Philips CDR3 TM 310412540100 Service Manual

Audio Circuit description of Compact Disc Recording

CL96532133_000.eps

081199

Concerning the third generation of Digital Audio Compact Disc

Recordable and Rewritable (reference set is CDR775)

Contents Page

1 Introduction

2 New in the 3rd generation sets

3. CD R-RW audio recorder

4 Power supply unit 20PS317

2

3

16

85

©

Copyright reserved 1999 Philips Consumer Electronics B.V. Eindhoven, The

Netherlands. All rights reserved. No part of this publication may be reproduced,

stored in a retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by JvO 9972 Service PaCE Printed in The Netherlands Subject to modification 5 3104 125 40100

2 1. Introduction 3rd Generation

1. Introduction

After the publication of the basics of Compact Disc Recordable

(4822 725 25242) with the applied Loader and IC’s for the first

and second CDR generation, now a new designed Loader, CD

Mechanism and “chipset” is applied in the 3rd generation sets.

With this publication you are informed about this actual

situation.

In principle the Recording method and the Recording discs

have not been changed, both have already been published in

the first two chapters of above mentioned basic publication,

now all efforts is given to explain the functioning of the 3rd

generation Digital Audio Compact Disc Recording set. In this

publication first of all the new features applied in these sets are

described, then the functional blockdiagram is explained in

detail. One chapter explains the Menu functions of the sets.

Finally the description of the functioning of the Switch Mode

Power Supply is given.

Personal notes

3rd Generation 2. New in the 3rd Generation sets 3

2. New in the 3rd Generation sets

The Digital Audio CD Recorder is offering more functionality,

with applications like audio buffer, DLR, CDText and a lot of

other integrated functions

1. Audio buffer

2. Improved stop modes (in recording from a digital and an

analogue source)

3. Synchronised start of recording also from ANALOGUE

sources

4. Sample Rate Converter 11-56 kHz (DAB = 32 kHz; DAT =

48 kHz)

5. Direct Line Recording

6. HD- CD recording (No playback of HD-CD)

7. Easy jog

8. CDR-loader equipped with a quick jump facility (Position

Control Sledge)

9. CD Text input, (album name / artist for disc and per track;

60 char.)

10. Fading in and fading out.

Personal notes

4 2. New in the 3rd Generation sets 3rd Generation

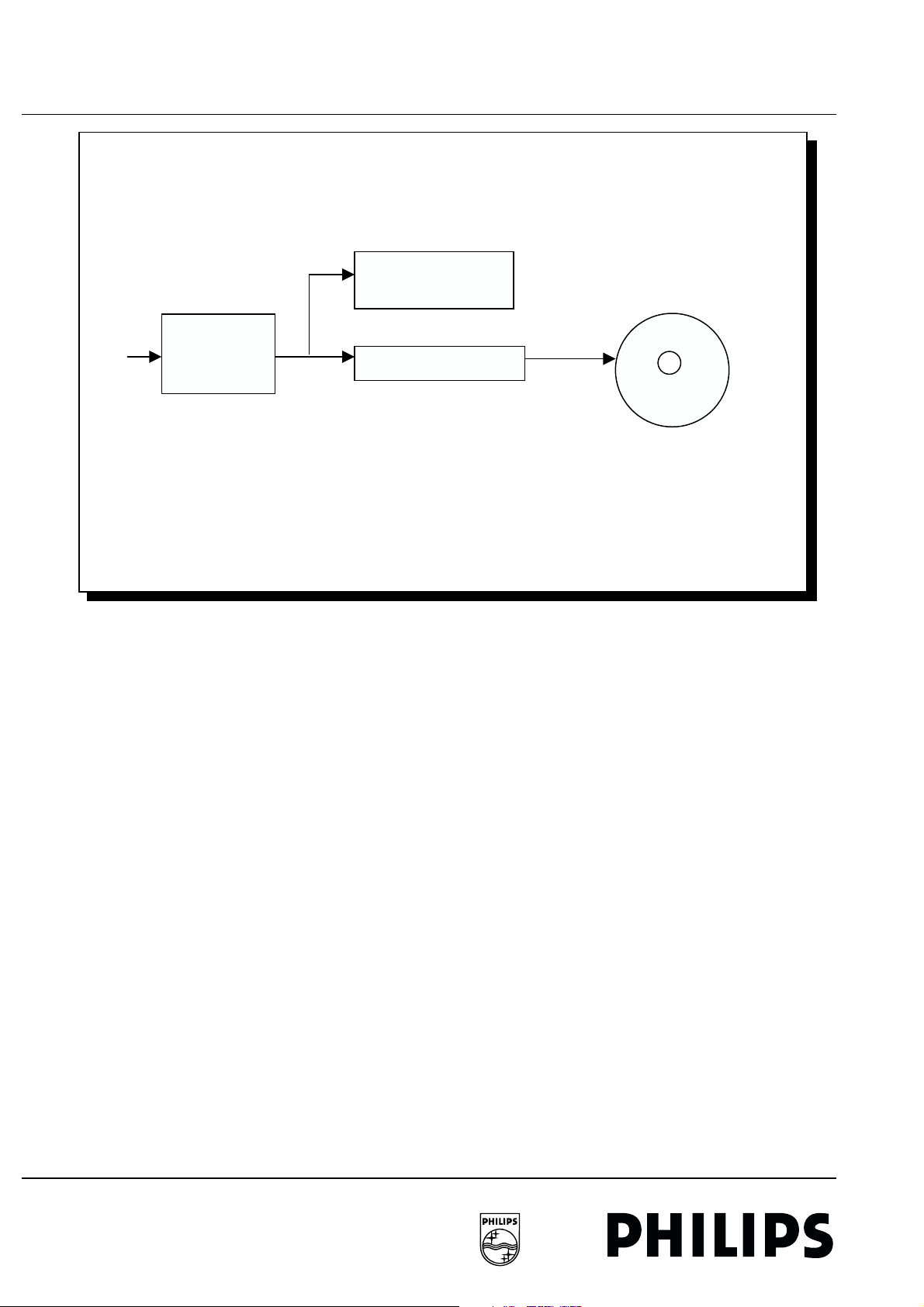

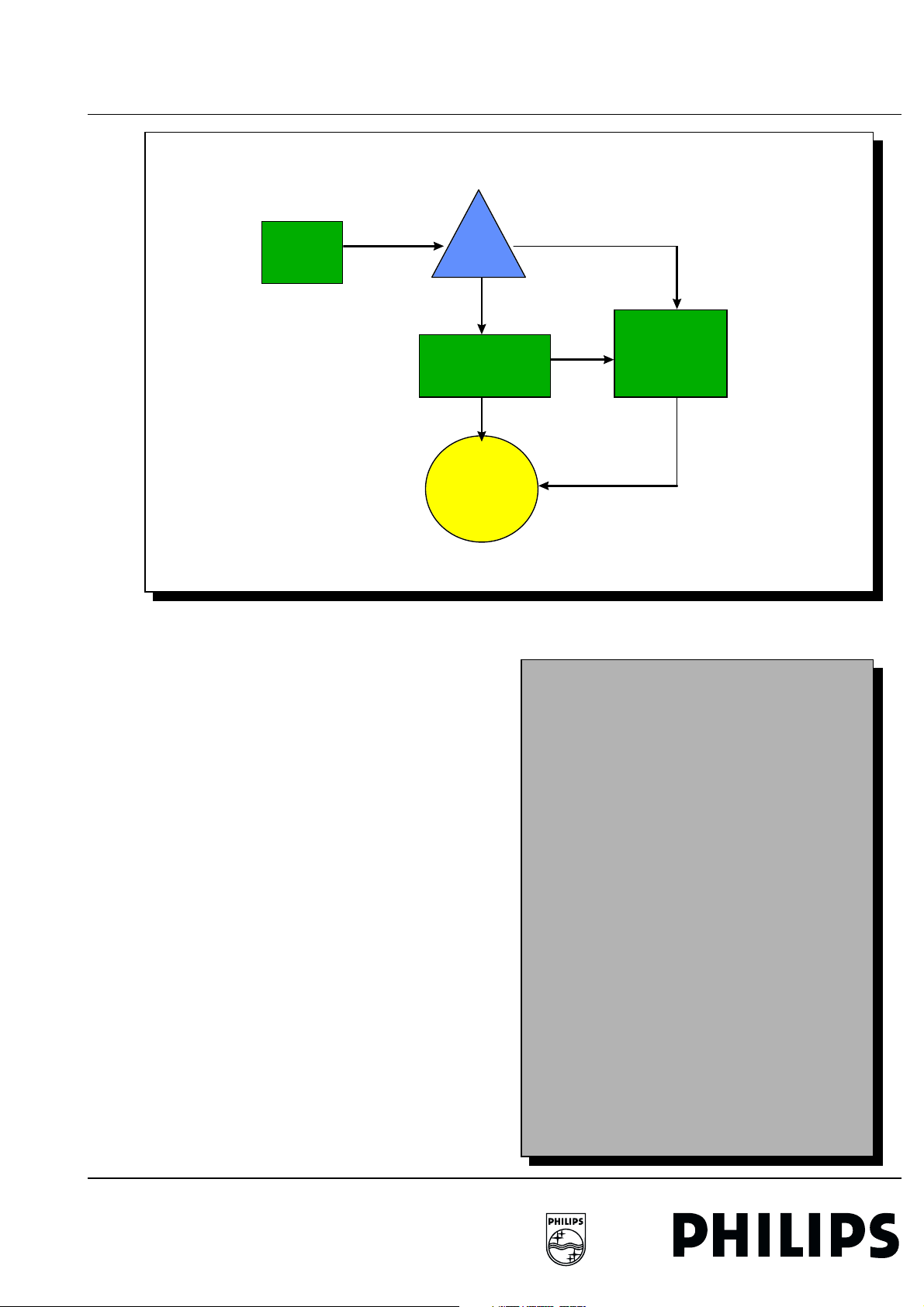

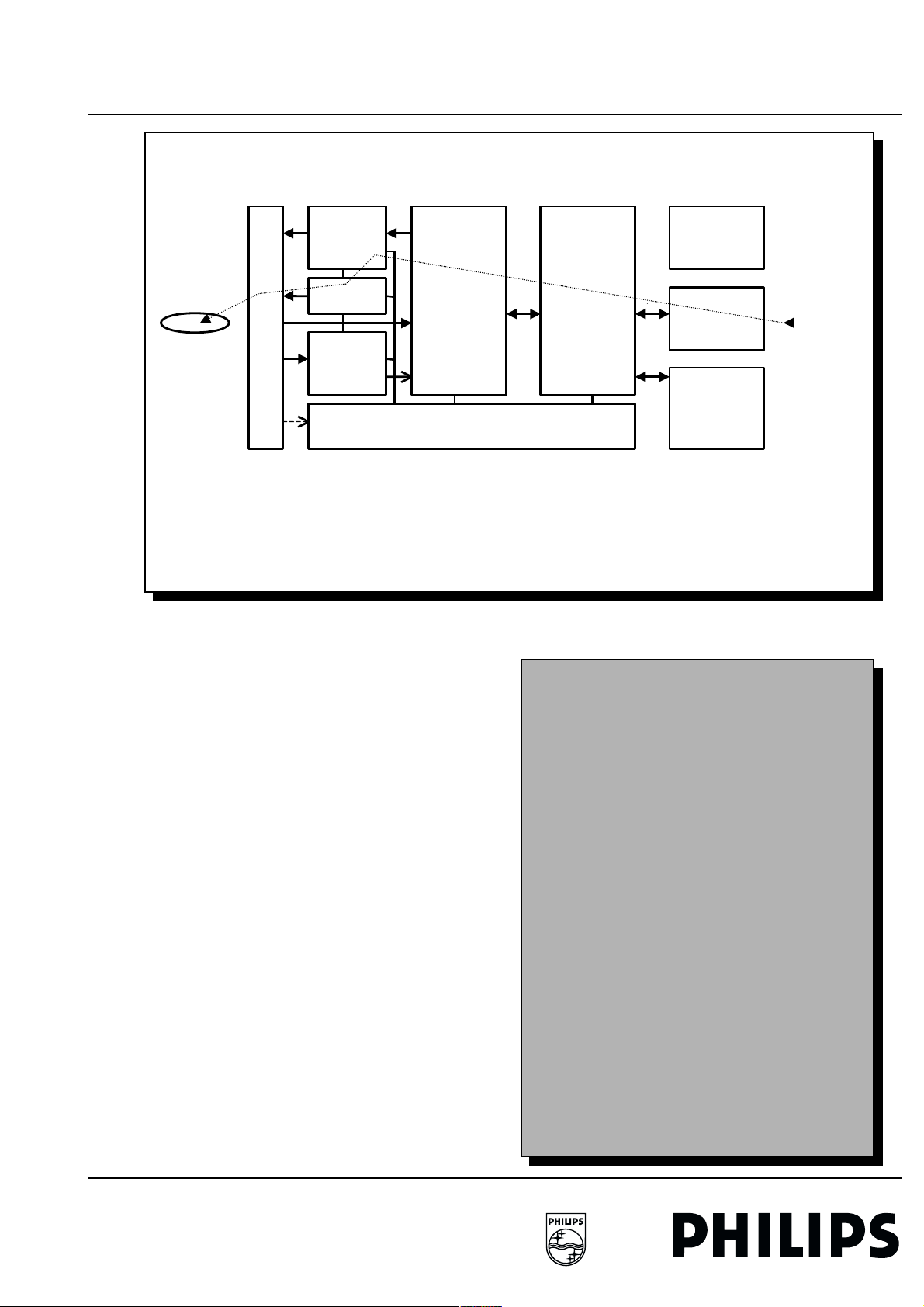

2.1 AUDIO BUFFER

2.1 AUDIO BUFFER

Output Stage

Digital o Analogue

Input Stage

Digital or

Analogue

BUFFER 3 seconds

DISC

The new DASP processing IC plus DRAM makes it possible to

introduce an advanced audio buffer with a capacity of several

seconds (0-3 sec.).

• No loss of music while starting a recording with

synchronised start (CD Sync).

• Synchronised start per track is possible now and also a

programmed disc can be copied in that programmed

following order.

• Perfect positioning when jumping to next / previous track.

Track increment will be positioned in exactly the same

position as the original.

• Synchronised start of analogue input signals is possible

with the application of the audio buffer.

• Better stop behaviour at analogue input signals is possible

by using the audio buffer.

• Recording can be stopped within 3 seconds without

‘damaging’ the CD.

• When entering an SCMS track, no recording will be made

of the first few seconds.

By applying the audio buffer it is possible to make perfect

recordings without any loss of music at the start of a track.

Above that all information available on the original disc will be

duplicated at exact the same spot of the disc to be recorded to.

By using this state-of-the-art technology, a perfect ‘bit-for-bit’

copying technique is applied.

Description of the functioning of the Audio buffer:

The audio (and track information) will pass through an audio

buffer that continuously holds several seconds (0 to 3 seconds)

in memory. In this way the recorder has enough time to

Figure 2-1

CL96532133_002.eps

determine the status of the input signal (music versus no music,

track increment, lead-out etc.), and will start the recording at the

right moment. The music is taken from the buffer.

081199

3rd Generation 2. New in the 3rd Generation sets 5

2.2 Improved STOP modes

2.2 Improved STOP mo des

The first and second generation recorders (without audio

buffer) have difficulties in detecting if the source has stopped.

With the audio buffer this is no longer a problem, and it provides

the opportunity to improve the stop behaviour. So now it is

possible to have perfect stopping of recordings, also when

analogue sources have been used as input.

This means there is no longer a 20 seconds silence at the end

of the recording for detecting the input signal has been stopped.

It also prevents the recorder stopping when the recorded music

contains a very silent passage.

The possibility to stop a recording which has just started (within

3 seconds), without having anything recorded on the (CDR) disc.

It provides the opportunity To be able to record properly from

CD changers

The description of the improved stop mode:

The functioning can be compared with the functioning of the

Audio buffer at recording start. HHowever at the stop mode the

decision is now taken at the input side of the signal. At any

moment there is a signal stop, the contents of the buffer is still

read out and then the recording stops at the correct moment.

