Pfeiffer Vacuum MaxiGauge TPG 256 A PT G28 760, MaxiGauge TPG 256 A PT G28 761 Operating Instructions Manual

A PASSION FOR PERFECTION

TPG 256 A

MaxiGauge™, vacuum measurement and control unit for Compact

Gauges

Operating Instructions

BG 5186 BEN / C (2013-12)

Validity

Firmware Version

Trademarks

This manual applies to products with part number:

• PT G28 760 with serial interfaces RS232C and

RS422

• PT G28 761 with serial interfaces RS232C and

RS422 and RS485 (addressable,

isolated) and RS422 (isolated)

The part number can be taken from the nameplate on

the rear panel, where the interfaces can be connected

as well (→ 12).

This manual is based on firmware version:

• BG 509 730 -K

If your unit does not behave as described in this document, please check whether it is equipped with this firmware version (→ 110).

Enter the firmware version number of your unit in the

space provided below:

• BG ..................... ..................... -.......

MaxiGauge™ INFICON GmbH

FullRange™ INFICON GmbH

We reserve the right to make engineering changes without notice.

2

BG 5186 BEN / C (2013-12) MaxiGauge.om

Contents

Validity 2

Firmware Version 2

Trademarks 2

Intended Use 6

1

2 Technical Data 8

3 Safety 15

4 Commissioning 17

4.1 Personnel 17

4.2 Set-Up, Assembly 17

4.3 Power Connection 18

4.4 Connecting the Gauges to sensor 21

4.5 control Control Connector 21

4.6 RS 232/422 Pinout Connector for Serial

Interfaces 23

4.7 RS 485/422 isol. Interface Port 23

4.8 relay Connector for Switch Contacts 23

5 Operating Elements and Modes 24

5.1 Operating Elements 24

5.2 Operating Modes (Overview) 27

5.2.1 «Measurement» Mode 28

5.2.2 «Setpoint» Mode 30

5.2.3 «General Parameter» Mode 31

5.2.4 «Sensor Parameter» Mode 32

5.2.5 «Sensor Control» Mode 33

5.2.6 «Test» Mode 34

6 Display Formats and Pressure Units 35

6.1 Display Formats 35

6.2 Pressure Units 36

6.3 Cursor 36

7 Operation 37

7.1 Personnel 37

7.2 Switching the Unit On and Off 37

7.3 Selecting the Operating Mode 39

7.4 «Measurement» Mode 40

7.4.1 Selecting the Measurement Point (Sensor) 40

7.4.2 Switching the Gauge On/Off (Sen-on/off) 41

7.4.3 Display of a Single Gauge / All Gauges

(Single/All) 41

7.5 «Setpoint» Mode 42

7.5.1 Selecting the Switching Function (Relay) 42

7.5.2 Assigning Measurement Points (Control

Sensor) 43

7.5.3 Defining the Threshold Values (Setpoint) 44

7.5.4 Underrange Control (UR-Control) 46

BG 5186 BEN / C (2013-12) MaxiGauge.om Contents 3

7.6 «General Parameter» Mode 48

7.6.1 Parameter Input Lock (Key-lock) 48

7.6.2 Selecting the Pressure Unit (Unit) 49

7.6.3 Display Resolution (Digits) 50

7.6.4 Bargraph (Bargraph) 51

7.6.5 Restoring Default Values (Default) 52

7.6.6 Defining an Interface (Interface) 53

7.6.7 Defining the Baud Rate (Baudrate) 54

7.6.8 Defining the Node Address (Address) 55

7.6.9 Screensave (Screensave) 56

7.6.10 Display Contrast (Contrast) 57

7.7 «Sensor Parameter» Mode 58

7.7.1 Selecting a Measurement Point (Sensor) 58

7.7.2 Gauge Identification (Type) 59

7.7.3 Offset Function (Offset) (zeroing) 60

7.7.4 Activating the Degas Routine (Degas) 63

7.7.5 Pirani Range Extension (Range-Ext) 64

7.7.6 Setting the Calibration Factor (Cal-Factor) 65

7.7.7 Setting the Measurement Value Filter (Filter) 66

7.7.8 Defining the Measurement Point Name

(Name) 68

7.8 «Sensor Control» Mode 69

7.8.1 Selecting the Controlled Gauge (Sensor) 71

7.8.2 Selecting the Controlling Source (Control) 71

7.8.3 Setting the «Sensor 1 ... 6» Control 72

7.8.4 Setting the «Extern» Control 72

7.8.5 Setting the «Manual» Control 73

7.8.6 Setting the «Hotstart» Control 74

7.9 Status Messages 75

7.10 Error Messages 77

8 Communication 80

8.1 Serial Interfaces 80

8.1.1 Connection Diagrams 80

8.1.2 Connection Cable 81

8.1.3 Data Transmission 82

8.2 Mnemonics 86

8.2.1 Measurement Values 87

8.2.2 Display 90

8.2.3 Switching Functions 91

8.2.4 Parameters 92

8.2.5 Interfaces 95

8.2.6 Error Messages 98

8.2.7 Test Programs for Pfeiffer Vacuum Service

Specialists 99

4

Contents BG 5186 BEN / C (2013-12) MaxiGauge.om

9 Maintenance and Care 103

9.1 Personnel 103

9.2 Cleaning 103

9.3 Maintenance 104

10 Accessories and Spare Parts 105

11 Decommissioning 107

Appendix 108

A: Validity Table 108

B: Conversion of Pressure Units 109

C: Equipment Test 109

D: Literature 113

EC Declaration of Conformity 116

For cross references to pages within this manual, the

symbol (→ XY) is used, for references to other docu-

ments, the symbol (→ [Z]).

BG 5186 BEN / C (2013-12) MaxiGauge.om Contents 5

1 Intended Use

The TPG 256 A TPG 256 A is a 6-port total pressure

measurement and control unit for Pfeiffer Vacuum Compact Gauges.

The unit has been engineered for use with the following

gauge families *

)

:

• TPR Pirani gauge

• PCR Combined Pirani/Capacitance gauge

• IKR Cold cathode gauge

• PKR Combined Pirani/cold cathode gauge

• IMR Hot ionization gauge High Pressure

(HP)

• PBR Combined Pirani/Bayard-Alpert hot

cathode ionization gauge (BA)

• CMR/ACR Capacitive gauge

• APR Piezoresistive gauge

The unit is suited for total pressure measurement in the

range of 10

-11

mbar to 50 bar (5×104 mbar). Through its

pressure dependent switching functions and the userprogrammable sensor control it can also perform a number of functions for controlling and monitoring vacuum

equipment and processes.

DANGER

Although this unit conforms to high quality and safety

standards and has been built and tested in accordance with current technology, bodily injury and property damage cannot be precluded if it is used in nonconforming applications (for purposes other than intended) or if it is not used with diligence.

Therefore, it is essential that you carefully study this

operating manual, especially the chapter "Safety".

Keep this operating manual in a convenient location

near your equipment.

6

BG 5186 BEN / C (2013-12) TPG 256 A

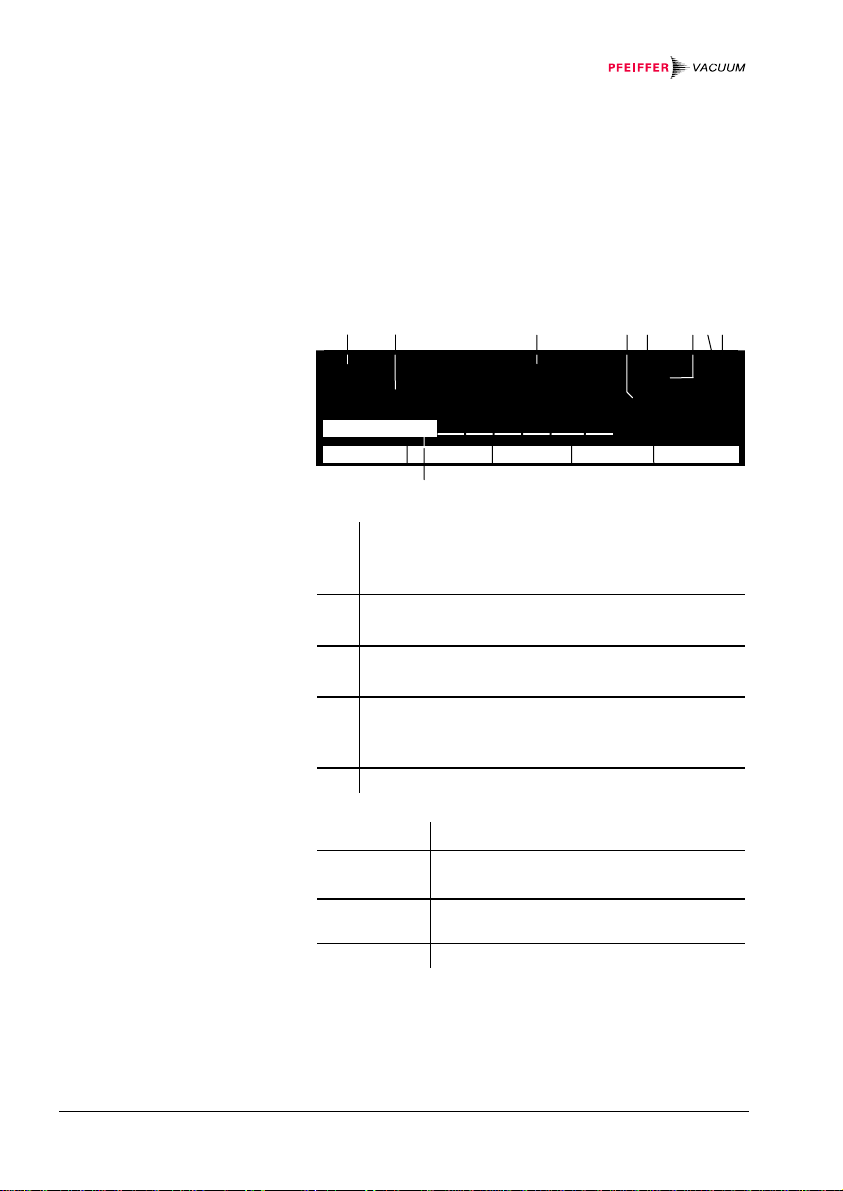

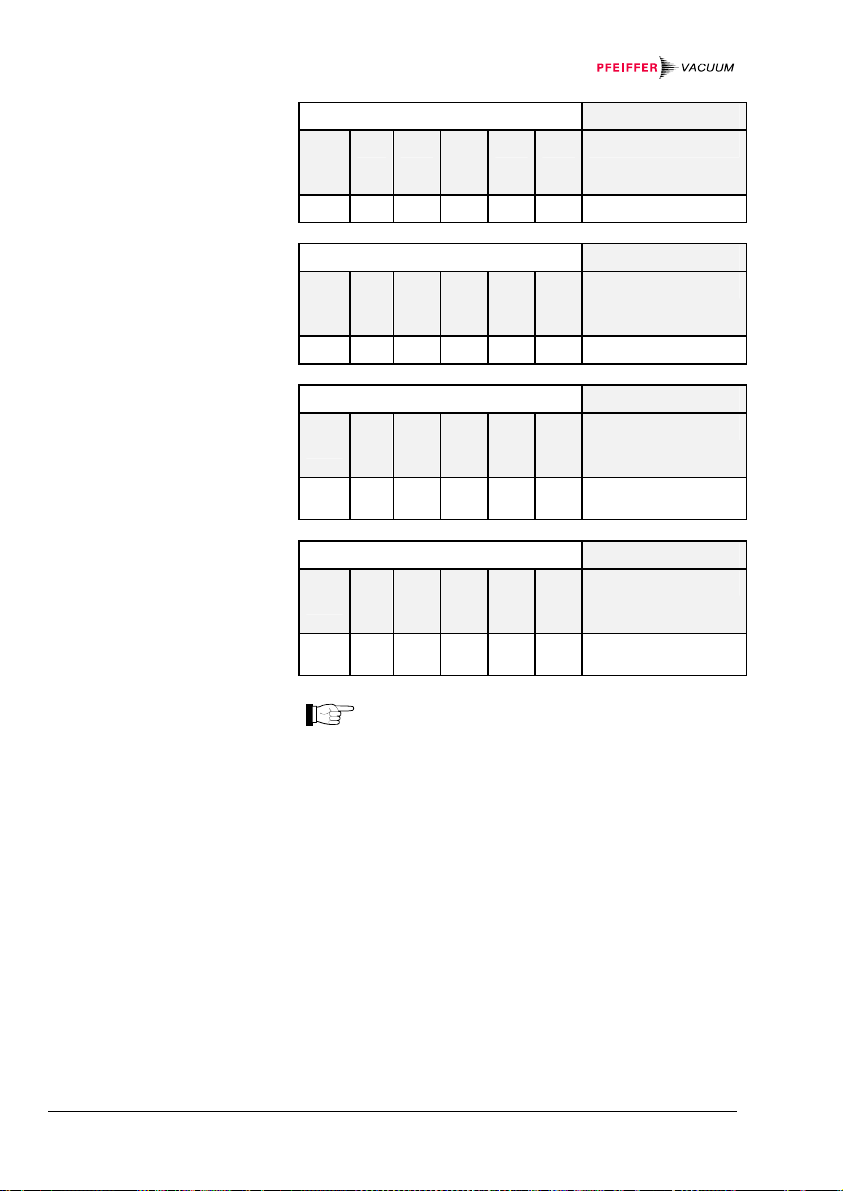

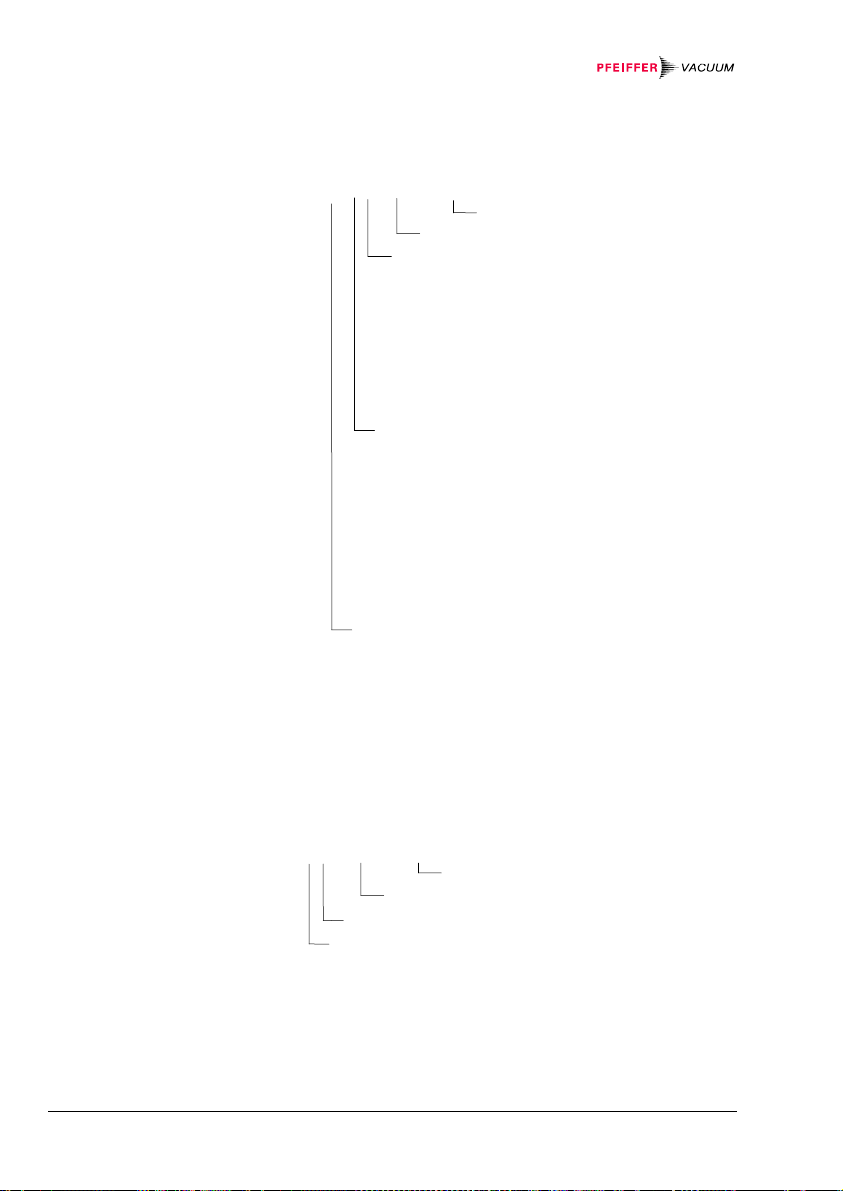

Figure 1:

Dimensions

Figure 2:

Nameplate

A Width of front panel 241 mm (½ 19" rack width)

B Mounting horizontal 224 mm

C Mounting vertical 76.2 mm

D Height of front panel 88 mm (2 height units)

E Installed depth 228.5 mm

F Installed width 207 mm

G Installed height 88 mm (2 height units)

Pfeiffer Vacuum, D-35614 Asslar

Typ:

No:

F-No:

V Hz VA

The nameplate is located on the rear panel.

