Philips 87LPC768 Datasheet

INTEGRATED CIRCUITS

87LPC768

Low power, low price, low pin count

(20 pin) microcontroller with 4 kB OTP

8-bit A/D,and Pulse Width Modulator

Preliminary specification 2000 May 02

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller

with 4 kB OTP 8-bit A/D, Pulse Width Modulator

GENERAL DESCRIPTION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FEATURES 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ORDERING INFORMATION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PIN CONFIGURATION, 20-PIN DIP AND SO PACKAGES 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOGIC SYMBOL 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BLOCK DIAGRAM 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PIN DESCRIPTIONS 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCTIONAL DESCRIPTION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enhanced CPU 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Functions 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog to Digital Converter 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/D Timing 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The A/D in Power Down and Idle Modes 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Code Examples for the A/D 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Comparators 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I2C Serial Interface 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interrupts 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Ports 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard Interrupt (KBI) 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oscillator 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Monitoring Functions 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Reduction Modes 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timer/Counters 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UART 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Watchdog Timer 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Features 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EPROM Characteristics 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ABSOLUTE MAXIMUM RATINGS 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC ELECTRICAL CHARACTERISTICS 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPARATOR ELECTRICAL CHARACTERISTICS 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/D CONVERTER DC ELECTRICAL CHARACTERISTICS 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC ELECTRICAL CHARACTERISTICS 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

87LPC768

2000 May 02

i

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with 4 kB

OTP 8-bit A/D, Pulse Width Modulator

GENERAL DESCRIPTION

The 87LPC768 is a 20-pin single-chip microcontroller designed for

low pin count applications demanding high-integration, low cost

solutions over a wide range of performance requirements. A

member of the Philips low pin count family, the 87LPC768 of fers

programmable oscillator configurations for high and low speed

crystals or RC operation, wide operating voltage range,

programmable port output configurations, selectable Schmitt trigger

inputs, LED drive outputs, and a built-in watchdog timer. The

87LPC768 is based on an accelerated 80C51 processor

architecture that executes instructions at twice the rate of standard

80C51 devices.

FEA TURES

•An accelerated 80C51 CPU provides instruction cycle times of

300–600 ns for all instructions except multiply and divide when

executing at 20 MHz. Execution at up to 20 MHz when

V

= 4.5 V to 6.0 V, 10 MHz when VDD = 2.7 V to 6.0 V.

DD

•Four-channel 10-bit Pulse Width Modulator

•Four-channel multiplexed 8-bit A/D converter. Conversion time of

9.3µS at f

= 20 MHz.

osc

•2.7 V to 6.0 V operating range for digital functions.

•4 K bytes EPROM code memory.

•128 byte RAM data memory.

•32-byte customer code EPROM allows serialization of devices,

storage of setup parameters, etc.

•Two 16-bit counter/timers. Each timer may be configured to toggle

a port output upon timer overflow.

•Two analog comparators.

•Full duplex UART.

2

•I

C communication port.

•Eight keypad interrupt inputs, plus two additional external interrupt

inputs.

•Watchdog timer with separate on-chip oscillator , requiring no

external components. The watchdog timeout time is selectable

from 8 values.

•Active low reset. On-chip power-on reset allows operation with no

external reset components.

•Low voltage reset. One of two preset low voltage levels may be

selected to allow a graceful system shutdown when power fails.

May optionally be configured as an interrupt.

•Oscillator Fail Detect. The watchdog timer has a separate fully

on-chip oscillator, allowing it to perform an oscillator fail detect

function.

•Configurable on-chip oscillator with frequency range and RC

oscillator options (selected by user programmed EPROM bits).

The RC oscillator option allows operation with no external

oscillator components.

•Programmable port output configuration options:

quasi-bidirectional, open drain, push-pull, input-only.

•Selectable Schmitt trigger port inputs.

•LED drive capability (20 mA) on all port pins.

•Controlled slew rate port outputs to reduce EMI. Outputs have

approximately 10 ns minimum ramp times.

•15 I/O pins minimum. Up to 18 I/O pins using on-chip oscillator

and reset options.

•Only power and ground connections are required to operate the

87LPC768 when fully on-chip oscillator and reset options are

selected.

•Serial EPROM programming allows simple in-circuit production

coding. Two EPROM security bits prevent reading of sensitive

application programs.

•Idle and Power Down reduced power modes. Improved wakeup

from Power Down mode (a low interrupt input starts execution).

Typical Power Down current is 1 µA.

•20-pin DIP and SO packages.

•Four interrupt priority levels.

87LPC768

2000 May 02

1

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

4 kB OTP 8-bit A/D, Pulse Width Modulator

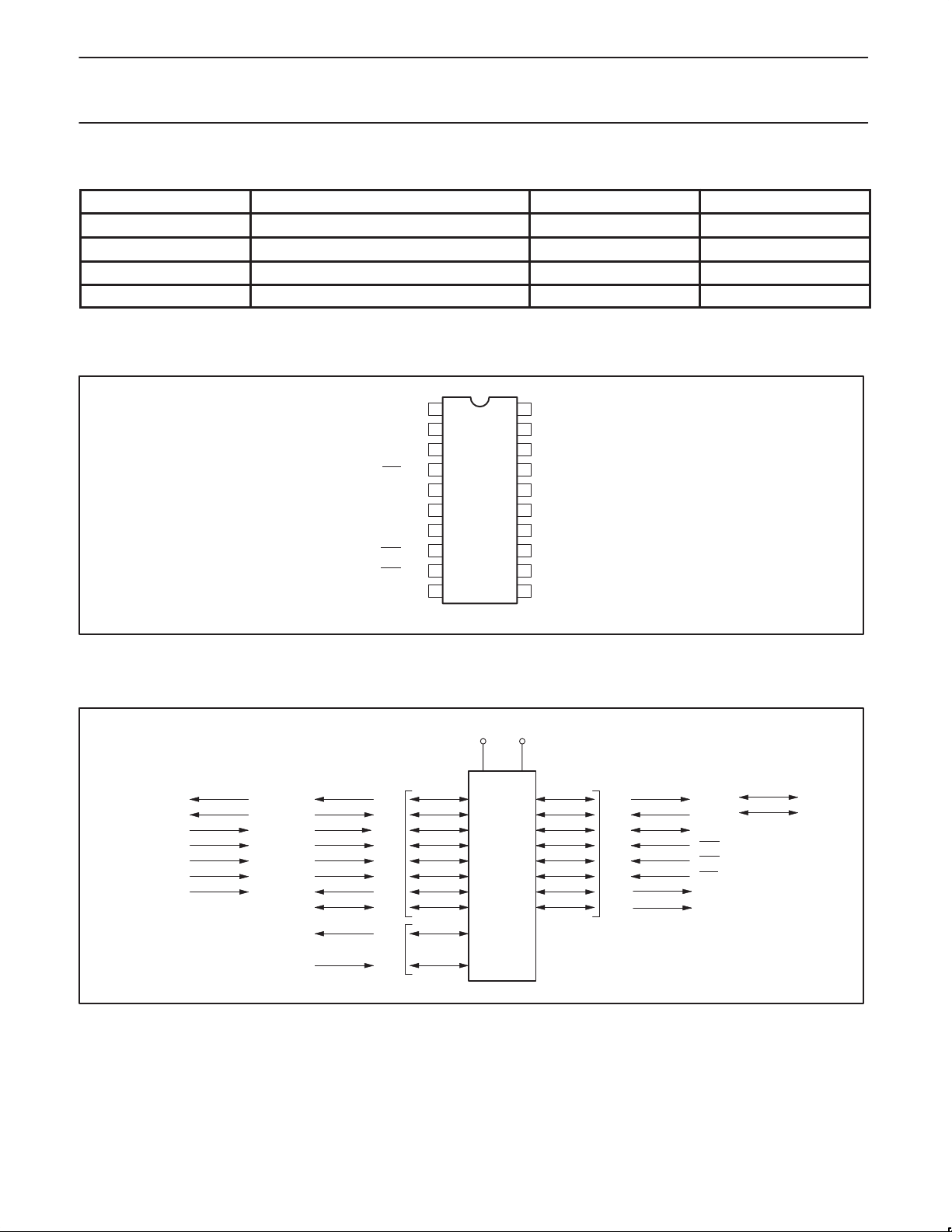

ORDERING INFORMATION

Part Number Temperature Range °C and Package Frequency Drawing Number

P87LPC768B N 0 to +70, Plastic Dual In-Line Package 20 MHz (5 V), 10 MHz (3 V) SOT146–1

P87LPC768B D 0 to +70, Plastic Small Outline Package 20 MHz (5 V), 10 MHz (3 V) SOT163–1

P87LPC768F N –45 to +85, Plastic Dual In-Line Package 20 MHz (5 V), 10 MHz (3 V) SOT146–1

P87LPC768F D –45 to +85, Plastic Small Outline Package 20 MHz (5 V), 10 MHz (3 V) SOT163–1

