Philips 170C5 Schematic

17" LCD Colour Monitor

Service

Service

Service

170C5

170C5BS/00

Horizontal frequencies

30 - 82 kHz

TABLE OF CONTENTS

Description Page

Important Safety Notice---- ------------------------------ 2

Technical Data ------------------------------------------3~4

Front view&Connection to PC------------------------5~6

On-Screen Display-----------------------------------------7

OSD lock/unlock,Aging mode----------------------------8

Pixel defect policy------------------------------------------9

Warning message----------------------------------------10

Factory Mode----------------------------------------------11

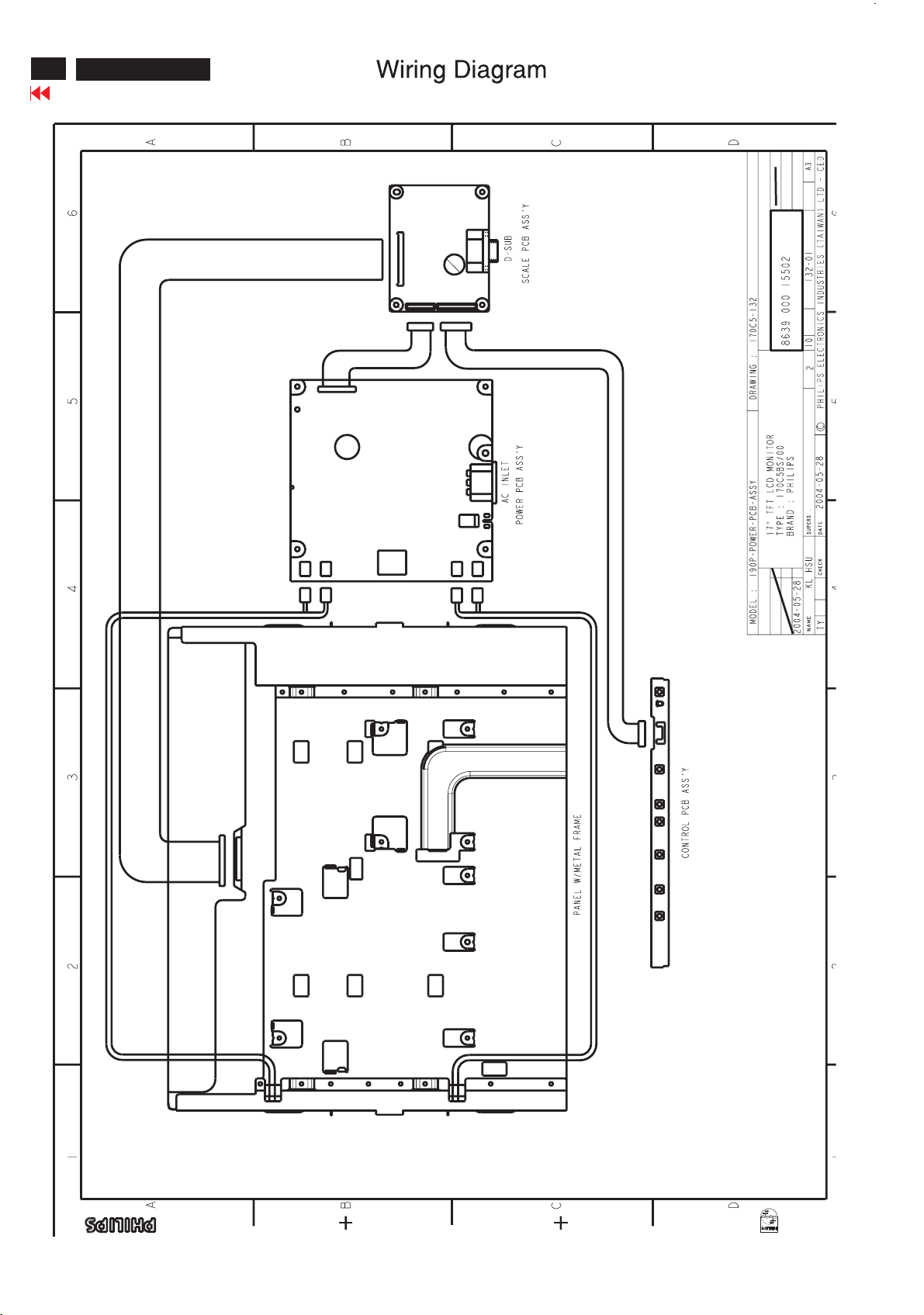

Wiring Diagram-------------------------------------------12

Mechanical Instructions----------------------------13~14

Electrical Instructions-----------------------------------15

DDC Instructions/DATA----------------------------16~21

SAFETY NOTICE

ANYPERSON ATTEMPTING TO SERVICE THISCHASSISMUSTFAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OFTHENECESSARYSAFETY PRECAUTIONSTO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENTCONTAINING HIGH VOLTAGES.

Description Page

ISP Instructions-------------------------------------22~23

Safety Test Requirements-----------------------------24

Function Block-------------------------------------------25

Scaler Diagram--------------------------------------26~29

Scaler Board C.B.A---------------------------------30~31

Control Diagram & C.B.A.------------------------------32

Power Diagram ----------.--------------------------33~34

Power board C.B.A.------------------------------------35

Exploded V

Recommended parts list-------------------------------37

Spare parts list-------------------------------------38~39

General product specification--------------------40~65

iew------------------------------------------- 36

CAUTION:USEASEPARATEISOLATION TRANSFORMER FOR THI SUNIT WHEN SERVICING.

REFER TO BACK COVER FOR IMPORTANTSAFETY GUIDELINES

Published by BCU Monitors Printed in Taiwan Copyright reserved Subject to modification F Jul . 9 2004

GBGB

3138 10610408

2

170C5 LCD

Go to cover page

Proper service and repair isimportant to the safe, reliable

operation of all HPConsumer Electronics Company**

Equipment. The service procedures recommended by HP and

described in this service manual are effective methods of

performing service operations. Some ofthese service

operations require the use of tools specially designed for the

purpose. The special tools should be used when and as

recommended.

It is important to note that this manual contains various

CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service

personnel. The possibility exists that improper service

methods may damage the equipment. It is also important to

understand that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. HP could not possibly know, evaluate and

advise the service trade of all conceivable ways in which

service might be done or of the possible hazardous

consequences of each way. Consequently, HP has not

undertaken any such broad evaluation. Accordingly, a

servicer who uses a service procedure or tool which is not

recommended by HP must first satisfy himself thoroughly that

neither his safety nor the safe operation of the equipment will

be jeopardized by the service method selected.

* * Hereafter throughout this manual, HP Consumer

Electronics Company will bereferred to as HP.

WARNING

Critical components having special safety characteristics are

identified with a bythe Ref. No. inthe parts list and

enclosed within a broken line*

(where several critical components are grouped in one area)

along with the safety symbol on the schematics or

exploded views.

Use of substitute replacement parts which do not have the

same specified safety characteristics may create shock, fire,

or other hazards.

Under no circumstances should the original design be

modified or altered without written permission from Philips.

Philips assumes no liability, express or implied, arising out of

any unauthorized modification of design.

Servicer assumes all liability.

*BrokenLine

FOR PRODUCTS CONTAINING LASER :

DANGER- Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

CAUTION- Use of controls or adjustments or

performance of procedures other than

those specified herein may result in

hazardous radiation exposure.

CAUTION- The use of optical instruments with this

product will increase eye hazard.

TO ENSURE THE CONTINUED RELIABILITY OF THIS

PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR PART

NUMBERS IN THE PARTS LIST SECTION OF THIS

SERVICE MANUAL.

Take care during handling the LCD module with backlight

unit

- Must mount the moduleusing mounting holes arranged infour

corners.

- Do not press onthe panel, edge of theframe strongly or electric

shock as this will result in damage to the screen.

- Do not scratch orpress on the panel withany sharp objects, such

as pencil or pen asthis may result in damage to the panel.

- Protect the module fromthe ESD as it maydamage the electronic

circuit (C-MOS).

- Make certain that treatment person s body are grounded through

wrist band.

- Do not leave themodule in high temperature andin areas of high

humidity for a long time.

- Avoid contact with water as it may ashort circuit within the module.

- If the surface ofpanel become dirty, please wipe it off with a soft

material. (Cleaning with a dirty or rough cloth may damage the

panel.)

Go to cover page

3

Support Color.

Type NR.

"

"

-

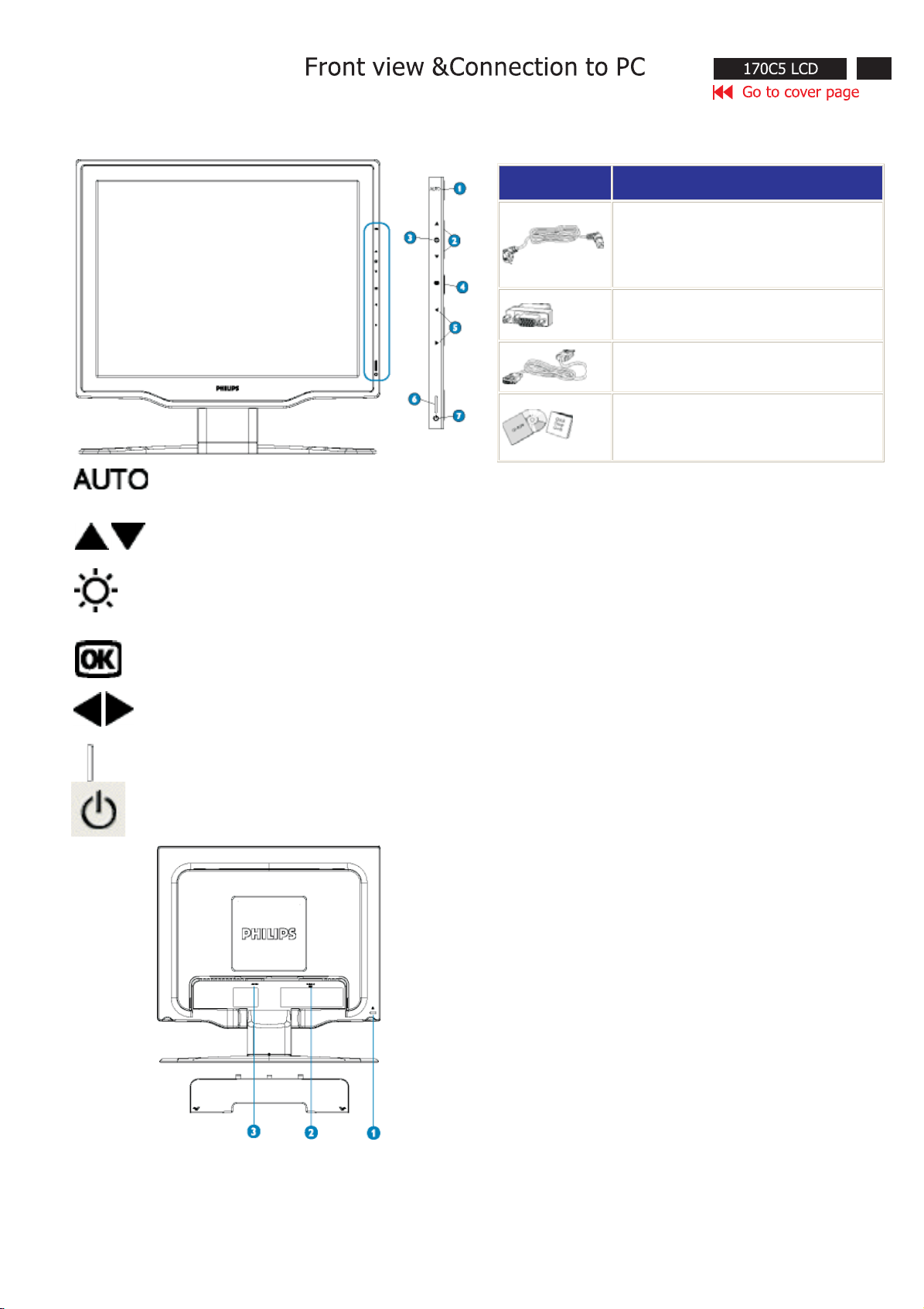

1.2.7.Controls Front side: DC power switch

OSD function key / OK

LEFT / RIGHT (Input Select)

