Service

DVD Player

DVP6600,DVP6620

DVP6600/93/37

DVP6620/55/98/93

Service Manual

TABLE OF CONTENTS

Chapter

. Technical Specifications……………………………………..............1-2

. Safety Instruction, Warning & Notes….……………………....….....1-3

. Mechanical and Dismantling Instructions…………........................2-1

. Region Code, Software Version& Upgrades……………...............

. Trouble Shooting Chart………………………………………………

. Wiring Diagram………………………………………..………..….….5-1

. Electrical Diagrams and Print-layouts..….…………………....….…6-1

. Set Mechanical&Packing Exploded view & Part list.......................7-1

. Revision list........................................................................8-1

.3-1

.4-1

©Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in aretrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Published by TCL-KC0745 Service Audio Printed in The Netherlands Subject to modification

Version 1.3

CLASS 1

LASER PRODUCT

GB

3139 785 32933

PHILIPS

Technical Specifications

TV standard (PAL/50Hz) (NTSC/60Hz)

Number of lines 625 525

Playback Multi standard (PAL/NTSC)

Video performance

Video DAC 12 bit, 108MHz

YPbPr: 0.7Vpp ---- 75 ohm

Video output 1Vpp ----- 75 ohm

Video format

Digital Compression MPEG 2 for DVD,SVCD

MPEG 1 for VCD

Div;®

DVD 50Hz 60Hz

Horiz resolution 720 pixels 720 pixels

Vertical resolution 576lines 480 lines

1-2

Audio performance

DA converter 24bits, 192KHz

DVD fs 96kHz 4Hz----44kHz

fs 48kHz 4Hz----22kHz

SVCD fs 48kHz 4Hz----22kHz

fs 44.1kHz 4Hz----20kHz

CD/ VCD fs 44.1kHz 4Hz----20kHz

Signal-Noise (1kHz) >90dB

Dynamic Range (1kHz) >80dB

Cross talk (1kHz) >70dB

Distortion/Noise (1kHz) >65dB

MPEG MP3 MPEG Audio L3

Connections

YpbPr output Cinch 3x

Video output Cinch( yellow)

Audio output (L+R ) Cinch (white/red)

Digital output 1 coaxial

IEC60958 for CDDA/ LPCM

IEC61937 for MPEG1/2,

Dolby Digital

HDMI Out

VCD 50Hz 60Hz

Horiz. resolution 352 pixels 352 pixels

Vertical resolution 288lines 240 lines

Audio format

Digital MPEG/AC-3/ Compressed Digital

PCM 16, 20, 24bits

fs, 44.1, 48, 96KHz

MP3(ISO 9660) 96,112,128,256kbps

& variable bit rate fs,32,

44.1,48 kHz

Analogue Sound Stereo

Dolby surround compatible downmix from Dolby Digital multi-channel

sound

Cabinet

Dimensions (w X h X d) 305 x 186 x 102 mm

Weight Approximately 1.4 kg

Power consumption

Power supply Rating 110V-120V;

50/ 60HZ

Power consumption <10W

Power consumption in standby mode <1W

Specifications subject to change without prior notice.

1-3

Safety instruction, Warning & Notes

Safety instruction

1. General safety

Safety regulations require that during a repair:

. Connect the unit to the mains via an isolation transformer.

. Replace safety components indicated by the symbol

only by components identical to the original ones. Any

other component substitution (other than original type)

may increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, you must

return the unit in its original condition. Pay, in particular,

attention to the following points:

. Route the wires/cables correctly, and fix them with the

mounted cable clamps.

. Check the insulation of the mains lead for external

damage.

. Check the electrical DC resistance between the mains

plug and the secondary side:

1) Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2) Set the mains switch the “on” position (keep the

mains cord unplug).

3) Measure the resistance value between the mains

plug and the front panel, controls, and chassis

bottom.

4) Repair or correct unit when the resistance

measurement is less than 1M

5) Verify this, before you return the unit to the

customer/user (ref. UL-standard no. 1492).

6) Switch the unit “off”, and remove the wire between

the two pins of the mains plug.

¡

.

2.Laser safety

This unit employs a laser. Only qualified service personnel

,

may remove the cover, or attempt to service this device

(due to possible eye injury).

Laser device unit

Type : Semiconductor laser GaAlAs

Wavelength : 650nm (DVD)

: 780nm (VCD/CD)

Output power : 7mW (DVD)

: 10mW (DVD /CD)

Beam divergence: 60 degree

Note: Use of controls or adjustments or performance of

procedure other than those specified herein, may result in

hazardous radiation exposure. Avoid direct exposure to

beam.

Warning

1-4

1.General

. All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handing during

repair can reduce life drastically. Make sure that, during

repair, you are at the same potential as the mass of the

set by a wristband with resistance. Keep components and

tools at this same potential. Available ESD protection

equipment:

1) Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable)

4822 310 10671.

2) Wristband tester 4822 344 13999.

. Be careful during measurements in the live voltage

section. The primary side of the power supply , including

the heat sink, carries live mains voltage when you

connect the player to the mains (even when the player is

“off”!). It is possible to touch copper tracks and/or

components in this unshielded primary area, when you

service the player. Service personnel must take

precautions to prevent touching this area or components

in this area. A “lighting stroke” and a stripe-marked

printing on the printed wiring board, indicate the primary

side of the power supply.

. Never replace modules, or components, while the unit is

“on”.

2. Laser

. The use of optical instruments with this product, will

increase eye hazard.

. Only qualified service personnel may remove the cover

or attempt to service this device, due to possible eye

injury.

. Repair handing should take place as much as possible

with a disc loaded inside the player.

. Text below is placed inside the unit, on the laser cover

shield:

CAUTION: VISIBLE AND INVISIBLE LASER

RADIATION WHEN OPEN, AVOID EXPOSURE

TO BEAM.

Notes: Manufactured under licence from Dolby

Laboratories. The double-D symbol is trademarks of Dolby

Laboratories, Inc. All rights reserved.

Notes

Lead-Free requirement for service

1-5

INDENTIFICATION:

Regardless of special logo (not always indicated)

One must treat all sets from 1.1.2005 onwards, according

next rules.

Important note

be treated in this way as long as you avoid mixing

solder-alloys (leaded/ lead-free). So best to always use

SAC305 and the higher temperatures belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

x Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solder-paste is

required, please contact the manufacturer of your

solder-equipment. In general use of solder-paste within

workshops should be avoided because paste is not easy

to store and to handle.

x Use only adequate solder tools applicable for lead-free

solder alloy. The solder tool must be able

o To reach at least a solder-temperature of 400°C,

o To stabilize the adjusted temperature at the

o To exchange solder-tips for different applications.

x Adjust your solder tool so that a temperature around

360°C

joint. Heating-time of the solder-joint should not exceed

~ 4 sec. Avoid temperatures above 400°C otherwise

wear-out of tips will rise drastically and flux-fluid will be

destroyed. To avoid wear-out of tips switch off un-used

equipment, or reduce heat.

x Mix of lead-free solder alloy / parts with leaded solder

alloy / parts is possible but PHILIPS recommends

strongly to avoid mixed

solder alloy types (leaded and lead-free). If one cannot

avoid, clean carefully the

solder-joint from old solder alloy and re-solder with new

solder alloy (SAC305).

: In fact also products a little older can also

solder-tip

– 380°C is reached and stabilized at the solder

x Use only original spare-parts listed in the

Service-Manuals. Not listed standard-material

(commodities) has to be purchased at external

companies.

x Special information for BGA-ICs:

- always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for

de-soldering always use highest lead-free

temperature profile, in case of doubt)

- lead free BGA-ICs will be delivered in so-called

‘dry-packaging’ (sealed pack including a silica gel

pack) to protect the IC against moisture. After

opening, dependent of MSL-level seen on

indicator-label in the bag, the BGA-IC possibly

still has to be baked dry. This will be

communicated via AYS-website.

Do not re-use BGAs at all.

x For sets produced before 1.1.2005, containing

leaded soldering-tin and components, all needed

spare-parts will be available till the end of the

service-period. For repair of such sets nothing

changes.

x On our website:

www.atyourservice.ce.Philips.com

You find more information to:

BGA-de-/soldering (+ baking instructions)

Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical information within

the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

2-1

Mechanical and Dismantling Instructions

Dismantling Instruction

The following guidelines show how to dismantle the player.

Step1: Dismantling Ass'y-Bottom Socket . First press the Snap1 at the same time slide the Bottom Socket follow the below

sign. then genttlely remove the Bottom Socket (Figure 1,2).

Snap1

Figure 1

Figure 2

2-2

Mechanical and Dismantling Instructions

Dismantling Instruction

Step2: Dismantling Top Cover. Slide the Top Cover follow the below arrowhead, then remove the 4 screws. (Figure 3,4)

Note: Make sure to operate gently.

Figure 3

Figure 4

2-3

Mechanical and Dismantling Instructions

Dismantling Instruction

Step3: Dismantle the Tray Ass’y . First remove 7 screws around the Tray Ass’y, then disconnect the1connector below the

Tray Ass’y. (Figure 5,6).

