OPERATING INSTRUCTIONS

TCP 350

Electronic Drive Unit

EN

Translation of the original instructions

PT 0092 BEN/O (1703)

Table of contents

Table of contents

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Product description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 The Pfeiffer Vacuum parameter set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.1 Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 Pictographs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.3 Instructions in the text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.4 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Improper use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Product identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.1 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Range of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3.1 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Connection panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 TCP 350 with connecting cable and M12 accessories connector. . . . . . . 11

4.2 TCP 350 with connecting cable and M8 accessories connector. . . . . . . . 12

4.3 TCP 350 with connecting cable and RJ45 accessories connector . . . . . . 13

5.1 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.1 Rack installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Connection "external pump" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.4 Earthing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.5 Accessory connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6 Connection "RS-485" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.6.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.6.2 Cross-linking via the connection RS-485 . . . . . . . . . . . . . . . . . . . 17

5.7 "SERVICE" connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.7.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.8 Connection "REMOTE". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.8.1 Pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.8.2 +24 V DC* Output / Pin 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.8.3 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.8.4 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.8.5 Relay contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.9 Connecting a measuring device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.10 Connecting to the mains power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1.1 Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 Parameter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.1 Annotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.2 Control commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.3 Status requests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2.4 Set value settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2

Table of contents

7 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.1 Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.1.1 Self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

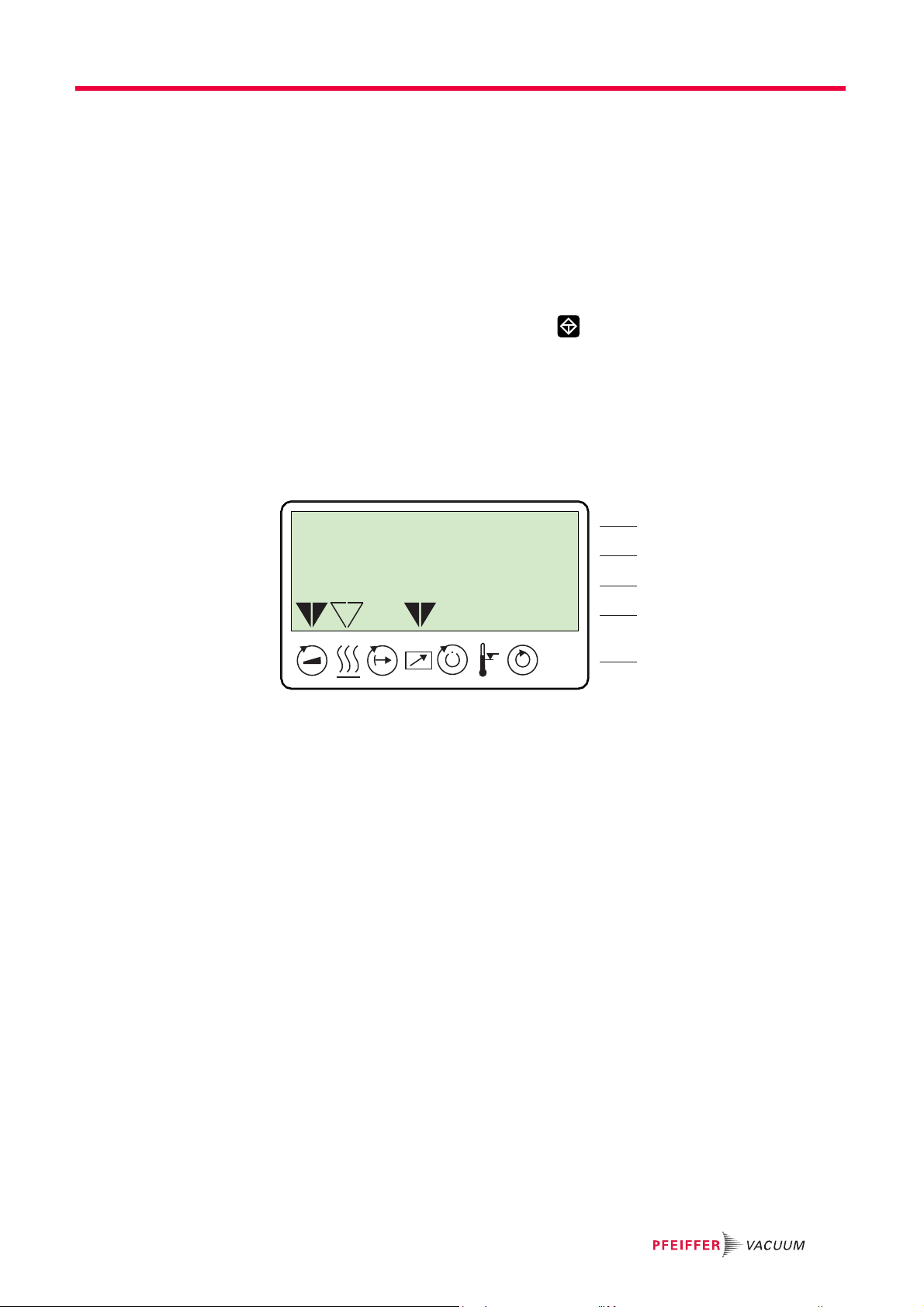

7.2 LC-Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.3 Symbol description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.4 Key functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.5.1 Selecting the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.5.2 Set parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.6 Configuring the connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.6.1 DO2 and relay on "REMOTE" . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.6.2 Analog output on "REMOTE" . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.6.3 Accessory connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8 Operation with the Pfeiffer Vacuum parameter set . . . . . . . . . . . . . . . . . . . 29

8.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.1.1 Factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.1.2 Checking the adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.1.3 Keypad lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.2 Rotation speed set value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.3 Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.3.1 Standard operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.3.2 REMOTE Priority ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.3.3 REMOTE Priority OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.4 Gas type dependent operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.5 Run-up time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.6 Adjusting the rotation speed switchpoint. . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.7 Rotation speed setting mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.8 Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.9 Operation mode backing pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.9.1 Continous operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.9.2 Intermittend operation (diaphragm pumps only) . . . . . . . . . . . . . . 32

8.10 Operation with accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.10.1 Air cooling/heating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.10.2 Vent modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.11 Pressure measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.11.1 Displaying the gauge type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.11.2 Displaying the active pressure value. . . . . . . . . . . . . . . . . . . . . . . 35

8.12 Monitoring the thermal load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.13 Switching on/off the pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.13.1 Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.13.2 Switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9 Pfeiffer Vacuum Protocol for "RS-485" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.1 Telegram frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.2 Telegrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.2.1 Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.2.2 Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.3 Applied data types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10 Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.2 Operation display via LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.2.1 Operation display via LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.3 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3

Table of contents

12 Technical data and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

12.1 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

12.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4

1 About this manual

1.1 Validity

This operating manual is for customers of Pfeiffer Vacuum. It describes the functioning

of the designated product and provides the most important information for safe use of

the unit. The description follows applicable EU guidelines. All information provided in this

operating manual refers to the current state of the product's development. The documentation remains valid as long as the customer does not make any changes to the product.

Up-to-date operating instructions can also be downloaded from

www.pfeiffer-vacuum.com.

1.2 Conventions

1.2.1 Safety instructions

The safety instructions in Pfeiffer Vacuum operating instructions are the result of risk

evaluations and hazard analyses and are oriented on international certification standards as specified by UL, CSA, ANSI Z-535, SEMI S1, ISO 3864 and DIN 4844. In this

document, the following hazard levels and information are considered:

About this manual

DANGER

Imminent danger

Indicates an imminent hazardous situation that will result in death or serious injury.

WARNING

Possibly imminent danger

Indicates an imminent hazardous situation that can result in death or serious injury.

CAUTION

Possibly imminent danger

Indicates an imminent hazardous situation that can result in minor or moderate injury.

NOTICE

Command or note

Command to perform an action or information about properties, the disregarding of

which may result in damage to the product.