Make sure that the voltage and frequency ratings conform with the local power supply system. The remaining

information is important for communication with the

Pfeiffer Vacuum customer service.

BG 5186 BEN / C (2013-12) MaxiGauge.om Technical data 7

2 Technical Data

Mechanical data

Power connection

Environment, standards

Dimensions

Weight 2.1 kg

19" rack installation

Voltage 90 ... 250 VAC / 50 ... 60 Hz

Power consumption 60 VA

Overvoltage category II

Protection class 1

Unit connector IEC 320 C14

Power switch Rear panel

Temperatures

Storage

Operation

Relative humidity Max. 80 % up to +31°C,

Use Indoors only

Contamination severity II

Protection class IP 30

Safety

EMC

→ Figure 1

→ Accessories,

-20 ... +60 °C

+ 5 ... +40 °C

decreasing to 50 % at +40 °C

maximum height 2000 m

→ 116

105

8

Technical data BG 5186 BEN / C (2013-12) MaxiGauge.om

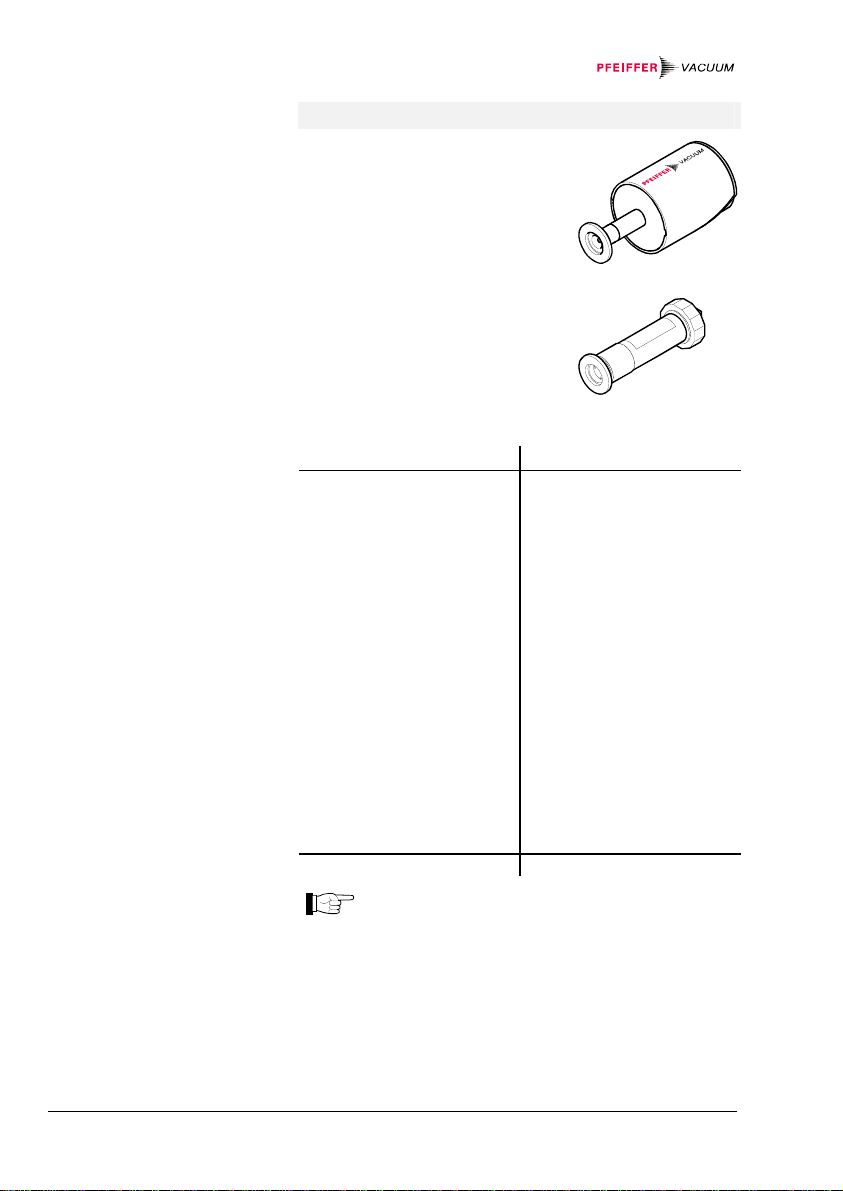

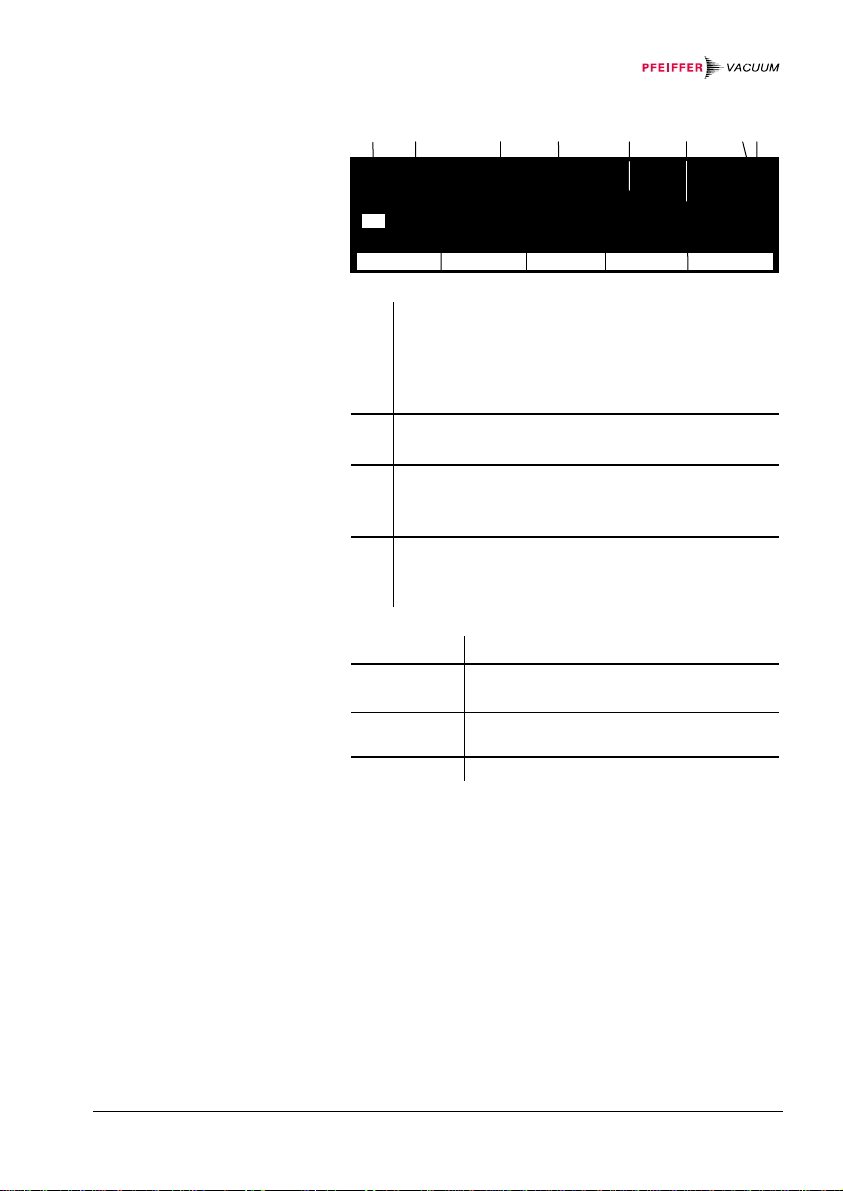

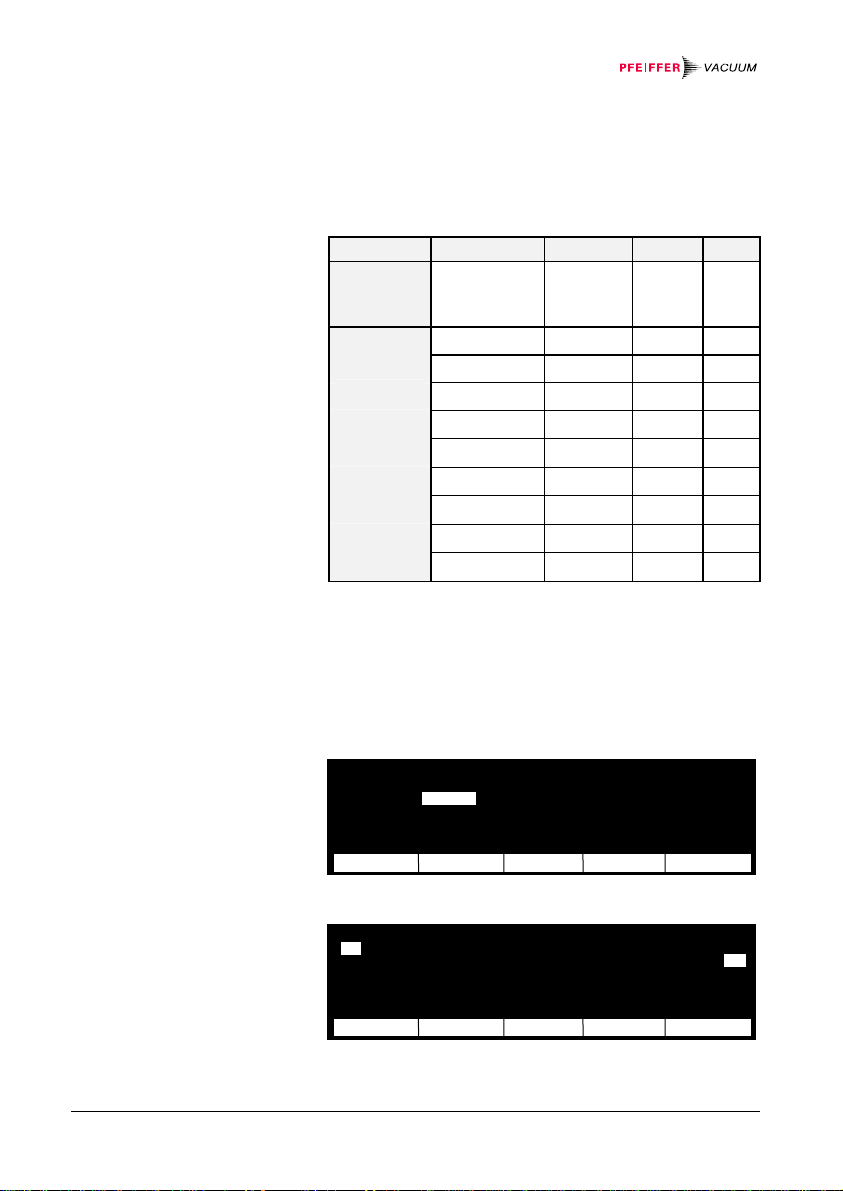

Figure 3:

Gauges

Logarithmic gauges

TPR

Compact Pirani Gauge

(Pirani gauge)

PCR

Compact Pirani Capacitance

Gauge

(Pirani/Capacitance gauge)

IKR

Compact Cold Cathode Gauge

(Cold cathode gauge)

PKR

Compact FullRange™ CC Gauge

(Pirani/Cold cathode gauge)

IMR

Compact Process Ion Gauge

(Pirani/High pressure gauge)

PBR

Compact FullRange™ BA Gauge

(Pirani/Bayard-Alpert gauge)

BG 5186 BEN / C (2013-12) MaxiGauge.om Technical data 9

Linear gauges

CMR/ACR

Compact Capacitance Gauge

(Capacitive gauge)

Gauge connections

APR

Compact Piezo Gauge

(Piezoresistive gauge)

Number 6

Compatible gauges

(→ [1] ... [18]

Compact Pirani Gauges

Compact Pirani Capacitance

Gauge

Compact Cold Cathode Gauges

Compact FullRange™ CC Gauges

Compact Process Ion Gauges

Compact FullRange™ BA Gauges

Compact Capacitance Gauges

Compact Piezo Gauges

Connector type, pin assignments

[18])

Pfeiffer Vacuum Compact

Gauges

TPR 250, TPR 260, TPR 261,

TPR 265, TPR 280, TPR 281

PCR 260, PCR 280

IKR 250, IKR 251, IKR 260,

IKR 261, IKR 270

PKR 250, PKR 251, PKR 260,

PKR 261

IMR 260, IMR 265

PBR 260

CMR 261, CMR 262, CMR 263,

CMR 264, CMR 271, CMR 272,

CMR 273, CMR 274, CMR 275;

CMR 361, CMR 362, CMR 363,

CMR 364, CMR 371, CMR 372,

CMR 373, CMR 374, CMR 375;

ACR 261, ACR 262, ACR 263,

ACR 274

APR 250, APR 260, APR 262,

APR 265, APR 266, APR 267

→ 20

With the exception of the IMR 265, PBR 260, CMR 27X

and CMR 37X, which can only be connected to ports 4 to

6, any compatible gauge type can be connected to any

analog output.

10

Technical data BG 5186 BEN / C (2013-12) MaxiGauge.om

Measured values

Gauge supply

Gauge control

Degas

Measurement ranges

Measurement error

Gain error

Offset error

→ Gauge

≤0.2 %

measurement signal

≤20 mV

Measurement rate 100 / s

Display rate 4 / s

Filter time constant

s

low

standard

fast

Voltage

Current

Sensor 1 to 3

Sensor 4 to 6

Fuse

Sensor 1 to 3

Sensor 4 to 6

2.1 s (f

320 ms (f

100 ms (f

= 0.075 Hz)

g

= 0.5 Hz)

g

= 1.6 Hz)

g

+24 VDC ± 5%

200 mA per gauge

600 mA per gauge

300 mA per gauge

1 A per gauge

(PTC element, self resetting after

unit is switched off)

Turning the gauge on / off

Manual

Automatic

Hot Start

External

Self-monitoring

Softkey (

Sen-on / Sen-off)

by gauge 1 ... 6 (

Sensor X)

(IKR, IMR by TPR, PKR, etc.)

adjustable setpoints, userassignable

IKR, PKR, IMR and PBR gauges

are turned on when the unit is

switched on

Individually for each gauge at the

«Control» connector

TTL high: +2 … 5 V = gauge off

TTL low: ≤+0.8 V = gauge on

Internal pull-up 3.3 kΩ to +5 V

IKR and IMR gauge turned off by

own measured value

Degas (PBR 260 only) Duration 3 min. (can be aborted)

