Page 1

F-2200 Series Vortex

Flow Meter Installation and

Operation Guide

For software version CF 4.7 and higher

12-15-08

1500 North Belcher Road • Clearwater, FL 33765 • Tel (727) 447-6140 • Fax (727) 442-5699

www.onicon.com • sales@onicon.com

Page 2

SAFETY INFORMATION

i

This meter was calibrated at the factory before shipment. To ensure correct use of the meter, please read

this manual thoroughly.

Regarding This Manual:

• This manual should be passed on to the end user.

• Before use, read this manual thoroughly to comprehend its contents.

• The contents of this manual may be changed without prior notice.

• All rights reserved. No part of this manual may be reproduced in any form without

ONICON’s written permission.

• ONICON makes no warranty of any kind with regard to this material, including, but not

limited to, implied warranties of merchantability and suitability for a particular purpose.

• All reasonable effort has been made to ensure the accuracy of the contents of this manual.

However, if any errors are found, please inform ONICON.

• ONICON assumes no responsibilities for this product except as stated in the warranty.

• If the customer or any third party is harmed by the use of this product, ONICON assumes no

responsibility for any such harm owing to any defects in the product which were not

predictable, or for any indirect damages.

Safety Precautions:

The following general safety precautions must be observed during all phases of installation,

operation, service, and repair of this product. Failure to comply with these precautions or with

speci c WARNINGS given elsewhere in this manual violates safety standards of design, manufacture,

and intended use of the product. ONICON Incorporated assumes no liability for the customer’s

failure to comply with these requirements. If this product is used in a manner not speci ed in this

manual, the protection provided by this product may be impaired.

The following symbols are used in this manual:

WARNING

!

Messages identi ed as WARNING contain information regarding the personal safety of individuals

involved in the istallation, operation or service of theis product.

CAUTION

!

Messages identi ed as CAUTION contain information regarding the potential damage to the product

or other ancillary products.

Messages identi ed as IMPORTANT NOTICE contain information critical to the proper operation of

the product.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

IMPORTANT NOTICE

3

Page 3

F-2200 Series Vortex Flow Meter Installation and Operation Guide

Addendum

December 12, 2008

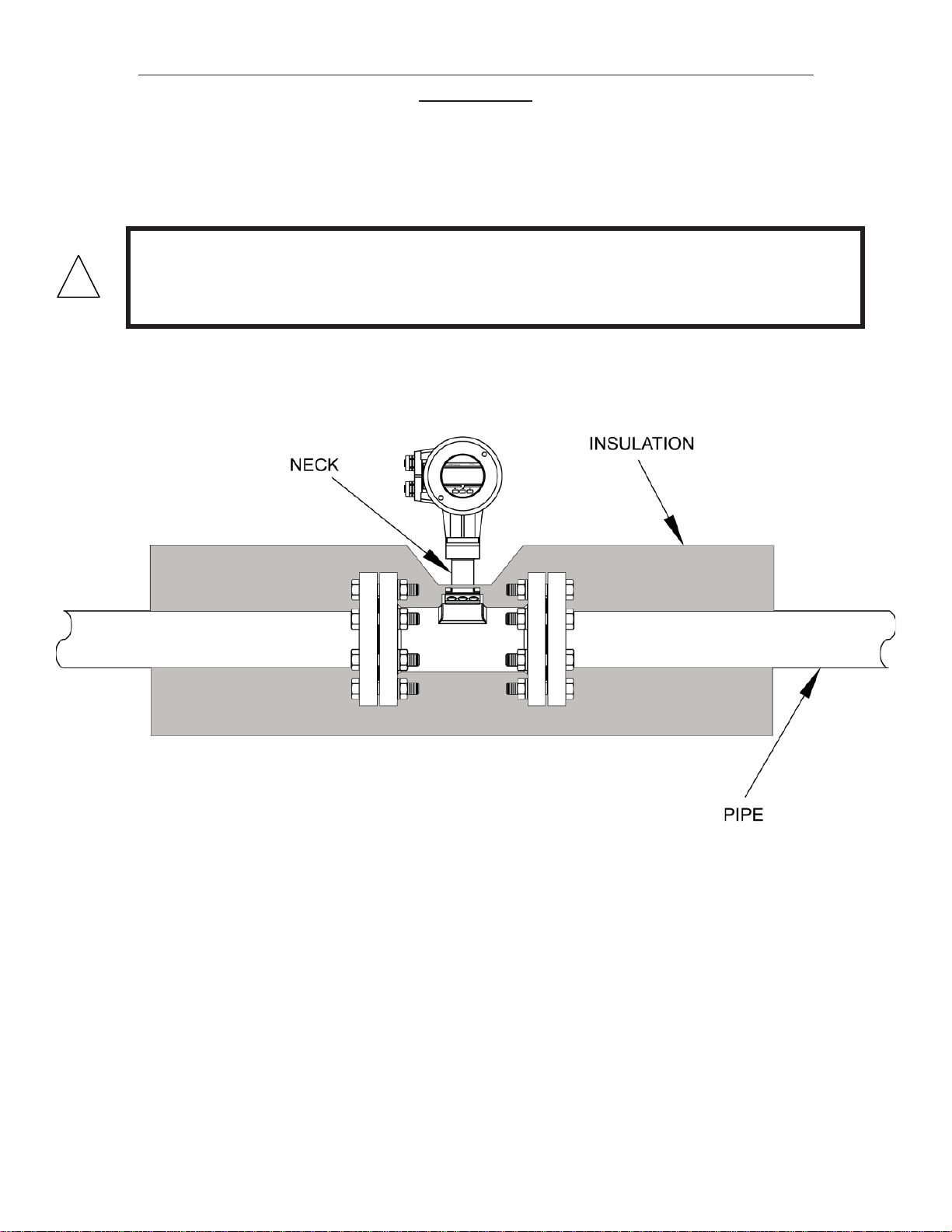

The drawing below illustrates the proper method for insulating the ow meter.

