Philips FM242 AA Service Manual

Colour Television Chassis

FM242

AA

Contents Page Contents Page

1 Technical Specifications, Connections, and 2

Chassis Overview

2 Safety Instructions, Maintenance, Warnings, 5

and Notes

3 Directions for Use 7

4 Mechanical Instructions 10

5 Service Modes, Error Codes, Fault Finding, 13

and Repair Tips

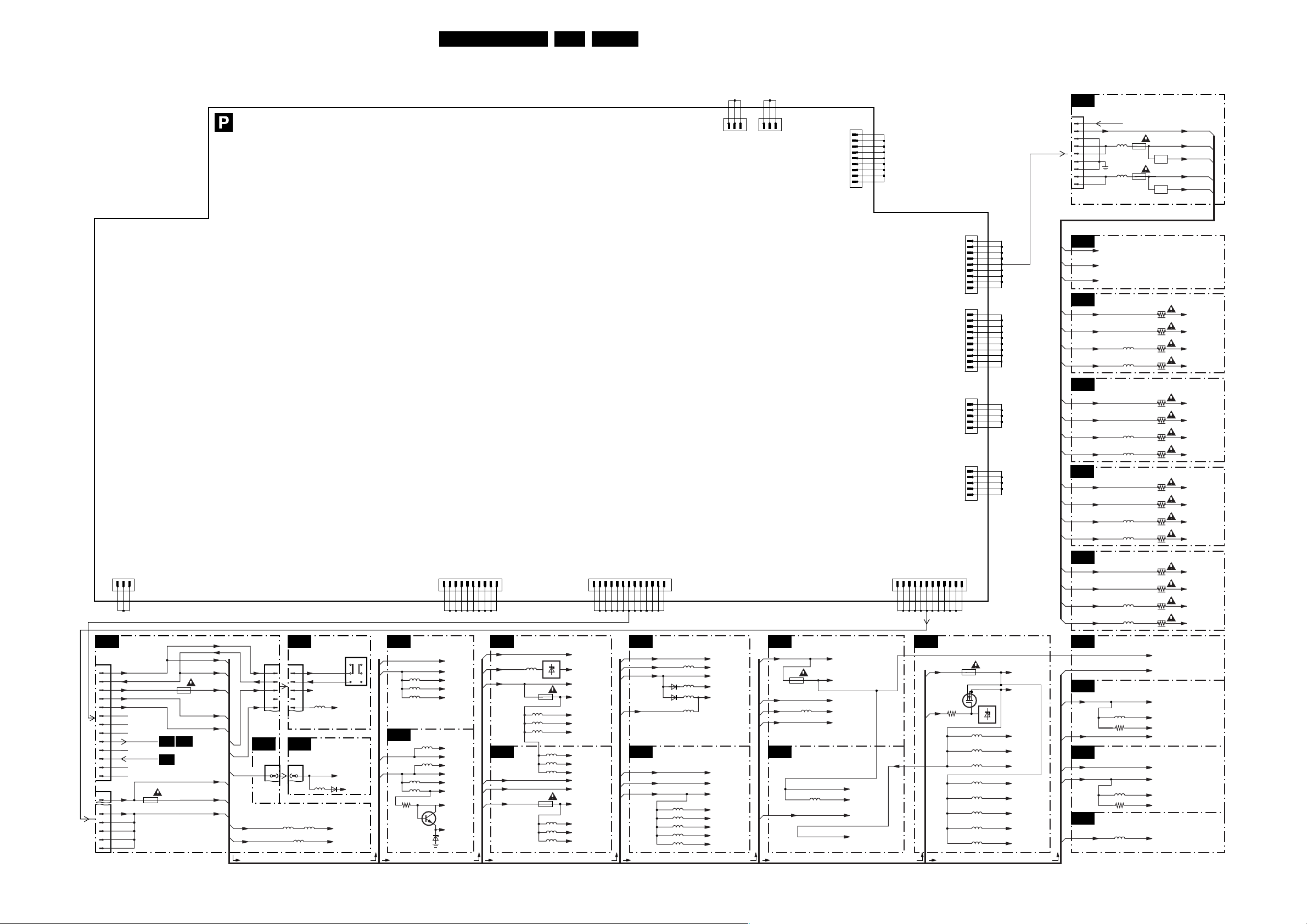

6 Block Diagrams, Test Point Overviews, and Wiring

Diagram

Block Diagram Video 19

Block Diagram Audio 20

Power Lines Overview 21

2

I

C-IC Overview 22

Testpoint Overview Audio Amplifier 23

Testpoint Overview Power Supply 24

Testpoint Overview SCAVIO Panel 25

Wiring Diagram 26

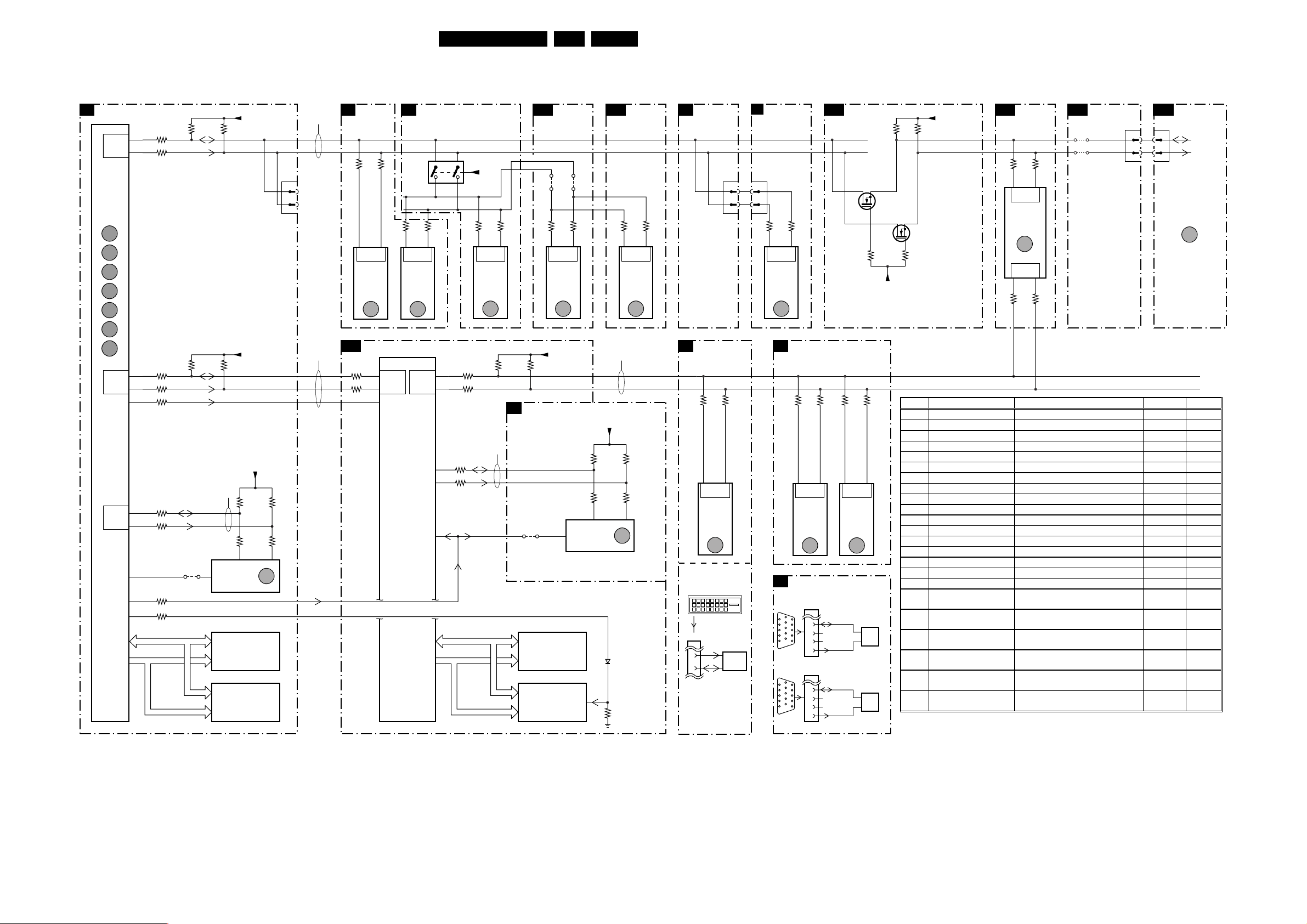

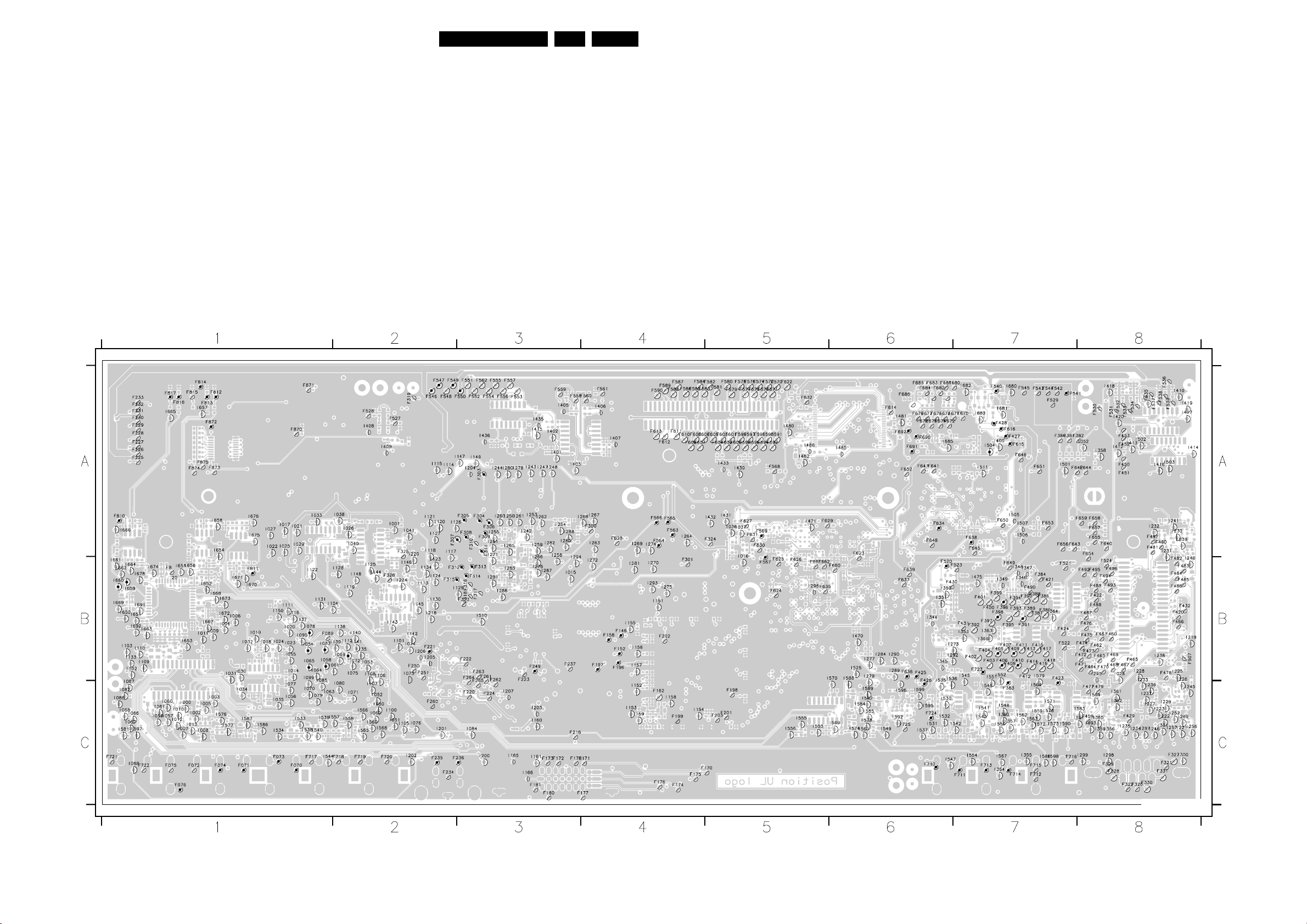

7 Electrical Diagrams and PWB lay-outs Diagram PWB

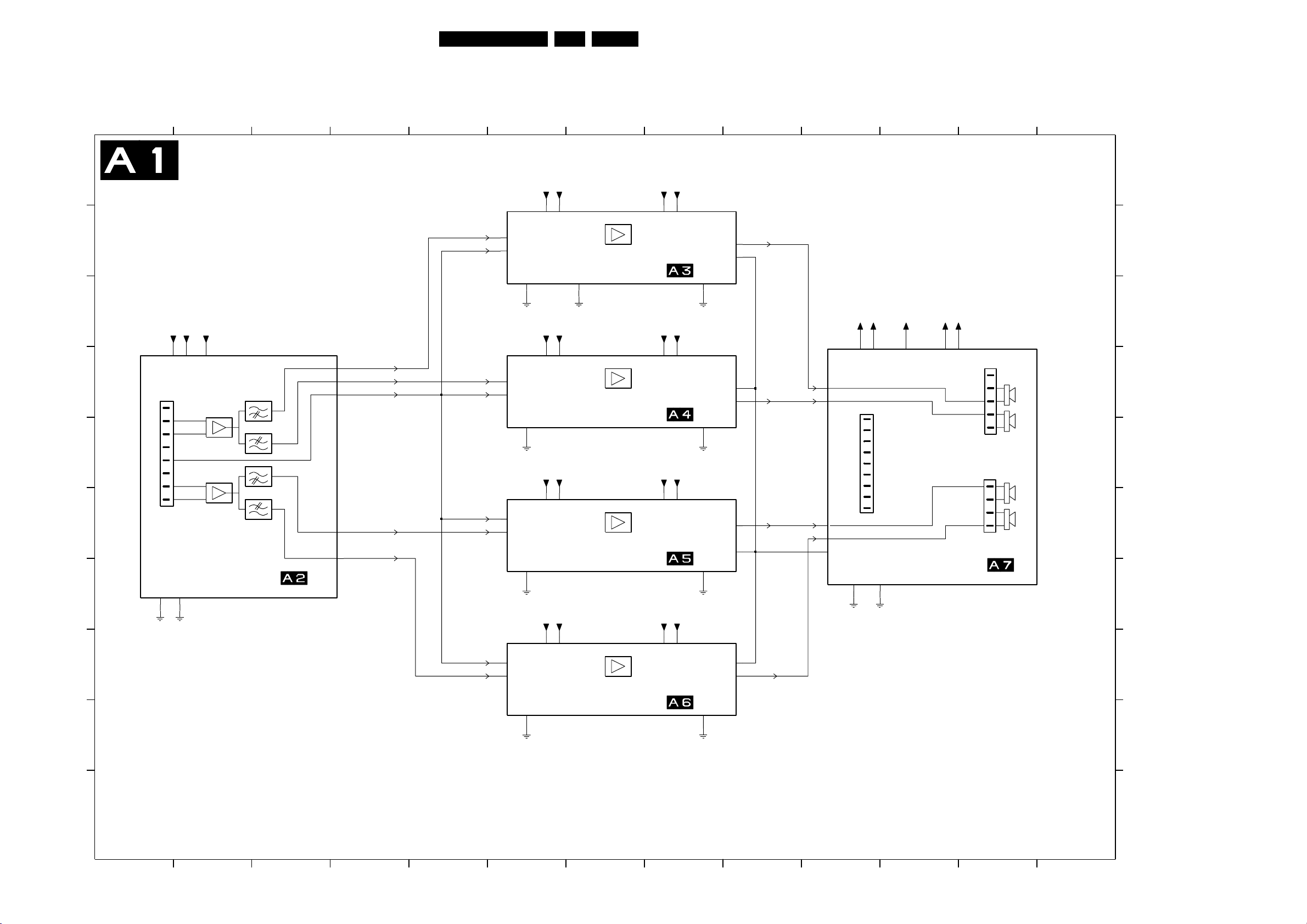

Audio Amplifier: DC Protection (Diagram A1) 27 34-35

Audio Amplifier: Filters (Diagram A2) 28 34-35

Audio Amplifier: Left High (Diagram A3) 29 34-35

Audio Amplifier: Left Low (Diagram A4) 30 34-35

Audio Amplifier: Right High (Diagram A5) 31 34-35

Audio Amplifier: Right Low (Diagram A6) 32 34-35

Audio Amp: Supply + DC Prot. (Diagram A7) 33 34-35

LED/Switch Panel (Diagram LD) 36 37

SCAVIO: Function Blocks (Diagr. SC1) 38 53-62

SCAVIO: Sync Selection (Diagr. SC2) 39 53-62

SCAVIO: Video Select.ion (Diagr. SC3) 40 53-62

SCAVIO: Video ADC (Diagr. SC4) 41 53-62

SCAVIO: Video Select. Decoder (Diagr. SC5) 42 53-62

SCAVIO: VGA Input (Diagr. SC6) 43 53-62

SCAVIO: Control Functions 1 (Diagr. SC7) 44 53-62

©

Copyright 2003 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

SCAVIO: Control Functions 2 (Diagr. SC8) 45 53-62

SCAVIO: Scaler Clock Gen. (Diagr. SC9) 46 53-62

SCAVIO: PW Scaler + Memory (Diagr. SC10) 47 53-62

SCAVIO: Back-End EPLD (Diagr. SC11) 48 53-62

SCAVIO: Back-End LVDS Out (Diagr. SC12) 49 53-62

SCAVIO: Audio Source Select. (Diagr. SC13) 50 53-62

SCAVIO: Audio Processor (Diagr. SC14) 51 53-62

SCAVIO: Audio Delay Line (Diagr. SC15) 52 53-62

VGA Connector Panel (Diagr. VGA) 63 64-65

8 Electrical Alignments 67

9 Circuit Descriptions 70

List of Abbreviations 81

10 Spare Parts List 83

11 Revision List 90

Published by CO 0363 Service PaCE Printed in the Netherlands Subject to modification EN 3122 785 13400

EN 2 FM242 AA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

1.1 Technical Specifications

1.1.1 Picture

Display : FHT plasma panel

Screen size : 42" (106 cm)

Resolution : 852 x 480 pixels

(pixel pitch

1.095 x 1.11 mm)

Contrast ratio : 1000 : 1

1.1.2 Sound

Maximum power : 30 Wrms (for version

with speakers)

1.2 Connections

1.2.1 Rear Connections

AUDIO IN

L

R

MAINS

! AllFunctional blocksshaded greyarerequired for

the"BasicConfiguration".

Theremainderisrequiredforthe"EnhancedConfiguration".

RS323

DVI-D

VGA2 VGA1

1.1.3 Miscellaneous

VGA1 VGA2 RC-OUT

Mains voltage : 95 - 264 V

Mains frequency : 50/60 Hz

