Philips 8xc554 DATASHEETS

INTEGRATED CIRCUITS

80C554/83C554/87C554

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D,

I2C, PWM, capture/compare, high I/O

Preliminary specification

Replaces datasheet 87C554 of 1998 Aug 14

IC20 Data Handbook

1999 Apr 07

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

DESCRIPTION

The 8xC554 Single-Chip 8-Bit Microcontroller is manufactured in an

advanced CMOS process and is a derivative of the 80C51

microcontroller family. The 87C554 has the same instruction set as

the 80C51. Three versions of the derivative exist:

•83C554—16k bytes programmable ROM

•80C554—ROMless version of the 83C554

•87C554—16k bytes EPROM

The 87C554 contains a 16k × 8 non-volatile EPROM, a 512 × 8

read/write data memory, five 8-bit I/O ports, one 8-bit input port, two

16-bit timer/event counters (identical to the timers of the 80C51), an

additional 16-bit timer coupled to capture and compare latches, a

15-source, four-priority-level, nested interrupt structure, an 8-input

ADC, a dual DAC pulse width modulated interface, two serial

interfaces (UART and I

oscillator and timing circuits. For systems that require extra

capability , the 8xC554 can be expanded using standard TTL

compatible memories and logic.

In addition, the 8xC554 has two software selectable modes of power

reduction—idle mode and power-down mode. The idle mode freezes

the CPU while allowing the RAM, timers, serial ports, and interrupt

system to continue functioning. Optionally, the ADC can be operated

in Idle mode. The power-down mode saves the RAM contents but

freezes the oscillator, causing all other chip functions to be

inoperative.

The device also functions as an arithmetic processor having

facilities for both binary and BCD arithmetic plus bit-handling

capabilities. The instruction set consists of over 100 instructions:

49 one-byte, 45 two-byte, and 17 three-byte. With a 16MHz crystal,

58% of the instructions are executed in 0.75µs and 40% in 1.5µs.

Multiply and divide instructions require 3µs.

2

C-bus), a “watchdog” timer and on-chip

FEATURES

•80C51 central processing unit

•16k × 8 EPROM expandable externally to 64k bytes

•An additional 16-bit timer/counter coupled to four capture registers

and three compare registers

•Two standard 16-bit timer/counters

•512 × 8 RAM, expandable externally to 64k bytes

•Capable of producing eight synchronized, timed outputs

•A 10-bit ADC with eight multiplexed analog inputs

•Fast 8-bit ADC option

•Two 8-bit resolution, pulse width modulation outputs

•Five 8-bit I/O ports plus one 8-bit input port shared with analog

inputs

2

•I

C-bus serial I/O port with byte oriented master and slave

functions

•On-chip watchdog timer

•Extended temperature ranges

•Full static operation – 0 to 16 MHz

•Operating voltage range: 2.7V to 5.5V (0 to 16MHz) and

4.5V to 5.5V (16 to 33 MHz)

•Security bits:

– ROM – 2 bits

– OTP/EPROM – 3 bits

•Encryption array – 64 bytes

•4 level priority interrupt

•15 interrupt sources

•Full-duplex enhanced UART

– Framing error detection

– Automatic address recognition

•Power control modes

– Clock can be stopped and resumed

– Idle mode

– Power down mode

•Second DPTR register

•ALE inhibit for EMI reduction

•Programmable I/O pins

•Wake-up from power-down by external interrupts

•Software reset

•Power-on detect reset

•ADC charge pump disable

•ONCE mode

•ADC active in Idle mode

1999 Apr 07

2

Philips Semiconductors Preliminary specification

B= 0C to 70C

F = 40 C to +85 C

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

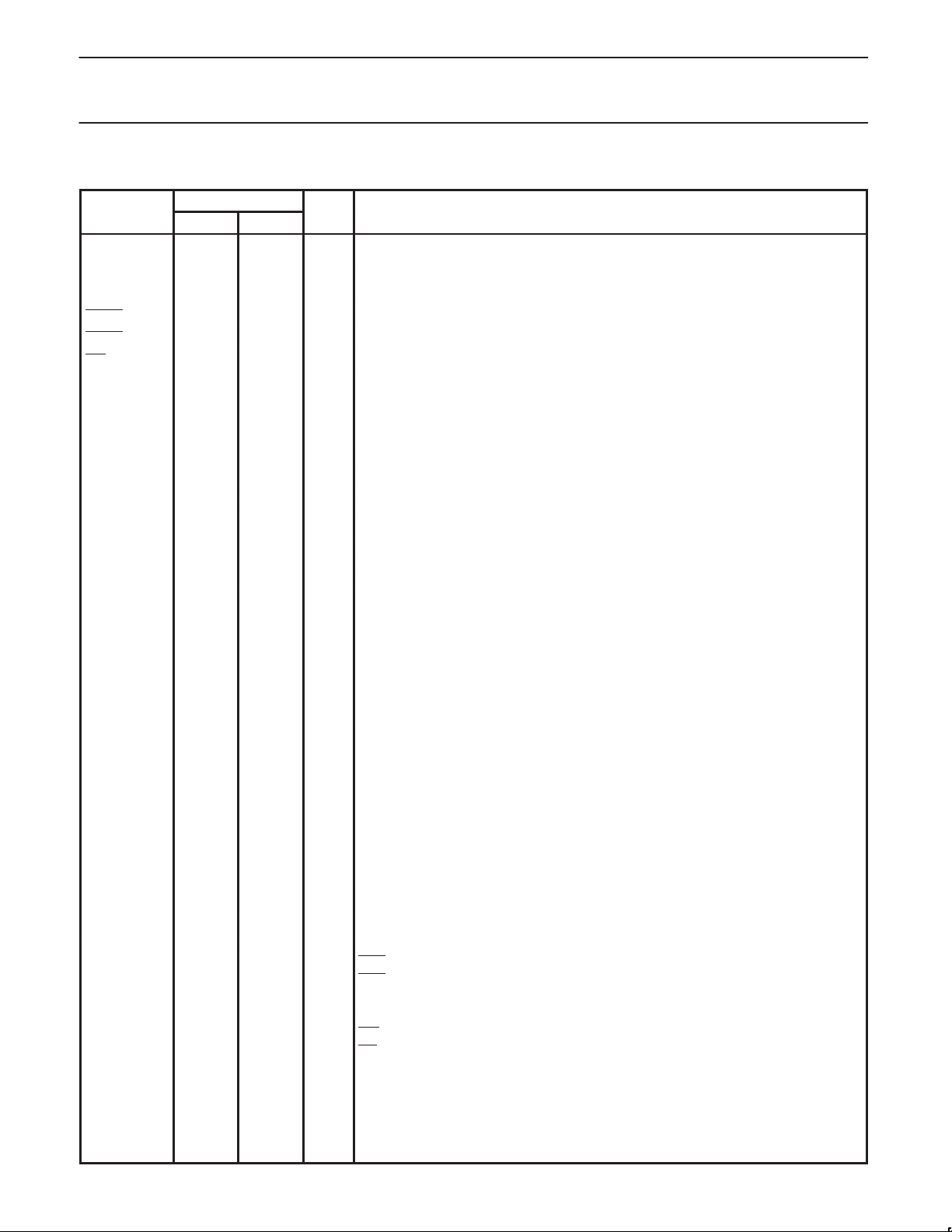

ORDERING INFORMATION

OTP/EPROM ROM ROMless TEMPERATURE °C AND PACKAGE

FREQ.

(MHz)

P87C554SBAA P83C554SBAA P80C554SBAA 0 to +70, Plastic Leaded Chip Carrier 16 SOT188–3

P87C554SFAA P83C554SFAA P80C554SFAA –40 to +85, Plastic Leaded Chip Carrier 16 SOT188–3

P ART NUMBER DERIVATION

DEVICE NUMBER (P87C554) OPERATING FREQUENCY MAX (S) TEMPERATURE RANGE (B) PACKAGE (AA)

