Philips DVDR-610, DVDR-615, DVDR-616 Service manual

DVD-Video Recorder DVDR610, DVDR615 & DVDR616

DVDR610/00/02/05/19/33, DVDR615/00/02/05/19/33

DVDR616/00/02/05

Contents Page Contents Page

1 Technical Specifications and Connection

Facilities

2 Safety Information, Gene ra l Notes 5

3 Directions for Use 7

4 Mechanical Instructions 9

5 Diagnostic Software 13

6

Block Diagrams, Waveforms, Wiring Diagram

Wiring Diagram 80

Waveforms 82

Testpoints 84

7

Circuit Diagrams and PWB Layouts

MOBO:Fronted Video (FV) (Diagram 1) 87

MOBO: In / Out Video (IOV) (Diagram 2) 88

MOBO: In / Out Audio (IOA) (Diagram 3) 89

MOBO: Power Supply (PS) (Diagram 4) 90

MOBO: Multi Sound Processing (M SP)(Diagram 5) 91

MOBO: Cinch Out (CINCH) (Diagram 6) 92

MOBO: Follow Me (FOME) (Diagram 7) 93

MOBO: Audio Converter( DA C_A DC ) (Diagram 9) 94

MOBO: Color UniT (CU) (Diagram 10) 95

MOBO: IR Blaster (IRB) (Diagram 11) 96

MOBO: Digital In/Out 1(DIGIO1) (Diagram 12) 97

MOBO: Digital In/Out 2(DIGIO2) (Diagram 10) 104

MOBO: Keyboard (KEY) (Diagram 11) 105

MOBO: Standby (STBY) (Diagram 12) 107

MOBO: Open / C lose (OPCL) (Diagram 13) 109

MOBO: 5-Way Switch (5WSW) (Diagram 14) 110

FEBE: FE OPU Interface (Diagram 1) 111

FEBE: Fe Cheetah 2 Pre-processing (Diagram 2) 112

FEBE: FE Laconic Pre-processing (Diagram 3) 113

FEBE: FE Drivers (Diagram 4) 114

FEBE: FE Centaurus 1.5 Processor (Diagram 5) 115

FEBE: FE Supply / BE Interface (Diagram 6) 116

FEBE: FE Tray Motor / Swich Conn. (Diagram 7) 117

©

Copyright 2004 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

2

77

87

FEBE: BE Chrysalis (Diagram 8) 118

FEBE: BE Flash, EEPROM & SDRAM (Diagram 9) 119

FEBE: BE DV In IEEE1394 (Diagram 10) 120

FEBE: BE Video In Processing (VIP) (Dia gram 11) 121

FEBE: BE Audio & Video In/Out (Diagram 12) 122

FEBE: BE Supply, Reset, UART, Enc. (Diagram 13) 123

LECO: Fe Opu Interface (Diagram 1) 134

LECO: Fe Pre-Processing (Diagram 2) 135

LECO: Febe Power Supply (Diagram 3) 136

LECO: Fe Drivers (Diagram 4) 137

LECO: Fe Processor (Diagram 5) 138

LECO: FeBe Interface (Diagram 6) 139

LECO: Be Debug Connectors (Diagra m 7) 140

LECO: Be LECO (Diagram 8) 141

LECO: Memory (Diagram 9) 142

LECO: IEE1934 (Diagram 10) 143

LECO: Be Video In (Diagram 11) 144

LECO: Be Audio/Video Out (Diagram 12) 144

LECO: Be Pheriphery (Diagram 13) 146

8 Alignments 157

9 Circuit-, IC Descriptions and List

of Abbreviations

10 Spare Parts List 219

10 Revision List 228

158

Published by KC 0428 Service PaCE Printed in the Netherlands Subject to modification EN 3122 785 14181

Version 1.1

EN 2 DVDR610/615/6161.

