(

)

OPERATING INSTRUCTIONS

Translation of the original instructions

PBR 260

Compact FullRange® BA Gauge

2017-02

BG 5171 BEN / B

Product Identification

In all communications with Pfeiffer Vacuum, please specify the information given

on the product nameplate. For convenient reference copy that information into the

space provided below.

Pfeiffer Vacuum, D-35614 Asslar

Typ:

No:

F-No:

V W

Validity

This document applies to products with part number

PT R27 000

(Flange DN 25 ISO-KF)

PT R27 001 (Flange DN 40 ISO-KF)

PT R27 002 (Flange DN 40 CF-R)

The part number (No) can be taken from the product nameplate.

If not indicated otherwise in the legends, the illustrations in this document correspond to the gauge with the vacuum connection DN 25 ISO-KF. They apply to

gauges with other vacuum connections by analogy.

We reserve the right to make technical changes without prior notice.

Intended Use

The PBR 260 Compact FullRange® BA Gauge has been designed for vacuum

measurement of non-flammable gases and gas mixtures in the pressure range of

-10

... 1000 hPa.

5×10

It must not be used for measuring flammable or combustible gases in mixtures

containing oxidants (e.g. atmospheric oxygen) within the explosion range.

The PBR 260 is part of the Pfeiffer Vacuum Compact Gauges family and can be

operated in connection with the MaxiGauge™ measurement and control unit

TPG 256 A or with another evaluation unit.

Functional Principle

Over the whole measurement range, the Compact FullRange® BA Gauge has a

continuous characteristic curve and its measuring signal is output as a logarithm of

the pressure.

The gauge functions with a Bayard Alpert hot cathode ionization and a Pirani

measurement system. In a defined overlapping pressure range, a mixed signal of

the two measurement systems is output. Above that range, a Pirani signal, below

that range, a hot cathode signal is output. The Pirani signal switches the hot

cathode measurement system on and off to prevent filament burn-out and

excessive contamination. The user can select among two switching on/off

thresholds.

Trademarks

MaxiGauge™ INFICON GmbH

FullRange

®

Pfeiffer Vacuum GmbH

2

BG 5171 BEN / B (2017-02) PBR 260

Contents

Product Identification 2

Validity 2

Intended Use 2

Functional Principle 2

Trademarks 2

1

Safety 4

1.1 Symbols Used 4

1.2 Personnel Qualifications 4

1.3 General Safety Instructions 4

1.4 Liability and Warranty 4

2 Technical Data 5

3 Installation 9

3.1 Vacuum Connection 9

3.1.1 Removing and Installing the Electronics Unit 10

3.1.2 Mounting the Extension 12

3.2 Power Connection 13

3.2.1 Use With MaxiGauge™ 13

3.2.2 Use With Other Evaluation Units 13

4 Operation 15

4.1 Measuring Principle, Measuring Behavior 15

4.2 Operational Principle of the Gauge 18

4.3 Degas 18

5 Maintenance 19

5.1 Maintenance 19

5.2 Adjusting the Gauge 19

5.3 Cleaning the Gauge 20

5.4 Installing the Baffle 20

5.5 Replacing the Baffle 22

5.6 Replacing the Sensor 23

5.7 What to Do in Case of Problems 23

6 Deinstallation 24

7 Returning the Product 26

8 Options 26

9 Spare Parts 26

10 Disposal 27

Appendix 28

A: Conversion Table for Pressure Units 28

B: Relationship Measuring Signal – Pessure 28

C: Gas Type Dependence 29

For cross-references within this document, the symbol (→ XY) is used, for cross-

references to other documents, the symbol (→ [Z]).

BG 5171 BEN / B (2017-02) PBR 260.oi 3

1 Safety

1.1 Symbols Used

1.2 Personnel Qualifications

1.3 General Safety

Instructions

1.4 Liability and Warranty

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and environmental damage.

Caution

Information on correct handling or use. Disregard can lead to malfunctions or

minor equipment damage.

Skilled personnel

All work described in this document may only be carried out by persons who

have suitable technical training and the necessary experience or who have been

instructed by the end-user of the product.

• Adhere to the applicable regulations and take the necessary precautions for the

process media used.

Consider possible reactions between the materials (→ 6) and the process

media.

Consider possible reactions (e.g. explosion) of the process media due to heat

generated by the product.

• Adhere to the applicable regulations and take the necessary precautions for all

work you are going to do and consider the safety instructions in this document.

• Before beginning to work, find out whether any vacuum components are contaminated. Adhere to the relevant regulations and take the necessary precautions when handling contaminated parts.

Communicate the safety instructions to other users.

Pfeiffer Vacuum assumes no liability and the warranty becomes null and void if the

end-user or third parties

• disregard the information in this document

• use the product in a non-conforming manner

• make any kind of changes (modifications, alterations etc.) to the product

• use the product with accessories not listed in the corresponding product

documentation.

The end-user assumes the responsibility in conjunction with the process media

used.

Gauge failures due to contamination or wear and tear, as well as expendable parts

(e.g. filament), are not covered by the warranty.

4

BG 5171 BEN / B (2017-02) PBR 260

2 Technical Data

Measurement

Emission

Degas

(only if p < 7.2×10

Output signal

Gauge identification

-6

hPa)

.

Measurement range (air, N2) 5×10

Overlapping range hot cathode – Pirani

high (default)

low

Accuracy

-8

... 10-2 hPa)

(10

Repeatability

-8

... 10-2 hPa)

(10

-10

… 1000 hPa

–3

5.5×10

2.0×10

… 2.0×10–2 hPa

–3

… 8.0×10–3 hPa

≈15 % reading

(after 5 min. stabilization)

≈5 % reading

(after 5 min. stabilization)

Gas type dependence → Appendix C

Switching on threshold (high) (default)

Switching off threshold (high) (default)

Switching on threshold (low)

Switching off threshold (low)

Emission current

(with decreasing pressure)

-6

7.2×10

hPa < p < 2.4×10-2 hPa

p ≤ 7.2×10

-6

hPa

Emission current switching

25 µA 5 mA

(with decreasing pressure)

5 mA 25 µA

2.4×10-2 hPa

-2

3.2×10

9.9×10

1.3×10

hPa

-3

hPa

-2

hPa

25 µA

5 mA

-6

7.2×10

hPa

3.2×10-5 hPa

(with increasing pressure)

Current ca. 16 mA / ca. 4.0 W

Control input signal 0 V / 24 V, PLC level, high active

Duration max. 3 min., followed by automatic stop

In degas mode, the PBR 260 keeps supplying measurement values the tolerances

of which can be higher than during normal operation.