P87C554 OTP

P83C554 ROM

S = 16 MHz

=–

P80C554 ROMless

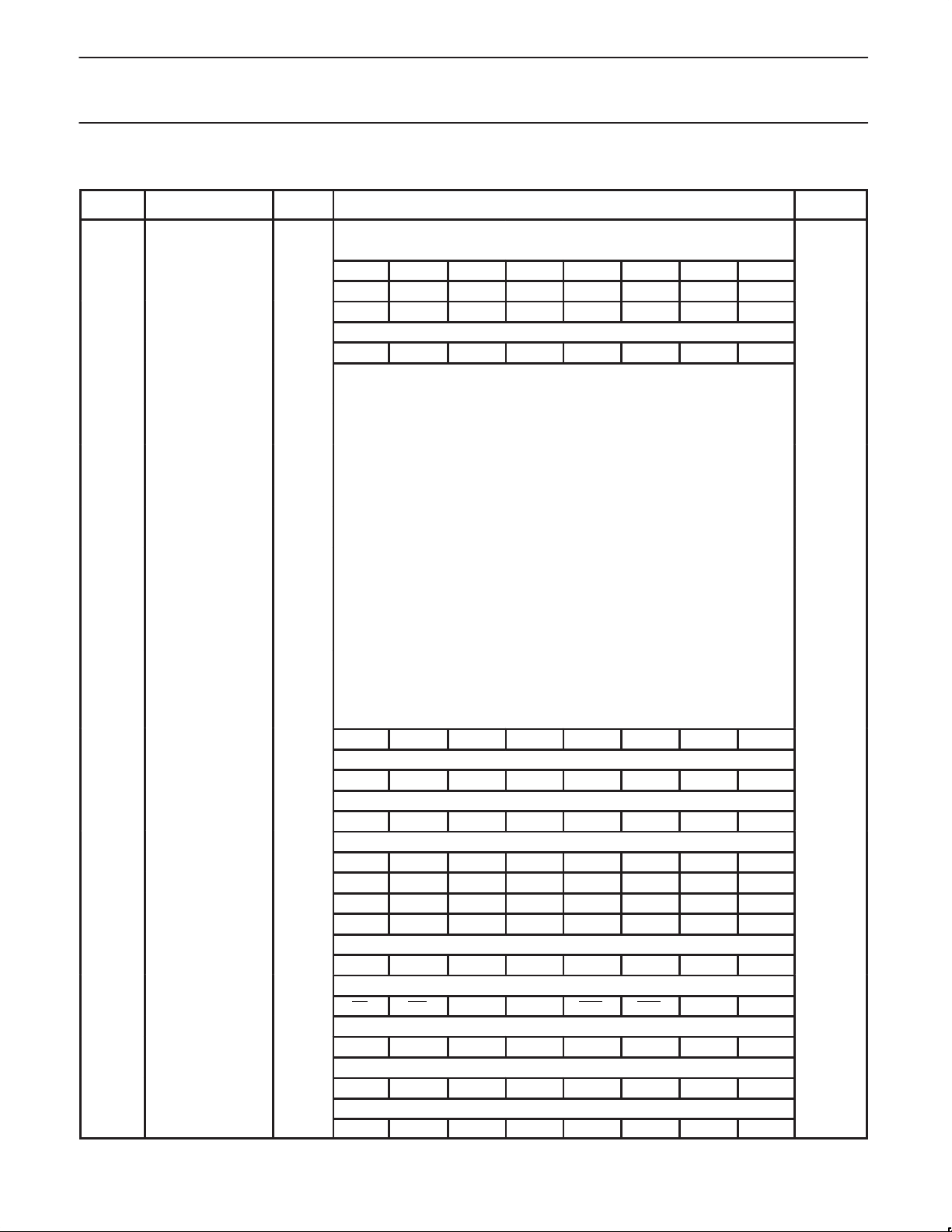

BLOCK DIAGRAM

DRAWING

NUMBER

AA = PLCC

XTAL1

XTAL2

EA

ALE

PSEN

3

3

0

2

WR

RD

AD0-7

A8-15

T0 T1 INT0 INT1

3 3 3 3

T0, T1

TWO 16-BIT

TIMER/EVENT

COUNTERS

PARALLEL I/O

PORTS AND

EXTERNAL BUS

80C51 CORE

EXCLUDING

ROM/RAM

CPU

SERIAL

UART

PORT

V

PROGRAM

MEMORY

16k x 8

OTP/ROM

8-BIT

PORT

DD

8-BIT INTERNAL BUS

16

FOUR

16-BIT

CAPTURE

LATCHES

V

SS

DATA

MEMORY

512 x 8 RAM

COUNTERS

T2

16-BIT

TIMER/

EVENT

PWM0 PWM1

DUAL

PWM

T2

16-BIT

16

COMPARA-

TORS

WITH

REGISTERS

AV

SS

AV

AV

REF

–+

STADC

DD

ADC

COMPARA-

TOR

OUTPUT

SELECTION

ADC0-7 SDA SCL

SERIAL

2

C PORT

I

T3

WATCHDOG

TIMER

115

0

ALTERNATE FUNCTION OF PORT 0

1

ALTERNATE FUNCTION OF PORT 1

2

ALTERNATE FUNCTION OF PORT 2

1999 Apr 07

3 3

P0 P1 P2 P3 TxD RxD P5 P4 CT0I-CT3I T2 RT2 CMSR0-CMSR5

3

ALTERNATE FUNCTION OF PORT 3

4

ALTERNATE FUNCTION OF PORT 4

5

ALTERNATE FUNCTION OF PORT 5

1 1 1 4

CMT0, CMT1

3

RST EW

SU00951

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

PIN CONFIGURATIONS

Plastic Quad Flat Pack pin functions

80 65

1

PQFP

24

25 40

64

41

NC = Not Connected

IC = Internally Connected (do not use)

Plastic Leaded Chip Carrier pin functions

9161

60

44

4327

Pin Function

47 PSEN

48 ALE/PROG

49 EA/V

50 P0.7/AD7

51 P0.6/AD6

52 P0.5/AD5

53 P0.4/AD4

54 P0.3/AD3

55 P0.2/AD2

56 P0.1/AD1

57 P0.0/AD0

58 AVref–

59 AVref+

60 AV

61 AV

62 P5.7/ADC7

63 P5.6/ADC6

64 P5.5/ADC5

65 P5.4/ADC4

66 P5.3/ADC3

67 P5.2/ADC2

68 P5.1/ADC1

Pin Function

1 P5.0/ADC0

2V

DD

3 STADC

4 PWM0

5 PWM1

6EW

7 P4.0/CMSR0

8 P4.1/CMSR1

9 P4.2/CMSR2

10 P4.3/CMSR3

11 P4.4/CMSR4

12 P4.5/CMSR5

13 P4.6/CMT0

14 P4.7/CMT1

15 RST

16 P1.0/CT0I

17 P1.1/CT1I

18 P1.2/CT2I

19 P1.3/CT3I

20 P1.4/T2

21 P1.5/RT2

22 P1.6/SCL

23 P1.7/SDA

10

CHIP CARRIER

26

Pin Function

24 P3.0/RxD

25 P3.1/TxD

26 P3.2/INT0

27 P3.3/INT1

28 P3.4/T0

29 P3.5/T1

30 P3.6/WR

31 P3.7/RD

32 NC

33 NC

34 XTAL2

35 XTAL1

36 V

37 V

38 NC

39 P2.0/A08

40 P2.1/A09

41 P2.2/A10

42 P2.3/A11

43 P2.4/A12

44 P2.5/A13

45 P2.6/A14

46 P2.7/A15

PLASTIC

LEADED

SS

SS

Pin Function

1 P4.1/CMSR1

2 P4.2/CMSR2

3NC

4 P4.3/CMSR3

5 P4.4/CMSR4

6 P4.5/CMSR5

7

P4.6/CMT0

8 P4.7/CMT1

9 RST

10 P1.0/CT0I

11 P1.1/CT1I

12 P1.2/CT2I

13

P1.3/CT3I

14 P1.4/T2

15 P1.5/RT2

16 P1.6/SCL

17 P1.7/SDA

18 P3.0/RxD

19 P3.1/TxD

20 P3.2/INT0

PP

SS

DD

SU00208

Pin Function

21 NC

22 NC

23 P3.3/INT1

24 P3.4/T0

25 P3.5/T1

26 P3.6/WR

27 P3.7/RD

28 NC

29 NC

30 NC

31 XTAL2

32 XTAL1

33 IC

34 V

SS

35 V

SS

36 V

SS

37 NC

38 P2.0/A08

39 P2.1/A09

40 P2.2/A10

LOGIC SYMBOL

V

SS

V

DD

XTAL1

XTAL2

V

EA/

PP

ALE/PROG

PSEN

AV

SS

AV

DD

AVref+

AVref–

STADC

PWM0

PWM1

ADC0-7

PORT 5

CMSR0-5

RST

EW

PORT 4

CMT0

CMT1

Pin Function

41 P2.3/A11

42 P2.4/A12

43 NC

44 NC

45 P2.5/A13

46 P2.6/A14

47 P2.7/A15

48 PSEN

49 ALE/PROG

50 EA/V

51 P0.7/AD7

52 P0.6/AD6

53 P0.5/AD5

54 P0.4/AD4

55 P0.3/AD3

56 P0.2/AD2

57

58 P0.0/AD0

59 AVref–

60 AVref+

PP

P0.1/AD1

Pin Function

61 AV

62 NC

63 AV

64 P5.7/ADC7

65 P5.6/ADC6

66 P5.5/ADC5

67 P5.4/ADC4

68 P5.3/ADC3

69 P5.2/ADC2

70 P5.1/ADC1

71 P5.0/ADC0

72 V

73 IC

74 STADC

75 PWM0

76 PWM1

77 EW

78 NC

79 NC

80 P4.0/CMSR0

PORT 0

CT0I

CT1I

CT2I

CT3I

T2

PORT 1PORT 2PORT 3

RT2

SCL

SDA

HIGH ORDER

ADDRESS AND

RxD/DATA

TxD/CLOCK

INT0

INT1

T0

T1

WR

RD

SS

DD

DD

SU00209

LOW ORDER

ADDRESS AND

DATA BUS

DATA BUS

SU00210

1999 Apr 07

4

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

PIN DESCRIPTION

PIN NO.

MNEMONIC PLCC QFP TYPE NAME AND FUNCTION

V

DD

STADC 3 74 I Start ADC Operation: Input starting analog to digital conversion (ADC operation can also

PWM0 4 75 O Pulse Width Modulation: Output 0.

PWM1 5 76 O Pulse Width Modulation: Output 1.

EW 6 77 I Enable Watchdog T imer: Enable for T3 watchdog timer and disable power-down mode.

P0.0-P0.7 57-50 58-51 I/O Port 0: Port 0 is an 8-bit open-drain bidirectional I/O port. Port 0 pins that have 1s written

P1.0-P1.7

P2.0-P2.7 39-46 38-42,

P3.0-P3.7

2 72 I Digital Power Supply: Positive voltage power supply pin during normal operation, idle and

16-23 10-17 I/O Port 1: 8-bit I/O port. Alternate functions include:

16-21 10-15 I/O (P1.0-P1.5): Programmable I/O port pins.

22-23 16-17 I/O (P1.6, P1.7): Open drain port pins.

16-19 10-13 I CT0I-CT3I (P1.0-P1.3): Capture timer input signals for timer T2.

20 14 I T2 (P1.4): T2 event input.

21 15 I RT2 (P1.5): T2 timer reset signal. Rising edge triggered.

22 16 I/O SCL (P1.6): Serial port clock line I2C-bus.

23 17 I/O SDA (P1.7): Serial port data line I2C-bus.

45-47

24-31 18-20,

23-27

24 18 RxD(P3.0): Serial input port.

25 19 TxD (P3.1): Serial output port.

26 20 INT0 (P3.2): External interrupt.

27 23 INT1 (P3.3): External interrupt.

28 24 T0 (P3.4): Timer 0 external input.

29 25 T1 (P3.5): Timer 1 external input.

30 26 WR (P3.6): External data memory write strobe.

31 27 RD (P3.7): External data memory read strobe.

power-down mode.

be started by software).

to them float and can be used as high-impedance inputs. Port 0 is also the multiplexed

low-order address and data bus during accesses to external program and data memory. In

this application it uses strong internal pull-ups when emitting 1s. Port 0 is also used to input

the code byte during programming and to output the code byte during verification.

Port 1 has four modes selected on a per bit basis by writing to the P1M1 and P1M2

registers as follows:

P1M1.x P1M2.x Mode Description

0 0 Pseudo–bidirectional (standard c51 configuration; default)

0 1 Push-Pull

1 0 High impedance

1 1 Open drain

Port 1 is also used to input the lower order address byte during EPROM programming and

verification. A0 is on P1.0, etc.

I/O Port 2: 8-bit programmable I/O port.

Alternate function: High-order address byte for external memory (A08-A15). Port 2 is also

used to input the upper order address during EPROM programming and verification. A8 is

on P2.0, A9 on P2.1, through A13 on P2.5.

Port 2 has four output modes selected on a per bit basis by writing to the P2M1 and P2M2

registers as follows:

P2M1.x P2M2.x Mode Description

0 0 Pseudo–bidirectional (standard c51 configuration; default)

0 1 Push-Pull

1 0 High impedance

1 1 Open drain

I/O Port 3: 8-bit programmable I/O port. Alternate functions include:

Port 3 has four modes selected on a per bit basis by writing to the P3M1 and P3M2

registers as follows:

P3M1.x P3M2.x Mode Description

0 0 Pseudo–bidirectional (standard c51 configuration; default)

0 1 Push–Pull

1 0 High impedance

1 1 Open drain

1999 Apr 07

5

Philips Semiconductors Preliminary specification

1

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

PIN DESCRIPTION (Continued)

PIN NO.

MNEMONIC PLCC QFP TYPE NAME AND FUNCTION

P4.0-P4.7

P5.0-P5.7 68-62,

RST 15 9 I/O Reset: Input to reset the 87C554. It also provides a reset pulse as output when timer T3

XTAL1 35 32 I Crystal Input 1: Input to the inverting amplifier that forms the oscillator, and input to the

XTAL2 34 31 O Crystal Input 2: Output of the inverting amplifier that forms the oscillator. Left open-circuit

V

SS

PSEN 47 48 O Program Store Enable: Active-low read strobe to external program memory.

ALE/PROG 48 49 O Address Latch Enable: Latches the low byte of the address during accesses to external

EA/V

PP

AV

REF–

AV

REF+

AV

SS

AV

DD

NOTE:

1. To avoid “latch-up” effect at power-on, the voltage on any pin at any time must not be higher or lower than V

respectively.

7-14 80, 1-2

4-8

7-12 80, 1-2

4-6

13, 14 7, 8 O CMT0, CMT1 (P4.6, P4.7): Timer T2 compare and toggle outputs on a match with timer T2.

71-64 I Port 5: 8-bit input port.

36, 37 34-36 I Digital ground.

49 50 I External Access: When EA is held at TTL level high, the CPU executes out of the internal

58 59 I Analog to Digital Conversion Reference Resistor: Low-end.

