Page 1

CD

-o

-,

I

-Il

0

-F,

B

Q

n

CD

CD

0

3

CD

C)

CD

Cj,

iI

.1

I

ik

1

I

IS

‘

.

S

J

Page 2

IMPORTANT

When

including

Read

all

using

instructions

an

the

electrical

following:

before

SAFETY

appliance,

using

basic

this

safety

household

INSTRUCTIONS

precautions

Sewing

should

machine.

always

be

followed,

Ak

DANGER

•

A

•

sewing

sewing

Always

machine

machine

unplug

WARNING

electric

•

Do

used

•

Use

attachments

•

Never

properly,

machine

or

mechanical

•

Never

openings

dust,

•

Keep

machine

•

Always

•

Do

not

•

Do

not

•

Switch

as

threading

•

Always

lubricating,

instruction

•

Never

•

Do

not

•

Do

not

administrated.

not

by

this

operate

operate

and

fingers

use

pull

the

unplug

drop

use

operate

allow

use

shock,

to

or

near

sewing

recommended

if

it

has

to

the

adjustment.

of

the

loose

away

needle.

the

bent

or

push

sewing

needle,

the

or

when

manual.

or

insert

outdoors.

where

-

from

before

be

children.

machine

this

been

nearest

the

sewing

Sewing

cloth.

from

proper

needles.

machine

sewing

To

should

the

relamping.

-

To

used

sewing

dropped

authorised

machine

all

needle

fabric

changing

making

any

object

aerosol

reduce

never

electric

reduce

or

injury

as

a

toy.

only

for

by

the

machine

or

machine

moving

plate.

while

stitching.

off

(“0”)

needle,

machine

any

other

into

(spray)

the

be

left

unattended

outlet

Replace

Close

attention

its

intended

manufacturer

if

it

has

damaged,

dealer

with

any

and

foot

parts.

The

wrong

when

threading

from

the

user

any

opening.

products

risk

immediately

bulb

with

the

or

controller

Special

It

making

risk

to

persons:

use

as

a

damaged

or

dropped

service

air

openings

care

plate

may

deflect

bobbin,

electrical

servicing

are

is

as

any

being

of

electric

when

plugged

after

same

type

of

necessary

described

contained

cord

into

center

adjustments

for

blocked.

free

from

is

required

can

cause

the

adjustment

or

outlet

used

needle

changing

using

and

rated

burns,

when

in

this

in

this

or

plug,

water.

examination,

Keep

the

accumulation

around

the

causing

in

when

removing

mentioned

or

where

in.

Always

before

5

this

manual.

manual.

if

it

Return

needle

the

presser

oxygen

shock:

unplug

cleaning.

Watt.

fire,

sewing

Use

is

not

working

the

repair;

ventilation

the

Sewing

to

break.

it

to

needle

foot,

covers,

in

the

is

machine

only

sewing

electrical

of

lint,

break.

area,

etc.

being

this

is

such

•

To

disconnect,

•

Do

not

SAVE

turn

unplug

by

THESE

all

controls

pulling

to

the

off

(“0”)

on

cord.

To

unplug,

position,

grasp

the

then

plug,

INSTRUCTIONS

remove

not

the

plug

cord.

from

outlet.

Page 3

Page 4

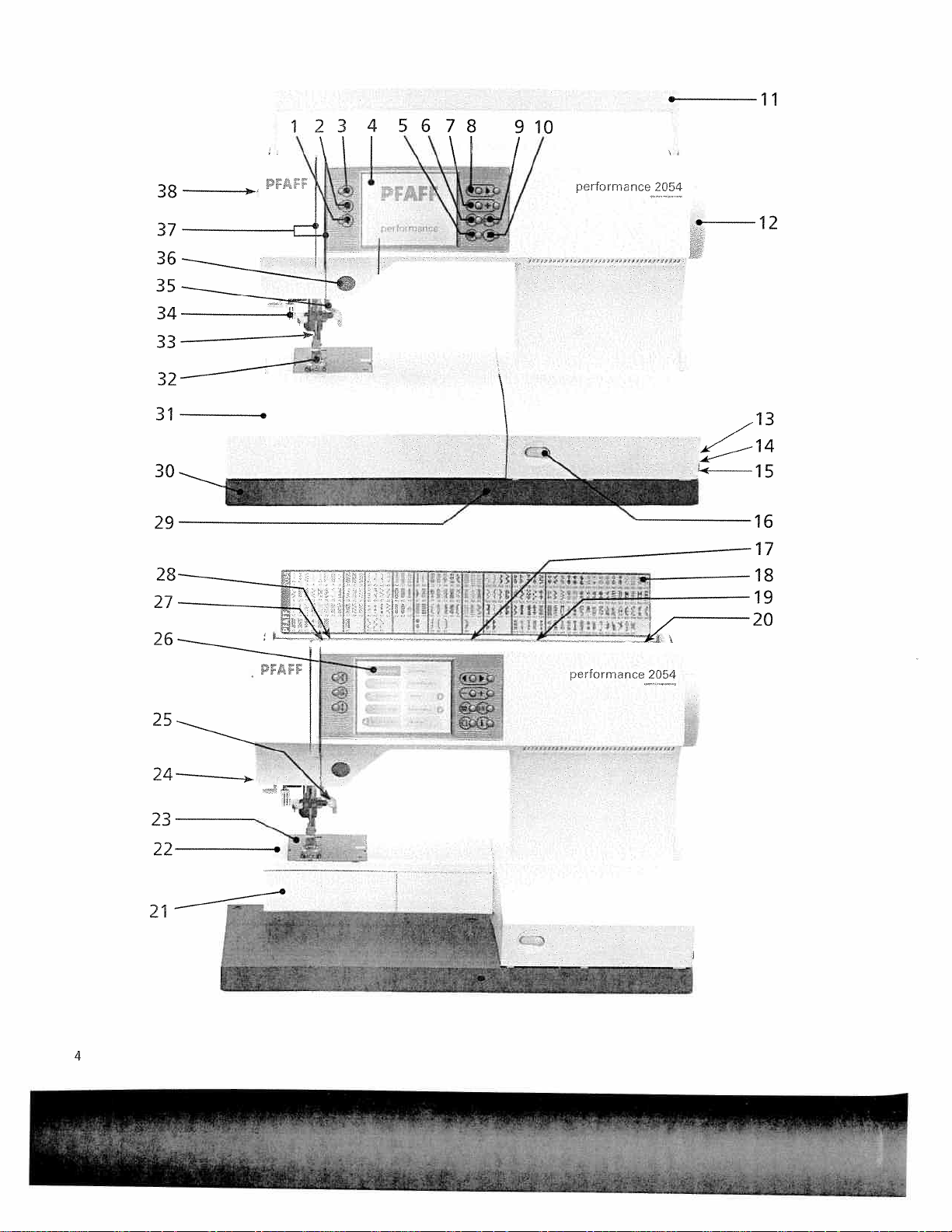

12345678

11

910

34

33

32

31

V

peiformance

2O4

a

12

3

15

16

i.

peJormance

2054

25

24

—

23

12

22

21

4

Page 5

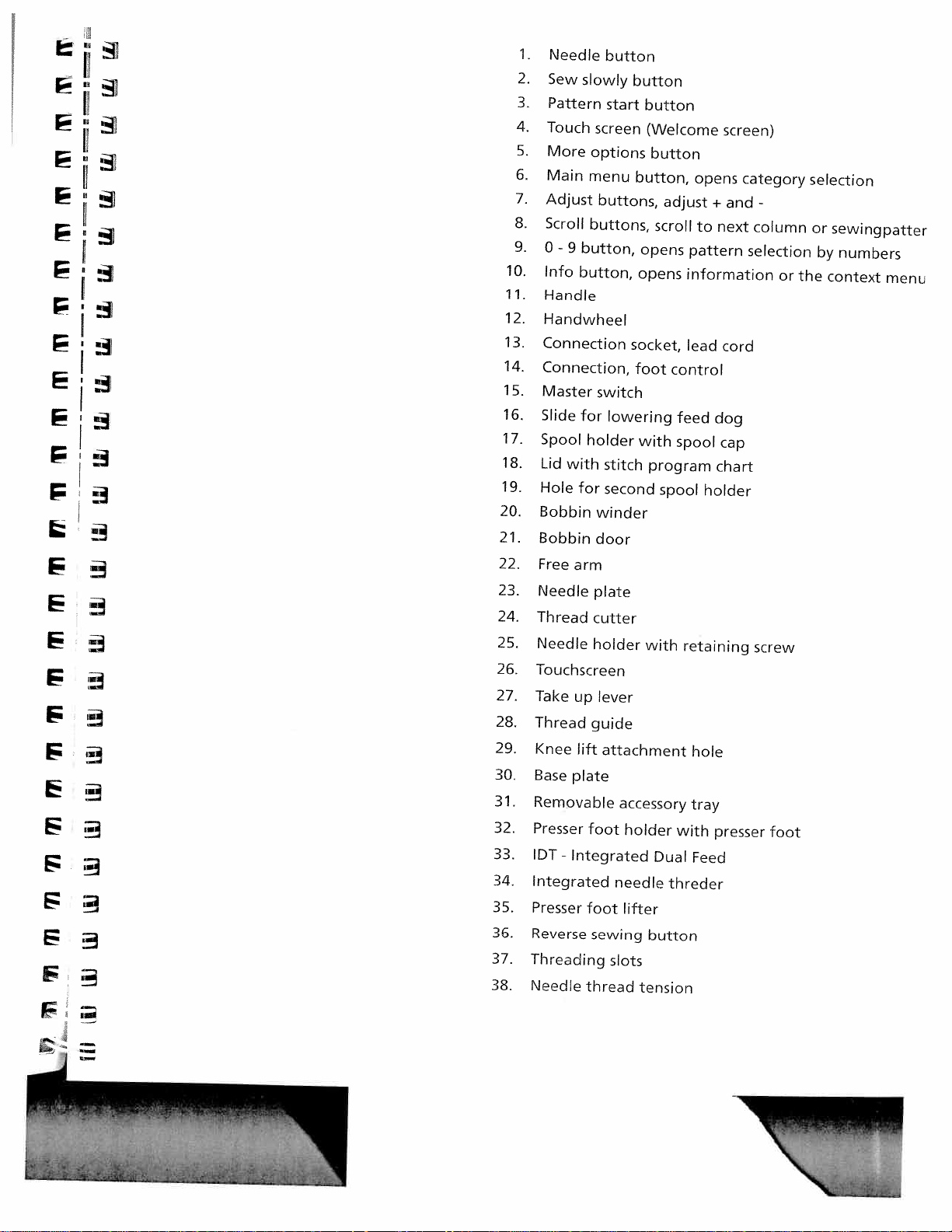

Needle

2.

Sew

3.

Pattern

4.

Touch

5.

More

6.

Main

7.

Adjust

8.

Scroll

9.

0

-

10.

Info

11.

Handle

12.

Handwheel

13.

Connection

14.

Connection,

15.

Master

16.

Slide

17.

Spool

18.

Lid

19.

Hole

20.

Bobbin

21.

Bobbin

22.

Free

23.

Needle

24.

Thread

25.

Needle

26,

Touchscreen

27.

Take

28.

Thread

29.

Knee

30.

Base

31.

Removable

32.

Presser

33.

IDT

34.

Integrated

35.

Presser

36.

Reverse

37.

Threading

38.

Needle

r-

—

slowly

screen

options

menu

buttons,

buttons,

9

button,

button,

switch

for

holder

with

for

winder

door

arm

plate

cutter

holder

up

lever

guide

lift

plate

foot

-

Integrated

foot

sewing

thread

button

button

start

button

(Welcome

button

button,

scroll

opens

opens

socket,

foot

lowering

with

stitch

program

second

with

attachment

accessory

holder

Dual

needle

lifter

button

slots

tension

adjust

pattern

information

lead

control

feed

spool

spool

retaining

hole

tray

with

threder

opens

+

to

holder

Feed

screen)