Output signal 0 … 10.2 V

Measurement range 0.774 V … 10 V

(5×10

-10

hPa … 1000 hPa)

Relationship voltage-pressure logarithmic, 0.75 V / decade

Error signals

0.3 V

0.5 V

→ 23

• hot cathode error

• Pirani error

• electronics unit not correctly

mounted on sensor

Underrange

Overrange

0.5 V < U < 0.774 V

10 V < U ≤ 10.2 V

(measuring signal limited to 10.2 V by

software)

Minimum load

10 kΩ

Resistor (pin 1, U

= 4.25 V)

max

17.2 kΩ referenced to supply common

BG 5171 BEN / B (2017-02) PBR 260.oi 5

pp

pp

Adjustment

Supply

Sensor cable

Grounding concept

Vacuum

Pirani

HV

ATM (<ATM> button)

Zero point adjustment (<ATM>

button)

automatic adjustment by hot cathode

system at p = 1 … 3×10-3 hPa

adjustment via <ATM> button (keep

button depressed for at least 5 seconds)

at atmospheric pressure

adjustment via <ATM> button (keep

button depressed for at least 2 seconds)

at ≤1×10

-4

hPa

Hot cathode factory calibrated, readjustment not

required

DANGER

The gauge may only be connected to supply and evaluation units

which conform to the requirements of a grounded protective extra-low

Voltage at gauge 20 … 30 V=

Power consumption

standard

degas

emission start (< 200 ms)

Power consumption ≤ 16 W

Fuse necessary 1) ≤ 1.25 AT

Voltage at the supply unit with

maximum cable length

Electrical connection Hirschmann compact connector

Tightening torque ≤ 0.2 Nm

Cable 5 poles plus shielding

Cable length max. 35 m (0.25 mm² conductor)

Vacuum flange-supply common conductively connected

Signal common-supply common conducted separately; only differential

Materials on the vacuum side

housing, supports, screens

feedthrough

isolator

cathode

cathode holder

Pirani element

Internal volume

DN 25 ISO-KF

DN 40 ISO-KF

DN 40 CF-R

Pressure max. 200 kPa (absolute)

voltage (PELV). The connection to the gauge has to be fused. 1)

2)

max. ripple 2 V

≤ 0.5 A

≤ 0.8 A

≤ 1.4 A

21 … 30 V

max. ripple 2 V

type GO 6, 6 poles, male

50 m (0.34 mm² conductor)

100 m (1.0 mm² conductor)

measurement admissible due to high

current consumption

stainless steel

NiFe nickel plated

glass

iridium, yttrium oxide

molybdenum

tungsten, copper

≤ 24 cm

≤ 24 cm

3

3

≤ 34 cm3

1)

The MaxiGauge™ fulfills these requirements.

2)

The minimum voltage of the power supply must be increased proportionally to the length of the sensor

cable.

6

BG 5171 BEN / B (2017-02) PBR 260

Ambiance

Dimensions

Admissible temperatures

storage

operation

bakeout

-20 °C … 70 °C

0 °C … 50 °C

+150 °C (without electronics unit or with

extension → 26)

Relative humidity

year's mean

during 60 days

≤ 65 % (no condensation)

≤ 85 % (no condensation)

Use indoors only

altitude up to 2000 m NN

Degree of protection IP 30

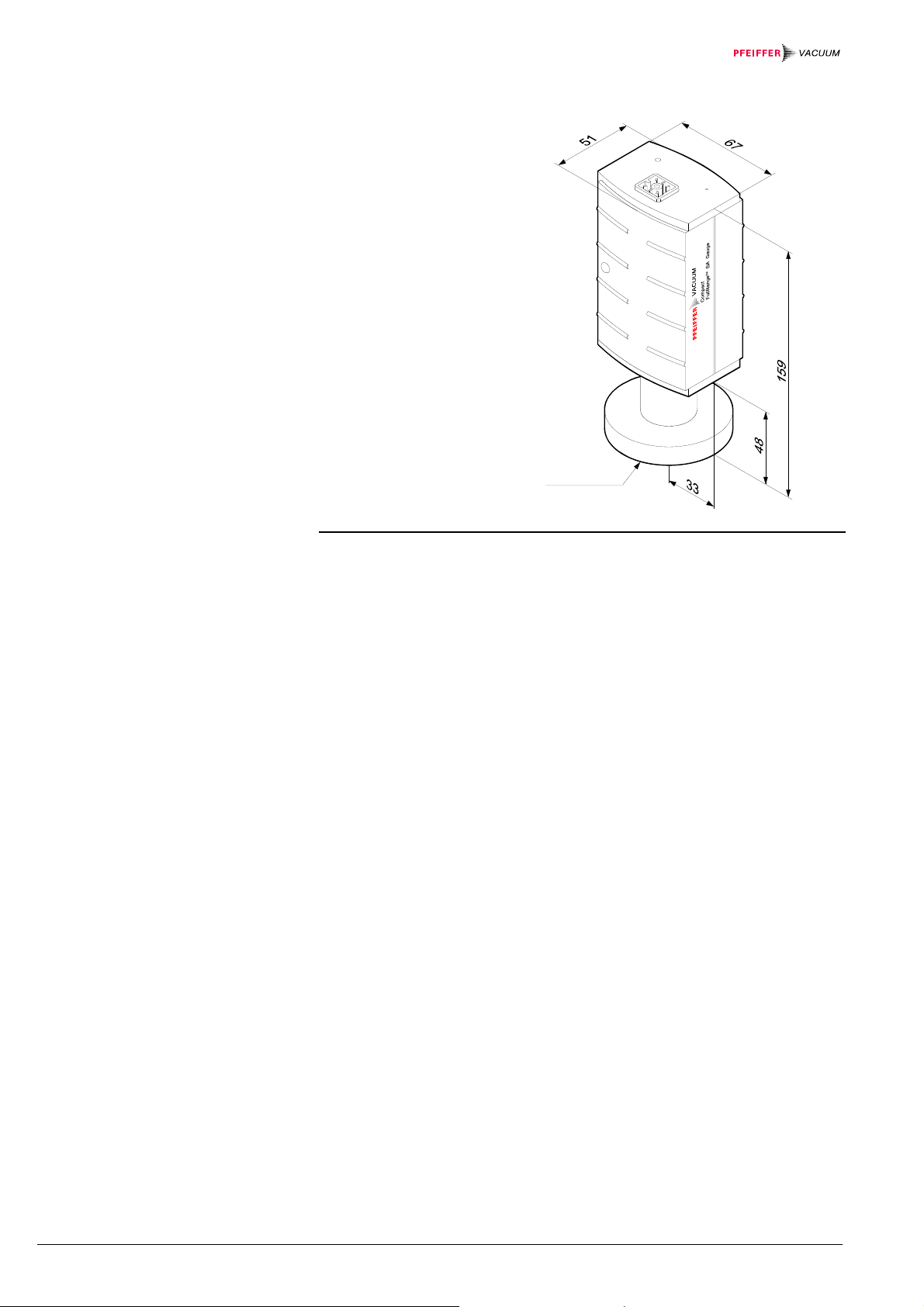

Flange DN 25 ISO-KF

Dimensions [mm]

DN 25 KF

Weight 285 g

Flange DN 40 ISO-KF

Dimensions [mm]

DN 40 KF

Weight 315 g

BG 5171 BEN / B (2017-02) PBR 260.oi 7

Flange DN 40 CF-R

Dimensions [mm]

DN 63 CF-R

Weight 550 g

8

BG 5171 BEN / B (2017-02) PBR 260

3 Installation

3.1 Vacuum Connection

DANGER: overpressure in the vacuum system > 100 kPa

If clamps are opened incorrectly or inadvertently, injury can be caused

by catapulted parts and your health can get damaged by leaking process media.