PIN CONFIGURATION, 20-PIN DIP AND SO PACKAGES

PWM3/CMP2/P0.0

PWM2/P1.7

PWM1/P1.6

RST

/P1.5

V

X1/P2.1

X2/CLKOUT/P2.0

/P1.4

INT1

SDA/INT0

/P1.3

SCL/T0/P1.2

1

2

3

4

5

SS

6

7

8

9

10

P0.1/CIN2B/PWM0

20

19

P0.2/CIN2A/BRAKE

18

P0.3/CIN1B/AD0

17

P0.4/CIN1A/AD1

16

P0.5/CMPREF/AD2

15

V

DD

14

P0.6/CMP1/AD3

13

P0.7/T1

12

P1.0/TxD

11

P1.1/RxD

87LPC768

LOGIC SYMBOL

PWM3

PWM0

BRAKE

AD0

AD1

AD2

AD3

CIN2B

CIN2A

CIN1B

CIN1A

CMPREF

CMP1

CLKOUT/X2

SU01361

V

V

DD

SS

TxDCMP2

RxD

T0

INT0

PORT 0PORT 2

T1

X1

PORT 1

INT1

RST

PWM1

PWM2

SCL

SDA

SU01362

2000 May 02

2

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

4 kB OTP 8-bit A/D, Pulse Width Modulator

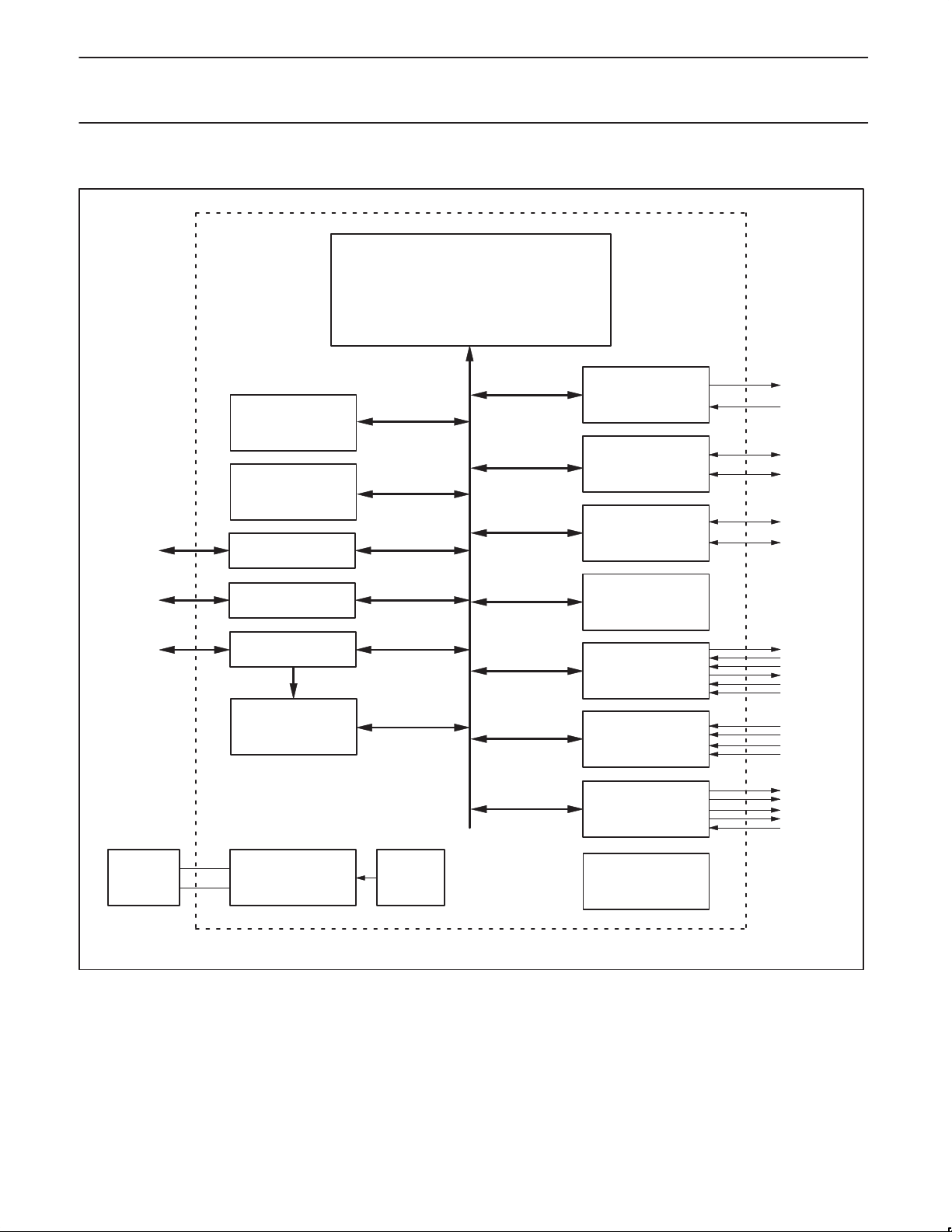

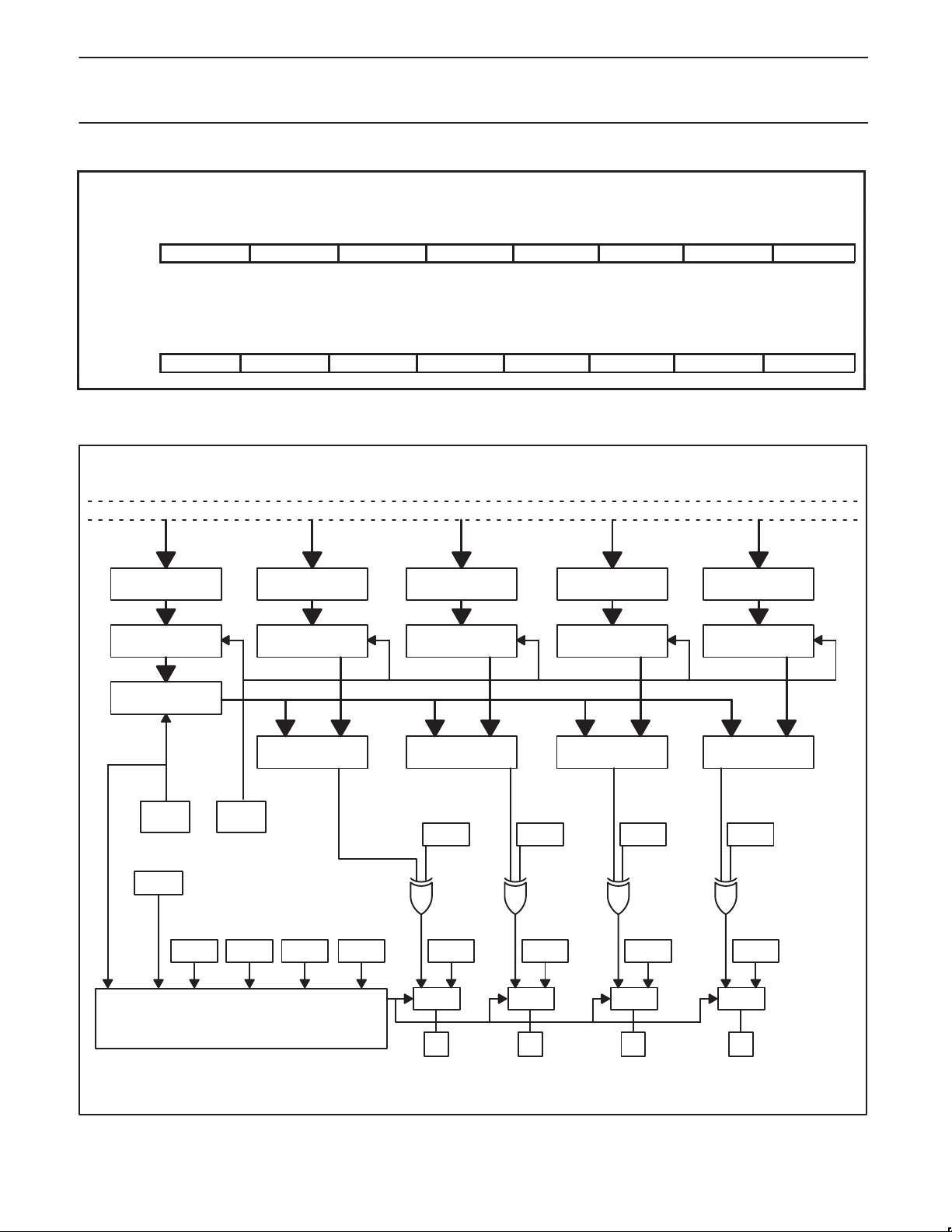

BLOCK DIAGRAM

ACCELERATED

80C51 CPU

INTERNAL BUS

4K BYTE

CODE EPROM

128 BYTE

DATA RAM

PORT 2

CONFIGURABLE I/OS

87LPC768

UART

I2C

TIMER 0, 1

CRYSTAL OR

RESONATOR

PORT 1

CONFIGURABLE I/OS

PORT 0

CONFIGURABLE I/OS

KEYPAD

INTERRUPT

CONFIGURABLE

OSCILLATOR

ON-CHIP

R/C

OSCILLATOR

WATCHDOG TIMER

AND OSCILLATOR

ANALOG

COMPARATORS

A/D

CONVERTER

PULSE WIDTH

MODULATOR

POWER MONITOR

(POWER-ON RESET,

BROWNOUT RESET)

