BG 5136 BEN / C

A PASSION FOR PERFECTION

EN

CMR 361 … CMR 365

Ceramic Capacitance Gauge

(2019-06)

Operating instructions

Product identification

The details on the rating plate are required when communicating

with Pfeiffer Vacuum. Therefore, you must specify these details.

2 BG 5136 BEN/C (2019-06)

Measuring range

min. (0 V)

F.S. (9 V)

max. (9.8 V)

[Pascal]

[Pascal]

[Pascal]

PT R24 600

½" tube

PT R24 601

DN 16 ISO-KF

PT R24 602

DN 16 CF-R

PT R24 603

8 VCR®

PT R24 610

½" tube

PT R24 611

DN 16 ISO-KF

PT R24 612

DN 16 CF-R

PT R24 613

8 VCR®

PT R24 620

½" tube

PT R24 621

DN 16 ISO-KF

PT R24 622

DN 16 CF-R

PT R24 623

8 VCR®

PT R24 630

½" tube

PT R24 631

DN 16 ISO-KF

PT R24 632

DN 16 CF-R

PT R24 633

8 VCR®

PT R24 640

½" tube

PT R24 641

DN 16 ISO-KF

PT R24 642

DN 16 CF-R

PT R24 643

8 VCR®

Validity

This document is applicable for products with the part numbers:

Type Part number Flange [hPa]

-1

CMR 361

CMR 362

CMR 363

CMR 364

CMR 365

10

101

10-2

100

10-3

10-1

10

10-2

10

10-3

-4

-5

The part number (P/N) can be obtained from the rating plate.

Figures with no designation relate to gauge CMR 361 with

vacuum connection DN 16 ISO-KF. These characteristics apply

for all other gauges accordingly.

We reserve the right to make technical changes without prior

notification.

All dimensions stated in mm.

[hPa]

1,000

100,000

100

10'000

10

1,000

1

100

0.1

10

[hPa]

1,100

110,000

110

11'000

11

1,100

1.1

110

0.11

11

BG 5136 BEN/C (2019-06) 3

Intended use

The Ceramic Capacitance Gauges from the CMR 36X series are

vacuum gauges and enable the measuring of absolute pressure

of gases in diverse measuring ranges (→ 3).

Function

The CMR gauge comprises a ceramic capacitive sensor element

and an electronic circuit that converts the capacity into a direct

voltage output signal.

The output signal is linear with the measured pressure and is

independent of the gas type being measured.

Type

VCR® Swagelok Marketing Co.

Patents

EP 1070239 B1, 1040333 B1

US patents 6528008, 6591687, 7107855, 7140085

Scope of delivery

1× CMR 36X gauge

1× stylus

1× calibration certificate

1× operating instructions German

1× operating instructions English

1× operating instructions French

4 BG 5136 BEN/C (2019-06)

Contents

Product identification 2

Validity 3

Intended use 4

Function 4

Type 4

Patents 4

Scope of delivery 4

1 Safety 6

1.1 Symbols used 6

1.2 Personnel qualifications 6

1.3 General safety instructions 7

1.4 Responsibilities and warranty 7

2 Technical data 8

3 Installation 13

3.1 Vacuum connection 13

3.2 Electrical connection 16

4 Operation 18

4.1 Indicate (to) 18

4.2 Calibrating the gauge 18

4.3 Factory reset 22

5 Dismantling 23

6 Maintenance, repair 24

7 Returning the product 25

8 Disposal of the product 25

Conversion table 27

ETL-Certification 27

EU-Declaration of Conformity 28

The (→ XY) symbol is used for page references within the text.

BG 5136 BEN/C (2019-06) 5

DANGER

WARNING

Caution

Skilled personnel

1 Safety

1.1 Symbols used

Information to prevent any kind of injury to persons.

Information to prevent extensive damage to property and the

environment.

Information on handling or use. Failure to observe can lead to

malfunctions or minor material damage.

