Page 1

Compact Disc Recorder 2nd Line Service Manual

CDR Mozart Module

CL 16532046_000.eps

030501

Contents Page Contents Page

1 Introduction and Technical Specifications 2

2 Safety- and Maintenance Instructions, Warnings

and Notes 4

3 Instructions for Use 7

4

Mechanical Instructions 7

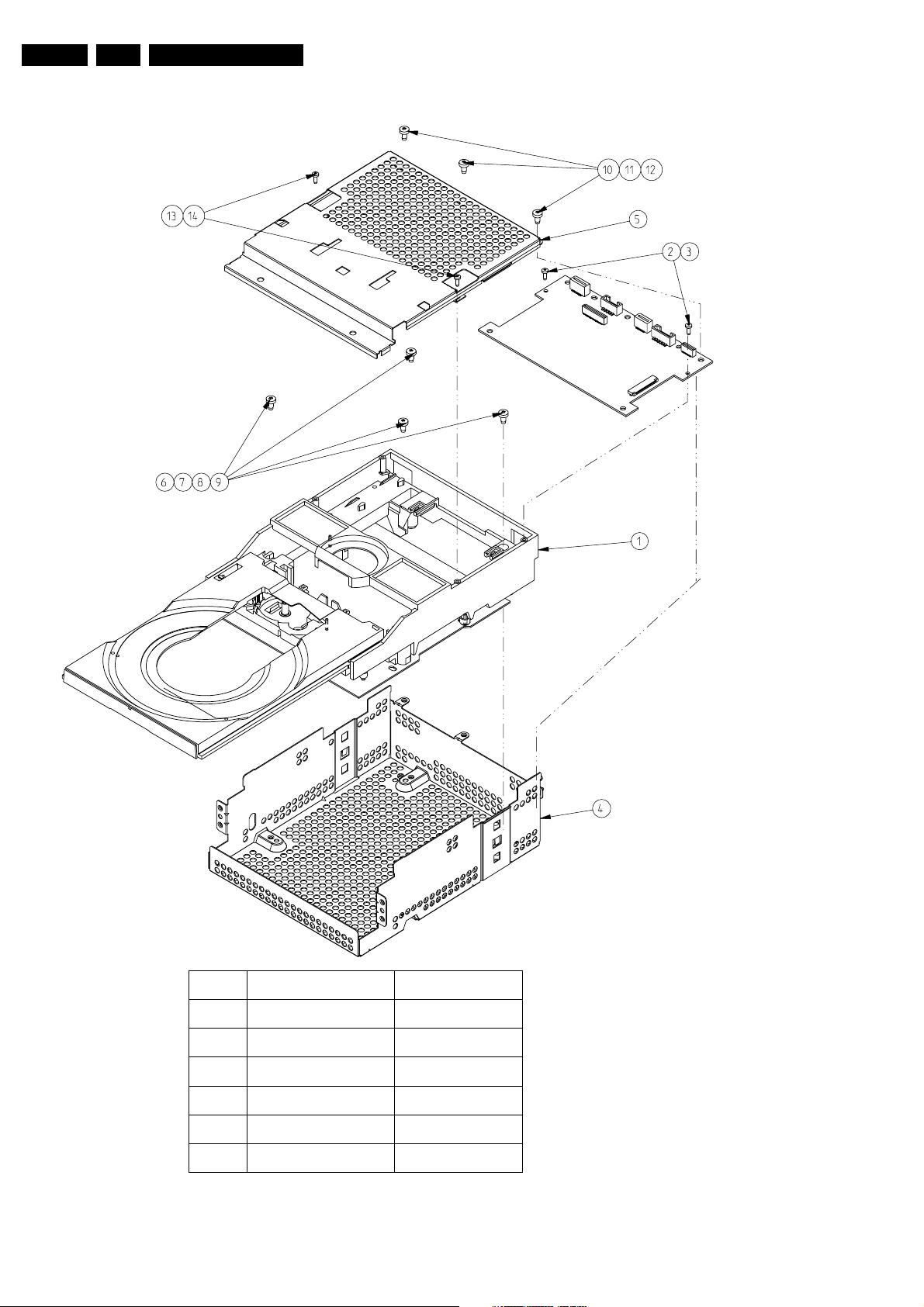

Exploded View CDR-Module 8

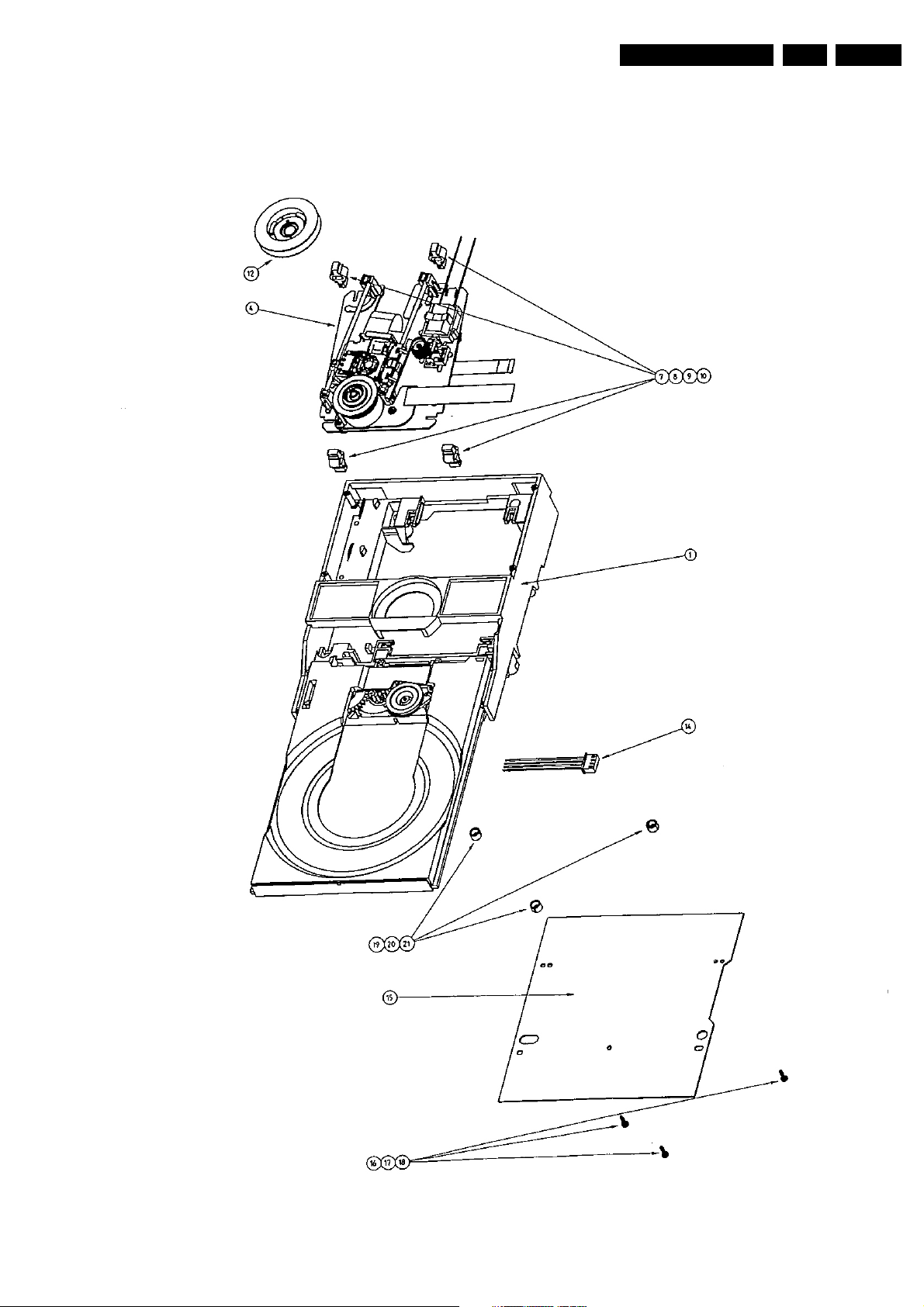

Exploded View VAE5020 9

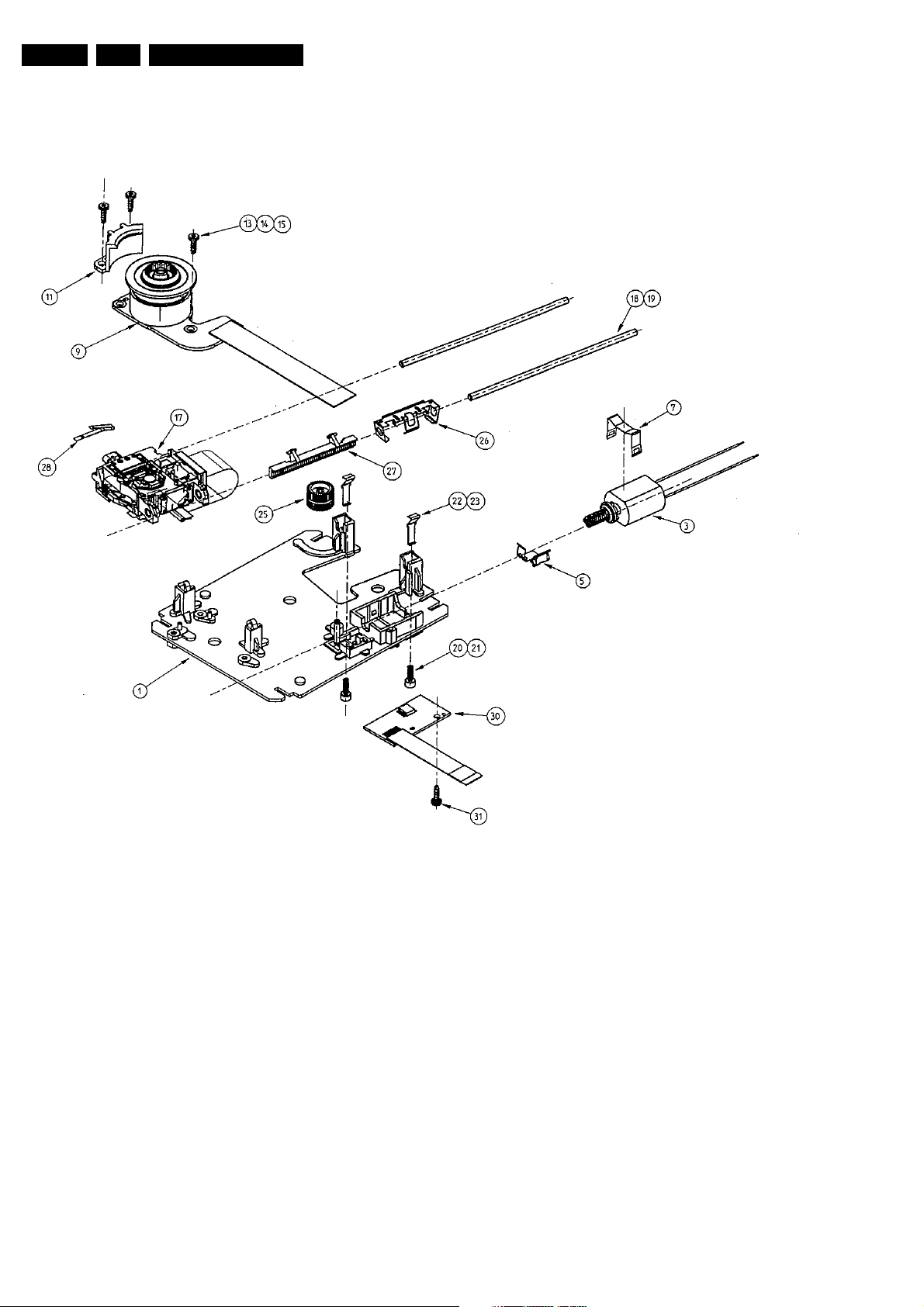

Exploded View VAM5020 10

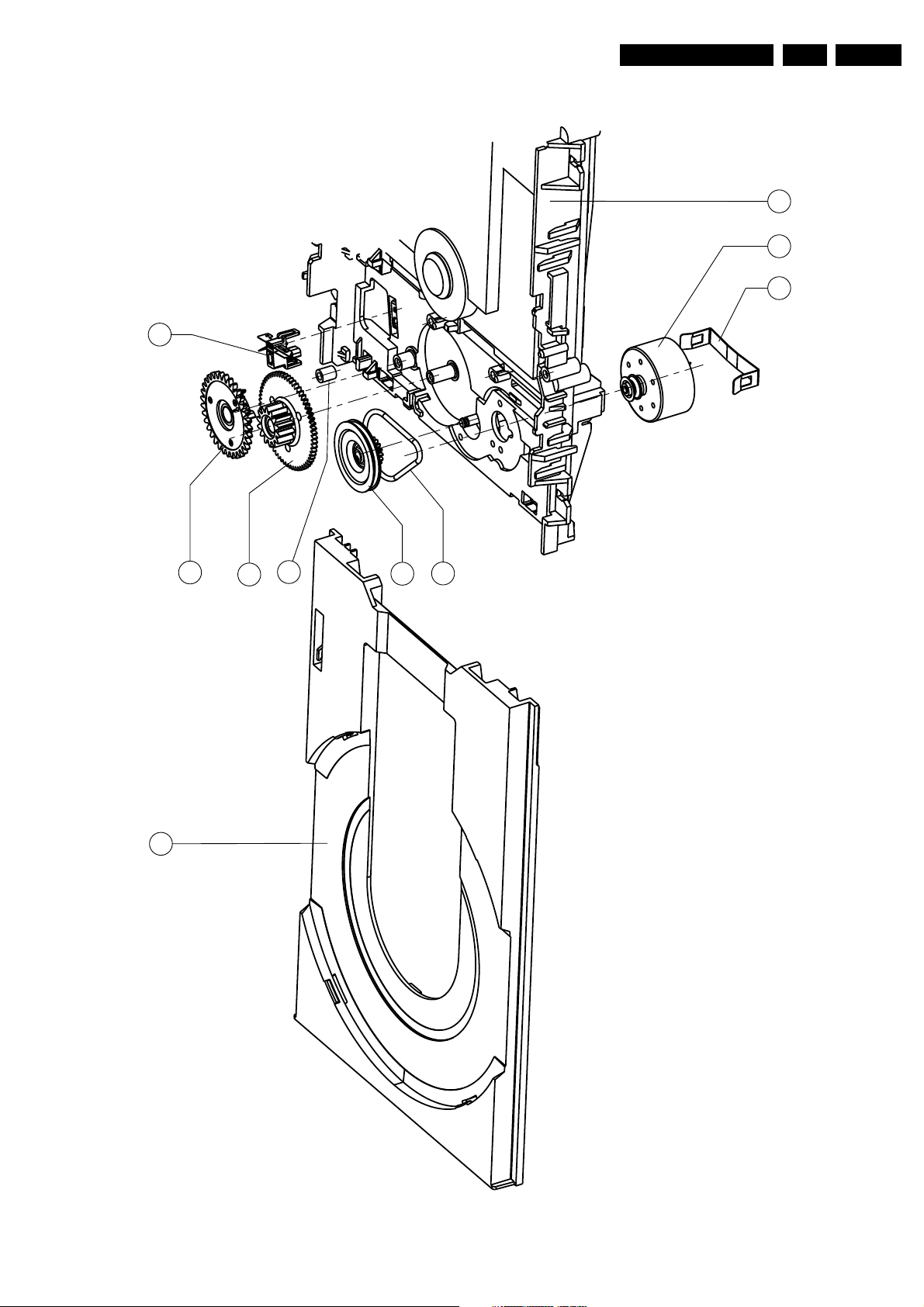

Exploded View Freya Loader 11

5 Trouble Shooting 12

6

Block Diagrams

Block Diagram Freya Module 25

Block Diagram Mozart Back-End Module 26

Electrical Diagrams and PWB’s Diagram PWB

7

Mozart Main Board(Diagram 1) 27 32-37

Mozart Main Board(Diagram 2) 28 32-37

Mozart Main Board(Diagram 3) 29 32-37

Mozart Main Board(Diagram 4) 30 32-37

Mozart Main Board(Diagram 5) 31 32-37

Mozart Main Board Testpoints 38-40

Freya Servo Board(Overview) 41 46-47

Freya Servo Board(Part 1) 42 46-47

Freya Servo Board(Part 2) 43 46-47

Freya Servo Board(Part 3) 44 46-47

Freya Servo Board(Part 4) 45 46-47

Freya Servo Board Testpoints(Bottom View) 48

©

Copyright 2001 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic, mechanical,

photocopying, or otherwise without the prior permission of Philips.

