Page 1

Philips Consumer Electronics Company

A Division of Philips Electronics North America Corporation

Se

Technical Service Data

Service Solutions Group

hnical Publications Dept.

Tec

P.O. Box 555

Jefferson City,TN 37760

, 401 E. Old Andrew Johnson Hwy.

c. 1A: Main Section

( DVDR600VR/37, MRV700VR/17 )

Specifications

Opera

Adjustment Proc

Schematic D

loded Views

Exp

Cabin

Sec. 2: Deck Mechanism Section

Sec. 3: DVD+RW Basic Engine

VA

For repair information on the Basic

gine.

En

MANUAL 5903

ting Instructions

edures

iagrams and CBA’s

et & Electrical Parts Lists

D8041 12NC:

3122 785 14850

71/RV007VRMXOVANGAM

DVD Recorder &

Video Cassette Recorder

Service Manual

73/RV006RDVDSPILIHPredroceR ettessaC oediV & redroceR DVD 3095 LAUNAM

PHILIPS

Model: DVDR600VR/37

AGNAVOX

M

Model: MRV700VR/17

DVD Recorder & Video Cassette Recorder

First Issue: 9/04

©2004 Philips Consumer Electronics Company

Page 2

Philips Consumer Electronics Company

A Division of Philips Electronics North America Corporation

Se

Technical Service Data

Service Solutions Group

hnical Publications Dept.

Tec

P.O. Box 555

Jefferson City,TN 37760

, 401 E. Old Andrew Johnson Hwy.

c. 1A: Main Section

( DVDR600VR/37, MRV700VR/17 )

Specifications

Opera

Adjustment Proc

Schematic D

loded Views

Exp

Cabin

MANUAL 5903

ting Instructions

edures

iagrams and CBA’s

et & Electrical Parts Lists

DVD Recorder &

Video Cassette Recorder

Service Manual

PHILIPS

Model: DVDR600VR/37

Model: MRV700VR/17

AGNAVOX

M

DVD Recorder & Video Cassette Recorder

First Issue: 9/04

©2004 Philips Consumer Electronics Company

Page 3

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all

Philips Consumer Electronics Com pany** Equipment. The service procedures

recommended by Philips and described in this service manual are effective

methods of performing service operations. Some of these service operations

require the use of tools specially designed for the purpose. The special tools

should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and

NOTICES which should be carefully read in orde r to minimize the risk of personal injury to service personnel. The possibility exists that improper service

methods may damage the equipment. It also is i mportant to understand that

these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE. Philips could not

possibly know, evaluate and advise the service trade of all conceivable ways

in which service might be done or of the possible hazardous consequences of

each way. Consequently, Philips has not undertaken any such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is

not recommended by Philips must first satisfy himself thoroughly that neither

his safety nor the safe operation of the equipment will be jeopardized by the

service method selected.

** Hereafter throughout this manual, Philips Consumer Electronics Company

will be referred to as Philips.

WARNING

Critical components having special safety characteristics are identified

with a # by the Ref. No. in the parts list and enclosed within a broken

line* (where several critical components are grouped in one area) along

with the safety symbol # on the schematics or exploded vie w s.

Use of substitute replacement parts which do not have the same specifie d

safety characteristics may create shock, fire, or other hazards.

Under no circumstances should the original design be modified or altered

without written permission from Philips. Philips assumes no liability,

express or implied, arising out of any unauthorized modification of

design. Servicer assumes all liability.

* Broken Line

Manufactured under license from Dolby Laboratories. "Dolby"

and the double-D symbol are trademarks of Dolby Laboratories.

Page 4

TABLE OF CONTENTS

[ Main Section ]

SPECIFICATIONS.................................................................................................................................................................1-1-1

IMPORTANT SAFETY PRECAUTIONS ................................................................................................................................1-2-1

STANDARD NOTES FOR SERVICING.................................................................................................................................1-3-1

FUNCTION INDICATOR SYMBOLS......................................................................................................................................1-4-1

PREPARATION FOR SERVICING.........................................................................................................................................1-5-1

OPERATING CONTROLS AND FUNCTIONS ......................................................................................................................1-6-1

REMOTE CONTROL OPERATION .......................................................................................................................................1-7-1

CABINET DISASSEMBLY INSTRU CTIONS .........................................................................................................................1-8-1

HOW TO INITIALIZE THE DVD RECORDER.......................................................................................................................1-8-8

ELECTRICAL ADJUSTMENT INSTRUCTIONS....................................................................................................................1-9-1

Adjustment Points and Test Points...................................................................................................................................1-9-2

FIRMWARE RENEWAL MODE.............................................................................................................................................1-10-1

REWORK PROCEDURE IEEE UNIQUE NUMBER..............................................................................................................1-10-2

BLOCK DIAGRAMS

Servo/System Control Block Diagram..............................................................................................................................1-11-1

Sub System Control Block Diagram.................................................................................................................................1-11-2

Video Block Diagram........................................................................................................................................................1-11-3

Video Input/Output Select Block Diagram........................................................................................................................1-11-4

Audio Block Diagram........................................................................................................................................................1-11-5

Audio Input/Output Select Block Diagram........................................................................................................................1-11-6

Hi-Fi Audio Block Diag r am...................................... .............................................................. .. .........................................1-11-7

Power Supply Block Diagram...........................................................................................................................................1-11-8

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS

Main 1/7 Schematic Diagram Parts Location Guide <VCR Section>...............................................................................1-12-2

Main 1/7 Schematic Diagram <VCR Section>.................................................................................................................1-12-3

Main 2/7, Sensor, Function & Jack-B Schematic Diagram <VCR Section>.....................................................................1-12-5

Main 3/7 Schematic Diagram <VCR Section>.................................................................................................................1-12-7

Main 4/7 Schematic Diagram <VCR Section>.................................................................................................................1-12-9

Main 4/7 Schematic Diagram Parts Location Guide <VCR Section>...............................................................................1-12-11

Main 5/7 Schematic Diagram Parts Location Guide <VCR Section>...............................................................................1-12-12

Main 5/7 Schematic Diagram <VCR Section>.................................................................................................................1-12-13

Main 6/7 Schematic Diagram <VCR Section>.................................................................................................................1-12-15

Main 6/7 Schematic Diagram Parts Location Guide <VCR Section>...............................................................................1-12-17

Main 7/7 Schematic Diagram Parts Location Guide <VCR Section>...............................................................................1-12-18

Main 7/7 & DVD Open/Close Schematic Diagram <VCR Section> .................................................................................1-12-19

Main CBA Parts Location Guide <VCR Section> ............................................................................................................1-12-21

Main CBA Top View <VCR Section>................................................................................................................................1-12-23

Main CBA Bottom View <VCR Section>..........................................................................................................................1-12-25

Function CBA Top/Bottom View <VCR Section>.............................................................................................................1-12-27

Jack-B CBA Top/Bottom View <VCR Section>................................................................................................................1-12-27

Front Schematic Diagram <VCR Section>.......................................................................................................................1-12-29

Front CBA Top/Bottom View <VCR Section>................................................................................................................... 1-12-31

Jack-A Schematic Diagram <VCR Section>....................................................................................................................1-12-33

Jack-A CBA Top/Bottom View <VCR Section>................................................................................................................1-12-33

Power Supply Schematic Diagram <VCR Section>.........................................................................................................1-12-35

Power Supply CBA Top View <VCR Section> .................................................................................................................1-12-37

Power Supply CBA Bottom View <VCR Section>............................................................................................................1-12-39

Junction-A CBA Top/Bottom View <VCR Section>..........................................................................................................1-12-40

Junction-B CBA Top/Bottom View <VCR Section>..........................................................................................................1-12-40

CPU 1/2 Schematic Diagram <DVD Section>..................................................................................................................1-12-41

CPU 2/2 Schematic Diagram <DVD Section>..................................................................................................................1-12-43

Digital Board Unit 1/10 Schematic Diagram <DVD Section> ..........................................................................................1-12-45

Digital Board Unit 2/10 Schematic Diagram <DVD Section> ..........................................................................................1-12-47

Digital Board Unit 3/10 Schematic Diagram <DVD Section> ..........................................................................................1-12-49

Digital Board Unit 4/10 Schematic Diagram <DVD Section> ..........................................................................................1-12-51

Digital Board Unit 5/10 Schematic Diagram <DVD Section> ..........................................................................................1-12-53

Digital Board Unit 6/10 Schematic Diagram <DVD Section> ..........................................................................................1-12-55

Digital Board Unit 7/10 Schematic Diagram <DVD Section> ..........................................................................................1-12-57

Digital Board Unit 8/10 Schematic Diagram <DVD Section> ..........................................................................................1-12-59

Digital Board Unit 9/10 Schematic Diagram <DVD Section> ..........................................................................................1-12-61

Digital Board Unit 10/10 Schematic Diagram <DVD Section> ........................................................................................1-12-63

Digital Board Unit Top View <DVD Section> ...................................................................................................................1-12-65

Digital Board Unit Bottom View <DVD Section> .............................................................................................................1-12-67

Digital Board Unit Test Point View <DVD Section> .........................................................................................................1-12-69

WAVEFORMS........................................................................................................................................................................1-13-1

WIRING DIAGRAM................................................................................................................................................................1-14-1

SYSTEM CONTROL TIMING CHARTS ................................................................................................................................1-15-1

IC PIN FUNCTION DESCRIPTIONS.....................................................................................................................................1-16-1

LEAD IDENTIFICATIONS......................................................................................................................................................1-17-1

ELECTRICAL PARTS LIST ...................................................................................................................................................1-18-1

EXPLODED VIEWS...............................................................................................................................................................1-19-1

MECHANICAL PARTS LIST..................................................................................................................................................1-20-1

