OPERATING INSTRUCTIONS

EN

TC 400

Electronic drive unit

Translation of the Original

Dear Customer,

Thank you for choosing a Pfeiffer Vacuum product. Your new turbopump is designed to

support you by its performance, its perfect operation and without interfering your individual

application. The name Pfeiffer Vacuum stands for high-quality vacuum technology, a

comprehensive and complete range of top-quality products and first-class service. With this

expertise, we have acquired a multitude of skills contributing to an efficient and secure

implementation of our product.

Knowing that our product must not interfere with your actual work, we are convinced that our

product offers you the solution that supports you in the effective and trouble-free execution of

your individual application.

Please read these operating instructions before putting your product into operation for the

first time. If you have any questions or suggestions, please feel free to contact info@pfeiffer-

vacuum.de.

Further operating instructions from Pfeiffer Vacuum can be found in the Download Center on

our website.

Disclaimer of liability

These operating instructions describe all models and variants of your product. Note that your

product may not be equipped with all features described in this document. Pfeiffer Vacuum

constantly adapts its products to the latest state of the art without prior notice. Please take

into account that online operating instructions can deviate from the printed operating

instructions supplied with your product.

Furthermore, Pfeiffer Vacuum assumes no responsibility or liability for damage resulting from

the use of the product that contradicts its proper use or is explicitly defined as foreseeable

misuse.

Copyright

This document is the intellectual property of Pfeiffer Vacuum and all contents of this

document are protected by copyright. They may not be copied, altered, reproduced or

published without the prior written permission of Pfeiffer Vacuum.

We reserve the right to make changes to the technical data and information in this document.

2/48

Table of contents

1 About this manual 7

1.1 Validity 7

1.2 Applicable documents 7

1.3 Target group 7

1.4 Conventions 7

2 Safety 9

2.1 General safety information 9

2.2 Safety instructions 9

2.3 Safety precautions 10

2.4 Limits of use of the product 11

2.5 Proper use 11

2.6 Foreseeable improper use 11

2.7 Functional safety 11

Table of contents

1.4.1 Instructions in the text 7

1.4.2 Pictographs 7

1.4.3 Stickers on the product 8

1.4.4 Abbreviations 8

3 Product description 13

3.1 Identifying the product 13

3.2 Product features 13

3.3 Function 13

3.4 Scope of delivery 13

3.5 Connections 14

4 Installation 15

4.1 Connection diagram 15

4.2 "remote" connection 16

4.2.1 Voltage supply 17

4.2.2 Inputs 18

4.2.3 Outputs 19

4.2.4 Relay contacts (invertible) 19

4.2.5 RS-485 19

5 Interfaces 20

5.1 Interface RS-485 20

5.1.1 Connection options 20

5.1.2 Cross-linked via the RS-485 connection 21

5.2 Pfeiffer Vacuum protocol for RS-485 interface 21

5.2.1 Telegram frame 21

5.2.2 Telegram description 22

5.2.3 Telegram example 1 22

5.2.4 Telegram example 2 22

5.2.5 Data types 23

6 Parameter set 24

6.1 General 24

6.2 Control commands 24

6.3 Status requests 27

6.4 Set value settings 28

6.5 Additional parameter for the DCU 29

7 Operation 30

7.1 Configuring the connections with the Pfeiffer Vacuum parameter set 30

7.1.1 Configuring the digital inputs 30

7.1.2 Configuring digital outputs and relays 30

3/48

Table of contents

7.1.3 Configuring the analog input 31

7.1.4 Configuring the analog output 31

7.1.5 Configuring the accessory connections 31

7.1.6 Select interfaces 32

7.2 Operating modes 32

7.2.1 Gas type-dependent operation 32

7.2.2 Set value power consumption 33

7.2.3 Run-up time 33

7.2.4 Rotation speed switch points 34

7.2.5 Rotation speed setting mode 35

7.2.6 Standby 35

7.2.7 Confirming the speed specification 36

7.2.8 Backing pump operating modes 36

7.2.9 Backing pump standby mode 37

7.2.10Operation with accessories 37

7.2.11Venting modes 38

7.3 Switching on the turbopump 38

7.4 Switching off the turbopump 39

7.5 Operation monitoring 39

7.5.1 Operating mode display via LED 39

7.5.2 Temperature monitoring 39

8 Recycling and disposal 40

8.1 General disposal information 40

8.2 Dispose of electronic drive unit 40

9 Malfunctions 41

9.1 General 41

9.2 Error codes 41

9.3 Warning and error messages when operating with DCU 44

10 Service solutions by Pfeiffer Vacuum 45

Declaration of conformity 47

4/48

List of tables

Tbl. 1: Stickers on the product 8

Tbl. 2: Abbreviations used in this document 8

Tbl. 3: Permissible ambient conditions 11

Tbl. 4: Data for use in safety-related applications in accordance with IEC 61508

Tbl. 5: Data for use in safety-related applications in accordance with

Tbl. 6: Features of the device variants 13

Tbl. 7: Connection description of the electronic drive unit 14

Tbl. 8: Terminal layout of 26-pin "remote" connection 17

Tbl. 9: Features of the RS-485 interface 20

Tbl. 10: Terminal layout of the RS-485 connecting socket M12 20

Tbl. 11: Explanation and meaning of the parameters 24

Tbl. 12: Control commands 27

Tbl. 13: Status requests 28

Tbl. 14: Set value settings 29

Tbl. 15: Parameter for DCU functions 29

Tbl. 16: Configuring parameters [P:062], [P:063] and [P:064] 30

Tbl. 17: Configuring parameters [P.019] and [P:024], or [P:045], [P:046], [P:047] and

Tbl. 18: Configuring parameter [P:057] 31

Tbl. 19: Configuring parameter [P:055] 31

Tbl. 20: Accessory connections 32

Tbl. 21: Parameter [P:060] 32

Tbl. 22: Characteristic nominal rotation speeds of the turbopumps 36

Tbl. 23: Backing pump operating modes 36

Tbl. 24: Behavior and meaning of the LEDs on the electronic drive unit 39

Tbl. 25: Error messages of the electronic drive unit 43

Tbl. 26: Warning messages of the electronic drive unit 44

Tbl. 27: Warning and error messages when using a DCU 44

List of tables

11

and IEC 62061

12

EN ISO 13849-1

31

[P:028]

5/48

List of figures

List of figures

Fig. 1: Standard panel TC 400 13

Fig. 2: Connection diagram for the electronic drive unit. Example: external circuit for

Fig. 3: Rotation speed setting mode pin 7 and pin 11 19

Fig. 4: Connection options via interface RS-485 20

Fig. 5: Networking of turbopumps with integrated electronic drive unit via interface

Fig. 6: Schematic diagram of power characteristics, example of heavy gases

Fig. 7: Rotation speed switch point 1 active 34

Fig. 8: Rotation speed switch points 1 & 2 active, [P:701] > [P:719] 34

Fig. 9: Rotation speed switch points 1 & 2 active, [P:701] < [P:719] 35

16

"remote"

21

RS-485

33

[P:027] = 0

6/48

1 About this manual

IMPORTANT

Read carefully before use.

Keep the manual for future consultation.

1.1 Validity

This operating instructions is a customer document of Pfeiffer Vacuum. The operating instructions describe the functions of the named product and provide the most important information for the safe use of

the device. The description is written in accordance with the valid directives. The information in this operating instructions refers to the product's current development status. The document shall remain valid

provided that the customer does not make any changes to the product.

1.2 Applicable documents

TC 400 Operating instructions

Declaration of conformity A component of these instructions

About this manual

1.3 Target group

These operating instructions are aimed at all persons performing the following activities on the product:

●

Transportation

●

Setup (Installation)

●

Usage and operation

●

Decommissioning

●

Maintenance and cleaning

●

Storage or disposal

The work described in this document is only permitted to be performed by persons with the appropriate

technical qualifications (expert personnel) or who have received the relevant training from Pfeiffer Vacuum.

1.4 Conventions

1.4.1 Instructions in the text

Usage instructions in the document follow a general structure that is complete in itself. The required action is indicated by an individual step or multi-part action steps.

Individual action step

A horizontal, solid triangle indicates the only step in an action.

►

This is an individual action step.

Sequence of multi-part action steps

The numerical list indicates an action with multiple necessary steps.

1. Step 1

2. Step 2

3. ...

1.4.2 Pictographs

Pictographs used in the document indicate useful information.

7/48

TC 400

Made in Germany

Input:

Output:

Ser.-No.: 12345678

Mod.:

M.-No.:

24 V / 48 V ± 10% 15 A

PM C01 800 A

0 - 48 V 12 A 0 - 1000 Hz

2019/01

warranty seal

About this manual

Note

Tip

1.4.3 Stickers on the product

This section describes all the stickers on the product along with their meaning.

Rating plate

The rating plate is located on the side of the electronic drive

unit.

Closure seal

The product is sealed ex-factory. Damaging or removing a closure seal results in loss of the warranty.