Rear side: D

Power cord socket

-SUB signal connector

UP / DOWN (Brightness key)

AUTO key

4

Go to cover page

9 832X624 49.7KHz 57.28 75Hz MAC

10 1024X768 60.0KHz 78.75 75Hz

11 1024X768 48.4KHz 65 60Hz

12 1152X870 68.7KHz 100 75Hz MAC

13 1152X900 71.8KHz 108 76Hz SUN Mode II

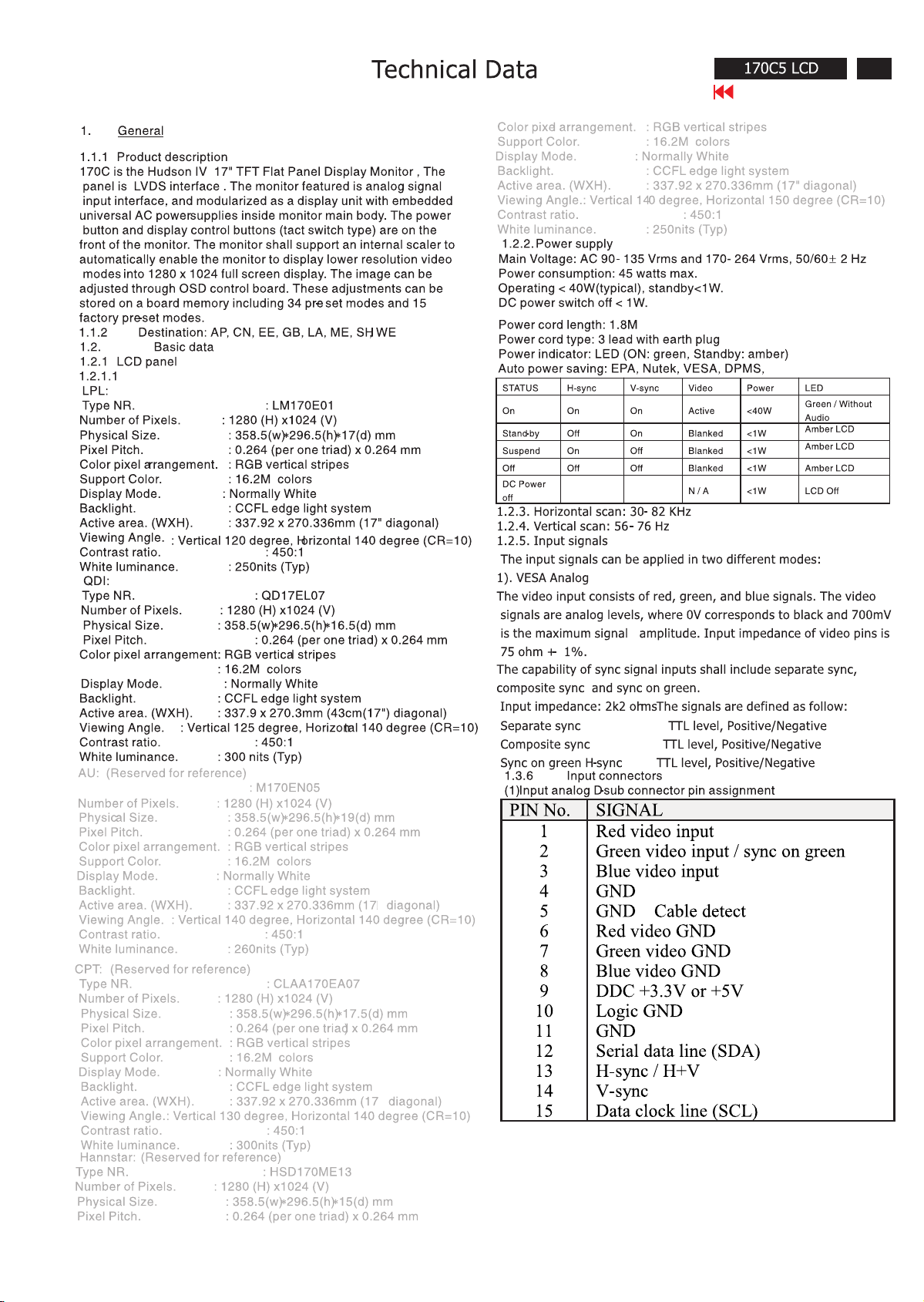

# Resolution H-Frequency Pixel rate V-Frequency Comment

1 640X350 31.5K 25.175 70Hz IBM VGA 10h

2 720X400 31.5K 28.322 70Hz IBM VGA 3h

3 640X480 31.5K 25.175 60Hz

4 640X480 35.0K 30.24 67Hz

5 640X480 37.9K 31.5 72Hz

6 640X480 37.5K 31.501 75Hz

7 640X480 43.3K 36 85Hz

8 800X600 35.2K 36 56Hz

9 800X600 37.9K 40 60Hz

10 800X600 48.1K 50 72Hz

11 800X600 46.9K 49.498 75Hz

12 800X600 53.7K 56.251 85Hz

13 832X624 49.7K/ 57.28 75Hz MAC

14 1024X768 48.4K 65 60Hz

15 1024X768 56.5K 75 70Hz

16 1024X768 60.0K 78.75 75Hz

17 1024X768 61.1K 83.096 76Hz IBM XGA-2

18 1024X768 68.7K 94.5 85Hz

19 1152X864 54.0K 79.9 60Hz Non-VESA

20 1152X864 63.9K 94.5 70Hz Non-VESA

21 1152X864 67.5K 108 75Hz

22 1152X870 68.7K 100 75Hz MAC

23 1152X900 61.8K 92.94 66Hz SUN Mode IV

24 1152X900 71.8K 108 76Hz SUN Mode II

25 1280X960 60.0K 108 60Hz

26 1280X960 75.0K 129.895 75Hz Non-VESA

27 1280X1024 64.0K 108 60Hz

28 1280X1024 71.7K 117 67Hz SUN Mode V

29 1280X1024 76.0K 130.223 72Hz DOS/V

30 1280X1024 80.0K 135 75Hz

31 1280X1024 81.1K 135.008 76Hz SUN Mode I

32 688X556 31.3K 27 50Hz TV-PAL

33 960X720 44.76K 57.58 60Hz

34 960X720 56.4K 72.42 75Hz

(2) Factory Preset modes (15 modes)

# Resolution H-Frequency Pixel rate V-Frequency Comment

1 640X350 31.5KHz 25.175 70Hz IBM VGA 10h

2 720X400 31.5KHz 28.322 70Hz IBM VGA 3h

3 640X480 37.5KHz 31.501 75Hz

4 640X480 35.0KHz 30.24 67Hz

5 640X480 31.5KHz 25.175 60Hz

6 800X600 35.2KHz 36 56Hz

7 800X600 46.9KHz 49.498 75Hz

8 800X600 37.9KHz 40 60Hz

14 1280X1024 64.0KHz 108 60Hz

15 1280X1024 80.0KHz 135 75Hz

Note :

1. Screen displays at 34 preset modes

2. Screen displays perfect picture at 15 preset modes

3. Screen displays visible picture with OSD warning when

input modes are other then 34 preset modes

2.1.3 Timing requirements

The analogue color LCD monitor must be capable of

displaying standard resolutions within the vertical frequency

range of 56 - 76 Hz, the horizontal scan range of 30 -82 KHz

and others modes which be defined as section 5.1.2.

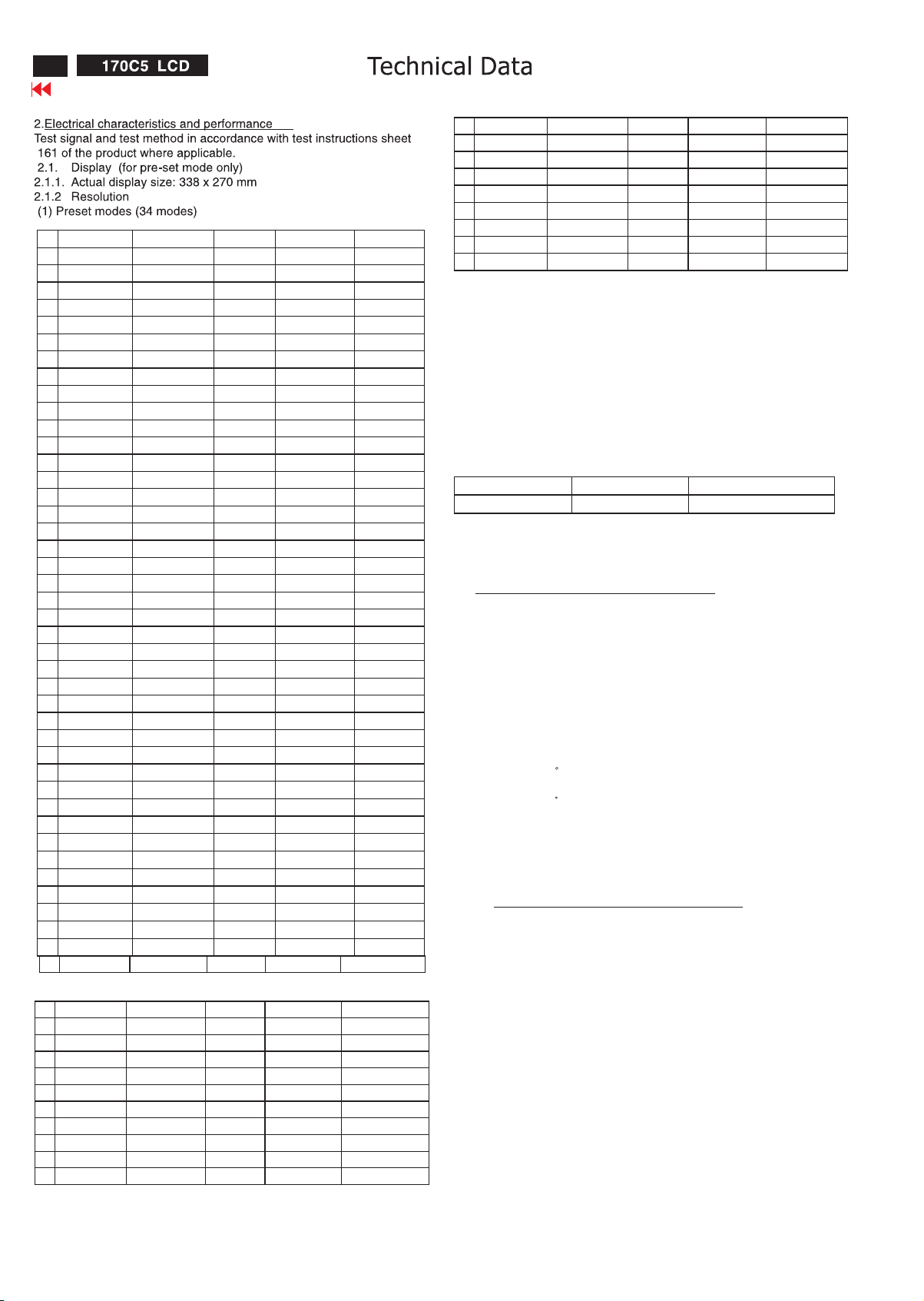

2.1.4 Brightness output (Video signal 0.7V ± 2 %)

+/-

use OSD to set R, G, B gain at 100%

measured by at screen center (position 5) as pattern1 on

next page

Brightness control Contrast control Light output unit: nits

100% 100% >= 200

2.1.4 Dimming range

Set the contrast at 50 %, Measure brightness at 0% and 100%

of brightness control the light output should be comply with

Luminance at brightness minimum

<30%

Luminance at brightness maximum

2.2 Scanning

2.2.1. Display mode : Multi-modes

2.2.2. Horizontal scanning

Sync polarity : Positive or negative

Scanning frequency : 30K - 82 K Hz

2.2.3. Vertical scanning

Sync polarity : Positive or negative

Scanning frequency : 56 - 76 Hz

2.3 White balance adjustment

9300°K CIE coordinates x = 0.283 + 0.02/- 0.02

y = 0.297 + 0.02/- 0.02

6500°K CIE coordinates x = 0.313 + 0.02/- 0.02

y = 0.329 + 0.02/- 0.02

2.4 Check brightness uniformity

Set contrast at 50% and turn the brightness to get average

above 200 nits.