Page

Page 5

SPECIFICATIONS

< VCR Section >

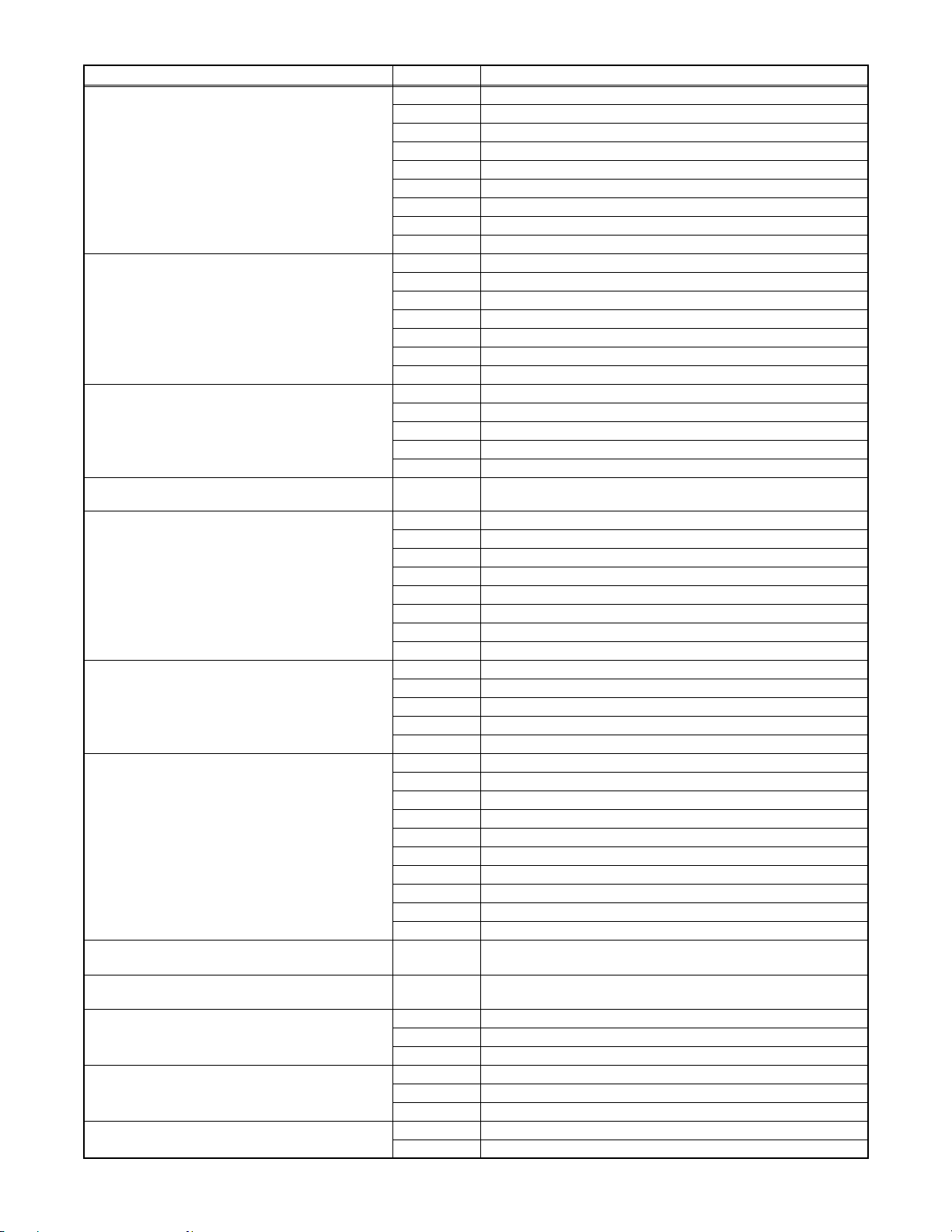

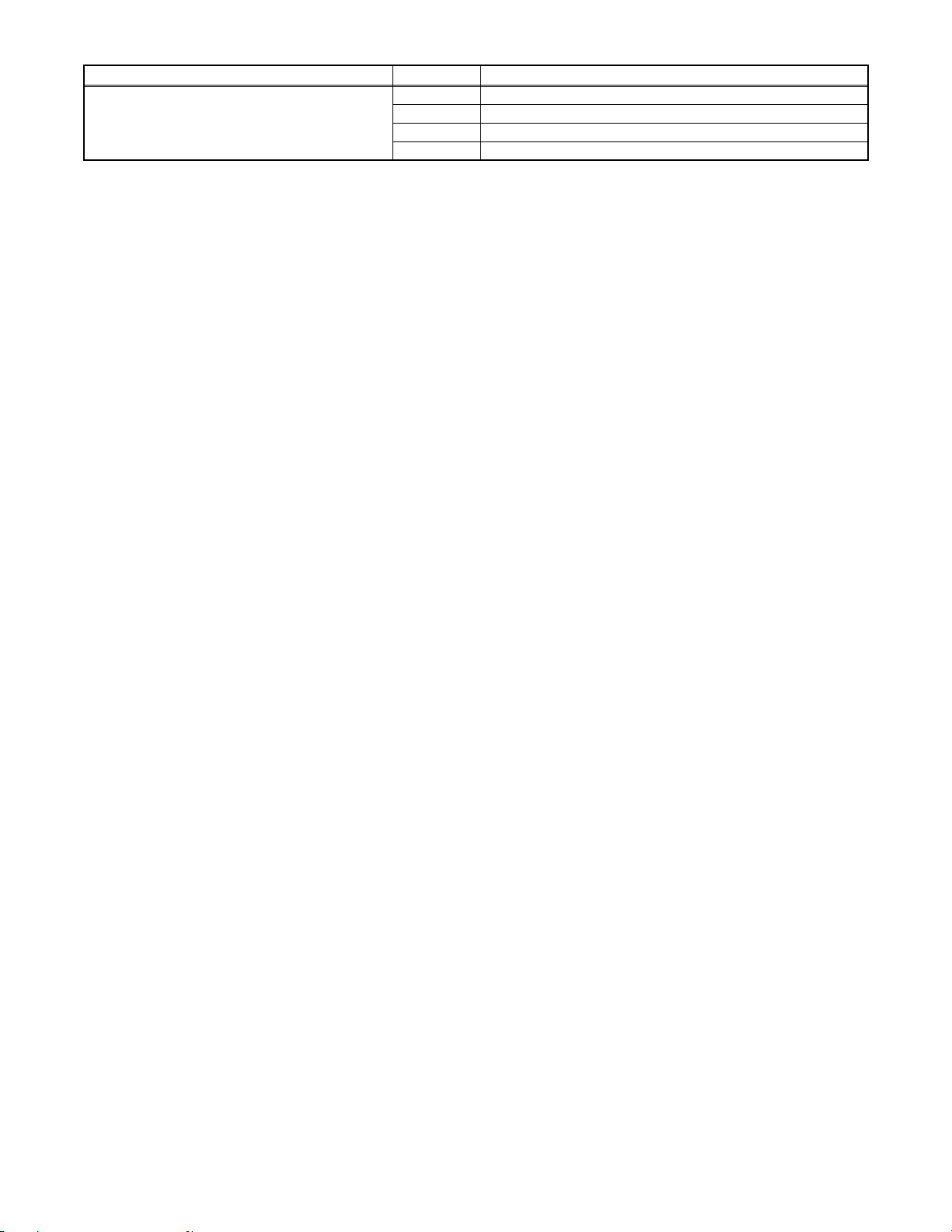

Description Unit Minimum Nominal Maximum Remark

1. Video

1-1. Video Output (PB) Vp-p 0.8 1.0 1.2 SP Mode

1-2. Video Output (R/P) Vp-p 0.8 1.0 1.2

1-3. Video S/N Y (R/P) dB 40 48 SP Mode

1-4. Video Color S/N AM (R/P) dB 38 44 SP Mode

1-5. Video Color S/N PM (R/P) dB 36 40 SP Mode

1-6. Resolution (R/P) Line 220 240 SP Mode

2. Servo

2-1. Jitter Low (R/P) µsec 0.05 0.15 SP Mode

2-2. Wow & Flutter (R/P) % 0.15 0.35 SP Mode

3. Normal Audio

3-1. Output (PB) dBV -10 -6 -2 SP Mode

3-2. Output (R/P) dBV -10 -6 -2 SP Mode

3-3. S/N (R/P) dB 40 44 SP Mode

3-4. Distortion (R/P) % 1.5 5.0 SP Mode

3-5. Freq. Response (R/P) at 100Hz dB -9.5 -3.5 2.5 SP Mode

(-20dB ref. 1kHz) at 8kHz dB -6.5 -0.5 5.5 SP Mode

4. Tuner

4-1. Video output (E-E) Vp-p 0.8 1.0 1.2 E-E Mode

4-2. Video S/N (E-E) dB 40 46 E-E Mode

4-3. Audio output (E-E) dBV -10 -6 -2 E-E Mode

4-4. Audio S/N (E-E) dB 40 44 E-E Mode

5. Hi-Fi Audio

5-1. Output (PB) dBV -12 -8 -4 SP Mode

5-2. Output (R/P) dBV -12 -8 -4 SP Mode

5-3. S/N (A WTD) dB 70 SP Mode

5-4. Freq. Response at 20Hz dB -4 0 +4 SP Mode

at 20kHz dB -4 0 +4 SP Mode

Other Specifications

Operating Temperature

Relative Humidity

Power Requirements

Power Consumption

Dimensions

Weight

41°F ( 5°C ) to 104°F ( 40°C )

30% to 80%

AC 120 V +/- 10%, 60 Hz +/- 0.5%

Power on: 43 W, Power off: 9.0 W

17.1” (W) x 3.9” (H) x 10.3” (D) / 435 mm (W) x 100 mm (H) x 26 2 mm (D)

11.0 lbs. (5.0 kg)

Test Tape ..... VFMS0001H6

Note: Nominal specs represent the desi gn specs. All units shou ld be able to approximate these. Some will exceed

and some may drop slightly below these specs. Limit s pecs represent the abs olute worst conditi on that still might

be considered acceptable. In no case should a unit fail to meet limit specs.

1-1-1 E9480SP

Page 6

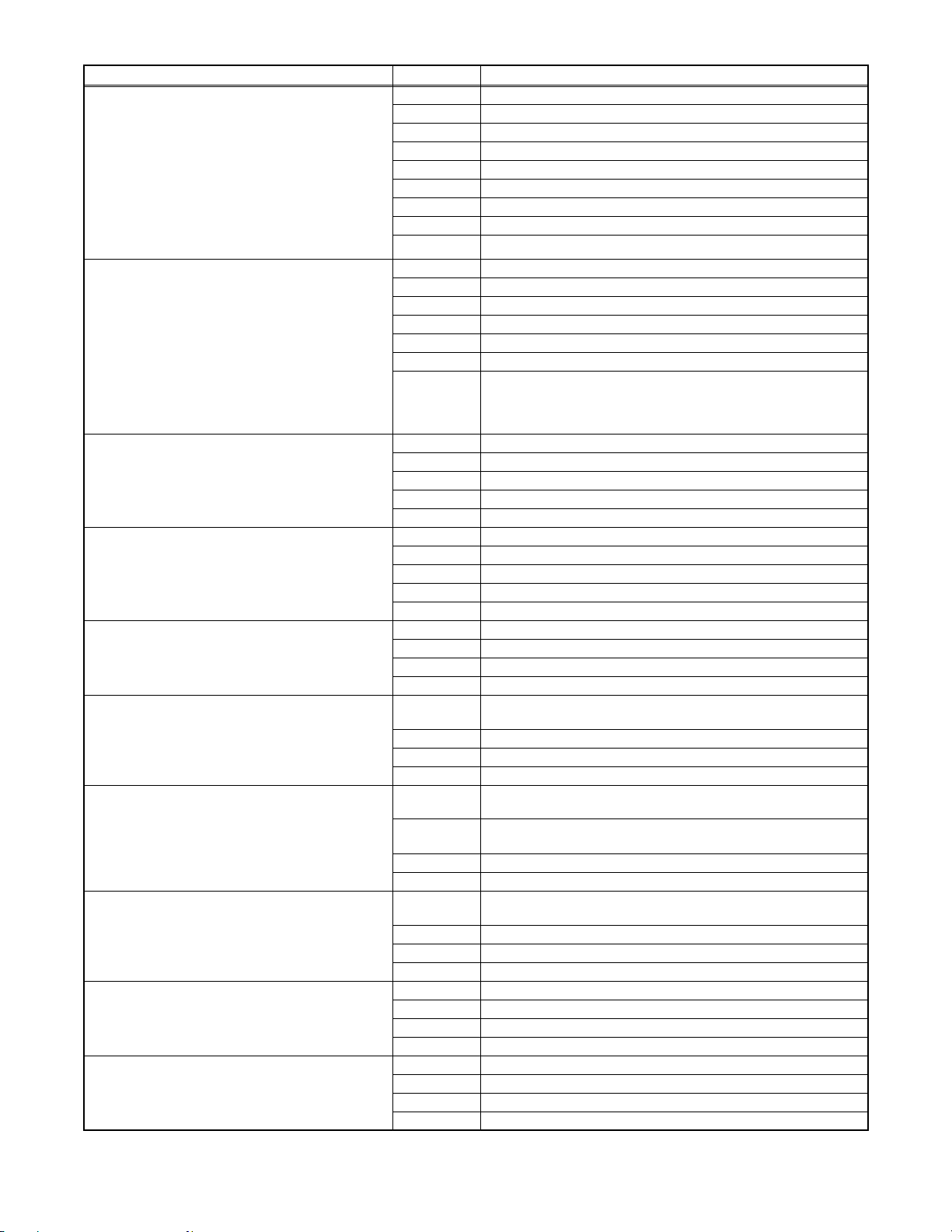

< DVD Section >

ITEM CONDITIONS UNIT NOMINAL LIMIT

1. VIDEO

1-1. Video Output 75 ohm load Vp-p 1.0

1-2. S-Video Output

Y (Luminance) 75 ohm load Vp-p 1.0

C (Chrominance) 75 ohm load Vp-p 0.300

1-3. Component Output

Y (Luminance) 75 ohm load Vp-p 1.0

Pb (Chrominance) 75 ohm load Vp-p 0.7

Pr (Chrominance) 75 ohm load Vp-p 0.7

2. AUDIO

2-1. Frequency Response

DVD

Video CD fs = 44.1 kHz Hz 4 ~ 20 k

Audio CD fs = 44.1 kHz Hz 4 ~ 20 k

2-2. Signal/Noise Ratio 1 kHz dB 80

2-3. Dynamic Range 1 kHz dB 80

2-4. Crosstalk 1 kHz dB 80

2-5. Distortion/Noise 1 kHz dB 80

NOTES:

1. All Items are measured without pre-emphasis unless otherwise specified.

2. Power supply : AC120 V 60 Hz

3. Load imp. : 100 k ohm

4. Ambient temperature : 5

fs = 96 kHz Hz 4 ~ 44 k

fs = 48 kHz Hz 4 ~ 22 k

°C ~ 40 °C

1-1-2 E9480SP

Page 7

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics whi ch are often not evident from visual inspection, nor can the protection

they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have special safety character istics are

identified by a # on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or other

hazards. The Product’s Safety is under review continuously and new instructions are issued whenever

appropriate. Prior to shipment from the factory, our

products are carefully inspected to confirm with the

recognized product safety and electrical codes of the

countries in which they are to be sold. However, in

order to maintain suc h comp liance, it is equall y impor tant to implement the following precautions when a set

is being serviced.

Precautions during Servicing

A. Parts identified by the # symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified re pla ce men ts.

Examples: RF converter s, RF cables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1)Wires covered with PVC tubing

2)Double insulated wires

3)High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1)Insulation tape

2)PVC tubing

3)Spacers

4)Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before soldering.

F. Observe that the wires do not conta ct heat produc -

ing parts (heats inks, oxide metal fil m resis tors, fusible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been replaced, check that

5 - 6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repair ed loc at ion s.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. Crimp type wire connector

The power transformer uses cri mp type con nec tors

which connect the power cord and the primary side

of the transformer. When replacing the transformer,

follow these steps carefully and precisely to prevent shock hazards.

Replacement procedure

1)Remove the old connector by cutting the wires at a

point close to the connector.

Important: Do not re-use a connector. (Discard it.)

2)Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

3)Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

4)Use a crimping tool to crimp the metal sleeve at its

center. Be sure to crimp fully to t he complete closure of the tool.

L. When connecting or disconnecting the internal con-

nectors, first, disconn ect the AC plug from the AC

outlet.

1-2-1 DVD_SFN1

Page 8

Safety Check after Servicing

Examine the area surrounding the repaired location for

damage or deteri oration. Observe that screws, par ts,

and wires have been returned to their original positions. Afterwards, do the following tests and confirm

the specified values to verify compliance with safety

standards.

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearanc e distance (d ) and (d’) be tween soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

AC Line Voltage Clearance Distance (d), (d’)

Chassis or Secondary Conductor

Primary Circuit Terminals

dd'

120 V

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs)

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks,

etc.) is lower than or equal to the specified value in the

table below.

Measuring Method (Power ON) :

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across the ter minals of load

Z. See Fig. 2 and the following table.

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i) Earth Ground (B) to:

120 V

≥ 3.2mm (0.126 inches)

0.15µF CAP. & 1.5kΩ RES.

Connected in parallel

Exposed Accessible Part

Z

1.5k

i≤0.5mA Peak Exposed accessible parts

0.15 F

Earth Ground

B

Power Cord Plug Prongs

AC Voltmeter

(High Impedance)

Fig. 1

Fig. 2

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

1-2-2 DVD_SFN1

Page 9

STANDARD NOTES FOR SERVICING

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are indicated

as shown.

Pin 1

3. The 1s t pin of every ma le con nec tor is i ndi ca ted a s

shown.

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

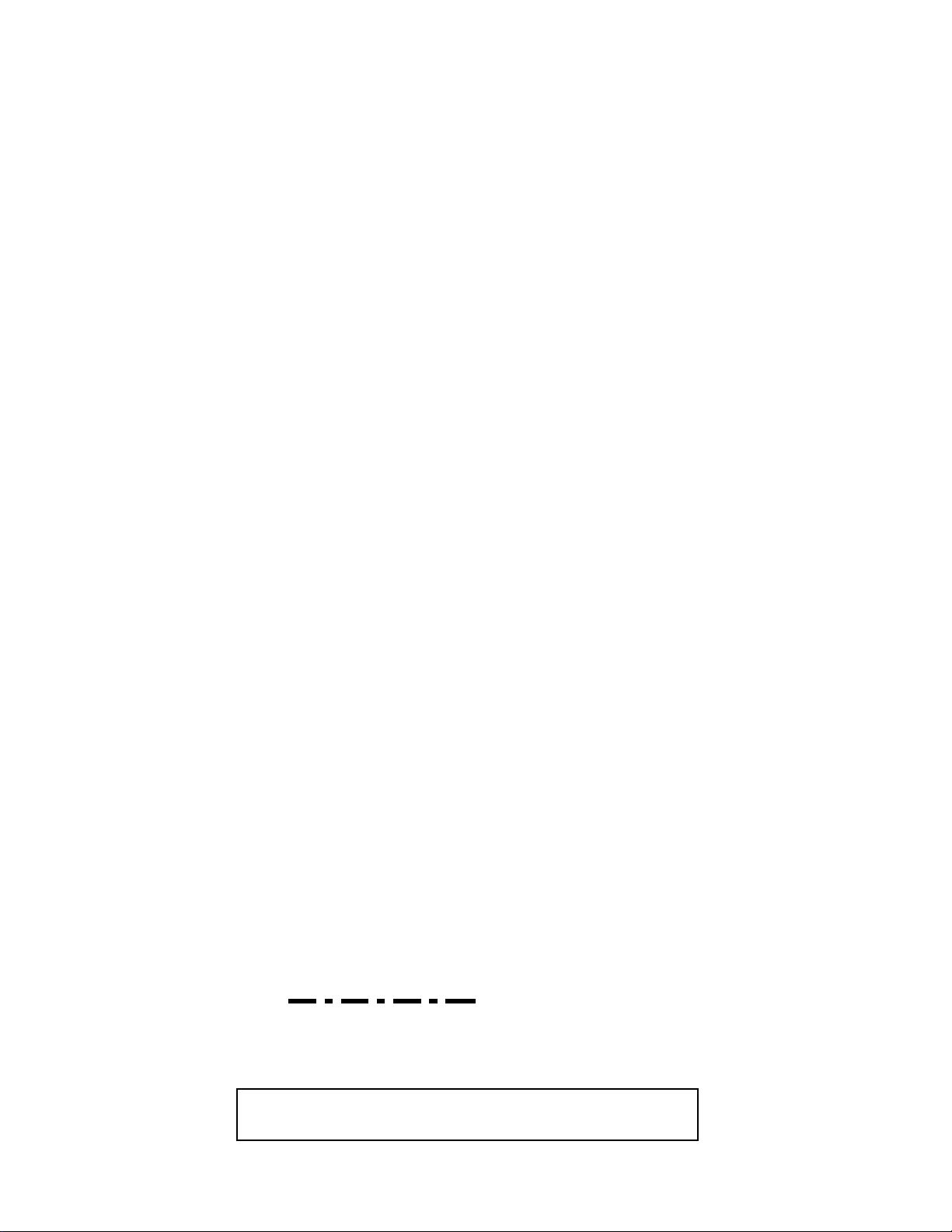

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:.

(1) Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Pin 1

Instructions for Connectors

1. When you conn ect or disconn ect t he FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

Fig. S-1-1

(2) Remove the flat pack-IC with tweezers while apply-

ing the hot air.

(3) Bottom of the flat pack-IC is f ixed with glue to the

CBA; when rem oving enti re flat pa ck-IC, first apply

soldering iron to ce nte r of th e f lat pack-IC a nd hea t

up. Then remove (glue will be melted). (Fig. S-1-6)

(4) Release the flat pack-IC from th e CBA usin g twee-

zers. (Fig. S-1-6)

Caution:

1. T he Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. D o not supply hot air to the chip par ts around the

flat pack-IC for over 6 seconds because damage to

the chip parts may occur. Put masking tape around

the flat pack-IC to protect other parts from damage.

(Fig. S-1-2)

1-3-1 E6STA

Page 10

3. The fla t pa ck-IC on the CBA is a ffi xed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when removing

it.

With Soldering Iron:

(1) Using desoldering braid, remove the solder from all

pins of the flat pack-IC. When you use solder flux

which is applied to all pins of the flat pack-IC, you

can remove it easily. (Fig. S-1-3)

CBA

Masking

Tape

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

(2) Lift each lead of the flat pack-IC upward one by

one, using a shar p pin or wire to which sol der will

not adhere (iron w ire). When h eating the p ins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

(3) Bottom of the flat pack-IC is f ixed with glue to the

CBA; when rem oving enti re flat pa ck-IC, first apply

soldering iron to ce nte r of th e f lat pack-IC a nd hea t

up. Then remove (glue will be melted). (Fig. S-1-6)

(4) Release the flat pack-IC from th e CBA usin g twee-

zers. (Fig. S-1-6)

Fig. S-1-4

1-3-2 E6STA

Page 11

With Iron Wire:

(1)Using desoldering braid, remove the solder from all

pins of the flat pack-IC. When you use solder flux

which is applied to all pins of the flat pack-IC, you

can remove it easily. (Fig. S-1-3)

(2) Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

(3) While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solde r

melts so as to lift the IC leads from the CBA contact

pads as shown in Fig. S-1-5.

(4)B ottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to c en ter o f the fl at pack-IC an d h eat

up. Then remove (glue will be melted). (Fig. S-1-6)

(5)Re lease the fl at pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

Note:

When using a solde ring iron, care must be taken

to ensure that the flat pack-IC is not being he ld by

glue. When the flat pack-IC is removed from the

CBA, handle it gently becau se it may be dama ged

if force is applied.

Hot Air Blower

2. Installation

(1) Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA so

you can install a replacement flat pack-IC more

easily.

