Page 1

296-12-19 008/002

Betriebsanleitung engl. 06.12

DOKU-SEAM-SYSTEM

3741

3745

Page 2

The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or

in part, is only permitted with our previous authorization and with written reference to the

source.

PFAFF Industriesysteme

und Maschinen AG

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Page 3

Index

Contents ................................................................................ Page

Register 01

................................................................................................. 5

1

Safety .................................................................................................................................... 7

1.01 Directives ...............................................................................................................................7

1.02 General notes on safety ......................................................................................................... 7

1.03 Safety symbols ......................................................................................................................8

1.04 Important points for the user ................................................................................................. 8

1.05 Operating and specialist personnel ........................................................................................ 9

1.05.01 Operating personnel .............................................................................................................. 9

1.05.02 Specialist personnel ............................................................................................................... 9

1.06 Danger warnings .................................................................................................................. 10

Register 02 ............................................................................................... 11

2

Input .................................................................................................................................... 14

2.01 General information ............................................................................................................. 14

2.02 Overview of the functions ................................................................................................... 15

2.03 Description of the functions ................................................................................................ 16

2.03.01 Overlapping functions .......................................................................................................... 16

2.03.02 Operating modes ................................................................................................................. 17

2.03.03 Tools ..................................................................................................................................... 17

2.04 Creating seam programs .....................................................................................................18

2.04.01 Sewing parameter input .......................................................................................................22

2.04.02 Input of action at beginning of seam sector ........................................................................ 23

2.04.03 Input of end of seam sector ............................................................................................... 24

2.04.04 Input of action at end of seam sector ................................................................................. 25

2.04.05 Thread force .........................................................................................................................27

2.05 Service ................................................................................................................................. 29

2.06 Cold start ............................................................................................................................. 30

2.07 Users – rights ....................................................................................................................... 31

2.08 Backup – restore .................................................................................................................. 33

2.09 Label-editor .......................................................................................................................... 35

2.10 Defi ning options and interfaces ........................................................................................... 37

Register 03 ...............................................................................................37

3

Betriebsanleitung ...............................................................................................................39

3.01 Proper use............................................................................................................................ 40

3.02 Specifi cations .......................................................................................................................41

3.03 Disposal of Machine ............................................................................................................42

3.04 Transportation, packing and storage .................................................................................... 43

3.04.01 Transportation to customer‘s premises ............................................................................... 43

Page 4

Index

Contents ................................................................................ Page

3.04.02 Transportation inside the customer‘s premises ................................................................... 43

3.04.03 Disposal of packing materials .............................................................................................. 43

3.04.04 Storage ................................................................................................................................ 43

3.05 Explanation of symbols ........................................................................................................ 44

3.06 Controls ...............................................................................................................................45

3.06.01 On/off switch / Sewing lamp switch .................................................................................... 45

3.06.02 Power bar ............................................................................................................................ 45

3.06.03 Keyboard on machine head .................................................................................................. 46

3.06.04 Pedal .................................................................................................................................... 48

3.06.05 Lever for lifting the presser foot ........................................................................................... 48

3.06.06 Knee switch (optional) .......................................................................................................... 49

3.06.07 Bobbin thread supply monitor ............................................................................................. 49

3.06.08 Adjustment of the stand height (optional) ........................................................................... 50

3.06.09 Touch-screen monitor .......................................................................................................... 50

3.06.10 Label-printer ......................................................................................................................... 51

3.06.11 Hand-held scanner ............................................................................................................... 51

3.06.12 PC ........................................................................................................................................51

3.07 Setting up ............................................................................................................................. 52

3.07.01 Log-in ................................................................................................................................... 52

3.07.02 Language selection .............................................................................................................. 52

3.07.03 Inserting the needle ............................................................................................................ 53

3.07.04 Winding the bobbin thread, regulating the winder tension (PFAFF 3741+ 3745 PLUS) ....... 54

3.07.05 Winding the bobbin thread, regulating the winder tension (PFAFF 3745 PREMIUM) .......... 55

3.07.06 Bobbin-changing/threading, and regulating the bobbin thread tension ................................ 56

3.07.07 Threading the needle thread (PFAFF 3741 PLUS + 3745 PLUS) ............................................57

3.07.08 Threading the needle thread (PFAFF 3745 PREMIUM) ..........................................................58

3.08 Sewing .................................................................................................................................59

3.08.01 Calling up / carry out the sewing operation (without camera for bobbin thread monitor) .... 59

3.08.02 Calling up / carry out the sewing operation (with camera for bobbin thread monitor) ......... 60

3.08.03 Regulating the needle thread tension (PFAFF 3741 + 3745 PLUS) ........................................ 62

3.08.04 Regulating the needle thread tension (PFAFF 3745 PREMIUM) ........................................... 64

3.08.05 Description of the functions ................................................................................................ 66

3.08.06 Concluding the sewing operation ........................................................................................ 68

3.09 Care and maintenance ......................................................................................................... 69

3.09.01 Servicing and maintenance intervals ................................................................................... 69

3.09.02 Cleaning the machine .......................................................................................................... 69

3.09.03 Lubricating ........................................................................................................................... 70

3.09.04 Checking/regulating the air pressure ................................................................................... 71

3.09.05 Emptying/cleaning the water bowl of the air fi lter/regulator ................................................ 71

3.10 Wearing parts ....................................................................................................................... 72

Page 5

Index

Contents ................................................................................ Page

Register 04

............................................................................................... 73

4

Adjustment ......................................................................................................................... 76

4.01 Notes on adjustment ........................................................................................................... 76

4.02 Tools, gauges and other accessories for adjusting ............................................................. 76

4.03 Abbreviations ....................................................................................................................... 76

4.04 Explanation of the symbols .................................................................................................. 76

4.05 Adjusting the basic machine ................................................................................................77

4.05.01 Basic position of the balance wheel (adjustment aid) .......................................................... 77

4.05.02 Zero position of the bottom and needle feed ...................................................................... 78

4.05.03 Feed dog motion of bottom feed dog and needle feed .......................................................79

4.05.04 Feeding motion of the bottom feed dog .............................................................................. 80

4.05.05 Height of the bottom feed dog ............................................................................................81

4.05.06 Feeding stroke difference ....................................................................................................82

4.05.07 Preliminary adjustment of the needle height ....................................................................... 83

4.05.08 Needle rise, hook clearance, needle height and bobbin case position fi nger ...................... 84

4.05.09 Bobbin case opener ............................................................................................................. 85

4.05.10 Bobbin winder ...................................................................................................................... 86

4.05.11 Thread check spring and thread regulator ............................................................................ 87

4.05.12 Sewing foot pressure ........................................................................................................... 88

4.05.13 Lubrication ...........................................................................................................................89

4.05.14 Reengaging the slip clutch ................................................................................................... 90

4.06 Adjusting the thread trimmer -900/81 .................................................................................. 91

4.06.01 Resting position of the roller lever / radial position of the control cam ................................ 91

4.06.02 Position and height of the thread catcher ............................................................................ 92

4.06.03 Knife pressure ......................................................................................................................93

4.06.04 Bobbin thread clamp spring ................................................................................................. 94

4.06.05 Manual cutting test .............................................................................................................. 95

4.07 Setup .................................................................................................................................... 96

4.07.01 Set reference position .......................................................................................................... 96

4.07.02 Stitch length adjustment ...................................................................................................... 97

4.07.03 Commissioning the scanner ................................................................................................ 98

4.07.04 Commissioning the camera ................................................................................................. 99

4.07.05 Adjustment of edge guide photocell ................................................................................. 102

4.08 Parameter settings ............................................................................................................. 103

4.08.01 Selecting and altering the parameters ............................................................................... 103

4.08.02 Parameter list ..................................................................................................................... 104

4.09 Description of the error messages .....................................................................................112

4.10 Inputs / Outputs ..................................................................................................................113

4.11 Pin assignment ...................................................................................................................114

4.12 Importend Sevice-information ............................................................................................117

Page 6

Index

Contents ................................................................................ Page

Register 05

............................................................................................. 117

5

Calibration ........................................................................................................................ 120

5.01 General information ........................................................................................................... 120

5.01.01 Calibration .......................................................................................................................... 120

5.01.02 Traceability ......................................................................................................................... 120

5.01.03 Standards ........................................................................................................................... 120

5.01.04 Gauging offi ce, German Calibration Offi ce DKD ................................................................ 121

5.02 Calibration procedure ......................................................................................................... 121

5.02.01 Check / adjust the needle reference position ..................................................................... 121

5.02.02 Check / adjust the trigger signals ....................................................................................... 122

5.02.03 Check the zero position of the monitor power signal ........................................................ 123

5.02.04 Checking the setting of the sewing head........................................................................... 124

5.02.05 Recording the characteristic thread strength curve ........................................................... 124

5.03 Checking the calibration (calibration result) ........................................................................ 127

Register 06 ............................................................................................. 127

6

Circuit diagrams ...............................................................................................................129

6.01 Pneumatics-switch diagram PFAFF 3741 + 3745 .............................................................. 129

6.02 Block diagram PFAFF 3741 + 3745 (with control unit P374 ED) ......................................... 130

6.03 Circuit diagrams ................................................................................................................. 132

Page 7

Register 01

Page 8

Page 9

7

Safety

1 Safety

1

.01 Directives

This machine is constructed in accordance with the European regulations contained in the

conformity and manufacturer’s declarations.

In addition to this Instruction Manual, also observe all generally accepted, statutory and

other regulations and legal requirements and all valid environmental protection regulations!

The regionally valid regulations of the social insurance society for occupational accidents or

other supervisory organizations are to be strictly adhered to!

1.02 General notes on safety

● This machine may only be operated by adequately trained operators and only after having

completely read and understood the Instruction Manual!

● All Notes on Safety and Instruction Manuals of the motor manufacturer are to be read be-

fore operating the machine!

● The danger and safety instructions on the machine itself are to be followed!

● This machine may only be used for the purpose for which it is intended and may not be

operated without its safety devices. All safety regulations relevant to its operation are to

be adhered to.

● When exchanging sewing tools (e.g. needle, roller presser, needle plate and bobbin),

when threading the machine, when leaving the machine unattended and during maintenance work, the machine is to be separated from the power supply by switching off the

On/Off switch or by removing the plug from the mains!

● Everyday maintenance work is only to be carried out by appropriately trained personnel!

● Repairs and special maintenance work may only be carried out by qualifi ed service staff

or appropriately trained personnel!

● Work on electrical equipment may only be carried out by appropriately trained personnel!

● Work is not permitted on parts and equipment which are connected to the power supply!

The only exceptions to this rule are found in the regulations EN 50110.

● Modifi cations and alterations to the machine may only be carried out under observance

of all the relevant safety regulations!

● Only spare parts which have been approved by us are to be used for repairs! We express-

ly point out that any replacement parts or accessories which are not supplied by us have

not been tested and approved by us. The installation and/or use of any such products can

lead to negative changes in the structural characteristics of the machine. We are not liable

for any damage which may be caused by non-original parts.

