Philips BDL5231V Schematic

Colour Television Chassis

18430_000_090213.eps

090213

QCG1.0S

LA

Contents Page Contents Page

1. Revision List 2

2. Technical Specifications, Connections, and Chassis

Overview 2

3. Precautions, Notes, and Abbreviation List 5

4. Mechanical Instructions 9

5. Service Modes, Error Codes, and Fault Finding 13

6. Alignments 17

7. Circuit Descriptions 22

8. IC Data Sheets 24

9. Block Diagrams, Test Point Overview

Wiring Diagram 52" 37

10. Circuit Diagrams and PWB Layouts

Main Board: HDMI Input 38

Main Board: DVI Input 39

Main Board: HDMI In Sequoia 40

Main Board: Display Port Input 41

Main Board: Digital Input Port 42

Main Board: VGA Input 43

Main Board: ISP 44

Main Board: AFE Sequoia 45

Main Board: Frame Store DDR interface 46

Main Board: Panel Interface Sequoia 47

Main Board: Panel Interface 48

Main Board: I2S Audio Input 49

Main Board: Analog Audio Input 50

Main Board: Low Power Monitor 51

Main Board: Sequoia Power 52

Main Board: OCM Peripherals 53

Main Board: OCM Low Bandwidth ADC 54

Main Board: Power Sequoia 55

Main Board: Power System 56

Main Board: SMCU 57

Main Board: Board to board connect 58

Extension Board: Video input 59

©

Copyright 2009 Koninklijke Philips Electronics N.V.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic, mechanical,

photocopying, or otherwise without the prior permission of Philips.

Extension Board: Analog input 60

Extension Board: Analog output 61

Extension Board: Board to board connect 62

Extension Board: Audio input 63

Extension Board: Audio amplifier 64

Extension Board: Speaker switch 65

Extension Board: RS232 66

Extension Board: GP IO and power 67

Extension Board: Fan control; RTC 68

Extension Board: PC power 69

IR LED board 70

Published by MB/JH 0963 BU TV Consumer Care, the Netherlands Subject to modification EN 3122 785 18431

2009-Mar-20

EN 2 QCG1.0S LA1.

Revision List

1. Revision List

Manual xxxx xxx xxxx.0

• First release.

Manual xxxx xxx xxxx.1

• Chapter 5 added section Fault Finding

.

2. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

2.1 Technical Specifications

2.2 Directions for Use

2.3 Connection Overview

2.4 Chassis Overview

Notes:

• Data below can deviate slightly from the actual situation,

due to the different set executions

• Specifications are indicative (subject to change).

2.1 Technical Specifications

For on-line product support please use the links in. Here is

product information available, as well as getting started, user

manuals, frequently asked questions and software & drivers.

Table 2-1 Described Model Numbers:

Model Number Styling Published in

BDL5231V/00

3122 785 18430

2.2 Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

2009-Mar-20

Technical Specifications, Connections, and Chassis Overview

18430_001_090122.eps

090218

1

6

9

5

1

6

9

5

(IN)

(IN)(OUT)

(OUT)

1

3

4

2

5 6 7 8 9

10 11

1

6

9

5

10000_005_090121.eps

090121

10000_047_090121.eps

090121

10000_04

8_090126.eps

090126

LN

E

10000_017_090121.eps

090227

19

1

18 2

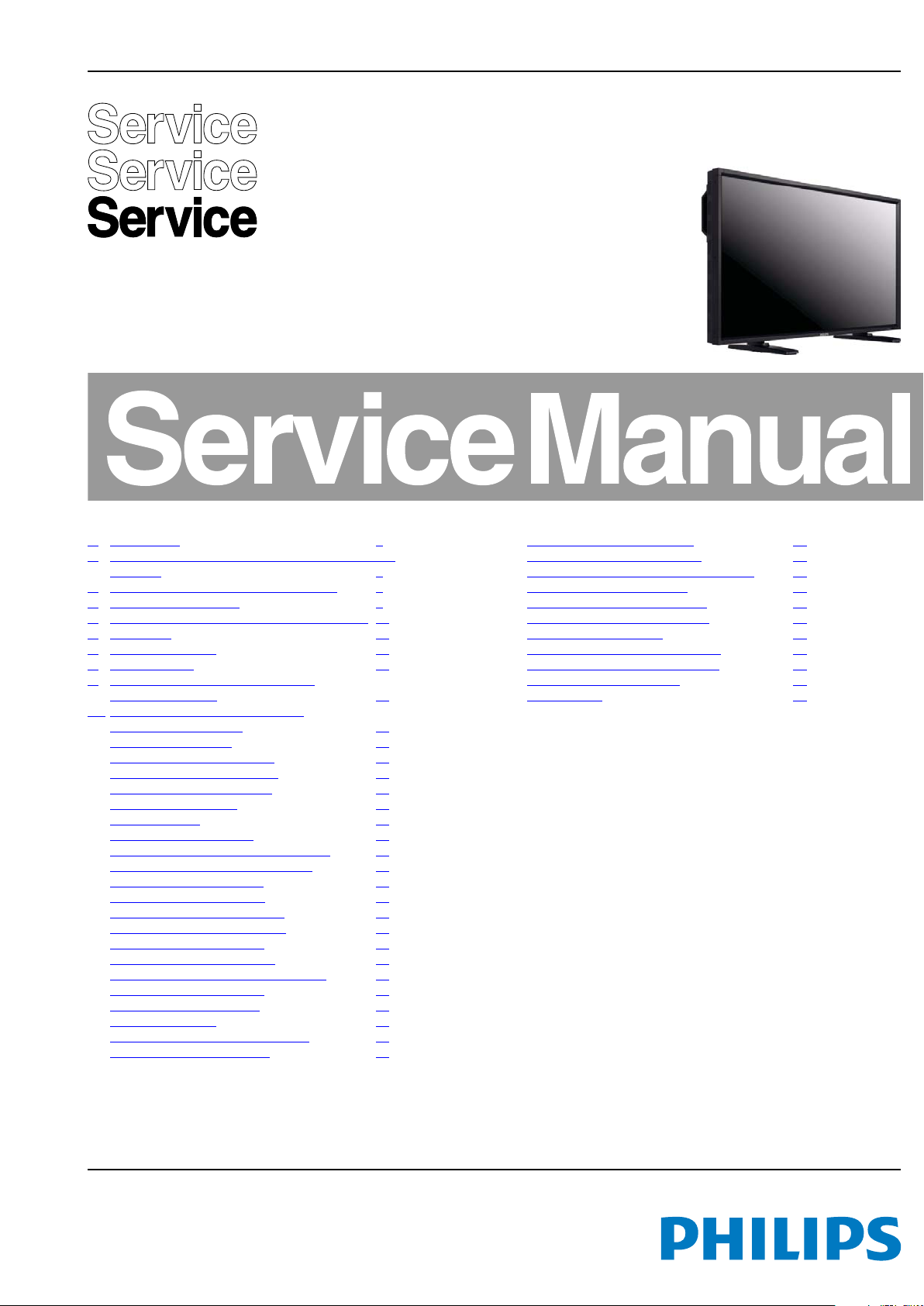

2.3 Connection Overview

EN 3QCG1.0S LA 2.

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk = Black, Bu = Blue, Gn = Green,

Gy = Grey, Rd = Red, Wh = White, and Ye = Yellow.

2.3.1 Side Connections

1 - External Control Connector (RS232-UART) Out - In

Figure 2-2 9-pin Sub-D Connector

1 -DCD Carrier Detect j

2 -RxD Receive j

3-TxD Transmit k

4 -DTR Data Terminal Ready k

5 -Gnd Ground H

6 -DSR Data Set Ready j

7 -RTS Request To Send k

8 -CTS Clear To Send j

9 -RI Ring Indicator j

2 - Mini Jack: Audio IN1 - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 10 kΩ jq

RMS

/ 10 kΩ jq

RMS

2 - Cinch: Audio IN 2 & 3 - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 10 kΩ jq

RMS

/ 10 kΩ jq

RMS

3 - Cinch: Audio - Out

Rd - Audio - R 0.5 V

Wh - Audio - L 0.5 V

/ 10 kΩ kq

RMS

/ 10 kΩ kq

RMS

Figure 2-1 Rear and Side I/O connections

4 - Spring Clip Speaker Connections: Audio - Out

Figure 2-3 Spring Clip Speaker Terminals

Bk - Speaker Left Gnd H

Rd - Speaker Left 5 W / 8 Ω j

Bk - Speaker Right Gnd H

Rd - Speaker Right 5 W / 8 Ω j

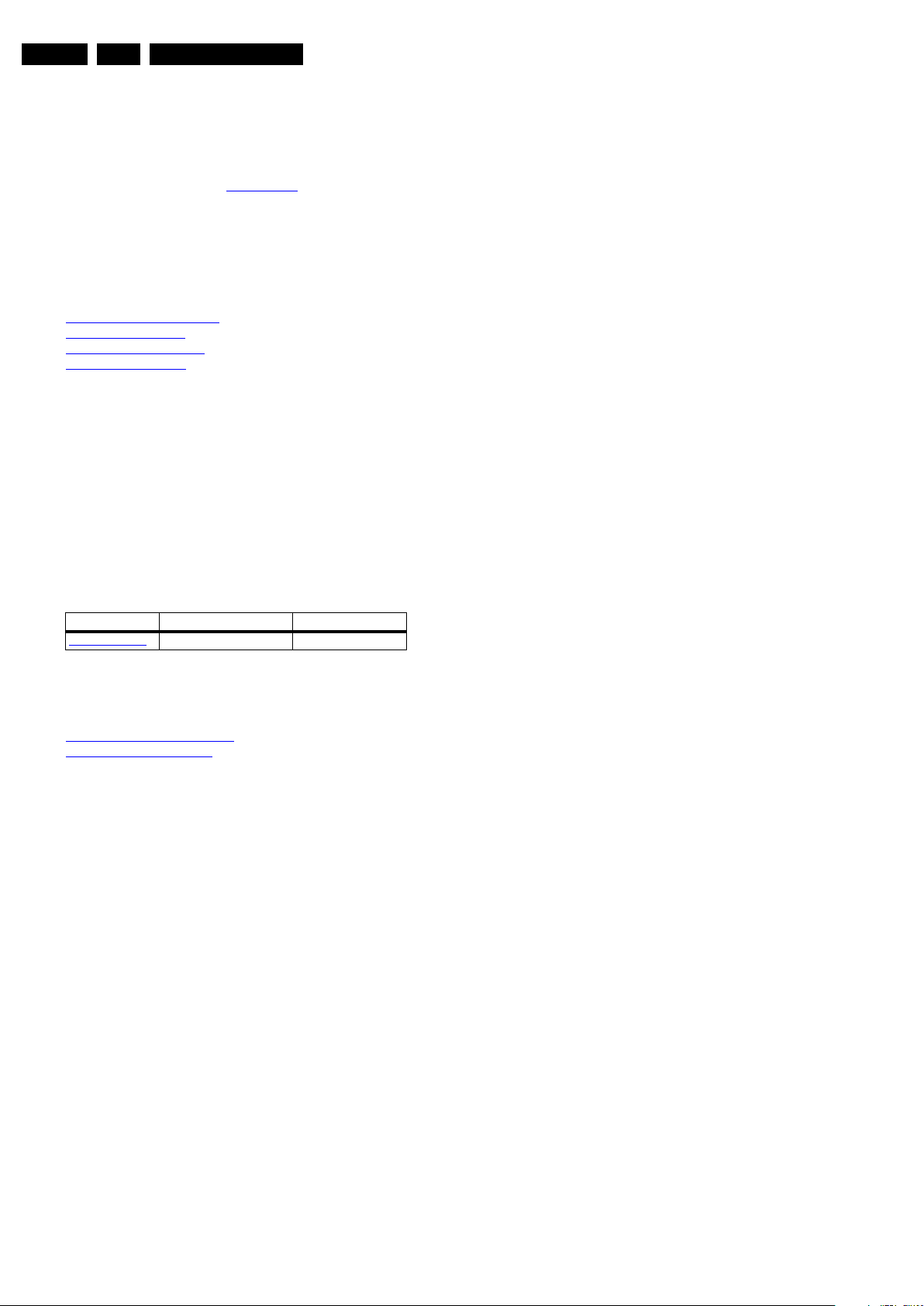

2.3.2 Rear Connections

5 - IEC C14 MAINS socket - In

L - Phase Power j

E - Earth Gnd H

3 - Zero Power j

6 - HDMI: Digital Video, Digital Audio - In

Figure 2-4 IEC C14 Mains socket

Figure 2-5 HDMI (type A) connector

2009-Mar-20

EN 4 QCG1.0S LA2.

1

6

10

11

5

15

10000_002_090121.eps

090127

Technical Specifications, Connections, and Chassis Overview

1 - D2+ Data channel j

2 - Shield Gnd H

3 - D2- Data channel j

4 - D1+ Data channel j

5 - Shield Gnd H

6 - D1- Data channel j

7 - D0+ Data channel j

8 - Shield Gnd H

9 - D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - n.c.

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

7 - DVI-D: Digital Video - In

1 8

916

17

C5

24

10000_003_090121.eps

090121

Figure 2-6 DVI-D connector

1-D2- j

2-D2+ j

3 - Shield Gnd H

4-D4- j

5-D4+ j

6 - DDC_SCL DDC clock k

7 - DDC_SDA DDC data jk

8-n.c.

9-D1- j

10 - D1+ j

11 - Shield Gnd H

12 - D3- j

13 - D3+ j

14 - +5V j

15 - Ground Gnd H

16 - HPD Hot Plug Detect j

17 - D0- j

18 - D0+ j

19 - Shield Gnd H

20 - D5- j

21 - D5+ j

22 - Shield Gnd H

23 - CLK+ j

24 - CLK- j

8 - VGA RGB 3 & RGB IN: Video RGB - In

Figure 2-7 VGA Connector

1 - Video Red 0.7 V

2 - Video Green 0.7 V

3 - Video Blue 0.7 V

4-n.c.

