Page 1

Color Television Chassis

ENTRY

EDGE

TOP A

TOP B

BJ2.4U/BJ2.5U

LA

ENTRY

EDGE

TOP A

TOP B

G_15930_000.eps

Contents Page Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 5

3. Directions for Use 7

4. Mechanical Instructions 8

5. Service Modes, Error Codes, and Fault Finding 15

6. Block Diagrams, Test Point Overviews, and

Waveforms

Wiring Diagram 37” Entry 39

Wiring Diagram 42” Top A 40

Wiring Diagram 42” Top B 41

Block Diagram Display Supply 37” Entry 42

Block Diagram Display Supply 42” Top 43

Display Supply (Sanken) 44

Block Diagram Platform Supply 42” Top 45

Block Diagram Video 46

Block Diagram Audio 47

Block Diagram Control 48

I2C IC’s Overview 49

Supply Lines Overview 37” Entry 50

Supply Lines Overview 42” Top 51

7. Circuit Diagrams and PWB Layouts Drawing PWB

LCD Supply (37”): Mains Filter + Standby (A1) 52 54-59

LCD Supply (37”): Supply (A2) 53 54-59

Ambi Light (Part 1) (AL1) 60 63

Ambi Light (Part 2) (AL2) 61 63

Ambi Light (Part 3) (AL3) 62 63

Platform Supply 42”: Aux Supply (AP1) 64 72-78

Platform Supply 42”: Stby Supply (AP2) 65 72-78

Platform Supply 42”: Filter (AP3) 66 72-78

Platform Supply 42”: Audio Left/Right (AP4) 67 72-78

Platform Supply 42”: Audio Prot / Mute (AP5) 68 72-78

Platform Supply 42”: Audio Sub Woofer (AP6) 69 72-78

Platform Supply 42”: Audio Centre (AP7) 70 72-78

©

Copyright 2006 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Platform Supply 42”: SRP List 71

Small Signal Board (B1-B12) 79-117 120-125

SRP List Explanation 117

SSB: SRP List Part 1 118

SSB: SRP List Part 2 119

External I/O Panel: Externals A (BE1) 126 128

External I/O Panel: Externals B (BE2) 127 128

Side I/O Panel (Top) (D) 129 130

Side I/O Panel (Entry) (D) 131 132

Control Board (Top) (E) 133 133

Control Board (Entry) (E) 134 134

LED Panel (Top) (J) 135 136

LED Panel (Entry) (J) 137 138

Standby & Audio Panel: Connections (SA1) 139 142-144

Standby & Audio Panel: Standby (SA2) 140 142-144

Standby & Audio Panel: Audio (SA3) 141 142-144

8. Alignments 145

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 150

Abbreviation List 170

IC Data Sheets 173

10. Spare Parts List 186

11. Revision List 201

200606

Published by EL 0666 BG CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 15910

Page 2

EN 2 BJ2.4U/BJ2.5U LA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connection Overview

1.3 Chassis Overview

Notes:

• Data below can deviate slightly from the actual situation,

due to the different set executions

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : LCD

Screen size : 37” (94 cm), 16:9

Resolution (HxV pixels) : 1366(*3)x768p

Min. contrast ratio : 800:1 (37”)

Min. light output (cd/m

Viewing angle (HxV degrees) : 176x176

Tuning system : PLL

TV Color systems : ATSC

Video playback : NTSC

Cable : Unscrambled digital

Tuner bands : VHF

Supported video formats : 640x480i - 1fH

Supported computer formats : 640x480 @ 60Hz

2

) : 550

: 42” (107 cm), 16:9

: 4500:1 (42”)

:NTSC

cable - QAM

: Digital cable ready -

CableCard

: UHF

: S-band

: Hyper-band

: 640x480p - 2fH

: 1280x720p - 3fH

: 1920x1080i - 2fH

: 800x600 @ 60Hz

: 1024x768 @ 60Hz

1.1.4 Miscellaneous

Power supply:

- Mains voltage (V

- Mains frequency (Hz) : 50/60

Ambient conditions:

- Temperature range (°C) : +5 to +40

- Maximum humidity : 90% R.H.

Power consumption (values are indicative)

- Normal operation (W) : ≈ 175 (37”)

- Standby (W) : < 0.6

Dimensions (WxHxD) : 110.5x61x9.7 cm

Weight (lbs) : 66.15 (37”)

) : 110 - 120 (37”)

AC

: 110 - 240 (42”)

: ≈ 263 (42”)

: 43.1x31.3x4.5 inch

: 50.4x34.3x4.5 inch

: 67.9 (42PF9731D)

: 83.8 (42PF9831D)

(37”)

(42PF9731)

(42PF9831D)

1.1.2 Sound

Sound systems : AV Stereo

Maximum power (W

1.1.3 Multimedia

Supported digital media : Compact Flash I & II

Supported file formats : JPEG

USB input : USB1.1 (12 Mbps)

) : 2 x 15 (37PF9431D &

RMS

:BTSC

42PF9731D)

: 2 x 12 W + 1 x 24 W

(42PF9831D)

: Memory Stick

: Microdrive (upto 2GB)

: SD / mini SD Card

: Multi Media Card

: Smart Media Card

:MP3

:MP3-pro

: Slideshow (.alb)

: USB2.0 (480 Mbps)

Page 3

Technical Specifications, Connections, and Chassis Overview

1.2 Connection Overview

Figure 1-1 Side and rear I/O connections 42” models

EN 3BJ2.4U/BJ2.5U LA 1.

G_15910_027.eps

230606

Note: The following connector color abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

1.2.1 Side Connections

Headphone (Output)

Bk - Headphone 32 - 600 ohm / 10 mW ot

Cinch: Video CVBS - In, Audio - In

Rd - Audio R 0.5 V

Wh - Audio L 0.5 V

Ye - Video CVBS 1 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm jq

PP

SVHS (Hosiden): Video Y/C - In

1 - Ground Y Gnd H

2 - Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

/ 75 ohm j

PP

P / 75 ohm j

PP

USB2.0

1234

E_06532_022.eps

300904

Figure 1-2 USB (type A)

1-+5V k

2 - Data (-) jk

3 - Data (+) jk

4 - Ground Gnd H

1.2.2 Digital Media Reader with USB2.0 (for 42” sets)

In 42” sets, a 6-in-1 card reader unit is available, which is

connected via USB to the Small Signal Board (see also par.

“Technical Specifications” -> “Multimedia”).

This unit also contains two USB2.0 connectors.

1.2.3 Rear Connections

POD: CableCARD Interface

68p - See diagram B10A jk

Service Connector (UART)

1 - UART_TX Transmit k

2 - Ground Gnd H

3 - UART_RX Receive j

HDMI 1 & 2: Digital Video, Digital Audio - In

19

18 2

1

E_06532_017.eps

250505

Figure 1-3 HDMI (type A) connector

1 - D2+ Data channel j

2 - Shield Gnd H

3 - D2- Data channel j

4 - D1+ Data channel j

5 - Shield Gnd H

6 - D1- Data channel j

7 - D0+ Data channel j

8 - Shield Gnd H

9 - D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - n.c.

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

Aerial - In

- - F-type (US) Coax, 75 ohm D

Page 4

EN 4 BJ2.4U/BJ2.5U LA1.

Technical Specifications, Connections, and Chassis Overview

AV1 Cinch: Video YPbPrHV- In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

Bk - H-sync 0 - 5 V jq

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

Bk - V-sync 0 - 5 V jq

AV1 Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

DIGITAL AUDIO Cinch: S/PDIF - In

Bk - Coaxial 0.2 - 0.6V

/ 75 ohm jq

PP

AV1 S-Video (Hosiden): Video Y/C - In

1 - Ground Y Gnd H

2 - Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

/ 75 ohm j

PP

P / 75 ohm j

PP

AV2 S-Video (Hosiden): Video Y/C - In

1 - Ground Y Gnd H

2 - Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

/ 75 ohm j

PP

P / 75 ohm j

PP

1.3 Chassis Overview

AV2 Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

AV3 Cinch: Video YPbPr - In

Rd - Video Pr 0.7 V

Bu - Video Pb 0.7 V

Gn - Video Y 1 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

DIGITAL AUDIO Cinch: S/PDIF - Out

Bk - Coaxial 0.4 - 0.6V

/ 75 ohm kq

PP

MONITOR OUT Cinch: Video CVBS - Out, Audio - Out

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm kq

PP

/10 kohm kq

RMS

/ 10 kohm kq

RMS

GEMSTAR Mini Jack: Remote Control - In/Out

1 - Ground Gnd H

2 - RXD j

3-TXD k

4-IR-OUT k

5 - RXD k

AMBI LIGHT PANEL

AL

PLATFORM SUPPLY

AP

& AUDIO PANEL

SMALL SIGNAL BOARD

B

CONTROL BOARD

E

LED PANEL

J

Figure 1-4 PWB/CBA locations

AMBI LIGHT PANEL

SDI PDP

POWER SUPPLY

SIDE I/O PANEL

EXTERNAL I/O PANEL

G_15910_013.eps

AL

D

BE

230606

Page 5

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 5BJ2.4U/BJ2.5U LA 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the "on" position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "on".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a color bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the “double-D symbol”, are

trademarks of Dolby Laboratories.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (µ= x10

nano-farads (n= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 Rework on BGA (Ball Grid Array) ICs

General

Although (LF)BGA assembly yields are very high, there may

still be a requirement for component rework. By rework, we

mean the process of removing the component from the PWB

and replacing it with a new component. If an (LF)BGA is

removed from a PWB, the solder balls of the component are

deformed drastically so the removed (LF)BGA has to be

discarded.

