Page 1

performance

User’s Guide

TM

Page 2

This household sewing machine is designed to comply with IEC/EN 60335-2-28 and UL1594.

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including

the following:

Read all instructions before using this household sewing machine. Keep the instructions at a

suitable place close to the machine. Make sure to hand them over if the machine is given to a third

party.

DANGER –TO REDUCE THE RISK OF ELECTRIC SHOCK:

• A sewing machine should never be left unattended when plugged in. The electrical socket, to

which the machine is plugged in should be easily accessible. Always unplug this sewing machine

from the electric outlet immediately after using and before cleaning, removing covers, lubricating

or when making any other user servicing adjustments mentioned in the instruction manual.

WARNING –TO REDUCE THE RISK OF BURNS, FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSON:

• Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used

by or near children.

• Use this sewing machine only for its intended use as described in this manual. Use only

attachments recommended by the manufacturer as contained in this manual.

• Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly,

if it has been dropped or damaged, or dropped into water. Return the sewing machine to the

nearest authorized dealer or service center for examination, repair, electrical or mechanical

adjustment.

• Never operate the sewing machine with any air openings blocked. Keep ventilation openings of

the sewing machine and foot control free from the accumulation of lint, dust, and loose cloth.

• Keep fingers away from all moving parts. Special care is required around the sewing machine

needle.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

• Do not use bent needles.

• Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

• Wear safety glasses.

• Switch the sewing machine off (“0”) when making any adjustment in the needle area, such as

threading needle, changing needle, threading bobbin, or changing presser foot, etc.

• Never drop or insert any object into any opening.

• Do not use outdoors.

• Do not operate where aerosol (spray) products are being used or where oxygen is being

administrated.

• To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• The foot control is used to operate the machine. Avoid placing other objects on the foot control.

• Do not use the machine if it is wet.

Page 3

• If the LED lamp is damaged or broken, it must be replaced by the manufacturer or its service

agent or a similarly qualified person, in order to avoid a hazard.

• If the cord connected with the foot control is damaged, it must be replaced by the manufacturer

or its service agent or a similarly qualified person, in order to avoid a hazard.

• This sewing machine is provided with double insulation. Use only identical replacement parts.

See instructions for Servicing of Double-Insulated Appliances.

SAVE THESE INSTRUCTIONS

FOR CENELEC COUNTRIES ONLY:

This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been given

supervision or instruction concerning use of the appliance in a safe way and understand the

hazards involved. Children shall not play with the appliance. Cleaning and user maintenance shall

not be made by children without supervision.

The noise level under normal operating conditions is less than 80dB(A).

The machine must only be used with foot control of type FR5 manufactured by Shanghai Binao

Precision Mould Co., Ltd.

FOR NON CENELEC COUNTRIES:

This sewing machine is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the sewing machine by a person responsible for their

safety. Children should be supervised to ensure that they do not play with the sewing machine.

The noise level under normal operating conditions is less than 80dB(A).

The machine must only be used with foot control of type FR5 manufactured by Shanghai Binao

Precision Mould Co., Ltd.

SERVICING OF DOUBLE INSULATED PRODUCTS

In a double-insulated product, two systems of insulation are provided instead of grounding. No

ground means is provided on a double-insulated product, nor should a means for grounding be

added to the product. Servicing of a double-insulated product requires extreme care and knowledge

of the system and should be done only by qualified service personnel. Replacement parts for a

double-insulated product must be identical to those parts in the product. A double-insulated

product is marked with the words ‘DOUBLE INSULATION’ or ‘DOUBLE INSULATED’.

Page 4

TABLE OF CONTENTS

1 Introduction ...............................................7

Machine Overview..........................................7

Front.............................................................7

Needle Area.................................................. 8

Right Side ..................................................... 8

Rear.............................................................. 8

Top...............................................................9

Accessory Tray..............................................9

Storing a Needle Plate.................................. 10

Function Buttons...........................................11

Presser Foot Up and Extra Lift...................... 11

Presser Foot Down and Pivot ....................... 11

Automatic Needle Threader ......................... 11

Cut Function ............................................... 12

Immediate Tie-Off ....................................... 12

Stitch Re-Start.............................................. 12

Needle Stop Up/Down ................................ 12

Start/Stop ................................................... 12

Reverse ....................................................... 12

Basic Gestures for the Multi-Touch

Screen ............................................................13

Accessories.................................................... 14

Included Accessories ................................... 14

Presser Feet ................................................... 15

Stitch Overview ............................................17

Utility Stitches ............................................. 17

Stitch Menu Overview ................................. 20

Alphabets ................................................... 20

2 Preparations ........................................... 21

Unpacking Machine ......................................21

Connect the Power Cord and Foot

Control ..........................................................21

Pack Away After Sewing .............................. 22

USB Ports ......................................................22

Using a USB device...................................... 22

Getting Started with WiFi and

mySewnet™ Cloud.........................................23

LED Lights .................................................... 23

Free Arm .......................................................23

Manual Thread Cutter ..................................23

Knee-Lift .......................................................24

Speed Control Lever .....................................24

Thread Sensor ...............................................24

Telescopic Thread Guide .............................. 25

Spool Pins......................................................26

Spool Caps .................................................... 26

Threads .........................................................27

Needles .........................................................28

Important Needle Information...................... 28

Changing the Needle .................................... 29

Threading......................................................30

Threading the Upper Thread ........................ 30

Automatic Needle Threader ......................... 32

Threading Tips and Hints ............................ 34

Threading for Twin Needle .......................... 35

Bobbin Winding ............................................ 37

Winding Through the Needle ....................... 38

Inserting the Bobbin...................................... 39

Changing the Bobbin Case............................40

IDT™ System (Integrated Dual Feed) ..........41

Engaging the IDT™ System.......................... 41

Disengaging the IDT™ System ..................... 41

Changing the Presser Foot ............................ 42

Remove Presser Foot.................................... 42

Attach Presser Foot ...................................... 42

Attaching the Sensormatic Buttonhole

Foot ...............................................................42

Changing to Straight Stitch Needle Plate .....43

3 The Multi-Touch Screen...................... 44

Multi-Touch Screen.......................................44

Gestures...................................................... 44

Start Page ......................................................45

Start Sewing ................................................ 45

Load From mySewnet™ ................................ 45

Open Help Center........................................ 45

mySewnet™ Blog..........................................45

Main Functions ............................................. 46

Save............................................................ 46

Home ......................................................... 46

Mode Switch ............................................... 46

Common Functions....................................... 46

OK.............................................................. 46

Cancel......................................................... 46

Touch & Hold ............................................. 46

Settings with Toggle Function ...................... 47

Help Center ................................................... 48

User’s Guide ............................................... 48

Getting Started ............................................ 48

Techniques and Tutorials ............................. 48

Sewing Instructions ..................................... 48

Stabilizer Guide........................................... 48

Settings.......................................................... 49

Sewing Settings ........................................... 49

Machine Settings ......................................... 52

WiFi Settings ............................................... 53

mySewnet™ Settings..................................... 53

Machine Information ................................... 53

Smart Toolbox ............................................... 54

Top Bar ..........................................................54

Help Center................................................. 54

Quick Help ................................................. 55

Main Menu ................................................. 55

Information Area ..........................................55

WiFi ........................................................... 56

mySewnet™ ................................................. 56

Recommendations ....................................... 56

Information................................................. 56

Page 5

Active Features............................................ 57

Menu Panel ...................................................57

Options Selected From the Menu Panel ......... 57

Toolbar .......................................................... 58

Customize Your Work Area ......................... 58

Full Screen View ........................................... 58

Base Bar .........................................................58

4 WiFi & mySewnet™ Services .............. 59

WiFi Introduction ......................................... 59

Getting Started With WiFi ............................ 59

Hidden Network ......................................... 59

Firmware Update Using WiFi ...................... 59

Firmware Update Using a USB Device......... 59

mySewnet™ Services ..................................... 60

mySewnet™ Account .................................... 60

mySewnet™ Cloud ....................................... 60

Used Space in mySewnet™ Cloud.................. 61

Installation of mySewnet™ cloud Sync

Tool for Computer ....................................... 61

mySewnet™ Portal........................................ 62

Troubleshooting Connectivity ......................62

5 Sewing....................................................... 64

Sewing Mode – Introduction ........................64

Sewing Mode – Overview ............................ 64

Getting Started with Sewing......................... 67

Load a Stitch From the Menu Panel............... 67

Select a Stitch From the Selection Menu......... 68

Load a Stitch from File Manager ................... 68

Sewing Recommendations............................ 69

Settings in Sewing Mode ..............................70

ActivStitch™ Technology ............................ 70

Automatic Presser Foot Lift .......................... 71

Automatic Thread Cutter ............................. 71

Free-Motion Options.................................... 71

Stitch Limiting Options ................................ 72

Needle Stop Position.................................... 73

Presser Foot Pressure ................................... 73

Options for Feed Dogs ................................. 73

Tie-Off Options ........................................... 73

Stitch Edit ......................................................74

Stitch Width ................................................ 74

Stitch Positioning......................................... 74

Stitch Length ............................................... 74

Stitch Density .............................................. 75

Mirroring .................................................... 75

Buttonhole Slit Length ................................. 75

Button Stitch Repetition ............................... 75

ActivStitch™ Technology ............................ 76

Free-Motion Options.....................................77

Dynamic Spring Foot 6D Free-Motion ........... 77

Spring Foot Free-Motion .............................. 77

Sensormatic Free-Motion.............................. 78

Tie-Off Options ............................................. 78

Stitch Repeat ................................................. 79

Save Stitch .....................................................80

Balance ..........................................................80

Sewing Programs ..........................................81

Tapering Stitches ......................................... 81

Taper Satin Stitch Exercise............................ 81

Stitch Repeat ............................................... 82

Patchwork Program ..................................... 82

Single Stitch Program................................... 82

Combining Programs................................... 82

Sewing Techniques .......................................83

Buttonholes................................................. 83

Sew On a Button.......................................... 84

Four Direction Sewing ................................. 84

Special Stitch Techniques.............................. 85

Ribbon Stitches............................................ 85

Stacking Stitches .......................................... 85

Floating Stitches .......................................... 86

Radiant Stitches ........................................... 87

Lace Edge Stitches ....................................... 87

Optional Feet Stitches .................................. 87

Pop-up Messages in Sewing ......................... 88

6 Sequence Creator ................................. 90

Sequence Creator — Introduction ................ 90

Sequence Creator – Overview....................... 91

Getting Started with Sequence Creator ........ 93

Load a Stitch ............................................... 93

Load a Font ................................................. 93

Adjust text and stitches ................................ 94

Delete a Stitch or Letter ................................ 94

Duplicate a Stitch or Letter ........................... 94

Replace a Stitch or Letter .............................. 94

Directional Stitches .......................................95

Sequence Commands....................................96

True Size........................................................96

Saving a Sequence......................................... 97

Sew Your Sequence.......................................97

Adjust the Entire Sequence...........................98

Using Sequence Creator in Sewing Mode ....98

Pop-up Messages in Sequence Creator.........99

7 Stitch Creator™ Feature .................. 100

Stitch Creator™ Feature – Introduction..... 100

Stitch Creator™ Feature – Overview ...........101

Getting Started with Stitch Creator™ ........ 102

Definition of a Stitch Point...........................102

Select Stitches/Stitch Points.........................102

Preview .....................................................103

Stitch Creator™ Edit Tools ........................ 103

Zoom.........................................................103

Move .........................................................103

Add a Stitch or Stitch Point .........................104

Duplicate Selected Stitch Point ....................104

Triple Stitch................................................104

Mirroring ...................................................104

Delete Selected Stitch Point .........................104

Edit a stitch made in Stitch Creator™........ 105

Load and Sew a Stitch................................. 105

Page 6

Saving a Stitch............................................. 105

Using Created Stitches in Sequence

Creator ........................................................ 105

Pop-up Messages in Stitch Creator™

Feature ........................................................ 105

8 Help Center .......................................... 106

Help Center – Introduction......................... 106

Help Center – Overview ............................. 106

User’s Guide ............................................... 107

Getting Started ............................................ 108

Techniques and Tutorials ........................... 109

Garment Techniques...................................109

Sewing Techniques .....................................110

Quilting Techniques ...................................110

Stabilizer Guide .......................................... 110

Projects ........................................................ 111

Project Viewer ............................................111

Video Player...............................................112

9 File Manager ........................................ 113

File Manager – Introduction ....................... 113

File Manager – Overview............................ 114

File Formats................................................. 116

Browse File Manager .................................. 116

Open a File or Folder .................................. 116

Multi-Select ................................................. 116

mySewnet™ Cloud Folder ........................... 116

USB Device.................................................. 116

List/Thumbnail View .................................117

Move up One Folder Level ..........................117

Organize...................................................... 117

Create New Folder......................................117

Rename a File or Folder ..............................117

Move a File or Folder ..................................117

Copy a File or Folder ..................................118

Delete a File or Folder .................................118

Pop-up Messages in File Manager.............. 118

WARNING –TO REDUCE THE RISK OF

BURNS, FIRE, ELECTRIC SHOCK, OR INJURY

TO PERSON: .............................................126

SAVE THESE INSTRUCTIONS ...................126

SERVICING OF DOUBLE INSULATED

PRODUCTS ...............................................127

Licenses ....................................................... 127

10 Maintenance ........................................ 120

Cleaning the Machine Exterior ................... 120

Removing the Needle Plate and Cleaning

the Bobbin Area .......................................... 120

Cleaning Under the Bobbin Area ............... 120

Replacing the Needle Plate ......................... 121

Troubleshooting.......................................... 121

Service .......................................................124

Non-Original Parts and Accessories .............124

Technical specification ................................ 124

11 IMPORTANT ......................................... 126

IMPORTANT SAFETY

INSTRUCTIONS ......................................... 126

DANGER –TO REDUCE THE RISK OF

ELECTRIC SHOCK:....................................126

Page 7

1 Introduction

1

2

3

4

5

6

7

8

9

10

6

11

6

12

13

14

15

16

17

18

19

20

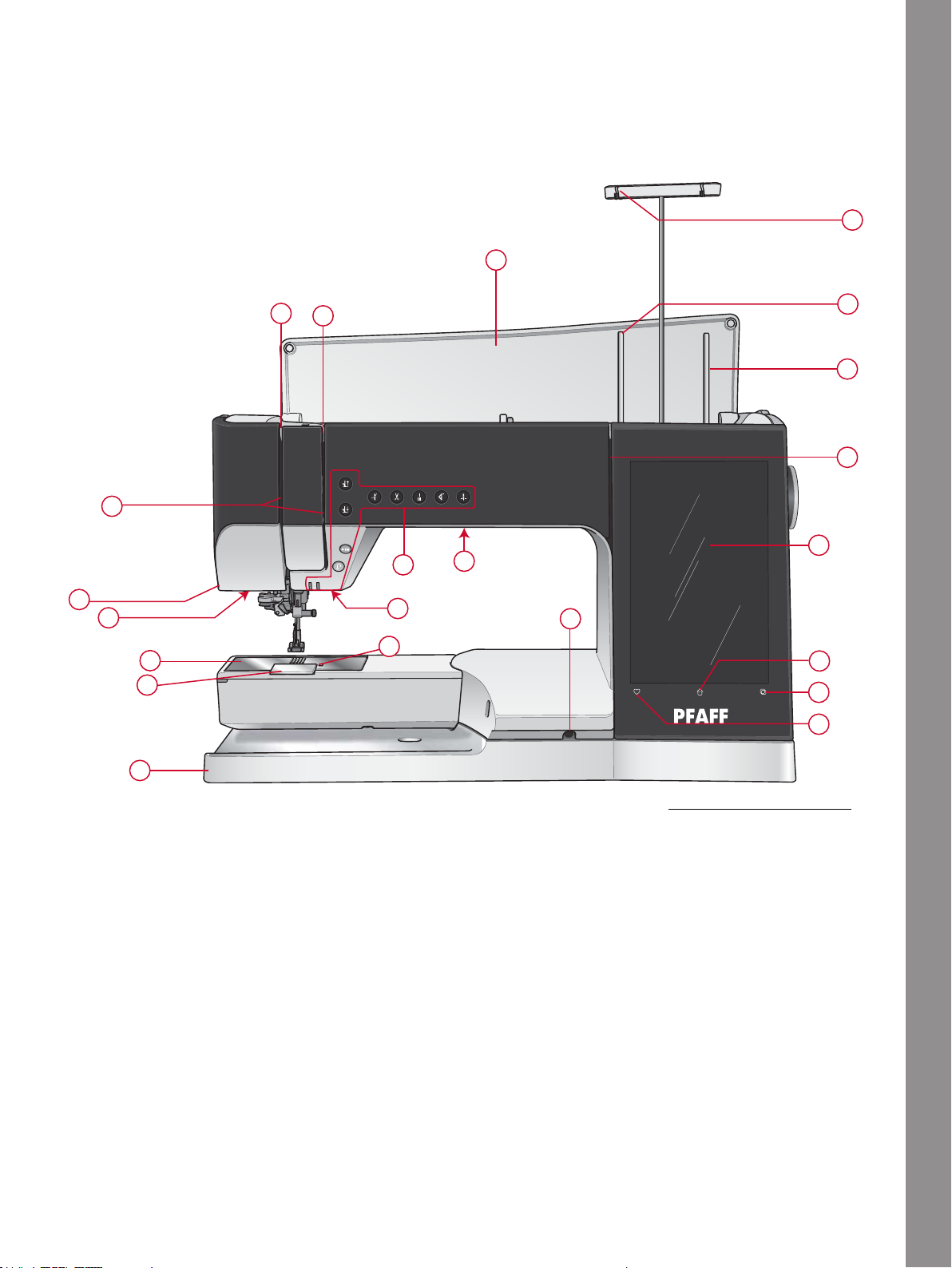

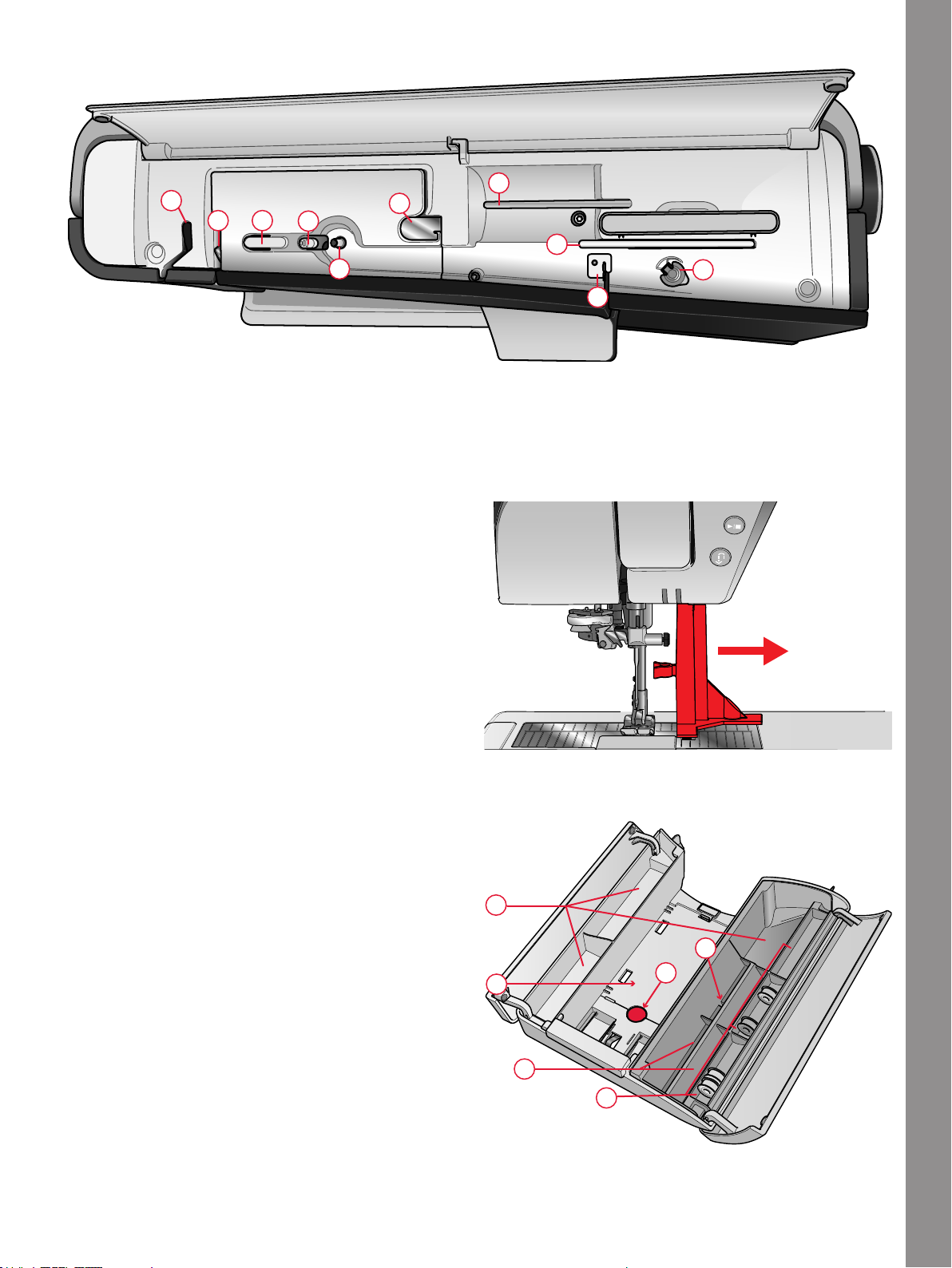

Machine Overview

Front

1. Lid

2. Thread tension discs

3. Thread take-up lever

4. Threading slot

5. Thread cutter

6. LED light

7. Needle plate

8. Bobbin cover

9. Bobbin cover release button

10. Base plate

Introduction

11. Function buttons, see Function Buttons, page 11 for

detailed description

12. Knee lifter socket

13. Save

14. Mode switch

15. Home

16. Multi-touch screen

17. Bobbin winding thread slot

18. Auxiliary spool pin

19. Main spool pin

20. Telescopic thread guide

7

Page 8

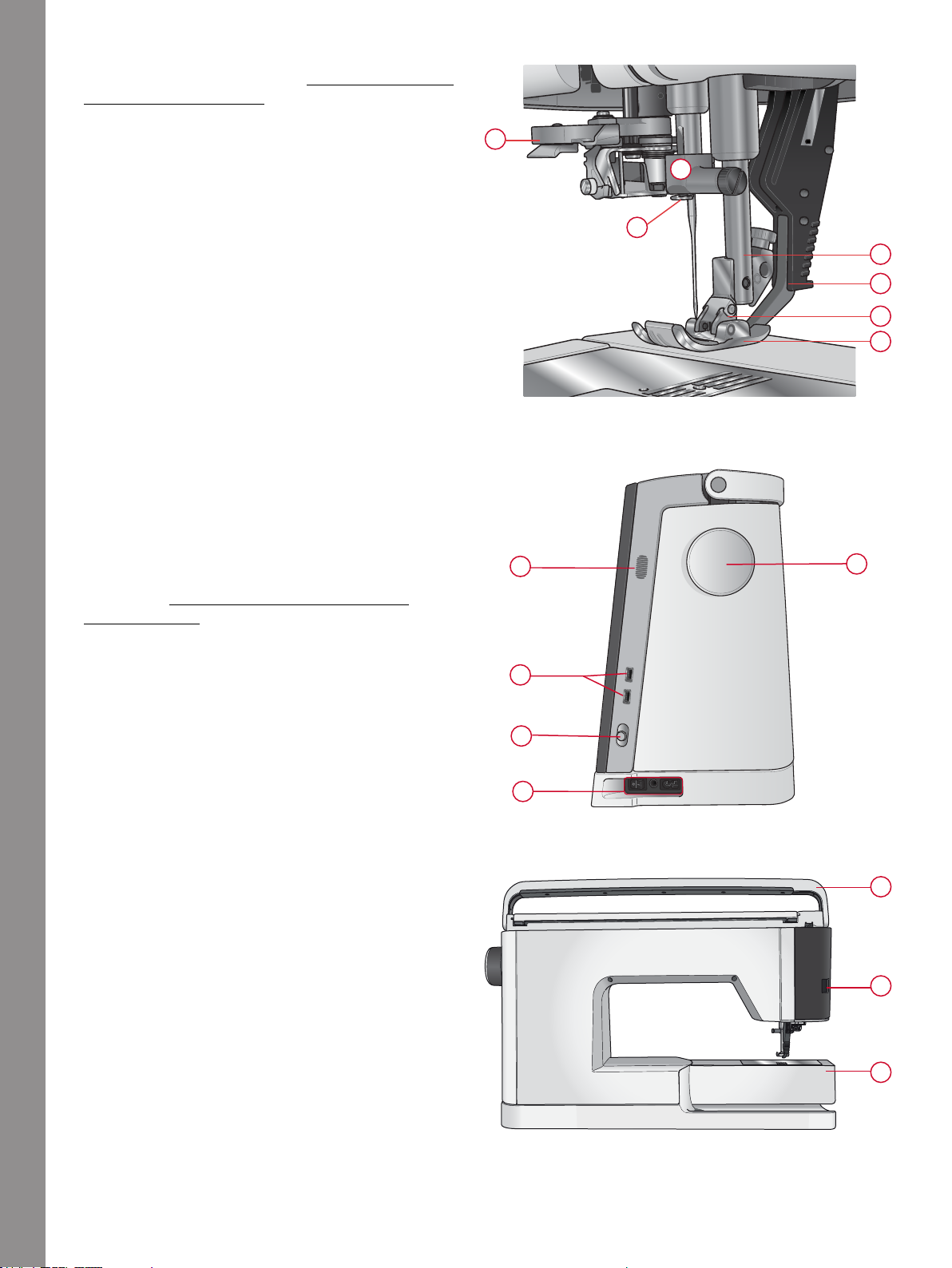

Needle Area

1

2

3

4

5

6

7

1

5

4

3

2

1

2

3

1. Automatic needle threader, see Using the Automatic

Needle Threader, page 33

2. Needle bar with needle clamp screw

3. Needle thread guide

4. Presser foot bar

5. IDT™

6. Presser foot ankle

7. Presser foot

Right Side

1. Handwheel

2. Speaker

3. Built-in USB ports

4. Speed control lever

5. ON/OFF switch, sockets for power cord and foot

control. See Connect the Power Cord and Foot

Control, page 21.

Introduction

Rear

1. Handle

2. Accessory socket

3. Free arm

8

Page 9

Top

2

3

4

5

6

7

8

10

9

1

2

3

4

5

1

6

1. Thread take-up lever

2. Thread tension discs

3. Thread cutter

4. Bobbin winder lever

5. Bobbin winder

6. Pre-tension thread guide

7. Main spool pin

8. Auxiliary spool pin

9. Bobbin winding thread guide

10. Thread tension disc for bobbin winding

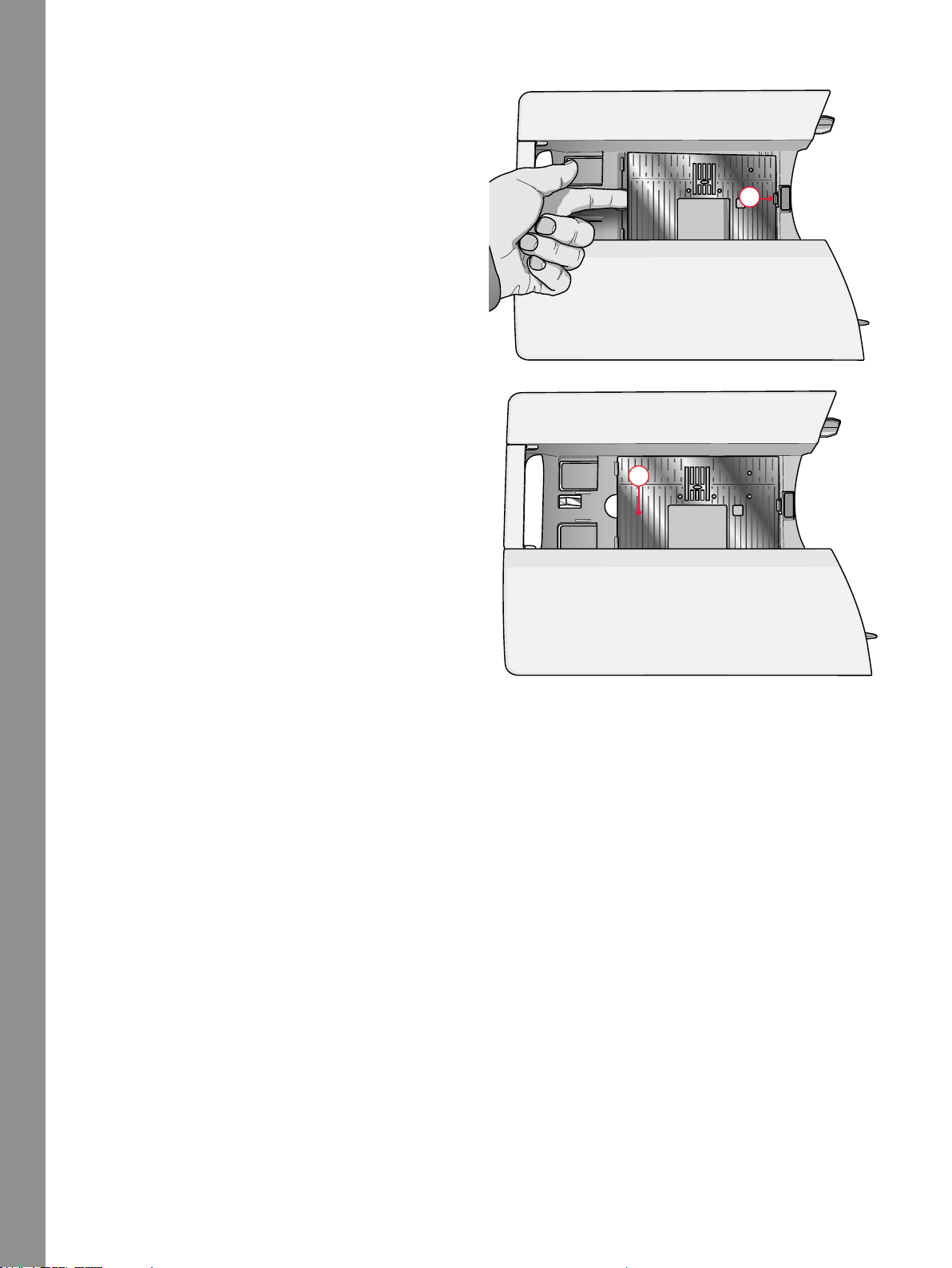

Note: The machine is delivered with two red safety catches;

one attached to the presser foot bar and one in the accessory

tray. These should all be removed before sewing.

Introduction

Accessory Tray

The accessory tray features special compartments for

presser feet and bobbins, plus space for needles and

other accessories. Store the accessories in the tray so

they are easily accessible.

1. Space for accessories

2. Space for needle plate

3. Spaces for presser feet

4. Spaces for bobbins

5. Space with hole for 5M Manual Buttonhole Foot

6. Safety catch (remove before sewing)

9

Page 10

Storing a Needle Plate

B

A

Store the needle plate not in use in the bottom of your

accessory tray.

1. Insert the right side of the plate into spring on the

right side (A), push it slightly. Lay it down (B) so

that the needle plate snaps into place.

2. To remove the plate, place a finger into the hole by

the left side of the plate, push it to the right and then

lift the plate.

Introduction

10

Page 11

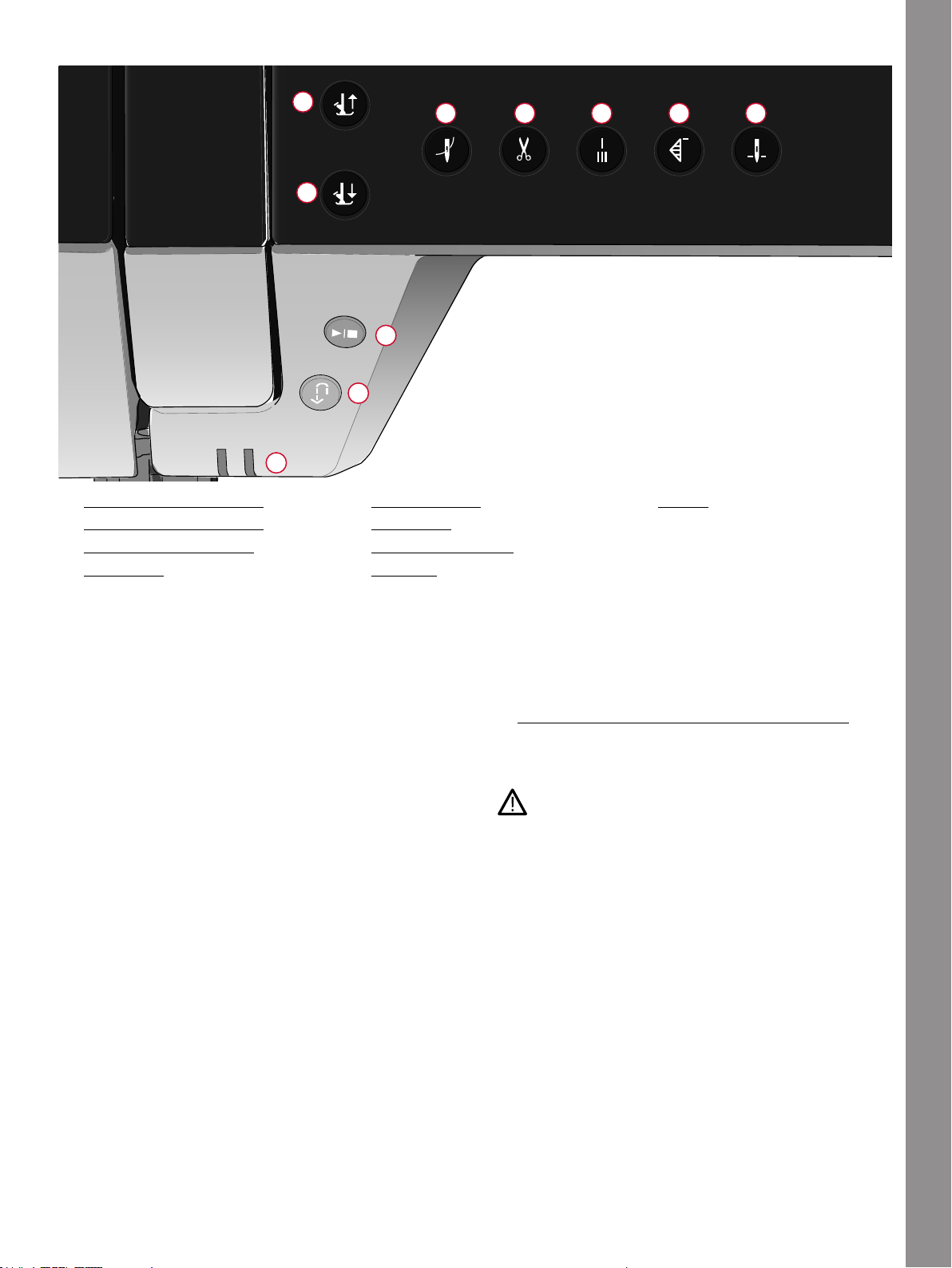

Function Buttons

2

3

4

5

6

8

9

7

1

10

1. Presser foot up and extra lift

2. Presser foot down and pivot

3. Automatic needle threader

4. Cut function

5. Immediate tie-off

6. Stitch restart

7. Needle stop up/down

8. Start/stop

Presser Foot Up and Extra Lift

Touch the presser foot up button once to raise the

presser foot. Touch again and the presser foot will raise

to extra lift position, and the feed teeth will be

automatically lowered to make it easier to get heavy

fabric under the presser foot.

Presser Foot Down and Pivot

The presser foot is lowered automatically when you start

sewing. To lower the presser foot before starting to sew,

touch the presser foot down and pivot button. The

presser foot will be completely lowered and the machine

9. Reverse

10. Indication Light

firmly holds the fabric. Touch presser foot down again to

go to pivot position.

Automatic Needle Threader

See Using the Automatic Needle Threader, page 33 to

learn how to place the thread for automatic needle

threading. When the thread is in place, touch this button

to thread the needle automatically.

To prevent damage to the automatic needle threader,

needle, presser foot or other attached accessories, read

the instructions carefully on how to use the

automatic needle threader before using it.

Introduction

11

Page 12

Cut Function

Touch the cut function button and your machine cuts

the upper and bobbin threads and raises the presser foot

and needle.

To cut threads at the end of a stitch or stitch sequence,

touch the cut function button while sewing. The

indicator light will intensify, alerting you that a cut is

requested. When the stitch or stitch sequence is

completed, your machine cuts the upper and bobbin

threads and raises the presser foot and needle.

Note: If automatic presser foot lift has been deselected in

temporary session settings the presser foot will not be raised

when using the cut function.

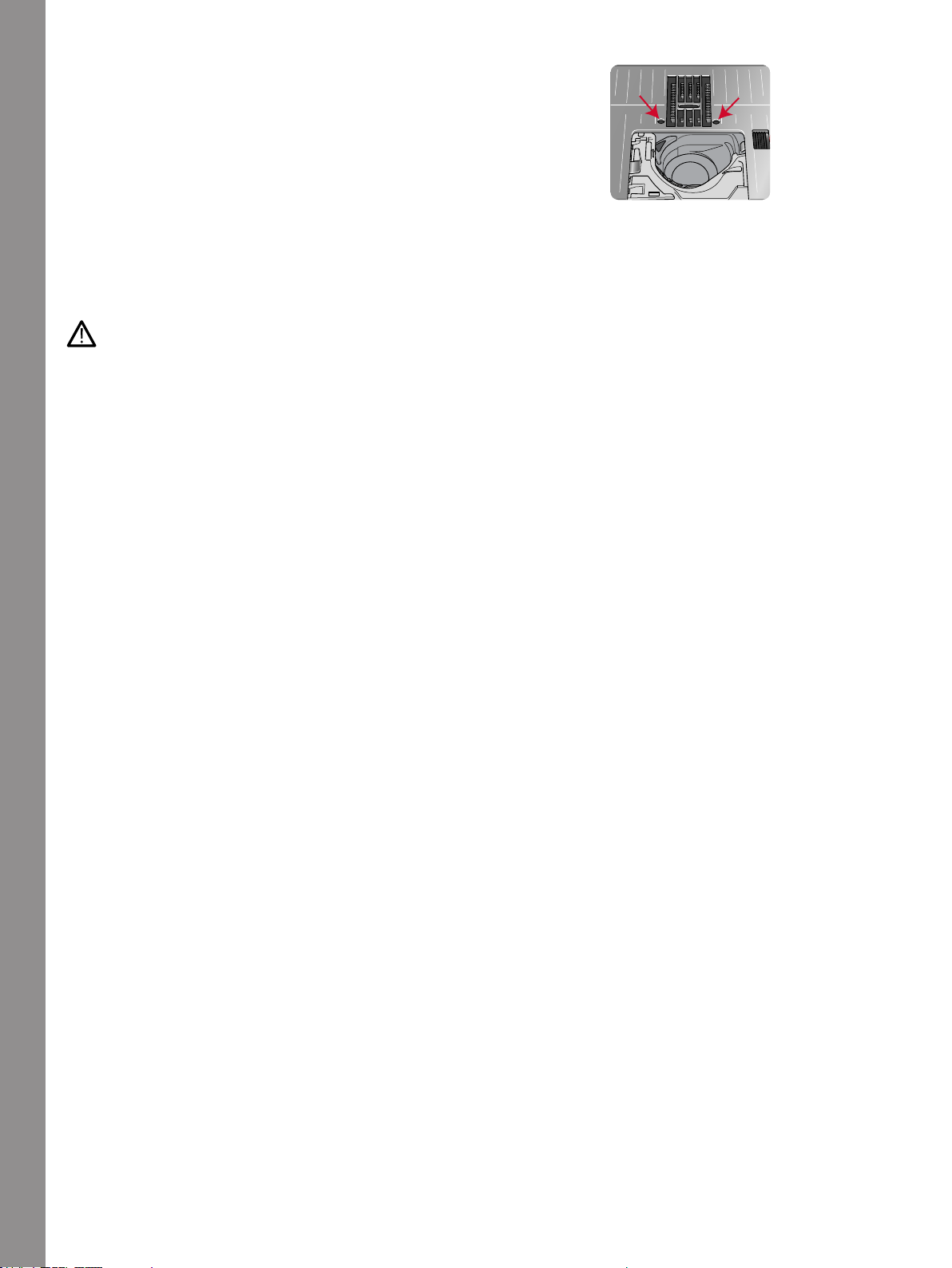

Some optional accessories are attached in the two

small circular holes in the needle plate just above the

bobbin cover. Do not use the cut function when an

accessory is attached in these holes as that may

interfere with the automatic thread cutter located

under the needle plate.

Immediate Tie-Off

Press immediate tie-off while sewing and your machine

sews a few tie-off stitches and stops automatically. By

touching the tie-off button once more while the action

indicator is lit, the function can be turned off.

Stitch Re-Start

When you stop sewing in the middle of a stitch, touch

stitch re-start to begin sewing at the beginning of the

stitch. The stitch or stitch sequence will remember any

Introduction

special settings you made.

Needle Stop Up/Down

Touch needle stop up/down to set the position of the

needle when you stop sewing. The needle will move up

or down when you touch the button. The indicator light

intensifies when needle stop down is set.

Tip: You can also tap the foot control to raise or lower the

needle once you stop sewing. Tapping the foot control does not

change the set stop position.

Start/Stop

Touch the start/stop button to start and stop the

machine sewing without using the foot control. Touch

start/stop to begin and touch again to stop.

Reverse

When reverse is active, the reverse indicator intensifies.

For permanent reverse, touch the reverse button once

before starting to sew. The reverse indicator will

intensify and the machine sews in reverse until you

touch the button again to cancel. If you press the reverse

button while sewing, the machine will sew in reverse for

as long as you keep the button pressed.

Reverse is also used when sewing manual buttonholes,

darning stitches and tapering stitches to step between

the parts of the stitch.

12

Page 13

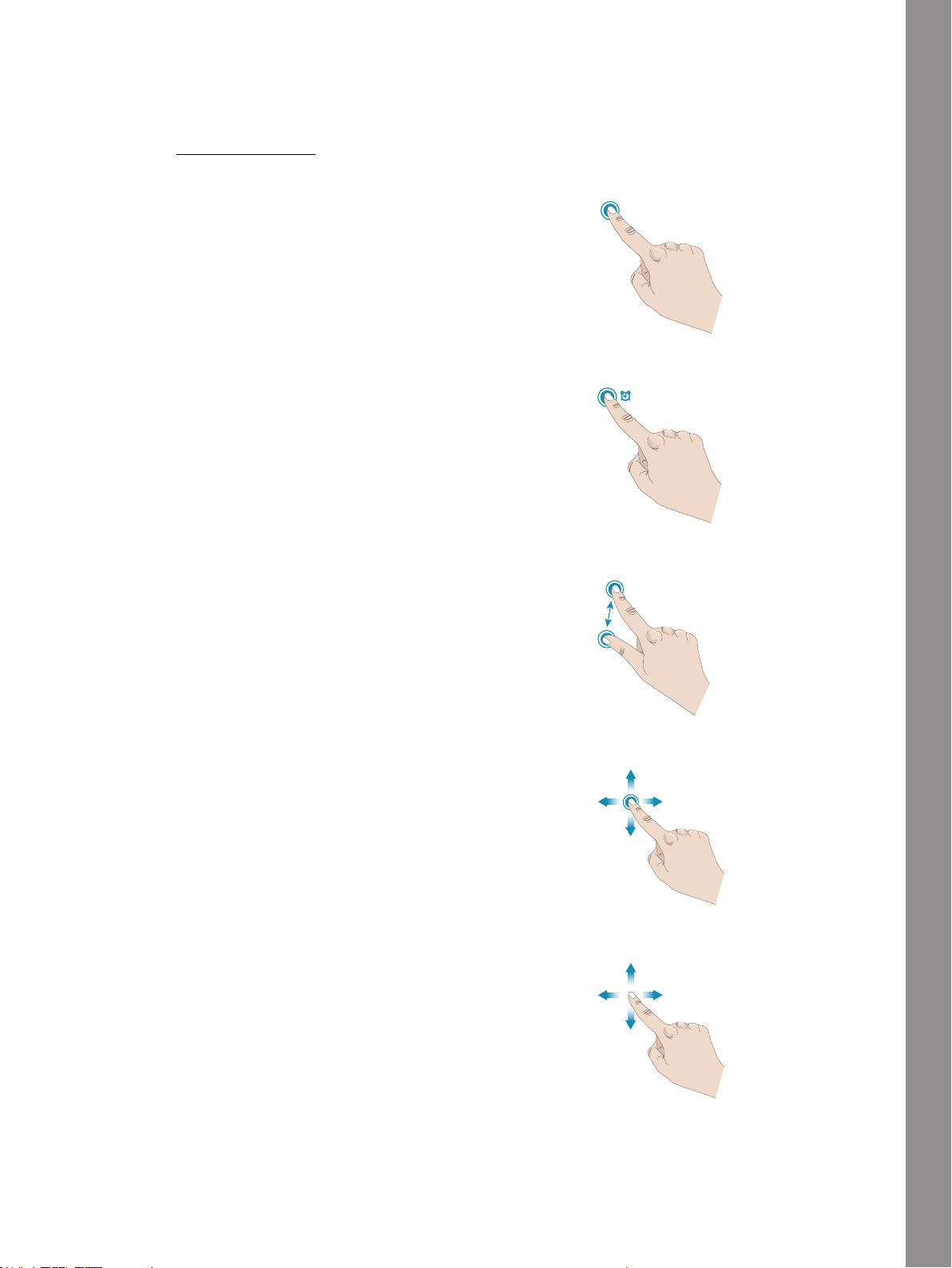

Basic Gestures for the Multi-Touch Screen

Easily navigate on the multi-touch screen with the

gestures described below. For more detailed

information, see Multi-Touch Screen.

Touch

Touch once on a button or setting on the screen to select.

Touch & Hold

Touch once without releasing for a few seconds to touch

& hold. Used on some buttons and screen areas to

access more options.

Pinch/Stretch

Touch with two fingers at the same time and without

releasing increase/reduce the distance between the

fingers to stretch (zoom in) or pinch (zoom out).

Touch and Move

Touch once on e.g a window on your screen and,

without releasing, move your finger to a different

position on the screen.

Swipe

Touch, move and release your finger in a swift gesture

to swipe. Left-right/right-left swipe is used to scroll

between stitch menus. Top-bottom/bottom-top swipe is

used to scroll within a stitch menu.

Introduction

13

Page 14

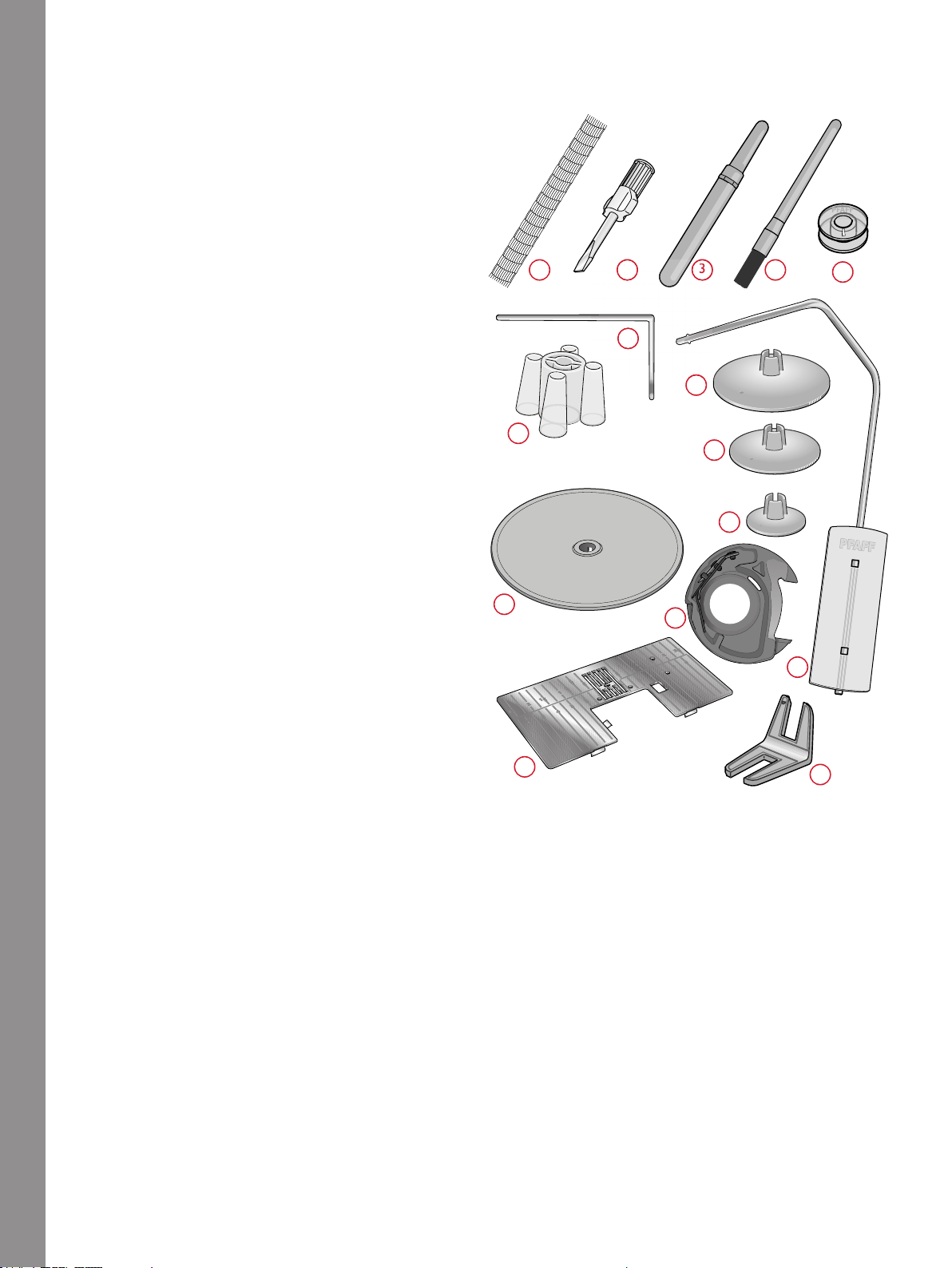

Accessories

1 2 3 4

6

5

7

9

8

10

11

12

13

14

15

2

3

6

Included Accessories

1. Thread net (4)

2. Screwdriver

3. Seam ripper

4. Brush

5. Bobbins (6)

6. Edge/Quilting guide (used attached to presser foot

ankle)

7. Thread cone holder (2)

8. Spool cap, large (2)

9. Spool cap, medium (2)

10. Spool cap, small (2)

11. Large spool holder

12. Bobbin case for straight stitch left (black)

13. Knee lift

14. Straight Stitch Needle Plate

15. Multipurpose tool/Button reed

Included Accessories Not in Picture

Introduction

• Soft cover for machine

• Foot control

• Power cord

• Needles

14

Page 15

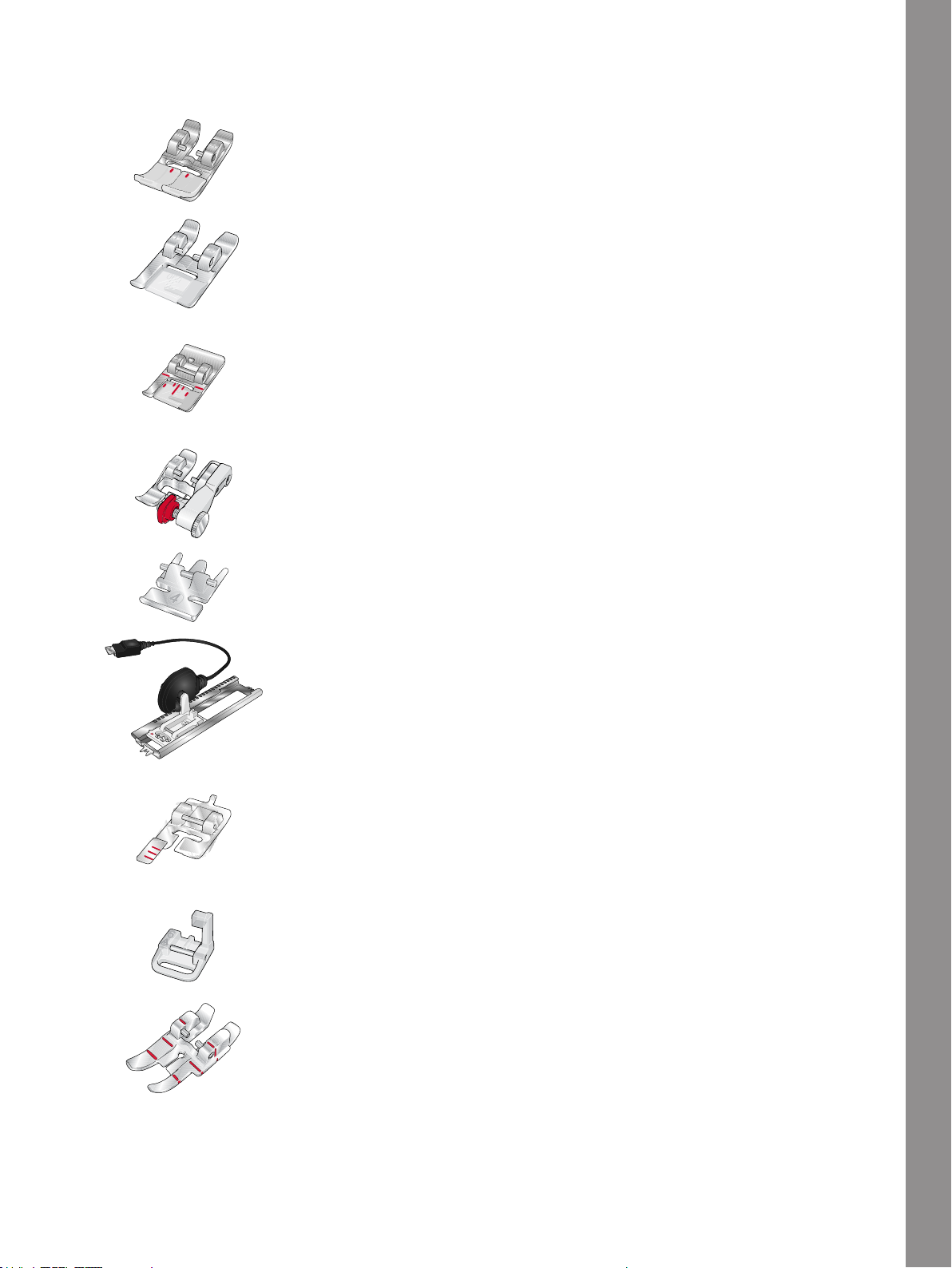

Presser Feet

Note: For the best sewing results, use only presser feet designed for and compatible with your performance icon™ machine.

OA -Standard Presser Foot for IDT™ System

(attached on the machine upon delivery)

This foot is used mainly for straight stitching and zigzag stitching with a stitch

length longer than 1.0 mm.

1A - Fancy Stitch Foot for IDT™ System

This foot is used for decorative stitches. The groove on the underside of the foot

is designed to flow smoothly over the stitches.

2A - Fancy Stitch Foot

When sewing decorative stitches or short zigzag stitches and other utility

stitches with less than 1.0mm stitch length, use this foot. The groove on the

underside of the foot is designed to flow smoothly over the stitches.

3 – Blindhem Foot for IDT™ System

This foot is used for blindhem stitches. The toe on the foot guides the fabric. The

red guide on the foot is designed to ride along the fold of the hem edge.

4 – Zipper Foot for IDT™ System

This foot can be snapped on either the right or the left of the needle, making it

easy to sew close to both sides of the zipper teeth. Move needle position to right

or left to sew closer to zipper teeth.

5A – Sensormatic Buttonhole Foot

When connected to the machine, the buttonhole is sewn in the length that has

been entered into the machine.

5M - Manual Buttonhole Foot

This foot is used for sewing manual buttonholes. Use the markings on the foot

to position the garment edge. The finger on the back of the foot holds cording

for corded buttonhole.

6A – Embroidery/Sensormatic Free Motion Foot

This foot is used for free motion sewing. This foot can also be used for darning.

¼″ Quilting Foot for IDT™ System

This foot is perfect for piecing and patchwork, especially when used in

conjunction with the straight stitch needle plate. The distance from the needle to

the outer edge of the right toe is ¼″ (6mm). The distance from the needle to the

inner edge of the right toe is ⅛″ (3mm).

Introduction

15

Page 16

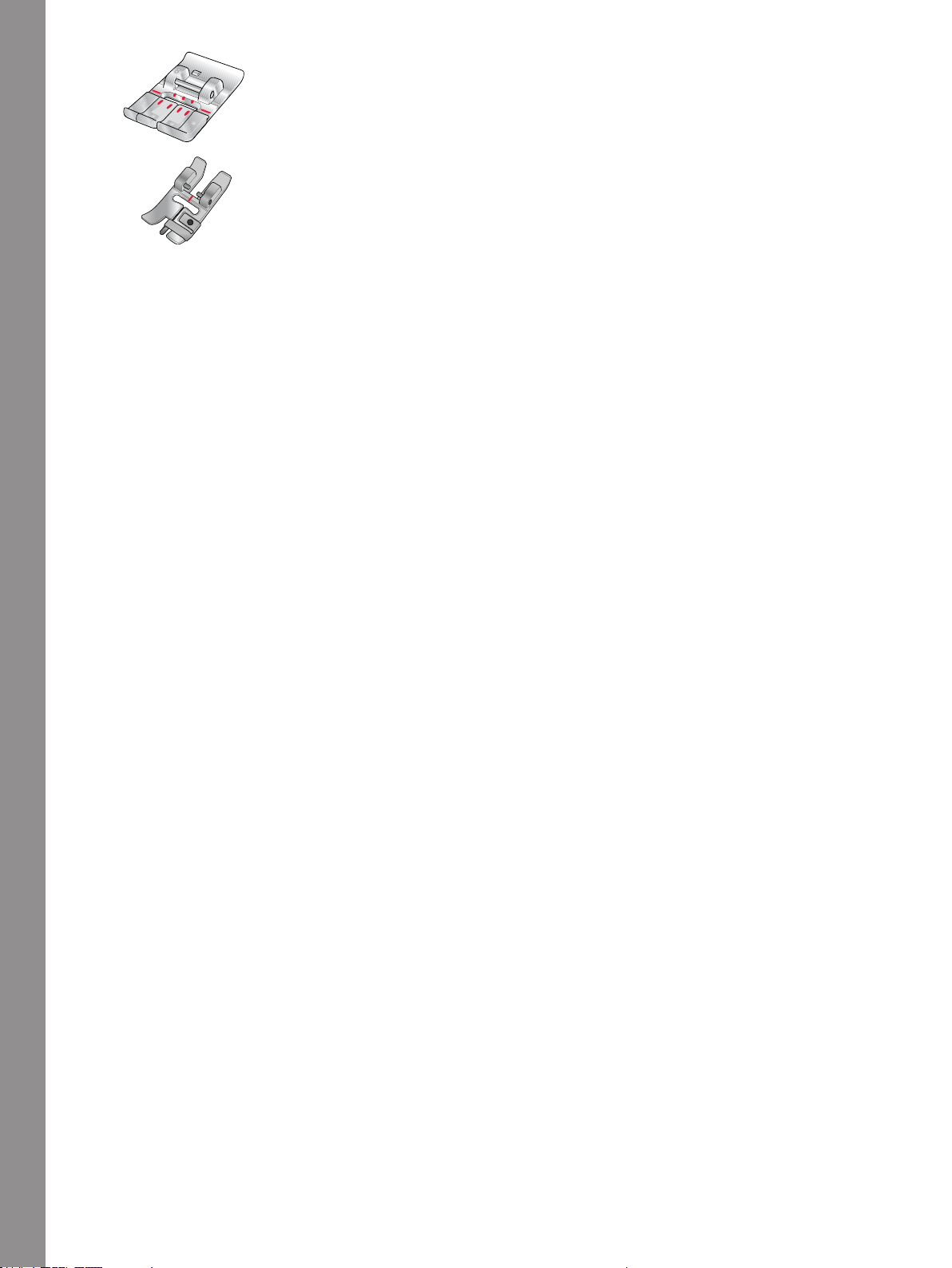

8 – Maxi Stitch Foot

This foot is used for side-motion stitches.

Bi Level Guide Foot for IDT™ System

The Bi Level Guide Foot is especially suitable for sewing the exclusive stitch

techniques such as Edge stitches and floating stitches. The underside of the

presser foot is designed to be higher on the right side, and has a guide in the

center, allowing the presserfoot to glide along a folded edge.

Introduction

16

Page 17

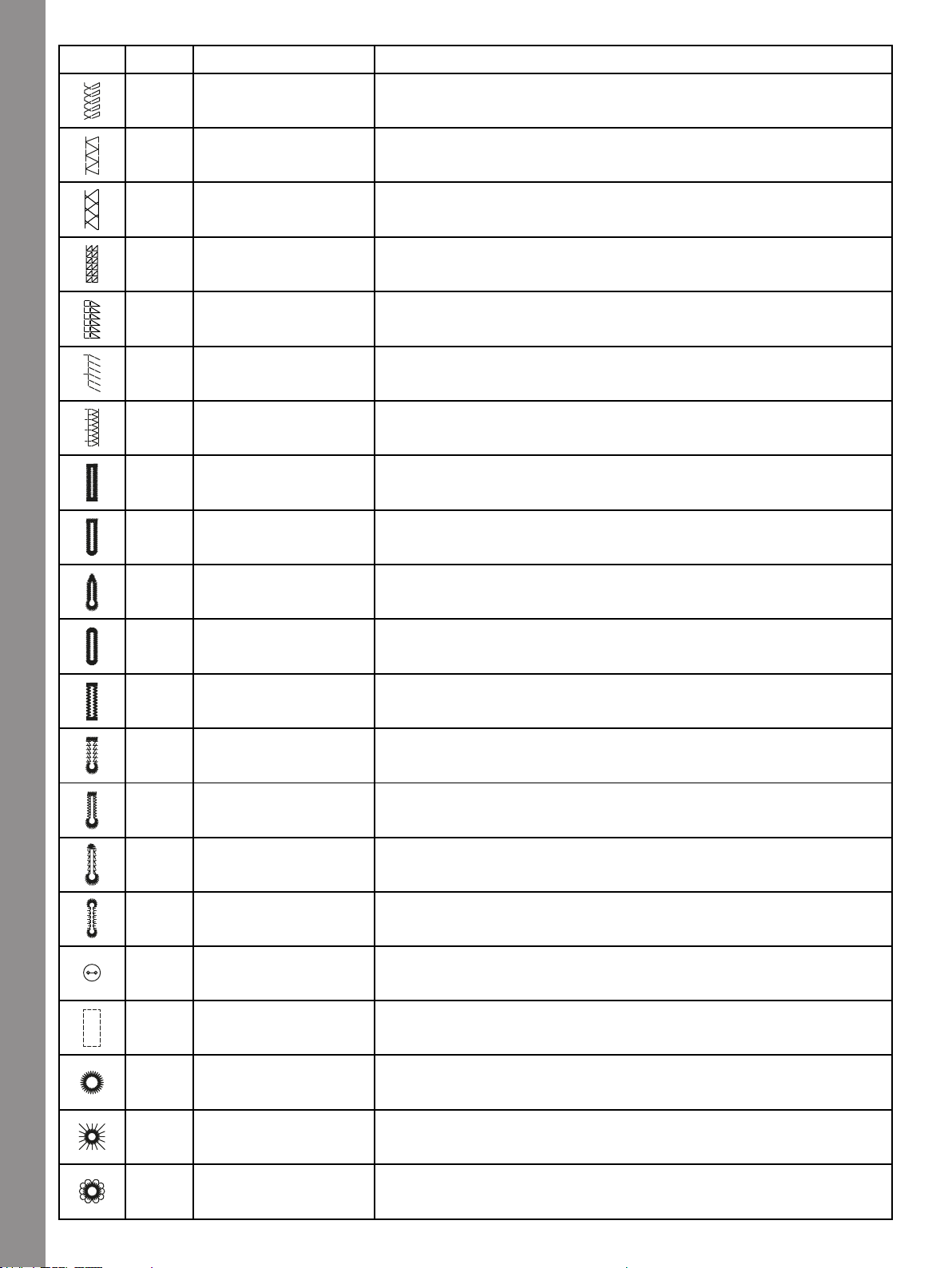

Stitch Overview

Utility Stitches

Stitch

№ Name

1.1.1

1.1.2

1.1.3

1.1.4

1.1.5

1.1.6

1.1.7

1.1.8

Straight stitch For seaming and topstitching.

Stretch triple straight

stitch

Stretch tricot stitch For sewing seams on stretch fabrics.

Basting stitch For all types of sewing.

Zigzag stitch For reinforcing seams, clean finish and stretch sewing.

Stretch triple zigzag

stitch

Three-step zigzag

stitch

Elastic stitch For stretch sewing, darning, patching and lace insertion.

Description

For reinforced seams and for top stitching.

Elastic stitch for decorative hems or topstitching.

For stretch sewing, darning, patching, edge finishing and decorative

sewing.

Introduction

1.1.9

1.1.10

1.1.11

1.1.12

1.1.13

1.1.14

1.1.15

1.1.16

1.2.1

Triple stretch stitch For stretch sewing, darning, patching, edge finishing and decorative

sewing.

Z-zigzag stitch For sewing appliqué.

Honeycomb stitch Decorative stitch for stretch fabrics and hems. Also used with elastic

thread in the bobbin.

Bridging stitch Joining fabrics and quilt batting, decorative stitch for quilting,

hemstitching.

Foundation elastic

stitch

Crosshem stitch Elastic decorative hem for stretch fabrics. Also suitable for joining

Blind hem stitch For sewing blind hems on woven fabrics.

Elastic blind hem stitch For sewing blind hems on stretch fabrics.

Closed overlock For sewing seams and overcasting stretch fabrics in one step.

Joining stitch for undergarments, terry cloth, leather, bulky fabrics

where overlapping the seams.

fabrics and quilt batting.

1.2.2

1.2.3

Elastic overcast For sewing seams and overcasting stretch fabrics in one step.

Overlock For sewing seams and overcasting stretch fabrics in one step.

17

Page 18

Stitch

№ Name

Description

1.2.4

1.2.5

1.2.6

1.2.7

1.2.8

1.2.9

1.2.10

1.3.1

1.3.2

Light knit fabric

patching

Closed overlock For patching, sewing hems, sewing seams and overcasting.

Closed overlock for

stretch

Mock cover hem Create the look of a serger cover hem for stretch fabrics.

Mock cover hem Create the look of a serger cover hem for stretch fabrics.

Open overlock blind

hem

Closed overlock blind

hem

Standard buttonhole Basic buttonhole for blouses, shirts and jackets. Also for pillowcases.

Rounded buttonhole

with crosswise tack

For patching and sewing hems in stretch fabrics.

For patching, sewing hems, sewing seams and overcasting in stretch

fabrics.

Create decorative overlock blind hem for woven fabrics.

Create decorative overlock blind hem for stretch fabrics.

Buttonhole for garments.

Introduction

1.3.3

1.3.4

1.3.5

1.3.6

1.3.7

1.3.8

1.3.9

1.3.10

1.3.11

Eyelet buttonhole with

pointed tack

Rounded buttonhole Buttonhole for light garments or jackets.

Stretch buttonhole Buttonhole for stretch fabrics.

Decorative eyelet

buttonhole

Decorative eyelet

buttonhole

Decorative eyelet

buttonhole

Decorative round

buttonhole

Button sewing

Bound buttonhole Foundation stitch for bound buttonhole.

Tailors buttonhole or decorative buttonhole.

Decorative buttonhole for jackets.

Decorative buttonhole for jackets.

Decorative heirloom buttonhole.

Decorative heirloom buttonhole.

For sewing on buttons or tacking.

18

1.4.1

1.4.2

1.4.3

Eyelet For belts, laces, heirloom sewing, etc.

Decorative Eyelet For belts, laces, heirloom sewing, etc.

Decorative Eyelet For belts, laces, heirloom sewing, etc.

Page 19

Stitch

№ Name

Description

1.4.4

1.4.5

1.4.6

1.4.7

1.4.8

1.4.9

1.4.10

Decorative Eyelet For belts, laces, heirloom sewing, etc.

Programmable darning

stitch

Programmable

reinforced darning

stitch

Bartack Reinforce pockets, shirt openings, belt loops as well as at lower end of

Denim bartack Reinforce pockets, shirt openings, belt loops as well as at lower end of

Decorative bartack Reinforce pockets, shirt openings, belt loops as well as at lower end of

Cross bartack Reinforce pockets, shirt openings and belt loops.

To darn or mend small holes, begin stitching over hole, touch reverse

for continuous darning and stop.

Darn and mend work clothes, jeans, table cloths and linen towels.

Stitch over hole, touch reverse for continuous darning and auto stop.

a zipper.

a zipper.

a zipper.

Introduction

19

Page 20

Stitch Menu Overview

There are several different stitch menus with stitches for all purposes. For detailed description of a stitch, use the

quick help function, see Quick Help.

Stitch Menu Name Sub Menus

1 — Utility Stitches

See also stitch table for

detailed descriptions.

2 — Quilt Stitches 1. Handlook quilt stitches

3 — Needle Art Stitches 1. Cross stitches

4 — Satin Stitches 1. Scallop edges

5 — Decorative Stitches 1. Leaves and flowers

6 — Miscellaneous Stitches 1. Bows and hearts

7 — Monogram Stitches

Introduction

1. Essential stitches

2. Overcast stitches

3. Buttonholes

4. Eyelets and darning stitches

2. Stippling stitches

3. Crazy patch stitches

2. Needlework stitches

3. Antique hand embroidery stitches

2. Satin elements

3. Borders

2. Art stitches

3. Ornamental stitches

4. Maxi art stitches

2. Animals

3. Fun stitches

1. Monogram 1

2. Monogram 2

8 — Stitch Techniques 1. Single ribbon stitches

2. Double ribbon stitches

3. Triple ribbon stitches

4. Stacking stitches

5. Floating stitches

6. Radiant stitches

7. Lace edge stitches

9 — Additional Stitches 1. Optional feet stitches

2. Four direction stitches

Alphabets

Stitch fonts are available in Block, Comic, Cyrillic, Grand,

Outline and Script alphabets.

20

Page 21

2 Preparations

1

2

3

Unpacking Machine

After lifting the machine out of the box and removing

all packing material and the plastic bag, wipe the

machine, particularly around the needle and needle

plate to remove any oil before sewing.

Note: Your performance icon™ machine is adjusted to

provide the best stitch result at normal room temperature.

Extreme hot and cold temperatures can affect the sewn results.

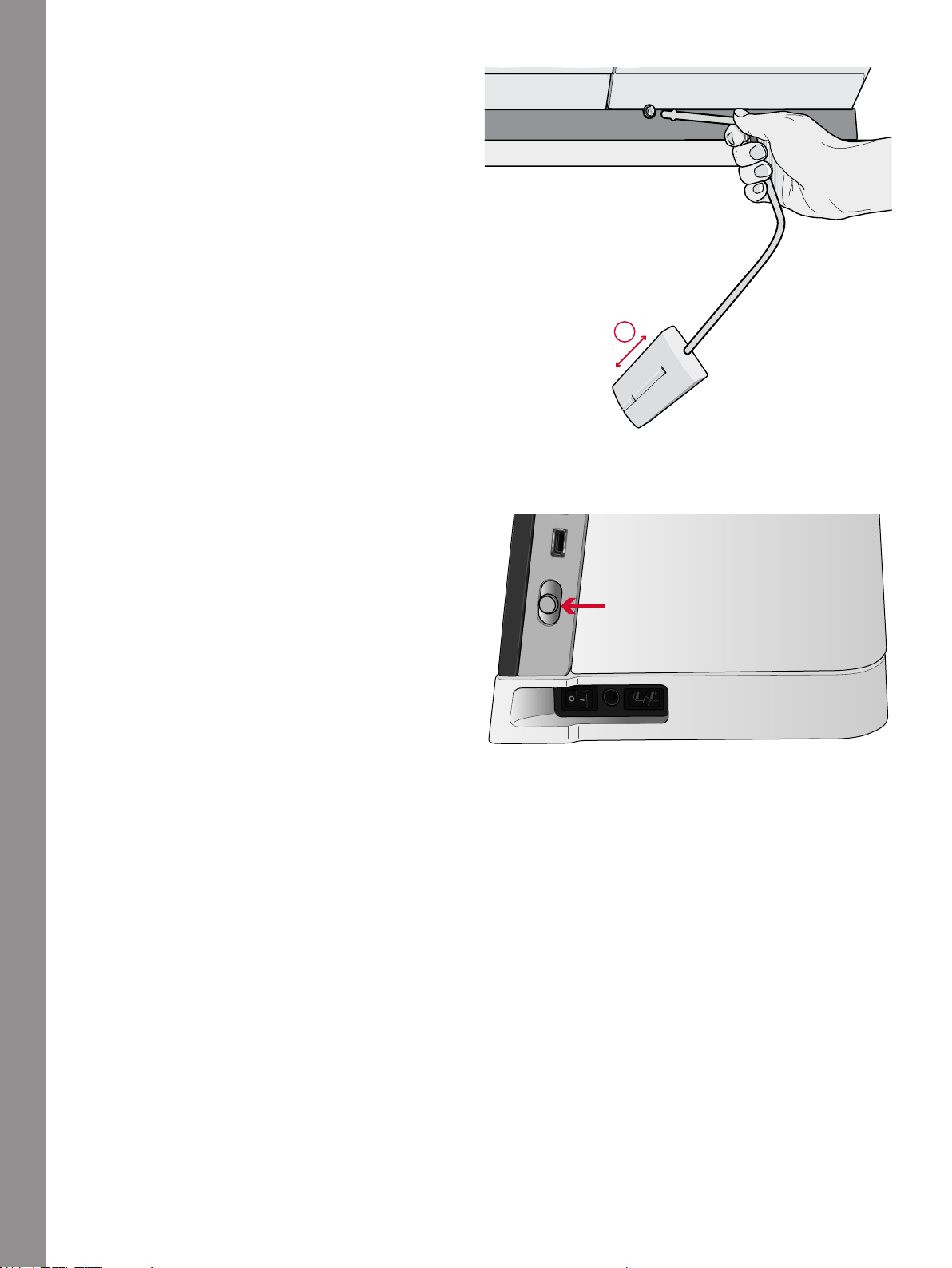

Connect the Power Cord and Foot Control

Among the accessories you will find the power cord and

the foot control.

Note: Before plugging in the foot control, check to ensure that

it is type "FR5" (see underside of foot control).

1. Pull out the cord from the foot control. Connect the

foot control cord to the front socket on the bottom

right side of the machine.

2. Connect the power cord to the rear socket on the

bottom right side of the machine. Plug the cord into

the wall socket.

3. Press the ON/OFF switch to "I" to turn on power

and light.

Preparations

For the USA and Canada

This sewing machine has a polarized plug (one blade

wider than the other). To reduce the risk of electric

shock, this plug is intended to fit in a polarized outlet

only one way. If the plug does not fit fully in the

outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet. Do

not modify the plug in any way.

21

Page 22

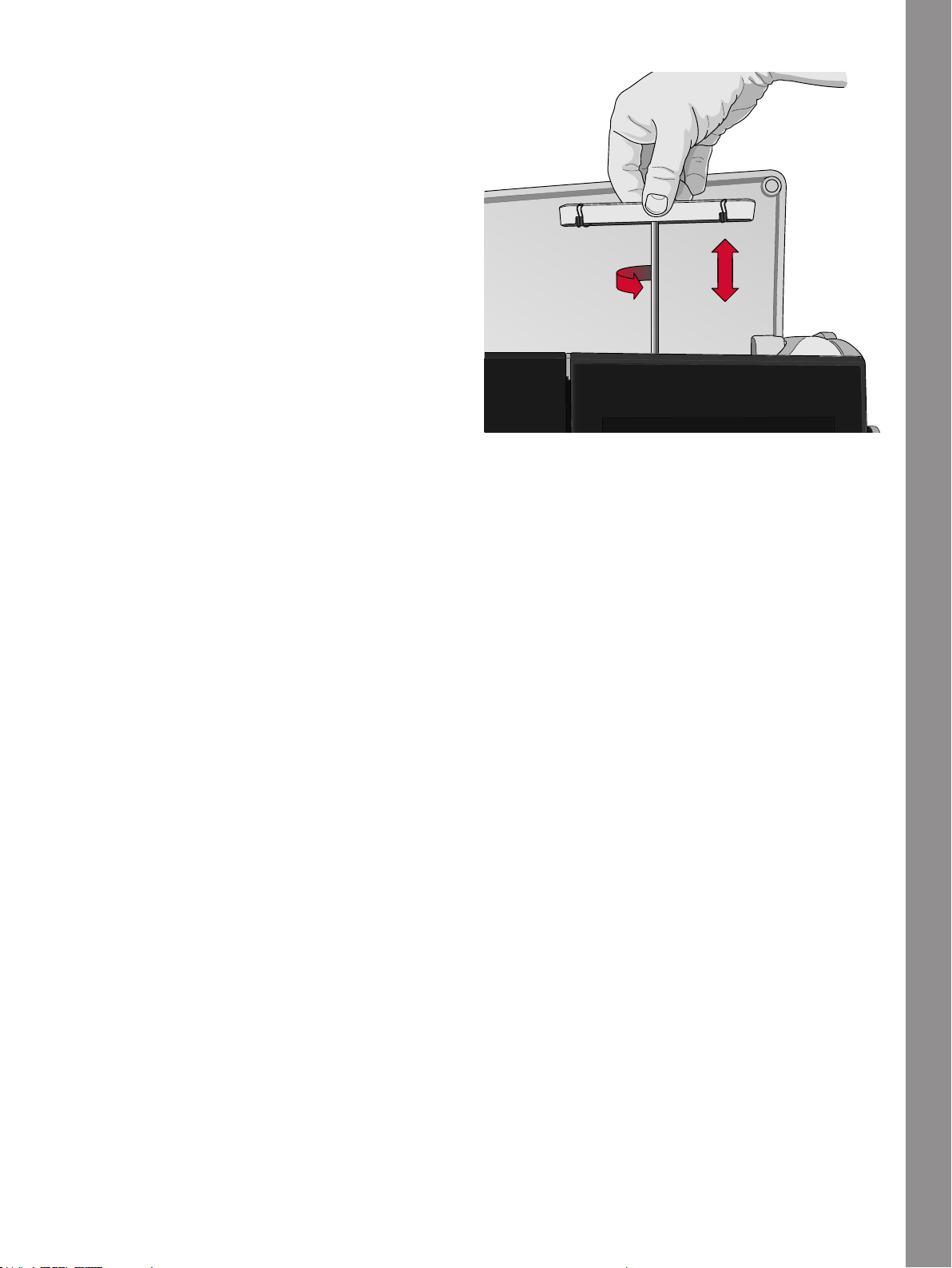

Pack Away After Sewing

1. Press the ON/OFF switch to "O".

2. Unplug the cord from the wall socket and then from

the machine.

3. Unplug the foot control cord from the machine. Pull

the cord gently and release. The cord will retract into

the foot control.

4. Place all accessories in the accessory tray. Slide the

tray on to the machine around the free arm.

5. Place the foot control in the space above the free arm.

6. Put on the soft cover.

Tip: The user’s guide and power cord can be stored in the back

pocket of the soft cover.

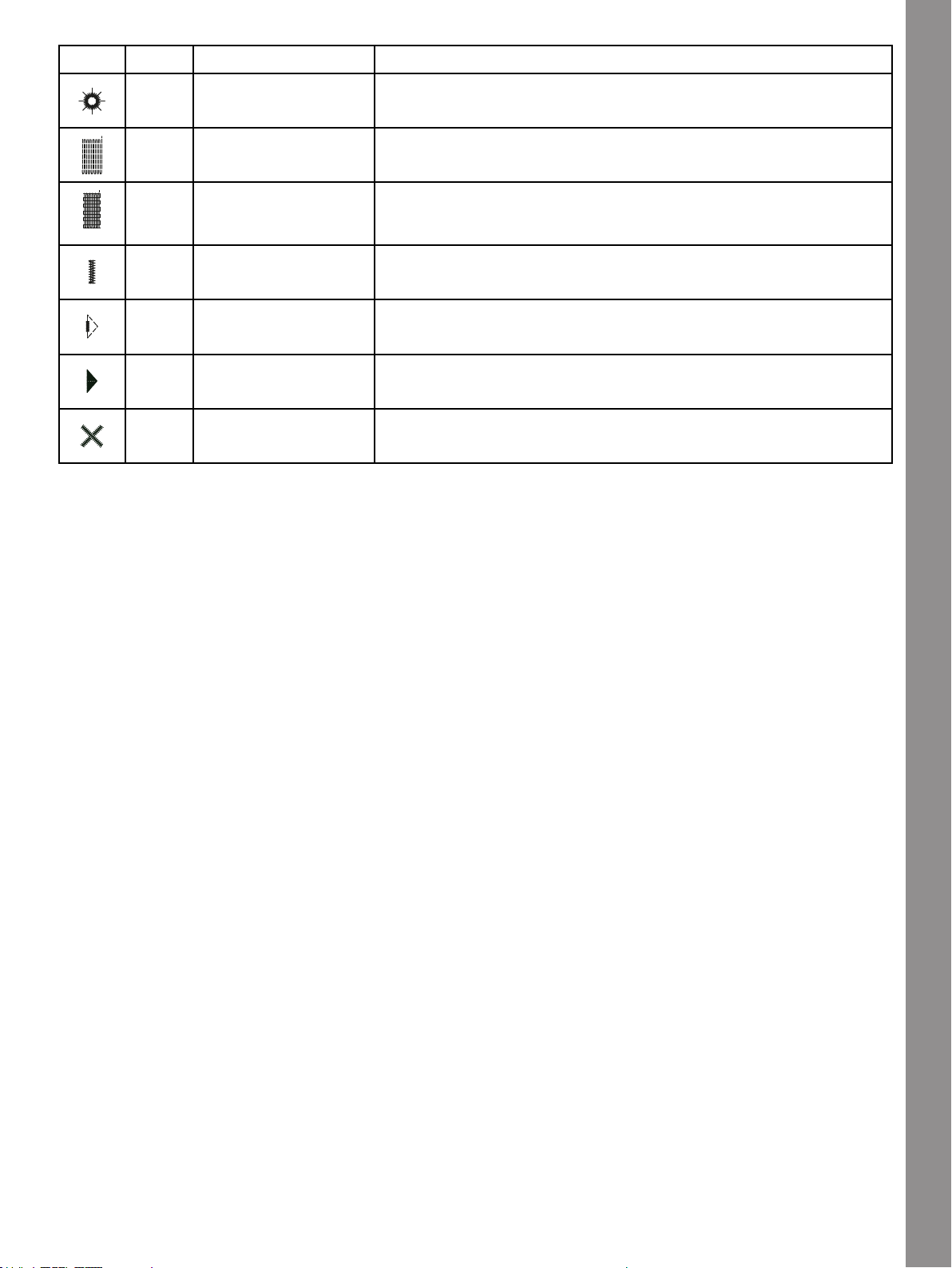

USB Ports

Your machine has two USB ports for connecting USB

devices such as a memory stick. USB plugs can only be

inserted one way – do not force them into the ports! To

remove, carefully pull the USB device out straight.

Note: Make sure that the USB stick you use has the format

FAT32.

Using a USB device

The external device button in file manager is only active

when a device is connected to a machine USB port.

Note: Do not remove the USB device if a loading spinner is

shown on the screen or while the file manager is shown.

Removing the device at that time can damage the files on your

Preparations

USB device.

22

Page 23

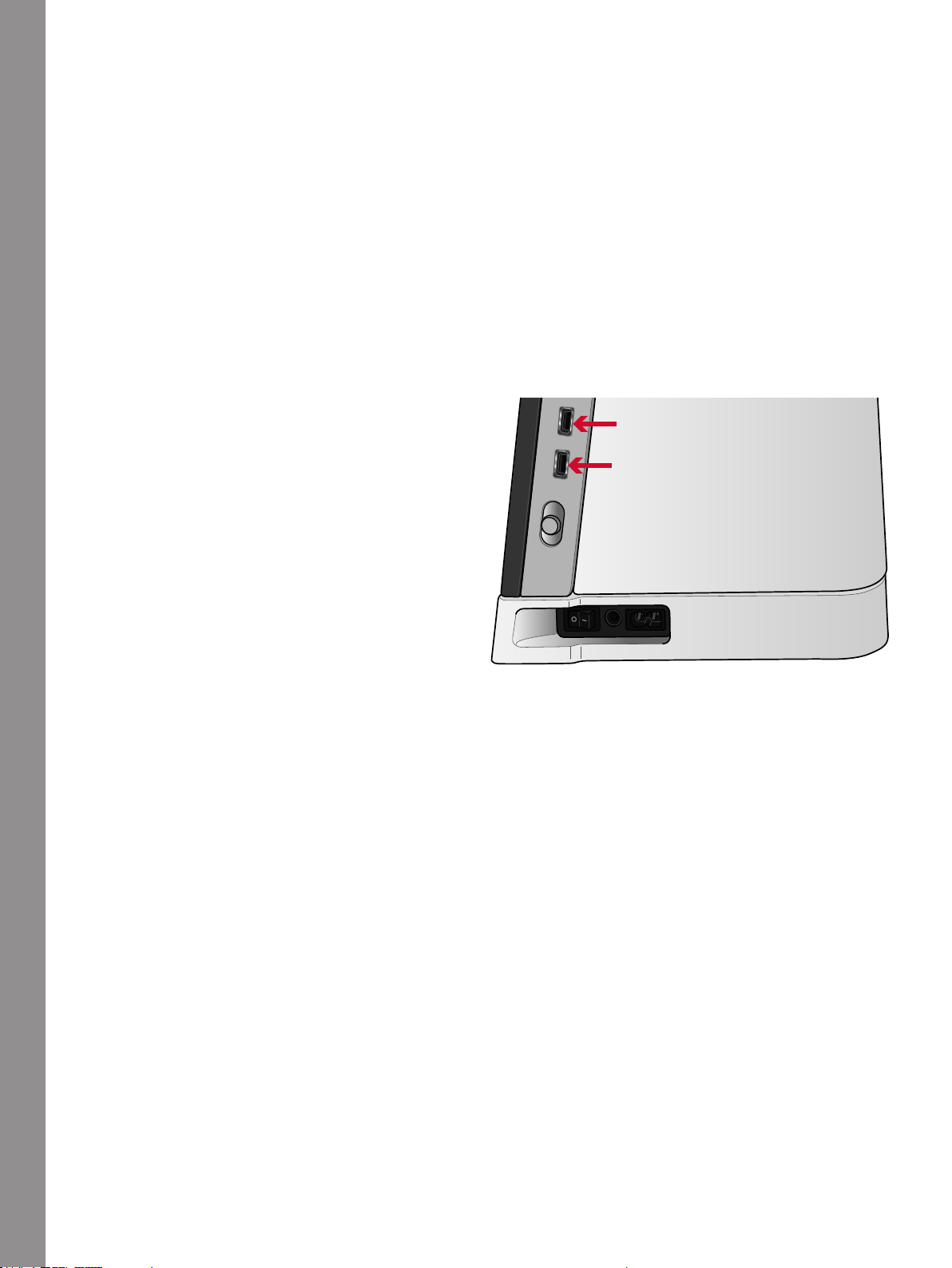

Getting Started with WiFi and mySewnet™ Cloud

Follow the steps below to connect your machine.

Connect to a Network with WiFi

Touch the WiFi button in the top left corner of the

screen. Select from the list of available networks. If your

network is password protected, you will be prompted to

enter the password to connect.

For more information, see WiFi Introduction.

Connect to mySewnet™ Cloud

When you have established a WiFi connection, touch the

mySewnet™ tab and touch the Sign in button. A web

view opens where you can log in. If you do not have a

user name and password, select Register to create an

account.

For more information, see mySewnet™ Cloud.

LED Lights

Your machine has LED lights which distribute the light

evenly over the sewing area and eliminate shadows.

You can adjust the brightness of the light in the settings

menu, see Machine Settings .

WiFi icon

mySewnet™ cloud icon

Preparations

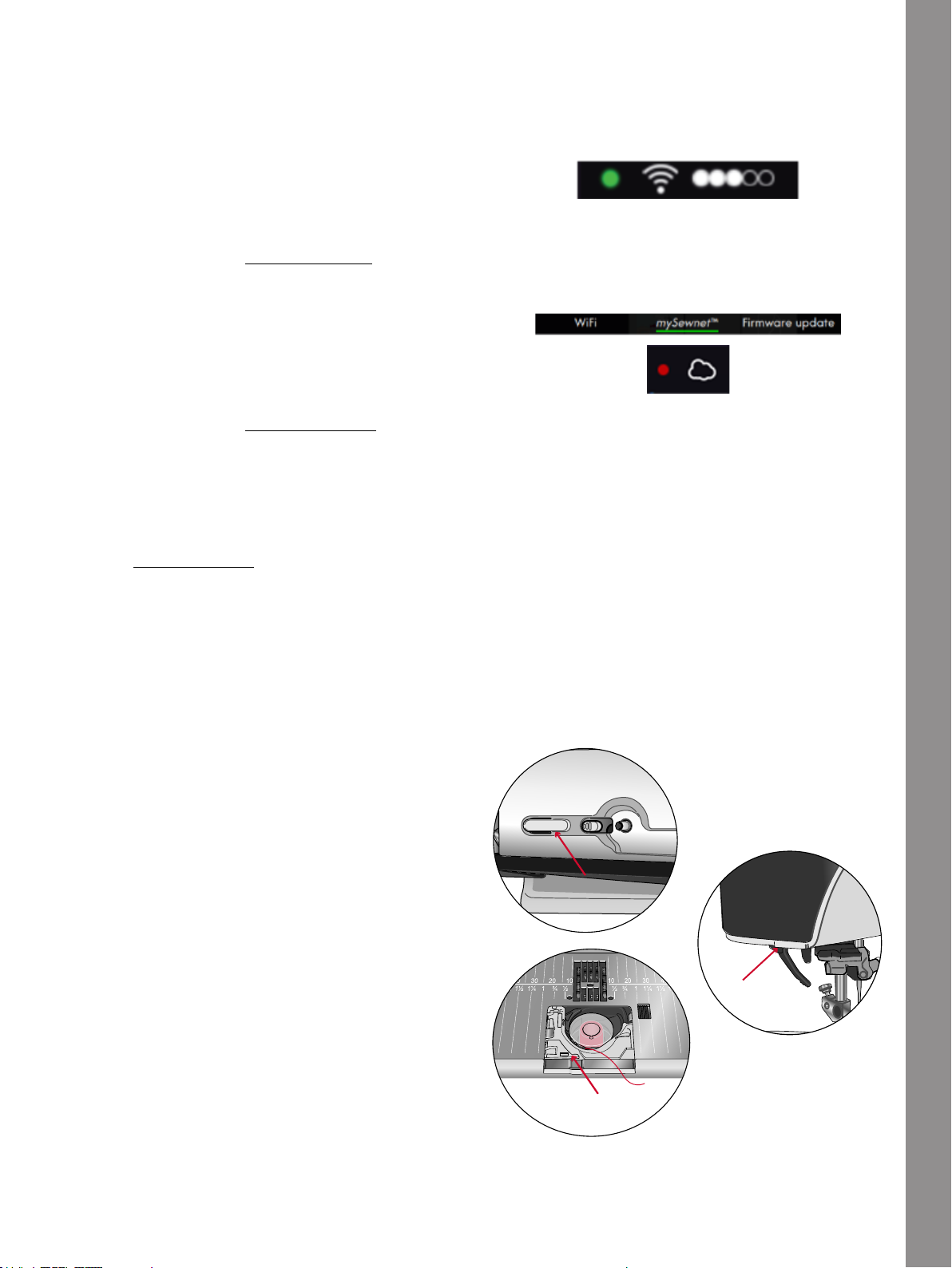

Free Arm

To use the free arm, slide off the accessory tray. When

attached, a hook keeps the accessory tray locked to the

machine. Remove the tray by sliding it to the left.

Manual Thread Cutter

There are three manual thread cutters on your machine.

The first one is close to the bobbin winder spindle for

cutting the thread after winding. The thread can be cut

from sides.

The second one is next to the bobbin area for cutting the

bobbin thread after placing the bobbin in the machine.

The third one is on the left side of the machine for

manually cutting top and bobbin threads. Pull both

threads into the cutter from the back to the front and

pull down quickly.

23

Page 24

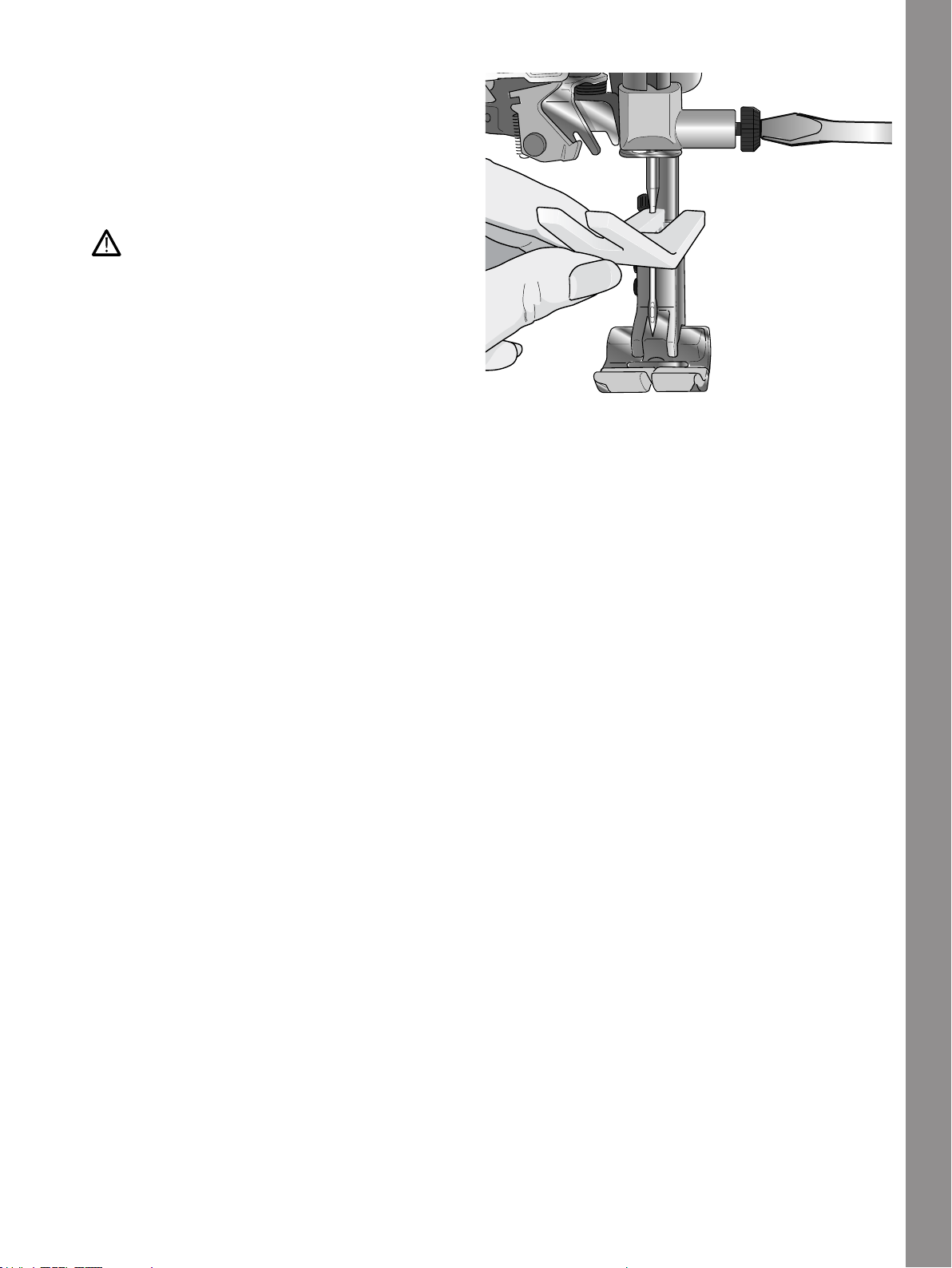

Knee-Lift

A

Your machine comes with an electronic knee-lifter that

allows you to lift the presserfoot with your knee. The

knee-lifter is very helpful when sewing, since it allows

you to handle the fabric with your hands while your

knee lifts the presser foot to the desired height.

Match the ribs on your knee-lifter with the notches in

the knee-lifter socket. Adjust the rectangular bar on the

knee-lift until it is positioned at a comfortable height for

you (A).

Move your knee lifter with your knee, and the presser

foot will raise. You can raise the presser foot to three

positions with your knee-lifter; pivot height, up, and

extra lift position. When moving the presser foot to the

extra lift position, the machine drops the feed teeth,

allowing you to easily place thick fabrics underneath the

presserfoot. The feed teeth will raise automatically

when you start to sew.

To remove the knee-lift, just pull it straight out of the

hole.

Speed Control Lever

The speed control lever sets the maximum sewing speed.

To increase sewing speed, slide the lever up, to decrease

sewing speed, slide the lever down.

A pop-up appears on screen when adjusting the slider,

indicating which speed level is set. The speed setting is

also shown in the information area.

Preparations

Thread Sensor

If the needle thread breaks or bobbin thread is running

low, the machine stops and a pop-up appears on the

screen.

If needle thread breaks: Remove the thread completely,

re-thread the machine and touch OK in the pop-up.

If bobbin thread is running low: You can continue

sewing without closing the pop-up before the bobbin

thread runs out completely. This gives you an

opportunity to plan where to stop and change the

bobbin. When the bobbin is replaced with a full one,

touch OK in the pop-up.

24

Page 25

Telescopic Thread Guide

The telescopic thread guide is always used when

threading your machine for sewing and bobbin winding.

The telescopic thread guide helps straighten the thread,

preventing it from tangling or breaking. The thread

guide together with the vertical spool pins make it

possible to successfully use very large thread cones.

Extending and Retracting the Telescopic Thread Guide

Hold the telescopic thread guide as illustrated and pull

it straight up, turn it until it clicks into place.

To retract, hold the thread guide and push it straight

down.

Preparations

25

Page 26

Spool Pins

BA

Your machine has two spool pins; a main spool pin and

an auxiliary spool pin. The spool pins are designed for

all types of thread.

Use the main spool pin (A) when threading the upper

thread and for bobbin winding through the needle. For

regular sewing and embroidery thread, use the main

spool pin in vertical position. Place the spool pin in the

horizontal position if you want to keep the machine

threaded and close the lid when you have finished

sewing. Remember to place the spool pin back in the

vertical position when you start to sew again.

Note: Tilting the spool pins is not possible with large thread

spools or cones.

You may get better results if you tilt the spool pin to the

horizontal position when using small spools of specialty

thread. See Threading Tips and Hints, page 34.

Use the auxiliary spool pin (B) when winding a bobbin

from a second spool of thread or for a second spool

when sewing with a twin needle.

Main spool pin (A) and auxiliary spool pin (B)

Spool Caps

Spool caps in three sizes are included with your

machine. For most types of thread spools, no spool cap

is needed except when the thread on the spool is

running low. If the thread is snagging on the top of the

thread spool, place a spool cap on top. Always use a

spool cap slightly larger than the thread spool to

Preparations

prevent the thread from snagging. The flat side of the

spool cap should be pressed firmly against the spool.

There should be no space between the spool cap and the

thread spool.

26

Page 27

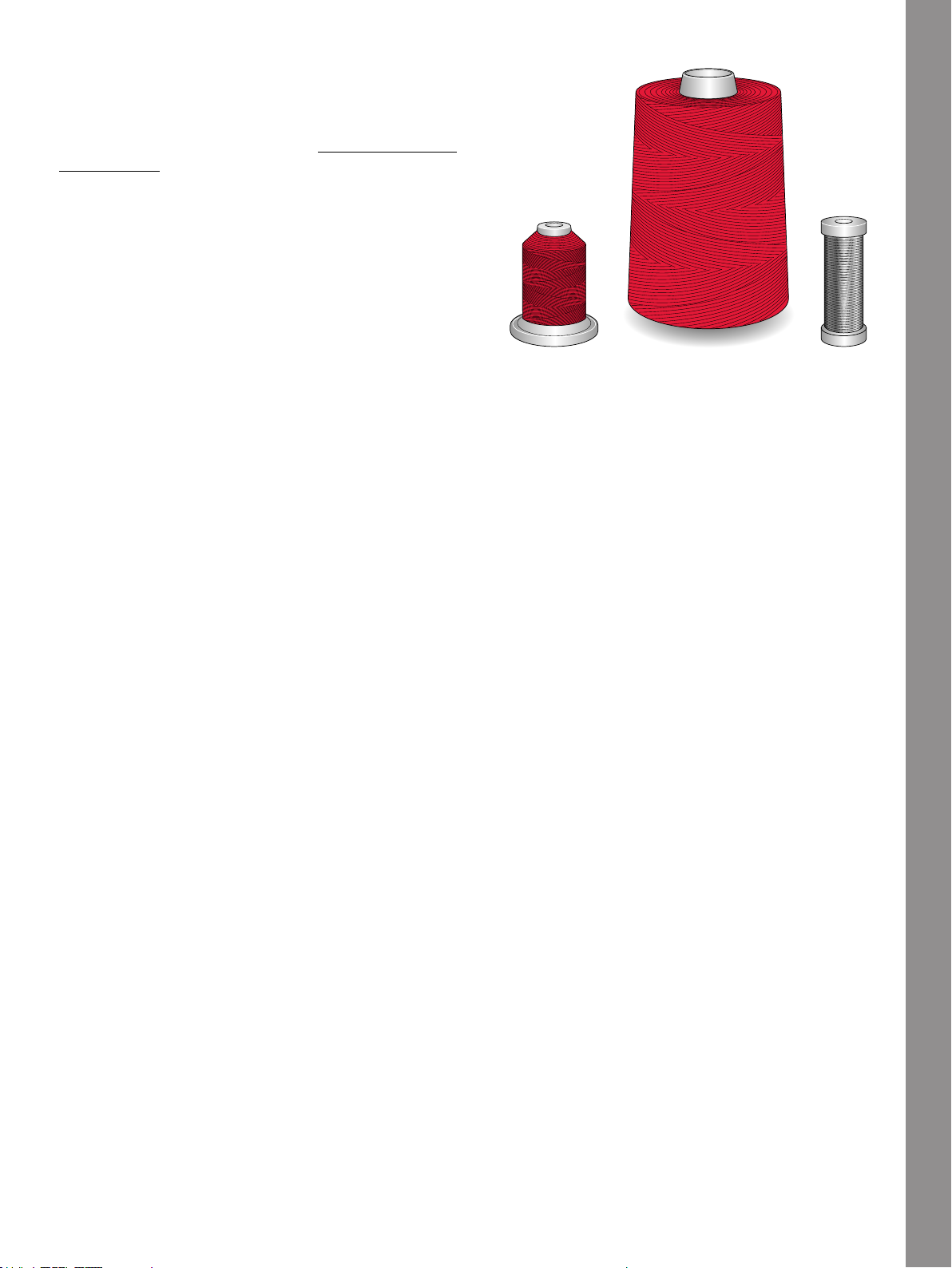

Threads

There are many threads on the market today developed

for different purposes.

Your performance icon™ machine is designed for all

types of threads and spool sizes. See Threading Tips and

Hints, page 34 for information on achieving optimal

results with different types of thread and different

sizes/styles of thread spools.

All Purpose Sewing Thread

All purpose sewing thread is made of synthetic, cotton

or cotton covered polyester. This type of thread is used

for most sewing projects, including garments, home

decor, and quilting.

Decorative Thread

Decorative thread is made from a variety of fibers:

rayon, polyester, acrylic or metallic. These threads

create a smooth glossy appearance for decorative

stitching.

Decorative thread is not typically used in the bobbin

unless both sides of the project will be seen. A light

weight, bobbin thread is often used in the bobbin

instead. The lighter weight thread does not build up

under the stitches.

Note: When using a metallic or a flat film thread, you may

need to use a needle with a larger eye and lower the speed.

Preparations

Transparent Thread

Transparent thread, also called monofilament thread, is

a single clear synthetic thread. It is used for quilting and

other sewing techniques. When winding a bobbin, wind

at half speed and fill the bobbin half full.

27

Page 28

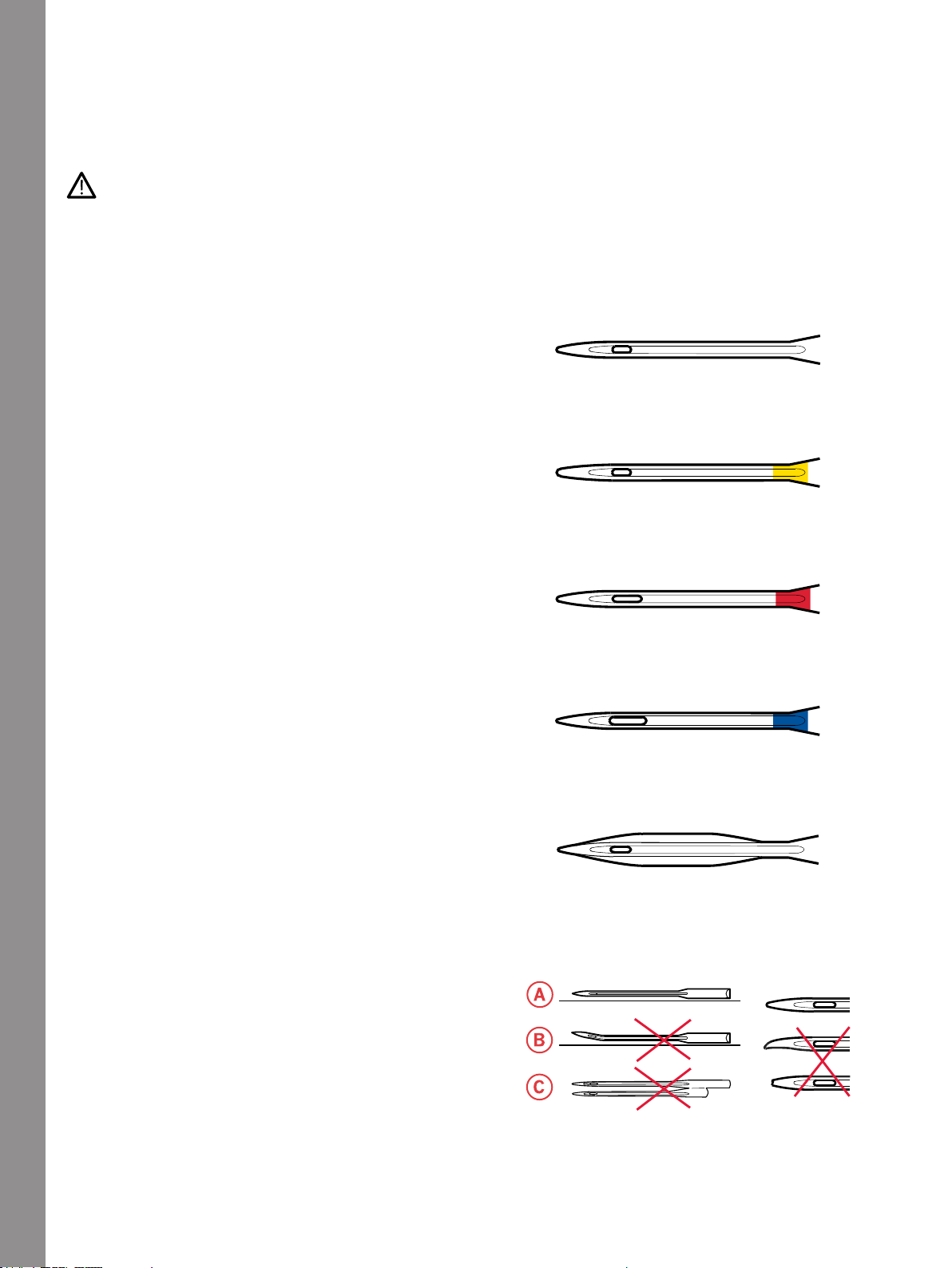

Needles

The sewing machine needle plays an important role in

successful sewing. Use only quality needles. We

recommend needles of system 130/705H. The needle

package included with your machine contains needles

of the most frequently used sizes.

Be sure to match the needle to the thread you are

using. Heavier threads require a needle with a larger

needle eye. If the needle eye is too small for the

thread the automatic needle threader may not work

properly.

Universal Needle

Universal needles have a slightly rounded point and

come in a variety of sizes. For general sewing in a

variety of fabric types and weights.

Stretch Needle

Stretch needles have a special scarf to eliminate skipped

stitches when there is a flex in the fabric. For knits,

swimwear, fleece, synthetic suedes and leathers.

Embroidery Needle

Embroidery needles have a special scarf, a slightly

rounded point and a slightly larger eye to avoid damage

to thread and materials. Use with metallic and other

specialty threads for decorative sewing.

Denim Needle

Preparations

Denim needles have a sharp point to penetrate tightly

woven fabrics without deflecting the needle. For canvas,

denim, microfibers.

Wing Needle

Wing needles have wide wings on the side of the needle

to poke holes in the fabric when sewing entredeux and

other hemstitches on natural fiber fabrics.

Important Needle Information

Change the needle often. Always use a straight needle

with a sharp point (A).

A damaged needle (B) can cause skipped stitches,

breakage or snapping of the thread. It can also damage

the needle plate.

Do not use asymmetrical twin needles (C), they can

damage your sewing machine.

28

Page 29

Changing the Needle

A

1. Use the hole in the multipurpose tool to hold the

needle.

2. Loosen the needle screw.

3. Remove the needle.

4. Insert the new needle using the multipurpose tool.

Push the new needle upwards with the flat side

away from you until it will go no further.

It is very important that the needle is inserted

all the way in order for the automatic needle

threader to work properly.

5. Tighten the needle screw carefully.

Preparations

29

Page 30

Threading

A

Make sure that the presser foot and needle are in the up

position.

Threading the Upper Thread

For most regular thread qualities and spool sizes,

threading the upper thread from the main (left) spool

pin in the vertical position is recommended for optimal

sewing results.

If you experience problems with the thread or sewing

result, there are alternative ways to position the thread

spool. See Threading Tips and Hints, page 34.

1. Hold the telescopic thread guide and pull it straight

up until it clicks into place.

2. Raise both spool pins to vertical position. Place the

thread spool on the main spool pin (left).

Using both hands, place the thread behind the left

clip on the telescopic thread guide (A). The thread

should run from right to left.

Preparations

Note: When using thread cones, place a cone holder on the

spool pin before placing the thread cone. This prevents the

thread cone from wobbling.

Tip: When removing the thread cone from the spool pin, the

cone holder might become stuck inside the thread cone. Push

it out gently from the top.

30

Page 31

3. Hold the thread with two hands as illustrated. Floss

B

A

C

D

E

F

the thread under the thread guide (A) from front to

back. Pull thread back into and through threading

slot (B).

Note: Continue to hold the thread lightly next to the

thread guide (A) throughout the threading process. This

will create a bit of tension on the thread and ensure that

the thread is properly seated in the threading path.

4. Pull the thread between the thread tension discs (C).

Thread down through the right threading slot and

then upwards through the left threading slot. Bring

the thread from the right into the take-up lever (D)

until it clicks into place (E), and down in the left

threading slot to the last thread guide (F) just above

the needle.

5. Thread the needle using the automatic needle

threader or manually.

Before using the automatic needle threader,

carefully read the instructions and

recommendations, see Using the Automatic

Needle Threader, page 33.

Preparations

31

Page 32

Automatic Needle Threader

Selecting Correct Thread/Needle Combination

The combination of the thread weight and the needle size is extremely important when using the automatic needle

threader. Unsuitable combinations, such as using a heavy weight thread for a fine needle, may cause damage to the

needle threader.

Avoid using fine needles with heavy fabrics to reduce the risk of bending the needle. Using the automatic needle threader

with a bent needle may cause damage to the needle threader.

Fabric Thread Needle

Woven

light

Chiffon, organza,

batiste, challis, crepe

de chine, etc.

Light weight threads:

• fine cotton, polyester or silk sewing thread

• rayon embroidery thread

Universal 130/705H

70/10-80/12

Woven

medium

Woven

heavy

Stretch

light

Stretch

medium

Preparations

Stretch

heavy

Leather Suede and leather Medium weight threads:

Calico, quilting

fabrics, crepe,

broadcloth, velvet,

etc.

Denim, tweed,

canvas, terrycloth,

etc.

Tricot, single knit

jerseys, etc.

Sweater knits,

double knit, velour,

swimwear, etc.

Sweater knits, fleece,

etc.

Medium weight threads:

• fine/normal cotton or polyester sewing thread

• rayon embroidery thread

Medium/heavy weight threads:

• normal cotton or polyester sewing thread

• top stitching thread

• rayon embroidery thread

Light weight threads:

• fine cotton or polyester sewing thread

• rayon embroidery thread

Medium weight threads:

• normal cotton or polyester sewing thread

• rayon embroidery thread

Medium weight threads:

• normal cotton or polyester sewing thread

• rayon embroidery thread

• normal cotton or polyester sewing thread

• rayon embroidery thread

Universal 130/705H

80/12-90/14

Universal 130/705H

90/14-110/18

Stretch 130/705H-S

75/11

Stretch 130/705H-S

90/14

Stretch 130/705H-S

90/14

Stretch 130/705H-S

90/14

Vinyl Vinyl, faux leather

and suede

Note: Specialty fabrics and threads may require a special needle for best stitch results. Refer to your PFAFF® retailer for more

information on needle types and sizes for your sewing needs.

32

Medium weight threads:

• normal cotton or polyester sewing thread

• rayon embroidery thread

Universal 130/705H

80/12

Page 33

Using the Automatic Needle Threader

A

B

C

The needle threader allows you to thread the needle

automatically by simply touching a button.

Make sure that the needle is inserted correctly and

pushed up all the way into the needle clamp before

using the automatic needle threader. Check that the

needle is not damaged or bent, and make sure to

match the thread weight and needle size according to

our recommendations in Selecting Correct Thread/

Needle Combination, page 32.

1. Place the thread under the hook (A) and pull it

between the discs (B) until it “clicks” into place.

2. Pull the thread up to the sewing head thread cutter

and cut excess thread by pulling the thread from

back to front in the thread cutter (C).

3. Touch the automatic needle threader button. The

presser foot is automatically lowered during the

threading sequence, and will rise again when

threading is finished.

The needle threader is designed to be used with needles size 70-120. You cannot use the needle threader with needles

size 65 or smaller, wing needles, twin needles or triple needles.

Specialty threads such as invisible and other stretchy threads, metallic or flat metallic threads, and some heavy weight

threads may not be caught correctly by the hook on the automatic needle threader. If this happens, the needle will not

be threaded. Try using the automatic needle threader again or thread the needle manually.

When threading the needle manually, make sure that the needle is threaded from front to back.

The automatic needle threader cannot be used with all optional accessories available for your performance icon™

machine. To avoid damage to the needle threader and/or optional accessory we recommend using the automatic needle

threader before attaching the accessory or thread the needle manually.

Preparations

33

Page 34

Threading Tips and Hints

There are many threads on the market today developed for different purposes. The quality and structure of the thread

as well as the shape and size of the thread spool can affect the behavior of the thread. Threads can also behave

differently if the spool is full or nearly empty.

If experiencing problems, try the tips and hints below.

Note: Always test sew on a scrap piece of fabric to check the sewing result.

If the thread spool is pulled up on the spool pin

When the thread on the spool is running low, the thread

can snag on the edge of the spool and pull the spool up

on the spool pin. Place a spool cap on top of the thread

spool to keep it in place. Always use a spool cap slightly

larger than the thread spool to prevent the thread from

snagging. The flat side of the spool cap should be

pressed firmly against the spool. There should be no

space between the spool cap and the thread spool.

If the thread slides down on the standing thread spool

Preparations

If the thread is of a quality that unwinds easily and

slides down on the standing thread spool it can get

caught under the thread spool around the spool pin and

break. Place the large spool holder on the spool pin with

the flat side up before placing the thread spool.

If the thread spool has the same diameter as the large

spool holder, place a thread net as illustrated from

below over the spool before placing it on the spool pin.

Note: To prevent snagging or increased thread tension on the

thread, the thread net should cover the lower part of the thread

spool only, not the top where the thread spool narrows.

34

Page 35

If the thread tangles or curls when unwinding from the spool

B

A

B

A

For smaller spools of specialty thread, the main spool

pin can be used in tilted position, allowing the thread to

roll off the spool.

Place the thread spool on the spool pin. Do not place a

spool cap on top of the spool as it may prevent the spool

from rotating. Pull thread up to the telescopic thread

guide and thread as described under Threading the

Upper Thread, page 30.

Threading for Twin Needle

Replace the sewing needle with a twin needle. Make

sure that the presser foot and needle are in the up

position.

1. Raise both spool pins to vertical position. Place a

thread spool on each spool pin.

Using both hands, place the thread from the main

spool pin behind the left clip on the telescopic

thread guide (A), from right to left, and then place

the thread from the auxiliary spool pin behind the

right clip on the telescopic thread guide (B), from

right to left.

Note: Do not place the thread from the auxiliary spool

pin behind both clips on the telescopic thread guide, as

this will create too much thread tension.

Note: When using large thread cones on the auxiliary spool

pin, place the large spool holder with the flat side up and a

cone holder on the spool pin before adding the thread cone.

2. Hold both threads with two hands as illustrated.

Floss the threads under the thread guide (A) from

front to back. Pull the threads together back into

and through threading slot (B).

Note: Continue to hold the threads lightly next to the

thread guide (A) throughout the threading process. This

will create a bit of tension on the threads and ensure that

the threads are properly seated in the threading path.

Preparations

35

Page 36

3. Pull the threads between the thread tension discs

C

D

E

F

(C). Make sure that you place one thread to the left

and one to the right side of the tension discs.

Thread down through the right threading slot and

then upwards through the left threading slot. Bring

the threads from the right into the take-up lever (D)

until they click into place (E), and down in the left

threading slot. One thread should be placed inside

the needle thread guide (F) and the other one

outside. Make sure the threads do not become

twisted together.

4. Thread the twin needle manually.

Do not use the automatic needle threader for

twin needle!

Note: The weight and irregular surface of specialty

threads such as metallic increases the amount of friction

on the thread. By reducing the tension, the risk of needle

breakage and thread breakage is reduced.

Preparations

36

Page 37

Bobbin Winding

A

B

C

F E

D

All types of thread, including specialty threads such as

invisible or other stretchy threads, metallic or flat

metallic threads, should be wound directly from the

auxiliary spool pin without passing the needle and

presser foot.

Note: Always wind specialty threads at lower speed.

1. Place a thread spool on the auxiliary spool pin.

Using both hands, pull the thread behind the right

clip on the telescopic thread guide (A). The thread

should run from right to left.

2. Bring the thread through bobbin winding thread

tension guide (B) from back to front and to the left.

Bring the thread through bobbin winding thread

guide (C) as illustrated.

For some specialty threads, following the

normal threading path will result in a bobbin

that is wound too tight. If this happens, bypass

thread tension (B) to reduce the amount of

tension on the thread. Pull the thread from

thread guide (A) directly to the bobbin instead.

Preparations

3. Thread through the slot in the bobbin (D) from the

inside to the outside.

Place the bobbin on the bobbin spindle (C). The

bobbin only fits on one way, with the logo facing

out.

The bobbins included are designed especially

for your performance icon™ machine. Do not

use bobbins from other machine models.

4. Push the bobbin winding lever (E) towards the

bobbin. A pop-up appears on screen. To adjust

winding speed drag the slider. Hold the thread end

firmly when starting to wind. Touch the play

button in the popup window and let the thread

wind a few turns. Touch the pause icon and cut the

loose thread end close to the bobbin. Press play

again.

5. When the bobbin is full, the bobbin winding lever

will move back and the winding will stop

automatically. The pop-up message closes. Remove

the bobbin and cut the thread using the bobbin

winding thread cutter (F).

37

Page 38

Winding Through the Needle

A

B

CFE

D

When using the same thread in the needle and bobbin, it

is convenient to wind a new bobbin directly through the

needle without having to unthread/re-thread your

machine.

We do not recommend winding speciality threads

such as invisible or other stretchy threads, metallic

or flat metallic threads through the needle. Very

heavy and coarse threads should not be wound

through the needle either as the thread tension can

become too high, causing the needle to break. Wind

specialty threads as described under Bobbin

Winding, page 37.

1. Make sure that the presser foot and needle are in

the up position.

2. Thread the machine as described under Threading

the Upper Thread, page 30.

3. Pull the thread from the needle, under the presser

foot and up to the right.

Note: Always use a metal presser foot when bobbin

winding from the needle.

4. Use both hands to bring the thread through bobbin

winding thread guide (A), up through the

threading slot and from left to right through thread

guide (B).

5. Thread through the slot in the bobbin (D) from the

inside to the outside.

Place the bobbin on the bobbin spindle. The bobbin

only fits on one way, with the logo facing out.

Preparations

The bobbins included are designed especially

for your performance icon™ machine. Do not

use bobbins from other machine models.

6. Push the bobbin winding lever (E) towards the

bobbin. A pop-up appears on screen. To adjust

winding speed drag the slider. Hold the thread end

firmly when starting to wind. Touch the play

button in the popup window and let the thread

wind a few turns. Touch the pause icon and cut the

loose thread end close to the bobbin. Press play

again.

Note: Always use a metal presser foot.

7. When the bobbin is full, the bobbin winding lever

will move back and the winding will stop

automatically. The pop-up message closes. Remove

the bobbin and cut the thread using the bobbin

winding thread cutter (F). Cut the free thread end

close to the bobbin.

38

Page 39

Inserting the Bobbin

1 2

3

4

A

B

C

D

Use only the bobbins designed for your performance

icon™ machine.

1. Open the bobbin cover by pushing the release button

(A) to the right. Remove the cover.

2. Place the bobbin in the bobbin case. It drops in only

one way with the logo facing up. The bobbin will

then rotate counterclockwise when you pull the

thread.

3. Place your finger on the bobbin to keep it from

turning as you pull the thread firmly to the right and

then to the left into the tension spring (B) until it

“clicks” into place. Continue threading around (C)

and to the right of the thread cutter (D).

4. Replace the bobbin cover. Pull the thread to the left

to cut.

Preparations

39

Page 40

Changing the Bobbin Case

2

1

B

C

D

3

4

E

The performance icon™ comes with two different

bobbin cases. Bobbincase (1) is mounted on the machine

at delivery and is used for most sewing. The second

bobbin case (2), is the Straight Stitch Bobbin Case. This

bobbin case is recommended to use when sewing a

straight stitch that has moved its needle position to the

left. A symbol will be shown in the information area on

your screen when the Straight Stitch Bobbin Case is

recommended.

1. Remove the presser foot. Open the bobbin cover by

pushing the release button (A) to the right. Remove

the cover.

2. Place the screwdriver under the needle plate as

shown and gently turn the screwdriver to pop off

the needle plate.

3. Remove the bobbin case holder (B) covering the

front part of the bobbin case by lifting it up. Remove

the bobbin case (C) by lifting it up.

4. Replace the bobbin case (D) and place the bobbin

case holder (E) back in place. Attach the needle plate.

Preparations

40

Page 41

IDT™ System (Integrated Dual Feed)

A

For sewing any fabric precisely, the PFAFF®

performance icon™ machine provides the ideal

solution: the integrated dual feed, IDT™ system. As on

industrial machines, the IDT™ system feeds the fabric

from the top and bottom at the same time. The material

is fed precisely, eliminating puckering on seams in light

weight fabrics such as silk and rayon. The dual feed

action of the IDT™ system prevents layers from shifting

while sewing, keeping quilt layers aligned and ensuring

a more perfect match when sewing plaid or striped

fabrics.

Engaging the IDT™ System

Important: For all work with the IDT™ system, use

presser feet with the center back cut-out (A).

Raise the presser foot to extra high position. Press the

IDT™ system down until it engages.

Note: Your machine is equipped with an IDT™ sensor which

will alert you if you should engage the IDT™.

Disengaging the IDT™ System

Raise the presser foot. Hold the IDT™ system with two

fingers at the ribbed ankle. Pull the IDT™ system down,

then pull it away from you to release the IDT™ system

slowly upward.

Preparations

41

Page 42

Changing the Presser Foot

Remove Presser Foot

Press the presser foot downwards until it disengages

from the presser foot holder.

Attach Presser Foot

Line up the pins on the foot with the gap underneath

the presser foot holder. Press upwards until the foot

snaps into place.

You can also use the presser foot up/down buttons to

raise or lower the presser foot holder. Place the presser

foot under the presser foot holder, so that the pins of the

foot snap onto the presser foot holder when lowered.

Preparations

Attaching the Sensormatic Buttonhole Foot

1. Snap on the Sensormatic Buttonhole Foot.

2. Insert the plug, with the three dots facing out, into

the accessory socket at the back of the sewing head.

42

Page 43

Changing to Straight Stitch Needle Plate

The Straight Stitch Needle Plate is used for certain

techniques in sewing mode, such as quilt piecing. The

smaller hole in the Straight Stitch Needle Plate supports

the fabric closer to the needle and helps prevent the

fabric from being pulled down into the bobbin area,

especially at the beginning and/or end of a seam.

1. Remove the presser foot. Open the bobbin cover by

pushing the release button (A) to the right. Remove

the cover.

2. Make sure that the feed teeth are lowered. Place the

screwdriver under the needle plate as shown and

gently turn the screwdriver to pop off the needle

plate.

Note: Lower the feed teeth by touching the presser foot up

and extra lift button.

Note: When changing the needle plate, clean any lint and

threads from the bobbin area.

3. With feed teeth lowered, position the Straight Stitch

Needle Plate so that it fits into the notches at the

back. Press the Straight Stitch Needle Plate down (B)

until it clicks into place. Replace the bobbin cover.

To prevent needle breakage or damage to the plate,

remove any accessory that is not compatible with the

Straight Stitch Needle Plate, such as twin needle.

Preparations

43

Page 44

3 The Multi-Touch Screen

Multi-Touch Screen

Your performance icon™ machine features a Multi-Touch Screen which is very easy to use. A few simple gestures –

touch, touch & hold, pinch/stretch, touch and move and swipe – are all you need to use the Multi-Touch Screen.

Gestures

Touch

Touch once on an icon or setting on the screen to select.

Touch & Hold

Touch once without releasing for a few seconds to touch

& hold. Used on some buttons and screen areas to

access more options.

Pinch/Stretch

Touch with two fingers at the same time and without

releasing increase/reduce the distance between the

The Multi-Touch Screen

fingers to stretch (zoom in) or pinch (zoom out).

This function is very useful when reading your user’s

guide to zoom in texts and pictures.

Touch and Move

Touch once and without releasing move your finger to a

different position on the screen to touch and move.

44

Page 45

Swipe

Touch, move and release your finger in a swift gesture

to swipe. Left-right/right-left swipe is used e.g. to scroll

between stitch menus. Top-bottom/bottom-top swipe is

used e.g. to scroll within a stitch menu.

Start Page

You can go to Sewing Mode directly from the Start Page.

The Start Page is shown every time you start your

performance icon™ machine. The Start Page is always

accessible through the Home button.

Start Sewing

Touch to open Sewing Mode. You can also touch & hold

to open the Selection Menu and select a stitch.

Read about how to get started sewing in the Sewing

chapter.

Load From mySewnet™

Touch Load from mySewnet™ to enter File Manager and

mySewnet™ cloud folder.

Read about mySewnet™ cloud folder in the File Manager

chapter.

Open Help Center

Touch to open the Help Center. This is where you will

find the built-in User's Guide, Getting Started,