CAUTION

!

Insulating the entire neck of the ow meter will increase heat transfer to the electronics enclosure

and may in some cases cause premature failure of the electronics.

F-2000 SERIES STEAM FLOW METER WITH INSULATION DETAIL

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

4

Page 4

TABLE OF CONTENTS

1.0 INTRODUCTION ..............................................................................................................7

1.1 Purpose of This Guide .............................................................................................. 7

1.2 Principal of Operation .............................................................................................. 7

1.3 Features and Speci cations ...................................................................................... 7

1.4 Additional Required Materials ................................................................................. 9

1.5 Working Environment ............................................................................................... 9

1.6 Serial Number ........................................................................................................... 9

2.0 UNPACKING .................................................................................................................... 10

2.1 Checking That You Have Received Everything ..................................................... 10

3.0 INSTALLATION INFORMATION ................................................................................... 11

3.1 Site Selection ........................................................................................................... 11

3.1.1 Flow direction and meter position .............................................................. 11

3.1.2 Maximum allowable difference between inside of meter body and

the connecting pipe ...................................................................................... 12

3.1.3 Straight, unimpeded inlet and outlet runs .................................................. 13

3.1.4 Minimizing pipe vibration ........................................................................... 14

3.1.5 Locating the meter in a pipeline that runs parallel to a wall ..................... 14

3.1.6 State of medium ........................................................................................... 14

3.1.6.1 Liquid Applications ..................................................................... 14

3.1.6.2 Steam or compressed gas applications ........................................ 14

3.2 Mechanical Installation .......................................................................................... 15

3.2.1 Orient the display for convenient viewing ................................................. 15

3.2.1.1 Liquid applications ...................................................................... 15

3.2.1.2 Steam or compressed gas applications ........................................ 16

3.2.2 Flanged type connections to ANSI B16.5 (Schedule 40) ............................ 16

3.2.3 Temperature Measurements ......................................................................... 17

3.3 Wiring Terminations ............................................................................................... 17

4.0 START-UP & TROUBLESHOOTING .............................................................................. 18

4.1 Start Up .................................................................................................................... 18

4.2 Measurement Mode ................................................................................................. 18

4.3 Operating the Display ............................................................................................. 19

4.4 Error Handling ......................................................................................................... 20

4.5 Troubleshooting Hints............................................................................................. 21

5.0 FLOW STRAIGHTENER CATALOG SHEET .................................................................. 22

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

5

Page 5

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

6

Page 6

SECTION 1.0: INTRODUCTION

We, at ONICON INCORPORATED, would like to thank you for purchasing our F-2200 Series Vortex Flow

Meter. As our valued customer, our commitment to you is to provide fast reliable service and assistance,

while continuing to offer you new products to meet your growing ow measurement needs.

1.1 PURPOSE OF THIS GUIDE

The purpose of this guide is to provide installation and commissioning procedures and basic

operating and servicing instructions for ONICON F-2200 Series Vortex Flow Meters.

WARNING

!

Only quali ed service personnel should attempt to install or service this equipment. Serious injury

may result from the improper installation or use of this equipment.

1.2 PRINCIPAL OF OPERATION

ONICON F-2000 series vortex ow meters utilize Karman’s vortex street principal to detect changes

in velocity in the medium owing around the titanium shedder bar and through the meter body. A

volumetric ow rate is then derived by utilizing the known cross-sectional area of the meter body

and the average velocity of the medium. When provided with optional temperature and/or pressure

compensation the F-2000 series ow meters are capable of calculating the required density

corrections necessary to provide direct mass ow measurement of liquids, steam or gases.

1.3 FEATURES AND SPECIFICATIONS

CONSTRUCTION

Meter body:

Casting: 316 stainless steel for diameters up to 4”

304 stainless steel for 6” and 8” diameters

Shedder bar: Unalloyed titanium

Shedder bar seal: Ni plated Inconnel

Damper pin o-ring:

Viton for, non-steam, -4° to 356° F

Kalrez 4079 for, non-steam, -4° to 428° F

Paro uor for steam, -4° to 464° F

Electronics enclosure:

Enclosure material: Die-cast aluminum

Enclosure viewing window: Tempered glass,

UV blocking

CALIBRATION

Each meter undergoes a 5 point velocity calibration

from 0-250 ft/sec

PROGRAMMING

Each meter is programmed at the factory based on application speci c data provided by the

customer. Field re-programmable via keypad, with coded access for security.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

7

Page 7

ACCURACY

Volumetric ow

±1% of reading accuracy (±2% for ¾” & smaller sizes)