category

and

next

cord

dog

cap

chart

presser

column

selection

or

screw

foot

selection

or

by

the

context

sewingpatter

numbers

menu

Page 6

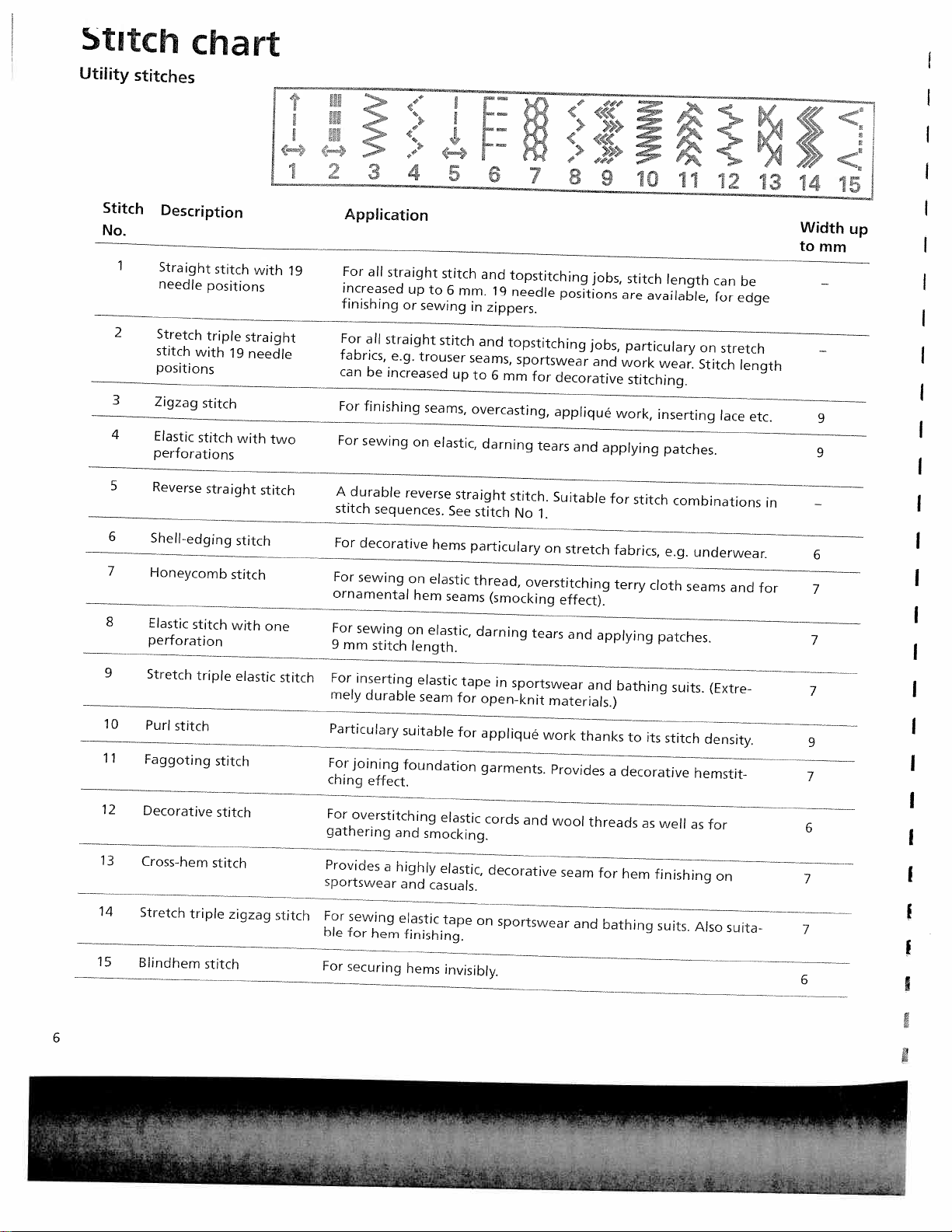

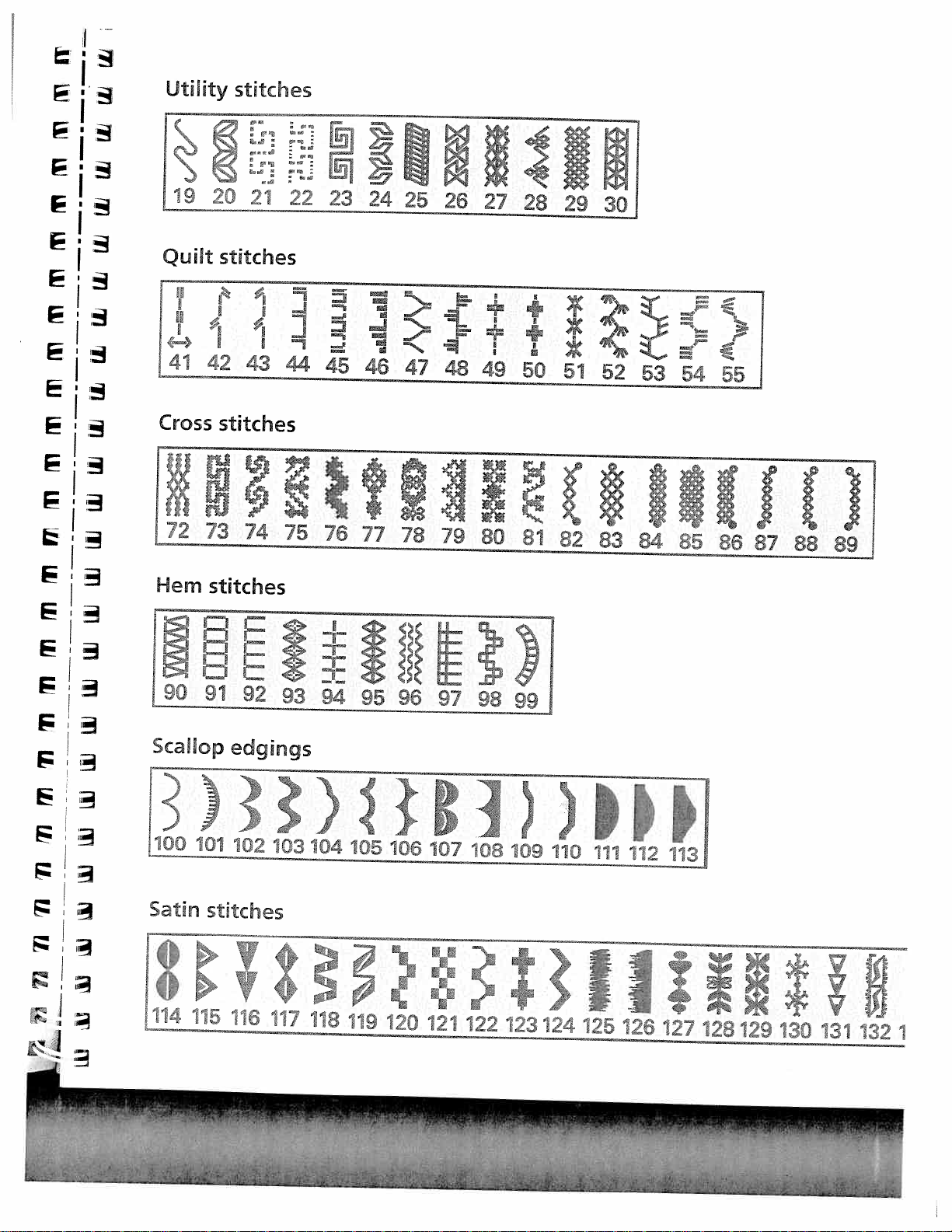

Stitch

Utility

stitches

chart

Stitch

No.

1

2

3

4

5

6

7

8

Description

Straight

needle

Stretch

stitch

positions

Zigzag

Elastic

perforations

Reverse

Shell-edging

Honeycomb

Elastic

perforation

positions

triple

with

stitch

stitch

straight

stitch

stitch

19

stitch

with

with

straight

needle

with

stitch

two

stitch

one

‘F

19

i!

>

-:

>

3

Application

For

all

increased

finishing

For

all

fabrics,

can

be

For

finishing

For

sewing

A

durable

stitch

sequences.

For

decorative

For

sewing

ornamental

For

sewing

mm

9

stitch

:‘

(%

I

4

straight

up

or

sewing

straight

e.g.

trouser

increased

seams,

on

reverse

on

hem

on

length.

c

5

stitch

to

6

stitch

up

elastic,

straight

See

hems

elastic

seams

elastic,

——

[

6

and

mm.

19

in

zippers.

and

seams,

to

6

mm

overcasting,

darning

stitch

particulary

thread,

(smocking

darning

topstitching

needle

topstitching

stitch.

positions

sportswear

for

decorative

appliqué

tears

Suitable

No

1.

on

overstitching

effect).

tears

<

>

<

1>

8

jobs,

and

stretch

and

d

>>>

<<‘C

9

jobs,

are

and

work

work,

applying

for

fabrics,

terry

applying

10

stitch

length

available,

particulary

wear.

stitching.

inserting

patches.

stitch

combinations

e.g.

cloth

patches.

11

can

on

Stitch

underwear.

seams

“Ic

<(

12

for

stretch

lace

and

be

edge

length

etc.

V

1

N

74

1

in

for

A

:

14

Width

to

mm

9

9

6

7

7

15!

up

9

Stretch

10

Purl

11

Faggoting

12

Decorative

13

Cross-hem

14

Stretch

15

Blindhem

6

stitch

triple

triple

stitch

stitch

stitch

stitch

zigzag

elastic

stitch

stitch

For

inserting

mely

durable

Particulary

For

joining

ching

effect.

For

overstitching

gathering

Provides

sportswear

For

sewing

ble

for

hem

For

securing

suitable

foundation

and

a

highly

and

elastic

finishing.

hems

elastic

seam

elastic

smocking.

elastic,

casuals.

tape

invisibly.

tape

for

for

in

sportswear

open-knit

appliqué

garments.

cords

decorative

on

sportswear

work

and

and

materials.)

thanks

Provides

wool

threads

seam

and

bathing

a

decorative

for

hem

bathing

to

its

stitch

as

well

finishing

suits.

suits.

(Extre

density.

hemstit-

as

for

on

Also

suita-

7

9

7

6

7

7

6

Page 7

%

r

/

?

A

f%

ISi

L.%.

&?

tJi

—

—

II!

3’

32

33

34

35

36

37

38

39

40

55

57

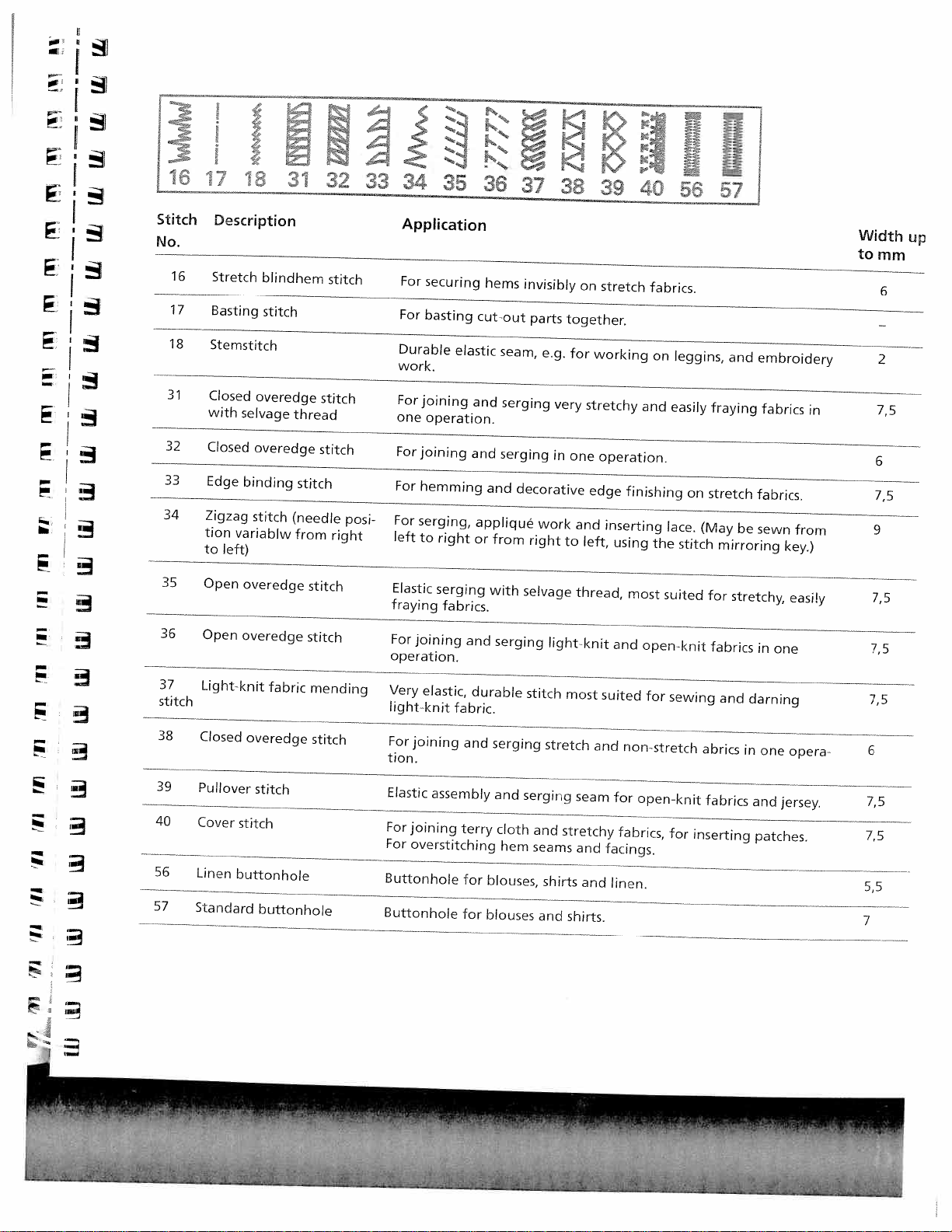

Stitch

No.

16

17

18

31

32

33

34

35

36

Description

Stretch

Basting

Stemstitch

Closed

with

selvage

Closed

Edge

binding

Zigzag

tion

variablw

to

left)

Open

overedge

Open

overedge

blindhem

stitch

overedge

overedge

stitch

stitch

thread

stitch

stitch

(needle

from

stitch

stitch

stitch

posi

right

Application

For

securing

For

basting

Durable

work.

For

joining

one

operation.

For

joining

For

hemming

For

serging,

left

to

right

Elastic

serging

fraying

For

joining

operation.

elastic

and

fabrics.

and

hems

cut-out

seam,

and

serging

serging

and

appliqué

or

from

with

serging

invisibly

parts

e.g.

very

in

decorative

work

right

selvage

light-knit

on

together.

for

working

stretchy

one

operation.

edge

and

to

left,

thread,

stretch

finishing

inserting

using

most

and

fabrics.

on

leggins,

and

easily

lace.

the

stitch

suited

open-knit

on

fraying

stretch

(May

mirroring

for

fabrics

and

embroidery

fabrics

fabrics.

be

sewn

stretchy,

in

one

from

key.)

easily

Width

to

in

up

mm

6

—

2

7,5

6

75

9

7,5

7,5

37

stitch

38

39

40

56

57

Light-knit

Closed

Pullover

Cover

Unen

Standard

fabric

overedge

stitch

stitch

buttonhole

buttonhole

mending

stitch

Very

elastic,

light-knit

For

joining

tion.

Elastic

For

joining

For

overstitching

durable

fabric.

and

assembly

terry

serging

and

cloth

hem

stitch

stretch

serging

and

seams

ButtonheforMouses,shtsandnen.

Buttonhole

for

blouses

and

most

and

seam

stretchy

and

shirts.

suited

non-stretch

for

fabrics,

facings.

for

sewing

open-knit

for

and

abrics

fabrics

inserting

darning

in

one

and

patches.

opera-

jersey.

6

75

75

—

Page 8

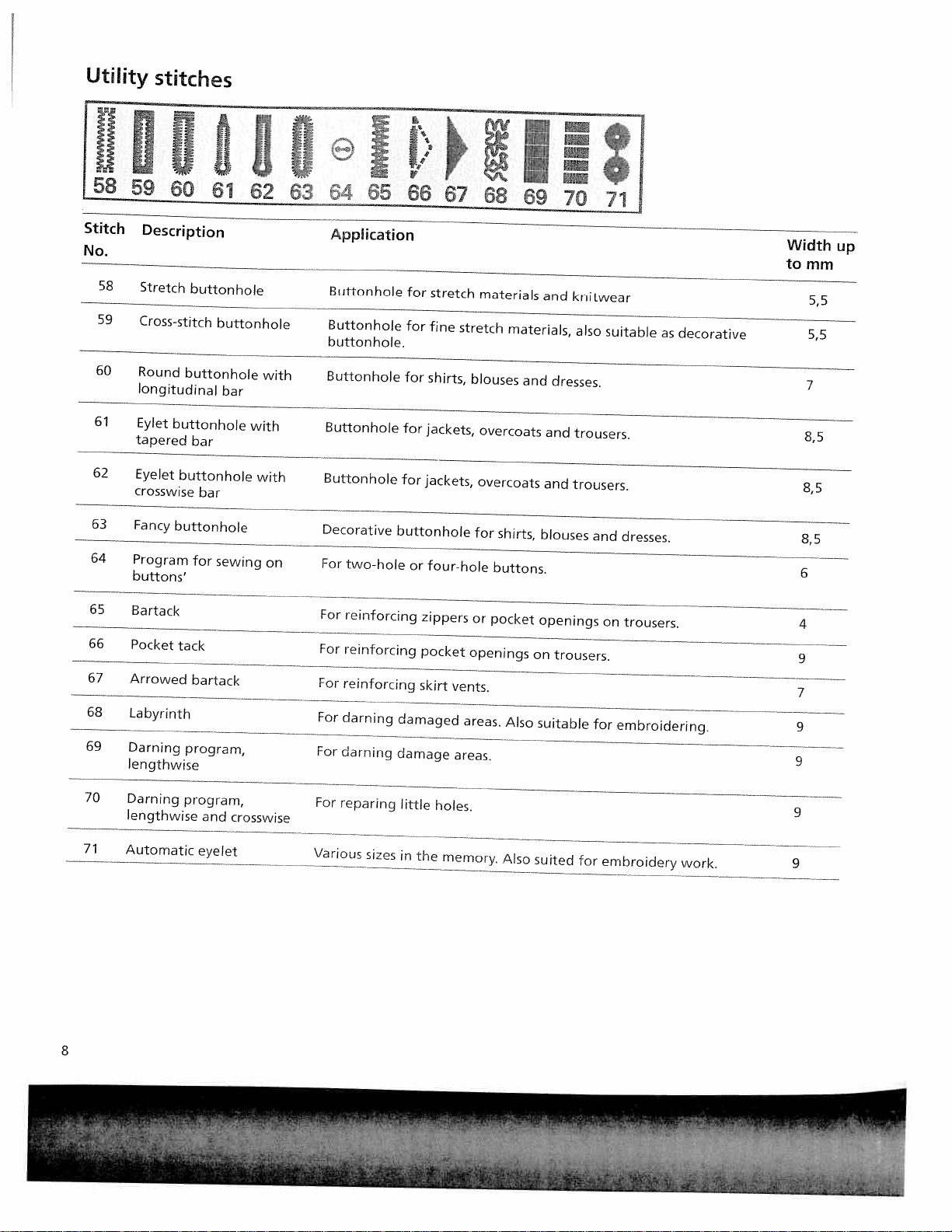

Utility

stitches

OOftROs1Di

58

59

60

61

62

63

465

66

67

68

69

70

71

Stitch

No.