Ambient temperature : + 5 to + 40 deg. C

Maximum humidity : 90% R.H.

Power consumption : around 380 W

Standby Power consumption : < 2 W

Weight : 35 kg

Dimensions (WxHxD) : Speakered version:

1215 x 657 x 90 mm

: Speaker-less version:

1070 x 660 x 90 mm

DVI-D

Y/C S

SVHS

AV2 AV1

L

R

AUDIOINAUDIO

CVBSB/Pb/Cb

IN

H

L

AV3

B/Pr/Cr

CL 16532099_010.eps

R

v

AUDIO

IN

260801

Figure 1-1 Rear Connections

RS232

1

6

5

9

Figure 1-2 RS232 connector (subD-9p)

1-

2 - TXD (UART)

3 - RXD (UART)

4 - RL_ICN (ICONN)

5 - Ground

6 - GL_ICN (ICONN)

7 - LD_ICN (ICONN)

8 - IR_TX (ICONN)

9 - IR_RX (ICONN)

10 - Ground

11 - Ground

Audio - In (DVI-D)

1 - Audio - L 0.5 Vrms / 1 kΩ

2 - Audio - R 0.5 Vrms / 1 kΩ

Audio - In (VGA2)

1 - Audio - L 0.5 Vrms / 1 kΩ

2 - Audio - R 0.5 Vrms / 1 kΩ

VGA1 - In

1

6

11

5

10

15

Figure 1-3 VGA Connector

1 - Red 0.7 Vpp / 75 Ω

2 - Green 0.7 Vpp / 75 Ω

3 - Blue 0.7 Vpp / 75 Ω

4-TXD

5 - Ground

6 - Red Ground

7 - Green Ground

8 - Blue Ground

9-RC

10 - Ground

11 - RXD

12 - DDC_SDA

13 - H-sync 0 - 5 V

14 - V-sync 0 - 5 V

15 - DDC_SCL

Audio - In (VGA1)

1 - Audio - L 0.5 Vrms / 1 kΩ

2 - Audio - R 0.5 Vrms / 1 kΩ

Technical Specifications, Connections, and Chassis Overview

EN 3FM242 AA 1.

VGA2 - Out

1

6

11

5

10

15

Figure 1-4 VGA Connector

1 - Red (0.7 Vpp/75 Ω)

2 - Green (0.7 Vpp/75 Ω)

3 - Blue (0.7 Vpp/75 Ω)

4-TXD

5 - Ground

6 - Red Ground

7 - Green Ground

8 - Blue Ground

9-

10 - Ground

11 - RXD

12 - DDC_SDA

13 - H-sync 0 - 5 V

14 - V-sync 0 - 5 V

15 - DDC_SCL

RC - Out

1-RC

DVI-D

18

916

17

C5

24

2 - Audio - L 0.5 Vrms / 10 kΩ

3 - Audio - R 0.5 Vrms / 10 kΩ

AV3: Audio/Video - In

1 - G/Y/Y 0.7 Vpp / 75 Ω

2 - B/Pb/Cb 0.7 Vpp / 75 Ω

3 - R/Pr/Cr 0.7 Vpp / 75 Ω

4-H

5-V

6 - Audio - L 0.5 Vrms / 10 kΩ

7 - Audio - R 0.5 Vrms / 10 kΩ

Figure 1-5 DVI-D Connector

1-RX2-

2-RX2+

3 - Ground

4-

5-

6 - DDC-SCL

7 - DDC-SDA

8-

9-RX1-

10 - RX1+

11 - Ground

12 -

13 -

14 - 5V_STBY_SW

15 - Ground

16 - 5V_STBY_SW

17 - RX0-

18 - RX0+

19 - Ground

20 -

21 - Ground

22 -

23 - RXC+

24 - RXC-

C5- Ground

AV2: SVHS - In

1 - Y Ground

2 - C Ground

3 - Y 1 Vpp / 75 Ω

4 - C / 16:9 0.3 Vpp / 75 Ω

AV2: Audio - In

1 - Audio - L 0.5 Vrms/10 kΩ

2 - Audio - R 0.5 Vrms/10 kΩ

AV1: Audio/Video - In

1 - CVBS 1 Vpp / 75 Ω

EN 4 FM242 AA1.

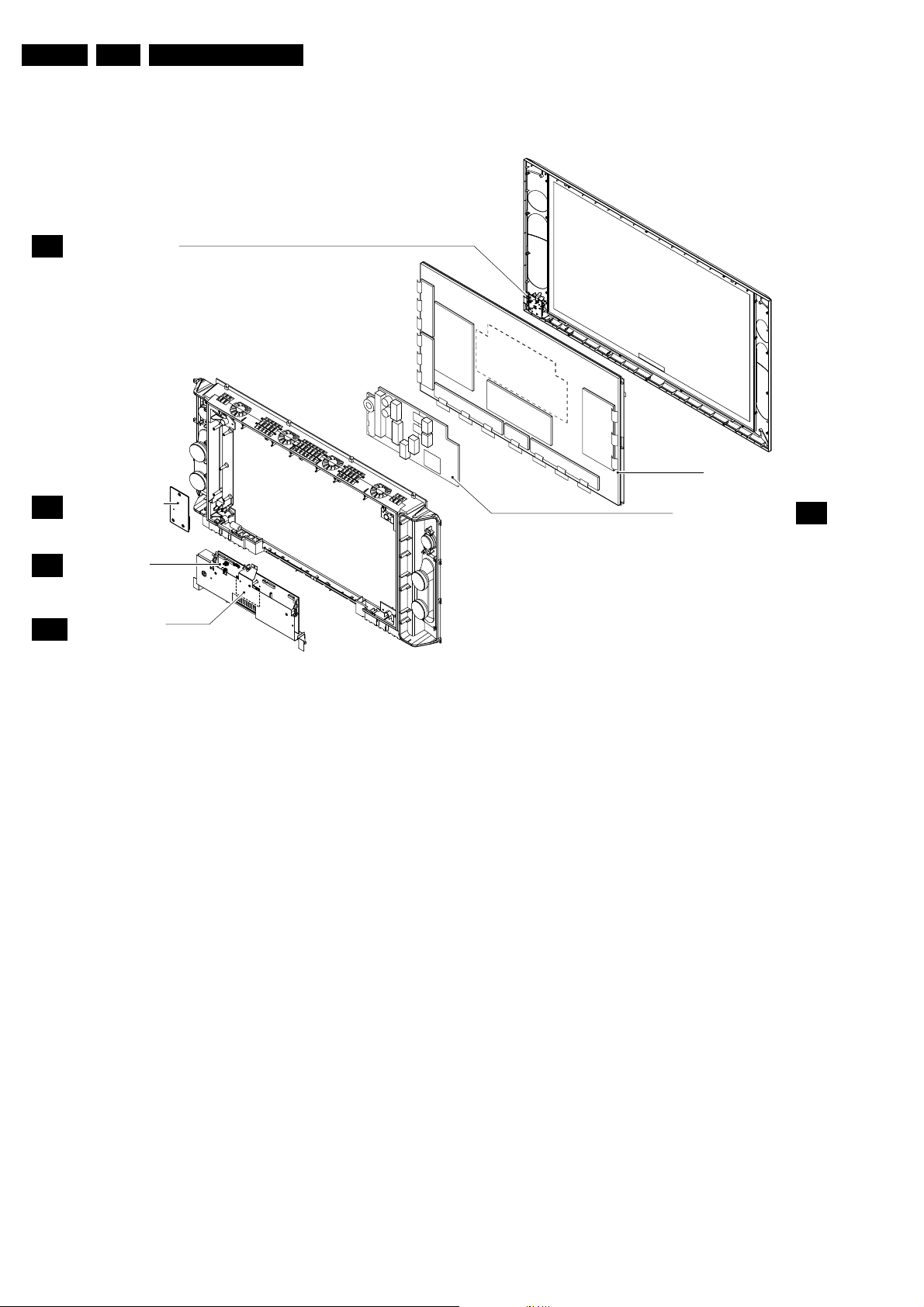

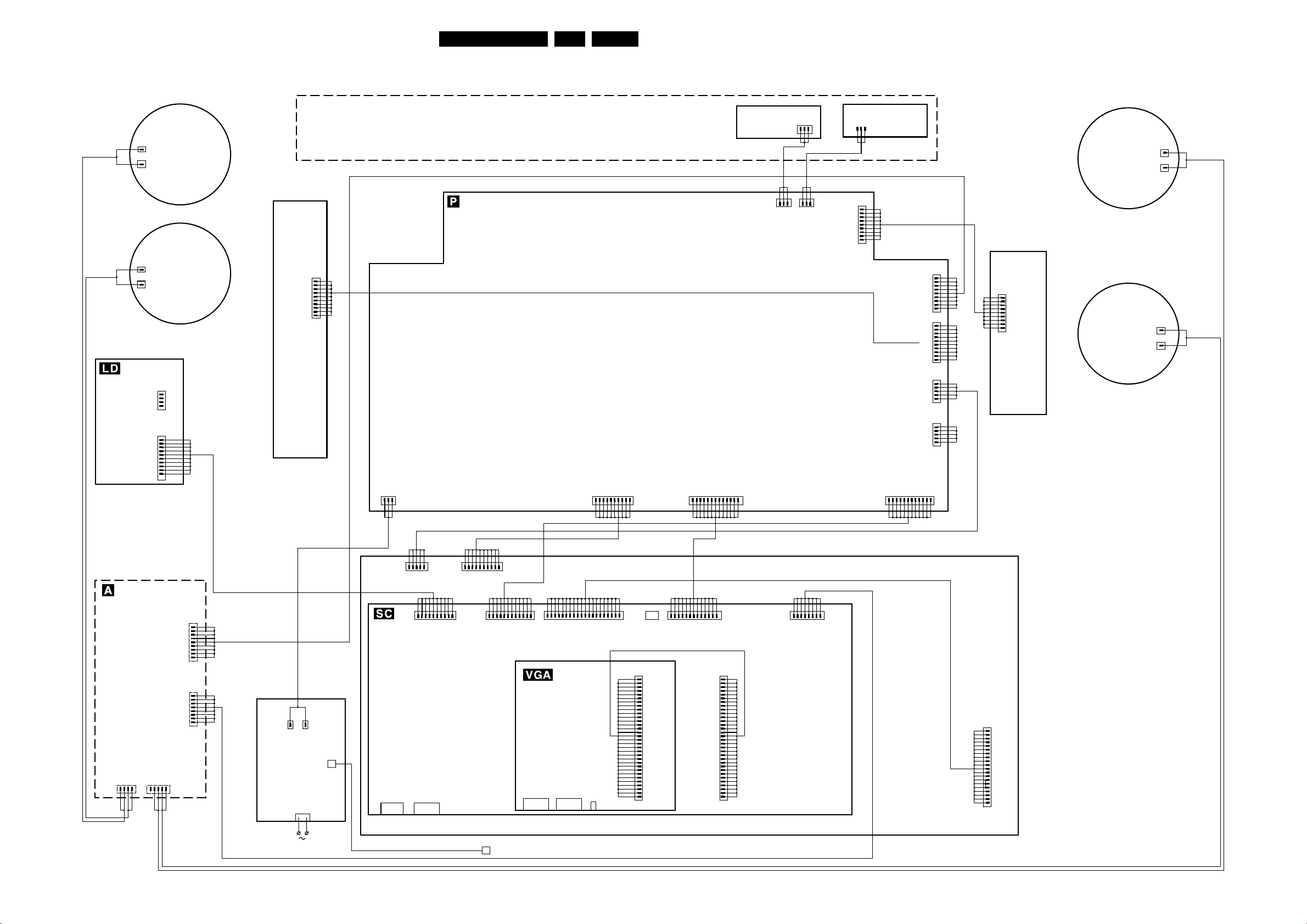

1.3 Chassis Overview

LED / SWITCH PANEL

LD

Technical Specifications, Connections, and Chassis Overview

Y-

Buffer

(up)

Y-Main

Y-

Buffer

(down)

A

SC

VGA

AUDIO AMPLIFIER

PANEL

SCAVIO PANEL

VGA CONNECTOR

PANEL

Logic-Buffer (E

)

SMPS

Figure 1-6 PWB Location

Logic Board

Logic-

B

uffer (F)

Logic-Buffer (G

X- Board

)

PLASMA DISPLAY PANEL

POWER SUPPLY PANEL

CL 36532011_010.eps

P

060303

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 5FM242 AA 2.

