TV-VCR Combination

Service

Service

14PV120

14PV125

14PV225

/07

/01/07/39/58

/01/07/39/58

Service

14PV422

14PV425

/01/07/39/58

/07

Service Manual

Contents

Chapter

Adjustment Procedure

Sec. 1:

Schematic Diagrams and CBA's

Exploded Views

Mechanical and Electrical Parts Lists

Survey of versions:

/01 PAL-BG, EURO

/07 PAL I, UK/IRELAND

/39 PAL/SECAM-BG+PAL/SECAM-L/L',FRANCE

/58 PAL-BG/DK+SECAM-BG/DK,EAST-EURO

Sec. 2:

Standard Maintenance

Mechanism Alignment Procedures

Disassembly / Assembly of Mechanism

Deck Exploded Views

For technical data reference is made to the Service Manual of

14PV374/01/07/39/58 & 14PV375/01/07/39/58 3103 785 22220.

The present Manual states only the differences.

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified

be used.

Published by BK 2003 Video Service Department Printed in Japan c

Copyright reserved Subject to modification GB 3103 785 22230

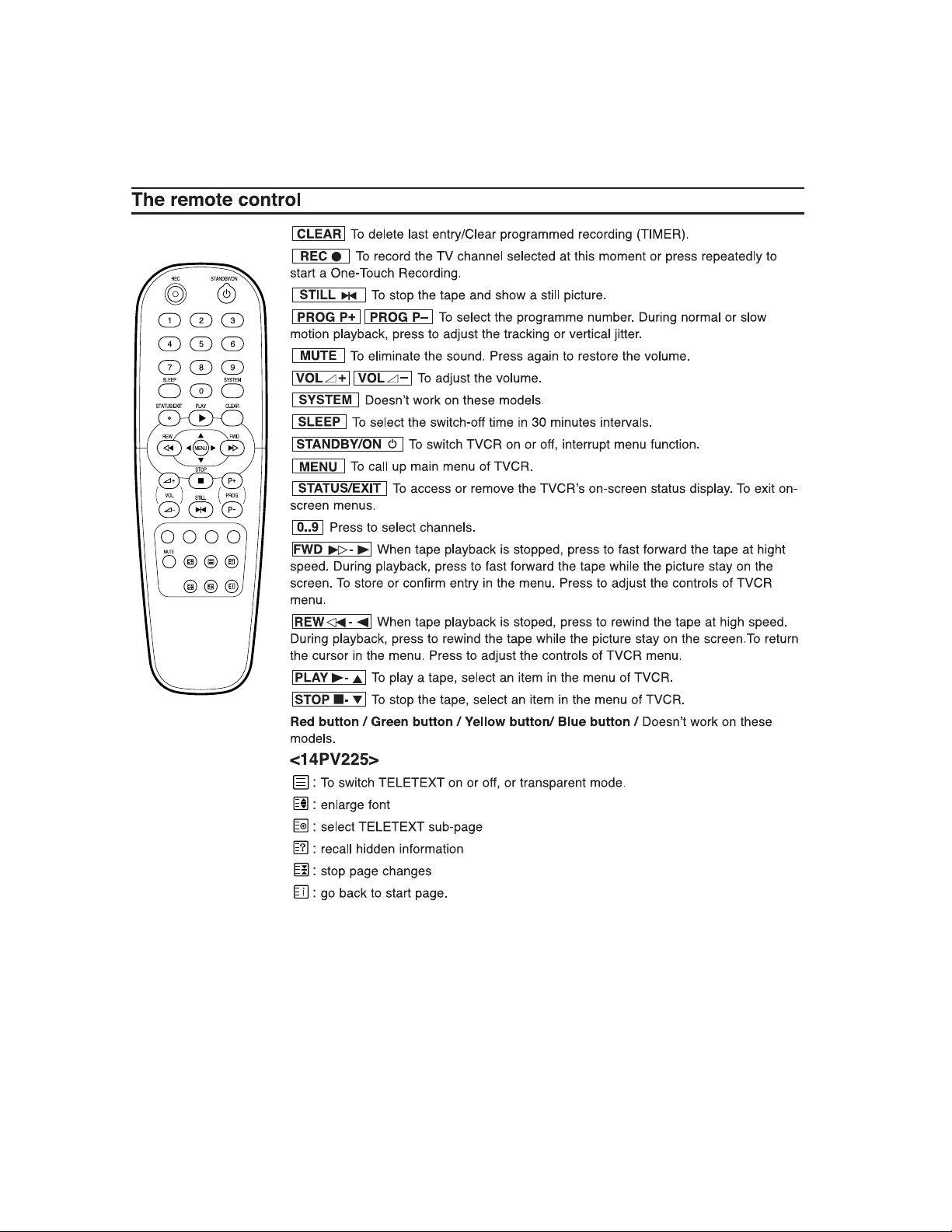

OPERATING CONTROLS AND FUNCTIONS

[ 14PV120/07, 14PV125/ ( 01, 07, 39, 58 ), 14PV225/ ( 01, 07, 39, 58 ),

14PV422/ ( 01, 07, 39, 58 ), 14PV425/07 ]

1-4-3 T6410IB

1-4-4 T6410IB

[

14PV120/07, 14PV125/ (01, 07, 39, 58), 14PV225/ (01, 07, 39, 58),

14PV422/ ( 01, 07, 39, 58 ), 14PV425/07 ]

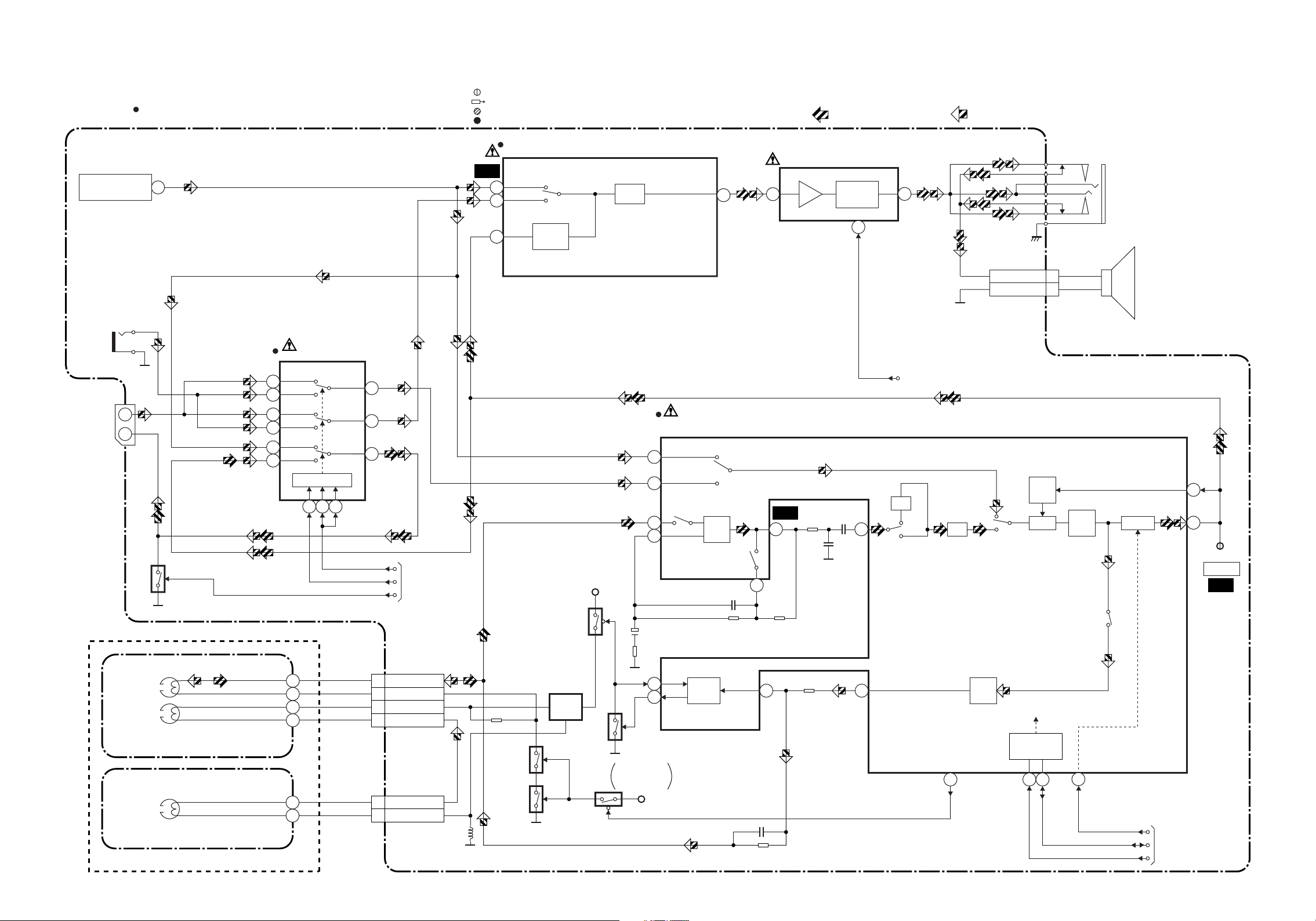

Servo/System Control Block Diagram

(DECK ASSEMBLY)

AC HEAD ASSEMBLY

CL402

CONTROL

HEAD

CYLINDER ASSEMBLY

PG

SENSOR

DRUM

MOTOR

M

LOADING

MOTOR

M

2CTL(+)

1CTL(-)

MAIN CBA

Q202 Q205Q201

ST-SENS.

SENSOR CBA

(ST-SENSOR)

CAPSTAN MOTOR

CAPSTAN

MOTOR

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

END-SENS.

SENSOR CBA

(END-SENSOR)

M

C-CONT

D-PFG

BLOCK DIAGRAMS

TIMER+5V

CN201

1CM+12V

2P-ON+5V(3)

3C-FG

4C-F/R

5

6FG-GND

7LD-CONT

8D-CONT

9

10M-GND

11AL+12V(1)

12VG

D201

S-LED

T-REEL

TEST POINT INFORMATION

AL+5V

RS201

WF3

CTL

SW212

LD-SW

Q204

RESET

CM+12V

P-ON+5V(3)

AL+12V(1)

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

REMOTE

SENSOR

TP001

AL+5V

+33V

IC201

(SERVO/SYSTEM CONTROL)

KEY-1

REMOTE

14

CTL AMP-OUT

97

95

CTL(+)

CTL(-)

94

LD-SW9

10

ST-SENS.

4

END-SENS.

T-REEL

80

34

RESET

C-FG

87

C-F/R

78

C-CONT

76

81

LD-CONT

77

D-CONT

90

D-PFG

KEY-2

REC LED

REC LED

P-ON-H

P-DOWN-L

I2C-OPEN

SP-MUTE

A-MUTE-H

EXT-L

SCART-H

SCART-MUTE

REC-SAFETY

D-REC-H

C-SYNC

DV-SYNC

V-ENV

C-ROTA

RF-SW

P, T, X

TRICK-H

SECAM-H

SCL

SDA

23

24

67

85

71

72

45

44

20

42

48

29

31

47

74

13

15

18

33

32

Comparison Chart of

Models & Marks

Model Mark

14PV225/07

14PV225/01

14PV225/58

14PV225/39

14PV422/07

SW201 SW205

7

8

D202 REC

D204 STANDBY

SW211

REC

SAFETY

6

KEY SWITCH

SW206 SW210

KEY SWITCH

AL+5V

P-ON-H

P-DOWN-L

IC202

6

SCL

5

SDA

7

CS

I2C-OPEN

SP-MUTE

A-MUTE-H

SCART-H

SCART-MUTE

D-REC-H

C-SYNC

DV-SYNC

V-ENV

C-ROTA

RF-SW

TRICK-H

SECAM-H

(MEMORY)

