Philips AZ1050 Service Manual

CD Stereo Radio Recorder

AZ1050

AZ1055

all versions

TABLE OF CONTENTS

chapter

Handling chip components and safety 1 - 1

Technical Specification & Service Tools 2 - 1

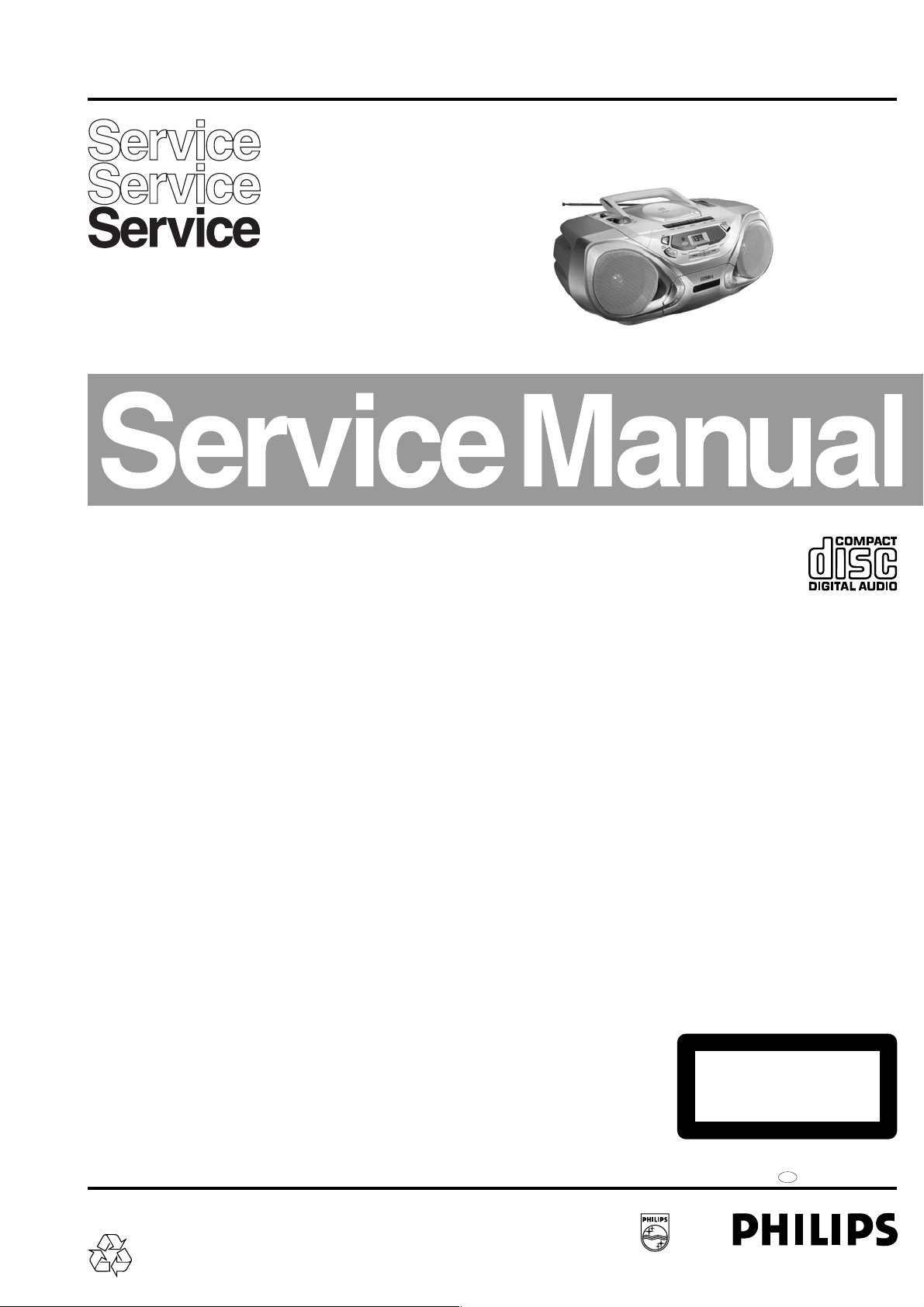

Service Measurement 2 - 2

Connections & Controls

Instructions for use

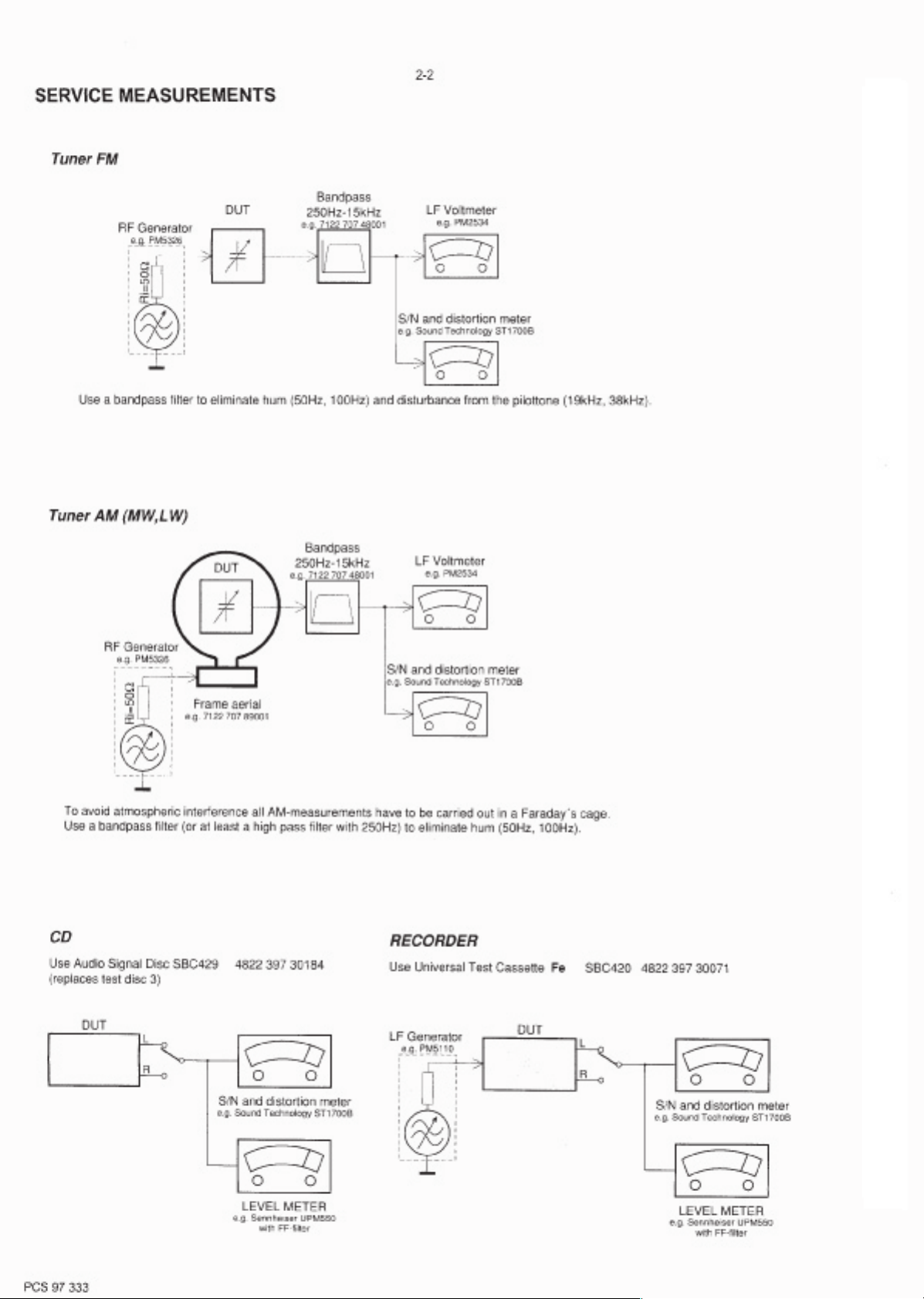

Disassembly Diagram 4 - 1

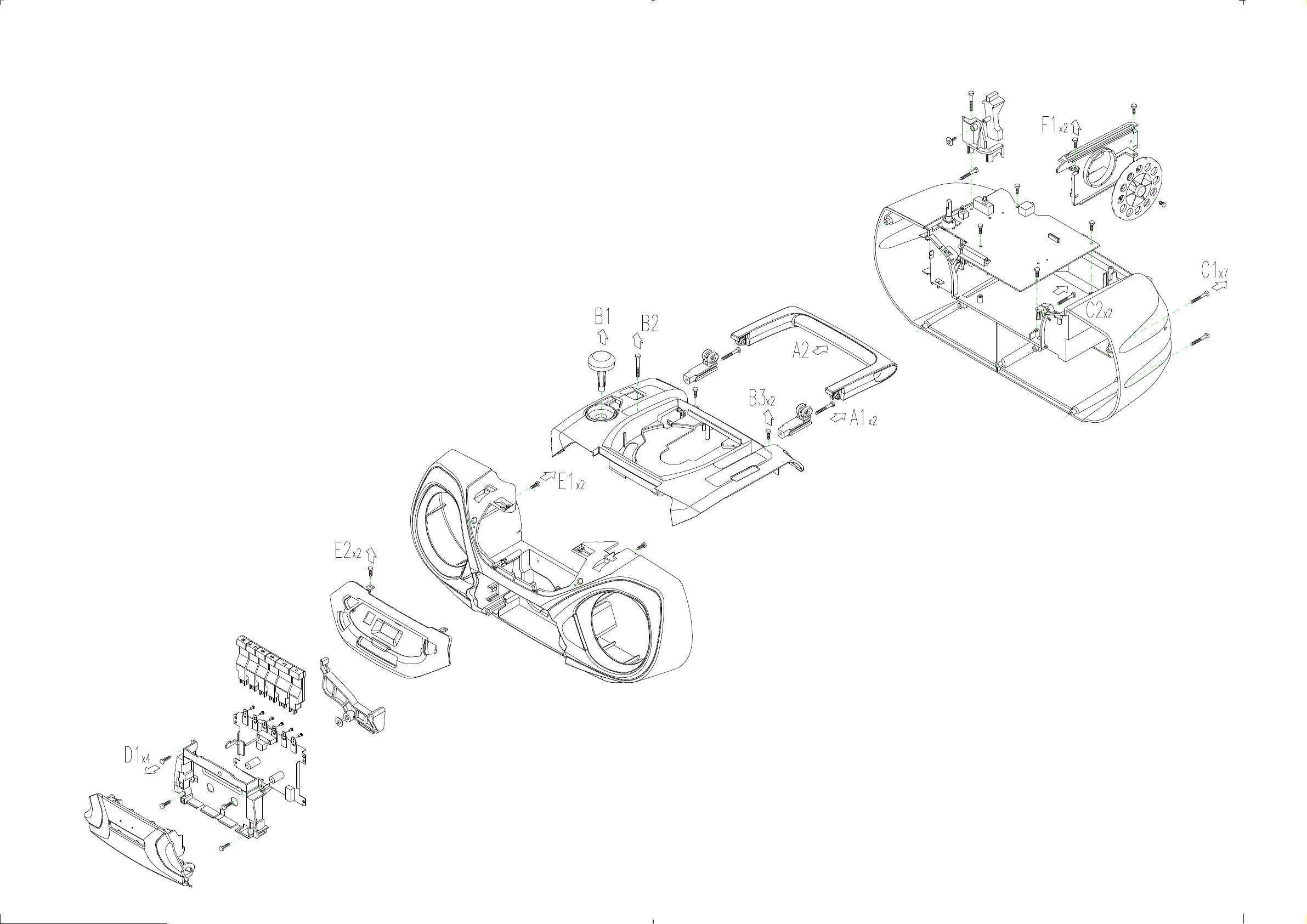

CD Service Test Program 4 - 2 to 4 - 3

Block Diagram

Wiring Diagram 5 - 2

TUNER BOARD

circuit diagram

layout diagram

COMBI BOARD

circuit diagram

layout diagram

..................................................

................................................

.................................................

...................................................

........................................

.............................................................

...........................................................

.......................................................

.......................................................

...............................................

....................................................

.............................

..........................

3 - 1

3 - 2 to 3 - 5

5 - 1

6 - 1

6 - 2

7 - 1, 7 - 3, 7 - 5

