Page 1

HDD & DVD Recorder

CLASS 1

LASER PRODUCT

DVDR3570H/75/97

DVDR3590H//75/97/93

Contents Page

1 Technical Specifications and Connection

Facilities 2

2 Safety Information, General Notes & Lead

Free Requirements 5

3 Directions for Use 7

4 Mechanical Instructions 10

5 Firmware Upgrading, Diagnostic Software,

Alignment and Test Procedures 14

6 Block Diagrams,Waveforms, Wiring Diagram 95

Overall block diagram 95

Wiring diagram 96

Waveforms of Analog Board 97

Waveforms of Digital Board 98

Waveforms of HDMI Board 99

Test Points Overview for HDMI Board 100

Test Points Overview for Analog Board 101

Test Points Overview for Digital Board 102

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Contents Page

7 Circuit Diagrams and PWB Layout 103

Analog Circuit Diagrams 103

Analog Layout Diagrams 106

Front Circuit Diagrams 108

Front Display/Connector Layout Diagrams 110

Front Standby Circuit & Layout Diagrams 111

LecoPlus INIT Circuit & Layout Diagrams 112

Digital Circuit Diagrams 113

Digital Layout Diagrams 121

HDMI Circuit Diagrams 123

HDMI Layout Diagrams 127

8 IC Internal Block Diagrams 129

Analog Board 129

Digital Board 131

HDMI Board 140

9 Exploded view & Service parts list 158

Exploded View of the set 158

Service parts list 159

10 Revision list 160

Published by KC-TE 0718 V&MA Printed in the Netherlands Subject to modification EN 3139 785 32804

Version 1.4

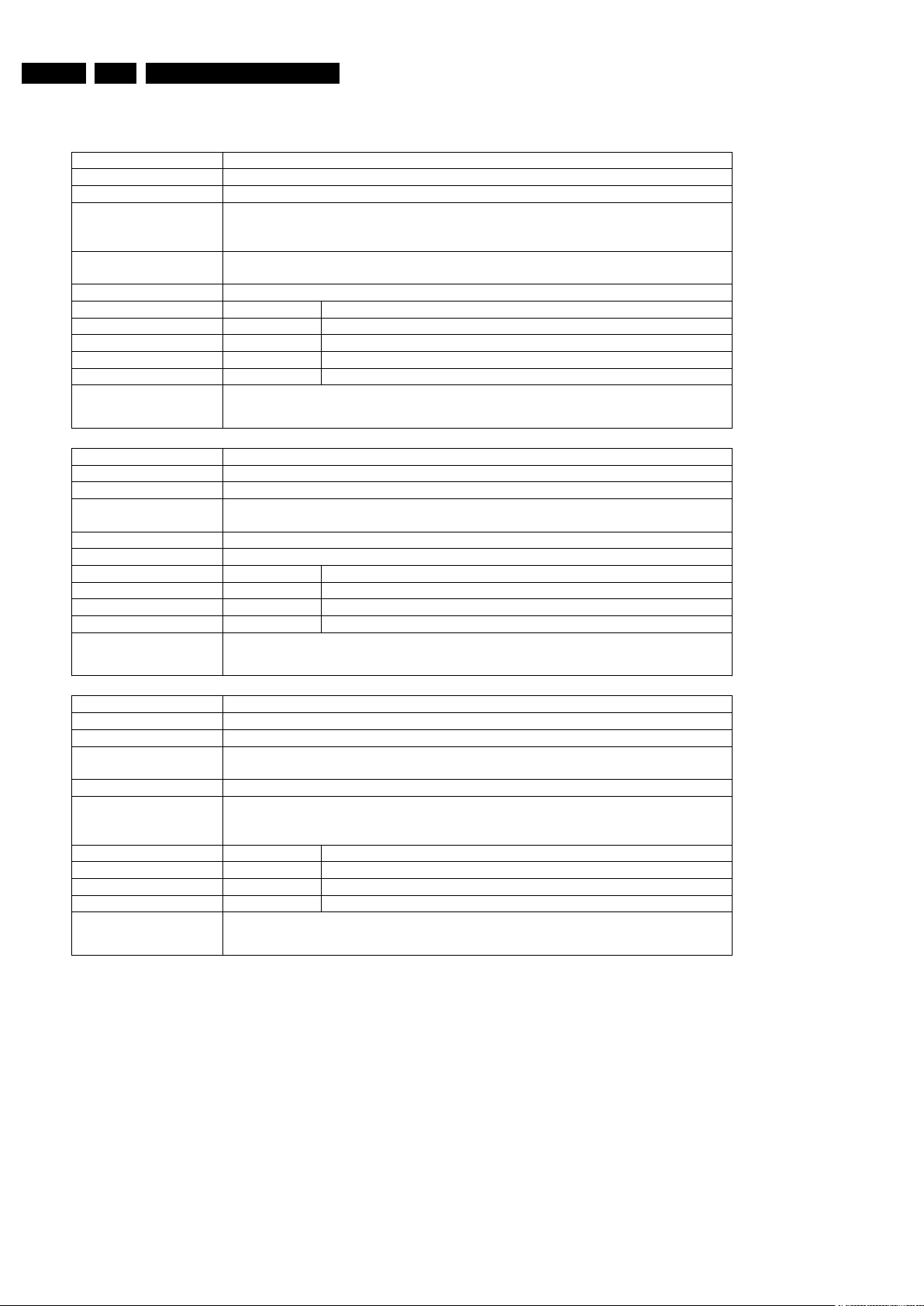

Page 2

EN 2 3139 785 328041. Technical Specifications and Connection Facilities

1. Technical Specifications and Connection Facilities

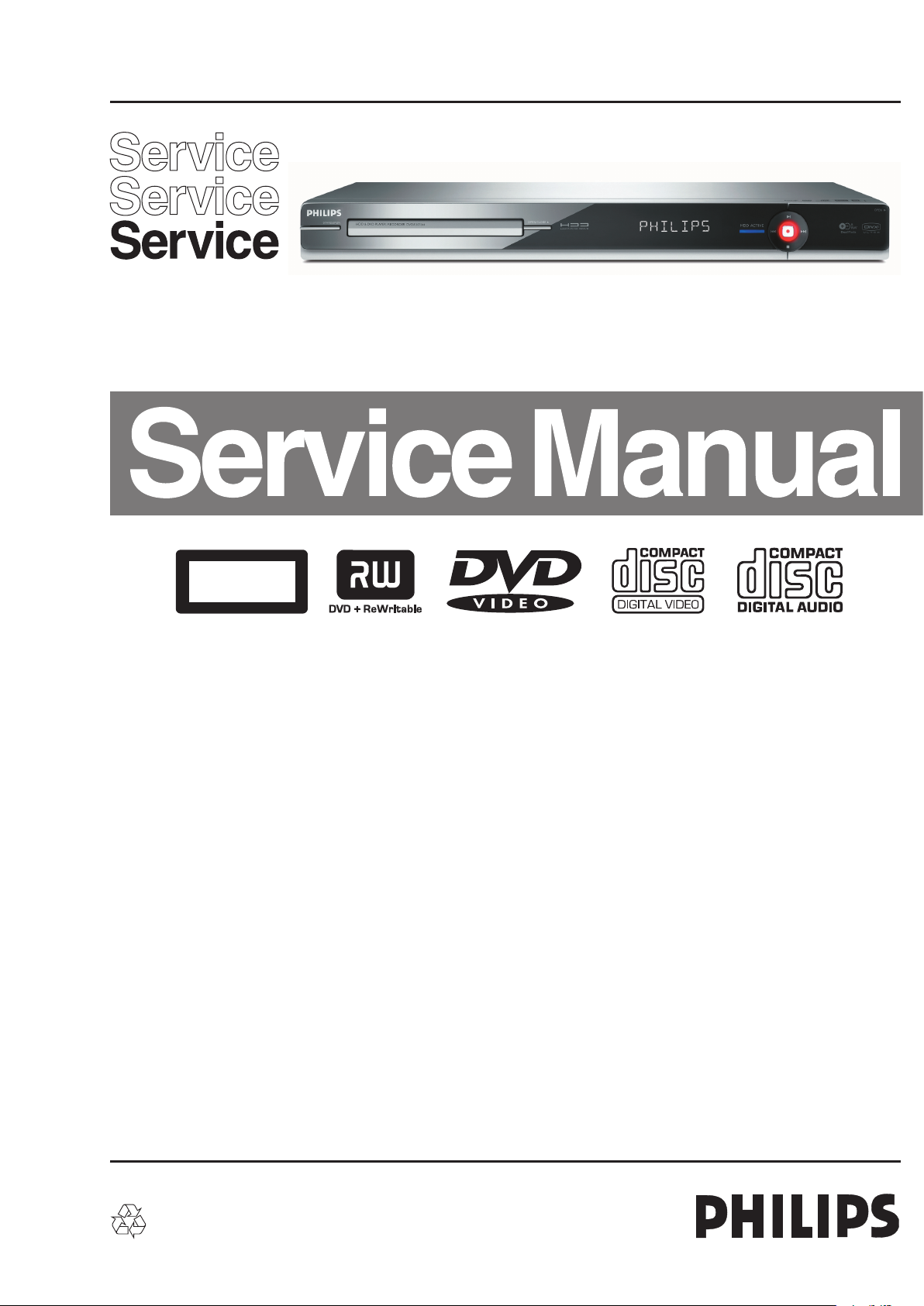

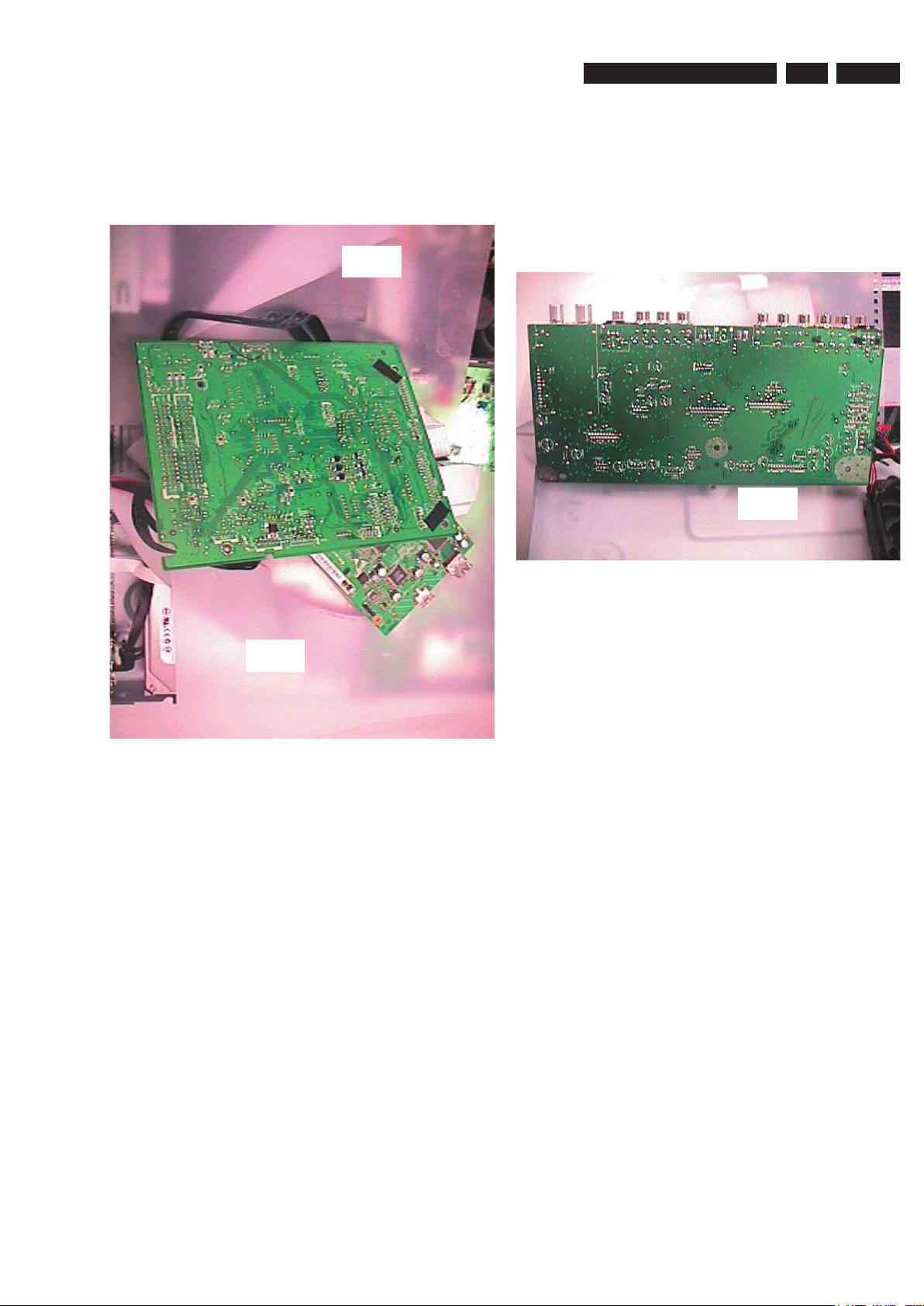

1.1 PCB Locations

PSU

Board

Basic Engine

Standby Board (Behind

the Front Cabinet)

1.2 General:

Power supply : 220-240V, ~50 Hz

Power consumption

DVDR3570H : 28 W

DVDR3590H : 35 W

Standby power consumption : < 3.7 W

1.3 RF Tuner (Analogue)

Test equipment: Fluke 54200 TV Signal generator

Test streams: Philips Standard test pattern

1.3.1 System

B/G, I, L/L’, D/K

1.3.2 RF - Loop Through:

Frequency range : 43 MHz – 860 MHz

Gain (ANT IN – ANT OUT)

without amplifier : -4dB ± 2dB

Gain (ANT IN – ANT OUT)

with amplifier : From 2dB + 3dB until

2dB – 2dB

1.3.3 Receiver:

Output of Cinch connector to be used for measurements

(direct output from front end)

Video Performance:

Frequency Response : 0 ± 4dB (0 to 4.4 MHz)

Group Delay : 0 ± 150 n sec

(0 to 4.4 MHz)

HDMI

Board

Analog Board

Digital Board

Front Board (Behind the

Front Cabinet)

Audio Performance:

Audio analogue Mono :

Frequency Response relative to

1 kHz :

S/N unweighted : ≥ 40dB (Quasi peak,

S/N weighted : ≥ 45dB (Quasi peak,

Harmonic distortion at 1 kHz : ≤ 1.5% (FM: ± 25 kHz)

Harmonic distortion at 1 kHz : ≤ 2 %

Audio NICAM Stereo/Dual :

Frequency Response relative to

1 kHz : 0 ± 3dB

S/N unweighted : ≥ 65dB (Quasi peak,

S/N weighted : ≥ 70dB (Quasi peak,

Harmonic distortion at 1 kHz : ≤ 0.5% (Headroom:

Channel Separation : ≥ 45dB

1.3.4 Tuning

Tuning Frequency Range : 45.25 MHz – 857 MHz

Antenna Level for 40dB luminance

S/N (video unweighted) at 75Ω : ≤ 40dBμV (High End)

Automatic Search Tuning:

Scanning time auto search without

RF Signal : < 2.5 min.

