Philips BY428 Datasheet

DISCRETE SEMICONDUCTORS

DATA SH EET

handbook, 2 columns

M3D118

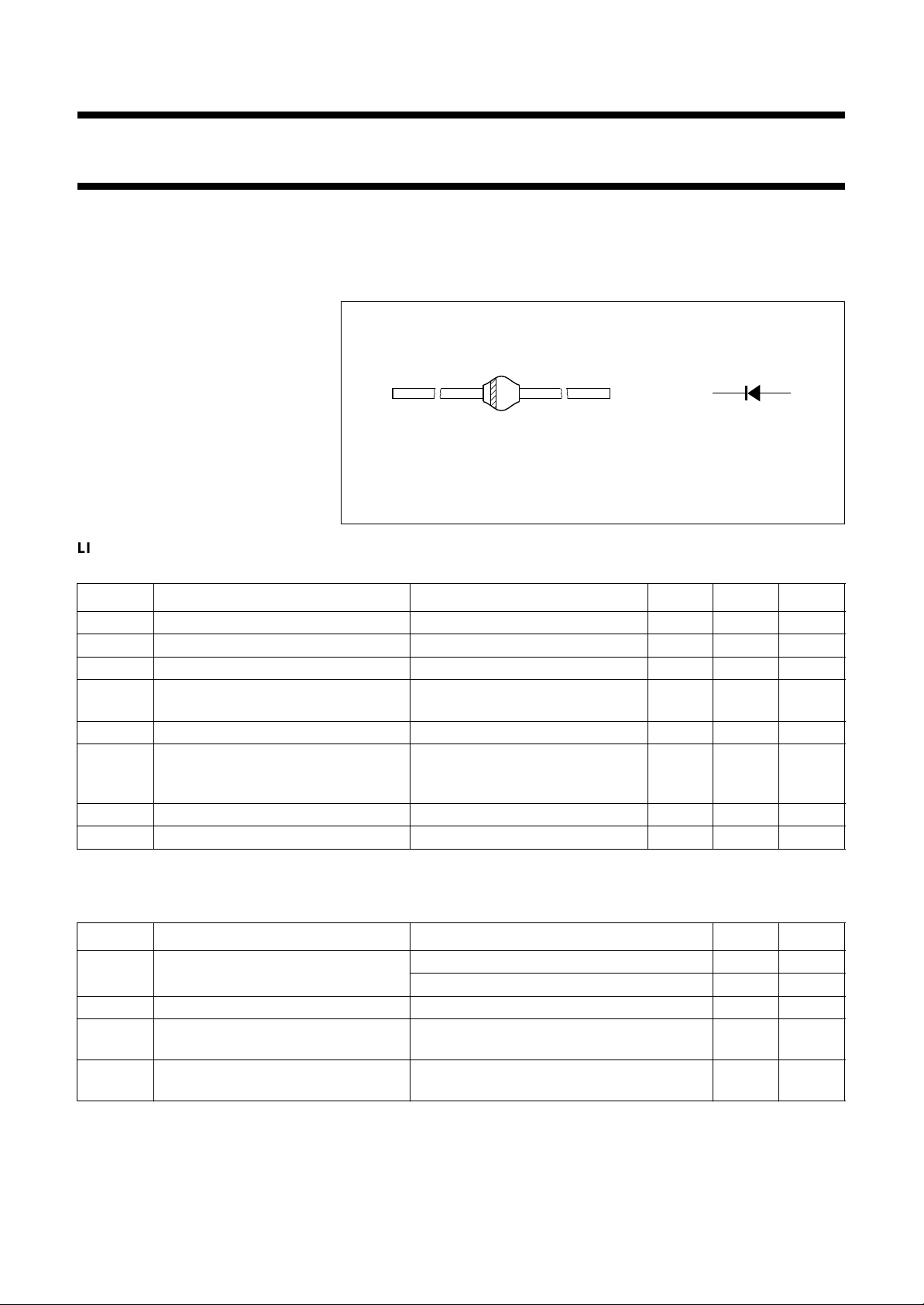

BY428

Damper diode

Product specification

Supersedes data of May 1996

File under Discrete Semiconductors, SC01

1996 Sep 26

Philips Semiconductors Product specification

Damper diode BY428

FEATURES

• Glass passivated

• High maximum operating

DESCRIPTION

Rugged glass package, using a high

temperature alloyed construction.

This package is hermetically sealed

and fatigue free as coefficients of

expansion of all used parts are

matched.

temperature

• Low leakage current

• Excellent stability

• Available in ammo-pack

ka

• Also available with preformed leads

for easy insertion.

2/3 page (Datasheet)

MAM104

APPLICATIONS

• Damper diode in high frequency

horizontal deflection circuits up to

Fig.1 Simplified outline (SOD64) and symbol.

64 kHz.

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

RSM

V

RRM

V

R

I

FWM

non-repetitive peak reverse voltage − 1500 V

repetitive peak reverse voltage − 1500 V

continuous reverse voltage − 1400 V

working peak forward current Ttp=80°C; lead length = 10 mm;

− 4A

see Fig.2

I

FRM

I

FSM

T

stg

T

j

repetitive peak forward current − 8A

non-repetitive peak forward current t = 10 ms half sinewave;

Tj=T

VR=V

prior to surge;

j max

RRMmax

− 50 A

storage temperature −65 +175 °C

junction temperature −65 +150 °C

ELECTRICAL CHARACTERISTICS

=25°C; unless otherwise specified.

T

j

SYMBOL PARAMETER CONDITIONS MAX. UNIT

V

F

I

R

t

rr

forward voltage IF= 4 A; Tj=T

= 4 A; see Fig.3 1.95 V

I

F

reverse current VR=V

; Tj= 150 °C 150 µA

Rmax

; see Fig.3 1.60 V

j max

reverse recovery time when switched from IF= 0.5 A to IR=1A;

250 ns

measured at IR= 0.25 A; see Fig.6

t

fr

forward recovery time when switched to IF= 5 A in 50 ns;

Tj=T

; see Fig.7

j max

250 ns

1996 Sep 26 2

Philips Semiconductors Product specification

Damper diode BY428

THERMAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS VALUE UNIT

R

th j-tp

R

th j-a

Note

1. Device mounted on an epoxy-glass printed-circuit board, 1.5 mm thick; thickness of Cu-layer ≥40 µm, see Fig.4.

For more information please refer to the

thermal resistance from junction to tie-point lead length = 10 mm 25 K/W

thermal resistance from junction to ambient note 1 75 K/W

mounted as shown in Fig.5 40 K/W

“General Part of Handbook SC01”

.

1996 Sep 26 3

Loading...

Loading...