Philips CDR775 Service Manual

Compact disc recorder

Service

CDR775

/oo

nCOJJPACT riBOMfWCT nOOMPACT HCOMPACT

togl

(ta

MOfTAlAUOtO MBtTAl AUDIO

oEtascB

PtGfTAlAUMO OHHTAL AUDIO

GQD§(S

SERVICING

For servicing CDR775, the set can divided into three parts.

1.

The display board (partly) 1 002, the I/O board 1004, the

headphone board (partly)

OFF & Standby LED board (partly) 1002 and the CD-out board

(partly) 1002 have to be repaired at component level. The power

supply unit 1003 is available as spare part, but can also be repaired

at component level.

2.

The CDR module (containing the CDR loader

1001 and loader bracket 82, 83) will be exchanged completely in

case of failure. This complete CDR module is available as spare

part. Defective modules have to be returned for central repair.

3. The CD module (containing the CD loader

1005 and loader bracket 132) is a new module with VAL1250

loader assy but also a separate CDM and separate loader

be available via service stock. The CD main board can be repaired

at component level.

Also available: Circuit Description " The Basics of Compact Disc

Recordable/Rewriteable". Service code number 4822 725 25242.

1002,

the IR board (partly) 1002, the ON/

81,

CDR main board

131,

CD main board

parts

will

Contents

1.

Technical Specifications

2.

Warning and Servicing Hints

3. User Instructions

4.

Mechanical Instructions

Wiring Diagram CDR

Wiring Diagram CD loader

Exploded View CDR

Exploded View CD loader

Dismantling Instructions

5. Electrical and Circuit Diagrams

Overall Blockdiagram

Display Board

IR / On/Off &Standby LED Board

Headphone / CD-out Board

I/O Board

Power supply unit

CD-Mainboard 1A

CD-Mainboard 1B

CD-Mainboard 1C

CD-Mainboard 2

6. Diagnostic Software

7. Faultfinding Trees

8. Faultfinding Guide

9. List of Abbreviations

10.

Partslist (mechanical and electrical)

Page

2

4

7

19

19

20

21

22

23

Diagram PWB

24

26

27

28

29

31

33

34

35

36

39

43

49

65

71

26

27

28

30

32

37/38

37/38

37/38

37/38

Copyright reserved 1999 Philips Consumer Electronics B.V. Eindhoven, The

Netherlands. All rights reserved. No part of this publication may be reproduced,

stored in a retrieval system or

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by RH 9969 Service DPS Hasselt

transmitted,

in any

form

or

by

Printed in the Netherlands

any

means,

electronic,

Subject to modification

PHILIPS

<§§> 3104 125 40030

Warnings and Servicing Hints

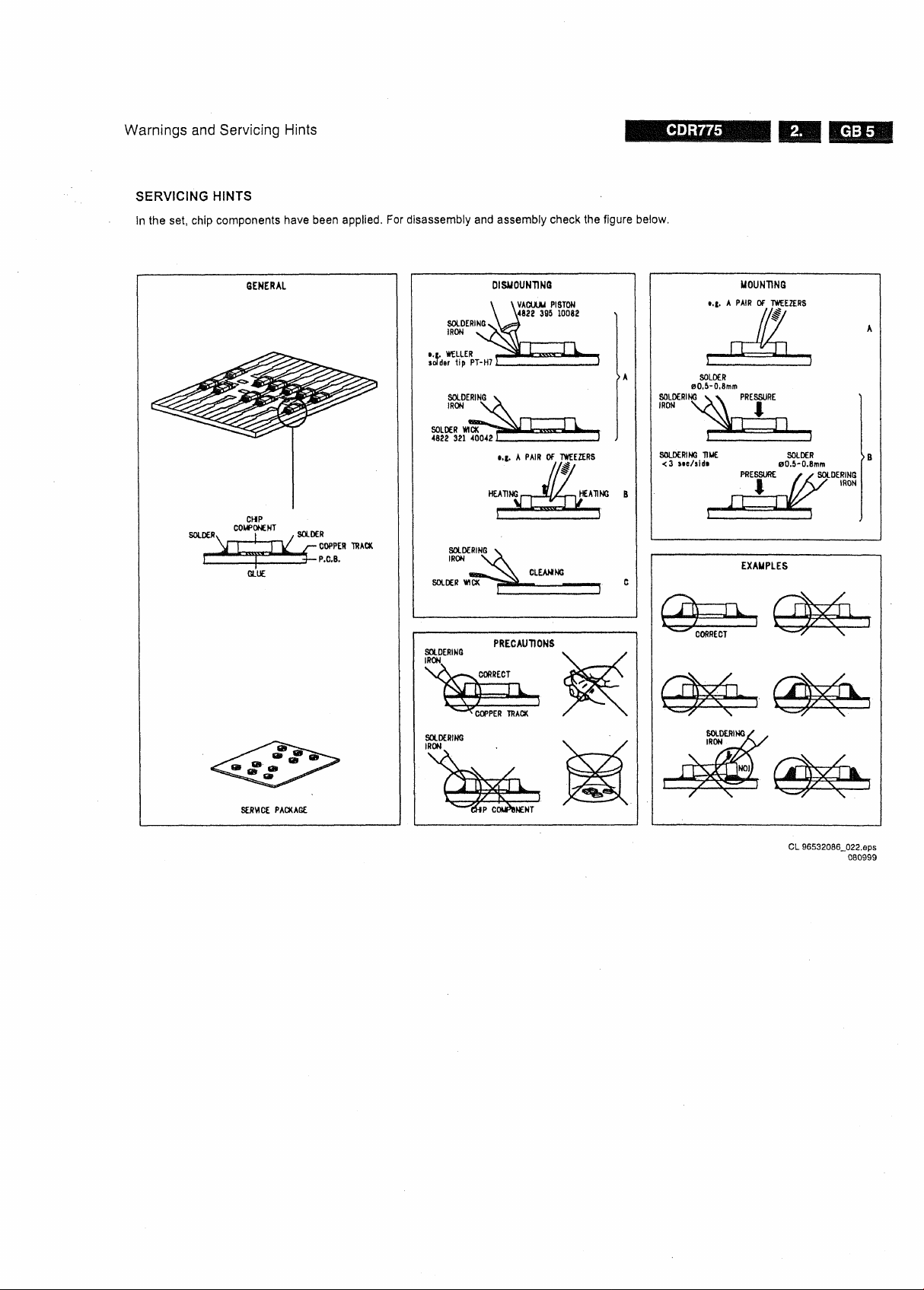

SERVICING HINTS

In the set, chip components have been applied. For disassembly and assembly check the figure below.

CL 96532086_022.eps

080999

CDR775

Warnings and Servicing Hints

SAFETY GUIDELINES FOR THE PROFESSIONAL SERVICE TECHNICIAN

Important

Proper service and repair is Important to the safe, reliable operation

of all Philips equipment. The service procedures recommended by

Philips and described In this service manual are effective methods of

performing service operations. Some of these service operations

require the use of tools specially designed for the purpose. The

special tools should be used when and as recommended,

It is Important to note that this manual contains various CAUTIONS

and NOTICES which should be carefully read In order to minimize the

risk of personal injury to service personnel. The possibility exists

that Improper service methods may damage the equipment. It also

Is Important to understand that these CAUTIONS and NOTICES

ARE NOT EXHAUSTIVE, Philips could not possibly know, evaluate

and advise the service trade of all conceivable ways In which service

might be done or of the possible hazardous consequences of each

way. Consequently, Philips has not undertaken any such broad

evaluation.

tool which Is not recommended by Philips must first satisfy himself

thoroughly that neither his safety nor the safe operation of the

equipment will be Jeopardized by the service method selected.

Safety Checks

After the original service problem has been corrected, a complete

safety check should be made. Be sure to check over the entire set,

not Just the areas where you have worked. Some previous servicer

may have left an unsafe condition, which could be unknowingly

passed on to your customer. Be sure to check all of the following:

Accordingly, a servicer who uses a service procedure or

Fire and Shock Hazard

1.

Be sure all components are positioned In such a way as to avoid

the possibility of adjacent component shorts. This is especially

important on those units which are transported to and from the

service shop.

2.

Never release a repaired unit unless all protective devices such

as insulators, barriers, covers, strain reliefs, and other

hardware have been installed according to the original design,

3. Soldering and wiring must be inspected to locate possible cold

solder Joints, solder splashes, sharp solder points, frayed

leads,

pinched leads, or damaged Insulation (Including the ac

cord).