SU01363

2000 May 02

3

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

4 kB OTP 8-bit A/D, Pulse Width Modulator

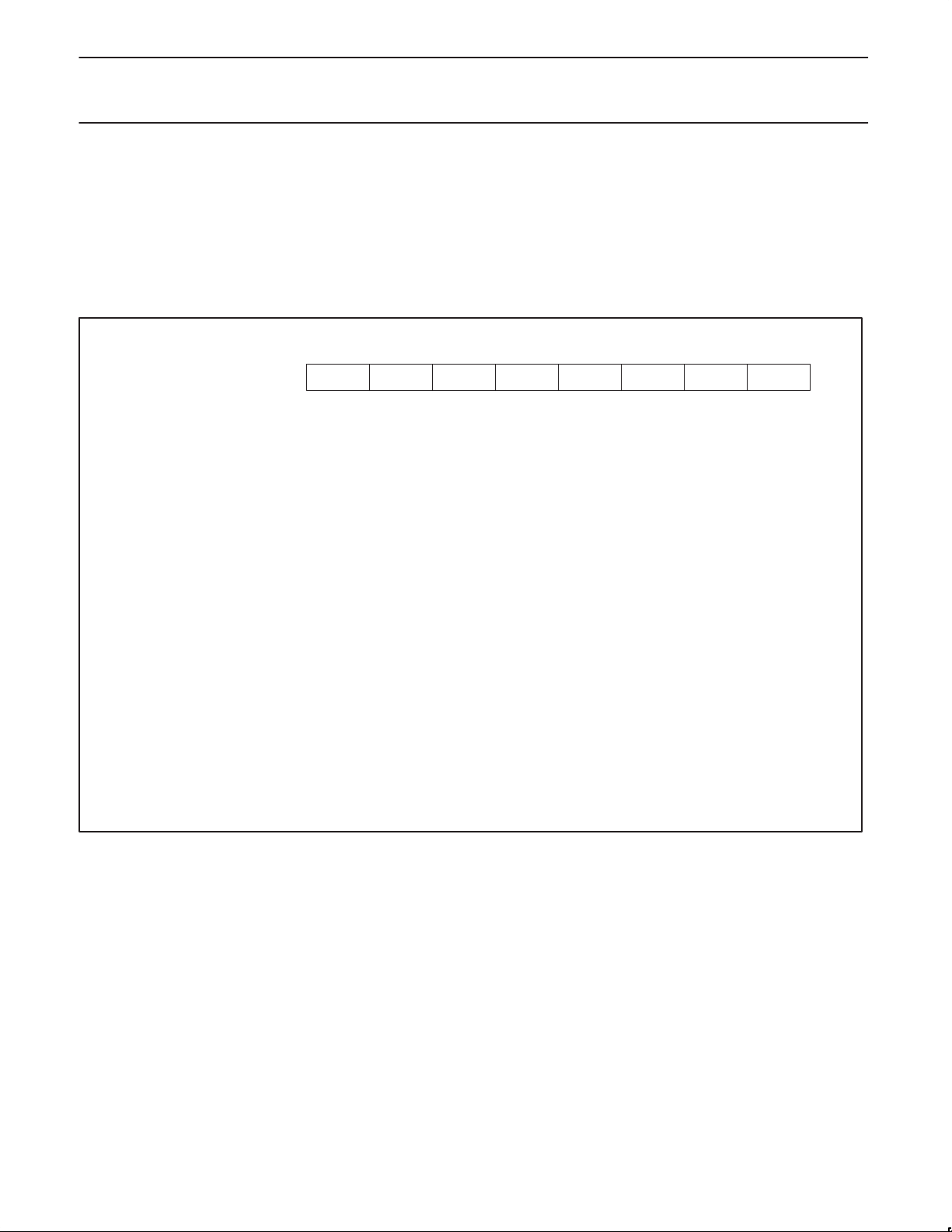

FFFFh

UNUSED CODE

MEMORY SPACE

32-BYTE CUSTOMER

CODE SPACE

(ACCESSIBLE VIA MOVC)

UNUSED CODE

MEMORY SPACE

4 K BYTES ON-CHIP

CODE MEMORY

INTERRUPT VECTORS

ON-CHIP CODE

MEMORY SPACE

FCFFh

FCE0h

1000h

0FFFh

0000h

SPECIAL FUNCTION

REGISTERS

(ONLY DIRECTLY

ADDRESSABLE)

128 BYTES ON-CHIP DATA

MEMORY

(DIRECTLY AND

INDIRECTLY

ADDRESSABLE)

16-BIT ADDRESSABLE BYTES

ON-CHIP DATA

MEMORY SPACE

FFh

80h

7Fh

00h 0000h

87LPC768

UNUSED SPACE

CONFIGURATION BYTES

UCFG1, UCFG2

(ACCESSIBLE VIA MOVX)

UNUSED SPACE

EXTERNAL DATA

MEMORY SPACE*

FFFFh

FD01h

FD00h

* The 87LPC768 does not support access to external data memory. However, the User Configuration Bytes

are accessed via the MOVX instruction as if they were in external data memory.

Figure 1. 87LPC768 Program and Data Memory Map

SU01386

2000 May 02

4

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

87LPC768

4 kB OTP 8-bit A/D, Pulse Width Modulator

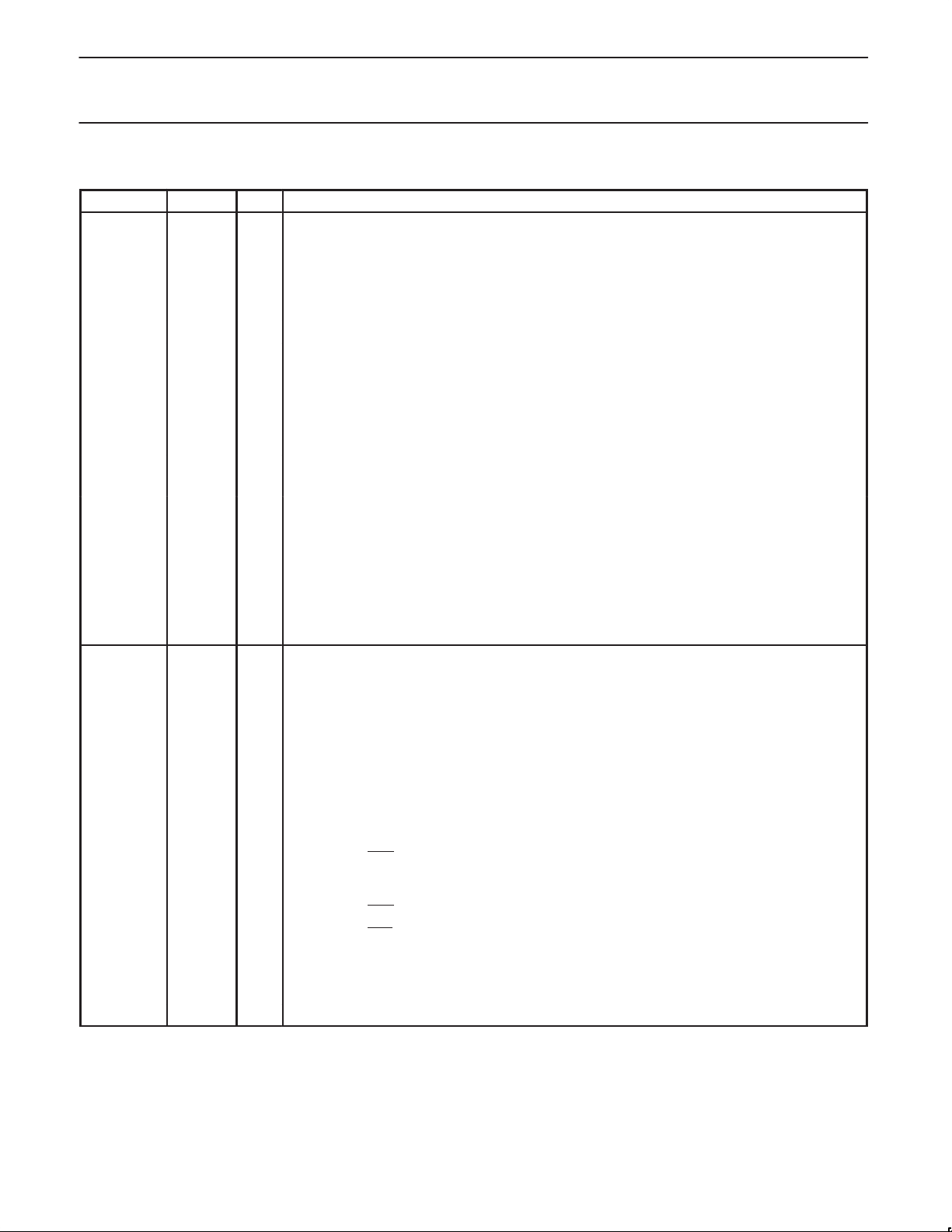

PIN DESCRIPTIONS

MNEMONIC PIN NO. TYPE NAME AND FUNCTION

P0.0–P0.7 1, 13, 14,

P1.0–P1.7 2–4, 8–12 I/O Port 1: Port 1 is an 8-bit I/O port with a user-configurable output type, except for three pins as noted

16–20

1 O P0.0 CMP2 Comparator 2 output.

20 I P0.1 CIN2B Comparator 2 positive input B.

19 I P0.2 CIN2A Comparator 2 positive input A.

18 I P0.3 CIN1B Comparator 1 positive input B.

17 I P0.4 CIN1A Comparator 1 positive input A.

16 I P0.5 CMPREF Comparator reference (negative) input.

14 O P0.6 CMP1 Comparator 1 output.

13 I/O P0.7 T1 Timer/counter 1 external count input or overflow output.

12 O P1.0 TxD Transmitter output for the serial port.

11 I P1.1 RxD Receiver input for the serial port.

10 I/O

9 I

8 I P1.4 INT1 External interrupt 1 input.

4 I P1.5 RST External Reset input (if selected via EPROM configuration). A low on this pin

3 O P1.6 PWM1 Pulse Width Modulator 1 output

2 O P1.7 PWM2 Pulse Width Modulator 2 output

I/O Port 0: Port 0 is an 8-bit I/O port with a user-configurable output type. Port 0 latches are configured in

the quasi-bidirectional mode and have either ones or zeros written to them during reset, as determined

by the PRHI bit in the UCFG1 configuration byte. The operation of port 0 pins as inputs and outputs

depends upon the port configuration selected. Each port pin is configured independently. Refer to the

section on I/O port configuration and the DC Electrical Characteristics for details.