2.1 Safety Instructions

Safety regulations require that during a repair:

• Connect the set to the mains via an isolation transformer

(> 800 VA).

• Do not operate the monitor without the front glass plate.

One function of this glass plate is to absorb IR radiation.

Without this glass plate, the level of radiation could

damage your eyes.

• Replace safety components, indicated by the symbol

only by components identical to the original ones.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay, in particular, attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the electrical DC resistance between the mains plug

and the secondary side (only for sets which have a mains

isolated power supply):

1. Unplug the mains cord and connect a wire between the

two pins of the mains plug.

2. Set the mains switch to the 'on' position (keep the

mains cord unplugged!).

3. Measure the resistance value between the pins of the

mains plug and the metal shielding of the tuner or the

aerial connection on the set. The reading should be

between 4.5 MΩ and 12 MΩ.

4. Switch 'off' the set, and remove the wire between the

two pins of the mains plug.

• Check the cabinet for defects, to avoid touching of any

inner parts by the customer.

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD ). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched 'on'.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

• Clean the glass plate in front of the plasma display with a

slightly humid cloth. If, due to circumstances, there is some

dirt between the glass plate and the plasma display, this

must be cleaned by a qualified service engineer (see

section “Mechanical Instructions”).

• Measure the direct voltages and oscillograms with regard

to the chassis ground (), or hot ground () as this is

called.

• The direct voltages and oscillograms shown in the

diagrams are indicative. Measure them in the Service

Default Mode (see section “Service Modes”).

,

• Where necessary, measure the voltages in the power

supply section both in normal operation () and in standby

(). These values are indicated by means of the

appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors

2.3.1 Schematic Notes

• All resistor values are in ohms and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kOhm).

• Resistor values with no multiplier may be indicated with

either an 'E' or an 'R' (e.g. 220E or 220R indicates 220

Ohm).

• All Capacitor values are expressed in Micro-Farads (µ =

-6

x10

), Nano-Farads (n = x10-9), or Pico-Farads (p = x10

12

).

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An 'asterisk' (*) indicates component usage varies. Refer to

the diversity tables for the correct values.

• The correct component values are listed in the Electrical

Replacement Parts List. Therefore, always check this list

when there is any doubt.

2.3.2 Rework on BGA ICs

General

Although (LF)BGA assembly yields are very high, there may

still be a requirement for component rework. By rework, we

mean the process of removing the component from the PWB

and replacing it with a new component. If an (LF)BGA is

removed from a PWB, the solder balls of the component are

deformed drastically so the removed (LF)BGA has to be

discarded.

Device removal

As is the case with any component, it is essential when

removing an (LF)BGA that the board, tracks, solder lands, or

surrounding components are not damaged. To remove an

(LF)BGA, the board must be uniformly heated to a temperature

close to the reflow soldering temperature. A uniform

temperature reduces the chance of warping the PWB.

To do this, we recommend that the board is heated until it is

certain that all the joints are molten. Then carefully pull the

component off the board with a vacuum nozzle. For the

appropriate temperature profiles, see the IC data sheet.

Area preparation

When the component has been removed, the vacant IC area

must be cleaned before replacing the (LF)BGA.

Removing an IC often leaves varying amounts of solder on the

mounting lands. This excessive solder can be removed with

either a solder sucker or solder wick. The remaining flux can be

removed with a brush and cleaning agent.

After the board is properly cleaned and inspected, apply flux on

the solder lands and on the connection balls of the (LF)BGA.

Note: Do not apply solder paste, as this has shown to result in

problems during re-soldering.

-

EN 6 FM242 AA2.

Device replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF)BGA should be

aligned under a microscope or magnifying glass. If this is not

possible, try to align the (LF)BGA with any board markers.

To reflow the solder, apply a temperature profile according to

the IC data sheet. So as not to damage neighbouring

components, it may be necessary to reduce some

temperatures and times.

Safety Instructions, Warnings, and Notes

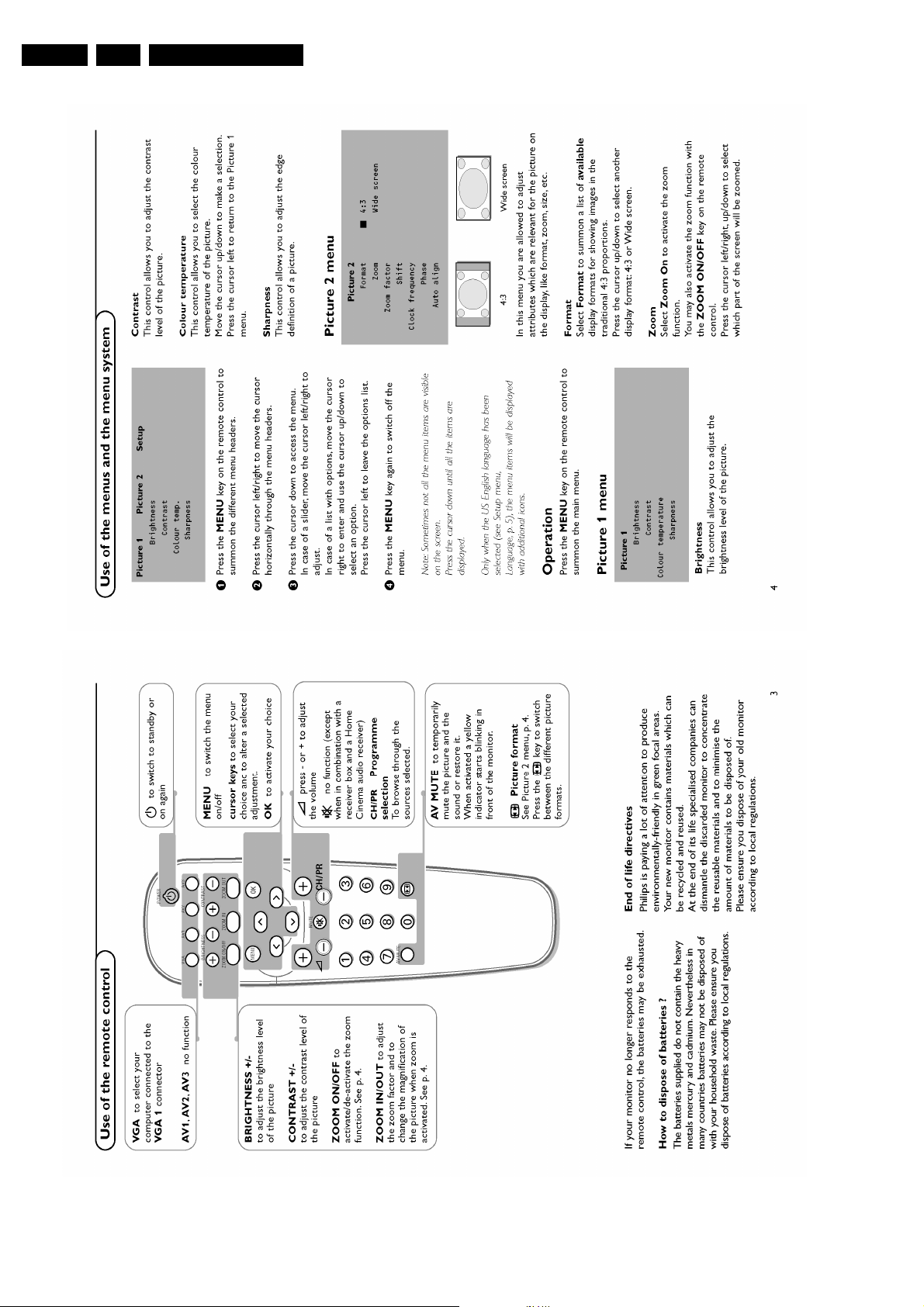

3. Directions for Use

Directions for Use

EN 7FM242 AA 3.

EN 8 FM242 AA3.

Directions for Use

Directions for Use

EN 9FM242 AA 3.

EN 10 FM242 AA4.

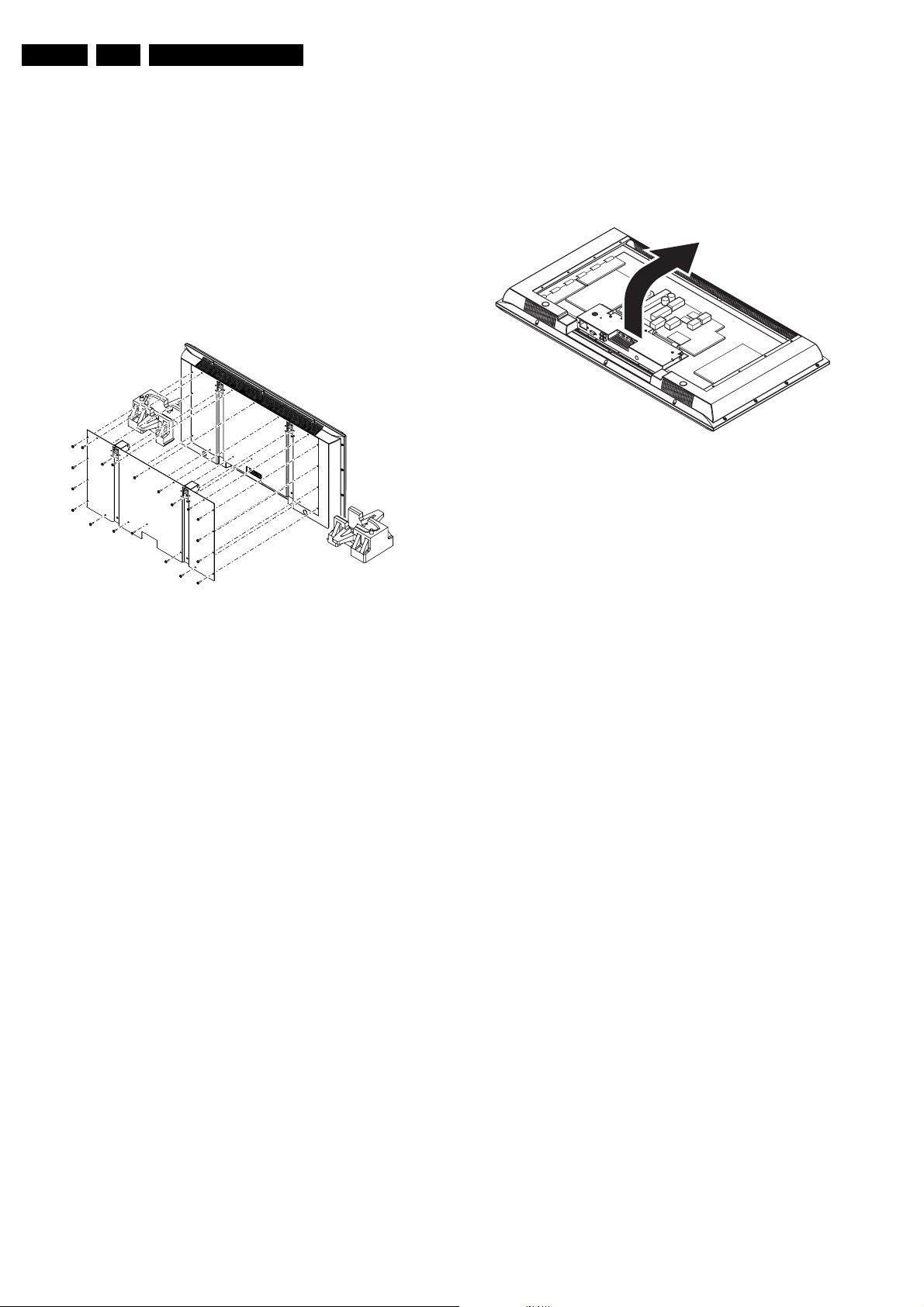

Mechanical Instructions

4. Mechanical Instructions

Index of this chapter:

• Service Position Monitor

• Rear Cover Removal

• Service Position Panels

• PDP and Glass Plate Replacement

• Re-assembly

Note: Figures below can deviate from the actual situation, due

to different set executions.

4.1 Service Position Monitor

Figure 4-1 Service Position

First, put the monitor in its service position. (Can be done via

buffers as showed on figure, but preferable via new service

position solution as described below. Still some improvising is

needed for service positions panels however). Therefore,

disconnect all cables connected to the monitor and take the

monitor of the wall (or tabletop stand). Then, fix the monitor to

the 2 service-poles. (the 2 poles together form a service-kit:

3122 785 90480; this service-stand can be used for 30” until

42” FTVs.

CL 16532099_041.eps

250901

4.3 Service Position Panels

4.3.1 SCAVIO Panel

Solder-side SCAVIO

B

CL 36532011_011.eps

Figure 4-2 Service position SCAVIO (1)

To access the panel:

1. Remove the cables from connectors 0320, 0305, 0301,

0319 and 0388 on the SCAVIO panel.

2. Remove the power cable from the mains power inlet to the

power supply (connector 0308).

3. Remove the five screws at the bottom of the SCAVIOpanel cover plate.

4. Hold the SCAVIO panel while removing the top screw, in

order to prevent that it will fall.

5. Take the panel out, and turn it 180 degrees, so that you

face the solder side of the SCAVIO panel.