Page 10

8

Safety

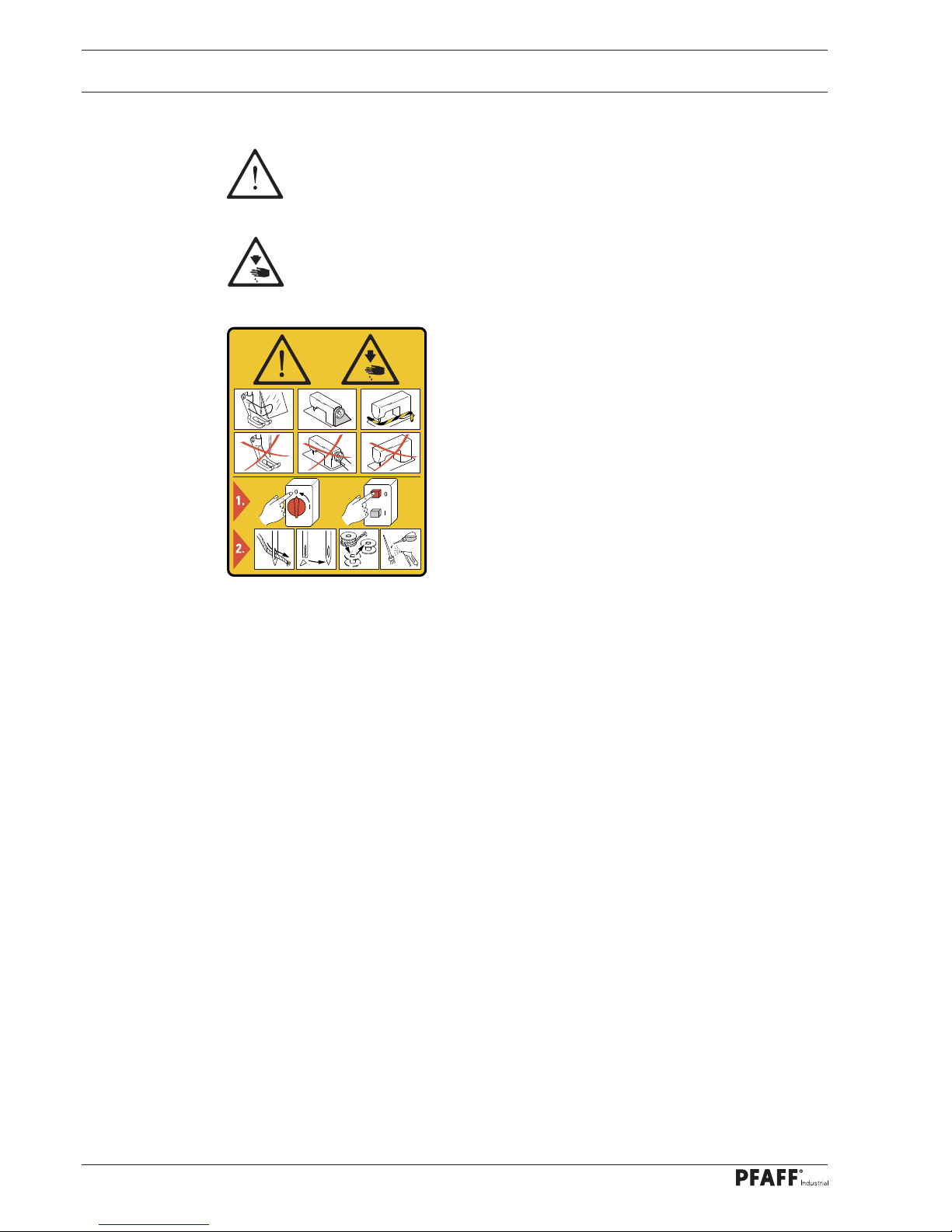

1.03 Safety symbols

Danger!

Points to be observed..

Danger of injury for operating and specialist personnel!

Caution

Do not operate without fi nger guard and safety devices.

Before threading, changing bobbin and needle, cleaning

etc. switch off main switch.

I

1.04 Important points for the user

● This Instruction Manual is an integral part of the machine and must be available to the

operating personnel at all times.

● The Instruction Manual must be read before operating the machine for the fi rst time.

● The operating and specialist personnel is to be instructed as to the safety equipment of

the machine and regarding safe work methods.

● It is the duty of the user to only operate the machine in perfect running order.

● It is the obligation of the user to ensure that none of the safety mechanisms are removed

or deactivated.

● It is the obligation of the user to ensure that only authorized persons operate and work

on the machine.

Further information can be obtained from your PFAFF agent.

Page 11

9

Safety

1.05 Operating and specialist personnel

1

.05.01 Operating personnel

Operating personnel are persons responsible for the equipping, operating and cleaning of

the machine as well as for taking care of problems arising in the sewing area.

The operating personnel is required to observe the following points and must:

● always observe the Notes on Safety in the Instruction Manual!

● never use any working methods which could adversely affect the safety of the machine!

● not wear loose-fi tting clothing or jewelery such as chains or rings!

● also ensure that only authorized persons have access to the potentially dangerous area

around the machine!

● always immediately report to the person responsible any changes in the machine which

may limit its safety!

1.05.02 Specialist personnel

Specialist personnel are persons with a specialist education in the fi elds of electrics, electronics and mechanics. They are responsible for the lubrication, maintenance, repair and adjustment of the machine.

The specialist personnel is obliged to observe the following points and must:

● always observe the Notes on Safety in the Instruction Manual!

● switch off the On/Off switch before carrying out adjustments or repairs, and ensure that

it cannot be switched on again unintentionally!

● wait until the luminous diode on the control box is no longer blinking or on before begin-

ning adjustment or repair work.

● never work on parts which are still connected to the power supply! Exceptions are explai-

ned in the regulations EN 50110.

● replace the protective coverings and close the electrical control box afer all repairs or

maintenance work!

Page 12

10

Safety

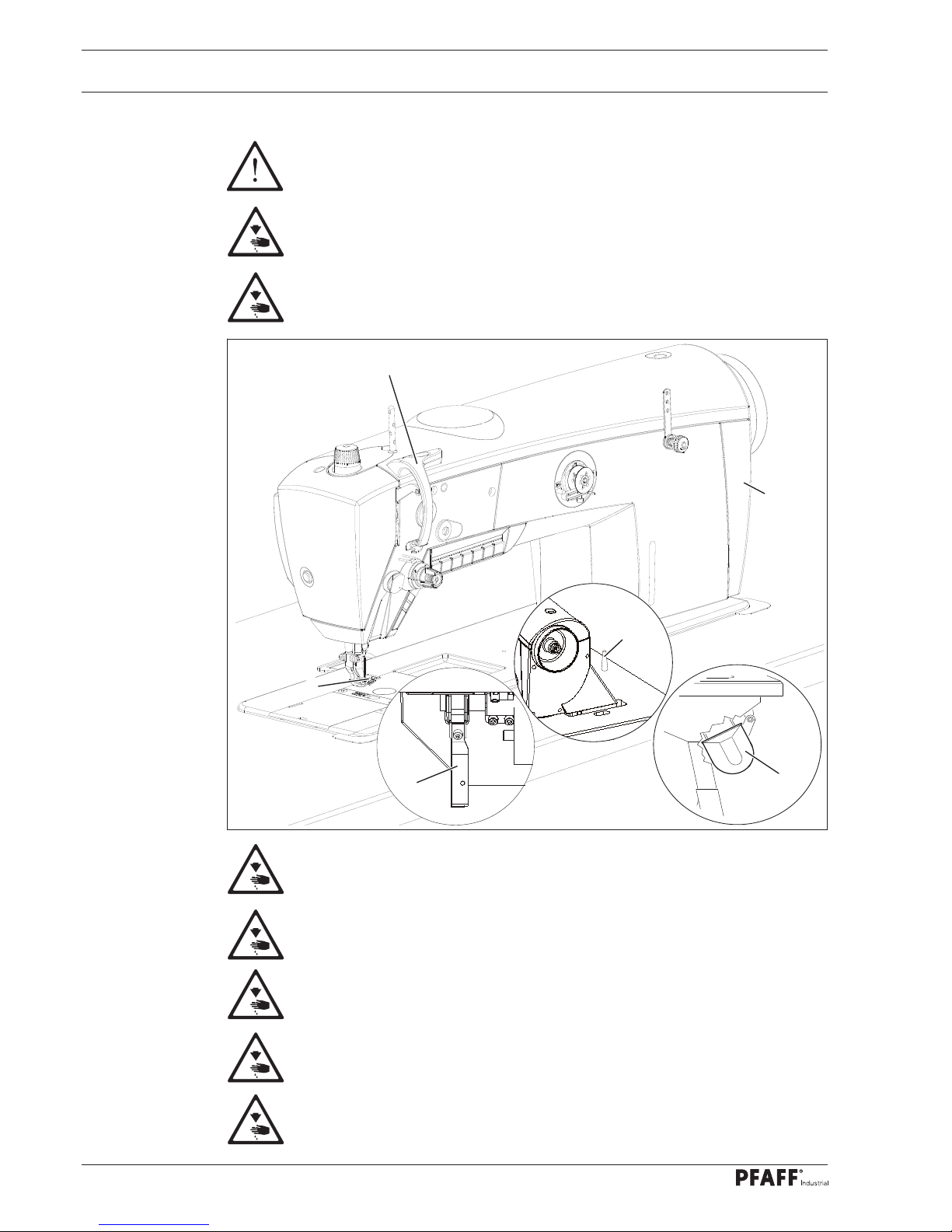

1.06 Danger warnings

A working area of 1 m must be kept free both in front of and behind the machine, so that easy access is possible at all times.

Never put your hands or fi ngers in the sewing area during sewing!

Danger of injury by the needle!

While setting or adjusting the machine do not leave any objects on the table nor

in the needle plate area! Objects may be trapped or fl ung out of the machine!

Do not run the machine without fi nger guard 1!

Danger of injury by up and down movement of needle!

Do not run the machine without take-up lever guard 2!

Danger of injury by moving take-up lever!

Do not run the machine without belt guards 3 and 4!

Danger of injury by rotating v-belt!

Do not operate the machine without tilt lock 5!

Danger of crushing between sewing head and table!

Do not operate the machine without support 6! Danger due to top-heavy

sewing head! Machine can tip over backwards when tilted!

Fig. 1 - 01

2

1

3

4

6

5

Page 13

PFAFF Industriesysteme und Maschinen AG, 67661 Kaiserslautern

Declaration of acknowledgement

of the documentation for the PFAFF-DOKU-SEAM-SYSTEM

Customer:................................................................................................................................................

Address:...................................................................................................................................................

Machine: PFAFF 3741 ................................... Serial-Nr.: ................................................................

Machine: PFAFF 3745 ................................... Serial-Nr.: ................................................................

PC-software: ................................................. Control software:.....................................................

Each person working on the PFAFF-DOKU-SEAM-SYSTEM must be familiar with and understand the

contents of these technical documents. The operating and qualifi ed personnel must be appropriately

authorised to handle the machine, i.e. qualifi ed and instructed. The operator promises to train his

personnel accordingly. Furthermore the user have to take care, to calibrate the machine, when the

control-box or the thread-force-sensor was changed.

We hereby confi rm that we have read and understood the documentation for the PFAFF-DOKU-SEAM-

SYSTEM

, and that in addition to the advice in the documentation, we will also follow the local safety and

accident prevention regulations.

Place:...................................................................................... Date:................................................

Operator:...................................................................................................................................................

Page 14

Page 15

Register 02

Page 16

Page 17

This instruction manual applies to

machines from software version 1.8

and serial number 2 763 625 onwards

Kurzanleitung zur Eingabe engl. 06.12

SHORT INSTRUCTIONS

FOR THE INPUT

3741

3745

Page 18

Input

14

2 Input

2

.01 General information

The effective pull of the needle thread (needle thread tension) is determined during sewing

for each stitch by means of a sensor installed in the needle thread path of the sewing machine.

In the process, through a special measuring principle, measuring errors, caused for example

by fl uctuating temperatures, can be ruled out.

The signals are evaluated on the PC and displayed on the touch-screen monitor on a user interface for Windows ® XP. The analysis of these signals gives information about the machine

setting and the quality of each individual stitch sewn.

The seam sector for which the system is to be activated (docu-seam sector) is determined

either by a sensor, by knee switch, with a pre-selected seam length or by stitch counting.