The Keyboard Interrupt feature operates with port 0 pins.

Port 0 also provides various special functions as described below.

PWM3 Pulse Width Modulator 3 output.

PWM0 Pulse Width Modulator 0 output.

BRAKE PWM brake input.

AD0 A/D channel 0 input.

AD1 A/D channel 1 input.

AD2 A/D channel 2 input.

AD3 A/D channel 3 input.

below. Port 1 latches are configured in the quasi-bidirectional mode and have either ones or zeros

written to them during reset, as determined by the PRHI bit in the UCFG1 configuration byte. The

operation of the configurable port 1 pins as inputs and outputs depends upon the port configuration

selected. Each of the configurable port pins are programmed independently. Refer to the section on I/O

port configuration and the DC Electrical Characteristics for details.

Port 1 also provides various special functions as described below.

I/O

I/O

P1.2 T0 Timer/counter 0 external count input or overflow output.

SCL I

P1.3 INT0 External interrupt 0 input.

SDA I2C serial data input/output. When configured as an output, P1.3 is open

2

C serial clock input/output. When configured as an output, P1.2 is open

drain, in order to conform to I

drain, in order to conform to I

resets the microcontroller, causing I/O ports and peripherals to take on their

default states, and the processor begins execution at address 0. When used

as a port pin, P1.5 is a Schmitt trigger input only.

2

C specifications.

2

C specifications.

2000 May 02

5

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

87LPC768

4 kB OTP 8-bit A/D, Pulse Width Modulator

MNEMONIC NAME AND FUNCTIONTYPEPIN NO.

P2.0–P2.1 6, 7 I/O Port 2: Port 2 is a 2-bit I/O port with a user-configurable output type. Port 2 latches are configured in the

7 O P2.0 X2 Output from the oscillator amplifier (when a crystal oscillator option is

6 I P2.1 X1 Input to the oscillator circuit and internal clock generator circuits (when

V

SS

V

DD

5 I Ground: 0V reference.

15 I Power Supply: This is the power supply voltage for normal operation as well as Idle and

quasi-bidirectional mode and have either ones or zeros written to them during reset, as determined by

the PRHI bit in the UCFG1 configuration byte. The operation of port 2 pins as inputs and outputs

depends upon the port configuration selected. Each port pin is configured independently. Refer to the

section on I/O port configuration and the DC Electrical Characteristics for details.

Port 2 also provides various special functions as described below.

selected via the EPROM configuration).

CLKOUT CPU clock divided by 6 clock output when enabled via SFR bit and in

Power Down modes.

conjunction with internal RC oscillator or external clock input.

selected via the EPROM configuration).

2000 May 02

6

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

87LPC768

4 kB OTP 8-bit A/D, Pulse Width Modulator

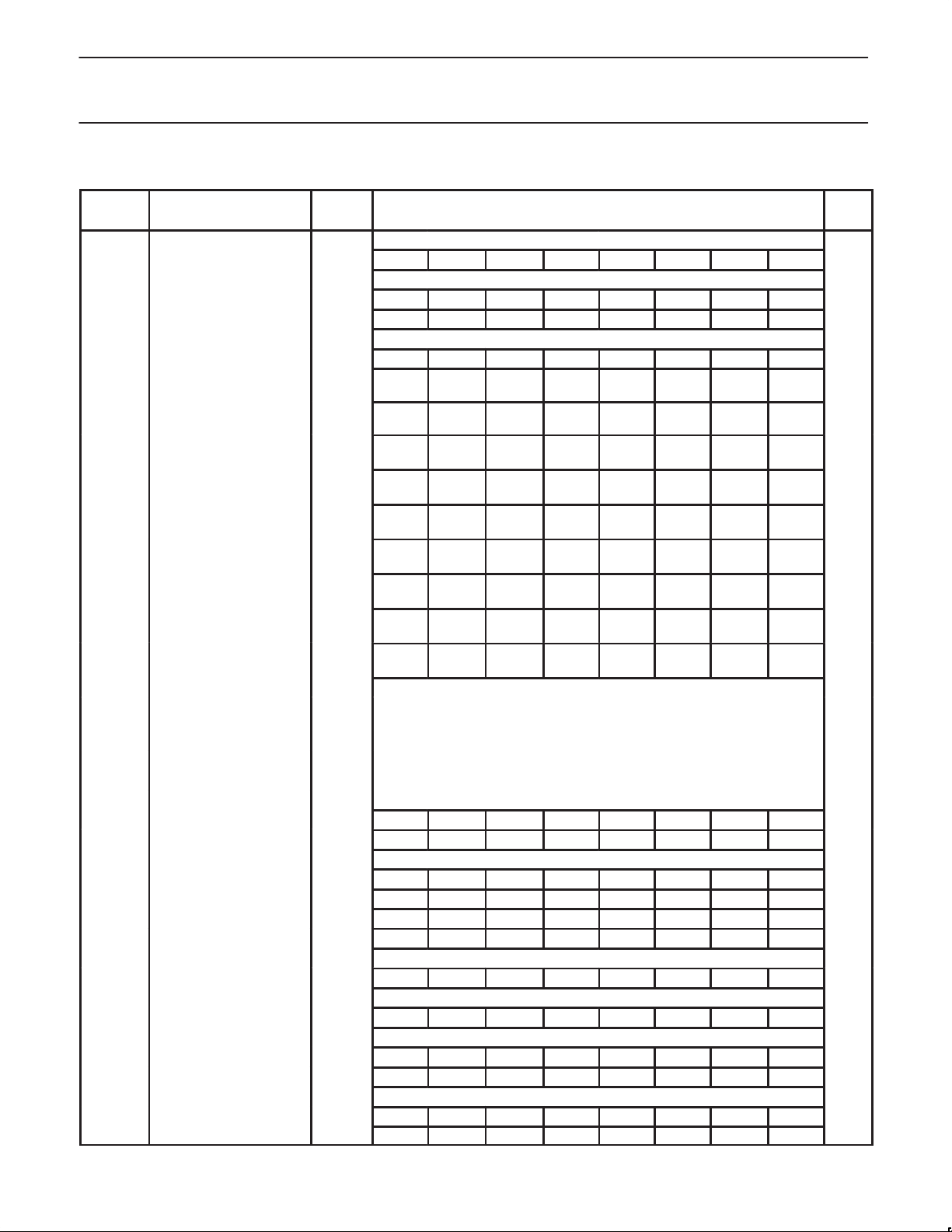

Table 1. Special Function Registers

Name Description

ACC* Accumulator E0h 00h

ADCON#* A/D Control C0h ENADC – – ADCI ADCS RCCLK AADR1 AADR0 00h

AUXR1# Auxiliary Function Register A2h KBF BOD BOI LPEP SRST 0 – DPS 02h

B* B register F0h 00h

CMP1#

CMP2#

CNSW0 PWM Counter Shadow

CNSW1 PWM Counter Shadow

CPSW0 PWM Compare Shadow

CPSW1 PWM Compare Shadow

CPSW2 PWM Compare Shadow

CPSW3 PWM Compare Shadow

CPSW4 PWM Compare Shadow

DAC0# A/D Result C5h 00h

DIVM#

DPTR: Data pointer (2 bytes)