58

59

60

61

62

63

64

65

66

67

68

69

Description

Stretch

Cross-stitch

Round

longitudinal

Eylet

buttonhole

tapered

Eyelet

crosswise

Fancy

buttonhole

Program

buttons’

Bartack

Pocket

tack

Arrowed

Labyrinth

Darning

lengthwise

buttonhole

buttonhole

buttonhole

bar

bar

buttonhole

bar

for

sewing

bartack

program,

with

with

with

on

Appication

Buttonhole

Buttonhole

button

Buttonhole

Buttonhole

Buttonhole

Decorative

For

two-hole

For

reinforcing

For

reinforcing

For

reinforcing

For

darning

For

darning

hole.

buttonhole

damage

for

stretch

for

fine

for

shirts,

for

jackets,

for

jackets,

or

four-hole

zippers

pocket

skirt

damaged

stretch

blouses

or

openings

vents.

areas.

areas.

materials

materials,

overcoats

overcoats

for

shirts,

buttons.

pocket

Also

and

and

and

and

blouses

openings

on

suitable

knitwear

also

dresses.

trousers.

trousers.

trousers.

suitable

and

dresses.

on

trousers.

for

embroidering.

as

decorative

Width

to

mm

5,5

7

8,5

8,5

8,5

6

4

9

7

9

9

up

70

Darning

lengthwise

71

Automatic

8

program,

and

eyelet

crosswise

For

reparing

Various

sizes

little

in

the

holes.

memory.

Also

suited

for

embroidery

work.

9

9

Page 9

C

P.

P.

P.

P.

Id,’

CD

9

J

I

It:j1

P.

P.

CD

0

Id,’

‘7

D’.

n

0

I

CD

3

CD

CD

vI

nTm

OJID

LLWLLLLLLLLLLLLLL1

t1

0

CD

1.0

1.0

ujuuu

U

cou

NV

w’Jw

f’

a

eeeee

1ff1ff

g

fl

Jfl

$h

aiUL

jA

aiIA

01

L

AJ

a

CD

VLdI

w.

.I’I1,

F44

Page 10

(D

0

CD

CD

VI

C

Page 11

in

in

iii

it

iii

in

a

ft

in

in

in

in

in

rn

ran

rn

Ti

i’ti

in

in

1’

Ti

n

rr

‘n

pyj

r

Page 12

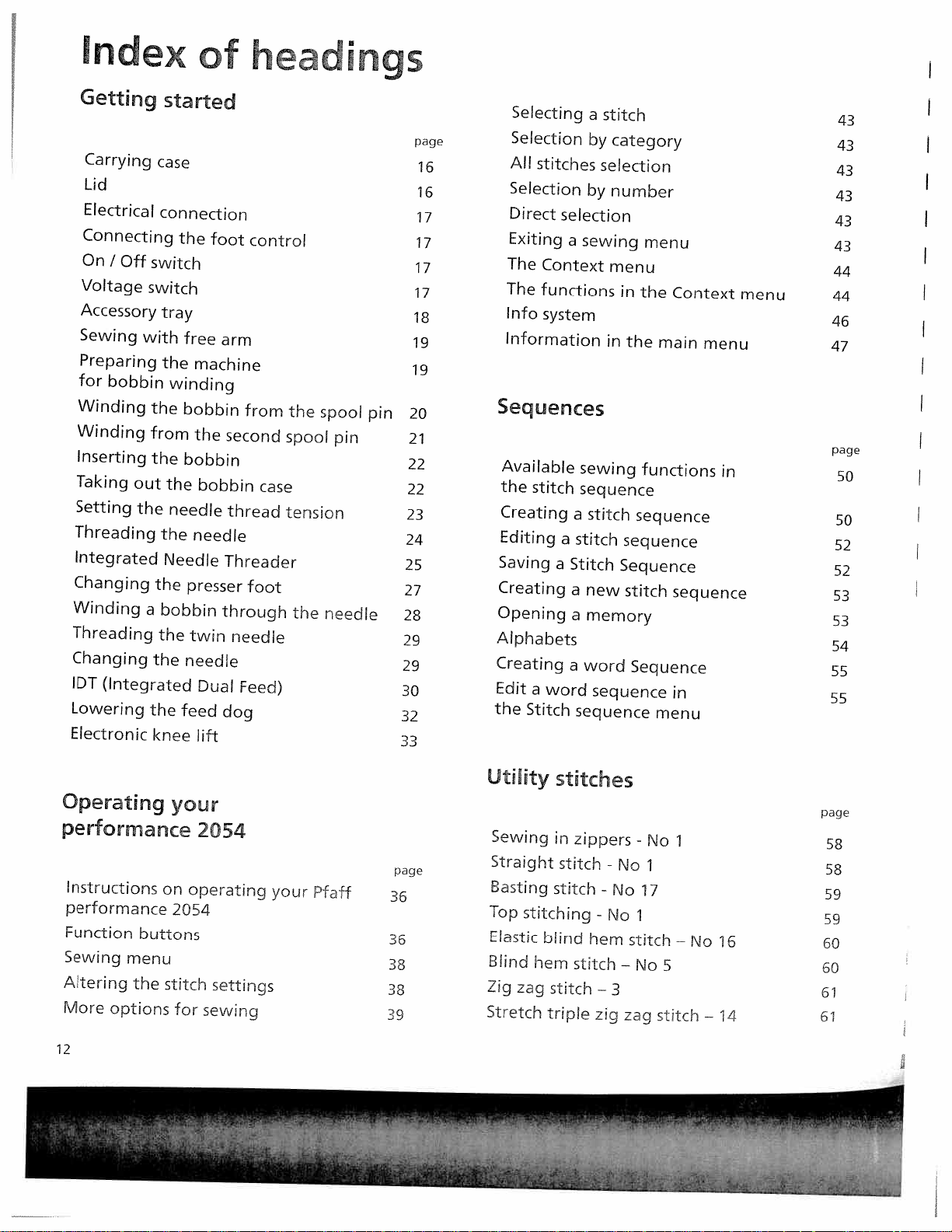

Index

of

headings

Getting

Carrying

Lid

Electrical

Connecting

On

/

Off

Voltage

Accessory

Sewing

Preparing

for

bobbin

Winding

Winding

Inserting

Taking

Setting

Threading

Integrated

Changing

Winding

Threading

Changing

IDT

(Integrated

Lowering

Electronic

started

case

connection

switch

switch

tray

with

the

the

from

the

out

the

the

the

Needle

the

a

bobbin

the

the

the

knee

the

foot

free

machine

winding

bobbin

the

bobbin

bobbin

needle

needle

presser

twin

needle

Dual

feed

lift

control

arm

from

second

case

thread

Threader

foot

through

needle

Feed)

dog

the

spool

tension

the

spool

pin

needle

pin

27

28

29

29

30

32

33

21

22

22

23

24

25

page

16

16

17

17

17

17

18

19

19

20

Selecting

Selection

All

stitches

Selection

Direct

Exiting

The

The

Info

selection

a

Context

functions

system

Information

Sequences

Available

the

stitch

Creating

Editing

Saving

Creating

Opening

Alphabets

Creating

Edit

the

a

word

Stitch

a

a

Stitch

a

a

a

a

stitch

by

category

selection

by

number

sewing

menu

in

sewing

sequence

a

stitch

stitch

new

memory

word

sequence

sequence

menu

in

the

the

main

functions

sequence

sequence

Sequence

stitch

Sequence

menu

Context

menu

sequence

in

in

menu

43

43

43

43

43

43

44

44

46

47

page

50

50

52

52

53

53

54

55

55

Operating

performance

Instructions

performance

Function

Sewing

Altering

More

12

buttons

menu

the

options

your

on

2054

stitch

for

2054

operating

settings

sewing

your

Pfaff

36

36

38

39

page

Utility

Sewing

Straight

Basting

Top

stitching

Elastic

Blind

Zig

zag

Stretch

stitches

in

stitch

stitch

blind

hem

stitch

triple

zippers

-

-

-

No

hem

stitch

—

zig

No

3

No

stitch

—

zag

-

17

1

No

No

1

stitch

page

1

58

58

59

59

—

No

16

5

60

60

61

—

14

61

Page 13

I

‘

•

I

•

I

!

I

I

F

F

F

F

L

Elastic

Honeycomb

Stretch

Darning

stitch

triple

with

Sewing-on

Repairing

Overlock

Buttonholes

Sewing

Eyelets—No

Automatic

Free

Gathering

Gathering

on

motion

Decorative

specialty

Quilting

Free

Motion

Nostalgia

Home

Fashion

Eyelets

Hemstitching

Cross

Twin

Tapering

Appliqué

Decorating

Stitch

needle

designs

Accessories

Standard

and

Felling

Appliqué

Pintuck

presser

accessories

foot

foot

foot

—

No

stitch

straight

the

elastic

patches

tears

stitches

buttons

71

darning

darning

with

straight

with

elastic

sewing

techniques

Embroidery

/Heirloom

sewing

feet

4

—

—

—

—

No

stitch

No

No

No

threads

7

stitch

4

64

69

stitch

62

62

—

No

2

—

No

4

—

No

1

—

No

7

62

63

63

63

64

65

68

68

69

70

71

71

page

74

79

81

83

85

86

87

88

90

91

93

page

96

98

98

99

Pintuck

Cording

Gathering

Knit

Ruffle

Open

Quilting

Eyelet

Bridging

1/4

Quilting

Free

Bias

Pintuck

Decorative

Non-stick

7/9

Couching/Braiding

Circular

Fringe

Narrow

Triple

Fancy

blade

foot

foot

edge/piping/beading

r

toe

appliqué

guide

plate

guide

inch

Quilting

of

motion

binder

Foot

Stitch

Foot

Hole

Cord

Embroidery

Presser

Edge

needle

patterns

Stabilizer

Maintenance

Changing

Cleaning

Changing

Bulb

Sewing

Technical

Package

the

the

removal

proberns

data

contents

the

quilt

with

Foot

needle

light

fabric

with

Foot

Foot

with

foot

foot

Guide

with

Foot

with

with

bulb

and

foot

with

layers

IDT

Guide

twin

plate

their

foot

IDT

with

IDT

IDT

needles

solutions

IDT

IDT

Page 14

Pt

Page 15

Page 16

PFRFF

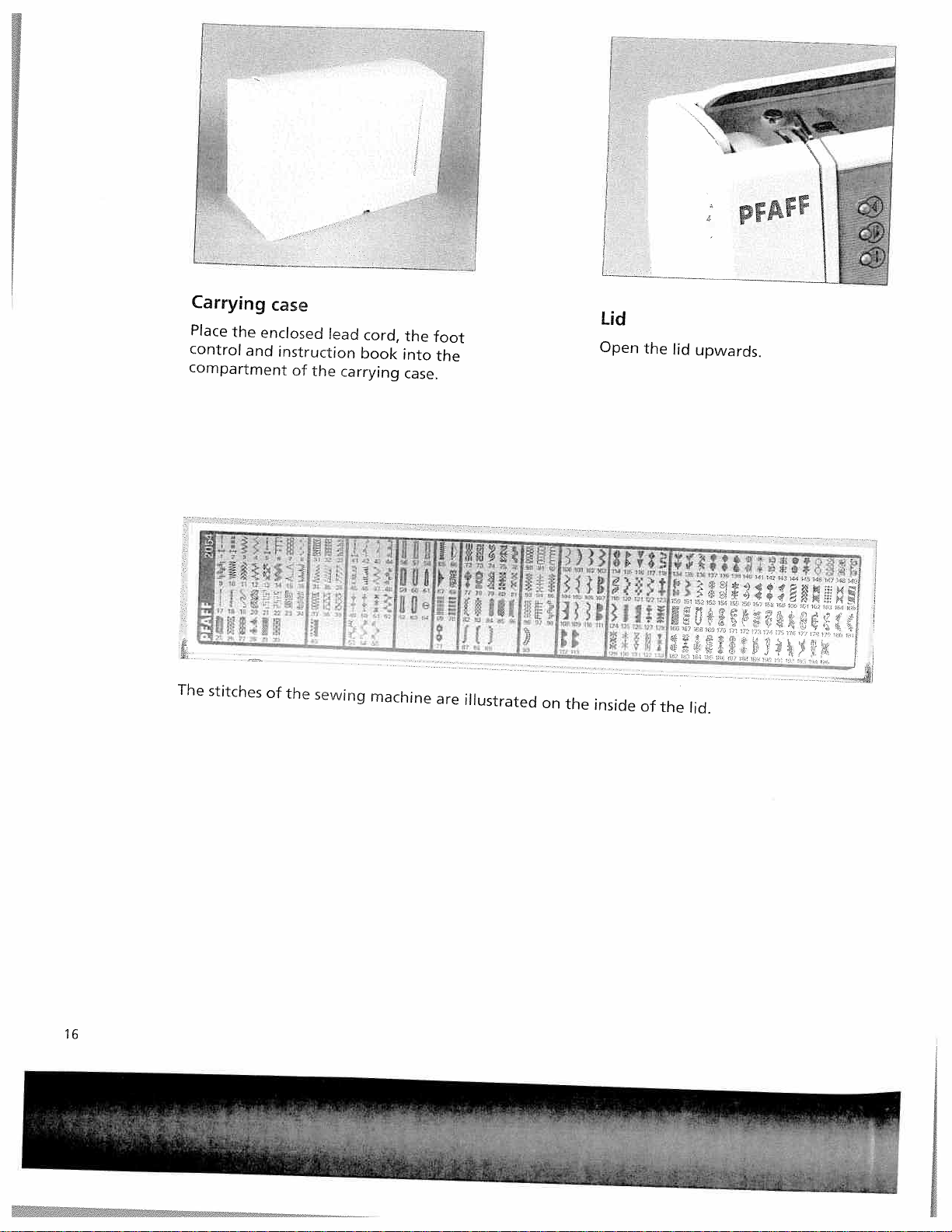

Carrying

Place

the

control

compartment

The

stitches

case

enclosed

and

of

lead

instruction

of

the

the

sewing

cord,

book

carrying

-

machine

‘

the

into

case.

fi

foot

the

jj

0

are

pL

illustrated

Lid

Open

the

lid

upwards.

