Page 1

-918/55

Supplement to the instruction

and adjustment manual for the

PFAFF 487, 489 and 5487

296-12-18 647/002

Betriebsanleitung engl. 06.2009

Page 2

The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or

in part, is only permitted with our previous authorization and with written reference to the

source.

PFAFF Industriesysteme

und Maschinen AG

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Page 3

Index

Contents ..................................................................................Page

1 Proper use............................................................................................................................. 5

2 Controls ................................................................................................................................ 6

2.01 Knee Switch ........................................................................................................................... 6

2.02 Control panel .......................................................................................................................... 6

2.03 Keyboard ................................................................................................................................7

3 Installation and commissioning ......................................................................................... 9

3.01 Connecting the plug-in connections and earth cables ........................................................... 9

3.02 Basic position of the machine drive unit .............................................................................. 10

3.02.01 With control unit P320 ED ................................................................................................... 10

3.02.02 With control unit P323 MS .................................................................................................. 12

4 Preparation ......................................................................................................................... 13

4.01 Selecting the program number ............................................................................................ 13

4.02 Inputting fullness ................................................................................................................. 14

4.03 Entering / altering the code number .................................................................................... 15

4.04 Adjusting the control panel .................................................................................................. 17

5 Sewing ................................................................................................................................ 18

5.01 Manual sewing..................................................................................................................... 18

5.01.01 Entering the seam start and seam end in manual sewing mode ........................................ 20

5.02 Sewing with fi xed programs ................................................................................................21

5.03 Programmed sewing ............................................................................................................23

5.03.01 Program interruption ............................................................................................................ 25

5.04 Error messages .................................................................................................................... 25

6 Input .................................................................................................................................... 26

6.01 Seam program input ............................................................................................................ 27

6.01.01 Basic settings for seam program input ................................................................................ 27

6.01.02 Seam program input with the "Creating/adjusting a program" functionen" .......................... 29

6.01.03 Seam program input with the "Creating/adjusting a program" function ............................... 31

6.01.04 Entering the functions at the beginning of the seam during seam programming ...................33

6.01.05 Entering the functions at the end of seam section during seam programming................... 34

6.02 Examples of how to create a seam program .......................................................................36

6.02.01 Example of a seam program input with the "creating/adjusting a program" function ..........36

6.02.02 Example of a seam program input using the "teach-in" function .......................................... 39

6.03 Seam program administration .............................................................................................. 41

7 Adjustment differing from the basic machine ................................................................. 43

7.01 Basic setting of the differential adjustment device .............................................................. 43

7.02 Parameter settings ............................................................................................................... 44

7.02.01 Overview of the parameter functions ..................................................................................44

7.02.02 Example of a parameter input .............................................................................................. 45

7.03 List of parameters ................................................................................................................ 46

Page 4

Index

Contents ..................................................................................Page

7.04 Sewing motor errors ............................................................................................................48

7.05 Explanation of the error messages ...................................................................................... 49

7.06 Table of inputs ...................................................................................................................... 50

7.07 Table of outputs ...................................................................................................................50

7.08 Service menu .......................................................................................................................51

7.09 Carry out a cold start ........................................................................................................... 52

7.10 Internet update of the machine software ............................................................................53

8 Circuit diagrams ................................................................................................................ 54

Page 5

Proper use

1 Proper use

The PFAFF 487-918/55, 489-918/55 and the PFAFF 5487-918/55 are single-needle,

ultra-high-speed sewing machines with programmable fullness control.

The PFAFF 487-918/55 and the 489-918/55 are used to sew lockstitch seams in

industry.

The PFAFF 5487-918/55 is used to sew two-thread chain stitch seams in industry.

Any and all uses of this machine which have not been approved of by the

manufacturer are considered to be inappropriate! The manufacturer cannot be

held liable for any damage caused by the inappropriate use of the machine!

The appropriate use of the machine includes the observance of all operational,

adjustment, maintenance and repair measures required by the manufacturer!

5

Page 6

Controls

2 GB

max.

2 Controls

2

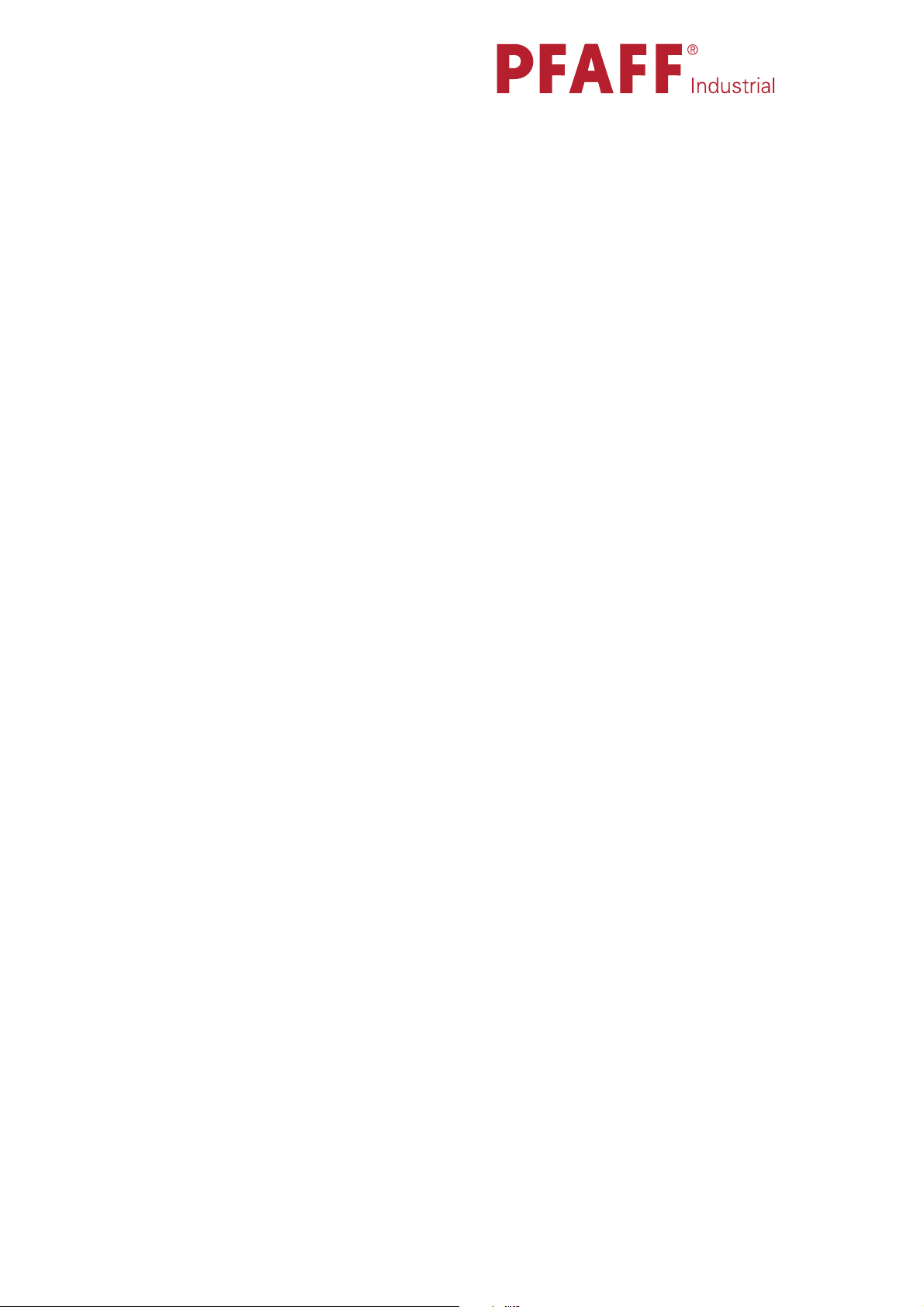

.01 Knee Switch

Manual sewing:

By operating knee switch ● 1 it is possi-

ble to alternate between two pre-set

amounts of fullness.

Programmed sewing:

By operating knee switch ● 1 the amounts

of fullness are changed according to the

program selected.