CON1

Figure 5

Figure 6

2-4

Mechanical and Dismantling Instructions

Dismantling Instruction

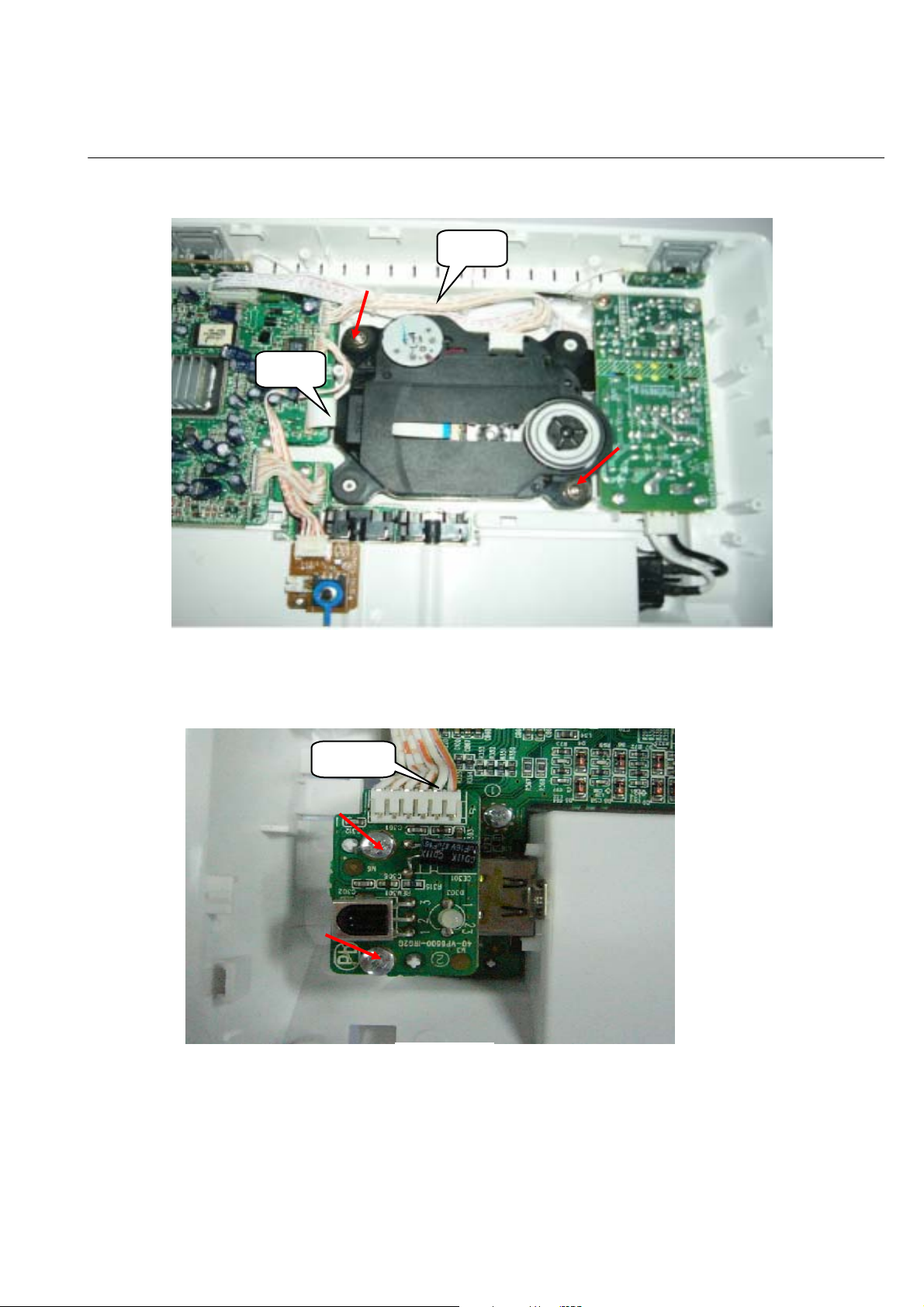

Step4: Dismantling Loader, disconnect the 2 connectors aiming in the below figure, and remove 2 screws around the

Loader. (Figure 7)

CON3

CON2

Step5: Dismantling Infra-red Board. Disconnect the 1 connector, then remove 2 screws around the Board.

(Figure 8)

CON4

Figure 7

Figure 8

2-5

Mechanical and Dismantling Instructions

Dismantling Instruction

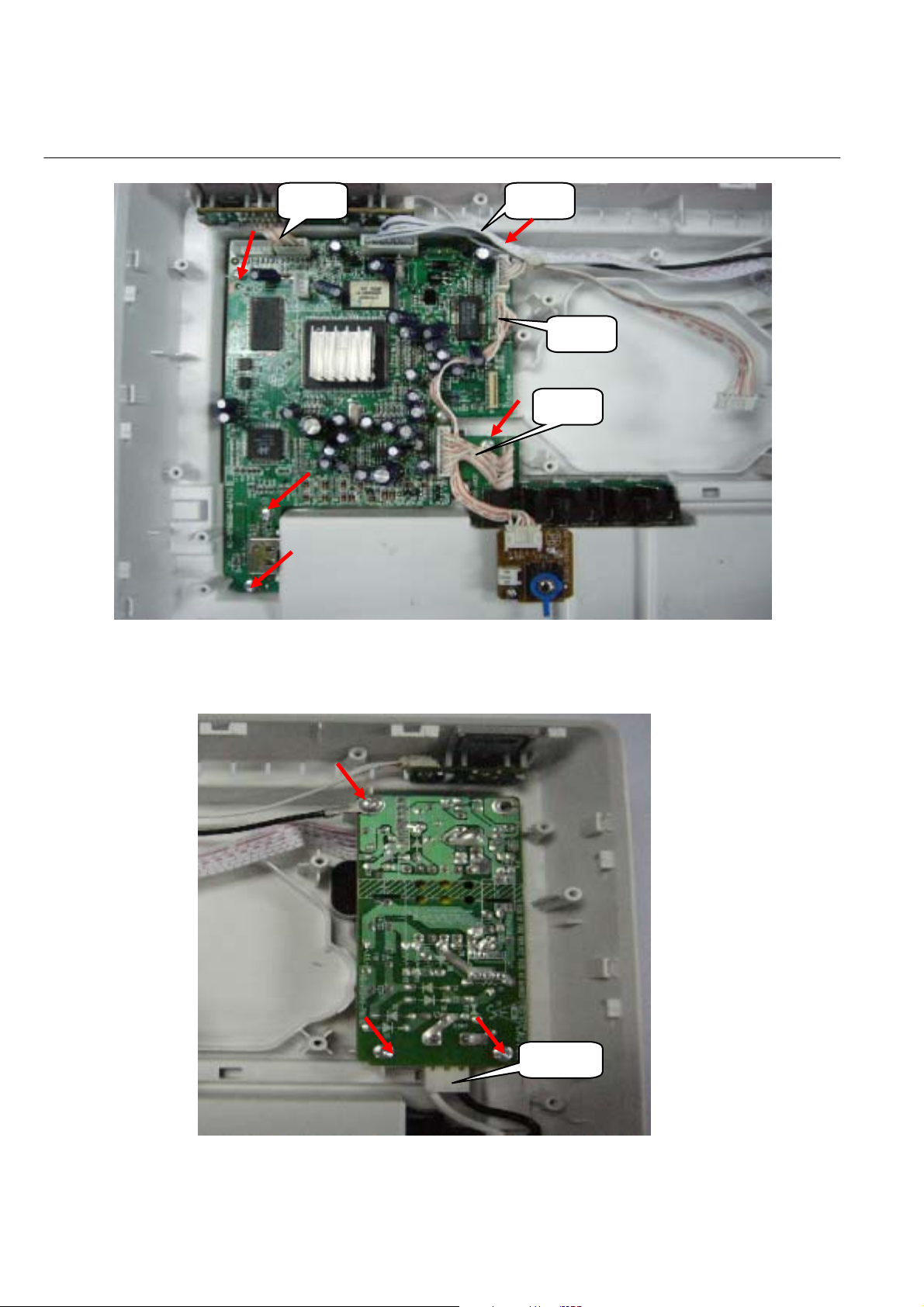

Step6: Dismantling Main Board, first disconnect the 4 connectors, and then remove 5 screws. (Figure 9)

CON5 CON6

CON7

CON8

Step7: Dismantling the Power Board. First disconnect the 1 connector, and then remove 3screws around the board.

(Figure 10)

CON9

2-6

Mechanical and Dismantling Instructions

Dismantling Instruction

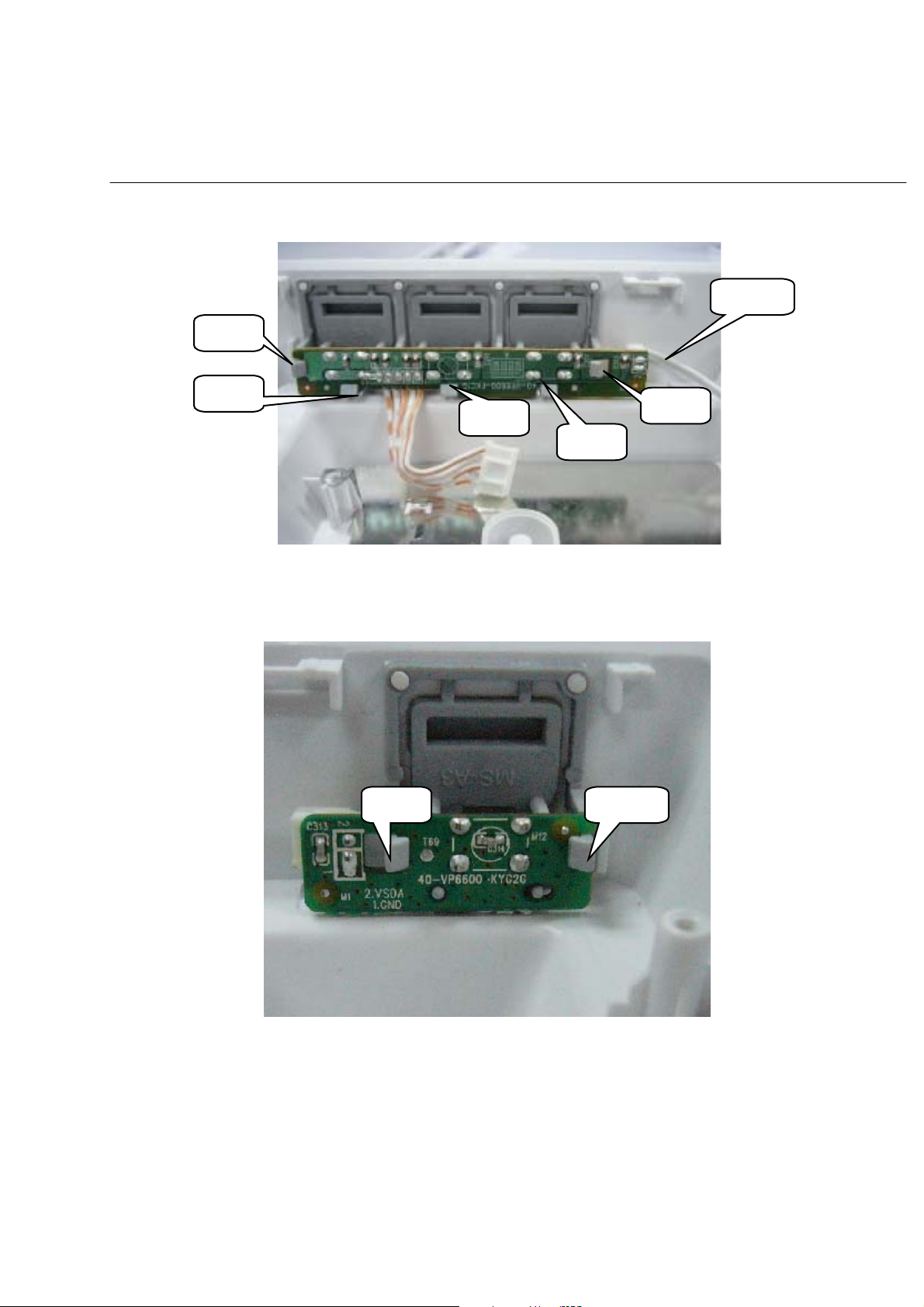

Step8: Dismantling Control Board. Disconnect the 1 connector, then release the snaps around the board. (Figure 11)