DPH Data pointer high byte 83h 00h

DPL Data pointer low byte 82h 00h

I2CFG#* I2C configuration register C8h/RD SLA VEN MASTRQ 0 TIRUN – – CT1 CT0 00h

I2CON#* I2C control register D8h/RD RDA T ATN DRDY ARL STR STP

I2DAT# I2C data register D9h/RD RDA T 0 0 0 0 0 0 0 80h

IEN0* Interrupt enable 0 A8h EA EWD EBO ES ET1 EX1 ET0 EX0 00h

IEN1#* Interrupt enable 1 E8h ETI – EC1 EAD – EC2 EKB EI2 00h

IP0* Interrupt priority 0 B8h – PWD PBO PS PT1 PX1 PT0 PX0 00h

IP0H# Interrupt priority 0 high byte B7h – PWDH PBOH PSH PT1H PX1H PT0H PX0H 00h

IP1* Interrupt priority 1 F8h PTI – PC1 PAD – PC2 PKB PI2 00h

IP1H# Interrupt priority 1 high byte F7h PTIH – PC1H PADH – PC2H PKBH PI2H 00h

Comparator 1 control

register

Comparator 2 control

register

Register 0

Register 1

Register 0

Register 1

Register 2

Register 3

Register 4

CPU clock divide-by-M

control

SFR

Address

ACh – – CE1 CP1 CN1 OE1 CO1 CMF1 00h

ADh – – CE2 CP2 CN2 OE2 CO2 CMF2 00h

D1h CNSW7 CNSW6 CNSW5 CNSW4 CNSW3 CNSW2 CNSW1 CNSW0 FFh

D2h – – – – – – CNSW9 CNSW8 FFh

D3h CPSW07 CPSW06 CPSW05 CPSW04 CPSW03 CPSW02 CPSW01 CPSW00 00h

D4h CPSW17 CPSW16 CPSW15 CPSW14 CPSW13 CPSW12 CPSW11 CPSW10 00h

D5h CPSW27 CPSW26 CPSW25 CPSW24 CPSW23 CPSW22 CPSW21 CPSW20 00h

D6h CPSW37 CPSW36 CPSW35 CPSW34 CPSW33 CPSW32 CPSW31 CPSW30 00h

D7h CPSW39 CPSW38 CPSW29 CPSW28 CPSW19 CPSW18 CPSW09 CPSW08 00h

95h 00h

C8h/WR SLAVEN MASTRQ CLRTI TIRUN – – CT1 CT0

D8h/WR CXA IDLE CDR CARL CSTR CSTP XSTR XSTP

D9h/WR XDAT x x x x x x x

MSB LSB

E7 E6 E5 E4 E3 E2 E1 E0

C7 C6 C5 C4 C3 C2 C1 C0

F7 F6 F5 F4 F3 F2 F1 F0

CF CE CD CC CB CA C9 C8

DF DE DD DC DB DA D9 D8

AF AE AD AC AB AA A9 A8

EF EE ED EC EB EA E9 E8

BF BE BD BC BB BA B9 B8

FF FE FD FC FB FA F9 F8

Bit Functions and Addresses

MASTER

– 80h

Reset

Value

1

1

1

1

1

1

1

1

1

1

2000 May 02

7

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

87LPC768

4 kB OTP 8-bit A/D, Pulse Width Modulator

Name

KBI# Keyboard Interrupt 86h 00h

P0* Port 0 80h T1 CMP1 CMPREF CIN1A CIN1B CIN2A CIN2B CMP2 Note 2

P1* Port 1 90h (P1.7) (P1.6) RST INT1 INT0 T0 RxD TxD Note 2

P2* Port 2 A0h – – – – – – X1 X2 Note 2

P0M1# Port 0 output mode 1 84h (P0M1.7) (P0M1.6) (P0M1.5) (P0M1.4) (P0M1.3) (P0M1.2) (P0M1.1) (P0M1.0) 00h

P0M2# Port 0 output mode 2 85h (P0M2.7) (P0M2.6) (P0M2.5) (P0M2.4) (P0M2.3) (P0M2.2) (P0M2.1) (P0M2.0) 00H

P1M1# Port 1 output mode 1 91h (P1M1.7) (P1M1.6) – (P1M1.4) – – (P1M1.1) (P1M1.0) 00h

P1M2# Port 1 output mode 2 92h (P1M2.7) (P1M2.6) – (P1M2.4) – – (P1M2.1) (P1M2.0) 00h

P2M1# Port 2 output mode 1 A4h P2S P1S P0S ENCLK T1OE T0OE (P2M1.1) (P2M1.0) 00h

P2M2# Port 2 output mode 2 A5h – – – – – – (P2M2.1) (P2M2.0) 00h

PCON Power control register 87h SMOD1 SMOD0 BOF POF GF1 GF0 PD IDL Note 3

PSW* Program status word D0h CY AC F0 RS1 RS0 OV F1 P 00h

PT0AD# Port 0 digital input disable F6h 00h

Description

SFR

Address

MSB LSB

87 86 85 84 83 82 81 80

97 96 95 94 93 92 91 90

A7 A6 A5 A4 A3 A2 A1 A0

D7 D6 D5 D4 D3 D2 D1 D0

Bit Functions and Addresses

Reset

Value

1

1

1

9F 9E 9D 9C 9B 9A 99 98

PWMCON0 PWM Control Register 0 DAh RUN XFER PWM3I PWM2I – PWM1I PWM0I – 00h

PWMCON1 PWM Control Register 1 DBh BKCH BKPS BPEN BKEN PWM3B PWM2B PWM1B PWM0B 00h

SCON* Serial port control 98h SM0 SM1 SM2 REN TB8 RB8 TI RI 00h

SBUF

SADDR# Serial port address register A9h 00h

SADEN# Serial port address enable B9h 00h

SP Stack pointer 81h 07h

TCON* Timer 0 and 1 control 88h TF1 TR1 TF0 TR0 IE1 IT1 IE0 IT0 00h

TH0 Timer 0 high byte 8Ch 00h

TH1 Timer 1 high byte 8Dh 00h

TL0 Timer 0 low byte 8Ah 00h

TL1 Timer 1 low byte 8Bh 00h

TMOD Timer 0 and 1 mode 89h GATE C/T M1 M0 GATE C/T M1 M0 00h

WDCON# Watchdog control register A7h – –

WDRST# Watchdog reset register A6h xxh

NOTES:

* SFRs are bit addressable.

# SFRs are modified from or added to the 80C51 SFRs.

1. Unimplemented bits in SFRs are X (unknown) at all times. Ones should not be written to these bits since they may be used for other

purposes in future derivatives. The reset value shown in the table for these bits is 0.

2. I/O port values at reset are determined by the PRHI bit in the UCFG1 configuration byte.

3. The PCON reset value is x x BOF POF–0 0 0 0b. The BOF and POF flags are not affected by reset. The POF flag is set by hardware upon

power up. The BOF flag is set by the occurrence of a brownout reset/interrupt and upon power up.

4. The WDCON reset value is xx11 0000b for a Watchdog reset, xx01 0000b for all other reset causes if the watchdog is enabled, and xx00

0000b for all other reset causes if the watchdog is disabled.

Serial port data buffer

register

99h xxh

8F 8E 8D 8C 8B 8A 89 88

WDOVF

WDRUN WDCLK WDS2 WDS1 WDS0 Note 4

2000 May 02

8

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

4 kB OTP 8-bit A/D, Pulse Width Modulator

FUNCTIONAL DESCRIPTION

Details of 87LPC768 functions will be described in the following

sections.

Enhanced CPU

The 87LPC768 uses an enhanced 80C51 CPU which runs at twice the

speed of standard 80C51 devices. This means that the performance of

the 87LPC768 running at 5 MHz is exactly the same as that of a

standard 80C51 running at 10 MHz. A machine cycle consists of 6

oscillator cycles, and most instructions execute in 6 or 12 clocks. A

user configurable option allows restoring standard 80C51 execution

timing. In that case, a machine cycle becomes 12 oscillator cycles.

In the following sections, the term “CPU clock” is used to refer to the

clock that controls internal instruction execution. This may

sometimes be different from the externally applied clock, as in the

case where the part is configured for standard 80C51 timing by

means of the CLKR configuration bit or in the case where the clock

is divided down via the setting of the DIVM register. These features

are described in the Oscillator section.

Analog Functions

The 87LPC768 incorporates analog peripheral functions: an Analog

to Digital Converter and two Analog Comparators. In order to give

the best analog function performance and to minimize power

consumption, pins that are being used for analog functions must

have the digital outputs and inputs disabled.

Digital outputs are disabled by putting the port output into the Input

Only (high impedance) mode as described in the I/O Ports section.

Digital inputs on port 0 may be disabled through the use of the

PT0AD register. Each bit in this register corresponds to one pin of

Port 0. Setting the corresponding bit in PT0AD disables that pin’s

digital input. Port bits that have their digital inputs disabled will be

read as 0 by any instruction that accesses the port.

device has a very limited number of pins, the A/D power supply and

references are shared with the processor power pins, V

The A/D converter operates down to a V

The A/D converter circuitry consists of a 4-input analog multiplexer

and an 8-bit successive approximation ADC. The A/D employs a

ratiometric potentiometer which guarantees DAC monotonicity.

The A/D converter is controlled by the special function register

ADCON. Details of ADCON are shown in Figure 2. The A/D must be

enabled by setting the ENADC bit at least 10 microseconds before a

conversion is started, to allow time for the A/D to stabilize. Prior to

the beginning of an A/D conversion, one analog input pin must be

selected for conversion via the AADR1 and AADR0 bits. These bits

cannot be changed while the A/D is performing a conversion.

An A/D conversion is started by setting the ADCS bit, which remains

set while the conversion is in progress. When the conversion is

complete, the ADCS bit is cleared and the ADCI bit is set. When

ADCI is set, it will generate an interrupt if the interrupt system is

enabled, the A/D interrupt is enabled (via the EAD bit in the IE1

register), and the A/D interrupt is the highest priority pending

interrupt.

