Philips DYNALITE DDRC1220FR-GL User Manual

DDRC1220FR-GL

To reduce the risk of re or electric shock, do not expose this device to rain or moisture. Installation, programming and maintenance must be

carried out by qualied personnel. All local wiring and electrical regulations must be followed when installing device.

Overview

• Single phase supply – One phase at 0.25 A

• 12 x feed-through outputs – Rated at 20 A

• Multiple wiring schemes supported – Controls Single Phase

and Neutral or Three Phase and Neutral (Star) wiring

• Powerful internal PLC – Custom scripts can provide process

control based on conditional logic

• DIN-rail mounting – 12 units wide

• Hardware override – Service override switch accessible from

front panel

12 x 20 A Relay Controller

Read Instructions – We recommend that you read this guide prior to

commencement of installation.

Manual Override Switches – These switches do not provide

permanent isolation. Isolate at the supply before performing work on

load circuits.

Special Programming – Once powered and terminated correctly

this device only operates in basic mode. Advanced functions are

commissioned via the Envision software. If commissioning services

are required, contact your local distributor.

Power Sources – This device should only be operated from the type

of supply specied on the front cover. This device must be earthed.

Feed-through output circuits – The load on a circuit should not

exceed the specied capacity of 20 A. Loads should be calculated to

ensure that the overall maximum capacity of 180 A is not exceeded.

This device should be fed via HRC fuse or MCB. Output circuits

are suitable for Single Phase or Three Phase Star (with Neutral)

only. Suitable for some Delta wiring installations, contact Distributor

Support for more information.

Mounting Location – Install in a dry, well-ventilated location. The

device may emit some mechanical noise during operation. Take this

into account when deciding the mounting location.

Data Cable – Use screened, stranded RS485 data cable with three

twisted pairs. Segregate from mains cables by at least 300 mm.

Connect devices in a ‘daisy chain’ conguration. A data cable that is

connected to an energized device is live. Do not cut or terminate live

data cables.

Installation – Installation must be done in accordance with local

wiring code (or wiring rules). Network topology for installation is Daisy

Chain. Installation of the home and building automation and control

system shall comply with HD60364-4-41.

Hardware Dimensions

Installation Steps

1. Mount the device on a DIN-rail inside an approved enclosure, in

compliance with local electrical codes.

2. Calculate loads to ensure no channels are overloaded, then

connect loads to the output channels. The maximum loads are:

Per Channel: 20 A at 240 VAC (resistive).

Max inrush 500 A (200 uS)

Total Device Load: 180 A (resistive)

3. Connect supply and load cables to each channel. Supported

supplies and wiring schemes are:

Single phase 100-240 VAC, 3 phase 400/230 VAC star, and

100-120/208-240 VAC delta 50/60 Hz supply not exceeding

240 VAC phase-to-ground and across load supply terminals.

All live feeds must be protected with fuses / circuit breakers

rated 20 A or lower. Relay open contact rated voltage must not

exceed 240 VAC. Supply over-voltage (surge) must not exceed

4 kV, as per IEC category III classication.

4. Connect a single phase 0.25 A feed to the control circuit supply

terminals. This device must be earthed.