Do not open any clamps while the vacuum system is pressurized. Use

the type of clamps which cannot be opened inadvertently (e.g. hose

clip clamping rings).

DANGER: hazardous voltages

Incorrectly grounded products can be extremely hazardous in the

event of a fault.

The gauge must be electrically connected to the grounded vacuum

chamber. This connection must conform to the requirements of a

protective connection according to EN 61010:

• CF flanges fulfill this requirement.

• For gauges with a KF flange, use a conductive metallic clamping

ring.

DANGER

DANGER

Caution

Caution: vacuum component

Dirt and damages impair the function of the vacuum component.

When handling vacuum components, take appropriate measures to

• The gauge should be mounted so that no vibrations occur.

• The gauge may be mounted in any direction. However, no particles and con-

densates should penetrate into the measuring chamber.

• Take appropriate measures to prevent overheating (

admissible operating temperature).

• The sensor can be baked out at up to 150 °C. For temperatures above 50 °C

the electronics unit must be removed (→ 10) or an extension (Option → 26)

must be mounted (→ 12).

• See dimensional drawings ( 7) for space requirements.

• If the flange connection can only be made without the electronics unit, remove

the electronics unit (→ 10).

• We recommend using a metal sealing (ultra sealing ring → 26) as vacuum

flange sealing because elastomer seals (Vitilan, FPM) can impair the measurement accuracy already in the 10

• The gauge is supplied with a built in grid. For potentially severely contaminating

applications and to protect the electrodes against light and fast particles

installation of the optional baffle (→ 26) is recommended (→ 22).

ensure cleanliness and prevent damages.

-6

hPa range through gas desorption.

→ Technical data for

BG 5171 BEN / B (2017-02) PBR 260.oi 9

Procedure

Remove the protective cap.

The protective cap

will be needed for

maintenance.

Make the flange connection.

3.1.1 Removing and Installing

the Electronics Unit

Tools / material required

Removal

Install the gauge in such a way that it need not be removed for adjustment

(→ 17, 19).

• Allen wrench 2.5 mm

10

BG 5171 BEN / B (2017-02) PBR 260

a) Unscrew the hexagon socket screw (1) on the side of the electronics unit (2).

Be careful not to lose the hexagon socket screw.

1

2

b) Remove the electronics unit without twisting it.

Mounting

a) Place the electronics unit on the sensor (3) (be careful to correctly position the

pins and the guide notch (4)).

4

3

b) Slide the electronics unit up to the mechanical stop and lock it with the hexagon

socket screw (1).

BG 5171 BEN / B (2017-02) PBR 260.oi 11

3.1.2 Mounting the Extension

Bakeout area

With the optional extension (→ 26) the sensor can also be baked during opera-

tion at temperatures up to 150 °C (only at p<10

furnishes inexact readings at higher temperatures).

-2

hPa, since the Pirani sensor

Caution

Caution: rising heat

If your gauge is installed vertically, heat can rise even through the

extension and possibly damage the electronics unit.

Mount the gauge horizontally.

123

Compact

FullRange

VACUUM

TM

BA Gauge

Procedure

Bakeout area

a) Remove the electronics unit (2) (→ 10).

b) Slide the sensor (3) into the extension (6) to the mechanical stop (be careful to

correctly position the pins and the guide notch (4)).

c) Secure the sensor with the hexagon socket screws (7).

4a

4

2

3

1

6

7

d) Slide the electronics unit (2) onto the extension until the mechanical stop is

reached (be careful to correctly position the pins and the guide notch (4a)).

e) Secure the electronics unit (2) with the hexagon socket screw (1).

12

BG 5171 BEN / B (2017-02) PBR 260

3.2 Power Connection

3.2.1 Use With MaxiGauge™

3.2.2 Use With Other

Evaluation Units

Procedure

If the gauge is used with a

MaxiGauge™ measurement and

control unit, a corresponding

sensor cable is required

(→ 26).

• Plug the connector into the

gauge and secure it with the

screw (tightening torque

≤ 0.2 Nm).

• Connect the other end of the

cable to the MaxiGauge™

and secure it.