8 Alignments, Adjustments 49

9 Circuit and Functional Description 50

List of Abbreviations 56

10 Mechanical and Electrical Spare Parts List 58

Published by DP 0170 Service DPS Hasselt Printed in the Netherlands Subject to modification

3122 785 60030

Page 2

GB 2 CDR Mozart1.

Introduction / Technical Specifications

1. Introduction / Technical Specifications

1.1 General

CD Recording Mozart Module is a module for playback of

Audio/Data CD’s (incl. CD R/W) and recording on Audio CDR and CD-R/W Disc consisting of:

• CD (Recording) Drive Mechanism

• Tray Loading Mechanism

• Front-end Board inclusive CD -Servo control Software

• Backend Board containing Application software

• Metal Encasing (for EMC Screening and mechanical

fixation)

Not included is the User Interface that has to be handled by

the Set front application. This user interface controls

functions that are set independently like: display and key

handling.

Note: The EMC screening is not mounted in some

applications.

The CD (Recording) Drive Mechanism, Tray Loading

Mechanism and Front-end Board part of the module can

have 2 different executions. One is called FREYA the other

RACOON. As information and repair activity about

RACOON is not defined yet, this part is not included in this

Service Manual.

Notice that both Mechanisms can not be interchanged, so

RACOON has to be replaced by RACOON, FREYA by

FREYA. As both parts can only be repaired with the help of

CDR-ComPair, the ComPair tool will contain the instructions

for both mechanisms.

1.3.2 Connector 1007: Control Interface

1. Ground (D) / (Shield)

C-Data

2. I

3. Ground (D)

C Clock

4. I

5. Reset

6. IRQREQ

1.3.3 Connector 1402: Audio Signal Interface

1. Analog In (Rec.) Left

2. Ground (A)

3. Analog In (Rec.) Right

4. Ground (A)

5. Analog Out (PB)Right

6. Ground (A)

7. Analog Out (PB) Left

1.3.4 Connector 1203: Digital In / out

1. +5 V

2. EBU Signal (output)

3. EBU Signal (input - optical) /Ground(D)

4. EBU Signal (input Coax)

5. Ground (D)

1.3.5 Connector 1205: CD Interface for MP3 Playback

1.2 Key Features / Functions

Playback Capability

• standard Audio/Data CD’s

– MP3/AAC audio format

– Software up-grade possibility via CD Disc

• fully (‘Red Book included CD-extra’) or unfinalized partly

recorded CD-R and CD-R/W Discs

Recording Capability

• Audio CD-R Discs

• Recording / Erasure of CD R/W Discs

Double speed recording (from EBU input only)

4x speed (only in some applications)

CD Text (Playback and Recording)

Audio Signal Inputs

• Analog (ADC on board)

• Digital (EBU)

Audio Signal Outputs

• Analog (DAC on board)

• Digital (EBU)

CD10 (Philips) CD-decoder connection for multiple CDplayback changers

1.3 Hardware interface

Interface connectors are located at the rear of the Module

and are accessible via a horizontal slot.

1.3.1 Connector 1214: Supply Interface

1. +5 V

2. +5 V

3. Ground (D)

4. Ground (D)

5. Ground (S) (motor ground)

6. +12 V

1. Ground

2. SDA (output / input)

3. SICL

4. RAB

5. SILD

6. Reset CD10

7. EBU Signal (input)

8. EBU Ground

1.3.6 Connector 1215: I/O Interface for Separate AD/DA

connections

1. EBU_OUT_ENGINE/GND

2. PROF_DIG_OUT/GND

3. EBU_CD10

4. GND

5. IIS_DATA1 / GND

6. IIS_CLK1 / GND

7. DEEMP

8. IIS_WLK1/GND

9. PWR_ON_RESET

10. IIS_CLK4

11. GND

12. IIS_WLK4

13. MUTE

14. IIS_DATA4

15. GND

16. CLK_16

17. KILL

1.3.7 Connector 1209: External DAC and ADC interface for

Better AD/DA (Optional)

1. MUTE

2. I2S_CLK2

3. GND

4. I2S_WS2

5. DEEMP

6. I2S_DATAO2

7. GND

Page 3

Introduction / Technical Specifications

GB 3CDR Mozart 1.

8. I2S_DATAI3

9. KILL

10. I2S_CLK3

11. GND

12. I2S_WS3

13. + 12Va

14. CLK_11

15. - 12Va

16. RST_ADDA

17. COPY_ANALOG

1.3.8 Connector 1201: Engine I/O

1. WCLK

2. BCLK

3. GND

4. Data_O

5. Data_I

6. GND

7. RCK

8. SFSY

9. SUB

10. FLAG

11. V4

12. MUTE

13. ATTI

14. DEEPI

15. GND

16. EBUOUT

17. GND

18. NRST

19. MAS-SLA

20. GND

21. SYSCLK

22. GND

23. EAN

24. SUR

25. CPR

26. TXD1

27. RXD1

28. +5V

29. +5V

30. GND

31. GND

32. GND

33. GND

34. +12V

35. +12V

36. +12V

1.4 Audio Performance CD Playback

Channel unbalance : < 0.3 dB

Frequency response : < 0.3dB for 20Hz -

20kHz

SNR (bipolar zero, unweighted) : > 95dB, 98 dB typ.

SNR (bipolar zero, A-weighted) : > 98dB, 100 dB typ.

Dynamic range : > 92dB, 96 dB typ

(1kHz.).

THD+N / S (20Hz - 20kHz) : > 85dB, 91 dB

typ.(1Khz)

Outband Attenuation : > 50dB for 30KHz.<

f<200kHz

Crosstalk (1kHz) : > 90dB, 100 dB typ.

Crosstalk (20Hz - 20kHz) : > 85dB, 93 dB typ.

Emphasis : 15/50s

Muting during access :

(Audio Signals Disc 1, track 1 (

99) : Typ. 69dB

unweighted

: Typ. 80dB A-

weighted

1.5 Audio Performance Analog Recording /

Digital Playback

Channel unbalance : < 0.5 dB

Frequency response : < 0.5dB for 20Hz -

20kHz

SNR (bipolar zero, unweighted) : > 84dB, 88 dB typ.

Dynamic range : > 86dB

THD + N / S (20Hz - 20kHz) : > 80dB, 85 dB typ.

Crosstalk (20Hz - 20kHz) : > 80dB at 1 kHz

Page 4

GB 4 CDR Mozart2.

Safety and Maintenance Instructions Warnings and Notes

2. Safety and Maintenance Instructions Warnings and Notes

GB

WARNING

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce

life drastically.

When repairing, make sure that you are

connected with the same potential as the

mass of the set via a wrist wrap with

resistance.

Keep components and tools also at this

potential.

F

ATTENTION

Tous les IC et beaucoup d'autres semiconducteurs sont sensibles aux décharges

statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu'aucune précaution

n'est prise a leur manipulation.

Lors de réparations, s'assurer de bien être

relié au même potentiel que la masse de

l'appareil et enfiler le bracelet serti d'une

résistance de sécurité.

Veiller a ce que les composants ainsi que les

outils que l'on utilise soient également a ce

potentiel.

D

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

über ein Pulsarmband mit Widerstand mit

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

auf diesem Potential.

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

F

Les normes de sécurité exigent que l'appareil soit remis a l'état d'origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

WARNUNG

NL

Alle IC's en vele andere halfgeleiders zijn

gevoelig voor elektrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie

kan de levensduur drastisch doen

verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente

ridatta in caso di non osservazione della piu

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello

della massa dell'apparecchio tramite un

braccialetto a resistenza.

Assicurarsi che i componenti e anche gli

utensili con quali si lavora siano anche a

questo potenziale.

WAARSCHUWING

I

AVVERTIMENTO

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden.

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l'apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

SHOCK, FIRE HAZARD SERVICE TEST:

CAUTION: After servicing this appliance and prior to returning to customer, measure the resistance between

either primary AC cord connector pins (with unit NOT connected to AC mains and its Power switch ON), and the

face or Front Panel of product and controls and chassis bottom,

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC

power is applied, and verified before return to user/customer.

Ref.UL Standard NO.1492.

NOTE ON SAFETY:

Symbol

: Fire or electrical shock hazard. Only original parts should be used to replace any part with symbol

Any other component substitution(other than original type), may increase risk or fire or electrical shock hazard.

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seuls habilités à

réparer votre appareil en panne.”

CL 96532086_021.eps

080999

Page 5

Safety and Maintenance Instructions Warnings and Notes

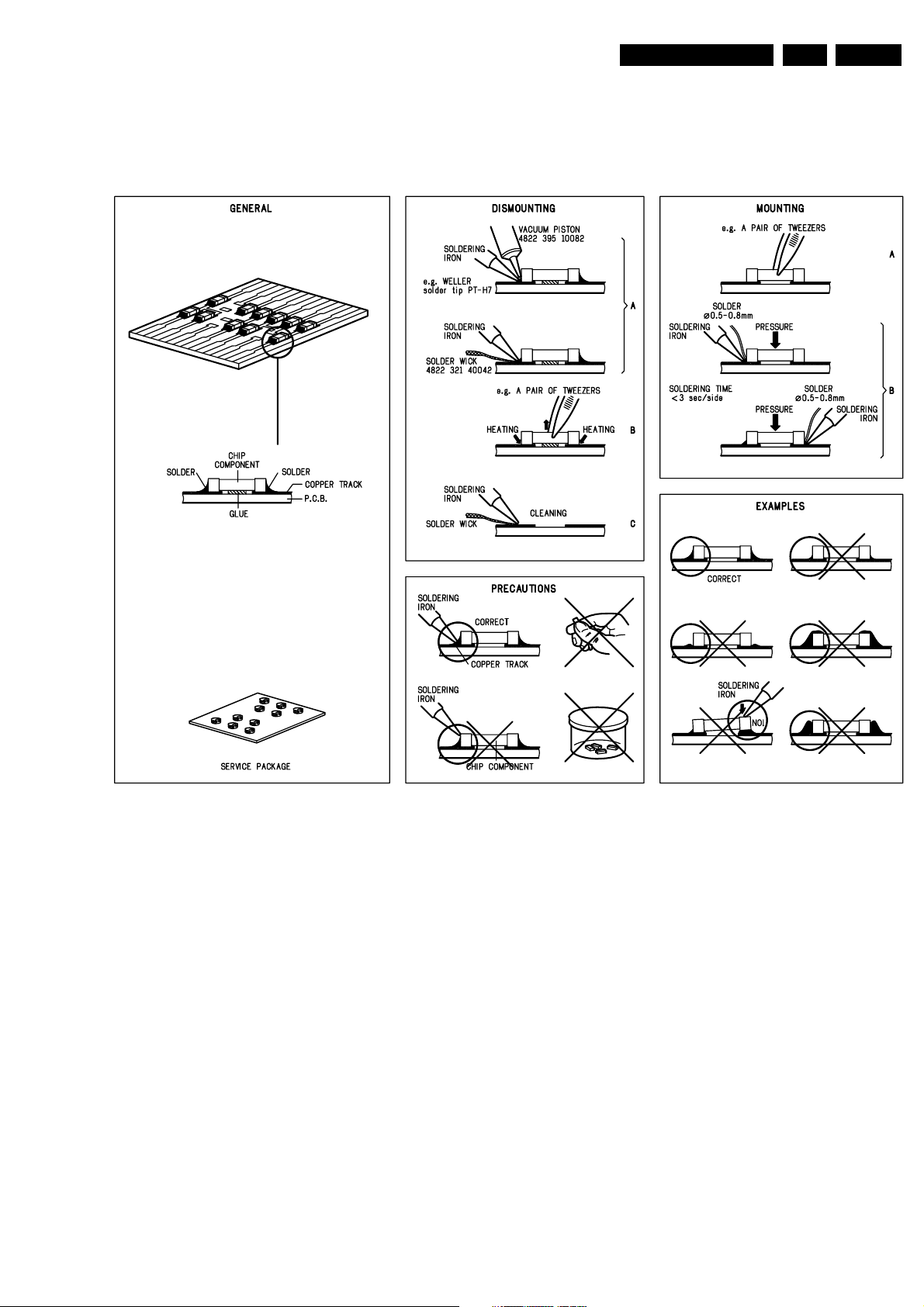

SERVICING HINTS

In the set, chip components have been applied. For disassembly and assembly check the figure below.

GB 5CDR Mozart 2.

CL 96532086_022.eps

080999

Page 6

GB 6 CDR Mozart2.

Safety and Maintenance Instructions Warnings and Notes

CL 96532086_023.eps

080999

Page 7

3. Instructions for Use

See Service Manual of concerned modelnumber in which the

instructions for use have been inserted. This chapter has not

been filled as this CDR Mozart Module is only a part of a

complete set.

4. Mechanical instructions

4.1 CD Recording Drive Mechanism

The CD (Recording) Drive Mechanism, Tray Loading

Mechanism and Front-end Board part of the module (also

called CD R/W BASIC ENGINE) can have 2 different

executions. One is called FREYA the other RACOON. As

information and repair activity about RACOON is not defined

yet, this part is not included in this Service Manual.

Notice that both Mechanisms can not be interchanged, so

RACOON has to be replaced by RACOON, FREYA by

FREYA. As both parts can only be repaired with the help of

CDR-ComPair, the ComPair tool will contain the instructions

for both mechanisms.

Instructions for Use

GB 7CDR Mozart 3.

Page 8

GB 8 CDR Mozart4.

Exploded View CDR-Module

Mechanical instructions

1001

ITEM DESCRIPTION CODENUMBER

1 VAE 5020/01 LOADER 9305 025 52001

2-3,13-14 SCREW PLASTITE M2x6 2511 076 50002

4 SHIELDING BOTTOM 3103 301 45360

5 SHIELDING TOP 3103 301 45370

6-12 SCREW TAPTITE M3x6 2511 077 00039

1001 MOZART BOARD

CL 16532046_001.eps

130701

Page 9

Exploded View VAE5020

Mechanical instructions

EXPLODED VIEW VAE5020

GB 9CDR Mozart 4.

ITEM CODENUMBER DESCRIPTION

1 3139 197 60100 FREYA LOADER ASSY

4 9305 022 52001 VAM5020/01

7 3139 194 00790 SUSPENSION

8 3139 194 00790 SUSPENSION

9 3139 194 00790 SUSPENSION

10 3139 194 00790 SUSPENSION

12 3139 197 60060 CLAMPER

15 3139 198 00280 FREYA2 SERVO BOARD

CL 16532046_002.eps

101001

Page 10

GB 10 CDR Mozart4.

Exploded View VAM5020

Mechanical instructions

EXPLODED VIEW VAM5020

ITEM CODENUMBER DESCRIPTION

1 3139 197 50100 OUTSERT MOUNTING PLATE ASSY

3 3139 198 00200 SLEDGE MOTOR ASSY

5 3139 191 20380 THRUST SPRING

7 4822 402 61558 CLAMPING BRACKET

9 3139 198 00230 FREYA 2 MOTOR AND TURNTABLE

11 3139 194 00660 MOTOR CATCH

13 3139 190 40100 PLASTIC SCREW 2 X 7

14 3139 190 40100 PLASTIC SCREW 2 X 7

15 3139 190 40100 PLASTIC SCREW 2 X 7

17 9305 011 24252 OPU-24.25

18 3139 191 20370 SPINDLE

19 3139 191 20370 SPINDLE

25 3139 194 00700 COMBI WHEEL

26 3139 191 20400 RACK SPRING

27 3139 194 00770 RACK

28 3104 141 21830 THIRD BEARING SPRING

30 3139 198 00270 Board-FLEX ASSY FREYA

31 3139 190 40100 PLASTIC SCREW 2 X 7

CL 16532046_005.eps

101001

Page 11

Exploded View Freya Loader

09

Mechanical instructions

GB 11CDR Mozart 4.

