Page 1

For servicing CDR8xx the set has to be divided into two parts:

1. Except for the CD-R/W module all workshops can repair the set on component level.

The Switched Mode Power Supply unit will be exchanged completely in case of a failure.

2.The CD-R/W module can only be repaired on component level with the help of ComPair.

With this tool diagnosing of the set can be done in an interactive way. In this tool also the adjustment procedure has

been implemented. The adjustment is absolutely necessary in case the CDR-Main Board and/or CD drive (CDR Loader)

is disconnected from the matched production combination.

Only designated workshops can perform these repairs!

Please send the complete set to the designated workshop.

Available circuit descriptions:

The Basics of Compact Disc Recordable/Rewritable

4822 725 25242

3rd generation Compact Disc Recording

3104 125 40100

(with reference to description of the Basic Engine)

2nd line Service Manual CDR Mozart Module

3122 785 60030

chapter

Technical Specification and Measurement setup................1-1, 1-2

Location of printed circuit boards............................................1-3

Warnings & Safety..................................................................2-1

Brief Operating Instructions...............................................3-1 to 3-3

Dismantling Instructions.....................................................4-1 to 4-9

Service hints......................................................................5-1 to 5-5

Service Test Program........................................................5-6 to 5-8

BLOCK DIAGRAMS ..........................................................6-1 to 6-5

WIRING DIAGRAM.................................................................6-6

POWER BOARD (for orientation only) ..............................7-1 to 7-2

DISPLAY BOARD..............................................................7-3 to 7-5

KEY left BOARD.....................................................................7-6

FRONT LED BOARD..............................................................7-6

INTERFACE BOARD........................................................7-7 to 7-8

chapter

HEADPHONE BOARD ...........................................................7-9

3CDC MODULE................................................................8-1 to 8-9

EXPLODED VIEWS

apparatus..........................................................................10-1

3CDC module...............................................................8-8 to 8-9

MECHANICAL PARTSLIST see Exploded views

ELECTRICAL PARTSLIST...................................................10-2 ff

CDR800/00/17

Published by MS 0137 Service Audio Printed in The Netherlands Subject to modification

© 3103 785 25100

Compact Disc Recorder

CLASS 1

LASER PRODUCT

©

Copyright 2001 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system or transmitted, in any form or by any means, electronic, mechanical, photocopying,

or otherwise without the prior permission of Philips.

CDR802/00S/01S

CDR820/00/17

CDR822/00S/01S

TABLE OF CONTENTS

SERVICING

Page 2

1-1

TECHNICAL SPECIFICATION

General:

Mains voltage : 220V-240V / 50-60Hz for /00

100V-240V /50-60Hz for /01

120V / 60Hz for /17

Power consumption : ≤ 18W

≤ 1W in stand by

Input / Output:

Analog in:

input sensitivity : ≤250mVrms

max. input voltage : 2,8Vrms

input impedance : 47kΩ

Analog out:

output level : 2V

rms±2dB

output impedance : 300Ω

Microphone in:*

input sensitivity : ≤1mV

rms

max. input voltage : 50mVrms

input impedance : 2kΩ

Digital in (acc. IEC958):

input level : 0,5Vpp

input impedance : 75Ω

Digital out (acc. IEC958):

output level : 0,5V

pp

output impedance : 75Ω

Headphone:

output level : max. 5V

rms at 100kΩ

output impedance : 120Ω

frequency response: 20 - 20.000 Hz ±3dB (typ. ±2dB)

distortion : ≤ 0,01% at 1 kHz and -6dB output level at 120Ω

channel difference : ≤ 3dB at 1 kHz

channel crosstalk : -73dB at 1kHz (typ. -80dB)

AUDIO PERFORMANCE

3CDC module:

To be measured on ANALOG OUT socket.

frequency response : 20 - 20.000 Hz ±0,3dB

signal/noise ratio : ≥ 114dB (120dB A-weighted)

distortion : -90dB at 1 kHz (-95dB typ.)

channel difference : ≤ 0,3dB at 1 kHz

channel crosstalk : -95dB at 1kHz(-100dB typ.)

de emphasis : 0 or 15/50µs switched automatically by subcode on the disc

laser

output power : 500µW

wave length : 780 ±20nm

CD-RW module:

To be measured on ANALOG OUT socket.

frequency response : 20 - 20.000 Hz ±0,3dB (±0,5dB recording)

signal/noise ratio : ≥ 114dB (120dB A-weighted)

distortion : -90dB at 1 kHz (-85dB recording)

channel difference : ≤ 0,3dB at 1 kHz (≤ 0,5dB recording)

channel crosstalk : -95dB at 1kHz (-85dB recording)

de emphasis : 0 or 15/50µs switched automatically by subcode on the disc

laser (laser class 3B)

output power : 1mW max. during reading

20mW max. during writing

wave length : 780 ±20nm

* not on all versions

Page 3

1-2

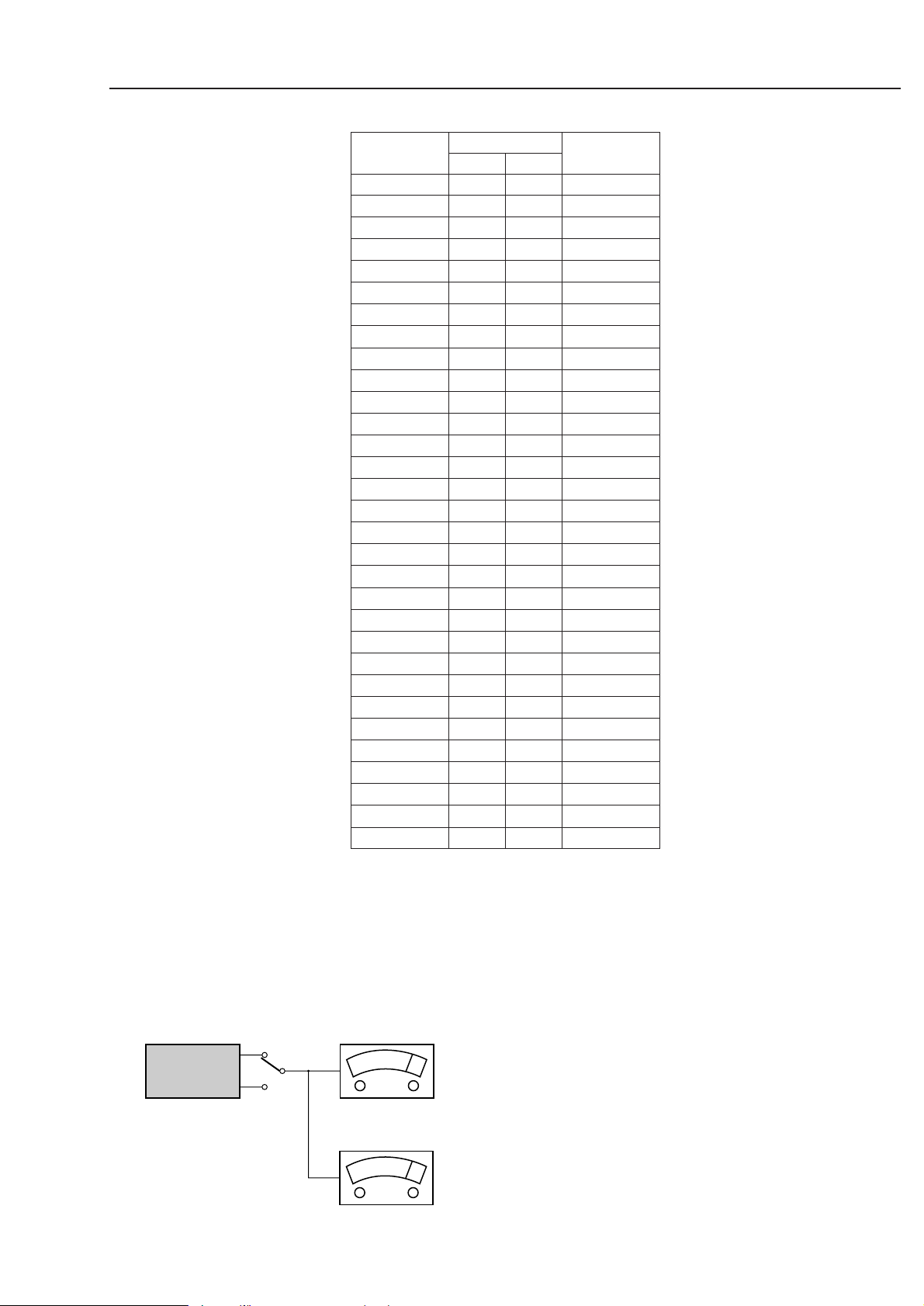

SYSTEM CODE

RC KEY

y

COMMAND CODE

CD

20 26 12

CDR

BRIGHTNESS

Standby

20 26 71

TRACK INCR.

- 26 114

CD TEXT

20 26 88

1

20 26 01

2

20 26 02

3

20 26 03

4

20 26 04

5

20 26 05

6

20 26 06

7

20 26 07

8

20 26 08

9

20 26 09

TEXT EDIT

20 26 82

0

20 26 00

PROGRAM

20 26 36

NO

20 26 49

YES

20 26 87

PLAY

20 26 53

¡

2

9

20 26 33

™

20 26 32

STOP

20 26 54

5

20 26 50

6

;

20 26 52

PAUSE

20 26 48

SHUFFLE

20 26 28

REPEAT

20 26 29

CD1

20 20 55

CD2

20 20 56

CD3

20 20 57

CDR

26 26 63

RC5 code RC283505, 130300

Remote Control:

RC5 commands

RC283505

TECHNICAL SPECIFICATION

L

R

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

S/N and distortion meter

e.g. Sound Technology ST1700B

DUT

CD

Use Audio Signal Disc SBC429 4822 397 30184

(replaces test disc 3)

MEASUREMENT SETUP

Page 4

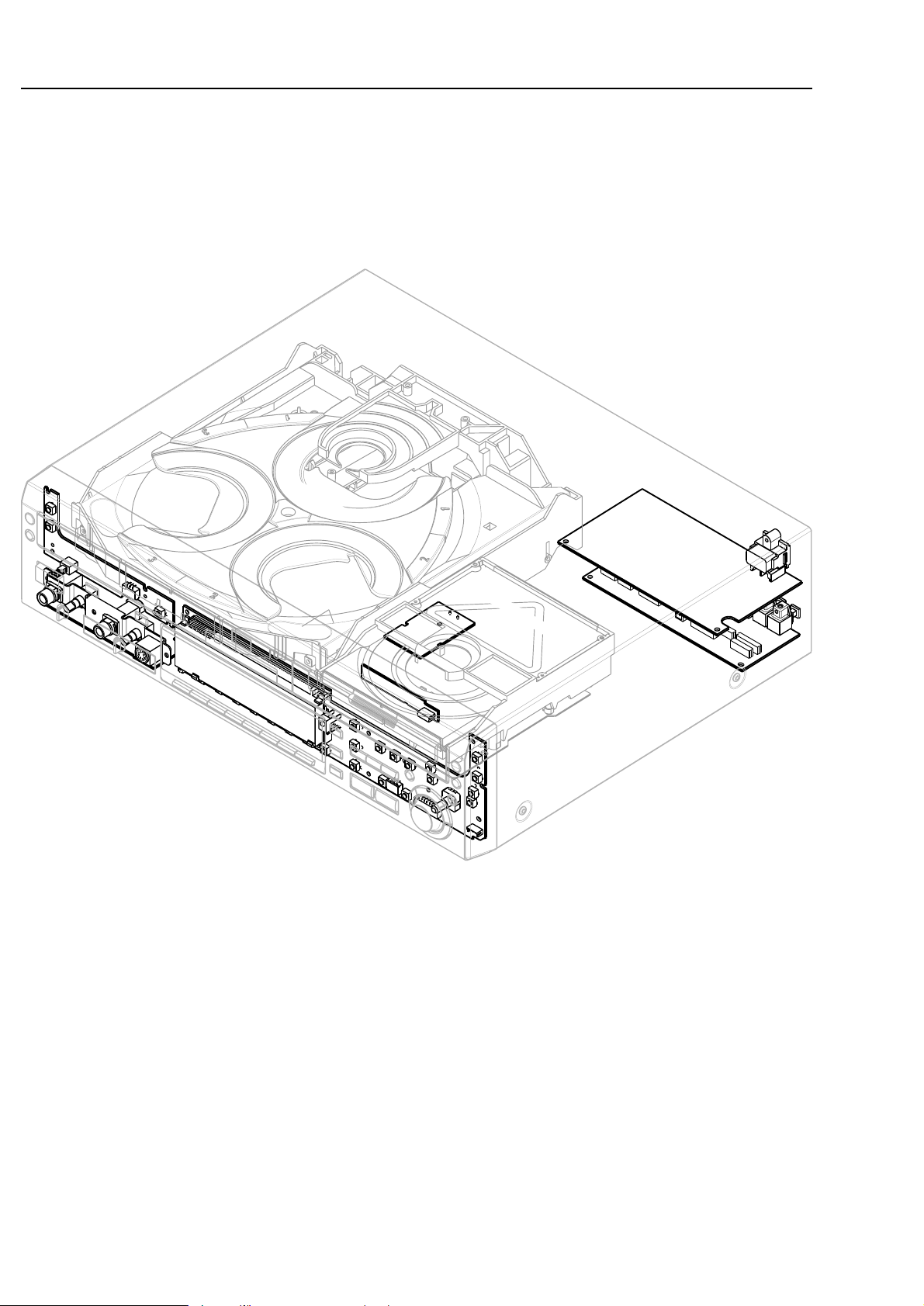

1-3

NTC

HEADPHONE BOARD

SWITCHED MODE

POWER SUPPLY

INTERFACE BOARD

FRONT-LED BOARD

DISPLAY BOARD

KEY left BO

ARD

Location of boards, CDR8xx, 100801

3CDC MODULE

CD-R/W MODULE

LOCATION OF PRINTED BOARDS

picture 1

Page 5

2-1

© WARNING

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically.