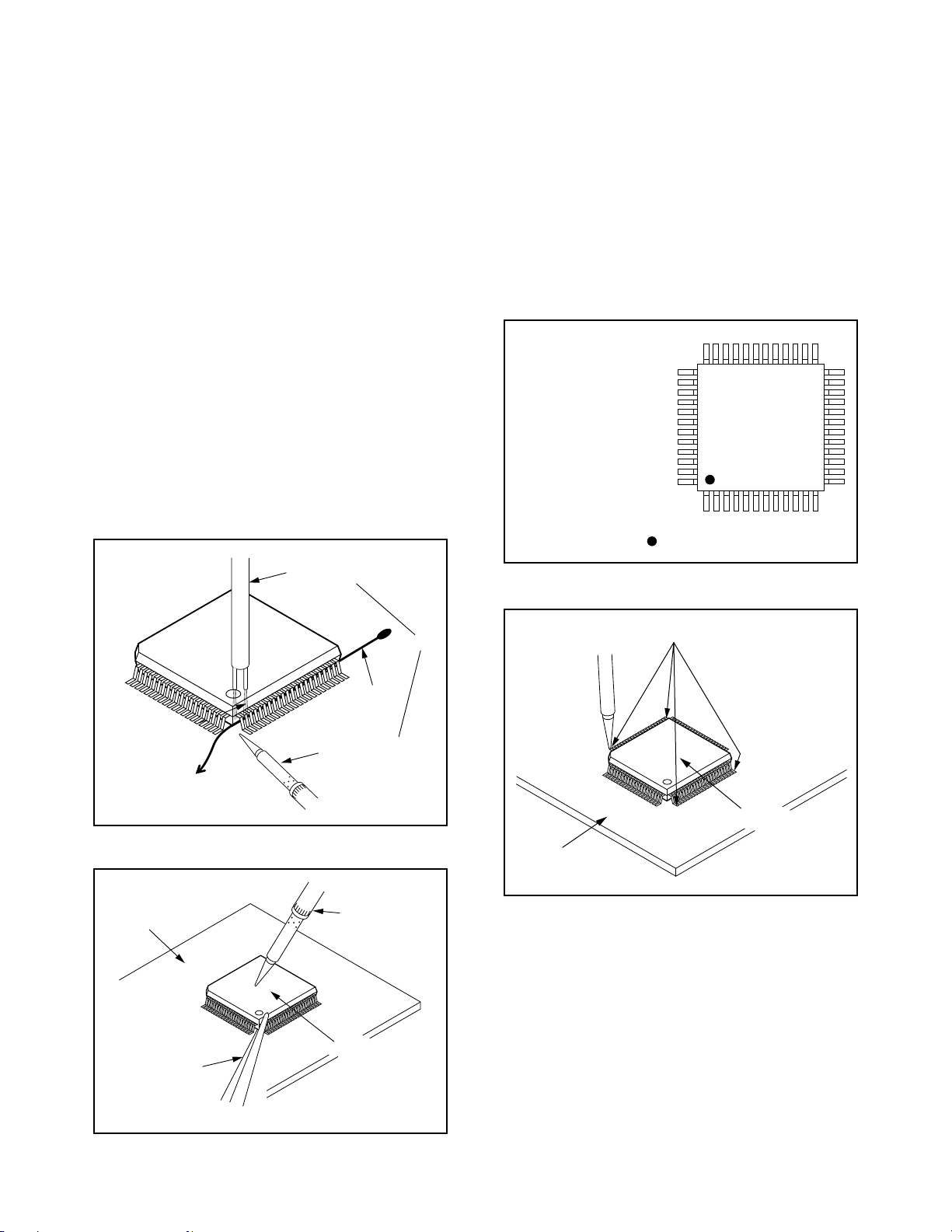

(2) The “I” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mar k matches the 1

on the PCB when positioning for installation. Then

presolder the four cor ners of the fl at pack-IC. (See

Fig. S-1-8.)

(3) Solder all pins of the flat pack-IC. Be sure that none

of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

To Solid

Mounting Point

CBA

Tweezers

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

Fig. S-1-6

1-3-3 E6STA

Page 12

Instructions for Handling

Semi-conductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential dif ference caused by electrostatic charge during unpacking or repair work.

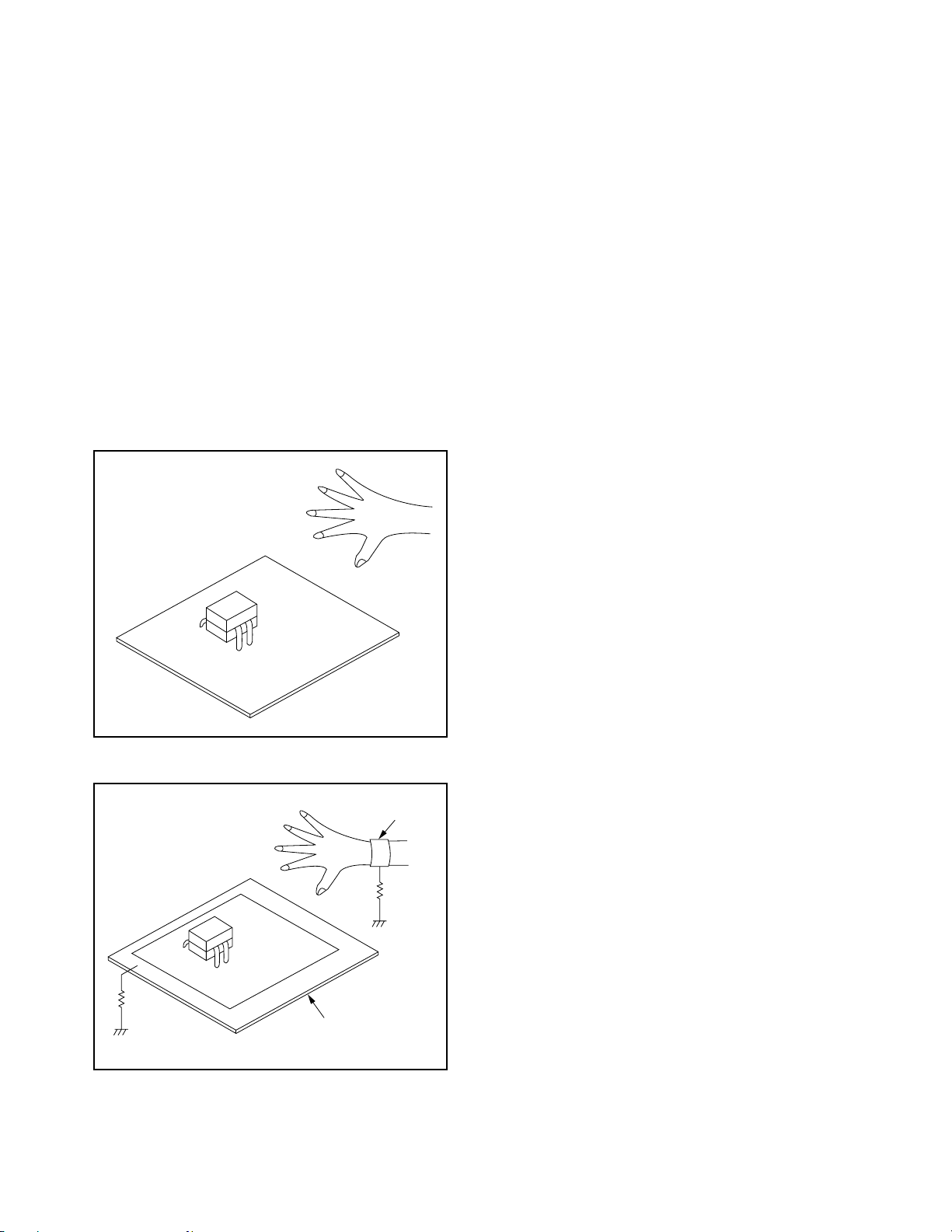

1. Ground for Human Body

Be sure to wear a grounding band (1M Ω) that is prop erly grounded to rem ove any static electr icity that may

be charged on the body.

2. Ground for Workbench

(1)Be sure to place a conductive sheet or copper plate

with proper grounding (1MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape thr ough the body grounding band, be careful to avoid contacting semi -conductors with your clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

1-3-4 E6STA

Page 13

FUNCTION INDICATOR SYMBOLS

< VCR Section >

Note:

If a mechanical malfunction oc curs, the power is tur ned off. When the power comes on again after that by

pressing [STANDBY-ON] button, an error message is displayed on the TV screen for 5 seconds.

Led Mode Indicator Active

When reel or capstan mechanism is not functioning

correctly

When tape loading mechanism is not functioning

correctly

When cassette loading mechanism is not functioning

correctly

When the drum is not working properly

P-ON+5V Power safety detection

TV screen

“A R” is displayed on a TV screen. (Refer to Fig. 1.)

“A T” is displayed on a TV scr een. (Refer to Fig. 2.)

“A C” is displayed on a TV screen. (Refer to Fig. 3.)

“A D” is displayed on a TV screen. (Refer to Fig. 4.)

“A P” is displayed on a TV screen. (Refer to Fig. 5.)

When reel or capstan mechanism is not functioning

correctly

A

R

Fig. 1

When tape loading me chanism is not func tioning correctly

A

T

Fig. 2

When cassette loadi ng mechanism is not functioning

correctly

When the drum is not working properly

A

D

P-ON+5V Power safety detection

A

P

Fig. 4

Fig. 5

A

C

Fig. 3

1-4-1 E9480FIS

Page 14

< DVD Section >

Note: If an error occurs, a message with the error number appears on the screen.

X X Y Y Z Z

Error code

Nucleus nmber

Nucleus group nmber

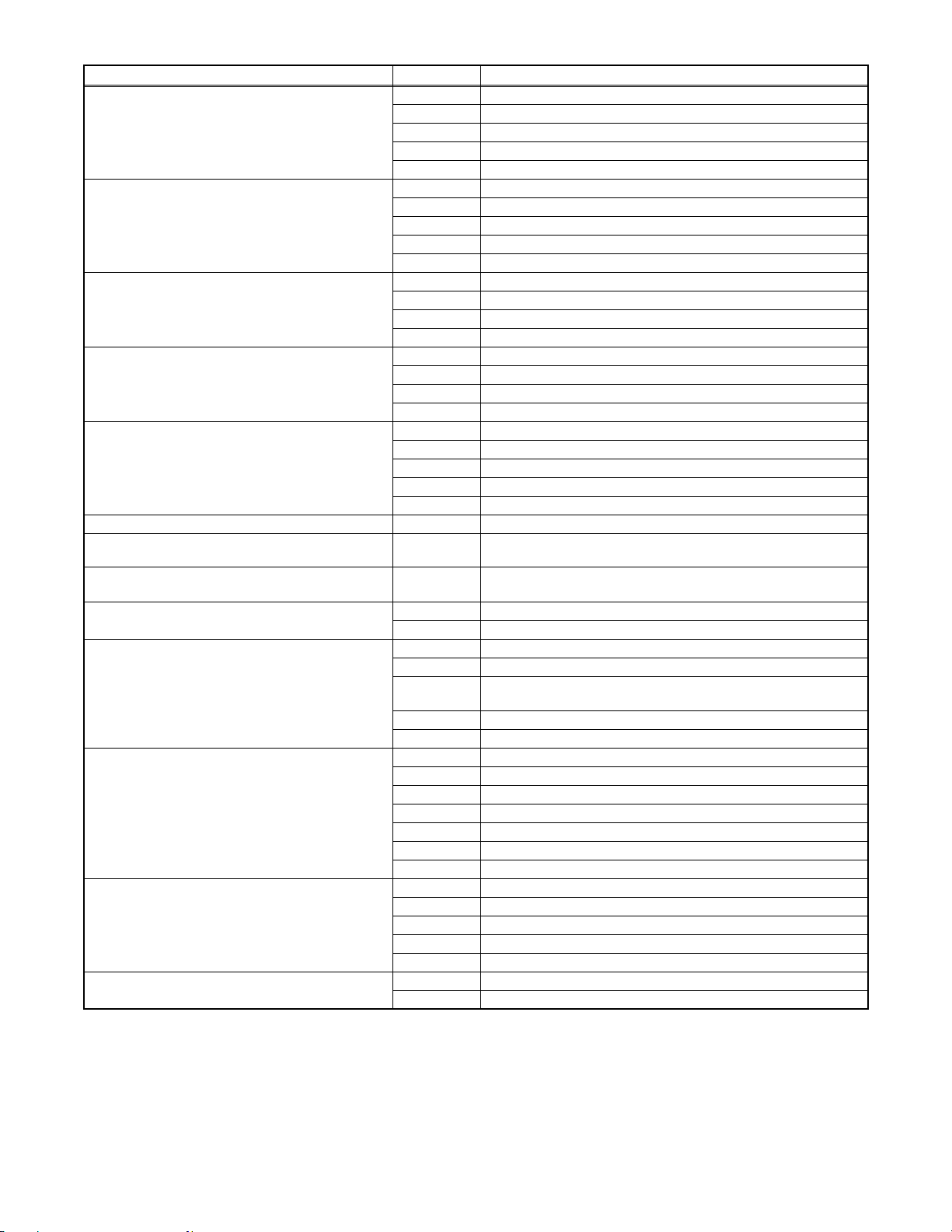

Description Error No. Error Description

Sends the device id and the module ids and revisions

of the Domino IC to the stdout port.

