Page 1

MAUSER

SPEZIAL

Serie

40

Adjustment

instructions

Pfaff

Industriemaschinen

GmbH

675

West-Germany

Kaisersiautern

Page 2

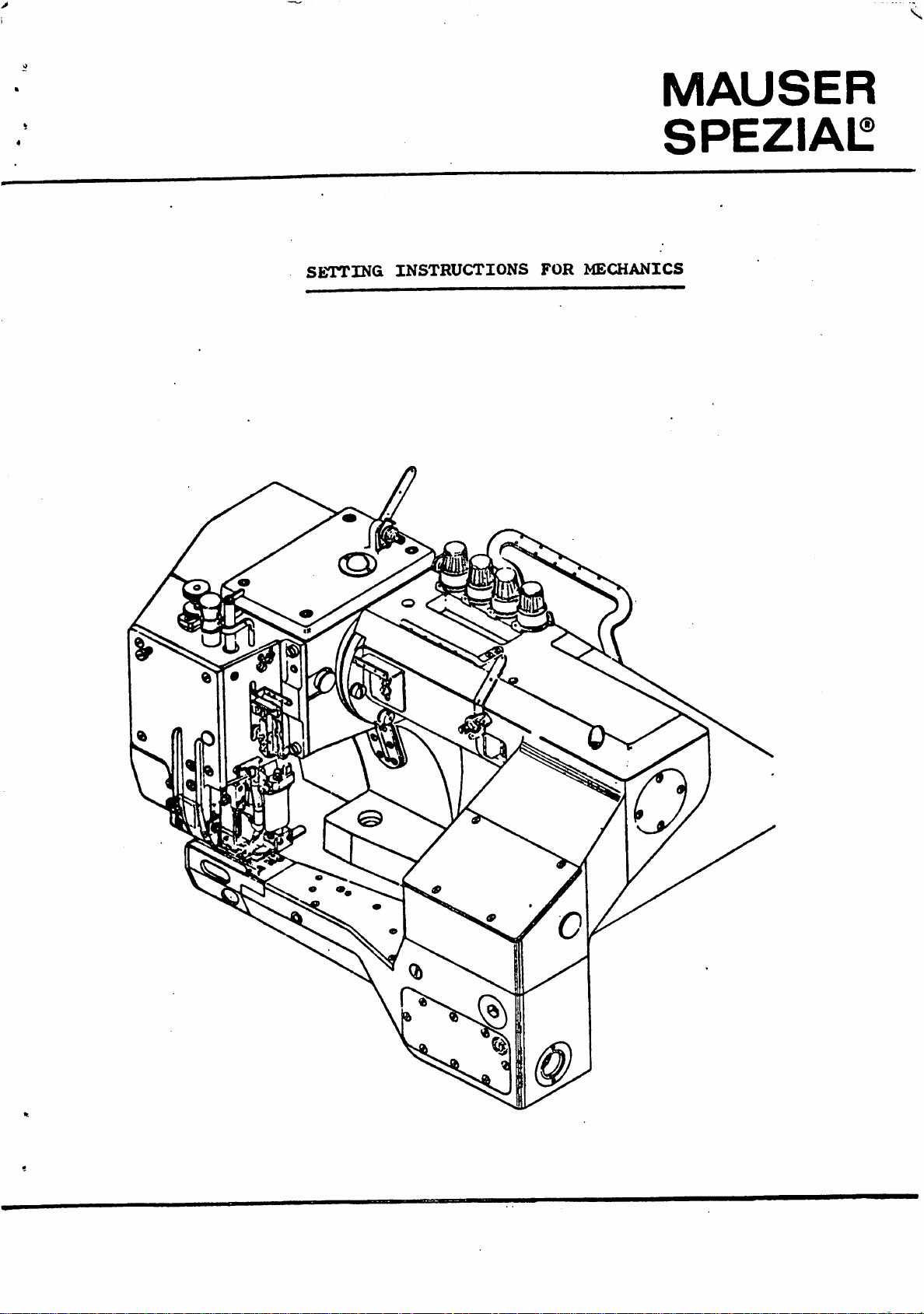

MAUSER

SPEZiAl^

SETTING

INSTRUCTIONS

FOR

MECHANICS

Page 3

Supplement

for

machines

to

the

with

service

low

needle-bar

manual

for

link

Mauser

Cl,

^0,

stroke

1«

3«

4.

5*

20.4

Needle

Looper

Needle

Looper

Elliptical

mm)

bar

height:

clearance:

rise:

avoiding

movement:

motion:

needle

stroke

Preliminary

Clearance

needle

fourth

From

of

2.^

1.8

Forwards:

from

needle:

looper

first

nun

to

first

29*5

between

plate

needle:

needle:

to

middle

2

mm,

mm,

adjustment:

and

9.3

tip

to

depending

needle

0.15

looper

top

point

middle

of

to

mm

mm

first

fourth

surface

of

mm

on

of

the

needle.

fabric.

6.

Check:

1.

2.

The

up

eyeaof

When

third

of

0.3

the

looper

at

the

the

ram

looper.

a

the

and

third

below

point

position

fourth

looper

fourth

is

needle

the

should

1 mm

needle.