Tbl. 1: Stickers on the product

1.4.4 Abbreviations

Abbreviation Meaning in this document

AI/AO Analog Input/Analog Output

AIC Ampere Interrupting Capacity

DC Direct Current

DCU Display Control Unit from Pfeiffer Vacuum

DI/DO Digital Input/Digital Output

f Rotation speed value of a vacuum pump (frequency, in rpm or Hz)

HPU Handheld Programming Unit, aid for controlling and monitoring parameters

I Electric amperage

LED Light Emitting Diode

[P:xxx] Electronic drive unit control parameters. Printed in bold as a three-digit number in

P Electrical Power

PE Protective Earth

R Electrical Resistance

remote 26-pole D-Sub connecting socket on the turbopump electronic drive unit

RS-485 Standard for a physical interface for asynchronous serial data transmission (Recom-

t Time

TC Electronic drive unit (Turbo Controller)

TMS Temperature Management System

U Electric voltage

square brackets. Frequently displayed in conjunction with a short description

Example: [P:312] software version

mended Standard)

8/48

Tbl. 2: Abbreviations used in this document

2 Safety

2.1 General safety information

The following 4 risk levels and 1 information level are taken into account in this document.

DANGER

Immediately pending danger

Indicates an immediately pending danger that will result in death or serious injury if not observed.

►

Instructions to avoid the danger situation

WARNING

Potential pending danger

Indicates a pending danger that could result in death or serious injury if not observed.

►

Instructions to avoid the danger situation

CAUTION

Potential pending danger

Indicates a pending danger that could result in minor injuries if not observed.

►

Instructions to avoid the danger situation

Safety

Danger of damage to property

Is used to highlight actions that are not associated with personal injury.

►

Instructions to avoid damage to property

Notes, tips or examples indicate important information about the product or about this document.

2.2 Safety instructions

All safety instructions in this document are based on the results of the risk assessment carried out in

accordance with Low Voltage Directive 2014/35/EU. Where applicable, all life cycle phases of the product were taken into account.

Risks during installation

DANGER

Danger to life from electric shock

Power supply packs that are not specified or are not approved will lead to severe injury to death.

►

Make sure that the power supply pack meets the requirements for double isolation between

mains input voltage and output voltage, in accordance with IEC 61010-1 IEC 60950-1 and

IEC 62368-1.

►

Make sure that the power supply pack meets the requirements in accordance with IEC 61010-1

IEC 60950-1 and IEC 62368-1.

►

Where possible, use original power supply packs or only power supply packs that correspond

with the applicable safety regulations.

NOTICE

9/48

Safety

DANGER

Danger to life from electric shock

When establishing the voltages that exceed the specified safety extra-low voltage (according to IEC

60449 and VDE 0100), the insulating measures will be destroyed. There is a danger to life from electric shock at the communication interfaces.

►

Connect only suitable devices to the bus system.

WARNING

Risk of injury due to incorrect installation

Dangerous situations may arise from unsafe or incorrect installation.

►

Do not carry out your own conversions or modifications on the unit.

►

Ensure the integration into an Emergency Off safety circuit.

Risks in the event of malfunctions

WARNING

Risk of injury from parts moving after a power failure or troubleshooting

The "pumping station" function of the electronic drive unit will remain active after a power failure or if

errors occur that shut down the vacuum pump or the system. When power is restored or after acknowledging a fault, the vacuum pump runs up automatically. There is a risk of injury to fingers and

hands if they enter the operating range of rotating parts.

►

Always keep the mains connection freely accessible so you can disconnect it at any time.

►

Remove present mating plugs or bridges from the electronic drive unit possibly before the mains

power returns, as these can cause an automatic run-up.

►

Switch the pump off using the "Pumping station" function (parameter [P:010]).

2.3 Safety precautions

Duty to provide information on potential dangers

The product holder or user is obliged to make all operating personnel aware of dangers

posed by this product.

Every person who is involved in the installation, operation or maintenance of the product

must read, understand and adhere to the safety-related parts of this document.

Infringement of conformity due to modifications to the product

The Declaration of Conformity from the manufacturer is no longer valid if the operator

changes the original product or installs additional equipment.

●

Following the installation into a system, the operator is required to check and re-evaluate the conformity of the overall system in the context of the relevant European Directives, before commissioning that system.

General safety precautions when handling the product

►

Use only power supply packs that comply with the applicable safety regulations.

►

Observe all applicable safety and accident prevention regulations.

►

Check that all safety measures are observed at regular intervals.

►

Recommendation: Establish a secure connection to the earthed conductor (PE); protection class

III.

►

Never disconnect plug connections during operation.

►

Keep lines and cables away from hot surfaces (> 70 °C).

►

Do not carry out your own conversions or modifications on the unit.

►

Observe the unit protection class prior to installation or operation in other environments.

►

Observe the protection class by ensuring the correct seating of the present sealing plugs.

►

Disconnect the electronic drive unit only once everything has come to a complete standstill and

when the mains power supply of the turbopump is interrupted.

10/48

2.4 Limits of use of the product

Installation location weatherproof (internal space)

Air pressure 750 hPa to 1060 hPa

Installation altitude max. 5000 m

Rel. air humidity max. 80 %, at T ≤ 31 °C,

Protection class III

Excess voltage category II

Permissible protection degree IP54

Degree of contamination 2

Ambient temperature +5 °C to +40 °C

Tbl. 3: Permissible ambient conditions

Notes on ambient conditions

The specified permissible ambient temperatures apply to operation of the turbopump at

maximum permissible backing pressure or at maximum gas throughput, depending on the

cooling type. The turbopump is intrinsically safe thanks to redundant temperature monitoring.

●

The reduction in backing pressure or gas throughput permits operation of the turbopump at higher ambient temperatures.

●

If the maximum permissible operating temperature of the turbopump is exceeded, the

electronic drive unit first reduces the drive output and then switches it off where necessary.

Safety

up to max. 50% at T ≤ 40°C

2.5 Proper use

●

The electronic drive unit is used exclusively for the operation of Pfeiffer Vacuum turbopumps and

their accessories.

2.6 Foreseeable improper use

Improper use of the product invalidates all warranty and liability claims. Any use that is counter to the

purpose of the product, whether intentional or unintentional, is regarded as misuse, in particular:

●

Connection to power supplies that do not comply with the provisions of IEC 61010 or IEC 60950

●

Operation with excessively high irradiated heat output

●

Use in areas with ionizing radiation

●

Operation in explosion-hazard areas

●

Use of accessories or spare parts that are not listed in these instructions

2.7 Functional safety

The TC 400 drive unit (electronic drive unit) executes the “Safe Limited Speed” safety function in accordance with EN 61800-5-2. In the event of excess rotation speed, the vacuum pump motor’s commutation switches off and brings the drive into a safe state.

Summary of characteristic data for use in safety-related applications:

Characteristics in accordance with IEC 61508 and IEC 62061

Characteristic Safety Integrity Level PFH PFD

Value SIL CL 2

1.1 * 10-8 / h 1 * 10

Proof Test Interval T

av

-3

20 a

Tbl. 4: Data for use in safety-related applications in accordance with IEC 61508 and

IEC 62061

11/48

Safety

Characteristics in accordance with EN ISO 13849-1

Characteristic Performance Level Category MTTF

d

Average diagnostic coverage DC

Value PL d Cat. 3 high (135 a) Medium (90 % - < 99 %)

Tbl. 5: Data for use in safety-related applications in accordance with EN ISO 13849-1

●

No proof test is required throughout the expected device lifetime of up to 20 years.

●

If you calculate your safety application with the specified values for 20 years, you will need to decommission the safety controller and return it to the manufacturer after 20 years. You must not

perform a proof test.

12/48

3 Product description

1 2 3 4

56

3.1 Identifying the product

►

To ensure clear identification of the product when communicating with Pfeiffer Vacuum, always

keep all of the information on the rating plate to hand.

►

Learn about certifications through test seals on the product or at www.certipedia.com with company ID no. 000021320.

3.2 Product features

The type TC 400 electronic drive unit is a permanent component of the turbopump. The purpose of the

electronic drive unit is to drive, monitor and control the entire turbopump.

Feature TC 400

Connection voltage TC 24 V DC ±10 % 48 V DC ±10 %

Connection panel Standard (RS-485) Standard (RS-485)

Turbopump HiPace 300, 400, 700, 800 300, 400, 700, 800

Tbl. 6: Features of the device variants

Product description

3.3 Function

Fig. 1: Standard panel TC 400

1 Connection "accessory B" 4 Connection "DC in"

2 “PV.can” service connection 5 "remote" connection

3 Connection "RS-485" 6 Connection "accessory A"

3.4 Scope of delivery

●

TC 400

●

Operating instructions

13/48

Product description

3.5 Connections

Tbl. 7: Connection description of the electronic drive unit

1)

DC in

Housing connector with bayonet lock for the voltage supply between Pfeiffer Vacuum power supply packs and the TC electronic drive unit.

accessory

M12 socket with screw lock for the connection of Pfeiffer Vacuum accessories. The

use of a Y-distributor permits the double allocation of a connection.