Generates a test-image of a selected video standard

on selected video output on the digital board. When no

input is given, the default values will be used. Use

nucleus DS_ANAB_VideoRouting to route the video

signal on the analogue board output.

Switches the test-image off. 010200 Stopping the test image generation succeeded.

Generate an audio sine signal on the audio output of

the digital board.

Stop generating the audio sine signal.

Generate an audio sine signal on the audio output of

the digital board for 4 seconds.

Mute the audio outputs of the digital board. 010600 Muting the audio succeeded.

De-mute the audio outputs of the digital board. 010700 De-muting the audio succeeded.

Check the connection to the DV-LED on the digital

board by switching it on.

Switch off the DV-LED on the digital board. 010900 Switching the DV-LED off succeeded

Peek a value on a specified address.

Poke a value on a specified address.

Check the communication between the IIC controller of

the Chrysalis and the EEPROM.

Check whether the EEPROM can be written to and

read from.

Make the EEPROM empty, containing all zeroes.

Modifies one or more locations in NVRAM and updates

the checksum of the section modified.

010000 Getting the information succeeded.

010100 Generating the test image succeeded.

010101 Failed to set up DENC.

010102 Invalid user input.

010103 Test image not supported.

010300 The sine signal was successfully generated.

010301 Generating the sine test audio failed.

010400 Switching off the audio sine signal succeeded.

010401 Failed to stop sine test audio.

010500 The sine signal burst was successfully generated.

010501 Generating the sine burst f ailed.

010502 Failed to stop the sine burst.

010800 Switching the DV-LED on succeeded.

011200 Peeking on the specified address succeeded.

011201 No address input.

011202 Invalid address.

011300 Poking the specified address succeeded.

011301 No address input.

011302 Invalid address/data.

030000 Something is properly read so the communication is OK.

030004 The communication with the NVRAM failed.

030005 The IIC bus initialisation failed.

030100 The write-read test succeeded.

030101 The IIC bus initialisation failed.

030102 The communication with the NVRAM failed.

030103 The read back value is different from the written value.

030200 The clearing of the NVRAM succeeded.

030201 There was an IIC error .

030202 Clearing the NVRAM failed.

030300 Modifying the NVRAM contents succeeded.

030301 Unable to initialise NVM.

030302 Modifying the NVRAM contents failed.

030303 Length out of range.

030304 Unable to decode length.

030305 Offset out of range.

030306 unable to decode offset.

030307 Unknown location specified.

030308 No location is specified.

030309 Number of values incorrect.

030310 Error creating checksum.

030311 Invalid data.

1-4-2 E9480FIS

Page 15

Description Error No. Error Description

Read out one or more locations in the NVRAM.

Write to a specific memory address.

Read from a specific memory address.

Get the device (revision) type i nformation of the FLASH

IC. (manufacturer and device ID)

Check whether the FLASH can be written to and read

from.

Read from a specific memory address.

Check the checksum of the application partitions by

recalculating and comparing partition checksums.

Calculate the checksum over all memory addresses.

Used to check entire FLASH contents.

Calculate a checksum over a selected number of

address locations.

Get the device (revision) type information of the VIP IC.

Check the communication between the IIC controller of

the Domino and the VIP IC.

Switch the clock output on.

030400 Value read.

030401 Unable to initialise NVM.

030402 Reading the NVRAM contents failed.

030403 Length out of range.

030404 Unable to decode length.

030405 Offset out of range.

030406 Unable to decode offset.

030407 Unknown location specified.

030408 No location is specified.

040200 Writing to the SDRAM succeeded.

040201 No address input.

040202 No data input.

040203 Address is not dividable by 4.

040204 Invalid data.

040205 Address out of rang e.

040206 Invalid address.

040300 Reading from the SDRAM succeeded.

040301 No address input.

040302 Address is not dividable by 4.

040303 Address out of rang e.

040304 Invalid address.

050000 Getting the informat ion from the FLASH succeeded.

050100 The FLASH write-read test succeeded.

050101 Wrong BALO signature.

050102 Wrong CONS signature.

050103 Invalid CONS base.

050104 Invalid CONS end address.

050105 All bits in the TEST region are filled with 0.

050106 The WriteRead test failed.

050107 The Write Failed.

050200 Reading the FLASH succeeded.

050201 No address input.

050202 Invalid address.

050203 Address is out of range.

050204 Address is not dividable by 2.

050300 The checksum is valid, the test succeeded.

050301 Wrong BSTB signature.

050302 Wrong BSTB checksum.

050303 Wrong BALO signature.

050304 Wrong BALO checksum.

050305 Wrong CONS signature.

050306 Wrong CONS checksum.

050307 Invalid BALO end address.

050308 Invalid CONS base.

050309 Invalid CONS end address.

050400 Calculating the checksum over all addresses succeeded.

050500 Calculating the checksum over selected addresses succeeded.

060000 Getting the informa tion from the VIP succeeded.

060001 The IIC bus initialisation failed.

060002 The communication with the VIP failed.

060100 Communicating with the VIP succeeded.

060001 The IIC bus initialisation failed.

060002 The communication with the VIP failed.

060200 Switching the clock output on succeeded.

060201 Switching the clock output on failed.

1-4-3 E9480FIS

Page 16

Description Error No. Error Description

Switch the clock output off.

Select an input video path to be switched to the

analogue output of the VIP.

Get the device (revision) type in formation of the 1394

Physical layer IC.

Check the accessibility of the 1394 Physical layer IC by

writing to and reading from a specific address.

Route a DV stream containing an audio and video

signal through the physical IC to the Domino. This will

be loopthrough to the video output of Domino.

Check whether a DV node can be detected by the

hardware.

Check the device type of the DENC in use.

Check the communication between the IIC controller of

the Domino and the DENC-IC.

Generate a test image and make it present on the

DENC-IC.

Switch off the generated test image.

Turn on MacroVision.

Turn off MacroVision.

Check the communication between the digital board

and the recorder drive by issuing an Inquiry command

over ATAPI bus.

Reset the basic engine.

Return the self-test results through the service port. 090200 Self test succeeded, no errors.

Get the version of the basic engine and that of the

optical unit.

Open the tray of the basic engine.

Close the tray of the basic engine.

060300 Switching the clock output off succeeded.

060301 Switching the clock output off failed.

060400 Selecting the input of the VIP succeeded.

060401 The user provided wrong input.

060402 The VIP was not accessible.

060405 This mode not available on SAA7118.

070100 Getting the informat ion from the physical layer IC succeeded.

070101 Missing PHY clock.

070102 Time-out error.

070103 1394 chip is not IEEE 1394a-2000 compliant.

070300 Communicating with the physical lay er IC succeeded.

070301 Missing PHY clock.

070302 Time-out error.

070303 Register write test failed.

070400 Routing the signals succeeded.

070405 Failed to initialise DENC.

070500 The node was detected OK.

070504 No node was detected.

080100 Communicating with the progressive scan DENC-IC succeeded.

080101 The IIC bus initialisation failed.

080102 No valid DENC detected.

080100 Communicating with the progressive scan DENC-IC succeeded.

080104 Communicating with the DENC failed.

080105 The IIC bus initialisation failed.

080200 The generation of the test image succeeded.

080201 The IIC bus initialisation failed.

080202 Unable to initialise the DENC.

080203 The generation of the test image failed.

080300 Turning off the test image succeeded.

080301 The IIC bus initialisation failed.

080302 The test image could not be tur ned off.

081000 Turning on MacroVision succeeded.

081001 The IIC bus initialisation failed.

081002 Unable to access DE NC.

081000 Turning off MacroVision succeeded.

081001 The IIC bus initialisation failed.

081002 Unable to access DE NC.

090000 Communicating with recorder drive succeeded.

090001 Recorder drive init fails.

090002 Recorder drive command fails.

090100 Resetting the Basic Engine s ucceeded.

090101 Recorder drive init fails.

090300 BE version OK.

090301 Recorder drive init fails.

090302 Recorder drive command fails.

090400 The command executed successfully.

090401 Recorder drive init fails.

090402 Recorder drive command fails.

090500 The command executed successfully.

090501 Recorder drive init fails.

090502 Recorder drive command fails.

1-4-4 E9480FIS

Page 17

Description Error No. Error Description

Write data to and read data from a DVD+RW disc

through the basic engine for verification of the writing.

Write data to and read data from a DVD+R disc

through the basic engine for verification of the writing.

Retrieve the statistical information from the basic

engine.

Reset the statistical information in the basic engine.

Get the error log from the basic engine.

Reset the error log in the basic engine.

090600 The command executed successfully.

090601 Sanyo drive init fails.

090602 Failed to close tray.

090603 Failed to get disc type.

090604 Not DVD+RW disc.

090605 Buffer wait failed.

090606 Write command failed. Sensekey = XX,YY,ZZ.

090607 Failed to synchronize cache. Sensekey = XX,YY,ZZ.

090608 Read command failed. Sensekey = XX,YY,ZZ.

090609 Data read back is different from written data.

090700 The command executed successfully.

090701 Sanyo drive init fails.

090702 Failed to close tray.

090703 Failed to get disc type.

090704 Not DVD+R disc.

090705 Buffer wait failed.

090706 Write command failed. Sensekey = XX,YY,ZZ.

090707 Failed to synchronize cache. Sensekey = XX,YY,ZZ.

090708 Read command failed. Sensekey = XX,YY,ZZ.

090709 Data read back is different from written data.

090710 Failed to read back NWA.

090711 Disc full, insert new DVD+R.

090800 The command executed successfully.

090801 There was a time-out while communicating.

090802 The Basic Engine returned an unexpected result.

090803 The BE returned an error code.

090804 No acknowledge received from BE.

090805 Communicating with the Basic Engine failed.

090806 The BE returned no info.

090900 The command executed successfully.

090901 There was a time-out while communicating.

090902 The Basic Engine returned an unexpected result.

090903 The BE returned an error code.

090904 No acknowledge received from BE.

090905 Communicating with the Basic Engine failed.

091000 The command executed successfully.

091001 There was a time-out while communicating.

091002 The Basic Engine returned an unexpected result.

091003 The BE returned an error code.

091004 No acknowledge received from BE.

091005 Communicating with the Basic Engine failed.

091006 The BE returned no info.

091100 The command executed successfully.

091101 There was a time-out while communicating.

091102 The Basic Engine returned an unexpected result.

091103 The BE returned an error code.

091104 No acknowledge received from BE.

091105 Communicating with the Basic Engine failed.

1-4-5 E9480FIS

Page 18

Description Error No. Error Description

This test measures the average jitter and b ler v alues. A

formatted DVD must be loaded into the engine before

executing this nucleus.