between

needle

shoulde

underside

pick

above

the

the

the

tip

be

of

Page 4

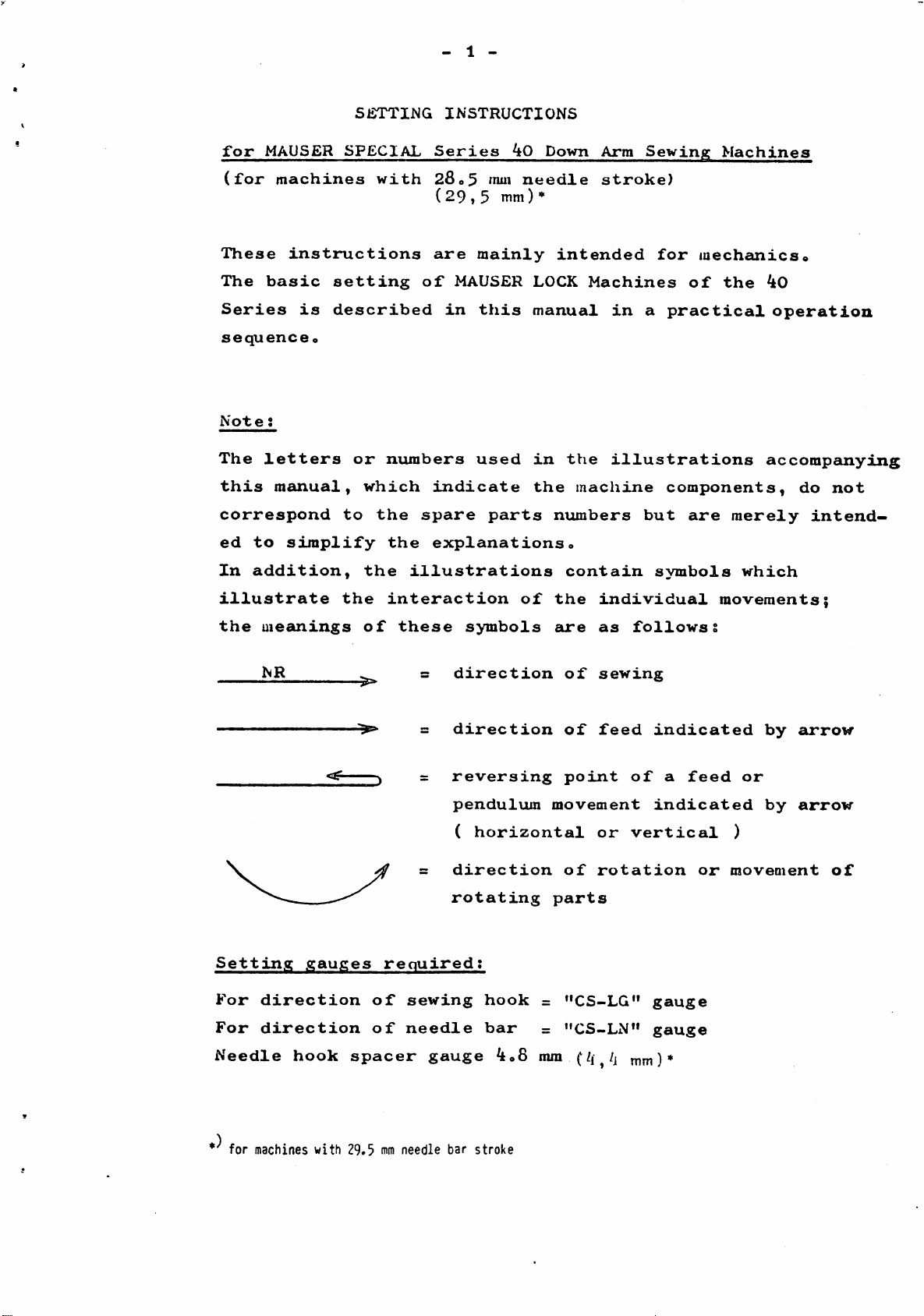

- 1 -

for

MAUSER

(for

machines

These

The

basic

Series

sequence

Note

The

this

s

letters

manual,

correspond

ed

to

SPECIAL

instructions

setting

is

described

o

or

to

simplify

S12TTING

with

numbers

which

the

the

INSTRUCTIONS

Series

2Se5

mm

(29,5

are

mainly

of

MAUSER LOCK

in

this

used

indicate

spare

explanationso

parts

kO

needle

mm)»

Down

intended

manual

in

the

the

numbers

Arm

stroke)

Machines

in

illustrations

machine

Sewinja;

for

mechanics«

of

a

practical

components,

but

are

Machines

the

kO

operation

accompanying

merely

do

intend

not

In

addition,

illustrate

the

meanings

NR

SettdLng

For

direction

gauges

the

the

interaction

of

these

required;

of

illustrations

symbols

=

direction

=

direction

reversing

pendulum

(

direction

rotating

sewing

of

horizontal

hook

contain

the

are

of

of

point

movement

of

parts

=

"CS-LG"

symbols

individual

as

followss

sewing

feed

or

rotation

indicated

of

indicated

vertical

gauge

which

movements;

by

arrow

a

feed

or

or

by

)

moveoient

arrow

of

For

direction

Needle

for

machines

hook

with

of

needle

spacer

29.5mmneedle

gauge

bar

bar

^08

stroke

=

"CS-LN"

mm

mm)*

gauge

Page 5

- 2 -

1.

2*

3«

4.

5*

6.

7»

8»

9*

Tlie

necessary

The

needle

Needle

check

Temporary

hook

Temporary

movement.

Temporary

Radial

Setting

movement

adjustment

Setting

CONTENTS

needle

arrangement

synchronization

setting

setting

the

the

stroke

hook

of

of

of

inclination

TABLE

system

feed

needle

needle

ot

the

of

and

bar

bar

hook

needle

transverse

height

deflection

vritlx

and

longitudinal

hook

the

"CS-LG" gauge

movement

10*

11.

12.

13*

l4.

15*

16.

17.

l8•

19*

20.

Setting

Final

hook

Final

Final

synchronization

movement

setting

setting

Alignment

Final

movement

setting

Stitch

Setting

Setting

Setting

Fitting

the

of

length

the

the

the

and

hook

of

needle

of

the

main

of

"lifting

and

needle

take—up

looper

setting

spacing

of

needle

bar

hook

and

differential

differential

stop

lever

thread

of

the

and

height

deflection

and

lowering"