7 - 2, 7 - 6

FRONT BOARD

circuit diagram

layout diagram

EXPLODED VIEWS DIAGRAM

cabinet

tape deck

Mechanical partslist

Electrical partslist

.......................................................

.......................................................

.................................................................

............................................................

.....................................................

...............................................

chapter

7 - 4

7 - 4

8 - 1

8 - 2

8 - 2

9 - 1 to 9 - 4

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified

be used.

C

Copyright 1995 Philips Consumer Electroncis B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system or transmitted, in any form or by any means, electronic, mechanical, photocopying,

or otherwise without the prior permission of Philips.

Printed in The Netherlands Copyright reserved Subject to modification

PCS 107 205

CLASS 1

LASER PRODUCT

GB

3140 785 22620Published by SS 0105 Service Audio

TECHNICAL SPECIFICATIONS

2-1

GENERAL

Mains voltage

Mains frequency-/00/05/10/14 : 50 Hz

Battery mains : 9 V (R20 x 6)

Power consumption : 5 W

Dimension (W x H x D) : 435 x 252 x 170 mm

Weight : 3.4 Kg

-/00/05/10/14

-/01/11 : 120 / 230 V

-/01/11 : 50 / 60 Hz

Remote : 3V (R6 x 2)

: 230 V

-/17 : 120 V

-/17 : 60 Hz

AMPLIFIER

Output power mains : 2 x 1.4 W

battery : 2 x 1.6 W

Speaker impedance : 2 x 4 ohm

Frequency response : 100 Hz - 10 kHz (±3dB)

TUNER - FM SECTION

Tuning range : 87.5 - 108 MHz

IF frequency : 10.7 MHz ± 0.2 MHz

Sensitivity : 14 dBf at 26dB S/N

Selectivity : 45 dB at 300kHz

IF rejection : 65 dB

Image rejection : 26 dB

TUNER - AM SECTION

Tuning range MW : 522 - 1607 kHz

-/17 : 520 - 1730 kHz

IF frequency : 468 kHz ± 3 kHz

Sensitivity MW : 1500 µV/m at 26dB S/N

Selectivity MW : 20 dB

IF rejection MW : 60 dB

Image rejection MW : 32 dB

AUDIO CASSETTE RECORDER

Number of tracks : 2 stereo

Tape speed : 4.76 cm/sec ± 3%

Wow & flutter : < 0.48 JIS UWTD

Fast wind/rewind C60 : < 120 sec.

Frequency response P/B : 125 - 8000 Hz

S/N ratio :

≥ 40 dB

COMPACT DISC

Frequency response : 100 Hz - 10 kHz

S/N ratio : 60 dB

Channel difference 1 kHz : < 3 dB

Channel crosstalk 1 kHz : 40 dB

Laser wavelength : 780 ± 20 nm

Laser light power : < 0.5 mW

SERVICE TOOLS

TORX T10 screwdriver with shaftlength 150mm.........................................4822 395 50423

TORX screwdriver set SBC 163...............................................................4822 295 50145

Audio signal disc SBC 429........