BG 5186 BEN / C (2013-12) MaxiGauge.om Technical data 11

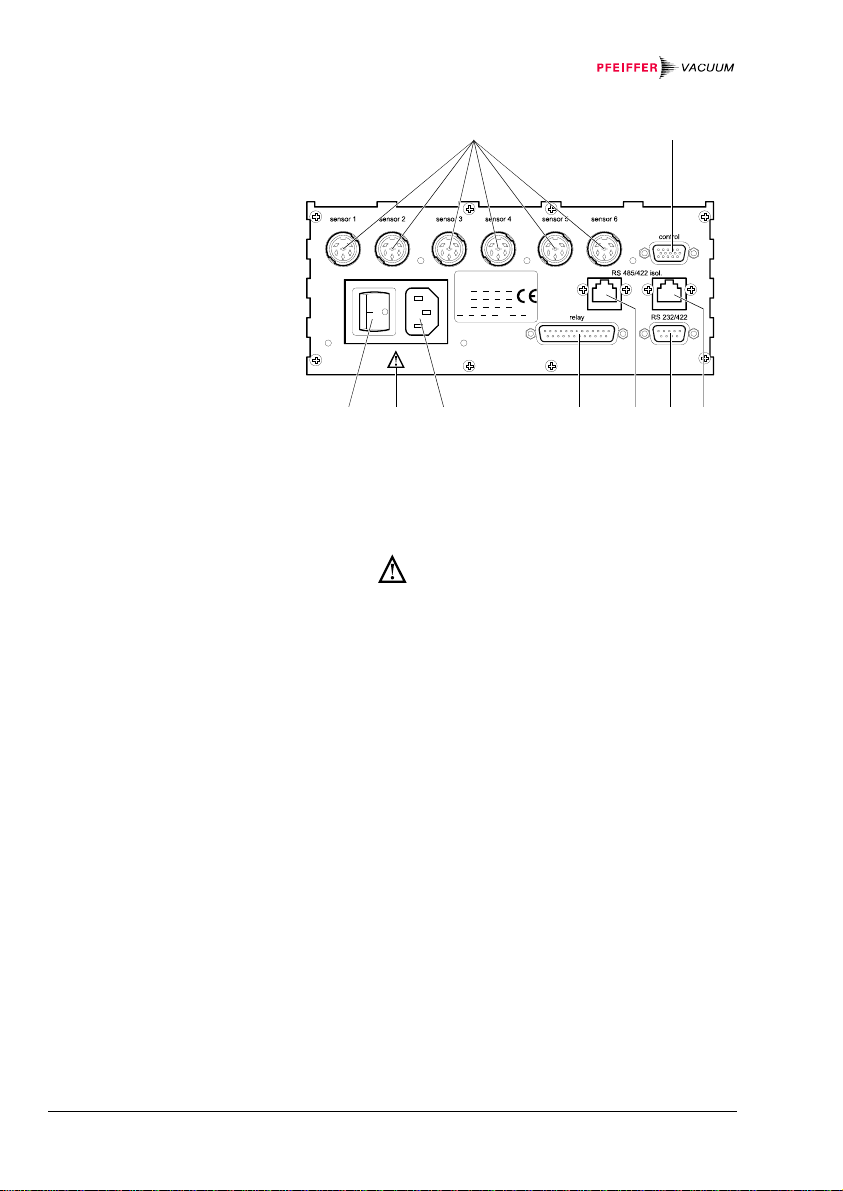

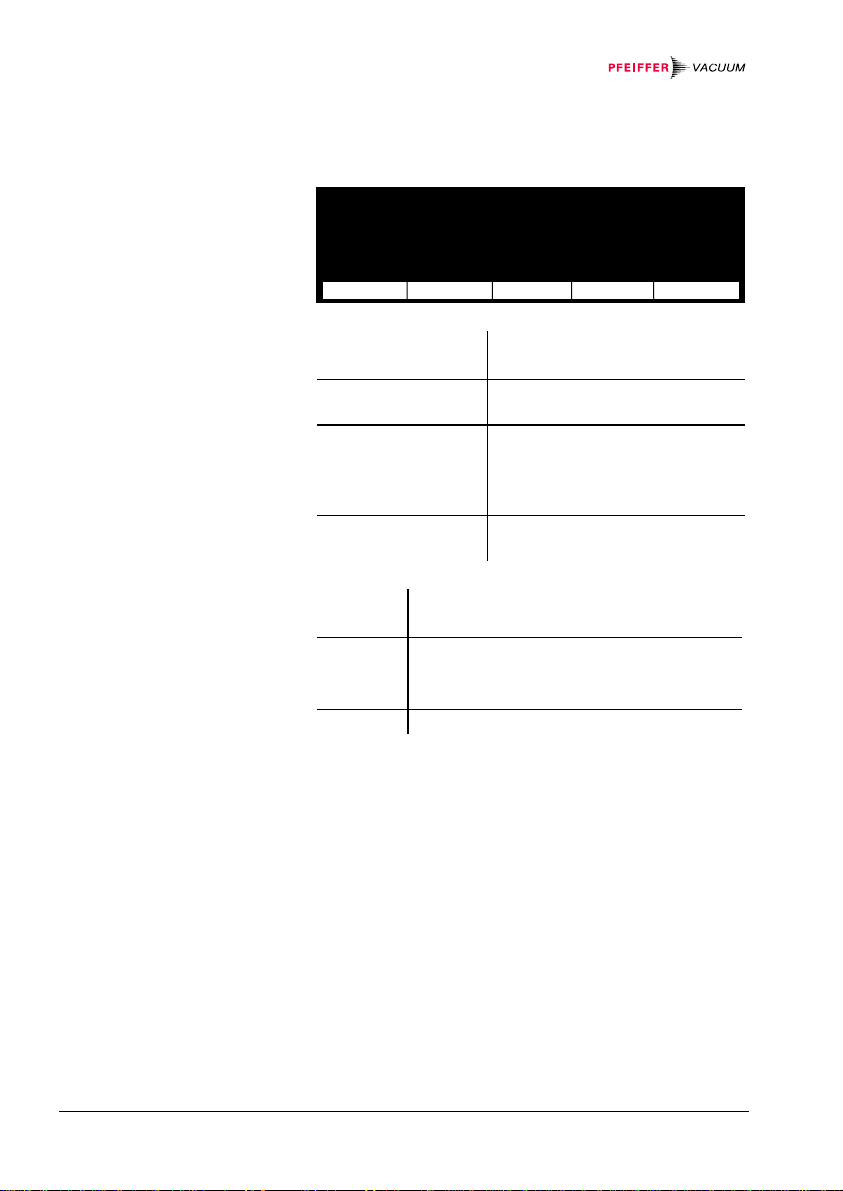

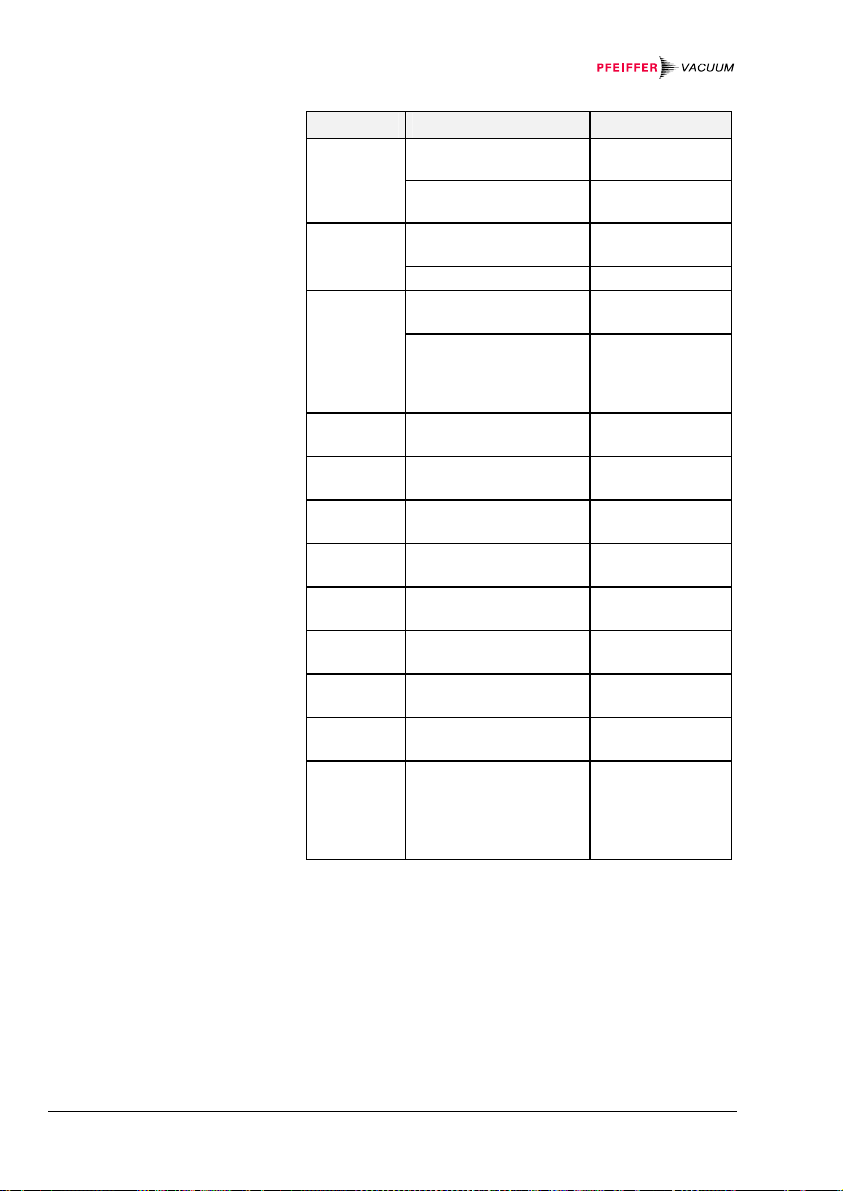

Figure 4:

Rear panel

67

1

5

1

5

6

6

234

234

1

5

6

234

ALCATEL, 7400 9 Annecy, France

Typ:

P/N:

S/N:

V Hz VA

1

5

6

1

5

234

1

5

6

6

234

234

2 9 1 84 35

TPG 256 A part number PT G28 760:

1

2

3

4

5

6

7

RS 232/422

relay

sensor 1 ...

... sensor 6

control

Pinout for serial interface RS232C or

RS422 (not isolated)

Connector for relay switch contacts

Power inlet 3-pin

Reference for fuses inside the unit

(replacement only by Pfeiffer Vacuum

Service)

Power switch

Connectors for gauges

Connector for control functions

TPG 256 A part number PT G28 761, additional features:

8,9

RS 485/422 isol.

Port for serial interface RS485

(addressable, isolated) and RS422

(isolated)

Connector types and pin assignments → 20 f.

12

Technical data BG 5186 BEN / C (2013-12) MaxiGauge.om

Switching functions

Error signal

Analog outputs

Computer interfaces

Number 6

Gauge assignment User-programmable

Response time 10 ms, if the measured value is

near the setpoint. For bigger differences, take the filter time constant into consideration.

Relay contacts Changeover switch, floating

Contact closed

Contact open

= 60 VDC / I

U

max

= 30 VAC / I

U

max

Vacuum better than setpoint

Vacuum worse than setpoint or

max

max

= 3 A

= 3 A

power switched off

Cycle life

mechanical

electrical

Connector type, pin assignment

7

5×10

cycles

1×105 cycles

→ 22

Response time 10 ms

Relay contact Changeover switch, floating

U

Contact closed

Contact open

= 60 VDC / I

max

= 30 VAC / I

U

max

No error

Error or mains power switched

max

max

= 3 A

= 3 A

off

Cycle life

mechanical

electrical

Connector type, pin assignment

7

5×10

5

1×10

→ 22

cycles

cycles

Number 6 (1 per gauge)

Voltage range 0 ... +10 V

Internal resistance

Relationship measurement signal-pressure

Connector type, pin assignment

Standard

Option (for PT G28 760)

660 Ω

→ Gauge used

→ 20

RS232C

RS422, not isolated

RS485, addressable, isolated

RS422, isolated

Protocol

RS232C

RS422, RS485

Connector type, pin assignment

ACK/NAK, ASCII

with 3 character mnemonics,

bi-directional data flow (masterslave)

(additional information → 80)