PV.can

M12 socket with screw lock and LED for the connection of an integrated pressure

measurement and for Pfeiffer Vacuum service purposes.

remote

High-density D-sub socket with 26 pins for connection and configuration of a remote control.

RS-485

M12 socket with screw lock for the connection of Pfeiffer Vacuum control panels or

PC. The use of a Y-distributor permits the integration into a bus system.

Device socket on the rear side of the electronic drive unit for the connection of the

turbopump.

14/48

1) "DC in" and "accessory" are described in the operating instructions of the turbopump.

4 Installation

4.1 Connection diagram

DANGER

Danger to life from electric shock

Power supply packs that are not specified or are not approved will lead to severe injury to death.

►

Make sure that the power supply pack meets the requirements for double isolation between

mains input voltage and output voltage, in accordance with IEC 61010-1 IEC 60950-1 and

IEC 62368-1.

►

Make sure that the power supply pack meets the requirements in accordance with IEC 61010-1

IEC 60950-1 and IEC 62368-1.

►

Where possible, use original power supply packs or only power supply packs that correspond

with the applicable safety regulations.

DANGER

Danger to life from electric shock

When establishing the voltages that exceed the specified safety extra-low voltage (according to IEC

60449 and VDE 0100), the insulating measures will be destroyed. There is a danger to life from electric shock at the communication interfaces.

►

Connect only suitable devices to the bus system.

Installation

WARNING

Risk of injury due to incorrect installation

Dangerous situations may arise from unsafe or incorrect installation.

►

Do not carry out your own conversions or modifications on the unit.

►

Ensure the integration into an Emergency Off safety circuit.

Contact load for the accessory connections to "accessory"

1. Note the maximum contact load of 200 mA per connection.

2. However, do not exceed the total sum of the load of all connections of 450 mA.

Potential-free connections

●

All inputs and outputs of the "remote” connections, "RS-485" and "PV.can" are galvanically separated from +UB .

●

The contacts of relays 1, 2 and 3 are potential-free.

15/48

4 1

5

23

32

5

1 4

13

4

2

A C

B

1

9

10

18

19

26

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

A

B

C

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Accessory BAccessory A

Remote

DC in

UB = + 24 / 48 V DC ± 10 %

PV.can

RS485

galvanically

separated from U

B

in this area

n.c.

24 V DC

Acc. B1

FE

Acc. B2

+ U

B

FE

GND

n.c.

24 V DC

Acc. A1

FE

Acc. A2

+ 24 V DC* out

DI Motor Pump

DI Pumping Station

DI Standby

DI1

DI2

DO1

DO2

DI3

AI+ 0-10 V DC

AI- GND

DI Error Ackn.

DI Remote Priority

Relay 1

Relay 1

Relay 1

Relay 2

Relay 2

Relay 2

Relay 3

Relay 3

AO1 / 0-10 V

DO Remote Prio Active

RS485 D-

RS485 D+

GND*

24 V DC* out

RS 485 D +

RS 485 D -

n.c.

GND*

Installation

Fig. 2: Connection diagram for the electronic drive unit. Example: external circuit for "re-

4.2 "remote" connection

The 26-pin D-sub connection with the "remote" designation offers the possibility to operate the electronic drive unit via remote control. The accessible individual functions are mapped to "PLC levels". The following specifications are the factory settings for the electronic drive unit. They can be configured with

the Pfeiffer Vacuum parameter set.

16/48

mote"

►

19

10

1926

Remove the remote plug from the TC 400 and connect a remote control.

►

Utilize the screened plug and cable.

Pin Assignment Description, factory setting

1 +24 V DC* output

Reference voltage for all digital inputs and outputs

(V+)

2 DI1 Enable venting (open: off, V+: on)

3 DI motor vacuum

Drive motor (open: off; V+: on)

pump

4 DI pumping sta-

open: off; V+: on and error acknowledgment

tion

5 DI standby Standby rotation speed (open: off, V+: on)

6 DI2 Heater (open: off, V+: on)

7 AI+ rotation

speed setting

mode

Setpoint in rotation speed setting mode;

2 - 10 V DC corresponds to 20 - 100% of the nominal rotation

speed

8 DO1 Speed-control switchpoint reached;

GND: no, V+: yes (I

9 DO2 GND: error, V+: no error (l

= 50 mA/24 V)

max

= 50 mA/24 V)

max

10 DI3 Sealing gas (open: off, V+: on)

11 AI rotation speed

Setpoint in rotation speed setting mode; GND

setting mode

GND

12 AO1 Actual speed; 0 to 10 V DC corresponds to 0 to 100%: R

> 10 kΩ

13 DI error acknowl-

Error acknowledgement: V+ pulse (min. 500 ms)

edgement

14 DI remote priority Operation via "remote" interface (open: off, V+: set and takes

priority over other digital inputs)

15 Relay 1 Connection with pin 16, if relay 1 inactive

16 Relay 1 Rotation speed switchpoint reached;

Relay contact 1 (U

= 50 V DC; I

max

17 Relay 1 Connection with pin 16, if relay 1 active

18 Relay 2 Connection with pin 19, if relay 2 inactive

19 Relay 2 No error; relay contact 2 (U

max

20 Relay 2 Connection with pin 19, if relay 2 active

21 Relay 3 Connection with pin 22, if relay 3 inactive

22 Relay 3 Warning; relay contact 3 (U

max

23 DO remote priori-tyGND: off, V+: remote priority active

= 1 A)

max

= 50 V DC; I

= 50 V DC; I

max

max

Installation

L

= 1 A)

= 1 A)

24 RS-485 D+ in accordance with the specification and Pfeiffer Vacuum pro-

tocol

25 RS-485 D- in accordance with the specification and Pfeiffer Vacuum pro-

tocol

26 Ground (GND*) Reference mass for all digital inputs and outputs

Tbl. 8: Terminal layout of 26-pin "remote" connection

4.2.1 Voltage supply

+24 V DC* output/pin 1

A connection with +24 V DC to pin 1 (active high) activates inputs 2 to 6, as well as the connections to

pins 10, 13 and 14. Alternatively, they can be activated via an external PLC. "PLC High level" activates

and "PLC Low level" deactivates the functions.

●

PLC High level: +13 V to +33 V

●

PLC Low level: -33 V to +7 V

17/48

Installation

4.2.2 Inputs

●

Ri: 7 kΩ

●

l

< 210 mA (with RS-485, where present)

max

The digital inputs at the "remote" connection are used to switch various electronic drive unit functions.

Inputs DI1 to DI2 are assigned functions in the factory. You can configure them via the RS-485 interface

and the Pfeiffer Vacuum parameter set.

DI1 (release venting)/pin 2

V+: Enable venting (venting as per venting mode)

open: Venting blocked (no venting occurs)

DI motor vacuum pump/pin 3

The turbopump starts up with activation of pin 4 (pumping station) and successful self-testing of the

electronic drive unit. The turbopump can be switched off and switched on again during operation with

the pumping station still activated. This will not initiate a venting action.

V+: Turbo pump motor on

open: Turbo pump motor off

DI pumping station/pin 4

Control of connected pumping station components (e.g. backing pump, venting valve, air cooling) and

start-up of the turbopump with simultaneously activated pin 3 (motor). Any pending error messages are

reset by eliminating the cause.

V+: Error acknowledgement and pumping station on

open: Pumping station off

DI standby/pin 5

In standby mode, the turbopump operates at a specified rotor speed < nominal rotation speed. The factory setting and recommended operation is 66.7 % of the nominal rotation speed.

V+: Standby activated

open: Standby off, operation at nominal rotation speed

DI2 (heater)/pin 6

V+: Heater on

open: Heater off

DI3 (sealing gas)/pin 10

V+: Sealing gas valve open

open: Sealing gas valve closed

DI error acknowledgment/pin 13

V+: Pending error messages reset when cause has been eliminated with a pulse of min. 500 ms

open: Inactive

DI remote priority/pin 14

V+: The "remote" connection has control priority over all other digital inputs.