Apply the pattern 1. It should comply with the following formula:

Minimum luminance of nine points (brightness)

>= 0.75 (Min.)

Maximum luminance of nine points (brightness)

2.5 Check Cross talk

Apply Pattern 2. Set contrast at 50% and brightness at 100 %.

Measure A.

Then output Pattern 3 and measure A’. The cross talk value:

ABS ( A - A’ )

'

'

¾¾¾¾¾¾¾¾¾ X 100 % < 1.5 % (Max)

A

2.6 Check picture flicker (B)

Apply a 1280*1024 /60Hz signal with pixel on/off pattern.

Set color temperature at original panel color.

Set brightness control at 100%, and contrast control at 50%.

Check picture flicker should not be visible.

5

Front view

Automatically adjustthe horizontal position, vertical

position, phase andclo ck setting.

UP and DOWN buttonsare used when adjusting the

OSD ofyour monitor.

BRIGHTNESS hotkey. When the UP and DOWN arrow

buttonsare presse d, the adjustment controls forthe

BRIGHTNESS will show up.

OK button w

hich when pressed will take you to the

OSD controls

LEFTand RIGHT buttons, likethe

UP and DOWN buttons, are also use d in adjusting

the OSD ofyour monitor.

Power LED

POWER button switchesyour monitor on.

AccessoryPack

Unpack all the parts.

Item Description

1) Power Cable (s ocket may differ for different countries)

2) Macintosh Adapter (optional)

3) VGA Signal Cable

4) E-DFU packagewithQuick Setup Guide and CD-ROM.

Rearview

1Kensington anti-thieflock

2 VGA input

3ACpower input

6

Go to cover page

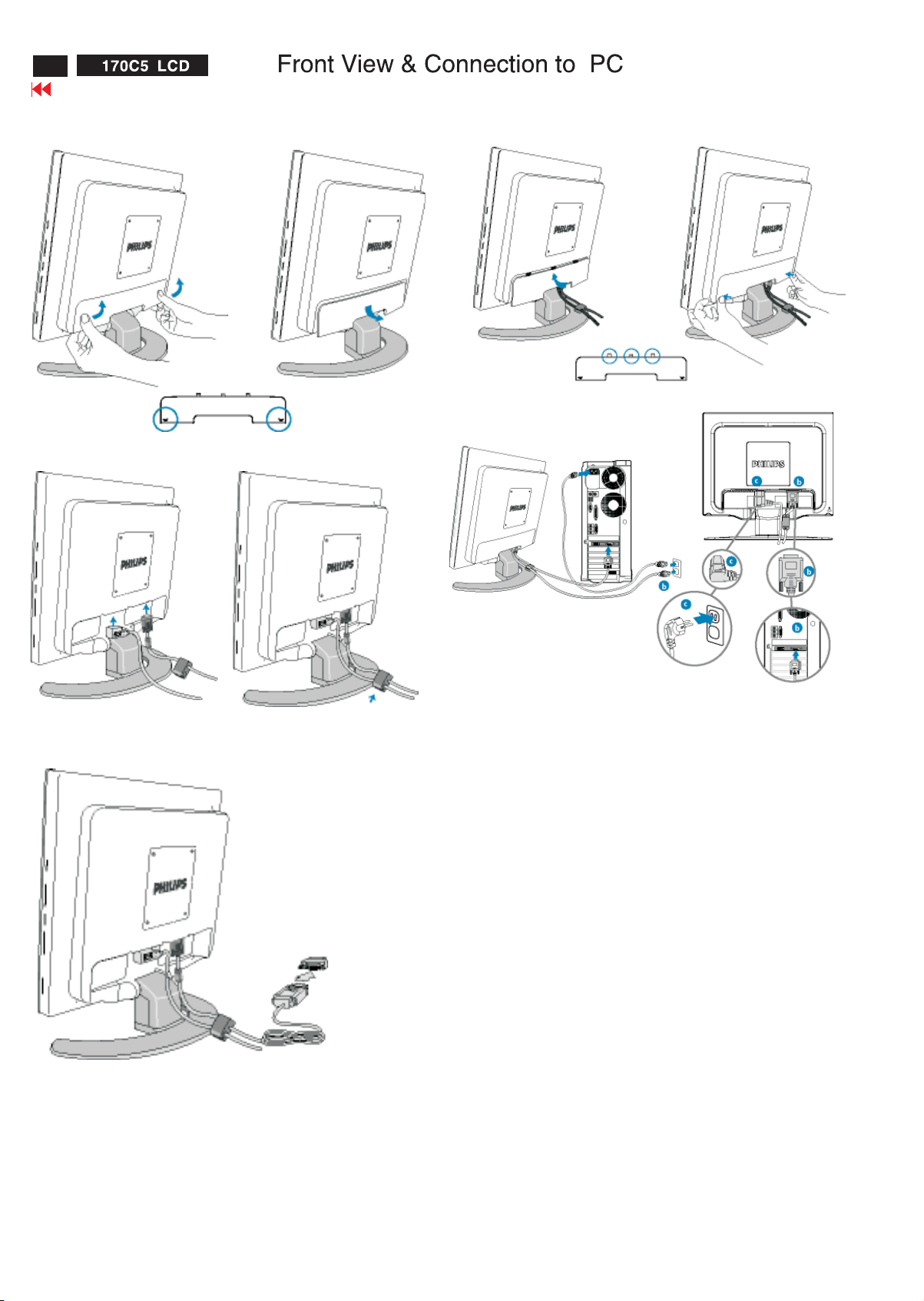

Connect the monitor to PC as followa:

Remove the cover

Plug the power cord into monitor firmly

Note: If you use an Apple Macintosh, you need to connect the

Connect to PC

(a) Turn off your computer and unplug its power cable.

(b) Connect the monitor signal cable to the video connector on the back of your computer.

(c) Plug the power cord of your computer and your monitor into a nearby outlet.

(d) Turn on your computer and monitor. If the monitor displays an image, installation is complete.

special Mac adapter to one

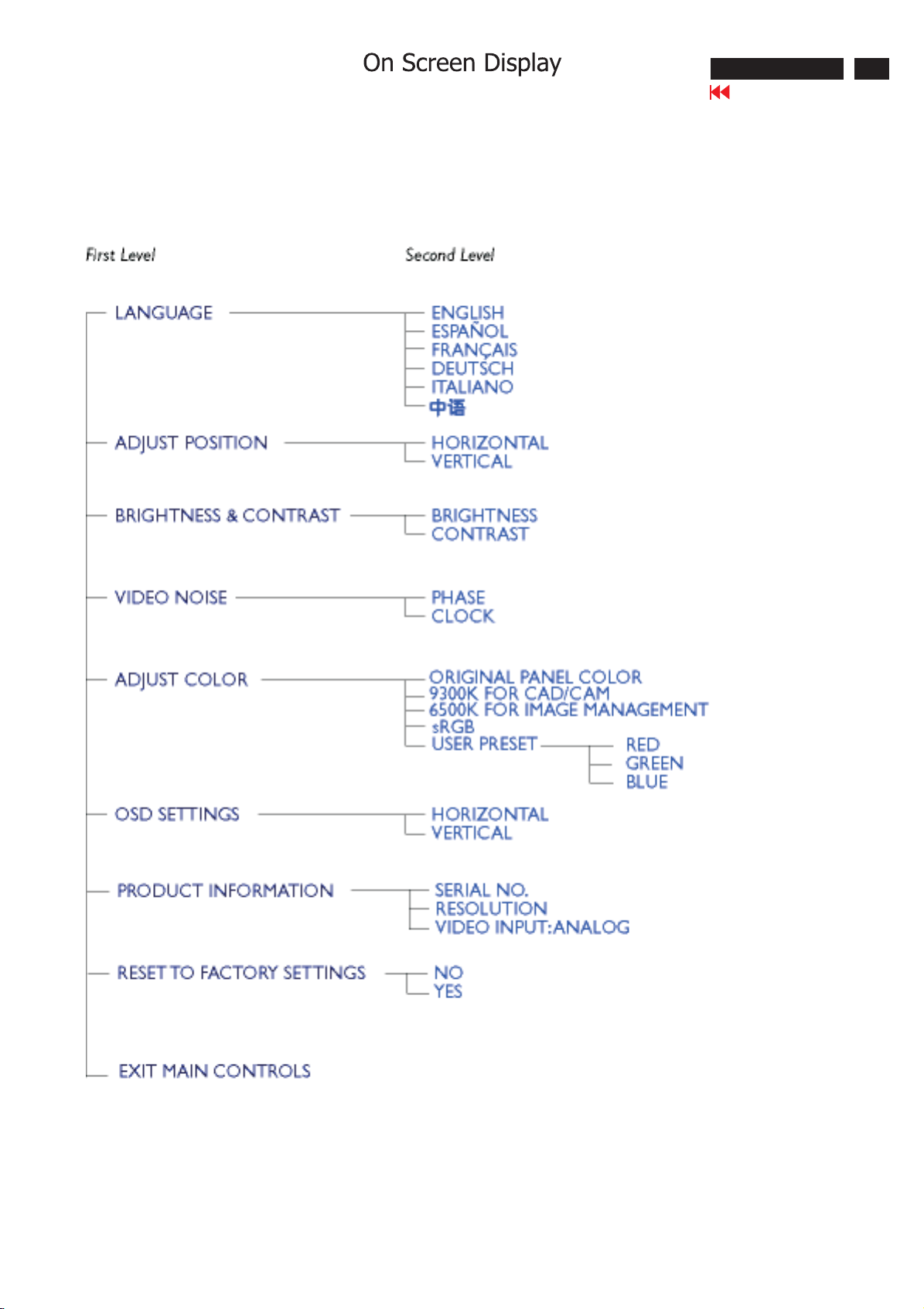

The OSD Tree

Below is an overall view of the structure of the On-Screen Display. You can use this as a reference when you want to

work your way around the different adjustments later on.