Only TXD and RXD used

Only TX+, TX-, RX+, RX- used

→ 22

BG 5186 BEN / C (2013-12) MaxiGauge.om Technical data 13

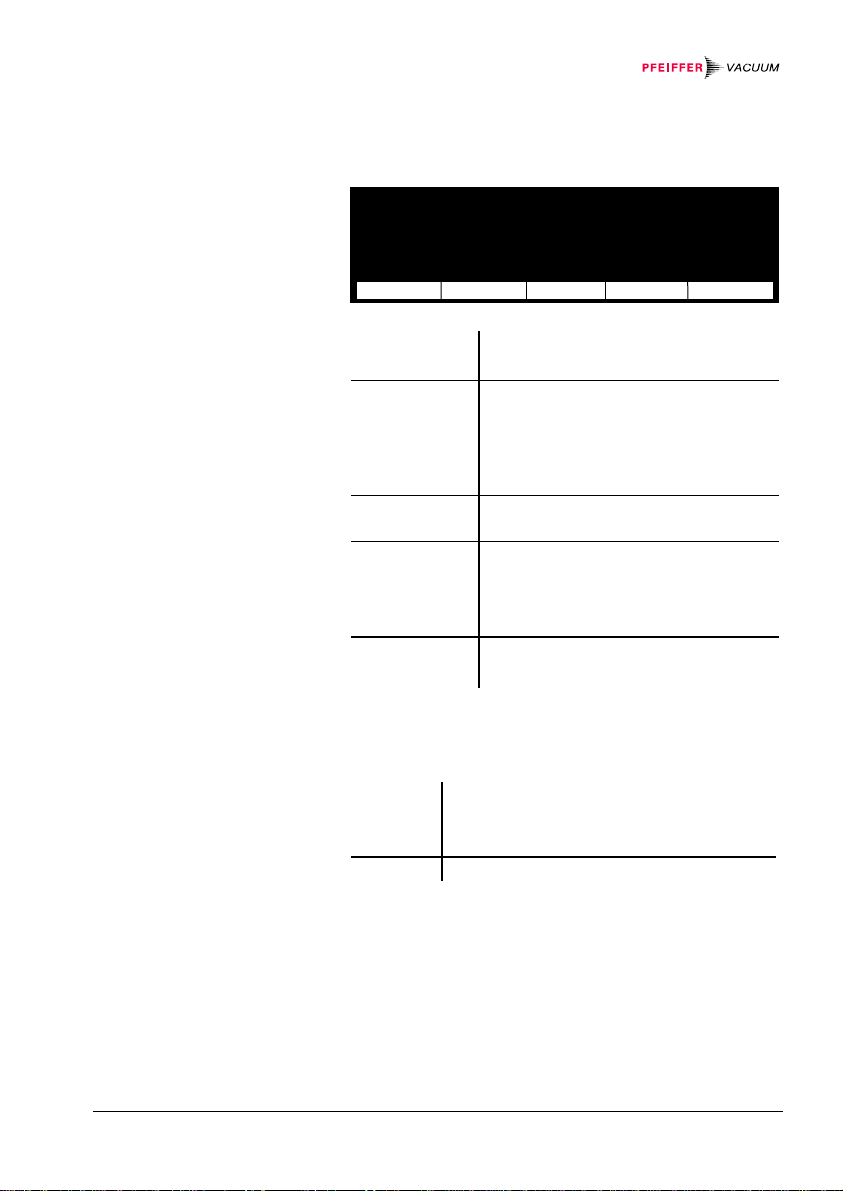

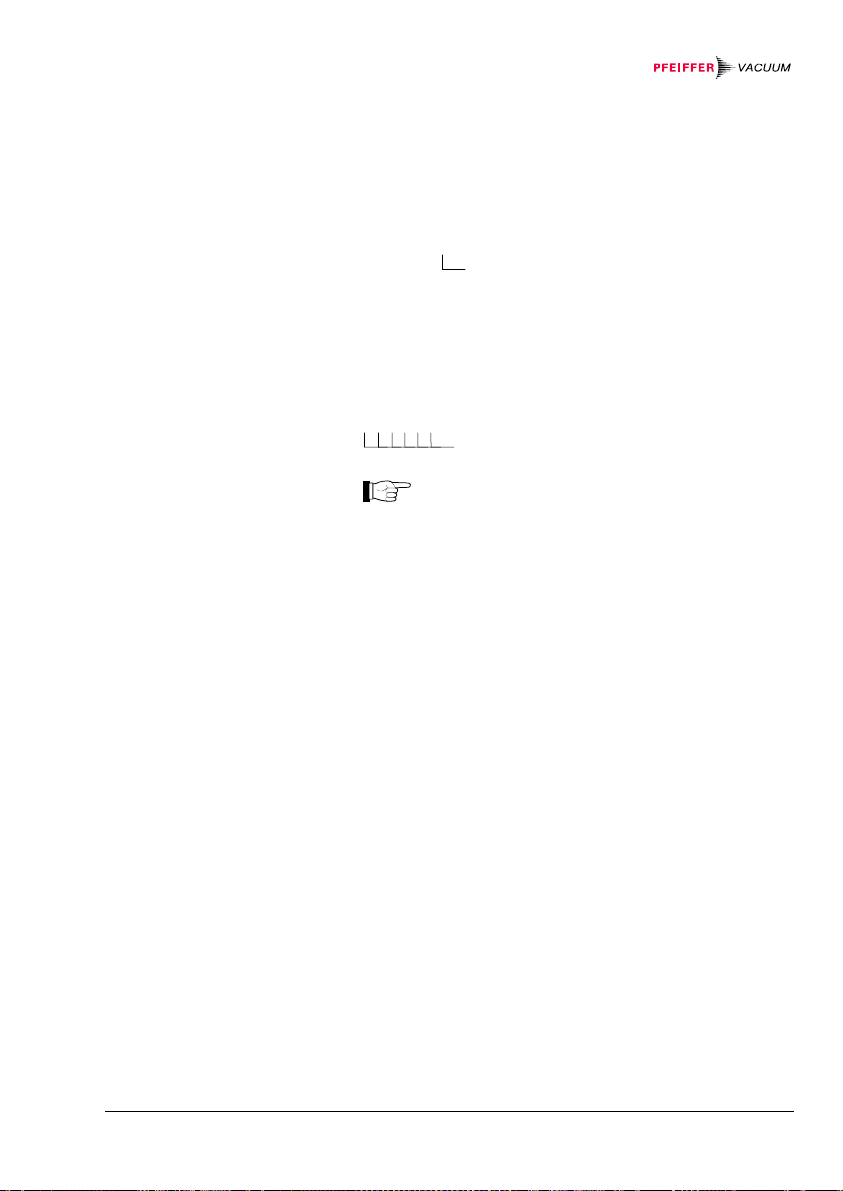

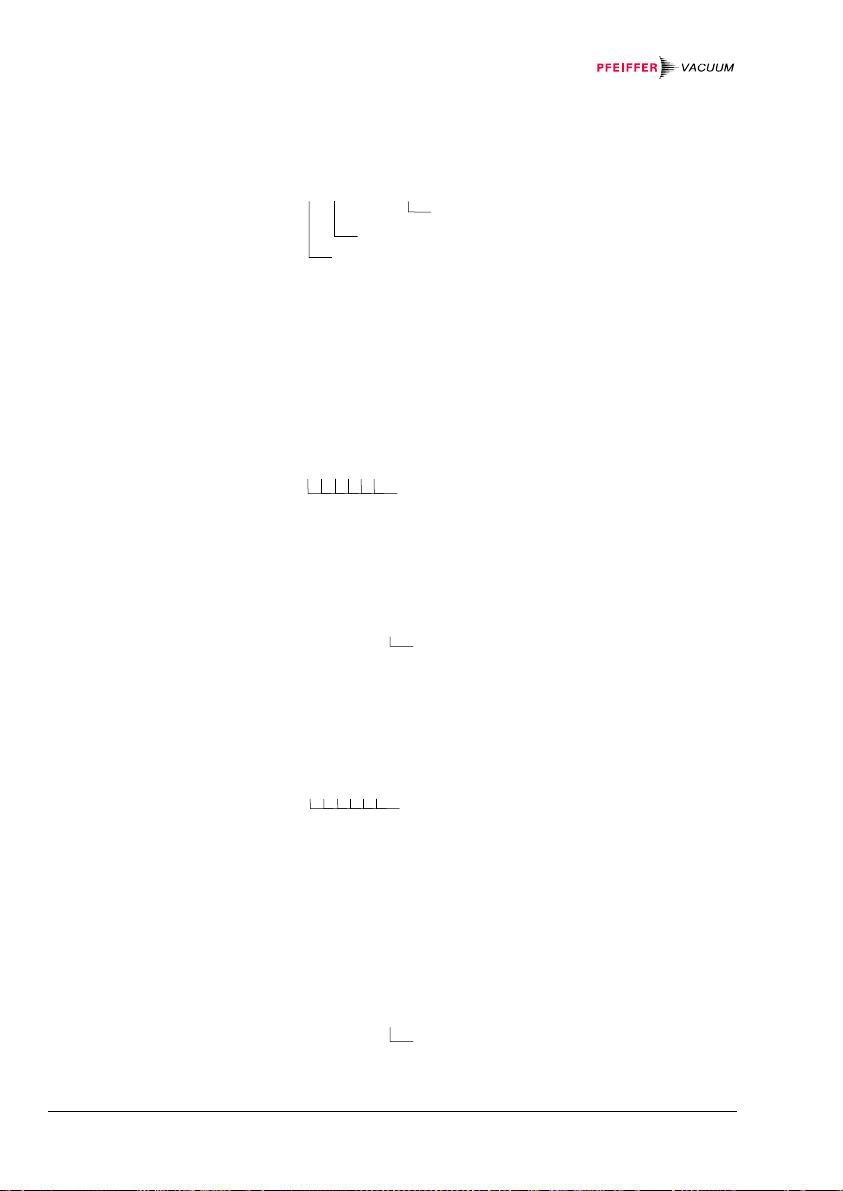

Figure 5:

Symbols for residual hazards

DANGER

Information on preventing any kind of physical injury.

Figure 6:

Symbol for special personal

qualifications

WARNING

Information on preventing extensive equipment and

environmental damage.

Caution

Information on correct handling or use. Disregard can

lead to malfunctions or minor equipment damage.

Skilled personnel

All work described in this document may only be

carried out by persons who have suitable technical

training and the necessary experience or who have

been instructed by the end-user of the product.

14 Safety

BG 5186 BEN / C (2013-12) TPG 256 A

3 Safety

3.1 Personnel

3.2 Danger, Caution,

and Note Symbols

3.3 Safety Information

3.4 Responsibility and

Warranty

Skilled personnel

Work on and with the TPG 256 A TPG 256 A may only

be carried out by persons with suitable technical

training and the necessary experience.

The opposite symbols together with explanatory text are

used to point out residual dangers inherent in conforming utilization and to emphasize important technical requirements.

• Take into account the relevant safety regulations

when doing installing and maintenance work.

Pfeiffer Vacuum declines any liability, and the warranty

becomes null and void if the operator or third parties

• utilize the product not according to the defined use

• disregard the technical data

• make any kind of changes (modifications, alterations,

etc.) to the product

• use the product with accessories not listed in the

product documentation.

BG 5186 BEN / C (2013-12) MaxiGauge.om Safety 15

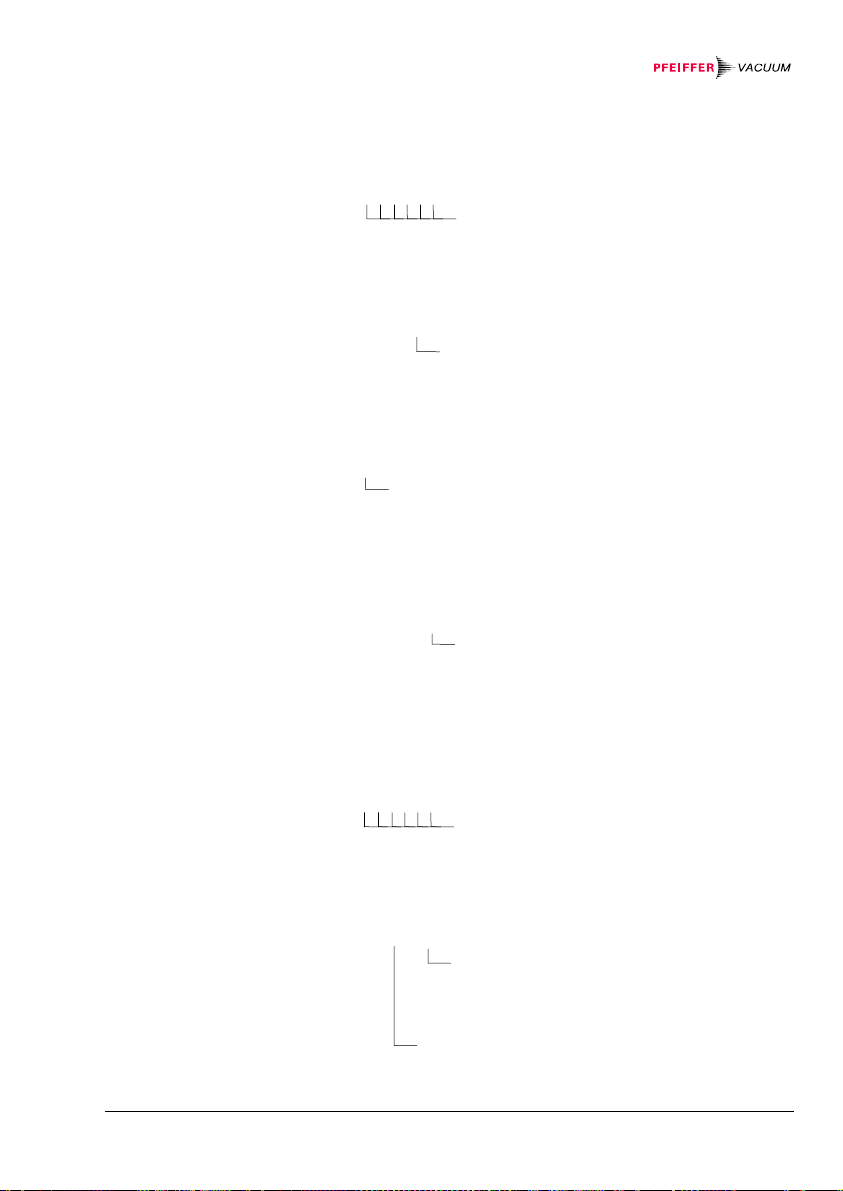

Figure 7:

Setup as desktop unit

Figure 8:

Connection cable

Make sure to provide for proper ventilation when using

the TPG 256 A as desktop unit. For this purpose, an

acrylic glass stand can be ordered as accessory

(→ Accessories 105).

Use a connection cable

with ground

conductor.

DANGER

If you can assume, for example for one of the

following reasons, that the unit is no longer safe to

operate, shut it down and secure it so that it cannot be

inadvertently turned on again:

a) the unit has sustained visible damage

b) it no longer functions

c) it has been stored for a longer period under unfa-

vorable conditions

d) it has been subjected to severe transport stress

DANGER

Any interruption of the protective ground inside or outside the unit, or disconnection of the protective ground

makes the equipment hazardous to operate (electric

shock).

16 Commissioning

BG 5186 BEN / C (2013-12) MaxiGauge.om

4 Commissioning

4.1 Personnel

4.2 Set-Up, Assembly

Skilled personnel

The unit may be put into service by skilled and suitably

trained persons only.

There are two possibilities for incorporating the unit into

a switching cabinet according to DIN 41 494:

a) Installation in a 19" rack frame (2 height units) to-

gether with a second unit or with a blanking plate

(

→ Accessories 105)

b) Installation in a 19" rack frame using an adapter

(3 height units, 63 length units, ¾ rack width)

→ Accessories 105)

(

Connection piece

PT 441 480-T

Blank panel

Direct installation in a 19"

frame

Installation with

an adapter

Maxi Gauge

Maxi Gauge

Frame width

Maxi Gauge

Maxi Gauge

PT 441 481

Adapter

PT 441 248-X

2 height units

Frame width

3 height units

With an acrylic glass stand (→ Accessories 106), it

can also be used as bench top unit.

Caution

Consider the specifications in the "Technical data"

with regard to the admissible ambient temperature, the

protection class and the voltages.

BG 5186 BEN / C (2013-12) MaxiGauge.om Commissioning 17

4.3 Power Connection

Before switching the unit on make sure that the operating voltage of the unit corresponds to the local line voltage. The power ratings are indicated on the product

nameplate on the rear panel of the unit.

Use only a 3-conductor power cable with protective

ground. The power connector may only be plugged into

a socket with a protective ground. This protection must

not be defeated by an extension cable without ground

conductor.

If the unit is to be installed in a rack, the power must be

supplied via a switched power distributor.

18 Commissioning

BG 5186 BEN / C (2013-12) MaxiGauge.om

Notes:

BG 5186 BEN / C (2013-12) MaxiGauge.om Commissioning 19

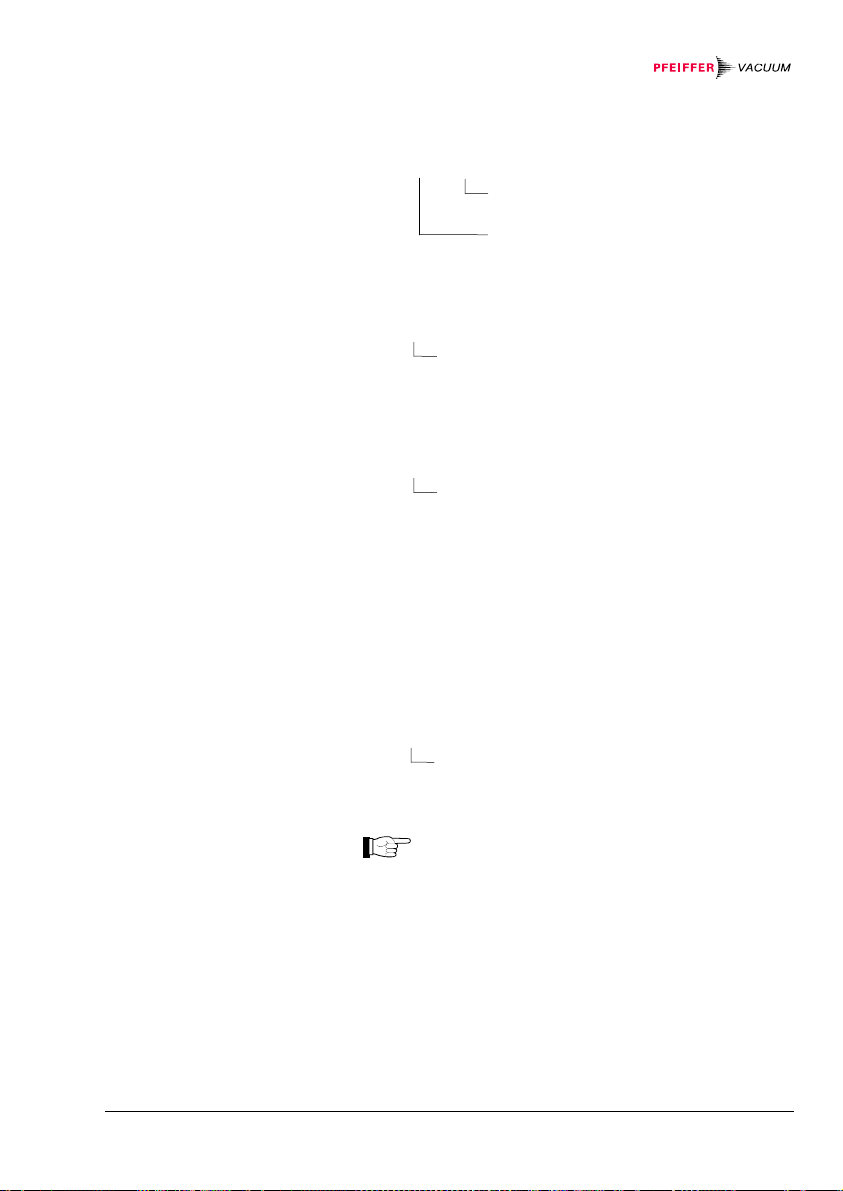

Figure 9:

Gauge connector sensor

Figure 10:

Control connector control

Pin assignment

1 Identification

2 GND

3 Measurement signal +

4 Measurement signal 5 Screen

6 Vcc

Pin assignment

1 Analog output sensor 1

2 Analog output sensor 2

3 Analog output sensor 3

4 Analog output sensor 4

5 Analog output sensor 5

6 Analog output sensor 6

7 GND

8 GND

9 GND

10 External control sensor 1

11 External control sensor 2

12 External control sensor 3

13 External control sensor 4

14 External control sensor 5

15 External control sensor 6

Amphenol C91B,

6-pin, female

6

5

4

1

2

3

Front view

D-Sub, high density,

15-pin, female

515110 6

11

Front view

20 Commissioning

BG 5186 BEN / C (2013-12) MaxiGauge.om

4.4 Connecting the

Gauges to sensor

4.5 control

Control Connector

Caution

Switch the unit off before connecting or removing any

gauges.

Connect the gauge to one of the six connectors sensor 1

… sensor 6 (PBR 260, IMR 265, CMR 27X and

CMR 37X only to sensor 4 … sensor 6) on the rear

panel of the unit by means of a shielded cable (electromagnetic compatibility). Connect only gauge types

specified in the "Technical Data".

Pre-fabricated connection cables as well as individual

parts for custom cable fabrication are available

(→ Accessories 105).

Configure the control connector as required. Plug it into

the control socket on the rear panel.

Caution

Use only shielded cables (electromagnetic compatibility).