Stop level (vision carrier) : ≥ 40dBμV

Maximum tuning error during

operation (drift) : ± 100 kHz

Maximum tuning error of a recalled

program : ± 62.5 kHz

HDD

0 ± 3dB

(100 Hz to 12 kHz)

22 Hz – 22 kHz)

CCIR 468)

(AM: m = 54% L/L’)

(40 Hz to 15 kHz)

22 Hz – 22 kHz)

CCIR 468)

System I – 21.1dB,

all others – 16.5dB)

≤ 60dBμV (Low End)

(Typical 3 minutes)

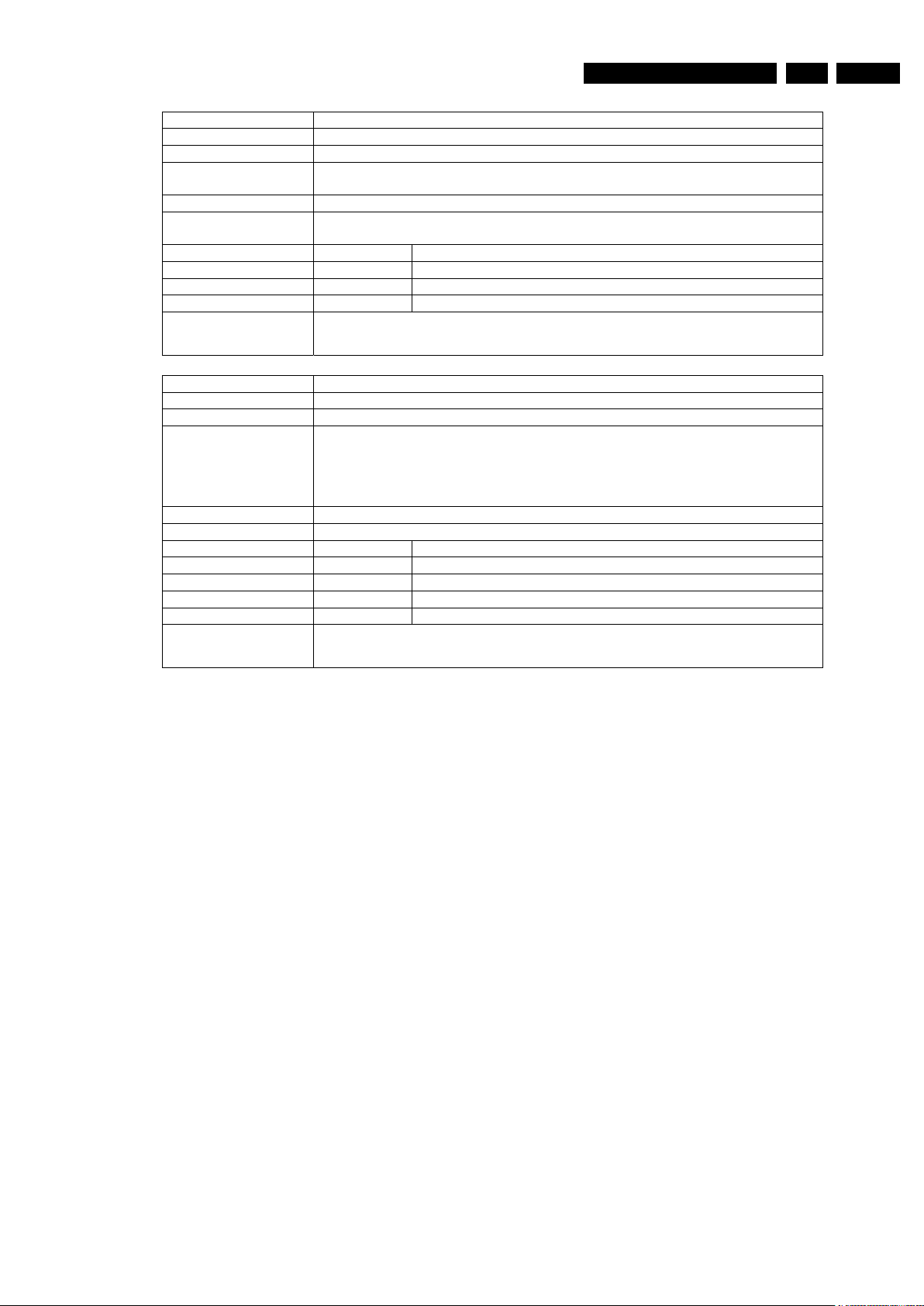

Page 3

EN 33139 785 32804 1.Technical Specifications and Connection Facilities

Tuning Principles:

Automatic system recognition

Manual Selection in “Store” mode

Storage of frequencies at each random

position number

1.4 Analog Inputs / Outputs

1.4.1 Audio/Video Front Input Connectors

(CAM 1) AUDIO – Cinch (L/R):

Input voltage : 2.2Vrms max

Input impedance : > 10kΩ

(CAM1) VIDEO – Cinch:

Input voltage : 1Vpp ± 3dB

Input impedance : 75Ω

1.4.2 Audio/Video Rear Input Connectors

AUDIO IN (AUDIO 1/2) – Cinch (L/R):

Input voltage : 2.2Vrms max

Input impedance : > 10kΩ

CVBS IN (VIDEO IN) – Cinch:

Input voltage : 1Vpp ± 3dB

Input impedance : 75Ω

S-VIDEO IN (VIDEO IN) – Hosiden:

According to IEC 933-5

Superimposed DC-level on pin 4 (load > 100kΩ)

< 2.4V is detected as 4:3 aspect ratio

> 3.5V is detected as 16:9 aspect ratio

Input voltage Y : 1Vpp ± 3dB

Input impedance Y : 75Ω

Input voltage C : 300mVpp ± 3dB

Input impedance C : 75Ω

COMPONENT VIDEO IN – Cinch (Y/Pb/Pr):

According to EIO-770-I-A, EIA-770-2

1.4.3 Audio/Video Output Connectors

(AUDIO OUT) AUDIO – Cinch (L/R):

Output voltage : 2Vrms max

Output impedance : > 10kΩ

(VIDEO OUT) CVBS OUT– Cinch:

Output voltage : 1Vpp ± 3dB

Output impedance : 75Ω

(VIDEO OUT) S-VIDEO OUT - Hosiden:

According to IEC 933-5

Superimposed DC-level on pin 4 (load > 100kΩ)

< 2.4V is detected as 4:3 aspect ratio

> 3.5V is detected as 16:9 aspect ratio

Output voltage Y : 1Vpp ± 3dB

Output impedance Y : 75Ω

Output voltage C : 300mVpp ± 3dB

Output impedance C : 75Ω

COMPONENT VIDEO OUT – Cinch (Y/Pb/Pr):

According to EIA-770-1-A, EIA-770-2-A

1.5 Digital Inputs / Outputs

1.5.1 CAM 2 DV IN (IEEE 1394 Digital Video Input)

Implementation Standard according:

IEEE Std 1394-1995

IEC61883 - Part1

IEC61883 - Part 2 SD-DVCR (02-01-1997)

Specification of consumer use digital VCR’s using 6.3mm

magnetic tape – dec.1994

Mechanical connection according to Annex of IEC 61883-1

1.5.2

(AUDIO OUT) COAXIAL DIGITAL OUT – Cinch

LPCM : according IEC 60958

MPEG 1, MPEG 2, AC3 : according IEC 61937

DTS : according IEC 61937 +

1.5.3 USB

Compatibility : USB 2.0

Type of connector : Series A Connector

1.5.4 HDMI Output

Compatibility : HDMI version 1.1

Type of connector : Type A connector

addendum

(19 pins)

1.6 Video Performance

1.6.1 SNR

PAL

RGB CVBS Y/C

≥ 55 dB Lumincance: ≥ 55 dB

NTSC

Y Pb Pr CVBS Y/C

≥ 55 dB Lumincance: ≥ 55 dB

1.6.2 Bandwidth

PAL

RGB CVBS Y/C

0.5 to 4 MHz:+1dB/

-2dB

4.8 MHz:-3dB 4.8 MHz:-3dB C:700 kHz

5.8 MHz:-6dB 5.8 MHz:-6dB

NTSC

YPbPr CVBS Y/C

4.2 MHz:-3dB 4.2 MHz:-3dB Y:

5.8 MHz:-6dB 5.8 MHz:-6dB C:≥ 700 kHz

With Pscan:

8.4MHz -3dB

Chroma: ≥ 55 dB (AM)

≥ 52 dB (PM)

Chroma: ≥ 54 dB (AM)

≥ 54 dB (PM)

0.5 to 4 MHz:+1dB/

-2dB

Y: ≥ 57 dB

C: ≥ 57 dB (AM)

≥ 54 dB (PM)

Y: ≥ 55 dB

C: ≥ 54 dB (AM)

≥ 54 dB (PM)

Y:

4.8MHz-3dB

4.2MHz-3dB

Page 4

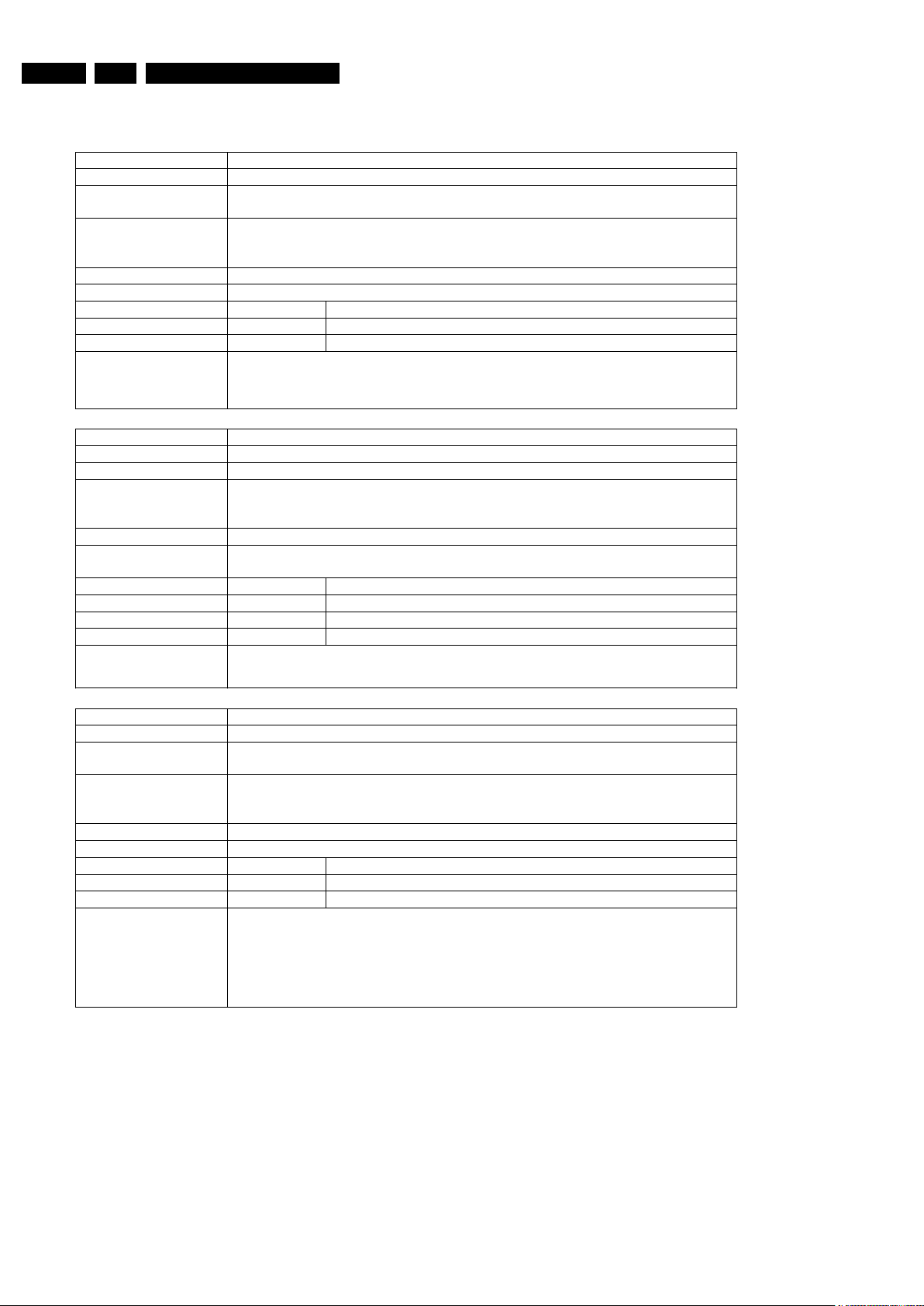

EN 4 3139 785 328041. Technical Specifications and Connection Facilities

1.7 Audio Performance CDDA (PCM)

1.7.1 Cinch Output Rear

Output voltage : 1.8Vrms ± 2dB

Channel unbalance : < 0.22dB

Crosstalk 1kHz : > 110 dB

Crosstalk 16Hz – 20kHz : > 110 dB

Signal to noise ratio (unweighted)

20Hz – 20kHz bandwidth limited :

Signal to noise ratio (A-weighted)

RMS 20Hz – 20kHz

bandwidth limited : > 112dBA (mute)

Dynamic range 1kHz : > 90dB

Distortion and noise 1kHz : > 85dB

Distortion and noise 16Hz – 20kHz : > 78dB

Mute (spin-up, pause, access) : > 78dB

> 95dB (mute)

1.8 Dimension and Weight

Set Dimension W x H x D : 435 x 43 x 324 mm

Net Weight : 3.8 kg

1.9 Laser Output Power & Wavelength

1.9.1 DVD

Output power during reading : 1.0mW

Output power during writing : 69mW

Wavelength : 658nm (at 25 °C)

1.11 Supported Disc Types and Media Speed for

Recording

Disc Media Speeds

DVD+R 1x - 16x

DVD+RW 2.4x - 8x

DVD-R 1x - 16x

DVD-RW 2.4x - 4x

DVD+R DL 2.4x

1.12 Diversity Matrix

DVDR3570H DVDR3590H

Hard Disk capacity 160 GB 250 GB

1.9.2 CD

Output power : 1.2mW

Wavelength : 783nm (at 25 °C)

1.10 Playability

Video Playback

1. Playback Media:

CD-R/CD-RW

DVD-R/-RW, DVD-Video, Video

CD/SVCD, DVD+R DL, DVD-R

DL, USB flash drive

2. Compression Formats:

MPEG2, MPEG1, DivX 3.11, DivX

4.x, DivX 5.x, DivX 6.0, MPEG4

Audio Playback

Playback Media:

1.

Audio CD, CD-R/R

DVD+R/+RW, DVD-R/-RW, MP3CD, MP3-DVD, USB flash drive,

WMA-CD

2. Compression Format:

Dolby Digital, MP3, MPEG2

Multichannel, PCM, WMA

3. MPEG1 bit rates: 64-384 kbps

and VBR

Still Picture Playback

1. Playback Media: CD-R/RW

DVD+R DL, DVD+R/+RW, DVDR/-RW, Picture CD, USB Digital

Camera (PTP), USB flash drive

2. Picture Compression Format:

JPEG, JPEG digital camera

photos

3. Picture enhancement: Slideshow

with MP3 playback, Create

albums, Rotate, Slideshow with

music playback, Zoom

, DVD+R/+RW,

, DVD+R DL,

W

,

x

x

x

x

x

x

x

x

Page 5

CLASS 1

LASER PRODUCT

2. Safety Information, General Notes & Lead Free Requirements

EN 53139 785 32804 2.Safety Information, General Notes & Lead Free Requirements

2.1 Safety Instructions

2.1.1 General Safety

Safety regulations require that during a repair:

• Connect the unit to the mains via an isolation transformer.

• Replace safety components, indicated by the symbol

only by components identical to the original ones. Any

other component substitution (other than original type)

may increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

• Route the wires/cables correctly, and fix them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the electrical DC resistance between the mains

plug and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the ‘on’ position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains

plug and the front panel, controls, and chassis

bottom.

4. Repair or correct unit when the resistance

measurement is less than 1 MΩ.

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

2.1.2 Laser Safety

This unit employs a laser. Only qualified service personnel

may remove the cover, or attempt to service this device (due

to possible eye injury).

2.2 Warnings

2.2.1 General

,

2.2.2 Laser

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD,

). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are at the same potential as the mass

of the set by a wristband with resistance. Keep

components and tools at this same potential.

Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable)

4822 310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the live voltage

section. The primary side of the power supply, including

the heatsink, carries live mains voltage when you

connect the player to the mains (even when the

player is ‘off’!). It is possible to touch copper tracks and/

or components in this unshielded primary area, when

you service the player. Service personnel must take

precautions to prevent touching this area or components

in this area. A ‘lightning stroke’ and a stripe-marked

printing on the printed wiring board, indicate the primary

side of the power supply.

• Never replace modules, or components, while the unit is

‘on’.

• The use of optical instruments with this product, will

increase eye hazard.

• Only qualified service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

• Repair handling should take place as much as possible

with a disc loaded inside the player.

• Text below is placed inside the unit, on the laser cover

shield:

Laser Device Unit

Type : Semiconductor laser

GaAlAs

Wavelength : 650 nm (DVD)

: 780 nm (VCD/CD)

Output Power : 20 mW

(DVD+RW writing)

: 0.8 mW

(DVD reading)

: 0.3 mW

(VCD/CD reading)

Beam divergence : 60 degree

Figure 2-1

Note: Use of controls or adjustments or performance of

procedure other than those specified herein, may result in

hazardous radiation exposure. Avoid direct exposure to beam.

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL

SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D’OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Figure 2-2

Page 6

EN 6 2.

2.3 Lead Free Requirement

Information about Lead-free produced sets

Philips CE is starting production of lead-free sets from

1.1.2005 onwards.

INDENTIFICATION:

Regardless of special logo (not always indicated)

One must treat all sets from 1 Jan 2005 onwards, according

next rules.

