TFT WXGA LCD TV

Service

Service

Service

Service

Service

Service

Chassis: TPT1.0A LA

37TA1800/93

42TA1800/93

37TA2000/93

42TA2000/93

Contents Page

1. Technical Specifications and Connections 2~4

2. Safety Instructions, Warnings and Notes 5

3. Directions for User 7

4. Mechanical Instructions 8~9

5. Wiring Diagram 10

Block Diagram 11~12

6. Circuits Diagrams & PWB Layouts

Chassis Overview & Exploded View 13~14

Diagram PWB

Contents

DSUB/DVI

HDMI

TUNNER

AV CONNECTOR

IO

CPU M30620SPGP

SVP-PX66-1

SVP-PX66-2

SVP-PX66-3

SVP-PX66-4

DDR 4Mx32

SOUND DELAY

AUDIO DECODER (Diagram S-B14)28 33~34

AUDIO AMP

POWER 1

POWER2

RESET

(Diagram S-A01)15 33~34

(Diagram S-A02)16 33~34

(Diagram S-A03)17 33~34

(Diagram S-A04)18 33~34

(Diagram S-A05)19 33~34

(Diagram S-A06)20 33~34

(Diagram S-A07)21 33~34

(Diagram S-A08)22 33~34

(Diagram S-A09)23 33~34

(Diagram S-A10)24 33~34

(Diagram S-B11)25 33~34

(Diagram S-B12)26 33~34

(Diagram S-B13)27 33~34

(Diagram S-B15)29 33~34

(Diagram S-B16)30 33~34

(Diagram S-B17)31 33~34

(Diagram S-B18)32 33~34

~6

Contents Page

Power Board(37 (Diagram P)35 36~37

SIDE AV Board (Diagram A)38 39~40

IR Board (Diagram I)41 42~43

KEY Board (Diagram K)44 45

7. Alignments

Electrical Instructions&Serial NO.Definition 46~50

S

oftware Updrade With ISPWriter 51~52

Circuit Descriptions and IC Data Sheets 53

8.

Circuit Description 54

IC Data Sheets 55~60

Repair Flow Chart 61~62

9. Spare Parts List 63~73

10.42 Supplement Material

"

Power Board(42") (Diagram P)74 75 ~76

Exploded View(42

11.Different Parts List 78~84

12.Revision List 85

")

Diagram PWB

")

77

Subject to modification Feb. 09 , 2006 EN: 3138 106 50050

PHILIPS

2

TPT1.0A LA

1. Technical Specifications and Connections

1. Technical Specifications and Connections

Index of this chapter:

1.1 Technical Specifications

1.2 Connections

Notes:

·

Some models in this chassis range have a different

mechanical construction. The information given here is

therefore model specific. At the moment of writing, not all

information was available (only the 37-inch TPT1.0A LA

model was available). As soon as the other models are

introduced, an update manual will be released.

·

Figures below can deviate slightly from the actual situation,

due to the different set executions.

·

Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1Vision

Panel Model CLAA370WA03 (Supplier CPT)

Display type : LCD

Display area(mm) : 819.6(H) X 460.8(V)

Number of Pixels : 1366(H) x 768(V)

Contrast ratio : Typical 1200:1

Light output (cd/m2) : >400

Response time (ms) : Trg:8,Tfg:8 (Gray to Gray)

Viewing angle (HxV degrees): 170/170 (L/R,U/D) (CR >10)

Pitch ( mm ) : 0.6(H) X 0.6(V)(37")

Color pixel arrangement : RGB vertical stripe

Display operating mode : Normally black

Color depth : 16.7M colors(8bits)

Brightness (cd/m^2) : 500(Center 1 points, Typ.)

Surface treatment : Hard coating(3H),

Electrical interface : LVDS

Outline Dimension(mm):877(H)X516.8(V)X55.5(D)(Typ.)(37")

Module weight (g) : 12,000(Typ.)

Backlight : 8 CCFL(37")

Horizontal scan : 30 ~ 63KHz

Vertical scan : 50 ~ 75 Hz

2 Sound

1.1.

Sound systems : Stereo

Maximum power :2x10W(37")

:

T420XW01 (Supplier AUO)(42")

(37")

930.25(H) x 523.01(V) (42")

178/178 (L/R,U/D) (CR >10)

0.68(H) X 0.68(V)(42")

983.0(H) x 576.0(V) x 54.2(D)(42")

16 CCFL(42")

(37")

(37")

(42")

Operating:

Temperature : 0 C to 40 C

O

O

Humidity : 10 to 90%(non condensing)

Altitude : 0 to 1,2000 feet

Air pressure : 645 mBAR

(guaranteed optical performance) : 5 to 35 C

(guaranteed functional performance) : 5 to 40 C

Storage

Temperature : -20 to 50 C

O

O

O

Humidity : 10 to 90% (non condensing )

Air pressure : 600 to 1100 mBAR ( non operating)

Note: recommend at 0 to 35 C, Humidity less than 60 %

Shipping

Temperature : -20 to 60 C

O

O

Humidity : 5 to 90% (non condensing )

Altitude : 0 to 40000 feet ( non operating )

Air pressure : 188 to 1100 ( non operating )

1.2 Connections

1.2.1Signal Connector(China model)

1 ). Tuner: PAL D/K for China model

Multi-standard for WE model

2 ) SPDIF OUT : Digital audio output (HDMI audio output)

3 ). PVR OUT : Composite video output (CVBS) and audio

R/L(RCA jack)

4 ). AV audio IN : AV1 and S-Video audio R/L(RCAjack)

5 ). AV1 IN : Composite video input (AV1)

6 ). S-Video 1 IN : S-video input (S-Video 1)

7 ). Comp video 1 IN : HDTV input with YPbPr format with audio R/L.

8 ). Comp video 2 IN : HDTV input with YPbPr format with audio R/L.

9 ). PC audio IN: audio R/L(mini-jack).

10). PC IN: VGA input (D-SUB connectors)

11). HDMI : digital video and audio input

12). speaker output : external speakers output connectors

13). earphone : earphone jack

14). AV2 IN : Composite video input (AV2 side)

15). AV audio IN : AV2 and S-Video side audio R/L(RCA jack)

16). S-Video IN : S-video input (S-Video side)

12

7

11

910

8

5

6

Fig1-1

2

4

1

3

1.1.

3 Miscellaneous

Power supply:

AC-input : 90V ~ 264VAC,

_

+

50/60 2Hz

Power consumption : 170W/Max(at PC mode),170W/

Max(at TV mode) with Audio

250W/Max(at PC mode),250W/

Max(at TV mode) with Audio(42")

Auto power saving : < 2W

Power cord length : 1.8M

Power cord type : European type and China type

Power indicator : LED (On: Blue ,Sleeping

mode: Amber )

(37")

1516

Fig1-2

1.2.2 Input signal

1.2.2.1 Signal type

1.2.2.1.1PC mode signal type:

a.Analog Video: 15 pin D-sub ,0.7 Vp-p linear, positive

polarity&separate sync.( TTL level, positive

or negative polarity)

b.Audio signal : 3.5mm stereo mini-jack

Level: Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

-Impedance > 10 k .

c.Signal source: Pattern generator format as attachment table

1to12.

Reference generator: CHROMA 2200 or QuantumData 802R

14

13

1. Technical Specifications and Connections

1.2.2.1.2TV mode signal type

RF Signal : Aerial input / 10mV(30-100dBuV)

Video signal : CVBS input ( RCA jack) / 1Vpp (300mV-sync,

700mV-video.)

S video input / 1VppY-signal, +/-300mV C-signal

SCART input: CVBS

Comp video in(YPbPr input)/ 1Vpp Y signal, +/-350mV Pb,Pr signal

HDMI:Digital interface with 4 channels TMDS signal

CVBS output ( RCA jack) / 1Vpp (300mV-sync, 700mV-video.)

Audio signal : Audio (1) R/L for AV IN(AV and S-Video).

Level: - Nominal : 0.5 V rms.

Audio (2) R/L for SCART IN

Level: - Nominal : 0.5 V rms.

Audio (3) R/L for Comp video IN.

Level: - Nominal : 0.5 V rms.

Audio (4) digital audio for HDMI Video IN.

1.2.2.1.3 PVR (CVBS) output:

Video: CVBS output 1Vpp / Impedance : 75

Audio: R/L output (from CVBS)

Level: - Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance < 1 k

1.2.2.1.4 Scart output: ( for WE model only)

Video: CVBS output 1Vpp / Impedance : 75

Audio: R/L output (from CVBS)

Level: - Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance < 1 k

1.2.2.1.5 SPDIF output: Serial digital audio output when input is HDMI.

1.2.2.1.6 Headphone

Audio: R/L output -10mW at 32

3.5mm stereo jack with switch

Impedance is between 8 and 600

1.2.2.2 TV system signal mode:

RF support:

China : PAL(D,K)

WE : PAL and SECAM(France).

CVBS/S-video: Support PAL, NTSC and SECAM colour system.

Comp video IN(YpbPr) : SDTV and HDTV, including 480i/p, 576i/p,

HDMI IN : 480P, 576P ,720P/50Hz , 720P/60Hz , 1080i/50Hz ,

1080i/60Hz

PVR (CVBS out) : Support PAL, NTSC and SECAM colour system.

1.2.2.3 Signal cab le

1.2.2.3.1 VGA s ignal cable

The input signals are applied to display through D-sub cable.

Length: 1.8 M +/- 50 mm (fixed)

Connector type: D-sub male.

15-pin D-sub VGA connector of the signal cable:

S SRGB signal ( for WE model only)

- Maximum : 1.5 V rms.

- Impedance > 10 k

- Maximum : 1.5 V rms.

- Impedance > 10 k

-Maximum : 1.5 V rms.

- Impedance > 10 k

.

.

.

720p 50/60Hz, 1080i 50/60Hz.

With DDC_2B pin assignments.

Blue connector thumb-operated jackscrews

.

.

.

.

.

.

TPT1.0A LA

1 Red video input

2 Green video input /SOG

3 Blue video input

4 GND

5 GND- cable detect

6 Red video ground

7 Green video ground

8 Blue video ground

9 DDC +3.3V (or 5V)

10 Logic ground

11 GND

12 Serial data line (SDA)

13 H. Sync / H+V

14 V. Sync

15 Data clock line (SCL)

1.2.2.3.2 HDMI for digital Video / Audio interface with pin assignment

as follows:

Pin No. Description

1RX2+

2GND

3RX2-

4RX1+

5GND

6RX1-

7RX0+

8GND

9RX0-

10 RXC+

11 GND

12 RXC-

13 CEC

14 NC

15 DDC clock

16 DDC data

17 GND

18 +5V POWER

19 Hot Plug Detect

1.2.2.3.3 CVBS

The input signals are applied to display through CVBS cable

Pin assignment

PIN NO. SIGNAL

1GND

2 CVBS

3 CVBS

4 CVBS

1.2.2.3.4 S-Video

The input signals are applied to display through S-Video cable

Pin assignment

PIN NO. SIGNAL

1GND

2GND

3GND

4GND

5GND

6LUMA

8 CHROMA

3

4

1.2.2.3.5 Component Video

1.2.2.3.6 SCART

TPT1.0A LA

The input signals are applied to display through Component

Video RCA Jack pin assignment

PIN NO. SIGNAL

1GND

2Redà Pr

3GND

4Blueà Pb

5GND

6GreenàY

Scart connector is only used in WE model. The Scart (Syndicat

des Constructeurs d'Appareils Radiorécepteurs et Televiseurs)

connector is used for combined audio and video connections.

1. Technical Specifications and Connections

Pin TV SCART

1 N/C

2 Right audio input

3 N/C

4 Audio ground

5 Blue ground

6 Left audio input

7 Blue output

8

0-2.5 volts (low) when:

TV output

4.5-7.5 volts (High-t o-6v) when :

-inputting picture format setting is '16:9',

9-12 volts (high -to-12v) wh en:

-inputing picture format setting is '4:3'

9 Green ground

10 N/C

11 Green output

12 N/C

13 Red ground

14 N/C

15 Red output

16

0volt (low)when:-pin8oftheTVscartis

low

or when:

- Composite video signal

1-3 volts (high ) when:

- video input setting is 'RGB',

17 Composite video output ground

18 Composite video input ground

19 N/C

20 Composite video input

21 Ground

2. Safety Instructions, Warnings and Notes

2. Safety Instructions, Warnings and Notes

TPT1.0A LA

5

index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require that during a repair:

·

Connect the set to the AC Power via an isolation

transformer (> 800 VA).

·

Replace safety components, indicated by the symbol ,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

·

Route the wire trees correctly and fix them with the

mounted cable clamps.

·

Check the insulation of the AC Power lead for external

damage.

·

Check the strain relief of the AC Power cord for proper

function.

·

Check the electrical DC resistance between the AC Power

plug and the secondary side (only for sets which have a AC

·

Power isolated power supply):

1. Unplug the AC Power cord and connect a wire

between the two pins of the AC Power plug.

2. Set the AC Power switch to the "on" position (keep the

AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

AC Power plug and the metal shielding of the tuner or

the aerial connection on the set. The reading should be

between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the AC Power plug.

·

Check the cabinet for defects, to avoid touching of any

inner parts by the customer.

2.2 Warnings

·

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD ). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

·

Be careful during measurements in the high voltage

section.

·

Never replace modules or other components while the unit

is switched "on".

