Philips 19PFL4322/45 Schematic

Colour Television Chassis

TPS1.0L

LA

19PFL4322/45

H_17350_000.eps

Contents Page Contents Page

1 Technical Specifications, Connections, and Chassis

Overview 2

2 Safety Instructions, Warnings, and Notes 5

3 Directions for Use 7

4 Mechanical Instructions 8

5 Service Modes, Error Codes, and Fault Finding 12

6 Block Diagrams, Test Point Overview, and

Waveforms

Wiring Diagram 18

Block Diagrams 19-21

7 Circuit Diagrams and PWB Layouts Diagram

Scaler Board: DC - DC Power (S-01) 22

Scaler Board: Lips & Inverter I/F (S-02) 23

Scaler Board: Tuner (S-03) 24

Scaler Board: Video Inputs (S-04) 25

Scaler Board: DSUB Input (S-05) 26

Scaler Board: DVI-D Input (S-06) 27

Scaler Board: MST96885LD/ALD (S-07) 28

Scaler Board: Flash ROM & SDRAM (S-08) 29

Scaler Board: Key, IR BD & ComPair I/F (S-09) 30

Scaler Board: ITV I/F (S-10) 31

Scaler Board: Panel I/F (S-11) 32

Scaler Board: Audio I/F (S-12) 33

Scaler Board: Audio Amplifier (S-13) 34

Waveform Diagram 45-47

Power Panel (P-01) 48

Power Panel (P-02) 49

Keyboard Control Panel (K) 52

IR & LED Panel (I) 55

Side AV Board (SA) 58

8 Alignments 61

9 Circuit Descriptions, Abbreviation List, and IC Data

Sheets 66

Abbreviation List 69

IC Data Sheets 72

10 Spare Parts List 76

11 Revision List 82

081007

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by CS 0771 BU CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 17351

2

TPS 1.0L LA

1. Technical Specifications,Connections,and Chassis Overview

1.Technical Specifications,Connections,and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connections

1.3 Chassis Overview

Notes:

Figures below can deviate slightly from the actual situation,

due to the different set executions.

Specifications are indicative (subject to change)

1.1 Technical Specifications

1.1.1 Technical Specifications

Panel : LCD

Display area(mm) : 410.4 mm X 256.5 mm

Number of Pixels : 1440(H) x 900(V)

Pitch ( mm ) : 0.285(H) x 0.285 mm(V) (19")

Display operating mode : Normally White

Color depth : 16.2M colors

Brightness (cd/m^2) : 300(Center 1 points, Typ.) Min :

230

Viewing angle(CR>10) : Viewing angle free

(R/L 85/85 (Typ.) ,U/D 80/80(Typ.))

(19")

Surface treatment : Hard coating 3H

Electrical interface : LVDS

Response Time : 5ms (Typ) (19")

Contrast ratio : Typical 850 : 1 Min : 500

Outline Dimension : 427.2 mm(H) x 277.4 mm(V) x

17.0(D) mm (Typ.) (19")

Module weight (g) : 2500g(Typ.) (19")

Backlight : 4 CCFL

Allowed signal mode specified

For 19PFL4322/45

PC timing table

Mode Resolution H. freq. / V. Standard

1 640 x 480 31.469Khz/59.9 VGA

2 800 x 600 35.156Khz/56.2 VESA

3 800 x 600 37.879Khz/60.3 VESA

4 1024 x 768 48.363Khz/60.0 VESA

5 1280 x 720 44.772kHz/59.8 CVT

6 1280 x 768 47.776kHz/59.8 CVT

7 1440 x 900 55.469kHz/59.9 CVT

TV system signal mode:

RF support: Latin PAL M/N, NTSC-M TV tuning systems

CVBS/S-video: Support PAL and NTSC colour system.

Comp video IN(YpbPr) : including 480i/p 60Hz , 576i/p 50Hz,720p

50/60Hz, 1080i 50//59/60Hz. , 1080p 50//59/60Hz

DVI (Video) IN : 480p, 576p, 720p 50/60Hz, 1080i 50/59/60Hz,

1080p 50/59/60Hz

1.1.2 Sound

Sound sy

Maximum power : 2 x 3W

stems : Mono / Stereo / Virtual Surround

1.1.3 Miscellaneous

Power Supply

AC-input : 90V ~ 264VAC, 50/60 2Hz

Power consumption : 70W/Max(at PC mode),70W/Max(at

TV mode) with Audio.

Power cord length 1.8m

Power cord type : European type and China type

Power indicator : LED (On: Blue ,Sleeping mode:

Amber )

Auto power saving : < 2W

Ambient conditions

Temperature : 0 to40°C

Humidity : 10 to 90%

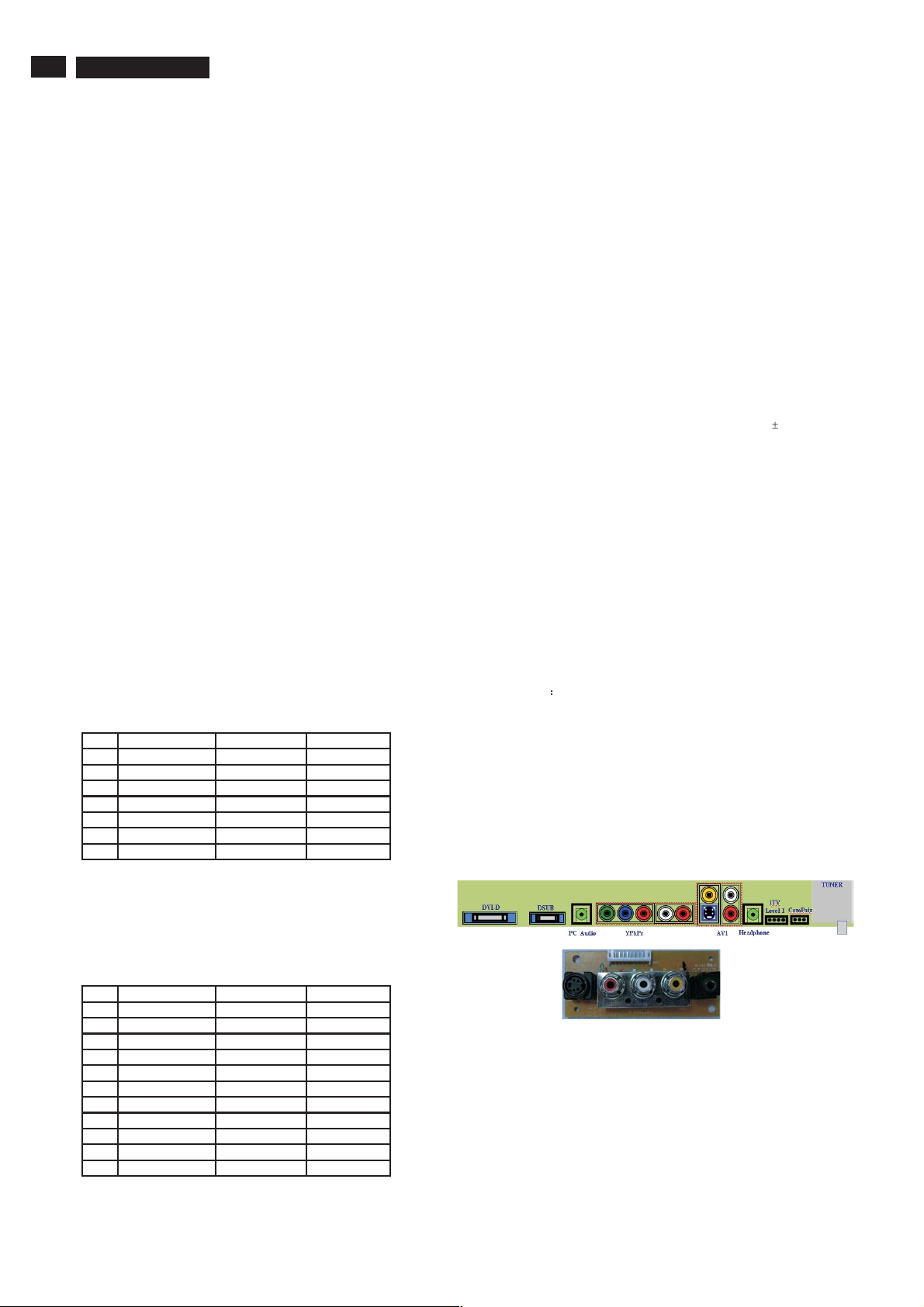

1.2 Connectors

1.2.1 I/O interface

1 Tuner: Latin PAL M/N, NTSC-M TV tuning systems

2 Compair

3 AV1 audio IN : AV1 and S-Video shared audio R/L(RCA jack)

4 AV1 IN : Composite video input (AV1)

5 CVI IN : Component input with YPbPr format with audio R/L.

6 PC audio IN: audio R/L(mini-jack).

7 PC IN: VGA input (D-SUB connectors)

8 DVI-D : digital PC and video input

9 Earphone : earphone jack

10 AV2 IN : Composite video input (AV2 side)

11 AV2 audio IN : AV2 and S-Video side audio R/L(RCA jack)

12 S-Video IN : S-video input (S-Video side)

Rx/Tx communicate

User modes - User timings can be stored by first in first out.

Auto adjustment an be used for optimal picture

performance. 11 video timings are reloaded in

factory prior to other user timings are stored.

User video timing specifications:

Mode Resolution H. freq. / V. Standard

1 640 x 350 31.469Khz/70.0 VGA

2 720 x 400 31.469Khz/70.0 VGA

3 640 x 480 35.000Khz/66.6 Macintosh

4 640 x 480 37.861Khz/72.8 VESA

5 640 x 480 37.500Khz/75.0 VESA

6 800 x 600 48.077Khz/72.1 VESA

7 800 x 600 46.875Khz/75.0 VESA

8 832 x 624 49.700Khz/75.0 Macintosh

9 1024 x 768 56.476Khz/70.0 VESA

10 1024 x 768 60.023Khz/75.0 VESA

11 1360 x 768 47.712kHz/60.0 CVT

1.2.2 PC mode signal type

a.Analog Video : 15 pin D-sub ,0.7 Vp-p linear, positive polarity &

separate sync.( TTL level, positive or negative

polarity)

b.Audio signal : 3.5mm stereo mini-jack

Level: Nominal : 0.5 V rms.

-Maximum :1.5Vrms.

-Impedance > 10 kW.

c.Signal source: Pattern generator format as attachment table 1 to 12.

Reference generator : CHROMA 2200 or QuantumData 802R

TV mode signal type

1. Technical Specifications, Connections and Chassis Overview

TPS 1.0L LA

3

RF Signal: Aerial input / 10mV(typical: 80dBuV; range: 30-100dBuV)

Video signal : CVBS input ( RCA jack) / 1Vpp (300mV-sync,

700mV-video.)

S video input / 1VppY-signal, +/-300mV C-signal

Comp video in(YPbPr input)/ 1Vpp Y signal,

+/-350mV Pb,Pr signal

DVI-D:Digital interface with 4 channels TMDS signal

Audio signal : Audio (1) R/L for AV IN(AV and S-Video).

Level: - Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance > 10 kW.

Audio (2) R/L for SCART IN

Level: - Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance > 10 k W.

Audio (3) Mini-jack audio for DVI

Headphone

Audio: R/L output -10mW at 32W.