BG 5186 BEN / C (2013-12) MaxiGauge.om Commissioning 21

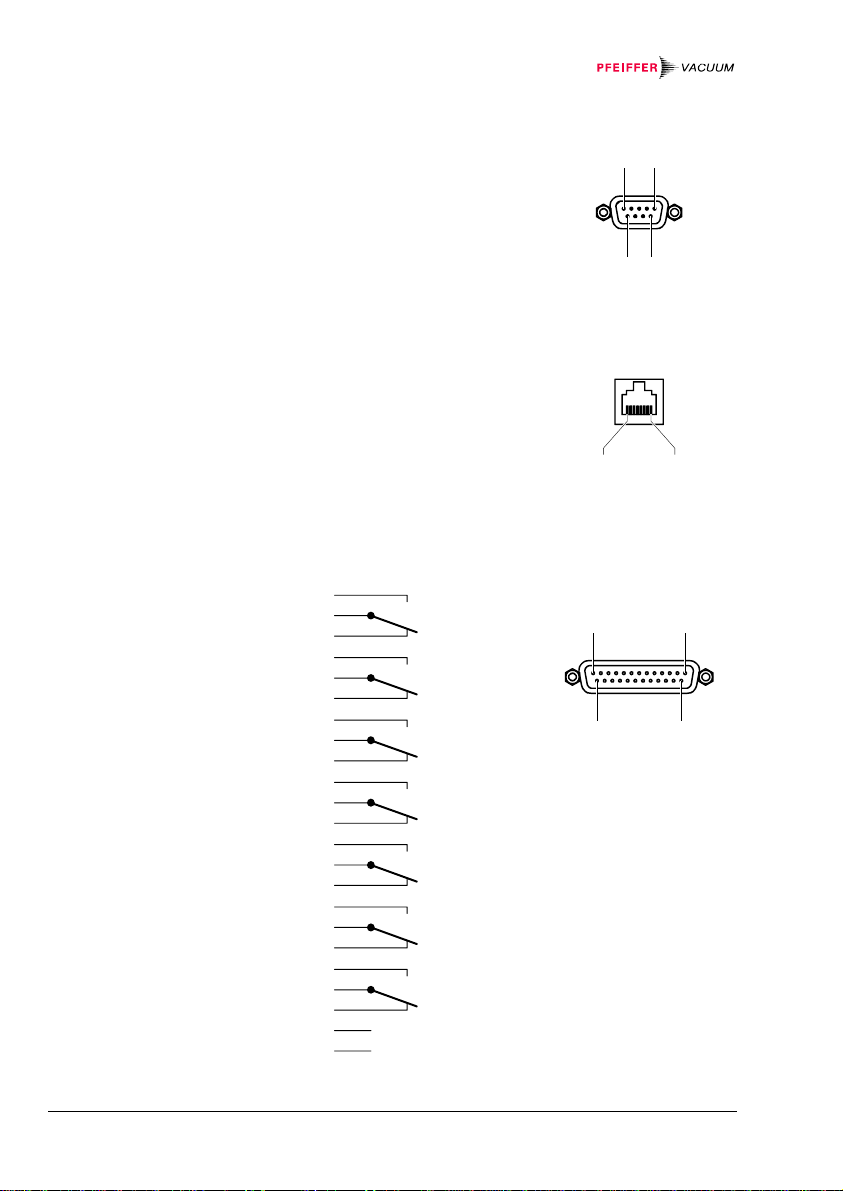

Figure 11:

RS 232/422

Pinout connector for serial

interfaces

Figure: 12

RS 485/422 isol.

Serial interface port

Figure 13:

relay

Connector for switch contacts

Pin assignment

1 Chassis

2 RXD (RS232C)

3 TXD (RS232C)

4 not connected

5 Signal Ground

6 RX+ (RS422)

7 RX- (RS422)

8 TX+ (RS422)

9 TX- (RS422)

Pin assignment

1 TX+

2 TX 3 RX+

4 not connected

5 not connected

6 RX 7 not connected

8 Isolation ground

Pin assignment

6

5

Relay A

4

10

9

Relay B

8

13

12

Relay C

11

18

17

Relay D

16

21

20

Relay E

19

24

23

Relay F

22

14

15

Error Relay

3

25

1.7

+24 V max. 200 mA

GND (Chassis)

D-Sub, 9-pin, male

165

9

Front view

RJ45, 8-pin

18

Front view

D-Sub, 25-pin,

female

13

25

1

14

Front view

22 Commissioning

BG 5186 BEN / C (2013-12) MaxiGauge.om

4.6 RS 232/422

Pinout Connector

for Serial Interfaces

4.7 RS 485/422 isol.

Interface Port

4.8 relay

Connector for

Switch Contacts

Connect the serial interface to the RS 232/422 pinout

connector on the back of the unit by means of a shielded

cable (electromagnetic compatibility).

Connect the serial interface to the RS 485/422 isol. port

on the back of the unit by means of a shielded cable

(electromagnetic compatibility).

The two connectors are linked 1:1. This allows for easy

integration of the TPG 256 A into a network.

Connect the peripheral components to the relay con-

nector on the back of the unit by means of a shielded

cable (electromagnetic compatibility).

WARNING

Only low voltages (→ 13) may be connected. Higher

voltages can damage equipment components.

A relay interface with changeover contacts for

250 V / 5 A is available as accessory (→ 105).

BG 5186 BEN / C (2013-12) MaxiGauge.om Commissioning 23

5 Operating Elements and Modes

5.1 Operating Elements

Softkeys

Power switch

The TPG 256 A is operated with the five softkeys on the

front panel (→ figure 14). The functions of these softkeys

vary depending on the operating mode the unit is in. The

current function is indicated by the LCD graphic display.

The mains power switch is located on the back of the

unit (→ figure 15). When the unit is on, the mains power

indicator (green LED) on the front panel is lit (→ figure

14).

When (Screensave) is activated, it may seem

that the unit is switched off (→ 56).

24 Operating elements and modes

BG 5186 BEN / C (2013-12) MaxiGauge.om

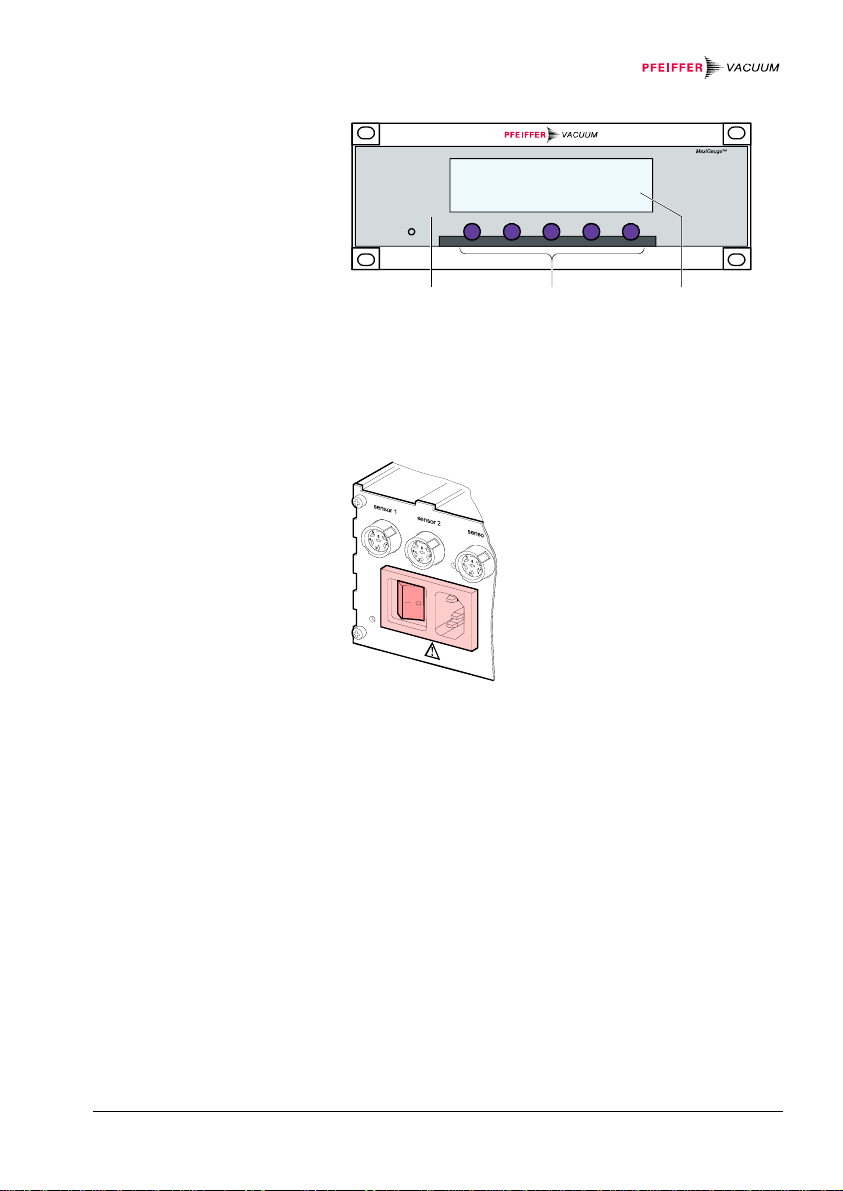

Figure 14:

Front panel

Figure 15:

Power switch

12 3

1 Mains power indicator (green LED): on / off

2 Display (LCD): Measured values and operation data

3 5 Softkeys (operating keys with varying functions)

BG 5186 BEN / C (2013-12) MaxiGauge.om Operating elements and modes 25

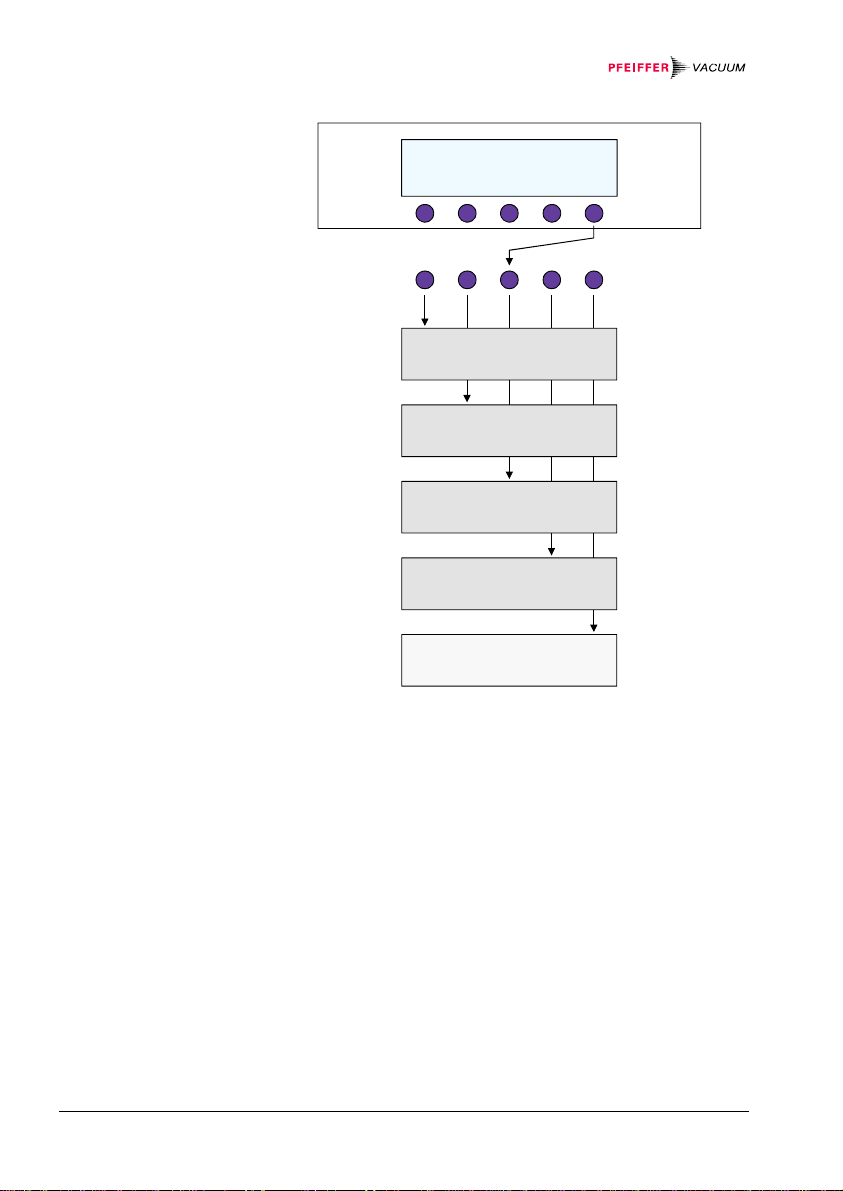

Figure 16:

Operating modes

Measurement Mode

Setpoint Mode

General Parameter Mode

Sensor Parameter Mode

Sensor Control Mode

Test Mode

26 Operating elements and modes

BG 5186 BEN / C (2013-12) MaxiGauge.om

5.2 Operating Modes

(Overview)

«Measurement»

«Setpoint»

«General Parameter»

«Sensor Parameter»

«Sensor Control»

«Test»

In «Measurement» mode, the TPG 256 A displays either

the measured value of one single gauge at a time in big

characters or the measured values of all gauges

simultaneously in small characters (→ 28, 40).

In «Setpoint» mode, a you can assign a switching function to a measurement point and define the corresponding setpoints (→ 30, 42).

In «General Parameter» mode, you can define the system parameters (for all connected gauges together)

(→ 31, 48).

In «Sensor Parameter» mode, you can define the relevant parameters for each gauge (→ 32, 58).

In «Sensor Control» mode, you can define how an individual gauge is switched on / off (→ 33, 69).

The «Test» mode is used for diagnostic and service purposes (troubleshooting). Special knowledge and skills

are necessary for this work (→ 34, 109).

BG 5186 BEN / C (2013-12) MaxiGauge.om Operating elements and modes 27

5.2.1 «Measurement»

S

All

Mode

Figure 17:

«Single» display

Display

Softkeys

If the MaxiGauge is operated with linear gauges

(CMR 261 … 375, APR 250 … 267), negative pressures

may be indicated.

Possible causes:

• negative drift

• offset correction activated with positive offset

³´μ ³´μ Ø´Ù ³´μ Ø´Ù offset A¡

óÅ ¸ ÆÚ Â ÆÚ cal B¢

ÆÇÈ » õÝ ×ºÕ õÝ C£

ÉÊË CH 2 Ó½¾ Û ¼½¾ ß Û mbar D¤

E¥

ª£ F¦

ª¢

ensor

Mode

Measurement point selected (from 1 ... 6)

Name of measurement point, 4 characters, userdefinable (→ 68)

Measured value or status (→ 35)

Unit of measurement (→ 49)

Offset correction activated (→ 60)

Calibration factor ≠ 1.00 (→ 65)

Designation of the switching function (A ... F)

(→ 42)

Controlling source (from 1 ... 6) (→ 43)

Bargraph (analog measured value) (→ 51)

Sensor Selection of measurement point

Sen-on *

Sen-off *

All Displaying the measured values of all

)

Turning the gauge on

)

Turning the gauge off

measurement points

Mode Activating the operating mode selection

*) This parameter is not available for all gauge types

(→ Validity table 108).

28 Operating elements and modes

BG 5186 BEN / C (2013-12) MaxiGauge.om

Figure 18:

S

5

«All» display

Display

Softkeys

1 CH 1 2.9E-02 mbar A¡

2 CH 2 244.5 mbar B¢

3 CH 3 1.3E-08 mbar cal C£

4 CH 4 9.9E-08 mbar degas D¤

CH 5 0.00530 mbar offset E¥

6 CH 6 no Sensor F¦

ensor Sen-off Single Mode

All measurement points (1 ... 6)

The selected measurement point is represented

inversely

Name of measurement point, 4 characters, userdefinable (→ 68)

Measured values or status (→ 35)

Unit of measurement (→ 49)

Calibration factor ≠ 1.00 (→ 65)

Sensor 4: Degas activated (→ 63)

Sensor 5: Offset correction activated (→ 60)

Designation of the switching function (A ... F)

(→ 42)

Controlling source (from 1 ... 6) (→ 43)

Sensor

Sen-on *

Sen-off *

Single Displaying the measured value of an

Selection of measurement point

)

Turning the gauge on

)

Turning the gauge off

individual measurement point

Mode Activating the operating mode selection

*) This parameter is not available for all gauge types

(→ Validity table 108).

BG 5186 BEN / C (2013-12) MaxiGauge.om Operating elements and modes 29

5.2.2 «Setpoint»

Mode

Figure 19:

«Setpoint» display

Display

Softkeys

³´μ Control Sensor 3

Setpoint high 5.00E-05 mbar

Setpoint low 2.00E-05 mbar

¼½¾ UR-Control off

Relay next ®¯ ¬− Return

C Switching function selected

(from A ... F)

Control Sensor Controlling source (1 ... 6) of

switching function C (→ 43)

Setpoint high Upper threshold of switching

function C (→ 44)

Setpoint low Lower threshold of switching

function C (→ 44)

UR-Control *

)

Behavior of switching function C

in case of underrange (→ 46)

Relay Selection of switching function (from

A ... F)

next Parameter selection

®¯ Increasing the value

¬− Decreasing the value

Return Returning to the «Measurement» mode

*) This parameter is not available for all gauge types

(→ Validity table 108).