regulation

movement

puller

trimmer

longitudinal

movement

feeder

feeder

blades

Page 6

- 3 -

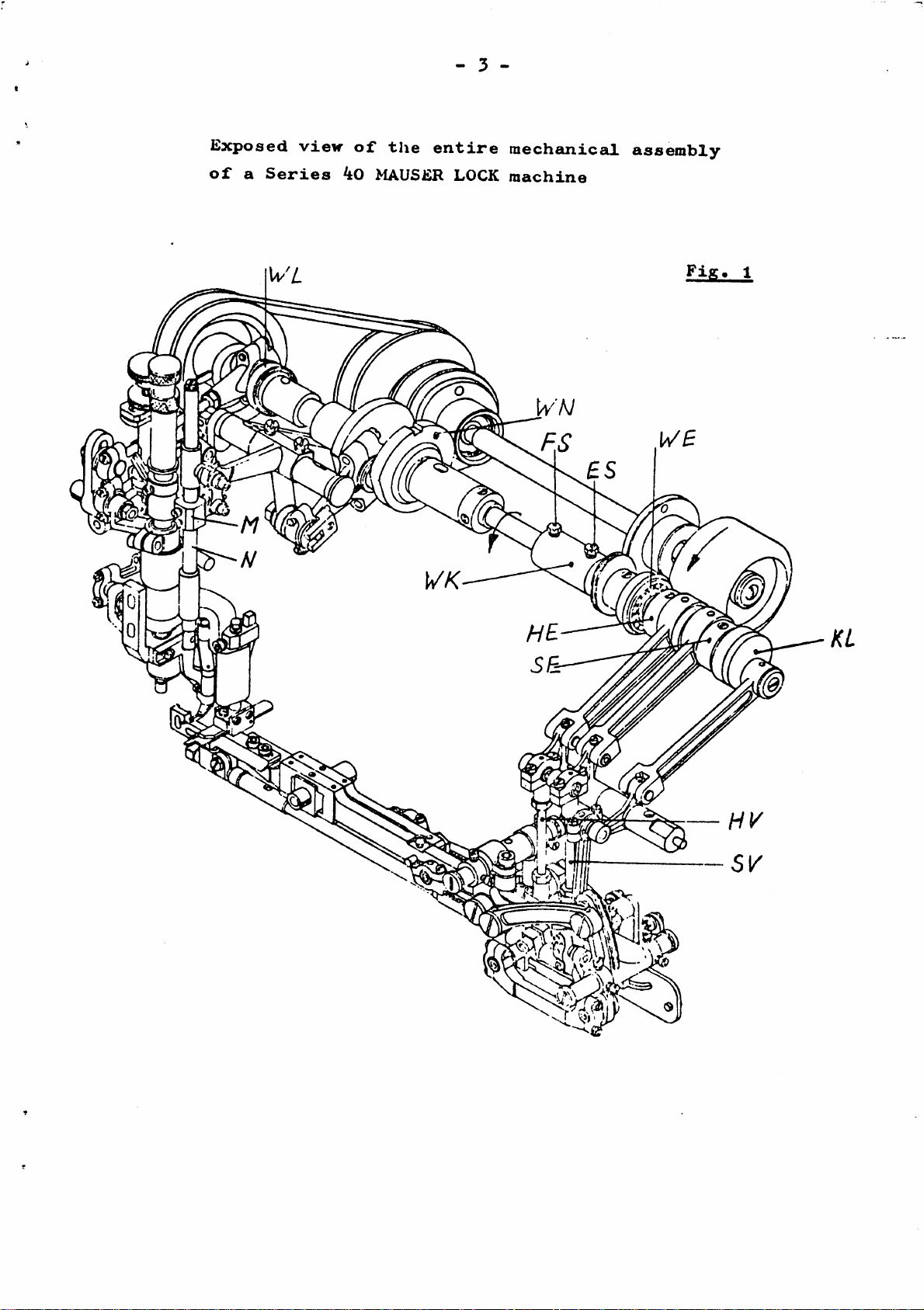

Lxposed

of

a

Series

view

of

the

40

MAUSiiR LOCK

entire

mechanicaJL

machine

assembly

Fig

Page 7

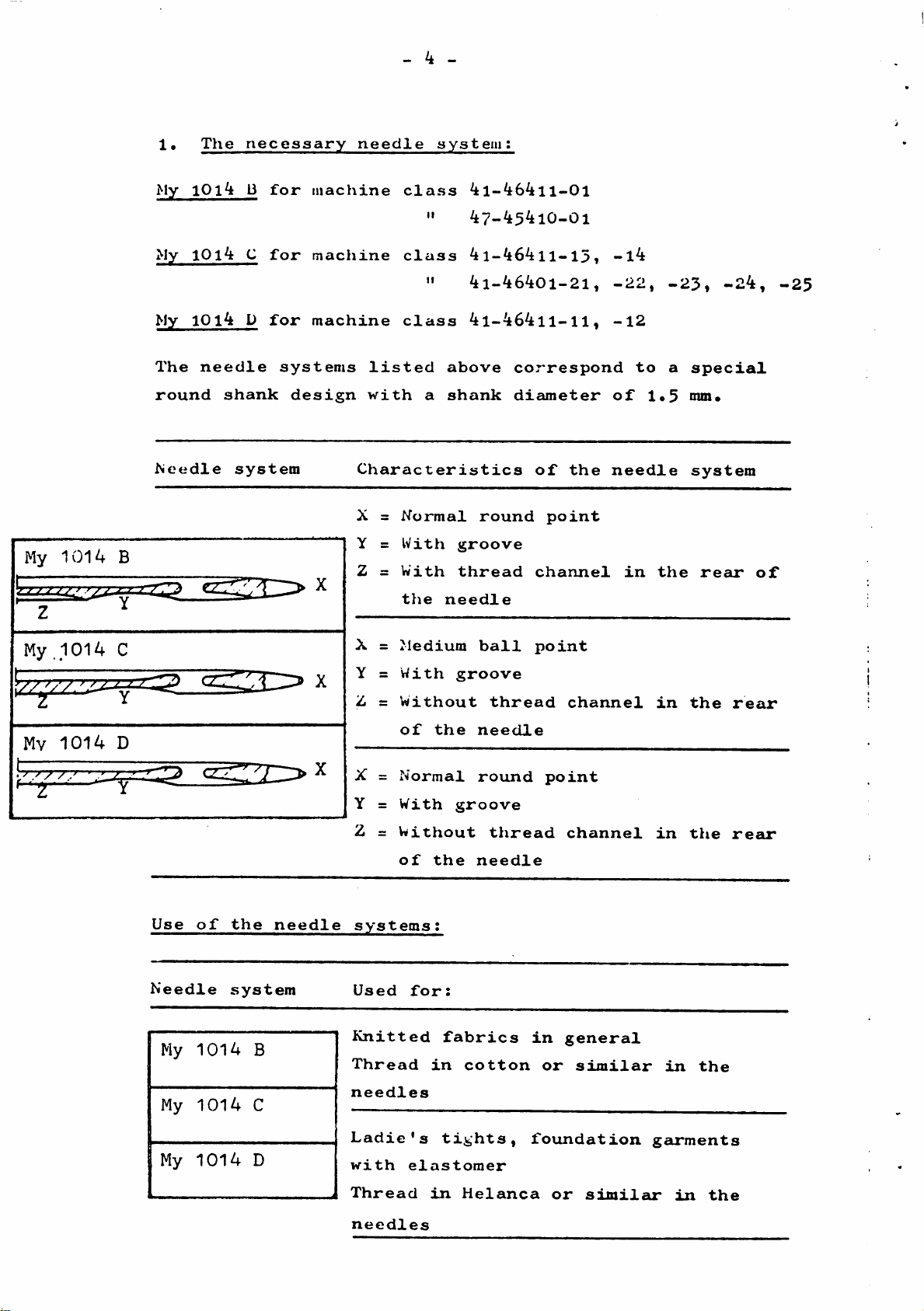

1•

My

My

My

The

The

10i3

1014

10l4

needle

necessary

for

C

for

D

for

systems

needle

machine

machine

machine

listed

- 4 -

system:

class

"

class

"

class

4l-464ll-01

47-45410-01

4l-464ll-l5,

4i-46401-21,

4l-464ll-ll,

above

correspond

-l4

-22,

-12

to

-23,

a

-24,

special

-25

My

1014

My.1014

iZ^ZZZZ^

Mv

1014

B

C

Y

D

round

Needle

shank

system

design

with

a

Characteristics

X =

Normal

Y =

Z =

X =

Y =

Z =

X =

Y =

Z =

With

With

the

Medium

With

Without

of

the

Normal

With

Without

needle

shank

groove

thread

groove

groove

round

ball

thread

needle

round

thread

diameter

of

point

channel

point

point

the

channel

channel

of

needle

in

1.5

the

in

in

nun.

system

rear

the

the

of

rear

rear

of

the

needle

Use

of

the

Needle

My

My

My

1

1014

1014

1014

needle

system

B

C

D

systems;

Used

Knitted

Thread

needles

Ladie's

with

Thread

needles

for:

fabrics

in

tights,

elastomer

in

cotton

Helanca

in

general

or

similar

foundation

or

simileu*

in

the

garments

in

the

Page 8

3•

Needle

- 5 -

check

Only

To

avoid

straight

surface

k•

The

new

needles

all

running

(fig.

Temporary

longitudinal

mechanism

must

risks,

before

3).

synchronization

hook

for

the

the

be

used

needles

use

movement

feeder

by

for

must

rolling

of

and

setting

be

checked

them

needle

longitudinal

up

and

on

the

hook

machine.

for

a

flat

move

ment

by

the

"WK"

The

situated

tlie

needle

(fig.

crank

movement)

l)

.

Tlie

synchronization

movement

The

basic

unadjusted

chronization

hook

movement«

drive

CcUi

adjustment

shaft

drive

l).

"KL"

is

firmly

therefore

machine

of

in

(for

the

the

"WE",

shaft

the

connected

of

starts

needle

suj)port

"WN"

the

only

of

a,

which

drive

first

arm

is

by

means

of

to

needle

be

set

for

exsimple,

movement

of

adjustably

the

the

and

at

with

the

machine

of

the

longitudinal

drive

longitudinal

the

shaft

completely

the

temporary

\>rita

the

connected

shaft

shaft

longitudinal

Fig.

is

controlled

coupling

hook

"WE"

hook

coupling

syn

4

to

(fig.

I

Page 9

Sett

- 6 -

ing:

Helease

the

fixing

shaft

Note:

The

"WE"

fixing

rotation)

4).