1

Fig. 2 - 01

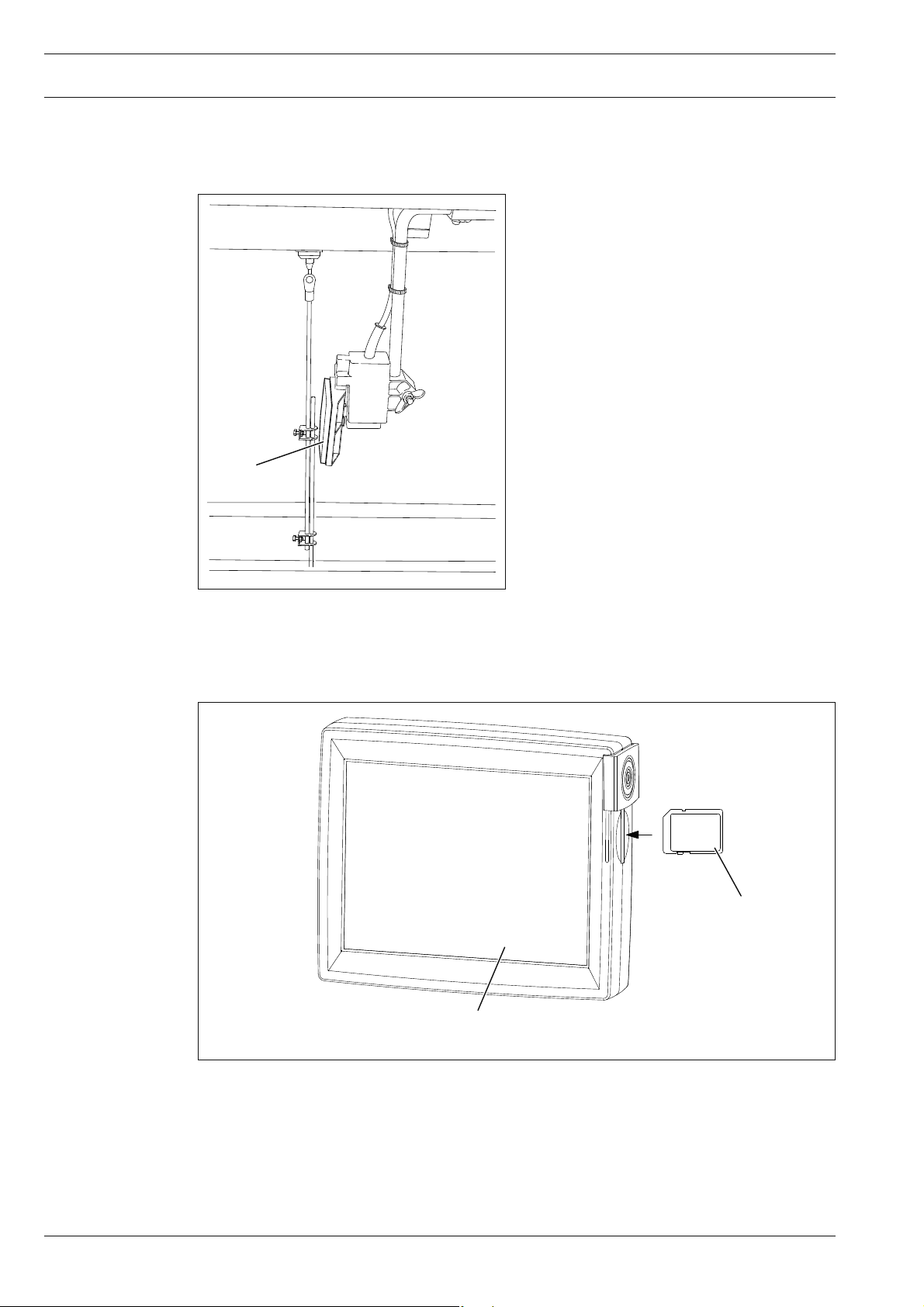

2.02 Control panel

2

1

Fig. 2 - 02

The current operating conditions are displayed on control panel 1. Operation takes place in a

constant dialogue between the control unit and the operator. For this purpose, depending on

the operating condition of the machine, different symbols and/or texts are displayed. If the

symbols or texts are framed, these show functions which can be selected by pressing the

appropriate position on the monitor. By pressing the corresponding function this is carried

out or switched on or off immediately, or a further menu appears, e.g. for entering a value.

6

Page 7

Controls

Activated functions are shown with inverted symbols. Unframed symbols or texts are only

used for display purposes and cannot be selected by pressing.

To read sewing programs or install machine software, use the sd-card 2 in the control

panel.

Description of the functions

Normal symbol = function switched off (inactive)

Inverted symbol = function switched on (active)

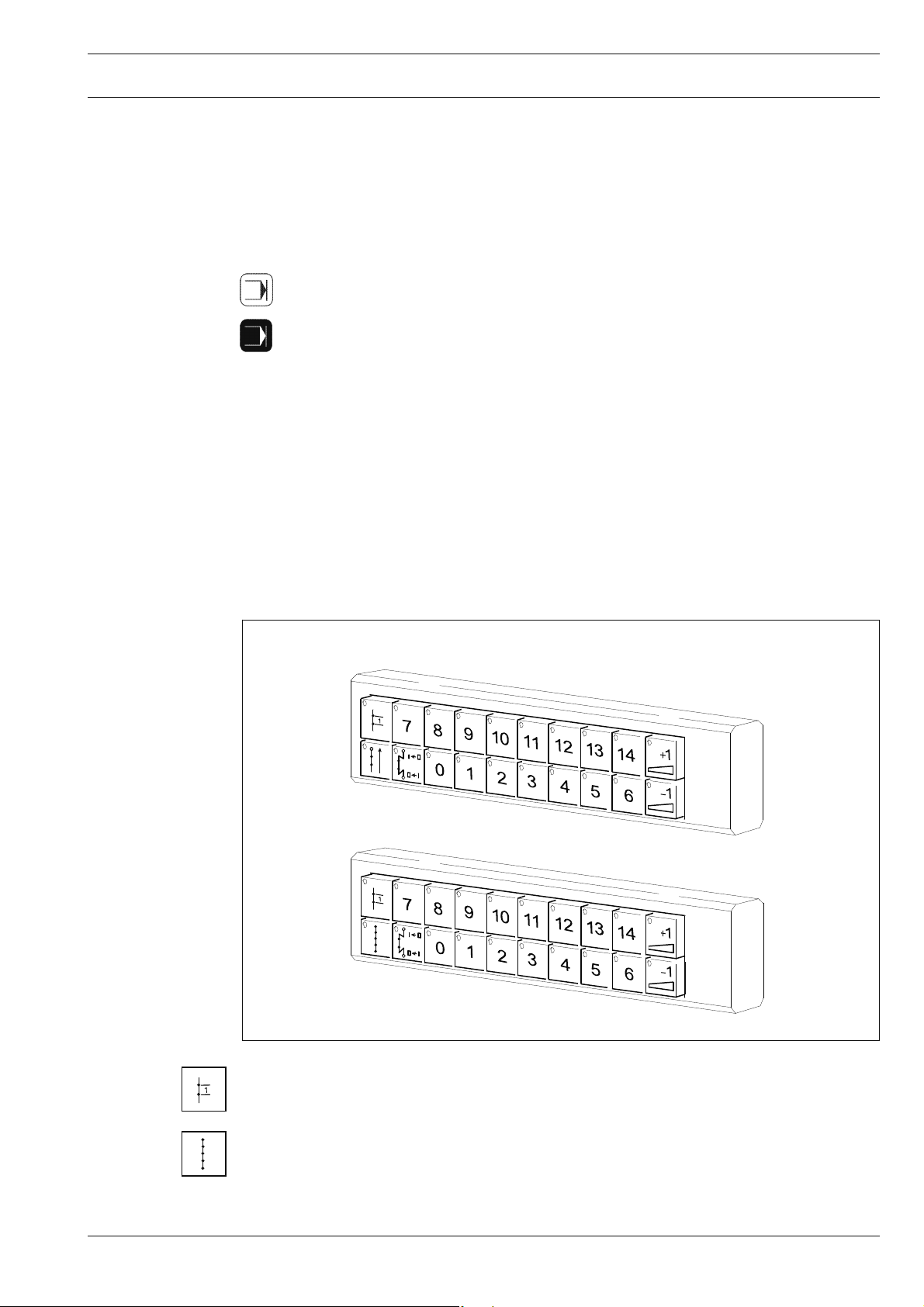

2.03 Keyboard

The keyboard is used for the quick operation of the machine during sewing and when selecting the fullness. With the corresponding LED of the 20 keys, active key functions are displayed (Function active = LED lit).

