Page 1

AN1651

Using the NE/SA5234 amplifier

Author: Les Hadley 1991 Oct

INTEGRATED CIRCUITS

Page 2

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

2

1991 Oct

Author: L. Hadley

I. SUMMARY

The NE/SA5234 is a unique low-voltage quad operational amplifier

specifically designed to operate in a broadly diverse environment. It

is an enhanced pin-for-pin replacement for the LM324 category of

devices. Supply conditions can range from 1.8V to 6.0V with a

resultant current drain of 2.8mA,-700µA per op amp.

Most notable are the input and output dynamic range characteristics

of the individual op amps. The common-mode input voltage can

actually exceed the positive and negative supply rails by 250mV

with no danger of output latching or polarity reversal. In addition, the

output of each op amp will swing to within 50mV of the supply rails

over the full supply range.

The frequency related characteristics are also above average for

low voltage devices in this class. Internal unity gain compensation

makes the NE5234 very resistant to any tendency to oscillate in low

closed-loop gain configurations. Even so, a unity-gain bandwidth of

2.5MHz is retained. Slew rate is 0.8V/µs and each op amp will

settle to a 1% of nominal level within 1.4µs.

II. DETAILED DESCRIPTION

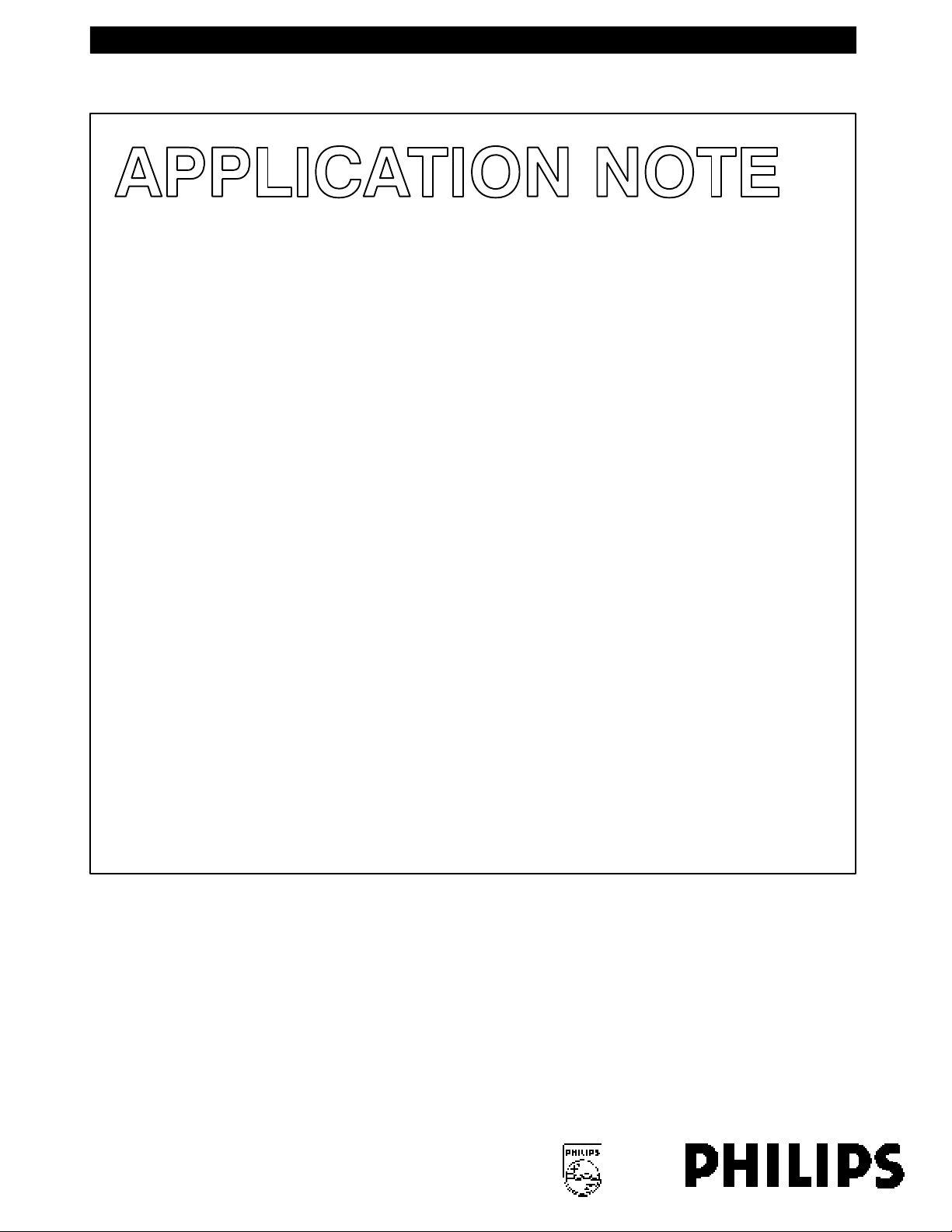

Input Stage

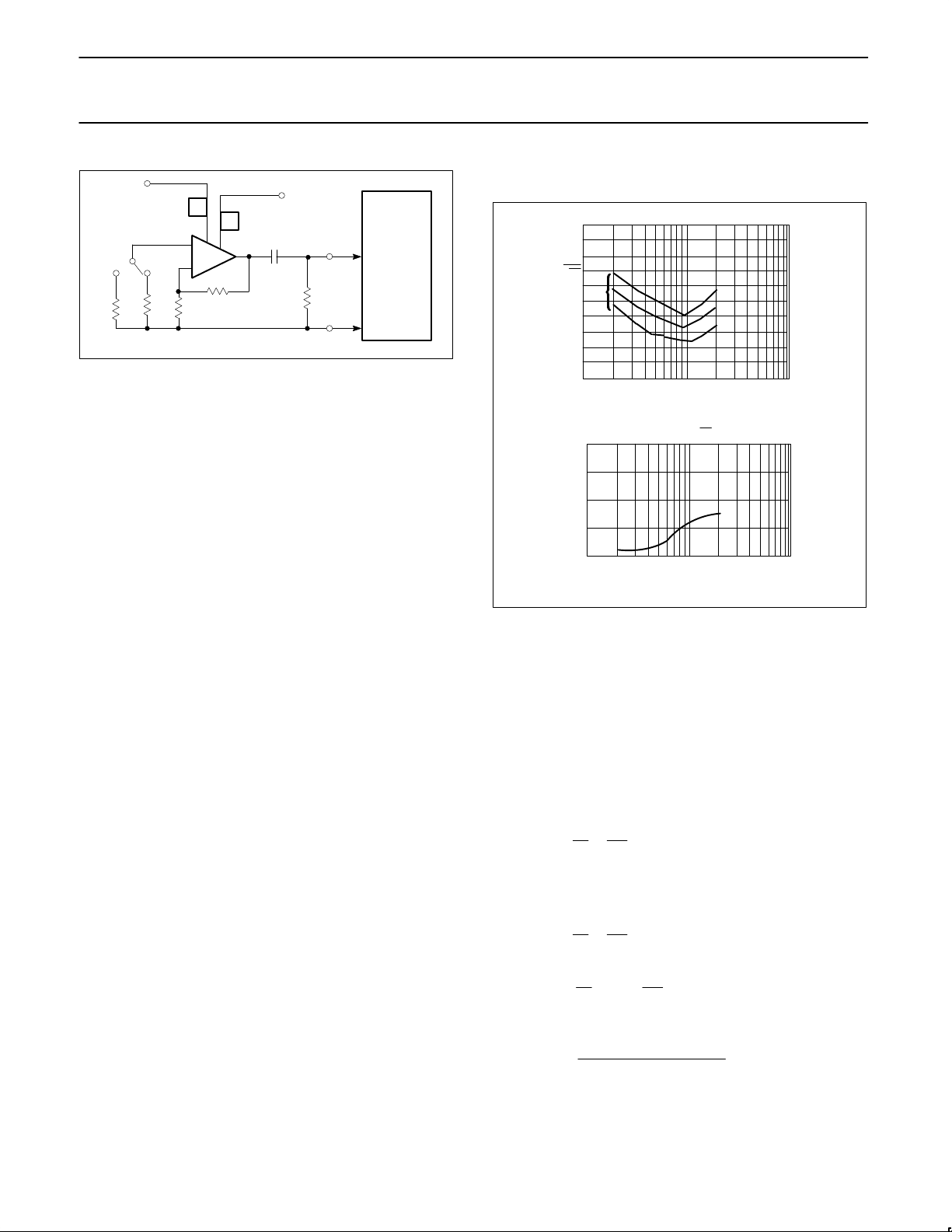

The input differential amplifier consists of a compound transistor

structure of parallel NPN and PNP transistors which account for the

unique over-drive characteristics of the NE5234. Referring to Figure

1, it is seen that the NPN pair, Q1 and Q2, allow the input to

operate in the common-mode input voltage range of 1V above V

EE

.