CON10

Snap2

Snap3

Snap4

Snap6

Snap5

Step9: Dismantling Open Door Board. Release the 2 snaps around the board. (Figure 12)

Snap7 Snap8

2-7

Mechanical and Dismantling Instructions

Dismantling Instruction

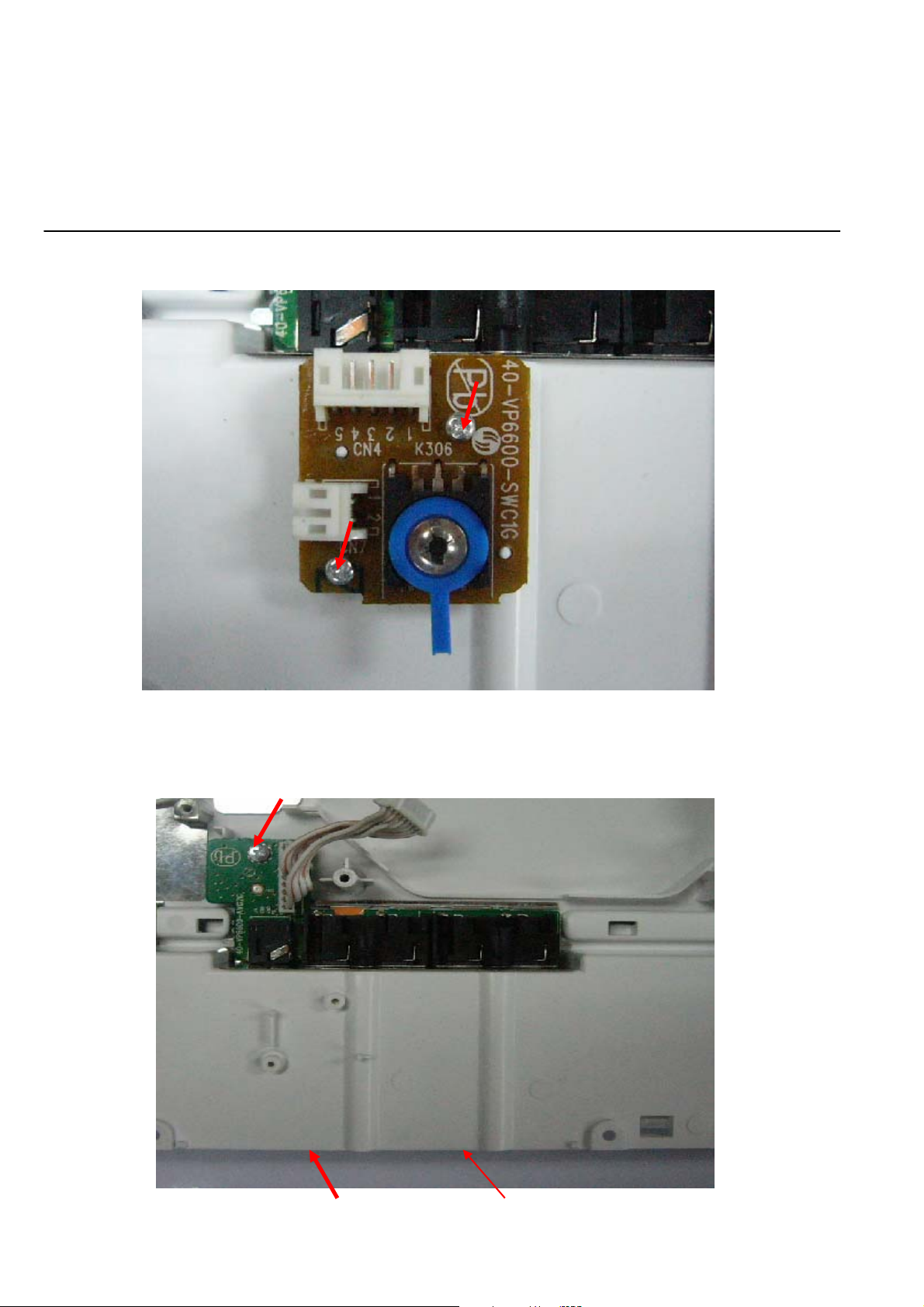

Step8: Dismantling CD Door Open/Close Board. Remove the 2 screws around the board. (Figure 13)

Step9: Dismantling AV Board . Remove the 3screws around the board. (Figure 14)

3-1

Software upgrade

Preparation to upgrade software

1) Start the CD Burning software and create a new CD project (Data Disc) with the following setting:

File Name: DVPXXXX_XX.BIN

Power on the set and open the tray, then press <5><5>

to check the File Name.

Note: It is required capital letter for the File System name.

2) Burn the data onto a blank CDR

A. Procedure for software upgrade:

1) Power on the set and insert the prepared Upgrade CDR.

2) The set will starts reading disc & response with the following display TV screen:

Upgrade File DETECTED

Upgrade?

Press Play TO START.

3) Press <OK> button to confirm, then screen will display :

Files coping…

UPGRADING…

4) The upgraded tray will automatically open when files coping complete, then take out the disc.

5) About 1 minute later, the trace will automatically close when upgrading complete.

C. Read out the software versions to confirm upgrading

1) Power on the set and press <Setup> button on the remote control.

2) Press <1><3><7><9> button.

The software version and other information are display on the TV screen as follows:

Version XX.XX.XX.XX (Main version)

SUB-VER XX.XX.XX.XX (software version of

application software)

8032 XX.XX.XX.XX

Servo XX.XX.XX.XX (software version of Servo)

RISC XX.XX.XX.XX

DSP XX.XX.XX.XX

Region Code XX

Caution: The set must not be power off during

upgrading, Otherwise the Main board will be

damaged entirely.

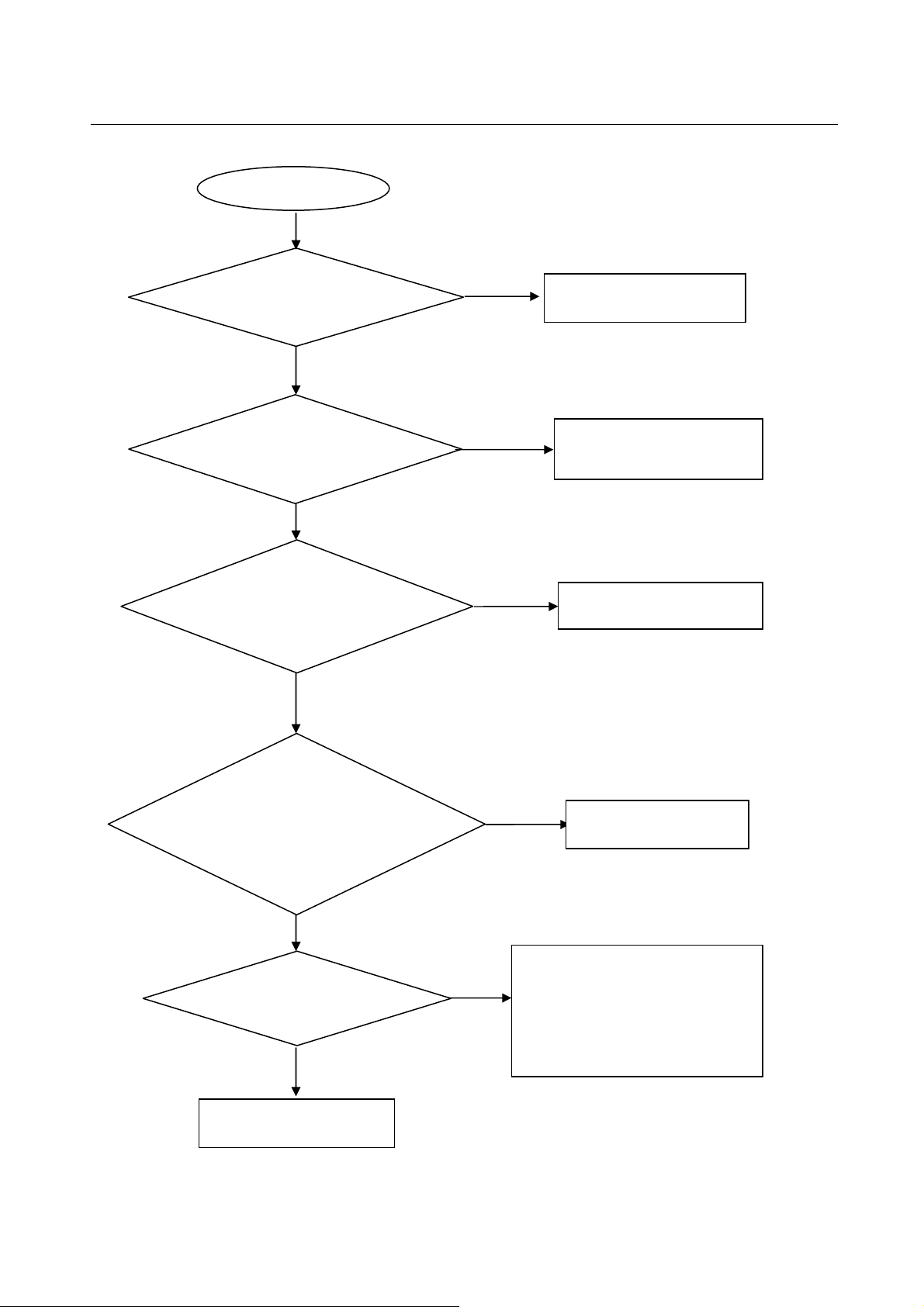

Spindle motor does not move

Motor no move

Go

4-1

Trouble shooting chart

Check the FFC connection

No

Correct connection

between 24P and the loader.

Yes

Check whether “AVCC”

(+5V) voltage is normal.

No

Check the AVCC power

supply

Yes

Check whether laser voltage

(2V for VCD & 2.2V for DVD)

on Collector of Q5 and Q6

No

Check/Replace Q6ǃQ5.

Yes

I

1.Whether voltage on pin 112 of

U2varies between 0 and 3.3V (3.3V

for VCD and 0V for DVD),

2.Whether peripheral components

are eroded or badly soldered.

Yes

Have no to focus

Yes

Check/Replace the loader

No

No

Check/ Replace Q3,Q4

1. Check U2 6pin RFO signals

2.If there are F+, F-, T+ and T-

signals output from U3.

