Page 1

EASY VISION RAD R4.2V2

LIST OF DOCUMENTATION IN THIS BINDER:

x SUBSYSTEM MANUAL

o

x

o

UNIT MANUAL Imager Compatibility

o

How to Read a DICOM Conformance Statement

Note:

LIST OF ALL BINDERS:

EasyVision RAD R4.2V2

x indicates document present

o

EasyVision RAD Release 4.2V2

4512 984 22362 REV AC 0.1

© 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 2

E

W

INTRODUCTION AND TECHNICAL DATA

Philips Medical Systems

SERVICE MANUAL

732

SUBSYSTEM

1

EasyVision RAD R4.2V2

INSTALLATION

SETTING-TO-WORK

FAUTFINDING

REPLACEMENT

PROGRAMMINGS

2

3

4

5

6

ADJUSTMENTS

Printed in Hamburg, Germany

DMC Hamburg

© 2003 Philips Medical Systems

ALL RIGHTS RESERVED

EXPLANATIONS

DRAWINGS

7

8

9

10

11

4512 984 22362 REV AC 1

12

Page 3

EasyVision RAD 4.2V2

SERVICE MANUAL - SUBSYSTEM

EasyVision RAD R4.2V2 Author: C. Siems

In case there are any questions concerning this manual,

please send this LOPAD via fax to 49/(0)40/5078 2481

File: EasyVision RAD_22362AC

List of pages and drawings (LOPAD) Manual Order No: 4512 984 22362

released: 11/2003

__________________

0.1

1

3.1

__________________

1-1...1-9 (a/03.1)

__________________

2-1...2-12 (a/03.1)

__________________

3-1...3-14 (a/03.1)

__________________

4-1...4-30 (a/03.1)

_________________

5-1...5-10 (a/03.1)

__________________

6-1...6-26 (a/03.1)

__________________

7-1...7-4 (a/03.1)

__________________

8-1...8-14 (a/02.0)

__________________

______________________

Z0 (a/02.0) A4

Z2-1 (99.0) A3

Z2-2 (99.0) A3

Z2-3 (99.0) A3

Z2-3.1 (03.0) A3

Z2-3.2 (03.0) A3

Z2-3.3 (03.0) A3

Z2-3.4 (03.0) A3

Z2-3.5 (03.0) A3

Z2-4 (99.0) A3

Z2-5 (99.0) A3

Z2-6 (99.0) A3

Z2-7 (99.0) A3

Z2-8 (99.0) A3

Z2-9 (99.0) A3

Z2-10 (99.0) A3

Z2-11 (99.0) A3

____________________

4512 984 22362 REV AC 3.1

© 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 4

Introduction And Technical Data Section 1

Section 1 Introduction & Technical Data

Contents

1.

INTRODUCTION..................................................................................................................................... 3

1.1. Documentation structure......................................................................................................................... 3

1.2. Technology.............................................................................................................................................. 4

1.3. Tools........................................................................................................................................................ 4

2.

PRODUCT DATA ................................................................................................................................... 5

2.1. Computers............................................................................................................................................... 5

2.2. Overview configuration............................................................................................................................ 5

2.3. Framebuffers........................................................................................................................................... 6

2.4. Monitors................................................................................................................................................... 6

2.5. Optical media drives................................................................................................................................ 6

2.6. Memory bank configurations................................................................................................................... 6

2.7. Connectivity............................................................................................................................................. 7

3.

EASYVISION RAD CONFIGURATIONS ............................................................................................... 8

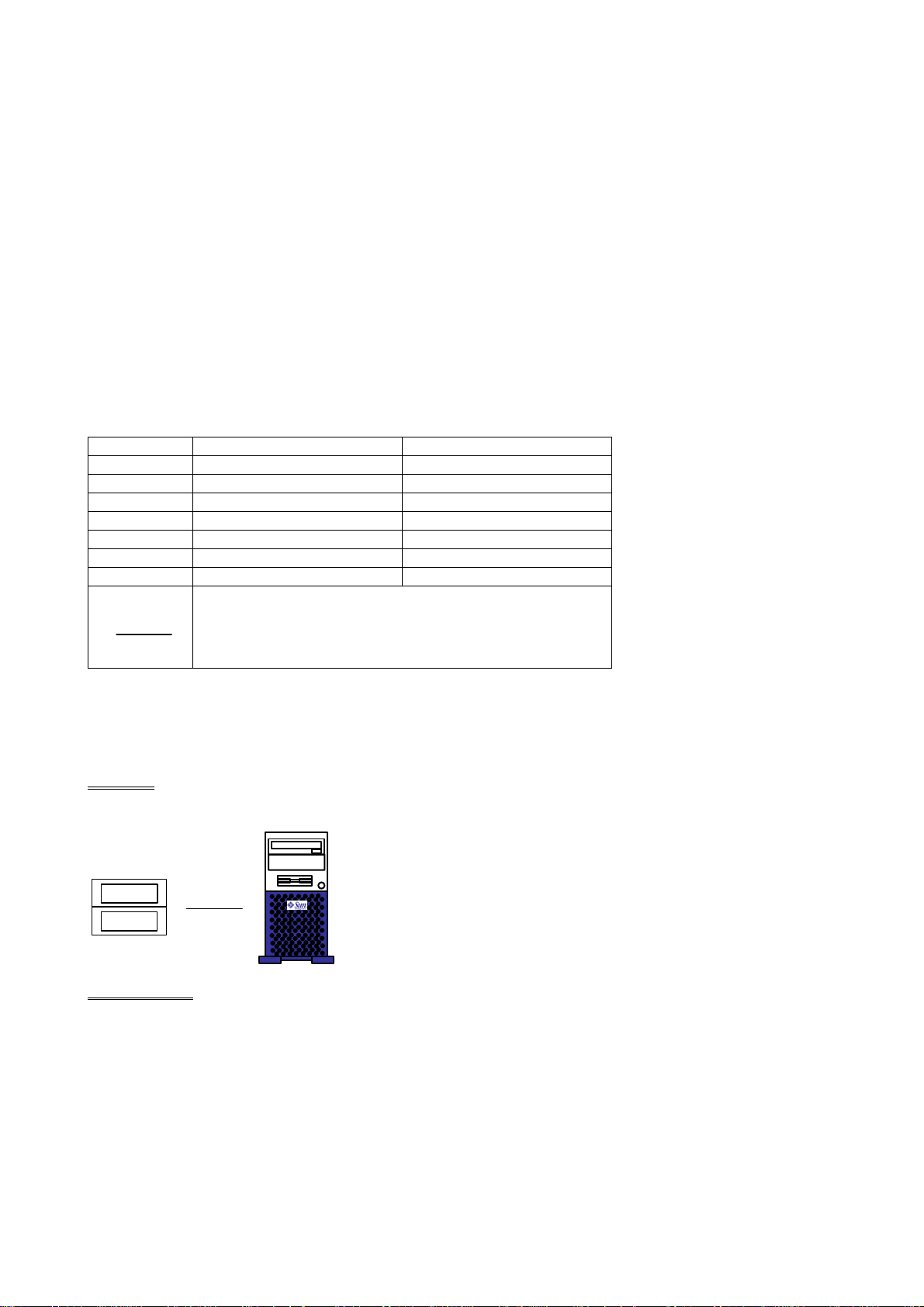

3.1. PCR standalone Configuration ............................................................................................................... 8

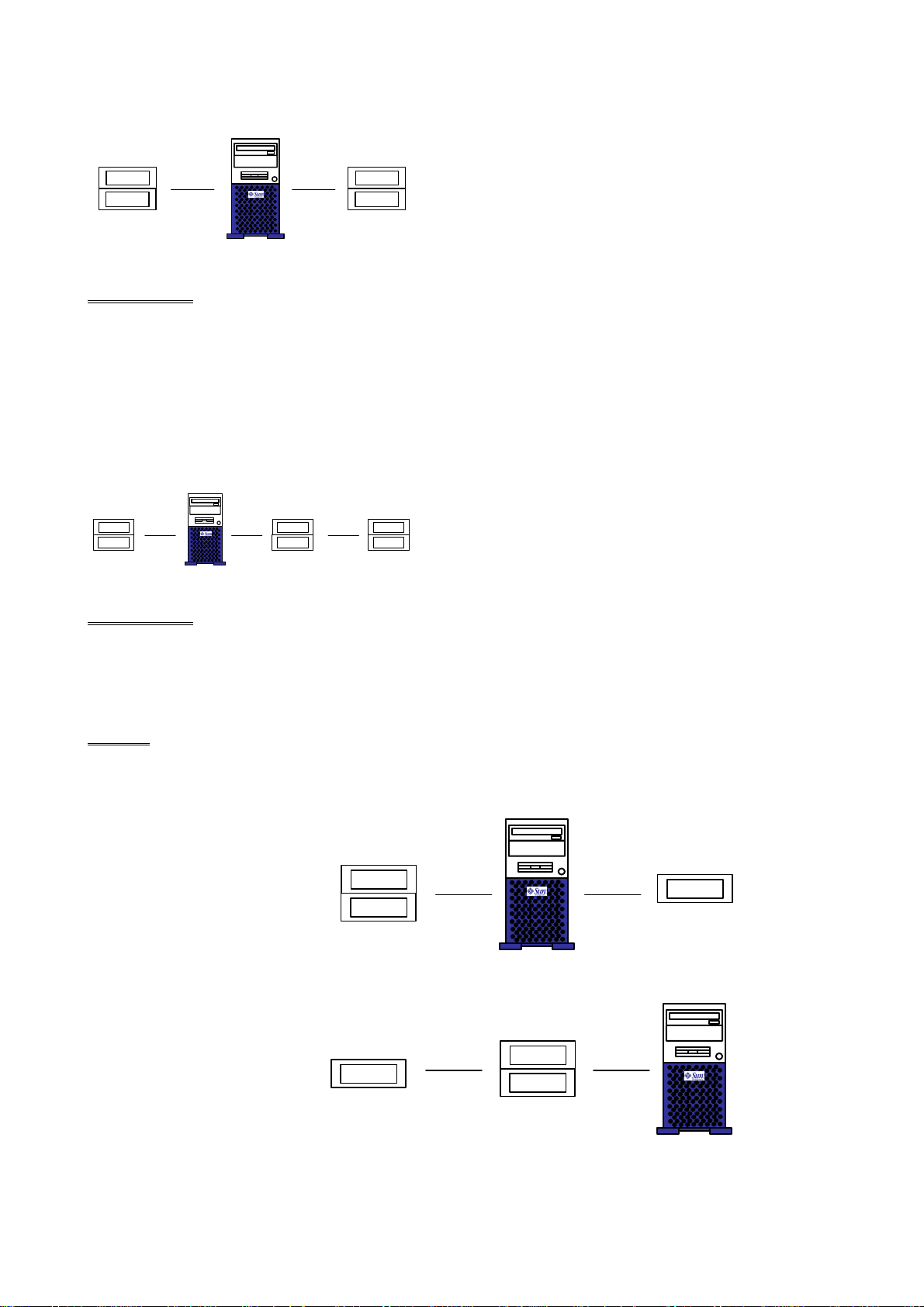

3.2. PCR Multi Reader configuration ............................................................................................................. 8

4.

NETWORK CONNECTIONS .................................................................................................................. 9

4.1. Client Server Clusters ............................................................................................................................. 9

5.

SAFETY REQUIREMENTS .................................................................................................................. 10

5.1. Electrostatic Discharge ......................................................................................................................... 10

EasyVision RAD R4 (a/03.1) 1-1

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 5

Section 1 Introduction And Technical Data

1-2 (a/03.1) EasyVision RAD R4

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 6

Introduction And Technical Data Section 1

1. INTRODUCTION

EasyVision RAD release 4.2 is a workstation as well as an acquisition system for PCR Readers. Beside that

the EasyVision RAD serves as an image processing system with printing capabilities. PCR Readers can

connect with both DMS interface and via Ethernet to an EasyVision RAD.

Moreover the EasyVision RAD 4.2 supports multi reader configurations with:

- 1 DMS Reader

- up to 2 network Readers

dependent on the performance of the hardware used.

The Single User Workstation

If there is only one EasyVision connected to one or more readers/USITs, the situation is like that before

release 4.2. To differentiate between such a single EasyVision RAD and those in a cluster configuration, we

call the single system a Single User Workstation.

The EasyServer

Within an EasyVision RAD cluster, the EasyVisions use a common place to store their images. The system

which does this is called the EasyServer. It controls the configuration of the cluster by controlling the

software licenses, it handles the import from modalities, the printing to film, and all communication outside

the cluster, for instance with the archive, external DICOM databases, or other clusters and workstations of

other vendors.

The Workspot (Client)

The EasyServer makes all images available to all EasyVisions in the cluster. The EasyVisions which also

run the RAD applications (the Workspots) don’t have an own image database and use the image database

of the RAD server. The hardware configuration of the Workspot may vary from an UltraSparc 60 with lots of

memory for fast and intensive image postprocessing, to a PC with a Java enabled Web Browser for basic

image viewing.

1.1. D

OCUMENTATION STRUCTURE

Delivered with the system

- System Manual EasyVision RAD 4.2

- Network Manual

- Printer Compatibility

Delivered with the software

- Release Bulletin EasyVision RAD 4.2 Level n

- DICOM Conformance Statement

Delivered with the Sun workstation

- Unit Manual EasyVision RAD Sun Ultra or SunBlade

Delivered with the monitor

- Unit Manual Monitor

EasyVision RAD R4 (a/03.1) 1-3

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 7

Section 1 Introduction And Technical Data

1.2. T

EasyVision RAD system are mostly sold as part of a PCR system treating the special needs of CR images.

Data can be imported from other modalities or other workstations as well.

EasyVision Release 4 is based on a client/server computing technology. This means a different configuration

will appear: Users on a workspot use information that resides in a database on a central server and is

received from a larger variety of sources.

ECHNOLOGY

1.3. T

To remove and replace EasyVision field replaceable units (FRUs), you will need the following tools and

materials:

• Standard toolkit

• Anti-static discharge kit

• Service network hub 10/100Mbit

• Service PC + null modem cable (25pin) for back-up of configuration files.

See Remote Service Manual for pin layout)

• Densitometer for laserprinter (e.g. X-Rite 331)

• Reflection densitometer for paperprinter (e.g. X-Rite 400)

• Hardcopy Unit test box

• Printer test tool

• Multimeter.