Mass ow

±1.5% of reading accuracy (±2.5% for ¾” & smaller sizes)

OPERATING TEMPERATURE RANGE

Media temperature

25° to 464° F

Ambient temperature

0° to 132° F

DISPLAY / USER INTERFACE

16x64 dot matrix LCD with 3 button keypad and magnetic pin programming

OUTPUT SIGNALS

Rate: 4-20mA, loop-powered

Supply voltage range: 14-36 VDC

Minimum load resistance: 100 ohms

Maximum load resistance is calculated as follows:

Max load = Vs – 12V Where Vs = supply voltage

0.020A

Total: Scaled output pulse, programmable

Optically isolated open collector, 0.5 hz maximum

Rating: 5-36 VDC, 100mA maximum

SUPPLY VOLTAGE:

14-36 VDC

PROCESS CONNECTIONS:

Standard: ANSI #300 anges

Optional: ANSI #600 anges

APPROVALS

Safety: Conforms to CE mark as per LVD, PED and EMC Directive

Enclosure: Conforms to IP 65 and IP 67

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

8

Page 8

1.4 ADDITIONAL REQUIRED MATERIALS

Installer is responsible for providing suitable anges and fasteners to connect the meter to the

process piping. In addition, most installations will also require one reducer, one expander, pipe

supports and a suf cient length of straight pipe (pipe diameter = meter size) to meet the installation

requirements outlined in this manual. Use of an optional ow recti er may be required in cases

where the available space is not suf cient to allow for proper upstream straight pipe run.

1.5 WORKING ENVIRONMENT

ONICON F-2000 series vortex ow meters are designed for use in industrial environments that are

free of corrosive liquids, fumes and excessive vibration. Do not expose the ow meter electronics

enclosure to direct sunlight. Install a sunshade if necessary. Do not expose the ow meter to intense

vibration. If necessary, provide additional support to the pipeline, at the meter location, to minimize

vibration. The rotating design of the electronics enclosure makes it easier to connect the power and

signal cables to the terminals in the rear of the enclosure. Rotate the enclosures as necessary before

installing the meter.

The ambient operating temperature range is 0° to 132° F.

1.6 SERIAL NUMBER

The serial number for your F-2000 series vortex ow meter is located on the metal identi cation

plate mounted on the side of the electronics enclosure. Please have this number available whenever

you contact ONICON for assistance.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

9

Page 9

SECTION 2.0: UNPACKING

F-2000 series vortex ow meters are shipped in one package. Additional items, if ordered, will be shipped

in separate packaging. All shipments are insured for damage in transit. Carefully inspect each package and

notify the freight carrier and ONICON immediately if any items arrive damaged.

2.1 ENSURING THAT YOU HAVE RECEIVED EVERYTHING

Standard Documentation

Each ONICON ow meter is serialized and supplied with a comprehensive documentation

package speci cally prepared for this meter. It includes the following items. Please notify

ONICON immediately if any discrepancies are found.

• Flow Meter

• The F-2000 Vortex Flow Meter Installation and Operation Guide

• The Flow Meter Calibration Data Sheet

• Magnetic programming pin

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

10

Page 10

SECTION 3.0: INSTALLATION INFORMATION

The F-2000 series vortex ow meter must be installed by a technician quali ed to work with pressurized

liquid, steam and/or gas ow and must conform to all federal, state and local building codes. ONICON will

be happy to assist with technical recommendations and to provide guidance via telephone or mail. On-site

engineering, installation and service are also available, at additional cost.

3.1 SITE SELECTION

Careful attention in locating the point in the piping system where the ow meter will be installed

will ensure accurate and reliable operation. When selecting an installation site, consider the criteria

contained in Section 1.5 WORKING ENVIRONMENT, as well as the following:

CAUTION

!

3.1.1 Flow Direction And Meter Position

The installation guidelines presented below are minimum requirements for the proper operation of

this ow meter.

The ow must always be in the direction of the arrow located on the meter body.

This will orient the bluff side of the vortex shedder bar so that it faces the incoming

ow (i.e. the upstream side).

For vertical pipe runs, ow must always be in the upward direction. Consult the

factory in the event that a downward owing pipe is the only available location.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

11

Page 11

The diagrams shown below illustrate the correct meter orientation for vertical and horizontal pipe.

3.1.2 Maximum Allowable Difference Between Inside Diameter Of Meter Body

And The Connecting Pipe

The table below provides the maximum allowable difference between the diameter of

the ow meter body and the connecting pipe.

Nominal Meter Size

(in.)

1” 1.05 0.016

1 1/2” 1.61 0.016

2” 2.07 0.024

3” 3.07 0.024

4” 4.03 0.024

6” 6.07 0.031

8” 7.98 0.039

Meter Body

Diameter (in.)

Maximum Pipe ID

Difference (in.)

Ensure that the bore of the locating pipes are smooth and without deposits,

scaling, or welding beads.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

12

Page 12

3.1.3 Straight, Unimpeded Inlet And Outlet Runs

D = Meter Size (Nominal diameter in inches)

With a ow straightener, the inlet pipe length may be reduced by 50%. For example, with a

control valve upstream, the inlet length is 25D instead of 50D. The minimum inlet pipe length

including the ow straightener must always be at least 12D.