16 12 13

11

06

08

10

05

04

04 4822 358 10266 BELT LOADER

05 PULLEY WHEEL

06 TRAY GEAR WHEEL

08 RACK GEAR WHEEL

09 3139 198 80010 SWITCH

CL 16532046_003.eps

10 4822 532 13097 TULE

11 3139 194 00800 TRAY BLACK

12 3139 197 50060 TRAY MOTOR ASSY

13 3139 194 00740 CHASSIS

16 MOTOR SPRING

040701

Page 12

GB 12 CDR Mozart5.

Trouble Shooting

5. Trouble Shooting

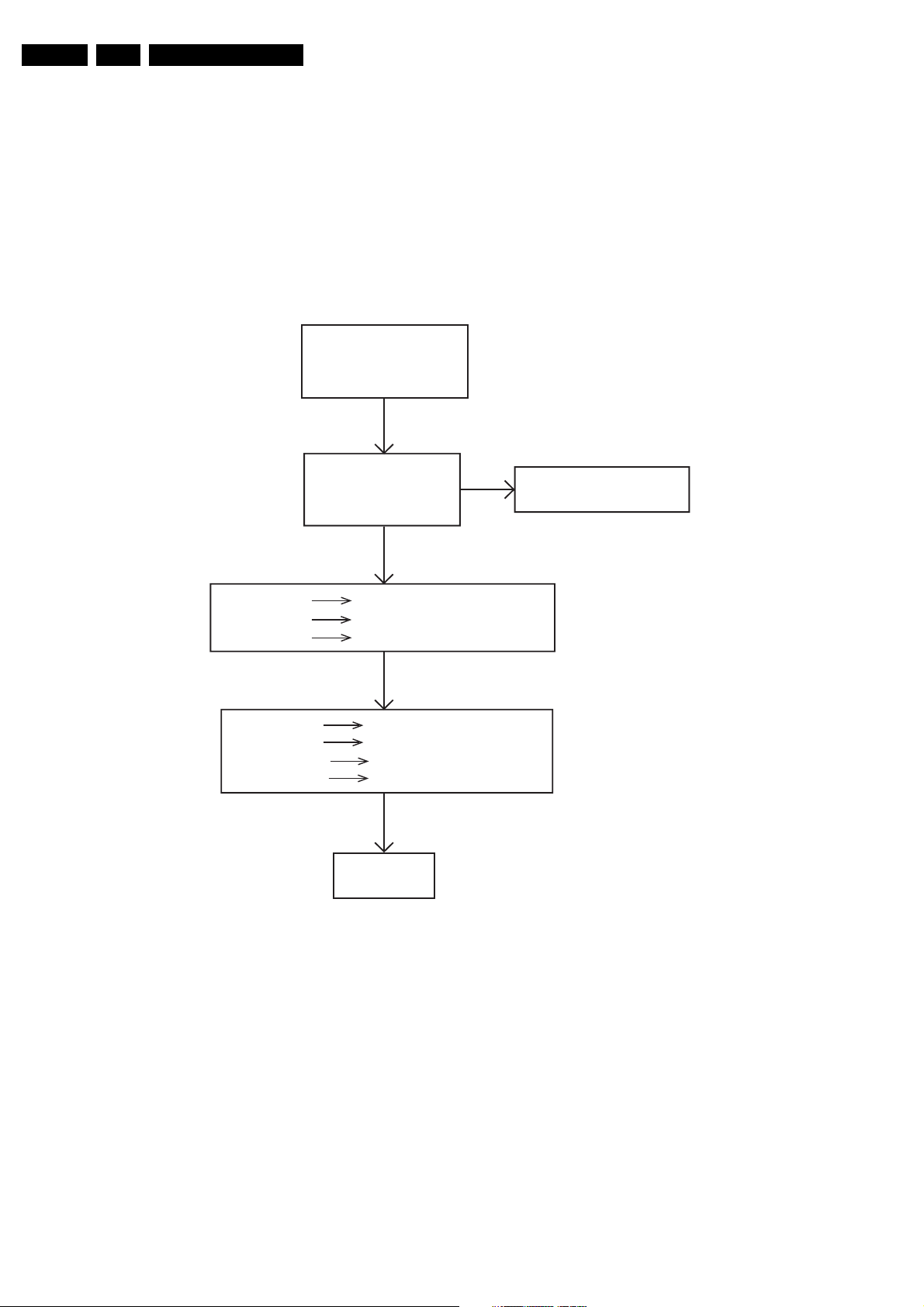

Power Part Check

Power Part Check

USE MOZART MAIN BOARD CIRCUIT DIAGRAM 3 AND MOZART MAIN BOARD BOTTOM-AND TOP VIEW: TEST POINTS

Switch On

Power Supply

-12V testpoint 5

+3V3 testpoint 6

+2V5 testpoint 7

+8VA testpoint 8

+5VA testpoint 9

-8VA testpoint 10

-5VA testpoint 11

+12V(+/-10%) testpoint 1

+5V(+/-10%) testpoint 2

+12V_MOT testpoint 3

+5V_BE testpoint 4

OK

NOK

Check IC 7202, R3222 and D6203

NOK

Check Voltage Regulator 7208

NOK

Check Voltage Regulator 7209

OK

NOK

Check Voltage Regulator 7201

NOK

Check IC 6204

NOK

Check IC 7200

NOK

Check IC 7200 and Diode 6202

OK

Power Part

OK

NOK

Check Power Supply Unit

Check Fuse 1211 and 1212

CL 16532046_006.eps

101001

Page 13

Trouble Shooting

GB 13CDR Mozart 5.

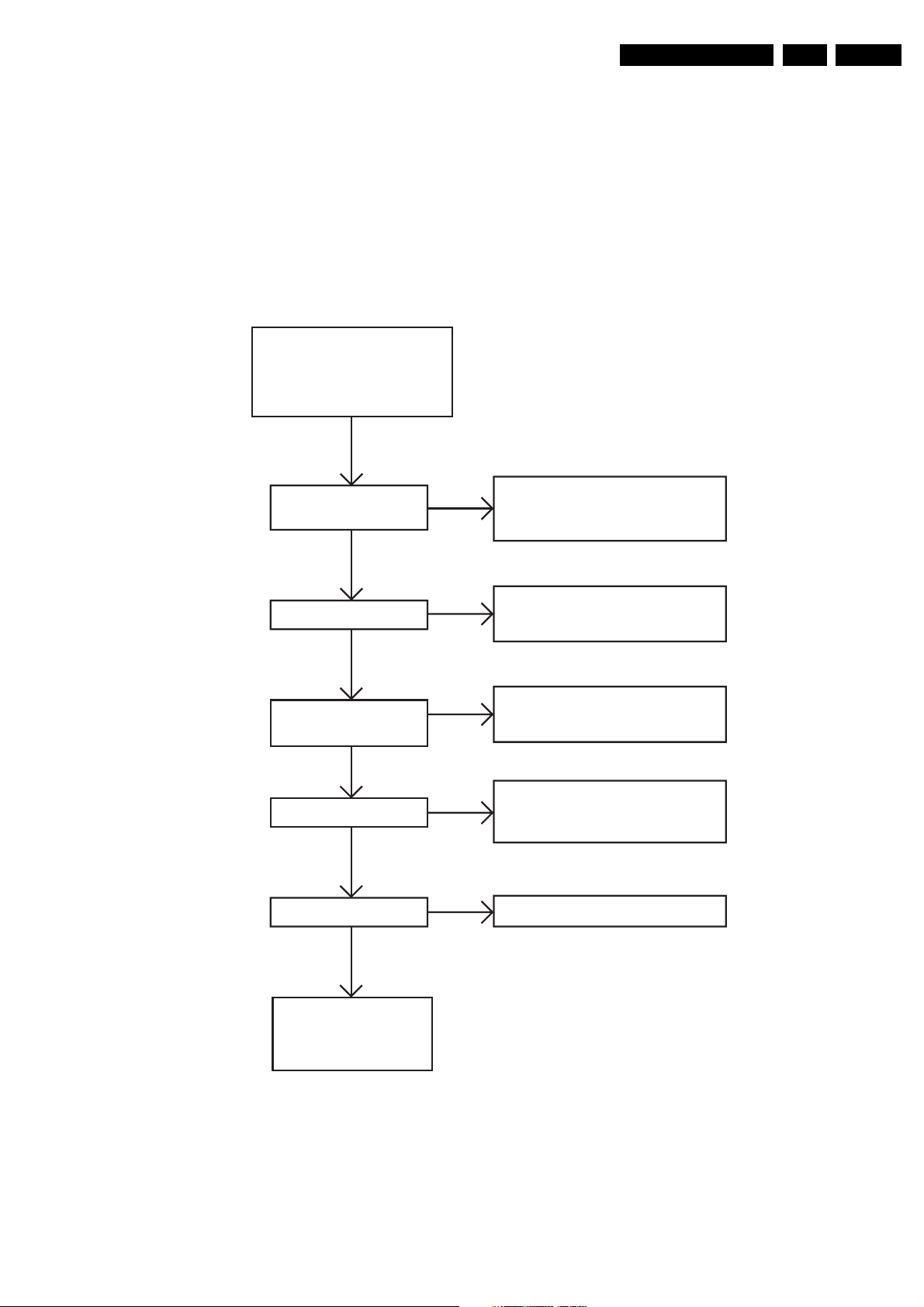

Power Part Check FREYA Servo

Board

Power Part Check FREYA Servoboard

USE FREYA SERVOBOARD CIRCUIT DIAGRAM3 AND FREYA SERVOBOARD BOTTOM-AND TOP VIEW: TEST POINTS

Switch On

Power Supply

+12V testpoint 12

+5V testpoint 13

OK

+3V3 testpoint 14

OK

FS30V testpoint 15

= +27V

OK

-8V testpoint 16

OK

-5V testpoint 17

NOK

NOK

NOK

NOK

NOK

- Check Mozart Back-end board

- Check Fuse 1543 and 1541

- Check D 6541, D6543

- Check Fuse 1501

- Check T 7020

- Check D 6554

- Check L 5554

- Check D 6547

- Check L 5553

- Check T 7547

- Check IC 7556

OK

Power Part

Freya mainboard

OK

CL 16532046_045.eps

101001

Page 14

GB 14 CDR Mozart5.