·

When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

··

Measure the voltages and waveforms with regard to the

chassis (= tuner) ground ( ), or hot ground ( ), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a color bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

··

Where necessary, measure the waveforms and voltages

with ( ) and without ( ) aerial signal. Measure the

voltages in the power supply section both in normal

operation ( ) and in stand-by ( ). These values are

indicated by means of the appropriate symbols.

The semiconductors indicated in the circuit diagram and in

··

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

·

Manufactured under license from Dolby Laboratories.

"Dolby" and the "double-D symbol", are trademarks of

Dolby Laboratories.

2.3.2 Schematic Notes

All resistor values are in ohms and the value multiplier is

·

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

Resistor values with no multiplier may be indicated with

·

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

All capacitor values are given in micro-farads (u= x10 ),

·

nano-farads (n= x10 ), or pico-farads (p= x10 ).

·

Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

An "asterisk" (*) indicates component usage varies. Refer

·

to the diversity tables for the correct values.

·

The correct component values are listed in the Electrical

Replacement Parts List. Therefore, always check this list

when there is any doubt.

-9

-12

-6

2.3.3 Rework on BGA (Ball Grid Array) Ics

General

Although (LF)BGA assembly yields are very high, there may still be

a requirement for component rework. By rework, we mean the

process of removing the component from the PWB and replacing it

with a new component. If an (LF)BGA is removed from a PWB, the

solder balls of the component are deformed drastically so the

removed (LF)BGA has to be discarded.

Device Removal

As is the case with any component that, it is essential when

removing an (LF)BGA, the board, tracks, solder lands, or

surrounding components are not damaged. To remove an(LF)BGA,

the board must be uniformly heated to a temperature close to the

reflow soldering temperature. A uniform temperature reduces the

chance of warping the PWB.To do this, we recommend that the

board is heated until it is certain that all the joints are molten.

Then carefully pull the component off the board with a vacuum

nozzle. For the appropriate temperature profiles, see the IC data

sheet.

Area Preparation

When the component has been removed, the vacant IC area must

be cleaned before replacing the (LF)BGA.Removing an IC often

leaves varying amounts of solder on the mounting lands. This

excessive solder can be removed with either a solder sucker or

solder wick. The remaining flux can be removed with a brush and

cleaning agent.After the board is properly cleaned and inspected,

apply flux on the solder lands and on the connection balls of

the (LF)BGA.

Note: Do not apply solder paste, as this has shown to result in

problems during re-soldering.

Device Replacement

The last step in the repair process is to solder the new component

on the board. Ideally, the (LF)BGAshould be aligned under a

microscope or magnifying glass. If this is not possible, try to align

the (LF)BGA with any board markers. To reflow the solder, apply a

temperature profile according to the IC data sheet. So as not to

damage neighbouring components, it may be necessary to reduce

some temperatures and times.

More Information

For more information on how to handle BGA devices, visit this

URL: (needs subscription,

www.atyourservice.ce.philips.com

not available for all regions). After login, "select Magazine", then

go to "Workshop Information". Here you will find Information on

how to deal with BGA-ICs.

6

TPT1.0A LA

2. Safety Instructions, Warnings and Notes

2.3.4 Lead Free Solder

Philips CE is going to produce lead-free sets (PBF) from

1.1.2005 onwards.

Lead-free sets will be indicated by the PHILIPS-lead-free logo

on the Printed Wiring Boards (PWB):

In case of doubt whether the board is lead-free or not (or with

mixed technologies), you can use the following method:

·

Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

·

De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

Caution must

which is coupled to the 12NC. For an overview of these

profiles, visit the website

(needs subscription, but is not available for all regions)

You will find this and more technical information within the

"Magazine", chapter "Workshop information".

For additional questions please contact your local repair help

desk.

: For BGA-ICs, you use the correct temperatureprofile,

www.atyourservice.ce.philips.com

Fig 2-1 Lead-free logo

This sign normally has a diameter of 6 mm, but if there is less

space on a board also 3 mm is possible.

In case of doubt wether the board is lead-free or not (or with

mixed technologies), you can use the following method:

·

Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

·

De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

Caution

which is coupled to the 12NC. For an overview of these

profiles, visit the website

(needs subscription, but is not available for all regions)

You will find this and more technical information within the

"Magazine", chapter "Workshop information".

For additional questions please contact your local repairhelpdesk.

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

·

is required,please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

soldering tin. The solder tool must be able

-To reach at least a solder-tip temperature of 400 C.

-To stabilise the adjusted temperature at the solder-tip.

-To exchange solder-tips for different applications.

·

- 380 C is reached and stabilised at the solder joint.

Heating time of the solder-joint should not exceed~4sec.

Avoid temperatures above 400 C, otherwise wear-out of

tips will rise drastically and flux-fluid will be destroyed. To

avoid wear-out of tips, switch "off" unused equipment or

reduce heat.

·

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If not to avoid, clean carefully the

solder-joint from old tin and re-solder with new tin.

Not listed standard material (commodities) has to be

purchased at external companies.

delivered in so-called "dry-packaging" to protect the IC

against moisture. This packaging may only be opened

short before it is used (soldered). Otherwise the body of the

IC gets "wet" inside and during the heating time the

structure of the IC will be destroyed due to high (steam-)

pressure inside the body. If the packaging was opened

before usage, the IC has to be heated up for some hours

(around 90C)fordrying (think of ESD-protection !).

Do not re-use BGAs at all!

·

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

: For BGA-ICs, you must use the correct temperatureprofile,

www.atyourservice.ce.philips.com

Use only lead-free soldering tin . If lead-free solder paste

·

Use only adequate solder tools applicable for lead-free

Adjust your solder tool so that a temperature around 360 C

Mix of lead-free soldering tin/parts with leaded soldering

Use only original spare-parts listed in the Service-Manuals.

·

·

Special information for lead-free BGAICs: these ICs will be

For sets produced before 1.1.2005, containing leaded

2.3.5 Practical Service Precautions

·

It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

·

Always respect voltages.

dangerous in themselves, they can cause unexpected

reactions - reactions that are best avoided. Before reaching

into a powered TV set, it is best to test the high voltage

insulation. It is easy to do, and is a good service precaution.

While some may not be

3. Directions for Use

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

TPT1.0A LA

7

8

TPT1.0A LA

4. Mechanical Instructions

Index of this chapter:

4.1 Assy/Panel Removal

4.2 Set Re-assembly

4.1 Assy/Panel Removal

Front view

Back view

4. Mechanical Instructions

Fig.5

Step 3. Remove IR, Side AV, Key board and Main shield assy as Fig.6~8.

a. Remove the 4 screws to remove the as Fig.6

b. Remove the 1 cable and 2 screws to remove Side AV board as Fig.7

c. Remove the 1 cable and 2 screws to remove IR board as Fig.7

d. Remove the 1 cable to remove Key board as Fig.7

e. Remove the the other 2 cables and 6 screws to remove the Main

shield assy as Fig.7~8

Fig.1

Fig.2

Step 1. Remove the stand and speaker.

a. Remove the 2 screws to remove the stand as Fig.3

Fig.3

b. Remove the 4 screws and 2 cables to remove the speaker as Fig.4

Fig.6

Fig.7

Fig.8

Step 4. Remove the Scaler and Power board.

a. Remove the 11 screws as Fig. 9

b. Remove the 12 screws to remove the Scaler and Power board as

Fig10~11

Step 2. Remove the Back cover as Fig.5.

Remove the 20 screws to remove the Back cover as Fig.5

a.

Fig.9

Fig.4

Fig. 10

4. Mechanical Instructions

4.2 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Notes:

a. While re-assembling, make sure that all cables are placed

and connected in their original position.

b. Pay special attention not to damage the EMC foams at the

SSB shielding. Check that EMC foams are put correctly on

Fig. 11

their places.

TPT1.0A LA

9

Step 5. Remove the Bezel assy as Fig.12~Fig.15 .

Remove the 5 screws

a. as Fig.12

b. Remove the 4 screws as Fig.13

c. Remove the 4 screws as Fig.14

d . as Fig.15

Remove the Bezel assy

In warranty, it is not allowed to disassembly the LCD panel, even the

backlight unit defect.

Out of warranty, the replacment of backlight unit is a correct way

when the defect is cused by backlight (CCFL,Lamp).

Fig. 12

Fig. 13

Fig. 14

Fig. 15

10

TPT1.0A LA

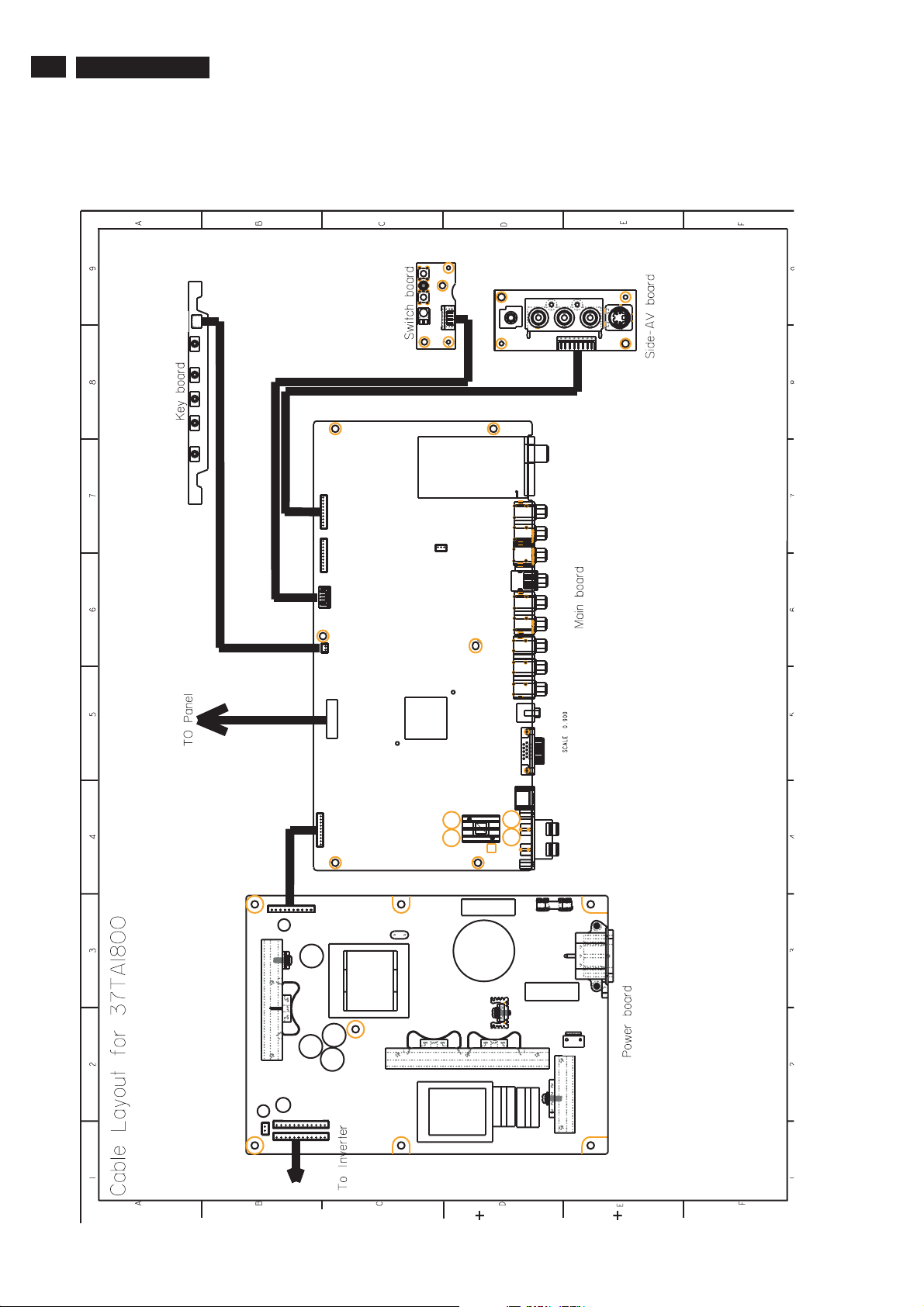

5. Block Diagram

Index of this chapter:

5.1

Wiring Diagram

5.2 Block Diagram

5.1 Wiring Diagram

5. Block Diagram

3138 14723781

3138 14723781

PHILIPS

PHILIPS

COMPONENT SIDE

8P

16308P1630

1

8

COMPONENT

1

2P

2

1921 2P1921

10

10PIN

10PIN

CN109

CN109

1

6

6PIN

6PIN

CN114

CN114

1

2

2PIN

2PIN

CN113

CN113

1

1

6P

19076P1907

6

3

1

CN112

CN112

3PIN

3PIN

10

CN117

CN117

10PIN

10PIN

COMPONENT SIDE

1

1089 10P1089 10P

1

10

1064

1063 12P1063 12P

1

1071

1

12

1088 12P1088 12P

12

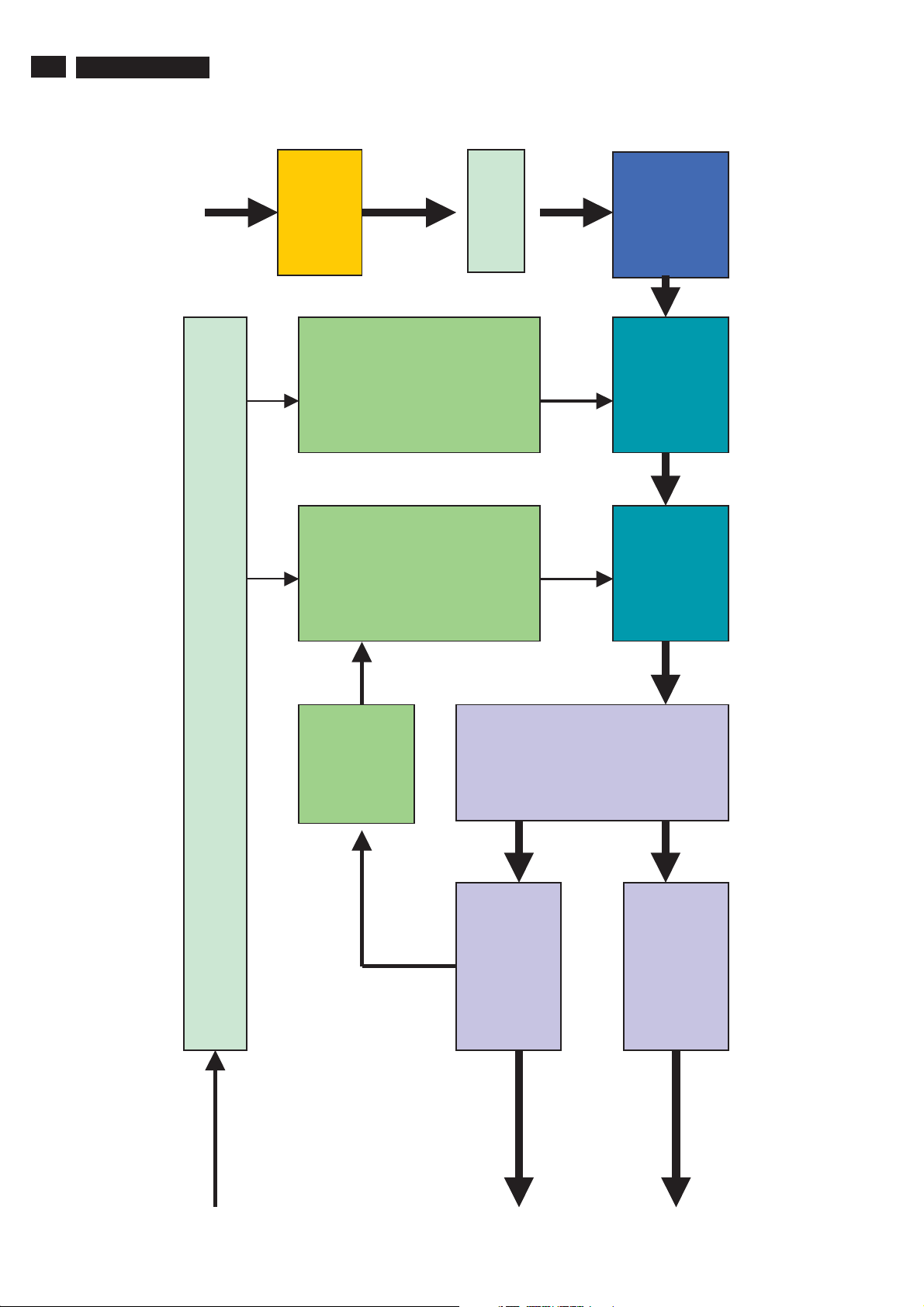

5.2 Block Diagram

Connector

HDMI

5. Block Diagram

Function block of scaler Board

Connector

DSUB

TPT1.0A LA

11

COMP1 R/L

COMP2 R/L

DSUB R/L

HDMI R/L

74HC4052D

+5V

SC3_IN_R

SC3_IN_L

SW4

CVBS2 R/L

SW3

CVBS1 R/L

SIF_OUT

RX5V1_DD

C_SCL

5V_SB

REMOTE_3V

HP_DET

KEYA

HDMI1_RX0/

1/2/3/C+-

RX5V1_DD

C_SDA

M24C02

POWER_ON

DDC_5V

HDMI_HOTPLUG

DETECT_VGA

PC_R/G/BIN

M24C02

SDA

SCL

24LC64

3.3V_SB

DDC_WP

SDAE

SCLE

DDCSDA

74LV4053PW

DDC_5V

ISP_SW

E_PAGE

DDCSCL

RX

TX

VGA_VSIN

VGA_HSIN

74LVC14ADT

5V_SB

PC_HSIN

PC_VSIN

PC_HSIN

PC_VSIN

3.3V_SB

3V_SDA

3V_SCL

1/2/3/C+-

CPU_RESET

PCA9512

3.3V_SB

HDMI1_RX0/

YPbPr1_Y/Pb/Pr

YPbPr2_Y/Pb/Pr

5V_SDA

5V_SCL

SIF_OUT

SV1_Y/C_MP

SV2_Y/C_MP

PC_R/G/BIN

CVBS2_MP

SVP-PX66

FQ1256

+5V

CVBS1_MP

TV_CVBS

HDMI_SPDIF

+5V

MSP3410G

HP_R_OUT

HP_L_OUT

TDA1308T

+5V

HP_ROUT

HP_LOUT

AR_DACM

AL_DACM

TPA3008D2

+16V

ROUT+/-

LOUT+/-

MSP_INT

5V_SDA

5V_SCL

SOUND_EN

SB_PWR

PANEL_PWR

INVERTER_ON_OFF

CPU_RESET

8051_RD#

8051_WR#

RY_BY

SST39VF088

FLASH

M30620SPGP

SRAM_ENABLE

8051_RD#

(NI)

for TT

8051_WR#

AD0-AD7

IS61LV256-12T

3.3V_SB

SRAM

AD0-AD7

A0-A19

CE#

3.3V_SB

RESET_H

PX_INT#

3V_SCL

3V_SDA

8051_ALE

8051_WR#

8051_RD#

8051_CS2PX

8051_A0-7

8051_AD0-7

SW4

SW3

A0-A14

PX_HMMI33

HDMI_MCLK

BRIGHT_ADJ

HDMI_SD0

CS4344

+5V

PX_VL18

PX_MCK0/0#

HDMI_SCK

HDMI_WS

PX_VD33

PX_VA18

PX_RAS#/CAS#

PX_CS0#

PX_WE#

PX_CLKE

K4D263238G-VC33

(2.5V)

DDR

PX_VDDMQ

PX_VD18

PX_DQS0-3

PX_MA0-11

PX_BA0-1

PX_VDDMQ

PX_VDDM

PX_MD0-31

12

TPT1.0A LA

90 ~ 264V

AC Input

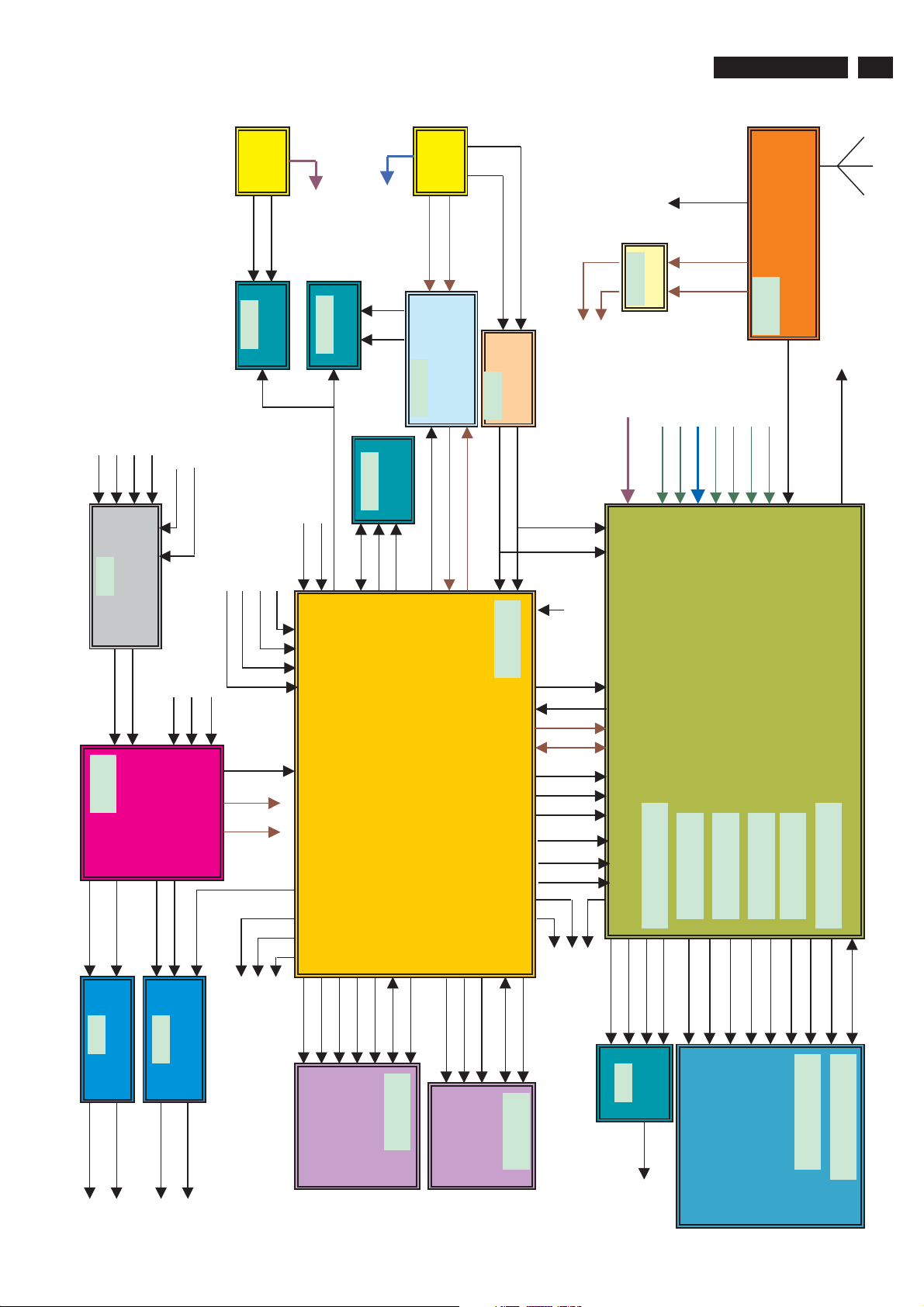

5. Block Diagram

Function block of power Board

AC Inlet

TCET1103(G)

Photo-coupler

FILTER

EMI

AC to DC

KBU8J

STW26NM60

PFC control

L6562 &

Control interface

Feedback

Protect /

network

TCET1103(G)

Photo-coupler

MBRF10H100CT

AC to DC

Transformer

EQ40

STW18NK80Z

PWM control

TEA1507P &

AC to DC

STPS40H100CW

Control from

scalerboard

16V 2.5A

Panel/scalar/

Audio

24V 7A_37”

Inverter board

24V 9A_42”

6.Circuit Diagram & PWB Layouts

Index of this chapter:

6.1 Chassis Overview

6.2 Exploded View

6.3 Scaler Board Schematic Diagram & Layouts

6.4 Power Board Schematic Diagram & Layouts

6.5 SIDE AV Schematic Diagram & Layouts

6.6 IR Schematic Diagram & Layouts

6.7 KEY Schematic Diagram & Layouts

Board

Board

Board

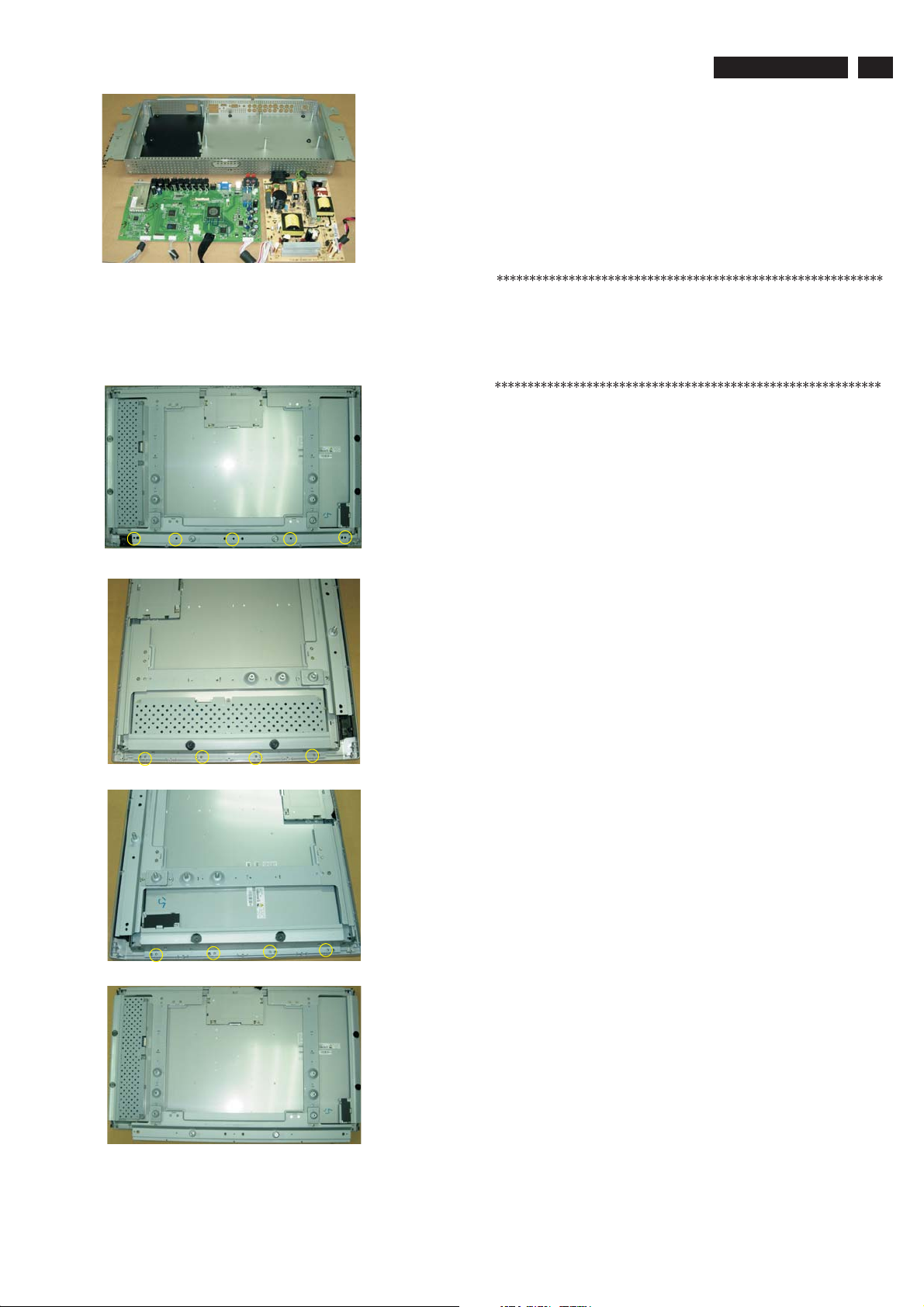

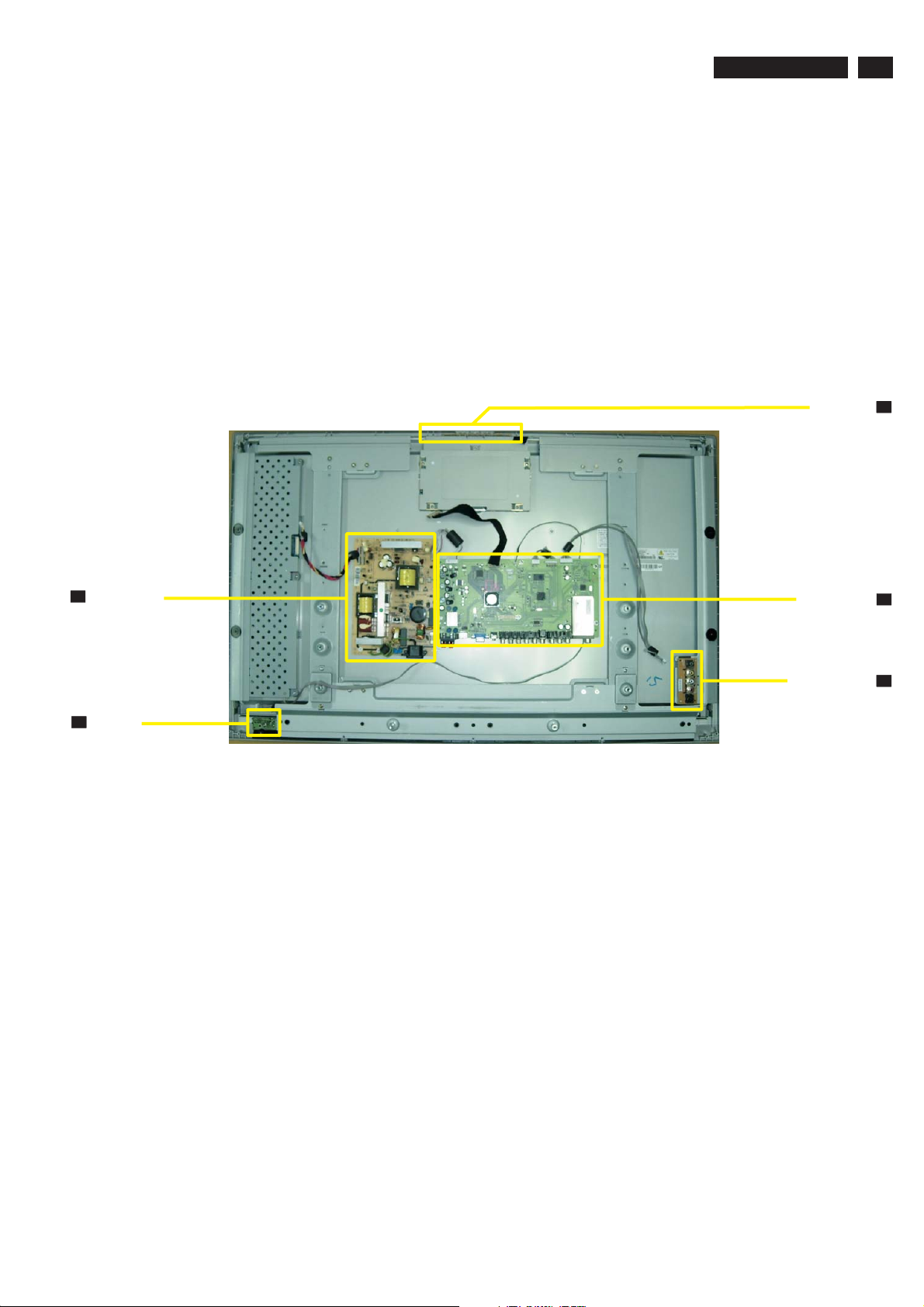

6.1 Chassi Overview

TPT1.0A LA

13

Power Board

P

I

IR Board

Key Board

Scaler Board

Side AV Board

K

S

A

14

6.2 37 Exploded View"