Example S/N:

Bottom line of typeplate gives a 14-digit S/N. Digit 5&6 is the year, digit 7&8 is

the week number, so in this case 1991 wk 18

So from 0501 onwards = from 1 Jan 2005 onwards

to be purchased at external companies.

• Special information for BGA-ICs:

- always use the 12nc-recognizable soldering temperature

profile of the specific BGA (for de-soldering always use

the lead-free temperature profile, in case of doubt)

- lead free BGA-ICs will be delivered in so-called ‘drypackaging’ (sealed pack including a silica gel pack) to

protect the IC against moisture. After opening, dependent

of MSL-level seen on indicator-label in the bag, the

BGA-IC possibly still has to be baked dry. (MSL=Moisture

Sensitivity Level). This will be communicated via AYSwebsite.

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products of

2004), containing leaded solder-alloy and components,

all needed spare-parts will be available till the end of the

service-period. For repair of such sets nothing changes.

• On our website www.atyourservice.ce.Philips.com

you find more information to:

BGA-de-/soldering (+ baking instructions)

Heating-profiles of BGAs and other ICs used in Philips-

sets

You will find this and more technical information within

the “magazine”, chapter “workshop news”.

For additional questions please contact your local repair-helpdesk.

Important note: In fact also products of year 2004 must be treated in this way as long as you

avoid mixing solder-alloys (leaded/ lead-free). So best to always use SAC305 and the higher

temperatures belong to this.

Due to lead-free technology some rules have to be respected by the

workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solder-pate

is required, please contact the manufacturer of your

solder-equipment. In general use of solder-paste within

workshops should be avoided because paste is not easy

to store and to handle.

• Use only adequate solder tools applicable for lead-free

solder alloy. The solder tool must be able

o To reach at least a solder-temperature of 400°C,

o To stabilize the adjusted temperature at the solder-

tip

o To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around

360°C – 380°C is reached and stabilized at the solder

joint. Heating-time of the solder-joint should not exceed

~ 4 sec. Avoid temperatures above 400°C otherwise

wear-out of tips will rise drastically and flux-fluid will be

destroyed. To avoid wear-out of tips switch off un-used

equipment, or reduce heat.

• Mix of lead-free solder alloy / parts with leaded solder

alloy / parts is possible but PHILIPS recommends strongly

to avoid mixed solder alloy types (leaded and lead-free).

If one cannot avoid or does not know whether product is

lead-free, clean carefully the solder-joint from old solder

alloy and re-solder with new solder alloy (SAC305).

• Use only original spare-parts listed in the ServiceManuals. Not listed standard-material (commodities) has

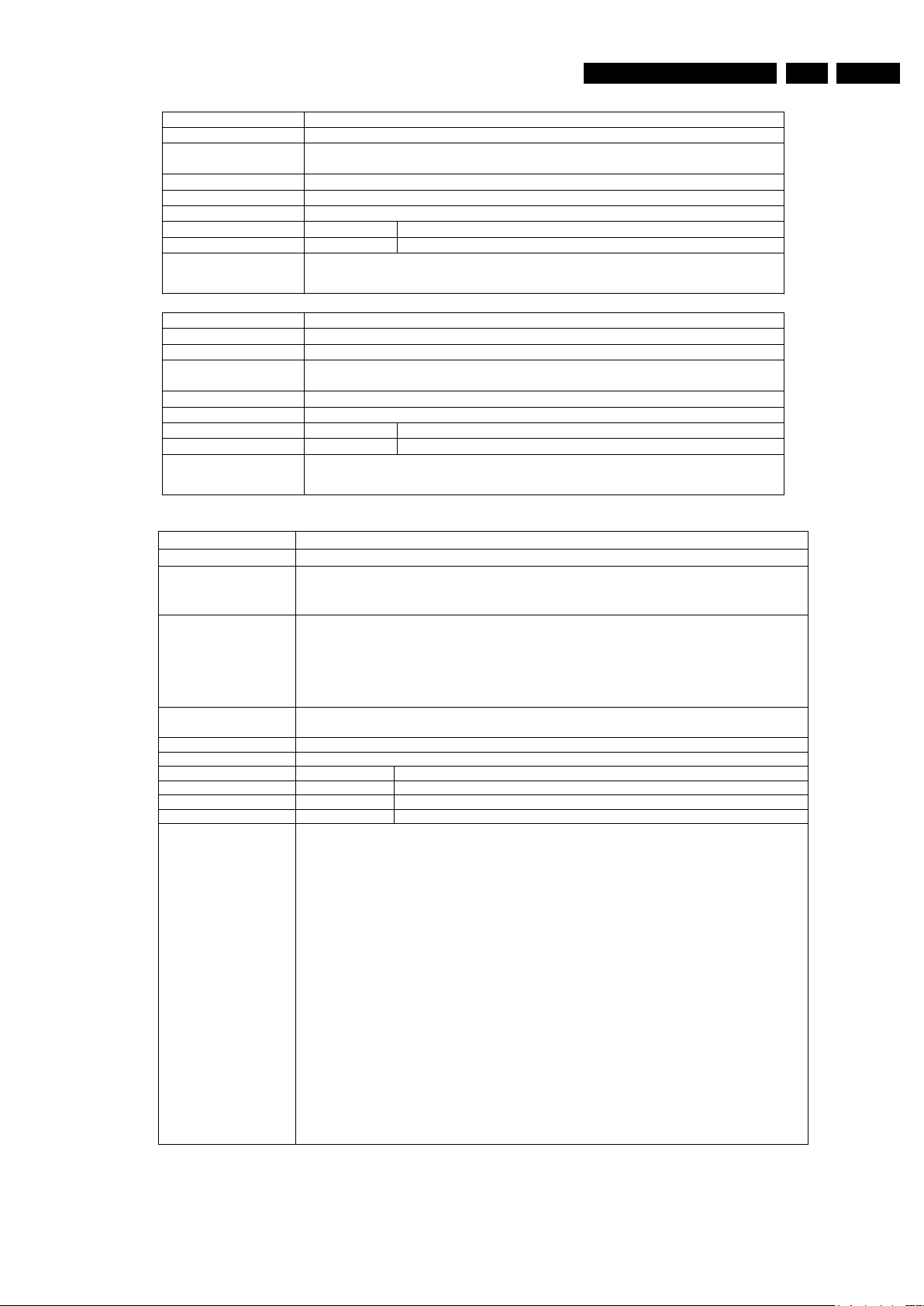

Page 7

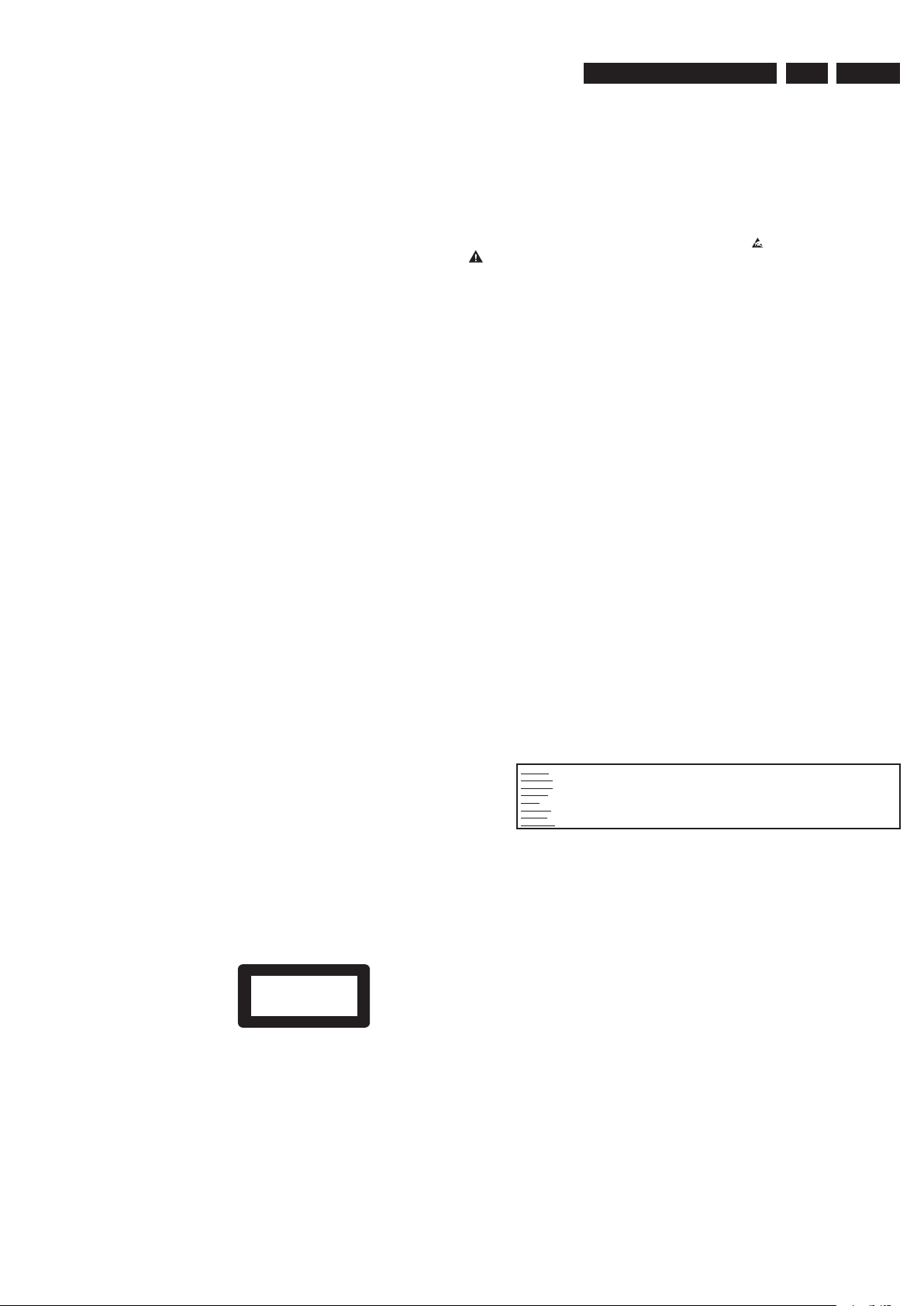

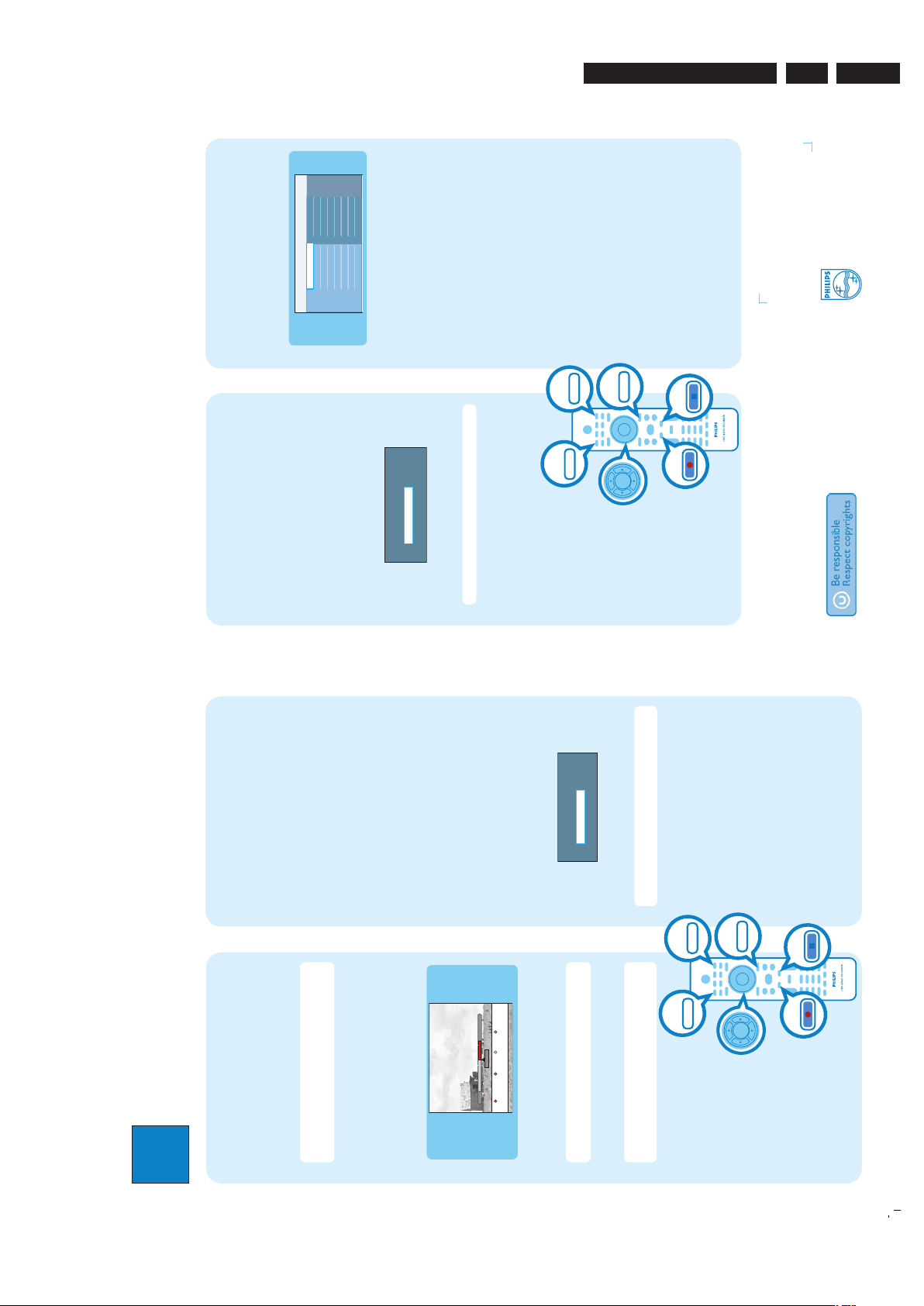

Hard Disk / DVD Recorder

DVDR3570H

DVDR3590H

Quick Start Guide

Connect

Set up

Enjoy

1

2

3

What’s in the box?

Hard Disk/ DVD Recorder

RF antenna cable

(connect between

recorder and TV)