Personal notes

6 2. New in the 3rd Generation sets 3rd Generation

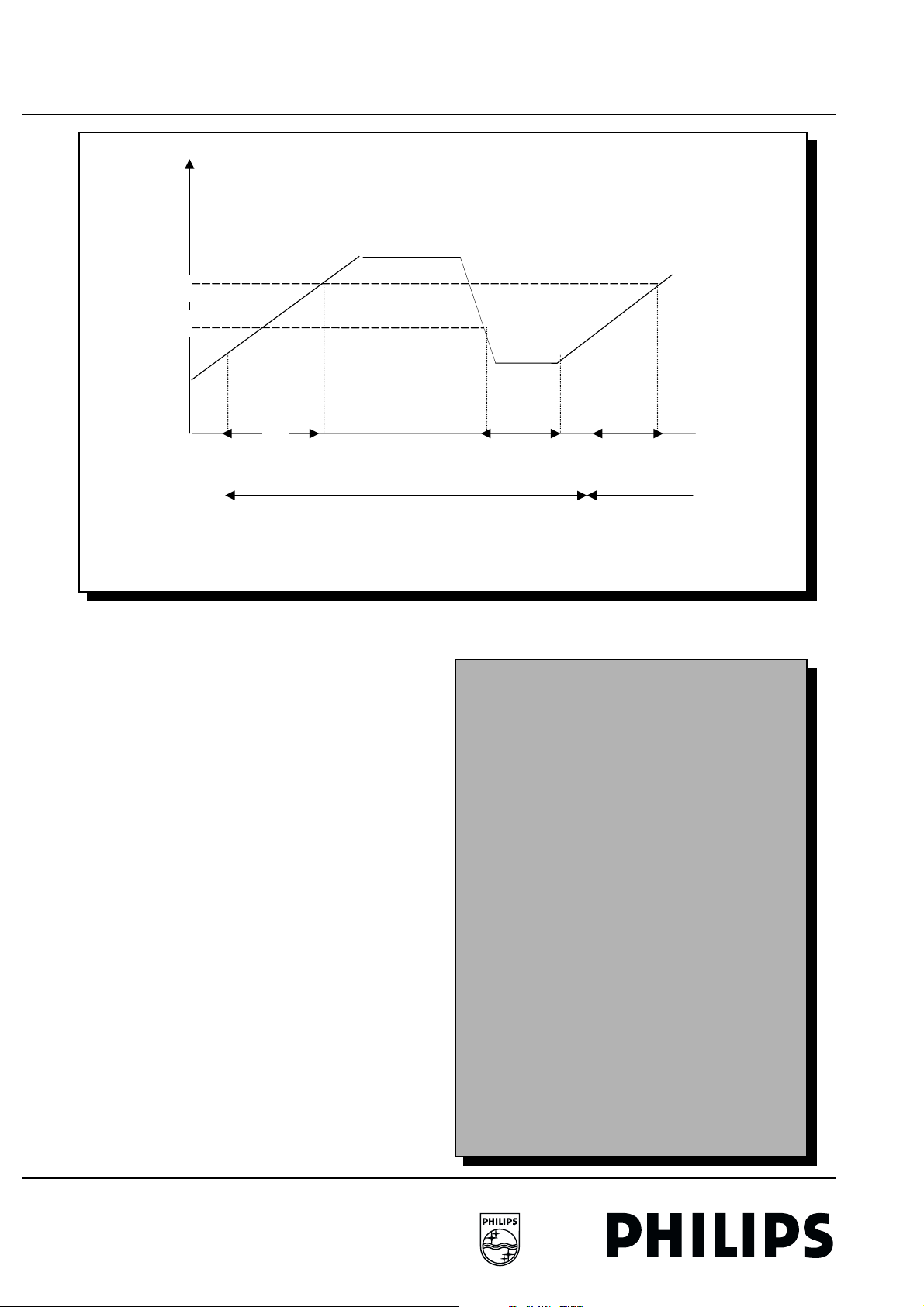

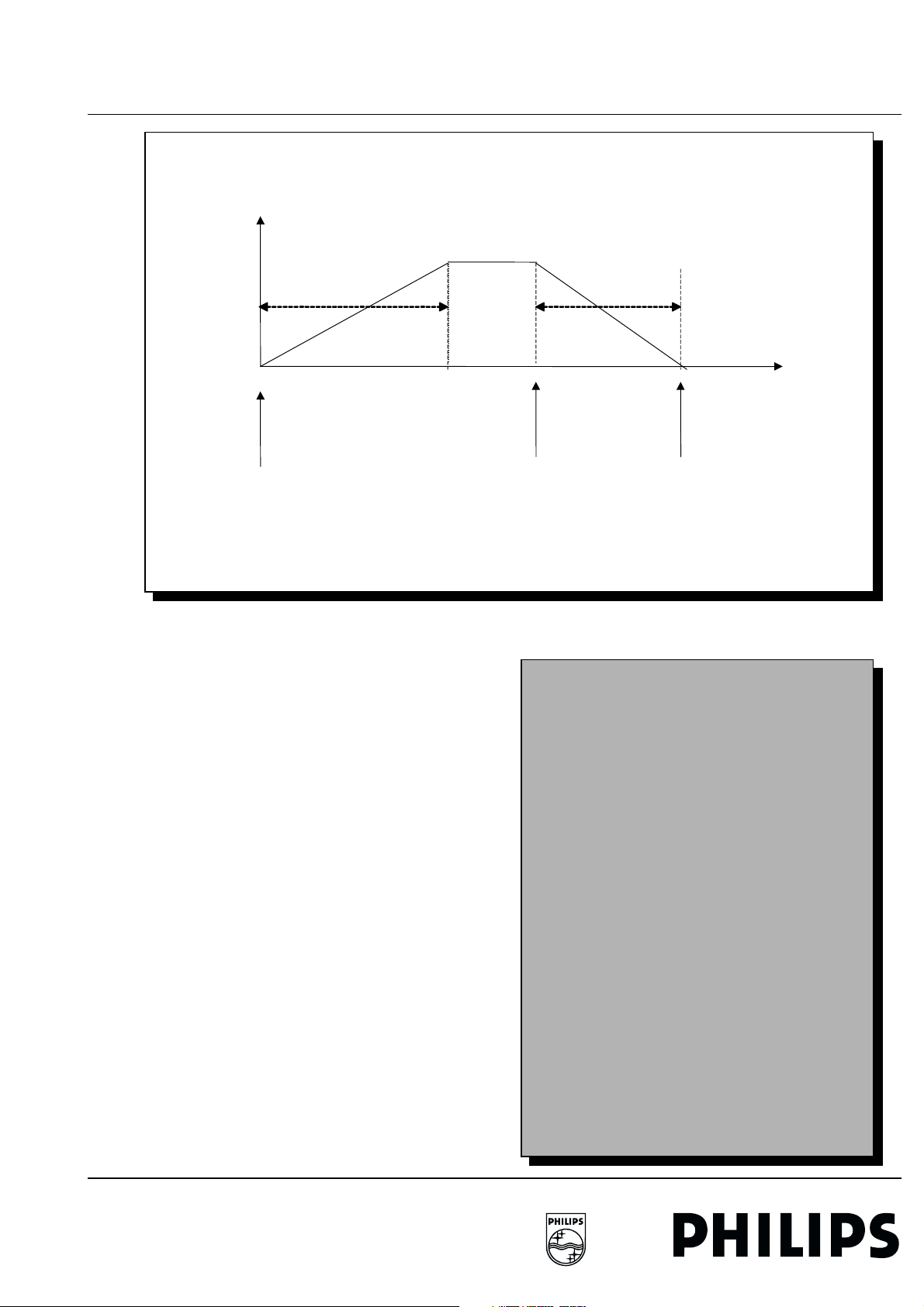

2.3 Analogue CD Sync.

2.3 Analogue CD Sync.

Level

dB

A

B

A

C

0 2 1 3 4 6 5

Track X Track X+1

The synchronised start of a recording ensures that the recorder

will only start when music is detected. This can be done with an

analogue source or a professional (digital) source without

subcode information as input.

Normally the digital information also contains the track start

information. This information is used to start a digital recording.

This kind of information is not available for analogue input

signals. In this case, the input level is continuously measured

with the help of the audio buffer. When the source has started,

the recorder senses a significant change in the input level and

starts recording (input level above -50dB). As the first seconds

are still in memory (audio buffer), the recorder will calculate a

certain period back in time and put this audio data on the disc.

It is called a virtual start point. See next figure.

Explanation :

0 Auto start active

1 Track transition is detected when audio goes above value A

2 The actual recording of the audio track will start at point 2. A

jump backwards is performed in the audio buffer” Time C” .

Virtual start point

3 &4 When audio goes below level B for a time D, a track

increment is detected

5 When audio rises again above value A

6 The recording of the new audio track will start at point 6

Figure 2-2

B

D

Personal notes

C

time

CL96532133_001

081199

3rd Generation 2. New in the 3rd Generation sets 7

2.4 Sample Rate Converter (SRC)

2.4 Sample Rate Convert er (SRC)

Recordings can be made from all kinds of digital sources (with

sampling frequencies from 12 kHz till 56 kHz).

• the sampling rates of the various digital sources are:

–CD44.1 kHz

–MD44.1 kHz

– DAB (Digital audio broadcasting) 32kHz or 48 kHz

– DAT32 kHz or 44.1 kHz or 48 kHz

–DCC44.1 kHz

• When you want to record from a source with a variable

Sample Rate Converter. This input signal should be pitchcontrolled.

The functioning of the Sample Rate Converter:

The input signal is sampled again with a frequency of about 68

MHz and reconstructed to give a signal with a sample

frequency of 44.1 kHz (the CD-sample frequency).

Personal notes

8 2. New in the 3rd Generation sets 3rd Generation

2.5 Direct Line Recording (DLR)

2.5 Direct Line Recording (DL R)

For the perfectionists among audio enthusiasts, Philips has

added a technique to make true ‘bit-for-bit’ recordings from

sources with a Sample Rate Frequency of 44.1 kHz +/- 100

ppm (CD and MD). In first and second generation sets, only the

CDR880 is the CD Recorder from Philips which is equipped

with the high-performance DLR technique. In all third

generation sets DLR is introduced for all models.

For more detailed information, see the below.

Direct Line recording (DLR)

There are two purposes for direct line recording.

The first one is to make a bit-to-bit copy without changing the

bits of the original digital source. Connected to a digital source

of a sample rate from 44.1kHz +/- 100ppm, the machine will

automatically tune his crystal in the same deviation. The speed

of the recorder will follow the speed of the connected source.

Now it is making a direct line recording Bit to Bit copy. This

however has it’s limits. The accuracy of the connected digital

source must be within the range of +/- 100 ppm (parts per

million). If the source exceeds the deviation of +/- 100 ppm, the

recorder will automatically switch over to Sample Rate

Conversion. During a recording it will never change back to

Direct Line Recording to avoid undesirable clicks in the audio

signal.

The second reason is to eliminate the jitter of the incoming

digital source (dejittering) . Imagine the source is within the

standard (44.1 kHz +/-100 ppm) but the deviation is changing

into a very high frequency. This will cause extra jitter in the

write pattern of the recorder. Also the quality of the audio will

be affected by this jitter. To prevent the extra jitter, a dejitter

system has been implemented in key component TDA1373N2.

This converts all jitter coming from the connected digital source

into a maximum of 50 Hz. This gives the benefit that the ‘writing

jitter’ is very stable.

What if you listen to a copy of an original and it occurs that you

hear a difference?

This depends to the quality of your CD player and the quality of

your original disc. The CD recorders from Philips meet the

needs of the standard known as SPDIF (Sony Philips Digital

Input Format) Every player should meet the requirements in the

digital standard norm IEC958 I/II (SPDIF) to safeguard a good

digital copying behaviour.

Personal notes

What is the advantage of DLR?

• A perfect copy of the source material (44.1 kHz), meaning a

true ‘bit-for-bit’ recording.

• It makes a bit-for bit coppy possible for HD- CD Recording

• To avoid digital information being transformed by the

Sample Rate Converter. Elimination of jitter from the

incoming digital source (‘dejittering’). The result is a clear

reproduction of the original material.

3rd Generation 2. New in the 3rd Generation sets 9

y

2.5 Direct Line Recording (DLR)

Source 44. KhZ

Description of the functioning of the Direct Line

Recording:

Yes

Tuneable

Cr

stal

Yes

CDR

Disc

Figure 2-3

No

No

Sample

Rate

Coverter

CL96532133_003.eps

Personal notes

081199

When a signal of 44.1 kHz is detected, the Sample Rate

Converter is by-passed and the digital bitstream is recorded

directly to the destination disc.

To be able to make a ‘bit-for-bit’ copy, it is essential that the

source information flow has the same speed as information flow

to the destination disc.

Therefore the input frequency (speed of the source disc) is

measured. A tuneable crystal accurately controls the speed of

the destination disc and keeps the speed within the limits of

max. +/-100 ppm (parts per million). If the speed deviates too

much, the Sample Rate Converter is activated.

To avoid audio disturbance, the recorder will never switch back

to DLR during a recording.

10 2. New in the 3rd Generation sets 3rd Generation

2.6 HDCD - recording

2.6 HDCD - recording

High-Density Compact Disc (HDCD) is not a 80 minutes disc

and is not a Super Audio CD, but a 16-bit coding system which

is able to replay on normal CD-players at 15-bit level and at

HDCD-players with an inserted filter on the 16th bit, the 15

other bits are decoded into a 20-bit Audio signal. So this HDCD

can replay at 20-bit with concerned signal noise ratio, but is also

backwards compatible on the existing CD-standard.

With a bit-for-bit DLR technology, HDCD-encoded CDs are

recorded in HDCD (High-Density Compact Disc) format. This

means that if you copy an HDCD disc using the digital output of

your CD player, the entire encoding technology is reproduced.

This proves that DLR technology really does make a bit-for-bit

copy of a CD without interrupting the audio data.

CD players with a built-in HDCD filter can playback the higher

sound quality of these discs.

The third generation CD recorders do not have that HDCD-filter

and -encoder built-in. This means that the third generation CD

recorder cannot playback at the HDCD quality of that disc, but

the normal CD Quality.

HDCD uses the same standard as a normal CD. You can play

HDCD discs on any CD player, anywhere in the world

However a HDCD prepared player gives from that HDCD-disc

a 20-bit dynamic range and a more natural instrumental sound.

If you have a CD player with an HDCD filter and DAC, then you

playback the recording with HDCD sound quality.

In short follows the description of the functioning of the HDCD

filter:

Personal notes

Encoding

HDCD converts analogue signals (ADC) first to 192 kHz or

176.4 kHz sampling frequency - with 24bit information. Then,

decimation takes place from 196 kHz / 176.4 kHz through 96

kHz / 88.2 kHz to a 44.1 kHz - 24bit data. After that, HDCD

extended dynamic range encoding is performed, which delivers

a 44.1 kHz - 16bit signal (CD standard).

To allow detection of HDCD afterwards dithering is done which

implements the HDCD detection code.

Dither = An analogue recognition noise is added to the input of

a digital processing or recording chain to reduce the effect of

quantizing error at low level signals. Dither must be added at

the input when digital recording is made.

At decoding the “noise” pattern of the 16th bit is recognised as

a HDCD identification pattern, so HDCD filter is switched on.

This filter converts the other 15 bits in a 20 bit audio data flow.

If at decoding such a HDCD-filter is not effective the remaining

16bits deliver a normal CD-sound.