59 60 I Analog to Digital Conversion Reference Resistor: High-end.

60 61 I Analog Ground

61 63 I Analog Power Supply

I/O Port 4: 8-bit programmable I/O port. Alternate functions include:

O CMSR0-CMSR5 (P4.0-P4.5): Timer T2 compare and set/reset outputs on a match with

timer T2.

Port 4 has four modes selected on a per bit basis by writing to the P4M1 and P4M2

registers as follows:

P4M1.x P4M2.x Mode Description

0 0 Pseudo-bidirectional (standard c51 configuration; default)

0 1 Push-Pull

1 0 High impedance

1 1 Open drain

ADC0-ADC7 (P5.0-P5.7): Alternate function: Eight input channels to the ADC.

overflows.

internal clock generator. Receives the external clock signal when an external oscillator is

used.

when an external clock is used.

memory. It is activated every six oscillator periods. During an external data memory

access, one ALE pulse is skipped. ALE can drive up to eight LS TTL inputs and handles

CMOS inputs without an external pull-up. This pin is also the program pulse input (PROG)

during EPROM programming.

program ROM provided the program counter is less than 16,384. When EA is held at TTL

low level, the CPU executes out of external program memory. EA is not allowed to float.

This pin also receives the 12.75V programming supply voltage (VPP) during EPROM

programming.

+ 0.5V or VSS – 0.5V,

DD

1999 Apr 07

6

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

Table 1. 87C554 Special Function Registers

SYMBOL DESCRIPTION

ACC* Accumulator E0H E7 E6 E5 E4 E3 E2 E1 E0 00H

ADCH# A/D converter high C6H xxxxxxxxB

ADCON# A/D control C5H ADC.1 ADC.0 ADEX ADCI ADCS AADR2 AADR1 AADR0 xx000000B

AUXR Auxillary 8EH – – – – – LVADC EXTRAM A0 xxxxx110B

AUXR1 Auxillary A2H ADC8 AIDL SRST GF2 WUPD O – DPS 000000x0B

B* B register F0H F7 F6 F5 F4 F3 F2 F1 F0 00H

CTCON# Capture control EBH CTN3 CTP3 CTN2 CTP2 CTN1 CTP1 CTN0 CTP0 00H

CTH3# Capture high 3 CFH xxxxxxxxB

CTH2# Capture high 2 CEH xxxxxxxxB

CTH1# Capture high 1 CDH xxxxxxxxB

CTH0# Capture high 0 CCH xxxxxxxxB

CMH2# Compare high 2 CBH 00H

CMH1# Compare high 1 CAH 00H

CMH0# Compare high 0 C9H 00H

CTL3# Capture low 3 AFH xxxxxxxxB

CTL2# Capture low 2 AEH xxxxxxxxB

CTL1# Capture low 1 ADH xxxxxxxxB

CTL0# Capture low 0 ACH xxxxxxxxB

CML2# Compare low 2 ABH 00H

CML1# Compare low 1 AAH 00H

CML0# Compare low 0 A9H 00H

DPTR:

DPH

DPL

IEN0*# Interrupt enable 0 A8H EA EAD ES1 ES0 ET1 EX1 ET0 EX0 00H

IEN1*# Interrupt enable 1 E8H ET2 ECM2 ECM1 ECM0 ECT3 ECT2 ECT1 ECT0 00H

IP0*# Interrupt priority 0 B8H – PAD PS1 PS0 PT1 PX1 PT0 PX0 x0000000B

IP0H Interrupt priority 0 high B7H – PADH PS1H PS0H PT1H PX1H PT0H PX0H x0000000B

IP1*# Interrupt priority1 F8H PT2 PCM2 PCM1 PCM0 PCT3 PCT2 PCT1 PCT0 00H

IP1H Interrupt priority 1 high F7H PT2H PCM2H PCM1H PCM0H PCT3H PCT2H PCT1H PCT0H 00H

P5# Port 5 C4H ADC7 ADC6 ADC5 ADC4 ADC3 ADC2 ADC1 ADC0 xxxxxxxxB

P4#* Port 4 C0H CMT1 CMT0 CMSR5 CMSR4 CMSR3 CMSR2 CMSR1 CMSR0 FFH

P3* Port 3 B0H RD WR T1 T0 INT1 INT0 TXD RXD FFH

P2* Port 2 A0H A15 A14 A13 A12 A11 A10 A9 A8 FFH

P1* Port 1 90H SDA SCL RT2 T2 CT3I CT2I CT1I CT0I FFH

P0* Port 0 80H AD7 AD6 AD5 AD4 AD3 AD2 AD1 AD0 FFH

Data pointer

(2 bytes):

Data pointer high

Data pointer low

DIRECT

ADDRESS

83H

82H

MSB LSB

AF AE AD AC AB AA A9 A8

EF EE ED EC EB EA E9 E8

BF BE BD BC BB BA B9 B8

FF FE FD FC FB FA F9 F8

C7 C6 C5 C4 C3 C2 C1 C0

B7 B6 B5 B4 B3 B2 B1 B0

A7 A6 A5 A4 A3 A2 A1 A0

97 96 95 94 93 92 91 90

87 86 85 84 83 82 81 80

BIT ADDRESS, SYMBOL, OR ALTERNATIVE PORT FUNCTION

00H

00H

RESET

VALUE

1999 Apr 07

7

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

00H

00H

00H

00H

00H

00H

RESET

VALUE

SYMBOL

P1M1 Port 1 output mode 1 92H xx000000B

P1M2 Port 1 output mode 2 93H xx000000B

P2M1 Port 2 output mode 1 94H 00H

P2M2 Port 2 output mode 2 95H 00H

P3M1 Port 3 output mode 1 9AH 00H

P3M2 Port 3 output mode 2 9BH 00H

P4M1 Port 4 output mode 1 9CH 00H

P4M2 Port 4 output mode 2 9DH 00H

PCON Power control 87H SMOD1 SMOD0 POF WLE GF1 GFO PD IDL 00x00000B

PSW Program status word D0H CY AC FO RS1 RS0 OV F1 P 00H

PWMP# PWM prescaler FEH 00H

PWM1# PWM register 1 FDH 00H

PWM0# PWM register 0 FCH 00H

RTE# Reset/toggle enable EFH TP47 TP46 RP45 RP44 RP43 RP42 RP41 RP40 00H

S0ADDR Serial 0 slave address F9H 00H

S0ADEN Slave address mask B9H 00H

S0BUF Serial 0 data buffer 99H xxxxxxxxB

S0CON* Serial 0 control 98H SM0/FE SM1 SM2 REN TB8 RB8 TI RI 00H

S1ADR# Serial 1 address DBH SLAVE ADDRESS GC 00H

SIDAT# Serial 1 data DAH 00H

S1STA# Serial 1 status D9H SC4 SC3 SC2 SC1 SC0 0 0 0 F8H

SICON#* Serial 1 control D8H CR2 ENS1 STA ST0 SI AA CR1 CR0 00H

SP Stack pointer 81H 07H

STE# Set enable EEH TG47 TG46 SP45 SP44 SP43 SP42 SP41 SP40 C0H

TH1

TH0

TL1

TL0

TMH2#

TML2#

TMOD Timer mode 89H GATE C/T M1 M0 GATE C/T M1 M0 00H

TCON* Timer control 88H TF1 TR1 TF0 TR0 IE1 IT1 IE0 IT0 00H

TM2CON# Timer 2 control EAH T2IS1 T2IS0 T2ER T2B0 T2P1 T2P0 T2MS1 T2MS0 00H

TM2IR#* Timer 2 int flag reg C8H T20V CMI2 CMI1 CMI0 CTI3 CTI2 CTI1 CTI0 00H

T3# Timer 3 FFH 00H

DESCRIPTION

Timer high 1

Timer high 0

Timer low 1

Timer low 0

Timer high 2

Timer low 2

DIRECT

ADDRESS

8DH

8CH

8BH

8AH

EDH

ECH

MSB LSB

9F 9E 9D 9C 9B 9A 99 98

DF DE DD DC DB DA D9 D8

8F 8E 8D 8C 8B 8A 89 88

CF CE CD CC CB CA C9 C8

BIT ADDRESS, SYMBOL, OR ALTERNATIVE PORT FUNCTION

* SFRs are bit addressable.

# SFRs are modified from or added to the 80C51 SFRs.

1999 Apr 07

8

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

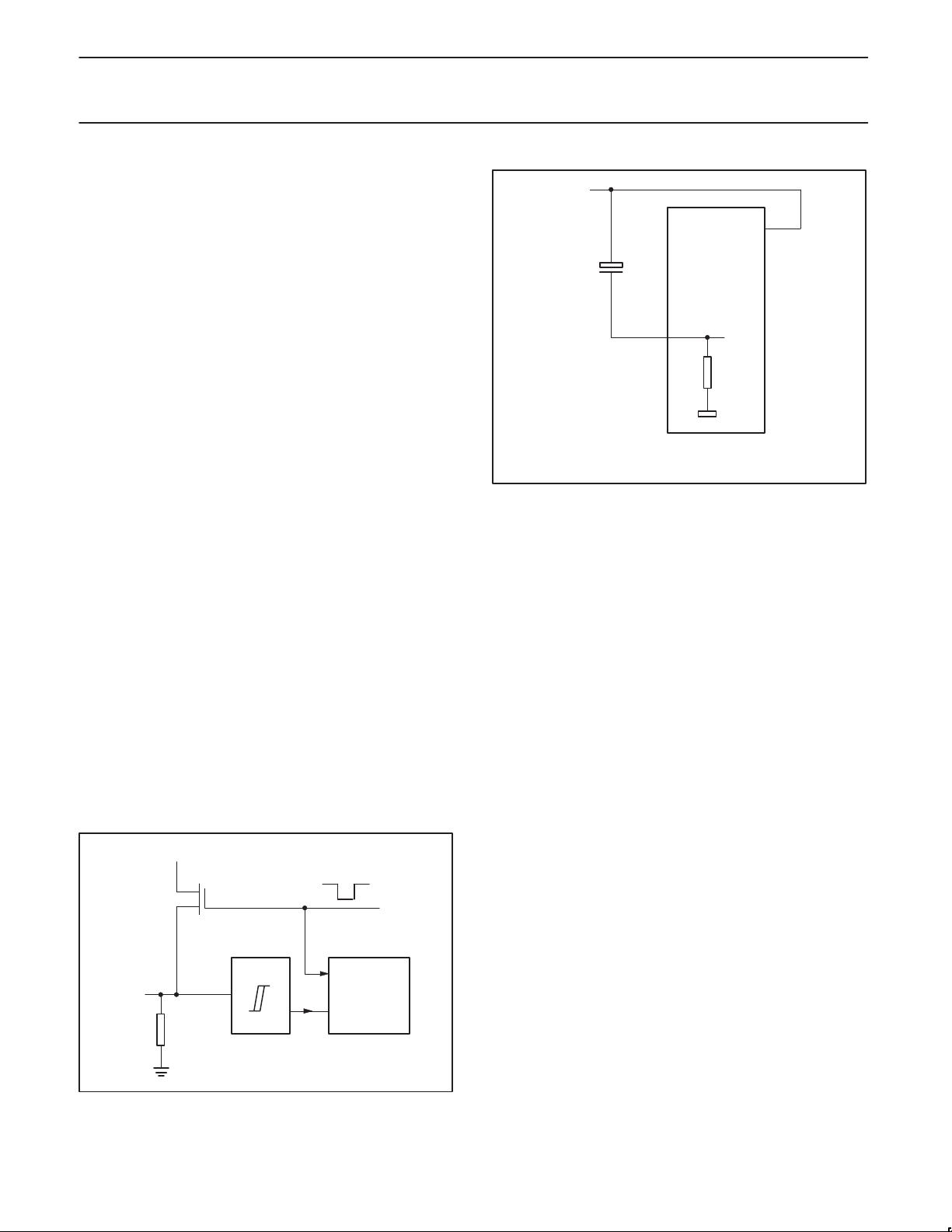

OSCILLA T OR CHARACTERISTICS

XTAL1 and XTAL2 are the input and output, respectively , of an

inverting amplifier . The pins can be configured for use as an on-chip

oscillator, as shown in the logic symbol.