Be certain to remove loose solder balls and aH other

loose foreign particles.

4.

Check across-the-line components and other components for

physical evidence of damage or deterioration and replace if

necessary. Follow original layout, lead length, and dress.

5. No lead or component should touch a resistor rated at 1 watt or

more.

Lead tension around protruding metal surfaces or edges

must be avoided.

6. Critical components having special safety characteristics are

Identified with a Aby the Ref. No. In the parts list and enclosed

within a broken line* (where several critical components are

grouped In one area) along with the safety symbol

A on the schematic diagrams and/or exploded views.

Replacement parts without the same safety characteristics

may create shock, fire, or other hazards.

7. When servicing any unit, always use a separate Isolation

transformer for the chassis. Failure to use a separate isolation

transformer may expose you to possible shock hazard, and

may cause damage to servicing instruments.

8. Many electronic products use a polarized ac line cord (one wide

pin on the plug). Defeating this safety feature may create a

potential hazard to the servicer and the user. Extension cords

which do not Incorporate the polarizing feature should n»ver be

used.

Fire and Shock Hazard (Continued)

9, After reassembly of the unit, always perform an ac leakage

test or resistance test from the line cord to all exposed metal

parts of the cabinet, Also, check all metal control shafts (with

knobs removed), antenna terminals, handles, screws, etc. to

be sure the unit Is safe to operate without danger of electrical

shock,

Broken line: an

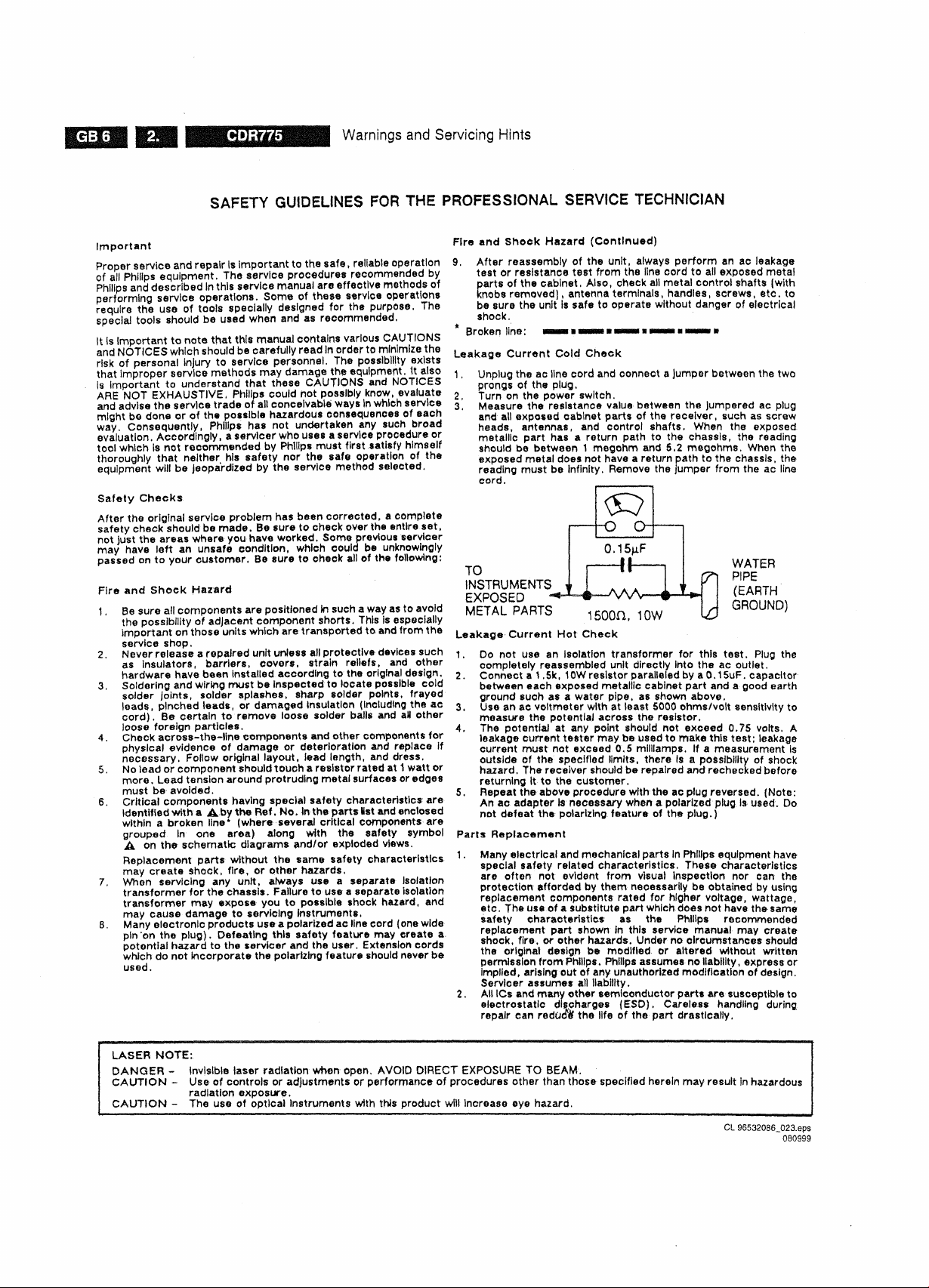

Leakage Current Cold Check

Unplug the ac line cord and connect a Jumper between the two

1,

prongs of the

Turn on the power switch.

Measure the resistance value between the Jumpered ac plug

and all exposed cabinet parts of the receiver, such as screw

heads, antennas, and control shafts. When the exposed

metallic part has a return path to the chassis, the reading

should be between 1 megohm and 5.2 megohms. When the

exposed metal does not have a return path to the chassis, the

reading must be Infinity. Remove the jumper from the ac line

cord.

TO

INSTRUMENTS

EXPOSED

METAL PARTS

Leakage Current Hot Check

1.

Do not use an isolation transformer for this test. Plug the

completely reassembled unit directly into the ac outlet.

2.

Connect a 1.5k, 10W resistor paralleled by a 0,15uF. capacitor

between each exposed metallic cabinet part and a good earth

ground such as a water pipe, as shown above.

3. Use an ac voltmeter with at least 5000 ohms/volt sensitivity to

measure the potential across the resistor.

4.

The potential at any point should not exceed 0.75 volts. A

leakage current tester may be used to make this test; leakage

current must not exceed 0.5 mllllamps. If a measurement Is

outside of the specified limits, there Is a possibility of shock

hazard.

returning It to the customer.

5. Repeat the above procedure with the ac plug reversed. (Note:

An ac adapter Is necessary when a polarized plug Is used. Do

not defeat the polarizing feature of the plug.)

Parts Replacement

1.

Many electrical and mechanical parts In Philips equipment have

special safety related characteristics. These characteristics

are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using

replacement components rated for higher voltage, wattage,

etc. The use of a substitute part which does not have the same

safety characteristics as the Philips recommended

replacement part shown in this service manual may create

shock, fire, or other hazards. Under no circumstances should

the original design be modified or altered without written

permission from Philips. Philips assumes no liability, express or

implied,

Servicer assumes all liability.

2.

All ICs and many other semiconductor parts are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce the life of the part drastically.

plug,

WATER

PIPE

(EARTH

1500H,

10VV

The receiver should be repaired and rechecked before

arising out of any unauthorized modification of design.

GROUND)

LASER NOTE:

DANGER - Invisible laser radiation when open. AVOID DIRECT EXPOSURE TO BEAM.

CAUTION - Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous

CAUTION - The use of optical Instruments with this product will Increase eye hazard.

radiation exposure.