This region is designated the N-mode region in Figure 3a.

Operation in the common-mode range below 1V transfers the input

stage into the P-mode of operation.

In the N-mode operating condition, collector current from Q1 and Q2

is summed in the output emitter node of Q10 and Q12 respectively.

Q1’s base is the non-inverting input and Q2’s base the inverting

input node for the amplifier.

V

CC

R10

R11

VB2

Q10

Q12

VB1

IB1

Q2

Q4Q3

Q5

SWITCH

Q9

R8 R9

Q6

Q7

Q8

I

P

I

N

V

BIAS

IN(–)

(+)

+

–

Q2

SL00630

Figure 1. NE5234 Input Stage

Linear operation between the two modes is governed by a current

steering circuit consisting of Q5,6 and 7 in conjunction with voltage

reference VB1. Operation in the

N-region of the common-mode range will automatically cause Q5 to

transfer the IB1 current source to Q7 and the NPN transistor pair Q1

and Q2. Operation below the 1V level at the inputs allows the

current from IB1 to be fed directly to Q3 and Q4 emitters giving them

priority in processing the signal and linearizing their transfer

function. (The sum of the NPN and PNP input pair currents remain

constant.)

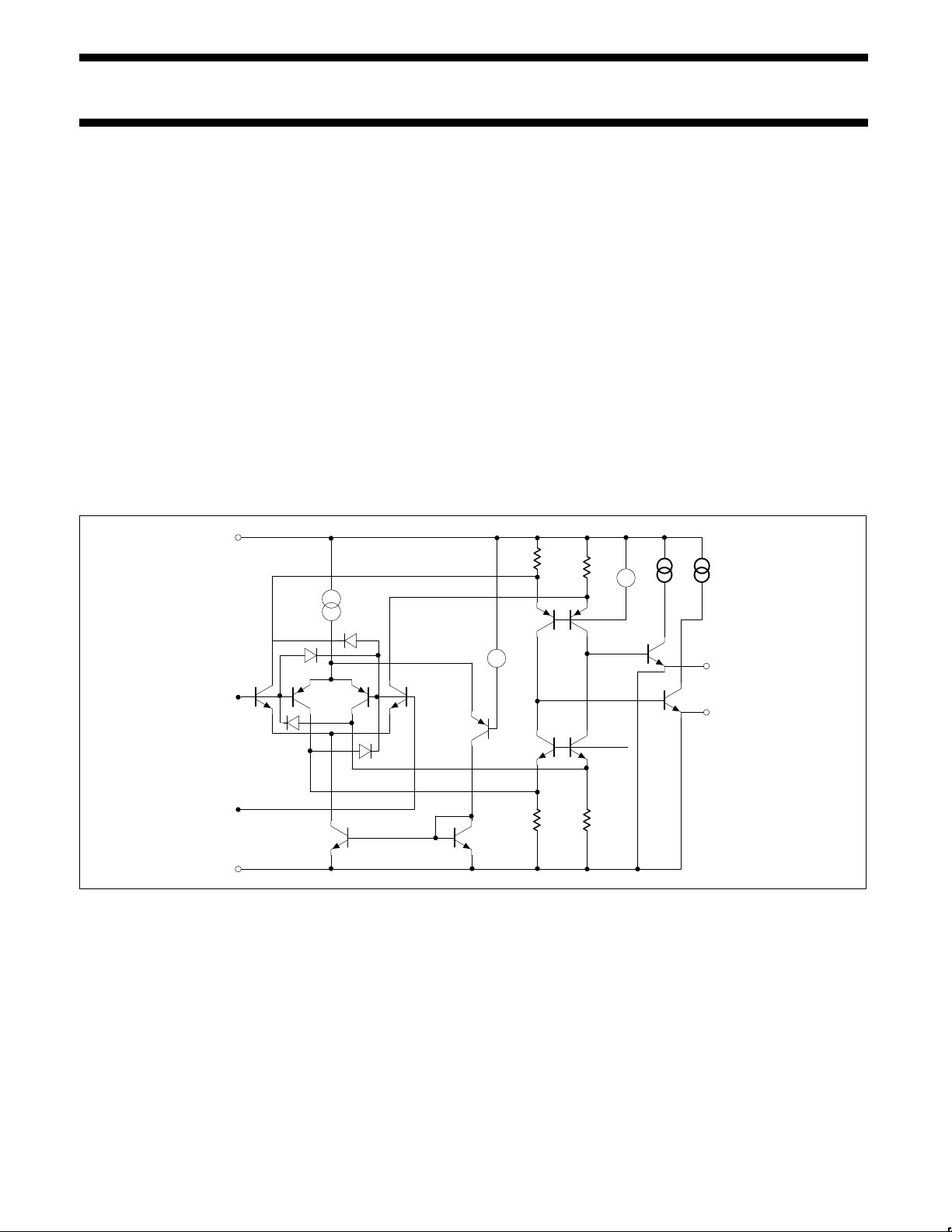

Operation in the common-mode range near the positive supply rail

would normally cause the input stage NPN transistor’s base

collector junction to become forward biased (base current flow

directly to the collector circuit) reversing the collector current flow

direction. In a conventional op amp, this would have the adverse

effect of reversing the output signal polarity as the operating region

is traversed by the input signal. (see Figure 2)

To prevent this from occurring, large geometry diode-connected

transistors are cross-connected to the opposite NPN collector, (Q1,

Q2). This current, in turn, is summed at the emitter of Q12 pulling it

above the V

CC

rail voltage and preventing polarity reversal. The

inverse condition occurs when Q2 is driven above the positive rail,

with Q10 emitter being pulled up and signal polarity preserved. (See

Figure 1)

Page 3

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

3

47k

47k

V

IN

V

OUT

V

CC

+

–

5V

CONVENTIONAL OP AMP PHILIPS NE5234

t

t

V

CC

V

OUT

V

OUT

V

IN

V

IN

V

GND

V

GND

V

GND

V

CC

5V

SL00569

Figure 2. Output Inversion Protection

6

5

4

3

2

1

0.5

-1

-0.1

+0.1

“N-MODE”

CMRR

V

EE

+1 < VCM < V

CC

“LARGE

SIGNAL”

CMRR

“N-MODE”

CMRR

V

EE

< VCM < VEE+0.5V

V

EE

V

OS

mV

COMMON MODE VOLTAGE (VOLTS)

NE5234 Common-Mode Operating Regions

SL00631

Figure 3.

For negative going input signals, which drive the inputs toward the

V

EE

rail and below, another set of diode-connected transistors come

into operation. These steer the current from the input into Q8 or Q9

emitter circuits again preventing the reversal effect.

Figure 3 shows graphically how the N and P mode transitions relate

to the common-mode input voltage and the offset voltage V

OS

.