Trouble Shooting

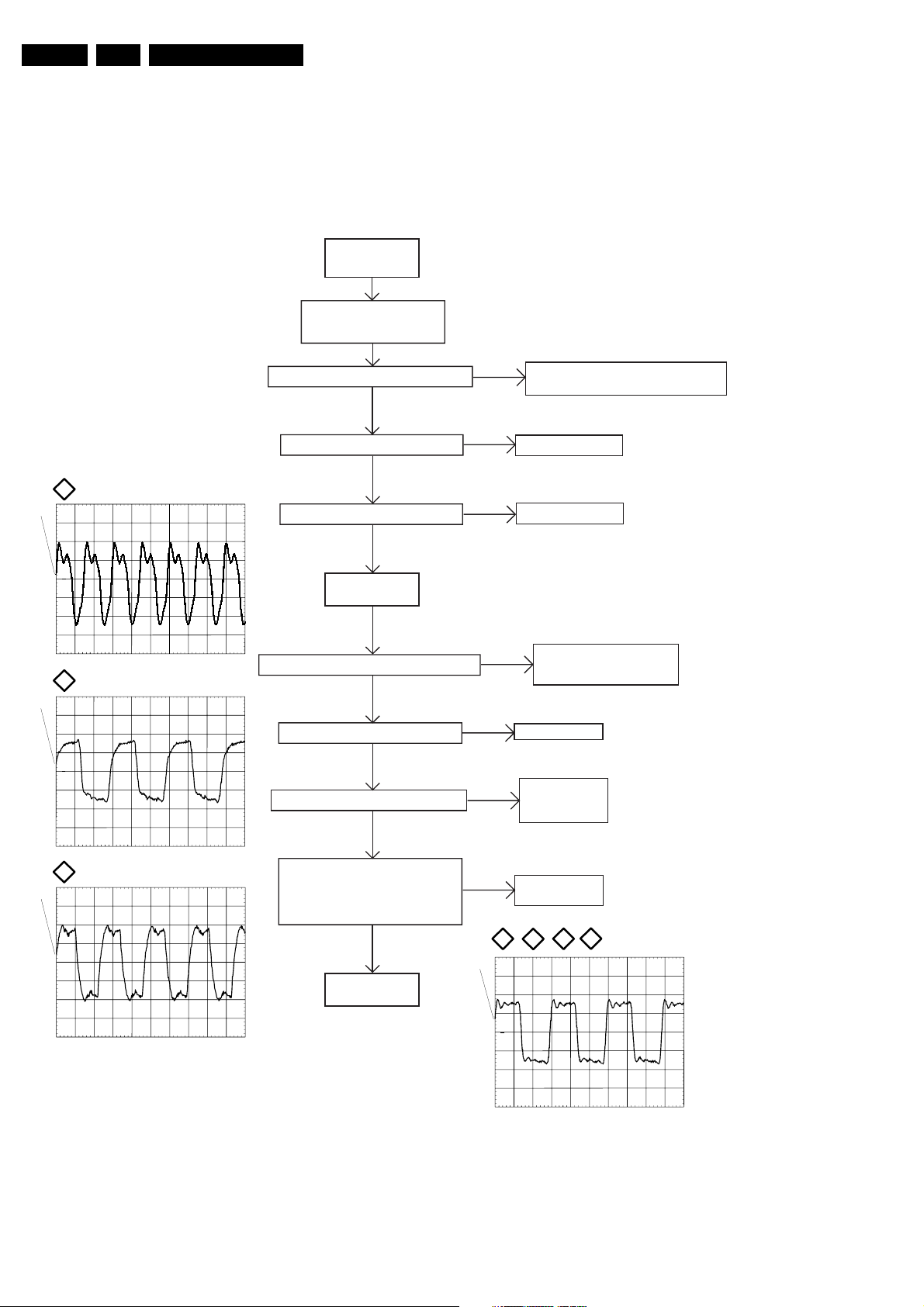

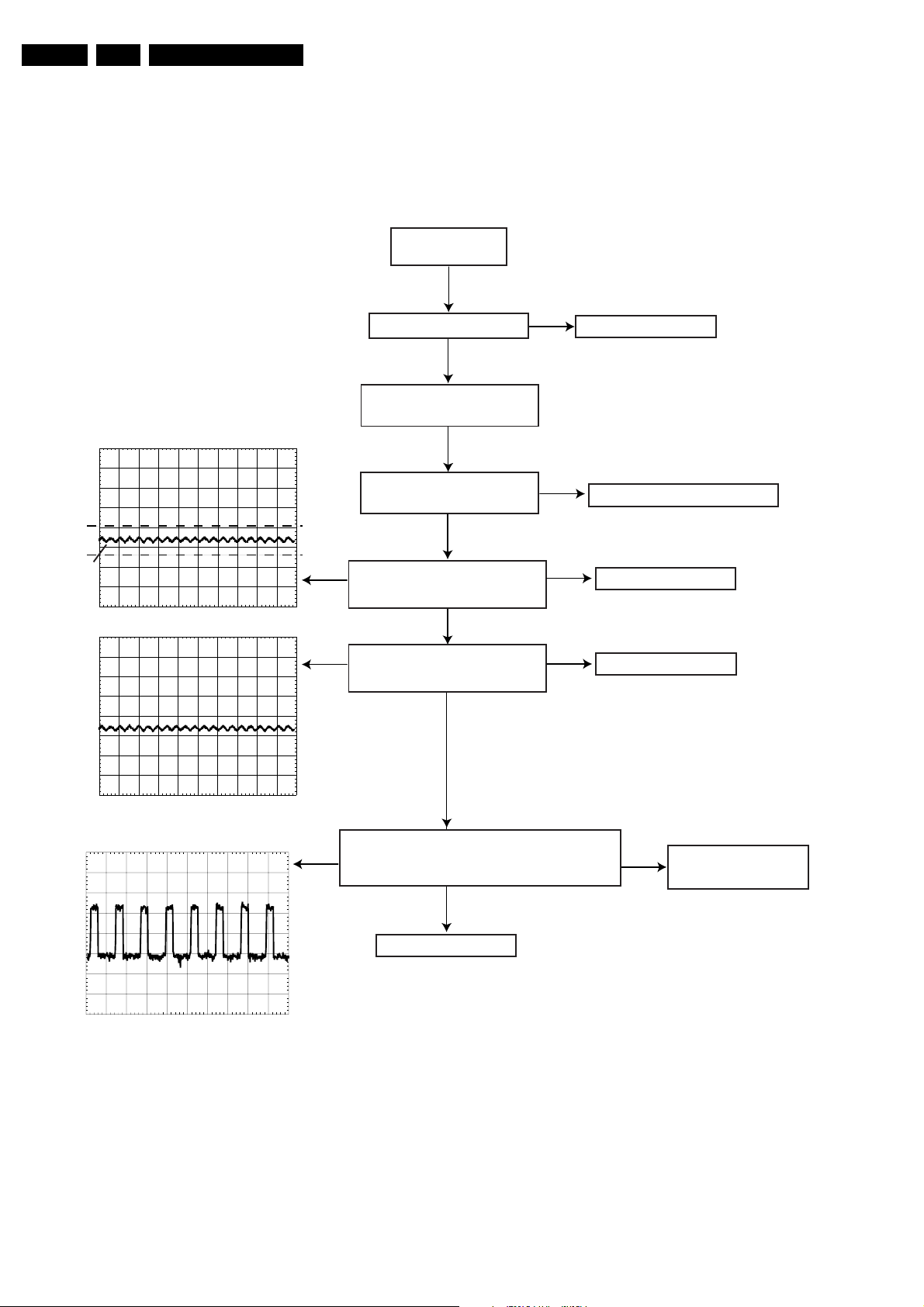

Reset & Clock Check

RESET & CLOCK CHECK

USE MOZART MAIN BOARD CIRCUIT DIAGRAM 1 AND MOZART MAIN BOARD BOTTOM-AND TOP VIEW: TESTPOINTS

Switch on the

Power Supply

Display uP generates

the Power On Reset

R4

ch1: pkpk= 4.50 V

ch1

ch1: freq= 33.8MHz

1

CH1 1.00 V~ MTB20.0ns ch1+

R5

ch1: pkpk= 3.34 V

ch1

ch1: freq= 16.9MHz

1

CH1 1.00 V~ MTB20.0ns ch1+

Power On Reset (+3V3) testpoint R1

OK

RST ADDA (+3V3) testpoint R2

OK

RST FREYA (+3V3) testpoint R3

OK

RESET Signals

OK

OK

MAIN_CLK 33,8688MHz testpoint R4

OK

SYS_CLK 16,9MHz testpoint R5

OK

FREYA_CLK 8,5MHz testpoint R6

OK

NOK

NOK

NOK

NOK

NOK

NOK

Check connection to Display board

Check IC7000

Check IC7000

Check IC7000

Check X-tal 1005

Check D6002 and D6003

Check IC7000

Check IC7000

Check IC7004

Check IC7012

Check R3019

R6

ch1: pkpk= 4.12 V

ch1

ch1: freq= 8.51MHz

1

CH1 1.00 V~ MTB50.0ns ch1+

DAC_CLK 16,9MHz testpoint R7

ADC_CLK 16,9MHz testpoint R8

IO_CLK 16,9MHz testpoint R9

IO_CLK ABBA testpoint R10

OK

CLOCK Signals

OK

NOK

Check IC7010

Check R3028

R7

R8

ch1: pkpk= 3.50 V

ch1

ch1: freq= 16.9MHz

1

CH1 1.00 V~ MTB20.0ns ch1+

R10

R9

CL 16532046_007.eps

101001

Page 15

Trouble Shooting

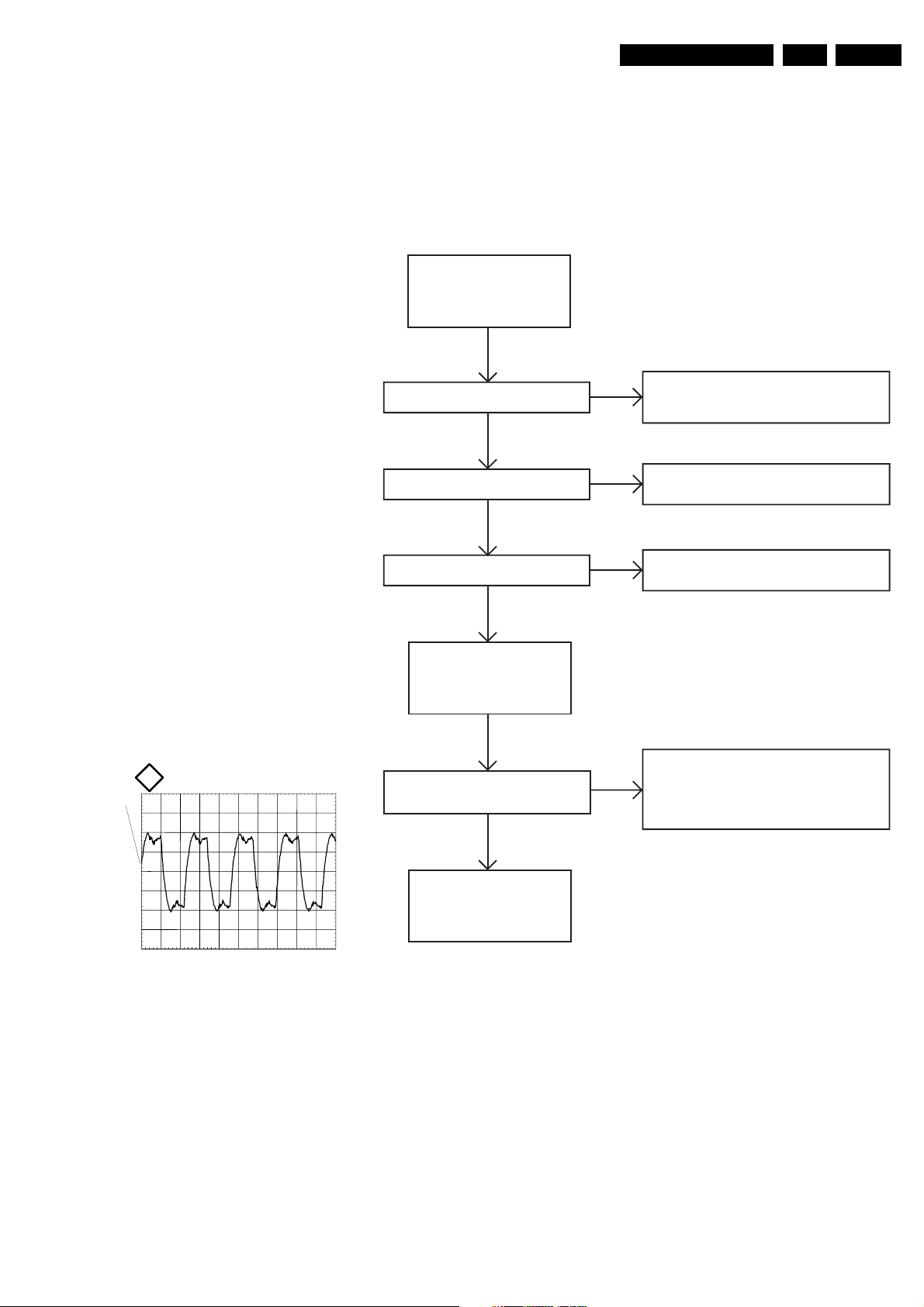

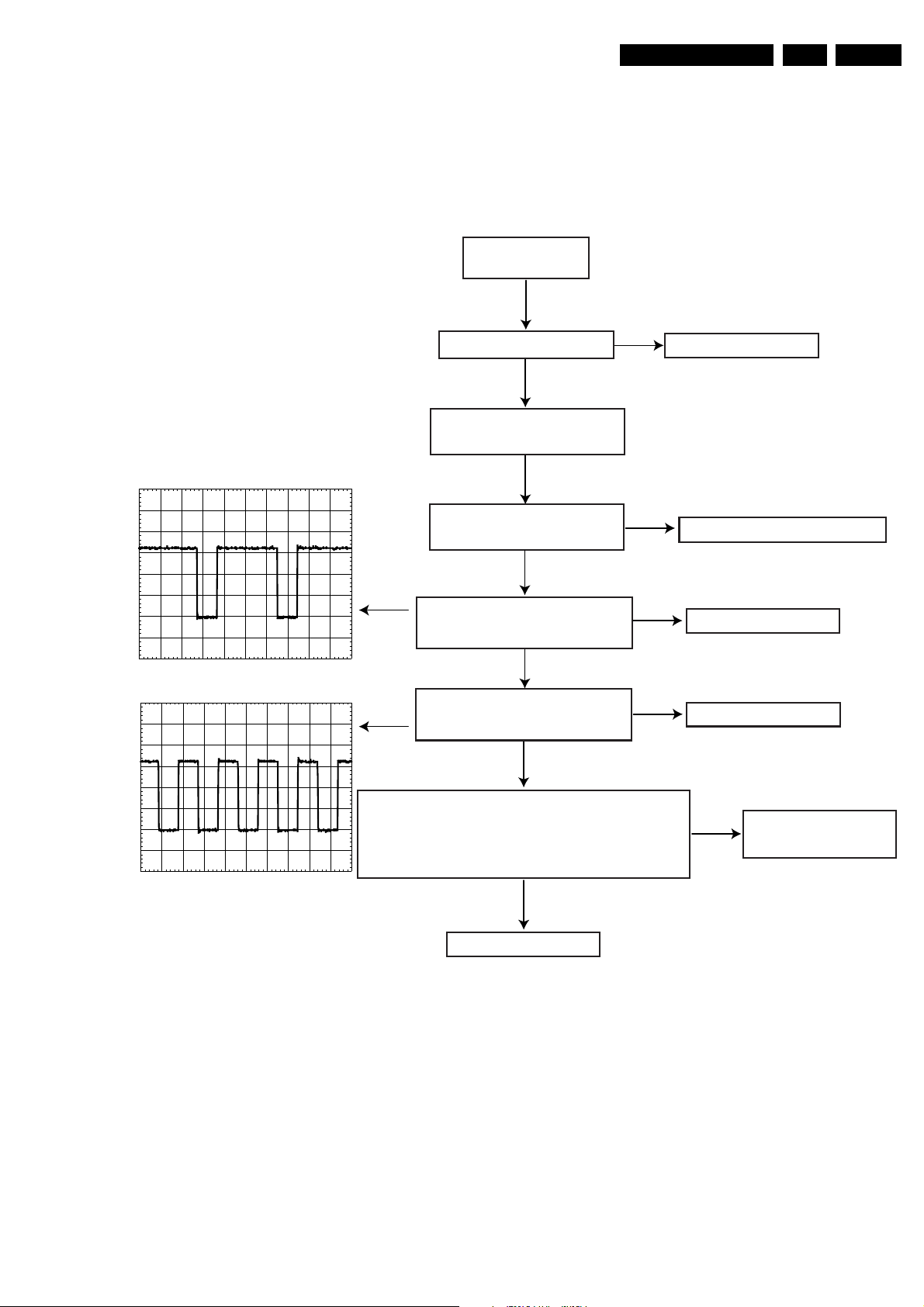

Reset & Clock Check FREYA Servo Board

Reset and Clock Check FREYA Servoboard

USE FREYA SERVOBOARD CIRCUIT DIAGRAM1 AND 4 AND FREYA SERVOBOARD BOTTOM-AND TOP VIEW: TEST POINTS

Switch On

Power Supply

GB 15CDR Mozart 5.

ch1

R14

ch1: pkpk= 4.12 V

ch1: freq= 8.51MHz

+3V3 on testpoint R11

OK

NRST-signal(+3V3) on testpoint R12

OK

RESET_N(low) on testpoint R13

OK

Reset part

OK

OK

SYSCLK = FREYA_CLK 8.5MHz

on testpoint R14

OK

NOK

NOK

NOK

NOK

Check connection from CDR Freya

Servoboard connector 1000 to

connector 1201 on CDR Mozart mainboard

- Check T 7108

- Check D 6020 and D 6021

- Check T 7107

- Check R 3153

Check connection from CDR Freya

Servoboard connector 1000 to

connector 1201 on CDR Mozart mainboard

- Check IC 7019

- Check IC 7018

1

CH1 1.00 V~ MTB50.0ns ch1+

Clock FREYA

OK

CL 16532046_046.eps

101001

Page 16

GB 16 CDR Mozart5.

Servo Drivers Check (Focus Servo)

SERVO DRIVERS CHECK

USE FREYA2 CIRCUIT DIAGRAM 1 and 3 AND FREYA SERVO BOARD BOTTOM- AND TOP VIEW: TESTPOINTS

FOCUS SERVO

Trouble Shooting

Switch on player

via ComPair mode

Execute "focus" tests

NOK

Check power part

Check reset and clock part

OK

FOCUS SERVO OK

Moving between

1V3 and 2V

VFO

GND

FOC-/FOC+

PM3392A

VFO

GND

CH1:500mV= MTB2.00us

PM3392A

CH1:500mV= MTB2.00us

PM3392A

OK

Check

S1V65

(=1V65) at

NOK

testpoint S9

OK

Execute "focus on" test

Check

VFO

signal

NOK

on testpoint S16 (TP59)

OK

Execute "focus off" test

Check

VFO

signal

NOK

on testpoint S16 (TP59,TP153)

OK

Check signal across

FOC+/FOC-

on testpoints S17 (TP57)

and S18 (TP58) when executing "focus on"

OK

Check R3002, R3065, C2054

Check MACE 7019

Check MACE 7019

NOK

Check driver 7003

Check MACE 7019

Check VAM5020

GND

CH1:50.0mV= MTB 500ms

ch1: freq= 1.61 Hz

FOCUS SERVO OK

CL 16532046_012.eps

101001

Page 17

Trouble Shooting

Servo Drivers Check (Radial Servo)

SERVO DRIVERS CHECK

USE FREYA2 CIRCUIT DIAGRAM 1 AND 3 AND FREYA SERVO BOARD BOTTOM- AND TOP VIEW: TESTPOINTS

RADIAL SERVO

Switch on player

via ComPair mode

OK

Execute "radial control" tests

NOK

Check power part

Check reset and clock part

RADIAL SERVO OK

GB 17CDR Mozart 5.