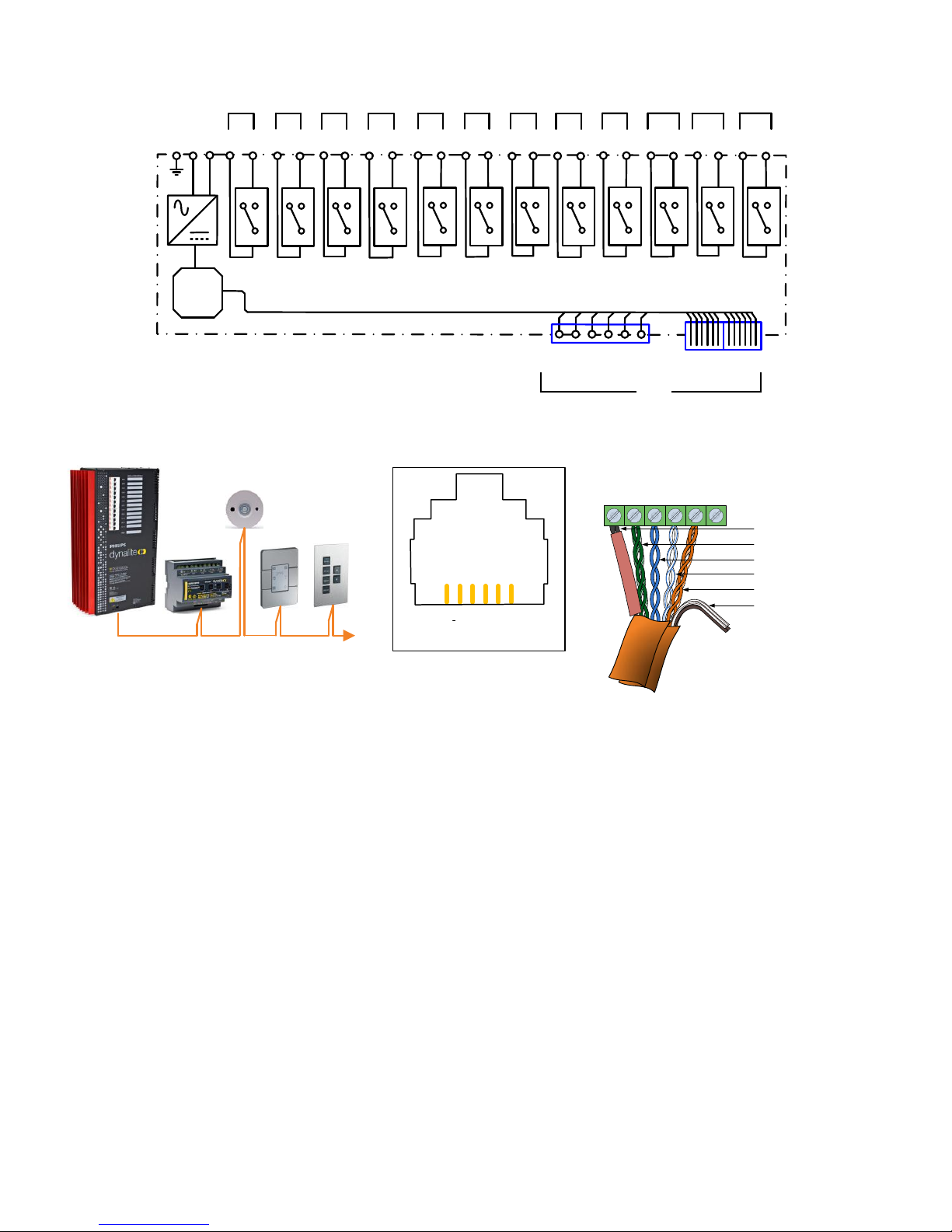

5. Connect data cables to the device as per the diagrams on the

next page.

6. If using the Auxiliary input, connect a dry contact device

in between the AUX and GND terminals. Keep cable runs

between the device and the dry contacts under ten meters and

use shielded twisted pair where possible. The function of the

Auxiliary input is congured during commissioning.

215 mm (8.5 in)

93 mm (3.6 in)

64 mm (2.5 in)

154 mm (6.1 in)

DDRC1220FR-GL Installation Instructions Rev 08 Specications subject to change without notice

Dynalite manufactured by WMGD Pty Ltd (ABN 33 097 246 921) Unit 6, 691 Gardeners Road Mascot NSW 2020 Australia Tel: +61 2 8338 9899 Fax: +61 2 8338 9333

E-Mail: support.controls@philips.com Web: www.philips.com/dynalite

Control Supply: 100-240 V 50/60 Hz single phase at 0.25 A, Over-voltage category III, maximum 4kV surge

Load Outputs: 12 x feed-through outputs at 20 A per channel, maximum total device load 180 A

1 Phase & Neutral, 3 Phase & Neutral Star. Some delta wiring supported.

Switching Device: Relay 50 A 230 VAC resistive (5000 VA lighting load rated), maximum 500 A (200 uS) inrush current

Supply Terminals: 1 x Phase, 1 x Neutral 1 x Earth, up to 5 mm2 cable per terminal

Load Terminals: 1 x Phase, 1 x Neutral 1 x Earth, up to 5 mm2 cable per terminal

User Controls: Service switch, Diagnostic LED

I/O: 1 x RS485 DyNet serial port

1 x AUX programmable dry contact input

DyNet DC Supply: 120 mA (capacity for approximately six panels)

Presets: 170

Programmable Logic: 8 tasks (most UPAN mnemonics supported)

Operating Conditions: Temperature: 0 to 50° C ambient, Humidity: 0 to 90% non-condensing

Storage & Transport: Temperature: -25 to 60° C ambient, Humidity: 0 to 90% non-condensing

Construction: Polycarbonate DIN-rail enclosure, (12 units wide), IP20, UL940-V0 rated

Dimensions: 93 mm x 215 mm x 64 mm (3.7” x 8.5” x 2.5”)

Weight: 0.76 kg

Certication: CE, RCM

Recommended Cable Type

Dynalite DYNET-STP-CABLE or equivalent shielded

three twisted-pair.

See datasheet for more information.

