DISCRETE SEMICONDUCTORS

DATA SH EET

M3D737

BGF802-20

CDMA800 power module

Product specification

Supersedes data of 2002 Nov 12

2003 Feb 24

Philips Semiconductors Product specification

CDMA800 power module BGF802-20

FEATURES

• Typical CDMAIS95 performance at a supply voltage of

28 V:

– Output power = 3 W

– Gain = 30 dB

– Efficiency = 18%

– ACPR < -53 dBc at 750 kHz and BW = 30 kHz

– ACPR < -69 dBc at 1.98 MHz and BW = 30 kHz.

• Low distortion to CDMA signals

• Excellent 2-tone performance

• Low die temperatures using copper flange

• Integrated temperature compensated bias

• 50 Ω input/output system

• Flat gain over frequency range.

APPLICATIONS

• Base station RF power amplifiers in the 869 to 894 MHz

frequency range

• CDMA IS95, CDMA2000, multi carrier applications

• Macrocell (driver stage) and Microcell (final stage).

PINNING - SOT365C

PIN DESCRIPTION

1 RF input

2V

3 RF output

Flange ground

Top view

Fig.1 Simplified outline.

S

1

23

MBL257

DESCRIPTION

25 W LDMOS power amplifier module for base station

amplifier applications in the 869 to 894 MHz range.

QUICK REFERENCE DATA

Typical RF performance at Tmb=25°C.

MODE OF OPERATION

f

(MHz)

V

(V)

DS

P

(W)

L

G

(dB)

p

η

(%)

ACPR

(dBc)

EVM

(%)

CW 869 to 894 28 25 29 48 −−

IS95 CDMA

(1)

869 to 894 28 3 30 18 −53

GSM EDGE 869 to 894 26 2.5 30 16 −65

−69

(2)

(3)

(4)

−

0.4

Notes

1. IS95 CDMA (Pilot, paging, sync and traffic codes 8−13).

2. ACPR 750 kHz at 30 kHz resolution bandwidth.

3. ACPR 1.98 MHz at 30 kHz resolution bandwidth.

4. ACPR 400 kHz at 30 kHz resolution bandwidth.

2003 Feb 24 2

Philips Semiconductors Product specification

CDMA800 power module BGF802-20

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134).

SYMBOL PARAMETER MIN. MAX. UNIT

V

S

P

D

P

L

T

stg

T

mb

CHARACTERISTICS

Tmb=25°C; VS= 28 V; PL= 3.0 W; f = 869 to 894 MHz; ZS=ZL=50Ω; unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

I

DQ

P

1dB

G

p

∆G

p freq

∆G

p pwr

∆ϕ

freq

G

OB

VSWR

in

H

2

H

3

IS95 CDMA (PL= 3 W average)

DC supply voltage − 30 V

input drive power − 100 mW

load power − 30 W

storage temperature −30 +100 °C

operating mounting base temperature −20 +90 °C

quiescent current (pin 2) PD= 0 mW 245 280 320 mA

load power at 1 dB gain compression 18 25 − W

power gain 28 30 32 dB

gain flatness over

− 0.2 1.0 dB

frequency range

gain flatness over power

PL= 30 mW up to 3 W −0.8 −0.2 0.2 dB

band

phase linearity over

− 0.2 − deg

frequency range

delay flatness − 200 − ps

out of band gain small signal, PD= 0 dBm;

f < 869 MHz, f > 894 MHz

−−G

Pimax

+1

note 1

dB

input VSWR − 1.6:1 2.0:1

second harmonic −−37 −34 dBc

third harmonic −−61 −58 dBc

stability VSWR ≤ 3 : 1 through all

phases; V

=25to28V

S2

ruggedness VSWR = 10 : 1 through all

phases; P

=5W

L

all spurious outputs more than 60 dB

below desired signal

no degradation in output power

η efficiency 15 18 − %

ACPR

ACPR

750 kHz

1.98 MHz

spectral regrowth;

measured in 30 kHz RBW

−−53 −49 dBc

−−69 −66 dBc

Note

1. G

is small signal in-band gain.