3rd Generation 2. New in the 3rd Generation sets 11

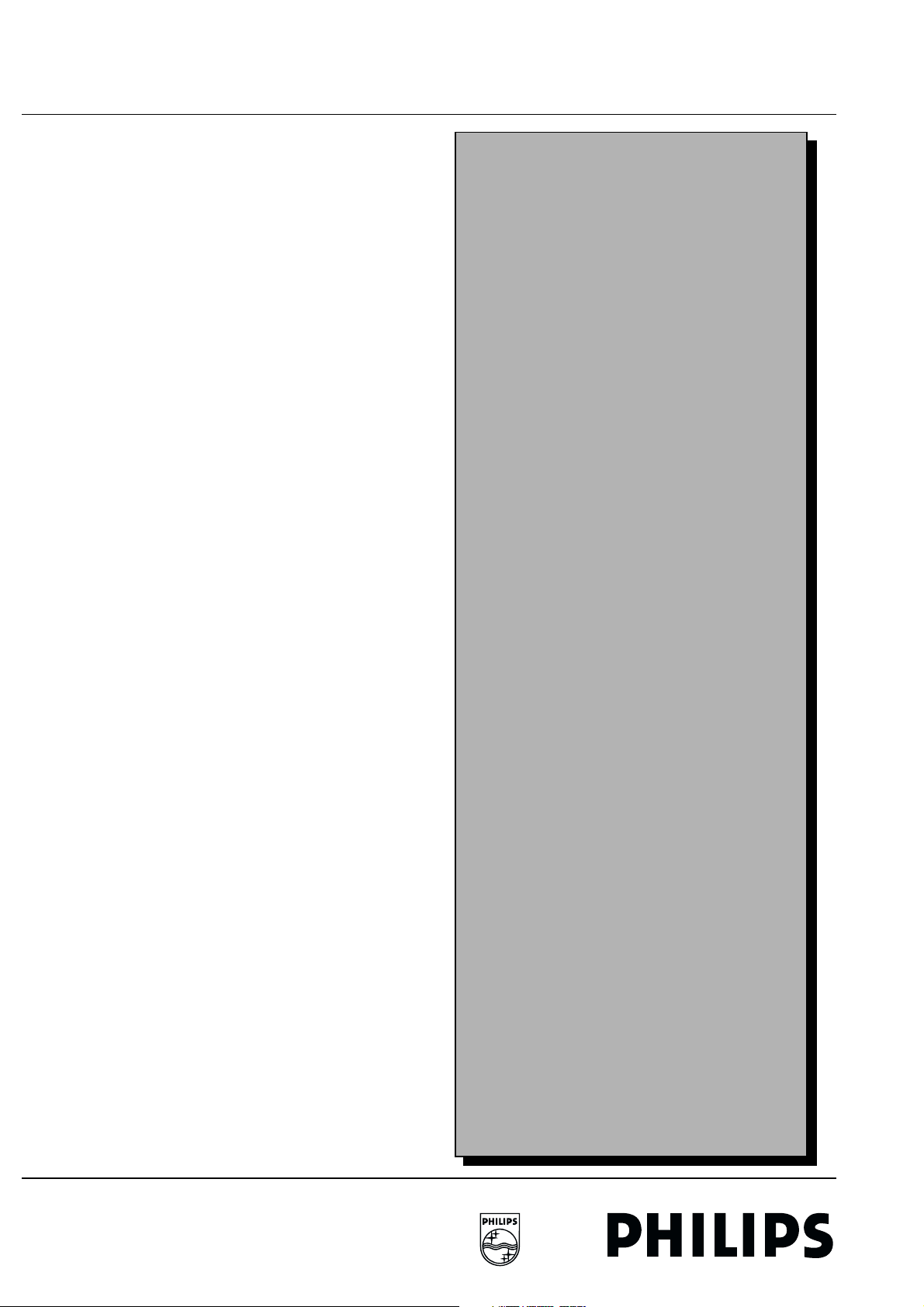

2.7 Easy jog knob

2.7 Easy jog knob

Rotary operation

The easy jog knob incorporates a whole heap of user control

possibilities in just one knob. Without the knob being operated

it will maintain the high level. Turning the knob clockwise briefly

connects pin B to GND followed by pin A. (pin B low level before

pin A) Turning the knob anti-clockwise briefly connects pin A to

GND followed by pin B. The pulses created this way arrive at

the display controller. The first pulse to arrive tells the controller

the direction of the rotation. Counting the pulses reveals the

amount of rotation. Combining and decoding this information,

the display controller will execute the appropriate task.

Pin 1 till 3 of the easy jog is in use for the rotary operation.

CL96532133_006.eps

Figure 2-4

Personal notes

12 2. New in the 3rd Generation sets 3rd Generation

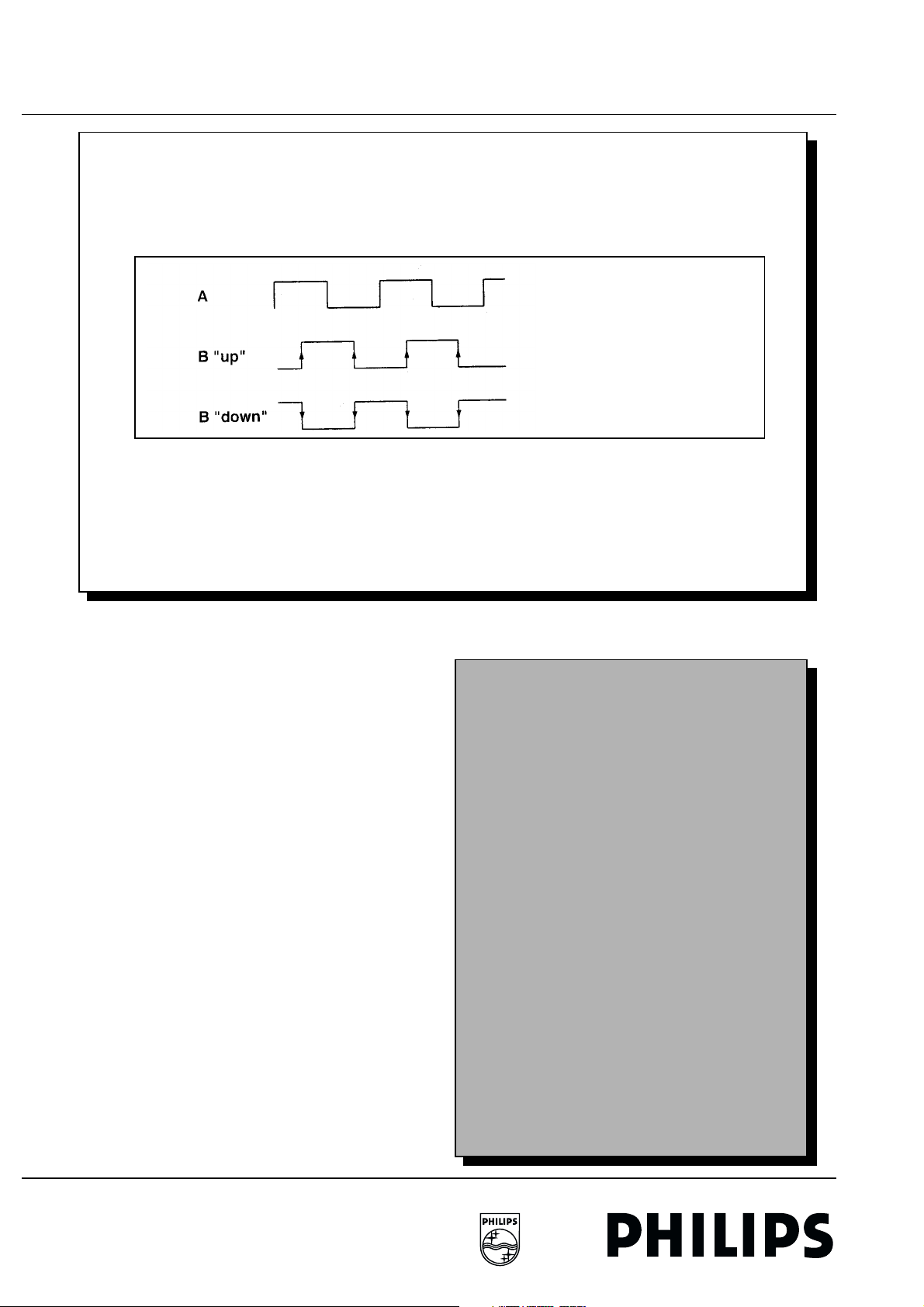

2.7 Easy jog knob

Push button operation

This button of the easy jog knob, is connected to the key matrix

lines and thus the operation is identical to all other displayboard

keys. Without being pressed, pin 4 of the easy jog maintains the

low level, pin 5 the high level. When pressed the scanning

signal goes through the closed contact of pins 4 and 5, and can

be checked at both pins.

Menu and Input level controller

With the easy jog knob functions the user can apply the menu

controller, the input level controller and the next or previous

function All these controls are important. The easy jog, in

particular, makes the controlling of the CD Recorder quicker

and more intuitive by rolling through the tracks of a CD or the

choice and selection of tasks.

Figure 2-5

Personal notes

CL96532133_004.eps

081199

3rd Generation 2. New in the 3rd Generation sets 13

2.8 CDRecorder Loader

2.8 CDRecorder Loader

The new feature in the loader is PCS ( Position Control Sledge)

on the CD Mechanism.

With this servo control system it can jump very quick and

precise to the wanted position on the disc.

Personal notes

14 2. New in the 3rd Generation sets 3rd Generation

2.9 CD Text editing (input, playback)

2.9 CD Text editing (input, playback)

(Notice: CD-text input from original disc and automatically

recorded, is only valid for doubledecks like CDR775!)

The new CD Text feature offers users the option of identifying

the disc while playing. However, creative users will be able to

find several other applications for this feature (e.g. you can give

personal names to songs, or if you have recorded your own

voice the ‘artist name’ can also show the performer’s name).

What can be done with this feature?

– PLAYBACK: Title and artist names of the disc and tracks

appear on the display.

– INPUT: The disc/track titles and artist names can be added

in the stop mode or during recording, independently of the

tracks being recorded.

– RECORDING: In the double decks CD Text recording is

possible. In that set CD Text is copied via an internal

connection from the original, if not protected by the disc

itselves (only valid for doubledecks like: CDR775).

– EDITING: Text can always be edited for a CD-RW disc, and

this can also be done for CD-R as long as the disc is NOT

finalised.

Text input is easy, by using the menu plus the easy jog control

or by using the remote control.

The user can select the album title, artist title, track titles or

track artists to make a text of max. 60 characters. The text will

be stored in the memory of the CD Recorder until the disc is

finalised. During finalising of the disc, the text is written to the

Table Of Contents (TOC).

As long as the disc is not finalised, the user is still able to

change the text (for both CD-R and CD-RW discs!).

For CD-RW discs, the text can always be changed.

CD TEXT MEMORY FULL

Although the memory capacity is more than sufficient, a

MEMORY FULL message may sometimes be displayed. The

user then has two options: either finalise a couple of discs, or

delete the text for some discs. The stored text for every

unfinalised disc can be reviewed or deleted by using the menu

(MEMORY VIEW function).

CD TEXT INPUT

Text input is very flexible and convenient:

The text menu is active in both STOP mode and RECORDING

mode.

– STOP mode: When a CD-R(W) disc with recorded audio

tracks is in the recorder, text for the recorded tracks can be

added.

– RECORDING mode: Text for 99 tracks can be added

completely independently of the track being recorded at that

time. This also applies even if the actual recording has not

(yet) been made. When the recording has stopped, the text

for the recorded audio tracks will be stored. (If auto finalise

was active and the text input menu is still open, the auto

finalise function is disabled.)

TEXT MEMORY / HANDLING

As the CD Text is part of the Table Of Contents, all text will stay

in the CD Recorder’s memory until that disc is finalised. (The

text can therefore still be edited as long as the disc is not

finalised.)

The memory can contain text for approximately 50 discs, each

with 20 tracks. (If only a disc title and artist name is used, text

for more than 100 discs can be stored.)

To prevent users from structurally not finalising discs, the

recorder will show a flashing message ‘UNFINALISED’ every

time the tray opens, together with the percentage of the

memory which is used (TEXT MEMORY xx%).

Personal notes

3rd Generation 2. New in the 3rd Generation sets 15

2.10 Automatic Fade-in / Fade-out

2.10 Automatic Fade-in / Fade-out

0dB

-100dB

Fade In

Value E

Start fad out

Value F

Time

Stop recording

(this key function is only available in CDR950)

Fading makes a smooth start and stop of the audio signal

possible, when recording parts of music. This is a more

sophisticated recording feature.

When user wants to make a recording where the start or end of

the music is not well defined (e.g. a song from a live concert, or

a recording from the radio).

When a recording starts, the signal is automatically ramped-up

to the adjusted recording level. When Stop is pressed, the

signal gradually fades down to silence. This feature, as well as

the start and/or stop time, can be set via the menu option of

CDR950. A label in the display shows that the ‘Fade function’ is

enabled or disabled.

< plaats hier tekening fade.prn >

In all other 3rd generation sets fading in and fading out can be

done manually via the input level adjustment with the easy jog

knob.

Notice: The changed recording level will be kept for all next

recordings! So to be sure for a new recording at 0dB level, first

of all control via easy jog the input recording level. This level is

corrected as well with analogue input signals as digital.