OOLS

1-4 (a/03.1) EasyVision RAD R4

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 8

Introduction And Technical Data Section 1

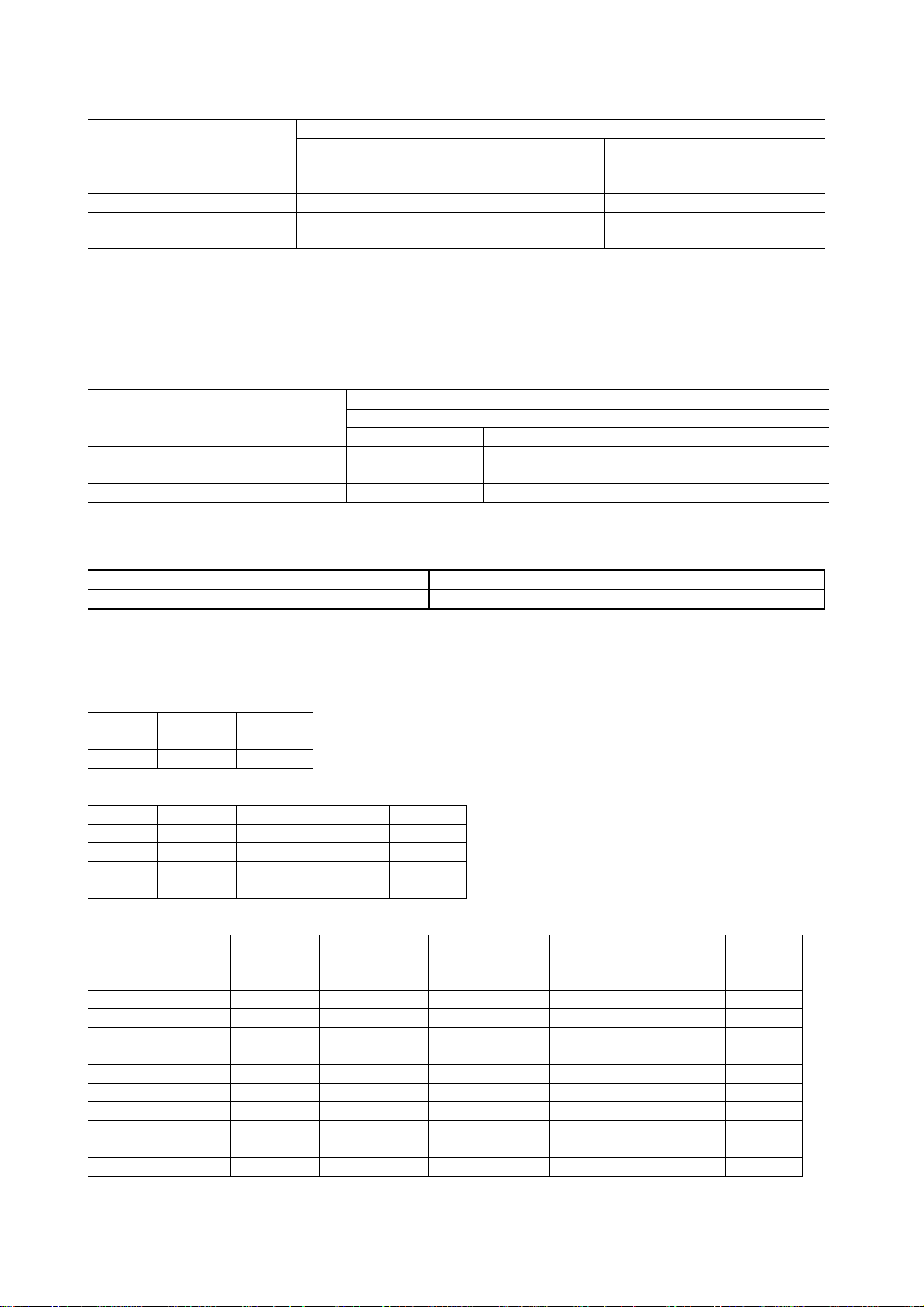

2. PRODUCT DATA

2.1. C

OMPUTERS

Ultra 10 Ultra 60 SunBlade 1000 Sun Blade 1500

Ultra 10: The Sun Ultra 10 is a single processor PCI based workstation/server using the UltraSPARC-

II 64-bit architecture. The system has a PC style mini-tower layout.

Ultra 60: The Sun Ultra 60 is PCI based workstation using the UltraSPARC-II 64-bit architecture. The

system has a PC style mini-tower layout and is functionally equivalent to the Sbus based

Ultra 2 workstation.

SunBlade

1000/ 2000:

The Sun Blade 1000/2000 workstation is a dual processor workstation that uses the

UltraSPARC III family of processors. The workstation offers super-scalar processor

technology, multiprocessing, high-performance memory interconnection, highbandwidth

input/output (I/O), and accelerated graphics.

SunBlade

1500

The Sun Blade 1500 workstation is a single processor workstation that uses the

UltraSPARC IIIi family of processors.

2.2. O

VERVIEW CONFIGURATION

Ultra 10 Ultra 60 SunBlade 1000/2000 SunBlade 1500

onboard SCSI-interface

IDE-interface

Ethernet interface

Min memory

Max. memory (MB)

Memory module

Memory bank config.

Internal disk

CD-ROM /DVD-ROM

PCI slots

Framebuffers

no Ultra SCSI, 40 MB/s Ultra Wide SCSI no

EIDE, 33 MB/s No No UltraDMA100

10/100 Mbit 10/100 Mbit 10/100 Mbit 10/100/1000BASE-T

256MB (2x128 MB) 256MB (4x64MB) 512MB (4x128MB) 512MB (4x128MB)

384-/512-/768 512-/ 768-/ 1024

768-/ 1280- / 1792

64- / 128- / 256 MB 64- / 128 MB 128-/256-/1024 MB 128 MB - 2GB

2 banks x 2 slots 4 banks x 4 slots 8 DIMM slots 4 slots

EIDE, 9.1 GB Ultra-SCSI, 9.1 GB UW-SCSI 2x 36GB 1x 80 GB IDE

CD-ROM EIDE, 24x CD-ROM SCSI DVD-ROM SCSI DVD-ROM IDE

4 4 4 5

Yes, 8 bit No No No

up to 8GB up to 8GB

(system disk)

1x 36GB SCSI

(image disk)

EasyVision RAD R4 (a/03.1) 1-5

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 9

Section 1 Introduction And Technical Data

2.3. F

RAMEBUFFERS

PseudoColor PGX

(+)

Color Greyscale

Pseudo Color

PCI/PGX

(+)

TrueColor

UPA/FFB

Ultra 10 (4xPCI + 1x UPA) Onboard* 3x 1x 2x

Ultra 60 (4xPCI + 2x UPA) No No 2x 2x

SunBlade 1000/2000

No No 2x 2x

(4xPCI + 2x UPA)

SunBlade 1500: XVR 500 or XVR100

• The Ultra 10 has an onboard framebuffer which cannot be removed.

• EasyVision cannot handle a mix of different types of framebuffers.

2.4. M

ONITORS

Display matrix: 1280 x 1024 Landscape oriented

Framebuffer type

Pseudo Color PGX

(+)

single head Yes Yes Yes,

18" Color 21" Color 21" Greyscale

Color Monitors Greyscale monitors

True Color (FFB) single head Yes Yes Yes,

Greyscale (Md2) dual head No No Yes

2.5. O

PTICAL MEDIA DRIVES

MD2/PCI

EasyStore OD Drive EasyStore CD-R drive

Pioneer DE-UH710 600MB (obsolete) Standard CD-R drive

2.6. M

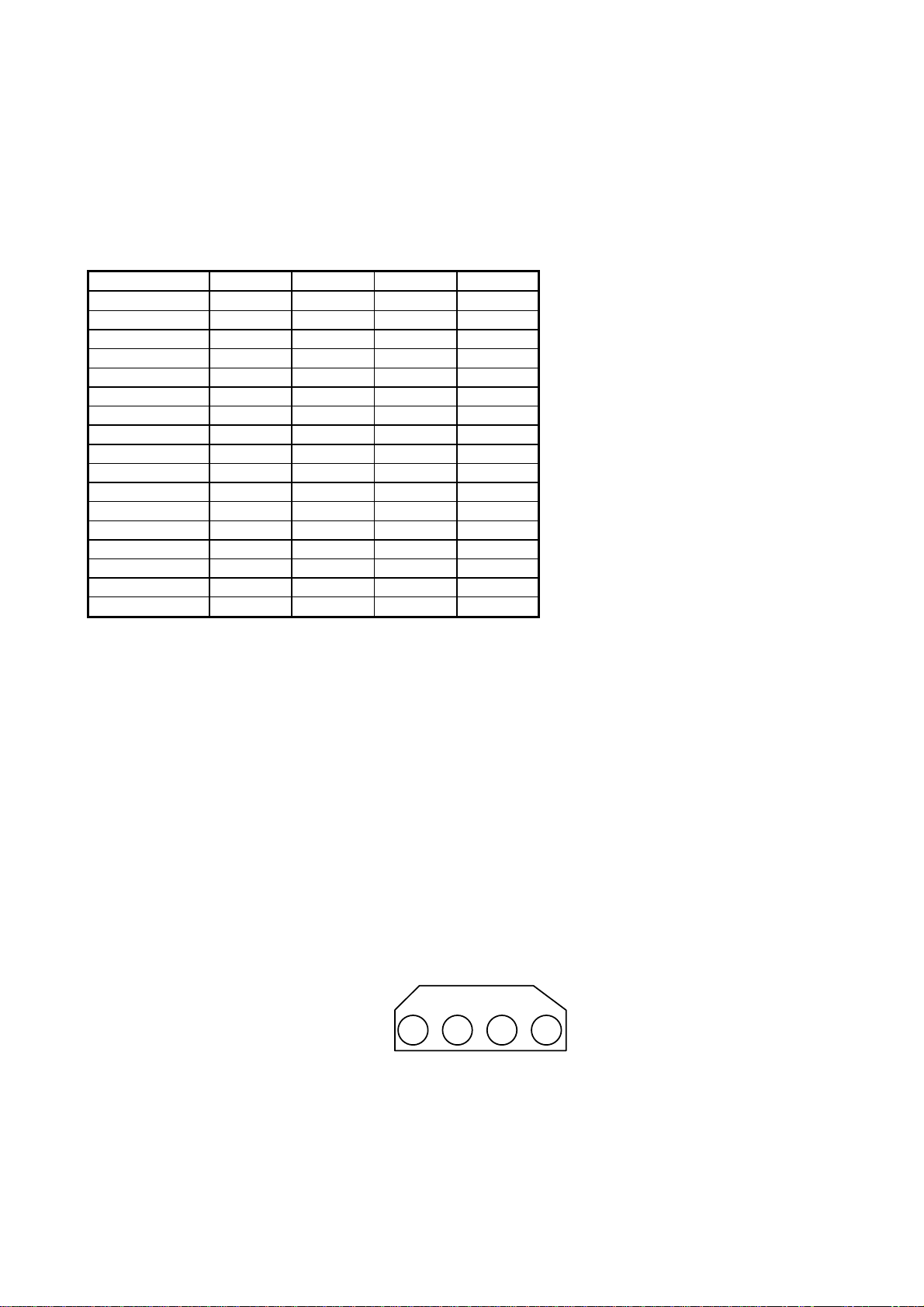

EMORY BANK CONFIGURATIONS

Ultra 10

Slot 1 Slot 2

Bank 1 128 128

Bank 2 128/256 128/256

Ultra 60

Slot 1 Slot 2 Slot 3 Slot 4

Bank 1 32 32 32 32

Bank 2 32 32 32 32

Bank 3 64/128 64/128 64/128 64/128

Bank 4 64/128 64/128 64/128 64/128

SunBlade 1500

SDRAM

Organization

Number of

DRAMs

Physical bank

per DIMM

Module

Configuration

DIMM

Capacity

Minimal

Memory

Maximum

Memory

128Mbit (32Mx4) 18 1 32Mx72 256MB 512MB 1GB

128Mbit (16Mx8) 18 2 2x(16Mx72) 256MB 512MB 1GB

256Mbit (32Mx8) 9 1 32Mx72 256MB 512MB 1GB

256Mbit (64Mx4) 18 1 64Mx72 512MB 1GB 2GB

256Mbit (32Mx8) 18 2 2x(32Mx72) 512MB 1GB 2GB

512Mbit (64Mx8) 9 1 64Mx72 512MB 1GB 2GB

512Mbit (128Mx4) 18 1 128Mx72 1GB 2GB 4GB

512Mbit (64Mx8) 18 2 2x(64Mx72) 1GB 2GB 4GB

1Gbit (256Mx4) 18 1 256Mx72 2GB 4GB 8GB

1Gbit (128Mx8) 18 2 2x(128Mx72) 2GB 4GB 8GB

1-6 (a/03.1) EasyVision RAD R4

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 10

Introduction And Technical Data Section 1

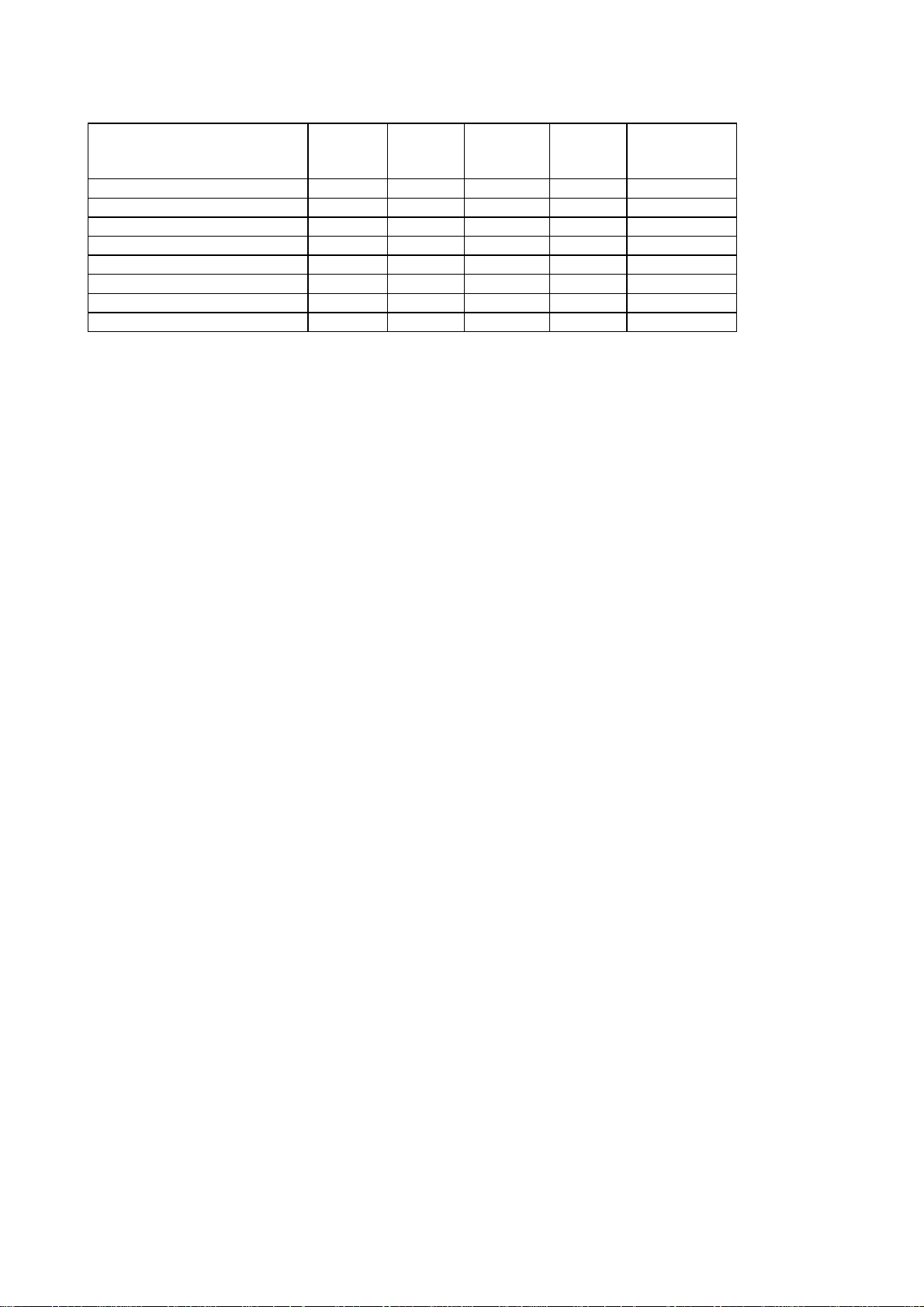

2.7. C

ONNECTIVITY

Connectivity

SCSI parallel

(DMS)

parallel

3M

parallel

printer

Ethernet

Interf.