SCL

SDA

SCL

SDA

EXT-L

SCL

SDA

14PV422/01

14PV422/58

14PV422/39

14PV125/07

14PV125/01

14PV125/58

14PV125/39

14PV125/39

14PV120/07

14PV425/07

FROM/TO POWER

SUPPLY BLOCK

FROM/TO CHROMA

BLOCK

FROM/TO AUDIO

BLOCK

FROM/TO VIDEO

BLOCK

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

1-7-15 1-7-16 T6410BLS

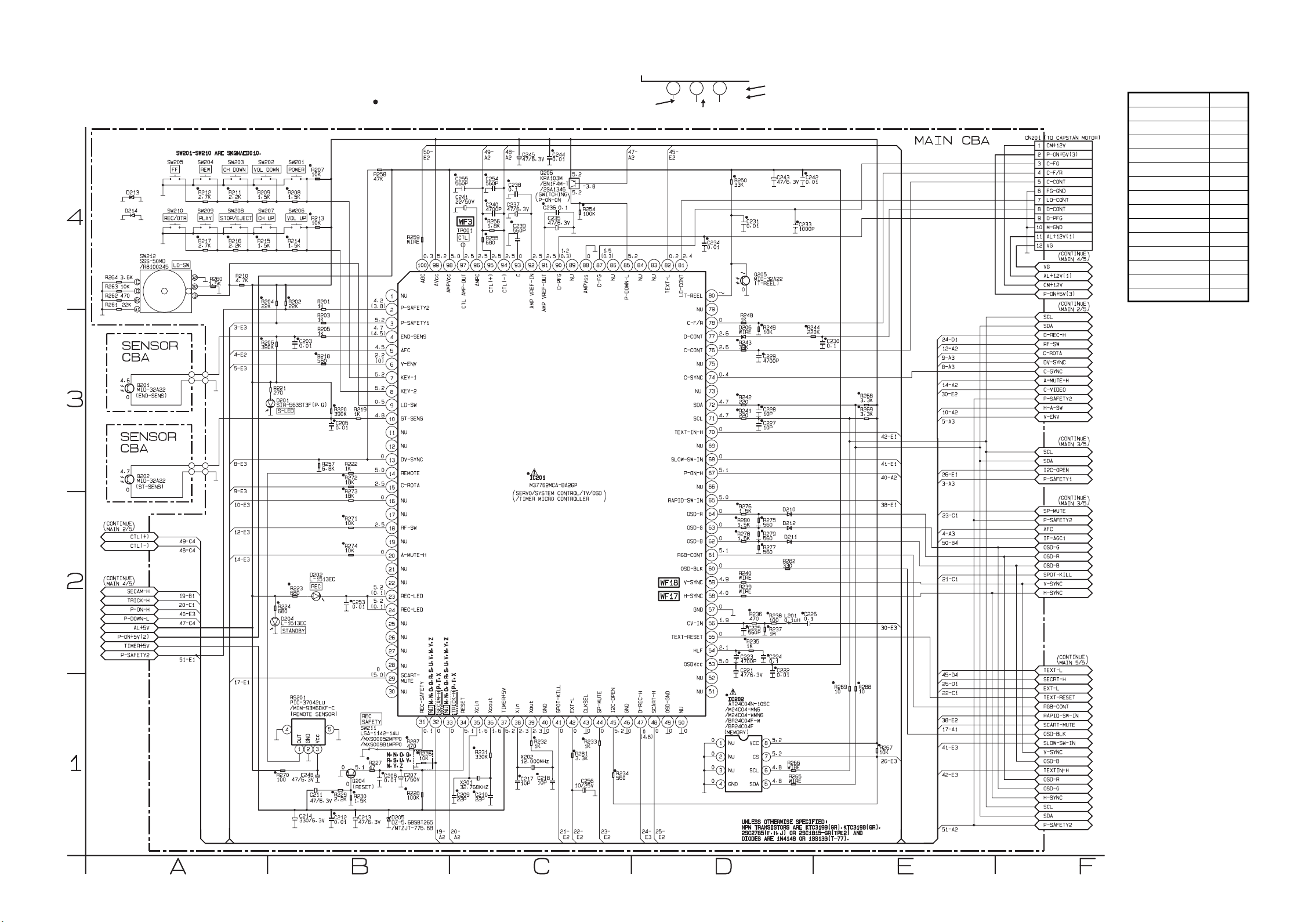

Video Block Diagram

" " = SMD

MAIN CBA

TO CHROMA BLOCK

TU001

VIDEO OUT

24

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

C-VIDEO

IC401

(VIDEO/AUDIO SIGNAL PROCESS)

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

FROM /TO

SERVO/SYSTEM

CONTROL BLOCK

65

SDA

SCL

REC-VIDEO SIGNAL PB-VIDEO SIGNAL MODE: SP/REC

69684643

7978

Comparison Chart of

Models & Marks

Model Mark

14PV225/07

14PV225/01

14PV225/58

14PV225/39

14PV422/07

14PV422/01

14PV422/58

14PV422/39

14PV125/07

14PV125/01

14PV125/58

14PV125/3914PV125/39

14PV120/07

14PV425/07

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

JK701

V-IN

JK703

V-IN

20

V-OUT

19

TO CHROMA

BLOCK

BUFFER

Q703

TU1-VIDEO

VIDEO

Q705

BUFFER

WF5

TP003

V-OUT

Q401

BUFFER

WF4

48

52

54

56

61

63

TUNER1

SCART

PB/EE

TUNER

PB/EE

MUTE

LINE

SCART

LINE

MUTE

BYPASS

AGC

CHARA.

INS.

1/2

FBC

PR

AGC VXO

58 59

Y. DELAY

LUMINANCE

SIGNAL

PROCESS

Y/C

MIX

SERIAL

DECORDER

R

P

CCD 1H DELAY

Y

+

C

CHROMINANCE

SIGNAL

PROCESS

R P R P

2928 44

21

REC FM

AGC

PB-H OUT

SP

HEAD

AMP

D-REC-H

RF-SW/C-ROTA

D-V-SYNC

V-ENV

C-SYNC

96

95

93

94

80

70

62

84

67

WF1

TP002

RF-SW

(DECK ASSEMBLY)

CL401

V(R)

1

V-COM

V(L)

2

3

D-REC-H

RF-SW

C-ROTA

D-V-SYNC

V-ENV

C-SYNC

TRICK-H

SECAM-H

IC471 (PAL/SECAM DECTECOTR)

CYLINDER ASSEMBLY

FROM/TO SERVO/SYSTEM

CONTROL BLOCK

P, T, X

VIDEO (R)

HEAD

VIDEO (L)

HEAD

28

29

17

12

16

14

1

PAL/SECAM

2

DETECTOR

TP010

GND

X401

4.43MHz

WF2

TP008

C-PB

WF6

1-7-17 1-7-18 T6410BLV

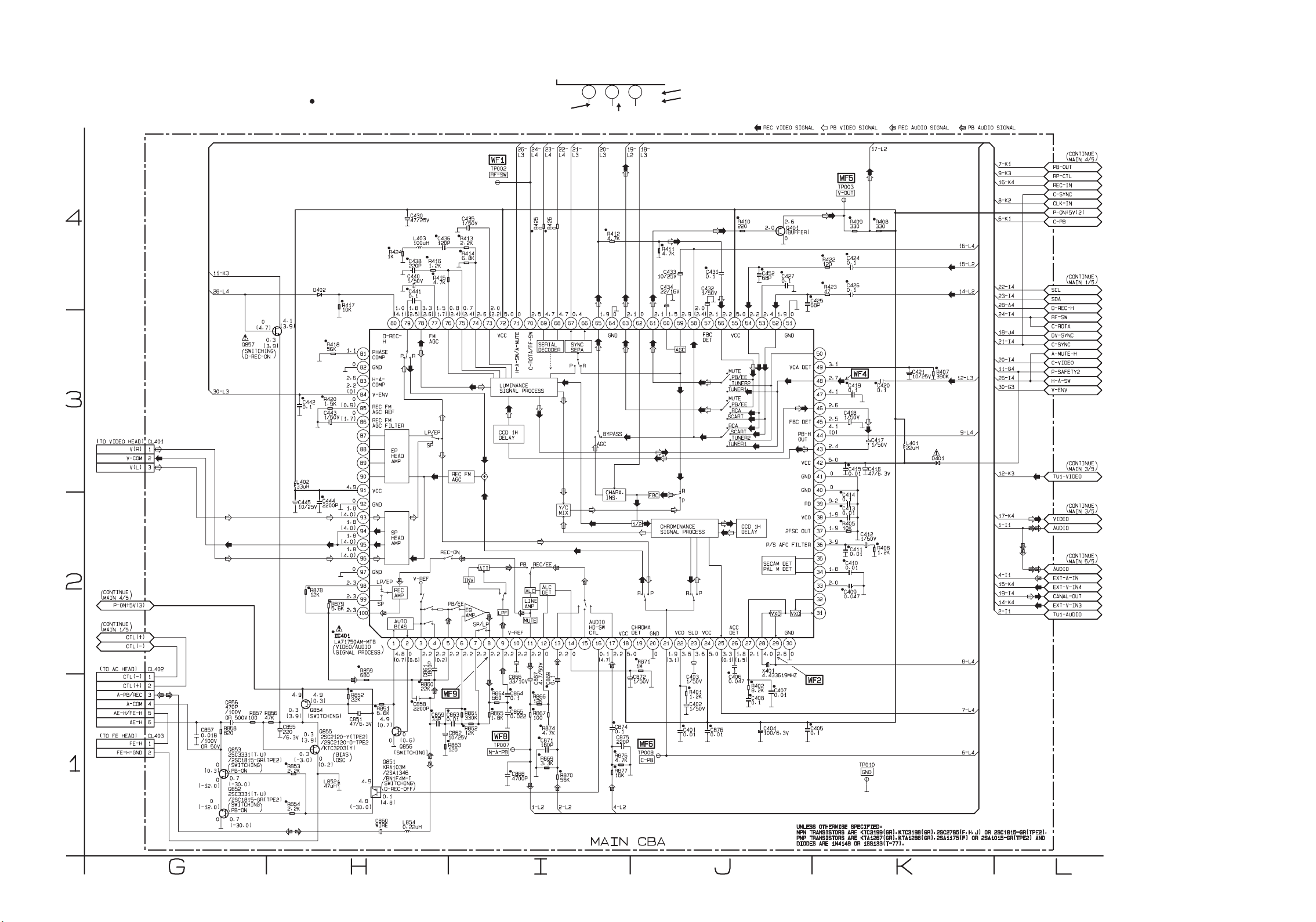

Audio Block Diagram

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

" " = SMD

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

PB-AUDIO SIGNAL REC-AUDIO SIGNAL Mode : SP/REC

TU001

AUDIO OUT

JK702

A-IN

A-IN

A-OUT

JK703

2

1

21

Q701

IC701 (SW)

1

2

5

3

13

12

SW CTL

1011 9

SCART-MUTE

15

4

14

SCART-H

EXT-L

FROM SERVO

/SYSTEM

CONTROL

BLOCK

WF7

52

53

54

(VIDEO/AUDIO/CHROMA/DEFLECTION/IF)

IC301

TUNER1

LINE

AUDIO

MUTE

+5V

ATT

50

IC401

(AUDIO SIGNAL PROCESS)

TUNER

13

LINE

17

PB-ON

5

6

EQ

AMP

SP/LP-ON

MAIN CBA

IC151 (AMP)

7

WF9

7

OUTPUT

AMP

MUTE

5

98

1

SP-MUTE

(FROM PIN 44 OF IC201)

INV

ATT

CN804

SP

SP-GND 1

R

P

ALC

DET

ALC

2

CL801

LINE

AMP

JK151

HEADPHONE JACK

SP151

SPEAKER

12

MUTE

11

TP007

A-OUT

WF8

(DECK ASSEMBLY)

AUDIO

HEAD

AUDIO

ERASE

HEAD

ACE HEAD ASSEMBLY

FULL

ERASE

HEAD

FE HEAD

REC-ON

71

A-MUTE-H

SDA

SCL

FROM/TO

SERVO/SYSTEM

CONTROL BLOCK

CL402

3 A-PB/REC

4 A-COM

6 AE-H

5 FE-H

CL403

1 FE-H

2 FE-H-GND

Q854

Q855

BIAS

OSC

Q856

Q853(PB=ON)

Q851

Q852(PB=ON)

1

2

SWITCHING

D-REC-OFF

+5V

AUTO

BIAS

3

100

REC

AMP

SERIAL

AUDIO HD-SW

DECODER

CONTROL

16

68 69

1-7-19 1-7-20 T6410BLA

Chroma Block Diagram

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

" " = SMD

M, N, O, P

IC901 (TELETEXT DECODER)

ADC/

DATA SLICER

DISPLAY

TIMING

I2C I/F

TELETEXT

DECODER

OSC/CLOCK

GENERATOR

TEXT CBA

FROM/TO

SERVO/SYSTEM

CONTROL BLOCK

I2C-OPEN

23

37

36

50

49

35

32

33

34

41

42

(NO CONNECTION)

CN303 is used for

adjustment at factory

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

X901

12MHz

OSC

SCL

SDA

CN901 CN751

5 5Y-SW-OUT

1 1V-SYNC

2 2H-SYNC

4 4SDA

3 3SCL

CN752CN902

2 2OSD-BLK

4 4OSD-B

6 6OSD-G

3 3OSD-R

CN303

INT.MONITOR

I2C-OPEN 2

SDA 4

SCL 5

1

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

Q706

Q702

+5V

Q711

Q704

IC301

40

10

11

43

REC VIDEO SIGNAL PB VIDEO SIGNAL

(VIDEO/AUDIO/CHROMA/DEFLECTION/IF)