PM3392A

VRA

GND

CH1:1.00 V= MTB 500ns

ch1:freq=532kHz

PM3392A

VRA

GND

CH1:1.00 V= MTB 500ns

ch1:freq=1.06MHz

OK

Check

S1V65

(=1V65) at

NOK

testpoint S9

OK

Execute "radial control on" test

Check

VRA

signal on

NOK

testpoint S13 (TP152)

OK

Execute "radial control off" test

VRA

Check

signal on

NOK

testpoint S13 (TP152)

OK

Check

RAD+

signal on testpoint S14 (TP53):

+4V2 (going to 6V8 when executing "radial control on")

Check

RAD-

signal on testpoint S15 (TP56):

+0V65 (going to 4V3 when executing "radial control off")

OK

Check R3002, R3065, C2054

Check MACE 7019

Check MACE 7019

NOK

Check driver 7003

Check MACE 7019

Check VAM5020

RADIAL SERVO OK

CL 16532046_013.eps

101001

Page 18

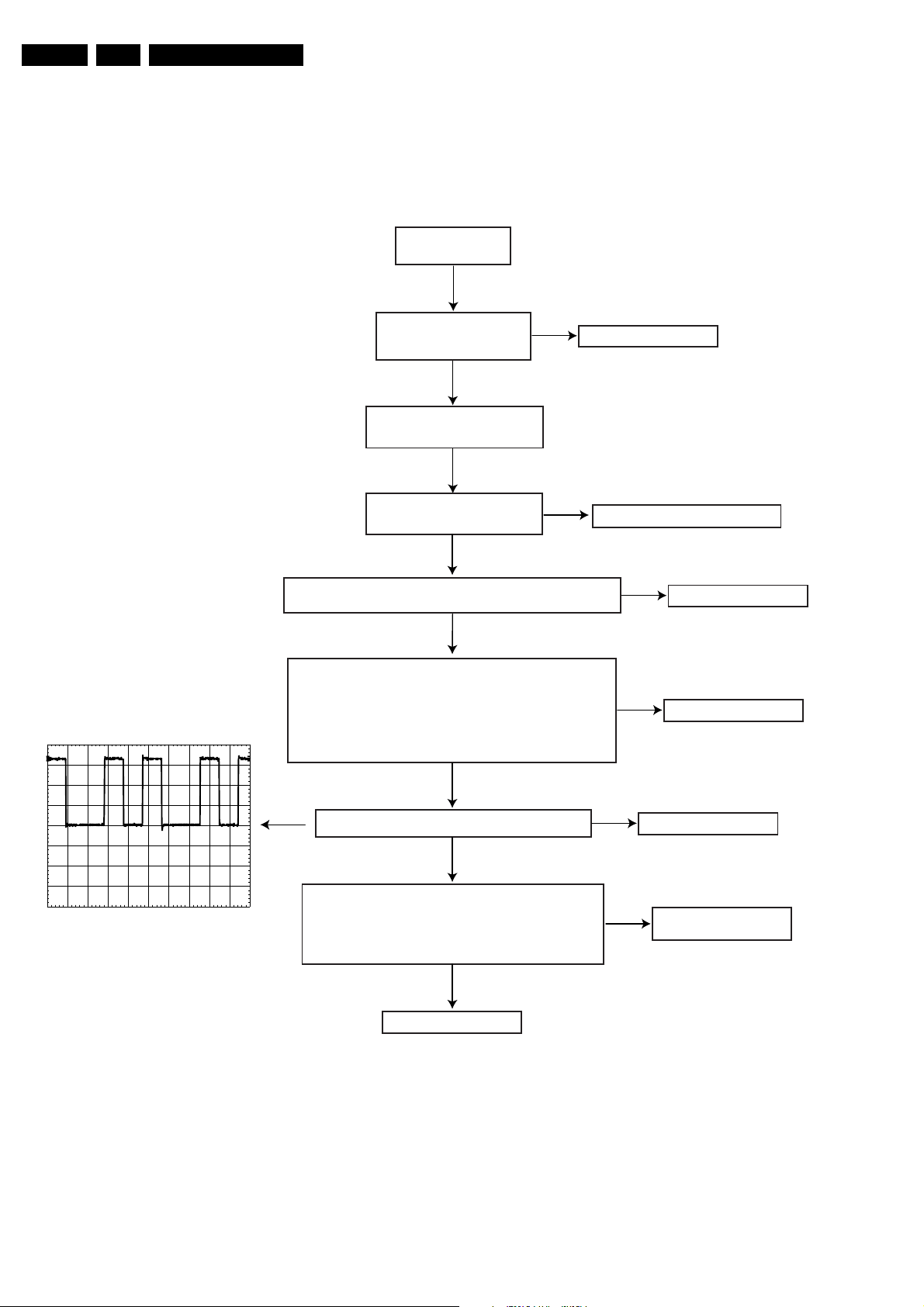

GB 18 CDR Mozart5.

Servo Drivers Check (Sledge Servo)

SERVO DRIVERS CHECK

USE FREYA SERVO BOARD CIRCUIT DIAGRAM 1 AND 3 AND FREYA SERVO BOARD BOTTOM- AND TOP VIEW: TESTPOINTS

SLEDGE SERVO

Trouble Shooting

Switch on player

via ComPair mode

VSL

GND

PM3392A

Execute "sledge inwards"

and "sledge outwards" tests

NOK

Check power part

Check reset and clock part

OK

Check

S1V65

testpoint S9

Check voltages testpoints S4, S5, S7, S8

(TP95, TP94, TP112, TP96) : +/- 1.6V

Check voltage testpoint S1 : if S1=0V then S3=0V

(TP 146) if S1=1V65 then 1V<S3<4V

Check voltage testpoint S2 : if S2=0V then S6=0V

(TP 147) if S2=1V65 then 1V<S6<4V

VSL

Check

signal at testpoint S10 (TP151)

(=1V65) at

OK

OK

if S1=3V3 then S3=5V

if S2=3V3 then S6=5V

OK

OK

SLEDGE SERVO OK

NOK

Check R3002, R3065, C2054

NOK

Check VAM5020

NOK

Check opamp 7010

NOK

Check MACE 7019

CH1:1.00 V= MTB 500ns

OK

Check

SL+

+3V (going to 5V4 when executing "sledge outwards")

Check

+5V4 (going to 3V4 when executing "sledge outwards")

signal at testpoint S11 (TP54) :

SL-

signal at testpoint S12 (TP55) :

OK

SLEDGE SERVO OK

NOK

Check driver 7003

Check MACE 7019

CL 16532046_014.eps

101001

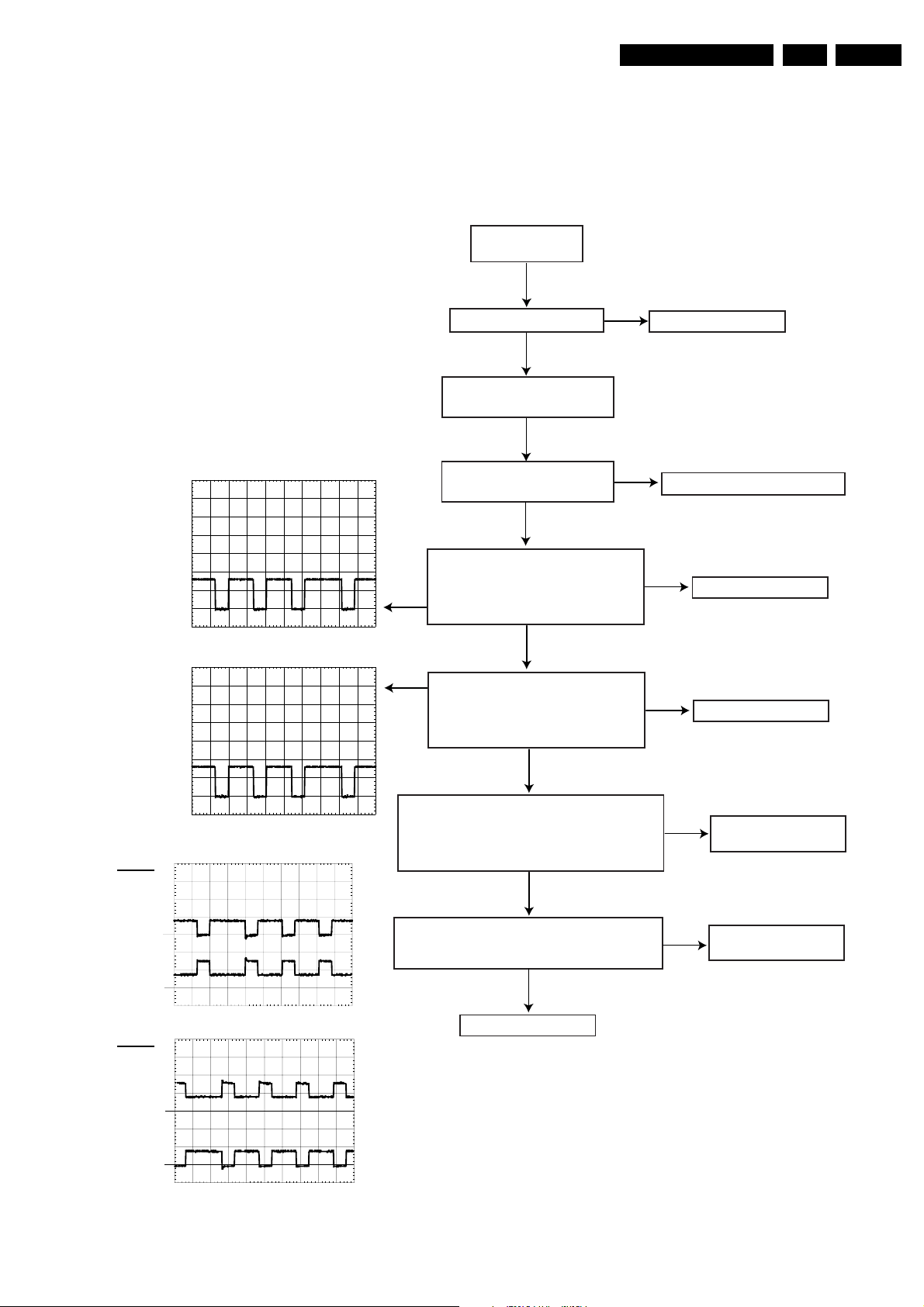

Page 19

Trouble Shooting

Servo Drivers Check (Tray Servo)

SERVO DRIVERS CHECK

USE FREYA SERVO BOARD CIRCUIT DIAGRAM 1 AND 3 AND FREYA SERVO BOARD BOTTOM- AND TOP VIEW: TESTPOINTS

TRAY SERVO

Switch on player

via ComPair mode

OK

Execute "TRAY" tests

NOK

Check power part

Check reset and clock part

OK

TRAY SERVO OK

GB 19CDR Mozart 5.

osc. a

GNDTR+

GNDTR-

osc. b

PM3392A

TRAYOUT

GND

CH1:2.00 V= MTB 500us

PM3392A

TRAYIN

GND

CH1:2.00 V= MTB 500us

PM3392A

TR+

TR-

CH1:5.00 V=

CH2:5.00 V= MTB 500us

PM3392A

Check

S1V65

(=1V65) at

testpoint S9

OK

Execute "tray open" test

Check

Tray Out

signal on testpoint S19

(TP177) during command

Tray In

(testpoint S20) stays at 3V2

OK

Execute "tray close" test

Check

Tray In

signal on testpoint S20

(TP176) during tray command

Tray Out

(testpoint S19) stays at 3V2

OK

Check

TR+

(testpoint S21;TP77),

TR-

(testpoint S22;TP78) :

- values without commands 4V2

- values during "tray open" command (osc. a)

- values during "tray close" command (osc. b)

OK

Check signal

TRAYSW

at testpoint S23 (TP79) :

3V3 during commands open and close,

0V after completion

OK

TRAY SERVO OK

NOK

Check R3002, R3065, C2054

NOK

Check MACE 7019

NOK

Check MACE 7019

NOK

Check driver 7019

Check VAL5020

NOK

Check VAL5020

GNDTR+

GNDTR-

TR+

TR-

CH1:5.00 V=

CH2:5.00 V= MTB 500us

CL 16532046_015.eps

101001

Page 20

GB 20 CDR Mozart5.

Trouble Shooting

Digital Audio Path During Playback

DIGITAL AUDIO PATH DURING PLAYBACK

USE FREYA SERVO BOARD CIRCUIT DIAGRAM 2 AND 4 AND

MOZART MAIN BOARD CIRCUIT DIAGRAM 1 AND 3 AND BOTH BOTTOM- AND TOP VIEW: TEST POINTS

DIGITAL AUDIO PLAYBACK

INSERT AUDIO SIGNALS DISC

START TRACK 15(1KHz 0dB)

HF2

eyepattern

HF-SIGNAL

ON TESTPOINT HF2 ?

(FREYA DIAGRAM 4)

YES

NO

0.5uS/DIV

CHECK CAHF-SIGNAL ON

-

TESTPOINT HF1 FOR ACTIVITY

-

CHECK TR 7103, 7102, 7105,

7109, 7361 AND IC 7360

A3 A4 A5

2,1168MHz

BCLK

44,1KHz

WCLK

DATA0

LEFT CHANNEL

0,5us/DIV

32

RIGHT CHANNEL

MSBMSB LSB

2.5V

>800mVpp

I2S-SIGNALS

ON TESTPOINTS

A3, A4, A5 ?

(FREYA DIAGRAM 4)

YES

DIGITAL SIGNAL

OUT OF CDR60 ON

TESTPOINT A24

(MOZART BOARD

DIAGR. 3)

YES

DIGITAL SIGNAL

EBU-OUT1 FROM MOZART

TESTPOINT A20

(MOZART BOARD

DIAGR. 1)

YES

DIGITAL SIGNAL

EBU_DIG_OPT_OUT

TESTPOINT A2

(MOZART BOARD

DIAGR. 3)

NO

NO

NO

NO

-

CHECK IC 7018

-

CHECK POWER SUPPLY D3V3

-

CHECK SYS CLK ON

TESTPOINT R14 (= 8,4672 MHz)

-

CHECK CONNECTION FROM CDR

FREYA BOARD CONN. 1000 TO CONN.1201

ON CDR MOZART MAIN BOARD

A2

A20 A24

ch1: pkpk= 1.30 V

ch1

-

CHECK IC 7000

-

CHECK TR 7011

-

ch1: freq= 1.85MHz

1

CH1 1.00 V~ MTB 500ns ch1+

CHECK R 3272

YES

DIGITAL AUDIO PLAYBACK

OK

CL16532046_010.eps

101001

Page 21

Trouble Shooting

Digital Audio Path During Recording

DIGITAL AUDIO PATH DURING RECORDING

USE FREYA SERVO BOARD CIRCUIT DIAGRAM 3 AND 4 AND

MOZART MAIN BOARD CIRCUIT DIAGRAM 1 AND 3 AND BOTH BOTTOM- AND TOP VIEW: TEST POINTS

A25

DIGITAL AUDIO PATH

DURING RECORDING

CONNECT DIGITAL INPUT FROM

EXTERNAL SOURCE AND

SELECT THE DIGITAL RECORDING

INPUT BY PRESSING SOURCE

CHECK DIGITAL SIGNAL

ON TESTPOINT A25

(MOZART DIAGRAM 3)

NO

-

ch1: pkpk= 1.30 V

ch1

ch1: freq= 1.85MHz

1

CH1 1.00 V~ MTB 500ns ch1+

CHECK CONNECTION

BETWEEN INTERFACE-BOARD AND

MOZART MAIN BOARD

GB 21CDR Mozart 5.

YES

CHECK I2S - SIGNALS

ON TESTPOINTS A3, A4 AND A26

(MOZART DIAGRAM 3)

YES

CHECK I2S - SIGNALS

ON TESTPOINTS A3, A4 AND A26

(FREYA DIAGRAM 4)

YES

CHECK EFMDATA AND

EFMCLOCK ON TESTPOINTS

A17 AND A18

(FREYA DIAGR. 4)

YES

NO

NO

NO

A4A3 A26

2,1168MHz

BCLK

44,1KHz

WCLK

0.5uS/DIV

DATA1

-

CHECK POWER SUPPLY IC 7000

-

CHECK IC 7000

-

CHECK CONNECTION FROM CDR

LEFT CHANNEL

FREYA BOARD CONN. 1000 TO CONN.1201

ON CDR MOZART MAIN BOARD

CHECK POWER SUPPLY IC 7018

-

-

CHECK I2C - SIGNAL OF IC 7018

-

CHECK IC 7018

32

RIGHT CHANNEL

MSBMSB LSB

A17

CHECK ACTIVITY

ON TESTPOINT A19

(FREYA DIAGRAM 3)

YES

DIGITAL AUDIO PATH

DURING RECORDING

OK

NO

CHECK POWER SUPPLY IC 7007

-

-

CHECK I2C - SIGNAL OF IC 7007

CHECK IC 7007

-

A18

CL06532018_011.eps

111000

Page 22

GB 22 CDR Mozart5.