USIT x

AC500/5000 x

PCR Preview Unit x

AC3/3000 PCR9000 (DMS) X

Printers 3M Interf. X

Printers DICOM x

Printers SCSI X

Printers PostScript X

EasyVision RAD R4 (a/03.1) 1-7

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 11

Section 1 Introduction And Technical Data

r

3. EASYVISION RAD CONFIGURATIONS

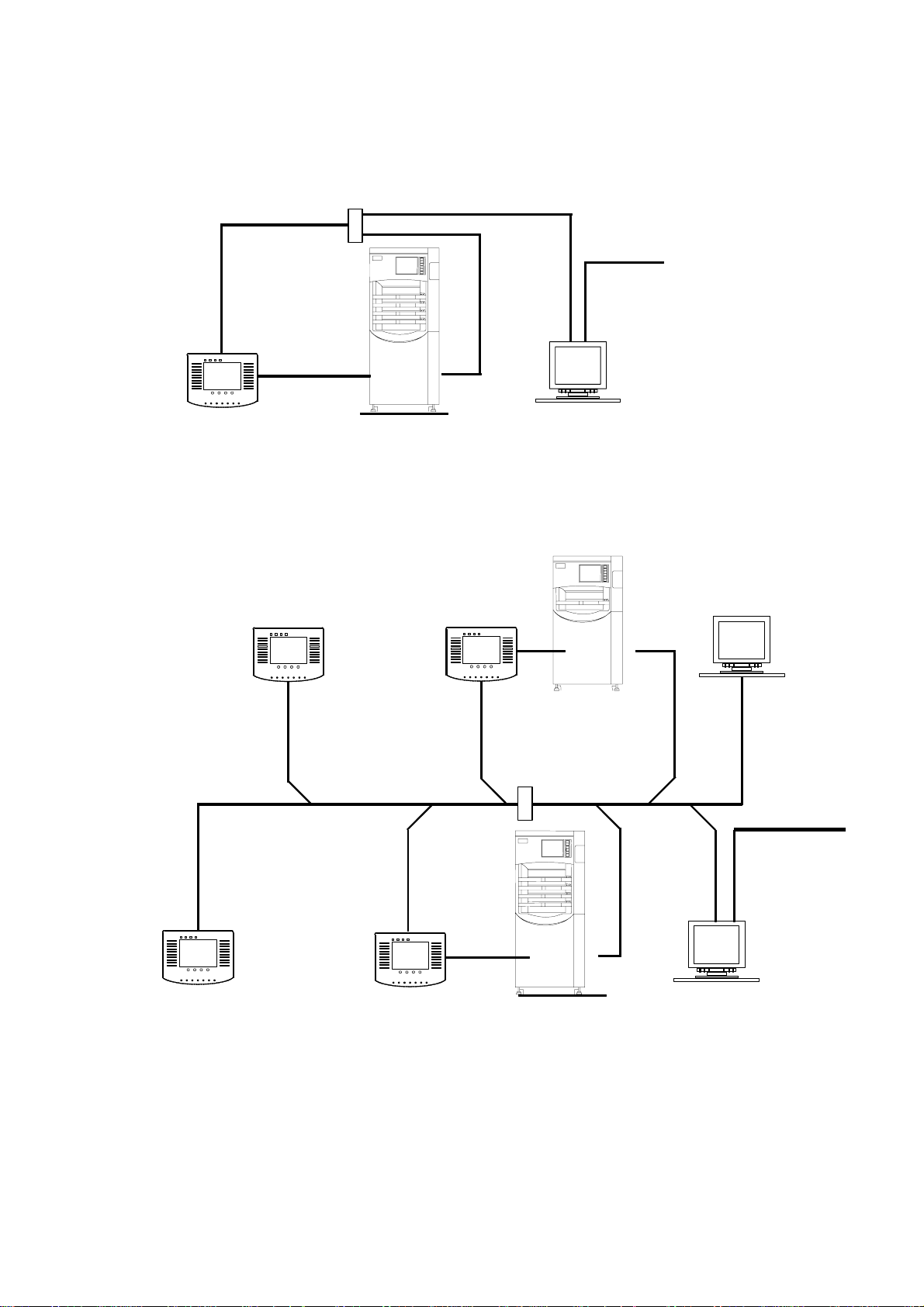

3.1. PCR

STANDALONE CONFIGURATION

hub

Fast Ethernet rec.

Local o

DICOM print

Server USIT EasyVision

Reader

IDT

Terminal Name : USIT 1

Terminal IP Address : 192.0.0.2

EV rad Names : EV 1

EV rad IP Adresse : 192.0.0.1

Display : EV1

Hosts : 192.0.0.1 EV1

192.0.0.3 AC 5000F

192.0.0.4 AC 5000E

IP Name : EV 1

IP Address : 192.0.0.1

3.2. PCR M

ULTI READER CONFIGURATION

Client USIT Reader USIT Reader

IDT

EasyVision

(Work spot)

Server Name : USIT 1

Server IP Address : 192.0.0.2

Terminal Name : USIT 3

Terminal IP Address : 192.0.0.4

EV rad Name : EV 1

EV rad IP Address : 192.0.0.1

Client USIT

Server Name : USIT 1

Server IP Address : 192.0.0.2

Terminal Name : USIT 2

Terminal IP Address : 192.0.0.3

EV rad Name : EV 1

EV rad IP Address : 192.0.0.1

Server Name : USIT 1

Server IP Address : 192.0.0.2

Terminal Name : USIT 4

Terminal IP Address : 192.0.0.5

EV rad Name : EV1

EV rad IP Address : 192.0.0.1

Display : EV1

Hosts : 192.0.0.1 EV1

192.0.0. 9 AC 500F-B

192.0.0.10 AC 500E-B

IP Name : EV 2

IP Address : 192.0.0.6

hub

Ethernet

Server USIT

Fast Ethernet

Hospital

Network

Reader

EasyVision

(server)

IDT

IP Name : EV 1

Terminal Name : USIT 1

Terminal IP Address : 192.0.0.2

EV rad Name : EV 1

EV rad IP Address : 192.0.0.1

Display : EV1

Hosts : 192.0.0.1 EV1

192.0.0.7 AC 5000F- A

192.0.0.8 AC 5000E- A

IP Address : 192.0.0.1

Remark:

Hostnames and IP Addresses are

examples and should be adapted to

the network

1-8 (a/03.1) EasyVision RAD R4

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 12

Introduction And Technical Data Section 1

4. NETWORK CONNECTIONS

Building blocks to build a network, like hubs, switches and other related parts, are NOT part of the

EasyVision delivery. These parts have to be purchased locally.

4.1. C

In this cluster concept two networks are determined. Network connection via Base-T Ethernet.

LIENT SERVER CLUSTERS

EasyVision RAD R4 (a/03.1) 1-9

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 13

Installation Section 2

Section 2 Installation

1.

2.

3.

4.

Contents

WHAT IS DELIVERED ........................................................................................................................... 3

TIME AND PERSONNEL NEEDED .......................................................................................................3

PHYSICAL INSTALLATION .................................................................................................................. 3

CABLING................................................................................................................................................ 4

4.1. SunBlade 1500........................................................................................................................................ 4

4.2. Ultra 10 / 60, SunBlade 1000 / 2000....................................................................................................... 5

4.3. Client / server network connection.......................................................................................................... 6

4.4. Ethernet Loopback Connector ................................................................................................................ 7

4.5. Laser Hardcopy Unit (point-to-point)....................................................................................................... 7

4.6. Mains Cables .......................................................................................................................................... 7

4.7. Cable Relief............................................................................................................................................. 7

5.

PERIPHERAL CABINETS...................................................................................................................... 8

5.1. SCSI-chain configurations ...................................................................................................................... 8

5.1.1. ULTRA 10 PTI 2 Configurations.......................................................................................................... 8

5.1.2. ULTRA 10 PTI 2 + PTI 1 Configurations ............................................................................................. 9

5.2. ULTRA 60 PTI 2 + PTI 1 Configuration ................................................................................................ 10

5.2.1. Onboard SCSI only............................................................................................................................ 10

5.2.2. Onboard SCSI and Twin SCSI card .................................................................................................. 10

5.3. SunBlade Configuration ........................................................................................................................ 11

6.

CONNECTING A PRINTER ................................................................................................................. 12

6.1. HardCopy Unit....................................................................................................................................... 12

6.2. SCSI Printer .......................................................................................................................................... 12

6.3. Network Printer ..................................................................................................................................... 12

6.4. Parallel Printer....................................................................................................................................... 12

7.

ADDING PERIPHERALS TO PERIPHERAL ENCLOSURE ............................................................... 13

8.

CONNECTIVITY ................................................................................................................................... 13

8.1. Printers .................................................................................................................................................. 13

8.2. NetView ................................................................................................................................................. 13

8.3. DICOM .................................................................................................................................................. 13

EasyVision RAD R4 (a/03.1) 2- 1

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 14

Section 2 Installation

2-2 (a/03.1) EasyVision RAD R4

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 15

Installation Section 2

1. WHAT IS DELIVERED

Ultra 10 / 60 / SunBlade

Memory

(Onboard) framebuffer

Keyboard + mouse

DVD /CD-ROM drive

Monitors

LCD: Color 18"

Peripherals

EasyStore (Optical Disc) PTI 2 (obsolete)

EasyStore (CD-R) PTI 1

Optional

Hardcopy unit board

Ethernet card (Quad / Single)

Dome Md2 greyscale framebuffer for 2 monitors

Creator card (True color)

Twin SCSI Card

The main part of this section describes the hardware installation per system. This can be a standalone

EasyVision, a Server or a Workspot! Look at the commercial order what is appropriate for your environment.

For a client/server environment installation, see chapter 4.3 Client / server.

Internal hard drive

CRT: Color 17", 21"; greyscale 21"

Image disks PTI 2

Memory Extension

2. TIME AND PERSONNEL NEEDED

The total installation can be done by just one person.

The total installation of a stand-alone EasyVision can be done within eight hours. Even the installation of a

small network can be completed within 8 hours.

3. PHYSICAL INSTALLATION

The software has been installed at the factory. The software installation keeps track of the SCSI chain

configuration. For this reason it is very important to build the same hardware configuration as assembled in

the factory. The SCSI chains on the SUN and corresponding peripheral cabinets are labeled with stickers

(SCSI-A, SCSI-B or SCSI-C).

If the SCSI chain changes for any reason (e.g. an option) the OS and AS software must be reinstalled!

There are no transport lockings.

• All components of the system should be placed on a table.

Do not place the system on the floor to avoid damage (kicking the system with feet, water (cleaning

personnel), dust and dirt etc.).

• Place peripheral cabinet(s) next to the Sun workstation.

• Place keyboard within reach on the table.

• Place mouse + mouse pad within reach on the table.

• Place the mains distribution unit within reach on the table. The mains distribution unit contains the

system power on/off switch.

EasyVision RAD R4 (a/03.1) 2- 3

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 16

Section 2 Installation

4. CABLING

NOTE

Check all external and internal interface cables (e.g., the SCSI cable to the image hard disk, CD-ROM), as

they may have moved during transport.

________________

• Connect the video cable from the monitor to the workstation's video connector.

• Connect the monitor power cable to the power distribution unit.

• Connect keyboard and mouse.

• Network kit or cable must be obtained locally. EasyVision can be connected to the network via a twisted

pair (TP) connection.