Technical Specifications and Connection Facilities

1. Technical Specifications and Connection Facilities

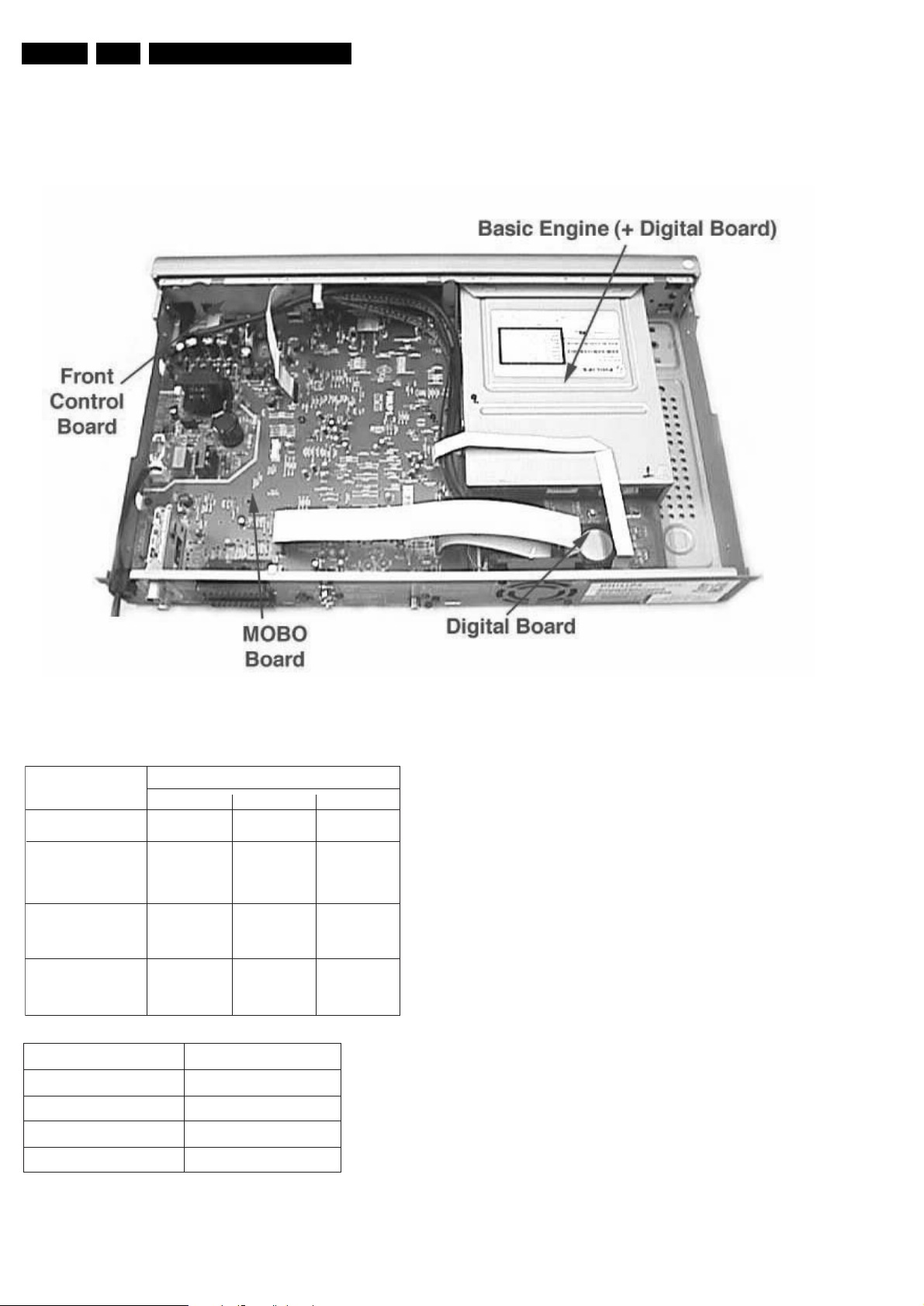

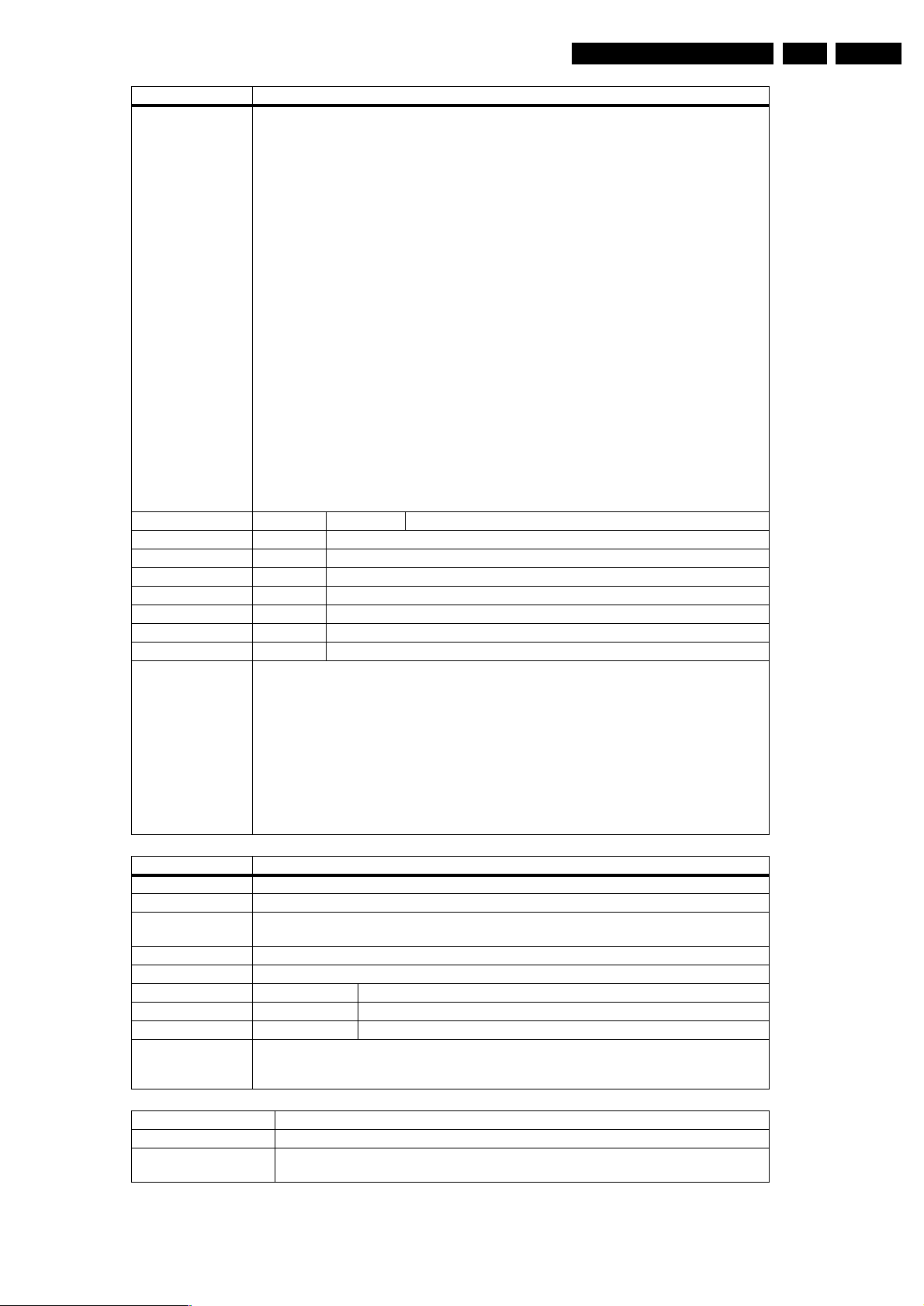

1.1 PCB Locations

1.2 Diversity Matrix and Read and Write speed 1.3 General:

Mains voltage : 198V-276V

Mains frequency : 43 Hz - 63Hz

Power consumption (record) : 27 W

Power consumption (AV loop through) : < 15W

Power consumption low power

stand-by : < 3 W

1.4 RF Tuner

Test equipment:Fluke 54200 TV Signal generator

Test streams:PAL BG Philips Standard test pattern

1.4.1 System:

PAL B/G, PAL D/K, SECAM L/L’, PAL I

1.4.2 RF - Loop Through:

Frequency range : 45 MHz - 860 MHz

Gain: (ANT IN - ANT OUT) : -6 dB to 0dB

1.4.3 Radio Interference:

input voltage /3 tone method (+40

dB min) : no limit

Module / Pcb Application

MOBO 04 E1

12NC: 3139 248 82891

VAU8041/11

DS version: E2_AV3_4

12NC: 9305 025 84111

FEBE pcb: 3104 128 09271

Drive: AV3.5

VAU8041/21

DS version: E1_AV3_4

12NC: 9305 025 84121

pcb: 3104 128 09281

Drive: AV3.5

LECOLITE U4.01L

DS version: OL22FEBE

12NC: 3139 247 10942

pcb: 3139 248 83791

Drive: D4.0

DVDR610/0x/19/33

Type of Disc (Function)

Read Speed CD

Read Speed DVD

Write Speed DVD+RW

Write Speed DVD+R

VFM RANGE

DVDR615/0x/19/33

x

x

x

x

x

Disc Rotation Speed

CAV 7x

CAV 4x

ZCAV 2.4x

ZCAV2.4x

DVDR616/0x/19/33

x

x

1.4.4 Receiver:

PLL tuning with AFC for optimum reception

Technical Specifications and Connection Facilities

EN 3DVDR610/615/616 1.

Frequency range: : 45.25 MHz - 857 MHz

Sensitivity at 40 dB S/N : ≥ 60dBµV at 75Ω

(video unweighted )

1.4.5 Video Performance:

Channel 25 / 503,25 MHz,

Test pattern: PAL BG PHILIPS standard test pattern,

RF Level 74 dBV

Measured on SCART 1

Frequency response: : 0.1- 4.00 MHz ± 3dB

Group delay ( 0.1 MHz - 4.4 MHz ) : 0 nsec ± 150nsec

1.4.6 Audio Performance:

Audio Performance Analogue - HiFi:

Frequency response at SCART 1

(L+R) output: : 100 Hz - 12 kHz / 0±

3dB

S/N according to DIN 45405, 7, 1967 :

and PHILIPS standard test pattern

video signal: : ≥ 50dB, unweighted

Harmonic distortion ( 1 kHz, ± 25

kHz deviation ): : ≤ 1.5%

Audio Performance NICAM:

Frequency response at SCART

1(L+R) output: : 40 Hz - 15 kHz 0 ±

3dB

S/N according to DIN 45405, 7, 1967 :

and PHILIPS standard test pattern

video signal: : ≥ 60 dB unweighted

Harmonic distortion (1 kHz): : ≤ 0.5 %

1.4.7 Tuning

Automatic Search Tuning

scanning time without antenna : typ. 3 min.

stop level (vision carrier) : ≥ 37dBµV

Maximum tuning error of a recalled

program : ± 62.5 kHz

Maximum tuning error during

operation : ± 100 kHz

Tuning Principle

automatic B,G, I, DK and L/L’detection

manual selection in "STORE" mode

1.5 Analogue Inputs / Outputs

1.5.1 SCART 1 (Connected to TV)

Pin Signals:

1 - Audio R 1.8V RMS

2 - Audio R

3 - Audio L 1.8V RMS

4 - Audio GND

5 - Blue/Chroma GND

6 - Audio L

7 - Blue out/

Chroma in 0.7Vpp ± 0.1V into 75 Ohm (*)

8 - Function

switch <2V = TV

>4.5V / <7V = asp. ratio 16:9 DVD

>9.5V / <12V = asp. ratio 4:3 DVD

9 - Green GND

10 - P50 control

11 - Green 0.7Vpp ± 0.1V into 75 Ohm (*)

12 - Nc

13 - Red/Chroma GND

14 - fast switch GND

15 - Red out/

Chroma out 0.7Vpp ± 0.1V into 75 Ohm (*)

± 3dB 0.3Vpp Chroma (burst)

16 - fast switch

RGB/ CVBS or Y <0.4V into 75 Ohm = CVBS

>1V / <3V into 75 Ohm = RGB

17 - Y/CVBS GND OUT

18 - Y/CVBS GND IN

19 - CVBS/Y 1Vpp ± 0.1V into 75 Ohm (*)

20 - CVBS/Y

21 - Shield

1.5.2 SCART 2 (Connected to AUX)

Pin Signals:

1 -Audio R 1.8V RMS

2-Audio R

3 -Audio L 1.8V RMS

4 -Audio GND

5 -Blue/Chroma GND

6 -Audio L

7 -Blue in/

Chroma out ± 3dB 0.3Vpp Chroma (burst)

8 -Function

switch

9 -Green GND

10 -P50 control

11 -Green in

12 -Nc

13 -Red/Chroma GND

14 -fa st s w i t c h GN D

15 -Red in/Chroma in

16 -fast switch

RGB/ CVBS or

Y

17 -CVBS GND OU T

18 -CVBS GND IN

19 -CVBS/Y/RGB

sync 1Vpp ± 0.1V into 75 Ohm (*)

20 -CVBS/Y

21 -Shield

(*) for 100% white

1.5.3 Audio/Video Front Input Connectors

Audio - Cinch

Input voltage : 2.2 Vrms

Input impedance : >10kΩ

Video - Cinch

Input voltage : 1 Vpp ± 3dB

Input impedance : 75 Ω

Video - YC (Hosiden)

According to IEC 933-5

Superimposed DC-level on pin 4 (load > 100kΩ)

< 2.4V is detected as 4:3 aspect ratio

> 3.5V is detected as 16:9 aspect ratio

Input voltage Y : 1Vpp ± 3dB

Input impedance Y : 75 Ω

Input voltage C : burst 300 mVpp ± 3

dB

Input impedance C : 75 Ω

1.5.4 Audio/Video Output rear Connectors

Audio- Cinch

Output voltage : 2Vrms max.

Output impedance : >10kΩ

Video- Cinch

Output voltage : 1 Vpp ± 3dB

EN 4 DVDR610/615/6161.

Technical Specifications and Connection Facilities

Output impedance : 75 Ω

Video - YC (Hosiden)

According to IEC 933-5

Superimposed DC-level on pin 4 (load > 100kohm)

< 2.4V is detected as 4:3 aspect ratio

> 3.5V is detected as 16:9 aspect ratio

Output voltage Y : 1Vpp +10/-15%

Output voltage C : 300mVpp +1/-4dB

1.6 Video Performance

All outputs loaded with 75 Ohm

SNR measurements over full bandwidth without weighting.

1.6.1 SCART (RGB)

SNR : > -65 dB on all output

Bandwidth : 4.8 MHz ± 2dB

1.7 Audio Performance CD

1.7.1 Cinch Output Rear

Output voltage 2 channel mode : 2Vrms ± 2dB

Channel unbalance (1kHz) : <1dB

Crosstalk 1kHz : >95dB

Crosstalk 16Hz-20kHz : >87dB

Frequency response 20Hz- 20kHz : ±0.2dB max

Signal to noise ratio : >85 dB

Dynamic range 1kHz : >83dB

Distortion and noise 1kHz : >83dB

Distortion and noise 16Hz-20kHz : >75dB

Intermodulation distortion : >70dB

Mute : >95dB

Outband attenuation: : >40dB above 30kHz

Specification of consumer use digital VCR’s using 6.3 mm

magnetic tape - dec.1994

Mechanical connection according:

Annex A of 61883-1

1.10 P50 System Control

Via SCART pin nr 10

1.11 Dimensions and Weight

Height of feet : 5.5mm

Apparatus tray closed : WxDxH :435 x 285x 65mm

Apparatus tray open : WxDxH :435 x 422x 65mm

Weight without packaging : app. 4 kg ± 0.5 kg

Weight in packaging : a pp. 6.5 kg

1.12 Laser Output Power & Wavelength

1.12.1 DVD

Output power during reading : 0.8mW

Output power during writing : 2 0mW

Wavelength : 6 60nm

1.12.2 CD

Output power : 0 .3mW

Wavelength : 7 80nm

1.7.2 Scart Audio

Output voltage 2 channel mode : 1.6Vrms ± 2dB

Channel unbalance (1kHz) : <1dB

Crosstalk 1kHz : >85dB

Crosstalk 16Hz-20kHz : >70dB

Frequency response 20Hz- 20kHz : ± 0.2dB max

Signal to noise ratio : >80 dB

Dynamic range 1kHz : >75dB

Distortion and noise 1kHz : >75dB

Distortion and noise 16Hz-20kHz : >50dB

Intermodulation distortion : >70dB

Mute (spin-up, pause, access) : >80dB

Outband attenuation: : >40dB above 25kHz

1.8 Digital Output

1.8.1 Coaxial

CDDA/ LPCM (incl MPEG1) : according IEC958

MPEG2, AC3 audio : according IEC1937

DTS : according IEC1937,

amendment 1

1.9 Digital Video Input (IEEE 1394)

1.9.1 Applicable Standards

Implementation according:

IEEE Std 1394-1995

IEC 61883 - Part 1

IEC 61883 - Part 2 SD-DVCR (02-01-1997)

Safety Information, General Notes

2. Safety Information, General Notes

EN 5DVDR610/615/616 2.