When repairing, make sure that you are connected with the

same potential as the mass of the set via a wristband with

resistance. Keep components and tools at this potential.

f ATTENTION

Tous les IC et beaucoup d´autres semi-conducteurs sont

sensibles aux décharges statiques (ESD). Leur longévite

pourrait être considérablement écourtée par le fait qu´aucune

précaution nést prise à leur manipulation.

Lors de réparations, s´assurer de bien être relié au même

potentiel que la masse de l´appareil et enfileer le bracelet

serti d´une résistance de sécurité.

Veiller à ce que les composants ainsi que les outils que l´on

utilise soient également à ce potentiel.

d WARNUNG

Alle ICs und viele andere Halbleiter sind empfindlich

gegenüber elektrostatischen Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kann die

Lebensdauer drastisch reduzieren.

Sorgen Sie dafür, daß Sie im Reparaturfall über ein Pulsarmband mit Widerstand mit dem Massepotential des

Gerätes verbunden sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls auf diesem

Potential.

ñ WAARSCHUWING

Alle IC´s en vele andere halfgeleiders zijn gevoelig voor

electrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan de levensduur

drastisch doen vermindern. Zorg ervoor dat u tijdens reparatie

via een polsband met weerstand verbonden bent met hetzelfde

potentiaal als de massa van het apparaat.

Houd componenten en hulpmiddelen ook op ditzelfde potentiaal.

i AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono sensibili alle scariche

statiche (ESD).

La loro longevità potrebbe essere fortemente ridatta in caso di

non osservazione della più grande cauzione alla loro

manipolazione. Durante le riparationi occorre quindi essere

collegato allo stesso potenziale che quello della massa

delápparecchio tramite un braccialetto a resistenza.

Assicurarsi che i componenti e anche gli utensili con quali si

lavora siano anche a questo potenziale.

©

Safety regulations require that the set be restored to its

original condition and that parts which are identical with

those specified be used.

Safety components are marked by the symbol

i

Le norme di sicurezza estigono che l´apparecchio venga

rimesso nelle condizioni originali e che siano utilizzati i

pezzi di ricambiago identici a quelli specificati.

Componenty di sicurezza sono marcati con

ñ

Veiligheidsbepalingen vereisen, dat het apparaat in zijn

oorspronkeliijke toestand wordt teruggebracht en dat

onderdelen, identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbool

s Varning !

Osynlig laserstrålning när apparaten är öppnad och

spärren är urkopplad. Betrakta ej strålen.

∂ Advarsel !

Usynlig laserstråling ved åbning når sikkerhedsafbrydere

er ude af funktion. Undgå udsaettelse for stråling.

ß Varoitus !

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen !

f

"Pour votre sécurite, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

ESD

SAFETY

d

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten. Der Originalzustand des Gerätes

darf nicht verändert werden. Für Reparaturen sind Originalersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol markiert.

f

Les normes de sécurité exigent que l`appareil soit remis

à l`état d`origine et que soient utilisées les pièces de

rechange identiques à celles spécifiées.

Les composants de sécurité sont marqués

CLASS 1

LASER PRODUCT

©

DANGER: Invisible laser radiation when open.

©

After servicing and before returning the set to customer

perform a leakage current measurement test from all

exposed metal parts to earth ground, to assure no

shock hazard exists.

The leakage current must not exceed 0.5mA.

AVOID DIRECT EXPOSURE TO BEAM.

©

AVAILABLE ESD PROTECTION EQUIPMENT :

anti-static table mat large 1200x650x1.25mm 4822 466 10953

small 600x650x1.25mm 4822 466 10958

anti-static wristband 4822 395 10223

connection box (3 press stud connections, 1MΩ) 4822 320 11307

extendible cable (2m, 2MΩ, to connect wristband to connection box) 4822 320 11305

connecting cable (3m, 2MΩ, to connect table mat to connection box) 4822 320 11306

earth cable (1MΩ, to connect any product to mat or to connection box) 4822 320 11308

KIT ESD3 (combining all 6 prior products - small table mat) 4822 310 10671

wristband tester 4822 344 13999

WARNINGS & SAFETY

Page 6

3-1

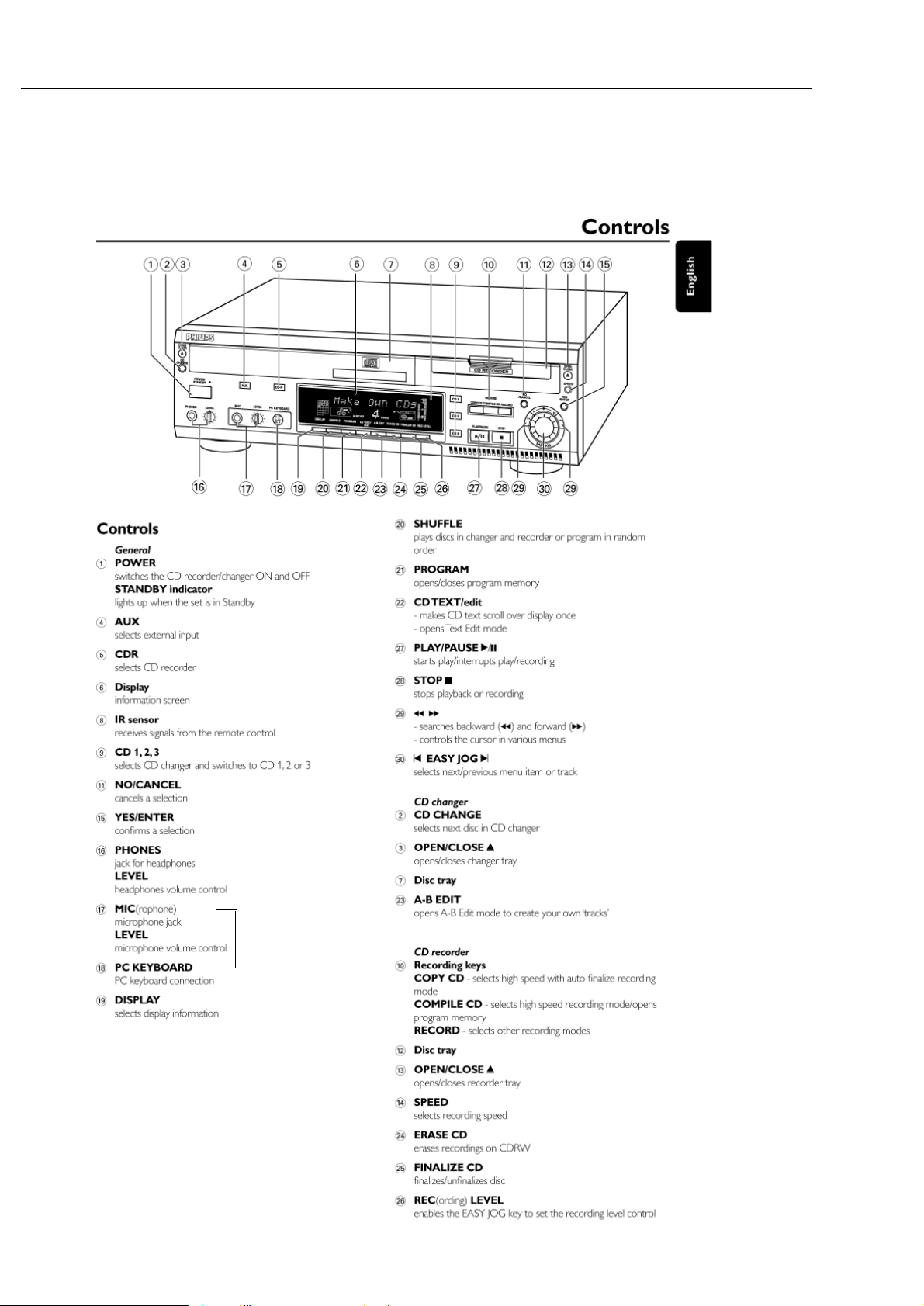

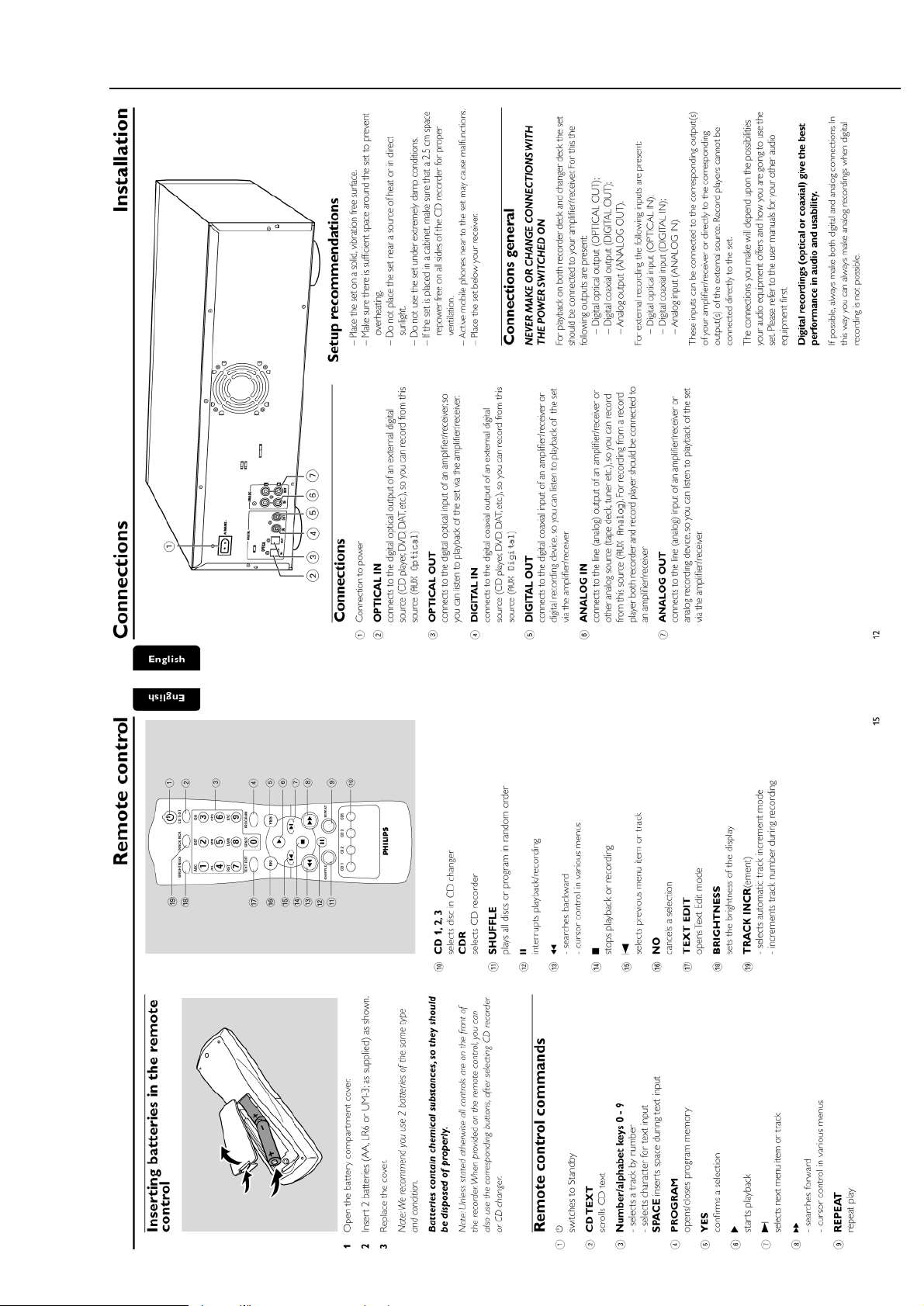

BRIEF OPERATING INSTRUCTIONS

The following excerpt of the Owner´s Manual serves as a very short introduction to the set.