Pi

2003 Feb 24 3

Philips Semiconductors Product specification

CDMA800 power module BGF802-20

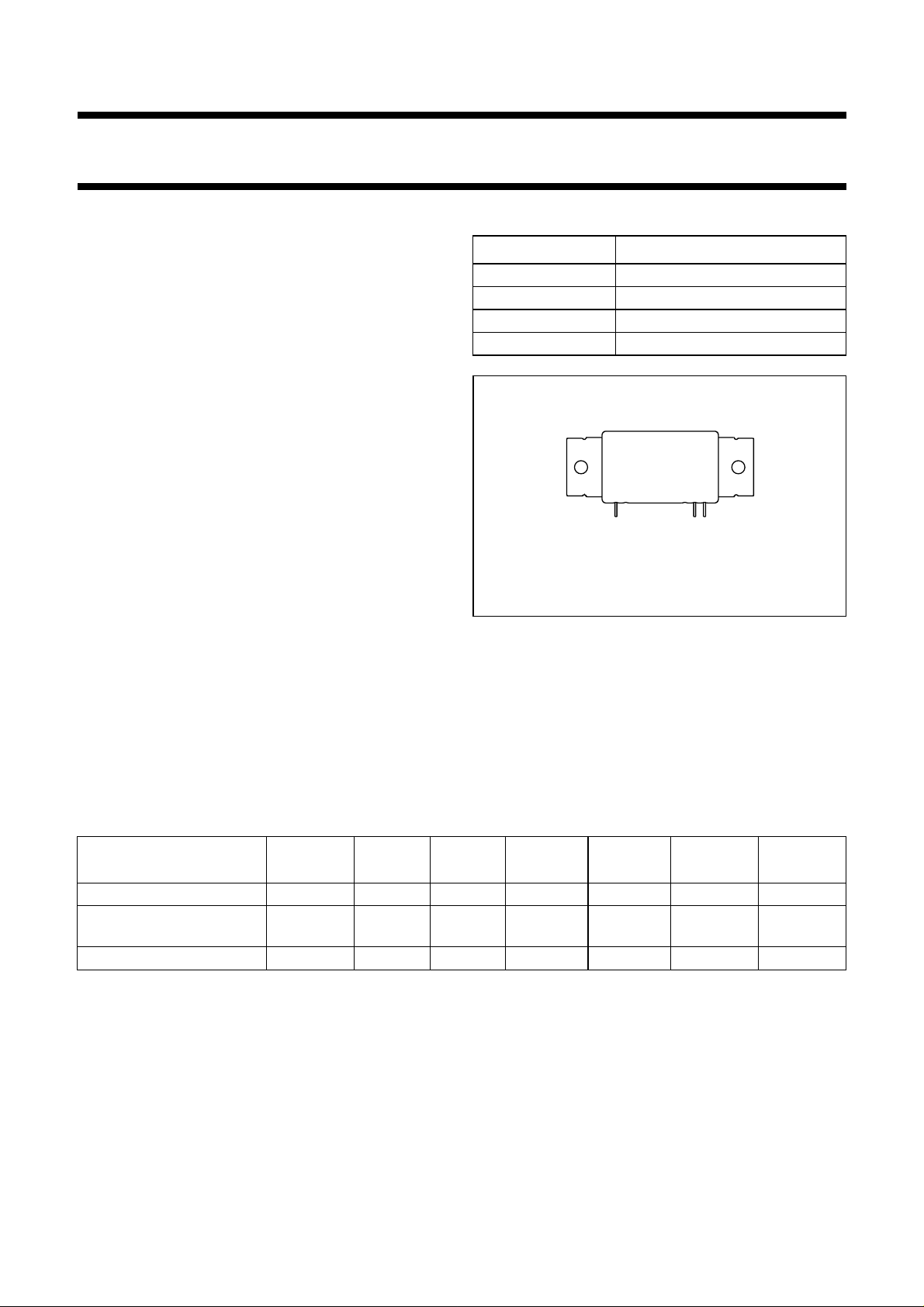

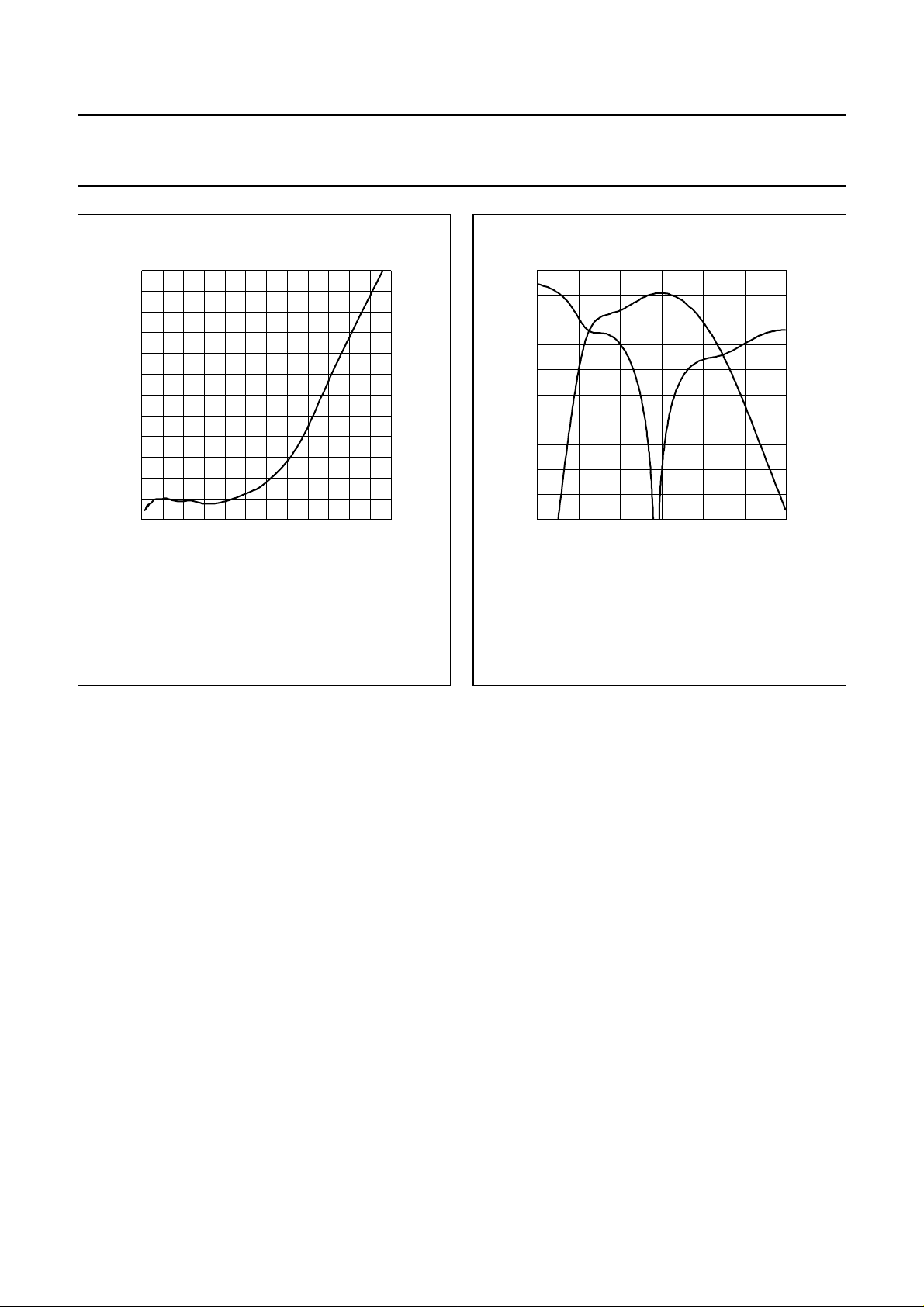

6

P

L (AV)

MBL762

(W)

30.4

handbook, halfpage

G

p

(dB)

30

29.6

29.2

28.8

024 8

f = 882 MHz.

G

p

η

Fig.2 IS95 power gain and efficiency as functions

of load power; typical values.

40

30

20

10

0

(%)

−40

handbook, halfpage

ACPR

η

750 kHz

(dBc)

−45

−50

−55

−60

−65

f = 882 MHz.

024 8

MBL763

6

P

L (AV)

(W)

Fig.3 ACPR at 750 kHz as a function of output

power; typical values.

6

P

L (AV)

MBL764

(W)

−60

handbook, halfpage

ACPR

1.98 MHz

(dBc)

−64

−68

−72

−76

024 8

f = 882 MHz.

Fig.4 ACPR at 1.98 MHz as a function of output

power; typical values.

30.4

handbook, halfpage

G

p

(dB)

30

29.6

29.2

28.8

28.4

28

010203051525

f = 882 MHz.

G

p

MBL765

η

PL (W)

Fig.5 CW power gain and efficiency as functions

of load power; typical values.