2.1 Safety Instructio ns

2.1.1 General Safety

Safety regulations require that during a repair:

• Connect the unit to the mains via an isolation transformer.

• Replace safety components, indicated by the symbol ,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

• Route the wires/cables correctly, and fix them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the electrical DC resistance between the mains plug

and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the 'on' position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains plug

and the front panel, controls, and chassis bottom.

4. Repair or correct unit when the resistance

measurement is less than 1 MΩ.

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

2.1.2 Laser Safety

This unit employs a laser. Only qualified service personnel may

remove the cover, or attempt to service this device (due to

possible eye injury).

2.2 Warnings

2.2.1 General

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD, ). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are at the same potential as the mass of

the set by a wristband with resistance. Keep components

and tools at this same potential.

Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the live voltage section.

The primary side of the power supply (pos. 1005), including

the heatsink, carries live mains voltage when you connect

the player to the mains (even when the player is 'off'!). It is

possible to touch copper tracks and/or components in this

unshielded primary area, when you service the player.

Service personnel must take precautions to prevent

touching this area or components in this area. A 'lightning

stroke' and a stripe-marked printing on the printed wiring

board, indicate the primary side of the power supply.

• Never replace modules, or components, while the unit is

‘on’.

2.2.2 Laser

• The use of optical instruments with this product, will

increase eye hazard.

• Only qualified service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

• Repair handling should take place as much as possible

with a disc loaded inside the player.

• Text below is placed inside the unit, on the laser cover

shield:

Laser Device Unit

Type : Semiconductor laser

GaAlAs

Wavelength : 650 nm (DVD)

: 780 nm (VCD/CD)

Output Power : 20 mW

(DVD+RW writing)

:0.8 mW

(DVD reading)

:0.3 mW

(VCD/CD reading)

Beam divergence : 60 degree

Figure 2-1

Note: Use of controls or adjustments or performance of

procedure other than those specified herein, may result in

hazardous radiation exposure. Avoid direct exposure to beam.

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

!

Figure 2-2

2.2.3 Notes

Dolby

Manufactered under licence from Dolby Laboratories. “Dolby”,

“Pro Logic” and the double-D symbol are trademarks of Dolby

Laboratories. Confidential Unpublished Works.

©1992-1997 Dolby Laboratories, Inc. All rights reserved.

Figure 2-3

Trusurround

TRUSURROUND, SRS and symbol (fig 2-4) are trademarks of

SRS Labs, Inc. TRUSURROUND technology is manufactured

under licence frm SRS labs, Inc.

Figure 2-4

EN 6 DVDR610/615/6162.

Video Plus

“Video Plus+” and “PlusCode” are registered trademarks of the

Gemstar Development Corporation. The “Video Plus+” system

is manufactored under licence from the Gemstar Development

Corporation.

Figure 2-5

Macrovision

This product incorporates copyright protection technology that

is protected by method claims of certain U.S. patents and other

intellectual property rights owned by Macrovision Corporation

and other rights owners.

Use of this copyright protection technology must be autorized

by Macrovision Corporation, and is intended for home and

other limited viewing uses only unless otherwise authorized by

Macrovision Corporation. Reverse engineering or disassembly

is prohibited.

Safety Information, General Notes

Directions For Use

3. Directions For Use

The following excerpt of the Quick Use Guide serves as an introduction to the set.

The complete Direction for Use can be downloaded in different languages from the internet site of Philips Customer Care Center:

www.p4c.philips.com

EN 7DVDR610/615/616 3.

EN 8 DVDR610/615/6163.

Directions For Use

Mechanical Instructions

4. Mechanical Instructions

EN 9DVDR610/615/616 4.

4.1 Dismantling and Assembly of the Set

For item numbers please see the exploded views in chapter 10.

4.1.1 Front Panel Assembly

– After removing the top cover, remove tray front 134+138,

see picture 4-1

– Remove the three screws 188

– Release the two snap hooks on the sides and remove the

front assembly

– Remove the 4 screws 186 to remove the front plate 184,

see picture 4-2

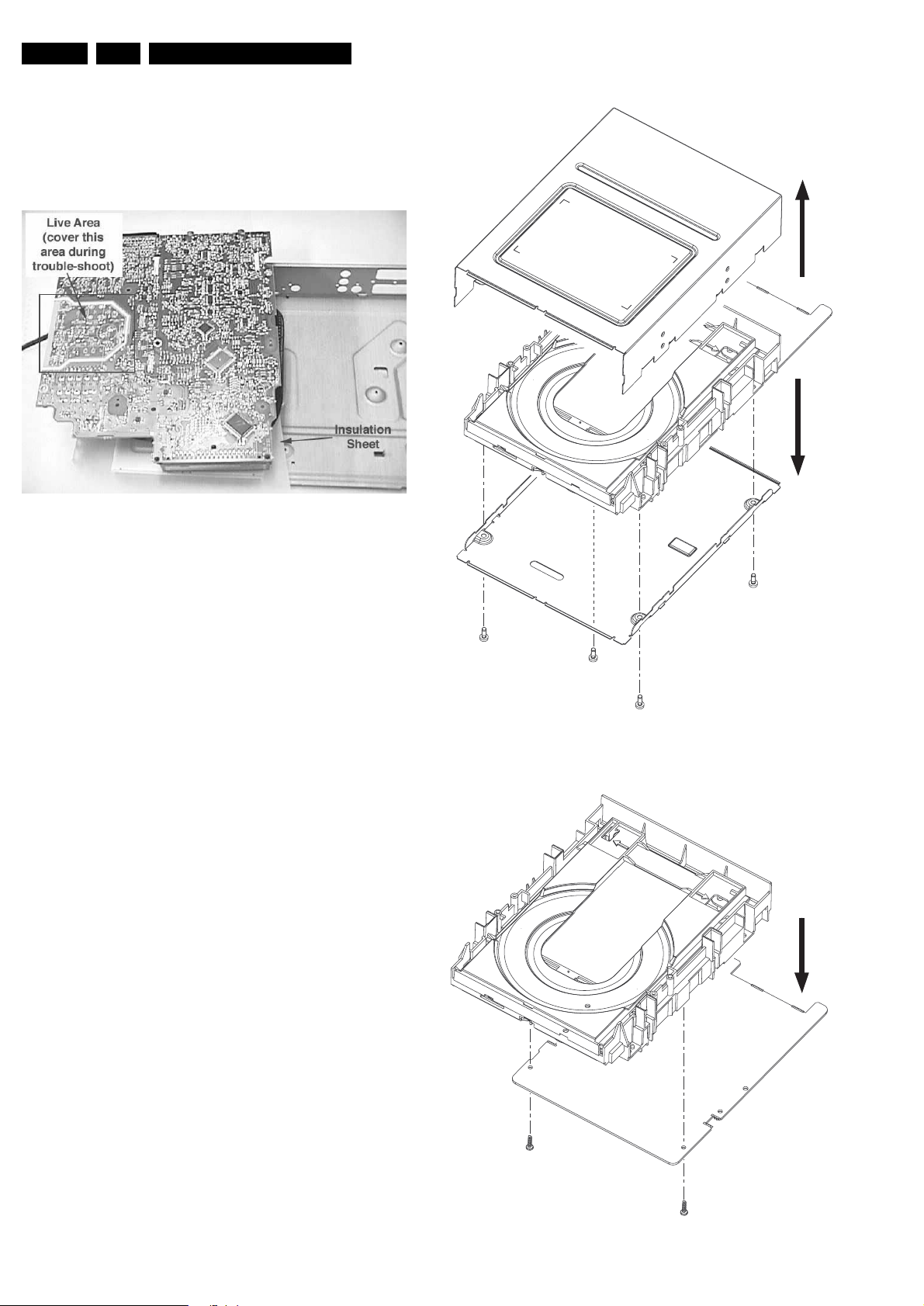

4.1.2 Basic Engine

– Remove the Front Panel Assembly as given in 4.1.1

– Remove the 6 screws 260, 269 to free the Basic Engine

– Remove the dust cover assembly 147 and 148

– Loosen 2 screws to remove bracket 256

– Loosen 4 screws to remove the Basic Engine metal casing

– Place the Basic Engine in the service position

Figure 4-3

Figure 4-1

Figure 4-2

Figure 4-4

EN 10 DVDR610/615/6164.

4.1.3 MOBO Board

– Remove the Front Panel assembly as given in 4.1.1

– Remove 6 screws 246 and 254

– Remove 4 screws 270

– Service position is achieved by flipping the MOBO board

above the Basic Engine

Mechanical Instructions

2

2

Figure 4-5

4.2 Dismantling and assembly of the Basic Engine

4.2.1 General

Follow the dismantling instructions in described order.

Do not place the unit with its PCB on a hard surface (e.g. table),

as it could damage the components on it.

Always place something soft (a towel or foam cushion) under it.

Never touch the lens of the OPU.

Take sufficient ESD measures during handling.

4.2.2 Dismantling the FEBE Board / Lecolite (LECO) Board

– Remove 4 screws to remove the metal case 150+180

– Remove 2 screws to separate the P.C. board 179 or 180

from the main Loader/Drive assembly

Note: After exchange of the PCB (or the Drive mechanism)

the complete Basic Engine has to be adjusted! Refer to

chapter 8 for adjustment instructions!

1

1

1

1

Figure 4-6 Basic Engine Module dismantling

2

1

1

Figure 4-7 Remove P.C. board

4.2.3 Dismantling the Tray

– Remove the encasing as described in 4.2.2

– Disengage the two holders that fix the tray [1] and pull out

the tray [2]

Mechanical Instructions

EN 11DVDR610/615/616 4.

1

2

Figure 4-8 Remove Tray

4.2.4 DVD-M (Drive Mechanism)

1

1

1

1

Figure 4-9 Remove DVD-M

4.2.5 Re - assembly

To re-assemble the module, do all processes in reverse order.

Take care of the following:

• Heat Paths:Put the 5 heat paths (gray rubber pieces) back

to their position on the ICs.

• Complete module: Place all wires/cables in their original

positions

• Emergency opening slot: Be sure that the slot for the

emergency tray opener is covered by adhesive tape!

2

1

Caution: Never try to align or repair the DVD-Module itself!

Only the factory can do this properly. Service engineers are

only allowed to exchange the sledge motor assy.

After Exchanging the DVD-M (or the PCB) the complete drive

has to be adjusted! Refer to chapter 8 for adjustment

instructions!