Note

1.2 Personnel qualifications

The work described in this document may only be carried out

by persons that have suitable technical training and the

necessary experience or have been trained accordingly by the

operating company.

6 BG 5136 BEN/C (2019-06)

1.3 General safety instructions

• When handling the respective process media, observe the

relevant guidelines and adhere to the safety measures.

Consider possible reactions between materials and process

media.

• All work is only permissible when observing the relevant

guidelines and adhering to the protective measures.

Additionally, observe the safety instructions specified in this

document.

• Inform yourself about any contamination before starting work.

When handling contaminated parts, observe the relevant

regulations and implement the safety measures.

Pass on safety instructions to all other users.

1.4 Responsibilities and warranty

Pfeiffer Vacuum shall assume no liability nor provide any

warranty if the operating company or a third party

• disregards this document

• does not use the product for its intended purpose

• tampers with the product in any way (conversions,

modifications, etc.)

• operates the product with accessories that are not listed in the

corresponding product documentation.

The operating company is responsible for the process media

being used.

Malfunctioning of the gauge as a direct result of contamination is

not covered by the warranty.

BG 5136 BEN/C (2019-06) 7

Measuring range

→ "Validity"

PT R24 640 … PT R24 643

0.5% of measured value

PT R24 640 … PT R24 643

0.02% F.S./ °C

PT R24 640 … PT R24 643

0.03% of measured value / °C

Resolution

0.003% F.S.

Gas type dependence

None

signal)

Voltage range

0 … +11 V

Measuring range

+1.0 … +9.8 V

Relation voltage-pressure

Linear

("over-range")

Output impedance

<10 Ω

Load impedance

10 kΩ (short-circuit-proof)

PT R24 640 … PT R24 643

130 ms

2 Technical data

Accuracy 1)

PT R24 600 … PT R24 633

Temperature influence at zero point

PT R24 600 …

PT R24 623

PT R24 630 … PT R24 633

Temperature influence in range

PT R24 600 … PT R24 633

0.2% of measured value

0.005% F.S./ °C

0.015% F.S./ °C

0.01% of measured value / °C

Output signal analog (measuring

Error signal <0.4 V (no supply,

sensor error)

>9.8 V (above the range

Response time

PT R24 600 … PT R24 633

30 ms

1)

Non-linearity, hysteresis, repeat accuracy within calibrated range

at 25 °C ambient temperature without influence of temperature

after 2 hours of operation.

8 BG 5136 BEN/C (2019-06)

supply earth

DANGER

leading to the gauge.

ripple

≤1 Vpp

(max. switch-on current)

(dependent on supply voltage)

≤1.0 W

(polyfuse)

voltage.

6-pin, contact pins

Measurement cable

5-pin, including shielding

Cable length

≤120 m (0.25 mm² conductor)

(R

conductor

≤1.0 Ω).

Earthing concept

Vacuum flange – signal earth

→ "Electric connection"

(10 Ω)

Identification of gauge

Supply

Resistance 13.2 kΩ against

The gauge may only be connected to supply devices or

measurement instruments that comply with the

requirements of the earthed protective extra low voltage

(PELV). Protection must be provided for the cable

Supply voltage

at the gauge

+14 … +30 VDC

Power input <500 mA

Power input

Internal fuse 1 AT (slow), automatic reset

Gauge is protected against polarity reversal of the supply

Electric connection Compact connector

Hirschmann , type GO 6,

Larger conductor cross sections are required for longer cables

Supply earth – signal earth arranged separately for

BG 5136 BEN/C (2019-06) 9

differential measurement

Material against vacuum

(28% Ni, 23% Co, 49% Fe)

Internal volume

≤3.6 cm3

PT R24 640 … PT R24 643

130 kPa

Burst pressure (absolute)

500 kPa

Permissible temperature

Bake out (when not in operation)