3.1.4 Minimizing Pipe Vibration

Pipe vibration caused, for example, by the action of pumps, valves, etc. will distort ow

measurements, particularly at low ow velocities. To minimize the effects of vibration,

support the pipeline on both sides of the meter in a direction perpendicular to both the

pipeline and the shedder bar axis.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

13

Page 13

3.1.5 Locating The Meter In A Pipline That Runs Parallel To A Wall

Wherever possible, the distance between the pipe centerline and the wall should be greater

than 20”. This will allow for access to the electronics enclosure compartment where wire

terminations are made. If adequate space is not available, rst connect all the cables to the

terminals in the connection compartment (power supply and outputs) and then run the wires

to an intermediate junction box (also see Section 3.2) before installing the meter.

3.1.6 State Of Medium

In all cases the meter requires a single-phase ow for proper operation. Liquid droplets in

the gas or vapor, solid particles in the gas or liquid and gas bubbles in the liquid are not

permitted.

3.1.6.1 Liquid Applications

When operating with liquids, the meter requires a minimum downstream pressure

to prevent cavitation. The formula used to determine the minimum downstream

pressure is as follows:

Pds(bar_g) > =(2.9*DP) + (1.3*Ps)-1.013

Where DP=pressure drop of the meter, in Bar, as determined by the ONICON sizing

program and Ps=saturation pressure, in Bar, at the operating temperature.

For any uid, a lter or strainer may be used to remove the solid particles. This is

especially important for meter sizes below 1” where a lter or a strainer is required.

3.1.6.2 Steam Or Compressed Gas Applications

In case of steam or compressed gas, a moisture separator should be used 50D

upstream of the meter if the dryness fraction is less than 95%.

IMPORTANT NOTE

i

Steam quality will affect the accuracy of the measurement. It is strongly recommended that a moisture

separator be installed upstream of the inlet straight pipe run for anything less than 95% dry steam.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

14

Page 14

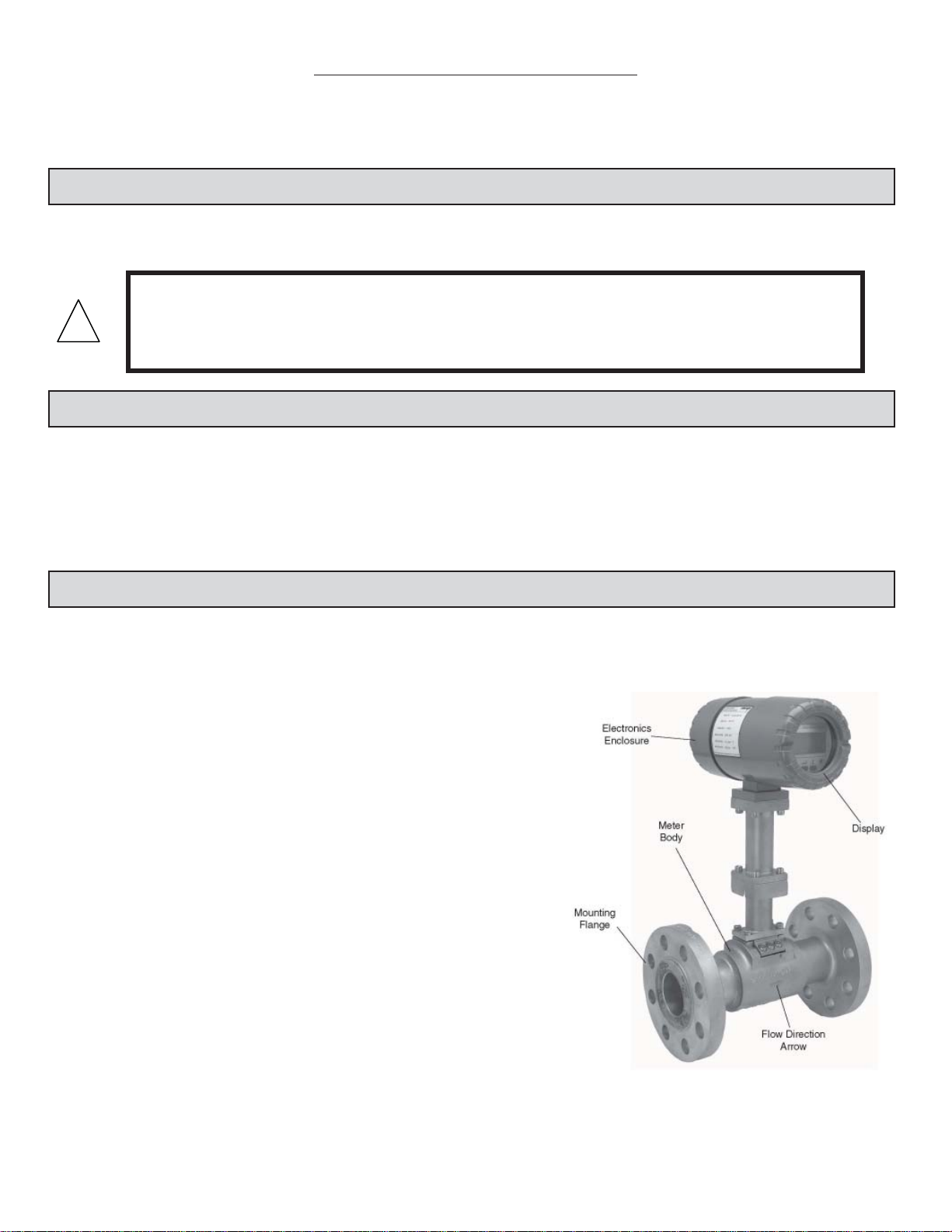

3.2 MECHANICAL INSTALLATION

3.2.1 Orient The Display For Convenient Viewing

Both the electronics enclosure and the display itself can be rotated to four different

orientations to change the viewing angle for the display. If necessary, this should be done

before the meter is installed.