60

50

40

30

20

10

0

(%)

η

2003 Feb 24 4

Philips Semiconductors Product specification

CDMA800 power module BGF802-20

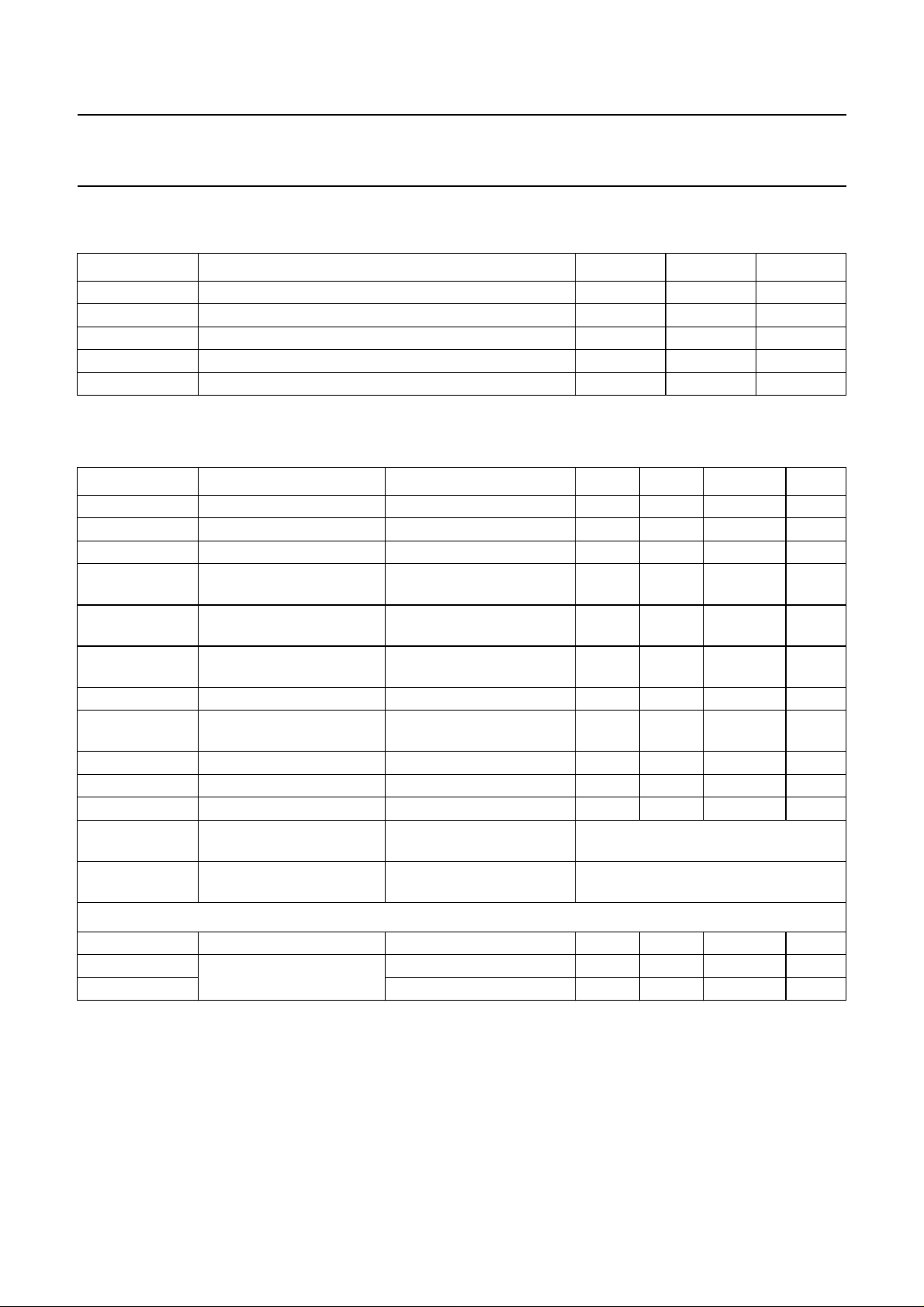

30.4

handbook, halfpage

G

p

(dB)

30

29.6

29.2

28.8

048 16

f1= 882 MHz; f2= 883 MHz.

G

p

12

η

P

L (AV)

Fig.6 Two tone power gain and efficiency as

functions of load power; typical values.

MBL766

(W)

48

36

24

12

0

(%)

12

P

L (AV)

MBL767

(W)

−20

handbook, halfpage

d

η

im

(dBc)

−30

−40

−50

−60

−70

048 16

f1= 882 MHz; f2= 883 MHz.

d3d

5

d

7

Fig.7 Two tone intermodulation distortion as

function of load power; typical values.