PFAFF 487-918/55, 489-918/55

PFAFF 5487-918/55

Fig. 2 - 03

Single stitch

If the single stitch key is pressed, the machine sews a single stitch. ●

Stitch condensation

(only on the PFAFF 5487)

The stitch condensation is switched on and off by pressing a key. ●

(When programming the seam: Sew the seam section with condensed stitches)

7

Page 8

Controls

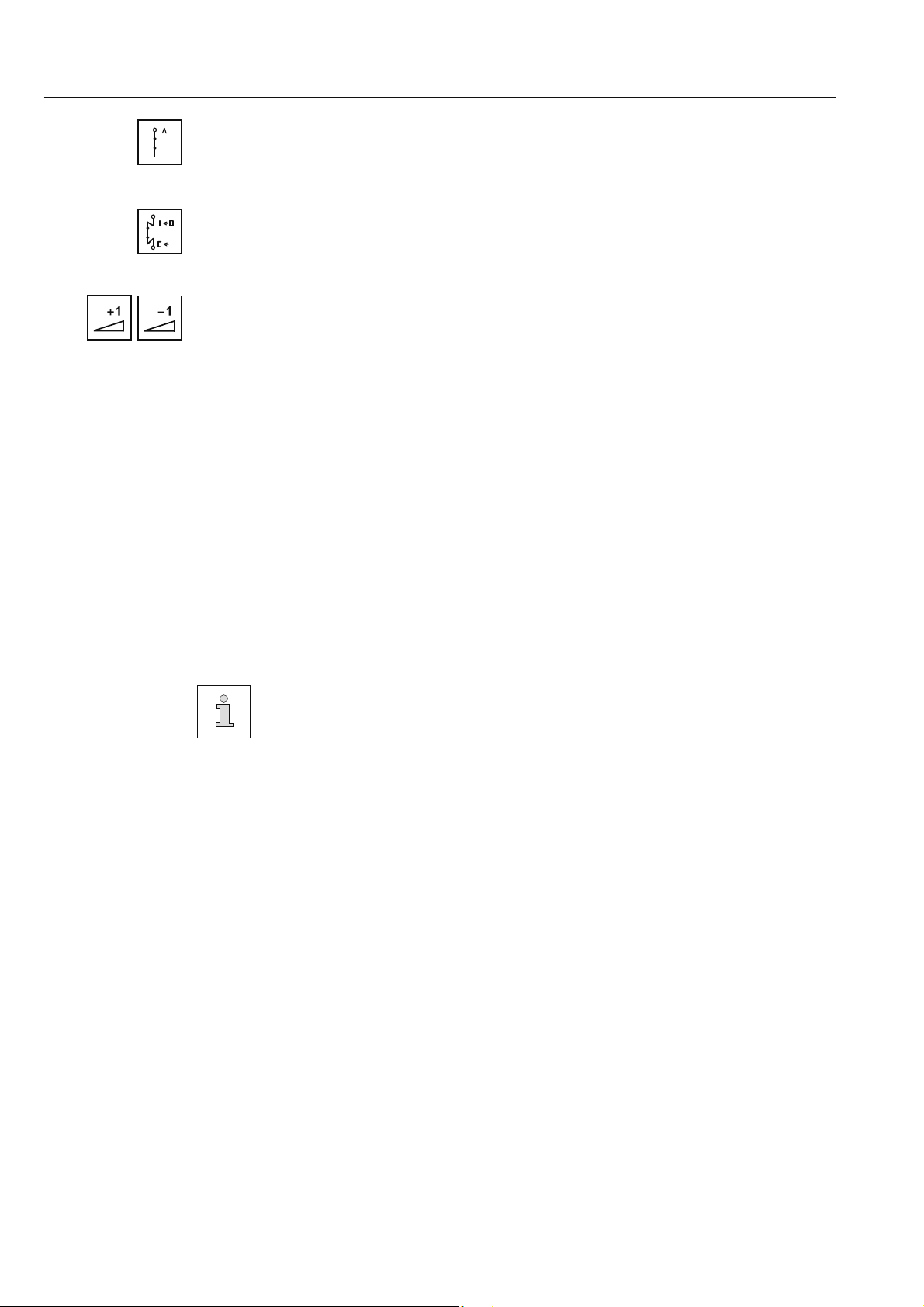

Reverse sewing direction (only on the PFAFF 487), 489

As long as the reverse sewing key is pressed, the machine sews in reverse. For the pro- ●

gramming and learning functions, the relevant seam section is programmed "in reverse".

Bartack suppression

If the bartack function is activated, by pressing this key once the next bartack and by ●

pressing it twice the next two bartacks are not sewn.

Correction value + / correction value -

If this key is pressed, the fullness value is increased or reduced in ● 2 steps. Fullness va-

lue 0 is not corrected. To make this possible, a correction value different to 0 must be

entered in parameter 209.

Number keys 0 - 14

The previously allocated amount of fullness is called up by pressing a key. ●

When two neighbouring number keys are pressed simultaneously, the corresponding

average value is selected.

In the manual sewing mode, the fullness can be allocated to the individual keys. The ●

current fullness value (which can be set on the touch-screen) is allocated to a key if it is

pressed for a long time (>3s). A bleep signalizes that the value has been saved.

Following values are pre-set and can be altered as described above.

Key 0: No fullness will be applied.

Key 14: Maximum fullness is selected.

The fullness values are designed for a basic stitch length of 2.5 mm. When se-

wing with shorter stitch lengths, the gathering intensity is increased, with lon-

ger stitch lengths it is reduced accordingly.

8

Page 9

Installation and commissioning

3 Installation and commissioning

The machine must only be mounted and commissioned by qualifi ed personnel!

All relevant safety regulations are to be observed!

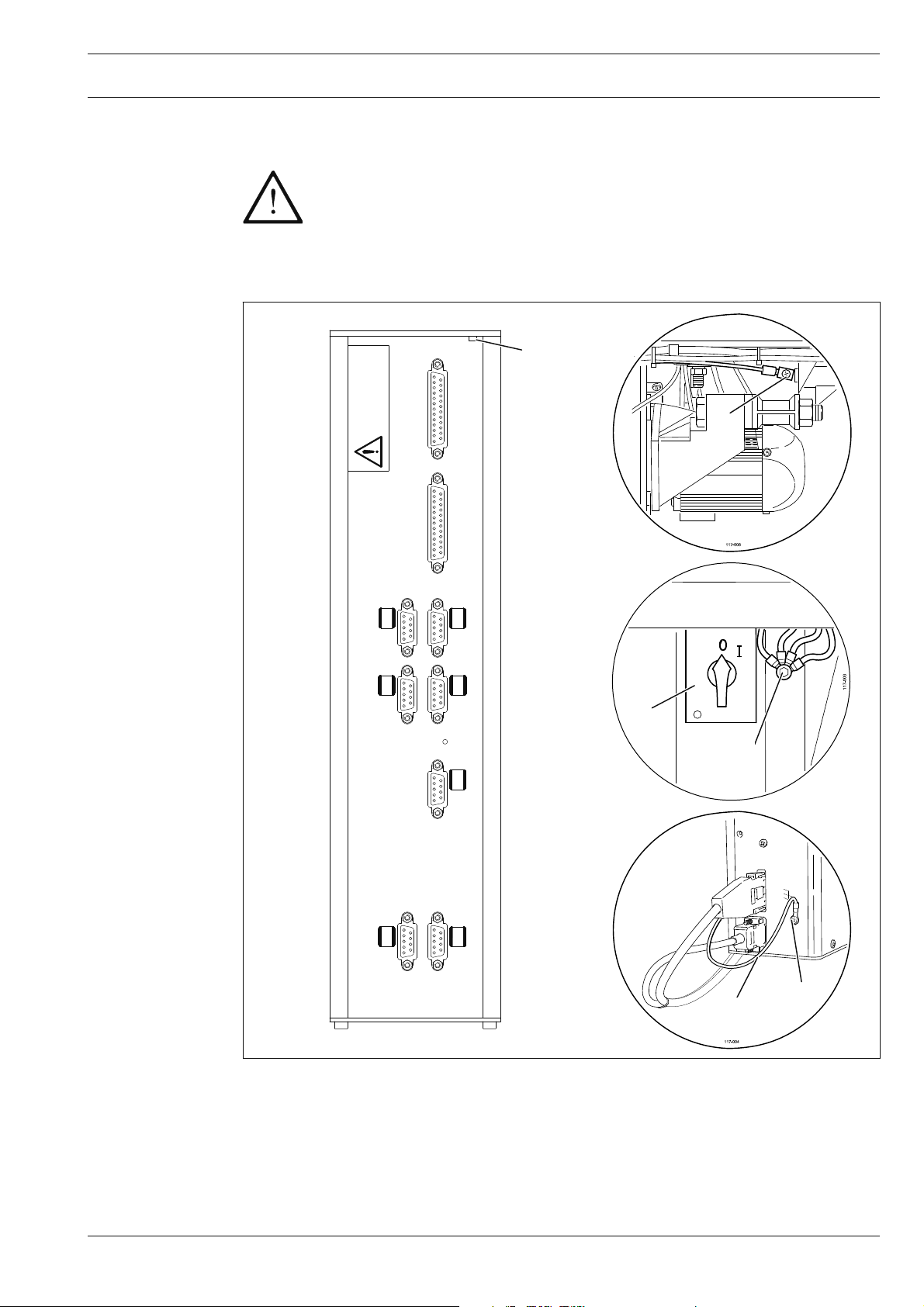

3.01 Connecting the plug-in connections and earth cables

C

ACHTUNG

ATTENTION

Vertauschungsgefahr

Danger of exchange

SSI

X1/B

Sollwertgeber

X11/B

Ausgänge

Eingänge

X13

X5

RS 232

X1/A

CAN-BUS

X11/A

Fadenwächter

X15

D

1

A

SM1

X4/B

SM2

X4/A

B

2

Fig. 3 - 01

Connect all plugs as labelled to the control box . ●

Screw the earth cable from the sewing head to earth point ● A.