The power can not be on or off

The power can’t be

on or off

Go

4-2

Trouble shooting chart

Check the power supply

on the power board is

normal.

Yes

Check if the J7on the front

board to J6 on the

decoder board is in good

contact.

Yes

Whether the connection

to J7 is broken.

Ye s

No

No

No

Repair the power board

Check/Correct

connection

Correct the connection

Yes

Whether there is 0V and

3.3V voltage difference on

Pin 201 PCON

Yes

of U4.

No

Replace U2

4-3

All output voltages on the power board is 0V or deviated.

All output voltages on

the power board is 0V or

deviated

Yes

Trouble shooting chart

Check whether

F1 is blown

No

Check whether there is

300V on C1,C2

Yes

Check whether 100KHz

oscillating signal on

Pin6 of U1

Yes

Yes

No

No

Replace F1

Replace C1,C2 if D1, D2, D3, D4 are

normal.

Check/ replace U1.

U1(PIN 3 - RC waveform)

U1(PIN 8 - Drain waveform)

Check if +5V, +3.3v, +12V,

-12V and -24V are short.

Yes

Check whether the components in the

short-circuit voltage are defected or eroded.

No

Check whether U2 are eroded.

Disc cannot be read.

Disc cannot be read.

Yes

4-4

Trouble shooting chart

Check the FFC connection

between 24P and the loader.

Yes

Check whether there is laser

voltage (2V for VCD and 2.2V for

DVD) on Collector of

Q6ǃQ5.

Yes

Check U4, U5, and

peripheral components are

eroded or badly soldered.

No

No

No

Check the loaded circuit

1.Check voltage on pin 44 of U4 varies

between 0 and 3.3V:

Æ3.3V for VCD

Æ0V for DVD

2.Check whether peripheral components

are eroded or defect

Re-solder or replace the defective parts

Yes

Check if there is RFO signal on

pin8 of CN2. (The normal RFO

signal is a clear reticulated wave)

Yes

Check the connection

between U4

Yes

Replace U4 or loader.

No

No

Check U4 and peripheral components

Correct connection

4-5

p

p

Only DVD disc or only disc except DVD can be played

Only DVD disc, or only disc

t DVD can be Played.

exce

Go

Trouble shooting chart

Check the FFC

connection between

24pin and the loader.

Yes

Check laser voltage (2V) output

on Collector of Q5 if pin 22 of U4

is at low level.

Yes

Check whether there

is voltage variance on

in 22 of U4.

No

No

No

Check the loaded circuit

Check the solder status on U2 and

peripheral components

check if bad solder exist on U2 and

peripheral components

Yes

Check whether pin 1 to pin38

of U2 and peripheral

components are badly

soldered, defected

Yes

Check Q5, Q6, Q8

whether in good

Yes

Change U2 or the loader.

No

Replace the bad spare parts

No

Correct connection

4-6

No display on LED, and buttons do not work

No display on LEDD,

and buttons do not work

Yes

Trouble shooting chart

Check whether there is

correct contact between J2

and J6

Yes

checkVCC(+5v) voltage

on the power and front

board

Yes

Check there are DATA

signals on J2 and J6on the

front board.

No

No

No

Correct connection

Fix power supply board top

a power supply for should

electric circuit

Check the U4’s pin

98,99,100,200,,R204,R206 arrive

Yes

Replace U2 or LED

Distorted audio and loud noise

Distorted audio and

loud noise

Yes

Check the power supply voltages

+12V and -12V to the operation

amplifying Q7 andQ8 are normal.

Yes

No

4-7

Check Q7and Q8

Trouble shooting chart

Check whether the

muting transistor Q31

andD23 are normal

Yes

Check whether the

muting transistor

Q26~Q30 are normal

Yes

Checking the U10 leads

the feet has no to break to

open

Yes

if the clock signal

89_AL, 89_AR output by

U2 are normal

No

No

No

Replace Q31 and D23

No

SACLK waveform

Replace Q26,Q30

Correct connection

Replace U10

SBCLK waveform SSLRCK waveform

Yes

Check whether the U2 or

U10powersupply normal

Yes

Replace U2 or U10

No

Check U10

Abnormal color of video picture

p

p

Abnormal color of

video

icture

Yes

4-8

Trouble shooting chart

Check whether the

27MHz out

Check whether the 3.3V

and 2.5V power supply

voltages on the decoder

board are normal.

Check whether the

video filter network

circuit is normal.

ut signal is

Yes

Yes

No

Check Y1, R15, R217, C17,C18,C98

No

Check other of power supply electric

circuit

No

Correct the connection

Yes

Check if the Y1 to Y6 signals on Pin

182 to 187 of U2 are normal

No

change U2

Remote reception is insensitive or fails.

prop

Remote reception is

insensitive or fails.

Go

4-9

Trouble shooting chart

Check if the remote

control works

erly.

Yes

Check if the power supply

voltage to the remote censor

is normal are normal.

Yes

Use an oscilloscope to check if there is

output waveform from the first pin IR of the

remote censor after pressing button on the

remote control.

Yes

No

No

Check battery

Check R315ǃCE301

No

REM301 (PIN 3 - RC waveform)

Check if there is IR

signal on pin 109 of U4

No

Correct connection

Yes

Change U4

IR waveform

No video picture, no sound.

y

g

No video picture,

no sound.

4-10

Trouble shooting chart

Check whether all the voltages

from the power board to the

decoder board are normal.

Yes

Check if the reset circuit consisting

of D3,R400 and CE10 is normal (at

a high level for tens of milliseconds,

then constantl

at 0V).

Yes

Check whether there is

27MHz si

nal output.

Yes

Checkifthere is 128MHz

signal output on R59

No

No

No

No

Check the loaded circuit

Change D3, and CE10

Crystal oscillator Y1 and

peripheral components

are defected or eroded.

Check whether short-circuit

or bad solder on U10

CVBS(L26 point) waveform

27M waveform

Check if short-circuit and bad

solder exist on Pin Y1

Yes

Reconnect the component in

short-circuit

SDRAM(R59 SDCLK) waveform

No

Yes Yes

No

Check U2.

5-1 5-1

A

B

C

D

E

DVP6600/XX,DVP6620/XX WIRING DIAGRAM

4 4

L

PbPr Y

COAX

AV BOARD

3 3

DVD LOADER

2 2

6PIN*2.0

SWITCH

BOARD

R

CVBS

COAX_SPDIF

PR_OUT

PB_OUT

Y_OUT

CVBS_C/OUT

CN4

9PIN*2.0

RCH_1

LCH_1

GND

CN3

9PIN*2.0

1

24

1

SL+

SL-

GND

SP+

SP-

LIMIT

6PIN*2.0

6

1

VSH-L33 + KHM313A

CN2

5PIN*2.0

5

LOAD-

TROUT

LOAD+

GND

TRIN

CN4

J7

IR

BOARD

HA1

24PIN*0.5

J1

J6 5PIN*2.0

IR

BLU

GND

GND

DV33

6PIN*2.0

MOTER

RED

DRIVER

AT5654

61

AUDIO

AMP&LPF

LR

MT1389HD

16M

FLASH

J2

1516

GND

VSDA

Stop_ctr

CON301

5PIN*2.0

KY BOARD

VIDEO LPF &

DRIVE

Y

COAX

CVBS

EEPROM

5PIN*2.0

VSCK

POWER_K

Pb

Pr

64M

MAIN BOARD

1

2

J5

1

GND

VSDA

2

SW BOARD

HDMI

MT1392

SDRAM

CON304

2PIN*2.0

P2

1

8PIN*2.5

CN1

7

+5V

5V

GND

GND

+12V

AGND

-12V

-24V

1

7

POWER

SUPPLY

CN202

7PIN*2.5

1 1

A

B

C

D

E

6-1 6-1

5

D D

4

3

2

1

Control Board Electric Diagram for DVP6600/93/37,DVP6620/55/98/93

Control

OPEN/CLOSE

C C

VSCK

Stop_ctr

POWER_K

C207

C206

1u,0603

B B

C208

0.1u

0.1u

K302 PLAY/PAUSE

2 1

3 4

K301 STOP

2 1

3 4

K304 POWER

2 1

3 4

VSDA

Stop_ctr

VSCK

POWER_K

VSDA

C200

1u,0603

C201

1u,0603

C202

0.1u

C205

0.1u

C203

0.1u

J5

2

1

CON2

CON301

5

4

3

2

1

A A

5

4

3

2

1

6-2 6-2

5

4

3

2

1

Power Board Electric Diagram for DVP6600/93/37,DVP6620/55/98/93

D D

F1

T2AL/250ac

D3

1N4007

D4

1N4007

L1

750uH

* CAUTION :

RV1

U1

FSDH321

DrainFBDrain

10K471

TR1

NTC 10

6

Drain

D1

1N4007

R1

56k 1/4W

D2

1N4007

222/400V

+

C1

22uF/250V

C5

D9

1N4007

FB1

2.2uH

R2

300K/1/4W

D8

1N4007

+

C2

22uF/250V

R3

300K/1/4W

++

CON1

AC INPUT

1 2

C C

837

THE PARTS MARKED WITH ARE IMPORTANT PARTS ON THE SAFETY.

PLEASE USE THE PARTS HAVING THE DESIGNATED PARTS NUMBER WITHOUT FAIL.