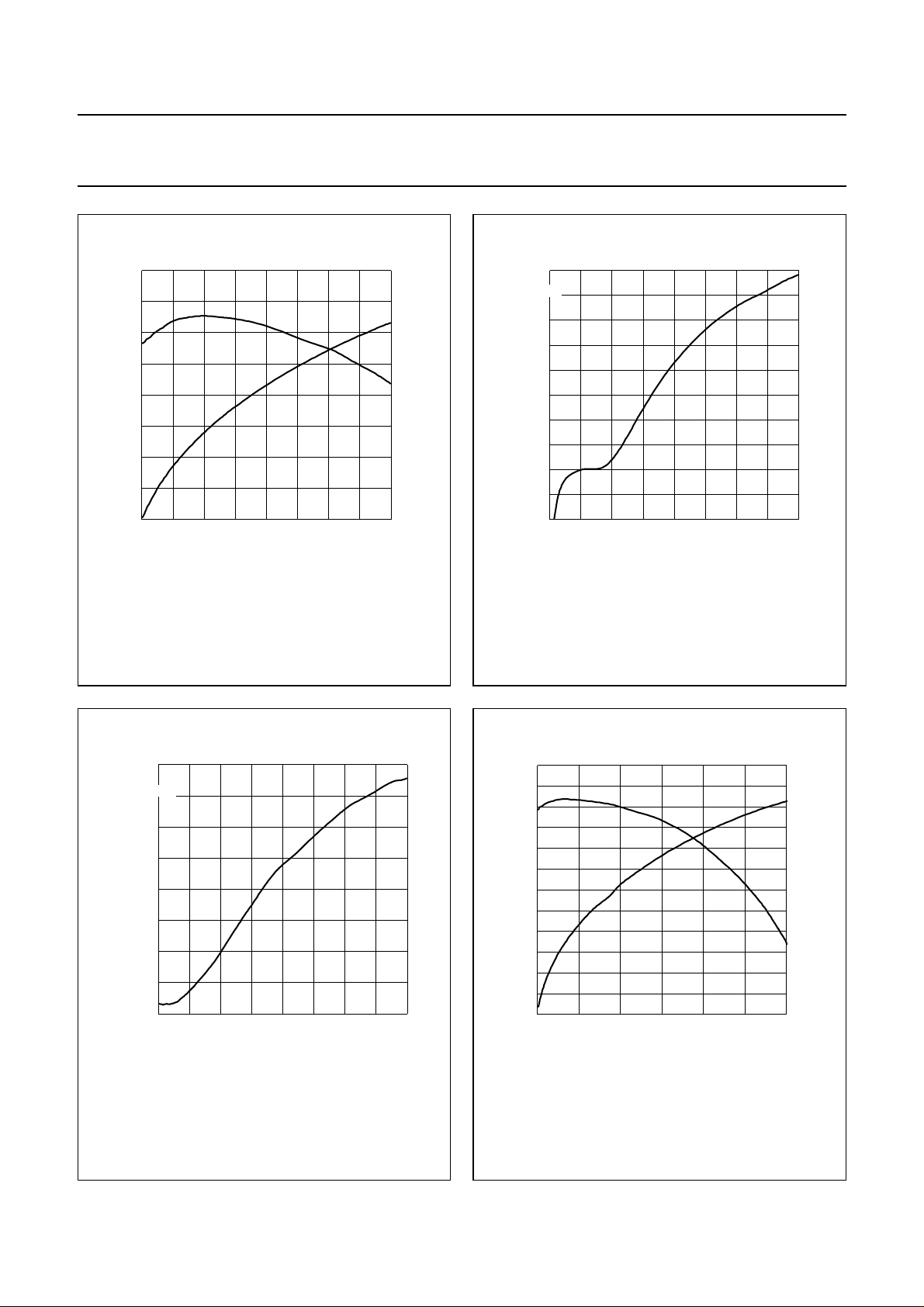

P

L (AV)

MBL768

(W)

−58

handbook, halfpage

ACPR

400 kHz

(dBc)

−60

−62

−64

−66

−68

0

f = 882 MHz.

412

82610

Fig.8 GSMEDGEACPRat400 kHz as a function

of load power; typical values.

P

L (AV)

MBL769

handbook, halfpage

4

EVM

rms

(%)

3

2

1

0

04 12

f = 882 MHz.

82610

Fig.9 GSM EDGE rms EVM as a function of load

power; typical values.

(W)

2003 Feb 24 5

Philips Semiconductors Product specification

CDMA800 power module BGF802-20

P

L (AV)

MBL770

12

handbook, halfpage

EVM

M

(%)

10

8

6

4

2

0

04 12

f = 882 MHz.

82610

Fig.10 GSM EDGE peak EVM asafunctionof load

power; typical values.