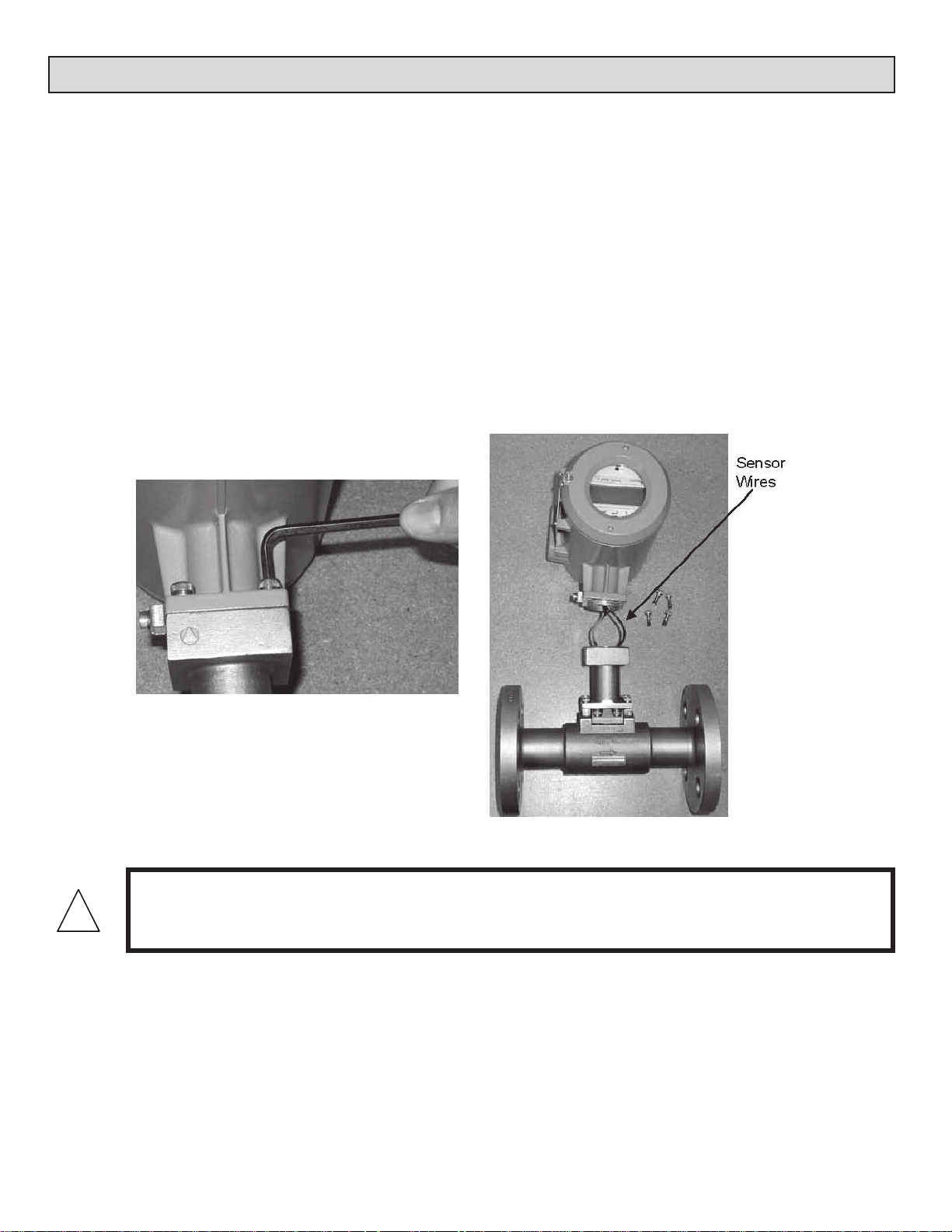

3.2.1.1 Rotating the electronics enclosure

The electronics enclosure is attached to the meter body with (4) 5mm Allen head

screws. To rotate the enclosure, you must rst remove the screws and then carefully

rotate the enclosure as needed. The interconnecting stem assembly is a conduit for

wires that connect the sensors to the circuitry contained in the enclosure. Care must

be taken to prevent these wires from being damaged when rotating the enclosure.

!

CAUTION

Make certain the sensor wires are not damaged when re-attaching the enclosure.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

15

Page 15

3.2.1.2 Rotating the display

To rotate the display, rst unscrew the cover using the special tool provided for this

purpose. Once the cover is removed, the (4) Philips head screws that secure the

display are exposed. To rotate the display, remove these screws and carefully move it

to the desired position making certain that the interconnecting cable is not damaged

in the process.