/ 75 Ω j

PP

/ 75 Ω j

PP

/ 75 Ω j

PP

5 - Ground Gnd H

6 - Ground Red Gnd H

7 - Ground Green Gnd H

8 - Ground Blue Gnd H

9-+5V

10 - Ground Sync Gnd H

+5 V jk

DC

11 - n.c.

12 - DDC_SDA DDC data jk

13 - H-sync 0 - 5 V j

14 - V-sync 0 - 5 V j

15 - DDC_SCL DDC clock jk

9 - VGA RGB 3 & RGB OUT: Video RGB - Out

1 - Video Red 0.7 V

2 - Video Green 0.7 V

3 - Video Blue 0.7 V

/ 75 Ω k

PP

/ 75 Ω k

PP

/ 75 Ω k

PP

4-n.c.

5 - Ground Gnd H

6 - Ground Red Gnd H

7 - Ground Green Gnd H

8 - Ground Blue Gnd H

9-+5V

+5 V jk

DC

10 - Ground Sync Gnd H

11 - n.c.

12 - DDC_SDA DDC data jk

13 - H-sync 0 - 5 V k

14 - V-sync 0 - 5 V k

15 - DDC_SCL DDC clock jk

10 - BNC: Video YPbPr - In

Wh - Video Y 1 V

Wh - Video Pb 0.7 V

Wh - Video Pr 0.7 V

/ 75 Ω jq

PP

/ 75 Ω jq

PP

/ 75 Ω jq

PP

11 - Cinch: Composite Video CVBS - In

Ye - Video CVBS 1 V

/ 75 Ω jq

PP

11 - S-Video (Hosiden): Composite Video Y/C - In

1 - Ground Y Gnd H

2 - Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

/ 75 Ω j

PP

P / 75 Ω j

PP

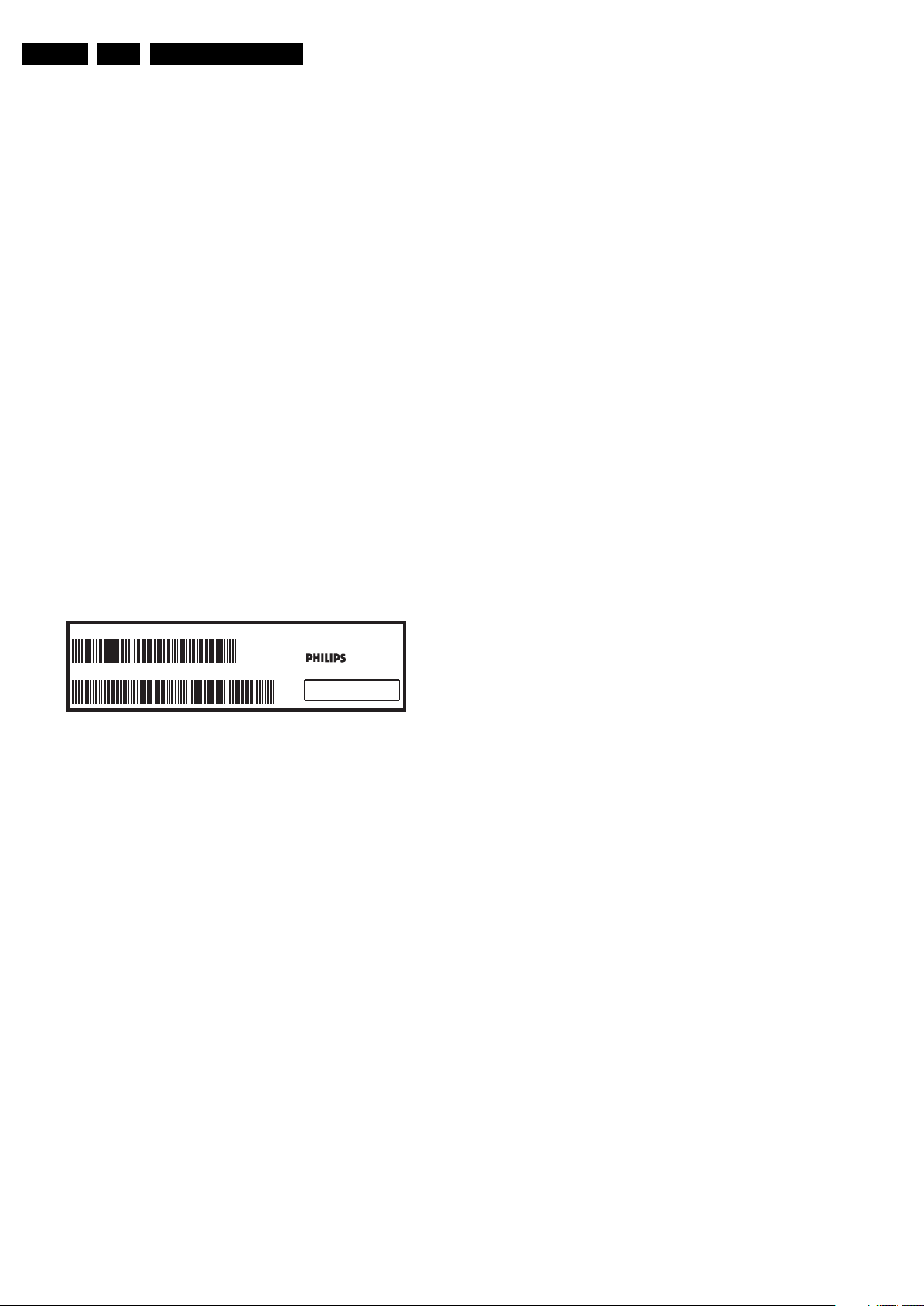

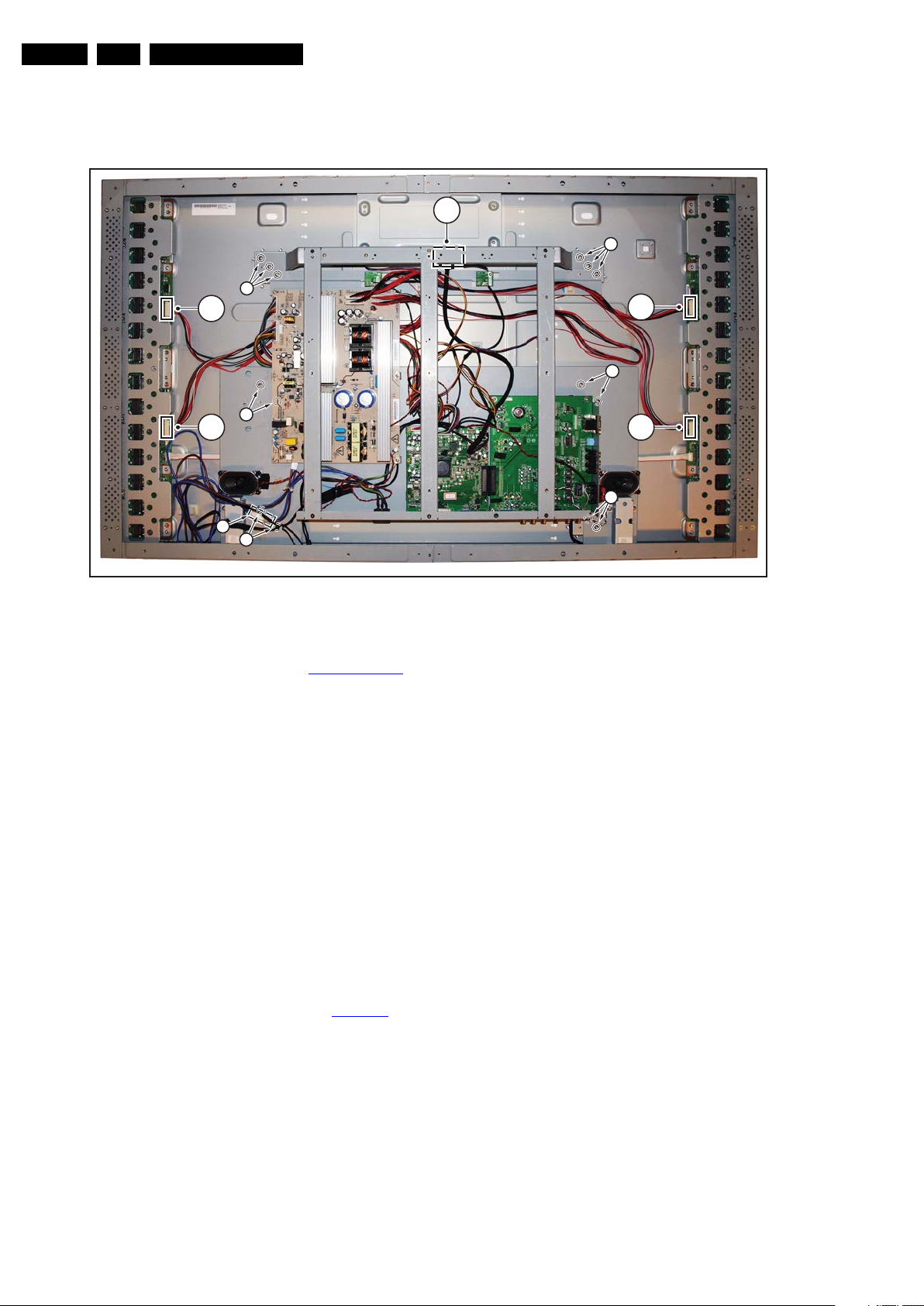

2.4 Chassis Overview

Refer to chapter 9. Block Diagrams, Test Point Overview for

PWB/CBA locations.

2009-Mar-20

11 - BNC: Composite Video CVBS - In

Wh - Video CVBS 1 V

/ 75 Ω jq

PP

11 - BNC: Composite Video CVBS - Out

Wh - Video CVBS 1 V

/ 75 Ω kq

PP

Precautions, Notes, and Abbreviation List

3. Precautions, Notes, and Abbreviation List

EN 5QCG1.0S LA 3.

Index of this chapter:

3.1 Safety Instructions

3.2 Warnings

3.3 Notes

3.4 Abbreviation List

3.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard. Of de set

ontploft!

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 MΩ and 12 MΩ.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

picture carrier at 475.25 MHz for PAL, or 61.25 MHz for

NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

3.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kΩ).

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates 220 Ω).

• All capacitor values are given in micro-farads (μ=× 10

nano-farads (n =× 10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed on the Philips

Spare Parts Web Portal.

3.3.3 Spare Parts

For the latest spare part overview, consult your Philips Spare

Part web portal.

3.3.4 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: http://www.atyourservice-magazine.com

“Magazine”, then go to “Repair downloads”. Here you will find

Information on how to deal with BGA-ICs.

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile.

Where applicable and available, this profile is added to the IC

Data Sheet information section in this manual.

-9

), or pico-farads (p =× 10

. Select

-12

-6

),

).

3.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

3.3 Notes

3.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode with a colour bar signal and stereo

sound (L: 3 kHz, R: 1 kHz unless stated otherwise) and

3.3.5 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin. If lead-free solder paste is

required, please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

2009-Mar-20

EN 6 QCG1.0S LA3.

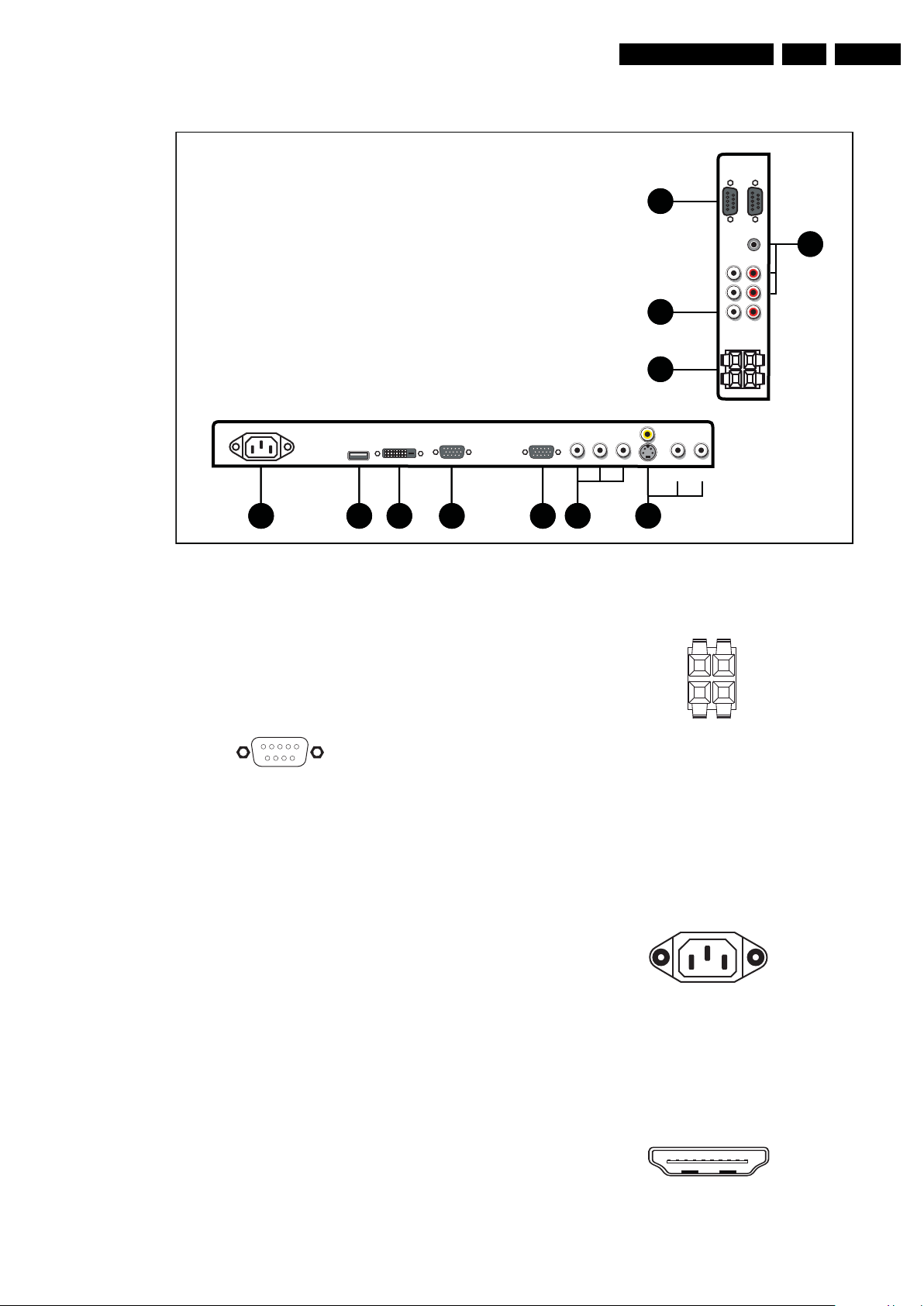

10000_024_090121.eps

090121

MODEL :

PROD.NO:

~

S

32PF9968/10

MADE IN BELGIUM

220-240V 50/60Hz

128W

AG 1A0617 000001

VHF+S+H+UHF

BJ3.0E LA

Precautions, Notes, and Abbreviation List

3.3.6 Alternative BOM identification

It should be noted that on the European Service website,

“Alternative BOM” is referred to as “Design variant”.