(W)

31

handbook, halfpage

s

21

(dB)

s

29

27

25

23

21

750 850 950 1050

11

s

21

s

f (MHz)

Fig.11 s-parameters as a function of frequency.

MBL771

11

0

−6

−12

−18

−24

−30

s

11

(dB)

2003 Feb 24 6

Philips Semiconductors Product specification

CDMA800 power module BGF802-20

MOUNTING RECOMMENDATIONS

General

LDMOST base station modules are manufacturedwith the

dies directly mounted onto a copper flange. The matching

and bias circuit components are mounted on a

printed-circuit board (PCB), which is also soldered onto

thecopperflange.ThediesandthePCBareencapsulated

in a plastic cap, and pins extending from the module

provideameansofelectricalconnection.Thisconstruction

allows the module to withstand a limited amount of flexing,

although bending of the module is to be avoided as much

as possible. Mechanical stress can occur if the bottom

surface of the module and the surface of the amplifier

casing (external heatsink) are not mutually flat. This,

therefore, should be a consideration when mounting the

module in the amplifier. Another cause of mechanical

stress can arise from thermal mismatch after soldering of

the pins. Precautions should be taken during soldering,

and efforts made to ensure a good thermal contact

between the flange and the external heatsink.

External heatsink (amplifier casing)

The module should always be mounted on a heatsink with

a low thermal resistance to keep the module temperature

as low as possible. The mounting area of the heatsink

should be flat and free from burrs and loose particles. We

recommend a flatness for the mounting area of between

50 µm concave and 50 µm convex. The 50 µm concave

value is to ensure optimal thermal behaviour, while the

50 µm convex value is intended to limit mechanical stress

due to bending.

CAUTION

During the following procedures ESD precautions should

be taken to protect the device from electrostatic damage.

PROCEDURE

1. Applyathin, evenly spread layer of thermal compound

to the module flange bottom surface. Excessive use of

thermal compound may result in increased thermal

resistance and possible bending of the of the flange.

Too little thermal compound will result in an increase

in thermal resistance.

2. Take care that there is some space between the cap

and the PCB. Bring the module into contact with the

external heatsink casing, ensuring that there is

sufficient space for excessive thermal compound to

escape.

3. Carefully align the module with the heatsink casing

mounting holes, and secure with two 3 mm bolts and

two flat washers. Initially tighten the bolts to “finger

tight” (approximately 0.05 Nm). Using a torque

wrench, tighten each bolt in alternating steps to a final

torque of 0.4 Nm.

4. After the module is secured to the casing, the module

leads may be soldered to the PCB. The leads are for

electrical connection only, and should not be used to

support the module at any time in the assembly

process.

A soldering iron may be used up to a temperature of

250 °C for a maximum of 10 seconds. Avoid contact

between the soldering iron and the plastic cap.

In order to ensure optimal thermal behaviour, the use of

thermal compound is recommended when mounting the

module onto the amplifier external heatsink.

The following recommended thermal compounds have a

thermal conductivity of >0.5 W/mK:

• WPS II (silicone-free) from Austerlitz-Electronics

• Comp. Trans. from KF

• 340 from Dow Corning

• Trans-Heat from E. Friis-Mikkelsen.

The use of thermal pads instead of thermal compound is

not recommended as the pads may not maintain a uniform

flatness over a period of time.

Mounting

PREPARATION

Ensure that the surface finishes are free from burrs, dirt

and grease.

2003 Feb 24 7

Electrical connections

The main ground path of all modules is via the flange. It is

therefore important that the flange is well grounded and

that return paths are kept as short as possible. An

incorrectly grounded flange can result in a loss of output

power or in oscillation.

The RF input and output of the module are designed for

50 Ω connections.

Incoming inspection

When incoming inspection is performed, use a properly

designed test fixture to avoid excessive mechanical stress

and to ensure optimal RF performance. Philips can deliver

dedicated test fixtures on request.

