Page 1

FILING INSTRUCTIONS

File this document in the binder

− RAD: BuckyDiagnost SYSTEM MANUAL

− − URF: DuoDiagnost SYSTEM MANUAL

URF: OmniDiagnost SYSTEM MANUAL

SERVICE MANUAL

NICOL Beam Limiting Device

NICOL ... V2 Collimator

9896 010 22…

746 NICOL ... V2 Collimator - 9896 010 22…

9896 010 22… (04.0) 0.5

Copyright 2004 Philips Medical Systems Nederland B.V.

ALL RIGHTS RESERVED

Page 2

SERVICE MANUAL

NICOL X-Ray Beam Limiting Device

9896 010 2216.

9896 010 2217.

9896 010 2223.

9896 010 2224.

For serial numbers, see list of pages and drawings.

Copyright 2004 Philips Medical Systems Nederland B.V.

All rights are reserved. Reproduction in whole or in part is prohibited without the written consent of the copyright owner

Use of the information contained herein in any form and / or by any means whatsoever is strictly reserved for Philips and its licenses.

Use of this manual by unauthorized persons is strictly prohibited.

Printed in The Netherlands (04.0) 1

PMSN Best

Page 3

X-Ray Beam Limting Device

SERVICE MANUAL - UNIT: NICOL X-Ray Beam Limiting Device

SYSTEM:

TYPE NO:.

9896 010 2216. NICOL RAD V2 Collimator

9896 010 2217. NICOL DuoD V2

Collimator

9896 010 2223. NICOL DuoD+iris V2 Collimator

9896 010 2224. NICOL OmniD V2 Collimator

Manual Code Number 4522 981 03586 Date: 17-03-2004

LIST OF PAGES and DRAWINGS

0.5 (04.0)

1 (04.0)

2

3 (04.0)

4

5 (04.0)

6 (04.0)

7 (04.0)

8 (04.0)

9 (04.0)

10 (04.0)

11 (04.0)

12 (04.0)

13 (04.0)

14 (04.0)

15 (04.0)

16 (04.0)

17 (04.0)

18 (04.0)

19 (04.0)

20 (04.0)

21 (04.0)

22 (04.0)

23 (04.0)

24 (04.0)

25 (04.0)

26 (04.0)

27 (04.0)

28 (04.0)

29 (04.0)

30 (04.0)

31 (04.0)

32 (04.0)

33 (04.0)

34 (04.0)

35 (04.0)

36 (04.0)

37 (04.0)

38 (04.0)

39 (04.0)

40 (04.0)

41 (04.0)

42 (04.0)

43 (04.0)

44 (04.0)

45 (04.0)

46 (04.0)

47 (04.0)

48 (04.0)

49 (04.0)

50 (04.0)

51 (04.0)

52 (04.0)

Z1-1 (03.0)

Z1-2 (03.0)

Z2-1 (03.0)

Z3-1 (03.0)

Z3-2 (03.0)

Z3-3 (03.0)

Z3-5 (03.0)

(04.0) 3

9896 010

2216.

2217.

2223.

2224.

Copyright 2004 Philips Medical systems Nederland B.V.

ALLRIGHTS RESERVED

Page 4

Contents NICOL X-Ray Beam Limiting Device

Contents

1

INTRODUCTION AND TECHNICAL DATA..........................................................................................7

1.1 Introduction ...........................................................................................................................................7

1.2 Options..................................................................................................................................................7

1.3 Versions................................................................................................................................................8

1.4 Equipment Identification and Labelling..................................................................................................8

1.5 Tools .....................................................................................................................................................8

1.6 Technical Data......................................................................................................................................9

1.6.1 Compatibility......................................................................................................................................9

1.6.2 Mechanical Data..............................................................................................................................10

1.6.3 Electrical Data .................................................................................................................................10

1.6.4 Software Data..................................................................................................................................11

1.6.5 Environmental Conditions for Transport and Storage ......................................................................11

1.6.6 Performance Data ...........................................................................................................................12

1.7 Compliance information ......................................................................................................................13

1.8 Conditions of Acceptability ..................................................................................................................14

1.9 Abbreviations and definitions ..............................................................................................................14

1.10 Manual history .................................................................................................................................15

2

INSTALLATION..................................................................................................................................16

2.1 Introduction .........................................................................................................................................16

2.1.1 Tools & Test Equipment ..................................................................................................................16

2.1.2 Supplied Items.................................................................................................................................16

2.2 Installation instructions........................................................................................................................16

2.2.1 Mounting the coupling flange assembly Nicol V2.............................................................................17

2.2.2 Mounting the coupling flange assembly...........................................................................................18

2.2.3 Centering the BLD with respect to the X-Ray tube...........................................................................18

2.2.4 Mounting the BLD on the X-Ray tube housing.................................................................................19

2.2.5 Electrical installation........................................................................................................................20

2.2.6 Checking the alignment of the light field and the X-Ray field ...........................................................22

2.3 Options................................................................................................................................................22

2.3.1 Installation AEP-meter.....................................................................................................................22

3

FAULT FINDING.................................................................................................................................23

3.1 Introduction .........................................................................................................................................23

3.2 Faultfind Strategy................................................................................................................................24

3.3 Indicators ............................................................................................................................................24

3.3.1 LA2: Power Supply Converter CAN interface (PSC_CAN) ..............................................................24

3.3.2 LA3: Shutter Iris Filter Light Controller (SIFLCO).............................................................................25

3.3.3 Measuring Points.............................................................................................................................26

3.3.4 Miscellaneous..................................................................................................................................26

4

REPLACEMENTS ..............................................................................................................................28

4.1 General ...............................................................................................................................................28

4.2 Replace (complete) BLD on the stand.................................................................................................28

4.3 Replace Aesthetic Cover.....................................................................................................................28

(04.0) 5

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 5

NICOL X-Ray Beam Limiting Device Contents

Replace Field Indication Plate.............................................................................................................28

4.4

4.5 Replace DSC Buttons .........................................................................................................................29

4.6 Replace DSC assembly ......................................................................................................................29

4.7 Replace LA2: PSC_CAN.....................................................................................................................31

4.8 Replace LA3: SIFLCO.........................................................................................................................32

4.8.1 Replace PROM LA3D17..................................................................................................................32

4.9 Replace Electronic Ruler.....................................................................................................................33

4.9.1 Connection electronic ruler..............................................................................................................34

4.10 Replace Mechanical Ruler...............................................................................................................35

4.11 Replace Lamp .................................................................................................................................36

4.12 Replace Micro-switch ......................................................................................................................37

4.13 Replace Micro-switch including Bracket...........................................................................................37

4.14 Replace Fan ....................................................................................................................................38

5

PROGRAMMING................................................................................................................................39

5.1 Introduction .........................................................................................................................................39

5.2 Hardware Programming ......................................................................................................................39

5.2.1 LA1: Backpanel ...............................................................................................................................39

5.2.2 LA2: Power Supply Converter & CAN Interface Board (PSC_CAN) ................................................39

5.3 Software Programming .......................................................................................................................39

6 ADJUSTMENTS .................................................................................................................................40

6.1 Centering the BLD with the X-Ray Tube .............................................................................................40

6.1.1 Introduction......................................................................................................................................40

6.1.2 Tools Required ................................................................................................................................40

6.1.3 Mounting the BLD Alignment Tool ...................................................................................................40

6.1.4 Checking the centering for PEI 9896 010 2216. ..............................................................................40

6.1.5 Adjusting the centring......................................................................................................................41

6.1.6 Checking the Centering for PEI’s 9896 010 2217., 9896 010 2223. and 9896 010 2224.................43

6.2 Field Indication Plate with Crossed-lines.............................................................................................44

6.3 X-Ray Field to Light Field....................................................................................................................45

6.3.1 Light Field Size Adjustment .............................................................................................................45

6.3.2 Lamp Adjustment After Replacing Lamp..........................................................................................45

6.3.3 Light Field Adjustment After Replacing Lamp ..................................................................................46

6.4 Electrical Adjustment...........................................................................................................................47

6.5 Software Adjustments .........................................................................................................................47

7

LIST OF FIGURES AND DRAWINGS................................................................................................48

P. PARTS LIST.......................................................................................................................................51

Z. DRAWINGS........................................................................................................................................52

6 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 6

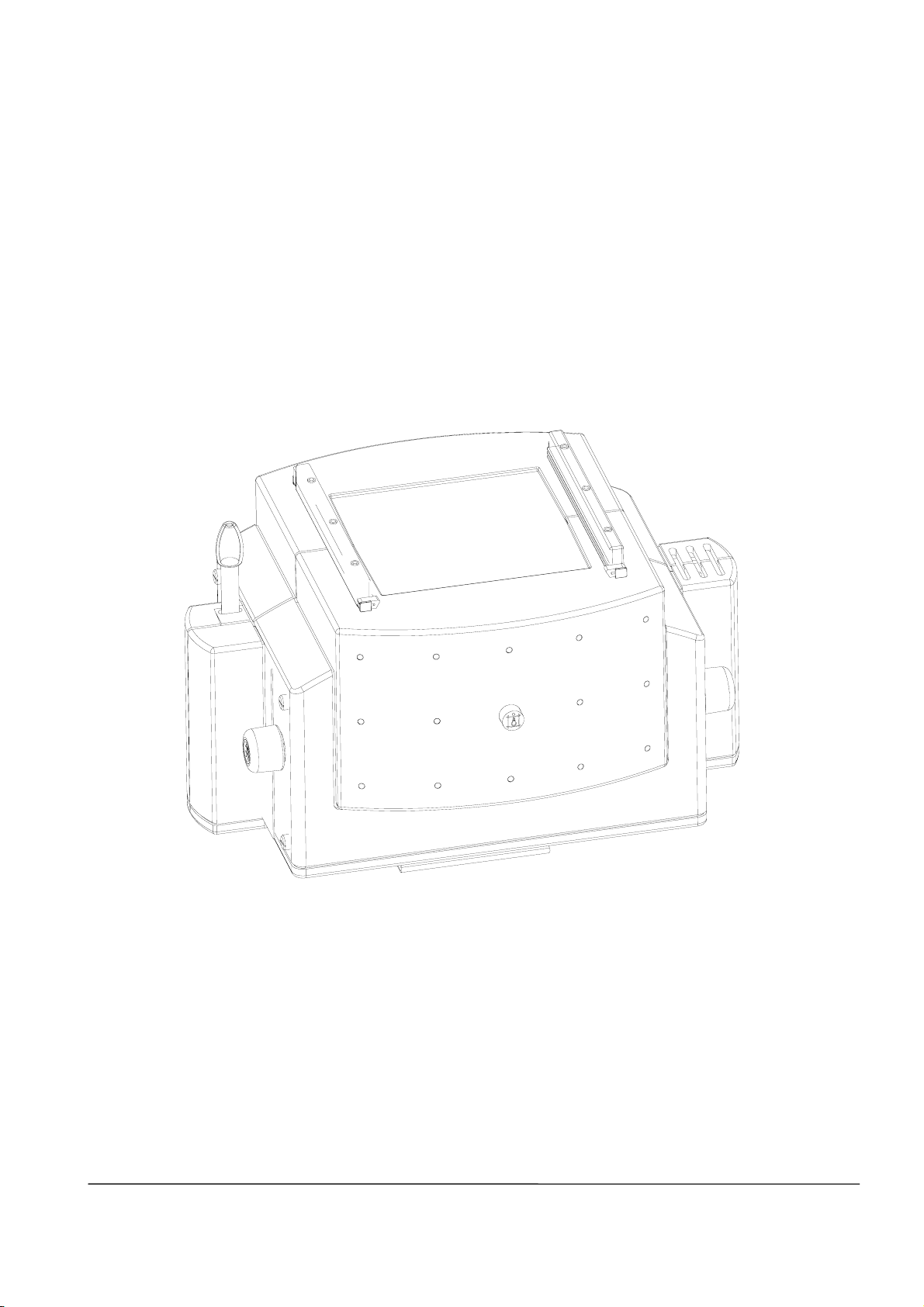

NICOL X-Ray Beam Limiting Device Introduction and Technical Data

1 INTRODUCTION AND TECHNICAL DATA

1.1 INTRODUCTION

This X-Ray Beam Limiting Device (BLD) is suitable for:

• RAD application 9896 010 2216. successor of 9896 010 22001

• RF applications with light and ruler 9896 010 2217. successor of 9896 010 22011

• RF applications as above plus filter and iris 9896 010 2223. successor of 9896 010 22091

• RF applications 9896 010 2224. successor of 9896 010 22101

The BLD, contains the following functions:

• Rectangular collimation, using rectangular shutters (main-, backup- and near focus shutters)

• Non rectangular collimation, using rectangular and iris shutters (iris on 9896 010 2223. and

9896 010 2224. only)

• Remotely controlled spectral filter (except for 9896 010 2217.)

