Page 1

Compact disc recorder 2nd line Service Manual

CDR570

CDR770

CDR775

CDR930

CDR950

Contents Page

1 Introduction 2

2 Safety- and maintenance instructions, warnings

and notes 3

3 Directions for use 6

Mechanical instructions 7

4

Loader CDL4009 7

CDL3800 8

Demounting CDL3800 9

Exploded view CDM3800 11

Cleaning lens 12

Lubricating 13

Service modes, faultfindingtrees and repair tips 14

5

Service modes 14

Faultfindingtrees 18

6 Blockdiagrams 33

7 Electrical diagrams and PWB’s 34

8 Alignments, Adjustments 75

9 Circuit description 76

List of abbreviations 77

10 Sparepart list 85

©

Copyright reserved 2000 Philips Consumer Electronics B.V. Eindhoven, The

Netherlands. All rights reserved. No part of this publication may be reproduced,

stored in a retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by JvO 0063 Service BG Audio Printed in the netherlands Subject to modification 5 3104 125 40110

Page 2

GB 2 CDR 3rd gen.1.

Technical Specifications/Introduction.

1. Technical Specifications/Introduction.

In this document the important issues for the mechanical and

electrical testing, adjusting, checking and diagnosing of the

Digital Audio CDR Module such as applied in so-called 3rd

generation CDR recorders is described.

In this first chapter is presented the introduction of the repair

manual for 2nd line repair workshops. In contains the repair

instructions of the CDR Module CDL4009 + Mainboard 4228.

All modules consist of the same loader + CDM part, the

mounting of the components on the Mainboard deviates form

each other. For that reason a separate CDR-module has been

defined for each type/modelnumber.

On top of that: Each mainboard connected to another CDM has

to adjusted before that module can be used. To have this

module on component level repaired this second line service

(repair) manual has to used in combination with the "first" line

service manual of mentioned typenumber. As long as the

adjustment instructions can not be carried out, the module has

to be exchanged by an adjusted one from Service stock in case

of repairs concerning CDM and/or Servo circuits.

Chapter 2 contains the required safety instructions, in chapter

3 a referring to the directions for use, as published in the

typenumber Service Manual, is made.

In chapter 4 the mechanical exploded view of the complete

module, the loading part and the CDM3800 is presented. This

chapter also includes the mounting, demounting, cleaning and

greasing instruction.

In chapter 5 the internal selfdiagnostics without opening the set

and use of other tools is described in the service modes. The

faultfinding trees and repair suggestions like the power supply

voltages for proper functioning of the mainboard are indicated

there too. This chapter also contains initialising and reset,

concerned measuring points are highlighted. For proper

functioning of all ICs the clockfrequencies have to be tested

and the importance of derived clockfrequencies is shown. and

and how to operate with the menu driven diagnostics. Via a PC

connection (serial input socket RS232C) the Menu Driven

Diagnostics feature is started.

To improve the interactivity and communication with the set/

module the COMPAIR (the for service designed computer

aided repair) tool is supported too by this CDR generation.

Details to be defined soonest and will be published by a service

information bulletin later on.

Via blockdiagrams of applied boards the common issues of all

boards are shown and in short explained in chapter 6.

In chapter 7 the circuit diagrams and printed wiring boards with

important measuring points are shown.

The adjustment of the laser current (only one important and

necessary adjustment has to be carried out, the rest of the

adjustments are calcultated from that parameter onwards) will

be presented in chapter 8. The needed PC program is under

investigation now and with the implentation of COMPAIR this

adjustment action will be explained. The method how to align

the software, if needed, is indicated here.

In chapter 9 reference is made to existing 3rd generation circuit

description in which publication a lot of details about the

functioning of the set is explained.

Also the list of abbreviations is inserted here.

Finally a survey of applied components and corresponding

service ordering numbers is given in chapter 10.

As the Mainboard 4228 is designed to be applied for several

modelnumbers this board contains a lot of optional

components.

The most extended board is modelnumber CDR775 where

double speed dubbing feature is applied too.

Page 3

Safety and Maintenance instructions warnings and notes

2. Safety and Maintenance instructions warnings and notes

GB 3CDR 3rd gen. 2.

GB

WARNING

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce

life drastically.

When repairing, make sure that you are

connected with the same potential as the

mass of the set via a wrist wrap with

resistance.

Keep components and tools also at this

potential.

F

ATTENTION

Tous les IC et beaucoup d'autres semiconducteurs sont sensibles aux décharges

statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu'aucune précaution

n'est prise a leur manipulation.

Lors de réparations, s'assurer de bien être

relié au même potentiel que la masse de

l'appareil et enfiler le bracelet serti d'une

résistance de sécurité.

Veiller a ce que les composants ainsi que les

outils que l'on utilise soient également a ce

potentiel.

D

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

über ein Pulsarmband mit Widerstand mit

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

auf diesem Potential.

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

F

Les normes de sécurité exigent que l'appareil soit remis a l'état d'origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

WARNUNG

NL

Alle IC's en vele andere halfgeleiders zijn

gevoelig voor elektrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie

kan de levensduur drastisch doen

verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente

ridatta in caso di non osservazione della piu

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello

della massa dell'apparecchio tramite un

braccialetto a resistenza.

Assicurarsi che i componenti e anche gli

utensili con quali si lavora siano anche a

questo potenziale.

WAARSCHUWING

I

AVVERTIMENTO

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden.

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l'apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

SHOCK, FIRE HAZARD SERVICE TEST:

CAUTION: After servicing this appliance and prior to returning to customer, measure the resistance between

either primary AC cord connector pins (with unit NOT connected to AC mains and its Power switch ON), and the

face or Front Panel of product and controls and chassis bottom,

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC

power is applied, and verified before return to user/customer.

Ref.UL Standard NO.1492.

NOTE ON SAFETY:

Symbol

: Fire or electrical shock hazard. Only original parts should be used to replace any part with symbol

Any other component substitution(other than original type), may increase risk or fire or electrical shock hazard.

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seuls habilités à

réparer votre appareil en panne.”

CL 96532086_021.eps

080999

Page 4

GB 4 CDR 3rd gen.2.

Safety and Maintenance instructions warnings and notes

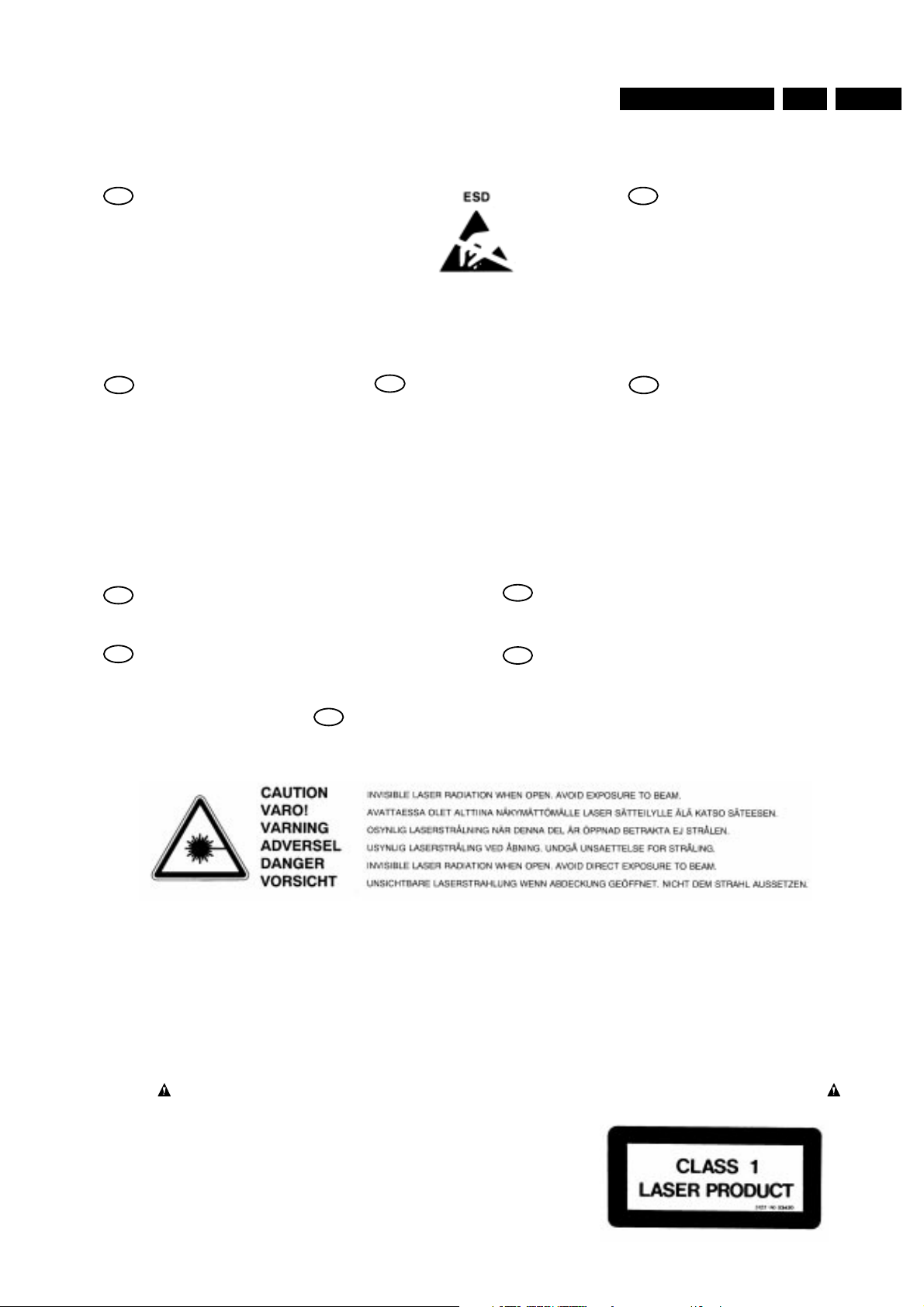

SERVICING HINTS

In the set, chip components have been applied. For disassembly and assembly check the figure below.

CL 96532086_022.eps

080999

Page 5

Safety and Maintenance instructions warnings and notes

GB 5CDR 3rd gen. 2.

CL 96532086_023.eps

080999

Page 6

GB 6 CDR 3rd gen.3.

3. Instructions for use

See service manual of concerned modelnumber in which the

instructions for use has been inserted. This chapter has not

been filled as this module of CDR Module CDL4009 +

Mainboard 4228 is only a part of a complete set.

Instructions for use

Page 7

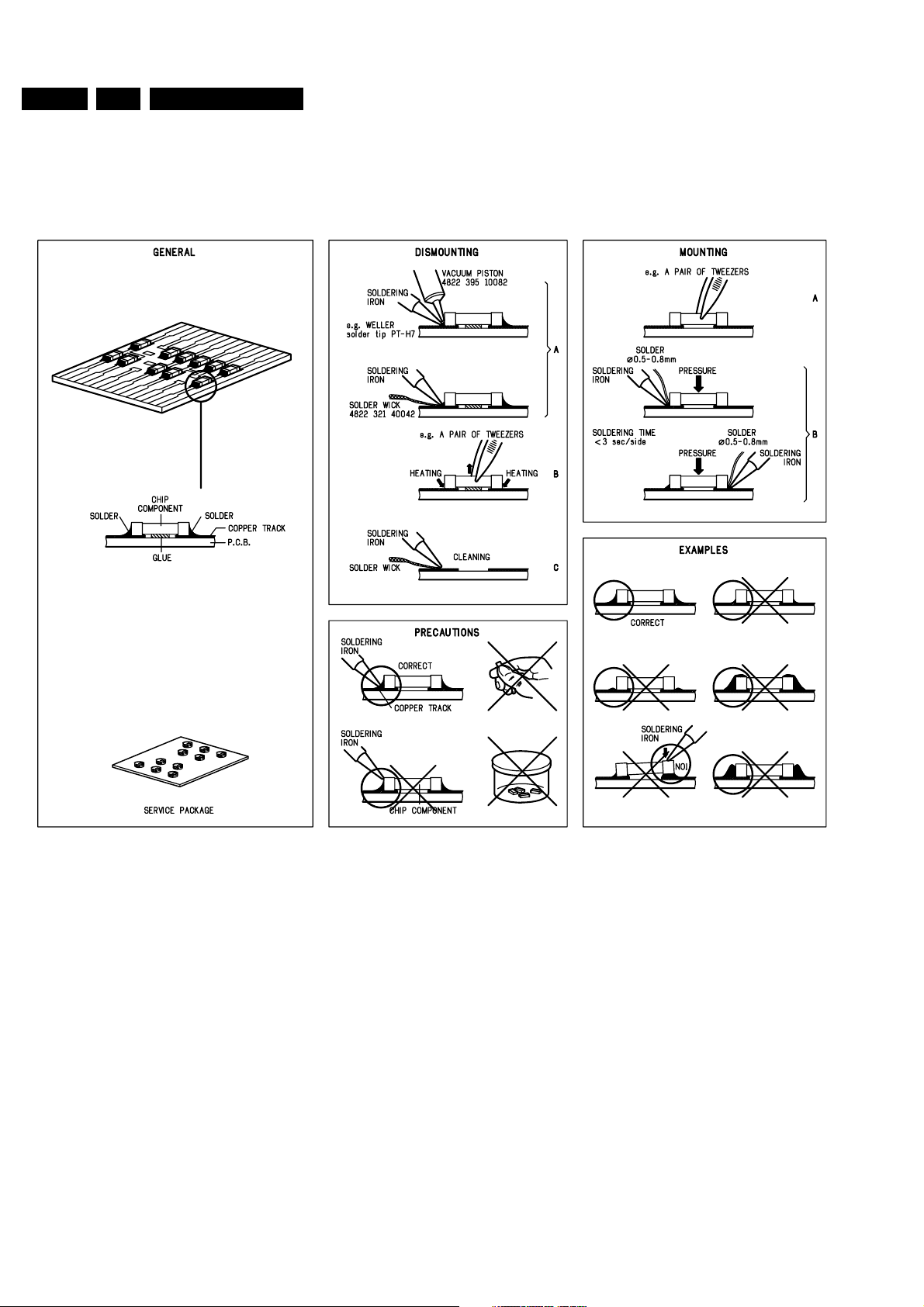

Mechanical instructions

4. Mechanical instructions

GB 7CDR 3rd gen. 4.

4.1 Loader CDL4009

CDL4009 consists of metal loader bracket item 82 and glued

on it an identification sticker (on which the module production

number and production code is printed); 4 suspension rubbers

items 76, 77, 78 and 79 which carry loader assembly item 81;

LOADER BRACKET

82

SUSPENSION

76

77 78 79

81

LOADER ASSY CDL

and on the bottom side the CDR mainboard 1001 is mounted.

Notice that mainboard is dependant to the applied set and has

to be adjusted to mounted CDM in loader in case of exchange.

See next figure, Loader CDL4009

97

MAIN BOARD CDR

1001

98 99

100

M3 X 6

82: LOADER BRACKET 3104 121 23900

81: LOADER ASSY CDL 9305 043 20900

76: SUSPENSION 3104 144 05730

CL06532018_001.eps

090300

To demount loader module CDL4009:

1. Mainboard item 1001. Beware of connections to CDM.

Optical pick-up unit has to be ESD protected!

2. Loosen suspensions 76, 77, 78 and 79 from metal loader

bracket 81

3. Take out Loader assy CDL

Figure 4-1

Page 8

GB 8 CDR 3rd gen.4.