With an earth cable connect earth point ● C and D to earth point A.

Screw the earth cable from the main switch ● 1 to earth point A.

Screw the earth cable ● 2 from the motor to earth point B.

9

Page 10

Installation and commissioning

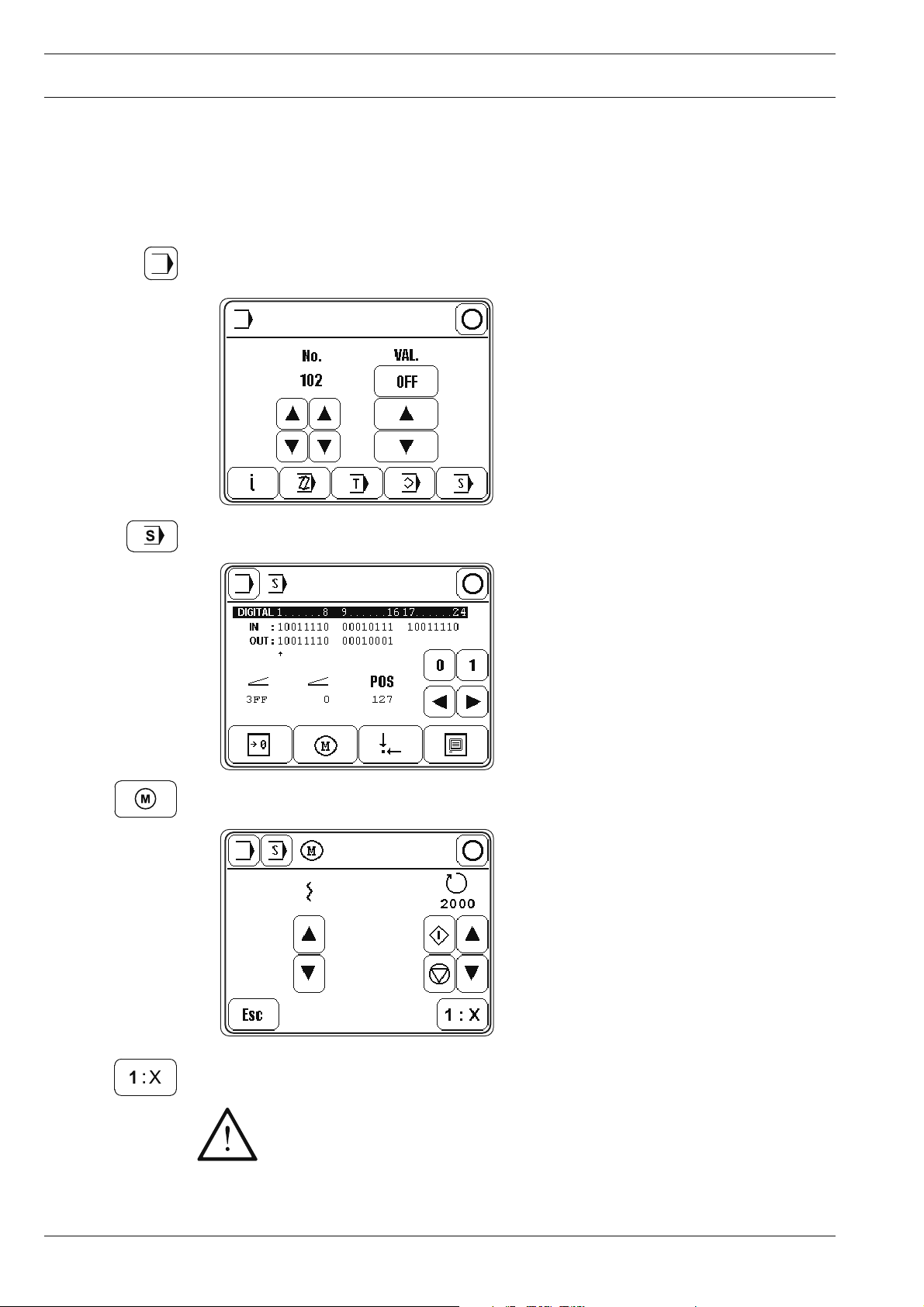

3.02 Basic position of the machine drive unit

3

.02.01 With control unit P320 ED

Switch on the machine. ●

Call up the input mode. ●

Call up the service function. ●

Call up the motor service function. ●

10

Press this key for the machine to learn the transmission ratio. ●

Attention!

After this key has been operated, the machine sews 3 stitches at a speed of

approx. 360 rpm.

Page 11

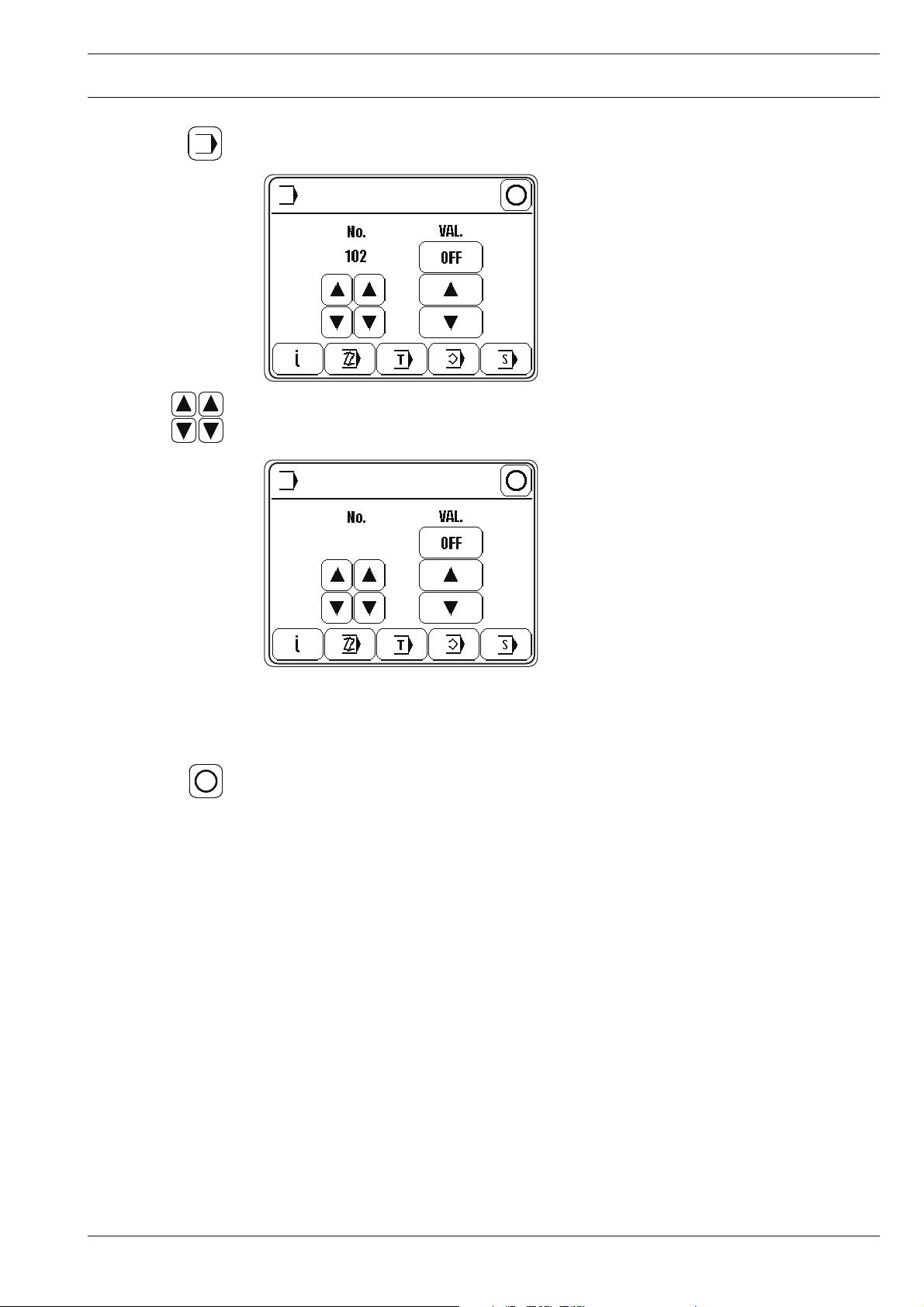

Installation and commissioning

Call up the input mode. ●

Call up parameter " ● 301".