SERIAL

I/F

INTELLIGENT

MONITORING

SYNC

SEPARATION

CHROMA

TRAP

CHROMA

BPF

LINE/PB

TUNER

LINE/PB

TUNER

CLOCK

CONTROL

CIRCUIT

Mode : SP/REC

MAIN CBA

34

36

X301

4.43MHz

32

Comparison Chart of

Models & Marks

Model Mark

14PV225/07

14PV225/01

14PV225/58

14PV225/39

14PV422/07

14PV422/01

14PV422/58

14PV422/39

14PV125/07

14PV125/01

14PV125/58

14PV125/39

14PV125/39

14PV120/07

14PV425/07

VIDEO

TU1-VIDEO

FROM

VIDEO BLOCK

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

SLOW-SW

RAPID-SW

FROM

VIDEO

BLOCK

OSD-B

OSD-G

OSD-R

C-VIDEO

JK703

8

16

7

11

15

IC201

(SYSTEM CONTROL/OSD)

56

C-VIDEO

TEXT-L

OSD-R

OSD-G

OSD-B

OSD-BLK

SLOW-SW-IN

RGB CONT

RAPID-SW-IN

WF18

V-SYNC

WF17

H-SYNC

82

64

63

62

60

68

61

65

59

58

IC703 (SW)

5

3

2

1

12

13

Q710

SW CTL

109 11

15

14

+5V

LUMA

SIGNAL

4

V-SYNC

PROCESS

CIRCUIT

H-SYNC

PROCESS

CIRCUIT

PROCESS

CIRCUIT

PAL

DECODER

BASE BAND

SECAM

DECODER

1H DELAY LINE

17

21

CL301A

27

20

28

OSD MIX/RBG MATRIX/

BLANKING

16

15

14

BLUE2

GREEN1

RED

3

TO

CRT/H.V. BLOCK

CL301B

30

WF10

13

12

WF11

6

7

31

INV

CL302A

FBP3

H-DRIVE2

ACL6

V-RAMP-FB5

V-DRIVE4

FROM/TO

CRT/H.V. BLOCK

CL302B

T6410BLC1-7-21 1-7-22

CRT/H.V. Block Diagram

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

" " = SMD

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

REC VIDEO SIGNAL PB VIDEO SIGNAL

Mode : SP/REC

FROM

POWER SUPPLY BLOCK

3

FROM/TO

CHROMA BLOCK

CL302A

3

6

5

4

H.V./POWER SUPPLY CBA

+B

DEF+B

JUNCTION-B

CBA

CN302CL302B

3 3FBP

2 2H-DRIVE

6 6ACL

5 5V-RAMP-FB

4 4V-DRIVE

CN552

Q533

H.DRIVE

WF12

Q551

H.OUTPUT

T552

1

5

3

4

T551 F.B.T.

10

IC551 (V-DEFLECTION CONTROL)

THERMAL

7

AMP

1

6

FOCUS VR

HV

F

S

11

8

7

9

6

SCREEN VR

PROTECTION

PUMP

UP

VCC

2

3

ANODE

FOCUS

SCREEN

HEATER 11

P-ON+160V 33

5

CL501BCL501A

WF13

CN551

L551

DEFLECTION-YOKE

5

4

3

1

VDRIVE

HDRIVE

ANODE

FROM CHROMA

BLOCK CL301A

CN301CL301B

2

4

3

JUNCTION-C

CBA

2 2RED

4 4GREEN

3 3BLUE

CN502

Q501

RED AMP

CRT CBA

Q502

GREEN AMP

JK501

FOCUS

WF15WF14

BLUE AMP

Q503

WF16

CN501

1-7-241-7-23

SCREEN

GND

R

G

B

HEATER

GND

T6410BLCRT

V501

CRT

Power Supply Block Diagram

W601

DG601

DEGAUSSING

COIL

CAUTION !

Fixed voltage power supply circuit is used in this unit.

If Main Fuse (F601) is blown, check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

SW601

POWER

CN601

F601

T4A/250V

PS602

L601,L602

LINE

FILTER

D601 - D604

BRIDGE

RECTIFIER

HOT COLD

T601

6

4

14

13

11

12

CAUTION

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAME TYPE T4A/250V FUSE.

TP503

+B

TP504

GND

+B

TO

CRT/H.V.

BLOCK

DEF+B

NOTE :

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

Q206

P-DOWN-L

(TO PIN85 OF IC201)

Q602

SWITCHING

Q603

LIMITER

2

1

4 1

3 2

IC601

ERROR

VOLTAGE DET

10

9

8

Q604

FEED

BACK

Q608

VR601

+B ADJ.

Q606Q605

+5V REG.

+8V REG.

Q607

CN602

AL+33V11

AL+9V8

AL+12V(2)7

AL+12V(1)3

4

P-DOWN-L

AL+5V

5

12

P-ON+8V

6

P-ON-L

CL603BCN603

11

8

7

3

4

5

12

6

JUNCTION-A CBA

11

12

8

7

3

4

5

6

CL603A

11

8

7

3

4

5

12

6

+5V

REG.

+5V

REG.

+5V

REG.

IC301

+5.7V

REG.

Q682

IC681

Q684

Q686

CM+12V

AL+33V

AL+9V

AL+12V(2)

AL+12V(1)

TIMER+5V

AL+5V

P-ON+8V

P-ON-H

(FROM PIN67 OF IC201)

P-ON+5V(2)

P-ON+5V(3)

P-ON+5V(1)

P-ON-ON

3955

1-7-25

H.V./POWER SUPPLY CBA

1-7-26

MAIN CBA

T6410BLP

[14PV120/07,14PV125/(01,07,39,57),14PV225/(01,07,39,57),14PV422/

(01,07,39,57),14PV425/07 ]

Main 1/5 Schematic Diagram Parts Location Guide

Ref No. Position Ref No. Position Ref No. Position Ref No. Position

CAPACITORS

C203

C205

C207

C208

C209

C210

C211

C212

C213

C214

C217

C218

C221

C222

C223

C224

C225

C226

C227

C228

C229

C230

C231

C233

C234

C235

C236

C237

C238

C239

C240

C241

C242

C243

C244

C245

C248

C253 B-2 R216 A-4 R264 A-4 RS201 B-1

C254

C255

C256 C-1 R219 B-3 R267 E-1

B-3

B-3

B-1

B-1

C-1

C-1

B-1

B-1

B-1

B-1

C-1

C-1

D-2

D-2

D-2

D-2

D-2

D-2

D-3

D-3

D-3

E-3 RESISTORS

D-4

D-4

D-4

C-4

C-4

C-4

C-4

C-4

C-4

C-4

D-4

D-4

C-4

C-4

B-1

C-4

C-4

CONNECTOR

CN201

DIODES

D201

D202

D204

D205

D206

D210

D211

D212

D213

D214

ICS

IC201

IC202

COIL

L201

TRANSISTORS

Q204

Q205

Q206

R201

R202

R203

R204

R205

R206

R207

R208

R209

R210

R211

R212

R213

R214

R215

R217

R218

F-5

B-3

B-2

B-2

B-1

D-3

D-2

D-2

D-2

A-4

A-4

C-3

D-1

D-2

B-1

D-4

C-4

B-4

B-4

B-3

B-4

B-3

B-3

B-4

B-4

A-4

A-4

A-4

A-4

B-4

B-4

A-4

A-4

B-3

RESISTORS RESISTORS

R220

R221

R222

R223

R224

R226

R227

R228

R229

R230

R231

R232

R233

R234

R235

R236

R237

R238

R239

R240

R241

R242

R243

R244

R248

R249

R250

R254

R255

R256

R257

R258

R259

R260

R261

R262

R263

R265

R266

B-3

B-3

B-3

B-2

B-2

B-1

B-1

B-1

B-1

B-1

C-1

C-1

C-1

C-1

D-2

D-2

D-2

D-2

D-2

D-2

D-3

D-3

D-3

D-3

D-3

D-3

D-3

C-4

C-4

C-4

B-3

B-4

B-4

A-4

A-4

A-4

A-4

D-1

D-1

R268

R269

R270

R271

R272

R273

R274

R275

R276

R277

R278

R279

R280

R281

R282

R287

R288

R289

SWITCH ES

SW201

SW202

SW203

SW204

SW205

SW206

SW207

SW208

SW209

SW210

SW211

SW212

TEST POINT

TP001

CRYSTAL OSCILATORS

X201

X202

MISCELLANEOU S

E-3

E-3

B-1

B-2

B-3

B-2

B-2

D-2

D-2

D-2

D-2

D-2

D-2

C-1

D-2

B-1

E-1

E-1

B-4

A-4

A-4

A-4

A-4

B-4

A-4

A-4

A-4

A-4

B-1

A-4

C-4

C-1

C-1

1-8-43

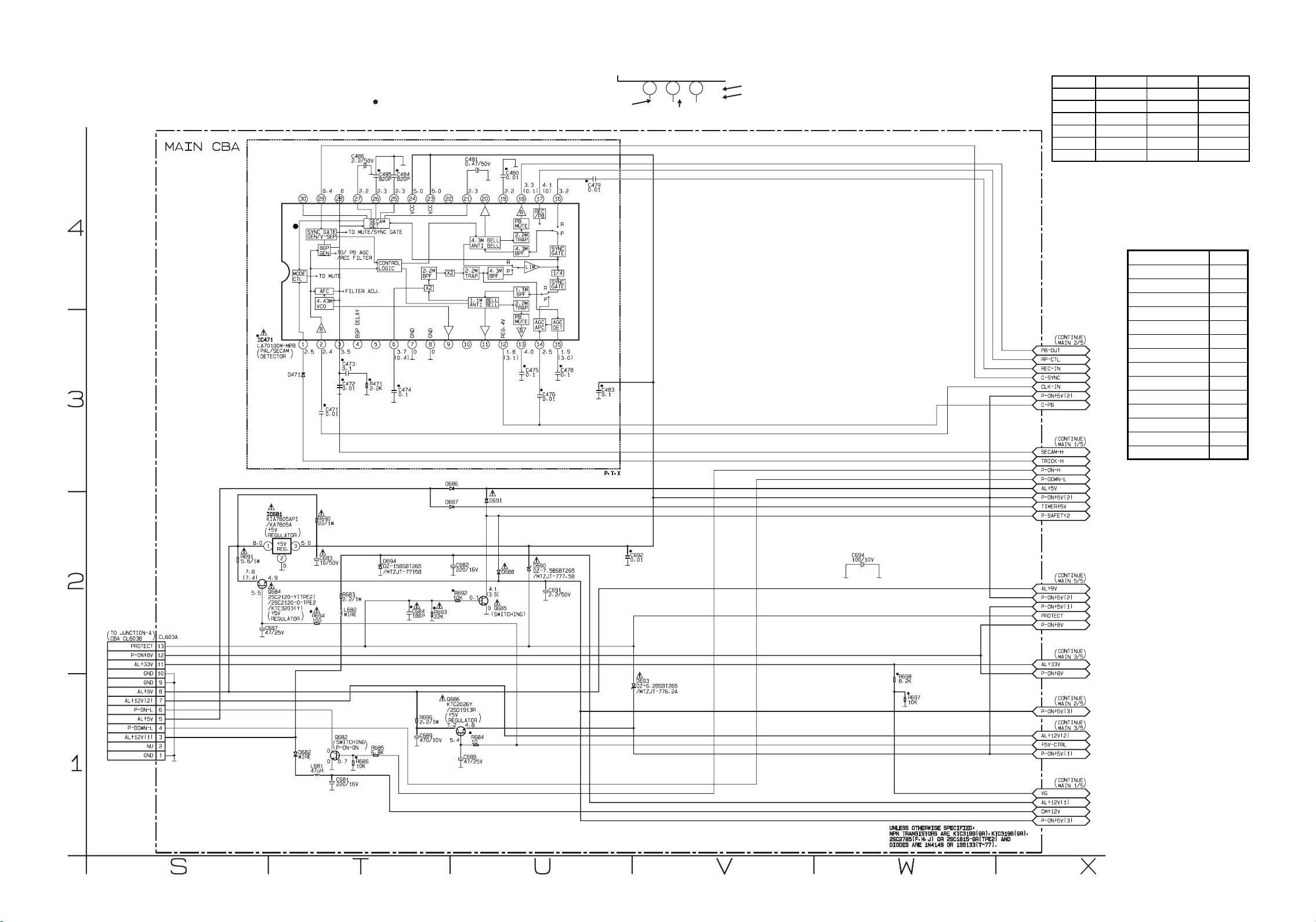

Main 1/5 Schematic Diagram

Comparison Chart of

MODEL MARK

14PV225/07 M

14PV225/01 N

14PV225/58 O

14PV225/39 P

14PV422/07 Q

14PV422/01 R

14PV422/58 S

14PV422/39 T

14PV125/07 U

14PV125/01 V

14PV125/58 W

14PV125/39 X

14PV120/07 Y

14PV425/07 Z

“ “ = SMD

Voltage indications for PLAY and REC modes on

the Schematic Diagrams are as shown below:

1 2 3

5.0

THE SAME VOLTAGE FOR

BOTH PLAY & REC MODES.