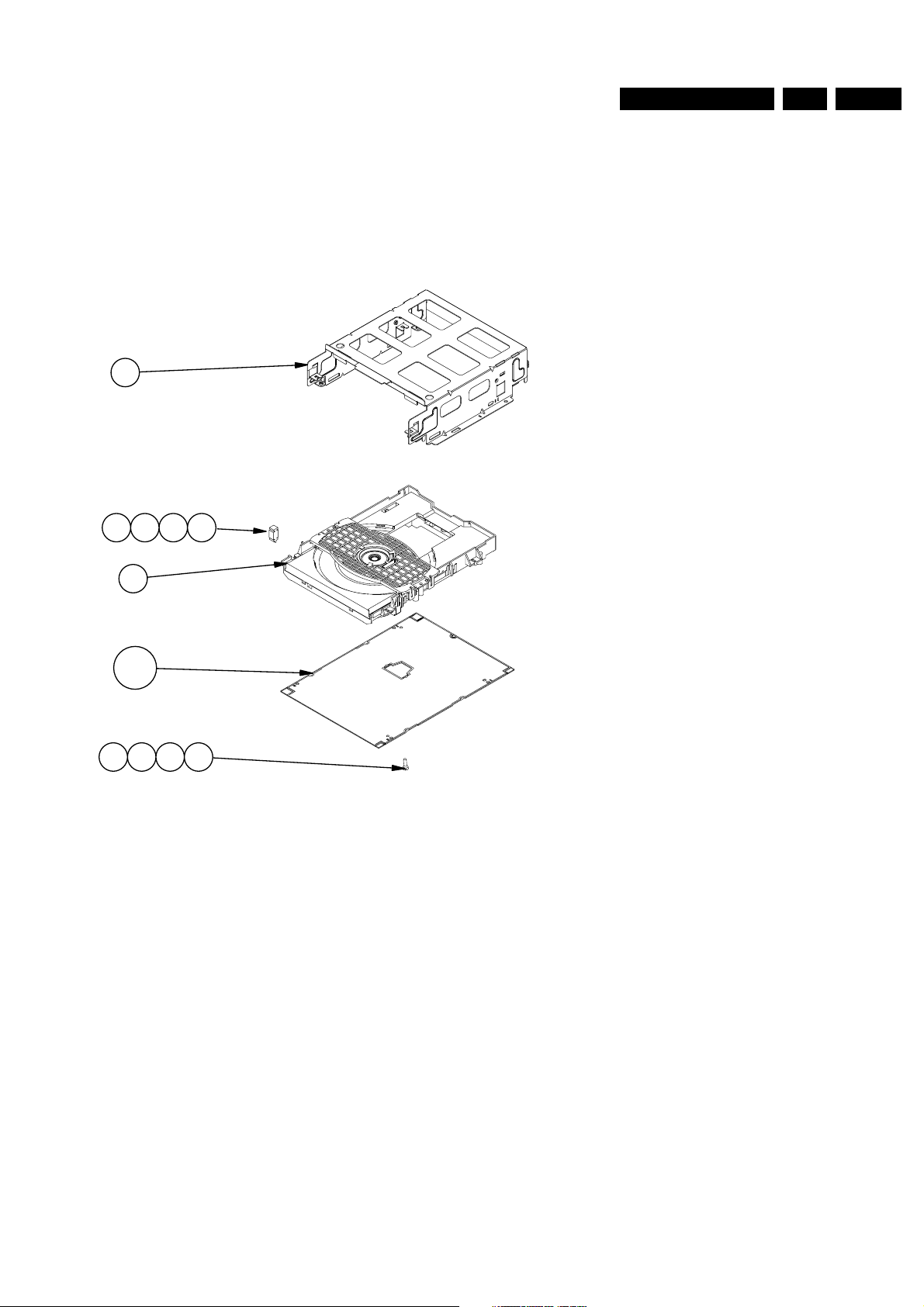

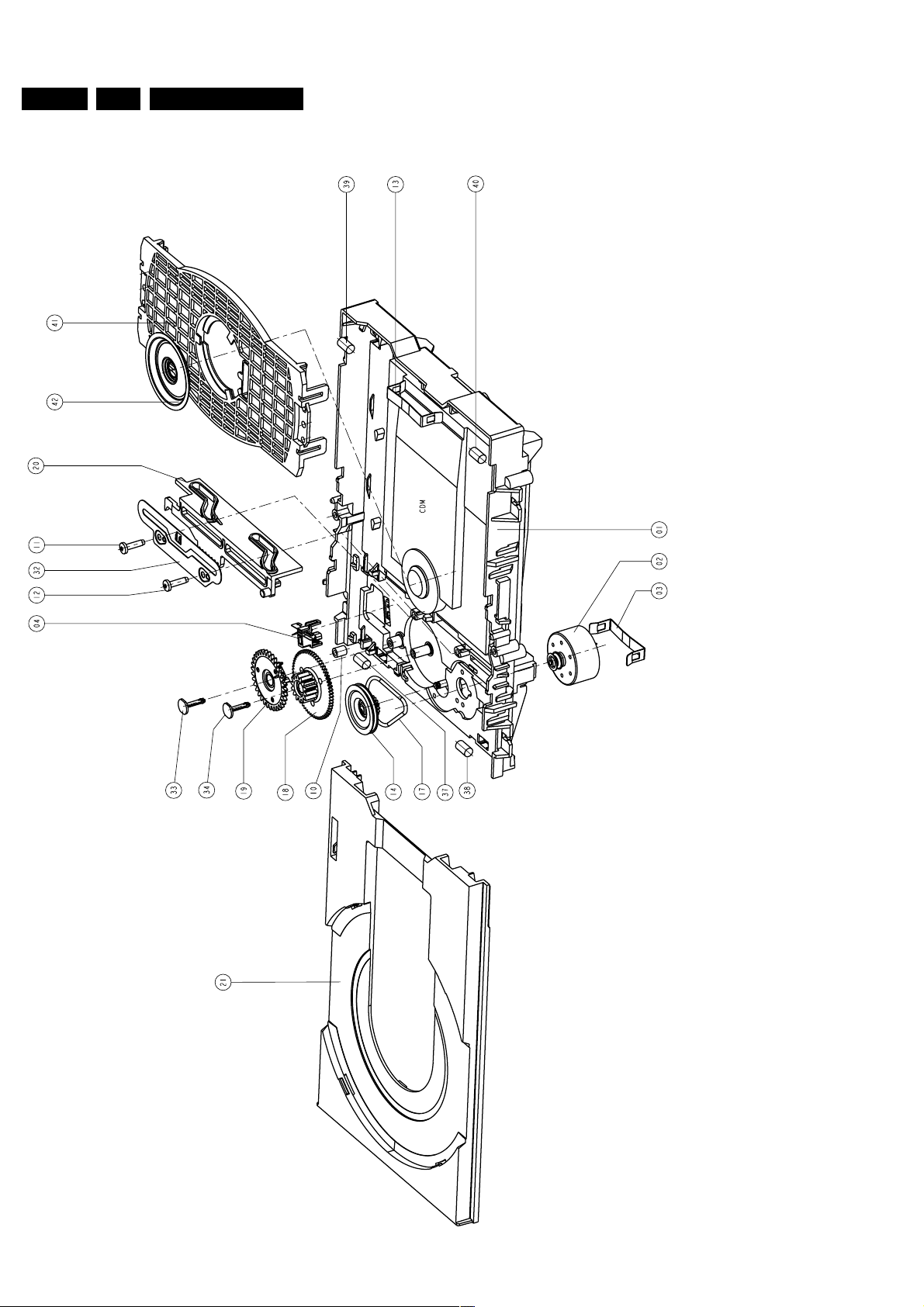

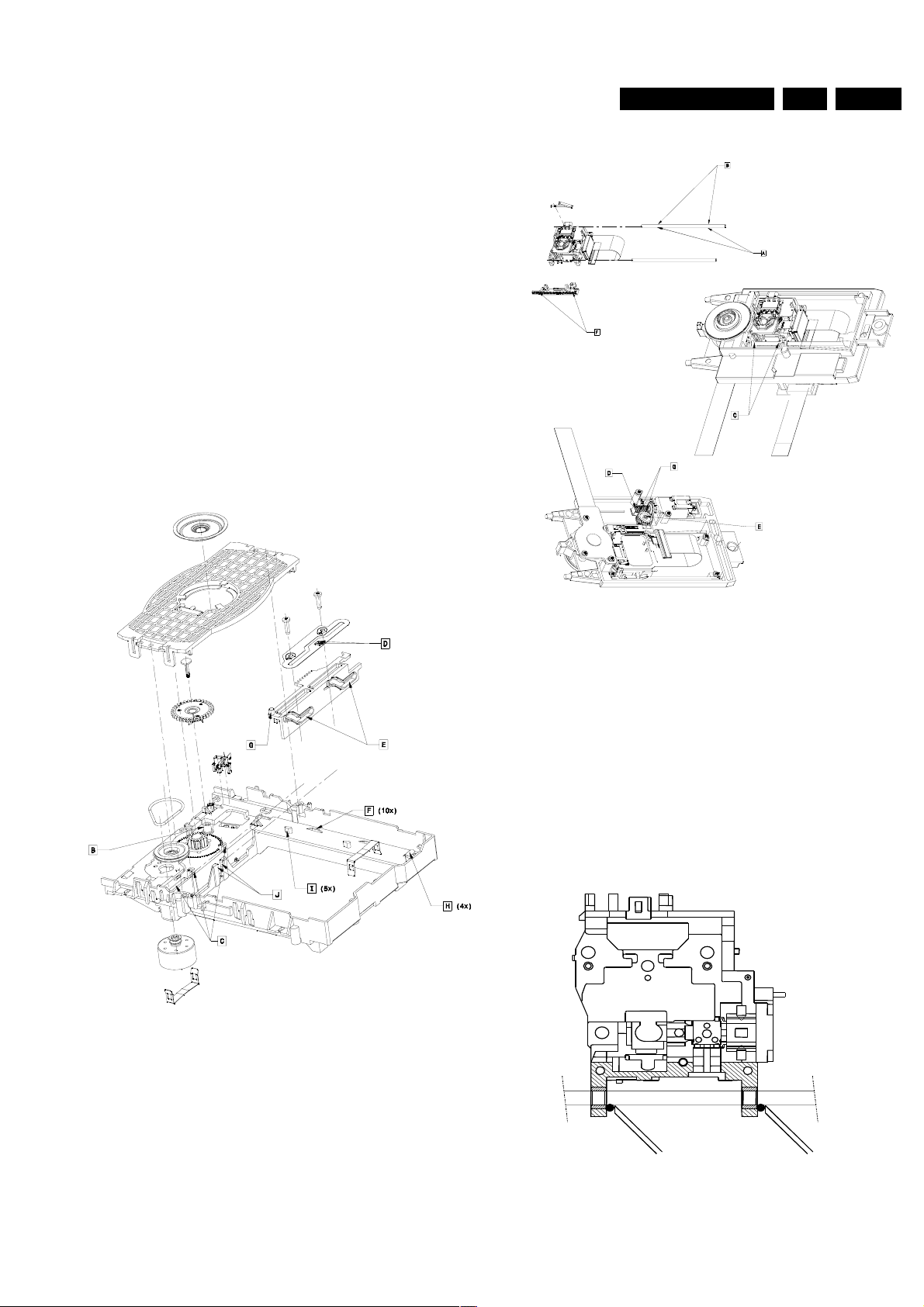

4.2 Exploded view CDL3800

Mechanical instructions

100300

CL06532018_002.eps

Figure 4-2

01 4822 691 10764 CHASSIS

02 4822 361 11131 TRAY MOTOR ASSY

03 4822 492 11709 MOTOR SPRING

04 4822 277 11838 SWITCH

10 4822 532 13097 TULE

13 4822 492 11709 MOTOR SPRING

14 4822 528 11295 PULLEY WHEEL

17 4822 358 10266 BELT

18 1822 522 10739 RACK GEAR WHEEL

19 4822 522 10741 TRAY GEAR WHEEL

20 4822 402 11221 RACK

21 4822 418 10421 TRAY BLACK

32 4822 492 11711 RACK SPRING

33 4822 535 10588 PLUG

34 4822 535 10588 PLUG

37 4822 466 12131 RUBBER

38 4822 466 12131 RUBBER

39 4822 466 12131 RUBBER

40 4822 466 12131 RUBBER

41 4822 466 12132 CLAMPER BRIDGE

42 4822 466 12133 CLAMPER

Page 9

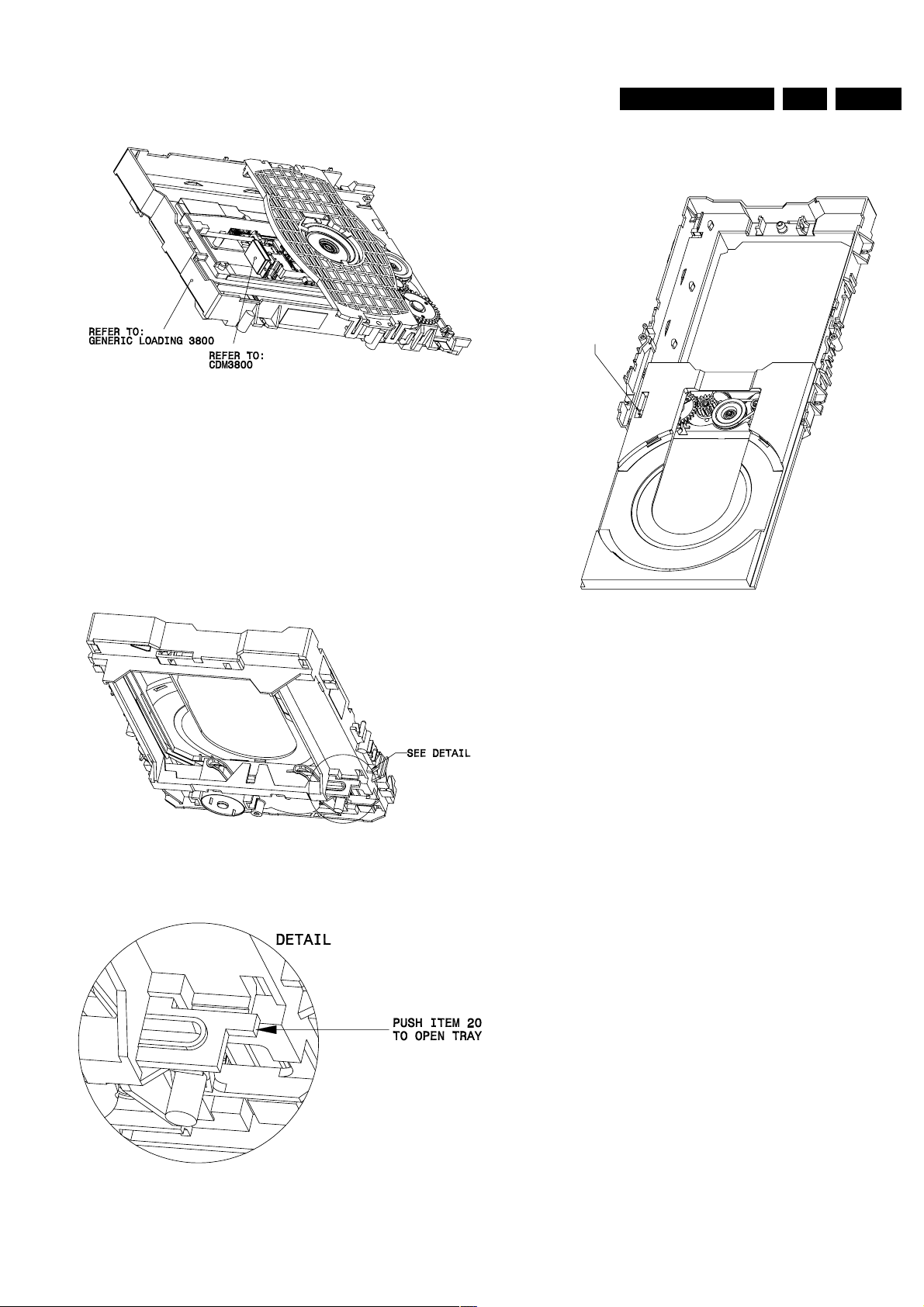

Mechanical instructions

PULL TO REMOVE TRAY

CL06532018_006.eps

210200

CL06532018_003.eps

090300

Figure 4-3

4.3 DEMOUNTING LOADER CDL3800

Remove the following items starting with:

(For the item numbers refer to the Exploded Views CDL3800,

figure 4.2)

GB 9CDR 3rd gen. 4.

Tray

Pull out the tray (item 21) until it stucks. Press the lock at the

left side of the tray upwards. Pull out the tray.

4.3.1 Release and remove tray

Push to open the tray on the rack (item 20)

Figure 4-4

CL06532018_004.eps

210200

Figure 4-6

Tray motor assey

Remove the tray motor belt (item 17).

Loosen the motorspring (item 3) with a pair of tweezers or a

screwdriver via the rectangular hole at the right side of the tray

motor.

Clamper bridge

Bend the locks-profiles on both sides of the clamper bridge

(item 41) carefully to the outside and lift up the clamper bridge.

CDM

Place the loader upside down and remove the motorspring

(item 13) with a pair of tweezers or a screwdriver, but hold the

CDM so it can’t fall down.

Rack

First remove the rack spring (item 32) by unscrewing items 11

and 12.

Figure 4-5

CL06532018_005.eps

210200

Page 10

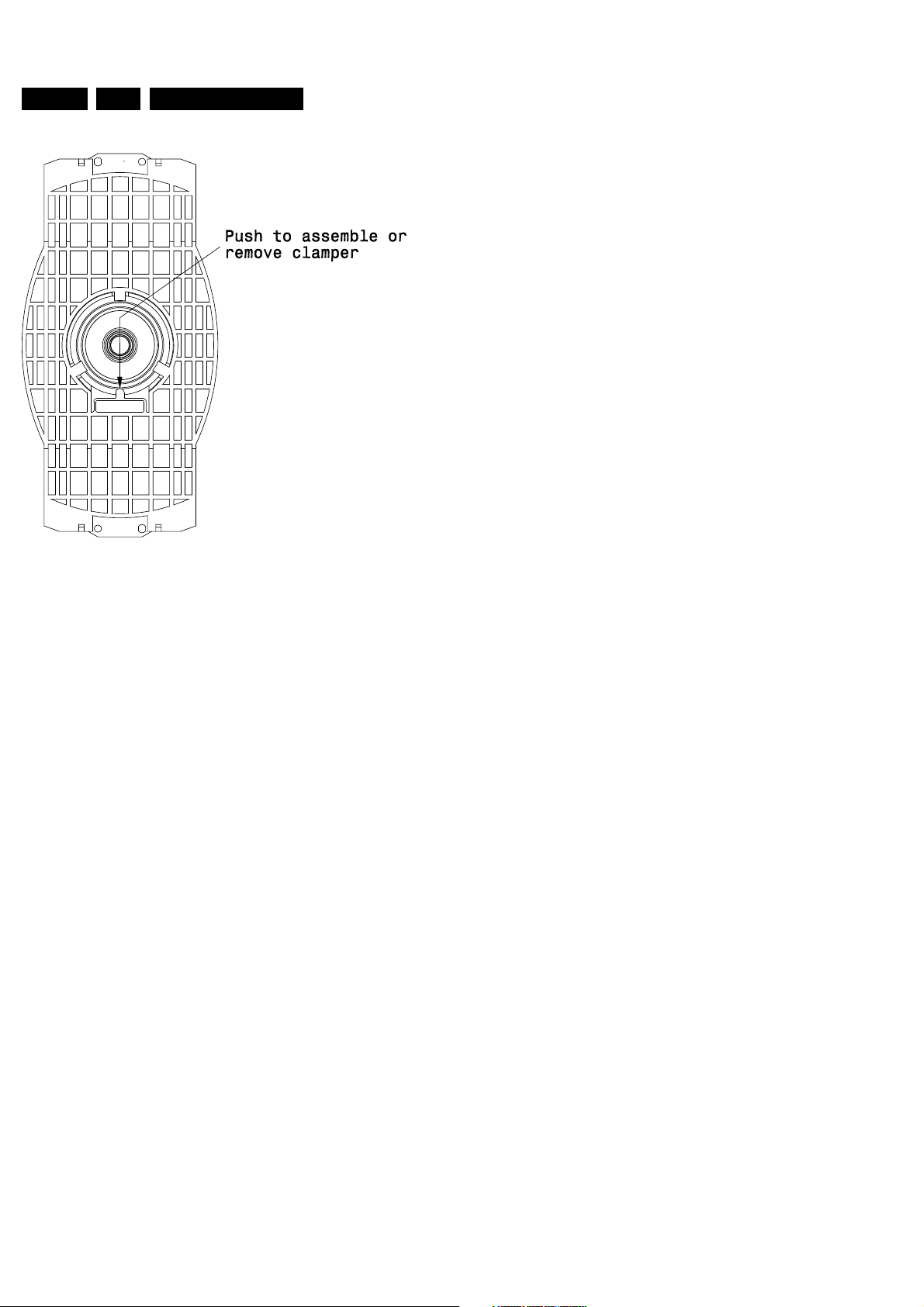

GB 10 CDR 3rd gen.4.

Clamper

Mechanical instructions

CL06532018_007.eps

210200

Figure 4-7

Page 11

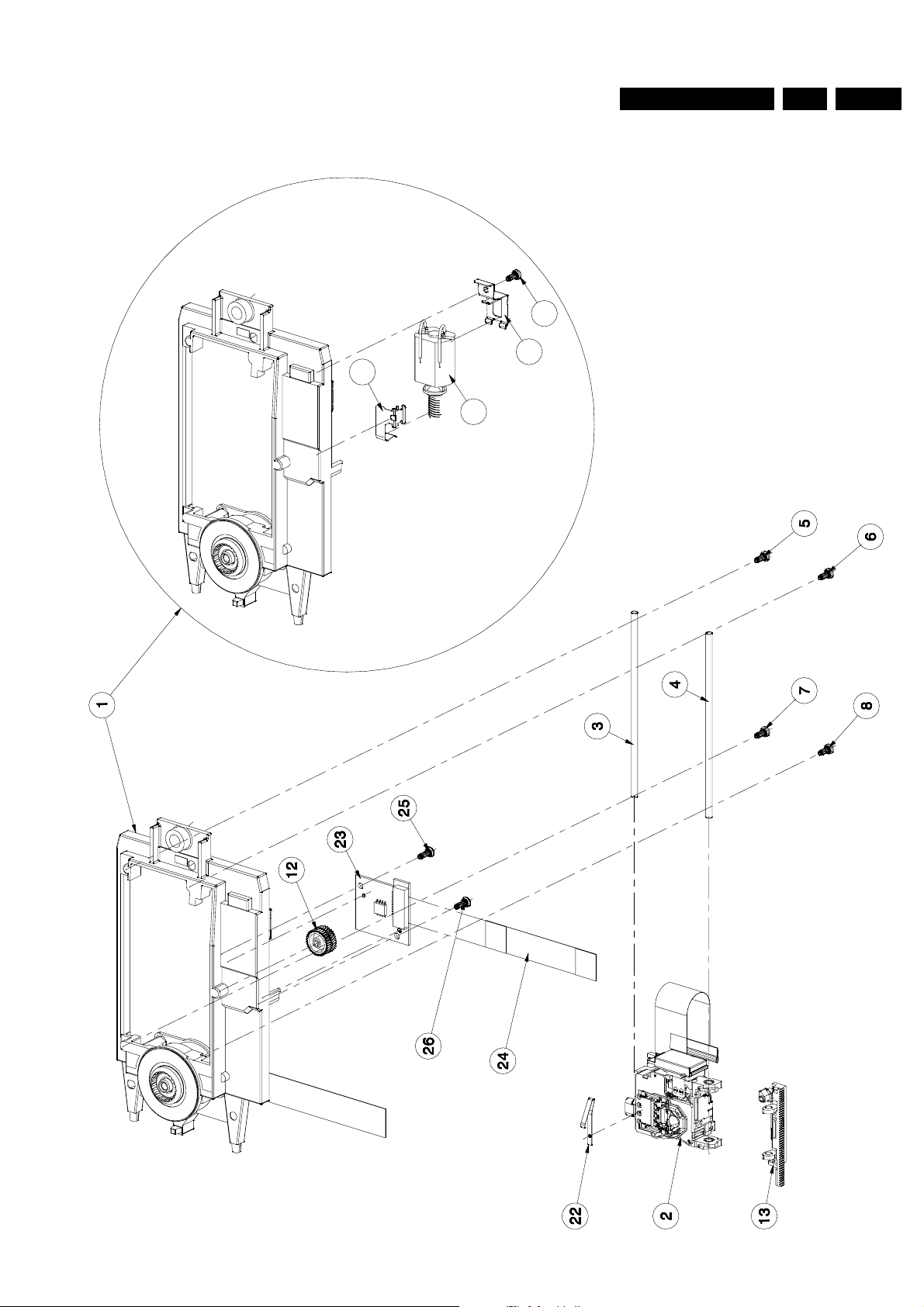

Mechanical instructions

4.4 Exploded view CDM3800

GB 11CDR 3rd gen. 4.