170C5 LCD

Go to cover page

7

8

170C5 LCD

Go to cover page

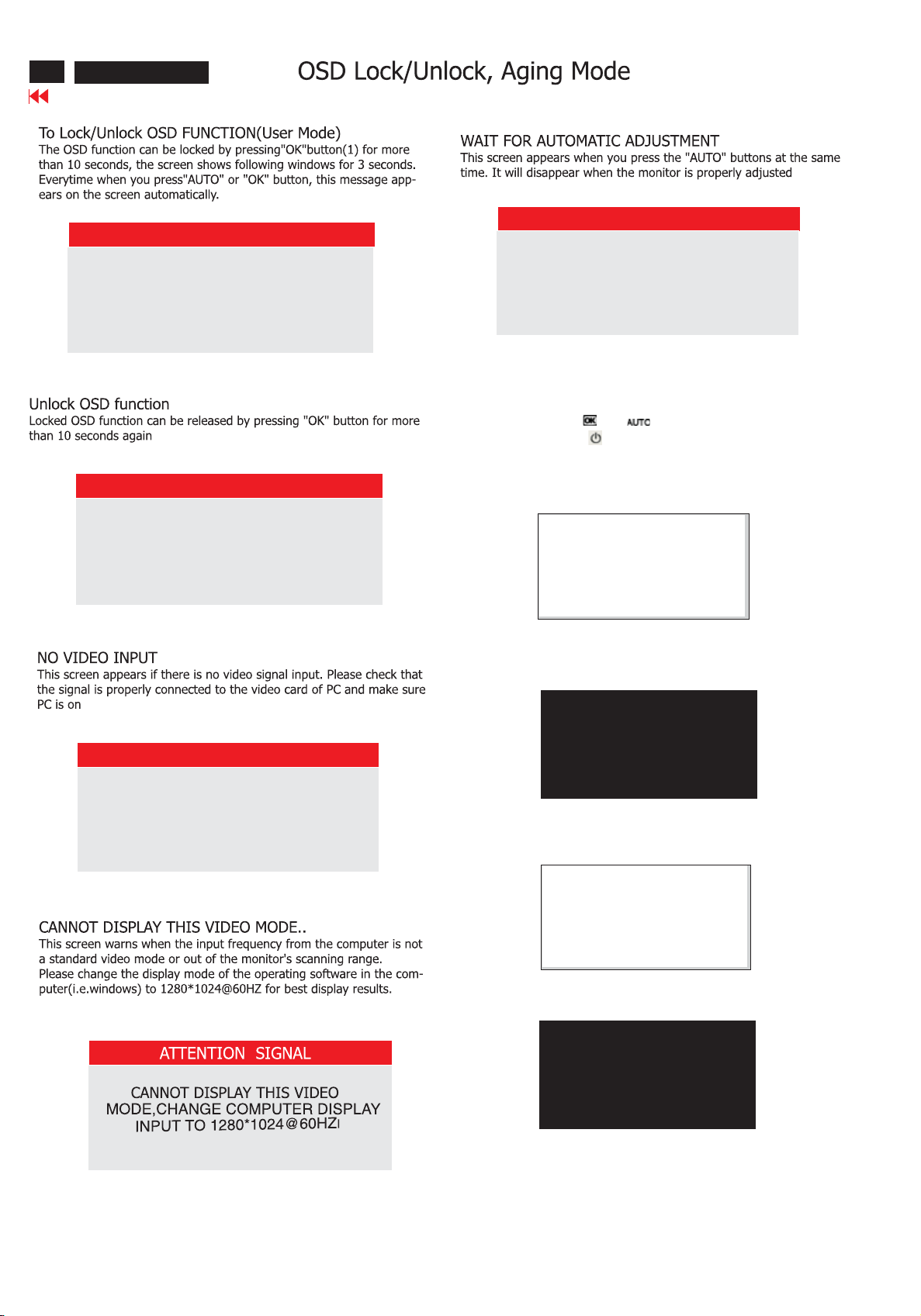

OSD MAIN CONTROLS LOCKED

ATTENTION SIGNAL

ATTENTION SIGNAL

WAITING FOR AUTOMATIC ADJUSTMENT

Access Aging.. Mode

Step 1 : Turn off LCD monitor, and disconnect Interface Cable between Monitor and PC.

Step 2 : [Push AUTO " " & " " buttons at the same time and

hold it]+[Press power " " button untill comes out " AGING screen"

] => then release all buttons.

ATTENTION SIGNAL

OSD MAIN CONTROLS UNLOCKED

ATTENTION SIGNAL

CHECK CABLE CONNECTION

Bring up:

AGING...

After 15 seconds, bring up:

After 15 seconds, bring up:

AGING...

After 15 seconds, bring up:

----------

---------repeatly

Connect Signal cable again=> go back to normal display

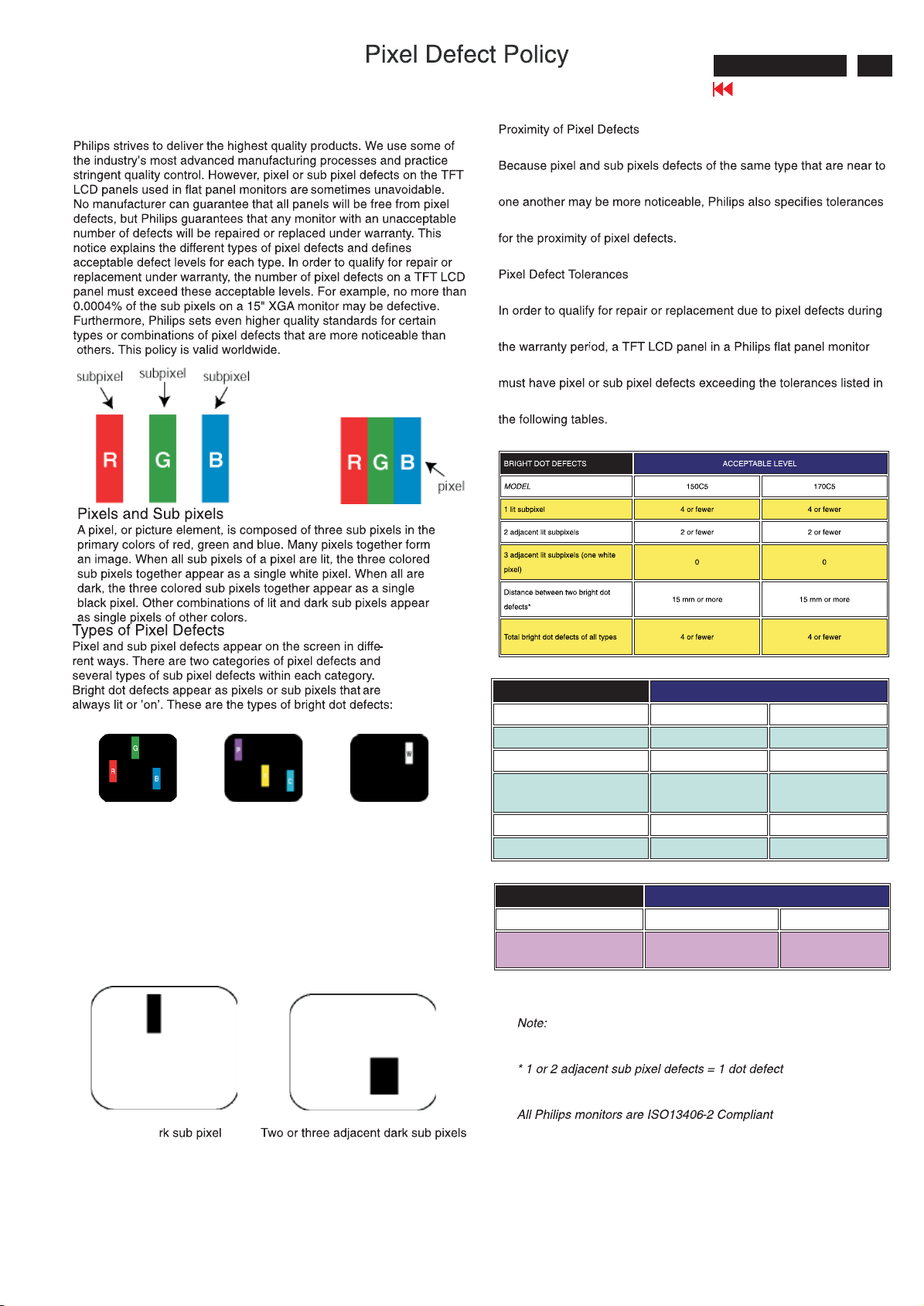

Philips' Flat Panel Monitors Pixel Defect Policy

170C5 LCD

Go to cover page

9

One lit red, green or blue sub pixel

Two adjacent lit sub pixels:

- Red + Blue = Purple

- Red + Green = Yellow

- Green + Blue = Cyan (Light Blue)

Three adjacent lit sub pixels (one

white pixel)

Black Dot Defects Black dot defects appear as pixels or sub pixels that

are always dark or 'off'. These are the types of black dot defects:

One da

BLACK DOT DEFECTS ACCEPTABLE LEVEL

MODEL 150C5 170C5

1 dark subpixel 4 or fewer 4 or fewer

2 adjacent dark subpixels 2 or fewer 2 or fewer

3 adjacent dark subpixels 0 0

Distance between two black dot defects * 15 mm or more 15 mm or more

Total black dot defects of all types 4 or fewer 4 or fewer

TOTAL DOT DE FECTS ACCEPTABLE LEVEL

MODEL 150C5 170C5

Total bright or black dot defects of all

types

5 or fewer 5 or fewer

10

170C5 LCD

Go to cover page

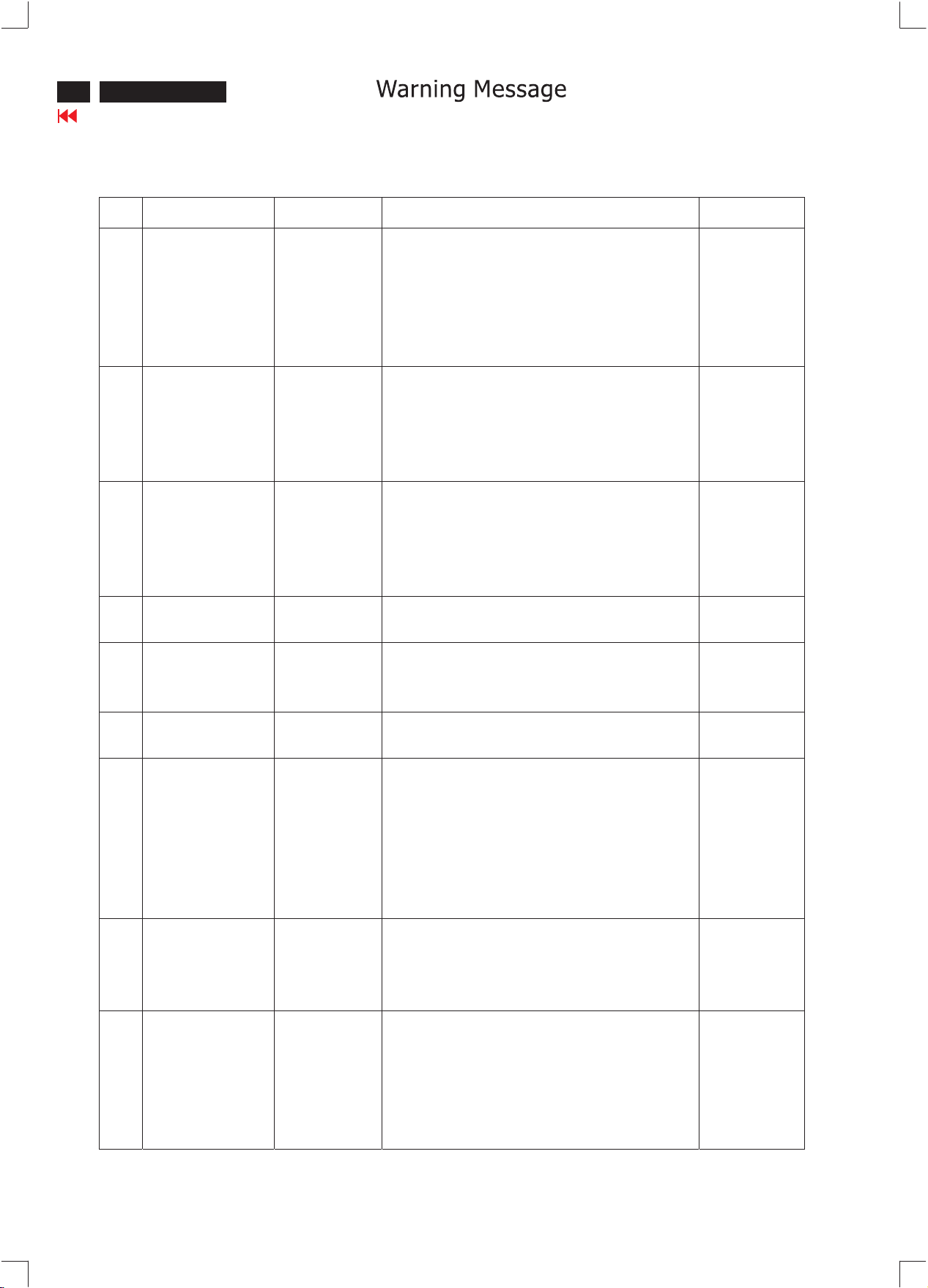

Warning Message Table

Item Attention Signals Display Time Condition Attention off

1 CANNOT DISPLAY

THIS VIDEO MODE,

CHANGE COMPUTER

DISPLAY

INPUT TO 1024X768

@60HZ

2 NO VIDEO INPUT 30 mins This message appears when there is no signal input but with

3 CHECK CABLE

CONNECTION

4 ENTERING SLEEP

MODE

5 WAITING FOR

AUTOMATIC

ADJUSTMENT

6 USE 1024 X 768 FOR

BEST RESULT

7 OSD MAIN CONTROLS

LOCKED

8 OSD MAIN CONTROLS

UNLOCKED

9 ATTENTION SIGNALON3secs This message will appear 3 seconds to indicate the attention

30 mins This warning appears when the input signal from your

computer is not in a standard video mode or is out of the

monitor’s scanning range. After 30 mins, monitor enters

sleeping mode.

cable while AC or DC while power on. After 30 mins, monitor

enters sleeping mode.

30 mins This message appears when a signal cable is disconnected

while monitor is working. After 30 mins, monitor enters

sleeping mode.

3secs This message appears when monitor is about to enter power

saving mode.

till auto adjustment

finished

On top of OSD

main menu

3 secs / or Till

"OSD MAIN

CONTROLS

UNLOCKED"

appear

3secs This message will appear 3 seconds to indicate the OSD

This message is displayed when the auto adjustment button

is pressed. It disappears when automatic adjustments are

completed.

The message will show up at the top of the OSD main menu

in red color when the input resolution is not the 1024x768.

This message will appear 3 seconds to indicate the OSD

MAIN CONTROLS status when to lock or un-lock it by

pressing “MENU(OK)”button for more than 10 seconds

while there is video input from PC. This function provides the

alternative that user can lock all the OSD main control in

case user don’t want the FOS performance setting to be

changed, for instance, during commercial exhibition.

MAIN CONTROLS status when to un-lock it by pressing

“MENU(OK)” button for more than 10 seconds while there is

video input from PC.

signals in ON or OFF status when to switch this function on

or off by pressing the AUTO button for more than 10

seconds while at no video input from PC.

No

Yes

Show floating

menu

“A T T E N T I O N

SIGNAL OFF”

Yes

Show floating

menu

“A T T E N T I O N

SIGNAL OFF”

No

No

Yes

No function when

push 10 secs (If

OSD lock then

attention off, not

any message and

only attention on)

No function when

push 10 secs

Yes

170C5 LCD

Go to cover page

11

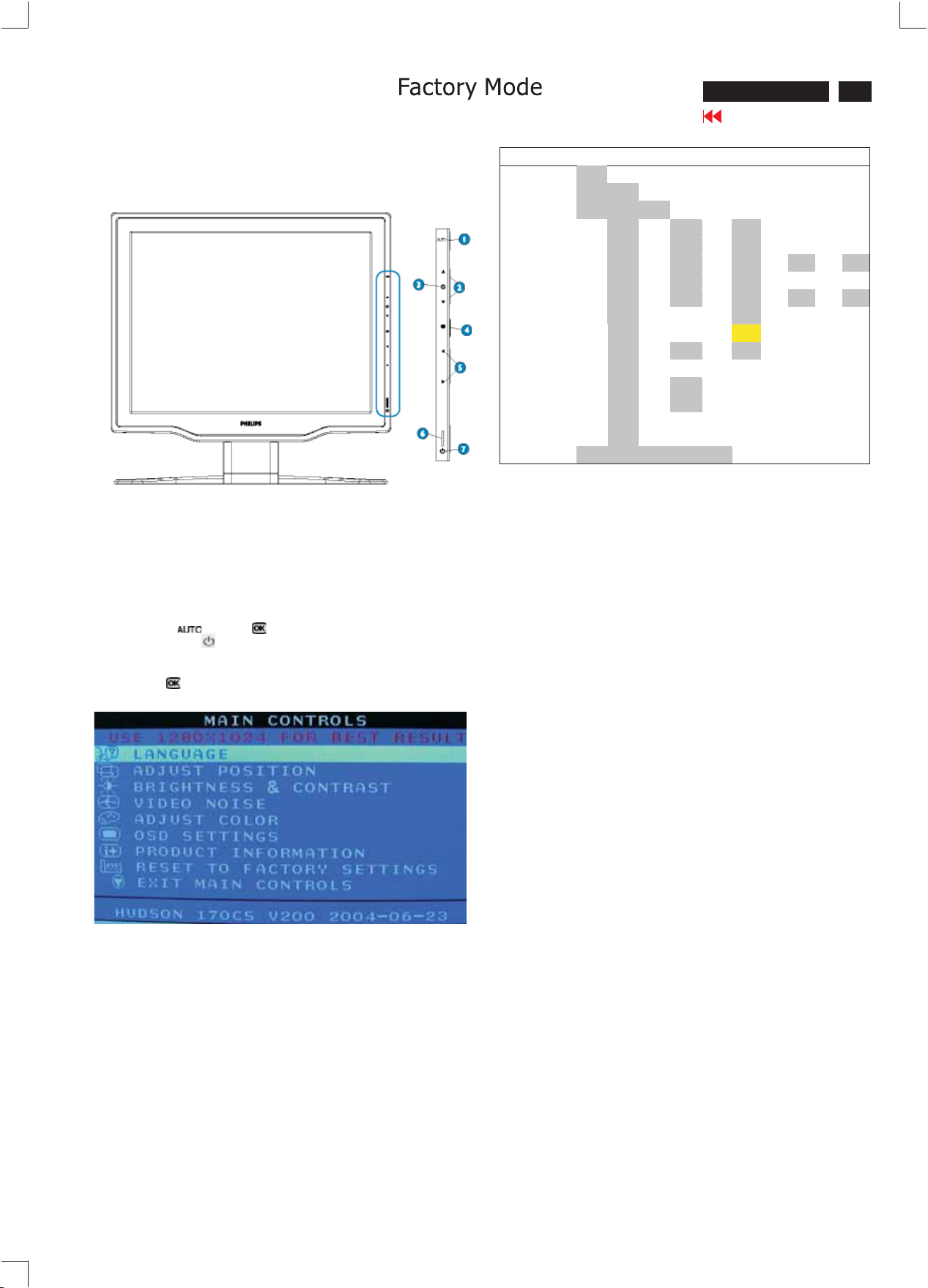

Front control panel

Access Factory Mode

How to get into Factory Mode Menu

Step1:

Turn off monitor.

Step2:

[Push AUTO " " & OK " " buttons at the same time and hold it]

+[Press power " " button untill comes out "Windows screen" ]

=> then release all buttons

Step3:

Press OK " " button, bring up Factory mode indication as shown

in Fig2.

Hudson 170C5 T024 2004 -01-06

BL :

SUB - BRI :

SUB - CON : 78 128 178

9300K R Xxx G xxx B xxx

6500K R Xxx G xxx B xxx

SRGB R Xxx G xxx B xxx B 255 C 128

OFFSET2 R Xxx G xxx B xxx

GAIN R Xxx G xxx B xxx M 255 m 0

AUTO-SUB OK! OSDTIMER 60

OFFSET1 R Xxx G xxx B xxx

SCALER:ADD:

NVRAM:ADD:

PANEL:

0

0 255

IDX : 40

VAL: READ

VAL: READ

LG

17

1024x768 48.3KHz @60Hz

WRITE

WRITE

BL blacklevel value

SUB-BRI : Brightness value range(Min Max)

SUB-C ONContrast value range(Min Mid Max)

SRGB-B : Brightness of sRGB

SRGB-C : Contrast of sRGB

Gain-m : Minimum value of User Gain

Gain-M: Maximum value of User Gain

AUTO-SUB: To d o Auto color function when push

Menu key in white pattern

OSDTIMER :OSD time out control(sec)

IDX : Limit current of inverter

SCA LER : Read/Write scaler register

Panel : HS (Hannstar panel)

CPT (CPT panel

)

LG (LG.Philips panel)

AU

QDI (Quanta Display Inc.)