5.0

~

(2.5)

INDICATES THAT THE VOLTAGE

IS NOT CONSISTENT HERE.

PLAY MODE

REC MODE

Models and Marks

1-8-44 1-8-45

T6410SCM1

Main 2/5 Schematic Diagram

“ “ = SMD

Voltage indications for PLAY and REC modes on

the Schematic Diagrams are as shown below:

1 2 3

5.0

THE SAME VOLTAGE FOR

BOTH PLAY & REC MODES.

5.0

~

(2.5)

INDICATES THAT THE VOLTAGE

IS NOT CONSISTENT HERE.

PLAY MODE

REC MODE

1-8-46

1-8-47

T6410SCM2

Main 2/5 Schematic Diagram Parts Location Guide

Ref No. Position Ref No. Position Ref No. Position Ref No. Position

CAPACITORS

C401

C402

C403

C404

C405

C406

C407

C408

C409

C410

C411

C412

C413

C414

C415

C416

C417

C418

C419

C420

C421

C424

C425

C426

C427

C430

C431

C432

C433

C434

C435

C436 H-4 D402 H-4 R422 K-4 TP010 K-1

C438

C440

C441

C442 H-3 L401 K-3 R426 I-4

J-1

J-1

J-2

J-1

J-1

J-2

J-1

J-1

K-2

K-2

K-2

K-2

K-2

K-2

K-3

K-3

K-3

K-3

K-3

K-3

K-3

K-4

J-4

K-4

J-4

H-4

J-4 CL401 G-3

J-4 CL402 G-1

J-4

J-4

I-4

H-4

H-4

H-4

C443

C444

C445

C452

C851

C855

C856

C857

C858

C859

C860

C861

C862

C863

C864

C865

C866

C867

C868

C869

C871

C872

C874

C875

C876

CONNECTORS

CL403

DIODES

D401

IC4 01

COILS

IC

H-3

H-2

H-2

J-4

H-1

H-1

G-1

G-1

H-1

H-1

H-1

H-2

H-1

I-1

I-1

I-1

I-2

I-1

I-1

I-1

I-1

J-1

I-1

I-1

J-1

G-1

K-3

H-2

L402

L403

L852

L854

TRANSISTORS

Q401

Q851

Q852

Q853

Q854

Q855

Q856

Q857

RESISTORS

R401

R402

R405

R406

R407

R408

R409

R410

R411

R412

R413

R414

R415

R416

R417

R418

R420

R423

R424

R425

H-3

H-4

H-1

H-1

J-4

H-1

G-1

G-1

H-1

H-1

H-1

H-3

J-1

J-1

K-2

K-2

K-3

K-4

K-4

J-4

J-4

I-4

I-4

I-4

H-4

H-4 TP002 I-4

H-4

H-3

H-3

K-4

H-4

I-4

RESISTORSCAPACITORS COILS

R851

R852

R853

R854

R856

R857

R858

R859

R860

R861

R862

R863

R864

R865

R866

R867

R869

R870

R871

R874

R876

R877

R878

R879

CRYSTAL OSCILATOR

X401

TEST POINTS

TP00 3

TP00 7

TP00 8

H-1

H-1

H-1

H-1

H-1

G-1

G-1

H-1

H-1

I-1

I-1

H-1

I-1

I-1

I-1

I-1

I-1

I-1

J-2

I-1

I-1

I-1

H-2

H-2

J-2

K-4

I-1

J-1

1-8-48

Main 3/5 Schematic Diagram Parts Location Guide

Ref No. Position Ref No. Position Ref No. Position

CAPACITORS

C001

C002

C006

C007

C008

C009

C012

C151

C152

C154

C155

C156

C157

C160

C301

C302

C303

C304

C305

C307

C308

C309

C310

C311

C312

C313

C314

C315

C316

C317

C318

C319

C320

C321

C322

C323

C324

C325

C326

C327

C328

C330 N-2 R153 P-4 TP006 R-4

C331

C332 N-3 R155 N-4

R-4

Q-4

P-4

Q-3

Q-3

R-3

Q-4

O-4

N-4

O-4

P-4

P-4

P-4

P-4

N-1

N-1

N-1

N-1

N-1

O-3

P-2

P-2

P-2

P-2

P-2

P-2

P-2

P-2

P-3

P-3

O-3

P-3

P-3

O-3

O-3

N-3

N-3

N-3

N-3

N-3

N-3

N-2

CAPACITORS RESISTORS

IC

N-2

N-2

P-3

M-3

M-3

P-1

N-2

M-3

N-3

R-1

M-4

M-3

M-4

O-4

O-4

P-1

P-1

P-1

P-3

P-2

O-4

N-1

M-4

Q-4

N-4

N-4

P-2

P-3

N-1

O-4

P-3

P-3

P-3

P-3

M-4

Q-4

P-4

R156

R301

R302

R303

R304

R305

R306

R307

R308

R309

R310

R311

R312

R313

R314

R315

R316

R317

R318

R320

R321

R322

R323

R324

R325

R326

R327

R328

R332

R333

R334

R335

R336

R339

R340

CRYSTAL OSCILATOR

X301 P-3

MISCELLANEOU S

JK151

TU00 1 R-4

TEST POINTS

C333

C334

C336

C338

C339

C340

C341

C344

C350

CONNECTORS

CL301A

CL302A

CN303

CN804

DIODES

D151

D152

D302

D303

D304

D305

D306

IC151

IC301

COILS

J418F3

L001

L151

L152

L302

L303

L304

L305

RESISTORS

R003

R004

R005

R006

R151

R152

R154

N-4

N-1

N-1

N-1

O-1

O-1

O-1

O-1

O-1

O-1

P-1

P-3

O-1

P-2

P-2

P-2

P-2

P-3

P-3

O-3

N-3

N-3

N-3

N-3

N-2

N-2

M-2

N-2

M-3

M-3

M-3

N-3

O-1

O-1

O-1

M-4

1-8-49

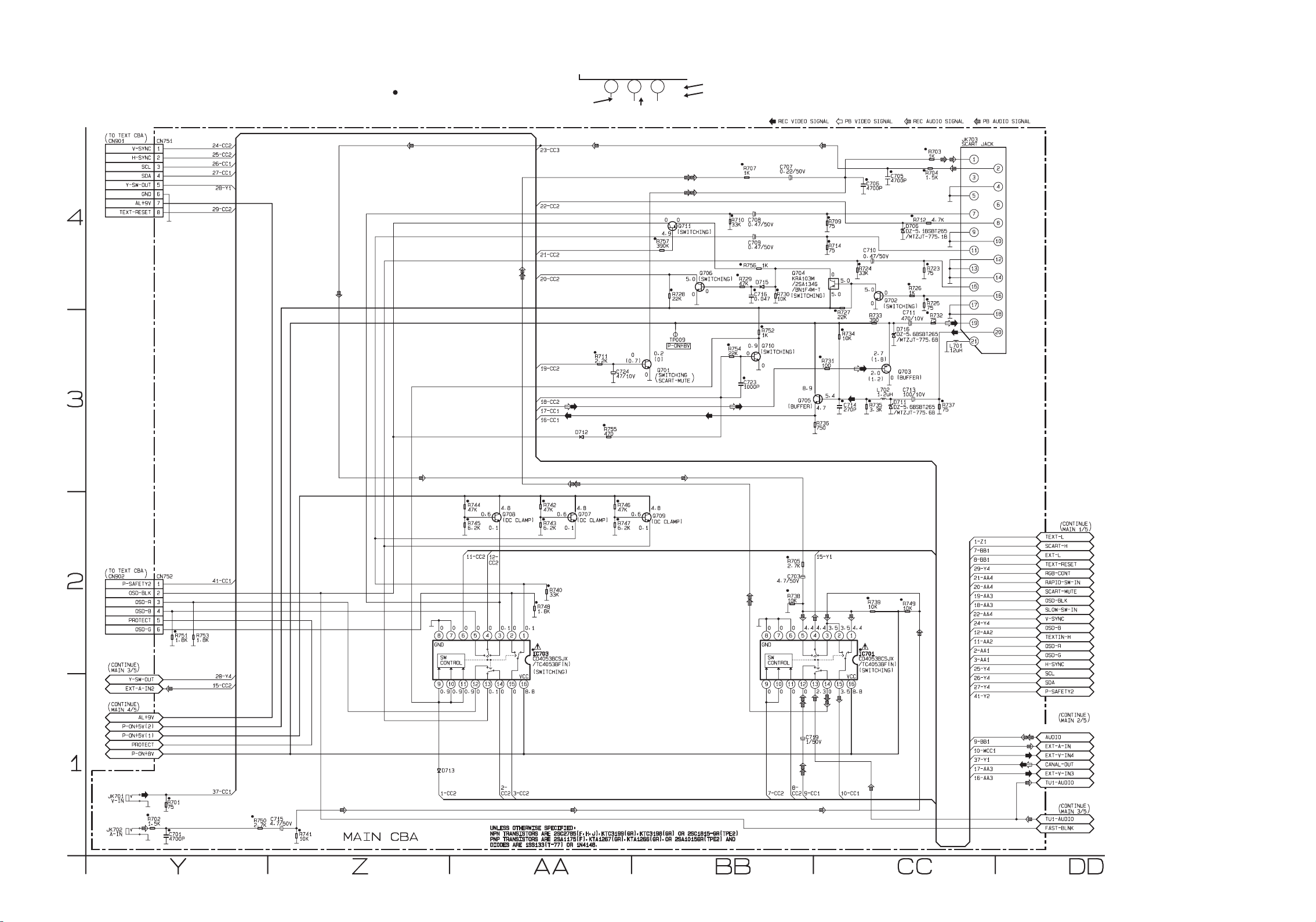

Main 3/5 Schematic Diagram

“ “ = SMD

Voltage indications for PLAY and REC modes on

the Schematic Diagrams are as shown below:

1 2 3

5.0

THE SAME VOLTAGE FOR

BOTH PLAY & REC MODES.

5.0

~

(2.5)

INDICATES THAT THE VOLTAGE

IS NOT CONSISTENT HERE.

PLAY MODE

REC MODE

1-8-50 1-8-51

T6410SCM3

Main 4/5 Schematic Diagram

Ref. No.

IC602

Ref. No.

Q682

Q684

Q685

Q686

03.10

0.1 3.1 0

00.60

123

3.2 0 1.9

07.90

ECB

Comparison Chart of

MODEL MARK

14PV225/07 M

14PV225/01 N

14PV225/58 O

14PV225/39 P

14PV422/07 Q

14PV422/01 R

14PV422/58 S

14PV422/39 T

14PV125/07 U

14PV125/01 V

14PV125/58 W

14PV125/39 X

14PV120/07 Y

14PV425/07 Z

“ “ = SMD

“ “ = SMD

Voltage indications for PLAY and REC modes on

the Schematic Diagrams are as shown below:

1 2 3

5.0

THE SAME VOLTAGE FOR

BOTH PLAY & REC MODES.

5.0

~

(2.5)

INDICATES THAT THE VOLTAGE

IS NOT CONSISTENT HERE.