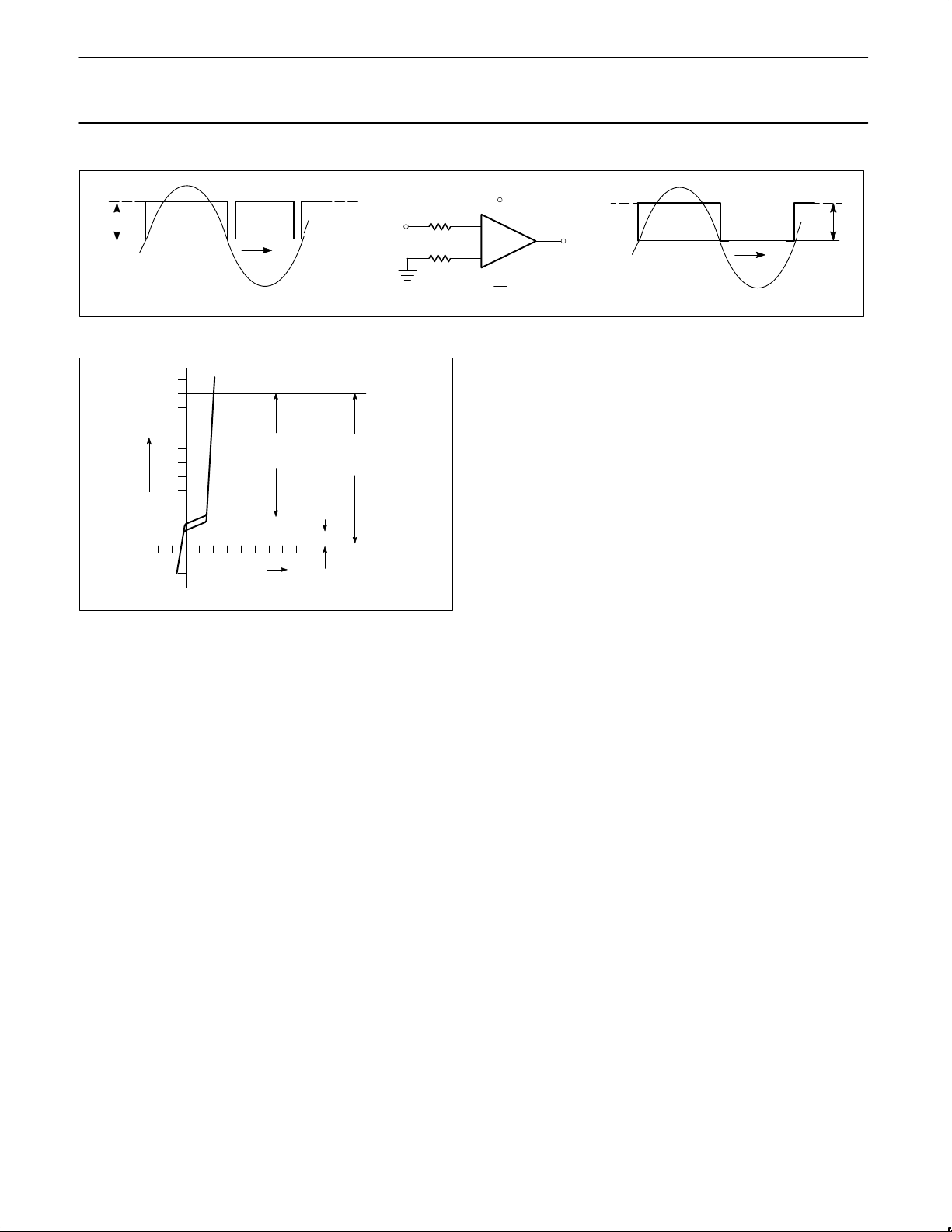

Intermediate Amplifier and Output Stage

(Figure 4)

The intermediate stage is isolated from the input amplifier by emitter

followers

to prevent any adverse loading effect. This stage adds gain to the

over all amplifier and translates levels for the following class-AB

current-control driver. Note that I

2

is the inverting input and I1 the

non-inverting input. The output is taken from multiple collectors on

the non-inverting side and provides matching for the following stage.

Class-AB control of the output stage is achieved by Q61 and Q62

with the associated output current regulators. These act to monitor

the smallest current of the non-load supporting output transistor to

keep it in conduction. Thus, neither Q71 or Q81 is allowed to cutoff

but is forced to remain in the proper Class-AB region.

Overload protection is provided by monitor circuits consisting of

R76-D2 for sinking and R86-D3 for sourcing condition at the output.

When the output current, source or sink, reaches 15 milliamperes,

drive current to the stage is shunted away from current sources IB6

or IB9 reducing base current to driver transistors Q72 and Q82

respectively.

The prevention of saturation in the output stage is achieved by

saturation detectors Q78 and Q88. When either Q71 or Q81

approaches saturation, current is shunted away from the driver

transistors, Q72 or Q83 respectively.

III. CHARACTERISTICS

Internal Frequency Compensation

The use of nested Miller capacitors C2 through C6, in the

intermediate and output sections, provides the overall frequency

compensation for the amplifier. The dominant pole setting capacitor,

C2, provides a constant 6dB/octave roll-off to below the unity gain

frequency of 2.5MHz. Figure 5 shows the measured frequency

response plot for various values of closed-loop gains.

Page 4

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

4

D2

I

B2

I

B4

I

B5

I

B6

I

B8

I

B7

I

B9

I

B3

V

B4

V

CC

I

2

I

1

V

EE

D3

CLASS

AB

CONTROL

Q61 Q62

Q83

Q85

Q81

Q82

Q71

Q75

Q72

Q78

Q53,54

Q51,52

C1

C2

C3

C4

C5

R82

C6

Q84

OUTPUT

INPUT

+

–

INTERMEDIATE STAGE CURRENT CONTROL CLASS AB OUTPUT

R85 R76

R86 R75

SL00632

Figure 4.