When a conversion is complete, the result is contained in the

register DAC0. This value will not change until another conversion is

started. Before another A/D conversion may be started, the ADCI bit

must be cleared by software. The A/D channel selection may be

changed by the same instruction that sets ADCS to start a new

conversion, but not by the same instruction that clears ADCI.

The connections of the A/D converter are shown in Figure 3.

The ideal A/D result may be calculated as follows:

Result + (VIN–VSS)x

87LPC768

and VSS.

supply of 3.0V .

DD

256

(round result to the nearest integer)

–V

V

DD

SS

DD

Analog to Digital Converter

The 87LPC768 incorporates a four channel, 8-bit A/D converter. The

A/D inputs are alternate functions on four port 0 pins. Because the

2000 May 02

9

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

87LPC768

4 kB OTP 8-bit A/D, Pulse Width Modulator

ADCON Address: C0h

Bit addressable

Reset Value: 00h

BIT SYMBOL FUNCTION

ADCON.7 ENADC When ENADC = 1, the A/D is enabled and conversions may take place. Must be set 10

ADCON.6 - Reserved for future use. Should not be set to 1 by user programs.

ADCON.5 - Reserved for future use. Should not be set to 1 by user programs.

ADCON.4 ADCI A/D conversion complete/interrupt flag. This flag is set when an A/D conversion is completed.

ADCON.3 ADCS A/D start. Setting this bit by software starts the conversion of the selected A/D input. ADCS

ADCI, ADCS

0 0 A/D not busy, a conversion can be started.

0 1 A/D busy, the start of a new conversion is blocked.

1 0 An A/D conversion is complete. ADCI must be cleared prior to starting a new conversion.

1 1 An A/D conversion is complete. ADCI must be cleared prior to starting a new conversion. This

ADCON.2 RCCLK When RCCLK = 0, the CPU clock is used as the A/D clock. When RCCLK = 1, the internal RC

ADCON.1, 0 AADR1,0 Along with AADR0, selects the A/D channel to be converted. These bits can only be written

AADR1, AADR0

0 0 AD0 (P0.3).

0 1 AD1 (P0.4).

1 0 AD2 (P0.5).

1 1 AD3 (P0.6).

76543210

ENADC - - ADCI ADCS RCCLK AADR1 AADR0

microseconds before a conversion is started. ENADC cannot be cleared while ADCS or ADCI

are 1.

This bit will cause a hardware interrupt if enabled and of sufficient priority. Must be cleared by

software.

remains set while the A/D conversion is in progress and is cleared automatically upon

completion. While ADCS or ADCI are one, new start commands are ignored.

A/D Status

state exists for one machine cycle as an A/D conversion is completed.

oscillator is used as the A/D clock. This bit is writable while ADCS and ADCI are 0.

while ADCS and ADCI are 0.

A/D Input Selected

SU01354

Figure 2. A/D Control Register (ADCON)

A/D Timing

The A/D may be clocked in one of two ways. The default is to use

the CPU clock as the A/D clock source. When used in this manner,

the A/D completes a conversion in 31 machine cycles. The A/D may

be operated up to the maximum CPU clock rate of 20 MHz, giving a

conversion time of 9.3 µs. The formula for calculating A/D

conversion time when the CPU clock runs the A/D is: 186 µs / CPU

clock rate (in MHZ). To obtain accurate A/D conversion results, the

CPU clock must be at least 1 MHz.

The A/D may also be clocked by the on-chip RC oscillator, even if

the RC oscillator is not used as the CPU clock. This is accomplished

by setting the RCCLK bit in ADCON. This arrangement has several

advantages. First, the A/D conversion time is faster at lower CPU

clock rates. Also, the CPU may be run at speeds below 1 MHz

without affecting A/D accuracy. Finally, the Power Down mode may

be used to completely shut down the CPU and its oscillator, along

2000 May 02

with other peripheral functions, in order to obtain the best possible

A/D accuracy. This should not be used if the MCU uses an external

clock source greater than 4 MHz.

When the A/D is operated from the RCCLK while the CPU is running

from another clock source, 3 or 4 machine cycles are used to

synchronize A/D operation. The time can range from a minimum of 3

machine cycles (at the CPU clock rate) + 108 RC clocks to a

maximum of 4 machine cycles (at the CPU clock rate) + 112 RC

clocks.

Example A/D conversion times at various CPU clock rates are

shown in Table 2. In Table 2, maximum times for RCCLK = 1 use an

RC clock frequency of 4.5 MHz (6 MHz - 25%). Minimum times for

RCCLK = 1 use an RC clock frequency of 7.5 MHz (6 MHz + 25%).

Nominal time assume an ideal RC clock frequency of 6 MHz and an

average of 3.5 machine cycles at the CPU clock rate.

10

Philips Semiconductors Preliminary specification

CPU Clock Rate

RCCLK = 0

Low power, low price, low pin count (20 pin) microcontroller with

4 kB OTP 8-bit A/D, Pulse Width Modulator

Table 2. Example A/D Conversion Times

RCCLK = 1

minimum nominal maximum

32 kHz NA 563.4 µs 659 µs 757 µs

1 MHz 186 µs 32.4 µs 39.3 µs 48.9 µs

4 MHz 46.5 µs 18.9 µs 23.6 µs 30.1 µs

11.0592 MHz 16.8 µs 16 µs 20.2 µs 27.1 µs

12 MHz 15.5 µs

16 MHz 11.6 µs

20 MHz 9.3 µs

Note: Do not clock ADC from the RC oscillator when MCU clock is greater than 4 MHz.

V

+ = V

AD0 (P0.3)

AD1 (P0.4)

AD2 (P0.5)

AD3 (P0.6)

00

01

10

11

A/D Converter

REF

V

REF

- = V

DD

SS

87LPC768

AADR1

AADR0

ADCON

Figure 3. A/D Converter Connections

The A/D in Power Down and Idle Modes

While using the CPU clock as the A/D clock source, the Idle mode

may be used to conserve power and/or to minimize system noise

during the conversion. CPU operation will resume and Idle mode

terminate automatically when a conversion is complete if the A/D

interrupt is active. In Idle mode, noise from the CPU itself is

eliminated, but noise from the oscillator and any other on-chip

peripherals that are running will remain.

The CPU may be put into Power Down mode when the A/D is

clocked by the on-chip RC oscillator (RCCLK=1). This mode gives

the best possible A/D accuracy by eliminating most on-chip noise

sources.

If the Power Down mode is entered while the A/D is running from the

CPU clock (RCCLK=0), the A/D will abort operation and will not

wake up the CPU. The contents of DAC0 will be invalid when

operation does resume.

DAC0

(A/D result)

SU01356

When an A/D conversion is started, Power Down or Idle mode must

be activated within two machine cycles in order to have the most

accurate A/D result. These two machine cycles are counted at the

CPU clock rate. When using the A/D with either Power Down or Idle

mode, care must be taken to insure that the CPU is not restarted by

another interrupt until the A/D conversion is complete. The possible

causes of wakeup are different in Power Down and Idle modes.

A/D accuracy is also affected by noise generated elsewhere in the

application, power supply noise, and power supply regulation. Since

the 87LPC768 power pins are also used as the A/D reference and

supply, the power supply has a very direct affect on the accuracy of

A/D readings. Using the A/D without Power Down mode while the

clock is divided through the use of CLKR or DIVM has an adverse

effect on A/D accuracy.

2000 May 02

11

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

87LPC768

4 kB OTP 8-bit A/D, Pulse Width Modulator

Code Examples for the A/D

The first piece of sample code shows an example of port configuration for use with the A/D. This example sets up the pins so that all four A/D

channels may be used. Port configuration for analog functions is described in the section Analog Functions.

; Set up port pins for A/D conversion, without affecting other pins.

mov PT0AD,#78h ; Disable digital inputs on A/D input pins.

anl P0M2,#87h ; Disable digital outputs on A/D input pins.

orl P0M1,#78h ; Disable digital outputs on A/D input pins.

Following is an example of using the A/D with interrupts. The routine ADStart begins an A/D conversion using the A/D channel number supplied

in the accumulator. The channel number is not checked for validity. The A/D must previously have been enabled with sufficient time to allow for

stabilization.

The interrupt handler routine reads the conversion value and returns it in memory address ADResult. The interrupt should be enabled prior to

starting the conversion.

; Start A/D conversion.

ADStart:

orl ADCON,A ; Add in the new channel number.

setb ADCS ; Start an A/D conversion.

; orl PCON,#01h ; The CPU could be put into Idle mode here.

; orl PCON,#02h ; The CPU could be put into Power Down mode here if RCCLK = 1.

ret

; A/D interrupt handler.

ADInt:

push ACC ; Save accumulator.

mov A,DAC0 ; Get A/D result,

mov ADResult,A ; and save it in memory.

clr ADCI ; Clear the A/D completion flag.

anl ADCON,#0fch ; Clear the A/D channel number.

pop ACC ; Restore accumulator.

reti

Following is an example of using the A/D with polling. An A/D conversion is started using the channel number supplied in the accumulator . The

channel number is not checked for validity. The A/D must previously have been enabled with suf ficient time to allow for stabili zation. The

conversion result is returned in the accumulator.

ADRead:

orl ADCON,A ; Add in the new channel number.

setb ADCS ; Start A/D conversion.