T1

5

4

3

2

6

7

9

8

12

11

R12

22(NU)

D5

FR102(NU)

D6

1N4148

D7

1N4148

C12

102/50V(NU)

L2

6.8uH

C3

+

10uF/50V(NU)

C4

+

47uF/25V

+

C6

47uF/25V

+12V

GND

-12V

-22V

+5V

CON2

8

-22V

7

-12V

6

GND

5

+12V

4

GND

3

GND

2

+5V

1

+5V

8X2.5 HEADER

D10

SR240

C11

0.1uF

3

U2

R10

220

1

U3

TL431

R8

2.2k

3

2

GND

B B

A A

Vcc

1

2

+

C9

10uF/50V

5

CS Startup

4 5

C10

0.1uF

R11

22

CY1

102/400Vac

43

12

PC123X92

4

10

R9

10k

1

+

C7

1000uF/16V

+

C8

470uF/16V

R7

11.3k 1%

R5

12k 1%

2

1

6-3 6-3

5

4

3

2

DV33

1

Main Board Electric Diagram for DVP6600/93/37,DVP6620/55/98/93: Power Board & Connector

[0R]

Q15

S8550

Q16

R247

1.3K

3904

R21

[0R]

NC

Q14

S8550

C16

R23

1u

22K

R241

1K

12

D2

4148

R244

3.3k

Q17

R202

C118

1UF

ZD1

18V

R249

4.7K

[0R]

+12V

BT3904

VCC

TO CD DOOR Control

board

CN2

2.0MM*5

-12V

NC

PCON/LED

MO_VCC

1

2

3

4

5

D26

RL207

R6

1R 1/2W

R252

10K

R4

6.8R 1W

RFV33

R253

10K

Control the PLAY/PAUSE

1u,0603

C116

POWER_K2

VSCK2

Stop_ctr

VSDA2

Stop_ctr

Control the OPEN/CLOSE

LOAD+

LOADTROUT

TRIN

0.1u

C108

MO_VCC

CE37

+

220uF/16V

MT1389HD (LQFP256) DVD MP Board for SANYO HD62/SONY

KHM313AAAPUH w/MT1392 HDMI

MD0278

D D

NAME

VCC

DV33

RFV33

TYPE

Digital 5V

Digital 3.3V

Servo 3.3V

DEVICE

SUPPLY

MT1389E

MT1389E

TO POWER BOARD

CN1

1

2.5mm*8

1

2

3

4

5

6

7

+5VD

+5VP

GND

GND

+P12V

GND

-P12V

1100mA

15mA

L41 FB AXIAL

30mA

AV33 Laser Diode 3.3V

V18

SD33

+12V

Digital 1.8V

Digital 3.3V SDRAM

Audio +12V

MT1389E

OP AMP.

-12V Audio -12V OP AMP.

AVDD5

DVDD3

C C

Audio 5V

Audio 3.3V

Audio DAC

Audio DAC

IR

URST#

PCON/LED

POWER_K

IR 2

URST# 2

PCON/LED 2

POWER_K 2

L62 FB AXIAL

C115

0.1u

C117

0.1u

R245

NC

R248

4.7K

L63 FB500R

R251

3.3k

NC

R246

22K

R250

22k

R201

RESET Circuit

DV33

B B

D3

1N4148

+

R400

10k

L3 FB500R R92

CE10

10uF/16v

URST#

R362

4.7K

R372

4.7K

load+ 2

load- 2

TROUT 2

TRIN 2

R373

4.7K

Blu_Ctr

R361

4.7K

R370 100

R369 100

R375 330

R374 100

DV33

R89

4.7K

100uF/16v NC

Red_Ctr

C111

0.1u

IR2

DV33

D1

1N4148 NC

R96

4.7K

CE9

4.7K

C113

1u,0603

R358

4.7K

+

DV33

C109

0.1u

DV33

R239 10R

L42 FB500R

MO_VCC

Q12

3904

R95

4.7K

R94

4.7K

R97

4.7K

C42

0.1uF

C110

0.1u

BLU

RED

C114

1u,0603

TO Key

Board

C104

100p

C112

1u,0603

MO_VCC

DV33

R93

91R

Q11

9012

Q10

9012

C105

100P

R90

82R

J2

5

4

3

2

1

TO IR

Board

BLU

J6

6

5

4

3

2

1

V18

R5

20K 1%

R17

12K 1%

Q1

SS8550

TR_B1

VCC

L4

FB500R

120mA

A A

AVCC

5

DV33

DV33

150mA

L5

FB500R

L65

FB500R

+

CE12

47uF/16v

DV33HD

RFV33AVCC

CB8

0.1uF

RFV33

4

REGO1

3

CB49

0.1uF

DV33

CE1

+

220uF/16v

TR_B2

REGO2

2

Q9

SS8550

R18

4.7K 1%

R19

10K 1%

CB50

0.1uF

+

CE2

220uF/16v

1

RED

6-4 6-4

Main Board Electric Diagram for DVP6600/93/37,DVP6620/55/98: MT1389HD & Frontend

C2 2200pF

R8 680k

R11

150k

R16 R/NC

SPSP+

IO_18

SLSL+

DV33

R22 10k

FF+

T+

TC/c

D/d

CD/DVD SW

RF

A/a

B/b

F

GND-PD

Vc(Vref)

Vcc

E

NC

VR-CD

VR-DVD

CD-LD

MD

HFM

NC

DVD-LD

GND-LD

SANYO

SF-HD60

G

1

2SK3018

MDI1

1

2

3

4

5

6

7

8

9

10

11

12

13

TOP

14

15

16

17

18

19

20

21

22

23

24

25

26

HA1

27

28

C

E

B

C

C176

47P

R36 10K

TR_B2

CB35

0.1uF

R20 1R

C173

100P

LIMIT

V18

D

2

S

3

2SK3018

GND

LD-DVD

AVCC1

MDI1

LD-CD

E

AVCC1

V20

GND

F

B

A

RFO

IOA

D

C

C177

47P

SL+

SL-

R37

10K

D D

C175

100P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

C C

CB84

NC

[470pF]

HEADER 24 SMD0.5 TOP

B B

2SB1132

1

MO_VCC

A A

5

RFV33

ADIN

OPOP+

R13

680k

STBYTCK

TROUTTDI

R28 10k

R29 10k

R30 100k

AVCC

+

L15

HD-62

10uH

KHM313A

Q5 8550

R34 4.7R

R35 4.7R

8550

Q6

F-

VOFC+

VOFC-

VOSL-

VOSL+

MOTR+

MOTR-

REG01

REG02

VINFC

RFV33

V1P4

V2P8

CB10

+

CE16

0.1uF

47uF/6.3v

C

B

A

D

RFO

C

B

A

D

AVCC

CE19

100uF/16v

C169

100P

2

LDO2

LDO1

RFV33

IOA

Very Important to

reduce Noise

C40

C/NC

V1P4

ADIN

DV33HD

C168

100P

R131(0),R132(0)

R34(10),R35(10)

R131(100),R132(100)

R34(4.7),R35(4.7)

+

CE20

47uF/6.3v

[10R]

[10R]

+

CE21

47uF/6.3v

F+

14

13

12

11

10

9

8

VCC1

2930

GNDGND

7

REV

6

FWD

5

4

VINSL

3

2

TRB1

1

CE27

47uF/16v

C34 1uF

C37 120pF/NC

T43

T45

T46

R79 0R

R80 0R

R31

R/NC

RFV33

+

R130

6.8R

V20

CB11

+

CE17

0.1uF

47uF/6.3v

C32 1uF

C33 1uF

C35 1uF

CB14

0.1uF

R32

R33 R/NC

CB46

5600pF

L14

FB

LDO2

CB29

0.1uF

LDO1

SPSP+

LOAD+

LOAD-

TRCLOSE

TROPEN

REGO1

REGO2

TR_B1

FOSO

C9

0.1uF

C36 1uF

CB15

0.1uF

CB30

0.1uF

C3

0.1uF/NC

R9 0R

OPO

R12

150k

LIMIT

C174

100P

L12

V18

FB

TDO TRCLOSE

TMS TRIN

IO_19 IOA

R25 0R

1

J1

1

2

3

4

5

6

6x1 W/HOUSING

CB73

0.1uF

CB13

0.1uF

C

3

B

E

C12

2200pF

RFV18

2N3904

R27 100k

2

Q3

R131

FMSO

R52

10k

100R

[0R]

T66

T67

TRSO

V1P4

STBY

13

R132

C178

47P

100R

[0R]

Q2

BT3904

13

2

Q4

2SK3018

FB

L13

C41

0.1uF

CB16

0.1uF

L16

10uH

C179

47P

U3

TR-

15

VOTK+

TR+ AALRCK

16

VOTK-

17

VOLD+

18

VOLD-

19

VCC2

20

NC

21

VCTL

22

PREGND

23

VINLD

24

NC

25

TR_B2

26

VINTK

27

BIAS

28

STBY

AM5888

CB37

0.1uF

4

PLLVDD3

CE22

100uF/6.3v

TEZISLV

C43

330pF

C6

2200pF

CB17

0.1uF

C44

330pF

RFVDD3

10

11

12

13

14

15

16

17

18

19

20

21

22

23

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

DV33HD

C28

0.1uF

1

AGND

2

DVDA

3

DVDB

4

DVDC

5

DVDD

6

DVDRFIP

7

DVDRFIN

8

MA

9

MB

MC

MD

SA

SB

SC

SD

CDFON

CDFOP

TNI

TPI

MDI1

MDI2

LDO2

LDO1

SVDD3

CSO/RFOP

RFLVL/RFON

SGND

V2REFO

V20

VREFO

FEO

TEO

TEZISLV

OP_OUT

OP_INN

OP_INP

DMO

FMO

TROPENPWM

PWMOUT1/V_ADIN9

TRO

FOO

VPLLVSS

CAPPAD

VPLLVDD3

USB_VSS

USBP

USBM

USB_VDD3

FG/V_ADIN8

TDI/V_ADIN4

TMS/V_ADIN5

TCK/V_ADIN6

TDO/V_ADIN7

DVDD18

IOA2

IOA3

IOA4

IOA5

IOA6

IOA7

HIGHA0

IOA18

IOA19

C45

0.1uF

C5

C4

0.01uF

0.1uF

CB47

0.1uF

E

F

C39

0.1uF

R/NC

DV33HD

V18

+

V1P4

CB12

+

CE18

0.1uF

47uF/6.3v

MDI1

MDI2

V2P8

V20

V1P4

OPO

OPOP+

DMO

FMO

TROPEN

TRO

FOO

USBVDD

ADIN

TDI

TMS

TCK

TDO

V18

A2

A3

A4

A5

A6

A7

A8

A18

A19

L17

FB500R

DV33HD

CB32

CB31

0.1uF

0.1uF

FOSO

TRSO

FMSO

DMSO DMO

MO_VCC

R47 20k

DMSO

R14 15k

C14 0.1uF

RFVDD3

C21 0.1uF

252

253

256

25524254

OSP

OSN

IREF

RFGC

AVDD3

HIGHA6

HIGHA7

DVDD3

A16

IOWR#

65

67

A14

A15

A16

PWR#

R40 27k

R41 27k

R42 15k

R43 10k

C46

0.015uF

V1P4

251

RFGND

HIGHA5

A13

V1P4

R10 100k

C23 0.033uF

C29

250

249

CRTPLP

HIGHA4

A12

A11

20pF

1000pF

C13

0.1uF

248

247

HRFZC

RFRPAC

HIGHA3

HIGHA2

73

A10

A9

C7 0.1uF

C8

RFVDD3

245

246

RFVDD3

RFRPDC

IOA20

HIGHA1

75747271706968

76

A20

PCE#

FOO

TRO

FMO

C10 0.1uF

RFVDD3A1

C26 0.047uF

244

243

ADCVSS

ADCVDD3

IOCS#

IOA1

7890796677

PRD#

242

LPFIN

LPFOP

IOCE#

AD0

AD0

3

JITFO

C128

1392_CLK

NC

CE52

R222

XI

234

33R

[NC]