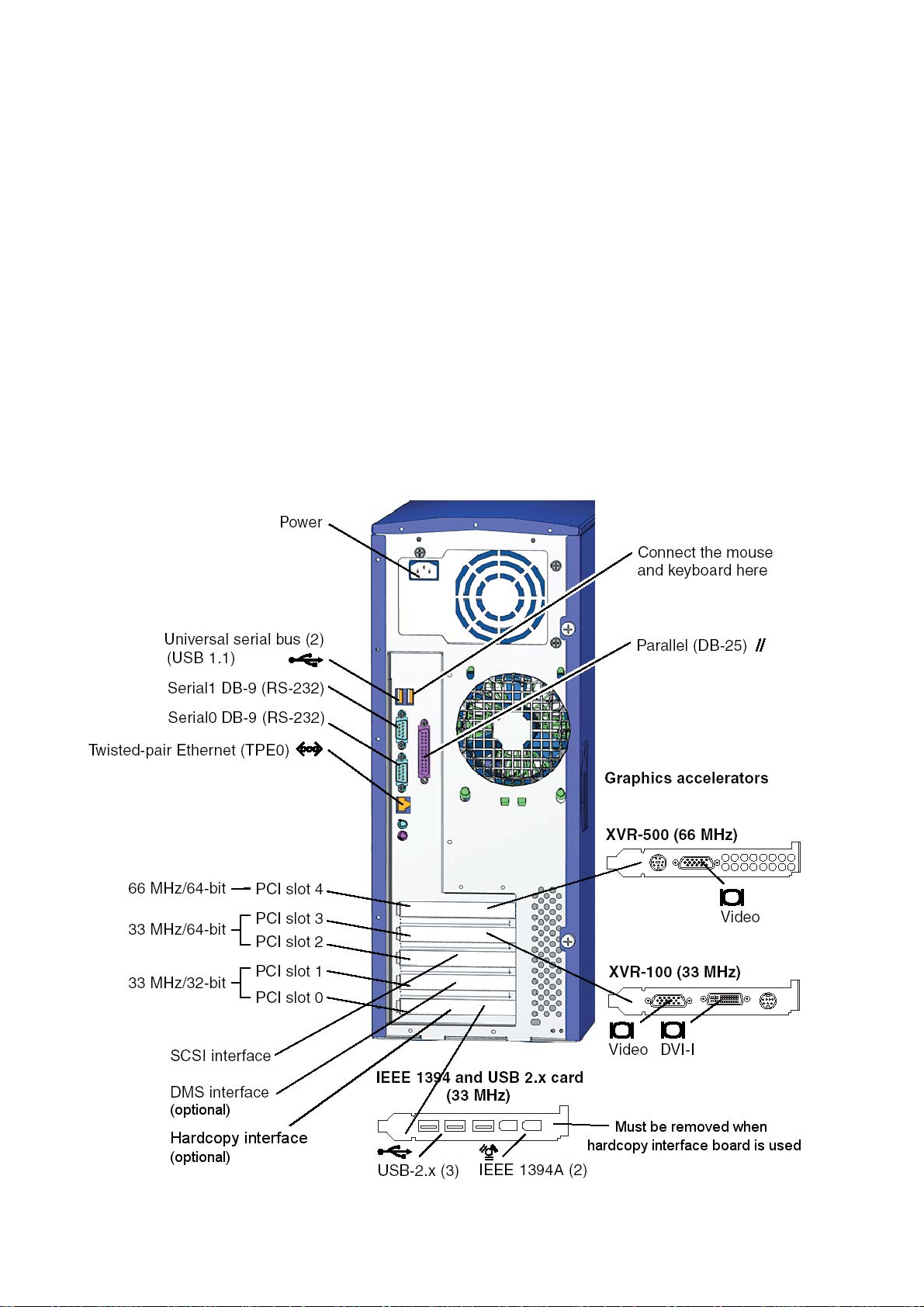

4.1. SUNB

LADE

1500

2-4 (a/03.1) EasyVision RAD R4

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 17

Installation Section 2

This figure illustrates the cable connections for the SunBlade 1500 workstation.

4.2. U

LTRA

10 / 60, SUNB

LADE

1000 / 2000

See Z drawings of appropriate Sun workstation for connections.

EasyVision RAD R4 (a/03.1) 2- 5

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 18

Section 2 Installation

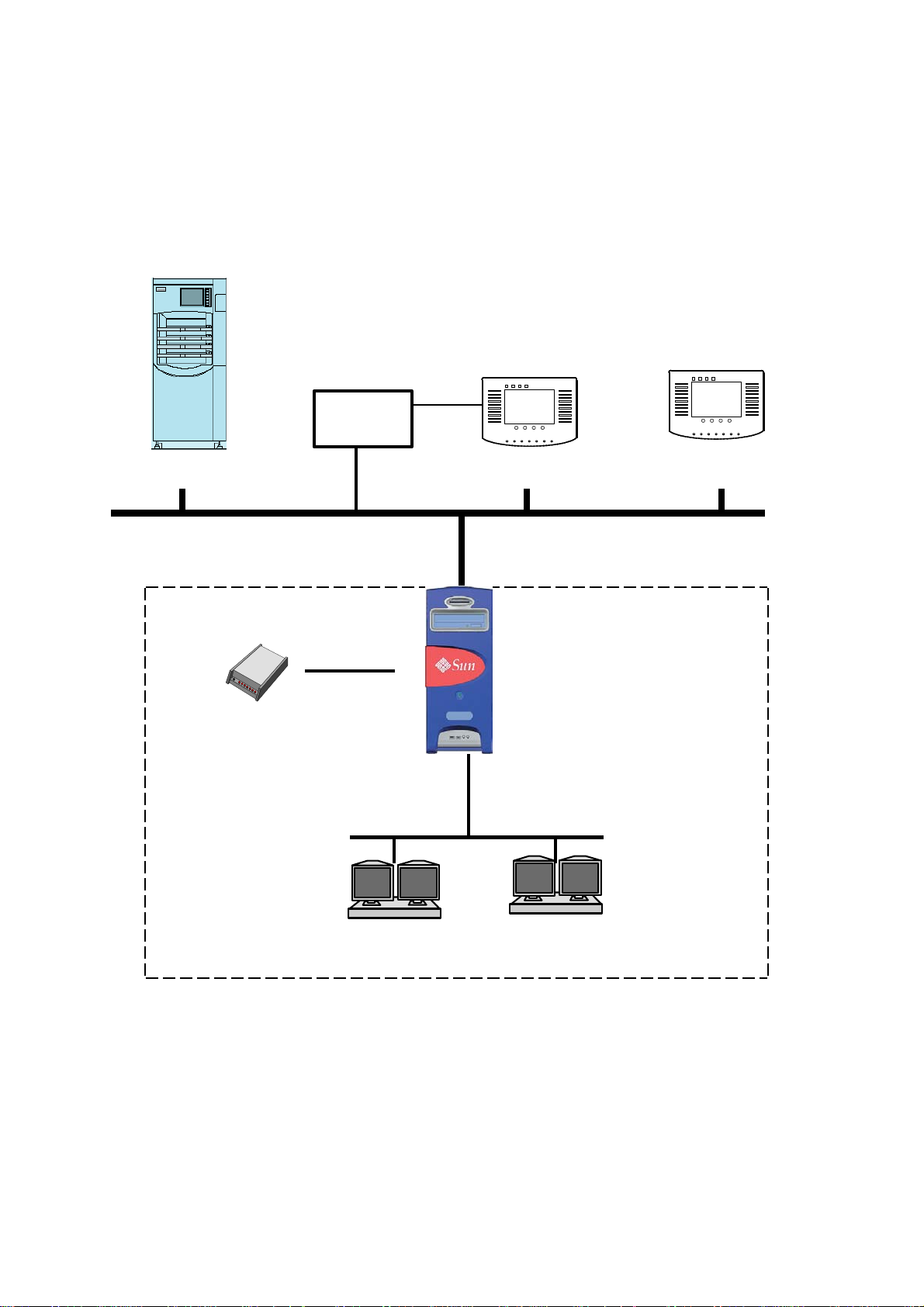

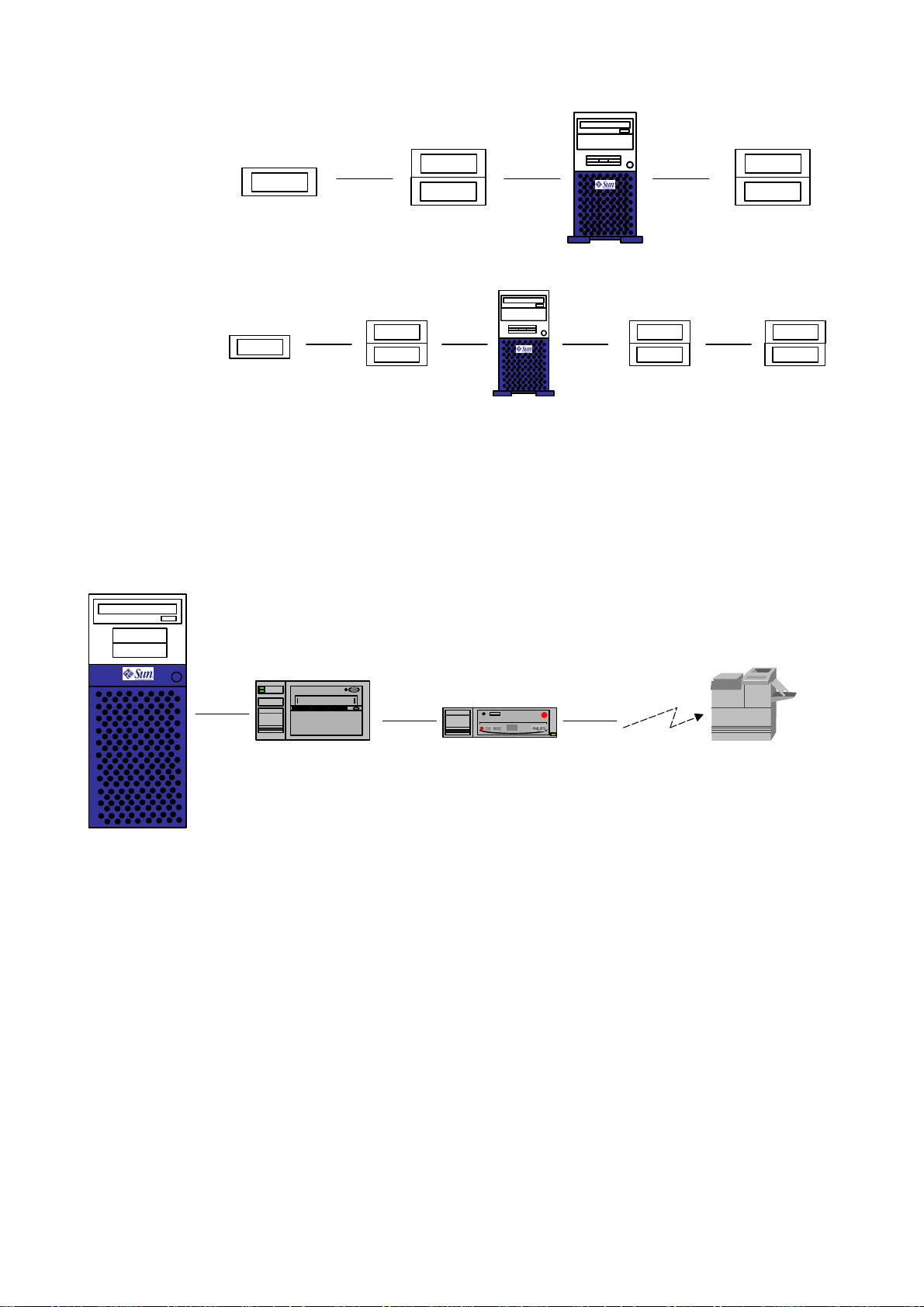

4.3. C

See Z drawings for cable diagrams.

Example:

LIENT / SERVER NETWORK CONNECTION

IDT

PreView

Unit

Reader

EasyVision RAD cluster

Modem

User Terminal

Server

network

Server

EasyVision RAD network

User Terminal

Client

Workspot #1

2-6 (a/03.1) EasyVision RAD R4

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Workspot #n

Page 19

Installation Section 2

4.4. E

The loopback connectors serves two purposes.

• If a network is not connected to EasyVision, connect the loopback connector to the Ethernet connection

at the end of the adaptor cable. This suppresses the UNIX message 'no carrier' (to console).

• Diagnostic purpose in Forth Diagnostics, see Unit Manual.

In case of a Single/Quad Ethernet card: The unused controllers must have an Ethernet loopback connector

4.5. L

Hardcopy units with point-to-point connection are connected to the EasyVision via split cable by a DATA

and CONTROL cable (SUB-D 37p connectors). Connect the Data and Control cables.

Ensure that the correct connections have been made for the DATA and CONTROL cables. Interchanging

Refer to the chapter "Connecting a Printer" in this Section 2.

4.6. M

THERNET LOOPBACK CONNECTOR

________________

ASER HARDCOPY UNIT (POINT-TO-POINT

these cables may destroy the hard copy interface board.

________________

AINS CABLES

NOTE

connected

NOTE

)

Fit the correct mains plug to the mains cable of the power distribution unit provided. A couple of mains plugs

are delivered with the system but if the correct one for your environment is not there, you will have to obtain

one locally.

• Connect the mains cable between the Sun workstation and the power distribution unit.

• Connect the mains cable between the peripheral cabinet(s) and the power distribution unit.

• Connect the mains cable between the monitor and the power distribution unit.

• Connect the mains cable to a mains wall socket.

• The hardcopy unit's power cable may now be connected to the mains supply (if relevant).

NOTE

Make sure that the HCU has been connected to the same mains distribution point as the EasyVision. This is

important to protect both the HCU interface of the EasyVision RAD and the interface of the HCU from

voltage differences dangerous for the electronic interface components.

4.7. C

Relieve the power cable, network cable and hardcopy cables with Ty-Raps or flexible cable wrapper

delivered.

ABLE RELIEF

EasyVision RAD R4 (a/03.1) 2- 7

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 20

Section 2 Installation

5. PERIPHERAL CABINETS

Note

The last peripheral cabinet in each SCSI chain must be terminated with a SCSI terminator.

________________

CAUTION

If the SCSI chain configuration has been changed, the OS and application software be re-installed

________________

5.1. SCSI-

Abbreviation Device SCSI

ID(1) Image Disk Wide SCSI (68 pin)

ID(2) Additional Image Disk 1 Wide SCSI (68 pin)

ID(3) Additional Image Disk 2 Wide SCSI (68 pin)

ID(4) Additional Image Disk 3 Wide SCSI (68 pin)

ES EasyStore (DOR) Narrow SCSI (50 pin)

CD-Rec EasyStore (CD-Recorder) Narrow SCSI (50 pin)

70cm

h

n

CHAIN CONFIGURATIONS

h: 68p UHD (Ultra High Density)

n: 68p FW (Fast Wide)

5.1.1. ULTRA 10 PTI 2 C

Desktop:

50cm

70cm

n

h

PTI 2 (1)

Configuration 1

ONFIGURATIONS

ID(1) ID(2) ES

X

X X

X

X X

X

X

PTI 2 (1)

2-8 (a/03.1) EasyVision RAD R4

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 21

Installation Section 2

PTI 2 (1) PTI 2 (2)

PTI 2 (1)

70cm

nn

h

70cm

h

Configuration 2

In case of 4 image disks, you may use 1 SCSI chain (See right hand side of configuration 3)

70cm

nn

h

PTI 2 (1)

70cm

hn

PTI 2 (2) PTI 2 (3)

50cm

n

50cm50cm

ES ID(1) ID(2) ID(3) ID(4)

X

X

PTI 2 (2)

NOTE

________________

50cm50cm50cm

X

X

X X

X

X

X X

PTI 2 (1) PTI 2 (2) PTI 2 (3)

ES ID(1) ID(2) ID(3) ID(4)

X X X

X X X X

X X X X X

Configuration 3

5.1.2. ULTRA 10 PTI 2 + PTI 1 C

Desktop:

Configuration 1

+

CD-R

50cm

PTI 2 (1)

Configuration 1

+

CD-R

30cm

ONFIGURATIONS

30cm

70cm

nn

h

150cm

h

PTI 1

50cm

hn

70cm

n

50cm

n

PTI 1

PTI 2 (1)

EasyVision RAD R4 (a/03.1) 2- 9

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 22

Section 2 Installation

Configuration 2

+

CD-Rec

30cm

50cm

hn

70cm

70cm

n

h

50cm

nn

50cm

PTI 1

Configuration 3

+

CD-Rec

30cm

PTI 1

50cm

n

5.2. ULTRA 60 PTI 2 + PTI 1 C

5.2.1. O

In case of 3 devices (or less), only the onboard SCSI card is available. The next figure shows the

configuration.