3.5mm stereo jack with switch

Impedance is between 8 and 600 W

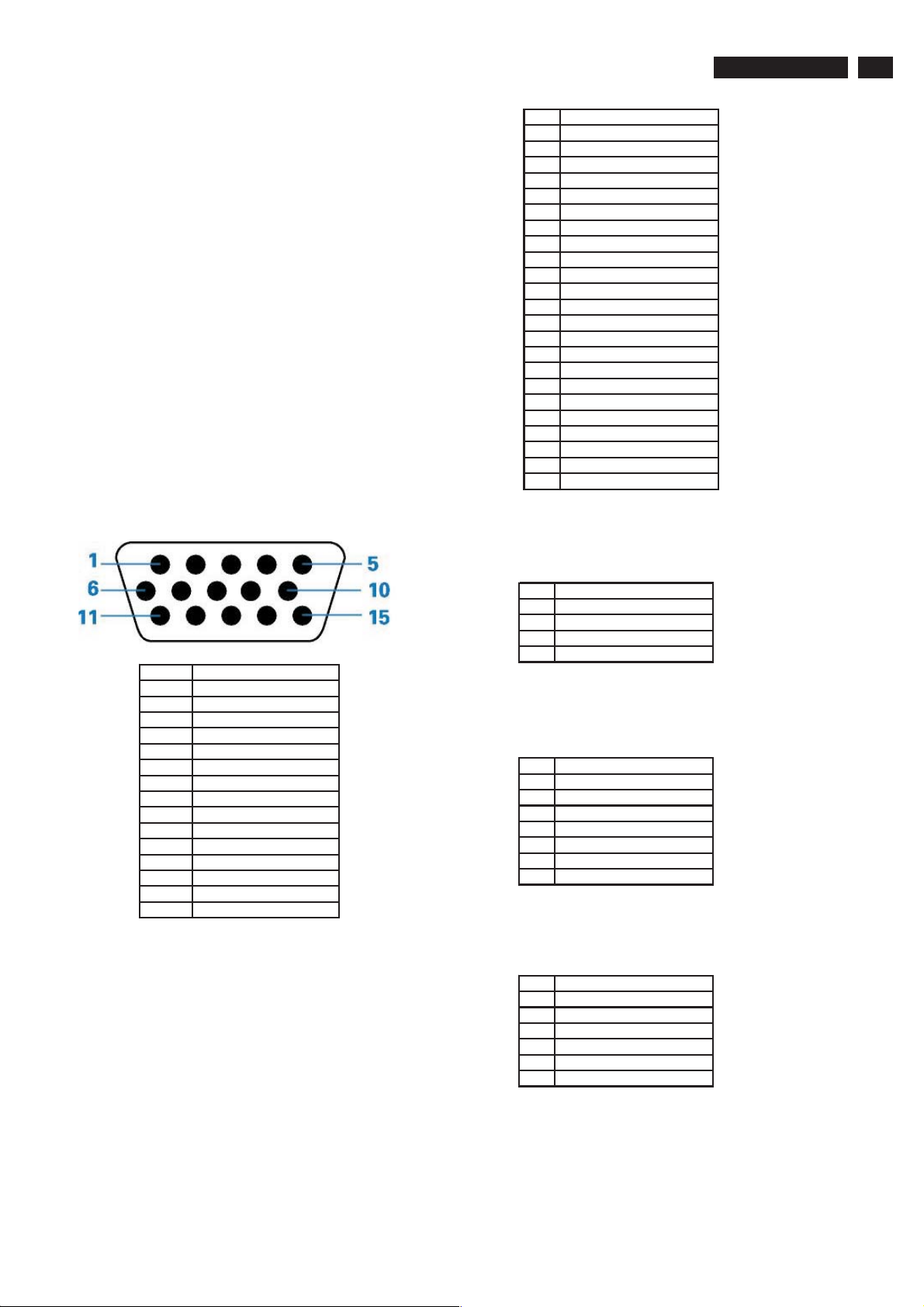

1.2.3 VGA Pin assignment

PIN No. SIGNAL

1 Red video input

2 Green video input /SOG

3 Blue video input

4GND

5 GND– cable detect

6 Red video ground

7 Green video ground

8 Blue video ground

9 DDC +3.3V (or 5V)

10 Logic ground

11 GND

12 Serial data line (SDA)

13 H. Sync / H+V

14 V. Sync

15 Data clock line (SCL)

1.2.4 24-pin DVI-D digital connect of signal cable.

.