Playability test disc SBC 444...................................................................4822 397 30245

Test disc 5 (disc without errors ) +

Test disc 5A (disc with dropout errors, black spots and fingerprints)

SBC 426/426A.....................................................................4822 397 30096

Burn in test disc (65 min. 1kHz signal at -30 dB level without “pause”)

Universal test cassette Fe SBC 420

..............................................................4822 397 30184

.....4822 397 30155

........................................................4822 397 30071

PCS 107 206

DISASSEMBLY DIAGRAM

A. To remove Handle

B. To remove Top Panel

C. To remove Front Cabinet Assy

D. To remove Tape Deck

E. To remove Front Panel

F. To remove Tuner Board

4-1 4-1

PCS 104 241

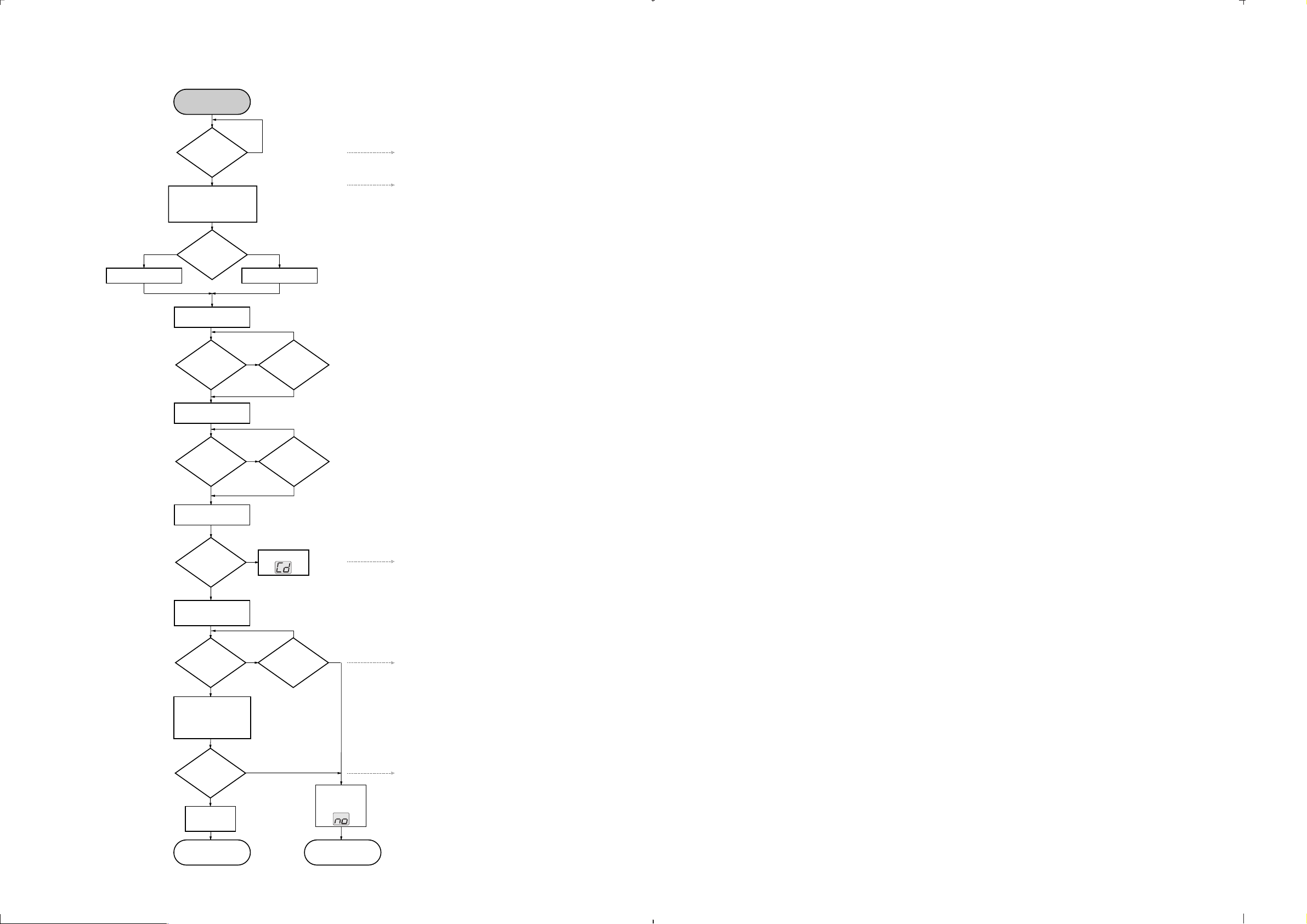

SERVICE TESTPROGRAM

4-2 4-2

NEXT button

N

pressed?

Display shows all

segments and flags

for checking open circuits.

see figure 1

N

NEXT button

pressed?

Display shows figure 2.

All alternate pins (2, 4, ..)

of the display are activated

for checking shortcircuits.

STOP button

N

pressed?

REPEAT

ALL

fig. 1

fig. 2

To enter Service

Testprogram hold

PLAY & STOP buttons

depressed while switching

CD mode on.

Display shows

version number

of the µP - software.

Slide servo, Radial servo, Focus servo, Disc motor

and Laser are switched off.

Mute is switched on via decoder IC.

DISPLAY TEST CD SERVO TEST

Y

Y

Y

SHUFFLE

PROGRAM

SHUFFLEREPEAT

FOCUS search

automatic

adjustment of

TRACK BALANCE

PLAY button

N

pressed?

Display shows

N N N N

PLAY button

pressed?

Display shows

objective moves up&down

disc motor for 160ms "on"

FOCUS found?