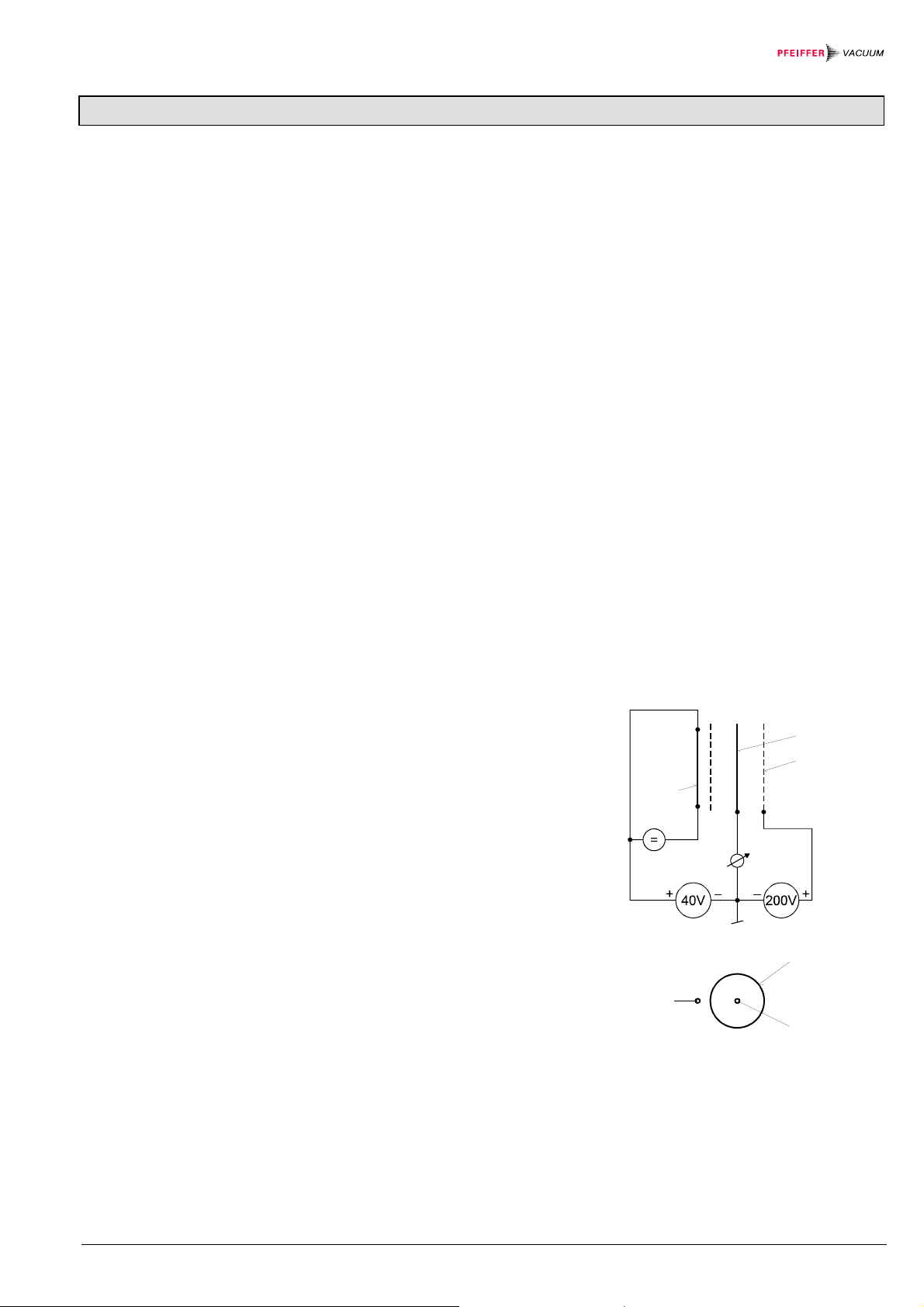

The gauge can also be used with other evaluation units. In such a case, an individual sensor cable can be made (preconfigured cables → 26).

Due to the high current consumption, only differential measurement between the

signal output (pin 2) and signal common (pin 3) is admissible.

Prepare the connector

(ordering number

→ 26).

Prepare the cable.

Solder the sensor cable according to the diagram.

Degas

17.2 k

Figure 1: Electrical connection

Pin 1 a) degas

b) identification

(U ≤ 4.25 V)

Pin 2 signal output

(measuring signal)

Pin 3 signal common GND

Pin 4 supply

Pin 5 supply common GND

Pin 6 shielding

2

3

1

4

5

6

Degas

3

4

+

–

+

–

2

1

6

5

Connector, soldering side

BG 5171 BEN / B (2017-02) PBR 260.oi 13

WARNING

The supply common (pin 5) and the shield (pin 6) must be

connected at the supply unit with protective ground.

Incorrect connection, incorrect polarity or inadmissible supply

Reassemble the connector.

At the other end of the cable, mount a connector which is compatible with

your evaluation unit.

Plug in the connector.

Secure the connector on the gauge with

the screw (tightening torque ≤ 0.2 Nm).

voltages can damage the gauge.

Connect the other end of the cable to your evaluation unit.

14

BG 5171 BEN / B (2017-02) PBR 260

4 Operation

4.1 Measuring Principle,

Measuring Behavior

Bayard Alpert

When the voltage is supplied, the measuring signal is available between pins 2 and

3. Over the whole measurement range, the measuring signal is output as a

logarithm of the pressure (relationship between measuring signal and pressure

→ Appendix B).

Allow for a stabilizing time of approx. 10 min. Once the gauge has been switched

on, permanently leave it on irrespective of the pressure.

The PBR 260 consists of two separate measuring systems (hot cathode Bayard

Alpert (BA) and Pirani).

The BA measuring system uses an electrode system according to Bayard Alpert

which is designed for a low x-ray limit.

The measuring principle of this system is based on gas ionization. Electrons

emitted by the hot cathode (F) ionize a number of molecules proportional to the

pressure in the measuring chamber. The ion collector (IC) collects the thus

generated ion current I

ment instrument. The ion current is dependent upon the emission current I

and feeds it to the electrometer amplifier of the measure-

+

, the

e

gas type, and the gas pressure p according to the following relationship:

= Ie × p × C

I

+

Factor C represents the sensitivity of the gauge. It is generally specified for N

The lower measurement limit is 5×10

For the whole range of 5x10

-10

-10

hPa (metal sealed).

hPa ... 10-2 hPa to be sensibly covered, a low

.

2

emission current is used in the high pressure range (fine vacuum) and a high

emission current is used in the low pressure range (high vacuum). The switching of

the emission current takes place at decreasing pressure at approx. 7.2×10

at increasing pressure at approx. 3.2×10

PBR 260 can temporarily (< 2 s) deviate from the specified accuracy.

-5

hPa. At the switching threshold the

-6

hPa,

IC

EC

F

(Degas 2.5V) (Degas 250V)

Fig. 1

Diagram of the BA measuring system

EC

F hot cathode (filament)

IC ion collector

F

EC electron collector (grid)

IC

BG 5171 BEN / B (2017-02) PBR 260.oi 15

U

Pirani

Within certain limits the thermal conductibility of gases is pressure dependent. This

physical phenomenon is used for pressure measurement in the thermal

conductance vacuum meter according to Pirani. A self adjusting bridge is used as

measurement circuit (see Fig. 2). A thin tungsten wire is used as sensor element.

Wire resistance and thus temperature are kept constant through a suitable control

circuit. The electric power supplied to the wire is a measure for the thermal conductance and thus the gas pressure. The basic principle of the self adjusting bridge

circuit is shown in Fig. 2.

B

–

+

PBR 260

Fig. 2

Measurement range

The bridge voltage U

is a measure for the gas pressure and is further processed

B

electronically (linearization, digitizing).

The PBR 260 covers the measurement range 5×10

-10

hPa … 1000 hPa.

• The Pirani constantly monitors the pressure.

• The hot cathode system (controlled by the Pirani) is only switched on when the

pressure drops below the set threshold (p

). The hot cathode will be ready for

on

operation after a few seconds' heating time, when the <EMI ON> lamp is lit.

• When the pressure rises above the setpoint (p

) the hot cathode is switched off

off

and the <EMI ON> lamp turns off.

In the upper pressure range, the Pirani reading and in the lower pressure range,

the hot cathode reading is output. In the overlapping range (p

combined signal of the two measuring systems is supplied (→ Fig. 3).

r

5 × 10

Hot cathode

-10

hPa

e

w

o

l

P

P

f

n

f

o

o

P

P

Pirani

r

e

p

p

u

1000 hPa

lower

… p

upper

), a

Fig. 3

16

BG 5171 BEN / B (2017-02) PBR 260

r

r

Defining the switching on/off

range

The PBR 260 has two definable switching on/off ranges with their corresponding

overlapping ranges. The switching on/off range is selected with the <P ↔ BA>

switch and should be chosen in such a way that it is situated outside the process

pressure range. The positions "high" (default) and "low" are available. Preferably,

"low" should be selected as contamination of the hot cathode system is reduced at

a lower pressure.