PLAY MODE

REC MODE

VOLTAGE CHART (Power off mode)

Models and Marks

1-8-52

1-8-53

T6410SCM4

Main 4/5 Schematic Diagram Parts Location Guide

Ref No. Position Ref No. Position

CAPACITORS

C471

C472

C473

C474

C475

C476

C478

C479

C480

C481

C483

C484

C485

C486

C681

C682

C683

C684

C687

C688

C689

C691

C692

C694

CONNECTOR

CL603A

DIODES

D471

D682

D686

D687 U-2 R698 W-1

T-3

T-3

T-3

T-3

U-3

U-3

U-3

U-4

U-4

U-4

U-3

T-4

T-4

T-4

T-1

U-2

T-2

T-2

S-2

U-1

T-1

U-2

U-2

W-2

S-2

T-3

T-1

U-3

DIODES

D688

D690

D691

D693

D694

ICS

IC471

IC681

COILS

L681

L682

TRANSISTORS

Q682

Q684

Q685

Q686

RESISTORS

R471

R681

R683

R684

R685

R686

R690

R691

R692

R693

R694

R696

R697

U-2

U-2

U-2

W-1

T-2

T-3

T-2

T-1

T-2

T-1

S-2

U-2

U-1

T-3

S-1

T-2

U-1

T-1

T-1

T-2

S-2

U-2

T-2

T-2

T-1

W-1

1-8-54

Main 5/5 Schematic Diagram Parts Location Guide

Ref No. Position Ref No. Position

RESISTORSCAPACITORS

ICS

Y-1

BB-2

CC-4

CC-4

AA-4

BB-4

BB-4

CC-4

CC-3

CC-3

CC-3

Z-1

BB-4

BB-1

BB-3

AA-3

Y-4

Y-2

CC-4

CC-3

AA-3

Z-1

BB-4

CC-3

CC-2

AA-2

CC-3

CC-3

BB-3

CC-4

CC-3

BB-4

BB-3

BB-4

AA-2

AA-2

BB-2

BB-3

BB-4

Y-1

Y-1

R705

R707

R709

R710

R711

R712

R714

R723

R724

R725

R726

R727

R728

R729

R730

R731

R732

R733

R734

R735

R736

R737

R738

R739

R740

R741

R742

R743

R744

R745

R746

R747

R748

R749

R750

R751

R752

R753

R754

R755

R756

R757

TEST POINTS

TP009

MISCELLANEOUS

JK701

JK702

C701

C703

C705

C706

C707

C708

C709

C710

C711

C713

C714

C715

C716

C719

C723

C724

CONNECTOR

CN751

CN752

DIODES

D706

D711

D712

D713

D715

D716

IC701

IC703

COILS

L701

L702

TRANSISTORS

Q70 1

Q70 2

Q70 3

Q70 4

Q70 5

Q70 6

Q70 7

Q70 8

Q70 9

Q71 0

Q71 1

RESISTORS

R701

R702

R703 CC-4 JK703 CC-4

R704 CC-4

BB-2

AA-4

CC-4

BB-4

AA-3

CC-4

CC-4

CC-4

CC-4

CC-4

CC-4

CC-3

BB-4

BB-4

BB-4

CC-3

CC-3

CC-3

CC-3

CC-3

CC-3

CC-3

BB-2

CC-2

AA-2

Z-1

AA-2

AA-2

AA-2

AA-2

AA-2

AA-2

AA-2

CC-2

Y-1

Y-2

BB-3

Y-2

BB-3

AA-3

BB-4

BB-4

BB-3

Y-1

Y-1

1-8-55

Main 5/5 Schematic Diagram

“ “ = SMD

Voltage indications for PLAY and REC modes on

the Schematic Diagrams are as shown below:

1 2 3

5.0

THE SAME VOLTAGE FOR

BOTH PLAY & REC MODES.

5.0

~

(2.5)

INDICATES THAT THE VOLTAGE

IS NOT CONSISTENT HERE.

PLAY MODE

REC MODE

1-8-56 1-8-57

T6410SCM5

CRT

ANODE

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

CRT CBA

BT6400F01021-B

FOCUS

SCREEN

WIRING DIAGRAM

CN804

SP-GND 1

SP 2

CL801

SP151

SPEAKER

WIRING DIAGRAM FOR SECTION 2 (DECK MECHANISM)

GND

D.Y.

HD

VD

Comparison Chart of

Models & Marks

Model Mark

14PV225/07

14PV225/01

14PV225/58

14PV225/39

14PV422/07

14PV422/01

14PV422/58

14PV422/39

14PV125/07

14PV125/01

14PV125/58

14PV125/3914PV125/39

14PV120/07

14PV425/07

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

W601

2

2

CL501B

HEATER1

GND

P-ON+160V3

CL501A

HEATER1

GND

P-ON+160V3

CN551

1

2

3

4

5

CN601

1

2

CN501

T551

FBT

H.V. / POWER SUPPLY CBA

BT6400F01021-A

JK703

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

CN502

GND 1

RED 2

BLUE 3

GREEN 4

CN552

GND 1

H-DRIVE 2

FBP 3

V-DRIVE 4

V-RAMP-FB 5

ACL 6

P-SAFETY1 7

GND 8

CN602

GND 1

NU 2

AL+12V(1) 3

P-DOWN-L 4

AL+5V 5

P-ON-L 6

AL+12V(2) 7

AL+9V 8

GND 9

GND 10

AL+33V 11

P-ON+8V 12

PROTECT 13

CN301

1

JUNCTION-C CBA

2

BT6400F01011

3

4

SENSOR CBA

(END-SENSOR)

BHB300F01013-A,B

SENSOR CBA

(ST-SENSOR)

BHB300F01013-A,B

1

2

3

JUNCTION-B CBA

4

BT6400F01011

5

6

7

8

CN603

1

2

3

4

5

6

7

JUNCTION-A CBA

8

BT6300F01011

9

10

11

12

13

CL301B

CL302BCN302

CL603B

10

11

12

13

CN201

CL301A

1

2

3

4

1

2

3

4

5

6

7

8

GND1

BLUE2

GREEN3

RED4

(NO CONNECTION)

CN303 IS USED FOR

ADJUSTMENT AT

FACTORY

CL302A

GND1

H-DRIVE2

FBP3

V-DRIVE4

V-RAMP-FB5

ACL6

P-SAFETY17

GND8

CN303

INT.MONITOR

1

I2C-OPEN2

GND3

SDA4

SCL5

MAIN CBA

CL603A

1

2

3

4

5

6

7

8

9

GND1

NU2

AL+12V(1)3

P-DOWN-L4

AL+5V5

P-ON-L6

AL+12V(2)7

AL+9V8

GND9

GND10

AL+33V11

P-ON+8V12

PROTECT13

BT6400F01011

CM+12V/20.5V

P-ON+5V(3)

C-FG

C-F/R

C-CONT

FG-GND

LD-CONT

D-CONT

D-PFG

M-GND

AL+12V(1)

VG

CL401

V(R)

V-COM

V(L)

CL402

CTL(-) 1

CTL(+) 2

A-PB/REC 3

A-COM 4

AE-H/FE-H 5

AE-H 6

CL403

FE-H 1

FE-H GND 2

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

V-SYNC1

H-SYNC

2

SCL3

SDA

4

Y-SW-OUT5

GND

6

AL+9V7

TEXT-RESET8

P-SAFETY 21

OSD-BLK

2

OSD-R3

OSD-B

4

PROTECT

5

OSD-G

6

CAPSTAN MOTOR

CN901CN751

1

2

3

4

5

6

7

8

CN902CN752

1

2

3

4

5

6

M

TEXT CBA

BT6400F01031

LOADING

MOTOR

CYLINDER ASSEMBLY

PG

SENSOR

DRUM

M

MOTOR

VIDEO

(R)

HEAD

VIDEO

(L)

HEAD

CONTROL HEAD

AUDIO HEAD

AUDIO ERASE

HEAD

AC HEAD ASSEMBLY

FE HEAD

FULL ERASE HEAD

1-10-3

M, N, O, P

1-10-4

T6410WI

IC PIN FUNCTION DESCRIPTIONS

[ 14PV120/07, 14PV125/ ( 01, 07, 39, 58 ), 14PV225/ ( 01, 07, 39, 58 ),

14PV422/ ( 01, 07, 39, 58 ), 14PV425/07 ]

Comparison Chart of Models and Marks

Model Mark

14PV225/07 M

14PV225/01 N

14PV225/58 O

14PV225/39 P

14PV422/07 Q

14PV422/01 R

14PV422/58 S

14PV422/39 T

14PV125/07 U

14PV125/01 V

14PV125/58 W

14PV125/39 X

14PV120/07 Y

14PV425/07 Z

IC 201 (TV/VCR Micro Computer)

“H” ≥ 4.5V, “L” ≤ 1.0V

Pin

Mark

No.

1-

2IN

3IN

4IN

5

6IN

7IN

8IN

9IN

10 IN

11 -

12 -

13

14 IN

IN/

OUT

IN AFC

IN/

OUT

Signal

Name

NU Not Used

P-SAFETY 2

P-SAFETY 1

END-SENS End-Sensor

V-ENV

KEY-1 Key 1 Input

KEY-2 Key 2 Input

LD-SW

ST-SENS Start-Sensor

NU Not Used

NU Not Used

D-V SYNC

REMOTE

Function

Power Sup ply

Failure Detection 2

Power Sup ply

Failure Detection 1

Automatic

Frequency Control

Signal

Video Envelope

Input

Loading Switch

Input

Artificial V-Sync

Output

Remote Signal

Input

Pin

Mark

No.

15 OUT

16 -

17 -

18 OUT

19 -

20

21 -

22 -

23 OUT

24 OUT

25 -

26 -

27 -

28 -

29 IN

30 -

31 IN

M,N,

O,Q,

R,S,

U,V,

32

W,Y,

Z

P, T , X

IN/

OUT

OUT A-MUTE-H

IN SECAM-H

Signal

Name

C-ROTA

NU Not Used

NU Not Used

RF-SW

NU Not Used

NU Not Used

NU Not Used

REC-LED

REC-LED

NU Not Used

NU Not Used

NU Not Used

NU Not Used

SCARTMUTE

NU Not Used

RECSAFETY

NU Not Used

-

Function

Color Phase Rotary

Changeover SIgnal

Video Head

Switching

Pulse

Audio Mute Control

Signal (Mute = “H”)

Recording LED

Control

Signal

Recording LED

Control

Signal

RAPID-Switch Input

Signal from Scart

Jack

Record Protection

Tab Detection

SECAM Mode at

High

1-12-4 T6410PIN

Pin

Mark

No.

M,N,

O,Q,

R,S,

U,V,

W,Y,

33

Z

P, T, X

34 IN

35 IN

36 OUT

37 -

38 IN

39 OUT

40 -

41 OUT

42 OUT

43 IN

44 OUT

45 IN

46 -

47

48 OUT

49 -

50 -

51 -

52 -

53

54 -

55 OUT

56 IN

57 -

58 IN

59 IN

60 OUT

IN/

OUT

OUT TRICK-H

OUT D-REC-H

Signal

Name

NU Not Used

-

RESET

XCIN Sub Clock 32 kHz

XCOUT Sub Clock 32 kHz

TIMER+5V Vcc

XIN Main Clock Input

XOUT Main Clock Output

GND GND

SPOT-KILL

EXT-L

CLKSEL Clock Select (GND)

SP-MUTE

I2C-OPEN

GND GND

SCART-H

OSD-GND OSD GND

NU Not Used

NU Not Used

NU Not Used

- OSDVcc OSDVcc

HLF HLF

TEXT-RESET Tele Text Reset

CV-IN Video Signal Input

GND GND

H-SYNC H-SYNC Input

V-SYNC V-SYNC Input

OSD-BLK

Function

Special Playback =

“H” in SECAM

Mode

System Reset

Signal (Reset=”L”)

Counter-measure

for Spot

External Input or

Playback = Output

Speaker Mute

Signal

White Balance

Adjust Mode

Judgment

Delayed Record

Signal

Switching Signal of

Scart Jack and

RCA Jack

Output for Picture

Cut off

Pin

Mark

No.

61 OUT

62 OUT

63 OUT

64 OUT

65 IN

66 -

67 OUT

68 IN

69 -

70 OUT

71 OUT

72

73 -

74 IN

75 -

76 OUT

77 OUT

78

79 -

80 IN

81 OUT

82 OUT

L

83

84 -

85 OUT

86 -

IN/

OUT

IN/

OUT

OUT C-F/R

Signal

Name

RGB-CONT RGB Control Signal

OSD-B Blue Output

OSD-G Green Output

OSD-R Red Output

RAPIT-SW-IN

NU Not Used

P-ON-H

SLOW-SW-IN

NU Not Used

TEXT-IN-H

SCL

SDA

NU Not Used

C-SYNC C-Sync Input

NU Not Used

C-CONT

D-CONT

NU Not Used

T- R E EL

LD-CONT

TEXT-L

NU Not Used

-

NU Not Used

P-DOWN-L

NU Not Used

Function

RAPID-Switch Input

Signal

Power On Signal at

High

Slow Switch Input

Signal

Tele Text Input

Signal at High

E2PROM/

CHROMA IC Tuner

Communication

Clock

E2PROM/

CHROMA IC Tuner

Communication

Data

Capstan Motor

Control Signal

Drum Motor Control

Signal

Capstan Motor

FWD/REV Control

Signal (FWD=”L”/

REV=”H”)

Take Up Reel

Rotation Signal

Loading Motor

Control Signal

Teletext Control

Signal

Power Voltage

Down Detector

Signal at Low

1-12-5 T6410PIN

Pin

Mark

No.