open: Remote priority inactive

duration

18/48

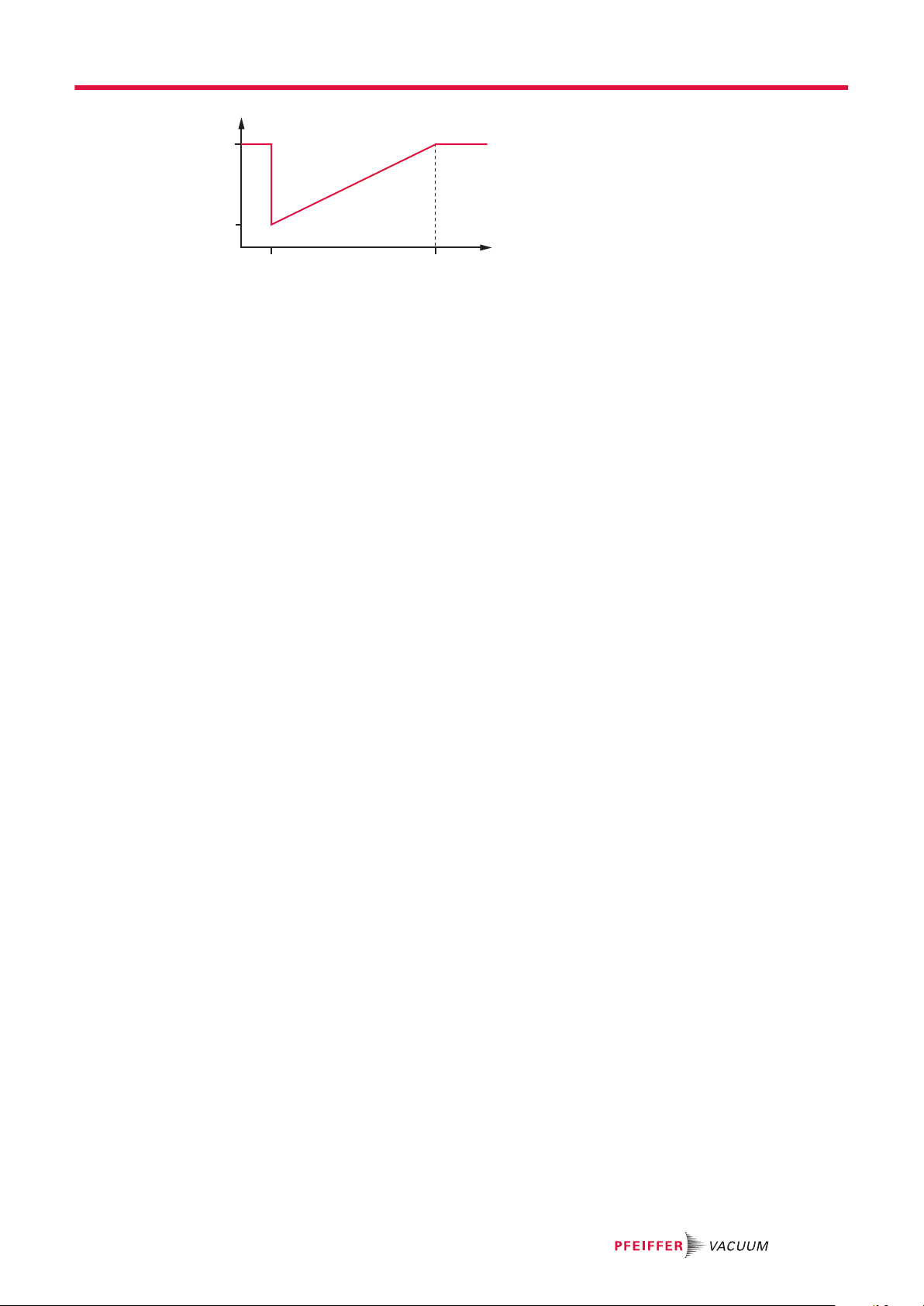

AI rotation speed setting mode/pin 7 and pin 11

The analog input serves as a rotation speed setpoint for the turbopump. An input signal of 2 to 10 V

between Al+ (pin 7) and GND (pin 11) corresponds to a rotation speed within the range of 20 to 100 %

of the nominal rotation speed. If the input is open or signals are below 2 V, the turbopump accelerates

to the nominal rotation speed.

100

20

2 10

f

(%)

U

(V)

4.2.3 Outputs

Installation

Fig. 3: Rotation speed setting mode pin 7 and pin 11

The digital outputs at the "remote" connection have a maximum load limit of 24 V/50 mA per output.

You can configure all outputs listed below with the Pfeiffer Vacuum parameter set via the RS-485 interface (description relates to factory settings).

DO1 (rotation speed switch point reached)/pin 8

Active high: After reaching the rotation speed switch point. Rotation speed switch point 1 has a factory

setting of 80% of the nominal rotation speed. This can be used for a “Ready for operation” message, for

example.

DO2 (no error)/pin 9

When the supply voltage has been connected, digital output DO2 permanently outputs 24 V DC, which

means “no error”. Active low: in case of error (group error message).

DO remote priority active/pin 23

Active high: The "remote" connection takes priority over all other potentially connected control units

(e.g. RS-485). Active low ignores the "remote" connection.

AO1 analog output 0 to 10 V DC/pin 12

You can pick off a speed-proportional voltage (0 to 10 V DC, equals 0 to 100% × f

output (load R ≥ 10 kΩ). You can assign additional functions (optionally current/power) to the analog

output via DCU, HPU or PC.

4.2.4 Relay contacts (invertible)

Relay 1/pins 15, 16 and 17

The contact between pin 16 and pin 15 is closed when the rotation speed drops below the switchpoint;

relay 1 is inactive. The contact between pin 16 and pin 17 is closed when the speed reaches the rotation speed switchpoint; relay 1 is active.

Relay 2/pins 18, 19 and 20

The contact between pin 19 and pin 18 is closed when an error is pending; relay 2 is inactive. The contact between pin 19 and pin 20 is closed in case of trouble-free operation; relay 2 is active.

Relay 3/pins 21 and 22

The contact between pin 21 and pin 22 is closed in case of inactive warning messages; relay 3 is inactive. The contact between pin 21 and pin 22 is open when warnings are pending; relay 3 is active.

4.2.5 RS-485

) at the analog

Nominal

Pin 24 and pin 25

You can connect a Pfeiffer Vacuum display and control unit (DCU or HPU) or an external PC via pin 24

and pin 25 at the "remote” connection of the electronic drive unit.

19/48

1 2

34

5

DCU 002

DCU 310 / 400

TC 400 / TM 700

HPU 001

RS-485

USB/RS-485-converter

Interfaces

5 Interfaces

5.1 Interface RS-485

The interface with the designation “RS-485” is intended for the connection of a Pfeiffer Vacuum display

and control unit (DCU or HPU) or an external computer. The connections are galvanically safe and are

isolated from the maximum supply voltage of the electronic drive unit. The electrical connections are optically decoupled internally.

Designation Value

Serial interface RS-485

Baudrate 9600 Baud

Data word length 8 bit

Parity none (no parity)

Start bits 1

Stop bits 1

Tbl. 9: Features of the RS-485 interface

Pin Assignment

1 RS-485 D+

2 +24 V output, ≤ 210 mA loading capacity

3 GND

4 RS-485 D-

5 not connected

5.1.1 Connection options

20/48

Tbl. 10: Terminal layout of the RS-485 connecting socket M12

Fig. 4: Connection options via interface RS-485

Connecting Pfeiffer Vacuum display and control panels or PC

At interface RS-485, one external control panel can be connected in each case.

1. Use the respective connection cable supplied with the control panel or from the range of accessories.

2. Use the option to connect a PC via the USB/RS-485 converter.

5.1.2 Cross-linked via the RS-485 connection

USB/RS-485-converter

TC 600 / 750

M12

RJ45

TC/TM

TC/TM

D+

D-

USB/RS-485-converter

RS 485

USB

PC

DANGER

Danger to life from electric shock

When establishing the voltages that exceed the specified safety extra-low voltage (according to IEC

60449 and VDE 0100), the insulating measures will be destroyed. There is a danger to life from electric shock at the communication interfaces.

►

Connect only suitable devices to the bus system.

Interfaces

Fig. 5: Networking of turbopumps with integrated electronic drive unit via interface RS-485

Connect the peripheral devices

The group address of the electronic drive unit is 962.

1. Install the devices according to the specification for RS-485 interfaces.

2. Make sure that all devices connected to the bus have different RS-485 device addresses [P:797].

3. Connect all devices to the bus with RS-485 D+ and RS-485 D-.

5.2 Pfeiffer Vacuum protocol for RS-485 interface

5.2.1 Telegram frame

The telegram frame of the Pfeiffer Vacuum protocol contains only ASCII code characters [32; 127], the

exception being the end character of the telegram C.R. Basically, a master (e.g. a PC) sends a

telegram, which is answered by a slave (e.g. electronic drive unit or transmitter).

a2 a1 a0 * 0 n2 n1 n0 l1 l0 dn ... d0 c2 c1 c0 C

a2 – a0 Unit address for slave

● Individual address of the unit ["001";"255"]

● Group address "9xx" for all identical units (no response)

* Action according to telegram description

● global address "000" for all units on the bus (no response)

n2 – n0 Pfeiffer Vacuum parameter numbers

R

21/48

Interfaces

I1 – I0 Data length dn to d0

dn – d0 Data in the respective data type (see chapter “Data types”, page 23).

c2 – c0 Checksum (sum of ASCII values of cells a2 to d0) modulo 256

C

R

carriage return (ASCII 13)

5.2.2 Telegram description

Data query --> ?

a2 a1 a0 0 0 n2 n1 n0 0 2 = ? c2 c1 c0 c

Control command --> !

a2 a1 a0 1 0 n2 n1 n0 l1 l0 dn ... d0 c2 c1 c0 c

Data response / Control command understood -->

a2 a1 a0 1 0 n2 n1 n0 l1 l0 dn ... d0 c2 c1 c0 c

Error message -->

a2 a1 a0 1 0 n2 n1 n0 0 6 N O _ D E F c2 c1 c0 c

_ R A N G E

_ L O G I C

R

R

R

R

NO_DEF Parameter number n2–n0 no longer exists

_RANGE Data dn–d0 outside the permissible range

_LOGIC Logical access error

5.2.3 Telegram example 1

Data query

Current rotation speed (parameter [P:309], device address slave: "123")

-->

?