≤110 °C at flange

50% at +40 °C

(mean sea level)

Protection category

IP 30

Flange, tube

Sensor and diaphragm

Connection sensor–diaphragm

Connection ceramic–metal

Maximum pressure (absolute)

PT R24 600 … PT R24 603

PT R24 610 …

PT R24 633

Stainless steel AISI 316L

Ceramic (Al

≥99.5%)

2O3

Glass ceramic solder

AgTiCu-hard solder, Vacon 70

300 kPa

200 kPa

Storage

Operation

–40 °C … +65 °C

+5 °C … +50 °C

Relative humidity ≤80% at temperatures

≤+31 °C reducing to

Use Indoors only,

altitude up to 2,000 m

10 BG 5136 BEN/C (2019-06)

69

23

55

DN 16 ISO-KF

DN 16 CF-R

OD½"

44

8 VCR

female

Weight

≤370 g

Dimensions [mm]

BG 5136 BEN/C (2019-06) 11

1 2 3 4 5 6 7 8 9

0.5

100

0

0.6

0.6

1.0

0.7

0.8

0.9

0.1

0.2

0.3

0.4

1.1

9.8

sensor error

underrange

overrange

sensor error

underrange

overrange

sensor error

underrange

overrange

sensor error

underrange

overrange

F.S.

Measuring signal U [V]

Pressure p [mbar]

hPa

Pa

Torr

c

0,125

12.5

0,094

Relation measuring signal analog – pressure

Example: Gauge CMR 361 with 1,000 hPa F.S.

Measuring signal U

12 BG 5136 BEN/C (2019-06)

p = (U - 1) × c (F.S.)

= 6 V

out

p = (6 V - 1 V) × 0.125 × 1,000 hPa

= 625 hPa

WARNING

drop to the floor.

DANGER

pieces suitable for overpressure.

DANGER

Use O-rings with an external centering ring.

3 Installation

WARNING: Risk of breakage

Impacts can destroy the ceramic sensor.

Avoid harsh impacts and never allow the product to

3.1 Vacuum connection

DANGER: Overpressure in the vacuum system

>100 kPa

Opening tensioning pieces with overpressure in the

vacuum system can lead to injuries as a result of

flying parts, and escaping process medium could

prove harmful to health.

Never open tensioning pieces when overpressure

is prevalent in the vacuum system. Use tensioning

DANGER: Overpressure in the vacuum system

>250 kPa

Elastomer seals (e.g. O-rings) are no longer

capable of withstanding the pressure for

KF-connections. This could prove harmful to health

due to escaping process medium.

BG 5136 BEN/C (2019-06) 13

DANGER

can be achieved by applying suitable measures.

Caution

damage.

Caution

Wear clean, lint-free gloves and use clean tools.

DANGER: Protective earth

Products that are not properly grounded can cause

fatal injuries in the event of a fault.

The gauge must be galvanically connected with the

earthed vacuum chamber. The connection must

comply with the requirements of a protective

bonding according to EN 61010:

• CF and VCR connections comply with this

requirement.

• An electrically conductive circlip must be used

for KF connections.

• Compliance with this requirement for ½"-tube

Caution: Vacuum components

Dirt and damage impair the function of the vacuum

component.

When handling vacuum components, observe the

rules relating to cleanliness and protection against

Caution: Area sensitive to contamination

Touching the product, or parts of the product with

bare hands will increase the rate of desorption.