87 IN

88

89 -

90

91 OUT

92 IN

93

94

95

96 -

97 OUT

98

99

100

IN/

OUT

IN D-PFG

IN/

OUT

IN/

OUT

IN AGC

Signal

Name

C-FG

- AMPVss AMPVss (GND)

NU Not Used

AMP VREFOUT

AMP VREF- INStandard Voltage

- C C Terminal

CTL (-) CTL (-)

CTL (+) CTL (+)

AMPC AMPC

CTL AMPOUT

- AMPVcc AMPVcc

-AVcc

Function

Capstan Motor

Rotation Detection

Pulse

Drum Motor Phase/

Frequency

Generator

Standard Voltage

Output

Input

Control Amp Output

A/D Converter

Power Input/

Standard

Voltage Input

Tuner IF Output

Signal

1-12-6 T6410PIN

LEAD IDENTIFICATIONS

[ 14PV120/07, 14PV125/ ( 01, 07, 39, 58 ), 14PV225/ ( 01, 07, 39, 58 ),

14PV422/ ( 01, 07, 39, 58 ), 14PV425/07 ]

2SK2647

S D G

LA78040A

IN G OUT

KIA7805API

KA7805A

AN7805F

TT2084LS-YB11

TT2138LS-YB11

2SC5884000RF

S: Souce

D: Drain

G: Gate

B C E

E: Emitter

C: Collector

B: Base

KRA103M

2SA1346

2SC1815-GR(TPE2)

2SC3331(T,U)

2SC2120-(O,Y)(TPE2)

KTC3203(Y)

KTA1266(GR)

E C B

PS2561L1-1-VL

PS2561L1-1-VW

LTV817MBF

LTV817MCF

AC

KE

E C B

TC4053BF(N)

CD4053BCSJX

16

PT204-6B-12

MID-32A22

C

E

2SC1627Y-TPE2

2SA950(Y,O)

KTA1271(Y)

2SC2482 TPE6

2SC3468(E,D)-AE

KTC3207

2SA1175(F)

KTA1267(GR)

KTC3198(GR)

9

81

2SD1913(R)

KTC2026Y

B C E

BN1F4M-T

KTC3199(GR)

2SC2785(J,H,F)

2SA1015-GR(TPE2)

M37762MCA-BA2GP

LA71750AM-MTB

80

51

50

IN G OUT

BR24C04F-W

AT24C04N-10SC

M24C04-MN6

BR24C04F

M24C04-WMN6

8

1

5

4

LA4224

8

1

SAA5265

52

1

5

1

8

LA70100M-MPB

30

4

27

1

16

15

26

100

49

64

1

M61209BFP

48

1

33

16

31

30

32

17

1-13-2 T6410LE

h

PRODUCT SAFETY NOTE: Products marked with a h

have special characteristics important to safety.

Before replacing any of these components, read carefully

the product safety notice in this service manual.

Don’t degrade the safety of the product through improper servicing.

NOTES:

C…..±0.25% D…..±0.5% F…..±1%

G…..±2% J…..±5% K…..±10%

M…..±20% N…..±30% Z…..+80/-20%

ELECTRICAL PARTS LIST

Pos.

C001 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C002 9965 000 14863 ELECTROLYTIC CAP. 47UF/25V M 1111111111111

C006 9965 000 13908 ELECTROLYTIC CAP. 1UF/50V M 1111111111111

C007 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C008 ELECTROLYTIC CAP. 1UF/50V M 1111111111111

C009 PCB JUMPER D0.6-P5.0 1111111111111

C012 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C151 ELECTROLYTIC CAP. 330UF/16V M 1111111111111

C152 CERAMIC CAP.(AX) X M 2200PF/16V 1111111111111

C154 ELECTROLYTIC CAP. 470UF/16V M 1111111111111

C155 ELECTROLYTIC CAP. 0.22UF/50V M H7 1111111111111

C156 CHIP CERAMIC CAP. B K 4700PF/50V 1111111111111

C157 ELECTROLYTIC CAP. 10UF/25V M H7 1111111111111

C160 CHIP CERAMIC CAP. CH J 390PF/50V 1111111111111

C203 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C205 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C207 ELECTROLYTIC CAP. 1UF/50V M H7 1111111111111

C208 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C209 CHIP CERAMIC CAP. CH J 22PF/50V 1111111111111

C210 CHIP CERAMIC CAP. CH J 22PF/50V 1111111111111

C211 ELECTROLYTIC CAP. 47UF/6.3V M H7 1111111111111

C212 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C213 ELECTROLYTIC CAP. 47UF/6.3V M H7 1111111111111

C214 ELECTROLYTIC CAP. 330UF/6.3V M 1111111111111

C217 CHIP CERAMIC CAP. CH D 10PF/50V 1111111111111

C218 CHIP CERAMIC CAP. CH D 10PF/50V 1111111111111

C221 ELECTROLYTIC CAP. 47UF/6.3V M H7 1111111111111

12 NC Description

MAIN CBA

JUNCTION A CBA

JUNCTION B CBA

JUNCTION C CBA

SENSOR CBA

POWER CBA

CRT CBA

TEXT CBA

MMA CBA

Consists of the following

MAIN CBA

CAPACITORS

14PV120/07

14PV125/01

14PV125/07

14PV125/39

14PV125/58

14PV225/01

14PV225/07

14PV225/39

14PV225/58

14PV422/01

1111111111111

1111111111111

1111111111111

1111111111111

1111111111111

1111111111111

1111111111111

1111111

14PV422/07

14PV422/39

14PV422/58

1-14-18

ELECTRICAL PARTS LIST

h

Pos.

C222 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C223 CHIP CERAMIC CAP.(MELF) Y K 2200PF/35V 1111111111111

C224 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C225 CHIP CERAMIC CAP. CH J 560PF/50V 1111111111111

C226 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C227 CHIP CERAMIC CAP. CH D 10PF/50V 1111111111111

C228 CHIP CERAMIC CAP. CH D 10PF/50V 1111111111111

C229 CHIP CERAMIC CAP.(MELF) Y K 4700PF/16V 1111111111111

C230 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C231 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C233 CHIP CERAMIC CAP.(MELF) Y K 1000PF/35V 1111111111111

C234 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C235 ELECTROLYTIC CAP. 47UF/6.3V M H7 1111111111111

C236 CHIP CERAMIC CAP. B K 0.047UF/50V 1111111111111

C237 ELECTROLYTIC CAP. 47UF/6.3V M H7 1111111111111

C238 CHIP CERAMIC CAP. B K 0.047UF/50V 1111111111111

C239 CHIP CERAMIC CAP. CH J 560PF/50V 1111111111111

C240 CHIP CERAMIC CAP.(MELF) Y K 4700PF/16V 1111111111111

C241 ELECTROLYTIC CAP. 22UF/50V M 1111111111111

C242 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C243 ELECTROLYTIC CAP. 47UF/6.3V M H7 1111111111111

C244 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C245 ELECTROLYTIC CAP. 47UF/6.3V M H7 1111111111111

C248 ELECTROLYTIC CAP. 47UF/6.3V M H7 1111111111111

C253 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C256 ELECTROLYTIC CAP. 10UF/25V M H7 1111111111111

C301 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C302 ELECTROLYTIC CAP. 1000UF/6.3V M 1111111111111

C303 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C304 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C305 ELECTROLYTIC CAP. 1UF/50V M 1111111111111

C307 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C308 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C309 FILM CAP.(P) 0.1UF/50V J 1111111111111

C310 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C311 ELECTROLYTIC CAP. 1000UF/6.3V M 1111111111111

C312 CHIP CERAMIC CAP.(MELF) B K 180PF/50V 1111111111111

C313 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C314 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C315 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C316 ELECTROLYTIC CAP. 1UF/50V M 1111111111111

C317 CHIP CERAMIC CAP. CH J 150PF/50V 1111111111111

C318 ELECTROLYTIC CAP. 1UF/50V M 1111111111111

C319 ELECTROLYTIC CAP. 1UF/50V M 1111111111111

C320 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C321 ELECTROLYTIC CAP. 1UF/50V M 1111111111111

C322 ELECTROLYTIC CAP. 470UF/10V M 1111111111111

C323 ELECTROLYTIC CAP. 47UF/25V M 1111111111111

C324 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C325 MYLAR CAP. 0.22UF/50V J 1111111111111

C326 ELECTROLYTIC CAP. 1UF/50V M 1111111111111

C327 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C328 MYLAR CAP. 0.22UF/50V J 1111111111111

C330 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C331 ELECTROLYTIC CAP. 47UF/10V M 1111111111111

C332 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C333 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C334 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C336 ELECTROLYTIC CAP. 47UF/10V M 1111111111111

12 NC Description

14PV120/07

14PV125/01

14PV125/07

14PV125/39

14PV125/58

14PV225/01

14PV225/07

14PV225/39

14PV225/58

14PV422/01

14PV422/07

14PV422/58

14PV422/39

1-14-19

ELECTRICAL PARTS LIST

h

Pos.

C338 CHIP CERAMIC CAP.(MELF) Y K 1000PF/35V 1111111111111

C339 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C340 CHIP CERAMIC CAP.(MELF) SL J 100PF/50V 1111111111111

C341 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C344 CHIP CERAMIC CAP.(MELF) Y K 1000PF/35V 1111111111111

C350 ELECTROLYTIC CAP. 220UF/10V M 1111111111111

C401 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C402 ELECTROLYTIC CAP. 1UF/50V M H7 1111111111111

C403 ELECTROLYTIC CAP. 1UF/50V M H7 1111111111111

C404 ELECTROLYTIC CAP. 100UF/6.3V H7 1111111111111

C405 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C406 CHIP CERAMIC CAP. B K 0.047UF/50V 1111111111111

C407 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C408 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C409 CHIP CERAMIC CAP. B K 0.047UF/50V 1111111111111

C410 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C411 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C412 ELECTROLYTIC CAP. 1UF/50V M H7 1111111111111

C413 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C414 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C415 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C416 ELECTROLYTIC CAP. 47UF/6.3V M H7 1111111111111

C417 ELECTROLYTIC CAP. 1UF/50V M H7 1111111111111

C418 ELECTROLYTIC CAP. 1UF/50V M H7 1111111111111

C419 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C420 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C421 ELECTROLYTIC CAP. 10UF/25V M H7 1111111111111

C424 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C425 CHIP CERAMIC CAP. CH J 68PF/50V 1111111111111

C426 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C427 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C430 ELECTROLYTIC CAP. 47UF/25V M 1111111111111

C431 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C432 ELECTROLYTIC CAP. 1UF/50V M H7 1111111111111

C433 ELECTROLYTIC CAP. 10UF/25V M H7 1111111111111

C434 ELECTROLYTIC CAP. 22UF/16V M H7 1111111111111

C435 ELECTROLYTIC CAP. 1UF/50V M H7 1111111111111

C436 CHIP CERAMIC CAP. CH J 120PF/50V 1111111111111

C438 CHIP CERAMIC CAP. CH J 220PF/50V 1111111111111

C440 ELECTROLYTIC CAP. 1UF/50V M H7 1111111111111

C441 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C442 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C443 ELECTROLYTIC CAP. 1UF/50V M H7 1111111111111

C444 CHIP CERAMIC CAP. B K 1000PF/50V 1111111111111

C445 ELECTROLYTIC CAP. 10UF/25V M H7 1111111111111

C452 CHIP CERAMIC CAP. CH J 68PF/50V 1111111111111

C471 CHIP CERAMIC CAP. B K 0.01UF/50V 1 1 1

C472 CHIP CERAMIC CAP. B K 0.01UF/50V 1 1 1

C473 CHIP CERAMIC CAP. F Z 0.1UF/50V 1 1 1

C474 CHIP CERAMIC CAP. F Z 0.1UF/50V 1 1 1

C475 CHIP CERAMIC CAP. F Z 0.1UF/50V 1 1 1

C476 CHIP CERAMIC CAP. B K 0.01UF/50V 1 1 1

C478 CHIP CERAMIC CAP. F Z 0.1UF/50V 1 1 1

C479 CHIP CERAMIC CAP. B K 0.01UF/50V 1 1 1

C480 CHIP CERAMIC CAP. B K 0.01UF/50V 1 1 1

C481 ELECTROLYTIC CAP. 0.47UF/50V M H7 1 1 1

C483 CHIP CERAMIC CAP. F Z 0.1UF/50V 1 1 1

C484 CHIP CERAMIC CAP. CH J 820PF/50V 1 1 1

C485 CHIP CERAMIC CAP. CH J 820PF/50V 1 1 1

12 NC Description

14PV120/07

14PV125/01

14PV125/07

14PV125/39

14PV125/58

14PV225/01

14PV225/07

14PV225/39

14PV225/58

14PV422/01

14PV422/07

14PV422/58

14PV422/39

1-14-20

ELECTRICAL PARTS LIST

h

Pos.