020300

CL06532018_012.eps

1.6

1.5

1.4

1.3

CDM 3800

Figure 4-8

Page 12

GB 12 CDR 3rd gen.4.

3104 147 01580 CDM3800 COMPLETE

Mechanical instructions

1: 4822 691 10765 MOUNTING PLATE ASSY

1.3: 4822 361 11132 SLEDGE MOTOR ASSY

2: 3104 147 12890 OPU-24.24

3: 4822 535 10591 THIRD BEARING AXLE

4: 4822 535 10591 AXLE

12: 4822 528 11297 COMBI WHEEL

13: 4822 522 10742 GEAR RACK ASSY

22: 3104 141 21830 THIRD BEARING SPRING

2100: 4822 126 13196 100nF 10% 25V

3100: ∆4822 051 20101 100Ω 5% 0,1W

5101: 4822 130 11531 SENSOR LT125A

4.5 Cleaning objective lens

4.5.1 CLEANING PRESCRIPTION OBJECTIVE LENS

• Cleaning fluid

The lens cleaner codenumber reads 4822 389 10026

• Procedure

• Take a clean cotton wool tipped stick and put Lenscleaner on the wool.

• Wipe the lens very softly with the wet wool end of the

stick by moving it forwards and backwards in the Ydirection. (see drawing)

• Take a dry cotton wool tipped stick and remove the

Lens-cleaner from the lens by moving it very softly

back and forth in the Y-direction (see drawing)

• During cleaning, take the necessary precautions in

order to prevent damage to the*Actuator (hinges, lens,

litze-wires) or OPU (ESD, ...) Do not remove axle (item

4, see drawing) from OPU, because the fixing screws

of axle are deforming it at it's end. On their turn these

deformings are damaging the hinges of the OPU when

loosening the axle.

• Application

This cleaning procedure is only applicable for the flat side

(upside) of the lens.

Never try to clean the round side (underside) of the lens

(replica-side).

With this cleaning procedure, fingerprints and dust can easily

be removed with very

soft and gently movements of the cotton wool tipped stick.

• Limitation

This cleaning procedure is only applicable in cases of

malfunctions of the product,

due to lens-problems. It's not ment to be applied on 100% of

the actuators, OPU's.

After cleaning, the product must be re-checked on it's

functionality.

Y

Figure 4-9

CL06532018_008.eps

210200

4

Page 13

Mechanical instructions

CL06532018_010.eps

020300

2x 1 DROP OF OIL

CL06532018_011.eps

020300

GB 13CDR 3rd gen. 4.

4.6 Lubricating

4.6.1 LUBRICATING INSTRUCTIONS FOR GENERIC LOADING

CDL3800

USE TRIBOL GREASE (1322 523 78101)

Be careful when lubricating the parts.

For parts and points to apply grease, refer to the drawing figure

4-10.

Avoid excess grease.

B. The bearing of the gearwheel. Grease on upper part of

cylindrical surface.

C. Guiding and 2 guiding pins of the rack on the chassis.

D. The guiding of the rackspring.*

E. The 2 guiding.profiles of the rack*

F. 10 guiding surface of the chassis on the tray.*

G. The guiding pin on the rack.*

H. On top (in the middle) of the 4 rubbers.*

I. Guiding on the chassis of the tray. Grease around the 5

guiding pins.*

J. The guiding ribs of the chassis for guiding the CDM-nose.*

o

=Lubricated with dosing apparatus.

*=Lubricated with a brush.

o

o

Between worm and combiwheel (item 12, 4822 528 11297)2x

Figure 4-10

CL06532018_009.eps

210200

Figure 4-11

Oiling the centrifuged bearings

USE MOBIL OIL SHC 629 (3104 129 52260)

Use dose apparatus

Place the needle against the bearing and axle.

Dose one (1) drop of oil there where the bearing touches the

axle (see drawing figure 4-12)

Repeat this handling for the second bearing

Move the OPU for a few times up and down.

REMARKS:

Do not use the oil on the axle alone. Always place the oil drop

against the bearing.

No oil on top of the OPU.

4.6.2 Lubricating instructions for CDM3800

USE TRIBOL GREASE (1322 523 78101)

The third bearing axle (item 3, 4822 535 10591) on the

upperside of the axle 2x

The third bearing axle on the bottomside of the axle 2x

The OPU bearing with Mobil Oil SHC 629 (see next paragraph)

The top of the worm

The pressed in axle on the top

The gear rack assy (item 13, 4822 522 10742) on the teeth2x

Figure 4-12

Page 14

GB 14 CDR 3rd gen.5.

Service modes, repair tips and faultfinding trees

5. Service modes, repair tips and faultfinding trees

5.1 Service modes

In this paragraph the internal selfdiagnostics without opening

the set and use of other tools is described.

Module is mounted in a set

Notice:

5.1.1 Dealer mode

The purpose of the dealer mode is to prevent people taking out

the CD inside the player at exhibitions, showrooms etc.. This

mode disables the open/close function of the player.

The dealer mode can be switched on and off pressing keys

[OPEN/CLOSE] and [STOP] of the CDR player simultaneously

while switching on the unit. The dealer mode is stored in the

flash memory and can only be changed by executing the above

actions.

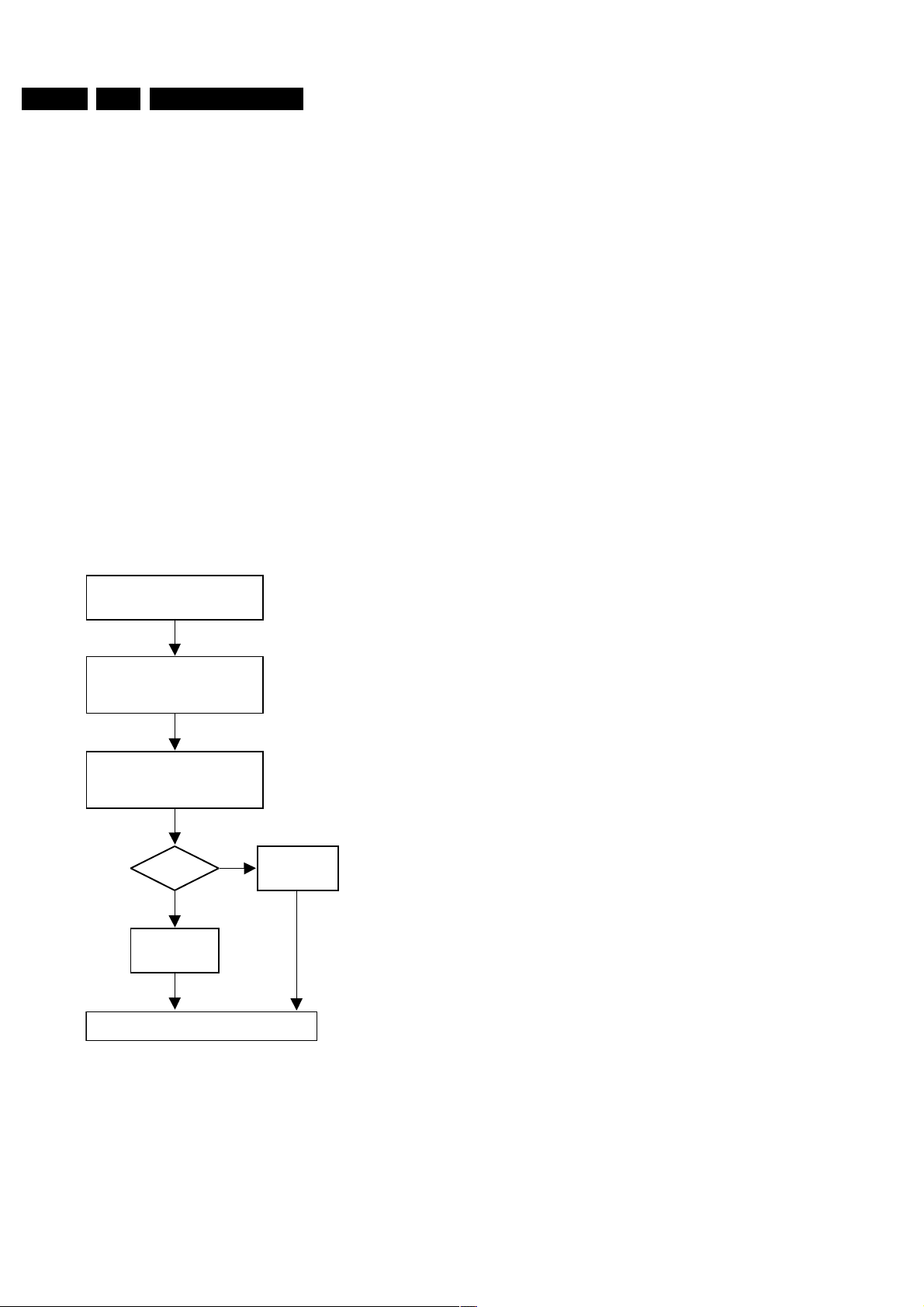

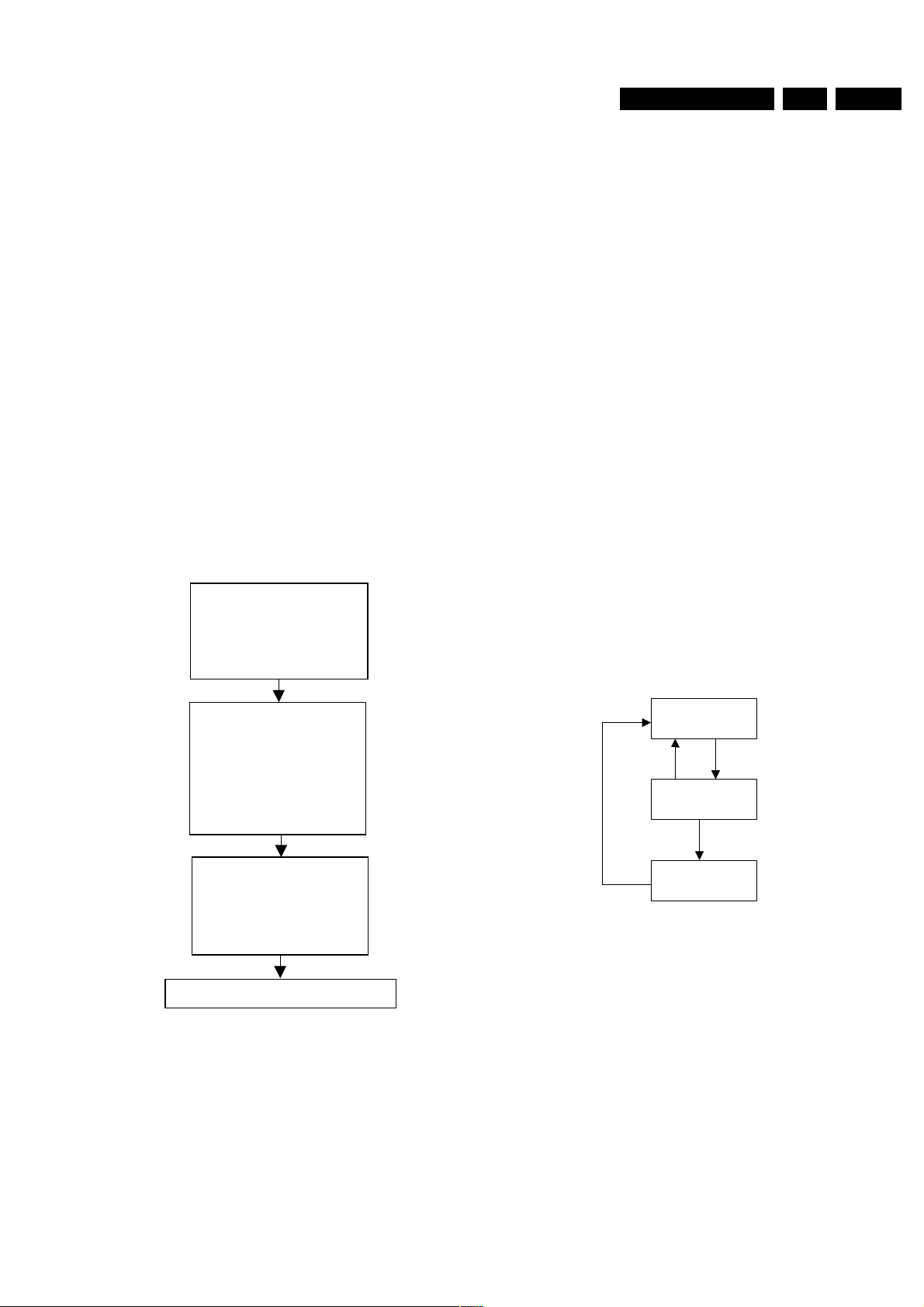

5.1.2 Dealer diagnostics

DEALER DIAGNOSTICS

(status of player)

If power ON,

switch power OFF

display. Pressing keys [F FWD] and [REWIND] simultaneously

while switching on the unit, starts the test. Switching off the unit

ends the test.

Requirements to perform the test

• Working keyboard to start up the test.

• Working local display to check the output messages.

Press <REWIND> + <FFWD>

simultaneously and switch

ON unit

Display blinks

“BUSY”

during test

NO

Set OK?

YES

Set displays

“

PASSED

To end test, switch OFF unit

”

Figure 5-1

Set displays

“ERROR”

CL96532086-024.eps

090999

Description

The intention of the dealer diagnostics is to give an indication

of the CDR player status. An inexperienced, even nontechnical dealer will/can perform the test. Tests are executed