L

I

F

on

the

inside

of

the

lid.

16

Page 17

vI

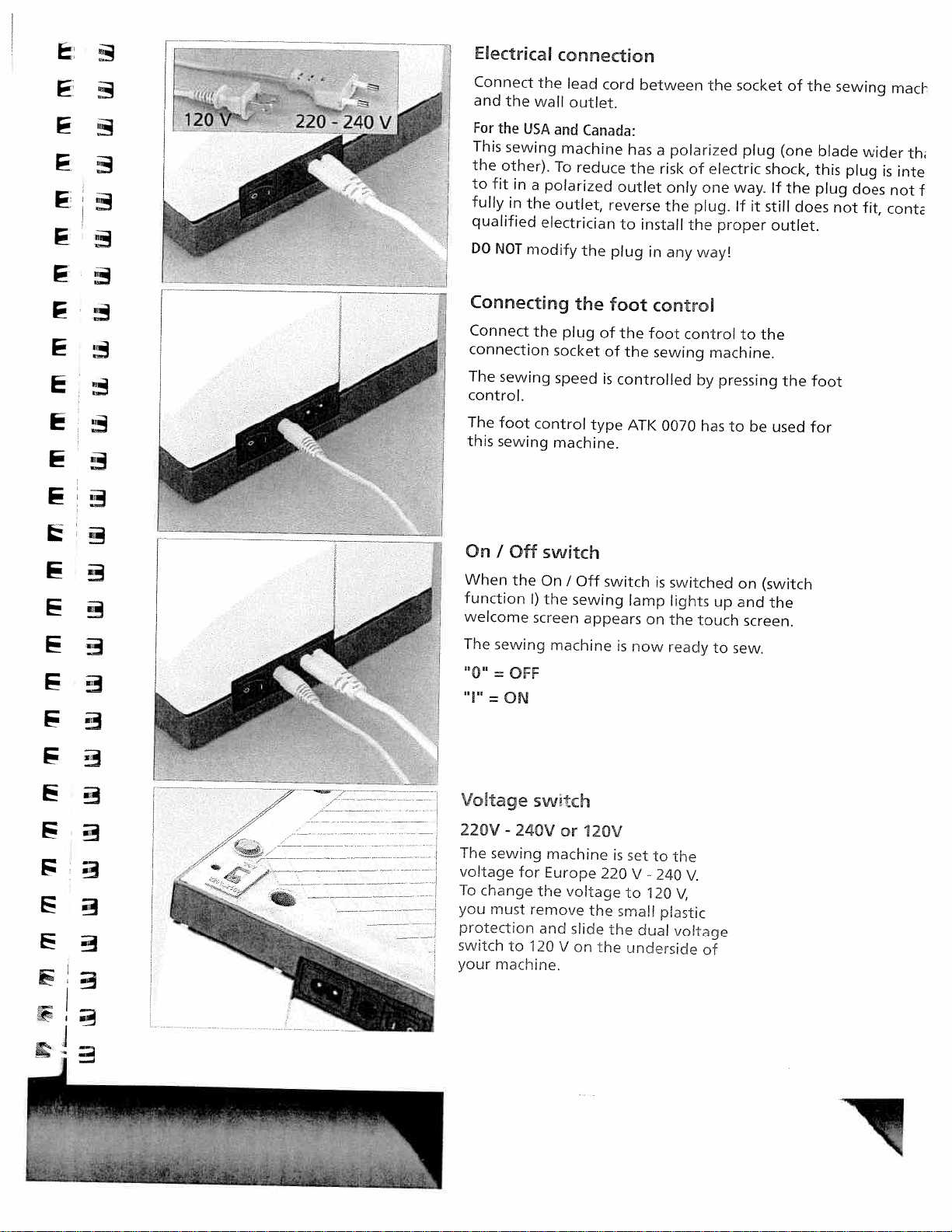

Electrkal

Connect

and

the

For

the

This

sewing

the

other),

to

fit

in

fully

in

qualified

DO

NOT

the

wall

USA

and

To

a

polarized

the

outlet,

electrician

modify

connection

lead

cord

outlet.

Canada:

machine

reduce

outlet

reverse

the

plug

between

has

the

to

install

a

risk

only

the

in

any

the

polarized

of

electric

one

plug.

the

wayl

socket

plug

way.

Ifitstill

proper

of

(one

shock,

If

the

outlet.

the

does

blade

this

plug

sewing

wider

plug

does

not

fit,

macb

is

not

cont

th

inte

f

Connecting

Connect

connection

I

The

sewing

control.

The

foot

this

sewing

On

I

Off

When

function

welcome

Er

The

the

sewing

=

OFF

=

ON

the

socket

speed

control

machine.

switch

On

I)

the

screen

machine

the

plug

Off

I

sewing

appears

foot

of

of

is

type

switch

control

the

foot

the

sewing

controlled

ATK

0070

is

lamp

on

is

now

control

by

has

switched

lights

the

touch

ready

to

machine.

pressing

be

to

on

up

and

screen.

to

sew.

the

the

used

(switch

the

foot

for

F

Voftage

swrch

220V-24OVorl2OV

The

sewing

/

—

voltage

To

change

you

must

protection

switch

your

machine.

for

to

machine

Europe

the

remove

and

120

V

voltage

the

slide

on

the

is

220

small

the

set

to

V

-

240

to

120

plastic

dual

underside

the

V.

V,

voltage

of

I

Page 18

L

—

Accessory

Open

the

your

left

area

on

the

lid

upwards

tray

accessory

index

the

left

finger

of

and

tray

on

the

towards

lid

by

the

and

placing

ridged

open

you.

Arranging

The

standard

with

numbers.

the

respective

accessory

the

accessories

Arrange

compartments

tray.

accessories

are

the

marked

parts

of

in

the

18

Page 19

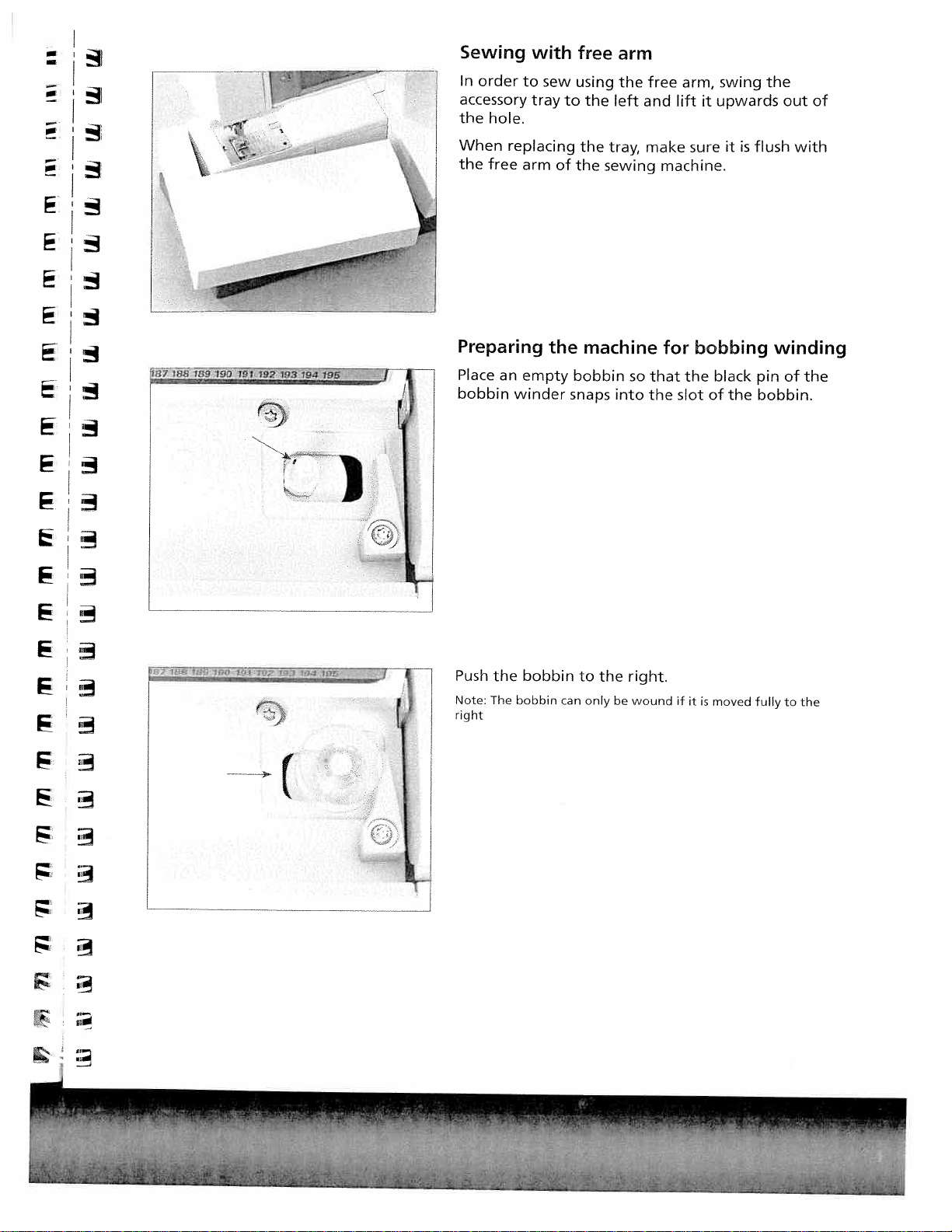

Sewing

1

order

0

0

0

In

accessory

the

When

the

hole.

replacing

free

with

to

tray

arm

sew

of

to

free

using

the

the

the

arm

the

left

tray,

sewing

free

and

make

machine.

arm,

it

lift

sureitis

swing

upwards

flush

the

out

of

with

E

E

Preparing

188

8)

189

190

191

192

193

194

195

Place

J

an

bobbin

Push

the

Note:

The

right

empty

winder

bobbin

bobbin

the

can

machine

bobbin

snaps

the

to

only

into

be

so

the

right.

wound

for

that

bobbing

the

slot

if

it

is

black

of

moved

the

winding

pin

of

bobbin.

fully

to

the

the

—i

dh

88

Page 20

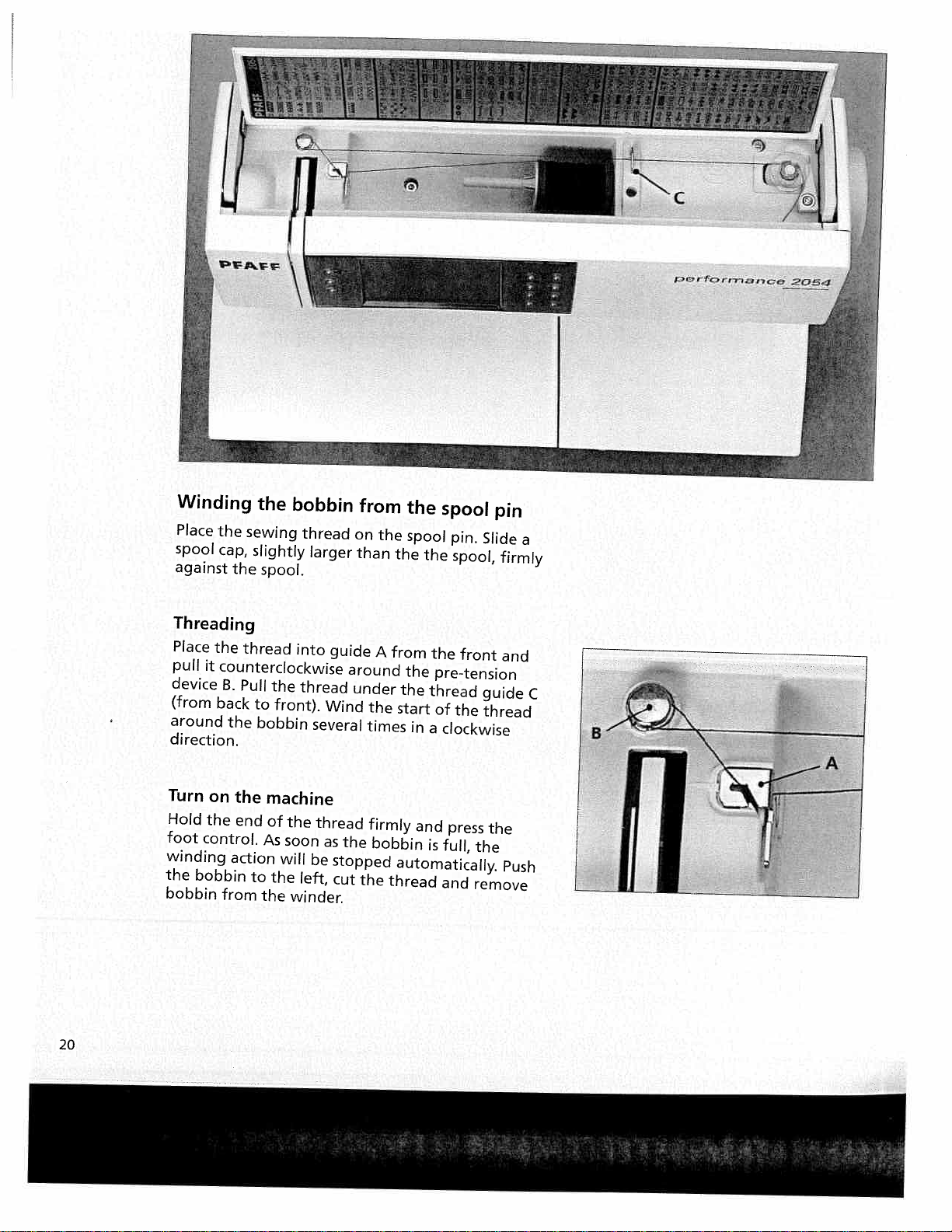

Winding

Place

the

spool

cap,

against

Threading

Place

the

pull

it

counterclockwise

device

(from

back

around

direction.