1 T.M.D.S. Data22 T.M.D.S. Data2+

3 T.M.D.S. Data2/4 Shield

4 No connect

5 No connect

6 DDC Clock

7 DDC Data

8 No connect

9 T.M.D.S. Data110 T.M.D.S. Data1+

11 T.M.D.S. Data1/3 Shield

12 No connect

13 No connect

14 +5V Power

15 Ground (for +5V)

16 Hot Plug Detect

17 T.M.D.S. Data018 T.M.D.S. Data0+

19 T.M.D.S. Data0/5 Shield

20 No connect

21 No connect

22 T.M.D.S. Clock Shield

23 T.M.D.S. Clock+

24 T.M.D.S. Clock-

1.2.5 CVBS

The input signals are applied to display through CVBS cable

Pin assignment

PIN SIGNAL

1GND

2CVBS

3CVBS

4CVBS

1.2.6 S-Video

The input signals are applied to display through S-Video cable

Pin assignment

PIN SIGNAL

1GND

2GND

3GND

4GND

5GND

6LUMA

7 CHROMA

1.2.7 Component Video

The input signals are applied to display through Component Video

RCA Jack pin assignment

PIN SIGNAL

1GND

2

Red à Pr

3GND

4

Blue à Pb

5GND

6 Green àY

4

TPS 1.0L LA

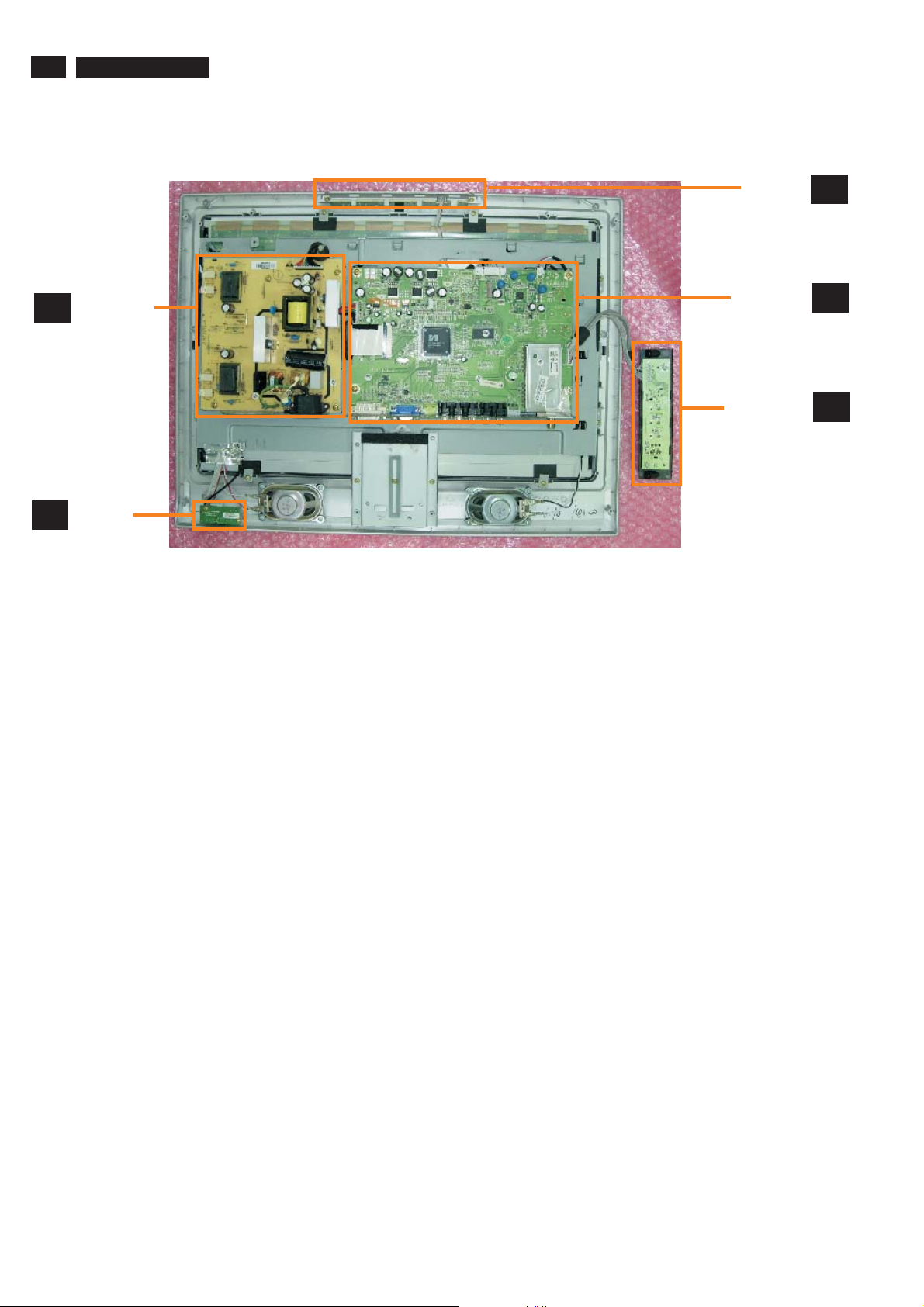

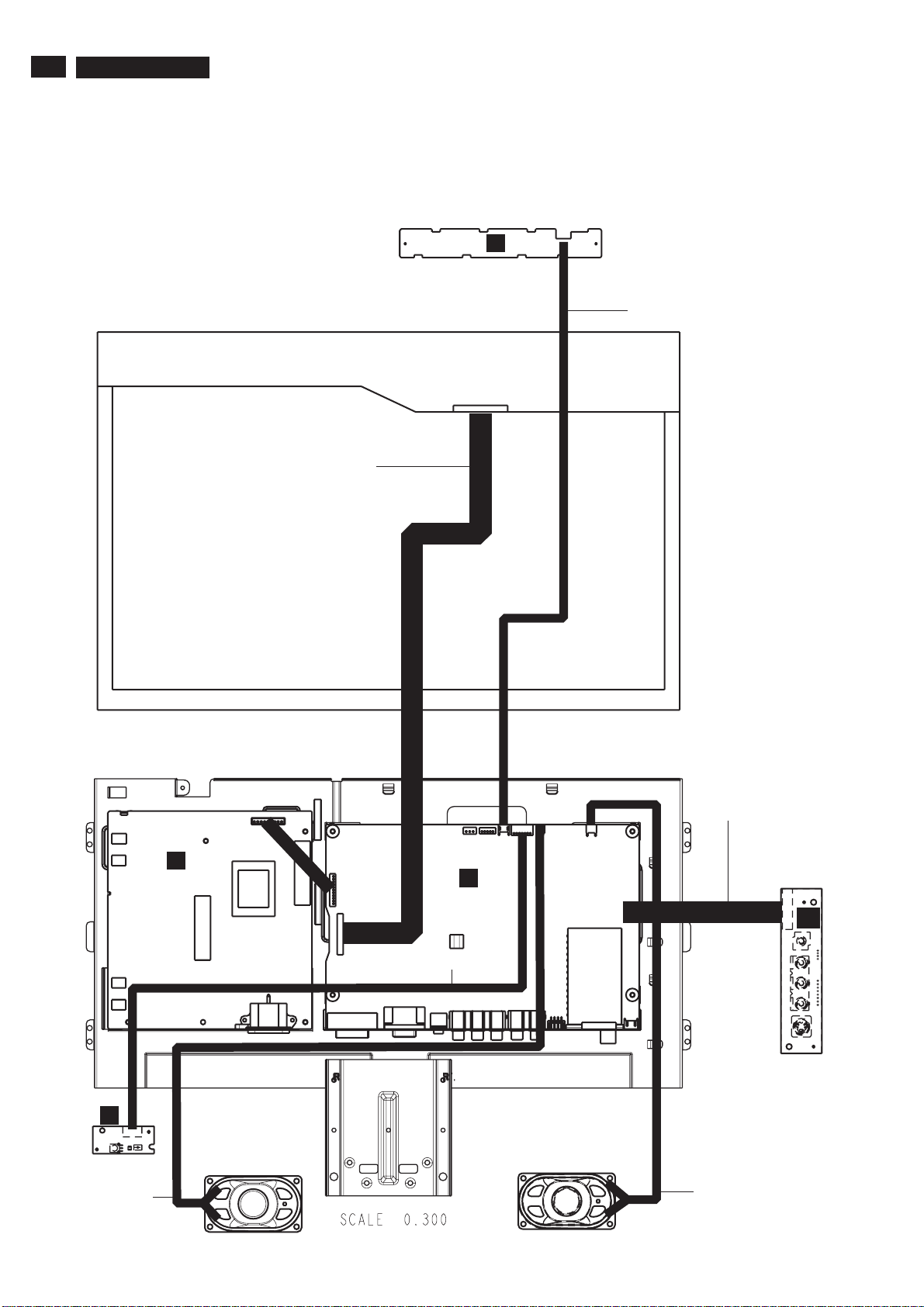

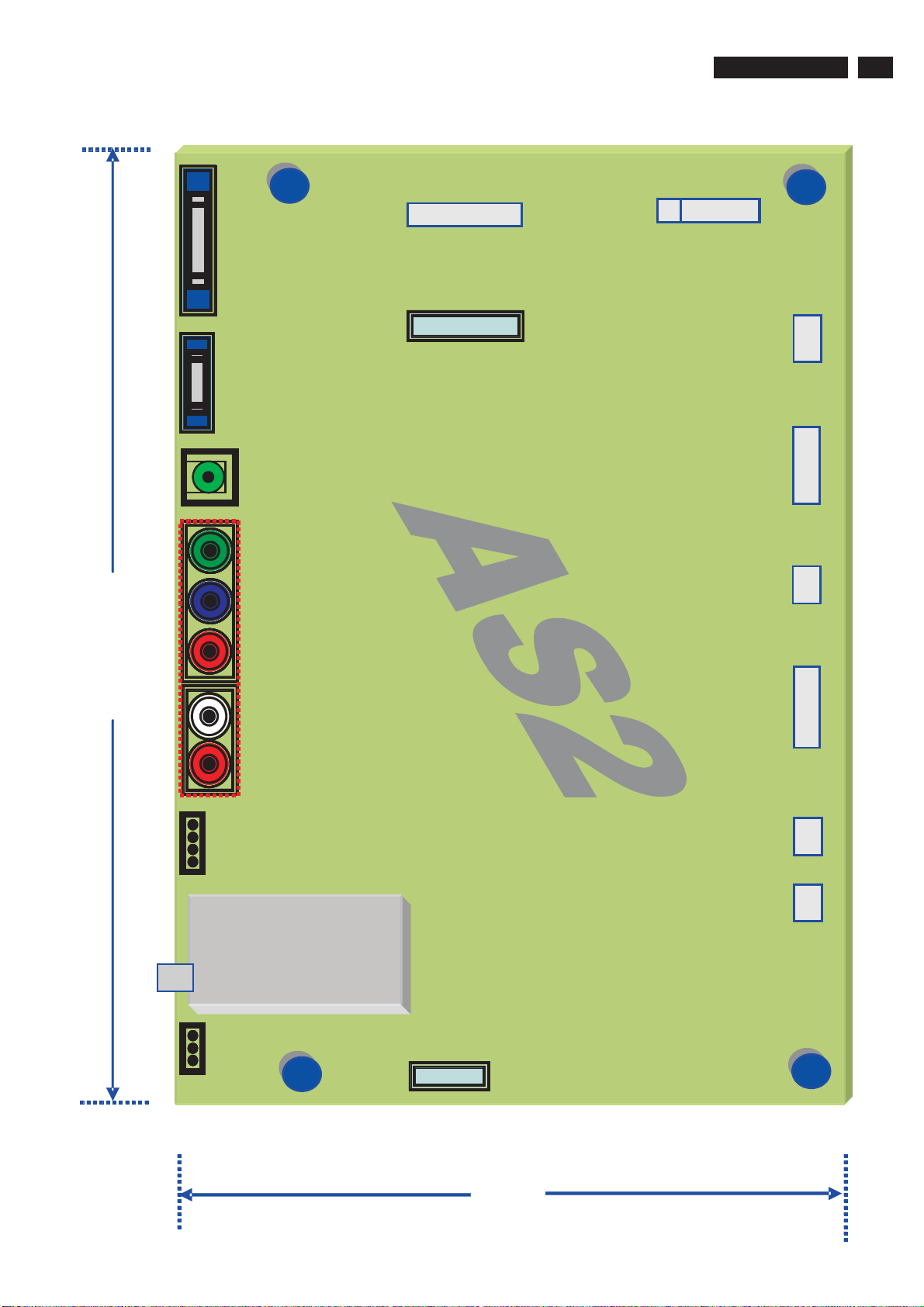

1.3 Chassis Overview

Type: 19PFL4322/45

1. Technical Specifications,Connections,and Chassis Overview

P

I

Power Board

IR Board

Key Board

Scaler Board

Side AV Board

K

S

SA

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 5TPS1.0LLA 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the “double-D symbol”, are

trademarks of Dolby Laboratories.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ= × 10

nano-farads (n= × 10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile,

which is coupled to the 12NC. For an overview of these profiles,

visit the website www.atyourservice.ce.philips.com (needs

subscription, but is not available for all regions)

You will find this and more technical information within the

“Magazine”, chapter “Repair downloads”.

For additional questions please contact your local repair help

desk.

2.3.4 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

-9

), or pico-farads (p= × 10

-12

-6

),

).

EN 6 TPS1.0L LA3.

Directions for Use

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

2.3.5 Alternative BOM identification

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production center (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

MODEL :

PROD.NO:

2.3.6 Board Level Repair (BLR) or Component Level Repair

(CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

2.3.7 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

• Always respect voltages. While some may not be

32PF9968/10

AG 1A0617 000001

Figure 2-1 Serial number (example)

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

MADE IN BELGIUM

220-240V 50/60Hz

~

VHF+S+H+UHF

BJ3.0E LA

S

E_06532_024.eps

128W

130606

3. Directions for Use

Refer to page 6.

3. Directions for Use

TPS 1.0E LA

7

8

TPS 1.0L LA

4. Mechanical Instructions

4. Mechanical Instructions

Index of this chapter:

4.1 Assy/Panel Removal

4.2 Set Re-assembly

4.1 Assy/Panel Removal

Note:Please put your mechine on a soft material to avoid to

scrape panel when you disassemble it.

Front view

Step 1. Remove the Base.

a. Remove the 2 screws as Fig.3~4.

b. Remove the 4 screws as Fig.5.

Fig.3

Back view

Fig.1

Fig.4

Fig.2

Fig.5

4. Mechanical Instructions

Step 2. Remove the Back cover.

a.

Remove the 6 screws .

b. Remove the 2 screws emove the back cover as Fig.7.

as Fig.6

, then r

Fig.6

Fig.7

TPS 1.0L LA

9

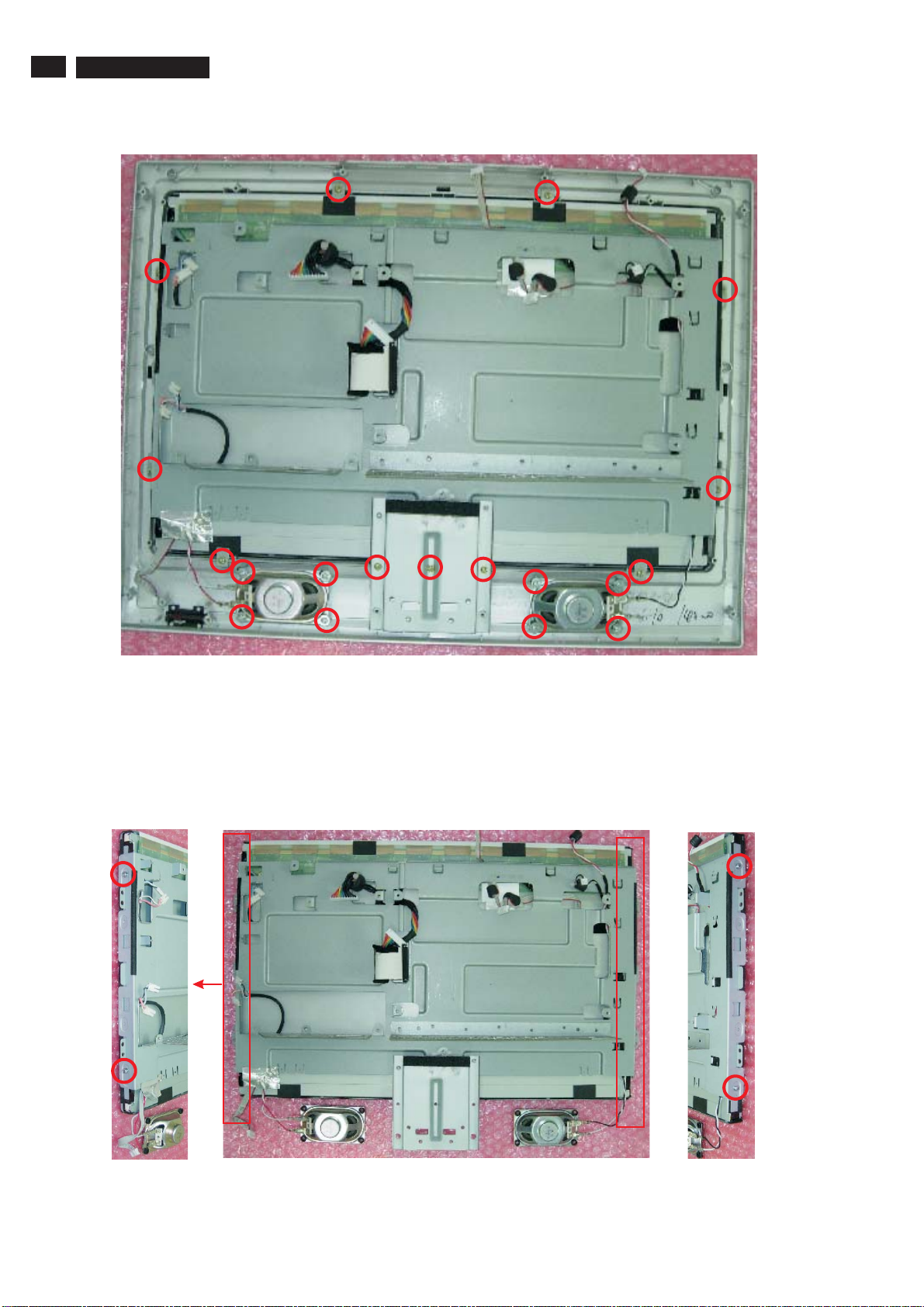

Step 3. Remove the Scaler, Power, IR ,Side AV and Key board as Fig.8 .

a. Remove the 11 screws and disconnect the 6 cables to remove the

scaler and Side AV board .

b. Remove the 6 screws and disconnect the 5 cables to remove the

Power board.

c. Remove the 2 screws and disconnect the 1 cable to remove the IR

board.

d. Remove the 2 screws and disconnect the 1 cable to remove the Key

board.

Fig.8

10

Step 4. Remove the Front bezel as Fig.9.

a. Remove the 19 screws to remove the Front bezel as Fig.9.

TPS 1.0L LA

4. Mechanical Instructions

Step 5. Remove the Frame assy as Fig.10~11.

Remove the 4 screws

a. as Fig.10.

b. Remove the as Fig.11.

Frame assy

Fig.9

Fig.10

4. Mechanical Instructions

TPS 1.0L LA

11

Fig.11

Insulation material

4.2 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Notes:

a. While re-assembling, make sure that all cables are placed

and connected in their original position.

b. Pay special attention not to damage the EMC foams at the

SSB shielding. Check that EMC foams are put correctly on

their places.

Fig.12

12

TPS 1.0L LA

5. Service Modes, Error Codes and Fault Finding

5. Service Modes, Error Codes and Fault Finding

index of this chapter:

5.1 CSM

5.2 Factory Mode

5.

3 Repair Flow Chart

5.1 CSM

It can display CSM windows message when press 1-2 3-6 5-4 on the button (RC) remote control in normal operation mode.

The following information is displayed on screen:

Set type:

Model type would be displayed on this item. 19PFL4322/45

Production code:

S/N would be displayed on this item.

SW main-processor:

TPS1.2A LA1C_ (current version)

SW other-processor:

N/A

Code 1:

5 last logged errors.

Code 2:

5 first logged errors.

Error code Event

0x01 Audio decoder error

0x02 IIC bus error

0x03 Tuner error

0x04 NVRAM error

0x05 Scaler chip error

Key (HDCP):

HDCP key valid or invalid status would be displayed on this item.