Trouble Shooting

Analog Audio Path During Playback

ANALOG AUDIO PATH DURING PLAYBACK

USE FREYA SERVO BOARD CIRCUIT DIAGRAM 2 AND 4 AND

MOZART MAIN BOARD CIRCUIT DIAGRAM 1 AND 3 AND BOTH BOTTOM- AND TOP VIEW: TEST POINTS

ANALOG AUDIO PLAYBACK

INSERT AUDIO SIGNALS DISC

START TRACK 15(1KHz 0dB)

HF2

HF-SIGNAL

ON TESTPOINT HF2 ?

(FREYA DIAGRAM 4)

YES

NO

0.5uS/DIV

CHECK CAHF-SIGNAL ON

-

TESTPOINT HF1 FOR ACTIVITY

CHECK TR 7103, 7102, 7105,

-

7109, 7361 AND IC 7360

A3 A4 A5 A27 A28 A29

2,1168MHz

BCLK

44,1KHz

WCLK

DATA0

LEFT CHANNEL

2.5V

0,5us/DIV

32

RIGHT CHANNEL

MSBMSB LSB

eyepattern

>800mVpp

I2S-SIGNALS

ON TESTPOINTS

A3, A4, A5 ?

(FREYA DIAGRAM 4)

YES

I2S-SIGNALS

ON TESTPOINTS

A27, A28 ,A29 ?

(MOZART DIAGRAM 3)

YES

AoutL AND AoutR

ON TESTPOINTS

A6 AND A7 ?

(MOZART DIAGR. 5)

YES

ANALOG AUDIO PLAYBACK

OK

NO

NO

CHECK IC 7018

-

-

CHECK POWER SUPPLY D3V3

-

CHECK SYS CLK ON

TESTPOINT R14 (= 8,4672 MHz)

CHECK CONNECTION FROM CDR

-

FREYA BOARD CONN. 1000 TO CONN.1201

ON CDR MOZART MAIN BOARD

-

CHECK IC 7000

-

CHECK IC 7311

-

CHECK IC 7300

-

CHECK KILL TR 7303, 7304, 7309,

7310

A6

A7

ch1: pkpk= 5.95 V

ch1

ch1: freq= 1.00kHz

1

CH1 2.00 V~ MTB 500us ch1+

CL 16532046_008.eps

101001

Page 23

Analog Audio Path During Recording

Trouble Shooting

GB 23CDR Mozart 5.

290200

CL06532018_024.eps

A17

CHECK POWER SUPPLY IC 7000

CHECK IC 7000

-

-

NO

S - SIGNALS

2

CHECK I

YES

(MOZART DIAGRAM 3)

ON TESTPOINTS A3, A4 AND A26

CHECK CONNECTION FROM CDR

FREYA BOARD CONN. 1000 TO CONN.1201

ON CDR MOZART MAIN BOARD

-

NO

S - SIGNALS

2

CHECK I

ON TESTPOINTS A3, A4 AND A26

YES

(FREYA DIAGRAM 4)

A18

CHECK POWER SUPPLY IC 7018

CHECK I2C - SIGNAL OF IC 7018

CHECK IC 7018

-

-

-

CHECK POWER SUPPLY IC 7007

-

NO

YES

A17 AND A18

(FREYA DIAGR. 4)

CHECK EFMDATA AND

EFMCLOCK ON TESTPOINTS

CHECK I2C - SIGNAL OF IC 7007

CHECK IC 7007

-

-

NO

YES

CHECK ACTIVITY

ON TESTPOINT A19

(FREYA DIAGRAM 3)

ANALOG AUDIO PATH

DURING RECORDING

OK

A9

A8

ch1: pkpk= 4.51 V

ch1: freq= 997 Hz

1

ch1

ANALOG AUDIO PATH

ANALOG AUDIO PATH DURING RECORDING

USE FREYA SERVO BOARD CIRCUIT DIAGRAM 3 AND 4 AND

MOZART MAIN BOARD CIRCUIT DIAGRAM 3, 4, 5 AND BOTH BOTTOM- AND TOP VIEW: TEST POINTS

APPLY AUDIO SIGNAL(1kHz 0dB)

DURING RECORDING

ON CONNECTOR 1402 PIN 1 AND 3 AND ROTATE

CH1 2.00 V~ MTB 500us ch1+

CHECK CONNECTION

BETWEEN INTERFACE BOARD AND

MOZART MAIN BOARD

-

NO

CHECK AUDIO SIGNAL

(MOZART DIAGRAM 5)

THE DISPLAY SHOWS -12 DB.

SELECT ANALOG RECORDING

INPUT BY PRESSING SOURCE

THE EASY JOG/ENTER KEY UNTIL

ON TESTPOINTS A8 AND A9

YES

A13

C SIGNAL OF IC7402

2

A12

A11

A10

ch1: pkpk= 3.23 V

CHECK I

CHECK IC 7402

-

ch1: freq= 1.00kHz

ch1

ADJUST WITH JOG KEY

CHECK IC 7401

-

NO

YES

(MOZART DIAGRAM 5)

CHECK AUDIO SIGNAL

ON TESTPOINTS A10 AND A11

RIGHT CHANNEL

MSBMSB LSB

32

LEFT CHANNEL

2,1168MHz

44,1KHz

A15A14 A16 A4A3 A26

CH1 2.00 V~ MTB 500us ch1+

1

CHECK POWER SUPPLY IC 7301

CHECK IC 7301

-

-

(MOZART DIAGRAM 4)

CHECK AUDIO SIGNAL

ON TESTPOINTS A12 AND A13

YES

BCLK

WCLK

DATA1

0.5uS/DIV

CHECK POWER SUPPLY IC 7312

CHECK IC 7312

-

-

NO

S - SIGNALS

2

CHECK I

YES

(MOZART DIAGRAM 4)

ON TESTPOINTS A14, A15 AND A16

Page 24

GB 24 CDR Mozart5.

Personal Notes:

Trouble Shooting

Page 25

6. Block Diagrams

Block Diagram FREYA Module

LOADER ASSY

TURN

TABLE

FS

PHOTO

DIODES

B1

B2

C4

C3

C1 C2

A1

A2

SLEDGE

TRAY

TRAY

SWITCH

M

MODULATOR

LASER

PDAR

RADIAL

FOCUS

M

M

+

FLEX

11p

FLEX

30p

FLEX

8p

4

MAINBOARD FREYA 2

1301

1008

FSA

IE

EPONRC

IW

WPONRC

IR

FS30V

CAHF

C1LF - C4LF

A1LF, A2LF

B1LF, B2LF

1306

SIN+, SINCOS+, COS-

1006

TRAYSW

FORWARD SENSE CIRCUIT

RECORDING

CDRW

TO CDR60

(HF DATA CAPTURE)

RAD+, RADFOC+, FOC-

SL+, SL-

TR+, TR-

EFMTIM3

LO9805

EPONRC

WPONRC

LDON

BIASC

ERON

RECORDING

CDRW

ALS

ASTROBE

AINTON

LDON

BIASC

AEGER

TZA1020

DIODE

STAGE

2

DIODE

STAGE

1

S2V9

GAP

REF

PCS PRE-AMP

NE532

7119, 7120

POWER

DRIVER

BA5938FM

Block Diagrams

FSON

FSOF

I-ERASE

I-WRITE

I-READ

PW

DALPHA

ERON

RECORDING

TIMING

I / O

DP4

+

RECORDING

ERON

RECORDING

FSCLR

ERASEC

P

MIN/MAX

CONTR

ALPHA

DETECTOR

BETA

DETECTOR

BALANCE

NORMALIZER

7010

7003

ALS

ASTROBE

AINTON

DALPHA

+ / -

I

RAD

FOCUS

SLEDGE

TRAY

UCOIL, VCOIL, WCOIL, U+, U-, V+, V-, W+, W-, HALL+, HALL-

7126D

FSRSFSWSRDGAIN

PWRITE

PWB

S2V9

S2V9

S2V9

S2V9

ALPHA0

A1, A2, CALF

TLN, MIRN

FEN, REN

RE

7050A, 7050B

LWRT

POR

N

N-1, N+1

I2C

XDAC

M62364

DAC

PWD

DAC

DAC

DAC

DAC

PWMIN

DAC

PWMAX

7050C

WOBBLE

FROM FORWARD

SENSE CIRCUIT

REFSIN, SINPHI, REFCOS, COSPHI

FSW

FSR

7008

DAC DAC

12

BIT

SHIFT

REGISTER

7126C

PERASE

PWD

PWD

DELTA P

PRCOARSE

PRFINE

PWB

7002

I2C

V

SHIFT

REG

TO MACE2 (PCS)

LWRT

E5V

EFMDATA, EFMCLK

7022

S2V9

7009

FTCH, FTCL

FSR, FSW

VRA, VFO, VSL

TRAYIN, TRAYOUT

TRAYSWF

LASDACDI

LASDACCK

LASDACLD

GB 25CDR Mozart 6.

HALL

MOTOR

DRIVER

BA6856FP

ATIPSYNC

PW

OPC

LASER

CONTROL

TRACK

COUNTER

PCS

SERVO

CONTROLS

PORT 5

PORT 4

7004

I2C BUS

OFFTRACK

LLP

HALL U, HALL V, HALL W

MOTO1

MOTOR/TACHO

OFFTRACK

INTERFACE

CDR60LWRT

LLP

EFMDATA

EFMCLK

ATIPSYNC

WOBBLE

RAM ROM

SPECIAL FUNCTION

REGISTERS

MACE2

SAA7399

ADC

AGC

REF

MODULATOR

CONTROL

EFM

MODULATOR

EFM CLOCK

GENERATOR

WOBBLE

PROCESSOR

BIT

DETECTOR

HF DATA

CAPTURE

HIN

7360

HFS0

HF AMP

FILTER

CAHF

FROM CDM3800

(PDAR)

7008

I2C

EEPROM

M24C16

PORT

REGISTERS

8051

CPU

TEST DEBUG

CDR60

SAA7392

DECODER

ENCODER

ERROR

CORRECTION

AND MEMORY

PROCESSOR

DEMODULATOR

RESET

SRSTN

SYST CLK

GENERATOR

SUBCODE

I / O

SUB - CPU INTERFACE

CDR60CS

CDR60INT

7019

MUTE, ATT, DEEMP

BE-RESET

I2S1-MS

PORT

REGISTERS

CLOCK

GEN

EBU

I2S

I / O

MRDN

MWRN

ALE

7018

CDR60PLL

TO CDR60

RAM

CDR60PLL

FROM MACE2

7015

I2S BUS

SUBCODE BUS

CD TEXT

DATA

BUS

DSA-CDR

7017

FLASH

EPROM

+12V

+5V

7016

DEMUX

ADDRESS

BUS

EBU_OUT

I2S1

1000

8001

FLEX

36p

1201

B

A

C

K

E

N

D

(

T

O

C

U

S

T

O

M

E

R

I

N

T

E

R

F

A

C

E

(

CL 16532046_016.eps

050701

Page 26

Block Diagram MOZART Back-End Module

MAINBOARD CDR2001

1201

CD R/W

B

A

4

EBU2 (Pb)

I2S1(in/out)

S

I

C

FLEX

36p

3

4

Mute, Attenuation, Deemphasis

3

CD TEXT

RS232

E

N

G

FREYA EAN

FREYA CLK

I

N

E

Block Diagrams

7004

/2

74LV74D

GB 26CDR Mozart 6.

1 23

1005

VCXO

7002

FILTER

CLK 33,86MHz

Xtrim

EBUIN2

I2S1 IN/OUT

2V5

CORE

SUPPLY

GND 3V3

I/O

SUPPLY

3V3 3V3

GND

SUPPLY

MOZART

GND GND

PLL

SUPPLY

OSC

7000

JTAG/BDM

CONTROL

ADRESS

DATA

7100

8

20

16

SDRAM

2MB

MCF5248

FREYA EAN

CLK 16

PLAYBACK

ROUTING

I2S

INTERFACE

CONTROL

7101

FLASH

Mute,

Kill out

Deem-

phasis

I2S2 I2S3

3

3

EBU4 Ext INI

EBU3 opt IN

COPY ANALOG

EBU Dig_Opt Out

Pro Dig Out

I2S4 IN

PWR ON RST

I2C

IRQ FRONT

3

1MB

C

D

M

O

D

U

L

E

Power

Supply

Unit

FLEX

8p

4

7311

1205

SDA,SICL,Rab, Sild

EBU1 (PB)

4

DAC ADC

ZERO

7300

OPAMP

circuitry

Reset CD10

7208

DC/DC

1214

+5V

6

GND

+12V

DC/DC

DC/DC

DC/DC

7209

7201

7202

-12V

DC/DC

7200

DC/DC

-8VA

6204

6202

3V3

2V5

+8VA

+5VA

-5VA

-8VA

1203

+5V

EBU DIG

OPT OUT

circuitry

EBU EXT INI

KILL

Kill

EBU3 COAX

Kill

1215

7010

BUFFER

2

KILL

ADC CLKDAC CLK

ANALOG

SWITCH

IO CLK 16

1

I2S

7312

7401

OPAMP

circuitry

Potmeter

7401

OPAMP

circuitry

EBU IN FREYA

7301

7400

7402

7400

D

CONTROL

INTERFACE

IRQ FRONT

2

I2C

PWR ON RST

FLEX

6p

1007 1417

5

I

S

P

L

A

B

O

A

R

D

Y

-12V

Kill

+12V

PWR ON RST

1402

A_Out_Left

A_Left_In

A_Out_Right

A_Right_In

+8VA-8VA

4

EBU DIG

OPT OUT

MUTE, ATT,

DEEMP.

EBU EXT INI

I2S

PRO DIG OUT

PWR ON RST

1209

IO CLK ABBA

I2S2 (DAC)

COPY ANALOG

I2S3 (ADC)

MUTE, ATT,

DEEMP.

DIGITAL

INTERFACE

5

FLEX

17p

SEPARATE AD/DA

INTERFACE

FLEX

13051304

17p

EXT. DAC/ADC

INTERFACE

1303

FLEX

7p

INTERFACE BOARD

AUDIO SIGNAL

INTERFACE

CL 16532046_017.eps

130701

Page 27

Electrical Diagrams & Print Layouts

7. Electrical Diagrams & Print Layouts

CDR Mozart Main Board Diagram 1

CDR MOZART MAIN BOARD - CIRCUIT DIAGRAM 1

GB 27CDR Mozart 7.