1 2 3 0 0 3 0 9 0 2 = ? 1 1 2 c

ASCII 49 50 51 48 48 51 48 57 48 50 61 63 49 49 50 13

Data response: 633 Hz

Current rotation speed (parameter [P:309], device address Slave: "123")

-->

1 2 3 1 0 3 0 9 0 6 0 0 0 6 3 3 0 3 7 c

ASCII 49 50 51 49 48 51 48 57 48 54 48 48 48 54 51 51 48 51 55 13

5.2.4 Telegram example 2

Control command

Switch on the pumping station (parameter [P:010], device address Slave: "042"

0 4 2 1 0 0 1 0 0 6 1 1 1 1 1 1 0 2 0 c

-->

ASCII 48 52 50 49 48 48 49 48 48 54 49 49 49 49 49 49 48 50 48 13

!

R

R

R

Control command understood

Switch on the pumping station (parameter [P:010], device address Slave: "042"

-->

0 4 2 1 0 0 1 0 0 6 1 1 1 1 1 1 0 2 0 c

ASCII 48 52 50 49 48 48 49 48 48 54 49 49 49 49 49 49 48 50 48 13

22/48

R

5.2.5 Data types

Interfaces

No. Data type Description Length

Example

l1 – l0

0 boolean_old Logical value (false/true) 06 000000 corresponds with

false

111111 corresponds with

true

1 u_integer Positive whole number 06 000000 to 999999

2 u_real Positive fixed point number 06 001571 corresponds with

15.71

3 u_expo Positive exponential number 06 1.2E-2 corresponds with

1,2 · 10

005E8 corresponds with

5 · 10

4 string Any character string with 6 charac-

06 TC_110, TM_700

-2

8

ters. ASCII codes between 32 and

127

6 boolean_new Logical value (false/true) 01 0 corresponds with false

1 corresponds with true

7 u_short_int Positive whole number 03 000 to 999

10 u_expo_new Positive exponential number. The

last of both digits are the exponent

with a deduction of 20.

11 string16 Any character string with 16 char-

06 100023 corresponds with

1,0 · 10

100000 corresponds with

1,0 · 10

3

-20

16 this-is-an-example

acters. ASCII codes between 32

and 127

12 string8 Any character string with 8 charac-

08 Example

ters. ASCII codes between 32 and

127

23/48

Parameter set

6 Parameter set

6.1 General

Important settings and function-related characteristics are factory-programmed into the electronic drive

unit as parameters. Each parameter has a three-digit number and a description. The use of the parameter is possible via Pfeiffer Vacuum displays and control panels, or externally via RS-485 using Pfeiffer

Vacuum protocol.

The vacuum pump starts in standard mode with factory default pre-set parameters.

Non-volatile data storage

When switching off or in the event of unintentional voltage drop, the parameters and the

operating hours stay saved in the electronics.

# Three digit number of the parameter

Display Display of parameter description

Description Brief description of the parameters

Functions Function description of the parameters

Data type Type of formatting of the parameter for the use with the Pfeiffer Vacuum protocol

Access type R (read): Read access; W (write): Write access

Unit Physical unit of the described variable

min. / max. Permissible limit values for the entry of a value

default Factory default pre-setting (partially pump-specific)

The parameter can be saved non-volatile in the electronic drive unit

Tbl. 11: Explanation and meaning of the parameters

6.2 Control commands

# Display Description Functions Data

001 Heating Heating 0 = off

1 = on

002 Standby Standby 0 = off

1 = on

004 RUTimeCtrl Run-up time

control

009 ErrorAckn Error ac-

knowledgement

010 PumpgStatn Pumping sta-

tion

012 EnableVent Enable vent-

ing

017 CfgSpdSwPt Configuration

rotation

speed switch

point

0 = off

1 = on

1 = Error acknowledgement 0 W 1 1

0 = off

1 = on and error acknowledg-

ment

0 = no

1 = yes

0 = Rotation speed switch

point 1

1 = Rotation speed switch

points 1 & 2

type

0 RW 0 1 0

0 RW 0 1 0

0 RW 0 1 1

0 RW 0 1 0

0 RW 0 1 0

7 RW 0 1 0

Access

type

Unit min. max. de-

fault

24/48

Parameter set

# Display Description Functions Data

019 Cfg DO2 Output DO2

configuration

023 MotorPump Motor vac-

uum pump

024 Cfg DO1 Configuration

output DO1

025 OpMode BKP Operation

mode backup

pump

026 SpdSetMode Rotation

speed setting

mode

027 GasMode Gas mode 0 = heavy gases

028 Cfg Remote Configuration

remote

030 VentMode Venting

mode

0 = Rotation speed switch

point reached

1 = No error

2 = Error

3 = Warning

4 = Error and/or warning

5 = Set rotation speed reached

6 = Pump on

7 = Pump accelerating

8 = Pump decelerating

9 = Always "0"

10 = Always "1"

11 = Remote priority active

12 = Heating

13 = Backing pump

14 = Sealing gas

15 = Pumping station

16 = Pump rotates

17 = Pump does not rotate

19 = Pressure switch point 1

underrun

20 = Pressure switch point 2

underrun

21 = Fore-vacuum valve, de-

layed

22 = Backing pump stand-by

0 = off

1 = on

Functions, see [P:019] 7 RW 0 22 0

0 = continuous operation

1 = interval operation

2 = Delayed switching on

3 = Delayed interval operation

0 = off

1 = on

1 = light gases

2 = Helium

0 = Standard

4 = Relay, inverted

0 = delayed venting

1 = no venting

2 = direct venting

type

7 RW 0 22 1

0 RW 0 1 0

7 RW 0 3 0

7 RW 0 1 0

7 RW 0 2 0

7 RW 0 4 0

7 RW 0 2 0

Access

type

Unit min. max. de-

fault

25/48

Parameter set

# Display Description Functions Data

035 Cfg Acc A1 Configuration

accessory

connection

A1

036 Cfg Acc B1 Configuration

accessory

connection

B1

037 Cfg Acc A2 Configuration

accessory

connection

A2

038 Cfg Acc B2 Configuration

accessory

connection

B2

041 Press1HVen Enable inte-

grated HV

Sensor (IKT

only)

045 Cfg Rel R1 Configura-

tion, relay 1

046 Cfg Rel R2 Configura-

tion, relay 2

047 Cfg Rel R3 Configura-

tion, relay 3

050 SealingGas Sealing gas 0 = off

055 Cfg AO1 Configuration

output AO1

057 Cfg AI1 Configuration

Input AI1

0 = fan

1 = Venting valve, closed with-

out current

2 = Heating

3 = Backing pump

4 = Fan (temperature control-

led)

5 = Sealing gas

6 = Always "0"

7 = Always "1"

8 = Power failure venting unit

9 = TMS Heating

10 = TMS Cooling

12 = Second venting valve

13 = Sealing gas monitoring

14 = Heating (bottom part tem-

perature controlled)

Functions, see [P:035] 7 RW 0 14 1

Functions, see [P:035] 7 RW 0 14 3

Functions, see [P:035] 7 RW 0 14 2

0 = off

1 = on

2 = On, when rotation speed

switch point reached

3 = On, when pressure switch

point underrun

Functions, see [P:019] 7 RW 0 22 0

Functions, see [P:019] 7 RW 0 22 1

Functions, see [P:019] 7 RW 0 22 3

1 = on

0 = actual rotation speed

1 = output

2 = current

3 = Always 0 V

4 = Always 10 V

5 = Follows AI1

6 = Pressure value 1

7 = Pressure value 2

8 = Fore-vacuum control

0 = Switched off

1 = Setpoint in rotation speed

setting mode

type

7 RW 0 14 0

7 RW 0 3 2

0 RW 0 1 0

7 RW 0 8 0

7 RW 0 1 1

Access

type

Unit min. max. de-

fault

26/48

Parameter set

# Display Description Functions Data

060 CtrlViaInt Control via

interface

061 IntSelLckd Interface se-

lection locked

062 Cfg DI1 Configuration

input DI1

063 Cfg DI2 Input DI2

configuration

064 Cfg DI3 Input DI3

configuration

1 = remote

2 = RS-485

4 = PV.can

8 = Fieldbus

16 = E74

255 = Unlock interface selec-

tion

0 = off

1 = on

Setting ≠ [P:063/064]

0 = Deactivated

1 = Enable venting

2 = Heating

3 = Sealing gas

4 = Run-up time monitoring

5 = Rotation speed mode

7 = Enable HV sensor

Functions, see [P:062]

Setting ≠ [P:062/064]

Functions, see [P:062]