NVM-Name:

Same as set type

5. Service Modes, Error Codes and Fault Finding

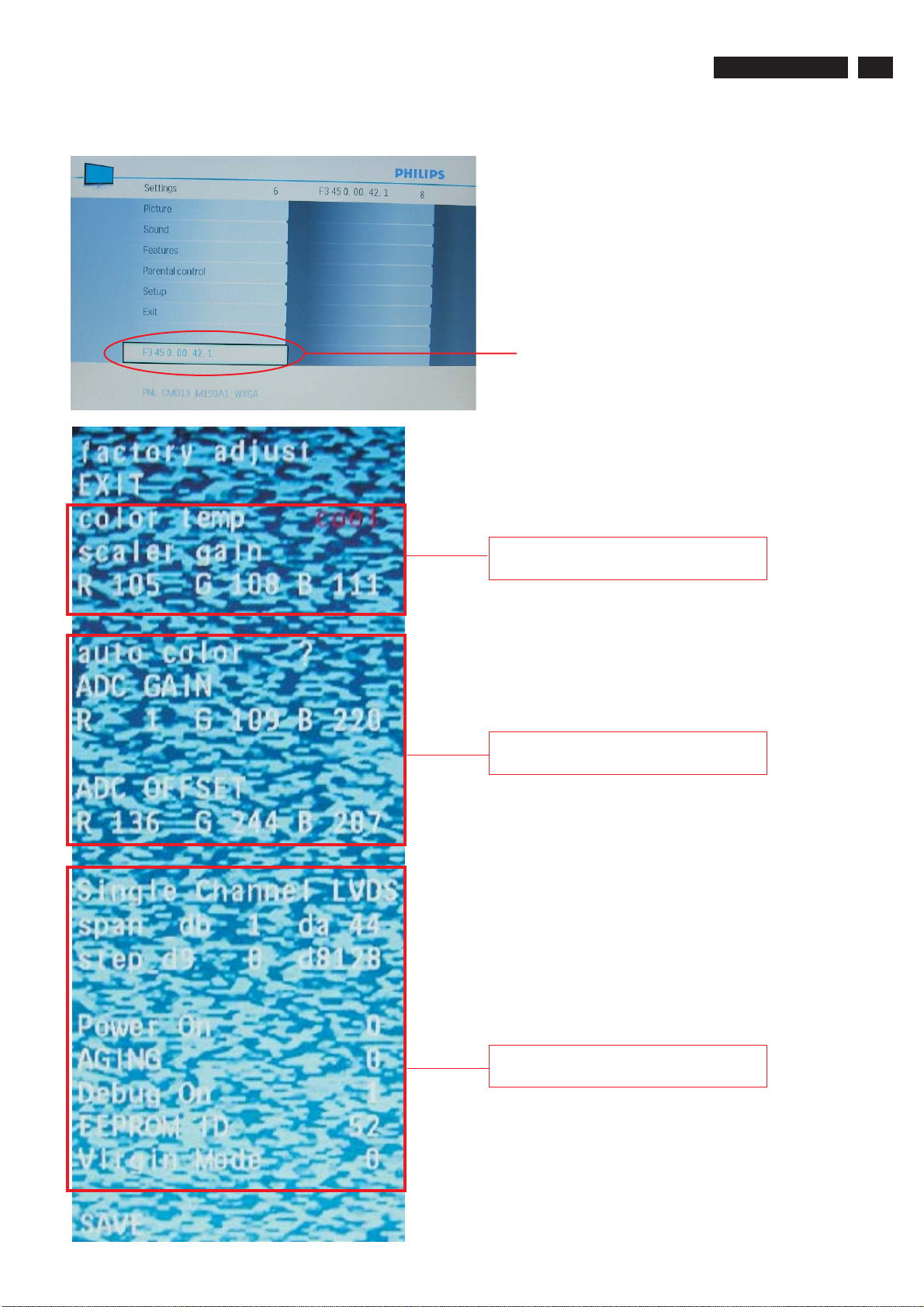

5.2 Factory Mode

Press "Menu062596 " on remote control then Press "Up " or "Down " button to move cursor to bottom item and then press

"OK " button to enter factory mode.

Factory indicate

TPS 1.0L LA

13

For white balance alignment

For auto color alignment

For design only, please don't adjust it.