5

About this manual

1.2.2 Pictographs

1.2.3 Instructions in the text

Prohibition of an action to avoid any risk of accidents, the disregarding

of which may result in serious accidents

Warning of a displayed source of danger in connection with operation of

the unit or equipment

Command to perform an action or task associated with a source of danger, the disregarding of which may result in serious accidents

Important information about the product or this document

1.2.4 Abbreviations

Work instruction: here you have to do something.

TCP: Electronic drive unit for turbopump, external with power supply

TC: Electronic drive unit for turbopump

DI / DO: Digital input / digital output

AI / AO: Analog input / analog output

[P:000]: Parameter of the electronic drive unit with number

6

2Safety

2.1 Safety precautions

Duty to inform

Each person involved in the installation or operation of the unit must read and observe

the safety-related parts of these operating instuctions.

The operator is obligated to make operating personnel aware of dangers originating

from the unit or the entire system.

Danger of unsafe electrical installation

Safe operation after installation is the responsibility of the operator.

Do not independently modify or change the pump and electrical equipment.

Make sure that the system is integrated in an emergency off safety circuit.

Consult Pfeiffer Vacuum for special requirements.

Danger of electric shock

In case of defect, the parts connected to the mains supply are under voltage.

Always keep the mains connection freely accessible so that you can disconnect it at

any time.

Safety

WARNING

WARNING

WARNING

Automatic start-up after power failure or malfunction acknowledgement

The function "pumping station" of the electronic drive unit remains active after power

failure or errors that lead to shut down the pump or the system. The turbopump runs up

automatically after power ist restored or malfunction acknowledgement.

Switch off the function "pumping station" if necessary.

Provide safety measures against interference in the high vacuum flange while the tur-

bopump is running.

CAUTION

Automatic start

After bridging the contacts Pin 1, 3, 4 on the connection "REMOTE" and setting up the

supply voltage, the turbopump will run up immediately.

Switch on the mains supply on the turbopump immediately before operation.

NOTICE

Damages to the pump and drive

Even after the mains power is switched off, the subsequently running pump delivers

electric power to the electronic drive unit. There is a danger of electric body contact by

premature separating the pump from the electronic drive unit.

Never separate the electronic drive unit from the pump when the mains power is con-

nected or the rotor is running.

● Observe all safety and accident prevention regulations.

● Always ensure a safe connection to the protective earthing conductor (PE, protection

class I).

● Regularly check the proper observance of all safety measures.

● Before carrying out any work disconnect the unit and all associated installations safely

from the mains.

● Do not loosen any plug connection during operations.

7

Safety

2.2 Proper use

● The unit has been accredited with protection class IP 20. Take necessary measures

when installing into ambient conditions, which afford other protection classes.

● Use as a desktop unit is only possible with a suitable cover.

● Observe fire protection specifications according IEC 61010 when installing in hous-

ings.

● Keep leads and cables well away from hot surfaces (> 70 °C).

● Only separate the pump and the electronic drive unit from each other after disconnect-

ing the supply voltage and the complete standstill of the pump.

NOTICE

EC conformity

The manufacturer's declaration of conformity becomes invalid if the operator modifies

the original product or installs additional components.

Following installation into a plant and before commissioning, the operator must check

the entire system for compliance with the valid EU directives and reassess it accordingly.

● The external electronic drive units TCP 350 are used exclusively for operating

HiPace® and CompactTurbo series Pfeiffer Vacuum turbopumps with a capacity of ≤

800 l/s.

● The external electronic drive unit TCP 350 serves as voltage supply, control and monitoring of a turbopump and connected peripherals.

● Only operate the pump with the respective electronic drive unit. The use of other than

the intended electronic drive units is not permitted.

2.3 Improper use

Improper use will cause all claims for liability and warranties to be forfeited. Improper use

is defined as usage for purposes deviating from those mentioned above, especially:

● connection to pumps or units which are not suitable for this purpose according to their

operating instructions

● connection to units which have exposed voltage-carrying parts

● connection to mains supplies, which do not confirm to the regulations IEC 61010 or

IEC 60950

● operation of the devices in areas with ionizing radiation

8

3 Product description

Mod: T CP 350

Mod.-Nr.: PM C01 740

Input: 115/230V -20/+15% 420 VA

Outpu t: 0 - 72 V 6,5 VA

0-1500 Hz

Made in Germany 2014/08

Ser. Nr.:78514xxx

TCP 350

1

2

3

6

8

4

9

10

11

7

5

3.1 Product identification

● The external electronic drive unit TCP 350 serves as voltage supply, control and monitoring of a turbopump and connected peripherals.

● For total pressure measurement the connection of a vacuum gauge is possible.

Characteristics TCP 350

Connection panel Standard

HiPace turbopump, suitable for TCP 80, 300, 400, 700, 800

Mains requirement: frequency (range) 50/60 Hz

Mains requirement: voltage (range) 100-120/200-240 (± 10%) V AC

Current consumption max. 4 A

Max. power consumption 420 VA

Mains requirement: internal fuse 5 A, slow blow

To correctly identify the product when communicating with Pfeiffer Vacuum, always have

the information from the rating plate available.

Product description

3.1.1 Scope of delivery

3.2 Function

Mod: TC P 350

Mod.-Nr.: PM C01 740

Input: 115/230V -20/+15% 420 VA

Output: 0 - 72 V 6,5 A

0-1500 Hz

Made in Germany 2014/08

Fig. 1: Example for a rating plate

Ser. Nr.:78514xxx

● TCP 350, external electronic drive unit for turbopumps

● Mating plug for the connection "REMOTE" on the TCP 350 (type dependent)

● Fixing materials

● Operating instructions

Fig. 2: TCP 350, Overview of controls and connections

1 LC display, illuminated

2Status icons

3 LEDs "Operation indicator"

4 Controls

5 Mains connection and main switch

6 "PUMP" connection

7 "REMOTE" connection

8 "RS485" connection

9 "SERVICE" connection

10 "GAUGE" connection

11 Earth connection PE

9

Product description

A

B

C

E

FG

H

J

K

L

M

NP

UVR

S

T

D

1

2

3

4

5

6

3.3 Range of application

3.3.1 Cooling

Pfeiffer Vacuum electronic drive units TCP 350 must be installed and operated in the following ambient conditions.

Installation location weather protected (indoors)

Protection category IP 20

Protection class I

Temperature +5 °C to +40 °C

Relative humidity max. 80 %, at T 31 °C, max. 50% at T 40 °C

Atmospheric pressure: 750 hPa - 1060 hPa

Installation altitude 2000 m max.

Degree of pollution 2

Overvoltage category II

Remarks to ambient conditions

The specified permissible ambient temperatures apply to operation of the turbopump at

maximum permissible fore-vacuum pressure or at maximum gas throughput depending

on the cooling method. The turbopump is intrinsically safe by a redundant temperature

monitoring.

● By reducing the fore-vacuum pressure or gas throughput, the turbopump can be op-

erated at higher ambient temperatures.

● If the maximum permissible operating temperature of the turbopump is exceeded, the

electronic drive unit reduces drive power first and switches off then, if necessary.

3.4 Connection panel

POWER/AC input

C14 device connector for connecting a power cable with a C13 socket type from

the Pfeiffer Vacuum accessories program.

PUMP

Round plug connection, socket, 19-pin with three-point bayonet coupling for con-

necting a Pfeiffer Vacuum turbopump with connection cables of various lengths

(max. 110 m in the standard version).

REMOTE

High Density D-Sub connector, 26-pin for connecting and configuring a remote

control.

RS485

RJ45 plug contact, 8-pin for connecting Pfeiffer Vacuum control devices (e.g.,

HPU) or a PC.

SERVICE

RJ45 plug contact, 8-pin. This interface is used exclusively for Pfeiffer Vacuum

Service purposes.

GAUGE

Round plug connection, socket, 6-pin for pressure measuring for connecting an

analog Pfeiffer Vacuum transmitter from the Active Line series.