30 Operating elements and modes

BG 5186 BEN / C (2013-12) MaxiGauge.om

5.2.3 «General Parameter» Mode

Figure 20:

«General Parameter» display

Display

Softkeys

Key-lock off Interface RS-485

Baudrate 19200

Unit mbar Address 0

Digits 3

Bargraph 1 Decade Screensave 5 h

Default set Contrast 10

next ®¯ ¬− Return

Key-lock Parameter input lock enabled or dis-

abled (→ 48)

Unit *)

Digits Resolution of the measured value dis-

Pressure unit (→ 49)

play (logarithmic gauges only)

(→ 50)

Bargraph

Default Loading the standard values of the

Bargraph (→ 51)

parameters (→ 52)

Interface

Baudrate

Address **) Software address of the interface

Type of the serial interface (→ 53)

Baud rate of the interface (→ 54)

(→ 55)

Screensave

Contrast

*) The pressure units depend on the gauges used

(→ Validity table 36).

)

**

This parameter is available for the RS485 interface only.

next Parameter selection

Screensave (→ 56)

Contrast of the display (→ 57)

®¯ Increasing the value

¬− Decreasing the value

Return Returning to the «Measurement» mode

BG 5186 BEN / C (2013-12) MaxiGauge.om Operating elements and modes 31

5.2.4 «Sensor Para-

S

meter» Mode

Figure 21:

«Sensor Parameter» display

Display

Softkeys

³´μ Type APR/CMR 1000 mbar

óÅ Offset on 157.6 mbar

ÆÇÈ CAL-Factor 1.010

ÉÊË Filter standard

Name CH 2

ensor next ®¯ ¬− Return

2 Measurement point selected (from

1 ... 6)

)

Type *

Family of gauge **) connected /

type of gauge connected (→ 59)

)

Offset ***

or

Degas ***

)

or

Range-Ext ***

Cal-Factor Calibration factor selected for

Activation of offset correction

(→ 60)

Activation of degas (→ 63)

)

Pirani range extension

measurement point 2 (→ 65)

Filter Measured value filter selected for

measurement point 2 (→ 66)

Name User-definable name for measure-

ment point (up to 4 characters)

(→ 68)

*) Depending on the type of gauge identified, the measurement

range may need to be indicated.

)

**

The family of linear including ACR gauges are displayed with

APR/CMR.

)

***

This parameter is not available for all gauge types

(→ Validity table 108).

Sensor Selection of measurement point

next Parameter selection

®¯ Increasing the value

¬− Decreasing the value

Return Returning to the «Measurement» mode

32 Operating elements and modes

BG 5186 BEN / C (2013-12) MaxiGauge.om

5.2.5 «Sensor Control»

S

Mode

Figure 22:

«Sensor Control» display

Display

Softkeys

Ò´Ô Control Hotstart

ñìí ON Power on

îïð OFF Selfcontrol

Ó½¾ OFF Threshold 9.00E-5 mbar

ensor next Return

5 Measurement point selected

(from 1 ... 6)

Control *

)

Controlling source of measure-

ment point 5 (→ 71)

ON Measurement point 5 is activa-

ted when the unit is switched on

OFF Selfcontrol Switching-off mode of measure-

ment point 5

OFF Threshold Switching-off threshold of

measurement point 5 in selfmonitoring mode

*) This parameter is not available for all gauge types

(→ Validity table 108).

Sensor Selection of measurement point

next Parameter selection

®¯ Increasing the value

¬− Decreasing the value

Return Returning to the «Measurement» mode

BG 5186 BEN / C (2013-12) MaxiGauge.om Operating elements and modes 33

5.2.6 «Test» Mode

Figure 23:

«Test» display

Display

Softkeys

Program BG509730-K

RAM A/D

EPROM I/O

EEPROM Interface

Display WDT-Ctrl auto

next Start Return

Program

RAM

EPROM

EEPROM

Display

A/D

I/O

Interface

WDT-Ctrl

Firmware version (→ 109)

RAM self-test (→ 110)

EPROM self-test (→ 110)

EEPROM self-test (→ 110)

Display self-test (→ 111)

Test analog/digital converter (→ 111)

Relay test (→ 111)

Test serial interface (→ 112)

Watchdog control (→ 112)

next Parameter selection

Start Starting a test sequence

Return Returning to the «Measurement» mode

The «Test» mode is only available if a key was

pressed while the unit was switched on.

34 Operating elements and modes

BG 5186 BEN / C (2013-12) MaxiGauge.om

6 Display Formats and Pressure Units

S

All

6.1 Display Formats

Figure 24:

Exponential representation

Figure 25:

Display formats

Both, exponential and floating point formats are used.

The format is changed over automatically. Pressures

indicated in «Pa» are displayed in exponential format

only.

³´μ óÐ ¿À ³´μ Ò´Ô ³´μ ¿À A¡

óÅ ÆÑÁ ÃÁ Â Â Â Â ÃÁ cal B¢

ÆÇÈ ÉÊÎ Á ×ºÕ ÷º ÌÏ Â Â Á C£

ÉÊË CH 2 Áß ÍÎ ¼½¾ æ½Ë ¼½¾ ÍÎ mbar D¤

E¥

+0.2 «¡

ª0 F¦

ensor

50 bar

Logarithmic

gauges

Mode

Linear

gauges

1000 mbar

Floating point format Floating point format

e.g. 4.3 e.g. 4.3

1 mbar

(or 1 Torr)

-11

10

mbar

e.g. 4.16E-01

Exponential format

BG 5186 BEN / C (2013-12) MaxiGauge.om Display formats / Pressure units 35

6.2 Pressure Units

S

2

6.3 Cursor

Figure 26:

Cursor (inverse representation

of parameter value)

Figure 27:

Cursor (inverse representation

of gauge / switching function)

Whether a particular pressure unit can be displayed or

not depends on the gauge used. The TPG 256 A allows

the selection of a specific pressure unit only if it is

possible to display the pressure in that unit over the

whole measurement range.

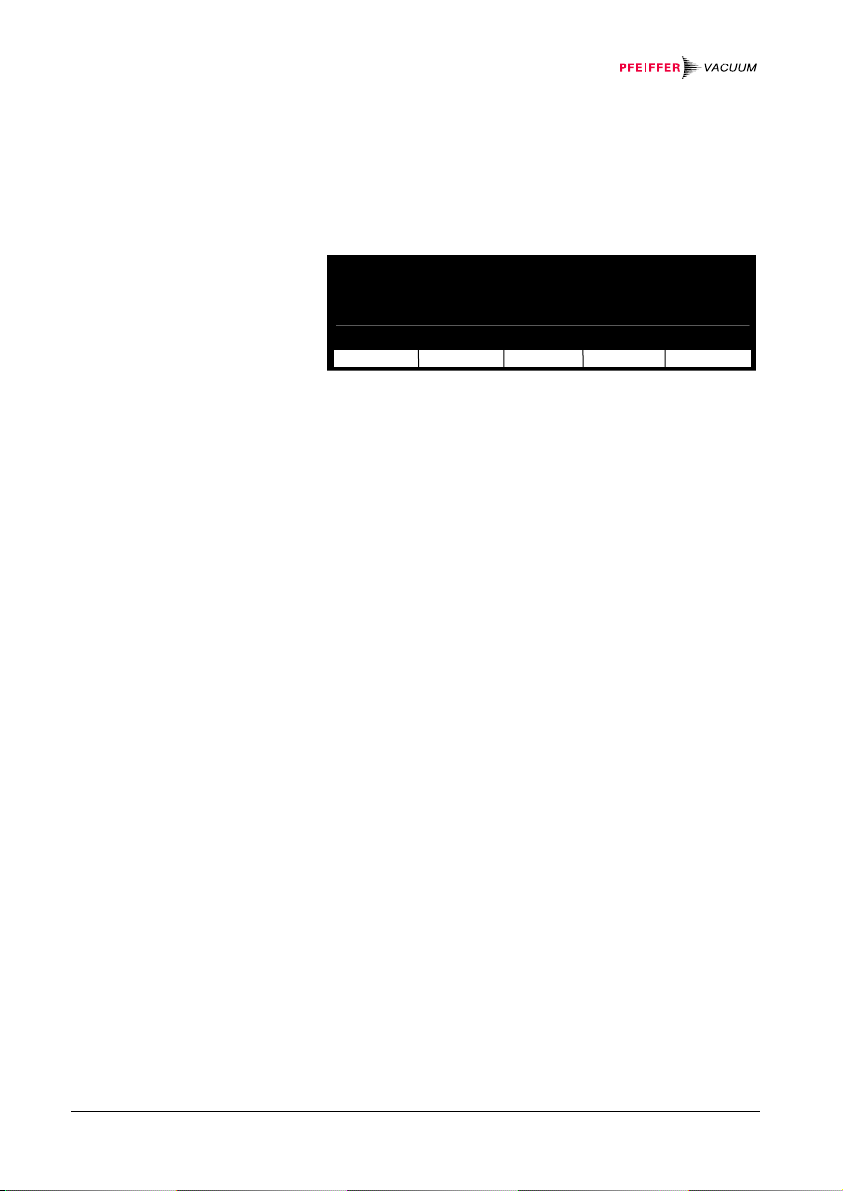

Gauge Range*) mbar/bar Torr Pa

Logarithmic 10

-11

…

mbar

1000 mbar

0.1 mbar

1 mbar

10 mbar

100 mbar

Linear 1000 mbar

2 bar

5 bar

10 bar

50 bar

Conversion of pressure units (→ 109)

*) Full scale value for linear gauges

The cursor points out a selected parameter (value), a

gauge or a switching function status «on» by representing it inversely.

Key-lock off Interface RS-485

Baudrate 19200

Unit Address 0

Digits 3

Bargraph 1 Decade Screensave 5 h

Default set Contrast 10

next ®¯ ¬− Return

mbar

1 CH 1 2.9E-02 mbar A¡

CH 2 4.16E-01 mbar B¢

3 CH 3 1.3E-08 mbar cal

4 CH 4 9.9E-11 mbar D¤

5 CH 5 0.0053 mbar offset E¥

6 CH 6 no Sensor F¦

ensor Sen-off Single Mode

C£

36 Display formats / Pressure units

BG 5186 BEN / C (2013-12) MaxiGauge.om

7 Operation

7.1 Personnel

7.2 Switching the Unit

On and Off

Power ON

Figure 28:

Power switch

Skilled personnel

The unit may only be operated by skilled and trained

persons that fully understand the possible hazards related to the corresponding application.

Check that all cables and gauges have been correctly

installed and that the specifications listed in the technical

data have been met.

Turn the unit on with the power switch (or centrally via a

switched power distributor if the unit is rack mounted).

The power switch is located on the rear panel of the unit.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 37

Figure 29:

Display after power ON

After power ON, the unit:

• automatically performs a self-test, and «TPG 256 A»

is displayed

• identifies the gauges connected

• activates parameters that were in effect before the

last power OFF

• switches to the «Measurement» mode for the measurement point selected before the last power OFF

• adapts the parameters if required (if other gauges

were previously connected)

Power OFF

• Turn the unit off with the power switch (or centrally via

a switched distributor if the unit is rack mounted).

Wait at least 10 seconds before turning the unit

on again in order for it to correctly initialize

itself.

38 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

7.3 Selecting the

S

All

S

Operating Mode

Figure 30:

Selecting the operating mode

Returning from other

operating modes

In the superset«Measurement» mode, you can call a

menu of further operating modes by pressing the [Mode]

softkey

Select the desired mode by pressing the corresponding

softkey:

• [Setpoint] «Setpoint» mode

• [Gen-Par] «General Parameter» mode

• [Sen-Par] «Sensor Parameter» mode

• [Sen-Ctrl] «Sensor Control» mode

³´μ óÐ ¿À ³´μ Ò´Ô ³´μ ¿À A¡

óÅ ÆÑÁ ÃÁ Â Â Â Â ÃÁ cal B¢

ÆÇÈ ÉÊÎ Á ×ºÕ ÷º ÌÏ Â Â Á C£

ÉÊË CH 2 Áß ÍÎ ¼½¾ æ½Ë ¼½¾ ÍÎ mbar D¤

E¥

«¡

ª0 F¦

ensor

ensor Gen-Par Sen-Par Sen-Ctrl Test

Mode

The «Test» mode can only be selected if a key was

pressed while the unit was switched on:

• [Test] «Test» mode

If you are in a lower mode, simply press the [Return]

softkey to return to the superset «Measurement» mode.

If you do not press any key for 1 minute, the display returns automatically to the «Measurement» mode.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 39

7.4 «Measurement»

S

S

All

Mode

Figure 31:

«Single» display

Figure 32:

«All» display

7.4.1 Selecting the

Measurement Point

(

Sensor)

In the superset «Measurement» mode, the unit displays

the measured values. If you are in another (lower) mode

and do not press any key for 1 minute, the unit returns

automatically to the «Measurement» mode.

(→ Overview «Measurement» mode 28).

³´μ óÐ ¿À ³´μ Ò´Ô ³´μ ¿À A¡

óÅ ÆÑÁ ÃÁ Â Â Â Â ÃÁ cal B¢

ÆÇÈ ÉÊÎ Á ×ºÕ ÷º ÌÏ Â Â Á C£

ÉÊË CH 2 Áß ÍÎ ¼½¾ æ½Ë ¼½¾ ÍÎ mbar D¤

E¥

«1

ª0 F¦

ensor

1 CH 1 2.9E-02 mbar A¡

2

CH 2 4.16E-01 mbar B¢

3 CH 3 1.3E-08 mbar cal C£

4 CH 4 9.9E-11 mbar D¤

5 CH 5 0.0053 mbar offset E¥

6 CH 6 no Sensor F¦

ensor Sen-off Single Mode

Mode

• The measurement point is indicated as a number on

the left of the display.

• Select the next measurement point with the [

Sensor]

softkey (in «Single» measurement mode, the corresponding number is increased whereas in «All», the

selected measurement point is represented inversely). After the measurement point 6 the display

changes to measurement point 1.

40 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

7.4.2 Switching the

Gauge On/Off

(

Sen-on/off)

7.4.3 Display of a Single

Gauge / All Gauges

(

Single/All)

• Press the [Sen-off] softkey to turn the selected

gauge off or the [

Sen-on] key to turn it on.

Caution

Turning a gauge on or off may affect the status of the

relays.

This parameter is not available for all gauge

types (→ Validity table 108).

• Press the [Single]/[All] softkey in order for the

unit to display either the measured value of one single gauge at a time or the measured values of all

gauges simultaneously (→ 40).

Status or error messages may be displayed

instead of measured values (→ Status messages 75, Error messages 77). After the

problem is remedied, the measured value is

again displayed correctly.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 41

7.5 «Setpoint» Mode

Figure 33:

«Setpoint» display

7.5.1 Selecting the

Switching Function

(

Relay)

In «Setpoint» mode, you can assign a controlling source

to a switching function and define the upper and lower

thresholds. Additionally, you can select the behavior of

the switching function in the event of an underrange.

(→ Overview «Setpoint» mode 30).

³´μ Control Sensor 3

Setpoint high 5.00E-05 mbar

Setpoint low 2.00E-05 mbar

¼½¾ UR-Control off

Relay next ®¯ ¬− Return

The switching function is represented as a letter on the

left of the display.

Selecting another switching function:

• Press the [

switching function (

Relay] softkey to choose the desired

A ... F).

The modifications are automatically stored in non-volatile

memory.

42 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

7.5.2 Assigning

S

All

Measurement

Points

(

Control Sensor)

Figure 34:

«Setpoint» display

«Measurement» display

The upper parameter line «Control Sensor» shows

which measurement point is assigned to a switching

function.

The corresponding measurement point has to be assigned to each switching function individually. In

«Measurement» mode, all assignments are displayed

simultaneously.

³´μ Control Sensor 3

Setpoint high 5.00E-05 mbar

Setpoint low 2.00E-05 mbar

¼½¾ UR-Control off

Relay next ®¯ ¬− Return

³´μ óÐ ¿À ³´μ Ò´Ô ³´μ ¿À A¡

óÅ ÆÑÁ ÃÁ Â Â Â Â ÃÁ cal B¢

ÆÇÈ ÉÊÎ Á ×ºÕ ÷º ÌÏ Â Â Á C£

ÉÊË CH 2 Áß ÍÎ ¼½¾ æ½Ë ¼½¾ ÍÎ mbar D¤

E¥

«¡

+0 F¦

ensor Sen-on

Mode

Assigning another measurement point:

• Select the «Setpoint» mode (if applicable) (→ 39)

• Press the [

Control Sensor» parameter

«

• Press the [

value «

• Press the [

next] softkey to select the

®¯]or [¬−] softkey to select a parameter

1 ... 6» (measurement points)

Return] softkey to return to the

«Measurement» mode

The modifications are automatically stored in non-volatile

memory.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 43

7.5.3 Defining the

Threshold Values

(

Setpoint)

Figure 35:

«Setpoint» display

The upper and lower thresholds are defined in the second and third parameter line.