To drive the device from an external clock source, XTAL1 should be

driven while XTAL2 is left unconnected. There are no requirements

on the duty cycle of the external clock signal, because the input to

the internal clock circuitry is through a divide-by-two flip-flop.

However, minimum and maximum high and low times specified in

the data sheet must be observed.

RESET

A reset is accomplished by either (1) externally holding the RST pin

high for at least two machine cycles (24 oscillator periods) or (2)

internally by an on-chip power-on detect (POD) circuit which detects

V

ramping up from 0V .

CC

To insure a good external power-on reset, the RST pin must be high

long enough for the oscillator to start up (normally a few

milliseconds) plus two machine cycles. The voltage on V

RST pin must come up at the same time for a proper startup.

For a successful internal power-on reset, the V

voltage must

CC

ramp up from 0V smoothly at a ramp rate greater than 5V/100 ms.

The RST line can also be pulled HIGH internally by a pull-up

transistor activated by the watchdog timer T3. The length of the

output pulse from T3 is 3 machine cycles. A pulse of such short

duration is necessary in order to recover from a processor or system

fault as fast as possible.

Note that the short reset pulse from Timer T3 cannot discharge the

power-on reset capacitor (see Figure 2). Consequently, when the

watchdog timer is also used to set external devices, this capacitor

arrangement should not be connected to the RST pin, and a

different circuit should be used to perform the power-on reset

operation. A timer T3 overflow, if enabled, will force a reset condition

to the 8XC554 by an internal connection, independent of the level of

the RST pin.

A reset may be performed in software by setting the software reset

bit, SRST (AUXR1.5).

V

DD

SCHMITT

TRIGGER

RST

ON-CHIP

RESISTOR

R

RST

RESET

CIRCUITRY

Figure 1. On-Chip Reset Configuration

and the

DD

OVERFLOW

TIMER T3

SU00952

V

DD

V

DD

2.2 µF

+

8XC554

RST

R

RST

SU00953

Figure 2. Power-On Reset

LOW POWER MODES

Stop Clock Mode

The static design enables the clock speed to be reduced down to

0 MHz (stopped). When the oscillator is stopped, the RAM and

Special Function Registers retain their values. This mode allows

step-by-step utilization and permits reduced system power

consumption by lowering the clock frequency down to any value. For

lowest power consumption the Power Down mode is suggested.

Idle Mode

In the idle mode (see Table 2), the CPU puts itself to sleep while

some of the on-chip peripherals stay active. The instruction to

invoke the idle mode is the last instruction executed in the normal

operating mode before the idle mode is activated. The CPU

contents, the on-chip RAM, and all of the special function registers

remain intact during this mode. The idle mode can be terminated

either by any enabled interrupt (at which time the process is picked

up at the interrupt service routine and continued), or by a hardware

reset which starts the processor in the same manner as a power-on

reset.

Power-Down Mode

To save even more power, a Power Down mode (see Table 2) can

be invoked by software. In this mode, the oscillator is stopped and

the instruction that invoked Power Down is the last instruction

executed. The on-chip RAM and Special Function Registers retain

their values down to 2.0V and care must be taken to return V

the minimum specified operating voltages before the Power Down

Mode is terminated.

Either a hardware reset or external interrupt can be used to exit from

Power Down. The Wake-up from Power-down bit, WUPD (AUXR1.3)

must be set in order for an external interrupt to cause a wake-up

from power-down. Reset redefines all the SFRs but does not

change the on-chip RAM. An external interrupt allows both the SFRs

and the on-chip RAM to retain their values.

To properly terminate Power Down the reset or external interrupt

should not be executed before V

is restored to its normal

CC

operating level and must be held active long enough for the

oscillator to restart and stabilize (normally less than 10ms).

CC

to

1999 Apr 07

9

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

Table 2. External Pin Status During Idle and Power-Down Modes

MODE

Idle Internal 1 1 Data Data Data Data Data High

Idle External 1 1 Float Data Address Data Data High

Power-down Internal 0 0 Data Data Data Data Data High

Power-down External 0 0 Float Data Data Data Data High

PROGRAM

MEMORY

ALE PSEN PORT 0 PORT 1 PORT 2 PORT 3 PORT 4

PWM0/

PWM1

With an external interrupt, INT0 and INT1 must be enabled and

configured as level-sensitive. Holding the pin low restarts the oscillator

but bringing the pin back high completes the exit. Once the interrupt

is serviced, the next instruction to be executed after RETI will be the

one following the instruction that put the device into Power Down.

POWER OFF FLAG

The Power Off Flag (POF) is set by on-chip circuitry when the V

level on the 8XC554 rises from 0 to 5V. The POF bit can be set or

cleared by software allowing a user to determine if the reset is the

result of a power-on or a warm start after powerdown. The V

must remain above 3V for the POF to remain unaffected by the V

level.

CC

CC

level

CC

Design Consideration

•When the idle mode is terminated by a hardware reset, the device

normally resumes program execution, from where it left off, up to

two machine cycles before the internal reset algorithm takes

control. On-chip hardware inhibits access to internal RAM in this

event, but access to the port pins is not inhibited. To eliminate the

possibility of an unexpected write when Idle is terminated by reset,

the instruction following the one that invokes Idle should not be

one that writes to a port pin or to external memory.

PCON

(87H)

ONCE Mode

The ONCE (“On-Circuit Emulation”) Mode facilitates testing and

debugging of systems without the device having to be removed from

the circuit. The ONCE Mode is invoked by:

1. Pull ALE low while the device is in reset and PSEN

2. Hold ALE low as RST is deactivated.

While the device is in ONCE Mode, the Port 0 pins go into a float

state, and the other port pins and ALE and PSEN

high. The oscillator circuit remains active. While the device is in this

mode, an emulator or test CPU can be used to drive the circuit.

Normal operation is restored when a normal reset is applied.

is high;

are weakly pulled

Reduced EMI Mode

The ALE-Off bit, AO (AUXR.0) can be set to disable the ALE output.

It will automatically become active when required for external

memory accesses and resume to the OFF state after completing the

external memory access.

01234567

PDGF0GF1WLEPOFSMOD0SMOD1

IDL

(LSB)(MSB)

BIT SYMBOL FUNCTION

PCON.7 SMOD1 Double Baud rate bit. When set to logic 1, the baud rate is doubled when the serial port SIO0 is being

PCON.6 SMOD0 Selects SM0/FE for SCON.7 bit.

PCON.5 POF Power Off Flag

PCON.4 WLE Watchdog Load Enable. This flag must be set by software prior to loading timer T3 (watchdog timer). It is

PCON.3 GF1 General-purpose flag bit.

PCON.2 GF0 General-purpose flag bit.

PCON.1 PD Power-down bit. Setting this bit activates the power-down mode. It can only be set if input EW

PCON.0 IDL Idle mode bit. Setting this bit activates the Idle mode.

If logic 1s are written to PD and IDL at the same time, PD takes precedence. The reset value of PCON is (00X00000).

1999 Apr 07

used in modes 1, 2, or 3.

cleared when timer T3 is loaded.

Figure 3. Power Control Register (PCON)

10

is high.

SU00954

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

Expanded Data RAM Addressing

The 8xC554 has internal data memory that is mapped into four

separate segments: the lower 128 bytes of RAM, upper 128 bytes of

RAM, 128 byte s S pecial Func tion Regist er (SFR), and 256 bytes

expanded RAM (EXTRAM).

The four segments are:

1. The Lower 128 bytes of RAM (addresses 00H to 7FH) are

directly and indirectly addressable.

2. The Upper 128 bytes of RAM (addresses 80H to FFH) are

indirectly addressable only.

3. The Special Function Registers, SFRs, (addresses 80H to FFH)

are directly addressable only.

4. The 256-bytes expanded RAM (ERAM, 00H – FFH) are indirectly

accessed by move external instruction, MOVX, and with the

EXTRAM bit cleared, see Figure 4.

The Lower 128 bytes can be accessed by either direct or indirect

addressing. The Upper 128 bytes can be accessed by indirect

addressing only . The Upper 128 bytes occupy the same address

space as the SFR. That means they have the same address, but are

physically separate from SFR space.

When an instruction accesses an internal location above address

7FH, the CPU knows whether the access is to the upper 128 bytes

of data RAM or to SFR space by the addressing mode used in the

instruction. Instructions that use direct addressing access SFR

space. For example:

MOV 0A0H,#data

accesses the SFR at location 0A0H (which is P2). Instructions that

use indirect addressing access the Upper 128 bytes of data RAM.

For example:

MOV @R0,#data

where R0 contains 0A0H, accesses the data byte at address 0A0H,

rather than P2 (whose address is 0A0H).

The ERAM can be accessed by indirect addressing, with EXTRAM

bit cleared and MOVX instructions. This part of memory is physically

located on-chip, logically occupies the first 256-bytes of external

data memory.

With EXTRAM = 0, the EXTRAM is indirectly addressed, using the

MOVX instruction in combination with any of the registers R0, R1 of

the selected bank or DPTR. An access to ERAM will not affect ports

P0, P3.6 (WR#) and P3.7 (RD#). P2 SFR is output during expanded

RAM addressing. For example, with EXTRAM = 0,

MOVX @R0,#data

where R0 contains 0A0H, accesses the ERAM at address 0A0H

rather than external memory. An access to external data memory

locations higher than FFH (i.e., 0100H to FFFFH) will be performed

with the MOVX DPTR instructions in the same way as in the

standard 80C51, so with P0 and P2 as data/address bus, and P3.6

and P3.7 as write and read timing signals. Refer to Figure 5.

With EXTRAM = 1, MOVX @Ri and MOVX @DPTR will be similar

to the standard 80C51. MOVX @ Ri will provide an 8-bit address

multiplexed with data on Port 0 and any output port pins can be

used to output higher order address bits. This is to provide the

external paging capability. MOVX @DPTR will generate a 16-bit

address. Port 2 outputs the high-order eight address bits (the

contents of DPH) while Port 0 multiplexes the low-order eight

address bits (DPL) with data. MOVX @Ri and MOVX @DPTR will

generate either read or write signals on P3.6 (#WR) and P3.7 (#RD).

The stack pointer (SP) may be located anywhere in the 256 bytes

RAM (lower and upper RAM) internal data memory. The stack may

not be located in the ERAM address space.

AUXR

Symbol Function

AO Disable/Enable ALE

EXTRAM Internal/External RAM (00H – FFH) access using MOVX @Ri/@DPTR

LVADC Enable A/D low voltage operation

— Not implemented, reserved for future use*.

NOTE:

*User software should not write 1s to reserved bits. These bits may be used in future 8051 family products to invoke new features. In that

case, the reset or inactive value of the new bit will be 0, and its active value will be 1. The value read from a reserved bit is indeterminate.