The complete Owners Manual can be downloaded in several languages from the Internet site of

Philips Customer Care Center ”P3C“: http://130.144.192.42/cgi-bin/newmpr/debt.pl

CDR82x only

CDR82x only

Page 7

3-2

BRIEF OPERATING INSTRUCTIONS

CDR82x only

Page 8

3-3

BRIEF OPERATING INSTRUCTIONS

CDR82x only

Page 9

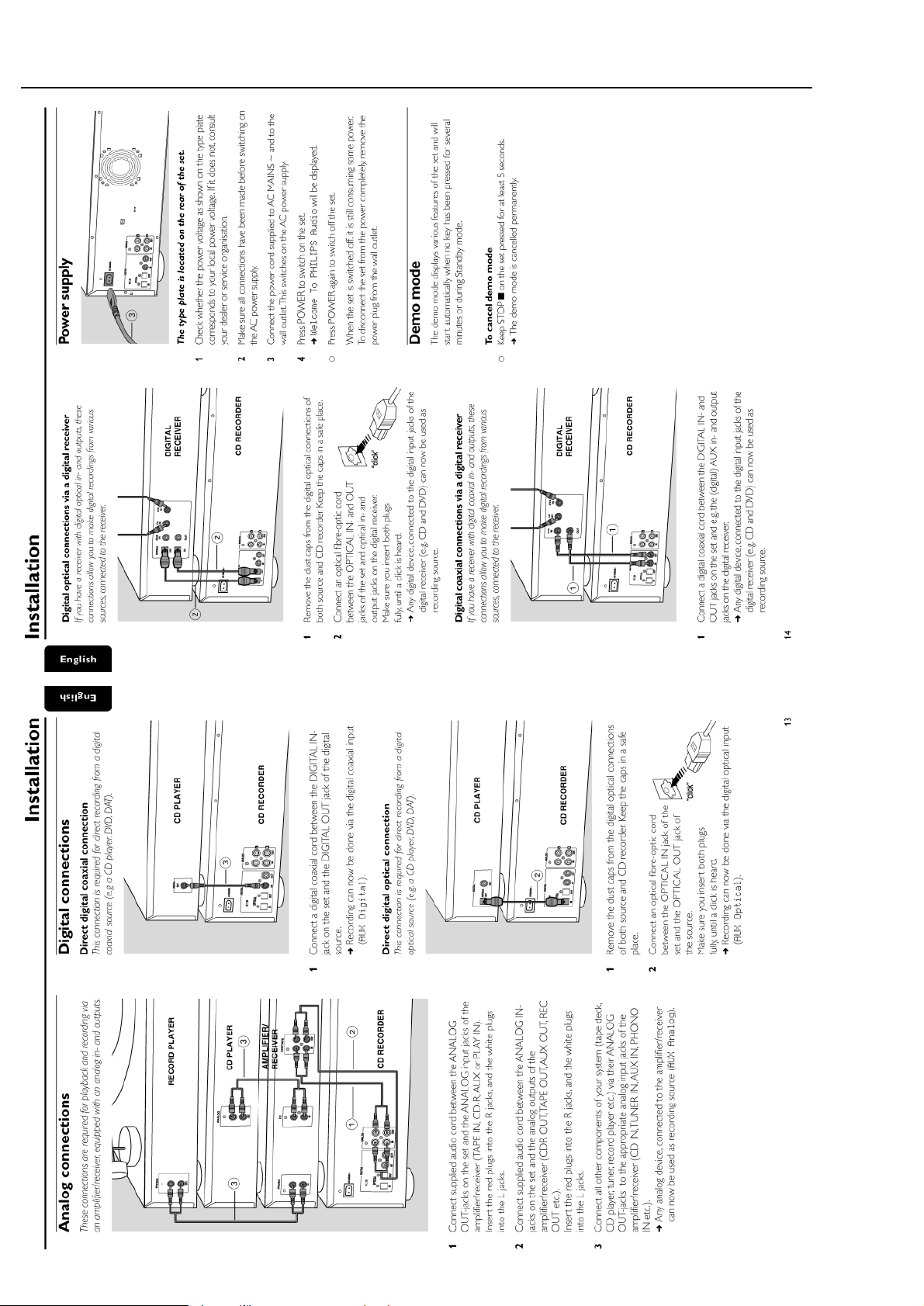

4-1

DISMANTLING INSTRUCTIONS

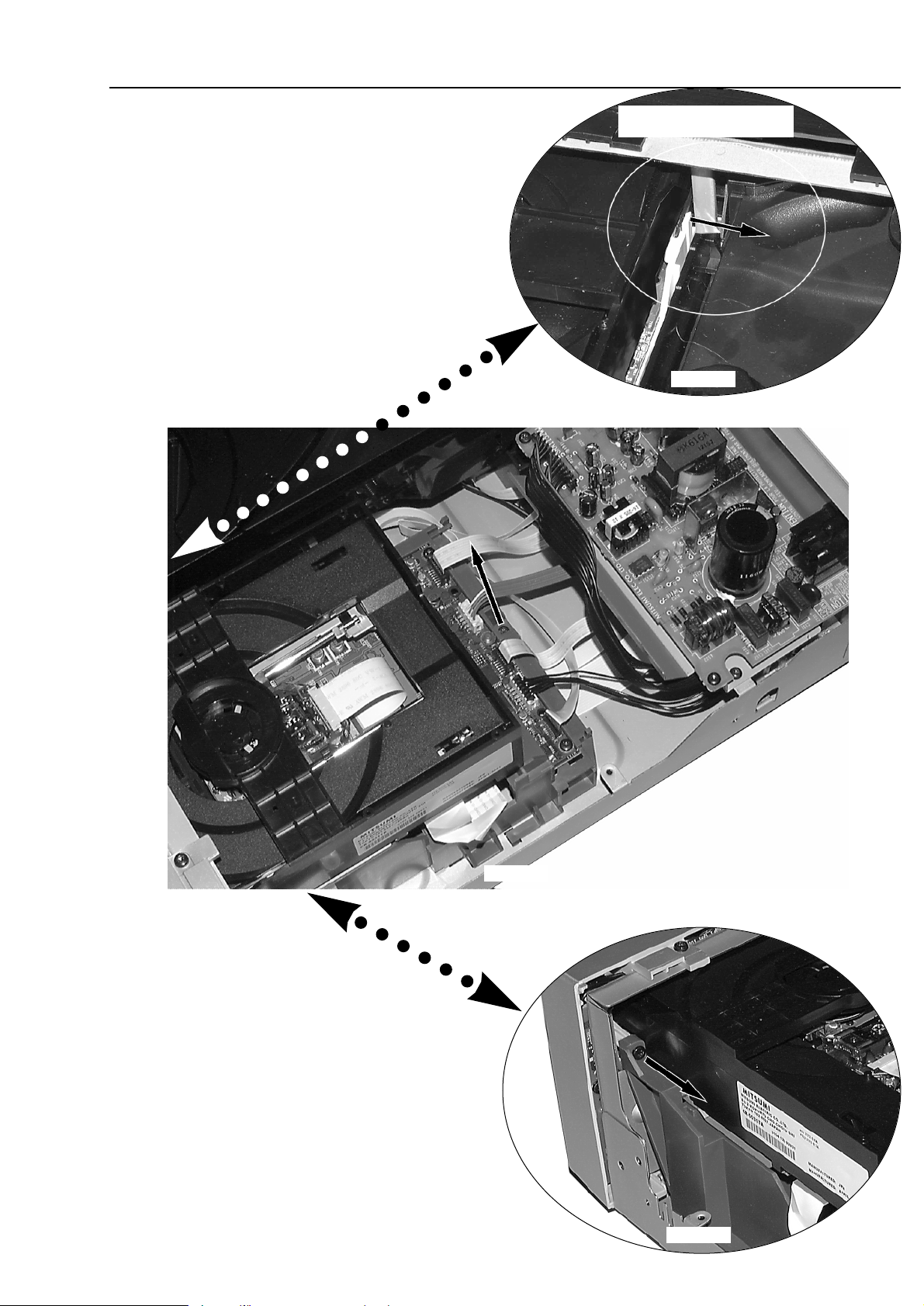

Dismantling the

Top Cover

picture 2

• Remove 9 screws as shown in picture 2.

• Raise top cover at the rear and pull it backwards.

Dismantling the

Tray Covers

To dismantle the ornamental cover, the tray has to be moved out first.

This can either be done by activating the Open/Close-key or manually.

In order to avoid unnecessary loading it is recommended to move the tray out manually a few centimetres.

To release the tray manually proceed as shown in pictures 3, 4 and 5. The tray will move out a little.

Afterwards it can be pulled out as far as convenient.

Release tray of 3 Disc Changer Release tray of CDR module

picture 4

picture 5

detail

picture 3

Page 10

4-2

DISMANTLING INSTRUCTIONS

Dismantling the

Front Cabinet

picture 8

• Remove top cover and ornamental covers from the trays first →see description on page 4-1.

• Move trays back to

closed

position.

• Loosen 5 screws as shown in pictures 8 and 9.

• Release catches on top (as shown in picture 8) and catch on frame of CDR module (see also picture 10).

• Turn front cabinet away.

• Place front cabinet as shown in picture 11.

• To release the cover from the catch on the tray, pull it

frontwards on bottom side as shown in picture 6 and 7.

• Pull the cover up.

picture 6

bottom view

Dismantling the

Tray Covers

continued

picture 7

Dismantling the ornamental cover

from the

CDR-tray

functions in the same manner.

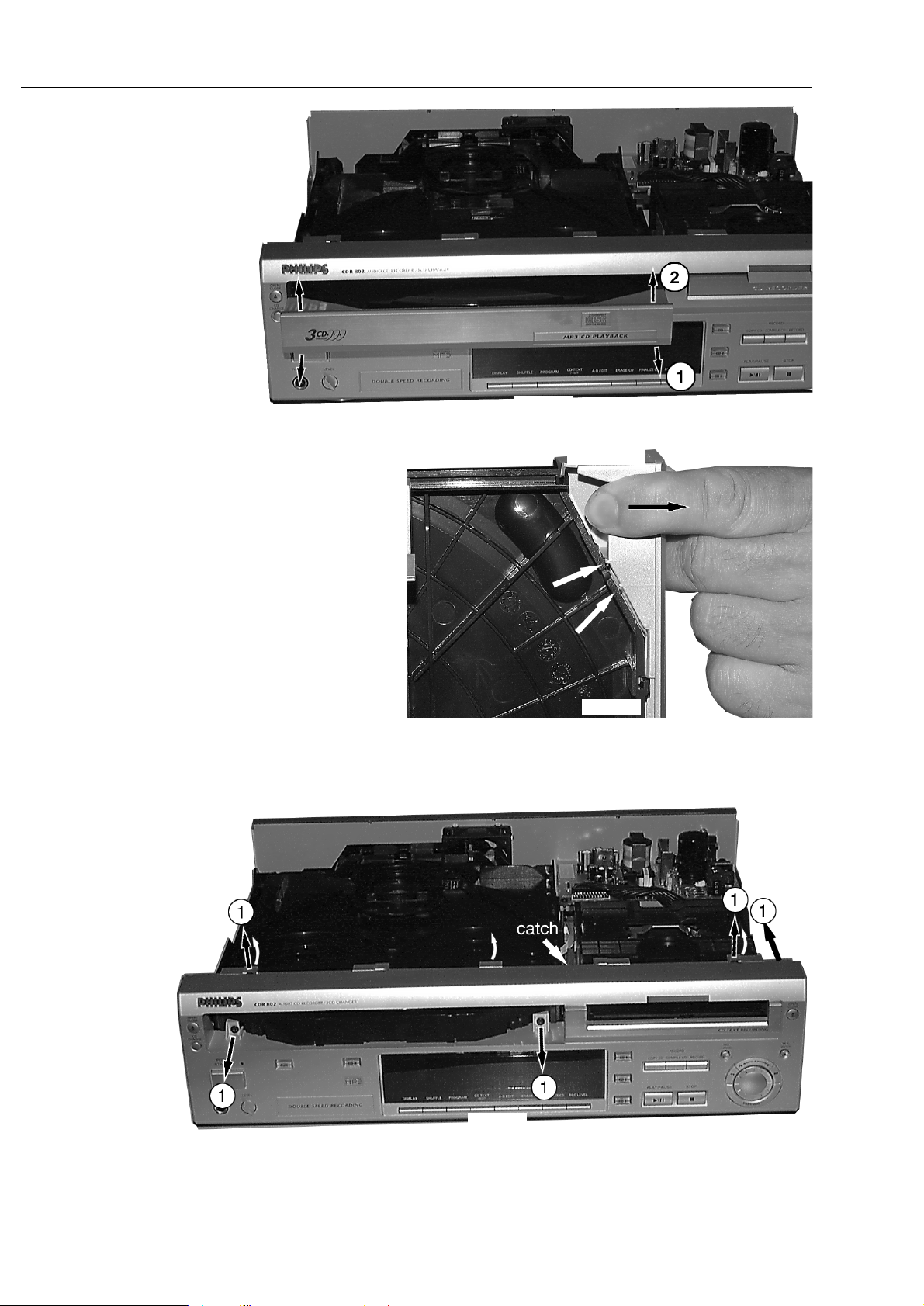

Page 11

4-3

DISMANTLING INSTRUCTIONS

Dismantling the

Front Cabinet

continued

picture 11

picture 9 picture 10

Page 12

4-4

DISMANTLING INSTRUCTIONS

• Loosen 2 screws at the rear as shown in picture 13.

• Move the complete module backwards.

• Pull the module on rear side up and turn it out.

→ see picture 14

• Put the module to a proper service position.

→ see also chapter SERVICE HINTS.

Dismantling the

3CDC module

• Remove top cover and ornamental cover from

the tray first → see description on page 4-1.

• Loosen 2 screws on front side →see picture 12.

picture 12

picture 13

picture 14

Page 13

4-5

DISMANTLING INSTRUCTIONS

Dismantling the

CDR module

• Remove top cover and ornamental cover from the tray first

→ see description on page 4-1.

• move tray back to

closed

position.

• to dismantle the complete module:

-loosen 1 screw to bottom cabinet on rear side

(see picture 16) and 1 screw to front cabinet

(see picture 17)

-disengage catch to front (see picture 15)

-move module backwards until catches to bottom cabinet

become free and pull it up.

picture 16

picture 15

Fixation by a catch on left

front-side

picture 17

Page 14

4-6

DISMANTLING INSTRUCTIONS

picture 18

Dismantling the

CDR module

continued

• Remove top cover and ornamental cover from the tray first

→ see description on page 4-1.

• to dismantle the Loader module:

-move tray completely out.

-loosen 4 screws to frame as shown in picture 18.

- put the module to a proper service position.

→ see also chapter SERVICE HINTS.

• to dismantle the MOZART Board:

-loosen 2 screws to frame as shown in picture 19.

-unlock flex foil connector and disconnect flex wire.

-pull the board out of it´s guidings (backwards).

- place the Mozart board to a proper service position.