301

Turn the balance wheel in the direction of rotation until the needle point, descending ●

from above, is fl ush with the top edge of the needle plate.

Conclude the input. ●

Switch off the machine. ●

11

Page 12

Installation and commissioning

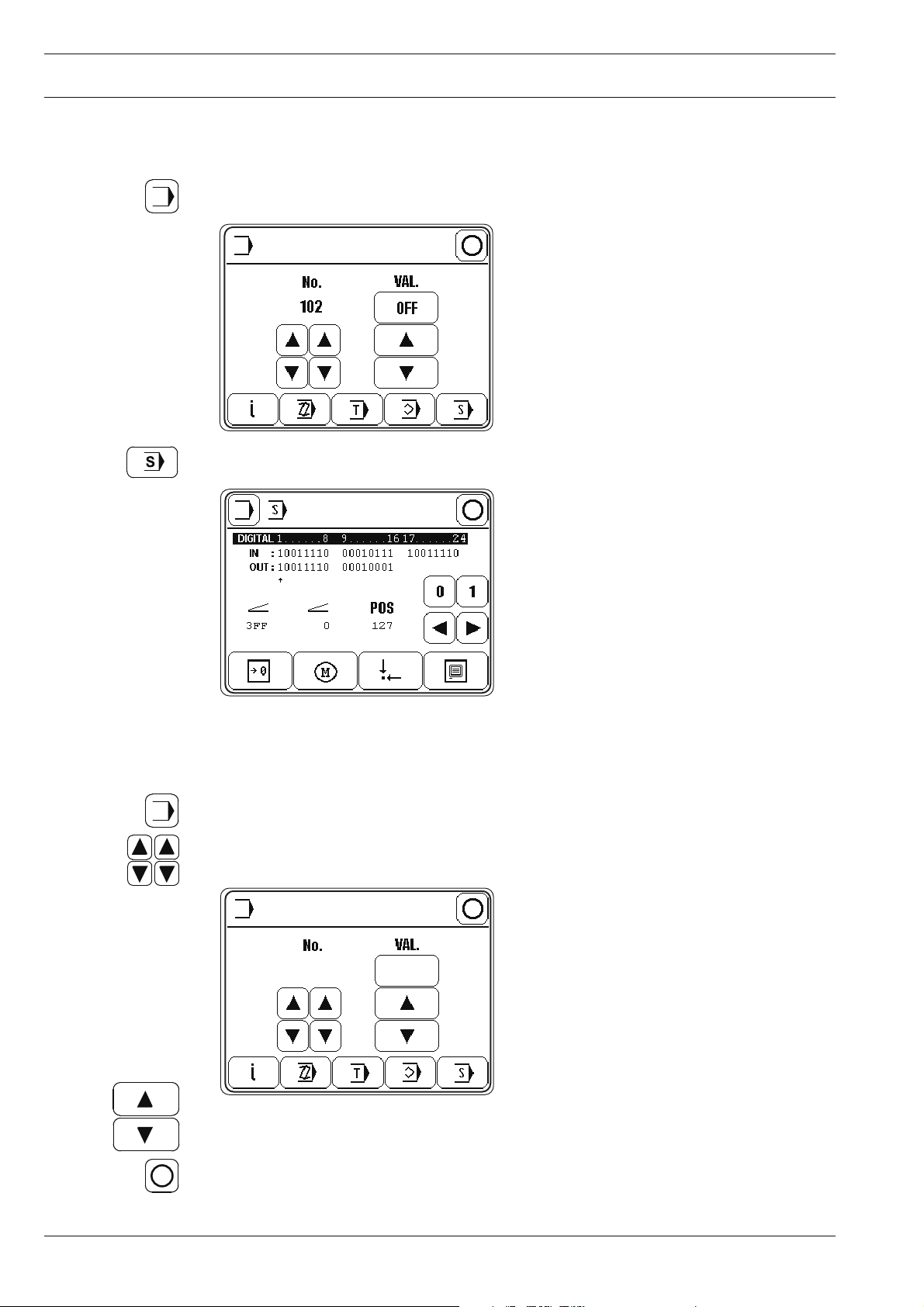

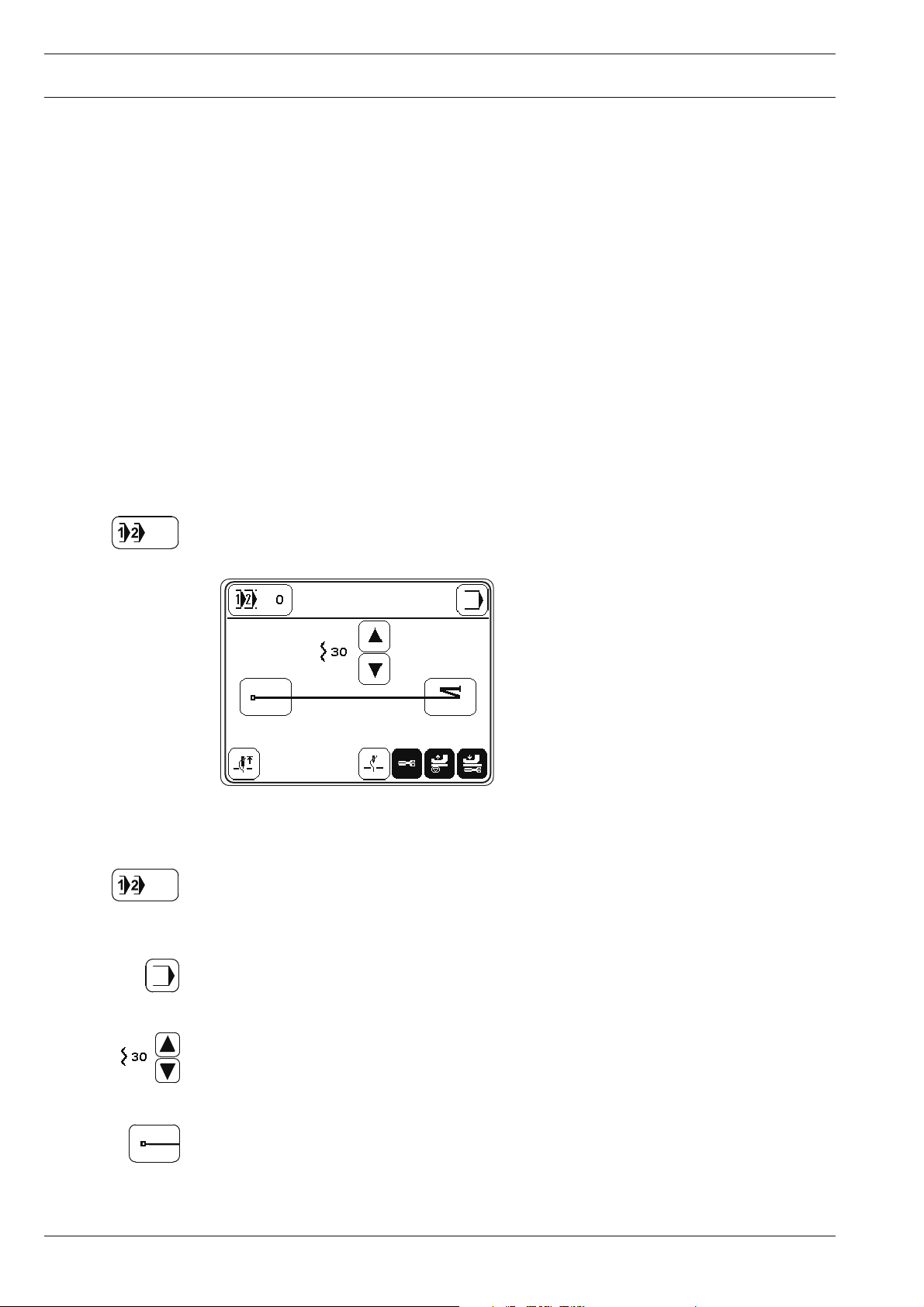

3.02.02 With control unit P323 MS

Switch on the machine. ●

Call up the input mode. ●

Call up the service function. ●

By turning the balance wheel in the sewing direction, ascertain the number of incre- ●

ments per turn (this maximum value appears under "POS" in the display before the reading jumps back to "0".

Call up the input mode. ●

Call up parameter " ● 721".

721

Enter the calculated max. value. ●

127

12

Conclude the input. ●

Switch off the machine. ●

Page 13

Preparation

4 Preparation

All regulations and instructions in this Instruction Manual are to be observed!

Special attention is to be paid to the safety regulations!

All preparation work is only to be carried out by appropriately trained personnel.