CL 96532086_023.eps

080999

Diagnostic Software

6. Diagnostic Software

6.1 Dealer mode

The purpose of the dealer mode is to prevent people taking out

the CD inside the player at exhibitions, showrooms etc.. This

mode disables the open/close function of the player,

The dealer mode can be switched on and off pressing keys

[OPEN/CLOSE] and [STOP] of

while switching on the unit. The dealer mode is stored in the

flash memory

actions.

and

can only be changed by executing the above

the

CDR player simultaneously

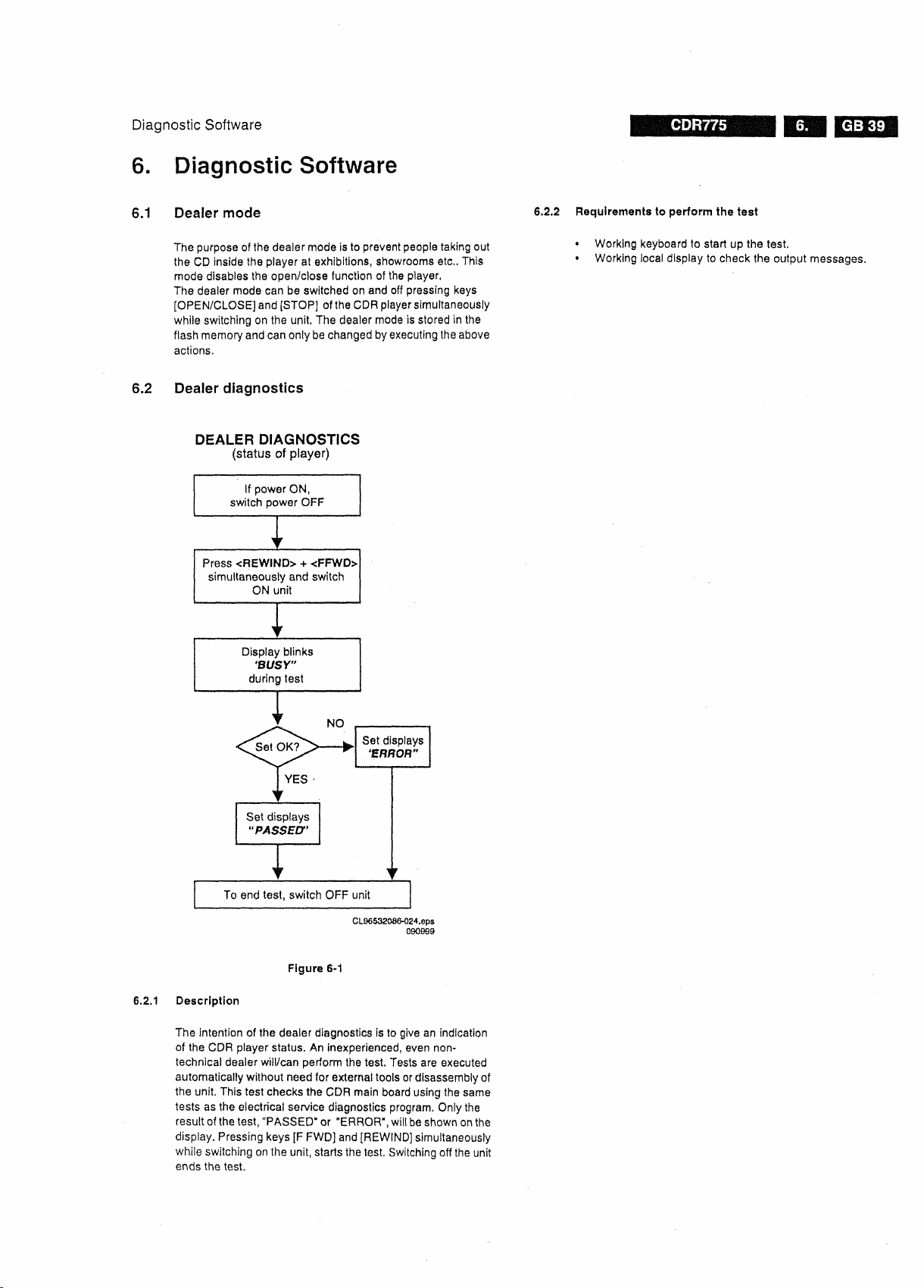

6.2 Dealer diagnostics

6.2.2 Requirements to perform the test

• Working keyboard to start up the test.

• Working local display to check the output messages.

CL96532086-024.eps

Figure 6-1

6.2.1 Description

The intention of the dealer diagnostics is to give an indication

of the CDR player status. An inexperienced, even

technical dealer will/can perform the test. Tests are executed

automatically without need for external tools or disassembly of

the unit. This test checks the CDR main board using the same

tests as the electrical service diagnostics program. Only the

result of

the

test,

display. Pressing keys [F FWD] and [REWIND] simultaneously

while switching on the unit, starts the test. Switching off

ends the test.

"PASSED" or "ERROR", will

090999

non-

be

shown on the

the

unit

CDB775

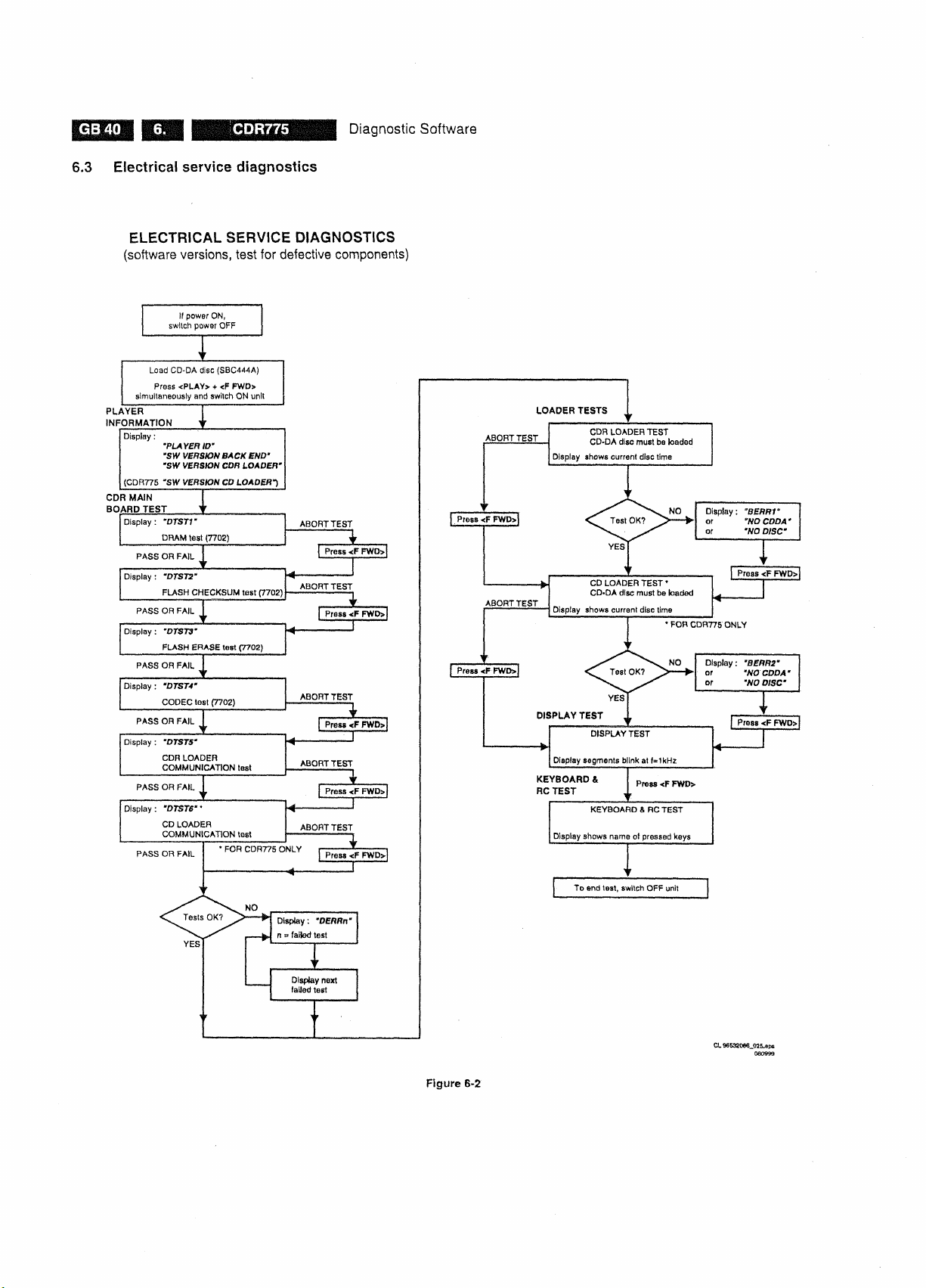

6.3 Electrical service diagnostics

ELECTRICAL SERVICE DIAGNOSTICS

(software

versions,

test for defective components)

Diagnostic Software

Figure 6-2

Diagnostic Software

CDR775

6.3.1 Description

The intention of the electrical service diagnostics is to show the

software versions present in the player and to direct the dealer

towards defective internal units. The units are : the CDR main

board,

the CDR loader, the CD loader

the keyboard/display board. A sequence of tests is executed

automatically. Some of the tests can be aborted or skipped

without the result being taken Into account. External tools or

disassembly of the unit is not necessary to get the diagnostic

information. Pressing keys [PLAY/PAUSE] and [F FWD]

simultaneously while switching on the unit, starts the test.