Display shows

disc motor turns.

N

PLAY button

pressed?

Display shows

STOP button pressed in any step returns

to begin of Service Testprogram.

Y

Y

N

Y

Y

To leave Service Testprogram switch

*

CD mode off.

Door switch is ignored Æ CD door can be opened.

*

SLIDE test DISC MOTOR test

NEXT button

pressed?

Y Y Y

Slide moves

outside as long as

button is hold

depressed.

To check Focus over the whole disc area

Slide - and Discmotor can also be activated

in FOCUS - test.

PREV. button

pressed?

Slide moves inside

as long as button

is hold depressed

or until

inner-switch

is activated.

while autom. track balance adjustment is active

as soon as track balance adjustment finished.

(1 - 6) indicates the actual setting.

MODE button

pressed?

Disc motor turns

clockwise

as long as button

is hold depressed.

(accelerate )

CD PLAY TEST

1)

The CD PLAY TEST is intended to be used

for continuously playing a disc in order to

detect intermittend or not reproducible

failures. The error code indicates where

the failure can be found.

1)

MODE button

pressed?

Y

CD is in normal

PLAY mode.

In case of failures

error codes acc. table 1

will be indicated

on the display.

POWER

switched off?

Y

Exit Service Testprogram

N

N

CD ERROR codes

Error number Error type

E0 Focus Error

Triggered when the focus is lost for more than 250ms during playing the CD.

E2 Slide-in error

Generated when the inner-switch did not close within approx. 4s when the pick up is

moved inside. Inner-switch or slide motor problems.

E3 Slide-out error

Generated when the inner-switch did not open within approx. 250ms when the pick up is

moved from the inner position outside. Inner-switch or slide motor problems.

E5 Jump error.

Triggered when the servo processor counts too less tracks in a defined time during JUMPS.

This can be caused by a disturbed HF-signal (the tracks cannot be recognized exactly),

slide motor problems, track servo problems or scratched discs.

E6 Subcode Error

No valid subcode for 300ms during PLAY.

E7 PLL lock error

When the PLL did not lock after 10 retries then this warning message is generated and

the servo is stopped and restarted (as if the user would have pressed STOP and then

PLAY immediately) to recover.

F0 Focus Search Error

Triggered when the focus could not be found within 3s when starting up the CD.

F2 Fatal Subcode Error

No valid subcode for more than 4s during PLAY.

Error type:

W = Warning Æ

F = Fatal Error

set continues operation, message remains on the display until next error occurs

or any key is pressed.

Æ set stops operation, message remains on the display.

(The set can only be operated again via a reset)

Error description

W

W

W

W

W

W

F

F

table 1

servtest EVA, 030398

Y

MODE button

pressed?

automatic

adjustment of

FOCUS GAIN

Y

MODE button

pressed?

automatic

adjustment of

TRACK GAIN

Y

MODE button

pressed?

RADIAL test

NEXT button

pressed?

CUE - mode

jumps in steps of

16 tracks forward

N

PLAY button

pressed?

Display shows

N

PLAY button

pressed?

Display shows

track servo switched on

N

PLAY button

pressed?

Display shows

Æ Play mode

MUTE is switched off

Y

N

Y

N

Y

N

Y

PREV button

pressed?

REVIEW - mode

jumps in steps of

16 tracks backwards

while autom. focus gain adjustment is active

as soon as focus gain adjustment finished.

(1 - 6) indicates the actual setting.

while autom. track gain adjustment is active

as soon as track gain adjustment finished.

(1 - 6) indicates the actual setting.

Purpose of RADIAL test:

To check if the Audio signal is reproduced.

Subcode info is ignored during this test Æ

If the CD player functions well in this testmode,

but not in the normal Play mode check quality

of the eye-pattern signal.

NN

Y

If the margin settings 0 or 7 are displayed the required

setting is possibly out of the adjustment range.

Æ check disc drive and/or electronic circuitry

PCS 99 154

mp Æ

mp Æ

mp Æ

mp Æ

Æ

mp Æ

mp Æ

m

mp ´

m

mp Æ

m

Æ

Æ

Æ

Æ

Æ

Æ

CD STARTUP PROCEDURE

BEGIN

+A(CD)

supplied to

CD part?

Decoder delivers CLOCK -

frequ. 4.23MHz to µP.

µP-RESET line Æ high

µP init. Decoder 7801.

Init. 7801 for ext. DAC Init. 7801 for int. DAC

µP moves slide inside

µP moves slide outside

(0,2s time-out starts)

Disc motor 100ms on

µP initializes Decoder

and Servo IC:

-start turntable

-adj. track bal. and gain

-read subcode (TOC)

Y

Level on

pin23

(CD-RESET)

after 100µs?

(4s time-out starts)

inner switch

closed?

Y Y

inner switch open?

Y Y

slide off

Door closed?

Y

Laser on

FOCUS search on

focus found? 3s time-out over?

Y

TOC

found?

Y

display shows

max. trackno.

STOP MODE STARTUP FAILED

CD switched on

(mode switch)

N

HIGHLOW

N

4s time-out over?

N

0,2s time-out over?

Display shows

N

N

N

N

N

N

4-3 4-3

Abbreviations and Pin-descriptions of CD ICs

SERVO PROCESSOR M62475FP

Remark: To check focus servo, slide servo, track servo and turntable

use service test program

- Battery empty?