→ see also chapter SERVICE HINTS.

picture 19

Page 15

4-7

DISMANTLING INSTRUCTIONS

Dismantling the

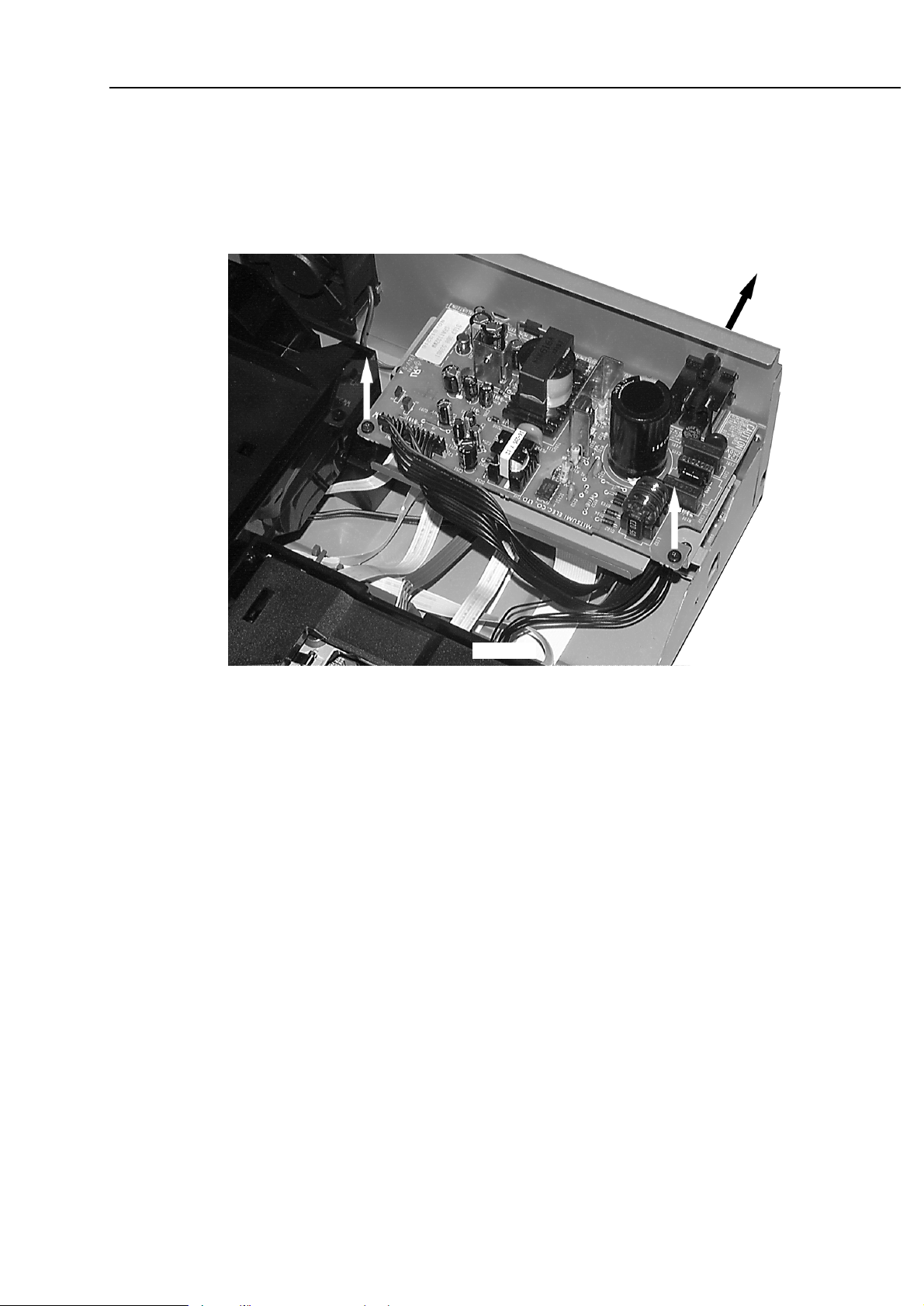

Power board

• Remove top cover first →see description on page 4-1.

• Loosen 3 screws as indicated in picture 20.

• Move the board backwards to release the mains socket.

• Lift it on the rear and turn it out.

picture 20

Page 16

4-8

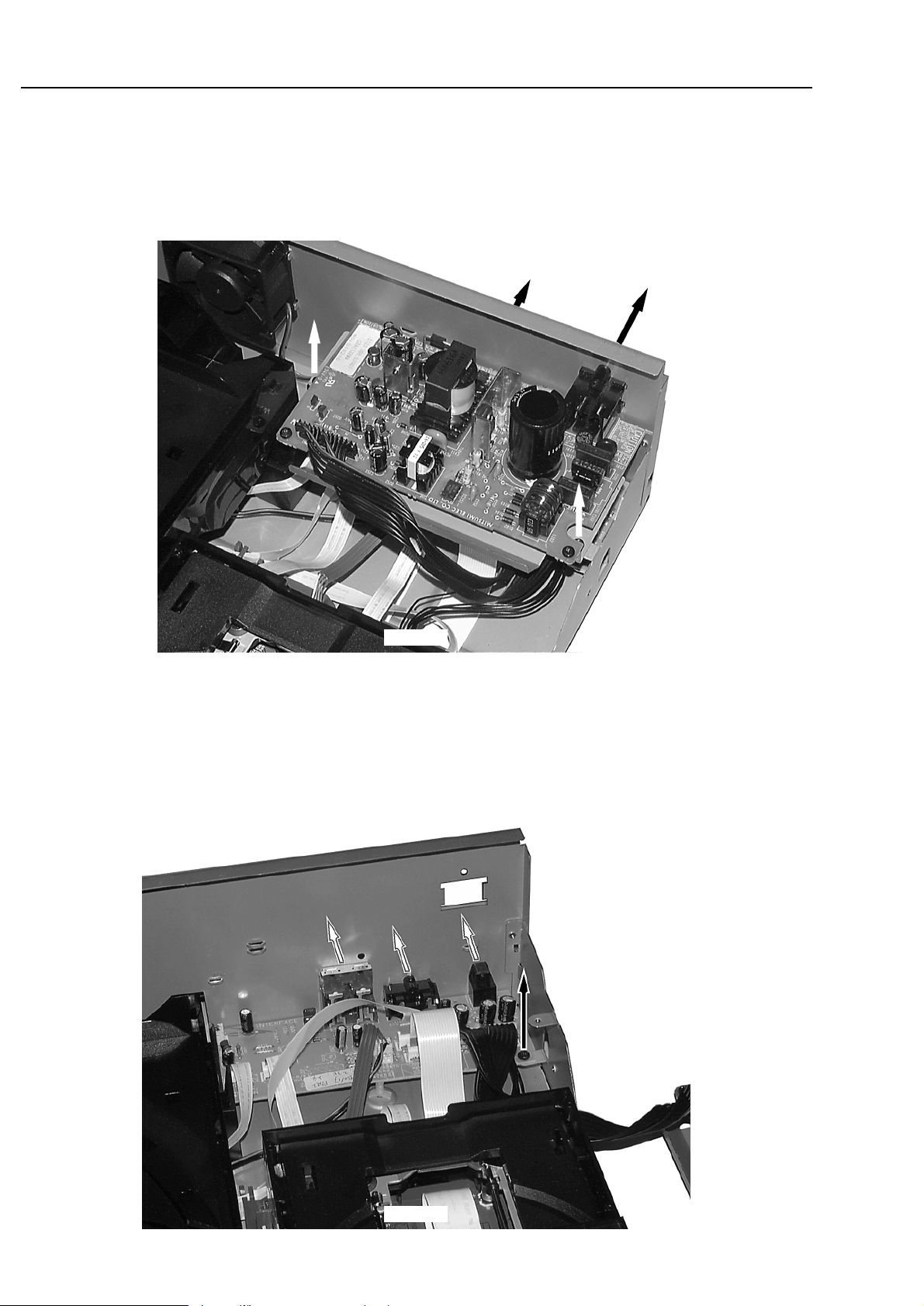

Dismantling the

Interface Board

• Remove top cover first →see description on page 4-1.

• Remove Power board inclusive metal screening plate.

- Loosen 4 screws as indicated in picture 21.

- Move the combination backwards to release the mains socket.

- Lift it on the rear and turn it out.

picture 21

DISMANTLING INSTRUCTIONS

• Loosen 1 screw from the board and 3 (4) screws from sockets at

the rear plate.

• Move the Interface board backwards to release the sockets.

• place the Interface board to a proper service position.

→ see also chapter SERVICE HINTS.

picture 22

Page 17

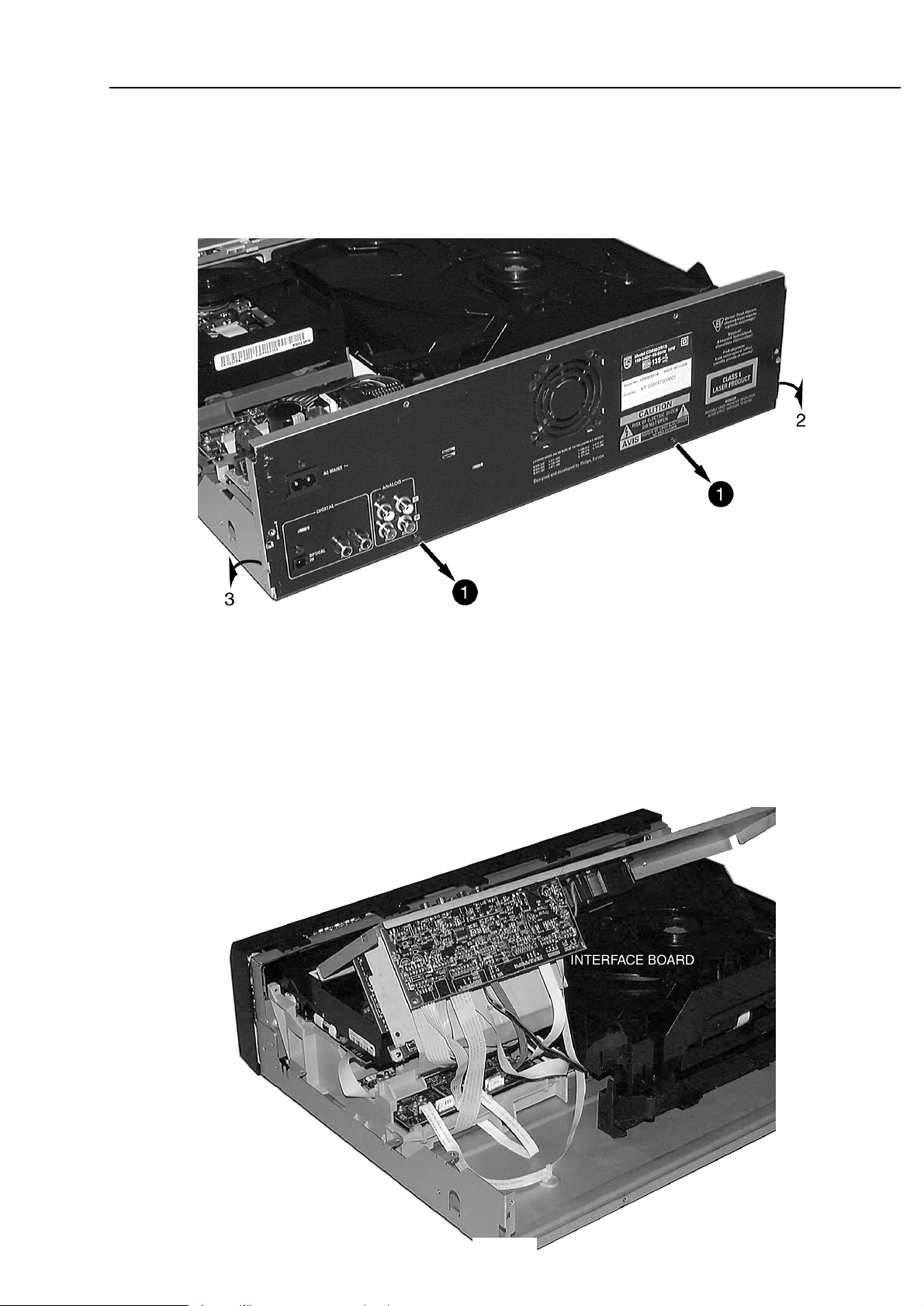

4-9

DISMANTLING INSTRUCTIONS

picture 23

Dismantling the

Interface Board

alternative

• Remove top cover first →see description on page 4-1.

• Loosen 2 screws as shown in picture 23.

• Disengage catches to bottom bottom cabinet.