6. Reconnect all cables. Use a standard power cable to

connect the mains directly to PSU-connector 0308, and

use the 'LED/Switch panel' service kit 3122 785 90410 (as

the original cable is too short).

Caution: When measuring, watch out for the 'hot' left heat sink

of the PSU!

200303

4.2 Rear Cover Removal

To be able to access or measure the panels, remove the rear

cover (metal back plate):

Warning: make sure that the mains power is disconnected

before you remove the metal back plate.

1. Remove all fixation screws of the back plate, as indicated

in the figure above (five at the top, five at each side, seven

at the bottom and the two larger ones just below the 'wall

mounting holes').

2. Remove the metal back plate. Make sure that wires and flat

foils are not damaged during plate removal.

Another way to measure the SCAVIO panel:

1. Remove the five screws at the bottom of the SCAVIOpanel cover plate.

2. Hold the SCAVIO panel while removing the top screw, in

order to prevent that it will fall.

3. Put a piece of paper (or cardboard) in front of the Power

Supply.

4. Take the panel out, and turn it upward [B], so that you face

the solder-side of the SCAVIO panel.

Caution: Make sure that the metal connector plate does not

touch any 'hot' part of the Power Supply (heatsink).

Mechanical Instructions

EN 11FM242 AA 4.

Component-side SCAVIO

CL 16532099_043.eps

250901

Figure 4-3 Service position SCAVIO (2)

To access the other side of the SCAVIO panel:

1. Disconnect all cables going to the SCAVIO panel.

2. Remove all screws at the connectors of the connector

plate, see figure 'Solder-side SCAVIO'.

3. Remove the three fixation screws that connect the SCAVIO

panel to the connector plate, see figure 'Component-side

SCAVIO'.

4. Reconnect the SCAVIO panel, be careful: do not make a

short-circuit!

4.3.4 Audio Amplifier Panel (only valid for “speaker”-version)

The solder-side of this panel is directly accessible. To access

the component-side, or to remove the whole panel, unscrew

the three fixation screws

4.3.5 LED/Switch Panel and Speakers

Plastic backcover

Foam cushion

4.3.2 VGA Connector Panel

How to remove the VGA Connector panel:

1. Squeeze the plastic pins that attach this panel to the

SCAVIO board, while you pull it carefully upwards.

2. Unplug the flat foil cable.

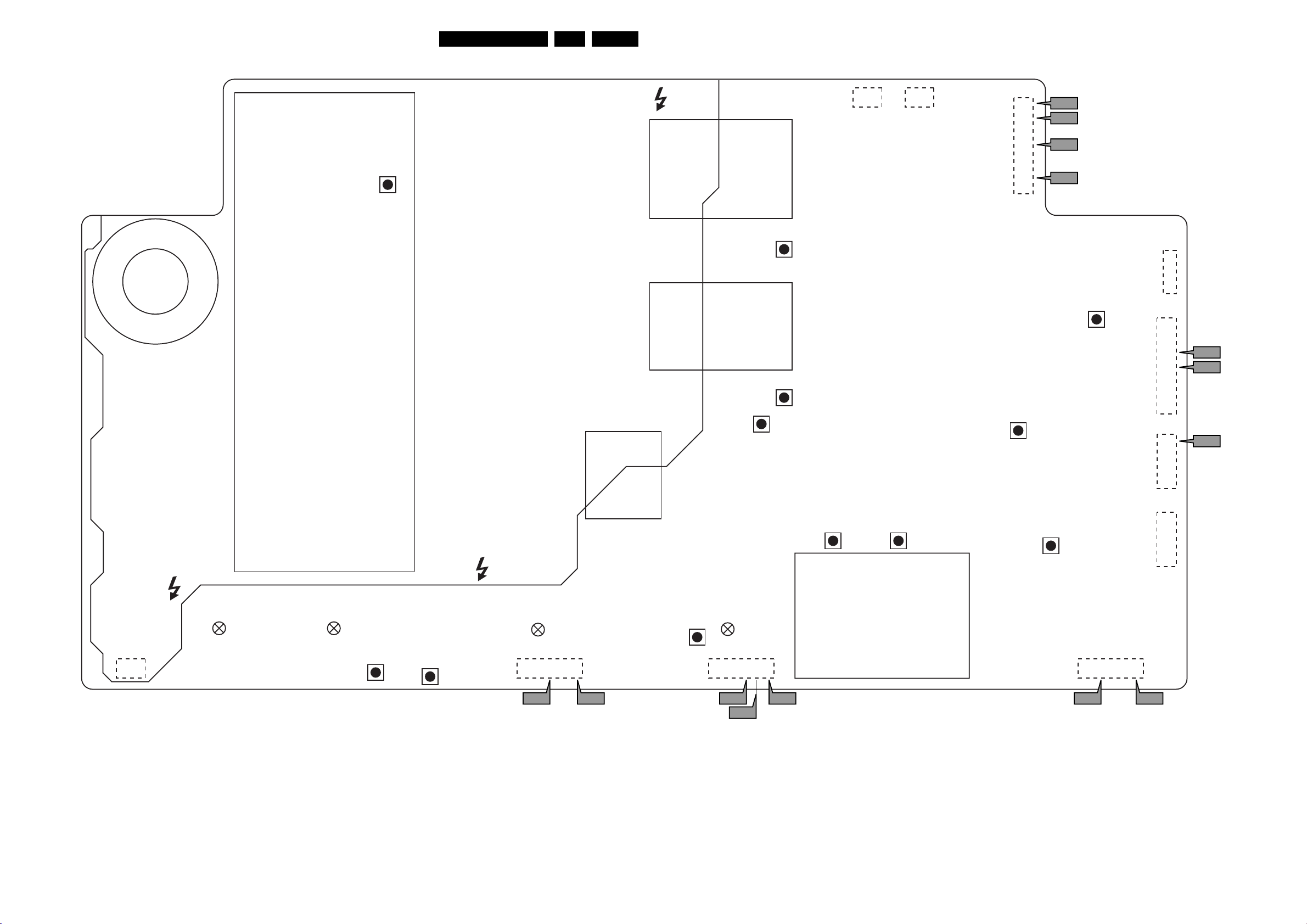

4.3.3 Power Supply Panel

CL 36532011_021.eps

Figure 4-4 Remove PSU

The supply panel can not be repaired by the network. As

measure points are accessible for possible re-alignment, there

is no further service-position.

To remove the panel unscrew the 9 screws (see drawing) and

disconnect the cables.

200303

CL 36532011_012.eps

170303

Figure 4-5 Service Position LED/Switch Panel and Speakers

To access or replace the LED/Switch panel and/or speakers:

1. Take the monitor from its service stand, and put it (face

down) on a soft surface (blanket or foam cushion), to

make sure that you do not damage the front glass plate.

2. Unscrew all fixation screws of the plastic back cover: five at

all sides.

3. Lift and remove the plastic back cover.

4. You can access now the LED/Switch panel and/or the

speakers.

4.3.6 LED/Switch panel

To measure the component-side, or to remove the LED/Switch

panel, unscrew one fixation screw (see enlarged part of figure

'LED/Switch Panel and Speakers'), and remove the panel.

4.3.7 Loudspeakers (if valid)

When you have removed the plastic back cover, you must

replace the speaker-box sealing foams (12nc: 3122 358

76221). This, to ensure that the loudspeakers are airtight.

Do not stretch the foam during mounting. Pay special

attention to the corners, to make sure that the foam is not

stretched and that it is pushed into the corners.

EN 12 FM242 AA4.

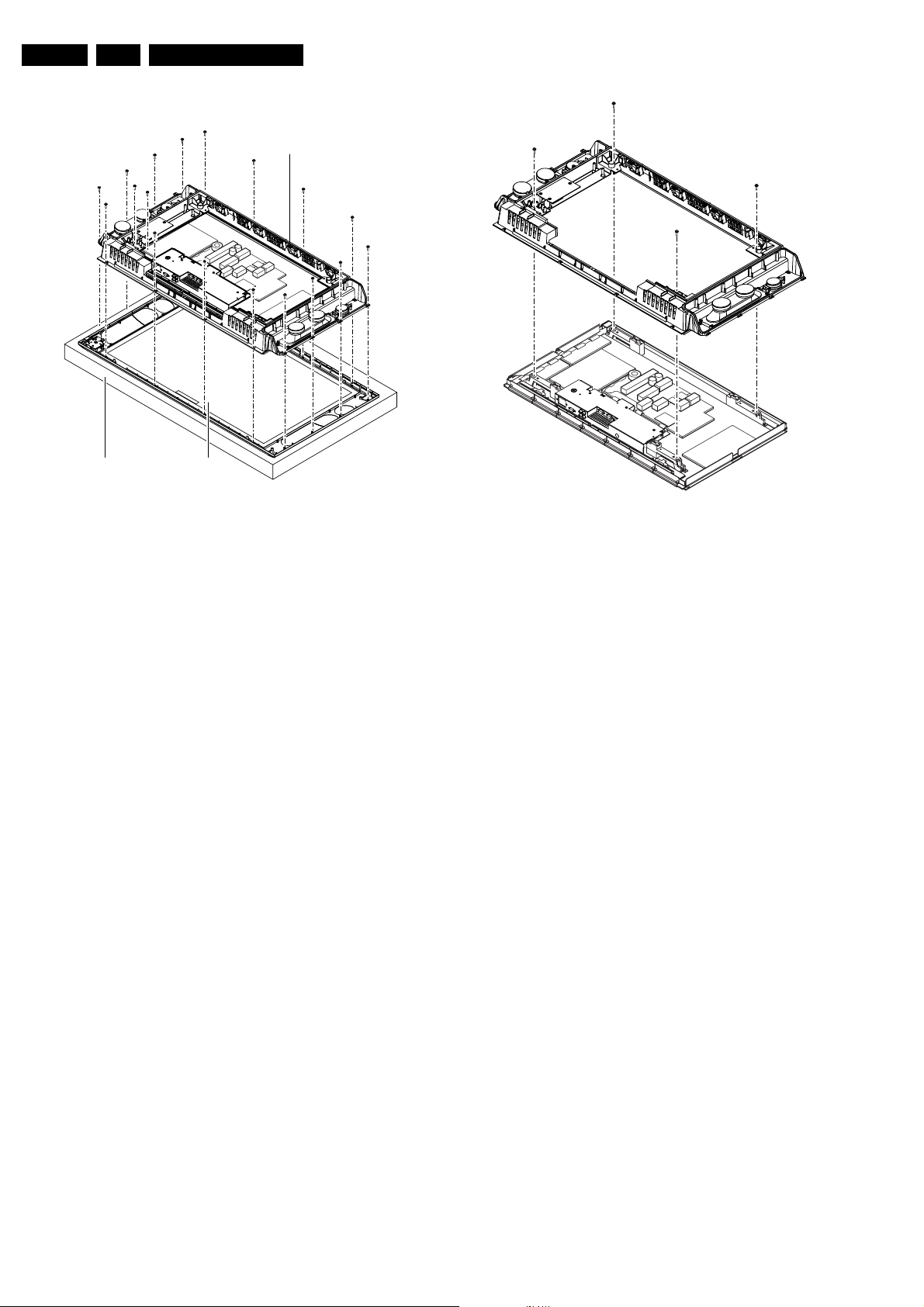

4.4 PDP and Glass Plate Replacement

Shielding frame

Front displayFoam cushion

Figure 4-6 Exchange Glass Plate

To exchange the glass plate

1. Take the monitor from its service stand, and put it (face

down) on a soft surface (blanket or foam cushion), to make

sure that you do not damage the front glass plate.

2. Remove the metal back plate as described in paragraph

'Rear Cover Removal'.

3. Unscrew all fixation screws of the plastic back cover: four

at the left and right side, three at the bottom and top side.

4. Lift and remove the plastic back cover.

5. Unscrew two fixation screws of the triangular shaped cable

holder at the left bottom, see figure 'Exchange Glass Plate'.

6. Unscrew all fixation screws of the (metallised) shielding

frame, four at both sides and four at the top and bottom,

see figure 'Exchange Glass Plate'.

7. Unplug the cable of the LED/Switch panel, connector 0320.

8. You can now remove the (metallised) shielding frame,

together with the PDP, Audio panel, Power supply and

SCAVIO panel attached to it, see figure 'Exchange Glass

Plate'.

Note: To prevent scratches, make sure to put the shielding

frame together with the PDP on a soft surface.

9. Replace the glass plate.

Mechanical Instructions

CL 36532011_013.eps

060303

4.5 Re-assembly

CL 36532011_014.eps

060303

Figure 4-7 Exchange PDP

To exchange the PDP panel:

1. Take out the SCAVIO panel and Power Supply panel.

2. Unscrew all fixation screws of the (metallised) shielding

frame (two at the top and two at the bottom, see figure

'Exchange PDP').

3. Replace the PDP.

To re-assemble the whole set, do all processes in reverse

order.

Notes:

• You must replace the speaker-box sealing foam, in case

the plastic rear cover has been (re)moved.

• While re-assembling, make sure all the cables are in their

original position and make sure all the EMC foams are

present to ensure 'EMC tightness'.