ADChk:

jnb ADCI,ADChk ; Wait for ADCI to be set.

mov A,DAC0 ; Get A/D result.

clr ADCI ; Clear the A/D completion flag.

anl ADCON,#0fch ; Clear the A/D channel number.

ret

2000 May 02

12

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

4 kB OTP 8-bit A/D, Pulse Width Modulator

Analog Comparators

Two analog comparators are provided on the 87LPC768. Input and

output options allow use of the comparators in a number of different

configurations. Comparator operation is such that the output is a

logical one (which may be read in a register and/or routed to a pin)

when the positive input (one of two selectable pins) is greater than

the negative input (selectable from a pin or an internal reference

voltage). Otherwise the output is a zero. Each comparator may be

configured to cause an interrupt when the output value changes.

Comparator Configuration

Each comparator has a control register, CMP1 for comparator 1 and

CMP2 for comparator 2. The control registers are identical and are

shown in Figure 4.

CMPn

Address: ACh for CMP1, ADh for CMP2

Not Bit Addressable

The overall connections to both comparators are shown in Figure 5.

There are eight possible configurations for each comparator, as

determined by the control bits in the corresponding CMPn register:

CPn, CNn, and OEn. These configurations are shown in Figure 6.

The comparators function down to a V

When each comparator is first enabled, the comparator output and

interrupt flag are not guaranteed to be stable for 10 microseconds.

The corresponding comparator interrupt should not be enabled

during that time, and the comparator interrupt flag must be cleared

before the interrupt is enabled in order to prevent an immediate

interrupt service.

87LPC768

of 3.0V .

DD

Reset Value: 00h

01234567

COnOEnCNnCPnCEn——

CMFn

BIT SYMBOL FUNCTION

CMPn.7, 6 — Reserved for future use. Should not be set to 1 by user programs.

CMPn.5 CEn Comparator enable. When set by software, the corresponding comparator function is enabled.

CMPn.4 CPn Comparator positive input select. When 0, CINnA is selected as the positive comparator input. When

CMPn.3 CNn Comparator negative input select. When 0, the comparator reference pin CMPREF is selected as

CMPn.2 OEn Output enable. When 1, the comparator output is connected to the CMPn pin if the comparator is

CMPn.1 COn Comparator output, synchronized to the CPU clock to allow reading by software. Cleared when the

CMPn.0 CMFn Comparator interrupt flag. This bit is set by hardware whenever the comparator output COn changes

Comparator output is stable 10 microseconds after CEn is first set.

1, CINnB is selected as the positive comparator input.

the negative comparator input. When 1, the internal comparator reference V

negative comparator input.

enabled (CEn = 1). This output is asynchronous to the CPU clock.

comparator is disabled (CEn = 0).

state. This bit will cause a hardware interrupt if enabled and of sufficient priority. Cleared by

software and when the comparator is disabled (CEn = 0).

Figure 4. Comparator Control Registers (CMP1 and CMP2)

is selected as the

ref

SU01152

2000 May 02

13

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

4 kB OTP 8-bit A/D, Pulse Width Modulator

COMPARATOR 1

+

–

COMPARATOR 2

+

–

CO1

OE1

CHANGE DETECT

CO2

OE2

CHANGE DETECT

(P0.4) CIN1A

(P0.3) CIN1B

(P0.5) CMPREF

(P0.2) CIN2A

(P0.1) CIN2B

CP1

V

ref

CN1

CP2

CN2

CMF1

87LPC768

CMP1 (P0.6)

INTERRUPT

CMP2 (P0.0)

CINnA

CMPREF

CINnA

Vref (1.23V)

CINnB

CMPREF

CPn, CNn, OEn = 0 0 0

+

–

CPn, CNn, OEn = 0 1 0

+

–

CPn, CNn, OEn = 1 0 0

+

–

Figure 5. Comparator Input and Output Connections

COn

COn

COn

CINnA

CMPREF

CINnA

V

(1.23V)

ref

CINnB

CMPREF

CMF2

CPn, CNn, OEn = 0 0 1

+

COn

–

CPn, CNn, OEn = 0 1 1

+

COn

–

CPn, CNn, OEn = 1 0 1

+

COn

–

INTERRUPT

SU01153

CMPn

CMPn

CMPn

2000 May 02

CPn, CNn, OEn = 1 1 0

CINnB

V

(1.23V) V

ref

+

COn

–

Figure 6. Comparator Configurations

14

CINnB

(1.23V)

ref

CPn, CNn, OEn = 1 1 1

+

COn

–

CMPn

SU01154

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

4 kB OTP 8-bit A/D, Pulse Width Modulator

Internal Reference Voltage

An internal reference voltage generator may supply a default

reference when a single comparator input pin is used. The value of

the internal reference voltage, referred to as V

Comparator Interrupt

Each comparator has an interrupt flag CMFn contained in its

configuration register . This flag is set whenever the comparator

output changes state. The flag may be polled by software or may be

used to generate an interrupt. The interrupt will be generated when

the corresponding enable bit ECn in the IEN1 register is set and the

interrupt system is enabled via the EA bit in the IEN0 register.

Comparators and Power Reduction Modes

Either or both comparators may remain enabled when Power Down

or Idle mode is activated. The comparators will continue to function

in the power reduction mode. If a comparator interrupt is enabled, a

change of the comparator output state will generate an interrupt and

CmpInit:

mov PT0AD,#30h ; Disable digital inputs on pins that are used

anl P0M2,#0cfh ; Disable digital outputs on pins that are used

orl P0M1,#30h ; for analog functions: CIN1A, CMPREF.

mov CMP1,#24h ; Turn on comparator 1 and set up for:

call delay10us ; The comparator has to start up for at

anl CMP1,#0feh ; Clear comparator 1 interrupt flag.

setb EC1 ; Enable the comparator 1 interrupt. The

setb EA ; Enable the interrupt system (if needed).

ret ; Return to caller.

, is 1.28 V ±10%.

ref

; for analog functions: CIN1A, CMPREF.

; – Positive input on CIN1A.

; – Negative input from CMPREF pin.

; – Output to CMP1 pin enabled.

; least 10 microseconds before use.

; priority is left at the current value.

Figure 7.

wake up the processor. If the comparator output to a pin is enabled,

the pin should be configured in the push-pull mode in order to obtain

fast switching times while in power down mode. The reason is that

with the oscillator stopped, the temporary strong pull-up that

normally occurs during switching on a quasi-bidirectional port pin

does not take place.

Comparators consume power in Power Down and Idle modes, as

well as in the normal operating mode. This fact should be taken into

account when system power consumption is an issue.

Comparator Configuration Example

The code shown in Figure 7 is an example of initializing one

comparator. Comparator 1 is configured to use the CIN1A and

CMPREF inputs, outputs the comparator result to the CMP1 pin,

and generates an interrupt when the comparator output changes.

The interrupt routine used for the comparator must clear the

interrupt flag (CMF1 in this case) before returning.

87LPC768

SU01189

Pulse Width Modulator

The 87LPC768 contains four Pulse Width Modulated (PWM)

channels which generate pulses of programmable length and

interval. The output for PWM0 is on P0.1, PWM1 on P1.6, PWM2

on P1.7 and PWM3 on P0.1. After chip reset the internal output of

the each PWM channel is a “1.” Note that the state of the pin will

not reflect this if UCFG1.5, PRHI, is set to a zero. In this case

before the pin will reflect the state of the internal PWM output a “1”

must be written to each port bit that serves as a PWM output. A

block diagram is shown in Figure 8.

The interval between successive outputs is controlled by a 10–bit

down counter which uses the internal microcontroller clock as its

input. When bit 3 in the UCFG1 register is a “1” the microcontroller

2000 May 02

clock, and therefore the PWM counter clock, has the same

frequency as the clock source defined by the FOSC bits in UCFG1.

When bit 3 in the UCFG1 register is a “0” the microcontroller and

PWM counter clocks operate at half the frequency of clock source

defined by the FOSC bits in UCFG1. When the counter reaches

underflow it is reloaded with a user selectable value. This

mechanism allows the user to set the PWM frequency at any integer

sub–multiple of the microcontroller clock frequency. The repetition

frequency of the PWM is given by:

f

= FC / (CNSW+1)

PWM

where CNSW is contained in CNSW0 and CNSW1 as described in

the following tables.

15

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

4 kB OTP 8-bit A/D, Pulse Width Modulator

CNSW0: Counter Shadow register 0

Addr: 0D1H

Reset Value: FFH

76543210

CNSW7 CNSW6 CNSW5 CNSW4 CNSW3 CNSW2 CNSW1 CNSW0

CNSW1: Counter Shadow register 1

Addr: 0D2H

Reset Value: FFH

76 54321 0

Unused Unused Unused Unused Unused Unused CNSW9 CNSW8

The word “Shadow” in the above refers to the fact that writes are not

into the register that controls the counter; rather they are into a

holding register. As described below the transfer of data from this

INTERNAL BUS

holding register, into the register which contains the actual reload

value, is controlled by the user’s program.