Remote Control

and 2 batteries

User

Manual

Audio/Video

cables

SUBTITLE

INFO SELECT EDIT SCART

AUDIO

PAUSE LIVE TV

1

Connect

ANTENNA-IN

TV-OUT

HDMI

OUT

MAINS

COAXIAL

DIGITAL OUT

CVBS OUT

S-VIDEO OUT

VIDEO OUT AUDIO OUT

AUDIO

COMPONENT

VIDEO OUT

P

B

P

R

Y

R

L

CVBS IN

S-VIDEO IN

AUDIO 2AUDIO 1

R

L

P

B

P

R

Y

COMPONENT VIDEO IN

EXT 1

R

L

EXT 2

R

COAXIAL

DIGITAL OUT

CVBS OUT

S-VIDEO OUT

VIDEO OUT AUDIO OUT

AUDIO

COMPONENT

VIDEO OUT

P

B

P

R

Y

R

L

D

C

E

B

A

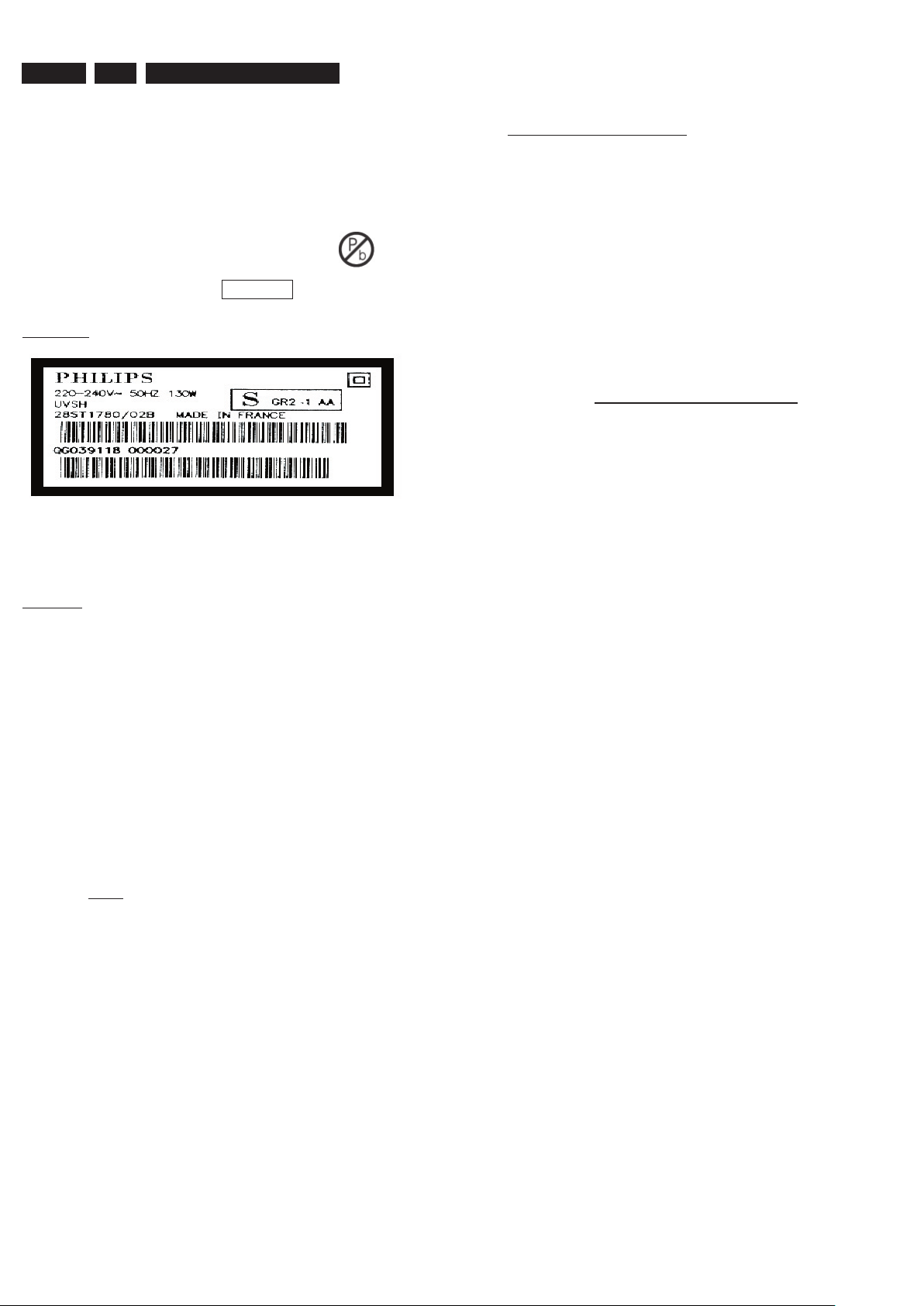

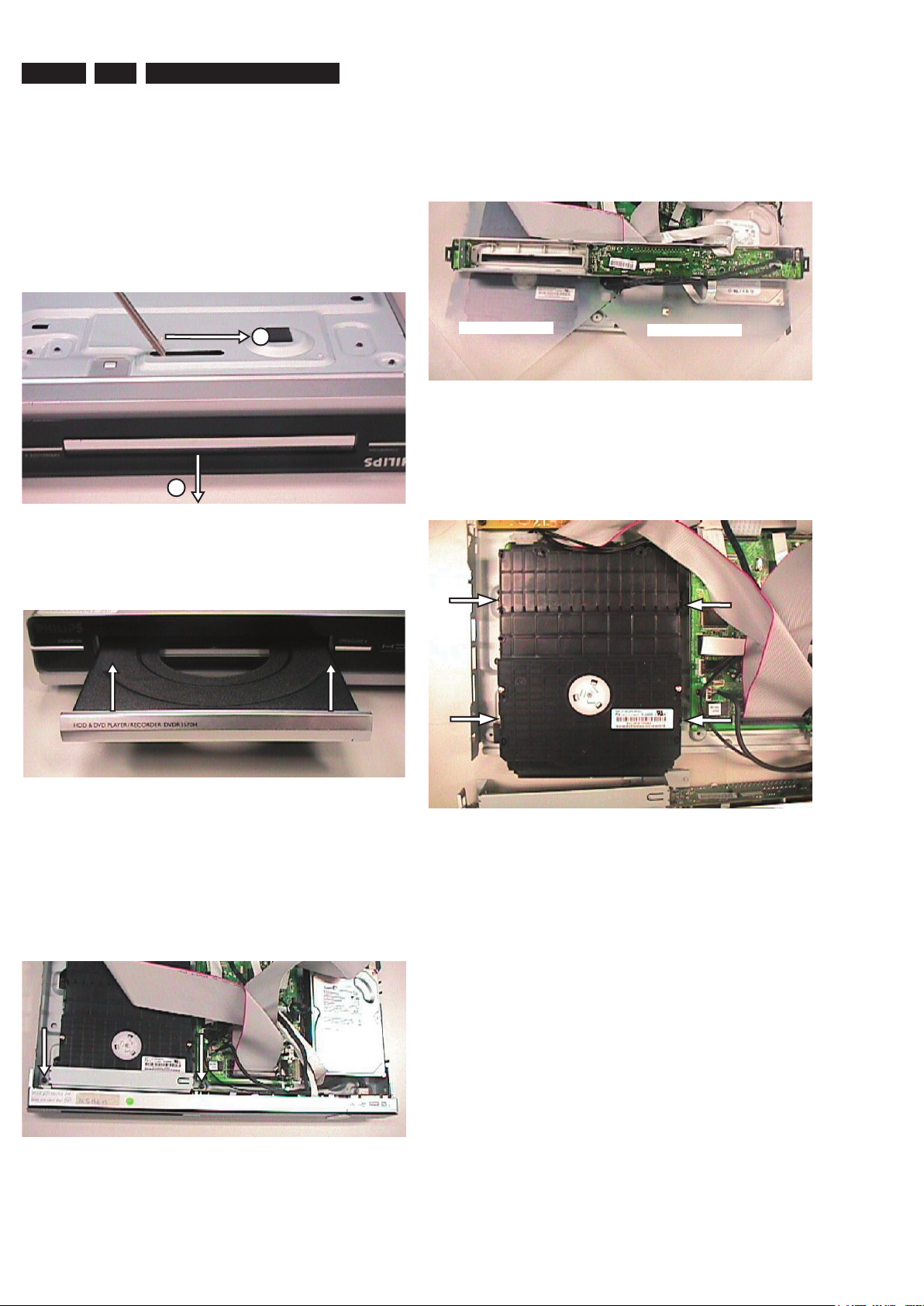

Before connecting

Select the most suitable connection (A or B) based on

the type of device you have and your home set up.

You can also refer to the accompanying User Manual for

other possible connections.

A

Connecting Recorder and TV

with antenna only

A Unplug the existing antenna cable from your TV and

connect it to the ANTENNA IN

socket on this

recorder.

B Connect an RF antenna cable (supplied) from the

TV-OUT

socket on this recorder to the

Antenna In socket on the TV.

C Connect a composite cable (supplied) from the

CVBS OUT socket on this recorder to the video

input socket on your TV.

D Connect an audio cables (supplied) from the

AUDIO OUT sockets on this recorder to the

audio input sockets on your TV.

E Plug in the power cable from the recorder to an AC

power outlet

ANTENNA-IN

TV-OUT

HDMI

OUT

MAINS

COAXIAL

DIGITAL OUT

CVBS OUT

S-VIDEO OUT

VIDEO OUT AUDIO OUT

AUDIO

COMPONENT

VIDEO OUT

P

B

P

R

Y

R

L

CVBS IN

S-VIDEO IN

AUDIO 2AUDIO 1

R

L

P

B

P

R

Y

COMPONENT VIDEO IN

EXT 1

R

L

EXT 2

RF

S-VIDEO

OUT

IN

AUDIO

R L

VIDEO

??

???????????????

D

C

B

A

CVBS IN

S-VIDEO IN

AUDIO 2AUDIO 1

R

L

EX T 2

E

A Keep the existing antenna connection from the

Cable Box/Satellite Receiver to your TV.

B Connect the CVBS IN and AUDIO IN sockets on

the recorder to the corresponding video and audio

output sockets on the Cable Box/Satellite Receiver.

�

Alternatively, you may use COMPONENT

VIDEO or S-VIDEO connection.

C Connect a composite cable (supplied) from the

CVBS OUT socket on this recorder to the video

input socket on your TV.

D Connect an audio cables (supplied) from the

AUDIO OUT sockets on this recorder to the

audio input sockets on your TV.

E Plug in the power cable from the recorder to an AC

power outlet.

2

Set up

B

Connecting Recorder and TV

with Cable TV or Satellite Receiver

Antenna

Television ( rear)

Philips Recorder (rear)

Philips Recorder (rear)

A

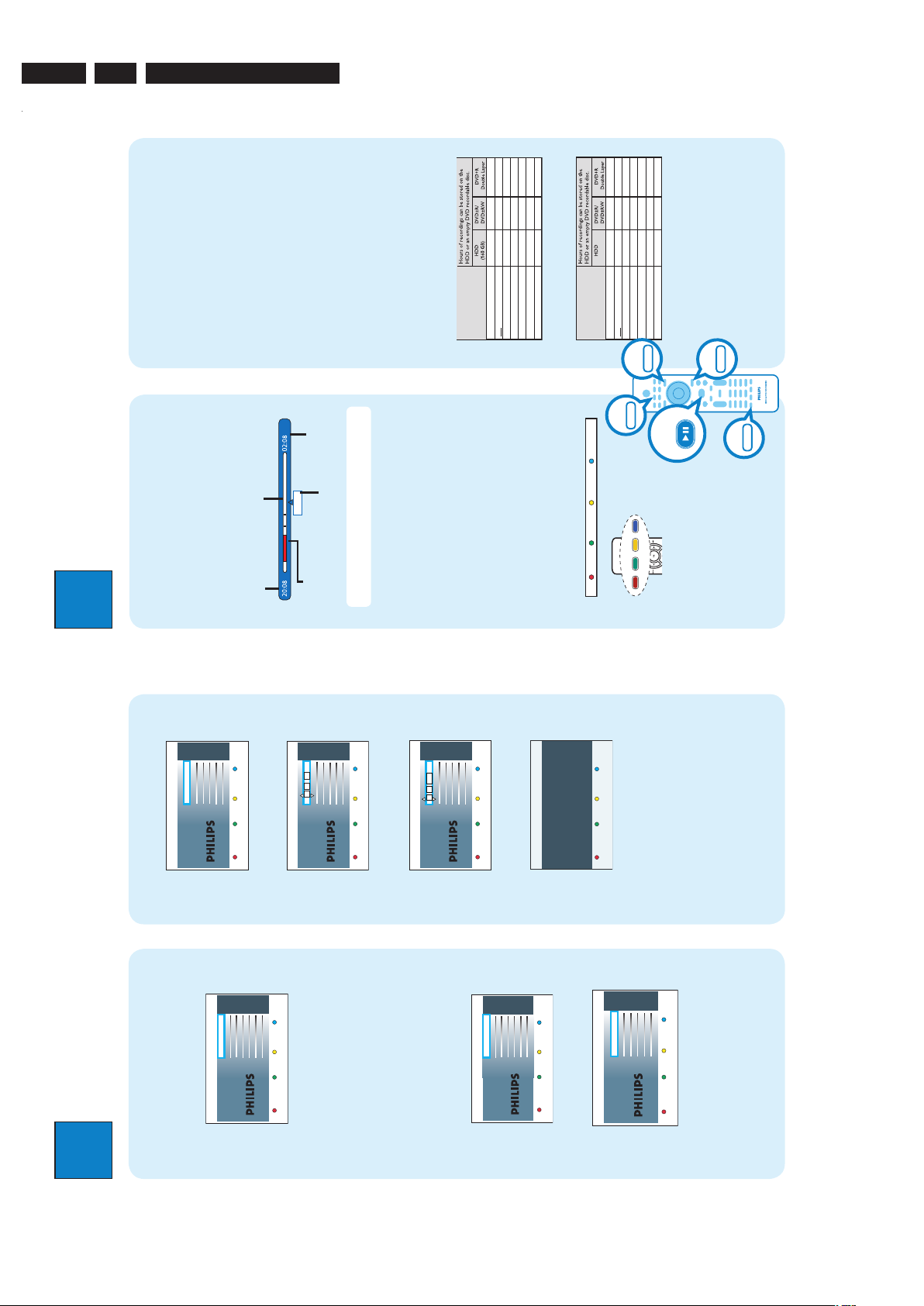

Finding the viewing channel

A Press STANDBY-ON on the recorder.

B Turn on the TV.

You should see the installation menu.

Menu Language

English

Please select your language.

Denes the languages of all

on-screen menu displays.

Next

Simpl Chinese

Trad Chinese

C In case you don’t see the recorder’s setting menu,

press the Channel Down button on the TVs remote

control repeatedly (or AV, SELECT,

°

button) until

you see the menu. This is the correct viewing

channel for the recorder.

B

Start initial installation

Use the recorder’s remote control and follow the on-

screen instructions to complete the installation.

A Select the desired language for this recorder’s on-

screen menu display and press the Green button to

continue.

Country Selection

AUS Australia

Country selection is

important for TV channels

search.

Next

BMU American B..

PRC China

RC Taiwan

NZ New Zealand�

ROK K

orea

SGP Singapore

HK Hong Kong

Previous

B Select the country you live and press the Green

button to continue.

Previous Next

Select the appropriate TV shape

according to the TV you have

connected.

TV shape

4:3 Letterbox

4:3 Panscan

16:9 Widescreen

C Select the appropriate TV shape in the way you

want the wide-screen movies to be displayed and

press the Green button to continue.

3

Enjoy

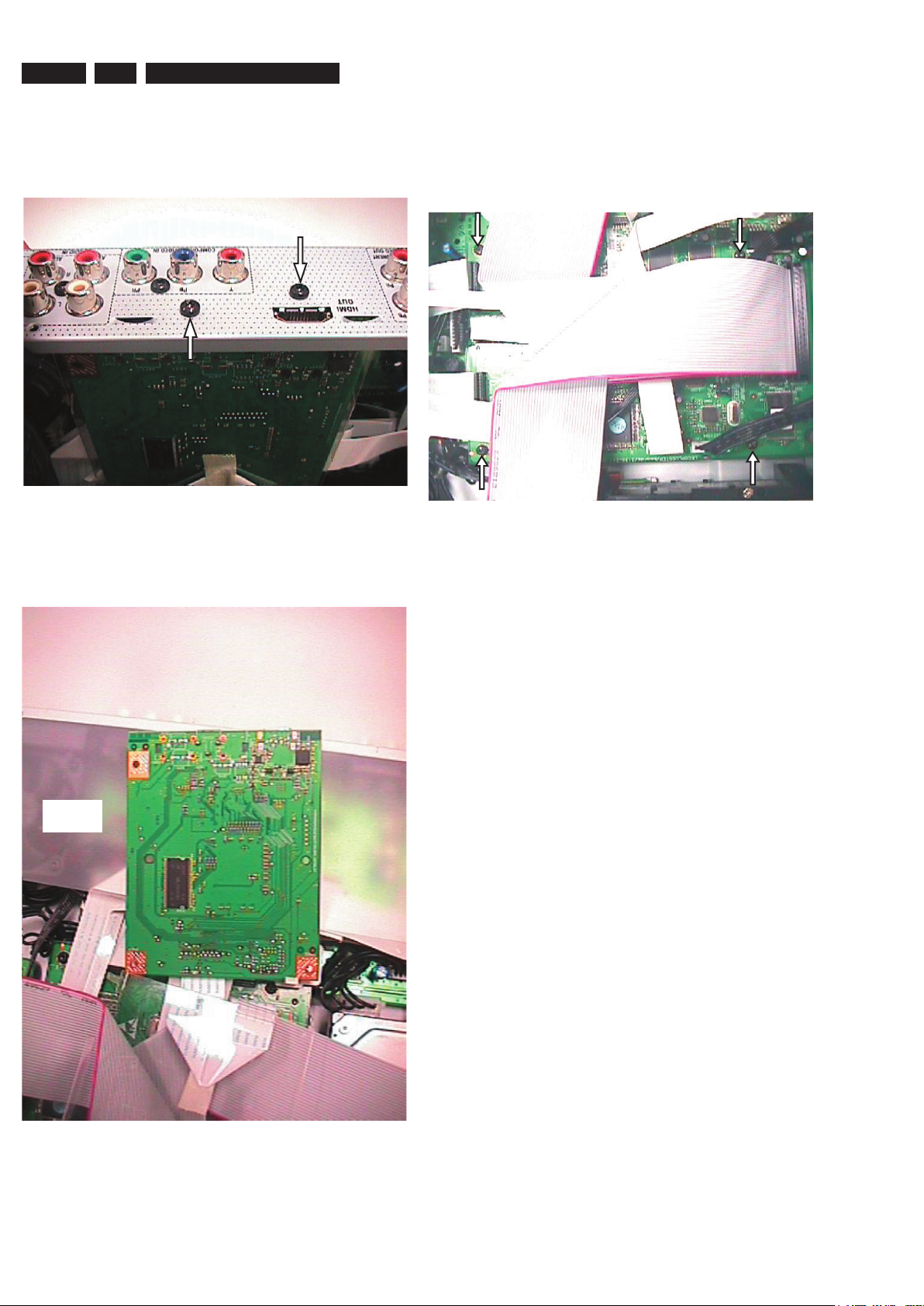

About the Time Shift Buffer

(TSB)

Once you turn on the recorder, the selected TV

programme will be stored in a temporary hard disk

storage called Time Shift Buffer ‘TSB’. The ‘TSB’ can

store up to 6 hours of programmes temporarily.