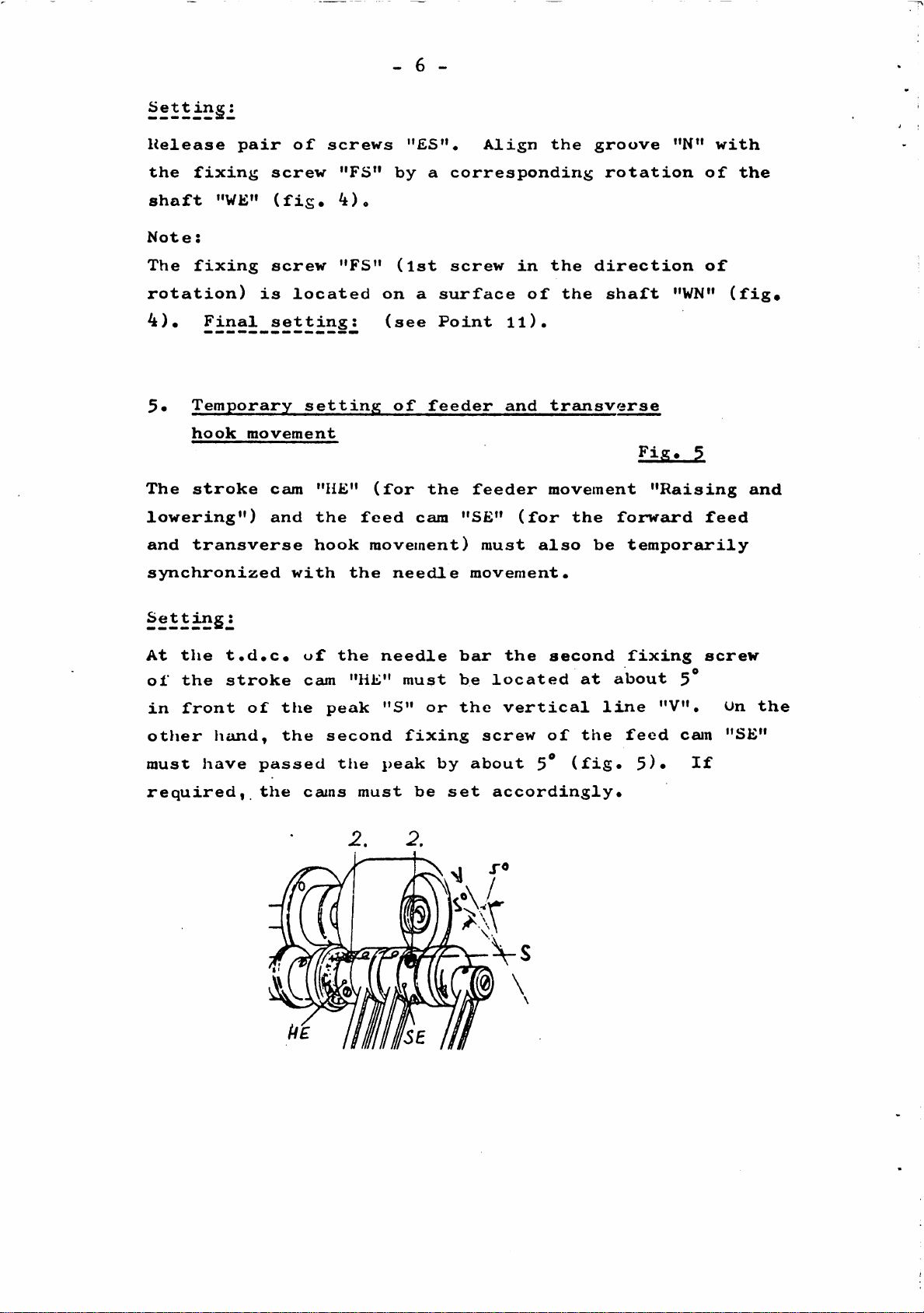

5*

The

Final

Temporary

hook

stroke

lowering")

and

transverse

synchronized

pair

screw

screw

is

setting:

movement

cam

and

of

(fig.

located

with

screws

setting

"HE"

the

hook

"FS"

^)o

"FS"

on

(for

feed

movement)

the

"£S"«

by

(1st

(see

of

needle

a

corresponding

screw

a

surface

Point

feeder

the

cam

"SE"

Align

in

of

ll).

and

feeder

(for

must

movement.

the

the

the

transverse

movement

the

also

be

groove

rotation

direction

shaft

£i£.

forward

temporarily

"N"

"WN"

"Raising

with

of

of

feed

the

(fig*

and

Setting:

At

the

of

the

in

front

otJier

must

required,

t.d.c.

stroke

hcUid,

have

of

passed

the

the

the

uf

cam

peak

second

cams

the

"HE"

tlie

must

needle

must

"S"

fixing

peak

be

s

or

by

bar

be

the

about

set

the

located

vertical

screw

5^

accordingly.

second

of

(fig.

at

the

about

line

fixing

feed

5)*

"V",

5*

cam

If

screw

On

"SE"