090

313815761281

MAIN SHIELD ASSY

TPT1.0A LA

6.Circuit Diagram & PWB Layouts

40

313815761291

BACK COVER ASSY

1054

313815864961

POWER PCB ASSY

1053

996500039547

SCALER BOARD_VISION-D

1050

823827720921

CPT CLAA370WA03

1055

96500039542

SIDE_AV_BOARD_VISION_D

BASE ASSY

313815761451

IR ASSY

996500039543

1056

996500039544

313815761441

FRONT BEZEL ASSY

1057

KEY BOARD

6.3.1 Scaler Schematic Diagram-ContentsBoard

S-01

6.Circuit Diagrams and PWB Layouts

TPT1.0A LA

15

16

TPT1.0A LA

6.3.2 Scaler Schematic Diagram - DSUB/DVIBoard

S-02

6. Circuit Diagrams and PWB Layouts

6.3.3 Scaler Schematic Diagram - HDMIBoard

S-03

6.Circuit Diagrams and PWB Layouts

TPT1.0A LA

17

18

TPT1.0A LA

6.3.4 Scaler Schematic Diagram - TUNNERBoard

S-04

6. Circuit Diagrams and PWB Layouts

6.3.5 Scaler Schematic Diagram - AV CONNECTORBoard

S-05

6.Circuit Diagrams and PWB Layouts

TPT1.0A LA

19

20

TPT1.0A LA

6.3.6 Scaler Schematic Diagram - IOBoard

S-06

6. Circuit Diagrams and PWB Layouts

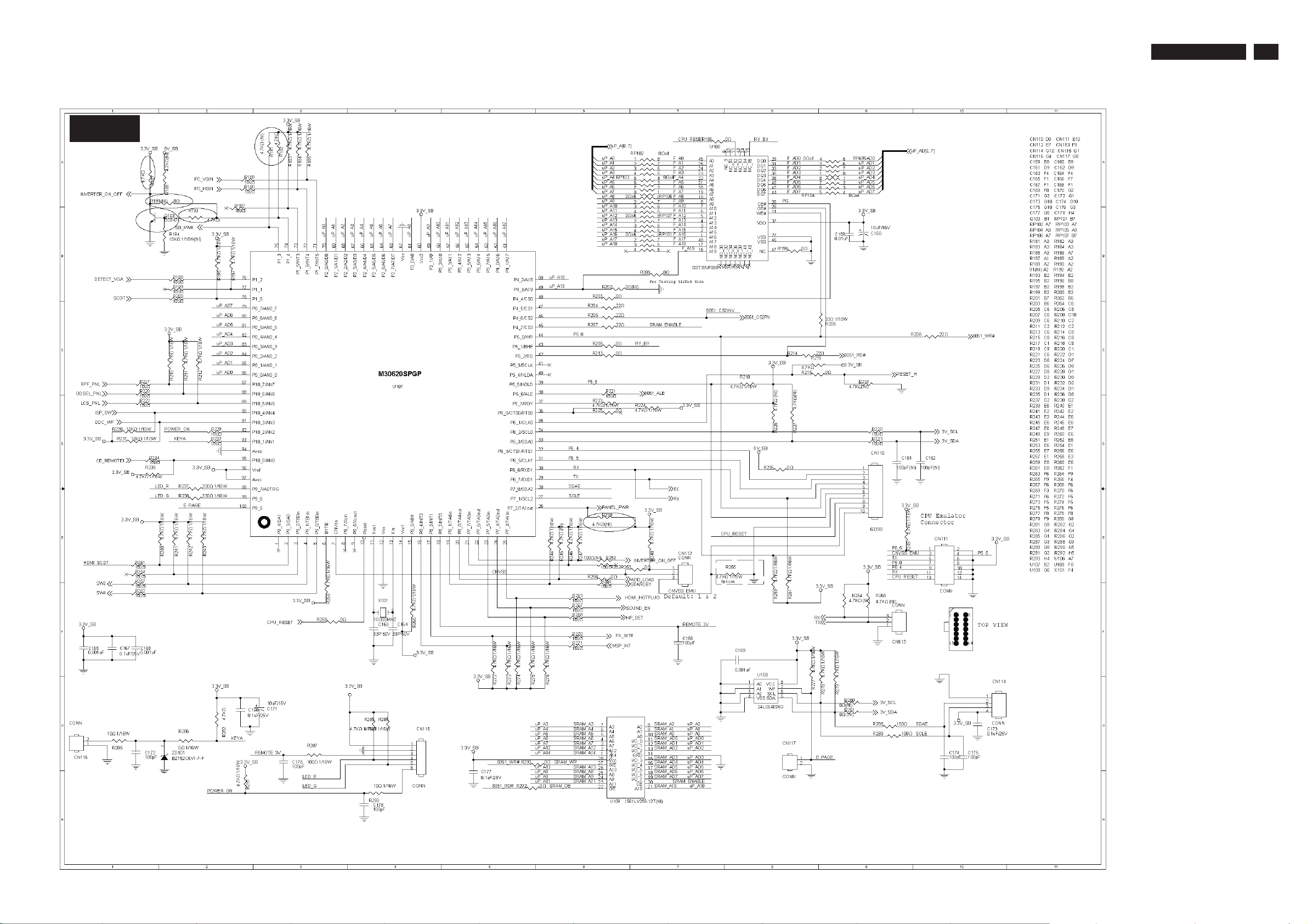

6.3.7 Scaler Schematic Diagram - CPU M30620SPGPBoard

S-07

6.Circuit Diagrams and PWB Layouts

TPT1.0A LA

21

22

TPT1.0A LA

6.3.8 Scaler Schematic Diagram - SVP-PX66-1Board

S-08

6. Circuit Diagrams and PWB Layouts

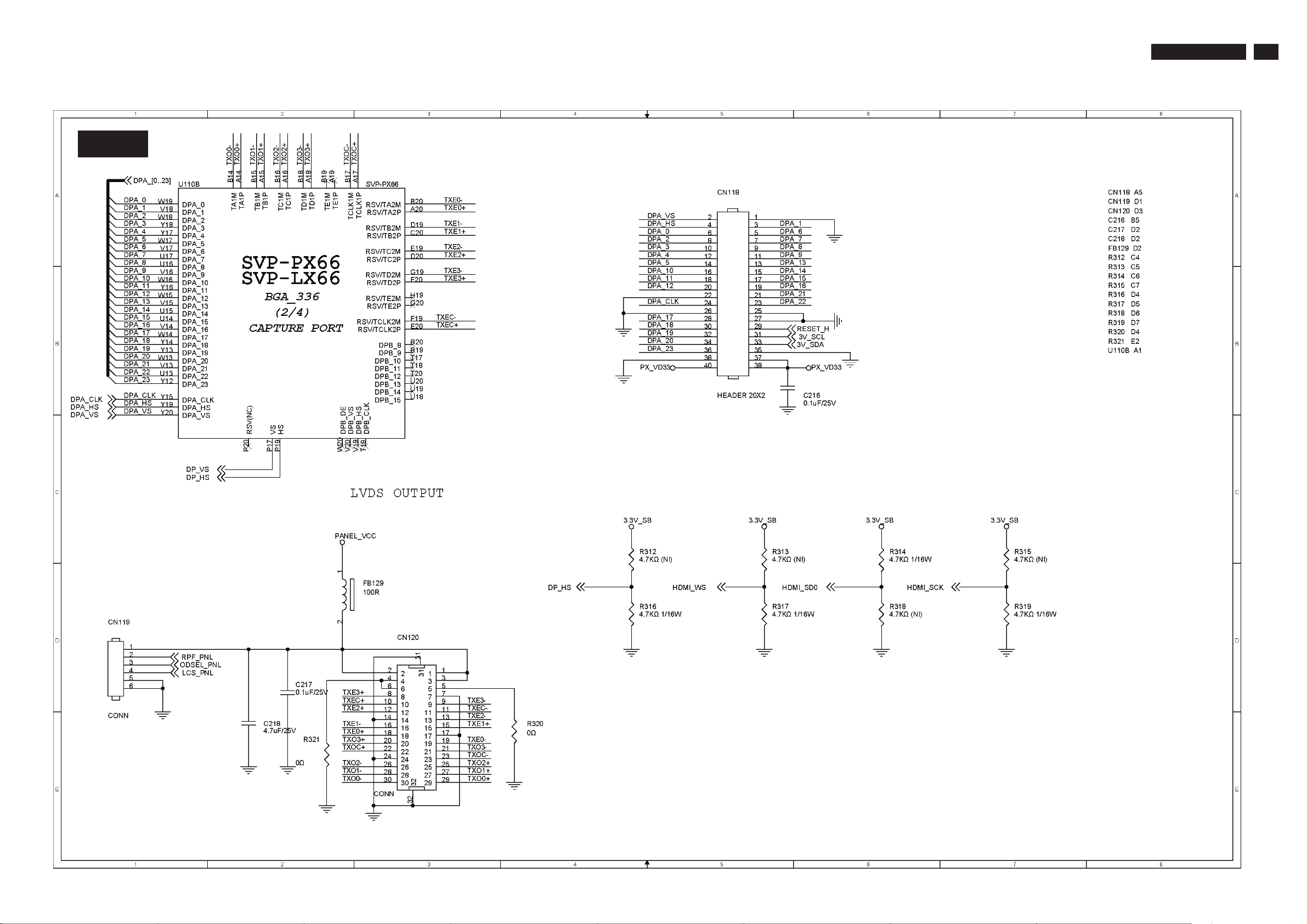

6.3.9 Scaler Schematic Diagram - SVP-PX66-2Board

S-09

6.Circuit Diagrams and PWB Layouts

TPT1.0A LA

23

24

TPT1.0A LA

6.3.10 Scaler Schematic Diagram - SVP-PX66-3Board

6. Circuit Diagrams and PWB Layouts

S-10

6.3.11 Scaler Schematic Diagram - SVP-PX66-4Board

S-11

6.Circuit Diagrams and PWB Layouts

TPT1.0A LA

25

26

TPT1.0A LA

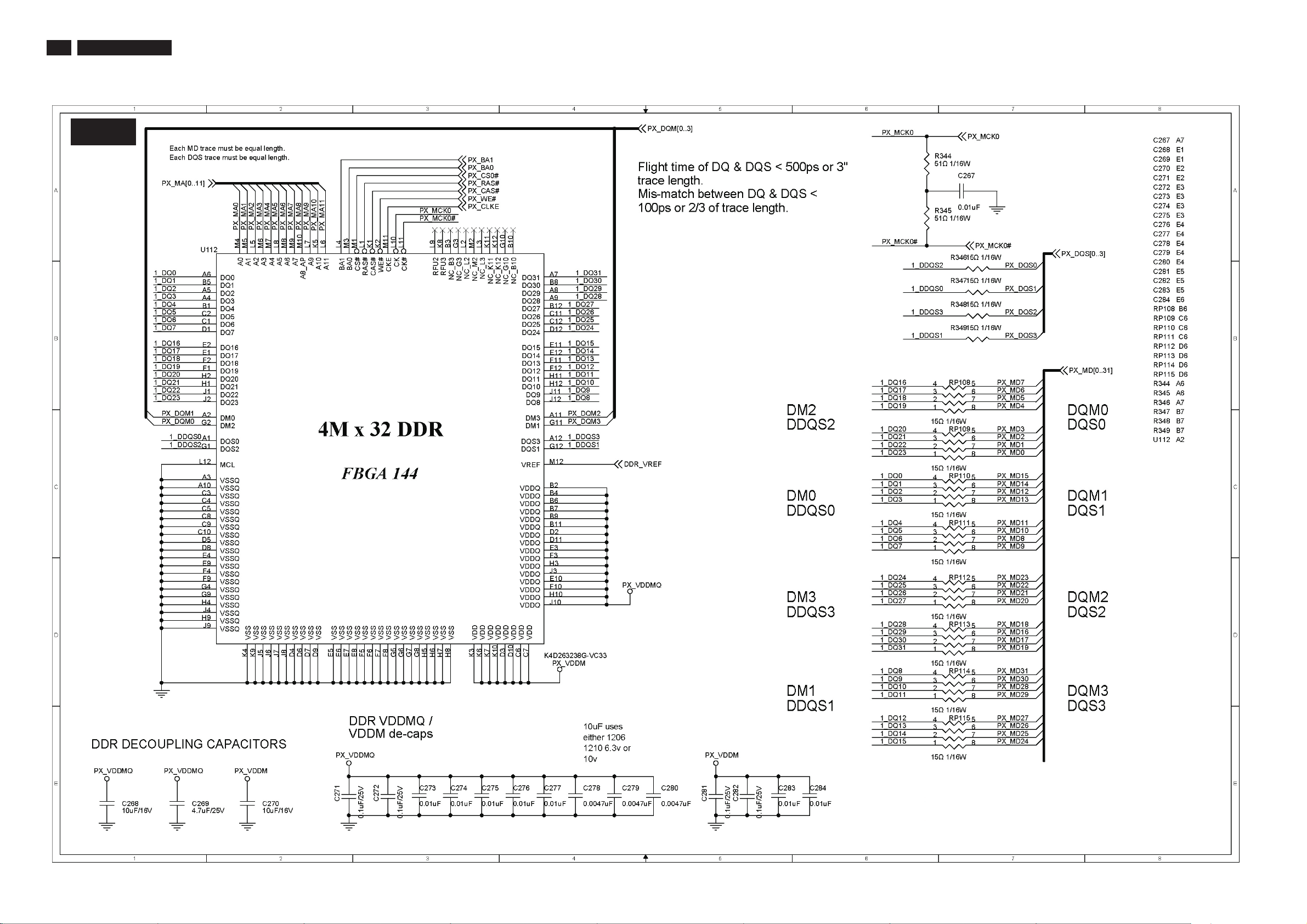

6.3.12 Scaler Schematic Diagram - DDR 4Mx32Board

S-12

6. Circuit Diagrams and PWB Layouts

6.3.13 Scaler Schematic Diagram - SOUND DELAYBoard

S-13

6.Circuit Diagrams and PWB Layouts

TPT1.0A LA

27

28

TPT1.0A LA

6.3.14 Scaler Schematic Diagram - AUDIO DECODERBoard

S-14

7. Circuit Diagrams and PWB Layouts

6.3.15 Scaler Schematic Diagram - AUDIO AMPBoard

S-15

6.Circuit Diagrams and PWB Layouts

TPT1.0A LA

29

30

TPT1.0A LA

6.3.16 Scaler Schematic Diagram - POWER 1Board

S-16

6. Circuit Diagrams and PWB Layouts

6.3.17 Scaler Schematic Diagram - POWER2Board

S-17

6.Circuit Diagrams and PWB Layouts

TPT1.0A LA

31

32

TPT1.0A LA

6.3.18 Scaler Schematic Diagram - RESETBoard

S-18

6. Circuit Diagrams and PWB Layouts

6.3.19 Scaler Board Layouts-1

S-19S-19

6.Circuit Diagrams and PWB Layouts

TPT1.0A LA

33

34

TPT1.0A LA

6.3.20 Scaler Board Layouts - 2

S-20

6. Circuit Diagrams and PWB Layouts

6.4 Power Board Schematic Diagram(37 )"

P

6.Circuit Diagrams and PWB Layouts

TPT1.0A LA

35

36

TPT1.0A LA

6.4 Power Board Layouts - 1(37")

P

6. Circuit Diagrams and PWB Layouts

6.4 Power Board Layouts - 2(37")

P

6.Circuit Diagrams and PWB Layouts

TPT1.0A LA

37

38

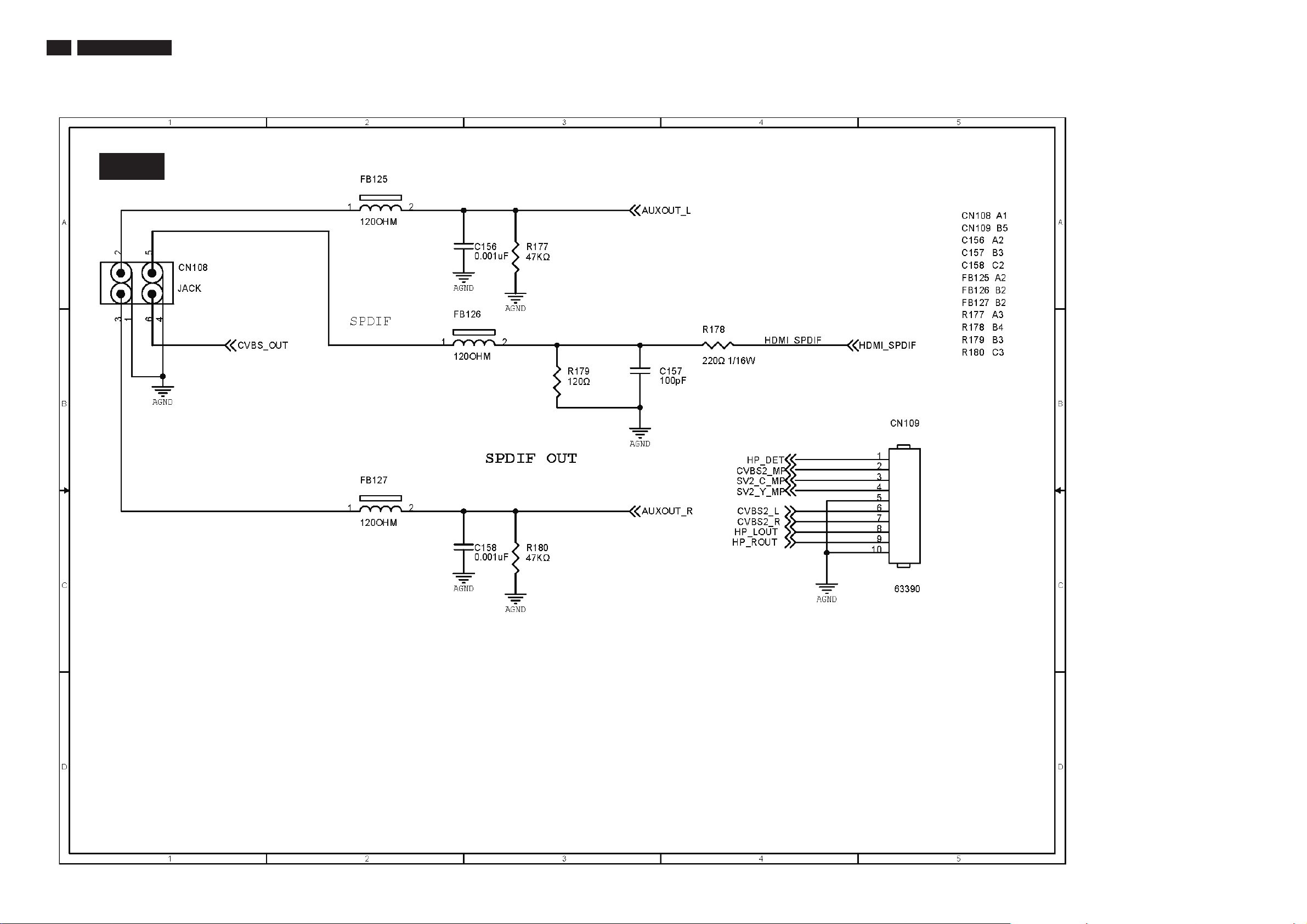

6.5 Side AV Board Schematic Diagram

TPT1.0A LA

6. Circuit Diagrams and PWB Layouts

6.5 SIDE AV Board Layouts-1

A

6.Circuit Diagram & PWB Layouts

TPT1.0A LA

39

40

6.5 SIDE AV Board Layouts-2

TPT1.0A LA

A

6. Circuit Diagrams and PWB Layouts

6.6 IR Board Schematic Diagram

6.Circuit Diagram & PWB Layouts

TPT1.0A LA

41

42

6.6 IR Board Layouts-1

TPT1.0A LA

I

6. Circuit Diagrams and PWB Layouts

6.6 IR Board Layouts-2

I

6.Circuit Diagram & PWB Layouts

TPT1.0A LA

43

44

6.7 KEY Board Schematic Diagram

TPT1.0A LA

6. Circuit Diagrams and PWB Layouts

6.Circuit Diagram & PWB Layouts

TPT1.0A LA

45

6.7 KEY Board Layouts-1

K

6.7 KEY Board Layouts-2

K

46

TPT1.0A LA

7. Alignments

7. Alignments

Index of this chapter:

7.1 Electrical Instructions

7.2 Software Updrade With ISPWriter

7

.1 Electrical Instructions&Serial NO. Definition

1. General points

1.1 During the test and measuring, supply a distortion free AC mains

voltage to the apparatus via an isolated transformer with low

internal resistance.

1.2 All measurements mentioned hereafter are carried out at a normal

mains voltage (90 - 142 VAC for NAFTA version, 195 -264 VAC for

EUROPEAN version, or 90 - 264 VAC for the model with full range

power supply, unless otherwise stated.)

1.3 All voltages are to be measurement or applied with respect to

ground,unless otherwise stated.

1.4 The test has to be done on a complete set including LCD panel in

a room with temperature of 25 +/- 5 degree C.

1.5 All values mentioned in these test instruction are only applicable of

a well aligned apparatus, with correct signal.