10

Wiring diagrams

4 Wiring diagrams

4.1 TCP 350 with connecting cable and M12 accessories connector

M

Fan

3

452

1

VAC

Mains input,

L

Heating

115/208/230

N

PE

N

PE

L

Identification

Ground

Ground signal

Gauges

TPR2XX/ PKR2XX/

CMR2XX/ ACR2XX/IKR2XX

1

2

346

GAUGE

12346

Pressure signal

TCP 350

123456789

REMOTE

PE

Supply voltage

5

5

11

12131415161718

10

Rf1

Turbopump HiPace®

BCDEFGH

A

TMP

PUMP

A

BCDEFGH

Rf1

Ground

19

{

ϑ

Rf2

{

Rf2

PTC

Motorphases

N.C.

N.C.

N.C.

N.C.N.C.

2021222324

{

Oilsensor

N.C.

N.C.

26

25

Relay box Heating

345

A1

J

L

+24VDC

RS485

221

N

Heat/TMS

Sensor

12345

Venting Valve

134

5

B1

RL

10 Ohm/m

M

Vent

Ground

PV-Service only

PV-Service only

RS232 receive

1

SERVICE

2

3

8

7

PV-Service only

PV-Service only

RS232 transmitt

566

4

8

7

P

V

R

N.C.

N.C.

Power

PV-Service only

RL

PE

L

N

PE

AC-INPUT

S

K

T

U

N.C.

N.C.

N.C.

+24VDC*

Venting on

Motor TMP on

Pumping Station on

Standby on

Switching output 2

Set rot speed 0-10V

N.C.

Heating on

FV-Pump

Switching output 1

Error Acknowledge

Remote priority

Uf/ Ui/ Up voltage

Relaiscontacts

switching point

Relaiscontacts

errormessage

{

contacts

Potentialfree

GND*

+24VDC*

N.C.

N.C.

N.C.

D+

GND*

D-

N.C.

N.C.

N.C.

RXD

N.C.

TXD.

GND*

N.C.

N.C.

Mains input

(90-135/185-265) VAC

11

Wiring diagrams

12346

5

A

BCDEFGH

L

R

V

M

J

P

K

N

S

T

U

Ground

Oilsensor

Motorphases

PTC

Rf1

Rf2

+24VDC

Heat/TMS

Sensor

Vent

N.C.

RL

PE

N.C.

N.C.

N.C.

Mains input

(90-135/185-265) VAC

L

N

PE

Power

{

TCP 350

SERVICE

RS485

REMOTE

AC-INPUT

12345

566

7

8

1

2

3

4

7

8

+24VDC*

Venting on

Motor TMP on

Pumping Station on

Standby on

Heating on

Uf/ Ui/ Up voltage

Set rot speed 0-10V

Switching output 1

Switching output 2

N.C.

FV-Pump

Error Acknowledge

Remote priority

{

{

{

GND*

Relaiscontacts

switching point

Relaiscontacts

errormessage

Potentialfree

contacts

123456789

10

11

12131415161718

19

2021222324

26

25

N.C.

N.C.

N.C.

N.C.

+24VDC*

GND*

D+

D-

TXD.

N.C.

N.C.

N.C.

GND*

N.C.

N.C.

RXD

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.N.C.

N.C.

Ground

RS232 transmitt

RS232 receive

PV-Service only

PV-Service only

PV-Service only

PV-Service only

PV-Service only

Identification

Ground

Pressure signal

Ground signal

Supply voltage

PE

1

2

346

5

A

BCDEFGH

Rf1

Rf2

Turbopump HiPace®

Gauges

TPR2XX/ PKR2XX/

CMR2XX/ ACR2XX/IKR2XX

RL

PUMP

B1

TMP

GAUGE

10 Ohm/m

M

341

134

341

Relay box Heating

L

N

N

PE

PE

L

Fan

Venting Valve

Heating

Mains input,

115/208/230

VAC

A1

ϑ

4.2 TCP 350 with connecting cable and M8 accessories connector

12

Wiring diagrams

12346

5

A

BCDEFGH

L

R

V

M

J

P

K

N

S

T

U

Ground

Oilsensor

Motorphases

PTC

Rf1

Rf2

+24VDC

Heat/TMS

Sensor

Vent

N.C.

RL

PE

N.C.

N.C.

N.C.

Mains input

(90-135/185-265) VAC

L

N

PE

Power

{

TCP 350

SERVICE

RS485

REMOTE

AC-INPUT

12345

566

7

8

1

2

3

4

7

8

+24VDC*

Venting on

Motor TMP on

Pumping Station on

Standby on

Heating on

Uf/ Ui/ Up voltage

Set rot speed 0-10V

Switching output 1

Switching output 2

N.C.

FV-Pump

Error Acknowledge

Remote priority

{

{

{

GND*

Relaiscontacts

switching point

Relaiscontacts

errormessage

Potentialfree

contacts

123456789

10

11

12131415161718

19

2021222324

26

25

N.C.

N.C.

N.C.

N.C.

+24VDC*

GND*

D+

D-

TXD.

N.C.

N.C.

N.C.

GND*

N.C.

N.C.

RXD

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.N.C.

N.C.

Ground

RS232 transmitt

RS232 receive

PV-Service only

PV-Service only

PV-Service only

PV-Service only

PV-Service only

M

Identification

Ground

Pressure signal

Ground signal

Supply voltage

PE

1

2

346

5

1

234

665

5

1

234

1

2

3

4

6

5

A

BCDEFGH

Rf1

Rf2

Turbopump 071/261/521

Relay box Heating

L

N

N

PE

PE

L

Gauges

TPR2XX/ PKR2XX/

CMR2XX/ ACR2XX/IKR2XX

RL

Fan

Heating

Mains input,

115/208/230

VAC

PUMP

FAN/HEAT

VENT

TMP

GAUGE

10 Ohm/m

alternative

Venting Valve

ϑ

4.3 TCP 350 with connecting cable and RJ45 accessories connector

13

Installation

5 Installation

5.1 Assembly

5.1.1 Rack installation

NOTICE

Ensure free convection

Incorrect installation can cause damage by over-heating or create a fire hazard.

Maintain a minimum distance of 50 mm from cooling vents to adjacent components

or boundaries.

Install the device upright.

The unit is fitted in a casing that is suitable for installation in 19"/3HE rack modules.

Insert the unit in the guiderails of a 19"/3HE rack and screw on the front panel secure-

ly with four fixing screws provided as part of the scope of supply.

Ensure sufficient air circulation if installed in enclosed housings.

Do not hinder device internal air flow and removal.

Ensure permissible ambient conditions in the rack cabinet (see p. 10, chap. 3.3).

5.2 Connections

Fig. 3: General overview of the connections on the TCP 350

14

5.3 Connection "external pump"

TCP 350

TMP

6

6.1

6.26.3

6.4 6.5

The external connection of a Pfeiffer Vacuum turbopump to the electronic drive unit TCP

350 is possible, using shielded connection cables of different lengths from the Pfeiffer

Vacuum accessories programme.

Danger of electric shock

The system is only free of voltages if the mains plug is disconnected.

Switch off the main switch and disconnect the mains plug before all work.

Secure against unintentional restarting.

Ensure the complete stop of the pump (f < 1).

Risk of tripping!

Risk of tripping when working in the installation area.

Place supply lines in such a way that no tripping hazards occur.

The cable for control and operation of the turbopump is uniquely designated by plugs and

sockets.

● Round connector, 18-pin for connecting to the TCP 350

● Socket, 8-pin with two control cables for accessories and earth cable for connecting

to the turbopump

Installation

WARNING

CAUTION

Connection to existing cable configurations

For special or existing configurations Pfeiffer Vacuum recommends the use of an adapter cable between the TCP 350 and an existing connection cable to the turbopump.

See the accessories recommendations for the turbopump in question.

Fig. 4: Connecting the turbopump to the electronic drive unit TCP 350

6 Connection "pump" to TCP

6.1 TCP connection cable - pump

6.2 Accessories connectors

Install the connection cable between the electronic drive unit and the turbopump.

Lock plug connections and secure the bayonet fittings.

Connect earth cable 6.4 from the connection cable directly with the earth terminal on

the turbopump with the enclosed fastening material 6.5.