³´μ Control Sensor 3

Setpoint high 5.00E-05 mbar

Setpoint low 2.00E-05 mbar

¼½¾ UR-Control off

Relay next ®¯ ¬− Return

Defining the threshold values:

• Select the «Setpoint» mode (if applicable) (→ 39)

• Press the [

Setpoint high» parameter

«

• Press the [

next] softkey to select the

®¯] or [¬−] softkey to increase /decrease

the upper threshold value

• Press the [

«

Setpoint low» parameter

• Press the [

next] softkey to select the

®¯] or [¬−] softkey to increase / decrease

the lower threshold value

• Press the [

Return] softkey to return to the

«Measurement» mode

A threshold that is outside the measuring range

is adjusted in such a way that it corresponds to

the lower (upper) range limit.

We recommend setting the threshold ½ decade

above the lower or ½ below the upper threshold

limit.

If both thresholds are outside the measuring

range, they are adjusted analogously in such a

way that a minimum hysteresis is achieved.

For logarithmic gauges, threshold values are

displayed in logarithmic or floating point format,

whereas for linear gauges, they are displayed

in floating point format only (→ Display formats

35).

The modifications are automatically stored in non-volatile

memory.

44 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

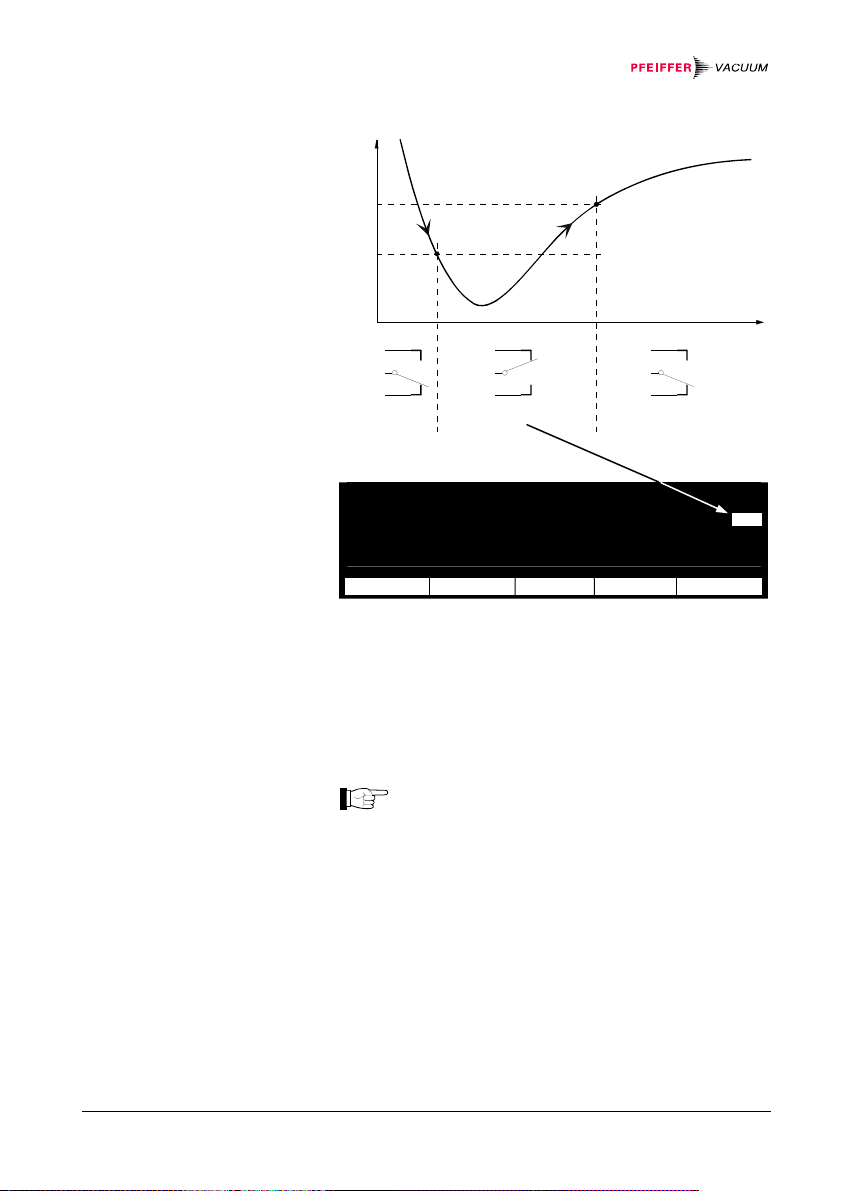

Figure 36:

S

C

Threshold values of a switching

function

Figure 37:

Inverse representation of the

selected switching function (

C3)

setpoint low

setpoint high

Pressure

u

l

a

v

d

e

r

u

s

a

e

M

Setpoint high

Setpoint low

Time

OnOff Off

Switching function

1 CH 1 2.9E-02 mbar A¡

2 CH 2 4.16E-01 mbar B¢

3 CH 3 1.3E-08 mbar cal

4 CH 4 9.9E-11 mbar D¤

5 CH 5 0.00530 mbar offset E¥

6 CH 6 no Sensor F¦

ensor Sen-off Single Mode

The setpoint low defines the pressure reading at

which the switching function is activated when the pressure is dropping.

setpoint high defines the pressure reading at

The

which the switching function is deactivated when the

pressure is rising.

If other gauge types were connected previ-

ously, the threshold may possibly have been

adapted automatically.

e

£

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 45

7.5.4 Underrange

Control

(

UR-Control)

Logarithmic gauges:

The minimum hysteresis between the upper

and lower threshold is at least 10% of the lower

threshold. This prevents an unstable state. If

you set the upper threshold lower than the

lower one, this minimum hysteresis is automatically applied.

Linear gauges:

The minimum hysteresis between the upper

and lower threshold is at least 1% of the

measurement range. This prevents an unstable

state. If you set the upper threshold lower then

the lower threshold, this minimum hysteresis is

automatically applied.

This parameter controls the behavior of the switching

function in the event of an underrange (→ Status messages 75).

An underrange may occur for one of the following reasons:

The pressure in the vacuum system is lower than the

lower limit of the measurement range

The gauge has not yet ignited

The discharge has failed

A fault has occurred

When the underrange control is enabled, an underrange

is interpreted as inadmissible measured value: The

switching function changes to «OFF».

When the underrange control is deactivated, the switching function remains «ON» in the event of an underrange.

The underrange control is deactivated by default.

46 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

Figure 38:

«Setpoint» mode display

³´μ Control Sensor 3

Setpoint high 5.00E-05 mbar

Setpoint low 2.00E-05 mbar

¼½¾ UR-Control off

Relay next ®¯ ¬− Return

Enabling/disabling the underrange control:

• Select the «Setpoint» mode (if applicable) (→ 39)

• Press the [

UR-Control» parameter

«

• Press the [

(underrange control enabled) or «

next] softkey to select the

®¯] or [¬−] softkey to select «On»

Off» (underrange

control disabled (default))

• Press the [

Return] softkey to return to the

«Measurement» mode

This parameter is not available for all gauge

types (→ Validity table 108).

If the pressure in the vacuum chamber may be

lower than the lower limit of the measurement

range of the gauge it may be advantageous to

select «

off».

When «On» is selected, the switching function

evaluation is suppressed for approx. 10 seconds after the gauge has been turned on or an

underrange has occurred. The switching function remains «OFF» for this time.

The modifications are automatically stored in non-volatile

memory.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 47

7.6 «General Parameter» Mode

Figure 39:

«General Parameter» display

7.6.1 Parameter Input

Lock (

Key-lock)

In «General Parameter» mode, you can define the system parameters for all connected gauges together.

(→ Overview «General Parameter» mode 31).

Key-lock off Interface RS-485

Baudrate 19200

Unit mbar Address 0

Digits 3

Bargraph 1 Decade Screensave 5 h

Default set Contrast 10

next ®¯ ¬− Return

The parameter input lock prevents inadvertent entries

and consequent malfunctions. When the parameter input

lock is enabled, only the «

Key-Lock» parameter for dis-

abling the input lock can be modified.

Turning the parameter input lock ON /OFF:

• Select the «General Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «Key-lock»

parameter

• Press the [

lock ON) or «

• Press the [

®¯] or [¬−] softkey to select «On» (input

Off» (input lock OFF(default))

Return] softkey to return to the

«Measurement» mode

If the input lock is enabled and you press a

softkey to modify any other parameter than

«

Key-lock», «locked» is displayed instead

of the function of the softkey pressed.

The modifications are automatically stored in non-volatile

memory.

48 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

7.6.2 Selecting the

Pressure Unit

(

Unit)

Figure 40:

«General Parameter» display

The unit can display the following pressure units:

(milli)bar, Torr, and Pascal.

Key-lock off Interface RS-485

Baudrate 19200

Unit mbar Address 0

Digits 3

Bargraph 1 Decade Screensave 5 h

Default set Contrast 10

next ®¯ ¬− Return

Selecting the pressure unit:

• Select the «General Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «Unit» pa-

rameter

• Press the [

Pa», or «mbar» (default) *

«

• Press the [

®¯] or [¬−] softkey to select «Torr»,

Return] softkey to return to the

)

«Measurement» mode

*) For linear gauges, a specific pressure unit can only be selected if

it is possible to display the measured pressure in that unit over

the whole measurement range of the gauge (→ table 36).

The modifications are automatically stored in non-volatile

memory.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 49

7.6.3 Display Resolution

(

Digits)

Figure 41:

«General Parameter» display

For observing even fine measurement value fluctuations,

the display can be increased from 2 to 3 digits. The

measured value will thus have a finer resolution. (Only

effective for logarithmic gauges.)

Key-lock off Interface RS-485

Baudrate 19200

Unit mbar Address 0

Digits 3

Bargraph 1 Decade Screensave 5 h

Default set Contrast 10

next ®¯ ¬− Return

Defining the number of digits:

• Select the «General Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «Digits» pa-

rameter

• Press the [

®¯] or [¬−] softkey to select «3» or «2»

(default)

• Press the [

Return] softkey to return to the

«Measurement» mode

When Range-Ext (→ 64) is on, the display resolution

of the PCR and TPR gauges in the pressure range

p<1.0E-4 mbar is reduced by one decimal digit.

The modifications are automatically stored in non-volatile

memory.

50 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

7.6.4 Bargraph

(

Bargraph)

Figure 42:

«General Parameter» display

The bargraph allows quick assessment of the measured

value and visual observation of the measurement

changes (trend).

Key-lock off Interface RS-485

Baudrate 19200

Unit mbar Address 0

Digits 3

Bargraph 1 Decade Screensave 5 h

Default set Contrast 10

next ®¯ ¬− Return

Adjusting the bargraph:

• Select the «General Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «Bargraph»

parameter

• Press the [

(bargraph deactivated), «

measurement range), or «

®¯] or [¬−] softkey to select «Off»

Sen-Range» (bar range =

1 Decade» (bar = meas-

urement value exponent (default))

• Press the [

Return] softkey to return to the

«Measurement» mode

The modifications are automatically stored in non-volatile

memory.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 51

7.6.5 Restoring Default

Values (

Figure 43:

«General Parameter» display

Default)

This parameter allows to restore all user defined / modified parameters to the factory setting.

Key-lock off Interface RS-485

Baudrate 19200

Unit mbar Address 0

Digits 3

Bargraph 1 Decade Screensave 5 h

Default set Contrast 10

next °± set ±² Return

Restoring the default parameters:

• Select the «General Parameter» mode (if applicable)

(→ 39)

• Press the [

next] to select the «Default set» pa-

rameter

The [

®¯] and [¬−] softkeys are represented as one sin-

gle symbol prompting the user to press them simultane-

°± set ±²].

ously: [

• Press both softkeys simultaneously to restore the

default values

• Press the [

Return] softkey to return to the

«Measurement» mode

Caution

Restoring the default values cannot be reversed!

The modifications are automatically stored in non-volatile

memory.

52 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

7.6.6 Defining an

Interface

(

Interface)

Figure 44:

«General Parameter» display

The serial interfaces are used for external control of the

unit as well as for transfer of measured data and modification of parameters (→ 13). The desired interface is

defined with the following parameter:

Key-lock off Interface RS-485

Baudrate 19200

Unit mbar Address 0

Digits 3

Bargraph 1 Decade Screensave 5 h

Default set Contrast 10

next ®¯ ¬− Return

Defining the interface:

• Select the «General Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «Interface»

parameter

• Press the [

RS-485» (serial interface RS485, isolated),

«

«

RS-422I» (serial interface RS422C, isolated),

RS-422» (serial interface RS422C, not isolated),

«

RS-232» (serial interface RS232C, not isolated

«

®¯] or [¬−] softkey to select among

(default))

• Press the [

Return] softkey to return to the

«Measurement» mode

Check whether the unit is equipped with all

interfaces listed above (→ 2, 12).

The modifications are automatically stored in non-volatile

memory.

Further information → 80.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 53

7.6.7 Defining the Baud

Rate (

Baudrate)

Figure 45:

«General Parameter» display

This parameter allows to set the baud rate for the serial

interface defined as «

Key-lock off Interface RS-485

Baudrate 19200

Unit mbar Address 0

Digits 3

Bargraph 1 Decade Screensave 5 h

Default set Contrast 10

next ®¯ ¬− Return

Interface» parameter value.

Setting the baud rate:

• Select the «General Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «Baudrate»

parameter

• Press the [

(baud), «

(baud), «

®¯] or [¬−] softkey to select among «300»

1200» (baud), «2400» (baud), «4800»

9600» (baud (default)), and «19200»

(baud)

• Press the [

Return] softkey to return to the

«Measurement» mode

The modifications are automatically stored in non-volatile

memory.

Further information → 80.

54 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

7.6.8 Defining the Node

Address

(

Address)

Figure 46:

«General Parameter» display

The RS485 interface allows to set up a network of max.

32 display units per interface. The node (or device) address can be set between 0 and 31.

Key-lock off Interface RS-485

Baudrate 19200

Unit mbar Address 0

Digits 3

Bargraph 1 Decade Screensave 5 h

Default set Contrast 10

next ®¯ ¬− Return

Defining the node address:

• Select the «General Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «Address»

parameter

• Press the [

value «

• Press the [

®¯] or [¬−] softkey to select a parameter

0 ... 31» (node address) (default = 0)

Return] softkey to return to the

«Measurement» mode

This parameter is only available for the RS485

interface.

The modifications are automatically stored in non-volatile

memory.

Further information → 80.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 55

7.6.9 Screensave

(

Screensave)

Figure 47:

«General Parameter» display

In order for the life of the CFL lamp to be prolonged

(half-life period approx. 20'000 hours), the backlighting

of the LC display can be switched off automatically after

an adjustable delay of 1 ... 99 hours while the LCD remains on.

Key-lock off Interface RS-485

Baudrate 19200

Unit mbar Address 0

Digits 3

Bargraph 1 Decade Screensave 5 h

Default set Contrast 10

next ®¯ ¬− Return

Adjusting the screensave function:

• Select the «General Parameter» mode (if applicable)

(→ 39)

• Press the [

Screensave» parameter

«

• Press the [

1 ... 99» (number of hours after which the back-

«

next] softkey to select the

®¯] or [¬−] softkey to select «Off» or

lighting of the LCD is to be switched off after a key

has been pressed) (Off = screensave deactivated

(default))

• Press the [

Return] softkey to return to the

«Measurement» mode

Press any softkey to reactivate the background

lighting. While the display is dark, all control or

selection functions of the softkeys are disabled.

The modifications are automatically stored in non-volatile

memory.

56 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

7.6.10 Display Contrast

(

Contrast)

Figure 48:

«General Parameter» display

This parameter allows to set the contrast of the LC display within a numeric range of 0 ... 20 according to your

individual requirements, such as ambient conditions and

viewing angle.

Key-lock off Interface RS-485

Baudrate 19200

Unit mbar Address 0

Digits 3

Bargraph 1 Decade Screensave 5 h

Default set Contrast 10

next ®¯ ¬− Return

Setting the display contrast:

• Select the «General Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «Contrast»

parameter

• Press the [

value «

®¯] or [¬−] softkey to select a parameter

0 ... 20» (minimum contrast ... maximum con-

trast) (default = 10)

• Press the [

Return] softkey to return to the

«Measurement» mode

The modifications are automatically stored in non-volatile

memory.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 57

7.7 «Sensor Para-

S

meter» Mode

Figure 49:

«Sensor Parameter» display

7.7.1 Selecting a

Measurement Point

(

Sensor)

In «Sensor Parameter» mode, you can define the parameters relevant for each measurement point.