the

Page 10

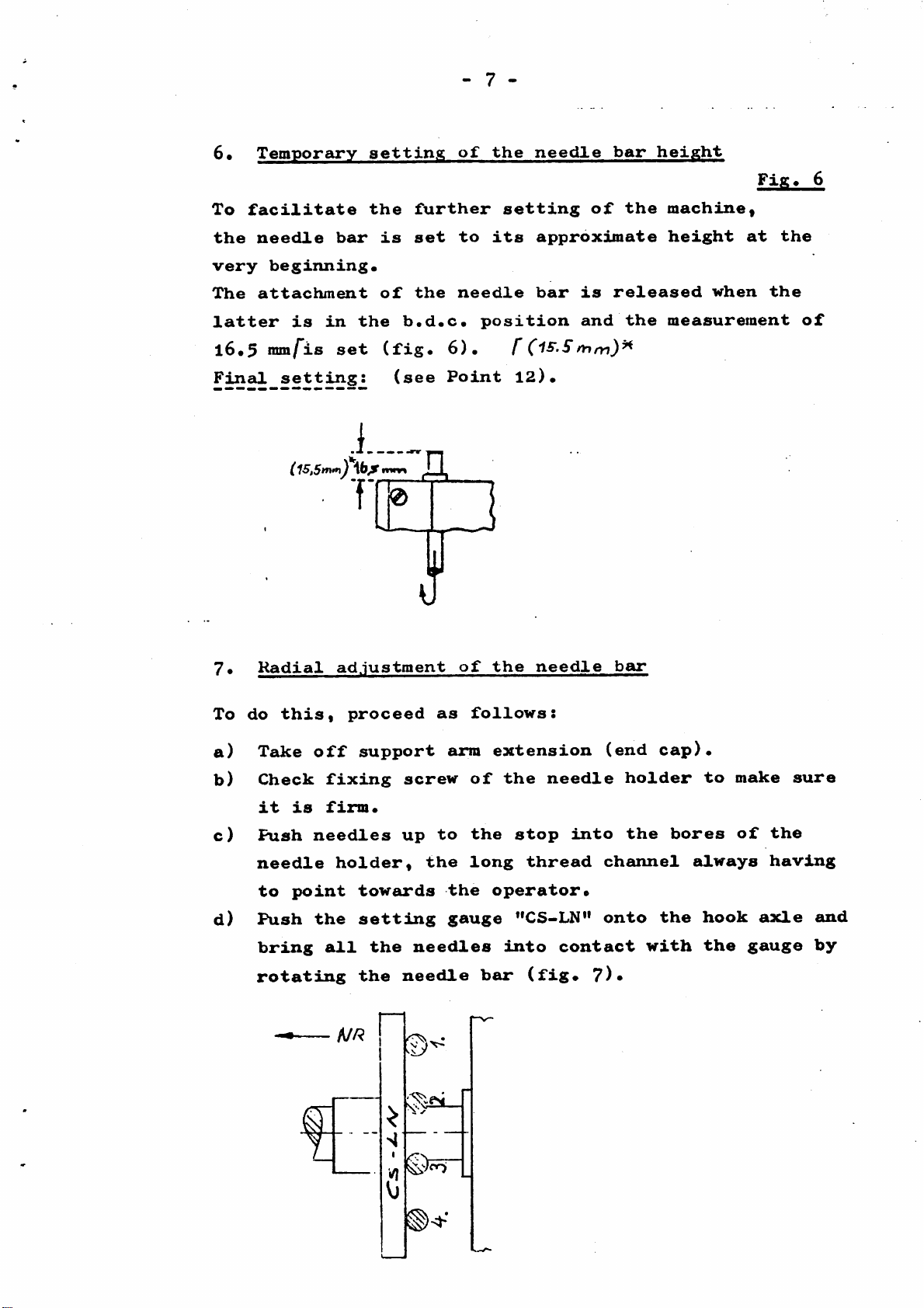

6*

To

the

Temporary

facilitate

needle

bar

setting

the

is

further

set

- 7 -

of

the

to

setting

its

needle

of

approximate

bar

the

height

machine«

height

at

Fig^

6

the

very

The

latter

l6*5

Final

7•

To

beginning*

attachment

mm/"is

setting:

C

Radial

do

this,

is

in

set

15,5nvn^

adjustment

of

the

(fig*

T

proceed

the

b.d.c*

(see

needle

position

6)* f

Point

]

of

as

follows:

the

bar

12)*

needle

is

and

released

the

bar

when

measurement

the

of

a)

b)

c)

d)

Take

Check

it

is

Push

needle

to

point

Push

bring

rotating

off

fixing

firm*

needles

holder,

the

all

A//?

support

screw

up

towards

settdLng

the

the

needle

n

arm

to

the

the

gauge

needles

extension

of

the

the

stop

long

operator*

"CS-LN"

dlnto

bcur

needle

thread

contact

(fig*

into

(end

holder

channel

onto

?)•

the

cap)*

the

with

bores

always

to

hook

the

make

of

axle

gauge

sure

the

having

and

by

Page 11

8.

The

Setting

movement

hook

the

passes

stroke

around

- 8 -

of

the

the

hook

needles

deflection

in

an

elliptical

path

which

movement

(cam "ES")

movement

supplier's

(width

1,8

2.0

(fig.

;^i-longit.

inm

mm

of

for

for

8).

is

(crank

(fig.

(length

works,

the

machines

macliines

hook

brought about by

"KL")

l).

of

ellipse)

movement

the

the

with

with

and

the

V/hereas

ellipse)

deflection

must

be

Helanca

cotton

the

hook

the

longitudinal

is

movement

set

threads

threads

longitudinal

deflection

determined

of

the

to

a

value

in

the

in

the

hook

movement

hook

in

the

hook

"X"

of;

needles

needles

or

Setting^

The

stroke

on

the

upwards,

"X"

segment

the

is

set

lever

dimension

by

"SQ".

adjustment the dimension

I2l

mz

Measure

Mount

dimension

hook

?h

-Hd

holder

6 I

"X"

as

"GH"

regulating

If

"X"

decreases,

"X"

increases

follows;

temporarily

the

the

ball

onto

ball

joint

with

(fig.

the

joint

is

adjusted

downward

9).

—'

Fig.

hook

shaft

"ti"

10

"G".

At

the

the

bearing

front

distance

bush

d.c.

"D"

(fig.

position

between

lOa).

the

of

the

hook

hook

holder

shaft

"GH"

measure

and

the

Page 12

At

the

"D"

has

9-

tli0

distance

and

been

Setting

gauge

opposite

"d"

correctly

d.«c«

"d"«

provides

the

hook

- 9 -

position

The

difference

the

adjusted*

inclination

of

dimension

the

of

with

"X"

hook

the

if

the

shaft

measured

the

ball

"CS-LG"

measure

values

joint

"Q»»

Insert

the

the

the

the

10*

To

a)

pin

hook

hook

hook

Setting

do

Push

the

nut

the

of

this,

hook

the

blade

fixing

blade

the

hook

"M".

into

hook

parallel

screw

is

CS-LG

the

proceed

hook

shaft

Tighten

the

inclination

parallel

hook

as

holder

"G"*

hook

against

"BS".

spacing

follows:

the

Check

to

"GH"

Engage

clamping

lever

gauge

the

the

and

"H"

"H"

gauge

again,

gauge

the

in

screw

and

push

"CS-LG".

and

to

(fig*

^3

FU.11.

hook

"GH"

"K"

lever

and

Apply

tighten

ensure

ll)*

apply

until

"H"

"H"

onto

that

onto

the

b)

combination

hand

Turn

feed

(dead

(fig*

the

until

centre)

of

12)* H

machine

the

"H"

hook

(fig.

and

balance

has

13).

"GH"

wheel

reached

can

in

still

its

the

be

direction

initial

moved

by

of

position

Page 13

c)

The

and

distance

the

tip

fc>etween

of

the

-

10

the

hook

-

centre

represents

o£

the

the

first

hook

needle

spacing*

Tlie

hook

needle.

the

hook

(fig.

setting

When

needle

without

l4).

the

must

spacing

By

shifting

tip

This

of

the

hook

be

causing

(4,4

is

hook

passes

lightly

mm)*

gauge

the

brought

adjustiiient

tip

any

deflection

(4.8

combination

into

to

5

behind

touched

Fig.

l4

r(4,4mm)*

i)l :

mm)/

contact

incorporates

the

rear

the

by

of

is

applied

of

needles,

the

the

of

with

the

tip

needlel

"HI'

the

the

the

of

to

and

first

the

gauge

axial

first

the

(fig.

first

"Gdi",

needle.

hook,

15)*

11.

To

a)

hook

do

Lift

by

Final

this,

synchronization

movement

the

turning

proceed

needle

the

—2.0

balance

(2',

Fig.

as

follows:

bar

by

trim

1mm)*

16

of

needle

2.0

wheel

and

mm/from

(fig.

longitudinal

its

d.c.

l6).