DEFAULT

12

170C5 LCD

Go to cover page

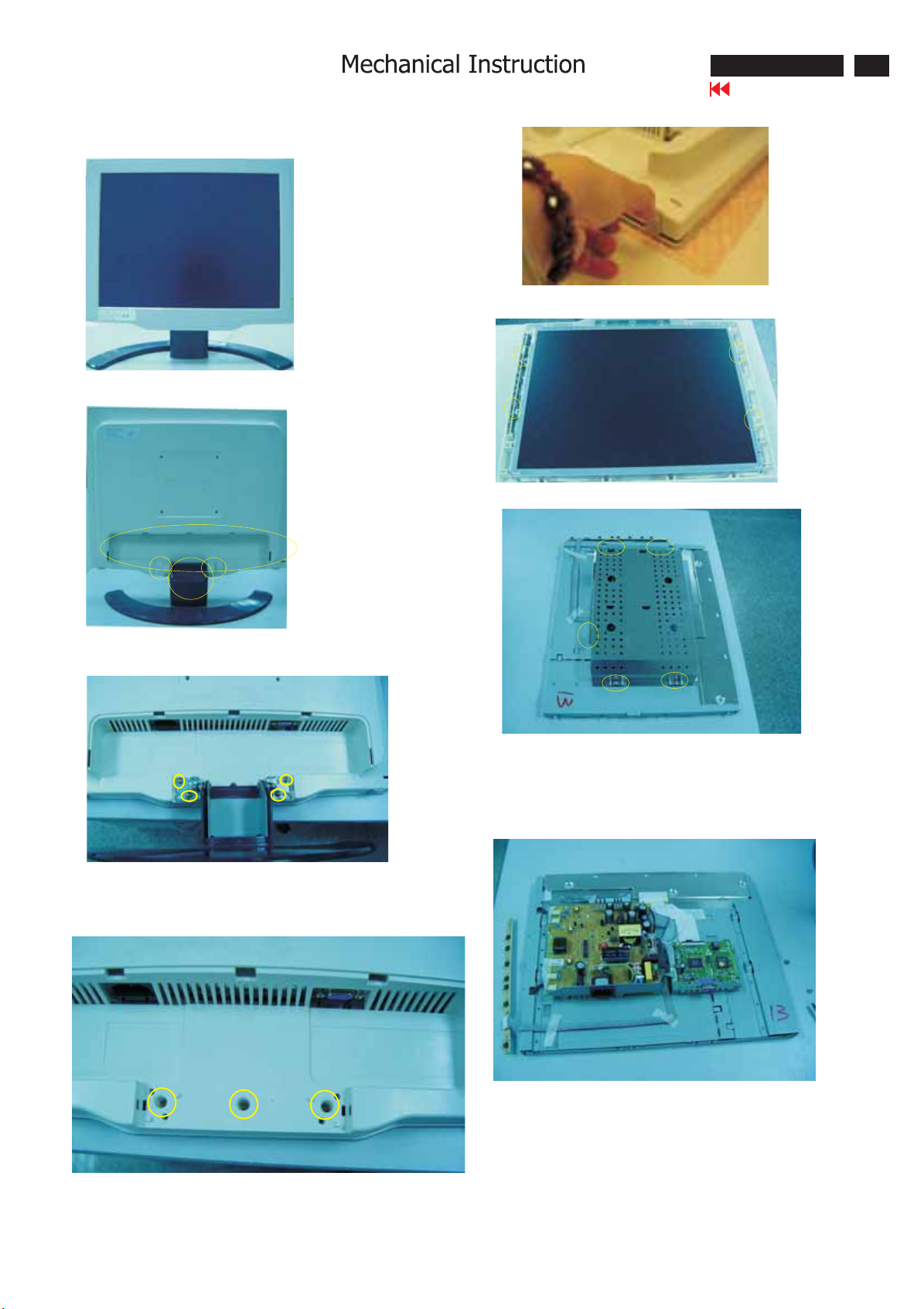

Front view

Back view, remove the cover as Fig.2

Fig.1

Fig.2

170C5 LCD

Go to cover page

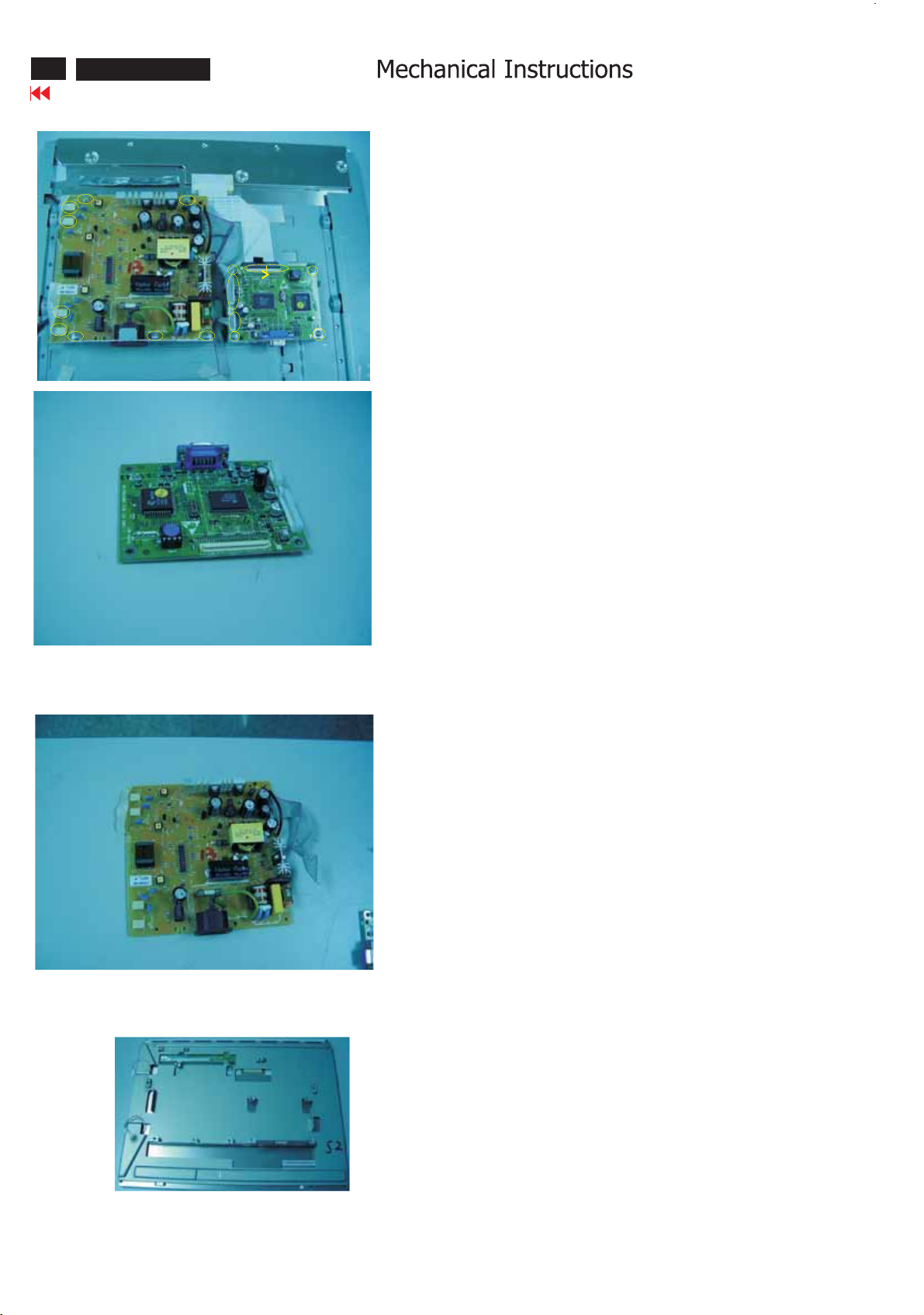

Fig.5

Open the clicks and then remove the back cover as Fig.6 and Fig.7

Fig.6

13

Remove the base:

unscrew the screws as Fig.3

Remove the front cover,

unscrew the screws as Fig.4 and the open the

clickasFig,5

Fig.3

Fig.7

Remove the Matel frame board

- Remove the four screws and

-Disconnect D-SUBhexagonal screws as shown in Fig7

- Remove the matel frame board as shown in Fig.8

Fig.8

Fig.4

Remove the power and scaler board

unscrew the screws and disconnect the connector as shown in Fig.9

14

170C5 LCD

Go to cover page

Fig.9

Fig.10

Fig.12

Fig.11

170C5 LCD

15

Go to cover page

.

"

"

16

170C5 LCD

Go to cover page

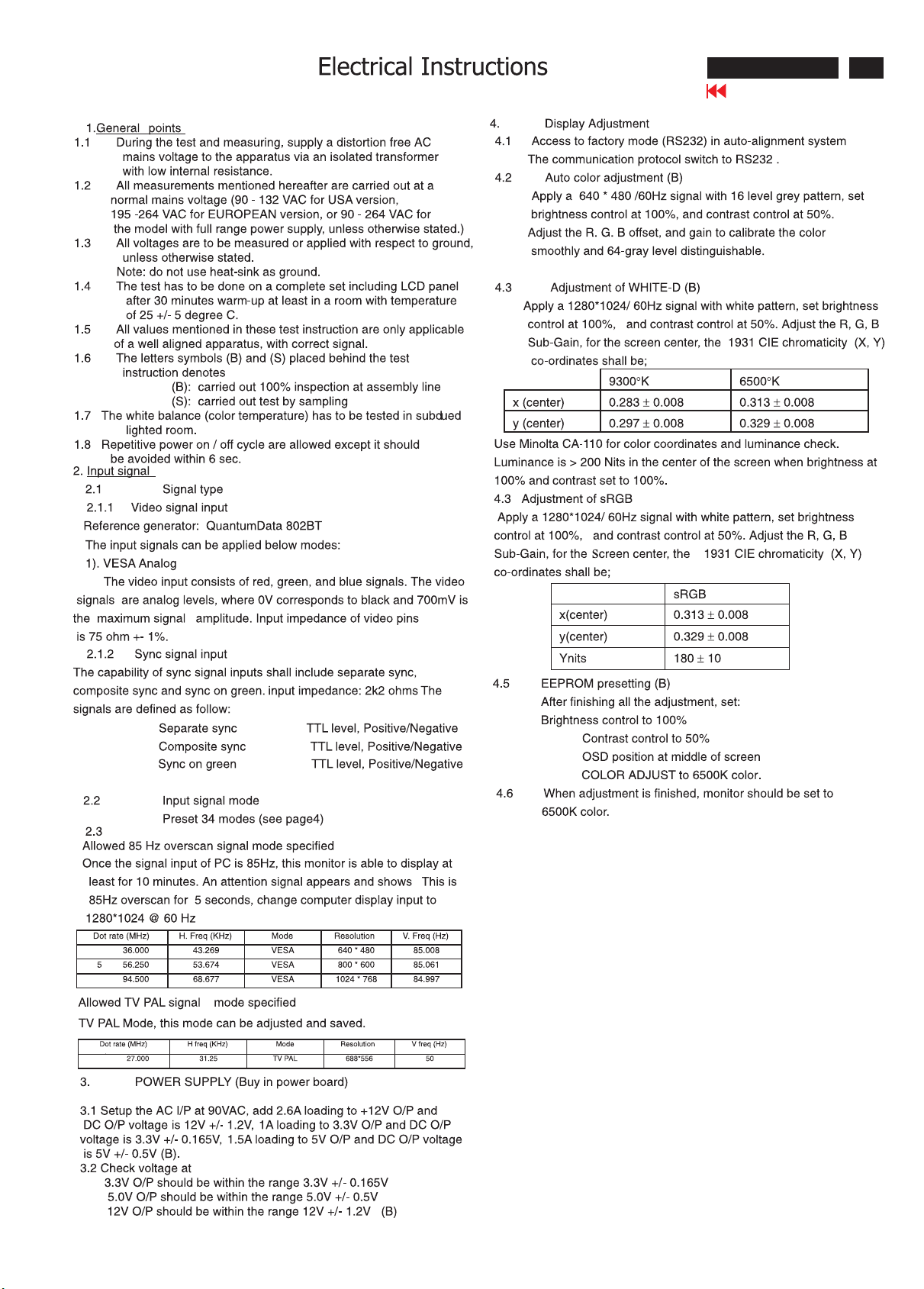

General

DDC Data Re-programming

In case the DDC data memory IC or main EEPROM which storage all

factory settings were replaced due to a defect, the serial numbers have

to be re-programmed" ".

It is advised to re-soldered DDC IC and main EEPROM from the old

board onto the new board if circuit board have been replaced, in this

case the DDC data does not need to be re-programmed.

Additional information

Additional information about DDC (Display Data Channel) may be

obtained from Video Electronics Standards Association (VESA). Extended

Display Identification Data(EDID) information may be also obtained from

VESA.