Caution

Since the switch position is polled only upon activation of the gauge,

the switching on/off range must be selected before the gauge is turned

on.

high

Switching on/off thresholds

of the hot cathode system

Overlapping ranges

Accuracy

low

2

high

3

-

0

1

×

5

.

5

×

4

.

2

2

-

-

0

0

1

1

×

2

.

3

PiraniHot cathode

2

5 × 10

-10

low

hPa

3

-

0

1

×

0

.

2

-

1000 hPa

0

1

×

0

.

2

3

2

-

-

0

0

1

1

×

×

3

9

.

.

9

1

PiraniHot cathode

3

-10

5 × 10

hPa

Switch position pon [hPa] p

high 2.4×10–2 3.2×10–2

low 9.9×10–3 1.33×10–2

Switch position p

lowe

high 5.5×10–3 2.0×10–2

low 2.0×10–3 8.0×10–3

The gauge is factory-calibrated. Adjustment may become necessary due to use

under different climatic conditions, extreme temperatures, contamination or aging

(→ 19).

The measurement accuracy is reduced in the pressure range above 1×10

and below 1×10

-8

hPa.

-

0

1

×

0

.

8

[hPa] p

off

uppe

1000 hPa

[hPa]

[hPa]

-2

hPa

BG 5171 BEN / B (2017-02) PBR 260.oi 17

Gas type dependence

4.2 Operational Principle of

the Gauge

4.3 Degas

Contamination

The measuring signal is gas type dependent. The relationship between the

measuring signal and the pressure is accurate for N

, O2, dry air and CO

2

(→ Appendix B). They can be mathematically converted for other gases

(→ Appendix C).

If the gauge is being operated with MaxiGauge™ measurement and control unit, a

calibration factor can be applied for correction of the reading (→ MaxiGauge™

TPG 256 A).

The measurement currents output by the Bayard Alpert and Pirani sensors are

converted into a pressure dependent frequency. A micro-controller converts that

frequency signal into a digital value of the measured total pressure. This value is

then supplied as analog signal from 0 to 10.20 V (pin 2 / pin 3), the valid measurement range being situated between 0.774 V and 10.00 V (atmospheric pressure). The output signal is limited to 10.20 V by the software.

In addition to converting the measuring signal, the micro controller's functions

include the monitoring of the emission and the calculation of the total pressure

based on the measurements from the two sensors.

Gauge failures due to contamination or wear and tear, as well as

expendable parts (e.g. filament), are not covered by the warranty.

Caution

Gauge failures due to contamination, as well as expendable parts

(filament), are not covered by the warranty.

Deposits on the electrode system of the hot cathode ionization gauge can lead to

unstable measurement readings.

Thus it is advisable to start the degas process of the anode at a pressure below

-6

7.2×10

can be activated via a MaxiGauge™ measurement and control unit, manually or

automatically by the control system (e.g. PLC). The PBR 260 automatically turns

the bakeout off after 3 minutes, if the bakeout has not been stopped before.

The degas process is activated when the control signal (pin 1) switches from OFF

(0 V) to ON (24 V). It is deactivated when the control signal switches from ON

(24 V) to OFF (0 V), or after a maximum of 3 minutes.

For a repeated degas process, the control signal first has to switch from ON (24 V)

to OFF (0 V), to then start degas again with ON (24 V). It is recommended that the

degas signal be set to OFF again through the systems control after 3 minutes of

bakeout, to achieve an unambiguous operating status.

The degas process is used for heating the electron collector grid to approx. 700 °C

through electron bombardment and thus cleaning the measuring element.

hPa (5 mA emission current). Depending on the application, this function

18

BG 5171 BEN / B (2017-02) PBR 260

5 Maintenance

5.1 Maintenance

5.2 Adjusting the Gauge

Adjustment under high vacuum

conditions

Adjustment at atmospheric

pressure

Required tools

Procedure

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to your health.

Before you begin to work, find out whether any parts are contaminated. Adhere to the relevant regulations and take the necessary

precautions when handling contaminated parts.

The gauge is factory calibrated. If used under different climatic conditions or in a

different position, through aging or contamination (→ 18), and after exchanging

the sensor (→ 23), the characteristic curve can be offset and readjustment may

be necessary. Only the Pirani system can be readjusted.

The Pirani system is automatically adjusted by the hot cathode system when the

gauge is activated (i.e. as soon as the pressure range 1 … 3×10

-3

hPa is reached).

• Pin approx. ø1.3 × 50 mm (e.g. a bent open paper clip)

Operate the gauge for approx. 10 minutes at atmospheric pressure. If the

gauge was operated before in the hot cathode range, a cooling-down time

of approx. 30 minutes is to be expected (gauge temperature = ambient

temperature)..

Zero Point Adjustment

Insert a pin through the opening marked <ATM> and push the button inside

for at least 5 s.

A zero point adjustment is recommended

• after the sensor has been exchanged

• as part of the usual maintenance work for quality assurance

BG 5171 BEN / B (2017-02) PBR 260.oi 19

Required tools

Procedure

• Pin approx. ø1.3 × 50 mm (e.g. a bent open paper clip)

The push button used for the adjustment at atmospheric pressure is also used for

the zero point adjustment (→ above).

5.3 Cleaning the Gauge

Operate gauge for approx. 10 minutes at a pressure of ≤1×10

-4

hPa.

Insert the pin through the opening marked <ATM> and push the button

inside for at least 2 s.

The adjustment is done automatically and ends after 2 minutes.

Small deposits on the electrode system can be removed by baking the anode

(Degas → 18). In the case of severe contamination the baffle can be exchanged

(→ 22). The sensor cannot be cleaned and must be replaced if it is severely

contaminated (→ 23).

For cleaning the outside, a moist cloth is usually sufficient. Do not use any

aggressive or abrasive cleaning agents.

Caution

Make sure that no liquids get inside the product. Allow the gauge to

dry thoroughly before putting it into operation again.

