Page 1

Service Manual

M4735A Defibrillator/Monitor

Verification Draft

29 June 2000

Page 2

Notice

About This Edition

Edition 1

Printed in the USA

Publication number M4735-90900

The information in this manual appli es

to the M4735A Heartstream XL

Release A.0.0. This informatio n is subject to change without notice.

Agilent Technologies shall not be liabl e

for errors contained herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this material.

Edition History

Edition 1, July, 2000

Copyright

Copyright © 2000

Agilent Technologies, Inc.

3000 Minuteman Road

Andover, MA 01810-1099 USA

(978) 687-1501

This document ma y not be photoc opied,

reproduced, or translated to another language without prior written consent of

Agilent Technologies.

WARNING

Radio Frequency (RF) interference

from nearby transmitting devices may

seriously degrade performance of the

M4735A. Electromagnetic compatibility with surrounding devices should be

assessed prior to using the defibrillator.

CAUTION

Use of supplies or accessories other

than those recommended by Agilent

Technologies may compromise product

performance.

THIS PRODUCT IS NOT INTENDED

FOR HOME USE.

IN THE U.S., FEDERAL LAW

RESTRICTS THIS DEVICE TO SALE

ON OR BY THE ORDER OF A PHYSICIAN.

Medical Device Directive

The M4735A Defibrillator/Monito r

complies with the requirements of the

Medical Device Directive 93/42/EEC

and carries the

ingly.

Authorized EU-representative:

Agilent Technologies GmbH

Herrenbergerstrasse 130

D-71034 Boeblingen,

Germany

Fax: +49-7031-14-2346

mark accord-

0123

ii

Page 3

Conventions

This manual uses the following text conventions:

Printed and On-Line

NOTE Notes contain additional information on servicing this product.

CAUTION Caution statements descr ibe cond ition s or acti ons that can resu lt in damag e to

the equipment or loss of data.

WA RN I N G Warning statements describe conditions or actions that can result in personal injury

or loss of life.

Te x t

Softkey

On-Line Only

Hypertext

represents messages that appear on the display

represents softkey labels that appear on the display

above or below the button to which they correspond

represent hypertext links, which will display as blue;

click on the link to go t o that d estin ation, then cl ick on

the destination to return.

iii

Page 4

This page intentionally left blank

iv

Page 5

Contents

Conventions

Printed and On-Line .......................................................................................................... iii

On-Line Only ................................................................................................................. iii

Hypertext ..........................................................................................................................iii

Introduction

Overview ....................................................................................................................1-1

Defibrillator/Monitor ...................................................................................................... 1-1

Batteries .......................................................................................................................... 1-2

Installation ......................................................................................................................1-2

Upgrades ......................................................................................................................... 1-2

Preventive Maintenance .................................................................................................. 1-2

Repair Philosophy ........................................................................................................... 1-3

Performance Verification and Safety Tests

Overview .........................................................................................................................2-1

Chapter Contents ............................................................................................................. 2-1

Mandatory Testing ......................................................................................................2-2

External Repairs/No Trouble Found ............................................................................... 2-2

Printer ..............................................................................................................................2-3

Internal Repairs ...............................................................................................................2-3

Test Matrix .................................................................................................................2-4

Test Equipment ...........................................................................................................2-8

Configuration and Diagnostic Modes ......................................................................2-10

Configuration Mode ...................................................................................................... 2-10

Diagnostic Mode ........................................................................................................... 2-11

The Software Support Tool ......................................................................................2-12

Using the Support Tool ................................................................................................. 2-12

Performance Verification .........................................................................................2-14

Visual Inspection ........................................................................................................... 2-15

Functional Checks ......................................................................................................... 2-16

Diagnostic Tests ............................................................................................................ 2-19

Safety Tests ..................................................................................................................2-39

Battery Capacity Test ....................................................................................................2-40

6/29/00

v

Page 6

Contents

Troubleshooting

Overview .........................................................................................................................3-1

Chapter Contents ............................................................................................................. 3-1

Repair Philosophy ........................................................................................................... 3-1

Equipment Required .......................................................................................................3-1

Troubleshooting and Repair Methodology ................................................................3-2

Methodology Overview .................................................................................................. 3-2

Initial Assessment ......................................................................................................3-3

Diagnosing External Failures .....................................................................................3-4

Diagnosing Internal Failures ......................................................................................3-5

Troubleshooting Tables ..............................................................................................3-6

Using the Tables ............................................................................................................. 3-6

General Problems .......................................................................................................3-8

Unit Unresponsive .......................................................................................................... 3-8

Error Codes ................................................................................................................... 3-10

System Messages .......................................................................................................... 3-12

Momentary Messages ...................................................................................................3-14

Audio Tones ................................................................................................................ 3-16

Extended Self Test Failures .......................................................................................... 3-17

Operational Problems ...............................................................................................3-18

ECG Monitoring ......................................................................................................... 3-18

SpO2 Monitoring .......................................................................................................... 3-20

Defibrillation and Cardioversion .................................................................................3-21

Pacing ............................................................................................................................3-24

Printer ........................................................................................................................... 3-25

Display .......................................................................................................................... 3-26

Audio ............................................................................................................................3-27

Keys .............................................................................................................................3-28

Battery and Charging Circuits ...................................................................................... 3-29

Data Card ......................................................................................................................3-30

Calling for Service ................................................................................................... 3-31

United States of America ..............................................................................................3-31

Canada ..........................................................................................................................3-31

Other International Areas .............................................................................................. 3-31

Equipment Information ................................................................................................. 3-31

Removal and Replacement

Overview .........................................................................................................................4-1

Chapter Contents ............................................................................................................. 4-1

Servicing Notes ..........................................................................................................4-1

Key Components ............................................................................................................. 4-1

Removal, Handling, and Replacement ........................................................................... 4-2

Tool Requirements .......................................................................................................... 4-3

vi

Page 7

Contents

Disposal ..........................................................................................................................4-3

External Assemblies ...................................................................................................4-4

User-replaceable Parts and Accessories .......................................................................... 4-5

User Maintenance ...........................................................................................................4-5

Printer Assembly ............................................................................................................. 4-6

Battery Cover ................................................................................................................ 4-10

Main Fuse ..................................................................................................................... 4-12

Battery Eject Assembly ................................................................................................ 4-14

Data Card Door .............................................................................................................4-16

Energy Select Knob ....................................................................................................4-17

Paddle Holders .............................................................................................................. 4-18

Labels ............................................................................................................................4-20

Label Descriptions ........................................................................................................ 4-20

Removing and Replacing Labels .................................................................................. 4-22

Opening the Case ..................................................................................................... 4-24

Discharge the Power Supply Capacitors ...................................................................... 4-24

Separate the Case ........................................................................................................ 4-26

Discharge the Defibrillator Capacitor .......................................................................... 4-30

Identifying Internal Subassemblies ...............................................................................4-32

Internal Assemblies - Top Case ................................................................................4-33

Lithium Backup Battery ................................................................................................ 4-34

Control PCA ................................................................................................................ 4-36

Shield Plate ...................................................................................................................4-40

Keyscan PCA ................................................................................................................ 4-42

Bezel Assembly .......................................................................................................... 4-48

Energy Select Switch .................................................................................................... 4-52

......................................................................................................................................4-53

Display Assembly .........................................................................................................4-54

Parameter PCA ............................................................................................................. 4-56

SpO2 PCA .................................................................................................................. 4-58

ECG Connector ............................................................................................................. 4-60

SpO2 Connector ............................................................................................................ 4-62

Speaker ....................................................................................................................... 4-64

AC Mains Connector ....................................................................................................4-66

ECG Out (Sync) Connector .......................................................................................... 4-69

Pacer Keypad ................................................................................................................ 4-70

Replacement Top Case .................................................................................................. 4-75

Internal Assemblies - Bottom Case ..........................................................................4-79

Battery PCA .................................................................................................................. 4-80

Defibrillator Capacitor ..................................................................................................4-84

Power PCA ................................................................................................................... 4-86

AC Power Module ........................................................................................................4-90

Patient Connector .......................................................................................................... 4-94

Replacement Bottom Case ............................................................................................ 4-97

Closing the Case .......................................................................................................4-99

vii

Page 8

Contents

Replacement Parts

Overview .........................................................................................................................5-1

Chapter Contents ............................................................................................................. 5-1

Ordering Replacement Parts .......................................................................................... 5-1

Ordering Supplies and Accessories ................................................................................ 5-1

Key Components ........................................................................................................... 5-2

Calling for Service ..................................................................................................... 5-3

United States of America ...........................................................................................5-3

Canada ........................................................................................................................ 5-3

Other International Areas ............................................................................................ 5-3

Special Tools ..............................................................................................................5-4

M4735A Unit Exchange Program ..............................................................................5-5

Replacement Parts Tables ...........................................................................................5-6

Electrical Assemblies ................................................................................................. 5-7

Control PCA ................................................................................................................... 5-7

Other Replacement PCAs ............................................................................................... 5-8

Other Electrical Assemblies ........................................................................................... 5-8

Individual Electrical Parts ............................................................................................... 5-9

Mechanical Assemblies ............................................................................................5-10

Bezel Assembly ............................................................................................................ 5-10

Pacer Keypad Assembly ............................................................................................... 5-11

Other Mechanical Assemblies ......................................................................................5-12