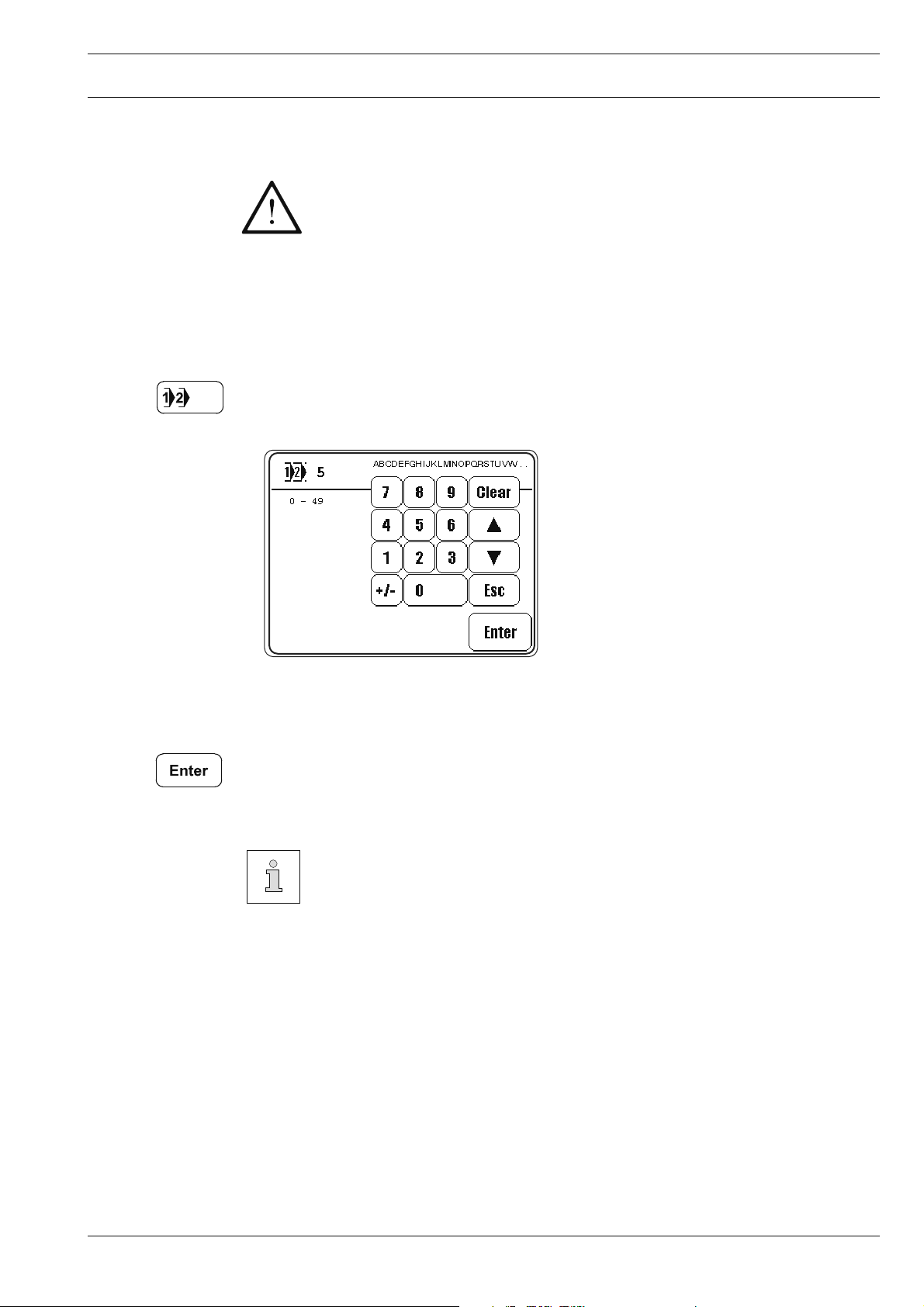

4.01 Selecting the program number

Switch on the machine. ●

Call up the program number input menu. ●

Select the desired program number. ●

Confi rm the selection and quit the selection menu. ●

The sewing method is determined by the program number selected,

see Chapter 5 Sewing.

Program number 0: Manual sewing

Program number 1 and 2: Sewing with fi xed programs

Program number 3 to 49: Programmed sewing

13

Page 14

Preparation

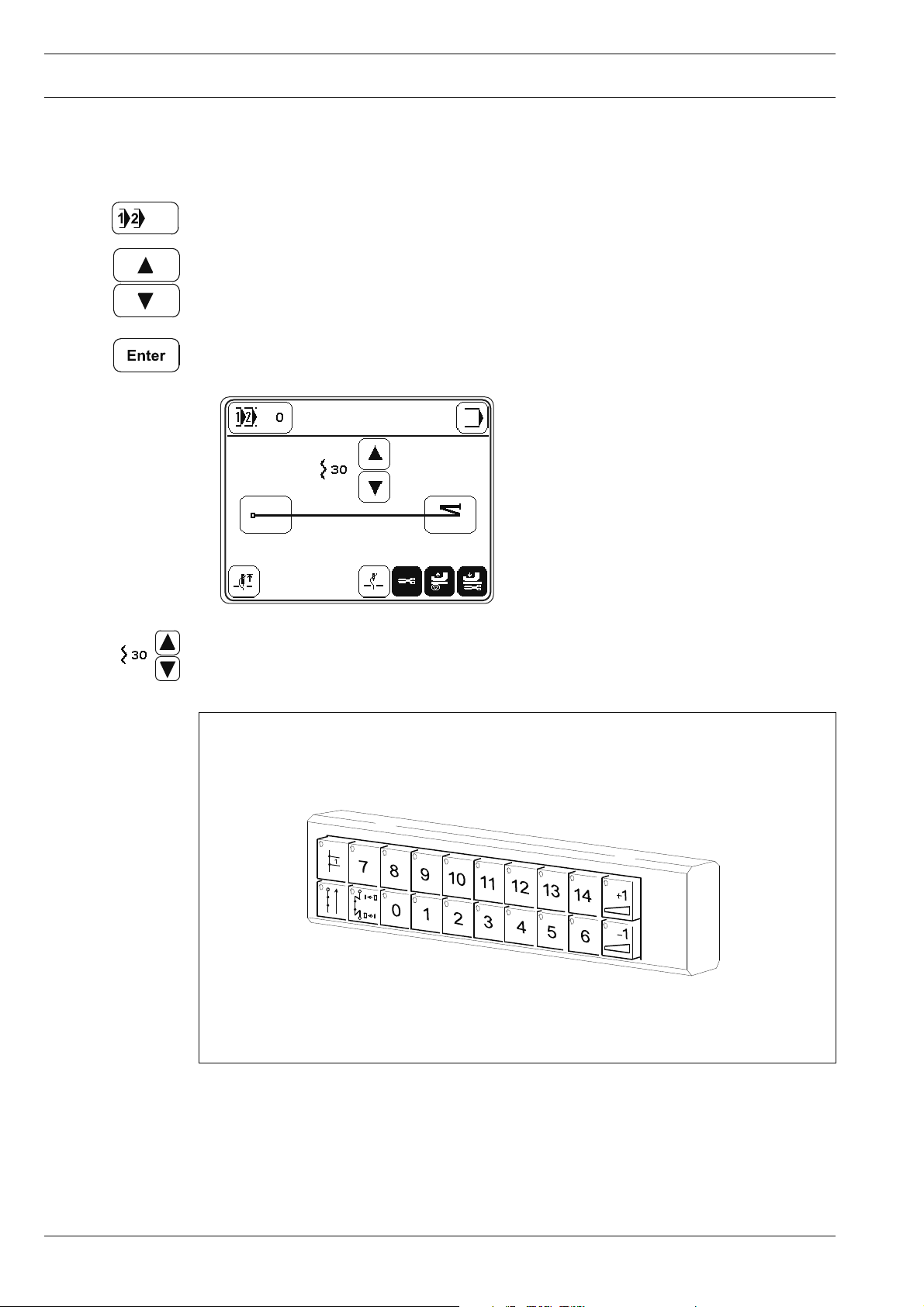

4.02 Inputting fullness

Switch on the machine. ●

Call up the program number input menu. ●

Select program number " ● 0"..

Confi rm the selection and quit the selection menu. ●

Enter the desired value with the appropriate arrow keys. ●

Fig. 4 - 01

If necessary, allocate the current fullness amount to one of the number keys ( ● 0-14) on

the keyboard. To do so, press the required key until a beep is heard.