Device Removal

As is the case with any component that, is being removed, it is

essential when removing an (LF)BGA, that the board, tracks,

solder lands, or surrounding components are not damaged. To

remove an (LF)BGA, the board must be uniformly heated to a

temperature close to the reflow soldering temperature. A

uniform temperature reduces the risk of warping the PWB.

To do this, we recommend that the board is heated until it is

certain that all the joints are molten. Then carefully pull the

component off the board with a vacuum nozzle. For the

appropriate temperature profiles, see the IC data sheet.

Area Preparation

When the component has been removed, the vacant IC area

must be cleaned before replacing the (LF)BGA.

Removing an IC often leaves varying amounts of solder on the

mounting lands. This excessive solder can be removed with

either a solder sucker or solder wick. The remaining flux can be

removed with a brush and cleaning agent.

After the board is properly cleaned and inspected, apply flux on

the solder lands and on the connection balls of the (LF)BGA.

Note: Do not apply solder paste, as this has been shown to

result in problems during re-soldering.

-9

), or pico-farads (p= x10

-12

-6

),

).

Page 6

EN 6 BJ2.4U/BJ2.5U LA2.

Safety Instructions, Warnings, and Notes

Device Replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF)BGA should be

aligned under a microscope or magnifying glass. If this is not

possible, try to align the (LF)BGA with any board markers.

So as not to damage neighbouring components, it may be

necessary to reduce some temperatures and times.

More Information

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

2.3.4 Lead-free Solder

Philips CE is producing lead-free sets (PBF) from 1.1.2005

onwards.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 5 and 6 refer to the production year, digits

7 and 8 refer to production week (in example below it is 1991

week 18).

MODEL :

PROD.NO:

32PF9968/10

AG 1A0617 000001

220-240V 50/60Hz

VHF+S+H+UHF

S

MADE IN BELGIUM

~

128W

BJ3.0E LA

E_06532_024.eps

130606

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard material (commodities) has to be

purchased at external companies.

• Special information for lead-free BGA ICs: these ICs will be

delivered in so-called "dry-packaging" to protect the IC

against moisture. This packaging may only be opened

shortly before it is used (soldered). Otherwise the body of

the IC gets "wet" inside and during the heating time the

structure of the IC will be destroyed due to high (steam-)

pressure inside the body. If the packaging was opened

before usage, the IC has to be heated up for some hours

(around 90°C) for drying (think of ESD-protection!).

Do not re-use BGAs at all!

• For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

In case of doubt whether the board is lead-free or not (or with

mixed technologies), you can use the following method:

• Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

• De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

Caution: For BGA-ICs, you must use the correct temperatureprofile, which is coupled to the 12NC. For an overview of these

profiles, visit the website www.atyourservice.ce.philips.com

(needs subscription, but is not available for all regions)

You will find this and more technical information within the

"Magazine", chapter "Repair downloads".

For additional questions please contact your local repair help

desk.

Figure 2-1 Serial number example

Regardless of the special lead-free logo (which is not always

indicated), one must treat all sets from this date onwards

according to the rules as described below.

P

b

Figure 2-2 Lead-free logo

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

2.3.5 Alternative BOM identification

In September 2003, Philips CE introduced a change in the way

the serial number (or production number, see Figure 2-1) is

composed. From this date on, the third digit in the serial

number (example: AG2B0335000001) indicates the number of

the alternative BOM (Bill of Materials used for producing the

specific model of TV set). It is possible that the same TV model

on the market is produced with e.g. two different types of

displays, coming from two different O.E.M.s.

By looking at the third digit of the serial number, the service

technician can see if there is more than one type of B.O.M.

used in the production of the TV set he is working with. He can

then consult the At Your Service Web site, where he can type

in the Commercial Type Version Number of the TV set (e.g.

28PW9515/12), after which a screen will appear that gives

information about the number of alternative B.O.M.s used.

If the third digit of the serial number contains the number 1

(example: AG1B033500001), then there is only one B.O.M.

version of the TV set on the market. If the third digit is a 2

(example: AG2B0335000001), then there are two different

B.O.M.s. Information about this is important for ordering

the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26 = 35 different B.O.M.s can

be indicated by the third digit of the serial number.

2.3.6 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

Page 7

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

Directions for Use

EN 7BJ2.4U/BJ2.5U LA 3.

Page 8

EN 8 BJ2.4U/BJ2.5U LA4.

Mechanical Instructions

4. Mechanical Instructions

Index of this chapter:

4.1 Cable Dressing

4.2 Service Positions

4.3 Assy/Panel Removal

4.4 Set Re-assembly

4.1 Cable Dressing

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Follow the disassemble instructions in described order.

4.2 Service Positions

For easy servicing of this set, there are a few possibilities

created:

• The buffers from the packaging.

• Foam bars (created for service).

• Aluminium service stands (created for Service).

Figure 4-1 Cable dressing

4.2.1 Foam Bars

G_15910_014.eps

E_06532_018.eps

Figure 4-2 Foam bars

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. By laying the TV

230606

170504

Page 9

Mechanical Instructions

EN 9BJ2.4U/BJ2.5U LA 4.

face down on the (ESD protective) foam bars, a stable situation

is created to perform measurements and alignments.

By placing a mirror under the TV, you can monitor the screen.

4.2.2 Aluminium Stands

E_06532_019.eps

170504

Figure 4-3 Aluminium stands (drawing of MkI)

The new MkII aluminium stands (not on drawing) with order

code 3122 785 90690, can also be used to do measurements,

alignments, and duration tests. The stands can be

(dis)mounted quick and easy by means of sliding them in/out

the "mushrooms". The new stands are backwards compatible

with the earlier models.

Important: For (older) FTV sets without these "mushrooms", it

is obligatory to use the provided screws, otherwise it is possible

to damage the monitor inside!.

Caution: never disconnect the speakers with a playing set,

because otherwise the class-D audio amplifiers could be

damaged.

4.3.3 Control Panel

The Control Panel can be taken out by removing the two T10

screws [1] that hold the plastic frame. See Figure “Control

panel removal”. The cable can not be disconnected from the

assy at this moment.

11

Figure 4-5 Control panel removal

G_15960_099.eps

070306

4.3 Assy/Panel Removal

4.3.1 Rear Cover

Disconnect the Mains/AC Power cord before you remove the

rear cover!

See figure “Rear Cover removal” for details.

1. Place the TV set upside down on a table top, using the

foam bars (see part “Foam Bars”).

Caution: do not put pressure on the display, but let the

monitor lean on the front cover.

2. Remove the stand.

3. Remove mushrooms [1].

4. Remove screws [2].

5. Lift the Rear Cover from the TV. Make sure that wires and

flat foils are not damaged while lifting the rear cover.

2

2

2

2

2

2

1

2

2

The assy is packed into two plastic frames. To unpack the

inner frame, lift the two clamps [1] of the outer frame and take

the inner frame out. See Figure “Control panel frame removal”.

11

12

G_15960_100.eps

070306

Figure 4-6 Control panel frame removal

2

2

To take the assy out of the inner frame, lift the two clamps of

the frame [2] and slightly pull the assy out. Only now the cable

can be disconnected.

When defective, replace the whole unit.

2

2

2

2

2

2

2

2

2

2

Figure 4-4 Rear Cover removal

4.3.2 Speakers

After removing the rear cover, you gain access to the speakers.

2

G_15910_015.eps

2

2

230606

Page 10

EN 10 BJ2.4U/BJ2.5U LA4.

4.3.4 Side I/O Panel

1. Remove the rear cover, as described previously.

2. Release clamp [1] and slide the PWB out of its casing.

3. Unplug connector [2] from the panel.

1

Mechanical Instructions

G_15990_151.eps

Figure 4-9 Memory Card reader / USB connector

1

120506

Figure 4-7 Side I/O Panel 1/2

2

Figure 4-8 Side I/O Panel 2/2

4.3.5 Memory Card reader / USB connector

G_15990_149.eps

120506

G_15990_150.eps

120506

4.3.6 Sanken Display Supply Panel

1. Mark connector [1] to avoid erroneous re-assembly.

2. Unplug connectors [1][2] from the panel.

3. Remove screws [3].

4. Take the panel out (it hinges on the right side).

3

2

1

3

2

3

3

2

3

3

3

2

3

1. Remove the rear cover, as described previously.

2. Release clamps [1] and slide the unit out of its plastic

frame.