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production centre (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

Figure 3-1 Serial number (example)

3.3.7 Board Level Repair (BLR) or Component Level Repair (CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

3.3.8 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

2009-Mar-20

3.4 Abbreviation List

0/6/12 SCART switch control signal on A/V

board. 0 = loop through (AUX to TV),

6 = play 16 : 9 format, 12 = play 4 : 3

format

2DNR Spatial (2D) Noise Reduction

3DNR Temporal (3D) Noise Reduction

AARA Automatic Aspect Ratio Adaptation:

algorithm that adapts aspect ratio to

remove horizontal black bars; keeps

the original aspect ratio

ACI Automatic Channel Installation:

algorithm that installs TV channels

directly from a cable network by

means of a predefined TXT page

ADC Analogue to Digital Converter

AFC Automatic Frequency Control: control

signal used to tune to the correct

frequency

AGC Automatic Gain Control: algorithm that

controls the video input of the feature

box

AM Amplitude Modulation

ANR Automatic Noise Reduction: one of the

algorithms of Auto TV

AP Asia Pacific

AR Aspect Ratio: 4 by 3 or 16 by 9

ASF Auto Screen Fit: algorithm that adapts

aspect ratio to remove horizontal black

bars without discarding video

information

ATSC Advanced Television Systems

Committee, the digital TV standard in

the USA

ATV See Auto TV

Auto TV A hardware and software control

system that measures picture content,

and adapts image parameters in a

dynamic way

AV External Audio Video

AVC Audio Video Controller

AVIP Audio Video Input Processor

B/G Monochrome TV system. Sound

carrier distance is 5.5 MHz

BLR Board-Level Repair

BTSC Broadcast Television Standard

Committee. Multiplex FM stereo sound

system, originating from the USA and

used e.g. in LATAM and AP-NTSC

countries

B-TXT Blue TeleteXT

C Centre channel (audio)

CEC Consumer Electronics Control bus:

remote control bus on HDMI

connections

CL Constant Level: audio output to

connect with an external amplifier

CLR Component Level Repair

COLUMBUS COlor LUMinance Baseband

Universal Sub-system

ComPair Computer aided rePair

CP Connected Planet / Copy Protection

CSM Customer Service Mode

CTI Color Transient Improvement:

manipulates steepness of chroma

transients

CVBS Composite Video Blanking and

Synchronization

DAC Digital to Analogue Converter

DBE Dynamic Bass Enhancement: extra

low frequency amplification

DDC See “E-DDC”

Precautions, Notes, and Abbreviation List

EN 7QCG1.0S LA 3.

D/K Monochrome TV system. Sound

carrier distance is 6.5 MHz

DFI Dynamic Frame Insertion

DFU Directions For Use: owner's manual

DMR Digital Media Reader: card reader

DMSD Digital Multi Standard Decoding

DNM Digital Natural Motion

DNR Digital Noise Reduction: noise

reduction feature of the set

DRAM Dynamic RAM

DRM Digital Rights Management

DSP Digital Signal Processing

DST Dealer Service Tool: special remote

control designed for service

technicians

DTCP Digital Transmission Content

Protection; A protocol for protecting

digital audio/video content that is

traversing a high speed serial bus,

such as IEEE-1394

DVB-C Digital Video Broadcast - Cable

DVB-T Digital Video Broadcast - Terrestrial

DVD Digital Versatile Disc

DVI(-d) Digital Visual Interface (d= digital only)

E-DDC Enhanced Display Data Channel

(VESA standard for communication

channel and display). Using E-DDC,

the video source can read the EDID

information form the display.

EDID Extended Display Identification Data

(VESA standard)

EEPROM Electrically Erasable and

Programmable Read Only Memory

EMI Electro Magnetic Interference

EPLD Erasable Programmable Logic Device

EU Europe

EXT EXTernal (source), entering the set by

SCART or by cinches (jacks)

FBL Fast BLanking: DC signal

accompanying RGB signals

FDS Full Dual Screen (same as FDW)

FDW Full Dual Window (same as FDS)

FLASH FLASH memory

FM Field Memory or Frequency

Modulation

FPGA Field-Programmable Gate Array

FTV Flat TeleVision

Gb/s Giga bits per second

G-TXT Green TeleteXT

H H_sync to the module

HD High Definition

HDD Hard Disk Drive

HDCP High-bandwidth Digital Content

Protection: A “key” encoded into the

HDMI/DVI signal that prevents video

data piracy. If a source is HDCP coded

and connected via HDMI/DVI without

the proper HDCP decoding, the

picture is put into a “snow vision” mode

or changed to a low resolution. For

normal content distribution the source

and the display device must be

enabled for HDCP “software key”

decoding.

HDMI High Definition Multimedia Interface

HP HeadPhone

I Monochrome TV system. Sound

2

I

C Inter IC bus

2

I

D Inter IC Data bus

2

I

S Inter IC Sound bus

carrier distance is 6.0 MHz

IF Intermediate Frequency

Interlaced Scan mode where two fields are used

to form one frame. Each field contains

half the number of the total amount of

lines. The fields are written in “pairs”,

causing line flicker.

IR Infra Red

IRQ Interrupt Request

ITU-656 The ITU Radio communication Sector

(ITU-R) is a standards body

subcommittee of the International

Telecommunication Union relating to

radio communication. ITU-656 (a.k.a.

SDI), is a digitized video format used

for broadcast grade video.

Uncompressed digital component or

digital composite signals can be used.

The SDI signal is self-synchronizing,

uses 8 bit or 10 bit data words, and has

a maximum data rate of 270 Mbit/s,

with a minimum bandwidth of 135

MHz.

ITV Institutional TeleVision; TV sets for

hotels, hospitals etc.

JOP Jaguar Output Processor

LS Last Status; The settings last chosen

by the customer and read and stored

in RAM or in the NVM. They are called

at start-up of the set to configure it

according to the customer's

preferences

LATAM Latin America

LCD Liquid Crystal Display

LED Light Emitting Diode

L/L' Monochrome TV system. Sound

carrier distance is 6.5 MHz. L' is Band

I, L is all bands except for Band I

LORE LOcal REgression approximation

noise reduction

LPL LG.Philips LCD (supplier)

LS Loudspeaker

LVDS Low Voltage Differential Signalling

Mbps Mega bits per second

M/N Monochrome TV system. Sound

carrier distance is 4.5 MHz

MIPS Microprocessor without Interlocked

Pipeline-Stages; A RISC-based

microprocessor

MOP Matrix Output Processor

MOSFET Metal Oxide Silicon Field Effect

Transistor, switching device

MPEG Motion Pictures Experts Group

MPIF Multi Platform InterFace

MUTE MUTE Line

NC Not Connected

NICAM Near Instantaneous Compounded

Audio Multiplexing. This is a digital

sound system, mainly used in Europe.

NTC Negative Temperature Coefficient,

non-linear resistor

NTSC National Television Standard

Committee. Color system mainly used

in North America and Japan. Color

carrier NTSC M/N= 3.579545 MHz,

NTSC 4.43= 4.433619 MHz (this is a

VCR norm, it is not transmitted off-air)

NVM Non-Volatile Memory: IC containing

TV related data such as alignments

O/C Open Circuit

OSD On Screen Display

OTC On screen display Teletext and

Control; also called Artistic (SAA5800)

P50 Project 50: communication protocol

between TV and peripherals

PAL Phase Alternating Line. Color system

mainly used in West Europe (color

carrier= 4.433619 MHz) and South

America (color carrier PAL M=

2009-Mar-20

EN 8 QCG1.0S LA3.

Precautions, Notes, and Abbreviation List

3.575612 MHz and PAL N= 3.582056

MHz)

PCB Printed Circuit Board (same as “PWB”)

PCM Pulse Code Modulation

PDP Plasma Display Panel

PFC Power Factor Corrector (or Pre-

conditioner)

PIP Picture In Picture

PLL Phase Locked Loop. Used for e.g.

FST tuning systems. The customer

can give directly the desired frequency

POD Point Of Deployment: a removable

CAM module, implementing the CA

system for a host (e.g. a TV-set)

POR Power On Reset, signal to reset the uP

Progressive Scan Scan mode where all scan lines are

displayed in one frame at the same

time, creating a double vertical

resolution.

PTC Positive Temperature Coefficient,

non-linear resistor

PWB Printed Wiring Board (same as “PCB”)

PWM Pulse Width Modulation

QRC Quasi Resonant Converter

QTNR Quality Temporal Noise Reduction

QVCP Quality Video Composition Processor

RAM Random Access Memory

RGB Red, Green, and Blue. The primary

color signals for TV. By mixing levels

of R, G, and B, all colors (Y/C) are

reproduced.

RC Remote Control

RC5 / RC6 Signal protocol from the remote

control receiver

RESET RESET signal

ROM Read Only Memory

RSDS Reduced Swing Differential Signalling

data interface

R-TXT Red TeleteXT

SAM Service Alignment Mode

S/C Short Circuit

SCART Syndicat des Constructeurs

d'Appareils Radiorécepteurs et

Téléviseurs

SCL Serial Clock I

SCL-F CLock Signal on Fast I

SD Standard Definition

SDA Serial Data I

SDA-F DAta Signal on Fast I

2

C

2

C bus

2

C

2

C bus

SDI Serial Digital Interface, see “ITU-656”

SDRAM Synchronous DRAM

SECAM SEequence Couleur Avec Mémoire.

Color system mainly used in France

and East Europe. Color carriers=

4.406250 MHz and 4.250000 MHz

SIF Sound Intermediate Frequency

SMPS Switched Mode Power Supply

SoC System on Chip

SOG Sync On Green

SOPS Self Oscillating Power Supply

SPI Serial Peripheral Interface bus; a 4-

wire synchronous serial data link

standard

S/PDIF Sony Philips Digital InterFace

SRAM Static RAM

SRP Service Reference Protocol

SSB Small Signal Board

STBY STand-BY

SVGA 800x600 (4:3)

SVHS Super Video Home System

SW Software

SWAN Spatial temporal Weighted Averaging

Noise reduction

SXGA 1280x1024

TFT Thin Film Transistor

THD Total Harmonic Distortion

TMDS Transmission Minimized Differential

Signalling

TXT TeleteXT

TXT-DW Dual Window with TeleteXT

UI User Interface

uP Microprocessor

UXGA 1600x1200 (4:3)

V V-sync to the module

VCR Video Cassette Recorder

VESA Video Electronics Standards

Association

VGA 640x480 (4:3)

VL Variable Level out: processed audio

output toward external amplifier

VSB Vestigial Side Band; modulation

method

WYSIWYR What You See Is What You Record:

record selection that follows main

picture and sound

WXGA 1280x768 (15:9)

XTAL Quartz crystal

XGA 1024x768 (4:3)

Y Luminance signal

Y/C Luminance (Y) and Chrominance (C)

signal

YPbPr Component video. Luminance and

scaled color difference signals (B-Y

and R-Y)

YUV Component video

2009-Mar-20

4. Mechanical Instructions

10000_018_090121.eps

090121

1

Required for sets

42"

1

Mechanical Instructions

EN 9QCG1.0S LA 4.

Index of this chapter:

4.1 Cable Dressing

4.2 Service Positions

4.3 Assy/Panel Removal

4.4 Set Re-assembly

4.1 Cable Dressing

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Follow the disassembly instructions in the described order.