14

TPS 1.0L LA

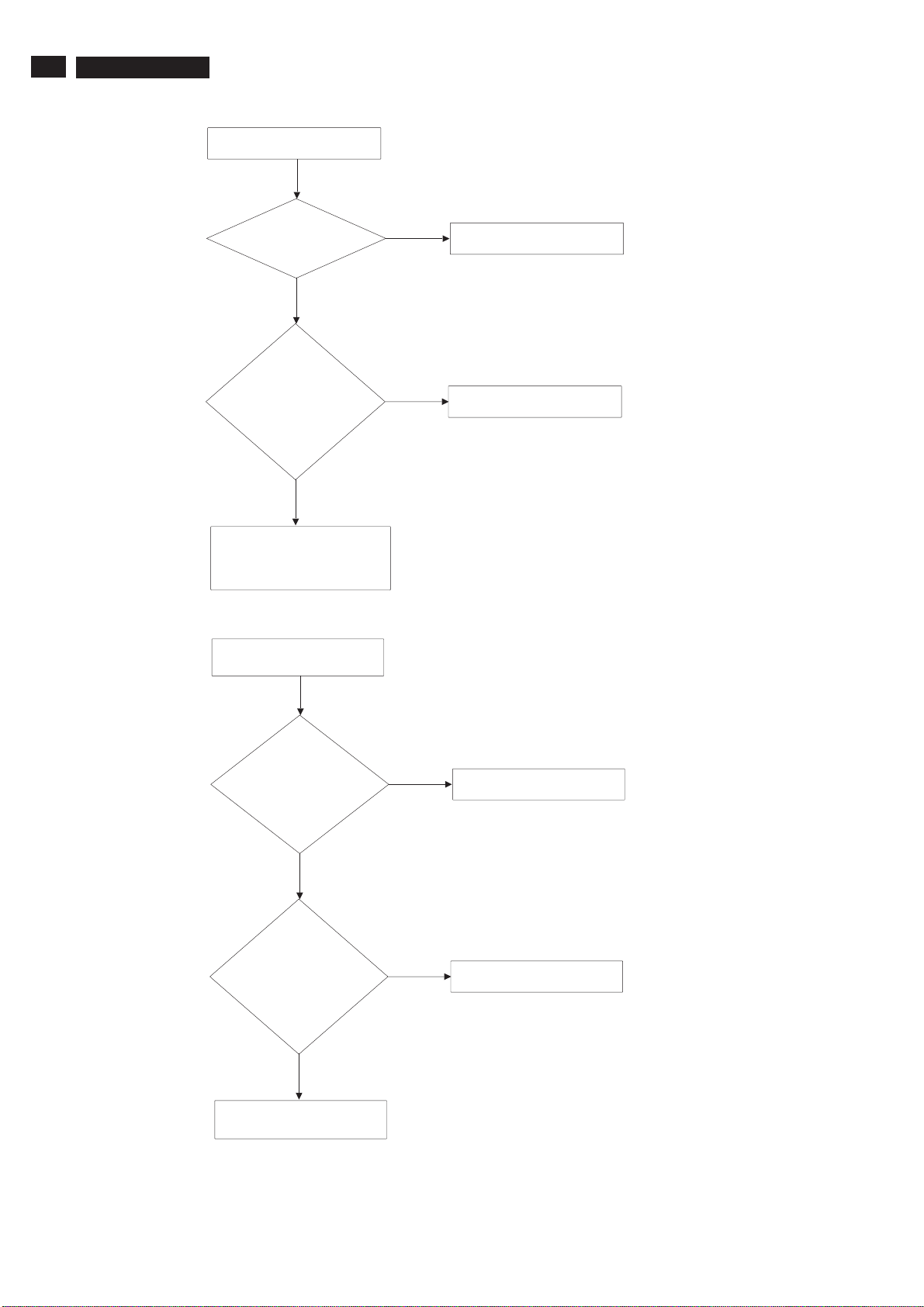

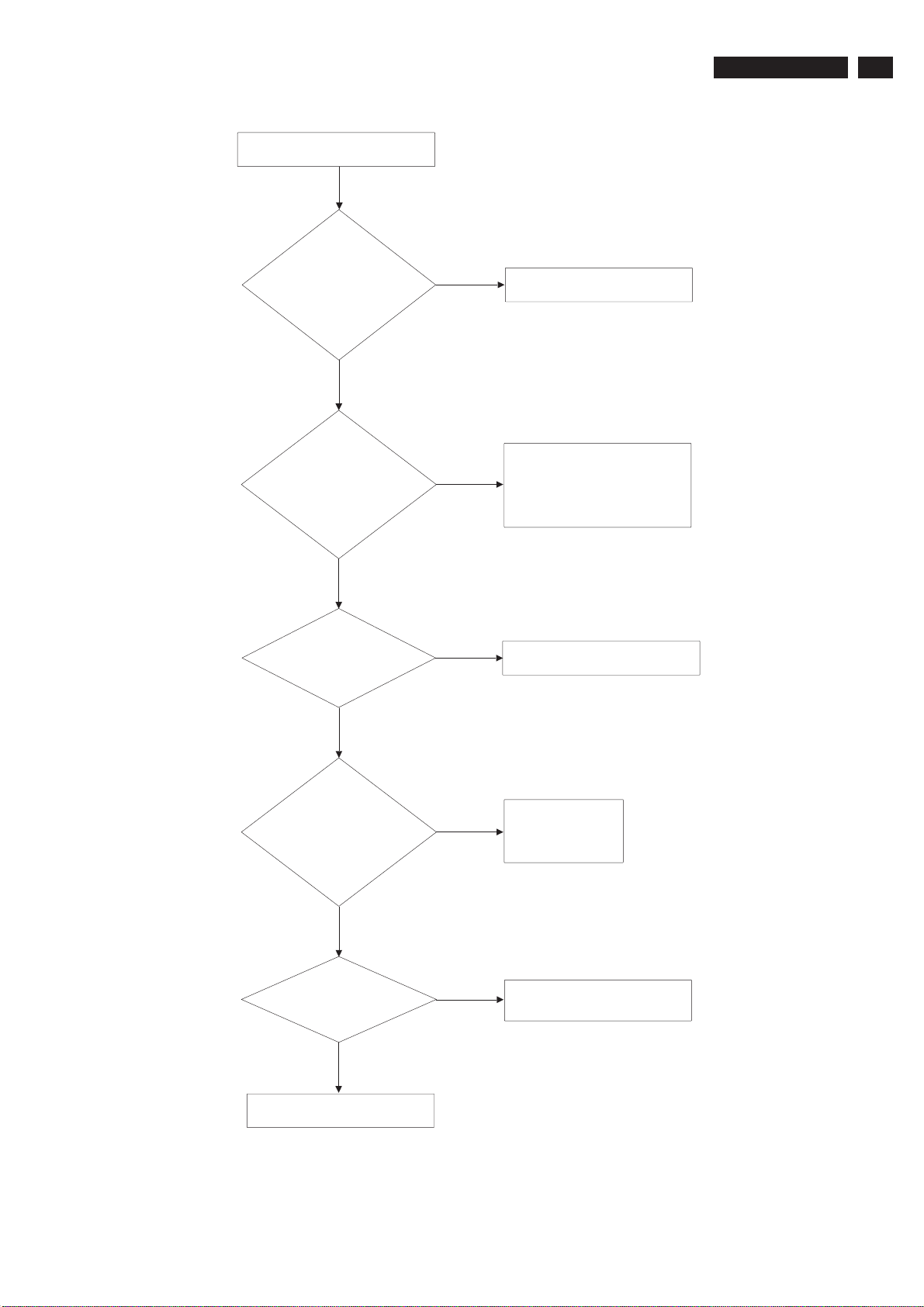

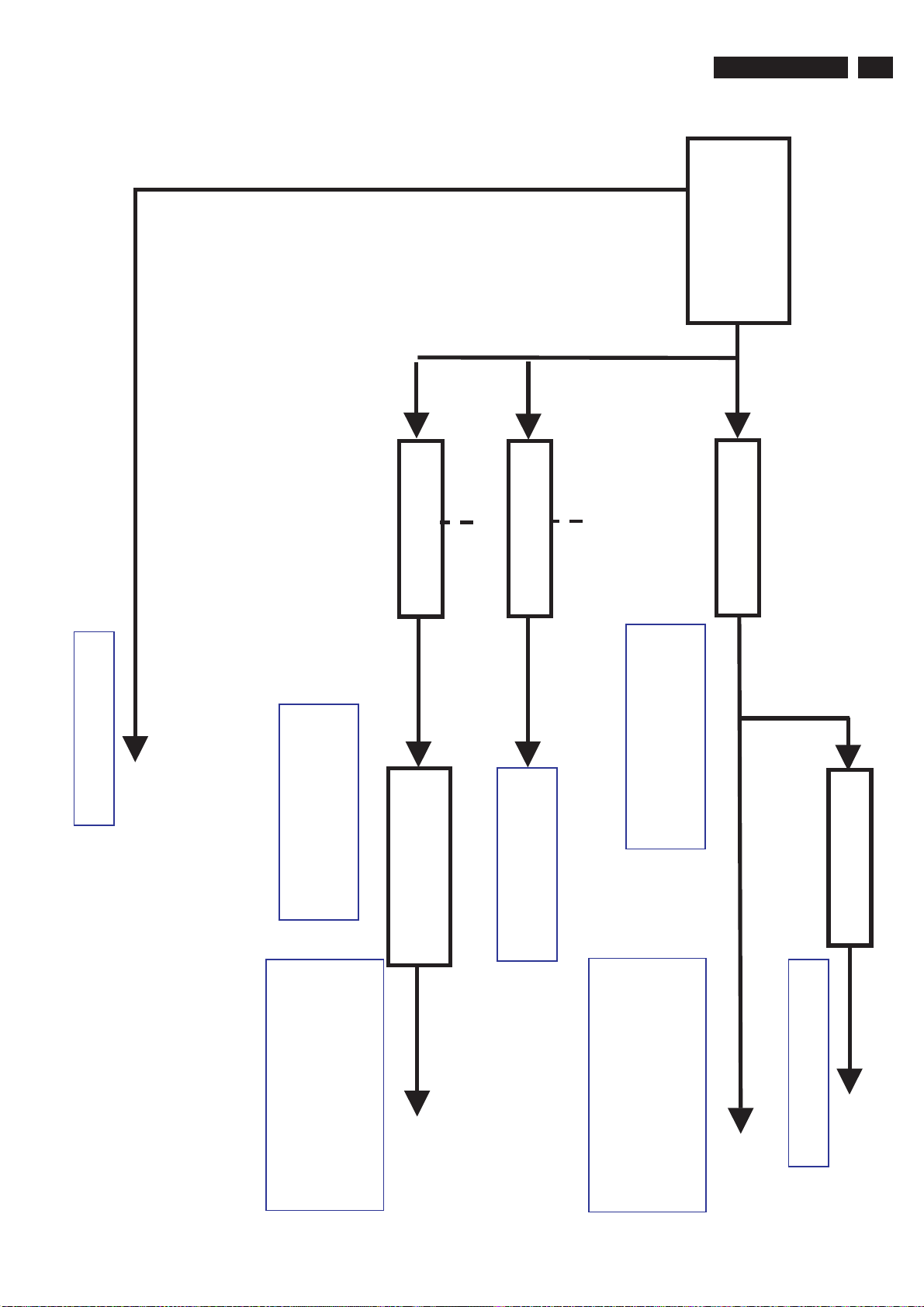

5.3 Repair flow chart

5. Service Modes, Error Codes and Fault Finding

1.No work/LED is off

Check if

power switch is

normal

Yes

Check

IR board CN001

pin1=0V,pin2=3.7V,

pin3=3V,pin4=2.85V

,pin5=5V,pin6

=3.3V

Yes

Check scaler board U102

pin1=14V,pin4=1.22V,

pin7=16V,pin8=5V,

2.No raster/picture too

dim

No

No

Replace Power switch

Check IR board

Check

Inverter board

CN852,pin1=16V,

pin5=0.9V,pin6

=3V

Yes

Check

Inverter board

U811 pin2=5V,Q821

pin=5,6=16V

Yes

Check scaler board

No

No

Check Scaler board

Check U811,Q821

5. Service Modes, Error Codes and Fault Finding

3.No picture/LED is green

Check

scaler board U102

pin1=14V,pin4=1.22V,

pin7=16V,pin8

=5V

Yes

No

Check power

TPS 1.0L LA

15

Check if

working voltage

U152,pin2=3.3V

pin3=5V

Yes

Check if clock

source X350

Yes

Check if

RGB,clk,H/V and

DE signal output 128

bits TTL

No

No

No

Check circuit around

each regulator and

eliminate short and

open situation

Replace X350

Try to replace

flash Rom

EEPROM

Yes

Check

resistors-network

Yes

Replace LVDS cable

No

Replace bad resistorsnetwork

16

TPS 1.0L LA

5. Service Modes, Error Codes and Fault Finding

4.No TV sound

Check if

tuner TU201 pin11

output IF signal

Yes

Check U301

5.No earthphone sound

No

Replace TU201

Check

U760 pin15=3.3V

Yes

Check U760

pin20=HPOUTL

pin6=HPOUTR

Yes

Replace Side AV Board

No

No

Eliminate short and open

situation

Replace U760

5. Service Modes, Error Codes and Fault Finding

6.No remote function

TPS 1.0L LA

17

Tty another

remote control

Yes

Check IR receiver

7.LED and function

key poor

Check circuit around

control board and cable

between control board

and scaler board

No

Replace one good

remote control

8.No HDMI picture

Enter CSM mode

to check item 6

Valid

Check Scaler Board

Invalid

Change U701 writen

HDCP KEY

18

TPS 1.0L LA

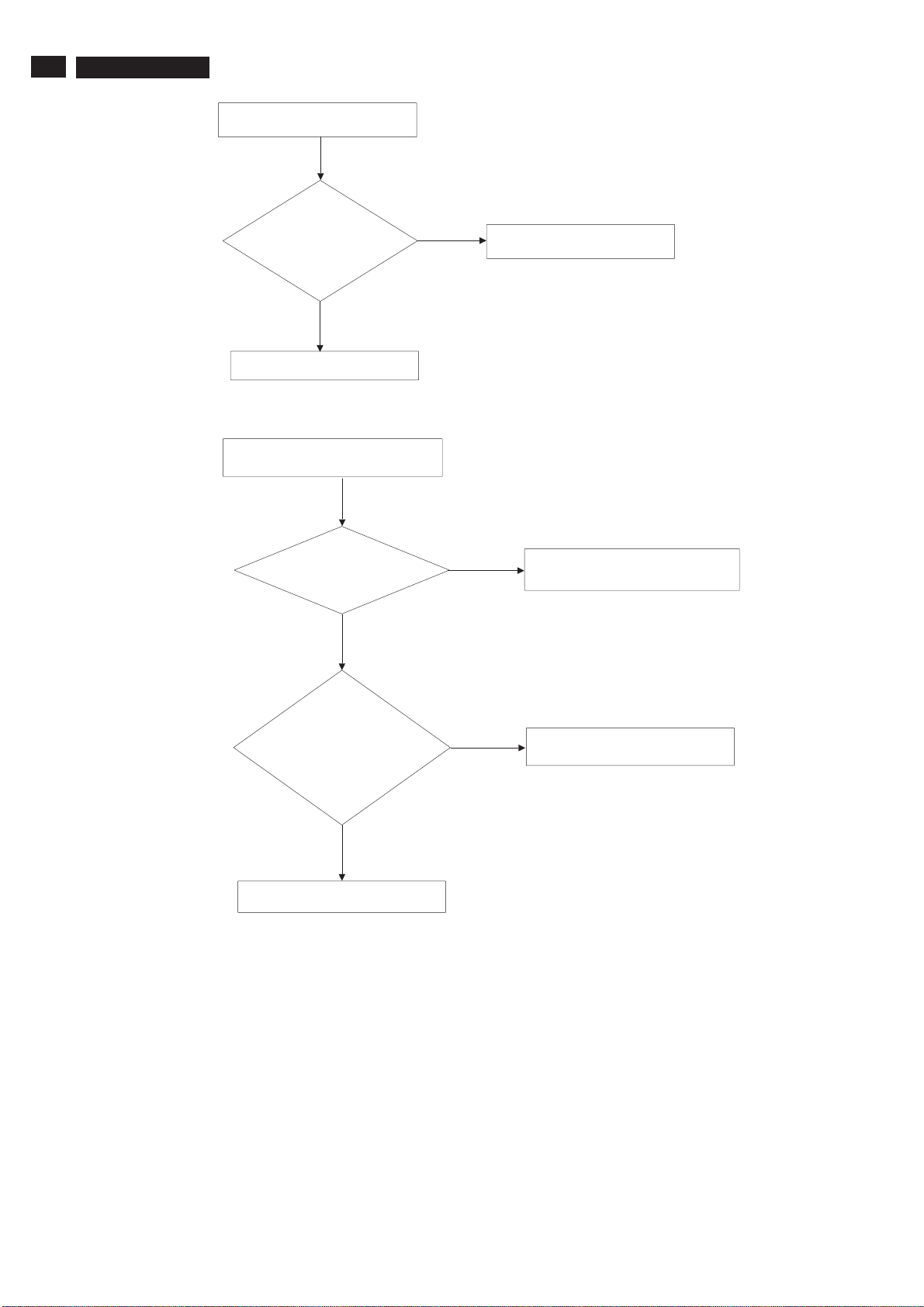

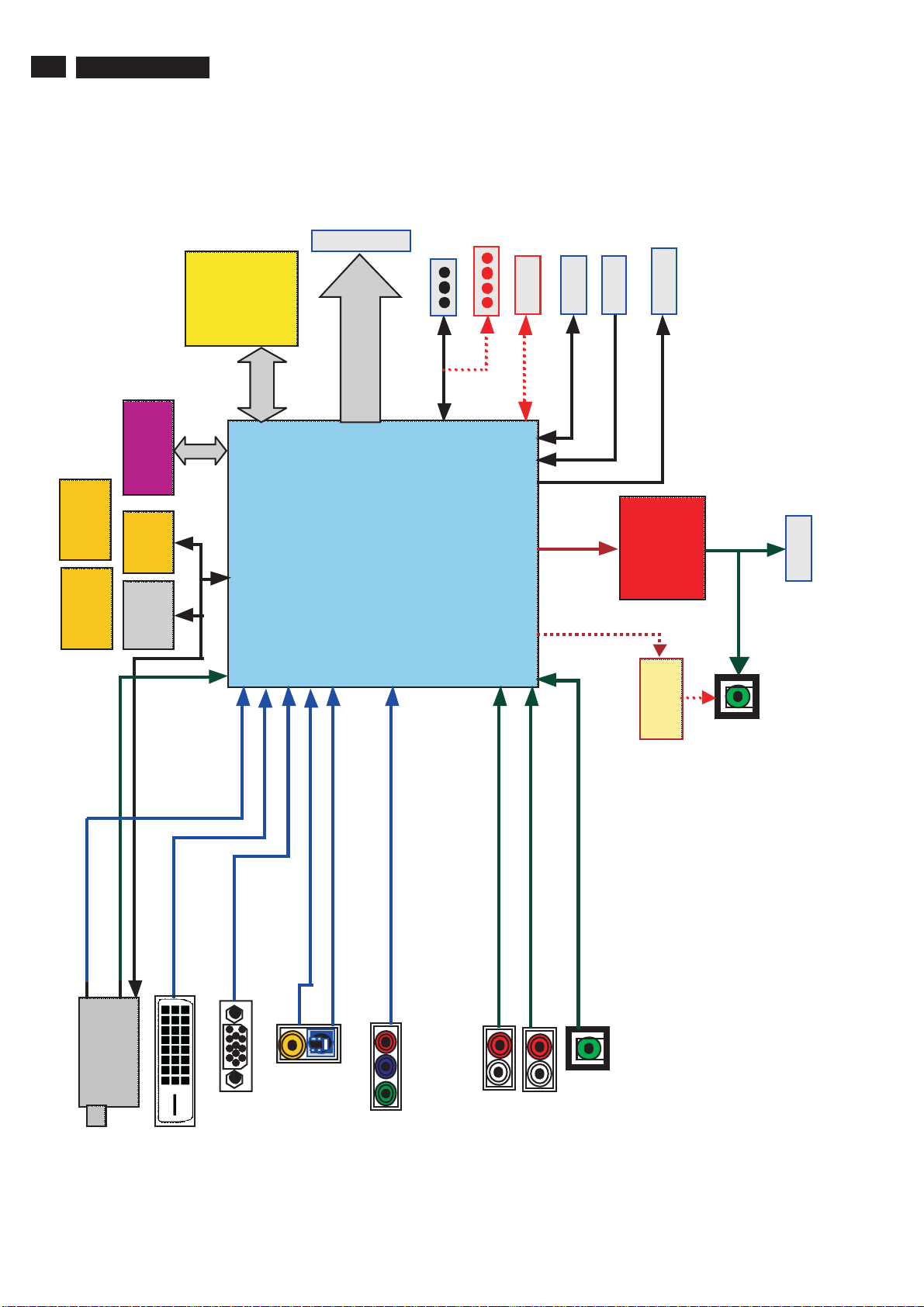

6. Block Diagram

Index of this chapter:

6.1

Wiring Diagram

6.2 Block Diagram

Type: 19PFL4322/45

6. Block Diagram

Wiring Diagram

089T179E30C918

K

CN020

4pin

095T8014 10938 FP

CN0201

I

6pin

095T8013 2982 FP

CN7302

CN7301

3pin

7pin

CN921

11pin

CN6201

2pin

P

CN7201

11pin

30pin

S

CN7501

095T8014 10938 FP

CN6202

2pin

CN7304

10pin

095T8014 10939 FP

CN0304

10pin

SA

095T8013 2979 FP

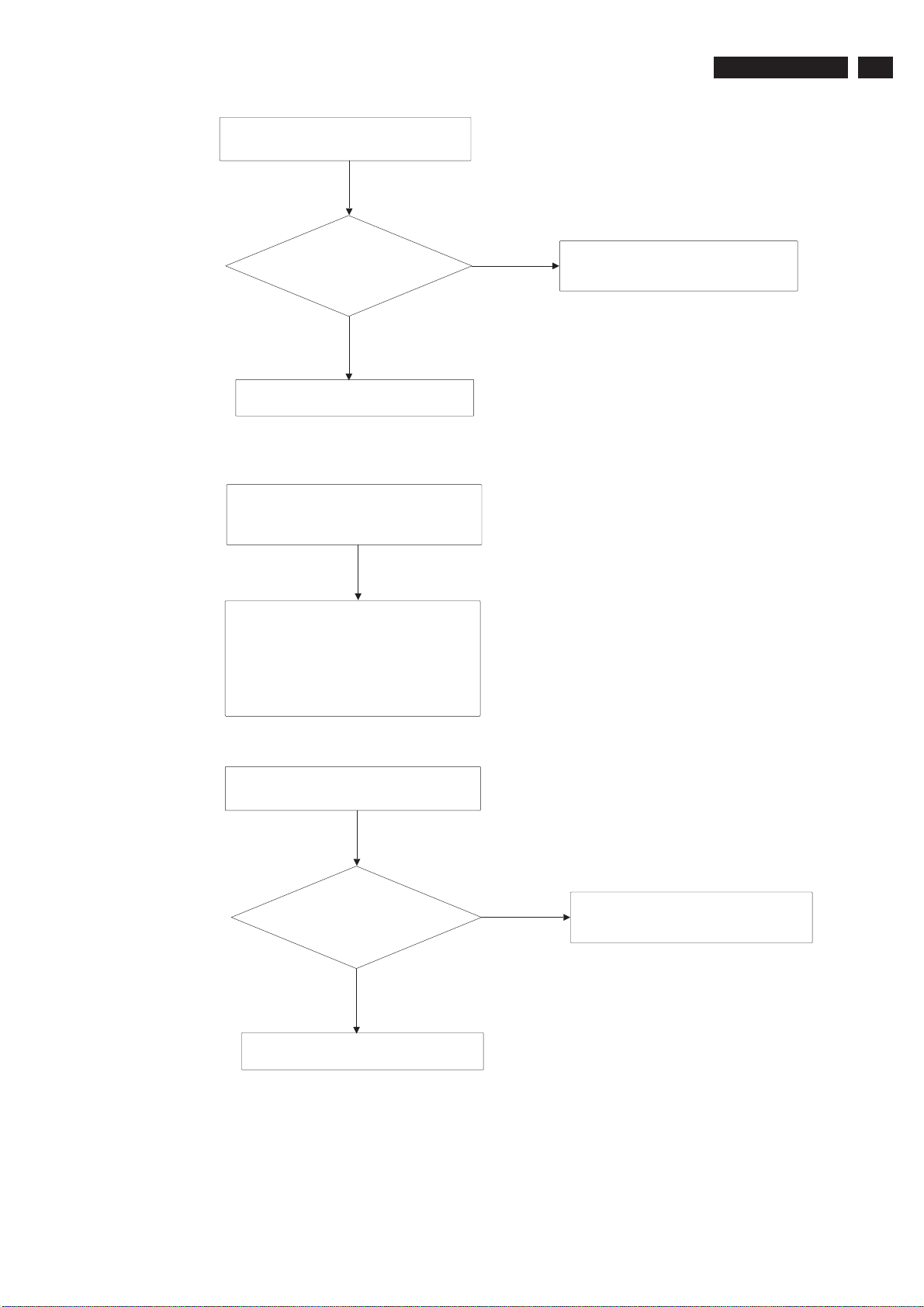

6.2 Block Daigram

6. Block Diagram

F3 - Latam : 19W" Entry

TPS 1.0L LA

19

230 mm

DVI-DDVI-D

DSUBDSUB

PC_AudioPC_Audio

YPbPr

"

20TTL

"

19 LVDS

INVERTER

PWR

PWR I-BD

I-BD

Key BD

Level 1

Level 1

iTV

iTV

ComPair

ComPair

IR BD

Speaker

TUNERTUNER

Side AV

150 mm

20

TPS 1.0L LA

19W Entry - System Block Diagram"

S-11

6. Block Diagram

LCD Panel

Com Pair

Cloning

(ITV-1)

Video I/F

(ITV-2)

IR Board

Key Board

LIPS control

24C02

S-06

24C02

S-05

S-08

DVI EDID

DSUB EDID

S-08

ROM

SPI Flash

24C16

HDCPK

24C32

NVRAM

SDRAM

SPI

S-07

S-07

I2C

S-09

UART1

TTL/LVDS

MST96885L

S-10

(5P)

S-10

(7P)

S-09

DAC

Line-out

(3P)

S-09

S-13

11P

S-02

AMP

TPA3005D2

1WAMP

TPA6203A

S-13

2x(2P)

(ITV-2)

HP/Bathroom

Speaker

L-R Speaker

CVBS0

SIF0

Tuner

S-03

MM

R1,G1,B1

DVI (CK,RX0,RX1,RX2)

S-06

DVI-D

S-05

D-SUB

Y0,C0

CVBS1

S-Video

CVBS

Y,Pb,Pr (R0,G0,B0)

S-04

S-04

Component-1

AUL1,AUR1

AUL0,AUR0

S-12

CVBSAudio

Component

Audio-1

AUL2,AUR2

S-12

S-12

PCAudio

Remark : Reserve only for ITV function

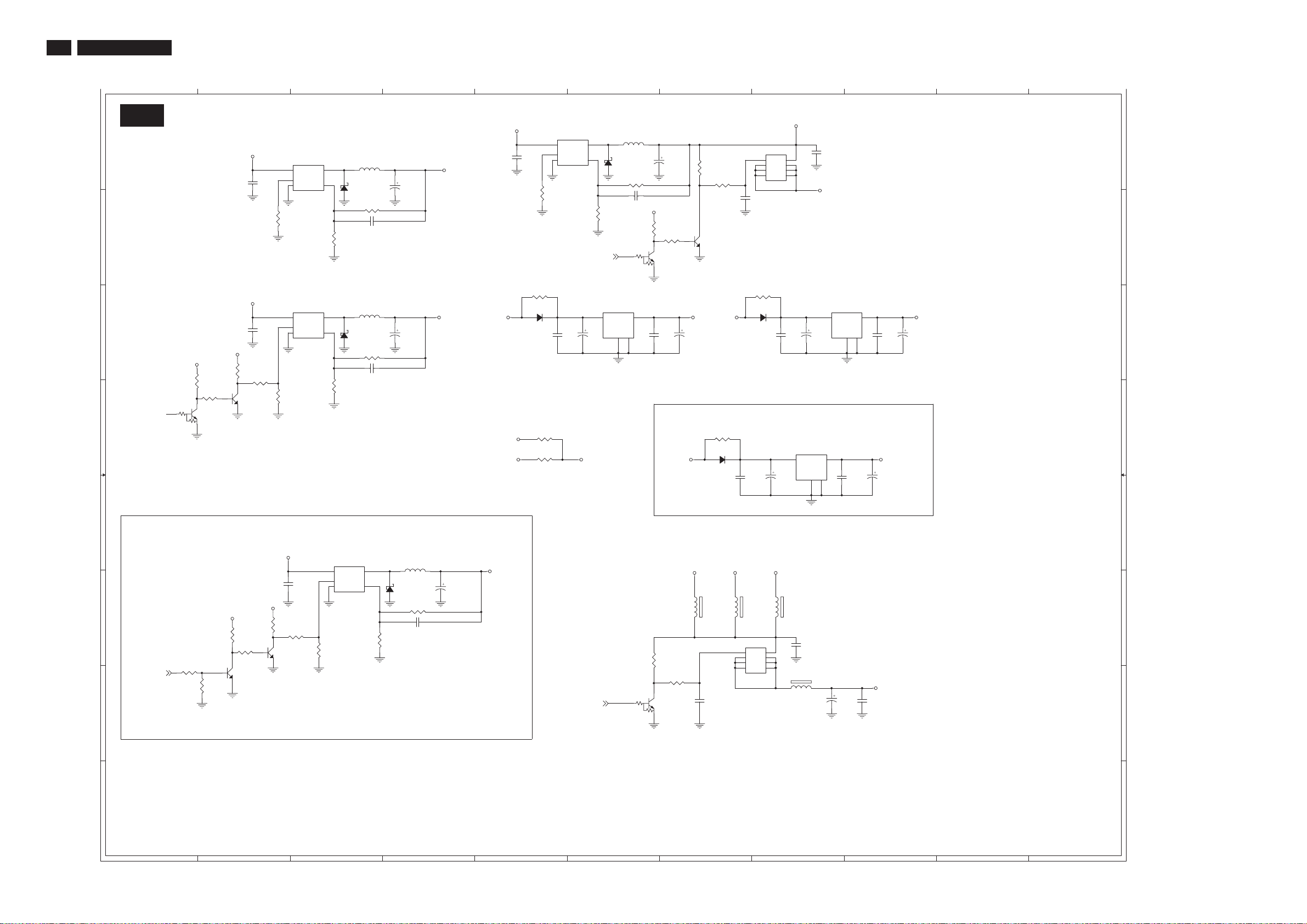

6. Block Diagram

Power Management

TPS 1.0L LA

LIPS

21

- U6201 ( AUD AMP)

+16V_AUDIO

- U6202 (Bath AMP)

- TU2101 (TUNER)

+16V

U7101 (AIC1596)

PWR_SW

+5V

U7104 (AME8815) or

(AIC1084/5)

+16V

U7105 (AIC1596)

+5V_ITV

- Panel (+5V)

- U7401 (Sync Slicer)

ITV_5V_SW

-

- U1101 (24C02 :D

U5101 (24C02 :DVI

SUB)

-

D)

For IR Board

+16V

U7102 (AIC1596)

+3V3_STBY

U7103 AME8815)

- U4201, 3 (SDRAM)

AVDD_AV, AVDD_MemPLL,,

VDDM

- U4103,5 (HDCP)

- U4202 (Flash ROM)

- U4101 (MST) : AVDD_SIF,

+3V3

- U4102,4 (NVRAM)