14

Page 15

Preparation

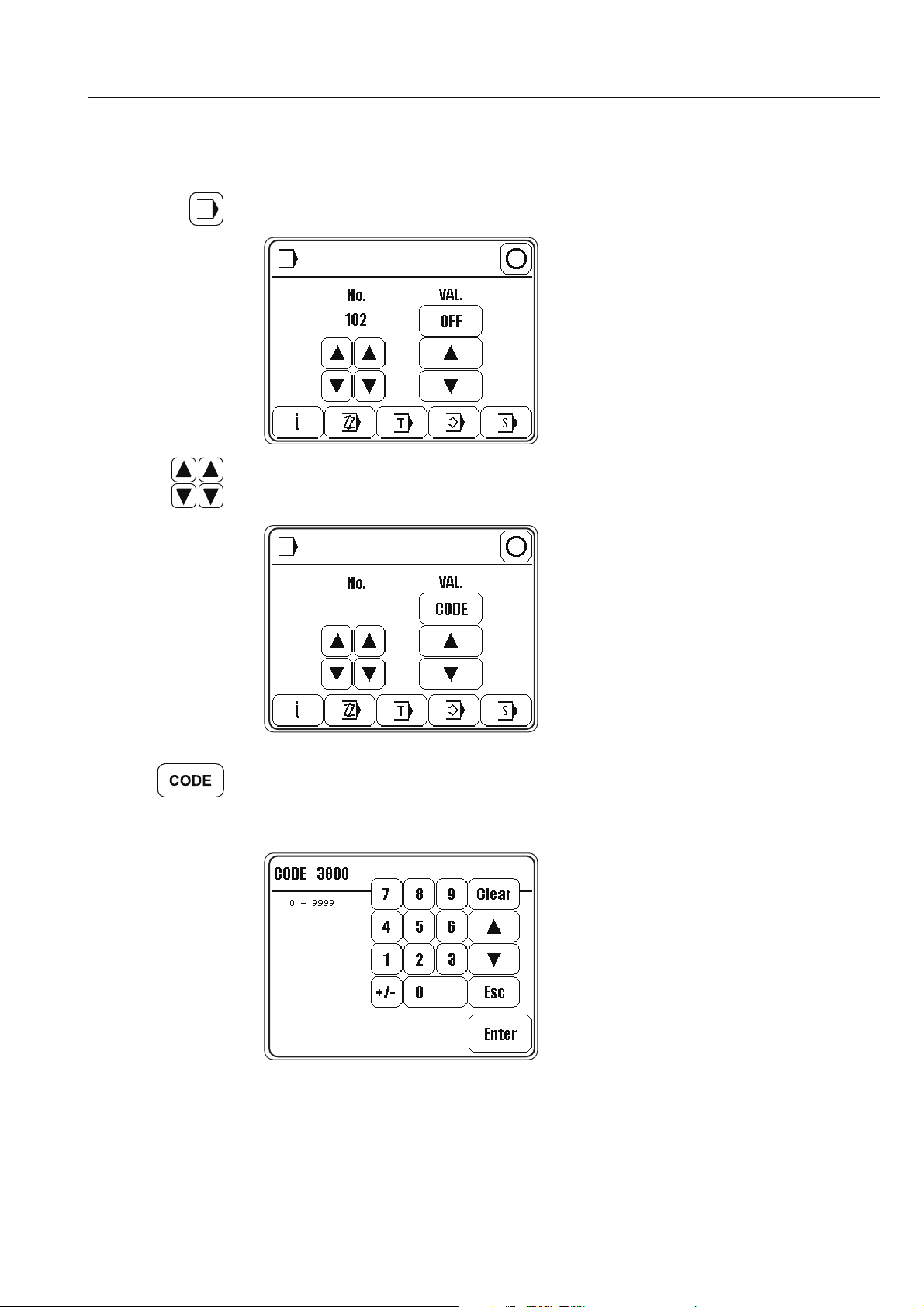

4.03 Entering / altering the code number

Switch on the machine. ●

Call up the input mode. ●

Select parameter " ● 800".

800

Select the code number input menu. ●

Enter the code number on the number keys (factory code setting is " ● 3800").

15

Page 16

Preparation

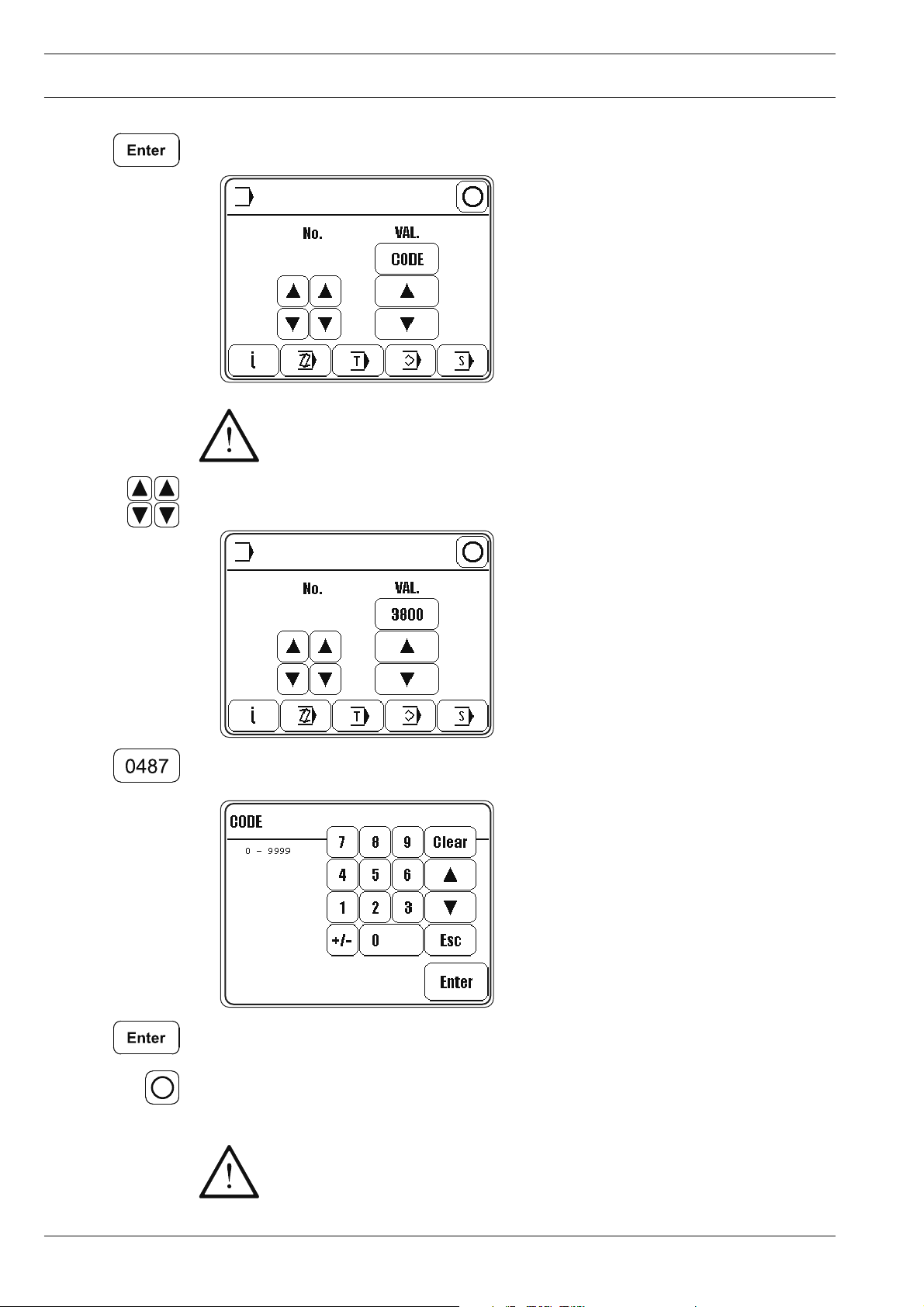

Take over the code number entered. ●

800

The code input remains stored until the machine is switched off at the main

switch. As long as the machine is not switched off, all parameters are freely ac-

cessible without having to enter the code number again.

Select parameter " ● 810"

800

Call up the code number input menu and enter the desired code number. ●

0487

Take over the new code number. ●

16

Conclude input. ●

Do not forget the code!

Without the appropriate code, the protected functions cannot be called up!

Help is then only possible through PFAFF service staff.