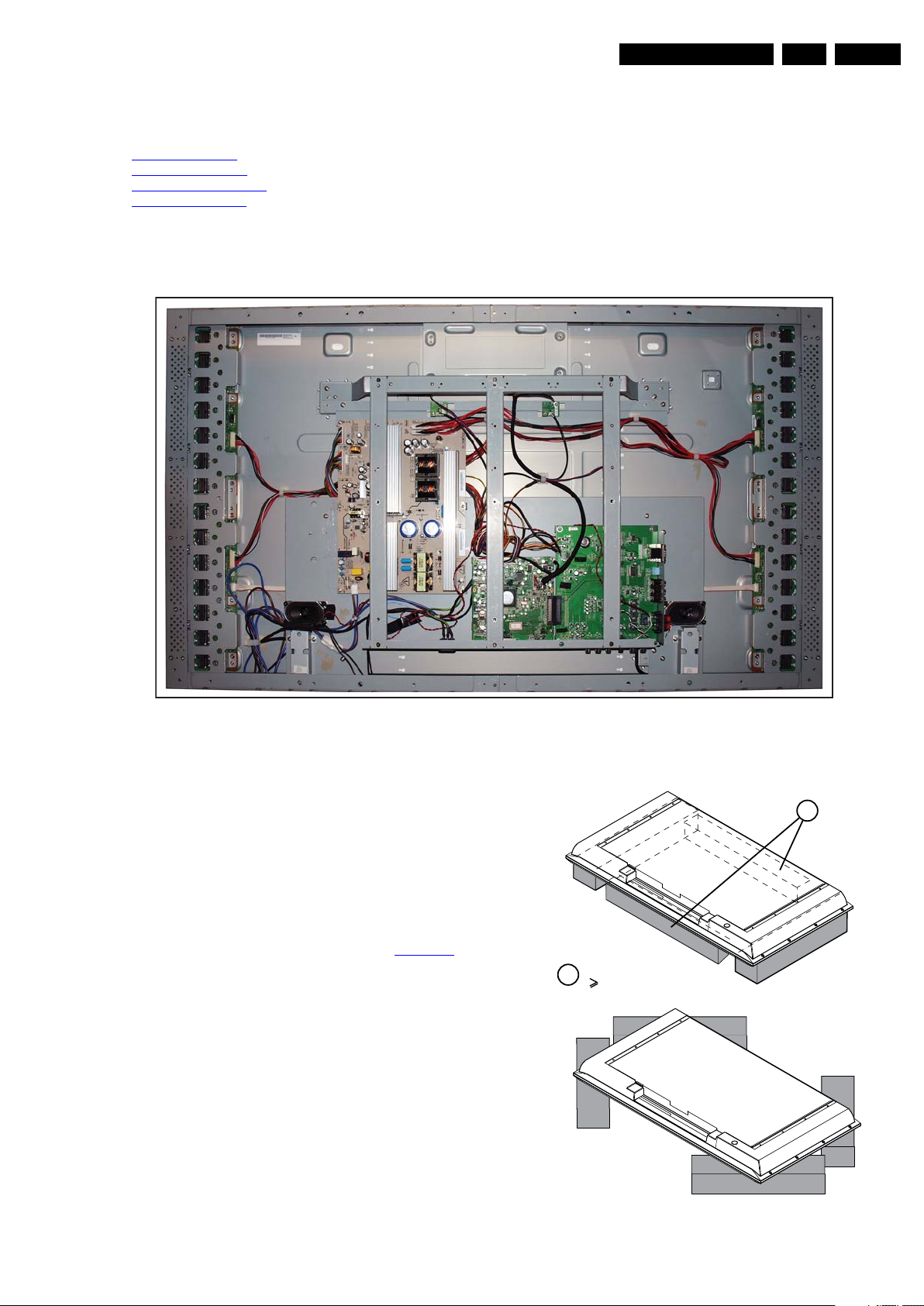

4.2 Service Positions

When moving or laying down an LCD set, at least two people

should handle the set. Avoid any impact towards the LCD set.

For easy servicing of this set, it must be placed screen down on

Foam bars (created for Service).

4.2.1 Foam Bars

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. See Figure 4-2

details. Sets with a display of 42" and larger, require four foam

bars [1]. Ensure that the foam bars are always supporting the

cabinet and never only the display. Caution: Failure to follow

these guidelines can seriously damage the display!

By laying the TV face down on the (ESD protective) foam bars,

a stable situation is created to perform measurements and

alignments. By placing a mirror under the TV, you can monitor

the screen.

4.3 Assy/Panel Removal

4.3.1 Stands

Figure 4-1 Cable dressing

for

18430_100_090206.eps

090206

For this set separately orderable stands are available. Remove

the stands before opening the set.

Figure 4-2 Foam bars

2009-Mar-20

EN 10 QCG1.0S LA4.

Mechanical Instructions

4.3.2 Rear Cover

Warning: Disconnect the mains power cord before you open

the set.

1. Place the set in the service position, see Service Positions

2. Remove the fixing screws from the handles and remove

the handles.

3. Remove all screws from the rear cover.

4. Lift the rear cover from the cabinet.

4.3.3 Front Cover

Before removing the front cover the rear cover should already

be removed.

1. Put the set with the back down on a flat table.

2. Remove all screws that secure the front cover.

3. Gently lift the cover from the set.

4.3.4 Temperature Sensor Panel

1. Place the set in the service position, see Service Positions

2. Disconnect the connector from the panel.

3. Remove the fixation screws and take out the board.

When defective, replace the whole unit.

4.3.5 Fan

1. Place the set in the service position, see Service Positions

2. Disconnect the respective connector from the SSB.

3. Remove the fan brackets fixation screws.

4. Take out the bracket with the fan.

5. Remove the fixation screws from the fan an take the fan out

of the bracket.

When defective, replace the fan.

4.3.7 Keyboard Control Panel

1. Place the set in the service position, see Service Positions

2. Remove the fixation screws that hold the keyboard control

.

4.3.8 Power Supply Switch

4.3.9 Main Supply Panel

.

4.3.10 Speakers

.

panel.

3. Take out the panel assembly and release the connector.

When defective, replace the whole unit.

1. Place the set in the service position, see Service Positions

2. Now the clips that hold the power switch can be released

via the backside of the switch.

When defective, replace the whole unit.

1. Place the set in the service position, see Service Positions

2. Unplug connectors.

3. Remove the grounding screw and cable.

4. Remove the all other fixation screws.

5. Take the board out.

When defective, replace the whole unit.

1. Place the set in the service position, see Service Positions

2. Unplug the respective speaker connector from the SSB.

3. Release the wiring.

4. Remove the fixation screws that hold the speaker and take

it from the set.

When defective, replace the whole unit.

.

.

.

.

4.3.6 LED / IR Panel

1. Place the set in the service position, see Service Positions

2. Disconnect the connector from the rear of the panel.

3. Remove the fixation screws and take out the board.

When defective, replace the whole unit.

.

2009-Mar-20

Mechanical Instructions

18430_101_090211.eps

090211

5

4 4 4 4 4 4 4 4 4 4 4

1

3

7

3

6

6

5

6

6

2

6

6

6

5

4

4

4

5

4

4

EN 11QCG1.0S LA 4.

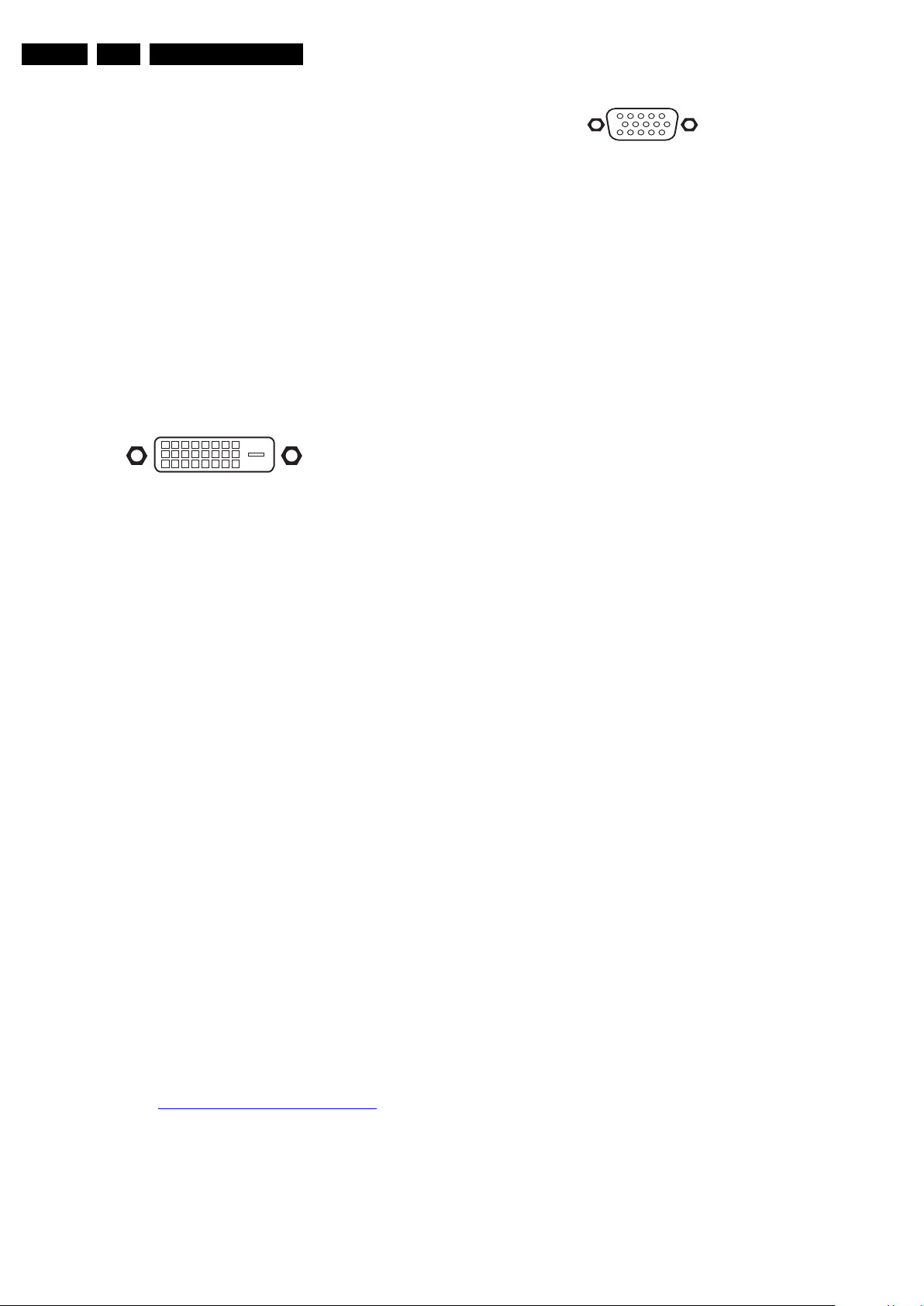

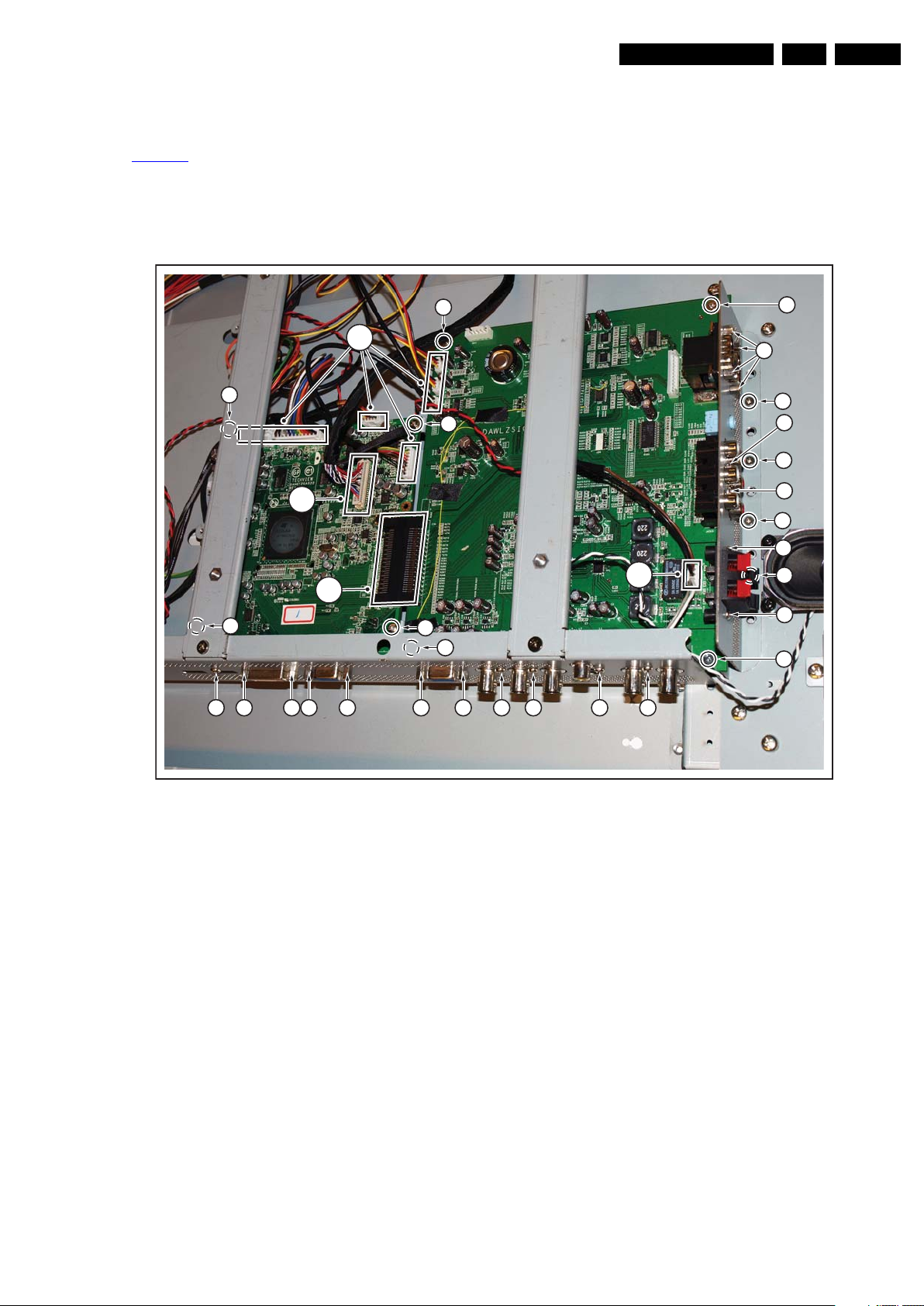

4.3.11 Small Signal Board (SSB)

The SSB is split in two parts connected by a 60 pin connector.

The main small SSB and the bigger extension board. See

Figure 4-3

1. Do NOT forget to unplug the LVDS connector [1] from the

2. Remove the screw [2] securing and grounding the LVDS

.

SSB. Important: Be careful, as this is a very fragile

connector!

cable.

3. Unplug the other connectors [3] from the SSB.

4. Remove all screws [4] securing the SSB connectors.

5. Remove all screws [5] securing the rim and take it out.

6. Remove all other screws [6].

7. Release connector [7] that interconnects the SSB with the

extension board.

8. Lift out the SSB and the extension board separately.

When defective, replace either the SSB or extension board.

Figure 4-3 SSB removal

2009-Mar-20

EN 12 QCG1.0S LA4.