– Remove encasing and P.C. board as described in 4.2.2

– Remove the Sealing strip 5 by uncatching it

– Loosen the 4 screws/washer [1] to remove the DVD-M [2]

Figure 4-10 Heat Paths

EN 12 DVDR610/615/6164.

4.3 Dismantling Instructions

Remove all the connections

DVDR BASIC ENGINE 1004

⇒

⇒ Remove Front Panel assembly

mounting

demounting

Remove 6 screws 260 and 269

Remove 2 screws 262

(assembly -> support bracket 256)

(assembly -> frame 224)

⇒

⇒

Mechanical Instructions

Uncatch dust cover assembly 147 + 148

from DVDR Basic Engine

⇒

In case the loader is defective and cannot be

opened electrically, you can open the tray

tray front 134 + 138

Manual opening of tray and removal of

It is possible to unlock the tray by means

of a screwdriver via a slot in the

⇒

as follows:

front and frame at the underside.

Open the unlocked tray.

.

Push the white pin of the slider at the

underside of the basic engine to the left

(seen from the front)

⇒

Remove 7 screws 220 & 240

Cover 196

⇒

DISMANTLING INSTRUCTIONS

See exploded view for item numbers

to remove

Lift the cover

⇒

→

demount the board

(board frame)

MOBO board 1001

Front Panel Assembly

the

open the tray and remove

⇒

- Remove the Front Panel assembly

- Remove the connections

- Remove 6 screws 246, 254

→

tray front 134 + 138

remove 3 screws 188

⇒

(board => backplate)

⇒ remove 4 screws 270

⇒

frame 224)

remove 4 screws 186 to

unlock the front from the

frame by releasing 2 snaps

on left and right

(front assy

⇒

⇒

remove the plate front 184

front)

→

Remove screws 172

of DV input cable

(board

Remove 2 screws 176

⇒

⇒

Front Control board

TR 06003_003

demount the board

⇒

300504

Figure 4-11

5. Diagnostic Software

Diagnostic Software

EN 13DVDR610/615/616 5.

Due to the complexity of the DVD recorder, the time to find a

defect in the recorder can become long. To reduce this time,

the recorder has been equipped with Diagnostic and Service

software (DS). The DS offers functionality to diagnose the

DVDR hardware and tests the following:

• Interconnections between components

• Accessibility of components

• Functionality of the audio and video paths

This functionality can be accessed via several interfaces:

1. End user/Dealer script interface

2. Command Interface

5.1 End User/Dealer Script Interface

5.1.1 Description

The End user/Dealer script interface gives a diagnosis on a

stand alone DVD recorder. During this mode, a number of

hardware tests (nuclei) are automatically executed to check if

the recorder is faulty. The diagnosis is simply a "fail" or "pass"

message. If the message "FAIL" appears on the display, there

is apparently a failure in the recorder. If the message "PASS"

appears, the nuclei in this mode have been executed

successfully. There can be still a failure in the recorder

because the nuclei in this mode don't cover the complete

functionality of the recorder.

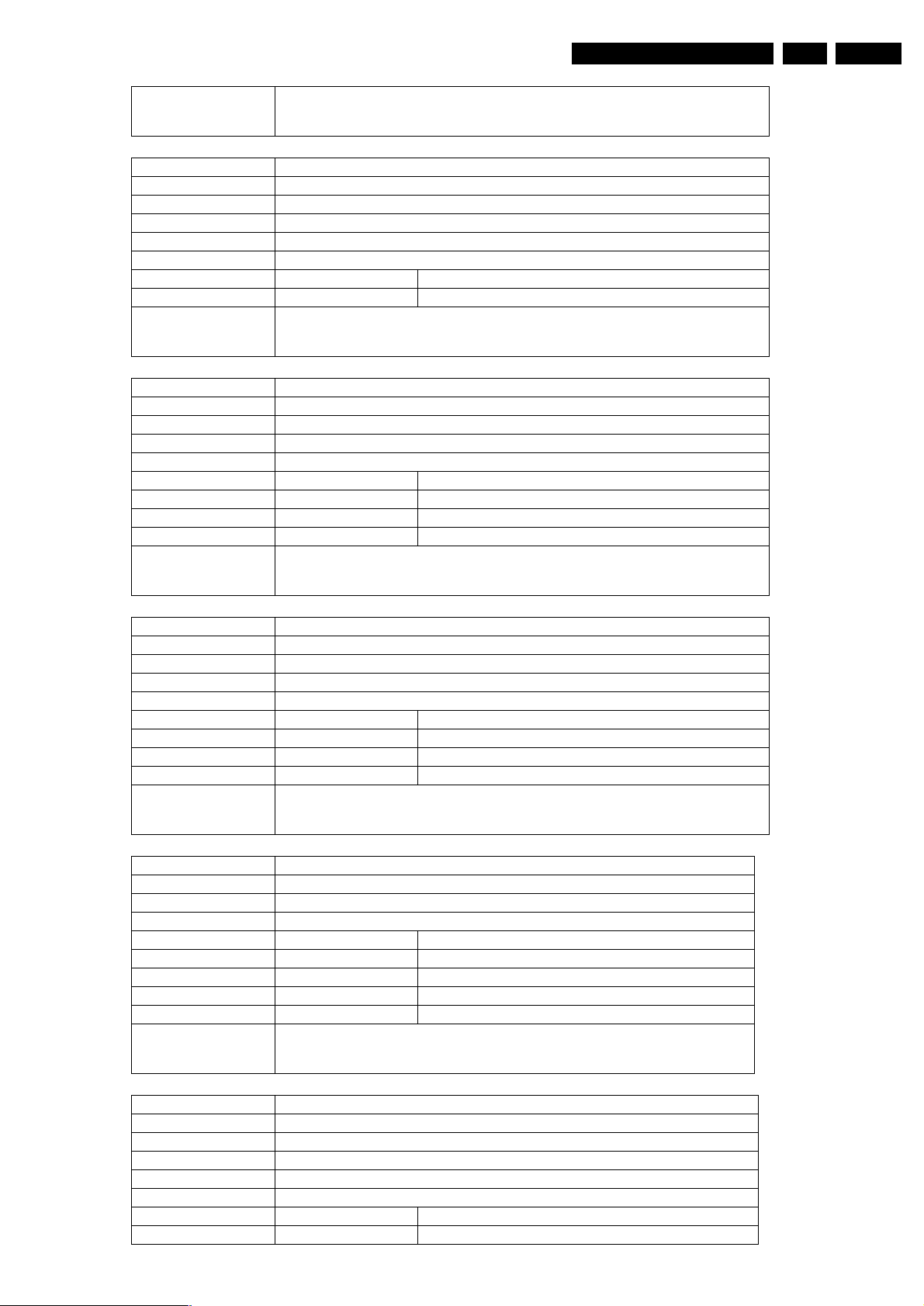

5.1.2 Structure

Unplug the power cord

Hold key <PLAY> pressed

while you plug the recorder

During the test, the display will show

the a sequence of nuclei under test

SET O.K.?

NO

YES

To exit DEALER SCRIPT, unplug the power cord

Figure 5-1

The End use/Dealer script executes all diagnostic nuclei that

do not need any user interaction and are meaningful on a

standalone DVD recorder.

TR 18029_001

120304

5.1.3 Contents

Included tests: 1.DS_ANAB_COMMUNICATIONECHO_NUC

2.DS_DCB_COMMUNICATIONECHO_NUC

3. DS_BROM_COMMUNICATION_NUC

4. DS_SYS_SETTINGSDISPLAY_NUC

5. DS_CHR_DEVTYPEGET_NUC

6. DS_CHR_INT_PIC_NUC

7. DS_CHR_DMA_NUC

8. DS_BROM_WRITEREAD_NUC

9. DS_NVRAM_COMMUNICATION_NUC

10. DS_NVRAM_WRITEREAD_NUC

11. DS_SDRAM_WRITEREADFAST_NUC

12. DS_FLASH_WRITEREAD_NUC

13.DS_FLASH_CHECKSUMPROGRAM_NUC

14.DS_SYS_HARDWAREVERSIONGET_NUC

15. DS_VIP_DEVTYPEGET_NUC

16. DS_VIP_COMMUNICATION_NUC

17. DS_DVIO_LINKDEVTYPEGET_NUC

18. DS_DVIO_PHYDEVTYPEGET_NUC

19. DS_DVIO_LINKCOMMUNICATION_NUC

20. DS_DVIO_PHYCOMMUNICATION_NUC

21.DS_PSCAN_COMMUNICATIONDENC_NUC

22.DS_PSCAN_COMMUNICATIONDEINTERLACER_NUC

23. DS_BE_COMMUNICATIONECHO_NUC

24.DS_ANAB_COMMUNICATIONIICNVRAM_NUC

25.DS_ANAB_COMMUNICATIONIICTUNER_NUC

26.DS_ANAB_COMMUNICATIONIICSOUNDPROCESSOR_NUC

27.DS_ANAB_COMMUNICATIONIICAVSELECTOR_NUC

28. DS_ANAB_CHECKSUMPROGRAM_NUC

EN 14 DVDR610/615/6165.