Figure 2-6

Personal notes

CL96532133_005.eps

081199

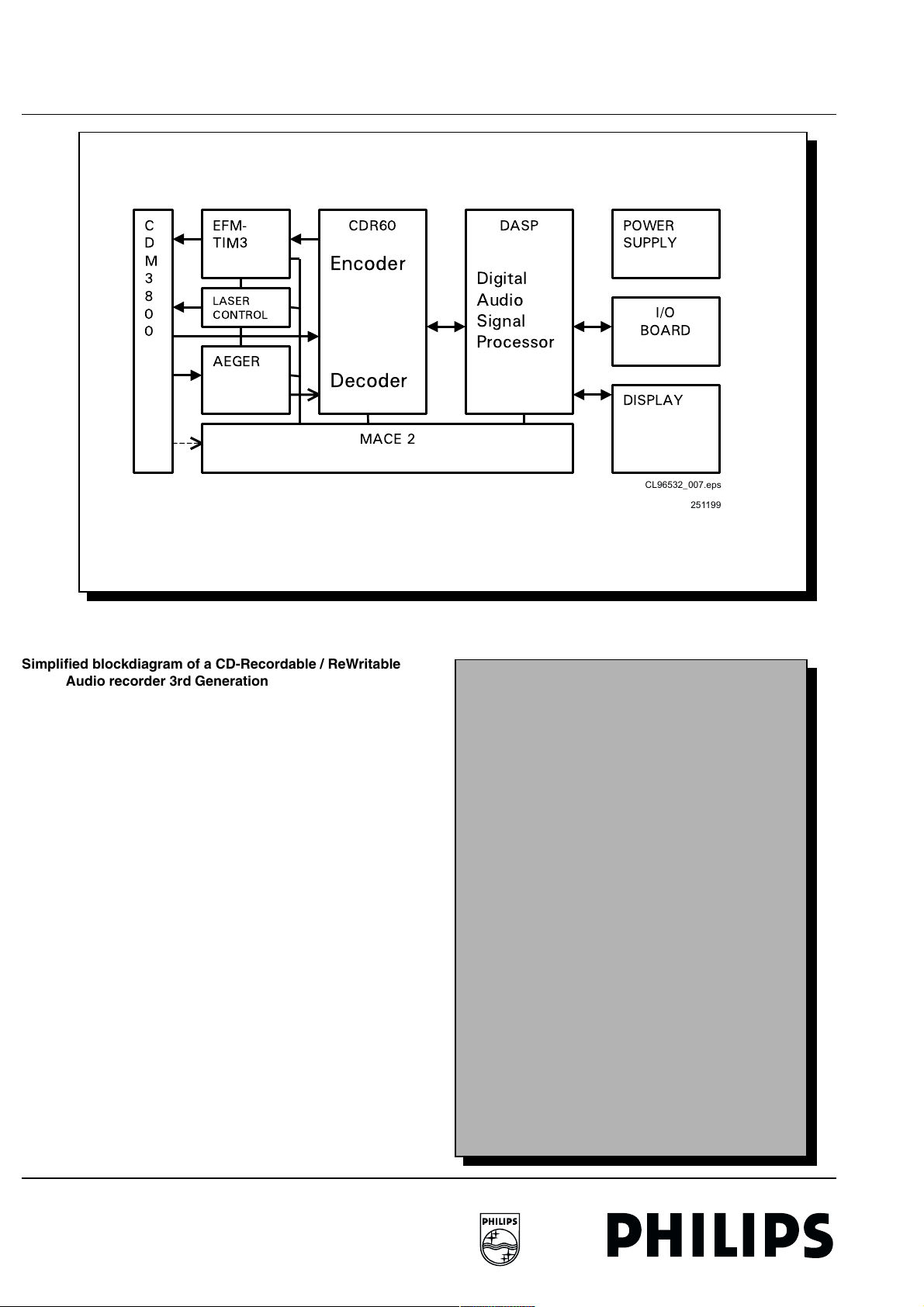

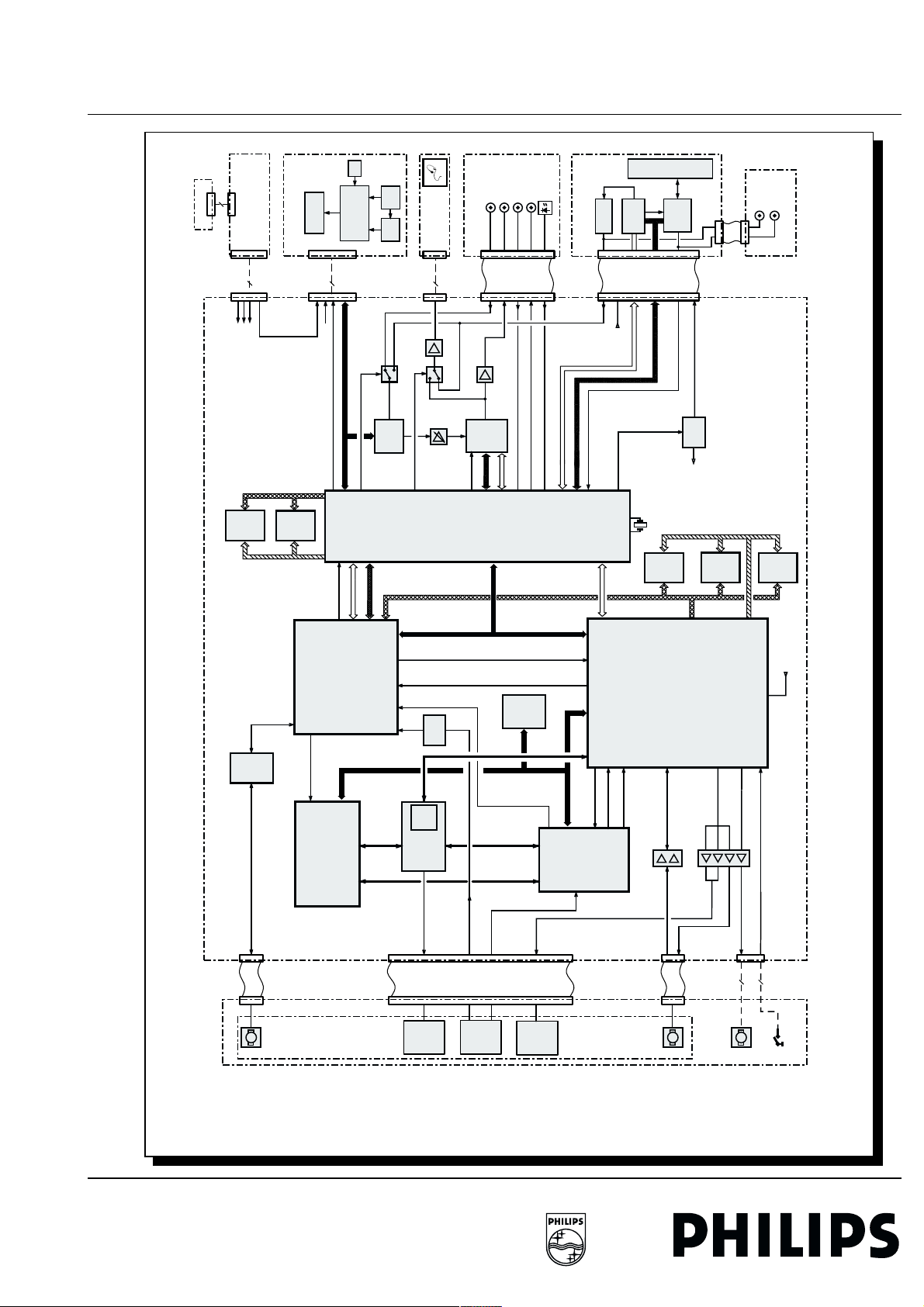

16 3. CD-Recordable/Rewritable Audio Recorder 3rd Generation

3.1 Blockdiagrams

3. CD-Recordable/Rewritable Audi o Recorder3.1Blockd iagrams

C

D

M

3

8

0

0

EFM-

TIM3

LASER

CONTROL

AEGER

CDR60

Encoder

Decoder

MACE 2

Simplified blockdiagram of a CD-Recordable / ReWritable

Audio recorder 3rd Generation

Figure 3-1

DASP

Digital

Audio

Signal

Processor

Personal notes

POWER

SUPPLY

I/O

BOARD

DISPLAY

CL96532_007.eps

251199

3rd Generation 3. CD-Recordable/Rewritable Audio Recorder 17

C

D

M

R

3.1 Blockdiagrams

EFMTIM3

3

8

LASER

CONTROL

CDR60

ENCODER

0

0

AEGE

DECODER

MACE 2

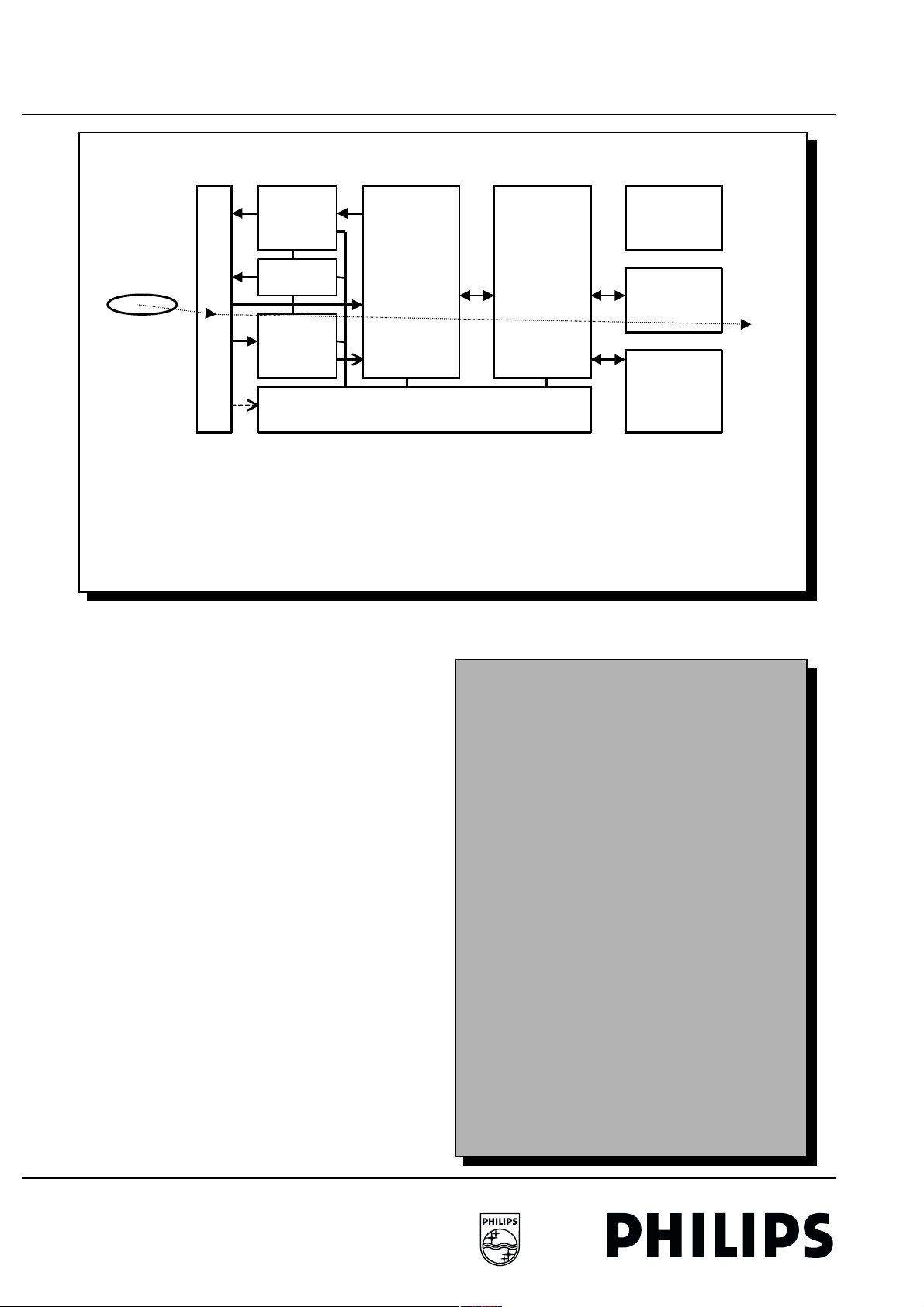

Simplified Recording blockdiagram

The Recording signal in above drawn simplified blockdiagram

is moving according to the following steps.

Starting at input side:

• the input signal at the I/O board is lead to

• the Digital Audio Signal Processor and then to

• the Encoder, from there to

• the EFM timer generator and then the signal is empowered

by

• the Laser Control onto

• the CDM3800 optical pickup unit.

The Compact Disc mechanism writes the EFMcoded

signal onto the disc. This recording process is controlled by

• the Aeger and

•the Mace.

Figure 3-2

DASP

DIGITAL

AUDIO

SOUND

Processor

Personal notes

POWER

SUPPLY

I/O

BOARD

DISPLAY

CL96532133_008.eps

251199

18 3. CD-Recordable/Rewritable Audio Recorder 3rd Generation

3.1 Blockdiagrams

C

D

M

3

8

0

0

EFMTIM3

LASER

CONTROL

AEGER

CDR60

ENCODER

DECODER

MACE 2

Figure 3-3

DASP

DIGITAL

AUDIO

SOUND

Processor

POWER

SUPPLY

I/O

BOARD

DISPLAY

CL96532133_009.eps

251199

Simplified Play-back blockdiagram

Also in Playback mode

• the Aeger and

• Mace will control the reading of the signal on the disc.

The read EFM signal is decoded in

• the Decoder and further processed in

• the Digital Audio Signal processor.

The analogue or digital output of that sound processor is lead

to the

• I/O board.

The MACE processor co-ordinates all activities which are

started by the user via

• the Front Keys and/or IR Remote control signals and the

results are displayed on Display unit. These activities are

processed by a slave microprocessor on the display board

and that slave communicates via the (master) DASP with

the (Basic Engine) Mace microprocessor.

On the next drawing a more extended blockdiagram of the

audio recorder is shown combined with an internal CD-player

(CDR775).

Personal notes

3rd Generation 3. CD-Recordable/Rewritable Audio Recorder 19

1302

ON/OFF

2 WIRES

7703

0206

POWER SUPPLY

0205

11 WIRES

1500

-8V

+5V

+12V

FLASH

ROM

7330

HALL

MOTOR

DRIVE, HALL FEEDBACK

UNIT

VDC1, VDC2, VFTD

DATA

BUS

7702

ADDRESS

BUS

DRIVER

BA6856FP

1113

DISPLAY ASSY

1119

F934

DRAM

7300

CDR60

EFMDATA, EFMCLK, LWRT

7008

EFMTIM3

DISPLAY

SAA7392

LO9805

15-BT-60GNK

10 WIRES

D5V

SYS-RESET

7701

A1 - A20 D16 - D31

EFM TIMING

7104

SLAVE DISPLAY

C BUS

2

I

SUBCODE BUS

DOBM-CDR

DECODER

ENCODER

GENERATOR

1050

EASY

CONTROLLER

TMP87CH74F

EXT-ANA-IN

CD-ANA-OUT

7401

7801

DIGITAL

POT

INT-COPY-ANA

S BUS 1

2

I

MOTOR CONTROL

CONTROL

LINES

CONTROL

LINES

JOG

KEYS

DS1807

SEL-HP-OUT

ATIPSYNC

OFFTRACK

LLP

CDR60PLL

HIN WOBBLE

CONTROL

7016

LINES

HEADPHONE

1400

3 WIRES

1410

7407 7408

ANA-OUT

7405

HF AMP

FILTER

XDAC

M62364

LASER

CONTROL

CD-ANA-OUT

ANALOG

IN

DASP

MCF5244

I/O BOARD

1400 1000

7409

ANALOG

OUT

7406

CODEC

UDA1341TS

S BUS 2/4

2

I

SYS-CLK-11W

DIGITAL AUDIO

SIGNAL

PROCESSOR

CONTROL

EXTERNAL

ANALOG IN

ANALOG OUT

ADC / DAC

L3 BUS

LINES

7207

EXTERNAL

COMMON

FLEX 14P

EXT-DIG-IN

DIGITAL IN

DATA

C

2

I

CONTROL

CONTROL

EXTERNAL

DIGITAL OUT

COMMON

DIG-OUT-C

EXT-OPT-IN

BUS

EEPROM

M24C08

7010

LINES

LINES

OPTICAL IN

DSA-CD

C BUS

2

I

AEGER

TZA1020

7309

CD PLAYER

1208

1708

S BUS 3-CD

2

DOBM-CD

I

7270

ALPHA0

ANALOG

ERROR SIGNAL

GENERATOR

FOR

DAC

UDA1320

SYS-RESET

SYS-CLK-16W (16.9344 Mhz)

DSA-CDR

MACE2

SAA7399

A1, A2, CALF

RECORDABLE

RC5

7207

uP

S87C654

FLEX 22P

1707

33.8688 MHz

7802

TLN, MIRN, FEN, REN, RE

7225

PCS PRE-AMP

NE532D

CD

DRIVE

7000

DECODER

SAA7324

SYS-CLK-8W (8.4672 Mhz)

7706A

/2

74F74D

SYS-CLK-BE

(8.4672 Mhz)

7208

RAM

MAD0 - MAD7

BASIC ENGINE

PROCESSOR

REFSIN, SINPHI, REFCOS, COSPHI

RAD

7240

POWER

DRIVER

BA5938FM

1209

ADDRESS

BUS

FLASH

EPROM

VRA, VFO, VSL

SLEDGE

FOCUS

251199

CD

ANALOG OUTCDDIGITAL OUT

1502

FLEX

7P

CL96532133_010.eps

CD OUT

7209

DEMUX

MA8 - MA17

SYS-CLK-BE

(8.4672 Mhz)