18430_102_090211.eps.eps

090211

2

2

2

2

1

4

4

4

4

3

4

4

4.3.12 LCD Panel

Important: Be sure to work in a dust free environment during

the following activities. In addition, the use of (fabric) hand

gloves is advised.

Mechanical Instructions

1. First remove front cover, back cover as described earlier.

2. Place the set in the service position, see Service Positions

3. Remove the PSU as described earlier.

4. Do NOT forget to unplug the LVDS connector [1] from the

SSB. Important: Be careful, as this is a very fragile

connector!

5. Unplug the connectors from the backlight inverters [2].

6. Release connector [3] to the main power switch.

7. Release the cabling to the keyboard and the IR/LED panel.

8. Now remove all screws at the side of the surrounding rims.

9. Gently remove the rims.

10. Remove the screws [4].

11. Now gently lift the complete subframe from the LCD panel.

When defective, replace the whole unit.

4.4 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position. See Figure 4-1

Figure 4-4 LCD panel disassembly

.

.

2009-Mar-20

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

EN 13QCG1.0S LA 5.

Index of this chapter:

5.1 Compatibility Mode

5.2 Service Mode

5.3 Fault Finding

5.1 Compatibility Mode

This chassis does not contain specific test points, since all

defective boards should be replaced.

Perform measurements under the following conditions:

• Environmental: t

• Service signal: 100% Full White signal

This monitor saves all previously made settings, unless

separately made user settings override this. All timings must be

properly phased, sized and centred. The aspect ratio is

depending on the input signal scaled and centred. At full screen

the input timing is set to completely fill the screen, regards less

of scaling artifacts.

5.1.1 Overscan

= 25 ±2°C, RH = 65 ±10%

env

AV over scan: 5~9%

HDMI over scan: No over scan for PC input, 5~9% for video

source.

PC: No over scan

5.1.2 Display Processor performance

The display processor performance (excluding scaling

artifacts) has to be judged according to the following

definitions:

• Compatibility mode: correctly recognizes the proper

resolution and applies the correct display scaling to the

image (i.e. a 1280 × 768 signal is properly recognized).

• Properly sized/centred: The entire image (use display mate

“side tics” pattern) perfectly fits the screen. Even one pixel

off in horizontal or vertical direction, makes this test fail.

• Properly phased: The display processor automatically

computes the correct A/D response so that a Win98

shutdown or all display mate moire patterns are correctly

displayed. Most critical on the panels native mode, no

unstableness of the image may be observed.

• HD compatibility: All HD timings have to work through

YPbPr, HDMI, and RGB.

Component over scan: 5~8%

5.1.3 Compatibility

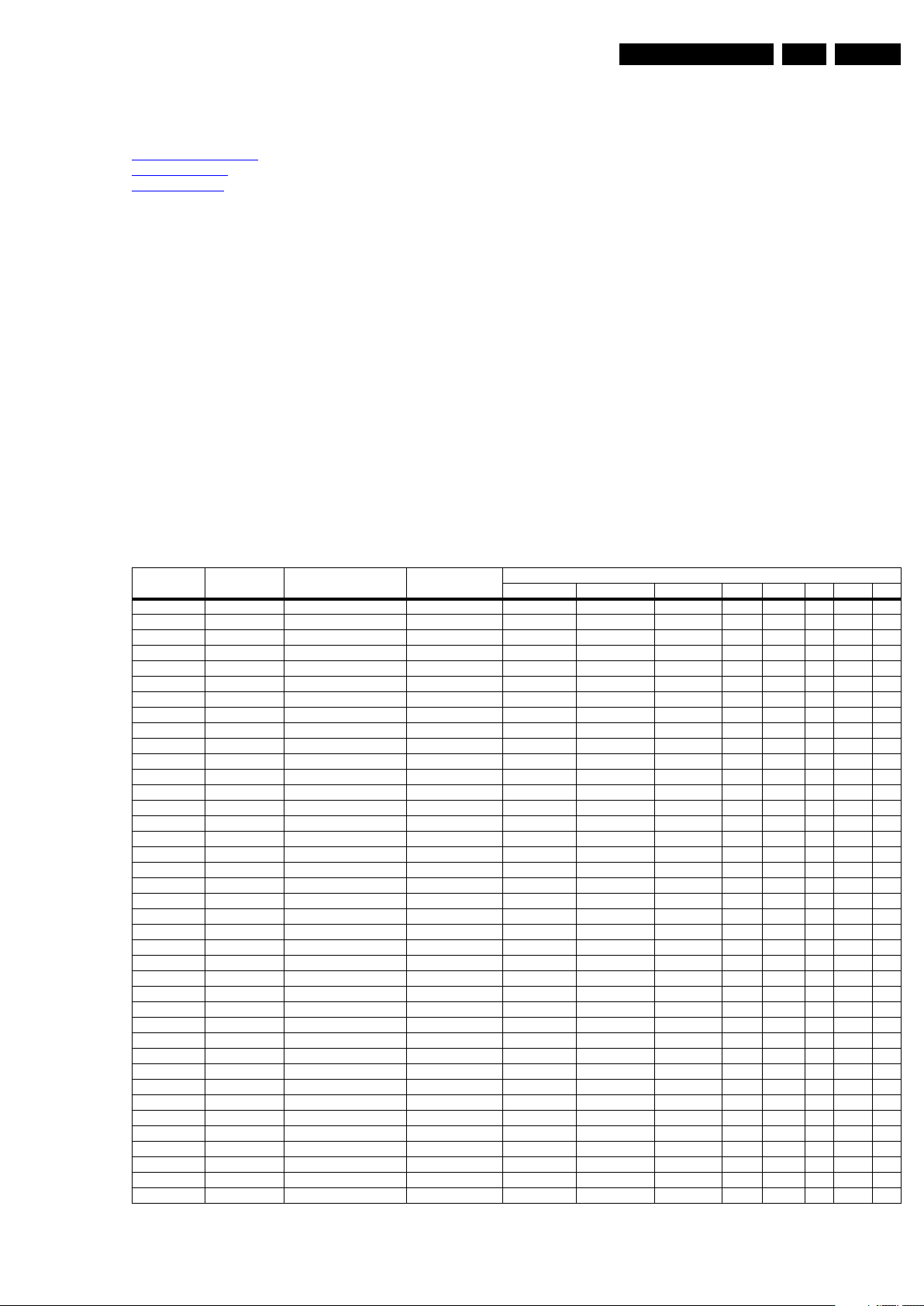

Resolution

720 × 400 85 37.9 kHz 35.500 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

640 × 480 60 31.5 kHz 25.175 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

640 × 480 72 37.9 kHz 31.500 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

640 × 480 75 37.5 kHz 31.500 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

800 × 600 56 35.1 kHz 36.000 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

800 × 600 60 37.9 kHz 40.000 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

800 × 600 72 48.1 kHz 50.000 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

800 × 600 75 46.9 kHz 49.500 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

848 × 480 60 31.0 kHz 33.750 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

1024× 768 60 48.4 kHz 65.000 MHz 1920 × 1 080 16 : 9 No No No Yes Yes Yes

1024× 768 70 56.5 kHz 75.000 MHz 1920 × 1 080 16 : 9 No No No Yes Yes Yes

1024× 768 75 60.0 kHz 78.750 MHz 1920 × 1 080 16 : 9 No No No Yes Yes Yes

1152× 864 75 67.5 kHz 108.000 MHz 1920 × 1 080 16 : 9 No No No Yes Yes Yes

1280× 768 60 47.4 kHz 68.250 MHz 1920 × 1 080 16 : 9 No No No Yes Yes Yes

1280× 768 60 47.8 kHz 79.500 MHz 1920 × 1080 16 : 9 No No No Yes Yes Yes

1280× 768 75 60.3 kHz 102.250 MHz 1920 × 1 080 16 : 9 No No No Yes Yes Yes

1280× 800 60 49.3 kHz 68.250 MHz 1920 × 1080 16 : 9 No No No Yes Yes Yes

1280× 800 60 49.7 kHz 79.500 MHz 1920 × 1080 16 : 9 No No No Yes Yes Yes

1280× 800 75 62.8 kHz 106.500 MHz 1 920 ×

1280× 960 60 60.0 kHz 108.000 MHz 1920 × 1 080 16 : 9 No No No Yes Yes Yes

1280× 1024 60 64.0 kHz 108.000 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

1280× 1024 75 80.0 kHz 135.000 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

1360× 768 60 47.7 kHz 85.500 MHz 1920 × 1080 16 : 9 No No No Yes Yes Yes

1366× 768 60 47.7 kHz 85.500 MHz 1920 × 1 080 16 : 9 No No No Yes Yes Yes

1400 × 1050 60 64.7 kHz 101.000 MHz 1920 × 1 080 16 : 9 No No No Yes Yes Yes

1440× 900 60 55.5 kHz 88.750 MHz 1920 × 1 080 16 : 9 No No No Yes Yes Yes

1200× 1600 60 75.0 kHz 162.000 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

1920× 1080 60 67.5 kHz 148.500 MHz 1920 × 1080 16 : 9 No No No Yes Yes Yes

1920× 1200 60 74.0 kHz 154.000 MHz 1 920 × 1080 16 : 9 No No No Yes Yes Yes

480i 60 60 Hz SD NTSC 1 920 × 1080 16 : 9 Yes Yes Yes No Yes No

480p 60 60 Hz ED 1 920 × 1080 16 : 9 Yes No Yes No Yes No

576i 50 50 Hz SD PAL 1920 × 1080 16 : 9 Yes Yes Yes No Yes No

576p 50 50 Hz ED 1 920 × 1080 16 : 9 Yes No Yes No Yes No

720p 50 50 Hz HD progressive 1920 × 1080 16 : 9 Yes No Yes No Yes No

720p 60 60 Hz HD progressive 1920 × 1080 16 : 9 Yes No Yes No Yes No

1080i 50 50 Hz HD interlaced 1 920 × 1080 16 : 9 Yes No Yes No Yes No

1080i 60 60 Hz HD interlaced 1 920 × 1080 16 : 9 Yes No Yes No Yes No

1080p 50 50 Hz Full HD 1920 × 1 080 16 : 9 Yes No Yes No Yes No

1080p 60 60 Hz Full HD 1920 × 1 080 16 : 9 Yes No Yes No Yes No

Refresh Rate

(Hz) Horizontal frequency Pixel Frequency

Aspect Ratio Handling

Full Screen Aspect Ratio Composite SVHS YPbPr RGB HDMI DVI

1080 16 : 9 No No No Yes Yes Yes

2009-Mar-20

EN 14 QCG1.0S LA5.

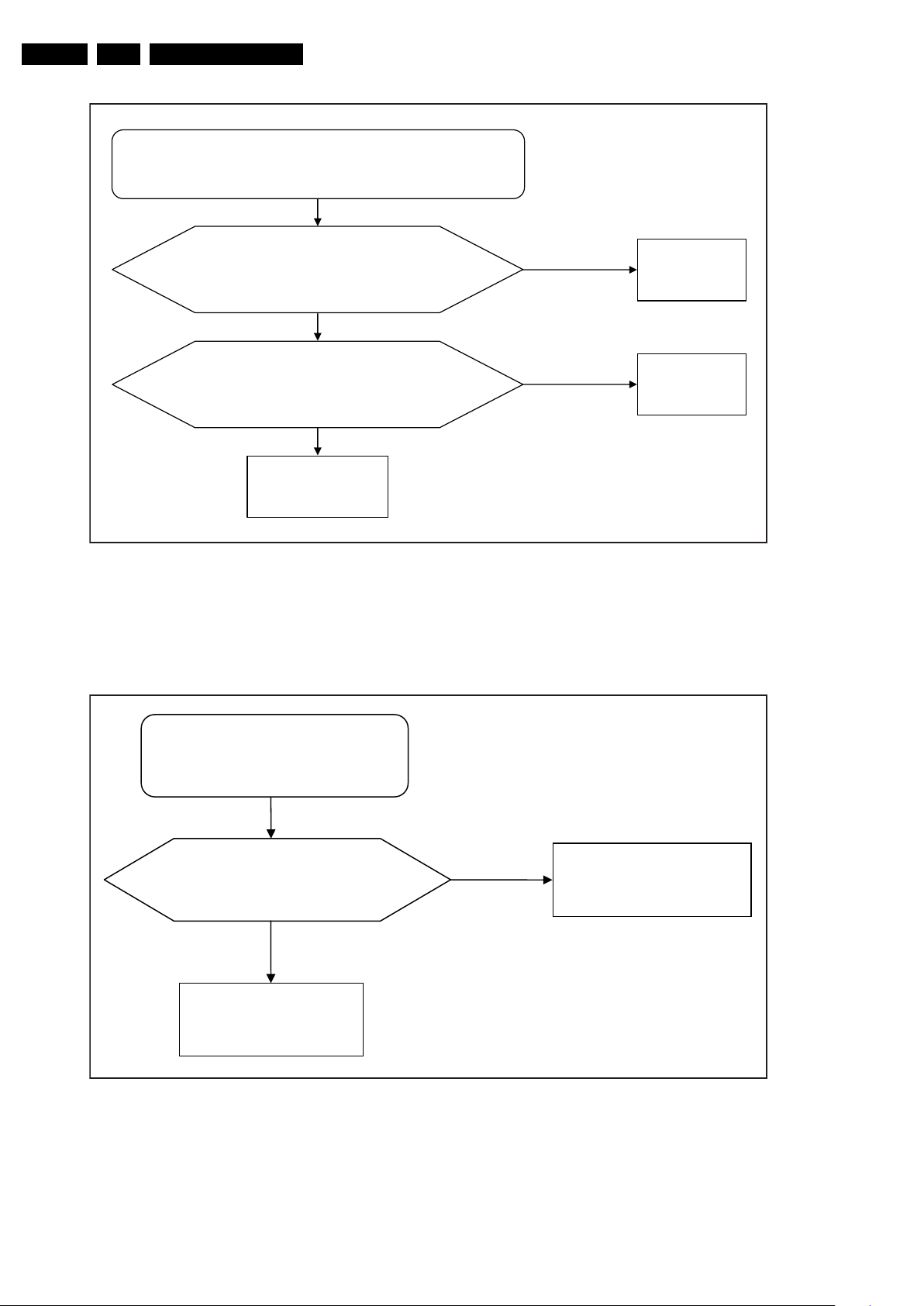

I_17540_007.eps

280108

18430_206_090317.eps

090317

Check SSB if

L56 1.2V correct?