Address = 8EH

Not Bit Addressable

— ————LVADC EXTRAM AO

Bit:

AO Operating Mode

0 ALE is emitted at a constant rate of 1/6 the oscillator frequency.

1 ALE is active only during a MOVX or MOVC instruction.

EXTRAM Operating Mode

0 Internal ERAM (00H–FFH) access using MOVX @Ri/@DPTR

1 External data memory access.

LVADC Operating Mode

0 Turns off A/D charge pump.

1 T urns on A/D charge pump. Required for operation below 4V.

76543210

Figure 4. AUXR: Auxiliary Register

Reset Value = xxxx x110B

SU00979A

1999 Apr 07

11

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

FF

ERAM

256 BYTES

00

FF

UPPER

128 BYTES

INTERNAL RAM

80 80

LOWER

128 BYTES

INTERNAL RAM

00

Figure 5. Internal and External Data Memory Address Space with EXTRAM = 0

Dual DPTR

The dual DPTR structure (see Figure 6) is a way by which the chip

will specify the address of an external data memory location. There

are two 16-bit DPTR registers that address the external memory,

and a single bit called DPS = AUXR1/bit0 that allows the program

code to switch between them.

The DPS bit status should be saved by software when switching

between DPTR0 and DPTR1.

DPS

BIT0

AUXR1

DPH

(83H)

DPL

(82H)

Figure 6.

DPTR1

DPTR0

EXTERNAL

DATA

MEMORY

SU00745A

FF

SPECIAL

FUNCTION

REGISTER

00

FFFF

0100

0000

EXTERNAL

DATA

MEMORY

SU00980

Note that bit 2 is not writable and is always read as a zero. This

allows the DPS bit to be quickly toggled simply by executing an

INC AUXR1 instruction without affecting the other bits.

DPTR Instructions

The instructions that refer to DPTR refer to the data pointer that is

currently selected using the AUXR1/bit 0 register. The six

instructions that use the DPTR are as follows:

INC DPTR Increments the data pointer by 1

MOV DPTR, #data16 Loads the DPTR with a 16-bit constant

MOV A, @ A+DPTR Move code byte relative to DPTR to ACC

MOVX A, @ DPTR Move external RAM (16-bit address) to

ACC

MOVX @ DPTR , A Move ACC to external RAM (16-bit

address)

JMP @ A + DPTR Jump indirect relative to DPTR

The data pointer can be accessed on a byte-by-byte basis by

specifying the low or high byte in an instruction which accesses the

SFRs. See application note AN458 for more details.

1999 Apr 07

12

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

AUXR1

Symbol Function

DPS Data Pointer Switch—switches between DPRT0 and DPTR1.

WUPD Enable wakeup from powerdown.

GF2 General Purpose Flag—set and cleared by the user.

SRST Software Reset

AIDL Enables the ADC during idle mode.

ADC8 ADC Mode Switch—switches between 10-bit conversion and 8-bit conversion.

NOTE:

*User software should not write 1s to reserved bits. These bits may be used in future 8051 family products to invoke new features. In that

case, the reset or inactive value of the new bit will be 0, and its active value will be 1. The value read from a reserved bit is indeterminate.

Address = A2H

Not Bit Addressable

ADC8 AIDL SRST GF2 WUPD 0 — DSP

Bit:

DPS Operating Mode

0 DPTR0

1 DPTR1

ADC8 Operating Mode

0 10-bit conversion (50 machine cycles)

1 8-bit conversion (24 machine cycles)

76543210

Figure 7. AUXR1: DPTR Control Register

Reset Value = 0000 00x0B

SU01081

1999 Apr 07

13

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

Enhanced UART

The UART operates in all of the usual modes that are described in

the first section of

Microcontrollers

detect by looking for missing stop bits, and automatic address

recognition. The UART also fully supports multiprocessor

communication as does the standard 80C51 UART.

When used for framing error detect the UART looks for missing stop

bits in the communication. A missing bit will set the FE bit in the

S0CON register. The FE bit shares the S0CON.7 bit with SM0 and

the function of S0CON.7 is determined by PCON.6 (SMOD0) (see

Figure 8). If SMOD0 is set then S0CON.7 functions as FE.

S0CON.7 functions as SM0 when SMOD0 is cleared. When used as

FE S0CON.7 can only be cleared by software. Refer to Figure 9.

Automatic Address Recognition

Automatic Address Recognition is a feature which allows the UART

to recognize certain addresses in the serial bit stream by using

Symbol Function

Data Handbook IC20, 80C51-Based 8-Bit

. In addition the UART can perform framing error

S0CON Address = 98H

Bit Addressable

SM0/FE SM1 SM2 REN TB8 RB8 Tl Rl

Bit: 76543210

(SMOD0 = 0/1)*

hardware to make the comparisons. This feature saves a great deal

of software overhead by eliminating the need for the software to

examine every serial address which passes by the serial port. This

feature is enabled by setting the SM2 bit in S0CON. In the 9 bit

UART modes, mode 2 and mode 3, the Receive Interrupt flag (RI)

will be automatically set when the received byte contains either the

“Given” address or the “Broadcast” address. The 9 bit mode

requires that the 9th information bit is a 1 to indicate that the

received information is an address and not data. Automatic address

recognition is shown in Figure 10.

The 8 bit mode is called Mode 1. In this mode the RI flag will be set

if SM2 is enabled and the information received has a valid stop bit

following the 8 address bits and the information is either a Given or

Broadcast address.

Reset Value = 0000 0000B

FE Framing Error bit. This bit is set by the receiver when an invalid stop bit is detected. The FE bit is not cleared by valid

frames but should be cleared by software. The SMOD0 bit must be set to enable access to the FE bit.

SM0 Serial Port Mode Bit 0, (SMOD0 must = 0 to access bit SM0)

SM1 Serial Port Mode Bit 1

SM0 SM1 Mode Description Baud Rate**

0 0 0 shift register f

OSC

/12

0 1 1 8-bit UART variable

1 0 2 9-bit UART f

OSC

/64 or f

OSC

/32

1 1 3 9-bit UART variable

SM2 Enables the Automatic Address Recognition feature in Modes 2 or 3. If SM2 = 1 then Rl will not be set unless the

received 9th data bit (RB8) is 1, indicating an address, and the received byte is a Given or Broadcast Address.

In Mode 1, if SM2 = 1 then Rl will not be activated unless a valid stop bit was received, and the received byte is a

Given or Broadcast Address. In Mode 0, SM2 should be 0.

REN Enables serial reception. Set by software to enable reception. Clear by software to disable reception.

TB8 The 9th data bit that will be transmitted in Modes 2 and 3. Set or clear by software as desired.

RB8 In modes 2 and 3, the 9th data bit that was received. In Mode 1, if SM2 = 0, RB8 is the stop bit that was received.

In Mode 0, RB8 is not used.

Tl Transmit interrupt flag. Set by hardware at the end of the 8th bit time in Mode 0, or at the beginning of the stop bit in the

other modes, in any serial transmission. Must be cleared by software.

Rl Receive interrupt flag. Set by hardware at the end of the 8th bit time in Mode 0, or halfway through the stop bit time in

the other modes, in any serial reception (except see SM2). Must be cleared by software.

NOTE:

*SMOD0 is located at PCON6.

= oscillator frequency

**f

OSC

Figure 8. S0CON: Serial Port Control Register

SU00981

1999 Apr 07

14

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

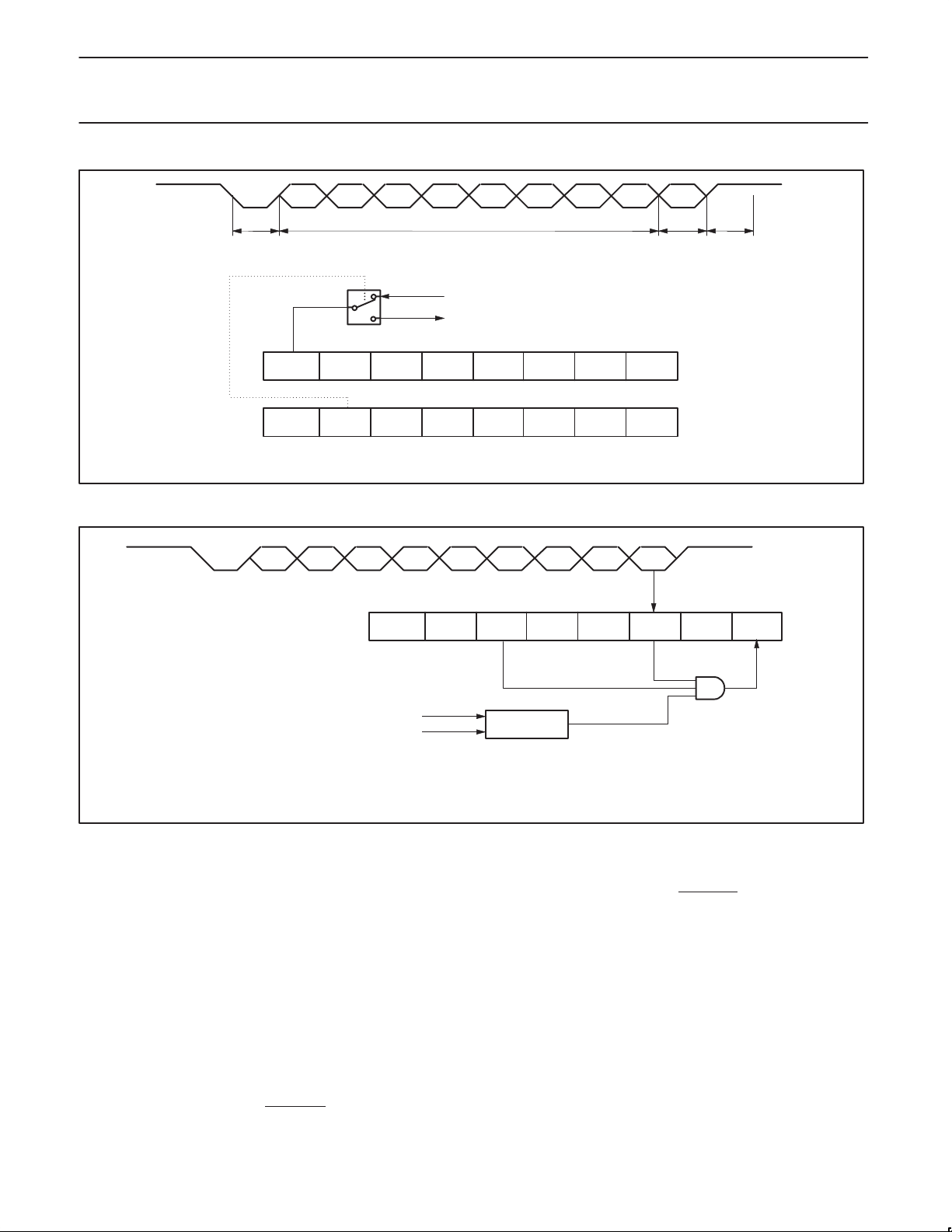

D0 D1 D2 D3 D4 D5 D6 D7 D8

START

BIT

SM0 / FE SM1 SM2 REN TB8 RB8 TI RI

SMOD1 SMOD0 POF WLE GF1 GF0 PD IDL

0 : S0CON.7 = SM0

1 : S0CON.7 = FE

DATA BYTE

SET FE BIT IF STOP BIT IS 0 (FRAMING ERROR)

SM0 TO UART MODE CONTROL

Figure 9. UART Framing Error Detection

D0 D1 D2 D3 D4 D5 D6 D7 D8

SM0 SM1 SM2 REN TB8 RB8 TI RI

1

1

1

0

11 X

ONLY IN

MODE 2, 3

SCON

(98H)

PCON

(87H)

STOP

BIT

SU00982

SCON

(98H)

RECEIVED ADDRESS D0 TO D7

PROGRAMMED ADDRESS

IN UART MODE 2 OR MODE 3 AND SM2 = 1:

INTERRUPT IF REN=1, RB8=1 AND “RECEIVED ADDRESS” = “PROGRAMMED ADDRESS”

– WHEN OWN ADDRESS RECEIVED, CLEAR SM2 TO RECEIVE DATA BYTES

– WHEN ALL DATA BYTES HAVE BEEN RECEIVED: SET SM2 TO WAIT FOR NEXT ADDRESS.