• Light source (including field indication plate with crossed lines, fan and light ON button) for

simulating the X-Ray Field

• Electronic Ruler (9896 010 2216.) for automatic measuring the Source Image distance

• Mechanical Ruler (9896 010 2217. and 9896 010 2223. and 9896 010 2224.) for manually

measuring the Source Image distance

• Swivel range -45° to +45°, with lock position at 0°Manual control of rectangular shutters (DSC),

by means of 2 continuously rotatable buttons

• Accessory Rails

• Aesthetic cover

• Plug & Play interface to X-ray tube assembly (see chapter 1.6.1 Compatibility page 9)

1.2 OPTIONS

Possible options for this BLD are:

• 9896 010 22071 transparent AEP-meter

• 4522 300 2417x NICOL DISC

• 4522 300 2418x NICOL P&P DISC

downgrade to conventional interface to X-ray tube assemblies

for upgrading of Nicol to X-ray tube assemblies with P&P interface

1

1

1

see chapter 1.6.1 Compatibility page 9

(04.0) 7

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 7

Introduction and Technical Data NICOL X-Ray Beam Limiting Device

ERSIONS

1.3 V

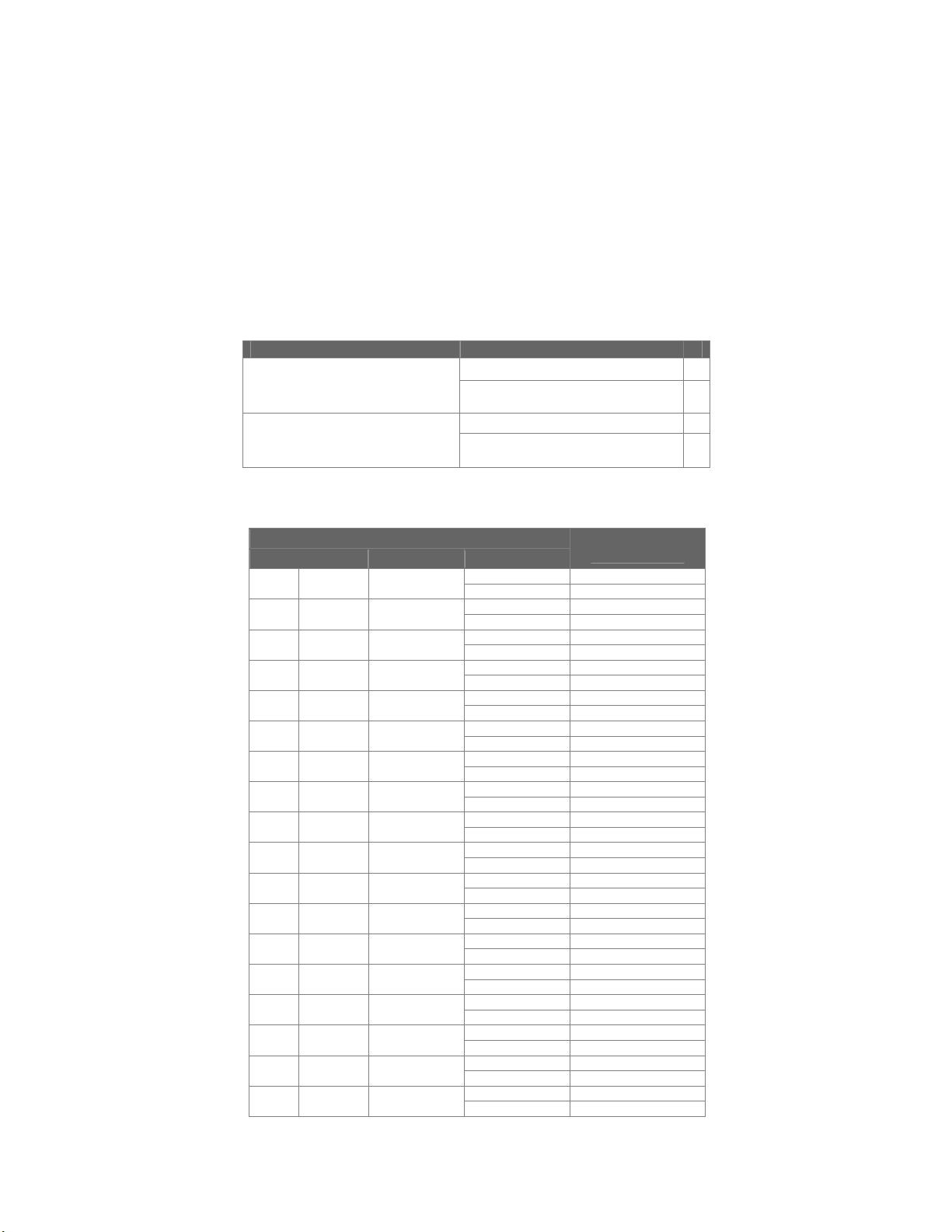

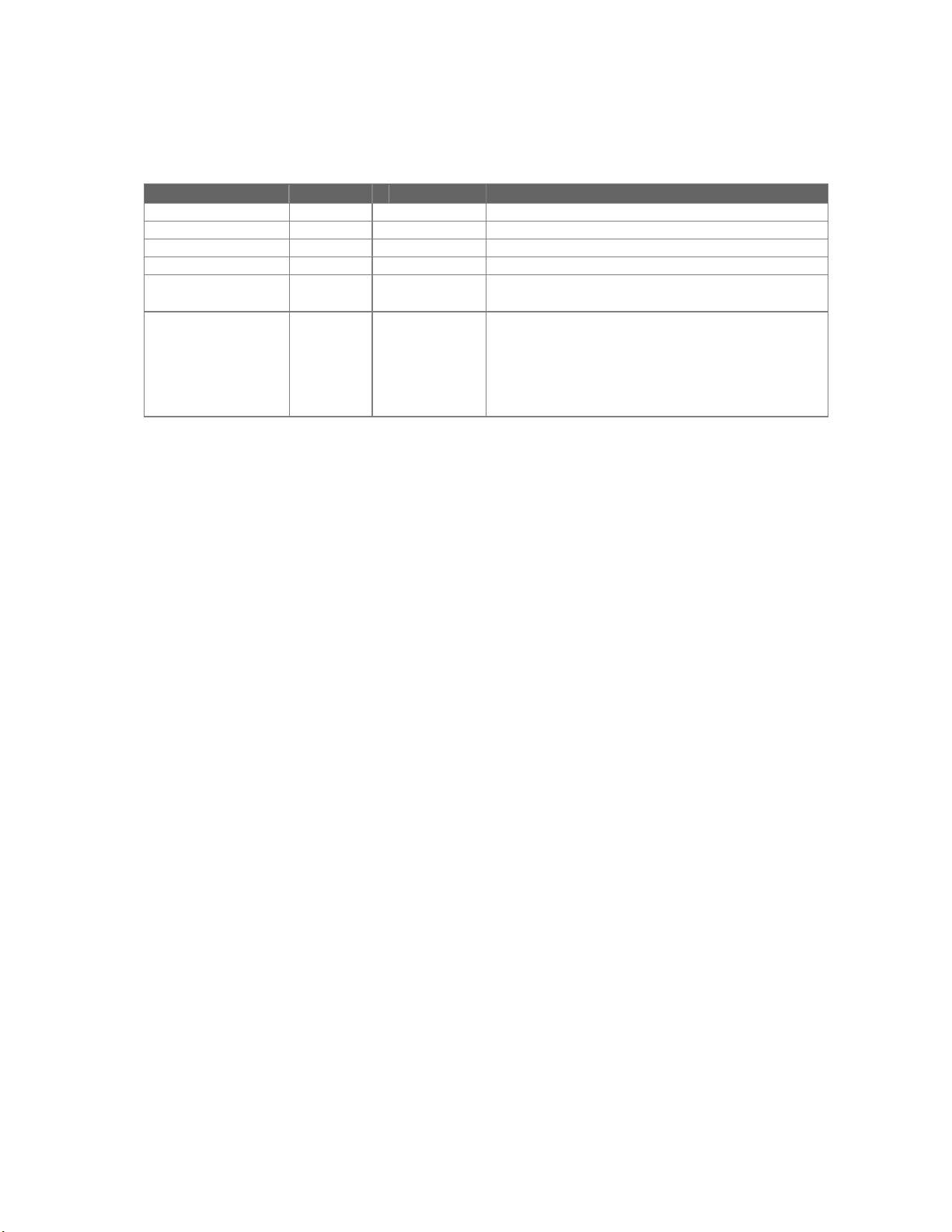

Table 1: Version survey

Functions

Rectangular collimation

Non rectangular collimation - DSC buttons

Remote Controlled Spectral Filter

Light/Light-button + fan + Field Indication Plate

Electronic Ruler

Mechanical Ruler Swivel

Accessory rail

Aesthetic cover

Option: AEP-meter transparent

9896 010

2216.

5

5 5 5 5

5

5 5 5 5

5

5 5 5 5

5

5

5

9896 010

2217.

5

-

- - -

5 5 5

5

5

5

9896 010

2223.

5

5 5

5 5

5

5

5

9896 010

2224.

5

5

5

5

1.4 EQUIPMENT IDENTIFICATION AND LABELLING

The BLD identification labels are located at the rear of the BLD, see item 1, Figure 31, page 49.

1.5 TOOLS

For software tools see the applicable system reference manual. For hardware tools, see chapter 2.1.1,

Tools & Test Equipment, page 16.