14 BG 5136 BEN/C (2019-06)

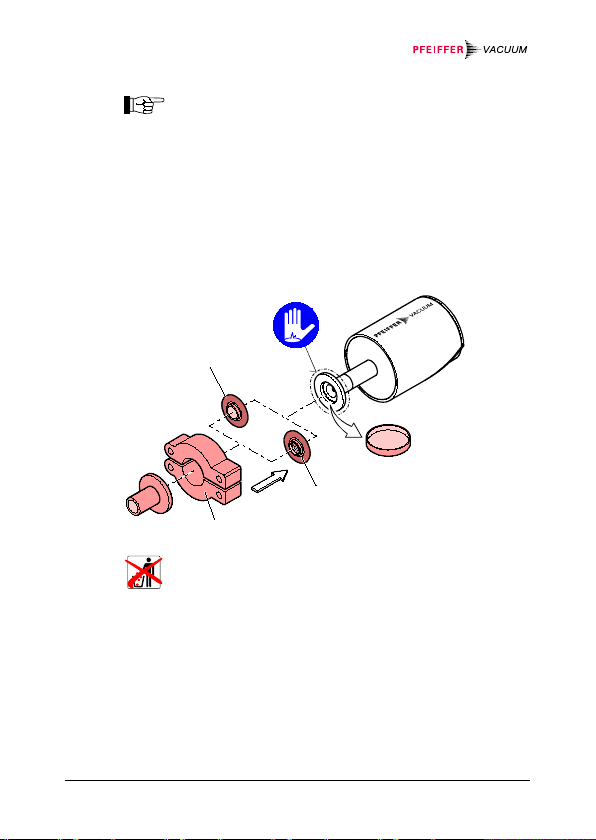

Clamp

Seal with centering ring

or

Seal with centering ring

and filter

Protective lid

Install the gauge vibration-free wherever possible. The

installation position is arbitrary. To prevent condensate and

particles accumulating in the measurement chamber, the

installation position should be horizontal or upright, and a seal

with centering ring and filter must be fitted where necessary.

If calibration of the gauge is possible in the installed condition,

you must ensure easy access to the buttons with a pin

(→ 18).

Remove the protective cap and connect the product to the

vacuum system.

BG 5136 BEN/C (2019-06) 15

Store the protective cap in a safe place.

DANGER

provided for the cable leading to the gauge.

3.2 Electrical connection

The gauge must be correctly connected to the vacuum

equipment (→ 13).

The gauge may only be connected to supply

devices or measurement instruments that comply

with the requirements of the earthed protective

extra low voltage (PELV). Protection must be

Earth loops, potential differences or EMC can influence

the measuring signal. Please observe the following

notes on installation to ensure optimum signal quality:

• Connect the cable shielding with the earth via the

connector housing on one side only. Leave the other

end of the shielding open.

• Connect the supply earth directly with protective earth

for power supply pack.

• Use the differential measuring input (separate signaland supply earth).

• Potential difference between supply earth and

housing ≤18 V (overvoltage protection)

16 BG 5136 BEN/C (2019-06)

If no measurement cable is present, a measurement cable

Electrical connection

Pin 1 Gauge identification

Pin 2 Signal output (measuring signal)

Pin 3 Signal common

Pin 4 Supply

Pin 5 Supply common

Pin 6 Chassis ground

Connector,

soldering side

2

5

3

1

6

4

–

+

–

+

2

3

1

4

5

100k

100nF

18 V

6

13K2

•

The cable must be shielded and grounded as

indicated in the above Illustration and the

Grounding concept *).

•

Connect the cable shield to ground on the

gauge side via Pin 6. Do not connect the other

side of the shield to prevent a ground circuit.

*)

→

"Technical Data"

can be fitted in accordance with the following diagram.

Connect the measurement cable to the gauge and secure

the cable connector using the locking screw.

Connect the measurement cable to the measurement

instrument.

BG 5136 BEN/C (2019-06) 17

Warm-up period

the specifications)

>¼ of an hour

calibration

>2 hours

ZERO

RUN

For factory

setting only

LED

Condition

Meaning

<RUN>

lights up

Measuring mode

range

4 Operation

Start up the gauge.

• for general pressure measurements (within

• for precision measurements and zero point

4.1 Indicate (to)

is flashing Other mode, error,

outside of measuring

4.2 Calibrating the gauge

The gauge is calibrated in the vertical upright position before

leaving the factory (→ "Calibration Test Report").