dB

100

80

60

40

20

0

10Hz 100Hz 1kHz 10kHz 100kHz 1MHz

FREQUENCY

10 10

6

G1000

SL00633

Figure 5. NE5234 Closed Loop Gain vs Frequency

Page 5

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

5

4

11

+

–

47k

5234

100

x10

HP

3585

SPECTRUM

ANALYZER

10Ω

600Ω

+2.5V

–2.5V

SL00634

Figure 6. Noise Test Circuit

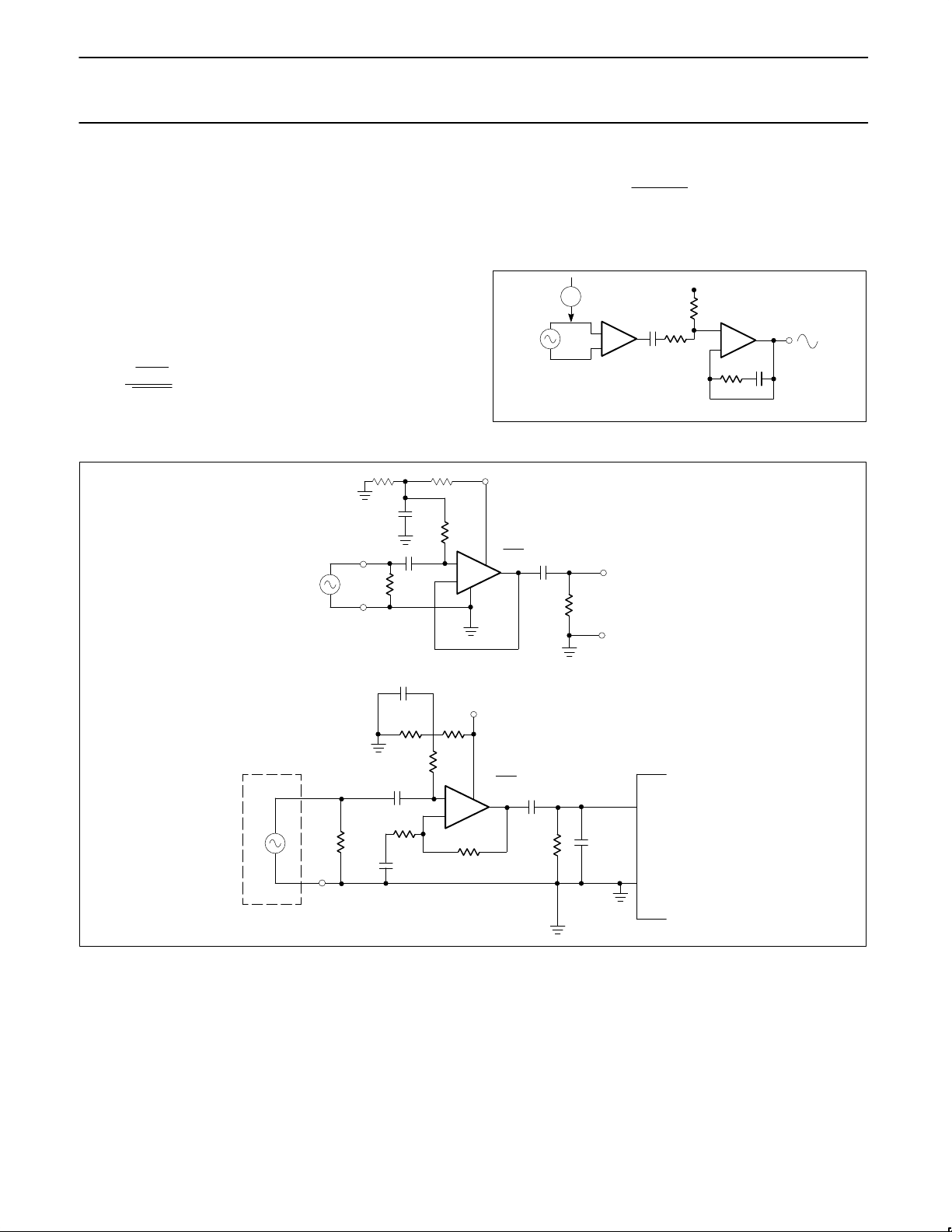

IV. NOISE REFERRED TO THE INPUT

The typical spectral voltage noise referred to each of the op amps in

the NE/SA5234 is specified to be 25nV/√Hz. Current noise is not

specified. In the interest of providing a balance of information on the

device parameters, a small sample of the standard NE5234s, were

tested for input noise current. While this data does not represent a

specification, it will give the designer a ball park figure to work with

when beginning a particular design with the device. For

completeness I have provided the corresponding spectral noise

voltage data for the same sample. The data was taken using an

HP3585A spectrum analyzer which has the capability of reading

noise in nV/√Hz.

The test circuit is shown in Figure 6. As is typical for such

measurements the amplifier under test is terminated at its input first

with a very low resistance, for the voltage noise reading, followed by

the same test with a high value of resistance to register the effect of

current noise. The amplifier is set to a non-inverting

closed-loop gain of 20dB. Dual supply operation was chosen to

allow direct termination of the input resistors to ground.

The measurements were made over the range from 200Hz to 2kHz.

Each sample is measured at 200Hz, 500Hz, 1kHz and 2kHz. The

data is averaged for each frequency and then the small sample

distribution is derived statistically giving the standard deviation

relative to the mean.

Referring to the graph in Figure 7a, the equivalent voltage noise is

seen to average 18 nV/√Hz. The 95% confidence interval is

determined to be approximately one nV/√Hz. The majority of the

errors which contribute to this measurement are due to the thermal

noise of the parallel combination of the feedback resistor network, in

addition to the 10Ω termination resistor on the non-inverting input.

At 300° Kelvin a 10Ω resistor generates 0.4 nV/√Hz and the

feedback network’s equivalent resistance of 90Ω generates

1.2nV/√Hz. Their order-of-magnitude difference from the main noise

sources allows them to be neglected in the overall calculation of

total stage noise.

Noise current is measured across a 47kΩ resistor and averaged in

the same manner. The thermal noise generated by this large

resistance is not insignificant. At room temperature it is 28nV/√Hz

and must be subtracted from the total noise as measured at the

output of the op amp in order to arrive at the equivalent current

generated noise voltage. Figure 7b shows the derived current

noise distribution for the small sample of 10 NE5234 devices. The

result shows that noise current in the 200Hz to 2kHz frequency is

typically 0.2pA/√Hz. The 1/f region was not determined for either

current or voltage noise.

95%

INT.

En for RS = 10Ω -nV/Hz

22

19

18

17

16

100 200 2000 10000

nV

Hz

Ǹ

a.

pAńHz

Ǹ

0.5

12

0.1

100

200

1k

2k

10000Hz

f

P

in 10

P

b.

SL00635

Figure 7. Typical Noise Current and Voltage vs Frequency

V. GUIDE LINES FOR MINIMIZING NOISE

When designing a circuit where noise must be kept to a minimum,

the source resistances should be kept low to limit thermally

generated degradation in the overall output response.

Orders-of-magnitude should be kept in mind when evaluating noise

performance of a particular circuit or in planning a new design. For

instance, a transducer with a 10kΩ source resistance will generate

2µV of RMS noise over a 20kHz bandwidth. Using the graphical

data above, total noise from a gain stage may be calculated.-

25nVń Hz

Ǹ

@ BWǸ+ 3.5V

RMS

(EQ. 1.)

Amplifier Noise Voltage

BW + 10kHz

Noise from source 10kΩ Resistance –

14nVń Hz

Ǹ

@ BWǸ+ 20V

RMS

(EQ. 2.)

Noise Voltage from source resistance

0.2pAń Hz

Ǹ

@ 103@ BWǸ+ 0.28V

RMS

(EQ. 3.)

Current generated noise

The total noise is the root-to-sum-of-the-squares of the individual

noise voltages –

+

)

)

Ǹ

(EQ. 4.)

+ 4.04V

RMS

En

(3.5)

2

(2.0)

2

(0.28)

2

To determine the signal-to-noise ratio of the stage we must first

choose a stage gain, make it 40dB, and a signal voltage magnitude

from the transducer which we will set at 10mV

. The resulting

RMS

Page 6

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

6

signal-to-noise ratio at the output of this stage is determined by first

multiplying the gain times the signal which gives 1V

RMS

with a

resultant noise of 400mV

RMS

. The signal-to-noise ratio is calculated

as

Sń N 20log

10

(1.0ń 4x10

* 4

) + 68dB

(EQ. 5.)

This is quite adequate for good quality audio applications.

Next assume that the bandwidth is cut to 3.0kHz with an input of

1mV

RMS

. The RMS noise is modified by the ratio of the root of the

noise channel bandwidths.

ƪ

Ǹ

20x10

3

Ǹ

ƫ @ EN + 1.6V

RMS

(EQ. 6.)

ƪ

*

*

ƫ

(EQ. 7.)

+ 56dB

+

–

+

–

1mV

RMS

e

n

x100

R

S

= 100Ω

1.6µV

e

n

x10

100kΩ

1mV

RMS

SIGNAL

SL00636

Figure 8.

UNITY GAIN

+

–

10k

100k

3

2

1

600Ω

2.2µF

1µF

R

L

= 600Ω

V

CC

+

V

CC

2

+

–

3

2

1

10k 10k

+

1k

100pF10k

4.7µF

1µF

1µF

600Ω

V

CC

2

40dB CIRCUIT

ST1700

DISTORTION

ANALYZER

V

CC

ST1700

SL00637

Figure 9. NE5234 THD Test Circuits

VI. MULTIPLE STAGE CONSIDERATIONS

Since multiple noise generators are non-coherent, their total effect is

the root-of-the-sum-of-the-squares of the various noise generators

at a given amplifier input.

This makes orders-of-magnitude lower noise sources less important

than the higher magnitude source. Therefore, when considering the

combined signal-to-noise of multiple stages of gain, the first stage in

a chain dominates making its design parameters the most critical.

For this reason it is good practice to make the preamp stage gain as

high as practical to boost signal levels to the second stage allowing

at least an order-of-magnitude above the second-stage noise. For

instance, a signal input which exceeds the input noise of the

following stage by a factor of 10:1 will only be degraded by 0.5% or

-46dB, neglecting the first-stage noise. If we use the preceding

example with a first-stage output signal of 100mV

RMS

and a 56dB

S/N, and an output noise of 0.16mV . Following this with a 10kHz

band limited gain-of-10 second-stage, with a 100kΩ noise source at

the non-inverting input, the combined S/N is calculated as follows:

(assume a 100Ω source resistance from amplifier #1)

The Second stage output noise is:

3

3x10

Amplified Noise = 160µV

RMS

SńN 20 log

10

100x10

1.6x10

3

4

A 56dB S/N will provide superior voice channel communications .