automatically without need for external tools or disassembly of

the unit. This test checks the CDR main board using the same

tests as the electrical service diagnostics program. Only the

result of the test, “PASSED” or “ERROR”, will be shown on the

Page 15

Service modes, repair tips and faultfinding trees

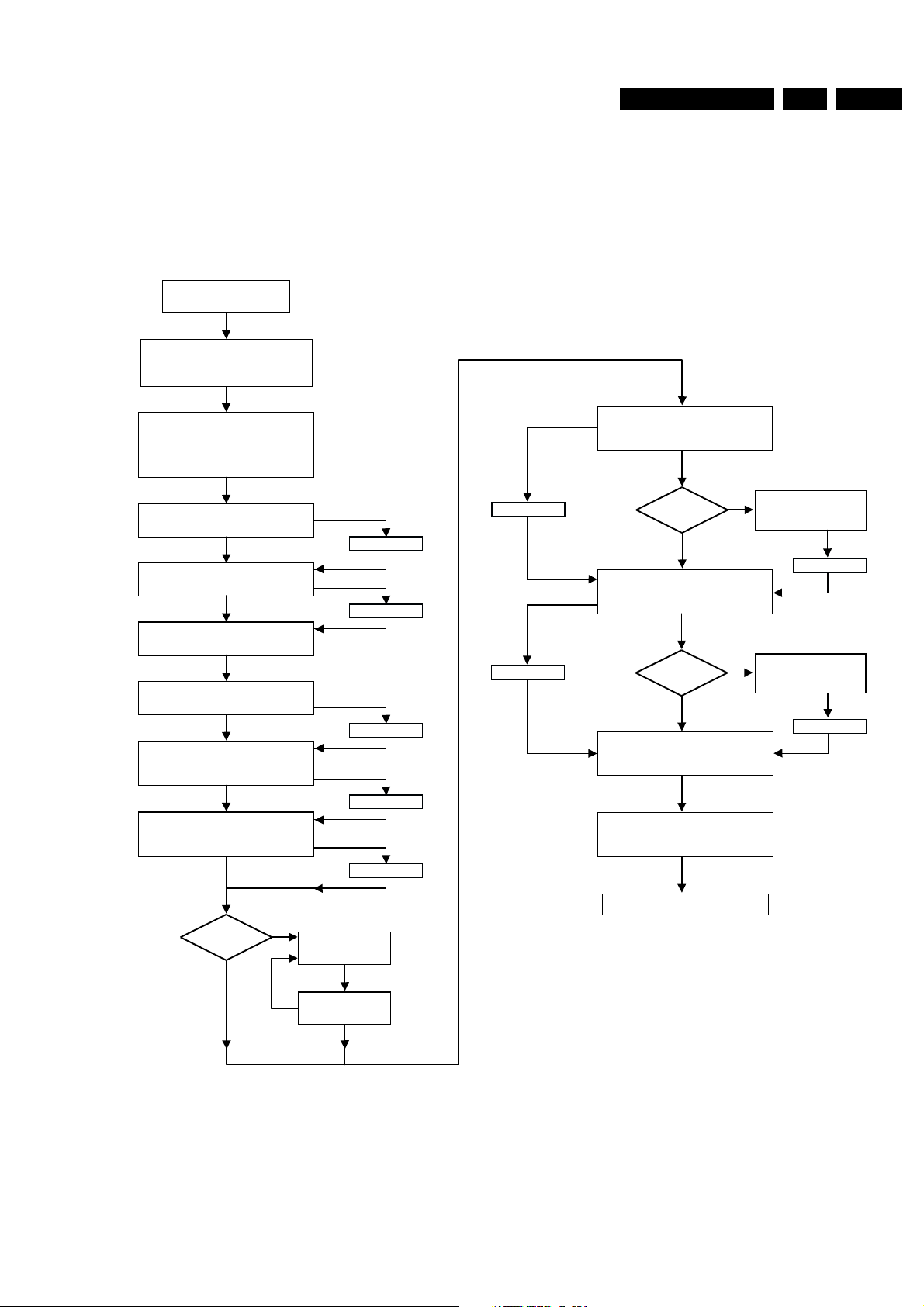

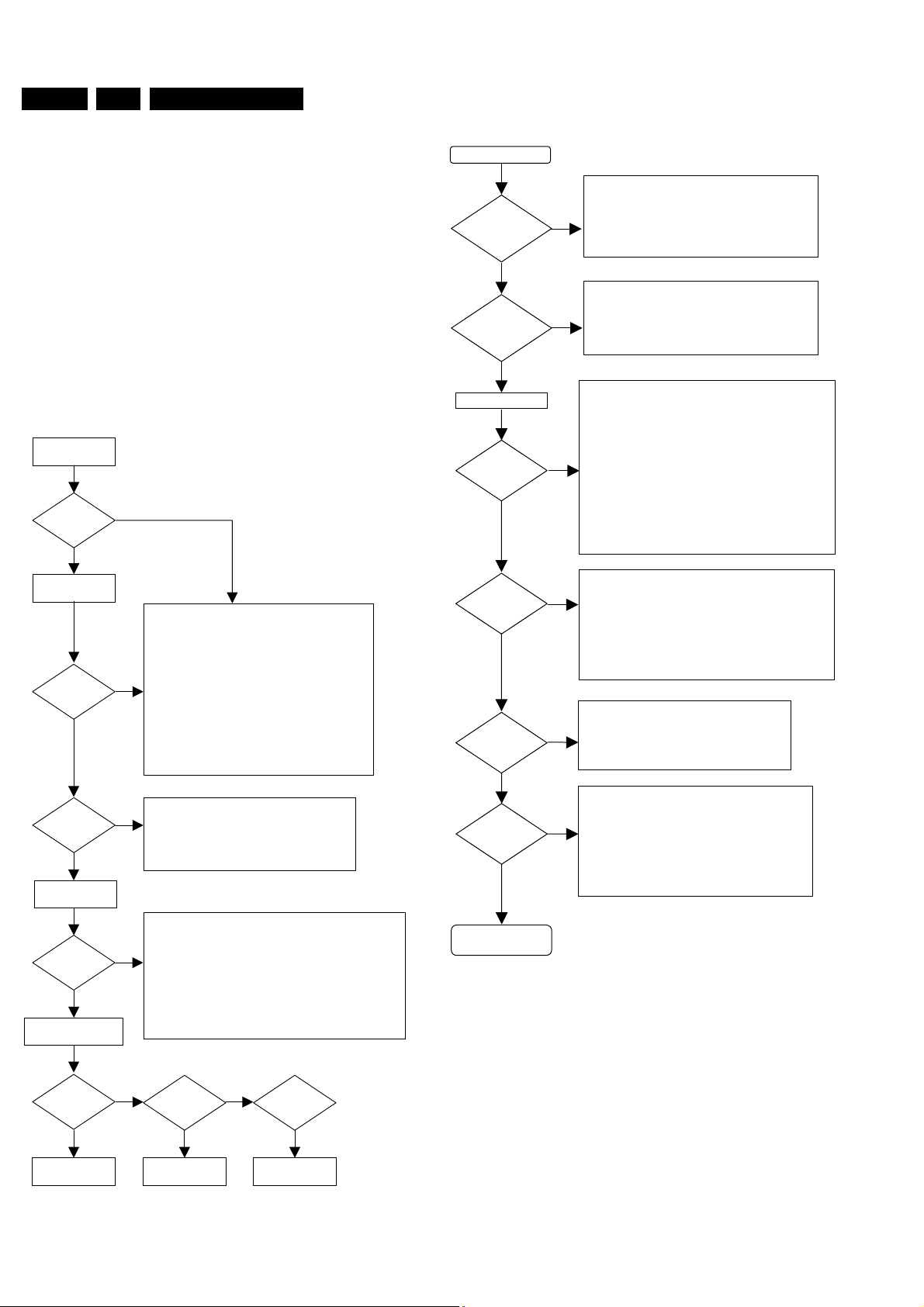

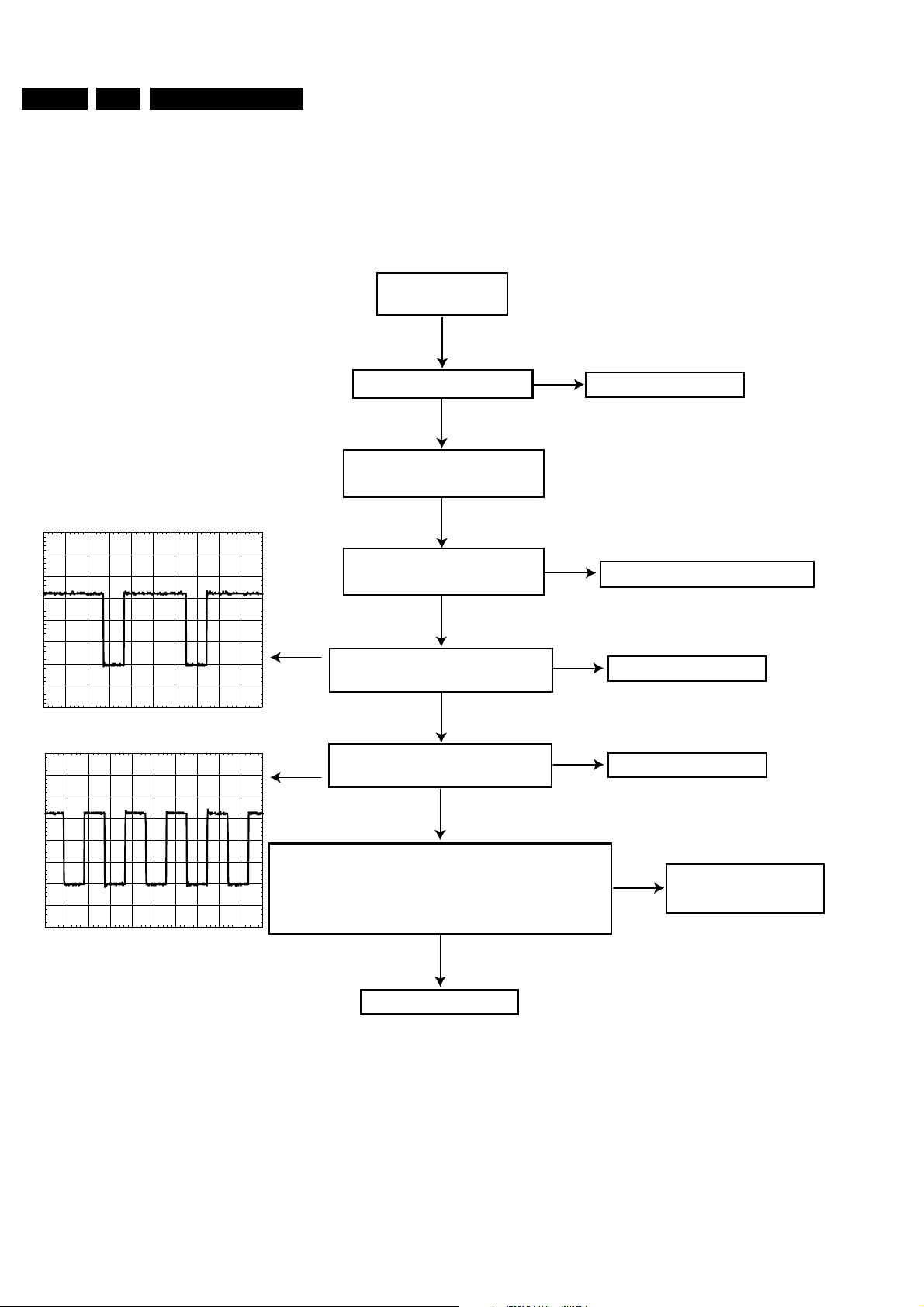

5.1.3 Electrical service diagnostics

ELECTRICAL SERVICE DIAGNOSTICS

(software versions, test for defective components)

If power ON,

switch power OFF

Load CD-DA disc (SBC444A)

Press <PLAY> + <F FWD>

simultaneously and switch ON unit

PLAYER

INFORMATION

Display :

"PLAYER ID"

"SW VERSION BACK END"

"SW VERSION CDR LOADER"

(CDR775

CDR MAIN

BOARD TEST

Display :

PASS OR FAIL

Display :

PASS OR FAIL

Display :

PASS OR FAIL

Display :

PASS OR FAIL

Display :

PASS OR FAIL

Display :

PASS OR FAIL

"SW VERSION CD LOADER"

"DTST1"

DRAM test (7702)

"DTST2"

FLASH CHECKSUM test (7703)

"DTST3"

FLASH ERASE test (7703)

"DTST4"

CODEC test (7406)

"DTST5"

CDR LOADER

COMMUNICATION test

"DTST6"

*

CD LOADER

COMMUNICATION test

* FOR CDR775 ONLY

)

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

LOADER TESTS

CDR LOADER TEST

CD-DA disc must be loaded

Display shows current disc time

Test OK?

YES

CD LOADER TEST *

CD-DA disc must be loaded

Display shows current disc time

Test OK?

YES

DISPLAY TEST

DISPLAY TEST

Display segments blink at f=1kHz

KEYBOARD &

RC TEST

KEYBOARD & RC TEST

Display shows name of pressed keys

Press <F FWD>

NO

Display :

or

or

* FOR CDR775 ONLY

NO

Display :

or

or

GB 15CDR 3rd gen. 5.

"BERR1"

"NO CDDA"

"NO DISC"

Press <F FWD>

"BERR2"

"NO CDDA"

"NO DISC"

Press <F FWD>

Tests OK?

YES

NO

Display :

n = failed test

Display next

failed test

"DERRn"

Figure 5-2

To end test, switch OFF unit

CL 96532086_025.eps

090300

Page 16

GB 16 CDR 3rd gen.5.

Service modes, repair tips and faultfinding trees

Description

The intention of the electrical service diagnostics is to show the

software versions present in the player and to direct the dealer

towards defective internal units. The units are : the CDR main

board, the CDR loader, the CD loader in case of a CDR775 and

the keyboard/display board. A sequence of tests is executed

automatically. Some of the tests can be aborted or skipped

without the result being taken into account. External tools or

disassembly of the unit is not necessary to get the diagnostic

information. Pressing keys [PLAY/PAUSE] and [F FWD]

simultaneously while switching on the unit, starts the test.

Switching off the unit ends the test.

Requirements to perform the test

• Working keyboard to start up the test.

• Working local display to check the output messages.

• A CD-DA disc with a minimum of 3 tracks in all trays to

perform the disc test.

Description of the tests

Player information

In this part of the test the following important information can be

checked without removing the cover :

• Recorder ID.

• SW-version back end of player.

• SW-version CDR loader.

• SW-version CD loader (only for CDR775).

CDR main board test

[F FWD] key. The message “DERRn” will be displayed with n

indicating the faulty test number.

If one of the tests is aborted with the [F FWD] key, no error

message will be displayed for this test. The flash data erase

test (“DTST3”) can not be aborted !

The CDR main board test consists out of :

performed by audio play-back of 5 seconds at the beginning,

middle and end of the disc.

CDR loader test

During the test, the current disc time is shown. In case of an

error the message “BERR1” will be displayed and the [F FWD]

key must be pressed to continue with the following test.

Pressing the [F FWD] key also aborts this test.

CD loader test

For CDR775 only. During the test, the current disc time is

shown. In case of an error the message “BERR2” will be

displayed and the [F FWD] key must be pressed to continue

with the following test. Pressing the [F FWD] key also aborts

this test.

Display test

All segments will blink at a frequency of 1 Hz. Pressing the [F

FWD] key will start the next test because the user has to check

for himself if all segments work properly.

Keyboard and remote control tests

The test will give the user the ability to test every key without

executing the function assigned to it. Therefore, the user needs

to press every key on the keyboard and the remote control. The

display will show the name of the key being pressed. Pressing

more than one key at once will give an unpredictable result

except for the service combinations : [PLAY/PAUSE] + [STOP],

[PLAY/PAUSE] + [F FWD], [F FWD] + [REWIND], [ERASE] +

[RECORD], [PLAY/PAUSE] + [RECORD], [OPEN/CLOSE] +

[PROGRAM].

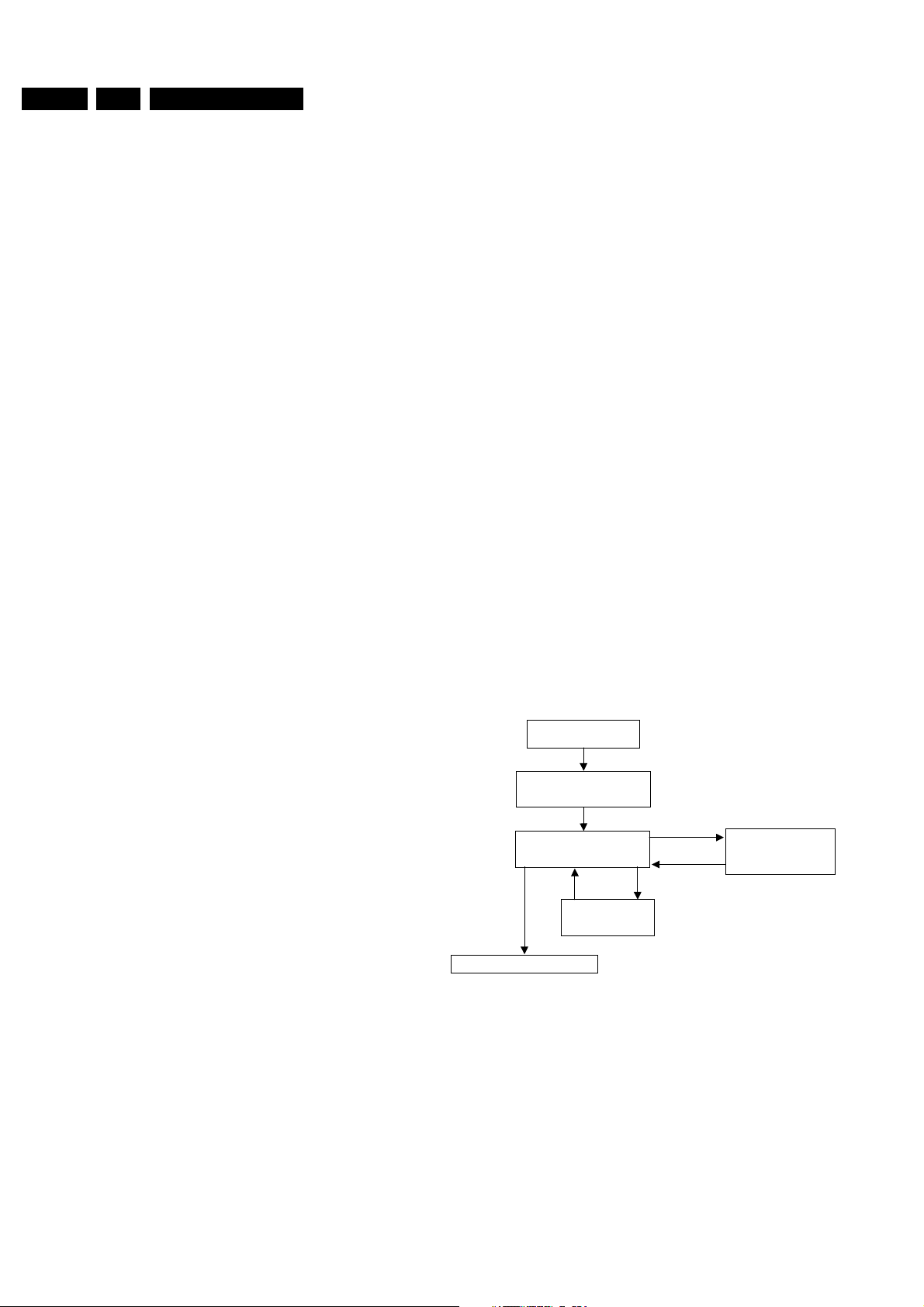

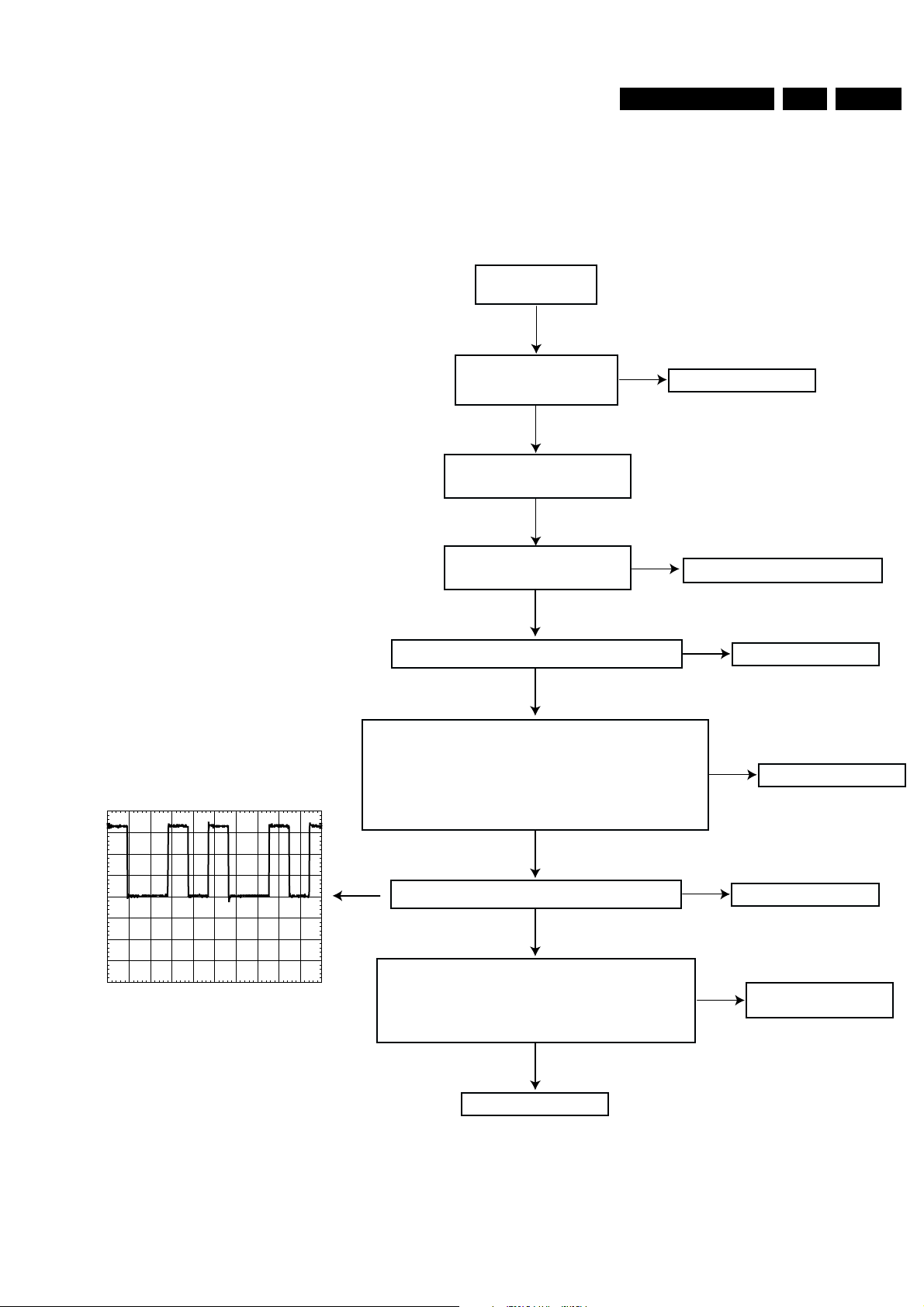

5.1.4 Mechanical service diagnostics

MECHANICAL SERVICE DIAGNOSTICS

(test for defective components)

DRAM test

Display : “DTST1”. The DRAM used for buffer management is

tested by writing, reading and verifying test patterns.

Flash checksum test

Display : “DTST2”. This test checks the checksum of the

player’s SW stored in the flash.

Flash data erase

Display : “DTST3”. During this test, all temporary information

(CDtxt) in the flash is erased.

CODEC (ADC/DAC) test

Display : “DTST4”. This test checks the CODEC IC by writing,

reading and verifying test patterns. The test is not applicable for

CDR950.

CDR communication test

Display : “DTST5”. The communication between the host

processor (DASP) and the CDR loader via the DSA-R-bus is

tested.

CD communication test

Display : “DTST6”). The communication between the host

processor (DASP) and the CD loader is tested. The test is only

applicable for CDR775.

Loader tests

These tests determine if the CDR loader and the CD loader in

case of a CDR775 work correctly. A CD-DA disc with a

minimum of 3 tracks needs to be inserted in both loaders. A

disc test is executed to check focus control, disc motor control,

radial control and jump grooves control. The disc test is

If power ON,

switch power OFF

Press <PLAY/PAUSE> + <STOP>

simultaneously and switch

ON unit

Display shows

Visual inspection

To end test, switch OFF unit

FOCUS TEST

SLEDGE TEST

Visual inspection

Display shows

“BUSY”

“BUSY”

<OPEN>

<

CLOSE>

<FWD><REWIND>

TRAY TEST

Visual inspection

Display shows

even if tray is blocked

Figure 5-3

Description

No external tools are required to perform this test. The cover

needs to be removed because the user has to check the

movements of the tray, focus and sledge visually. Pressing

keys [PLAY/PAUSE] and [STOP] simultaneously while

switching on the unit, starts the test. Switching off the unit ends

the test. In case of a CDR775, one can check the CD loader

mechanics in the same way by pressing the above key

combination on the CD player keys.

Requirements to perform the test

• Working keyboard to cycle through the tests and to start up

the test.

• Working local display to check the output messages.

“OPENED”

CL96532086_026.eps

080999

Page 17

Service modes, repair tips and faultfinding trees

CL06532018_071.eps

030300

GB 17CDR 3rd gen. 5.

Description of the tests

Focus control test

The focussing lens is continuously moving up and down. The

display reads “BUSY”.

Sledge control test

After pressing [F FWD] the sledge continuously moves up and

down. Pressing [REWIND] stops the sledge at the position it is

in and the focus control test resumes. The display reads

“BUSY”.

Tray control test

This test starts from within the focus control test routine.

Pressing [OPEN/CLOSE] moves the tray in or out. In the tray

open position one can initiate focus and sledge tests by

pressing [F FWD]. One has to stop these tests pressing

[REWIND] before it is possible to close the tray again.

Depending on the action the display reads “OPEN”,

“OPENED”, “CLOSE” or “BUSY”.

5.1.5 DC-erase service mode

DC ERASE SERVICE MODE

(erasement of complete CD-RW)

Load CD-RW disc

Press

<ERASE> + <RECORD>

simultaneously and switch

ON unit

unit before completion of the test, leaves the disc in an

unpredictable state. In such case only a complete DC-erase

procedure can recover the CD-RW disc.

Requirements to perform the test

• Functional CDR player.

• A CD-RW audio disc must be present in the tray.