Setting ≠ [P:062/063]

type

7 RW 1 255 1

0 RW 0 1 0

7 RW 0 7 1

7 RW 0 7 2

7 RW 0 7 3

Access

type

Unit min. max. de-

fault

Tbl. 12: Control commands

6.3 Status requests

# Display Description Func-

300 RemotePrio Remote priority 0 = no

302 SpdSwPtAtt Rotation speed switchpoint

reached

303 Error code Error code 4 R

304 OvTempElec Overtemperature electronic

drive unit

305 OvTempPump Overtemperature vacuum

pump

306 SetSpdAtt Target speed reached 0 = no

307 PumpAccel Vacuum pump accelerating 0 = no

308 SetRotSpd Set rotation speed (Hz) 1 R Hz 0 999999

309 ActualSpd Actual rotation speed (Hz) 1 R Hz 0 999999

310 DrvCurrent Drive current 2 R A 0 9999.99

311 OpHrsPump Operating hours vacuum

pump

312 Fw version Firmware version electronic

drive unit

313 DrvVoltage Drive voltage 2 R V 0 9999.99

314 OpHrsElec Operating hours electronic

drive unit

tions

1 = yes

0 = no

1 = yes

0 = no

1 = yes

0 = no

1 = yes

1 = yes

1 = yes

Data

type

0 R 0 1

0 R 0 1

0 R 0 1

0 R 0 1

0 R 0 1

0 R 0 1

1 R h 0 65535

4 R

1 R h 0 65535

Access

type

Unit min. max. de-

fault

27/48

Parameter set

# Display Description Func-

tions

315 Nominal Spd Nominal rotational speed

(Hz)

316 DrvPower Drive power 1 R W 0 999999

319 PumpCycles Pump cycles 1 R 0 65535

326 TempElec Temperature electronics 1 R °C 0 999999

330 TempPmpBot Temperature pump bottom

part

336 AccelDecel Acceleration/deceleration 1 R rpm/s 0 999999

337 SealGasFlw Sealing gas flow 1 R sccm 0 999999

342 TempBearng Temperature bearing 1 R °C 0 999999

346 TempMotor Temperature motor 1 R °C 0 999999

349 ElecName Name of electronic drive

unit

354 HW Version Hardware version electron-

ic drive unit

360 ErrHist1 Error code history, item 1 4 R

361 ErrHist2 Error code history, item 2 4 R

362 ErrHist3 Error code history, item 3 4 R

363 ErrHist4 Error code history, item 4 4 R

364 ErrHist5 Error code history, item 5 4 R

365 ErrHist6 Error code history, item 6 4 R

366 ErrHist7 Error code history, item 7 4 R

367 ErrHist8 Error code history, item 8 4 R

368 ErrHist9 Error code history, item 9 4 R

369 ErrHist10 Error code history, item 10 4 R

397 SetRotSpd Set rotation speed (rpm) 1 R rpm 0 999999

398 ActualSpd Actual rotation speed (rpm) 1 R rpm 0 999999

399 NominalSpd Nominal rotation speed

(rpm)

Data

type

1 R Hz 0 999999

1 R °C 0 999999

4 R

4 R

1 R rpm 0 999999

Access

type

Unit min. max. de-

fault

Tbl. 13: Status requests

6.4 Set value settings

# Display Description Func-

tions

700 RUTimeSVal Set value run-up time 1 RW min 1 120 8

701 SpdSwPt1 Rotation speed switch point 1 1 RW % 50 97 80

707 SpdSVal Set value in rotation speed set-

ting mode

708 PwrSVal Set value power consumption 7 RW % 10 100

710 Swoff BKP Backing pump switch-off

threshold for interval operation

711 SwOn BKP Backing pump switch-on

threshold for interval operation

717 StdbySVal Set value rotation speed at

standby

719 SpdSwPt2 Rotation speed switch point 2 1 RW % 5 97 20

2) Depending on the pump type

Data

type

2 RW % 20 100 65

1 RW W 0 1000 0

1 RW W 0 1000 0

2 RW % 20 100 66.7

Access

type

Unit min. max. default

100

2)

28/48

Parameter set

# Display Description Func-

tions

720 VentSpd Venting rotation speed at de-

layed venting

721 VentTime Venting time at delayed venting 1 RW d 6 3600 3600

730 PrsSwPt 1 Pressure switch point 1 10 RW hPa

732 PrsSwPt 2 Pressure switch point 2 10 RW hPa

739 PrsSn1Name Name sensor 1 4 R

740 Pressure 1 Pressure value 1 10 RW hPa

742 PrsCorrPi 1 Correction factor 1 2 RW

749 PrsSn2Name Name sensor 2 4 R

750 Pressure 2 Pressure value 2 10 RW hPa

752 PrsCorrPi 2 Correction factor 2 2 RW

777 NomSpdConf Nominal rotation speed confir-

mation

791 SlgWrnThrs Sealing gas flow warning

threshold

797 RS485Adr RS-485 interface address 1 RW 1 255 1

Tbl. 14: Set value settings

Data

type

7 RW % 40 98 50

1 RW Hz 0 1500 0

1 RW sccm 5 200 15

Access

type

Unit min. max. default

6.5 Additional parameter for the DCU

Additional parameter in the control panel

The basic parameter set is set in the electronic drive unit ex-factory. For controlling connected external components (e.g. vacuum measuring instruments), additional parameters

(extended parameter set) are available in the corresponding Pfeiffer Vacuum display and

control panels.

●

Refer to the corresponding operating instructions of the respective components.

●

Select the extended parameter set with parameter [P:794] = 1.

# Display Description Functions Data

340 Pressure Actual pressure value

(ActiveLine)

350 Ctr Name Display and control

panel: type

351 Ctr Software Display and control

panel: software version

738 Gauge type Type of pressure gauge 4 RW

794 Param set Parameter set 0 = Basic pa-

rameter set

1 = Extended

parameter set

795 Servicelin Insert service line 7 RW 795

type

7 R hPa

4 R

4 R

7 RW 0 1 0

Access

type

Unit min. max. de-

1·10

-10

1·10

3

fault

Tbl. 15: Parameter for DCU functions

29/48

Operation

7 Operation

7.1 Configuring the connections with the Pfeiffer Vacuum parameter set

The electronic drive unit is pre-configured with the factory default basic functions and is ready for operation. For individual requirements, you can configure most connections for the electronic drive unit with

the parameter set.

7.1.1 Configuring the digital inputs

Option Description

0 = Deactivated Connection not operational

1 = Enable venting Control corresponds to parameter [P:012]

2 = Heating Control corresponds to parameter [P:001]

3 = Sealing gas Control corresponds to parameter [P:050]

4 = Run-up time control Control corresponds to parameter [P:004]

5 = Rotation speed mode Control corresponds to parameter [P:026]

7 = Enable HV sensor Control corresponds to parameter [P:041] (0 or 1 only)

Tbl. 16: Configuring parameters [P:062], [P:063] and [P:064]

7.1.2 Configuring digital outputs and relays

Meaning of "active" in the description

●

for all digital outputs: V+ active high

●

for all relays: contact changeover in accordance with the settings [P:028]

Option Description

0 = Rotation speed switchpoint

reached

1 = No error active, with trouble-free operation

2 = Error active, if the error message is active

3 = Warning active, if a warning message is active

4 = Error and/or warning active, if an error and/or warning is active

5 = Set rotation speed reached active, once the set rotation speed switch-point is reached

6 = Pump on active, if pumping station on, motor on and no error

7 = Pump accelerating active, if pumping station on, current rotation speed < set rota-

8 = Pump decelerating active if pumping station on, current rotation speed > set rota-

9 = Always "0" GND for the control of an external device

10 = Always "1" +24 V DC for the control of an external device

11 = Remote priority active active, if the remote priority is active

12 = Heating Control corresponds to parameter [P:001]

13 = Backing pump Control corresponds to parameters [P:010] and [P:025]

14 = Sealing gas Control corresponds to parameter [P:050]

15 = Pumping station Control corresponds to parameter [P:010]

16 = Pump rotates active, if rotation speed > 1 Hz

17 = Pump does not rotate active, if rotation speed < 2 Hz

18 = TMS steady state

3)

active, once the switchpoint is reached

tion speed

tion speed

Pumping station off, rotation speed > 3 Hz

active, if TMS set temperature stabilized

30/48

3) Only for vacuum pumps with a temperature management system (TMS)

Option Description

19 = Pressure switch point 1 undershot

20 = Pressure switch point 2 undershot

21 = Fore-vacuum valve, delayed +24 V DC time-delayed after pumping station on

22 = Backing pump stand-by Control of backing pump standby mode

Tbl. 17: Configuring parameters [P.019] and [P:024], or [P:045], [P:046], [P:047] and [P:028]

7.1.3 Configuring the analog input

Option Description

0 = Switched off Connection not operational

1 = Setpoint in rotation speed setting

mode

Tbl. 18: Configuring parameter [P:057]

7.1.4 Configuring the analog output

Operation

Control corresponds to parameters [P:730] ([P:740] < [P:730])

Control corresponds to parameters [P:732] ([P:750] < [P:732])

Rotation speed setting mode via pin 7 (0 - 10 V) and pin

11 (GND)

Option Description

0 = rRtation speed Rotation speed signal; 0 - 10 V DC = 0 - 100% × f

1 = Output Output signal; 0 - 10 V DC = 0 - 100% × P

2 = Current Current signal; 0 - 10 V DC = 0 - 100% × I

3 = Always 0 V Always GND

4 = Always 10 V Output of permanent 10 V DC

5 = Follows AI1 Follows analog input 1

6 = Pressure value 1 Pressure value signal;

7 = Pressure value 2

0 V: Error

1 V: Not reached

1.5 - 8.5 V for sensor RPT p (hPa) = 10

1.5 - 8.5 V for sensor IKT p (hPa) = 10

9 V: Exceed

8 = Fore-vacuum control Fore-vacuum signal; Control of Pfeiffer Vacuum turbo pumping stations

Tbl. 19: Configuring parameter [P:055]

7.1.5 Configuring the accessory connections

Electronic drive unit TC 400 accessory connection

The electronic drive unit of the turbopump offers space for the connection of maximum 4

accessory devices. M12 connector sockets with the designation "accessory" are available

for this purpose.