+1.6mV

RMS

NOISE

Page 7

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

7

(EQ. 8.)

ƪ

(0.163x10

* 3)2

)

ǒ

4KT @ 100 @ 10,000

Ǹ

Ǔ

2

Ǹ

ƫ

@ 10

+ 1.6mV

+

+

*

The amplified output signal = 1V

RMS

(EQ. 10.)

Sń N + 20 log

10

ǒ

1

1.6x10

* 3

Ǔ

+ 56dB

UNITY GAIN

3

0

0.1

V

1.0

UNITY GAIN

3

0

0.1

V

1.1

a. b.

LM324

NE5234

UNITY GAIN

0.8

0

0.1

V

1.1

c.

SL00638

VCC = 1.8V

VCC = 2.0V

VCC = 3.0V

Figure 10. THD vs Supply Voltage for 1V

RMS

Output

RL = 600Ω

R

L

= 10kΩ

3

P

0

0.1

V 0.9

THD for VCC = 1.8V

-RL = 10k/600Ω

2.5

0

0.1

V 1.1

VCC = 2V

RL = 10k/600Ω

RL = 600Ω

RL = 10kΩ

c.b.

RL = 10kΩ

VCC = 3.0V

GAIN = 40dB

2

0

0.1

V 1.1

a.

SL00639

Figure 11. THD vs Load

A series of tests are shown to allow you to see just how resistant

this device is to generating clipping distortion. Two different gain

configurations were chosen to demonstrate this particular feature:

unity gain non-inverting and 40dB non-inverting. The test set-up

K

BoltzmanȀsConstant

1.38x10

23

Joule

DegKelvin

(EQ. 9.)

T+300oK ; BW+10kHz

Note that there is no effect from the second-stage thermally

generated resistor noise due to the dominating effect of the

first-stage amplified noise being much greater than the input noise of

the second-stage. In addition the equivalent noise resistance of the

second-stage is essentially the output resistance of the first-stage

plus any series resistance used in coupling the two. This is the

parallel combination of source resistance with input terminating or

biasing resistance.

VII. LOW HARMONIC DISTORTION

The NE/SA5234 is extremely well adapted to reducing harmonic

distortion as it relates to signal level and head room in audio and

instrumentation circuits. Its unique internal design limits overdrive

induced distortion to a level much below that experienced with other

low voltage devices. As will be shown, the device is capable of

operating over a wide supply range without causing the typical

clipping distortion prevalent in companion operational amplifiers of

this class.

was as shown in Figure 9. The Harmonic Distortion analyzer used

to make the measurements was a Storage Technology ST1700.

The test frequency is 1kHz. For single supply operation, as

previously covered, the amplifier should be biased to half the supply

voltage to minimize distortion. Operation with dual supplies is

simpler from a parts count standpoint as isolation capacitors are not

required. Also the time constants associated with charging and

discharging these is eliminated . Figure 10a,b and c shows the total

harmonic distortion in percent versus input voltage level at 1kHz in

V

for a non-inverting, unity gain NE5234. The load on the

RMS

amplifier output is 10kΩ. Beginning with a supply voltage of 1.8V

and an input level of 0.1V

remains there up to an input level just over 0.5V

increases to 0.4% for for 0.6V

For a 2V supply, the input levels increase to 0.65V

0.7V

, respectively for similar levels of distortion. With a supply

RMS

voltage of 3.0V the input may be increased to 1V

rises to 0.2% and 1.1V

, distortion is well below 0.2% ad

RMS

(1.7V

RMS

for only 0.8% THD. Operation with a

RMS

P-P

).

(1.4V

RMS

RMS

before THD

RMS

600Ω load will only raise the THD figures slightly . By way of

comparison, Figure 10c shows the greatly reduced dynamic range

experienced when an LM324 is plugged into the test socket in place

of the NE5234. Note that The THD is completely off scale for the

case of 1.8 and 2.0V supply, then is barely usable for the low level

end of the 3.0V supply example. Figure 11a, b, and c demonstrates

the effect on harmonic distortion when closed loop gain is increased

to 40dB in the non-inverting mode. It is evident that little increase in

THD levels result. The graphs for the 2.0 and 3.0V supply case also

include additional information on the effect of a 600Ω load on

distortion.

and

P-P

) and

Page 8

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

8

VIII. GAIN-BANDWIDTH VS CLOSED LOOP FREQUENCY RESPONSE

Figure 5 shows the small signal frequency response of the NE5234

versus closed-loop gain in dB. The test circuit is shown in Figure 6.

The plot is taken from measured data and thus shows how each

value of closed-loop gain coincides with the open-loop response

curve. The NE/SA5234’s open-loop gain response has a uniform

6dB/octave roll-off which continues beyond 2.5MHz. This factor

guarantees each op amp in the IC a high stability in virtually any

gain configuration. In making these measurements, dual supplies of

±2.5V were used in order to allow a grounded reference plane and

no coupling capacitors which might cause frequency related errors.

A critical parameter which affects the reproduction quality of

complex waveforms is the gain-bandwidth-product of the operational

amplifier. Essentially, this is a measure of the maximum frequency

handling characteristics of any operational amplifier for a given

closed-loop gain. As is evident from the graph, the NE/SA5234 has

a 2.5MHz unity gain cross-over frequency — much higher than most

other low voltage op amps. For comparison, the µA741 has a

gain-bandwidth-product of 1MHz, as do the LM324 and the

MC3403.

IX. LOOP-GAIN

The dynamic signal response of any closed-loop amplifier stage is a

function of the Loop-gain of that particular stage. Loop-gain is equal

to the open-loop gain in dB, at a given frequency, minus the

closed-loop gain of the stage. The greater the Loop-gain, the lower

the transfer function error of the device. Essentially, any parametric

error is reduced by the factor of the Loop-gain. This includes output

resistance and output signal voltage accuracy. It is good practice

then to maximize Loop-gain to the degree that stage gain may be

sacrificed for bandwidth. In some cases it is actually better to use

two stages of gain in order to preserve signal quality than to use one

high gain stage. Of course, there is a trade-off between the

aforementioned factors that affect the signal-to-noise ratio of the

stage and optimizing the Loop-gain. For example, a voice-band

audio stage which requires 3kHz bandwidth, should be limited to a

closed-loop gain of 40dB for lowest distortion in the output signal.

For higher quality audio applications requiring a 20kHz bandwidth,

the closed-loop gain must be limited to 20dB. This results in a

Loop-gain of 20dB at the highest signal frequency.

A second consideration in the list of frequency dependent

parameters is the effect of amplifier slew rate. Not only is it

frequency dependent but it is also a function of signal amplitude, as

we shall see in the next section.

LOOP

GAIN

A

OL

A

CL

f

S

f

u

-6dB/Octave

SL00640

Figure 12.

X. SLEW RATE RESPONSE

The slew rate of an operational amplifier determines how fast it can

respond to a signal, and is measured in volts-per-microsecond. The

NE5234 has a typical slew rate of 0.8V/µs. Let us see just what this

means in terms of signal handling capability. If a sinusoidal input

signal, V

S

, is used as reference, it is specified by its frequency and

peak amplitude, V

P

as follows:

(EQ. 11.)

V

S

+ VPsin (2p f t)

2

VOLTS PK

0.02

2000 2000000

(Hz)

VPK = 1.096V

VPK = 630mV

VPK = 100mV

SL00641

Figure 13. Slew Rate Limiting Amplitude vs Frequency

Slew Rate (SR) is the time-rate-of-change of the signal voltage

during any complete cycle, that is over the range of 0 to 2π. This

amounts to taking the time derivative of the sine wave which results

in multiplying the cosine by the factor ‘2πf’.