5.1.6 Burn in mode

Description:

The Burn In mode is an endless cycle of:

• DC-Erase to erase the CDRW disc with maximum laser

power.

• Recording a CDRW disc

• Finalising at double speed

The Burn In mode is used to test intermittent faults of the

loader.

Requirements to perform the test:

• Working Local Keyboard: needed to start up the test.

• Working Local Display: all output messages must be

displayed on the local display.

• Analog source connected to the CDR99 player

• CDRW disc in tray

Burn in sequence

– Initialisation

The ‘Burn In’ mode is initiated by pressing the PAUSE> and

key on the local keyboard at the same time, and then switching

the POWER switch on.

– Continuous loop

The following picture shows the burn in sequence.

Display shows:

mm

ER mm:ss

“

:remaining minutes

”

ss :remaining seconds

TOTAL

and

REM

are also

illuminated

Display shows:

PASSED

“

”

when the erase function is

completed

ERROR

“

”

if DC ERASE fails

To end test, switch OFF unit

CL96532086_027.eps

080999

Figure 5-4

Description

This test is initiated by pressing [ERASE] and [RECORD]

simultaneously while switching on the unit. The player will

erase a complete CD-RW disc (including PMA and ATIP lead

out area) at speed N=2. The display shows the countdown of

the remaining time required for the operation to complete. The

format is “ER mm:ss”, where “mm” are the remaining minutes

and “ss” the remaining seconds. After completion the message

“PASSED” is shown, and the player has to be switched off and

on again to start up in normal operating mode. Switching off the

Burn in sequence

DC erase

error Erase complete without error

Finalise

complete with

or without

error

Continuously do DC erase, record complete CDRW and then

finalise until the player is powered off.

When an error is detected during writing, the DC erase

procedure is called again., the disc will be DC erased and the

cycle starts again.

During the test the display shows the number of hours for which

the test is running and the number of errors detected during the

test. The display looks as follows : “HH BI RE FE”

HH : number of hours on

“BI” : burn in mode, digits 3

RE : number of errors

Write CDRW

Write complete without error

Finalise

Figure 5-5

digits 1 and 2

and 4

detected during DC

erase and write

CDRW modes on

digits 7 and 8

Page 18

GB 18 CDR 3rd gen.5.

Service modes, repair tips and faultfinding trees

FE : number of errors

detected during

finalise modes on

digits 10 and 11

If started up with a disc other than a

CDRW disc the display shows : ”WRONG DISC”,

if no disc is inserted display : “NO DISC”.

– End of test

To exit the Burn In mode, power off the player.

5.2 Faultfinding Trees

The faultfinding trees and repair suggestions like the power

supply voltages for proper functioning of the mainboard are

indicated here.

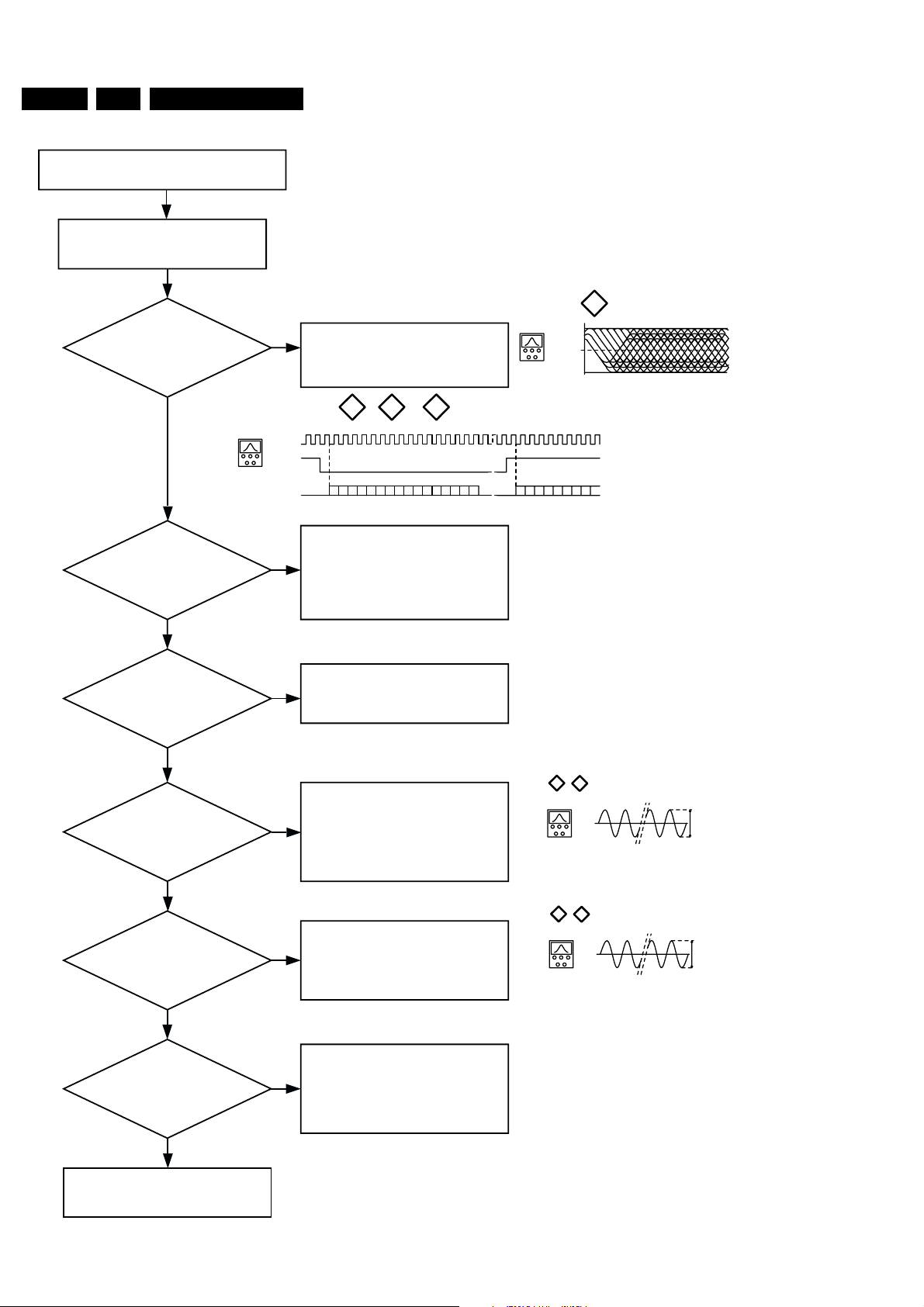

5.2.1 CDR-Module

NO DISC LOADED

SWITCH ON POWER

STBY LED?

YES

PRESS <DISPLAY>

DISPLAY?

YES

DISPLAY:

"INSERT DISC"

YES

PRESS

<OPEN/CLOSE>

TRAY?

YES

INSERT DISC

PRESS <OPEN/CLOSE>

NO

CHECK:

• MAINS, MAINS CABLE

• POWER SUPPLY (SEE FAULT FINDING GUIDE PSU)

⇒

WIRING

⇒

ON/OFF SWITCH

⇒

FUSES

⇒

NO

• DISPLAY (SEE FAULT FINDING GUIDE DISPLAY BOARD)

CHECK:

NO

• WIRING

• POWER SUPPLY VOLTAGES

• ELECTRICAL SERVICE DIAGNOSTICS:

CHECK:

• DISPLAY BOARD (SEE FAULT FINDING GUIDE DISPLAY BOARD)

NO

• MECHANICAL SERVICE DIAGNOSTICS:

VOLTAGES

⇒

WIRING

⇒

SUPPLY VOLTAGES

⇒

CLOCK SIGNAL 8MHz

⇒

CONTROL SIGNALS

⇒

KEYBOARD

⇒

STANDBY LED

⇒

ELECTRICAL SERVICE DIAGNOSTICS:

DISPLAY TEST, KEYBOARD TEST

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

⇒

WIRING

⇒

SUPPLY VOLTAGES

⇒

CLOCK SIGNAL 8MHz

⇒

CONTROL SIGNALS

⇒

KEYBOARD

⇒

ELECTRICAL SERVICE DIAGNOSTICS:

DISPLAY TEST, KEYBOARD TEST

REPLACE CDR MODULE IF ERROR OCCURS

"DERRn"

CD-DA DISC LOADED

DISC

DETECTION &

READING?

YES

DISPLAY:

“CD”

&

T.O.C. INFO?

YES

PRESS <PLAY>

ANALOG

AUDIO

OUT?

YES

DISTORTION?

NO

HEADPHONE?

YES

DIGITAL

AUDIO

OUT?

YES

PLAY BACK OF CD-DA

DISCS OK

CHECK:

• WIRING

• POWER SUPPLY VOLTAGES

NO

• ELECTRICAL SERVICE DIAGNOSTICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

CHECK:

• DISC: DIRT, SCRATCHES, DAMAGED...

NO

• ELECTRICAL SERVICE DIAGNOSTICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

CHECK:

AUDIO CONNECTIONS & CABLES

•

I/O BOARD

•

⇒

FLEX CONNECTION

⇒

+5V (pin 8 conn. 1000)

⇒

NO

• ELECTRICAL SERVICE DIAGNOSTICS:

CHECK:

YES

•

•

• ELECTRICAL SERVICE DIAGNOSTICS:

KILL VOLTAGE (pin 7 conn. 1000):

-8V DURING PLAY

⇒

KILL TRANSISTORS 7006,7007,7008, 7009

PLAY AUDIO SIGNALS DISC TRACK 15:

⇒

SIGNAL OF 5.4 VPP ON PINS 1 AND 3 OF CONN.

1000

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

AUDIO CONNECTIONS & CABLES

I/O BOARD

⇒

FLEX CONNECTION

⇒

+5V (pin 8 conn. 1000)

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

CHECK:

WIRING OF HEADPHONE/IR BOARD

•

NO

• ELECTRICAL SERVICE DIAGNOSTICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

CHECK:

AUDIO CONNECTIONS & CABLES

•

I/O BOARD

•

NO

⇒

FLEX CONNECTION

⇒

+5V (pin 8 conn. 1000)

⇒

• ELECTRICAL SERVICE DIAGNOSTICS:

DIGITAL OUT TRANSFORMER 5450, IC7005

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

Figure 5-7

"DERRn"

"DERRn"

"DERRn"

"DERRn"

"DERRn"

"DERRn"

CL 96532076_017.eps

290799

CD-DA DISC

LOADED?

SEE CD-DA DISC

FAULT FINDING

CD-R DISC

LOADED?

YESYES

SEE CD-R DISC

FAULT FINDING

Figure 5-6

NONO

CD-RW DISC

LOADED?

YES

SEE CD-RW DISC

FAULT FINDING

CL 96532076_016.eps

290799

Page 19

Service modes, repair tips and faultfinding trees

VFTD, VDC1,

VDC2

o

Servo

Part

CD-R DISC LOADED

CHECK:

DISC

DETECTION &

READING?

YES

DISPLAY:

“CD R”

OPC INFO?

YES

CD-R DISC PARTIALLY

RECORDED OR EMPTY

START MANUAL

RECORDING FROM

ANALOG SOURCE

LEVEL

ADJUSTABLE?

YES

START RECORDING

FROM DIGITAL

SOURCE

DIGITAL IN?

OPTICAL IN?

YES

RECORDING

SUCCESSFUL?

YES

SET OK

NO

• WIRING

• POWER SUPPLY VOLTAGES

• ELECTRICAL SERVICE DIAGNOSTICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

NO

&

NO

NO

NO

DISPLAY:

“CD”

&

T.O.C. INFO?

YES

FINALISED CD-R DISC

LOADED

SEE CD-DA DISC

FAULT FINDING

CHECK:

AUDIO CONNECTIONS & CABLES

•

• DISPLAY BOARD (SEE FAULT FINDING GUIDE DISPLAY BOARD)

•

⇒

EASY JOG KNOB

⇒

I2C COMMUNICATION

⇒

ELECTRICAL SERVICE DIAGNOSTICS:

• ELECTRICAL SERVICE DIAGNOSTICS:

CHECK:

•

•

• ELECTRICAL SERVICE DIAGNOSTICS:

CHECK:

• ELECTRICAL SERVICE DIAGNOSTICS:

KEYBOARD TEST

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

AUDIO CONNECTIONS & CABLES

I/O BOARD

⇒

FLEX CONNECTION

⇒

+5V (pin 8 conn. 1000)

⇒

IC7005, OPTICAL RECEIVER 6000

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

"DERRn"

CHECK:

NO

• DISC: DIRT, SCRATCHES, DAMAGED...

• ELECTRICAL SERVICE DIAGNOSTICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

"DERRn"

"DERRn"

"DERRn"

Figure 5-8

"DERRn"

CL 96532076_018.eps

290799

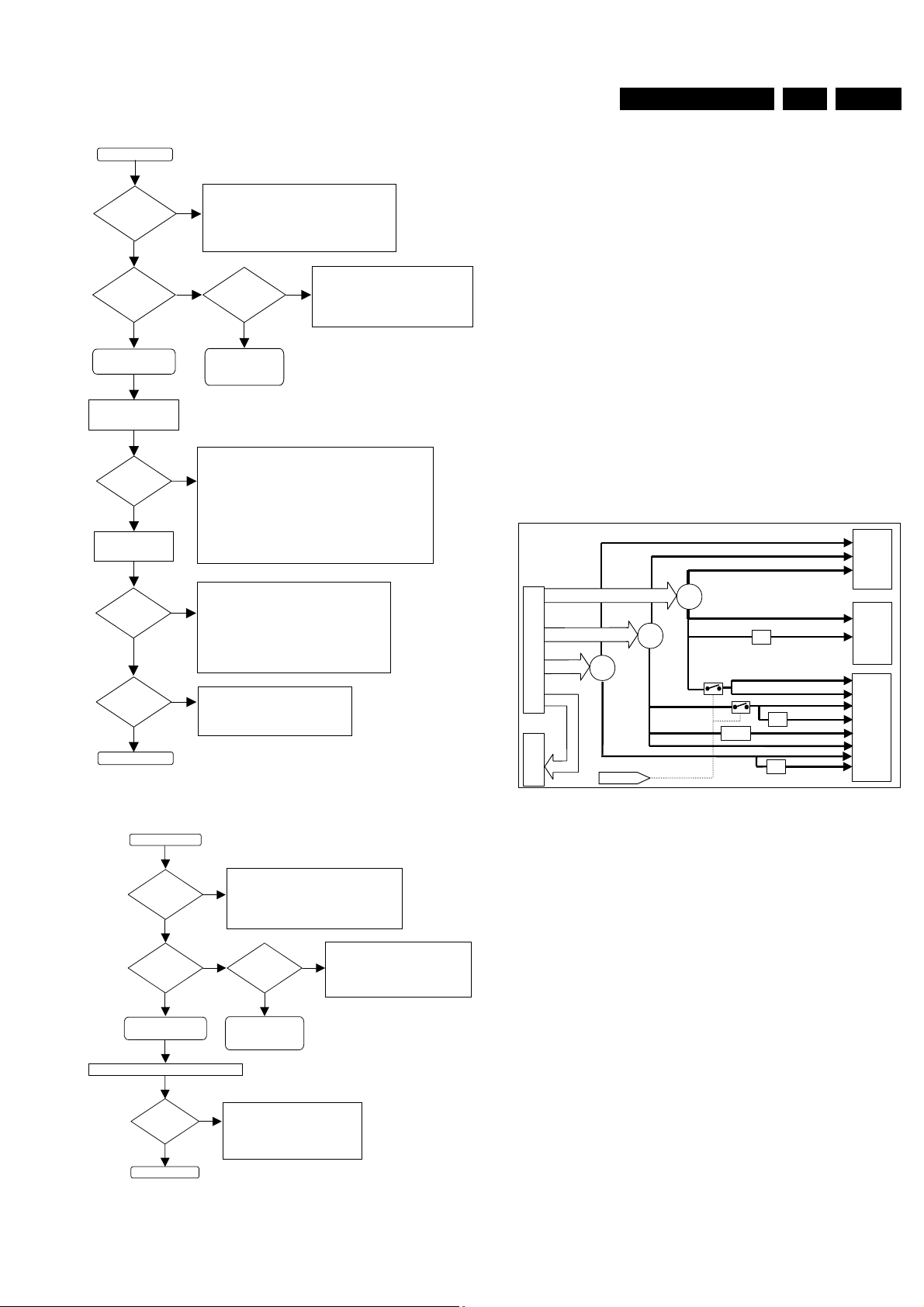

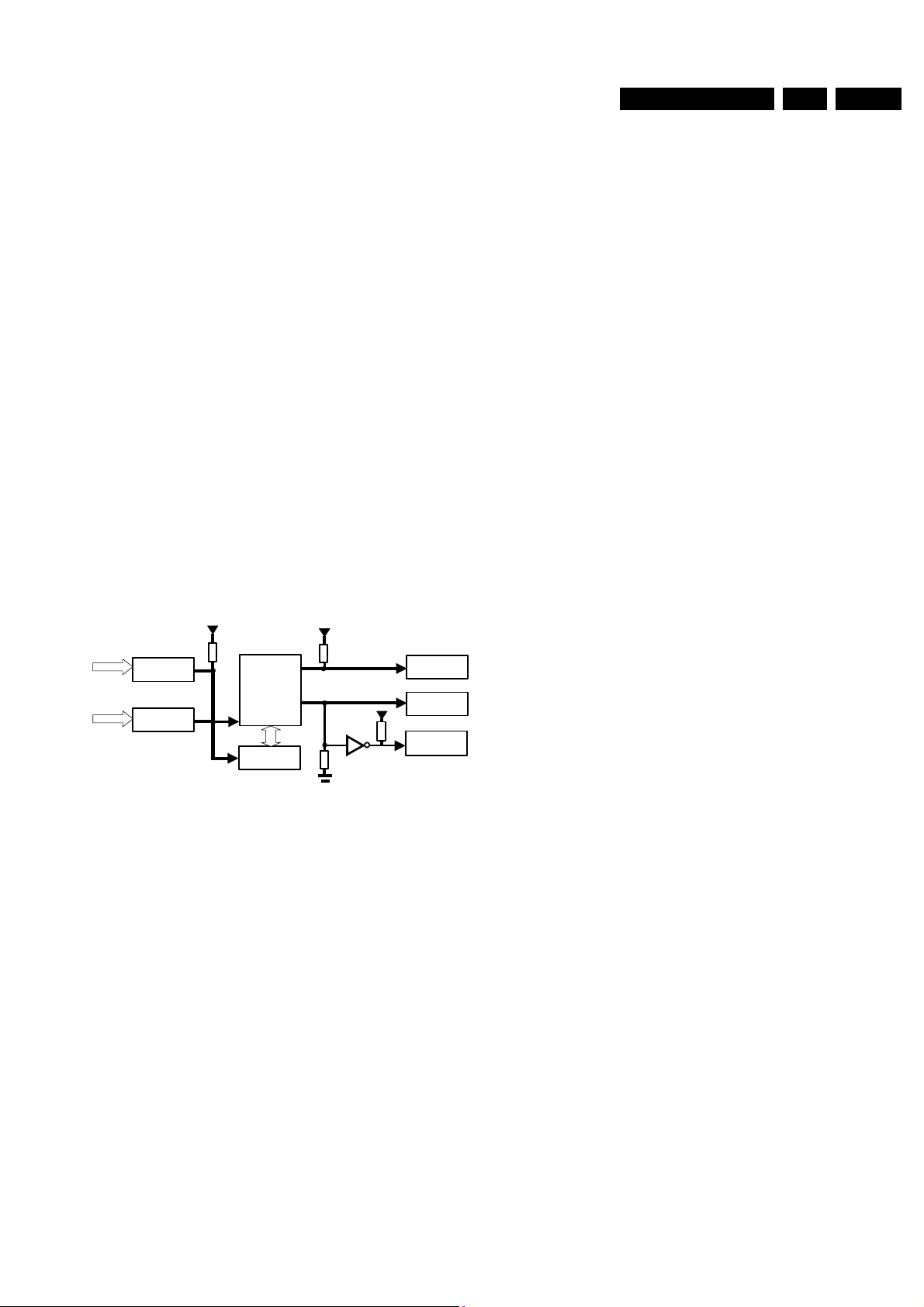

5.2.2 Mainboard

Power supply part on mainboard

• Description.