1.6 The letters symbols (B) and (S) placed behind the test instruction

denotes

(B): carried out 100% inspection at assembly line

1.7 The white balance (color temperature), has to be tested in subdued

1.8 Repetitive power on/off cycle are allowed except it should be

2. Input and output signal

2.1.1 PC mode signal type

2.1.2 TV mode signal type

2.1.3 PVR (CVBS) output:

(S): carried out test by sampling

lighted room.

avoided within 6 sec.

a.Analog Video:15 pin D-sub ,0.7 Vp-p linear, positive polarity&

separate sync.( TTL level, positive or negative polarity)

b.Audio signal : 3.5mm stereo mini-jack

Level: Nominal : 0.5 V rms.

c.Signal source: Pattern generator format as attachment table

Reference generator : CHROMA 2200 or QuantumData 802R

RF Signal : Aerial input / 10mV(typical: 80dBuV; range:

30-100dBuV)

Video signal : CVBS input ( RCA jack) / 1Vpp (300mV-sync,

700mV-video.) S video input / 1VppY-signal, +/-300mV C-signal

SCART input: CVBS, S, SRGB signal ( for WE model only) Comp

video in(YPbPr input)/ 1Vpp Y signal, +/-350mV Pb,Pr signal

HDMI:Digital interface with 4 channels TMDS signal

CVBS output ( RCA jack) / 1Vpp (300mV-sync, 700mV-video.)

Audio signal : Audio (1) R/L for AV IN(AV and S-Video).

Audio (2) R/L for SCART IN

Audio (3) R/L for Comp Video IN.

Audio (4) digital audio for HDMI Video IN.

Video: CVBS output 1Vpp / Impedance : 75

Audio: R/L output (from CVBS)

Level: - Nominal : 0.5 V rms.

&Serial NO. Definition

- Maximum : 1.5 V rms.

-Impedance > 10 k

1to12.

Level: - Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance > 10 k

Level: - Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance > 10 k

Level: - Nominal : 0.5 V rms.

-Maximum : 1.5 V rms.

- Impedance > 10 k .

.

.

.

.

- Maximum : 1.5 V rms.

- Impedance < 1 k

2.1.4 Scart output: ( for WE model only)

Video: CVBS output 1Vpp / Impedance : 75

Audio: R/L output (from CVBS)

Level: - Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance < 1 k

2.1.5 SPDIF output: Serial digital audio output when input is HDMI

2.1.6 Headphone

Audio: R/L output - 10mW at 32

3.5mm stereo jack with switch

Impedance is between 8 and 600

2.2 PC Input signal mode

2.2.1 PRESET VIDEO RESOLUTION

The analogue color LCD monitor must be capable of

displaying standard resolutions within the vertical

frequency range of 50 - 75 Hz, and horizontal scan

range of 30 - 63 KHz .

Use the CHROMA-2250 or QuantumData 802R

generator as the standard signal timing source.

Mode 3, 7, 8, 12, 15, 16 are preset modes that

should pass QA inspection.

Mode 1, 2, 4, 5, 6, 9, 10, 11, 13, 14 will run auto

adjustment only, and W/O QA

checking.

Table 1. PC timing table

Mode Resolution H. freq. / V. freq Standard

1. 640 x 350 31.469Khz/70.087Hz VGA

2. 720 x 400 31.469Khz/70.087Hz VGA

3. 640 x 480 31.469Khz/59.940Hz VGA

4. 640 x 480 35.000Khz/66.667Hz Macintosh

5. 640 x 480 37.861Khz/72.809Hz VESA

6. 640 x 480 37.500Khz/75.000Hz VESA

7. 800 x 600 35.156Khz/56.250Hz VESA

8. 800 x 600 37.879Khz/60.317Hz VESA

9. 800 x 600 48.077Khz/72.188Hz VESA

10. 800 x 600 46.875Khz/75.000Hz VESA

11. 832 x 624 49.700Khz/75.000Hz Macintosh

12. 1024 x 768 48.363Khz/60.004Hz VESA

13. 1024 x 768 56.476Khz/70.069Hz VESA

14. 1024 x 768 60.023Khz/75.029Hz VESA

15. 1280 x 720 44.772kHz/59.855 Hz CVT

16. 1280 x 768 47.776kHz/59.87Hz CVT

2.3 TV input signal Channel and pattern

2.3.1 TV Table 2. China model

Table 2. RF Signal Distribution Table (PAL)

.

.

.

.

.

7. Alignments

TPT1.0A LA

47

Frequency Carries

S/N CH

Video Sound

1 AU2 64.25 MHz

2 C8 184.25 MHz

AU10

3

4 S26 343.25 MHz

5 C13 471.25 MHz

6 I23 487.25 MHz

209.25 MHz

(E12)

69.75

MHz

190.75

MHz

214.75

MHz

349.25

MHz

477.75

MHz

493.25

MHz

Pattern

TV System

Picture

Color Bar +

PAL B/G (7M)

PAL D/K (8M) 100% White Mono 6.5

PAL B/G(7M) Philips Circle Mono 5.5 1KHz

PAL I (8M) 100% White + Circle Mono 6.0 Music 16 : 9

PAL D/K (8M)

PAL I (8M)

Multiburst +

Greyscale

Color Bar +

Greyscale Mono 6.5

Color Bar +

Multiburst Mono 6.0 Music

Sound System

System

Sound SAP

Mono 5.5 Music

Sweep

20Hz ~

20KHz

Remark

Attched

Teletex Information

7 C56 855.25 MHz

861.75

MHz

PAL D/K(8M) Checkerboard Mono 6.5 Music

2.4 Comp video input mode

Comp video detail timing

(For Quantune Data setting with Q802G or 802R in YPbPr mode)

Table 3. Comp video timing table

Item 1920X1080i 60Hz 1280X720P 60Hz 1920X1080i 50Hz 1280X720P 50Hz

Pixel rate 74.25MHz (13.468 ns) 74.25MHz (13.468 ns) 74.25MHz ( 13.468ns ) 74.25MHz (13.468 ns)

Horizontal

33.75KHz 45KHz 28.125KHz 37.5KHz

Frequency

Active 1920 pixels(25.859 us) 1280 pixels(17.239 us) 1920 pixels (25.859 us) 1280 pixels (17.239 us)

Blank 280 pixels (3.771 us) 370 pixels (4.983 us) 720 pixels ( 9.697 us ) 700 pixels (9.428 us)

Period 2200 pixels (29.630us) 1650 pixels (22.222 us) 2640 pixels ( 35.556us ) 1980 pixels (26.667 us)

Pulse delay 88 pixels (1.186 us) 110 pixels (1.482 us) 528 pixels ( 7.111 us ) 440 pixels (5.926 us)

Pulse width 44 pixels (0.593 us) 40 pixels (0.539 us) 44 pixels ( 0.593 us ) 40 pixels (0.539 us)

Vertical

60 Hz 60 Hz 50 Hz 50 Hz

Frequency

Active 1080 lines (42.000

720 lines (16.0 ms) 1080 lines ( 38.4 ms ) 720 lines (19.2 ms)

ms)

Blank 45 lines (1.333 ms) 30 lines (0.667 ms) 45 lines (1.6 ms ) 30 lines (0.8 ms)

Period 1125 lines (33.333ms) 750 lines (16.667 ms) 1125 lines ( 40 ms ) 750 lines (20 ms)

Pulse delay 2 lines (0.059 ms) 5 lines (0.111 ms ) 2 lines ( 0.071 ms ) 5 lines (0.133 ms )

Pulse width 5 lines (0.148 ms) 5 lines (0.111 ms) 5 lines (0.178 ms ) 5 lines (0.133 ms)

EQ before 0 line 0 line 0 line 0 line

EQ after 1 line 0 line 1 line 0 line

Scan Interlace Progressive Interlace Progressive

Sync type ACS ACS ACS ACS

Video kind Analog YPbPr (ITU-R

BT.709)

Analog YPbPr (ITU-R

BT.709)

Analog YPbPr (ITU-R

BT.709 )

Analog YPbPr (ITU-R

BT.709)

48

TPT1.0A LA

7. Alignments

Item 720X576P

Pixel rate 27 MHz

Horizontal

Frequency

Active 720 pixels

Blank 144 pixels

Period 864 pixels

Pulse delay 12 pixels

Pulse width 64 pixels

Vertical

Frequency

Active 576 lines

Blank 49 lines

Period 625 lines

Pulse delay 5 lines

Pulse width 5 lines

EQ before 0 line 0 line 2 line 3 line

EQ after 0 line 0 line 2 line 3 line

Scan Progressive Progressive Interlace Interlace

Sync type ACS ACS ACS ACS

Video kind Analog

50Hz

(37.037 ns)

31.25 KHz 31.5KHz 15.625KHz 15.734KHz

(26.667 us)

(5.333 us)

(42.000 us)

(0.444 us)

(2.370 us)

50 Hz 60 Hz 50 Hz 59.94 Hz

(18.442 ms)

(1.568 ms )

(20.000 ms)

(0.160 ms)

(0.160 ms)

YPbPr

(SMPTE

RP177)

720X480P

60Hz

27.027MHz

(37.000 ns)

720 pixels

(26.640 us)

138 pixels

(5.106 us)

858 pixels

(31.746 us)

16 pixels

(0.592 us)

62 pixels

(2.294 us)

480 lines

(15.238 ms)

45 lines

(1.429 ms)

525 lines

(16.667 ms)

9 lines

(0.287 ms)

6 lines

(0.190 ms)

Analog

YPbPr

(SMPTE

RP177)

720X576i

50Hz

13.5MHz

( 74.074 ns )

720 pixels

(53.333 us)

144 pixels

( 10.667 us )

864 pixels

( 64.00 us )

12 pixels

( 0.889 us )

64 pixels

( 4.741 us )

576 lines

( 36.864 ms )

49 lines

(3.136 ms )

625 lines

(40ms)

2 lines

( 0.128 ms )

3 lines

(0.192 ms )

Analog YPbPr

(SMPTE

RP177 )

720X480i

60Hz

13.5MHz

( 74.074 ns )

720 pixels

(53.333 us)

138 pixels

( 10.222 us )

858 pixels

( 63.556 us )

19 pixels

( 1.407 us )

62 pixels

( 4.593 us )

480 lines

( 30.507

ms )

45 lines

(2.860 ms )

525 lines

( 33.367

ms )

4 lines

( 0.254 ms )

3 lines

(0.191 ms )

Analog

YPbPr

(SMPTE

RP177 )

2.5 HDMI input mo de

1 1440x480i/59Hz, 60Hz, 1440x576i/50Hz

2 720x480p/59Hz, 60Hz,

720x576p/50Hz,

3 1440x480p/59Hz, 60Hz,

1440x576p/50Hz

4 1280X720p, 50Hz , 59Hz, 60Hz

5 1920X1080i, 50Hz, 59Hz, 60Hz

Apply full white pattern, select smart setting to be PERSONAL.

Adjusting Normal SCALER GAIN RG B

to reach W/D and

luminanceinfactorymode

Adjust Normal R, G, B in factory OSD. The 1931 CIE

chromaticity (X, Y) co-ordinates shall be:

Table 4. Reading with Minolta CA-110.

Picture Mode x y

Normal (Original)

0.283 ± 0.005 0.297± 0.005

Luminance > 400 cd/m2in the center of the screen when

Smart picture at contrast 100% and brightness 100%.

4.1.3 Set color temp is "WARM" or "COOL", their gains are

as table 5.They should be saved in EEPROM by the

auto-alignment station of factory.

Table 5. relationship between three kinds of color temp

Normal Warm Cool

Scaler R Gain

Scaler G Gain

R' R' R'-10

G' G'-5 G'-9

Scaler B Gain B' B'-20 B'

4.1.4 This group setting about color temp is also applied in

TV/ Comp1 video 1/Comp video 2 /S-video 1/ S-video

2/ AV1/AV2/PC. It means that TV/AV1/AV2/S-video 1/

S-video 2/ Comp1 video 1/Comp video 2 /PC use one

same setting.

5. PC mode Display Adjustment

5.1 WHITE-D adjustment (B)

5.1.1 At factory mode apply 1024X768 @60Hz mode with TVBAR100

pattern in QuantumData 802R/ 802G/802BT as figure 1. . Set

smart picture at "Normal" , and set Brightness and contrast to be

50%.

Activate AUTO-COLOR function for auto ADC offset and gain

setup.

3. Power supply

3.1 Setup the AC I/P at 264 VAC and 90VAC , and power board

provide two DC Output

1. The DC output voltage is 24V ± 1V DC for Inverter and Scaler

board Measured point between pin3(+24V) and pin6(GND) at

item CN122 of scaler board

2. The DC output voltage is 16V ± 1VDCforScalerandAudio

board Measured point between pin1(+16V) and pin6(GND) at

item CN122 of scaler board

3.2 Any adjustment is not needed.

4. TV Mode display adjust

4.1 White balance adjustment (B)

4.1.1 General set-up:

Equipment Requirements: Color analyzer.

Input requirements:

Input Signal Type: RF signal

Set to PAL D/K system, frequency=184.25MHz ( for China

model ) with white pattern of 100%

Input Signal Strength : 10mV (80 dBuV) terminal voltage.

Input Injection Point : TV Tuner input

4.1.2 Color Temp Alignment (B)

Figure 1. TVBAR100

5.1.2 Apply full white pattern , check picture must satisfy table 6.

Table 6. Reading with Minolta CA-210.

Picture Mode x y

Normal (Original)

0.283 ± 0.015 0.297± 0.015

Luminance> 400 cd/m2in the center of the screen when

both PC Brightness and Contrast control are 100%.

5.2 Display quality adjustment

Use timing mode as described in 2.2, and uses the POPO (pixel

on pixel off) pattern to adjust the clock until no stripe and adjust

the phase until clear picture.(AUTO ADJUST hot key: press

Volume - and Volume + keys together for 1 second.)