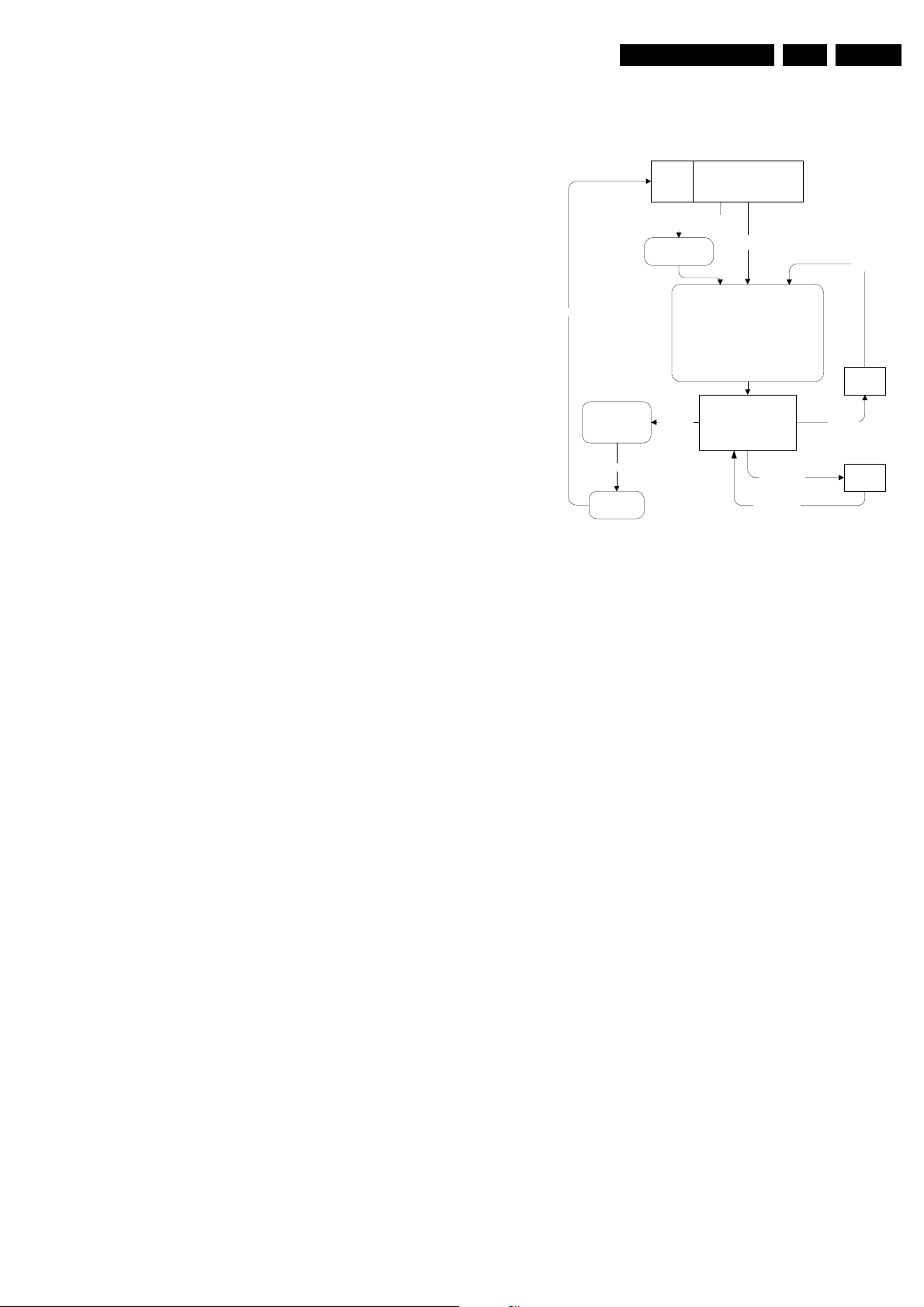

Service Modes, Error Codes and Fault Finding

NORMAL OPERATION

(and all other states)

Override software

protections

Ignore all "Service unfriendly" m odes.

Start blinking LED sequence to s how the

error codes according to the blinking LED

procedure.

Lineair audio and video settings are set to

50% (middle value) except volume (set to

low volume level, 25% of max)

"UNDO" ignore all

"Service unfriendly

modes"

STANDBY

Service Default Mode

Display SDM in "top line"

(all other OSD off).

Blinking LED sequence.

OFF

SAM

Short SDM pins

(also works from Standby)

RC sequence

"00" or

"Standby"

Reset to last status

RC button.

Mains OFF

Mains ON

RC sequence

"0-6-2-5-9-6-MENU"

RC-code

0-6-2-5-9-6-OSD

or INFO+

RC-code

0-6-2-5-9-6-menu

Normal

operation

CL 16532099_100.pdf

260901

5. Service Modes, Error Codes and Fault Finding

Index of this chapter:

1. Test points

2. Service Modes

3. Problems and Solving Tips (related to CSM)

4. ComPair

5. Error Codes

6. The Blinking LED Procedure

7. Protections

8. Repair Tips

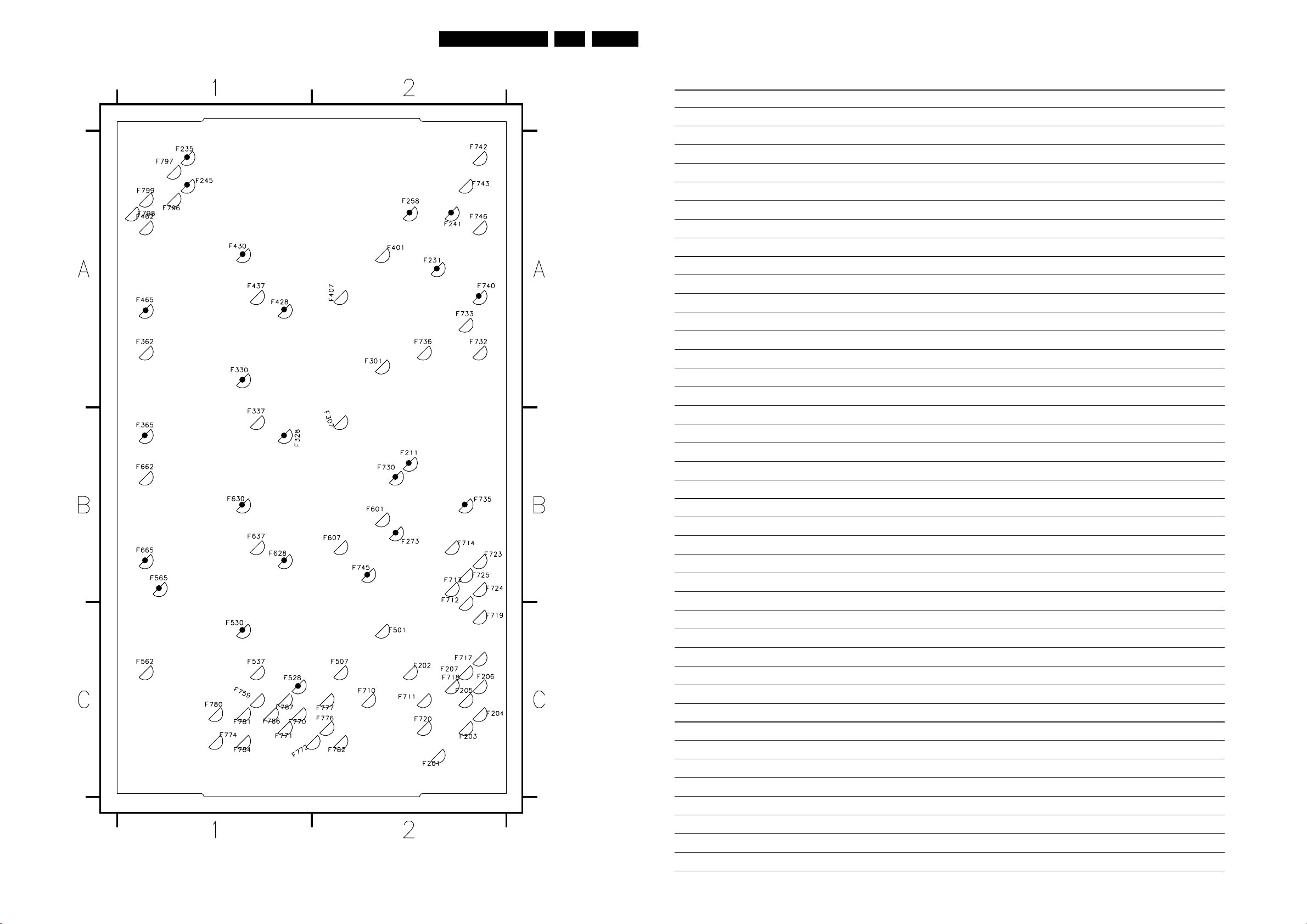

5.1 Test Points

The chassis is equipped with test points (I- and F-points)

printed on the circuit board assemblies. See test point

overviews in section “Block Diagrams”

Perform measurements under the following conditions:

• Service Default Mode.

• Video: colour bar signal (via PC or VGA-generator).

• Audio: 1 kHz, 2 V

5.2 Service Modes

(via PC or VGA-generator).

PP

EN 13FM242 AA 5.

5.2.1 Service Default Mode (SDM)

Service Default Mode (SDM) and Service Alignment Mode

(SAM) offer several features for the service technician, while

the Customer Service Mode (CSM) is used for communication

between a Philips Customer Care Centre (P3C) and a

customer.

There is also the option of using ComPair, a hardware interface

between a computer (see requirements) and the FTV chassis.

It offers the ability of structured trouble shooting, test pattern

generation, error code reading, software version readout and

software upgrading.

Minimum requirements: a Pentium Processor, Windows 9x/NT/

2000/XP, and a CD-ROM drive (see also paragraph

“ComPair”).

Note: This FM242-monitor has different as the FM24, not a

internal pdp-testpattern that can be enabled via the SAMmenu

A test pattern however can be generated.

How?

Select via ComPair-tool the right hex-address (sub

address 0080 and then PS (Pattern Select) (00 full window

black; 01~04 full window white, red, green, blue) and more

variants until 17)

It however only works when set is signalled (Scavio and

pdp, needs a sync). This is less nice solution as in FM24.

Switch off the pattern again via hex-code 0080 and 0

Purpose

• To create a pre-defined setting to get the same

• To override SW protections (only when SDM is entered via

• To start the blinking LED procedure.

Specifications

• All picture settings at 50% (brightness, contrast, etc.).

• Colour temperature is set to 'normal'.

• Bass, treble and balance at 50%; volume at 25%.

• All service-unfriendly modes (if present) are disabled, like:

• Video blanking,

• Slow de-mute,

• Anti ageing,

• Automatic switch to Standby when no sync signals are

measurement results as given in this manual.

the 'service pins' on connector 0382).

received.

Figure 5-1 SDM Flowchart

How to enter SDM

Use one of the following methods:

• Use the standard RC-transmitter and key in the code

062596, directly followed by the MENU button.

• Short jumpers 1 and 2 of connector 0382 on the SCAVIO

panel.

After entering SDM, a blank screen is visible, with SDM in the

upper left side for recognition. The Blinking LED procedure is

started and will indicate any possible errors via the (orange)

front LED.

How to navigate

To toggle to the SAM mode, use a standard customer RCtransmitter and key in the code 062596, directly followed by the

OSD (i+) key.

How to exit

Use one of the following methods (the set returns to its last

status):

• Switch the set to STANDBY by pressing the power button

on the remote control transmitter (if you switch the set 'off'

by removing the Mains power, the set will return in SDM,

when the Mains power is re-applied).

• Use the standard RC-transmitter and key in the code 00.

5.2.2 Service Alignment Mode (SAM)

Purpose

• To perform (software) alignments.

• Easy way to identify the commercial type number of the

set.

• Easy identification of the used software versions.

• To display (or clear) the error code buffer.

• View operational hours.

Specifications

• Operation hours counter.

• Software version reading.

• Error buffer reading and erasing.

• Software alignments.

EN 14 FM242 AA5.

RC button,

e.g. P+ or P-

STANDBY

Do not store

settings made

during alignments

RC button,

e.g. P+ or P-

"UNDO" ignore

all "Service

unfriendly

modes"

"Standby"

Settings made

during alignments

are stored

STANDBY

NORMAL OPERATION

RC sequence "0-6-2-5-9-6-OSD "(for Europe & A/P)

RC sequence "0-6-2-5-9-6-INFO+" (for USA/LatAm)

Short SAM pins (works also from Standby)

RC sequence

"00"

or

or

Ignore all "Ser vice

unfriendly" mod es

Service Alignment Mode

Display "SAM" top level

menu

Upper menu selection

(with cursor buttons)

Lower menu selection

(with cursor buttons)

RC-code "0-6-2-5-9-6-OSD"

RC-code "0-6-2-5-9-6-INFO+"

RC-code "0-6-2-5-9-6-MENU" -

Service Modes, Error Codes and Fault Finding

Mains ON

OFF

(Settings made

during alignments

are stored)

Mains OFF

or

SAM submenus

(whitepoints, align-

ments, etc.)

Figure 5-2 SAM Flowchart

How to enter

Use one of the following methods:

• Use a standard RC-transmitter and key in the code 062596

directly followed by the OSD (i+) button

Note: the OSD (i+) is not available on the original FM242

remote control, therefore use another Philips remote

control (e.g. MG, EMG or A10).

• Short jumpers 3 and 4 of connector 0382 on the SCAVIO

panel.

The following screen is visible:

Service Alignment Menu General

Type Nr. - AG Code 42FD9945/01 **00 00

SW Version OTC AAAAAB-X.Y_xxxxx

SW Version PW AAAABC-X.Y_xxxxx

SW Version EPLD AAAABC-X.Y_xxxxx

Errors 1 xx xx xx xx xx

Errors 2 xx xx xx xx xx

Operational hours xx

Reset error buffer Press OK to reset

Store Press OK to store

CL 26532011_016.eps

SDM

CL 16532099_101.pdf

260901

200303

4. SW Version PW (AAAABC-X.Y-xxxxx). See description

above.

5. SW Version EPLD (AAAABC-X.Y-xxxxx). See description

above.

6. Errors 1. Gives the last five errors of the error buffer. The

last detected error is displayed at the most left position.

The errors are displayed as 2 digit numbers and separated

by a space. When less than 10 errors occurred, the rest of

the line(s) is empty. In case of no errors the text 'No Errors'

is displayed behind menu item 'Errors 1'. See paragraph

5.5 for a description.

7. Errors 2. Gives the first five errors of the error buffer. The

last detected error is displayed at the most left position.

8. Operational hours. The Operations Hours indicate the

time that the display was active with half an hour resolution.

It represents the system hours (OTC), not the PDP hours.

9. Reset error buffer. Erase the contents of the error buffer.

Press 'OK' on your remote control to activate. The content

of the error buffer is cleared.

10. Store. This will store the performed alignments. Press 'OK'

on your remote control to activate.

Note: if you do not want to store the performed alignments,

leave the SAM mode via code 00 on your remote control.

Do not activate the 'store' item.

How to navigate

Use one of the following methods:

• Select the sub-menu's (upper line) with the CURSOR

LEFT/RIGHT keys on the remote control transmitter.

• Select the menu items with the CURSOR UP/DOWN keys.

With the CURSOR LEFT/RIGHT keys it is possible to:

– Activate the selected menu item.

– Change the value of the selected menu item.

• To toggle to the SDM mode, use the standard customer

RC-transmitter and key in the code 062596, directly

followed by the MENU key.

How to exit

Use one of the following methods:

• Switch the set 'off' (with the Mains switch or by pulling the

Mains cord).

Note: new alignment settings are always stored, even

when item 'store' was not activated!

• Switch the set to 'standby' by pressing the power button on

the remote control transmitter.

Note: new alignment settings are always stored, even

when item 'store' was not activated!

• Use the standard RC-transmitter and key in the code 0 0.

Note: new alignment settings are not stored (except when

item 'store' was activated)!

5.2.3 Customer Service Mode (CSM)

Figure 5-3 SAM Menu 'General'

1. Type Nr. Gives the commercial type number of the

monitor, e.g. 42FD9945/01.

2. AG Code. Is not implemented.

3. SW Version OTC (AAAAAB-X.Y-xxxxx).

Note: You will find details of the latest software versions in

the chapter 'Software Survey' of the 'Product Survey Colour Television' publication, which is published four

times each year.

• A = the chassis name (FM23 for 32" displays or FM242

for 42" SDI-displays).