XO

233

XTALI

RFV18

232

XTALO

RFVDD18

+

ADACVDD

231

230

RFGND18

ADACVDD2

10uF/16v

CE31

1000uF/10v

CE50

4.7uF

228

229

ALF/(CTR)

ADACVDD1

C27 0.047uF

241

LPFIP

PLLVDD3

240

239

LPFON

PLLVDD3

+

10uF/16v

C11 0.47uF/NC

JITFN

238

237

236

PLLVSS

IDACEXLP

JITFN

JITFO

235

JITFO

MT1389HD

Pin Assignment v1.5

A17

IOA21

AD6

AD4

AD3

AD2

AD1

DVSS

AD1

AD5

86

848382

81

80

85

AD2

AD5

AD3

AD4

AD6

DVDD18

IOA0

DVSS

ALE

AD7

91

87

93

92

88

89

V18

ALE

A17

AD7

A0

URST_1392

T79

T78

AACLK ACLK

C1 1000pF

R7 750k

CE49

+

10uF/16v

89_AL

89_AR

224

225

222

226

223

227

AVCM

ARF(SW)

AL/SDATA2

AR/SDATA1

ALS/SDATA0

ARS/SDATA3

UWR#

URD#

DVDD3

UP1_2

UP1_3

UP1_4

949596979899100

POWER_K

VSCK

URD#

UWR#

T70

R88 33R

L60 FB75R

CB60

0.1uF

CE51

221

220

219

ADACVSS1

ADACVSS2

UP1_5

UP1_6

101

102

SCL

SDA

VSDA

C133

NC

+

APLLVDD3

218

217

APLLVSS

APLLCAP

APLLVDD3

UP1_7

UP3_0

UP3_1

103

104

UP3_1

UP3_0

JITFN

CE30

100uF/6.3v

+

ASPDIF

215

216

SPDIF

UP3_4

105

106

RXD

TXD

ALRCK

V18

AASDAT3

MUTEC

213

214

212

DVDD18

ASDATA4

MC_DATA

UP3_5

ICE

PRST#IRINT0#

107

108

109

IR

URST#

R26

1k

0.1uF

AACLK

AABCK

211

210

ACLK

ABCK

ASDATA3

DQM0

110

111

INT0#

DQM0

ADACVDD

APLLVDD3

DACVDD3

CB79

0.1uF

CB48

0.1uF

ASPDIF_CON

ADACVDD

AALRCK

209

208

207

ALRCK

DVDD3

IO_19

RD7

112

113

114

DQ7

IO_19

DQ6

CB80

Red_Ctr

Red_Ctr

206

SPBCK

SPLRCK

RD6

RD5

115

DQ4

DQ5

205

116

CB9

0.1uF

Blu_Ctr

AASDAT2

AASDAT1

Blu_Ctr

PCON/LED

204

203

202

201

SPDATA

SPMCLK

ASDATA2/GPO_0

ASDATA1/GPO_1

RD4

RD3

DVDD3

RD2

117

118

120

119

DQ1

DQ2

DQ3

R87 33R

AASDAT2

AASDAT3

R379 0R

R380 0R

Stop_ctr

200

199

198

GPIO_3

GPIO_4

RCLKB/GPIO_5

RD15

RD1

RD0

122

121

123

DQ14

DQ15

DQ0

+

RVREF/GPIO_6

RD14

2

L7 FB500R

CE14

10uF/16v

AASDAT0

VREF

DACVDD3

FS

197

196

195

194

193

FS

VREF

YUV0/CIN

DACVDDC

DACVSSC

YUV1/Y

ASDATA0/GPO_2

DACVDDB

YUV2/C

DACVSSB

YUV3/CVBS

DACVDDA

YUV4/G

DACVSSA

YUV5/B

YUV6/R

VSYNC/V_ADIN1

YUV7

HSYNC/V_ADIN2

DVSS

IO_17

C0/IO_0

C1/IO_1

DVDD18

C2/IO_2

C3/IO_3

C4/IO_4

DVDD3

C5/IO_5

C6/IO_6

C7/IO_7

YUVCLK/IO_8

Y0/IO_9

Y1/IO_10

Y2/IO_11

Y3/IO_12

Y4/IO_13

DVDD18

Y5/IO_14

Y6/IO_15

Y7/IO_16

DVDD3

RA11

DVSS

RCLK

DVDD3

DVDD18

RA10

RCS#

RAS#

CAS#

RWE#

DQM1

DVDD3

IO_18

RD13

RD12

RD11

RD9

RD10

124

125

126

128

127

ABCKAABCK

R285 33R

R287

ASDAT3

C137

33R

NC

DV33B

DV33B DV33HD

R398

0R

DACVDD3

C30

C/NC

YUV0

192

191

190

189

188

187

186

185

184

183

182

181

180

179

178

177

176

175

174

173

172

171

170

169

168

167

166

165

164

163

162

161

160

159

158

157

156

155

RA4

154

RA5

153

RA6

152

RA7

151

RA8

150

RA9

149

148

147

CKE

146

145

144

RA3

143

RA2

142

141

RA1

140

RA0

139

138

BA1

137

BA0

136

135

134

133

132

131

130

129

RD8

U2

MT1389HD

DQ9

DQ10

DQ11

DQ12

DQ13

ASDAT2

C17,C18 s hould join the ground in one point!

DV33HD

C129

NC

[0.1uF]

PH1

XO

1

.

DV33HD

AASDAT1

Use it to connect the shell of the crystal to ground.

V18

DACVDD3

YUV3

DACVDD3

YUV4

YUV5

YUV6

M1

C0

C1

C2

C3

C4

C5

C6

C7

R221 33R

VCK

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

MA4

MA5

MA6

MA7

MA8

MA9

MA11

DCKE

DCLK

MA3

MA2

MA1

MA0

MA10

BA1

BA0

CS#

RAS#

CAS#

WE#

DQM1

IO_18

DQ8

R280 33R

R283 33R

C136

NC

CB18

0.1uF

CB23

0.1uF

92_DV33

RxD

TxD

C73

C74

100P

100P

RS-232

IR

VSCK

C167

VSDA

100P

CB20

CB19

0.1uF

0.1uF

CB25

CB26

0.1uF

0.1uF

C132

NC

ASDAT0AASDAT0

ASDAT1

R15 220k

27MHz

C17

22p

C131NC

1392_VCK

FS

VREF

C38

0.1uF

J3

1

2

3

4

4x1 W/HOUSING

IR 1

VSCK 1

VSDA 1

V18

CB21

0.1uF

DV33HD

CB27

0.1uF

C134

NC

Y1

C18

22p

R24

560R

CB22

0.1uF

+

220uF/16v

CE3

1

CE14/CE30/CE31

closed to IC's pin

R217 33R

URST_1392

PCON/LED

M1

1392_VCK

POWER_K

C166

1uF

YUV[1..6]

VIDEO INTERFACE

A[0..20]

A[0..20] 3

AD[0..7]

PRD#

PWR#

PCE#

FLASH

MA[0..11]

DQ[0..15]

BA[0..1]

BA[0..1] 3

DQM[0..1]

DQM[0..1] 3

DCLK

DCLK 3

DCKE

DCKE 3

CAS#

CAS# 3

RAS#

RAS# 3

WE#

WE# 3

CS#

CS# 3

MEMORY

SCL

SDA

ASDAT[0..2]

ALRCK

ACLK

ABCK

ASPDIF

AUDIO INTERFACE

UP3_0

UP3_1

INT0#

URST_1392 5,6

M1

MUTEC

TRIN

TROUT

TROPEN

TRCLOSE

1392_CLK

ASDAT[0..3]

C[0..7]

Y[0..7]

89_AL

89_AR

URST#

POWER_K

YUV[1..6] 4

AD[0..7] 3

PRD# 3

PWR# 3

PCE# 3

MA[0..11] 3

DQ[0..15] 3

SCL 3,5,6

SDA 3,5,6

IIC

ASDAT[0..2] 5,6

ALRCK 5,6

ACLK 6

ABCK 5,6

ASPDIF 5,6

UP3_0 6

UP3_1 6

INT0# 6

XI

C98

15p

PCON/LED 1

MUTEC 5

TRIN 1

TROUT 1

TROPEN 1

TRCLOSE 1

1392_CLK 6

1392_VCK 6

ASDAT[0..3] 5,6

C[0..7] 6

Y[0..7] 6

89_AL 5

89_AR 5

URST# 1

POWER_K 1

5

4

3

2

1

6-5 6-5

5

4

3

2

1

Main Board Electric Diagram for DVP6600/93/37,DVP6620/55/98/93: SDRAM & FLASH

DV33 SD33

DV33 DV33A

L59 FB500R

D D

+

CE25

47uF/16v

16Mb

R54 0R

A20

U7

MA0

23

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

MA10

MA11

DBA0

C C

B B

DBA1

SDCLK

SDCKE

DCS#

DRAS#

DCAS#

DWE#

DQM0

DQM1

A0

24

A1

25

A2

26

A3

29

A4

30

A5

31

A6

32

A7

33

A8

34

A9

22

A10/AP

35

A11

20

BA0/A13

21

BA1/A12

38

CLK

37

CKE

19

CS

18

RAS

17

CAS

16

WE

15

DQML

39

DQMH

36

NC

40

NC

54

VSS

41

VSS

28

VSS

ESMT M12L64164A-7T

SDRAM64M

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

VCC

VCC

VCC

VCCQ

VCCQ

VCCQ

VCCQ

VSSQ

VSSQ

VSSQ

VSSQ

DQ7

2

DQ6

4

DQ5

5

DQ4

7

DQ3

8

DQ2

10

DQ1

11

DQ0

13

DQ8

42

DQ9

44

DQ10

45

DQ11

47

DQ12

48

DQ13

50

DQ14

51

DQ15

53

SD33

1

14

27

SD33

3

9

43

49

6

12

46

52

DV33A

DV33A

R61

10k

PCE#

PRD#

PWR#

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

AA20

AA201

INTEL FLASH:R289=0 ohm, R54=

OPEN

R289 NC

U8

25

A0

24

A1

23

A2

22

A3

21

A4

20

A5

19

A6

18

A7

8

A8

7

A9

6

A10

5

A11

4

A12

3

A13

2

A14

1

A15

48

A16

17

A17

16

A18

9

A19

10

A20

15

INTEL

26

CE

28

OE

11

WE

12

RESET

MX29LV160

TSOP 48 pin

WP/ACC

BYTE

VCC

GND1

GND2

AMD /SST FLASH: R54=0 ohm,

R289=OPEN

DV33

U9

1

CB51

R63

1k

R62

1k

A A

SCL

SDA

0.1uF

NC

2

NC

3

NC

4 5

GND SDA

EEPROM 24C16

SOP8

VCC

WP

SCL

8

7

6

DV33

SCL

SDA

C75

100P

DV33DV33

C76

100P

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

CB76

0.1uF

AA20

AA201

AD0

29

AD1

31

AD2

33

AD3

35

AD4

38

AD5

40

AD6

42

AD7

44

30

32

34

36

39

41

43

A0

45

R60 0R

14

47

37

27

46

DV33

R1

4.7K

R3

10

R2

NC/0

DV33A

CB52

0.1uF

M1

2

L19 FB500R

CB38

0.1uF

DBA0 BA0

SDCKE DCKE

SD33

SD33

CB39

0.1uF

R59 33R

CB40

0.1uF

CB75

NC

CB41

0.1uF

CS#DCS#

RAS#DRAS#

CAS#DCAS#

WE#DWE#

BA1DBA1

DCLKSDCLK

CB42

0.1uF

CB43

0.1uF

CB44

0.1uF

DRAM

DQ[0..15]