An example of the trade off between signal amplitude and frequency

is shown below for the NE5234 slew rate of 0.8V/µs. As shown in

Figure 13, the maximum allowable amplitude signal which can be

reproduced is determined by the slew rate response line which gives

peak output volts versus frequency in Hertz.

Mathematically, slew rate is determined, by the equation below, as

the derivative of the sine wave signal. The resultant slew rate

function changes with both frequency and amplitude.

Page 9

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

9

Slew Rate + V

P

(2p f) cos (2p f t)

Note that maximum slew rate occurs where the input sine wave

signal crosses the values of 0, π, and 2π on the radian axis. To get

a feel for what this means in regards to the typical low voltage

circuit, let us consider a 1V

RMS

sinusoidal input to a unity gain

amplifier. The peak voltage in the above equation is 1.414V. One

can then calculate the required slew rate to faithfully reproduce this

signal for various signal frequencies. Or with a given slew rate and

a required peak signal amplitude, the maximum frequency before

slew rate limiting occurs may be determined. For example using the

above amplitude of 1V

RMS

, and the slew rate of the NE5234 which

is 800,000V/sec, one determines that the highest frequency

component which may be reproduced before slew rate distortion

occurs is:

800,000 V/sec / 2π

• 1.414 volts peak = 90,090Hz. A graphical

representation of this relationship is shown in Figure 13. By using

this graph along with the information in the preceding Figure 10 and

Figure 11, which relate usable signal levels versus power supply

voltage, the dynamic behavior of a particular design may be

predicted. For instance, given a single supply configuration

operating at 2.0V, Figure 10b shows an upper limit to input

amplitude of 0.7V

RMS

, or about 1V peak for 1% THD. Using this

level with the data in Figure 13 leads to a figure of 116kHz as an

upper frequency limit for a unity gain amplifier stage operating at 2V

DC.

(EQ. 12.)

dV

S

d t

+ VPw cos w t

+ Slew Rate

4

R

S

V

CC

+

V

CC

2

R

S

A

1

A

4

C

S

C

L

R

R

+

–

+

A

A

+

V

CC

2

VIN INPUT ISOLATION

R

f

–

SL00642

Figure 14. Single Supply Biasing in Cascade

XI. PROCEDURES

Single Supply Operation

When the NE/SA5234 is used in an application where a single

supply is necessary, input common-mode biasing to half the supply

is recommended for best signal reproduction. Referring to Figure

14, a simplified inverting amplifier input stage is shown with the

simplest form of resistive divider biasing. The value of the divider

resistance R is not critical and may be increased above the 10kΩ

value shown as long as the bias current does not interfere with

accuracy due to DC loading error. However the divider junction

must be kept at a low AC impedance This is the purpose of bypass

capacitor C

S

. Its use provides transient suppression for signals

coming from the supply bus. A low cost 0.1µF ceramic disk or chip

capacitor is recommended for suppressing fast transients in the

microsecond and sub-microsecond region.

Foil capacitors are simply too inductive for any high frequency

bypass application and should be avoided. If low frequency noise

such as 60Hz or 120Hz ripple is present on the supply bus, an

electrolytic capacitor is added in parallel as shown. The

common-mode input source resistance, R

S

, should also be matched

within a reasonable tolerance for maximizing the rejection of induced

AC noise.

The output of the first stage is now fixed at the common mode bias

voltage and the amplified AC signal is referenced to this constant

value. Capacitive coupling to the inverting input is of course

required to prevent the bias voltage from being multiplied by the

stage gain. Second stage biasing may now be provided by the

output voltage of the first stage if non-inverting operation is used in

the former. For lowest noise in a high gain input stage, the

magnitude of the input source resistance is critical; low values of

resistance are preferred over high values to minimize thermally

generated noise.

Non-Inverting Stage Biasing

Non-inverting operation of an amplifier stage with single supply is

similar to the previous example but the bias resistor R

S

must now be

sufficiently high to allow the signal to pass

without significant attenuation. The input source resistance reflects

the output resistance of the preceding stage or other sourcing

device such as a bridge circuit of relatively high impedance. A

simple rule of thumb is to make the bias resistor an order of

magnitude larger than the generator resistance. Again the feed

back network must be terminated capacitively. In this case R1 and

the generator resistance should be matched and then R

S

is matched

to the feedback resistance ,R

F

.

In all cases proper bypassing of the NE5234 supply leads (Pins 4

and 11) is very important particularly in a high noise environment.

Bypass capacitors must be of ceramic construction with the shortest

possible leads to keep inductance low. Chip capacitors are superior

in this respect complimenting the increased use of surface mounted

integrated devices. Note that both the NE5234D and the automotive

grade SA5234D are available and are the surface mount versions of

the device.

Page 10

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

10

+

–

10k

4

11

R

S

V

CC

2

RR

R1

R

F

C1

CC

V

CC

SL00643

Figure 15. Non-Inverting Biasing

NE/SA5234

–

+

A1

R

SH

= 250Ω

RECEIVE UNIT

T

R

A

N

S

4700Ω

+

–

A2

SL00644

Figure 16. A 4-20mA Current Loop

+

–

4

11

V

O

1

3

2

1.2M

V2

4.3k

12k

12k

+5.0V

1.2MΩ

4.3k

4.3k

1k

|V2 – V1| V

O

5.9mV

25.6mV

46.6mV

0.5V

2.50V

4.63V

4.3k

S.G. S.G.

+5.0V

S.G.: Matched Strain Gauge elements

SL00645

Figure 17. Strain Gauge Amplifier

+

–

4

11

1

3

2

4.3k

12kΩ

+V

CC

1.2MΩ

4.3k

4.3k

4.3k

SIGNAL

COM

S.G. S.G.

12kΩ

Two-wire, Twisted-pair

Shielded Line

1.2M

SL00646

Figure 18. Remote Strain Gauge

CMOS

+3V

4-6V DC

+

–

+

–

4V

VR

+

–

SL00647

Figure 19. Solar Regulator

Page 11

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

11

APPLICATIONS EXAMPLES

Instrumentation

Strain Gauge Bridge Amplifier

The circuit below shows a simple strain gauge circuit with a gain of

100 (40dB) and operated from a single supply. The chart illustrates

the transfer function of the circuit for a single order-of-magnitude

signal differential range from the bridge beginning with 5mV up to

50mV. The circuit is operated from a single 5V supply, but could

equally as well be configured to use a dual balanced supply. It is

immediately evident that the wide common-mode output range of

the NE5234 is very advantageous in handling this wide range of

signals with good linearity due to this feature.

A variation on this particular idea is the remote strain gauge circuit

operating from a three wire line, one of which is the shield. This

full-differential input circuit has balanced

input resistance to afford good common-mode noise rejection

characteristics. Resistors are metal film or deposited carbon.

Supply leads must be carefully bypassed close to the NE/SA5234

with ceramic or chip monolithic capacitors to give optimum noise

performance. As shown, an auxiliary sub-regulator may be added to

improve the overall DC stability of the bridge signal voltage. A

regulator capable of providing the necessary few milliamperes at

somewhat reduced voltage for the transducer is shown in one of the

following examples. This makes use of one of the op amps in the

same device package to provide the voltage regulation. Note that

the use of multiple op amps within a single package minimizes the

possibility of thermal drift and mismatched response from various

DC parameters.

Multiple sets of transducers may be constructed from The

NE/SA5234 or the NE5234D surface mount device to form a

compact and stable instrumentation package. This is useful for

transducer applications in

the measurement of pressure, strain, position and temperature,

which have similar circuit configurations. First order temperature

compensation of the transducers such as semiconductor strain

gauges, or resistive units may be achieved by using one of the

gauges as a reference device only. It is thermally coupled to the

same member as the active gauge, as shown in the example.

(Figure 18)

A 4 to 20mA Current Loop

Some instrumentation installations require the 4-20mA current loop.

This addition to the above bridge transducer circuit examples is

demonstrated in Figure 16.