Figure 10. UART Multiprocessor Communication, Automatic Address Recognition

Mode 0 is the Shift Register mode and SM2 is ignored.

Using the Automatic Address Recognition feature allows a master to

selectively communicate with one or more slaves by invoking the

Given slave address or addresses. All of the slaves may be

contacted by using the Broadcast address. Two special Function

Registers are used to define the slave’s address, SADDR, and the

address mask, SADEN. SADEN is used to define which bits in the

SADDR are to b used and which bits are “don’t care”. The SADEN

mask can be logically ANDed with the SADDR to create the “Given”

address which the master will use for addressing each of the slaves.

Use of the Given address allows multiple slaves to be recognized

while excluding others. The following examples will help to show the

versatility of this scheme:

Slave 0 SADDR = 1100 0000

SADEN = 1111 1101

Given = 1100 00X0

COMPARATOR

SU00045

Slave 1 SADDR = 1100 0000

SADEN = 1111 1110

Given = 1100 000X

In the above example SADDR is the same and the SADEN data is

used to differentiate between the two slaves. Slave 0 requires a 0 in

bit 0 and it ignores bit 1. Slave 1 requires a 0 in bit 1 and bit 0 is

ignored. A unique address for Slave 0 would be 1100 0010 since

slave 1 requires a 0 in bit 1. A unique address for slave 1 would be

1100 0001 since a 1 in bit 0 will exclude slave 0. Both slaves can be

selected at the same time by an address which has bit 0 = 0 (for

slave 0) and bit 1 = 0 (for slave 1). Thus, both could be addressed

with 1100 0000.

1999 Apr 07

15

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

In a more complex system the following could be used to select

slaves 1 and 2 while excluding slave 0:

Slave 0 SADDR = 1100 0000

SADEN = 1111 1001

Given = 1100 0XX0

Slave 1 SADDR = 1110 0000

Slave 2 SADDR = 1110 0000

In the above example the differentiation among the 3 slaves is in the

lower 3 address bits. Slave 0 requires that bit 0 = 0 and it can be

uniquely addressed by 1110 01 10. Slave 1 requires that bit 1 = 0 and

it can be uniquely addressed by 1110 and 0101. Slave 2 requires

that bit 2 = 0 and its unique address is 1110 0011. To select Slaves 0

and 1 and exclude Slave 2 use address 1110 0100, since it is

necessary to make bit 2 = 1 to exclude slave 2.

The Broadcast Address for each slave is created by taking the

logical OR of SADDR and SADEN. Zeros in this result are trended

as don’t-cares. In most cases, interpreting the don’t-cares as ones,

the broadcast address will be FF hexadecimal.

Upon reset SADDR (SFR address 0A9H) and SADEN (SFR

address 0B9H) are leaded with 0s. This produces a given address

of all “don’t cares” as well as a Broadcast address of all “don’t

cares”. This effectively disables the Automatic Addressing mode and

allows the microcontroller to use standard 80C51 type UART drivers

which do not make use of this feature.

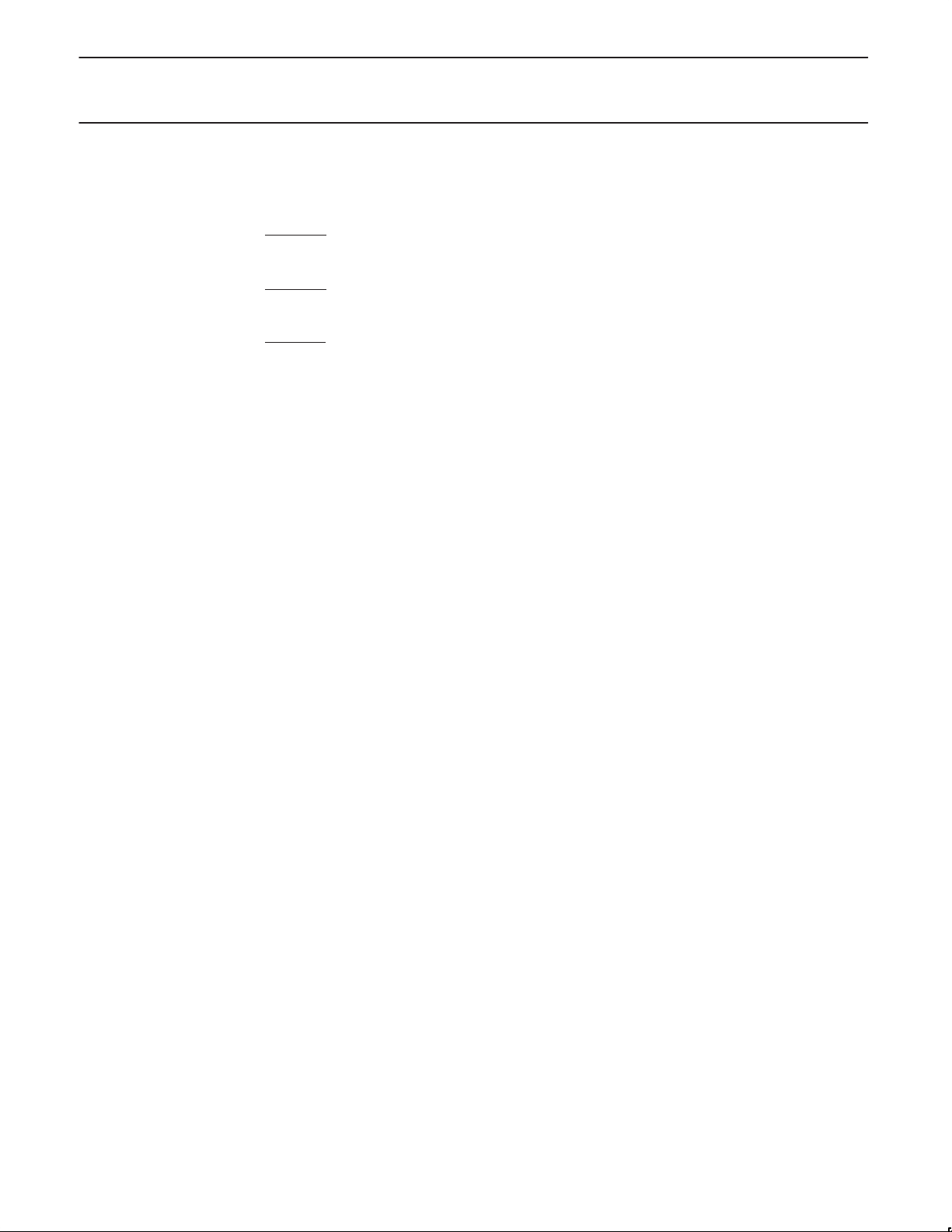

Timer T2

Timer T2 is a 16-bit timer consisting of two registers TMH2 (HIGH

byte) and TML2 (LOW byte). The 16-bit timer/counter can be

switched off or clocked via a prescaler from one of two sources:

f

/12 or an external signal. When Timer T2 is configured as a

OSC

counter, the prescaler is clocked by an external signal on T2 (P1.4).

A rising edge on T2 increments the prescaler, and the maximum

repetition rate is one count per machine cycle (1MHz with a 12MHz

oscillator).

The maximum repetition rate for Timer T2 is twice the maximum

repetition rate for Timer 0 and Timer 1. T2 (P1.4) is sampled at

S2P1 and again at S5P1 (i.e., twice per machine cycle). A rising

edge is detected when T2 is LOW during one sample and HIGH

during the next sample. To ensure that a rising edge is detected, the

input signal must be LOW for at least 1/2 cycle and then HIGH for at

least 1/2 cycle. If a rising edge is detected before the end of S2P1,

the timer will be incremented during the following cycle; otherwise it

will be incremented one cycle later. The prescaler has a

programmable division factor of 1, 2, 4, or 8 and is cleared if its

division factor or input source is changed, or if the timer/counter is

reset.

Timer T2 may be read “on the fly” but possesses no extra read

latches, and software precautions may have to be taken to avoid

misinterpretation in the event of an overflow from least to most

significant byte while Timer T2 is being read. Timer T2 is not

loadable and is reset by the RST signal or by a rising edge on the

input signal RT2, if enabled. RT2 is enabled by setting bit T2ER

(TM2CON.5).

When the least significant byte of the timer overflows or when a

16-bit overflow occurs, an interrupt request may be generated.

SADEN = 1111 1010

Given = 11 10 0X0X

SADEN = 1111 1100

Given = 1110 00XX

Either or both of these overflows can be programmed to request an

interrupt. In both cases, the interrupt vector will be the same. When

the lower byte (TML2) overflows, flag T2B0 (TM2CON) is set and

flag T20V (TM2IR) is set when TMH2 overflows. These flags are set

one cycle after an overflow occurs. Note that when T20V is set,

T2B0 will also be set. To enable the byte overflow interrupt, bits ET2

(IEN1.7, enable overflow interrupt, see Figure 11) and T2IS0

(TM2CON.6, byte overflow interrupt select) must be set. Bit TWB0

(TM2CON.4) is the Timer T2 byte overflow flag.

To enable the 16-bit overflow interrupt, bits ET2 (IE1.7, enable

overflow interrupt) and T2IS1 (TM2CON.7, 16-bit overflow interrupt

select) must be set. Bit T2OV (TM2IR.7) is the Timer T2 16-bit

overflow flag. All interrupt flags must be reset by software. To enable

both byte and 16-bit overflow, T2IS0 and T2IS1 must be set and two

interrupt service routines are required. A test on the overflow flags

indicates which routine must be executed. For each routine, only the

corresponding overflow flag must be cleared.

Timer T2 may be reset by a rising edge on RT2 (P1.5) if the Timer

T2 external reset enable bit (T2ER) in T2CON is set. This reset also

clears the prescaler. In the idle mode, the timer/counter and

prescaler are reset and halted. Timer T2 is controlled by the

TM2CON special function register (see Figure 12).

Timer T2 Extension: When a 12MHz oscillator is used, a 16-bit

overflow on Timer T2 occurs every 65.5, 131, 262, or 524 ms,

depending on the prescaler division ratio; i.e., the maximum cycle

time is approximately 0.5 seconds. In applications where cycle times

are greater than 0.5 seconds, it is necessary to extend Timer T2.

This is achieved by selecting fosc/12 as the clock source (set

T2MS0, reset T2MS1), setting the prescaler division ration to 1/8

(set T2P0, set T2P1), disabling the byte overflow interrupt (reset

T2IS0) and enabling the 16-bit overflow interrupt (set T2IS1). The

following software routine is written for a three-byte extension which

gives a maximum cycle time of approximately 2400 hours.