Connector Assemblies .................................................................................................. 5-12

Individual Mechanical Parts ......................................................................................... 5-13

Labels .......................................................................................................................5-14

Instruction Label Sets ................................................................................................... 5-14

Case Label Sets ............................................................................................................. 5-16

Other Labels .................................................................................................................5-17

Supplies & Accessories ............................................................................................5-18

Key Components ......................................................................................................5-21

Theory of Operation

Overview .........................................................................................................................6-1

PCA Descriptions .......................................................................................................6-2

Control PCA ................................................................................................................... 6-2

Power PCA ..................................................................................................................... 6-3

Parameter PCA ............................................................................................................... 6-3

Keyscan PCA .................................................................................................................. 6-3

SpO2 PCA .......................................................................................................................6-4

Battery PCA ....................................................................................................................6-4

Battery .............................................................................................................................6-4

AC Power Module ..........................................................................................................6-4

Printer ..............................................................................................................................6-4

viii

Page 9

Contents

System Level Interconnections ..................................................................................6-5

System Functional Descriptions ............................ .................. ................... ................ 6-6

Signal and Data Flow ...................................................................................................... 6-6

ECG Monitoring Functions ............................................................................................ 6-7

Patient impedance functions ........................................................................................... 6-7

SpO2 Monitoring Functions ...........................................................................................6-8

Defibrillation Functions .................................................................................................. 6-9

Pacing Functions ........................................................................................................... 6-11

Audio Functions ............................................................................................................ 6-11

Display Functions ......................................................................................................... 6-11

Indicator Functions .......................................................................................................6-11

Key Functions ............................................................................................................... 6-11

Energy Select Switch .................................................................................................... 6-12

Printing Functions ......................................................................................................... 6-12

Battery/Power Functions ............................................................................................... 6-12

Lithium Backup Battery ................................................................................................ 6-15

Data Card ......................................................................................................................6-15

Specifications

Overview .........................................................................................................................7-1

Specifications .............................................................................................................7-1

Defibrillator ....................................................................................................................7-1

ECG Monitoring ............................................................................................................. 7-3

Display ............................................................................................................................ 7-4

Battery .............................................................................................................................7-4

Thermal Array Printer .....................................................................................................7-5

Noninvasive Pacing ........................................................................................................ 7-6

SpO2/Pulse Oximetry ...................................................................................................... 7-6

Event Storage ..................................................................................................................7-6

General ............................................................................................................................7-7

Environmental .................................................................................................................7-7

Waveforms - 150J ......................................................................................................7-8

Waveforms - 200J .................................................................................................7-11

Symbol Definitions ..................................................................................................7-14

Safety Considerations ...............................................................................................7-16

Electromagnetic Compatibility ................................................................................7-19

Reducing Electromagnetic Interference ........................................................................ 7-19

Restrictions for Use ...................................................................................................... 7-20

Immunity Level ............................................................................................................. 7-20

ix

Page 10

Contents

This page intentionally left blank.

x

Page 11

1Introduction

This Service Manual provides the information needed to successfully service the Agilent M4735A Heartstrea m XL Defi bril lato r/Mon itors . The i ntende d user s of t his man ual are technical personnel who have been trained in the safe and proper servicing of

the M4735A. 1

Overview

In this chapter, you’ll find general information that you should become familiar with before servicing the M4735A. Detailed information regarding controls, operation, and capabilities of the instrument can be found in the User’s

Guide (M4735-91900) that was shipped with the product. We recommend

you review the User’s Guide before servicing this device. Th is Service Man -

ual assumes you are familiar with the controls and with basic operations.

Defibrillator/Monitor

The M4735A is a biphasic, semi-automatic external defibrillator. This portable, lightweight device offers two modes of operation for defibrillation:

l

Semi-Autom atic External Defibrillat ion (AED) Mode

l

Manual Mode

1

In AED Mode, the M4735A analyzes the patient’s ECG and advises the clinician whether or not to deliver a shock. Defibrillation is performed through

multifunction defi b electrode pads.

In Manual Mode, the M4735A turns control of the defibrillation process over

to the clinician. The c li ni ci an a nal yze s the patient’s ECG, decides if defibrillation is advised, and deter mines t he ener gy s etti ng for def ibrill ation . Defibr illa tion is performed eit her through mu ltifunc tion defib el ectrode pa ds or throu gh

paddles.

Manual Mode also allows the c linician to perform synchroni zed cardiover sion

and offers optional noninvasive pacing (using a monophasic waveform).

ECG monitoring can be accomplished in either mode using one of 3 methods:

l

ECG from the defib pads

l

3-lead ECG using separate monitoring electrodes

l

Optional 5-lead ECG using separate monitoring electrodes.

Optional pulse oximetry (SpO

well.

The M4735A automatically stores critical events, such as shocks and alarm

violations, in its internal memo ry. An Event Summary may be printed at any

time. The M4735A also enables you to store data and events on an M3510A

) monitoring is available in both modes, as

2

1-1

6/29/00

Page 12

Overview

Data Card for downloading to the CodeRunner Web Data Management System.

Batteries

The M4735A is powered by a rechargeable Sealed Lead Acid (SLA) battery

(M3516A). Proper care of these batteries will ensure that they have the

energy required to operate the M4735A and deliver the appropriate therapy

(See "Battery Maintenance" section in User’s Guide).

NOTE The defibrillator will take longer to charge when powered with AC without a

battery installed. To ensure optimal performance, alwa ys have a fully char ged

battery in the defibrillator, even when using AC power.

Installation

The M4735A does not require installation. The User’s Guide describes the

setup required before pla ci ng the devi ce into service, as well as configuration

options.

Upgrades

Upgrades are availabl e to add spe cific funct ionalit y to units in the fi eld. As of

the publication of this manual, these upgrades are:

l

M4738A Pacing Upgrade (adds pacing).

l

M4739A SpO2 upgrade. (adds SpO2).

Consult your sales representative or dealer or distributor for the latest details.

Preventive Maintenance

Preventive maintenance and periodic operational checks are intended to be

performed by the user. Both topics are covered i n the Ma inten ance cha pter o f

the User’s Guide.

1-2 Introduction

Page 13

Overview

Repair Philosophy

Defibrillator/Monitor

The repair philosophy of the M4735A i s subassembly repl acement. Examp les

of subassemblies are the printer, the Control Printed Circuit Assembly (PCA),

and selected connectors and other items. Repairs that involve replacing components on a PCA are not supported.

CAUTION Individual component replacement should not be attempted outside of a fac-

tory authorized repair facility. Component level repair is extremely difficult

due to the extensive use of surface mount technology and the high parts-density on the circuit boards. Unauthorized component replacement can impair

performance of the M4735A.

Batteries

The repair philosophy for the SLA battery (M3516A) is unit replacement.

These items are not repaired in the field.

For information on ordering replacements, see "Supplies & Accessories" on

page 5-18.

1

M4735A Service Manual 1-3

Page 14

Overview

This page intentionally left blank.

1-4 Introduction

Page 15

2 Performance Verification and Safety Tests

Overview

This chapter describes the tests and inspections required to verify performance of the M4735A Portable Defibrillator/Monitor.

Chapter Contents

The major sections of this ch apter are as fo llows:

Section Page

Mandatory Testing 2-2

Test Matrix 2-4

Test Equipment 2-8

Configuration and Diagnostic Modes 2-10

The Software Support Tool 2-12

Performance V eri fic ati on 2-14

2

2-1

6/29/00

Page 16

Mandatory Testing

Mandatory Testing

The Performa nce Verification Tests in this chapter are intended to verify

proper operation of the M4735A following repair. The level of testing

required corresponds to the t ype of r epair p erforme d, and is divide d into 3 c ategories: External/No Trouble Found, Printer Replacement, and Internal

Repairs. Each of these categories is described below.

External Repairs/No Trouble Found

External Repairs are those involving the repair or replacement of one or

more of the items below. No Trouble Found applies when no malfunction

can be found, or when the problem appears to be due to improper use. In

either situation, the key point is that the case has not been opened.

l

External paddles

l

Internal paddles and/or adapter cable

l

Paddle holders

l

Pads adapter cable

l

ECG cable

l

SpO2 cable or sensor

l

Battery

l

Labels

l

AC Power cord

l

Consumables (ECG monitoring electrodes, multifunction defibrillation pads, printer paper)

l

Main fuse (on Battery PCA)

l

Data Card Door Assembly

l

Battery Ejec t Assembly

The following testing is required after an External Repair or when the out-

come of the service is No Trouble Found (when the case has not been

opened):

l

Perform the Visual Inspection (page 2-15).

l

Run the Extended Self Test (page 2-22).

l

Print and Verify the System Log (page 2-20).

2-2 Performance Verification and Safety Tests

Page 17

Mandatory Testing

Printer

If the printer was replaced , and the case was not opened, the following tests

are required:

l

Perform the Visual Inspection (page 2-15).

l

Run the Extended Self Test (page 2-22).

l

Run the Printer Test (page 2-27).

l

Print and Verify the System Log (page 2-20).

Internal Repairs

If the case was opened (regardless of what the repair involved), all of the Performance Verification Tests must be performed, beginning with "Visual

Inspection" on page 2-15.

2

M4735A Service Manual 2-3

Page 18

Test Matrix

Test Matrix

The matrix in Table 2-1 summarizes performance verification tests and

inspections for the M4735A; including test name, test or inspection to perform, expected test results, and data to record.