8 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 8

NICOL X-Ray Beam Limiting Device Introduction and Technical Data

ECHNICAL DATA

1.6 T

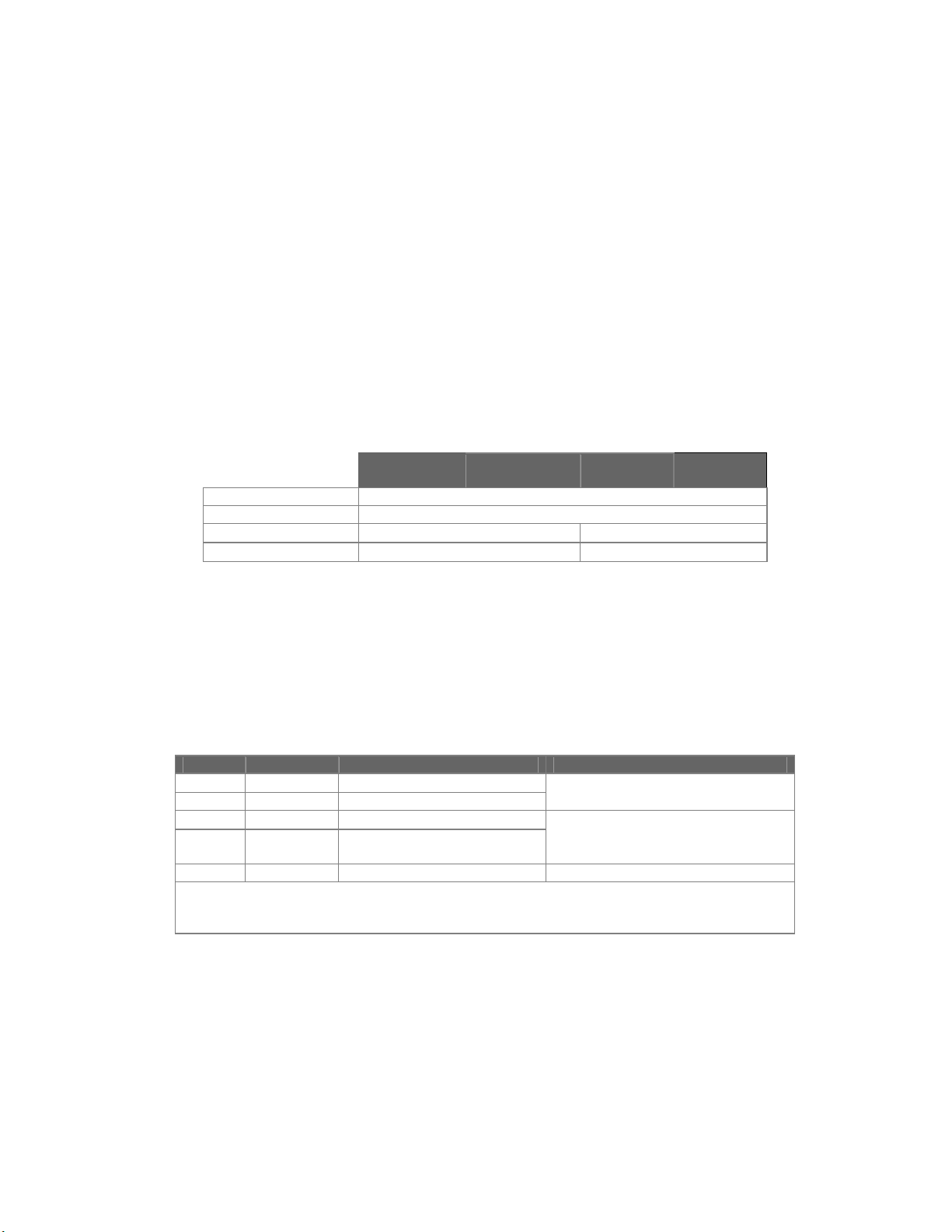

1.6.1 COMPATIBILITY

The BLD is compatible with:

X-Ray tube assemblies indicated in Table 3 in combination with NICOL Beam Limiting Devices as

configured in

• Table 2.

Table 2: Nicol configurations

Nicol Configurations With service kit

Nicol RAD 9896 010 22001

Nicol DuoD 9896 010 22011

Nicol DuoD+iris 9896 010 22091

Nicol OmniD 9896 010 22101

Nicol RAD V2 9896 010 2216.

Nicol DuoD V2 9896 010 2217.

Nicol DuoD+iris V2 9896 010 2223.

Nicol OmniD V2 9896 010 2224.

Table 3: Compatibility Overview

None A

NICOL P&P DISC 4522 300 2418x

None

NICOL DISC 4522 300 2417x

B

C

D

X-ray tube assembly

Tube Housing 12nc

MRC 200 0310 ROT-GS 1004

MRC 200 0407 ROT-GS 1004

MRC 200 0508 ROT-GS 1003

MRC 200 0508 ROT 1003

MRM 0410 ROT-GS 2502

MRM 0508 ROT-GS 2502

SRM 0608 ROT-GS 505

SRM 0511 ROT-GS 501

SRM 0612 ROT 501

SRO 33100 ROT 351

SRO 33100 ROT 350

SRM 2250 ROT-GS 500

SRM 2250 ROT-GS 504

SRM 0612 ROT 504

SRO 2550 ROT 350

SRO 0951 ROT 350

RO 1648 ROT 350

RO 1750 ROT 350

NICOL

configuration

9890 000 85091 A, D

9890 000 85092

9890 000 85101

9890 000 85102

9890 000 85141 A, D

9890 000 85142

9890 000 85131

9890 000 85132

9890 000 63271 A, D

9890 000 63272

9890 000 63261

9890 000 63262 B, C

9890 000 85181 A, D

9890 000 85182

9890 000 03821

9890 000 03822 B, C

9890 000 63911

9890 000 63912

9874 006 23112

9890 000 85851 B, C

9874 005 16122

9890 000 85841

9890 000 03841

9890 000 03842 B, C

9890 000 63841

9890 000 63842

9890 000 85001

9890 000 85002 B, C

9874 004 23122

9890 000 85831

9890 000 63181

9890 000 63182 B, C

9890 000 85301

9890 000 85302

9890 000 85281

9890 000 85282 B, C

B, C

A, D

B, C

B, C

A, D

B, C

B, C

A, D

B, C

A, D

A, D

B, C

A, D

A, D

B, C

A, D

A, D

B, C

A, D

A, D

B, C

A, D

A, D

B, C

A, D

(04.0) 9

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 9

Introduction and Technical Data NICOL X-Ray Beam Limiting Device

• Bucky Diagnost TH and Digital Diagnost for 9896 010 2216.

• Duo Diagnost for 9896 010 2217. and 9896 010 2223.

• Omni Diagnost Eleva for 9896 010 2224.

• CAN-CMS CIA (ISO-CAN 2a) standard

NOTE

The compatibility list is subject to change without notice!

________________

1.6.2 MECHANICAL DATA

• tube housing interface : standard BLD coupling flange

• BLD coupling flange -focus distance : 64mm

• Dimensions and Weight : see Table 4

Table 4: Dimensions and weight

9896 010

2216.

9896 010

2217.

9896 010

2223.

9896 010

Dimensions (lxwxh) 38.2 x 28.2 x22.4 [cm3]

Packing dimensions 52 x 42 x 35 [cm3]

Net weight

Gross weight

± 130N ± 140N

± 160N ± 170N

1.6.3 ELECTRICAL DATA

• Power Supply interface : LA2X2 (see Table 5: Power Supply Interface)

Control interface : LA2X1/LA2X11 (see Table 6: CAN Interface)

•

protective earth interface : LAX100

•

Table 5: Power Supply Interface

LA2X2 Mnemonic Description Specification

1 +24V +24V

2 0V24 0V of +24V 1.5A

3 +12V +12V

4 0V12 0V of +12V 8.3A

SH Shield connected to housing

Connector-type: 4p. Mate-N-Lock

24V DC ± 20%

12.0V DC ± 0.1V

100W

2224.

10 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 10

NICOL X-Ray Beam Limiting Device Introduction and Technical Data

Table 6: CAN Interface

LA2X1

LA2X11

Mnemonic Description

1 - reserved

2 CAN-L CAN-L bus line (dominant low)

3 0VCAN 0V of CAN supply voltage

4 - reserved

5 - reserved

6 0VCAN 0V of CAN supply voltage

7 CAN-H CAN-H bus line (dominant high)

8 RSTCAN Reset-line CAN

9 +12VCAN +12V CAN supply voltage

(I

= 150mA, I

max

= 30mA)

typ

SH Shield

connector-type: LA2X1 shielded 9-pole miniature sub-D connector male

LA2X11 shielded 9-pole miniature sub-D connector female

NOTE

The electrical cables are NOT included in the delivery

________________

1.6.4 SOFTWARE DATA

The SW is located on a single PROM, see Table 7:

Item code number contains code number Location

NICOL RAD V2 9896 010 2216. 1 prom NICOL R1.3.1 4522 166 10705 LA3D17 see Z3-3

NICOL DuoD V2 9896 010 2217. 1 prom NICOL R1.3.1 4522 166 10705 LA3D17 see Z3-3

NICOL DuoD+iris V2 9896 010 2223. 1 prom NICOL R1.3.1 4522 166 10705 LA3D17 see Z3-3

NICOL OmniD V2 9896 010 2224. 1 prom NICOL R1.3.1 4522 166 10705 LA3D17 see Z3-3

Table 7: SW overview

NOTE

The SW release is subject to changes without notification!

________________

1.6.5 E

NVIRONMENTAL CONDITIONS FOR TRANSPORT AND STORAGE

• Ambient temperature range : -25 - +70 °C

• Relative humidity : 5 - 95 %

• Atmospheric pressure range : 70 - 110 kPa

(04.0) 11

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 11

Introduction and Technical Data NICOL X-Ray Beam Limiting Device

1.6.6 P

ERFORMANCE DATA

Rectangular shutters

• two pairs of independent, symmetrically moving main shutters, 3mm thick lead (mechanically

coupled to backup shutters and near focus shutters)

• max. aperture : 2 x 14.4° (image receptor area 510mm at SID=100cm)

minimum field size : < 2 x 2 mm (at SID=100cm)

•

Iris

• 4 circular shaped iris segments, lead 3mm thick, in combination with the rectangular shutters

• max iris segment aperture : 18.8° (image receptor area 680mm at SID=100cm)

• max circular aperture : 14.4° (image receptor area 510mm at SID=100cm)

• minimum field size : 90mm (at SID=100cm)

Spectral Filter

• Remote controlled, discontinuous rotatable filter disk, containing four selectable filter positions.

For filter material and thickness, see Table 8: Filter material/position assignment.

• Filter switch time : < 350 ms (for adjacent filters)

< 700 ms (full range)

Table 8: Filter material/position assignment

9896 010 2216.

9896 010 2224.

9896 010 2223.

material Aleq

Filter

position

9896 010

2217.

material Aleq

@75kV

Position 0 no filter - no filter Position 1 1 mm Al + 0.1 mm Cu 4.0 mm 1 mm Al + 0.1 mm Cu 4.0 mm

Position 2 1 mm Al + 0.2 mm Cu 6.5 mm 1 mm Al + 0.2 mm Cu 6.5 mm

Position 3

No filter(s)

2 mm Al 2.0 mm 1 mm Al + 0.3 mm Cu 11.0 mm

Light

• Light source : 12V/100W halogen lamp

• Light intensity : > 193 lux (at SID=100 cm)

• X-Ray/Light Field accuracy : < 2% of SID in two directions

(including all X-Ray tube assembly tolerances)

< 2.5 mm (at SID = 100 cm for BLD only)

• Contrast ratio : > 4

• Maximum duty cycle : 80%, max. on time 8 min.

• Lamp on period : 5 - 60 s (SW programmable, accuracy ±0.1s)

• Lamp switch off

2

temp. : 75°C

Ruler

• Range : 30 - 205 cm

• Accuracy : 1.4 cm (at SID=70 cm)

: 4 cm (at SID=205 cm)

• Resolution : 1 mm

@75kV

2

When the BLD has reached a temperature of 75°C, the lamp is switched off automatically (SW-

controlled). It is no longer possible to switch on the lamp, until the temperature is <75°C.

12 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 12

NICOL X-Ray Beam Limiting Device Introduction and Technical Data

Swivel

• Range : +/- 45°

• Accuracy : 0.1° at 0° lock position

General

• Leakage radiation : <43 cGy/hr (or < 50 mR/hr) at 100cm.

• Inherent filtration : 0.22m Al equivalent @ 75kV (spectral filter NOT included)

• Max. X-Ray tube voltage : 150 kV

• Max. X-Ray tube power : 500W (for 9896 010 2216., for any filter)

350W (for 9896 010 2217., 9896 010 2223.

and 9896 010 2224., any filter)

• Cold reset/warm reset : <30 s/<5 s

1.7 COMPLIANCE INFORMATION

Philips products comply with relevant international and national standards and laws. Information on

compliance will be supplied on request by your local PMS representative, or by:

Philips Medical Systems

PO Box 10.000

5680 DA Best

The Netherlands

Facsimile: +31 40 276 2205

Philips products comply with relevant international and national law and standards on EMC (ElectroMagnetic Compatibility) for this type of equipment when used as intended.

Such laws and standards define both the permissible electromagnetic emission levels from equipment

and its required immunity to electromagnetic interference from external sources.