position

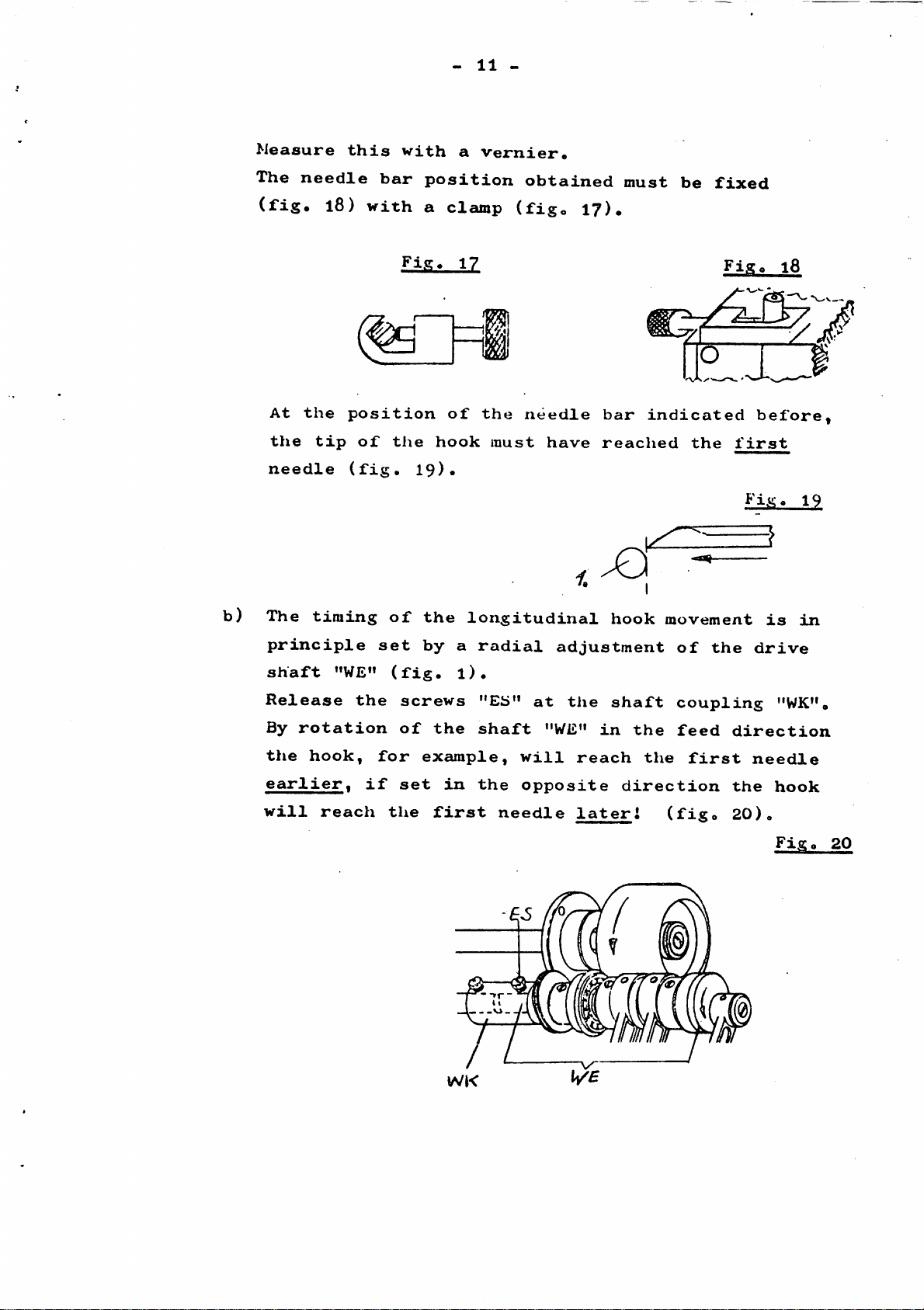

Page 14

-

11

-

Measure

The

needle

(fig.

At

the

the

needle

18)

tip

this

bar

with

position

of

the

(fig.

with

position

a

19)-

a

clamp

of

hook

vernier.

obtained

(fig.

the

needle

must

have

17).

bar

reached

must

indicated

be

the

fixed

Fig.

3

first

18

before,

5

b)

The

timing

principle

shaft

Release

By

rotation

the

hook,

earlier,

will

"WE"

reach

the

if

of

set

(fig.

for

the

the

by

screws

of

the

example,

set

first

longitudinal

a

radial

l).

"Eb"

shaft

in

the

needle

adjustment

at

the

"WE"

will

opposite

in

reach

later!

hook

shaft

the

the

direction

movement

of

the

coupling

feed

(fig.

direction

first

the

20).

9

is

drive

"WK".

needle

hook

Fig.

in

20

WK

Page 15

-

12

-

12•

Move

needle

(fig.

needle

1*2

The

the

21).

mm

f(fig*

distance

simplify

or

comparative

Example:

Aus)^

1.5|x

the

The

releasing

Note:

The

setting

hook up

by

turning

eye

and

this,

_

needle

height

the

setting

The

the

must be

one

dimension*

of

fixing

of

the

of

the

to

the

the

balance

needle

left-hand

bar

wheel

edge

in

heigh't

of

the

distance between the upper

lower

uses

diameter

the needle bar

screws on the

needle

edge

determined

the

needle

of

0.8

bar

height

of

the

by

mm=1.2

"N"

hook

estimating#

diameter

can be

driver

must be

the

fourth

feed

edge

blade

as

a

mm

distance.

adjusted

"M"

(fig.

carried

direction

of

the

must

be

To

reference

after

l).

out

with care, so

under

The hook

needles.

5)

determines

radial

Point

•

Final

produces

position.

setting

runs

Hie

the

that

7

is

through

feed

the

direction

the

maintained!

of

the

an

cam

deflection

direction

hook

elliptical

"SE"

on

movement

of

the

of

the needle bar adjusted

hO

Fig.

a

1/

deflection

path

the drive shaft

of

hook

movement

movement

around

the

hook

"WE"

and

with

21

the

(fig.

its

n

W"®"

♦

i

~~(E)~

t!

Page 16

If

of

the

tip

the

the

hook

passes

feed

hook

deflection

cam

track

behind

"SE"

up

the

-

has

to

stroke

needles

13

the

-

been

must

correctly

reversing

be

(starting

point

Ool^mm

set,

when

from

the

(d«c»)

the

position

drift

of

hook

"A")

must

a)

(fig.

The

be

Turn

the

(fig.

Now

"GH"

22).

moment

set

the

tip

23).

measure

and

of

as

follows:

balance

of

the

the

reversal

hook

the

bearing

wheel

has

distance

bush

Fig.

of

in

reached

"d"

the

the

(fig.

2kA

hook

feed

the

=3

between

2^a).

deflection

direction

first

Fig.

the

needle

hook

stroke

until

23

holder

b)

c)

Continue

until

point

be

0.15mm

Note:

With

feeder

Check

first

the

(d.c.).

the

motion

the

needle

to

turn

hook

more

adjustment

position

has

acc.

the

shaft

Now

than

balance

"G"

measure

the

described

been

of

to

fig.

distance

set

the

has

hook

13

wheel

the

at

reached

distance

above,

the

tip

and

in

"d"

same

correct

in

the

its

"D",

(fig.

the

timel

relation

feed

front

24b).

timing

if

direction

reversing

which

of

to

necessary.

must

the

the

Page 17

To

a)

•

do

Attach

Alignment

this,

proceed

the

of

main

support

-

as

1^

and

follows:

arm

-

differential

extension

(end

feeder

cap)

and

fix

feeders*

b)

Align

*nain

bolt

c)

The

carried

screws

independently.

position

the

the

feeder*

"B"

height

needle

Position

differential

accordingly

adjustment

out

"C"

first).

project

plate

25

Relscise

on

the

The

needle

eccentric

by

(fig,

feeder

screw

(fig*

of

The

main

feeders

a

complete

25),

plate

25)*

the

and

horizontally

"A"

and

differential

bolt

feeder

should

tooth

"D"

at

fix*

turn

(release

can

the

height

to

eccentric

feeder

be

adjusted

highest

out

the

is

of

of

the

feeder

Longitudinal

the

Differential

Main

main

height

feeder

pngl'tudinal

the

main

feeder

differential

setting

fedder

feeder

ad.lustmefat

setting

of

Page 18

-

15

-

15*

The

by

At

the

of

reached

Alternatively,

needle

Note:

If

the

direction,

Final

feeder

"raising

the

the

rising

the

the

feeders

feed

correct

needle

the

descends.

feed

setting

movement

and

cam

"HE"

setting

second

plate

top

edge

the

cam "HE"

will

they

lift

will

of

the

lowering"

(fig.

of

needle

when

of

same

situation

is

adjusted

earlier.

lift

"raising

feeder

26).

the

becomes

the

the

needle

later.

feed

rising

if

and

lowering"

movements

cam "HE",

visible

feeders

plate

must

in

adjusted

occur

the

are

the

at

the

have

(fig.

when

direction

in

the

produced

eye

top

edge

also

27a).

the

of

movement,

opposite

of

HHIMi

a)

Stitch

The

stitch

adjustment

the

rocker

material

between

needle

len.eth

being

about

length

of

arm

plate

and

the

"TK"

sewn,

5

fo

differential

is

regulated

feeder

(fig.

the

6

stitches

movement

28).

usual

per

regulation

by

a

corresponding

connection

Depending

stitch

10

length

mm

on

seam

"TS"

the

veiries

length.

at

Page 19

b)

The

quick-action

-

scale

16

-

adjustment

for

ordinary,

<S>

differential

inside

can

arrangement

(fig.

Waviness

corresponding

Gathering

is

The

the

17•

Setting

Penetration

be

29).

avoided

neutral

ordinary

of

the

selected

of

(in

the

into

and

support

"S"

the

selection

the

by

selecting

position

feed

needle

the

stretch

by

and

scvn

case

mode

fabric

arm*

releasing

adjusting

material

of

the

of

(fig*

stop

feed

of

the

extremely

stretch

the

may

is

The

the

the

is

differential

control

29).

deflect

situated

required

safety

control

counteracted

fine

feed

lever

the

at

type

locking

lever

fabric)

''ST".

represents

needles

the

feed

of

by

feed

"SH"

a

"DT".

from

their

across

stop

normal

transverse

is

direction

the

tip

adjustable

sion

Setting:

During

stop

(d.c*)

about

circumstances

the

needle

"TV"

the

swings

of

0*1

tip

(fig*

to

of

of

penetration

prevent

of

sewing

the

in

(fig*

return

towards

the

mm

from

the

50b)*

hook*

its

50a)*

stop,

be

hook

seams

a

deflection

and

attacliment

movement

the

the

the

pushed

always

path

etc*)*

thus

Tlie

heedles*

latter

needles*

aside

a

needle

of

passes

(particuleurly

The

purpose

of

the

possible

stop

to

the

feeder

the

feeders,

At

must

by

The

the

be

needles

closely

needles

"NA"

the

at

needle

when

of

collision

is

carrier

the

reversing

a

distance

must

stop,

behind

sewing

the

needle

in

the

with

horizontally

exten

needle

point

under

so

the

of

no

that

first

Page 20

-

17

-

close!

Fig♦

30a

Note:

Adjustment

position

Setting

The

take-up

"KL", which

shaft

fore

"WN"

needle

only

of

of

lever

is

at

be

the

the

needle

the

take-up

movement

adjustably

the

connection

and

the

adjusted

KL

stitch

take—up

at

length

stop

in

lever

is

connected

the

does

relation

movement

not

produced by

to

point

lever

"SY". Hie synchronism

movements

connection

to

the

»'SY"

chauige

the

the

crankshaft

needle

can

(fig,

the

needles!

drive

there

3l).

Figo

51

Page 21

-

18

-

Description

K =

LW

Rocker

lever

=

Ball

to

LP

=

Claw

movement

HL =

Vertically

guide

EX = Cam

path.

HS =

When

follows:

a)

Support

thread

setting

Set

adjust

for

the

of

tl\e

arm

path.

joint

element

position.

"SP"

setting

for

guide

the

length

components:

for

adjusting

adjustably

the

length

for

adjustable

the

"SP"

take-up

of

of

adjusting

the

direction

horizontal

.

lever

the

take-up

the

arranged

the

holder

motion,

length

tad£e-up

the

for

of

setting

lever

on

the

take-up

movable

the

of

proceed

movement

of

the

rocker

lever

lever

take-up

the

take-up

path.

thread

movable

as

at

arm

lever

the

Co,

Fig.

rocker

Note:

If

lever

it

m

32

the

is

arm

ball

movement

increased.

"K"

joint

Pis-

as

is

shown

"LW"

reduced.

33

in

is

fig.

adjusted

When

32.

upwards,

adjusted

O © ©

1

V

V

Fig.

the

downwards,

SP

©(5

ifrtt

3^

b)

Set

highest

varies

also

eccentric

point

by

fig.

90**

3l)*

bush

"X"

from

"EX"

of

the

as

the

direction

shown

eccentric

in

of

fig.

motion

sewing

33•

in

The

this

"NR"

case

(see

Page 22

c)

Set

the

movable

-

thread

19

-

guide»

d)

♦Set

the

ment

♦The

by

a

3l)*

point

by

about

cover

the

Setting

Place

vertically

the

movable

Release

andf

distance

movable

of

the

height

vertical

The

of

thread

third

the

the

screw

by

swivelling

of

thread

support

of

lower

the

second

the

thread

can

needle

take-up

take-up

to

thread

thread

"BS"

1

inra

between

guide

"HS"

the

movable

displacement

edge

slide

(fig.

lever

lever

guide

on

the

of

"SP"

needle

thickness

freely

34).

into

thickness

the

lever

"SP"

(figso

thread

"SP"

rocker

of

must

(at

its

(the

the

by

34

the

the

"F",

between

support

"F"

(fig.

arm

first

needle

horizontal

and

3l).

guide

"SP"

support

be

lower

letter's

so

that

the

in

relation

35).

"K"

take-up

and

(see

lever

displace

is

"HL"

than

t.d.c,)

the

second

adjust

fig.

and

set

(fig«

the

and

it

to

32)

must

have

spacing

the

time,

must

Set

crankshaft

reached

fourth

a

be

the

movement)

its

of

about

needle

thread-thickness

set

by

rotating

moment

is,

of

"KL"

as

left-hand

3

nun

(figs.

Cat.3mm

the

(for

already

between

31

distance

the

take-up

the

d.c.

the

and

take-up

lever

drive

of

described,

position),

tip

35)®

to

the

lever

movement.

the

connected

of

At

the

fourth

take-up

the

(fig.

set

hook

same

The

lever

to

the

and

needle

33).

the

way

needle

which

drive

makes

shaft

this

"WN"

at

connection

the

adjustable

joint

"SY"

(fig.

in

a

3l)*

Page 23

At

the

rear

of

the

-

20

machine

-

body

take

off

the

round

cover

release

"SY"

and

each

movement

plate

with

"WN"

other,

by about

36).

both

a 7

have

after

0.8

(for

fixing

mm

been

the

to

presser

hex.

take-up

the

1.0

screws

box

correctly

lever

needle

mm

from

foot

of

spanner.

adjusted

bar

its

lifting

the

shaft

If

commences

has

already

t.d.c.

linkage)

connection

the

shafts

in

relation

its

return

descended

position

and

"KL"

to

(fig.

f) Carry out the

guide "SP".

on

the

one hand

hook

of

the

radial

The

take-up

position the cover thread

second

needle

(figs.

task

to

setting

of

the

place

lever

the

and on

behind

36 and 37)*

Fig*

of

the

movable

cover

the

the

36

movable

thread guide

thread

other

first

onto

hand

and

thread

is

the

to

the

The

pendulum

fixed

adjusted.

guide

running

by

"SP"

adjustment

to

the

The

must

the

is

movement

design,

cover

be

placed

left,

carried

of

but

thread

until

out

the

its

onto

at

from

near

thread

radial

the

the

the

guide

amplitude

the

take-up

edge

screw

movable

"X".

"BS"

"SP"

lever

(fig.

is

must

thread

The

bo

"FL"

37)

Page 24

19

The

Setting

purpose

the

of

looper

the

-

looper

21

thread

thread

-

puller

puller

is

to

control

the

quantity

looper

thread

avoided

Setting;

a)

Turn

of

(or

and

by

the

the

moved

sewing

hook)

consequent

accurate

balance

looper

movement

inadequate

adjustment.

wheel

in

thread

a

Fig,

the

at

Unchecked

stitch

5fi

forward

each

phase

formation

direction

release

of

are

the

of

until

cam

Release

adjustable

"FE"

edge

b) For

first

until

the

tration

The

"G"

The

taking

sideways

the

"FE"

until

"X"

the

tui*n

the

plane

thread

at

the

radial

care

edge

assumes

the

fixing

thread

the

(fig,

radial

the

point

"Y"

of

the

pick-up

peak

adjustment

that

between

marked

the

position

screws

pick-up

wiper

58),

wire

adjustment

balance

of

the

of

the

sewing

rear

of

the

the

of

cam

its

looper

cam

"X"

of

"BS"

plate

"D"

of

wheel

descending

the

hook),

must

release

is

fixed

"FE"

the

shown

and

forms

the

in

hook

now

edge

with

thread

and

thread

move

"PL"

thread

the

fourth

eye

shed

can

the

in

fig,

towards

a

tangent

forward

(fig.

the

"A"

the

slide

pick-up

pick-up

58a,

the

horizontally

the

pick-up

direction

needle

39

looper

(fig,

screws

freely

of

cam

reaches

=

illus

thread

^O).

"S",

plate

cam

the

"PL"

or

the

presser

spring.

Fig»

39

Page 25

.

22

-

20*

1.

Fitting

Lower

the

presser

the

blade

must

a

After

foot,

right-hand

ment

machine

be

neat

has

and

(fixed)

is

ground

and

grinding,

the

tip

been

setting

blade.

foot.

screw

now

reliable

of

edge

completed,

pulled

to

our

the

the

of

If

cut

the

the

The

the

8657

out

trimmer

can

blade

blade

3rd

Fig*

trimmer

lower

blade

must

of

othei*wise

is

needle.

the

kO

blades

be

the

presser

grinding

pushed

being

machine

blade

has

released.

flush

After

screw

to

be

foot

template,

not

be

into

with

is

fixed

sharpened,

The

and

guaranteed.

the

the

this

8657

in

since

presser

adjust

must

2.

be

tightened

Upper

the

trimmer

the

hex.

trimmer

pulled

with

the

distance

our

blade

upper

lever

tion

by

blade

this

be

adjustment

tightened

trimming

(moving)

shaft.

screw

shaft

out

of

trimmer

is

from

edge

is

of

now

rotation

overlaps

blades

again

blades^

86^7

must

the

pushed

the

the

brought

the

has

again.

is

(see

If

situated

be

trimmer

grinding

into

lower

blade

into

of

the

lower

been

The

now

illustration).

The

the

blade

released.

support

template.

the

edge

is

about

the

balance

blade

made,

relative

correct

upper

in

the

trimmer

of

the

extreme

wheel

by

the

(see

blade

has

to

top

The

blade

and

must

After

support

blade

0.5

mm.

left-hand

until

about

hex.

position

illustration).

is

be

sharpened,

of

the

is

be

grinding,

seat

The

0.4

screw

of

fixed

now

ground

until

blade

the

mm.

8647

the

to

posi

upper

After

in

the

the

must

Page 26

-

23

-

Befestigungsschraube

864?

Obermesser

Untermeaser

Messersitz

ca•

Die

Nadeln

fur

0,5

Spitze

das

mm

Befestigungsschraube

8657

ca.

0,4

fur

das

mm

Obermesser

Untermesser

=

=

s

=

=

=

~

=

Fixing

the

upper

upper

lower

blade

0.5

mm

The

tip

is

now

right-hand

needle

needles

Fixing

the

lower

0.4

mm

screw

blade

blade

seat

approx.

of

flush

screw

approx.

blade

the

edge

blade

864?

lower

with

865?

of

the

for

for

the

blade

3rd

fOrdtjf

Ob^masser

Ctf

(^S/mn

Obarmess^

Untermesser

^1

tiessersff£

Page 27

-

24

-

Df'e

Sfe^f"

c^gr

J

Bg/'fs/ffgtfngj'sehr^obe

fur

(/es

i/ntgrmessers

/Ttchfstn

S6S7y^_

digs

(/nfwr/rMfsser

r\\4

! X oc|oo ^

3.2

1/^

Xl¥mm

,.

I j ^

Ad.iustment

i.

The

stretcher

the

bearing

outcentred

path

I

g.-TTta-t^giht

looSer

The

noint

thread

over

distance

the

guiding

is

horizontally

between

and

IIo

adjustment

thread

stretcher

looper

of

looner

of

0p1

stretchero

the

thread

of

of

looper

must

bach

nun

the

the

looper

"X"

feeder

the

run

in

a

stretcher

of

thread

stretcher

Bearing

thread

=

for

looper

stretcher

Differential

Page 28

3.

Position

of

the

looper

thread

-

25

stretcher

-

at

its

front

dead

centre.

a)

\Ihen

centre,

the

b)

The

will

starting

thread

4.

After

the

longitudinal

longitudinal

a)

When

released

b)

When

released

the

looper.

final

only

stretcher

an

looper

the

the

looper

the

e^e

position

result

point

extreme

thread

stitch

too

stitch

too

(right

travel

travel

length

late

length

soon

Position

thread

marked

of

when

must

change

stretcher

of

from

from

stretcher

xxx

the

sewing.When

looper

dead

release

of

of

the

the

is

reduced,the

the

is

extended,

the

must

centre),

the

the

main

looper

point

point

stitch

must

has

lock

reached

flush

thread

the

looper

the

looper

length,the

be

corrected,because

feeder

thread

looper

of

the

the

of

the

Looper

V

with

stretcher,

point

thread.

carrier

stretcher.

looper

looper

looper

its

front

the

reaches

of

the

position

determines

thread

thread

thread

thread

back

dead

back

however,

its

looper

the

will

stretcher.

will

stretcher.

of

of

the

be

be

\

Page 29

Looper

pick-up

fault

-

26

-

left

needle

Whenalooper

needle-thread loop.

pick-up

fault

occurs,

the

looper

thread

lays

itself

O)

around

the

Page 30

-

27

-

Needle

pick-up

fault

left

needle

Whenaneedle

pick-up

needle-thread loop.

fault

occurs,

the

looper-threod

loop

passes

o

through

the

r

*

Page 31

\

i.«

Pfaff,D6750

Gedruckt in der Bundesrepublik Deutschiand •Printed in West Germany • imprime'en •Impreso en la R.F.A.

Kaiserslautern,

Postfach

3020/3040,

Telex:

045753

Loading...

Loading...