3. Unplug the USB connector from the SSB panel, and the

power cable from the platform PSU.

33

G_15910_016.eps

230606

Figure 4-10 Sanken Display Supply Panel

The Sanken Display Supply Panel comes as a buy-in panel

and is a black-box for Service. When defective, replace the

whole panel.

Page 11

4.3.7 Platform Supply Panel

See figure “Supply Panel” for details.

2

Mechanical Instructions

6 6

6 6 6

2

2

EN 11BJ2.4U/BJ2.5U LA 4.

1

3

2

1

2

1

2

Figure 4-11 Supply Panel

1. Unplug connectors [1].

2. Remove screws [2].

3. Take the panel out (it hinges at the left side).

4.3.8 Small Signal Board (SSB) and Main I/O Panel

Caution: it is absolutely mandatory to remount all different

screws at their original position during re-assembly. Failure to

do so may result in damaging the SSB.

2

2

G_15910_017.eps

230606

6 6 6

Figure 4-13 Bottom SSB shield

For removing Rear I/O Panel (see figure “Rear I/O”):

1. Unplug connector [9].

2. Remove screws [10].

3. Remove the panel from the set.

7

8

10

Figure 4-14 Rear I/O panel

4.3.9 Subframe Lift

Before the LCD Display Panel, the AmbiLight Diffusor Frame

and/or the LED Panel can be taken out, the Subframe must be

lifted.

G_15930_079.eps

190606

10

10

9

10

G_15930_080.eps

190606

1. Unplug connector [1]. See figure “Rear SSB shield”.

2. Unplug USB connector [2].

3. Remove black clip from LVDS connector.

4. Carefully unplug the fragile LVDS connector.

5. Remove screws [5] and [6]. See figure “Bottom SSB

shield”.

6. Remove rear and bottom shield.

7. Unplug connectors [7].

8. Remove screws [8].

9. Remove SSB from the set.

2

4

555

3

5

5

5

1

5

5

G_15930_078.eps

Figure 4-12 Rear SSB shield

5

190606

1

1

G_15910_018.eps

230606

Figure 4-15 SSB lift -1-

1. Remove screws [1].

2. Lift the SSB without unplugging the connectors; put the

SSB upwards-down.

Page 12

EN 12 BJ2.4U/BJ2.5U LA4.

3

1. Remove screws [3].

2. Place the SSB back in its original position.

3

Figure 4-16 SSB lift -2-

5

Mechanical Instructions

3

3

G_15910_019.eps

230606

1. Pull Side I/O Panel / Memory Card Reader / USB

Connector downwards and place it in the centre of the set.

2. Mark connector [8] on right AmbiLight Inverter Panel to

avoid erroneous re-assembly. Unplug connector.

3. Unplug connectors [9].

4. Unplug LVDS connector from LCD Panel. Caution: this is

a very fragile connector!

5. Release horizontal cable that leads from left to right

AmbiLight Inverter Panel from its clamps.

G_15910_022.eps

230606

6

4

G_15910_020.eps

230606

Figure 4-17 Subframe lift -1-

1. Unplug speakers.

2. Unplug two most right connectors [4] on the SSB.

3. Unplug connector 1M10 [5] on Platform Supply Panel that

leads to left AmbiLight Inverter Panel.

4. Unplug connector 1M59 [6] on SSB that leads to left

AmbiLight Inverter Panel.

5. Remove right vertical bracket as described in section

“AmbiLight Inverter Panel”.

8

Figure 4-19 Subframe lift -3-

2 2

2

1

1

2

2

2

2

1

1

2

G_15910_023.eps

2

2

230606

Figure 4-20 Subframe lift -4-

1. Carefully lift the subframe from the set.

2. Remove remaining left vertical bracket. During reassembly, reconnect the earth-cable.

3. Remove T15 tapping screws that hold horizontal brackets

[1].

4. Remove T10 parker screws [2].

5. Take out both horizontal brackets.

9

Figure 4-18 Subframe lift -2-

G_15910_021.eps

230606

4.3.10 Speaker Compartment

See figure “Speaker Compartment” for details.

Page 13

Mechanical Instructions

EN 13BJ2.4U/BJ2.5U LA 4.

2

1

2

2

1 1

Figure 4-21 Speaker Compartment

1. Remove screws [1] inside the frame and on the outer rim

that are indicated with an arrow.

2. Push back the clamps [2] and take out the frame.

4.3.11 AmbiLight Diffusor Frame

Before the AmbiLight lamp units can be removed, the

AmbiLight diffusor frame must be lifted. Before this, the

speaker frame must be removed, as described earlier in this

chapter. See figure “AmbiLight diffusor frame removal” for

details.

2

1

G_15910_024.eps

230606

1

1

1

1

1

1

2

G_15910_025.eps

230606

Figure 4-22 AmbiLight Diffusor frame removal

1. Remove tapping T10 screws [1] that are indicated with an

arrow.

2. Release earth-cable and cable that leads to the LED Panel

from its clamps [2].

3. Carefully lift the plastic frame from the set. See Figure

“AmbiLight diffusor frame lift”.

Figure 4-23 AmbiLight diffusor frame lift

Now the AmbiLight lamp units can be removed from the frame.

Each of them is fixed with T10 parker screws: both on the inside

and on the outside of the frame.

G_15960_104.eps

070306

Page 14

EN 14 BJ2.4U/BJ2.5U LA4.

4.3.12 LED Panel

1. After the AmbiLight diffusor frame has been removed, the

LED Panel is accessible.

2. Remove the T10 mounting screws that hold the panel.

3. Take out the panel.

When defective, replace the whole unit. Reconnect the earthcable during re-assembly.

4.3.13 LCD Panel

When the AmbiLight Diffusor frame has been lifted, the LCD

Panel can be removed from the set.

4.4 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position. See figure "Cable

dressing".

• Pay special attention not to damage the EMC foams on the

SSB shields. Ensure that EMC foams are mounted

correctly.

Mechanical Instructions

Page 15

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

EN 15BJ2.4U/BJ2.5U LA 5.

Index of this chapter:

5.1 Test Points

5.2 Service Modes

5.3 Stepwise Start-up

5.4 Service Tools

5.5 Error Codes

5.6 The Blinking LED Procedure

5.7 Protections

5.8 Fault Finding and Repair Tips

5.9 Software Upgrading

5.1 Test Points

As most signals are digital, it will be almost impossible to

measure waveforms with a standard oscilloscope. Therefore,

waveforms are not given in this manual. Several key ICs are

capable of generating test patterns, which can be controlled via

ComPair. In this way it is possible to determine which part is

defective.

Perform measurements under the following conditions:

• Service Default Mode.

• Video: Color bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Service Modes

Service Default Mode (SDM) and Service Alignment Mode

(SAM) offer several features for the service technician, while

the Customer Service Mode (CSM) is used for communication

between a Customer Helpdesk and a customer.

There is also the option of using ComPair, a hardware interface

between a computer (see requirements below) and the TV

chassis. It offers the ability of structured troubleshooting, test

pattern generation, error code reading, software version

readout, and software upgrading.

Minimum requirements for ComPair: a Pentium processor,

Windows 95/98, and a CD-ROM drive (see also paragraph

“ComPair”).

in the channel map and could be different from the one

corresponding to the physical channel 3.

• All picture settings at 50% (brightness, color, contrast).

• All sound settings at 50%, except volume at 25%.

• All service-unfriendly modes (if present) are disabled, like:

– (Sleep) timer.

– Child/parental lock.

– Picture mute (blue mute or black mute).

– Automatic volume levelling (AVL).

– Auto switch "off" (when no video signal was received

for 10 minutes).

– Skip/blank of non-favorite pre-sets.

– Smart modes.

– Auto store of personal presets.

– Auto user menu time-out.

How to Activate SDM

Use one of the following methods:

• Use the standard RC-transmitter and key in the code

“062596”, directly followed by the “MENU” button.

Note: It is possible that, together with the SDM, the main

menu will appear. To switch it "off", push the “MENU”

button again.

• Short for a moment the two solder pads [1] on the SSB,

with the indication “SDM”. They are located outside the

shielding. Activation can be performed in all modes, except

when the set has a problem with the Stand-by Processor.

See figure “SDM service pads”.

1

5.2.1 Service Default Mode (SDM)

Purpose

• To create a pre-defined setting, to get the same

measurement results as given in this manual.

• To override SW protections (only applicable for protections

detected by stand-by processor) and make the TV start up

to the step just before protection (a sort of automatic

stepwise start up). See paragraph “Stepwise Start Up”.

• To start the blinking LED procedure (not valid in protection

mode).