Check whether there is a disc inside the BE.

Read the TOC from the disc. This gives a good

indication if the BE works properly.

Enables Automatic Pattern Verification tool on

DVD+RW disc. Start, stop and type of pattern to be

used can be configured by the user. Return pass/fail

result.

Enables Automatic Pattern Verification tool on DVD+R

disc. Start, stop and type of pattern to be used can be

configured by the user. Return pass/fail result. Note

that the nucleus does not check that the write address

is the correct next available address according to the

DVD+R disc. This must be taken care of by the user,

otherwise the write command will fail.

Set the region code in the AV3.

091200 Optimising jitter succeeded.

091201 There was a time-out while communicating.

091202 The Basic Engine returned an unexpected result.

091203 The Basic Engine returned an error code.

091204 No acknowledge received from BE.

091205 Unable to send tray in.

091206 Unable to read the disc.

091207 No disc is loaded.

091208 Unknown disc is loade d.

091209 Unabl e to enter service mode.

092100 There was a disc inside the set.

092101 Unable to load the tray.

092102 Error received fr om BE .

092400 A disc is loaded, TOC info if echoed.

092401 Unable to load the tray.

092402 The BE has not returned TOC info.

092403 Error received fr om BE .

092600 The command executed successfully.

092601 Not enough in put parameters.

092602 Invalid start address.

092603 Invalid End address.

092604 Invalid pattern.

092605 Sanyo drive init fails.

092606 Failed to close tray.

092607 Failed to get disc type.

092608 Not DVD+RW disc.

092609 Buffer wait failed.

092610 Write command failed. Sensekey = XX,YY,ZZ.

092611 Failed to synchronize chase. Sensekey = XX,YY,ZZ.

092612 Read command failed. Sensekey = XX,YY,ZZ.

092613 Data read back is different from written data.

092700 The command executed successfully.

092701 Not enough in put parameters.

092702 Invalid start address.

092703 Invalid End address.

092704 Invalid pattern.

092705 Sanyo drive init fails.

092706 Failed to close tray.

092707 Failed to get disc type.

092708 Not DVD+R disc.

092709 Buffer wait failed.

092710 Write command failed. Sensekey = XX,YY,ZZ.

092711 Failed to synchronize chase. Sensekey = XX,YY,ZZ.

092712 Read command failed. Sensekey = XX,YY,ZZ.

092713 Data read back is different from written data.

092800 The command executed successfully.

092801 There was a time-out while communicating.

092802 The Basic Engine returned an unexpected result.

092803 The BE returned an error code.

092804 No acknowledge received from BE.

092805 Communicating with the Basic Engine failed.

092806 The user provided wrong input.

1-4-6 E9480FIS

Page 19

Description Error No. Error Description

Read the region code from the AV3.

Reset the region counter in the AV3.

Adjust the DVD-M (with the OPU) with PCBA. (So

adjusts the two PCBS to each other)

Check the communication between the digital board

and the DCB by issuing an echo command.

Get the version of the DCB

Light the entire display of the DCB, and clear the

display after confirmation.User confirmation is

necessary.The REC and PLAY keys on the local

keyboard are used for this confirmation.The PLAY key

confirms that the test pattern is OK and the REC key

indicates an error. The STOP key is used to exit this

nucleus at any time. The keyboard can also be used for

the same purpose. The O or o key confirms that the

test pattern is OK and the N or n key indicates the user

wants to go to the next test or that there is an error . The

rest of the keys of the keyboard are used to exit this

nucleus at any time.

Check all keys of the keyboard by confirming the keycode displayed of each key. The PLAY key is used to

confirm this nucleus. However, this key is also part of

the keyboard test itself. Also the REC and STOP keys

are used to exit the test.With the REC key the user

signals a failure, while the STOP key signals the

abortion of the test by the user. To use one of these

three keys for confirmation,failur e or abortion, the user

needs to hold the key pressed down for more than one

second. Pressing the keyboard will also stop the test at

any time.

092900 The command executed successfully.

092901 There was a time-out while communicating.

092902 The Basic Engine returned an unexpected result.

092903 The BE returned an error code.

092904 No acknowledge received from BE.

092905 Communicating with the Basic Engine failed.

093000 The command executed successfully.

093001 There was a time-out while communicating.

093002 The Basic Engine returned an unexpected result.

093003 The BE returned an error code.

093004 No acknowledge received from BE.

093005 Communicating with the Basic Engine failed.

093100 The command executed successfully.

093101 There was a time-out while communicating.

093102 The Basic Engine returned an unexpected result.

093103 The BE returned an error code.

093104 No acknowledge received from BE.

093105 Communicating with the Basic Engine failed.

093106 Unabl e to enter service mode.

093107 This nucleus is not supported by the engine.

100000 Communicating with the DCB succeeded.

100001 DCB could not be ac cess ed by the analogue board.

100002 There was no response from the analogue board.

100003 The error code returned from the analogue board is unknown.

100004 There was no response from the front panel.

100100 Retrie ving the v ersion of the DCB succeeded.

100101 DCB could not be ac cess ed by the analogue board.

100102 There was no response from the analogue board.

100103 The error code returned from the analogue board is unknown.

100200 Lighting the entire display succeeded.

100201 DCB could not be ac cess ed by the analogue board.

100202 There was no response from the analogue board.

100203 The error code returned from the analogue board is unknown.

100206 The DCB did not light all labels.

100207 The user skipped the rest of the test.

100208 The user returned an unknown confirmation.

100400 All the keys on the keyboard have been pressed.

100401 DCB could not be ac cess ed by the analogue board.

100402 There was no response from the analogue board.

100403 The error code returned from the analogue board is unknown.

100404 Not all the keys w ere pressed.

100405 In valid key code returned.

100406 DCB Keyboard; test failed.

100407 DCB Keyboard; test aborted.

100408 Failed to clear FP buffer.

100409 Test stopped from service port.

1-4-7 E9480FIS

Page 20

Description Error No. Error Description

Check the interface between the remote control and

the DCB by checking the key-code displayed. At least

one key must be tested. The test can be exited by

pressing the STOP-,REC-, or PLAY-key on the local

keyboard. The user should press PLAY to indicate a

successful test. The REC-key is pressed if the test

failed, and ST OP can be pressed to abort the test. The

keyboard can also be used for the same pur pose .The

O or o key stops the test and the N or n key indicates

an error. The rest of the keys of the keyboard are used

to abort this test at any time.

Switch the record LED on, and after confirmation off.

The user confirms by pressing the REC key, ST OP ke y,

or the PLAY key on the local keyboard. The PLAY key

confirms that the LED is on and the REC key indicates

an error. The STOP key signals the abortion of the test

by the user. The keyboard can also be used for the

same purpose . The O or o key confirms that the test

pattern is OK and the N or n key indicates an error or

that the user wants to go to the next test. The rest of

the keys of the ke yboard are used to e xit this n ucleus at

any time. After that the nucleus switches the LED off.

Check the communication between the digital board

and the analogue board by issuing some echo string.

Check the communication between the digital board

and the NVRAM on the analogue board.

Check the communication between the digital board

and the tuner on the analogue board.

Check the communication between the digital board

and the data slicer on the analogue board.

Check the communication between the digital board

and the sound processor on the analogue board.

Check the communication between the digital board

and the A/V-selector on the analogue board.

Get the hardware version of the analogue board.

Get the software version of the boot software of the

analogue board.

100500 Remote Control test succeeded.

100501 DCB could not be ac cess ed by the analogue board.

100502 There was no response from the analogue board.

100503 The error code returned from the analogue board is unknown.

100504 DCB Remote control; no user input received.

100505 DCB Remote control; test failed.

100506 DCB Remote control; test aborted.

100507 Failed to clear FP buffer.

100508 Test stopped from service port.

100600 Switching Led on succeeded.

100601 DCB could not be ac cess ed by the analogue board.

100602 There was no response from the analogue board.

100603 The DCB did not light all the leds.

100604 The user skipped the rest of the test.

100605 The user returned an unknown confirmation:

100606 The error code returned from the analogue board is unknown.

110000 Communicating with the analogue board succeeded.

110001 The test returned the wrong string.

110002 Communicating with the analogue board failed.

110103 The analogue board returned an unexpected result.

110104 Receiving character failed.

110100 Communicating with the NVRAM on the analogue board succeeded.

110101 The analogue board could not communicate with the NVRAM.

110102 Communicating with the analogue board failed.

110103 The analogue board returned an unexpected result.

110104 The write-read test failed.

110200 Communicating with the tuner on the analogue board succeeded.

110201 The analogue board could not communicate with the tuner.

110202 Communicating with the analogue board failed.

110203 The analogue board returned an unexpected result.

110300

110301 The analogue board could not communicate with the data slicer.

110302 Communicating with the analogue board failed.

110303 The analogue board returned an unexpected result.

110400

110401

110402 Communicating with the analogue board failed.

110403 The analogue board returned an unexpected result.

110500

110501 The analogue board could not communicate with the A/V selector.

110502 Communicating with the analogue board failed.

110503 The analogue board returned an unexpected result.

110600 Reading the hardware version succeeded.

110601 The segment containing the hardware version could not be found.

110602 Communicating with the analogue board failed.

110603 The analogue board returned an unexpected result.

110700 Reading the boot-software version succeeded.

110701 The segment containing the boot-software v ersion could not be f ound.

110702 Communicating with the analogue board failed.

110703 The analogue board returned an unexpected result.

Communicating with the data slicer on the analogue board

succeeded.

Communicating with the sound procesor on the analogue board

succeeded.

The analogue board could not communicate with the sound

processor.

Communicating with the A/V selector on the analogue board

succeeded.

1-4-8 E9480FIS

Page 21

Description Error No. Error Description

Get the software version of the download software of

the analogue board.

Get the software version of the application software of

the analogue board.

Get the software version of the diagnostic software of

the analogue board.

Check the checksum of the several part itions by

recalculating and comparing partition checksums.

Perform the routing of the video paths on the analogue

board.

Perform the routing of the audio paths on the analogue

board.

Set the tuner to receive a valid audio and video signal

Perform an IIC write and read action on the analogue

board

Set the clock to the value passed through in the YYYY

MM DD HH MM SS format.

Generate a 1 kHz signal on pin 7 (INT) of the clock IC.

Store the clock IC correction value in NVRAM.

110800 Reading the download-software version succeeded.

110801

110802 Communicating with the analogue board failed.

110803 The analogue board returned an unexpected result.

110900 Reading the application-software version succeeded.

110901

110902 Communicating with the analogue board failed.

110903 The analogue board returned an unexpected result.

111000 Reading the diagnostics-software version succeeded.

111001

111002 Communicating with the analogue board failed.

111003 The analogue board returned an unexpected result.

111100 Checksum calculation succeeded.

111101

111102 Communicating with the analogue board failed.

111103 Communicating with the analogue board failed.

111104 The analogue board returned an unexpected result.

111200 Routing the video on the analogue board succeeded.

111201 Routing the video on the analogue board failed.

111202 The user provided wrong input.

111203 Communicating with the analogue board failed.

111204 The analogue board returned an unexpected result.

111300 Routing the audio on the analogue board succeeded.

111301 Routing the audio on the analogue board failed.

111302 The user provided wrong input.

111303 Communicating with the analogue board failed.

111304 The analogue board returned an unexpected result.

111400 Setting the tuner ch annel succeeded.

111401 Setting the tuner channel failed.

111402 The user provided wrong input.

111403 Communicating with the analogue board failed.

111404 The analogue board returned an unexpected result.

111500 Reading and writing IIC on the analogue board succeeded.

111501 Reading or writing IIC on the analogue board failed.

111502 The user provided wrong input.

111503 Communicating with the analogue board failed.

111504 The analogue board returned an unexpected result.

111600 Adjusting the clock succeeded.

111601 Adjusting the clock failed.

111602 The user provided wrong input.

111603 Communicating with the analogue board failed.

111604 The analogue board returned an unexpected result.

111700 Generating the signal on the designated pin succeeded.

111701 Generating the signal on the designated pin failed.

111702 Communicating with the analogue board failed.

111703 The analogue board returned an unexpected result.

111800 Storing the correction value for the clock in NVRAM succeeded.

111801 Storing the correction value for the clock in NVRAM failed.

111802 Invalid input; default value stored.

111803 Communicating with the analogue board failed.

111804 The analogue board returned an unexpected result.

111805 The user provided wrong input.

The segment containing the download-software version could not be

found.