C486 ELECTROLYTIC CAP. 2.2UF/50V M H7 1 1 1

C681 ELECTROLYTIC CAP. 220UF/16V M 1111111111111

C682 ELECTROLYTIC CAP. 220UF/16V M 1111111111111

C683 ELECTROLYTIC CAP. 10UF/50V M 1111111111111

C684 CHIP CERAMIC CAP.(MELF) SL J 100PF/50V 1111111111111

C687 ELECTROLYTIC CAP. 47UF/25V M 1111111111111

C688 ELECTROLYTIC CAP. 47UF/25V M 1111111111111

C689 ELECTROLYTIC CAP. 470UF/10V M 1111111111111

C691 ELECTROLYTIC CAP. 2.2UF/50V M 1111111111111

C692 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V 1111111111111

C694 ELECTROLYTIC CAP. 100UF/10V M 1111111111111

C701 CHIP CERAMIC CAP.(MELF) Y K 4700PF/16V 1111111111111

C703 ELECTROLYTIC CAP. 4.7UF/50V M 1111111111111

C705 CHIP CERAMIC CAP.(MELF) Y K 4700PF/16V 1111111111111

C706 CHIP CERAMIC CAP.(MELF) Y K 6800PF/16V 1111111111111

C707 ELECTROLYTIC CAP. 0.22UF/50V M 1111111111111

C708 ELECTROLYTIC CAP. 0.47UF/50V M 1111111111111

C709 ELECTROLYTIC CAP. 0.47UF/50V M 1111111111111

C710 ELECTROLYTIC CAP. 0.47UF/50V M 1111111111111

C711 ELECTROLYTIC CAP. 470UF/10V M 1111111111111

C713 ELECTROLYTIC CAP. 100UF/10V M 1111111111111

C714 CHIP CERAMIC CAP. CH J 270PF/50V 1111111111111

C715 ELECTROLYTIC CAP. 4.7UF/50V M 1111111111111

C716 CHIP CERAMIC CAP. B K 0.047UF/50V 1111111111111

C719 ELECTROLYTIC CAP. 1UF/50V M 1111111111111

C723 CHIP CERAMIC CAP.(MELF) Y K 1000PF/35V 1111111111111

C724 ELECTROLYTIC CAP. 47UF/10V M 1111111111111

C851 ELECTROLYTIC CAP. 47UF/6.3V M H7 1111111111111

C855 ELECTROLYTIC CAP. 220UF/6.3V M H7 1111111111111

C856 CERAMIC CAP. B K 470PF/100V 1111111111111

C857 FILM CAP.(P) 0.018UF/100V J 1111111111111

C858 CHIP CERAMIC CAP. B K 2200PF/50V 1111111111111

C859 CHIP CERAMIC CAP.(MELF) SL J 33PF/50V 1111111111111

C860 PCB JUMPER D0.6-P5.0 1111111111111

C861 CERAMIC CAP.(AX) X M 1800PF/16V 1111111111111

C862 ELECTROLYTIC CAP. 10UF/25V M H7 1111111111111

C863 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

C864 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C865 CHIP CERAMIC CAP. B K 0.022UF/50V 1111111111111

C866 ELECTROLYTIC CAP. 33UF/10V H7 1111111111111

C867 ELECTROLYTIC CAP. 4.7UF/50V M H7 1111111111111

C868 CHIP CERAMIC CAP.(MELF) Y K 4700PF/16V 1111111111111

C869 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C871 CHIP CERAMIC CAP.(MELF) B K 150PF/50V 1111111111111

C872 ELECTROLYTIC CAP. 1UF/50V M H7 1111111111111

C874 CHIP CERAMIC CAP. F Z 0.1UF/50V 1111111111111

C875 CHIP CERAMIC CAP. CH J 220PF/50V 1111111111111

C876 CHIP CERAMIC CAP. B K 0.01UF/50V 1111111111111

1005 3143 027 10191 TUN IF V+U PLL IEC BGDKI 03 1 1 1 1 1 1 1 1 1 1

1005 3143 027 10201 TUN IF V+U PLL IEC BGDKIL 03 1 1 1

5000 3143 021 00011 COI DEGAUS FUNAI 1111111111111

8000 3143 021 00031 EARTH CABLE 1111111111111

8016 2422 070 98211 MAINSCORD EUR 2A5 1M7 JH BK B 1 1 1 1 1 1 1 1 1

8016 2422 070 98218 MAINSCORD UK 5A 1M8 BK B 1 1 1 1

CL604 9965 000 18088 WIRE ASSEMBLY 1P/45 1111111111111

CN201 9965 000 13840 FFC/FPC CONNECTOR, 12P 1111111111111

CN301 9965 000 05261 CONNECTOR 4P TUC-P04X-B1 1111111111111

12 NC Description

MISCELLANEOUS

CONNECTORS

14PV120/07

14PV125/01

14PV125/07

14PV125/39

14PV125/58

14PV225/01

14PV225/07

14PV225/39

14PV225/58

14PV422/01

14PV422/07

14PV422/58

14PV422/39

1-14-21

ELECTRICAL PARTS LIST

h

Pos.

CN302 9965 000 13916 CONNECTOR, 8P TUC-P08X-B1 1111111111111

CN303 9965 000 13841 CONNECTOR BASE, 5P TUC-P05P-B1 1111111111111

CN603 9965 000 18089 CONNECTOR 13P TUC-P13X-B1 1111111111111

CN751 9965 000 13842 CONNECTOR BASE, 8P TUC-P08P-B1 1111111111111

CN752 9965 000 13843 CONNECTOR BASE, 6P TUC-P06P-B1 1111111111111

CN804 9965 000 13844 STRAIGHT CONNECTOR BASE 1111111111111

D151 9965 000 13848 ZENER DIODE MTZJT-777.5B 1111111111111

D152 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D201 9965 000 05250 LED SIR-563ST3F P 1111111111111

D202 9965 000 13846 LED(RED) L-1513EC 1111111111111

D204 9965 000 13846 LED(RED) L-1513EC 1111111111111

D205 9965 000 05249 ZENER DIODE MTZJT-775.6B 1111111111111

D206 PCB JUMPER D0.6-P5.0 1111111111111

D210 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D211 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D212 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D213 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D214 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D302 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D303 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D304 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D305 9965 000 11153 ZENER DIODE MTZJT-778.2B 1111111111111

D306 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D401 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D402 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D471 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1 1 1

D682 PCB JUMPER D0.6-P10.0 1111111111111

D686 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D687 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D688 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D690 9965 000 13848 ZENER DIODE MTZJT-777.5B 1111111111111

D691 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D693 9965 000 18090 ZENER DIODE MTZJT-776.2A 1111111111111

D694 9965 000 18091 ZENER DIODE MTZJT-7715B 1111111111111

D706 9965 000 12904 ZENER DIODE DZ-5.1BSBT265 1111111111111

D711 9965 000 05249 ZENER DIODE MTZJT-775.6B 1111111111111

D712 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D713 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D715 4822 130 32778 SWITCHING DIODE 1SS133(T-77) 1111111111111

D716 9965 000 05249 ZENER DIODE MTZJT-775.6B 1111111111111

IC151 9965 000 13853 AUDIO AMP LA4224 1111111111111

IC201 9965 000 18092 MICRO COMPUTER M37762MCA-BA2GP 1111111111111

IC202 9965 000 13030 IC:MEMORY BR24C04F-W 1111111111111

IC301 9965 000 18093 IC:CHROMA/IF 1 CHIP M61209BFP 1111111111111

IC401 9965 000 12180 IC:Y/C/A LA71750AM-MTB 1111111111111

IC471 9965 000 13927 IC:SECAM LA70100M-MPB 1 1 1

IC681 9965 000 13851 VOLTAGE REGULATOR KIA7805API 1111111111111

IC701 9965 000 13852 IC:SWITCH TC4053BF(N) 1111111111111

IC703 9965 000 13852 IC:SWITCH TC4053BF(N) 1111111111111

JK151 9965 000 13855 HEADPHONE JACK MSJ-035-10A B 1111111111111

JK701 4822 265 11659 RCA JACK(YELLOW) MSP-281V4-B 1111111111111

JK702 4822 265 11661 RCA JACK(WHITE) MSP-281V1-B 1111111111111

JK703 9965 000 13854 SKIRT JACK 21P HRC-21V-02P 1111111111111

L001 PCB JUMPER D0.6-P5.0 1111111111111

12 NC Description

DIODES

IC’s

JACK

COILS

14PV120/07

14PV125/01

14PV125/07

14PV125/39

14PV125/58

14PV225/01

14PV225/07

14PV225/39

14PV225/58

14PV422/01

14PV422/07

14PV422/58

14PV422/39

1-14-22

ELECTRICAL PARTS LIST

h

Pos.

J418F3 9965 000 05627 CHOKE COIL 47UH-K 1111111111111

L151 9965 000 18094 INDUCTOR 1.8UH-J-26T 1111111111111

L152 9965 000 13856 INDUCTOR 1.0UH-J-26T 1111111111111

L201 9965 000 13857 INDUCTOR 0.10UH-K-26T 1111111111111

L302 9965 000 13858 INDUCTOR 33UH-J-26T 1111111111111

L303 PCB JUMPER D0.6-P7.5 1111111111111

L304 PCB JUMPER D0.6-P7.5 1111111111111

L305 PCB JUMPER D0.6-P5.0 1111111111111

L401 9965 000 13859 INDUCTOR 22UH-J-26T 1111111111111

L402 9965 000 13858 INDUCTOR 33UH-J-26T 1111111111111

L403 9965 000 13893 INDUCTOR 100UH-J-26T 1111111111111

L681 9965 000 05627 CHOKE COIL 47UH-K 1111111111111

L682 PCB JUMPER D0.6-P7.5 1111111111111

L701 9965 000 13860 INDUCTOR 12UH-J-26T 1111111111111

L702 9965 000 13861 INDUCTOR 1.2UH-J-26T 1111111111111

L852 9965 000 05705 INDUCTOR 47UH-K-5FT 1111111111111

L854 9965 000 18095 INDUCTOR 0.22UH-K-26T 1111111111111

Q204 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

Q205 9965 000 18096 PHOTO TRANSISTOR MID-32A22 1111111111111

Q206 4822 130 10145 RES. BUILT-IN TRANSISTOR KRA103M 1111111111111

Q401 4822 130 42959 TRANSISTOR KTA1266(GR) 1111111111111

Q682 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

Q684 4822 130 42292 TRANSISTOR 2SC2120-Y(TPE2) 1111111111111

Q685 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

Q686 9965 000 13863 TRANSISTOR 2SD1913(R) 1111111111111

Q701 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

Q702 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

Q703 4822 130 42959 TRANSISTOR KTA1266(GR) 1111111111111

Q704 4822 130 10145 RES. BUILT-IN TRANSISTOR KRA103M 1111111111111

Q705 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

Q706 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

Q707 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

Q708 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

Q709 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

Q710 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

Q711 4822 130 42959 TRANSISTOR KTA1266(GR) 1111111111111

Q851 4822 130 10145 RES. BUILT-IN TRANSISTOR KRA103M 1111111111111

Q852 4822 130 10097 TRANSISTOR 2SC3331(T) 1111111111111

Q853 4822 130 10097 TRANSISTOR 2SC3331(T) 1111111111111

Q854 4822 130 42959 TRANSISTOR KTA1266(GR) 1111111111111

Q855 4822 130 42292 TRANSISTOR 2SC2120-Y(TPE2) 1111111111111

Q856 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

Q857 9965 000 05643 TRANSISTOR 2SC2785(F) 1111111111111

R003 9965 000 09896 CARBON RES. 1/4W J 10K OHM 1111111111111

R004 9965 000 09896 CARBON RES. 1/4W J 10K OHM 1111111111111

R005 CHIP RES.(1608) 1/10W J 47K OHM 1111111111111

R006 CHIP RES.(1608) 1/10W J 47K OHM 1111111111111

R151 METAL OXIDE FILM RES. 1W J 12 OHM 1111111111111

R152 CHIP RES.(1608) 1/10W J 5.6K OHM 1111111111111

R153 CHIP RES.(1608) 1/10W J 4.7K OHM 1111111111111

R154 CHIP RES.(1608) 1/10W J 5.6K OHM 1111111111111

R155 CARBON RES. 1/4W J 47 OHM 1111111111111

R156 CARBON RES. 1/4W J 47 OHM 1111111111111

R201 CARBON RES. 1/4W J 1K OHM 1111111111111

R202 CHIP RES.(1608) 1/10W J 22K OHM 1111111111111

R203 CARBON RES. 1/4W J 1K OHM 1111111111111

R204 CHIP RES.(1608) 1/10W J 22K OHM 1111111111111

12 NC Description

TRANSISTORS

RESISTORS

14PV120/07

14PV125/01

14PV125/07

14PV125/39

14PV125/58

14PV225/01

14PV225/07

14PV225/39

14PV225/58

14PV422/01

14PV422/07

14PV422/58

14PV422/39

1-14-23

ELECTRICAL PARTS LIST

h

Pos.