• Move rear plate backwards and turn it to a proper service position

→ see picture 24.

picture 24

Page 18

5-1

SERVICE HINTS

SERVICE TOOLS

TORX T10 screwdriver with shaftlength 150mm ......................................4822 395 50423

TORX screwdriver set SBC 163 ..............................................................4822 295 50145

Audio signal disc SBC 429......................................................................4822 397 30184

Playability test disc SBC444...................................................................4822 397 30245

Test disc 5 (disc without errors) +

Test disc 5A (disc with dropout errors, black spots and fingerprints)

SBC 426/426A ....................................................................4822 397 30096

Burn in test disc (65 min. 1kHz signal at -30dB level without "pause") ...4822 397 30155

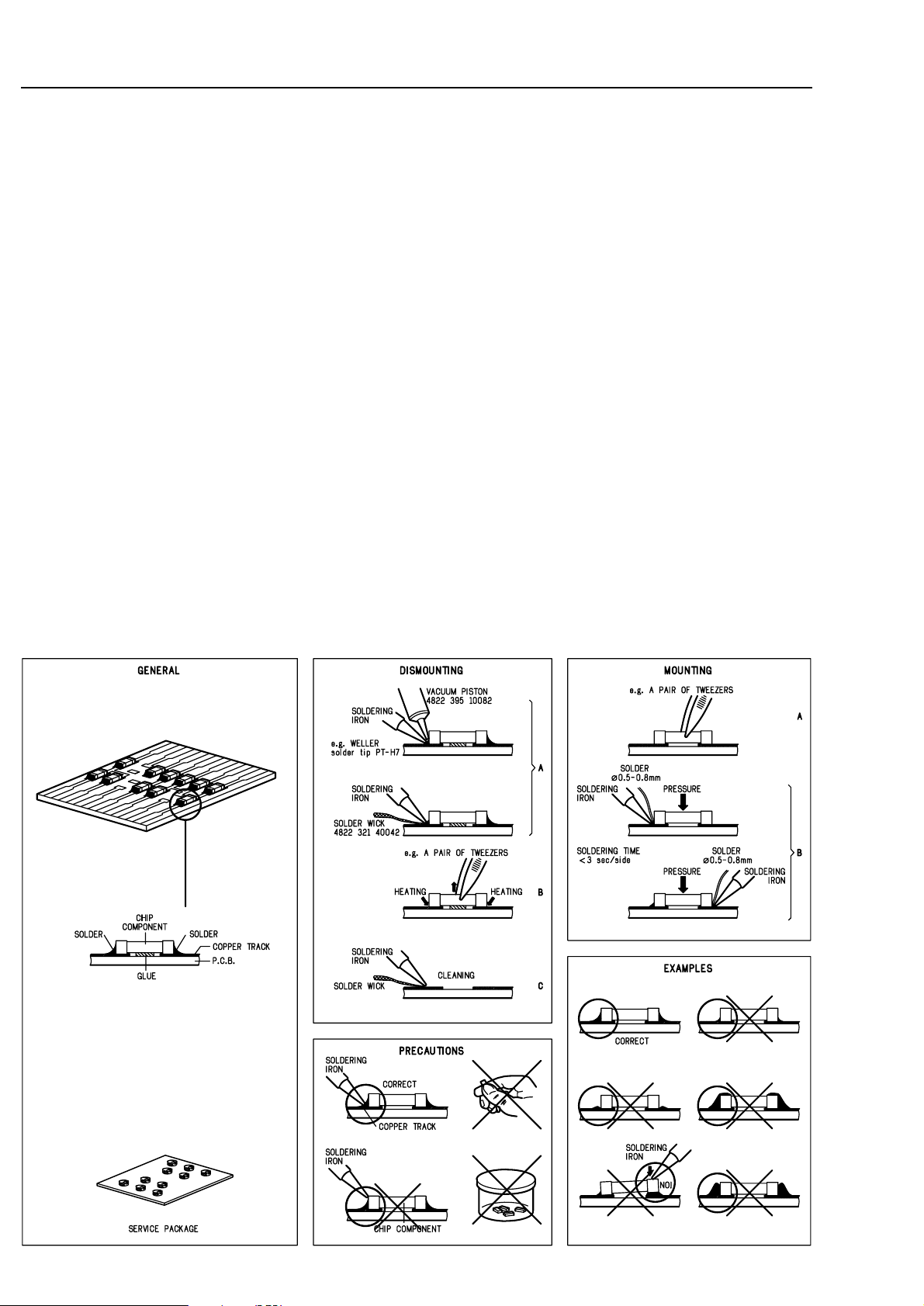

HANDLING CHIP COMPONENTS

DEALER MODE

The sets are equipped with a special DEALER MODE.

This mode blocks the trays of the CDC- and CDR module to

prevent customers from fetching out CDs from exhibition sets.

The Dealer mode can be switched on/off as follows:

1) Switch the set with the Remote Control to [Standby]

2) Press the

[DISPLAY] key at least for 5s

→ Display shows

TRAYS LOCKED else UNLOCKED

DEMO MODE

The DEMO MODE displays various features of the set and

will start automatically when no key has been pressed for

several minutes or during Standby mode.

The Demo mode can be switched on/off as follows:

1) Switch the set with the Remote Control to [Standby]

2) Press the

[STOP] key on the set at least for 5s

→ Display shows

DEMO ON else DEMO OFF

Page 19

5-2

SERVICE HINTS

General Service position

For measurements on: Power Board

For manual release of: 3CDC tray

CDR tray

Service position

Front Board

For dismantling instructions see chapter 4-1 to 4-3

picture 25

picture 26

Page 20

5-3

SERVICE HINTS

Service position

3CDC Module

picture 28

picture 27

Service position

CDR Module

picture 29

For dismantling instructions see chapter 4-5.

For dismantling instructions see chapter 4-4.

Page 21

5-4

Service position

CDR Loader

(Basic Engine)

picture 30

Service position

MOZART Board

(Back-end)

picture 31

picture 32

SERVICE HINTS

For dismantling instructions see chapter 4-6.

For dismantling instructions see chapter 4-6.

Page 22

5-5

SERVICE HINTS

Service position

Power Board

picture 33

For dismantling instructions see chapter 4-7.

Service position

Interface Board

picture 34

For dismantling instructions see chapter 4-8.

picture 35

For dismantling instructions see chapter 4-9.

Page 23

5-65-6

N

Y

KEY TEST

Display shows

1)

Numbers acc. table 2

are indicated as long as a

button is held depressed.

If a button is pressed

on the Remote Control

KEY RC is shown

and the ; flag flashes.

FFWD 6

button

pressed?

STOP

button

pressed?

N

Y

10

OPEN/CLOSE

(CDR)

FINALIZE CD

SPEED

(CDR820 only))

ERASE CD

COPY CD

CDR

AUX

CD1

20

21

22

23

24

25

99

CD2

5

KEY KEY CODE

exit test

2

3

4

5

6

7

8

9

12

15

11

RECORD

COMPILE CD

14

13

16

17

CD3

CD TEXT

/EDIT

DISPLAY

SHUFFLE

CD CHANGE

PLAY/PAUSE

OPEN/CLOSE

(CDC)

ON/OFF

18

STOP

A-B EDIT

1

0

PROGRAM

REC LEVEL

YES

/ENTER

NO

/CANCEL

6

KEY KEY CODE

KEY CODES

table 2

1)

If the ON/OFF switch is in the position

OFF

, all other keys

are blocked and display will show

99

as long any key is

held depressed.

SERVICE TESTPROGRAM

VARIOUS TESTS

CDR8xx servtest various, 07.09.01

N

Y

FORMAT EEPROM

Display shows

for 2s.

EEPROM is cleared and

default values are stored.

CD TEXT

button

pressed?

This test should only be used to clear

the EEPROM in case of a µP-"hangup".

Attention: all data are set to default values,

BLACK BOX data are not cleared.

KEY --

DISPLAY

button

pressed?

STOP

button

pressed?

N

N

Y

Y

Display shows all

segments and flags (dimmed)

for checking open circuits.

see figure 1

All LEDs are switched on.

DISPLAY TEST

fig. 1

N

Y

QUARTZ TEST

Display shows

1220±37Hz can be measur.

on (pin 27 of µP).

STOP

button

pressed?

N

Y

REW 5

button

pressed?

Tact frequency µP

(divided 10MHz)

1

10M

NEW

VXX

S

*

To leave Service Testprogram plug mains cord off.

*

In the main menu the sound settings (volume, ...),

trays and carousel work as in normal mode.

Display shows

version number

of the µP - software.

stands for Service mode

stands for Version number

of the software used in the

Front (Display) µP.

To enter Service

Testprogram hold

PLAY & CD3

buttons

depressed while

plugging mainscord in.

On/Off switch in pos.

ON

S-CDR80-VXX

Insert CD-DA disc

before starting the test

NY

Plug mains cord off

to exit

END-USER DIAGNOSTICS

Display shows:

FAILED

Display shows:

PASSED

END-USER DIAGNOSTICS

(CDR module)

To enter

END-USER DIAGNOSTICS

hold

PLAY & REC LEVEL

buttons depressed while

plugging mainscord in.

On/Off switch in pos.

ON

TEST O.K.?

Display shows for 3s each:

• Software version of

MOZART (flash ROM 7101)

• Software version of

basic engine processor

(flash EPROM 7017)

SDRAM TEST 7100

Display shows:

DTST1

CHECKSUM TEST 7101

Display shows:

DTST2

ERASE TEST 7101

Display shows:

DTST3

COMMUNICATION TEST

(UART-BUS)

Display shows:

DTST4

Flash Proms are set

to default settings.

Test planned for future software versions

- not implemented in all sets

PASS

N

Y

EEPROM TEST

Display shows

ERR

Display shows

Testpattern is written to

address 1

and

read back again

PROGRAM

button

pressed?

STOP

button

pressed?

Test ok?

N

Y

N

Y

NTC XX

N

Y

TEMPERATURE

(NTC) TEST

Display shows

XX = value in °C

AUX

button

pressed?

STOP

button

pressed?

N

Y

CDR80x

CDR82x

SERVICE TESTPROGRAM

VARIOUS TEST

Page 24

5-7 5-7

OPEN/CLOSE

button

pressed?

Y

NEXT

6

button

pressed?

N

Y

PREV

5

button

pressed?

N

Y

PLAY

button

pressed?

N

Y

CDR

MECHANICAL TEST

CDR

DC-ERASE MODE

SLIDE TESTFOCUS TEST TRAY TEST TURNTABLE

TEST

Display shows:

SLIDE

for visual inspection only

OPEN/CLOSE

button

pressed?

N

Y

N

Y

N

Slide moves

continuously in/out.

Display shows:

OPEN

(even when tray is blocked)

Tray opens.

Display shows:

CLOSE

(even when tray is blocked)

Tray closes.

Dependent on the

moving direction,

slide moves to inner

or outer end position.

N

Y

STOP

button

pressed?

Exit Mech. Testprogram

SERVICE TESTPROGRAM

CDR MODULE

Objective moves

continuously up/down.

Display shows:

FOCUS

PREV

5

button

pressed?

N

Y

YES

button

pressed?

N

Y

Turntable motor

is switched on.

Display shows:

DISC

PREV

5

button

pressed?

CD-RW disc

inserted?

N

Y

DC-ERASE

finished?

N

Y

BURN IN MODE

CDR MODULE

Display shows:

HH BI RE FE

DC-ERASE MODE

starts.

Record complete disc

from analog source

with normal speed.

Display shows:

HH BI RE FE

Complete disc

recorded?

N

Y

Error detected?

N

Y

Finalize disc

with double speed.

Display shows:

HH BI RE FE

HH stands for the number of hours

the test was running

BI stands for Burn In test

RE number of errors detected during

DC erase and write mode

FE number of errors detected during

Finalizing the disc

Turntable motor

is switched off.

Focus servo

is switched off.

CDR8xx servtest CDR module, 030901

STOP button

pressed?

Y

N

Display shows:

WRONG DISC

or

NO DISC

TESTS PLANNED FOR FUTURE SOFTWARE VERSIONS

- NOT IMPLEMENTED IN ALL SETS

N

Y

STOP button

pressed?

Y

N

Display shows:

WRONG DISC

or

NO DISC

Disc erased?

N

Y

N

Y

Complete disc will be

erased with double speed.

(starting from PMA-area

up to and including

ATIP leadout area)

The display shows the

countdown of the

remaining time required

to complete the operation:

ER mm ss

Display shows:

PASSED

mm: remaining minutes

ss: remaining seconds

STOP

button

pressed?

Exit DC-ERASE Mode

Note: With the DC-Erase mode the CD-RW can be

changed back in its original state, like a new disc.

Stopping the erase-function by switching power off

will leave the disc in an unpredictable status!

CD-RW disc

inserted?

TEST O.K.?

NN

Y

Y

N

Y

Y

CDR

ELECTRICAL TEST

Insert CD-DA disc

before starting the test

MODULE INFORMATION

MOZART BOARD DIAGNOSTIC

CDR - LOADER TEST

SDRAM TEST 7100

Display shows:

DTST1

CHECKSUM TEST 7101

Display shows:

DTST2

ERASE TEST 7101

Display shows:

DTST3

COMMUNICATION TEST

(UART-BUS)

Display shows:

DTST4

Display shows:

DERR

n

n=number of failed test

Display shows next error

FFWD

6 button

pressed?

N

Y

FFWD

6 button

pressed?

Y

FFWD

6 button

pressed?

Y

FFWD

6 button

pressed?

all errors shown?

N

N

N

TEST O.K.?

NN

Y

Y

Display shows:

BERR 1

Display shows:

PASSED

for 3s

FFWD

6 button

pressed?

CD-DA disc

inserted?

Display shows actual

playing time.

The test is performed by

playing 5s at beginning,

5s in the middle and 5s at

the end of the disc.

N

Y

Display shows:

NO DISC

FFWD

6 button

pressed?

Note: The BURN-IN mode is an endless cycle of

*

DC erase, to erase the CD-RW disc with max. laser power

*

Recording a CD-RW disc with speed N=1

*

and Finalizing with double speed

This test is intended to check the quality of a CDR loader and

to detect intermittent failures.

Exit CDR electrical Test Exit CDR electrical Test

Display shows for 5s:

MO XXXX BXXXX

• MO xxxx stands for

Software version of

MOZART

(flash ROM 7101)

• Bxxxx stands for

Software version of

Basic engine processor

(flash EPROM 7017)

With the

DISPLAY

button the info on the display can be toggled

to indicate either the status of burn in test or the temperature

measured via the NTC.

1)

1)

1)

1)

S

*

To leave Service Testprogram plug mains cord off.

*

In the main menu the sound settings (volume, ...),

trays and carousel work as in normal mode.

Display shows

version number

of the µP - software.

To enter Service

Testprogram hold

PLAY & CD3

buttons

depressed while

plugging mainscord in.

On/Off switch in pos.

ON

S-CDR80-VXX

CDR

button

pressed?

N

Y

N

Y

FINALIZE

button

pressed?

ERASE CD

button

pressed?

N

Y

RECORD

button

pressed?

N

Y

VXX

stands for Service mode

stands for Version number

of the software used in the

Front (Display) µP.

SERVICE TESTPROGRAM

CDR MODULE

Page 25

5-85-8

SERVICE TESTPROGRAM

CD/CDC MODULE

CDR8xx/CD servtest, 030901

OPEN/CLOSE

button

pressed?

NEXT

6

button

pressed?

N

Y

PREV

5

button

pressed?

N

Y

PLAY

button

pressed?

N

Y

CD or CDC

MECHANICAL TEST

SLIDE TESTFOCUS TEST TRAY TESTTURNTABLE

TEST

Display shows:

SLIDE

for visual inspection only

OPEN/CLOSE

button

pressed?