●

The accessory connections have been preconfigured ex factory.

●

After connecting preconfigured accessory devices, these are immediately ready for operation according to the factory settings.

●

The use of other accessories for turbopumps is possible and requires settings in the

configuration of the electronic drive unit.

●

The desired accessory output is configured via RS-485 using Pfeiffer Vacuum display

and control units or a PC.

●

You can find detailed information in the “Electronic drive unit TC 400” operating instructions.

Nominal

max

max

(U-5.5 V)

(U-10.5 V)

31/48

Operation

Procedure

►

Carry out the configuration of the connections via parameter [P:035], [P:036], [P:037] or [P:038].

Option Description

0 = Fan (continuous operation) Control via pumping station parameters

1 = Venting valve, closed without

current

2 = Heating Control via heating and speed switch point reached parameters

3 = Backing pump Control via parameter pumping station and backing pump operat-

4 = Fan (temperature controlled) Control via parameter pumping station and temperature threshold

5 = Sealing gas Control via parameter pumping station and sealing gas

6 = Always "0" GND for the control of an external device

7 = Always "1" +24 V DC for the control of an external device

8 = Power failure venting unit Control via parameter enable venting. When using a power failure

9 = TMS Heater

10 = TMS Cooling

13 = Sealing gas monitoring Control via parameter pumping station and sealing gas

14 = Heating (bottom part temperature controlled)

4)

5)

Control via parameter enable venting. When using a venting valve

closed without current

ing mode

value

venting unit

Control via TMS switchbox

Control of the cooling water supply TMS

Control of the heating. Control via bottom part heating parameter

Tbl. 20: Accessory connections

7.1.6 Select interfaces

The option "Control via Interface" serves the display of the interface currently active in the electronic

drive unit. The communication interfaces thus automatically achieve control priority.

Option Description

1 = remote Operation via connection “remote”

2 = RS-485 Operation via connection “RS-485”

4 = PV.can For service purposes only

8 = Fieldbus Operation via fieldbus

16 = E74 Operation via connection “E74”

Tbl. 21: Parameter [P:060]

7.2 Operating modes

7.2.1 Gas type-dependent operation

Turbopump destruction due to gases with too high molecular masses

The pumping of gases with impermissible high molecular masses leads to the destruction of the turbopump.

►

Make sure that the gas mode is set correctly by [P:027] in the electronic drive unit.

►

Consult Pfeiffer Vacuum before you use gases with higher molecular masses (> 80).

NOTICE

32/48

4) Only for vacuum pumps with a temperature management system (TMS)

5) Only for vacuum pumps with a temperature management system (TMS)

[P:708]

D

FB

A

C

E

P

max

P

f

N

f

Operation

High gas throughput and high rotation speed lead to strong friction heating of the rotor. To avoid overheating, power to rotation speed characteristics are implemented in the electronic drive unit. The power

characteristic enables the operation of the turbopump at any rotation speed with the maximum permissible gas throughput without thermally overloading the turbopump. The maximum power consumption depends on the gas type. 3 characteristics are available for the parameterization in order to completely

exhaust the turbopump's capacity for each gas type.

Fig. 6: Schematic diagram of power characteristics, example of heavy gases [P:027] = 0

P Power consumption C-D Power characteristic in gas mode "0" (gases with molecu-

f Rotation speed A-B Power characteristic in gas mode "1" (gases with molecu-

P

Maximum power consump-

max

tion

f

Nominal rotation speed

N

Setting the gas mode

1. Check the current gas mode set with parameter [P:027].

2. Set the parameter [P:027] to the required value.

3. If necessary, set a lower frequency in rotation speed setting mode in order to avoid rotation speed

fluctuations.

The turbopump runs up with maximum power consumption. When the nominal respective set rotation

speed is reached, the electronic drive unit automatically switches over to the chosen power characteristic of the selected gas mode. An increase in the power consumption initially compensates an increasing

gas throughput to keep the rotation speed constant. However, the turbopump heats up higher due to

increasing gas friction. When the gas-type-dependent maximum power is exceeded, the electronic drive

reduces the rotation speed until a permissible balance between power and gas friction is achieved.

7.2.2 Set value power consumption

Set parameter [P:708]

When setting the specified power consumption below 100%, the run-up time is extended.

1. Set the parameter [P:708] to the required value in %.

2. Where necessary, adjust the parameter [P:700] RUTimeSVal to avoid error messages when

starting up.

lar mass > 39, e.g. Argon)

lar mass ≤ 39)

E-F Power characteristic in gas mode "2" (Helium)

7.2.3 Run-up time

The turbopump run-up is time-monitored ex-factory. There are various causes of prolonged run-up

times, for example:

●

Excessive gas throughput

●

Leak in system

●

Setpoint of the run-up time too low

Set parameter [P:700]

1. Where applicable, eliminate any external and application-related causes.

2. Adjust the run-up time with parameter [P:700].

33/48

Process

f

(%)

t

t

t

[P:010]

[P:302]

[P:701]

[P:017] = 0

0

1

0

1

Process

f

(%)

t

t

t

[P:010]

[P:302]

[P:701]

[P:719]

[P:017] = 1

0

1

0

1

Operation

7.2.4 Rotation speed switch points

You can use the rotation speed switch point for the “turbopump operational for the process” message.

Exceeding or underrunning the active rotation speed switch point activates or deactivates a signal at the

pre-configured output on the electronic drive unit and at the status parameter [P:302].

Rotation speed switch point 1

Fig. 7:

Adjusting rotation speed switch point 1

Signal output and status parameters are based on the set value for the rotation speed switch

point 1 [P:701].

1. Set the parameter [P:701] to the required value in %.

2. Set the parameter [P:017] to "0".

Rotation speed switch points 1 & 2

Fig. 8: Rotation speed switch points 1 & 2 active, [P:701] > [P:719]

Rotation speed switch point 1 active

34/48

Process

f

(%)

t

t

t

[P:010]

[P:302]

[P:719]

[P:701]

[P:017] = 1

0

1

0

1

Operation

Fig. 9: Rotation speed switch points 1 & 2 active, [P:701] < [P:719]

Setting the rotation speed switch points 1 & 2

1. Set the parameter [P:701] to the required value in %.

2. Set the parameter [P:719] to the required value in %.

3. Set the parameter [P:017] to "1".

When the pumping station [P:010] is switched on, rotation speed switch point 1 is the signal generator.

When the pumping station is switched off, the signal output and status request orientate at rotation

speed switch point 2. The signal output is subject to the hysteresis between both switchpoints.

7.2.5 Rotation speed setting mode

The rotation speed setting mode reduces the speed and hence the pumping speed of the turbopump.

The pumping speed of the turbopump changes proportional to its rotation speed. Standby mode is ineffective during rotation speed setting mode. The set value in rotation speed setting mode [P:707] sets

the set rotation speed. The rotation speed switch point varies with the set rotation speed. Underrunning

or exceeding the set value in rotation speed setting mode activates or deactivates the status signal

[P:306] SetSpdAtt.

Permissible variable rotation speed

Values in the rotation speed setting mode or standby mode are subject to the permissible

rotation speed range of the respective vacuum pump (technical data). Underrunning the

minimum permissible value leads to the warning message Wrn100. The electronic drive

unit automatically adjusts the set rotation speed to the next valid value.

Set the rotation speed setting mode

1. Set the parameter [P:707] to the required value in %.

2. Set the parameter [P:026] to "1".

3. Check the set rotation speed (parameter [P:308] or [P:397]).

7.2.6 Standby

Pfeiffer Vacuum recommends standby mode for the turbopump during process and production stops.

When standby mode is active, the electronic drive unit reduces the rotation speed of the turbo pump.

Standby mode is ineffective during rotation speed setting mode. The factory setting for stand-by mode

is 66.7 % of the nominal rotation speed. Underrunning or exceeding the set value in standby mode activates or deactivates the status signal [P:306] SetSpdAtt.