R205 CARBON RES. 1/4W J 1K OHM 1111111111111

R206 CHIP RES.(1608) 1/10W J 390K OHM 1111111111111

R207 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R208 CHIP RES.(1608) 1/10W J 1.5K OHM 1111111111111

R209 CHIP RES.(1608) 1/10W J 1.5K OHM 1111111111111

R210 CARBON RES. 1/4W G 4.7K OHM 1111111111111

R211 CHIP RES.(1608) 1/10W J 2.2K OHM 1111111111111

R212 CHIP RES.(1608) 1/10W J 2.7K OHM 1111111111111

R213 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R214 CHIP RES.(1608) 1/10W J 1.5K OHM 1111111111111

R215 CHIP RES.(1608) 1/10W J 1.5K OHM 1111111111111

R216 CHIP RES.(1608) 1/10W J 2.2K OHM 1111111111111

R217 CHIP RES.(1608) 1/10W J 2.7K OHM 1111111111111

R218 CHIP RES.(1608) 1/10W J 560 OHM 1111111111111

R219 CARBON RES. 1/4W J 1K OHM 1111111111111

R220 CHIP RES.(1608) 1/10W J 390K OHM 1111111111111

R221 CARBON RES. 1/4W J 270 OHM 1111111111111

R222 CARBON RES. 1/4W J 1K OHM 1111111111111

R223 CHIP RES.(1608) 1/10W J 680 OHM 1111111111111

R224 CHIP RES.(1608) 1/10W J 680 OHM 1111111111111

R226 CHIP RES.(1608) 1/10W J 10K OHM 1 1 1 1 1 1 1 1 1 1

R227 CHIP RES.(1608) 1/10W J 47 OHM 1111111111111

R228 CHIP RES.(1608) 1/10W J 100K OHM 1111111111111

R229 CHIP RES.(1608) 1/10W J 2.2K OHM 1111111111111

R230 CHIP RES.(1608) 1/10W J 1.5K OHM 1111111111111

R231 CHIP RES.(1608) 1/10W J 330K OHM 1111111111111

R232 CHIP RES.(1608) 1/10W J 1K OHM 1111111111111

R233 CHIP RES.(1608) 1/10W J 1K OHM 1111111111111

R234 CHIP RES.(1608) 1/10W J 560 OHM 1111111111111

R235 CHIP RES.(1608) 1/10W J 1K OHM 1111111111111

R236 CHIP RES.(1608) 1/10W J 470 OHM 1111111111111

R237 CHIP RES.(1608) 1/10W J 1M OHM 1111111111111

R238 CHIP RES.(1608) 1/10W J 100 OHM 1111111111111

R239 PCB JUMPER D0.6-P5.0 1111111111111

R240 PCB JUMPER D0.6-P5.0 1111111111111

R241 CHIP RES.(1608) 1/10W J 220 OHM 1111111111111

R242 CHIP RES.(1608) 1/10W J 220 OHM 1111111111111

R243 CHIP RES.(1608) 1/10W J 39K OHM 1111111111111

R244 CHIP RES.(1608) 1/10W J 220K OHM 1111111111111

R248 CARBON RES. 1/4W J 1K OHM 1111111111111

R249 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R250 CHIP RES.(1608) 1/10W J 33K OHM 1111111111111

R254 CHIP RES.(1608) 1/10W J 100K OHM 1111111111111

R255 CHIP RES.(1608) 1/10W J 680 OHM 1111111111111

R256 CHIP RES.(1608) 1/10W J 1.8K OHM 1111111111111

R257 CARBON RES. 1/4W J 6.8K OHM 1111111111111

R258 CARBON RES. 1/4W J 47K OHM 1111111111111

R259 PCB JUMPER D0.6-P5.0 1111111111111

R260 CARBON RES. 1/4W G 1.5K OHM 1111111111111

R261 CARBON RES. 1/4W G 22K OHM 1111111111111

R262 CARBON RES. 1/4W G 470 OHM 1111111111111

R263 CARBON RES. 1/4W G 10K OHM 1111111111111

R264 CARBON RES. 1/4W G 3.6K OHM 1111111111111

R265 PCB JUMPER D0.6-P5.0 1111111111111

R266 PCB JUMPER D0.6-P5.0 1111111111111

R267 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R268 CHIP RES.(1608) 1/10W J 3.3K OHM 1111111111111

R269 CHIP RES.(1608) 1/10W J 3.3K OHM 1111111111111

R270 CHIP RES.(1608) 1/10W J 100 OHM 1111111111111

12 NC Description

14PV120/07

14PV125/01

14PV125/07

14PV125/39

14PV125/58

14PV225/01

14PV225/07

14PV225/39

14PV225/58

14PV422/01

14PV422/07

14PV422/58

14PV422/39

1-14-24

ELECTRICAL PARTS LIST

h

Pos.

R271 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R272 CHIP RES.(1608) 1/10W J 18K OHM 1111111111111

R273 CHIP RES.(1608) 1/10W J 18K OHM 1111111111111

R274 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R275 CHIP RES.(1608) 1/10W J 560 OHM 1111111111111

R276 CHIP RES.(1608) 1/10W J 1.5K OHM 1111111111111

R277 CHIP RES.(1608) 1/10W J 560 OHM 1111111111111

R278 CHIP RES.(1608) 1/10W J 1.5K OHM 1111111111111

R279 CHIP RES.(1608) 1/10W J 560 OHM 1111111111111

R280 CHIP RES.(1608) 1/10W J 1.5K OHM 1111111111111

R281 CHIP RES.(1608) 1/10W J 3.3K OHM 1111111111111

R282 CARBON RES. 1/4W J 330 OHM 1111111111111

R287 CHIP RES.(1608) 1/10W J 470 OHM 1111111111111

R288 CHIP RES.(1608) 1/10W 0 OHM 1111111111111

R289 CHIP RES.(1608) 1/10W 0 OHM 1111111111111

R301 CHIP RES.(1608) 1/10W J 1.2K OHM 1111111111111

R302 CHIP RES.(1608) 1/10W J 4.7K OHM 1111111111111

R303 CHIP RES.(1608) 1/10W J 100 OHM 1111111111111

R304 CHIP RES.(1608) 1/10W J 2.7K OHM 1111111111111

R305 CHIP RES.(1608) 1/10W J 1.2K OHM 1111111111111

R306 CHIP RES.(1608) 1/10W J 100 OHM 1111111111111

R307 CHIP RES.(1608) 1/10W J 1.2K OHM 1111111111111

R308 CHIP RES.(1608) 1/10W J 100 OHM 1111111111111

R309 CHIP RES.(1608) 1/10W J 1.2K OHM 1111111111111

R310 CHIP RES.(1608) 1/10W J 1K OHM 1111111111111

R311 CARBON RES. 1/4W J 12 OHM 1111111111111

R312 CHIP RES.(1608) 1/10W J 100 OHM 1111111111111

R313 CHIP RES.(1608) 1/10W J 220K OHM 1111111111111

R314 CHIP RES.(1608) 1/10W J 4.7K OHM 1111111111111

R315 CHIP RES.(1608) 1/10W J 150K OHM 1111111111111

R316 CARBON RES. 1/4W J 15K OHM 1111111111111

R317 CARBON RES. 1/4W J 220K OHM 1111111111111

R318 CHIP RES.(1608) 1/10W J 6.8K OHM 1111111111111

R320 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R321 CHIP RES.(1608) 1/10W J 220 OHM 1111111111111

R322 CHIP RES.(1608) 1/10W J 3.3K OHM 1111111111111

R323 CHIP RES.(1608) 1/10W J 15K OHM 1111111111111

R324 CHIP RES.(1608) 1/10W J 4.7K OHM 1111111111111

R325 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R326 CHIP RES.(1608) 1/10W J 6.8K OHM 1111111111111

R327 PCB JUMPER D0.6-P5.0 1111111111111

R328 CHIP RES.(1608) 1/10W J 47K OHM 1111111111111

R332 CHIP RES.(1608) 1/10W J 100 OHM 1111111111111

R333 CHIP RES.(1608) 1/10W J 100 OHM 1111111111111

R334 CHIP RES.(1608) 1/10W J 100 OHM 1111111111111

R335 CARBON RES. 1/4W J 100 OHM 1111111111111

R336 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R339 CHIP RES.(1608) 1/10W 0 OHM 1111111111111

R340 CHIP RES.(1608) 1/10W 0 OHM 1111111111111

R401 CHIP RES.(1608) 1/10W J 1.2K OHM 1111111111111

R402 CHIP RES.(1608) 1/10W J 8.2K OHM 1111111111111

R405 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R406 CHIP RES.(1608) 1/10W J 1.2K OHM 1111111111111

R407 CHIP RES.(1608) 1/10W J 390K OHM 1111111111111

R408 CHIP RES.(1608) 1/10W J 330 OHM 1111111111111

R409 CHIP RES.(1608) 1/10W J 330 OHM 1111111111111

R410 CHIP RES.(1608) 1/10W J 220 OHM 1111111111111

R411 CHIP RES.(1608) 1/10W J 4.7K OHM 1111111111111

R412 CHIP RES.(1608) 1/10W J 4.7K OHM 1111111111111

12 NC Description

14PV120/07

14PV125/01

14PV125/07

14PV125/39

14PV125/58

14PV225/01

14PV225/07

14PV225/39

14PV225/58

14PV422/01

14PV422/07

14PV422/58

14PV422/39

1-14-25

ELECTRICAL PARTS LIST

h

Pos.

R413 CHIP RES.(1608) 1/10W J 2.2K OHM 1111111111111

R414 CHIP RES.(1608) 1/10W J 6.8K OHM 1111111111111

R415 CHIP RES.(1608) 1/10W J 4.7K OHM 1111111111111

R416 CHIP RES.(1608) 1/10W J 1.2K OHM 1111111111111

R417 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R418 CHIP RES.(1608) 1/10W J 56K OHM 1111111111111

R420 CHIP RES.(1608) 1/10W J 1.5K OHM 1111111111111

R422 CHIP RES.(1608) 1/10W J 150 OHM 1111111111111

R423 CHIP RES.(1608) 1/10W J 33 OHM 1111111111111

R424 CHIP RES.(1608) 1/10W J 1K OHM 1111111111111

R425 CHIP RES.(1608) 1/10W 0 OHM 1111111111111

R426 CHIP RES.(1608) 1/10W 0 OHM 1111111111111

R471 CHIP RES.(1608) 1/10W J 2.2K OHM 1 1 1

R683 METAL OXIDE FILM RES. 1W J 2.2 OHM 1111111111111

R684 CHIP RES.(1608) 1/10W J 10 OHM 1111111111111

R685 CARBON RES. 1/4W J 6.8K OHM 1111111111111

R686 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R690 METAL OXIDE FILM RES. 1W J 22 OHM 1111111111111

R691 METAL OXIDE FILM RES. 1W J 5.6 OHM 1111111111111

R692 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R693 CHIP RES.(1608) 1/10W J 22K OHM 1111111111111

R694 CHIP RES.(1608) 1/10W J 100 OHM 1111111111111

R696 METAL OXIDE FILM RES. 1W J 2.2 OHM 1111111111111

R697 CHIP RES.(1608) 1/10W J 10K OHM 1111111111111

R698 CHIP RES.(1608) 1/10W J 8.2K OHM 1111111111111

R701 CHIP RES.(1608) 1/10W J 75 OHM 1111111111111

R702 CHIP RES.(1608) 1/10W J 1.5K OHM 1111111111111

R703 CHIP RES.(1608) 1/10W J 1K OHM 1111111111111

R704 CHIP RES.(1608) 1/10W J 1.5K OHM 1111111111111

R705 CHIP RES.(1608) 1/10W J 2.7K OHM 1111111111111

R706 CHIP RES.(1608) 1/10W J 1K OHM 1111111111111

R707 CHIP RES.(1608) 1/10W J 1K OHM 1111111111111

R708 CHIP RES.(1608) 1/10W J 1.5K OHM 1111111111111

R709 CHIP RES.(1608) 1/10W J 75 OHM 1111111111111

R710 CHIP RES.(1608) 1/10W J 33K OHM 1111111111111

R711 CHIP RES.(1608) 1/10W J 2.2K OHM 1111111111111

R712 CHIP RES.(1608) 1/10W J 4.7K OHM 1111111111111

R714 CHIP RES.(1608) 1/10W J 75 OHM 1111111111111

R723 CHIP RES.(1608) 1/10W J 75 OHM 1111111111111

R724 CHIP RES.(1608) 1/10W J 33K OHM 1111111111111

R725 CHIP RES.(1608) 1/10W J 75 OHM 1111111111111

R726 CHIP RES.(1608) 1/10W J 1K OHM 1111111111111

R727 CHIP RES.(1608) 1/10W J 22K OHM 1111111111111

R728 CHIP RES.(1608) 1/10W J 22K OHM 1111111111111

R729 CHIP RES.(1608) 1/10W J 47K OHM 1111111111111