No

Yes

No Power

Yes

Change

SSB

change I/O

board

No

Change

I/O-board

Separate I/O board

(connect SSB, PSU)

CN7 pin5 +5 Vs = 5 V

Correct ??

Yes

No

Check whether LED,

is on or not?

Separate SSB,

Check CN7 pin5

+5 Vs = 5 V

Change

SSB

No

Service Modes, Error Codes, and Fault Finding

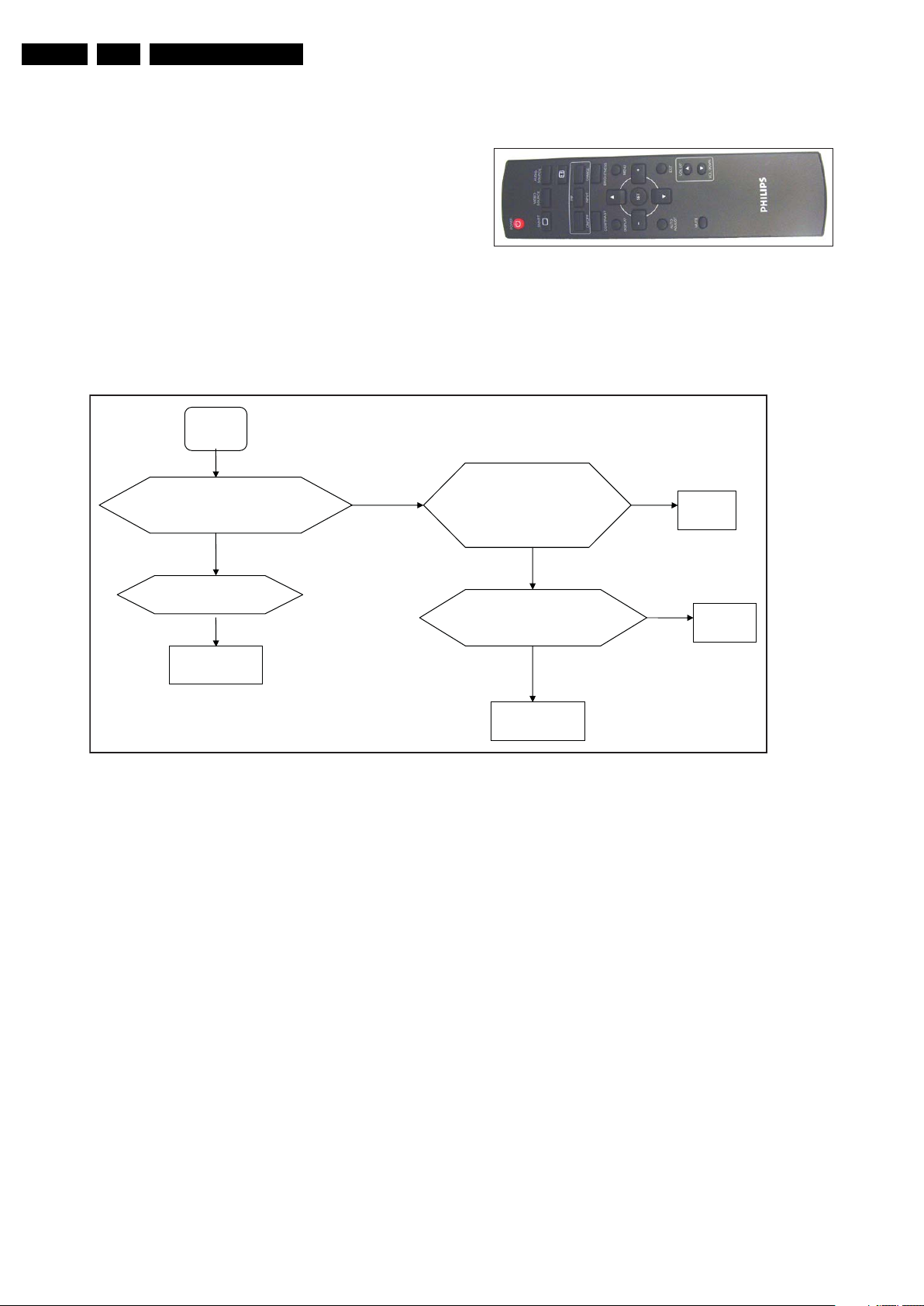

5.2 Service Mode

5.2.1 Factory Mode

There are two ways to enter the factory mode:

1. On the set:

• Push the y button and turn on the AC power.

2. With the remote control:

• Turn on the set and provide a signal source on an input

(this to prevent to enter the power save mode). On the

remote control press “-”, “-”, “+”, “+”, “-”, “+”, “-”, “+”,

“SET”, “MENU”.

• Please note that this set does not respond on the

standard Philips remote controllers, but only responds

to the with the set supplied remote control.

5.3 Fault Finding

• When in the factory mode at the top right of the menu

an “F” is displayed.

• To exit the factory mode turn off the set.

Figure 5-1 Remote control.

2009-Mar-20

Figure 5-2 No power.

Service Modes, Error Codes, and Fault Finding

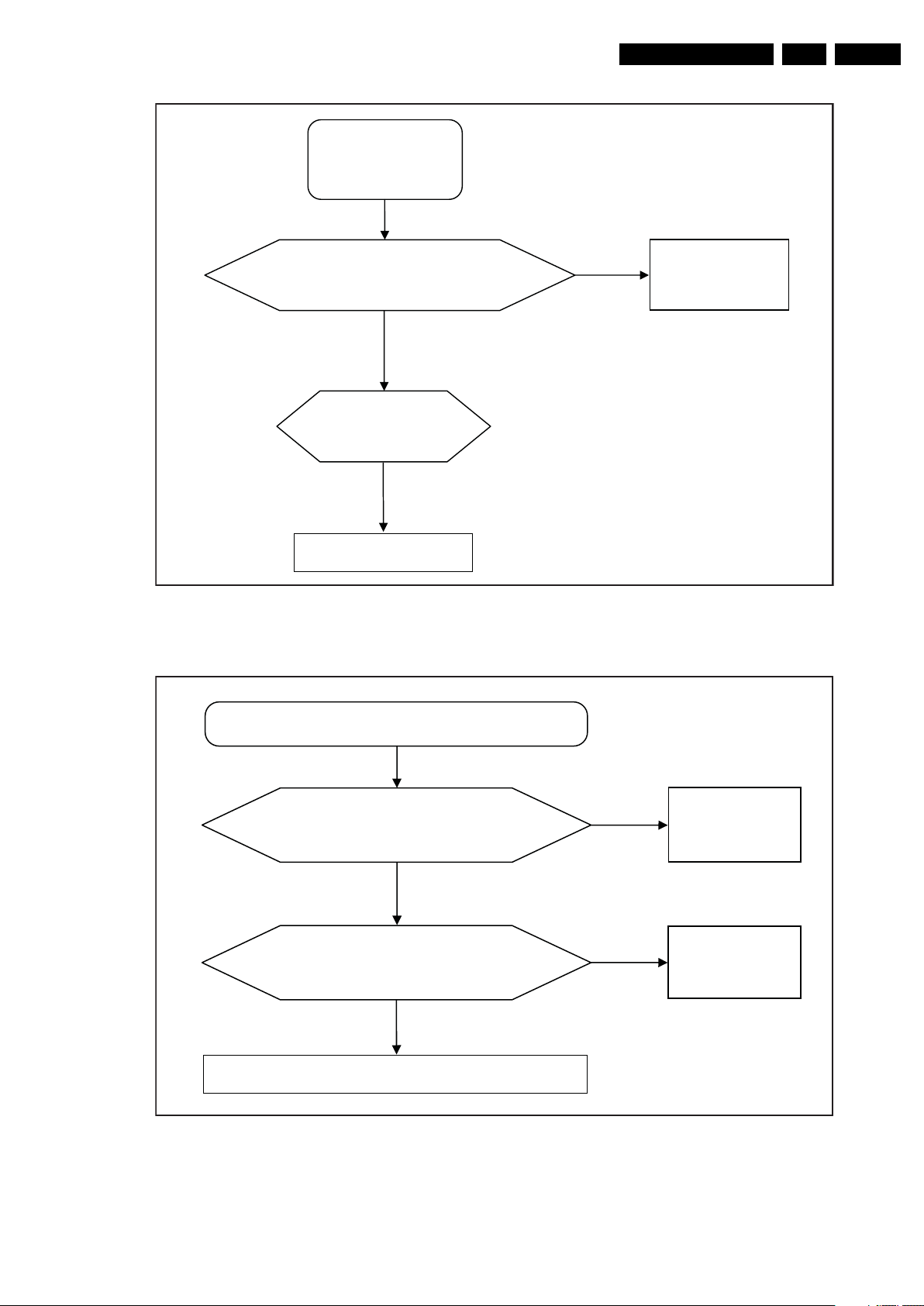

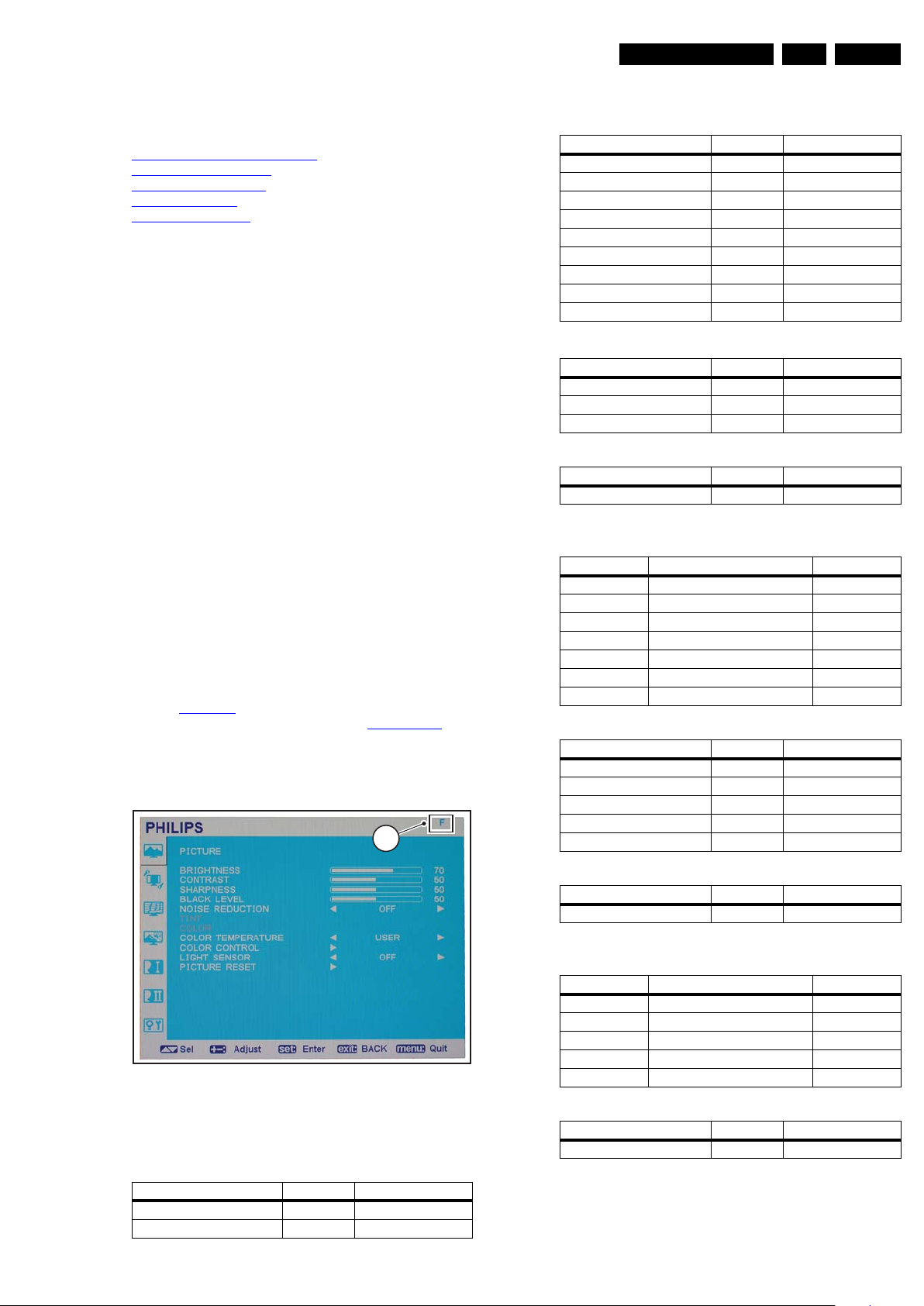

18430_207_090317.eps

090317

Change

power board

No

No

Yes

Check Power board CN8

Pin 11 3.3 V correct?

Change SSB

Check LCD panel

No picture

No backlight

18430_208_090317.eps

090317

No characters, missing colour

No

Check SSB CN8

Pin1 to 5, 12 V correct?

Change

SSB

Yes

Yes

Check LVDS cable

No

Change

LVDS cable

Check LCD panel

EN 15QCG1.0S LA 5.

Figure 5-3 No picture, No backlight.

Figure 5-4 No characters, missing colour.

2009-Mar-20

EN 16 QCG1.0S LA5.