6.3 "Pump" connection

6.4 PE earth cable

6.5 Fasteners

15

Installation

M4

5.4 Earthing

Pfeiffer Vacuum recommends to connect an appropriate earthing wire to derive applicative interferences.

Fig. 5: Installing the earthing connection

5.5 Accessory connection

There are two connections (M8, M12 or RJ45) on the TCP 350 - turbopump connecting

cable for the following accessories:

– A1 or FAN/HE AT: Air cooling or heating

200 mA

● I

max

– B1 or VENT: vent valve only

● I

200 mA

max

A1

B1

A1

B1

FAN/HEAT

VENT

TCP 350

Fig. 6: Connection cable TCP 350 - turbopump with variants of the accessory connection

For connection and operation of the accessory please refer to the relevant operating

instructions of the turbopump.

Connect the accessory control cable to the appropriate connection on the connecting

cable.

Configure settings and controls via the interfaces of the electronic drive unit (only ap-

plies to A1, or FAN/HEAT).

Special features:

The connected accessories are activated after commissioning the electronic drive unit.

Use adapters from the Pfeiffer Vacuum accessory range for the turbopump to ensure

compatibility with existing configurations.

Do not connect a relaybox for the backing pump to the connecting cable; instead use

an adapter cable connected to the TCP 350 electronic drive unit "Remote" output.

Use a sealing gas throttle instead of a sealing gas valve.

TMP

16

5.6 Connection "RS-485"

1 ....

D+ D-TCD+ D-TCD+ D-

D+

D-

TIC 001/

USB/RS485-converter

RS 485

5.6.1 Connections

A Pfeiffer Vacuum display and control panel (DCU or HPU) or an external PC can be

connected to the electronic drive unit via the connection designated "RS-485". The interface is electrically isolated from the maximum supply voltage of the electronic drive unit.

The electrical couplings are optically decoupled internally.

Designation Value

Serial interface RS-485

Baud rate 9600 bauds

Data word length 8 bits

Parity none (no parity)

Start bits 1

Stop bits 1

Pin Assignment

1 not connected

2 +24 V output 150 mA max. load

3 not connected

4 not connected

5 RS485 D+

6GND

7 RS485 D8 not connected

The connection of respectively one external operating unit is possible on the interface

RS-485.

A USB interface (PC) can be connected via the USB/RS-485-converter.

Installation

5.6.2 Cross-linking via the connection RS-485

Danger of electric shock

The insulation measures of the bus system are designed only for use with safety extralow voltage.

Connect only suitable devices to the bus system.

Establish the connections according to the specification of the interface RS-485.

Connect all units with RS-485 D+ and RS-485 D- to the bus.

● The group address of the electronic drive unit is 988.

● All units connected to the bus must have differing RS-485 device addresses [P:797].

Connecting to an external bus system

It is only possible to connect to an external bus system (e.g., Profibus DP, DeviceNet)

on devices with a connection gateway TIC 253 or TIC 263. The simultaneous use of the

RS485 interface is not possible in this case.

● The field bus option cannot be retrofitted on the standard device.

CAUTION

17

Installation

1 ....

19

1018

1926

5.7 "SERVICE" connection

5.7.1 Connections

The connection labelled "SERVICE" on the electronic drive unit is used exclusively for

service and configuration purposes. The RS-232 interface is safely electrically isolated

from the maximum supply voltage that can occur in the electronic drive unit. The electrical connections are optically decoupled internally.

Designation Value

Serial interface RS-232

Baud rate 9600 bauds

Data word length 8 bits

Parity none (no parity)

Start bits 1

Stop bits 1..2

Pin Assignment

1 Service only

2 Service only

3 RS 232 RxD

4 RS 232 TxD

5 Service only

6GND

7 Service only

8 Service only

5.8 Connection "REMOTE"

Remote control is possible via the 26-pin D-sub connector labelled "REMOTE" on the

electronic drive unit. The accessible individual functions are mapped to "PLC levels".

Input signals Output signals

– PLC High level: +13 to +33 V DC

– PLC Low level: -33 to +7 V DC

–Ri: 7 kΩ

Table 1: Logic levels of digital inputs and outputs on REMOTE

Shielded connectors and cables must be used.

The following information display the factory setting. Configuration is possible

using the Pfeiffer Vacuum parameter set.

5.8.1 Pin assignment

Pin Function Description, factory setting

1 +24 V DC* output (V+) Reference voltage for all digital inputs and outputs:

2 DI1 Release vents; Low: off; High: on

3 DI motor pump Drive motor; Low: off; High: on

4 DI Pumping station Low: off; High: on

5 DI Standby Standby speed; Low: off; High: on

6 DI2 Heater; Low: off; High: on

7 AI+ rotation speed setting

mode

8 DO1 Speed-control switching point reached;

9 DO2 Low: Fault; High: no faults (I

10 not assigned

11 DO control backing pump Backing pump ON; Low: no; High: yes (I

12 AO voltage Vf, Vp, Vi 0-10 V DC is equivalent to 0-100%; R

13 DI Fault acknowledge-

ment

– High level: +20 to +28 V DC

– Low level: 0 to +3 V DC

Default in rotation speed setting mode;

2-10 V DC is equivalent to 20-100% of the nominal speed

Low: no; High: yes (I

Fault acknowledgement High: Pulse (min. 500 ms)

= 50 mA)

max

max

= 50 mA)

max

> 10 kΩ

L

= 50 mA)

18

Pin Function Description, factory setting

14 DI Remote priority Control via interface "REMOTE"; low: off; high: set and takes priority

15

Relay 1

16

17

18

Relay 2

19

20

21 not assigned

22 not assigned

23 not assigned

24 not assigned

25 not assigned

26 Earth (GND*) Reference earth for all digital inputs and outputs:

5.8.2 +24 V DC* Output / Pin 1

Inputs 2 - 6 and the connections to Pins 13, 14 are activated by connecting them with

+24 V DC to Pin 1 (active high). They can also be activated via an external PLC.

5.8.3 Inputs

The digital inputs at connection "REMOTE" are used to connect various functions of the

electronic drive unit.

Installation

over keypad or RS485

Connection with pin 16, relay 1 active = switching point reached

Relay contact 1 (V

Connection with pin 16, relay 1 inactive = switching point not reached

Connection with pin 19, relay 2 active = no fault

Relay contact 2 (V

Connection with pin 19, relay 2 inactive = fault

= 50 V DC; I

max

= 50 V DC; I

max

max

max

= 1 A)

= 1 A)

DI1 (Enable venting) / Pin 2

V+ : Venting is enabled (venting according to venting mode)

open: Venting locked (no venting is performed)

DI Motor pump / Pin 3

After Pin 4 (pumping station) is activated and the electronic drive unit successfully completes the self-test, the turbopump is placed into operation. During operation, the turbopump can be switched off and on again, while the pumping station remains switched

on. The turbopump is not vented thereby.

V+ : Turbopump motor on

open: Turbopump motor off

DI Pumping station/Pin 4

Connected pumping station components are actuated (e.g., backing pump, air cooling)

and if pin 3 (motor) is activated at the same time, the turbopump is switched on.

V+ : Pumping station on

open: Pumping station off

DI Standby / Pin 5

In standby mode, the turbopump operates at a specified rotor speed < nominal rotation

speed. Factory setting and recommended operation are 66.7 % of the nominal rotation

speed.

V+ : Standby activated

open: Standby off, operation at nominal rotation speed

DI2 (Heating) / Pin 6

V+ : Heating on

open: Heating off

19

Installation

f(%)

100

20

210

DI Error acknowledgement / Pin 13

V+ : Reset ongoing error messages when cause has been eliminated with a pulse of

min. 500 ms duration.

open: Inactive

DI Remote/Pin 14

Active High: The "REMOTE" connection takes priority over the operation via keypad or

interface.

● Activated individual functions cannot be changed via the keypad or interface.

● Individual functions deactivated via "REMOTE" can be controlled using the keypad or

interface.