MA[0..11]

BA[0..1]

DQM[0..1]

DCLK

DCKE

CAS#

RAS#

WE#

CS#

PCE#

PRD#

PWR#

A[0..20]

AD[0..7]

SCL

SDA

DQ[0..15]2

MA[0..11]2

BA[0..1]2

DQM[0..1]2

DCLK2

DCKE2

CAS#2

RAS#2

WE#2

CS#2

PCE#2

PRD#2

PWR#2

A[0..20]2

AD[0..7]2

FLASH

SCL2,5,6

SDA2,5,6

IIC

5

4

3

2

1

6-6 6-6

5

4

3

2

1

D D

C C

Main Board Electric Diagram for DVP6600/93/37,DVP6620/55/98/93: VIDEO OUT

AVCC

AVCC

D6

1N4148

D8

1N4148

D4

1N4148

D5

1N4148

PR_OUT

PR_OUT

PB_OUT

YUV3

R67

82

[75 1%]

the first value is valid

when using scart

C92

47pF

L29

C96

220pF

C97

220pF

1.8uH

L32

1.8uH

C58

47pF

C64

47pF

YUV5 PB_OUT

R69

75 1%

YUV6

R73

75 1%

YUV[1..6]

AVCC

D10

CE40

C53

47pF

1N4148

D11

1N4148

+

100uF/16v

CVBS_C/OUT

CVBS_C/OUT 5

L26

1.8uH

R291

82

[NC]

YUV[1..6] 2

AVCC

D7

YUV4 Y_OUT

R72

75 1%

B B

A A

L24

1.8uH

C61

100pF

C62

100pF

1N4148

D9

1N4148

Y_OUT

5

4

3

2

1

6-7 6-7

5

4

3

2

1

Main Board Electric Diagram for DVP6600/93/37,DVP6620/55/98/93:AUDIO OUT

D D

D20

1N4148

+

CE44

100uF/16V

470uF/16V

Q31

9012

CE45

RCH

LCH

Q26

9012

COAX_SPDIF

100pF

R332

220R

+

1N4148

C94

D19

1N4148

D23

100pF

R324

NC

[0R]

C93

Q30

9012

R323

C91

100pF

R325

NC

[0R]

NC[0R]

D22

1N4148

MUTE

C143

102

D25

1N4148

[NC]

C144

102

PR_OUT

PB_OUT

Y_OUT

CVBS_C/OUT

+

R306

+

R317

+12V

CE28

100uF/25v

MUTE

100uF/25v

MUTE

R359100

+

R78

100

R307470R

[NC]

R360

100

CE46

R84

100

R319470R

[NC]

-12VB

+

+12VB

Q7

BT3904

Q8

BT3904

LCH

RCH

MUTEC2

+12VB

DV33

R328 NC

R329 NC

DV33

MUTEC

MO_VCC

R327

NC

[0R]

[0R]

R331

22k

AVCC

NC

R326

[0R]

D21

1N4148

[0R]

R335

3.3k

R336 330R

R338 10K

C68

3300pF

[1000pF]

C72

3300pF

[1000pF]

R75

5.1K 1%

[31K]

R81

5.1K 1%

[31K]

R83

470R1%

[5.1K]

C65 560pF

[100pF]

-12VB

R77

470R1%

[5.1K]

U10A

-

2

+

3

8 4

+12VB

C141

0.1uF

C69 560pF

[100pF]

-12VB

U10B

-

6

+

5

8 4

+12VB

When using AK4385,"value" is valid

When using interal

DAC,"Implementation" is valid

1

NJM4558 OPA

7

NJM4558 OPA

C138

0.1uF

10uF/16v

10uF/16v

-12V

CE53

100K

CE54

100K

89_AL

C C

89_AR

B B

C66

[10uF/16v]

+

C70

+

[10uF/16v]

R76

NC

[10k]

R82

NC

[10k]

C145

102

NC(2.0*9)

9

8

7

6

5

4

3

2

1

CN3

COA_SPD

HDMI_SPD

COA_SPD

R70 100

CVBS_C/OUT

U4

1

NO

IN

2

GND

V+

3 4

NC COM

TS5A3157

R339 NC

[0R]

R340 NC

[0R]

6

5

R71

100

ASPDIF

89_AL2

89_AR2

DV33HD

C60

ASPDIF 2,6

CVBS_C/OUT

ASPDIF_CONHDMI_SPD

ASPDIF

CB1

0.1uF

C59

0.1uF

330pF

89_AL

89_AR

COAX_SPDIF

mute circuit

R342

-12VB

100k

2

1

A A

5

4

3

6-8 6-8

5

4

3

2

1

Main Board Electric Diagram for DVP6600/93/37,DVP6620/55/98/93: HDMI OUT MT1392&KARAOK

D D

L33

5mA

35mA

FB500R

L34

FB500R

L35

FB500R

HDMI_SCL

HDMI_SDA

92_DV33

92_SCL SCL

92_SDA SDA

92_INT0#

C C

92_DV33

B B

R218

R/NC

L36

5mA

FB500R

L37

70mA

FB500R

INT0#

CB64

HDMI_SCLUP3_0

HDMI_SDAUP3_1

CB69

0.1uF

+

CE35

100uF/6.3v

1392_VCK

92_DV33

0.1uF

C0

C1

C2

C3

C4

C5

C6

C7

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

DVDD18V18

CB70

0.1uF

DVDD18

ASDAT0

ASDAT2

ASDAT1

ACLK

ALRCK

ABCK

80

AD1

AD0

ACK

ABCK

ALRCK

DVDD18

1

DVSS

2

C0

3

C1

4

C2

5

C3

6

C4

7

C5

8

C6

9

C7

10

DVDD33

11

VCK

12

DVSS

13

Y0

14

Y1

15

Y2

16

Y3

17

Y4

18

Y5

19

Y6

20

Y7

SSCK

SSD

DVDD18

RST

PWDN

CLK

INT

21222325242627282930313233343536373839

92_SDA

URST_1392

92_SCL

92_INT0#

1392_CLK

R227

R226

1k

10k

ASDAT3

AD3

AD2

DVSS

A7/GPO0

HDMI_SPD

B

R

SPDIF

A6/GPO1

TRAP2/GPO2

TRAP1/GPO3

TRAP2

TRAP1

TRAP0

1392DAC_AVDD3

G

AVSS

AVSS

AVSS

AVDD

AVDD

TRAP0/GPO4

MSCK/GPO5

MSD/GPO6

GPO7

GPO8

GPO9

MSCK

MSD

FS_1392

VREF_1392

61626364656667686970717273747576777879

FS

VREF

AVDD

SWING

AVSS

TX2+

TX2-

AVDD

TX1+

TX1-

AVSS

TX0+

TX0-

AVDD

TCK+

TCKAVSS

AVSS

AVDD

AVDD

PLLC1

PLLC0

AVSS

GPO10

HTPLG

40

U15

MT1392E HDMI TX PROCESSOR

SPQFP80/SMD

HPD

GPO7

R229

R/NC

1392PLL_AVDD3

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

R220

510R

0603-R

R219

C99

560R

0.1uF

1392_AVDD3

TX2+

TX2-

TX1+

Differential Signal !

TX1-

No through hole & shorter is better !

100 ohm - Impedance

TX0+

TX0-

TXC+

TXC-

1392PLL_AVDD3

DV33

C100

5600pF

T94

PLLC0

+

CE34

DV33

92_DV33

TX2- F_TX2-

TX1+

TX1-

TX0+

TX0-

TXC+

TXC-

47uF/16v

1392DAC_AVDD3

CB63

CB61

0.1uF

CB62

0.1uF

0.1uF

1392_AVDD3

CB65

CB66

0.1uF

0.1uF

1392PLL_AVDD3

CB68

CB67

0.1uF

0.1uF

Differential Signal !

No through hole & shorter is better !