CAUTION

!

• Do not remove enclosure covers in any wet environment

• Keep dirt and debris out of electronics enclosure

• Keep threads lubricated (silicone based lubricant)

• Do not over tighten covers. Use special tool for removal only.

3.2.2 Flanged-Type Connection To Ansi B16.5 (Schedule 40)

Meter sizes

3/8”, 1/2”, 3/4”, 1”, 1 1/2”, 2”, 3”, 4”, 6”, 8”

Pipe anges

To ANSI: #300 standard,

#600 optional

Gaskets are supplied with anged units.

Center the ow meter by sight.

Check the ange connections for leak-tightness

after the ow meter installation.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

16

Page 16

3.3.2 Temperature Measurements

ONICON F-2000 series vortex meters are supplied with an internal PT 1000 type RTD

temperature sensor located within the shedder bar. This sensor provides an accurate

temperature measurement at the point where the ow rate is being measured. Flow meters

supplied with this option will display the medium temperature and deliver an output signal

that is temperature compensated for mass and/or normalized ow.

3.3 WIRING TERMINATIONS

The standard F-2000 series vortex meter is a 2-wire loop powered device. Wiring connections are shown

below.

CAUTION

• Do not remove enclosure covers in any wet environment

!

• Keep dirt and debris out of electronics enclosure

• Keep threads lubricated (silicone based lubricant)

• Do not over tighten covers. Use special tool for removal only.

4-20 mA

100 ohms

minimum

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

17

Page 17

SECTION 4.0: START UP AND TROUBLESHOOTING

i

4.1 START UP

When the power is applied to the F-2000 series vortex meter, alphanumeric characters will appear

on the display. Initially, the meter will operate in a “TEST” mode where self diagnostic checks are

performed on the pre-ampli er and sensor circuits. Following this, con guration data is loaded

from the non-volatile memory and the program advances to the measurement mode.

IMPORTANT NOTE

i

!

4.2 MEASUREMENT MODE

In the measurement mode, the display

indicates real-time ow, temperature and/

or pressure data in the appropriate units.

The top line of the display indicates the

current measured value. The second line

of the display indicates the programmed

units of measurement.

There are two options for displaying data in

the measurement mode. The display may

be set to automatically scroll through each

menu page or it may be set to manually step

through the menu pages using the up arrow

key to advance each page. Displays operating

in the cyclic mode will advance through

each page every 6 seconds.

The meter should be installed and powered for at least 15 minutes before media is allowed to ow

through the meter.

Flow velocity through the meter should be increased gradually until full ow is achieved.

CAUTION

IMPORTANT NOTE

When measuring steam ow, condensate may form on the cool surfaces of the meter and piping

system when the system is started up for the rst time (causing faulty measurement).

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

18

Page 18

4.3 OPERATING THE DISPLAY

i

Please read the entire procedure before proceeding. Wiring diagrams are located in the Appendix. A

worksheet for checking off the following steps and recording measured values is located on the next

page.

key Hall

Eect Switch

key Hall

Eect Switch

key Hall

Eect Switch

Display page scroll

(measurement mode)

IMPORTANT NOTE

Do not attempt to enter the program mode without rst contacting ONICON service.

There are 3 user interface switches located immediately below the display. Each switch performs a

separate function. The table below describes the function of each switch. There are also 3

corresponding Hall Effect switches that perform the same functions. The Hall Effect switches may be

activated without removing the display cover, using the magnet provided with the meter. Place the

magnet against the cover in proximity to the Hall Effect switch to activate.

!

CAUTION

• Do not remove enclosure covers in any wet environment.

• Keep dirt and debris out of electronics enclosure.

• Keep threads lubricated (silicone based lubricant).

• Do not over tighten covers. Use special tool for removal only.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

19

Page 19

4.4 ERROR HANDLING

The meter can detect errors in either the test or the measurement modes. When in the measurement

mode, a blinking vertical bar will appear in the top left corner of the display indicating an error has

been detected. If the error reporting function is enabled, error messages will be displayed as separate

menu pages. The rst line of the error menu page indicates the total number of errors and the second

line displays the error message. Measurement mode error messages are listed below.

Error Message

(display second line)

NO SIGNAL No signal from the vortex

LOW FREQ. Vortex frequency is too low Check for fl ow rate lower than specifi ed mini-

HIGH FREQ. Vortex frequency is too high Check for fl ow rate higher than specifi ed maxi-

LOW FLOW Flow rate lower than speci-

HIGH FLOW Actual fl ow rate higher than

INV. CONFIG. Confi guration data in non-

ISO FAIL Checked

AMP FAIL Pre-amplifi er section has

PIEZO FAIL Piezo wires broken Contact ONICON.

CHECK INST Flow signal quality is bad Check: 1) Flow rate, if OK; 2) Check for

LOW SIGNAL Vortex signal amplitude too

HIGH SIGNAL Vortex sensor signal

LOW.TEMP.PHY. Operating temperature is

HIGH.TEMP.PHY. Operating temperature is

T.SENS.SHORT Temperature sensor/wires

T.SENS.OPEN Temperature sensor open

during

power-

on only

Type Description Corrective Action

Required

No fl ow. Also check for any other errors dur-

sensor

fi ed range

specifi ed range

volatile memory is not valid

Sensor isolation has failed Contact ONICON.

failed

low

amplitude too high

lower than the physical limit

higher than the physical limit

short circuit

circuit

ing power-on diagnostics. If there is a sensor

problem, contact ONICON.

mum. Contact ONICON.

mum. Contact ONICON.