We recommend setting the zero point for initial

operation.

Long-term operation and contamination can lead to a zero point

shift, and may also necessitate a periodic zero adjustment.

18 BG 5136 BEN/C (2019-06)

Perform a zero adjustment for identical and constant ambient

F.S.

U / 90°

1000 hPa

≈2 mV

100 hPa

≈10 mV

10 hPa

≈50 mV

1 hPa

≈300 mV

0.1 hPa

≈1.8 V

for zero adjustment

0.11 hPa

<1×10-5 Torr

<1×10-5 hPa

<1×10-5 mbar

conditions and with the same installation position in which the

gauge is normally used.

The output signal is dependent upon the installation position.

Shifting from a vertical upright position to a horizontal position

constitutes:

∆

If the gauge is operated with a measurement instrument,

the zero adjustment must be performed at the

measurement instrument for the entire measuring

system: Calibrate the gauge first, and then the

measurement instrument.

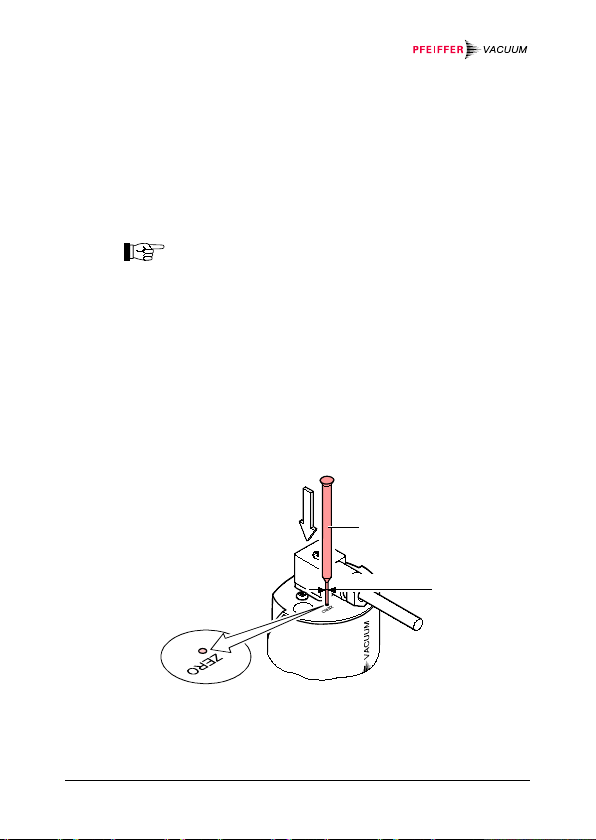

4.2.1 <ZERO> Adjust

Evacuate the gauge up to the pressure stipulated in the

following table:

Recommended ultimate pressure

BG 5136 BEN/C (2019-06) 19

1,100 hPa

110 hPa

11 hPa

1.1 hPa

If the ultimate pressure is too high during zero adjustment

(>25% of F.S.), zero is no longer achievable and the LED

<RUN> starts flashing. In this case, first activate the factory

settings and then calibrate the zero point again (→ 22).

<4×10-2 Torr

-3

<4

×10

Torr

-4

<4

×10

Torr

-5

<4

×10

Torr

<5×10-2 hPa

-3

<5

×10

hPa

-4

<5

×10

hPa

-5

<5

×10

hPa

<5×10-2 mbar

-3

<5

×10

mbar

-4

<5

×10

mbar

-5

<5

×10

mbar

Operate the gauge for at least 2 hours (until the measured

Press the button

max. ø1.1 mm

value stabilizes).

Push the <ZERO> button briefly with a pin (max. ø1.1 mm). The

zero point is calibrated automatically. The LED <RUN>

continues to flash until calibration is complete (duration ≤8 s).