100 ohm - Impedance

R350 10R

R351 10R

R352 10R

R353 10R

R354 10R

R355 10R

R367 10R

R368 10R

R215

1.5k

VCC

R216

1.5k

VCC

F_TX2+TX2+

F_TX1+

F_TX1F_TX0+

F_TX0F_TXC+

F_TXC-

T95

C79

C80

100P

100P

L11

FB

R224 R/NC

HPD

R389

47K

HDMI_VCC

CB71

0.1uF

URST_1392

C[0..7]

Y[0..7]

ASDAT[0..3]

ALRCK

ACLK

ABCK

UP3_0

UP3_1

SCL

SDA

INT0#

1392_CLK

1392_VCK

URST_1392 2,5

C[0..7] 2

Y[0..7] 2

ASDAT[0..3] 2,5

ALRCK 2,5

ACLK 2

ABCK 2,5

UP3_0 2

UP3_1 2

SCL 2,3,5

SDA 2,3,5

INT0# 2

1392_CLK 2

1392_VCK 2

2221

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20 23

P2

HDMI TYPE-A

HDMI_TYPE_A

R231

R/NC

R232

R/NC

R230

R/NC

92_A7

92_A6

TRAP2

TRAP1

TRAP0

A A

5

R233

R/NC

R234

R/NC

DV33

CB72

0.1uF

4

U16

1

NC

VCC

2

NC

3

4 5

WP

NC

SCL

GND SDA

EEPROM 24C08

SOP8

8

7

6

CB78

0.1uF

R235

1k

C77

100P

R236

1k

MSCK

MSD

C78

100P

3

2

1

6-9 6-9

5

D D

4

3

2

1

Main Board Electric Diagram for DVP6600/93/37,DVP6620/55/98/93: IR

+

CE301

47uF

R315

100 ohm

DV33

5

4

REM301

REM

VCC45

GND

3

2

IR

1

IR

C312

C306

47pF

0.1u

C C

C302

2

STANDBY

D303

BLU

1

RED

3

DV33

IR

BLU

RED

C303

1u,0603

C301

100p

C304

1u,0603

100P

J7

6

5

4

3

2

1

B B

A A

5

4

3

2

1

6-10 6-10

5

4

3

2

1

D D

Main Board Electric Diagram for DVP6600/93/37,DVP6620/55/98/93 : AV

AV_OUT

COAX_SPDIF

PR_OUT

PB_OUT

Y_OUT

CVBS_C/OUT

RCH_1

LCH_1

NC(2.0*9)

9

8

7

6

5

4

3

2

1

CN4

LCH_1

CVBS_C/OUT

RCH_1

L46 FB500R

L47 FB500R

L48 FB500R

C154

102

C153

102

C155

102

1

7

6

3

5

4

2

GND

DET

T1

CVBS

DET2

Y

C

EAR016

C C

J4

CN5

1

2

3

4

Y_OUT

COAX_SPDIF

L45 FB500R

100pF

C152

C156

101

CN6

1

2

3

4

PB_OUT

PR_OUT

L43 FB500R

L44 FB500R

C150

100pF

C151

100pF

B B

A A

5

4

3

2

1

6-11 6-11

5

D D

4

3

2

1

Main Board Electric Diagram for DVP6600/93/37,DVP6620/55/98/93 : OPEN/CLOSE KY

C C

CON304

VSDA

2

C313

100pF

1

K303 OPEN/CLOSE

2 1

3 4

VSDA

C314

100pF

B B

A A

5

4

3

2

1

6-12 6-12

Switch Board Print_Layout (Bottom Side) for DVP6600/93/37,DVP6620/55/98/93

6-13 6-13

Control Board Print_Layout (Bottom Side) for DVP6600/93/37,DVP6620/55/98/93

6-14 6-14

Power Board Print_Layout (Bottom Side) for DVP6600/93/37,DVP6620/55/98/93

6-15 6-15

Main Board /AV Board / IR Board /Switch Board Print_Layout (Top Side) for DVP6600/93/37,DVP6620/55/98/93

6-16 6-16

Main Board /AV Board / IR Board /Switch Board Print_Layout (Bottom Side) for DVP6600/93/37,DVP6620/55/98/93

It s a general Mechanical ExplodedView forDVP6600/93/37,Detailed

informationplease refer to Model set.

A2is assembled component for location29,31,34 .

A

.

A1is assembled component for loaction1,2,3

7-1

A

DVP6600/93/37,DVP6620/55/98/93 Mechanical Exploded View

3is assembled component for loaction36,37,38,39,40,41,42

4 is assembled component for loaction 4,5,6,7,8,9,10,11,12,13

DVP6600/93 Packing View

7-2

ACCESSORIES IN GIFT BOX

PAC-8:POLY BAG PAC -3˖Remote Control

PAC-13:Power Cord

PAC-16: Service hot line PAC-17:Service guarantee PAC-18:Pass Label PAC-7:Operation manual PAC-19: World wide guarantee

PAC-9:ACCESSORIES

PAC-14: Battery

PAC-15:AV Cable

X

M

3

5

E

6

E

M

3

7

L

M

7-3

DVP6620/93 Spare Part List

Electrical PARTS LIST

No 12NC No. Part Name Q'ty

15 996510006348 ASSY- MAIN BD 1

18 996510006858 IR Board 1

19 996510015378 DVD LOADER(AHD OPU) 1

21 996510006349 ASSY- PW BD 1

22 996510006350 AV BD 1

24 996510006353 ASSY- SW BD 1

32 996510006352 ASSY- SW BD 1

35 996510006351 ASSY- SW BD 1

MECHANICAL & ACCESSORIES PARTS LIST

No 12NC No. Part Name Q'ty

10 996510011365 STRAP 1

11 996510011366 MOTOR 1

12 996510011362 ATHEY WHEEL 1

3RCAM 996510007599 3RCA/M TO 3RCA/M L=1.5M 1

4 996510009931 CD DOOR 1

5 996510011744 Tray frame 1

6621 996510000409 FLEX CABLE 1

6622 996510006356 PH-6Y/JC-6Y,L=130 1

6623 996510006357 PH-5Y/JC20-5Y L=40 1

6624 996510006358 PH-9Y/SAN-9Y L=40 1

6625 996510001222 HS 6P PH-6Y/PH-6Y 1

7 996510011363 ATHEY WHEEL 1

9 996510011364 MOTOR WHEEL 1

A1 996510011361 Assy-Front Cover 1

A2 996510009932 Assy-Rear Panel 1

A3 996510007604 Assy-Bottom Socket 1

FUSE 996510001780 FUSE 2A 250V 5X20MM 1

PAC1 996510009930 DISPLAY BO

PAC10 996510006860 RIGHT POLYFOA

PAC1

PAC1

PAC1

PAC17 996500033761 SERVICE GUARANTE

PAC19 996510008988 WORLD-WIDE GUARANTEE 1

PAC2 996510006859 LEFT POLYFOA

PAC

PAC

PAC8 996510008699 POLYFOA

QSGC 996510009102 QUG IN S-CHINESE 1

QSGE 996510009103 QUG IN UK-ENGLISH 1

996510009517 POWER CORD 1

996510008503 AUDIO CABL

996500042132 SERVICE HOT LINE 1

996510007598 REMOTE CONTROL 1

996510009929 OPERATION MANUA

1

1

1

1

1

1

1

7-4

DVP6600/93/37 and DVP6620/55/98 Spare Part List

ENCASING & ACCESSORIES PARTS LIST SCREW LIST

No 12NC Part Name Q'ty No 12NC Part Name Q''ty

A1 996510006364 Ass'y-Top Cover for DVP6600/93/37 1 - 996510008699 POLYBAM for DVP6600/93 DVP6620/55/98 1

Ass'y-Top Cover for DVP6620/98 D-BOX 996510007601 DISPLAY BOX for DVP6620/55 1

996510007603 Ass'y-Top Cover for DVP6620/55 996510007608 DISPLAY BOX for DVP6620/98

4 996510006363 CD Door for DVP6600/93/37 1 - DISPLAY BOX for DVP6600/37

996510009931 CD DOOR for DVP6620/55/98 996510008700 DISPLAY BOX for DVP6600/93

A4 996510006367 OTHER PART for DVP6600/93 1 - 996510001175 POWER CORD for DVP6620/55 1

996510006367 OTHER PART for DVP6600/37 - 996510001537 POWER CORD for DVP6620/98

996510007606 OTHER PART for DVP6620/55/98 - 996510006371 POWER CORD for DVP6600/37

15 996510006348 Main Board for DVP6600/93,DVP6620/55/98 1 SCREWS

16 - Shield for DVP6600/37 1 13 - SCREW 1

- Shield for DVP6620/55 14 - S/T SCREW B 2.6 X 8 BF 4

18 - Rubber PAD 4 17 - SCREW 2

19 996500035358 DVD Loader for DVP6600/93,DVP6620/55/98 1 20 - S/T SCREW B 3 X 8 BF 3

21 - Power Board for DVP6600/37 1 23 - S/T SCREW B 3 X 8 BF 1

996510006349 Power Board for DVP6600/93,DVP6620/55/98 25 - Binding Head Screw 1

22 996510006350 AV Board for DVP6600/93/37,DVP6620/55/98 1 27 - S/T SCREW B 2.6 X 8 BF 2

24 996510006353 ASSY- SW BD for DVP6600/93/37,DVP6620/55/98 1 30 - S/T SCREW 4

26 - Shield 1 Connector parts&FUSE

28 996510006858 IR Board for DVP6600/93, DVP6620/55/98 1 3RCA/M 996510007599 3RCA/M TO 3RCA/M L=1.5M for DVP6620/55/98 1

A2 996510006366 Ass'y-Rear Panel for DVP6600/93 1 3RCA/M - 3RCA/M TO 3RCA/M L=1.5M for DVP6600/37 1

- Ass'y-Rear Panel for DVP6600/37 F1 996510001780 FUSE for DVP6600/93 1

996510007605 Ass'y-Rear Panel for DVP6620/55/98 HA1 996510000409 HS 24PIN for DVP6600/93,DVP6620/55/98 1

32 996510006352 ASSY- SW BD for DVP6600/93/37,DVP6620/55/98 1 J7 996510006356 PH-6Y/JC-6Y,L=130 for DVP6600/93,DVP6620/55/98 1

33 - Connector 1 6623 996510006357 PH-5Y/JC20-5Y L=40 for DVP6600/93,DVP6620/55/98 1

35 996510006351 ASSY- SW BD for DVP6600/93/37,DVP6620/55/98 1 6602 996510008698 PH-5Y/JC20-5Y L=40 1

A3 - Ass'y-Bottom Socket for DVP6600/37/93 1 CN4 996510006358 PH-9Y/SAN-9Y L=40 for DVP6600/93,DVP6620/55/98 1

996510007604 Ass'y-Bottom Socket for DVP6620/55/98 996510001222 PH-6Y/PH-6Y for DVP6600/93,DVP6620/55/98 1

Accessories parts

RC 996510007598 REMOTE CONTROL for DVP6620/55/98 1

996510006354 REMOTE CONTROL for DVP6600/37/93

996510006362 POWER CORD FOR DVP6600/93 1

996510008988 WORLD-WIDE GUARANTEE for DVP6600/93

IFU

996510007600 OPERATION MANUAL for DVP6620/55 1

- OPERATION MANUAL for DVP6600/37

996510007607 OPERATION MANUAL for DVP6620/98

996510006359 OPERATION MANUAL for DVP6600/93

REVISION LIST

Version 1.0

* Initial release

Version 1.1

*Include /98/55 for DVP6620 models

*Updated the ENCASING&ACCESSORIES PARTS LIST

* Updated the MECHANICAL PARTS LIST

Version 1.2

*Correction of Partcode to Philips 12nc

Version 1.3

* Include /93 for DVP6620 model

8-1

*Updated the ENCASING&ACCESSORIES PARTS LIST

*Updated the MECHANICAL PARTS LIST

Loading...

Loading...