The most important part of an electrical function is the power

supply. Without it will never operate. The power supplies as

well analog as digital equipment. For these reasons the power

supply is split-up in different sections. One for the digital

electronics, one for the servo controls and one for the AUDIO

part. The servo controls are the big consuming parts with high

peak-currents, also introducing disturbances in the power lines.

The audio part needs very “clean” power, because noise and

ripples have there reflection in the audio signals, specially in S/

N and THD+N. Some of the power supplies are switched off,

this to reduce consumption in case of standby.

The different power supplies are delivered to the PCB via

connector 1500 This is a 11 pole connector with following

voltages on it: +5V, +12V, -8V, VFTD, VDC1 and VDC2.

The last 3 voltages are not used on the main PCB, but are

meant for the FTD (Fluorescent Tube Display). They are

directly routed to connector 1705.

The other voltages are split up in different functions on the

PCB. The following block-diagram gives an indication of that

implementation.

+5V

1500

1705

+12V

-8V

Power_up.

3V3

DC to DC

-5V

-8VA

+12VA

+5VA

D5V

D3V3

D5VS

L5V

12VPWR

+9SRVPWR

FS30V

L12V

A-8V

L-5V

GB 19CDR 3rd gen. 5.

CL06532018_013.eps

Part

Audi

Part

Digital

030300

CD-RW DISC LOADED

NO

DISC

DETECTION &

READING?

YES

DISPLAY:

“CD RW”

OPC INFO?

YES

CD-RW DISC PARTIALLY

RECORDED OR EMPTY

START ERASING OF LAST RECORDED TRACK

ERASING

SUCCESSFUL?

YES

SET OK

NO

&

CHECK:

NO

• ELECTRICAL SERVICE DIAGNOSTICS:

•

CHECK:

• WIRING

• POWER SUPPLY VOLTAGES

• ELECTRICAL SERVICE DIAGNOSTICS:

REPLACE CDR MODULE IF

OR

"BERRn"

DISPLAY:

“CD”

&

T.O.C. INFO?

YES

FINALISED CD-RW DISC

LOADED

SEE CD-DA DISC

FAULT FINDING

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

IF DISC CORRUPTED TRY DC ERASE

ERROR OCCURS

NO

"DERRn"

"DERRn"

CHECK:

• DISC: DIRT, SCRATCHES, DAMAGED...

• ELECTRICAL SERVICE DIAGNOSTICS:

REPLACE CDR MODULE IF

OR

Figure 5-9

"BERRn"

ERROR OCCURS

"DERRn"

CL 96532076_019.eps

Figure 5-10

• Power supply to main board.

Power supply enters the BOARD via connector 1500. Pinning

as follows:

Connector 1500

pin 1: VDC2 : 3V8 (10%

pin 2: VFTD : -38V (5%

pin 3: VDC1 : 3V8 (10%

pin 4: GND : Ground.

pin 5: D5V : +5V (5%

pin 6: D5V : +5V (5%

pin 7: GND : Ground.

pin 8: GND : Ground.

pin 9: GND : Ground.

pin 10: 12V : 12V (10%

pin 11: -8V : -8V (10%

290799

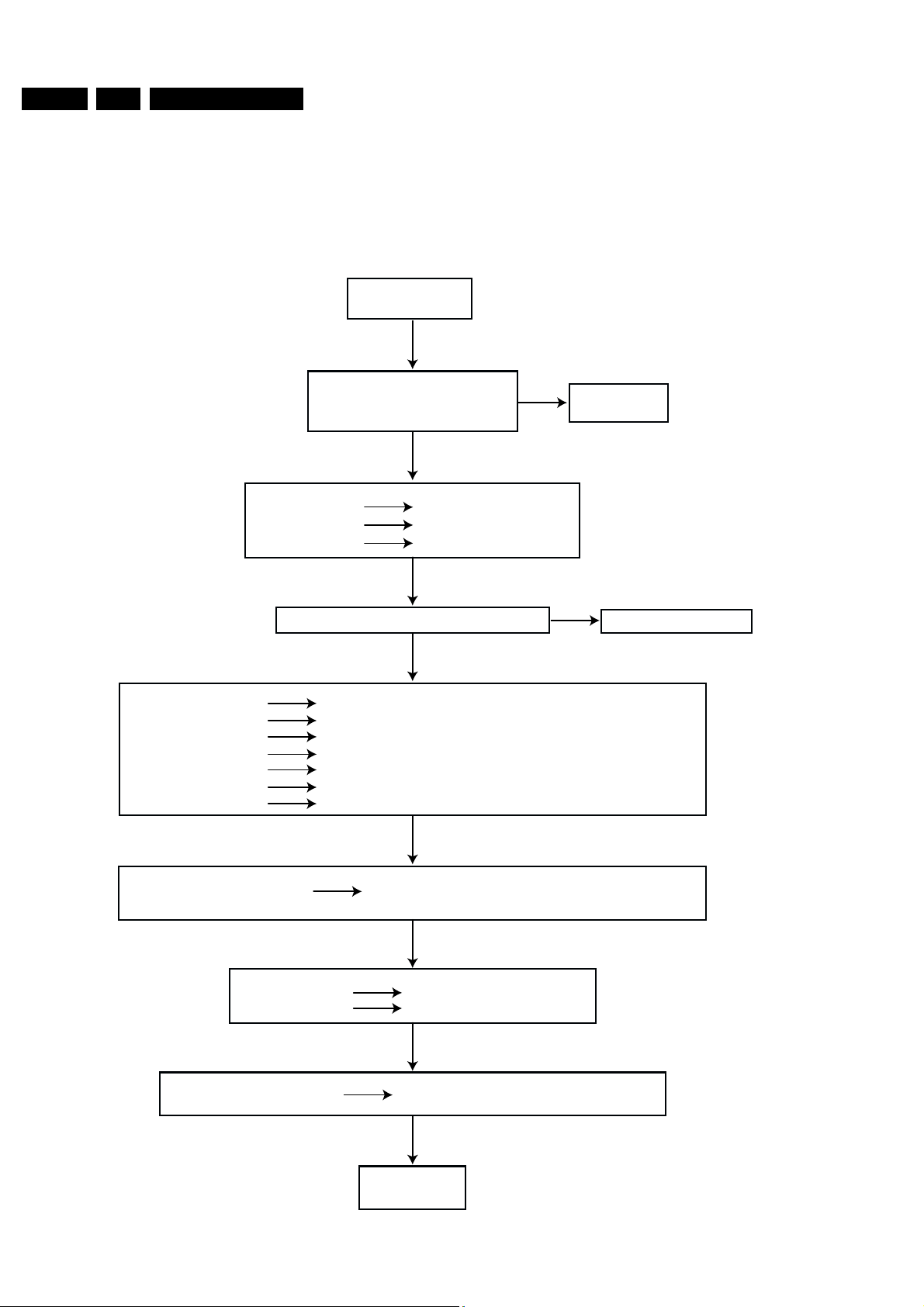

Page 20

GB 20 CDR 3rd gen.5.

Service modes, repair tips and faultfinding trees

POWER PART CHECK

USE CDR MAIN BOARD CIRCUIT DIAGRAM 7 AND CDR MAIN BOARD BOTTOM VIEW : POWER PART TEST POINTS

Switch on player,

exit stand by mode

+5V (+/-5%) conn. 1500 pin 5 and 6

+12V (+/-10%) conn. 1500 pin 10

- 8V (+/- 10%) conn. 1500 pin 11

OK

5VA testpoint 1

D3V3 testpoint 2

D5V testpoint 3

POWER_UP

NOK

L5V testpoint 5

+12VA testpoint 6 Check fuse 1541

P12V testpoint 7

12VPWR testpoint 8 Check fuse 1541, T7527, T7528

+9SRVPWR testpoint 9 Check fuse 1541, T7527, T7528

L12V testpoint 10 Check fuse 1541, safety resistors 3541 and 3542, T7527, T7528

NOK

OK

signal = +3V3 at testpoint 14

OK

Check fuse 1543, T7520, T7523, T7524D5VS testpoint 4

Check fuse 1543, T7520, T7523, T7524

Check fuse 1541

Check fuse 1542

Check fuse 1542, IC7535

Check fuse 1543

NOK

Check power

supply unit

NOK

Check IC7270 MACE

FS30V

= +27V at testpoint 11

A-8V testpoint 12

L-5V testpoint 13 Check T7525, T7549, IC7556

KILL

voltage at testpoint 14

-8V during normal operation

NOK

OK

Check safety resistor 3545, opamp 7521, T7526, T7522,

T7529, T7548, D6554, D6501, D6500

OK

NOK

NOK

Check T7525, T7549

OK

Check T7560, T7561, T7562, T7563, D6553

OK

POWER PART

OK

Figure 5-11

CL06532018_015.eps

290200

Page 21

Service modes, repair tips and faultfinding trees

MC33464

3V0

MC33464

4V7

MASTER

DASP

Display

Basic Engine

MACE

CD loader

80C52 alike

+3V3

+5V

+3V3

+3V3

+5V

AM29LV800BB

Reset & Clock

Master reset.

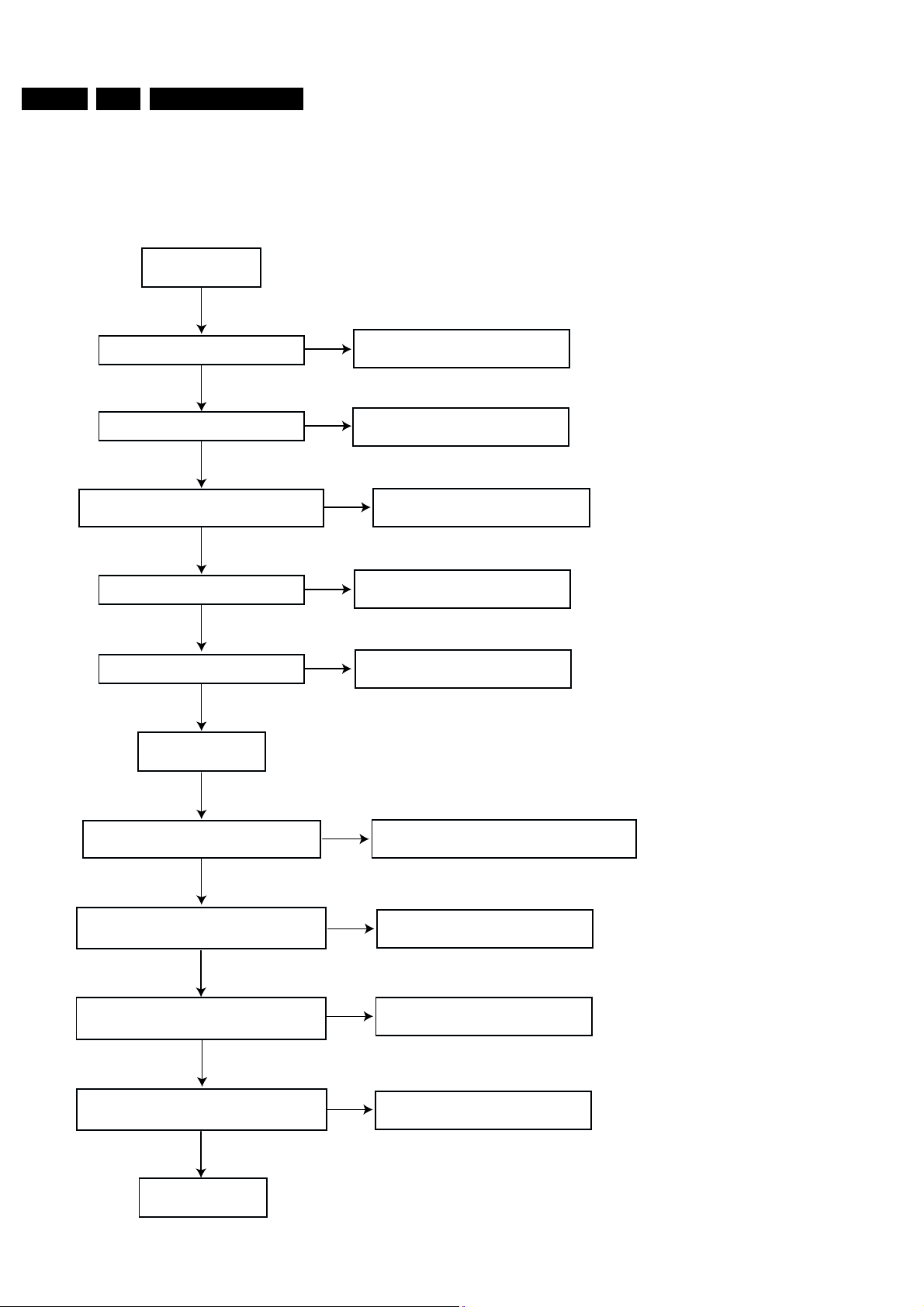

Since the Mainboard is more or less mix-mode between +3V3

and +5V devices, special treatment for the RESET behavior is

wishful. Controlling the RESET only from 1 power supply could

lead to collisions between different devices, damaging the

internal I/O structure of the devices. To avoid this the +3V3 and

the +5V are guarded by a special device. These devices keep

the output low as long as the power supply is not stable or is

not above the required level. As soon as the power supply is

stable it switches the output to “HIGH-Z”. The output is an open

collector type. From then onwards the line can be controlled by

means of external pull-up resistors. Benefit of the opencollector devices is that several of those devices can be tight

together at the outputs. In our case we used a device on the

+5V and one on the +3V3. This means that both power supplies

need to be stable before the RESET of the Master processor is

released.

Resetting several processors in the same structure by means

of the power supplies invokes certain risks. The duration of

initialization after reset is processor and Code depending. It

can lead to hang-up in those cases that communication

between the processors is “time” driven. Meaning that only in a

certain time frame the establishment of the communication-bus

must take place. If not successful the Bus hangs!

To avoid these kinds of problems, only 1 RESET is depending

on the power supply, and this is the RESET of the Master

controller. The same master controller will then take care of the

RESET of the other devices. In the next figure this is explained.

GB 21CDR 3rd gen. 5.

CL06532018-014.eps

Figure 5-12

For further measurings see next reset and clock flowcharts.

230200

Page 22

GB 22 CDR 3rd gen.5.

Service modes, repair tips and faultfinding trees

RESET & CLOCK CHECK

USE CDR MAIN BOARD CIRCUIT DIAGRAMS 4, 9 AND 10 AND CDR MAIN BOARD BOTTOM VIEW : RESET & CLOCK TESTPOINTS

Switch on player,

exit stand by mode

MRESET

high (3V3) testpoint R1

OK

BE_RESET

OK

SYS_RESET display

OK

SYS_RESET CD

OK

SRSTN

high (3V3) testpoint R5

OK

RESET SIGNALS OK

low testpoint R2

high (3V3) testpoint R3

low testpoint R4

NOK

NOK

NOK

NOK

Check power part

Check reset devices 7704 and 7710

Check DASP (IC7701)

NOK

Check DASP (IC7701)

Check T7707

Check MACE (IC7270)

* FOR CDR775/776 ONLY

MAIN_CLOCK

SYS_CLK_11B

SYS_CLK_16W

SYS_CLK_8W

SYS_CLK_BE

CLOCK SIGNALS OK

33.8688MHz testpoint R6

OK

11.2896MHz testpoint R7

OK

16.9344MHz testpoint R8

OK

8.4672MHz testpoint R9

8.4672MHz testpoint R9

OK

NOK

NOK

NOK

NOK

Check X-TAL 1707, IC7705, D6701, D6702

Check DASP (IC7701), IC7708

Check DASP (IC7701)

Check IC7706

CL06532018_016.eps

Figure 5-13

290200

Page 23

Service modes, repair tips and faultfinding trees

p

g

/

GB 23CDR 3rd gen. 5.

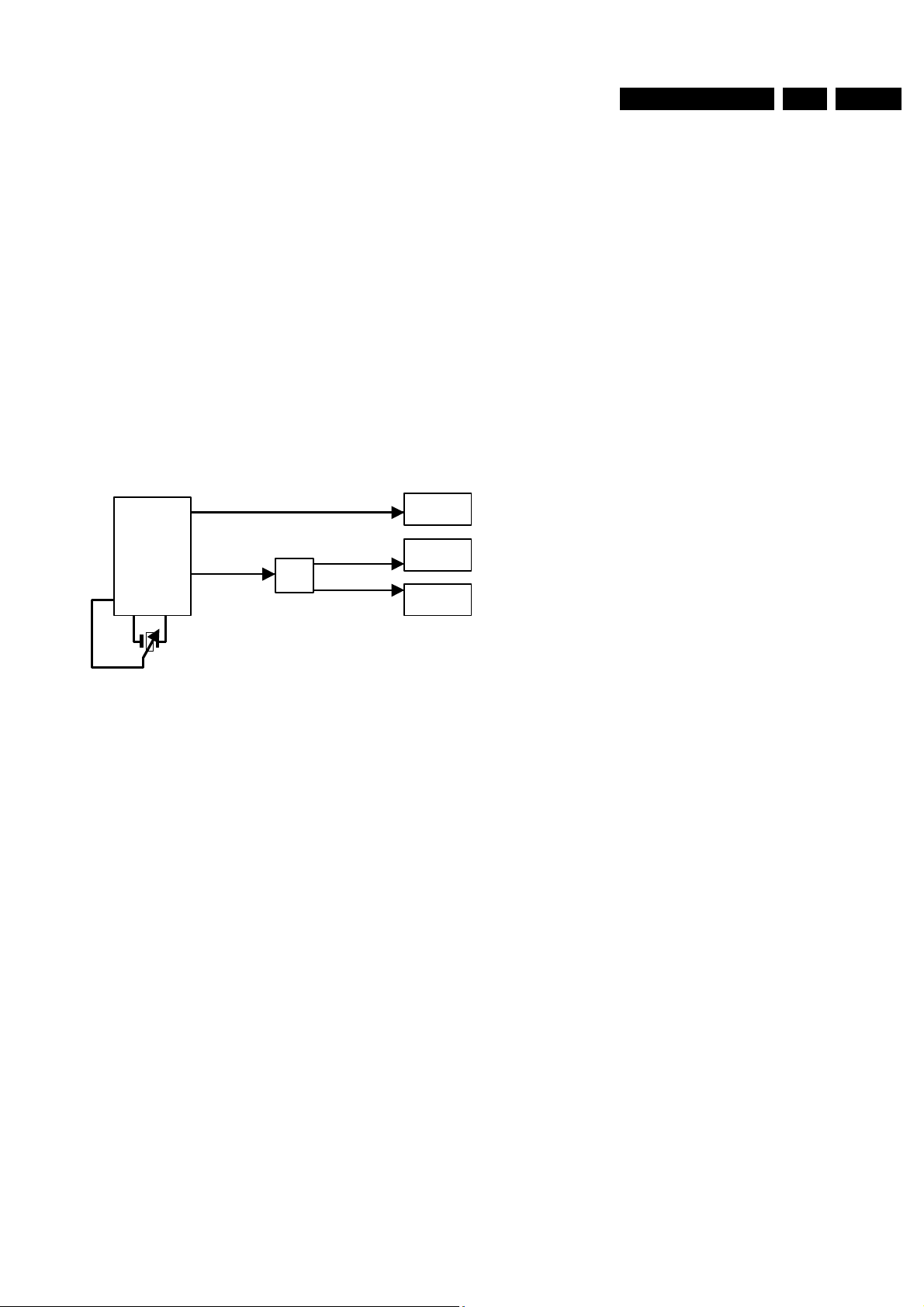

The clockgeneration

All microprocessors or digital devices need a clock. The clock

is usually made by means of resonators or crystals depending

on the speed and the accuracy that is requested. The clock can

also differ from device to device so that more then one crystal

is needed. The cheapest and “system wise” best way is only 1

crystal. The derived clocks are then Phase related to each

other.

On the CDR MAIN 99 the DASP is generating all clock signals.

Not only the systemclock for the processor itself, but also for

the basic engine processor and even the systemclock for the

ADDA part which is directly related to the 44.1kHz. sample

frequency. To be able to do this a 33.8688Mhz. crystal with

25ppm accuracy is connected to the internal oscillator of the

DASP. Internal the clock signal is multiplied by means of a PLL.