OVINT: PUSH ACC ;save accumulator

PUSH PSW ;save status

INC TIMEX1 ;increment first byte (low order)

;of extended timer

MOV A,TIMEX1

JNZ INTEX ;jump to INTEX if ;there is no overflow

INC TIMEX2 ;increment second byte

MOV A,TIMEX2

JNZ INTEX ;jump to INTEX if there is no overflow

INC TIMEX3 ;increment third byte (high order)

INTEX: CLR T2OV ;reset interrupt flag

POP PSW ;restore status

POP ACC ;restore accumulator

RETI ;return from interrupt

Timer T2, Capture and Compare Logic: Timer T2 is connected to

four 16-bit capture registers and three 16-bit compare registers. A

capture register may be used to capture the contents of Timer T2

when a transition occurs on its corresponding input pin. A compare

register may be used to set, reset, or toggle port 4 output pins at

certain pre-programmable time intervals.

The combination of Timer T2 and the capture and compare logic is

very powerful in applications involving rotating machinery,

automotive injection systems, etc. Timer T2 and the capture and

compare logic are shown in Figure 13.

1999 Apr 07

16

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

IEN1 (E8H)

TM2CON (EAH)

01234567

ECT1ECT2ECT3ECM0ECM1ECM2ET2

BIT SYMBOL FUNCTION

IEN1.7 ET2 Enable Timer T2 overflow interrupt(s)

IEN1.6 ECM2 Enable T2 Comparator 2 interrupt

IEN1.5 ECM1 Enable T2 Comparator 1 interrupt

IEN1.4 ECM0 Enable T2 Comparator 0 interrupt

IEN1.3 ECT3 Enable T2 Capture register 3 interrupt

IEN1.2 ECT2 Enable T2 Capture register 2 interrupt

IEN1.1 ECT1 Enable T2 Capture register 1 interrupt

IEN1.0 ECT0 Enable T2 Capture register 0 interrupt

Figure 11. Timer T2 Interrupt Enable Register (IEN1)

T2MS1T2P0T2P1T2BOT2ERT2IS0T2IS1

BIT SYMBOL FUNCTION

TM2CON.7 TSIS1 Timer T2 16-bit overflow interrupt select

TM2CON.6 T2IS0 Timer T2 byte overflow interrupt select

TM2CON.5 T2ER Timer T2 external reset enable. When this bit is set,

TM2CON.4 T2BO Timer T2 byte overflow interrupt flag

TM2CON.3 T2P1

TM2CON.2 T2P0

Timer T2 may be reset by a rising edge on RT2 (P1.5).

Timer T2 prescaler select

ECT0

(LSB)(MSB)

01234567

T2MS0

(LSB)(MSB)

Reset Value = 00H

SU01083

Reset Value = 00H

T2P1 T2P0 Timer T2 Clock

0 0 Clock source

0 1 Clock source/2

1 0 Clock source/4

1 1 Clock source/8

TM2CON.1 T2MS1

TM2CON.0 T2MS0

T2MS1 T2MS0 Mode Selected

0 0 Timer T2 halted (of f)

0 1 T2 clock source = f

1 0 Test mode; do not use

1 1 T2 clock source = pin T2

Figure 12. T2 Control Register (TM2CON)

Timer T2 mode select

OSC

/12

SU01084

1999 Apr 07

17

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

off

f

osc

T2

RT2

T2ER

External reset

S

S

S

S

S

S

TG

TG

STE RTE

1/12

enable

INTCT0I

CTI0

CT0 CT1 CT2 CT3

Prescaler T2 Counter

R

R

R

R

R

R

T

T

P4.0

P4.1

P4.2

P4.3

P4.4

P4.5

P4.6

P4.7

I/O port 4

CT1I

CT2I

CTI1

COMP

CMO (S)

S = set

R = reset

T = toggle

TG = toggle status

INTINT

CTI2

8-bit overflow interrupt

16-bit overflow interrupt

INT

T2 SFR address:

COMP

CM1 (R)

TML2 = lower 8 bits

TMH2 = higher 8 bits

Figure 13. Block Diagram of Timer 2

INT

CT3I

COMP

CM2 (T)

INT

CTI3

INT

SU00757

Capture Logic: The four 16-bit capture registers that Timer T2 is

connected to are: CT0, CT1, CT2, and CT3. These registers are

loaded with the contents of Timer T2, and an interrupt is requested

upon receipt of the input signals CT0I, CT1I, CT2I, or CT3I. These

input signals are shared with port 1. The four interrupt flags are in

the Timer T2 interrupt register (TM2IR special function register). If

the capture facility is not required, these inputs can be regarded as

additional external interrupt inputs.

Using the capture control register CTCON (see Figure 14), these

inputs may capture on a rising edge, a falling edge, or on either a

rising or falling edge. The inputs are sampled during S1P1 of each

cycle. When a selected edge is detected, the contents of Timer T2

are captured at the end of the cycle.

Measuring Time Intervals Using Capture Registers: When a

recurring external event is represented in the form of rising or falling

edges on one of the four capture pins, the time between two events

can be measured using Timer T2 and a capture register . When an

event occurs, the contents of Timer T2 are copied into the relevant

capture register and an interrupt request is generated. The interrupt

service routine may then compute the interval time if it knows the

previous contents of Timer T2 when the last event occurred. With a

12MHz oscillator, Timer T2 can be programmed to overflow every

524ms. When event interval times are shorter than this, computing

the interval time is simple, and the interrupt service routine is short.

For longer interval times, the Timer T2 extension routine may be

used.

Compare Logic: Each time Timer T2 is incremented, the contents

of the three 16-bit compare registers CM0, CM1, and CM2 are

compared with the new counter value of Timer T2. When a match is

found, the corresponding interrupt flag in TM2IR is set at the end of

the following cycle. When a match with CM0 occurs, the controller

sets bits 0-5 of port 4 if the corresponding bits of the set enable

register STE are at logic 1.

1999 Apr 07

18

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

CTCON (EBH)

BIT SYMBOL CAPTURE/INTERRUPT ON:

CTCON.7 CTN3 Capture Register 3 triggered by a falling edge on CT3I

CTCON.6 CTP3 Capture Register 3 triggered by a rising edge on CT3I

CTCON.5 CTN2 Capture Register 2 triggered by a falling edge on CT2I

CTCON.4 CTP2 Capture Register 2 triggered by a rising edge on CT2I

CTCON.3 CTN1 Capture Register 1 triggered by a falling edge on CT1I

CTCON.2 CTP1 Capture Register 1 triggered by a rising edge on CT1I

CTCON.1 CTN0 Capture Register 0 triggered by a falling edge on CT0I

CTCON.0 CTP0 Capture Register 0 triggered by a rising edge on CT0I

Figure 14. Capture Control Register (CTCON)

When a match with CM1 occurs, the controller resets bits 0-5 of port

4 if the corresponding bits of the reset/toggle enable register RTE

are at logic 1 (see Figure 15 for RTE register function). If RTE is “0”,

then P4.n is not affected by a match between CM1 or CM2 and

Timer 2. When a match with CM2 occurs, the controller “toggles”

bits 6 and 7 of port 4 if the corresponding bits of the RTE are at

logic 1. The port latches of bits 6 and 7 are not toggled.

Two additional flip-flops store the last operation, and it is these

flip-flops that are toggled.

Thus, if the current operation is “set,” the next operation will be

“reset” even if the port latch is reset by software before the “reset”

operation occurs. The first “toggle” after a chip RESET will set the

port latch. The contents of these two flip-flops can be read at STE.6

and STE.7 (corresponding to P4.6 and P4.7, respectively). Bits

STE.6 and STE.7 are read only (see Figure 16 for STE register

function). A logic 1 indicates that the next toggle will set the port

latch; a logic 0 indicates that the next toggle will reset the port latch.

CM0, CM1, and CM2 are reset by the RST signal.

The modified port latch information appears at the port pin during

S5P1 of the cycle following the cycle in which a match occurred. If

the port is modified by software, the outputs change during S1P1 of

the following cycle. Each port 4 bit can be set or reset by software at

any time. A hardware modification resulting from a comparator

match takes precedence over a software modification in the same

cycle. When the comparator results require a “set” and a “reset” at

the same time, the port latch will be reset.

01234567

CTN1CTP1CTN1CTP2CTN2CTP3CTN3

Timer T2 Interrupt Flag Register TM2IR: Eight of the nine Timer

T2 interrupt flags are located in special function register TM2IR (see

Figure 17). The ninth flag is TM2CON.4.

The CT0I and CT1I flags are set during S4 of the cycle in which the

contents of Timer T2 are captured. CT0I is scanned by the interrupt

logic during S2, and CT1I is scanned during S3. CT2I and CT3I are

set during S6 and are scanned during S4 and S5. The associated

interrupt requests are recognized during the following cycle. If these

flags are polled, a transition at CT0I or CT1I will be recognized one

cycle before a transition on CT2I or CT3I since registers are read

during S5. The CMI0, CMI1, and CMI2 flags are set during S6 of the

cycle following a match. CMI0 is scanned by the interrupt logic

during S2; CMI1 and CMI2 are scanned during S3 and S4. A match

will be recognized by the interrupt logic (or by polling the flags) two

cycles after the match takes place.

The 16-bit overflow flag (T2OV) and the byte overflow flag (T2BO)

are set during S6 of the cycle in which the overflow occurs. These

flags are recognized by the interrupt logic during the next cycle.

Special function register IP1 (Figure 17) is used to determine the

Timer T2 interrupt priority. Setting a bit high gives that function a

high priority , and setting a bit low gives the function a low priority.

The functions controlled by the various bits of the IP1 register are

shown in Figure 17.

CTP0

(LSB)(MSB)

Reset Value = 00H

SU01085

1999 Apr 07

RTE (EFH)

01234567

RO41RP42RP43RP44RP45TP46TP47

BIT SYMBOL FUNCTION

RTE.7 TP47 If “1” then P4.7 toggles on a match between CM1 and Timer T2

RTE.6 TP46 If “1” then P4.6 toggles on a match between CM1 and Timer T2

RTE.5 RP45 If “1” then P4.5 is reset on a match between CM1 and Timer T2

RTE.4 RP44 If “1” then P4.4 is reset on a match between CM1 and Timer T2

RTE.3 RP43 If “1” then P4.3 is reset on a match between CM1 and Timer T2

RTE.2 RP42 If “1” then P4.2 is reset on a match between CM1 and Timer T2

RTE.1 RP41 If “1” then P4.1 is reset on a match between CM1 and Timer T2

RTE.0 RP40 If “1” then P4.0 is reset on a match between CM1 and Timer T2

Figure 15. Reset/Toggle Enable Register (RTE)

19

RP40

(LSB)(MSB)

Reset Value = 00H

SU01086

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

STE (EEH)

TM2IR (C8H)

01234567

SP41SP42SP43SP44SP45TG46TG47

BIT SYMBOL FUNCTION

STE.7 TG47 Toggle flip-flops

STE.6 TG46 Toggle flip-flops

STE.5 SP45 If “1” then P4.5 is set on a match between CM0 and Timer T2

STE.4 SP44 If “1” then P4.4 is set on a match between CM0 and Timer T2

STE.3 SP43 If “1” then P4.3 is set on a match between CM0 and Timer T2

STE.2 SP42 If “1” then P4.2 is set on a match between CM0 and Timer T2

STE.1 SP41 If “1” then P4.1 is set on a match between CM0 and Timer T2

STE.0 SP40 If “1” then P4.0 is set on a match between CM0 and Timer T2

Figure 16. Set Enable Register (STE)