N

Y

Y

N

Y

N

Slide moves

continuously in/out.

Display shows:

OPEN

(even when tray is blocked)

Tray opens.

Display shows:

CLOSE

(even when tray is blocked)

Tray closes.

Dependent on the

moving direction,

slide moves to inner

or outer end position.

N

Y

STOP

button

pressed?

Exit Mech. Testprogram

Objective moves

continuously up/down.

Display shows:

FOCUS

PREV

5

button

pressed?

N

Y

YES

button

pressed?

N

Y

Turntable motor

is switched on.

Display shows:

DISC

PREV

5

button

pressed?

Focus servo

is switched off.

Turntable motor

is switched off.

TESTS PLANNED FOR

FUTURE SOFTWARE VERSIONS

- NOT IMPLEMENTED IN ALL SETS

N

Y

CD or CDC

LOADER TEST

TEST O.K.?

NN

Y

Y

Display shows:

BERR 1

Display shows:

PASSED

for 3s

Tray opens

FFWD

6 button

pressed?

CD-DA disc

inserted?

Display shows actual

playing time.

The test is performed by

playing 5s at beginning,

5s in the middle and 5s at

the end of the disc.

N

Y

Display shows:

WRONG DISC

or

NO DISC

OPEN/CLOSE

button

pressed?

N

Y

CD1

button

pressed?

Exit CD electrical Test Exit CD electrical Test

VXX

S

*

To leave Service Testprogram plug mains cord off.

*

In the main menu the sound settings (volume, ...),

trays and carousel work as in normal mode.

Display shows

version number

of the µP - software.

stands for Service mode

To enter Service

Testprogram hold

PLAY & CD3

buttons

depressed while

plugging mainscord in.

On/Off switch in pos.

ON

S-CDR80-VXX

CD2

button

pressed?

N

Y

stands for Version number

of the software used in the

Front (Display) µP.

set continues operation, message remains on the display until next error occurs

or any key is pressed.

Error number Error type

Error type:

Error description

E1000 Focus Error

Triggered when the focus is lost for more than 250ms while playing the CD.

E1006 Subcode Error

No valid subcode for 300ms during

PLAY

.

Slide-out error

Generated when the inner-switch did not open within approx. 250ms when the pick up is

moved from the inner position outside. Inner-switch or slide motor problems.

E1002

E1003

Slide-in error

Generated when the inner-switch did not close within approx. 6s when the pick up is

moved inside. Inner-switch or slide motor problems.

W

E1020 Focus Search Error

Triggered when the focus could not be found within 4s when starting up the CD.

F

W

W

E1001 Radial error

Triggered when the radial servo is not on track for a certain time during playing the CD.

W

W

W

W

W = Warning →

F = Fatal Error

→ set stops operation, message remains on the display.

CD ERROR CODES

table 1

E1005 Jump error.

Triggered when the servo processor counts too less tracks in a defined time during JUMPS.

This can be caused by a disturbed HF-signal (the tracks cannot be recognized exactly),

slide motor problems, track servo problems or scratched discs.

E1008 Disc motor error

Generated when the CD could not reach 75% of speed during startup within 1,2s.

W

E1007 PLL lock error

When no valid subcode was found within 300ms PLL is checked. If PLL is locked E1006

will be indicated else E1007 and the servo is stopped and restarted once again to recover

(as if the user would have pressed

STOP

and then

PLAY

immediately).

The

CD PLAY TEST

is intended to be used

for continuously playing a disc in order to

detect intermittent or not reproducible

failures. The error code indicates where

the failure can be found.

1)

Y

CD PLAY TEST

1)

(CD BURN IN TEST)

N

CD is in normal

PLAY

mode.

In case of failures

error codes acc. table 1

will be indicated

on the display.

MAINS CORD

plugged off?

N

Y

Exit Service Testprogram

CD3

button

pressed?

With the

DISPLAY

button the info on the

display can be toggled to indicate either

the status of

CD PLAY TEST

or

the temperature measured via the NTC.

2)

2)

SERVICE TESTPROGRAM

3CDC MODULE

Page 26

6-1 6-1

1307

0053

17

1304

51

1303

71

0052

15

7324F

74LVU04D

+IC

LINE_IN

1314B

DIG IN

7312

OPT. IN

1315B

+F -F

-30V

+5V

+5V EVER

+F-F-30V

+5V EVER

+12V

+5V +IC +3V3aV_AMP1+ -12V

0054

16

V_AMP1-+3V3d

HP_L

HP_R

ANA IN_R

ANA OUT_L

EBU IN COAX

ANA OUT_R

ANA IN_L

-12V

+12V

LM833D

V_AMP1+

V_AMP1-

1315A

1314A

DIGITAL

OUT

7324E

74LVU04D

+IC

7324A-D

5300

7320

74LVU04D

+IC

1306

12

1301

12

NTC

FAN

FAN CONTROL

INTERFACE BOARD

ANALOG

OUT

ANALOG

IN

15 1

1308

91

POWER_ON

POWER_ON

FAN

MUTE

3CDC SW Info

3CDC SH STR

3CDC SH CLK

3CDC SH DATA

3CDC SW Info

3CDC SH STR

3CDC SH CLK

3CDC SH DATA

NTC

EBU IN OPT.

EBU OUT

+5V

+12V

+5V

+5V

+12V

LEVEL SHIFT

BUFFER

CON1

CN101

12 1

8

1

(Supply) ON/OFF

+5V EVER

-F1

+F1

-30V

+5V

+12V

EBU IN CD10

+5V

AUDIO SIGNAL INTERFACE

DIGITAL IN / OUTCONTROL INTERFACE

SUPPLY INTERFACE

CD INTERFACE

RESET CD10

CD10 SDA

CD10 SCL

CD10 RAB

CD10 SILD

-12V

CD - CHANGER MODULE

for details see

separate block diagram

SWITCHED MODE

POWER SUPPLY

for details see

separate block diagram

CDR MODULE

for details see

separate block diagram

HEADPHONE-

MICROPHONE

BOARD

14021007 1203

1205

1761 15

1660

+12V

-12V

HP_L

HP_R

7660

3676

+12V

-12V

NJM4556AM

HEAD-

PHONE

I2C DATA

I2C CLK

RESET

EBU OUT

EBU EXT. IN

EBU IN OPT.

ANALOG IN (REC) L

ANALOG IN (REC) R

ANALOG OUT (PB) R

ANALOG OUT (PB) L

8

1

EBU

PORE

SDA

SICL

RAB

SILD

1802

IRQ

1805

91

SW Info

SHR STR

SHR CL

SHR DATA

+5V

NC

NC

+10V

1214

16

+5V

+5V

+12V

16

1302

61

1662

CDR80x, 200401

DISPLAY BOARD

FRONT-LED BOARD

KEY BOARD

left

7414

7409

MICROPROCESSOR

M30218MAFP

7403

5VST

RC5

KEY 1

JOG A

JOG B

KEY 2

2

KEY MATRIX

RESET

EEPROM

RESET

1416

1

3

1414

1

3

0051

-30V

+F-F

1

3

30

35 - 881689

63

VCC1

VCC2

99 VREF

100 AVCC

97AVSS

65VSS1

14VSS2

VEE

1400

10MHz

1394 959291 15

12

+5VST

I2C DATA

I2C CLK

+µP

+µP

+µP

23

98

96

21

19

20

5

8

6

LED red

LED blue

LED red

LED blue

+5V

+5V

blue

Rec/Pb indication

red

+5V

7

1

LED AUX

LED CDR

KEY0

ON/OFF

LED Stby

IR EYE

1485

1

7

LED AUX

LED CDR

KEY0

ON/OFF

LED Stby

POWER_ON

NTC

f

0

1418

+F -F

-30V +5V +5VST

FAN

MUTE

3CDC SW Info

3CDC SH STR

3CDC SH CLK

3CDC SH DATA

IRQ CDR

IRQ CDR

RESET CDR

I2C CLK

RESET CDR

I2C DATA

1417

+5VST

+µP

STDBY AUX CDR

ON/OFF

offon

KEY MATRIX

1480

15 11 6

TEXT TOTAL TRACK TIME TOTAL REM

STEP

CD

RW

CD

RW

COMPILE CD TRACK PROG

RECORD IN PROGRESS

SHUFFLE REPEAT ALL EDIT

REC TRACK TIME

123456789

10 11 12 13 14 15 16 17 18 19 20 +

ANALOG

FINALIZE ALC

DIGITAL

OPTICAL

12

12

JOG CONTROL

1457

I2C BUS

I2C BUS

BLOCK DIAGRAM

CDR80x

Page 27

6-26-2

1307

0053

17

1304

51

1303

71

0052

15

7324F

74LVU04D

+IC

LINE_IN

1314B

DIG IN

7312

OPT. IN

1315B

+F -F

-30V

+5V

+5V EVER

+F-F-30V

+5V EVER

+12V

+5V +IC +3V3aV_AMP1+ -12V

0054

16

V_AMP1-+3V3d

HP_L

HP_R

ANA IN_R

ANA OUT_L

EBU IN COAX

ANA OUT_R

ANA IN_L

-12V

+12V

LM833D

V_AMP1+

V_AMP1-

1315A

1314A

DIGITAL

OUT

7324E

74LVU04D

+IC

7324A-D

5300

7320

74LVU04D

+IC

1306

12

1301

12

NTC

FAN

FAN CONTROL

INTERFACE BOARD

ANALOG

OUT

ANALOG

IN

15 1

1308

91

POWER_ON

POWER_ON

FAN

MUTE

3CDC SW Info

3CDC SH STR

3CDC SH CLK

3CDC SH DATA

3CDC SW Info

3CDC SH STR

3CDC SH CLK

3CDC SH DATA

NTC

EBU IN OPT.

EBU OUT

+5V

+12V

+5V

+5V

+12V

LEVEL SHIFT

BUFFER

CON1

CN101

12 1

8

1

(Supply) ON/OFF

+5V EVER

-F1

+F1

-30V

+5V

+12V

EBU IN CD10

+5V

AUDIO SIGNAL INTERFACE

DIGITAL IN / OUTCONTROL INTERFACE

SUPPLY INTERFACE

CD INTERFACE

RESET CD10

CD10 SDA

CD10 SCL

CD10 RAB

CD10 SILD

-12V

CD - CHANGER MODULE

for details see

separate block diagram

SWITCHED MODE

POWER SUPPLY

for details see

separate block diagram

CDR MODULE

for details see

separate block diagram

HEADPHONE-

MICROPHONE

BOARD

14021007 1203

1205

1761 15

1660

+12V

-12V

HP_L

HP_R

7660

3676

+12V

-12V

NJM4556AM

HEAD-

PHONE

I2C DATA

I2C CLK

RESET

EBU OUT

EBU EXT. IN

EBU IN OPT.

ANALOG IN (REC) L

ANALOG IN (REC) R

ANALOG OUT (PB) R

ANALOG OUT (PB) L

8

1

EBU

PORE

SDA

SICL

RAB

SILD

1802

IRQ

1805

91

SW Info

SHR STR

SHR CL

SHR DATA

+5V

NC

NC

+10V

1214

16

+5V

+5V

+12V

DISPLAY BOARD

FRONT-LED BOARD

KEY BOARD

left

7414

7409

MICROPROCESSOR

M30218MAFP

7403

5VST

RC5

KEY 1

JOG A

JOG B

KEY 2

2

KEY MATRIX

RESET

EEPROM

RESET

1416

1

3

1414

1

3

0051

-30V

+F-F

1

3

30

35 - 881689

63

VCC1

VCC2

99 VREF

100 AVCC

97AVSS

65VSS1

14VSS2

VEE

1400

10MHz

1394 959291 15

12

+5VST

I2C DATA

I2C CLK

+µP

+µP

+µP

23

98

96

21

19

20

5

8

6

LED red

LED blue

LED red

LED blue

+5V

+5V

blue

Rec/Pb indication

red

+5V

7

1

LED AUX

LED CDR

KEY0

ON/OFF

LED Stby

IR EYE

1485

1

7

LED AUX

LED CDR

KEY0

ON/OFF

LED Stby

POWER_ON

NTC

f

0

1418

+F -F

-30V +5V +5VST

FAN

MUTE

3CDC SW Info

3CDC SH STR

3CDC SH CLK

3CDC SH DATA

IRQ CDR

IRQ CDR

RESET CDR

I2C CLK

RESET CDR

I2C DATA

1417

+5VST

+µP

STDBY AUX CDR

ON/OFF

offon

KEY MATRIX

1480

15 11 6

TEXT TOTAL TRACK TIME TOTAL REM

STEP

CD

RW

CD

RW

COMPILE CD TRACK PROG

RECORD IN PROGRESS

SHUFFLE REPEAT ALL EDIT

REC TRACK TIME

123456789

10 11 12 13 14 15 16 17 18 19 20 +

ANALOG

FINALIZE ALC

DIGITAL

OPTICAL

12

12

JOG CONTROL

1457

I2C BUS

1305

117

1215

117

MUTE

CLK_16

I2S DATA 4

I2S WLK 4

I2S CLK 4

KILL

CLK_16

I2S DATA 4

I2S WLK 4

I2S CLK 4

PWR ON RESET

DEEMP

I2S CLK1/GND

I2S DATA1/GND

EBU CD10

PROF_DIG_OUT

EBU OUT ENGINE/GND

I2S WLK1/GND

MUTE

NC

NC

NC

NC

I2S BUS

7322

UDA1360TS

MIC_L

MIC_R

MICROPHONE

ADC

1663

PC KEY-

BOARD

+5V

Kb DATA

Kb CLK

GND

1664

41

+5V

Kb DATA

Kb CLK

0055

4

1

22, 25

7313

OPT.OUT

1661

7661

+12V

-12V

LM833D

7662

+12V

-12V

LM833D

3677

MIC_L

MIC_R

MICROPHONE

1302

8 1

18

1662

PF2-KEYBOARD INTERFACE

I/O INTERFACE EXT. ADC/DAC

MUTE

CDR82x, 200401

I2C BUS

BLOCK DIAGRAM

CDR82x

Page 28

6-3 6-3

SDA

VCC

DOBM

D1-D5

D2-D4

7814

1876 1875

1877 1878

7873

TDA7073

HEF4094BT

LD ONLD ON

LD

MON

CD/RW

HF IN

V1

D1

D2

D3

D4

R1,R2

MOT1

REGISTER

SHIFT

SIGNAL PROCESSOR

CD10

SAA7324 (SAA7325)

TRAY

MOTOR

CAROUSEL

MOTOR

SL

D5

VDD

D3

D2

D0

RA

FO

DIODES

PHOTO

D3D2

D5D1

D4

INNER SWITCH

SWITCH INFO

LASER &

MONITOR

DIODE

TURNTABLE

MOTOR

DISC

CD MECHANISM

CAROUSEL

TRAY

MAINBOARD

DATA

SHR_CL

7801

+3,3V

7802

LASER CONTROL

&

HF AMPLIFIER

TZA1024

(TZA1025)

38

42

40

39

5,17,21,52,57

64

1

13

+5V

2

4

5

7

V4

61

2

ISLICE

3

63 51

10

11

6,14

2

3

STB

1

12

11

1,3

2

2

4

1,3

2

4

2

3

5

1

3

1

5

10

9

+3,3V

SCL

SILD

RESET

Blockdiagram 3CDC-LC(Herman) 2001-09-13

+5V

+4V

+3,3V

+10V

7815

+5V

6801

BLOCK DIAGRAM 3CDC-LC

+10V

15

16

5V1

V

t

EN1

CD DRIVE UP/DOWN SWITCH

1881

1880

TRAY SWITCH

1882

CD POS.1 SWITCH

POS. RECOGNITION

6

7

4

5

1882 closed if carousel is in Position 1.