Low:Remote priority inactive

AI Rotation speed setting mode / Pin 7 and Pin 26

The analog input defines the set rotation speed of the turbopump. An input signal of 2 10 V between AI+ (Pin 7) and GND (Pin 26) corresponds to a rotation speed within the

range of 20 - 100% of the nominal rotation speed. If the input is open or signals fall below

2 V, the pump is accelerated up to nominal rotation speed.

U(V)

5.8.4 Outputs

5.8.5 Relay contacts

The digital outputs on the "REMOTE" connection can handle a max. load of 50 mA per

output. Some outputs are configurable with the Pfeiffer Vacuum parameter set via the

RS-485 interface (description relates to factory settings).

DO1 (Rotation speed switchpoint attained) / Pin 8

Active high after the rotation speed switchpoint is attained. Rotation speed switchpoint 1

is factory-set to 80% of the nominal rotation speed. It can, for example, be used for a

"pump operational" message.

DO2 (No errors) / Pin 9

When the supply voltage has been established, digital output DO2 permanently outputs

24 V DC which means "no errors". Active low in case of error (collective error message).

AO analog output 0-10 V DC / Pin 12

● 0 - 10 V DC is equivalent to 0 - 100 % x f

Nominal

A voltage Vf can be tapped via the analog output; it is proportional to the turbopump

speed (load R ≥ 10 kΩ). Alternatively, either the current (V

) or output (Vp) can be as-

i

signed via keypad input or interface.

20

Relay 1 / Pin 15, 16 and 17

The contact between pin 16 and pin 15 is closed if the speed switching point is reached

or exceeded - relay 1 is active. The contact between pin 16 and pin 17 is closed if the

speed switching point is not reached or undershot - relay 1 is inactive. Relay control follows digital output pin 8.

Relay 2 / Pin 18, 19 and 20

The contact between pin 19 and pin 18 is closed in case of trouble-free operation - relay

2 is active. The contact between pin 19 and pin 20 is closed if an error has occurred relay 2 is inactive. Relay control follows digital output pin 9.

5.9 Connecting a measuring device

The connector socket labelled "Gauge" can be used to operate a Pfeiffer Vacuum pres-

sure measuring device from the ActiveLine series.

Installation

Gauges P

TPR 2xx 5 · 10-4hPa 1000 hPa

IKR 2xx 2 · 10

PKR 2xx 5 · 10

CMR x61 1 · 10

CMR x62 1 · 10

CMR x63 1 · 10

Table 2: Usable types of gauges for TCP 350

min

5.10 Connecting to the mains power supply

WARNING

Danger of unsafe electrical installation

Safe operation after installation is the responsibility of the operator.

Do not independently modify or change the pump and electrical equipment.

Make sure that the system is integrated in an emergency off safety circuit.

Consult Pfeiffer Vacuum for special requirements.

WARNING

Danger of electric shock

In case of defect, the parts connected to the mains supply are under voltage.

Always keep the mains connection freely accessible so that you can disconnect it at

any time.

(hPa) P

-9

hPa 0,01 hPa

-9

hPa 1000 hPa

-1

hPa 1100 hPa

-2

hPa 110 hPa

-3

hPa 11 hPa

max

(hPa)

Order the mains cable separately (see "accessories").

Switch off the main switch 5 on the electronic drive unit to position "0".

Plug mains cable into the mains connection "AC in".

Lock the mains cable with the mounting bracket.

Connect the mains cable to the mains.

Always ensure a safe connection to the protective earthing conductor (PE, protection

class I).

21

The Pfeiffer Vacuum parameter set

6 The Pfeiffer Vacuum parameter set

6.1 General

All function-relevant variables of a turbopump are anchored in the electronic drive unit as

parameters. Each parameter has a three-digit number and a designation. Parameters

can be used via Pfeiffer Vacuum display and control units or via RS-485 with the Pfeiffer

Vacuum protocol.

Additional parameters in the control unit

For the control of connected external components (e.g. vacuum measurement devices)

there are additional parameters fixed in the respective Pfeiffer Vacuum display and control unit.

Please consider the respective operating instructions.

6.1.1 Conventions

Parameters are displayed in square brackets as a three-digit number in bold font. The

designation may also be stated if necessary.

Example: [P:312] Software version

6.2 Parameter overview

6.2.1 Annotation

# Three figure number of the parameter

Display Display of the parameter name in the LCD

* = Representation as a symbol, if necessary

Designation Short description of the parameter

Functions Functional description of the parameter

Data type Type of formatting of the parameter for the use within the Pfeiffer Vacuum pro-

tocol

Access method R: read access; W: write access

Unit Physical unit of the described characteristic

min / max Permissible limits for value input

default Factory settings (partially specific of the pump type)

Parameter can be stored non volatile in the electronic drive unit and may be re-

used after resetting of the mains supply.

Parameter set and Pfeiffer Vacuum display and control unit

Pfeiffer Vacuum display and control units show the basic parameter set by default.

Parameter [P:794] = 1 (Display of all available parameters).

6.2.2 Control commands

# Display Designation Functions

Unit min max default

001 Heating Heating 0 = off

002 Standby Standby 0 = off

004 RUTime ctr Run-up time control 0 = off

008 Keys lockd Keys locked 0 = off

1

009

010 Pump stat. Pumping station 0 = off

22

Fault acknowledgement 1 = Fault acknowledgement 0 W 1 1

1 = on

1 = on

1 = on

1 = keys locked

1 = on

Data type

Access

0RW 0 1 0 x

0RW 0 1 0 x

0RW 0 1 1 x

0RW 0 1 0

0RW 0 1 0 x

The Pfeiffer Vacuum parameter set

# Display Designation Functions

012 Vent enab Enable venting 0 = no

019 Conf. Out 2 Configuration output DO2 0 = mains "OFF" or fault

023 Motor TMP Motor pump 0 = off

025 OpMode BKP Backing pump operating mode 0 = continuous operation

026 OpMode TMP Rotation speed setting mode 0 = off, ultimate speed operation

027 gas mode Gas mode 0 = heavy gases

028 Opmode Rem Operating mode interfaces 0 = no priorities

030 Vent mode Venting mode 0 = delayed venting

035 Conf IO Accessory output configuration 0 = Heating

055 Conf AO1 Configuration output AO1 0 = actual speed

095 RstCstVals Reset to factory settings (relates to actuating in-

structions and setpoints)

1. *

1 = yes

1 = mains "OFF" or fault

or warning

2 = mains "OFF" or fault

or turbopump drive "OFF"

1 = on

1 = intermittent operation

1 = on, rotation speed setting mode

1 = light gases

1 = Remote priority, for pin 14 active high

1 = do not vent

2 = vent directly

2 = Fan

1 = output:

2 = current

no

yes

* = No text display of the parameter, instead symbol or key operated

Unit min max default

Data type

Access

0RW 0 1 0 x

7RW 0 2 1 x

0RW 0 1 0 x

7RW 0 1 0 x

7RW 0 1 0 x

7RW 0 1 0 x

7RW 0 1 0 x

7RW 0 2 0 x

7RW 0 2 0 x

7RW 0 2 0 x

0W - - no x

6.2.3 Status requests

# Display Designation Functions

300* Remote priority 0 = no

1 = yes

301 Oil defic Operating fluid deficiancy no

yes

302* Rotation speed switchpoint attained 0 = no

1 = yes

303 Error code Error code no Err

Err XXX

Wrn XXX

304* Excess temperature electronic drive unit 0 R

305* Excess temperature pump 0 R

306* Set rotation speed attained 0 R

307* Pump accelerating 0 R

308 Set rotspd Set rotation speed (Hz) 1 R Hz 0 2000

309 Act rotspd Actual rotation speed (Hz) 1 R Hz 0 2000

310 TMP I-mot Drive motor current 2 R A 00:00 15:00

311 TMP Op hrs Pump operating hours 1 R h 0 65535 x

312 PCS Softw. Electronic drive unit software version 4 R 999999

313 TMP DClink Drive motor voltage 2 R R 0 127.50

314 Drv Op hrs Electronic drive unit operating hours 1 R h 0 65535 x

315 TMP finspd Nominal rotation speed (Hz) 1 R Hz 0 2000

316 TMP Power Drive motor output 1 R W 0 500

319 Cycl count Pump cycles 1 R 0 65535 x

335 HeatType Accessory connector assignment 0 = Heating

2 = Air cooling

340 Pressure Actual pressure value (ActiveLine) 7 R hPa 1E-12 1.0E3

349 Drv Name Drive type electronic drive unit 4 R TCP350

Unit min max default

Data type

Access

0R 0 1

0R 0 1

0R 0 1

4R

7 R 0 255

23

The Pfeiffer Vacuum parameter set

# Display Designation Functions

352 Drv Softw. Software version motor control 4 R 999999

354 HW version Hardware version electronic drive unit 4 R

360 Past Err 1 Error code history, item 1 last error message 4 R x

361 Past Err 2 Error code history, item 2 4 R x

362 Past Err 3 Error code history, item 3 4 R x

363 Past Err 4 Error code history, item 4 4 R x

364 Past Err 5 Error code history, item 5 4 R x

365 Past Err 6 Error code history, item 6 4 R x

366 Past Err 7 Error code history, item 7 4 R x

367 Past Err 8 Error code history, item 8 4 R x

368 Past Err 9 Error code history, item 9 4 R x

369 Past Err 10 Error code history, item 10 4 R x

Unit min max default

Data type

Access

* = No text display of the parameter, instead symbol or key operated

6.2.4 Set value settings

# Display Designation Functions

700 TMP RUTime Run-up time desired value 1 RW min 1 120 8 x

701 Switch pnt Set rotation speed 1 RW % 50 97 80 x

707 TMProt set Setpoint in rotation speed setting mode 2 RW % 20.0 100.0 50.0 x

710 BkP Poff Backing pump switch-off threshold for intermittent

711 BkP Pon Backing pump switch-on threshold for intermittent

717 Stbyrotset Rotation speed setpoint in standby operation 2 RW % 20 100 66.7 x

720 Vent frequ Venting frequency in % of ultimate speed 7 RW % 40 98 50 x

721 Vent time Venting time 1 RW d 6 10800 3600 x

738 Gauge type Type of pressure gauge noGaug

777 PumpRotMax Confirmation of nominal rotation speed (Hz) 1 RW Hz 0 2000 777 x

794 Param. set Parameter set 0 = Basic parameter set

795 Servicelin Insert service line 7 RW 309

797 Address Device address 1RW 1 255 1 x

operation

operation

TPR2xx

IKR2xx

PKR2xx

CMRx61

CMRx62

CMRx63

1 = Extended parameter set

Unit min max default

Data type

Access

1RWW 0 10000 x

1RWW 0 10000 x

1RW 0 6 0 x

7RW 0 1 0

24

7Operation

7.1 Switching on

Switch on the main switch 5 to position "1".

7.1.1 Self-test

The TCP carries out a self-test and a check of the connected units after switch-on. The

duration of the self-test is approx. 5 s and is visualized in the display with a progress bar.

Reset malfunction messages using key , if necessary.

On commissioning the electronic drive unit, or after changing the connected turbopump,

the error message E777 appears in the display.

Reset error E777 by setting the valid nominal rotation speed of the respective pump

(see p. 29, chap. 8.2).

7.2 LC-Display

Operation

721: Venting time

---> 3600 s

795

1

2

3

4

5

The four line LCD visualizes the functions of the TCP.

Functions are assigned as follows:

– Line 1: Number and name of the selected parameter (e.g. 721: Vent time).

– Line 2: relevant value for the selected parameter. The arrow –––► indicates Edit

mode.

– Line 3 with two functions:

– Function 1: Current messages concerning operation and control will be displayed.

– Function 2: presentation of a required second parameter in the format [Parameter

number: value]. The function for this line can be set via parameter [P:795] Servic-

elin in Line 1. All parameters can be accessed with "Servicelin". Error messages

will be displayed independently of the selected function.

– Line 4: presentation of the current equipment status by arrows that point to the asso-

ciated symbols.

– Line 5: Symbols (see below)

25

Operation

7.3 Symbol description

Symbol Description Arrow Explanation

Pump accelerates

= [P:307]

-NO

YES

Preselection heating

= [P:001]

Standby

= [P:002]

Equipment remote controlled

= [P:300]

Switchpoint reached

= [P:302]

Excess temperature - No excess temperatures

Ultimate speed reached

= [P:306]

- No preselection

Preselection heating, switchpoint not attained

Heating On, switchpoint attained

-OFF

ON

-NO

YES

-NO

YES

Excess temperature turbopump = [P:305]

Excess temperature turbo-electronics = [P:304]

Excess temperature turbopump and turbo-electronics

-NO

YES

7.4 Key functions

4 short-travel keys (softkeys) constitute the operator interface for the TCP.

Key Application/Example Explanation

Reset (error acknowledgement) acknowledges errors (red

LED illuminates)

[309]: ActualSpd

[308]: SetRotSpd

[310]: DrvCurrent

[311]: OpHrsPump

[001]: Heating

–––► off

Simultaneous

[001]: Heating

on

[010]: PumpgStatn

on / off

Scroll back through parmeters

Scrolls back one parameter

Scroll forwards through parameters

Scrolls forwards one parameter

Change value (Edit mode)

Access to displayed value, if possible

(Arrow–––► is displayed)

Confirm value (Parameter selection mode)

Accept changed value

("change confirmed" is displayed)

Pumping station ON/OFF

switches pumping station on or off.

corresponds to parameter [010]: "PumpgStatn"

26

7.5 Operation

All function-relevant variables of a turbopump are anchored in the electronic drive unit as

parameters. Each parameter has a three-digit number and a designation. Parameters

can be used via Pfeiffer Vacuum display and control units or via RS-485 with the Pfeiffer

Vacuum protocol.

The value of a parameter is always readable. Editable parameters are adjustment commands and target values (See the operating instructions for the respective electronic

drive unit for this purpose).

7.5.1 Selecting the parameters

Preselect parameter number using the (backwards) or (forwards) keys.

– Fast scrolling by pressing and keeping the relevant key depressed.

● The selected parameter appears in line 1, the corresponding value in line 2.

7.5.2 Set parameters

Select a parameter.

Simultaneously press keys and .

● The edit mode for the selected parameter is active.

● At the beginning of the second line an arrow ( –––►) appears.

Operation

Using keys , to decrease or increase the value, respective to change op-

tions.

Simultaneously press keys and .

● If line 3 = empty (see P:795), the following will be displayed: "change confirmed"

● The parameter is set.

● Edit mode for the parameter is ended. The arrow ( –––►) disappears.

Edit mode( –––►) will disappear again automatically under the following conditions and without accepting the value to be changed:

● Input disruption or no key operation for more than 10s.

● If an error occurs.

● Key "Pumping station ON/OFF" has been pressed.

● If line 3 = empty , "data not changed" will be displayed.

Start pump by pressing "Pumping station ON/OFF" key

The "Pumping station" key only controls the parameter [P:010]. All components connected via the electronic drive unit will be activated or deactivated according to their

configuration.

Ensure that the parameter [P:023] is also switched on for powering-up the tur-

bopump.

27

Operation

7.6 Configuring the connections

7.6.1 DO2 and relay on "REMOTE"

Configuration via parameter [P:019] .

● In the description "active" means (trouble-free):

– For DO2: V+ active high

– For relay 2: Active contact change

● Pending errors mean:

– For DO2: low

– For relay 2: inactive

Option Description

0 = mains "OFF" and/or fault

2 = mains "OFF" and/or fault and/or drive OFF

7.6.2 Analog output on "REMOTE"

Configuration via parameter [P:055].

DO2 "low" and relay 2 inactive1 = mains "OFF" and/or fault and/or warning

Option Description

0 = Rotation speed Speed signal; 0 - 10 V DC = 0 - 100 % x f

1 = output: Output signal; 0 - 10 V DC = 0 - 100 % x P

2 = current Current signal; 0 - 10 V DC = 0 - 100 % x I

7.6.3 Accessory connection

Configuration via parameter [P:035] .