This circuit makes use of the remote transducer bridge previously

described and adds current loop signaling capability. The

voltage-to-current converter consists of an additional op amp from

the same NE/SA5234 package combined with a single transistor to

drive the current loop. The sensitivity is actually in mA/V, or

transconductance, which is equal to 1/R

SH

. This sensitivity in this

particular example is set to 4mA/V. Thus, with a bridge amplifier

having a differential gain of 100, an input of 10mV will produce a

4mA output current and 50mV will produce a 20mA output. Of

course the line resistance plus receiver resistance must be within

the voltage compliance range of the supply voltage to guarantee

linear operation over the total range. A negative supply may be

used if it is preferred to have the current loop referenced to ground.

DC Regulators and Servos

Closely related to DC and low frequency AC linear transducers are

DC regulators and servo circuits. The proliferation of many battery,

and solar powered remote instrumentation packages results in a

need for adaptable circuits which may readily be made up from

existing stock ICs. The examples given here are quite simple, but

can be very useful to the designer when economy and size are at a

premium.

Solar Regulator for 3-Volt CMOS

Working with small instrumentation packages which are to operate

from solar photovoltaic cells may bring a need for simple

sub-regulators for MOS circuits requiring only a few milliamperes of

drain current. Figure 19 shows a simple low voltage regulator

making use of the particularly excellent DC characteristics of the

NE/SA5234. The regulator becomes an integral part of any

functional analog signal processing package such as an

environmental data instrumentation unit. The low current drain of

the the typical 3V or 5V MOS digital IC allows one sub regulator to

serve up to 10 or more such devices. If the instrument package is to

be subjected to wide temperature variations, the SA5234 is

recommended. A second op amp in the package may serve as a

low battery alarm with tone modulator as in radio links, or simple

logic level comparator. Overcurrent protection is easily added within

the regulator loop to detect short circuit failures and automatically

limit the current.

DC Servo-amps

Servo control systems for low voltage motor drives require high

gain-accuracy and good DC stability for many applications.

Applications such as the position control of air flow vanes, servo

valves, and optical lenses or apertures, are typical examples.

Figure 20 demonstrates one simple DC motor servo application with

position control feedback. The motor is a 3V permanent magnet

rotor type used in micro-position applications and is adaptable to

battery supply environments.

Position information is received from a multi-turn potentiometer to

give adequate resolution. The input voltage may be generated from

another potentiometer which is remote from the motor drive unit

proper, or from a D/A converter output for micro processor controlled

systems. The input voltage range is 1.0 to 3.0V and the supply

voltage is 4.5V.

Page 12

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

12

IC-1

NE5234

20kΩ

10kΩ

V

CC

VR1

VR2

10kΩ

150

150

150

150

IC-2

NE5234

BDX45

BDX42

+

–

+

–

+

–

+

–

A3

A2

A4

A5

A6

A1

+

–

+

–

PM

MOTOR

100

1

V

REF

R

S

C

L

C

S

100kΩ

VR1-3 = 1.4V

+4.5VDC

10Ω

10Ω

0.1µF

0.1µF

4

VR2

SL00648

Figure 20. Full Bridge Motor Drive

Active filters

The NE5234 is easily adapted to use in a variety of active filter

applications. Its high open-loop gain and excellent unity gain

stability make it ideal for high-pass,

band-pass and low-pass configurations operated with low voltage

single supplies. Its low output impedance also makes it capable of

obtaining low noise operation without resorting to separate high

current buffers.

Figure 21a shows the circuit for a VCVS low-pass filter with dual

supply biasing and 600Ω output termination. Figure 21b is a

band-pass filter with AC coupled gain network for single supply

operation.

Communications and Audio

Stereo Bridge Amplifier

Figure 22 shows two NE5234 ICs in a bridge amplifier application.

The choice of split supplies allows DC coupling, both from the input

signal source and to the load. The gain is set to a nominal 20dB.

Either inverting or non-inverting operation is available. The inverting

input impedance is chosen as 600Ω in order to match standard

audio impedance lines within a system. The use of two such

amplifiers will provide stereo operation to +10dBm for a 600Ω load.

Voice Operated Microphone

The processing of voice transmissions for communications channels

is generally coupled with the need for keeping the signal-to-noise

ratio high and the intelligibility optimized for a given channel

bandwidth. In addition, when a circuit is battery operated and

portable, the requirement to obtain maximum battery life becomes

important. The circuit example shown here is aimed at filling the

need for a portable voice operated transmitter, cordless phone, or

tape recorder. It utilizes the Philips Semiconductors NE5234 quad

op amp in conjunction with the new low-voltage NE578 compandor

to create an audio processor capable of operating in just such an

environment. Both devices are operational to a low battery voltage

of 2.0V. In addition the design further conserves current by

automatically shifting the NE578 compandor to standby during the

period when no transmissions are being made. Total current

consumption at 3.0V is 2.8mA for the NE5234. In the active mode

the NE578 draws 1.4mA and this drops to 170µA in the standby

mode. This amounts to reducing the supply current demand by

approximately 25% in the ‘listen mode’.

Page 13

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

13

Figure 23 shows the VOX audio circuit example. A description of

its operation for voice activated transmission follows.

Audio generated by the electret microphone is fed into the

non-inverting input of preamp A1 and the signal amplified by 12dB.

The biasing is accomplished by the resistive divider which provides

a level of half the supply voltage which is connected through a 100k

resistor to the non-inverting terminal of A1. This automatically

provides ratiometric common mode biasing set at V

CC

/2 for the

device. This level is then transferred directly to the following

amplifier, A2, setting its DC operating point. The DC gain of both

stage A1 and A2 are unity so the cumulative DC error is not

multiplied by stage gain. The peak voice level is approximately

100mV

RMS

at the input to A1 from the microphone and this is

boosted to 400mV

RMS

. The feedback network gain has a low

frequency corner at 160Hz and is flat up to the intersection of the

closed loop gain with the open loop gain curve at nearly 500kHz.

This would increase the noise bandwidth to an excessive degree

unnecessary for voice channel communication. A band limiting

network is, therefore, inserted across the feedback resistor to limit

response to a nominal 5kHz.

Amplifier stage A2 is used to provide high level audio to the

rectifier-filter stage for the rapid generation of a DC control signal for

operating the voice activated switch function. Stage A2 gain is set

to 20dB in order to allow activation of the voice channel on the rising

edge of the first voice syllable. An attack time of 20ms is

implemented by adjusting the input charging impedance (R

S

)

between the rectifier and the A2 amplifier output. AC coupling must

be used to isolate the DC common-mode voltage of the amplifier

from the rectifier/storage capacitor and to allow only audio

frequencies to drive the switching circuit. Amplifier A3 provides a

high impedance unity gain buffer to allow a very slow decay rate to

be applied to the time constant capacitor, C

T

. The output of the

storage capacitor reaches approximately 3.2V for a 250ms duration

600Hz burst signal. Diode D1 (1N914) provides a negative clamp

action which forces the full peak-to-peak voltage from A2 to charge

the storage capacitor. D2 then acts to charge the capacitor to the

peak input voltage minus one diode drop, 0.7V . Finally, the buffered

DC control signal is fed to A4 which acts as a threshold comparator

with extremely high gain and controlled hysteresis. This provides a

positive going signal for releasing the NE578 from its inhibit mode

when voice input is present. The NE578 is switched from standby

mode when voice input is present. The NE578 is switched from

standby mode to the active state by raising the voltage on Pin 8 of

the device above 2V. Shutting the audio channel off requires this pin

to be driven below 100mV. This demands the extremely wide output

voltage swing of the NE5234 in order to reach this near to the

negative rail voltage. The voltage threshold of the comparator, A4,

is adjustable by use of the sensitivity control, R

S

. It is used to allow

the activation level to be raised or lowered depending upon the

ambient audio level in the transmitter vicinity.