NBOARD

SCSI

PTI 2 (EasyStore + Image Disk)

ONLY

PTI 2 (1)

50cm

hn

PTI 2 (1)

ONFIGURATION

70cm

50cm

70cm

n

h

n

PTI 2 (2)

PTI 2 (2)

50cm

n

Printer

50cm

n

PTI 2 (2)

50cm

nn

Onboard SCSI

5.2.2. O

In case of more than 3 devices, a twin SCSI card is needed. The next figure shows the configuration.

NBOARD

SCSI

AND TWIN

50cm

nn n

SCSI

PTI 1 (CD-Rec)

CARD

15cm

SCSI booster

+ 3m cable

2-10 (a/03.1) EasyVision RAD R4

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 23

Installation Section 2

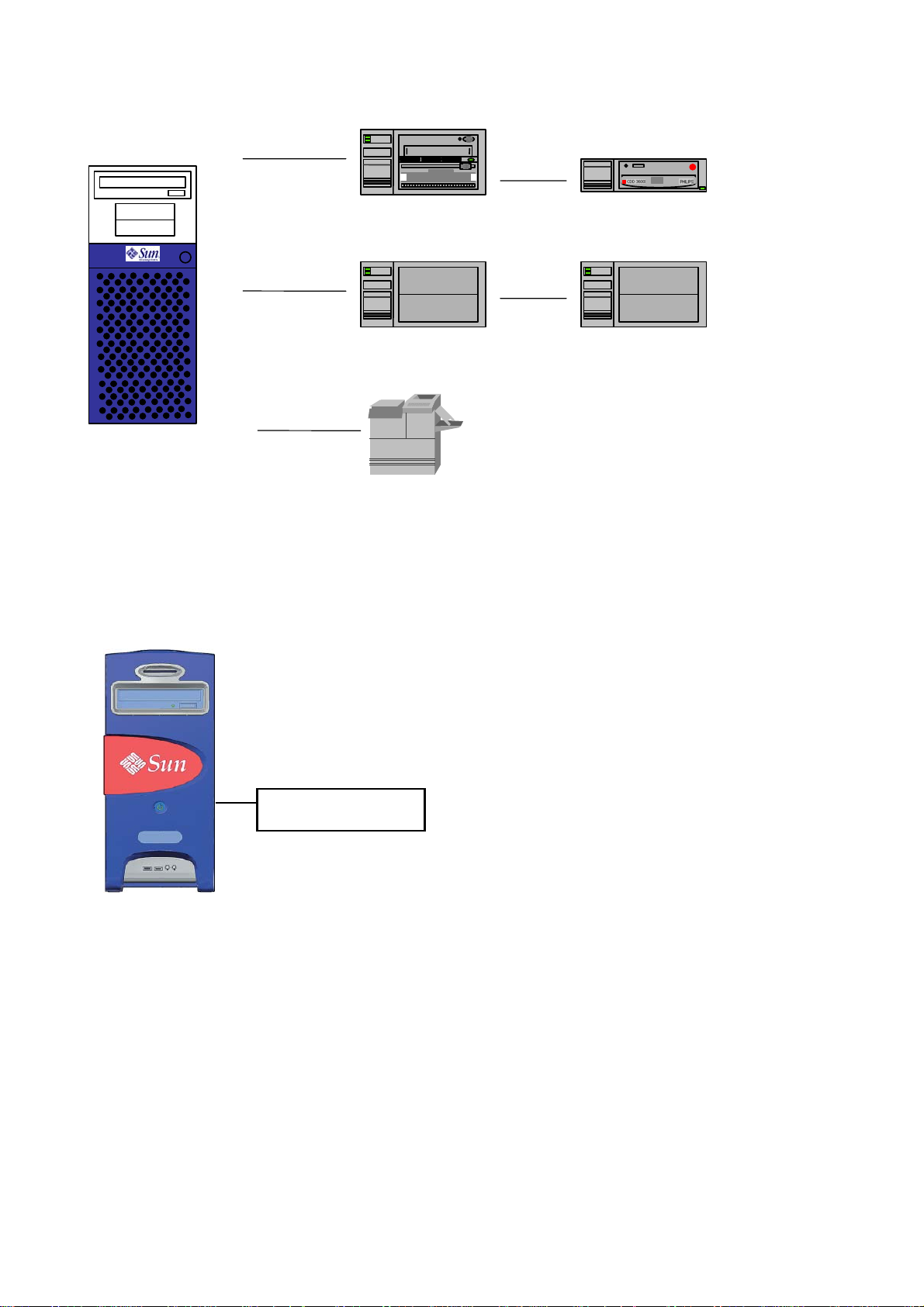

5.3. SUNB

PTI 2 (EasyStore

70 cm

h

Twin SCSI 1

70 cm

h

Twin SCSI 2

< 300 cm

n

Onboard SCSI

LADE CONFIGURATION

n

n

n

PTI 1 (CD-Rec )

50 cm

nn

2x PTI 2 (4x image disk)

50 cm

nn

Printer

A twin SCSI card is built in. The image disk has a internal connection to the SCSI card. A CD-R drive is

connected externally to the SCSI card.

PTI EasyStore CD-R

EasyVision RAD R4 (a/03.1) 2- 11

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 24

Section 2 Installation

6. CONNECTING A PRINTER

See Z drawings for connection possibilities.

6.1. H

In the service manual Imager Compatibility you will find a compatibility list of the hardcopy units supported

by the EasyVision. Furthermore you will find the settings for the various hardcopy units, when connected to

EasyVision. Usually the HCU service engineer will configure the HCU and will have the information

necessary to do this. In some cases however he may not be aware of special settings when connecting to

EasyVision.

6.2. SCSI P

Note: The maximum length of a SCSI chain, including the printer SCSI cable, is 3 meters !!!

See Z drawings.

To connect an SCSI Printer, remove the SCSI terminator from the peripheral enclosure.

Connect the printer SCSI-cable and SCSI adapter narrow/narrow between the SCSI connector of the

peripheral enclosure and the printer itself or if relevant to a SCSI booster.

Put the SCSI terminator on the second SCSI connector of the printer or in case of a SCSI booster the

termination is done by the SCSI extender (so no external terminator required).

For detailed installation information of SCSI printers please refer to the installation manual delivered with the

printer.

6.3. N

ARDCOPY UNIT

RINTER

ETWORK PRINTER

The network printer is connected to the network.

6.4. P

A PostScript printer can be connected to the parallel port (max. length - 3m).

ARALLEL PRINTER

2-12 (a/03.1) EasyVision RAD R4

Copyright © 1999-2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 25

Setting to Work Section 3

Section 3 Setting to Work

Contents

1.

2.

2.1.

2.2.

2.3.

3.

3.1.

3.2.

3.3.

4.

5.

5.1.

5.2.

5.3.

5.3.1. Verification of the Density Calibration ................................................................................................. 9

5.4.

INTRODUCTION ................................................................................................................................. 3

POWER ON......................................................................................................................................... 3

Power On Self Test and OpenBoot PROM phases ............................................................................ 3

Start-up Menu...................................................................................................................................... 3

Configuration / Customization ............................................................................................................. 3

POWER OFF....................................................................................................................................... 4

Power-off in Application Mode............................................................................................................. 4

Power-off in Service Mode .................................................................................................................. 4

When the System Does Not Respond Normally ................................................................................. 4

MONITOR ADJUSTMENT.................................................................................................................. 5

HARD COPY UNIT CALIBRATION.................................................................................................... 5

Introduction.......................................................................................................................................... 5

Preconditions....................................................................................................................................... 5

HCU Density Calibration ..................................................................................................................... 5

Pixel Size calibration ......................................................................................................................... 10

5.5.

6.

Checking the Results ........................................................................................................................ 11

EASYVISION RAD / HCU CALIBRATION FORM ........................................................................... 13

EasyVision RAD R4 (a/03.1) 3-1

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 26

Section 3 Setting to Work

3-2 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 27

Setting to Work Section 3

1. INTRODUCTION

The operating system, application software and license file are factory installed. For software configuration

and customization see Release Bulletin.

2. POWER ON

Check if the mains switch of the Sun computer and its peripheral devices are in the ON position.

Switch on the complete system by switching on the switch of the power distribution box. The light on the

mains switch box is always on when power is applied to it.

2.1. P

After power on the factory-defined Power On Self Test (POST) phase and the OpenBoot PROM phase are

performed automatically (see also chapter "Sun Troubleshooting Overview", paragraphs "Factory Defined

Boot Mode" and "After Power Is Switched On").

POST phase

During the POST phase the blinking Caps Lock LED on the keyboard will tell you the POST is in progress.

At successful completion of the POST phase the OpenBoot PROM firmware takes control.

OpenBoot PROM phase

During the OpenBoot PROM phase (high level POST) you will first see "Testing Memory" on the screen. If

the OpenBoot PROM phase passes error free the system will boot automatically. If an error occurs, a

message on the screen will appear telling you which unit failed.

Now the system should boot, as the SunOS and Application Software has already been loaded at the

factory.

2.2. S

OWER ON SELF TEST AND OPENBOOT

TART-UP MENU

PROM

PHASES

After boot up the system will display the Start- up Menu. If no selection (number + <Enter>) is made within

10sec, automatically the Application will be started!

1. Start Application

2. Start Customizing

3. Go to Service Menu

4. Go to Installation/Configuration Menu

0. Shutdown

Select item 4 to start the configuration program.

2.3. C

Regarding configuration please refer to the Release Bulletin EasyVision RAD Release 4.2.chapter

configuration.

Regarding customization refer to the instructions for use of the EasyVision RAD.

ONFIGURATION

/ C

USTOMIZATION

EasyVision RAD R4 (a/03.1) 3-3

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 28

Section 3 Setting to Work

3. POWER OFF

3.1. P

Client/Server environment: If you turn the EasyServer off, the database is no longer accessible for the

Before switching off the power exit the application as follows:

1. Click

2. Click

3. Click [Confirm].

4. From the start-up menu select 0 Shutdown.

5. When shutdown has completed indicated by the OK prompt switch off the power.

3.2. P

OWER-OFF IN APPLICATION MODE

________________

.

.

OWER-OFF IN SERVICE MODE

NOTE

clients.

1. Exit service mode.

2. From the start-up menu select 0 Shutdown.

3. When shutdown has completed indicated by the OK prompt switch off the power.

3.3. W

To halt a system that is hung, or frozen, and unresponsive to commands:

1. Press <Stop>+<A>.

2. When the ok prompt appears, boot the operating system by entering boot.

3. The system should start up normally.

If the system does not respond to the mouse and keyboard, pressing <Stop>+<A> will not be effective. You

may have to switch the power off, wait at least 10 seconds, and switch the power back on again. Then try

HEN THE SYSTEM DOES NOT RESPOND NORMALLY

NOTE

pressing <Stop>+<A> once more.

________________

3-4 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 29

Setting to Work Section 3

4. MONITOR ADJUSTMENT

The brightness and contrast settings are not factory set. To adjust the settings the monitor must be switched

on for at least 30 minutes. Please refer to the Instructions For Use of the EasyVision RAD for how to adjust

the monitor(s).

Should two monitors be placed next to each other pay particular attention to the fact that brightness

perception may differ, depending on the position with respect to the monitor. You must sit in the central

position to verify if there is equal brightness.

NOTE

When you configured EasyVision you should have selected "Normal" for the Monitor correction. (see

Release Bulletin chapter: Configuration). The other selections (Dark and Bright) are only necessary if this

procedure does not give the correct results.

________________

5. HARD COPY UNIT CALIBRATION

5.1. I

After the system has been configured and customized, the correct density calibration (gamma correction

curve) and the pixel size calibration must be carried out on the EasyVision.

The HCU calibration is necessary to establish a correction (curve) between the EasyVision RAD and a

printer (HCU). This correction adapts the EasyVision printing chracteristics to individual deviations of the

printer chracteristics such as laser power adjustment, film chracteristics, developer chemistry or temperature

etc.

The HCU calibration is done in two major steps:

1. The density calibration (Gamma Correction) with HCU calibration and verification of it

2. The pixel size calibration

Note: Both the density calibration and pixel calibration have to be carried out for all media of all printers

connected.

5.2. P

The hard copy unit is setup properly with respect to its configuration (this has to be done by the printer

manufacturers service engineer)

The printers self-calibration has been checked or corrected (manufacturers service engineer or hospital

personnel)

The densitometer has been calibrated and is operating correctly (Philips service personnel)

5.3. HCU D

NTRODUCTION

RECONDITIONS

ENSITY CALIBRATION

In order to use only the test image PrinterCalibration in its original unmodified condition all testimages must

be deleted and then loaded again.

1. Start the application

2. Click

EasyVision RAD R4 (a/03.1) 3-5

.

.