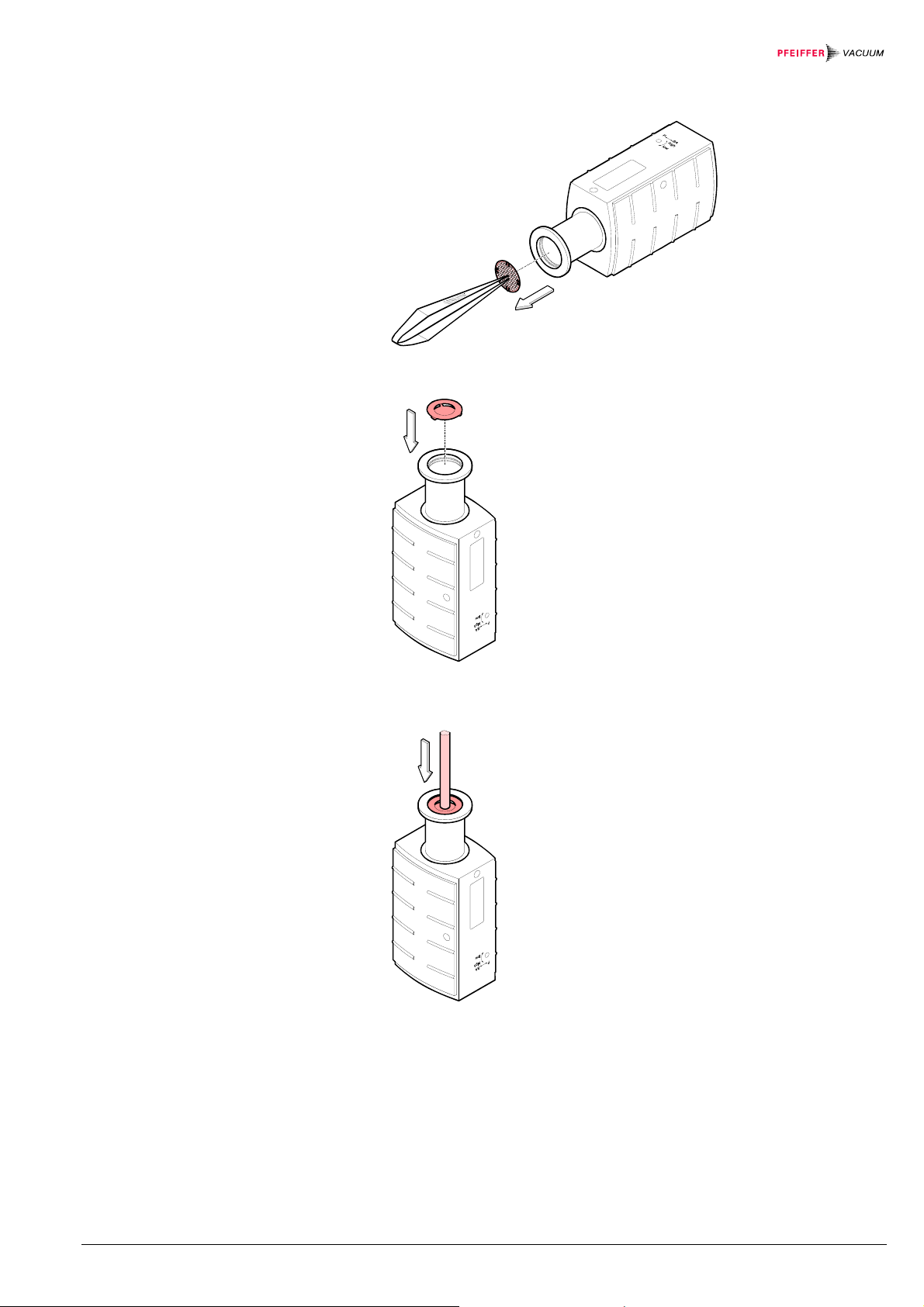

5.4 Installing the Baffle

Tools / material required

In severely contaminating processes and to optically protect the measurement

electrodes against light and fast particles, replacement of the built-in grid by the

optional baffle is recommended (→ 26).

Caution

Caution: dirt sensitive area

Dirt prolongs the pumpdown process.

Always wear clean, lint-free gloves and use clean tools when working

• Baffle (→ 26)

• Tweezers

• Stick (e.g. pencil)

in this area.

20

BG 5171 BEN / B (2017-02) PBR 260

Procedure

a) Carefully remove the grid with pointed tweezers.

b) Carefully place the baffle onto the sensor opening.

c) With a stick carefully press the baffle down in the middle until it catches in the

sensor opening.

BG 5171 BEN / B (2017-02) PBR 260.oi 21

5.5 Replacing the Baffle

Tools / material required

Procedure

In case of severe contamination the baffle can be replaced.

Caution

Caution: dirt sensitive area

Dirt prolongs the pumpdown process.

Always wear clean, lint-free gloves and use clean tools when working

• New baffle (→ 26)

• Screw driver No. 1

• Stick (e.g. pencil)

a) Carefully remove the baffle with the screw driver.

in this area.

b) Carefully place new baffle onto the sensor opening.

c) With a stick carefully press the baffle down in the middle until it catches in the

sensor opening.

22

BG 5171 BEN / B (2017-02) PBR 260

5.6 Replacing the Sensor

Tools / material required

Procedure

5.7 What to Do in Case of

Problems

Replacement is necessary, when

• the sensor is severely contaminated

• the sensor is faulty, e.g. filament broken.

Gauge failures due to contamination or wear and tear, as well as

expendable parts (e.g. filament), are not covered by the warranty.

• Allen wrench AF 2.5

• Spare sensor (→ 26)

a) Deinstall the gauge (→ 24).

b) Remove the electronics unit from the faulty sensor and mount it on the new

sensor (→ 10).

c) Mount the gauge (→ 9).

d) Adjust the gauge (→ 19).

Problem Possible cause Correction

No measuring signal No supply voltage Turn on the power supply

Connection cable defec-

Check connection cable

tive or not correctly

plugged in

Measuring signal 0.3 V Hot cathode error

Gauge in an undefined

condition

Turn gauge off and on

again (reset)

Replace sensor (→ 23)

(sensor faulty)

Measuring signal 0.5 V Pirani error

Replace sensor (→ 23)

(sensor faulty)

Electronics unit not

Check connection

correctly mounted on

sensor

Gauge does not switch

over to BA at low pres-

Pirani zero point out of

tolerance

Carry out a zero point

adjustment (→ 19)

sures

In case of an error, it may be helpful to first turn the voltage supply off and

on again after 5 s.

BG 5171 BEN / B (2017-02) PBR 260.oi 23

6 Deinstallation

Procedure

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health.

Before beginning to work, find out whether any parts are contaminated. Adhere to the relevant regulations and take the necessary

precautions when handling contaminated parts.

Caution

Caution: vacuum component

Dirt and damages impair the function of the vacuum component.

When handling vacuum components, take appropriate measures to

ensure cleanliness and prevent damages.

Vent the vacuum system.

Put the gauge out of operation.

Unplug the connection cable.

Remove the gauge from the vacuum system.

24

BG 5171 BEN / B (2017-02) PBR 260

Place the protective cap.

BG 5171 BEN / B (2017-02) PBR 260.oi 25

7 Returning the Product

WARNING

WARNING: forwarding contaminated products

Products returned to Pfeiffer Vacuum for service or repair should

preferably be free of harmful substances (e.g. radioactive, toxic,

caustic or microbiological).

Adhere to the forwarding regulations of all involved countries and

forwarding companies and enclose a completed declaration of con-

*)

Form under www.pfeiffer-vacuum.com

tamination

Products that are not clearly declared as "free of harmful substances" are decontaminated at the expense of the customer.