1883

1883 open if carousel is in a valid Play-Position.

Closed if the tray is in one endposition.

Open during movement.

Open if the drive is in one endposition.

Closed during movement.

VDD (pin 16)

EN1 (pin 15)

Power on

FOCUS

MOTOR

RADIAL

MOTOR

SLEDGE

MOTOR

MOTOR

TURNTABLE

55

54

56

59

19

15

34

3

7803

M63000

TTM+

TTM-

SLEDGEB-

SLEDGEB+

RADB-

RADB+

FOCB-

FOCB+

5

6

3

4

2

8

7

7

RAB

1802

RESET

SDA

EBU OUT

EBU

EBU_GND

1

GND

5

3

SHR-DATA

2

SHR_CL

4

1

SHR_STR

NC

SWITCH INFO

1805

6

8

9

1805

CDR Version

Communication CD10

with CDR Module-µP

Communication

with Front-µP

Digital Audio

SICL

SILD

+5V

NC

+10V

GND

Supply

SPEEDSEL

Low = 4x speed

Low = 2x speed

High = 1x speed

High amplification

(4x speed)

Low amplification

(1x and 2x speed)

CDR Version

VAM2201, VAM2202, VAM2204

RAB

41

7805

7804

EQSELEQSEL

62

12

to/from

CDR Module

MOZART Board

1205

to/from

Interface Board

1308

BLOCK DIAGRAM

3CDC MODULE

Page 29

6-46-4

MOZART

IC

CORE

SUPPLY

I/O

SUPPLY

SUPPLY

SUPPLY

PLL

OSC

JTAG/BDM

SDRAM

2MB

1MB

FLASH

CONTROL

ADRESS

DATA

CONTROL

EBUIN2

I2S

1 IN/OUT

/2

74LV74D

MCF5248

7100

7101

7000

7004

DC/DC

7201

DAC ADC

OPAMP

circuitry

Potmeter

ANALOG

SWITCH

3

I2S2 I2S3

3

7312

7301

7401

7402

7311

7300

16

20

8

3

DC/DC

6204

GND

DC/DC

DC/DC

DC/DC

DC/DC

7202

7200

7208

7209

+5V

+12V

3V3

2V5

-12V

-8VA

-5VA

-8VA

EBU1 (PB)

Reset CD10

SDA,SICL,Rab, Sild

PWR ON RST

CLK 16

PLAYBACK

ROUTING

FREYA EAN

FREYA EAN

Mute, Attenuation, Deemphasis

RS232

CD TEXT

I2S1(in/out)

EBU2 (Pb)

1201

1205

1214

C

D

C

M

O

D

U

L

E

OPAMP

circuitry

7401

7400

7400

1203

1215

13051304

1402

1303

+5VA

+8VA

"MOZART" BOARD CDR2001

EBU Dig_Opt Out

EBU4 Ext INI

Pro Dig Out

EBU3 opt IN

EBU3 COAX

BUFFER

ADC CLKDAC CLK

ZERO

A_Left_In

A_Right_In

A_Out_Left

A_Out_Right

+8VA-8VA

INTERFACE BOARD

D

I

S

P

L

A

Y

B

O

A

R

D

I2C

IRQ FRONT

VCXO

FILTER

Xtrim

CLK 33,86MHz

2V5

GND 3V3

3V3 3V3

GND

GND GND

1007 1417

1 23

4

5

5

6

FLEX

36p

FLEX

8p

FLEX

17p

FLEX

7p

+5V

IO CLK 16

I2S

1

KILL

I2S

4

PWR ON RST

MUTE, ATT,

DEEMP.

EBU EXT INI

EBU EXT INI

EBU DIG

OPT OUT

PRO DIG OUT

EBU IN FREYA

PWR ON RST

I2C

IRQ FRONT

2

4

4

3

4

3

FREYA CLK

2

7010

Kill

KILL

circuitry

7002

1005

B

A

S

I

C

E

N

G

I

N

E

Mute,

Deem-

phasis

Kill out

FLEX

CONTROL

INTERFACE

AUDIO SIGNAL

INTERFACE

SEPARATE AD/DA

INTERFACE

DIGITAL

INTERFACE

6p

I2S4 IN

EBU DIG

OPT OUT

OPAMP

circuitry

6202

CD R/W

I2S

INTERFACE

030901

1802

COPY ANALOG

0052

BLOCK DIAGRAM

CDR MODULE

Page 30

6-5 6-5

D207

Q202

BLOCK DIAGRAM

SWITCHED MODE POWER SUPPLY /

European & USA version (/00 & /17)

CN101

MAINS SOCKET

F101

T2A

Lightning

Protection

L101, L102

EMI-filter

T102

6,8V

22V

+5V EVER

overvoltage

protection

Q151

PC151

PC102

switch on/off

regulation

regulation

IC251

D251

D252

Q152

R152

C105

C251

D201

D206

C206

CON1

1

12

ON/OFF

+5V EVER

+F1

-F1

-30V

+5V

+12V

-12V

Q251

Q202

22V

T101

27V

+12V

overvoltage

protection

C208

D203

C204

-12V

C202

D202

C201

+5V

+5V

IC201

Q101

Q104

on/off

switching

transistor

reference

PC101

Q103

R222

R209

D204

D208

C205

-30V

+F

-F

switching

transistor

reference

Blockdiagram SMPS CDR8xx, 040901

BLOCK DIAGRAM

SWITCHED MODE POWER SUPPLY /

WorldWide version (/01)

Blockdiagram SMPS CDR8xxWW, 040901

T102

6,8V

+5V EVER

overvoltage

protection

PC151

PC102

switch on/off

regulation

regulation

IC251

D251

D252

R152

C105

C251

Q251

22V

27V

T101

+5V

IC201

Q101

reference

PC101

switching

transistor

sense

reference

54

8

7

1

2

3

S

3

4

6

2

I

sense

out

on/off

Vcc

GND

feedback

5

8

7

1

R

Q

Vcc

BUFFER

OVERVOLTAGE

PROTECTION

OSCILLATOR

BIAS

PWM

+

-

-

IC101

PWM CONTROLLER

CN101

MAINS SOCKET

F101

T2A

Lightning

Protection

L101, L102

EMI-filter

IC151

PWM CONTROLLER

CON1

1

12

ON/OFF

+5V EVER

+F1

-F1

-30V

+5V

+12V

-12V

D201

D206

C206

Q202

27V

+12V

overvoltage

protection

C208

D203

C204

-12V

C202

D202

C201

+5V

R209

D204

D208

C205

-30V

+F

-F

BLOCK DIAGRAM

POWER SUPPLY

Page 31

6-66-6

LED_blue

FFC SIDE ENTRY

EH TOP ENTRY

EH SIDE ENTRY

DIPMATE

BOARD to BOARD JQ

FFC TOP ENTRY

LEGEND

PH TOP ENTRY

PH SIDE ENTRY

XH SIDE ENTRY

FLASH TOP ENTRY

FFC TOP ENTRY

CABLE 1 to n

1mm PITCH

1203

+F

-F

-30V

+5Vever

ON/OFF

+12V

+12V

GND

GND

+5V

+5V

-12V

112

CON1

GND

CD10 SDA

CD10 SCL

CD10 RAB

CD10 SILD

Reset CD10

EBU IN CD10

EBUGND

1802

+5V

EBUOUT

EBUINOpt./GNDD

EBUINCoax

GNDD

1

ANA OUT LEFT

GND A

ANA OUT RIGHT

GND A

ANA IN RIGHT

GND A

ANA IN LEFT

175668

1402

+5V

+5V

GNDD

GNDD

GNDS

+12V

1

1214

GNDD/Shield

I2C-Data

GNDD

I2CClock

Reset

IRQREQ

11

1007

GND

SDA

SICL

RAB

SILD

(RESET)PORE

EBU

EBUGND

8

1

1205

NC

SHR_DATA

SHR_CL

SHR_STR

SW_INFO

+10V

GND

+5V

NC

19

1805

1416

Key_ON/OFF

LED_Stby

LED_AUX

LED_CDR

Key0

GND_Key

GND

1

7

GND

I2C_Data

GND

I2C_CLK

Reset

IRQ CDR

16

1417

3CDC_SH_Data

3CDC_Sh_CLK

3CDC_Sh_Str

3CDC_SW_Info

Mute

Fan

Power_ON

GND

GND

+5V_ever

+5V

NTC

-30V

-F

+F

115

13

13

1418

LED_red

+5V

1414

LED_red

+5V

LED_blue

0051

HP RIGHT

+12V

HP LEFT

-12V

GND

MIC RIGHT/GND

GNDMIC

MIC LEFT

1662

ON/OFF

LED_Stdby

LED_AUX

LED_CDR

Key0

GND_Key

GND

17

1485

8006(195mm)

OP-HR/3p

8007(220mm)

OP-HR/12p

8004(160mm)

OP-PH/6p

CD R/W MODULE 2001

MOZART BOARD

componentside view

KEY BOARD left

copperside view

HEADPHONE

BOARD

componentside view

SWITCHED MODE

POWER SUPPLY

componentside view

16

18

FRONT LED BOARD

copperside view

CD-CHANGER MODULE

3CDC-LC (CDR 2x)

MAIN BOARD

componentside view

13141315

NTC

HP RIGHT

+12V

HP LEFT

-12V

GND

MICRIGHT/GND

GNDMIC

MICLEFT

NC

SHR_DATA

SHR_CL

SHR_STR

SW_INFO

+10V

GND

+5V

NC

1308

+5V

EBUOUT

EBUINOpt./GNDD

EBUINCoax

GNDD

15

18 7 1

1306

ANA

OUT LEFT

GND A

ANA OUT

RIGHT

GNDAANA INRIGHT

GND A

ANA

INLEFT

1

19

1303

+5V

+5V

GNDD

GNDD

GNDS

+12V

16

0054

3CDC_SH_Data

3CDC_Sh_CLK

3CDC_Sh_Str

3CDC_SW_info

Mute

Fan

Power_ON

GND

GND

+5V_ever

+5V

NTC

-30V-F+F

115

1307

+F

-F

-30V

+5Vever

ON/OFF

+12V

+12V

GND

GND

+5V

+5V

-12V

1715

0053

0052

1

1301

7313 7312

Optical

IN

Optical

OUT

Digital

IN/OUT

Line

IN/OUT

8009(220mm)

OP-HR/2p

1304

FAN

1302

INTERFACE BOARD

componentside view

DISPLAY BOARD

copperside view

8005(80mm)

FFC1,25/7p/ AD

to chassis

8011

8011 for layout stage .5 only

will be replaced by a contact spring

from layout stage .6 onwards

(100mm)

8016(340mm)

FFC1,25/15p/ AD

8008(340mm)

FFC1,25/6p/BD

8001(140mm)

PH/5p

8003(160mm)

FFC1,25/7p/BD

(8007, part of Changer Module)

FFC1,0/ 8p/ AD

8014(340mm)

FFC1,25/9p/ AD

wiring diagram CDR80x/82x, 300801

(340mm)

8012(480mm)

onlyCDR80x

FFC1,25/6p/ BD

KILL

CLK_16

GNDD

IIS_DATA4

MUTE

IIS_WLK4

GNDD

IIS_CLK4

PWR_ON_RESET

IIS_WLK1/GNDD

DEEMP

IIS_CLK1/GNDD

IIS_DATA1/GNDD

GNDD

EBU_CD10

PROF_DIG_OUT

EBU_OUT_ENGINE/GNDD

117

1215

8002(140mm)

only CDR82x

17 1

KILL

CLK_16

GNDD

IIS_DATA4

MUTE

IIS_WLK4

GNDD

IIS_CLK4

PWR_ON_RESET

IIS_WLK1/GNDD

DEEMP

IIS_CLK1/GNDD

IIS_DA

TA1/GNDD

GNDD

EBU_CD10

PROF_DIG_OUT

EBU_OUT_ENGINE/GNDD

1305

FFC1,0/17p/ AD

8013(480mm)

onlyCDR82x

FFC1,25/8p/ BD

Kb_+5V

Kb_Data

Kb_CLK

GND

1

4

0055

Kb_+5V

Kb_Data

Kb_CLK

GND

1664

8017(100mm)

OP-HR/4p

only CDR82x

14

WIRING DIAGRAM

For service code numbers of flexfoil cables see mechanical partslist.