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 30

Section 3 Setting to Work

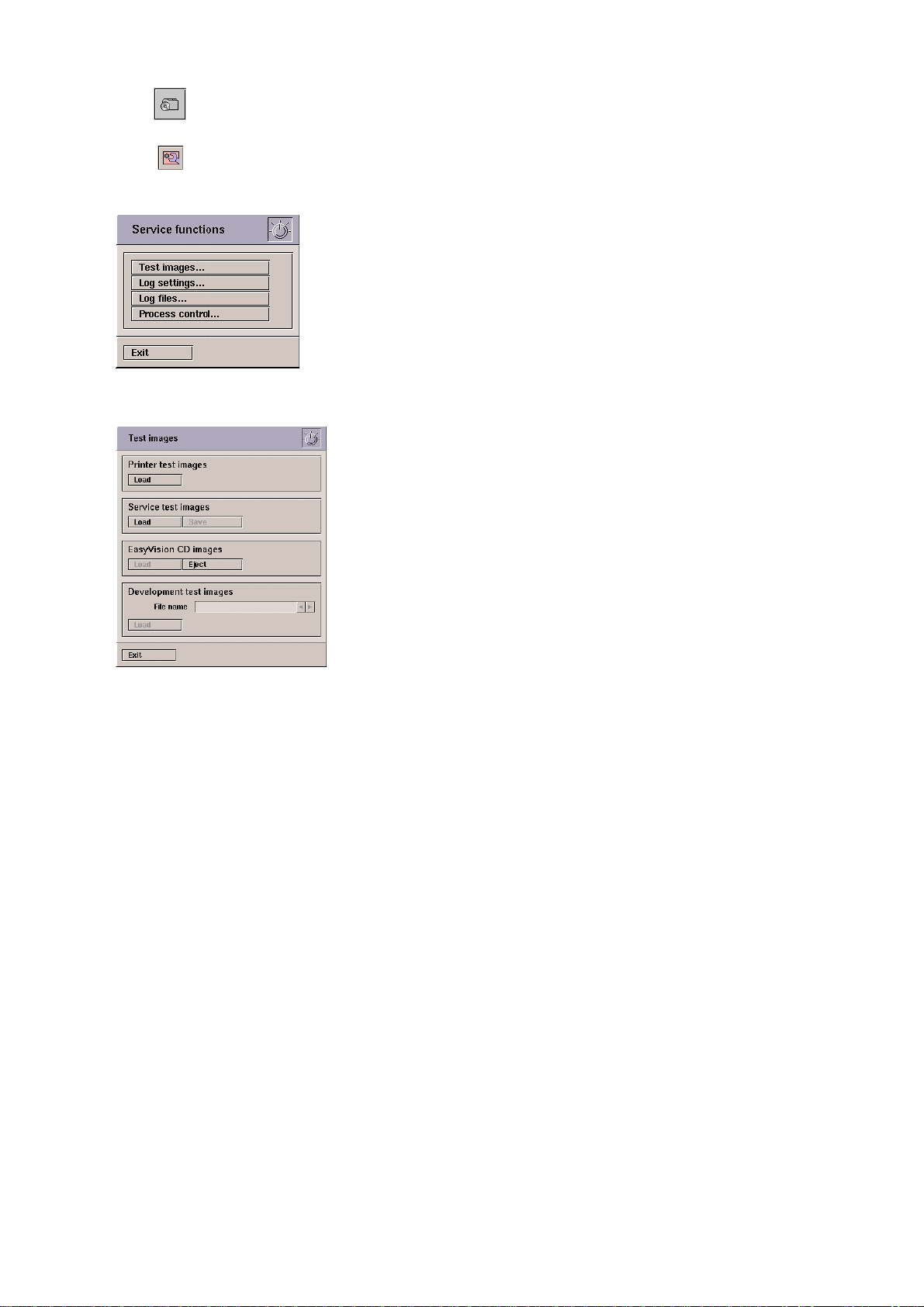

3. Click .

4. Click

.

5. The Service functions window is displayed:

6. Click [Test images]. The Test images window is displayed.

7. In the area Printer test images click [Load]. 23 test images are loaded into the database.

8. Click [Exit].

9. Exit the application and go to Service Menu.

10. Select 4. Printer Menu:

Service Menu

1. Diagnostics Menu (sunvts and product diagnostics)

2. Sun OS Menu (optical disk format and Sun Os commands)

3. File Menu (file transfer and manipulation commands)

4. Printer Menu (printer tests)

5. Monitor Menu (Monitor test images and adjustment)

6. PCR Systems (PCR diagnostics menu)

11. Select 1 HCU Calibration:

Printer Menu

1 HCU Calibration (start hardcopy unit calibration)

2 Start Printer Status Request

3 Start Data Channel Printer Test

4 Start Printer Test

5 Start S-bus/PCI Printer Visual Interface Test

0 Return to Service Menu

The Hard Copy Unit start screen is displayed. HCU Gamma correction and pixel correction must be

carried out for all configured printers and media sizes.

3-6 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 31

Setting to Work Section 3

12. Right-click on the printer select spiral icon and select the printer you want to calibrate:

Note: The printer identification strings such as dicom_0_de25sj in the example above tells you that

this is the DICOM printer No. 0 (the first) connected to the EasyVision RAD with the IP node name

de25sj. The relation about which identification string belongs to which physical printer must be

taken from the file /easydata/configuredPrinters.dat at the EasyVision RAD with the node name

de25sj (in this example).

13. Click

to open the hardcopy gamma correction window.

14. Right-click on the spiral icon Media and select the media in the hardcopy unit you want to calibrate the

printer for.

EasyVision RAD R4 (a/03.1) 3-7

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 32

Section 3 Setting to Work

15. Click [Print Calibrate].

13

12

4 5

11

6

14

3

7

2

10

15

1

8

16

9

16. Click [Print]. Wait until the Printing Active panel disappears to indicate that printing is complete.

17. Click [Exit].

18. Measure the density of the 16 grey squares in all 4 arrays.

Start with the darkest grey level: No.1 (Calibrate the densitometer first!)

It is important to measure all 4 arrays (4 times 16 density values = 64 density values). This is

necessary because of the tolerances between the darkest and the lightest areas on the film.

The maximum density must be between 2.9 and 3.1 optical density.

Fill in all measured density values in the Imager Calibration Form at the end of this chapter. Start

with the table EasyVision RAD calibration and fill in the 16 values of an array of 16 squares in one

column e.g. upper left upper right etc. (Don’t use the original form make copies of it for spare).

The result will be all 4 density numbers of all matching grey levels in one row.

Take the 4 readings belonging to one grey level (1 row) calculate the average and enter the result in

the column average of that grey level. Repeat this for all 16 grey levels.

Enter the 16 averages in the row 'Measured density' in the Hard Copy Gamma Correction screen

on the EasyVision; use the TAB key to always select the nearest field on the right

Check whether Application default Standard has been selected.

3-8 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 33

Setting to Work Section 3

Click [Save].

Select Specific. Only that media type will be calibrated which is displayed under Media at the top left

of the Hard Copy Gamma Correction panel.

All: in which the calibration is valid for all media types for the printer selected

Matching: in which the calibration is valid for all media of the same size of the printer selected

Click [Save].

Click [Exit] to terminate the Hard Copy Gamma Correction.

5.3.1. V

ERIFICATION OF THE DENSITY CALIBRATION

Checking the results of the Hard Copy calibration, proceed as follows.

1. Make sure the same printer has been selected as in the calibration procedure.

2. Right-click the printer select spiral icon

and select the printer you want to check.

Note: The printer identification strings such as dicom_0_de25rb in the example above tells you: this is

the DICOM printer No. 0 (the first) connected to the EasyVision RAD with the IP node name de25rb.

3. Click [Print Verify].

4. Click [Print]. The printing active panel is displayed and the verification film is printed.

EasyVision RAD R4 (a/03.1) 3-9

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 34

Section 3 Setting to Work

5. Click [Exit].

6. Perform the measurement on the verification film as described in 5.2 step 18 on page 8.

7. Enter the measured density values in the column average of the Calibration Verification form.

8. Transfer the density numbers of the row Target density from the Hard Copy Gamma Correction screen

to the column Target density of the Verification form.

Example

9. At this point the calibration procedure is finished.

5.4. P

IXEL SIZE CALIBRATION

• Make sure the same printer has been selected as in density calibration.

• Click

.

3-10 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 35

Setting to Work Section 3

• Left-click [Media] until your selected media size appears.

• Right-click on the Units selection spiral until

your preferred unit of length is displayed.

• Click [Print] in the Hardcopy Pixel Size calibration panel.

• Measure the distances of Length X and Length Y on the film as accurately as possible with a ruler. If X

and Y do not match, enter the lengths individually in their respective fields. The field resolution displays

the number of pixels per unit of length selected.

• Select either Specific or All Matching Sizes in the Save Media dialog box:

Specific in which only the selected media will be calibrated; (recommended)

All Matching Sizes in which all media of the same size on the selected printer will be calibrated.

NOTE

The selection "Specific" may be repeated for other supported media.

________________

• Click [Save] in the Hardcopy pixel size calibration panel.

• Click [Exit] to terminate the Hard Copy Pixel Size calibration.

• Click [Exit] to terminate the Hard Copy calibration.

5.5. C

HECKING THE RESULTS

• Select the printer you want to check

• click on the information icon on the top icon bar to check the results and the status of the calibration

The Printer information status panel will be displayed:

This panel supplies information about which media are calibrated (both density and pixel) on the

selected printer plus additional information.