The docu-seam system compares the established thread pull with the previously entered

limit values and issues an evaluation of the seam on the touch-screen monitor. If the seam

is a good seam, an appropriate signal is given to the PC interface and a label can be printed,

which can then be attached to indicate the appropriate quality of the seam. The label can be

designed individually with an editor.

The docu-seam system also activates a missed stitch recognition function and, depending

on how it is set, reacts to following types of error:

- missed stitch,

- needle thread breakage, end of needle thread

- bobbin thread breakage, end of bobbin thread

- broken needle

- deviations from edge guide

The use of specifi ed materials can be ensured and documented through the prompt to enter

appropriate codes (e.g. scanning of barcodes for thread spindle, material, bobbin).

All inputs, for separate user groups, can be carried out directly over the user interface of the

touch screen monitor. Several languages are available for the user interface. All data entered

and established can be processed on standard databases and spreadsheets.

Page 19

Input

15

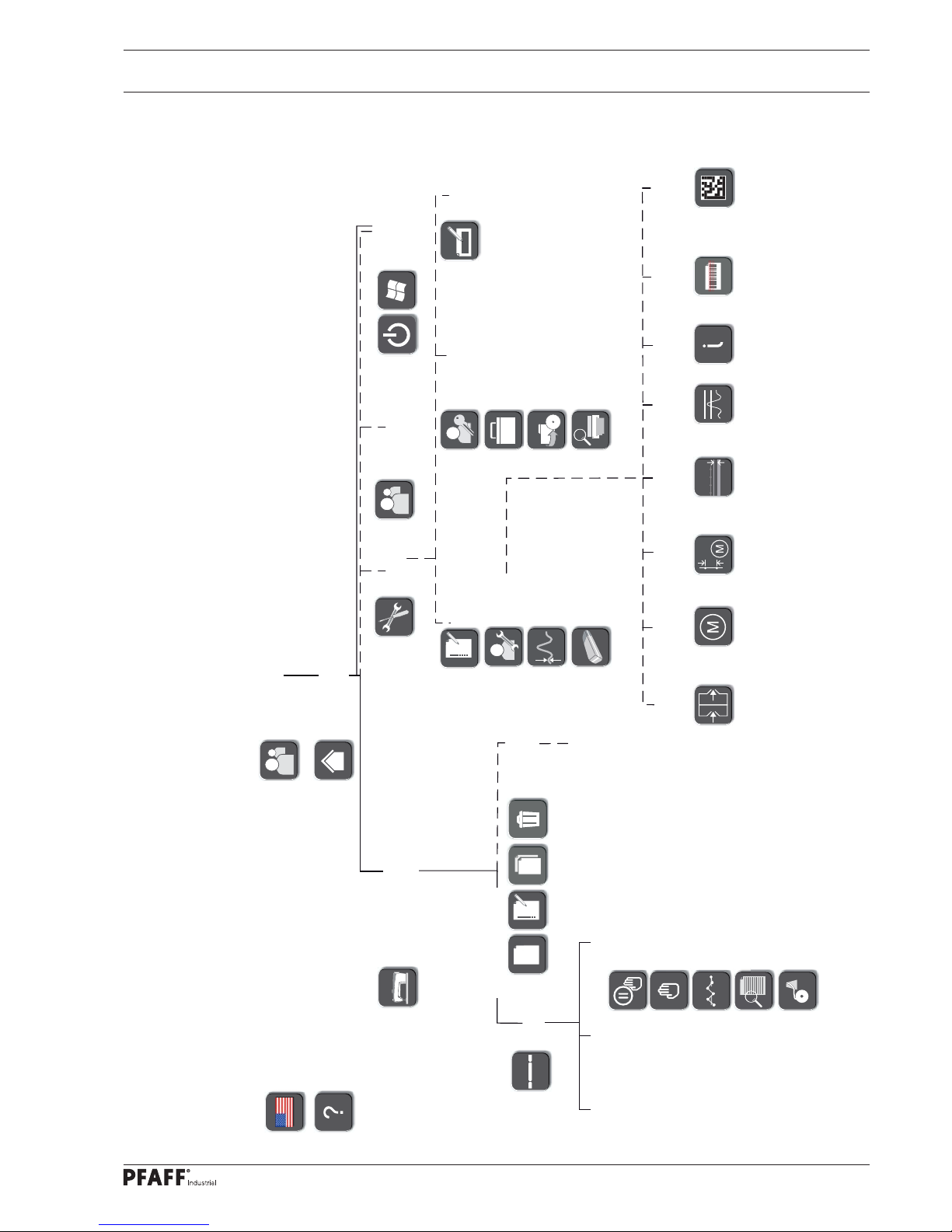

2.02 Overview of the functions

Pop-ups:

- Instruction box

- Error

- Warning - Keyboard

- Language selection

- Help mode

- Log-in

- Selection of oper-

ating mode

- Tools

- Change of

user

- Switch off

switch to

desktop /

computer

- Seam program selection +

configuration

- Production

Pop-ups:

- Error

- Warning

Info

display

Switch to:

- Manual interruption

- Manual sewing

- Test seam

- Work instructions

- Winding

Popups:

- Settings

- Seam program

creation

Work instructions

- Label- editor

- Users and rights

- Equipment + interfaces

- Backup and restore

- Evaluation and printing

- Parameterization

- Service

- Calibration

- Cold start

Inputs/outputs

Feed

regulator

configuration

Thread

force

Drives

Sensors

Version

Scanner

commissioning

Camera

commissioning

Page 20

Input

16

2.03 Description of the functions

Each function is selected by tapping the appropriate symbols on the touchscreen monitor.

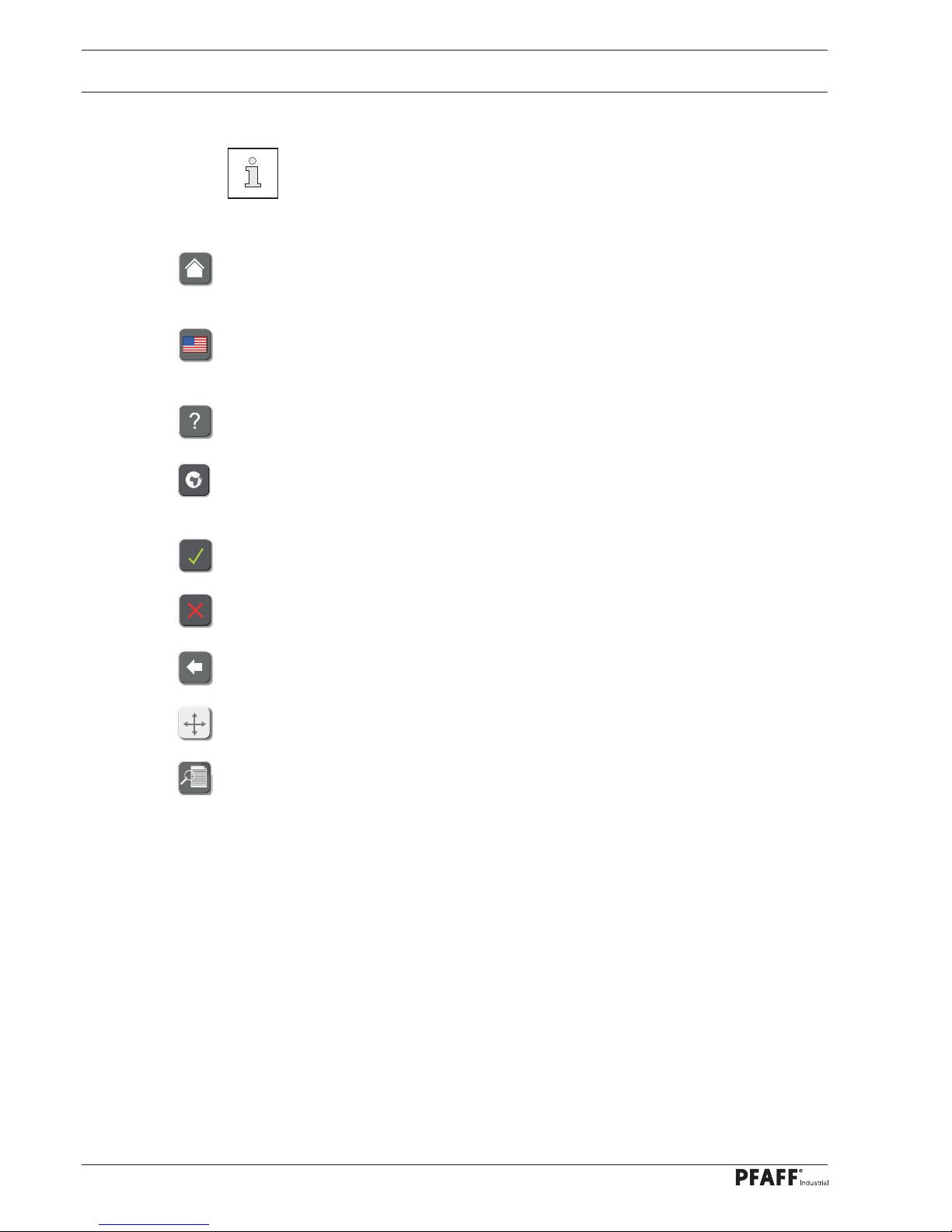

2.03.01 Overlapping functions

Mode selection

The menu for selecting the operating mode is called up, see Chapter 2.03.02 Operating

modes.

Choice of language

A menu for selecting the language setting is opened, see Chapter 8 Setting up in the Instruction Manual.

Help mode

After calling up the help mode, the next function selected is described.

Online help

After activation of the help module, the online help can be called up, including language and

document selection.

Confi rm

The selection is confi rmed, entered or altered values are saved.

Stop

The selection process is cancelled, entered or altered values are not saved.

Back

The superordinate level is selected.

Drag and Drop

With this function it is possible to move the window to any position.

Work order

With this function, a previously created work order can be displayed.

Page 21

Input

17

2.03.03 Tools

Parameterization

A menu is called up for adjusting the parameters, see Adjustment Manual.

Service

The service menu is called up, see Chapter 2.05 Service.

Calibration

A menu is called up for calibrating the machine, see Calibration Instructions.

Cold start

A cold start is carried out, see Chapter 2.06 Cold Start.

Users – Rights

A menu is called up for entering users and rights, see Chapter 2.07 Users – Rights.

Equipment and Interfaces

A menu is opened for allocating work aids to corresponding COM-interfaces, see

Chapter 2.10 Defi ning options and interfaces.

Backup and Restore

A menu is called up for carrying out a backup or a restoration, see Chapter 2.08 Back-up –

Restore.

Evaluation and print function

A selected docu-seam with all relevant values is displayed.

Label editor

A menu is called up for editing labels, see Chapter 2.09 Label editor.

2.03.02 Operating modes

Selecting and confi guring seam programs

Functions for selecting, processing and creating seam programs are called up, see Chapter

2.04 Creating seam programs.

Tools

A menu is called up for selecting functions for the sewing head, control unit and printer.

Change of user

The box for entering the user is called up.

Desktop

The application is concluded and the Windows desktop is called up. This function is only displayed for the logged-in administrator or supervisor.

Shut down the computer

The application is concluded and the computer is shut down. This function is only displayed

for the logged-in operator or guest.