Following calibration of the zero point, the gauge returns

automatically to measuring mode. The LED <RUN>

lights up.

The LED <RUN> flashes

• if the transmitter is indicating a negative output signal

(> 22 mV) with ultimate pressure, or

• if calibration of the zero point has failed.

4.2.2 <ZERO> Adjust with ramp function

The ramp allows the zero point to be set with an established

reference pressure that is within the measuring range of the

gauge.

20 BG 5136 BEN/C (2019-06)

Furthermore, an offset of the characteristic can be set with the

max. ø1.1 mm

Keep the button

depressed

ramp in order to

• compensate an offset from the measurement system, or

• to generate a slightly positive zero point for a 0 … 10 V

AD-converter.

The offset should not be greater than 2% of the F.S. (+160 mV).

A greater positive offset will exceed the upper measuring range

limit.

Recommended procedure for offset adjustment for

measurement systems: → Note 19.

Operate the gauge for at least ¼ of an hour (until the

measured value stabilizes).

Push the <ZERO> button with a pin (max. ø1.1 mm), and

hold pressed. The LED <RUN> starts to flash. After 5 s, the

zero-adjust value is continuously (ramp) changed from the

current output value until the button is released or the

setting limit (max. 25% F.S.) is reached. The signal is

issued with a delay of approx. 1 s at the signal output.

BG 5136 BEN/C (2019-06) 21

Press the <ZERO> button again:

second)

<RUN> changes briefly)

Fine adjustment

within 0...3 s:

Zero-adjust value changes by one

unit (press button approx. 1 x every

Direction change

within 3...5 s:

If the <ZERO> button is not pressed again within a period of

5 s, the gauge returns to measuring mode.

The LED <RUN> starts to flash when the gauge indicates a

negative output signal.

Zero-adjust setting changes the

direction (flash frequency of the LED

4.3 Factory reset

All parameters set/changed by the user (e.g. zero point, filter)

are reset to the standard values (factory settings).

A reset of the standard values cannot be undone.

Load factory settings:

Shutting down the gauge.

Hold the <ZERO> button pressed ≥5 s during

commissioning of the gauge.

22 BG 5136 BEN/C (2019-06)

WARNING

drop to the floor.

DANGER

the safety measures are adhered to.

Caution

damage.

5 Dismantling

WARNING: Risk of breakage

Impacts can destroy the ceramic sensor.

Avoid harsh impacts and never allow the product to

DANGER: Contaminated parts

Contaminated parts can be harmful to health and to

the environment.

Inform yourself about any contamination before

starting work. Observe the applicable guidelines

when handling contaminated parts and make sure

Caution: Vacuum components

Dirt and damage impair the function of the vacuum

component.

When handling vacuum components, observe the

rules relating to cleanliness and protection against

BG 5136 BEN/C (2019-06) 23

Caution

Caution: Area sensitive to contamination

Wear clean, lint-free gloves and use clean tools.

Touching the product, or parts of the product with

bare hands will increase the rate of desorption.

Vent the vacuum system.

Shut down the gauge.

Loosen the locking screw and remove the measurement

cable.

Dismantle the gauge from the vacuum system and fit the

protective cap.

6 Maintenance, repair

The product is maintenance-free, provided that orderly operating

conditions are upheld.

Malfunctioning of the gauge as a direct result of

contamination is not covered by the warranty.

We recommend that you check the zero point

periodically (→ 19).

Pfeiffer Vacuum shall assume no responsibility nor provide any

warranty if the operating company or a third party performs the

repair work.

24 BG 5136 BEN/C (2019-06)

WARNING

Contamination *) to be included.

DANGER

the safety measures are adhered to.

7 Returning the product

WARNING: Shipping of contaminated products

Contaminated products (e.g. by radioactive, toxic,

corrosive or microbiological means) can be harmful

to health and to the environment.