Specifications

Table 5-1 SDM default settings

Region Freq. (MHz)

Europe, AP-PAL/Multi 475.25 PAL B/G

NAFTA, AP-NTSC, LATAM 61.25 (ch. 3) NTSC M

• Tuning frequency 61.25 MHz for NTSC: The TV shall tune

to physical channel 3 only if channel 3 is an analog channel

or if there is no channel 3 installed in the channel map. If

there is a digital channel installed in channel 3, then the

frequency to which the set will tune, would be as specified

Default

system

G_15930_084.eps

190606

Figure 5-1 SDM service pads

After activating this mode, “SDM” will appear in the upper right

corner of the screen (if you have picture).

How to Navigate

When you press the “MENU” button on the RC transmitter, the

set will toggle between the SDM and the normal user menu

(with the SDM mode still active in the background).

How to Exit SDM

Use one of the following methods:

• Switch the set to STAND-BY via the RC-transmitter.

• Via a standard customer RC-transmitter: key in “00”sequence.

Page 16

EN 16 BJ2.4U/BJ2.5U LA5.

Service Modes, Error Codes, and Fault Finding

5.2.2 Service Alignment Mode (SAM)

Purpose

• To perform (software) alignments.

• To change option settings.

• To easily identify the used software version.

• To view operation hours.

• To display (or clear) the error code buffer.

How to Activate SAM

Via a standard RC transmitter: key in the code “062596”

directly followed by the “INFO” button. After activating SAM

with this method a service warning will appear on the screen,

you can continue by pressing the red button on the RC.

Contents of SAM:

• Hardware Info.

– A. VIPER SW Version. Displays the software version

of the VIPER software (main software) (example:

BJ24U-1.2.3.4_12345 = AAAAB_X.Y.W.Z_NNNNN).

• AAAA= the chassis name.

• B= the region: A= AP, E= EU, L= Latam, U = US.

• X.Y.W.Z= the software version, where X is the

main version number (different numbers are not

compatible with one another) and Y is the sub

version number (a higher number is always

compatible with a lower number). The last two

digits are used for development reasons only, so

they will always be zero in official releases.

• NNNNN= last five digits of 12nc code of the

software.

– B. SBY PROC Version. Displays the software version

of the stand-by processor.

– C. Production Code. Displays the production code of

the TV, this is the serial number as printed on the back

of the TV set. Note that if an NVM is replaced or is

initialized after corruption, this production code has to

be re-written to NVM. ComPair will foresee in a

possibility to do this.

• Operation Hours. Displays the accumulated total of

operation hours (not the stand-by hours). Every time the

TV is switched "on/off", 0.5 hours is added to this number.

• Errors. (Followed by maximal 10 errors). The most recent

error is displayed at the upper left (for an error explanation

see paragraph “Error Codes”).

• Defective Module. Here the module that generates the

error is displayed. If there are multiple errors in the buffer,

which are not all generated by a single module, there is

probably another defect.Take into account that not all

errors will create a defective module message.

• Reset Error Buffer. When you press “cursor right” and

then the “OK” button, the error buffer is reset.

• Alignments. This will activate the “ALIGNMENTS” submenu.

• Dealer Options. Extra features for the dealers.

• Options. Extra features for Service.

• Initialize NVM. When an NVM was corrupted (or replaced)

in the former EMG based chassis, the microprocessor

replaces the content with default data (to assure that the

set can operate). However, all preferences and alignment

values are gone now, and option numbers are not correct.

Therefore, this was a very drastic way. In this chassis, the

procedure is implemented in another way: The moment the

processor recognizes a corrupted NVM, the “initialize

NVM” line will be highlighted. Now, you can do two things

(dependent of the service instructions at that moment):

– Save the content of the NVM via ComPair for

development analysis, before initializing. This will give

the Service department an extra possibility for

diagnosis (e.g. when Development asks for this).

– Initialize the NVM (same as in the past, however now it

happens conscious).

Note: When you have a corrupted NVM, or you have replaced

the NVM, there is a high possibility that you will not have picture

any more because your display option is not correct. So, before

you can initialize your NVM via the SAM, you need to have a

picture and therefore you need the correct display option. To

adapt this option, use ComPair. The correct HEX values for the

options can be found in the table below.The display option

code (decimal) is also available on the option code sticker

located inside the TV mentioned by “Screen Diversity” e.g. 044.

Remark: use always 3 digits for the display option code, for “7”

=> “007”.

Page 17

Service Modes, Error Codes, and Fault Finding

s

EN 17BJ2.4U/BJ2.5U LA 5.

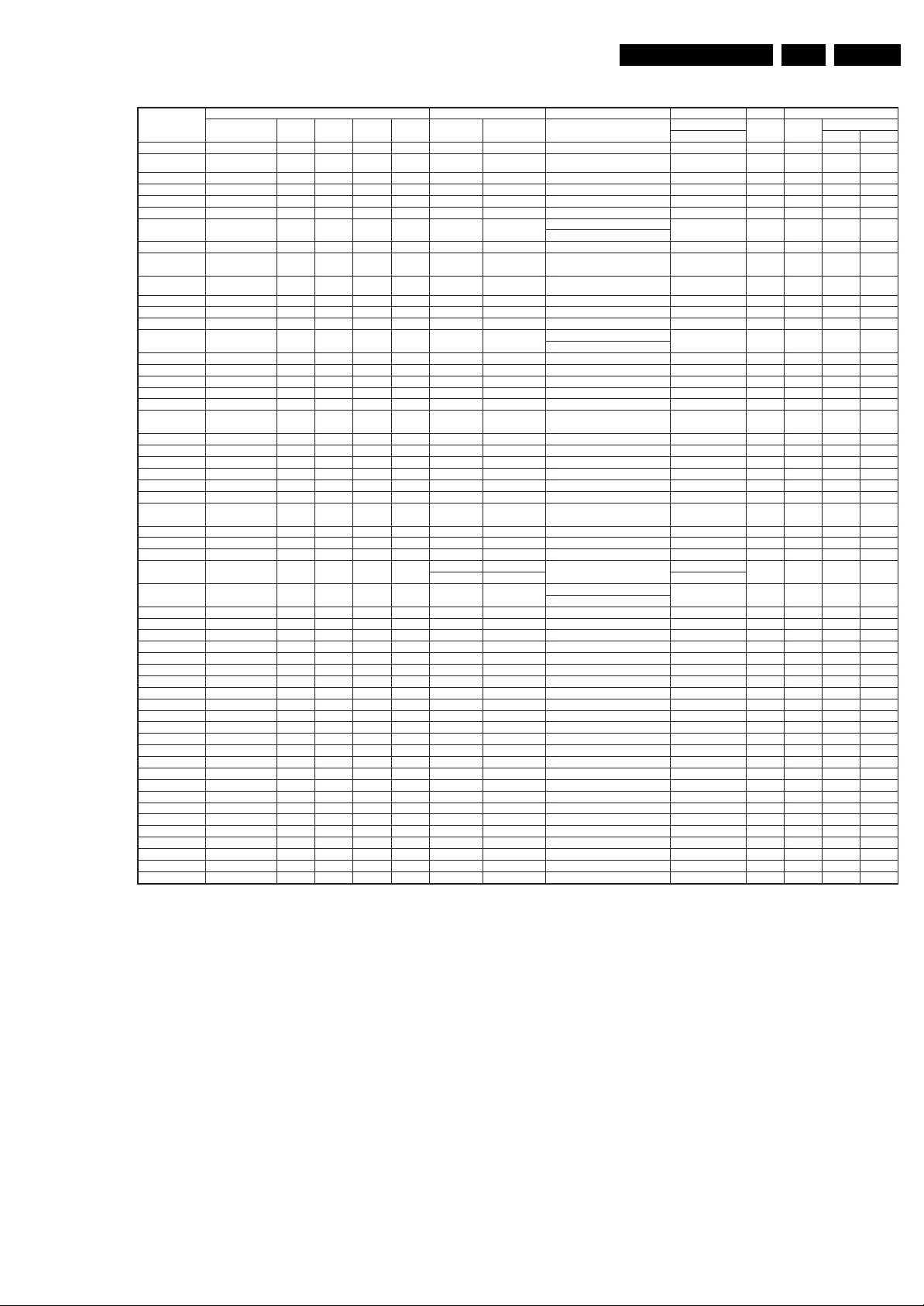

Displays

Div.Displays

Display Type Brand

0 PDP SDI 42 768p 1024 V3_SA42AX-****-Rev,2

Clarification Resolution Year

Size

(Inch)