This gives the systemclock on which the processor runs

internally. This systemclock is then again devided internally to

have the systemclock for the ADDA, which is 11.2896Mhz, and

the 16,9344Mhz. which divided by 2 gives the systemclock for

the BE part. In this way only 1 crystal is required. The same

8.4672MHz. is also routed to the CD-module in case of a

CDR775 player.

11.2896MHz.

DASP

Master

rocessor

16.9344MHz.

(SYS_CLK_16M)

(SYS_CLK_11M)

8.4672MHz.

(SYS_CLK_BE)

ADDA

Basic

en

ine

2

8.4672MHz.

(SYS_CLK_8W)

CD-

loader

NOTICE:THE TESTS, AS PROVIDED BY THE MENU

DRIVEN DIAGNOSTICS, ARE NOT SUPPOSED TO BE

MIXED RANDOMLY, ESPECIALLY TESTS LIKE ‘LASER ON’

AND ‘FOCUS ON’. IT IS ASSUMED THAT THE PERSON

THAT USES THE MDD KNOWS IN WHICH ORDER THESE

TESTS CAN BE EXECUTED.

The MDD module communicates with two entities:

the terminal emulator on the PC. The MDD receives

instructions (test to be executed) and transmits the menu to be

shown and the test results;

the Audio Engine module. It instructs the Audio Engine via the

interface field which test should be executed. The test result is

retrieved from the interface field.

Requirements

The functionality of the Menu Driven Diagnostics module is to

implement Menu Driven Diagnostics for service purposes.

When the CDR recorder is connected to a PC via an interface

board 7104 086 91111, connection cable 3104 157 11122 and

a RS232 cable (available at PC shop), the service technician

can select via a menu on the PC screen which test should be

perfomed. The result of the test is also shown on the PC

screen. No special test tool is needed for the PC; any terminal

emulation program can be used (for example, HyperTerminal

under Windows95/NT).

The last occurred error during a test session can be retrieved

via the menu.

The RS232 connector should be soldered to pins:

1818-1 = Rx

1818-4 = Gnd

1818-2 = Tx

33.8688MHz.

25ppm.

Figure 5-14

PC help on mainboard diagnostics

A couple of the diagnostics are only possible with the help of a

PC. The DASP micro controller will contain an interface with

the external world; this interface is realised via a serial RS232

connector that is accesible inside the player. It can be

accessed from the outside world by means of test pins and

connector 1818 and interface board 7104 086 91111.

Via those test pins a terminal emulator can be connected. Then

menus will come up that give the opportunity to enter all Audio

Engine commands. This includes the commands on Bit Engine

Level (transparant). This terminal emulator functionality is part

of the embedded software, so no external software is needed.

It can also read out the User Profile Logging of Bit Engine. This

can show the hours that the loader really was in recording

mode.

This diagnostic tool is activated if communication is detected

on the RS232 interface during power up. The baud rate for both

is 19k2 baud.

Details of the diagnostic tool are given in chapter 5.2.3 of this

publication: Menu Driven Diagnostics.

Also in preparation is the interactive COMPAIR tool. Then the

PC communicates in an active form with the set and compares

the result for making the next decision. With MDD the

technician has to take the next active step from his experiences

onwards.

5.2.3 Menu Driven Diagnostics

In this paragraph the specification of the software requirements

for the Menu Driven Fault Finding Diagnostics is given. It will

give a clear and unambiguous description of what the Menu

Driven Diagnostics (MDD) do.

CL96532133_028.eps

131299

General Constraints

It is advised to connect the connection cable 3104 157 11122

to the Mainboard connector 1818 mounted just under the

loader (topview). Via this cable also the powersupply for the

interface board 7104 086 91111 is arranged when it is

connected to connector 1000 on interfaceboard. To start this

application at powering on; for 5 seconds the Rx and Tx output

pin of the mainboard connector should be short circuited. This

temporarily short circuit indicates the internal CDR software

program to switch onto Menu Driven Diagnostics. This short cut

can easily be done via the switch (1009) on the interface board.

To communicate with the PC the RS232 cable has to be

connected to output connector 1010 on the interface board and

the switch (1009) should be released.

When switching on the CDR, two possibilities exist:

the RS232 cable is not connected. The application is executed

(no MDD mode);

the RS232 connector is connected; Rx and Tx are short

circuited for more than 5 seconds then the Menu Driven

Diagnostics is started. By connecting via connection cable to

interface and from there via the RS232 cable onto the PC, so

the MDD can transmit the main menu to the PC.

User Interfaces

RS232 interface

The CDR recorder transmits the menu to be shown and the test

results to the PC via connection cable 3104 157 11122,

interface board 7104 086 91111 and a RS232 cable. It receives

the selection of the user, chosen in the menu.

Hardware Interfaces

RS232 interface

The communication via RS232 should be set to the following

settings:

Baudrate:19200

Databits:8

Stopbits1

Parity:none

Handshaking:none

Page 24

GB 24 CDR 3rd gen.5.

Service modes, repair tips and faultfinding trees

Data Communication Interfaces

Communication between the CDR recorder and the PC is

straightforward: everything the CDR recorder transmits to the

PC is shown on the PC screen. Data, transmitted from the PC

to the CDR775, is treated as a choice from the currently shown

menu.

All functionality of the MDD has to be part of the CDR775

software; the PC can only use a terminal emulation program.

Menu Structure and Test Results

This chapter describes the structure of the menus and the

results of the tests, as shown on the PC screen.

Menu Structure

When starting up, the PC screen is cleared and the software

version and the main menu (level 1) are shown. From the main

menu, one of the sub menus (level 2) can be selected. These

sub menus contain other sub menus and/or a number of tests

that can be executed. The menus are shown below. ‘>>’

indicates that when this option is selected, a new menu will be

shown.

Level 1 Mainmenu:

MAIN MENU

1 General tests >>

2 Retrieve last occurred error

3 Recorder module test >>

4 Playback module test >>* *Only used for the CDR775

5 Select adjust program CDM

6 Download new program

When a test is running, a ‘test running indicator’ (a dot) is

showed on the screen every second, When a test has been

executed, the screen is cleared and the result of the test (if any)

and the menu, separated by one empty line, are showed.

Three types of tests exist:

Tests that return PASSED or FAILED, like the DRAM test.

When a test has been executed, the result is showed on the PC

screen;

Tests that return a value, the message ‘PASSED, xxx’ (with xxx

is the returned value) is showed on the PC screen;

Tests that don’t return anything, like the ‘laser on’ test. Most of

these tests require a visual check of the service person. When

one of these tests is executed, ‘PASSED, visual check’ is

showed on the PC.

Level 2 menus

When a submenu is selected in the main menu, the level 2

menus are showed . These sub menus contain other sub

menus and/or a number of tests that can be executed.

GENERAL TESTS MENU

1 Check DRAM

2 CHECK FLASH>>

3 Check ADC/DAC

4 Check LCD

RECORDER MODULE TEST MENU

1 communication test

2 Tray >>

3 Laser >>

4 Focus >>

5 Radial >>

6 Sledge >>

7 Miscellaneous >>

8 Jump grooves >>

5 Turntable motor >>

6 Radial >>

7 Sledge >>

8 Miscellaneous >>

Level 3 menus

CHECK FLASH MENU

1 Check FLASH

2 Manufacturar-ID and

3 Device ID

TRAY MENU

1 Open tray

2 Close tray

LASER MENU

1 Laser off

2 Laser on, read

3 Laser on, write*---------------*’Laser on, write’ only used for the

recorder module

FOCUS MENU

1 Focus on

2 Focus off

TURNTABLE MOTOR

1 Turntable motor ON

2 Turntable motor OFF

RADIAL MENU

1 Radial control on

2 Radial control off

SLEDGE MENU

1 Sledge inwards

2 Sledge outwards* ----------------*Sledge stays outwards for the

recorder module; sledge moves inwards after 300 ms for

playback module

JUMP GROOVES MENU

1 Jump grooves to inside

2 Jump grooves to middle

3 Jump grooves to outside

MISCELLANEOUS MENU

1 Start player

2 Stop player

3 Calibrate CD >>* ----------------*Only used for recorder module

4 Get user profile logging

5 Erase CD-RW*-------------------*Only used for recorder module

6 Read firmware version**------**CD firmware version for CDmodule, CDR firmware version for CDR-module

CALIBRATE CD MENU *--------*Only used for recorder module

1 Calibrate CD, N=1

2 Calibrate CD, N=2

3 Get last OPC values

End of test

These diagnostics can be quitted by powering off the player

PLAYBACK MODULE TEST MENU

1 communication test

2 Tray >>

3 Laser >>

4 Focus >>

Page 25

Service modes, repair tips and faultfinding trees

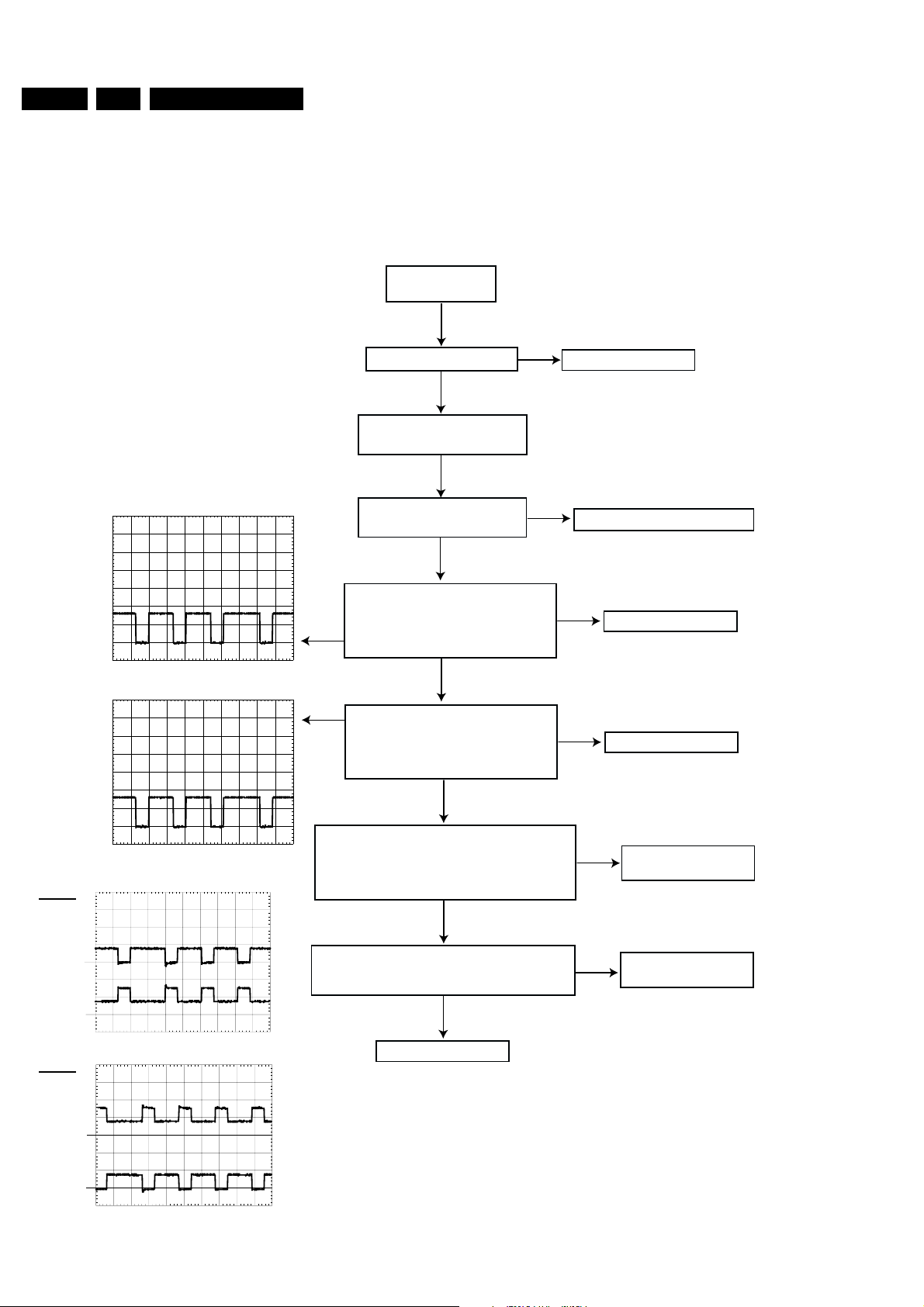

5.2.4 Servo drivers check

SERVO DRIVERS CHECK

USE CDR MAIN BOARD CIRCUIT DIAGRAMS 1, 3 AND 4 AND CDR MAIN BOARD BOTTOM VIEW : SERVO DRIVERS TESTPOINTS

FOCUS SERVO

Switch on player

in MDD mode

Execute "focus" tests

NOK

Check power part

Check reset and clock part

GB 25CDR 3rd gen. 5.

OK

FOCUS SERVO OK

Moving between

1V3 and 2V

GND

VFO

GND

FOC-/FOC+

PM3392A

VFO

CH1:500mV= MTB2.00us

PM3392A

CH1:500mV= MTB2.00us

PM3392A

OK

Check

S1V65

(=1V65) at

testpoint S9

OK

Execute "focus on" test

Check

VFO

signal at testpoint S16

OK

Execute "focus off" test

Check

VFO

signal at testpoint S16

OK

Check signal across

FOC+/FOC-

and S18 when executing "focus on"

OK

NOK

NOK

NOK

at testpoints S17

Check IC7215, T7201, T7202

Check MACE 7270

Check MACE 7270

NOK

Check driver 7240

Check MACE 7270

Check CDM3800

GND

CH1:50.0mV= MTB 500ms

ch1: freq= 1.61 Hz

FOCUS SERVO OK

Figure 5-15

CL06532018_017.eps

290200

Page 26

GB 26 CDR 3rd gen.5.

Service modes, repair tips and faultfinding trees

SERVO DRIVERS CHECK

USE CDR MAIN BOARD CIRCUIT DIAGRAMS 1, 3 AND 4 AND CDR MAIN BOARD BOTTOM VIEW : SERVO DRIVERS TESTPOINTS

RADIAL SERVO

Switch on player

in MDD mode

OK

Execute "radial control" tests

NOK

Check power part

Check reset and clock part

RADIAL SERVO OK

PM3392A

VRA

GND

CH1:1.00 V= MTB 500ns

ch1:freq=532kHz

PM3392A

VRA

GND

CH1:1.00 V= MTB 500ns

ch1:freq=1.06MHz

OK

NOK

Check

S1V65

(=1V65) at

testpoint S9

OK

Execute "radial control on" test

Check

VRA

signal at testpoint S13

NOK

OK

Execute "radial control off" test

Check

VRA

signal at testpoint S13

NOK

OK

Check

RAD+

signal at testpoint S14 :

+4V2 (going to 6V8 when executing "radial control on")

Check

RAD-

signal at testpoint S15 :

+0V65 (going to 4V3 when executing "radial control off")

OK

Check IC7215, T7201, T7202

Check MACE 7270

Check MACE 7270

NOK

Check driver 7240

Check MACE 7270

Check CDM3800

RADIAL SERVO OK

Figure 5-16

CL06532018_018.eps

290200

Page 27

Service modes, repair tips and faultfinding trees

SERVO DRIVERS CHECK

USE CDR MAIN BOARD CIRCUIT DIAGRAMS 3 AND 4 AND CDR MAIN BOARD BOTTOM VIEW : SERVO DRIVERS TESTPOINTS

SLEDGE SERVO

GB 27CDR 3rd gen. 5.

Switch on player

in MDD mode

VSL

PM3392A

Execute "sledge inwards"

OK

and "sledge outwards" tests

NOK

Check power part

Check reset and clock part

OK

Check

S1V65

(=1V65) at

NOK

testpoint S9

OK

Check voltages testpoints S4, S5, S7, S8 : +/- 1.6V

OK

Check voltage testpoint S1 : if S1=0V then S3=0V

if S1=1V65 then 1V<S3<4V

if S1=3V3 then S3=5V

Check voltage testpoint S2 : if S2=0V then S6=0V

if S2=1V65 then 1V<S6<4V

if S2=3V3 then S6=5V

OK

SLEDGE SERVO OK

Check IC7215, T7201, T7202

NOK

Check CDM3800

NOK

Check opamp 7225

GND

CH1:1.00 V= MTB 500ns

Check

VSL

signal at testpoint S10

OK

Check

SL+

signal at testpoint S11 :

+3V (going to 5V4 when executing "sledge outwards")

Check

SL-

signal at testpoint S12 :

+5V4 (going to 3V4 when executing "sledge outwards")

OK

SLEDGE SERVO OK

Figure 5-17

NOK

NOK

Check MACE 7270

Check driver 7240

Check MACE 7270

CL06532018_019.eps

290200

Page 28

GB 28 CDR 3rd gen.5.

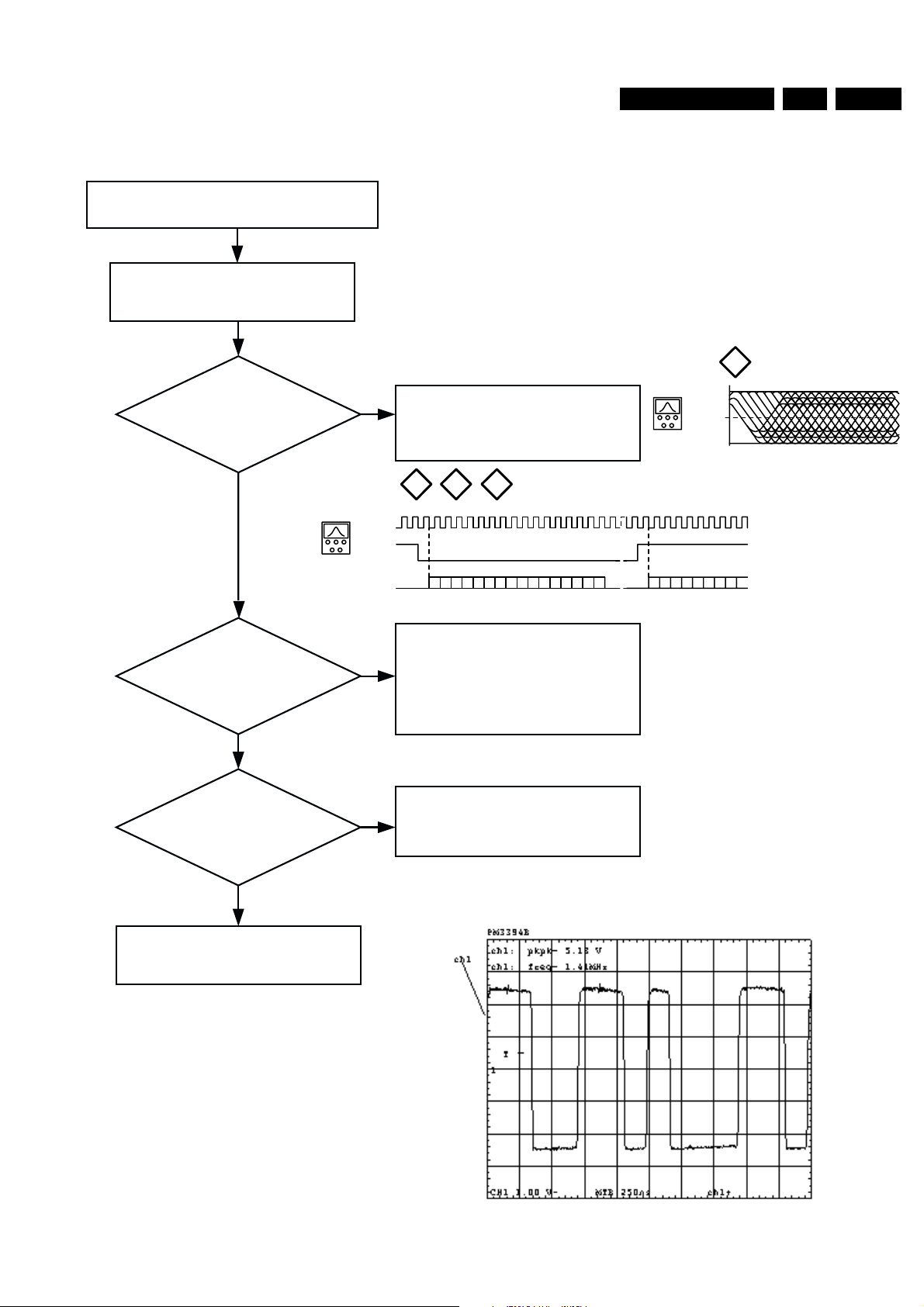

SERVO DRIVERS CHECK

USE CDR MAIN BOARD CIRCUIT DIAGRAMS 3 AND 4 AND CDR MAIN BOARD BOTTOM VIEW : SERVO DRIVERS TESTPOINTS

TRAY SERVO

Service modes, repair tips and faultfinding trees

Switch on player

in MDD mode

OK

Execute "TRAY" tests

NOK

Check power part

Check reset and clock part

OK

TRAY SERVO OK

osc. a

GNDTR+

GNDTR-

osc. b

PM3392A

TRAYOUT

GND

CH1:2.00 V= MTB 500us

PM3392A

TRAYIN

GND

CH1:2.00 V= MTB 500us

PM3392A

TR+

TR-

CH1:5.00 V=

CH2:5.00 V= MTB 500us

PM3392A

Check

S1V65

(=1V65) at

NOK

testpoint S9

OK

Execute "tray open" test

Check

Tray Out

signal at testpoint S19

during command

Tray In

(testpoint S20) stays at 3V2

OK

Execute "tray close" test

Check

Tray In

signal at testpoint S20

during tray command

Tray Out

(testpoint S19) stays at 3V2

OK

Check

TR+

(testpoint S21),

TR-

(testpoint S22) :