Page 22

Input

18

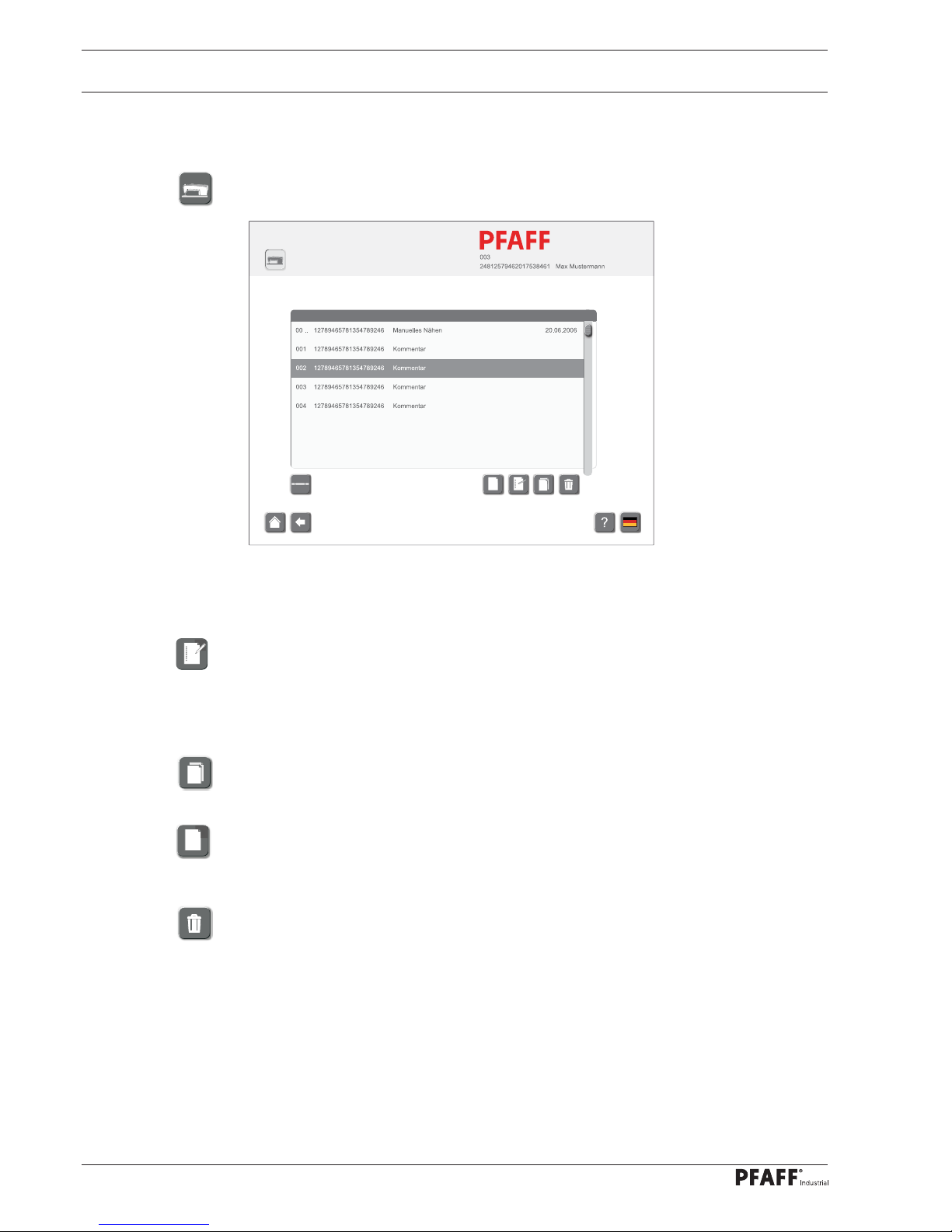

2.04 Creating seam programs

● Log-in as supervisor.

● Call up the seam program selection function.

There are several possibilities of how to create a seam program.

● Select a seam program from the list.

● Edit an existing seam program.

or

● Select a seam program from the list.

● Copy a seam program to create a new seam program on the basis of an existing one.

or

● Create a new seam program.

or

● Deleting a seam programme.

20.06.2006

20.06.2006

23.07.2006

24.07.2006

Industrial

Page 23

Input

19

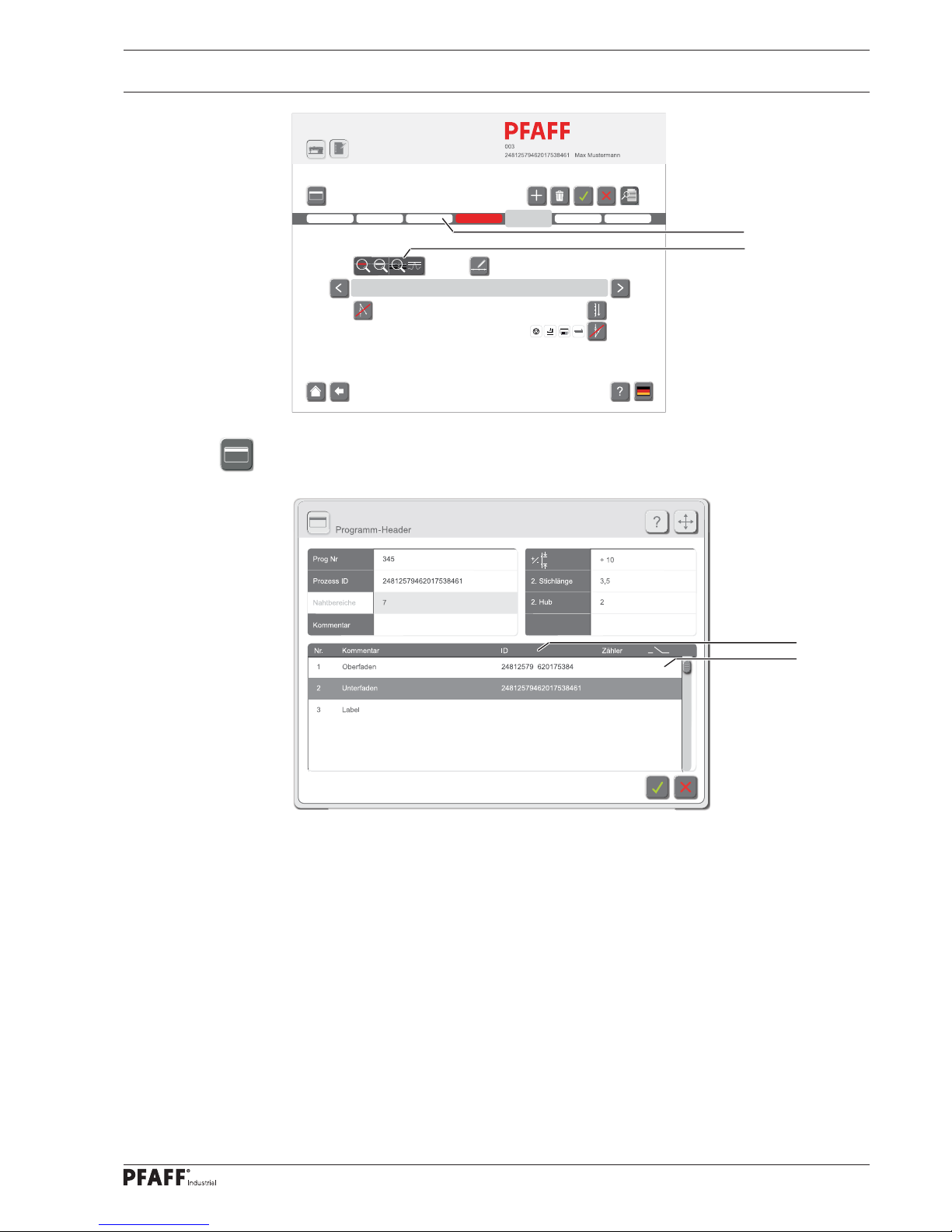

● Call up the Program Header function.

Industrial

1

2

● If necessary, enter/change the program number, process-ID and comment.

● Enter the value for the stitch length correction dependent on the material.

● Enter/change the value for the second stitch length (can be called up with the appropriate

key on the machine head).

● Enter/change the value for the second stroke (can be called up with the appropriate key

on the machine head).

● Enter top thread and bobbin thread ID in input fi eld 3, or scan in via hand scanner to

activate this function later in input fi eld 4.

Control will then only accept sewing material with that ID.

4

Material

@ @ @

1

1

X

X

0

1

5

6

0

0

Artikel 2b

3

4

Page 24

Input

20

Input Scan Options with wildcard characters in the program-header

1. With input of $$ before a character string or $$ after a character string, only the character

string is controlled, true or not true.

All characters before or after the character string are only documented

Sample:

Header input: $$123456789$$

Bar code : 888881234567895555 OK documented in the protocol

Bar code : 77777712345678933333 OK documented in the protocol

Bar code 888881234567805555 nicht OK, Error not documented in the protocol.

2. Enter @ @ @ in input fi eld 3.

The control will not carry out any adjustments, IDs will only be logged.

● Select the data for printing the end label (value "1" = print label each time;

value "10" = print label every tenth time).

● Select seam section from sector 1.

● If necessary, delete selected seam section.

● If necessary, insert seam section after the selected seam section.

● With function 2 specify the following for the selected seam sector.

- Activate/deactivate docu-seam sector

- Activate/deactivate missed stitch recognition function

- Activate/deactivate edge guide recognition function

- Specify thread strength, see Chapter 2.04.05 Sensors

● Call up the menu for entering the sewing parameters and enter the appropriate values,

see Chapter 2.04.01 Sewing parameter input.

● Call up the menu for entering the action at beginning of the seam sector. Depending on

the action selected, the symbol may be different. In this example the "double start bartacks" action is selected.

Page 25

Input

21

● Select the action and enter/change the appropriate values, see Chapter 2.04.02 Input of

action at beginning of seam sector.

● Call up the menu for the input of the recognition of the end of the seam sector. Depend-

ing on the function selected, the symbol may be different. In this example the "recognition of the end of the seam section by knee switch" is selected.

● Select the function for the recognition of the end of the seam sector and, if necessary,

enter/change the appropriate values, see Chapter 2.04.03 Input of end of seam sector.

● Call up the menu for entering the action at the end of the seam sector. Depending on the

action selected, the symbol may be different. In this example the "condensed end stitches" action is selected.

● Select the action and, if necessary, enter the label number, see Chapter 2.04.04 Input of

action at end of seam sector.

● If necessary, shift the seam sector within the seam.

● After entering/editing the desired seam sectors, save the seam program and quit the

seam program function.

● Call up the production function.