When returning a product to Pfeiffer Vacuum, put it in a tight and impact resistant

package.

*)

.

8 Options

9 Spare Parts

Ordering number

Sensor cable for connection to MaxiGauge™ measurement

and control unit

3 m

6 m

10 m

Hirschmann connection socket

GO 6 WF, 6 poles, angled, female

Extension, 100 mm

Baffle

PT 448 250-T

PT 448 251-T

PT 448 252-T

B 4707 283 MA

PT 590 300-T

PT 120 125-T

When ordering spare parts, always indicate:

• all information according to the product nameplate

• description and ordering number according to the spare parts list

Ordering number

Sensor PBR 260, flange DN 25 ISO-KF (Allen wrench included) PT 120 121-T

Sensor PBR 260, flange DN 40 ISO-KF (Allen wrench included) PT 120 122-T

Sensor PBR 260, flange DN 40 CF-R (Allen wrench included) PT 120 123-T

Electronics unit PBR 260 (Allen wrench included) PT 120 120-T

26

BG 5171 BEN / B (2017-02) PBR 260

10 Disposal

Separating the components

Contaminated components

Other components

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health.

Before beginning to work, find out whether any parts are contaminated. Adhere to the relevant regulations and take the necessary

precautions when handling contaminated parts.

WARNING

WARNING: substances detrimental to the environment

Electronic components must be disposed of in accordance with special

regulations.

Dispose of such products in accordance with the relevant local regu-

After disassembling the product, separate its components according to the following criteria:

Contaminated components (radioactive, toxic, caustic, or biological hazard etc.)

must be decontaminated in accordance with the relevant national regulations,

separated according to their materials, and recycled.

Such components must be separated according to their materials and recycled.

lations.

BG 5171 BEN / B (2017-02) PBR 260.oi 27

Appendix

A: Conversion Table for

Pressure Units

B: Relationship Measuring

Signal – Pessure

Conversion formula

Conversion curves

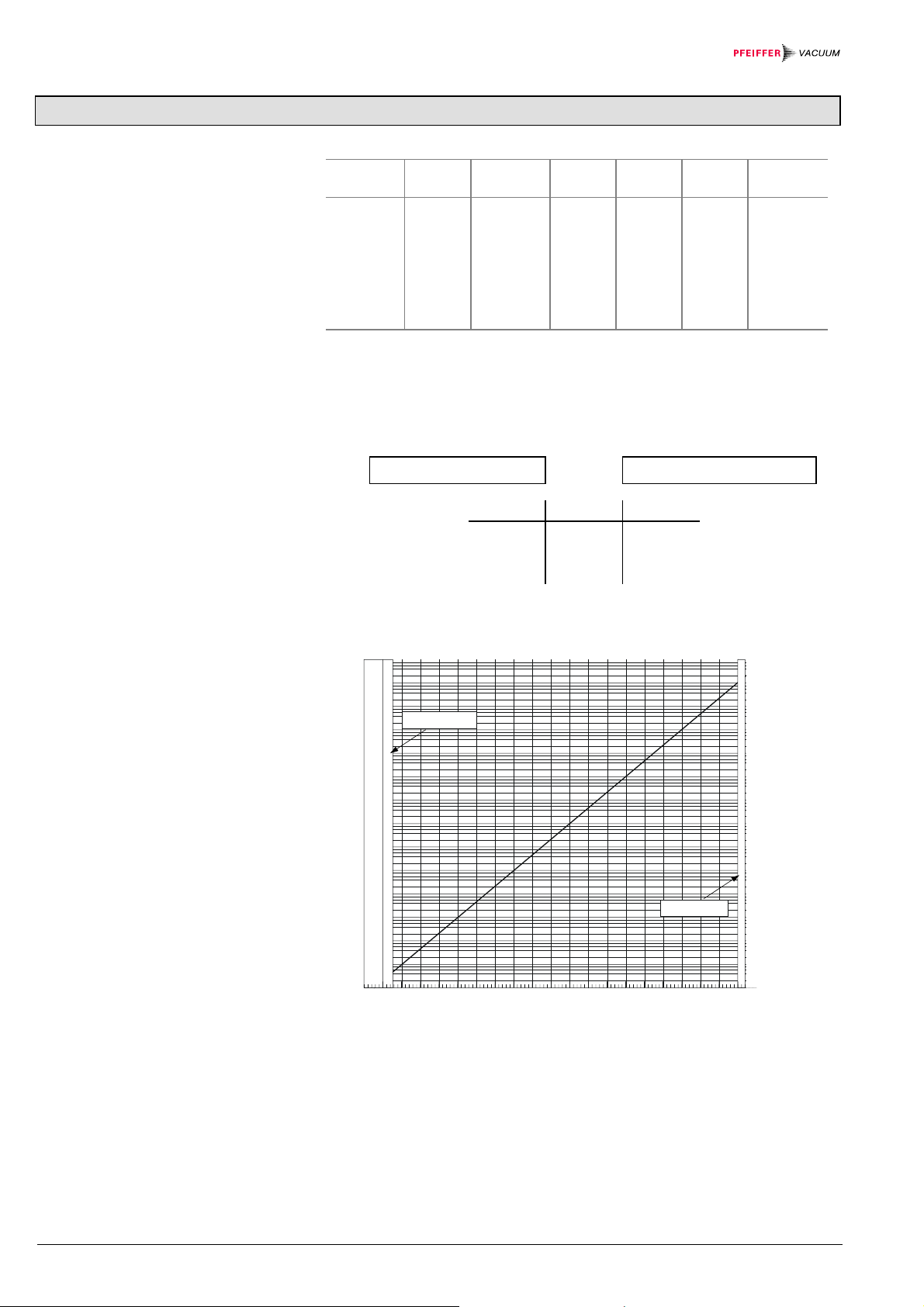

mbar bar Pa hPa kPa Torr

mm HG

mbar 1 1×10-3 100 1 0.1 0.75

bar 1×103 1 1×105 1×103 100 750

Pa 0.01 1×10-5 1 0.01 1×10-3 7.5×10-3

hPa 1 1×10-3 100 1 0.1 0.75

kPa 10 0.01 1×103 10 1 7.5

Torr

1.332 1.332×10-3133.32 1.3332 0.1332 1

mm HG

1 Pa = 1 N/m2

p = 10

(U-7.75)/0.75+c

U = 0.75×(logp-c)+7.75

U p c

[V] [hPa] 0

[V] [Pa] 2

[V] [Torr] -0.125

Pressure p [hPa]

1E+04

1E+03

1E+02

1E+01

1E+00

1E–01

1E–02

1E–03

1E–04

1E–05

1E–06

1E–07

1E–08

1E–09

1E–10

0.00.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

underrange

Sensor error

Measuring signal U[V]

overrange

28

BG 5171 BEN / B (2017-02) PBR 260

Conversion table

C: Gas Type Dependence

Below 10-3 hPa

(Hot cathode range)