Option Description

0 = Heating Control via heating and rotation speed switchpoint reached parameters

1 = TMS Heater* Control via TMS switchbox

2 = fan Control via pumping station parameters

* Only when using pumps with a temperature management system (TMS)

Nominal

max

max

28

Operation with the Pfeiffer Vacuum parameter set

8 Operation with the Pfeiffer Vacuum parameter set

8.1 General

8.1.1 Factory settings

The electronic drive unit is pre-programmed in the factory. This guarantees proper, reliable turbopump operation without the need for additional configuration.

Restore factory settings via parameter [P:095] if necessary.

– Attention! All customized settings will be lost.

8.1.2 Checking the adjustments

Before operating with parameters, check set values and control commands for their

suitability for the pumping process.

Remove the remote plug from electronic drive unit if required.

8.1.3 Keypad lock

The control keys on the front of the electronic drive unit can be locked against unauthorised use.

Locking of the keypad via parameter [P:008].

– All of the keypad input functions are disabled.

– It is still possible to scroll through the parameter list.

The keypad can only be unlocked by:

– Interfaces RS485/RS232

– De-energising through power OFF. The connected pump must run down complete-

ly to idle (f = 0).

8.2 Rotation speed set value

The typical nominal rotation speed of a turbopump is factory-set in the electronic drive

unit. If the electronic drive unit is replaced or a different pump type is used, the reference

set value of the nominal rotation speed must be confirmed. This procedure is part of a

redundant safety system for avoiding excess rotation speeds.

Adjust the parameter [P:777] according to the pump type.

Once the nominal rotation speed is attained, the pump will run idle unless additional gas

loads are entered. Depending on process or application requirements, the nominal rotation speed can be reduced in rotation speed setting mode or standby mode.

Pump type Nominal rotation speed, settings for [P:777] in Hz

CompactTurbo 071 P 1500

CompactTurbo 261/262 P 1000

CompactTurbo 261 P C 833

CompactTurbo 521 P 833

CompactTurbo 521 P C 715

HiPace 60 P 1500

HiPace 80 1500

HiPace 300 1000

HiPace 400 820

HiPace 700 820

HiPace 800 820

29

Operation with the Pfeiffer Vacuum parameter set

8.3 Remote control

There are basically three remote control options with different priorities. The advantage

of the remote control feature is the ability to connect multiple electronic drive units via

"REMOTE".

8.3.1 Standard operation

Standard operation generally means operation via TCP 350 keypad without explicit prioritisation of user interfaces. Beyond this, controls and functions are supported via the

RS-485 interface. Similarly, the switching functions of the "REMOTE" connection are

available if connected.

Parameter [P:028] = 0

● Exception: Connecting pin 14 on REMOTE with +24 V DC assigns priority to the

functions on this connection and locks them for the other interfaces.

8.3.2 REMOTE Priority ON

Connection "REMOTE" on the electronic drive unit has priority over all the functions of

the other interfaces.

Parameter [P:028] = 1

Pin 14 = active High

● Exception: Error acknowledgement is still possible via the corresponding key.

8.3.3 REMOTE Priority OFF

Connection "REMOTE" on the electronic drive unit does not have priority over the functions of the other interfaces.

Parameter [P:028] = 1

Pin 14 = active low

● Exception: Error acknowledgement is not possible via pin 13 until pin 14 "active high"

again.

8.4 Gas type dependent operations

Danger of the pump being destroyed

Pumping of gases with a higher molecular mass in the wrong gas mode can lead to destruction of the pump.

Ensure the gas mode is correctly set.

Contact Pfeiffer Vacuum before using gases with a greater molecular mass (> 80).

Friction causes the rotor to heat up severely under gas load and high rotation speed. To

avoid overheating, the electronic drive unit has implemented power-rotation speed-characteristics, whereby the pump can be operated at every rotation speed with the maximum allowable gas load without danger of damage. The maximum power consumption

depends on the gas type. Three characteristics are available in order to completely exhaust the pump's capacity for each gas type.

NOTICE

30

● Gas mode "0" for gases with the molecular mass >39, e.g. argon.

● Gas mode "1" for gases with the molecular mass 39.

● Power characteristics according to the technical data of the turbopump.

Check and set-up the gas mode via [P:027].

Operation with the Pfeiffer Vacuum parameter set

[P:708]

DB

A

C

Run-up

P

max

Rotation speed

Power

f

N

C-D = Gas mode "0"

A-B = Gas mode "1"

Fig. 7: Principle of power characteristics lines for gas type dependent operations,

e.g. gas mode = 0

The turbopump runs up with maximum power consumption. When the nominal and/or set

rotation speed is reached, the pump automatically switches over to the chosen power

characteristic of the selected gas mode. Increasing gas load is initially compensated by

a rise in power consumption in order to keep the rotation speed constant. Increasing gas

friction, however, causes the turbopump to heat up more severely. When the gastypedependent maximum power is exceeded, the rotation speed of the turbopump is reduced

until an equilibrium between permissible power and gas friction is attained.

To avoid rotation speed fluctuations, Pfeiffer Vacuum recommends setting a some-

what lower frequency in rotation speed setting mode.

8.5 Run-up time

The run-up of the turbopump is time-monitored ex factory. There are various causes of

prolonged run-up times, e.g.:

● Too high gas loads

● Leakage in the system

● The set value run-up time is too low

Eliminate any external and application-related causes.

Adjust the run-up time via parameter [P:700].

8.6 Adjusting the rotation speed switchpoint

The rotation speed switchpoint can be used for the message "Pump operational for the

process". Overrunning or underrunning the active rotation speed switchpoint activates or

deactivates a signal at the pre-configured output on the electronic drive unit and at the

status parameter [P:302].

Adjust the parameter [P:701] to the desired value in %.

Signal output and status parameter [P:302] are based on the set value for rotation speed

switchpoint 1 [P:701].

8.7 Rotation speed setting mode

The rotation speed setting mode reduces the rotation speed and hence the throughput

of the turbopump. The pumping speed of the turbopump changes proportional to rotation

speed. Standby mode is ineffective during rotation speed setting mode. The set rotation

speed is adjusted by the set value in rotation speed setting mode [P:707]. The rotation

speed switchpoint varies with the set rotation speed. Underrunning or overrunning the

set value in rotation speed setting mode activates and deactivates the status signal

[P:306] * respectively.

31

Operation with the Pfeiffer Vacuum parameter set

* Adjust the parameter [P:707] to the desired value in %.

Parameter [P:026] = 1

Query parameters [P:308] .

8.8 Standby

Pfeiffer Vacuum recommends standby mode for the turbopump during process and production stops. When standby mode is active, the electronic drive unit reduces the rotation

speed of the turbopump. Standby mode is ineffective during rotation speed setting mode.

The factory setting for the set value in standby mode is 66.7 % of the nominal rotation

speed. Underrunning or overrunning the set speed in standby mode activates or deactivates the status signal [P:306] *.

* Adjust the parameter [P:717] to the desired value in %.

Parameter [P:026] = 0

Parameter [P:002] = 1

Query parameters [P:308] .

8.9 Operation mode backing pump

Operation of a connected backing pump via the electronic drive unit depends on the

backing pump type.

Connect the control lead of the relay box to the "remote" connection of the electronic

drive unit using an adapter cable.

Adjust the parameter [P:025] to the desired value.

8.9.1 Continous operation

At the same time as "Pumping station on" the electronic drive unit sends a signal to the

pin 11 to switch on the backing pump. This signal can also be used to control a forevacuum safety valve.

8.9.2 Intermittend operation (diaphragm pumps only)

Intermittend operation can extend the life expectancy of the membrane of a connected

diaphragm pump. Either a diaphragm pump with built-in semiconductor relay or an interconnected relay box with semiconductor relay is required for intermittend operation. The

backing pump is switched on and off in dependence of the turbopump's power consumption. A relation to the supplied fore-vacuum pressure is derived from the power consumption. The switching off and switching on thresholds for the backing pump are adjustable.