The segment containing the application-software version could not be

found.

The segment containing the diagnostics-software version could not be

found.

Either the segment could not be found or the checksum was not

correct.

1-4-9 E9480FIS

Page 22

Description Error No. Error Description

111900 Storing the reference voltage f or the tuner in NVRAM succeeded.

111901 Storing the reference voltage for the tuner in NVRAM failed.

Store the reference voltage for the tuner in NVRAM.

Store the frequency table in NVRAM. The frequency

table is passed through the error-string provided to the

nucleus.

Store the external presets in NVRAM.

Measure the audio signal corresponding to 0dB per

channel and store it as correction value in NVRAM

Check communication to VCR module via SIO interface

Get the hardware version and type of the digital board. 120000 Getting the hardware version and type of the digital board succeeded.

Get the version of the boot stub software on the digital

board.

Get the version of the download software on the digital

board.

Get the version of the application software on the

digital board.

Upload the contents of the NVRAM on the analogue

board or the digital board to the service PC, by using

the X-modem protocol.

Download a file with the contents of the NVRAM f or the

analogue board or the digital board from the service

PC to the recorder, by using the X-modem protoc ol.

Set the IEEE 1394 unique ID.

Get the IEEE1394 unique ID.

111902 The user provided wrong input.

111903 Communicating with the analogue board failed.

111904 The analogue board returned an unexpected result.

112000 Downloading the frequency table in NVRAM succeeded.

112001 Downloading the frequency table in NVRAM failed.

112002 The user provided wrong input.

112003 Communicating with the analogue board failed.

112004 The analogue board returned an unexpected result.

112100 Storing the external presets in NVRAM succeeded.

112101 Storing the exter nal preset s in NVRAM failed.

112102 Communicating with the analogue board failed.

112103 The analogue board returned an unexpected result.

112200 Storing the bargraph adjustment values in NVRAM succeeded.

112201 Storing the bargraph adjustment values in NVRAM failed.

112202 Communicating with the analogue board failed.

112203 The analogue board returned an unexpected result.

112300 Communication to VCR succeeded.

112201 Communicating with the analogue board failed..

112302 Wrong SIO CRC received.

112303 No SIO data received.

112304 The analogue board returned an unexpected result.

120100 Getting the Boot software version succeeded.

120200 Getting the Download software version succeeded.

120300 Getting the Application software version succeeded.

120301 Invalid CONS base address.

120500 Download succeeded.

120501 User input is n ot valid.

120502

120503 Something went wrong while transferring the data.

120504 User cancelled the upload.

120600 Download succeeded.

120601 The write to NVRAM failed.

120602 Timeout. Too many retries.

120603 A file was sent with a wrong header.

120604 User cancelled the download.

120605 User input is n ot valid.

120606 Unknown Error.

120700 Setting the unique DV ID succeeded.

120701 User input is n ot valid.

120702 Setting the unique DV ID failed.

120703 Write succeeded, but checksum is corr upt .

120704 Error initialising I2C.

120800 Getting the unique DV ID succeeded.

120801 Getting the unique DV ID failed.

Something went wrong while copying the data from NVRAM to

SDRAM .

1-4-10 E9480FIS

Page 23

Description Error No. Error Description

120900 Writing the data over IIC succeeded.

120901 No input specified.

120902 In valid Bus ID number.

120903 No IIC address.

120904 Invalid IIC address.

120905 No number of bytes input.

Perform an IIC write action on the digital board.

Perfo r m an IIC read action on the digital board.

Perform an UART write action on the digital board on a

specified UART.

Perfo r m an UART read action on the digital board on a

specified UART

The video signal, which is determined by the user

input, is routed from the input to the output. Input is set

with the routing nucleus 1112. All outputs are enabled.

Audio loopthrough is also enabled by this nucleus.

Stop routing the audio/video input to all the outputs.. 121400 VideoLoopthroughStop succeeded.

Set the slash version of the system.

Get the slash version of the system.

(Re-) Virginize the recorder. User data in the NVRAM

of the analogue board is cleared.

Turn on the virgin mode functionality (e.g. the auto

channel search upon startup).

120906 Invalid number of bytes.

120907 No Data.

120908 Number of bytes must be > 0 and < 18.

120909 Invalid Data.

120910 Not enough data bytes.

120911 IIC Write fail ed.

120912 IIC init f ailed.

121000 Reading the data ov er IIC succeeded.

121001 No input specified.

121002 In valid Bus ID number.

121003 No IIC address.

121004 Invalid IIC address.

121005 No number of bytes input.

121006 Invalid number of bytes.

121007 Number of bytes must be > 0 and < 101.

121008 IIC Read failed.

121009 IIC init f ailed.

121100 Writing the bytes to the UART succeeded.

121101 The user provided wrong input.

121102 Writing to the UART failed.

121200 Reading the data from the UAR T succeeded.

121201 The user provided wrong input.

121202 Reading the data from the UAR T failed.

121300 Video LoopthroughStart succeeded.

121302 Invalid input parameters.

121303 Failed to initialise DENC.

121304 Failed to initialise VIP.

121305 DSW not ready for this setting yet.

121700 Setting the slash version succeeded.

121701 Invalid slash version, default version is set.

121702 Setting the slash version failed.

121703 The user provided wrong input.

121705 No DS errCode known for analogue board error:

121706 There was no response from the analogue board.

121800 Getting the slash version succeeded.

121801 Getting the slash version f ailed.

121802 The IIC write failed.

121803 The IIC read failed.

121804 There was no response from the analogue board.

121805 No DS errCode known for analogue board error:

121900 Virginization succeeded.

121901 Virginization on the Analogue Board failed.

121903 No DS errCode known for analogue board error:

121904 There was no response from the analogue board.

122000 Turning on the virgin mode succeeded.

122001 urning on VirginMode on the Analogue Board failed.

122003 No DS errCode known for analogue board error:

122004 There was no response from the analogue board.

1-4-11 E9480FIS

Page 24

Description Error No. Error Description

Turn off the virgin mode functionality (e.g. the auto

channel search upon startup).

122100 Turning off the virgin mode succeeded.

122101 Turning off VirginMode on the Analogue Board failed.

122103 No DS errCode known for analogue board error:

122104 There was no response from the analogue board.

1-4-12 E9480FIS

Page 25

PREPARATION FOR SERVICING

How to Enter the Service Mode

About Optical Sensors

Caution:

An optical sensor system is used for the Tape Start

and End Sensors on this equipment. Carefully read

and follow the instructions below. Otherwise the unit

may operate erratically.

What to do for preparation

Insert a tap e into the Deck Mechan ism Assembly and

press the PLAY button. The tape will be loaded into

the Deck Mechanism Assembly. Make sure the power

is on, connect TP204 (S-INH) to GND. This will stop

the function of Tape Start Sensor, Tape End Sensor

and Reel Sensors. (If these TPs are c onne ct ed before

plugging in the unit, the function of the sensors will

stay valid.) See Fig. 1.

Q236

Q238

TP204

S-INH

Fig. 1

Note: Because the Tape End Se nsors are in active, do

not run a tape all the way to the start or the en d of the

tape to avoid tape damage.