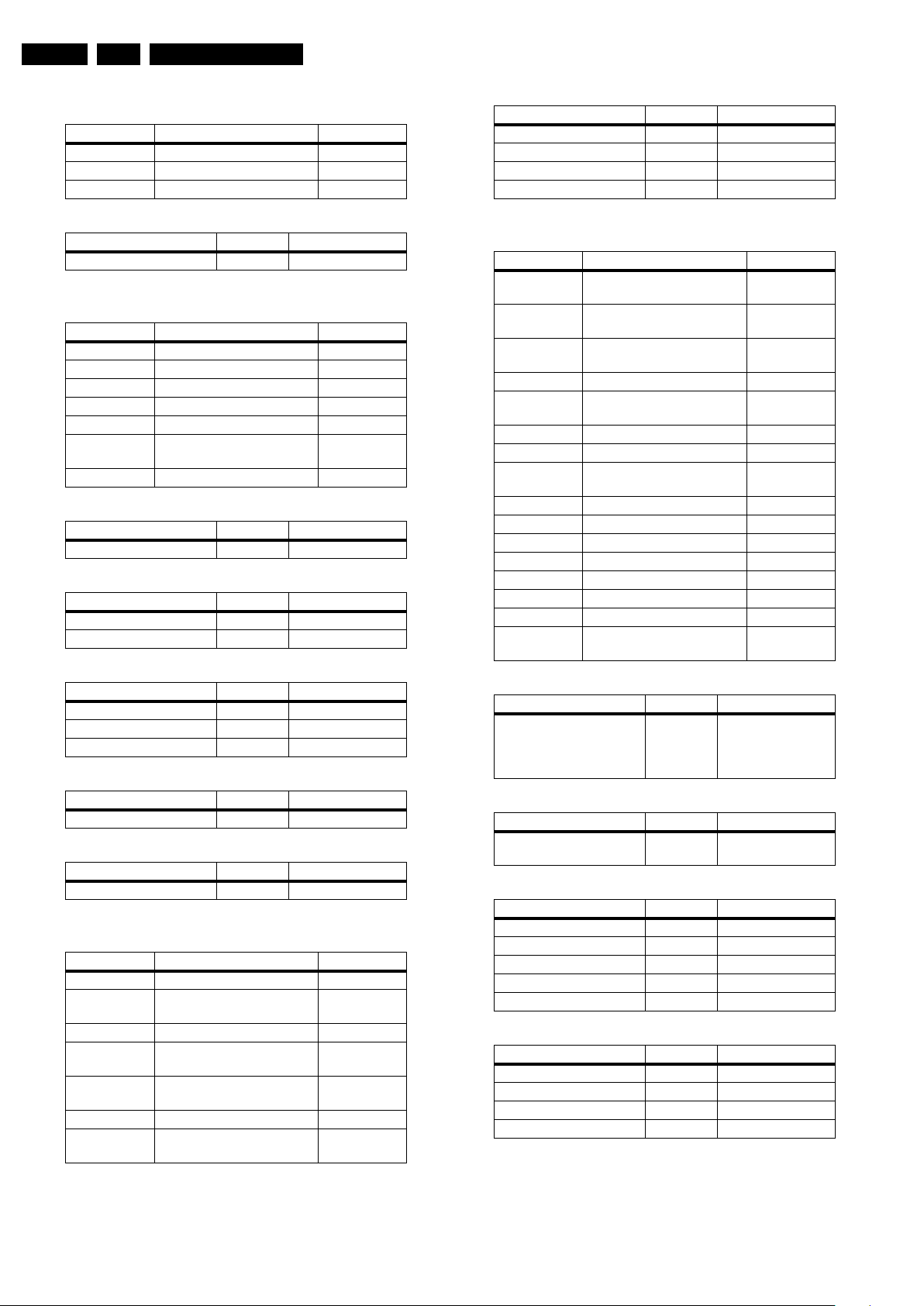

18430_209_090317.eps

090317

Check input on CN6 if

pin 13 H-sync and pin 14 V-sync

are correct?

Yes

Check PC

No

Check correctness of the VGA cable

No

VGA continuosly shows no signal

Change

VGA cable

Yes

Change

SSB

18430_210_090317.eps

090317

Change

video cable

Yes

Check whether the video

cable is correct

Change I/O

board

Video-mode continuously

shows no signal

!

No

Service Modes, Error Codes, and Fault Finding

Figure 5-5 VGA continuously shows no signal.

Figure 5-6 Video-mode continuously shows no signal.

2009-Mar-20

6. Alignments

Alignments

EN 17QCG1.0S LA 6.

Index of this chapter:

6.1 General Alignment Conditions

6.2 Hardware Alignments

6.3 Software Alignments

6.4 Option Settings

6.5 Software upgrade

6.1 General Alignment Conditions

Perform all electrical adjustments under the following

conditions:

• Power supply voltage (depends on region):

– AP-NTSC: 120 V

– AP-PAL-multi: 120 - 230 V

– EU: 230 V

AC

– LATAM-NTSC: 120 - 230 V

– US: 120 V

AC

or 230 VAC / 50 Hz (± 10%).

AC

/ 50 Hz (± 10%).

AC

/ 50 Hz (± 10%).

/ 50 Hz (± 10%).

AC

/ 60 Hz (± 10%).

• Connect the set to the mains via an isolation transformer

with low internal resistance.

• Allow the set to warm up for approximately 25 minutes.

• Measure voltages and waveforms in relation to correct

ground (e.g. measure audio signals in relation to

AUDIO_GND).

Caution: It is not allowed to use heatsinks as ground.

• Test probe: R

> 10 MΩ, Ci < 20 pF.

i

• Use an isolated trimmer/screwdriver to perform

alignments.

6.2 Hardware Alignments

This chassis does not contain any hardware alignments.

6.3 Software Alignments

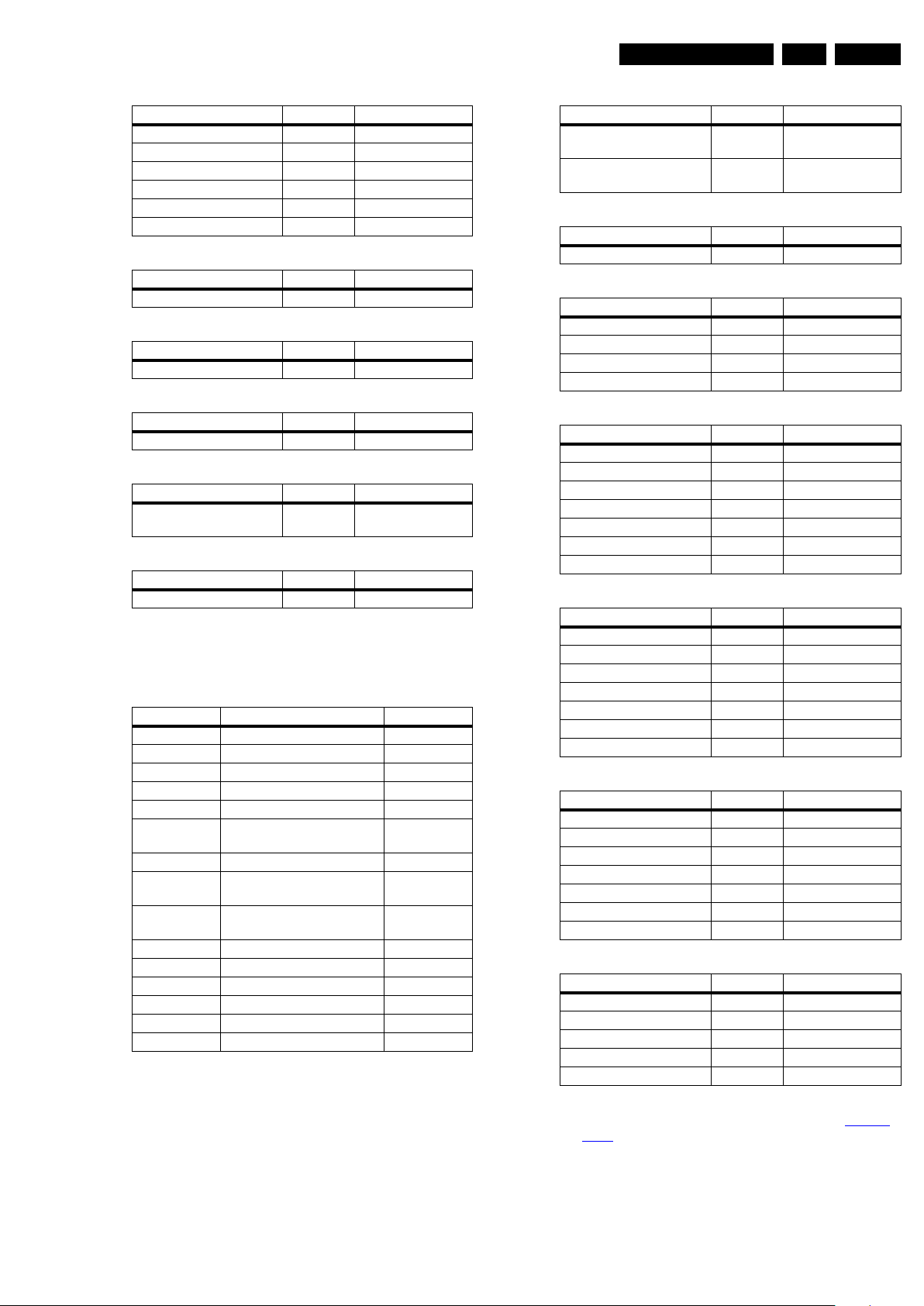

Refer to Figure 6-1 for details.

Put the set in the Factory mode see section Factory Mode

“F” [1] in the picture menu indicates the set is in factory mode.

Use the navigation keys to browse through the menu. Note that

even when in Factory mode, no icon for the Factory Setting

defaults is shown.

Setting Range Default value

Sharpness 0 to 100 50

Black level 0 to 100 50

Noise reduction - OFF

Tint 0 to 100 50

Color 0 to 100 50

Color temperature 9300 K

Color control Submenu -

Light sensor - OFF

Picture reset Submenu -

Color control

Setting Range Default value

User R 0 to 255 128

User G 0 to 255 128

User B 0 to 255 128

Picture reset

Setting Range Default value

Picture reset Yes/No No

6.3.2 Screen defaults

Setting Range Default value

H position 0 to 100 50

V position 0 to 100 50

Clock 0 to 100 20

Clock phase 0 to 100 0

Zoom mode Full, Real, Custom, Normal Full

Custom zoom Submenu -

Screen reset Submenu -

. The

Custom zoom

Setting Range Default value

Zoom 0-100 0

H zoom 0-100 0

V zoom 0-100 0

H position 0-100 50

1

V position 0-100 50

Figure 6-1 Factory Mode Indication

6.3.1 Picture defaults

Setting Range Default value

Brightness 0 to 100 70

Contrast 0 to 100 50

18430_201_090212.eps

090212

Screen reset

Setting Range Default value

Screen reset Yes/No No

6.3.3 Audio defaults

Setting Range Default value

Balance 0 to 100 50

Treble 0 to 100 50

Bass 0 to 100 50

Speaker Internal/External Internal

Audio reset Submenu -

Audio reset

Setting Range Default value

Audio reset Yes/No No

2009-Mar-20

EN 18 QCG1.0S LA6.

Alignments

6.3.4 PIP defaults

Setting Range Default value

PIP size Small, Middle, Large Small

PIP audio Main, Sub Main

PIP reset Submenu -

PIP reset

Setting Range Default value

PIP reset Yes/No No

6.3.5 Configuration 1 defaults

Setting Range Default value

Auto adjust Submenu -

Power save Submenu -

Language en, de, ru, cn, pl, fr, it, es, tr English

Panel saving Submenu -

Color system - N/A

Configuration reset

Factory reset Submenu -

Auto adjust

Setting Range Default value

Auto adjust - N/A

Power save

Setting Range Default value

RGB On/Off Off

Video On/Off Off

Panel saving

Setting Range Default value

Cooling fan Auto, On Auto

Brightness On/Off Off

Pixel Shift On/10-900 Off

Configuration reset

Setting Range Default value

Configuration reset Yes/No No

Factory reset

Setting Range Default value

Factory reset Yes/No No

6.3.6 Configuration 2 defaults

Setting Range Default value

OSD turn off 0 to 120 50

Information

OSD

Sleep timer 1 to 24 hrs. / Off Off

OSD H

position

OSD V

position

Flip OSD On/Off Off

Monitor information

Submenu -

1 to 10 sec / Off 10 sec

0 to 100 50

0 to 100 50

Submenu -

Monitor information

Setting Range Default value

Model name - Type number

Serial no - Serial number

Operating hours - Operating hours

SW version - Software version

6.3.7 Advanced option defaults

Setting Range Default value

Input

resolution

Black level

expansion

Gamma

selection

Scan mode - Overscan

Scan

conversion

Film mode - Auto

IR control Submenu -

Keyboard control

Tiling Submenu -

Heat status Submenu -

Date and time Submenu -

Schedule Submenu -

Monitor ID Submenu -

DDC/CI On/off On

Smart power Off/Medium/High Off

Advanced

option reset

IR control

Setting Range Default value

IR control Normal,

Keyboard control

Setting Range Default value

Keyboard control Lock/

Tiling

Setting Range Default value

H monitors 1-5 1

V monitors 1-5 1

Position 1-25 1

Frame comp. No/Yes No

Enable No/Yes No

Heat status

Setting Range Default value

Cooling fan 1 On/Off -

V monitors 1-5 -

Temperature sensor 1 - -

Temperature sensor 2 - -

Auto Auto

--

Native, 2.2, 2.4, S gamma Native

- Progressive

Submenu -

Submenu -

Normal

Primary,

Secondary,

Lock

Unlock

Unlock

2009-Mar-20

Alignments

EN 19QCG1.0S LA 6.

Date and time

Setting Range Default value

Year 2000/2099 2000

Month 01-12 01

Day 01-31 01

Hour 00-23 00

Minute 00-59 00

Daylight saving time On/off Off

Schedule

Setting Range Default value

Schedule setting by user - -

Monitor ID

Setting Range Default value

Monitor ID - 1

DDC/CI

Setting Range Default value

DDC/CI On/Off On

Smart power

Setting Range Default value

Smart power Medium/

High/Off

Advanced option reset

Setting Range Default value

Advanced option reset Yes/No No

6.3.8 Factory Setting defaults

Remark: The entry for the factory setting is not visible, but is

located below the Advanced option menu. This menu is only

available when the set is in factory mode.

