Diaphragm Vacuum Pump

PK 800 202 B N/D (0501)

MVP 030

MVP 015-4

Betriebsanleitung • Operating Instructions

2

1. Safety Precautions .................................. 3

1.1. For Your Orientation........................................................... 3

1.2. Pictogram Definitions........................................................ 3

2. Understanding The Pump........................ 4

2.1 Main Features..................................................................... 4

2.2. Differences Between The Pump Types.......................... 4

3. Installation ............................................... 5

3.1. Setting Up The Pump And Location ................................ 5

3.2. Connecting The Vacuum Side.......................................... 5

3.3. Connecting The Exhaust Side .......................................... 5

3.4. Connecting To Mains Power............................................ 5

4. Operations ................................................ 6

4.1. Important Information ....................................................... 6

4.2. Switching ON/OFF The Pump........................................... 6

4.2. Intermittent Operations..................................................... 6

5. What To Do In Case Of Breakdown?...... 7

6. Maintenance ............................................ 8

6.1. Precautionary Measures During Maintenance Work ..8

6.2. Cleaning And Replacing Valves And Membranes.........8

6.3. Dismantling The Pump ...................................................... 8

6.4. Assembling The Pump....................................................... 8

7. Service .................................................... 10

8. Technical Data ....................................... 11

8.1. Substances Which Come Into Contact With The

Medium.............................................................................. 11

8.2. Dimensions........................................................................ 12

9. Spare Parts ............................................. 12

10. Accessories............................................ 12

Contamination Declaration ......................... 14

Conformity Declaration ................... last page

Index

Page

Please note:

Current operating instructions are also available via

www.pfeiffer-vacuum.net.

3

Danger of damage to the pump or system.

CAUTION

1. Safety Precautions

☞ Read and follow all the instructions in this manual.

☞ Inform yourself regarding:

☞ Hazards which can be caused by the pump;

☞ Hazards which can arise in your system;

☞ Hazards which can be caused by the medium being

pumped.

☞ Avoid exposing any part of the body to vacuum.

☞ Observe all safety and accident prevention regulations.

☞ Check regularly that all safety requirements are being

complied with.

☞ Do not carry out any unauthorised conversions or

modifications on the pump.

☞ When returning the pump to us please note the shipping

instructions in Section 7.

☞ Do observe strictly the proper use.

Danger of personal injury.

WARNING

Modifications reserved

1.2. Pictogram Definitions

Danger of burns from touching hot parts.

WAR N IN G

1.1. For Your Orientation

Instructions in the text

➡ Operating instructions: Here you have to do something!

Symbols used

The following symbols are used throughout in the

illustrations:

Vacuum flange

Exhaust flange

Power supply connection

Position numbers

Identical components and accessories parts have the same

position numbers in all illustrations.

Attention to particularly important information

on the product, handling the product, or to a

particular part of the documentation.

☞

PLEASE NOTE

Danger of an electric shock.

WAR N IN G

Proper use

–The Diaphragm Pump MVP 015-4/030 may only be used for

the purpose of generating vacuum.

–Do not pump corrosive or explosive gases.

– Do not pump liquids.

–Do not operate the pump in locations where there is an

explosion hazard.

–Accessories other than those named in this manual may

not be used without the agreement of Pfeiffer Vacuum.

– Do not use the connecting line between the heads of the

pump as a handle.

– Equipment must be connected only to a suitable fused and

protected electrical supply and a suitable earth point.

–Ensure that installation is in compliance with limitations

from the degree of protection, see section “Technical

Data“.

Improper Use

The following are regarded as improper:

–The pumping of corrosive gases (except with corrosive

gas processes version).

–The pumping of explosive gases.

–Operating the pump in locations where there is an explosi-

on hazard (a special version for this application is

available on request).

– The pumping of gases which are contaminated with

particles, dust and condensate.

–The Pump may not be used for the purpose of generating

pressure.

– The pumping of liquids.

–Connection to pumps and units which is not permitted

according to their operating instructions.

– Connection to units which contain touchable and voltage

carrying parts.

IImmpprrooppeerr uussee wwiillll ccaauussee aannyy rriigghhttss rreeggaarrddiinngg lliiaabbiilliittyy aanndd

gguuaarraanntteeeess ttoo b

bee ffoorrffeeiitteedd..