- U4101 (MST) : AVVD_DVI,

AVDDA, AVDD_MPLL, VDDP

+3V3_STBY

U4101 (MST) : VDDC

+1V8

22

TPS 1.0L LA

7. Circuit Diagrams and PWB Layouts

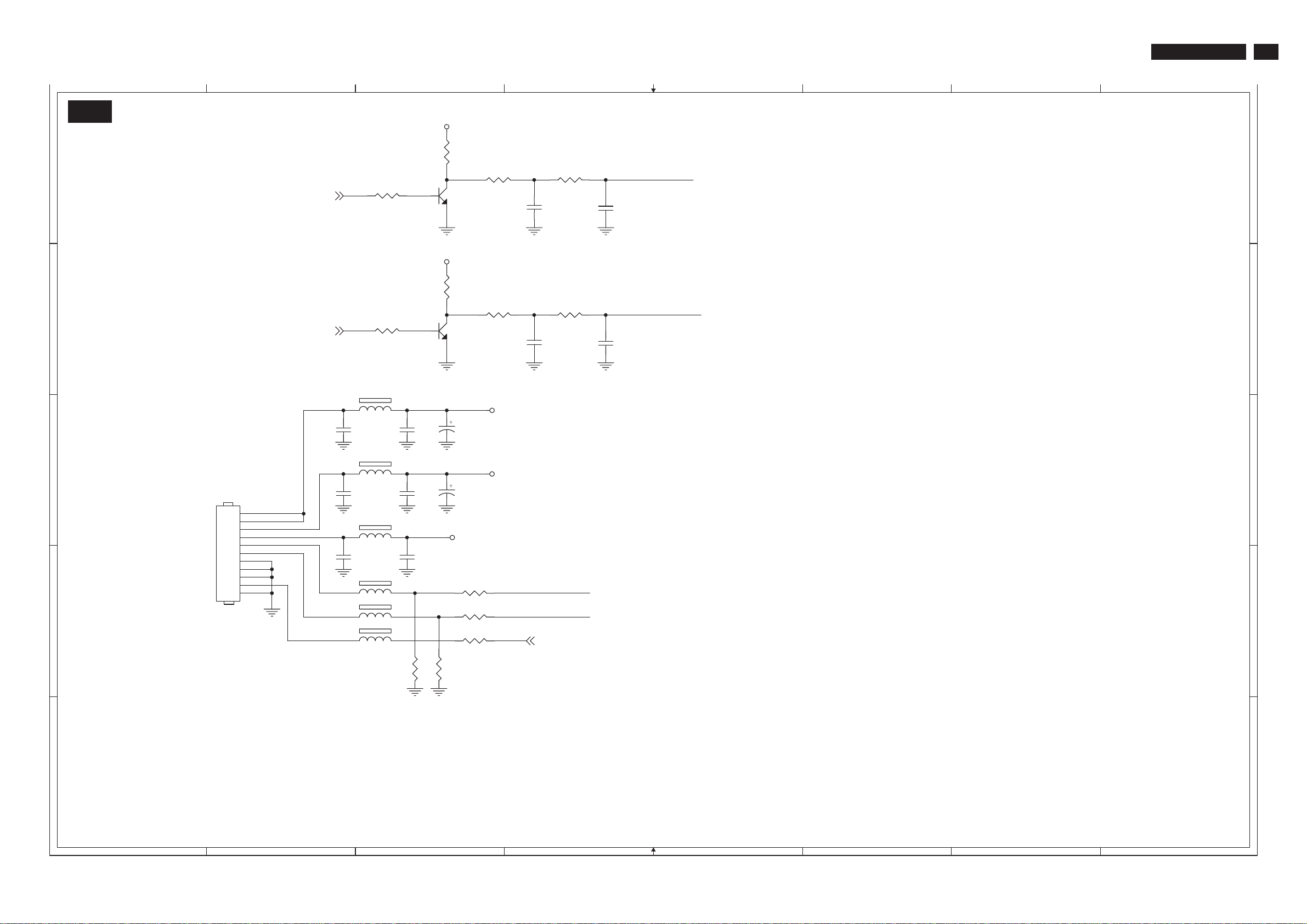

ScalerBoardSchematic Daigram-DC-DC POWER

1

2

S-01

A A

B B

C C

+5V_STBY

47K

R7126

R7127

3

R7130

33K(NC)

Q7102

MUN2211J

1

1K

R7131

47K(NC)

ITV_5V_SW7

D D

E E

F F

G G

2

ITV_12V_SW2,7

2

+5V_STBY

2

+16V

R7109

220K

3

Q7107

BC847C

1

R7128

47K(NC)

R7129

1K(NC)

3

Q7105

BC847C(NC)

1

+16V

+16V

C7104

0.1uF

C7125

0.1uF

R7110

100R

2

+16V

3

1

R7114

220K(NC)

Q7108

BC847C(NC)

1

5

3 4

0R

R7103

1

5

3 4

R7116

0R(NC)

+16V

U7101

IN

OUT

ON/OFF

GND FB

AIC1596-33PM5

U7106

IN

OUT

ON/OFF

GND FB

AIC1596-50PM5

C7107

0.1uF(NC)

R7115

100R(NC)

3

2

ZD7101

SSA34-E3

1

R7104 0R

C7106 0.1uF(NC)

R7105

0R(NC)

2

ZD7104

SSA34-E3

1

R7117 0R

C7127 0.1uF(NC)

R7118

0R(NC)

L7101

35uH

L7104

35uH

2

2

FOR iTV (LEVEL 2)

U7102

1

5

3 4

AIC 1596-12PM5(NC)

R7106

0R(NC)

IN

OUT

ON/OFF

GND FB

2

C7105

470uF 25V

C7126

470uF 25V

2

ZD7102

SSA34-E3(NC)

1

R7107 0R(NC)

C7109 0.1uF(NC)

R7108

0R(NC)

L7102

35uH(NC)

4

+3V3_STBY

+5V_ITV

C7108

470uF 25V(NC)

+3V3_STBY

+12V

+5V_ITV

+5V

+16V

5

C7118

0.1uF

R7121

0R05(NC)

1 2

AK

0R05(NC)

1

5

3 4

R7111

0R

D7103

S1D

R7132

R7133

0R05

U7105

IN

OUT

ON/OFF

GND FB

AIC1596-50PM5

C7110

0.1uF

PANEL_PWR7

2

R7113

0R(NC)

PWR_SW7

U7103

AME8815AEGT180Z

1

VIN

C7113

10uF 50V

6

L7103

35uH

2

ZD7103

SSA34-E3

1

R7112 0R

C7120 0.1uF(NC)

2

VOUT

GND

TH

234

2

+5V_STBY

47K

R7124

3

Q7101

MUN2211J

1

C7111

0.1uF

+5V_PANEL+5V_PANEL

56K

R7119

3

Q7104

MUN2211J

1

C7119

470uF 25V

R7125

1K

R7120

75K

2

+1V8

C7114

100uF 10V

1

2

7

R7101

100K

3

Q7106

BC847C

1

1 2

FB7102

220R(NC)

C7122

330N 25V

R7102

390K

R7123

0R05 (NC)

D7104

AK

GF1D(NC)

+5V

+5V_PANEL

1

2

4 5

3

2

1

4 5

3

2

1

C7132

330N 25V

R7122

0R05(NC)

1 2

AK

C7128

0.1uF(NC)

FB7104

220R

Q7103

GS

D

D

D

D

D

D

SI5441DC

8

+5V_STBY

Q7109

GS

6

D

D

7

D

D

8

D

D

SI5441DC

D7102

S1D

C7112

0.1uF

FOR 3V3 PANEL

U7107

AME8815AEGT330Z(NC)

1

C7130

10uF 50V(NC)

+3V3_PANEL+12V

1

FB7103

220R(NC)

2

6

7

8

FB7106

1 2

220R

VIN

C7121

0.1uF

C7133

0.1uF

+5V

C7115

10uF 50V

VOUT

GND

234

TH

U7104

AME8815AEGT330Z

1

VIN

VOUT

GND

234

C7129

0.1uF(NC)

C7123

10uF 50V

TH

C7131

100uF 10V(NC)

PANEL_VCC

C71240.1uF

9

C7116

0.1uF

+3V3_PANEL

+3V3

C7117

100uF 10V

10

C7104 A2

C7105 A4

C7106 B3

C7107 F2

C7108 F4

C7109 F4

C7110 C5

C7111 C6

C7112 C8

C7113 C6

C7114 C7

C7115 C8

C7116 C9

C7117 C9

C7118 A5

C7119 A6

C7120 B6

C7121 F8

C7122 G7

C7123 G8

C7124 G9

C7125 C2

C7126 C4

C7127 C3

C7128 D7

C7129 D8

C7130 D8

C7131 D9

C7132 B7

C7133 A8

D7102 C7

D7103 C5

D7104 D7

FB7102 F7

FB7103 F8

FB7104 F7

FB7106 G8

L7101 A3

L7102 E4

L7103 A6

L7104 C3

Q7101 B6

Q7102 D1

Q7103 F7

Q7104 G6

Q7105 F2

Q7106 B7

Q7107 D2

Q7108 F2

Q7109 A8

R7101 A7

R7102 A7

R7103 B2

R7104 B3

R7105 B3

R7106 F3

R7107 F4

R7108 F3

R7109 C2

R7110 C2

R7111 A5

R7112 A6

R7113 B6

R7114 F2

R7115 F2

R7116 D2

R7117 C3

R7118 C3

R7119 F6

R7120 G7

R7121 C5

R7122 C7

R7123 D7

R7124 B6

R7125 B6

R7126 C1

R7127 D2

R7128 F2

R7129 F2

R7130 F1

R7131 G1

R7132 D5

R7133 D5

U7101 A3

U7102 E3

U7103 C6

U7104 C8

U7105 A5

U7106 C3

U7107 D8

ZD7101 A3

ZD7102 F3

ZD7103 A6

ZD7104 C3

11

H H

1

2

3

4

5

6

7

8

9

10

11

7.Circuit Diagrams and PWB Layouts

TPS 1.0L LA

23

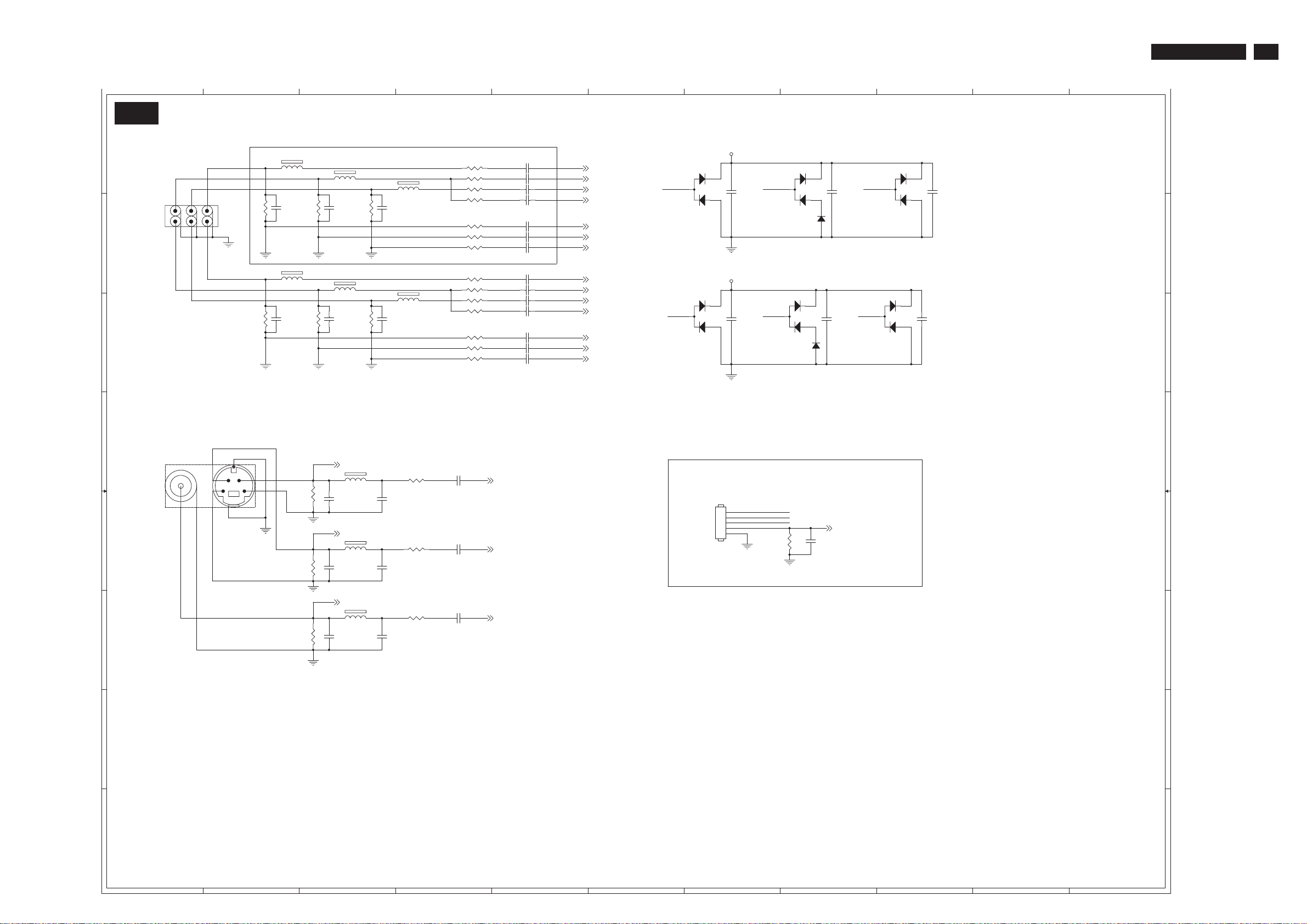

ScalerBoardSchematic Diagram-LIPS &INVERTER I/F

1

S-02

A A

B B

C C

CN7201

1

2

3

4

5

6

7

8

9

10

11

D D

63391 11P 2.0MM

For LIPS/PS

2

BL_ADJ7

BL_EN7

R7204 10K

R7208 10K

FB7201

1 2

120R

C7205

0.1uF

FB7202

1 2

120R

C7208

0.1uF

FB7206

1 2

120R(NC)

C7211

0.1uF(NC)

1 2

FB7203 120R

1 2

FB7204 120R

1 2

FB7205 120R

R7212

0R(NC)