EasyVision RAD R4 (a/03.1) 3-11

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 36

Section 3 Setting to Work

3-12 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 37

Setting to Work Section 3

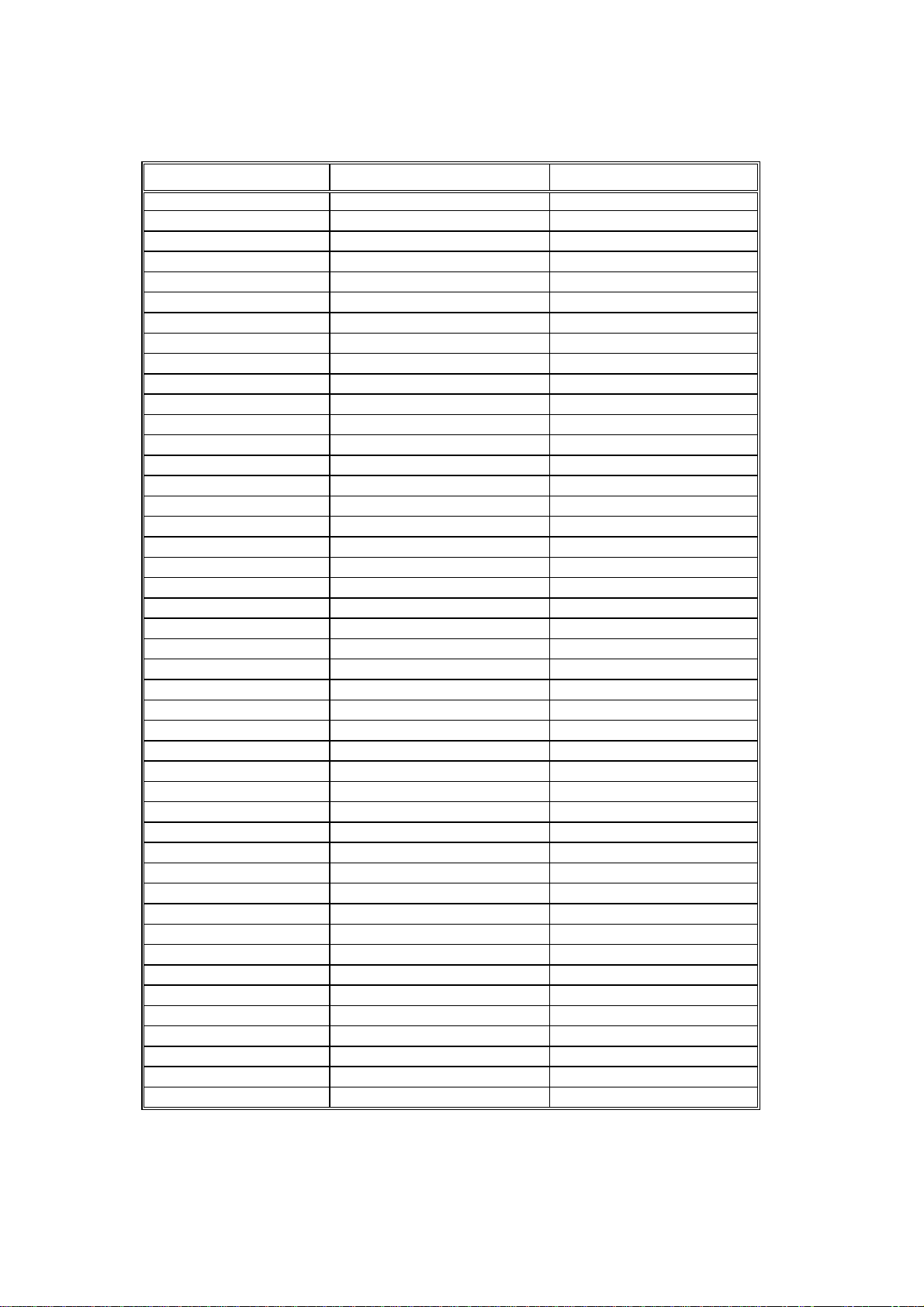

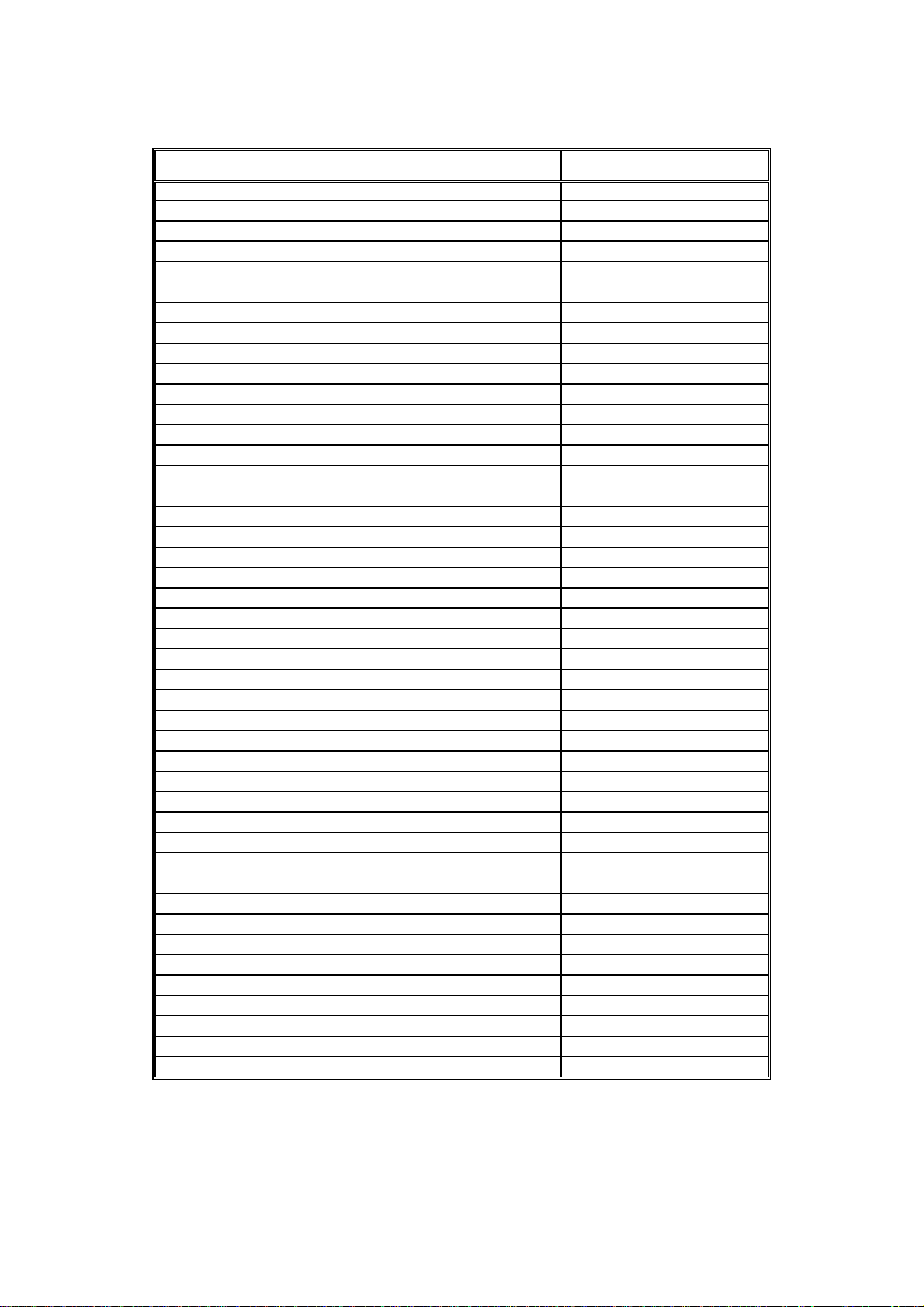

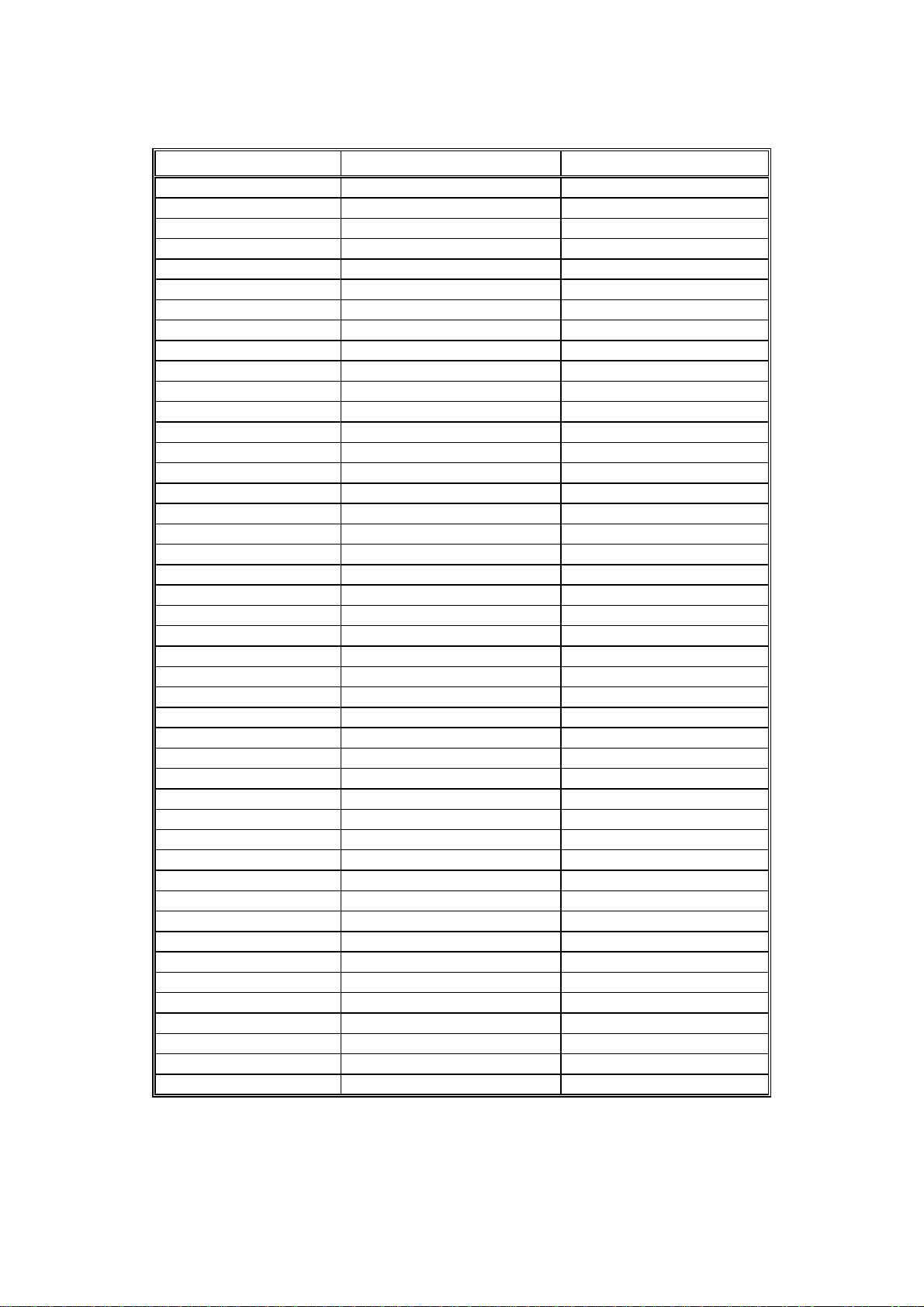

6. EASYVISION RAD / HCU CALIBRATION FORM

EasyVision Calibration Form

Printer Model : Format:

EasyVision Calibration

Upper

Left Right Left Right Density in o. D. in [%] error error necessary

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

Upper Lower Lower Average Target Deviation Dev. Lower Upper Calibration

limit limit

Calibration Verification

Upper Upper Lower Lower Average Target Deviation Dev. Lower Upper Calibration

Left Right Left Right Density in o. D. in [%] error error successfull

limit limit

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

Date: System:

Time: Operator:

EasyVision RAD R4 (a/03.1) 3-13

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 38

Section 3 Setting to Work

3-14 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 39

Fault Finding Section 4

Section 4 Faultfinding

Contents

1.

2.

3.

4.

4.1.

4.1.1. Ultra 10 ................................................................................................................................................ 7

4.1.2. Ultra 60 ................................................................................................................................................ 8

4.1.3. SunBlade 1000/2000........................................................................................................................... 9

4.1.4. SunBlade 1500 .................................................................................................................................. 10

INTRODUCTION ................................................................................................................................. 3

CLIENT/SERVER ENVIRONMENT .................................................................................................... 4

EASYVISION RAD R4.2V2 CLUSTER NETWORK........................................................................... 5

SUN SPARC COMPUTERS ............................................................................................................... 6

NON-VOLATILE RAM (NVRAM) PARAMETERS............................................................................... 7

5.

5.1.

5.1.1. Diagnostics Menu .............................................................................................................................. 11

5.1.2. SunOS Menu ..................................................................................................................................... 12

5.1.3. File Menu........................................................................................................................................... 12

5.1.4. Printer Menu ...................................................................................................................................... 13

5.1.5. Monitor Menu..................................................................................................................................... 13

5.1.6. PCR systems menu........................................................................................................................... 13

5.1.6.1. File Transfer Settings Menu........................................................................................................... 13

5.1.6.2. File Transfer Menu......................................................................................................................... 14

5.1.6.3. Serial Interface Menu..................................................................................................................... 14

5.1.6.4. PCR Reader Documentation ......................................................................................................... 15

5.2.

5.2.1. Diagnostics Menu .............................................................................................................................. 16

5.2.2. SunOS Menu ..................................................................................................................................... 16

5.2.3. File Menu........................................................................................................................................... 17

5.2.4. Printer Menu ...................................................................................................................................... 18

5.3.

6.

6.1.

6.1.1. /easy/service/images/export.............................................................................................................. 22

6.2.

6.2.1. /VAR/ADM/CDSLOG ......................................................................................................................... 23

SERVICE MENU ............................................................................................................................... 11

Service Menu via Sun Console ......................................................................................................... 11

Service Menu via Serial Port ............................................................................................................. 16

PCR Systems Menu (remote) ........................................................................................................... 18

FILE SYSTEM ................................................................................................................................... 22

/DBADMIN ......................................................................................................................................... 22

/easydata ........................................................................................................................................... 22

7.

7.1.

7.2.

7.3.

7.4.

7.5.

7.5.1. Application Context Name ................................................................................................................. 28

EasyVision RAD R4 (a/03.1) 4-1

EASYVISION LOG FILES................................................................................................................. 25

Collecting log files.............................................................................................................................. 26

TCP Connection ................................................................................................................................ 27

Association PDU Types..................................................................................................................... 27

Accepted presentation contexts ........................................................................................................ 28

Local / Peer information..................................................................................................................... 28

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 40

Section 4 Fault Finding

7.5.2. Local max Data PDU Length............................................................................................................ 28

7.5.3. Peer max Data PDU Length............................................................................................................. 29

7.5.4. Implementation Identification notification .......................................................................................... 29

7.5.5. Max Operations ................................................................................................................................. 29

7.6.

Verifying syntaxes ............................................................................................................................. 29

7.6.1. Syntax errors ..................................................................................................................................... 30

7.7.

Closing DICOM connection ............................................................................................................... 30

4-2 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems Nederland B.V.

ALL RIGHTS RESERVED

Page 41

Fault Finding Section 4

1. INTRODUCTION

The next chapters describe a top-down method to troubleshoot client/server configurations.

In case of a standalone system you can start with chapter 4 Sun SPARC computers.

Overview of Faultfinding tools:

• Power On Self Test (POST)

• Service Menu tests

− Diagnostics

− UNIX

• Forth Toolkit

• Logfiles

• SUN VTS

In case of a black screen, check keyboard cabling.

See SPARCstation Unit manual

See chapter 5 Service Menu

See SPARCstation Unit manual

See chapter 7 EasyVision log files

See Answerbook on distribution CD

(Open windows Canvas, pop-up menu, Answerbook)

NOTE

________________

EasyVision RAD R4 (a/03.1) 4-3

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 42

Section 4 Fault Finding

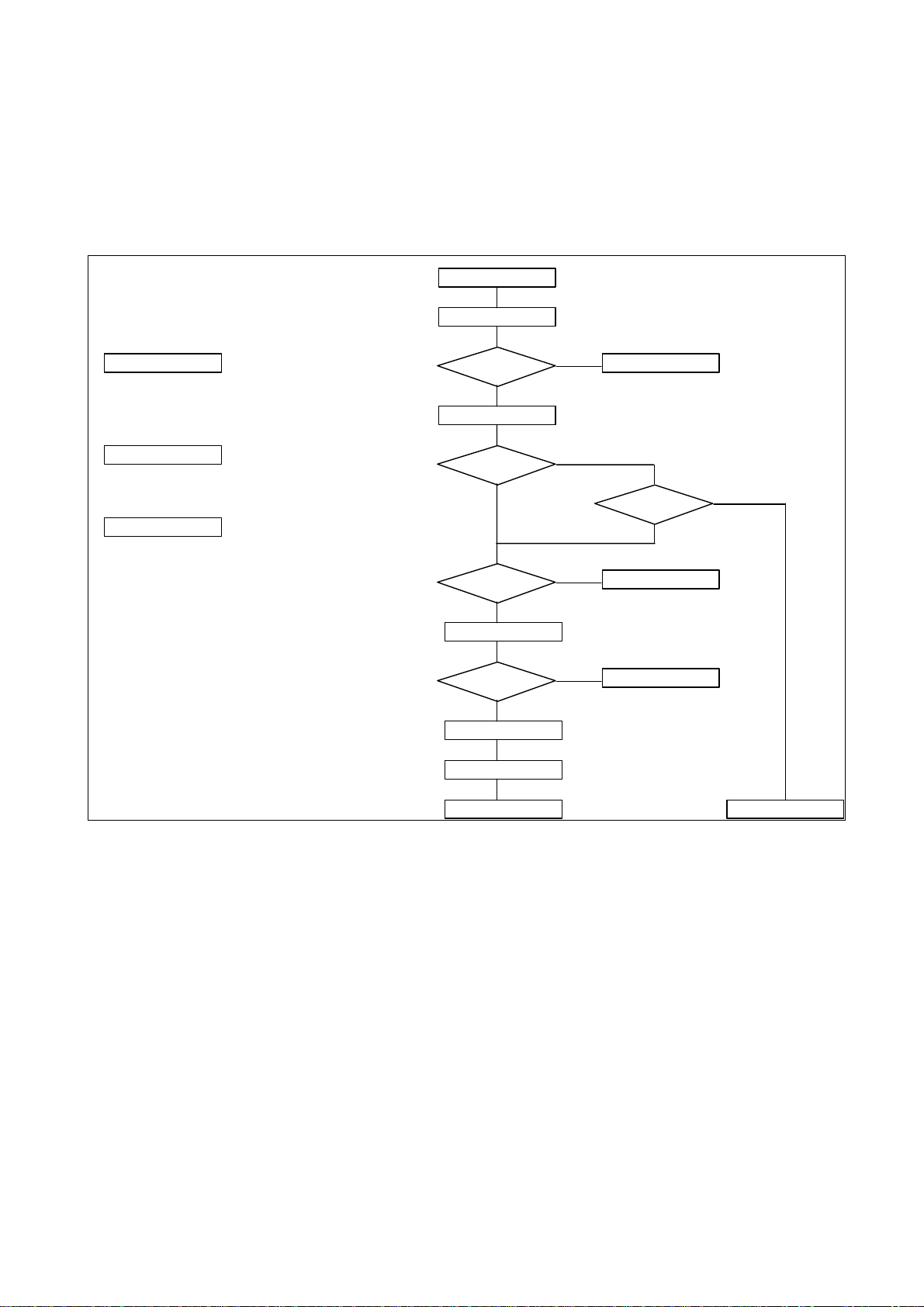

2. CLIENT/SERVER ENVIRONMENT

Flow Chart:

EV Cluster Power-on

EasyServer in

application ?

Yes

Workspots in

application ?

Yes

Cluster

configured?

Yes

No

No

No

System Power-on

System Power-on

see Release Bulletin

DataBase

No

EV Networking

accessible?

Yes

Application

4-4 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems Nederland B.V.

ALL RIGHTS RESERVED

Page 43

Fault Finding Section 4

3. EASYVISION RAD R4.2V2 CLUSTER NETWORK

A typical EasyVision RAD Release 4 / PCR network looks like the picture below. There are two networks:

The EasyVision cluster network (fast ethernet) and the modality network (standard Ethernet).

Another remark at this picture is that because the EasyServer is connected to two networks, it also has two

IP addresses (static router functionality), one for each network device (Ethernet controller).