4

2. Understanding The Pump

2.1. Main Features

2.2. Differences Between The Pump Types

Features Unit MVP 030 MVP 015-4

Volume flow rate

at 1000 mbar and

50 Hz l/min 20 15

Pump stages three-stage four-stage

Connection of the 1-->2 in parallel 1-->2 in series

membrane heads 3-->4 in series 3-->4 in series

Final pressure

at 50 Hz mbar < 1.0 < 0.5

Mains connection Connecting cable hard-wired in

terminal box, without mains switch

MVP 030

MVP 015-4

Diaphragm Vacuum Pump MVP 015-4

1Membrane head 1

2Membrane head 2

3Membrane head 3

4Membrane head 4

5Vacuum flange (direct screw joint

6Voltage supply

7Exhaust (silencer)

9Capacitor

74 9 63

51

2

The diaphragm pump can be applied in all areas where an oilfree, dry vacuum is required.

Particularly the pump is suitable as backing pump for many

Pfeiffer Vacuum turbopumps in applications involving light

gas loads only.

Further applications:

–Pumping stations

–Plants

Research

Laboratories

Analytical

Chemistry

Leak detection

5

3. Installation

3.1. Setting Up The Pump And Location

➡ Place pump on a smooth, even surface.

➡ Anchor the pump if it is to be erected in a stationary positi-

on.

➡ Avoid mechanical stresses due to rigid connections. Insert

elastic hoses or resilient elements as couplings between

the pump and rigid pipes.

➡ Anchoring is not necessary if the pump is not erected in a

stationary position.

➡ Maximum ambient temperature +12 ... +40 °C.

➡ Where rack installation is involved, ensure adequate venti-

lation. If pump is installed above 1000 m above mean sea

level check compatibillity with applicable safety require-

ments, e. g. DIN VDE 0530 (motor may overheat due to

insufficient cooling).

3.2. Connecting The Vacuum Side

– Remove locking cap on intake connection.

– Make connection between the vacuum system and pump

as short as possible.

–Connect pump with intake connection to the apparatus.

–If liquid - which would generate vapours - is present in the

system to be evacuated, a condensate trap must be fitted

upstream of the pump.

3.3. Connecting The Exhaust Side

Pressure can rise to dangerous levels in exhaust

lines. Therefore, lay exhaust side lines without

shut-off units. Do not connect the exhaust side

with a closed system on account of the danger

of bursting.

In certain applications, exhaust gases and vapours can be

very hot and represent a health and/or environment hazard.

Lay lines from the pump sloping downwards so that

condensate cannot run back into the pump, otherwise fit a

separator.

3.4. Connecting To Mains Power

The pump is driven by AC motors with the following possible

variants:

230 V + 5% / -10%, 50 Hz

120 V + 5% / -10%, 60 Hz

Power connections must comply with local

regulations. Voltage and frequency information

given on the rating plate must correspond to the

mains voltage and frequency values. The pump

may only be connected to mains current with

earthed conductor.

WAR N IN G

CAUTION

Pump versions where the thermostatic winding

protection protrudes must be appropriately

wired to ensure the motor is protected.