Full HD

Clear

LCD

Ver Output

Res

Hor Output

Res

1 PDP SDI v3 50 768p 1366 V3-S50HW-XD03-v0,0

2 PDP FHP 42 1024i 1024 A1-FPF42C128128UC-52-v01 NA 10 (8)

3 LCD LPL 30 768p 1280

4 LCD LPL 37 768p 1366

5 LCD LPL 42 768p 1366

6 LCD Sharp 32 768p 1366

7 PDP SDI V3 42 480p 852

8 PDP FHP 37 1024i 1024

10 LCD AUO 30 768p 1280

11 LCD LPL 32 768p 1366

12 LCD AUO 32 768p 1366

13 LCD Sharp 37 768p 1366

13 LCD Sharp 37 768p 1366

14 LCD LPL 42 X 1080p 1920

15 PDP SDI 37 480p 852

16 PDP FHP 37 1080i 1024

17 PDP FHP 42 1080i 1024

18 PDP FHP 55 768p 1366

19 LCOS VENUS 720p 1280 NA

20 LCOS VENUS X 1080p 1920

21 LCD LPL 26 768p 1366 LC260WX2 - SL01 - v1,0

22 LCD LPL 32 X 768p 1366

23 PDP LG 42 480p 852

24 PDP SDI V4 42 480p 852

25 PDP SDI V5 42 768p 1024

26 PDP FHP A2 42 1024i 1024

27 PDP SDI HD V5” SDI V5 50 768p 1366

28 LCD Sharp 37 X 1080P 1920

29 LCD AUO 32

31 LCD Sharp 37 X X 1080P 1920

32 LCD LPL 20 768p 1366

33 LCD QDI 23 768p 1366

34 ECO PTV 51 1080i 1366

35 ECO PTV 55 1080i 1366

36 ECO PTV 61 1080i 1366

37 PDP FHP A3 42 1024I 1024

38 DLP 50 720p 1280

39 DLP 60 720p 1280

40 LCD Sharp 2.3 32 768p 1366

41 LCD LPL 42 X 768p 1366

42 PDP SDI V4 63 768p 1366

43 LCD Sharp 3.0 37 X 768p 1366

44 LCD Sharp 2.3 37 768p 1366

45 LCD LPL 26 768p 1366 LC260WX2 - SLB2 - v0,0

46 LCD LPL 32 768 p 1366

47 LCD LPL 42 768p 1366

48 LCD QDI 26 768p 1366

49 LCD AUO 26 768p 1366

50 LCD AUO 32 768p 1366

51 LCD AUO 37 768p 1366

52 LCD AUO 32 768p 1366

53 LCD LPL 37 768p 1366

54 PDP LGE 42 768p 1024

720p 12809 LCOS XION

p

768p 1366

Code nr Dimming

PWM

analog Full Baby

NA 8

NA 10 (8)

LC300W01-A3P7-v2.1 analog 8

LC370W01-A6K1-v1.0 analog 8

LC420W02-A6-v1.0 analog 8

ASV1-LQ315T3LZ13

ASV2.2

V3_S42SD-YD05-v0.2 NA 8

A1_PFP37C128128UB-71-

v0.1

analog

NA 10

Xion1,05-v0.01 NA 8

T296XW01-v0.5 analog 8

LC32CW01-A6K1v1.0 analog 8

T315XW01V0-v0.1 PWM 8

ASV2_LQ370T3LZ21

ASV2.2LQ370T3LZ44

Asv2.3 (1e samples) PWM (analog)

LC420WU1-SL01-v0.0 PWM 8

Tbd

analog 8

NA

NA

NA

FPF55C17196UA-51-v04 NA 10

NA

LC320WX2-SL01 analog 8

PDP42x2#56# Rev.00 NA 8

V4_S42SD-YD07-v0.0 NA 10 (8)

PWM 8

V4-S42AX-YD01-Rev0.1 NA 10 (8)

FPF42C128128UD-51 NA 8

V4-S50HW-XD04-v0.2 NA 10(8)

LQ370D3LZ1x ASV2.2 analog 10(8)

T315XW01-V3-V0.1 8

LW370D3LZ1xASV3.0

(1e sample)

LQ370D3LZ1x ASV3.0 PWM 10(8)

LC200WX1-SL01 tbd

QD23HL tbd

FPF42128135UA

?

ASV 2.3 PWM (analog) 8

LC420WX2-SLA1 analog

ASV 3.0 PWM

ASV 2.3 PWM (analog)

LCD320W01-SL06 PWM 8

SLB1 PWM 8

QD26HDL02 PWM 8

T260XW02 V4 PWM 8

T315XW01 V9 PWM 8

T370XW01 V1 PWM 8

T315XW02V5 PWM 8

LC370WX01-SL04 PWM 8

LGE 42” XGA X3 NA 10

PWM

(analog)

PWM 10(8)

NA n.a. (8)

NA n.a. (8)

NA

NA

NA

NA?

NA

PWM 8

Nr of bit

8

n.a. (8)

10

10

2k5

X

X

X

S *

X

XX

XX

X

X

XX

S

S

XX

XX

S

S

S

S

S

2k6

X

X

X

X30 LCD Sharp 37 X X 1080p 1920

S

S

S

S

S

X

X

X

X

X

X

E_06532_030.eps

X

220606

Figure 5-2 Display option code overview

Note: Be very careful which display option code you choose,

make sure it’s the original one (“Screen Diversity” on the option

code sticker).In case the wrong display option code is used the

TV can start rebooting.

• Store. All options and alignments are stored when

screen, move the “CURSOR UP/DOWN” key to display the

next/previous menu items.

• With the “CURSOR LEFT/RIGHT” keys, it is possible to:

– (De) activate the selected menu item.

– (De) activate the selected submenu.

pressing “cursor right” and then the “OK”-button

• SW Maintenance.

– SW Events. Not useful for service purposes. In case of

specific software problems, the development

department can ask for this info.

– HW Events. Not useful for service purposes. In case of

specific software problems, the development

department can ask for this info.

How to Exit SAM

Use one of the following methods:

• Press the “MENU” button on the RC-transmitter.

• Switch the set to STAND-BY via the RC-transmitter.

Note: As long as SAM is activated, it is not possible to change

a channel. This could hamper the White Point alignments

because you cannot choose your channel/frequency any more.

How to Navigate

• In SAM, you can select the menu items with the “CURSOR

UP/DOWN” key on the RC-transmitter. The selected item

will be highlighted. When not all menu items fit on the

Workaround: after you have sent the RC code “062596 INFO”

you will see the service-warning screen, and in this stage it is

still possible to change the channel (so before pressing the

“OK” button).

Page 18

EN 18 BJ2.4U/BJ2.5U LA5.

Service Modes, Error Codes, and Fault Finding

5.2.3 Customer Service Mode (CSM)

Purpose

When a customer is having problems with his TV-set, he can

call his dealer or the Customer Helpdesk. The service

technician can then ask the customer to activate the CSM, in

order to identify the status of the set. Now, the service

technician can judge the severity of the complaint. In many

cases, he can advise the customer how to solve the problem,

or he can decide if it is necessary to visit the customer.

The CSM is a read only mode; therefore, modifications in this

mode are not possible.

How to Activate CSM

Key in the code “123654” via the standard RC transmitter.

Note: Activation of the CSM is only possible if there is no (user)

menu on the screen!

How to Navigate

By means of the “CURSOR-DOWN/UP” knob on the RCtransmitter, you can navigate through the menus.

Contents of CSM

• SW Version (example: BJ24U-1.2.3.4_12345). Displays

the built-in main software version. In case of field problems

related to software, software can be upgraded. As this

software is consumer upgradeable, it will also be published

on the Internet.

• SBY Processor Version. Displays the built-in stand-by

processor software version. Upgrading this software will be

possible via a PC and a ComPair interface (see chapter

Software upgrade).

• Set Type. This information is very helpful for a helpdesk/

workshop as reference for further diagnosis. In this way, it

is not necessary for the customer to look at the rear of the

TV.In case you have no picture, the set type and the serial

number are also located at the bottom of the front from the

TV.There you should find a sticker with the mentioned data

on it.Note that if an NVM is replaced or is initialized after

corruption, this set type has to be re-written to NVM.

ComPair will foresee a possibility to do this.

• Production Code. Displays the production code (the serial

number) of the TV. Note that if an NVM is replaced or is

initialized after corruption, this production code has to be

re-written to NVM. ComPair will foresee a possibility to do

this.

• Code 1. Gives the latest five errors of the error buffer. As

soon as the built-in diagnose software has detected an

error the buffer is adapted. The last occurred error is

displayed on the leftmost position. Each error code is

displayed as a 2-digit number. When less than 10 errors

occur, the rest of the buffer is empty (00). See also

paragraph Error Codes for a description.

• Code 2. Gives the first five errors of the error buffer. See

also paragraph Error Codes for a description.

• Headphone Volume. Gives the last status of the

headphone volume, as set by the customer. The value can

vary from 0 (volume is minimum) to 100 (volume is

maximum). Change via ”MENU”, “TV”, “SOUND”,

“HEADPHONE VOLUME”.

• Dolby. Indicates whether the received transmitter

transmits Dolby sound (“ON”) or not (“OFF”). Attention: The

presence of Dolby can only be tested by the software on

the Dolby Signaling bit. If a Dolby transmission is received

without a Dolby Signaling bit, this indicator will show “OFF”

even though a Dolby transmission is received.

• Sound Mode. Indicates the by the customer selected

sound mode (or automatically chosen mode). Possible

values are “STEREO” and “VIRTUAL DOLBY

SURROUND”. Change via “MENU”, “TV”, “SOUND”,

“SOUND MODE”. It can also have been selected

automatically by signaling bits (internal software).