Turn

on

Hold

the

foot

control.

winding

the

bobbin

bobbin

from

the

B.

the

the

end

action

the

sewing

slightly

spool.

thread

Pull

to

bobbin

machine

of

As

to

the

bobbin

the

front).

the

soon

will

the

winder.

thread

larger

into

thread

several

thread

be

left,

guide

around

under

Wind

as

the

stopped

cut

from

on

than

the

times

firmly

bobbin

the

the

A

from

thread

the

spool

spool

pin.

the

the

spool,

the

front

the

pre-tension

the

thread

start

of

the

in

a

clockwise

and

press

is

full,

automatically.

and

pin

Slide

firmly

and

guide

thread

the

the

Push

remove

a

C

20

Page 21

r,fcrn,?O5a

E

F

F

F

FR

RR

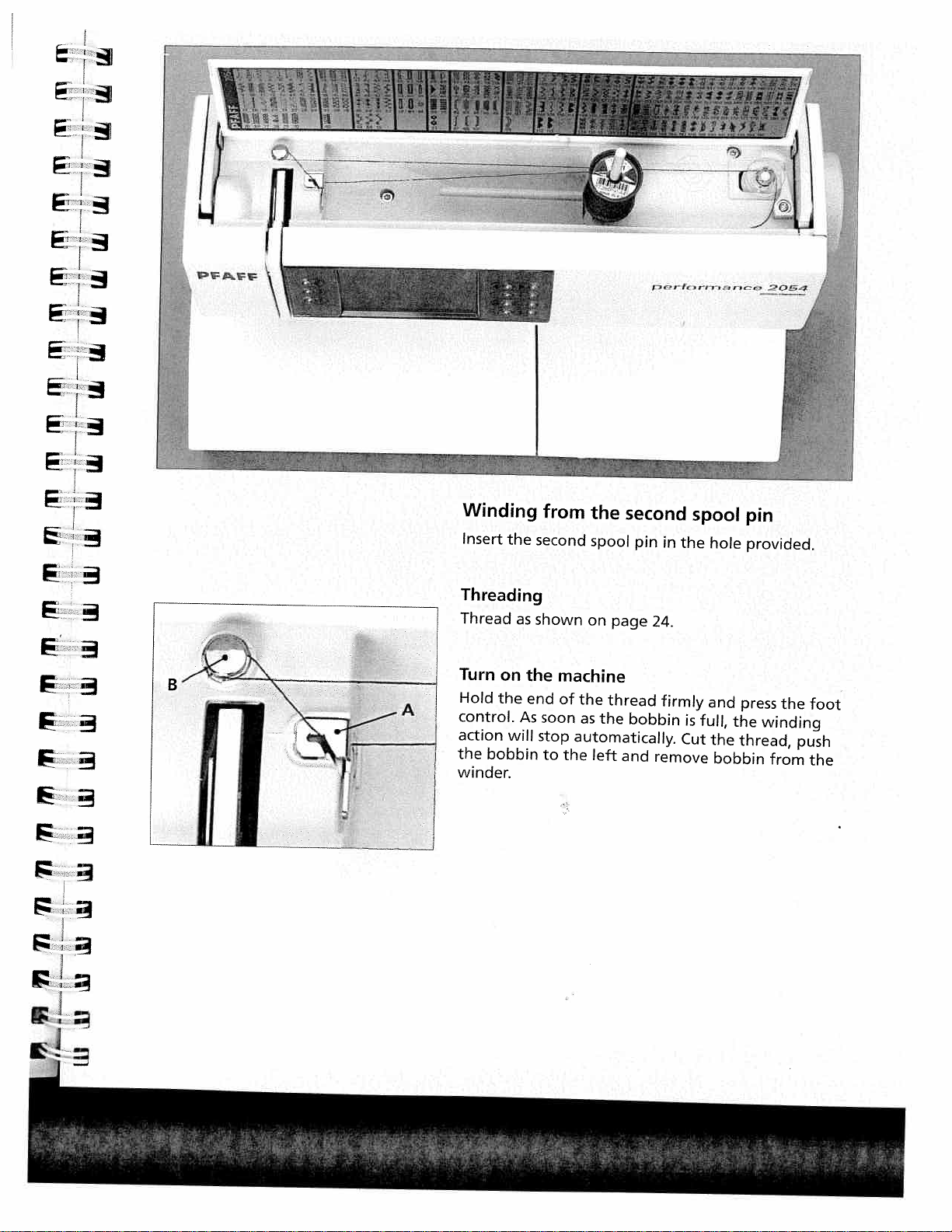

Winding

Insert

the

Threading

Thread

Turn

on

Hold

the

control.

action

the

winder.

will

bobbin

as

the

end

As

from

second

shown

machine

of

soon

stop

automatically.

to

the

on

the

as

the

spooi

page

thread

the

left

second

pin

24.

bobbin

and

remove

in

the

firmly

is

Cut

spool

hole

and

full,

the

bobbin

pin

provided.

press

the

winding

thread,

the

from

foot

push

the

Page 22

Bobbin

Open

the

swinging

door

bobbin

it

open

door

towards

Taking

at

the

left

the

side

front

Lift

and

machine.

the

the

pull

empty

out

latch

the

Release

bobbin

the

of

the

bobbin

bobbin

bobbin

case

the

latch

out

of

out

the

case

case

of

and

bobbin

the

take

case.

Inserting

Insert

case.

When

through

spring

(see

arrow),

Check:

When

must

turn

Inserting

Lift

latch

fully

onto

Opening

face

upwards.

check:

Pull

bobbin

case

the

slot

B

until

clockwise.

the

E

pin

D

the

must

the

full

doing

you

and

of

bobbin

bobbin

bobbin

A,

then

it

rests

pull

bobbin

push

of

C

the

not

fall

so,

pull

under

in

the

thread,

the

the

bobbin

thread

out

in

the

the

the

case

bobbin

sewing

case

sharply.

of

the

bobbin

thread

tension

opening

the

bobbin

case

hook.

must

The

hook.

A

-B

22

Page 23

!

pFAFF

4

Setting

Set

the

using

the

The

normal

decorative

the

required

markings

setting

stitches,

needle

amount

thread

on

the

for

sewing

darning

the

of

tension

and

tension

needle

dial.

4

-

5.

is

buttonhole

thread

For

using

sewing

tension

3.

EI

FH

Thread

For

sure

balanced

meet

The

Bobbin

fabric:

The

thread

The

Top

fabric:

The

thread

The

For

thread

fabric.

tension

the

best

the

needle

with

between

following

thread

needle

tension

thread

threadisvisible

needle

tension

thread

decorative

should

stitch

one

the

is

thread

is

tension

thread

is

tension

stitches

be

appearance

and

bobbin

another,

two

valid

visible

is

tension

too

loose.

must

tension

too

tight.

must

visible

fabric

for

be

on

be

and

on

and

thread

i.e.

the

layers.

general

on

the

is

too

corrected.

the

underside

is

too

corrected.

buttonholes

the

underside

durability

tensions

threads

sewing

top

tight

loose

side

or

or

the

evenly

work:

the

of

the

top

of

make

are

of

the

bobbin

the

bobbin

the

Page 24

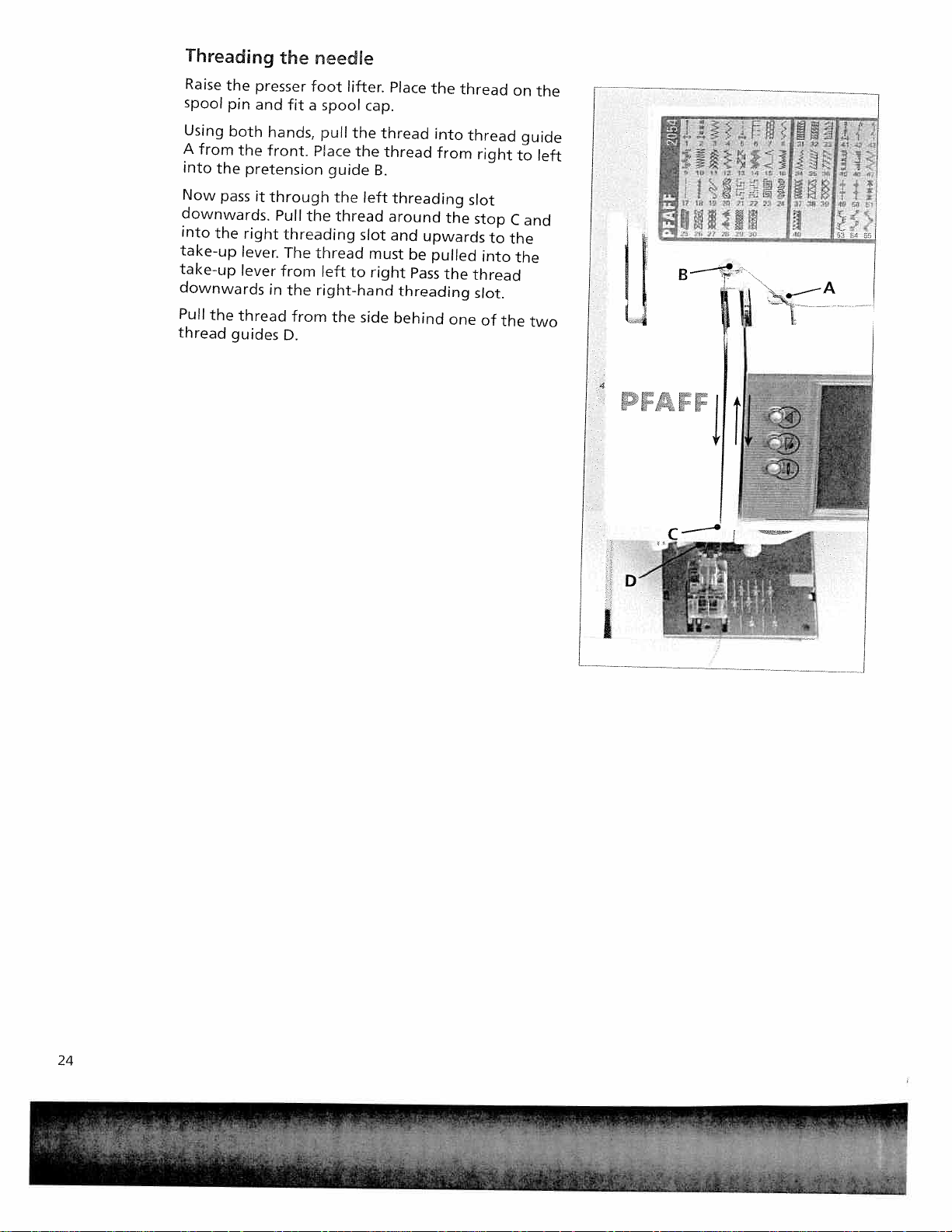

Threading

Raise

the

spool

pin

Using

both

A

from

into

the

Now

pass

downwards.

into

the

take-up

take-up

downwards

Pull

the

thread

guides

the

presser

and

hands,

the

front.

pretension

it

through

Pull

right

threading

lever.

The

lever

from

in

thread

D.

fit

the

from

foot

a

the

needle

lifter.

spool

cap.

pull

the

Place

the

guide

the

left

thread

slot

thread

left

to

right-hand

the

side

Place

thread

thread

B.

threading

around

and

must

right

behind

the

into

from

the

upwards

be

pulled

Pass

the

threading

thread

one

thread

right

slot

stop

to

into

thread

slot.

of

the

on

to

C

the

the

the

guide

left

and

two

TTTTT

[[7

I

I

!1LJ’

24

I

Page 25

-

—

—

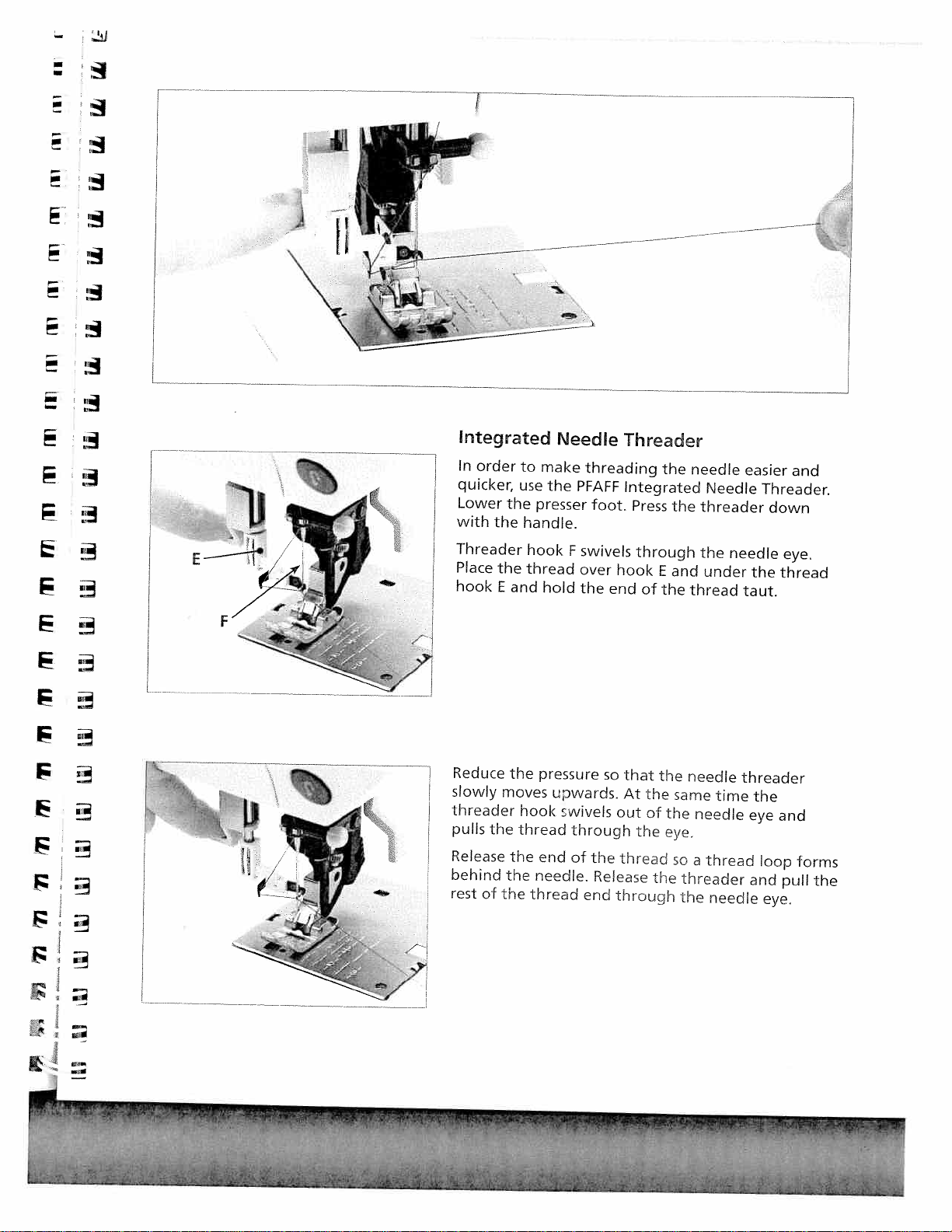

Integrated

In

order

quicker

Lower

with

Threader

Place

hook

the

the

E

the

and

to

make

use

the

presser

handle.

hook

thread

hold

Needle

threading

PFAFF

foot.

F

swivels

over

the

Threader

Integrated

Press

through

hook

end

of

the

E

the

the

and

needle

Needle

threader

the

under

thread

easier

needle

the

taut.

and

Threader.

down

eye.

thread

F

Reduce

slowly

threader

pulls

Release

behind

rest

the

of

the

moves

hook

thread

the

the

the

pressure

upwards.

end

needle.

thread

rvvivels

through

of

the

Release

end

so

that

At

out

thread

through

the

the

of

the

the

needle

same

the

eye.

so

threader

the

time

needle

a

thread

needle

threader

the

eye

and

loop

and

eye.

pull

forms

the

Page 26

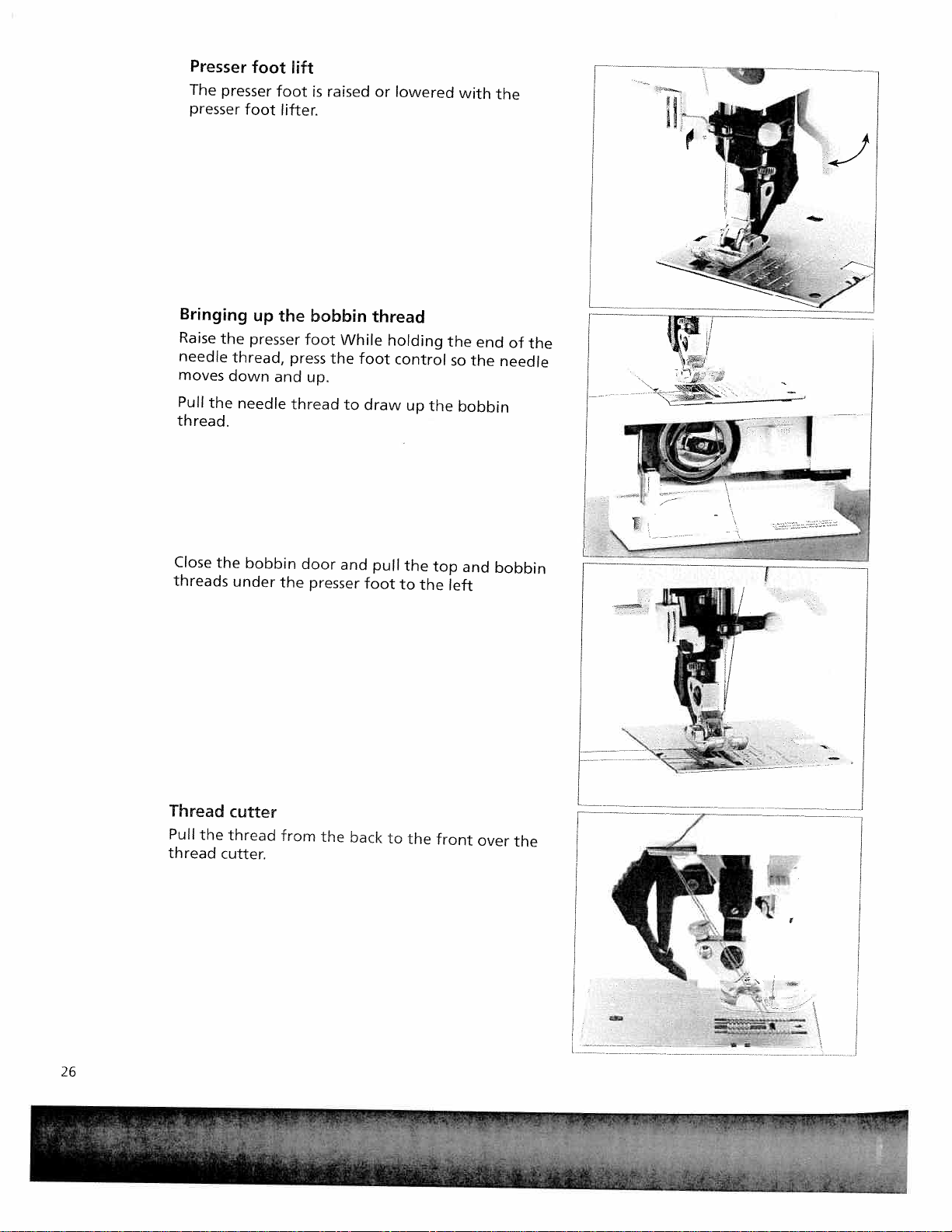

Presser

The

presser

presser

foot

foot

‘ift

foot

lifter.

is

raised

or

lowered

with

the

-‘-

Bringing

Raise

needle

moves

Pull

the

thread.

Close

threads

the

down

the

up

presser

thread,

needle

bobbin

under

the

and

the

bobbin

foot

press

up.

thread

door

presser

While

the

to

and

thread

foot

draw

pull

foot

holding

control

up

the

to

the

the

top

the

so

bobbin

and

left

the

end

of

needle

bobbin

the

ii

\

1

26

Thread

Pull

thread

the

cutter

thread

cutter.

from

the

back

to

the

front

over

the

V

4E

‘

4

Page 27

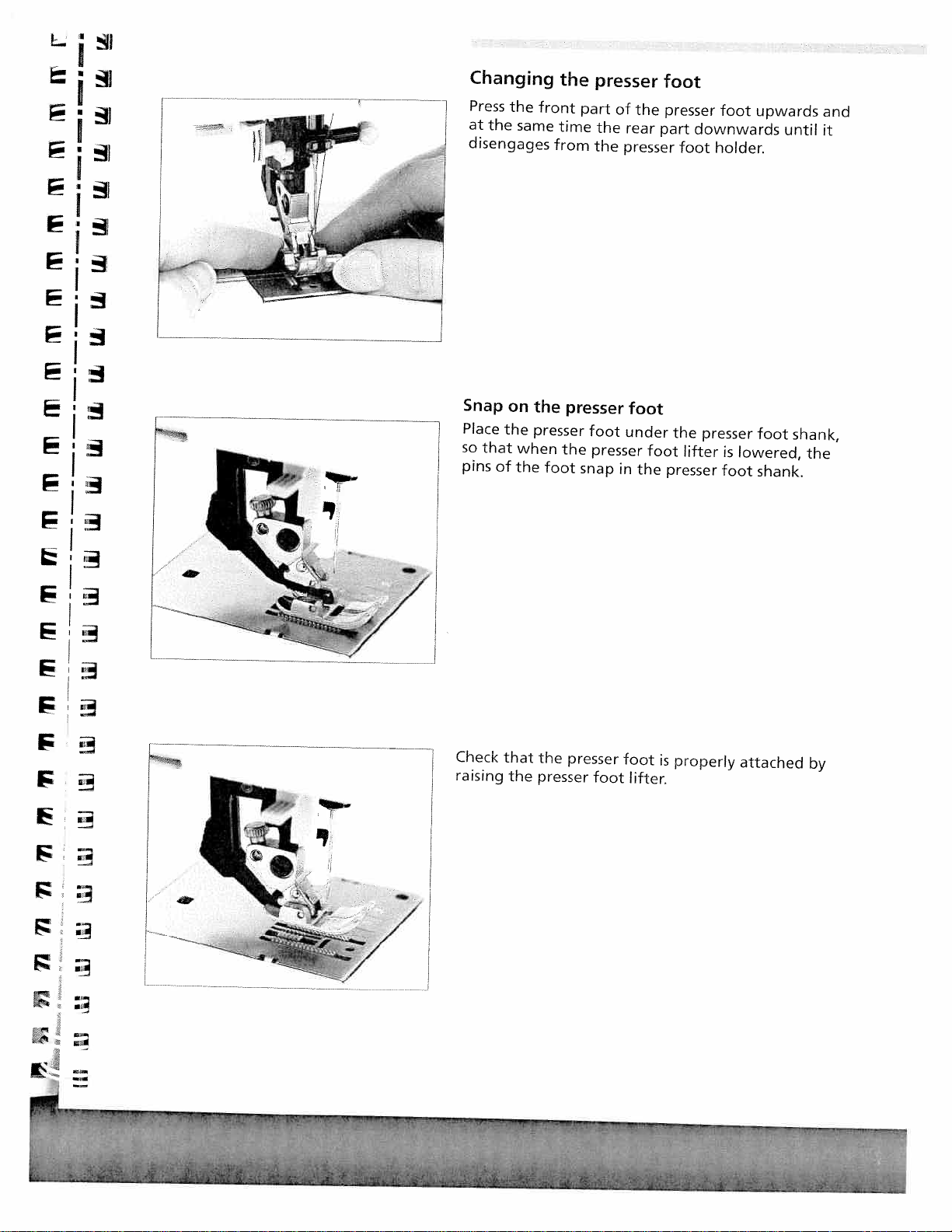

Snap

•

Place

so

pins

Changing

Press

the

at

the

same

disengages

on

the

that

when

of

the

the

front

time

from

the

presser

presser

the

foot

presser

part

the

the

foot

presser

snap

of

the

rear

presser

foot

under

in

the

part

foot

foot

presser

downwards

foot

the

lifter

presser

foot

holder.

presser

is

foot

upwards

foot

lowered,

shank.

until

shank,

the

and

it

11%

Check

that

the

presser

raising

.i

the

presser

foot

foot

lifter.

is

properly

attached

by

Page 28

L

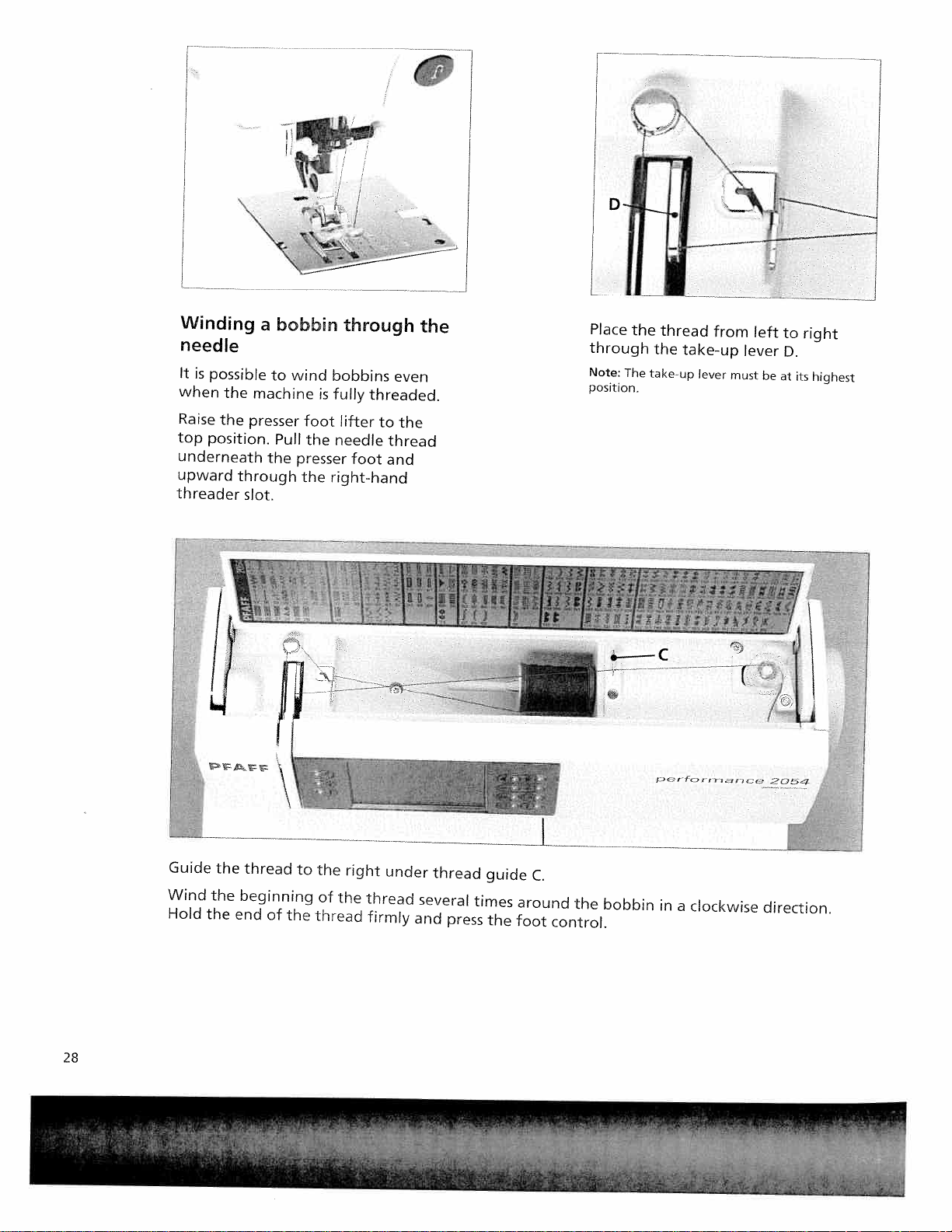

Winding

needle

It

is

possible

when

the

Raise

the

top

position.

underneath

upward

threader

a

to

machine

presser

the

through

slot.

—

bobbin

wind

foot

Pull

the

presser

the

-

through

bobbins

fully

is

lifter

needle

foot

right-hand

-—

even

threaded.

to

the

thread

and

—

—

the

—---

--—------—-———

Place

through

Note

posItion

—--

The

----—---

the

thread

the

take-up

from

take-up

ever

—

must

left

lever

be

at

to

D.

right

its

highest

$J(2

fCfl

rngnc(.

Guide

the

thread

Wind

the

beginning

Hold

the

end

28

of

the

to

the

of

the

thread

right

under

thread

firmly

thread

several

and

press

guide

times

the

C.

around

foot

the

control.

bobbin

in

a

clockwise

‘(jt,3

direction.

Page 29

F

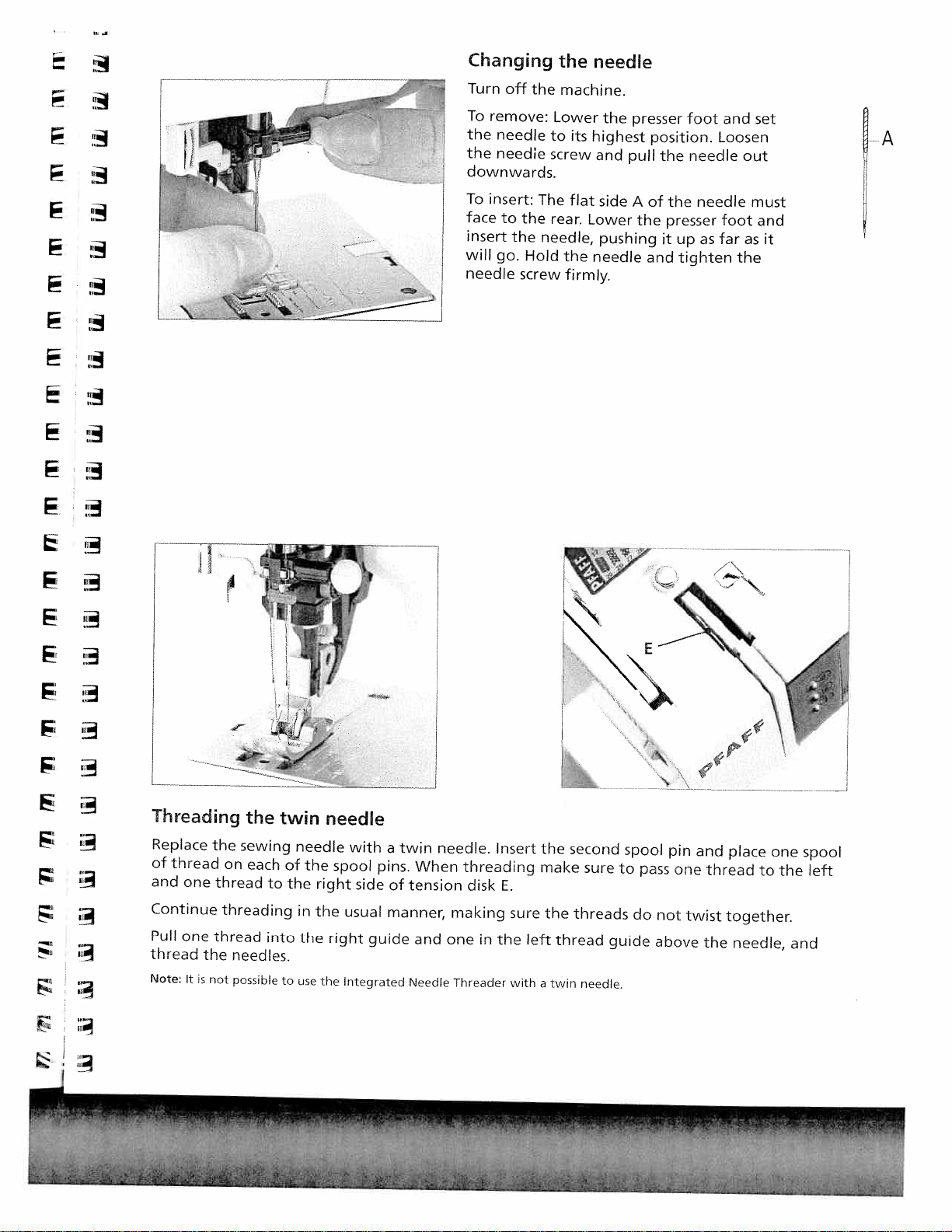

Changing

Turn

off

To

remove:

the

needle

the

needie

downwards.

To

insert:

face

to

the

insert

the

will

go.

Hold

needle

screw

the

to

screw

The

rear.

needle,

the

machine.

Lower

its

flat

Lower

the

firmly.

need’e

the

highest

and

pull

side

pushing

needle

presser

position.

the

Aofthe

the

presser

it

and

foot

needle

needle

up

as

tighten

and

Loosen

out

must

foot

far

as

the

set

BA

and

it

F

F

F

F

F

F

ii

Threading

Replace

of

and

Continue

Pull

thread

Note:

thread

one

one

It

is

the

thread

the

not

the

sewing

on

each

thread

threading

needles.

possible

to

into

twin

needle

of

the

in

the

to

use

the

right

the

need’e

with

spool

usual

right

the

Integrated

side

a

pins.

of

manner,

guide

twin

When

tension

and

Needle

needle.

threading

disk

making

one

Threader

in

Insert

E.

sure

the

with

left

the

make

the

thread

twin

a

second

sure

threads

needle.

spool

to

do

guide

pass

pin

one

not

above

and

twist

place

thread

together.

the

to

needle,

one

the

spool

left

and

Page 30

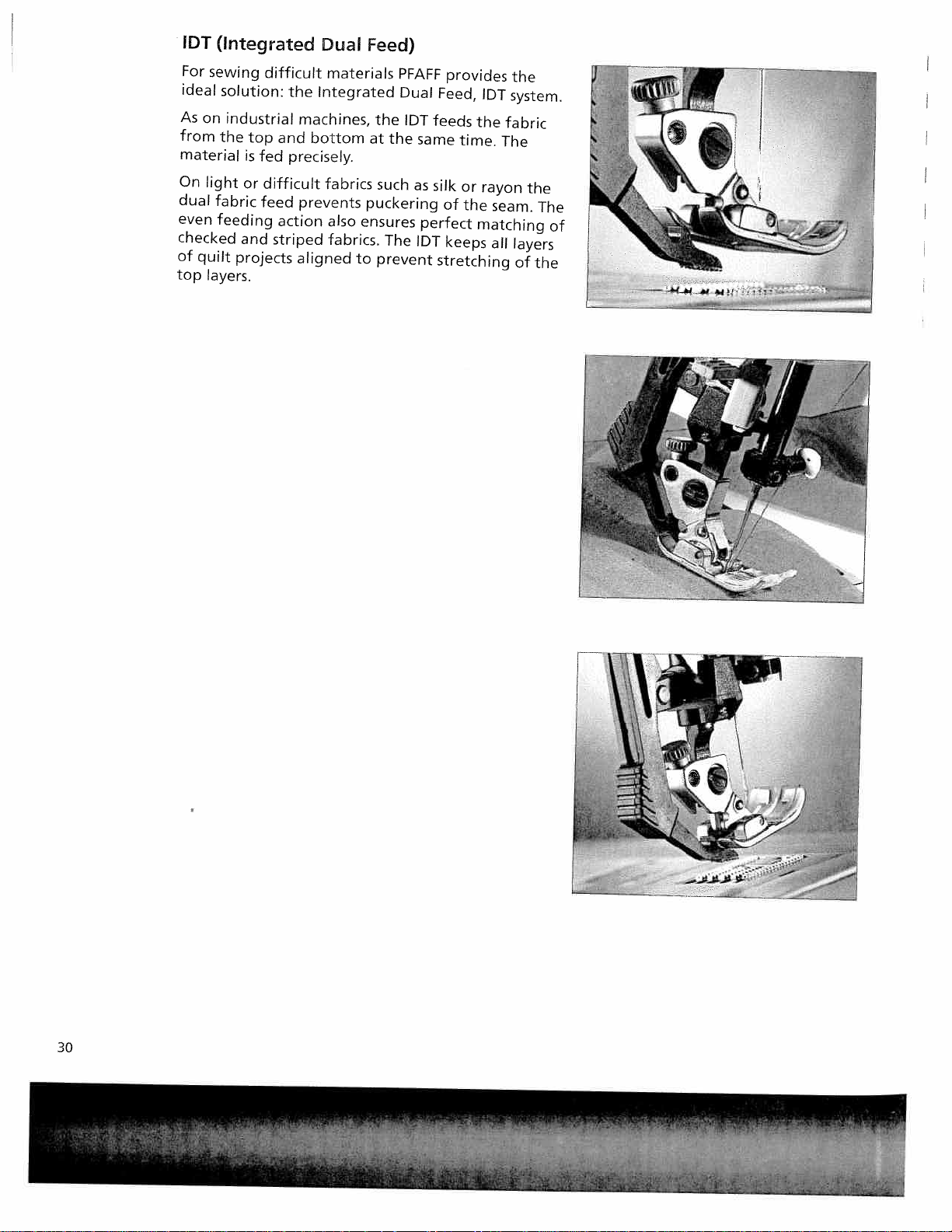

IDT

For

sewing

ideal

As

on

from

material

On

light

dual

fabric

even

checked

of

quilt

top

layers.

(Integrated

difficult

solution:

industrial

the

top

and

is

fed

or

difficult

feed

feeding

and

striped

projects

action

Duai

materials

Integrated

the

machines,

bottom

precisely.

fabrics

prevents

also

fabrics.

aligned

Feed)

the

the

at

such

puckering

ensures

The

to

prevent

PFAFF

Dual

IDT

feeds

same

as

silk

perfect

IDT

provides

Feed,

IDT

the

time.

or

rayon

of

the

matching

keeps

stretching

the

system.

fabric

The

seam.

all

layers

of

the

The

of

the

30

r

Page 31

Engaging

Important:

Dual

cut

out.

Raise

IDT

down

‘—

\

Feed,

the

the

For

use

presser

until

IDT

all

sewing

presser

foot.

it

engages.

feet

Press

with

with

the

the

the

black

IDT

center

-

Integrated

elbow

back

of

the

4jjE:

\

Stripes

to

Disengaging

Hold

the

black

Pull

the

IDT

and

release

and

the

even

down,

the

plaids

feed

the

elbow

IDT

of

IDT

then

slowly

match

the

of

the

back

perfectly

IDT.

IDT

away

upward.

with

due

two

from

fingers.

the

machine

Page 32

Lowering

For

certain

lowered.

Raise

the

To

bring

sewing

presser

the

the

feed

feed

work

foot

dog

dog

such

before

back

as

lowering

up

move

free-motion

the

the

slide

quilting

feed

to

dog.

the

or

Push

right.

darning

slide

the

feed

dog

has

to

be

A

to

the

left.

You

To

can

engage

also

14

the

lower

feed

the

dog

feed

move

dog

the

by

slide

opening

to

the

the

left.

hook

cover

and

-

moving

slide

H

B

to

the

right.

32

Page 33

i

I

1

Electronic

Your

Pfaff

lift

for

1.

Push

Note:

2.

Adjust

at

a

comfortable

If

you

•

Now

To

press

you

remove

knee

performance

regulating

the

knee

the

fiat

the

rectangular

the

can

guide

the

side

knee

knee

‘ift

the

lift

fully

must

height

the

lift,

presser

face

for

lift

fabric

pull

2054

into

upwards.

bar

to

the

foot

on

you.

with

it

provided

is

the

the

right,

gently

height.

provided

knee

the

both

out

with

hole

lift

presser

hands.

of

the

an

until

electronic

on

the

it

is

foot

hole.

machir

position

will

kn

raise

1.

ir

Ii

‘“‘

2.

0

‘3

Page 34

r1

--

Page 35

0

CD

U

—

0

I

CD

-o

SR

I.i

III

SI

0

3

n

CD

0

isa,

1”

i’

r’

ii

!Il

1fI

1

w

‘

4.

r

tt

‘I

t

(D

(D

z

€D

z

g3

(D

I

fP

4

I

Page 36

instructions

Pfaff

Turn

screen

menu,

menu

touching

Sewing

Touch

able

Touch

Pop-up

also

the

performance

on

your

to

stitch

is

visible.

the

functions

OR

to

select

esc

messages

close

the

foot

control.

machine

close

selection

appropriate

to

close

a

,

to

continue

messages

it,

Your

new

are

on

operating

andawelcome

Your

machine

menu,

Pfaff

for

the

a

window,

function.

without

closed

by

2054

is

sewing

performance

icon

on

machine

save

saving

simply

switching

your

always

menu

the

can

your

by

touching

on

screen

ready

2054

touch

be

individually

altered

any

the

appears.

to

or

stitch

is

operated

screen.

settings

settings.

the

function

Touch

sew

when

sequence

altered.

screen.

or

by

and

by

the

main

be

You

can

pressing

Function

::

Touch

or

Touch

Needle

Touch

in

to

you

manually

Yo

When

automatically

fabric

If

the

when

function

Press

Tip:

You

buttons

St[tch

Stitch

re-start

program

Sew

slow

Sew

up

that

slow

I

Needle

the

lower

position

set

whether

take

your

raise

ach[sembetween

you

press

icon

the

reverse

remains

again

can

pre

set

the

has

to

down

up

I

down

and

foot

the

presser

the

lowered

is

touched

button

active.

to

deactivate

presser

to

already

reduce

when

how

off

the

foot

again.

foot

return

sewing

to

far

foot

foot.

“No”,

contro

the

is

touched.

height

been

set

you

the

This

the

to

the

the

stop

presser

control.

“low”=3

again,

allows

needle

function.

in

the

start

started.

to

half

needle

sewing.

goes

But

context

foot

The

the

you

the

of

speed.

to

mm,

presser

to

menu.

a

stitch

automatically

A

window

is

raised

basic

setting

“medium”=6

foot

to

pivot

the

up

position,

needle

See

down

page

sequence

stop

opens

when

is

to

mm

is

turn

the

xx-yy

—

36

Page 37

F

F

F

F

E

Reverse

This

button

e

If

•

•

•

•

•

•

•

•

EE

Touch

for

action

selection

been

Info:

page

Touch

adjust

you

reverse

For

the

When

on

the

If

you

initiated

In

the

determine

you

If

determine

These

Selection

Sewing

numerical

Fonts.

been

Stitch

Function

Main

selection

I

I

I

I

I

I

I

sewing

has

press

for

permanent

machine

the

function

touch

have

via

Patchwork’,

the

are

programming

the

buttons

menus:

menus:

order.

Moves

actively

sequence:

field

has

added

actively

If

more

by

page

stitch

parameter

them

with

menu

this

button

several

this

button

as

long

reverse,

sews

screen.

activated

this

button.

length

length

Scrolls

Selects

the

stitch

selected.

Moves

been

to

selected.

than

one

with

field

buttons

the

to

of

all

stitches.

button

functions

as

you

in

reverse

is

activated,

the

“Tapering’

of

of

have

the

sequence

the

selected

stitch

information

this

buttons.

icon

Function

switch

while

sewing,

keep

press

this

until

tie-off

the

seams

the

length

the

buttonhole

several

by

column

next

stitch

for

sequence

or

stitch

field

back

the

button

the

button

you

press

reverse

a

program,

and

“Darning’

with

this

ofabuttonhole,

seam

functions

or

by

or

the

previous

cursor

sequence

changing

step

after

page

balance

buttons.

by

after

the

is

step

machine

pressed.

before

the

sewing

tie-off

button.

with

page

to

the

cursor

stitch.

a

preview

available,

on

to

sews

starting

button

arrow

at

the

programs,

you

this

select

stitch

input

after

Stitch

field

you

the

display

the

main

in

in

to

agair

appe

end

buttc

stit

a

field

the

ha

scr

rn

s

i:

ye

0-9

Opens

More

Opens

selected

Info

Opens

Touch

Touch

Button

the

stitch

options

the

more

stitch.

button

information

this

button

and

hold

selection

button

options

Context

I

the

or

to

context

open

button

by

window,

menu

the

until

number.

for

menu.

info

the

processing

menu.

contex

menu

modifyin

or

opens.

Page 38

Sewing

The

1.

2.

selecting

3.

Function

The

indicates

field

appear

Icon

m

+

Actively

sewing

Status

It

is

always

changing

Action

sequence

figure

appears

status

Inactive,

Active,

Active,

menu

menu

bar,

a

field,

the

and

field

in

the

when

the

but

the

selected,

is

where

active

sewing

where

action

changing

with

the

selected

in

the

the

function

can

not

function

divided

the

and

function.

the

field

function

upper

function

be

can

the

into

activated

is

automatically

chosen

activated

is

a

stitch.

buttons

left

corner

stitch

number.

field.

button

cannot

unactivated.

be

unactivated,

function

three

sewing

stitch

is

pressed.

be

selected.

is

selected.

sections.

is

by

and

of

the

In

More

functions

updated

displayed.

touching

parameter

function

Sequence

options

are

by

selecting

In

the

the

setting.

field

a

preview

window

shown.

stitch

screen

or

for

Aftering

OFor

buttons.

moves

left

in

Stitch

with

Stitch

pattern

Pattern

stitches,

increase

buttons.

Balance.

the6

Density.

edges

changing

the

straight

There

to

the

nine

width.

the

EZ

length.

with

scallop

or

buttons.

change

and

buttonholes,

the

stitch

stitch.

are

right

positions.

You

buttons.

You

the

length.

stitches

reduce

Fine

tune

the

patternlength

settings

Move

19

in

can

can

For

decorative

the

your

stitch

the

needle

nine

positions.

change

change

buttons.

and

length

stitch

with

or

needle

positions

the

the

stitches,

some

of

the

balance

density,

the

—Z

buttonhole

-

stitch

length

utility

stitch

of

positions

available.

The

needle

width

buttonholes,

stitches.

with

with

satin

buttons,

length

with

(max

(max

6

You

the

stitches,

without

the

+

The

moves

mm)

scallop

9

can

Lz.

needle

to

mm)

of

satin

the

the

38

Page 39

Side

side.

-

End

m

This

sequence

“m+”

An

adjustment

can

also

change

occurs

If

you

settings.

at

exit

to

Each

to

icon

icon.

be

takes

the

a

For

side

mirroring.

stitch

end

mirroring.

stores

menu

is

adjusted

place

next

screen,

aving

is

mirrored

the

stitch

appears

reflected

during

immediately,

repeat.

the

stitch

the

basic

Mirror

Mirror

immediately

stitches

individually.

stitches

in

stitch

a

automatically

sewing.

with

settings

settings,

With

all

are

pre

and

end

to

sequence.

by

actively

on

the

some

other

reset

set

itincontext

sequences

end.

The

selecting

screen.

Utility

stitches

to

the

side

stitch

All

settin

stitches

the

default

ment

to

ft

ft

chan

F

F

F

E

F

F

More

By

functions

functions

displayed

Icons

Ok

esc

{.

options

touching

in

OK.

saved.

window

further

Closing

modified

Tie

off

four

stitches.

usually

button

Tie

off

four

stitches.

end

function

Raise

at

the

automatically.

raised

If

the

raised

button

The

Needle

for

that

in

the

The

You

or

settings

without

at

after

is

touched.

at

presser

start

10.5

•

at

the

for

you

iEE

processing

can

the

status

More

More

can

also

another

settings

start.

This

a

new

end.

The

Touch

The

foot.

of

the

If

mm

when

and

end

is

pressed.

up

down

I

sewing

can

be

selected

bar.

options

options

press

dialogue

can

be

saving.

being

The

start

icon

stitch

end

the

machine

The

seam

this

function

icons

of

the

call

or

modifying

window

window

the

made.

You

saved.

of

is

only

is

of

the

Reverse

ties

machine

and

the

machine

are

seam

overrides

upadialogue

the

are

visible.

closes

foot

control.

window

close

a

window

the

seam

active

selected

raise

is

selected,

or

seam

button

off

will

it

active,

pattern

the

at

or

or

and

lower

at

stops.

the

Raise

the

window

stitch.

Selected

and

The

remains

or

stitch

the

start

when

stitch

to

trigger

stops.

end

the

presser

presser

when

presser

all

without

the

is

the

the

with

Only

functions

settings

More

open

is

tied

of

a

Stitch

tied

the

presser

of

the

foot

foot

Reverse

foot

furth

sewing

are

options

so

that

the

off

seam

re-stE

off

with

Tie

foot

seam

is

is

only

functi

are

wit[

an

off

alv

Page 40

Free

lowered

on

the

motion

automatically

foot

control.

sewing

When

to

the

activated

free

motion

the

presser

position

foot

by

is

stepping

Single

single

single

status

seam

Touch

the

number

screen.

Twin

width

It

remains

after

Touch

This

needle

pat

Programmable

length

length.

Press

it

will

sewn

this

function.

stitch.

stitches.You

stitch.

bar.

Tieoff

or

stitch.

)

needle

of

your

active

the

machine

the

icon

function

from

for

joining

the

reverse

be

tied

in

your

Pattern

The

a

little

of

repetitions

safety.

stitch

even

again

must

the

machine.

seam

button

off.

specified

and

can

also

number

automatically

is

longer

With

in

order

after

has

been

to

be

switched

length

together

All

subsequent

length

of

and

with

a

switched

switch

several

when

stitch

define

repetitions

window

a

c÷

this

function,

to

use

stitch

off

off

function.

you

seams

until

sequences

number

a

are

performed

appears,

confirm

a

twin

has

been

off

and

the

function.

when

Specify

pieces

reach

your

are

pat

is

pressed

can

displayed

you

needle.

changed,

you

of

fabric

now

be

sewn

of

stitches

at

the

to

by

touching

reduce

back

on

remove

particular

a

of

desired

automatically

to

deactivate

as

in

end

change

the

including

again.

the

equal

length,

as

the

of

twin

seam

a

the

the

It

Symmetrical

starts

mm.

IIi:

Symmetrical

starts

button

.

Asymmetrical

stitch

9

mm.

Dkt

Asymmetrical

starts

button

with

at

is

starts

at

is

0

(max)

touched.

with

(max)

touched.

tapering

mm

tapering

9

mm

tapering

0

tapering

9

mm

and

mm

It

It

and

stops

and

stops

(increase).

becomes

(reduce).

tapers

with

(increase).

and

becomes

(reduce).

tapers

with

wider

The

to

the

The

to

the

The

width

0

mm

needle

The

wider

0

mm

needle

width

until

width

width

it

when

in

until

when

in

of

reaches

of

the

the

of

of

the

the

the

the

it

the

zigzag

reverse

lower

the

reaches

zigzag

reverse

lower

zigzag

(max)

zigzag

position

stitch

9

stitch

position

(max)

stitch

40

Page 41

The

When

selection

the

menus

Welcome

screen

turned

is

off

the

main

menu

appears.

Note.

if

you

point,

this

opens.ifyou

more

the

machine

press

corresponding

the

press

the

the

starts

foot

foot

to

control

sewing

control

sew.

once

once

menu

at

UtiHty

stitches

Stitches

This

menu

a

variety

OVerCastrng

Stitches

This

menu

overcasting.

The

closed

overcasting

Antique

Stitches

This

patch

41

menu

quilting.

Crosstitches

1

-30

provides

sewing

31

-

provides

overedge

quift

-55

provides

40

in

one

stitches

selection

a

techniques.

selection

a

stitches

operation.

selection

a

stitch

of

all

of

stitch

canbeused

of

quilt

types

types

for

stitches

that

suitable

joining

suitable

you

and

can

for

for

use

qraz

fc

Stitches

72

-89

Pre-programmed

borders.

lndividual

designs.

Decorative

This

menu

They

are

sub-divided

stitches

includes

selection.

Hemstitches

Stitches

90

Scalloped

clothing.

Stitches

100-

allow

-

99

edging,

113

cross

cross

a

stitches

stitches

selection

into

four

you

to

for

sewing

allow

of

different

create

you

allow

you

decorative

heirloom

decorative

to

create

to

program

stitches.

categories

stitches.

edges

traditional

your

for

ease

on

table

owr

of

liner

Page 42

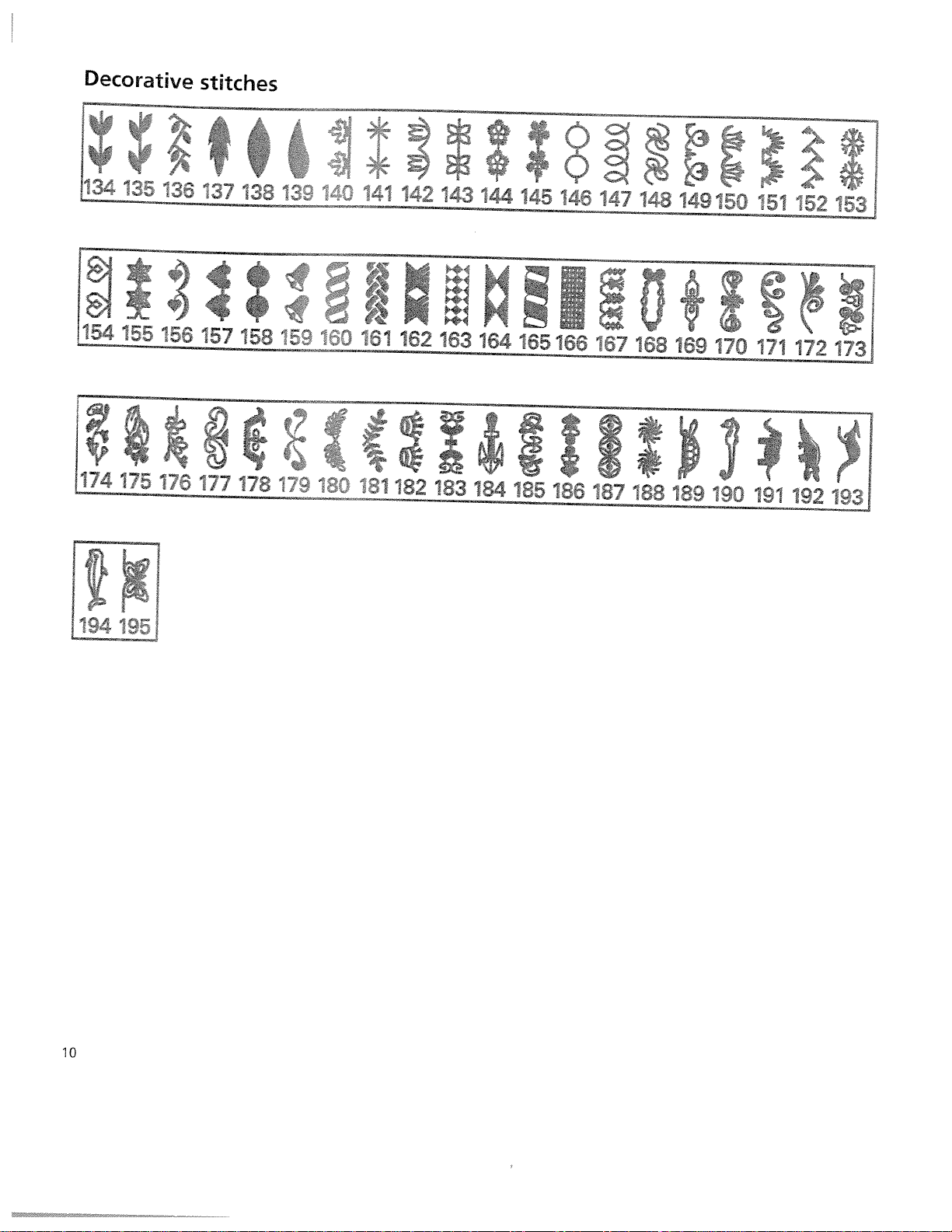

•

Satin

stitches

range

home.

Stitches

•

Decorative

which

ideal

for

three-dimensional

Stitches

Animal

garments.

Stitches

Buttonholes

of

options

114-

can

be

decorative

167

stitches

134-

have

133

stitches.

sewn

-188

which

195.

three-dimensional

a

for

embellishing

Stitches

individually

borders.

decorative

are

floral

are

especially

134-145

to

Stitches

stitches

patterns.

look

garments

are

create

146

which

Stitches

suitable

or

leaves

larger

-

166

can

for

that

items

are

189

offer

for

and

flowers

motifs.

pictorial

be

combined.

-

195

childrens

a

They

are

wide

the

are

or

Stitches

This

menu

and

one

designed

Darning

Stitches

This

menu

various

plackets/slit

The

fully

areas

and

Alphabets

This

menu

upper

Stitch

In

this

and

sequence

menu,

stitches.

56

-

64

provides

program

for

and

bartacks

65

-

71

provides

different

and

automatic

darning

provides

lower

you

a

specific

attaching

case

can

a

selection

for

sewing

a

selection

bartacks

darning

tears

a

selection

letters,

create

on

application

are

for

belt

programs

or

small

of

numbers

sewing

of

8

different

buttons.

and

of

bartacks,

reinforcing

loops.

holes.

various

sequences

fabric.

are

and

Each

darning

pocket

for

fonts.

symbols.

buttonhole

buttonhole

stitches,

corners,

repairing

One

font

from

the

styles

style

The

skirt

damaged

includes

machine’s

is

42

Page 43

0

C,,

r

¶

DCD

-

0

0

-n

I

B

0

n

CD

cr

ml

I

1..

LI

J

Page 44

Selecting

There

are

a

several

stitch

waystoselect

a

stitch.

B

Selection

Touch

This

sewing.You

buttons.

You

stitch.

visible.

All

In

numerical

Touch

You

the

To

“Utility

category

can

When

stitches

this

menu,

“All

can

L

select

Selection

by

can

touch

order.

stitches”

browse

buttons.

stitch,

a

by

category

stitches”.

contains

browse

any

stitchtoselect

you

open

selection

all

stitches

in

through

touch

number

30

the

the

the

stitches

one

are

main

the

column

screen

displayed

menu.

menu

icon

for

that

atatime

and

it

the

one

that

are

open

most

one

page

suitable

important

after

stitch.

for

with

the

the

screen

another

atatime

utility

for

settings

in

pressir

by

that

an

B

B

B

B

B

B

B

B

B

B

Touch

Enter

delete

The

three

that

does

“Invalid

The

pop

Direct

When

pressing

through

Exiting

•

The

touching

•

Scroll

•

Touch

stitch

the

digits

not

stitch

up

selection

sewing

in

a

the

the

sewing

a

main

with

the

button

number

button

entered,

are

exist

number!”

message

fE

stitches

menu

(

the

number

open

to

deletes

is

entered,amessage

is

closed

menu,

buttons.

in

numerical

to

and

they

a

different

You

the

confirm

are

when

menu

can

twice.

arrow

called

be

buttons

selection

the

can

up

(ZZ.

button

selection

by

right

deleted

the

stitch

scroll

order.

again

by

touching

hand

from

displayed:

is

display

can

back

any

at

number

digit.

the

is

be

and

time

menu.

ok

more

If

left.

touched.

selected

forwards

by

than

Ifastitcl

by

Page 45

The

Context

Adjust

settings.

screen

All

Open

this

Press

If

subordinate

being

The

Windows

with

“context”

the

button

this

the

Context

saved.

functions

the

basic

contrast.

settings

You

can

Info

to

button

window

for

altering