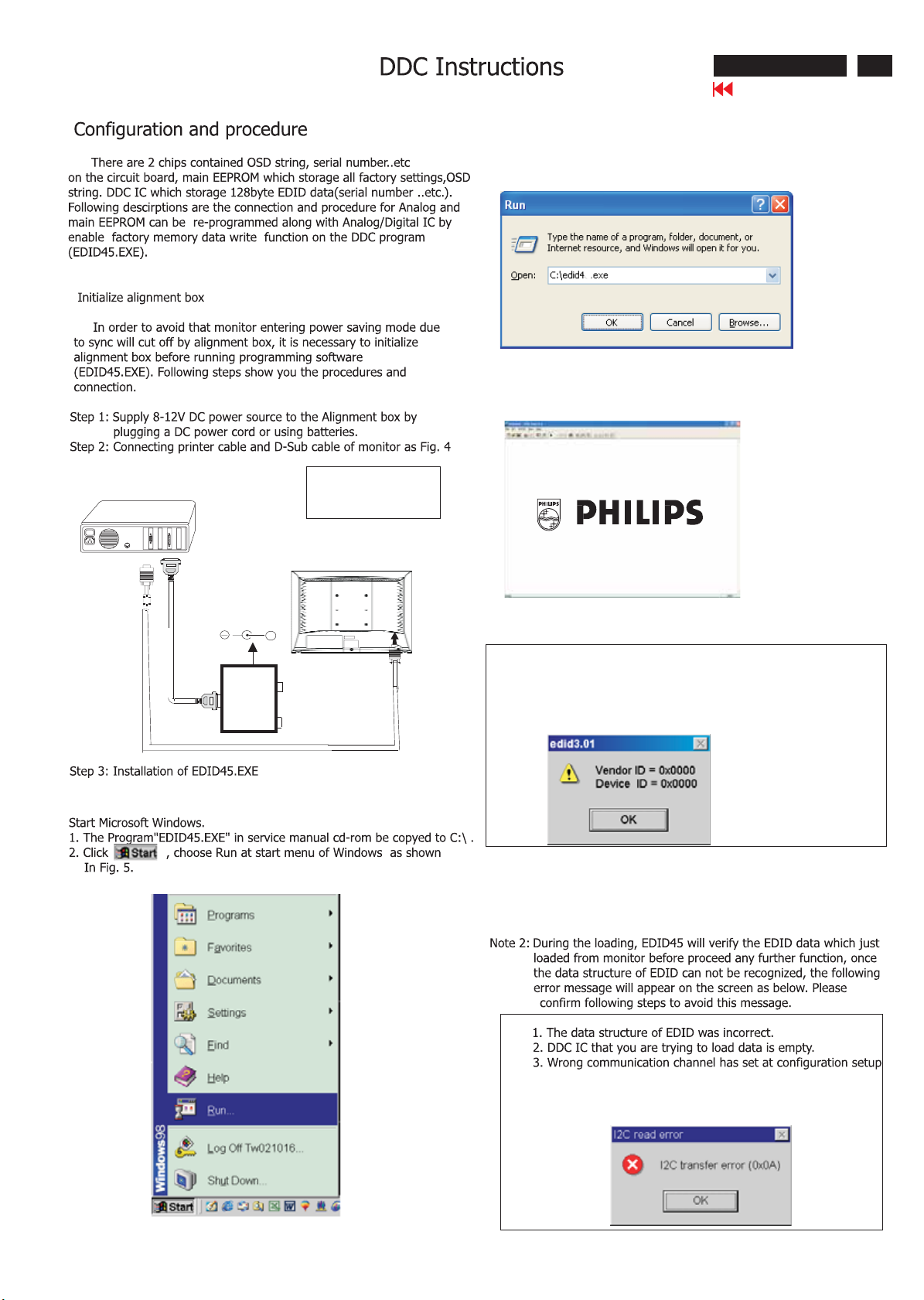

Analog DDC IC, & EEPROM

System and equipment requirements

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98 .

Y o Install the EDID_PORT_Tool under Win2000/XP . As

ou have t

Fig. 1 .

Fig. 1Fig. 1

Note: The alignment box has already build-in a batteries socket for

DC 8~12V

Power

indicator

batteries (8~12V)

using as power source. Pull out the socket by

remove four screws at the rear of box. Please do not forget that

remove batteries after programming. The energy of batteries can

only drive circuits for a short period of time.

To Printer port

To Monitor

D-sub cable

Fig. 3Fig. 3

A. Cody the "UserPort.sys" to C:\WINNT\system32\drivers(win2000)

C:\WINDOWS\system32\drivers(winXP)

B. Running " io.exe" everytime, Before you start to programming

edid data .

3. EDID45.EXE program .

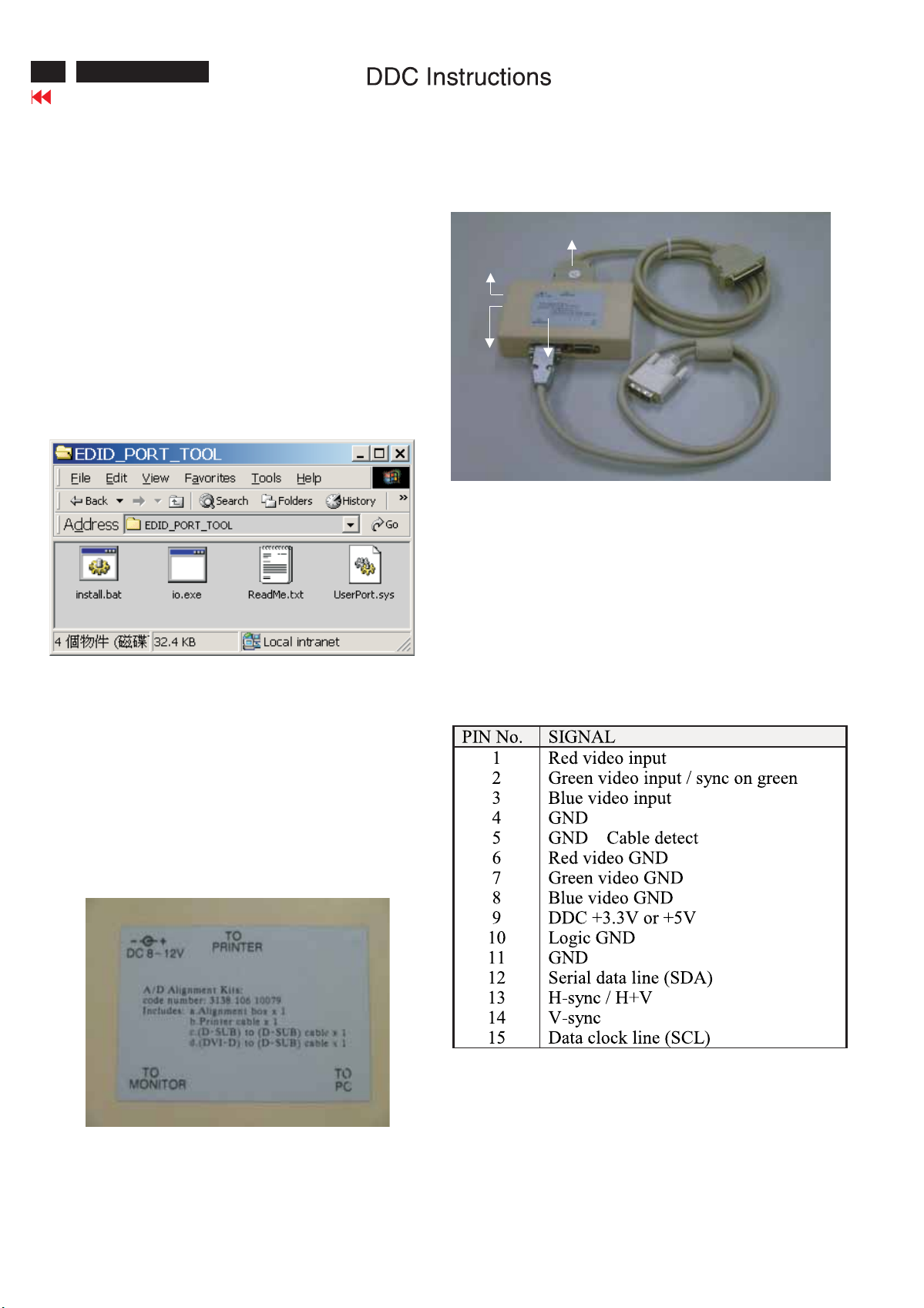

4. A/D Alignment kits (3138 106 10079):

inclusion : a. Alignment box x1 (as Fig. 2)

Fig. 2Fig. 2

Pin assignment

A. 15-pin D-Sub Connector

-

b. Printer cable x1

c. (D-Sub) to (D-Sub) cable x1

170C5 LCD

Go to cover page

3. At the submenu, type the letter of your computer's hard disk drive

followed by :EDID45 (for example, C:\EDID45, as shown in Fig. 6).

5

Fig. 6

4. Click button. The main menu appears (as shown in Fig. 7).OK

This is for initialize alignment box.

17

PC

DC Power

8-12 V

Fig. 4

To printer port (LTP1)

Printer

Port

Method 1: Start on DDC program

1=Power connector

2=D-SUB connector

+

To

Monitor

To P C

1

TO VIDEO CARD

----->

----->

2

Fig. 7

Note 1: If the connection is improper, you will see the following error

message (as shown in Fig. 8) before entering the main menu.

Meanwhile, the (read EDID) function will be disable. At this

time,

please make sure all cables are connected correctly and

Fig. 8

1

Fig. 5

Fig. 9

18

170C5 LCD

Go to cover page

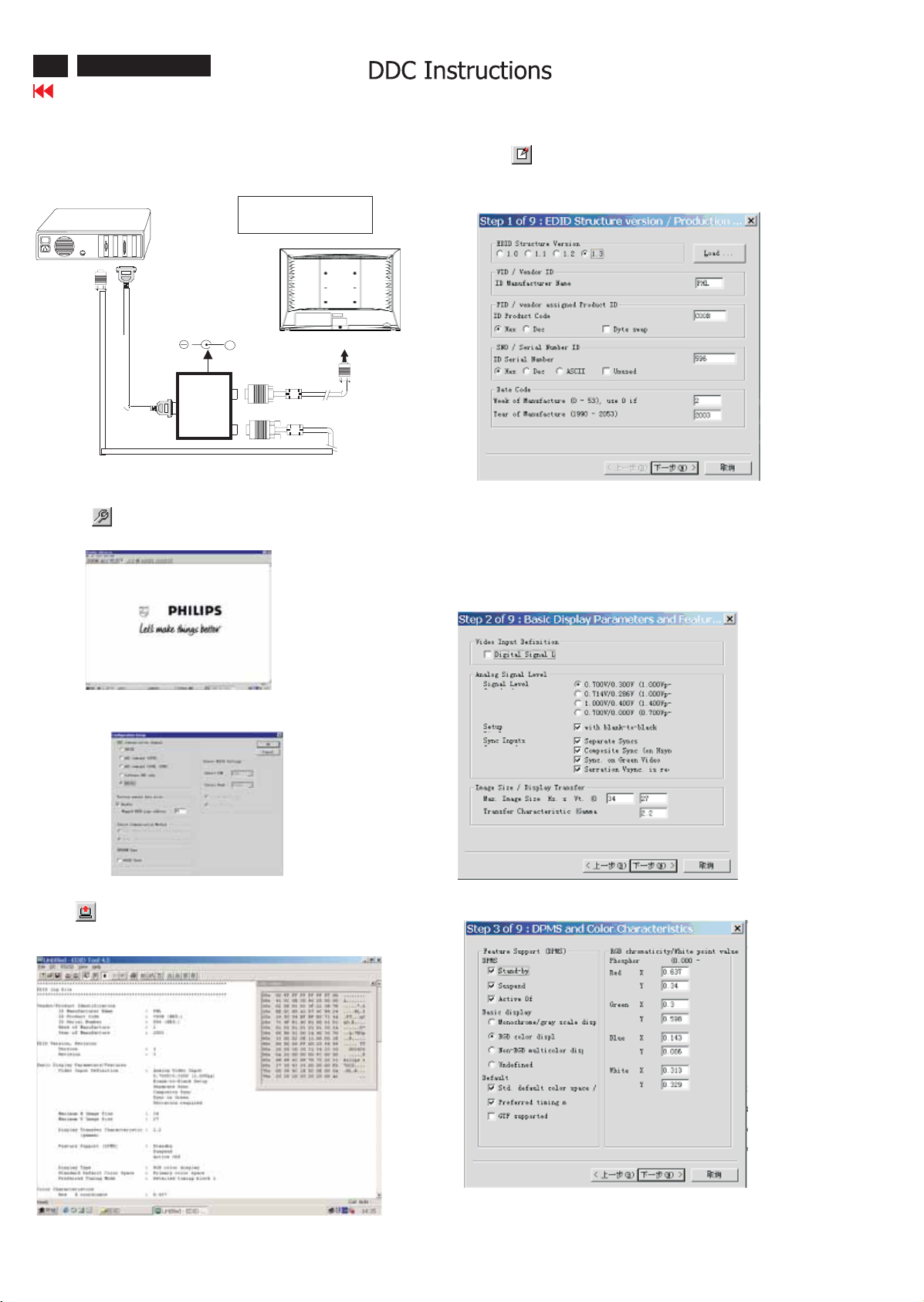

Re-programming Analog DDC IC

Step 1: After initialize alignment box, connecting all cables and

box as shown in Fig. 10

PC

DC Power

8-12V

To printer port (LTP1)

Printer

Port

To PC Video port (D-sub)

Step 2: Read DDC data from monitor

1. Click icon as shown in Fig. 11 from the tool bar to bring up

the Channels "Configuration Setup" windows as shown in Fig. 12.