• IEC 60601-1 "Medical electrical equipment. Part 1: General requirements for safety" (second edition 1988, including

amendment nr. 1 (1991), amendment nr. 2 (1995))

• IEC 60601-1-2 "Medical electrical equipment. Part 1: General requirements for safety. 2. Collateral Standard:

Electromagnetic compatibility - Requirements and tests" (second edition, 2001)

• IEC 60601-1-3 "Medical electrical equipment. Part 1: General requirements for safety. 3. Collateral Standard: General

requirements for radiation protection in diagnostic X-ray equipment" (first edition, 1994-07)

• IEC 60601-1-4 "Medical electrical equipment. Part 1: General requirements for safety. 4. Collateral Standard:

Programmable electrical medical systems" (first edition, 1996-05)

• UL 2601-1 "Medical electrical equipment, Part 1: General requirements for safety" (second edition, October 1997)

• CAN/CSA -C22.2 No. 601.1-M90 "Medical Electrical Equipment. Part 1: General requirements for safety" (November

1990, including Supplement C22.2 No. 601.1S1-94 and Amendment nr. 2 (1998))

• 21CFR, Subchapter J

•

IEC 60601-2-28 "Medical electrical equipment. Part 2: Particular requirements for the safety of X-ray source assemblies

and X-ray tube assemblies for medical diagnosis" (first edition, 03-1993)

(04.0) 13

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 13

Introduction and Technical Data NICOL X-Ray Beam Limiting Device

ONDITIONS OF ACCEPTABILITY

1.8 C

The BLD is compatible with:

• X-ray tube assemblies, which meet the requirements as specified in the table below.

Leakage Radiation

≤ 0.43 mGy/h (≤ 50mR/h)

at conditions 150kV, 3mA and 100cm

distance.

Values of loading factors concerning leakage radiation

For RAD

<500 µSv/h

at conditions 150kV, 500W, 12000

mAs/h, 100cm distance.

For DuoD/DuoD+iris/OmniD <500 µSv/h

at conditions 150kV, 350W, 8400

mAs/h, 100cm distance

Inherent Filtration

≥2.5 mm Aleq

at conditions 150kV, 3mA

Distance Focus - Coupling Flange Interface Plane

64mm ± 2mm

• X-ray systems, which meet the requirements as specified in the table below.

Misalignment of the edges of the of visually defined Field with

≤ 1% of SID

the respective edges of the X-ray Field along either the length

or the width of the visually defined field.

Alignment of the centre of the radiographic X-ray Field with the

≤ 1.5% of SID

center of the image receptor

1.9 ABBREVIATIONS AND DEFINITIONS

Abbreviation Explanation

AEP Area Exposure Product

Aleq Aluminum equivalency

BLD Beam Limiting Device

DuoD Duo Diagnost

FRU Field Replaceable Unit

FSE Field Service Engineer

OmniD Omni Diagnost

PMS Philips Medical Systems

P&P Plug & Play

RAD Radiography

RF Radiography / Fluoroscopy

SID Source Image Distance

V2 Version 2

Protective Earth (ground)

14 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 14

NICOL X-Ray Beam Limiting Device Introduction and Technical Data

1.10 M

ANUAL HISTORY

Original Text : English

Date Version Name Reason of changes

19th June 1999 99.0 P.W.M. Sijbers First Version

9th September 1999 99.1 P.W.M. Sijbers

31st August 2000 00.0 P.W.M. Sijbers

31st October 2001 01.0 P.W.M. Sijbers

3rd December 2003 03.0 P.W.M. Sijbers

17th March 2004 04.0 P.W.M. Sijbers

• NICOL OmniD (9896 010 2224.) added.

• Chapter Conditions of Acceptability added.

• Document updated due to changed PEI-

numbers

• Chapter “1.6.1 Compatibility” extended for

new tubes and Nicol V2

• Chapter “2.2.1 Mounting the Coupling

Flange Nicol V2” added

(04.0) 15

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 15

Installation NICOL X-Ray Beam Limiting Device

2 INSTALLATION

2.1 INTRODUCTION

This chapter contains general instructions about the installation of the BLD. For specific information at

system level, refer to the relevant system reference manual.

2.1.1 TOOLS & TEST EQUIPMENT

• Standard Service Toolkit

• BLD alignment tool, code number 4522 980 31521, available from Service Logistics Best.

2.1.2 S

The BLD is delivered as part of a pre-installed system or in a single package, always containing:

2.2 I

Whenever replacing a BLD, no centering is required, provided the coupling flange is left on the X-Ray

UPPLIED ITEMS

• BLD (including aesthetic cover)

• Coupling flange assembly (to mount and adjust the BLD on the X-Ray tube housing)

• Four countersunk screws (M6x25mm) (used for mounting the shipping bracket to the coupling

flange, also are intended to mount the coupling flange to the X-Ray tube housing)

• Service Manual (No Operator Manual supplied)

NSTALLATION INSTRUCTIONS

• Remove the items from the packing and check them against paragraph 2.1.2 Supplied Items,

for completeness.

• Install according sequence table below

NOTE

tube housing.

________________

1 Chapter 2.2.1 Chapter 2.2.2

2 - Chapter 2.2.3

3 Chapter 0 Chapter 0

4 Chapter 2.2.5 Chapter 2.2.5

5 Chapter 2.2.6 Chapter 2.2.6

Installation

NICOL V2

Table 9 Installation sequence

Installation NICOL V2

as replacement of NICOL

16 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 16

NICOL X-Ray Beam Limiting Device Installation

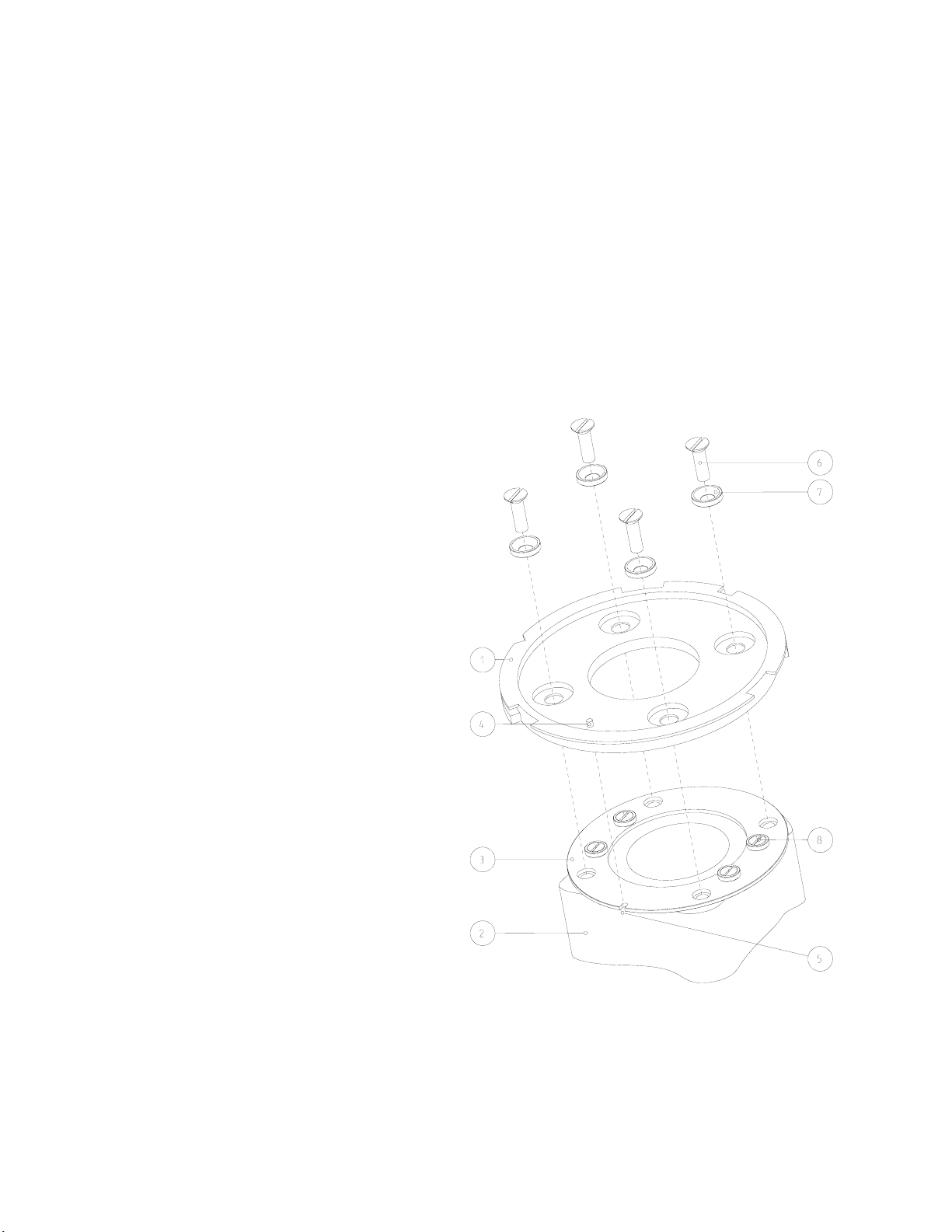

2.2.1 M

OUNTING THE COUPLING FLANGE ASSEMBLY NICOL

V2

This chapter describes the mounting procedure in case a pre-aligned X-ray Tube Assembly is used.

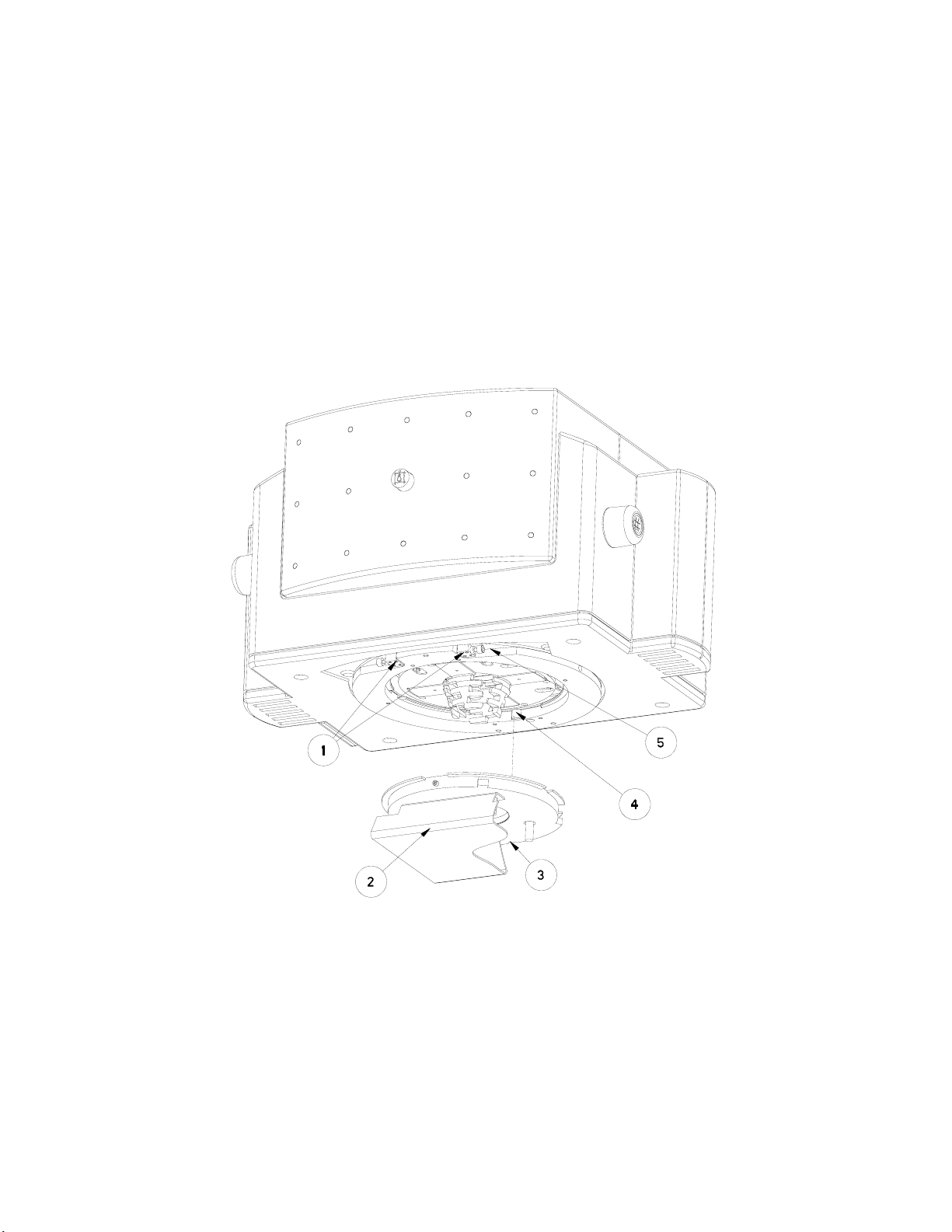

• Unscrew the locking plate screw (item 5, Figure 3, page 19) from each of the two locking plates

(item 1, Figure 3) and push them outwards as far as possible.

• Remove the shipping bracket (item 2, Figure 3) together with the coupling flange (item 3, Figure

3) from the BLD

• Unscrew the shipping bracket from the coupling flange (countersunk screws M6 x 25 mm must

be reused to mount the coupling flange on the tube housing.)

NOTE

Check the screw required length (25 mm) in the applicable tube housing service documentation.

At least 5 mm must be screwed into the tube housing.

________________

• Place the coupling flange (item 1,

Figure 1) on the X-Ray tube

housing (item 2, Figure 1) with

factory mounted alignment ring

(item 3, Figure 1)

• Positioning the reference pin (item

4, Figure 1) to the notch (item 5,

Figure 1) of the alignment ring.

Secure it with the four countersunk

•

screws M6 x 25 mm (item 6, Figure

1) and rings (item 7, Figure 1 )

• For screw length, see note above.

• Proceed with chapter 0 page 19.

CAUTION

Never loosen lacquered screws

(item 8, Figure 1. This will ruin the factory

alignment of the focus.

For realignment, the X-ray Source

assembly must be returned to Hamburg.

________________

Figure 1: Mounting the P&P coupling flange

(04.0) 17

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 17

Installation NICOL X-Ray Beam Limiting Device

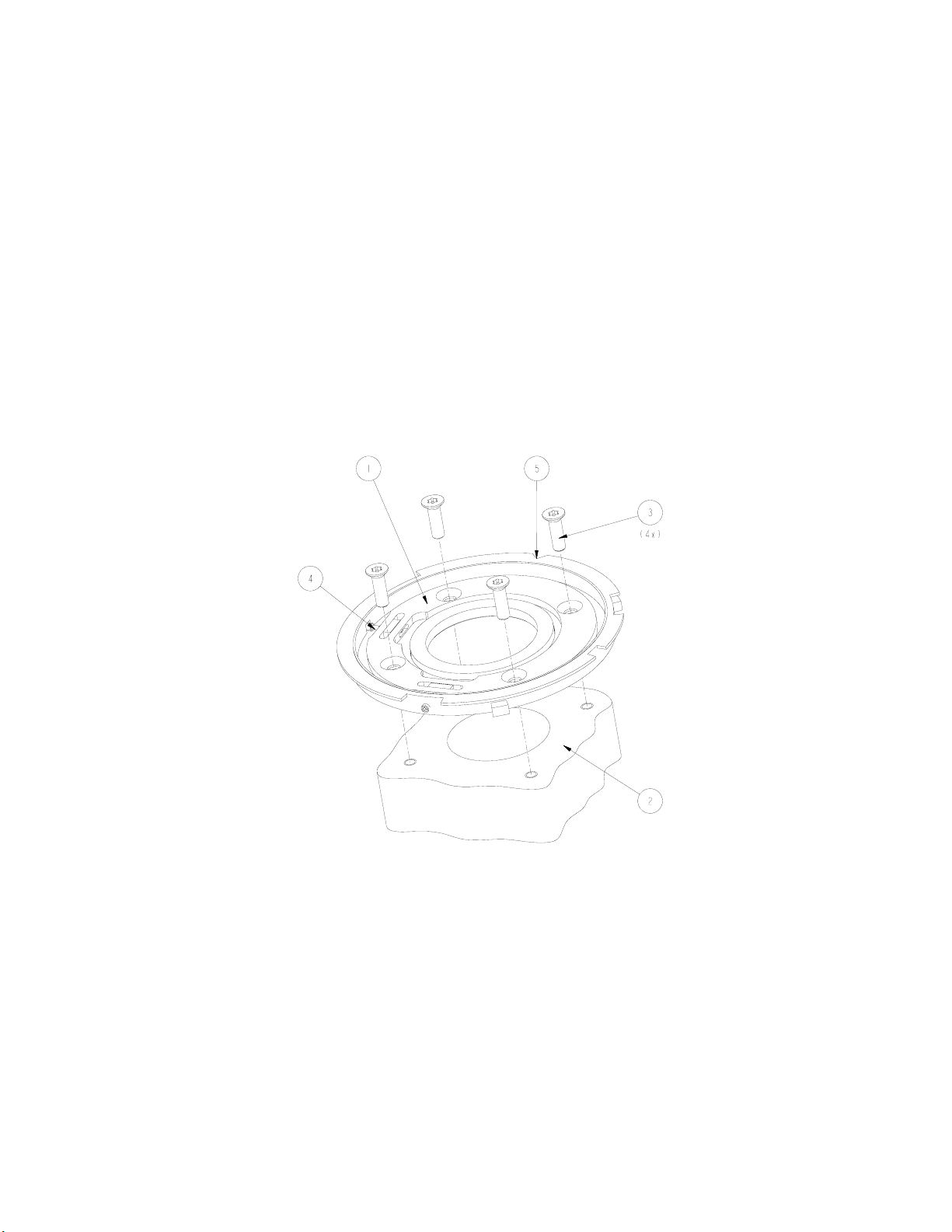

2.2.2 M

OUNTING THE COUPLING FLANGE ASSEMBLY

• Unscrew the locking plate screw (item 5, Figure 3, page 19) from each of the two locking plates

(item 1, Figure 3) and push them outwards as far as possible.

• Remove the shipping bracket (item 2, Figure 3) together with the coupling flange (item 3, Figure

3) from the BLD

• Unscrew the shipping bracket from the coupling flange (countersunk screws M6 x 25 mm must

be reused to mount the coupling flange on the tube housing.)

NOTE

Check the screw required length (25 mm) in the applicable tube housing service documentation.

At least 5 mm must be screwed into the tube housing.

________________

• Place the coupling flange (item 1, Figure 2) on the X-Ray tube housing (item 2, Figure 2),

positioning the 0° notch (item 5, Figure 2) to the rear of the X-Ray tube housing, and secure it

with the four countersunk screws M6 x 25 mm, item 3, Figure 2. (see note above)

Figure 2: Mounting the coupling flange assembly

2.2.3 CENTERING THE BLD WITH RESPECT TO THE X-RAY TUBE

All BLD functions have been accurately centered in the factory, relative to the central axis; any further

centering has to be done by adjusting the coupling flange assembly of the BLD with respect to the XRay focus. The specified alignment tool must be used.

The centering procedure is described in paragraph 6.1.4, page 40.

This procedure must be carried out:

• After replacement of NICOL DISC 4522 300 2417x

• After replacement of the X-Ray tube, configurations A and D of Table 3.

• NOT for replacements of NICOL and NICOL V2

18 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 18

NICOL X-Ray Beam Limiting Device Installation

2.2.4 M

Carefully mount the BLD to the coupling flange, in order not to DAMAGE the near focus shutters!

OUNTING THE

• Slide the two locking plates (item 1, Figure 3) outwards as far as possible.

• Mount the BLD on the coupling flange assembly, with the 0° locking mechanism (item 4, Figure

3) to slide into the notch (item 3) of the coupling flange

• Slide the two locking plates inwards to their end stop

• Secure the two locking plates to the coupling plate with the two screws (item 5)

• Check whether the BLD is properly secured

BLD

ON THE

AY TUBE HOUSING

X-R

NOTE

________________

Figure 3: Mounting the BLD to the coupling flange

NOTE

It is strongly advised, to mount the BLD on the X-Ray tube housing without removing the aesthetic

covers first. This allows a better grip of the heavy BLD, and prevents damage to the ruler, when lifting

the BLD by holding the ruler by accident.

________________

(04.0) 19

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 19

Installation NICOL X-Ray Beam Limiting Device

2.2.5 E

LECTRICAL INSTALLATION

• Mount the BLD first according

chapter 0, page 19.

Removal of Aesthetic Cover

• Remove the DSC knobs (item 1,

Figure 4), by pulling the knobs

outward.

• Remove the accessory rails

(item 2, Figure 4), by loosening

the 6 screws.

• Remove the 2 screws, (item 3,

Figure 4)

• Remove the two aesthetic

covers (items 4 and 5, Figure 4),

first lift item 4, and then lift item

5.

NOTE

When reassembling the Aesthetic covers,

be sure that the ruler guidance, item 6

Figure 4 page 20 is mounted correctly

between front and rear covers.

________________

Figure 4: Remove Aesthetic Cover

Removal of Ruler Side Plate

• In case of electronic ruler

(9896 010 2216.)

disconnect connector

LA5X1, item 4 Figure 5.

• Remove the side plate

(item 1, Figure 5) using the

4 screws (items 2).

Figure 5: Remove Ruler Side Plate

20 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 20

NICOL X-Ray Beam Limiting Device Installation

Electrical installation

• Connect male CAN cable 9p D-connector : LA2X1 (see Figure 6)

• Connect female CAN cable 9p D-connector : LA2X11

• Connect power cable 4p Mate-N-Lock : LA2X2

• Connect yellow/green protective earth : LAX100

Reinstall the ruler side plate

•

• For 9896 010 2216. only, reconnect ruler connector, LA5X1 and pay attention to proper ruler

cable guidance, see chapter 0 page 34, especially Figure 15 page 34.

• Switch on the Power and check whether

− LED LA3H1 (green) is ON

− LED’s LA3H2 (red) and are switched OFF within 30s (typical: approximately 15s).

− LED LA3H4 (yellow) is switched OFF (time is system dependant).

• Reinstall the two aesthetic covers, including the accessory rail and DSC knobs.

• Check whether the BLD is positioned correctly in the 0°-swivel position. When trying to swivel

the BLD with little force, no noticeable play may be present.

Figure 6: Electrical Installation

CAUTION

Be sure that during reinstallation of the aesthetic covers, the micro-switch for the lamp,

item 1, Figure 6, is not damaged!

________________

(04.0) 21

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 21

Installation NICOL X-Ray Beam Limiting Device

2.2.6 C

HECKING THE ALIGNMENT OF THE LIGHT FIELD AND THE

X-R

AY FIELD

1. Select large focus, 60 kV and 5 mAs

2. Place a loaded cassette (24 cm x 30 cm) on the

table top

(a)

(b)

cassette

washer (d)

3. Set SID = 100 cm (Use ruler)

4. Center the X-Ray tube on the cassette

5. Place a washer (d) on the right hand-top of the

cassette

6. Switch on the light and place four copper strips (c)

on the edge (a) of the Light Field

W1

L1

W2

L2

7. Make an exposure

8. Develop the film

9. Measure the differences L1, L2, W1 and W2

between the outer edge of each copper strips

image and the corresponding edge of the X-Ray

lightfield (a)

X-Ray Field (b)

(c)

Field (b).

10. The values L1 + L2 and W1 + W2 shall NOT

exceed 2cm (representing 2% of the SID)

Figure 7: Check X-Ray/Light Field

11. Note the measured values

12. Repeat preceding steps 1 till 11, with small focus selected.

The alignment procedure is described in paragraph 6.3, X-Ray Field to Light Field, page 45.

PTIONS

2.3 O

2.3.1 INSTALLATION AEP-METER

It is possible to install an optional AEP-meter in the accessory rail.

For the installation we refer to:

• relevant system reference manual for removal of the aesthetic cover and

• Service manual of the AEP-meter.

22 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 22

NICOL X-Ray Beam Limiting Device Fault Finding

3 FAULT FINDING

NOTE

NOT described in this document, is how to find to an FRU,

based on error messages, which are sent from the BLD to the system via the CAN.

This is described in the applicable system documentation, see the relevant system reference manual.

________________

NTRODUCTION

3.1 I

This chapter describes:

• indicators and measuring points for each PCB

• miscellaneous complaints and/or problems

Also for each problem, possible fault causes and/or solutions are given.

However to get feedback from the field as soon as possible, a very high FRU level is defined. So only

a very limited spare parts list is available.

In case of problems, the complete BLD has to be exchanged. The defect BLD, together with a clear

NOTE

problem description, has to be returned to Best as soon as possible!

________________

(04.0) 23

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 23

Fault Finding NICOL X-Ray Beam Limiting Device

AULTFIND STRATEGY

3.2 F

It is advised to start/perform faultfinding based on error messages as described in the relevant system

documentation, see system reference manual. Only if this is not possible, or does not lead to a

solution for the problem, this chapter may be of help. The faultfinding directly points to some basic

FRU’s (PCB’s and BLD) and a few FRU’s which are cheap and easy to replace.

3.3 INDICATORS

LED indicators are present on PCB’s LA2 and LA3.

The explanation of the LED indicators is given in Table 10 and Table 11. The location of the LED’s on

the PCB’s is given in Z3-2 to Z3-3.

3.3.1 LA2: P

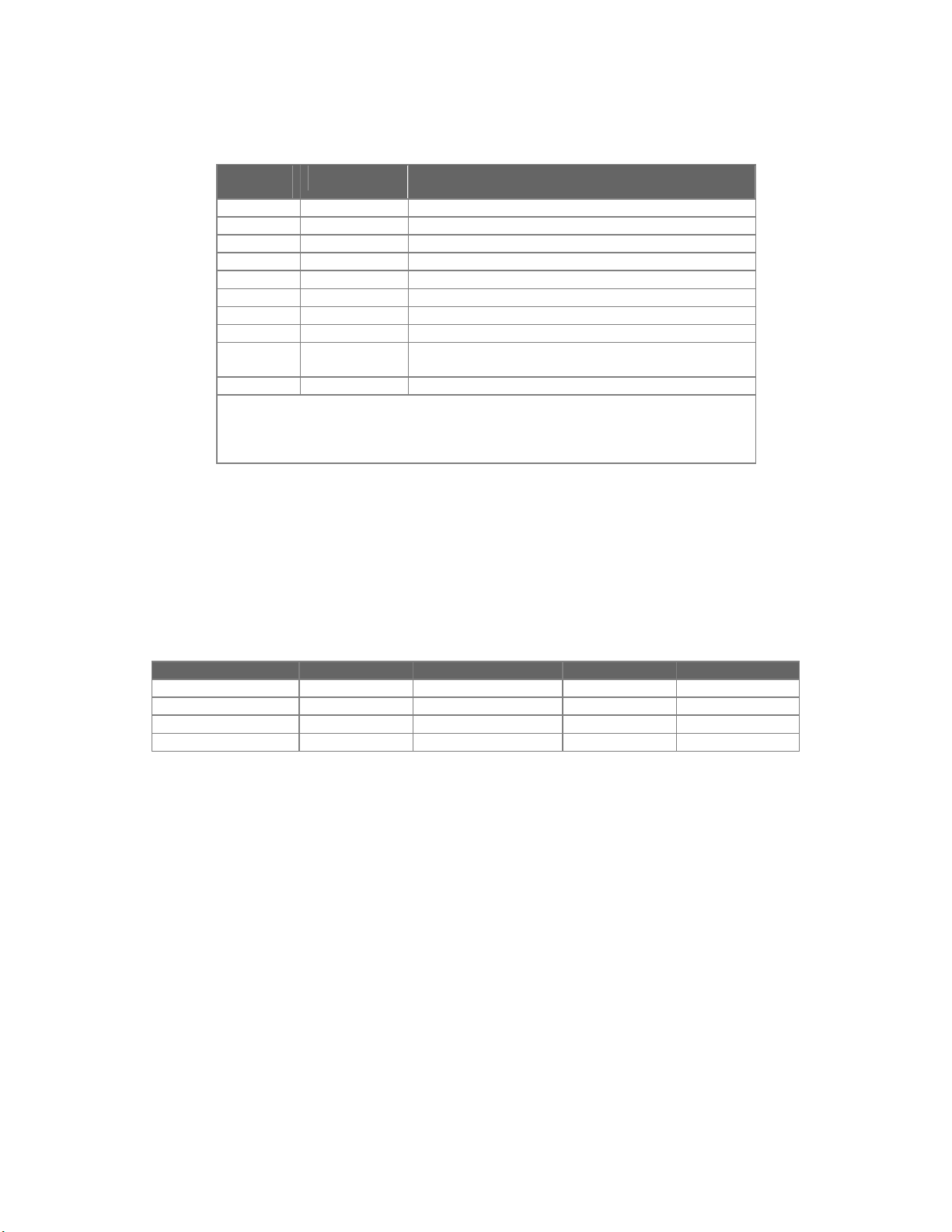

Number Color Description Faultfinding and solutions

LA2H1 green +24V present In case H1 is OFF:

LA2H2 green +5V present In case H2 is OFF and H1 is ON:

LA2H3 green +5V CAN

LA2H4 green +12V lamp

OWER SUPPLY CONVERTER

Table 10: Indicators LA2

• check system power supply

• check cable connection from system to LA2X2

• replace LA2

• replace BLD

• check +24V (LA2MP1)

• remove LA3, when H2 is lit now, check voltage, and if

OK, replace LA3

• replace LA2

• replace BLD

• In case H3 is OFF:

present

present

Refer to Z3-2 for positions on the PCB

• check system CAN power supply

• check cable connection from system to LAX1 and

LAX11

• replace LA2

• replace BLD

In case H4 is OFF:

• check system power supply

• check cable connection from system to LA2X2

• replace LA2

• replace BLD

CAN

INTERFACE

(PSC_CAN)

24 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 24

NICOL X-Ray Beam Limiting Device Fault Finding

3.3.2 LA3: S

HUTTER IRIS FILTER LIGHT CONTROLLER

(SIFLCO)

Table 11: Indicators LA3

LA3H1

green

[5V]3

LA3H2

red

[PCB]

LA3H3

yellow

[CONHW]

LA3H4

yellow

[CAN]

Faultfinding and solutions

OFF OFF OFF OFF In case H1 to H4 are OFF:

• check power supply using LA2 indicators (and

applicable measuring points)

• replace LA2 (PSC_CAN)

• replace LA3

• replace BLD

ON ON

(blinking)

OFF ON PCB Power On Self Test running

Note: after switching on the power, the self-test is running

(LED’s blinking) for approximately 15 seconds.

ON OFF OFF OFF Application running

ON OFF *4 ON No CAN communication:

• check cable connection from system to LA2X1, LA2X11

• check system

• replace LA2 (PSC_CAN)

• replace LA3

• replace BLD

ON OFF ON * PCB connected HW defect:

(use error logging at system level to identify the function

and FRU that is malfunctioning)

• shutter/iris/filter ⇒ replace BLD

• temp sensor 1 ⇒ replace LA2 (PSC_CAN)

• temp sensor 2 ⇒ replace LA3 (SIFLCO)

• fan ⇒ replace fan

• lamp ⇒ check cable LA2X5/LA2X6

⇒ check LA2H4

⇒ check whether +12V is present

after power up within .... s

⇒ replace Lamp

ON ON OFF OFF PCB Power On Self Test failed

ON ON OFF ON

• replace LA3 (SIFLCO)

ON ON ON OFF

ON ON ON ON PCB Power On Self Test not started or failed

• no PROM, or PROM incorrectly placed

• wrong HW or SW version

• replace LA3 (SIFLCO)

Refer to Z3-3 for positions on the PCB

3

[text] represents corresponding text on PCB, close to LED

4

LED may be both ON or OFF (don’t care)

(04.0) 25

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 25

Fault Finding NICOL X-Ray Beam Limiting Device

3.3.3 M

EASURING POINTS

Table 12: Measuring Points

LA1: SYBA LA2: PSC_CAN LA3: SIFLCO LA5: RUCO

MP1 0V24 0V24 0V24

MP2 +24V +24V +24V

MP3 0V5 0V5 0V5

MP4 +5V +5V +5V

MP5 0V12

MP6 LIGHT_ON reserved

MP7 +12V

MP8 0VCAN

MP9 +12VCAN

Refer to Z3-1 to Z3-5 for the position on the PCB’s

3.3.4 MISCELLANEOUS

Table 13: Miscellaneous faultfinding

Function Fault Description Faultfinding & Solution

Light lamp can not be switched on via

switch LAS1

lamp can not be switched on via

CAN

check connection LA3X5

•

check lamp voltage

•

replace lamp

•

check micro-switch (Exchange micro-switch)

•

exchange BLD

•

• check for CAN connection if LA3H4 is ON (see

Table 11, page 8)

• check lamp voltage, LA2MP6 is 12V with respect

to LA2MP5

• replace lamp

Area defined by Light Field not

(completely) on film

• See 2.2.6 Checking the alignment of the light

field and the X-Ray field, page 22

• Size incorrect: See chapter 6.3.1 Light Field Size

Adjustment page 45

• Light Field shifted with respect to the X-Ray

Field: See chapter 6.3.3 Light Field Adjustment

After Replacing Lamp page 46

General

BLD does NOT function/start-up

Ruler (electronic) ruler values NOT

BLD does NOT function/start-up

after replacement DSC button

BLD no function at all

correct

• exchange BLD

check whether the correct DSC assembly is

•

mounted at the appropriate position

• exchange BLD

• replace ruler, see 4.9 Replace Electronic Ruler,

page 33

• Replace PCB, see 4.8 Replace LA3: SIFLCO

page 32

Swivel

0° position NOT stable (to much

• exchange BLD

play)

26 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 26

NICOL X-Ray Beam Limiting Device Fault Finding

Function Fault Description Faultfinding & Solution

Shutters

shutters do not close completely

(during start-up only)

• Backup shutters (item 3, Figure 8) or near focus

shutters (item 2) close before main shutters,

exchange BLD

Note:

During application shutters can NOT be fully closed.

shadow images on exposed film

• Coupling between main shutters (item 1, Figure

8) and near focus shutters (item 2) and/or backup

shutters (item 3) not correct, exchange BLD.

How to check?

1. Switch of power

2. Fully close main shutters (item 1) manually

3. Check near focus shutter opening (item 2)

4. 3 mm ≤ x ≤ 4.4 mm

5. Check backup shutters (item 3)

6. 2.4 mm ≤ y ≤ 3.8 mm

7. Repeat steps for shutters not visible in Figure

8

• Coupling between main shutters and followshutters (item 4) incorrect, exchange BLD.

Figure 8: Shutter identification and verification

DSC

Replaced DSC button does not

No movement shutters when

DSC knobs are rotated.

function

• Exchange DSC assembly.

• Exchange BLD.

• Check whether the correct DSC assembly is

mounted at the appropriate position, DSC-A

assembly at lamp side, DSC-B assembly at ruler

side.

• Check whether the DSC-A connector is correctly

mounted onto LA1X16.

• Check whether the DSC-B connector is correctly

mounted onto LA1X6.

Spectral

Filter

Filter not correctly positioned,

visible in images

• Replace LA3

• Exchange BLD

•

(04.0) 27

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 27

Replacements X-Ray Beam Limiting Device

4 REPLACEMENTS

ENERAL

4.1 G

•

• Never unplug connectors (LA1X7, LA1X12 and LA1X14) while power is switched on!

• Never touch lamp parts when lamp has been switched on for a long time, they may be very hot!

EPLACE (COMPLETE

4.2 R

For replacement of the complete BLD, see also chapter 2.2 Installation instructions, page 16

1. Place the BLD and X-Ray tube housing of the Stand (if possible) in the upright down position

2. Secure the Stand!

3. Open shutters as far as possible, using the DSC buttons.

4. Switch off the power!

5. Remove the Aesthetic Cover, see paragraph 2.2.5, page 20.

6. Remove the Ruler Side Plate, see paragraph 2.2.5

7. Remove the connectors, see paragraph 2.2.5

8. Replace BLD using procedure as described in paragraph 2.2.4

WARNING

Never put down the BLD on near focus shutter assembly.

Use external non-metal support(s) for the BLD.

________________

Switch off the power, when working with the BLD!

) BLD

Never lift the BLD, by holding the ruler, this to prevent damage to the ruler!

ON THE STAND

WARNING

________________

4.3 REPLACE AESTHETIC COVER

The Aesthetic Cover consists of three parts, which are always delivered together. They can be

replaced completely or as single parts.

1. For replacement front and/or rear cover see paragraph 2.2.5, page 20.

2. For replacement of the bottom plate see paragraph 4.14, page 38.

3. Assemble in reverse order.

4. Be sure that the ruler guidance item 6, Figure 4, page 20 is mounted correctly between the front

and rear cover.

5. Check BLD for correct functioning.

4.4 REPLACE FIELD INDICATION PLATE

1. Place the BLD and X-Ray tube housing of the Stand (if possible) in the upright down position

2. Remove the Aesthetic Cover, see paragraph 2.2.5, page 20.

3. Replace the field indication plate, item 7, Figure 4, page 20.

4. Assemble in reverse order.

28 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 28

NICOL X-Ray Beam Limiting Device Replacements

4.5 R

EPLACE

DSC B

UTTONS

1. Replace the DSC buttons, items 1, Figure 4, page 20, by pulling them outwards.

2. Assemble in reverse order.

4.6 REPLACE DSC ASSEMBLY

The DSC-A assembly is situated at the lamp

whereas the

side

DSC-B assembly

at the ruler side. (On the flat-cable of the DSC

assembly is indicated DSC-A respectively DSCB). It is not necessary to remove the BLD from

the X-Ray tube housing assembly for

replacement of the DSC assemblies.

CAUTION

When the lamp has been used, the lamp and its

surrounding material might be (“very”) hot.

________________

is situated

Figure 9: Removal iris motor assembly

Replace DSC-A assembly

1. Remove the Aesthetic Cover, see paragraph

2.2.5, page 20.

2. Be sure the power is switched OFF.

3. Remove the Lamp Side Plate, see paragraph

4.14, page 38.

4. Loosen the 2 screws, item 2 and 3, Figure 10,

page 29.

DSC-A

5. Remove DSC-A assembly, item 1, Figure 10,

page 29.

6. Remove iris motor assembly (only in case of

PEI 9896 010 2223.)

a) Disconnect connector LA1X10, item 3,

Figure 9, page 29 and LA1X11.

b) Loosen the 2 screws, both items 1, Figure

9.

c) Remove the iris motor assembly, item 2,

Figure 10: Replacement DSC-A assembly

7. Disconnect DSC connector LA1X16.

Figure 9.

8. Replace the DSC-A assembly and reassemble

(including iris motor) in reverse order.

9. Check proper functioning of the replaced DSC button after the power is switched ON

.

(04.0) 29

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 29

Replacements X-Ray Beam Limiting Device

Replace DSC-B assembly

1. Remove the Aesthetic Cover, see

paragraph 2.2.5, page 20.

2. Be sure the power is switched OFF.

3. Remove the Ruler Side Plate, see

paragraph 2.2.5

4. Disconnect DSC connector LA1X6.

5. Loosen the 2 screws, item 2 and 3, Figure

11, page 30.

6. Remove DSC-B assembly, item 1, Figure

11, page 30.

7. Replace the DSC-B assembly and

reassemble in reverse order.

8. Check proper functioning of the replaced

DSC button after the power is switched ON.

DSC-B

Figure 11: Replacement DSC-B assembly

WARNING

Be sure that the correct DSC assembly, see spare parts list, is mounted at the appropriate side of the

BLD. If interchanged, the BLD will not start up (so no CAN connection will be established) or the DSC

function will not become available.

________________

30 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 30

NICOL X-Ray Beam Limiting Device Replacements

EPLACE

4.7 R

LA2: PSC_CAN

1. Follow the instructions 1 - 7 of paragraph 4.2.

2. Remove the field indication plate, item 5, Figure 12

3. With Power still switched off, gently open rectangular shutters manually (Do NOT push shutters

downwards)

4. Remove connectors/fastons LA2X5 and LA2X6, see item 6, Figure 12.

5. Remove the 3 screws and washers (items 1, Figure 12).

6. A: Pop up the board LA2 (item 2) gently and

B: slide the board out of the BLD very carefully!

7. Re-assemble in reverse order. Be sure that the board connector (item 3) is positioned exactly in the

correct position onto the backpanel connector (item 4).

8. Check correct positioning of the connectors LA2X3 / LA1X1, observe via 2 holes in the long side of

the BLD (near item 4) and perpendicular to the connector via the short side of the BLD!

9. Check whether connectors/fastons LA2X5 and LA2X6, see item 6, Figure 12, are connected

correctly.

WARNING

Please check and double-check whether connector LA2X3 is correctly mounted to LA1X1!!!

________________

: Remove

B

A: Pop-up

Figure 12: Replace LA2 PSC_CAN

(04.0) 31

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 31

Replacements X-Ray Beam Limiting Device

EPLACE

4.8 R

LA3: SIFLCO

1. Follow the instructions 1 - 5 of paragraph 4.2.

2. Remove micro-switch connector LA3X5.

3. Remove the 4 sunken screws (items 2, Figure 13) from the LA3 Cover-plate (item 1, Figure 13) and

remove the LA3 Cover-plate

4. Remove 2 screws and washers (items 4) from LA3.

5. Remove the LA3, item 3, by lifting the board (connectors LA3X1 respectively LA3X2 from LA1X3

respectively LA3X4)

6. Exchange PROM LA3D17, see 4.8.1, page 32.

7. Reassemble in reverse order. Be sure that the board connectors (item 6) are positioned exactly in

the correct position onto the backpanel connectors (item 5).

8. Check correct positioning of the connectors LA3X1 respectively LA3X2 onto LA1X3 respectively

LA3X4

Figure 13: Replace LA3 SIFLCO

4.8.1 REPLACE PROM LA3D17

1. Follow steps 1-4 of paragraph 4.8

2. Remove PROM LA3D17 from socket, see Z3-3, by using an appropriate IC extractor

3. Place correct PROM into socket and check correct position, see Z3-3.

4. Reassemble in reverse order, steps 5-6 of paragraph 4.8

For safe handling of PCB’s and PROM’s we refer to ESD Precautions as described in Section 4:

Planned Maintenance Instruction Modules (4522 983 24611 or 4535 440 04161)

32 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 32

NICOL X-Ray Beam Limiting Device Replacements

EPLACE ELECTRONIC RULER

4.9 R

Figure 14: Replace Electronic Ruler

1. Secure the stand if necessary

2. Switch off the Power.

3. Remove the aesthetic cover, see paragraph 2.2.5, page 20.

4. Disconnect connector LA5X1 (item 4, Figure 14)

5. Remove the ruler Side-plate, see paragraph 2.2.5

6. Remove electrical ruler assembly (item 1, Figure 14) from the ruler Side-plate (item 3, Figure 14),

by loosening the three screws (item 2, Figure 14)

7. Mount new electrical ruler assembly and reconnect LA5X1.

8. Check whether the ruler can be pulled out smoothly.

9. Check whether the ruler winds up completely when released.

10. Reassemble in reverse order.

11. Switch on the power again.

12. Check whether the ruler value is correctly sent to the system via CAN. See applicable system

reference manual(s).

NOTE

With the aesthetic cover removed, the ruler can give incorrect values, so for the final check of the

ruler, the aesthetic cover has to be mounted!

________________

(04.0) 33

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 33

Replacements X-Ray Beam Limiting Device

4.9.1 C

ONNECTION ELECTRONIC RULER

Figure 15: Connect electrical ruler cable

Figure 15 page 34 gives in more detail, the connection of the cable of the electronic ruler. In case of

connection/disconnection of the electronic ruler cable, following steps have to be taken:

1. Remove ruler side plate, see chapter 2.2.5 page 20.

2. Remove connector LA1X5 (item 5 Figure 15) and cable (item 2 Figure 15). Cable must be

removed by pulling connector LA5X1 (item 1 Figure 15) through the hole (item 4 Figure 15) in

LA1.

3. Replace cable in reverse order

4. Mount ruler side plate, see chapter 2.2.5 page 20, while

5. Guiding ruler cable (item 3) together with power supply and CAN cable(s) through cable guidance.

34 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 34

NICOL X-Ray Beam Limiting Device Replacements

4.10 R

EPLACE MECHANICAL RULER

1. Remove the aesthetic cover, see paragraph 2.2.5, page 20.

2. Remove mechanical ruler assembly (item 1, Figure 16) from the ruler Side-plate (item 3, Figure

16), by loosening the three screws (item 2, Figure 16)

3. Mount new mechanical ruler assembly.

4. Check whether the ruler can be pulled out smoothly.

5. Check whether the ruler winds up when released.

Figure 16: Replace Mechanical Ruler

(04.0) 35

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 35

Replacements X-Ray Beam Limiting Device

4.11 R

EPLACE LAMP

CAUTION

Never touch the halogen lamp with

your fingers!

________________

1. Remove the aesthetic cover,

paragraph 2.2.5, page 20.

2. Remove Lamp Side Plate (item

1, Figure 17) by loosening the 4

screws (item 2, Figure 17)

3. Remove the protective cap of

the lamp, item 3, Figure 18, by

loosening the screw (item 4,

Figure 18)

4. Remove the lamp (item 1,

Figure 18) from the lamp-holder

(item 2)

5. Mount the new lamp in the

lamp-holder (Never touch with

your fingers)

6. Check whether the lamp pins

are placed in the lamp-foot as

far as possible!

Figure 17: Remove Lamp Side Plate

7. Check the alignment of the X-Ray Field with respect to the light Field, see chapter 2.2.6 page 22.

8. Reassemble in reverse order.

Attention!

Position

micro-switch

(item 8),

maximally

outwards!

Figure 18: Replacement Lamp

36 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 36

NICOL X-Ray Beam Limiting Device Replacements

4.12 R

EPLACE MICRO-SWITCH

1. Remove the aesthetic cover, paragraph 2.2.5, page 20.

2. Switch Power OFF.

3. Disconnect connector LAX5.

4. Remove the micro-switch (items 6 till 10, Figure 18 page 36).

5. Replace the micro-switch (item 8, Figure 18 page 36), reusing items 5, 6, 7, 9 and 10 and reconnect LAX5. Be sure the micro-switch is positioned maximally outwards before tightening the

screws.

6. Switch Power ON

7. Check proper functioning of the micro-switch.

8. Reassemble the aesthetic cover.

9. Check proper functioning of the micro-switch, with aesthetic cover reassembled.

WARNING

Maximum torque for tightening the screws items 6, Figure 18 page 36 = 11Ncm

________________

4.13 REPLACE MICRO-SWITCH INCLUDING BRACKET

1. Remove the aesthetic cover, paragraph 2.2.5, page 20.

2. Switch Power OFF.

3. Disconnect connector LAX5.

4. Remove the micro-switch including the bracket (items 5 till 10, Figure 18 page 36).

5. Replace the micro-switch including the bracket and re-connect LAX5. Be sure the micro-switch is

positioned maximally outwards before tightening the screws.

6. Switch Power ON

7. Check proper functioning of the micro-switch.

8. Reassemble the aesthetic cover.

9. Check proper functioning of the micro-switch, with aesthetic cover reassembled.

(04.0) 37

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 37

Replacements X-Ray Beam Limiting Device

4.14 R

EPLACE FAN

Figure 19: Replace Fan

1. Remove the BLD from the X-Ray tube assembly, see paragraph 4.2 and put BLD carefully in

upright down position.

2. Remove lamp side plate, item 3, Figure 19 using the four screws (item 4, Figure 19).

3. Remove bottom plate, item 1, Figure 19 , using the four screws, item 2 and washers item 8.

4. Remove ventilation shaft, item 5, Figure 19, from fan.

5. Disconnect fan connector LA1X17.

6. Remove fan, item 7, using the four screws, item 6, Figure 19).

7. Mount new fan

8. Reassemble the BLD in reverse order.

NOTE

Items 2 have to be fixed using Loctite 243 (screw lock)

________________

9. Check whether fan functions correctly, by switching on the lamp, using the light-button on the BLD.

38 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 38

NICOL X-Ray Beam Limiting Device Programming

5 PROGRAMMING

5.1 INTRODUCTION

This chapter describes the jumper settings for each board. The settings of other BLD programmable

functions, that must be changed with a software service tool are NOT described here, see relevant

Systems reference manual.

5.2 HARDWARE PROGRAMMING

5.2.1 LA1: B

Jumper Position Description Delivery Position

W1 1 - 2

5.2.2 LA2: P

ACKPANEL

2 - 3

OWER SUPPLY CONVERTER

Table 14: Programming LA1

BLD configured as frontal collimator (BLD1)

BLD configured as lateral collimator (BLD2)

Refer to Z3-1 for the position on the PCB

& CAN I

1 - 2

NTERFACE BOARD

(PSC_CAN)

Table 15: Programming LA2

Jumper Position Description Delivery Position

W1 1 - 2

none

W2

BLD programmed as CAN end node

BLD NOT an end node

Refer to Z3-2 for the position on the PCB

jumper NOT mounted

jumper

never

mounted!

5.3 SOFTWARE PROGRAMMING

All software programming is done at system level via the CAN interface. For this purpose, we refer to the

applicable system reference manual(s). Some examples of software programming at system level are:

• manual shutter speed

• shutter move limits (= radiation angle)

• BLD orientation (with respect to X-Ray tube housing)

• default Spectral Filter value

• spectral filter value assignment

• light timer settings

• default shutter position at reset

(04.0) 39

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 39

Adjustments NICOL X-Ray Beam Limiting Device

6 ADJUSTMENTS

This procedure only to be carried out:

• After replacement of NICOL DISC 4522 300 2417x

• After replacement of the X-Ray tube, configurations A and D of Table 3.

•

ENTERING THE

6.1 C

for replacements of NICOL and NICOL V2

NOT

BLD

WITH THE

X-R

AY TUBE

6.1.1 I

NTRODUCTION

For perfect attachment of the BLD to the X-Ray tube housing, it is necessary that the BLD axis coincides

with the median perpendicular line that passes through the center, between the two tube foci. Use BLD

alignment tool, see Figure 32, page 50. Ideally, the resulted picture consists of two concentric circles. In

reality there will be different pictures for small and large focus, see

Figure 22

, page 41.

6.1.2 TOOLS REQUIRED

The BLD alignment tool, code number 4522 980 31521

6.1.3 M

OUNTING THE

BLD A

The BLD alignment tool can be mounted:

• if the coupling flange assembly is not mounted, first perform this procedure as described in

paragraph 2.2.2, page 18.

• if the coupling flange assembly is mounted, similar procedure as for BLD mounting, see

paragraph 0, page 19.

6.1.4 C

HECKING THE CENTERING FOR

To check the BLD centering relative to the X-Ray tube, proceed as follows:

1. Prepare a film cassette (with screen) oriented in the plane perpendicular to the central ray, with the

edges of the film parallel to the longitudinal axis of the tube.

2. Set the following data: 65kV, 30mAs, SID=100mm (or more)

3. Make an exposure with small focus (SF)

Develop the film and determine:

• the center MA of the projection of ring A (see Figure 20)

• the center MB of the projection of ring B (see Figure 20)

• Draw the system coordinates on the film in the A-direction and B-

direction with reference to the film edges. (the positive directions

can be derived from the mark at the right-hand top of the film)

4. Measure the distances P and Q on the film

5. Make an exposure with

Develop the film and determine:

• the center MA of the projection of ring A (see Figure 21)

LIGNMENT TOOL

Mark the right hand top of the film!

focus (LF)

large

PEI 9896 010 2216.

NOTE

________________

B-direct ion

-a +a

A-direct ion

small focus

+b

P

MB

MA

-b

Q

mark

Figure 20: SF alignment

40 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 40

NICOL X-Ray Beam Limiting Device Adjustments

the center MB of the projection of ring B (see Figure 21)

•

• Draw the system coordinates on the film in the A-direction and B-

direction with reference to the film edges. (the positive directions

can be derived from the mark at the right-hand top of the film)

6. Measure the distances R and S on the film

7. The coupling flange is correctly adjusted when the film image of the

small focus is a mirror image with respect to that of the large focus (see

Figure 22) In this case the following applies:

B-direct ion

-a +a

S

large focus

+b

R

MA

MB

mark

|P| = |-R| ± 0.3mm

|Q| = |-S| ± 0.3mm

8. Further correction is not recommended because the adjustment can

become worse due to measuring errors during the correction

A-direct ion

-b

procedure.

Figure 21: LF alignment

If the above tolerances have

B-direction

been fulfilled, remove the BLD

small focus

+b

mark

large focus

+b

mark

alignment tool and proceed to

BLD mounting as described in

paragraph 0, page 19. If not,

proceed to paragraph 6.1.5.

-a +a

MA

P

MB

Q

-a +a

R

MA

S

MB

P = - R

A-direction

-b

Q = - S

-b

Figure 22: Requirement for alignment

6.1.5 ADJUSTING THE CENTRING

To adjust the BLD centering with the X-Ray tube, proceed as follows:

1. Measure the distances A, B, C and D (see Figure 23) and enter them as default values in Table 17

below.

2. Determine: Ta = (P + R)/2

Ub = (Q + S)/2

Va = Ta x Z

Wb = Ub x Z

with the factor Z derived from the following table, depending on the selected SID:

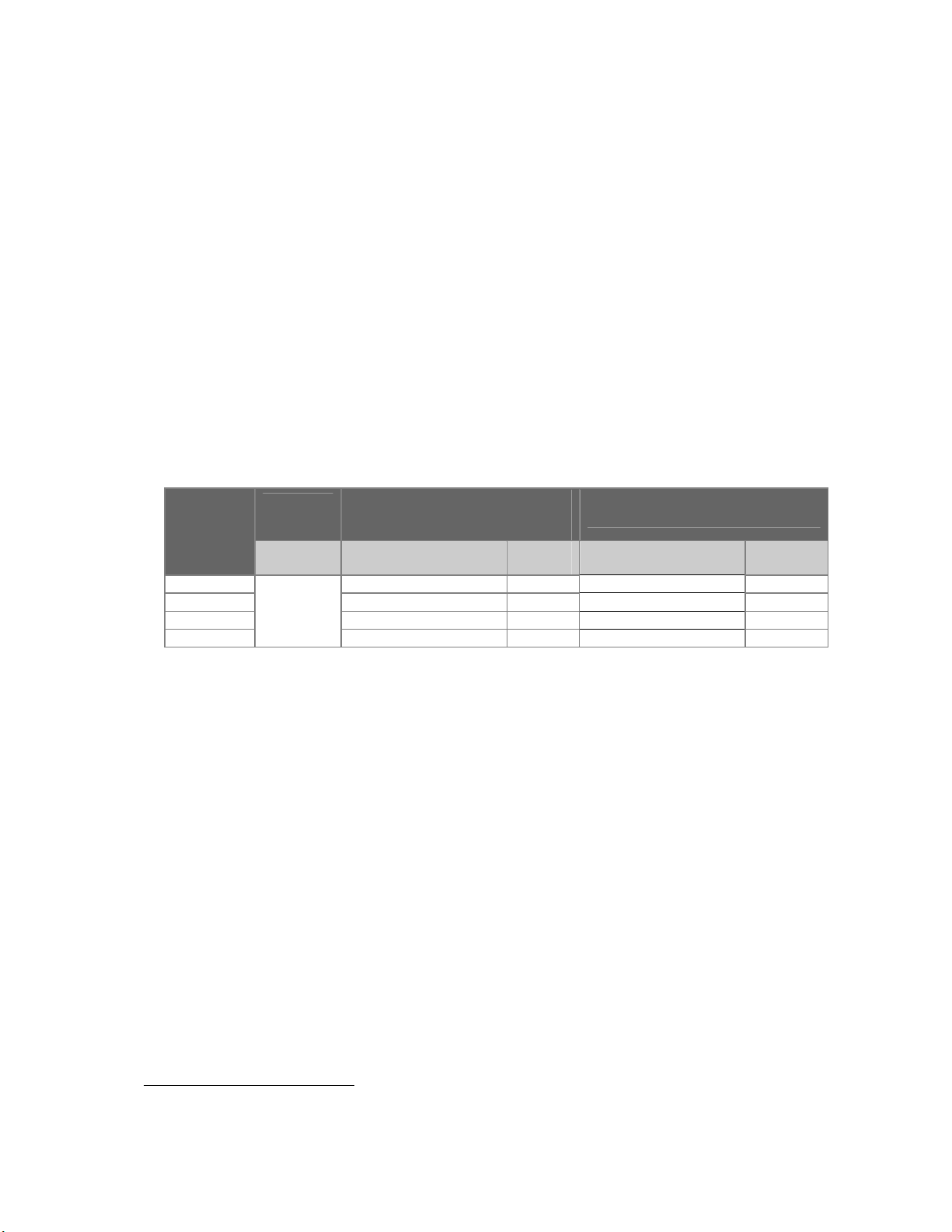

Table 16: Z-factor

SID [mm] 1250 1100 1000 900 800 700

Z 0.40 0.46 0.50 0.55 0.62 0.70

(04.0) 41

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 41

Adjustments NICOL X-Ray Beam Limiting Device

3. Calculate the corrected value of A, B, C and D as follows:

Corrected A = default A + Va

Corrected B = default B + Wb

Corrected C = default C - Wb

Corrected D = default D - Va

And enter them as corrected values in Table 17 below.

4. Loosen the four coupling flange assembly countersunk

screws a quarter turn.

5. Rotate the adjusting screws (Items W) to obtain the

corrected values of distances A, B, C and D.

6. Tighten the four countersunk screws, taking care that the

adjustment does NOT change.

7. Refer to paragraph 6.1.4 to check the centering.

Table 17: Centering correction values

Default values Corrected values

A

B

C

D

Example:

The following values Va = + 0.5mm and Wb = -1mm are the result of measurements and calculations.

Figure 23: Adjusting the centering

A

-a

W

C

W

+b

D

-b

B

+a

Table 18: Centering correction values (example)

Default values Corrected values

A 2.5mm 3(+0.5)mm

B 3.0mm 2(-1.0)mm

C 2.5mm 2(-0.5)mm

D 3.0mm 4(+1.0)mm

42 (04.0)

ALL RIGHTS RESERVED

Copyright © 2004 Philips Medical Systems Nederland B.V.

9896 010

2216.

2217.

2223.

2224.

Page 42

NICOL X-Ray Beam Limiting Device Adjustments

6.1.6 CHECKING THE CENTERING FOR PEI’S 9896 010 2217., 9896 010 2223. AND 9896

010 2224.

To check the BLD centering relative to the X-Ray tube, proceed as follows:

1. For details see relevant system reference manual(s)

2. Start fluoroscopy with

grey outer circle, observed on monitor.

3. If not, stop fluoroscopy and loosen the four coupling flange assembly countersunk screws, see

Figure 23, page 42, a quarter turn.

4. Rotate the adjusting screws (Items W, Figure 23, page 42) in such a way, that the white circle

becomes concentric with respect to the grey outer circle, observed on monitor.

Take care of necessary X-Ray precautions!

5. Tighten the four countersunk screws, taking care that the adjustment does NOT change.

6. Check whether the alignment does not change too much, when switching to large focus. (For

requirements see relevant system reference manual)

focus selected and check whether the white circle is concentric with the

small

Figure 24: SF alignment during Fluoroscopy

(04.0) 43

9896 010

ALL RIGHTS RESERVED

2216.

2217.

2223.

2224.

Copyright © 2004 Philips Medical Systems Nederland B.V.

Page 43

Adjustments NICOL X-Ray Beam Limiting Device

6.2 FIELD INDICATION PLATE WITH CROSSED-LINES

Preconditions for the Field Indication Plate adjustment:

• The X–ray field and light field should be correctly aligned.

• The output window of the BLD must be parallel to the receptor plane.

• The SID should be as large as possible (100 cm or more).

• Check whether the field indication plate is mounted correctly onto the adjusting strip, item 2

Figure 25

Procedure (refer to Figure 25, Page 44)

1. Close the vertical shutters (shutters A) manually, by using the corresponding DSC-button, to an

opening at receptor or table, of approximately 30 mm. (lamp automatically switches on)

2. Open the horizontal shutters (shutters B) completely (use corresponding DSC-button).

3. Loosen the two screws (items 3, Figure 25) and move the adjusting strip (item 2) and the Field

Indication Plate (item 1, Figure 25) so that the center of the Field Indication Plate cross-lines is

parallel and within 2.5 mm of the light field center line.

4. Close the horizontal shutters to an opening at receptor or table of approximately 30 mm.