CTI1CTI2CTI3CMI0CMI1CMI2T2OV

BIT SYMBOL FUNCTION

TM2IR.7 T2OV Timer T2 16-bit overflow interrupt flag

TM2IR.6 CMI2 CM2 interrupt flag

TM2IR.5 CMI1 CM1 interrupt flag

TM2IR.4 CMI0 CM0 interrupt flag

TM2IR.3 CTI3 CT3 interrupt flag

TM2IR.2 CTI2 CT2 interrupt flag

TM2IR.1 CTI1 CT1 interrupt flag

TM2IR.0 CTI0 CT0 interrupt flag

SP40

(LSB)(MSB)

01234567

CTI0

(LSB)(MSB)

Reset Value = C0H

SU01087

Reset Value = 00H

Interrupt Flag Register (TM2IR)

01234567

IP1 (F8H)

BIT SYMBOL FUNCTION

IP1.7 PT2 Timer T2 overflow interrupt(s) priority level

IP1.6 PCM2 T imer T2 comparator 2 interrupt priority level

IP1.5 PCM1 T imer T2 comparator 1 interrupt priority level

IP1.4 PCM0 T imer T2 comparator 0 interrupt priority level

IP1.3 PCT3 Timer T2 capture register 3 interrupt priority level

IP1.2 PCT2 Timer T2 capture register 2 interrupt priority level

IP1.1 PCT1 Timer T2 capture register 1 interrupt priority level

IP1.0 PCT0 Timer T2 capture register 0 interrupt priority level

Timer 2 Interrupt Priority Register (IP1)

Figure 17. Interrupt Flag Register (TM2IR) and Timer T2 Interrupt Priority Register (IP1)

PCT1PCT2PCT3PCM0PCM1PCM2PT2

PCT0

(LSB)(MSB)

Reset Value = 00H

SU01088

1999 Apr 07

20

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

Timer T3, The Watchdog T imer

In addition to Timer T2 and the standard timers, a watchdog timer is

also incorporated on the 8xC554. The purpose of a watchdog timer

is to reset the microcontroller if it enters erroneous processor states

(possibly caused by electrical noise or RFI) within a reasonable

period of time. An analogy is the “dead man’s handle” in railway

locomotives. When enabled, the watchdog circuitry will generate a

system reset if the user program fails to reload the watchdog timer

within a specified length of time known as the “watchdog interval.”

Watchdog Circuit Description: The watchdog timer (Timer T3)

consists of an 8-bit timer with an 11-bit prescaler as shown in

Figure 18. The prescaler is fed with a signal whose frequency is

1/12 the oscillator frequency (1MHz with a 12MHz oscillator). The

8-bit timer is incremented every “t” seconds, where:

t = 12 × 2048 × 1/f

(= 1.5ms at f

OSC

OSC

= 16MHz; = 1ms at f

= 24MHz)

OSC

If the 8-bit timer overflows, a short internal reset pulse is generated

which will reset the 8xC554. A short output reset pulse is also

generated at the RST pin. This short output pulse (3 machine

cycles) may be destroyed if the RST pin is connected to a capacitor.

This would not, however, affect the internal reset operation.

Watchdog operation is activated when external pin EW

When EW

is tied low, it is impossible to disable the watchdog

is tied low.

operation by software.

How to Operate the Watchdog Timer: The watchdog timer has to

be reloaded within periods that are shorter than the programmed

watchdog interval; otherwise the watchdog timer will overflow and a

system reset will be generated. The user program must therefore

continually execute sections of code which reload the watchdog

timer. The period of time elapsed between execution of these

sections of code must never exceed the watchdog interval. When

using a 16MHz oscillator, the watchdog interval is programmable

between 1.5ms and 392ms. When using a 24MHz oscillator, the

watchdog interval is programmable between 1ms and 255ms.

In order to prepare software for watchdog operation, a programmer

should first determine how long his system can sustain an

erroneous processor state. The result will be the maximum

watchdog interval. As the maximum watchdog interval becomes

shorter, it becomes more dif ficult for the programmer to ensure that

the user program always reloads the watchdog timer within the

watchdog interval, and thus it becomes more difficult to implement

watchdog operation.

The programmer must now partition the software in such a way that

reloading of the watchdog is carried out in accordance with the above

requirements. The programmer must determine the execution times

of all software modules. The effect of possible conditional branches,

subroutines, external and internal interrupts must all be taken into

account. Since it may be very difficult to evaluate the execution

times of some sections of code, the programmer should use worst

case estimations. In any event, the programmer must make sure

that the watchdog is not activated during normal operation.

The watchdog timer is reloaded in two stages in order to prevent

erroneous software from reloading the watchdog. First PCON.4

(WLE) must be set. The T3 may be loaded. When T3 is loaded,

PCON.4 (WLE) is automatically reset. T3 cannot be loaded if

PCON.4 (WLE) is reset. Reload code may be put in a subroutine as

it is called frequently. Since Timer T3 is an up-counter, a reload

value of 00H gives the maximum watchdog interval (510ms with a

12MHz oscillator), and a reload value of 0FFH gives the minimum

watchdog interval (2ms with a 12MHz oscillator).

In the idle mode, the watchdog circuitry remains active. When

watchdog operation is implemented, the power-down mode cannot

be used since both states are contradictory. Thus, when watchdog

operation is enabled by tying external pin EW

low, it is impossible to

enter the power-down mode, and an attempt to set the power-down

bit (PCON.1) will have no effect. PCON.1 will remain at logic 0.

f

OSC

1999 Apr 07

/12

EW

PRESCALER (11-BIT)

WRITE T3

CLEAR

INTERNAL BUS

TIMER T3 (8-BIT)

LOAD LOADEN

INTERNAL

RESET

CLEAR

WLE

PCON.4 PCON.1

INTERNAL BUS

Figure 18. Watchdog Timer

21

OVERFLOW

LOADEN

PD

V

DD

P

RST

R

RST

SU00955

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

During the early stages of software development/debugging, the

watchdog may be disabled by tying the EW

stage, EW

may be tied low to complete the debugging process.

pin high. At a later

Watchdog Software Example: The following example shows how

watchdog operation might be handled in a user program.

;at the program start:

T3 EQU 0FFH ;address of watchdog timer T3

PCON EQU 087H ;address of PCON SFR

WATCH-INTV EQU 156 ;watchdog interval (e.g., 2x100ms)

;to be inserted at each watchdog reload location within

;the user program:

LCALL WATCHDOG

;watchdog service routine:

WATCHDOG: ORL PCON,#10H ;set condition flag (PCON.4)

MOV T3,WATCH-INV ;load T3 with watchdog interval

RET

If it is possible for this subroutine to be called in an erroneous state,

then the condition flag WLE should be set at different parts of the

main program.

Serial I/O

The 8xC554 is equipped with two independent serial ports: SIO0

and SIO1. SIO0 is a full duplex UART port and is similar to the

Enhanced UART serial port. SIO1 accommodates the I

2

C bus.

SIO0: SIO0 is a full duplex serial I/O port identical to that of the

Enhanced UART except Time 2 cannot be used as a baud rate

generator. Its operation is the same, including the use of timer 1 as a

baud rate generator.

Port 5 Operation

Port 5 may be used to input up to 8 analog signals to the ADC.

Unused ADC inputs may be used to input digital inputs. These

inputs have an inherent hysteresis to prevent the input logic from

drawing excessive current from the power lines when driven by

analog signals. Channel to channel crosstalk (Ct) should be taken

into consideration when both analog and digital signals are

simultaneously input to Port 5 (see, D.C. characteristics in data

sheet).

Port 5 is not bidirectional and may not be configured as an output

port. All six ports are multifunctional, and their alternate functions

are listed in the Pin Descriptions section of this datasheet.

Pulse Width Modulated Outputs

The 8xC554 contains two pulse width modulated output channels

(see Figure 19). These channels generate pulses of programmable

length and interval. The repetition frequency is defined by an 8-bit

prescaler PWMP, which supplies the clock for the counter. The

prescaler and counter are common to both PWM channels. The 8-bit

counter counts modulo 255, i.e., from 0 to 254 inclusive. The value

of the 8-bit counter is compared to the contents of two registers:

PWM0 and PWM1. Provided the contents of either of these registers

is greater than the counter value, the corresponding PWM0

PWM1

output is set LOW. If the contents of these registers are

or

equal to, or less than the counter value, the output will be HIGH. The

pulse-width-ratio is therefore defined by the contents of the registers

PWM0 and PWM1. The pulse-width-ratio is in the range of 0 to 1

and may be programmed in increments of 1/255.

Buffered PWM outputs may be used to drive DC motors. The

rotation speed of the motor would be proportional to the contents of

PWMn. The PWM outputs may also be configured as a dual DAC. In

this application, the PWM outputs must be integrated using

conventional operational amplifier circuitry. If the resulting output

voltages have to be accurate, external buffers with their own analog

supply should be used to buffer the PWM outputs before they are

integrated. The repetition frequency f

, at the PWMn outputs is

PWM

give by:

f

f

PWM

2 (1 PWMP) 255

This gives a repetition frequency range of 123Hz to 31.4kHz (f

OSC

OSC

=

16MHz). At fosc = 24MHz, the frequency range is 184Hz to 47.1Hz.

By loading the PWM registers with either 00H or FFH, the PWM

channels will output a constant HIGH or LOW level, respectively.

Since the 8-bit counter counts modulo 255, it can never actually

reach the value of the PWM registers when they are loaded with

FFH.

When a compare register (PWM0 or PWM1) is loaded with a new

value, the associated output is updated immediately. It does not

have to wait until the end of the current counter period. Both PWMn

output pins are driven by push-pull drivers. These pins are not used

for any other purpose.

Prescaler frequency control register PWMP Reset Value = 00H

PWMP (FEH) 765 43210

MSB LSB

PWMP.0-7 Prescaler division factor = PWMP + 1.

Reading PWMP gives the current reload value. The actual count of

the prescaler cannot be read.

Reset Value = 00H

PWM0 (FCH)

PWM1 (FDH)

PWM0/1.0-7} Low/high ratio of PWMn

765 43 210

MSB LSB

(PWMn)

255 (PWMn)

Analog-to-Digital Converter

The analog input circuitry consists of an 8-input analog multiplexer

and a 10-bit, straight binary, successive approximation ADC. The

A/D can also be operated in 8-bit mode with faster conversion times

by setting bit ADC8 (AUXR1.7). The 8-bit results will be contained in

the ADCH register. The analog reference voltage and analog power

supplies are connected via separate input pins. For 10-bit accuracy,

the conversion takes 50 machine cycles, i.e., 37.5µs at an oscillator

frequency of 16MHz, 25µs at an oscillator frequency of 24MHz. For

the 8-bit mode, the conversion takes 24 machine cycles. Input

voltage swing is from 0V to +5V . Because the internal DAC employs

a ratiometric potentiometer , there are no discontinuities in the

converter characteristic. Figure 20 shows a functional diagram of the

analog input circuitry.

The ADC has the option of either being powered off in idle mode for

reduced power consumption or being active in idle mode for

reducing internal noise during the conversion. This option is selected

by the AIDL bit of AUXR1 register (AUXR1.6). With the AIDL bit set,

the ADC is active in the idle mode, and with the AIDL bit cleared, the

ADC is powered off in idle mode.

1999 Apr 07

22

Philips Semiconductors Preliminary specification

80C51 8-bit microcontroller

16K/512 OTP/ROM/ROMless, 8 channel 10 bit A/D, I2C, PWM,

80C554/83C554/87C554

capture/compare, high I/O

PWM0

ADC0

ADC1

ADC2

ADC3

ADC4

ADC5

ADC6