1-5-1 E9480PFS

Page 26

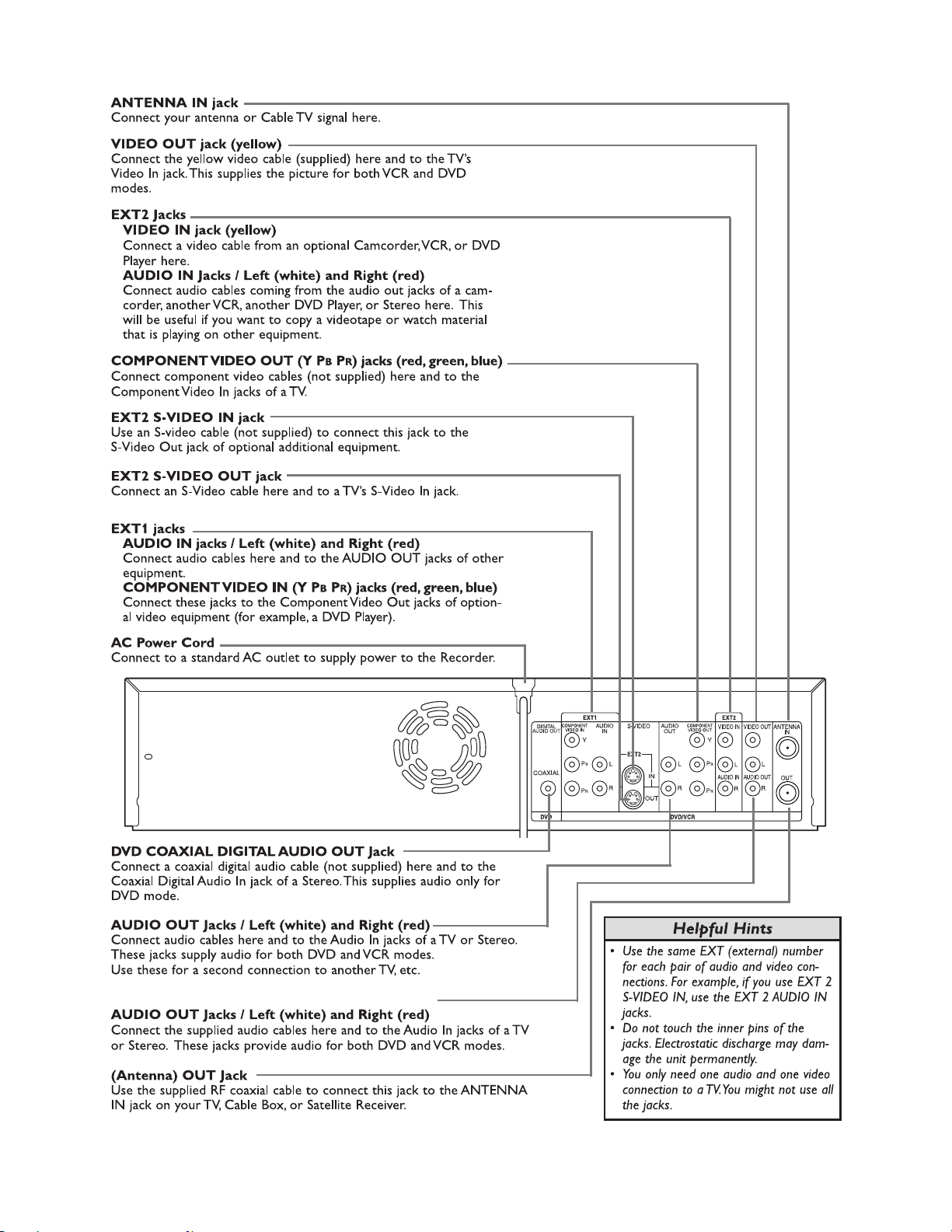

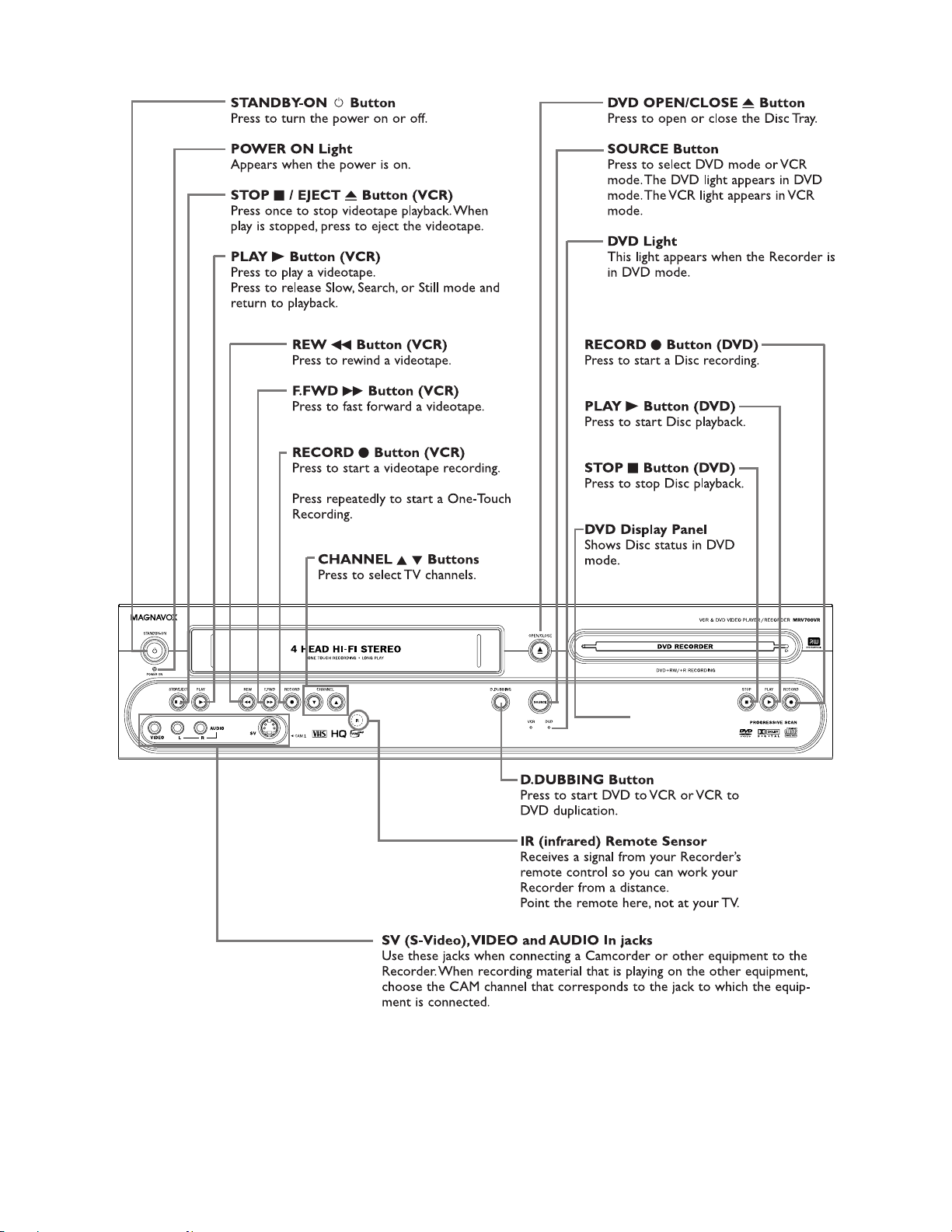

OPERATING CONTROLS AND FUN CTIONS

[ DVDR600 VR/37 ]

1-6-1 E9480IB

Page 27

1-6-2 E9480IB

Page 28

1-6-3 E9480IB

Page 29

[ MRV700VR/17 ]

1-6-4 E9480IB

Page 30

1-6-5 E9480IB

Page 31

1-6-6 E9480IB

Page 32

[ DVDR600 VR/37 ]

REMOTE CONTROL OPERATION

1-7-1 E9480IBR

Page 33

1-7-2 E9480IBR

Page 34

[ MRV700VR/17 ]

1-7-3 E9480IBR

Page 35

1-7-4 E9480IBR

Page 36

CABINET DISASSEMBLY INSTRUCTIONS

Comparison Chart of Models and Marks

Model Mark

DVDR600VR/37 A

MRV700VR/17 B

1. Disassembly Flowchart

This flowchar t indicates the disassembly steps to gain

access to item(s ) to be ser v iced. When reasse mbling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[9] FFC

Friction Plate

[10] Rear

Panel Unit

[11] Power

Supply CBA

[13] PCB

Holder

[14] Rear

Panel

[17] VCR

Chassis Unit

[20] Main

CBA

[21] CPU

CBA Unit

[1] T op Cover

[2] Front

Assembly

[5] Jack-A

CBA

[6] Jack-B

CBA

[12] DC

Fan Motor

[23] Front

Bracket R

[22] Deck

Pedestal

[18] Deck

Assembly

[19] Function

CBA

[3] Front

Bracket

[4] Radiation

Sheet

[7] DVD Mecha

& FE Assembly

[8] Digital Board

Unit

[15] Front CBA

[16] Bracket R

2. Disassembly Method

ID/

LOC.

No.

PART

Fig.

No.

[1] Top Cover D1 6(S-1) ---

Front

[2]

[3]

[4]

[5]

[6]

Assembly

Front

Bracket

Radiation

Sheet

Jack-A

CBA

Jack-B

CBA

D2

D2 2(S-2), 2(S-3) ---

D2 ---------- ---

D3 3(S-5) ---

D3 2(S-6) ---

DVD

Mecha &

FE

D4

[7]

Assembly

Digital

[8]

Board

D4

Unit

FFC

[9]

Friction

D5 2(S-10) ---

Plate

Rear

[10]

Panel Unit

D5

Power

[11]

Supply

D6

CBA

DC Fan

[12]

[13]

[14]

Motor

PCB

Holder

Rear

Panel

D6 2(S-15) ---

D6 3(S-16) ---

D6 ---------- ---

[15] Front CBA D7 3(S-17), *CN214 --[16] Bracket R D7 2(S-18) ---

VCR

[17]

Chassis

D7

Unit

REMOVAL

REMOVE/*UNHOOK/

UNLOCK/RELEASE/

UNPLUG/DESOLDER

*2(L-1), Tra y Panel,

*5(L-2), *3(L-3),

*CN204, *CN205

2(S-7), 2(S-8),

*CN207, *CN208,

*CN211, *CN213,

Connector 1109,

Connector 1704

4(S-9), Connector

1102

5(S-11), 3(S-12), (S-

13), *CN209, *CN210

4(S-14), AC Cord,

Earth Plate

5(S-19), 5(S-20),

(S-21)

Note

1

1-1

1-2

1-3

1-4

1-5

1-6

1-7

---

---

---

---

---

1-8-1 E9480DC

Page 37

ID/

LOC.

No.

[18]

[19]

PART

Deck

Assembly

Function

CBA

REMOVE/*UNHOOK/

Fig.

UNLOCK/RELEASE/

No.

UNPLUG/DESOLDER

(S-22), (S-23),

D8

Desolder

Note

D8 Desolder ---

2

3

[20] Main CBA D8 ---------- ---

REMOVAL

[21]

[22]

[23]

↓

(1)

CPU CBA

Unit

Deck

Pedestal

Front

Bracket R

↓

(2)

4(S-24), *C N215,

D8

*CN216

---

D9 8(S-25) ---

(S-26), 2(S-27),

D9

iLink Cable [ A ]

↓

(3)

↓

(4)

---

↓

(5)

Note:

(1): Identification (location) No. of parts in the figures

(2): Name of the part

(3):Figure Number for reference

(4): Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P=Spring, L=Locking Tab, S=Screw ,

CN=Connector

*=Unhook, Unlock, Release, Unplug, or Desolder

e.g. 6(S-1) = six Screws (S-1),

5(L-1) = five Locking Tabs (L-1)

(5):Refer to “Reference Notes.”

Reference Notes

aligning the hole of C am Gear with the pin of LDSW, the sh aft of Cam Gear with the hol e of LD-SW

as shown in F ig. D8.

(S-1)

(S-1)

[1] T op Cover

(S-1)

Fig. D1

(S-2)

[3] Front

[4] Radiation Sheet

(S-2)

(S-3)

Bracket

CN204

CN205

Trya Panel

(L-2)

CAUTION 1: Locking Tabs (L-1), (L-2) and (L-3) are

fragile. Be careful not to break them.

1-1. Connect the wall plu g to an AC outlet and press

the [OPEN/CLOSE] button to open the tray.

1-2. Remove the Tray Panel by releasing two locking

tabs (L-1 ).

1-3. Press the [OPEN/CL OSE] button again to close

the tray.

1-4. Press the [POWER] button to turn the power off.

1-5. Unplug the AC cord.

1-6. Disconnect connectors CN204 and CN205.

1-7. Release five Locking Tabs (L-2). Then release

three Locking Tabs (L-3), and remove the Front

Unit.

2. When re ass em bling, s old er wire j ump er s a s s hown

in Fig. D8.

3. Before installing the Deck Assembly, be sure to

place the pin of LD-SW on M ain CBA as shown in

Fig. D8. Then, install the Deck Assembly while

(L-1)

(L-1)

(L-2)

[2] Front

Assembly

(L-3)

(L-2)

Fig. D2

1-8-2 E9480DC

Page 38

[5] Jack-A CBA

(S-5)

(S-6)

(S-12)

(S-13)

[9] FFC Friction Plate

(S-11)

(S-10)

[7] DVD

Mecha

& FE

Assembly

(S-7)

[6] Jack-B CBA

(S-8)

Fig. D3

(S-12)

CN210

[14] Rear Panel

[10] Rear

Panel Unit

(S-12)

CN209

Fig. D5

Connector 1109

Connector 1704

(S-9)

Connector

1102

CN208

(S-9)

[8] Digital

Board Unit

(S-9)

CN213

CN207

CN211

Fig. D4

AC Cord

Hook

[11] Power

Supply CBA

(S-14)

(S-14)

(S-14)

(S-16)

(S-15)

(S-16)

[12] DC Fan Motor

[13] PCB

Holder

Earth Plate

Fig. D6

1-8-3 E9480DC

Page 39

(S-19)

(S-20)

(S-20)

(S-19)

(S-19)

(S-20)

CN214

(S-20)

(S-21)

[17] VCR

Chassis

Unit

(S-17)

(S-20)

(S-17)

(S-18)

[16]

Bracket R

[15]

Front

CBA

Fig. D7

1-8-4 E9480DC

Page 40

FE Head

CN215

Cylinder

Assembly

ACE Head

Assembly

[18] Deck

Assembly

(S-24)

[21] CPU CBA

Unit

Pin

SW202

LD-SW

(S-24)

CN216

(S-22)

[19] Function

CBA

(S-23)

Desolder

[20] Main

CBA

Lead with

blue stripe

(S-24)

From

ACE Head

Assembly

[20] Main CBA

LD-SW

Lead with

blue stripe