• Tuner Frequency. Not applicable for US sets.

• Digital Processing. Indicates the selected digital mode.

Possible values are “STANDARD” and “PIXEL PLUS”.

Change via “MENU”, “TV”, “PICTURE”, “DIGITAL

PROCESSING”.

• TV System. Gives information about the video system of

the selected transmitter.

– M: NTSC M signal received

– ATSC: ATSC signal received

• Center Mode. Not applicable.

• DNR. Gives the selected DNR setting (Dynamic Noise

Reduction), “OFF”, “MINIMUM”, “MEDIUM”, or

“MAXIMUM”. Change via “MENU”, “TV”, “PICTURE”,

“DNR”

• Noise Figure. Gives the noise ratio for the selected

transmitter. This value can vary from 0 (good signal) to 127

(average signal) and to 255 (bad signal). For some

software versions, the noise figure will only be valid when

“Active Control” is set to “medium” or “maximum” before

activating CSM.

• Source. Indicates which source is used and the video/

audio signal quality of the selected source. (Example:

Tuner, Video/NICAM) Source: “TUNER”, “AV1”, “AV2”,

“AV3”, “HDMI 1”, “SIDE”. Video signal quality: “VIDEO”, “SVIDEO”, “RGB 1FH”, “YPBPR 1FH 480P”, “YPBPR 1FH

576P”, “YPBPR 1FH 1080I”, “YPBPR 2FH 480P”, “YPBPR

2FH 576P”, “YPBPR 2FH 1080I”, “RGB 2FH 480P”, “RGB

2FH 576P” or “RGB 2FH 1080I”. Audio signal quality:

“STEREO”, “SPDIF 1”, “SPDIF 2”, or “SPDIF”.

• Audio System. Gives information about the audible audio

system. Possible values are “Stereo”, ”Mono”, “Mono

selected”, “Analog In: No Dig. Audio”, “Dolby Digital 1+1”,

“Dolby Digital 1/0”, “Dolby Digital 2/0”, “Dolby Digital 2/1”,

“Dolby Digital 2/2”, “Dolby Digital 3/0”, “Dolby Digital 3/1”,

“Dolby Digital 3/2”, “Dolby Digital Dual I”, “Dolby Digital

Dual II”, “MPEG 1+1”, “MPEG 1/0”, “MPEG 2/0”. This is the

same info as you will see when pressing the “INFO” button

in normal user mode (item “signal”). In case of ATSC

receiving there will be no info displayed.

• Tuned Bit. Not applicable for US sets.

• Preset Lock. Indicates if the selected preset has a child

lock: “LOCKED” or “UNLOCKED”. Change via “MENU”,

“TV”, “CHANNELS”, “CHANNEL LOCK”.

• Lock After. Indicates at what time the channel lock is set:

“OFF” or e.g. “18:45” (lock time). Change “MENU”, “TV”,

“CHANNELS”, “LOCK AFTER”.

• TV Ratings Lock. Indicates the “TV ratings lock” as set by

the customer. Change via “MENU”, “TV”, “CHANNELS”,

“TV RATINGS LOCK”. Possible values are: “ALL”,

“NONE”, “TV-Y”, “TV-Y7”, “TV-G”, “TV-PG”, “TV-14” and

“TV-MA”.

• Movie Ratings Lock. Indicates the “Movie ratings lock” as

set by the customer. Change via “MENU”, “TV”,

“CHANNELS”, “MOVIE RATINGS LOCK”. Possible values

are: “ALL”, “NR”, “G”, “PG”, “PG-13”, “R”, “NC-17” and “X”.

• V-Chip Tv Status. Indicates the setting of the V-chip as

applied by the selected TV channel. Same values can be

shown as for “TV RATINGS LOCK”.

• V-Chip Movie Status. Indicates the setting of the V-chip

as applied by the selected TV channel. Same values can

be shown as for “MOVIE RATINGS LOCK”.

• Options 1. Gives the option codes of option group 1 as set

in SAM (Service Alignment Mode).

• Options 2. Gives the option codes of option group 2 as set

in SAM (Service Alignment Mode).

• AVL. Indicates the last status of AVL (Automatic Volume

Level): “ON” or “OFF”. Change via “MENU”, “TV”,

“SOUND”, “AVL”. AVL can not be set in case of digital

audio reception (e.g. Dolby Digital or AC3)

• Delta Volume. Indicates the last status of the delta volume

for the selected preset as set by the customer: from “-12”

to “+12”. Change via “MENU”, “TV”, “SOUND”, “DELTA

VOLUME”.

• HDMI key validity. Indicates the key’s validity.

• IEEE key validity. Indicates the key’s validity (n.a.).

Page 19

Service Modes, Error Codes, and Fault Finding

EN 19BJ2.4U/BJ2.5U LA 5.

• POD key validity. Indicates the key’s validity, this will only

work with an authentic POD card.

• Digital Signal Quality. not applicable

How to Exit CSM

Press any key on the RC-transmitter (with exception of the

“CHANNEL +/-”, “VOLUME”, “MUTE” and digit (0-9) keys).

5.2.4 Service Mode of Converter Boards for Ambi Light

Purpose

To switch on the lamps manually in case I

2

C-bus triggering

fails.

The Service Mode can be activated by disconnecting

connectors 1M59 and 1M49 and then by shorting for a moment

the two solder pads [1] on the Ambi Light Inverter Panel. See

figure “Service Mode pads AmbiLight panel”.

1

The microprocessor performs the following tasks:

• Dimming of Ambi Light by means of PWM.

• Translation of I

2

C-bus commands to PWM.

• Switches the Ambi Light board to protection if needed (in

case of protection only the lamps switch off, no set

protection is triggered).

There are two ways of protection: parallel arcing protection and

serial arcing protection.

Parallel arcing protection is performed by sensing the switching

frequency. In case of short circuit of the transformer output, this

frequency > 100 kHz and the board goes into protection.

Serial arcing protection is performed by detection of arc in

ground wire of the lamp units. In this case, the protection pulse

is transmitted via an opto-coupler.

Protection can be disabled by short-circuiting diode 6112 or

capacitor 2173 or by connecting pin 8 of the microprocessor to

ground.

Repair Tips

In case only one or no lamp unit at all works, probably the

+12Vb (12 - 13 V) is not available or the fuse is broken. Check

for broken MOSFETS or check if they are switched off properly

by the transistors connected to the PWM outputs of the

microprocessor.

In case the Ambi Light switches off after two seconds, serial

arcing or parallel arcing protection is active. Serial arcing

protection can be excluded by disconnecting the opto-coupler;

check for bad solder joints on transformer or lamp units.

Parallel arcing protection can be disabled by grounding pin 8 of

the microprocessor. Usually the switching frequency (normally

63 kHz) will then be too high. Possible causes are one

MOSFET of the converter has no gate drive or is broken, or

there is a short-circuit of the output of the transformer.

G_15950_049.eps

Figure 5-3 Service Mode pads AmbiLight panel

In this chassis, both single and double fitted boards can be

used. The double fitted boards are used in sets with 3 or 4

sided Ambi Light units whereas the single fitted boards are

used in sets with 2 sided Ambi Light units. A double fitted board

can drive 2 lamp units (6 lamps) and a single fitted board can

drive 1 lamp unit (3 lamps).

The double fitted boards are supplied by +12Va and +12Vb.

The microprocessor is supplied by +12Va.

Therefore, if only +12Va is available, lamp unit B will not work.

See figure “Building blocks of Converter Board” for details.

+12Va

Stab.