123

{EMUL_PST3,EMUL_PST2,EMUL_PST1,EMUL_PST0,EMUL_DATA3,EMUL_DATA2,EMUL_DATA1,EMUL_DATA0,EMUL_PSTCLK,EMUL_DSCLK,EMUL_BKPT,EMUL_DSI,EMUL_DSO,EMUL_RESET,PWR_ON_RST}

3023-C

3

+3V3

+3V3

EMUL_PST2

EMUL_PST0

PWR_ON_RST

+3V3

81

4K7

4K7

4K73014-A

18

4K7

36

4K7

45

I023

R7

DAC_CLK16

R8

ADC_CLK16

R9

4324

F004

R10

IO_CLK_ABBA

4K7

+3V3

10K

3425-A

18

MUTE_DAC_FREYA

+3V3

F002

F003

F005

I021

33M8688

560p

Start-Up DSW

3002

1M

1005

CX-11F

7002-A

MC34072

1

3008

12K

6003

2032

OPTION

1000-2

1000-1

2

4

6

8

10

12

14

16

18

20

22

24

26

1000-4

1000-6

1000-8

1000-10

1000-12

1000-14

1000-16

1000-18

1000-20

1000-22

1000-24

1000-26

3003

330R

1000-3

1000-5

1000-7

1000-9

1000-11

1000-13

1000-15

1000-17

1000-19

1000-21

1000-23

1000-25

3021

4K7

+3V3M

+3V3M

+3V3M

+3V3M

+3V3M

1

3

5

7

9

11

13

15

17

19

21

23

25

3014-C

3014-D

I022

PWR_ON_RST

EMUL_DATA2

EMUL_DATA0

3023-A

EMUL_PST2

EMUL_PST0

3012

3013 4K7

I045

560p

2029

I046

3423

270K

BB147

3000

+12V

4R7

2033

4u7

100n

I026

3007

3

8

4

15K

IO_CLK16

2

10n

2014

I027

4K7

3009

A

+3V3

+3V3

10K

10K

3006

3425-D

45

EMUL_PST3

EMUL_PST1

B

C

{CD10_SDA,CD10_RAB,CD10_SILD,CD10_SCL,RESET_CD10}

{MUTE_DAC_FREYA,DAC_DEEPI,FREYA_DEEPI,FREYA_ATTI}

{CDTEXT_RCK,CDTEXT_SFSY,CDTEXT_SUB}

{MUTE,FREYA_MS,FREYA_MUTE,RESET_FREYA,RST_ADDA}

{TOOL_TXD,TOOL_RXD,FREYA_TXD,FREYA_SUR,FREYA_RXD,FREYA_CPR}

EMUL_BKPT

EMUL_DSCLK

EMUL_DSI

10K

3425-C

EMUL_DSO

36

EMUL_PST3

EMUL_PST1

EMUL_DATA3

EMUL_DATA1

EMUL_PSTCLK

D

E

R4

F

2028

I024

3005

6002

BB147

I025

I047

10K

F001

3004

270K

2030

33n

G

H

7002-B

MC34072

7

5

8

6

4

I

{IIC_CLK,IIC_DATA}

45678

+3V3

6

10K

3425-B

27

OPTION

+3V3M

4001

MUTE

FREYA_MS

FREYA_MUTE

TOOL_RXD

FREYA_CPR

FREYA_RXD

5005

100MHZ

74LVC125A

3028-B

7

3

2

100R

74LVC125A

3028-A

8

1

6

100R

74LVC125A

2035

100n

3028-D

5

4

8

100R

74LVC125A

3028-C

36

11

100R

+3V3

3090

10K

7005

4K7

3023-D

MC33464N

54

2

IN

FREYA_MUTE

MUTE_DAC_FREYA

DAC_DEEPI

FREYA_MS

CDTEXT_RCK

CDTEXT_SFSY

CDTEXT_SUB

RESET_FREYA

MUTE

FREYA_DEEPI

FREYA_ATTI

TOOL_TXD

TOOL_RXD

FREYA_TXD

FREYA_SUR

FREYA_RXD

FREYA_CPR

RST_ADDA

I044

7010-A

14

2

7

1

7010-B

14

5

7

4

7010-C

14

9

7

10

7010-D

14

12

7

13

1

RESET_

5

NC

GND

3

4

2016

1n

R3

KILL_OUT

FREYA_FLAG

3014-B

27

+3V3CLK

74LVC74AD

14

3094

9

100R

813

7

+3V3

5007

100MHZ

7012-D

74LVC00AD

4K7

R5

7004-B

12

13

SYSCLK_8

EMUL_DSCLK

EMUL_BKPT

EMUL_DSI

EMUL_DSO

R1

CD10_SDA

CD10_SCL

CD10_SILD

CD10_RAB

RESET_CD10

R2

I031

SYSCLK_16

SYSCLK_8

10

11

12

14

11

SYSCLK_16

7

7012-C

74LVC00AD

9

10

COPY_ANALOG

+3V3M

3023-B

72

4K7

F031

F033

F035

3027-C

F037

F039

F041

3087-D 4 5

F046

3041-A

F044

3024-B

F052

3024-D

F050

3024-C

F048

3042-A 1 8

3027-A 1

3040-D

3027-D 4

F063

3041-B

F065

F069

3049 47R

4K7 3011

I039

OPTION

74LVC74AD

EMUL_PST1

4K7

3010

7012-A

74LVC00AD

2

1

14

8

7

+3V3M

+3V3M

+3V3M

3026-B

3026-D

45

4K7

3026-A

3026-C

36

27

4K7

4K7

I032

36

47R

47R

18

47R

27

47R

813086-A

47R

45

47R

3

6

47R

47R

8

47R

45

47R

5

47R

27

47R

F072

47R3050

+5V

3015

10K

10K

3016

+3V3

5004

7004-A

3056

47R

100MHZ

14

5

61

7

14

3

4

5

7

47R

7000

18

MCF5248

4K7

E12

TCK

F11

TRST|DSCKL

E13

TMS|BKPT

D11

TDI|DSI

D10

TDO|DSO

P12

RSTI

C11

HIZ

L9

USB-DMNS|GPIO7

F4

USB-DPLS|GPIO6

L4

USB-XVER|GPIO5

L8

USB-TXDPLS|GPIO4

L6

USB-TXDMNS|GPIO3

H3

USB-ISENABLE|GPIO2

L11

USB-SUSPEND|GPIO55

K11

USB-AFEENABLE|GPIO56

D6

USB-TXENABLE|GPIO8

F12

RCK|GPIO43

F13

SFSY|GPIO44

G12

SUBR|GPIO45

A13

TOUT0|GPO10

N11

TOUT1|GPO11

B13

TIN0|GPI10

P11

TIN1|GPI11

D7

TXD1|GPO12

D8

RTS1|GPO13

B7

RXD1|GPI12

D9

CTS1|GPI13

A9

TXD2|GP014

A10

RTS2|GPO15

B10

RXD2|GPI14

B11

CTS2|GPI15

CRIN

H14

+5V

SYSCLK_16

F007

+3V3CLK

2031

100n

4

+3V3CLK

3

2

3426

100R

2047

100n

7012-B

74LVC00AD

14

6

7

4002

OPTION

SYSCLK_16

EMUL_DATA1

EMUL_DATA2

EMUL_DATA0

EMUL_PSTCLK

F016

F015

F022

F023

3429

D13

A11

B12

A12

CNPSTCLK|GPIO58

DBDCDDATA0|GPIO31

DBDCDDATA1|GPIO32

DBDCDDATA2|GPIO33

XTRIM|GPO39

CL11|GPO41

CL16|GPO42

CROUT

F14

H13

G14

G13

47R

3001

+3V3CLK

FREYA_CLK

47R

3019

4003

SYSCLK_8

EMUL_PST0

EMUL_DATA3

F024

A14

DBDCDDATA3|GPIO34

SCL

E4

D4

3087-B 47R27

3087-C

IIC_CLK

5001

EMUL_PST1

EMUL_PST2

EMUL_PST3

F018

F021

F017

F020

100n

2004

F3

E3

B14

C14

C13

D14

PAD_VDD

PAD_GND

DBDCPST0|GPIO35

DBDCPST1|GPIO36

DBDCPST2|GPIO37

DBDCPST3|GPIO38

MOZART

SCLK2|GPIO19A7SCLK3|GPIO18

SCLK|GPIO17

SDA

SDATAI1|GPI18B9SDATAI3|GPI21

IRCK1|GPIO63

SDATAO1|GPO16

N13

L12

L13

K13

N14

47R

47R

47R3040-B 2 7

8

36

45

45

3040-A 47R1

3022-D 47R

3041-D

IIS_BCLK_DAC

IIS_DATAI_FREYA

IIS_DATAO_FREYA

IIS_BCLK_FREYA

IIS_WS_FREYA

IIC_DATA

100MHZ

2000

4u7

100n

100n

100n

100n

2005

2007

2006

2008

J3

H4

PAD_VDD1L3PAD_VDD2P4PAD_VDD3K8PAD_VDD4

PAD_GND1K3PAD_GND2M4PAD_GND3L5PAD_GND4

SCLK4|GPIO25

IRCK2|GPIO20B8IRCK3|GPIO23

IRCK4|GPIO26

SDATAO2|GPO18

L14

P13

M13

M14

P14

47R45

47R3022-B 2 7

47R3042-C 3 6

47R3022-C 3 6

36

3022-A 47R18

3042-D

3040-C 47R

IIS_DATAI_EXT

IIS_WS_EXT

IIS_BCLK_EXT

IIS_DATAI_ADC

IIS_BCLK_ADC

IIS_WS_ADC

IIS_WS_DAC

IIS_DATAO_DAC

{IIS_BCLK_FREYA,IIS_WS_FREYA,IIS_DATAI_FREYA,IIS_DATAO_FREYA}

910111213

+2V5

5002

100MHZ

+3V3M

100n

100n

100n

2011

2012

D12

J4

PAD_VDD6C4PAD_VDD7

PAD_GND6D5PAD_GND7

CORE_GND

EBULN2|GPI28

EBULN3|GPI29

EBULN4|GPI30

EBUOUT1|GPO27

EBUOUT2|GPO28

P10

A8

N9

P9

47R

47R

3036

3035

I040

I034

G4

CORE_VDD

+3V3M

4K73063-A

18

2043

100n

F012

2001

4u7

100n

100n

2013

2015

K5

K10

E10

K6

L10

CORE_VDD1L7CORE_VDD2

CORE_VDD3E9CORE_VDD4E8CORE_VDD5E5CORE_VDD6

CORE_GND1K7CORE_GND2

CORE_GND3

DATA16N7DATA17P7DATA18N6DATA19P6DATA20P5DATA21N4DATA22N5DATA23F2DATA24G1DATA25G2DATA26

P8

F076

F081

F082

F078

F084

F074

F087

D(17)

D(21)

D(20)

D(16)

D(19)

D(18)

+5V

2K2

3095

I036

3K3

3096

A1

F011

100n

2009

2010

K9

E11

M11

PAD_VDD5

PAD_GND5

SDATAI4|GPI24

EBULN1|GPI27

K12

N10

I041

F010

{IIS_BCLK_EXT,IIS_WS_EXT,IIS_DATAI_EXT}

{IIS_BCLK_ADC,IIS_WS_ADC,IIS_DATAI_ADC}

{IIS_BCLK_DAC,IIS_WS_DAC,IIS_DATAO_DAC}

+3V3

5000

F013

100n

2017

CORE_GND4E7CORE_GND5E6CORE_GND6

DATA27H2DATA28J1DATA29J2DATA30K1DATA31

H1

F086

F077

F075

F079

F089

D(22)

D(26)

D(25)

D(24)

D(23)

PROF_DIG_OUT

OPTION

EBU_EXT_IN

EBU_OPT_IN

EBU_IN_FREYA

EBU_IN_CD10

100MHZ

2002

4u7

100n

100n

2020

2019

H12

G11

J11

K14

OSCVDD

OSCGND

PLLGVDD

PLLGGND

SDLDQM|LWE

SDUDQM|UWE

SDRAM-CS2|GPIO0

F080

F083

F085

F088

D(30)

D(29)

D(28)

D(27)

+5V

7011

BFS20

A20

4013

+2V5

5003

100MHZ

100n

2021

J13

J12

J14

H11

A1

A2

A3

PLL1VDD

PLL1GND

PLLCVDD

PLLCGND

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

SDRAM_CS1

SDRAS

SDCAS

SDWE

BCLKE

BCLK

TEST1

TEST2

TEST3

TEST4

OE|GPIO9

RW|GPO40

CS0A6CS1|GPIO1

N12

E14

A1

47R3041-C 3 6

47R

47R3087-A

27

18

27

3042-B

3027-B 47R

F091

F090

OE

WE

D(31)

CS_FLASH

I037

100R

3097

IIC_DATA

IIC_CLK

F014

2003

F019

100u

F025

B6

A5

B5

A4

B4

A3

B3

A2

C1

C2

B1

B2

K2

L1

L2

M1

D1

D2

M2

N1

D3

G3

K4

I012

P3

F1

I014

N2

N8

I016

P1

P2

I018

N3

E1

I020

E2

I033

C3

M3

M12

C12

3063-B

27

PROF_DIG_OUT

F092

4K7

F028

F030

F034

F038

F042

F045

F049

F053

F056

F058

F060

I013

I017

I019

4K7

3063-C

F073

I035

F026

F029

F032

F036

F040

F043

F047

F051

F055

F057

F059

3024-A

81

3086-B

3085-A

18

3085-B

3085-C

36

3085-D

45

3086-D

3086-C

36

+3V3M

36

A(10)

A(11)

A(12)

A(13)

A(14)

A(15)

A(16)

A(17)

A(18)

A(19)

A(20)

A(21)

A(22)

A(23)

I038

68R

100p

2044

OPTION

+5V

+5V

PWR_ON_RST

IRQ_FRONT

4K7

4K7

3089

3088

3104 123 4289.3

A(1)

A(2)

A(3)

A(4)

A(5)

A(6)

A(7)

A(8)

A(9)

3032

3099

330R

3098

82R

47R

47R27

47R

47R3084

47R27

47R

47R

47R45

47R

+5V

4K7

3063-D

45

F061

F062

F064

IRQ_FRONT

F066

F067

F068

F070

F071

6001

TLMG3100

FREYA_EAN

100p

2037

2036

{CS_FLASH,OE,WE}

D(16:31)

{SDLDQM,SDUDQM,SDRAM_CS1,SDRAS,SDCAS,SDWE,BCLKE,BCLK}

SDLDQM

SDUDQM

SDRAM_CS1

SDRAS

SDCAS

SDWE

BCLKE

BCLK

OPTION

EBU_DIG_OPT_OUT

I028

3427

I042

F093

220R

I043

3428

3018

220R

I029

220R

3017

220R

I030

1n

100p

F096

2046

F094

1n

2024

CL 16532046_018.eps

A(1:23)