Permissible variable rotation speed

Values in the rotation speed setting mode or standby mode are subject to the permissible

rotation speed range of the respective vacuum pump (technical data). Underrunning the

minimum permissible value leads to the warning message Wrn100. The electronic drive

unit automatically adjusts the set rotation speed to the next valid value.

35/48

Operation

Setting the related parameters

1. Set the parameter [P:717] to the required value in %.

2. Set the parameter [P:026] to "0".

3. Set the parameter [P:002] to "1".

4. Check the set rotation speed (parameter [P:308] or [P:397]).

7.2.7 Confirming the speed specification

The typical nominal rotation speed of a turbopump is preset at the factory in the electronic drive unit. If

the electronic drive unit is replaced or a different pump type is used, the reference set value of the nominal rotation speed is cleared. The manual confirmation of the nominal rotation speed is part of a redundant safety system as a measure for preventing excess rotation speed.

HiPace Confirmation of nominal rotation speed [P:777]

300 1000 Hz

400 / 700 / 800 820 Hz

Tbl. 22: Characteristic nominal rotation speeds of the turbopumps

Required aids

●

A connected Pfeiffer Vacuum display and control unit.

●

Knowledge of the configuration and setting of electronic drive unit operating parameters.

Set parameter [P:777]

►

Set the parameter [P:777] according to the pump type.

Once the nominal rotation speed is reached, the turbopump will run at idle without additional gas

throughput. Depending on process or application requirements, the nominal rotation speed can be reduced in rotation speed setting mode or stand-by mode.

7.2.8 Backing pump operating modes

Operation of a connected backing pump via the electronic drive unit depends on the backing pump type.

Operating mode [P:025] Recommended booster pump

"0" Continuous operation All backing pumps

"1" Interval mode Diaphragm pumps only

"2" Delayed switching on All backing pumps

"3" Delayed interval mode Diaphragm pumps only

Tbl. 23: Backing pump operating modes

Setting continuous operation

With "pumping station on", the electronic drive unit sends a signal to the configured accessory connection to switch on the backing pump.

1. Set the parameter [P:025] to "0".

2. Use this signal for the control of a fore-vacuum safety valve.

Set interval operation and determine the switching threshold

Interval operation extends the service life of the diaphragm of a connected diaphragm pump. Either a

diaphragm pump with a built-in semiconductor relay or an interconnected relay box with a semiconductor relay is required for interval operation. The electronic drive unit switches the backing pump on or off

depending on the power consumption of the turbopump. A relationship to the fore-vacuum pressure results from the power consumption. The backing pump operating mode offers adjustable switch-on and

switch-off thresholds. Fluctuations in the power consumption of idling turbopumps and varying fore-vacuum pressures of the backing pumps require individual settings of the interval operation.

Pfeiffer Vacuum recommends interval operation between 5 and 10 hPa. A pressure gauge and a dosing

valve are required to set the switching thresholds.

1. Set the parameter [P:025] to "1".

2. Switch on the vacuum system with the parameter [P:010] ("pumping station").

3. Wait for the run-up.

36/48

Operation

4. Allow the gas to run via the dosing valve and set the fore-vacuum pressure to 10 hPa.

5. Read the drive power at parameter [P:316] and note the value.

6. Set the switch-on threshold of the backing pump with parameter [P:711] to the determined drive

power for a 10 hPa fore-vacuum pressure.

7. Reduce the fore-vacuum pressure to 5 hPa.

8. Read the drive power at parameter [P:316] and note the value.

9. Set the switch-off threshold of the backing pump with parameter [P:710] to the determined drive

power for a 5 hPa fore-vacuum pressure.

Delayed switching on

Simultaneous switching on of the backing pump and turbopump may cause undesired gas flow. To

avoid this, depending on the process or application requirements, you can operate the backing pump

with a delayed switch-on. The delayed switch-on depends on the rotation speed of the turbopump. The

delayed switch-on has a fixed value of 360 rpm in the electronic drive unit.

●

Switch-off threshold, parameter [P:710]

●

Switch-on threshold, parameter [P:711]

●

Delay 8 s.

1. Set the parameter [P:025] to "2".

2. Use this signal for the control of a fore-vacuum safety valve.

Delayed interval operation

Fluctuations during the interval operation may lead to the underrunning or exceeding the switching

thresholds. To avoid undesired switching of the backing pump you can operate the interval operation

using a switching delay, depending on the process or application requirements. The delay is depending

on a permanently uninterrupted exceedence or undershot of the specified switching threshold.

●

Switch-off threshold, parameter [P:710]

●

Switch-on threshold, parameter [P:711]

●

Delay 8 s.

1. Set the parameter [P:025] to "3".

2. Use this signal for the control of a fore-vacuum safety valve.

7.2.9 Backing pump standby mode

In case you are using a Pfeiffer Vacuum backing pump with rotation speed control, this can be used in

standby mode by configuring the digital output [P:019] or [P:024]. The power consumption of the turbopump has a direct influence on the rotation speed of the backing pump.

Configuring the stand-by mode

1. Establish the connection of the backing pump using a suitable connecting cable.

2. Set parameter [P:019] or [P:024] to "22" (backing pump stand-by mode).

3. Find the respective standby rotation speed from the corresponding operating instructions of the

backing pump.

7.2.10 Operation with accessories

Installation and operation of accessories

Pfeiffer Vacuum offers a series of special, compatible accessories for its products.

●

Information and ordering options for approved accessories can be found online.

●

The following accessories are not included in the scope of supply.

Procedure

►

Carry out the configuration of the connections via parameter [P:035], [P:036], [P:037] or [P:038].

Configuring the heating

Activation of the connected housing heating depends on the rotation speed switch point 1 (factory setting 80% x f

►

Switch the heating on or off with parameter [P:001].

Configuring the fan

1. Set the selected parameter to “0” for continuous operation of the fan.

2. Set the selected parameter to “4” for temperature-controlled operation of the fan.

Nominal

).

37/48

Operation

Configuring the sealing gas valve

►

Using parameter [P:050], switch a connected sealing gas valve on or off via the pre-configured

output.

Monitoring the sealing gas

1. Set the selected parameter to "13".

2. Set the parameter [P:791] to the desired sealing gas flow for the warning threshold.

3. Query the sealing gas flow via parameter [P:337].

Configuring the bottom part heating

The accessory output controls the heating cartridges that maintain the bottom part of the turbopump at

maximum temperature. The control is carried out according to pump-specific requirements, depending

on the current power input of the vacuum pump and the switch point.

1. Set the selected parameter to "14".

2. Switch the heating on or off with parameter [P:001].

3. Query the bottom part temperature via parameter [P:330].

7.2.11 Venting modes

The function "pumping station" enables the venting mode of the turbopump after switching off. The signal output is carried out with a fixed delay.

Selecting the venting mode

1. Set parameter [P:012] to "1".

2. Select the venting mode with parameter [P:030] (3 possible modes).

Delayed venting

1. Configure the beginning and the time for the venting after "pumping station off" depending on the

rotation speed of the turbopump.

2. Set parameter [P:030] to "0".

3. With parameter [P:720], set the venting speed to the nominal rotation speed in %.

4. With parameter [P:721], set the venting speed in s.

The venting valve opens for the set venting time. In case of a power failure, the venting starts when

underrunning the set venting speed. The venting period depends on the residual energy delivered by

the turning rotor. The venting process stops, when power is restored.

No venting

In this operating mode, the venting is deactivated.

►

Set parameter [P:030] to "1".

Direct venting

Venting starts with a delay of 6 s after “pumping station off”. When the pumping station function is

switched back on, the venting valve closes automatically. After a power failure, the venting starts after

underrunning a fixed type-specific rotation speed. The venting process continues, when power is restored.

►

Set parameter [P:030] to "2".

7.3 Switching on the turbopump

The function "pumping station" [P:010] comprises the turbopump operation with control of all connected

accessory devices (e.g. backing pump).

Procedure

After successfully completing the self-test, the electronic drive unit resets pending and corrected error

messages. The turbopump starts and all connected accessory devices start operation according to their

configuration.

1. Set the parameter [P:023] to "1".

–

The parameter [P:023] switches on the motor of the turbopump.

2. Set the parameter [P:010] to "1".

38/48

7.4 Switching off the turbopump

Procedure

The electronic drive unit switches off the turbopump and activates pre-set accessory options (e.g. venting ON, backing pump OFF).

1. Set the parameter [P:010] to "0".

2. Wait until the turbopump comes to a complete standstill.

3. Disconnect the power supply according to the operating instructions of the turbopump or the power supply pack.

7.5 Operation monitoring

7.5.1 Operating mode display via LED

LEDs on the electronic drive unit show the basic operating states of the vacuum pump. A differentiated

error and warning display is only possible for operation with the Pfeiffer Vacuum display and control unit

or a PC.

LED Symbol LED status Display Meaning

Off Currentless

On, flashing "pumping station OFF", rotation speed

Green

Yellow Off No warning

On, inverse flashing "pumping station ON", set rotation speed not