Philips Semiconductors Product specification

CDMA800 power module BGF802-20

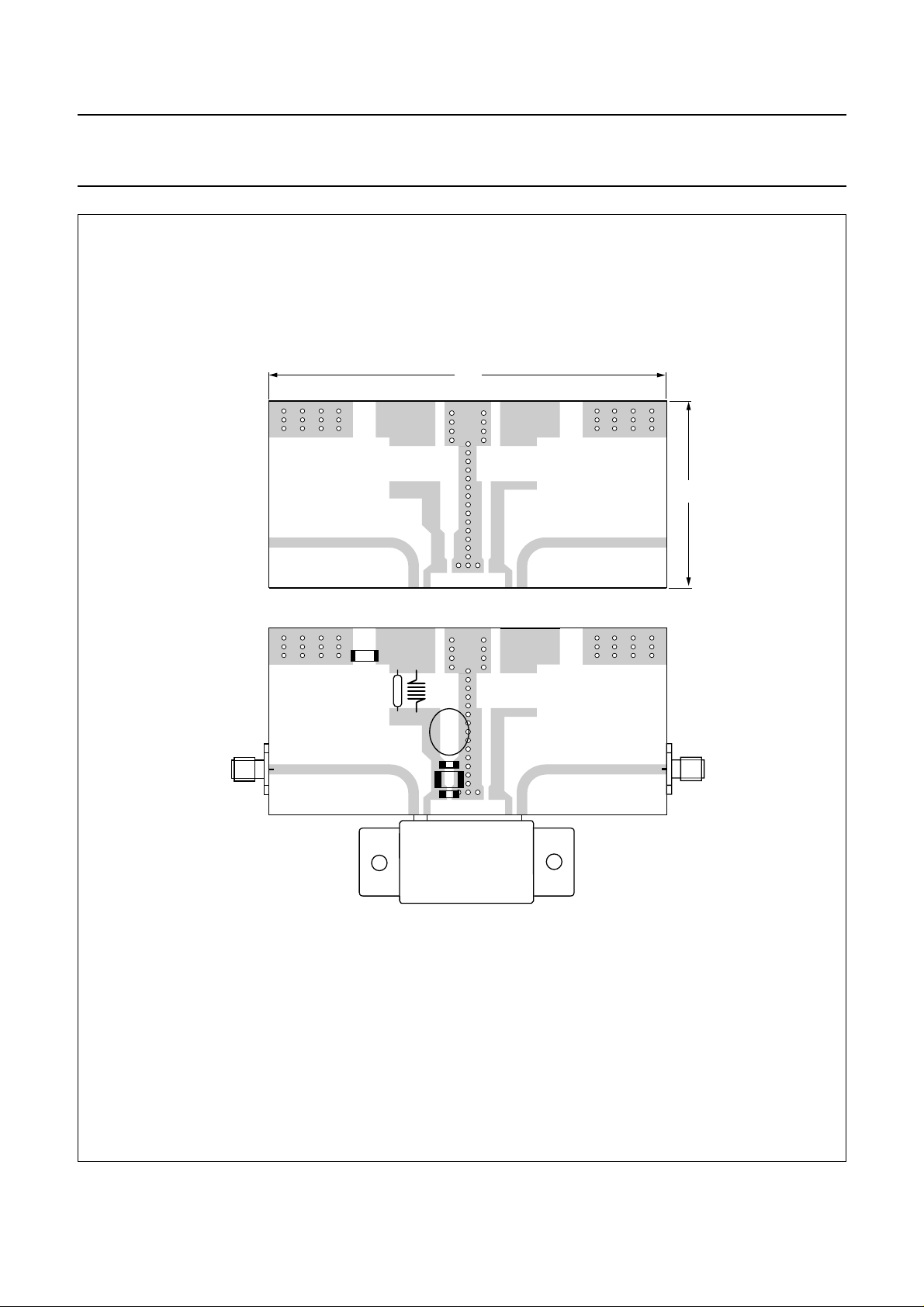

APPLICATION INFORMATION

handbook, halfpage

TEMPERATURE

COMPENSATED

GATE BIAS

C1

C2

C3

C4

+

Z

50 Ω

input

1

MBL781

R1 L1

C5

V

S

Z

2

50 Ω

output

Fig.12 Test circuit.

List of components (see Figs 12 and 13)

COMPONENT DESCRIPTION VALUE

CATALOGUE

NUMBER

C1, C3 multilayer X7R ceramic chip capacitor 100 nF; 50 V

C2, C5 tantalum SMD capacitor 10 µF; 35 V

C4 electrolytic capacitor 100 µF; 35 V

L1 grade 4S2 Ferroxcube bead 4330 030 36300

R1 metal film resistor 2322 195 13109

Z

, Z

1

2

stripline; note 1 50 Ω

Note

1. The striplines are on a double copper-clad printed-circuit board (RO5880) with εr= 2.2 and thickness = 0.79 mm.

2003 Feb 24 8

Philips Semiconductors Product specification

CDMA800 power module BGF802-20

handbook, full pagewidth

output

50 Ω

90

42

C5

C4

C2

C3

L1

input

50 Ω

C1

Z

1

R1

Z

2

DUT

Dimensions in mm.