Board select

+5V

Inverters

µ

Processor

PWM out

+12Va

I²C

060406

Lamp unit A

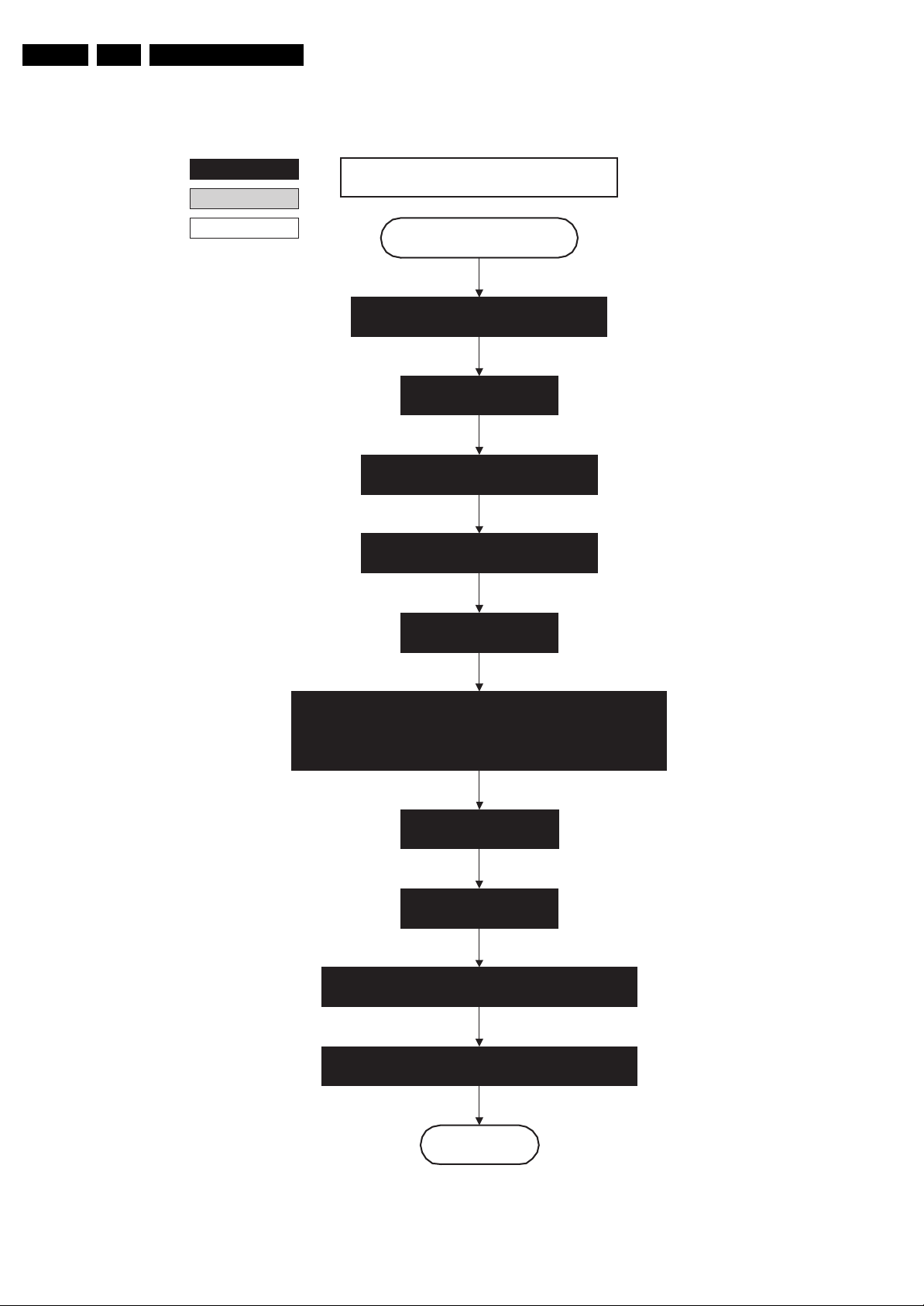

5.3 Stepwise Start-up

The stepwise start-up method, as known from FTL/FTP sets is

not valid any more. The situation for this chassis is as follows:

when the TV is in a protection state detected via the Stand-by

Processor (and thus blinking an error) and SDM is activated via

shortcutting the pins on the SSB, the TV starts up until it

reaches the situation just before protection. So, this is a kind of

automatic stepwise start-up. In combination with the start-up

diagrams below, you can see which supplies are present at a

certain moment.

Important to know here is, that if e.g. the 3V3 detection fails

(and thus error 11 is blinking) and the TV is restarted via SDM,

the Stand-by Processor will enable the 3V3, but will not go to

protection now. The TV will stay in this situation until it is reset

(Mains/AC Power supply interrupted).

The abbreviations “SP” and “MP” in the figures stand for:

• SP: protection or error detected by the Stand-by

Processor.

• MP: protection or error detected by the VIPER Main

Processor.

Protection

+12Vb (12

-13V)

Figure 5-4 Building blocks of Converter Board

Lamp unit B

G_15950_050.eps

060406

Page 20

EN 20 BJ2.4U/BJ2.5U LA5.

Service Modes, Error Codes, and Fault Finding

Off

Mains

“off”

Mains

“on”

- WakeUp requested

- Acquisition needed

Stand-by

(Off St-by)

- POD Card remove

- Tact SW pushed

- No data Acquisition required

and no POD present

- Tact SW pushed

- WakeUp requested

- Acquisition needed

d

POD

Stand-by

On

Only applicable for sets with CableCARDTM slot (POD)

*

Figure 5-5 Transition diagram

No data Acquisition

required and

*

Stand-by

POD present

GoToProtec

Semi

GoToProtection

tion

WakeUp

requested

- St-by requested

- Tact SW pushed

WakeUp

requested

Protection

Active

GoToProtection

F_15400_095.eps

020206

Page 21

Service Modes, Error Codes, and Fault Finding

EN 21BJ2.4U/BJ2.5U LA 5.

Off

Mains is applied

Standby Supply starts running.

+5V2, 1V2Stb, 3V3Stb and +2V5D become present.

In case of PDP 3V3 Vpr to CPU PDP becomes present.

st-by µP resets

All I/O lines have a “high” default state:

- Assert the Viper reset.

- Sound-Enable and Reset-Audio should remain “high”.

- NVM power line is “high”, no NVM communication possible.

Initialise I/O pins of the st-by µP, start keyboard scanning, RC

detection, P50 decoding. Wake up reasons are “off”.

In case of FHP PDP: Switch PDPGO “low”

CPUGO (inverse of the stby I/O line POD-MODE) and PDPGO

are then both “low” and the PDP is in the “low power” mode.

ECO Baby Jaguar??

No

Switch “low” the NVM power reset line. Add a 2ms delay

before trying to address the NVM to allow correct NVM

Switch “on” all supplies by switching LOW the POD-MODE

+5V, +8V6, +12VS, +12VSW and Vsound are switched on

initialization.

and the ON-MODE I/O lines.

Wait 50ms and then star t polling the detect-

5V, detect-8V6 and detect-12V every 40ms.

Yes Yes

Stand-by or

Protection

If the protection state was left by short circuiting the

SDM pins, detection of a protection condition during

startup will stall the startup. Protection conditions in a

playing set will be ignored. The protection mode will

not be entered.

- Switch Sound-Enable and Reset-Audio “high”.

They are “low” in the standby mode if the

standby mode lasted longer than 2s.

*

Auto Protection

Line High??

Switching the POD-MODE and the

Switching the POD-MODE

low in an FHP PDP set

makes the CPUGO go “high”

and starts the PDP CPU.

except in an FHP PDP Cold

Boot

“on” mode “low” in an SDI PDP se t

makes the PDP supplies go to the

*

“on” mode. Within 4 seconds, a

valid LVDS must be sent to the

display to prev ent protection.

(valid for V3 version)

*

The availab ility of the supplies is check ed through d etect signals (deliver ed by

dedicated detect-IC's) going to the st-by µP. These signals are available for

+12V, +8V6, +5V, +1V2 and +2V5. A low to high transition of the signals should

occur within a certain time after toggling the standby line. If an observers is

detected before the time-out elapses, of course, the process should continue in

order to minimize start up time.

action holder: MIPS

action holder: St-by

autonomous action

Audio Error

SP

*

detect-5V

received within

2900 ms after POD-MODE

Switching the PDPGO “high”

will give a visual artefa ct and

should only be done if really

necessary.

To part B To part B

Only applicable for sets with CableCARDTM slot (POD)

*

toggle?

Yes

activate +5V supply detection algorithm

detect-12VSW received within

2900 ms after POD-mode

toggle?

Yes

activate +12VSW supply

detection algorithm

Enable the +1V2 supply (ENABLE-1V2)

Start polling the detect-1V2 every 40ms

No

*

Yes

No

FHP PDP Set?

Yes

Switch PDPGO high :

PDP should start: 5V, 8V6 and

12V are activated

detect-5V

received within

2900 ms after PDPGO

toggle?

+12V error

SP

No need to wait for the 8V6 detection at this point.

within 6300 ms after POD-mode toggle?

Startup shall not wait for this detection

detect-8V6 received

and continue startup.

No

+8V6 error

SP

No

+5V error

No

SP

*

Yes

activate +8V6 supply

detection algorithm

return

F_15400_096a.eps

230606

Figure 5-6 “Off” to “Semi Stand-by” flowchart (part 1)

Page 22

EN 22 BJ2.4U/BJ2.5U LA5.

Service Modes, Error Codes, and Fault Finding

From part A

No

From part B

detect-1V2

received within

250ms?

Yes

Enable the supply for

+2.5V and +3.3V (ENABLE-3V3)

Start polling the detect-3V3 every 40ms

detect-3V3

received within

250 ms?

Yes

Activate supply detection algorithms for

+1V2 and +3V3

SUPPLY-FAULT I/O line

is High?

Yes

Enable the supply fault detection

interrup t

action holder: MIPS

action holder: St-by

autonomous action

No

+1.2V error

SP

No separate enable and

detect is present for the +2V5

supply in the Baby Jaguar.

+3.3V errorNo

SP

Supply fault errorNo

SP

No

No

Release viper reset

Feed warm boot script(2)

Set I²C slave address

of Standby µP to (A0h)

Detect EJTAG debug probe

(pulling pin of the probe interface to

ground by inserting EJTAG probe)

EJTAG pro be

connected ?