Check all preset 6 modes.

7. Alignments

5.3 Check the analog interface cable

Check the color poor & noise condition of 64 gray scale pattern.

6. Comp video Mode display adjust

6.1 White balance adjustment (B)

Gener al set-up:

Equipment: Quantum Data Pattern Generator 801GD or 802G or 802R;

Apply 1080i/50Hz, and the pattern TVBAR100 is shown in figure 1.

Alignment method:

Initial Set-up: Set Smart picture as "Personal" (Brightness=50,

Color=50, Contrast=50); Access to factory OSD first, then to

enable AUTO-COLOR to get HD ADC OFFSET and HD ADC

GAIN. Check 64 gray scales can be distinguishable.

6.2 Color Temp Alignments : Check chromaticity (X, Y) co-ordinates

specification as table 6. Lu mi nan ce> 400 c d/m

screen in RICH mode.

7. HDMI mode displ ay adjus tment

7.1 Preset HDMI HDCP key

7.1.1 Download HDCP Key

The 284 bytes HDCP key has been programmed in PX66.

7.1.2 HDMI Vid eo HDCP Key Test

(1) Use pattern generator

Equipment: Quantum 802R or 802BT or equivalent equipments.

Pattern: Standard HdcpProd Pattern (It's color bar)

Timin: As section 2.5.

Result : The PASS information should be shown on the screen.

(2) Use DVD Player:

Equipment: 1.Pioneer (model: DV-S969AVi) or equivalent

equipments.

2.DVD disk with "Macro Vision "protection.

Result : The picture should be shown Normally.

8. Preset EEPROM d ata

8.1 Factory OSD

"062596" => MENU key to enter factory OSD. ( or VOL+ + CH+

in keypad )

, : Move and change value

: selected

Press MENU or : key to activate OK, SAVE, and EXIT.

EXIT

COLOR TEMP NORMAL (WARM, COOL)

GAIN R ? G ? B ?

AUTO COLOR OK

ADC GAIN R ? G ? B ?

ADCOFFSET R? G? B?

SAVE

8.2 Smart picture setting and is as below.

TV

RF PERSONAL RICH NATURAL SOFT MULTIMEDIA

Contras t 50 65 55 40 80

Brightness 50 55 50 55 40

Color 50 65 55 43 65

Sharpnes s 30 30 30 20 40

2

in the center of the

TPT1.0A LA

AV1/AV2

CVBS PERSONAL RICH NATURAL SOFT MULTIMEDIA

Contras t 50 70 60 40 80

Brightness 50 40 45 50 35

Color 50 65 60 50 75

Sharpnes s 30 45 30 20 40

S-video1/S-videoside

S PERSONA L RICH NATURAL SOFT MULTIMEDIA

Contras t 50 70 60 40 80

Brightness 50 45 48 50 40

Color 50 65 60 50 75

Sharpnes s 30 45 30 20 40

Comp video 1 / Comp

video 2

Comp vi deo PERSONAL RICH NATURA L SOFT MULTIMEDIA

Contras t 50 60 55 50 70

Brightness 50 55 60 60 50

Color 50 58 55 40 65

Sharpnes s 30 50 40 20 50

Comp video 1 / Comp

video 2

Comp vi deo PERSONAL RICH NATURA L SOFT MULTIMEDIA

Contras t 50 60 55 40 70

Brightness 50 35 40 40 30

Color 50 60 55 40 65

Sharpnes s 30 50 40 20 50

HDMI

HDMI PERSONAL RICH NATURAL SOFT MULTIMEDIA

Contras t 50 65 55 40 70

Brightness 50 28 30 40 25

Color 50 75 65 50 80

Sharpnes s 30 50 40 20 50

Smart Sound personal setting is as below.

Smart sound OSD

TREBLE 50

BASS 50

PERSONAL

speech

MUSIC

movie

multimedia

BALANCE 0

TREBLE 33

BASS 33

BALANCE 0

TREBLE 54

BASS 58

BALANCE 0

TREBLE 50

BASS 67

BALANCE 0

TREBLE 58

BASS 67

BALANCE 0

( 480i / 576i )

49

50

8.3 Factory settings:

TPT1.0A LA

The user OSD should have the following factory default values

after pushing reset to factory. And personal smart setting will

return to default.

PC Mode

Picture

Color temp

Brightness

Contrast

Sound

Smart Sound

Incredible Surround

Features

Picture format

PIP

Size

Input

Position

Sound

TV Mode

Picture

Smart Picture

Color temp

Picture format

Sound

Smart Sound

Incredible Surround

Feature

NR

Volume

Default for out of factory (except reset tp factory setting)

Source TV(Channel 2)

Language

Normal

50

50

Movie

Off

Full Screen

Off

TV

1

PC

Rich

Cool

Widescreen

Movie

Off

Off(onlyTV:ON)

20

(Chinese)

7. Alignments

Serial NO. Definition

Serial number (6 digits)

Production year/week code

Service version change code

BOM (bill of Material) code

Sit code (Production center) according

BZ CODE ( AR---CZECH REPUBLIC,

VN--HUNGARY(SZR), BZ--SUZHOU,

DS--DONG GUAN)

7. Alignments

7.2 Software Updrade With ISPWriter

A. Install

1. Run SETUP.exe in ISPWriter2 folder

2. Copy all files in ISP3Writer3 folder to ..\Program Files\Trident\

ISPWriter2

B. Use.

3Step

3.1 Tr iden t tool (3138 106 10549)

Connect the PC with the UART_422 board by the RS232 cable and

connect UART_422 board "con2" to system board D_sub port. And

plug USB cable to PC.

TPT1.0A LA

Press the OPEN button to open the COM port of the PC.

The COM port parameter can be set in Communication Settings

Dialog (Diagram 2).

By CommPort->Setting, the Communication Settings Dialog can be

opened, if the COM isnot opened.

5. Press the BIN button to select the bin file which will be programmed

into the flash.

The toolbar will be changed as Diagram 3.

51

3.2 P_Har mony tool (12nc=3138 106 10198)

Connect the PC with P_Harmony tool by the RS232 cable and connect

P_Harmony tool to system board D_Sub port. P_Harmony tool power on.

Yellow and Red led ON

4.RunISPWriter3.exe, you will see the below window (Diagram 1).

5.1. (Config ure)

Press the CONFIG button to open the Config Dialog(Diagram 4), in

this dialog, please select the correct CPU

or select the correct StartAddress.

These information will be saved into the ISPWriter3.ini file. You can

directly edit the ISPWriter3.ini file by editing tool.

Diagram 4

6. Enter the ISP mode

You will see some information in the textbox when CPU enters the

ISP mode.

Just like below:

PH_ISP_VER003 , Please use ISPWriter3 !!!

ISPWriter3:

UART:115200,n,8,1

Version: 3.01

BuildTime:Apr 19 2006-11:10:51

Maker Chip and input

52

6.1.

6.2

7. Program

Press the PROG button to start the programming.

TPT1.0A LA

CPU enters ISP mode by hardware way, if PC software (

ISPWriter3.exe) does not send any data during 30 seconds, the

CPU will leave ISP mode and go on to continue normal boot

operation (To run TV application).

When the system power-on, if the "Power" key on keypad is

pressed and be keep for 3 seconds, the CPU will enter ISP mode

and send information by UART.

7. Alignments

8. Reboot

After finish the programming, AC power OFF à ON can

reboot the system.

8. Circuit Descriptions and IC Data Sheets

8. Circuit Descriptions and IC Data Sheets

Index of this chapter

8.1 Trouble shooting

8.2 Circuit Description

8.3 IC Data Sheets

8.4 Repair Flow Chart

8.1 Trouble Shooting

TPT1.0A LA

53

Symptoms

No power

No picture

No Sound

No AV Signal

S-VHS Color Becomes Faint

TV Only Produces MONO Sound

Remote Does Not Work

TV Displays Wrong Channel or

No Channels

color or no picture

Items to Check and Actions to follow

·

Check the TV power cord. Unplug the TV, wait 10 seconds, then reinsert the plug into the outlet and

push the POWER button again.

·

Check that the outlet is not on a wall switch.

·

Be sure the fuse is not blown on the AC power strip, if one is being used.

·

Check antenna/cable connections. Are they properly secured to the TV s ANT75. plug?

·

Try running the Auto Store feature to find all available channels.

·

Press the AV button on the remote to make sure the correct signal source is selected.

·

If using an accessory device, be sure that it is functioning properly.

·

If in PC Mode, a video signal MUST BE present or the TV will turn off.

·

Check the VOLUME buttons.

·

Check the MUTE button on the remote control.

·

If you re attempting to hook up auxiliary equipment, check the audio jack connections.

'

·

Check whether AV and S-Video sockets connected simultaneously.

·

Unplug socket for S-Video connection. Reconnect the S-Video socket of the TV carefully to the VCR

socket.

·

If using a cable box with RF only type connections, the signal coming from the cable box will be

produced in MONO only.

·

Check Sound control setting. Change setting to Stereo.

·

Check the batteries. Place lithium cell in the remote. Be sure the (+) and (-) ends of the batteries

line up as marked inside the battery compartment.

Clean the remote control and the remote control sensor window on the TV.

·

·

Check the TV power cord. Unplug the TV, wait 10 seconds,then reinsert the plug into the outlet and

push the POWER button again.

·

Be sure the fuse is not blown on the AC power strip, if one is being used.

·

Check to be sure the TV outlet is not on a wall switch.

·

Be sure that the remote is in the correct operating mode.

·

Be sure the remote is pointed at the Remote Sensor Window on the TV. See page 2 of the Quick

Use Guidefor details.

·

Repeat channel selection.

·

Add the desired channel numbers (using the CHANNEL EDIT control) into the TVs memory.

·

Run the Auto Store feature to find all available channels.

'

54

TPT1.0A LA

8. Circuit Descriptions and IC Data Sheets

8.2 Circuit Description

Description of Scaler board

There are video processing and some audio function in scaler board. The 37/42TA1800 uses Trident SVP-PX66 as Scaler engine, which has

embedded Analog D-SUB, digital HDMI receiver, scaling input signal to panel OSD mapping and simple 3D de-interlacer. The extra DDR is to

accomplish video frame rate conversion and to provide OSD and de-interlacer with enough memory.

The external CPU (M30620SPGP) can provide control signals such as backlight control, RC (Remote Control), detect keypad input, IIC I/O

communication, TV tuning control, sound control and power control .

Embedded Video decoder is used to execute all video signal processing except HDTV. HDTV is go through embedded ADC converter. 3D comb

and 3D de-interlacer are included in scaler. Scaler can decode CC, TT, V-chip data to display.

In west Europe and AP model, Tele-text (TT) function is necessary, but China Model is no need. In NAFTA model Close-Caption (CC) function is

necessary.

One audio decoder MSP34XXG is used for TV sound processing, and output to TPA3800D2 . Post D-class amplifier is in scaler board.

Fig 1 37/42TA1800 block diagram

Description of TV system

A TV tuner with remote control will be mandatory for AP, China, West Europe and NAFTA production models.

Tuner and sound decoder deviation:

WE NAFTA A P China

Tuner FQ1216ME/I H-5 FQ1236/F H-5 FQ1216PN/I H-5 FQ1256/I H-5

94TPASEALL 3P 94TNTSC MA 1P 94TNPALALL P1 94T PA LBDI 1P

MSP

MSP3450G-QI-B8V3 MSP3440G-QI-B8V3 MSP3410G-QI-B8V3 MSP3410G-QI-B8V3

56G 593504 56G 593 7 56G 593901 56G 593901

8.3 IC Data Sheets

8

.3.1 IC Data Sheets-CS4344(U111)