- check +A,

- mode switch o.k.?

check: - +A(CD), +B(CD), +LASER, +M,

- time constant of reset circuit

- Pin 32 of µP 7800 HIGH ?

- Pin 30 of µP 7800, if 4.23 MHz o.k.

check: - door switch

Y

startup proc.

stopped,

display shows

check: - Laser light on ?

Check pin 38 of 7803 and LASER CONTROL circuit

- Focus Servo

check: - Motor control pin 27 of Decoder 7801 and

Disc Motor driver 7805

- HF Signal by using service testprogram

CDstartup EVA, 080997

Pin Name Direction Description

1-3

A, B, C

4-5

E, F

6 SGT

7 TE - - Inverting input of track error amplifier

8 TEGain - Gain control pin of track error amplifier

9 TG1 - Track Gain 1 - switch: controls the gain of the track servo amplifier

10 TE out - Track Error amplifier output

11 TC/Shock - Track Cross/Shock detector input

12 TS + - Non inverting input of track servo amplifier

13 TG2 not connected Track Gain 2 - switch: controls the gain of the track servo amplifier

14 TS - - Inverting input of side servo amplifier

15 TS out

16 SS + - Non inverting input of slide servo amplifier

17 SS - - Inverting input of slide servo amplifier

18 Slide out

19 DET. FILTER 20 BIAS

21 GND - Ground connection pin (negative supply)

22 MLA/DIS

23 JP1/SG

24 MCK

25 MSD

26 D

out

27 C

LPF

28 I

REF

29 V

CC

30 FS

OUT

31 FS - - Inverting input of focus serco amplifier

32 FEGain - Gain control pin of focus error amplifier

33 FE - - Inverting input of focus error amplifier

34 SGF

35 C

FSR

36 ALPC + - Non inverting input of Automatic Laser Power amplifier

37 ALPC - - Inverting input of Automatic Laser Power Control amplifier

38 ALPC

39 MRC - Connection pin for capacitor of Mirror detector

OUT

40 HF

41 HFI - Inverting input of HF amplifier

42 ABC - Sum output of amplified A, B and C input (central photo diode signal input)

SERVO PROCESSOR M65824FP

Pin Name Direction Description

1 Anal. V

2 ADJCLK not connected Clock output for servo adjustment; f=88.2kHz

3 LOCK not connected Lock monitor / low disc rotation output

4 CKSEL - System clock selection. Low=8.4672MHz, high=16.9344MHz

5 RESET

6 C423

7 C846 not connected 8.4672MHz clock output

8 XI

9 DVSS - Digital system ground

10 XO

11 TEST - Normal / Test selection input. Testmode = high

12 SBCO not connected Subcode serial output

13 SCCK - Shift clock input for subcode data read

14 SYCLK not connected Frame lock status output. Lock = high

15 EFFK not connected EFM frame clock output. Duty = 50%

16 KILLB not connected Digital silence mute output. Digital zero = low

17 EST1 not connected Error monitor output 1

18 EST2 not connected Error monitor output 2

19 HF

20 TLC - Slice level control signal output

21 LPF - PLL loop filter

22

23 DSPS - Digital system power supply

24 SBQS not connected Interrupt signal to read out subcode Q data. Read = low

25 CRCF not connected Subcode Q-channel Cyclic Redundance Check Flag output. CRC o.k. = high level

26 SCAND not connected Subcode sync signal detection. Sync = high

27 PWM

28 DVDD2 - Digital interface power supply 2

29 DVSS2 - Digital system ground 2

30 MCK

31 MSD

32 MLAB

33 EXP1

34 EXP2

35 CGREF

36 AMPREF not connected Op-amp for LPF reference voltage setting

37 LOUT/DO

38 LNEG not connected Charge pump output (left channel) / Ext.DAC mode: Wordclock output

39 ROUT/DSCK

40 RNEG/LRCK

41 IREF - Current reference

42 Anal. V

Dig. V

SS

DD

DD

Diode array Æ Servo processor

Diode array Æ Servo processor

Servo processor Æ Track error ampl. Input

Servo processor Æ Servo driver

Servo processor Æ Motor driver

Servo processor Æ external electronic

Servo processor

Servo processor

Servo processor

Servo processor

Servo processor Æ mp

-

- Reference current input

- Positive supply connection pin (4V - 5.5V)

Servo processor Æ Servo driver

Servo processor

Focus error ampl. Input

- Charge capacitor for Focus Search triangle-generator

Servo processor Æ Laser driver

Servo processor Æ Decoder

- Analog system ground

Signal processor

Signal processor Æ mp

X-Tal Æ Signal processor

Signal processor Æ X-Tal

Servo processor Æ Signal processor

- Digital interface power supply

Signal processor Æ Motor driver

Signal processor

Signal processor

Signal processor

Signal processor

Signal processor

Signal processor

Signal processor

Signal processor

Signal processor

- Analog system power supply

Current input (central photo diode signal input)

Current input (satellite photo diode signal input)