Page 26

Input

22

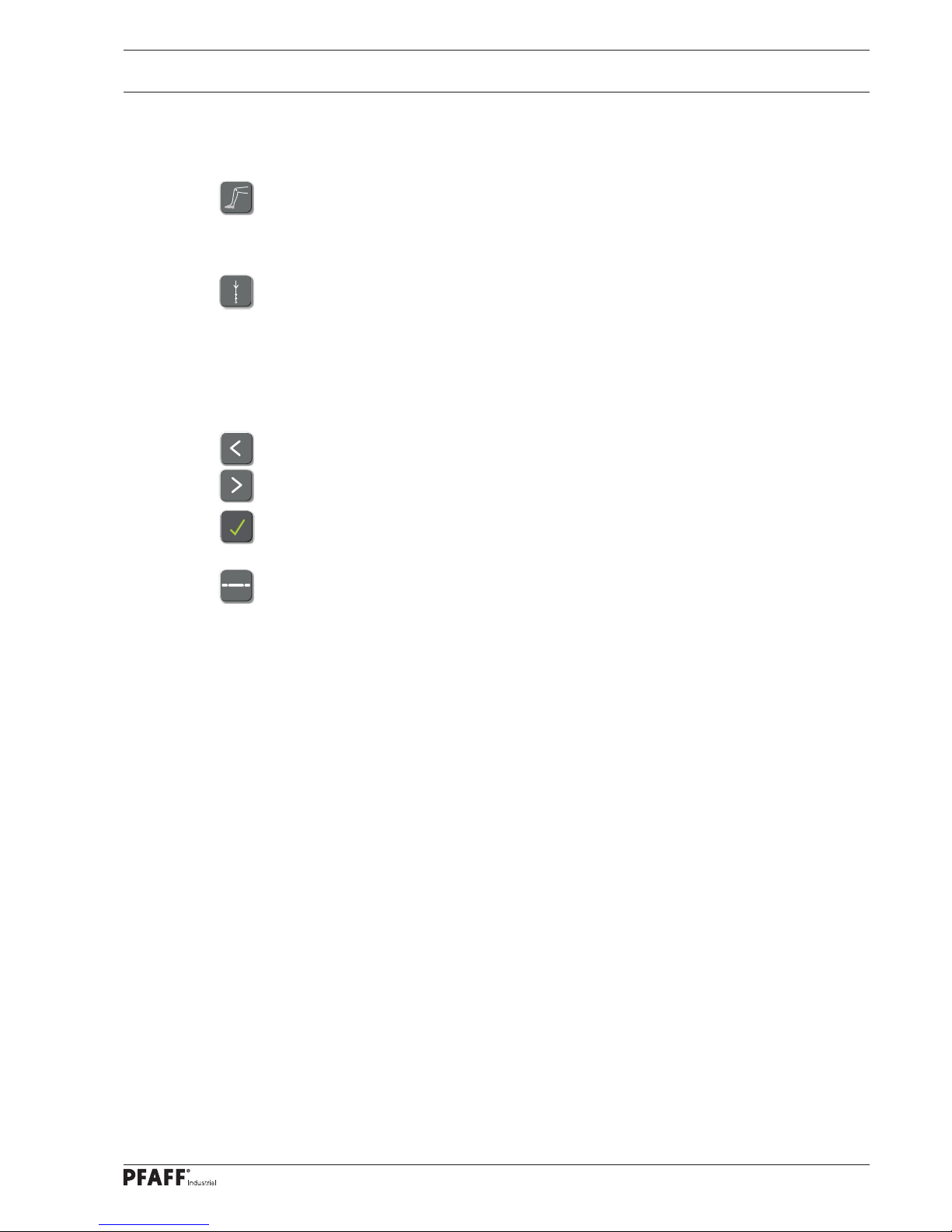

Description of the functions

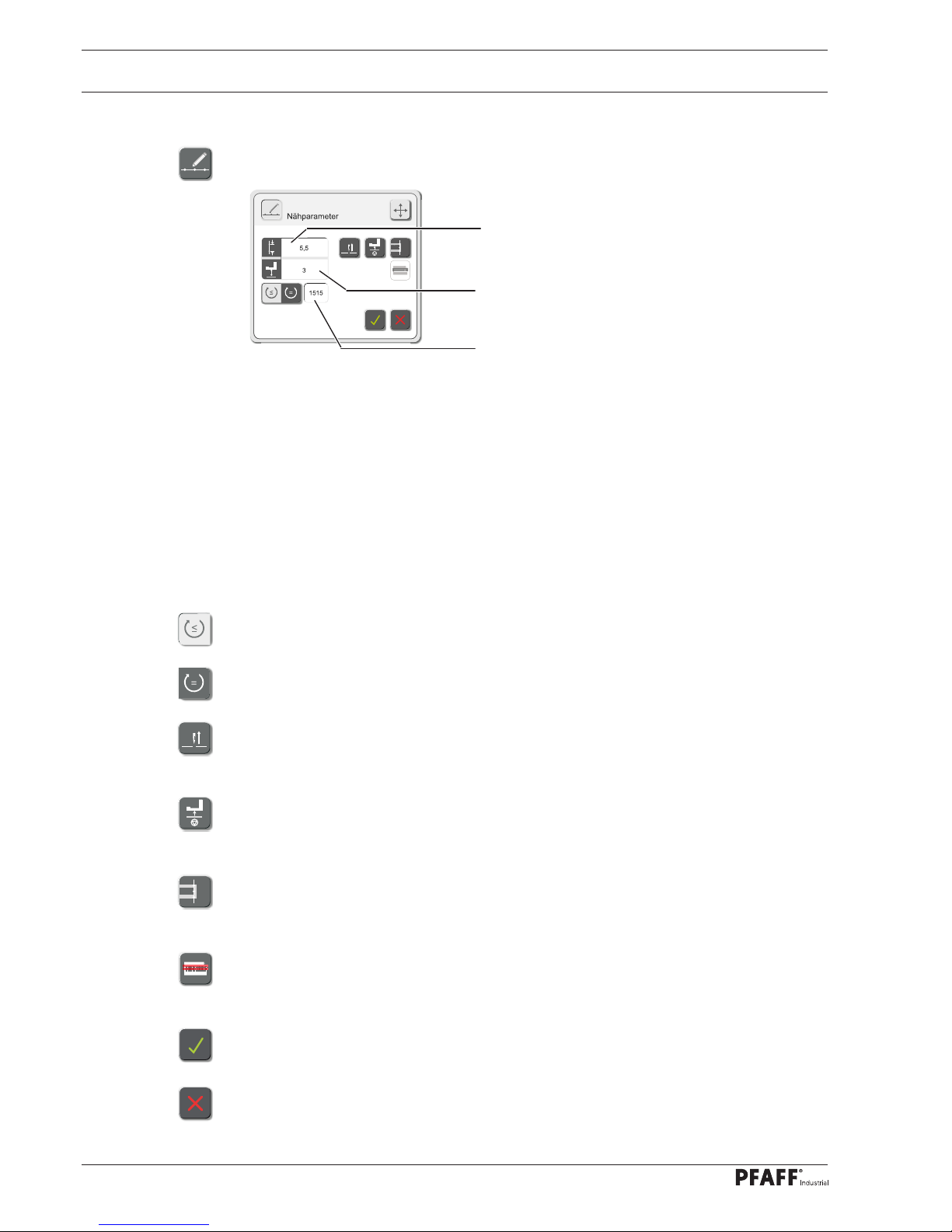

Stitch length input

After tapping area 1, the input menu for the stitch length in the current seam sector is called

up.

Sewing foot lift input

After tapping area 2, the input menu for the presser foot lift in the current seam sector is

called up.

Speed input

After tapping area 3 the input menu for the speed in the current seam sector is called up.

This function is used to select the variable speed. The speed can be adjusted with the pedal

position up to the maximum value (This function is activated in the example).

This function is used to select the constant speed. The speed cannot be adjusted with the

pedal position.

Needle raised at stop

This function is switched on or off for the current seam sector. If the function is switched on,

the needle moves to the top position when sewing stops.

Foot raised at stop

This function is switched on or off for the current seam sector. If the function is switched on,

the foot is raised when sewing stops.

Sew in label (only after a docu-seam area)

This function is switched on or off for the current seam sector. If the function is switched on,

a label is sewn in after the seam sector has been completed.

Scan label

This function is switched on or off for the current seam sector. If the function is switched on,

the label must be scanned.

Conclude the input

The input is concluded by taking over the selection and the entered values.

Stop the input

The input is concluded without taking over the selection and the entered values.

1

2

3

2

.04.01 Sewing parameter input

● In seam programming call up the menu for sewing parameter input.

Page 27

Input

23

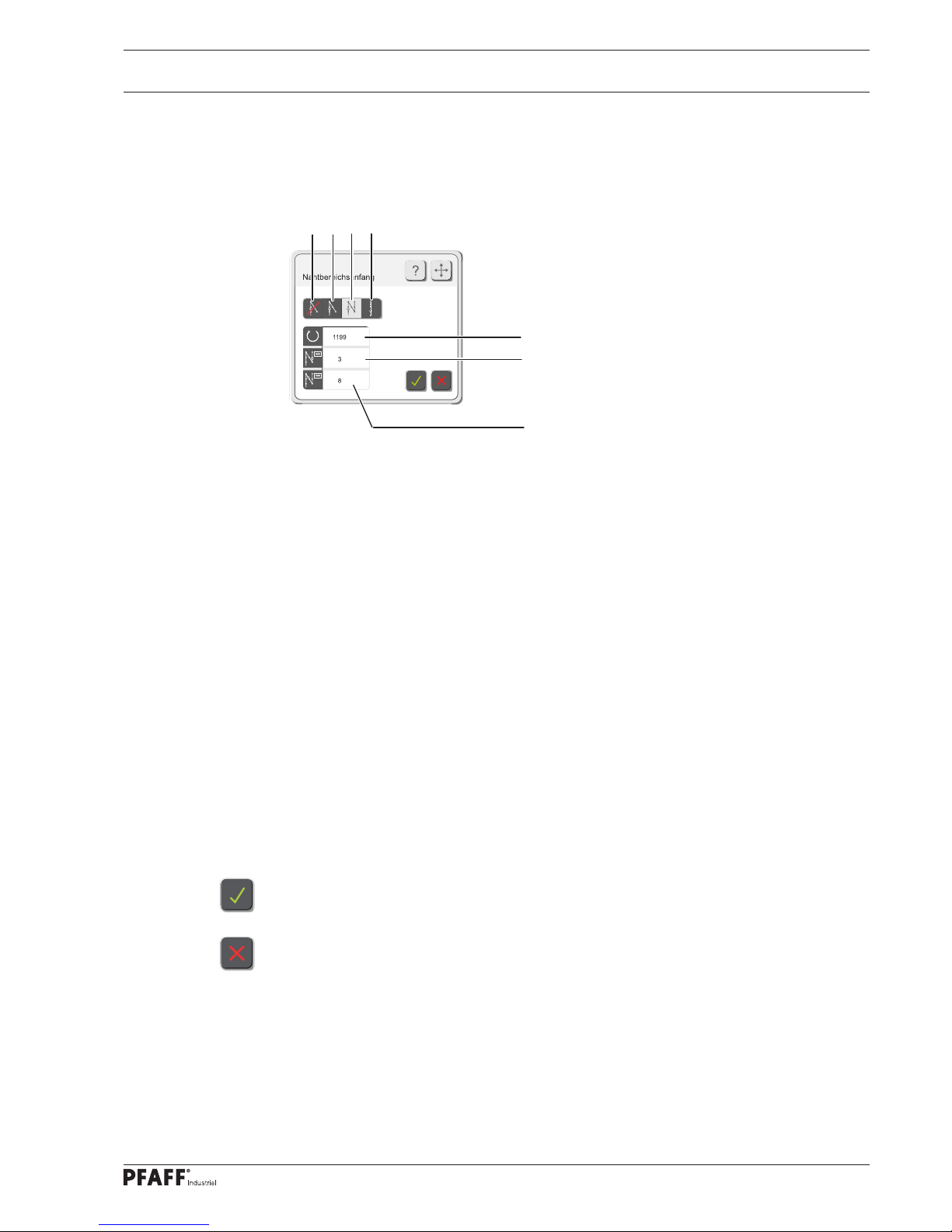

Description of the functions

Start bartacks and condensed start stitches off

After selecting function 1, neither a start bartack nor a condensed start stitch is sewn at the

beginning of the seam sector.

Start bartack

After the selection of this function and the input of the values for the tack speed in sector 5,

as well as the number of bartacks, the start bartack at the beginning of the seam sector is

sewn with the corresponding values.

Double start bartack (currently active)

After the selection of this function and the input of the values for the tack speed in sector 5,

the number of forward stitches in sector 6 and the number of reverse stitches in sector 7,

the double start bartack at the beginning of the seam sector is sewn with the corresponding

values.

Condensed start stitches

After the selection of this function and the input of the values for the stitch length and the

number of stitches, the condensed stitches at the beginning of the seam sector are sewn

with the corresponding values.