CAUTION

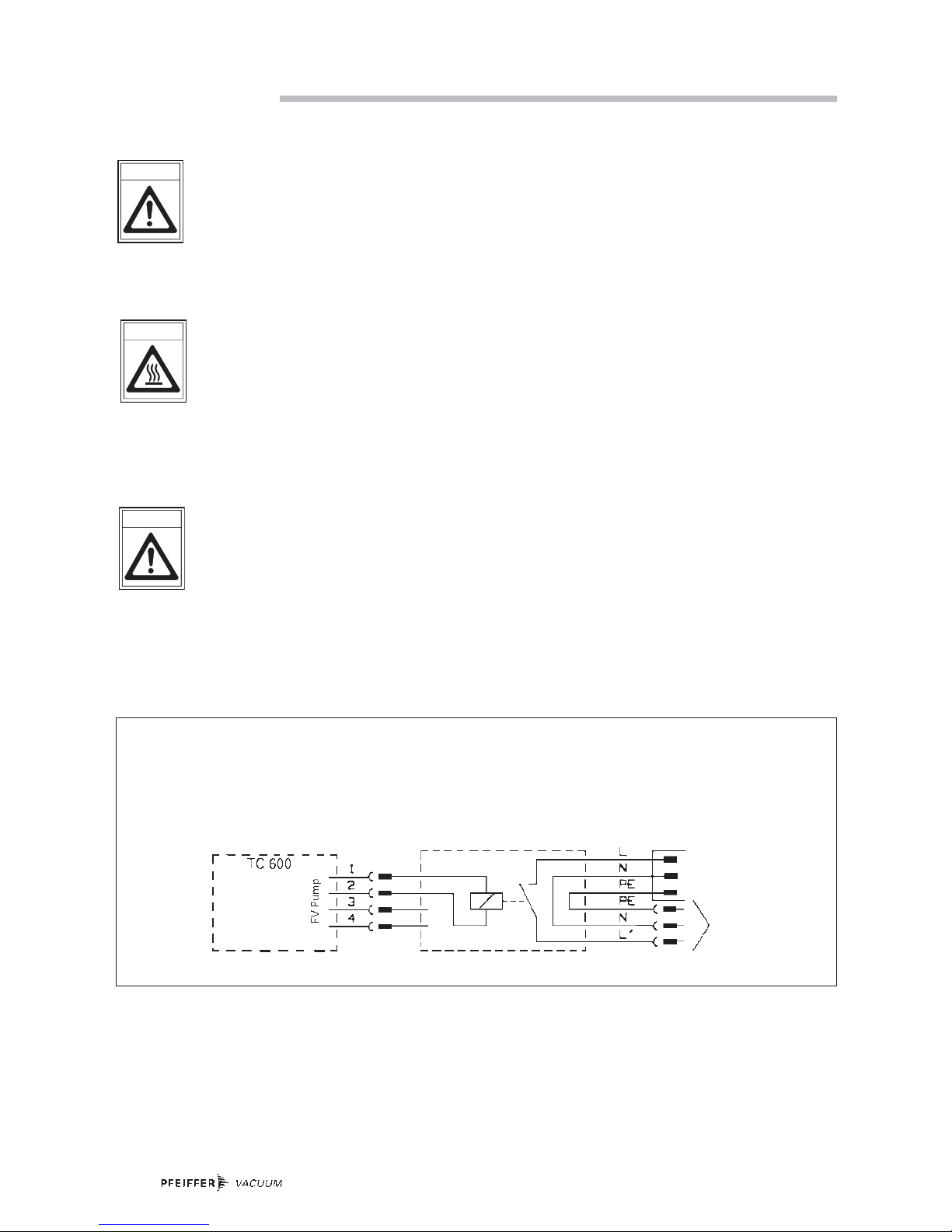

Normal version

Motor

6

4.3 Intermittent Operations

To prolong the life of diaphragm pumps, intermittent

operations can be selected with lesser gas throughputs of

< 0.18 mbar l/s. This means that, dependent on the turbo

pump power take-up, the backing pump will be switched on

and off. Turbo pump power take-up is dependent on the forevacuum pressure and gas throughput.

–By comparing the power take-up with an upper and a

lower limit value, the relative switch-on duration with

lesser gas throughputs can be reduced to approx. 1 to 60%

–To avoid too frequent switching on, the buffer volume in

the fore-vacuum line should amount to < 0.5 liter from

approx. 0.018 mbar l/s.

Possible intermittent operations variations are shown in the

following diagram:

Connection of Diaphragm Vacuum Pump with with relay box on TC 600 for intermittent operations

roughing pump

MVP series

Relaybox

PM 041 937 GT

4. Operations

4.1. Important Information

Before starting, ensure that impermissibly high

pressures cannot build up on the pressure side.

Interchanging the connections causes

dangerous excess pressure levels.

The pumps should only start, when the pressure difference is max. 1 bar between admission and exhaust,

because the motor will be blocked and damage.

When the pump is running, surfaces and motor

casing become hot.

WAR N IN G

CAUTION

4.2 Switching ON/OFF The Pump

The pump can be switched on and off at all times.

Prevent internal condensation, transfer of

liquids or dust. The diaphragm and valves will

be damaged, if liquids are pumped in significant

amount over lengthy periods!

If the pump is subjected to condensates it

should be allowed to run for a few minutes

under atmospheric pressure before switching

off.

CAUTION

7

5. What To Do In The Case Of Breakdowns ?

PPrroobblleemm PPoossssiibbllee ccaauussee RReemmeeddyy

Pump does not attain final pressure

•

Condensate in the pump

•

Run pump for a longer period under

atmospheric pressure

•

Valves/diaphragms defective/dirty •Clean or replace valves and diaphragms,

see section 6.