Signal generator output to track servo, sends 1700Hz for adjustment procedure

Output of track servo amplifier

Output of slide servo amplifier

Pin for connection of DETection FILter capacitor of ADJUST LOGIC

Reference Voltage output Vcc/2 of internal BIAS-generator

Serial interface Microprocessor Latch control/DIScharge control for adjustment

Serial interface Jump control line/Signal Generator input line for adjustment

Serial interface Clock input line

Serial interface Data input line

Serial interface Data output line

Pin for connection of Low Pass Filter capacitor of ADJUST LOGIC

Output of focus servo amplifier

Signal generator output to focus servo, sends 1300Hz for adjustment procedure

Output of Automatic Laser Power Control amplifier

Output of HF amplifier

to external ac-coupling capacitor

System reset (low level = active)

4.2336MHz clock output

Crystal oscillator input

Crystal oscillator output

HF signal input

Disc motor driving (Pluse Width Modulation) output

p interface shift Clock input

p interface Serial Data I/O line

p interface Latch clock input (internal 22k pull up resistor)

Versatile input pin (internal 4.7k pull up resistor)

Versatile input pin (internal 4.7k pull up resistor)

Charge-pump for LPF reference current input

Audio signal output (left channel) / Ext. DAC mode: Audio serial data output

Audio signal output (right channel) / Ext. DAC mode: Data shift clock output

Charge pump output (right channel) / Ext.DAC mode: L/R clock output

PCS 99 155

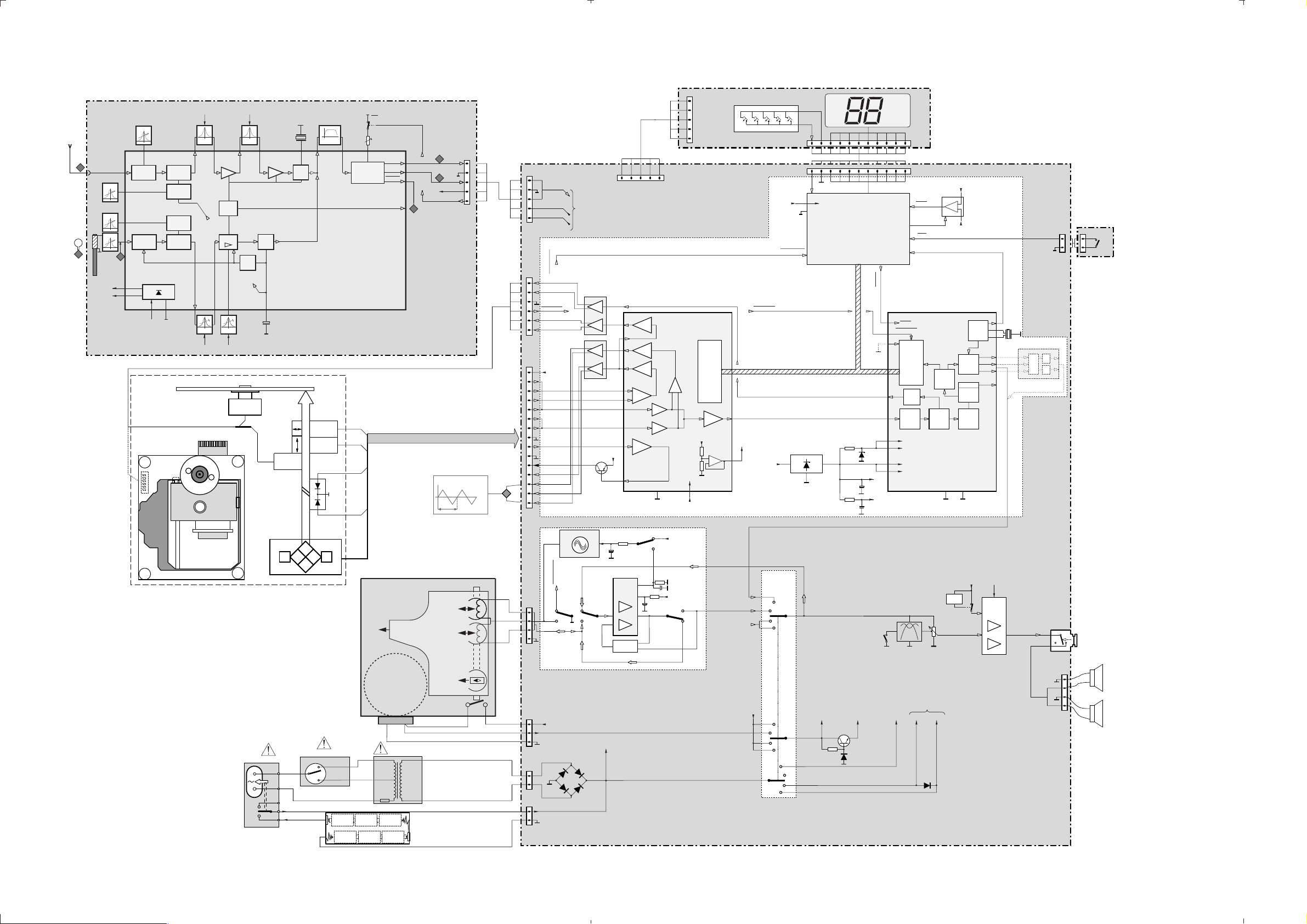

BLOCK DIAGRAM

5-1 5-1

TELESCOPIC

ANTENNA

TUNER BOARD

A

FM-Osc.

AM-Osc.