Recommended Cable Color Coding

Green/White Pair Paralleled for GND

Orange/White Pair Paralleled for +12VDC

Blue/White Pair Blue for DATA+

White for DATA-

Brown/White Pair Spare, use for SHIELD on unshielded cables

SHLD

GND

D+

D-

+12V

Aux

Shield

Green/Green white

Blue

Blue white

Orange/Orange white

Brown/Brown white

+VE

+VE

D –

D +

GND

GND

RS485 DyNet network

Product Specications

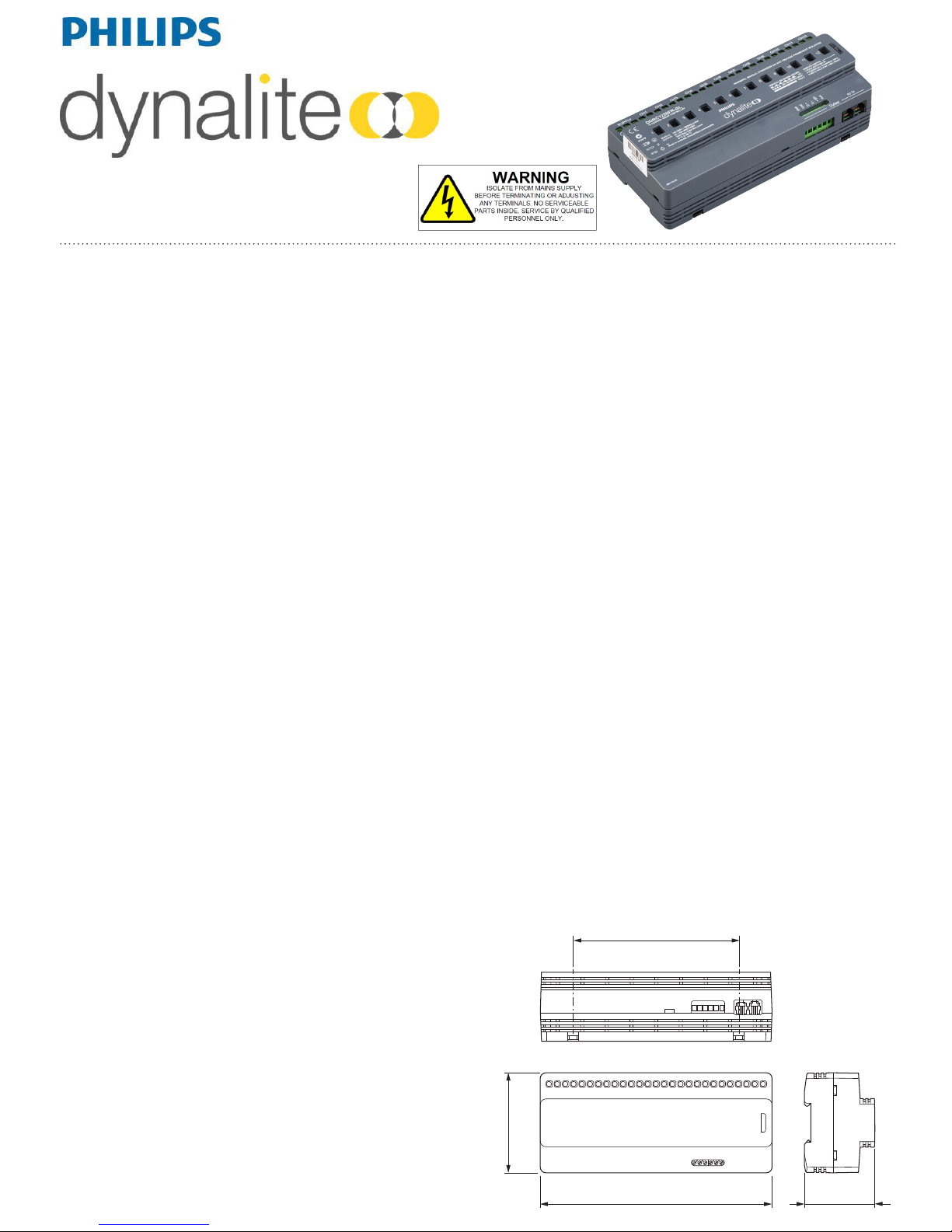

Electrical Diagram

Supply:

100-240V

1 Phase

0.25A

E

µP

NLIN

OUT

CH1

CH2

CH3

CH4

+VE

D +

D -

GND

Shield

AUX

CH5

CH6

CH7

CH8 CH9

CH10 CH11

CH12

DyNet

RS485

2 x RJ12

IN

OUT

IN

OUT

IN

OUTINOUT

IN

OUTINOUT IN

OUTINOUT

IN

OUTINOUT IN

OUT

Data Cable Connection

Loading...

Loading...