Products should be free of contaminants during

delivery wherever possible. Observe the shipping

guidelines of the respective countries and transport

companies. Completed Declaration of

*)

Form available at www.pfeiffer-vacuum.de

Products not clearly declared "Free of contamination" will be

decontaminated at your cost.

If you do not include a completed Declaration of Contamination,

all delivered products will be immediately returned with costs.

8 Disposal of the product

DANGER: Contaminated parts

Contaminated parts can be harmful to health and to

the environment.

Inform yourself about any contamination before

starting work. Observe the applicable guidelines

when handling contaminated parts and make sure

BG 5136 BEN/C (2019-06) 25

WARNING

substances in accordance with local regulations.

WARNING: Environmentally hazardous substances

Products or parts thereof (mechanical and

electrical components, operating fluid, etc.) can

cause environmental damage.

Dispose of the environmentally hazardous

Breaking down the components

After the product has been dismantled, the components must be

separated into the following categories for disposal:

• Contaminated components

Contaminated components (radioactive, toxic, corrosive,

microbiological etc.) must be decontaminated in accordance

with the regulations of the respective country, separated by

material type and disposed of accordingly.

• Non-contaminated components

These components must be separated by material type and

recycled.

26 BG 5136 BEN/C (2019-06)

mm Hg

mbar

1

1×10-3

100 1 0.1

0.75

bar

Pa

0.01

1×10-5 1 0.01

1×10-3

7.5×10-3

hPa

1

1×10-3

100 1 0.1

0.75

kPa

10

0.01

1×103

10 1 7.5

Torr

mm Hg

1 Pa = 1 N/m2

Conversion table

mbar bar Pa hPa kPa Torr

1×103 1 1×105 1×103 100 750

1,332 1,332×10-3 133.32 1.3332 0.1332 1

ETL-Certification

3103457

ETL LISTED

The products CMR 361 … CMR 365

• conform to the UL Standard

UL 61010-1

• are certified to the CSA Standard

CSA C22.2 # 61010-1

BG 5136 BEN/C (2019-06) 27

Aßlar, Monday, April 18, 2016

Managing Director

EU-Declaration of Conformity

Pfeiffer Vacuum, hereby confirms that the following product

conforms to EMC Directive 2014/30/EU and RoHS Directive

2011/65/EU.

Ceramic Capacitance Gauge

CMR 361 … CMR 365

Standards

Harmonized standards and applied national standards and

specifications:

• EN 61000-6-2:2005

• EN 61000-6-3:2007 + A1:2011

• EN 61010-1:2010

control equipment)

• EN 61326-1:2013

control equipment)

Manufacturer/Signatures

Pfeiffer Vacuum GmbH, Berliner Straße 43, D-35614 Aßlar

(EMC immunity to interference)

(EMC immunity to interference)

(Safety regulations for electrical measuring and

(EMC requirements for electrical measuring and

Dr. Ulrich von Hülsen

28 BG 5136 BEN/C (2019-06)

Notes

BG 5136 BEN/C (2019-06) 29

Notes

30 BG 5136 BEN/C (2019-06)

Notes

BG 5136 BEN/C (2019-06) 31

A PASSION FOR PERFECTION

Vacuum solutions

from a single source

Complete

range of products

Competence in

theory and practices

Are you looking for a perfect

vacuum solution?

Then contact us at:

Translation: English BG 5136 BEN / C (2019-06)

Worldwide, Pfeiffer Vacuum stands f or innovative and

customized vacuum solutions, technologic al perfection,

competent consultation and reliable serv ice.

From an individual component through to com plex systems:

We are the only vacuum technology pro vider to offer a

complete range of products.

Take advantage of our know-how and our tr aining offer!

We will support you in system planning, and we offer first-classon-site service worldwide.

Pfeiffer Vacuum GmbH

Headquarters ● Germany

Tel.: +49 6441 802-0

info@pfeiffer-vacuum.de

www.pfeiffer-vacuum.de

Loading...

Loading...