1=Power connector

2=D-SUB connector

+

To

Monitor

To P C

1

2

----->

----->

Fig. 10

Step 3: Modify DDC data (verify EDID version, week, year)

1. Click (new function) icon from the tool bar, bring up

Step1of9asshowninFig.14.

EDID45 DDC application provides the function selection and

text change (select & fill out) from Step 1 to Step 9.

Fig. 14

Step 4: Modify DDC data (Monitor Serial No.)

Next1. Click , bring up Fig. 15.

Fig. 11

2. Select the DDC2Bi as the communication channel.

As shown in Fig. 12.

Fig. 12

3. Click OK button to confirm your selection.

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig. 13.

Fig. 15

2. Click , bring up Fig. 16.Next

Fig. 13

Don't close this screen. --->

Fig. 16

170C5 LCD

Go to cover page

19

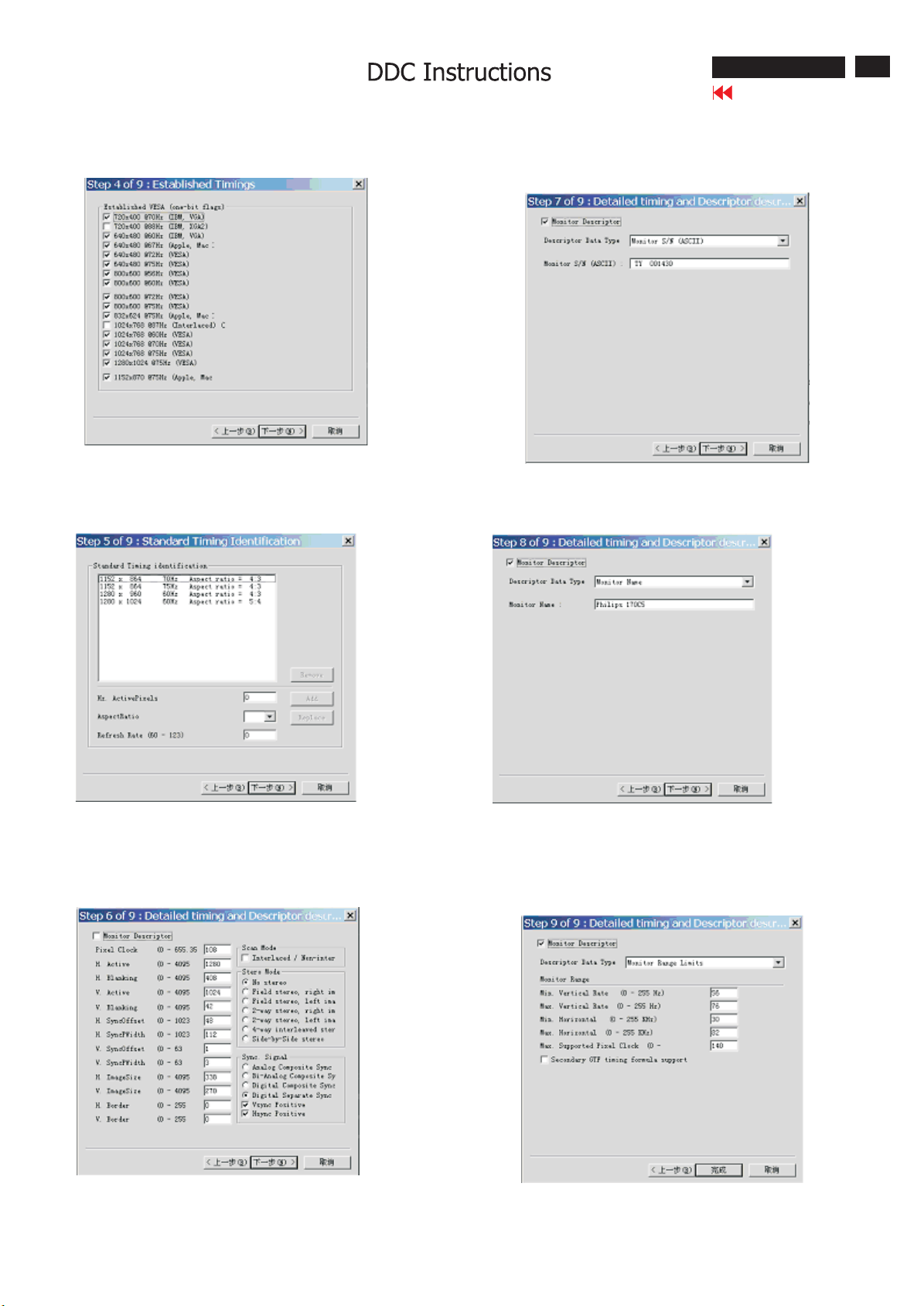

3. Click , bring up Fig. 17.Next

4. Click , bring up Fig. 18.Next

6. Click , bring up Fig. 20.Next

- Serial number can be filled up or be changed at this moment.

Fig. 17

Fig. 20

7. Click , bring up Fig. 21.Next

5. Click , bring up Fig. 19.Next

Fig. 18

Fig. 19

Fig. 21

8. Click , bring up Fig. 20.Next

Fig. 22

20

170C5 LCD

Go to cover page

21

X

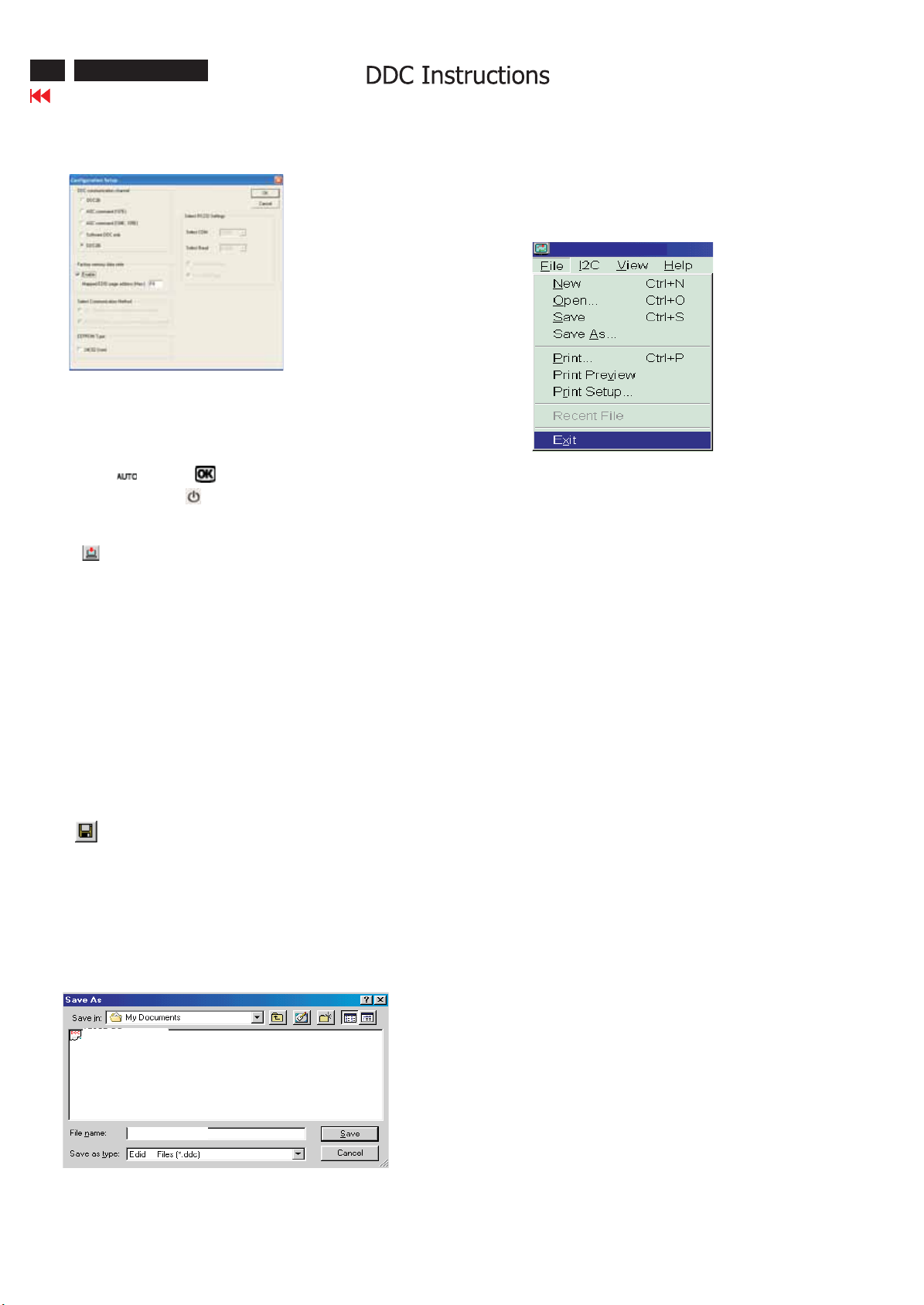

Step 5: Write DDC data

1. Configuration should be as Fig. 23. And press OK.

Fig. 23

2. Access Factory Mode

Step1:

Turn off monitor.

Step2:

[Push AUTO " " & OK " " buttons at the same time and

hold it ] + [Press power " " button untill comes out "Windows

screen"

3. Click (Write EDID) icon from the tool bar to write DDC data.

Bring up "Writing 0%~100%, ready" a progressing bar on the left

down corner.

4. Turn off/on monitor

Step 7: Exit DDC program

Pull down the File menu and select Exit as shown in Fig. 25.

Fig. 25

5. Press the OK button to bring up the OSD main manu.

6. Press the DOWN button to select PRODUCTION INFORMATION

press the OK button to confirm our selection.

7. Re-confirm the serial Number is updated.

Step 6: Save DDC data

Sometimes, you may need to save DDC data as a text file for using

in other IC chip. To save DDC data, follow the steps below:

1. Click (Save) icon (or click "file"-> "save as") from the tool bar

And give a file name as shown in Fig. 24.

The file type is EDID45 file (*.ddc) which can be open in WordPad.

By using WordPad, the texts of DDC data & table (128 bytes, hex

code) can be modified. If DDC TEXTS & HEX Table are completely

correct, it can be saved as .ddc flie to re-load it into DDC IC for DDC

Data application.

150S5-DDC

170C5-DDC

2. Click .Save

C:\My documents\170C5-DDC

45

Fig. 24

Loading...

Loading...