•

Leak in system

•

Repair leak

Unusual operating noises Valves/diaphragms defective See maintenance in section 6.

Dirt in the working chamber Clean working chamber.

Silencer loose or missing Check silencer; clean or replace.

Valves defective Change valves.

Motor fan defective Change motor fan.

Con-rod or motor bearing defective Inform Pfeiffer-Service.

Pump does not start No mains voltage Check power supply.

Phase failure Check fuse.

Motor overheating Allow the motor to cool down and

depress mains switch off/on.

Ambient temperature < 12 °C Warm pump.

Dirty valves/diaphragms See maintenance in section 6.

Over-pressure in the exhaust line Open exhaust line (open exhaust valve).

Pump switches off

•

Sticking diaphragms

•

Clean pump (see section 6.)

•

Wrong mains voltage

•

Correct as per rating plate

8

6. Maintenance

6.1. Precautionary Measures During Maintenance Work

Whenever working on the pump ensure the

motor cannot get switched on.

If necessary, remove pump from the system for

inspection. Before dismantling allow the pump

to cool down.

➡ Only dismantle the pump as far is necessary to effect

repairs.

➡ Use only benzin or the like for cleaning. Do not use

solvents.

6.2. Cleaning And Replacing Valves And

Membranes

Under normal operating conditions, the pump is maintenance

free. The valves and the diaphragms are wear parts. If the

rated ultimate vacuum is no longer achieved, the pump interior, the diaphragms and the valves must be cleaned and the

diaphragms and valves must be checked for cracks or other

damage.

Depending on individual cases it may be efficient to check

and clean the pump heads on a regular basis. In case of

normal wear the

lliiffeettiimmee ooff tthhee ddiiaapphhrraaggmmss aanndd vvaallvveess iiss >>

1100000000 ooppeerraattiinngg hhoouurrss

.

There can be different numbers of washers 17

in each membrane head. Ensure the correct

assignment for mounting when dismantling the

membrane heads. Don’t confuse the washers

17.

6.3. Dismantling The Membrane Head

➡ Allow the pump to cool down before dismantling.

➡ Using an SW 14 key, unscrew direct screw joint (20) of

interhead connection (10) on diaphragm head 1 (see marks

on the housing).

➡ As far as possible place pump on its side so that the head

to be dismantled points up.

➡ Using an SW 3 key, unscrew the four Allan head screws

(11) and remove head cover (12), taking care with the two

valve plates (13) and sealing rings (14).

➡ Remove intermediate plate (15).

➡ Use a small screwdriver to carefully ease out diaphragm

(16) and manually unscrew from the connecting rod (righthand thread). Look out for possible washers (17).

➡ Clean all parts with alcohol and examine diaphragms,

valves and seals for possible damage and renew as

necessary. If a new diaphragm is to be fitted, the washers

(17) of the old diaphragm must be used again otherwise

the pump will not attain the required pressure.

CAUTION

CAUTION

6.4. Assembling The Membrane Head

➡ Assemble all parts in reverse order. The connecting rod

should be positioned in the upper dead point when fitting

the diaphragm. Ensure correct positioning of all parts.

➡ Check correct sealing ring seating.

➡ Re-make hose connection and re-tighten direct screw

joint (20).

➡ Test pump for function.

9

11 12 13 14

15 16 17

Dismantling the membrane head

11 Allan head screw

12 Head cover

13 Valve plate

14 Sealing ring

15 Intermediate plate

16 Diaphragm

17 Washer

9 4 10a 1

11120 10 2 7 5

1Membrane head 1

2Membrane head 2

4Membrane head 4

5Vacuum flange (direct screw

joint)

7Exhaust (silencer)

9Capacitor

10 Interhead connection 1-2

10a Interhead connection 2-3

11 Allan head screw

20 direct screw joint

10

7. Service

Repair orders are carried out according to our

general conditions of sale and supply.

➡ If repairs are necessary, please send the unit together

with a short damage description to your nearest Pfeiffer

Vacuum Service Center.

☞

PLEASE NOTE

Do Make Use Of Our Service Facilities

In the event that repairs are necessary to your pumping

station, a number of options are available to you to ensure

any system down time is kept to a minimum:

–Have the pump repaired on the spot by our Pfeiffer

Vacuum Service Engineers;

–Return the individual components to the manufacturer for

repairs;

– Replace individual components with a new value

exchange units.

