER

NO

YES

IS Y-C PRESENT

COMMING FROM THE

PIP MODULE

YES

PIP MODULE

NO

IS Y-C PRESENT

ON PINS 11 AND 10

OF 7150

COMB FILTER

YES

IS Y,R-Y, B-Y PRESENT

ON PINS 28,29, AND30

OF 7150

YES

IC 7150

NO

YES

NO

IF Y, R-Y, B-Y

PRESENT ON PINS

27, 31, AND 32 OF

7150

IC 7150

YUV PANEL

JUMPERS FOR NON

YUV SETS

NO

YES

page 17

Page 20

Dear Servicers,

Welcome to the New Internet version of Service Reporter

and Technical Training Manual .

Philips Technical Training is proud to reinstate this

valuable form of update training in a more timely format.

This first issue is a test to determine the value of this

information to you as a servicer.

Please review the material presented in both the Service

Reporter and Technical Training Manual .

Please also answer the accompanying survey form and

either fax or mail it to:

Philips Technical Training

PO Box 555

Jefferson City, TN 37760

Fax # 865-475-0221

or send us your comments by e-mail at:

TECHNICAL.TRAINING@PHILIPS.COM

Sincerely,

Philips Technical Training Department

Page 21

Service Reporter Survey

Please answer the following questions by selecting a rating of 1 through 5 (1 being the lowest

grade and 5 being the highest.)

1. Rate the Service Reporter article’s ability to increase your knowledge of the circuit

discussed?

1 2 3 4 5

2. How do you rate the need to ask further questions on this circuit?

1 2 3 4 5

3. Rate your ease of accessibility to articles accessible 24/7 via the Internet as is this one?

1 2 3 4 5

4. Rate how much you would like to suggest subjects for the Service Reporter on which you

need additional information?

1 2 3 4 5

5. Rate how much you like the Internet as a medium for easily accessible service information?

1 2 3 4 5

6. How do you rate the ability to access this information and print it out for your use, as you

need it?

1 2 3 4 5

7. Rate the Training Manual’s ability to increase your knowledge of the circuit discussed?

1 2 3 4 5

Thank you for your interest in and assistance to Philips Technical

Training.

Please mail or fax to: Philips Technical Training

PO Box 555

Jefferson City, TN 37760

Fax # 865-475-0221

Loading...

Loading...