Page 32

-30,7V -29,2V

-29,9V

4,8±0,45V

floating

4,5/0V

5±0,25V

5±0,25V

12

+0,6

/

-1,2

V

-11,5

+1,5

/

-1,1

V

-29,3±2,2V

typ.-25V

typ.-20V

300V

300V

5V

5V

5V

4V

5V

4V

12V

-12V

-32V

-20V

-25V

2,5V

2,5V

1,2V

0V

4,5V

300V

1,9V

1,9V

0,1V

16,5V

-0,3V

0,2V

0,2V

1,1V

1,1V

6V

1,1V

. . . V DC VOLTAGES MEASURED IN

STOP MODE

UNLESS STATED OTHERWISE

MAINS VOLTAGE 230V (120V

USA

)

PRIMARY MEASURED AGAINST

JUNCTION D103/D104

EVM

V

Switched Mode Power Supply / EU + USA version (/00/17)

to Interface Board

0052/0053

.......

USA

for USA version only

LEGEND

Switched Mode Power Supply, EU+USA versions, 300701

(SRA1134EK+SRA1133UC combined)

EU version USA version

22

USA

470k

USA

470k

USA

2200pF

USA

10

USA

1000pF

USA

220/200

USA

33n/400

USA

100p/1k

USA

0,01/50

USA

2200p/50

USA

220/1

USA

180k

USA

27k

USA

18k

USA

180k

USA

30V

27V

22V

6,8V

3V

22V

7-1 7-1

for orientation only

POWER BOARD / copper side view

USA and European version

SMPS CDR8xx,EU+USA, 300701

SRA1134EK+SRA1133UC

R111

R202

R203

R210

R204

C110

C113

R153

R156

R256

R257

R252

R212

R213

R254R253

C207

C152

C153

C109

POWER BOARD / component side view

USA and European version

L102

L101

R101

C102

C101

CN101

Z101

F101

R114

R104

R106

Q103

Q101

D110

R102

R151

R155

Q152

Q151

R152

D151

D153

R103

D109

D203

R222(R221

USA

)

R201

IC201

D108

R117

R112

R115

D111

R120

C108

Q104

R108

C105

D101

D103

D104

D102

R158

T101

T102

R119

C11

R154

C111

PC151

PC101

PC102

D201

C201

C202

C203

L201

L202

D202

C208

C210

C205

C253

C211

C254

C251

IC251

L204

Q202

Q251

L251

R251

D207

R220

R255

CON 1

C206

L203

D208

D251

D252

D204

C204

D206

R205

R209

SMPS CDR8xx,EU+USA, 300701

SRA1134EK+SRA1133UC

Page 33

. . . V DC VOLTAGES MEASURED IN

STOP MODE

UNLESS STATED OTHERWISE.

MAINS VOLTAGE 230V/120V.

PRIMARY MEASURED AGAINST

JUNCTION D103/D104.

EVM

V

-30,7V -29,2V

-29,9V

4,8±0,45V

floating

4,5/0V

5±0,25V

5±0,25V

12

+0,6

/

-1,2

V

-11,5

+1,5

/

-1,1

V

-29,3±2,2V

typ.-25V

typ.-20V

5V

5V

4V

12V

-12V

-32V

-20V

-25V

2,5V

5V

5V

4V

2,5V

0V

4,5V

0,1V

16V

0V

1,2/2,1V

1/2,4V

300/160V

300/160V0,8V

5,9V

300/160V

3,4V

1,1/1,4V

1/1,2V

1,3V/2,7V

Switched Mode Power Supply / World Wide version (/01)

Switched Mode Power Supply, WW version, 300701

(SRA1132WW)

.......

USA

for USA version only

LEGEND

to Interface Board

0052/0053

IC101

45

Vcc

Out

Osc

GND

Feed

back

Osc on/off

I

sense

18

45

18

30V

27V

6,8V

22V

27V

7-27-2

POWER BOARD / copper side view

World Wide version

SMPS CDR8xx,WW, 310701

SRA1132WW

R202

C215

R203

R210

C216

R204

C114

R115

R113

R118

C113

C106

R119

R120

R256

R257

R252

R212

R213

R254R253

C207

R255

C151

C109

POWER BOARD / component side view

World Wide version

SMPS CDR8xx,WW, 310701

SRA1132WW

L102

L101

R101

C102

C101

CN101

Z101

F101

R152

C105

D101

D103

D104

D102

Q101

D111

R151

R114

R116

IC101

R117

D110

R107

D108

IC151

D112

R131

R132

R133

D107

C110

R105

C152

C112

T101

T102

C111

PC151

C211

C254

C253

C251

IC251

L204

L251

R251

D251

D252

C205

Q202

Q251

D207

R220

CON 1

L203

L202

D202

D208

C208

C210

C206

D204

R209

D203

L205

R201

IC201

PC101

PC102

D201

C201

C202

C203

L201

C204

D206

R205

R217

for orientation only

Page 34

7-3 7-3

GRID BUFFERS

1664

14850051

1007 1307

F454 I15

F455 G15

F456 G15

F457 G15

F458 G15

F459 G15

F460 G15

F461 H15

F462 E15

F463 E15

F464 E15

F465 E15

F466 E15

F421 C15

F422 C15

F423 C15

F424 C15

F425 D15

F426 G12

F427 G13

F428 H11

F429 H12

F430 H11

F431 H12

F433 I12

F434 I11

F435 I12

F436 I11

F437 I12

F438 J11

F439 J12

F440 J11

F441 J12

F442 K11

F443 K12

F444 K11

F445 K12

F446 K11

F447 K12

F448 J15

F449 K15

F450 K15

F451 K15

F452 I15

F453 I15

7408 K9

7409 J1

7410 G13

7411 G15

7412 I14

7413 I15

7414 C9

7415 K15

7416 K4

7417 A1

7418 A2

F400 G2

F401 G3

F402 G2

F403 G3

F404 H3

F405 H3

F406 B11

F407 E10

F408 F10

F409 J4

F410 A4

F411 B11

F412 A15

F413 A15

F414 B15

F415 B15

F416 B15

F417 B15

F418 B15

F419 B15

F420 C15

3495 I14

3496 I14

3498 J14

3499 I8

3500 J15

3501 K14

3502 K15

3503 I10

3504 I10

3505 K5

3506 K4

3510 E12

3511 G11

3512 G12

3513 I1

3514 B1

3515 B2

3516 C13

5400 B13

5402 J15

6400 A11

6428 K7

6429 K5

6431 K6

6432 K9

6433 K10

6434 I9

7402 A10

7403 I3

7405 E12

7406 K6

7407 K8

3461 H12

3462 H12

3463 H12

3464 I12

3465 I12

3466 J12

3467 J12

3468 J12

3469 K12

3470 K12

3471 E12

3472 F13

3473 F13

3474 A4

3475 B11

3477 K6

3478 K5

3479 K8

3480 K8

3481 K10

3482 K9

3484 J2

3485 K2

3486 J2

3487 K2

3488 C15

3489 F14

3490 G14

3491 H14

3492 G15

3493 H14

3494 H15

13 14 15 16

A

B

C

D

E

F

G

H

I

J

K

A

B

C

D

E

F

G

H

I

J

K

0055 J15

1400 F11

1414 I15

1416 F15

1417 D15

33343536

12345678910111213141516

12345678

*

*

*

for CDR82x only

GND

I2C_Data

GND

CDR80x: 3514, 3515 = 0 Ohm

EEPROM

KEY LIGHTING

(CDR82x)

SPEED

CD3

CD2

CD1

YES

I2C_CLK

Reset

IRQ

ROTARY ENCODER

10MHz

IR EYE

RESET

DISPLAY BOARD

9101112

1418 A15

1419 I9

1420 G12

1421 H13

1422 H13

1423 H13

1424 I13

1425 I13

1426 J13

1427 J13

1428 K13

1429 K13

1430 K13

1431 G13

1432 H12

1433 H12

1434 H12

1435 I12

1436 I12

1437 J12

1438 J12

1439 K12

1440 K12

1441 K12

2400 I4

2401 J4

2402 J10

2403 J10

2404 G12

blue

for

CDR82x

only

2405 G13

2406 E11

2407 E10

2408 F10

2409 F11

2410 F12

2411 E13

2412 F12

2413 B4

2414 B11

2415 B13

2416 J1

2418 C13

2420 D15

2421 A2

3400 C1

3401 C1

3402 C1

3403 D1

3404 D1

3405 D1

3406 D1

3407 D1

3408 E1

3409 E1

3410 E1

3411 E1

3412 E1

3413 E1

3414 F1

3415 F1

3416 F1

3417 F1

3418 F1

3419 G1

3420 I5

3421 I5

3422 K14

3423 I6

3424 I6

3425 I6

3426 I7

3427 I8

3428 I8

3429 I8

3430 J8

3431 I5

3432 I5

3433 I6

3434 I7

3435 I8

3436 I8

3437 J9

3438 I4

3439 I4

3440 J4

3441 I10

3442 I9

3443 G10

3444 G10

3445 G10

3446 G10

3447 G10

3448 G10

3449 G11

3450 H11

3451 H11

3452 H11

3453 I11

3454 I11

3455 J11

3456 J11

3457 J11

3458 K11

3459 K11

3460 G12

7

69 68

60659 56 55 54 48 47 46 45 44 4342 41 40

98

32 31 30 29 28 27 26 25 2453 52 51 50549

7402

23 22 21 20219 18 17 16 15 1413 121110

10n

2420

1

39 38 37

180p

2421

CDR80x: 3474= 3,9 Ohm

CDR82x: 3474= 0 Ohm

**

**

for CDR82x only

CDR82x: 3514, 3515 = 120 Ohm

2R2

3516

D

1K

3420

D

100n

2406

D

3474

3R9

2414

47u

2413

47u

15p

2409

D

100n

D

D

D

2400

3440

1K

100R

3438

GP1U28XP

7403

3

GND4MT

1OUT

VSUP

2

D

3439

10K

7405

BC847B

1K

2410

10n

2412

10n

3471

2n2

220K

3473

D

2401

KEY

1400

CSTS

2411

D

D

F410

D

F406

3472

220K

F409

D

10K

3475

15p

2408

BZX79-B3V9

6400

D

2402

10n

24

MT1 MT2

5

10K

3442

10K

EC12E24404

1419

13

F412

3441

F411

560R

3454

390R

3453

270R

3452

150R

3450

220R

3451

1n

2404

+5V+5V

2403

10n

1433

1435

Finalize

1434

Rec_Level

CD3

CD2

1432

1K2

34563458

3K9 820R

3455

1K8

3457

10K

3459

1440

Shuffle

1441

Display

Text

1438

Track_Edit

1439

Prog.

1513

1436

Erase

1437

262524

23

302928

34

1663 8999

65 14

10

11

79

2221201918

17

12

33

735

4

8

6

27

46454443424140393837

83

3635

82 81

80

60

59

58

578556

55

5453525150494847

84

77

76

75

74

73

72

71

70

698668

67

66

64

62

61

95 94 93 92 91 90 100

97 32931

1

2

88 87

78

470R

3428

M30218MAFP

7414

98 96

470R

3427

2

3

4

5

6

7

8

9

3435

470R

FFC

1418

1

10

11

12

13

14

15

470R

3425 220R

3433

from/to_Interface_Board

3424

100R

470R

820R

3426

470R

3429

3430

3436

470R

3437

470R

470R

3443

470R

3445

3444

470R

470R

3432

100R

3423

220R

3431

3434

470R

3421

2K7

F405

F407

D

100n

2407

F404

2u2

5400

470R

3448

3447

470R

68K

3402

3446

470R

68K

68K

3400

68K

3401

3403

F402

F400

F401

F408

F403

3410

68K

68K

3411

68K

3408

3409

68K

3404

68K

68K

3406

3407

68K

68K

3418

68K

3405

3419

68K

68K

3416

68K

3417

68K

3412

3414

68K

68K

68K

3415

D

3413

D

47u

2415

D

F436

F438

F434

F440

F442

KEY

F444

1431

F446

390R

KEY

CD1

3462

220R

3464 3461

150R

3463

270R

2405

1n

2K7

3449

F428

F430

F426

Compl_CD

No

1423

Rec_type

1422

1421

3468

3K9

3469 3466

820R1K8

3465

560R1K2

34673470

10K

1429

O/C_CDR

1430

>>

1427

Speed

Stop

1426

Yes

1428

Play/Pause

1425

<<

1424

F435

F437

F439

F445

F441

F447

F443

KEY

CD-CD

1420

from/to_CD_R/W_Module

1

2

3

4

5

6

KEY

from/to_Mic/Headphone_Board

DIPMATE

0055

1

2

3

4

FE-ST-VK-N

1417

to_Front_LED_Board

1414

EH-B

1

2

3

F429

3460

2K7

F431

F433

F427

F418

F420

F417

F415

5

6

7

F414

F416

from/to_Key_Left_Board

FE-ST-VK-N

1416

1

2

3

4

D

F413

F425

KEY

D

F424

D

F423

F422

F419

F421

7410

BC857B

3492

100R

BC857B

7411

100R

3490

3493

10K

10K

3491

3496

10K

D

10K

3489

BC847B

7412

10K

3495

D

2K7

3494

7407

BC847B

3480

D

BC847B

7406

10K10K

3478

D

7413

BC847B

3481

100R

4K7

3487

+5V

3486

4K7

3488

6K8

D

BC847B

7408

3485

10K

3482