TRAYIN, TRAYOUT

TRAYSWF

TRAY

1330

CDR MAIN BOARD

CDL 4009

LOADER ASSY

CDM3800

OVERALL BLOCK DIAGRAM CDR775

IR, IW, IE

&

FORWARD

SENSE

CAHF

FLEX 30P

PHOTO

1000

FLEX 11P

M

TURN

TABLE

LASER

A1LF, A2LF, B1LF, B2LF

C1LF - C4LF

DIODES

RAD+, RAD-

FOC+, FOC-

RADIAL

FOCUS

SIN+, SIN-

COS+, COS-

1220

SL+, SL-

FLEX 10P

M

SLEDGE

1200

TR+, TR-

2 WIRES

TRAYSW

2 WIRES

M

TRAY

TRAY

SWITCH

Figure 3-4 Overall blockdiagram

20 3. CD-Recordable/Rewritable Audio Recorder 3rd Generation

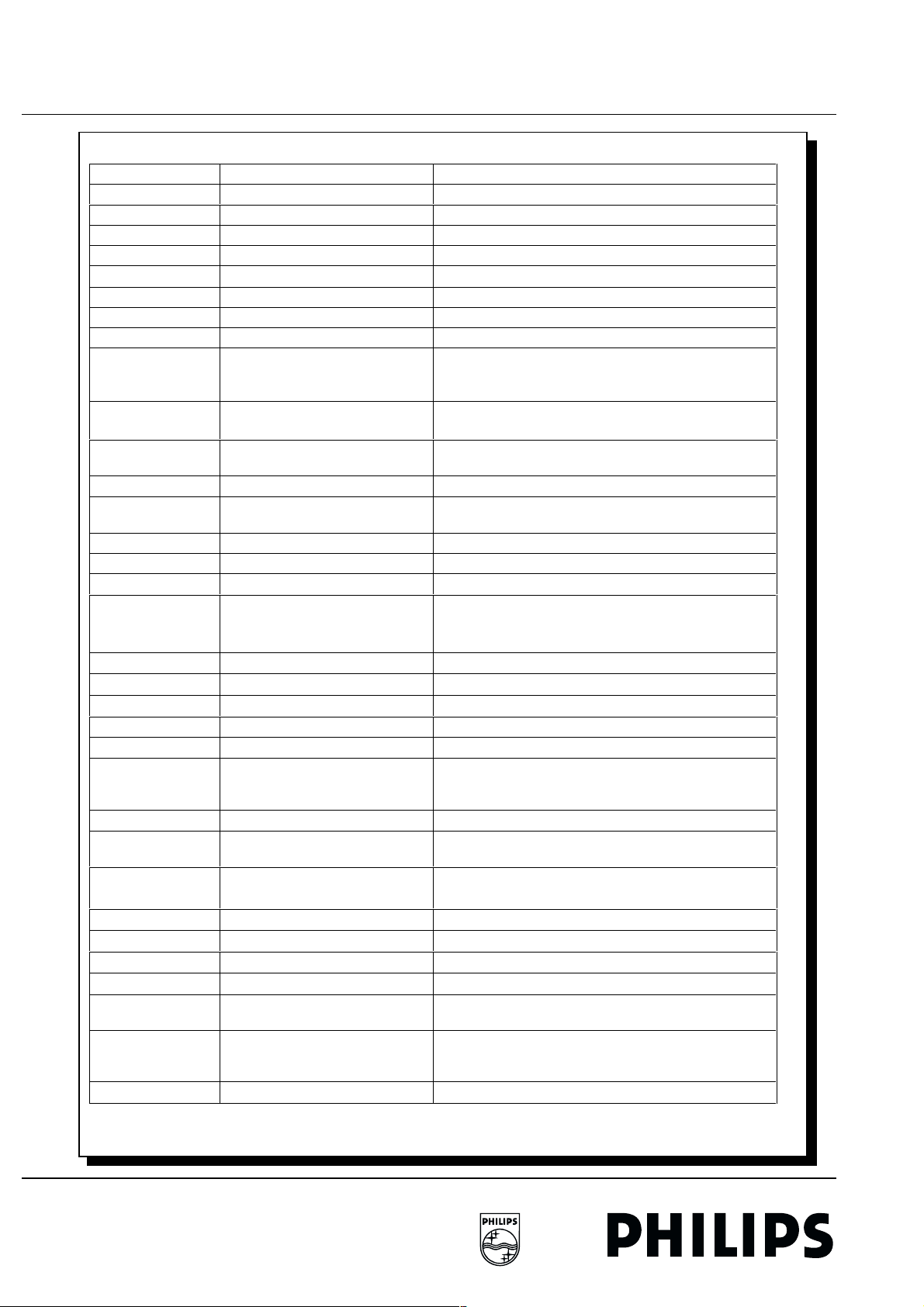

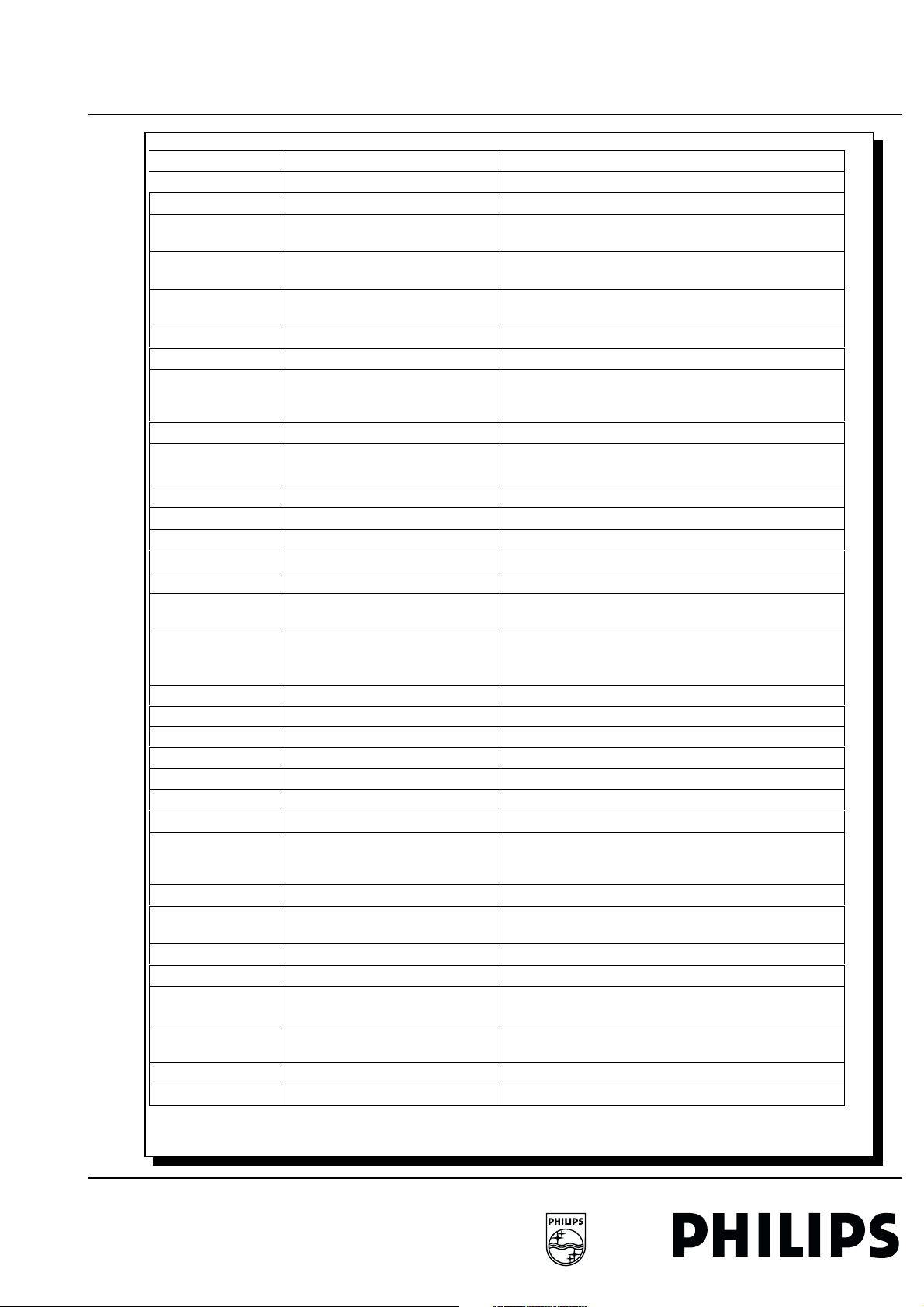

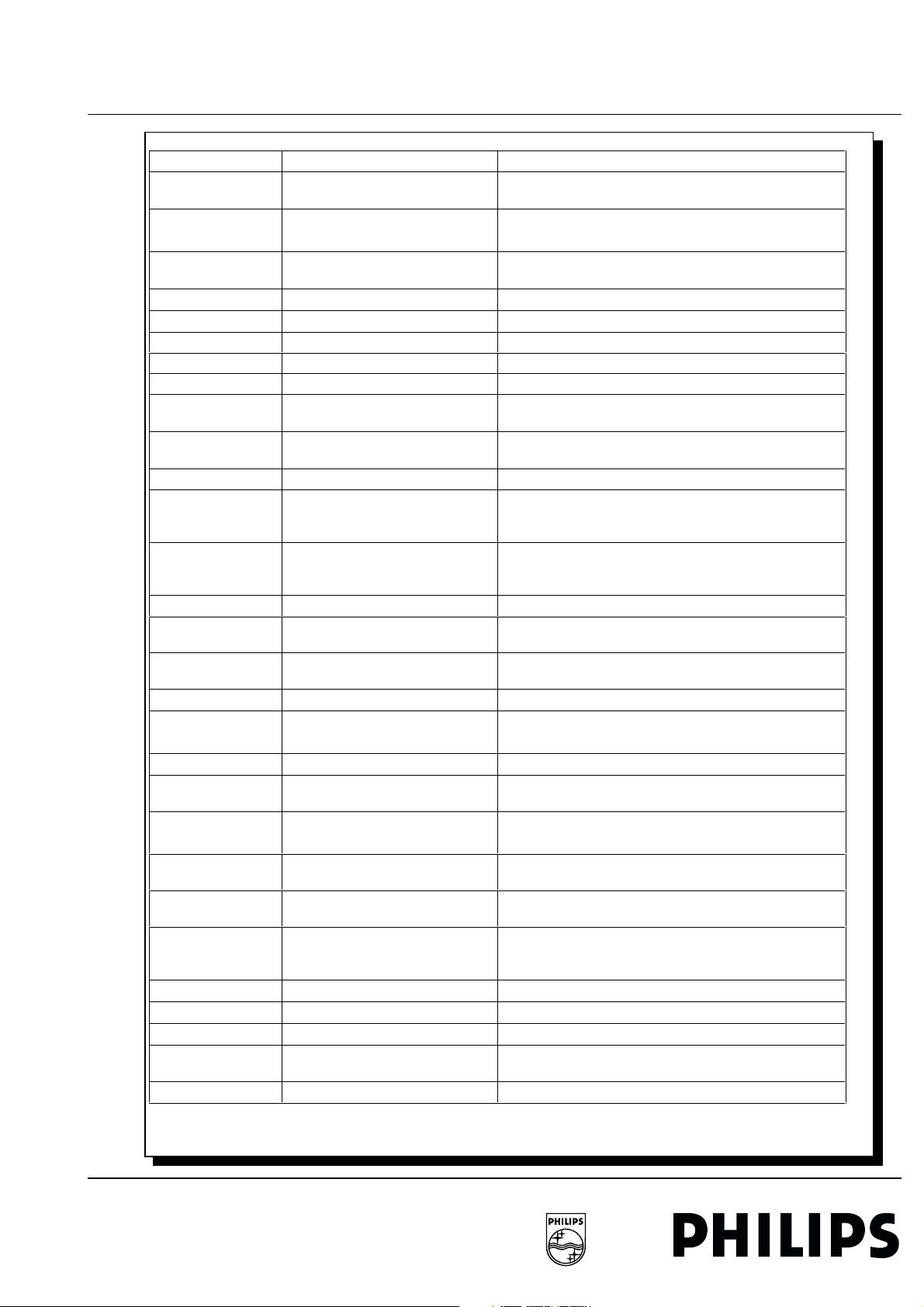

SIGNAL NAME SIGNAL FLOW FUNCTION AND DESCRIPTION

+12V main supply voltage from PSU +12V supply voltage from PSU

+12VA supply voltage +12V supply voltage for Audio part

+5V main supply voltage from PSU +5V supply voltage from PSU

+5VA supply voltage +5V supply voltage for Audio part

+9SRVPWR IC7558 → IC7240 PoWeR supply for SeRVo driver IC

12VPWR supply voltage +12V supply voltage for servo part

-8V main supply voltage from PSU -8V supply voltage from PSU

-8VA supply voltage -8V supply voltage for Audio part

A(1:20) IC7701 → R3818,R3819,

R3820, R3821, R3897

IC7703

A(10:20) IC7701 → R3819, R3820,

R3821 → IC7702

A1

A1LF, A2LF CONN1000 → IC7010 satellite photo diodes A1, A2 current output

A2

A-8V supply voltage -8V supply voltage for servo part

AEGER Analog Error signal GEnerator for Recordable

AINTON

ALE IC7270 → R3213 → IC7209,

ALPHA0 IC7270 → IC7010 analog voltage mode output from OPC D/A converter

ALS IC7008 → IC7010 Alpha Loop Switch (to AEGER)

ASTROBE IC7008 → IC7010 Alpha STROBE (to AEGER)

ATIP Absolute Time In Pre-groove (sync signal)

ATIPSYNC

ATT IC7270 → R3717, R3722

B1LF, B2LF

BCLK IC7701 → R3898A → IC7300 I2S1 BitCLocK from DASP to CDR60 (playback and

BE_RESET

BIASC IC7008 → R3056 BIAS Current switch CDRW output

BKPT CONN1819, R3907 → IC7701 JTAG mode select / debug mode BreaKPoinT

C1LF, .. , C4LF

CAGAIN R3016,R3115 → IC7010 set-point laser power on disc, current input

CAHF CONN1000 → C2374 Central Aperture (central photo diodes) High

CALF IC7010 → IC7270 Central Aperture (central photo diodes) Low-pass

CAS0

IC7010 → IC7270

IC7010 → IC7270

IC7008 → IC7010

IC7300

IC7270 → R3230

IC7300 → IC7270

IC7270 → IC7701

CONN1000 → IC7010

IC7701 → R3261 → IC7270

IC7701 → R3716

CONN1000 → IC7010

IC7701 → IC7702

→

Address lines 1 to 20 between DASP and flash ROM

Address lines 10 to 20 between DASP and DRAM

amplitude of the “land” reflection relative to the

average EFM, voltage output, OPC input

amplitude of the “pit” reflection relative to the average

EFM, voltage output, OPC input

Alpha INTegrator ON (to AEGER)

Address Latch Enable; external address latch strobe

line, freeze address when low

ATIP SYNC signal

ATTenuation request from MACE2 to audio DAC,

active low; means that the output can be attenuated in

case of search activities

satellite photo diodes B1, B2 current output

record)

Basic Engine RESET, active high

Central photo diodes C1, C2, C3, C4 current output

Frequency current output (C1+C2+C3+C4)