Conclude the input

The input is concluded by taking over the selection and the entered values.

Stop the input

The input is concluded without taking over the selection and the entered values.

2.04.02 Input of action at beginning of seam sector

● Call up the menu for the input of the action at the beginning of the seam, see Chapter

2.04 Creating seam programs.

1

5

2

3

4

6

7

Page 28

Input

24

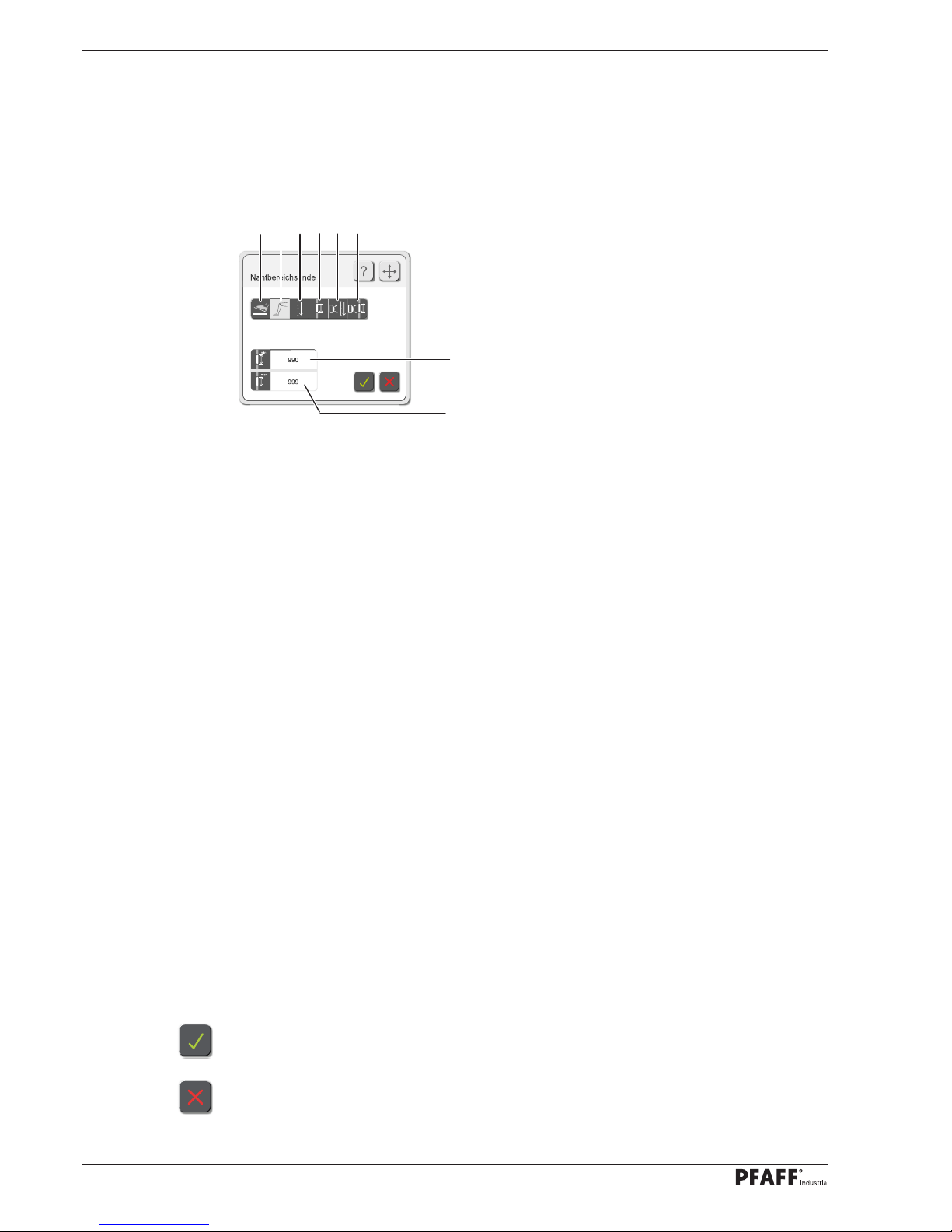

2.04.03 Input of end of seam sector

● Call up the input for the recognition of the end of the seam sector, see Chapter 2.04 Cre-

ating seam programs.

1

2

345

6

7

8

Description of the functions

End of seam sector by pedal function

After function 1 has been selected, the end of the seam sector is started with the pedal

function.

End of seam sector by knee switch

After function 2 has been selected, the end of the seam sector is started with the pedal

function. The minimum number of stitches for the seam sector is defi ned with sector 7, the

maximum number with sector 8.

End of seam sector by stitch counting

After function 3 has been selected and following the input of the value for the number of

stitches, the end of the seam sector is started after the corresponding number of stitches

have been sewn.

End of seam sector by seam length

After function 4 has been selected and following the input of the value for the seam length,

the end of the seam sector is started after the corresponding seam length has been sewn.

End of seam sector by sensor with stitch counting

After function 5 has been selected and following the input of the values for the maximum

and minimum number of stitches, the end of the seam sector is started by sensor according

to the number of stitches entered.

End of seam sector by sensor with seam length

After function 6 has been selected and following the input of the values for the maximum

and minimum seam length, the end of the seam sector is started by sensor within the corresponding lengths given.

Conclude the input

The input is concluded by taking over the selection and the entered values.

Stop the input

The input is concluded without taking over the selection and the entered values.

Page 29

Input

25

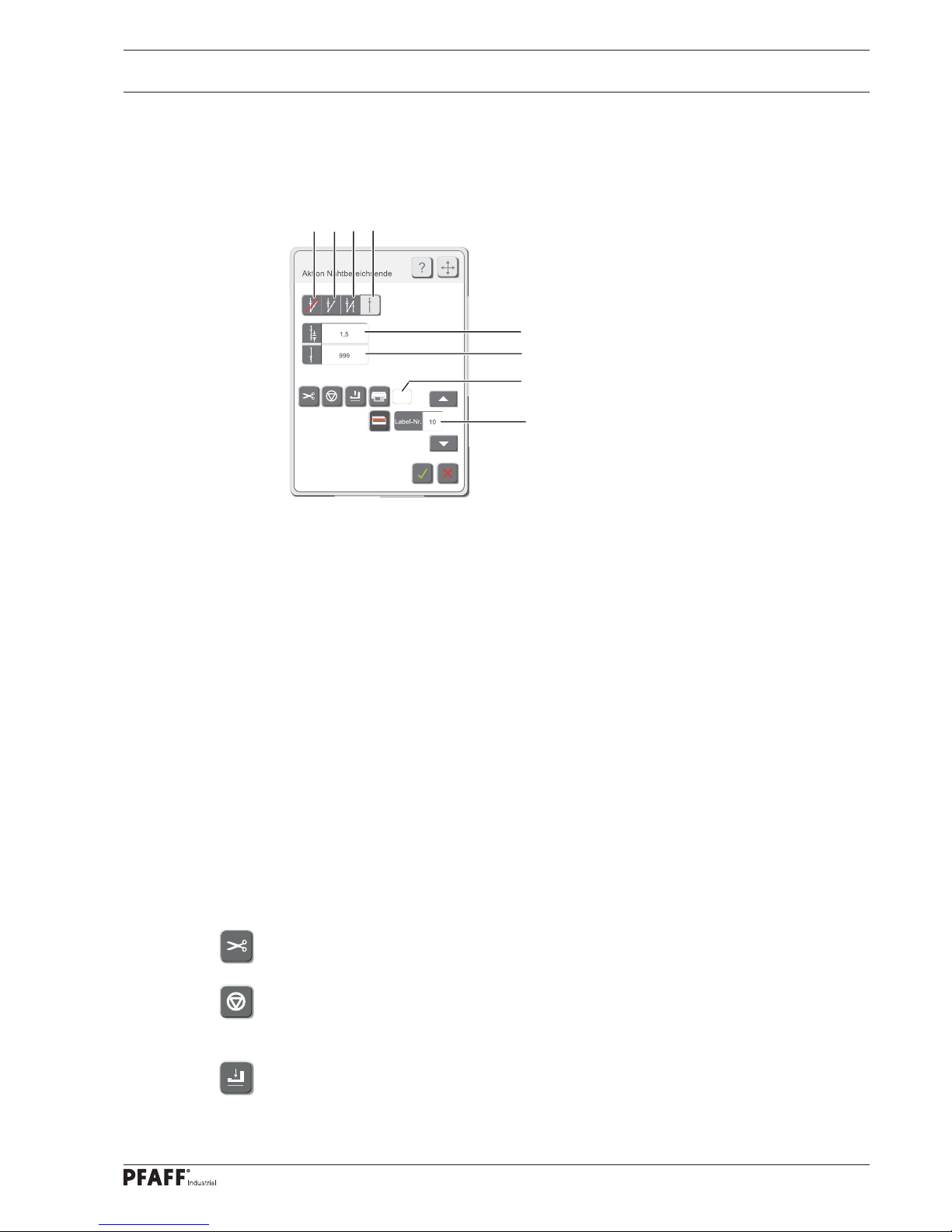

2.04.04 Input of action at end of seam sector

● Call up the menu for the input of the actions at the end of the seam, see Chapter 2.04

Creating seam programs.

Description of the functions

End bartacks and condensed end stitches off

After selecting function 1, neither an end bartack nor a condensed end stitch is sewn at the

end of the seam sector.

End bartack

After the selection of this function 2 and the input of the values for the tack speed, as well

as the number of bartacks, the end bartack at the end of the seam sector is sewn with the

corresponding values.

Double end bartack

After the selection of this function 3 and the input of the values for the tack speed, the

number of forward stitches and the number of reverse stitches, the double end bartack is

sewn at the end of the seam sector with the corresponding values.

Condensed end stitches (currently active)

After the selection of this function 4 and the input of the values for the stitch length in sector 5 and the number of stitches in sector 6, the condensed stitches at the end of the seam

sector are sewn with the corresponding values.

Thread trimming on/off

This function is used to switch thread trimming at the end of the seam sector on or off.

Sewing stop

This function is switched on or off. If the function is switched on, the machine stops at the

end of the seam sector.

Foot lowered

This function is switched on or off. If the function is switched on, the foot remains down at

the end of the seam sector.

1

1

5

2

3

4

6

8

7

Page 30

Input

26

Print label on/off

This function is used to switch the label printing function at the end of the seam sector on or

off.

Selection of the label

The label, which is to be attached, can be selected in sector 7.

Label payout

The number of labels to be printed can be selected in range 8.

Scan label

This function is switched on or off for the current seam sector. If the function is switched on,

the label must be scanned.

Conclude the input

The input is concluded by taking over the selection and the entered values.

Stop the input

The input is concluded without taking over the selection and the entered values.

Page 31

Input

27

2.04.05 Thread force

● Call up the menu for entering the parameters for the sensor in the seam programming

menu or from the service menu.

Description of the functions

Hard top limit value

The limit value is entered in sector 1. In the docu-seam area this value must never be exceeded.

Hard bottom limit

The limit value is entered in sector 2. In the docu-seam area the value must never be lower

than this limit.

Bottom limit for missed stitch recognition

The limit value is entered in sector 3. If the value falls below this limit, a missed stitch is

recognised.

450

400

150

20

200

3

Fadenkraft

1

2

3

4

6

7

PFAFF 3741 PLUS

PFAFF 3745 PLUS

450

400

150

20

200

300

3

Fadenkraft

1

2

3

4

5

6

7

8

9

10

PFAFF 3745 PREMIUM

Page 32

Input

28

Soft top limit

The limit value is entered in sector 4 In the docu-seam area this value may be exceeded a

few times. The number of tolerance stitches is entered in sector 7.