r

s

0

r

s

05

00

Diagnostic Software

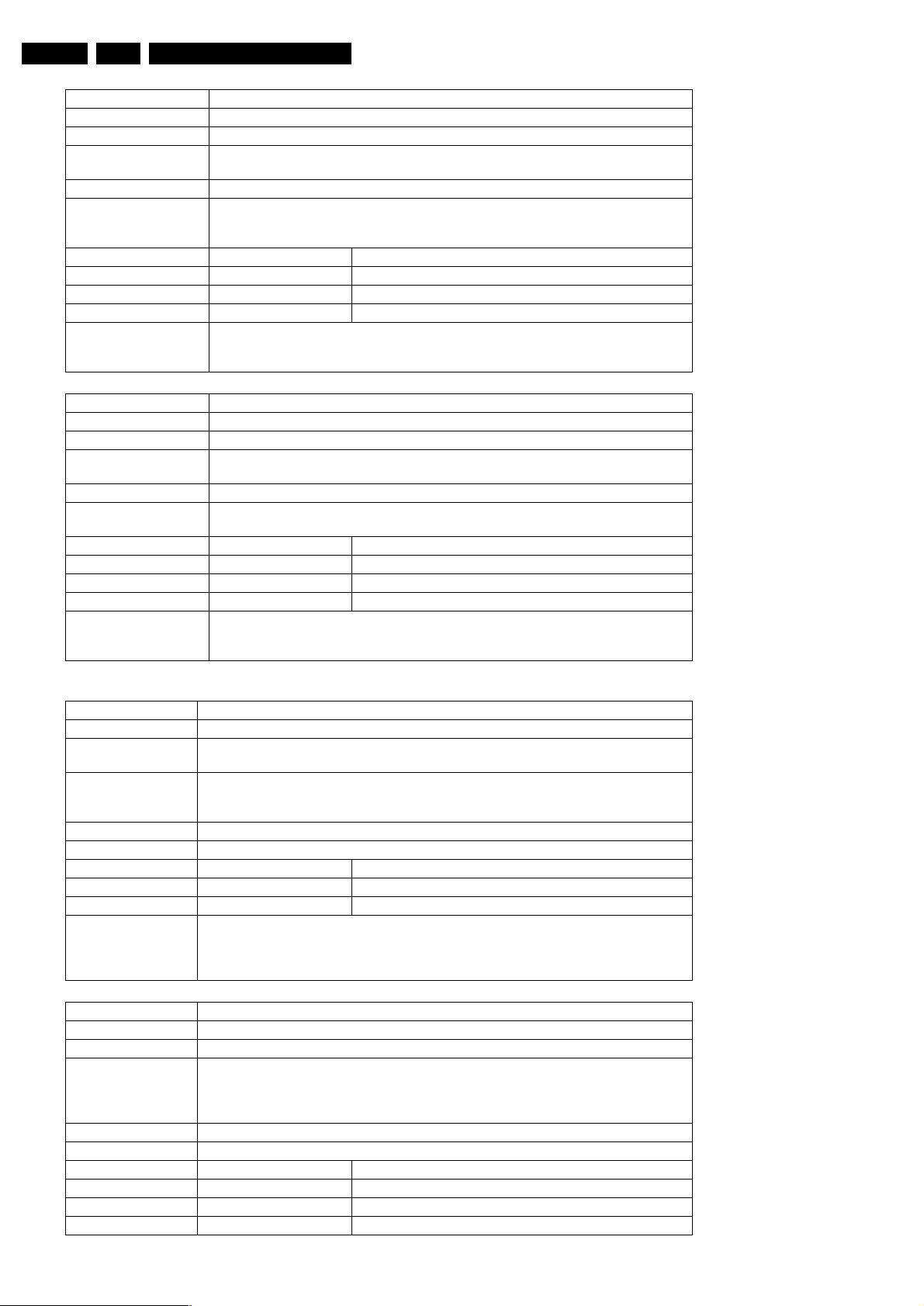

5.2 Player Script Interface

5.2.1 Trade Mode

TRADE MODE

When the recorder is in Trade Mode, the recorder cannot be

controlled by means of the front key buttons, but only by means

of the remote control.

IF TRADE MODE OFF

UNPLUG THE RECORDER

PRESS 2 KEYS

SIMULTANEOUSLY

<STOP> + <OPEN/CLOSE>

PLUG THE RECORDER

RECORDER IS IN TRADE MODE

WHEN PRESSING FRONT

KEYS, THE RECORDER

DOESN'T RESPOND

IF TRADE MODE ON

UNPLUG THE RECORDER

PRESS 2 KEYS

SIMULTANEOUSLY

<STOP> + <OPEN/CLOSE>

PLUG THE RECORDER

RECORDER IS IN NORMAL MODE

WHEN PRESSING FRONT

KEYS, THE RECORDER

WILL RESPOND

CL 16532095_071.eps

Figure 5-2

5.2.2 Virgin mode

If you want that the recorder starts up in Virgin mode, follow this

procedure:

• Unplug the recorder

• plug the recorder again while you keep the STAND BY/ON

key pressed

• the set starts up in Virgin mode.

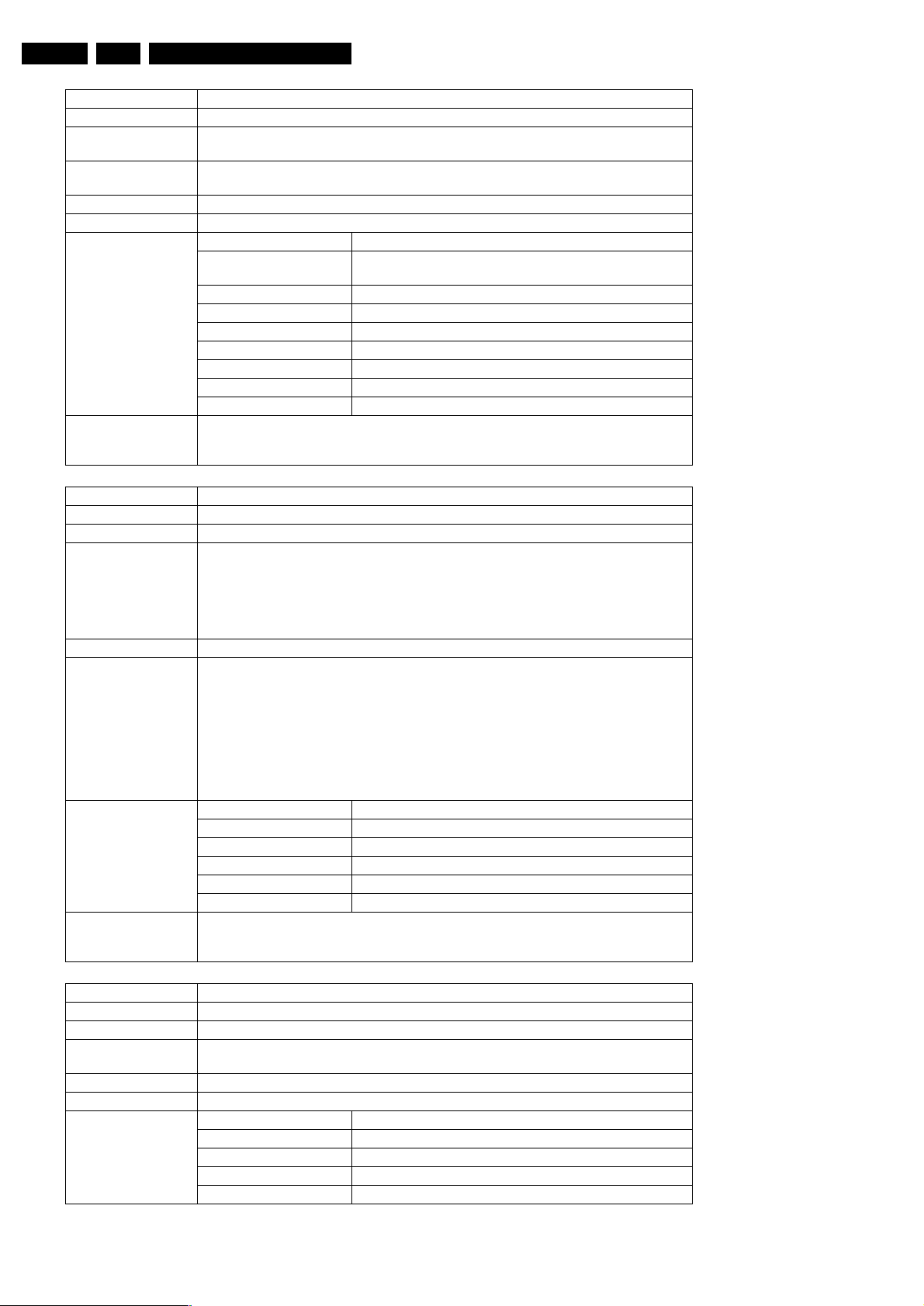

5.3 Menu and Command Mode Interface

5.3.1 Nuclei Numeration

Each nucleus has a unique number of four digits. This number

is the input of the command mode.

[ XX YY ]

Nucleus number

Nucleus group numbe

Figure 5-3

Group number Group name

0Scripts

1 Codec (e.g. Chrysalis, Leco)

2 Boot EE PR O M

3NVRAM

4 SDRAM

5Flash

6 Video Input Processor

7DVIO

8* Progressive Scan

9 Basic Engine

10* Display and Control Board

11* Analogue Board

12 System

13* Electronic Program Guide Board

14* PCMCIA

150801

CL 06532152_012.ep

05120

15* HDMI

16 Analogue Slave Processor

17 Analogue Board EEPROM

18 Video Matrix

19 Audio Matrix

20 Front End

21* Hard Disk

22* Digital Terrestrial Tuner Module

* Not applicable for DVDR610, DVDR615 & DVDR616 Range

5.3.2 Error Handling

Each nucleus returns an error code. This code contains six

numerals, which means:

[ XX YY ZZ ]

Error code

Nucleus number

Nucleus group numbe

Figure 5-4

The nucleus group numbers and nucleus numbers are the

same as above.

5.3.3 Command Mode Interface

Set-Up Physical Interface Components

Hardware required:

•Service PC

• one free COM port on the Service PC

• special cable to connect DVD recorder to Service PC

The service PC must have a terminal emulation program (e.g.

Hyperterminal) installed and must have a free COM port (e.g.

COM1). Activate the terminal emulation program and check

that the port settings for the free COM port are: 19200 bps, 8

data bits, no parity, 1 stop bit and no flow control. The free COM

port must be connected via a special cable to the RS232 port

of the DVD recorder. This special cable will also connect the

test pin, which is available on the connector, to ground (i.e.

activate test pin).

Code number of PC interface cable: 3122 785 90017

Activation of Diagnostic Software

1. Pull the mains cord from the recorder and reconnect it

again (reboot).

2. The next welcome message will appear on the PC:

Welcome screen D&S program

Figure 5-5

Now, the prompt 'DS:>' will appear. The diagnostic software is

now ready to receive commands. The commands that can be

given are the numbers of the nuclei. If you see above shown

screen, continue with paragraph 'Nuclei Codes'.

CL 06532152_013.ep

12

Diagnostic Software

EN 15DVDR610/615/616 5.

3. It is possible that the next messages will appear when

starting the DVD+RW for the first time

Error messages D&S program

Figure 5-6a

Error messages D&S program

Enter "Y" to program a safe string. With this automatically

generated string the board will work in principle but it has to be

checked if all board settings were detected correctly.

Diversity String Input

4. Execute nucleus 1226 to enter the string. Please see

chapter 8.4 for details

Nucleus 1226 execution with string

Figure 5-7

5. To check if the hardware info is filled correctly, you can

execute nucleus 1228.

Nucleus 1228 info example

Figure 5-6b

In these cases, the boot EEPROM of the Digital Board does not

contain the required string with the hardware information. To

update the Digital Board with the correct string, nucleus 1226

must be executed.

See next section 'Diversity String Input'.

There can also be the next error message.

Figure 5-8

6. Exit the 'Terminal' program.

Figure 5-6c

7. Reboot the DVD recorder to allow the software to start.

EN 16 DVDR610/615/6165.