• B = the region (E= Europe, A= Asia Pacific, U= NAFTA,

L= LATAM; in our case G = Global).

• (if valid) C = the configuration name (B= Basic, E=

Enhanced; for PW & EPLD-software this will be named

B).

• X = the main software version number.

• Y = the sub software version number.

• x = last five digits of 12nc code.

Purpose

When a customer is having problems with his TV-set, he can

call his dealer or helpdesk. The service technician can than ask

the customer to activate the CSM, in order to identify the status

of the set. Now, the service technician can judge the severe

ness of the complaint. In many cases, he can advise the

customer how to solve the problem, or he can decide if it is

necessary to visit the customer.

The CSM is a read only mode, therefore modifications in this

mode are not possible.

Service Modes, Error Codes and Fault Finding

Normal operati on mode

Key in sequence: 1-2-3-6-5-4 on RC

Store current picture, sound and feature settings for later

retrieval (only store if needed to go back to normal

operation).

Set pre-defined picture, sound and feature settings (to be

able to see and hear if the set is working pr operly and to be

able to read the CSM information).

Ignore service unfriendly options

Volume up/down

Numerical key,

external

If other key

= standby

"Cursor right"

To previous CSM page

Restore picture, sound and

feature settings (that were

stored during entry)

Display CSM information screen

"Cursor left"

Other key,

e.g. "menu"

mains off

Figure 5-4 CSM Flowchart

How to enter

Use the standard customer RC-transmitter and key in the code

123654.

When CSM is entered, the values of brightness, contrast, etc.

are set to 50% (of max. value), and volume is set to 25%, to

ensure that you always have a picture and sound.

After switching 'on' the Customer Service Mode, the following

screen will appear:

Customer Service Menu 1

1 - Type Nr. - AG Code 42FD9945/01

2 - SW Version OTC AAAAAB-X.Y_xxxxx

3 - SW Version PW AAAABC-X.Y_xxxxx

4 - SW Version EPLD AAAABC-X.Y_xxxxx

5 - Code 1 xx xx xx xx xx

6 - Code 2 xx xx xx xx xx

7 - Volume xx

8 - Brightness xx

9 - Contrast xx

Customer Service Menu 2

10 - Colour xx

11 - Tint xx

12 - Sharpness xx

13 - Soundmode xx

14 - Source xx

15 - AV Mute xx

Figure 5-5 CSM Menu

To next CSM page

Increase/decrease

volume

Switch to prese t/

channel or external

Standby

(when the set is switched on,

picture, sound and feature

settings (that were stored

during entry) are restored)

Off

(when the set is switched on,

picture, sound and feature

settings (that were stored

during entry) are restored)

CL 16532099_103.pdf

CL 36532011_015.eps

200303

260901

EN 15FM242 AA 5.

• (if valid) C = the configuration name (B= Basic, E=

Enhanced).

• X = the main software version number.

• Y = the sub software version number.

• x = last five digits of 12nc code.

3. SW Version PW (AAAABC-X.Y-xxxxx). See description

above.

4. SW Version EPLD (AAAABC-X.Y-xxxxx). See description

above.

5. Code 1. Gives the last five errors of the error buffer. The

last detected error is displayed at the most left position.

The errors are displayed as 2 digit numbers and separated

by a space. When less than 10 errors occurred, the rest of

the line(s) is empty. In case of no errors, the text 'No Errors'

is displayed behind menu item 'Code 1'. See paragraph

“Error Buffer” for a description.

6. Code 2. Gives the first five errors of the error buffer. The

last detected error is displayed at the most left position.

7. Volume. Gives the last volume status for the selected

source, as set by the customer.

8. Brightness. Gives the last brightness status for the

selected source, as set by the customer.

9. Contrast. Gives the last contrast status for the selected

source, as set by the customer.

10. Colour (not present in Basic configuration). Gives the last

colour status for the selected source, as set by the

customer.

11. Tint (only for NTSC Enhanced configuration). Gives the

last tint status for the selected source, as set by the

customer.

12. Sharpness. Gives the last sharpness status for the

selected source, as set by the customer.

13. Source. Gives the selected source, as set by the

customer.

14. AV Mute. Indicates if AV Mute is 'on' or 'off'.

How to navigate

Use one of the following methods:

• Switch to the other CSM page with the CURSOR LEFT/

RIGHT keys on the remote control.

• You can increase/decrease volume with the VOLUME UP/

DOWN keys on the remote control.

• You can switch to another source with the NUM/EXT keys

on the remote control.

How to exit

Use one of the following methods:

• Press the MENU key of the remote control transmitter.

• Switch the set to 'standby' with the Power switch on the

remote control.

• Switch the set 'off' with the Mains power switch.

5.3 Problems and Solving Tips (Related to CSM)

5.3.1 Picture Problems

Note: Below described problems are all related to the monitor

settings. The procedures to change the value (or status) of the

different settings are described.

1. Type Nr. AG Code. Gives the commercial type number of

the monitor, e.g. 42FD9945/01. AG Code is not

implemented.

2. SW Version OTC (AAAAAB-X.Y-xxxxx) Note: You will find

details of the latest software versions in the chapter

'Software Survey' of the 'Product Survey - Colour

Television' publication, which is published four times each

year.

• A = the chassis name (FM23 for 32" displays or FM242

for 42" SDI-displays).

• B = the region (E= Europe, A= Asia Pacific, U= NAFTA,

L= LATAM or G = Global).

Picture too dark or too bright

Increase/decrease the BRIGHTNESS and/or the CONTRAST

value when the picture improves after you have switched on

the Customer Service Mode. The new value is automatically

stored.

White line around picture elements and text

Decrease the SHARPNESS value when the picture improves

after you have switched on the Customer Service Mode. The

new value is automatically stored.

Snowy picture and/or unstable picture

A scrambled or decoded signal is received.

EN 16 FM242 AA5.

Service Modes, Error Codes and Fault Finding

Black and white picture

Increase the COLOUR value when the picture improves after

you have switched on the Customer Service Mode. The new

value is automatically stored.

Menu text not sharp enough

Decrease the CONTRAST value when the picture improves

after you have switched on the Customer Service Mode. The

new value is automatically stored.

5.3.2 Sound Problems

(if valid, related to speaker-version yes or no)

No sound from left or right speaker

Check item 'Volume' in the CSM mode. If value is low, increase

the volume level. The new value is automatically stored.

No sound or sound too loud (after channel change/ switching on)

Increase/decrease the VOLUME level when the volume is OK

after you switched on the CSM. The new value is automatically

stored.

5.4 ComPair

5.4.1 Introduction

ComPair (Computer Aided Repair) is a service tool for Philips

Consumer Electronics products. ComPair is a further

development on the European DST (Dealer Service Tool),

which allows faster and more accurate diagnostics. ComPair

has three big advantages:

• ComPair helps you to quickly get an understanding on how

to repair the chassis in a short time by guiding you

systematically through the repair procedures.

• ComPair allows very detailed diagnostics (on I

is therefore capable of accurately indicating problem areas.

You do not have to know anything about I

yourself because ComPair takes care of this.

• ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the

microprocessor is working) and all repair information is

directly available. When ComPair is installed together with

the SearchMan electronic manual of the defective chassis,

schematics and PWBs are only a mouse click away.

5.4.2 Specifications

ComPair consists of a Windows based faultfinding program,

and an RS232 cable between PC and the (defective) product.

The ComPair faultfinding program is able to determine the

problem of the defective monitor. ComPair can gather

diagnostic information in two ways:

• Automatic (by communication with the monitor): ComPair

can automatically read out the contents of the entire error

buffer. Diagnosis is done on I2C level. ComPair can send

and receive commands to the micro controller of the

monitor, and so can access the I2C bus of the monitor. In

this way, it is possible for ComPair to communicate (read

and write) to devices on the I2C busses of the FTV monitor.

• Manually (by asking questions to you): Automatic

diagnosis is only possible if the micro controller of the

monitor is working correctly and only to a certain extend.

When this is not the case, ComPair will guide you through

the faultfinding tree by asking you questions (e.g. Does the

screen give a picture? Click on the correct answer: YES /

NO) and showing you examples (e.g. Measure test-point

F7 and click on the correct oscillogram you see on the

oscilloscope). You can answer by clicking on a link (e.g.

2

C level) and

2

C commands

text or a waveform picture) that will bring you to the next

step in the faultfinding process.

By a combination of automatic diagnostics and an interactive

question / answer procedure, ComPair will enable you to find

most problems in a fast and effective way.

Beside fault finding, ComPair provides some additional

features like:

• Software upgrading (upload possible to OTC and PW

Scaler).

• Emulation of the (European) Dealer Service Tool (DST).

• If both ComPair and SearchMan (Electronic Service

Manual) are installed, all the schematics and the PWBs of

the set are available by clicking on the appropriate

hyperlink. Example: Measure the DC-voltage on capacitor

C2228 (Schematic/Panel) of the SCAVIO panel. Click on

the 'Panel' hyperlink to automatically show the PWB with a

highlighted capacitor C2568. Click on the 'Schematic'

hyperlink to automatically show the position of the

highlighted capacitor.

5.4.3 How to Connect

1. First, install the ComPair Browser software on your PC

(read the installation instructions carefully).

2. Connect an RS232 interface cable between a free serial

(COM) port on your PC and the RS232 connector on the

FM242 plasma monitor.

3. Switch the plasma monitor 'off' and 'on' again (with the

Mains switch).

4. Start the ComPair program and follow the instructions.

Note: once the set is in ComPair mode, the front LED will blink

red, at a frequency of 0.3 Hz.

5.4.4 How to Order

ComPair order codes:

• Starter kit ComPair32 software (registration version): 3122

785 60040.

• ComPair32 CD (update): 3122 785 60070.

• Starter kit SearchMan32 software: 3122 785 60050.

• SearchMan32 CD (update): 3122 785 60080.

Note: The RS232 cable is not included. It is a standard cable

(9p sub-D male-to-female) that can be obtained by a computer

store. It is supplied however with the ComPair interface (4822

727 21631), necessary for servicing other Philips TVs.

5.5 Error Buffer

The error code buffer contains all detected errors since the last

time the buffer was erased. The buffer is written from left to

right. When an error occurs that is not yet in the error code

buffer, it is written at the left side and all other errors shift one

position to the right.

5.5.1 How to Read the Error Buffer

Use one of the following methods:

• On screen via the SAM (only if you have a picture).

Examples:

–Errors: 6 0 0 0 0, error code 6 is the last and only

detected error.

–Errors: 9 6 0 0 0, error code 6 was first detected and

error code 9 is the last detected (newest) error.

• Via the blinking LED procedure (when you have no

picture). See paragraph “The blinking led procedure”.

•Via ComPair.

Service Modes, Error Codes and Fault Finding

EN 17FM242 AA 5.

5.5.2 How to Clear the Error Buffer

The error code buffer is cleared in the following cases:

• By activation of the 'Reset error buffer' command in the

SAM menu.

• When you transmit the code 062599 with a standard

remote control transmitter.

5.5.3 Error Codes

Table 5-1 Error code overview

Error Device Description Item Diagr.

1 TEA6422D Audio switch

2 MSP3451G Sound proces-

3 PCF8574-

SCAVIO

4 PCF8591 AD-DA expand-er7530 SC8

5 FS6377 Clock generator 7570 SC9

6 PCF8574-PSU I/O expander

7 24C16 OTC NVM OTC 7430 SC7

8 24C16 PW NVM PW 7580 SC9

9 SAA7118 Video decoder

10 AD9887 ADC/TMDS re-

11 SDA9400 De-interlacer

12 EP1K30QC EPLD processor 7656 SC11

13 PDP I2C error of the

20 Download comm. Errors during

21 CSP comm. CSP time-out er-

40 Temperature alarm Detections of

70 Over voltage Vs, Va, +5V,

71 Vs under voltage Vs under voltage Black

72 Va under voltage Va under voltage Black

73 +5V under voltage +5V under volt-

74 +3V3 under voltage +3V3 under volt-

75 DC-PROT Audio amplifier

Notes:

• In case of non-intermittent faults, clear the error buffer

before you begin the repair. This to ensure that old error

codes are no longer present.

• If possible, check the entire contents of the error buffer. In

some situations, an error code is only the result of another

error code and not the actual cause (e.g., a fault in the

protection detection circuitry can also lead to a protection).

• In case error 70 occurs, the belonging over-voltage line

cause can be located via measuring. (via measuring all 4

voltages simultaneously with an oscilloscope). Chosen

(only Enhanced)

sor

I/O expander

SCAVIO

PSU

(only Enhanced)

ceiver

(only Enhanced)

PDP

downloading

ror

over-temperature

+3V3 overvoltage

age

age

protection

7798 SC13

7812 SC14

7540 SC8

7370 P3

7225 SC5

7170 SC4

7280 SC5

Black

P

box

P

box

P

box

Black

P

box

Black

P

box

Black

P

box

FM242-workshops will be trained how to do so. (special

document will be generated for this).

5.6 The Blinking LED Procedure

Via this procedure, you can make the contents of the error

buffer visible via the front LED (orange colour).This is

especially useful when there is no picture. When no errors are

present, the LED will stay green.

When the SDM is entered, or when code 062500 is entered

with the remote control, the LED will blink the contents of the

error-buffer.

Error-codes ≥ 10 are shown as follows:

1. n long blinks of 750 ms, which is/are an indication of the

decimal digit,

2. a pause of 1.5 s,

3. n short blinks (n = 1-9),

4. when all the error-codes are displayed, the sequence

finishes with a LED blink of 3 s,

5. the sequence starts again.

Example of error buffer: 12 9 6 0 0

After entering SDM:

1. 1 long blink of 750 ms followed by a pause of 1.5 s,

2. 2 short blinks followed by a pause of 3 s,

3. 9 short blinks followed by a pause of 3 s,

4. 6 short blinks followed by a pause of 3 s,

5. 1 long blink of 3 s to finish the sequence,

6. the sequence starts again.

5.7 Protections

You can read the error codes of the error buffer via the service

menu (SAM), the blinking LED procedure, or via ComPair. If a

fault situation is detected an error code will be generated and if

necessary, the set will be put in the protection mode. Blinking

of the red LED at a frequency of 5 Hz indicates the protection

mode.

In some error cases, the microprocessor does not put the set

in the protection mode. The error codes are indicated by an

orange front LED.

To get a quick diagnosis the chassis has three service modes

implemented:

• The Customer Service Mode (CSM): easy way to read out

the status of the set.

• The Service Default Mode (SDM): start-up of the set in a

predefined way.

• The Service Alignment Mode (SAM): adjustment of the set

via a menu and with the help of test patterns.

Exceptional ‘protection’ situation

There exists one ‘protection’ (due to too high internal settemperature), where the set does not switch to ‘protection’mode but to Standby-mode. This protection is not logged into

the error-buffer.