Filtered signal (DC coupled EFM signal), voltage

output, OPC input

Column Address Strobe DRAM for upper byte

3rd Generation 3. CD-Recordable/Rewritable Audio Recorder 21

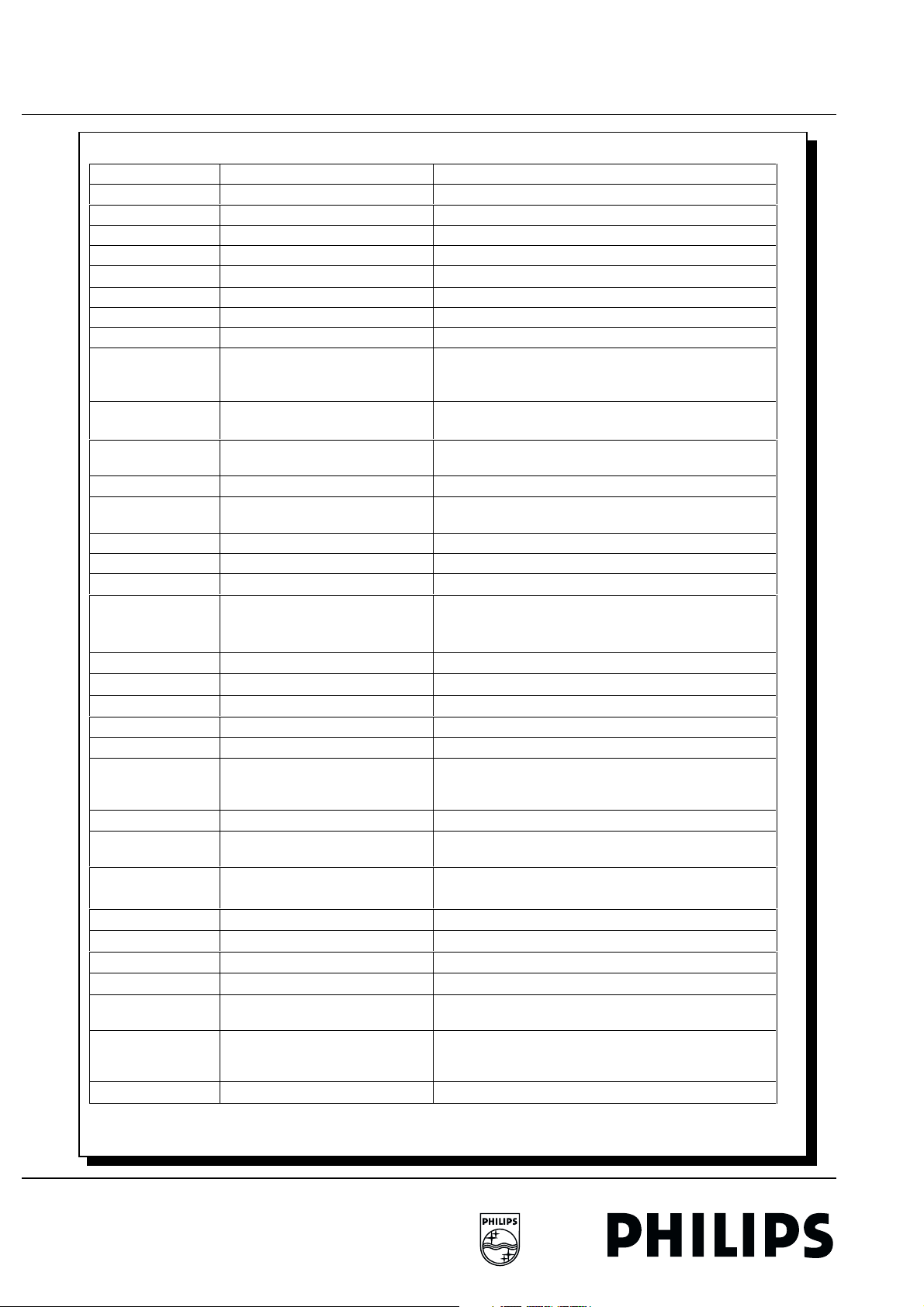

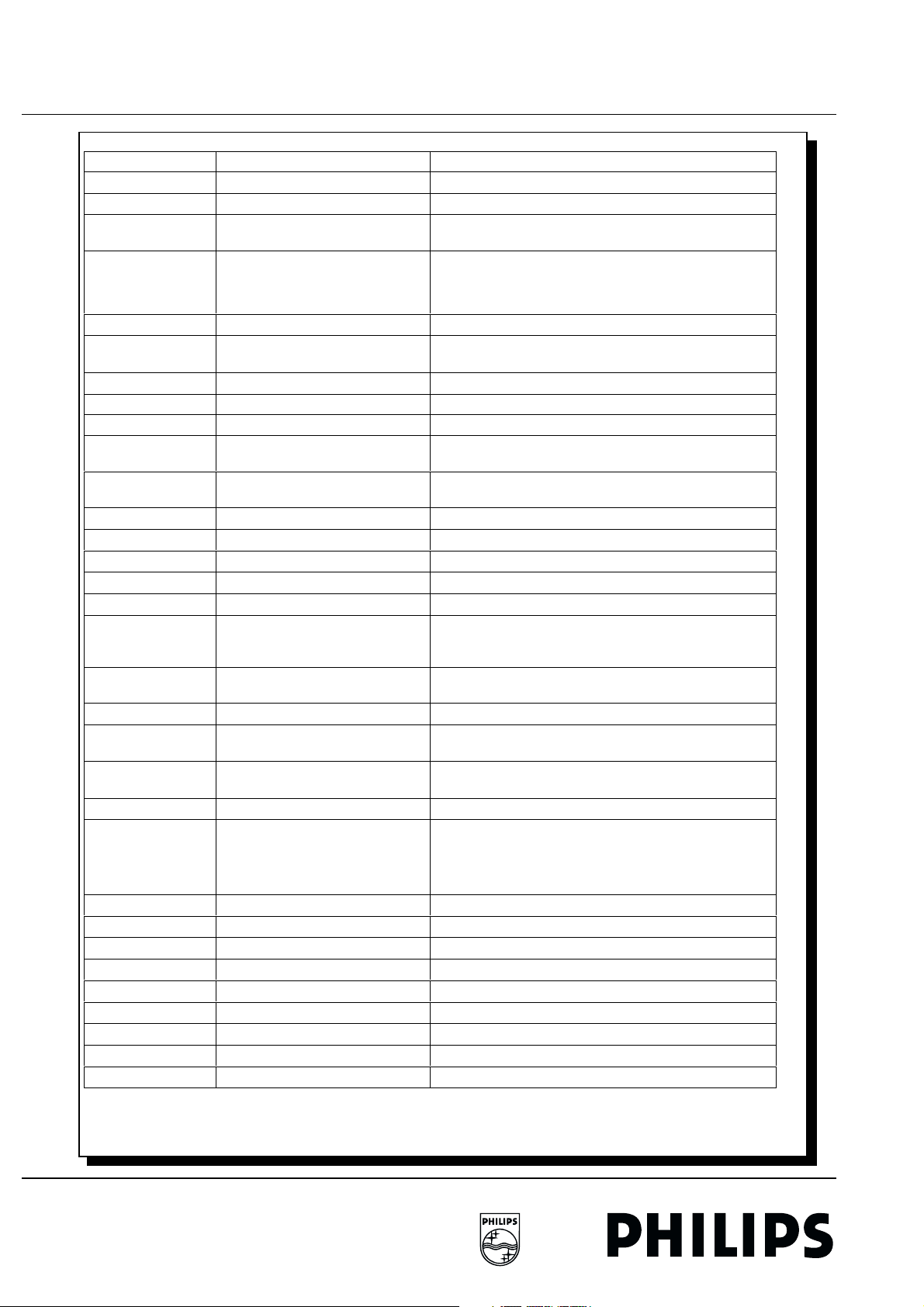

SIGNAL NAME SIGNAL FLOW FUNCTION AND DESCRIPTION

CAS1 IC7701 → IC7702 Column Address Strobe DRAM for lower byte

CDR IC7008 → IC7355 CDR strategy detected output (active high)

CDR60CFLG IC7300 → R3382B

CONN1812

CDR60CL1

CDR60CS

CDR60INT

CDR60LWRT IC7300 → R3048 CDR60 Laser WRiTe control output

CDR60MEAS1 IC7300 → R3382A

CDR60PLL IC7270 → R3305 → IC7300 CDR60 clock multiplier enable, active high

CDRW IC7355D → IC7355C

CLK_OUT IC7701 → R3771 → CONN1819 system CLocK OUT

CLK_SYS

COS- CONN1220 → IC7225B Hall feedback signal from sledge motor

COS+ CONN1220 → IC7225B Hall feedback signal from sledge motor

CSFLASH IC7701 → IC7703 Chip Select for FLASH or boot device

CSRAM

D(16:31) IC7701 ↔ R3822, R3823,

D3V3 supply voltage +3,3V supply voltage for Digital part

D5V supply voltage +5V supply voltage for Digital part

D5VS supply voltage +5V supply voltage for Servo part

DALPHA IC7010 → R3037 ALPHA error signal for laser power control

DASP Digital Audio Signal Processor

DATAI IC7701 → R3898C → IC7300 I2S1 DATA In from DASP to CDR60 (recording)

DATAO IC7300 → R3314 → IC7701 I2S1 DATA Out from CDR60 to DASP (playback)

DEEMP

DELTAP IC7016 → R3126 DELTA Power current source drive signal from XDAC

DIG_OUT_C

DISPLAY_INT

DMON IC7270 → R3324 power save at stop, active low

DOBM_CD CONN1708, C2731 → R3757 →

DOBM_CDR

DRAM_RW

DSA_ACK_CD IC7701 ↔ R3830 ↔ R3831 Data/Strobe/Acknowledge serial communication

IC7300 → R3382C

CONN1812

IC7270 → R3235B → R3702,

IC7300

IC7300 → IC7270

CONN1812

IC7355D → CONN1000

IC7701 → R3727, R3731

IC7270 → R3235A → R3703,

IC7802

R3824, R3825 ↔ IC7703,

IC7702

IC7270 → R3719, R3724

IC7270 → IC7701

IC7701 → R3706 → C2707,

CONN1400

F934 → R3812, IC7701

R3903 → IC7701

IC7300 → R3382D → C2379,

IC7701

IC7701 → IC7702

→

→

→

serial output of error corrector status information of the

CDR60-decoder, to be measured at test connector

output of CLock signal for testing system clock of IC

CDR60 at test connector

CDR60 Chip Select, active high

CDR60 INTerrupt line, active low

serial output of information about jitter, PLL frequency

and asymmetry of bit recovery block in CDR60, to be

measured at test connector

inverted CDR-strategy-detected signal

oscillator output

Chip Select SRAM, active low

Databus bit 16 to 31 between DASP, flash ROM and

DRAM

DE-EMphasis control for audio DAC from MACE2,

active high; means that de-emphasis is needed in

digital filter

Common DIGital OUTput (consumer)

DISPLAY INTerrupt

Digital Output (EBU output) from CD player in

CDR775 to DASP

Digital Output (EBU output) from CDR60 to DASP

Read/Write strobe for DRAM

22 3. CD-Recordable/Rewritable Audio Recorder 3rd Generation

SIGNAL NAME SIGNAL FLOW FUNCTION AND DESCRIPTION

+12V main supply voltage from PSU +12V supply voltage from PSU

+12VA supply voltage +12V supply voltage for Audio part

+5V main supply voltage from PSU +5V supply voltage from PSU

+5VA supply voltage +5V supply voltage for Audio part

+9SRVPWR IC7558 → IC7240 PoWeR supply for SeRVo driver IC

12VPWR supply voltage +12V supply voltage for servo part

-8V main supply voltage from PSU -8V supply voltage from PSU

-8VA supply voltage -8V supply voltage for Audio part

A(1:20) IC7701 → R3818,R3819,

R3820, R3821, R3897

IC7703

A(10:20) IC7701 → R3819, R3820,

R3821 → IC7702

A1

A1LF, A2LF CONN1000 → IC7010 satellite photo diodes A1, A2 current output

A2

A-8V supply voltage -8V supply voltage for servo part

AEGER Analog Error signal GEnerator for Recordable

AINTON

ALE IC7270 → R3213 → IC7209,

ALPHA0 IC7270 → IC7010 analog voltage mode output from OPC D/A converter

ALS IC7008 → IC7010 Alpha Loop Switch (to AEGER)

ASTROBE IC7008 → IC7010 Alpha STROBE (to AEGER)

ATIP Absolute Time In Pre-groove (sync signal)

ATIPSYNC

ATT IC7270 → R3717, R3722

B1LF, B2LF

BCLK IC7701 → R3898A → IC7300 I2S1 BitCLocK from DASP to CDR60 (playback and

BE_RESET

BIASC IC7008 → R3056 BIAS Current switch CDRW output

BKPT CONN1819, R3907 → IC7701 JTAG mode select / debug mode BreaKPoinT

C1LF, .. , C4LF

CAGAIN R3016,R3115 → IC7010 set-point laser power on disc, current input

CAHF CONN1000 → C2374 Central Aperture (central photo diodes) High

CALF IC7010 → IC7270 Central Aperture (central photo diodes) Low-pass

CAS0

IC7010 → IC7270

IC7010 → IC7270

IC7008 → IC7010

IC7300

IC7270 → R3230

IC7300 → IC7270

IC7270 → IC7701

CONN1000 → IC7010

IC7701 → R3261 → IC7270

IC7701 → R3716

CONN1000 → IC7010

IC7701 → IC7702

→

Address lines 1 to 20 between DASP and flash ROM

Address lines 10 to 20 between DASP and DRAM

amplitude of the “land” reflection relative to the

average EFM, voltage output, OPC input

amplitude of the “pit” reflection relative to the average

EFM, voltage output, OPC input

Alpha INTegrator ON (to AEGER)

Address Latch Enable; external address latch strobe

line, freeze address when low

ATIP SYNC signal

ATTenuation request from MACE2 to audio DAC,

active low; means that the output can be attenuated in

case of search activities

satellite photo diodes B1, B2 current output

record)

Basic Engine RESET, active high

Central photo diodes C1, C2, C3, C4 current output

Frequency current output (C1+C2+C3+C4)