Diagnostic Software

Command overview Digital Board

Below you will find an overview of the nuclei, their numbers,

and their error codes. This overview is preliminary and subject

to modifications.

Note: AV3 in the overview includes also the AV3.5 drive.

CODEC HOST CONTROLLER (CHR)

Nucleus Name DS _CHR_DevTypeGet

Nucleus Number 100

Description Retrieves the device id, the module ids and revisions of the Codec and returns them to the

stdout port.

Technical -

Determine the codec id by means of comparing version ids of the modules.-

Read the module-id register of every module and display it to the user.

Execution Time Less than 1 second.

User Input None

Error Number Description

10000 Getting the information succeeded

10001 Wrong codec id detected

Example DS:> 100

010000:

Device ID 710 0

Codec ID PNX7100_C

F-BCU (0x0102) 1.0 INTC (0x011d) 1.0 PCI-XIO(0x0113) 1.0

SIF (0x013b) 1.0 EJTAG (0x0104) 0.1 S-BCU (0x0102) 1.0

(0x010a) 1.0 CONFIG (0x013f) 1.1 RESET (0x0123) 1.0

DEBUG (0x0116) 0.0 UART0 (0x0107) 0.1 UART1 (0x0107) 0.1

UART2 (0x0107) 0.1 UART3 (0x0107) 0.1 I2C0 (0x0105) 0.1

I2C1 (0x0105) 0.1 GPIO (0x013c) 1.0 SYNC (0x013a) 1.0

DISP0 (0xa015) 1.12 DISP1 (0xa00f) 1.1 OSD (0x0136) 0.1

SPU (0xa00e) 0.0 MIXER (0x0137) 1.0 DENC (0x0138) 1.0

CCIR (0x0139) 1.0 VDEC (0x0133) 0.2 PARSER (0xa00d) 0.0

DV (0xa00c) 0.0 BEI (0xa00a) 0.1 IDE (0xa009) 0.1

SGDX (0xa008) 1.0 B YT E (0xa00b) 0.1 OUTPUT (0xa003) 1.0

ACOMP (0xa000) 1.0 VFE (0xa001) 0.1 VCOMP (0xa002) 1.0

SCR (0x0000) 0.0 SIFF (0xa011) 0.1 WMD (0xa010) 0.0

AUDIO0 (0xa015) 1.12 AUDIO1 (0xa00f) 1.1 PSCAN (0xa018) 0.1

Test OK @

Nucleus Name DS_CHR_TestImageOn

Nucleus Number 101

Description Generates a test-image of a selected video standard on selected video output on the digital

Technical -Validate the user input.

Execution Time 6 seconds.

board. When no input is given, the default values will be used (see user input description below). Make sure to use the proper nuclei to route the video signal on the analogue board to get

the videosignal to the proper output.

-Initialise the SYNC module.

-Initialise the DISPLAY module.

-Initialise the MIXER module.

-Initialise the DENC module.

-Set the selected video standard.

-Generate the selected test image in memory.

-Start the DISPLAY module.

-Start the MIXER module.

-Start the DENC module according to the selected test image id.

Diagnostic Software

Nucleus Name DS_CHR_TestImageOn

User Input The user has to decide which test image, video standard and video output must be used:

Test image id:

0 VERTICAL_C OLOURBAR (default)

1 HORIZONTAL_COLOURBAR

2 WHITE

3 YELLOW

4 CYAN

5 GREEN

6 MAGENTA

7 RED

8 BLUE

9 BLACK

10GRAY

11TEST_IMAGE_FOR_PROGRESSIVE_ SC AN

Video standard:

PAL (default)

NTSC

Video output

ALL CVBS and YC and RGB (default)

CVBS

YC

RGB

YUV

PSCAN progressive scan

Error Number Description

10100 Generating the test image succeeded.

10101 Invalid input was provided.

10102 The Codec SYNC-module cannot be initialised.

10103 The Codec MIXER-module cannot be initialised.

10104 The Codec VPP-module cannot be initialised.

10105 The Codec DENC-module cannot be initialised.

10106 T he digital board hardware information is corrupt

Example DS:> 101

010100:

Test OK @

EN 17DVDR610/615/616 5.

DS:> 101 0 pal cvbs

010100:

Test OK @

DS:> 101 4 ntsc yc

010100:

Test OK @

Nucleus Name DS_CHR_TestImageOff

Nucleus Number 102

Description Switches the test-image off.

Technical -

Execution Time Less than 1 second.

User Input None

Error Number Description

Example DS:> 102

Nucleus Name DS_CHR_SineOn

Nucleus Number 103

Description Generate an audio sine signal on the audio output of the digital board. Note: Left channel

Stop the DENC module.

10200 Stopping the test image generation succeeded

10201 The Codec DENC-module failed.

010200:

Test OK @

6kHz, right channel 12 kHz sine. Make sure to route the signal first.

EN 18 DVDR610/615/6165.

Diagnostic Software

Technical - De-mute the analogue board

Execution Time Less than 1 second

User Input None

Error Number Description

Example DS:> 103

Nucleus Name DS_CHR_SineOff

Nucleus Number 104

Description Stop generating the audio sine signal

Technical - Reset the audio block of the Codec

Execution Time Less than 1 second.

User Input None

Error Number Description

Example DS:> 104

- Set fifo parameters for audio

- Set the volume

- Set the I2S outputs and configuration paths

- Set the decoder mode

- Configure the audio decoder

- Put the AC3 audio in the fifo

- Send ‘prepare’ command to the audio decoder

- Send ‘play’ command to the audio decoder

10300 The sine signal was successfully generated

10301 The analogue board could not be de-muted

10302 The audio decoder did not initialise

10303 The dsp2 of the audio decoder did not configure

10304 The dsp1 of the audio decoder did not configure

10305 There was a delay-error before starting

10306 Wrong input was given to the decoder function

10307 Wrong input was given to the decoder function @@@@@

10308 The audio decoder did not get into the 'prepared' state

010300:

Test OK @

10400 Switching off the audio sine signal succeeded

10401 Failed to reset the audio decoder

010400:

Test OK @

Nucleus Name DS_CHR_SineBurst

Nucleus Number 105

Description Generate an audio sine signal on the audio output of the digital board for 4 seconds.

Technical - Call the DS_CHR_SineOn nucleus

Execution Time 4 seconds

User Input None

Error Number Description

Example DS:> 105

Nucleus Name DS_CHR_MuteOn

Nucleus Number 106

Description Mute the audio outputs of the digital board

Technical - Send the 'Mute' command to the audio decoder

Execution Time Less than 1 second.

User Input None

Error Number Description

Note: Left channel 6kHz, right channel 12 kHz sine with some known hick-ups

- Delay for 4 seconds

- Call the DS_CHR_SineOff nucleus

10500 The sine signal burst was successfully generated

10501 The delay did not succeed during the burst

10502 The audio sine could not be generated

010500:

Test OK @

10600 Muting the audio succeeded

Diagnostic Software

EN 19DVDR610/615/616 5.

Example DS:> 106

Nucleus Name DS_CHR_MuteOff

Nucleus Number 107

Description De-mute the audio outputs of the digital board

Technical - Send the ‘DeMute’ command to the audio decoder

Execution Time Less than 1 second.

User Input None

Error Number Descr iption

Example DS:> 107

Nucleus Name DS_CHR_DvLedOn

Nucleus Number 108

Description Check the connection to the DV-LED on the digital board by switching it on

Technical - Write to the PIO pin to light the DV LED

Execution Time Less than 1 second.

User Input None

Error Number Descr iption

Example DS:> 108

010600:

Test OK @

10700 De-muting the audio succeeded

010700:

Test OK @

10800 Switching the DV-LED on succeeded

10801 Switching the DV-LED on failed

010800:

Test OK @

Nucleus Name DS_CHR_DvLedOff

Nucleus Number 109

Description Switch off the DV-LED on the digital board

Technical - Write to the PIO pin to switch off the DV LED

Execution Time Less than 1 second.

User Input None

Error Number Descr iption

10900 Switching the DV-LED off succeeded

10901 Switching the DV-LED off failed

Example DS:> 109

010900:

Test OK @

Nucleus Name DS_CHR_MacroVisionOn

Nucleus Number 110

Description Turn on MacroVision.

Technical - Set some registers of the DENC module in the Codec.

Execution Time Less than 1 second.

User Input None

Error Number Descr iption

11000 Turning on MacroVision succeeded

11001 Turning on MacroVision failed

Example DS:> 110

011000:

Test OK @

Nucleus Name DS_CHR_MacroVisionOff

Nucleus Number 111

Description Turn off MacroVision.

Technical - Set some registers of the DENC module in the Codec.

Execution Time Less than 1 second.

User Input None

Error Number Descr iption

11100 Turning off MacroVision succeeded

EN 20 DVDR610/615/6165.

11101 Turning off MacroVision failed

Example DS:> 111

011100:

Test OK @

Nucleus Name DS_CHR_Peek

Nucleus Number 112

Description Peek a value on a specified address

Technical - Check the user input

- Read out the address specified

- Check whether the address to be read is aligned on 4 bytes

Execution Time Less than 1 second.

User Input The address to peek on

Error Number Description

11200 Peeking on the specified address succeeded

11201 Peeking on the specified address failed, wrong user input

11202 Peeking on the specified address failed due to misalignment

Example DS:> 112 0xa0700000

011200: Value read = 0x000001BD

Test OK @

Nucleus Name DS_CHR_Poke

Nucleus Number 113

Description Poke a value on a specified address

Technical - Check the user input

- Change the value on the address specified

- Check whether the address to be modified is aligned on 4 bytes

Execution Time Less than 1 second.

User Input The address to poke and the value: <address><value>

Error Number Description

11300 Poking the specified address succeeded

11301 Poking the specified address failed, wrong user input

11302 Poking the specified address failed due to misalignment

Example DS:> 113 0xa0700000 0xaabbccdd

011300:

Test OK @

Diagnostic Software

Nucleus Name DS_CHR_INT_PICInterrupts

Nucleus Number 114

Description Test all interrupts of the priority interrupt controller

Technical - Install interrupt handlers

Execution Time Less than 1 second.

User Input Error Number Description

Example DS:> 114

Nucleus Name DS_CHR_DMA_TestDMA

Nucleus Number 115

Description Test the memory to memory DMA transfer

Technical - Create a block with known data in memory

Execution Time Less than 2 seconds.