FERRITE

ANTENNA

AM-RF

B

V

A

Stab

V

B

Stab

ext. DAC

only

+Laser

+M

1350

DBB

SHUFFLE

PROGRAM

23

CD-reset

5

Inner Switch

33

34

27

PWM

HF

19

42

23

22

28

+A(CD)

1820

X

reset

frontend

1814

11

11

1812

32

watchdog

13

27

30

in

DATA INTERFACE

motor

control

PLL

VDD analog

VDD logic

VDD 1

VDD 2

reset

door

VOLUME

to 1201

RESET

7801

DECODER

M65824

audio

processor

digital

PLL

1 29

3300

+B(CD)

+

-

4.23MHz

soft

on/off

+M

Clock

Generator

l/r clk

left data

DAC

right

flags

error

control

EFM

demod.

POWER STAGE

+A(on)

TA8227P

on/off

10

40

37

39

18

7300

6

8

+A

5803

8.46MHz

L/R CLK

DSCK

left, right out

ext. DAC (opt.)

TDA1311A/N2

2

3

data

1

interface

EVA Blockdiagr., 160398

1809 1808

8

D/A

6

D/A

HEADPHONE

1302

1301

-

LEFT

+

-

RIGHT

+

2

2

1807

door

1

switch

1

p

-

4

1

Left

4Ω

+

Right

4Ω

+

1900

5

V

A V

Stab

FM

FM

Osc.

AM

Osc.

AM

FM-IF 1 FM-IF 2

10,7 MHz 10,7 MHz

AM/FM

Indicat.

AFC

1514 10 20

AM-IF 1 AM-IF 2

FM-RF

16

FM

frontend

Mixer

23

24

18

AM

Frontend

C

12

8

Mixer

STABILIZER

625

Vcc

V

A V

Stab

DISC

FLEX WIRE

a

t

n

b

r

Inner

switch

m

o

e

t

o

d

i

r

l

s

l

u

e

t

pick up

unit

CD-drive

CD 97 DA11

CD94V5T1

B

Stab

Discr.

LF filter

FM

Det.

285 29

9 27

7111321

AM

Det.

IF2

IF1

AM IF

AGC

AFC

AGC/AFC

468kHz468kHz

B

Stab

DISC

MOTOR

TRACK

SERVO

FOCUS

SERVO

C

C

C

DAB

DAB

DAB

(for /01/11 only)

1007

Laser

diode

Monitor

diode

F

F

F

VOLTAGE

SELECTOR

PHOTO DIODE

ARRAY

1006

MAINS-SOCKET

1

2

SLIDE

SERVO

E

5

4

3

+

AM/FM

switch

7102

VCO

left

Stereo

right

Decoder

stereo

tuning indicator

7101

RADIO IC

TEA 5711T

Th. 115˚C

BATTERY COMPARTMENT

(R20)

6 x 1.5V

3

5V

0V

stereo stereomono

2

left

1

right

+A

Vcc

+A

152kHz, 50mV

FLEX WIRE

Focus search

Service step 2

0.3s

2

3

30

26

TAPE TRANSPORT

right

PLAY

permanent

magnet

erase head

MOTOR

+-

5001

(Tuner)

(FM)

pp

left

on /off

1101

5

1

N S

1

COMBI BOARD

1201

5

Tuner L

Tuner R

+A

(Tuner)

+A

(FM)

1

1810

1

Disc Disc +

Inner Switch Inner Switch

Slide +

Slide -

6

1811

15

+Laser

E

F

B+D

A+C

Monitor

Laser

Track Focus +

1601

1204

1202

1203

1

1

4

3

1

1

2

2

1

Track +

Focus -

+A

+A (TAPE)

6250

6251 6252

+Battery

+

2V

-

CD Synchro

Bias Oscillator

CD Synchro

Rec

Pb

Rec

4x 1N4002

to/from

source switch

MOTOR DRIVER

SERVO DRIVER

Rec

Pb

Pb

Rec

6253

!

1

1901

CD - PART

PWM

DISC

18

SLIDE

FOCUS

TRACK

+Laser

7854

REC/PB - AMPLIFIER

16261626

+A

16

30

15

4

5

1

2

36

28

7625

Rec/Pb

Amplifier

AN7318S

Feedback

SLIDE

FOCUS

TRACK

+

E - F

-

ALPC

1626

Rec

5

7803

SERVO PROCESSOR

M62475

A+B+C+D

Vcc

21 29

+B(CD)

Rec

+B (TAPE)

Pb

ALC

+B (TAPE)

Pb

1626

Rec

Rec

KEY

+B (CD)

GND

RC5

RC5'

Vcc

SERIAL DATA INTERFACE

-

+

FRONT BOARD

MODE

PREV

NEXT

40

HF

HF

REF

20

CD

Tuner

PLAY

CD Synchro

DISC MOTOR

4V

PWM

eye-pattern

+A(CD)

SOURCE

SWITCH

1250

CD

Tape

Pb

FM

AM

+A

CD

Tape

FM

AM

STOP

1

1

key in

12 1, 35-40

39

+M

16

8

TB 2us/Div

TB=0,5 us/DIV

Rec

CD

Tape

FM

AM

REPEAT

ALL

VDD

VSS

+A(on) +B(Tape) +A(FM) +A(Tuner)

MICRO PROCESSOR

TMP47C422F

+B(CD)

7800

PCS 104 242

Loading...

Loading...