Setpoint

(only on the PFAFF 3745 PREMIUM)

The Setpoint is entered in sector 5.

Soft bottom limit

The limit value is entered in sector 6. In the docu-seam area it is possible to drop below this

level a few times. The number of tolerance stitches is entered in sector 7.

Tolerance stitches

The number of tolerance stitches is entered in sector 7. The number of tolerance stitches is

used to defi ne how often the thread strength within the docu-seam area may exceed or drop

below the soft limits.

Thread tension control (only on the PFAFF 3745 PREMIUM)

Pressing the button 8 deactivates the function "Thread tension control" during sewing,

button 9 reactivates the function.

Pressing button 10 activates the function "Thread tension control" at the end of the

range only.

Conclude the input

The input is concluded by taking over the selection and the entered values.

Stop the input

The input is concluded without taking over the selection and the entered values.

Page 33

Input

29

2.05 Service

In the service menu the states of the digital and analogue inputs are displayed. The outputs

can be set and reset manually. In addition functions for adjusting the drives, the sensors and

the edge guide can be called up, and information about the status of software and fi rmware

displayed.

Only the supervisor and administrator have access to the service menu.

● Log-in as administrator or supervisor.

● Select the "tools" function.

● Call up the service menu.

Descriptions of the functions in the service menu

Inputs/outputs

After this function has been selected, the machine’s inputs are displayed. Outputs can set

and reset manually. The pedal function can be checked.

Drives

After this function has been selected, the motor functions can be checked and the value for

the motor reference position altered.

Feed regulator confi guration

After this function has been selected, the feed regulator can be confi gured.

Edge guide on/off

After this function has been selected, the adjustment function of the edge guide can be

switched on or off.

Sensors

After this function has been selected, the current value for the thread strength is displayed.

Adjustment to the thread strength and bobbin thread recognition can be made.

Industrial

Page 34

Input

30

Version

After this function has been selected, the current status of the machine’s software and

fi rmware is displayed.

Scanner

For scanner commissioning, please see chapter 4.07.03 in the settings manual.

Camera

For camera commissioning, please see chapter 4.07.04 in the settings manual.

2.06 Cold start

When a cold start is carried out, all altered parameter for the sewing head are

deleted and set back to default values (status at the time of delivery)!

● Log-in as administrator.

● Select the "tools" function.

● Select the "cold start" function.

Page 35

Input

31

● In order to change data for a specifi c user, the relevant entry (name 1, code 2, or user

group 3) is selected from the list and edited via the entry fi eld.

● Functions can be activated/deactivated by clicking on relevant columns ( X = function acti-

vated, - function deactivated).

● Create a new user.

● Select a user from the list and delete.

2.07 Users – rights

A user ID must be entered at initial power up of the machine.

On delivery of the machine, the user ID "pfaff" must be entered.

Any number of users can be added and/or edited. The rights of individual users are defi ned

by allocating the users to relevant user groups.

User groups

- Administrator

- Supervisor

- Operator

- Guest

Only the administrator can create and edit users, and assign users to specifi c user groups.

● Log-in as administrator.

● Select the "tools" function.

● Call up the menu for entering the users and their rights.

Benutzer-ID

pfaff

41 Admin ******* Admin X X X X X X X X

42 Bechmount ******* Einrichter X X X X X X X X

43 Müller ******* Bediener - - X - X - - -

44 König ******* Bediener - - X - X - - -

45 Mustermann ******* Gast - - - - - - - -

1

2

3

Page 36

Input

32

Function descriptions

Docu-seam can be ended

Label copy can be created

Manual seam interruption can be switched on

Test seam mode can be activated

Seam programme can be activated

Production can be interrupted

Seam programme can be created

Docu-seam error can be ignored

Page 37

Input

33

2.08 Backup – restore

During a back-up the current database is saved. The backup can be saved on the hard disk of

a PC or on an external data carrier (e.g. USB-stick). A backup should be carried out by the supervisor at regular intervals.

● Log-in as administrator.

● Select the "tools" function.

● Call up the menu for making a backup or for starting the restoration function.

● Click on window 1 at fi rst backup.

● Select target directory and start backup of the database.

● Select time, day, and month for backup.

● The day is specifi ed in numbers (1 = Monday).

● Place a checkmark next to the relevant window in order to allow the backup to proceed at

the specifi ed time and date.

The PC associated with the machine must be switched on at the set backup

time.

● In order to revert to a previous status, select the function "Restore".

● Select the relevant directory containing backup data, and start the restore process.

● Max. data base size and monitoring mode setting in window 2

Importing a seam programme

Select the relevant seam programme from the transfer database.

Initialising the database

By selecting this function all previously recorded sewing protocol data will be deleted.

Make sure to create a backup fi rst!

After a restore or a database initialisation, the program will have to be restarted.

1

1

12:00

2

Page 38

Input

34

Daten base explorer

Shows the data base content.

Daten base setting

Select your data base type and the data base connection ( see window 3 and 4).

3 4

Page 39

Input

35

2.09 Label-editor

With the label editor it is possible to create various labels individually and to store them.

● Log-in as administrator or supervisor

● Select the "tools" function.

● Call up the label editor.

● Select the desired label (label number) by tapping the arrow keys 1.

● If necessary, change the size of the label by tapping the selection boxes 2 and 3.

● Select the desired label element by tapping an item from list 4.

● Activate the selected label element with function 5. The label element is shown as a

preview.

● If necessary edit the selected label element with function 6.

● If necessary change the size of the selected label element with function 7.

● After tapping box 8, enter the text for the selected label element.

● If necessary select variables (time, date, counter etc.) for the selected label element with

function 9.

● If necessary change the font of the selected label element with function 10.

● If necessary, change format via function 11 .

● If necessary, change element via function 12.

● If necessary add more label elements, or deactivate existing label elements with

function 5.

PFAFF 3745

Hochformat

46

90

Industrial

1

3

2

4

5

6

7

8

9

10

11

12

Page 40

Input

36

If a picture element is selected from list 13, the symbol 14 appears on the monitor.

● Select an appropriate label element (e.g. "picture 1) by tapping it on list 13.

● Select the desired picture fi le with function 14. The picture appears as a preview.

The picture element can be shifted as described above and the size changed.

● Carry out a test print-out of the label by selecting function 15.

● Save the changes and quit the label editor function.

● The entry mode deactivated without applying the selection.

Hochformat

46

90

Industrial

13

14

15

Page 41

Input

37

2.10 Defi ning options and interfaces

In this function, options like label printer, thread type, material type, service, and day counter, as well as control interfaces can be defi ned.

● Log on as administrator or setter.

● Select function "Tools".

● Call up function "Options and interfaces".

● Defi ne relevant threads by inputting their barcode, thread thickness, thread type, and

thread manufacturer in the entry window 1 for top and bobbin threads.

● Input relevant material by entering the barcode, material number, and material type in the

entry window 2.

If no thread and material are selected, any type of thread or material can be

used.

If material and thread were selected, only the selected items can be used.

● Input label printer in window 3.

● Input label printer in window 4 .

● Defi ne print process for protocol printing

in window 5.

1

2

3

KEY Barcode Nummer Name Hersteller Oberfaden Unterfaden

1 091027001 80/3 Serafi l

Amann X X

KEY Barcode Nummer Name Hersteller

1 091027001 091111

0 01 L eder

4

5

CAP A4+

Page 42

Input

38

● Operation-specifi c data is entered in win-

dow 11.

● Input number of stitches until neele

change in window 6 (once preset

threshold value 7 is reached, the error

message "Change needle“ will be

displayed; a re-set of the actual value will

re-start the count).

6

7

● A daily or weekly parts counter can be

specifi ed in window 8.

● The counter start value can be entered in

window 'Actual value'.

8

● Relevant machine equipment must be

selected in window 10.

● Selecting "3741" will suppress functions.

10

11

The programme will have to be restarted after any changes!

9

Page 43

Register 03

Page 44

Page 45

This instruction manual applies to

machines from software version 1.8 and

serial number 2 763 625 onwards

Betriebsanleitung engl. 06.12

INSTRUCTION MANUAL

3741

3745

Page 46

40

Proper use

3.01 Proper use

The PFAFF 3741 PLUS is a workplace with a single-needle, lockstitch, special high-speed

sewing machine with bottom and needle feed, mechanical tensioning, a mechanical bobbin

winder, and a large hook and docu-seam system.

The PFAFF 3745 PREMIUM is a workplace with a single-needle, lockstitch, special high-

speed sewing machine with unison feed, electrically controlled tensioning, an electrical

bobbin winder, and a large or extra large hook and docu-seam system.

The PFAFF 3745 PLUS is a workplace with a single-needle, lockstitch, special high-speed

sewing machine with unison feed, mechanical tensioning, a mechanical bobbin winder, and

a large hook and docu-seam system.

The machines are used for sewing lockstitch seams in fi elds requiring safety seams, e.g. in

the automotive industry.

Any and all uses of this machine which have not been approved of by the

manufacturer are considered to be inappropriate! The manufacturer cannot be

held liable for any damage caused by the inappropriate use of the machine!

The appropriate use of the machine includes the observance of all operational,

adjustment, maintenance and repair measures required by the manufacturer!

Page 47

41

Specifi cations

3.02 Specifi cations

❋

Stitch type: .........................................................................................................301 (lockstitch)

Needle system: .............................................................................................................. 134-35

Version: ...................................................................................................................... BN9, CN9

Needle size in 1/100 mm

Version BN9: ............................................................................................................... 80 – 100

Version CN9: .............................................................................................................. 110 – 140

Max. stitch length:

Version CN9: ....................................................................................................................9 mm

Max.thread size (synthetic):

Version CN9: .................................................................................................................... 15/3

▲

Maximum speed: ...................................................................................................... 3800 spm.

Presser foot clearance: ..................................................................................................20 mm

Clearance width: ..........................................................................................................350 mm

Clearance height: ......................................................................................................... 120 mm

Bed plate dimensions: .......................................................................................640 x 200 mm

Ambient temperature

85% rel. humidity (condensation not permitted): ...................................................... 5 – 40° C

Noise data:

Noise emission level at workplace with a sewing speed of 2400 spm: ............LpA < 80 dB(A)

■

(Noise measurement in accordance with DIN 45 635-48-A-1, ISO 11204, ISO 3744, ISO

Motor data: ...................................................................................... See name plate on motor

Air consumption per switch cycle: ...............................................................................0.146 NI

Net weight of sewing head: .................................................................................approx. 72 kg

Gross weight of sewing head : .............................................................................approx. 82 kg

❋

Subject to alterations

▲

synthetic, or other sizes of comparable thread types

■

KpA = 2,5 dB

Page 48

Disposal of Machine

42

3.03 Disposal of Machine

● Proper disposal of the machine is the responsibility of the customer.

● The materials used for the machine are steel, aluminium, brass and various plastic

materials. The electrical equipment comprises plastic materials and copper.

● The machine is to be disposed of according to the locally valid pollution control regula-ti-

ons; if necessary, a specialist ist to be commissioned.

Care must be taken that parts soiled with lubricants are disposed of separately

according to the locally valid pollution control regulations!

Page 49

Transportation, packing and storage

43

3.04 Transportation, packing and storage

3

.04.01 Transportation to customer‘s premises

The machines are delivered completely packed.

3.04.02 Transportation inside the customer‘s premises

The manufacturer cannot be made liable for transportation inside the customer‘s premises

nor to other operating locations. It must be ensured that the machines are only transported

in an upright position.

3.04.03 Disposal of packing materials

The packing materials of this machine comprise paper, cardboard and VCE fi bre. Proper disposal of the packing material is the responsibility of the customer.