Fluctuations in the power consumption of idling turbopumps and type-dependent varying

fore-vacuum pressures of the backing pumps require the switching thresholds to be set

separately for the intermittend mode.

Pfeiffer Vacuum recommends the intermittend mode between 5 and 10 hPa. A pressure

gauge and a dosing valve are required to set the switching thresholds.

Switch on the vacuum system via the function "pumping station" and await the run-up.

Generate a fore-vacuum pressure of 10 hPa by gas inlet via dosing valve.

Read and note the parameter [P:316].

Adjust the switch on threshold backing pump via parameter [P:711] to the determined

drive power for a fore-vacuum pressure of 10 hPa.

Reduce the fore-vacuum pressure to 5 hPa.

Read and note the parameter [P:316].

Adjust the switch off threshold backing pump via parameter [P:710] to the determined

drive power for a fore-vacuum pressure of 5 hPa.

32

8.10 Operation with accessories

Depending on the configuration, various accessories can be connected to the turbopump

and controlled via parameter of the electronic drive unit.

Operation with the Pfeiffer Vacuum parameter set

33

Operation with the Pfeiffer Vacuum parameter set

8.10.1 Air cooling/heating

It is necessary to select the accessory device via parameters [P:035].

Display of the selected accessory via parameters [P:335].

If air cooling is connected, it is immediately activated after switching on the pumping station with parameter [P:010].

The ability to operate a connected housing heater depends on the rotation speed switchpoint via parameter [P:701].

Switch heating on or off with parameter [P:001].

Exceeding or dropping below the rotation speed switchpoint controls the operation of the

housing heater. The operating condition is represented by the symbol in the LCD display.

8.10.2 Vent modes

The turbopump can be vented only after the function "pumping station" has been

switched off. Signals are sent to configured outputs with a fixed delay of 6 s. There are

three options for operation with a venting valve connected.

Enable venting via parameter [P:012].

Select the venting mode via parameter [P:030].

Delayed venting

Start and venting time after "pumping station off" are configurable and depend on the rotation speed of the turbopump.

Parameter [P:030] = 0

Adjust the venting rotation speed in % of the nominal rotation speed via parameter

[P:720].

Adjust the venting time in s via parameter [P:721].

If the venting rotation speed is underrun, the venting valve will open for the set venting

time. In the event of a power failure, venting will occur if the set venting rotation speed is

underrun. In this case, the venting period depends on the residual energy delivered by

the moving rotor. When power is restored, the venting process is interrupted.

No venting

No venting is performed during this operation mode.

Parameter [P:030] = 1

Direct venting

Start and venting time are not configurable. Venting starts with a delay of 6 s after "pumping station off". When the function "pumping station" is switched on renewed, the venting

valve closes automatically. In the event of a power failure, venting will occur if an anchored type-specific rotation speed is underrun. When power is restored, the venting

process is interrupted.

34

Parameter [P:030] = 2

8.11 Pressure measurement

Pressure measurement with the TCP

An exact pressure measurement is not possible with the TCP. This is particularly true

with linear gauges in the lower pressure range.

Use suitable measuring instrument.

8.11.1 Displaying the gauge type

Select or enter parameter [P:738] Gaugetype.

Gauges with identical surge impedance are only recognized as a group (e.g. CMR?).

Manual input of the exact gauge type is also possible via the parameter [P:738].

Display example Meaning

TPR 2xx Gauge TPR 280 connected

CMR ? Gauge of the CMR Group connected, exact type not yet set

noGaug No pressure gauge connected

8.11.2 Displaying the active pressure value

Select parameter [P:340] Pressure.

Operation with the Pfeiffer Vacuum parameter set

Display example Meaning

–––––– mbar No pressure gauge connected

< 5E-4mbar Measuring range not reached (dependent on the device)

> 1E3mbar Measuring range exceeded (dependent on the device)

6.3E-9mbar Valid pressure measurement

id fam mbar Gauge type not yet identified; see [P:340]

Error Error in pressure gauge

8.12 Monitoring the thermal load

If threshold values are overrun, output signals from temperature sensors allow the pump

to be brought to a safe condition. Depending on pump type, temperature threshold values for warnings and error messages are saved fixed in the electronic drive unit . For

information purposes, various status queries are prepared in the parameter set.

35

Operation with the Pfeiffer Vacuum parameter set

8.13 Switching on/off the pump

Start pump by pressing "Pumping station ON/OFF" key

The "Pumping station" key only controls the parameter [P:010]. All components connected via the electronic drive unit will be activated or deactivated according to their

configuration.

Ensure that the parameter [P:023] is also switched on for powering-up the tur-

bopump.

8.13.1 Switching on

The function "pumping station" comprises turbopump operation with control of all connected accessories (e.g. backing pump).

Parameter [P:023] = 1

Parameter [P:010] = 1

After successfully completing a self-test, the electronic drive unit switches on the turbopump motor and all connected accessories as per their configuration.

When the pumping station is activated, the motor of the turbopump can be switched off

and on via the function [P:023].

8.13.2 Switching off

Parameter [P:010] = 0

The electronic drive unit switches off the turbopump and activates preset accessory options (e.g. venting ON, backing pump OFF).

36

Pfeiffer Vacuum Protocol for "RS-485"

9 Pfeiffer Vacuum Protocol for "RS-485"

9.1 Telegram frame

The telegram frame of the Pfeiffer Vacuum protocol contains only ASCII code characters

[32; 127], the exception being the end character of the message

(e.g. a PC) sends a telegram, which is answered by a slave (e.g. electronic drive

unit or gauge).

a2 a1 a0 * 0 n2 n1 n0 l1 l0 dn ... d0 c2 c1 c0

a2 - a0 Unit address for slave

– Individual address of the unit ["001";"255"]

– Group address "9xx" for all identical units (no response)

– global address "000" for all units on the bus (no response)

* Action (see p. 37, chap. 9.2)

n2 - n0 Pfeiffer Vacuum parameter numbers

l1 - l0 Data length dn ... d0

dn - d0 Data in data type concerned (see p. 38, chap. 9.3)

c2 - c0 Checksum (sum of ASCII values of cells a2 to d0) modulo 256

C

R

carriage return (ASCII 13)

C

. Basically, a master

R

C

R

9.2 Telegrams

a2 a1 a0 1 0 n2 n1 n0 0 6 N O _ D E F c2 c1 c0

9.2.1 Example 1

Data request ?

a2 a1 a0 0 0 n2 n1 n0 0 2 = ? c2 c1 c0

C

Control command !

a2 a1 a0 1 0 n2 n1 n0 l1 l0 dn ... d0 c2 c1 c0

C

Data response / control command understood

a2 a1 a0 1 0 n2 n1 n0 l1 l0 dn ... d0 c2 c1 c0

C

Error message

C

_RANGE

_LOGI C

NO_DEF The parameter n2 - n0 does not exist

_RANGE Data dn - d0 are outside the permitted range

_LOGIC Logic access violation

Data request

Actual rotation speed (parameter [P:309], device address slave: "123")

? 1230030902=?112

ASCII 49 50 51 48 48 51 48 57 48 50 61 63 49 49 50 13

C

R

R

R

R

R

Data response: 633 Hz

Actual rotation speed (parameter [P:309], device address slave: "123")

1231030906000633037

ASCII 49 50 51 49 48 51 48 57 48 54 48 48 48 54 51 51 48 51 55 13

C

R

37

Pfeiffer Vacuum Protocol for "RS-485"

9.2.2 Example 2

Control command

Switch on pumping station (parameter [P:010], device address slave: "042")

! 0421001006111111020

ASCII 4852504948484948485449494949494948504813

Control command understood

Switch on pumping station (parameter [P:010], device address slave: "042")

! 0421001006111111020

ASCII 4852504948484948485449494949494948504813

9.3 Applied data types

Data type Description Size l1 - l0 Example

0 - boolean_old Boolean value (false / true) 06 000000 / 111111

1 - u_integer Positive integer number 06 000000 to 999999

2 - u_real Positive fixed point number 06 001571 equal to 15.71

4 - string String 06 TC_400

6 - boolean_new Boolean value (false / true) 01 0 / 1