No

Cold boot?

Yes

Release viper reset

Feed cold boot script(1)

Release PNX2015 reset 100ms after

Viper reset is released

Bootscript ready

in 1250 ms?

Yes

Set I²C slave address

of Standby µP to (64h)

RPC start (comm. protocol)

Yes

Release viper reset

Feed initializing boot script (3)

disable alive mechanism

Release PNX2015 reset 100ms

after Viper reset is released

No

Flash to RAM image

transfer succeeded

within 30s?

Yes

Viper SW initialization

succeeded

within 20s?

Code = 5

Switch Viper in reset

No

Code = 53

To part C To part C To part C To part C

F_15400_096b.eps

Figure 5-7 “Off” to “Semi Stand-by” flowchart (part 2)

260505

Page 23

Service Modes, Error Codes, and Fault Finding

EN 23BJ2.4U/BJ2.5U LA 5.

From part B From part B From part B

Yes

from standby µP.

SDI PDP

Set?

No

FHP PDP

Set?

Switch “on” the LVDS output of

*

the PNX2015 with a correct

clock frequency within 4s after

Yes

switching the POD and “on”

mode to prevent PDP display

supply protection.

These LVDS items are

SDI V3 displ ay only ! !

Yes

Send ST BYEN = 1

to PDP displ ay (I²C)

PFCON = 1

VCCON = 1

Wait until Viper starts to

communicate

3-th try?

Yes

Log Code as

error code

SP

Wait 10ms

Switch the NVM reset

line HIGH.

Disable all supply related protections and

switch off the +2V5, +3V3 DC/DC converter.

Wait 5ms

switch off the remaining DC/DC

converters

Switch POD- MODE an d ON-MODE

I/O line “high”.

*

Enable Alive check mechanism

MIPS reads the wake up reason

Wait for the +8V6 to be detected if not yet present. (if

it does not come, the standby µP will enter a

protection mode, this is not a dead end here)

PWR-OK- PDP

received within 10s

after POD and “on” mode

toggle ?

Yes

Init SDI PDP

Switch LVDS back off if

end state is not the active

state.

Switch PDPGO “ low”

*

action holder: MIPS

action holder: St-by

autonomous action

No

Log display

error and enter

protection mode

SP

No

Start 4 seconds preheating timer in case of

a LPL scanning backlight LCD set.

AVIP needs to be started before the MPIF in order to have a good clock distribution.

AVIP default power-up mode is Standby. The Viper instructs AVIP via I²C to enable all the

PLLs and clocks and hence enter to Full Power mode.

Initialize PNX2015 HD subsystem

MPIFs should be initialized

MPIF should deliver 4 observers:

POR= 0; normal operation

MSUP = 1: Main supply is present

ASUP = 1; audio supply is present

ROK = 1; reference frequency is present (coming from AVIP)

All observers present with correct state?

Yes

Initialize tuners and HDMI

Initialize source selectio n

Initialize video processing ICs

- Spider (if available)

No

Init FHP PDP

Log appropriate

Observer error

Do not enter semi-standby state in case of an LPL

scanning backlight LCD set before 4 s preheating timer has

elapsed.

Only applicable for sets with CableCARDTM slot (POD)

*

Figure 5-8 “Off” to “Semi Stand-by” flowchart (part 3)

Initialize Columbus

Initialize 3D Combfilt er

Initialize AutoTV

Semi-Stand-by

F_15400_096c.eps

020206

Page 24

EN 24 BJ2.4U/BJ2.5U LA5.

Service Modes, Error Codes, and Fault Finding

action holder: MIPS

action holder: St-by

autonomous action

32" / 37" / 42" LCD LPL

Semi Standby

Wait until previous on-state is left more than 2

seconds ago. (to prevent LCD display problems)

Assert RGB video blanking

and audio mute

Initialize audio and video processing ICs and

functions according needed use case.

Wait until QVCP generates a valid LVDS output

clock.

Switch “on” 12V LCD supply

(LCD-Power-on)

Start to apply valid interface signals to the module (LVDS) within a time

frame of min. 17.5ms to max. 67.5ms after supply switch “on”.

In implementation, use 25ms, this makes it compatible with 37HD"Sharp

(t=17.5ms is the supply switch-on delay taken into account)

Wait 250ms (min. = 200ms)

Switch “off” RGB blanking

Switch “on” LCD lamp after valid, stable video, corresponding

to the requested output is delivered by the Viper

Switch Audio-Reset and sound enable “low” and demute

Active

Figure 5-9 “Semi Stand-by” to “Active” 32” / 37” / 42” LCD LPL flowchart

F_15570_011.,eps

210605

Page 25

Service Modes, Error Codes, and Fault Finding

32" LCD LPL scanning backlight

EN 25BJ2.4U/BJ2.5U LA 5.

The assumption he re is that a fast

toggle (<2s) can only happen during ON>SEMI ->ON. In these st ate s, th e Vipe r is

still active and can pro vide the 2 s delay.

If the transition ON->SEMI->STBY->SEMI-

>ON can be made in less than 2s, we

have to de lay the semi -> stby transition

until the requirement is met.

Semi Standby

Wait until previous on-state is left more than 2

secon d s ago. (to prevent LCD display problems)

Assert RGB video blanking

and audio m ut e

Initialize audio and video processing IC's and

functions according needed use case.

Wait until QVCP generates a valid lvds output

clock.

Switch on 12V LCD supply

(LCD-Power-on)

action holder: M I P S

action holder: St-by

autonomous ac tion

Start to apply valid interface signals to the module (LVDS) within a

time frame of min. 17.5ms to max. 67.5ms after supply switch on.

In implementation, use 25ms, this makes it compatible with 32"Sharp

(t=17.5ms is the supply switch-on delay taken into account)

Switch off backlight (FMS scan rate conversion interface) to

prevent backlight to freerun after preheating phase.

Set scanning backlight to Normal scanning using the

FMS scan rate conversion interface.

Switch off RGB blanking

Switch on LCD lamp after valid, stable video, corresponding

to the requested output is delivered by the Viper

Switch Audio-Reset and sound enable low and demute

(see CHS audio LdspMute interface).

Active

Figure 5-10 “Semi Stand-by” to “Active” 32” LCD LPL Scanning Backlight flowchart

G_15910_009.eps

230606

Page 26

EN 26 BJ2.4U/BJ2.5U LA5.

Service Modes, Error Codes, and Fault Finding

32" / 37" / 42" LCD LP L &

32" LCD LPL sca nni ng

backlight

action holder: M IP S

Active

action holder: St-by

autonomous action

Mute al l sound outputs.

Switch reset-audio and sound-enable

Wait 250ms (m in. = 200ms)

Switch off 12V LCD supply within a time frame of min.

0.5 ms to max. 50ms after LVDS switch off.

(Viper I/O: LCD_P WR_ON)

lines high

switch off LCD lamp

Mute al l video outputs

Switch off LVDS signal

(Viper I/O: PD-LVDS)

Semi Standby

Figure 5-11 “Active” to “Semi Stand-by” flowchart

F_15570_012.eps

230606

Page 27

Service Modes, Error Codes, and Fault Finding

Semi Stand by

Delay transition until ramping down of ambient light is

finished. *)

EN 27BJ2.4U/BJ2.5U LA 5.

action holder: MIPS

action holder: St-by

autonomous action

Switch ambient light to passive mode with RGB

values on zero. *)

transfer Wake up reasons to the

Stand by µP.

Images are re-transferred to DDR-RAM from

Flash RAM (verification through checksum)

MIPS image completes the application reload,

stops DDR-RAM access, puts itself in a

sleepmode and signals the standby µP when the

standby mode can be entered.

DDR-RAM is put in self refresh mode and the images

are kept in the hibernating DDR-RAM.

Wait 5ms

Switch Viper in reset state

*) If this is not performed and the set is

switched to standby when the ramping of

the EPLD is still ongoing, the lights will

remain lit in standby.

Important remark:

release reset audio and sound-

enable 10 sec after entering

standby to save power

Wait 10ms

Switch the NVM reset line HIGH.

Disable all supply related protections and switch off

the +2V5, +3V3 DC/DC converter.

Wait 5ms

switch off the remaining DC/DC converters

Switch OFF all supplies by switching HIGH the POD-

MODE and the ON-MODE I/O lines.

Stand by

For PDP this means CPUGO

becomes low.

G_15960_133.eps

100306

Figure 5-12 “Semi Stand-by” to “Stand-by” flowchart

Page 28

EN 28 BJ2.4U/BJ2.5U LA5.

Service Modes, Error Codes, and Fault Finding

POD

transfer Wake up reasons to the

Stand by µP.

Images are re-transferred to DDR-RAM from

Flash RAM (verification through checksum)

MIPS image completes the application reload,

stops DDR-RAM access, puts itself in a

sleepmode and signals the standby µP when the

standby mode can be entered.