When the set becomes too warm, an ‘On Screen Display’message will be showed set is going to switch to Standby. After

some time set can be switched on again. (It is very unlikely this

will happen. For that reason this performance has been

accepted).

Temperature error

The monitor will switch to standby

automatically.

Please allow cool down.

EN 18 FM242 AA5.

5.8 Repair Tips

If one of the errors of the error buffer points to a defective

supply, then the supply-panel must be send for central repair.

If the symptoms (still to be communicated; e.g. when VS-value

is too high some pixels do not extinguish, when VS-value is too

low some pixels do not enlighten) match with a possible

misalignment of a supply-line, this supply-line could be

checked, and re-aligned.

Only do this if there is a slight spec-violation.

In case it does not help, re-align to the previous wrong setting,

to keep cause-image in tact, for central repair workshop.

Replace supply panel by a new one, and match the supply with

the pdp. (See alignment instructions in chapter “Alignments”).

Service Modes, Error Codes and Fault Finding

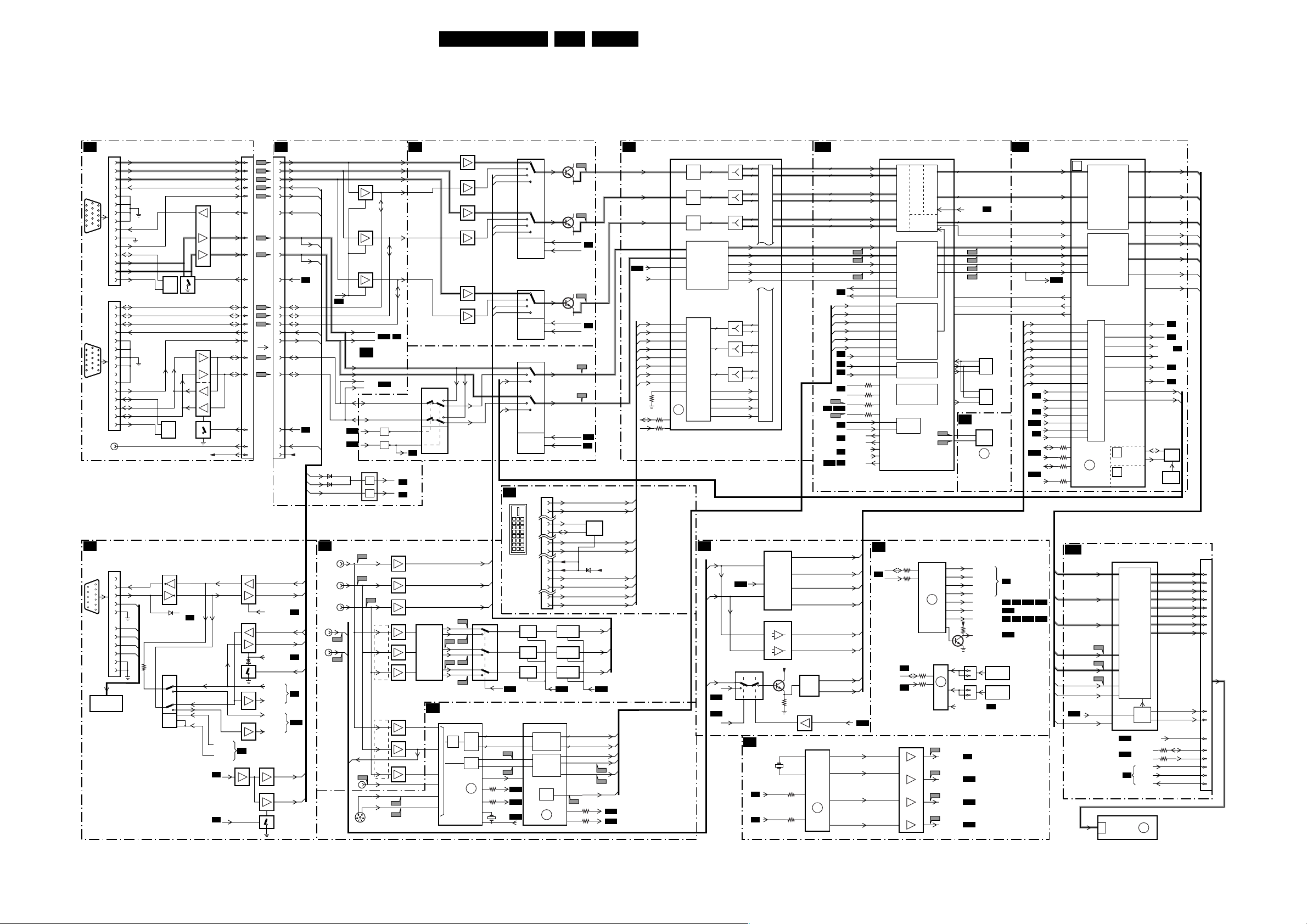

Block Diagrams, Testpoint Overviews, and Wiring Diagram

6. Block Diagrams, Testpoint Overviews, and Wiring Diagram

Block Diagram Video

VIDEO

VGA

VGA

CONNECTOR

0371 0318 0318

VGA1-R

1

VGA1-G

2

VGA1-B

3

VGA1-TXD

4

VGA1 IN

15P"D"SHELL

CONNECTOR

5

6

6

1

11

7

2

12

7

8

3

13

9

8

4

14

10

15

VGA2

IN/OUT

15P"D"SHELL

CONNECTOR

6

11

7

12

8

13

9

14

10

15

RC-OUT

SC6

RS-232

IN/OUT

5

10

4

9

3

8

2

7

1

6

BLOCK DIAGRAM

5

1

2

3

4

5

RS 232 INPUT

CONTROL

RC-VGA1

9

10

VGA1-RXD

11

DCC-SDA-1

12

VGA1-H

13

VGA1-V

14

DCC-SCL-1

ST24FC21

VGA2-R

VGA2-G

VGA2-B

VGA2-TXD

VGA2-RXD

DDC-SDA-2

VGA2-H

VGA2-V

DDC-SCL-2

RXD

TXD

5

DDC

7

NVM

7904

DDC

NVM

7907

ST24FC21

+5V-STBY-SW +5V-STBY-SW

7352

ST3232E

11

14

12

13

6366

PS-232-ACT

SC7

3913

7340 A+B

74HC4052D

1

TXD-OTC

3

5

TXD-PW

12

13

14

10

9

LOGIC

6

15

0372

1

2

3

4

5

6

7

8

9

N.C.

10

11

12

13

14

15

0376

1

2

3

RL_ICN

4

5

GL_ICN

6

LD_ICN

7

IR_TX

8

IR_RX

9

10

11

SEE

6

1

13

9

2

11

6

7900

EBOX-PRESENT

10

7937

7940

7910

VGA1-R

VGA1-G

VGA1-B

VGA1-TXD

VGA1-RXD

9

RC-VGA1

4

VGA1-H

10

VGA1-V

VGA2-R

VGA2-G

VGA2-B

VGA2-TXD

VGA2-RXD

8

VGA2-H

VGA2-V

3

12

5

VGA-OUTN

7915

SELECT-3

SELECT-2

SC8

SC7

TXD-2

RXD-2

RC

RC-CONTR

11

9

10,13

3

5

7310

SC8

2

4

6

12

13

15

8

10

29

17

19

21

27

28

23

25

31

30

32

7303 C+D

7303 A+B

1.4

7315, 7316

7325, 7326

SC6

F303

31

F304

29

F305

27

F308

21

F309

20

18

F306

25

F307

23

4

F311

16

F312

14

F313

12

6

5

F314

10

F315

8

2

3

1

12

VGA2-TXD

8

VGA2-RXD

SELECT-4

26VGA1-RXD

VGA1-TXD

SELECT-1

VGA1-RXD

TXD-OTC

RXD-OTC

TDX-PW

RXD-PW

73237322

RC-OUT

7320

RC-VGA1

7321

VGA

INPUT

SC8

SC8

SC7

SC10

VGA1-R

VGA1-G

VGA1-B

VGA1-TXD

VGA1-RXD

RC-VGA1

VGA1-H

VGA1-V

(EBOX-

PRESENT)

SC7

TV MODE

VGA2-TXD

VGA2-RXD

VGA2-H

VGA2-V

VGA2OUTN

SC6

RC-OUT

6379

6378

SC3

R/Pr/Cr

G/Y/Y

B/Pb/Cb

2fh 1fh 2fh

V

H

VGA2OUTN

SC6

SC10

SC10

VGA1-V

VGA1-H

VGA1-RXD

VIDEO SELECTION

& MATRIX

AV3 (HD)

V-HD-EXT

F072

H-HD-EXT

F075

AV1

7311-A

7311-B

7311-C

VGA1-H

VGA1-V

11

F071

F070

Y-H D

F073

251

SVHS

SC2

VGA1-V

VGA1-H

VGA2-V

VGA2-H

VGA2-V

VGA2-H

VGA2-EN

VGA2-OUT

7370 A+B

O.S.

O.S.

F074

AV2

34

SC11

SYNC

SELECTION

SC11

7060

7065

75

9

R

G

B

Pr

Y

Pb

1Fh

Cr

Y

Cb

CVBS

C

Y

SC3

VGA2-R

VGA2-G

VGA2-B

SC7

VGA2-EN NOT

VGA2-OUTN

SC6

SYNC-ACT

SC7

UART-ACT

SC7

7141

7138

7135

70792Fh

7074

7084

1fh BUFFER

7117

Cr

7113

Ys

7121 Y-HD

Cb

F236

F235

VIDEO SELECTION

7007 A+C

74HCT4053T

14

4

6

11-9

7088

7090

MATRIX

LOGIC

RGB

SC5

MATRIX-SEL

8x

8x

H-DEC

V-DEC

clock

PW-SDA

3250

3250

PW-SCL

VGA1-R

VGA2-R

R-2Fh

R-YUV

VGA1-G

VGA2-G

G-2Fh

G-YUV

VGA1-B

VGA2-B

B-2Fh

B-YUV

VGA1-V

VGA2-V

VGA1-H

VGA2-H

SC4

4

15

14

Y-D E C

UV-DEC

F240

F247

1250

VIDCLK

24.576MHz

SC11

V-HD

12,14

H-HD

1,5

SC10

2

4

1

5

15

11

12

14

2

4

1

5

2

4

15

11

SC9

SC9

7146

74HC4052D

LOGIC

7158

74HC4052D

LOGIC

7009

74HC4052D

LOGIC

DVI-D INPUT

DVI-D INPUT SOCKET

7102

CLAMP

7103

CLAMP

7104

CLAMP

7280

SDA 9400

23

22

54

0375

INTERLACER

CLOCK

7145

7148

7151

7154

7157

7160

12

13

5

3

R-2Fh

G-2Fh

B-2Fh

7089

I054

74HCT4053D

R-NTSC

R-ATSC53

I058

I065

G-NTSC

G-ATSC21

I072

I078

B-NTSC

B-ATSC123

I083

VIDE-SELECTION

DECODER

DECODER DE-INTERLACER

7225

SAA7118C

VIDEO

DE-

ADC

CODER

SYNC

CNTRL

P4

ERR

9

10

14

16

17

18

23

24

SYNC

7129

F146

3

7130

F152

13

9

VIDEO-SEL-1

VIDEO-SEL-2

7131

VIDEO-SEL-1

VIDEO-SEL-2

V-ADC

H-ADC

SYNC-SEL

VIDEO-SEL-2

7100-B

BLANKING

7100-C

BLANKING

7100-A

BLANKING

SC11

HD-CLAMPN

SC8

F158

SC8

F211

F210

SC10

SC8

SCL

DDC

SDA65

EPROM

6210

R-YUV

G-YUV

B-YUV

8x8xY-OUT

UV-OUT

61

V OUT-DEINT

60 H OUT-DEINT

V PEN

62

CLKOUT-DEINT

26

F249

PW-SDA

3284

21

3285

20

PW-SCL

10

3

9

10

3

13

9

10

1

2

6

7

9

DE-

ERR

11

19FM242 AA 6.

SC11

HD-BLANKN

F246

F245

SC10

SC10

SC4

RX2-

RX2+

7215

ST24FC21

RX1-

RX1+

+5V-STBY-SW

RXD-

RXD+

RXC+

RXC-

VIDEO SELECTION - ADC

119R-ADC

110G-ADC

100B-ADC

GBLKSPL

SC10

GCOAST

RXO+

RXO-

RX1+

RX1-

RX2+

RX2-

RXC+

RXC-

PW-SDA

3209

PW-SCL

3210

7170

AD9887KS

81V-ADC

82H-ADC

93

94

62

63

59

60

56

57

65

66

53RTHERM DATACK

ERR

92

91

ADC-TMDS PW EPLD

8x

ADC

8x

ADC

8x

ADC

SYNC. PROC

+

CLOCK

GENERATION

8x

8x

TMDS

RECEIVER

8x

DE

SC2

H-SYNC

V-SYNC

SYNC SELECTION

& SWITCHING

Y-H D

C-SYNC-OUT

SC11

SC11

H-PRESNT

10

H-HD-EXT

2

1

8x

8x

8x

8x

8x

8x

8x

8x

8x

8x

8x

8x

V-HD-EXT

75 OHM-ON

SC11

7007-B

74HCT4053D

10 6

SC9

MUXES

7000 - 7002

7006 - 7010

PROCESSING

7025 A-B

LM319D

COMPARATOR

10

5

15

VGA2-EN-NOT

SCALER - CLOCK

GENERATOR

24.576 MHz

SC7

SC7

V-SYNC

H-SYNC

+

-

+

-

SDA-1

SCL-1

SCALER-PW164-MEMORY

SC10

8x GRE (0-7)

8x GRO (0-7)

8x GGE (0-7)

8x GGO (0-7)

8x GBE (0-7)

8x GBO (0-7)

138

139

140

134

137

7

12

+5B

7040

LM 1881M

2

3051

7060

3571

3570

16

SYNC

SLICER

7570

FS6377

5

6

GENERATOR

1

CLOCK

ERR

SC5

SC11

V-SYNC-TTL

V-SYNC-POL-N

H-SYNC-TTL

H-SYNC-POL-N

V-SYNC-CMP

H-SYNC-CMP

C-SYNC-LM

1

V-SYNC-LM

3

VGA2-EN

5

ADVS

ADHS

ADSOG

GCLK

ADDE

F615

F616

15

13

12

10

SC11

SC4

SC7

SC7

SC9

SC7

SC6

SC2

SC8

SC3

F619

F633

F618

CLKOUT-DEINT

8x UV-OUT

VOUT-DEINT

HOUT-DEINT

PW-START

PW-PRESET

SDA-2

SCL-2

PW-SDA

PW-SCL

RXD-PW

TXD-PW

VGA2-OUT

VGA2-EN

VIDEO-SEL-1

VIDEO-SEL-2

SYNC-SEL

SC10

GBLKSPL

GCOAST

8x Y-OUT

VPEN

MCLK

3608

3606

3604

3605

7605

PW164

CONTROL FUNCTIONS

SC8

SDA1

SC7

SCL1

SC7

SDA1

SCL1

SC7

7574

74LVC125A

5

9

GRAPHICS PORT

SYNC

DECODER

AND

TIMER

YUV

TO

RGB

CLOCK

GEN

MICRO-

PROCESSOR

UART

3541

15

14

3540

PIXEL PROC.