IDT

Reader

EasyVision RAD

Modem

R4.2

User Terminal

Server

Single / Quad card

Onboard card

EasyVision R4.x network

10/100 Mbit

Server

User Terminal

PCR network

10/100 Mbit

Client

Workspot #1

In case of problems:

• Use ping command, see Service Manual Networking

• Check cables

• Check IP addresses

• Check Fast Ethernet HUB (led indicator)

• Check Ethernet Controllers

See Network Manual for detailed information.

EasyVision RAD R4 (a/03.1) 4-5

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Workspot #n

Page 44

Section 4 Fault Finding

4. SUN SPARC COMPUTERS

For EasyVision RAD Release 4.2V2 the following Sun SPARC computers are used:

Ultra 10, Ultra 60, SunBlade (see belonging Unit Manual).

Flow Chart:

System Power-on Faultfinding

System Power-on

Run POST

Run POST

- diag-switch? NVRAM parameter = true

Read POST results

For POST results see Unit Manual

Forth Toolkit

For Forth Toolkit results see Unit Manual

Start-up Menu?

No

Read POST results

Identification?

No

ok

Prompt?

No

Press Stop-A

ok

Prompt?

No

Reboot System

Press Stop-A

Yes

Yes

Yes

Goto Service Menu

Solved ?

No

Forth ToolKit

Forth ToolKit

Yes

Forth ToolKit

Repair

4-6 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems Nederland B.V.

ALL RIGHTS RESERVED

Page 45

Fault Finding Section 4

4.1. NON-VOLATILE RAM (NVRAM) PARAMETERS

4.1.1. U

LTRA

10

Parameter name

-

-

scsi-initiator-id 7 7

keyboard-click? false false

keymap

ttyb-rts-dtr-off false false

ttyb-ignore-cd true true

ttya-rts-dtr-off false false

ttya-ignore-cd true true

ttyb-mode 9600,8,n,1,- 9600,8,n,1,ttya-mode 9600,8,n,1,- 9600,8,n,1,pcia-probe-list 1,2 1,2

pcib-probe-list 1,3,2,4,5 1,3,2,4,5

mfg-mode off off

diag-level max min

#power-cycles 74

system-board-serial # 5014450026841 (example)

system-board-date 35bd5758 (example)

fcode-debug? false false

output-device screen screen

input-device keyboard keyboard

load-base 16384 16384

boot-command boot boot

auto-boot? true true

watchdog-reboot? false false

diag-file

diag-device net net

boot-file

boot-device disk disk net

local-mac-address? false false

ansi-terminal true true

screen-#columns 80 80

screen-#rows 34 34

silent-mode? false false

use-nvramrc? false false

nvramrc devalias pgx24 /pci@1f,0..

security-mode none none

security-password

security-#badlogins 0

oem-logo 00 00 00 00 00 00 00 00 ...

oem-logo? true false

oem-banner

oem-banner? false false

hardware-revision

last-hardware-update

diag-switch? false false

Value

Default Value

EasyVision RAD R4 (a/03.1) 4-7

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 46

Section 4 Fault Finding

4.1.2. U

LTRA

60

Parameter name

-

keyboard-click? false false

keymap

ttyb-rts-dtr-off false false

ttyb-ignore-cd true true

ttya-rts-dtr-off false false

ttya-ignore-cd true true

ttyb-mode 9600,8,n,1,- 9600,8,n,1,ttya-mode 9600,8,n,1,- 9600,8,n,1,pcia-probe-list 1,2 1,2

pcib-probe-list 1,3,2,4,5 1,2,2,4,5

mfg-mode off off

dial-level max min

#power-cycles 74

system-board-serial # 5014450026841 (example)

system-board-date 35bd5758 (example)

fcode-debug? false false

output-device screen:r1280x1024x76 screen

input-device keyboard keyboard

load-base 16384 16384

boot-command boot boot

auto-boot? true true

watchdog-reboot? false false

diag-file

diag-device net net

boot-file /kernel/unix

boot-device disk disk net

local-mac-address? false false

ansi-terminal true true

screen-#columns 80 80

screen-#rows 34 34

silent-mode? false false

use-nvramrc? false false

nvramrc

security-mode none none

security-password

security-#badlogins 0

oem-logo 00 00 00 00 00 00 00 00 ...

oem-logo? true false

oem-banner

oem-banner? false false

hardware-revision

last-hardware-update

diag-switch? false false

-

Value

Default Value

4-8 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems Nederland B.V.

ALL RIGHTS RESERVED

Page 47

Fault Finding Section 4

4.1.3. SUNB

Parameter name

test-args

diag-passes 1 1

enclosure-type 540-3256-15 No default

banner-name SUNW,Sun-Blade-1000 No default

energystar-enabled? true No default

pcia-probe-list 4,1 4,1

pcib-probe-list 5,6,1,2,3,4 5,6,1,2,3,4

local-mac-address? true false

fcode-debug? false false

silent-mode? false false

scsi-initiator-id 7 7

oem-logo 00 00 00 00 00 00 00 00 ...

oem-logo? true false

oem-banner

oem-banner? false false

ansi-terminal true true

screen-#columns 80 80

screen-#rows 34 34

ttyb-rts-dtr-off false false

ttyb-ignore-cd true true

ttya-rts-dtr-off false false

ttya-ignore-cd true true

ttyb-mode 9600,8,n,1,- 9600,8,n,1,ttya-mode 9600,8,n,1,- 9600,8,n,1,output-device screen screen

input-device keyboard keyboard

load-base 16384 16384

auto-boot? true true

boot-command boot boot

diag-file

diag-device net net

boot-file

boot-device disk disk net

use-nvramrc? true false

nvramrc

security-mode none No default

security-password No default

security-#badlogins 0

#power-cycles

diag-script none none

diag-level min min

diag-switch? false false

error-reset-recovery boot boot

LADE

1000/2000

Value

Default Value

EasyVision RAD R4 (a/03.1) 4-9

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 48

Section 4 Fault Finding

4.1.4. SUNB

Parameter name

tpe-link-test? true true

scsi-initiator-id 7 7

keyboard-click? false false

keymap

ttyb-rts-dtr-off false false

ttyb-ignore-cd true true

ttya-rts-dtr-off false false

ttya-ignore-cd true true

ttyb-mode 9600,8,n,1,- 9600,8,n,1,ttya-mode 9600,8,n,1,- 9600,8,n,1,pcia-probe-list 4,1 4,1

pcib-probe-list 5,6,1,2,3,4 5,6,1,2,3,4

mfg-mode off off

diag-level min min

#power-cycles

system-board-serial

system-board-date

fcode-debug? false false

output-device screen screen

input-device keyboard keyboard

load-base 16384 16384

boot-command boot boot

auto-boot? true true

watchdog-reboot? false false

diag-file

diag-device net net

boot-file

boot-device disk disk net

local-mac-address? true false

ansi-terminal true true

screen-#columns 80 80

screen-#rows 34 34

silent-mode? false false

use-nvramrc? true false

nvramrc

security-mode none No default

security-password No default

security-#badlogins 0

oem-logo 00 00 00 00 00 00 00 00 ...

oem-logo? true false

oem-banner

oem-banner? false false

hardware-revision

last hardware update

diag-switch? false false

LADE

1500

Value

Default Value

4-10 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems Nederland B.V.

ALL RIGHTS RESERVED

Page 49

Fault Finding Section 4

5. SERVICE MENU

5.1. S

To access the service menu environment select 3 Go to Service Menu in the StartUp menu. Then at the

password: prompt enter password

1. Diagnostics Menu (sunvts and product diagnostics)

2. SunOs Menu (optical disk format and Sun Os commands)

3. File Menu (file transfer and manipulation commands)

4. Printer Menu (printer tests)

5. Monitor Menu (Monitor test images and adjustment)

6. PCR Systems (PCR diagnostics menu)

0 Logout

5.1.1. D

ERVICE MENU VIA SUN CONSOLE

Service Menu

===========

Enter the number of your choice: 1

IAGNOSTICS MENU

Diagnostics Menu

================

1. Start SunVts (Sunvts hardware diagnostics)

After using SunVTS, use ëExit...í in the workspace pop-up menu

to return to this menu

2. Start EasyStore DOR Test (sa0)

3. Start CT/MR input DOR Test (sa1)

4. Start Dials Test

5. Check Modemís SW Settings

Type ~. to quit the check and return to this menu.

6. Initialize Modem

7. Set Speed of Serial port

8. Start PCI Reader Interface Test

0. Return to the service menu

Enter the number of your choice: 0

Select 8. Start PCI Reader Interface Test

The System will prompt:

Connect PCR Reader testbox. Press <Enter> to continue :

after the testbox has been connected and powered press Enter, The system will respond:

PCR Reader Interface test takes about 5 seconds

if the system didn’t detect any fault condition it will return the message

PCR Reader Interface test succeeded

press <Enter> to continue

If the system detects any fault condition during this test run, i.e. if power is not applied to the test box or the

test cable is not connected to the Sun computer the system will respond:

EasyVision RAD R4 (a/03.1) 4-11

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 50

Section 4 Fault Finding

poll control line , timed out

PCR Reader Interface test failed

Press <Enter> to continue :

Caution

The test program will finish the test with the following message

even if the test box was not connected during the test.

ëReader Interface Testí ended normal, status 0

Control channel and Data channel are both ok up to test box

Press <Enter> to continue:

after pressing <Enter> the system will output the Diagnostics Menu

There is no detailed error handling available which is capable to detect different levels of faulty conditions

and which allows conclusions on errors.

5.1.2. SUNOS M

SunOs Menu

==========

1. Optical Disk Format Menu.

2. SunOs: a C-shell is started in the service directory.

Type ëexití to return to this menu.

3. ADB Convert (synchronize Anatomy DataBase and Processing Keys)

3. SunOS: OpenWindows is started in the service-directory

Use ëExit...í in the workspace pop-up menu to return to this menu

0 Return to the service menu

Enter the number of your choice: 0

5.1.3. F

1 Logfiles Inspection (a C-shell is started in the log directory)

Use 'ls -l', 'more', 'tail -31l' to examine

the logfiles.

Type 'exit' to return to this menu.

2 Images Inspection (a C-shell is started in the images directory)

Use 'ls -l' to examine the image files.

Type 'exit' to return to this menu.

3 Create file /tmp/logfiles.zip containing logfiles and config files.

0 Return to Service Menu

ILE MENU

File Menu

=========

Enter the number of your choice:

ENU

4-12 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems Nederland B.V.

ALL RIGHTS RESERVED

Page 51

Fault Finding Section 4

5.1.4. P

5.1.5. M

5.1.6. PCR

RINTER MENU

Printer Menu

============

1 HCU Calibration (start hardcopy unit calibration)

2 Start Printer Status Request

3 Start Data Channel Printer Test

Data is sent to the HCU via the data channel, then

press print on the HCU control panel for output

4 Start Printer Test

5 Start S-bus/PCI Printer Visual Interface Test (Led board required)

0 Return to Service Menu

Enter the number of your choice:

ONITOR MENU

Monitor Menu

============

1 Start Monitor Color Map Test

2 Show LCD testimage (POPO_1288x1024.gif)

0 Return to Service Menu

Enter the number of your choice:

SYSTEMS MENU

PCR Systems Menu

================

1 File Transfer- and Compression Settings Menu

2 File Transfer Menu (log and image file transfer)

3 ADB Convert (synchronize Anatomy Data Base and Processing Keys)

4 Set Serial Interface Parameters

5 PCR Reader Documentation

0 Return to Service Menu

Enter the number of your choice:

5.1.6.1. File Transfer Settings Menu

File Transfer Settings Menu:

============================

Actual Configuration:

EasyVision RTAC: sz/rz

EasyVision RTAC: sz/rz

Compression: Zip

EasyVision RAD R4 (a/03.1) 4-13

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 52

Section 4 Fault Finding

1 EasyVision RTAC: Use kermit (works only with modem

terminal

2 EasyVision RTAC: Use kermit connections)

3 EasyVision RTAC: Use sz/rz (works only with modem terminal

4 EasyVision RTAC: Use sz/rz connections)

5 EasyVision RTAC: Use ftp (works only with TCP/IP and ftp-

server running on RTAC host)

6 Zip (mostly used compression SW on DOS based

computers)

7 UNIX compress ( tar| mostly used compression SW on UNIX

based computers)

0 Return to Service Menu

Enter the number of your choice:

5.1.6.2. File Transfer Menu

File Transfer Menu

==================

Actual Configuration: RTAC EasyVision : sz/rz

EasyVision RTAC sz/rz

Compression: Zip

1 Collect & Send Logfiles

2 Send Image Files (Menu)

3 Manual File Transfer (a C-shell is started: go to the directory

where you want to send/receive files from/to.

Then start the desired protocol by typing its

name followed by the appropriate arguments:)

0 Return to Service Menu

Enter the number of your choice:

5.1.6.3. Serial Interface Menu

Serial Interface Menu:

======================

Actual Configuration:

Device: ttyb

Mode: Modem

N Set Mode to Nullmodem (RTAC-cable-EV)

M Set Mode to M odem (RTAC-modem-EV)

!!! NOTE !!!

Donít forget to (re)set this flag to Modem

if Modem connection is desired later on!

!!! NOTE !!!

0 Return to Service Menu

Enter the number of your choice:

4-14 (a/03.1) EasyVision RAD R4

Copyright © 2003 Philips Medical Systems Nederland B.V.

ALL RIGHTS RESERVED

Page 53

Fault Finding Section 4

5.1.6.4. PCR Reader Documentation

5 PCR Reader Documentation

PCR Reader Documentation

Insert the CD-ROM containing the PCR Reader Documentation

and press Return to continue:

OpenWindows and the Acrobat Reader will be started.

On ‘File’ and ‘Open’ the 'Open' window of the Acrobat Reader will be displayed.

Double click on the line /cdrom/ac500 or /cdrom/ac5000 to select the appropriate system.

The documentation files available on this CD-ROM are listed In the ‘Files’ area on the right)

Double click on the line of the document you want to open and view.

The first page of the document will be displayed

EasyVision RAD R4 (a/03.1) 4-15

Copyright © 2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 54

Section 4 Fault Finding

5.2. S

Service Menu

============

5.2.1. D

ERVICE MENU VIA SERIAL PORT

login: Service

Password: <Enter HostID>

Last login: Tue Dec 2 14:13:51 on term/b

PMSN-ICS Solaris 2.5.1 adapted for EasyVision June 1996

+-----------------------------------------------------------------+

| WARNING : Access for authorised persons only |

+-----------------------------------------------------------------+

Last local login: Tue Dec 2 11:26:37 MET 1997

1 Diagnostics Menu (sunvts and product diagnostics)

2 SunOS Menu (optical disk format and SunOS commands)

3 File Menu (file transfer and manipulation commands)

4 Printer Menu (Printer tests)

0 Logout

Enter the number of your choice: