Page 1

Color Television Chassis

CT2.0U

RA

G_15870_001.eps

300606

Contents Page Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 5

3. Directions for Use 7

4. Mechanical Instructions 8

5. Service Modes, Error Codes, and Fault Finding 14

6. Block Diagrams, Test Point Overviews, and

Waveforms

Wiring Diagram 35

Block Diagram Video (SSB Only) 36

Block Diagram Audio (SSB Only) 37

Control & Clock Signals (SSB Only) 38

I2C (SSB Only) 39

Supply Lines Overview (SSB Only) 40

7. Circuit Diagrams and PWB Layouts Diagram PWB

SSB: DC / DC (B1A) 41 71-76

SSB: Supply + RS232 (B1B) 42 71-76

SSB: Channel Decoder (B2A) 43 71-76

SSB: Main Tuner (B2B) 44 71-76

SSB: MPIF Main: Video Source Selection (B3A) 45 71-76

SSB: MPIF Main: Supply (B3B) 46 71-76

SSB: MPIF Main: IF & SAW Filter (B3C) 47 71-76

SSB: MPIF Main: Audio Source Selection (B3D) 48 71-76

SSB: MPIF Main: Audio Amplifier (B3E) 49 71-76

SSB: PNX2015: Audio / Video (B4A) 50 71-76

SSB: PNX2015: DV I/O Interface (B4B) 51 71-76

SSB: PNX2015: Tunnelbus (B4C) 52 71-76

SSB: PNX2015: DDR Interface (B4D) 53 71-76

SSB: PNX2015: Standby & Control (B4E) 54 71-76

SSB: PNX2015: Supply (B4F) 55 71-76

SSB: PNX2015: Display Interface (B4G) 56 71-76

SSB: Viper: Control (B5A) 57 71-76

SSB: Viper: Main Memory (B5B) 58 71-76

SSB: Viper: A/V + Tunnelbus (B5C) 59 71-76

©

Copyright 2006 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

SSB: Viper: Supply (B5D) 60 71-76

SSB: Viper: EEPROM (B5E) 61 71-76

SSB: Miscellaneous (B5F) 62 71-76

SSB: Video DAC (B6) 63 71-76

SSB: HDMI: Supply (B7A) 64 71-76

SSB: HDMI: I/O + Control (B7B) 65 71-76

SSB: Analog I/O (B7C) 66 71-76

SSB: UART (B7D) 67 71-76

SSB: Audio: Amplifier (B8A) 68 71-76

SSB: Audio: Connectors (B8B) 69 71-76

SSB: SRP List 70

MTV512 Board (2-->9) 77-84

Power Button Board (2): Connector 85

Power Button Board (3): IR Receiver 86

Power Button Board (4): LED Driver 87

Thermal Board 88

Side I/O Panel (1-->4) 89-92

8. Alignments 93

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 98

Abbreviation List 101

IC Data Sheets 104

10. Spare Parts List 110

11. Revision List 116

Published by JH 0667 BG CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 15870

Page 2

EN 2 CT2.0U RA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connection Overview

1.3 Chassis Overview

Notes:

• Data below can deviate slightly from the actual situation,

due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : Projection, DLP HD5

Screen size : 50” (127 cm), 16:9

Resolution (HxV pixels) : 1280 x 720p

Min. contrast ratio : 1200:1

Min. light output (cd/m

Tuning system : PLL

TV Color systems : ATSC

Video playback : NTSC

Cable : Unscrambled digital

Tuner bands : VHF, UHF, S, Hyper

Supported video formats : All inputs 240p, 480i,

Supported computer formats : 640x480 @ 60Hz

2

) : 395 (50”)

: 60” (152 cm), 16:9

: 310 (60”)

:NTSC

cable - QAM

480p, 720p, 1080i

: 800x600 @ 60Hz

: 1024x768 @ 60Hz

: 1280x768 @ 60Hz

1.1.4 Miscellaneous

Power supply:

- Mains voltage (V

- Mains frequency (Hz) : 57 - 63

Ambient conditions:

- Temperature range (°C) : +5 to +35

- Maximum humidity : 90% R.H.

Power consumption (values are indicative)

- Normal operation (W) : < 230

- Standby (W) : < 1

Dimensions (WxHxD in inch) : 51.57x37.05x21.26

Weight, stand included (kg/lbs) : 45/100 (50”)

) : 108 - 132

AC

(50”)

: 60.83x41.22x25 (60”)

: 55/121 (60”)

1.2 Connection Overview

Note: The following connector color abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

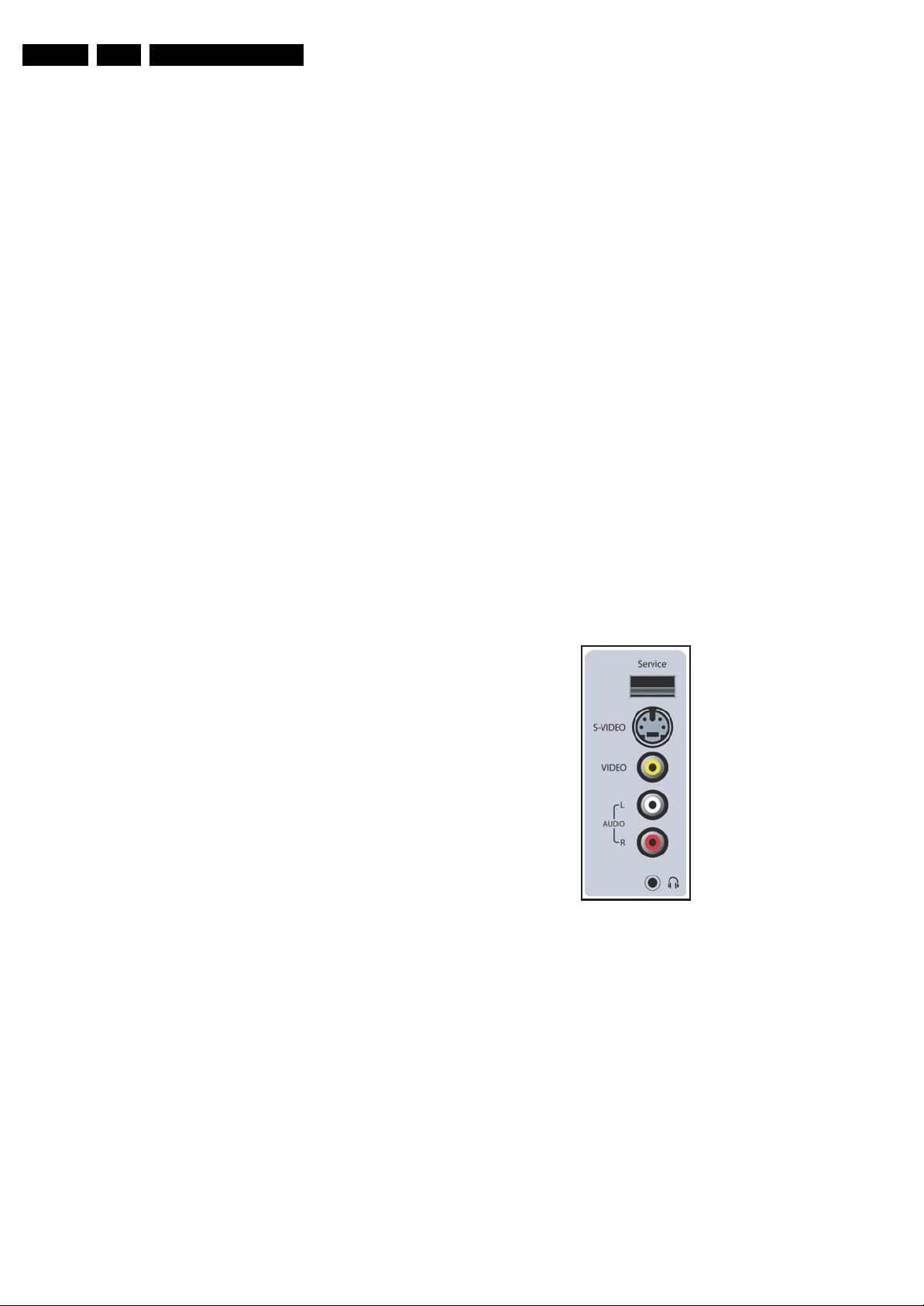

1.2.1 Side Connections

1.1.2 Sound

Sound systems : AV Stereo

Maximum power (W

1.1.3 Multimedia

USB input : USB1.1

) : 2 x 10

RMS

:BTSC

: Dolby Digital (AC3)

G_15870_025.eps

Figure 1-1 Side I/O connections

S-Video (Hosiden): Video Y/C - In

1 -Ground Y Gnd H

2 -Ground C Gnd H

3 -Video Y 1 V

4 -Video C 0.3 V

Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

100706

/ 75 ohm j

PP

P / 75 ohm j

PP

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

Mini Jack: Audio Headphone - Out

Bk - Headphone 32 - 600 ohm / 10 mW ot

Page 3

Technical Specifications, Connections, and Chassis Overview

EN 3CT2.0U RA 1.

USB1.1

1234

E_06532_022.eps

300904

Figure 1-2 USB (type A)

1-+5V k

2 -Data (-) jk

3 -Data (+) jk

4 -Ground Gnd H

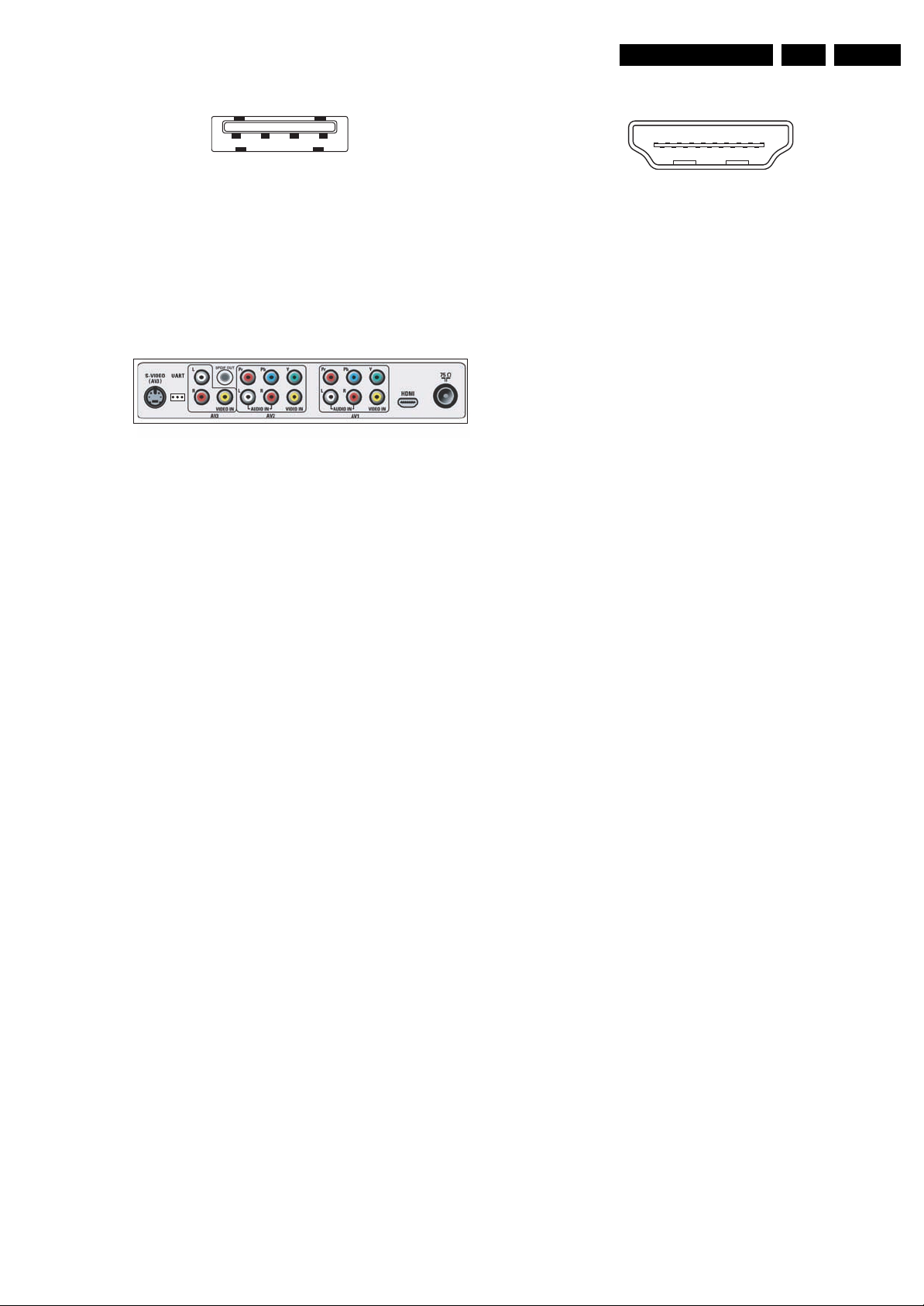

1.2.2 Rear Connections (under side)

Figure 1-3 Rear connections (under side)

AV3 S-Video (Hosiden): Video Y/C - In

1 -Ground Y Gnd H

2 -Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

/ 75 ohm j

PP

P / 75 ohm j

PP

Service Connector (UART)

1 - UART_TX Transmit k

2 - Ground Gnd H

3 - UART_RX Receive j

G_16570_024.eps

100706

HDMI 1: Digital Video, Digital Audio - In

19

1

18 2

E_06532_017.eps

250505

Figure 1-4 HDMI (type A) connector

1 - D2+ Data channel j

2 - Shield Gnd H

3 - D2- Data channel j

4 - D1+ Data channel j

5 - Shield Gnd H

6 - D1- Data channel j

7 - D0+ Data channel j

8 - Shield Gnd H

9 - D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - n.c.

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

Aerial - In

- - F-type (US) Coax, 75 ohm D

AV3 Cinch: Audio - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

RMS

RMS

AV3 Cinch: Video CVBS - In

Ye - Video CVBS 1 V

/ 75 ohm jq

PP

Cinch: S/PDIF - Out

Bk - Coaxial 0.4 - 0.6V

AV2 Cinch: Video YPbPr - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

/ 75 ohm jq

PP

PP

PP

AV2 Cinch: Video CVBS - In

Ye - Video CVBS 1 V

/ 75 ohm jq

PP

AV2 Cinch: Audio - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

RMS

RMS

AV1 Cinch: Video YPbPr - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

/ 75 ohm jq

PP

PP

PP

AV1 Cinch: Video CVBS - In

Ye - Video CVBS 1 V

/ 75 ohm jq

PP

/ 10 kohm jq

/ 10 kohm jq

/ 75 ohm kq

PP

/ 75 ohm jq

/ 75 ohm jq

/ 10 kohm jq

/ 10 kohm jq

/ 75 ohm jq

/ 75 ohm jq

AV1 Cinch: Audio - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

Page 4

EN 4 CT2.0U RA1.

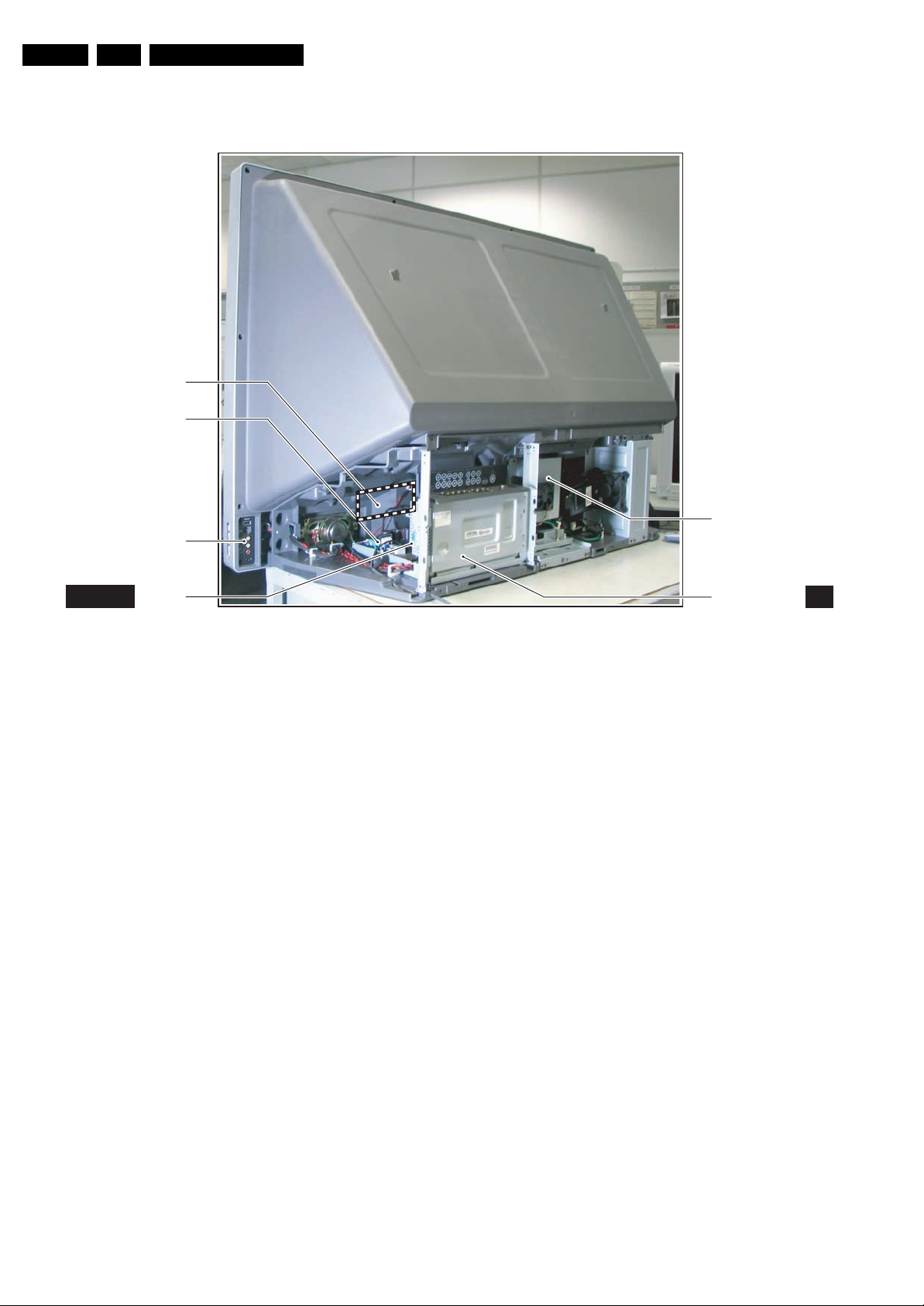

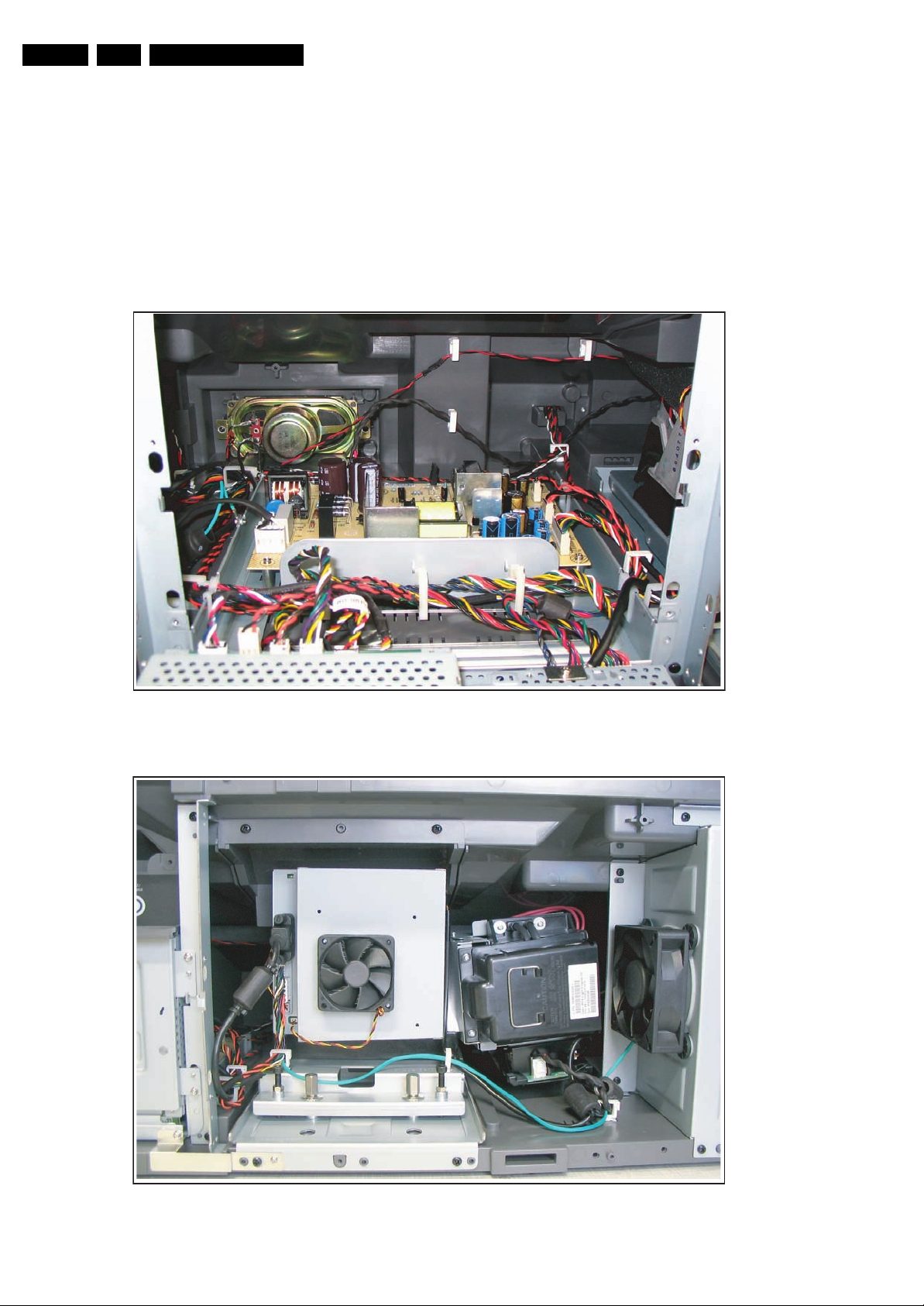

1.3 Chassis Overview

ON/OFF BUTTON

IR RECEIVER

POWER SUPLY

Technical Specifications, Connections, and Chassis Overview

KEYBOARD

MTV512

SIDE I/O

MTV512

BOARD

Figure 1-5 PWB/CBA locations

G_15870_026.eps

100706

LIGHT ENGINE

SMALL SIGNAL

BOARD

B

Page 5

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 5CT2.0U RA 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the "on" position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Warnings

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (µ= x10

nano-farads (n= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 Rework on BGA (Ball Grid Array) ICs

General

Although (LF)BGA assembly yields are very high, there may

still be a requirement for component rework. By rework, we

mean the process of removing the component from the PWB

and replacing it with a new component. If an (LF)BGA is

removed from a PWB, the solder balls of the component are

deformed drastically so the removed (LF)BGA has to be

discarded.

-9

), or pico-farads (p= x10

-12

-6

),

).

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "on".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Device Removal

As is the case with any component that, is being removed, it is

essential when removing an (LF)BGA, that the board, tracks,

solder lands, or surrounding components are not damaged. To

remove an (LF)BGA, the board must be uniformly heated to a

temperature close to the reflow soldering temperature. A

uniform temperature reduces the risk of warping the PWB.

To do this, we recommend that the board is heated until it is

certain that all the joints are molten. Then carefully pull the

component off the board with a vacuum nozzle. For the

appropriate temperature profiles, see the IC data sheet.

Area Preparation

When the component has been removed, the vacant IC area

must be cleaned before replacing the (LF)BGA.

Removing an IC often leaves varying amounts of solder on the

mounting lands. This excessive solder can be removed with

either a solder sucker or solder wick. The remaining flux can be

removed with a brush and cleaning agent.

After the board is properly cleaned and inspected, apply flux on

the solder lands and on the connection balls of the (LF)BGA.

Note: Do not apply solder paste, as this has been shown to

result in problems during re-soldering.

Device Replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF)BGA should be

Page 6

EN 6 CT2.0U RA2.

Safety Instructions, Warnings, and Notes

aligned under a microscope or magnifying glass. If this is not

possible, try to align the (LF)BGA with any board markers.

So as not to damage neighbouring components, it may be

necessary to reduce some temperatures and times.

More Information

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

2.3.4 Lead-free Solder

Philips CE is producing lead-free sets (PBF) from 1.1.2005

onwards.

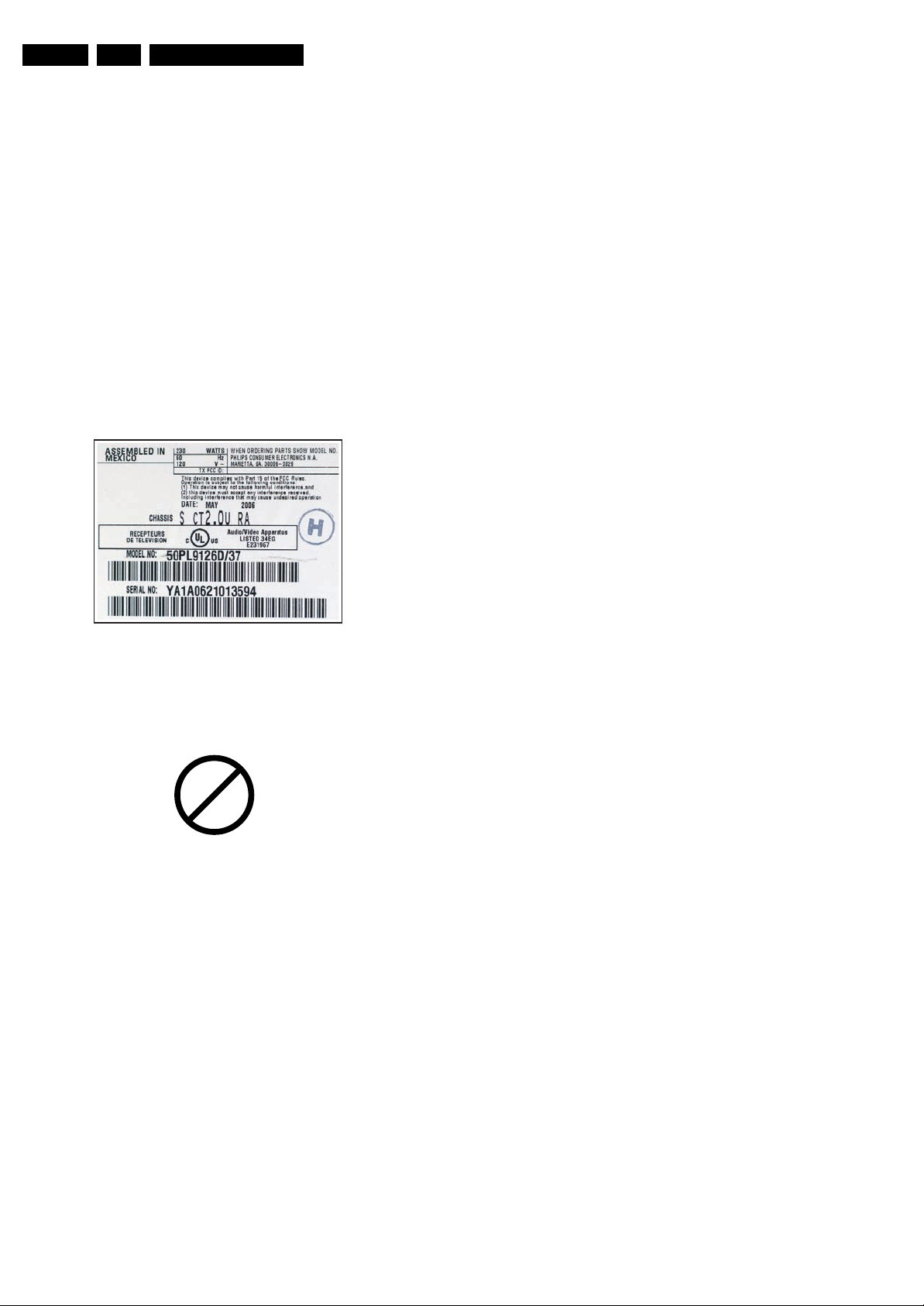

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 5 and 6 refer to the production year, digits

7 and 8 refer to production week (in example below it is 1991

week 18).

G_15870_063.eps

Figure 2-1 Serial number example

Regardless of the special lead-free logo (which is not always

indicated), one must treat all sets from this date onwards

according to the rules as described below.

P

b

Figure 2-2 Lead-free logo

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilise the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilised at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

100706

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard material (commodities) has to be

purchased at external companies.

• Special information for lead-free BGA ICs: these ICs will be

delivered in so-called "dry-packaging" to protect the IC

against moisture. This packaging may only be opened

shortly before it is used (soldered). Otherwise the body of

the IC gets "wet" inside and during the heating time the

structure of the IC will be destroyed due to high (steam-)

pressure inside the body. If the packaging was opened

before usage, the IC has to be heated up for some hours

(around 90°C) for drying (think of ESD-protection!).

Do not re-use BGAs at all!

• For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

In case of doubt whether the board is lead-free or not (or with

mixed technologies), you can use the following method:

• Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

• De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

Caution: For BGA-ICs, you must use the correct temperatureprofile, which is coupled to the 12NC. For an overview of these

profiles, visit the website www.atyourservice.ce.philips.com

(needs subscription, but is not available for all regions)

You will find this and more technical information within the

"Magazine", chapter "Repair downloads".

For additional questions please contact your local repair help

desk.

2.3.5 Alternative BOM identification

In September 2003, Philips CE introduced a change in the way

the serial number (or production number, see Figure 2-1) is

composed. From this date on, the third digit in the serial

number (example: AG2B0335000001) indicates the number of

the alternative BOM (Bill of Materials used for producing the

specific model of TV set). It is possible that the same TV model

on the market is produced with e.g. two different types of

displays, coming from two different O.E.M.s.

By looking at the third digit of the serial number, the service

technician can see if there is more than one type of B.O.M.

used in the production of the TV set he is working with. He can

then consult the At Your Service Web site, where he can type

in the Commercial Type Version Number of the TV set (e.g.

28PW9515/12), after which a screen will appear that gives

information about the number of alternative B.O.M.s used.

If the third digit of the serial number contains the number 1

(example: AG1B033500001), then there is only one B.O.M.

version of the TV set on the market. If the third digit is a 2

(example: AG2B0335000001), then there are two different

B.O.M.s. Information about this is important for ordering

the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26 = 35 different B.O.M.s can

be indicated by the third digit of the serial number.

2.3.6 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

Page 7

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

Directions for Use

EN 7CT2.0U RA 3.

Page 8

EN 8 CT2.0U RA4.

Mechanical Instructions

4. Mechanical Instructions

Index of this chapter:

4.1 Cable Dressing

4.2 Assy/Panel Removal

4.3 Set Re-assembly

4.1 Cable Dressing

Notes:

• Several models in this chassis range have a different

mechanical construction, the instructions given in this

chapter are therefore very model specific.

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Follow the disassemble instructions in described order.

Figure 4-1 Cable dressing 1/3 (PSU etc., SSB/MTV module detached from the frame)

G_16570_065.eps

100706

Figure 4-2 Cable dressing 2/3 (Light Engine, rear)

G_16570_066.eps

100706

Page 9

Mechanical Instructions

EN 9CT2.0U RA 4.

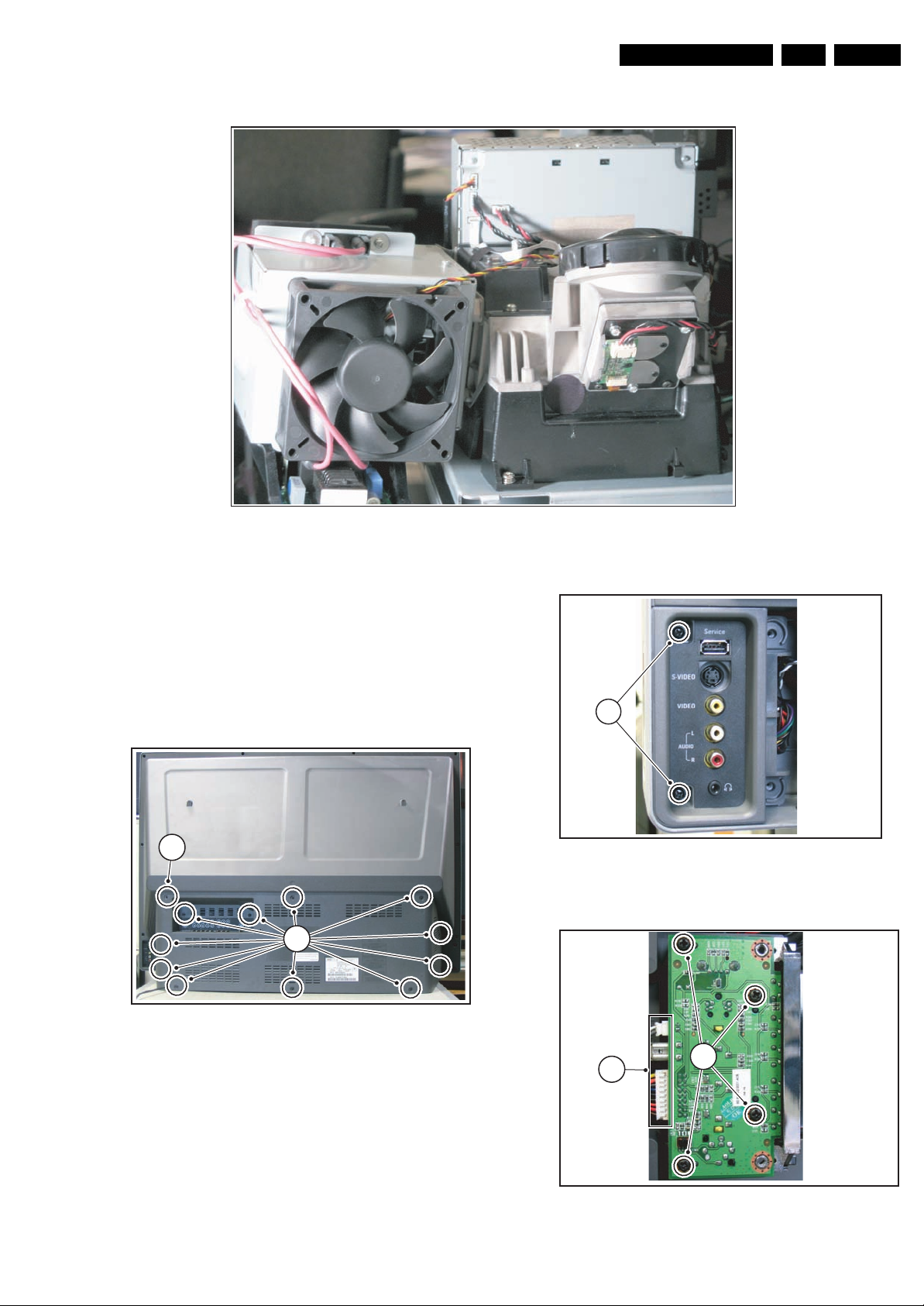

Figure 4-3 Cable dressing 3/3 (Light Engine, front)

4.2 Assy/Panel Removal

4.2.1 Rear Cover

Caution: Disconnect the Mains/AC Power cord before you

remove the rear cover!

1. Remove fixation screws [1].

2. Remove the rear cover.

1

1

G_16570_067.eps

100706

1

G_15870_028.eps

Figure 4-5 Keyboard / Side I/O module removal

070706

Figure 4-4 Rear cover removal

4.2.2 Keyboard / Side I/O Panel

1. Remove the rear cover, as described previously.

2. Remove screws [1].

3. Take out the module.

4. Unplug connectors [2].

5. Remove screws [3].

When defective, replace the whole unit.

G_15870_027.eps

070706

2

3

G_15870_029.eps

Figure 4-6 Keyboard / Side I/O panel removal

110706

Page 10

EN 10 CT2.0U RA4.

Mechanical Instructions

4.2.3 Front Cover

1. Remove the rear cover, as described previously.

2. Remove the keyboard / side I/O panel.

3. Remove screws [1].

4. ‘Open’ the front cover just far enough to gain access to the

connector [2] of the on/off button / IR receiver panel.

5. Unplug connector [2].

6. Carefully remove the front cover and put it in a safe place.

1

1

1

1

1

1

1

1

1

1

1

1

G_15870_030.eps

070706

4.2.5 Right Speaker

1. Remove the rear cover, as described previously.

2. Unplug the connectors.

3. Remove the fixation screws.

4. Remove the speaker.

4.2.6 Left Speaker

1. Remove the rear cover, as described previously.

2. Remove screws [1].

3. Loosen screws [2] for approx. 3 turns.

4. Remove screws [3].

5. Pull fan bracket [4] towards you, against the heads of

screws [2].

6. Pull air duct [5] gently towards you, to create a wider

access to the speaker.

7. Unplug the connectors from the speaker.

8. Remove the fixation screws of the speaker.

9. Remove the speaker.

10. After replacement, carefully position air duct [5] and fan

bracket [4] before you tighten the screws. The positioning

pins near screws [1] must be correctly in place.

Figure 4-7 Front cover removal 1/2

2

Figure 4-8 Front cover removal 2/2

4.2.4 Power Switch / IR Receiver Board

1. Remove the front cover, as described previously.

2. Remove screws [1].

G_15870_031.eps

070706

21 3

Figure 4-10 Air duct 1/2

5

4

G_15870_033.eps

100706

5

1

1

G_15870_032.eps

Figure 4-9 Power switch / IR receiver board

070706

4

Figure 4-11 Air duct 2/2

G_15870_034.eps

070706

Page 11

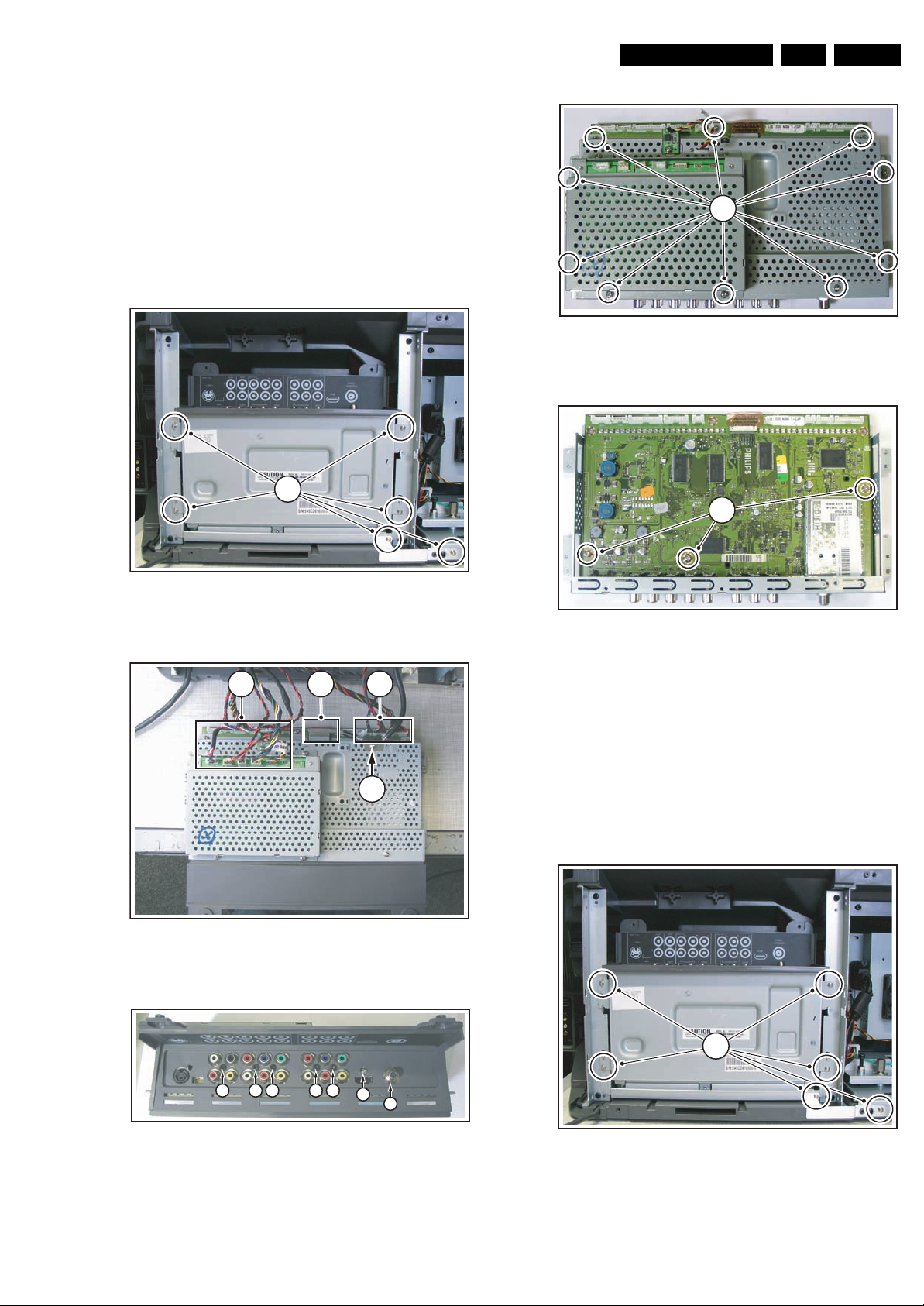

4.2.7 Small Signal Board (SSB)

1. Remove the rear cover, as described previously.

2. Remove screws [1].

3. Take out the SSB assy and put it directly behind the set.

4. Remove screw [2].

5. Carefully unplug the fragile LVDS connector [3].

6. Unplug connectors [4].

7. Remove screws [5] and nut [6].

8. Remove screws [7].

9. Lift the shield (together with the MTV512 module) from the

SSB module.

10. Remove screws [8].

1

Mechanical Instructions

7

Figure 4-15 SSB top shield

8

EN 11CT2.0U RA 4.

G_15870_038.eps

070706

Figure 4-12 SSB fixation

4 3 4

Figure 4-13 SSB connectors

G_15870_035.eps

2

G_15870_036.eps

070706

110706

Figure 4-16 SSB board

4.2.8 Micro Processor Board (MTV512)

1. Remove the rear cover, as described previously.

2. Remove screws [1].

3. Take out the SSB assy and put it directly behind the set.

4. Unplug connectors [2].

5. Remove screws [3].

6. Lift the MTV module from the SSB module.

7. Remove fixation screws [4] from the serial connector.

8. Remove screws [5].

G_15870_039.eps

100706

5 5 5 5 5

Figure 4-14 SSB I/O panel

5

6

G_15870_037.eps

070706

1

Figure 4-17 SSB fixation

G_15870_035.eps

070706

Page 12

EN 12 CT2.0U RA4.

Mechanical Instructions

4.2.9 Power Supply Unit (PSU)

1. Remove the rear cover, as described previously.

2. Remove screws [1].

3. Take out the SSB assy and put it directly behind the set.

3

4. Unplug connectors [2].

5. Remove screws [3].

2

3

Figure 4-18 MTV512 module

5

4

G_15870_040.eps

100706

Figure 4-20 SSB fixation

3

1

G_15870_035.eps

070706

3

2

3

Figure 4-19 MTV512 board

G_15870_041.eps

100706

3

Figure 4-21 Power supply unit

G_15870_042.eps

3

100706

Page 13

Mechanical Instructions

EN 13CT2.0U RA 4.

4.2.10 Projection Screen Removal

1. Remove the front cover, as described previously.

2. Remove screws [1].

3. Remove the fixation strips [2].

1 1 1 1 1 1 1 1

1

1

2

1

1

Figure 4-22 Projection screen

4.2.11 Projection Lamp Replacement

1. Remove the rear cover, as described previously.

2. Remove screws [1].

3. Pull out the lamp unit with grip [2].

4. Remove nut and lock washer [3].

5. Remove screws [4].

1

1

1

1111111

G_15870_043.eps

100706

4.2.12 Light Engine Removal

1. Remove rear cover, as described previously.

2. Unplug connectors [1].

3. Remove screws [2].

4. Pull the light engine out of the set.

2 2

1

2

2 2

Figure 4-25 Light engine

4.3 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

G_15870_046.eps

100706

1

Figure 4-23 Projection lamp 1/2

4

3

2

G_15870_044.eps

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position. See figures "Cable

dressing".

• Pay special attention not to damage the EMC foams on the

SSB shields. Ensure that EMC foams are mounted

correctly.

100706

4

Figure 4-24 Projection lamp 2/2

G_15870_045.eps

100706

Page 14

EN 14 CT2.0U RA5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Service Modes

5.3 Stepwise Start-up

5.4 Service Tools

5.5 Error Codes

5.6 The Blinking LED Procedure

5.7 Protections

5.8 Fault Finding and Repair Tips

5.9 Software Upgrading

5.1 Test Points

As most signals are digital, it will be almost impossible to

measure waveforms with a standard oscilloscope. Therefore,

waveforms are not given in this manual. Several key ICs are

capable of generating test patterns, which can be controlled via

ComPair. In this way it is possible to determine which part is

defective.

Perform measurements under the following conditions:

• Service Default Mode.

• Video: Color bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Service Modes

Service Default Mode (SDM) and Service Alignment Mode

(SAM) offer several features for the service technician, while

the Customer Service Mode (CSM) is used for communication

between a Customer Helpdesk and a customer.

There is also the option of using ComPair, a hardware interface

between a computer (see requirements below) and the TV

chassis. It offers the ability of structured troubleshooting, test

pattern generation, error code reading, software version

readout, and software upgrading.

Minimum requirements for ComPair: a Pentium processor,

Windows 95/98, and a CD-ROM drive (see also paragraph

“ComPair”).

in the channel map and could be different from the one

corresponding to the physical channel 3.

• All picture settings at 50% (brightness, color, contrast).

• All sound settings at 50%, except volume at 25%.

• All service-unfriendly modes (if present) are disabled, like:

– (Sleep) timer.

– Child/parental lock.

– Picture mute (blue mute or black mute).

– Automatic volume levelling (AVL).

– Auto switch "off" (when no video signal was received

for 10 minutes).

– Skip/blank of non-favorite pre-sets.

– Smart modes.

– Auto store of personal presets.

– Auto user menu time-out.

How to Activate SDM

Use one of the following methods:

• Use the standard RC-transmitter and key in the code

“062596”, directly followed by the “MENU” button.

Note: It is possible that, together with the SDM, the main

menu will appear. To switch it "off", push the “MENU”

button again.

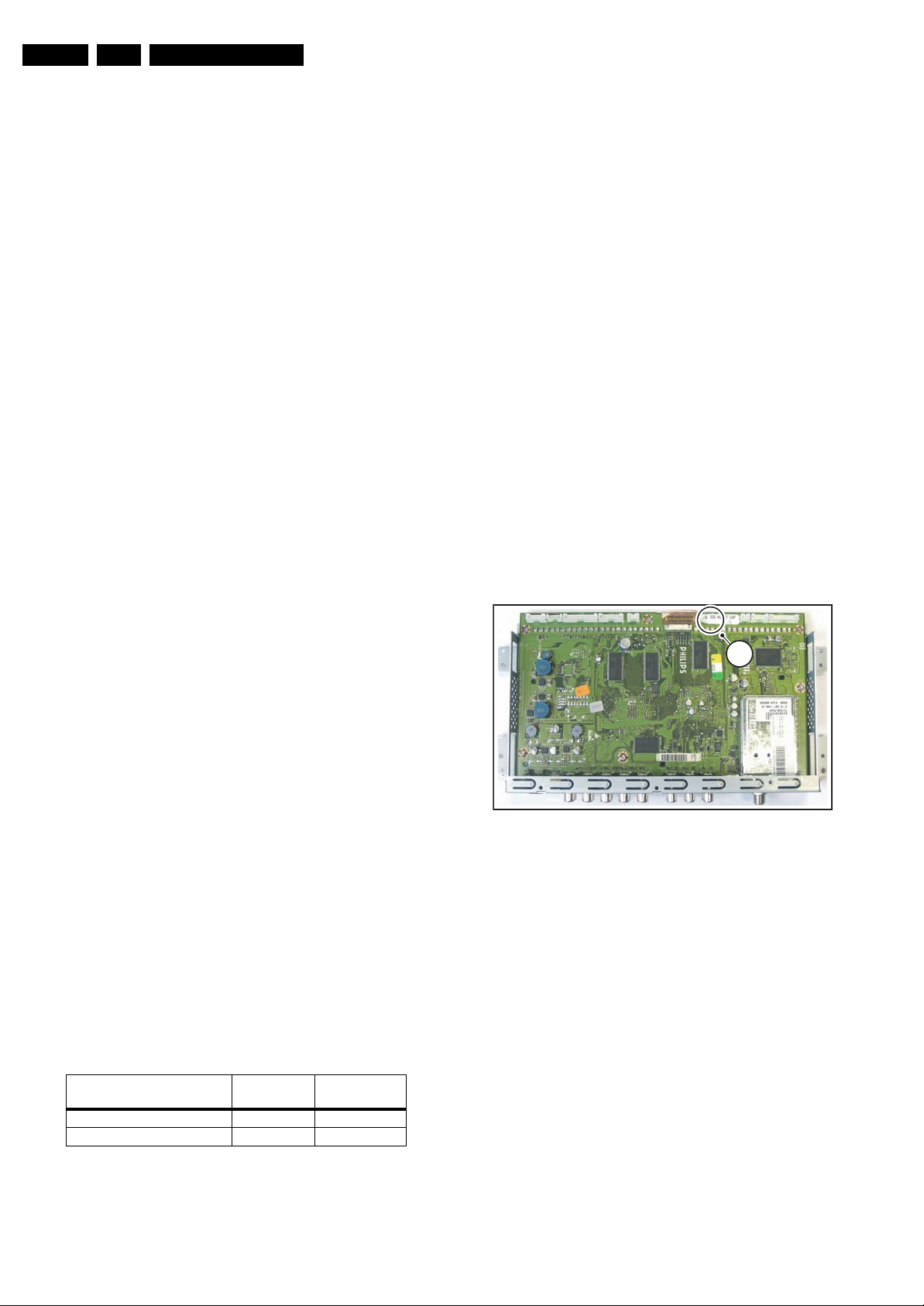

• Short for a moment the two solder pads [1] on the SSB,

with the indication “SDM” (on the picture they are located

underneath the sticker). They are located outside the

shielding. Activation can be performed in all modes, except

when the set has a problem with the Stand-by Processor.

See figure “SDM and SPI service pads”.

1

5.2.1 Service Default Mode (SDM)

Purpose

• To create a pre-defined setting, to get the same

measurement results as given in this manual.

• To override SW protections (only applicable for protections

detected by stand-by processor) and make the TV start up

to the step just before protection (a sort of automatic

stepwise start up). See paragraph “Stepwise Start Up”.

• To start the blinking LED procedure (not valid in protection

mode).

Specifications

Table 5-1 SDM default settings

Region Freq. (MHz)

Europe, AP-PAL/Multi 475.25 PAL B/G

NAFTA, AP-NTSC, LATAM 61.25 (ch. 3) NTSC M

• Tuning frequency 61.25 MHz for NTSC: The TV shall tune

to physical channel 3 only if channel 3 is an analog channel

or if there is no channel 3 installed in the channel map. If

there is a digital channel installed in channel 3, then the

frequency to which the set will tune, would be as specified

Default

system

Figure 5-1 SDM and SPI service pads

After activating this mode, “SDM” will appear in the upper right

corner of the screen (if you have picture).

How to Navigate

When you press the “MENU” button on the RC transmitter, the

set will toggle between the SDM and the normal user menu

(with the SDM mode still active in the background).

How to Exit SDM

Use one of the following methods:

• Switch the set to STAND-BY via the RC-transmitter.

• Via a standard customer RC-transmitter: key in “00”sequence.

5.2.2 Service Alignment Mode (SAM)

Purpose

• To perform (software) alignments.

• To change option settings.

• To easily identify the used software version.

• To view operation hours.

• To display (or clear) the error code buffer.

G_15870_047.eps

100706

Page 15

Service Modes, Error Codes, and Fault Finding

EN 15CT2.0U RA 5.

How to Activate SAM

Via a standard RC transmitter: key in the code “062596”

directly followed by the “INFO” button. After activating SAM

with this method, a service warning will appear on the screen,

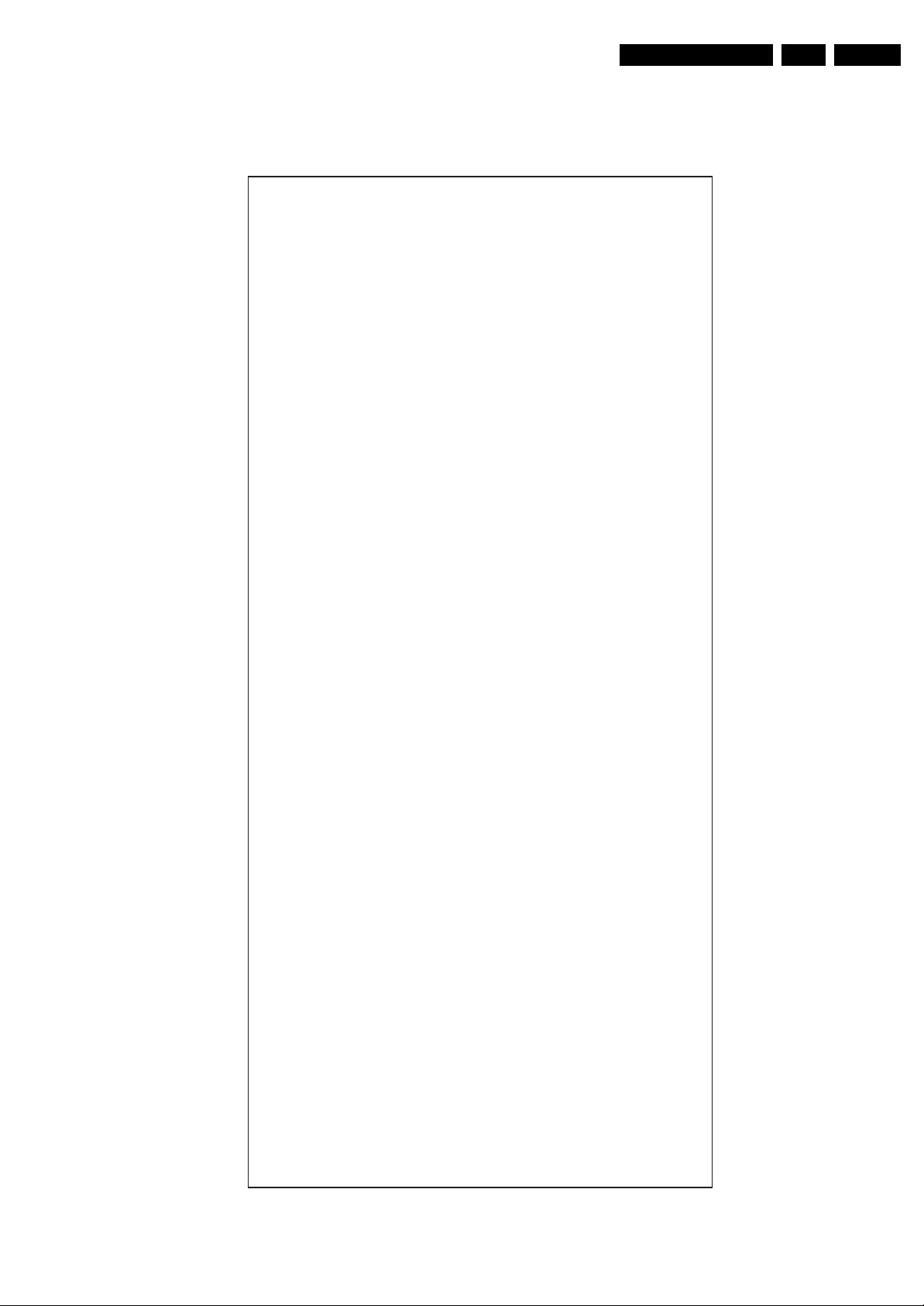

SAM-menu

Hardware info A. SW version

Operation hours 289

Errors No Errors

Defective module

Reset error buffer Start now

Alignments General Tuner AGC 32

Dealer options

Options

Initialise NVM

Store

SW maintenance

DLP Menu

ED10U-1.0.1.0_07892

B. SBY PROC version

001.008.002.014

C. Production code

YA1A0621013594

Whitepoint Color temperature

Personal options

PIP/DS

Data

Display

Video repro Picture processing

Source selection

Audio repro Subwoofer internal present Off / On

Miscellaneous

Option numbers Group 1 00016 00000 00033 14979

Store (completed)

SW events

HW events

DLP Status

DLP Setting

White point red

White point green

White point blue

Red BL offset

Green BL offset

Picture mute

Virgin mode

2 CS Korea

Dualscreen

EPG

RRT

Screen

Scanning backlight

Dimming backlight

Comb filter

Ambient light

MOP

HDMI1 None / With analog audio / Without analog audio

HDMI2 None / With analog audio / Without analog audio

USB version

IEEE1394 Not present

Ethernet

SPDIF inputs

Acoustic system

Alternative tuner

Tuner type

Hotel mode

Group 2 00038 00000 00544 00000

Store

Display

Clear

Test reboot

Display

Clear

Thermal Degree

Fan1 Rotation Rate

Fan2 Rotation Rate

Lamp Life

MTV512 MCU Version

Bright-R 0

Bright-G 0

Bright-B 0

Contrast-R 100

Contrast-G 100

Contrast-B 100

Reset lamp life

Gamma

Test Pattern Ok

you can continue by pressing the red button on the RC. Then

you have access to the following menu:

Normal / Warm / Cool

127

127

127

7

7

Off / On

Off / On

Off

None / One tuner ds / Two tuner ds

Off / On

No / Yes

038 (50” Coretronic DLP)

Off / On

Off / On

No spider

None / 2D comb / 3D comb

Off / Mono / Stereo

Off / On

None / USB 1.1 / USB 2.0 + Cardreader

Off

None / 1 connector / 2 connectors

None / ... / 50DLP / 60DLP

Philips

TD1336s

Off

Store (completed)

Start now (push OK to view log-file)

Start now (push OK to clear log-file)

Start now (push OK to reboot)

Start now (push OK to view log-file)

Start now (push OK to clear log-file)

33

NORMAL

NORMAL

162 H

A18

Ok

Film / Graphic / Video

G_15870_064.eps

100706

Figure 5-2 SAM menu

Page 16

EN 16 CT2.0U RA5.

Contents of SAM:

• Hardware Info.

– A. VIPER SW Version. Displays the software version

of the VIPER software (main software) (example:

ED10U-1.2.3.4_12345 = AAAAB_X.Y.W.Z_NNNNN).

• AAAA= the chassis name.

• B= the region: A= AP, E= EU, L= Latam, U = US.

• X.Y.W.Z= the software version, where X is the

main version number (different numbers are not

compatible with one another) and Y is the sub

version number (a higher number is always

compatible with a lower number). The last two

digits are used for development reasons only, so

they will always be zero in official releases.

• NNNNN= last five digits of 12nc code of the

software.

– B. SBY PROC Version. Displays the software version

of the stand-by processor.

– C. Production Code. Displays the production code of

the TV, this is the serial number as printed on the back

of the TV set. Note that if an NVM is replaced or is

initialized after corruption, this production code has to

be re-written to NVM. ComPair will foresee in a

possibility to do this.

• Operation Hours. Displays the accumulated total of

operation hours (not the stand-by hours). Every time the

TV is switched "on/off", 0.5 hours is added to this number.

• Errors. (Followed by maximal 10 errors). The most recent

error is displayed at the upper left (for an error explanation

see paragraph “Error Codes”).

• Defective Module. Here the module that generates the

error is displayed. If there are multiple errors in the buffer,

which are not all generated by a single module, there is

probably another defect. It will then display the message

“UNKNOWN” here.

• Reset Error Buffer. When you press “cursor right” and

then the “OK” button, the error buffer is reset.

• Alignments. This will activate the “ALIGNMENTS” submenu.

• Dealer Options. Extra features for the dealers.

• Options. Extra features for Service.

• Initialise NVM. When an NVM was corrupted (or replaced)

in the former EMG based chassis, the microprocessor

replaces the content with default data (to assure that the

set can operate). However, all preferences and alignment

values are gone now, and option numbers are not correct.

Therefore, this was a very drastic way. In this chassis, the

procedure is implemented in another way: The moment the

processor recognizes a corrupted NVM, the “initialize

NVM” line will be highlighted. Now, you can do two things

(dependent of the service instructions at that moment):

– Save the content of the NVM via ComPair for

development analysis, before initializing. This will give

the Service department an extra possibility for

diagnosis (e.g. when Development asks for this).

– Initialize the NVM (same as in the past, however now it

happens conscious).

Service Modes, Error Codes, and Fault Finding

Note: When you have a corrupted NVM, or you have replaced

the NVM, there is a high possibility that you will not have picture

any more because your display option is not correct. So, before

you can initialize your NVM via the SAM, you need to have a

picture and therefore you need the correct display option. To

adapt this option, use ComPair. The correct HEX values for the

options can be found in the table below.

Page 17

Service Modes, Error Codes, and Fault Finding

(

(8)

(A1)

(8)

g

g

g

(V3)

g

g

(A2)

(

)

g

p

(

g)

(

)

(8)

(8)

(8)

(8)

(A3)

(

)

g)

g

p

(

)

(

)

(

g)

p

p

EN 17CT2.0U RA 5.

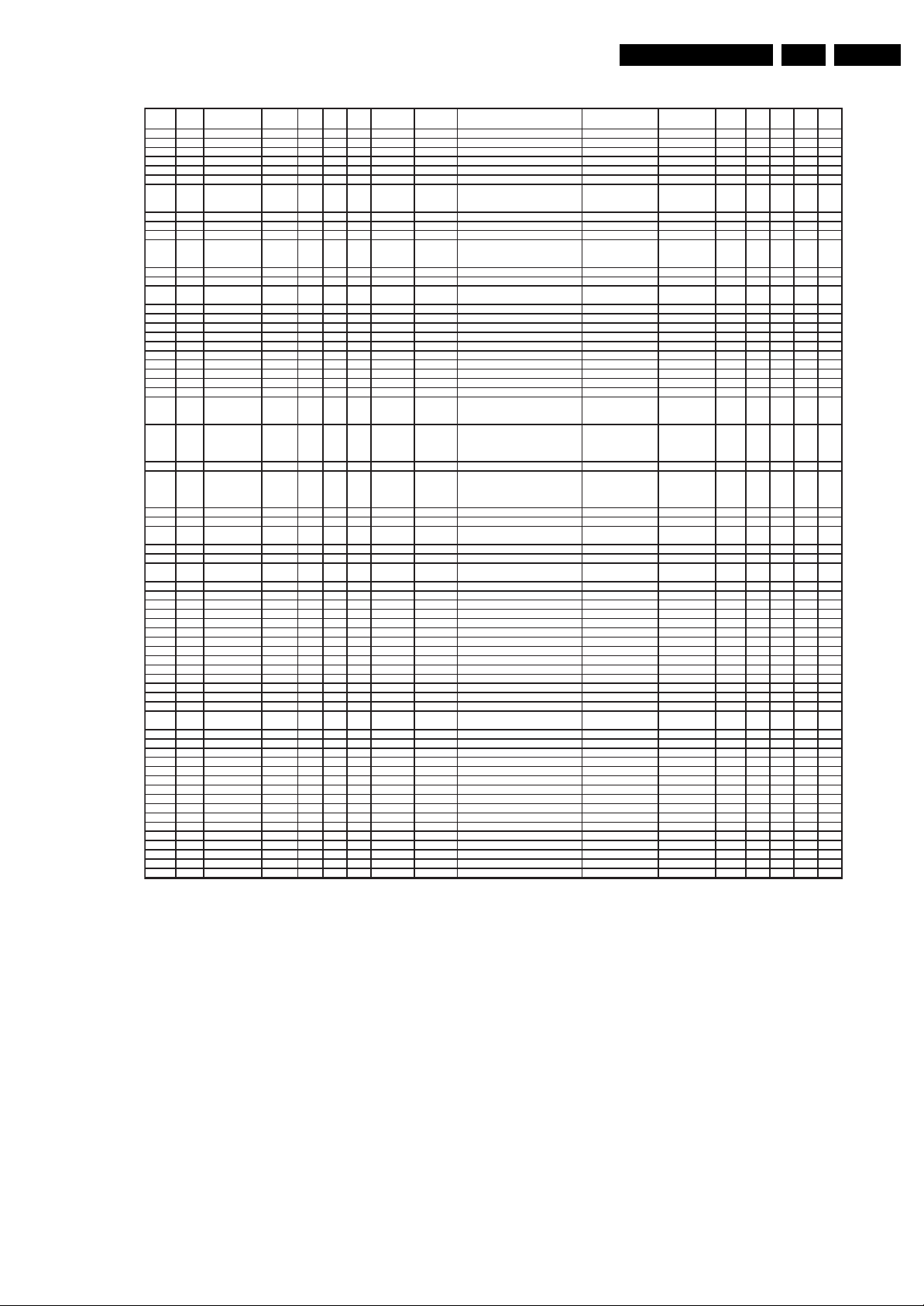

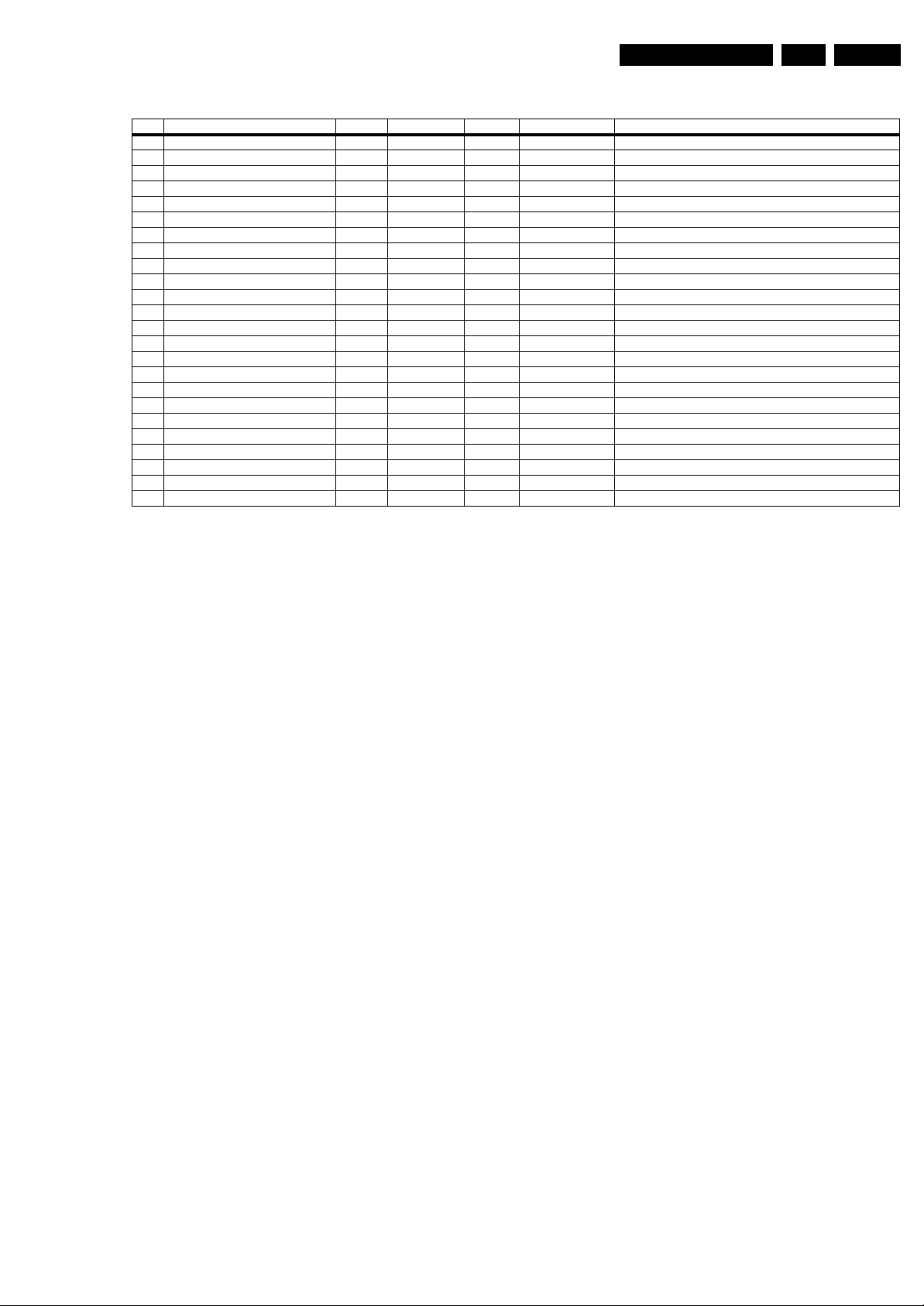

Display

option

000 00 PDP SDI 42” 768p 1024

001 01 PDP SDI 50” 768p 1366

002 02 PDP FHP 42” 1024i 1024

003 03 LCD LPL 30” 768p 1280 LC300W01-A3P7 9322 198 00682 analo

004 04 LCD LPL 37” 768p 1366 LC370W01-A6 9322 220 87682 analo

005 05 LCD LPL 42” 768p 1366 LC420W02-A6 9322 226 39682 analo

006 06 LCD Sharp 32” 768p 1366 LQ315T3LZ13 (ASV1)

007 07 PDP SDI 42” 480p 852

008 08 PDP FHP 37” 1024i 1024

009 09 LCOS XION 720p 1280 n.a. n.a. NA 8

010 0A LCD AUO 30” 768p 1280

011 0B LCD LPL 32” 768p 1366 LC320W01-A6K1 9322 217 44682 analo

012 0C LCD AUO 32” 768p 1366 T315XW01V5 9322 231 69682 PWM 8

013 0D LCD Sharp 37” 768p 1366 LQ370T3LZ21 (ASV2)

014 0E LCD LPL 42” X 1080p 1920 LC420WU1-SL01 9322 228 99682 PWM 8

015 0F PDP SDI 37” 480p 852

016 10 PDP FHP 37” 1080i 1024

017 11 PDP FHP 42” 1080i 1024

018 12 PDP FHP 55” 768p 1366

019 13 LCOS VENUS 720p 1280 n.a. n.a. NA

020 14 LCOS VENUS X 1080p 1920 n.a. n.a. NA

021 15 LCD LPL 26” 768p 1366 LC260WX2-SL01 9322 221 01682 PWM 8 S *

022 16 LCD LPL 32” X 768p 1366 LC320WX2-SL01

023 17 PDP LGE 42” 480p 852

024 18 PDP SDI 42” 480p 852

025 19 PDP SDI 42” 768p 1024

026 1A PDP FHP 42” 1024i 1024

027 1B PDP SDI 50” 768p 1366

028 1C LCD Sharp 37” X 1080P 1920 LQ370D3LZ13

029 1D LCD AUO 32” 768p 1366 T315XW01-V3

030 1E LCD Sharp 37” X X 1080p 1920 LW370D3LZ1x (ASV 3 first samples) not used PWM 10(8) X

031 1F LCD Sharp 37” X X 1080P 1920 LK370D3LZ33

032 20 LCD LPL 20” 768p 1366 LC200WX1-SL01 9322 222 90682 tbd S

033 21 LCD QDI 23” 768p 1366

034 22 ECO PTV 51” 1080i 1366 ? NA n.a.

035 23 ECO PTV 55” 1080i 1366 ? NA n.a.

036 24 ECO PTV 61” 1080i 1366 ? NA n.a.

037 25 PDP FHP 42” 1024I 1024

038 26 DLP 50” 720p 1280 ? NA 10 S

039 27 DLP 60” 720p 1280 ? NA 10 S

040 28 LCD Sharp 32” 768p 1366 LK315T3LZ43

041 29 LCD LPL 42” X 768p 1366 LC420W X2-SLA1 9322 240 80682 analo

042 2A PDP SDI 63” 768p 1366

043 2B LCD Sharp 37” X 768p 1366 LK370T3LZ63

044 2C LCD Sharp 37” 768p 1366 LK370T3LZ53

045 2D LCD LPL 26” 768p 1366 LC260WX2-SLB2 9322 234 13682 PWM 8 X

046 2E LCD LPL 32” 768 p 1366 LC320W01-SL06 9322 230 03682 PWM 8 S

047 2F LCD LPL 42” 768p 1366 LC420W02-SLB1 9322 234 12682 PWM 8 X

048 30 LCD QDI 26” 768p 1366 QD26HL02-REV01

049 31 LCD AUO 26” 768p 1366 T260XW02V4 9322 231 90682 PWM 8 X

050 32 LCD AUO 32” 768p 1366 T315XW01V9 9322 231 89682 PWM 8 S

051 33 LCD AUO 37” 768p 1366 T370XW01V1 9322 233 78682 PWM 8 S

052 34 LCD AUO 32” 768p 1366 T315XW02V5

053 35 LCD LPL 37” 768p 1366 LC370WX1-SL04 9322 233 19682 PWM 8 S

054 36 PDP LGE 42” 768p 1024

055 37 LCD LPL 42" X 1080p 1920

056 38 LCD LPL 47" X 1080p 1920 PWM X

057

058

059

060 3C LCD Tbd ? X 768p 1366

061 3C LCD Tbd ? X 768p 1366

HEX

Display type

Brand SIZE

Full HDClear

LCD

Resolution

vertical

Resolution

horizontal

Code number 12 NC

S42AX-YD01

PP42AX-007A) 9322 225 38682

S50HW-XD03 9322 215 26682

FPF42C128128UC-52

LQ315T3LZ23 (ASV2.2)(5Vtcon)

LQ315T3LZ23 (ASV2.2)(12Vtcon)

S42SD-YD05

FPF37C128128UB-72 9322 217 56682

T296XW01

T296XW01V2

T296XW01V3

LQ370T3LZ44 (ASV2.2)

S37SD-YD02 9322 217 39682

not used not used

FPF42C128135UA-52 9322 235 43682

not used not used

not used not used

S42SD-YD07(PP42SD-015A) (V4)

S42SD-YD07(PP42SD-015B) (V4)

S42SD-YD07(PP42SD-015F) (V4)

S42AX-YD01(PP42AX-007A) (V4)

S42AX-YD01(PP42AX-008A) (V4)

S42AX-YD01(PP42AX-008B) (V4)

S42AX-YD02(PP42AX-009A) (W1)

FPF42C128128UD-51

S50HW-XD04(PP50HW-005A) (V4)

S50HW-XD04(PP50HW-005B) (V4)

S50HW-XD04(PP50HW-005E) (V4)

S50HW-YD01(PP50HW-010A) (W1)

QD23HL02 REV01

QD23HL02 REV01(03)

FPF42C128135UA-52

S63HW-XD04 see

QD26HL02-REV02

PDP42X3 see

LC420WU2-SLA1 8204 001 50441

100/120Hz 1

100/120Hz final

st

silicon

ASV2.2

ASV 3

ASV 2.3

ASV 3

ASV 2.3

9322 235 43682

Dimming

NA 8

NA 10

9322 212 78682

9322 209 35682

9322 226 58682

9322 226 16682

9322 215 27682

9322 206 49682

9322 219 45682

9322 213 33682

? analog 8

9322 241 46682

9322 226 37682

9322 226 96682

9322 233 81682

9322 225 38682

9322 226 95682

9322 233 80682

9322 240 08682

not used

9322 226 54682

9322 226 97682

9322 233 79682

9322 240 25682

9322 228 48682 analo

see

artslist for 12NC

9322 242 22682

9322 223 91682

9322 232 69682

9322 235 32682 PWM (analo

artslist for 12NC

see partslist for 12NC

9322 235 83682

9322 227 29682

9322 235 05682

see

artslist for 12NC

artslist for 12NC

NA 10

analog 8

NA 8

NA 10

analog 8

NA

NA

NA X

NA 10

analo

NA 8

NA 10 (8) X

NA 10 (8) X X

NA 8

NA 10(8) X X

PWM

PWM 10

tbd S

NA

NA X

PWM

PWM

PWM 8 S

PWM 8 X

NA 10 X

PWM X

PWM 10 X

PWM 10 X

bits (1)

analo

analo

Nr. of

2k5 2k6

full

8

8X

8X

8X

8X

10(8)X

8X

XX

8X

XX

XX

2k6

baby

2k7

S

S

S

Figure 5-3 Display type table

• Store. All options and alignments are stored when

pressing “cursor right” and then the “OK”-button

• SW Maintenance.

– SW Events. Not useful for service purposes. In case of

specific software problems, the development

department can ask for this info.

– HW Events. Not functional at the moment this manual

is released, description will be published in an update

manual if the function becomes available.

• Operation hours PDP. Displays the accumulated total of

PDP operation hours.

How to Navigate

• In SAM, you can select the menu items with the “CURSOR

UP/DOWN” key on the RC-transmitter. The selected item

will be highlighted. When not all menu items fit on the

screen, move the “CURSOR UP/DOWN” key to display the

next/previous menu items.

E_06532_030.eps

220606

• With the “CURSOR LEFT/RIGHT” keys, it is possible to:

– (De) activate the selected menu item.

– (De) activate the selected submenu.

How to Exit SAM

Use one of the following methods:

• Press the “MENU” button on the RC-transmitter.

• Switch the set to STAND-BY via the RC-transmitter.

Note: As long as SAM is activated, it is not possible to change

a channel. This could hamper the White Point alignments

because you cannot choose your channel/frequency any more.

Workaround: after you have sent the RC code “062596 INFO”

you will see the service-warning screen, and in this stage it is

still possible to change the channel (so before pressing the

“OK” button).

Page 18

EN 18 CT2.0U RA5.

Service Modes, Error Codes, and Fault Finding

5.2.3 Customer Service Mode (CSM)

Purpose

When a customer is having problems with his TV-set, he can

call his dealer or the Customer Helpdesk. The service

technician can then ask the customer to activate the CSM, in

order to identify the status of the set. Now, the service

technician can judge the severity of the complaint. In many

cases, he can advise the customer how to solve the problem,

or he can decide if it is necessary to visit the customer.

The CSM is a read only mode; therefore, modifications in this

mode are not possible.

How to Activate CSM

Key in the code “123654” via the standard RC transmitter.

Note: Activation of the CSM is only possible if there is no (user)

menu on the screen!

How to Navigate

By means of the “CURSOR-DOWN/UP” knob on the RCtransmitter, you can navigate through the menus.

Contents of CSM

• SW Version (example: ED10U-1.2.3.4_12345). Displays

the built-in main software version. In case of field problems

related to software, software can be upgraded. As this

software is consumer upgradeable, it will also be published

on the Internet.

• SBY Processor Version. Displays the built-in stand-by

processor software version. Upgrading this software will be

possible via a PC and a ComPair interface (see chapter

Software upgrade).

• Set Type. This information is very helpful for a helpdesk/

workshop as reference for further diagnosis. In this way, it

is not necessary for the customer to look at the rear of the

TV-set. Note that if an NVM is replaced or is initialized after

corruption, this set type has to be re-written to NVM.

ComPair will foresee a possibility to do this.

• Production Code. Displays the production code (the serial

number) of the TV. Note that if an NVM is replaced or is

initialized after corruption, this production code has to be

re-written to NVM. ComPair will foresee a possibility to do

this.

• Code 1. Gives the latest five errors of the error buffer. As

soon as the built-in diagnose software has detected an

error the buffer is adapted. The last occurred error is

displayed on the leftmost position. Each error code is

displayed as a 2-digit number. When less than 10 errors

occur, the rest of the buffer is empty (00). See also

paragraph Error Codes for a description.

• Code 2. Gives the first five errors of the error buffer. See

also paragraph Error Codes for a description.

• Headphone Volume. Gives the last status of the

headphone volume, as set by the customer. The value can

vary from 0 (volume is minimum) to 100 (volume is

maximum). Change via”MENU”, “TV”, “SOUND”,

“HEADPHONE VOLUME”.

• Dolby. Indicates whether the received transmitter

transmits Dolby sound (“ON”) or not (“OFF”). Attention: The

presence of Dolby can only be tested by the software on

the Dolby Signaling bit. If a Dolby transmission is received

without a Dolby Signaling bit, this indicator will show “OFF”

even though a Dolby transmission is received.

• Sound Mode. Indicates the by the customer selected

sound mode (or automatically chosen mode). Possible

values are “STEREO” and “VIRTUAL DOLBY

SURROUND”. Change via “MENU”, “TV”, “SOUND”,

“SOUND MODE”. It can also have been selected

automatically by signaling bits (internal software).

• Tuner Frequency. Not applicable for US sets.

• Digital Processing. Indicates the selected digital mode.

Possible values are “STANDARD” and “PIXEL PLUS”.

Change via “MENU”, “TV”, “PICTURE”, “DIGITAL

PROCESSING”.

• TV System. Gives information about the video system of

the selected transmitter.

– M: NTSC M signal received

– ATSC: ATSC signal received

• Center Mode. Not applicable.

• DNR. Gives the selected DNR setting (Dynamic Noise

Reduction), “OFF”, “MINIMUM”, “MEDIUM”, or

“MAXIMUM”. Change via “MENU”, “TV”, “PICTURE”,

“DNR”

• Noise Figure. Gives the noise ratio for the selected

transmitter. This value can vary from 0 (good signal) to 127

(average signal) and to 255 (bad signal). For some

software versions, the noise figure will only be valid when

“Active Control” is set to “medium” or “maximum” before

activating CSM.

• Source. Indicates which source is used and the video/

audio signal quality of the selected source. (Example:

Tuner, Video/NICAM) Source: “TUNER”, “AV1”, “AV2”,

“AV3”, “HDMI 1”, “SIDE”. Video signal quality: “VIDEO”, “SVIDEO”, “RGB 1FH”, “YPBPR 1FH 480P”, “YPBPR 1FH

576P”, “YPBPR 1FH 1080I”, “YPBPR 2FH 480P”, “YPBPR

2FH 576P”, “YPBPR 2FH 1080I”, “RGB 2FH 480P”, “RGB

2FH 576P” or “RGB 2FH 1080I”. Audio signal quality:

“STEREO”, “SPDIF 1”, “SPDIF 2”, or “SPDIF”.

• Audio System. Gives information about the audible audio

system. Possible values are “Stereo”, ”Mono”, “Mono

selected”, “Analog In: No Dig. Audio”, “Dolby Digital 1+1”,

“Dolby Digital 1/0”, “Dolby Digital 2/0”, “Dolby Digital 2/1”,

“Dolby Digital 2/2”, “Dolby Digital 3/0”, “Dolby Digital 3/1”,

“Dolby Digital 3/2”, “Dolby Digital Dual I”, “Dolby Digital

Dual II”, “MPEG 1+1”, “MPEG 1/0”, “MPEG 2/0”. This is the

same info as you will see when pressing the “INFO” button

in normal user mode (item “signal”). In case of ATSC

receiving there will be no info displayed.

• Tuned Bit. Indicates if the selected preset is automatically

tuned (via “Automatic Installation” in the setup menu) or via

the automatic tuning system of the TV. In this case “Tuned

bit” will show “YES”. If the TV was not able to auto-tune to

the correct frequency, this item will show “NO”. So if “NO”

is displayed, it could indicate that the customer has

manually tuned to a frequency which was too far from a

correct frequency, that the TV was not able to auto-tune

any more.

• Preset Lock. Indicates if the selected preset has a child

lock: “LOCKED” or “UNLOCKED”. Change via “MENU”,

“TV”, “CHANNELS”, “CHANNEL LOCK”.

• Lock After. Indicates at what time the channel lock is set:

“OFF” or e.g. “18:45” (lock time). Change “MENU”, “TV”,

“CHANNELS”, “LOCK AFTER”.

• TV Ratings Lock. Indicates the “TV ratings lock” as set by

the customer. Change via “MENU”, “TV”, “CHANNELS”,

“TV RATINGS LOCK”. Possible values are: “ALL”,

“NONE”, “TV-Y”, “TV-Y7”, “TV-G”, “TV-PG”, “TV-14” and

“TV-MA”.

• Movie Ratings Lock. Indicates the “Movie ratings lock” as

set by the customer. Change via “MENU”, “TV”,

“CHANNELS”, “MOVIE RATINGS LOCK”. Possible values

are: “ALL”, “NR”, “G”, “PG”, “PG-13”, “R”, “NC-17” and “X”.

• V-Chip Tv Status. Indicates the setting of the V-chip as

applied by the selected TV channel. Same values can be

shown as for “TV RATINGS LOCK”.

• V-Chip Movie Status. Indicates the setting of the V-chip

as applied by the selected TV channel. Same values can

be shown as for “MOVIE RATINGS LOCK”.

• Options 1. Gives the option codes of option group 1 as set

in SAM (Service Alignment Mode).

• Options 2. Gives the option codes of option group 2 as set

in SAM (Service Alignment Mode).

• AVL. Indicates the last status of AVL (Automatic Volume

Level): “ON” or “OFF”. Change via “MENU”, “TV”,

“SOUND”, “AVL”. AVL can not be set in case of digital

audio reception (e.g. Dolby Digital or AC3)

Page 19

Service Modes, Error Codes, and Fault Finding

g

p

p

)

g

p

g

g

EN 19CT2.0U RA 5.

• Delta Volume. Indicates the last status of the delta volume

for the selected preset as set by the customer: from “-12”

to “+12”. Change via “MENU”, “TV”, “SOUND”, “DELTA

VOLUME”.

• HDMI key validity. Indicates the key’s validity.

• IEEE key validity. Indicates the key’s validity (n.a.).

• POD key validity. Indicates the key’s validity (n.a.).

• Digital Signal Quality. Indicates quality of the received

digital signal (0= low).

How to Exit CSM

Press any key on the RC-transmitter (with exception of the

“CHANNEL +/-”, “VOLUME”, “MUTE” and digit (0-9) keys).

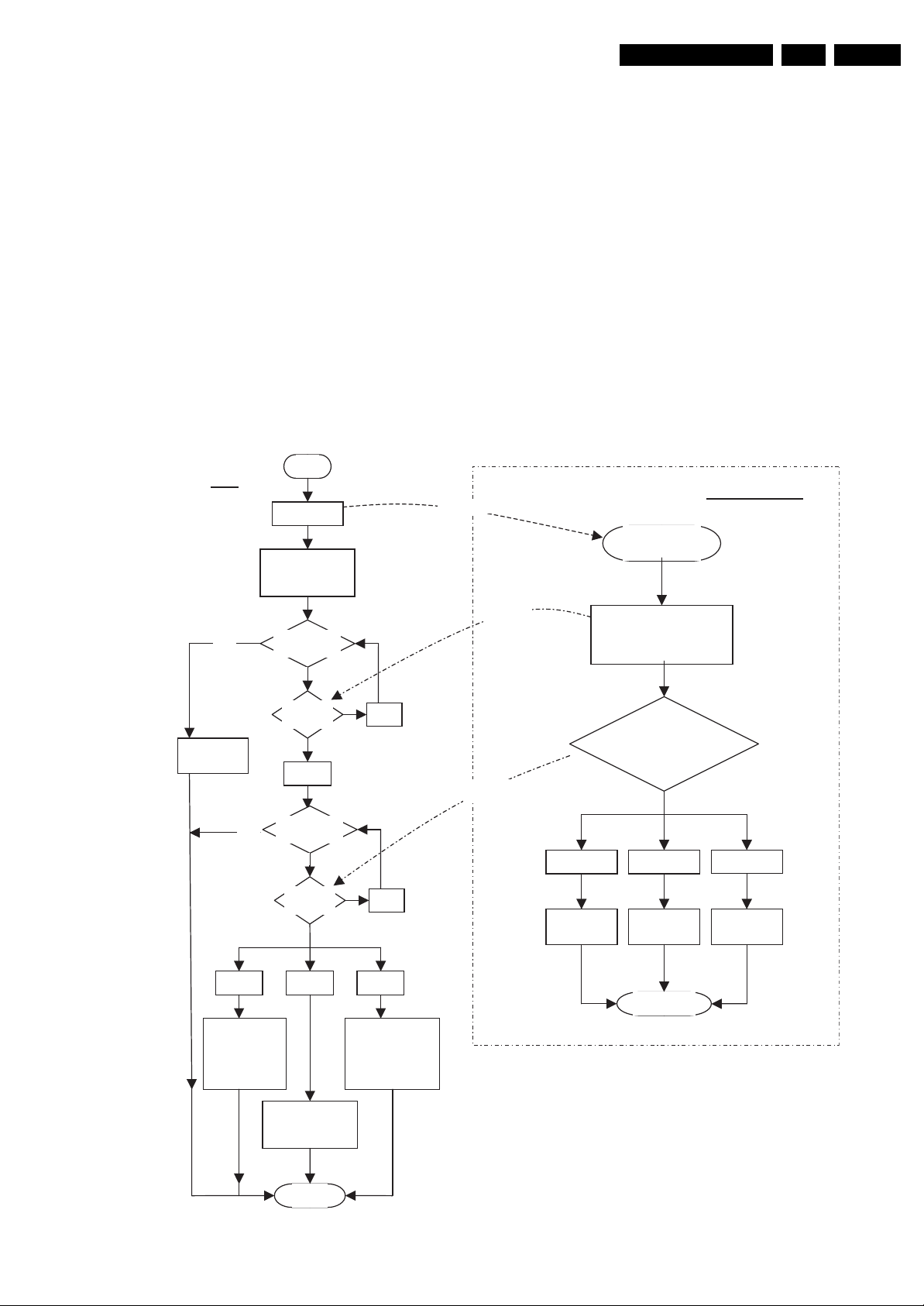

5.3 Stepwise Start-up

The stepwise start-up method, as known from FTL/FTP sets is

not valid any more. The situation for this chassis is as follows:

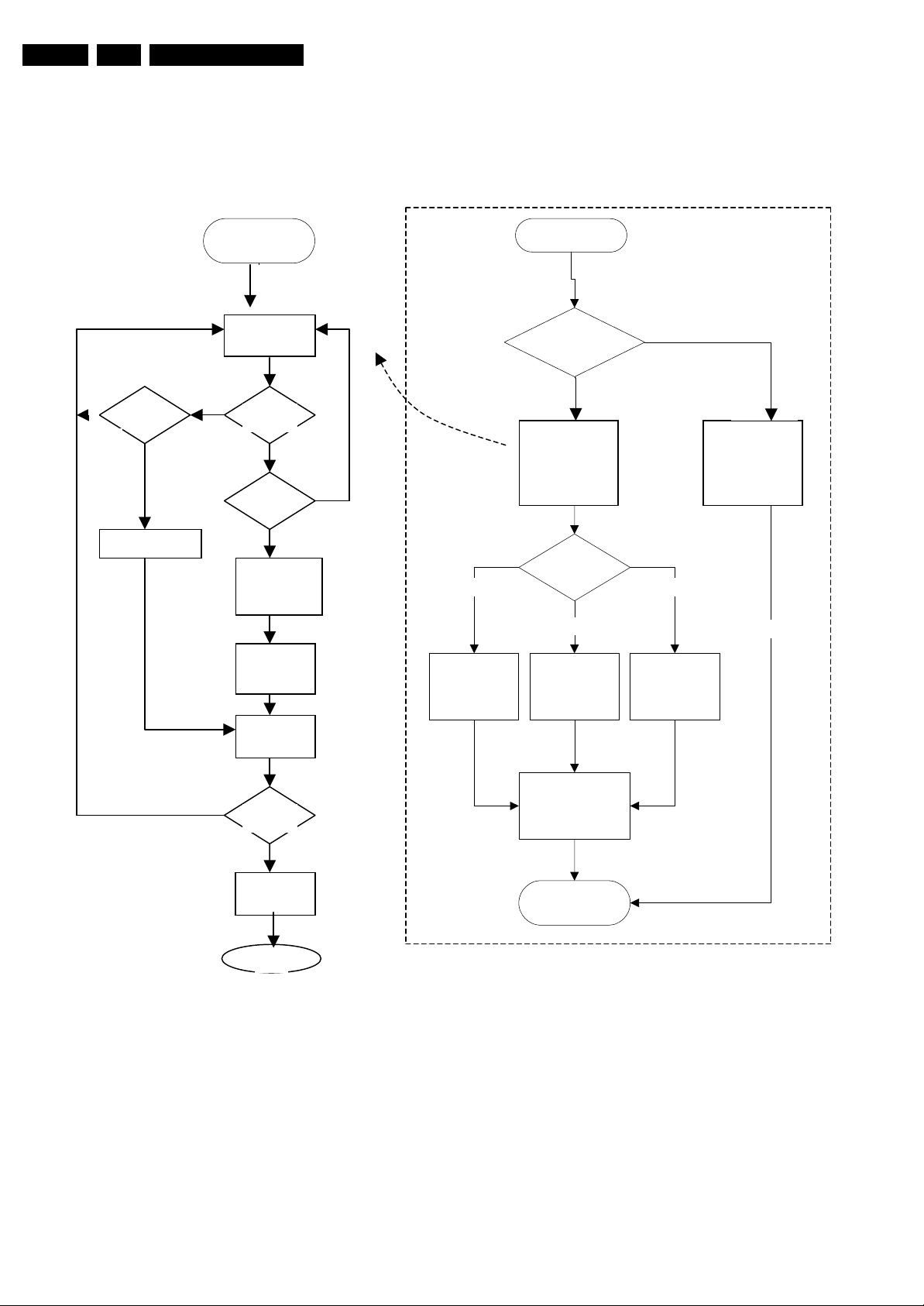

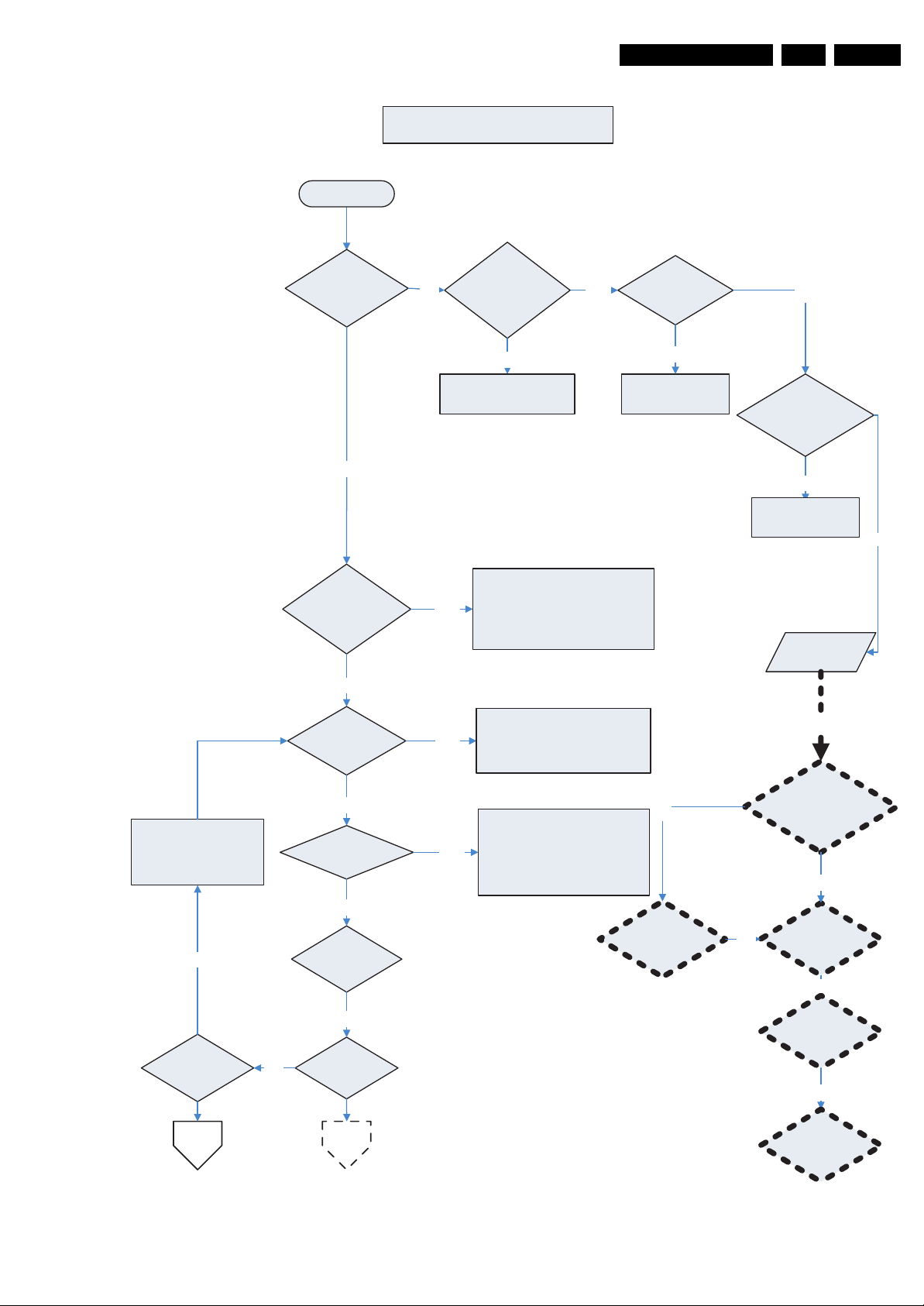

Power Management

Power On Command Sequence

start

SSB

12V turn on

yes

EBJ initialize

13 sec to com

Video blank and

Power time

audio mu

35 sec?

no

(max.

plete).

te

out

12V to MCU

Send

message

when the TV is in a protection state detected via the Stand-by

Processor (and thus blinking an error) and SDM is activated via

shortcutting the pins on the SSB, the TV starts up until it

reaches the situation just before protection. So, this is a kind of

automatic stepwise start-up. In combination with the start-up

diagrams below, you can see which supplies are present at a

certain moment.

Important to know here is, that if e.g. the 3V3 detection fails

(and thus error 11 is blinking) and the TV is restarted via SDM,

the Stand-by Processor will enable the 3V3, but will not go to

protection now. The TV will stay in this situation until it is reset

(Mains/AC Power supply interrupted).

The abbreviations “SP” and “MP” in the figures stand for:

• SP: protection or error detected by the Stand-by

Processor.

• MP: protection or error detected by the VIPER Main

Processor.

MTV 512 MCU

MCU initialize

(minimum 15sec

to com

lete

MCU send “initialize complete”

to SSB.

Note: This message shall be sent

at 1 sec interval till SSB Ack

for a

eriod of 10 sec

Fatal Comm

Error -

ShutDown

comm to mcu and

Stop chking “I am

.

yes

CCA

Mode

SSB suspend

maintain 12V.

alive” msg

Check

message

MCU init

com

lete

Check m

ode

timeout 2 sec?

no

Check

mode

Normal

Mode

Send cca table and

video mute off to

MCU

End

No

messa

No

messa

ISP mode

SSB suspend

comm to mcu and

maintain 12V. Stop

chking “I am alive”

msg

MCU check mode send “Mode”

message to SSB.

Note: This message shall be sent at

0.2 sec interval till SSB Ack for

Send

messa

e

CCA Mode Normal mode

Set UART

MUX procedure

aperiodof1sec

MCU send “I

am alive”

messa

e

End

ISP mode

Set UART

MUX procedure

SSB and MTV512 MCU will execute the initialization

procedure upon receiving 12V. A buffer of 10 sec is

catered where “initialize complete” message is sent every

second for 10 times to ensure that SSB will receive this

message even in the situa tion of MTV512 MCU complete

initialization earlier than SSB.

G_15870_048.eps

120706

Figure 5-4 Power management - Power on

Page 20

EN 20 CT2.0U RA5.

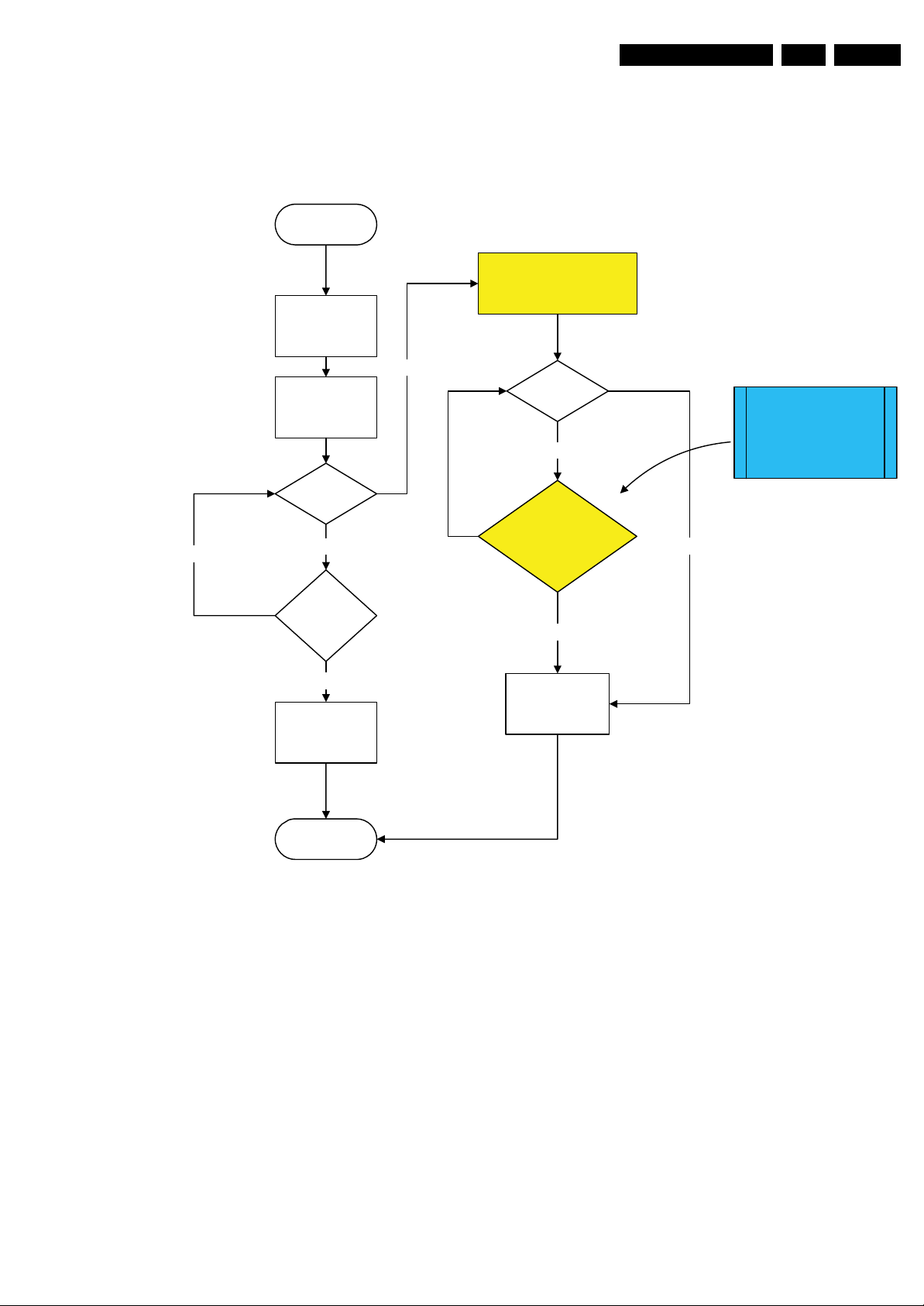

p

Service Modes, Error Codes, and Fault Finding

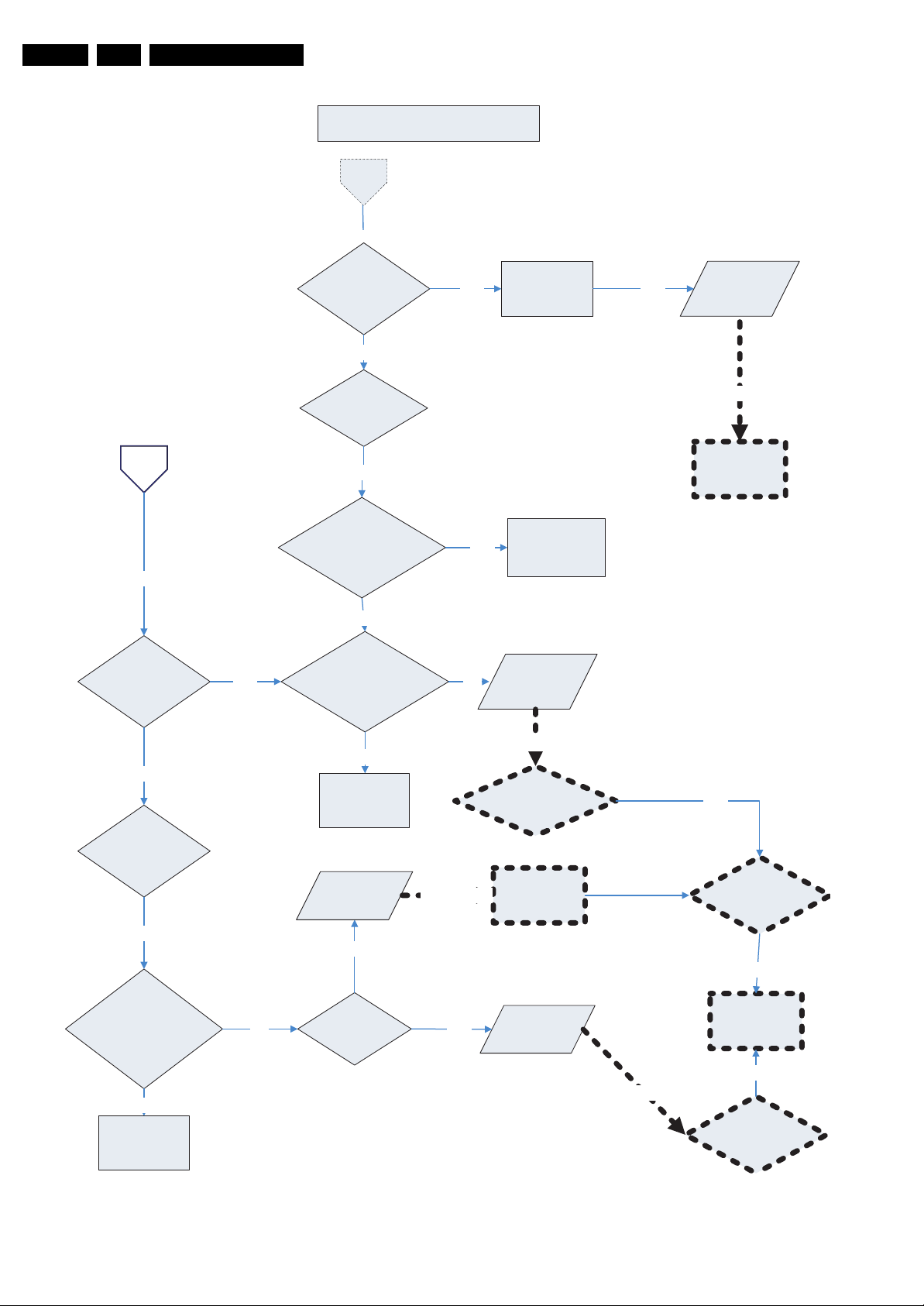

Abnormal State Detection

The MTV512 MCU shall turn-off OE system when any abnormal state occurs. Triggering of the state is

shown

Time out?

no

Set time out error

no

yes

Host(running time)

Check “I am alive”

message

Check “I am

alive” msg

“I am alive”

no

Error” msg to MCU,

MCU, TV5ceed

Host check whicnormal

Error exceptocess ion pr

state be triggered and execute

message

message

receive?

critical?

Received abnormal

message from MCU

TV510 send “Get

and upog

“Erro

to error exception

appropriate procedure

yes

yes

Error

present ?

yes

n receivin

SSB send

r” data from

“

get error” msg

10 pro

to

MCU

MCU return

error to

h one ab

SSB

SSB store

error in error

buffer

no

Lamp fail

Turn on lamp

LED

MCU (running time)

Abnormal detection

yes

Found abnormal state

Send “I am

alive” msg to

Send abnormal

SSB,

message to host

indicating

critical error

Check state

Thermal too high

Turn on thermal

LED

MTV 512 MCU

no

Send “I am

alive” msg to

SSB ,

indicating no

error

Fan rotation to low

normal

Turn on thermal

& lamp LED

simultaneously

no

n

Error

critical ?

yes

Error

end

exception

rocess

end

Shut down OE

system

end

G_15870_049.eps

110706

Figure 5-5 Power management - Error detected

Page 21

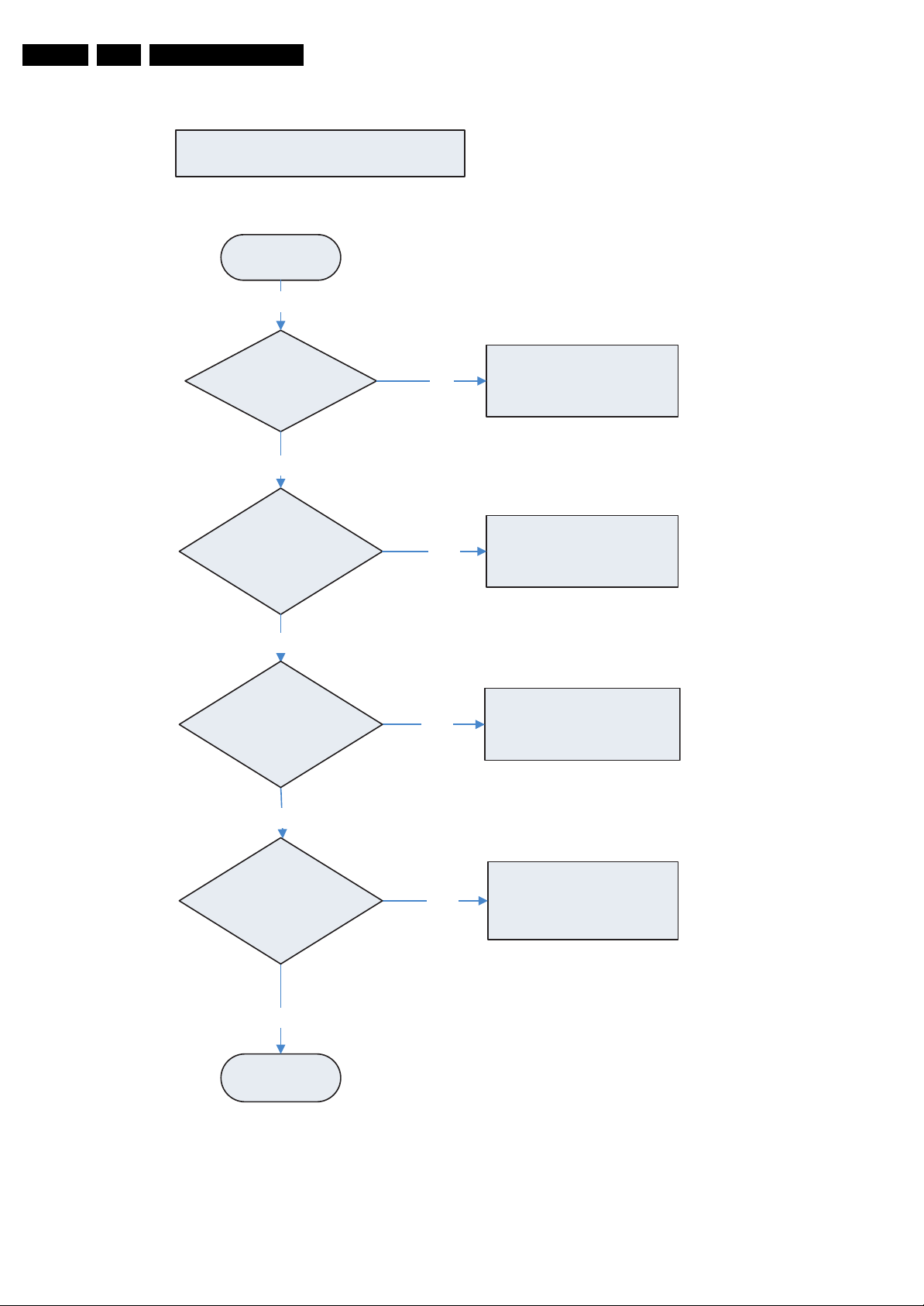

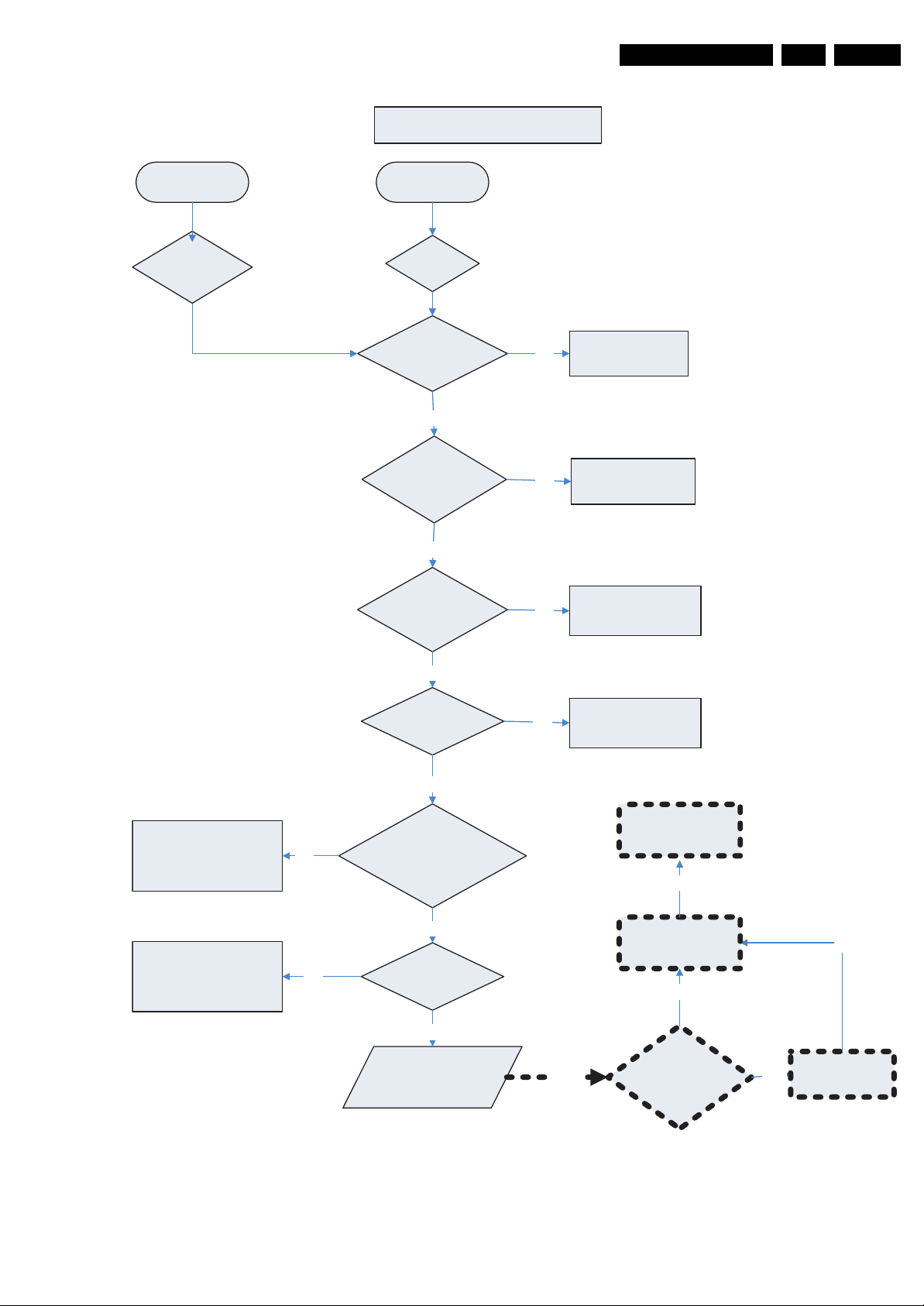

Service Modes, Error Codes, and Fault Finding

Power Off Command Sequence

The power-off sequence is as follows:

Start

Host get power-off

command

SSB mute

TV510 mute video

video and audio

on

10 SEC count

down done?

Other keys or no key press

no

YES

Host sends Power down mode

enter”“ to MCU

60 sec count

down done?

no

Chk ‘Power down mode

exit’ or “I am alive

command”command ?

EN 21CT2.0U RA 5.

MCU send message

“I am alive” or “power-

down mode exit”msg to host

After 60 sec

Key press?

Have warm-up key

SSB unmute and

run wake-up

procedure

end

Figure 5-6 Power management - Power off

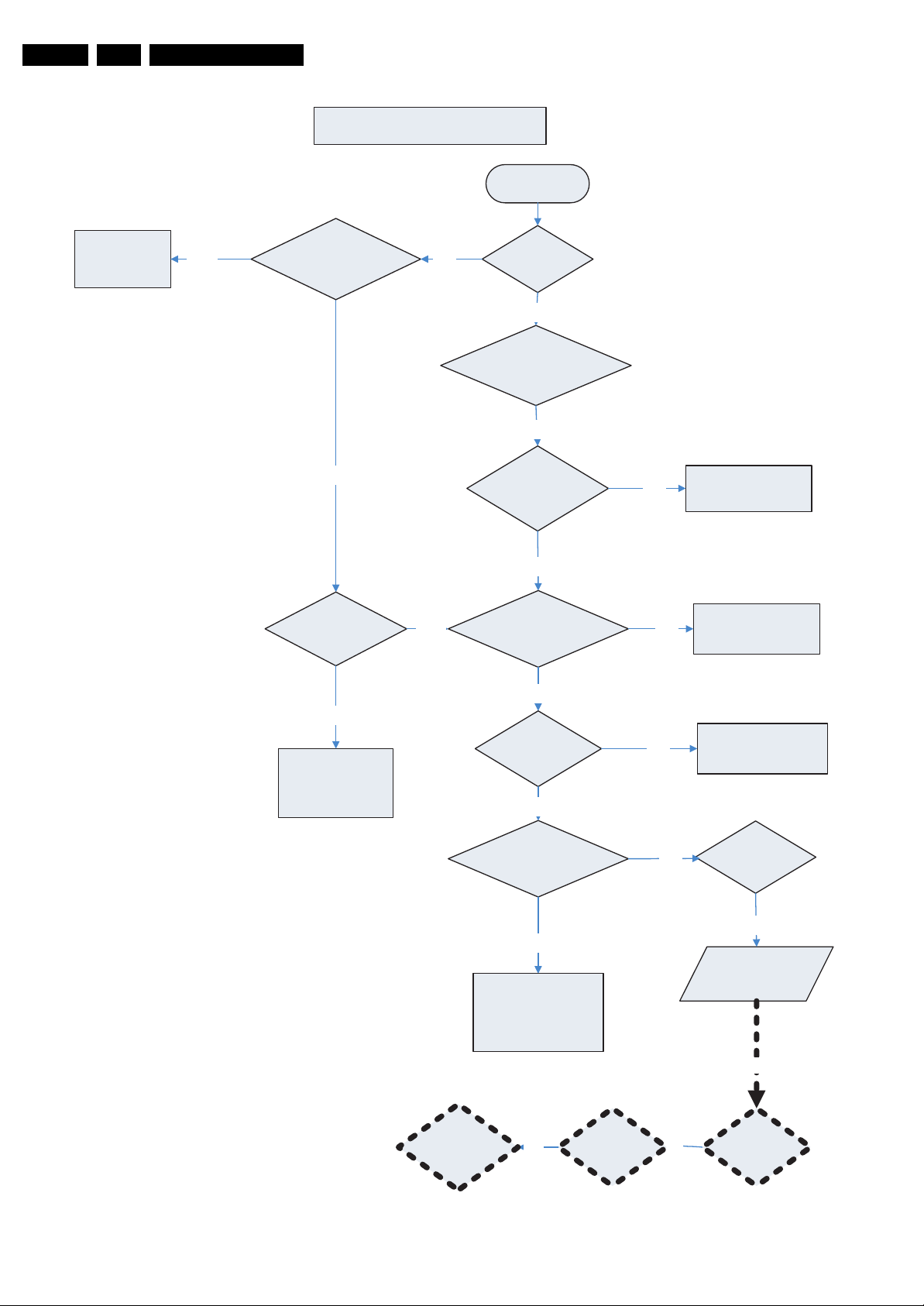

5.4 Service Tools

5.4.1 ComPair

Introduction

ComPair (Computer Aided Repair) is a service tool for Philips

Consumer Electronics products. ComPair is a further

development on the European DST (service remote control),

which allows faster and more accurate diagnostics. ComPair

has three big advantages:

1. ComPair helps you to quickly get an understanding on how

to repair the chassis in a short time by guiding you

systematically through the repair procedures.

2. ComPair allows very detailed diagnostics (on I

is therefore capable of accurately indicating problem areas.

You do not have to know anything about I

yourself because ComPair takes care of this.

3. ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the

microprocessor is working) and all repair information is

directly available. When ComPair is installed together with

2

C level) and

2

C commands

Received command

Host Power-off 12v

the Force/SearchMan electronic manual of the defective

chassis, schematics and PWBs are only a mouse click

away.

Specifications

ComPair consists of a Windows based fault finding program

and an interface box between PC and the (defective) product.

The ComPair interface box is connected to the PC via a serial

(or RS-232) cable.

For this chassis, the ComPair interface box and the TV

communicate via a bi-directional service cable via the service

connector(s).

The ComPair fault finding program is able to determine the

problem of the defective television. ComPair can gather

diagnostic information in two ways:

• Automatically (by communicating with the television):

ComPair can automatically read out the contents of the

entire error buffer. Diagnosis is done on I

ComPair can access the I

ComPair can send and receive I

2

C/UART bus of the television.

2

C/UART commands to

G_15870_050.eps

110706

2

C/UART level.

Page 22

EN 22 CT2.0U RA5.

Service Modes, Error Codes, and Fault Finding

the microcontroller of the television. In this way, it is

possible for ComPair to communicate (read and write) to

devices on the I

2

C/UART buses of the TV-set.

• Manually (by asking questions to you): Automatic

diagnosis is only possible if the microcontroller of the

television is working correctly and only to a certain extent.

When this is not the case, ComPair will guide you through

the fault finding tree by asking you questions (e.g. Does the

screen give a picture? Click on the correct answer: YES /

NO) and showing you examples (e.g. Measure test-point I7

and click on the correct oscillogram you see on the

oscilloscope). You can answer by clicking on a link (e.g.

text or a waveform picture) that will bring you to the next

step in the fault finding process.

By a combination of automatic diagnostics and an interactive

question / answer procedure, ComPair will enable you to find

most problems in a fast and effective way.

How to Connect

This is described in the chassis fault finding database in

ComPair.

Caution: It is compulsory to connect the TV to the PC as

shown in the picture below (with the ComPair interface in

between), as the ComPair interface acts as a level shifter. If

one connects the TV directly to the PC (via UART), ICs will be

blown!

TO

UART SERVICE

CONNECTOR

TO

I2C SERVICE

CONNECTOR

When multiple errors occur (errors occurred within a short time

span), there is a high probability that there is some relation

between them.

Basically there are three kinds of errors:

• Errors detected by the Stand-by Processor. These

errors will always lead to protection and an automatic start

of the blinking LED for the concerned error (see paragraph

“The Blinking LED Procedure”). In these cases SDM can

be used to start up (see chapter “Stepwise Start-up”).

• Errors detected by VIPER that lead to protection. In this

case the TV will go to protection and the front LED will blink

at 3 Hz. Further diagnosis via service modes is not possible

here (see also paragraph “Error Codes” -> “Error Buffer” > “Extra Info”).

• Errors detected by VIPER that do not lead to

protection. In this case the error can be read out via

ComPair, via blinking LED method, or in case you have

picture, via SAM.

5.5.2 How to Read the Error Buffer

Use one of the following methods:

• On screen via the SAM (only if you have a picture). E.g.:

– 00 00 00 00 00: No errors detected

– 06 00 00 00 00: Error code 6 is the last and only

detected error

– 09 06 00 00 00: Error code 6 was first detected and

error code 9 is the last detected error

• Via the blinking LED procedure (when you have no

picture). See next paragraph.

•Via ComPair.

PC VCR I2CPowe r

Figure 5-7 ComPair interface connection

How to Order

ComPair order codes:

• ComPair Software: ST4191.

• ComPair Interface Box: 4822 727 21631.

• AC Adapter: T405-ND.

• ComPair Quick Start Guide: ST4190.

• ComPair interface extension cable: 3139 131 03791.

• ComPair UART interface cable: 3122 785 90630.

Note: If you encounter any problems, contact your local

support desk.

5.5 Error Codes

5.5.1 Introduction

The error code buffer contains all detected errors since the last

time the buffer was erased. The buffer is written from left to

right, new errors are logged at the left side, and all other errors

shift one position to the right.

When an error has occurred, the error is added to the list of

errors, provided the list is not full or the error is a protection

error.

When an error occurs and the error buffer is full, then the new

error is not added, and the error buffer stays intact (history is

maintained), except when the error is a protection error.

To prevent that an occasional error stays in the list forever, the

error is removed from the list after 50+ operation hours.

9V DC

E_06532_021.eps

180804

5.5.3 How to Clear the Error Buffer

Use one of the following methods:

• By activation of the “RESET ERROR BUFFER” command

in the SAM menu.

• With a normal RC, key in sequence “MUTE” followed by

“062599” and “OK”.

• If the content of the error buffer has not changed for 50+

hours, it resets automatically.

5.5.4 Error Buffer

In case of non-intermittent faults, clear the error buffer before

you begin the repair (before clearing the buffer, write down the

content, as this history can give you significant information).

This to ensure that old error codes are no longer present.

If possible, check the entire contents of the error buffer. In

some situations, an error code is only the result of another error

code and not the actual cause (e.g., a fault in the protection

detection circuitry can also lead to a protection).

There are several mechanisms of error detection:

• Via error bits in the status registers of ICs.

• Via polling on I/O pins going to the stand-by processor.

• Via sensing of analogue values on the stand-by processor.

• Via a “not acknowledge” of an I

2

C communication

Take notice that some errors need more than 90 seconds

before they start blinking. So in case of problems wait 2

minutes from start-up onwards, and then check if the front LED

is blinking.

Page 23

Service Modes, Error Codes, and Fault Finding

Table 5-2 Error code overview

Error Description Error/Prot Detected by Device Defective module Result

3I2C3 P Stby µP n.a. I2C3_blocked Protection + Error blinking

5 VIPER does not boot (hardware failure) P Stby µP PNX8550 Protection + Error blinking

6 5V supply P Stby µP n.a. Control Protection + Error blinking

8 1.2V DC/DC P Stby µP n.a. Protection + Error blinking

11 3.3V DC/DC P Stby µP n.a. Protection + Error blinking

12 12V supply P Stby µP n.a. Protection + Error blinking

14 Class D amplifiers P Stby µP Class D Supply Protection + Error blinking

17 MPIF1 Audio Supply (ASUP) E VIPER KN10241C IF I/O Error logged

18 MPIF1 ref freq (ROK) E VIPER KN10241C IF I/O Error 32, 31, 18, 17, and 16 logged

25 Supply fault P Stby µP DC/DC Supply Protection + Error blinking

27 Phoenix E VIPER PNX2015B HD subsystem No error logged

29 AVIP1 E VIPER PNX3000 AV input processor 1 Errors 29, 32, 31, 18, 17, and 16 logged

32 MPIF1 E VIPER KN10241C Analog Front End 1 Errors 32, 18, 17, and 16 logged

34 Tuner1 E VIPER Tuner 1 No picture, error logged

37 Channel decoder E VIPER NXT2003 Channel decoder 1 Errors 34 and 37 logged

43 Hi Rate Front End E VIPER TDA8751 HDMI Error logged

44 Main NVM P VIPER M24C32 NVM Error logged + Error blinking 3 times

53 VIPER - HW peripheral problem P Stby µP PNX8550 Control Protection + Error blinking

65 GdeInitCommunicationFailure P PTV GDE / HCS Protection + Error blinking

67 System Integrity Failure E PTV GDE HCS Error logged

71 Overheating E CDE / HCS MTV512 CDE Lamp off, right red LED on, Errors 67 and 71 logged

72 Fan speed too low E CDE / HCS MTV512 CDE Lamp off, left + right red LED on, Errors 67 and 72 logged

73 Lamp broken E CDE / HCS MTV512 CDE Lamp off, left red LED on, Errors 67 and 73 logged

74 MCU initialisation failure E CDE / HCS MTV512 CDE

EN 23CT2.0U RA 5.

Extra Info

• Error 1 (I

2

C bus 1 blocked). When this error occurs, the TV

will go to protection and the front LED will blink at 3 Hz.

Now you can partially restart the TV via the SDM shortcut

pins on the SSB. Depending on the software version it is

possible that no further diagnose (error code read-out) is

possible. With the knowledge that only errors 1, 2, 4, and

63 result in a 3 Hz blinking LED, the range of possible

defects is limited.

• Error 2 (I

2

C bus 2 blocked). When this error occurs, the

TV will go to protection and the front LED will blink at 3 Hz.

Now you can partially restart the TV via the SDM shortcut

pins on the SSB. Due to hardware restriction (I

the fast I

2

C bus) it will be impossible to start up the VIPER

2

C bus 2 is

and therefore it is also impossible to read out the error

codes via ComPair or via the blinking LED method. With

the knowledge that only errors 1, 2, 4, and 63 result in a 3

Hz blinking LED, the range of possible defects is limited.

When you have restarted the TV via the SDM shortcut pins,

and then pressed "CH+" on your remote control, the TV will

go to protection again, and the front LED blink at 3 Hz

again. This could be an indication that the problem is

related to error 2.

• Error 3 (I

on I

2

C bus 3 blocked). There are only three devices

2

C bus 3: VIPER, Stand-by Processor, and NVM. The

Stand-by Processor is the detection device of this error, so

this error will only occur if the VIPER or the NVM is blocking

the bus. This error will also be logged when the NVM gives

no acknowledge on the I

2

C bus (see error 44). Note that if

the 12 V supply is missing (connector 1M46 on the SSB),

the DC/DC supply on the SSB will not work. Therefore the

VIPER will not get supplies and could block I

a missing 12 V can also lead to an error 3.

• Error 4 (I

• Error 5 (I

severe hardware problem around the VIPER (supplies not

OK, VIPER completely dead, I

2

C bus 4 blocked). Same remark as with error 1.

2

C bus 5 blocked). This error will point to a

2

C link between VIPER and

2

C bus 3. So,

Stand-by Processor broken, etc...).

• Error 7 (8.6 V error). Except a physical problem with the

8.6 V itself, it is also possible that there is something wrong

with the Audio DC Protection: see paragraph "Hardware

Protections" for this.

• Error 12 (12 V error). Except a physical problem with the

12 V itself, it is also possible that there is something wrong

with the Audio DC Protection: see paragraph "Hardware

Protections" for this.

• Error 14 (Audio supply). This error is triggered in case of

too low voltage of the audio supplies and therefore a drop

of the audio supply voltage of below approx. 9 V per supply

rail (or lower than 18 V rail to rail). Also a DC voltage of

higher than 1 V DC on the speakers will lead to protection

and error 14 blinking. For LCD sets this circuit can be found

on schematic SA3, for PDP sets this can be found on

schematic C. It should be noted that for 26-inch models

there is only a supply link between the amplifiers and the

stand-by µC whereas in all other models this link is

implemented by Audio-Prot line pin 7 on 1 M02.

• Error 29 (AVIP1). This error will probably generate extra

errors. You will probably also see errors 32 (MPIF) and

error 31 (AVIP 2). Error 29 and 31 will always be logged

together due to the fact that both AVIPs are inside the

PNX2015 and are on the same I

2

C bus. In this case start

looking for the cause around AVIP (part of PNX2015).

• Error 31 (AVIP2). See info on error 29.

• Error 34 (Tuner 1). When this error is logged, it is not sure

that there is something wrong with the tuner itself. It is also

possible that there is something wrong with the

communication between channel decoder and tuner. See

schematic B2B.

• Error 37 (Channel decoder). This error will always log

error 34 (tuner) extra. This is due to the fact that the tuner

2

I

C bus is coming from the channel decoder.

• Error 44 (NVM). This error will never occur because it is

masked by error 3 (I

for error 3 checks on an I

2

C bus 3). The detection mechanism

2

C acknowledge of the NVM. If

NVM gives no acknowledge, the stand-by software

assumes that the bus is blocked, the TV goes to protection

and error 3 will be blinking.

• Error 53. This error will indicate that the VIPER has started

to function (by reading his boot script, if this would have

failed, error 5 would blink) but initialization was never

completed because of hardware peripheral problems

(NAND flash, ...) or software initialization problems.

Possible cause could be that there is no valid software

loaded (try to upgrade to the latest main software version).

5.6 The Blinking LED Procedure

5.6.1 Introduction

The blinking LED procedure can be split up into two situations:

Page 24

EN 24 CT2.0U RA5.

Service Modes, Error Codes, and Fault Finding