Switching off the unit ends the test.

6.3.2 Requirements to perform the test

• Working keyboard to start up the test.

• Working local display to check the output messages.

• A CD-DA disc with a minimum of 3 tracks in all trays to

perform the disc test.

6.3.3 Description of the tests

Player

Information

In this part of

checked without removing the cover:

• SW-version back end of player.

• SW-version CD loader (only for CDR775).

CDR main board

[F FWD] key. The message "DERRn" will be displayed with n

indicating the faulty test number.

If one of the tests is aborted with the [F FWD] key, no error

message will be displayed for this test. The flash data erase

test

("DTST3")

The CDR main board test consists out of:

the

test the following Important Information can be

Recorder ID.

SW-version CDR loader.

test

can not be aborted !

in

case of a CDR775 and

disc test is executed to check focus control, disc motor control,

radial control and jump grooves control. The disc test is

performed by audio play-back of 5 seconds at the beginning,

middle and end of the disc.

CDR

loader

During the test, the current disc time is shown. In case of an

error the message

key must be pressed to continue with the following test.

Pressing the [F FWD] key also aborts this test.

CD loader

For CDR775 only. During the test, the current disc time is

shown.

displayed and the [F FWD] key must be pressed to continue

with the following test. Pressing the [F FWD] key also aborts

this test.

Display test

All segments will blink at a frequency of 1 Hz. Pressing the [F

FWD] key will start the next test because the user has to check

for himself if all segments work properly.

Keyboard

The test will give the user the ability to test every key without

executing the function assigned to

to press every key

display will show the name of the key being pressed. Pressing

more than one key at once will give an unpredictable result

except for

[PLAY/PAUSE] + [F FWD], [F FWD] + [REWIND], [ERASE] +

[RECORD], [PLAY/PAUSE] + [RECORD], [OPEN/CLOSE] +

[PROGRAM].

test

"BERR1"

test

In case of an error the message "BERR2" will be

and

remote

on

the

service combinations: [PLAY/PAUSE] + [STOP],

will be displayed and the [F FWD]

control tests

it.

the keyboard and the remote

Therefore, the user needs

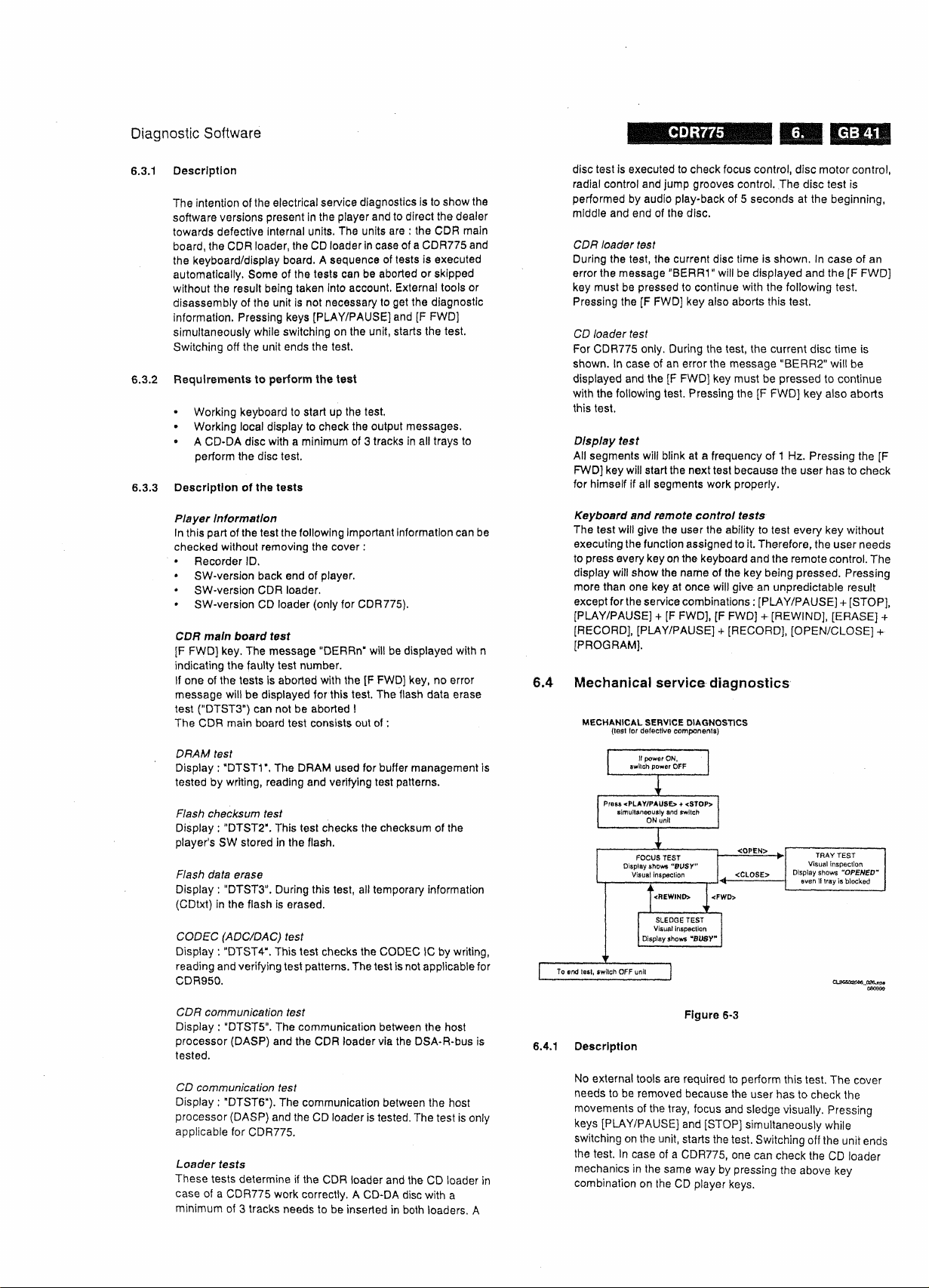

6.4 Mechanical service diagnostics

control.

The

DRAM test

Display :

tested by writing, reading and verifying test patterns.

CDR950.

tested.

processor (DASP) and the CD loader is

applicable for CDR775.

These tests determine if the CDR loader and the CD loader in

case of a CDR775 work correctly. A CD-DA disc with a

minimum of 3 tracks needs to be inserted in both loaders. A

"DTST1",

Flash

checksum

Display : "DTST2". This test checks the checksum of the

player's SW stored in the flash.

Flash data erase

Display : "DTST3". During this test, all temporary information

(CDtxt) in the flash is erased.

CODEC

(ADC/DAC)

Display : "DTST4". This test checks the CODEC IC by writing,

reading and verifying test

CDR

communication

Display : "DTST5". The communication between the host

processor (DASP) and the CDR loader via the DSA-R-bus is

CD

communication

Display : "DTST6"). The communication between the host

Loader tests

The DRAM used for buffer management is

test

test

patterns.

test

test

The test is not applicable for

tested.

The test is only

6.4.1 Description

No external tools are required to perform this test. The cover

needs to be removed because the user has to check the

movements of the tray, focus and sledge visually. Pressing

keys [PLAY/PAUSE] and [STOP] simultaneously while

switching on the unit, starts the

the test. In case of a CDR775, one can check the CD loader

mechanics in the same way by pressing the above key

combination on the CD player keys.

test.

Switching off the unit ends

BSEM HH

IHQ^^HH Diagnostic Software

6.4.2 Requirements to perform the test

• Working keyboard to cycle through the tests and to start up

the test.

Working local display to check the output messages.

6.4.3 Description of the tests

Focus control test

The focussing lens is continuously moving up and down. The

display reads "BUSY".

Sledge control test

After pressing [F FWD] the sledge continuously moves up and

down.

Pressing [REWIND] stops the sledge at the position it is

in and the focus control test resumes. The display reads

"BUSY".