8. Circuit Descriptions and IC Data Sheets

TPT1.0A LA

55

56

TPT1.0A LA

8. Circuit Descriptions and IC Data Sheets

8.3.2 IC Data Sheets-M30620SPGP(U107)

Block Diagram

8. Circuit Descriptions and IC Data Sheets

TPT1.0A LA

57

58

TPT1.0A LA

8. Circuit Descrfiptions and IC Data Sheets

8.3.3 IC Data Sheets-PCA9512(U132)

BLOCK DIAGRAM

8. Circuit Descriptions and IC Data Sheets

TPT1.0A LA

59

8.3.4 IC Data Sheets-SVP-PX66LX66(U110)

Block Diagram

60

PIN Configuration

TPT1.0A LA

8.Circuit Descriptions and IC Data Sheets

8.4 Repair Flow Chart

8. Circuit Descriptions and IC Data sheets

TPT1.0A LA

61

1.No work/LED is off

Check if

power switch is

normal

Yes

Check

power board 1089

pin1,2=16V,pin3=24V,

pin4=1.8V,pin5=

4.6V

Yes

Check IR board cn001

pin1=3.3V,pin3=3.1V,

pin4=0.4V,pin5=3.3V,

pin6=3.3V

2.No raster/picture too

dim

No

Replace Power switch

No

Check power board

3.No picture/LED is green

Check

power board 1088,

pin1~5=24V,pin6=

2.6V pin7=6.1V

Yes

Check if

working voltage

R240,R241,R242,

R243=3.3V

Yes

Check if clock

source X101

Yes

No

Check power board

Check circuit around

No

each regulator and

eliminate short and

open situation

No

Replace X101

Check

power board 1088,

pin1~5=24V,pin6=

2.6V pin7=6.1V

Yes

Check

power board 1089

pin1,2=16V,pin3=24V,

pin4=2.6V,pin5=

6.1V

Yes

Check scaler board

No

Check power board

No

Check power board

Check if

U110 RGB,

clk,H/V and DE signal

output 128 bits

TTL

Yes

Check

resistors-network

Yes

Replace LVDS cable

Yes

Replace LCD panel

Try to replace

No

flash Rom

EEPROM

No

Replace bad resistorsnetwork

62

TPT1.0A LA

4.No TV sound

Check if

TU101

tuner pin11

output IF

signal

Yes

Check U118

5.No earthphone sound

Check U118

pin17=DACA_R

pin18=DACA_L

No

No

8. Circuit Descriptions and IC Data Sheets

6.No remote function

Replace TU101

Check IR receiver

7.LED and function

key poor

Check circuit around

control board and cable

between control board

Replace U118

and scaler board

Tty another

remote control

Yes

Replace one good

No

remote control

Yes

Check

U120=5V

Yes

Check

CN033=5V

Yes

Replace Side AV Board

No

Replace U120

Eliminate short and open

No

situation

8.No HDMI picture

Check U111

has HDMI code

Yes

Check Scaler Board

Write HDMI code in

No

U111

9. Spare Parts List

Model : 37TA1800/ 93(CPT ) 12N C: 8639 000 17108

Item Philips 12NC DESCRIPTION TPV18NC

Mec hanical Par ts

458 3138 154 17881 PLAST IC H AND LE

459 3138 154 17891 SM ALL PLASTI C HANDLE

91 3138 157 61171 BKT -SPKBX-BOT TOM ASSY

99 3138 157 61211 BKT- RB ASSY

90 3138 157 61281 MAIN SH IELD AS SY

40 3138 157 61291 BACK COVER A SSY

30 3138 157 61441 FR ONT BEZ EL ASSY

50 3138 157 61451 BASE ASSY

Packi ng Parts

139 3138 156 36362 P.E. BAG 275X320 M M

460 3138 156 41611 P.E. BAG( 1000 X 700)

454 3138 156 42181 C USHI ON - BT M- BA-L

450 3138 156 42601

464 3138 156 42661 C ARTON-BOTTO M

451 3138 156 42671 C USHI ON-TOP- TL

452 3138 156 42681 C USHI ON-TOP- TR

Access ory

145 3138 155 24611 U SER'S M ANUAL

1070 9965 000 39546 POW ER C ORD 89G414A15N LS1

1060 9965 000 39545 RE MOTE C ONTR OLLER 98T RASW 1BTPH R

mi scel lanea

6 3138 198 74741 CBLE -390 10/110/10- 020 AWG 26

7 8238 277 32098 LSP BOX 8R 10W ( FS- 0000085AC)

2 8238 277 32103 IR BOAR D C ABLE 46412

3 8238 277 32104 CPT INVER TER C ABLE JF E 46424

5 8238 277 32105 37" K EY BOARD W IRE JFE 46425

4 8238 277 32106 37" C PT LVD S CABLE JFE 46428

1 8238 277 32107 SID E AV BOAR D C ABLE 46413

LCD Panel

1050 8238 277 20921 CP T CLAA370WA03

PCB As sy

1053 9965 000 39547 SC ALER BOAR D_VISION_D CBPF 6T2DP1

1054 3138 158 64961 POW ER PC B ASSY 37"

1055 9965 000 39542 SID E_AV_BOAR D_VISION _D PT PF6PA1

1056 9965 000 39543 IR IRPF6PA1

1057 9965 000 39544 KEY BO ARD KEPF 6PA1

PCB As sy

1053 9965 000 39547 SC ALER BOAR D_VISION_D CBPF 6T2DP1

Vari ous

CN 120 9965 000 39574 C ONN ECTOR 30P 33L803330FP

C112 9965 000 39616 CH IP 5PF - 0.5PF 50V N PO 65G060350931

C115 9965 000 39616 CH IP 5PF - 0.5PF 50V N PO 65G060350931

C117 9965 000 39616 CH IP 5PF - 0.5PF 50V N PO 65G060350931

C119 9965 000 39613 CE R1 0603 N PO 5V 220P P M 5 R 65G 060322131

C131 9965 000 39620 0.01U F -10% 50V X7R 65L060310332

C157 9965 000 31254 CH IP 100PF 50V N PO 65T060310132

C159 9965 000 39620 0.01U F -10% 50V X7R 65L060310332

C163 9965 000 39573 CA P CHIP 0603 33P 50V N PO /- 5% 65G060333031J

C164 9965 000 39573 CA P CHIP 0603 33P 50V N PO /- 5% 65G060333031J

C166 9965 000 31254 CH IP 100PF 50V N PO 65T060310132

C172 9965 000 31254 CH IP 100PF 50V N PO 65T060310132

C174 9965 000 31254 CH IP 100PF 50V N PO 65T060310132

C175 9965 000 31254 CH IP 100PF 50V N PO 65T060310132

C176 9965 000 31254 CH IP 100PF 50V N PO 65T060310132

C178 9965 000 31254 CH IP 100PF 50V N PO 65T060310132

C188 9965 000 39611 0.01U F -10% 50V X7R 65G060310332

C198 9965 000 39618 CH IP 10U F 16V X5R 65G 120610615

C218 9965 000 39619 CHIP 4.7U F 25 V Y5V 65G120647527

C224 9965 000 31079 1UF - 10% 6V X7R 65T080510517

C225 9965 000 31326 CH IP 10U F 16V Y5V 65T120610617

C226 9965 000 31326 CH IP 10U F 16V Y5V 65T120610617

C229 9965 000 31326 CH IP 10U F 16V Y5V 65T120610617

C231 9965 000 31326 CH IP 10U F 16V Y5V 65T120610617

C234 9965 000 31326 CH IP 10U F 16V Y5V 65T120610617

C235 9965 000 31326 CH IP 10U F 16V Y5V 65T120610617

C237 9965 000 31326 CH IP 10U F 16V Y5V 65T120610617

C238 9965 000 31326 CH IP 10U F 16V Y5V 65T120610617

C239 9965 000 31326 CH IP 10U F 16V Y5V 65T120610617

C242 9965 000 31326 CH IP 10U F 16V Y5V 65T120610617

C244 9965 000 31326 CH IP 10U F 16V Y5V 65T120610617

TPT1.0A LA

C248 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C250 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C252 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C254 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C258 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C260 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C262 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C264 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C266 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C267 9965 000 39620 0.01UF -10% 50V X7R 65L060310332

C268 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C269 9965 000 39619 CHIP 4.7UF 25 V Y5V 65G120647527

C270 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C291 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C292 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C293 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C294 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C296 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C298 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C299 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C300 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C303 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C304 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C305 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C306 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C307 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C309 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C311 9965 000 39573 CAP CHIP 0603 33P 50V NPO /-5% 65G060333031J

C312 9965 000 39573 CAP CHIP 0603 33P 50V NPO /-5% 65G060333031J

C313 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C314 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C315 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C316 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C317 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C318 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C319 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C320 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C321 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C323 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C325 9965 000 39612 CHIP 1UF 16VX7R 0603 65G060310512

C327 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C328 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C331 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C332 9965 000 31254 CHIP 100PF 50V NPO 65T060310132

C334 9965 000 39571 1000UF 20% 25V 105C 67G3051024L

C334 9965 000 39572 1000UF 20% 25V 85C 67L3091024T

C335 9965 000 31083 CHIP 0.47UF 25V Y5V 65T080547422

C336 9965 000 31254 CHIP 100PF 50V NPO 65T060310132

C347 9965 000 39614 CER2 0603 Y5V 16V 220N P 8020 R 65G060322417Z

C349 9965 000 39617 CHIP 1UF 25V X7R 0805 65G080510522GP

C351 9965 000 39614 CER2 0603 Y5V 16V 220N P 8020 R 65G060322417Z

C354 9965 000 39614 CER2 0603 Y5V 16V 220N P 8020 R 65G060322417Z

C355 9965 000 39614 CER2 0603 Y5V 16V 220N P 8020 R 65G060322417Z

C357 9965 000 39614 CER2 0603 Y5V 16V 220N P 8020 R 65G060322417Z

C359 9965 000 39617 CHIP 1UF 25V X7R 0805 65G080510522GP

C360 9965 000 31259 CHIP 220PF 50V NPO 65T060322132

C366 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C367 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C369 9965 000 31254 CHIP 100PF 50V NPO 65T060310132

C370 9965 000 31254 CHIP 100PF 50V NPO 65T060310132

C371 9965 000 31083 CHIP 0.47UF 25V Y5V 65T080547422

C381 9965 000 39615 CHIP 0.047UF 50V X7R 65G060347332

C387 4822 124 12342 100UF 35V 20% 203803155101

C387 9965 000 39570 100UF -20% 35V 105 D C 67G3051016T

C390 9965 000 39615 CHIP 0.047UF 50V X7R 65G060347332

C394 4822 124 12342 100UF 35V 20% 203803155101

C394 9965 000 39570 100UF -20% 35V 105 D C 67G3051016T

C400 4822 124 12342 100UF 35V 20% 203803155101

C400 9965 000 39570 100UF -20% 35V 105 D C 67G3051016T

C416 9965 000 39615 CHIP 0.047UF 50V X7R 65G060347332

C420 9965 000 39619 CHIP 4.7UF 25 V Y5V 65G120647527

C422 9965 000 31326 CHIP 10UF 16V Y5V 65T120610617

C424 9965 000 39620 0.01UF -10% 50V X7R 65L060310332

CP101 9965 000 39569 CHIP ARRAY 0.1UF 8P 65G602K1048T

CP102 9965 000 39569 CHIP ARRAY 0.1UF 8P 65G602K1048T

CP103 9965 000 39569 CHIP ARRAY 0.1UF 8P 65G602K1048T

CP104 9965 000 39569 CHIP ARRAY 0.1UF 8P 65G602K1048T

CP105 9965 000 39569 CHIP ARRAY 0.1UF 8P 65G602K1048T

CP106 9965 000 39569 CHIP ARRAY 0.1UF 8P 65G602K1048T

CP107 9965 000 39569 CHIP ARRAY 0.1UF 8P 65G602K1048T

R106 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R107 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R108 9965 000 39553 RST SM 0603 RC0603 47K P 61L0603473

R110 9965 000 39605 CHIPR 470 OHM -5% 1/16W 61L0603471

R112 9965 000 39595 CHIPR 10K OHM -5% 1/16W 61L0603103

R113 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R114 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

63

64

R115 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R116 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R117 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R118 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R119 9965 000 39609 CHIPR 75 OHM -5% 1/16W 61L0603750

R120 9965 000 39609 CHIPR 75 OHM -5% 1/16W 61L0603750

R121 9965 000 39609 CHIPR 75 OHM -5% 1/16W 61L0603750

R122 9965 000 39600 CHIPR 2.2K OHM -5% 1/16W 61L0603222

R123 9965 000 39600 CHIPR 2.2K OHM -5% 1/16W 61L0603222

R124 9965 000 39595 CHIPR 10K OHM -5% 1/16W 61L0603103

R125 9965 000 39561 CHIPR 1K OHM -5% 1/16W 61L0603102

R126 9965 000 39601 CHIPR 22K OHM -5% 1/16W 61L0603223

R135 9965 000 39553 RST SM 0603 RC0603 47K P 61L0603473

R186 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R189 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R190 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R191 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R192 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R196 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R198 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R199 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R200 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R201 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R203 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R204 9965 000 39599 CHIPR 22 OHM -5% 1/16W 61L0603220

R205 9965 000 39599 CHIPR 22 OHM -5% 1/16W 61L0603220

R206 9965 000 39603 CHIPR 33 OHM -5% 1/10W 61L0603330

R207 9965 000 39599 CHIPR 22 OHM -5% 1/16W 61L0603220

R208 9965 000 39599 CHIPR 22 OHM -5% 1/16W 61L0603220

R209 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R210 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R211 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R212 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R213 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R214 9965 000 39599 CHIPR 22 OHM -5% 1/16W 61L0603220

R216 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R221 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R225 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R228 9965 000 39595 CHIPR 10K OHM -5% 1/16W 61L0603103

R230 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R231 9965 000 39595 CHIPR 10K OHM -5% 1/16W 61L0603103

R232 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R233 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R234 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R235 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R236 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R237 9965 000 39604 CHIP 330 OHM 1/10W 61L0603331

R238 9965 000 39604 CHIP 330 OHM 1/10W 61L0603331

R251 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R252 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R253 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R254 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R255 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R256 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R257 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R258 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R260 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R261 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R262 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R263 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R266 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R267 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R268 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R269 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R270 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R271 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R282 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R283 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R284 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R285 9965 000 39593 CHIP 10 OHM 1/10W 61L0603100

R286 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R287 9965 000 39594 CHIPR 100 OHM -5% 1/16W 61L0603101

R291 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R293 9965 000 39593 CHIP 10 OHM 1/10W 61L0603100

R294 9965 000 39595 CHIPR 10K OHM -5% 1/16W 61L0603103

R295 9965 000 39595 CHIPR 10K OHM -5% 1/16W 61L0603103

R296 9965 000 39595 CHIPR 10K OHM -5% 1/16W 61L0603103

R297 9965 000 39609 CHIPR 75 OHM -5% 1/16W 61L0603750

R298 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R299 9965 000 39603 CHIPR 33 OHM -5% 1/10W 61L0603330

R306 9965 000 39551 RST SM 0603 JUMP MAX 0R0 5 R 61L0603000

R314 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R316 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472

R317 9965 000 39606 CHIPR 4.7K OHM -5% 1/16W 61L0603472