Setting Range Default value

Burn in On/off (see note 1) Off

Hours running Submenu -

Factory reset Submenu -

ADC adjust Submenu -

Brightness Submenu -

Color

temperature

Input timing Submenu -

Baud rate 2400, 4800, 9600, 19200,

EDID write

protect

ISP mode On/Off Off

OSD display On/off On

Frame lock On/off On

DDR control Submenu N/A

Version Submenu -

SSC Submenu N/A

Note:

1. This function turns enables a monitor to burn in without an

input signal by showing the following burn in pattern cycle:

white, black, red, green, blue.

Submenu -

38400, 57600, 115200

On/off On

Off

9600

Hours running

Setting Resetable Default value

Resetable on Yes Monitor power on

time

Unresetable on No monitor power on

time

Factory reset

Setting Range Default value

Factory reset Yes/No No

ADC adjust

Setting Range Default value

D sub ADC adjust Submenu -

BNC ADC adjust Submenu -

YPbPr ADC adjust Submenu -

Video ADC adjust Submenu -

Dsub ADC adjust

Setting Range Default value

Auto setup - -

ADC R-gain 0-255 255

ADC G-gain 0-255 255

ADC B-gain 0-255 255

ADC R-offset 0-255 96

ADC G-offset 0-255 91

ADC B-offset 0-255 92

BNC ADC adjust

Setting Range Default value

Auto setup - -

ADC R-gain 0-255 255

ADC G-gain 0-255 255

ADC B-gain 0-255 255

ADC R-offset 0-255 96

ADC G-offset 0-255 91

ADC B-offset 0-255 92

YPbPr ADC adjust

Setting Range Default value

Auto setup - -

ADC R-gain 0-255 255

ADC G-gain 0-255 255

ADC B-gain 0-255 255

ADC R-offset 0-255 96

ADC G-offset 0-255 91

ADC B-offset 0-255 92

Video ADC adjust

Setting Range Default value

Auto setup - -

Y-gain 0-2048 1024

Y-offset 0-255 0

Color 0-2 048 1024

IRE 0-255 0

ADC alignment for ANALOG inputs

1. Enter the Factory mode as described in section Factory

Mode.

2. Enter the Factory Setting defaults.

3. Go to item “ADC ADJUST”.

4. Select proper input to adjust.

5. Select “AUTO SETUP” and press “SET”.

6. ADC is aligned.

2009-Mar-20

EN 20 QCG1.0S LA6.

Alignments

Brightness

Setting Range Default value

PC max brightness 0 to 255 255

PC min brightness 0 to 255 0

Video max brightness 0 to 255 255

Video min brightness 0 to 255 0

Color temperature

Setting Range Default value

Color temperature 5000K,

6500K,

7500K,

9300K,

10000K,

11000K

R-gain 0 to 255 128

G-gain 0 to 255 128

B-gain 0 to 255 128

R-offset 0 to 50 0

G-offset 0 to 50 0

B-offset 0 to 50 0

Input timing

Setting Range Default value

HDMI input Auto,

Video, PC

DVI-D input Auto,

Video, PC

PC-A input Auto,

Video, PC

11000K

Auto

Auto

Auto

DRAMCLK

Setting Range Default value

On/Off On/Off Off

Amplitude 0-127 0

Period 0-31 0

AUDDS1

Setting Range Default value

On/Off On/Off Off

Amplitude 0-3 0

Period 0-63 0

AUDDS2

Setting Range Default value

On/Off On/Off Off

Amplitude 0-3 0

Period 0-63 0

AUDDS3

Setting Range Default value

On/Off On/Off Off

Amplitude 0-255 0

Period 0-255 0

AUDDS4

Setting Range Default value

On/Off On/Off Off

Amplitude 0-255 0

Period 0-255 0

DDR control

Setting Range Default value

Write T0 0-255 0

Read T0 even 0-255 0

Read T0 odd 0-255 0

Write T1 0-255 0

Read T1 even 0-255 0

Read T1 odd 0-255 0

Write T2 0-255 0

Read T2 even 0-255 0

Read T2 odd 0-255 0

Write T3 0-255 0

Read T3 even 0-255 0

Read T3 odd 0-255 0

Version

Setting Range Default value

Version ID - -

SSC

Setting Range Default value

DRAMCLK Submenu -

AUDDS1 Submenu -

AUDDS2 Submenu -

AUDDS3 Submenu -

AUDDS4 Submenu -

DDDS Submenu -

VDDS1 Submenu -

VDDS2 Submenu -

DDDS

Setting Range Default value

On/Off On/Off On

Amplitude 0-255 3

Period 0-255 6

VDDS1

Setting Range Default value

On/Off On/Off Off

Amplitude 0-255 0

Period 0-255 0

VDDS2

Setting Range Default value

On/Off On/Off Off

Amplitude 0-255 0

Period 0-255 0

6.4 Option Settings

Not applicable.

2009-Mar-20

6.5 Software upgrade

18430_202_090213.eps

090213

18430_203_090213.eps

090213

18430_204_090213.eps

090213

18430_205_090213.eps

090213

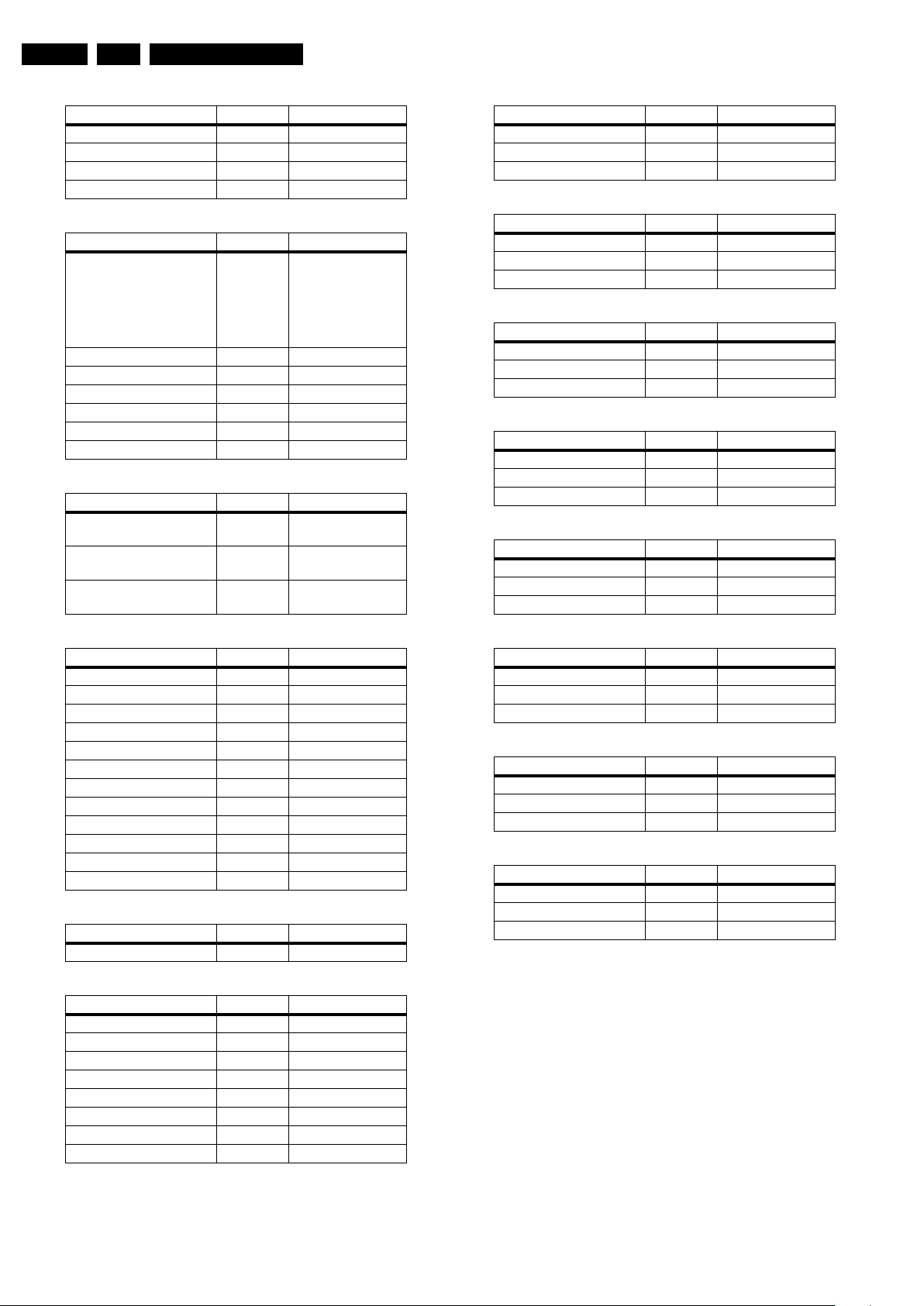

6.5.1 Hardware

Connect the cable of RS232 with PC COM port by jump wire.

6.5.2 Software

1. Install the Serial upgrade program GProbe5.1.0.17.EXE on

a PC and run it.

2. Check “Options”, “Connection settings”, “Serial”, “Port” and

“Baud Rate”, see Figure 6-2

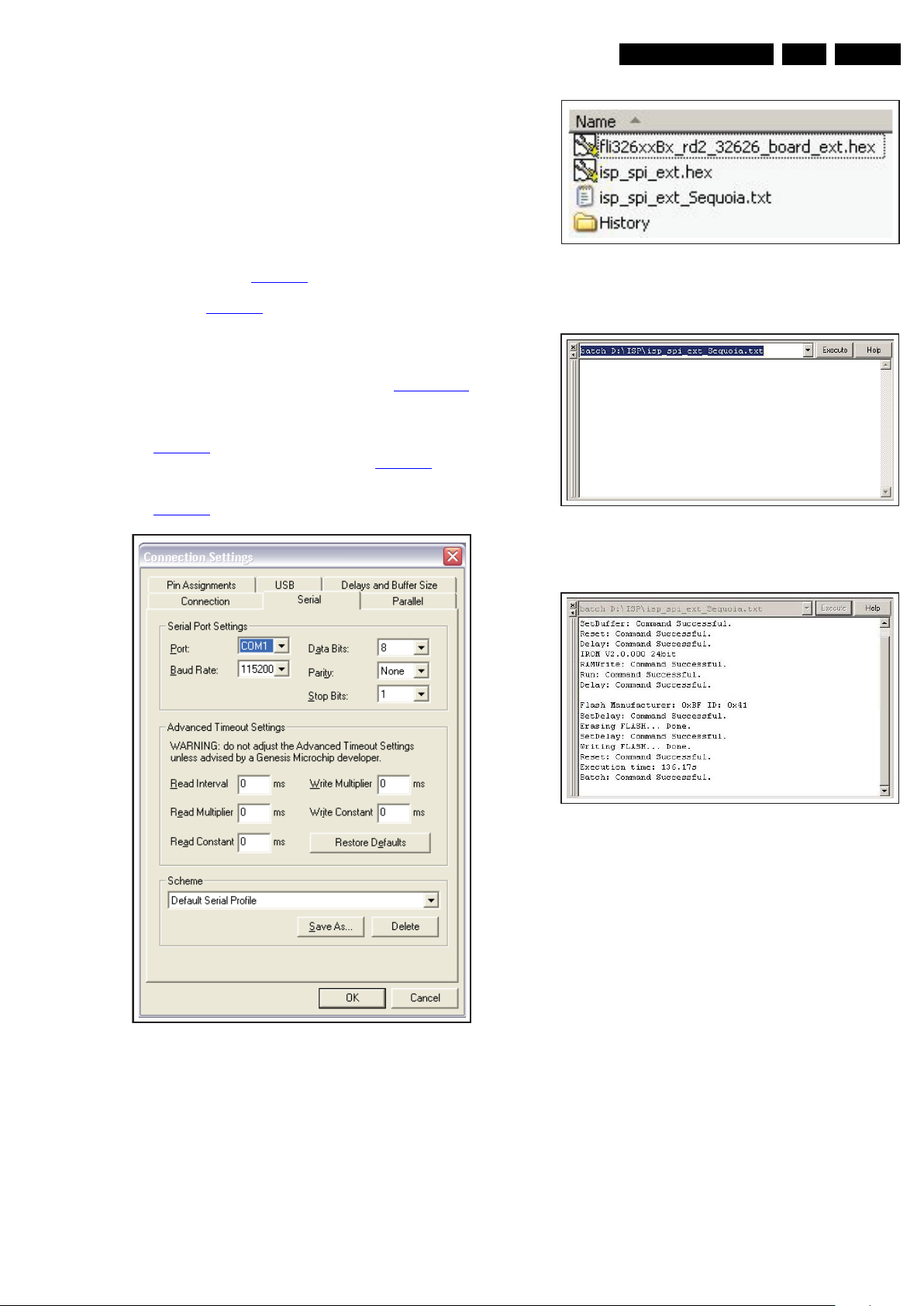

3. Make a directory called ISP on e.g. C-drive and copy the

files, see Figure 6-3

4. The latest Firmware file must be renamed into:

“fli326xxBx_rd2_32626_board_ext.hex”.

5. In the “Execute” field enter: “batch D:\ISP\

isp_spi_ext_Sequoia.txt”.

6. Put the set in the Factory mode, see section Factory Mode

7. Press UP on the remote control to enter Factory Setting

defaults and set the ISP MODE to ON.

8. Click the Execute button in the GProbe program, see

Figure 6-4

.

9. Erasing and programming will start, see Figure 6-5

10. Monitor will show a black screen. When ready (see GProbe

command window) the monitor will show picture again, see

Figure 6-5

.

.

.

Alignments

EN 21QCG1.0S LA 6.

Figure 6-3 File names

.

.

Figure 6-4 Gprobe Execute

Figure 6-5 Gprobe Erasing and programming

Figure 6-2 Gprobe connection setup

2009-Mar-20

Loading...

Loading...