87LPC768

10 BIT SHADOW

REGISTER

10 BIT COUNTER

REGISTER

10 BIT COUNTER

RUN XFER

BRAKE

BKCH BKPS BPEN BKEN

BRAKE CONTROL LOGIC

10 BIT SHADOW

REGISTER

10 BIT COMPARE

REGISTER

AB AB AB AB

A>B A>B A>B A>B

10 BIT SHADOW

REGISTER

10 BIT COMPARE

REGISTER

PWM3I

PWM3B

2:1 MUX

PWM2I

PWM2B

2:1 MUX

10 BIT SHADOW

REGISTER

10 BIT COMPARE

REGISTER

PWM1I

PWM1B

2:1 MUX

10 BIT SHADOW

REGISTER

10 BIT COMPARE

REGISTER

PWM0I

PWM0B

2:1 MUX

2000 May 02

PWM3

PWM2

Figure 8. PWM Block Diagram

16

PWM1

PWM0

SU01364

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

4 kB OTP 8-bit A/D, Pulse Width Modulator

The width of each PWM output pulse is determined by the value in

the appropriate compare shadow registers, CPSW0 through

CPSW4, CPSW0–3 for bits 0–7 and CPSW4 for bits 7 and 8. When

the counter described above reaches underflow the PWM output is

forced high. It remains high until the compare value is reached at

which point it goes low until the next underflow. The number of

microcontroller clock pulses that the PWM

by:

t

= (CNSW – CPSWn+1)

HI

A compare value greater than the counter reload value results in the

PWM output being permanently high. In addition there are two

CPSW0: Compare Shadow register 0

Addr: 0D3H

Reset Value: 00H

765432 1 0

CPSW07 CPSW06 CPSW05 CPSW04 CPSW03 CPSW02 CPSW01 CPSW00

CPSW1: Compare Shadow register 1

Addr: 0D4H

Reset Value: 00H

765432 1 0

CPSW17 CPSW16 CPSW15 CPSW14 CPSW13 CPSW12 CPSW11 CPSW10

output is high is given

n

special cases. A compare value of all zeroes, 000, causes the

output to remain permanently high. A compare value of all ones,

3FF, results in the PWM output remaining permanently low. Again

the compare value is loaded into a shadow register. The transfer

from this holding register to the actual compare register is under

program control.

The register assignments are shown below where the number

immediately following “CPSW” identifies the PWM output. Thus

CPSW0 controls the width of PWM0, CPSW1 the width of PWM1

etc. In the case of two digits following “CPSW,” e.g. CPSW00, the

second digit refers to the bit of the compare value. Thus CPSW00

represents the value loaded into bit 0 of the PWM0 compare register

87LPC768

CPSW2: Compare Shadow register 2

Addr: 0D5H

Reset Value: 00H

765432 1 0

CPSW27 CPSW26 CPSW25 CPSW24 CPSW23 CPSW22 CPSW21 CPSW20

CPSW3: Compare Shadow register 3

Addr: 0D6H

Reset Value: 00H

765432 1 0

CPSW37 CPSW36 CPSW35 CPSW34 CPSW33 CPSW32 CPSW31 CPSW30

CPSW4: Compare Shadow register 4

Addr: 0D7H

Reset Value: 00H

765432 1 0

CPSW39 CPSW38 CPSW29 CPSW28 CPSW19 CPSW18 CPSW09 CPSW08

The overall functioning of the PWM module is controlled by the

contents of the PWMCON0 register. The operation of most of the

control bits is straightforward. For example there is an invert bit for

each output which causes results in the output to have the opposite

value compared to its non-inverted output. The transfer of the data

from the shadow registers to the control registers is controlled by the

PWMCON0.6 while PWMCON0.7 allows the PWM to be either in

the run or idle state. The user can monitor when underflow causes

the transfer to occur by monitoring the Transfer bit, PWCON0.6.

When the transfer takes place the PWM logic automatically resets

this bit.

The fact that the transfer from the shadow to the working registers

only occurs when there is an underflow in the counter results in the

need for the user’s program to observe the following precautions. If

PWMCON1 is written with Transfer set without Run being enabled

the transfer will never take place. Thus if a subsequent write sets

Run without Transfer the compare and counter values will not be

those expected. If Transfer and Run are set, and prior to underflow

there is a subsequent load of PWMCON0 which sets Run but not

Transfer, the transfer will never take place. Again the compare and

counter values that existed prior to the update attempt will be used.

As outlined above the Transfer bit can be polled to determine when

the transfer occurs. Unless there is a compelling reason to do

otherwise, it is recommended that both Run, PWMCON0.7, and

Transfer, PWMCON0.7, be set when PWMCON0 is written.

When the Run bit, PWMCON0.7, is cleared the PWM outputs take

on the state they had just prior to the bit being cleared. In general

this state is not known. In order to place the outputs in a known

2000 May 02

17

Philips Semiconductors Preliminary specification

Low power, low price, low pin count (20 pin) microcontroller with

87LPC768

4 kB OTP 8-bit A/D, Pulse Width Modulator

state when Run is cleared the Compare registers can be written to

either the “always 1” or “always 0” so the output will have the output

desired when the counter is halted. After this PWMCON0 should be

written with the Transfer and Run bits are enabled. After this is

done PWMCON0 to is polled to find that the Transfer has taken

place. Once the transfer has occurred the Run bit in PWMCON0

can be cleared. The outputs will retain the state they had just prior

to the Run being cleared. If the Brake pin (see discussion below in

PWMCON0: PWM Control register 0

Addr: 0DAH

Reset Value: 00H

BIT SYMBOL FUNCTION

PWMCON0.7 RUN 0= Counter Halted & Preset Value loaded. If Brake is asserted, PWMx output will be equal to the

PWMCON0.6 XFER 0= Counter & Compare shadow registers are not connected to the active registers

PWMCON0.5 PWM3I 0= PWM3 output is non–inverted. Output is a ‘1’ from the start of the cycle until compare; ’0’

PWMCON0.4 PWM2I 0= PWM2 output is non–inverted. Output is a ‘1’ from the start of the cycle until compare; ’0’

PWMCON0.2 PWM1I 0= PWM1 output is non–inverted. Output is a ‘1’ from the start of the cycle until compare; ’0’

PWMCON0.1 PWM0I 0= PWM0 output is non–inverted. Output is a ‘1’ from the start of the cycle until compare; ’0’

76543210

RUN XFER PWM3I PWM2I – PWM1I PWM0I –

value of the corresponding PWMxB bit (PWMCON1[3:0]). If Brake is not asserted, PWMx

output will be equal to the Value after compare

1= Counter run

1= Shadow register contents transferred to active registers, at the next Counter underflow This bit

is auto–cleared by hardware after the data transfer from shadow to active registers

thereafter.

1= PWM3 output is inverted. Output is a ‘0’ from the start of the cycle until compare; ’0’ thereafter.

thereafter.

1= PWM2 output is inverted. Output is ‘0’ from the start of the cycle until compare; ’1’ thereafter.

thereafter.

1= PWM1 output is inverted. Output is ‘0’ from the start of the cycle until compare; ’1’ thereafter.

thereafter.

1= PWM0 output is inverted. Output is ‘0’ from the start of the cycle until compare; ’1’ thereafter.

section concerning the operation of PWMCON1) is not used to

control the brake function, the “Brake when not running” function can

be used to cause the outputs to have a given state when the PWM

is halted. This approach should be used only in time critical

situations when there is not sufficient time to use the approach

outlined above since going from the Brake state to run without

causing an undefined state on the outputs is not straightforward. A

discussion on this topic is included in the section on PWMCON1.

The Brake function, which is controlled by the contents of the

PWMCON1 register, is somewhat unique. In general when Brake is

asserted the four PWM outputs are forced to a user selected state,

namely the state selected by PWMCON1 bits 0 to 3.

As shown in the description of the operation of the PWMCON1

register if PWMCON1.4 is a “1” brake is asserted under the control

PWMCON1.7, BKCH, and PWMCON1.5, BPEN. As shown if both

are a “0” Brake is asserted. If PWMCON1.7 is a “1” brake is

asserted when the run bit, PWMCON0.7, is a “0.” If PWMCON1.6 is

a “1” brake is asserted when the Brake Pin, P0.2, has the same

polarity as PWMCON1.6. When brake is asserted in response to

this pin the RUN bit, PWMCON0.7, is automatically cleared. The

combination of both PWMCON1.7 and PWMCON1.5 being a “1” is

not allowed.

Since the Brake Pin being asserted will automatically clear the Run

bit, PWMCON0.7, the user program can poll this bit to determine

when the Brake Pin causes a brake to occur. The other method for

detecting a brake caused by the Brake Pin would be to tie the Brake

Pin to one of the external interrupt pins. This latter approach is

2000 May 02

SU01387

needed if the Brake signal can be of insufficient length to ensure

that it can be captured by a polling routine.

When, after being asserted, the condition causing the brake is

removed, the PWM outputs go to whatever state that had

immediately prior to the brake. This means that in order to go from

brake being asserted to having the PWM run without going through

an indeterminate state care must be taken. If the Brake Pin causes

brake to be asserted the following prototype code will allow the

PWM to go from brake to run smoothly.

•Rewrite PWMCON1 to change from Brake Pin enabled to S/W

Brake

•Write CPSW.(0:4) to always “1”, 11 h, or always “0” 00 h, to give

brake pattern

•Set PWMCON0 to enable Run and Transfer.

•Poll Brake Pin until it is no longer active. When no longer active:

18

Loading...

Loading...