Converter will continue to display actual fl ow

rate. However, accuracy of measurement may

suffer.

Corrective action depends on application process. If the fl ow rate exceeds the maximum

value it may damage the sensor physically.

Contact ONICON.

Contact ONICON.

excessive pipe vibration and upstream fl ow

disturbances; 3) Contact ONICON.

Check: 1) Flow rate, if OK; 2) Contact ONICON.

This occurs in cases of high density medium.

Check 1) Flow rate, if OK 2) Contact ONICON.

Take corrective action depending on the process.

Take corrective action immediately. This will

cause damage to the shedder bar as well as

to the electronics.

Indicates a fault in the temperature sensor.

Contact ONICON.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

20

Page 20

4.5 TROUBLESHOOTING HINTS

REPORTED

PROBLEM

A non-zero fl ow indi-

cated when no actual

fl ow is in the pipe.

“CHECK INST.” error

is displayed when no

fl ow is in the pipe.

POSSIBLE

SOLUTIONS

• Mains interference due to improper Earth ground connection. The protective

Earth PE terminal should be properly grounded (see page 17).

• Excessive mechanical vibration in the pipe. If so, support the pipeline near the

meter perpendicular to both the axis of the pipe and the axis of the shedder

bar.

• This problem may also be solved by reducing the factory set gain. (Contact

ONICON for assistance.)

NOTE: By reducing the gain, the minimum measurable fl ow rate will go up

by the factor which is approximately equal to the square root of the gains

(odd gains new gain). If the minimum fl ow with reduced gain is above the

minimum fl ow which is required to be measured, then reducing the gain is

not the permanent solution. Then the installaion should be corrected and

also the vibrations should be eliminated.

The display should normally indicate 0.0 fl ow rate, LOW FLOW or LOW SIGNAL

when there is no fl ow in the pipe. The additional CHECK INSTALL error (fl ow

rate = 0.0 or some steady or fl uctuating value) is an indication of:

• Improper/inadequate earthing

• Excessive pipe vibration

Flow rate inidcated is

0.0 even with fl ow in

the pipe.

The fl ow indicated

responds to changes

in the fl ow but the

indicated value does

not correspond to the

actual fl ow rate. Also

“CHECK INST.” Error

may appear intermittently.

• The vortex sensor cable is disconnected or is not properly connected.

• Flow sensor is faulty. Contact ONICON for assistance.

• The meter is not properly centered on the pipeline. The axis of the meter bore

should be aligned with that of the pipe.

• Gaskets at the meter are protruding into the pipe bore. The gaskets must not

project into the effective cross-section of the pipe.

• Irregularities on the surface of the pipe bore. The pipe bore should be free from

irregularities at the welded joints, dirt, deposits and excessive surface roughness.

• The Vortex signal is distorted due to a bi-phase medium. Bi-phase media are

not permitted. Use a moisture separator for wet steam applications to remove

the moisture droplets from the steam. Use suitable fi lters in gas applications to

remove solid particles from the fl owing gas. • Incorrect angular position of the

meter. Refer to Section 3.1.1 for the allowable mounting positions.

• Insuffi cient upstream/downstream pipe lengths. Check that the upstream/

downstream pipe lengths are of the correct minimum length as given in

Section 3.1.3.

• Error in meter factor K-Factor programming. Contact ONICON for assistance.

• Check that the fl ow direction and the direction arrow on the meter body agree.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