3.04.04 Storage

If the machine is not in use, it can be stored as it is for a period of up to six months, but It

should be protected against dust and moisture.

If the machine is stored for longer periods, the individual parts, especially the surfaces of

moving parts, must be protected against corrosion, e.g. by a fi lm of oil.

Page 50

Explanation of symbols

44

3.05 Explanation of symbols

In this instruction manual, work to be carried out or important information is accentuated by

symbols. These symbols have the following meanings:

Note, information

Cleaning, care

Lubrication

Maintenance, repairs, adjustment, service work

(only to be carried out by technical staff)

Page 51

45

Controls

● To switch the control system of the

machine on or off, turn main switch 1.

Please note that when

activating the machine, the

machine must be activated

fi rst, and then the power bar.

● Switch the sewing lamp, which is inte-

grated in the machine head, on or off by

operating switch 1.

● Switch 2 regulates the brightness of the

sewing lamp.

128-

0

3.06.02 Power bar

● Switch 1 is used to switch the complete

power supply of the PC components (PC,

touch-screen monitor, hand-held scanner,

printer etc.) on or off.

If an individual device is not

activated after the power bar

has been switched on, please

check, if the switches of the individual devices are activated.

Fig. 6 - 02

1

3.06 Controls

3

.06.01 On/off switch / Sewing lamp switch

Fig. 6 - 01

1

2

Page 52

46

Controls

3.06.03 Keyboard on machine head

● The machine has a keyboard with 8 keys to activate different functions.

● In the keys 2 – 7 there are yellow LEDs. These shine when the respective function has

been allocated to key 1.

● Green LEDs are located above the keys 2 - 7. These shine when the function has been

activated.

● Above key 1 there are two symbol lamps.

Lamp A indicates the status of the bobbin thread control.

Lamp B shines when the minimum level of the oil supply has been reached.

● When the keys 1 – 8 are operated, the functions listed below are carried out.

Key 1: The functions of the keys 2 - 7 can be allocated to this key.

To program key 1, simultaneously press one of the keys 2 - 7 and key 1 for approx.

3 seconds. The function of the selected key is taken over and the yellow LED in

this key lights up

Key 2: Reverse sewing or intermediate backtacks during the seam.

The following setting is confi gured via parameter 634:

Set value ON = Feed adjustment when machine has stopped and when

machine is running

OFF = Feed adjustment only when machine is running

Fig. 6 - 05

2

1

3 4 5 6 7 8

B

A

Page 53

47

Controls

Key 3: Needle position change

(under Parameter 695 other functions can be assigned to this key)

Set value 1 = needle raised without trimming

2 = needle position change

3 = single stitch

4 = single stitch in reverse

5 = moving forwards to needle position step by step

6 = programmable tack on / off

7 = proceed to next sewing range

Key 4: Calling up the pre-selected top feed lift

(Diode on = 2nd lift, diode off = standard lift)

This button is without function in the model PFAFF 3741.

Key 5: Bartack suppression for one bartack

(under Parameter 780 other functions can be assigned to this key)

Set value 1 = tack inversion (once)

2 = tack suppression (all tacks switched off)

3 = reverse move to needle position stepby step

4 = Edge trimmer on /off

5 = programmable tack on / off

Key 6: Calling up the pre-selected stitch length

(Diode on = 2nd stitch length, diode off = standard stitch length

Key 7: Threading aid

Needle rises without thread trimming, thread clamp is opened, thread

tension is released and the motor start inhibitor is activated.

If the key is operated again, the motor start inhibitor is deactivated.

Key 8: EMERGENCY key

Needle rises without thread trimming, thread clamp is opened, thread

tension is released, presser foot is raised and the motor start inhibitor is

activated. If the key is operated again, the motor start inhibitor is deactivated.

The method for setting parameters is described in the settings manual,

and may only be carried out by certifi ed professionals!

Page 54

48

Controls

0 +1

-1 -2

3.06.04 Pedal

● With the on/off switch on

0 = Machine stop

+1 = Sew

- 1 = Raise presserfoot

- 2 = Trim thread (on machines with

thread trimmer)

Fig. 6 - 04

Fig. 6 - 05

3.06.05 Lever for lifting the presser foot

● The sewing foot can be lifted by raising

lever 1.

1

Page 55

49

Controls

3.06.06 Knee switch (optional)

● If the knee switch is operated, the docu-

seam sector is switched on or off.

Fig. 6 - 06

1

3.06.07 Bobbin thread supply monitor

● When the residual thread amount is

reached, symbol lamp A fl ashes.

● After the next thread trimming action, a

corresponding message is shown on the

touch-screen monitor.

● After the bobbin has been changed

and the message acknowledged, the

operating process can be continued.

Fig. 6 - 07

A

Page 56

50

Controls

3.06.09 Touch-screen monitor

● All necessary inputs are carried out on

the touch-screen monitor. The appropriate operating mode, messages, parameters etc. are displayed.

Fig. 6 - 09

128-024

3.06.08 Adjustment of the stand height (optional)

● The stand height can be adjusted by ope-

rating switch-key 1 accordingly.

Fig. 6 - 08

1

Page 57

51

Controls

3.06.10 Label-printer

● The label printer 1 is used for printing the

label.

Fig. 6 - 10

1

3.06.11 Hand-held scanner

● With the aid of the hand-held scanner, af-

ter pressing key 1 it is possible to read

user and process data. For example, the

user log-in, the input of material, needle

thread and bobbin thread data can be carried out with the hand-held scanner.

Fig. 6 - 11

1

3

.06.12 PC

Never switch off the PC, if the PC has not been shut down completely!

Danger of data loss!

Page 58

Setting up

52

3.07 Setting up

All instructions and regulations in this instruction manual must be observed.

Special attention should be given to all safety regulations.

All setting-up work may only be carried out by appropriately trained personnel.

3.07.01 Log-in

● Switch on the machine on the power bar and wait until the PC has started.

● Tap on the input box 1.

A box for entering the user appears.

● Enter user.

● Confi rm input.

If the user has an ID-card with appropriate barcode, alternatively the user can

be entered with the use of the hand-held scanner.

3.07.02 Language selection

● Carry out the log-in.

● Call up the menu for language selection.

● Select the desired language (fl ag).

The selected language is immediately taken over for the complete application.

Max Mustermann

Benutzer-ID

Industrial

1

Page 59

Setting up

53

3.07.03 Inserting the needle

Only change the needle when

the threading aid is activated!

Danger of injury if the machine

suddenly starts running!

Only use needles from the system intended for the machine,

see Chapter 3 Specifi cations!

● Activate the threading aid on the machine head by pressing the key.

● Loosen screw 1.

● Insert the needle as far as possible. The long needle groove must be facing left.

● Tighten screw 1.

● Switch off the threading aid on the machine head again by pressing the key.

Fig. 7 - 03

1

Page 60

Setting up

54

3.07.04 Winding the bobbin thread, regulating the winder tension

(PFAFF 3741+ 3745 PLUS)

● Draw the thread from the reel stand through guide hole 1 into the bobbin winder tension

unit 2 and then behind the thread clamp 3.

● Cut off the thread in thread clamp 3. The thread is retained.

● Place empty bobbin 4 on the bobbin winder spindle.

● To switch on the bobbin winder, push up lever 6.

The bobbin is wound during sewing.

● The bobbin winder stops automatically, when the bobbin 4 is fi lled suffi ciently.

● Remove full bobbin 4 and cut off the thread in thread clamp 3.

● The tension of the thread on bobbin 4 can be adjusted on the bobbin winder tension unit 2.

● The volume of thread on bobbin 4 can be adjusted with screw 7.

Fig. 7 -04

4

5

3

6

7

1

2

Page 61

Setting up

55

The requirement for the following steps is that the machine is in the production mode, see

Chapter 9 Sewing.

● Select the "winding" function.

● Pull the thread from the reel stand through guide 1 into bobbin winder tension unit 2 and

then behind thread clamp 3.

● Break off the thread in the thread clamp. The thread is then secured.

● Set the empty bobbin 4 on the bobbin winder spindle 5.

● Press up lever 6 to switch on the bobbin winder.

● Enter or scan in the bobbin number.

If no thread classifi cation is required, enter the value "0".

After the bobbin number has been entered, the bobbin winder starts

automatically and stops again, when bobbin 4 has been fi lled suffi ciently.

● Remove the full bobbin 4 and break off the thread in the thread clamp.

● The tension of the thread on bobbin 4 can be set on the bobbin winder tension unit 2.

● The thread amount on bobbin 4 can be adjusted with screw 7.

4

5

3

6

7

1

2

Fig. 7 -05

3.07.05 Winding the bobbin thread, regulating the winder tension

(PFAFF 3745 PREMIUM)

Page 62

Setting up

56

Only change the bobbin when the threading aid is activated!

Danger of injury if the machine suddenly starts running!

● Activate the threading aid on the machine head by pressing the key.

● Press down the spring lock and open the bedplate slide.

● Raise latch 1 and remove the bobbin.

● Place the fi lled bobbin in the hook so that the bobbin turns in the direction of the arrow

when the thread is pulled.

● Turn down latch 1.

● Pull the thread through slot 2 to pull beak 3 into hole 4.

● Call up the “tools” function.

● Call up the service menu.

● Select the "Thread force" function.

● Thread the bobbin thread through the

sensor as shown in Fig. 7-06a and pull it

through evenly.

● Compare the displayed value with the

standard value and, if necessary, adjust

the bobbin thread tension accordingly

with screw 6.

● Close the bedplate slide.

● Switch off the threading aid on the machine

head again by pressing the key.

3.07.06 Bobbin-changing/threading, and regulating the bobbin thread tension

Fig. 7 -06 Fig. 7 -06a

5

2

3

4

6

1

Page 63

Setting up

57

Only thread the needle thread when the threading aid is activated!

Danger of injury if the machine suddenly starts running!

● Activate the threading aid on the machine head by pressing the key.

● Thread the needle thread as shown in Fig. 7 - 07.

● Switch off the threading aid on the machine head again by pressing the key.

3.07.07 Threading the needle thread (PFAFF 3741 PLUS + 3745 PLUS)

Fig. 7 - 07

2

1

Page 64

Setting up

58

Only thread the needle thread when the threading aid is activated!

Danger of injury if the machine suddenly starts running!

● Activate the threading aid on the machine head by pressing the key.

● Thread the needle thread as shown in Fig. 7 - 08.

● Switch off the threading aid on the machine head again by pressing the key.

3.07.08 Threading the needle thread (PFAFF 3745 PREMIUM)

Fig. 7 - 08

Page 65

Sewing

59

3.08 Sewing

The machine may only be operated by appropriately trained personnel! The

operating personnel must ensure that only authorised persons are in the danger

zone of the machine!

Following conditions must be fulfi lled for sewing:

● All safety equipment must be attached, see Chapter 1.06 Danger warnings.

● The machine must be set up and commissioned in accordance with the set-up instruc-

tions.

● The setting up work must have been carried out, see Chapter 7 Setting up.

3.08.01 Calling up / carry out the sewing operation

(without camera for bobbin thread monitor)

After the user’s log-in, following steps must be carried out:

● Call up the seam program selection function.

● Select the desired program from the list.

As an alternative to the manual seam program selection, the appropriate seam

program can also be selected with the hand-held scanner, if a corresponding

barcode is available.

● Call up the production function.

● Insert the material.

● Start the production process by operating the pedal.

20.06.2006

20.06.2006

23.07.2006

24.07.2006

Industrial

Page 66

Sewing

60

3.08.02 Calling up / carry out the sewing operation

(with camera for bobbin thread monitor)

After the user’s log-in, following steps must be carried out:

● Call up the seam program selection function.

● Select the desired program from the list.