3

2

2

C7206

0.1uF

0.1uF

C7209

C7212

0.1uF(NC)

+5V

R7201

1K

R7202 10K

3

Q7201

BC847C

1

+5V

R7205

1K

R7206 2K2

3

Q7202

BC847C

1

C7213

470uF 25V

C7210

100uF 25V

+12V_ITV

R7209 47R

R7210 47R

R7211 47R

R7213

10K

+16V

+16V_AUDIO

INVERTER_ON_OFF

4

R7203 10R

1U

C7201

R7207 10R

C7203

1U(NC)

BRIGHT_ADJ

ITV_12V_SW 1,7

BRIGHT_ADJ

C7202

0.1uF

INVERTER_ON_OFF

0.1uF

C7204

5

6

7

CN7201 C2

C7201 A4

C7202 A4

C7203 B4

C7204 B4

C7205 C2

C7206 C3

C7208 C2

C7209 C3

C7210 C3

C7211 C2

C7212 C3

C7213 C3

FB7201 B3

FB7202 C3

FB7203 D3

FB7204 D3

FB7205 D3

FB7206 C3

Q7201 A3

Q7202 B3

R7201 A3

R7202 A3

R7203 A4

R7204 A3

R7205 B3

R7206 B3

R7207 B4

R7208 B3

R7209 D3

R7210 D3

R7211 D3

R7212 D3

R7213 D3

8

E E

1

2

3

4

5

6

7

8

24

TPS 1.0L LA

7. Circuit Diagrams and PWB Layouts

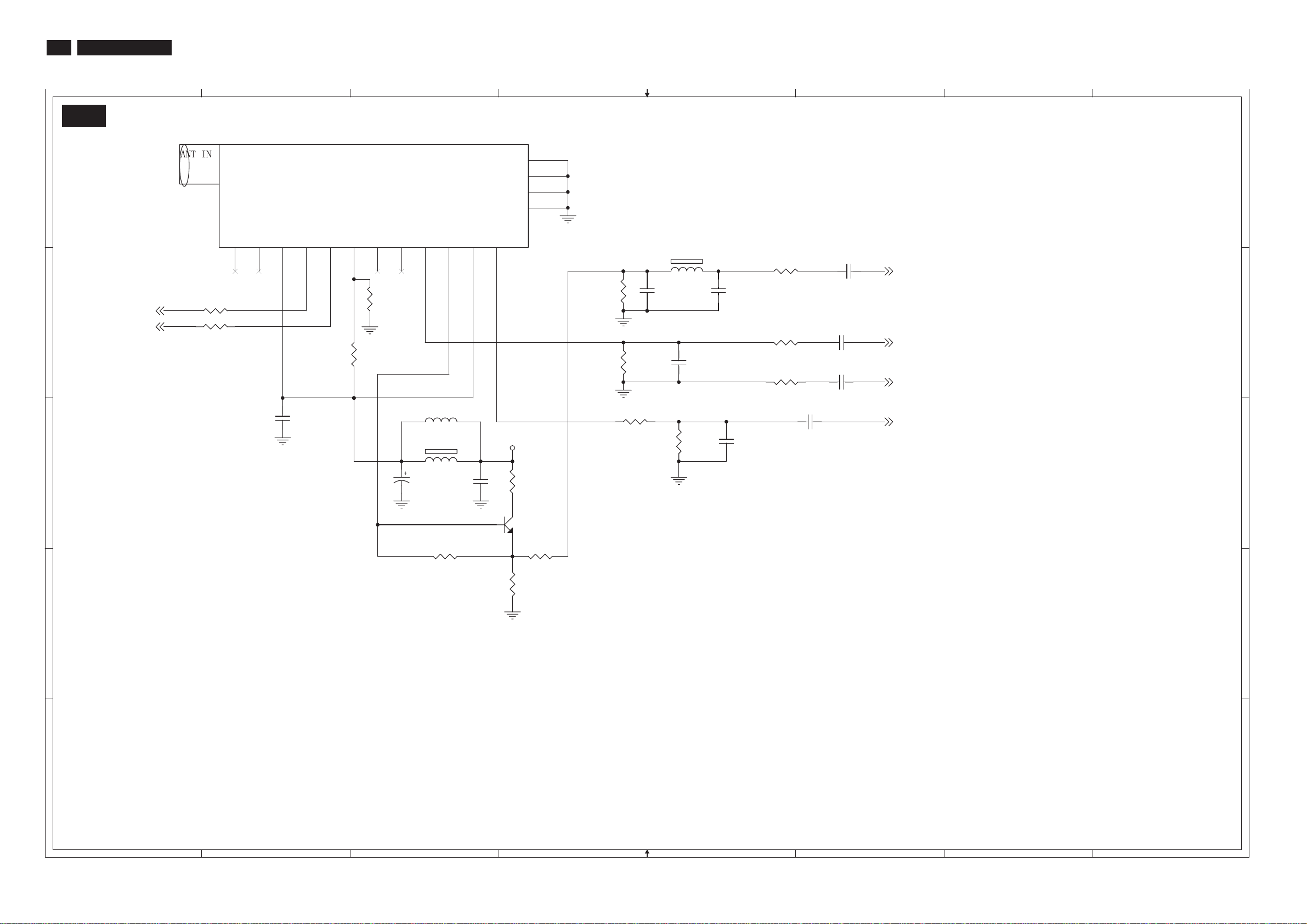

ScalerBoardSchematic Daigram- TUNER

1

2

3

4

5

6

7

8

S-03

TU2101 FQ1236/F H-5 TUNER

15

TH1

A A

+5VSCL

SDA

AS_TU

NC

AS_IF

2ND IF SOUND

N.C.

N.C

3

4

2

1

I2C_SCL7,10

B B

C C

I2C_SDA7,10

R2105 47R

R2106 47R

C2108

0.1uF

5

6

R2107

0R(NC)

9

0R

R2103

CVBS

10

11

22uH(NC)

1 2

C2110

1000uF 16V

L2101

FB2102

100R

AF O/P

+5V,IF

13

12

14

C2111

0.1uF

TH2

TH3

TH4

+5V

16

17

18

R2115

10K(NC)

TV_CVBS

R2104

75R 1%

TV_SIF

MONO

1 2

FB2101 30R

C2103

330P(NC)

R2109

2K2(NC)

R2111 10K(NC)

R2112

10K(NC)

22P

C2106

C2101

100P(NC)

C2104

330P(NC)

R2102 47R

R2108 0R

R2110 0R

C2105 0.1uF

C2107 0.1uF

C2109 0.1uF(NC)

C2102 47N

TUNER_CVBS 7

SIFP0 7

SIFM0 7

AUMONO 7

C2101 C5

C2102 B6

C2103 B4

C2104 B5

C2105 B6

C2106 B5

C2107 B6

C2108 C2

C2109 C6

C2110 C3

C2111 C3

FB2101 B5

FB2102 C3

L2101 C3

Q2101 C3

R2101 D4

R2102 B5

R2103 B3

R2104 B4

R2105 B2

R2106 B2

R2107 B2

R2108 B5

R2109 B4

R2110 B5

R2111 C4

R2112 C5

R2113 C3

R2114 C4

R2115 C4

TU2101 A1

3

Q2101

2

BC847C(NC)

R2101

0R(NC)

1

R2114

0R

R2113

0R

D D

E E

1

2

3

4

5

6

7

8

ScalerBoardSchematic Diagram-VIDEO INPUTS

1

2

S-04

7.Circuit Diagrams and PWB Layouts

3

4

5

6

7

8

9

10

11

TPS 1.0L LA

25

A A

R_PR2

G_Y2

B_PB2

32659

1

4

6

7

8

7

PR1

Y1

PB1

1

8

3

5

CN2201

2PJ-AV30-B01

B B

C C

D D

CN2202

5105-840-165-65(NC)

E E

F F

R2206

75R 1%

R2225

75R 1%(NC)

2

4

1 2

FB2208 30R(NC)

C2231

R2226

10P(NC)

75R 1%(NC)

1 2

FB2201 30R

R2207

75R 1%

C2206

10P(NC)

R2201

75R 1%

R2216

75R 1%

R2219

75R 1%

1 2

FB2209 30R(NC)

C2232

R2227

10P(NC)

75R 1%(NC)

1 2

FB2202 30R

R2208

75R 1%

C2207

10P(NC)

SV_Y0_SIDE 9

1 2

FB2205 30R

C2201

330P(NC)

SV_C0_SIDE 9

1 2

FB2206 30R

C2221

330P(NC)

AV_CVBS_SIDE 9

1 2

FB2207 30R

C2224

330P(NC)

1 2

FB2210 30R(NC)

C2233

10P(NC)

1 2

FB2203 30R

C2208

10P(NC)

R2214

47R

C2219

330P(NC)

R2215

47R

C2222

330P(NC)

R2220

47R

C2225

330P(NC)

C2218 47N

C2220 47N

C2226 47N

47R 5%(NC)

R2221

47R 5%(NC)

R2222

47R 5%(NC)

R2223

R2224 470R(NC)

47R 5%(NC)

R2228

47R 5%(NC)

R2229

47R 5%(NC)

R2230

R2202 47R

R2203 47R

R2204 47R

R2205 470R

R2209 47R

R2210 47R

R2211 47R

SV_Y0 7

SV_C0 7

AV_CVBS 7

C2227 47N(NC)

C2228 47N(NC)

C2229 47N(NC)

C2230 1N(NC)

C2234 47N(NC)

C2235 47N(NC)

C2236 47N(NC)

C2202 47N

C2203 47N

C2204 47N

C2205 1N

C2209 47N

C2210 47N

C2211 47N

PR2+

Y2+

PB2+

SOY2

PR2Y2PB2-

PR1+

Y1+

PB1+

SOY1

PR1Y1PB1-

PR2+ 7

Y2+ 7

PB2+ 7

SOY2 7

PR2- 7

Y2- 7

PB2- 7

PR1+ 7

Y1+ 7

PB1+ 7

SOY1 7

PR1- 7

Y1- 7

PB1- 7

D2206

R_PR2 G_Y2 B_PB2

3

BAV99(NC)

D2202

PR1 Y1 PB1

3

BAV99(NC)

+3V3_ESD

2

C2237

0.1uF(NC)

1

+3V3_ESD

2

C2215

0.1uF(NC)

1

For BS Model

CN2203

1

2

3

4

5

63385 5P 2.0mm (NC)

BAV99(NC)

75R 1%(NC)

D2207

3

BAV99(NC)

D2203

3

BAS32L(NC)

R_PR2

G_Y2

B_PB2

R2231

D2205

BAS32L(NC)

D2201

2

1

2

1

2

1

2

AK

1

C2240

0.1uF(NC)

AK

C2216

0.1uF(NC)

FBL2 7

C2238

0.1uF(NC)

BAV99(NC)

D2204

3

BAV99(NC)

D2208

3

CN2201 B1

CN2202 D1

2

C2239

0.1uF(NC)

1

2

C22170.1uF(NC)

1

CN2203 E7

C2201 E3

C2202 B5

C2203 B5

C2204 C5

C2205 C5

C2206 C2

C2207 C3

C2208 C3

C2209 C5

C2210 C5

C2211 C5

C2215 C7

C2216 C8

C2217 C9

C2218 D4

C2219 E3

C2220 E4

C2221 E3

C2222 E3

C2224 F3

C2225 F3

C2226 F4

C2227 A5

C2228 A5

C2229 A5

C2230 B5

C2231 B2

C2232 B3

C2233 B3

C2234 B5

C2235 B5

C2236 B5

C2237 A7

C2238 A8

C2239 A9

C2240 E8

D2201 C8

D2202 C6

D2203 C7

D2204 C8

D2205 B8

D2206 A6

D2207 A8

D2208 A9

FB2201 B2

FB2202 B3

FB2203 B3

FB2205 D3

FB2206 E3

FB2207 F3

FB2208 A2

FB2209 A3

FB2210 A3

R2201 D3

R2202 B4

R2203 B4

R2204 C4

R2205 C4

R2206 C2

R2207 C3

R2208 C3

R2209 C4

R2210 C4

R2211 C4

R2214 D4

R2215 E4

R2216 E3

R2219 F3

R2220 F4

R2221 A4

R2222 A4

R2223 A4

R2224 B4

R2225 B2

R2226 B3

R2227 B3

R2228 B4

R2229 B4

R2230 B4

R2231 E7

G G

H H

1

2

3

4

5

6

7

8

9

10

11

Loading...

Loading...