+3V

–

+

600Ω

a. VCVS Low Pass Filter

+

–

RR

R1

R4

C1

C1

R5

C2

C2

R2

R3

+5V

b. VCVS Band Pass Filter

R

i

R

f

R1

R2

–3V

V

OUT

V

OUT

V

IN

V

IN

SL00649

Figure 21. Active Filters

6kΩ

600Ω

10kΩ

10kΩ

2

3

1

6

5

7

9

10

8

13

12

14

–

+

AUDIO IN

LEFT

AUDIO IN

RIGHT

4

11+–

LEFT CHANNEL

OUT

RIGHT CHANNEL

OUT

NE/SA5234

#1

BRIDGE AMP #2

NE5234

–

+

–

+

–

+

+3V

PIN

X(–1)

–3V

SL00650

Figure 22. Stereo Bridge Amp

Page 14

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

14

10kΩ

10kΩ

10kΩ

12kΩ

40.2kΩ

2.2MΩ

10kΩ

2.2kΩ

220Ω

0.15µF

1µF

4.7µF

1nF

0.47µF

25kΩ

25kΩ

18kΩ

+ –

+

–

+

–

+

–

+

–

A1

A2

A3 A4

100kΩ

4

11

19

8

16

12

11

10

9

74.2V

OFF

ON

0V

X1

D2

D1

C

t

R

A

+4.5V

MIC

R

D

+4.5V

R

3

NE578

NE5234

R

S

SENS.

ADJ.

SL00651

Figure 23. VOX Audio System

Other critical parameters in this type of circuit are the attack and

decay times of the RC network which controls the operation of the

voice operated switch. Attack time determines how quickly the

circuit activates after a quiet period, and the decay time sets how

long the transmitter channel stays active between words. It is

important to reach an optimum balance between the two time

constants in order to allow unbroken transmissions of good quality

and no lost syllables. A 100 to 1 attack/decay ratio is used in this

particular application and this is primarily set by the value of R

A

and

R

D

. A typical delay of two seconds is easily accomplished. Due to

extremely high input impedance of the buffer stage A3, R

D

may be

in the 1 to 2MΩ range allowing a reasonable value of storage

capacitor to be used.

The Audio Channel

Audio input from the preamplifier, A1, is fed directly to Pin 14 of the

NE578 compandor. Referring to Figure 24, which shows the

internal diagram of the device, it can be seen that this is the

compressor portion of the NE578. There is the option in this system

to operate either in a 2:1 compressor mode or an automatic level

control mode, (ALC). The compressor mode simply makes a 2:1

reduction in the amplitude dynamic range of the input signal and

brings it up to the chosen nominal 0dB output level which is

programmable from 10mV

RMS

to 1V

RMS

. In this particular example

it is programmed for a 0dB level of 0.42V

RMS

which is approximately

1V

P-P

. This allows for a standardized output level with good

characteristics for FM modulation where peak deviation must be

controlled. Figure 25 shows the input-output characteristics of the

compressor and ALC.

The compressor also has an attack time determined by capacitor C6

on Pin 11. Attack time is 10k * C6, decay time equals four times this

value. An auxiliary amplifier stage is used following the NE578 in

order to allow bandwidth and special forms of equalization to be

implemented. Note that 2:1 compression in a transmission will

enhance the channel dynamic range and may be used with no

further processing at the receiver, but feeding the received signal

through the complimentary 2:1 expandor will achieve even greater

enhancement of the recovered audio. The NE578 contains both

operations in the same package. Please refer to Philips

Semiconductors applications note AN1762 by Alvin K. Wong for

complete information on these compandor circuits using the NE578.

Fiber Optic Receiver for Low Frequency Data

(Figure 26)

This application makes use of the NE/SA5234 to detect photo-optic

signals from either fiber or air transmitted IR (Infra-red) pulses. The

signal is digitally encoded for the highest signal-to-noise ratio. The

received signal is sensed by an IR photo diode which has its

cathode biased to half the supply voltage (2.5V). The first gain

stage is configured as a transimpedance amplifier to allow

conversion from the microampere diode current signals to a voltage

output of approximately 10mV

0-P

. The second stage provides a

gain-of-ten amplifier to raise this signal level to 1V peak amplitude.

This stage is directly coupled from the preamplifier stage in order to

provide the necessary common-mode voltage of 2.5V . Its gain

control network is capacitively coupled to prevent DC gain as is

required in single supply configurations. Since this is essentially a

pulse gain stage, low frequency gain below the signal repetition rate

is not needed. The third stage acts in a limiting amplifier

Page 15

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

15

configuration and its output is squared to swing approximately 5V ,

the standard TTL level. Again common-mode biasing is passed

along from each of the stages up to the last in order minimize parts

and simplify circuit layout. The final stage is a simple buffer

amplifier to allow the receiver to drive a low impedance long wire

line of 600Ω to 900Ω resistance. Some rise time response

adjustment may be required. This is easily achieved following stage

three by using R

T-CT

to limit the rate of change of the signal voltage

prior to the buffer. Note that the last stage acts as a zero-crossing

detector. This maximizes noise immunity by allowing a transition

only after the third stage output voltage has risen above 2/3V

CC

.

Phase inversion may be accomplished, if the logic level signals are

polarity reversed, by making stage 3 inverting and AC coupling the

input signal with a sufficiently large capacitor to reduce droop.

Stage 3 must then be biased by connecting its non-inverting node to

bias point ‘A’. This provides a 2.5V threshold for the proper

switching operation of the stage. However, care must be taken not

allow the network’s time constant to become code dependent as to

the average low frequency signal components or errors will result in

the output signal.

The advantage of this particular circuit is that it has the simplicity of

single supply operation along with the capability of a large output

swing making it fully TTL compatible

REFERENCES:

Philips Semiconductors. Linear Data Manual, Volume 2 : Industrial.

Sunnyvale: 1988.

Wong, Alvin K. Companding with the NE577 and NE578..Philips

Semiconductors Applications Note AN1762 : September 1990.

1

2

3

4

5

6

7

10

11

12

16

15

14

13

V

REF

V

CC

GND

COMP

IN

BANDGAP

I

REF

Σ

Σ

∆G

∆G

EXPANDOR

COMP.

GAINCELL

GAINCELL

RECT.

V

CC

GND

COMP

CAP2

COMP

CAP1

GCELL

IN

COMP

OUT

RECT

IN

V

REF

EXP

OUT

EXP

CAP

RECT

IN

EXP

IN

RECT.

C3

C1

R1*

C2

R2*

C4

10µF

2.2µF

10µF

10µF

C8

C7

C6

R3*

C5

+

+

+

+

+

+

+

10µF

2.2µF

10µF

C9

+

10µF

2.2µF

+

8

9

+

C10

R4

10µF

SUM

IN

PWRDN/

PWRDN

C11

1nF

*R1, R2 and R3 are 1% resistors.

30k 30k 10k

10k

10k

10k

10k

5k

10k

8.6k

MUTE

MUTE

TO

PIN 4

NE578

SL00652

Figure 24. Block Diagram of NE578 Test and Application Circuit

Page 16

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

16

42µV

420µV

+16dB

0dB

-20dB

-40dB

-60dB

-80dB

+16.0

0.0

-20

-40

-60

-80

+12.0

A

B C

D

TRANSMISSION

MEDIUM

DB dBM

+10.68

-5.32

-25.32

-45.32

-65.32

-85.32

+6.68

EXPANDOR

OUT

COMPRESSION

IN

V

RMS

2.65V

420mV

42mV

4.2mV

1.67V

(COMPRESSOR

OUT)

(EXPANDOR

IN)

REL LEVEL ABS LEVEL

[ ]

1

2

[ ]

2

INPUT TO ∆G

AND RECT

SL00653

Figure 25. NE570/571/SA571 System Level

+

–

+

–

+

–

+

–

A

R

+5V

1V

1k

5k

10mV

10k

+V

CC

C

T

R

T

100k

2/3 V

CC

I

O

C

S

R

t

R

1

+5V

1.0

+5V

4

1k

SL00654

Figure 26. Fiber Optic Data Receiver

Page 17

Philips Semiconductors Application note

AN1651Using the NE/SA5234 amplifier

1991 Oct

17

+3V

+

–

M

+

–

+

–

+

–

-3V

4

11

1N9683

6

5

7

9

10

8

2

3

1

13

12

14

NE5234

1/100

1N9683

SL00655

Figure 27. Half Bridge Servo

Loading...

Loading...