Tray control test

This test starts from within the focus control test routine.

Pressing [OPEN/CLOSE] moves the tray in or out. In the tray

open position one can initiate focus and sledge tests by

pressing [F

[REWIND] before it is possible to close the tray again.

Depending on the action the display reads "OPEN",

"OPENED",

6.5 DC-erase service mode

FWD].

One has to stop these tests pressing

"CLOSE" or "BUSY".

i.5.1 Description

This test is initiated by pressing [ERASE] and [RECORD]

simultaneously while switching on the unit. The player will

erase a complete CD-RW disc (including PMA and ATIP lead

out area) at speed N=2. The display shows the countdown of

the remaining time required for the operation to complete, The

format is "ER mm:ss", where "mm" are the remaining minutes

and

"ss"

the remaining seconds. After completion the message

"PASSED"

on again to start up in normal operating

unit before completion of the test, leaves the disc in an

unpredictable state. In such case only a complete DC-erase

procedure can recover the CD-RW disc.

5.5.2 Requirements to perform the test

•• Functional CDR player.

* A CD-RW audio disc must be present in the tray.

is shown, and the player has to be switched off and

mode.

Switching off the

Figure 6-4

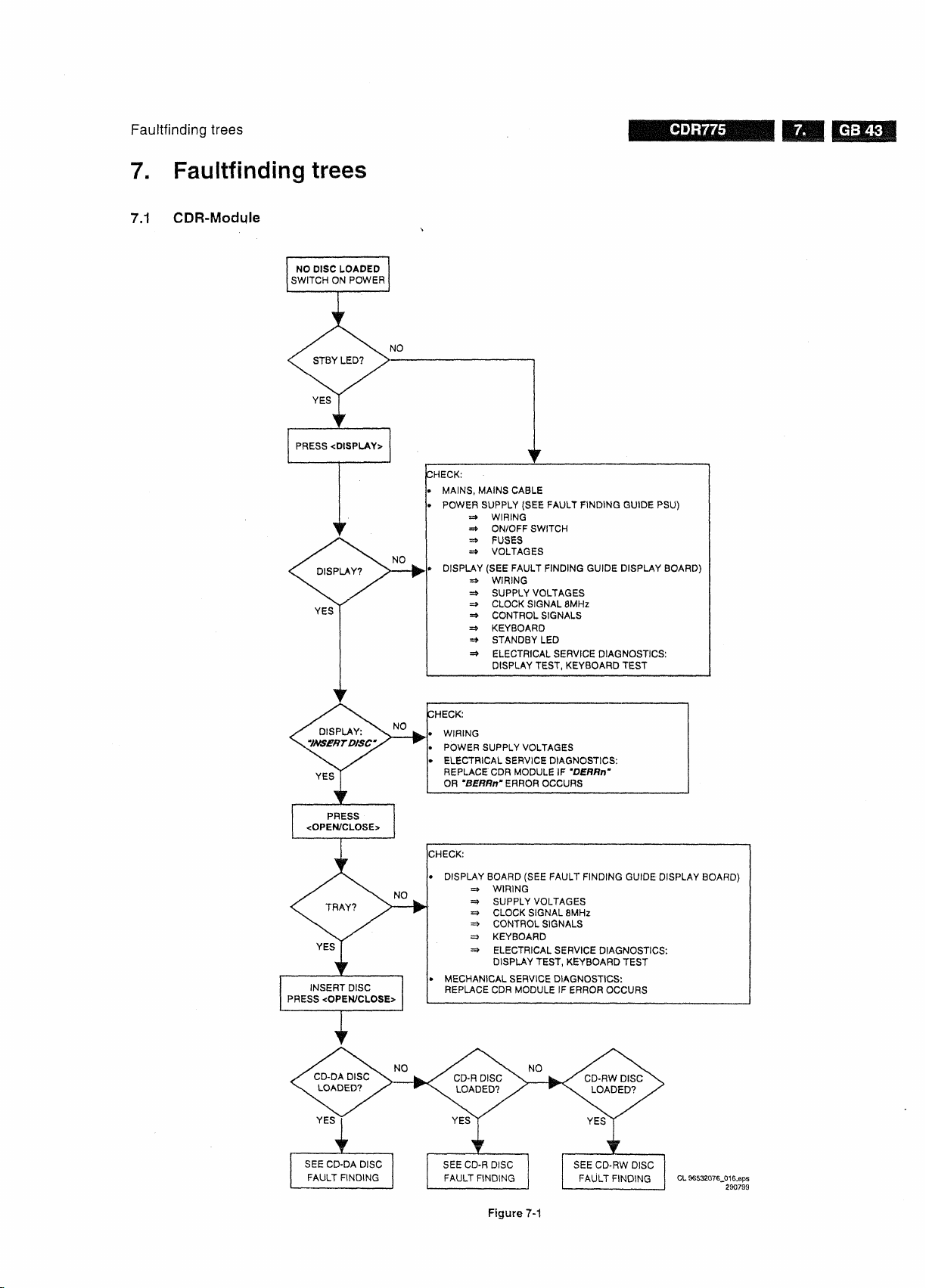

Faultfinding trees

7. Faultfinding trees

7.1 CDR-Module

CDR775

Figure 7-1

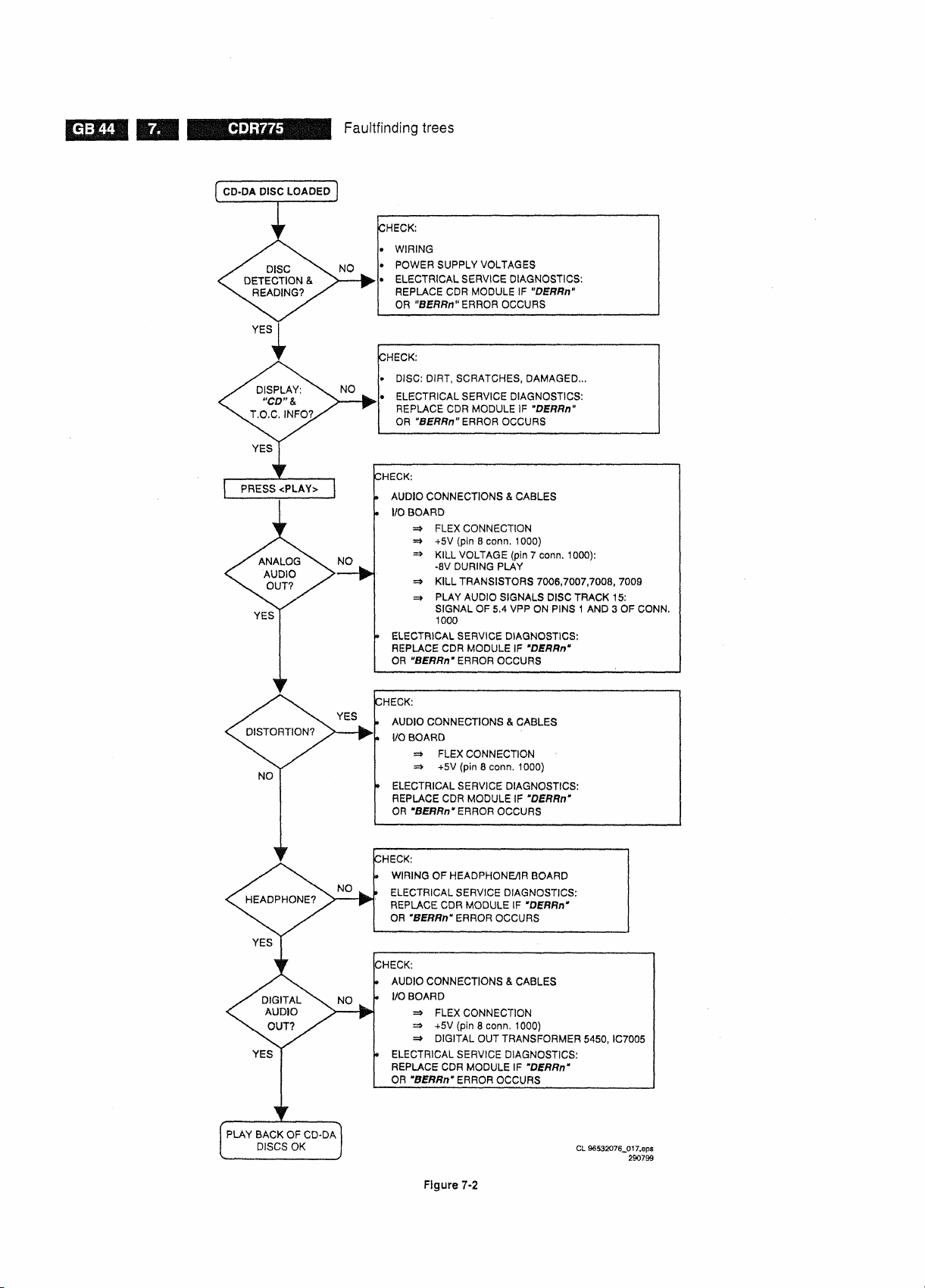

CDR775

Faultfinding trees

Figure

7-2

Faultfinding trees

CDR775

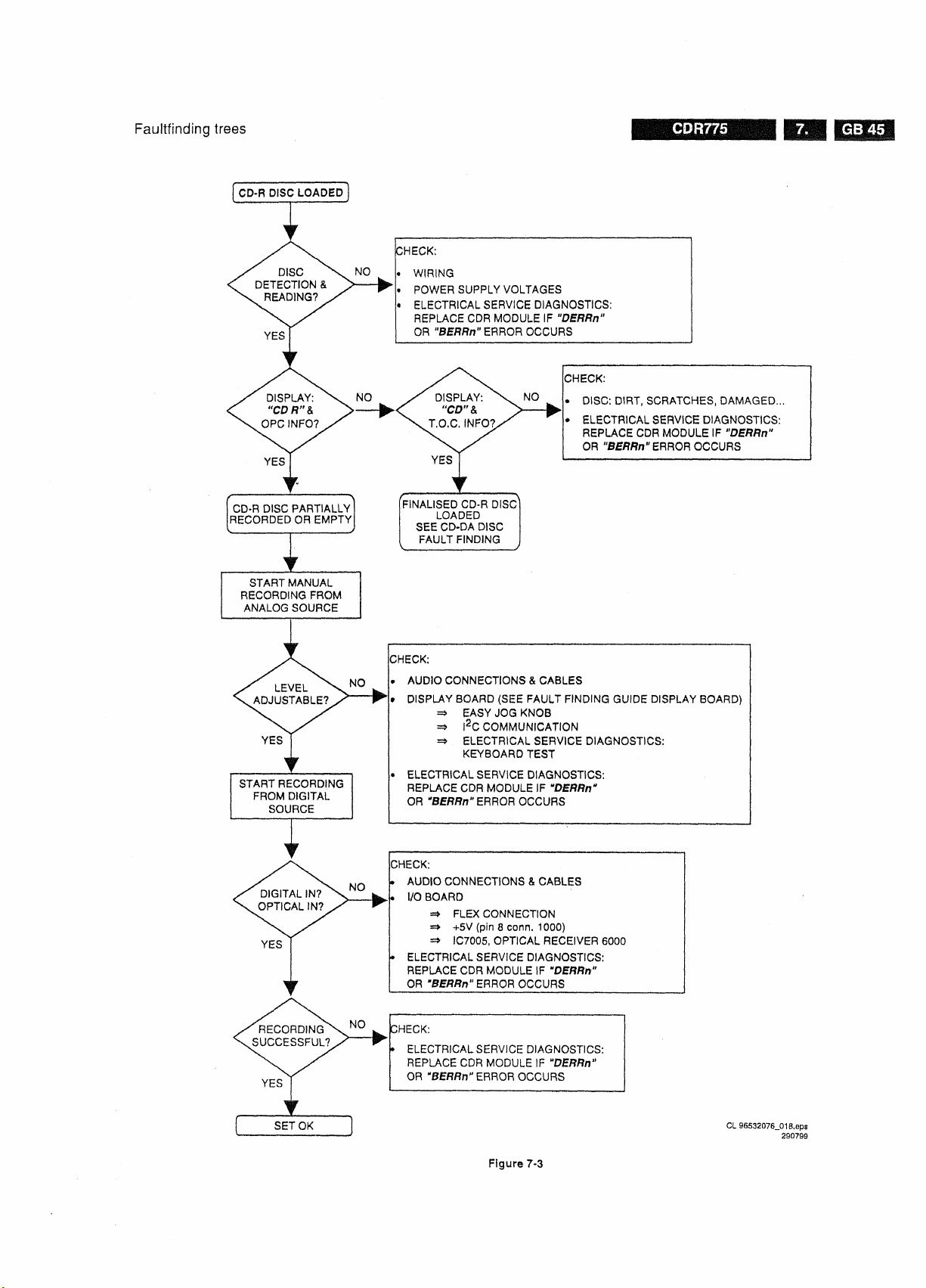

Figure

7-3

CDR775

Faultfinding trees

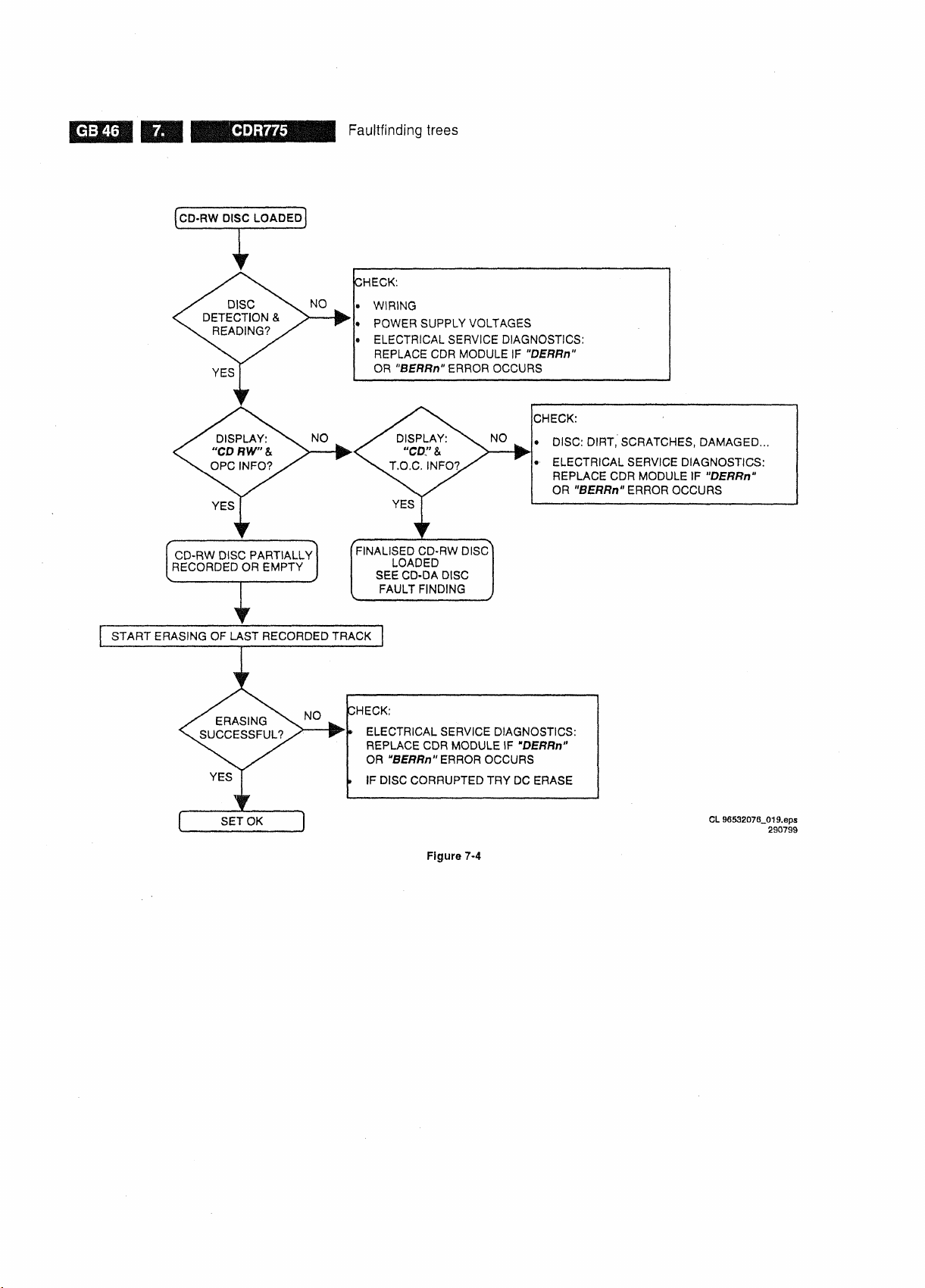

Faultfinding trees

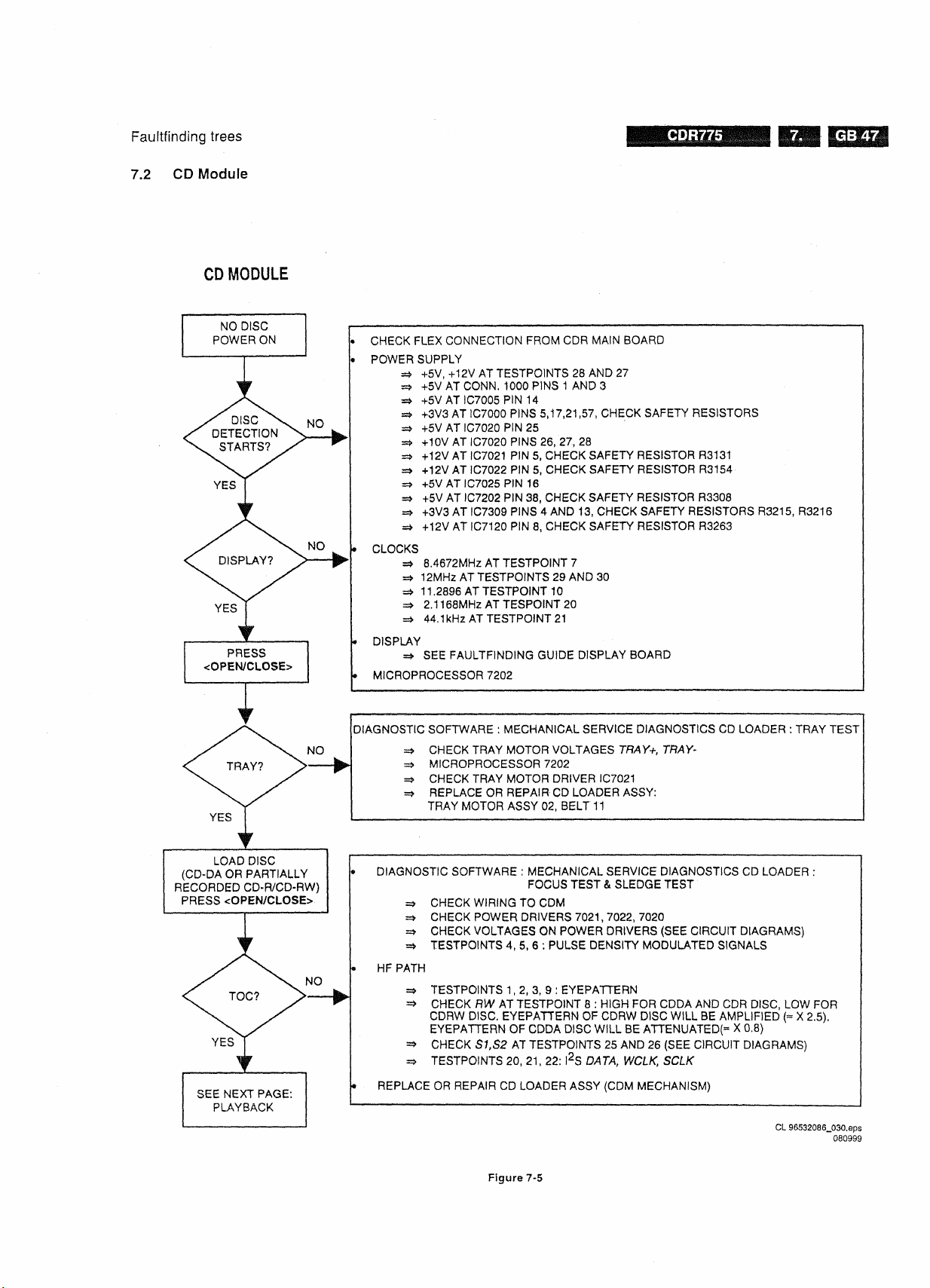

7.2 CD Module