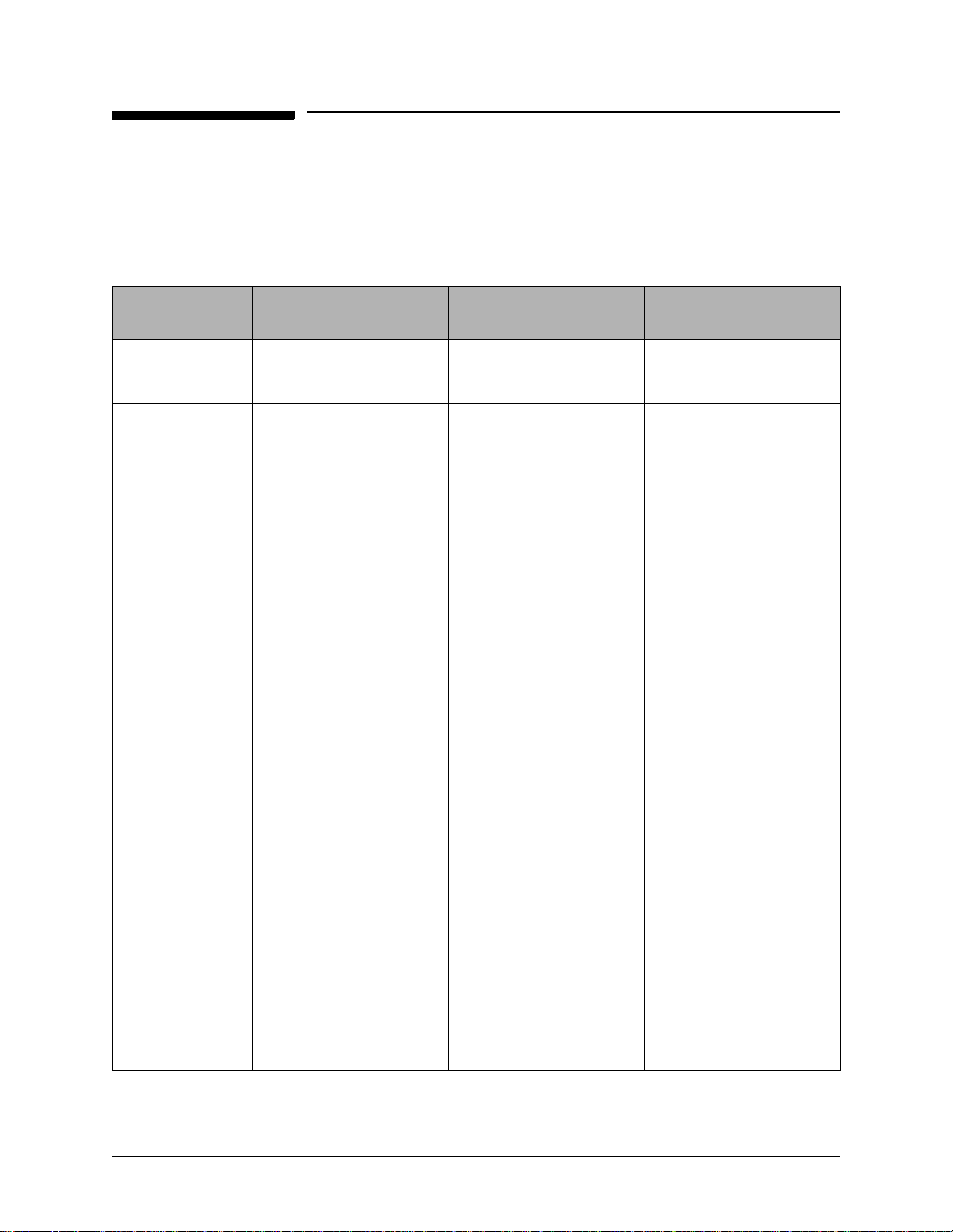

Table 2-1 Performance Verification and Safety Tests

Test Group Name

Visual Inspection

(V)

Functional

Checks (F)

Extended Self

Test (X)

Test or Inspection to

Perform

Inspect unit, accessor ies,

cables, etc. as described

on page 2-15.

In normal Operating Mode,

perform the following functional checks:

• ECG (page 2-16). • W aveform c lear on displa y;

• Shock Advisory (page 2-

17).

• Synchronized Cardioversion (page 2-18).

(page 2-18). • 95% -100%

• SpO

2

In Diagnostic Mode, run

the Extended Self Test

(page 2-22). Includes Data

Card Test and time/date

check.

Expected Test Results

• No unusual damage, no

corrosion: x=p.

• All functions respond as

expected

HR correct on display; HR

alarm works

• Shock Advised only when

appropriate

• Shock delivered with correct timing

"Pass" reported on all tests

applicable to the device configuration and options: x=p.

Data to Record

x = p (pass) or f(fail)

V:x

Example V:p

F:x

Example F:p

X:x

Example X:p

User Interface

Tests (U)

• In Diagnostic Mode, run

the following tests (page

2-25):

• Controls Test • All keys respond as

• Display Test • Visual Pass assessment by

• Audio Test • Audio Pass assess ment by

• Printer Test • Print quality: visual Pass

All responses as expected.

expected

service personnel

service personnel.

assessment by serv ice personnel

• Print speed: 25 mm

(1.25mm)

± 5%

U:x

Example: U:p

2-4 Performance Verification and Safety Tests

Page 19

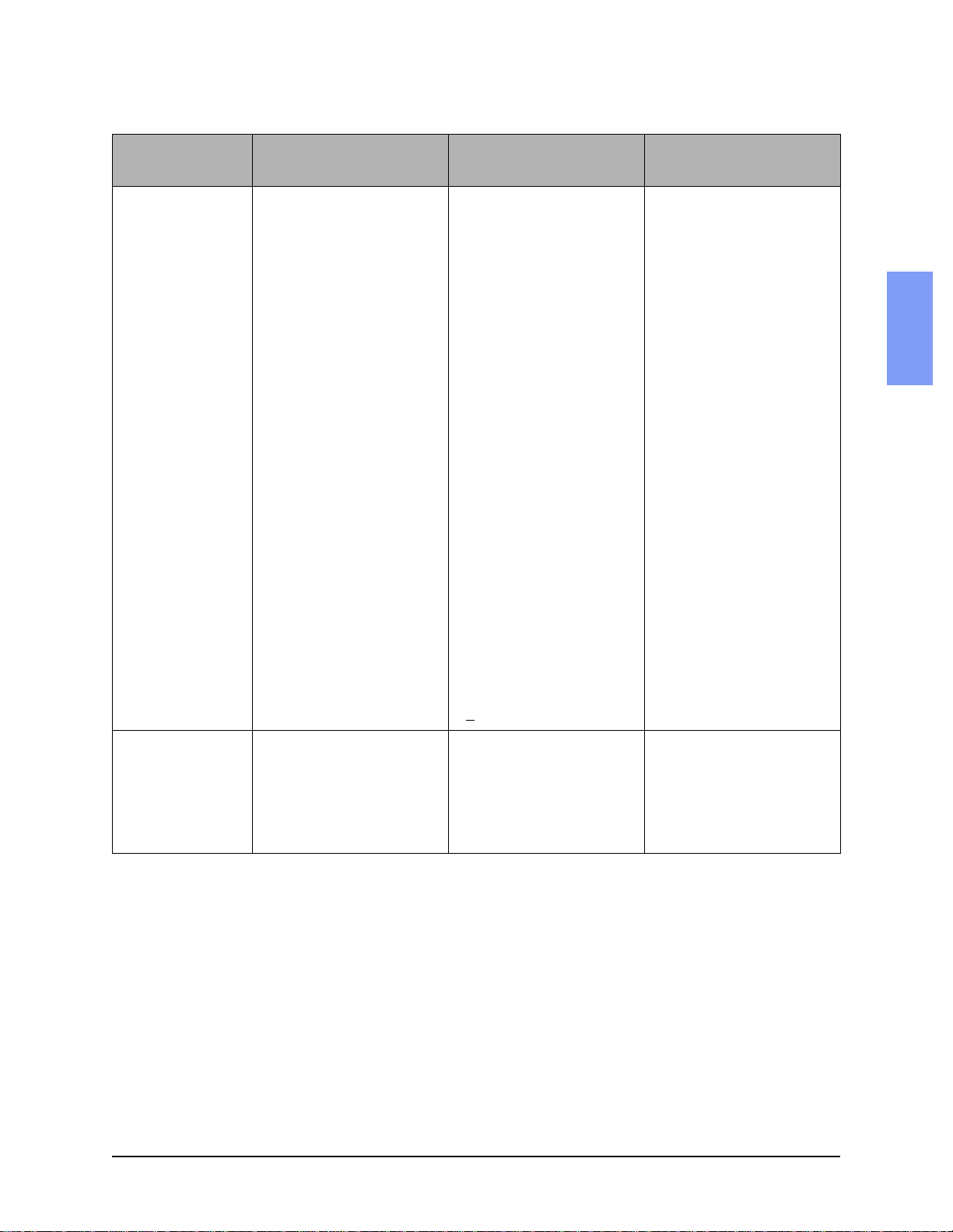

Table 2-1 Performance Verification and Safety Tests

Test Matrix

Test Group Name

ECG Tests (E) In Diagnostic Mode, run

Test or Inspection to

Perform

the ECG T ests (page 2-29):

• Status messages (lead,

pad, DSP)

• DC offset • Ignore - used only in fac-

Amplifier gain

• Pads Peak to Peak (Monitor) - aaaa

• Leads Peak to Peak (Diagnostic) - bbbb

Amplifier noise

• Leads Peak to Peak (Diagnostic) - cc

• Pads Peak to Peak (Monitor) - dd

Expected Test Results

All data within limits, all

checks pass: x=p

• "Good" displayed for all

three

tory manufacturing.

• 1000mV ±10%

• 1000mV

• 0 ± 30uV

• 0 ± 30uV

±10%

Data to Record

x = p (pass) or f(fail)

E: aaaa,bbbb,cc,dd,

ee,fff f,x

Example:

E:1000,1000,20,20,

50,2000,p

2

PCI measurement

• PCI - Paddles in Pockets – ee• 50 ± 30 Ω

• PCI - Paddles open – ffff • >

Pacing Test (P) In Diagnostic Mode, run

the Pacing Test (page 2-

33):

• 30 mA – aa • 30 mA ± 5 mA

• 200mA – bbb • 200mA± 20 mA

1250 Ω

P:aa,bbb

Example: P:31,198

M4735A Service Manual 2-5

Page 20

Test Matrix

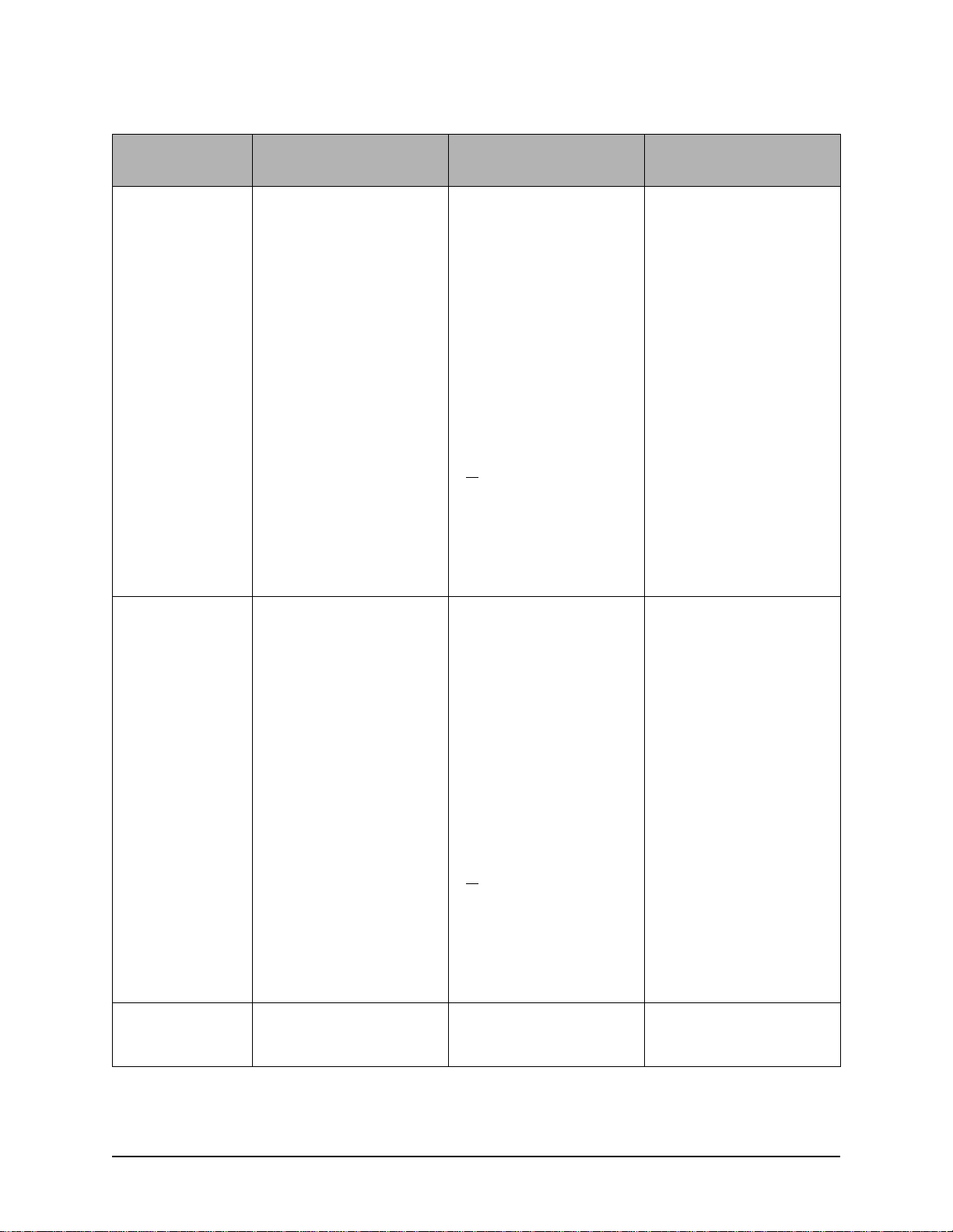

Table 2-1 Performance Verification and Safety Tests

Test Group Name

Defibrillator T es t AC Power (DA)

(if AC Power used

in normal operation)

Test or Inspection to

Perform

Using only AC power,

enter Diagnostic Mode

and run the Defibrillator

Test (AC Power at 200J)

(page 2-35):

Expected Test Results

Measured by

Defibrillator Analyzer:

• Delivered energy - aaa

• 200

± 30J

Displayed by

M4735A:

• Available Energy after

Shock

• Msec to charge – bbbbb • <

• Delivered energy - ccc • Actual delivered energy

• Impedance - dd • 42 to 57 Ω

• Defib errors • None (0)

• 0

15000 msec

(aaa) ±7%

Data to Record

x = p (pass) or f(fail)

DA:aaa,bbbbb,ccc,dd

Example:

DA:198,13000,195 ,48

Defibrillator T es t Battery Power

(DB)

Defibril lator Disarm Test (D)

Using only battery power,

enter Diagnostic Mode

and run the Defibrillator

Test (Battery Power at

200J) (page 2-36).

Measured by

Defibrillator Analyzer

• Delivered energy - aaa • 200 ± 30 J

Displayed by

M4735A

• Available Energy after

Shock

• Msec to charge – bbbb • <

• Delivered energy - ccc • Actual delivered energy

• Impedance - dd • 42 to 57 Ω

• Defib errors • None (0)

Enter Diagnostic Mode

and run the Defibrillator

Disarm Test (page 2-38)

• 0

3000 msec

(aaa)

±7%

All readings as expected:

x=p

DB:aaa,bbbb,ccc,dd

Example:

DB:198,2545,200,50

D:x

Example: D:p

2-6 Performance Verification and Safety Tests

Page 21

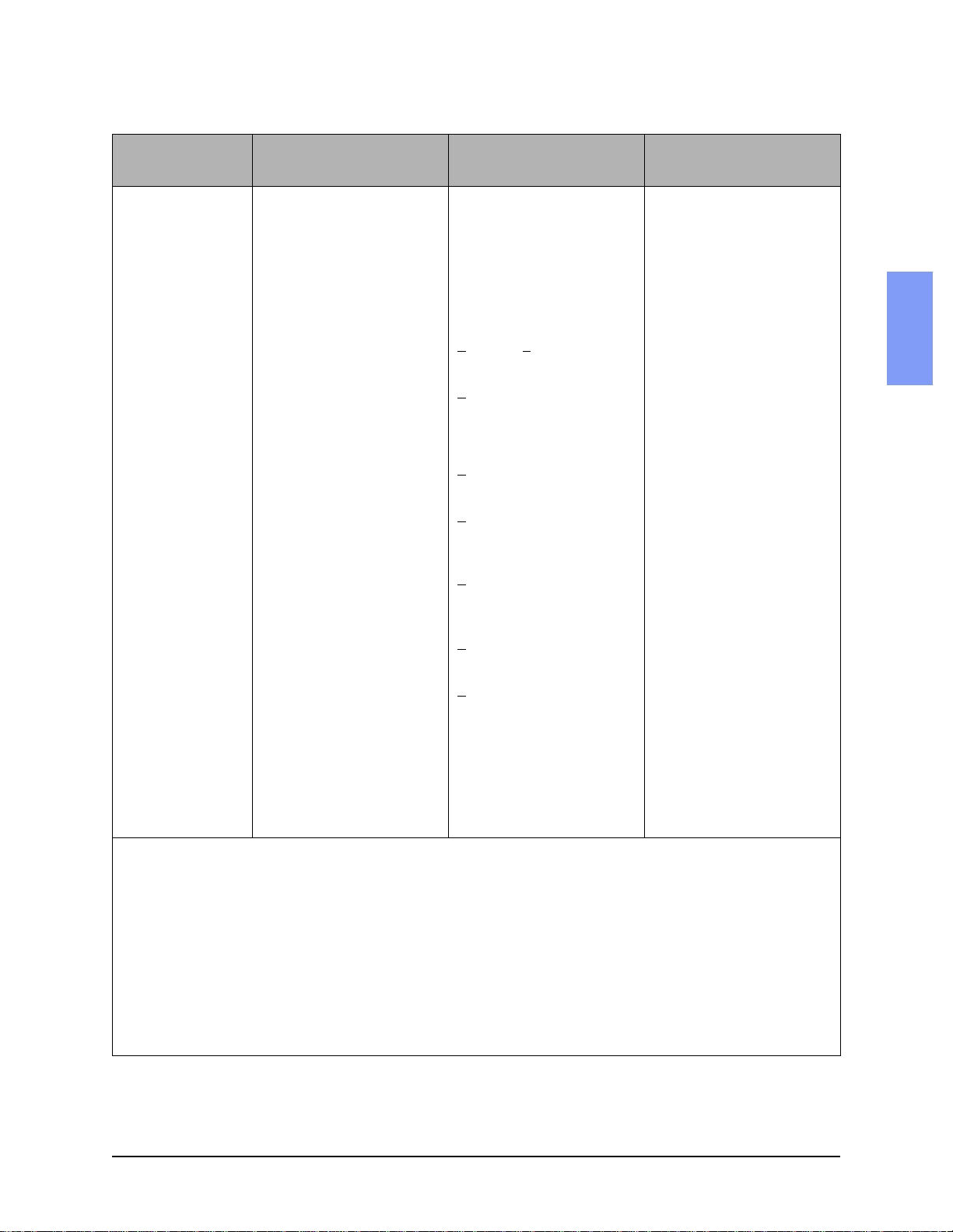

Table 2-1 Performance Verification and Safety Tests

Test Matrix

Test Group Name

Safety Test (S) Test both leads and pads,

Test or Inspection to

Perform

and indicate test results

as follows:

External Leads: t=C

External Pads: t=B

Earth Leakage

Earth Leakage

(Normal Co ndition) - aaa

Earth Leakage

(Single Fault) - bbbb

Patient Lead Leakage

• Source

(Normal Condition) - ccc

• Source

(Single Fault Condition) ddd

• With Mains on appli ed p art

(Single Fault condition) eeee

Expected Test Results

< 500 uA (< 300 uA UL)

<

1000 uA

CF/ BF Applied Parts

< 10 uA/100 uA

<

50 uA/500 uA

50 uA/5000 uA

<

Data to Record

x = p (pass) or f(fail)

S:aaa,bbbb,

t,ccc,ddd,eeee,fff,ggg;

t,ccc,ddd,eeee,fff,ggg

Example: S:125,150,

C,10,40,40,10,40;

B,90,150,2500,90,250

2

• Auxiliary

(Normal Condition) - fff

• Auxiliary

(Single Fault Condition) ggg

Note: All leakage current

tests include both Normal

and Reverse Polarity Conditions.

Report worst case values.

Note: When recording test results, separate results within a test by commas; separate tests by a semicolon (;); and

use no empty spaces. For example:

V:x;F:x;X:x;U:x;E: aaaa,bbbb,cc,dd,ee,ffff,x;P:aa,bbb;

DA:aaa,bbbbb,ccc,dd;DB:aaa,bbbb,ccc,dd;D:x;

S:aaa,bbbb,t,ccc,ddd,eeee,fff,ggg;t,ccc,ddd,eeee,fff,ggg

V:p;F:p;X:p;U:p;

DA:198,13000,195,48;DB:198,2545,200,50;D:p;

S:125,150,C,10,40,40,10,40;B,90,150,2500,90,250

E:1000,1000,20,20,50,2000,p;P:31,198;

< 10 uA/100 uA

<

50 uA/500 uA

M4735A Service Manual 2-7

Page 22

Test Equipment

Test Equipment

Table 2-2 lists the equipment needed to pe rf orm t he Performance Verification

tests, and provides specifications for commercially available analyzers and

simulators. Test equipment is called out within each test procedure when

needed. In addition, a digital voltmeter is also useful.

A 50 ohm test load is available from Agilent Technologies (M1781A).

Table 2-2 Equipment List

Equipment/Test Specifications

ECG Simulator

Calibrated Leads ECG simulator

• Amplitude accuracy ±2%

• Rate accuracy ±2%

Calibrated Paddles

• Amplitude accuracy ±2%

• Rate accuracy ±2%

Defibrillator Analyzer

Waveform compatibility Meets all specs below using biphasic

Load resistance: 50 Ω ±1% (non-inductive)

Maximum energy: ≥ 200 joules

Maximum voltage: ≥ 2500 V

Maximum current: ≥50 A

Measurement accuracy:

• ≥ 20 joules: ≤ ±2% of reading

• < 20 joules: ≤ ±0.4 joules

Cardioversion measurement range: –150 to +150 ms

ECG simulator

truncated exponential waveform.

2-8 Performance Verification and Safety Tests

Page 23

Table 2-2 Equipment List

Equipment/Test Specifications

Pacer tester

Load impedance: ≤400 Ω

measurement accuracy

Current

• 30 mA–50 mA: <±2 mA

• 50 mA–200 mA: <±4%

measurement accuracy

Rate

• 40–180 ppm: <±0.5%

Waveform duration accuracy:

• 40–180 ppm: ±1ms

Test Equipment

2

M4735A Service Manual 2-9

Page 24

Configuration and Diagnostic Modes

Configuration and Diagnostic Modes

The instructions below describe how to enter Configuration Mode and Diagnostic Mode.

Configuration Mode

These instructions describe briefly how to use Configuration Mode. See the

User’s Guide for details on configuration settings and what effect they have.

1. Power off.

Make sure the unit’s power is off.

2. Insert a Data Card.

If you intend to save the configuration to a Data Card (or load the configuration from a Data Card), insert the Data Card now.

NOTE To avoid possible confusion, designate one Data Card as the "Configuration

Card" and label it c le arl y. Keep this card physically separate from cards used

by the clinical staf f for data storage.

3. Enter Configuration Mode.

Press softkeys 4 and 5 at the same time, and hold them down while turning the power on. See Figure 2-1 for softkey numbering.

4. Select and manage Configuration choices.

l

To select a configuration, press the and softkeys to move up

ENTER

Settings

item is highlighted. Then

Save Settings

Save Settings to

or down the list until the desired

press the softkey to access those settings.

l

To print out a strip with all the current configuration choices, select

Print All Settings

l

To store the configuration settings on a data card, select

to Data Card

Data Card? press .

l

To load configuration settings from a Data Card, select Load Settings

ENTER

and press .

and press . When prompted with

SAVE

from Data Card and pres s . When pr ompte d wi th Load Settings

from Data Card? press .

5. Exit Configuration Mode.

ENTER

ENTER

LOAD

To exit Configuration Mode, turn the unit off. Remove the Data Card.

2-10 Performance Verification and Safety Tests

Page 25

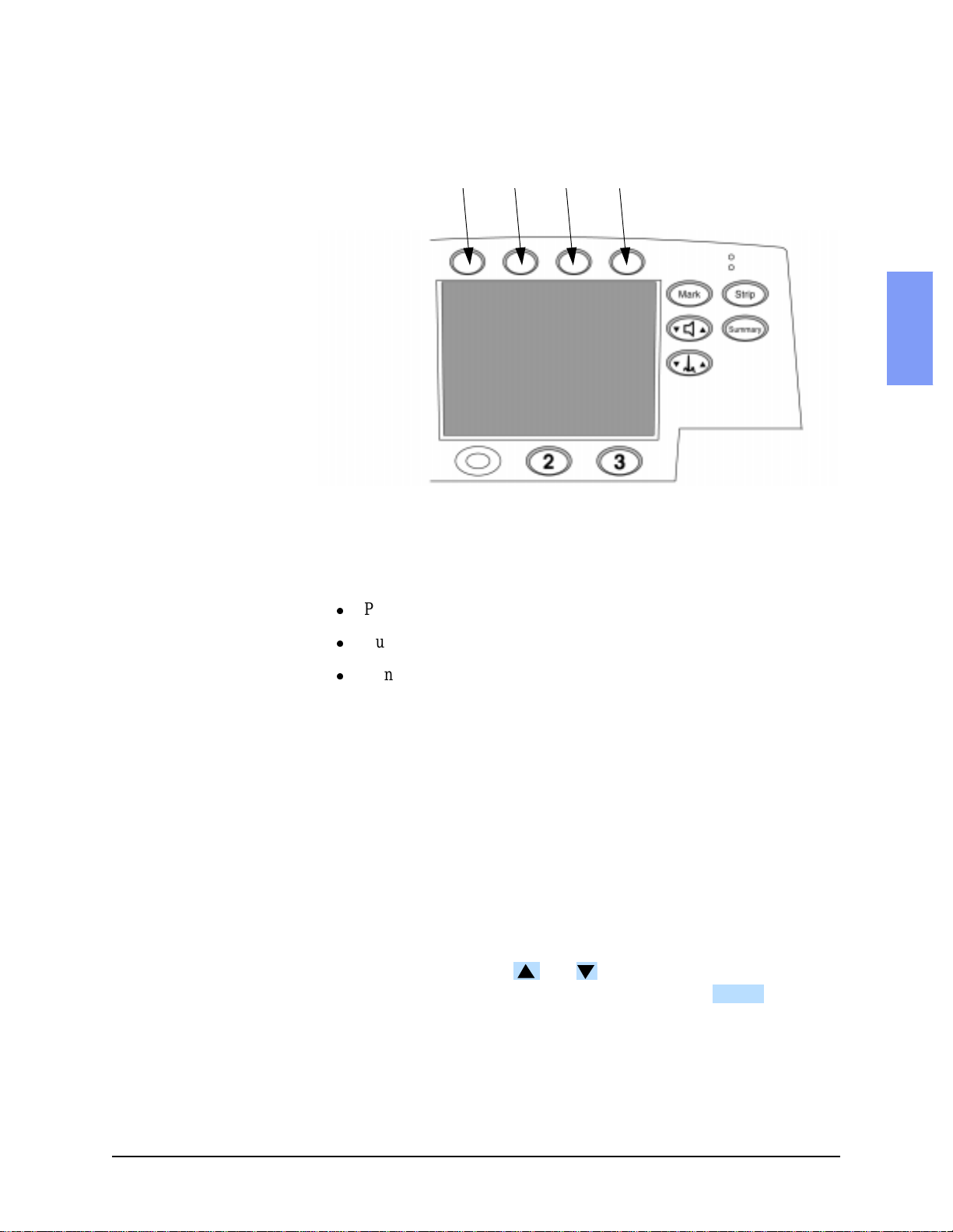

Figure 2-1 Softkey Numbers

Softkeys

4 5 6 7

Configuration and Diagnostic Modes

2

Diagnostic Mode

These instructions describe how to enter Diagnostic Mode. Once in Diagnostic Mode, you can do the following:

l

Print the System Log. See "System Log" on page 2-20.

l

Run the Extended Self Test. See "Extended Self Test" on page 2-22.

l

Run other Diagnostic Tests. See "Diagnostic Tests" on page 2-19.

1. Power off.

Make sure the unit’s power is off.

2. Enter Diagnostic Mode.

Press softkeys 4 and 6 at the same time, and hold them down while turning the power on. See Figure 2-1 for softkey numbering.

3. Wait for the unit to initialize.

This may take several seconds. The unit is ready to proceed when the

screen cursor responds to softkey inputs.

4. Select the desired test or function.

To select a test, press the and softkeys to move up or down the

list until the desir ed te st is h ighli ghted. Then p ress the softkey to

start that test.

ENTER

5. Exit Diagnostic Mode.

To exit Diagnostic Mode, turn the unit off.

M4735A Service Manual 2-11

Page 26

The Software Su pport Tool

The Software Support Tool

The Software Support Tool (M4735-87890) allows field service personnel to

perform 2 tasks: 1) to enable the SpO

number. These tasks need to be performed under the following circumstances:

l

The Control PCA has been replaced.

The Control PCA contains all the operating software, configured

for the installed hardware. It also contains the unit’s serial numbe r,

which was programmed in during manufacturing.

The new Control PCA must be programmed to recognize the

hardware installed in this unit, and to contain that unit’s

serial number.

l

The unit has received an upgrade adding the SpO2 capability.

The added hardware will not be automatically recognized. The

Control PCA must be programmed to recognize the new hardware

installed.

option, and 2) to program in the serial

2

Using the Support Tool

1. Prepare the unit.

a. Have unit power off, and have either a fresh battery installed or the

AC power cord plugged in.

b. Insert the Support Tool data card into the unit.

c. Turn unit power on.

2. Follow the screen prompts.

a. Select whether SpO

b. Program in the unit’s serial number.

l

If this is an Sp O2 upgrade, the serial number should already be

present. In this case, verify it against the factory-applied label on

the bottom of the case.

l

If this is a Control PCA replacement, program in the serial number found on the factory-applied label on the bottom of the case

using the softkeys as i nstructe d on the screen. Be sure to program

it in accurately, as the serial number is used for all repair history

tracking.

hardware is installed or not as appropriate.

2

c. Check all the displayed information carefully before proceeding.

l

If the displayed information is correct, follow the screen prompts

to save the configuration.

2-12 Performance Verification and Safety Tests

Page 27

The Software Support Tool

l

If any of the information is incorrect, follow the prompts to NOT

save the configuration, then start over by powering the unit off,

then back on.

3. Turn off the power and remove the Data Card.

4. Check the customer configuration.

a. Turn the unit back on and enter Configuration Mode (see "Configura-

tion Mode" on page 2-10).

b. Print the configuration and check it against the printout from before

the servici ng began. Reset the configuration (or load it from a Data

Card) as needed.

5. Verify performance.

Perform Performance Verification Testing as described in "Performance

Verification and Safety Tests" starting on page 2-1.

2

M4735A Service Manual 2-13

Page 28

Performance Verification

Performance Verificatio n

This section gives instructions for running Performance Verification tests on

the M4735A. The tests are seque nced to check more basic fu nctions fi rst, and

then build on that to check more complex functions. We recommend you

perform these tests in this sequence. If desired, you can make copies of the

Test Results Matrix (page 2-4) and use it to record results.

The Performance Verification tests include:

Section Page

Visual Inspection 2-15

Functional Checks 2-16

Diagnostic Tes ts 2-19

Safety Tests 2-39

Battery Capacity Test 2-40

2-14 Performance Verification and Safety Tests

Page 29

Performance Verification

Visual Inspection

1. Inspect the unit.

Inspect the entire unit, especially paddles, power cord, printer, battery,

cables, and sensors for signs of the following.

l

Wear or damage to paddles, cables, and adapters.

l

Wear or damage to patient cables and associated strain reliefs.

l

Mechanical damage to case, membrane switches, speaker cover,

ambient light sensor cover, display window.

l

Loose or missing hardware.

l

Evidence of liquid spill. Check inside the printer bucket and

clean out any ac cumulation using glove s and an appr oved c leaner.

l

Residue on the therm al printhead.

l

Printer roller wear.

l

Wear or damage to power cord and associated strain relief.

l

Corrosion on connector pins, printer parts, or battery contacts.

2

Pass: Only normal wear, no damage serious enough to inhibit

performance. No corrosion visible.

2. Check the consumables.

Check the ECG electrodes and defibrillator pads for freshness (data code

or expiration date) and condition.

Pass: Electrodes and pads are within their expiration date and

appear usable. Packaging is unopened and shows no tears or punctures.

No corrosion visible on connector sockets, electrodes, or pads.

M4735A Service Manual 2-15

Page 30

Performance Verification

Functional Checks

The following functional checks exercise the basic functions of the defibrilla-

tor/monitor. They are intended as a broad check of the unit’s performance,

and are designed to complement (not replace) the Diagnostic Tests described

later.

If all elements of a test pass, record that test as a P A SS and re tu rn to the main

diagnostic menu by pressing . If there is any failure, begin trouble-

shooting and repairing as needed. See "Troubleshooting" on page 3-1.

The Functional Checks include:

Check Page

ECG Functional Checks 2-16

Shock Advisory Functional Check 2-17

MAIN

Synchronized Cardiovers ion Funct ional

Check

Sp02 Functional Check 2-18

2-18

ECG Functional Checks

This section describes how to check the oper ation of the ECG func tions. Each

of the ECG checks assumes the unit and the simulator are still set up as they

were at the end of the previous ECG check.

To check ECG display and Heart Rate (HR) functions:

1. Set up the simulator.

a. Connect the ECG simulator to both the Pads input and the 3- or

5-lead ECG cable.

b. Set the simula tor for normal sinus rhythm (NSR), 1mV amp litude, at

some nominal rate (e.g., 60 bpm).

2. Set up the M4735A.

Set the M4735A to Manual operating mode (not Diagnostic Mode).

3. Check the displayed ECG.

Using the softkey, verify that the display shows a normal

ECG with a clean baseline for both Pads and Lead II.

LEAD SELECT

4. Check the Heart Rate (HR).

Verify that the Heart Rate (HR) displayed is correct.

5. Check Leads Off.

a. Disconnect the ECG simulator from the pads cable and ver ify that the

display shows a das hed li ne in pla ce of the wavefo rm and t hat the u nit

both alarms and gives the Pads Off message

b. If using a 5-lead ECG cabl e, set the unit to monitor from th e V lead.

2-16 Performance Verification and Safety Tests

Page 31

Performance Verification

ANALY ZE

ANALY ZE

c. Disconnect each of the ECG leads f rom the simulator one at a time,

and verify that the display shows a dashed line in place of the waveform and that the unit both alarms and gives the

To check ECG printing functions:

6. Reconnect the simulator.

Leads Off

message.

Connect the simulator to the M4735A as described in step 1 above.

7. Print a strip.

a. Print a strip; verify that it shows a normal ECG with a clea n baseline .

b. Verify that th e date, t ime, an d configur atio n inform ation p rinte d at the

top of the strip is correc t.

Shock Advisory Functional Check

This section describes how to check the Shock Advisory function.

1. Set up the simulator.

a. Connect the ECG simulator to the pads cable.

b. Set the simula tor for normal sinus rhythm (NSR), 1mV amp litude, at

some nominal rate (e.g., 60 bpm).

2

2. Set up the M4735A.

Set the M4735A to AED Mode.

3. Check Shock Advisory with NSR.

a. Press .

b. Verify that the defibrillator responds with

4. Check Shock Advisory with Asystole.

a. Set the simula tor to Asystole (or turn the simulator off) and press

ANALY ZE

No Shock Advised

.

.

b. Verify that the defibrillator still responds with

5. Check Shock Advisory with VF.

a. Set the simulator to VF (Ventricular Fibrillation) and press

No Shock Advised

.

.

b. Verify that the defibrillator responds with Shock Advised and charges

up to 150J. If the unit is configured to do so, verify that it automatically prints a strip of the event.

WA RN I NG Do not discharge the stored energy unless you are certain the simulator contains a

50 ohm test load.

M4735A Service Manual 2-17

Page 32

Performance Verification

c. If the simulator contains a 50 ohm test load, discharge the stored

energy into th e te st load . If i t do es not , or you ar e not sure, wait until

the defibrillator reports

Shock cancelled

before proceeding.

Synchronized Cardioversion Functional Check

This section descri bes how to c heck the sy nchronize d cardiove rsion fu nction.

1. Set up the simulator and the analyzer.

a. Connect the ECG simulator to the ECG cable. Connect the defi br il la -

tor analyzer to the pads cable.

b. Set the simula tor for normal sinus rhythm (NSR), 1mV amp litude, at

some nominal rate (e.g., 60 bpm).

2. Set up the M4735A.

Set the defibrillator to Manual Mode, and press .

3. Check Cardioversion.

a. Verify that sync markers appear on the display, at the peak or on the

falling side of the QRS complex. Adjust the size of the displayed

ECG as needed to view it more clearly.

b. Select an energy of 5 J. Press then press and hold

CHARGE SHOCK

until the shock is delivered (at next QRS).

c. Verify on the defibrillator analyzer that the shock was delivered, and

was 5J ±2J.

d. If the unit is configured to do so, veri fy that it prints a strip with the

correct information on it (waveform, text).

e. Verify on the defibrillator analyzer that the delay between the peak of

the QRS and the delivered shock was <

60 msec.

Sp02 Functional Check

This check only needs to be performed if SpO2 is installed.

1. Connect the sensor.

Attach the SpO

2. Check SpO

a. Activate Manual Mode and press the SpO

b. The SpO

value is less t han 95 %, check that y our f ing er is full y in sert ed in to the

sensor and properly positioned.

transducer to your finger and connect it to the M4735A.

2

.

2

softkey to turn SpO2 on.

2

value displayed should be in the range of 95-100%. If the

2

2-18 Performance Verification and Safety Tests

Page 33

Performance Verification

Diagnostic Tests

The M4735A includes an extensive set of Diagnostic Tests, which test the

major hardware components of the defibrillator.

The Diagnostic Tests include:

Test Page

System Log 2-20

Extended Self Test 2-22

User Interface Tests 2-25

ECG Tests 2-29

Pacing Test 2-33

Defibrillator Test (AC Power At 200 J) 2-35

Defibrillator Test (Battery Power At 200 J ) 2-36

Defibrillator Disarm Test 2-38

2

M4735A Service Manual 2-19

Page 34

Performance Verification

System Log

The System Log includes the unit’s serial number, hardware configuration,

and a listing of error codes. The System Log should be printed each time a

Performance Verification Test is run.

1. Enter Diagnostic Mode.

See "Diagnostic Mode" on page 2-11.

2. Print the System Log.

a. Select

b. The printer will prin t the System Log stri p. See " Sample Sys tem Log

Print Log

and press .

ENTER

Printout" on page 2-21.

3. Check the System Log.

a. Check hardware and options.

l

Check the printout to veri fy the print ed result s are consis tent with

the hardware in place. Check options installed (SpO

, pacing)

2

and the unit’s serial number (on the bottom of the case).

l

If the printout is not c o rr ec t, i nve st igate and resolve the source of

the mismatch. Then reset t he hardwar e options and ser ial number

as needed using the Support Software Tool. See "The Software

Support Tool" on page 2-12.

b. Check for M4735A errors.

If there are device errors reported in the System Log:

l

Check the time and date stamps to see if they are recent errors or

not.

l

Consult Table 3-2 "Error Codes" on page 3-10 to identify the

errors.

l

Begin troubleshootin g as nee ded (See "Troubleshooting" on page

3-1. )

2-20 Performance Verification and Safety Tests

Page 35

Figure 2-2 Sample System Log Printout

M4735A SYSTEM LOG

Firmware Versions Error Codes

Main: 06 90007 18:33 19 MAY 2000

DSP: 02

196: 06.00

Performance Verification

Key: 01

SpO2: 02.42 01.04

Language: English

Serial Number: US01000241

Options: Pacer SpO2

Shocks: 2

2

M4735A Service Manual 2-21

Page 36

Performance Verification

Extended Self Test

The Extended Self Test checks that all internal processors are operating and

communicating with each other.

If all results are as described, the unit passes this test. Return to the main

Diagnostic Test menu by pressing .

If there is any fa ilure, be gin troubl eshootin g and repa iring th e unit as needed.

See "Troubleshooting" on page 3-1, and Table 3-6 "Extended Self Test Failures" on page 3-17.

NOTE Be sure the printer has paper and that the printer door is closed. No paper or

an open door will generate an erroneous

1. Connect the test load to the pads cable.

2. Access the Diagnostic Test menu.

See "Diagnostic Mode" on page 2-11.

3. Run the test.

MAIN

Fail

in the

Timebase

test.

Extended Self Test

Select

and press . The printout should appear

ENTER

similar to Figure 2-3.

Figure 2-3 Sample Extended Self Test Printout

M4735A EXTENDED SELF TEST 18:48 5/19/2000

RAM: Pass

ROM: Pass

System: Pass

Data Card: Not Tested

CODEC: Pass

IRDA: Not Tested

Timebase: Pass

Defib: Pass

FE: Pass

SpO2: Pass

Pacer: Pass

2-22 Performance Verification and Safety Tests

Page 37

4. Check the results.

a. Check the time and date.

l

Check the printout to verify that the time an d date are cor rect.

l

If they are not, reset them using the Configuration Mode. See

"Configuration Mode" on page 2-10.

b. Check the test results.

The results of the following tests will appear on the display and

on the printout:

l

RAM

Tests the Read Only Memory (ROM).

l

ROM

Tests the Random Access Memory (RAM).

l

System

Tests the integrity of the core processing system and checks

the Lithium backup battery.

Performance Verification

2

l

l

l

l

Data Card

The Data Card test writes a small file to the data card,

reads it back and checks it, then erases that file. If no

Data Card is present, the test result will be

Not Tested

.

CODEC

The processor turns on the CODEC (coding/decoding) chip

(used for voice prompts), and gets an acknowledgement

that it’s ready to receive data. It does not give the CODEC

actual data to process.

IRDA

Tests the infrared communications port. If no active

infrared device is within range, the test result will be

Not Tested

Timebase

The Timebase test compares the Real Time clock to the System

clock to check for discrepancies. It does not test the SpO

or the Biphasic clock.

clock

2

.

M4735A Service Manual 2-23

Page 38

Performance Verification

l

DEFIB

The Defib test charges the defibrillator capacit or and then

disarms it. It does not deliver the energy outside the unit.

The pads cable and test load must be connected for the test

to run; otherwise the test result will be

l

FE

Not Tested.

The Front End (FE) test checks that the main processor is

communicating with the Digita l Signal Proces sor (DSP), and tha t

the DSP is communicating with both ECG front ends (pads and

leads). It does not test the quality of the ECG measurement.

l

SP02

(if SpO

option installed)

2

This tests that communicati on with the SpO

PCA is working. It

2

does this by reading the software revision back from the PCA.

It does not test the quality of the SpO

l

Pacer

(if Pacing option installed)

measurement.

2

The Pacer test has the Pacer deliver current into the test box , and

measures that the current delivered was what was expected. The

pads cable and test load must be connected for the test to run;

otherwise the test result will be

Not Tested.

2-24 Performance Verification and Safety Tests

Page 39

Performance Verification

User Interface Tests

The User Interface Tests exercise the functions that interact with the user.

Each of the User Interface t ests as sumes the unit an d the simulat or are stil l set

up as they were at the end of the previous User Interface check.

If all results are as described, the unit passes that test. Return to the main

Diagnostic Test menu by pressing .

If there is any fa ilure, be gin troubl eshootin g and repa iring th e unit as needed.

See "Troubleshooting" on page 3-1 and the following specific tables:

l

Table 3-11 "Operational Problems - Printer" on page 3-25.

l

Table 3-12 "Operational Problems - Display" on page 3-26.

l

Table 3-13 "Operational Problems - Audio Tones/Voice Prompts" on

page 3-27.

l

Table 3-14 "Operational Problems - Keys" on page 3-28.

To test the Controls (keys):

1. Access the Diagnostic Test menu.

MAIN

2

See "Diagnostic Mode" on page 2-11.

2. Start the Controls Test.

Controls Test

Select

and press . The screen will display a map of

ENTER

the front panel keys.

3. Test the softkeys.

Press each of the numbered softke ys in t urn. See Fi gure 2- 1 on page 2-11

for numbering of softkey s. Each softk ey number on the display sh ould be

highlighted each time that key is pressed.

Don’t press Softkey #4 at this time. This will return you to t he

MAIN

Main diagnostic mode menu.

4. Test the ECG and Audio keys.

Test each of the ECG Size and Vo l u m e keys. See Figure 2-1 on page 2-11

for location of th ese keys.Each key should show a highlighted ("p lus ")

+

when the up arrow on the key is pressed, and show a highlighted

("minus") when the down arrow is pressed.

5. Test the printer keys.

Test each of the printer control keys (Strip, Summary, and Mark). Each

corresponding label on the display should be highlighted each time that

key is pressed.

-

6. Test the pacing keys.

Test each of the Pacing keys. The displayed labels for Pacer, Start/Stop

and Mode should be highlighted each time that key is pressed. The dis-

M4735A Service Manual 2-25

Page 40

Performance Verification

played labels for

Rate

and

Output

should show a highlighted ("plus")

+

when the up arrow on the key is pressed, and show a highlighted

("minus") when the down arrow is pressed.

7. End the test.

Press Softkey #4 to return to the Main diagnostic mode menu.

To test the display:

1. Run the Display Test.

Display Test

Select

MAIN

and press .

ENTER

The display should turn completely light, then completely dark, then a

light vertical bar should scroll across the screen from left to right.

2. Test the LEDs.

The display will show a softkey label. Press thi s s oft key and

TEST LEDs

verify that the indicators in the Main and Pacing keypads each light in

turn. The

3. End the test.

AC Power

Press Softkey #4 to return to the Main diagnostic mode menu.

and

MAIN

Batt Charge

LEDs will not

light as part of this test.

-

To test the audio output:

1. Start the Audio Test.

Audio Test

Select

and press . The screen will d isp lay t he

ENTER

menu.

2. Select and run the desired test.

a. Press the and softkeys to move up or down the list to select

the desired test. Then press to begin that test.

Check the

Shutdown Warning

ENTER

and the

Voice Prompt

; the

other responses are given for reference. The results should

be as described below.

Press to end that test and return to the main

CANCEL

audio test menu.

l

Message Alert - A repeating series of 3 short tones, followed by a

pause.

l

Heart Rate Alarm - 1 sustained tone of moderately high pitch.

l

Charge Done Tone - 1 sustained tone of lower pitch than the Heart

Rate Alarm.

l

Auto Disarm Warning - A repeating series of 1 short tone and a

pause.

Audio Test

2-26 Performance Verification and Safety Tests

Page 41

l

CANCEL

Shutdown Warning

high/low pitch.

l

Voice Prompt

3. End the test.

Performance Verification

- A repeating series of tones of alternating

- Voice should be clear and understandable.

Press Softkey #4 to return to the Main diagnostic mode menu.

MAIN

To test the printer:

1. Start the Printer Test.

a. Select

2. Check the pri nt quality.

a. Verify that the test pa tterns on the strip are as indicated in

Printer Test

and press .

ENTER

Figure 2-4.

b. Check for white lines (printhead elements stuck off) or black lines

(printhead elements stuck on).

c. Check area "A" for stray ma rks or lines.

d. The area of Figure 2 -4 la beled "C" co ntain s pri ntouts of al l cha racte rs

and symbols. Verify that they are readable.

3. Stop the printout.

Press to end the test and return to the main Diagnostic Test

menu.

2

4. Verify the print speed.

Measure between the long tick marks (B in Figure 2-4) to verify paper

speed. Distance should be 25mm ± 5% (±1.25 mm).

5. Check the printer status detection.

a. Open the printer door and press the

Strip

key. The unit should sound

a series of 3 tones indicating a printer problem.

b. Take out the paper, close the door, and press the Strip key. The unit

should sound a series of 3 tones indicating a printer problem.

M4735A Service Manual 2-27

Page 42

Performance Verification

Diagonal lines

Vertical bars

Diamonds

Figure 2-4 Printer Test Output

2-28 Performance Verification and Safety Tests

Page 43

Performance Verification

ECG Tests

These instructions describe how to test the ECG functions.

Each of the ECG tests assumes the unit and the simulator are still set up as

they were at the end of the previous ECG test.

If all results are as desc ribed, the unit p asses that portion of the test. Return to

the main Diagnostic Test menu by pressing .

If there is any fa ilure, be gin troubl eshootin g and repa iring th e unit as needed.

See "Troubleshooting" on page 3-1 and Table 3-7 "Operational Problems ECG Monitoring (Pads or Leads)" on page 3-18.

1. Start the test.

a. Access the Diagnostic Test menu as described in "Diagnostic Mode"

on page 2-11.

MAIN

2

b. Select

c. The display should look similar to Figure 2-5:

Figure 2-5 ECG Test Display

ECG Test

and press .

ENTER

MAIN ENTER

ECG TEST

Selected Lead: Lead I

AC Line Filter: 60 Hz On

Leads FE Status: Good

Pads FE Status: Good

DSP Status: Good

DC Offset: xxxx

Pea k to Peak:

Diagnostic: 1050

Monitor: 1090

PCI: 51 Off

2.

Check the se ttings.

a. AC Line Filter

The AC Line Filter should be set to the correct frequency

for your area.

If the setting is incorrect, access the Configuration Mode and correct

it. See "Configuration Mode" on page 2-10.

M4735A Service Manual 2-29

Page 44

Performance Verification

b. Selected Lead

This setting does not matter at this point. It will be changed later.

3. Change the settings as needed.

a. To temporarily change the settings of

Selected lead

AC Line filter

or

,

press the and softkeys to highlight the parameter, then press

(and release) to select it.

NOTE The available choices for Selected Lead will depend on whether the unit is

ENTER

configured for 3-lead or 5-lead ECG monitoring.

b. After a few seconds the highlighted selection will begin to blink, and

the and softkeys will allow you change the selection to

another of the values available. When the value you want is dis-

played, press to set that value.

NOTE These changes are onl y tempo rary, and will not overr ide the c onfigu rati on set

ENTER

in Configuration Mode.

4. Check the ECG Status messages.

The 3 status messages (

The

Leads FE

test checks that communication is working between

l

Lead FE, Pad FE, DSP

) should all be

GOOD

.

the Leads Front End ( FE) and the Digital Signal Processor (DSP) .

The

Pads FE

test checks that communication is working between

l

the Pads FE and the DSP.

The

DSP

test checks that communication is working between the

l

DSP and the re st of the monitor.

5. DC Offset.

This test is for manufacturing use only and should be ignored.

6. Test the ECG amplifier.

These tests measure both the gain and the noise of the two ECG amplifiers (Leads and Pads). Both use the Peak to Peak reading.

The Peak to Peak reading measures the peak to peak amplitude of the sig-

nal appearing on the selected ECG input. If the simulator’s calibrated

output is 1.0 mV, then the Peak to Peak reading should be 1000 ± 10%

(±100) for both Monitor and Diagnostic. If the simulator output is cali-

brated to some other value, the displayed value should be (1000 x simulator output) ±10%.

NOTE The diagnostic frequency response is only available when using the ECG

Leads input. When the unit is set to Pads, the display will indicate dashes

(-----) for the Diagnostic Peak-to Peak value.

2-30 Performance Verification and Safety Tests

Page 45

Performance Verification

a. Perform the ampl ifier gain test:

1. Connect the ECG simulator to the pads cable. Set the simulator

output for sine wave, 2 Hz or 10 Hz, 1 mV peak-to-peak.

2. Following the instructions under Step 3 on page 2-30 for chang-

ing settings, set

Selected lead

to

Pads

. Only the

Monitor

frequency

response will be available.

3. Wait for the displayed value under

4. The displayed value should be 1000 ±10% (± 100). Record t his as

Monitor

to stabilize.

"aaaa".

5. Connect the ECG simulator to the ECG leads cable.

6. Following the instructions under Step 3 on page 2-30 for chang-

ing settings, set

7. Wait for the displayed value under

8. The displayed value should be 1000 ±10% (± 100). Record t his as

Selected lead

to

Lead II

Diagnostic

.

to stabilize.

"bbbb".

b. Perform the ampl ifier noise test:

1. Turn the simul ator of f. Leave it conn ected t o the ECG cable, and

Selected lead

leave

2. Wait for the displayed value under

3. The displayed value should be 0 ± 30 uV. Record this as "cc".

set to

Lead II

.

Diagnostic

to stabilize.

If the unit exhibi ts more th an 30 uV of noise, try repositi oning the

cable or unit to minimize external interference. Also try various

combinations of having the ECG simulator turned on or off, and

(if applicable) whether the simulator is plugged into the AC

mains. Refer to C hapter 7 for more information about reducing

electromagnetic int er fe rence.

2

4. Following the instructions under Step 3 on page 2-30 for chang-

ing settings, set Selected lead to Pads.

5. Connect the simulator to the pads cable.

6. Wait for the displayed value under Monitor to stabiliz e.

7. The displayed value should be 0 ± 30 uV. Record this as "dd".

M4735A Service Manual 2-31

Page 46

Performance Verification

7. Test the PCI function.

This test checks the PCI (Patient Contact Indicator) function. The PCI

measurement is used to detect Pads Off and Paddles Off, and to light the

Patient Contact Indicator LEDs on PCI-equipped paddle sets. It is an

approximate measurement only - the impedance value used to adjust the

defibrillation wave for m is a se par at e meas ure me nt , made dur ing del ive ry

of the shock. See "Theory of Operation" beginning on page 6-1 for more

details.

a. Connect a set of external paddles to the M4735A.

b. If the PCI setting is

On

, turn it

Off

now by pressing the Volume Up and

Down arrow keys simultaneously. (See Figure 2-1 on page 2-11.)

c. Remove the paddles fr om their hold ers and hold them firmly togeth er ,