- values without commands 4V2

- values during "tray open" command (osc. a)

- values during "tray close" command (osc. b)

OK

Check signal

TRAYSW

at testpoint S23 :

3V3 during commands open and close,

0V after completion

OK

TRAY SERVO OK

Check IC7215, T7201, T7202

NOK

Check MACE 7270

NOK

Check MACE 7270

NOK

Check driver 7240

Check CDL4009

NOK

Check CDL4009

GNDTR+

GNDTR-

TR+

TR-

CH1:5.00 V=

CH2:5.00 V= MTB 500us

Figure 5-18

CL06532018_020.eps

290200

Page 29

Service modes, repair tips and faultfinding trees

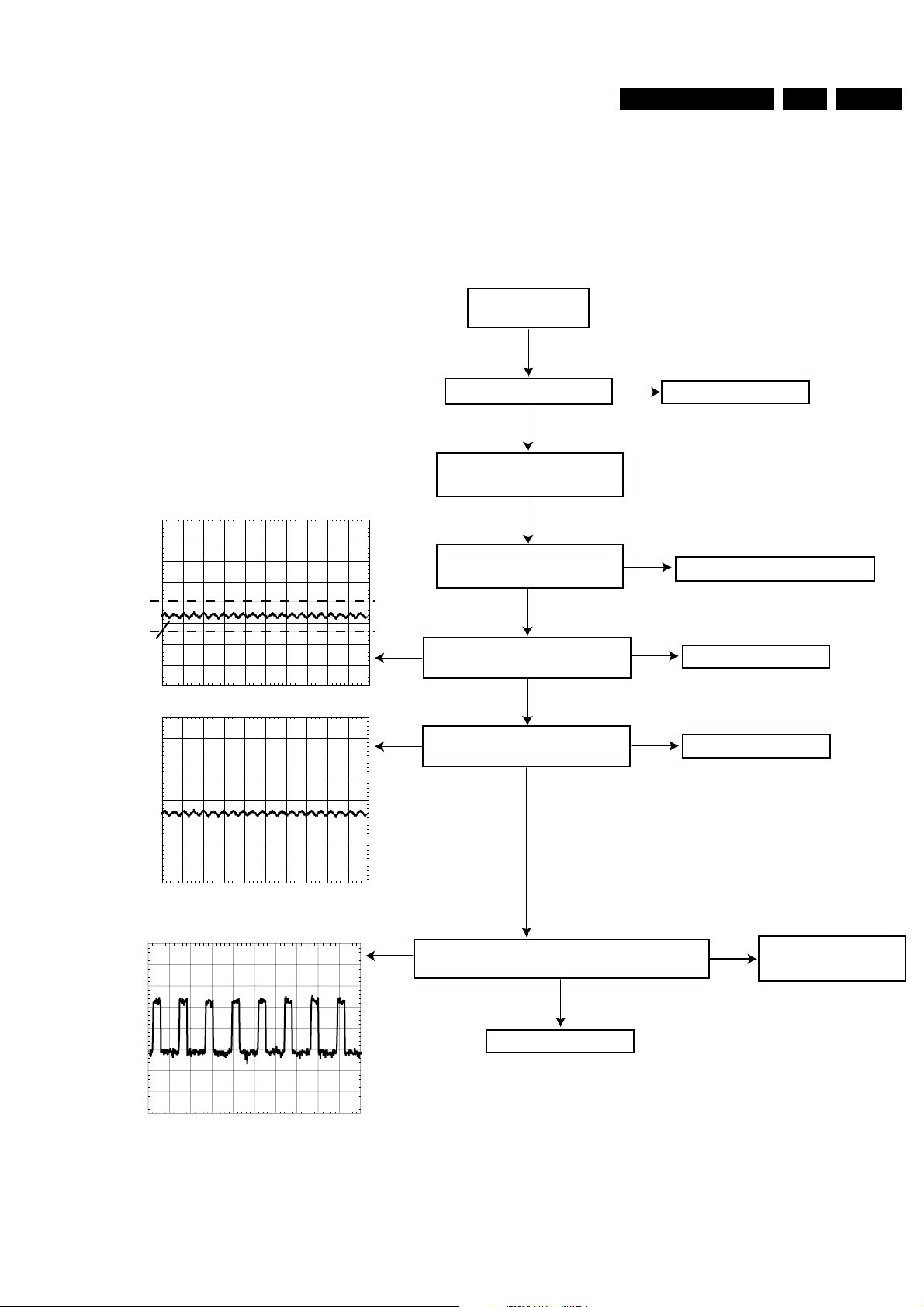

5.2.5 Audio signal check

DIGITAL AUDIO PLAYBACK

INSERT AUDIO SIGNALS DISC

START TRACK 15(1KHz 0dB)

GB 29CDR 3rd gen. 5.

HF-SIGNAL

ON TESTPOINT HF2 ?

(DIAGRAM 5)

YES

I2S-SIGNALS

ON TESTPOINTS

A14,A15,A16 ?

(DIAGRAM 5)

YES

DIGITAL SIGNAL

OUT OF DASP ON

TESTPOINT A24

(DIAGRAM 9)

0.5uS/DIV

NO

NO

NO

CHECK CAHF-SIGNAL ON

-

TESTPOINT HF1 FOR ACTIVITY

-

CHECK TR 7375,7373,7371,

7370,7361AND IC 7360

A14 A15 A16

2,1168MHz

BCLK

44,1KHz

WCLK

DATA0

LEFT CHANNEL

-

CHECK IC 7300

-

CHECK POWER SUPPLY D3V3

-

CHECK SYS CLK BE ON

TESTPOINT R10 (= 8,4672 MHz)

-

CHECK POWER SUPPLY IC 7701

-

CHECK IC 7701

0,5us/DIV

32

RIGHT CHANNEL

MSBMSB LSB

HF2

eyepattern

2.5V

>800mVpp

YES

DIGITAL AUDIO PLAYBACK

OK

Figure 5-19

TESTPOINT A24

CL06532018_021.eps

290200

Page 30

GB 30 CDR 3rd gen.5.

ANALOG AUDIO PLAYBACK

INSERT AUDIO SIGNALS DISC

START TRACK 15(1KHz 0dB)

HF-SIGNAL

ON TESTPOINT HF2 ?

(DIAGRAM 5)

YES

I2S-SIGNALS

ON TESTPOINTS

A14,A15,A16 ?

(DIAGRAM 5)

YES

0.5uS/DIV

NO

NO

Service modes, repair tips and faultfinding trees

CHECK CAHF-SIGNAL ON

-

TESTPOINT HF1 FOR ACTIVITY

-

CHECK TR 7375,7373,7371,

7370,7361AND IC 7360

A14 A15 A16

2,1168MHz

BCLK

44,1KHz

WCLK

DATA0

LEFT CHANNEL

CHECK IC 7300

-

-

CHECK POWER SUPPLY D3V3

-

CHECK SYS CLK BE ON

TESTPOINT R10 (= 8,4672 MHz)

32

2.5V

0,5us/DIV

RIGHT CHANNEL

MSBMSB LSB

HF2

eyepattern

>800mVpp

I2S-SIGNALS

ON TESTPOINTS

A10,A11,A12 ?

(DIAGRAM9)

YES

VoutL AND VoutR

ON TESTPOINTS

A19 AND A20 ?

(DIAGRAM 6)

YES

AUDIO-SIGNAL

ON TESTPOINTS

A21 AND A22 ?

(LINE OUT)

YES

AUDIO-SIGNAL

ON TESTPOINTS

A25 AND A26 ?

(HEADPHONE)

NO

NO

NO

CHECK POWER SUPPLY IC 7701

-

-

CHECK IC 7701

CHECK POWER SUPPLY IC 7406

-

-

CHECK SAFETY RESISTORS

R3411 AND R3439

-

CHECK V

CHECK IC 7409

-

CHECK POWER SUPPLY IC 7409

-

-

CHECK KILL TR 7412 AND 7413

-

CHECK KILL TR 7410 AND 7411

-

CHECK IC 7408

FOR CDR 775 CHECK IC 7407

-

REF

= 1,65V ON PIN 28

19

20

2ms/DIV

21

22

2ms/DIV

0V

2.4Vpp

4,2Vpp

YES

ANALOG AUDIO PLAYBACK

OK

Figure 5-20

CL06532018_022.eps

290200

Page 31

Service modes, repair tips and faultfinding trees

GB 31CDR 3rd gen. 5.

DIGITAL AUDIO PATH

DURING RECORDING

CONNECT DIGITAL INPUT FROM

EXTERNAL SOURCE AND

SELECT THE DIGITAL RECORDING

INPUT BY PRESSING SOURCE

CHECK DIGITAL SIGNAL

ON TESTPOINT

A23

(DIAGRAM9)

YES

CHECK FLEX - CONNECTOR

-

NO

BETWEEN I/O-BOARD AND

MAINBOARD

BCLK

WCLK

0.5uS/DIV

DATA1

A23

A14A13 A15

2,1168MHz

44,1KHz

LEFT CHANNEL

32

RIGHT CHANNEL

MSBMSB LSB

CHECK I2S - SIGNALS

ON TESTPOINTS A13, A14 AND A15

(DIGRAM 9 AND 5)

YES

CHECK EFMDATA AND

EFMCLOCK ON TESTPOINTS

A17 AND A18

(DIAGRAM1)

YES

CHECK ACTIVITY

ON TESTPOINT A27

(DIAGRAM1)

YES

DIGITAL AUDIO PATH

DURING RECORDING

OK

NO

NO

NO

-

CHECK POWER SUPPLY IC 7701

-

CHECK IC 7701

CHECK POWER SUPPLY IC 7300

-

-

CHECK I2C - SIGNAL OF IC 7300

-

CHECK IC 7300

CHECK POWER SUPPLY IC 7008

-

-

CHECK I2C - SIGNAL OF IC 7008

CHECK IC 7008

-

A18

A17

Figure 5-21

CL06532018_023.eps

290200

Page 32

GB 32 CDR 3rd gen.5.

CHECK POWER SUPPLY IC 7406

CHECK SAFETY RESISTORS

-

-

A10A9 A11

R3411 AND R3439

CHECK Vref = 1,65V ON PIN 28

-

32

2,1168MHz

BCLK

Service modes, repair tips and faultfinding trees

RIGHT CHANNEL

MSBMSB LSB

LEFT CHANNEL

44,1KHz

WCLK

DATA1

0.5uS/DIV

A12 A14 A15

A17

CHECK POWER SUPPLY IC 7701

CHECK IC 7701

-

-

CHECK POWER SUPPLY IC 7300

CHECK I2C - SIGNAL OF IC 7300

CHECK IC 7300

-

-

-

A18

CHECK POWER SUPPLY IC 7008

CHECK I2C - SIGNAL OF IC 7008

CHECK IC 7008

-

-

-

290200

CL06532018_024.eps

NO

YES

(DIAGRAM 9)

CHECK I2S - SIGNALS

ON TESTPOINTS A9, A10 AND A11

5.44Vpp

0V

A2

A1

CHECK FLEX - CONNECTOR

BETWEEN I/O - BOARD AND

MAINBOARD

-

NO

CHECK I2S - SIGNALS

ON TESTPOINTS A13, A14 AND A15

TRACK 15 1KHz 0dB

AUDIO SIGNALS DISC

2ms/DIV

CHECK POWER SUPPLY IC 7401

CHECK IC 7401

-

-

YES

(DIGRAM 9 AND 5)

2.68Vpp

0V

A4

A3

2ms/DIV

NO

YES

(DIAGRAM1)

A17 AND A18

CHECK EFMDATA AND

EFMCLOCK ON TESTPOINTS

A6

CHECK POWER SUPPLY IC 7801

-

-

A5

CHECK I2C - SIGNAL OF IC 7801

CHECK IC 7801

-

NO

CHECK ACTIVITY

ON TESTPOINT A27

739mVpp

0V

(DIAGRAM1)

2ms/DIV

YES

CHECK POWER SUPPLY IC 7405

-

ANALOG AUDIO PATH

OK

DURING RECORDING

2.44Vpp

0V

A8

A7

CHECK IC 7405

-

2ms/DIV

THE DISPLAY SHOWS -12 DB.

SELECT ANALOG RECORDING

ANALOG AUDIO PATH

APPLY AUDIO SIGNAL(1kHz 0dB)

DURING RECORDING

THE EASY JOG/ENTER KEY UNTIL

ON CONNECTOR 1400 AND ROTATE

NO

(DIAGRAM 6)

CHECK AUDIO SIGNAL

INPUT BY PRESSING SOURCE

ON TESTPOINTS A1 AND A2

YES

NO

YES

(DIAGRAM 6)

CHECK AUDIO SIGNAL

ON TESTPOINTS A3 AND A4

CHECK AUDIO SIGNAL

ON TESTPOINTS A5 AND A6

Figure 5-22

(DIAGRAM 6)

YES

NO

YES

(DIAGRAM 6)

CHECK AUDIO SIGNAL

ON TESTPOINTS A7 AND A8

Page 33

Alignments & Adjustments

8. Alignments & Adjustments

Each CDR-module composed from CDRloader and

CDRmainboard has to be matched via SW filled

parameters.This adjustment processed in the factory is under

investigation to have it implemented into the COMPAIR tool. As

long as this adjustment is not possible to be executed in

secondline service workshop, the swop of modules and a

central repair has to be continued. Adjustment only has to be

done at replacement of CDM and concerned servo circuits.

Other repairs (audio signals, replacement of adapted Flash

roms etc) can be done without infringing the adjusted

components.

As soon as COMPAIR CDR is installed this chapter will be

adapted via a service information.

Flash Rom IC 7208 (MACE-ROM) is mounted on a socket and

can be replaced after lifting up the loader part above it. Flash

Rom IC 7703 (DASP-ROM) has to be soldered.

Take care for both ICs Firmware loaded components are

mounted.

In case a module is offered with SW versions 1.4 and 91.48, the

complete CDR-module should be replaced.

For SW versions 1.23 and 91.63, IC7703 and IC7208 have to

be replaced by the latest SW verions.

GB 75CDR 3rd gen. 8.

Page 34

GB 76 CDR 3rd gen.9.

9. Circuit description

9.1 Description

A separate circuit description concerning the 3rd generation

CDR recorders is available with order number 3104 125 40100

Circuit description

Page 35

Circuit description

9.2 List of Abbreviations

GB 77CDR 3rd gen. 9.

CL06532018_026.eps

290200

Page 36

GB 78 CDR 3rd gen.9.

Circuit description

CL06532018_027.eps

290200

Page 37

Circuit description

GB 79CDR 3rd gen. 9.

CL06532018_028.eps

290200

Page 38

GB 80 CDR 3rd gen.9.

Circuit description

CL06532018_029.eps

290200

Page 39

Circuit description

GB 81CDR 3rd gen. 9.

CL06532018_030.eps

290200

Page 40

GB 82 CDR 3rd gen.9.

Circuit description

CL06532018_031.eps

Page 41

Circuit description

GB 83CDR 3rd gen. 9.

CL06532018_032.eps

290200

Page 42

GB 84 CDR 3rd gen.9.

Circuit description

CL06532018_033.eps

290200

Page 43

Spareparts List

10. Spareparts List

ELECTRICAL PARTSLIST MAINBOARD CDR'99

ITEM CODENUMBER DESCRIPTION CDR775 CDR570 CDR770 CDR950

1000 482226710666 30 P. FEM. + + + +

1541 482225251173 19398E1(1,000A) + + + +

1542 482225251173 19398E1(1,000A) + + + +

1543 482225251173 19398E1(1,000A) + + + +

1707 482224210757 33.868 000MHZ SM 20P CX-11F + + + +

1708 482226760409 CONN 22P FEMALE + - - 1820 482226710666 30 P. FEM. - - - +

2001 482212612105 CER2 0805 X7R 50V 33NF PM5 + + + +

2002 482212614585 100NF 10% X7R 0805 50V + + + +

2003 482212614585 100NF 10% X7R 0805 50V + + + +

2009 482212233753 150PF 5%NP0 50V + + + +

2010 482212233753 150PF 5%NP0 50V + + + +

2011 482212614585 100NF 10% X7R 0805 50V + + + +

2012 482212614585 100NF 10% X7R 0805 50V + + + +

2013 482212614585 100NF 10% X7R 0805 50V + + + +

2014 482212614585 100NF 10% X7R 0805 50V + + + +

2015 482212614585 100NF 10% X7R 0805 50V + + + +

2016 482212614585 100NF 10% X7R 0805 50V + + + +

2018 482212613694 68PF 1% NP0 63V + + + +

2019 482212614585 100NF 10% X7R 0805 50V + + + +

2020 482212613188 15NF 5% X7R 63V + + + +

2021 482212233177 10NF 20% X7R 50V + + + +

2022 482212233177 10NF 20% X7R 50V + + + +

2023 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2024 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2025 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2026 222286115272 CER1 0805 NP0 50V + + + +

2027 222286115272 CER1 0805 NP0 50V + + + +

2028 532212232531 100PF 5%NP0 50V + + + +

2029 532212232531 100PF 5%NP0 50V + + + +

2030 532212231647 1NF10%X7R 63V + + + +

2031 482212614585 100NF 10% X7R 0805 50V + + + +

2032 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2033 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2037 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2038 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2039 482212233177 10NF 20% X7R 50V + + + +

2040 482212233172 390PF 5% NP0 50V + + + +

2041 532212234099 470PF10%X7R 63V + + + +

2042 532212233538 150PF 2%NP0 63V + + + +

2043 532212231647 1NF10%X7R 63V + + + +

2044 482212613486 15PF 2% NP0 63V + + + +

2045 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2046 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2047 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2048 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2049 532212611579 3,3NF10%X7R 63V + + + +

2050 482212614238 CER2 0603 X7R 50V 2N2 COL R + + + +

2052 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2053 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2054 482212614238 CER2 0603 X7R 50V 2N2 COL R + + + +

2056 532212611579 3,3NF10%X7R 63V + + + +

2057 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2058 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2059 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2060 532212611579 3,3NF10%X7R 63V + + + +

2061 482212411947 10UF 20% 16V + + + +

CL06532018_087.eps

010300

GB 85CDR 3rd gen. 10.

Page 44

GB 86 CDR 3rd gen.10.

ITEM CODENUMBER DESCRIPTION CDR775 CDR570 CDR770 CDR950

2063 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2078 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2080 482212614238 CER2 0603 X7R 50V 2N2 COL R + + + +

2081 532211680853 560PF 5%NP0 63V + + + +

2082 482212614238 CER2 0603 X7R 50V 2N2 COL R + + + +

2083 482212613956 68PF 5% NP0 63V CASE 0603 + + + +

2084 482212232627 2.7NF10%X7R 50V + + + +

2126 482212614585 100NF 10% X7R 0805 50V + + + +

2207 482212614305 100NF 10% X7R 16V 0603 CER2 + + + +

2208 482212614585 100NF 10% X7R 0805 50V + + + +