Local Pfeiffer Vacuum representatives can provide full

details.

Before Returning:

➡ Dismantle all accessories.

➡ Attach a clearly visible notice: “Free of contamination” (to

the unit being returned, the delivery note and accompany-

ing paperwork).

Harmful substances" are substances and preparations as

defined in current legislation. Pfeiffer Vacuum will carry out

the decontamination and invoice this work to you if you have

not attached this note. This also applies where the operator

does not have the facilities to carry out the decontamination

work. Units which are contaminated microbiologically, explosively or radioactively cannot be accepted as a matter of

principle.

Fill Out The Contamination Declaration

➡ In every case the "Contamination Declaration" must be

completed diligently and truthfully.

➡ A copy of the completed declaration must accompany the

unit; any additional copies must be sent to your local

Pfeiffer Vacuum Service Center.

Please get in touch with your local Pfeiffer Vacuum representatives if there are any questions regarding contamination.

Decontaminate units before returning or

possible disposal. Do not return any units which

are microbiologically, explosively or radioactively contaminated.

Returning Contaminated Units

If contaminated units have to be returned for

maintenance/repair, the following instructions concerning

shipping must be followed without fail:

➡ Neutralise the pump by flushing with nitrogen or dry air.

➡ Seal all openings to the air.

➡ Seal pump or unit in suitable protective foil.

➡ Ship units only in appropriate transport containers.

WARNING

11

8. Technical Data

SSiizzee UUnniitt MMVVPP 003300 MMVVPP 001155--44

Connections

Intake side DN 16 ISO-KF/G 1/8“ G 1/8“+silencer

Pressure side DN 16 ISO-KF/G 1/8 G 1/8“+silencer

Nominal volume flow rate at 1000 mbar

50 Hz l/min 20 15

60 Hz l/min 24 18

Volume flow rate at 10 mbar

50 Hz l/min 6 4

60 Hz l/min 7 4,5

Final pressure mbar ≤ 1.0 ≤ 0.5

Permissible exhaust pressure mbar 1050 1050

Leakrate to vacuum chamber

when pump is switched off mbar l/sec ≤ 5.10

-3

≤ 5.10

-3

Integral Leakrate mbar l/sec ≤ 1.10

-3

≤ 1.10

-3

Max. operating altitude (a. s. l.) m approx. 2000 approx. 2000

Max. permissible gas- and

environment temperature °C +12 ... +40 +12 ... +40

Overload protection

(coiled temperature switch) °C 118 118

Noise level dB(A) ca. 52 ca. 52

Motor (insulation material class B) IP 54 IP 54

Power at 230 V 50 Hz W 80 80

Power at 115 V 60 Hz W 80 80

Weight, approx. kg 7.5 7.5

PPuummpp ccoommppoonneennttss SSuubbssttaanncceess iinn ccoonnttaacctt wwiitthh tthhee mmeeddiiaa

((

MVP 030, MVP 015-4)

Diaphragm EPDM

Valves EPDM

Pump head Aluminium

Tupe PVC

Swivelling screw-fitting Aluminium

Silencer Polyamide

8.1. Substances Which Come Into Contact

With The Medium

12

8.2. Dimensions

9. Spare Parts

When ordering accessories and spare parts please be sure to state the full part number. When ordering spare parts please state

additionally the unit type and unit number (see rating plate). Please use this list as an order form (by taking a copy).

PPooss.. DDeessccrriippttiioonn PPiieecceess SSiizzee NNuummbbeerr CCoommmmeennttss//rreelleevvaanntt OOrrdd.. QQuuaannttiittyy

MMVVPP 003300 MMVVPP 001155--44

Spare parts pack contains 2 PK 050 094 -AT not included in the

all necessary wear parts: delivery consignment

7 Silencer 1 PO 920 791 E not included in the

delivery consignmen

10.Accessories

PPooss.. DDeessccrriippttiioonn PPiieecceess SSiizzee NNuummbbeerr CCoommmmeennttss//rreelleevvaanntt OOrrdd.. QQuuaannttiittyy

Relaybox roughing pumps, 1 phas. 5A for 1 94 x 65 x 57 (mm) PM 041 937 GT not included in the

connection on TC 600 or TC 100 with delivery consignment

TCS 010

13

Tradename Chemical name Danger class Precautions associated Action if spillage or human

Product name (or Symbol) with substance contact

Manufacturer

1.