Measuring signal U

[V]

[hPa]

Pressure p

[Torr]

[Pa]

<0.5 Sensor error

>0.50 … <0.774 underrange

0.774 5×10

-10

3.75×10

1.00 1×10-9 7.5×10

-10

5×10-8

-10

1×10-7

1.75 1×10-8 7.5×10-9 1×10-6

2.5 1×10-7 7.5×10-8 1×10-5

3.25 1×10-6 7.5×10-7 1×10-4

4.00 1×10-5 7.5×10-6 1×10-3

4.75 1×10-4 7.5×10-5 1×10-2

5.50 1×10-3 7.5×10-4 1×10-1

6.25 1×10-2 7.5×10-3 1×100

7.00 1×10-1 7.5×10-2 1×101

7.75 1×100 7.5×10-1 1×102

8.50 1×101 7.5×100 1×103

9.25 1×102 7.5×101 1×104

10.00 1×103 7.5×102 1×105

>10.00 … 10.20 V overrange

For gases other than air the pressure can be determined by means of a simple

conversion formula:

p

= K × indicated pressure

eff

where Gas type K

Air (N2, O2) 1.0

Xe 0.4

Kr 0.5

Ar 0.8

H

2.4

2

Ne 4.1

He 5.9

These conversion factors are mean values.

BG 5171 BEN / B (2017-02) PBR 260.oi 29

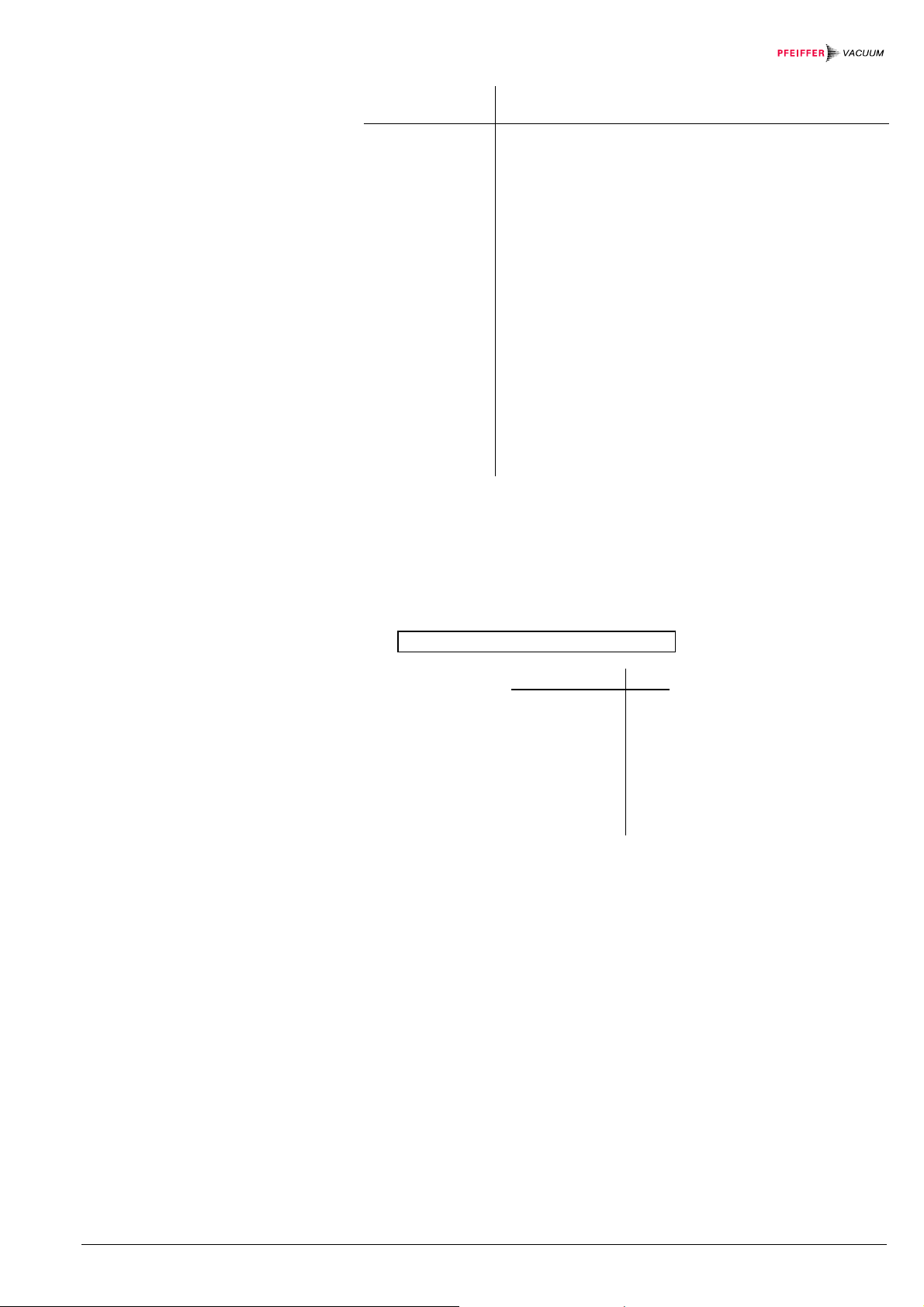

Above 10–2 hPa

(Pirani range)

p (hPa)

2

10

8

6

4

2

1

10

8

6

4

2

0

10

8

6

4

2

–1

10

8

6

4

2

Water vapor

–2

10

–3

10

24

Indication range

above 10

–2

10

6

8

24

H2He Ne

-2

hPa

–1

10

68

2468246824

0

10

Air

N

2

O

2

CO

CO

2

Ar

Freon 12

Kr

Xe

1

10

p

eff

68

(hPa)

2

10

A mixture of gases and vapors is often involved. In this case, accurate

determination is only possible with a partial-pressure measuring instrument.

Caution

30

BG 5171 BEN / B (2017-02) PBR 260

Notes

BG 5171 BEN / B (2017-02) PBR 260.oi 31

VACUUM SOLUTIONS FROM A SINGLE SOURCE

Pfeiffer Vacuum stands for innovative and custom vacuum solutions worldwide,

technological perfection, competent advice and reliable service.

COMPLETE RANGE OF PRODUCTS

From a single component to complex systems:

We are the only supplier of vacuum technology that provides a complete product portfolio.

COMPETENCE IN THEORY AND PRACTICE

Benefit from our know-how and our portfolio of training opportunities!

We can support you with your plant layout and provide first-class on-site-service worldwide.

Are you looking for a

perfect vacuum solution?

Please contact us:

Pfeiffer Vacuum GmbH

Headquarters ● Germany

T +49 6441 802-0

info@pfeiffer-vacuum.de

www.pfeiffer-vacuum.com

bg5171ben/ b

Loading...

Loading...