User Input Error Number Description

- Generate interrupts

- Test whether all interrupts were received

11400 Testing all the PIC interrupts succeeded

11401 Testing all the PIC interrupts failed

011400:

Test OK @

- Copy this block to the consecutive area using 3 different DMAs

- Check whether all DMAs transferred the data properly

11500 The testing of the DMAs succeeded

11501 The initialisation of the DMAs failed for one or more DMA

11502 One or more DMAs failed the test

Diagnostic Software

EN 21DVDR610/615/616 5.

Example DS:> 115

011500:

Test OK @

Boot EEPROM (BROM)

Nucleus Name DS_BROM_Communication

Nucleus Number 200

Description Check the communication between the IIC controller of the Chrysalis and the boot EE-

PROM

Technical - Initialise IIC

Execution Time Less than 1 second.

User Input None

Error Number Descr iption

Example DS:> 200

- Read something from th e EEPROM

20000 The data is properly read so the communication is OK

20001 The IIC bus was not accessible

20002 There was a timeout reading the device

20003 The IIC acknowledge was not received

20004 An IIC-bus error occurred

20005 The IIC bus initialisation failed

20006 An unexpected IIC error occurred

020000:

Test OK @

Nucleus Name DS_BROM_WriteRead

Nucleus Number 201

Description Check whether the Boot EEPROM can be written to and read from

Technical - Initialise IIC

- Write something to the

- Read from the same location and check whether it is the same as written

Execution Time Less than 1 second.

User Input None

Error Number Descr iption

20100 The write-read test succeeded

20101 The write-read test failed

20102 An IIC-bus error occurred

20103 There was a timeout reading the device

20104 The IIC bus was not accessible

20105 The IIC acknowledge was not received

20106 Got unknown IIC bus error

20107 The IIC bus initialisation failed

Example DS:> 201

020100:

Test OK @

EEPROM

NVRAM

Nucleus Name DS_NVRAM_Communication

Nucleus Number 300

Description Check the communication between the IIC controller of the Codec and the EEPROM

Technical - Initialise IIC

Execution Time Less than 1 second.

User Input None

Error Number Descr iption

- Read from a location in NVRAM

30000 Something is properly read so the communication is OK

30001 The IIC bus was not accessible

30002 There was a timeout reading the device

30003 The IIC acknowledge was not received

30004 The communication with the device failed

30005 The IIC bus initialisation failed

30006 @@@@@@

EN 22 DVDR610/615/6165.

Diagnostic Software

Example DS:> 300

Nucleus Name DS_NVRAM_WriteRead

Nucleus Number 301

Description Check whether the EEPROM can be written to and read from

Technical - Initialise IIC

Execution Time Less than 1 second

User Input None

Error Number Description

Example DS:> 301

Nucleus Name DS_NVRAM_Clear

Nucleus Number 302

Description Make the EEPROM empty, containing all zeroes.

Technical - Initialise IIC

Execution Time 16 seconds

User Input None

Error Number Description

Example DS:> 302

030000:

Test OK @

- Backup data from location to modify

- Write to location and read it back again

- Write back the backed up data to the location to leave the NVRAM as found

30100 The write-read test succeeded

30101 The IIC bus could not be initialised

30102 There was an NVRAM IO error

30103 The value could not be read back from the NVRAM

030100:

Test OK @

- Create a memory block filled with zeroes

- Write this block to the NVRAM

30200 The clearing of the NVRAM succeeded

30201 There was an IIC error

30202 Clearing the NVRAM failed

030200:

Test OK @

Nucleus Name DS_NVRAM_Modify

Nucleus Number 303

Description Modifies one or more locations in NVRAM and updates the checksum of the section

Technical - Initialise IIC

Execution Time Less than 1 second

User Input 1. The location that must be modified

Error Number Description

modified

- Decode user input

- Modify the NVRAM as indicated

- Validate the NVRAM by calculating the checksum and storing it

i.e. "ALL" "BOOT" "DIAGNOS TICS" "DOWNLOAD" "CONFIG" "RECORDER" or

no string if an offset from the base address of the NVRAM is required

2. The offset and data which to put on the selected location

<offset> <length> <data>

30300 Modifying the NVRAM contents succeeded

30301 Unable to initialise NVM

30302 Modifying the NVRAM contents failed

30303 length out of range

30304 unable to decode length

30305 offset out of range

30306 unable to decode offset

30307 unknown location specified

30308 no location is specified

30309 number of values incorrect

30310 There was an IIC error

Diagnostic Software

EN 23DVDR610/615/616 5.

Example DS:> 303 DIAGNOSTICS 5 1 0x5a

Nucleus Name DS_NVRAM_Read

Nucleus Number 304

Description Read out one or more locations in the NVRAM

Technical - Initialise IIC

Execution Time Less than 1 second

User Input 1. The location which must be read i.e. "ALL" "BOOT" "DIAGNOSTICS" "DOWN LOAD"

Error Number Descr iption

Example 304 DIAGNOSTICS 0 6

030300: Section is modified successfully

Test OK @

- Decode user input

- Read from the NVRAM and return this info to the user

"CONFIG" "RECORDER" or no string if an offset from the base address of the NVRAM

is required

2. The offset and number of bytes to read

<offset> <length>

30400 Value read

30401 Unable to initialise NVM

30402 Reading the NVRAM contents failed

30403 length out of range

30404 unable to decode length

30405 offset out of range

30406 unable to decode offset

30407 unknown location specified

30408 no location is specified

030400: Value read = 0x00 0x00 0x00 0x00 0x00 0x5A

Test OK @

SDRAM

Nucleus Name DS_SDRAM_WriteRead

Nucleus Number 400

Description Check all data lines, address lines and memory locations of the SDRAM

Technical - Test the databus

Execution Time 11 seconds for 32 Mb

User Input None

Error Number Descr iption

Example DS:> 400

Nucleus Name DS_SDRAM_WriteReadFast

Nucleus Number 401

Description Check all data lines and address lines of the SDRAM

Technical - Test the databus

Execution Time Less than 1 second

User Input None

Error Number Descr iption

Example DS:> 401

- Test the address bus

- Test the integrity of the device itself (memory locations)

23 seconds for 64 Mb

40000 The write-read test succeeded

40001 The data bus contains an error

40002 The address bus contains an error

40003 The SDRAM itself contains an error

040000:

Test OK @

- Test the addressbus

40100 The write-read test succeeded

40101 The data bus contains an error

40102 The address bus contains an error

040100:

Test OK @

EN 24 DVDR610/615/6165.

Nucleus Name DS_SDRAM_Write

Nucleus Number 402

Description Write to a specific memory address

Technical - Decode the user input and check its ranges and alignment on 4 bytes

- Write the data to the SDRAM

Execution Time Less than 1 second

User Input 1. The location that must be modified

( SDRAM starts at address 0xA0000000 )

2. The value to put on the selected location

Error Number Description

40200 Writing to the SDRAM succeeded

40201 Writing to the SDRAM failed; Wrong user input

40202 Address is not dividable by 4

Example DS:> 402 0xa1000010 0xad112222

040200:

Test OK @

Nucleus Name DS_SDRAM_Read

Nucleus Number 403

Description Read from a specific memory address

Technical - Decode the user input and check the ranges

- Read from the SDRAM and return this info to the user

Execution Time Less than 1 second

User Input The location from which the data must be read

( SDRAM starts at address 0xA0000000 )

Error Number Description

40300 Reading from the SDRAM succeeded

40301 Reading from the SDRAM failed; Wrong user input

40302 Address is not dividable by 4

Example DS:> 403 0xa1000010

040300: Value read = 0xAD112222

Test OK @

Diagnostic Software

FLASH

Nucleus Name DS_FLASH_DevTypeGet

Nucleus Number 500

Description Get the device (revision) type information of the FLASH IC. (type, manufacturer, device ID

and size)

Technical - Set the timing for the flash writing

Execution Time Less than 1 second

User Input None

Error Number Description

Example DS:> 500

Nucleus Name DS_FLASH_WriteRead

Nucleus Number 501

Description Check whether the FLASH can be written to and read from

Technical - Find the test segment in flash

Execution Time Less than 1 seconds.

User Input None

Error Number Description

- Write a command sequence to determine device type information

- Return the information to the user

50000 Getting the information from the FLASH succeeded

50001 Getting the information from the FLASH failed

050000: Found FLASH memory:

NOR AMD 29DL640G 8MB,NOR AMD 29DL640G 8MB

Test OK @

- Read the data into SDRAM

- Modify the data

- Write this data from SDRAM to FLASH and verify it by reading back again

50100 The FLASH write-read test succeeded

50101 The test segment could not be found

50102 All bits is the TEST region are filled with 0 (region exhausted)

Diagnostic Software

50103 The WriteRead test failed

50104 The Write Failed

Example DS:> 501

050100:

Test OK @

Nucleus Name DS_FLASH_Read

Nucleus Number 502

Description Read from a specific memory address in FLASH

Technical - Decode the user input and check the ranges and whether the address is aligned on

4 bytes

- Read the data and return this to the user

Execution Time Less than 1 seconds.

User Input The location from which data must be read

( FLASH starts at address 0xB8000000 )

Error Number Description

50200 Reading the FLASH succeeded

50201 Reading the FLASH failed; Wrong user input

50202 Address is not dividable by 4

Example DS:> 502 0xb8000000

050200: Value read = 0x3C08A000

Test OK @

EN 25DVDR610/615/616 5.

Nucleus Name DS_FLASH_ChecksumProgram

Nucleus Number 503

Description Check the checksum of the application partitions by recalculating and comparing partition

Technical - Determine the number of segments

Execution Time 6 seconds

User Input None

Error Number Description

Example DS:> 503

Nucleus Name DS_FLASH_CalculateChecksum

Nucleus Number 504

Description Calculate the checksum over all memory addresses. Used to check entire FLASH contents

Technical - Run the checksum calculation algorithm all flash memory addresses

Execution Time 6 seconds

User Input None

Error Number Description

Example DS:> 504

checksums

- Find the application in each segment and determine its checksum

- Check whether the checksums stored match the newly calculated

50300 The checksum is valid, the test succeeded

50301 The checksum is invalid

050300:

BootCode checksum is: 0xBABE5B6F, which is correct

Diagnostics checksum is : 0xBABEBAFF, which is correct

Download checksum is: 0xBABEEDBF, which is correct

Application checksum is : 0xBABE8EEC, which is correct

Test OK @

50400 Calculating the checksum over all addresses succeeded

050400: The Checksum = 0xBABE30A4

Test OK @

Nucleus Name DS_FLASH_CalculateChecksumFast

Nucleus Number 505

Description Calculate a checksum over a selected number of address locations

Technical - Run the checksum calculation algorithm on a selected number of flash memory

Execution Time 6 seconds

User Input None

Error Number Description

addresses

50500 Calculating the checksum over selected addresses succeed-

ed

EN 26 DVDR610/615/6165.