1

2

3

4

5

6

1007

FE-BP-A1

101001

CONTROL

1000-1 A2

1000-10 B2

1000-11 B2

1000-12 B2

1000-13 B2

1000-14 B2

1000-15 B2

1000-16 B2

1000-17 B2

1000-18 B2

1000-19 B2

1000-2 A2

A

1000-20 B2

1000-21 B2

1000-22 B2

1000-23 C2

1000-24 C2

1000-25 C2

1000-26 C2

1000-3 A2

1000-4 A2

1000-5 A2

1000-6 A2

B

1000-7 A2

1000-8 A2

1000-9 B2

1005 F2

1007 H13

2000 A8

2001 A9

2002 A10

2003 A11

2004 B8

2005 B8

2006 B8

C

2007 B8

2008 B8

2009 B9

2010 B9

2011 B9

2012 B9

2013 B9

2014 H2

2015 B9

2016 C5

2017 B10

2019 B10

D

2020 B10

2021 B10

2024 I12

2028 F1

2029 F2

2030 G1

2031 G7

2032 G2

2033 G2

2035 G4

2036 I12

E

2037 I12

2043 G9

2044 H11

2046 I12

2047 H7

3000 G2

3001 F7

3002 F2

3003 F2

3004 F1

3005 H1

3006 A1

F

3007 G3

3008 H2

3009 H2

3010 H6

3011 E6

3012 D3

3013 D3

3014-A E3

3014-B E5

3014-C E3

3014-D E3

3015 F7

G

3016 F6

3017 I13

3018 I13

3019 H7

3021 C2

3022-A G8

3022-B G8

3022-C G8

3022-D G8

3023-A D3

3023-B B6

H

3023-C A3

3023-D A4

3024-A D11

3024-B C6

3024-C D6

3024-D C6

3026-A B7

3026-B B6

3026-C B6

3026-D B6

3027-A D6

3027-B F11

I

3027-C C6

3027-D D6

3028-A G4

3028-B F4

3028-C H4

3028-D H4

3032 F12

3035 F9

3036 F9

3040-A G8

3040-B G8

3040-C G8

3040-D D6

3041-A C6

3041-B D6

3041-C F10

3041-D G8

3042-A D6

3042-B F10

3042-C G8

3042-D G8

3049 E6

3050 E6

3056 G6

3063-A F9

3063-B E11

3063-C E11

3063-D C12

3084 D11

3085-A D11

3085-B D11

3085-C D11

3085-D D11

3086-A C6

3086-B D11

3086-C D11

3086-D D11

3087-A F10

3087-B G7

3087-C G7

3087-D C6

3088 I11

3089 I11

3090 A5

3094 G5

3095 G9

3096 G9

3097 G11

3098 G12

3099 H12

3423 F2

3425-A B3

3425-B B4

3425-C A1

3425-D A1

3426 H7

3427 H13

3428 H13

3429 B7

4001 C4

4002 I7

4003 I7

4013 H10

4324 H3

5000 A10

5001 A8

5002 A9

5003 A10

5004 G6

5005 F4

5007 H5

6001 F12

6002 F2

6003 F2

7000 B7

7002-A H2

7002-B H1

7004-A G6

7004-B G5

7005 A4

7010-A F4

7010-B G4

7010-C G4

7010-D H4

7011 G10

7012-A H6

7012-B H7

7012-C I5

7012-D H5

F001 H1

F002 F4

F003 G4

F004 H3

F005 H4

F007 G7

F010 H9

F011 A9

F012 A9

F013 A10

F014 A11

F015 A7

F016 A7

F017 A8

F018 A8

F019 A11

F020 A8

F021 A7

F022 A7

F023 A7

F024 A7

F025 B11

F026 B11

F028 B11

F029 B11

F030 B11

F031 B6

F032 C11

F033 C6

F034 C11

F035 C6

F036 C11

F037 C6

F038 C11

F039 C6

F040 C11

F041 C6

F042 C11

F043 C11

F044 C6

F045 C11

F046 C6

F047 C11

F048 D6

F049 C11

F050 C6

F051 C11

F052 C6

F053 C11

F055 C11

F056 C11

F057 D11

F058 D11

F059 D11

F060 D11

F061 D12

F062 D12

F063 D6

F064 D12

F065 D6

F066 D12

F067 D12

F068 D12

F069 D6

F070 D12

F071 D12

F072 E6

F073 E11

F074 F9

F075 F10

F076 F9

F077 F10

F078 F9

F079 F10

F080 F10

F081 F9

F082 F10

F083 F10

F084 F9

F085 F10

F086 F10

F087 F9

F088 F10

F089 F10

F090 F10

F091 F10

F092 F11

F093 H12

F094 H12

F096 I12

I012 D11

I013 D11

I014 D11

I016 D11

I017 D11

I018 D11

I019 D11

I020 D11

I021 E2

I022 F3

I023 F3

I024 F1

I025 G2

I026 G2

I027 H2

I028 H13

I029 I13

I030 I13

I031 F5

I032 B7

I033 E11

I034 H9

I035 F11

I036 G10

I037 G10

I038 G11

I039 F6

I040 G9

I041 H9

I042 H13

I043 H13

I044 F4

I045 F2

I046 F2

I047 G2

12345678910111213

Page 28

Electrical Diagrams & Print Layouts

CDR Mozart Main Board Diagram 2

CDR MOZART MAIN BOARD - CIRCUIT DIAGRAM 2

GB 28CDR Mozart 7.

1234567891011121314

A(1:23)

{SDLDQM,SDUDQM,BCLKE,BCLK,SDRAM_CS1,SDWE,SDCAS,SDRAS}

{CS_FLASH,OE,WE}

D(16:31)

A

+3V3MEM

2103

100n

B

C

D

E

F

A(16)

A(15)

A(14)

A(13)

A(12)

A(11)

A(10)

A(9)

A(17)

A(18)

A(19)

A(20)

A(21)

A(22)

OPTION

SDLDQM

SDUDQM

BCLK

BCLKE

7105

GM72V661641CT

27

VCC11VCC214VCC3

23

A0

24

A1

25

A2

26

A3

29

A4

30

A5

31

A6

32

A7

33

A8

34

A9

22

A10-AP

35

A11

21

BA1-A12

20

BA0-A13

15

DQML

39

38

37

36

40

8MB

DQMU

CLK

CKE

NC1

NC2

VSS128VSS254VSS341VSSQ16VSSQ212VSSQ346VSSQ4

VCCQ13VCCQ2

S

D

R

A

M

943

VCCQ3

49

VCCQ4

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

RAS_

CAS_

WE_

CS_

52

2

4

5

7

8

10

11

13

42

44

45

47

48

50

51

53

18

17

16

19

D(16)

D(17)

D(18)

D(19)

D(20)

D(21)

D(22)

D(23)

D(24)

D(25)

D(26)

D(27)

D(28)

D(29)

D(30)

D(31)

SDRAS

SDCAS

SDWE

SDRAM_CS1

A(1:23)

A(16)

A(15)

A(14)

A(13)

A(12)

A(11)

A(10)

A(9)

A(17)

A(18)

A(19)

A(20)

SDLDQM

SDUDQM

BCLK

BCLKE

2105

100n

7100

GM72V161621

21

A0

22

A1

23

A2

24

A3

27

A4

28

A5

29

A6

30

A7

31

A8

32

A9

20

A10

19

A11

14

DQML

36

DQMU

35

CLK

34

CKE

33

NC1

37

NC2

F102

I202

5101

100MHZ

25

VCC11VCC2

VCCQ17VCCQ213VCCQ338VCCQ4

S

D

R

A

M

2MB

VSS126VSS250VSSQ14VSSQ210VSSQ3

41

44

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

RAS_

CAS_

WE_

CS_

VSSQ4

47

+3V3MEM

2100

100n

2102

100n

2104

100n

2106

100n

2

3

5

6

8

9

11

12

39

40

42

43

45

46

48

49

17

16

15

18

4K7

4K7

3102-B

3102-A

3102-C

36

27

D(16)

D(17)

D(18)

D(19)

D(20)

D(21)

D(22)

D(23)

D(24)

D(25)

D(26)

D(27)

D(28)

D(29)

D(30)

D(31)

SDRAS

SDCAS

SDWE

SDRAM_CS1

4K7

4K7

3102-D

45

18

A(1)

A(2)

A(3)

A(4)

A(5)

A(6)

A(7)

A(8)

A(9)

A(10)

A(11)

A(12)

A(13)

A(14)

A(15)

A(16)

A(17)

A(18)

A(19)

CS_FLASH

OE

WE

+3V3MEM

+3V3MEM

3110

4K7

I201

7101

Am29LV800B

25

A0

24

A1

23

A2

22

A3

21

A4

20

A5

19

A6

18

A7

8

A8

7

A9

6

A10

5

A11

4

A12

3

A13

2

A14

1

A15

48

A16

17

A17

16

A18

26

CE_

28

OE_

11

WE_

12

RESET_

47

BYTE_

+3V3MEM

VCC

F

L

A

S

H

VSS146VSS2

2108

100n

37

27

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15|A-1

RY|BY_

OPTION FOR IIC ADRESSES

+3V3MEM

+3V3MEM

+3V3MEM

4K7

10K

3115

3116

4K7

10K

4K7

3111

3113

29

DQ0

31

DQ1

33

DQ2

35

DQ3

38

DQ4

40

DQ5

42

DQ6

44

DQ7

30

DQ8

32

DQ9

34

36

39

41

43

45

15

14

NC4

13

NC3

NC

10

NC2

9

I200

D(16)

D(17)

D(18)

D(19)

D(20)

D(21)

D(22)

D(23)

D(24)

D(25)

D(26)

D(27)

D(28)

D(29)

D(30)

D(31)

F103

A(20)

3109

D(16)

D(17)

D(18)

+3V3MEM

1K

3112

10K

3114

1110 G1

1120 G2

1130 G3

1140 G4

1150 G5

2100 A8

2102 B8

2103 B7

2104 B8

2105 B7

2106 B8

2107 H8

2108 B12

2110 G1

A

2111 G1

2112 H1

2113 H1

2114 G2

2115 G2

2116 H2

2117 H2

2118 H4

2119 G4

2120 H4

2121 H4

2122 H3

B

2123 H3

2125 H3

2126 G5

2127 G5

2128 H5

2129 H5

2130 G4

2131 G3

2132 G3

3102-A F9

3102-B F9

C

3102-C F8

3102-D F9

3109 E13

3110 F11

3111 B13

3112 C13

3113 B14

3114 C14

3115 B14

3116 C14

5100 G8

5101 A7

D

7100 C7

7101 B11

7105 C2

F100 G8

F102 F7

F103 E12

I200 E12

I201 F11

I202 A8

E

F

G

1110

1n

2111

1n

2112

1n

H

HGND1

2113

100n

1120

HGND2

2114

1n

2115

1n

2116

1n

2117

1n

1130

HGND4

2132

1n

2131

1n

2122

1n

2123

1n

2125

1n

1234

OPTION

AGND

AGND

1140

HGND3

2130

2119

2118

2120

2121

1150

HGND5

21262110

2127

2128

2129

1n

1n

1n

1n

+3V3

5100

100MHZ

2107

F100

+3V3MEM

4u7

3104 123 4289.3

CL 16532046_019.eps

1n

AGND

1n

AGND

1n

1n

1n

G

H

101001

5 6 7 8 9 10 11 12 13 14

Page 29

Electrical Diagrams & Print Layouts

CDR Mozart Main Board Diagram 3

CDR MOZART MAIN BOARD - CIRCUIT DIAGRAM 3

12345678910111213

{IIS_WS_FREYA,IIS_BCLK_FREYA,IIS_DATAO_FREYA,IIS_DATAI_FREYA}

{CDTEXT_RCK,CDTEXT_SFSY,CDTEXT_SUB}

{FREYA_MUTE,FREYA_ATTI,FREYA_DEEPI,FREYA_MS}

{FREYA_SUR,FREYA_CPR,FREYA_TXD,FREYA_RXD}

{CD10_SDA,CD10_SCL,CD10_RAB,CD10_SILD}

{TOOL_RXD,TOOL_TXD,IIC_CLK,IIC_DATA}

IIC_CLK

TOOL_TXD

TOOL_RXD

33p

4K7

3273

2223

R6

+3V3

2289

5212

5211

100MHZ

100n

5210

100MHZ

100n

7214

BFS20

3281

390R

100n

+3V3

3283

3282

2294

2295

2296

I244

1K5

I241

390R

100n

100n

100n

3284

3285

F246

F248

1212

T500mA

446

I216

3K3

1K5

2

2291

100n

I243

F254

2290

3

1

3286

2K2

+3V3

I248

5225

100MHZ

100n

5

100n

2

7215

74HC1GU04

+5BE

31

+12V_MOT

+12V

4

+5V

{MUTE,IIS_BCLK_DAC,IIS_WS_DAC,DAC_DEEPI,IIS_DATAO_DAC,IIS_DATAI_ADC,KILL,IIS_BCLK_ADC,IIS_WS_ADC,IO_CLK_ABBA,RST_ADDA,COPY_ANALOG}

45678910

2293

NC

1208-4

IIC_DATA

1208-3

1208-2

1208-1

4

+12V

1210

A

B

C

D

E

F

G

H

I

CDRW

CD

RESET_CD10

PSU

A26 A5 A4 A3

1201

I266

1

I267

2

3

4

I268

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

I265

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1205

1

I276

2

I277

3

I278

4

I279

5

6

F244

I253

7

8

FMN

+3V3

10K

1214

PH

F255

1

2

3

4

5

F256

6

F211

100R

3297

100R

3298

F213

F214

I245

3299

100R

F215

I246

3270

F216

47R

F217

F218

3236-A

I247

F220

3236-B

F221

3236-C

36

F223

3236-D

I249

3235-D

4

47R

I250

3235-C

3

47R

F227

3203

47R

F230

3235-B

F231

F232

3235-A

18

F233

3212-D

45

47R

3212-C

36

47R

3212-B

27

47R

3212-A

18

3271

47R

47R

3274

47R

3370

3211

4K7

F247

F249

F251

F252

F253

3240

100R

1

5

F226

6

1211

T800mA

446

GND_MOT

+3V3

4K7

2201

33p

2202

I212

2204

2206

2207

2212

47R27

47R

47R45

47R27

47R

2241

2242

2243

2244

2245

7205

BC847B

IIS_WS_FREYA

IIS_BCLK_FREYA

33p

IIS_DATAI_FREYA

33p2203

IIS_DATAO_FREYA

33p

CDTEXT_RCK

33p

CDTEXT_SFSY

CDTEXT_SUB

33p

33p

47R

8

2222

I215

2226

33p

I217

2228

33p

I218

2229

33p

2231

33p

2233

33p

2234

33p

2235

33p

2236

33p

2237

33p

2238

33p

2239

33p

2240

33p

2605

1n

GND_MOT

GND_MOT

33p

330p

330p

330p

330p

3255

3210

5201

2604

100n

5202

100MHZ

I214

FREYA_FLAG

33p

FREYA_MUTE

FREYA_ATTI

FREYA_DEEPI

EBU_IN_FREYA

RESET_FREYA

FREYA_MS

100u

2299

2600

100u

47R

4210

OPTION

FREYA_CLK

FREYA_EAN

FREYA_CPR

FREYA_SUR

FREYA_RXD

FREYA_TXD

+5BE

+12V_MOT

CD10_SDA

CD10_SCL

CD10_RAB

CD10_SILD

2274

2275

123

4

3

2

1

1

I256

EBU_COAX

3267

47R

2292

100n

3222

4R7

2284

+12V

+8VA

+5V

+5V

7220

74HC1GU04

I213

I242

GB 29CDR Mozart 7.

F214 A2

111001

3208 H12

3209 I12

3210 G2

3211 H1

3212-A G2

3212-B F1

3212-C F2

3212-D F1

3213 B6

3214 C6

3215 C6

3216 C6

3217 D6

3218 D6

3219 D6

3220 D6

3221 E6

3222 I5

3225 A12

3229 A12

3231 H12

3235-A D2

3235-B D2

3235-C C2

3235-D C2

3236-A B2

3236-B B2

3236-C B2

3236-D C2

3240 A2

3248 A8

3249 A9

3250 A9

3251 A9

3252 A9

3253 A10

3255 G2

3262 H6

3263 H6

3264 H6

3265 H7

3266 F6

3267 G5

3270 A2

3271 G1

3272 A12

3273 B4

3274 G2

3275 A6

3276 A6

3277 A6

3278 A6

3279 A6

3280 A7

3281 G3

3282 G3

3283 F3

3284 F4

3285 G4

3286 F5

3287 A12

3288 C11

3289 C11

3290 D11

3291 D11

3292 D11

3293 D11

3294 E11

3295 E11

3296 E11

3297 A1

3298 A1

3299 A1

4201 B10

4202 B8

4203 G6

4204 C12

4205 C12

4206 D12

4207 D12

4208 D12

4210 H2

5201 I2

5202 I2

5203 I9

5204 I6

5205 I9

5210 I3

5211 I3

5212 H3

5215 A7

5220 A10

5225 F4

5230 H12

5235 I12

5240 F6

6202 G9

6203 H9

6204 C7

7200 F7

7201 B7

7202 H7

7205 H2

7208 D7

7209 E7

7210 A9

7211 B9

7212 A6

7213 B6

7214 G3

7215 G4

7220 G5

F210 A13

F211 A2

F212 A13

F213 A2

F215 A2

F216 B2

F217 B2

F218 B1

F219 C9

F220 B1

F221 B1

F222 E13

F223 B1

F224 D13

F225 D13

F226 C2

F227 C2

F228 D9

F230 D1

F231 D1

F232 D1

F233 D1

F235 D9

F236 D13

F238 E9

F241 C11

F242 F10

F243 C13

F244 G1

F245 G10

F246 H4

F247 I1

F248 I4

F249 I1

F250 I10

F251 I1

F252 I1

F253 I1

F254 I4

F255 I1

F256 I1

I210 A12

I211 A13

I212 A2

I213 I6

I214 B3

I215 B2

I216 I4

I217 B2

I218 B2

I220 C7

I225 G7

I226 H7

I227 H7

I228 H8

I229 H8

I230 I7

I231 I7

I232 I8

I233 A6

I234 A7

I235 A9

I236 A10