2.

3.

4.

5.

5. Legally Binding Declaration

I hereby declare that the information supplied on this form is complete and accurate. The despatch of equipment will be in

accordance with the appropriate regulations covering Packaging, Transportation and Labelling of Dangerous Substances.

Name of Organisation: _______________________________________________________________________________

Address: _____________________________________ Post code: _____________________________________

Tel.: ______________________________________________________________________________________

Fax: _____________________________________ Telex: ________________________________________

Name: ______________________________________________________________________________________

Job title: ______________________________________________________________________________________

Date: _____________________________________ Company stamp: ________________________________

Legally binding signature: _____________________________________________________________________________

Declaration of Contamination of Vacuum Equipment and Components

The repair and/or service of vacuum components will only be

carried out if a correctly completed declaration has been

submitted. Non-completion will result in delay.

The manufacturer could refuse to accept any equipment

without a declaration.

This declaration can only be completed and signed by authorised and qualified staff:

1. Description of component:

- Equipment type/model: _________________________

- Code No.: __________________________

- Serial No.: __________________________

- Invoice No.: __________________________

- Delivery Date: __________________________

3. Equipment condition

- Has the equipment been used?

yes ❐ no ❐

- What type of pump oil was used?

___________________________________________

-Is the equipment free from potentially harmful

substances?

yes ❐ (go to section 5)

no ❐ (go to section 4)

4. Process related contamination

of equipment

-toxic yes ❐ no ❐

-corrosive yes ❐ no ❐

- microbiological hazard*) yes ❐ no ❐

-explosive*) yes ❐ no ❐

-radioactive*) yes ❐ no ❐

-other harmful substances yes ❐ no ❐

*) We will not accept delivery of any equipment that has been radioactively or microbiologically contaminated without written

evidence of decontamination!

2. Reason for return:

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

Please list all substances, gases and by-products which may have come into contact with the equipment:

14

im Sinne folgender EU-Richtlinien:

pursuant to the following EU directiv es:

- Maschinen/

Machinery

98/37/EG (Anhang/

Annex

IIA)

- Elektroma gnetische Verträglichkeit/

Electromagnetic Compatibility

89/336/EWG

- Niederspannung/

Low Voltage

73/23/EWG

Hiermit erklären wir, dass das unten aufg eführte Produkt den Bestimm ungen d er EU-Maschinenrichtlinie 98/37/E G, der EU-Richtlinie über Elektro magnetisch e Verträglichkeit 89/336/EW G und der

EU-Nie d erspannun gsrichtlinie 73/23/E W G e ntspricht.

We hereby c ertify, that the product specified belo w is in accordance with the provision of EU Machin ery

Directive 98/37/EEC, EU Electro magentic Co mpatibility Directive 89/336/EEC and E U Lo w Voltage

Directive 73/23/EEC.

Produkt/

Produc t

:

MMVVPP 0033 00

MMVVPP 00 11 55 --22

Angew e n det e Richtlinien, harmonisierte Normen u n d ange wen d ete nationale Norm e n:

Guidelines, harmonised standards, national standards w hich h a v e been applied:

DDIINN EENN IISSOO 1122110000--11 DDIINN EENN IISSOO 1122110000--22

EENN 5555 001144 EENN 5500 008811--11

EENN 229944 EENN 5500 008822--11

EENN 6600 220044--11 EENN 6600 555555--22,, -

-33

EENN 6600 333355--11 EENN 11001122--22

Unterschrift/

Signature:

Unterschriften:

(W. Dondorf)

Geschäftsführer

Managing Director

Pfeiffer Vacuum GmbH

Berliner Str. 43

35614 Asslar

Germany

Konformitätserklärung

Declaration of Conformity

Konf.I/2003

Pfeiffer Vacuum Technology AG · Headquarters/Germany

Tel. +49-(0) 64 41-8 02-0 · Fax +49-(0) 64 41-8 02-2 02 · info@pfeiffer-vacuum.de · www.pfeiffer-vacuum.net

Yo u r V a c u u m Te c h n o l o g y E x p e r t s i n

Tu r b o P u m p s

Rotary Vane Vacuum Pumps

Roots Pumps

Dry Vacuum Pumps

Leak Test Units

Val ves

Flanges, Feedthroughs

Vacuum Measurement

Gas Analysis

System Technology

Service

Loading...

Loading...