(→ Overview «Sensor Parameter» mode 32).

³´μ Type APR/CMR 1000 mbar

óÅ Offset on 157.6 mbar

ÆÇÈ CAL-Factor 1.010

ÉÊË Filter standard

Name CH 2

ensor next ®¯ ¬− Return

The measurement point to which the displayed parameters apply is shown as a big figure (1 ... 6) on the left

of the display.

• Select the «Sensor Parameter» mode (if applicable)

(→ 39)

• Press the [

urement point (from

Sensor] softkey to select the next meas-

1 ... 6).

58 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

7.7.2 Gauge Identifi-

S

cation (

Figure 50:

«Sensor Parameter» display

Type)

The TPG 256 A automatically identifies any connected

Pfeiffer Vacuum gauges. For linear gauges, a

measurement range is displayed additionally as parameter value *

)

behind the gauge type **). This parameter value has to be adjusted according to the connected gauge type.

*) This parameter is not available for all gauge types

(→ Validity table 108).

)

**

The family of linear gauges are displayed with APR/CMR.

³´μ Type APR/CMR 1000 mbar

óÅ Offset on 157.6 mbar

ÆÇÈ CAL-Factor 1.010

ÉÊË Filter standard

Name CH 2

ensor next ®¯ ¬− Return

Adjusting the measurement range:

• Select the «Sensor Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «APR/CMR»

(linear gauge types identified) parameter

• Press the [

0.1 mbar», «1 mbar», «10 mbar», «100 mbar»,

«

1000 mbar» (default), «2 bar», «5 bar», «10

«

bar

• Press the [

®¯] or [¬−] softkey to select among

», and «50 bar»

Return] softkey to return to the

«Measurement» mode

The modifications are automatically stored in non-volatile

memory.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 59

7.7.3 Offset Function

S

(

Offset) (zeroing)

Figure 51:

«Sensor Parameter» display

Activating /

deactivating the offset

function

Zero adjustment

The offset function allows the zero of linear gauges to be

aligned to the currently measured value (uncorrected

outputsignal of the gauge) within a range of -5 ... +110%

of the Full Scale setting. It affects the:

display

switching functions (threshold value display)

analog outputs of the unit

serial interfaces

³´μ Type APR/CMR 1000 mbar

óÅ Offset on 157.6 mbar

ÆÇÈ CAL-Factor 1.010

ÉÊË Filter standard

Name CH 2

ensor next ®¯ ¬− Return

• Select the «Sensor Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «Offset» pa-

rameter

• Press the [

correction activated) or «

®¯] or [¬−] softkey to select «on», (offset

off» (offset correction de-

activated) (default) (the previously saved offset value

displayed at the right hand side of the «

on»/«off»

parameter value)

This function can be used for two different purposes:

There are two methods for adjusting the zero of a linear

gauge. Note, however, that the actual pressure must be

lower than the lower limit of the measurement range of

the gauge:

− Set the zero by adjusting the „ZERO“ potentiometer

of the gauge (

→ [16] … [18])

− With the offset function of the measurement and

control unit set the current pressure reading to zero

60 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

Zeroing at any

pressure

Procedure for the second method:

• at a pressure lower than the lower limit of the measurement range of the gauge, activate the offset

function («

• press the [

saved offset value (at the right hand side of «

the displays of the [

Actual] and [Zero]

[

• press the [

on»)

next] softkey to select the previously

on»);

®¯] and [¬−] softkeys change to

Actual] softkey to accept the currently

measured value (zero deviation) as new offset value.

(If you like to set the offset value to zero, press the

[

Zero] softkey).

• press the [

Return] softkey to return to the

«Measurement» mode

The advantage of the second method is that no direct

access to the potentiometer of the gauge is required.

The pressure reading of the measurement and control

unit can be set to zero at any pressure within the measurement range. All subsequent readings will then be

relative to that pressure and may therefore be positive or

negative. This method allows for monitoring of pressure

variations during a process.

The procedure is the same as for the second method.

This parameter is not available for all gauge

types (→ Validity table 108).

The modifications are automatically stored in non-volatile

memory.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 61

Example:

S

When the offset function is activated, the stored offset

value is subtracted from the currently measured value.

³´μ Type APR/CMR 1000 mbar

óÅ Offset on 10.3 mbar

ÆÇÈ CAL-Factor 1.000

ÉÊË Filter standard

Name CH 2

ensor next ®¯ ¬− Return

Currently

measured

value

10.3 10.3 0 10.3

17.4 10.3 7.1 17.4

7.4 10.3 -2.9 7.4

Stored

offset value

Display with

offset

activated:

offset

Display with

offset

deactivated:

When the zero of the gauge is adjusted with the

"ZERO" potentiometer, the offset function must

be deactivated.

The offset values are preserved when the unit

is switched off.

62 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

7.7.4 Activating the

S

Degas Routine

(

Degas)

Figure 52:

«Sensor Parameter» display

Contamination of the electrode system of the Compact

Fullrange™ BA Gauge (PBR 260) can cause instabilities

of the measured values.

The degassing routine is used for cleaning the electrode

system by heating the electron collector grid to approx.

700 °C by electron bombardment.

It normally takes 3 minutes but it can be aborted at any

stage.

óÐ Type PBR

ÆÑÁ Degas on

ÉÊÎ CAL-Factor 1.010

Á Filter standard

Name CH 4

ensor next ®¯ ¬− Return

To activate or abort the degassing routine:

• Select the «Sensor Parameter» mode (if applicable)

→ 39)

(

• Press the [

next] softkey to select the «Degas» pa-

rameter

• Press the [

activated) or «

• Press the [

®¯] or [¬−] softkey to select «on», (Degas

off» (Degas deactivated) *

Return] softkey to return to the

)

(default)

«Measurement» mode

*) After conclusion of the ≈3 min. degassing routine, the «Degas»

parameter automatically goes back to «off» (default).

• The Degas function is only available for

sensor connectors 4 to 6.

• The degassing routine can only be

started («

on») when the corresponding

gauge is turned on.

• When Degas = «

message «

on», the status

Degas» is displayed in

«Measurement» mode.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 63

7.7.5 Pirani Range

S

Extension

(

Range-Ext)

Figure 53:

«Sensor Parameter» display

Activate/deactivate

Pirani range

extension

The display and setpoint adjustment range of the PCR

und TPR gauges can be extended.

óÐ Type PCR

ÆÑÁ Range-Ext off

ÉÊÎ CAL-Factor 1.010

Á Filter standard

Name CH 4

ensor next ®¯ ¬− Return

• Select the «Sensor Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «Range-Ext»

parameter

• Press the [

range extension activated) or «

®¯] or [¬−]softkey to select «on», (Pirani

off» (Pirani range

extension deactivated) (default)

• Press the [

Return] softkey to return to the

«Measurement» mode

64 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

7.7.6 Setting the

S

Calibration Factor

(

Cal-Factor)

Figure 54:

«Sensor Parameter» display

For logarithmic gauges

For linear gauges

The calibration function allows to adjust the measured

value of a gauge. It is predominantly used for correcting

the measured values of logarithmic gauges for gases

other than N

linear gauges. The calibration factor affects the:

display *

switching functions (threshold value display) *

analog outputs of the unit

serial interfaces *

*) For IMR 260, IMR 265, and PBR 260 (p≤10–1 mbar) in the hot

cathode measurement range only.

³´μ Type TPR

óÅ

ÆÇÈ CAL-Factor 1.010

ÉÊË Filter standard

Name CH 2

ensor next ®¯ ¬− Return

and for correcting the full scale values of

2

)

)

)

Each of the six gauges can be calibrated in the following

way:

• Select the «Sensor Parameter» mode (if applicable)

(→ 39)

• Press the [

«

Cal-Factor» in the following way:

next] softkey to select the

• Press the [®¯] or [¬−] softkey to adjust the parameter

value «

0.10 ... 1.00 (default) ... 9.99» (the value

increases or decreases by

0.01)

• If you hold down the softkey continually, the step size

changes automatically to

• Press the [

«Measurement» mode

Return] softkey to return to the

0.1

• Press the [®¯] or [¬−] softkey to adjust the parameter

value «

0.500 ... 1.000 (default) ... 2.000» (the

value increases or decreases by

0.001)

• If you hold down the softkey continually, the step size

changes automatically to

• Press the [

Return] softkey to return to the

0.01

«Measurement» mode

The modifications are automatically stored in non-volatile

memory.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 65

7.7.7 Setting the

S

Measurement

Value Filter

(

Filter)

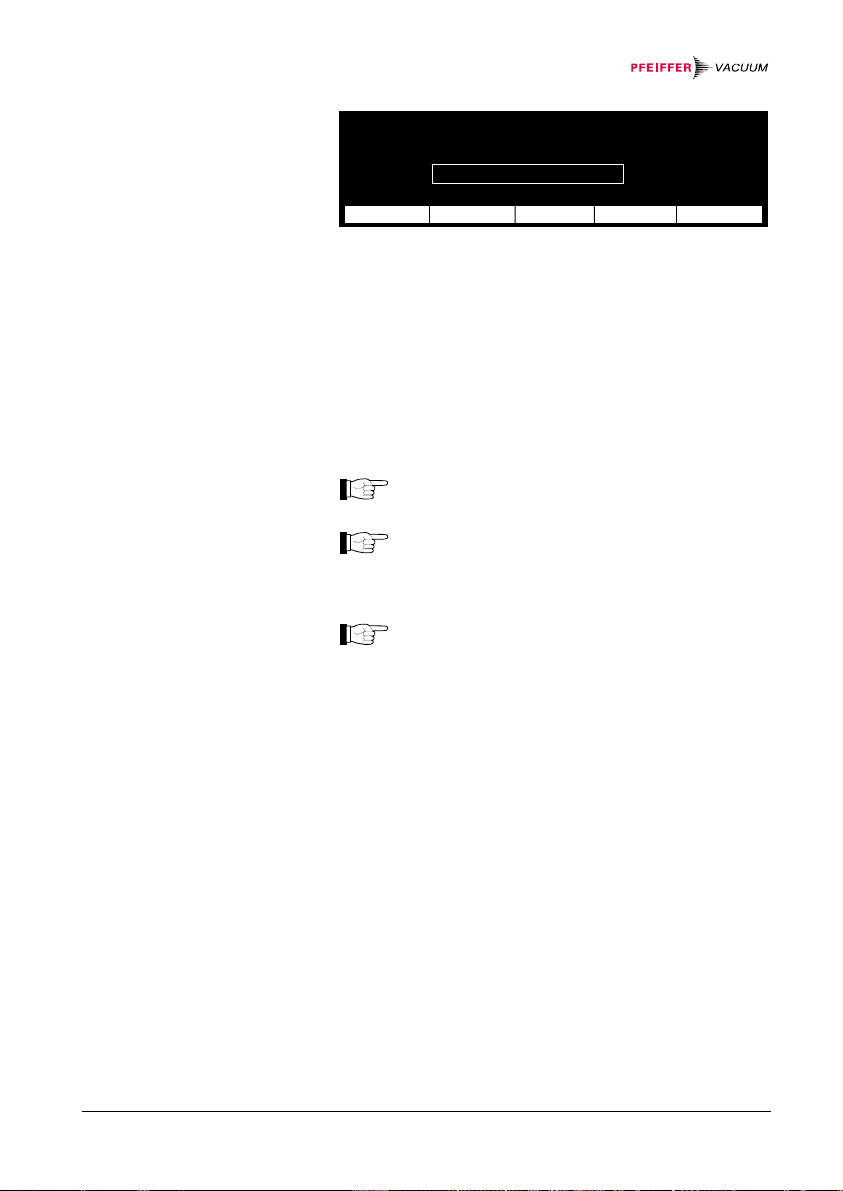

Figure 55:

«Sensor Parameter» display

Standard Filter

Figure 56:

Measurement value filter

Standard

The measurement value filter allows better evaluation of

unstable or faulty measurement signals. It affects the:

display

switching functions (threshold value display)

analog outputs of the unit

serial interfaces

³´μ Type APR/CMR 1000 mbar

óÅ Offset on 157.6 mbar

ÆÇÈ CAL-Factor 1.010

ÉÊË Filter standard

Name CH 2

ensor next ®¯ ¬− Return

For each of the six gauges, a filter can be set in the following way:

• Select the «Sensor Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «Filter» pa-

rameter

• Press the [

fast», «slow» and «standard» (default) pa-

«

®¯] or [¬−] softkey to select among

rameter value (→ following explanations)

• Press the [

Return] softkey to return to the

«Measurement» mode

The modifications are automatically stored in non-volatile

memory.

Default setting with a good relationship between response and sensitivity of the display and the switching

functions to changes in measured values.

p

66 Operation

t

BG 5186 BEN / C (2013-12) MaxiGauge.om

Slow Filter

Figure 57:

Measurement value filter

Fast Filter

Figure 58:

Measurement value filter

Slow

Fast

Choose «slow» if the display and the switching functions

should not respond to small changes in measured values. As a consequence, the unit will respond more

slowly to changes in measured values.

p

t

Choose «fast» if the display and the switching functions

should respond quickly to fluctuations in measured values. As a consequence, the unit will respond faster to

interference in measured values.

p

t

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 67

7.7.8 Defining the

S

Measurement Point

Name (

Figure 59:

«Sensor Parameter» display

Name)

The measurement point name is shown on the display

as CH 1, CH 2 ... CH 6 (CH = channel).

These 4 characters can be overwritten with any combination of characters comprising letters, digits or spaces.

This may be useful, for instance, for differentiating

gauges in a system or for certain functional designations.

³´μ Type APR/CMR 1000 mbar

óÅ Offset on 157.6 mbar

ÆÇÈ CAL-Factor 1.010

ÉÊË Filter standard

Name CH 2

ensor next ®¯ ¬− Return

Defining the measurement point name:

• Select the «Sensor Parameter» mode (if applicable)

(→ 39)

• Press the [

next] softkey to select the «Name» para-

meter (the cursor jumps automatically to the first digit)

• Press the [

value «

®¯] or [¬−] softkey to select a parameter

A ... Z» (default: C), «0 ... 9», « », (first char-

acter of the name)

• Press the [

• Press the [

value «

next] softkey to select the next digit

®¯] or [¬−] softkey to select a parameter

A ... Z» (default: H), «0 ... 9», « », (second

character of the name)

• Select the third (default: space) and the fourth

(default: digit 1 ... 6) character of the name as described above

• Press the [

Return] softkey to return to the

«Measurement» mode

The modifications are automatically stored in non-volatile

memory.

68 Operation

BG 5186 BEN / C (2013-12) MaxiGauge.om

7.8 «Sensor Control»

Mode

Gauge control

possibilities

In «Sensor Control» mode *), you can define how cold

cathode, and FullRange™ and ionization gauges are

turned on/off by other gauges or control devices.

*) This parameter is not available for all gauge types

(→ Validity table 108).

(→ Overview «Sensor Control» mode 33).

When defining the control options, note that:

• only the gauge control configurations shown on table

«Sensor Control» (→ 70 ff) are valid

• the Pirani and all linear gauges are always active after the TPG 256 A has been switched on

• «Hot Start» means that the gauge is automatically

turned on when the power is switched on. After power

on the hot start control settings (→ 74) are applied

for turning the gauge off. This operating mode allows

for automatic continuation of the measurement after a

power failure.

• a gauge cannot be turned off by a «Hot Start».

• a gauge cannot turn itself on when a certain pressure

is reached

• both, cold cathode and linear gauges for a full scale

pressure range ≥1000 mbar (1 bar) cannot be used

as control sources

• the six «Ext-Ctl» inputs are permanently assigned to

the six gauge ports.

BG 5186 BEN / C (2013-12) MaxiGauge.om Operation 69

Figure 60:

Table «Sensor Control»

Controlled Controlling source

sensor TPR/PCR PKR IMR / PBR

1 ... 1E-3*) 1 ... 1E-5 -

IMR/

PBR

on

off

IKR on

off

1 ... 1E-3*) 1 ... 1E-5 -

1E-2 ... 1E-3*)1E-2 ... 1E-5 1E-2 ... 5E-10

1E-2 ... 1E-3*)1E-2 ... 1E-5 1E-2 ... 5E-10

Controlled

sensor

APR / CMR

IMR/

PBR

on

off

IKR on

off

/ ACR

1 mbar

1 ... 1E-3 1 ... 1E-2 1 ... 1E-1

1 ... 1E-3 1 ... 1E-2 1 ... 1E-1

1E-2 ... 1E-3 1E-2 -

1E-2 ... 1E-3 1E-2 -

Controlling source

F.S.

APR / CMR

/ ACR

10 mbar

F.S.

APR / CMR