Filtered signal (DC coupled EFM signal), voltage

output, OPC input

Column Address Strobe DRAM for upper byte

3rd Generation 3. CD-Recordable/Rewritable Audio Recorder 23

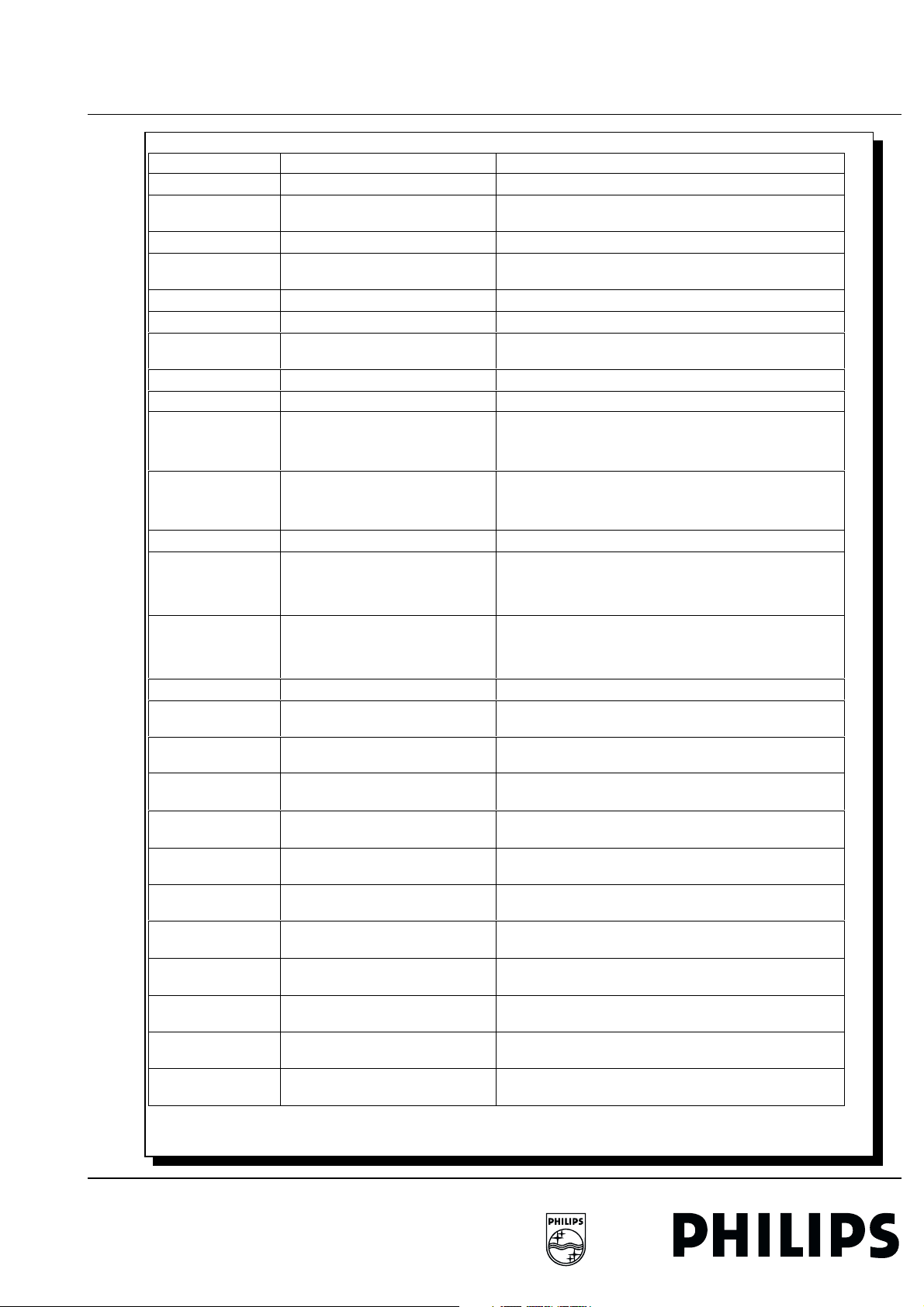

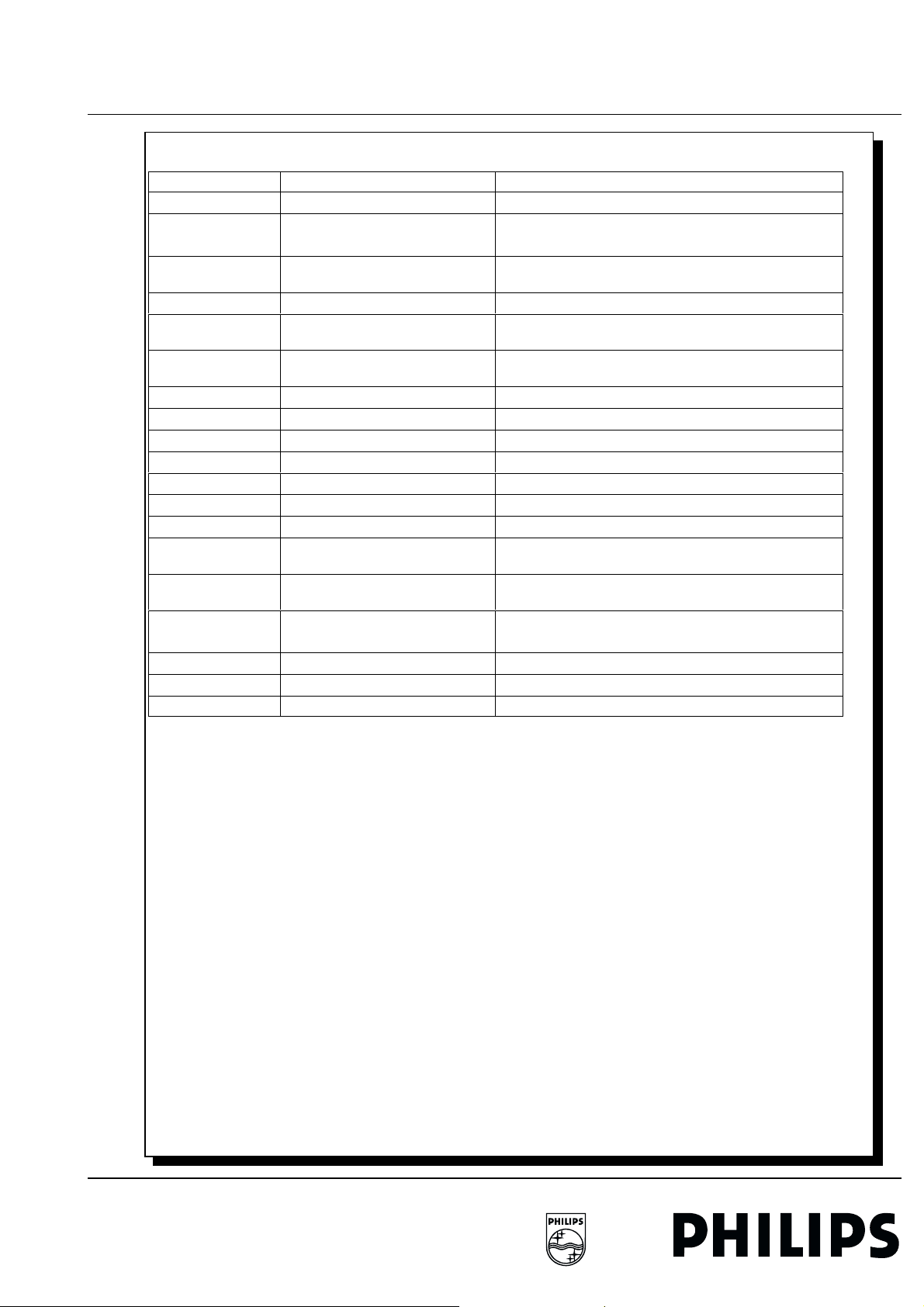

SIGNAL NAME SIGNAL FLOW FUNCTION AND DESCRIPTION

FSON IC7008 → R3051 Forward Sense photo diode sampling ON

FSR R3040 → IC7270 Forward Sense signal while Reading for read control

loop

FSRS IC7008 → IC7126D Forward Sense photo diode Read Sampling

FSW R3050 → IC7270 Forward Sense signal while Writing for write control

loop

FSWS IC7008 → IC7126C Forward Sense photo diode Write Sampling

FWEN IC7270 → IC7208, R3806 Flash EPROM Write ENable

HALL_U, HALL_V,

IC7330 → IC7300, CONN1812

HALL_W

HFS0 IC7270 → R3249 → IC7360 select HF circuit

I2C Inter IC

I2C_CLK

IC7701, R3711 → R3715

C2709 → F934

IC7701, R3711 → IC7801

I2C_DATA IC7701, R3712 ↔ R3713

C2708, R3714 ↔ F934

IC7701, R3712 ↔ IC7801

I2CL

R3248B → IC7207, R3247C

I2CSCL IC7207 → IC7008

IC7207 → IC7010

IC7207 → R3248B

I2CSDA IC7207 ↔ IC7008

IC7207 ↔ IC7010

IC7207 ↔ R3248A

I2DA

R3248A ↔ IC7270,R3247D

I2S_BCLK_AI IC7701 → R3814 → IC7406 I2S4 Bit CLocK for CODEC (ADC for CDR950) Analog

I2S_BCLK_AO

I2S_BCLK_CD

IC7701 → R3894A → IC7406

CONN1708, C2739 → R3834

IC7701

I2S_BCLK_MIC

CONN1708, C2739 → R3834

IC7701

I2S_DATA_AI

I2S_DATA_AO

IC7406 → IC7701

IC7701 → R3894C → IC7406

I2S_DATA_CD CONN1708, C2738 → R3836 →

IC7701

I2S_DATA_MIC CONN1708, C2738 → R3836 →

IC7701

I2S_WS_AI

IC7701 → R3743 → IC7406

I2S_WS_AO IC7701 → R3894B → IC7406 I2S2 Word CLocK for CODEC (DAC for CDR950)

I2S_WS_CD CONN1708, C2740 → R3833 →

IC7701

HALL feedback signals from turn table motor via hall

motor driver

I2C CLocK line used for display slave processor and

→

digital potmeter

↔

I2C DATA line used for display slave processor and

digital potmeter

I2C CLock line

I2C Serial CLock line

I2C Serial DAta line

I2C DAta line

Input (record from analog source)

I2S2 Bit CLocK for CODEC (DAC for CDR950) Analog

Output

I2S3 Bit CLocK from CD player (record n=2) (CDR775

→

only)

I2S3 Bit CLocK from MICrophone (CDR950 only)

→

I2S4 DATA from CODEC (ADC for CDR950) Analog

Input (record from analog source)

I2S2 DATA for CODEC (DAC for CDR950) Analog

Output

2

S3 DATA from CD player (record n=2) (CDR775

I

only)

2

S3 DATA from MICrophone (CDR950 only)

I

I2S4 Word CLocK for CODEC (ADC for CDR950)

Analog Input (record from analog source)

Analog Output

2

S3 Word CLocK from CD player (record n=2)

I

(CDR775 only)

24 3. CD-Recordable/Rewritable Audio Recorder 3rd Generation

SIGNAL NAME SIGNAL FLOW FUNCTION AND DESCRIPTION

I2S_WS_MIC CONN1708, C2740 → R3833

IC7701

I2S1_MS IC7270 → R3910, IC7701 I2S1 Master-Slave interrupt from MACE2

IE T7121 → CONN1000 laser Erase drive current signal

INT_COPY_ANA

IR T7135 → CONN1000

IW T7122 → CONN1000

KEY_PRESSED

KILL T7560, T7561, R3560

KILL_OUT IC7701 → R3532 disables the KILL activity from the PSU; 1 = no kill,

L12V supply voltage +12V supply voltage for servo/Laser part

L3_CLK IC7701 → R3725 → IC7406 L3 interface CLocK line / control CODEC (not for

L3_DATA

L3_MODE IC7701 → R3735 → IC7406 L3 interface MODE line selects data or address

L5V supply voltage +5V supply voltage for servo/Laser part

L-5V supply voltage -5V supply voltage for servo/Laser part

LASCK

LASDACCK R3248D ↔ IC7016 ClocK line DAC LASer control

LASDACDI R3248C ↔ IC7016 Data line DAC LASer control

LASDACLD R3212 ↔ IC7016 LoaD line DAC LASer control

LASDD

LASLD IC7270 ↔ R3238 ↔ R3212

LEFT CONN1708, C2743 → IC7401C,

LLP IC7270 → IC7300 Laser Low Power (active high), switches the laser from

LWRT R3048 → IC7008 Laser WRiTe control input

MA(16:17) IC7270 ↔ IC7208 bank switch higher address lines

MA(8:15)

MACE2 Mini All Cd Engine (minus decoder + OPC + PCS +

MAD(0:7)

MIRN IC7010 → IC7270 MIRror Normalized (disc reflection) current output

MOTO1 IC7300 → IC7355A turn table MOTOr control output

IC7701 → R3721 → IC7401

IC7701 → R3721 → R3410

T7135 → R3056

T7135 → IC7008

T7122 → D6003

IC7706B → R3816 → IC7701

→

CONN1400, R3424, R3428

IC7701 ↔ R3728 ↔ IC7406

IC7270 ↔ R3248D

IC7270 ↔ R3248C

IC7270 ↔ R3232

IC7407C

IC7270 ↔ IC7802 ↔ IC7208

IC7270 ↔ IC7209 ↔ IC7802 ↔

IC7208 ↔ IC7300

→

I2S3 Word CLocK from MICrophone (CDR950 only)

select INTernal COPY ANAlog (in case of copy

protected disc or track on CD drive) (CDR775 only)

laser Read drive current signal

laser Write drive current signal

KEY PRESSED interrupt

KILL signal from power supply part to audio outputs

0 = kill active

CDR950)

L3 interface DATA line with CODEC (not for CDR950)

transfer mode for CODEC (not for CDR950)

ClocK line DAC LASer control

Data line DAC LASer control

LoaD line DAC LASer control

audio output LEFT channel from CD-player in CDR775

write to read power whenever the device tends to go

offtrack

address bus high byte

extra RAM)

bi-directional data bus / address bus low byte

3rd Generation 3. CD-Recordable/Rewritable Audio Recorder 25

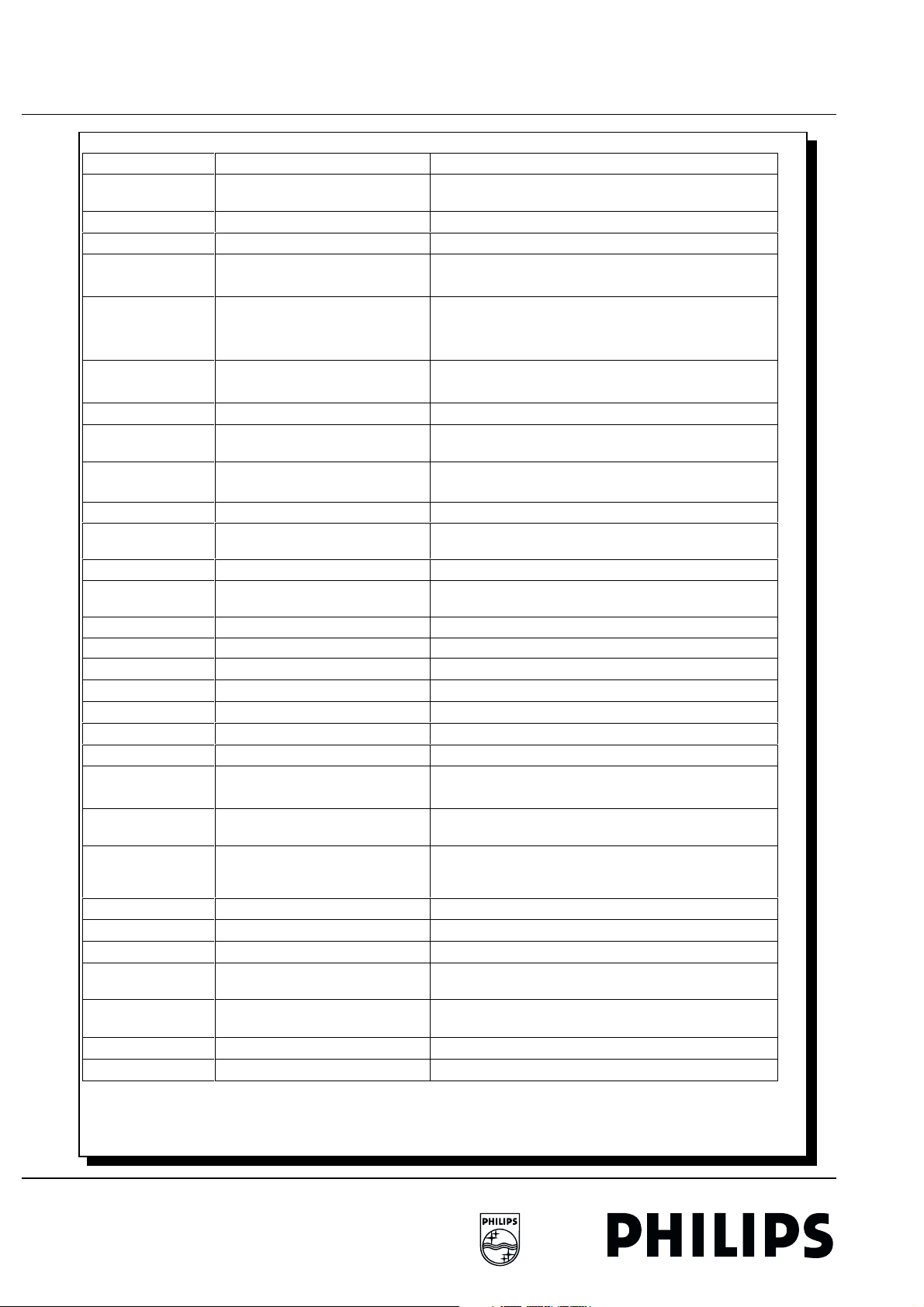

SIGNAL NAME SIGNAL FLOW FUNCTION AND DESCRIPTION

MRDN IC7270 → R3276 → R3242A,

IC7802, IC7300

MUTE IC7270 → R3718, R3723

IC7270 → IC7701

MWRN IC7270 → R3280 → R3242B,

IC7802, IC7300

NMUTE IC7701 → R3726, IC7406 MUTE output, low active

OFFTRACK

OPC Optimum Power Calibration

P12VKILL supply voltage +12V supply voltage for KILL-circuit

PCS Position Control Sledge

PCSCOS IC7225B, C2229 → IC7270,

PCSSIN IC7225A, C2227 → IC7270,

PDAR Photo Diode Amplifier Recordable

PERASE R3036, R3031, R3030, R3029,

POWER_UP IC7270 → R3243C,R3556,

PPN

PRCOARSE IC7016 → R3057 drive signal from Power Read COARSE DAC for read

PRFINE

PROF_EBU

PSENn IC7270 → R3260 → IC7208

PW R3081 → IC7008 Write Power signal to OPC input of MACE2

PWB IC7001C → IC7016 drive signal to XDAC's for write and erase current

PWD IC7016 → IC7002B

PWMAX

PWMIN IC7016 → R3072 PW MINimum signal from DAC used for determining

PWRITE R3035, R3026, R3025, R3024,

RAD- IC7240 → CONN1000 Radial actuator drive signal negative connection

RAD+ IC7240 → CONN1000 Radial actuator drive signal positive connection

RAS0

RCK IC7300 → R3319 → IC7701 EIAJ subcode clock from CDR60 to DASP (CD text

RDGAIN1

IC7270 → IC7300

CONN1812

CONN1812

R3028, R3027, R3020

IC7002C, R3043, T7113

R3538

IC7010 → IC7050C

IC7016 → R3058

IC7701 → CONN1820

IC7270 → R3231

IC7016 → IC7002C

IC7016 → R3073

R3023, R3022, R3021 →

IC7002B, R3044, T7124

IC7701 → IC7702

IC7008 → R3054

→

Master ReaD, read strobe for external peripherals,

active low

MUTE control from MACE2 to DASP, active low

Master WRite, write strobe for external peripherals,

active low

OFFTRACK detection flag

Position Control Sledge COS feedback signal

Position Control Sledge SIN feedback signal

laser Power switch for ERASE

standby pin, high level activates essential powers

necessary for full function; overrules HI_POWER

setting

Push-Pull signal, Normalized, balanced, voltage output

current source

drive signal from Power Read FINE DAC for read

current source

PROFessional digital output (CDR950 only)