21

Page 21

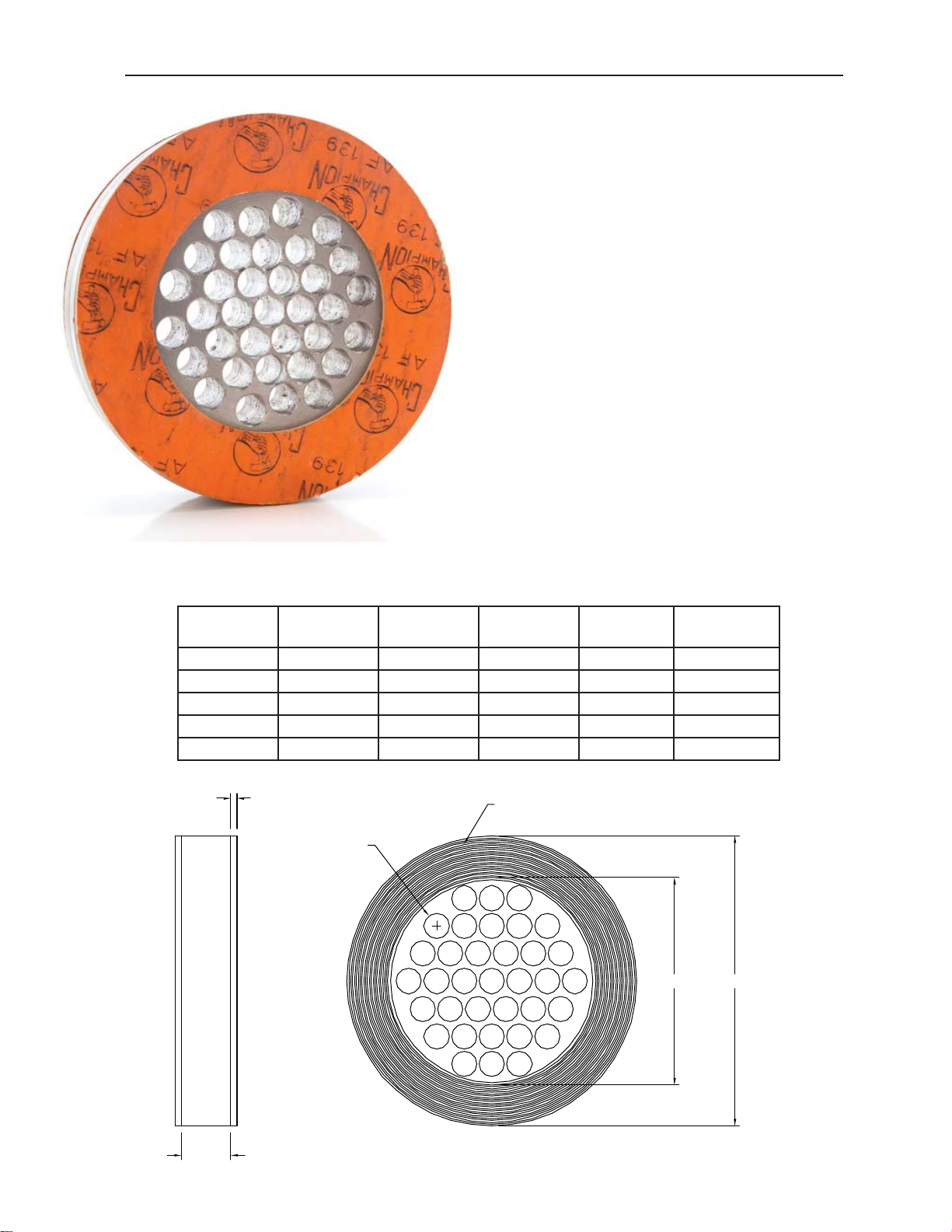

SECTION 5.0: FLOW STRAIGHTENER FOR VORTEX FLOW METERS

DESCRIPTION

The optional ow straightener accessory for

ONICON F-2000 Series Vortex Flow Meters is a

wafer-style ow conditioner that is designed to be

installed between two recessed anges (provided

by installer) that are located a speci ed distance

upstream of the ow meter.

Use of a ow straightener signi cantly reduces the

upstream straight pipe length requirement for

ONICON Vortex Flow Meters.

The size of the straightener should always match

the meter size (as opposed to the original pipe size).

The ow straightener is made of 304/A 351 CF8

stainless steel.

TABLE 1 - ALL DIMENSIONS SHOWN IN INCHES

SIZE DIM A DIM B DIM C DIM D NUMBER OF

HOLES

2” 3.93 1.0625 .28 2.14 35

3” 5.31 1.0625 .43 3.24 35

4” 6.26 1.0625 .55 4.22 35

6” 8.50 1.0625 .78 6.07 35

8” 10.62 1.0625 1.02 7.98 35

0.125

GASKET THICKNESS, NOMINAL

DIM C

SERRATIONS SHOWN LOCATED UNDER GASKET, IF PROVIDED

NOTE: DIMENSION D INDICATES I.D. FOR SERRATIONS

DIM D DIM A

0497

DIM B

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

22

8-06

Page 22

ECCENTRIC REDUCER, NOTE 2

UPSTREAM

OBSTRUCTION

SEE TABLE 1

BALL/GATE VALVE FULLY

TWO 90’S OUT OF PLANE 22 DIA 20 DIA

ONICON F-2000 SERIES STEAM METER, NOTE 1

FLOW STRAIGHTENER, NOTE 3

DIMENSION B 2 DIAMETERS 5 DIAMETERS

MINIMUM UPSTREAM PIPE RUN

DIMENSION A

MINIMUM DOWNSTREAM PIPE RUN

REQUIRED DIMENSIONS FOR INSTALLATIONS WITH FLOW STRAIGHTENER

DIMENSION A DIMENSION B

UPSTREAM

OBSTRUCTION

TOTAL UPSTREAM

PIPE RUN

DISTANCE BETWEEN

FLOW METER AND

STRAIGHTENER

SINGLE 90 12 DIA 10 DIA

TEE 12 DIA 10 DIA

RDCR/EXPNDR 12 DIA 10 DIA

TWO 90’S SAME PLANE 17 DIA 15 DIA

17 DIA 15 DIA

OPEN

CONTROL VALVE 27 DIA 25 DIA

PRV 27 DIA 25 DIA

300# ANSI FLANGE

(600# ANSI FLANGE OPTNL)

NOTES

1. Consult ONICON for meter size and applicable meter pipe run for each application. Install

according to manufacturer’s recommendations.

2. Provide eccentric reducer and expander when required.

3. Provide fl ow straightener when required to meet recommended minimum upstream pipe run

requirements.

4. Flanges provided by contractor. Recessed fl anges are required for wafer fl ow straightener

installation.

F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

23

Loading...

Loading...