Diagnostic Software

Example DS:> 505

050500: The Checksum = 0xBABEB064

Test OK @

Video Input Processor (VIP)

Nucleus Name DS_VIP_DevTypeGet

Nucleus Number 600

Description Get the device (revision) type information of the VIP IC

Technical - Initialise IIC

- Read out the device (revision) type information of the VIP IC

Execution Time Less than 1 second

User Input None

Error Number Description

60000 Getting the information from the VIP succeeded

60001 The IIC bus initialisation failed

60002 The was an error getting the information from the VIP

60003 Type not according to type stored in HW diversity string

Example DS:> 600

Nucleus Name DS_VIP_Communication

Nucleus Number 601

Description Check the communication between the IIC controller of the Codec and the VIP IC

Technical - Initialise IIC

Execution Time Less than 1 second

User Input None

Error Number Description

Example DS:> 601

060000: Found SAA7118

Test OK @

- Read data from a location in the VIP

60100 Communicating with the VIP succeeded

60101 The IIC bus was not accessible

60102 There was a timeout reading the device

60103 The IIC acknowledge was not received

60104 The communication with the device failed

60105 The IIC bus initialisation failed

060100:

Test OK @

Nucleus Name DS_VIP_ClockO utputOn

Nucleus Number 602

Description Switch the clock output on

Technical - Initialise IIC

Execution Time Less than 1 second

User Input None

Error Number Description

Example DS:> 602

Nucleus Name DS_VIP_ClockOutputOff

Nucleus Number 603

Description Switch the clock output off

Technical - Initialise IIC

Execution Time Less than 1 second

User Input None

Error Number Description

- Set the clock output through IIC

60200 Switching the clock output on succeeded

60201 Switching the clock output on failed

060200:

Test OK @

- Reset the clock output through IIC

60300 Switching the clock output off succeeded

60301 Switching the clock output off failed

Diagnostic Software

EN 27DVDR610/615/616 5.

Example DS:> 603

Nucleus Name DS_VIP_SelectInput

Nucleus Number 604

Description Select an input video path to be switched to the analogue output pin (AOUT) of the VIP

Technical - Check the user input

Execution Time Less than 1 second

User Input The input to select, see table below.

Error Number Description

Example DS:> 604 1

Table 5-1

Channel number Description

1 CVBS_Y_IN_A

2 CVBS_OUT_B

3 CVBS_Y_IN_B

4 CVBS_Y_IN_C

6C_IN

8G_IN

9Y_IN

13 B_IN

14 U_IN

18 R_IN

19 V_IN

Available channels for input of the 7118 and their description

060300:

Test OK @

- Initialise IIC

- Read out the VIP id

- Write the set of registers required for the input specified

60400 Selecting the input of the VIP succeeded

60401 The user provided wrong input

60402 The VIP was not accessible

60402 An unsupported VIP was found

060400:

Test OK @

Table 5-2

Channel number Description

1 CVBS_Y_IN_B

2 CVBS_OUT_B_VIP

4C_IN_VIP

7 CVBS_Y_IN_B

Digital Video Input Output (DVIO)

Nucleus Name DS_DVIO_LinkDevTypeGet

Nucleus Number 700

Description Get the device (revision) type information of the 1394 Link layer IC

Technical - Initialise the PIO pins on the Codec

Execution Time Less than 1 second

User Input None

Error Number Description

Example DS:> 700

Nucleus Name DS_DVIO_PhyDevTypeGet

Nucleus Number 701

Available channels for input of the 7115 and their description

- Read out the ID register

70000 Getting the information from the link layer IC succeeded

70001 Getting the information from the link layer IC failed

70002 Type not according to type stored in HW diversity string

070000: Device type of the link layer IC: ffc00301

Test OK @

EN 28 DVDR610/615/6165.

Description Get the device (revision) type information of the 1394 Physical layer IC

Technical - Initialise the PIO pins of the Codec-Write the PHY

- access regist er in the Link chip to indicate phy read access

- Wait until the link chip has obtained the value from the phy-chip

- Read this out and filter the data to be returned to the user

Execution Time Less than 1 second

User Input None

Example DS:> 701

070100: Physical layer IC: VendorID: 0x006037, ProductID: 0x412801

Test OK @

Nucleus Name DS_DVIO_LinkCommunication

Nucleus Number 702

Description Check the acc essibility of the 1394 Link layer IC by writing to and reading from a specific

address

Technical - Initialise the PIO pins of the chrysalis

- Write a pattern to the CYCTM register of the link chip

- Read back and verify the pattern

Execution Time Less than 1 second

User Input None

Error Number Description

70200 Communicating with the link layer IC succeeded

70201 Communicating with the link layer IC failed

70202 Result of nucleus not according to HW diversity string

Example DS:> 702

070200:

Test OK @

Diagnostic Software

Nucleus Name DS_DVIO_PhyCommunication

Nucleus Number 703

Description Check the accessibility of the 1394 Physical layer IC by writing to and reading from a spe-

Technical - Initialise the PIO pins of the Codec

Execution Time Less than 1 second

User Input None

Error Number Description

Example DS:> 703

Nucleus Name DS_DVIO_Routing

Nucleus Number 704

Description Route a DV stream containing an audio and video signal through the physical and link layer

Technical - Initialise the DMA to transfer 5 frames PAL/NTSC

Execution Time 6-10 seconds (6 when OK, 10 when no stream or error)

User Input None

cific address

- Initialise IIC

- Write the data to be written to the phy-chip to the link chip first

- Wait until the link chip indicates that the data has been written to the PHY

- Write the PHY-access register in the Link chip to indicate PHY read access

- Wait until the link chip has obtained the value from the PHY-chip

- Test whether the value read back equals the one previously written

70300 Communicating with the physical layer IC succeeded

70301 The physical layer IC was not accessible

70302 Communicating with the physical layer IC failed

70303 Result of nucleus not according to HW diversity string

070300:

Test OK @

ICs to the Codec. This test works for both NTSC and PAL.

- Initialise the DV demultiplexer

- Initialise the 1394 interface and start reception of the DV stream

- Check whether the stream was copied to memory properly by the byte input interface

(port to memo r y type DMA)

Diagnostic Software

Error Number Description

70400 Routing the signals succeeded

70401 The 1394 link chip could not be initialised properly

70402 There was a syntax error in the DV stream

70403 DMA could not copy DV stream to memory. Stream connect-

ed?

70404 DMA not working properly

Example DS:> 704

070400:

Test OK @

Nucleus Name DS_DVIO_DetectNode

Nucleus Number 705

Description Check whether a DV node can be detected by the hardware. This test works for both NTSC

and PAL.

Technical - Initialise the 1394 interface

- Detect whether a node is in range

Execution Time 3 or 5 seconds (3 when OK, 5 when no stream or error)

User Input None

Error Number Description

70500 The node was detected OK

70501 The 1394 link chip could not be initialised properly

70502 Unable to write to 1394 PHY chip

70503 Unable to read from 1394 PHY chip

70504 No node was detected

Example DS:> 705

070500:

Test OK @

EN 29DVDR610/615/616 5.

Nucleus Name DS_DVIO_DetectStream

Nucleus Number 706

Description Check whether a DV stream can be detected by the hardware. T his test works for bot h

Technical - Initialise the 1394 interface

Execution Time 3 or 5 seconds (3 when OK, 5 when no stream or error)

User Input None

Error Number Description

Example DS:> 706

NTSC and PAL.

- Start receiving the stream

- Detect whether the stream is OK

70600 The stream was detected

70601 The 1394 link chip could not be initialised properly

70602 No stream detected

070600:

Test OK @

Progressive Scan (PSCAN)

Nucleus Name DS_P SCAN_DencDevTypeGet

Nucleus Number 800

Description Retrieve the device type information from the progressive scan DENC IC

Technical Execution Time Less than 1 second

User Input None

Error Number Description

80000 Retrieving the device type information succeeded

80001 The IIC bus was not accessible

80002 There was a timeout reading the device

80003 The IIC acknowledge was not received

80004 Communicating with the progressive scan DENC-IC failed

80005 The initialisation of the IIC bus failed

Example DS:> 800

080000: Device Type xxxx t.b.d.

Test OK @

EN 30 DVDR610/615/6165.

Nucleus Name DS_PSCAN_CommunicationDenc

Nucleus Number 801

Description Check the communication between the IIC controller of the chrysalis and the progressive

scan DENC-IC

Technical - Initialise IIC

- Write data to a register of the DENC through IIC

Execution Time Less than 1 second

User Input None

Error Number Description

80100 Communicating with the progressive scan DENC-IC succeed-

80101 The IIC bus was not accessible

80102 There was a timeout reading the device

80103 The IIC acknowledge was not received

80104 Communicating with the progressive scan DENC-IC failed

80105 The initialisation of the IIC bus failed

80106 The read data is not the same as the written data

80107 No chip was expected

Example DS:> 801

080100:

Test OK @

Nucleus Name DS_PSCAN_TestImageOn

Nucleus Number 802

Description Generate the test images that are present on the progressive scan IC.

Technical - Determine whether the user wanted a HATCH or a FRAME image pattern

- Initialise the PIO pins of the Codec

- Initialise IIC

- Reset the DENC

- Enable the 27Mhz clock

- Send all settings for the pattern to the DENC through IIC

Execution Time Less than 1 second

User Input In case of ADV7196:

When no input is given “HATCH” is the default

-“HATCH”

-“FRAME”

Remark:

“HATCH” is a crosshatch test pattern (horizontal and vertical white lines are display ed

against a black background)

“FRAME” is a uniform coloured frame/field test pattern (default white).

In case of FLI2300: Nothing.

Error Number Description

80200 The generation of the test image succeeded

80201 Unable to initialise

80202 Unable to reset DENC

80203 Unable to generate image

80204 No chip was expected

Example DS:> 802 HATCH

080200:

Test OK @

Diagnostic Software

ed

PSCAN IC

Nucleus Name DS_PSCAN_TestImageOff

Nucleus Number 803

Description Switch off the generated test image

Technical - Initialise IIC

- Send the default DENC settings to the DENC through IIC

Execution Time Less than 1 second

User Input None

Error Number Description

80300 Turning off the test image succeeded

80301 Unable to initialise

80302 IIC Error during writing PSCAN IC

80303 No chip was expected

PSCAN IC

Loading...

Loading...