Program Store ENable; external ROM output enable

line, active low

sources and VCAGAIN

drive signal from XDAC for write and erase current

sources

PW MAXimum signal from DAC used for determining

set point for laser power during writing

set point for laser power during writing

laser Power switch for WRITE

Row Address Strobe DRAM

interface)

forward sense ReaD GAIN switch 1

26 3. CD-Recordable/Rewritable Audio Recorder 3rd Generation

SIGNAL NAME SIGNAL FLOW FUNCTION AND DESCRIPTION

RDGAIN2 IC7008 → C2027 forward sense ReaD GAIN switch 2

RDGAIN3 IC7008 → C2060 forward sense ReaD GAIN switch 3

RE IC7010 → IC7215A Radial Error signal for fast track counting, voltage

output

RECORDING IC7008 → IC7010

IC7008 → CONN1000

IC7008 → IC7355C

REN

RIGHT CONN1708, C2742 → IC7401A,

RXD_TOOL CONN1818 → IC7701 Receive of UART for test TOOL

S1V65 Referenve Voltage 1.65V delivered by IC7215B for Servo part

S2V9 Reference Voltage 2.9V delivered by IC7010 for Servo part

SEL_HP_OUT IC7701 → R3720 → IC7407 SELect HeadPhone OUTput in DJ-mode (for CDR775

SFSY IC7701 → R3756 → IC7300 EIAJ subcode synchronisation from DASP to CDR60

SIN- CONN1220 → IC7225A Hall feedback signal from sledge motor

SIN+ CONN1220 → IC7225A Hall feedback signal from sledge motor

SL- IC7240 → R3265 → CONN1220 SLedge motor drive signal negative connection

SL+

SRSTN IC7270 → R3243B, IC7300 Slave ReSeT out (CDR60 reset), active low

STANDBY IC7270 → R3807 → R3887

SUB IC7701 → R3710 → IC7300 EIAJ subcode data from DASP to CDR60 (CD text

SYS_CLK_11W

SYS_CLK_16W IC7701 → R3894D→ IC7706A 16.9344 MHz SYStem CLocK for producing

SYS_CLK_8W

SYS_CLK_BE IC7706A → R3826 → IC7270 SYstem CLocK Basic Engine (8.4672 MHz)

SYS_RESET IC7701 → R3758

TCK CONN1819 → R3906, IC7701 JTAG ClocK signal

TDSO

TERMB IC7270 ↔ CONN1818 UART connection with MACE

TLN IC7010 → IC7270 Track Loss Normalized current output

TR- IC7240 → CONN1200 TRay motor drive signal negative connection

TR+

TRACE99_RXD CONN1818 → R3838, IC7701 TRACE99 test tool receive data

TRACE99_TXD IC7701 → CONN1818 TRACE99 test tool transmit data

TRAYIN IC7270 → IC7240 move TRAY IN line, active low

IC7010 → IC7270

IC7407A

IC7240 → CONN1220

IC7701

IC7701 → R3732 → IC7406

IC7706A → R3815

CONN1708

CONNF934

IC7701 → R3770 → T7707

→

CONN1708

IC7701 → CONN1819

IC7240 → CONN1200

→

→

RECORDING output (active high)

Radial Error Normalized current output

audio output RIGHT channel from CD-player in

CDR775

only)

(CD text interface)

SLedge motor drive signal positive connection

→

STANDBY pin, high level activates essential powers

necessary for full function; overrules HI_POWER

setting

interface)

11.2896 MHz SYStem CLocK for AD/DA datapath

SYS_CLK_BE

SYstem CLocK CD player (8.4672 MHz) (CDR775

only)

SYStem RESET to display assy (and CD player for

CDR775)

JTAG Serial Data Out / debug data out

TRay motor drive signal positive connection

3rd Generation 3. CD-Recordable/Rewritable Audio Recorder 27

SIGNAL NAME SIGNAL FLOW FUNCTION AND DESCRIPTION

TRAYOUT IC7270 → IC7240 move TRAY OUT line, active low

TRAYSW Œ CONN1200 → R3747

Œ CONN1200 → R3748

TRAYSWF

TXD_TOOL IC7701 → CONN1818 Transmit of UART for test TOOL

U+, U-, V+, V-,

W+, WUCOIL, VCOIL,

WCOIL

VCAGAIN IC7016 → IC7005A set-point laser power on disc, voltage output

VDC1 CONN1500 → CONNF934 supply voltage for display assy

VDC2

VFO IC7270 → R3295 → R3244 FOcus actuator drive output

VFTD CONN1500 → CONNF934 Voltage Fluorescent Tube Display (display assy)

VRA

VSL IC7270 → R3299 → IC7240 SLedge actuator drive output

WCLK IC7701 → R3898B → IC7300 I2S1 WordCLocK from DASP to CDR60 (playback and

WOBBLE IC7050C → IC7300 analog WOBBLE signal of pre-groove detected by

WPON

WPONO IC7008 → R3106 Write Power ON Open drain output

WPONRC R3003 → CONN1000 Write Power ON (after RC circuit)

XDAC multiplying DAC

R3748, C2214 → IC7270

CONN1330 → IC7330

IC7330 → CONN1330 drive signals for turn table motor

CONN1500 → CONNF934

IC7270 → R3297 → R3254

Œ IC7008 → R3009

Œ IC7008 → C2009

TRAY SWitch signal from loader assy

Filtered TRAY SWitch signal, low is completely out or

in

hall feedback signals from turn table motor to hall

motor driver

supply voltage for display assy

RAdial actuator drive output

record)

PPN-signal

Write Power ON

28 3. CD-Recordable/Rewritable Audio Recorder 3rd Generation

3.1 Blockdiagrams

The Start-up

First of all we have to describe the starting process at the

moment the set is switched on.:

STARTING PROCESS:

1. Powering up the powersupply,

2. Running hardware reset procedures and frequency /

clocksettings,

3. Starting initialisation control.

INITIALISATION CONTROL:.

• Due to optical, electrical and mechanical tolerances in CDRecorders, the properties of the servo signals can vary. In

general, without proper signal processing, a simple

controller function cannot cope with this. Therefore during

manufacture or active control, adjustments become

inevitable to compensate for these signal imperfections.

The manufacture measurements and concerned

adjustment values are stored in EEPROM of the CDR

Loader Module (In central repair procedure!).

• All other adjustments of servoloops are processed in the

start-up procedure of the set. This can take a longer startup time as normally for Audio equipment, but is known from

Personal Computer start-ups.

• The servo also cares that the spot accesses a required

position as fast as possible. This access system (PCS) has

to be automatically calibrated during start-up too.

The Writing

WRITING Process:

On the more extended overall blockdiagram with the double

deck application (CD-player module + CDR-recorder module)

the most important -components of the CD-Recordable/

ReWritable Audio Recorder are shown. The electrical signal

flow of the recording signal from the analogue input on the

connector board is as follows:

• the analogue recording signal can at first be adjusted to the

desired level

• by the digitally controlled potentiometer (DIGITAL POT) and

then

• the analogue signal is converted into digital signal A/D

Conversion (CODEC) via I2S format (I2S bus 2/4) to

• the Digital Audio Signal Processor (DASP);

• the external-digital-in signal as well as the external-optical-

in signal are both directly connected to the DASP too, one

of these input signals will be converted into I2S format (I2S

bus 1), from this databus the data are sent to

• the Encoder part of the Decoder, Encoder & Motorcontrol IC

(CDR60) which converts the signal into a EFMpattern, then

the information flow is lead to

• EFM timing generator (EFMTIM3) where the last

preparations are done.

• Via the Laser control the lasercurrent is controlled and

• The laser in the Optical Pick Up unit of CDM 3800 will be

empowered in

• processing the signal onto the disc. The processing of all

these activities is mastered by

• the Basic engine processor (MACE2).

• The servo drivers of the CDM (AEGER) are driven by

commands from the Basic engine processor (MACE2) too.

• the scanning of input keys is processed by the slave display

controller on the display board.

The analogue inputs are pre-amplifiers which adapt the signal

level to the operational level. Adjustments can be done about

the recording level. Prevent over-amplification of the analogue

signal because clipped audiosignals are registered as mutes

and are "damaging" the recording quality. For that it is better to

have a "safe" input level. After that the analogue audio signal

will be converted in CODEC into the I2S format.

The digital input from the IEC958 standard format with data in

Biphase marked code needs no adjustment and will be

transferred into the I2S format too by DASP. The subcode

information of the digital input signal will be processed to the

subcode information for the new CD-R or CD-RW disc. The I2S

signal is converted into the CIRC/EFM format in the CDR60

encoder. Each input audiosignal is worked up to the EFM

format which will be written on the disc via the EFMTIM and the

Laser control. The laser in the optical pick-up unit on the CD

mechanism CDM3800 processes the data onto the disc.

In case both inputs (analogue and digital) are supplying signals,

preference is given to the digital input source.

The digital input, but also the I2S signal from the analogue

input, are connected to DASP (Digital Audio Signal Processor)

which uses the input signal (see DLR) or calculates a new

digital output signal (see SRC). It also can operate the signal

with a number of functions like: Buffer, internal digital Fade-In

and Fade-Out, digital Balance etc. Via the DASP Digital out port

the digital output of the processed signal is available. So for

monitoring the “re-worked” digital output signal can be used.

The DASP microprocessor part on the Main board let the Slave

Display Controller on the Displayboard scan the keyboard for

commands from the user. After that the DASP executes that

command. The DASP is the master processor of the set. It coordinates all functions within the set. The writing process in the

CDR-loader is controlled by the components of the Basic

Engine part (BE). The basic engine part consists out of a/o.

CDR60, Mace, Aeger, EFMTIM and Lasercontrol on the Main

Board, together with the mechanical CDR-loader parts. In the

BE-part the reading and writing moments are started and the

laserdiode in the Optical pick-up unit of the CD Mechanism will

be actuated at correct level (reading CD, reading CD-RW,

writing CD-R, writing CD-RW, erasing CD-RW) and the

laserlight intensity will be processed onto the disc.

During the writing operation the wobble processing takes care

for the track following of the pregroove. This is done during the

reading moments. At the same time the disc rotation is

controlled via the ATIP-pregroove wobble information. As long

as the recording disc is not finalised the ATIP information is

processed for controlling CDM, even in playback mode.

When reading a conventional or finalised disc the driver control

is switched to the well-known EFM-motorcontrol and the

wobble processing is switched off.

3rd Generation 3. CD-Recordable/Rewritable Audio Recorder 29

3.1 Blockdiagrams

The AEGER IC (Analogue Error signal Generator for Erasable

and Recordable CD) contains normalizer circuits. These

internal circuits amplify all signals from the Optical Pick-up Unit

to the same average level as the total reflected signal. By this

adaptation all photodiode signals are brought to a "normal"

level. Now servo signals like Focus-error, Radial-error can be

processed better. Even the HF-signal will be equalised in the

AEGER.

The Reading

READING process:

The parts which provide output signals are in principal the same

stages as known from the conventional CD-player where the

EFM signal is recovered into the audiosignal:

• the decoder part of the Decoder, Encoder & Motor control

IC (CDR60) decodes to I2S datapath bus format, from this

to

• the Digital Audio Signal Processing (DASP) but also to

• the D/A conversion in CODEC.

• the digital outputs are received from DASP.

• the analogue output from CODEC.

Notice that the signal available for monitoring in the recording

mode is not the recorded signal but it is only the input I2S signal

to CDR60 which can be controlled. In case the original input

signal is an analogue input this signal can activate automatic

track increment. If the output level via the internal monitor

indicates a signal below -60 dB for 4 seconds, the next track will

be generated. In the digital input mode the subcode information

indicates the next track.

All these functions are processed by the DASP software

program in the Flash ROM IC on the MAIN Board.

The Functioning

In the following an example is given of the use of a Recordable

disc and in short all activities in the recorder are described.

After that the power has been switched on and resets have

been executed, then the initialisation process will run and servo

loops will be calibrated. When [open tray] key has been

activated, the unrecorded disc (e.g. CD-R) will be put on the

tray. Close the tray and the PCS (Position Control Sledge)

function will store all relevant information of the disc like

dimensions, total length, track distance, etc. into memory. Then

it can jump later on very quick to each desired position on the

disc. It starts in jumping to the lead-in area to read the

information which might be stored overthere. Because it is an

unrecorded disc there is no information in the lead-in. Now the

spot has been moved under the PMA area and the Mace

processor switches over to so-called "ATIP-mode", pregroove

information. The brand-new disc has not been recorded before

so there is no information too. In the pregroove the recorder

finds a recommended Optimum Power Calibration value. Now

this recommended power is taken as the middle of the 15 steps

to make a test recording on the pregroove in the Power

Calibration Area of the disc.

After recording, the written value is being read. If the intensity

of the reading signal corresponds with the desired value the

power ok sign is indicated and the corresponding OPC-value is

stored. (See basics paragraph 3.2.2.2.) If after one run the ideal

value is not found the next 15 steps are written on the disc. This

procedure can be repeated 4 times. All figures of the disc are

stored in the memory of the microprocessor.

After this OPC procedure, the user can decide to make a

recording of a piece of music. This will be written in the first

track, "under" the pregroove on the reflection layer of the disc

in the recording layer area.

Note: the ATIP information on pregroove remains. Only by

diffracting the dye-layer new information is stored on "pit" spots.

As long as disc is not finalised the recorder is able to read ATIP

information.

To stop the recording the [stop] key has to be activated. The

writing continues to the next subcode sync and some (EFM)frames more; according to the defined General Linking rules.

(See basics paragraph 2.5.5.6. General linking rules; General

Linking Rules are in the meantime adapted to the practical

experience. It is no longer necessary to use 26 EFM frames, but

now 15 frames are already sufficient.) First after recording

those 15 frames the CD-R drive stops recording in the data

area of the disc. Immediately, all stored information in the

microprocessor, like disc number and the number of registered

tracks, will be written down in the PMA of the disc. (See basics

paragraph 3.2.2.2)

After that procedure the tray is allowed to bring the disc outside

the recorder.

To continue the recording on the same disc the close key has

to be activated. Now still there is no information on the lead-in

area but only in the PMA the key identification information of the

disc has been found. For each new record a new OPC is made.

In this area it is possible to record only a maximum of 99

testrecordings.

However with the temporary table of contents in the PMA of the

disc, the microprocessor knows the last track and drives the

spot (Optical pick-up unit) to the end of that recorded track. To

link to that position the recorder looks for the last recorded

subcode sync framenumber. When the recording should start,

the recorder starts reading at first the last 15 EFM-frames to

assure the timing of the registered signal with the timing of the

new recording signal. After those 15 EFM-frames the writing

starts. In this way there exists a continuous EFM pattern on the

disc which is adapted to the conventional standard.

For CD-R discs the Power Calibration Area (PCA) can only

record a maximum of 99 OPC testrecordings. To prevent that

to often loaded discs are full without any recording the last

(99th) OPC recording is used for all further recordings. So user

should prevent loading discs to often without making a

recording, to prevent misadjustments of OPC value.

The CD-RW disc does not have this limitation. After 99 OPC

records have been stored in the PCA and the next OPC has to

recorded then at first PCA will be erased and again 99 OPC

values can be stored.

Loading...

Loading...