VIDEO

PORT

7540

PCF8574A

3532

3531

32

6

8

1112

8x DRE (0-7)

8x DGE (0-7)

SCALER

SC9

DCK EXT

8x DBG (0-7)

PARITY PARITY-OUT

F637

F639

F634

F638

7630

M29W160DT

DATA

FLASH

ADD

ROM

CNTRL

7628

CY62126

DATA

ADD

SRAM

CNTRL

PW-NVM

SC9

7580

M24C32

SDA

EXP.

ERR

10

I/O

3

9

F566

F565

F563

F564

F569

F567

7530

PCF8591

ADC

ERR

4

5

6

7

9

10

11

12

7563

1

4

2

3

VIDCLK

(24.567 MHz)

VXCA

(18.432 MHz)

MCLK

(120 MHz)

DCKEXT

(36 MHz)

5

SCL

6

SELECT-1

SELECT-2

SELECT-3

SELECT-4

VIDEO-SEL-1

POWER-DOWN

VIDEO-SEL-2

3548

MSP-RESET

0315

1

2

0316

1

2

TEMP3-SENSOR

SC5

SC14

AUDIO

SC10

SC10

NVM

ERR

8

TEMPSENSOR S1

(OPTIONAL)

TEMPSENSOR S2

(OPTIONAL)

P3

SC6

SC6

SC12

SC6 SC3

SC14

SC11

SC3

BACK-END-EPLD

DVS

DHS

DEN

DCLK

FBX MODE

1-2 FH

SYNC

SC5

SC6

SC10

SC8

SC10

SC12

SC10 SC11

SC10 SC11

SC12

V-SYNC-TTL

V-SYNC-POL-N

H-SYNC-TTL

H-SYNC-POL

C-SYNC-LM

V-SYNC-LM

V-SYNC-COMP

H-SYNC-COMP

VGA1-V

VGA1-H

VGA2-V

VGA2-H

SYNC-SEL

VIDEO-SEL-1

VIDEO-SEL-2

PW-SDA

PW-SCL

SDA-1-3V3

3664

SCL-1-3V3

3662

7656-A+B+C

EP1K30FC256

A

SC12

8x R-OUT (0-7)

8x G-OUT (0-7)

8x B-OUT (0-7)

V-SYNC-OUT

H-SYNC-OUT

BLANK-OUT

PARITY-OUT

SC10

PWDWN--LVDS

DIGITAL

CONTRAST

SYNC

DELAY

SYNC

PROC.

ERR

12

BACK-END-LVDS OUTP

7670

DS90CC385M

50-56

2-4

6-8

10-15

16,18-20

22-25

F619

28

F690

27

F692

30

25

DCLK

31

32

B

CONTROLS

C

SUPPLY

& GROUND

SC12

SC12

PLASMA

DISPLAY

PANEL

LVDS

TTL PARALLEL

TO

LVDS

(LVDS

ENCODER)

TTL

LVD S

POWER DOWN

SDA-1-3V3

SCL-1-3V3

PDP-GO

SC7

CPU-GO

IRQ-PDP

PDP

8x R-OUT (0-7)

8x G-OUT (0-7)

8x B-OUT (0-7)

V-SYNC-OUT

H-SYNC-OUT

BLANK-OUT

PWRDWN-LVDS

75 OHM-ON

SC2

H-PRESENT

SC2

HD_BLANKN

HD_CLAMPN

C-SYNC-OUT

SC2

TV MODE

SC6

V-HD

H-HD

7655

EPC2

DATA

CNTRL

PROM

585

PROG

SOCKET

48

TX OUT0-M

47

TX OUT0-P

46

TX OUT1-M

45

TX OUT1-P

42

TX OUT2-M

41

TX OUT2-P

38

TX OUT3-M

37

TX OUT3-P

3837TX CLK OUT-M

TX CLK OUT-P

3680

3684

ERR

30

CL 26532038_001.eps

SC3

PDP

INTERFACE

CONNECTOR

PDP-GO

CPU-GO

IRQ-PDP

0318

19

17

15

13

11

9

3

1

7

5

4

14

18

8

10

6

150402

Block Diagrams, Testpoint Overviews, and Wiring Diagram

Block Diagram Audio

20FM242 AA 6.

AUDIO

AUDIO SOURCE

SC13

SELECT

L

AUDIO

VGA IN

R

L

AUDIO

FLEX

VGA

R

L

AUDIO

DVI-D

R

L

AV1

AUDIO

CVBS

R

L

AV2

AUDIO

YC

R

AV3

L

AUDIO

RGB

YPbPr

R

YCbPr

SC1-L

SC1-R

D-CTR-NIL

D-CTR-ONE

CONTROL

LED

LD

PANEL

7107

RC

RECEIVER

2

6127

1101

4

ON/OFF

5

SWITCH

6

7120

F713

F714

1

4

SC8

SC6

GREEN

RED

F710

F711

RS-232

IN/OUT

2

6

2

A

6

B

2

6

7800 A+B

74HC4053D

2

12

7718

POWER-OK

RS232 INPUT

5

10

4

9

3

8

2

7

1

6

6103

2

3

7

1

2

3

7714

LM833D

7734

LM833D

7754

LM833D

0376

1

2

3

4

5

6

7

8

9

10

11

10,11

7103

7105

1

7

1

7

1

7

15

14

ANTI PLOP

+9V-STBY

7801

7802

BLOCK DIAGRAM

RXD

TXD

RL_ICN

GL_ICN

LD_ICN

IR_TX

IR_RX

GREEN-LED

RED-LED

RC-IN

LIGHT-SENSOR-IN

+8V6

+5V-STBY-SW

+9V-STBY-SW

+9V-STBY

L4

R4

L5

R5

L6

R6

L2

R2

L3

R3

L1

R1

7803

SEE

VIDEO

N.C.

L1

L2

L3

L4

L5

L6

R1

R2

R3

R4

R5

R6

7805

7806

AUDIO-ENABLE

SC14

0320

1

2

3

4

5

6

7

8

9

10

5798

+8V6

SC8

0320

1

2

3

4

5

6

7

8

9

10

10

11

25

24

23

20

19

18

7798

TEA6422D

3

ERR

4

5

6

9

MATRIX

SWITCH

7807

7808

CONTROL

FUNCTIONS 2

ICON_NOT

ICON_NOT

1

LD_ICN

GL_ICN

RL_ICN

SC7

IR_TX

IR_RX

SC7

+8V6

+5V-STBY-SW

+9V-STBY-SW

+9V-STBY

SC14

3795

28 SDA-AUDIO

3794

27

12 PRE-OUT1-L

13

PRE-OUT1-R

SC15

AUDIO

DELAY LINE

A

B

7555

74HC4053D

2

1

12

13

5

3

7550

74HC4053D

2

1

12

13

AUDIO-PROCESSOR

SCL-AUDIO

GREEN_LED

15

14

RED_LED

4

15

14

BLOCK DIAGRAM

RC

VIDEO

I2SDATA-IN1

I2SDATA-IN2

B

7879

TC74HC590AF

RC

SC6

SEE

7812

MSP3415G

3

2

17

21

40

41

DEMO-

DULATOR

PRE-

SCALE

DAC

DIGITAL

DAC

SOUND

7874

TC74HC590AF

F872

CONTROL FUNCTIONS 1

SC7

SC6

SC6

7517

ADM 810

RESET

DSP

PROC.

VGA1-H

VGA1-V

2

ERR

2

I2S-DATA-OUT

I2S-CLOCK

DACM-L

DAC

DACM-R

DAC

7870

TC74HC590AF

7432

7433

RESET

SC13

SERVICE PINS

0382

1

3

5

7

9

+5V

SDA-AUDIO

SCL-AUDIO

13

12

16

14

27

26

8

9

3130L

R

5 18.432 MHz VXCA

6

7x

7x

1415

6MHz

OTC-H

RESET

SC7

SC10

PW_FLASH_RESET

ICONN_NOT

SC8

STANDBY

SC8

SC10

PW-START

SC8

POWER-OK

CPU-GO

PDP-GO

SC12

IRQ-PDP

SC6 RC-CNTL

SC10

PW-RESET

SC10

PW-START

SC8 FAN-SP2

SC8 FAN-SP1

SC6 UART-ACT

SC6

SYNC-ACT

GND-LED

RED-LED

RC

LIGHT-SEN-IN

2

SDM

4SAM

6CMP

8

10

3813

3812

4810

4811

A

B

I660

I659

7841

LM833D

3

6

7851

LM833D

3

6

7861

TS462CD

2

6

SC9

SDA-1

SCL-1

1

7

F813

1

7

1

7

AUDIO DELAY PROC.

A

7880

CY7C199B

RAMCOUNTER COUNTER "D" F.F. "D" F.F.

SERVICE-IN

3419

3380-C

3422

3421

SCL-1

SDA-1

16

17

83

84OTC-V

74

109

120

119

95

96

116

115

93

110

108

95

104

103

99

98

114

113

100

105

106

SC7

7x8x

7383

SAA5801H

7881

74HCT573

8x

FRAME

OTC

ERR

91

ERR

92

ERR

93

ERR

94

ERR

95

ERR

96

ERR

97

8x

82

86

85

88

87

89

90

91

92

43

42

40

41

SC13

F816

SC7

F817

3404-C

3404-D

3404-A

3404-B

3402-D

3402-C

3402-B

3402-A

3464-D

3464-C

3464-A

3464-B

L-POS

L-NEG

AUDIO-ENABLE

D-CTR-ONE

D-CTR-NIL

7882

74HCT573

SDA-NVM-1

SCL-NVM-1

RESET

SC7

ROM-CS

RAM-CS

ROM-OE

RAM-OE

DATA

ADDRESS

CONTROL

DATA

ADDRESS

CONTROL

SC6

RS_232_ACT

F812

SC1-L

SC1-R

17

15

F383

F427

SDA-1

F428

SCL-1

F425

SDA-2

F426

SCL-2

RXD-OTC

TXD-OTC

R-POS

R-NEG

10

0388

7

6

5

4

3

2

1

4884

24 ms MONITOR

4894

40 ms TV

SEE

IIC DIAGRAM

SC10

SC6

7430

MC24C32

5

6

NVM

ERR

7

7

7510 - 74 LVCOOAD

1

2

9

7506

AM29DL164DT

DUAL

BANK

FLASH

ROM

7500

MSM51V18165F

DRAM

7435

A2

0388

88

7

6

5

4

3

2

1

FILTERS

+9V-STBY A

I2S-DATA-IN1

I2S-DATA-IN2

6

11

26

28

7515,7516

12

L-POS

L-NEG

AUDIO-ENABLE

R-POS

L-NEG

CS

OE

CS

OE

FLASH

RESET

7225

LM833DT

3

2

5

6

3207

3222

7211

BC857BM

AUDIO

A3

AMPL-

1730

2.5A

7735,7736

STAB

1740

2.5A

7745,7746

STAB

A4

A5

A6

7302

7402

7502

7602

L-HIGH

AUDIO

AMPLL-LOW

AUDIO

AMPLR-HIGH

AUDIO

AMPLR-LOW

F730

F735

F740

F745

7315

LM311D

2

3

7415

LM311D

2

3

7515

LM311D

2

3

7615

LM311D

2

3

A3

A4

A5

A6

7260-A

LM833DT

3

1

2

3259

F231

3220

1

7238-A

LM833DT

F241

3240

7

F211

TO

0302

P6

POWER

SUPPLY

3

1

2

3234

7260-B

LM833DT

5

7

6

3274

7238-B

LM833DT

5

7

6

3244

SUPPLY & DC PROTECTION

A7

0302

9

8

7

6

5

4

3

2

1

L-HIGH

L-LOW

AU-EN-NOT

R-HIGH

L-HIGH

DC-PROT

+9V-STBY

F258

F235

F273

F245

8

1,4

8

1,4

8

1,4

8

1,4

OUT_PROT

VSDN-POS

VCC-10-POS

VSDN-NEG

VCC-10 -NEG

7

7

7

7

3315

3328

F328

3318

3415

3428

F428

3418

3515

3528

F528

3518

3615

3628

F628

3618

OUT_LH

OUT_LL

OUT_RH

OUT_RL

VCC-10-POS

VCC-10-NEG

VCC-10-POS

VCC-10-NEG

VCC-10-POS

VCC-10-NEG

VCC-10-POS

VCC-10-NEG

VCC_10_POS

3749

VCC_10_NEG

F330

F430

F530

F630

3755

3765

2760

3330

7330

2330

2355

7355

3355

3430

7430

2430

2455

7455

3455

3530

7530

2530

2555

7555

3555

3630

7630

2630

2655

7655

3655

3770 3771 3780

+9V-STBY

+9V-STBY A

6750

2759

6760

7755

3337

3362

3437

3462

3537

3552

3637

3662

7751

7365-2

IRF7343

G

F365

G

7365-1

IRF7343

7465-2

IRF7343

G

F465

G

7465-1

IRF7343

7565-2

IRF7343

G

F565

G

7565-1

IRF7343

7665-2

IRF7345

G

F665

G

7665-1

IRF7345

5753

3751

7761

DC-PROT

5335

D

S

D

S

7340

D

S

D

S

7440

D

S

D

S

7540

D

S

D

S

7640

3781

CL 26532038_002.eps

VSDN-POS

5365

2355

5366

VSDN-NEG

OUT_PROT

A7

5435

VSDN-POS

5465

2465

5460

VSDN-NEG

OUT_PROT

A7

5535

VSDN-POS

5565

2565

5560

VSDN-NEG

OUT_PROT

A7

5335

VSDN-POS

5665

2665

5660

VSDN-NEG

OUT_PROT

A7

DC-PROTECT

7753

BC857BW

3752

150402

OUT_LH

OUT_LL

OUT_RH

OUT_RL

0303

0304

5

L-HIGH

4

3

2

1

L-LOW

R-HIGH

4

3

2

1

R-LOW

Block Diagrams, Testpoint Overviews, and Wiring Diagram

Power Lines Overview

21FM242 AA 6.

SC8

0319

0305

1

2

3

4

5

6

7

8

9

10

11

12

13

1

8

9

10

11

12

8004

AC LINE

3

VCC

NC

AC NEUTRAL

1

CONTROL FUNCTIONS 2

+9V-STBY

+9V-STBY-SW

+8V6

+5V-STBY-SW