Press INFO to display the Time Shift video bar.

22:04:30

Note The contents in the time shift video bar will be

cleared when you press STANDBY ON (2).

Watch TV – Pause live TV

Your Philips Recorder allows you to control the TV

programme. You can PAUSE it as if you were in control

of the live broadcast.

A Turn on your recorder to the live TV mode and

press P +/- to select a TV programme.

B Press PAUSE LIVE TV to suspend it.

C Press PAUSE LIVE TV again to continue.

D To return to live broadcast, press LIVE TV.

Colour Softkeys function

Delete Copy Child Lock Protect

The colour functions shown on the

menu can be accessed by pressing the

matching colour coded buttons on the

remote control.

Current time

of playback

Selected clips for

recording

Programmes

stored in the ‘TSB’

Start time of the

programme

Present time

Satellite dish/

Cable TV wall outlet

PAUSELIVETV

Television ( rear)

D Press OK to start automatic analogue channel

search.

Previous Skip

Channel search

Start Auto search

E Once complete, press the Green button to

continue.

Previous Next

Time setting is required for

making recordings.

Time

00

00

:

AM

F Enter the correct time in the entry field and press

OK to confirm.

Previous Next

Date setting is required to

make recordings. Please

make sure it is correct.

Date

31

01

2007

G Enter the correct date in the entry field and press

OK to confirm.

You have successfully completed the installation

of your recorder.

System is now ready for use.

Previous Done

Installataion Complete

H The installation is completed now, press the Green

button to close the menu.

EN 73139 785 32804 3.Directions For Use

3. Directions For Use

The following except of the Quick Use Guide serves as an introduction to the set.

The Complete Direction for the Use can be downloaded in different languages from the internet site of Philips Customer care Center:

www.p4c.philips.com

Page 8

EN 8 3139 785 328043. Directions For Use

2

Set up

A

Finding the viewing channel

A Press STANDBY-ON on the recorder.

B Turn on the TV.

You should see the installation menu.

Menu Language

English

Please select your language.

Denes the languages of all

on-screen menu displays.

Next

Simpl Chinese

Trad Chinese

C In case you don’t see the recorder’s setting menu,

press the Channel Down button on the TVs remote

control repeatedly (or AV, SELECT,

°

button) until

you see the menu. This is the correct viewing

channel for the recorder.

B

Start initial installation

Use the recorder’s remote control and follow the on-

screen instructions to complete the installation.

A Select the desired language for this recorder’s on-

screen menu display and press the Green button to

continue.

Country Selection

AUS Australia

Country selection is

important for TV channels

search.

Next

BMU American B..

PRC China

RC Taiwan

NZ New Zealand�

ROK K

orea

SGP Singapore

HK Hong Kong

Previous

B Select the country you live and press the Green

button to continue.

Previous Next

Select the appropriate TV shape

according to the TV you have

connected.

TV shape

4:3 Letterbox

4:3 Panscan

16:9 Widescreen

C Select the appropriate TV shape in the way you

want the wide-screen movies to be displayed and

press the Green button to continue.

3

Enjoy

About the Time Shift Buffer

(TSB)

Once you turn on the recorder, the selected TV

programme will be stored in a temporary hard disk

storage called Time Shift Buffer ‘TSB’. The ‘TSB’ can

store up to 6 hours of programmes temporarily.

Press INFO to display the Time Shift video bar.

Now

22:04:30

Note The contents in the time shift video bar will be

cleared when you press STANDBY ON (2).

Watch TV – Pause live TV

Your Philips Recorder allows you to control the TV

programme. You can PAUSE it as if you were in control

of the live broadcast.

A Turn on your recorder to the live TV mode and

press P +/- to select a TV programme.

B Press PAUSE LIVE TV to suspend it.

C Press PAUSE LIVE TV

again to continue.

D To return to live broadcast, press LIVE TV.

Colour Softkeys function

Delete Copy Child Lock Protect

The colour functions shown on the

menu can be accessed by pressing the

matching colour coded buttons on the

remote control.

Current time

of playback

Selected clips for

recording

Programmes

stored in the ‘TSB’

Start time of the

programme

Present time

About the internal hard disk

drive

This recorder’s hard disk drive can be used as a Media

Jukebox, allowing you to store and playback your TV

programmes, videos, music and photos les.

Press HOME on the remote control to access your

contents stored in the { Hard Disk }.

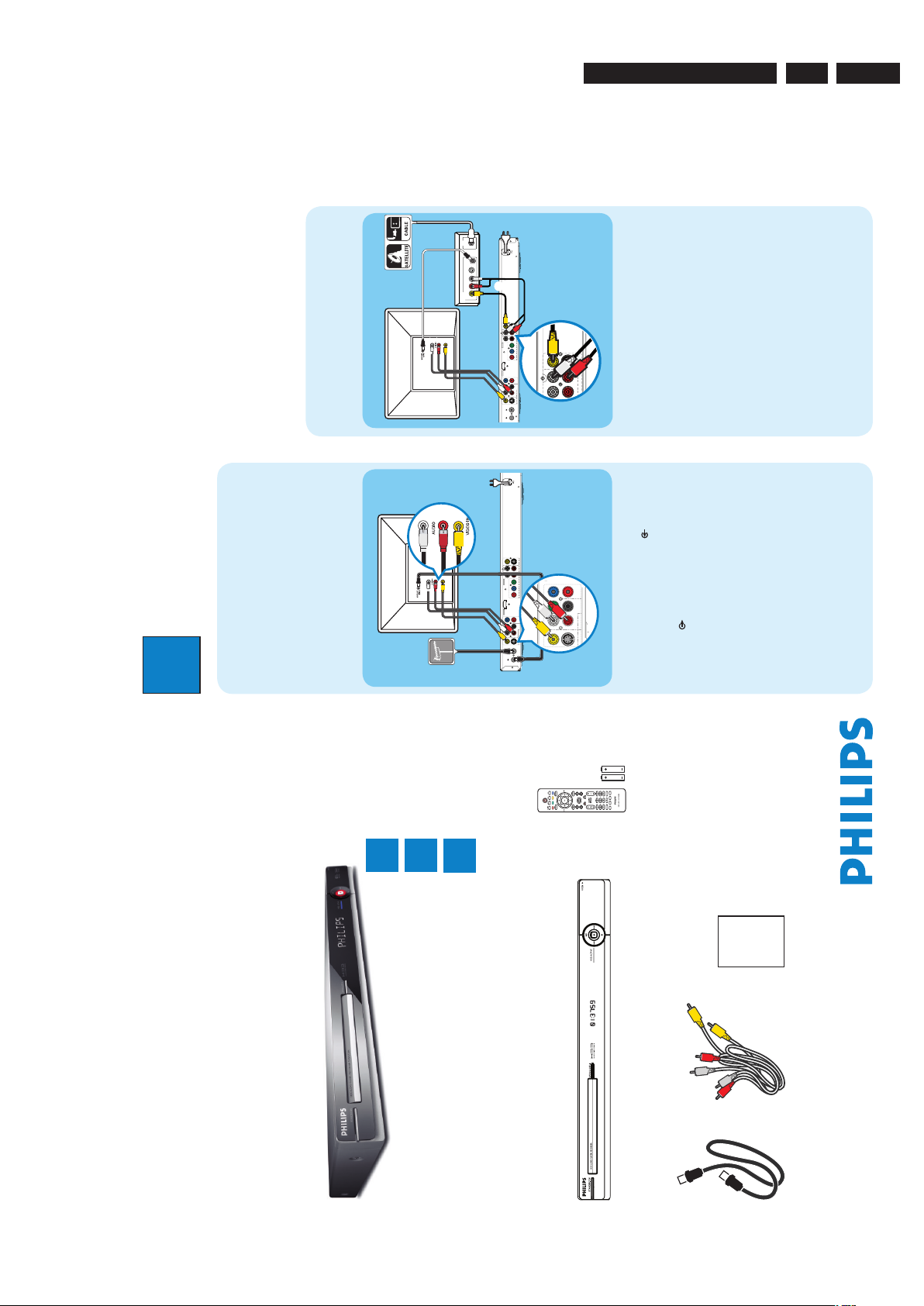

Select a record mode

Select an appropriate recording mode is important as it

determines the picture quality and recording time to the

hard disk.

A Before recording, press OPTIONS on the

remote control.

B Select { Settings } in the menu and press OK.

C Move to { Recording } and press � right.

D Move to { Record mode } and press � right.

E Select a record mode and press OK to confirm.

DVDR3570H

Record Mode

HQ (high quality)

SP (standard play)

SPP (standard play plus)

LP (long play)

EP (extended play)

SLP (super long play)

SEP (super extended play)

122.53468

2345566890

135

180

1

hr 55 mins

3 hrs 40 mins

4 hrs 35 mins

5 hrs 30 mins

7 hrs 20 mins

11 hrs 5 mins

14 hrs 45 mins

DVDR3590H

Record Mode

HQ (high quality)

SP (standard play)

SPP (standard play plus)

LP (long play)

EP (extended play)

SLP (super long play)

SEP (super extended play)

122.53468

407796

115

153

230

300

1

hr 55 mins

3 hrs 40 mins

4 hrs 35 mins

5 hrs 30 mins

7 hrs 20 mins

11 hrs 5 mins

14 hrs 45 mins

(250GB)

INFO

HOME

LIVE TV

OPTIONS

PAUSE LIVE TV

D Press OK to start automatic analogue channel

search.

Previous Skip

Channel search

Start Auto search

E Once complete, press the Green button to

continue.

Previous Next

Time setting is required for

making recordings.

Time

00

00

:

AM

F Enter the correct time in the entry field and press

OK to confirm.

Previous Next

Date setting is required to

make recordings. Please

make sure it is correct.

Date

31

01

2007

G Enter the correct date in the entry field and press

OK to confirm.

You have successfully completed the installation

of your recorder.

System is now ready for use.

Previous Done

Installataion Complete

H The installation is completed now, press the Green

button to close the menu.

Page 9

3

Enjoy

Need help?

User Manual

See the user manual that came with your Philips Recorder

Online

Go to www.philips.com/welcome

2007 © Koninklijke Philips N.V.

All rights reserved.

12 NC 3139 245 27481

www.philips.com

Hard Disk / DVD Recorder

Quick Start Guide

What’s in the box?

Hard Disk/ DVD Recorder

RF antenna cable

(connect between

recorder and TV)

Audio/Video

cables

Record to hard disk

A

Record current TV programme

A Press REC to start recording. It can record up to

6 hours.

Note To set the recording time length, press REC

repeatedly to extend the recording time in 30-minute

increments, up to 6 hours.

B To stop the recording before the scheduled time,

press STOP.

B

Mark a speci c content in the Time

Shift Buffer for recording

23:30

22:13

21:00

Cancel Rec.

More Info

A Press left or right to search for the scene

where you want to record.

B Press REC

to start recording from here.

Note Pressing the Red button will cancel the

recording.

C Press right to search for the scene to end the

recording, then press STOP.

Note The title will be marked in red and the

recording will only take effect when you turn off the

recorder.

Copy TV programmes or les

A

Copy TV programmes from hard

disk

A Insert a recordable DVD into the recorder.

B Press HDD LIST on the remote control.

C Select a title to copy and press the Green button

on the remote control for { Copy }.

D The making disc copy information appears. Press

the Green button again to start copying.

B

Copy les from USB

You can only copy the data les (MP3, WMA, DivX and

JPEG) from your USB device to the recorder’s hard disk

drive or recordable DVD.

A Insert your USB device to the USB port at the front

panel of the recorder.

B Press USB on the remote control to view the

content menu.

C Use keys to reach the file you want to

copy.

D Press the Green button on the remote control for

{ Copy }.

Target for copy.

Choose destination for copy.

To Disc

To Hard Disk

E Select the destination for copying and press OK to

confirm.

Note If select { To Disc }, insert an empty

recordable DVD into the recorder.

F Press OK again to start copying.

HDD LIST

USB

REC

STOP

HOME

Start playback

A

Playback from hard disk

A Press HOME.

Disc Tray

USB

Recordings

Video les

Music

Photo

Source Content

Hard Disk

B Select { Hard Disk } and press right.

C Select the contents type and press right.

D Use keys to reach the title/file you want

to play and press u to start playback.

B

Playback from disc

A Hold down STOP until the disc tray opens. Load a

disc and close the disc tray.

B Press HOME and select { Disc Tray }.

C Use keys to reach the title/file you want

to play and press u to start playback.

C

Playback from USB device

A Insert the USB device to the USB port.

B Press USB to show the contents list.

C Select the contents type and press right.

D Select a data file

(MP3, WMA, DivX and JPEG)

and

press u to start playback.

C

Copy les from Disc

Copy prohibited contents cannot be copied to this

recorder.

A Insert a CD/DVD into the recorder.

B Press HOME and select { Disc Tray }.

C Use keys to reach the title/file you want to

copy.

D Press the Green button on the remote control for

{ Copy }.

Target for copy.

Choose destination for copy.

To USB

To Hard Disk

E Select the destination for copying and press OK to

confirm.

Note Only data les are able to copy to USB device.

F Press OK again to start copying.

HDD LIST

USB

REC

STOP

HOME

EN 93139 785 32804 3.Directions For Use

Page 10

EN 10 3139 785 328044. Mechanical Instructions

4. Mechanical Instructions

Note: The position numbers given here refers to the

Exploded view on chapter 8.

4.1 Dismantling of the DVD Tray cover manually

1) Insert a screwdriver into the slot provided at the bottom

of the set and push in the direction as shown in Figure1 to

unlock before sliding the Tray cover 110 out.

1

2

Figure 4-1: Unlock the tray loader

2) Remove the Tray cover 110 as shown in Figure 2.

Insulation Sheet

Figure 4-4: Front Panel Service Position

Insulation Sheet

4.3 Dismantling of the Basic Engine

1) Remove 4 mounting screws as shown in figure 5 to

dismantle the Basic Engine. 1007.

Figure 4-2: Remove the tray cover

4.2 Dismantling of the Front Panel

1) Remove 7 screws to loosen Top cover 240.

2) Remove 2 screws to loosen the Plate Front Loader 183

and detach the Front Cabinet Assembly P001 as shown

in Figure 3. The Front Panel Service Position is shown in

Figure 4.

Figure 4-3: Unscrew the screws to detach front panel

Figure 4-5: Basic Engine mounting screw

Page 11

EN 113139 785 32804 4.Mechanical Instructions

2) Flip the Basic Engine over to remove 4 screws from

the PCB protection plate. Service Position of the Basic

Engine is shown in Figure 6.

Insulation Sheet

Figure 4-6: Basic Engine Service Position

4.4 Dismantling of the PSU Board

1) Remove 3 screws to loosen the PSU Board 1004 as

shown in Figure 7.

2) Service position for PSU Board is given in Figure 8.

Insulation Sheet

Figure 4-8: PSU Board Service Position

4.5 Dismantling of the HDD

1) Remove 4 screws to loosen the HDD assembly (HDD

1005 and HDD Bracket 186 attached together by the

screws 271, for DVDR3590H there also includes HDD

Damper 191 and HDD Suspension Bracket 192) as

shown in figure 9.

Figure 4-7: PSU remove mounting screws

Figure 4-9: Remove mounting screws for HDD

2)

Flip over the HDD

271. Remove the screws to dismantle the HDD 1005 from

the HDD assembly

Notes: Only the special type of screws as described in

Service Parts List must be used for position number 271.

Using improper screws may damage the mounting holes on

the HDD.

.

Assembly to see the mounting screws

.

Page 12

EN 12 3139 785 328044. Mechanical Instructions

4.6 Dismantling of HDMI Board

1) Remove 2 screws to loosen the HDMI Board 1006 and

HDMI Shield 190 form the Rear Plate 230. The mounting

screws are shown in figure 10.

Figure 4-10: Remove mounting screws for HDMI Board

2) Remove the HDMI Shield 190 for HDMI Board Service

Position. The HDMI Board Service Position is shown in

figure 11.

4.7 Dismantling of the Digital Board

1) Remove the HDMI Board first, and remove the HDMI

Bracket 131 by unscrewing one screw.

2) Then remove 4 screws to loosen the Digital Board 1003

as shown in Figure 12.

Figure 4-12: Remove mounting screws for Digital Board

Insulation

Sheet

Figure 4-11: HDMI Board Service Position.

Page 13

EN 133139 785 32804 4.Mechanical Instructions

3) Service position for Digital Board is given in Figure 13. (It

may be necessary to remove the Digital Board Bracket

187 and take out the cables beneath it to make it easier to

flip over the digital board. Put the insulation sheets under

the PC Boards. Refer to the set-wiring diagram in chapter

6 and make it sure to have the correct cable connections

among the PC Boards.)

Insulation

Sheet

4.8 Dismantling of the Analog Board

1) Remove the HDMI Board 1006 with its Shield 190 and

the HDMI bracket 189 first. Remove 3 screws that attach

the Analog Board 1001 to the Frame 161. Remove 6

more screws that attach the Analog Board 1001 to the

rear panel 230. Then dismantle the Analog Board. It may

be easier to dismantle the Analog Board if the rear panel

230 is detached first by removing 3 more screws.

2) Service position for Analogue Board is given in Figure 12.

Insulation

Sheet

Insulation

Sheet

Figure 4-13: Digital Board Service Position

Figure 4-14: Analogue Board Service Position (Rear Plate

230 detached)

Page 14

EN 14 3139 785 32804 Firmware Upgrading & Diagnostic Software5.

5. Firmware Upgrading and Useful Firmware Hints, Diagnostic

Software, Alignment and Test Procedures

5.1 Firmware Upgrading

5.1.1. Preparation to upgrade firmware

1. Unzip the zip-archive file

2. Start the CD Burning software and create a new CD project (data disc) with the following settings:

3. Place the content of the zip-archive into the root directory of the new CD project.

4. Burn the data onto a blank CDR or CD-RW

5.1.2. Procedure to apply the firmware upgrade:

Notes: There are 2 upgrade processes supported: - Normal Upgrade and Forced Download.

For normal upgrading, power up the set, open the tray, insert the upgrade disc, close the tray and follow the on screen

instruction. For forced download upgrading, follow the procedures described below.

1. Hold the <Record> + <Next> buttons down and Power up the set.

2. The tray opens and set will display:

DOWNLOAD −>……….PUT DISC

3. Insert the prepared Upgrade CDROM and close the tray.

4. The set will display:

INIT DSC −> DOWNLOAD −>……….

The whole process takes less than 10 minutes

Note: Do not press any buttons or interrupt the mains supply during the upgrading process, otherwise the set may

becomes defective.

5. When the upgrade is completed the tray will open automatically and the set will display:

REMOVE

6. Close the tray and the set will display:

DONE

Then the firmware upgrade process is completed successfully.

File system: Joliet

Format: MODE 2: CDROM XA

Recording mode: SINGLE SESSION (TRACK-AT-ONCE), FINALIZED CD

Note: Long file name is necessary for the preparation of the upgrade disc

5.1.3. How to read out the firmware version to confirm set has been upgraded:

Notes: In order to check the firmware version of the set, user version info screen should be accessed. Follow the

procedure below for checking user version info screen.

1. Power up the set

2. Press <OPTIONS> button on the Remote control and go to <Settings> option

3. Then go to <Setup> and choose <Version Info> by pressing OK.

4. The TV connected to the set will display the user version info as shown below for checking software version:

Version Info

Royal Philips

DVDR3570H

Software version: 01.00

Please visit our website

www.philips.com/support

for further software

updates and additional information

Developer name: Royal Philips

Product name (xxxx = model number): DVDRxxxxH (DVDR3570H in the example above)

Official SW release number: Software Version (xx.xx = release): xx.xx (01.00 in the example above)

5. Press <OPTIONS> button to exit.

Page 15

5.2. Procedure for checking Development Version Info Screen

Notes: For detail software information such as Slash Version, Drive Software Version, etc of the set,

the development version info screen should be accessed.

1) Power up the set

2) Press <OPTIONS> button on the Remote control and go to <Settings> option

3) Then go to <Setup> and choose <Version Info> by pressing OK.

4) When the user version info screen is appeared, press the blue key on the remote control.

5) The TV connected to the set will display the Development Version Info Screen as shown below:

Version Info

(c)PHILIPS 2006 Version Information:

DI L+06_7/751731 SV 11602

BE 52.07.02.15 ASP 1,18,1,10

C1_7 20070224_1659 pro lecoplusleadV2 <void>

EPG: DPMS:P_DPM

Digital Board Info: (DI: Digital Board, L+06_7: Digital Board name, 75: Hardware ID for EU Non EPG, 1731: SW

BUILD ID for recorder application in the example)

Slash Version (xxxxx = version): SV xxxxx (11602 for /51 in the example above)

Drive SW Version (yy.yy = model, xx.xx = version): BE yy.yy.xx.xx (Model 52.07, Version 02.15 in the example)

ASP Software and VFD Driver Version Number: (1,18: ASP software version number, 1,10: version number of

VFD Driver

Detailed Build Information: (C1_7: Branch Information, 2007: year, 02: month, 24: date, 16: Hour, 59: minute in

the above example)

EPG: DPMS:P_DPM (internal to the recorder application.)

EN 153139 785 32804 5.Firmware Upgrading & Diagnostic Software

5.3 Procedure for Formatting HDD drive

1) Press and Hold the <Previous> + <Stop> key combination while powering on the mains.

2) The set will start to display “FMT KEY”, and then it will show “FMT HDD” while formatting HDD.

3) If the formatting is completed successfully, the set will display “FMT DONE”. If the formatting is failed, it will show “FMT FAIL”

Notes: Do not power off the set immediately when the “FMT DONE” is seen. Wait until the time or - - : - - is displayed before powering

off the set.

5.4. Procedure to Virginize the set

Notes: All the user information will be lost after virginizing the set. Follow the procedure below to virginize the set.

1) Press and hold down the Standby key on the front while connecting to the power outlet.

2) Release the keys when the scrolling messages appear on VFD.

3) Press standby key again and follow the instructions when the set wakes up.

5.5 HDD replacement procedure.

When a defective HDD is replaced by a brand new HDD,

1. Install the new HDD.

2. Upgrade the software (forced download) with the upgrade disc to the latest software (follow the procedures described in 5.1.2)

3. Format the HDD (follow the procedures described in 5.3)

Then the HDD is ready to use. Some of the user information may be lost after HDD Replacement.

Page 16

EN 16 3139 785 32804 Firmware Upgrading & Diagnostic Software5.

Diagnostic Softwa re

D ue to the co mplexity of the DVD rec order, the time to find a

de fect in the rec order can become long. To r educe this ti me ,

th

e recorder has been equipped wi th D iagn ostic and Serv ice

so

ft ware (DS ). Th e DS o ff ers functionali ty t o diagnose the

DV

DR hardware and te st s th e fo ll owing:

• I

nterconnec tions between co mponent

s

• A

cc essibility of com ponents

•

F unctionality of the audio and video paths

Th

is f unc tionalit y ca n be acces sed via se veral in terf aces :

1.

End user/Dealer script interfa ce

2.

Comm and Inte rfac

e

Fi

gu re 5-1

Th

e En d use/Dealer scr ip t ex ecutes all diagnostic nuc lei t ha t

do

not ne ed any use r interaction and are meaningful on a

st

andalone DV D re corder.

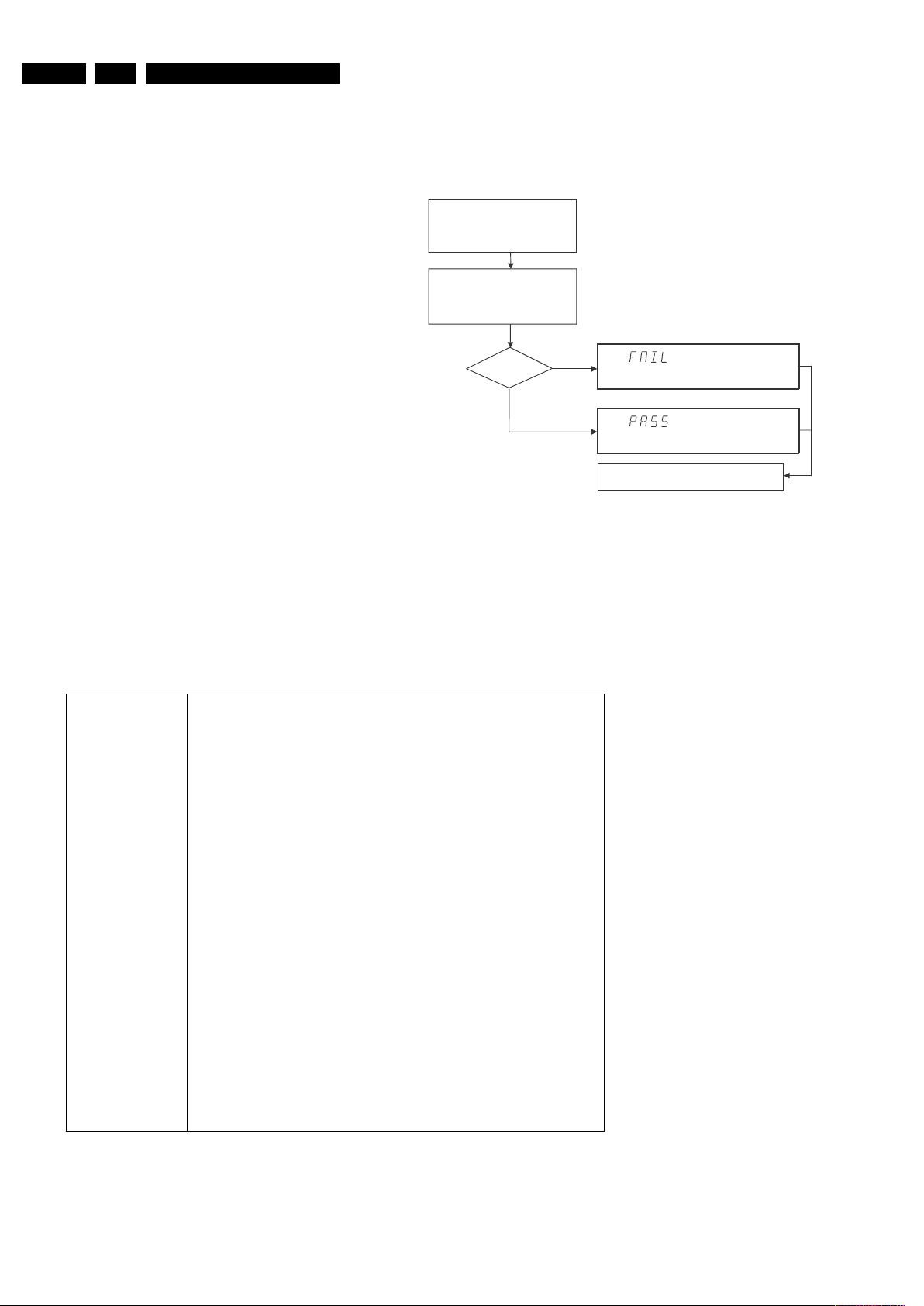

Hold k ey <PLAY> pressed

while you plug the recorder

Unplug the power cord

SET O.K.?

YE S

NO

To ex it DEALER SCRIPT, unplug th e power cord

During the test, the display will show

the a sequence of nuclei under test

TR 18029_001

12

0304

The End user/Dealer script interface gives a diagnosis on a

stand alone DVD recorder. During this mode, a number of

ha

rdware tests (nuclei) are automatically executed to check if

the recorder is faulty. Th

e diagnosis is simply a "fail" or "pass"

m

essage. If the message "FAIL" appears on the display, there

i

s apparently a failure in the recorder. If the message "PASS"

ap

pears, the nuclei in this mode have been executed

su

ccessfully. There can be still a failure in the recorder

be

cause the nuclei in this mode do not cover the complete

functionality of the recorder.

I

n

cluded tests:

1. DS_CHR_DEVTYPEGET_NUC

2. DS_SDRAM_WRITEREADFAST_NUC

3. DS_FLASH_DEVTYPEGET_NUC

4. DS_FLASH_CHECKSUMPROGRAM_NUC

5. DS_VIP_COMMUNICATION_NUC

6. DS_VIP_DEVTYPEGET_NUC

7. DS_DVIO_LINKDEVTYPEGET_NUC

8. DS_DVIO_PHYCOMMUNICATION_NUC

9. DS_DVIO_PHYDEVTYPEGET_NUC

10. DS_BE_COMMUNICATIONECHO_NUC

11. DS_BE_VERSIONGET_NUC

12. DS_SYS_HARDWAREVERSIONGET_NUC

13. DS_SYS_SOFTWAREVERSIONBOOTGET_NUC

14. DS_SYS_SOFTWAREVERSIONDOWNLOADGET_NUC

15. DS_SYS_SOFTWAREVERSIONAPPLGET_NUC

16. DS_SYS_DVIDNUMBERGET_NUC

17. DS_SYS_SLASHVERSIONGET_NUC

18. DS_SYS_SETTINGSDISPLAY_NUC

19. DS_SYS_BUILDINFOGET_NUC

20. DS_ASP_COMM_NUC

21. DS_ASP_VERSION_NUC

22. DS_FRE_COMM_NUC

23. DS_HDD_COMMUNICATION_NUC

24. DS_HDD_VERSION_NUC

25. DS_USB_DEVTYPEGET_NUC

5.6 End User/Dealer Script Interface

5.6.1 Description

5.5.2 Structure

5.

6.2 Contents

Page 17

22 DTTM*

23 USB

5.7 Menu and Command Mode Interface

5.7.1 Nuclei Numeration

Each nucleus has a unique number of four digits. This number

is

the input of the command mode.

Figure 5-2

Gr

oup number Group name

[ XX YY ]

Nucleus number

Nucleus group number

CL 06532152_012.eps

051200

5.7.3 Command Mode Interface

Se t-Up Physical Interface Component s

Har dware required:

• S ervice P

C

• o

ne free CO M po rt on the Serv ic e PC

• s

pecial c able to c onnect D VD re corder to Ser vice PC

Th

e ser vice PC must have a terminal em ul at ion program (e.g.

Hy

perterminal) in stalled and mu st hav e a fr ee C OM port ( e.g.

CO

M1 ). A ctiv at e the te rm inal em ulation program and chec k

th

at the port s ettings for th e free CO M por t are: 19200 bps, 8

da

ta bit s, no pa rity, 1 s top bit a nd no flow c ontro l. T he fr ee C OM

po

r t mus t be c onnected via a s pecial c able to the RS 232 port

of

the DVD recor der. Thi s s pecial ca bl e will also connec t the

te

st pin, which is available on the connec tor , t o ground (i.e.

ac

tivat e test pin).

C

ode number of PC interface cable : 3122 785 90017

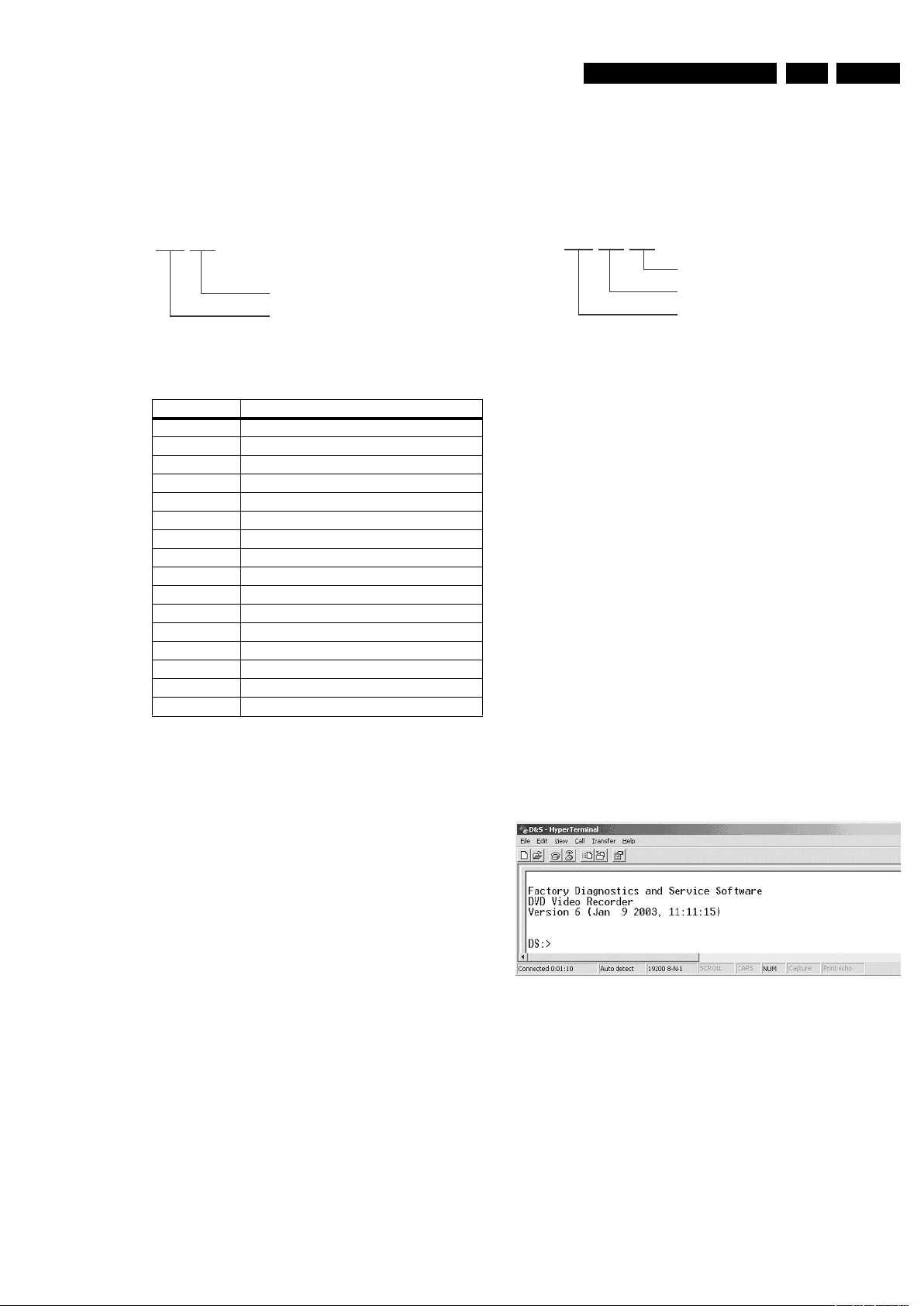

Act ivation of Diagnostic Software

1. Pu ll the ma ins co rd from t he re corder and reconnec t it

a gai n (reboo t) .

2.

The next welc ome mes sage wi ll a ppear on t he PC

:

We

lcome screen D&S program

F

i gu re 5-4

No

w , the prom pt 'DS :>' wil l appear . The diagnostic software is

no

w ready t o re ceive comm ands. The com mands t hat can be

gi

ve n are th e num bers of the nuclei. If you see above shown

sc

reen, c ontinue with para

g

raph 'Nuclei Cod es'.

5.7.2 Error Handling

Ea ch nucleus returns an er ror code. This c ode c ontains six

nu

m erals, w hi ch m eans:

F

i gu re 5-3

T

he nucleus group number s an d nuc leus num bers are the

sa

me as above.

[ XX YY ZZ ]

Error code

Nucleus number

Nucleus group numbe r

CL 06532152_013.ep s

05 12 00

1 Codec (e.g. LeCo+)

0 Scripts

2 Boot EEPROM*

3 NVRAM (EEPROM of FLASH)*

4 SDRAM (or DDR-RAM)

5 FLASH

6 Video Input Processor

7 DVIO

9 Basic Engine

12 System

15 HDMI

16 Analogue Slave Processor

20 F

ront End

21 Hard Disk

* Not applicable for DVDR3570H,

EN 173139 785 32804 5.Firmware Upgrading & Diagnostic Software

Page 18

EN 18 3139 785 32804 Firmware Upgrading & Diagnostic Software5.

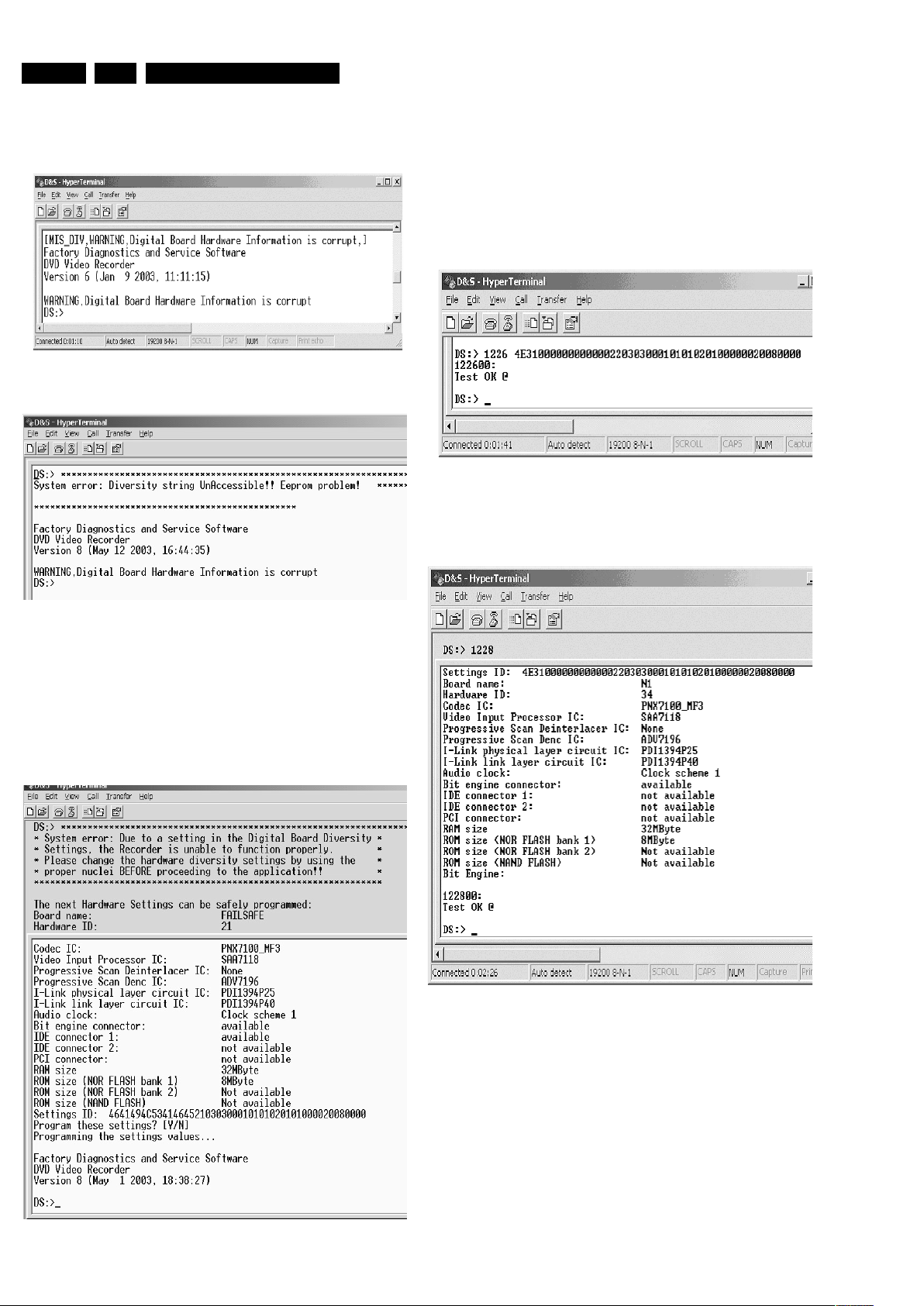

3. It is possible that the next messages will appear when

starting the DVD+RW for the first time

Er

ror messages D&S program

Figure 5-5a

Er

ror messages D&S program

Figure 5-5b

In these cases, t

he boot EEPROM of the Digital Board does not

contain the required string with the hardware information. To

u

pdate the Digital Board with the correct string, nucleus 1226

m

ust be executed.

See next section 'Diversity S

tring Input'.

There can also be the next error m

essage.

Figure 5-5c

Enter "Y" to program a safe string. With this automatically

g

enerated string the board will wo

rk in principle but it has to be

checked if all board settings were detected correctly.

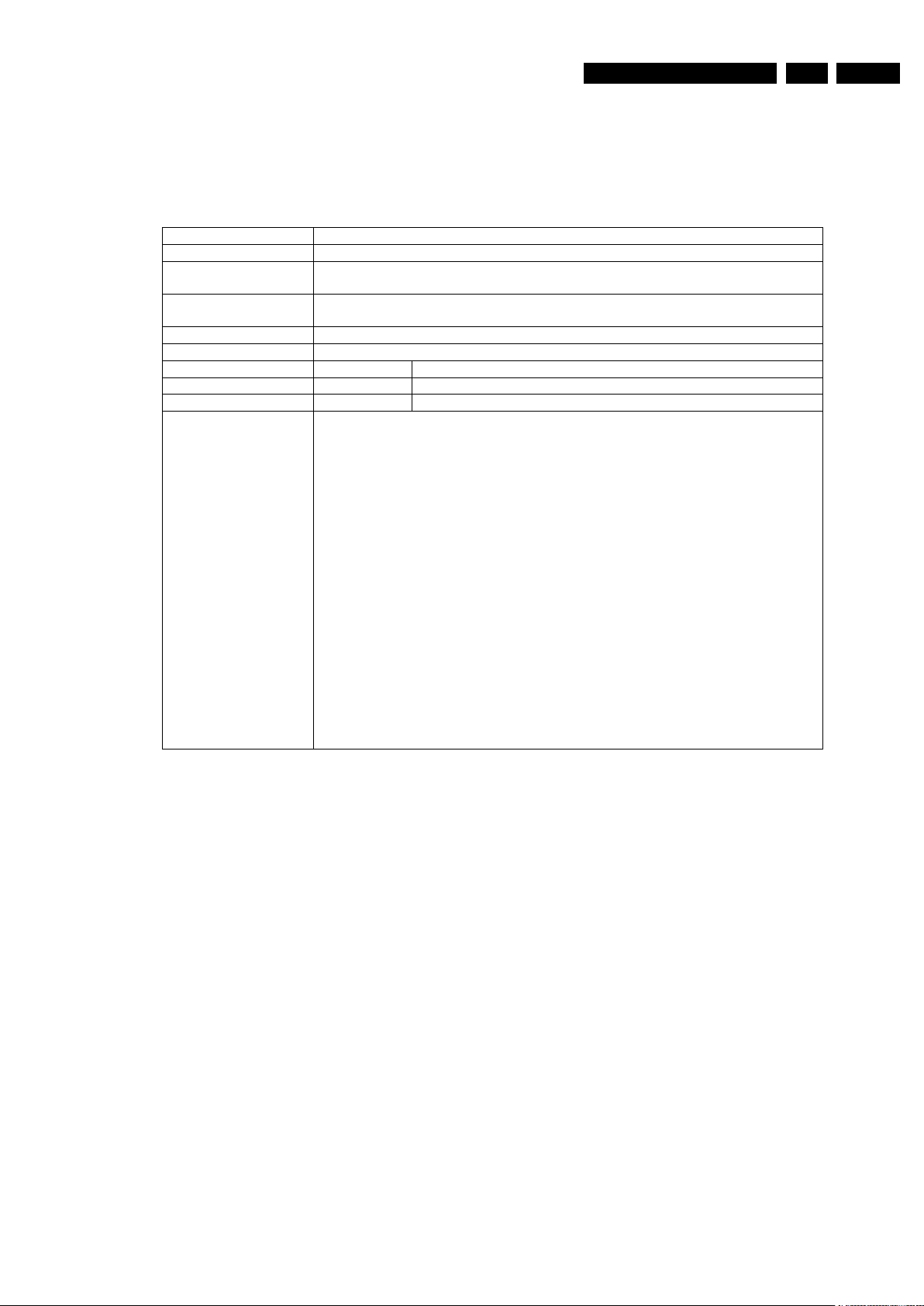

Diversity String Input

4. Execute nucleus 1226 to enter the string. Please see

chapter 8 for details

Nucleus 1226 execution with string

Figure 5-6

5

. To check if t

he hardware info is filled correctly, you can

execute nucleus 1228.

Nucleus 1228 info example

F

igure 5-7

6

. Exit t

he 'Terminal' program.

7. Reboot the DVD recorder t

o allow the software to start.

Page 19

Command overview Digital Board

Nucleus Name

DS_CHR_DevTypeGet

Nucleus Number 100

Description Retrieves the device id, the module ids and revisions of the Codec and returns

them to the stdout port.

Technical - Determine the codec id by means of comparing version ids of the modules.

- Read the module-id register of every module and display it to the user.

Execution Time Less than 1 second.

User Input None

Error Number Description

10000 Getting the information succeeded

10001 Wrong codec id detected

Example

DS:> 100

010000:

Device ID 7300

Codec ID PNX7350

F-BCU (0x0102) 4.0 INTC (0x011d) 3.0

SIF (0xa04b) 2.0

BOOT (0x010a) 3.1 CONFIG (0x013f) 5.0 RESET (0x0123) 5.0

CLOCK (0x013e) 7.0 DEBUG (0x0116) 0.1 UART0 (0x0107) 1.2

UART1 (0x0107) 1.2

I2C0 (0x0105) 0.1 I2C1 (0x0105) 0.1 GPIO (0x013c) 3.1

SYNC (0x013a) 4.0

OSD (0x0136) 1.0 SPU (0xa00e) 1.1 MIXER (0x0137) 3.0

DENC (0x0138) 5.0 CCIR (0x0139) 2.1 VDEC (0x0133) 1.0

PARSER (0xa00d) 0.0 DV (0xa00c) 0.0

IDE0 (0xa009) 1.2 IDE1 (0xa009) 1.2 SGDX (0xa008) 4.0

BYTE (0xa00b) 1.0 OUTPUT (0xa003) 8.0 ACOMP (0xa000) 8.0

VFE (0xa001) 8.0 VCOMP (0xa002) 8.0 SCR (0xa004) 8.0

SIFF (0xa011) 3.0

PSCAN (0xa05d) 0.1

ADEC (0x0134) 1.1 IR (0x0131) 2.0 AOI (0xa08c) 0.0

PIP (0xa04d) 1.0 AVLINK (0x3601) 2.1 USBLINK(0xa08e) 0.0

MSVD (0xa087) 0.0 FEBCU (0xa05e) 1.0 BM (0xa085) 0.0

BMI (0xa084) 0.0 DISP (0xa04d) 1.0

Test OK @

Below you will find an overview of the nuclei, their numbers,

and their error codes. This overview is preliminary and

subject to modifications.

Codec Host Controller (CHR)

EN 193139 785 32804 5.Firmware Upgrading & Diagnostic Software

Page 20

EN 20 3139 785 32804 Firmware Upgrading & Diagnostic Software5.

Nucleus Name

DS_CHR_TestImageOn

Nucleus Number 101

Description Generates a test-image of a selected video standard on selected video output

on the digital board. When no input is given, the default values will be used (see

user input description below). Make sure to use the proper nuclei to route the

video signal on the VIP to get the video signal to the proper output.

Technical - Validate the user input.

- Initialise the SYNC module.

- Initialise the DISPLAY module.

- Initialise the MIXER module.

- Initialise the DENC module.

- Set the selected video standard.

- Generate the selected test image in memory.

- Start the DISPLAY module.

- Start the MIXER module.

- Start the DENC module according t

o the selected test image id.

Execution Time 6 seconds.

User Input The user has to decide which test image, video standard and video output must

be used: < Test image id > < Video standard > < Video output >

Test image id:

0 VERTICAL_COLOURBAR (default)

1 HORIZONTAL_COLOURBAR

2 WHITE

3 YELLOW

4 CYAN

5 GREEN

6 MAGENTA

7 RED

8 BLUE

9 BLACK

10 GRAY

11 TEST_IMAGE_FOR_PROGRESSIVE_SCAN

Video standard:

PAL Standard PAL 50 Hz (default)

NTSC Standard NTSC 60 Hz

Video output:

ALL CVBS and YC and RGB signals are enabled (default)

ALL_RGB CVBS and YC and RGB signals are enabled (default)

ALL_YUV CVBS and YC and YUV signals are enabled

CVBS CVBS signal is enabled

YC YC signal are enabled

RGB CVBS, and RGB signals are enabled

YUV YUV signals are enabled

PSCAN Progressive scan is enabled

Error Number Description

10100 Generating the test image succeeded.

10101 Invalid input was provided.

10102 The Codec SYNC-module cannot be initialised.

10103 The Codec MIXER-module cannot be initialised.

10104 The Codec VPP-module cannot be initialised.

10105 The Codec DENC-module cannot be initialised.

10106 The digital board hardware information is corrupt

Example

DS:> 101

010100:

Test OK @

DS:> 101 0 pal cvbs

010100:

Test OK @

DS:> 101 4 ntsc yc

010100:

Test OK @

Page 21

EN 213139 785 32804 5.Firmware Upgrading & Diagnostic Software

Nucleus Name

DS_CHR_TestImageOff

Nucleus Number 102

Description Switches the test-image off.

Technical - Stop the DENC module.

Execution Time Less than 1 second.

User Input None

Error Number Description

10200 Stopping the test image generation succeeded

10201 The Codec DENC-module failed.

Example

DS:> 102

010200:

Test OK @

Nucleus Name

DS_CHR_SineOn

Nucleus Number 103

Description Generate an audio sine signal on the audio output of the digital board.

Note: Left channel 6kHz, right channel 12 kHz sine. Make sure to route the

signal first.

When ‘SPDIF’ is entered as a parameter, the SPDIF path will be activated

correctly to generate a PCM sine wave on the digital audio output.

Technical - De-mute the analogue board

- Set fifo parameters for audio

- Set the volume

- Set the I2S outputs and configuration paths

- Set the decoder mode

- Configure the audio decoder

- Put the AC3 audio in the fifo

- Send ‘prepare’ command to the audio decoder

- Send ‘play’ command to the audio decoder

Execution Time Less than 1 second

User Input None or ‘SPDIF’

Error Number Description

10300 The sine signal was successfully generated

10301 The analogue board could not be de-muted

10302 The audio decoder did not initialise

10303 The dsp2 (DUET) of the audio decoder did not configure

10304 The dsp1 (PALM) of the audio decoder did not configure

10305 There was a delay-error before starting

10306 Wrong input was given to the decoder function

10307 Wrong input was given to the decoder function @@@@@

10308 The audio decoder did not get into the ‘prepared’ state

Example

DS:> 103

010300:

Test OK @

DS:> 103 spdif

010300:

Test OK @

Nucleus Name

DS_CHR_SineOff

Nucleus Number 104

Description Stop generating the audio sine signal

Technical - Reset the audio block of the Codec

Execution Time Less than 1 second.

User Input None

Error Number Description

10400 Switching off the audio sine signal succeeded

10401 Failed to reset the audio decoder

Example

DS:> 104

010400:

Test OK @

家电维修资料网,免费下载各种维修资料

Page 22

EN 22 3139 785 32804 Firmware Upgrading & Diagnostic Software5.

Nucleus Name

DS_CHR_SineBurst

Nucleus Number 105

Description Generate an audio sine signal on the audio output of the digital board for 4

seconds.

Note: Left channel 6kHz, right channel 12 kHz sine with some known hick-ups

Technical - Call the DS_CHR_SineOn nucleus

- Delay for 4 seconds

- Call the DS_CHR_SineOff nucleus

Execution Time 4 seconds

User Input None

Error Number Description

10500 The sine signal burst was successfully generated

10501 The delay did not succeed during the burst

10502 The audio sine could not be generated

Example

DS:> 105

010500:

Test OK @

Nucleus Name

DS_CHR_MuteOn

Nucleus Number 106

Description Mute the audio outputs of the digital board

Technical - Send the ‘Mute’ command to the audio decoder

- Activate the ‘audio mute’ PIO pin

Execution Time Less than 1 second.

User Input “PIO” to just use the PIO pin mute. When muting using this, also de-mute using

this as this works ‘paired’.

Error Number Description

10600 Muting the audio succeeded

10601 Muting the audio through the PIO-pin failed

Example

DS:> 106

010600:

Test OK @

DS:> 106 PIO

010600:

Test OK @

Nucleus Name

DS_CHR_MuteOff

Nucleus Number 107

Description De-mute the audio outputs of the digital board

Technical - Send the ‘DeMute’ command to the audio decoder

- Deactivate the ‘audio mute’ PIO pin

Execution Time “PIO” to just use the PIO pin de-mute. Only de-mute using this when you muted

using the PIO parameter, as this works ‘’paired.

User Input None

Error Number Description

10700 De-muting the audio succeeded

10701 De-muting the audio through the PIO-pin failed

Example

DS:> 107

010700:

Test OK @

DS:> 107 PIO

010700:

Test OK @

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 23

EN 233139 785 32804 5.Firmware Upgrading & Diagnostic Software

Nucleus Name

DS_CHR_MacroVisionOn

Nucleus Number 110

Description Turn on MacroVision.

Technical - Set some registers of the DENC module in the Codec.

Execution Time Less than 1 second.

User Input None

Error Number Description

11000 Turning on MacroVision succeeded

11001 Turning on MacroVision failed

Example

DS:> 110

011000:

Test OK @

Nucleus Name

DS_CHR_MacroVisionOff

Nucleus Number 111

Description Turn off MacroVision.

Technical - Set some registers of the DENC module in the Codec.

Execution Time Less than 1 second.

User Input None

Error Number Description

11100 Turning off MacroVision succeeded

11101 Turning off MacroVision failed

Example

DS:> 111

011100:

Test OK @

Nucleus Name

DS_CHR_Peek

Nucleus Number 112

Description Peek a value on a specified address

Technical - Check the user input

- Read out the address specified

- Check whether the address to be read is aligned on 4 bytes

Execution Time Less than 1 second.

User Input The address to peek on

Error Number Description

11200 Peeking on the specified address succeeded

11201 Peeking on the specified address failed, wrong user input

11202 Peeking on the specified address failed due to misalignment

Example

DS:> 112 0xa0700000

011200: Value read = 0x000001BD

Test OK @

Nucleus Name

DS_CHR_Poke

Nucleus Number 113

Description Poke a value on a specified address

Technical - Check the user input

- Change the value on the address specified

- Check whether the address to be modified is aligned on 4 bytes

Execution Time Less than 1 second.

User Input The address to poke and the value: <address><value>

Error Number Description

11300 Poking the specified address succeeded

11301 Poking the specified address failed, wrong user input

11302 Poking the specified address failed due to misalignment

Example

DS:> 113 0xa0700000 0xaabbccdd

011300:

Test OK @

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 24

EN 24 3139 785 32804 Firmware Upgrading & Diagnostic Software5.

Nucleus Name

DS_CHR_INT_PICInterrupts

Nucleus Number 114

Description Test all interrupts of the priority interrupt controller

Technical - Install interrupt handlers

- Generate interrupts

- Test whether all interrupts were received

Execution Time Less than 1 second.

User Input Error Number Description

11400 Testing all the PIC interrupts succeeded

11401 Testing all the PIC interrupts failed

Example

DS:> 114

011400:

Test OK @

Nucleus Name

DS_CHR_DMA_TestDMA

Nucleus Number 115

Description Test the memory to memory DMA transfer

Technical - Create a block with known data in memory

- Copy this block to the consecutive area using 4 different DMAs

- Check whether all DMAs transferred the data properly

Execution Time Less than 2 seconds.

User Input Error Number Description

11500 The testing of the DMAs succeeded

11501 The initialisation of the DMAs failed for one or more DMA

11502 One or more DMAs failed the test

Example

DS:> 115

011500:

Test OK @

Nucleus Name

DS_CHR_PioGet

Nucleus Number 116

Description Get a value from a PIO pin

Technical - Decode user input

- Read the PIO input register of the cod

ec and return the requested pio line

value

Execution Time Less than 1 second.

User Input <PIN>

where PIN is the pio pin to get (0..31)

Error Number Description

11600 Getting PIO value succeeded

11601 Invalid parameter

Example

DS:> 116 15

011600: Value read = 0x1

Test OK @

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 25

EN 253139 785 32804 5.Firmware Upgrading & Diagnostic Software

Nucleus Name

DS_CHR_PioSet

Nucleus Number 117

Description Set a value on a PIO pin. Make sure that the pin is configured as output first

Technical - Decode user input

- Update the PIO output register of the codec

Execution Time Less than 1 second.

User Input <PIN> <VALUE>

where PIN is the pio pin to set (0..31)

and VALUE the value of the pin (0..1)

Error Number Description

11700 Setting PIO value succeeded

11701 Invalid parameter

Example

DS:> 117 15 0

011700:

Test OK @

Nucleus Name

DS_CHR_PioConfig

Nucleus Number 118

Description Configure a PIO pin

Technical - Decode user input

- Update the PIO configuration

register of the codec

Execution Time Less than 1 second.

User Input <PIN> <DIR>

where PIN is the pio pin to set (0..31)

and DIR the direction of the pin (0=IN 1=OUT)

Error Number Description

11800 Setting PIO configuration succeeded

11801 Invalid parameter

Example

DS:> 118 14 0

011700:

Test OK @

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 26

EN 26 3139 785 32804 Firmware Upgrading & Diagnostic Software5.

SDRAM (SDRAM OR DDR-RAM)

Nucleus Name

DS_SDRAM_WriteRead

Nucleus Number 400

Description Check all data lines, address lines and memory locations of the RAM

Technical - Test the data bus

- Test the address bus

- Test the integrity of the device itself (memory locations)

Execution Time 11 seconds for 32 Mb

23 seconds for 64 Mb

User Input None

Error Number Description

40000 The write-read test succeeded

40001 The data bus contains an error

40002 The address bus contains an error

40003 The RAM itself contains an error

Example

DS:> 400

040000:

Test OK @

Nucleus Name

DS_SDRAM_WriteReadFast

Nucleus Number 401

Description Check all data lines and address lines of the RAM

Technical - Test the data bus

- Test the address bus

Execution Time Less than 1 second

User Input None

Error Number Description

40100 The write-read test succeeded

40101 The data bus contains an error

40102 The address bus contains an error

Example

DS:> 401

040100:

Test OK @

Nucleus Name

DS_SDRAM_Write

Nucleus Number 402

Description Write to a specific un-cached memory address

Technical - Decode the user input and check its ranges and alignment on 4 bytes

- Write the data to the RAM

Execution Time Less than 1 second

User Input 1. The location that must be modified

(RAM starts at address 0xA0000000)

2. The value to put on the selected location

Error Number Description

40200 Writing to the RAM succeeded

40201 Writing to the RAM failed; Wrong user input

40202 Address is not dividable by 4

Example

DS:> 402 0xa1000010 0xad112222

040200:

Test OK @

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 27

EN 273139 785 32804 5.Firmware Upgrading & Diagnostic Software

Nucleus Name

DS_SDRAM_Read

Nucleus Number 403

Description Read from a specific un-cached memory address

Technical - Decode the user input and check the ranges

- Read from the RAM and return this info to the user

Execution Time Less than 1 second

User Input The location from which the data must be read

(RAM starts at address 0xA0000000)

Error Number Description

40300 Reading from the RAM succeeded

40301 Reading from the RAM failed; Wrong user input

40302 Address is not dividable by 4

Example

DS:> 403 0xa1000010

040300: Value read = 0xAD112222

Test OK @

Nucleus Name

DS_SDRAM_DmaWriteRead

Nucleus Number 404

Description Write a pattern to the entire RAM using DMA and check the data

Technical - Check if the Stack pointer is not in the write range

- Clear a 64kb block and then fill it with a pattern

- Initialise the DMA controller and write the data to the SDRAM

- Then check if all the data was written correctly (except descriptor tables)

- Repeat the process 4 times with 4 different patterns

Execution Time 24 seconds

User Input None.

Error Number Description

40400 Writing to the RAM succeeded

40401 Stack area definition ERROR!

40402 DMA controller could not be initialised.

40403 Not all data was transferred correctly

Example

DS:> 404

040400:

Test OK @

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 28

EN 28 3139 785 32804 Firmware Upgrading & Diagnostic Software5.

FLASH (FLASH)

Nucleus Name

DS_FLASH_DevTypeGet

Nucleus Number 500

Description Get the device (revision) type information of the FLASH ICs. (type,

manufacturer, device ID and size)

Technical - Set the timing for the flash writing

- Write a command sequence to determine device type information

- Return the information to the user

Execution Time Less than 1 second

User Input None

Error Number Description

50000 Getting the information from the FLASH succeeded

50001 Getting the information from the FLASH failed

Example

DS:> 500

050000: Found FLASH memory:

NOR AMD 29DL640G 8MB,NOR AMD 29DL640G 8MB

Test OK @

Nucleus Name

DS_FLASH_Read

Nucleus Number 502

Description Read from a specific memory address in FLASH

Technical - Decode the user input and check the ranges and whether the address is

aligned on 4 bytes

- Read the data and return this to the user

Execution Time Less than 1 second.

User Input The location from which data must be read

(FLASH starts at address 0xB8000000)

Error Number Description

50200 Reading the FLASH succeeded

50201 Reading the FLASH failed; Wrong user input

50202 Address is not dividable by 4

Example

DS:> 502 0xb8000000

050200: Value read = 0x3C08A000

Test OK @

Nucleus Name

DS_FLASH_ChecksumProgram

Nucleus Number 503

Description Check the checksum of the application partitions by recalculating and

comparing partition checksums

Technical - Determine the number of segments

- Find the application in each segment and determine its checksum

- Check whether the checksums stored match the newly calculated

Execution Time 6 seconds

User Input None

Error Number Description

50300 The checksum is valid, the test succeeded

50301 The checksum is invalid

Example

DS:> 503

050300:

BootCode checksum is: 0xBABE5B6F, which is correct

Diagnostics checksum is: 0xBABEBAFF, which is correct

Download checksum is: 0xBABEEDBF, which is correct

Application checksum is: 0xBABE8EEC, which is correct

Test OK @

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 29

EN 293139 785 32804 5.Firmware Upgrading & Diagnostic Software

Nucleus Name

DS_FLASH_CalculateChecksum

Nucleus Number 504

Description Calculate the checksum over all memory addresses. Used to check entire

FLASH contents

Technical - Run the checksum calculation algorithm on all flash memory addresses

Execution Time 6 seconds

User Input None

Error Number Description

50400 Calculating the checksum over all addresses succeeded

Example

DS:> 504

050400: The Checksum = 0xBABE30A4

Test OK @

Nucleus Name

DS_FLASH_CalculateChecksumFast

Nucleus Number 505

Description Calculate a checksum over a selected number of address locations

Technical - Run the checksum calculation algorithm on a selected number of flash

memory addresses

Execution Time 6 seconds

User Input None

Error Number Description

50500 Calculating the checksum over selected addresses succeeded

Example

DS:> 505

050500: The Checksum = 0xBABEB064

Test OK @

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Nucleus Name

DS_FLASH_EraseFlfs

Nucleus Number 506

Description

Erase the complete Flash File system segment in flash memory. This will erase all non

volatile data including diversity string, DV unique ID number and DivX model ID.

- Initialise Flash access

- Search in flash for the segment with the “FLFS” and “FLF2” signature

Technical

- Ask the user whether he is sure to erase all data

- If available erase the sector containing the FLFS signature

- If available erase the sector containing the FLF2 signature

Important note:

This nucleus will erase all data, make sure to reboot after this and program a

diversity string

Execution Time About 1 second per block erased.

User Input None

Error Number Description

50600 FLFS successfully erased

50601 User aborted the test

50602 FLFS segment is not available

Examples

* Beware that when nucleus 506 erases DivX model ID, the DivX VOD registration code of the set will change.

The set will not play back the previously purchased (downloaded) videos from DivX Video On Demand service.

Refer to section 5.11 “Setting DivX Model ID” for details

DS:> 506

Do you readlly want to erase the entire FLFS ? [Y /N(Default)] :y

Erasing FLFS...

050600: All data has been erased

Test OK @

DS:> 506

Do you readlly want to erase the entire FLFS ? [Y /N(Default)] :n

FLFS not erased.

050601: User abort

Test OK @

DS:> 506

Do you readlly want to erase the entire FLFS ? [Y /N(Default)] :y

Erasing FLFS...

050602: No FLFS segment found

Error @

Page 30

EN 30 3139 785 32804 Firmware Upgrading & Diagnostic Software5.

VIDEO INPUT PROCESSOR (VIP)

Nucleus Name

DS_VIP_DevTypeGet

Nucleus Number 600

Description Get the device (revision) type information of the VIP IC

Technical - Initialise IIC

- Read out the device (revision)

type information of the VIP IC

Execution Time Less than 1 second

User Input None

Error Number Description

60000 Getting the information from the VIP succeeded

60001 The IIC bus initialisation failed

60002 The was an error getting the information from the VIP

60003 Type not according to type stored in HW diversity string

Example

DS:> 600

060000: Found SAA7136

Test OK @

Nucleus Name

DS_VIP_Communication

Nucleus Number 601

Description Check the communication between the IIC controller of the Codec and the VIP

IC

Technical - Initialise IIC

- Read data from a location in the VIP

Execution Time Less than 1 second

User Input None

Error Number Description

60100 Communicating with the VIP succeeded

60101 The IIC bus was not accessible

60102 There was a timeout reading the device

60103 The IIC acknowledge was not received