C0R775

•pMiiiap»|»iMM

Figure 7-5

CDR775

Faultfinding trees

Faultfinding Guide

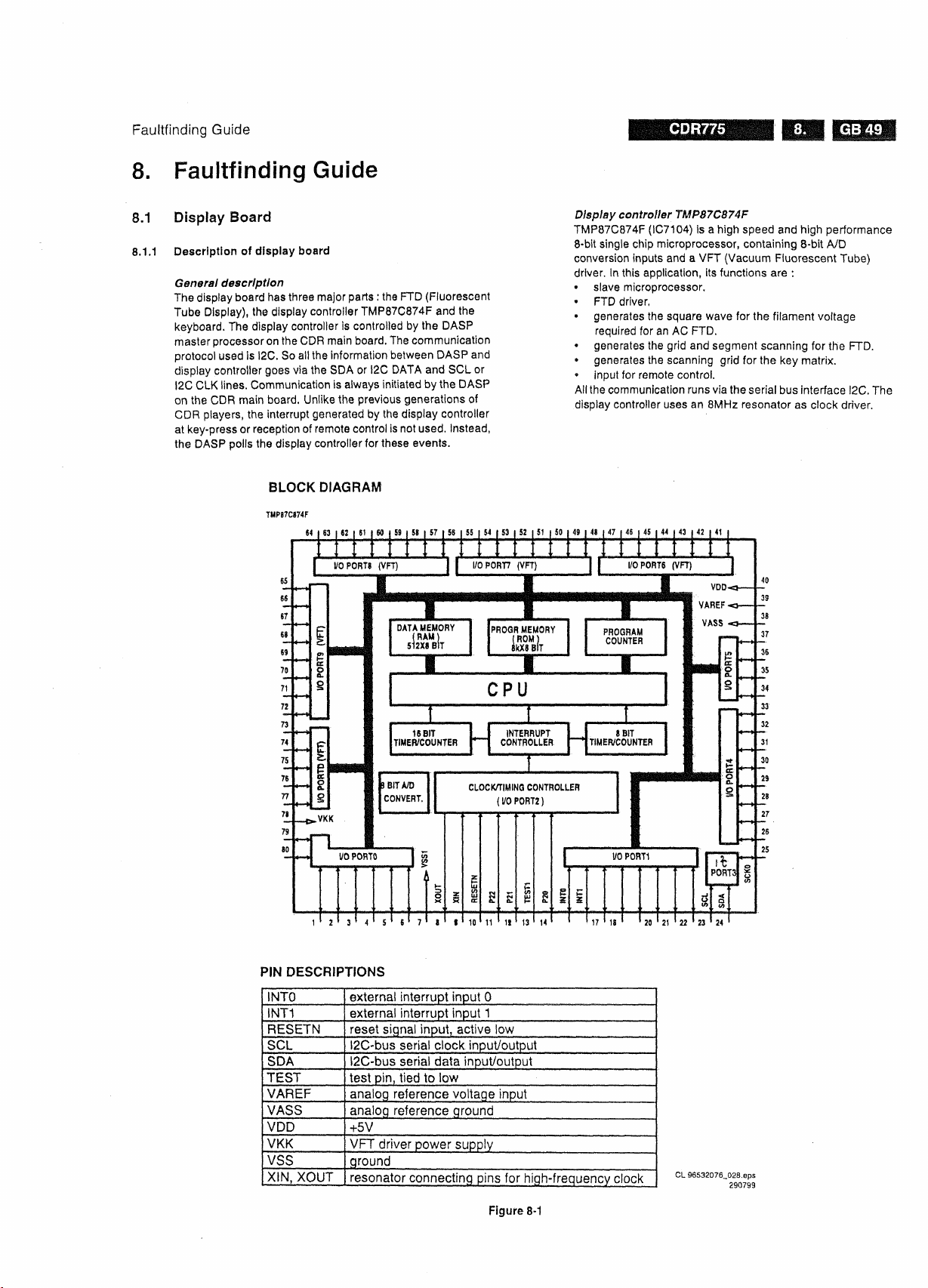

8. Faultfinding Guide

CDR775

8.1 Display Board

8.1.1 Description

General description

The display board has three major parts : the FTD (Fluorescent

Tube Display), the display controller TMP87C874F and

keyboard.

master processor

protocol used

display controller goes via the SDA

I2C CLK lines. Communication is always initiated by the DASP

on the CDR main board. Unlike the previous generations

CDR players, the interrupt generated by the display controller

at key-press or reception of remote control is not

the DASP polls the display controller for these events.

of

display board

The display controller Is controlled by the DASP

on

the CDR main

is

I2C. So all the information between DASP and

board.

