Page 1

The real passion for sewing!

Owner’s manual

Page 2

This household sewing machine is designed to comply with IEC/EN 60335-2-28 and UL1594

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the following:

Read all instructions before using this household sewing machine.

DANGER - To reduce the risk of electric shock:

• A sewing machine should never be left unattended when plugged in. Always unplug this sewing machine from

the electric outlet immediately after using and before cleaning.

• Always unplug before relamping. Replace bulb with same type rated 5 Watt.

WARNING - To reduce the risk of burns, fire, electric

shock, or injury to persons:

• Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near

children or infirm person.

• Use this sewing machine only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

• Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water. Return the sewing machine to the nearest authorized dealer or

service center for examination, repair, electrical or mechanical adjustment.

• Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing

machine and foot controller free from the accumulation of lint, dust, and loose cloth.

• Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

• Do not use bent needles.

• Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

• Switch the sewing machine off (“0”) when making any adjustment in the needle area, such as threading needle,

changing needle, threading bobbin, or changing presser foot, etc.

• Always unplug the sewing machine from the electrical outlet when removing covers, lubricating, or when

making any other user servicing adjustments mentioned in the instruction manual.

• Never drop or insert any object into any opening.

• Do not use outdoors.

• Do not operate where aerosol (spray) products are being used or where oxygen is being administrated.

• To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

SAVE THESE INSTRUCTIONS

Page 3

Congratulations!

Congratulations on purchasing your new PFAFF® performance™

2058! Pfaff performance 2058 is the perfect companion for those

who love to sew. It’s ease of use and unlimited features will free

your creative engergies and turn your ideas into reality.

Before you start, please spend some time reading these operating

instructions. You will soon discover how easy it is to use your Pfaff

performance 2058.

Give free rein to your imagination and discover your own passion

for sewing together with one of the greatest sewing machines in the

world - performance 2058 from Pfaff.

Page 4

1:4

Table of content

1

2

3

4

Introduction

Overview of your machine 1:9

Standard presser feet and accessories 1:10

Stitch chart 1:12

Lid 1:17

Carrying case 1:17

Sewing with free arm 1:17

Accessory tray 1:18

Preparations

Voltage switch 2:2

Electrical connection 2:2

Connecting the foot control 2:

2

On/off switch 2:2

Presser foot lift 2:3

Changing the presser foot 2:3

The IDT (Integrated Dual Feed) 2:

4

Lowering the feed dogs 2:5

Bobbin winding 2:6

Inserting the bobbin and bobbin case 2:9

Threading your machine 2:10

Integrated needle threader 2:11

Bringing up the bobbin thread 2:12

Thread cutter 2:12

Changing the needle 2:13

Threading the twin needle 2:13

Correct thread tension - How to get it 2:14

Electronic knee lift 2:15

Operating your performance

Operating your machine 3:2

Function buttons 3:2

Main menu 3:4

Selection menus 3:4

Selecting a stitch 3:6

Sewing menu 3:7

Altering the stitch settings 3:7

More options for sewing 3:

9

Context menu 3:11

Info system 3:15

Utility sewing

Getting started 4:2

Straight stitch - No 1 4:3

Sewing in zippers - No 1 4:3

Three-step zigzag stitch - No 4 4:3

Topstitching - No 1 4:4

Basting stitch - No 17 4:4

Gathering with straight stitch - No 1 4:4

Blindhem stitch - No 15 4:5

Stretch Blindhem stitch - No 16 4:5

Rolled hem with straight stitch - No 1 4:5

Overlock stitches 4:6

Buttonholes 4:7

Sewing on buttons - No 60 4:10

Eyelets - No 59 4:10

Automatic darning - No 74 and 75 4:11

Free motion darning - No 1 and 3 4:12

Page 5

1:5

5

6

7

8

Decorative sewing

General notes on decorative sewing 5:2

Combined borders 5:2

Twin needle sewing 5:3

Cross stitch 5:3

Tapering 5:4

Quilting 5:5

Free-motion sewing 5:9

Nostalgia/Heirloom 5:10

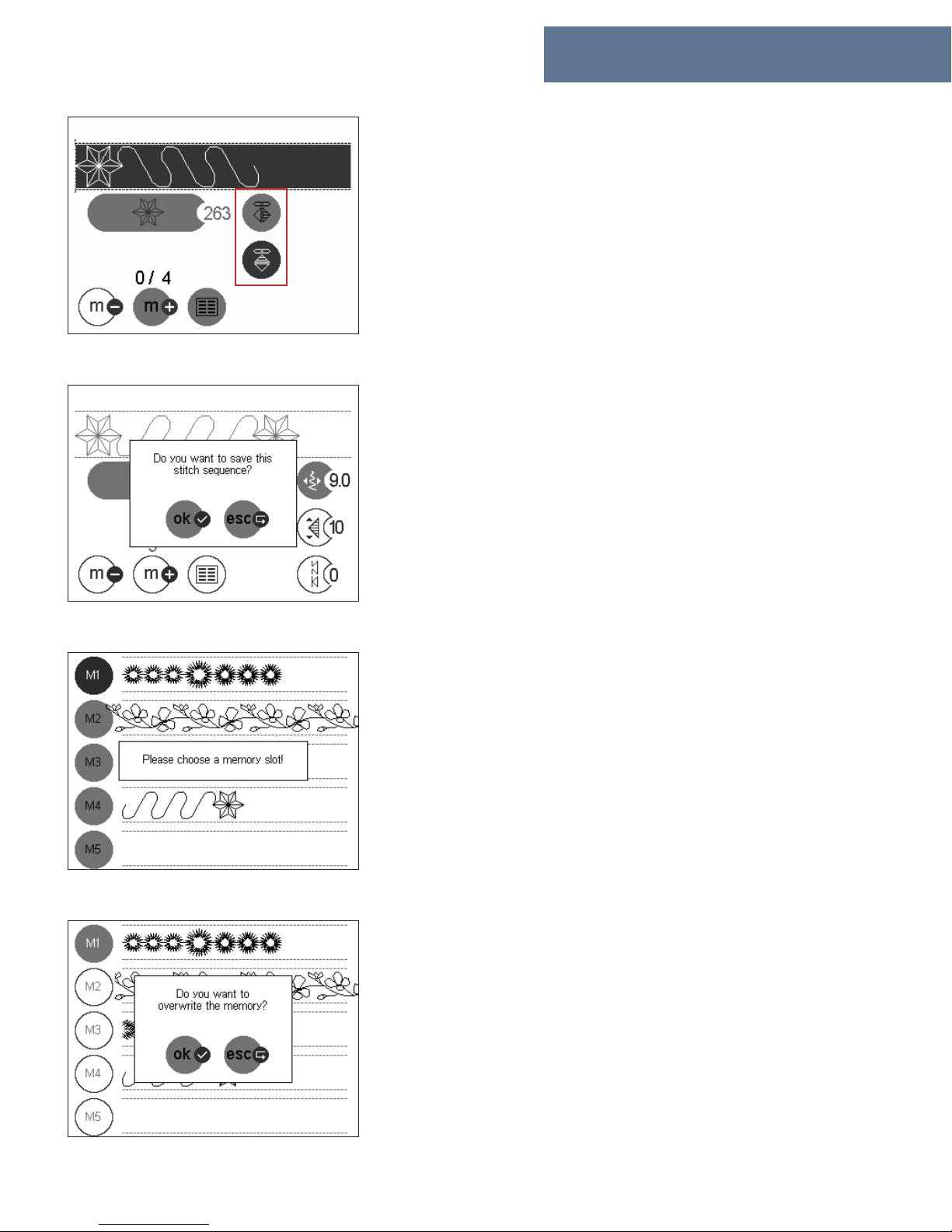

Stitch sequences

Stitch sequences 6:2

Creating a new stitch sequence 6:

3

Altering the settings of a selected stitch 6:4

Editing a stitch sequence 6:4

Saving a stitch sequence 6:5

Alphabets 6:6

Creating an alphabet sequence 6:

7

Combine alphabet and stitch sequences 6:7

Stitch Creator

Stitch Creator 7:2

Creating a new stitch 7:4

Add excisting stitches 7:4

Editing a stitch 7:5

Saving a stitch 7:6

Sewing a stitch 7:6

Maintenance

Changing the needle plate 8:2

Cleaning 8:2

Changing the lightbulb 8:3

Sewing problems and their solutions 8:4

Index 8:6

Technical data 8:

11

Package contents 8:

11

Intellectual property 8:11

Table of content

Page 6

1:6

Some fabrics have a lot of excess dye which can cause discoloration

on other fabric but also on your sewing machine. This discoloring

may be very difficult or impossible to remove.

Fleece and denim fabric, especially red and blue, often contain a lot

of excess dye.

If you suspect that your fabric/ready-to-wear garment contains

a lot of excess dye, always pre-wash it before sewing to avoid the

discoloring.

Page 7

Introduction

Page 8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

33

32

34

35

36

37

1:8

Page 9

1:9

Introduction

Overview of your machine

1. Pattern restart button

2. Sew slow button

3. Needle up/down button

4. Scroll buttons

5. Function field buttons

6. Main menu button

7. Selection by number button

8. More options button

9. Info button/Context menu

10. Reverse sewing button

11. Touch screen

12. Handle

13. Handwheel

14. Connection socket, lead cord

15. Connection socket, foot control

16. On/off switch

17. Slide for lowering the feed dogs

18. Spool holder with spool cap

19. Lid with stitch chart

20. Hole for second spool holder

21. Thread cutter for bobbin winding

22. Bobbin winder

23. Bobbin door

24. Free arm

25. Needle plate

26. Thread cutter

27. Needle holder with retaining screw

28. Take-up lever

29. Thread guide

30. Knee lift attachment hole

31. Removable accessory tray

32. Presser foot holder with presser foot

33. IDT - Integrated Dual Feed

34. Integrated needle threader

35. Presser foot lifter

36. Threading slots

37. Needle thread tension

Page 10

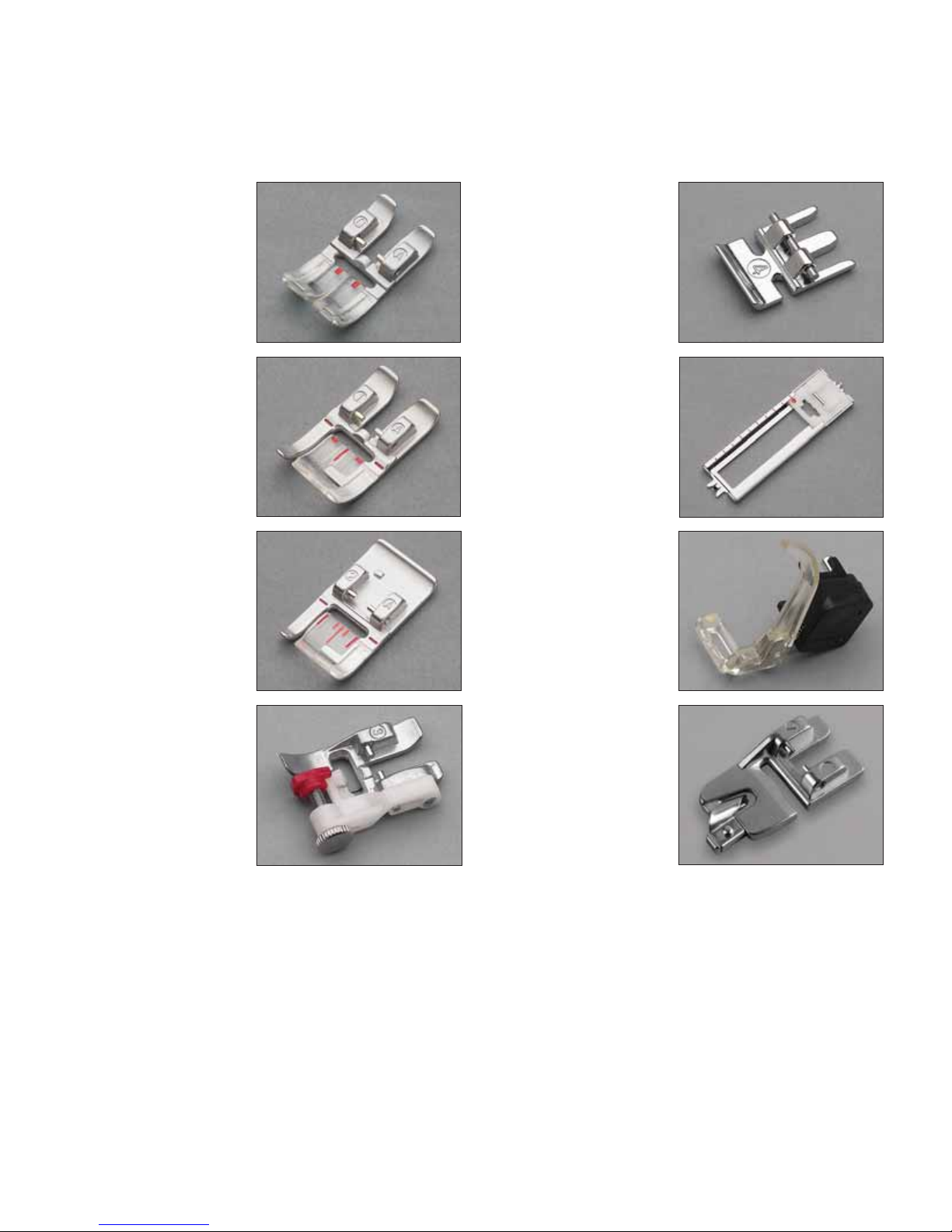

1:10

Standard presser feet and accessories

Rolled hem foot 3 mm

with IDT, No. 7

Darning foot, No. 6

Blindhem and overlock

foot with IDT, No. 3

Standard presser foot

with IDT, No. 0A

(attached on the machine

upon delivery)

Fancy stitch foot with

IDT, No. 1A

Fancy stitch foot, No. 2A

Zipper foot with IDT,

No. 4

Buttonhole foot, No. 5A

Page 11

1.

2.

3.

4.

5.

6.

10.9.8.7.

1:11

Introduction

Sensormatic buttonhole guide, No. 10

Edge guide

Bulb remover/Needle plate changer

1. Bobbins

2. Spool cap medium (attached on the

machine upon delivery)

3. Spool cap small

4. Spool cap large

5. Needle box

6. Felt pad

7. Stylus

8. Second spool holder

9. Seam ripper

10.

Brush

Page 12

1:12

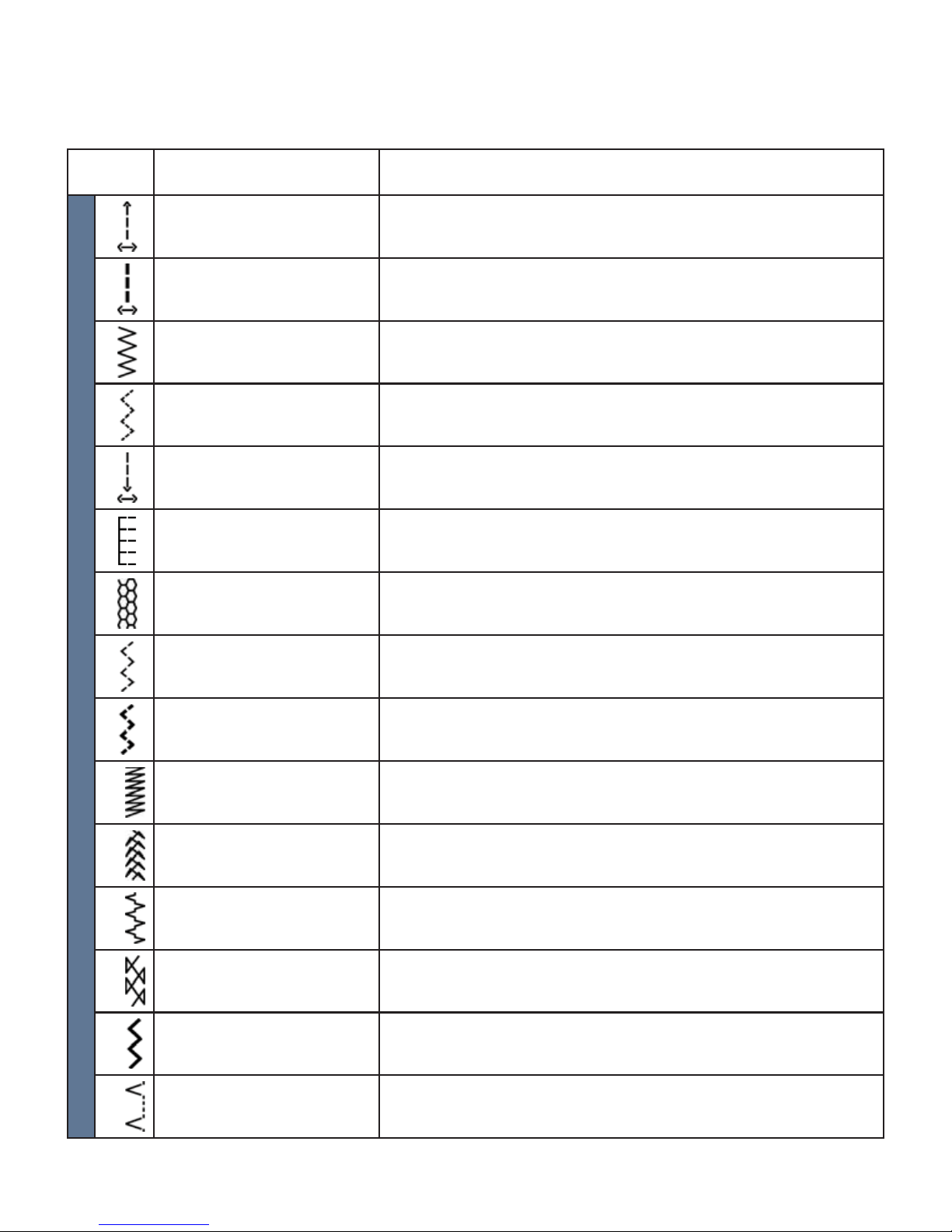

Stitch chart

Stitch Description Application

Utility stitches

1.

Straight stitch with 19 needle

positions

For all straight stitch and topstitching jobs. Stitch length can be

increased up to 6mm. 19 needle positions are available, for edge

finishing or sewing in zippers.

2.

Stretch triple straight stitch

with 19 needle positions

For reinforced seams, particulary on stretch fabrics, e.g. trouser

seams, sportswear and work wear. Stitch length can be increased up

to 6mm for decorative topstitching.

3.

Zigzag stitch For finishing seams, appliqué work, inserting lace etc.

4.

Three-step zigzag stitch Strong stitch for seam finishes, overcasting, sewing on elastic,

darning tears and applying patches.

5.

Straight stitch reverse Program permanent reverse for decorative sequences. 19 needle

positions are available.

6.

Elastic overcast stitch Use to seam and overcast on woven and stretch fabrics.

7.

Honeycomb stitch Elastic, decorative stitch for ornamental hem finishing on stretch

fabric and decorative elastic application.

8.

Elastic stitch Strong stitch for seam finishes, sewing on elastic, darning tears and

applying patches.

9.

Triple stretch stitch For sewing elastic on sportswear or swimwear. (Extremely durable

seam for open-knit materials).

10.

Z-Zigzag stitch For finishing seams, inserting lace and particulary suitable for

appliqué work thanks to its stitch density.

11.

Bridging stitch For bridging, decorative hemstitching and crazy quilting.

12.

Foundation elastic stitch For joining overlapped seams on bulky fabrics such as leathers and

terry cloth.

13.

Cross hem stitch Provides a highly elastic, decorative seam for hems on sportswear

and casual wear.

14.

Stretch triple zigzag stitch Elastic stitch for decorative hems and topstitching.

15.

Blindhem stitch For securing hems invisibly on woven fabrics.

Page 13

1:13

Introduction

16.

Elastic blindhem stitch For securing hems invisibly and finishing the edge on stretch fabrics.

17.

Basting stitch For basting project pieces together. 19 needle positions are available.

18.

Lightning stretch stitch For joining light weight stretch fabrics and decorative embellishment.

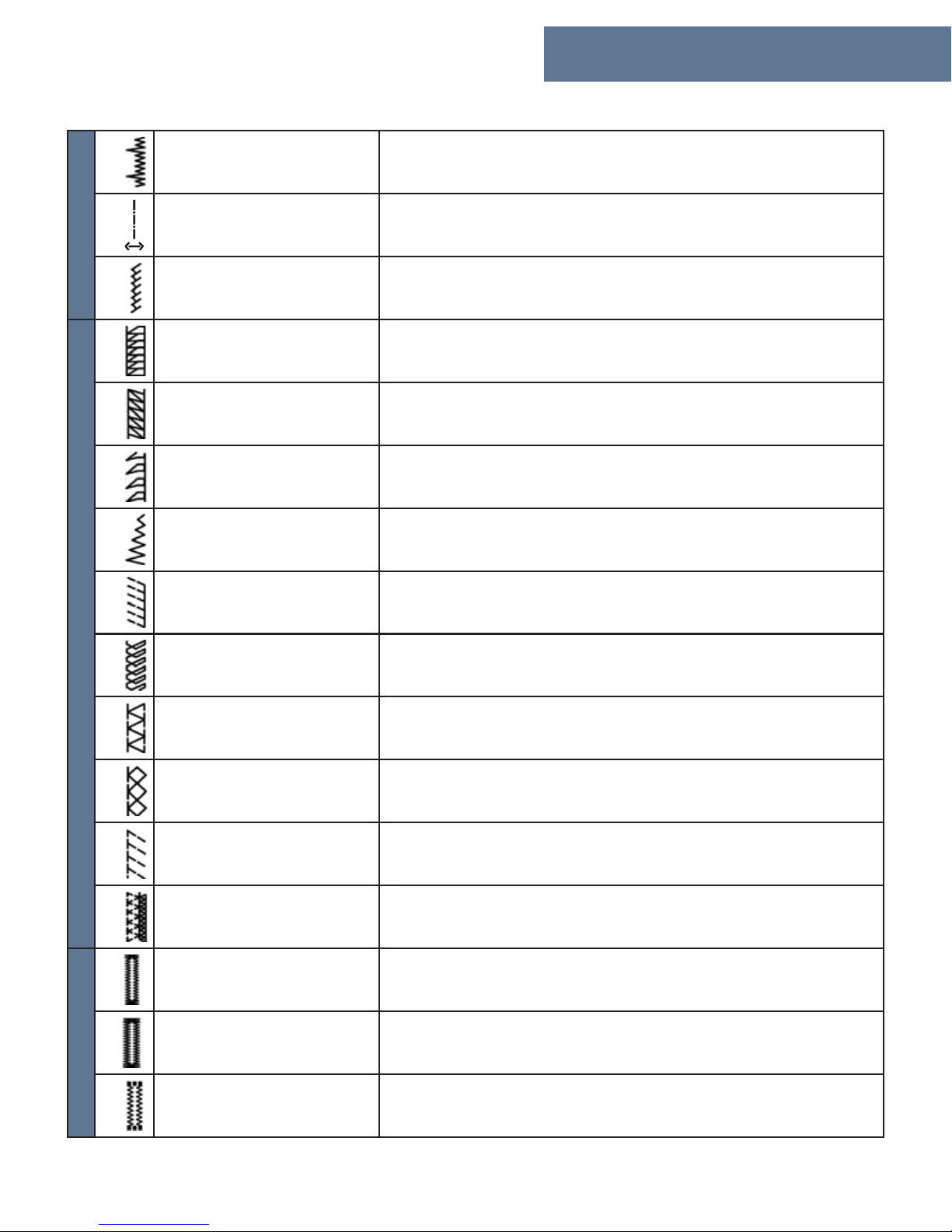

Overlock stitches

30.

Closed overlock stitch For joining and overcasting stretch fabrics in one operation. The

closed seam prevents fabric edges from fraying.

31.

Closed overlock stitch For joining and overcasting in one operation.

32.

Open overlock stitch For joining and overcasting stretch fabrics in one operation.

33.

Zigzag stitch, right or left

needle position.

For appliqué, couching over cords and creating eyelets.

34.

Overlock stitch For joining and overcasting stretch fabrics in one operation.

35.

Light-knit fabric patching

stitch

Use to mend light jersey knits. Also for a decorative hem and

neckling finish.

36.

Closed overlock stitch For joining and overcasting stretch fabrics in one operation.

37.

Stretch knit overlock stitch Join and overcast open knit fabrics and jersey.

38.

Standard overlock stitch For joining and overcasting stretch fabrics in one operation.

39.

Reinforced overlock stitch For joining and overcasting fabrics. The knited edge reinforces and

prevents fraying on the raw edge.

Buttonholes

50.

Linen buttonhole Buttonhole for blouses, shirts and linen.

51.

Standard buttonhole Basic buttonhole for blouses and shirts, jackets and pillow closures.

52.

Stretch buttonhole Buttonhole for stretch fabrics.

Page 14

1:14

Buttonholes

53.

Cross stitch buttonhole Decorative buttonhole for jackets and for embellishing other

garments.

54.

Eyelet buttonhole with

pointed bartack

Professional tailor’s buttonhole for denim jackets and trousers.

55.

Rounded buttonhole with

lengthwise tack

Buttonhole for shirts, jackets and trousers.

56.

Professional eyelet

buttonhole

Buttonhole for denim jackets and trousers. Or as a decorative effect

for kitchen or shower curtains. Add rings through the buttonholes to

hang the curtains.

57.

Decorative buttonhole with

triangle tack

Decorative buttonhole for jackets and for embellishing other

garments.

58.

Round ends buttonhole Use for light weight garments or jackets.

59.

Eyelet Create eyelets for garments and home textiles. Also great for

decorating nostalgia projects.

60.

Button sewing program For applying two-hole or four-hole buttons.

61.

Rounded buttonhole with

pointed bartack

Buttonhole for shirts, jackets and trousers.

62.

Eyelet buttonhole with

lengthwise bartack

Professional tailor's buttonhole, for denim jackets and trousers. Or

as a decorative effect for kitchen and shower curtains. Add rings

through the buttonholes to hang the curtains.

63.

Rounded end buttonhole

with crosswise tack

Buttonhole for shirts, jackets and trousers.

Darning and bartack

70.

Bartack For applying belt loops and reinforcing pockets.

71.

Denim bartack Decorative bartack for trousers and skirt pockets.

72.

Decorative bartack Decorative bartack for trousers and for reinforcing skirt vents.

73.

Stippling stitch Use for quilting and as a darning stitch for mending rips and tears.

74.

Programmable darning stitch For darning damaged areas.

75.

Programmable reinforced

darning stitch

For darning and repairing damaged areas. Reinforced by horizontal

stitches.

Page 15

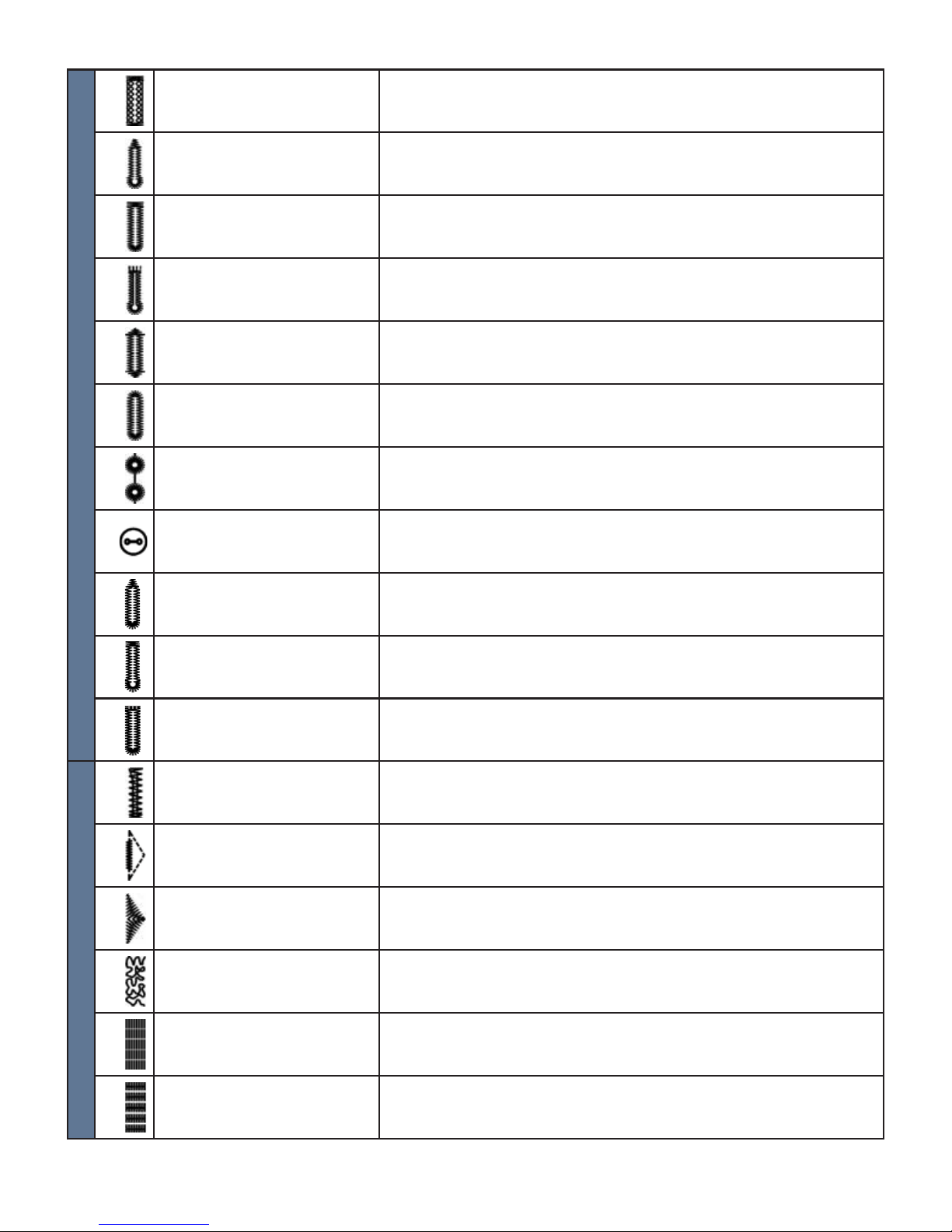

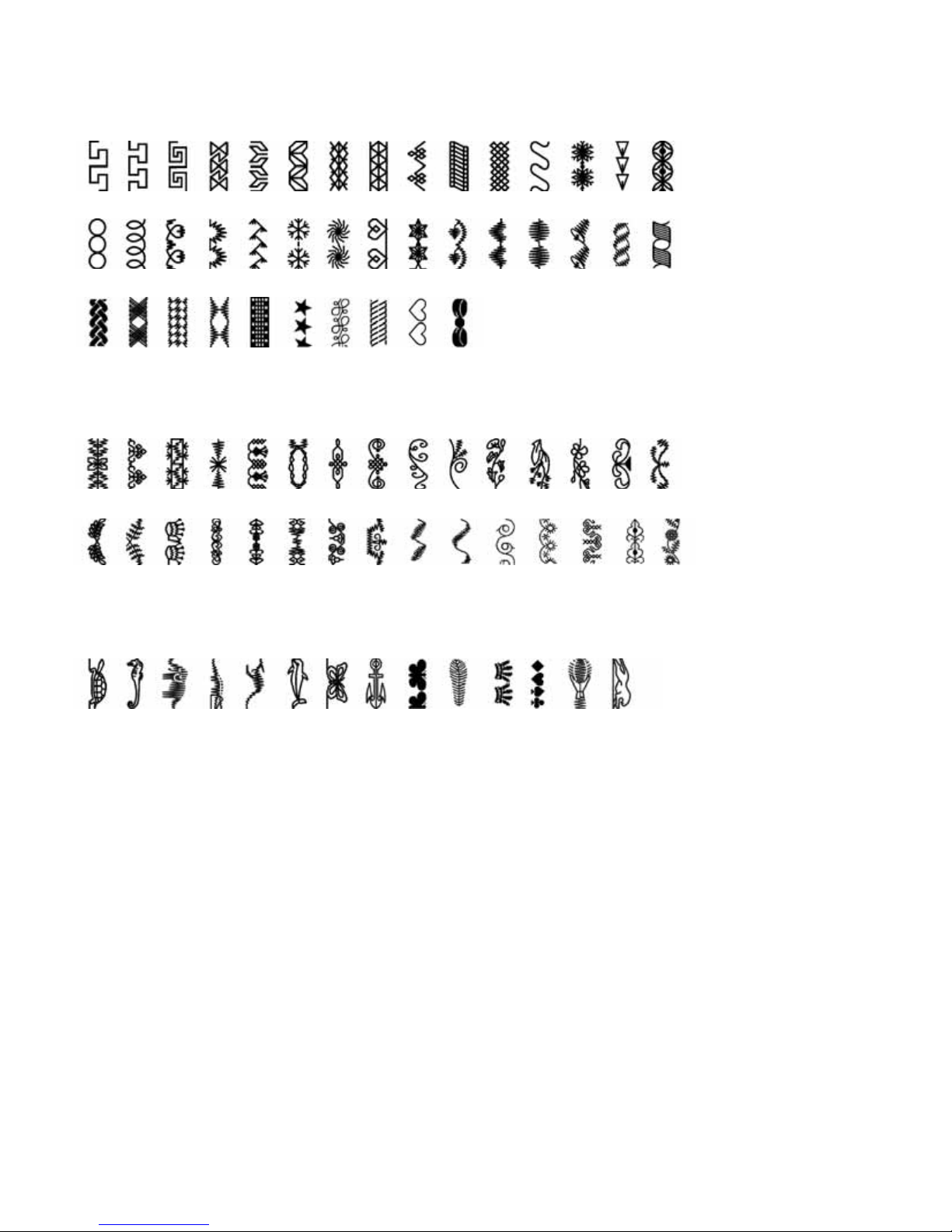

80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96

100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119

130 131 132 133 134 135 136 137 138 139

140 141 142 143 144 145 146 147 148 149

160 161 162 163 164 165 166 167 168 169 170 171 172 173 174

190 191 192 193 194 195 196 197 198 199 200 201 202 203 204 205 206

220 221 222 223 224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239

1:15

Introduction

Antique quilting

Cross stitches

Hem stitches

Antiqe hand embroidery stitches

Scallop edges

Satin stitches

Leaves and flowers

Page 16

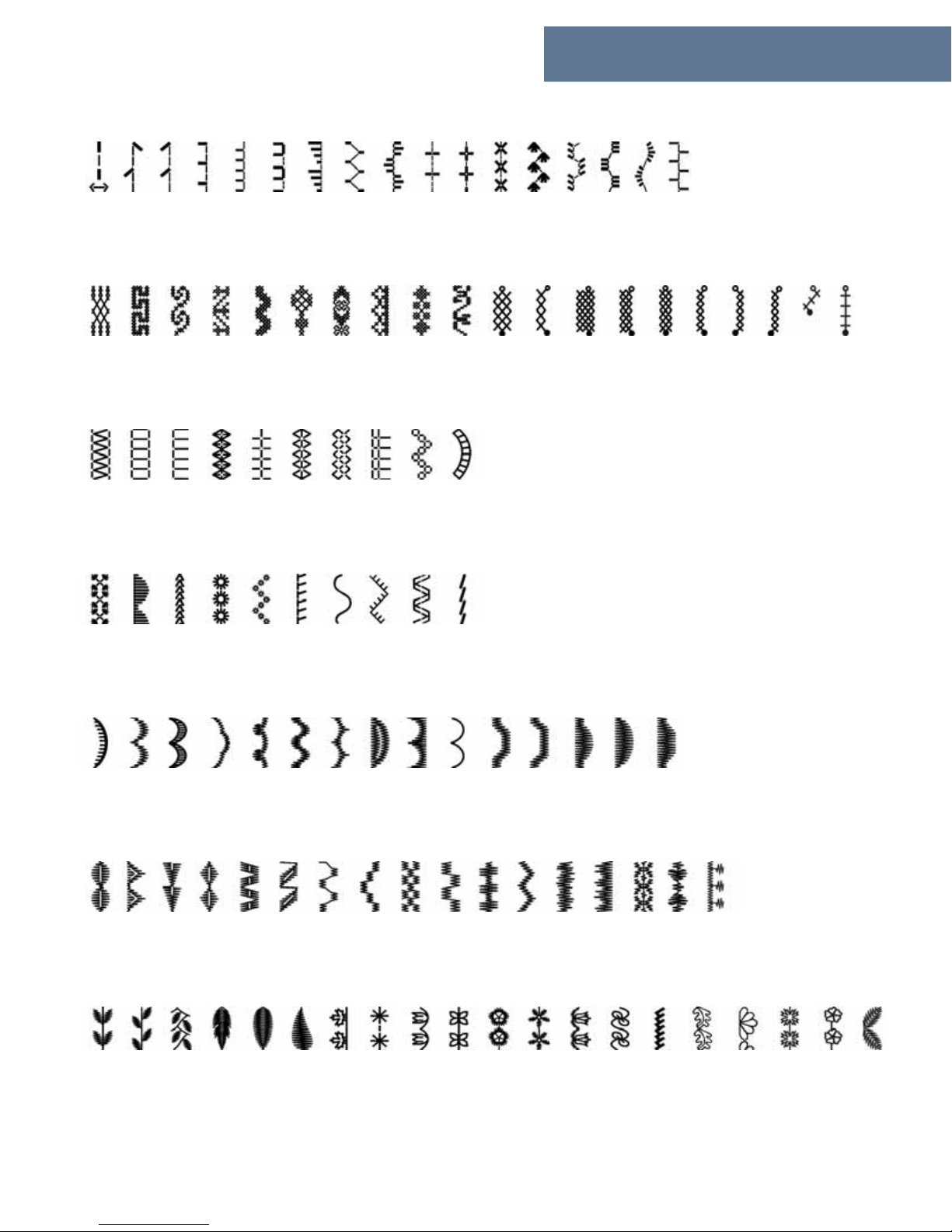

240 241 242 243 244 245 246 247 248 249 250 251 252 253 254

255 256 257 258 259 260 261 262 263 264 265 266 267 268 269

270 271 272 273 274 275 276 277 278 279

290 291 292 293 294 295 296 297 298 299 300 301 302 303 304

305 306 307 308 309 310 311 312 313 314 315 316 317 318 319

330 331 332 333 334 335 336 337 338 339 340 341 342 343

1:16

Art stitches

Ornamental stitches

Fun stitches

Page 17

1:17

Introduction

Lid

Lift the lid to open. All stitches are displayed on the inside of the lid.

Sewing with free arm

In order to sew using the free arm, swing the accessory tray to the left

and lift it up out of the hole.

When replacing the accessory tray, insert the pin into the hole and

swing the tray to the right to close until it is flush with the free arm of

the sewing machine.

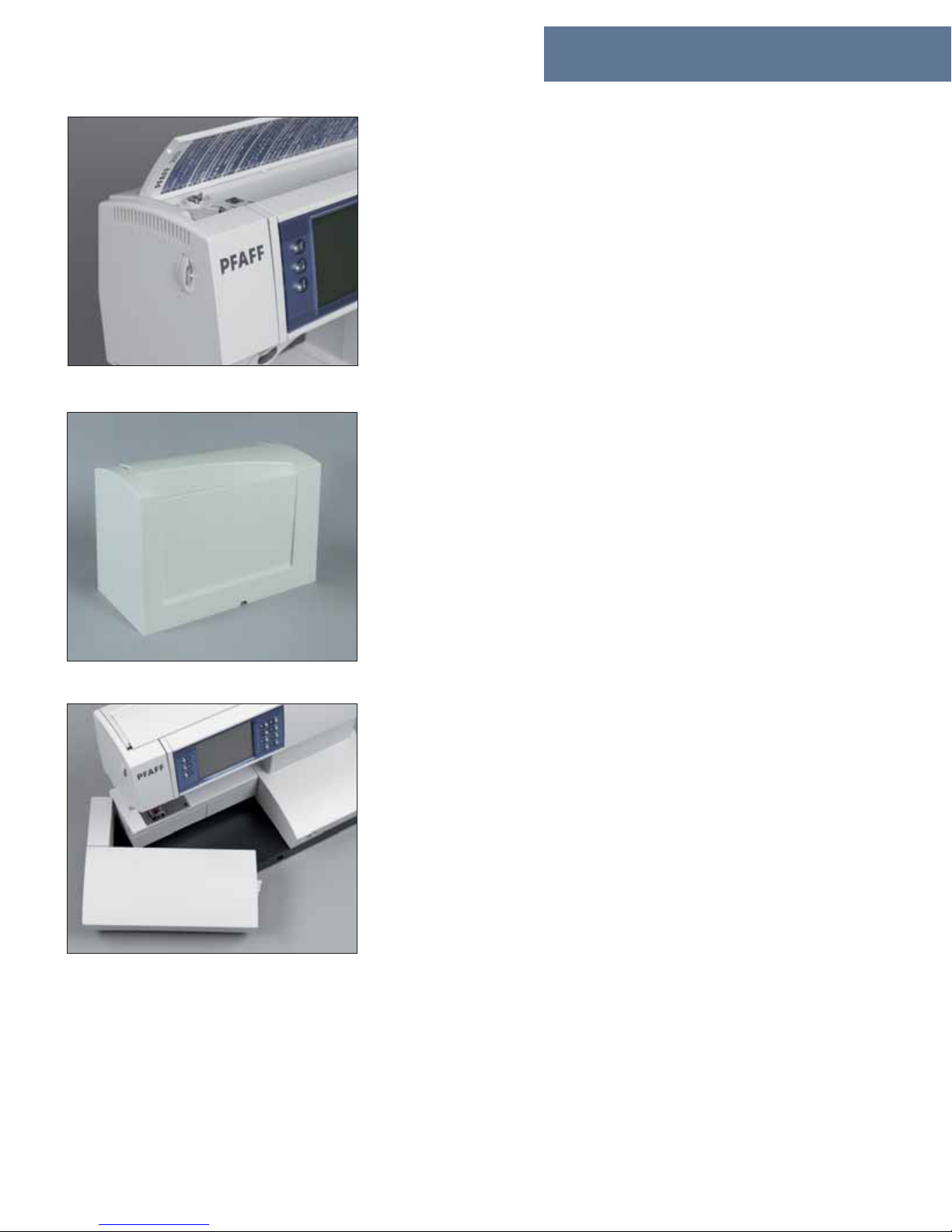

Carrying case

Use the hard carrying case to protect your machine when transporting

it. The machine’s integrated handle can be accessed through a slot in

the top back of the case. There is a convenient storage compartment to

hold the lead cord, foot control and instruction book.

Page 18

1:18

Accessory tray

Open the accessory tray by placing your left index finger on the ridged

area to the left side of the lid and pull it towards you.

Arranging the accessories

The standard accessory feet are marked with numbers. Arrange the

feet in the respective numbered compartments of the accessory tray.

Put the remaining accessories in the open spots like the picture to the

right shows.

Page 19

Preparations

Page 20

2:2

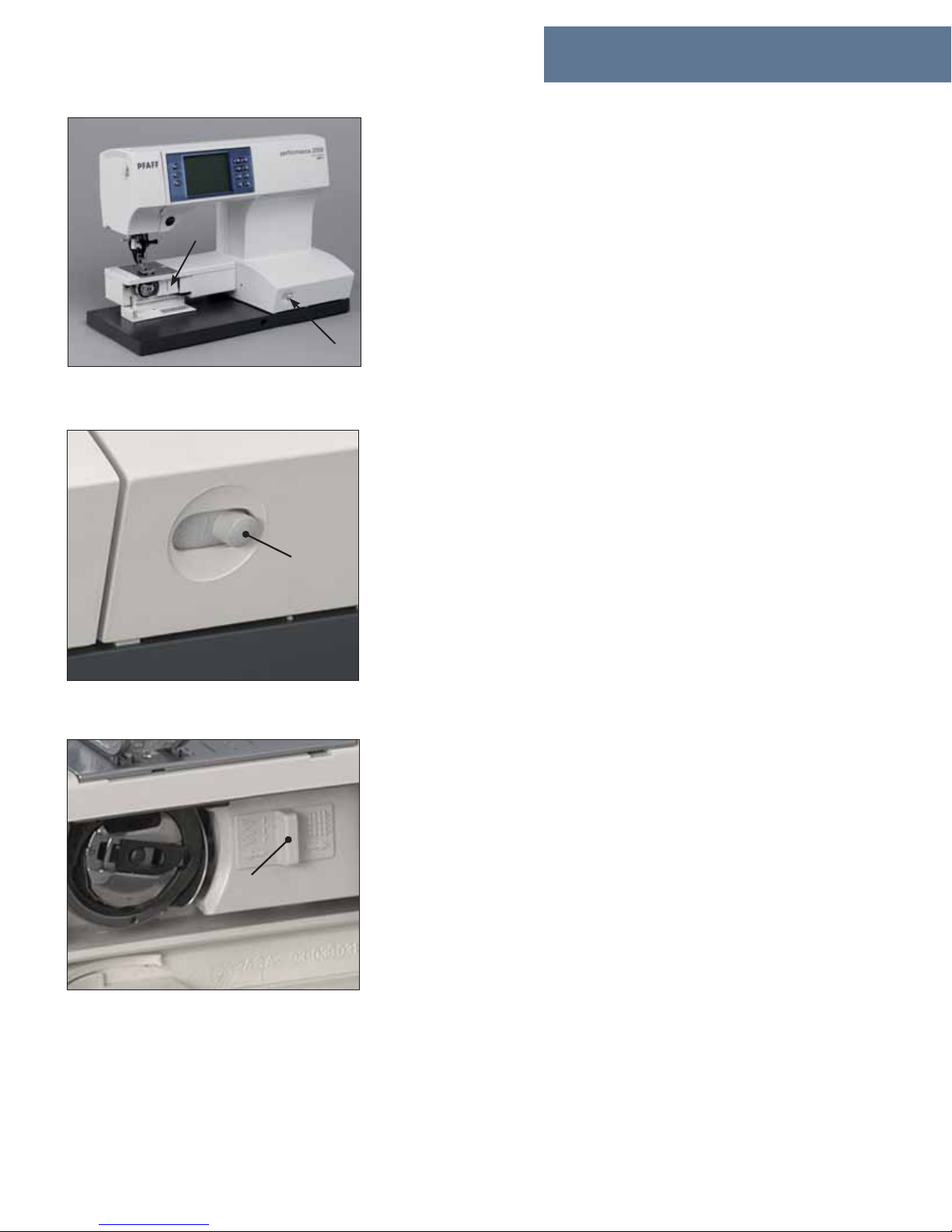

Voltage switch

220V - 240V / 120V

The sewing machine is set to the voltage 220 V - 240 V. To change the

voltage to 120 V (US/Canada), you must set the voltage switch on the

underside of the machine to 120 V.

If you are unsure of the correct voltage for your country, please check

with your authorized Pfaff dealer before plugging in your machine.

On/off switch

When the on/off switch is switched on (switch function I) the sewing

lightbulb lights up and the welcome screen appears on the touch

screen.

The sewing machine is now ready to function.

”0” = OFF

”I” = ON

Connecting the foot control

Connect the plug of the foot control to the connection socket of the

sewing machine.

The sewing speed is controlled by pressing the foot control.

The foot control type AT 0070 must be used for this sewing machine.

Electrical connection

Connect the lead cord between the socket of the sewing machine and

the wall outlet.

For the USA and Canada:

This sewing machine has a polarized plug (one blade wider than

the other). To reduce the risk of electric shock, this plug is intended

to fit in a polarized outlet only one way. If the plug does not fit

fully in the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet.

DO NOT modify the plug in any way!

Page 21

2:3

Preparations

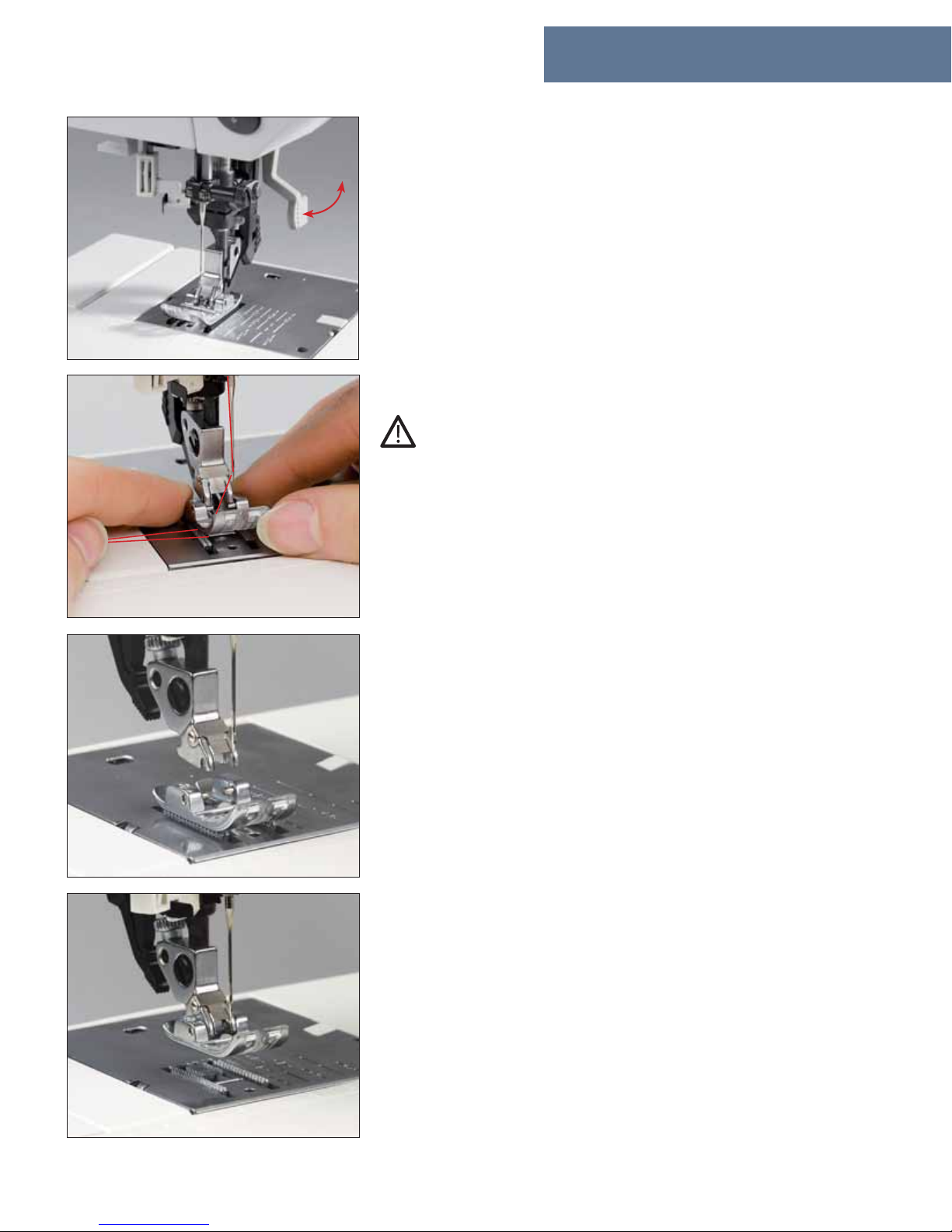

Changing the presser foot

Turn off the on/off switch

Snap off the presser foot

Press the front part of the presser foot up and, at the same time the rear

part down until it disengages from the presser foot holder.

Presser foot lift

The presser foot is raised manually by swinging the presser foot lift up

to the right. It is lowered by swinging it down to the left. See page 3:9

on how to raise and lower your presser foot automatically.

Check that the presser foot is properly attached by raising the presser

foot lift.

Snap on the presser foot

Place the presser foot under the presser foot holder, so that when the

presser foot lift is lowered the pins of the foot snap onto the presser

foot holder.

Page 22

2:4

The IDT (Integrated Dual Feed)

For sewing any fabric precisely Pfaff provides the ideal solution: the

Integrated Dual Feed, IDT system.

As on industrial machines, the IDT feeds the fabric from the top and

bottom at the same time at the same stitch length. The fabric is fed

precisely.

On light fabrics such as silk or rayon the dual feed prevents puckering

of the seam.

The even feeding action also ensures perfect matching of checked and

striped fabrics. The IDT keeps all layers of quilt projects aligned to

prevent stretching of the top layers.

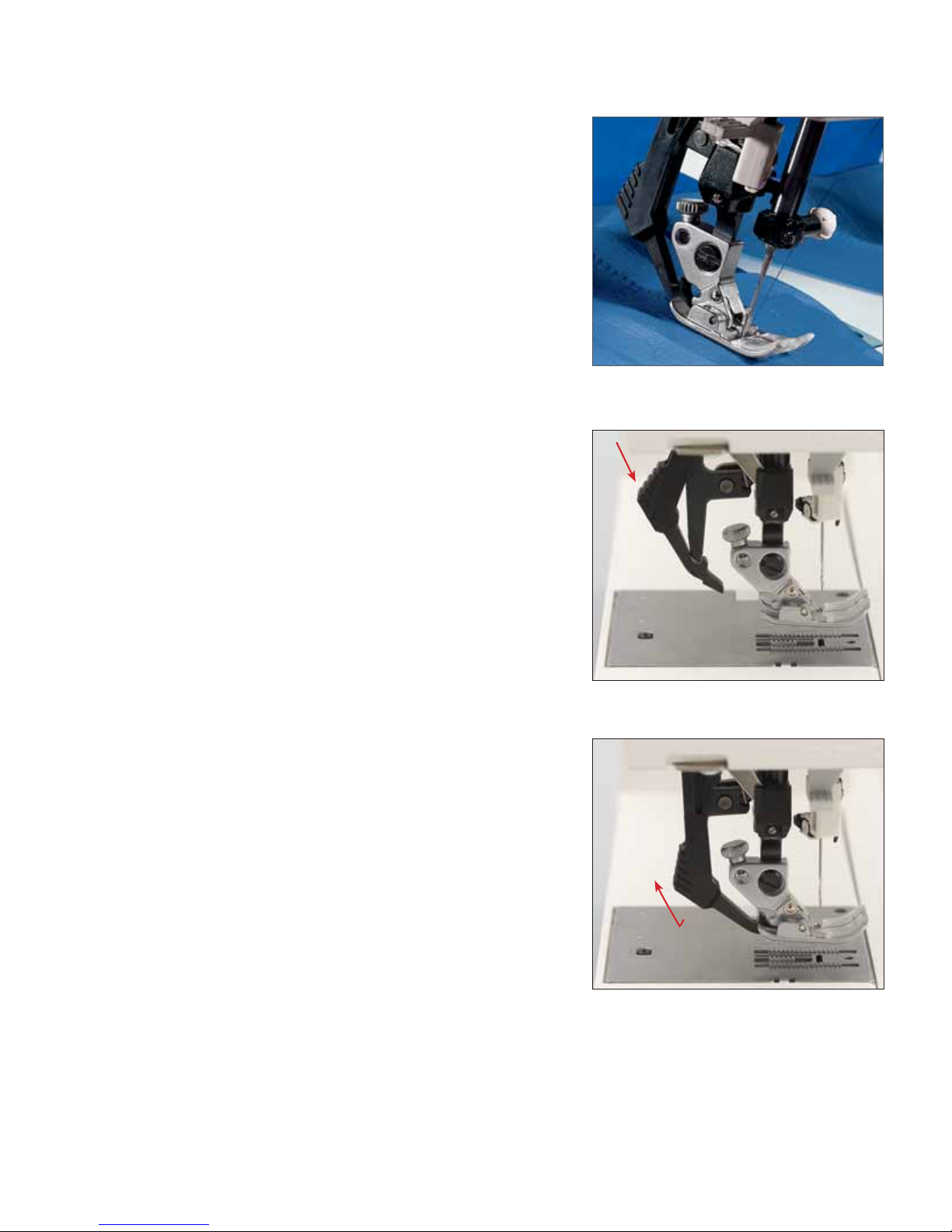

Disengaging the IDT

Raise the presser foot. Hold the IDT with two fingers on either side

of the black ribbed elbow. Press the IDT down, then release it slowly

guiding it back and up away from you.

Engaging the IDT

Raise the presser foot. Press the IDT down until it engages.

Important: For all work with the Integrated Dual Feed IDT, use

presser feet with the center back cut-out.

Page 23

2:5

A

B

A

B

Preparations

Lowering the feed dogs

For certain sewing work such as free-motion quilting, embroidery or

darning, the feed dogs must be lowered. On your sewing machine

there are two different methods for lowering the feed dogs, one on the

outside of the machine and one inside the bobbin door.

For either method:

Raise the presser foot before lowering the feed dogs. Push slide A or B

to the left.

To bring the feed dogs back up move the slide to the right.

Page 24

2:6

C

Bobbin winding

Preparing the machine for bobbin winding

Place an empty blue bobbin on the bobbin winder aligning the small

rectangular hole on the bottom side of the bobbin with the small

white pin of the bobbin winder. The Pfaff logo is facing up.

Push the bobbin to the right.

Note: The bobbin can only be wound if it is moved fully to the

right.

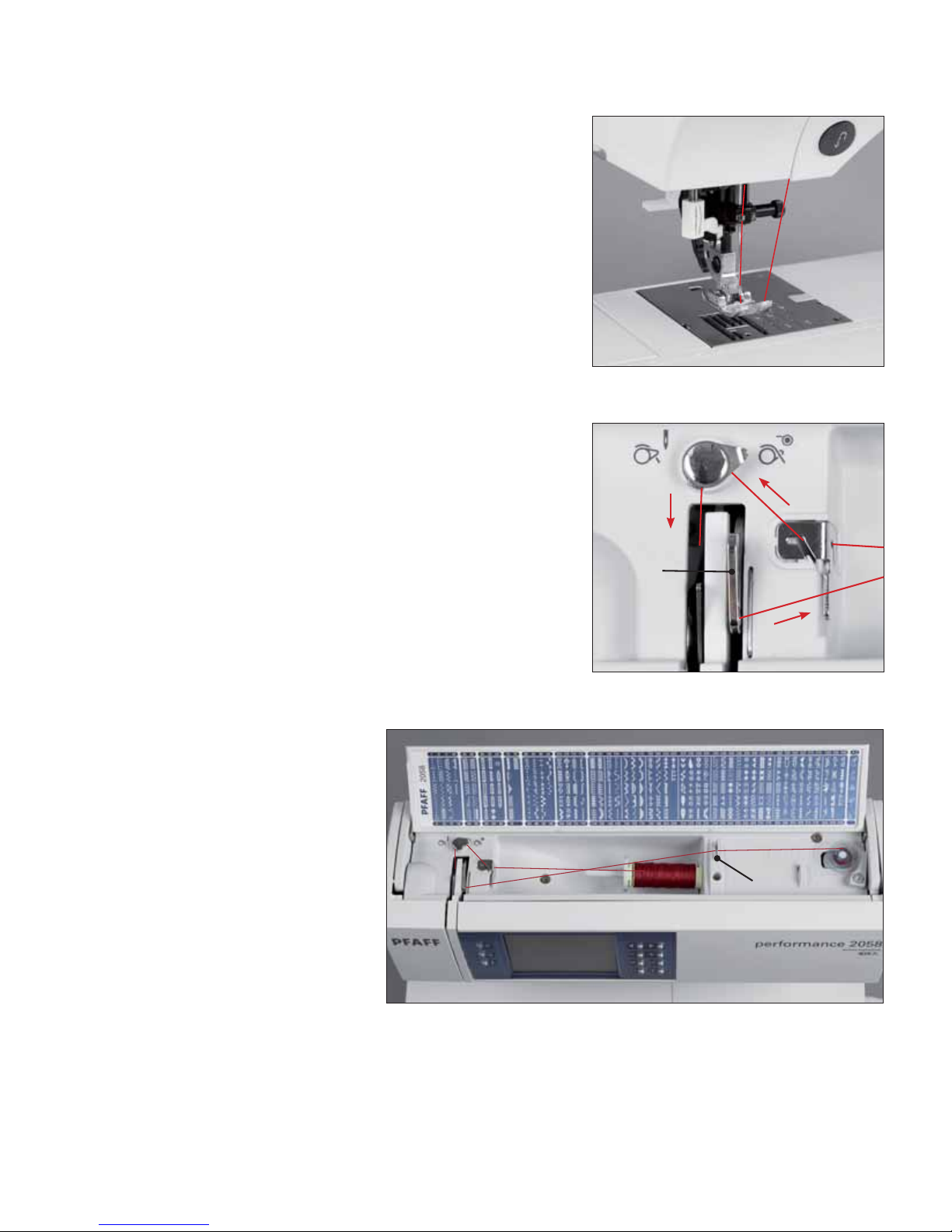

Winding the bobbin from the spool pin

Place the sewing thread on the spool

pin. Slide a spool cap firmly against the

spool. Three different spools caps to

accomodate any type of thread spool are

included with your machine. Choose a

spool cap that is the same size or slightly

larger in diameter than the spool.

Page 25

2:7

A

B

Preparations

Threading

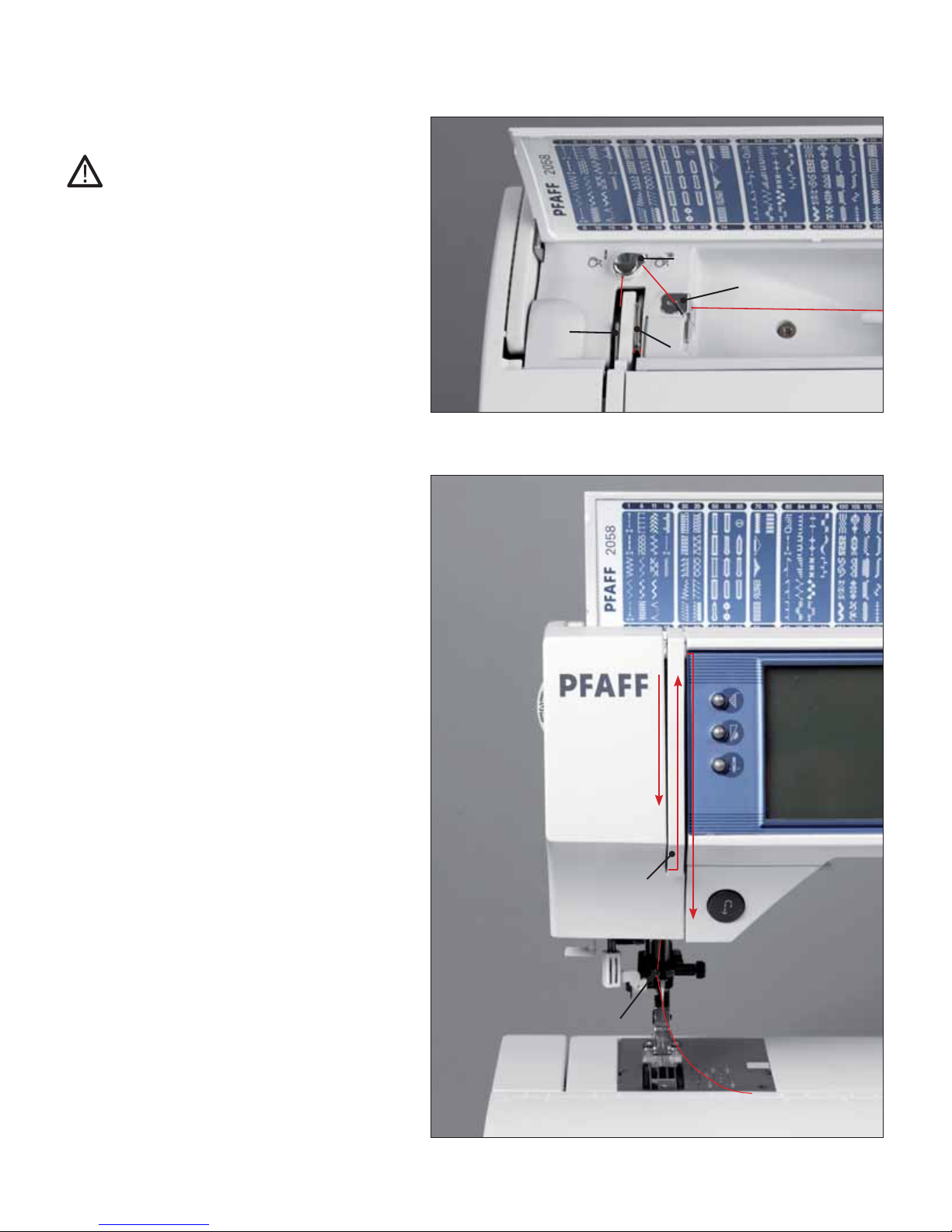

Place the thread into guide A from front to back and pull it counterclockwise ABOVE the pre-tension disc B. Pull the thread under the

thread guide C from back to front (see page 2:6). Wind the thread tail

around the bobbin several times in a clockwise direction.

Winding

Turn on the machine. Hold the end of the thread firmly and press the

foot control. As soon as the bobbin is full the winding action will stop

automatically. Push the bobbin to the left, cut the thread and remove

the bobbin from the winder.

Winding from the second spool pin

Insert the second spool pin in the hole

provided. Place the sewing thread on the

second spool pin.

Thread and wind in the same way as

shown above.

Page 26

2:8

D

C

Winding the bobbin through the needle

It is possible to wind the bobbin even when the machine is threaded.

Raise the presser foot to the up position. Pull the needle thread

underneath the presser foot and up through the right-hand threading

slot.

Pull the thread under the thread guide C

(from back to front).

Place an empty blue bobbin on the bobbin

winder aligning the small rectangular

hole on the bottom side of the bobbin

with the small white pin of the bobbin

winder. The Pfaff logo is facing up.

Wind the thread tail clockwise several

times around the bobbin. Turn on the

machine. Hold the thread tail firmly and

press the foot control.

As soon as the bobbin is full the winding

action will be stopped automatically.

Push the bobbin to the left, cut the thread

and remove the bobbin from the winder.

Pull the thread from left to right through the take-up lever D.

Important: The take-up lever must be at its highest position.

Page 27

2:9

A

B

Preparations

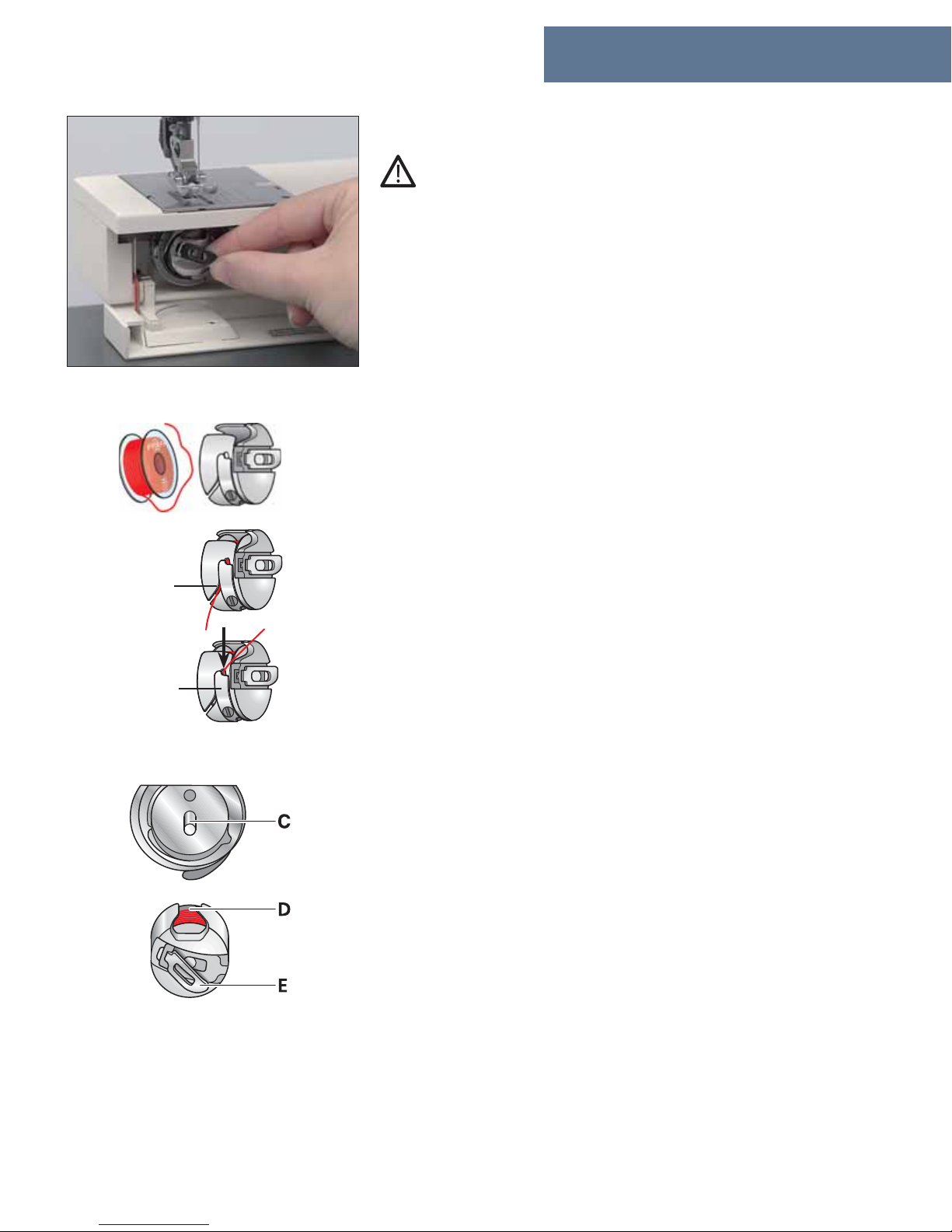

Inserting the bobbin and bobbin case

Turn off the on/off switch

Swing away the accessory tray to see the bobbin door. Open it by

pulling it towards you.

Lift the latch of the bobbin case and pull the bobbin case out of the

machine. Release the latch and take the empty bobbin out of the

bobbin case.

Inserting the bobbin case

Lift latch E and push the bobbin case fully onto pin C of the sewing

hook. Opening D of the bobbin case must face up.

Check: Pull the bobbin thread sharply. The bobbin case must not

fall out of the hook.

Inserting the bobbin

Insert the full bobbin (with the Pfaff logo facing towards the bobbin

case) in the bobbin case. When doing so, pull the thread through slot

A, then under tension spring B until it rests in the opening (see arrow).

Check: Hold the bobbin case with the bobbin facing towards you.

When you pull the thread, the bobbin must turn clockwise.

Page 28

2:10

A

B

D

F

C

E

Threading your machine

Turn off the on/off switch

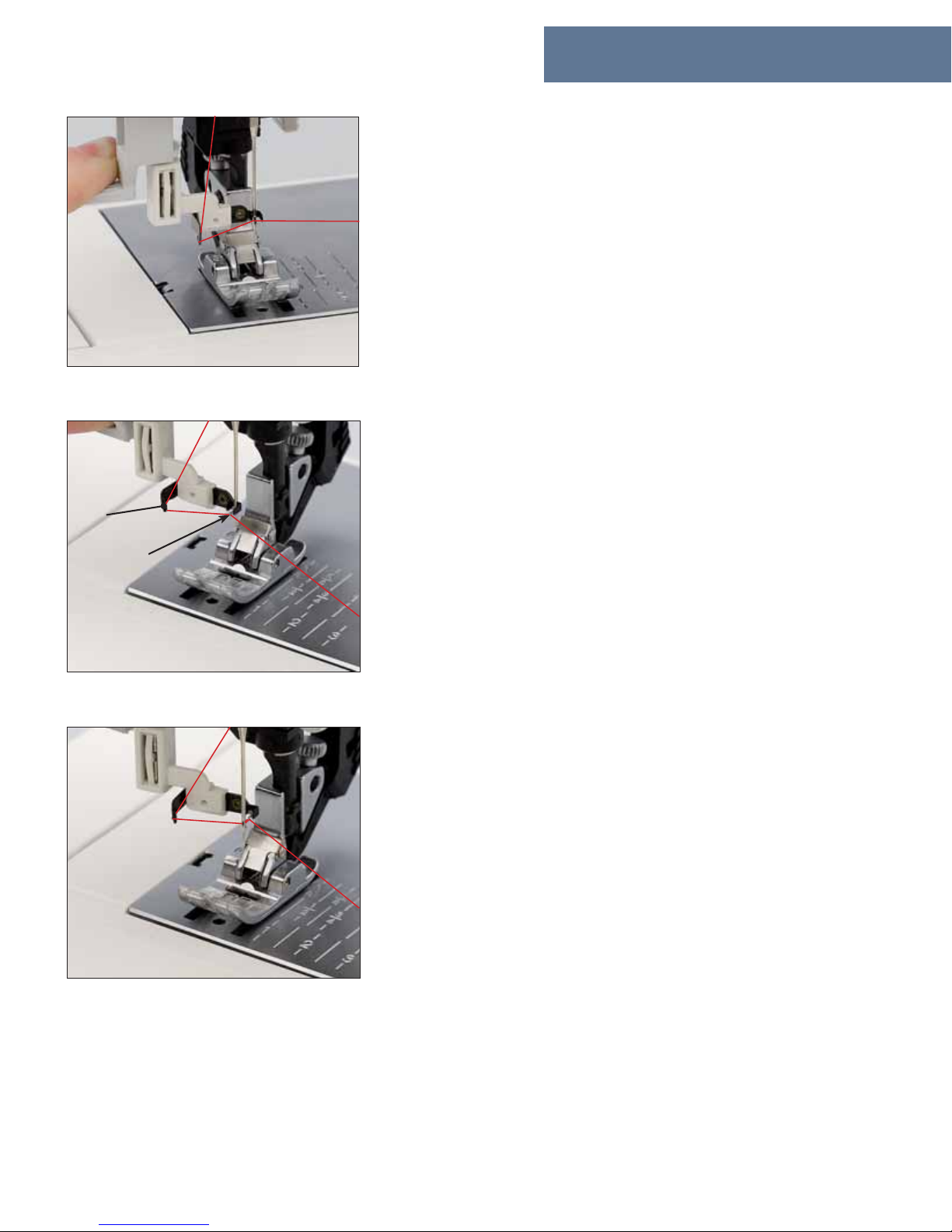

Raise the presser foot. Place the thread on the

spool pin and fit a spool cap, either the same

size or slightly larger than the spool, on top of

the spool.

Using both hands, pull the thread into thread

guide A from the front.

Place the thread from the right underneath the

pre-tension disc B.

Now pass it through the tension disk C in the

left threading slot.

Pull the thread down, around the stop D, into

the right threading slot and up to the take-up

lever E. The thread must be pulled into the takeup lever from left to right.

Pass the thread down in the right-hand

threading slot.

Pull the thread from the side behind the left

thread guide F.

Page 29

2:11

F

E

Preparations

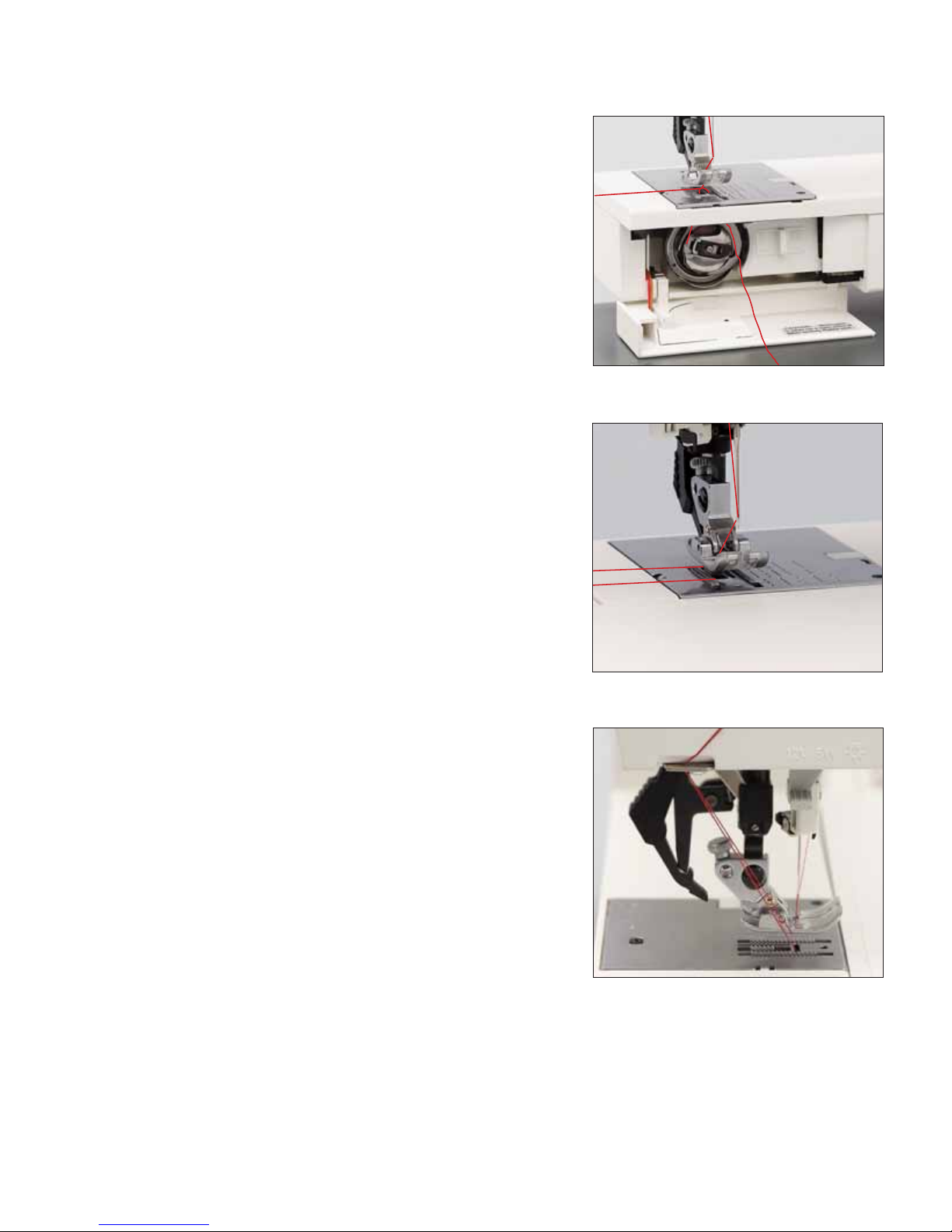

Integrated needle threader

In order to make threading the needle easier and quicker, use the Pfaff

Integrated needle threader. Lower the presser foot. Pull the threader

lever straight down with the handle.

Reduce the pressure so the needle threader slowly moves upwards.

At the same time the threader hook swivels out of the needle eye and

pulls the thread through the eye.

Release the end of the thread so a thread loop forms behind the needle.

Release the threader and pull the rest of the thread end through the

needle eye.

Threader hook F swivels through the needle eye. Bring the thread

around hook E and back across the front of the needle eye. Hold the

end of the thread taut and slide it up to catch the threader hook F.

Page 30

2:12

Bringing up the bobbin thread

Raise the presser foot. While holding the end of the needle thread,

press the foot control so the needle moves down and up one time.

Pull the needle thread to draw up the bobbin thread.

Thread cutter

Pull the threads from the back to the front over the thread cutter.

Close the bobbin door and pull the top and bobbin threads under the

presser foot to the left.

Page 31

2:13

C

Preparations

Changing the needle

Turn off the on/off switch

To remove: Lower the presser foot and set the needle to its highest

position. Loosen the needle screw and pull down on the needle to

remove.

To insert: The flat side of the needle must face to the rear. Keep the

presser foot down and insert the needle, pushing it up as far as it will

go. Hold the needle and tighten the needle screw firmly.

Threading the twin needle

Turn off the on/off switch

Replace the sewing needle with a twin needle. Insert the second spool

pin and place one spool of thread on each of the spool pins. On the

vertical spool pin, place a spool cap and a felt pad underneath the

spool of thread.

When threading make sure to pass one thread to the left and one

thread to the right side of tension disk C.

Continue threading in the usual manner, making sure the threads do

not twist together.

Pull one thread into the right thread guide above the needle, and the

other thread into the left. Thread the needles.

Note: It is not possible to use the Integrated Needle Threader with a

twin needle.

Page 32

2:14

Correct thread tension - How to get it

Set the required amount of the needle thread tension using the

markings on the tension dial.

The normal thread tension for sewing is 4 - 5. For decorative stitches,

darning or sewing buttonholes, the normal setting should be 3.

The information system of your sewing machine gives you

recommendations on the touch screen for the correct needle thread

tension for each stitch (see ”Information in the sewing menu” page

3:15).

Thread tension

For the best stitch appearance and durability make sure the needle and

bobbin thread tensions are balanced with one another, i.e. the threads

evenly meet between the two fabric layers.

The following is valid for general sewing work:

Bobbin thread is visible on the top side of the fabric:

The needle thread tension is too tight.

The needle thread tension must be reduced.

Top thread is visible on the underside of the fabric:

The needle thread tension is too loose.

The needle thread tension must be increased.

Note: For decorative stitches and buttonholes the top thread should

be visible on the underside of the fabric.

Page 33

2:15

Preparations

Electronic knee lift

Your sewing machine comes with an electronic

knee lift for regulating the presser foot height. It

is useful when you need both of your hands to

guide the fabric.

1. Push the knee lift, with the flat side facing

up, into the hole on the front baseplate of

your machine.

2. Adjust the rectangular bar on the knee lift

until it is positioned at a comfortable height

for you.

If you press the knee lift to the right, the presser

foot will raise. Now you can guide the fabric

with both hands.

To remove the knee lift, pull it gently straight

out of the hole.

Page 34

Page 35

Operating your

performance 2058

Page 36

1

4

3

2

5

6

7

8

9

3:2

Operating your machine

Your sewing machine is easily operated by using the touch screen and

the function buttons, located on the front of your machine.

When you turn on your machine a welcome text appears on the

display. Touch the screen to enter the main menu.

The machine is now ready to sew and you can start selecting stitches,

adjusting settings, activating sewing functions and creating your own

stitches and stitch sequences.

When you touch the display, your sewing machine can help with popup messages and with the information system. Pop-up messages are

closed simply by touching the message on the screen or pressing the

foot control.

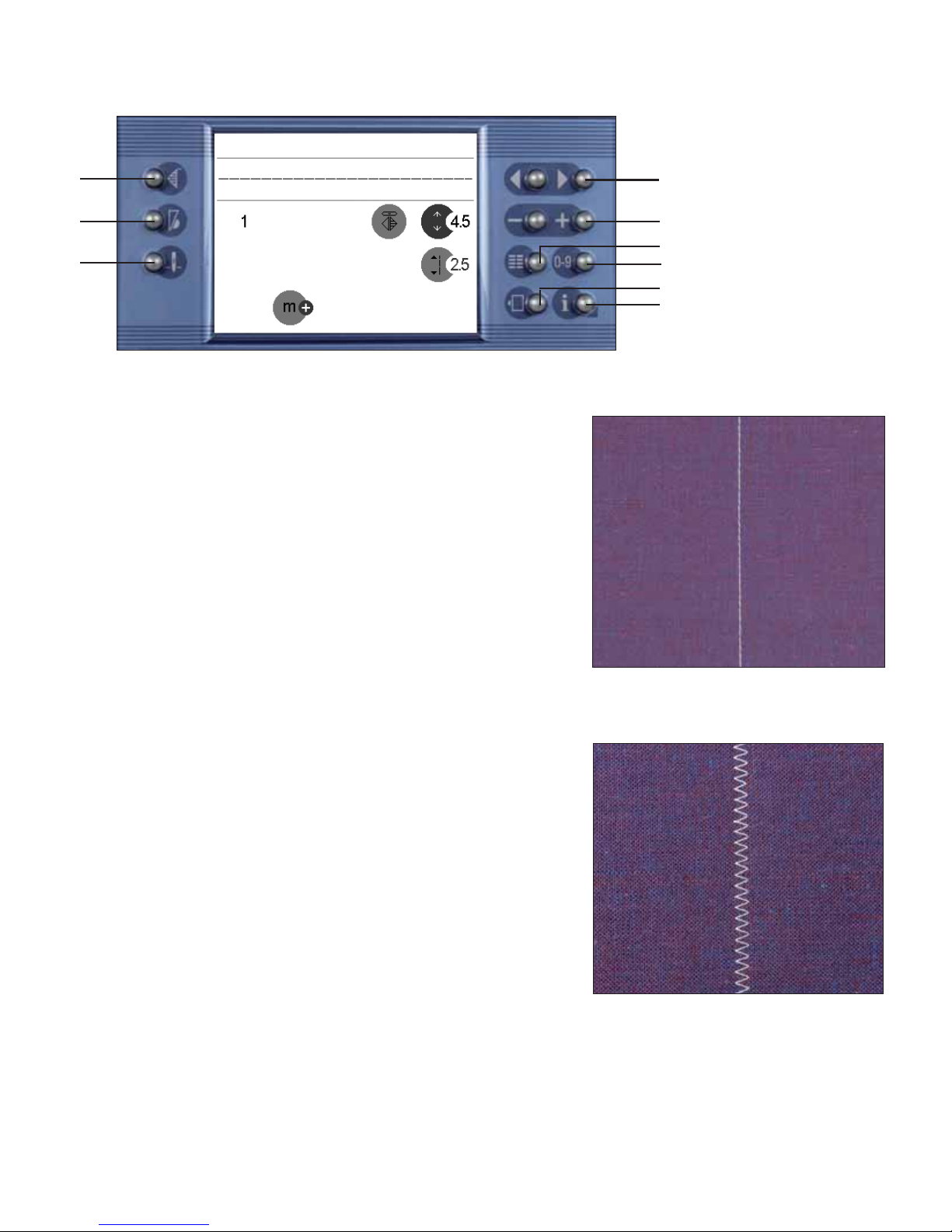

Function buttons

1. Pattern restart

Press pattern restart to return to the starting point of a stitch or stitch

sequence.

2. Sew slow

Sew slow can be activated when you are in a sewing menu for a

selected stitch. The function reduces sewing to half speed. An icon on

the status bar indicates that the function is activated. Press the button

again to deactivate the function.

3. Needle up/down

Needle up/down can be activated when you are in a sewing menu

for a selected stitch. Press the button to set the needle to automatically

stay in the down position when you stop sewing. A window opens to

set whether and how high the presser foot will raise when you take

your foot off the foot control. You can choose between ”No”, ”low”

(3mm), ”medium” (6mm) and ”high” (9mm). When you press the foot

control again the presser foot is automatically lowered. This function is

great for pivoting your fabric. An icon on the status bar indicates that

the function is activated. Press the needle up/down button again to

deactivate the function.

Check: If the screen is too dark or too

light, you need to adjust the contrast.

See page 3:12 for instructions.

Page 37

3:3

Operating your performance 2058

Note: The needle height can also change with a short tapping on

the foot-control.

4. Scroll buttons

These buttons have following functions:

• In the selection menu: Scroll through stitches and sequences by

column or page.

• In the sewing menu: Select the next or the previous stitch in

numerical order.

• In the stitch sequence menu: Move the cursor in the action field or

scroll through the stitches in the preview field.

• In the stitch creator menu: Move the selection point in the

workspace stitch by stitch.

• In the information system: Scroll through multiple pages.

5. Function field buttons

Touch stitch parameter icons (width, length, balance) and adjust the

settings with these buttons.

6. Main menu button

Press this button to go back to the main menu. Sometimes you may

need to press the button more than once to close all open windows.

7. Selection by number button

Open the stitch selection by number.

8. More options button

Open the more options window for processing or modifying a selected

stitch.

9. Info button/Context menu

Press the button once to open the info system. Long touch the button

to open the context menu.

10. Reverse sewing

This button has the following functions:

• Quick reverse: Press the button while sewing. The machine sews in

reverse for as long as you hold the button.

• Permanent reverse: Press the button before starting to sew. The

machine sews in reverse until you press the button again. When the

function is activated, a reverse sewing arrow appears on the touch

screen.

• If you have activated the tie-off program, tie-off at the end is

initiated via this button.

• In the ”patchwork”, ”tapering” and ”darning” programs, you

determine the length of the seams with this button.

• When you are programming a buttonhole, you determine the

length of the buttonhole seam with this button.

10

Page 38

6

3:4

Main menu

When you have turned on your machine and touched the welcome

screen the main menu appears. From here you enter the selection

menus to select stitches by category or create your own stitches and

stitch sequences. When you touch any of the icons on the screen new

windows are opened for each menu. You can always go back to the

main menu by pressing the main menu button (6).

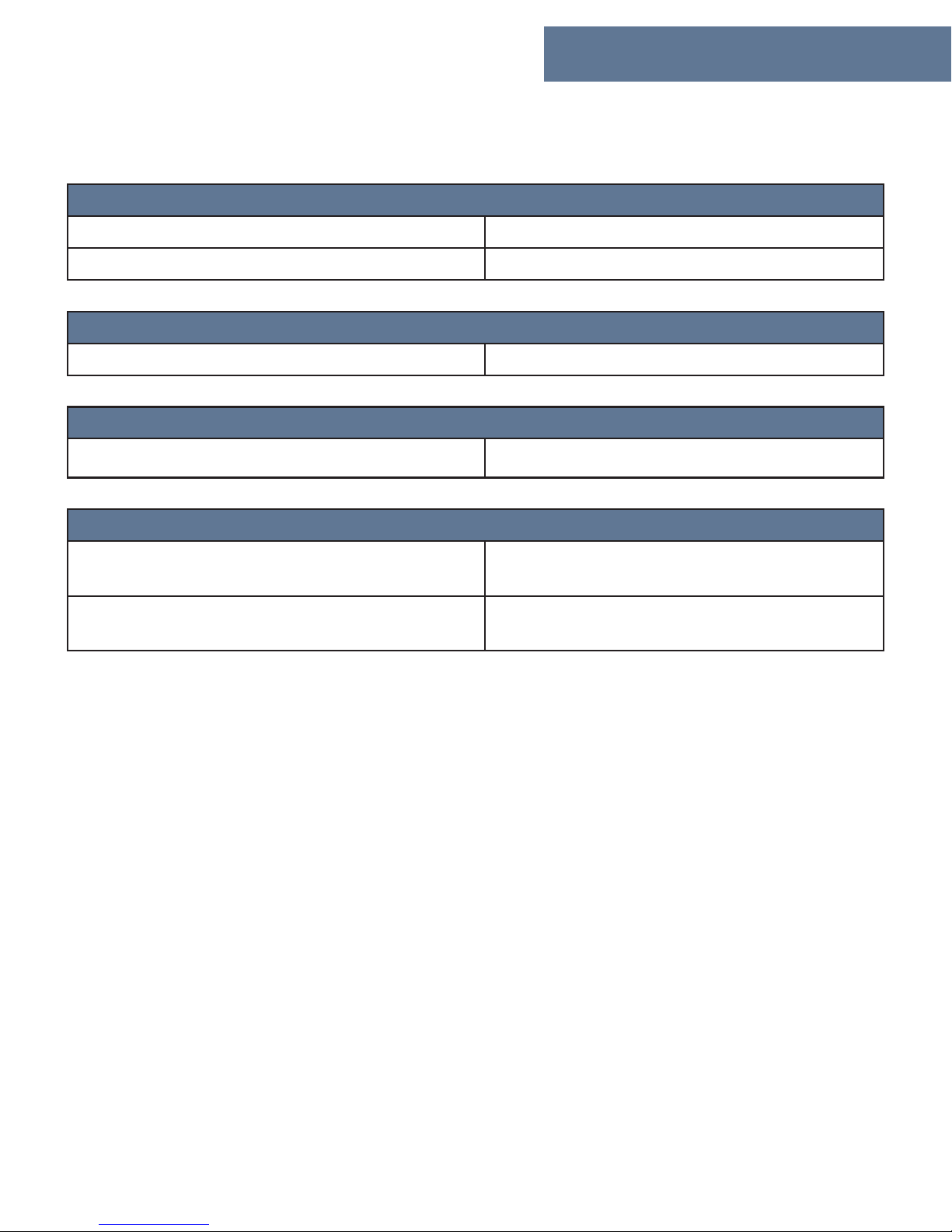

Selection menus

Utility stitches

Stitches 1-18

This menu provides a selection of stitch types that you can use for a

variety of sewing techniques.

Overlock stitches

Stitches 30-39

This menu provides a selection of all stitch types suitable for

overcasting or joining and overcasting in one operation.

Antique quilt stitches

Stitches 80-96

This menu provides a selection of quilt stitches suitable for crazy patch

quilting.

Cross stitches

Stitches 100-119

Pre-programmed cross stitches allow you to create traditional borders.

Individual cross stitches (110-119) allow you to program your own

designs.

Page 39

3:5

Operating your performance 2058

Decorative stitches

This menu includes a selection of decorative stitches suitable for

embellishing garments or items for the home.

They are sub-divided into eight different categories for ease of

selection.

• Hemstitches. Stitches 130-139.

• Antique hand embroidery stitches. Stitches 140-149.

• Scallop edges. Stitches 160-174.

• Satin stitches. Stitches 190-206.

• Leaves and flowers. Stitches 220-239.

• Art stitches. Stitches 240-279.

• Ornamental stitches. Stitches 290-319.

• Fun stitches. Stitches 330-343.

Buttonholes

Stitches 50-63

This menu provides a selection of 12 different buttonhole styles,

one automatic eyelet and one program for sewing on buttons. Each

buttonhole style is designed for a specific application and fabric.

Darning and bartacks

Stitches 70-75

This menu provides a selection of bartacks and darning stitches. The

various bartacks are for reinforcing pocket corners, skirt plackets/slits

and attaching belt loops. The fully automatic darning programs are for

repairing damaged areas and darning tears or small holes.

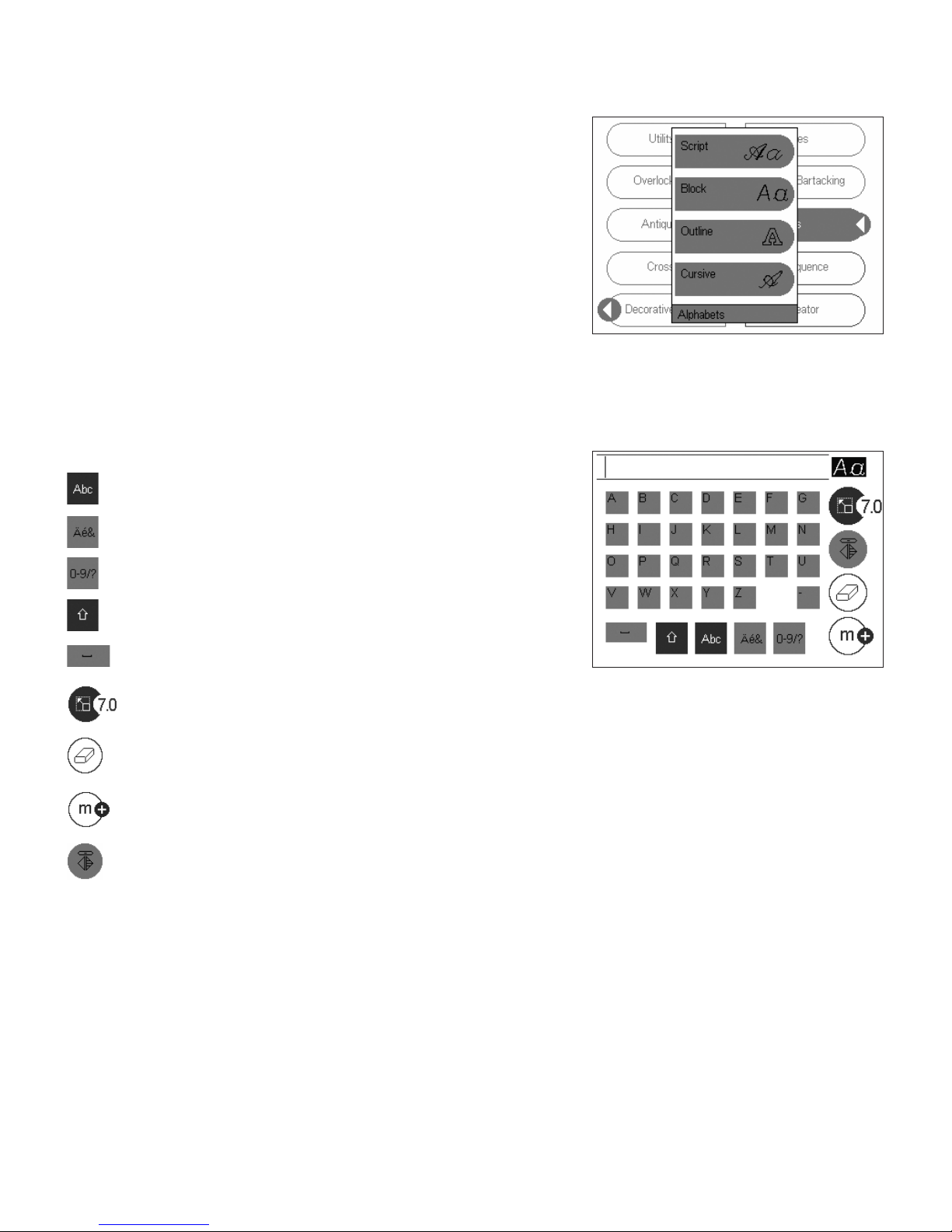

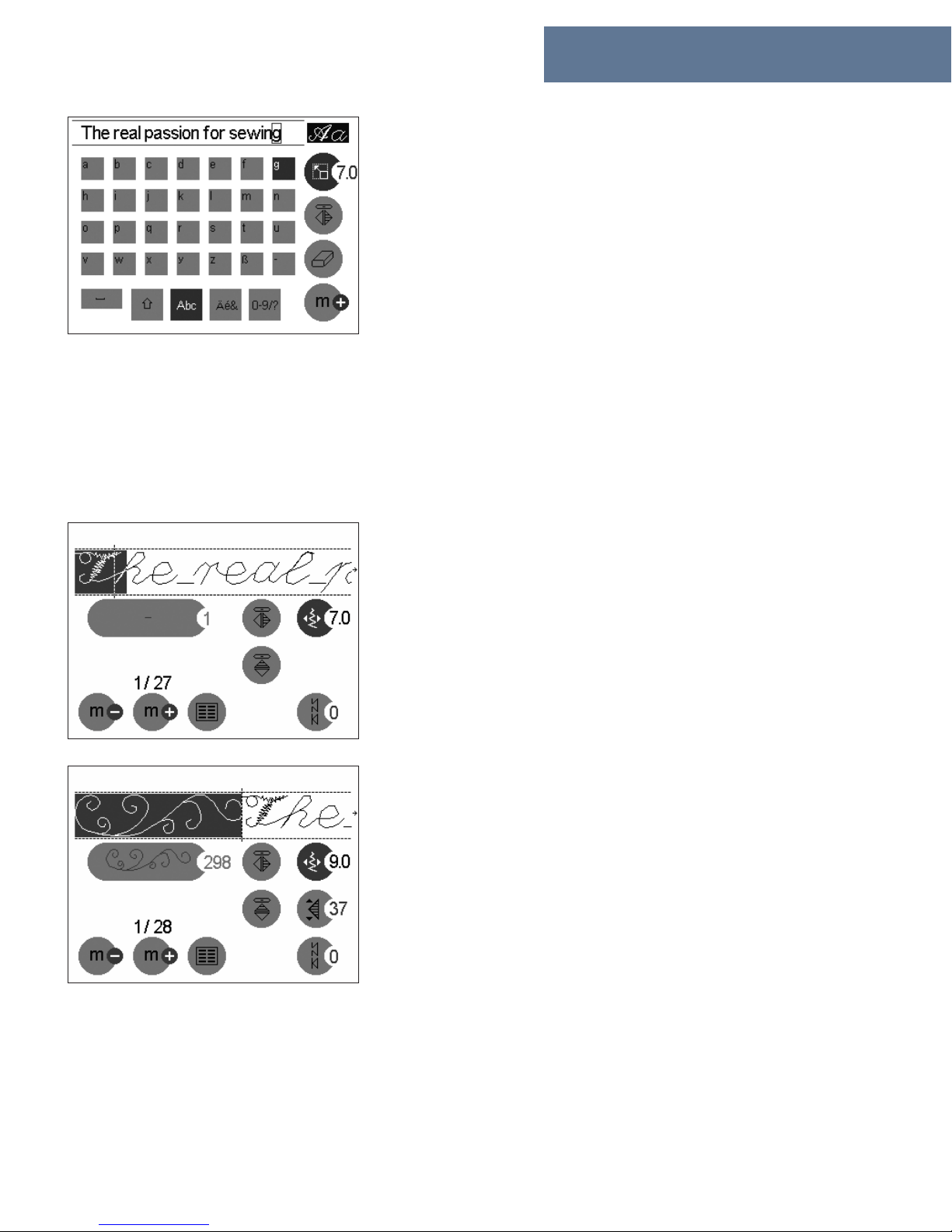

Alphabets

This menu provides a selection of four fonts: Script, Block, Outline and

Cursive. The alphabets include numbers and symbols. The Script and

Block alphabets include lower case letters.

Stitch sequence

In this menu you can store your own stitch sequences. Select an empty

M-memory to create and store a new stitch sequence, or a full memory

to use or overwrite an already stored sequence. Your sewing machine

can store up to 50 sequences.

Stitch Creator

In this menu you can customize, create and store your own stitches.

Select an empty S-memory to create and store a new stitch, or a full

memory to use or overwrite an already stored stitch. Your sewing

machine can store up to 30 stitches created in Stitch Creator.

Page 40

3:6

Selecting a stitch

There are several ways to select a stitch:

Selection by category

Touch ”Utility stitches” from the main menu.

This category contains 18 stitches that are suitable for utility sewing.

You can browse one page at a time with the scroll buttons (4) or by

touching the scroll bar (A) on the screen.

By pressing the scroll buttons (4) or by touching the scroll bar (A) on

the screen you can continue to browse through all stitches.

You select a stitch by touching it on the screen and the sewing menu

opens for that stitch.

Selection by number

Press the selection by number button (7) to call up a stitch by number.

A pop-up will open with a number pad.

Enter the stitch number and confirm by touching ”ok”.

The eraser icon (B) deletes the right hand digit. If a stitch number that

does not exist is entered, a pop-up message is displayed:

”Invalid stitch number!”

Touch the pop-up message to close it.

Direct selection

When you are in the sewing menu for your selected stitch you can use

the scroll buttons (4) to select a different stitch. Scroll back and forth

through the stitches in numerical order. After the last stitch you will

find stitches created and stored in Stitch Creator.

B

A

Page 41

1

2

3

4

1

2

3

5

3:7

Operating your performance 2058

Sewing menu

The sewing menu is divided into three sections:

1. Status bar, where the activated sewing functions are shown. The

status bar is always active and automatically updated when a

function is activated or deactivated.

2. Action field, where the selected stitch is displayed.

3. Function field, with sewing functions and stitch parameter settings.

The figure in the upper left corner of the function field indicates the

selected stitch number.

Icon status

1. Inactive, the function can not be activated.

2. Active, the function can not be deactivated.

3. Inactive, the function can be activated.

4. Active, the function is selected and can be deactivated.

Altering the stitch settings

Needle position. For straight stitches. Touch the icon and move

the needle position with the function field buttons (5). There are 19

needle positions available. The + button moves the needle in nine

steps to the right. The - button moves the needle in nine steps to the

left.

Stitch width. Touch the icon and change the stitch width with the

function field buttons (5).

Stitch length. Touch the icon and change the length of the stitch

with the function field buttons (5).

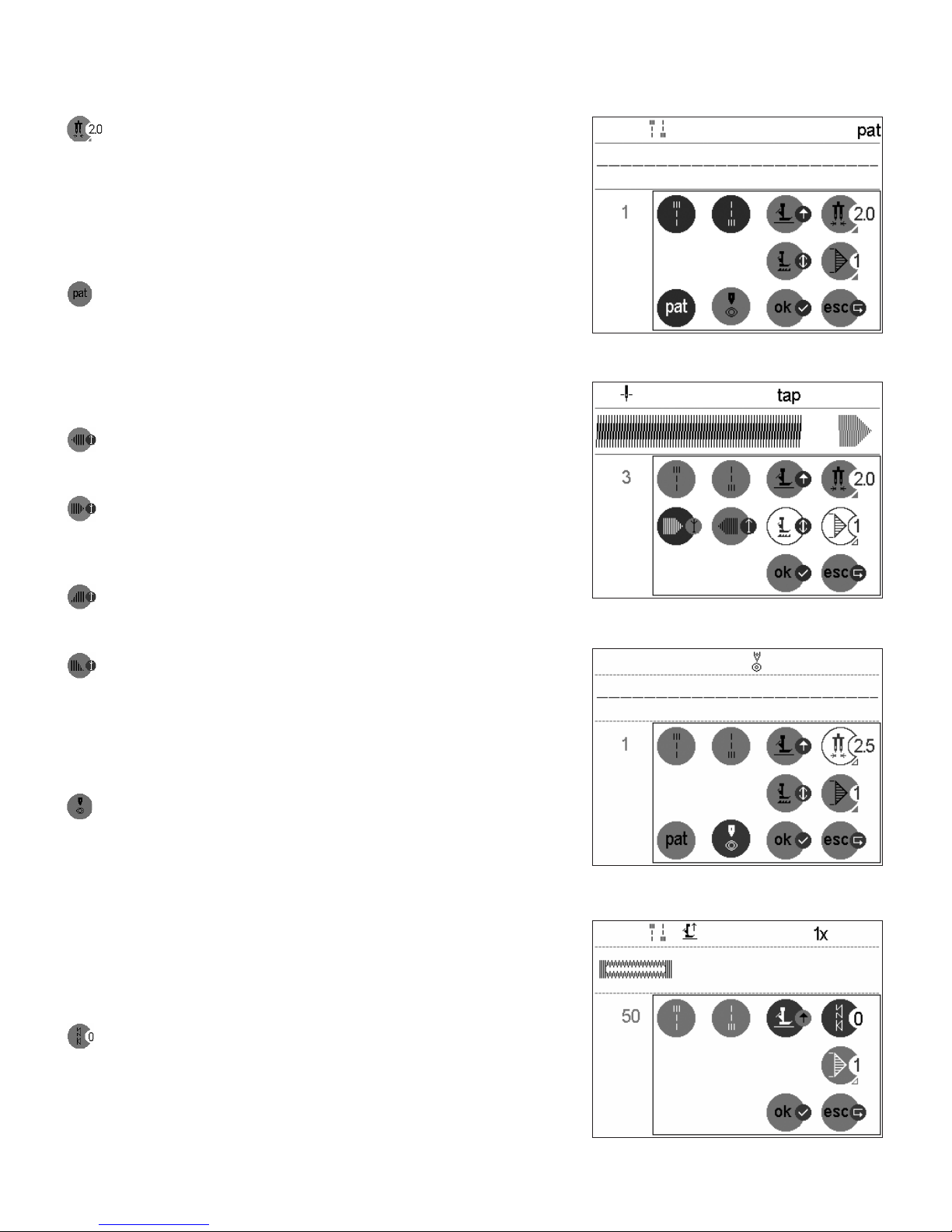

Pattern length. For decorative stitches, buttonholes, satin stitches,

scalloped edges and some utility stitches. Touch the icon and

increase or reduce the length of the stitch with the function field

buttons (5).

Balance. Touch the icon and fine tune the stitch balance with the

function field buttons (5).

Density. For satin stitches, scalloped edges and buttonholes.

Touch the icon and change the stitch density with the function

field buttons (5), without changing the length of the pattern or

buttonhole.

Side to side mirroring. Touch the icon to mirror a stitch or a

sequence side to side.

End to end mirroring. Touch the icon to mirror a stitch or a

sequence end to end.

Add a stitch to a sequence. The stitch sequence menu appears

automatically by touching the icon.

Page 42

3:8

For buttonhole and darning programs. In the darning programs

(no. 74-75) the function is automatically activated. Use the reverse

button (10) to determine the length of the first seam. The following

seams will automatically be sewn in the same length.

Finish buttonholes manually. Use the function if the sensormatic

buttonhole guide has not been inserted.

If the settings are changed the font turns italic and a small arrow above

or below the figures indicates if the settings are increased or decreased.

Note: If you exit a sewing menu, the settings are reset to default.

For saving your own settings go to ”Stitch parameters” in the

context menu (see page 3:13).

Buttonhole programs

Use the buttonhole foot no. 5A and the sensormatic buttonhole guide

no. 10 to sew perfect buttonholes on all kinds of fabric. See page 4:7

for instructions on changing to the buttonhole foot and inserting the

sensormatic buttonhole guide.

Buttonholes can be sewn in three different ways:

1. Enter the length directly on the screen in mm (recommended).

Touch the pattern length icon and set the size of the buttonhole slit

with the function field buttons (5). The buttonhole will be sewn

automatically to fit the button.

2. Length setting while sewing

. Touch the ”prog” icon. Sew the

forward buttonhole seam and press the reverse button (10) when

you have reached the correct buttonhole size. A mark appears

in the ”prog” icon. The rest of the buttonhole will be finished

automatically. The mark in the icon means that the buttonhole is

automatically saved and can be repeated as many times as you

wish. To program a different buttonhole length, without leaving the

menu, you must first touch the ”prog” icon to remove the mark and

then sew the new buttonhole. Touch the ”prog” icon once more to

deactivate and be able to choose other functions.

Note: If the sensormatic buttonhole guide has not been inserted you

will have to finish the buttonhole manually by pressing the reverse

button (10).

3. Finish buttonholes manually. If the sensormatic buttonhole guide

has not been inserted the buttonhole can be finished manually.

Activate ”man” by touching the icon. The forward buttonhole

column will be sewn in the length you enter on the screen. The

reverse buttonhole column will be finished after you have pressed

the reverse button (10). When the buttonhole is finished, touch

Page 43

3:9

Operating your performance 2058

the ”man” icon again and a mark will appear. This means the

buttonhole is saved and you can repeat the buttonhole in the same

size automatically. Touch the ”man” icon once more to deactivate

the function.

Note: If you find that the buttonhole columns don’t look the same

you can change the balance of the buttonhole. Touch the balance

icon in the more options window (8) and change the left column

with the function field buttons (5), touching + to open the density

and - to lessen the density.

More options for sewing

By touching the more options button (8) you can call up a dialog

window with more functions for processing or modifying a stitch.

Only sewing functions that can be used with the stitch are visible.

Activated functions are displayed in the status bar.

Icons in the more options window

Ok. Saves all the settings and closes the more options window.

You can also press the foot control to save without closing the more

options window and be able to make further settings.

Escape. Closes the window without the modified settings being

saved.

Tie off at start. The start of the stitch is tied off with four stitches.

Tie off at end. The end of the stitch is tied off with four stitches.

Touch the reverse button (10) to trigger the function. The machine

ties off and stops.

Raise presser foot. The machine will automatically raise the

presser foot when the machine stops and lower it when you start

sewing again. If both the presser foot raise and tie off at end

functions are activated, the presser foot is only raised when the

seam has been tied off.

Note: The settings of the presser foot in the needle up/down

function override the raise presser foot function (see page 3:2).

Free-motion sewing. Activate the free-motion program to make

sure that the tension is engaged and the presser foot height

automatically adjusts providing free fabric movement while

creating a perfect stitch.

Single stitch. A stitch or a stitch sequence can be sewn as a single

stitch. You can also set a single stitch to be repeated a number of

times. Long touch the icon until a window appears. Change the

number of repetitions with the function field buttons (5), confirm

by touching the window. You can repeat a single stitch up to 99

times. The number of repetitions are displayed in the status bar.

Tie-off is automatically performed at the beginning and at the end

of the stitch.

Page 44

3:10

Twin needle safety. With this function, you reduce the width of

your stitch in order to use a twin needle. To set the correct needle

spacing of your twin needle, long touch the icon until a window

appears. Set the needle spacing with the function field buttons (5)

and confirm by touching the window. The function remains active

even after a stitch has been changed, including after the machine

has been switched off and on. Touch the icon again to deactivate

the function.

Programmable seam length function for straight stitch. Specify a

particular seam length for joining together several pieces of fabric

of equal length. Tie-off is automatically activated. Press the reverse

button (10) when you reach your desired length, the machine ties

off and stops. All subsequent seams are now automatically sewn in

your specified length until you deactivate the function by touching

the icon again.

Symmetrical tapering, increase. For zigzag stitch no. 3. The width

of the zigzag stitch starts with 0mm and becomes wider until it

reaches the selected maximum stitch width.

Symmetrical tapering, reduce. For zigzag stitch no. 3. The width

of the zigzag stitch starts at the selected maximum stitch width and

tapers to 0mm when the reverse button (10) is pressed. It stops with

the needle in the down position.

Asymmetrical tapering, increase. For zigzag stitch no. 33. The

width of the zigzag stitch starts with 0mm and becomes wider until

it reaches the selected maximum stitch width.

Asymmetrical tapering, reduce. For zigzag stitch no. 33. The

width of the zigzag stitch starts at the selected maximum stitch

width and tapers to 0mm when the reverse button (10) is pressed. It

stops with the needle in the down position.

Note: See page 5:4 for further instructions on using the tapering

function

Straight stitch safety. Select this function when using a straight

stitch needle plate and/or a straight stitch presser foot to lock the

center needle position (4.5mm) for all straight stitches to prevent

damage to the needle, presser foot or needle plate. This function

remains active even after a stitch has been changed, including after

the machine has been switched off and on. To sew with a stitch that

is not supported by the straight stitch safety the function must be

deactivated. Touch the icon again to deactivate the function and go

back to normal sewing.

Note: Twin needle and straight stitch safety cannot be used at the

same time.

Balance for buttonholes. Touch the icon and fine tune the stitch

balance with the function field buttons (5).

Page 45

3:11

Operating your performance 2058

Context menu

In the context menu you can alter the basic settings or functions for the

sewing machine. Long touch the info button (9) to open the context

menu. Press this button again to close the menu. The menu will also

close when a dialogue window has been confirmed with ”ok” or ”esc”.

If the context menu is closed with the info button when a sub window

is open, the settings will not be saved.

The context menu offers specific functions for each menu. Some of the

functions are available from all menus.

Select language (Available from main menu)

With this function you select the language of your sewing machine.

Touch ”Select language”, to open the language selection window,

and touch the language of your choice. The window closes when a

language has been selected.

Audio signal (Available from all menus)

With this function you can choose an audio signal to be heard when

you touch icons, press buttons and when pop-up messages appear.

Touch ”Press button” to turn on or off the audio signal for icons and

buttons. Touch ”Message texts” to turn on or off the audio signal

for pop-up messages. If the audio signal is activated the icon is

highlighted. Touch ”ok” to save your settings.

Options for messages (Available from main, sewing, sequence and

stitch creator menus)

In this menu you can switch off the warning message that

automatically appears in the machine when the bobbin thread is

running out. You can also specify whether the machine should stop

when the warning appears. An X means that the function is switched

on. All functions are active as default. Touch “ok” to save your

settings.

Page 46

3:12

Calibration (Available from main menu)

If you touch an icon on the touch screen and it does not respond,

or the function next to it is activated instead, the screen needs to be

calibrated.

Touch ”Calibration” and three circles appear in three of the corners.

The circle in the upper left corner is flashing. Touch the area inside the

flashing circle with your stylus until you hear a beep, to fix the first

point. Fix the two following points in the same way. The calibration

display closes after finished calibration.

To cancel the calibration press the info button (9).

If the calibration fails, a pop-up message appears: ”Entry cannot be

accepted!”. In this case the calibration needs to be done again.

Welcome screen (Available from main menu)

The welcome screen that appears when the machine is switched on

can be deactivated. Touch the icon ”Welcome screen” to toggle on/off.

The context menu closes automatically when you touch the icon. If

the welcome screen is activated the icon is highlighted in the context

menu.

Raise presser foot (Available from main, sewing, sequence and stitch

creator menus)

You can preset the presser foot to raise automatically to a certain

position every time needle up/down is activated.

”Display window selection” is the standard setting. With this setting a

selection window for the presser foot will appear every time you press

the needle up/down button (3), see page 3:2.

Contrast (Available from all menus)

In this menu you can adjust the contrast of the touch screen. Use the

function field buttons (5) or the arrows on the screen to adjust the

contrast setting between 0-30. Touch the contrast window, outside the

arrows to close the menu and save the settings.

Page 47

3:13

Operating your performance 2058

Stitch parameters (Available from sewing menu)

The stitch parameter function in your sewing machine lets you store

your favorite settings for each stitch. You can adjust a stitch for a

specific fabric or application or just save the stitch settings you like to

use.

You can always go back to default settings without losing your saved

favorite settings. The saved settings can be deleted or overwritten with

new settings.

The stitch parameter window is divided into three sections. In the top

section (A), you select what kind of settings you want to save or delete,

stitch parameters or sewing functions.

Sewing functions are:

Tie-off

Presser foot raise

Mirroring

Single stitch

Programmable seam

length

Stitch parameters are:

Needle position

Stitch length

Stitch width

Pattern length

Stitch balance

Stitch density

In the left section (B), you decide if you want to use your own stored

settings (custom setting) or the default settings.

In the right section (C), you choose to save new settings as custom, or

delete previously saved settings.

Save your favorite settings:

Select the stitch you wish to use and adjust the settings of the stitch in

the sewing menu. Long touch the info button (9) to open the context

menu. Touch ”Stitch parameters”. Select the stitch parameter icon or

the sewing function icon or both, in the top section (A), depending on

what kind of settings you want to save. An X appears in the selected

icon. Touch the save icon in the right section (B), to save the settings

as custom. The window closes, your favorite settings are stored in the

machine and automatically activated.

Note: If you want to delete previously saved settings you can either

touch the delete icon or overwrite the old settings by saving new

settings.

Use custom or default settings:

Select the stitch you wish to use. Long touch the info button (9) to open

the context menu. Touch ”Stitch parameters” in the context menu. The

stitch parameter window opens. Touch the icon for custom setting in

the left section (B), to use your own stored settings for the stitch, or the

icon for default setting, to use the default setting. The window closes

when you have made your selection.

A

B

C

Page 48

3:14

Revert to original settings (Available from main and stitch selection

menus)

This function will revert all custom settings for all stitches to the

default settings, without deleting them. If the icon is touched the

machine asks if you want to revert the settings. Touch “ok” or “esc” to

confirm or reject.

Note: If you revert to original settings you can still go back and

reactivate the saved custom settings of your stitches in the stitch

parameter window, see page 3:13.

Delete all (Available from main menu)

This function will delete all your stored sequences and created stitches

plus all your custom stitch settings. If the icon is touched, a dialogue

window appears: ”Do you want to delete all stitch parameters plus

all stitch sequences plus all created stitches?” Touch ”ok” or ”esc” to

confirm or reject.

Delete all parameters (Available from all stitch selection menus)

This function deletes all custom settings for all stitches. If the icon

is touched, a dialogue window appears: ”Do you want to delete the

parameters of all stitches?” Touch ”ok” or ”esc” to confirm or reject.

Delete all stitch sequences (Available from sequence memory

selection menu)

This function deletes all stored stitch sequences. If the icon is touched,

a dialogue window appears: ”Do you want to delete all stitch

sequences?” Touch ”ok” or ”esc” to confirm or reject.

Delete all created stitches (Available from stitch creator memory

selection menu)

This function deletes all stitches created and stored in the stitch creator

memory. If the icon is touched, a dialogue window appears: ”Do you

want to delete all created stitches?” Touch ”ok” or ”esc” to confirm or

reject.

Machine test (Available from main menu)

This function is for Pfaff certified service technicians only.

Version (Available from main menu)

The current software version number in your machine is shown here.

Page 49

3:15

Operating your performance 2058

Info system

Your sewing machine has an info system function to help you using

the machine. The function can be called up at any time by pressing the

info button (9). The info system includes instructions on preparing the

machine for sewing, information on using the sewing functions and

recommendations regarding accessories and settings. You get different

information depending on in which menu you are when you press the

button.

Info texts may extend over several pages. The numbers in the upper

right corner show the current page number and the total amount of

pages that the selected info text extends over. Use the scroll buttons (4)

to browse through the pages.

Press the info button (9) again to close the info system.

Information in the main menu

If you press the info button (9) in the main menu the info system gives

you the following information:

• Threading the top thread

• Threading the needle

• Bobbin winding

• Bobbin winding through the needle

• Inserting a bobbin

Touch the icon for the desired information. Press the scroll buttons (4)

to scroll through multiple pages.

Information about a stitch in the sewing menu

If you press the info button (9) when in a sewing menu the info system

gives you the following information:

• Needle size/type recommendation

• IDT engaged or disengaged

• Recommended presser foot

• Recommended needle thread tension

For tapering, patchwork, buttonhole sewing, quilt stitches and the

darning program the information is more detailed.

Page 50

3:16

Information in the more options window

When you press the info button (9) in the more options window you

get information about the different sewing functions.

The following functions are described:

• Tie-off

• Free-motion sewing

• Raise presser foot

• Single stitch

• Twin needle

• Patchwork program

• Tapering

• Straight stitch safety

Touch the icon for each function to read the information. Press the

scroll buttons (4) to browse through multiple pages.

Page 51

Utility Sewing

Page 52

1

4

3

2

5

6

7

8

9

4:2

Getting started

To begin sewing on your new sewing machine, do a straight stitch

first.

When you turn on your machine a welcome text appears on the

display. Tap the foot control and the straight stitch is automatically

selected. Take a piece of fabric, fold it and place it under the presser

foot. Engage the IDT. Line up the edges of your fabric with your

preferred seam allowance. When you begin to sew the presser foot is

lowered automatically. If you want to sew longer or shorter stitches,

change the stitch length by touching the stitch length icon on the

screen and pressing the function field buttons (5). You will see the

length of your stitch on the display.

To sew a zigzag stitch, press the right scroll button (4) twice and you

will see the zigzag stitch no. 3 on the display. Take another piece of

fabric and place it under the presser foot. Line up the edges of your

fabric with your preferred seam allowance. When your begin to sew

the presser foot is lowered automatically. To change the width of the

stitch touch the stitch width icon on the screen and press the function

field buttons (5). The width of your stitch will be shown on the display.

Page 53

4:3

Utility Sewing

Straight stitch - No 1

Stitch no. 1 is the basic straight stitch in center needle position. The

stitch length can be increased up to 6mm. Your sewing machine has 19

needle positions that can be adjusted by the needle position icon and

function field buttons (5).

Change the needle position of the straight stitch to sew in a zipper or

topstitch along the edge of a collar.

Use the needle up/down button (3) to easily pivot at collar points.

Sewing in zippers - No 1

There are different ways to sew in zippers. Follow the directions

included with your pattern for best results.

The zipper foot can be snapped to the presser foot ankle on the left or

right, depending on how you will insert your zipper.

Important: If the presser foot is attached on the right side, the

needle must be moved to the right. If the foot is attached on the left,

the needle must be moved to the left.

For all types of zippers it is important to sew close to the teeth of the

zipper. Set the needle position so it enters close to the edge of the

zipper teeth by using one of the 19 needle positions available.

Three-step zigzag stitch - No 4

Stitch no. 4 can be used to overcast raw edges. Make sure the needle

pierces the fabric on the left side and overcasts the edge on the right

side.

Stitch no. 4 can also be used as an elastic stitch to add stretch to

pajamas, skirts and sportswear seams.

Page 54

B

A

4:4

Topstitching - No 1

The straight stitch can be sewn in 19 different needle positions

allowing you to guide the presser foot along the fabric edge for

topstitching. The distance between the rows of topstitching is

determined by the needle positions.

Use the guide marks on the needle plate, or the edge guide to topstitch

further from the fabric edge. The edge guide is inserted into hole A

and is secured with set screw B.

Basting stitch - No 17

With stitch no. 17 you can baste. When you press the foot control, the

machine will sew one stitch at a time. Press the foot control again for

each stitch. Your sewing machine has 19 needle positions that can be

adjusted with the needle position icon and function field buttons (5).

• Lower the feed dogs and disengage the IDT.

• Place the fabric under the presser foot.

• Sew one stitch, then move the fabric the required amount to the

rear. Continue to sew one stitch at a time until you finish basting.

Tip: Light fabrics are easier to baste with long straight stitches

(6mm) using stitch no. 1, letting the machine feed your fabric.

Gathering with straight stitch - No 1

A straight stitch can be used to gather your fabric when making

sleeves, cuffs, skirts or valances. To obtain neat and even gathers you

should sew two or three rows of gathering stitches.

• Set your stitch length to 6.0mm. Lower the needle thread tension to

3.

• Mark the first gathering line on the right side of the fabric. Sew

along this line. Leave about 4 - 5 inches (10-13 cm) of thread at the

beginning and end of the seam.

• Sew 1 or 2 more rows of stitching, using the edge of the presser foot

as a guide.

• Gather the fabric by pulling the bobbin (bottom) threads to the

desired fullness.

• Distribute the gathers evenly and knot the thread ends together to

secure the gathering.

Page 55

B

A

4:5

Utility Sewing

Blindhem stitch - No 15

The blindhem stitch is used to make invisible hems on skirts, trousers

and home dec projects.

• Finish the edge of the hem.

• Fold and press the hem allowance to the wrong side.

• Fold the hem back on itself so approximately 3/8” (1 cm) of the

finished edge extends beyond the fold. The wrong side of your

project should now be facing up.

• Place the fabric under the presser foot so that the fold runs along

edge guide A.

• When the needle swings into the fold it should catch a small

amount of fabric. If the stitches are visible on the right side, adjust

edge guide A by turning adjusting screw B, until the stitch that

catches the hem just barely shows.

Stretch blindhem stitch - No 16

The stretch blindhem stitch is especially suitable for stretchy fabrics,

because the zigzag in the stitch lets the seam stretch. The hem is

finished and sewn at the same time. There is no need to finish the raw

edge first on most knits.

Create the blindhem as described above.

Rolled hem with straight stitch - No 1

Use the rolled hem foot no. 7 to finish the edges of blouses, scarves,

or ruffles without having to iron the edges beforehand. Hemming

prevents the edges from fraying and produces a neat and durable edge

finish.

• Double-fold the fabric edge (about 1/8 inch / 3mm per fold).

• Place the folded fabric edge under the rolled hem foot and sew a

few stitches to secure.

• Turn the hand wheel towards you until the needle is at its lowest

point. Raise the presser foot and slide the fabric into the scroll of the

foot.

• While sewing, guide the fabric edge evenly into the foot. When rollhemming, make sure the raw edge of the fabric butts against the

left edge of the opening in the rolled hem foot. Be careful that the

fabric does not run underneath the right side of the presser foot.

Page 56

4:6

Overlock stitches

For elastic, knits and stretch fabrics, your sewing machine provides

a selection of overlock stitches. These stitches join multiple layers of

fabric and overcast them in one operation. These stitches can stretch

and are more durable than standard stitches.

Closed overlock stitch - No 31

When sewing fabrics that fray easily select stitch 31. With this stitch an

additional edge thread protects the fabric edge against further fraying.

Closed overlock stitch - No 36

This stitch is suitable for sewing a hem on your garment. Use foot no.

0 or 3.

Fold your fabric 3/8” (1 cm) and stitch the closed overlock on the

right side of the folded fabric. When you have finished, cut away the

unnecessary fabric.

Stretch knit overlock stitch - No 37

This stitch can be used for open-knit and heavy knit fabrics. Garment

seams can be joined effortlessly with this stitch.

Tip: Use Blindhem foot No. 3 when sewing overcast seams. This

guides the fabric more precisely and prevents tunneling of the seam

at wider stitch widths. Adjust the stitch width and guide of the foot

to ensure that the right swing of the needle clears the raw edge of

the fabric and the pin of the presser foot.

Overlock stitch - No 38

The overlock stitch no. 38 can be used for joining or edge-finishing

fabrics that do not fray excessively.

Page 57

4:7

Utility Sewing

Buttonholes

There are 12 buttonhole styles built-in to your sewing machine. Each

buttonhole is especially adapted for a particular use and fabric type.

Your sewing machine is equipped with the sensormatic buttonhole

guide and sensor technology to ensure that every buttonhole is sized

accurately. Beautiful buttonholes can be sewn on even the most

difficult fabrics like velvet or heavy knits.

See page 3:8 for instructions on how to program the size of your

buttonhole.

Inserting the sensormatic buttonhole guide

Push the metal part of the sensormatic buttonhole guide into the slot

under the two arrows at the back of the needle plate. The white plastic

part goes over the needle plate, covering the feed dogs.

Slide the guide towards you until there is a small gap between the

needle plate and the guide as shown in the picture.

Inserting the sensormatic buttonhole guide activates the sensor.

Attaching buttonhole foot - No. 5A

Attach buttonhole foot No. 5A to sew buttonholes (see ”Changing the

presser foot” on page 2:3).

Before starting to sew, pull the slide of the foot towards you until the

red arrow matches the second red mark.

Page 58

4:8

Buttonhole with gimp cord

Buttonholes that are sewn with gimp cord under the satin stitch

columns are more stable, durable and professional looking. Use pearl

cotton or regular gimp thread.

• Insert the sensormatic buttonhole guide.

• Place the center of a length of gimp cord over the metal hook

extending from the center back of the buttonhole foot. Pass the cord

ends under the foot and pull up into the right and left guides on the

front of the presser foot.

• Snap on the buttonhole foot. Before starting to sew, move the foot

to align the arrow with the second red mark. Buttonholes 50, 51, 52

or 53 work well for this technique. Follow the instructions on page

3:8 of how to program the size of your buttonhole.

• After completing the buttonhole, pull the ends of gimp cord until

the loop of thread is hidden under the buttonhole bartack.

• Thread the gimp cord ends into a hand sewing needle and pull

them to the wrong side of the garment. Tie the gimp threads and

cut off the excess thread.

Eyelet buttonhole with gimp cords

• Insert the sensormatic buttonhole guide. Place the center of a length

of gimp cord over the metal hook extending from the center front

of the buttonhole foot. Pass the cord ends under the foot and pull

them up into the right and left guides on the back of the presser

foot.

• Snap on the buttonhole foot and pull the slide of the foot towards

you until the back white part of the foot touches the back of the

slide. The red arrow will match the first red mark. Before starting

to sew, press the needle up/down button (3). See page 3:8 for

instructions on how to program the size of your buttonhole.

Page 59

4:9

Utility Sewing

• Sew the right side of the buttonhole.

• After the machine sews the first few stitches of the curved end pull

the gimp cords out of the metal hook with a straight stitch pin.

Warning: Do not lift the presser foot from the fabric surface!

• Gently pull the gimp cord on the left towards the rear until the loop

is just in front of the needle. Carefully sew the curve, guiding the

gimp cord under the stitching.

• After sewing the left side of the buttonhole, thread the gimp cords

into a hand sewing needle and pull them to the wrong side of the

garment. Tie the gimp cords and cut off excess cord.

The round buttonhole with gimp cord is sewn in the same way.

Tip: This buttonhole is particularly attractive when sewn with a

heavier-weight thread.

Buttonhole tips

• Buttonholes that are to be sewn very close to a reinforced edge,

may sometimes not feed optimally with the buttonhole foot because

of the bulk at the edge of the fabric. In this case, use presser foot 1A

with the Integrated Dual Feed engaged.

• Buttonholes should always be stabilized before sewing.

• Fabrics that shift or stretch easily should be reinforced with watersoluble or lightweight stabilizer.

• Buttonholes are particularly stable and durable if a gimp cord is

inserted while sewing.

• Linen buttonholes are particularly attractive if you use a heavierweight thread and a topstitch needle.

• Buttonholes are normally selected a little larger than the button

diameter. It is important to always sew a test buttonhole on the

same fabric/stabilizer as your project to be sure that you have

selected the correct size.

Page 60

4:10

Sewing on buttons - No 60

The Button sewing program no. 60 allows you to sew on two and four

hole buttons easily.

• Remove the presser foot and lower the feed dogs. (Make sure the

IDT is disengaged).

• Mark the button position on your fabric. Place the button on the

marked fabric.

• Turn the handwheel towards you and position the button so the

needle enters the left hole in the button.

• Lower the presser foot lift. The button will be held in place by the

shank of the foot. Turn the handwheel to make sure the needle also

enters the right hole of the button.

• Continue sewing on the button. The machine will complete the

program and stop.

Tip: You can also use a sew on button foot available from your

authorized Pfaff dealer as an optional accessory.

Eyelets - No 59

To stitch eyelets on a belt or linen items, select stitch no. 59.

Select the single stitch function in the more options window (8) to sew

one eyelet at a time.

Page 61

4:11

Utility Sewing

Automatic darning - No 74 and 75

Stitches no. 74 and 75 is for strengthening damaged areas of fabric and

repairing tears.

• Stitch over the damaged area a little longer than your tear.

• Press the reverse button (10); the machine finishes sewing the

darning program and the darning length is saved.

The saved darning length can now be repeated as often as needed.

Depending on the type of fabric, the darning pattern may shift slightly

out of square. You can straighten the pattern using the balance

adjustment capability.

Touch the balance icon and fine tune the stitch balance with the

function field buttons (5).

Note: To give the best strength to the darning stitch it should be

slightly out of square.

To straighten a pattern that shifts this way, correct the balance in the

plus-section.

To straighten a pattern that shifts this way, correct the balance in the

minus-section.

Page 62

A

B

4:12

Free-motion darning – No 1 and 3

• Remove the standard presser foot. Make sure the needle is at its

highest position. Carefully loosen the screw (A) until the cross hole

(B) is accessible. Squeeze the darning foot gently together and guide

the pin of the foot into the cross hole of the presser foot holder as

far as it will go. The black “C-shaped” guide should place itself

around the presser bar. The long, plastic arm must be behind the

needle set screw. Tighten the screw (A).

• Lower the feed dogs. Hoop your project to be repaired in a round

embroidery hoop.

• Select straight stitch no. 1 or zigzag stitch no. 3. Select the freemotion sewing icon in the more options window (8). As you begin

sewing, the darning foot automatically engages in the darning

position.

• Draw up the bobbin thread and sew a few stitches to secure. Cut

the threads close to the project and continue sewing.

• Repair the damaged area/hole by guiding the fabric evenly

forwards and backwards slightly longer than the length of the

repair area.

• When you have covered the damaged area, turn the fabric 90

degrees and stitch over the area again. Darning in both directions

over a tear will produce a stronger repair.

• To remove the darning foot loosen the screw (A), squeeze the foot

together and pull it out to the right. Tighten the screw (A).

Tip: Remember, when sewing with the feed dogs lowered, the

stitch length is determined by you. An even, medium-to-fast

sewing speed will allow you to sew a more consistent length of

straight stitch. Sewing too slowly may cause small knots to appear

on the reverse side of your work.

Page 63

Decorative Sewing

Page 64

1

4

3

2

5

6

7

8

9

5:2

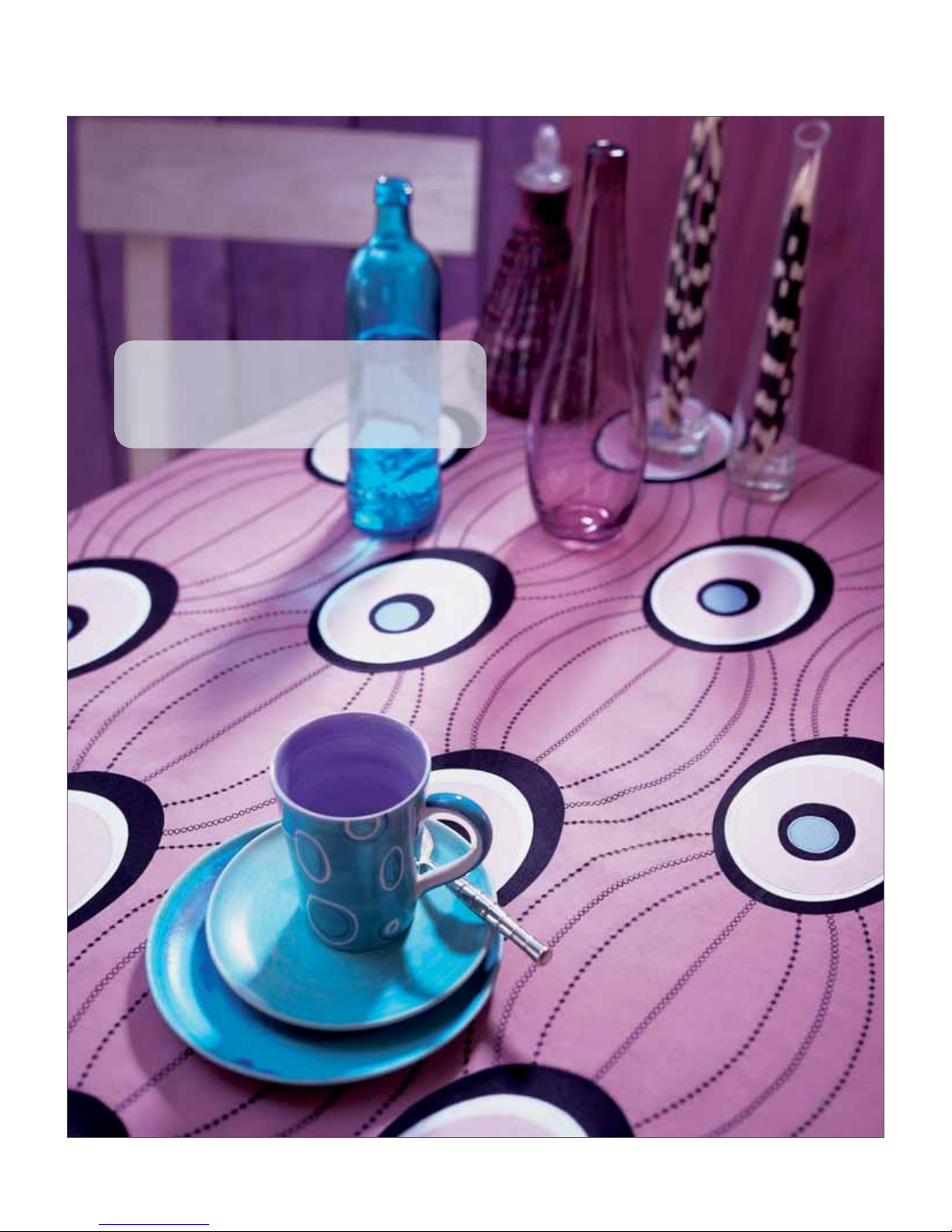

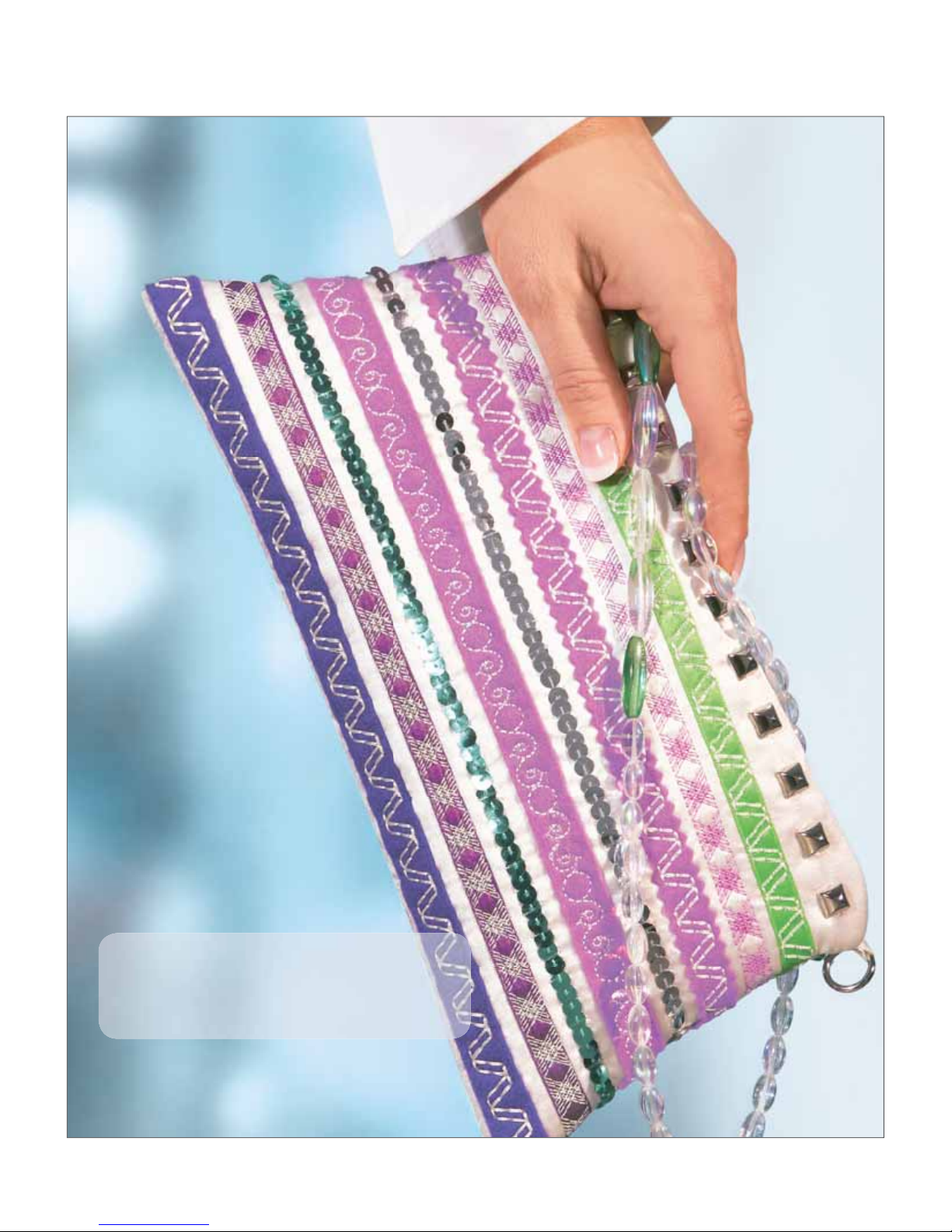

General notes on decorative sewing

To enhance your own home textiles or garments your sewing machine

offers you a wide variety of fancy and decorative stitches. Create a

greater variety of embellishments by combining different patterns,

colors and sizes. Use specialty decorative threads to enhance the lovely

stitching.

Always use stabilizers under fabric when sewing decorative stitches.