Fig.13 Printed-circuit board and component layout.

2003 Feb 24 9

MBL780

Philips Semiconductors Product specification

CDMA800 power module BGF802-20

PACKAGE OUTLINE

Plastic rectangular single-ended flat package; flange mounted; 2 mounting holes; 3 in-line leads SOT365C

D

A

F

y

E

L

DIMENSIONS (mm are the original dimensions)

UNIT Qb Zc

A

0.56

mm

9.5

9.0

0.46

0.3

0.2

30.1

29.9

1

D

E

e

18.6

2.54

18.4

e

20.32

U

q

23

b

e

1

0 10 20 mm

1

3.3

3.1

3.7

3.3

e

scale

L

4.0

3.55

3.8

3.45

w M

Z

41.75

41.65

UFpq

48.4

48.0

U

p

U

15.4

15.2

3

A

v

A

vw

0.3 0.25

c

Q

y

12.8

0.1

12.6

3

U

2

U

1

U

U

2

1

7.75

1.1

7.55

0.0

OUTLINE

VERSION

SOT365C

IEC JEDEC JEITA

REFERENCES

2003 Feb 24 10

EUROPEAN

PROJECTION

ISSUE DATE

01-06-06

02-11-13

Philips Semiconductors Product specification

CDMA800 power module BGF802-20

DATA SHEET STATUS

LEVEL

DATA SHEET

STATUS

(1)

PRODUCT

STATUS

(2)(3)

DEFINITION

I Objective data Development This data sheet contains data from the objective specification for product

development. Philips Semiconductors reserves the right to change the

specification in any manner without notice.

II Preliminary data Qualification This data sheet contains data from the preliminary specification.

Supplementary data will be published at a later date. Philips

Semiconductors reserves the right to change the specification without

notice, in order to improve the design and supply the best possible

product.

III Product data Production This data sheet contains data from the product specification. Philips

Semiconductors reserves the right to make changes at any time in order

to improve the design, manufacturing and supply. Relevant changes will

be communicated via a Customer Product/Process Change Notification

(CPCN).

Notes

1. Please consult the most recently issued data sheet before initiating or completing a design.

2. The product status of the device(s) described in this data sheet may have changed since this data sheet was

published. The latest information is available on the Internet at URL http://www.semiconductors.philips.com.

3. For data sheets describing multiple type numbers, the highest-level product status determines the data sheet status.

DEFINITIONS

DISCLAIMERS

Short-form specification The data in a short-form

specification is extracted from a full data sheet with the

same type number and title. For detailed information see

the relevant data sheet or data handbook.

Limiting values definition Limiting values given are in

accordance with the Absolute Maximum Rating System

(IEC 60134). Stress above one or more of the limiting

values may cause permanent damage to the device.

These are stress ratings only and operation of the device

attheseoratanyotherconditions above those given in the

Characteristics sections of the specification is not implied.

Exposure to limiting values for extended periods may

affect device reliability.

Application information Applications that are

described herein for any of these products are for

illustrative purposes only. Philips Semiconductors make

norepresentationor warranty that such applications willbe

suitable for the specified use without further testing or

modification.

Life support applications These products are not

designed for use in life support appliances, devices, or

systems where malfunction of these products can

reasonably be expected to result in personal injury. Philips

Semiconductorscustomersusing or selling these products

for use in such applications do so at their own risk and

agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes Philips Semiconductors

reserves the right to make changes in the products including circuits, standard cells, and/or software described or contained herein in order to improve design

and/or performance. When the product is in full production

(status ‘Production’), relevant changes will be

communicated via a Customer Product/Process Change

Notification (CPCN). Philips Semiconductors assumes no

responsibility or liability for the use of any of these

products, conveys no licence or title under any patent,

copyright, or mask work right to these products, and

makes no representations or warranties that these

products are free from patent, copyright, or mask work

right infringement, unless otherwise specified.

2003 Feb 24 11

Philips Semiconductors – a w orldwide compan y

Contact information

For additional information please visit http://www.semiconductors.philips.com. Fax: +31 40 27 24825

For sales offices addresses send e-mail to: sales.addresses@www.semiconductors.philips.com.

© Koninklijke Philips Electronics N.V. 2003

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Printed in The Netherlands 613524/04/pp12 Date of release: 2003 Feb 24 Document order number: 9397 750 10698

SCA75

Loading...

Loading...