The communication

or

I2C DATA and SCL or

used.

the

of

Instead,

Display controller TMP87C874F

TMP87C874F (IC7104) Is a high speed and high performance

8-bit

single chip microprocessor, containing

conversion inputs and a VFT (Vacuum Fluorescent Tube)

driver. In this application, its functions are

• slave microprocessor.

• FTD driver,

• generates the square wave for the filament voltage

required for an AC FTD.

• generates the grid and segment scanning for the FTD.

• generates the scanning grid

• input

for

remote control.

All

the communication runs via the serial bus interface I2C. The

display controller uses an 8MHz resonator as clock driver.

for

8-bit

A/D

:

the key matrix.

PIN DESCRIPTIONS

INTO

INT1

RESETN

SCL

SDA

TEST

VAREF

VASS

VDD

VKK

VSS

XIN,

XOUT

external interrupt input 0

external interrupt input 1

reset signal input, active low

l2C-bus serial clock input/output

l2C-bus serial data input/output

test pin, tied to low

analog reference voltage input

analog reference ground

+5V

VFT driver power supply

ground

resonator connecting pins for high-frequency clock

Figure 8-1

CL 96532076_028.eps

290799

CDR775

Faultfinding Guide

8.1.2 Test instructions

Supply

voltages

The display board receives several voltages via connector

1119 (and connector

• VFTD : -38V ±5% measured at pin 2 of conn. 1119.

• VDC1-VDC2 : 3V8

conn.

• +5V : +5V ±5% measured at pin 10 of

Voltages VFTD, VDC1 and VDC2 are produced in the power

supply unit and sent to the display board via the CDR main

board.

D5V.

Clock

As clock driver for the display controller, a resonator of 8 MHz

(1110) is used. The signal can be measured at pins 8 and 9 of

the display controller: 8 MHz ±5%.

Control signals

RESET

The reset signal comes via pin 4 of conn. 1119 from the DASP

master processor

reset is low active. It should be kept low during power up for at

least 3 machine cycles with supply voltage in operating range

and a stable clock signal

sec).

The high signal is 3V3 because the DASP operates on 3V3.

I2CDA

These lines connect to the DASP master processor via

respectively pin 5 and pin 7 of

and pin 1 of conn. 1121 for CDR570/930). When there Is no

communication, they should have the high level (+5V), The

oscillogram below gives an indication of how these signals

should look like.

1119.

conn.

1121 for CDR770).

The +5V voltage is produced on the CDR main board as

signal

During normal

TA/I2C

1121

for CDR570/930).

±10%

measured between pin 1 and 3 of

conn.

on

the CDR main board (SYS_RESET). The

(1

machine cycles 12 x

operation,

CLK

the reset should be high (3V3).

conn.

1119 (pin 5 of

1119 (pin 4 of

1/Fc(8MHz)

conn.

1119

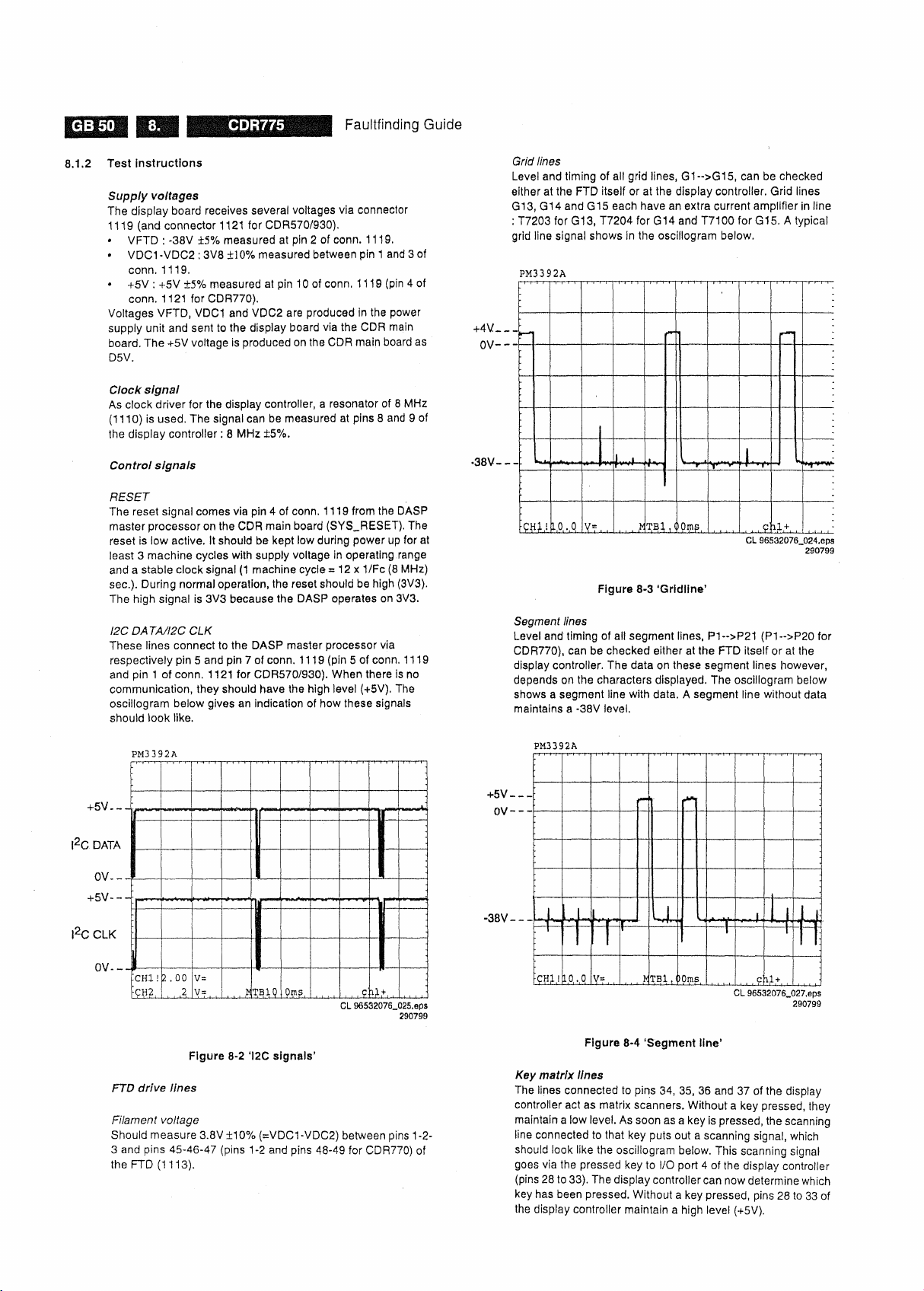

Grid lines

Level and timing of all grid lines, G1-->G15, can be checked

either at the FTD itself or at the display controller. Grid lines

G13,

G14andG15 each have an extra current amplifier in line

: T7203 for G13, T7204 for G14 and T7100 for G15, A typical

grid line signal shows in the oscillogram below.

Figure 8-3 'Gridline'

Segment lines

Level and timing of all segment lines, P1-->P21 (P1-->P20 for

CDR770), can be checked either at the FTD itself or at the

display controller. The data on these segment lines however,

depends on the characters displayed. The oscillogram below

shows a segment line with data. A segment line without data

maintains a -38V level.

Figure 8-2 'I2C signals'

FTD drive lines

Filament voltage

Should measure 3.8V ±10%

3 and pins 45-46-47 (pins 1-2 and pins 48-49 for CDR770) of

the FTD (1113).

(=VDC1

-VDC2) between pins 1 -2-

Figure 8-4 'Segment line'

Key matrix lines

The lines connected to pins 34, 35, 36 and 37 of the display

controller act as matrix scanners. Without a key pressed, they

maintain a low

line connected to that key puts out a scanning signal, which

should look like the oscillogram below. This scanning signal

goes via the pressed key to I/O port 4 of the display controller

(pins 28 to

key has been pressed. Without a key pressed, pins 28 to 33 of

the display controller maintain a high level (+5V).

level.

As soon as a key is pressed, the scanning

33).

The display controller

can

now determine which