Page 17

Preparation

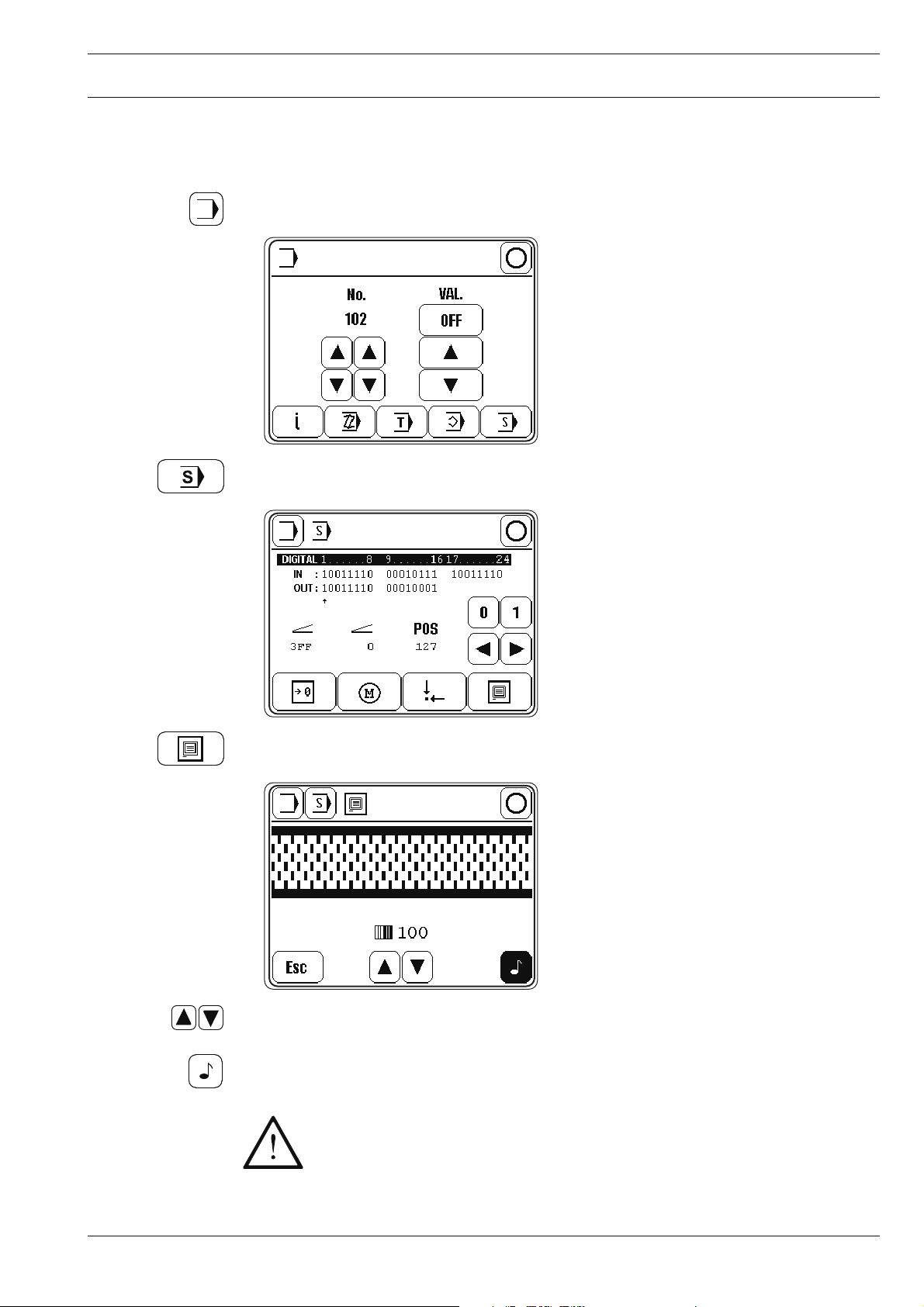

4.04 Adjusting the control panel

Switch on the machine. ●

Call up the input mode. ●

Select the service menu. ●

Select control panel functions. ●

Change the display contrast. ●

Switch the key tone off or on. ●

Never reduce the display contrast to the extent, that the display can no longer

be read!

17

Page 18

Sewing

5 Sewing

5.01 Manual sewing

In the sewing mode all relevant settings for the sewing operation are displayed on the

screen and can be altered with the corresponding functions.

In the sewing mode a difference is made between manual sewing, sewing with fi xed pro-

grams and programmed sewing.

The selection is made with the corresponding program number:

0: Manual sewing

1 and 2: Sewing with fi xed programs

3 to 49: Programmed sewing

(with up to 15 seam sections for both the left and right seam)

In the manual sewing mode the fullness values are displayed on the control panel and can

be altered directly by using appropriate function, just as the functions at the beginning and

the end of the seam and the needle and sewing foot positions.

Switch on the machine and select program number "0", see Chapter 4.01 Selecting the pro-

gram number.

18

Explanation of the functions

Program selection

This opens the menu for entering the program number, see Chapter 4.01 Selecting the program number.

Input mode

Exit the sewing mode and select the input mode.

Fullness

Alters the value for fullness, see Chapter 4.02 Inputting fullness

Seam start

Opens the menu for entering the functions at the beginning of the seam, see Chapter

5.01.01 Entering the seam start and seam end functions in the manual sewing mode.

Page 19

Sewing

Seam end

Opens the menu for entering the functions at the end of the seam, see Chapter 5.01.01 Entering the seam start and seam end functions in the manual sewing mode.

Needle raised

Moves the needle to its highest position

Needle position raised

When this function is activated, the needle moves to its highest position after sewing stops.

Thread trimming

When the function is activated, enables thread trimming with the pedal function.

Sewing foot raised

When this function is activated, the sewing foot is raised after sewing stops.

Sewing foot lowered after thread trimming

When this function is activated, the sewing foot is not raised after thread trimming.

Sewing is carried out with the pedal functions. ●

19

Page 20

Sewing

5.01.01 Entering the seam start and seam end in manual sewing mode

After the appropriate function has been selected, the menu for entering the value for con-

densed stitches or for backtacks appears.

PFAFF 487, 489 PFAFF 5487

PFAFF 487 ● , 489

Switch on the single start backtack function and call up the menu for entering the values.

(1 – 9 stitches can be entered).

or

Switch on the double start backtack function and call up the menu for entering the values. ●

(1 – 9 stitches can be entered).

PFAFF 5487 ●

Switch on the condensed stitches function and call up the menu for entering the values.

(1 – 30 stitches can be entered).

In each case change the number of stitches for the condensed stitches or the number of ●

backtack stitches with the appropriate arrow keys.

Change the value for the maximum speed during the condensed stitches or backtacking ●

operation (100 – 1500 spm can be entered).

Choose whether the condensed stitches or the backtacking operation at the beginning of ●

the seam should be carried out at a fi xed speed (normal symbol) or at a pedal-controlled

speed (inverse symbol).

Conclude the input. ●

20

In the manual sewing mode, the functions for the seam end are entered in the same way ●

as those for the seam start.

Page 21

Sewing

5.02 Sewing with fi xed programs

Fixed programs are stored under the program numbers 1 and 2.

The fi xed programs are used for the quick and easy production of seams with different

amounts of fullness. When sewing with fi xed programs, 2 or 3 seam sections are sewn af-

ter each other. With the knee switch it is possible to move to the next section. The fi xed pro-

grams are designed as cyclic running programs, i.e. at the end of the last seam section, the

machine moves back to the fi rst seam section. The fullness value can be selected for each

seam section, the settings for needle and foot positions apply to all sections and can be alte-

red at any time with the appropriate function.

The fullness values are designed for a basic stitch length of 2.5 mm. When se-

wing with shorter stitch lengths, the gathering intensity is increased, with lon-

ger stitch lengths it is reduced accordingly.

Switch on the machine and select program number " ● 1" or "2", see Chapter 4.01 Selecting

the program number.

Explanation of the displays and functions

Program selection

This opens the menu for entering the program number, see Chapter 4.01 Selecting the

program number.

Seam section

Shows the number of seam sections in the sewing program.

Input mode

Exit the sewing mode and select the input mode.

Fullness

Alters the fullness value, see Chapter 4.02 Inputting fullness.

Seam start

Opens the menu for entering the functions at the beginning of the seam, see Chapter

5.01.01 Entering the seam start and seam end functions in the manual sewing mode.

Seam end

Opens the menu for entering the functions at the end of the seam, see Chapter 5.01.01 Entering the seam start and seam end functions in the manual sewing mode.

21

Page 22

Sewing

Needle raised

Moves the needle to its highest position

Needle position raised

When this function is activated, the needle moves to its highest position after sewing stops.

Thread trimming

When the function is activated, enables thread trimming with the pedal function.

Sewing foot raised

When this function is activated, the sewing foot is raised after sewing stops.

Sewing foot lowered after thread trimming

When this function is activated, the sewing foot is not raised after thread trimming.

Sewing is carried out with the pedal functions. ●

22

Page 23

Sewing

5.03 Programmed sewing

With the program numbers 3 - 49 it is possible to call up previously programmed seams. In

programmed sewing all seam sections for pre-gathering a sleeve are set in one seam pro-

gram. The information about the seam program, such as program number, number of pro-

grammed seam sections, programmed comments is displayed.

For better orientation a seam sketch is shown with the programmed seam sections. The

seam start, seam end, the seam sections already sewn, the current seam section and the

seam sections still to be sewn are illustrated by symbols and different types of lines with dif-

ferent thicknesses. For the current seam section the corresponding parameters for seam

section number, fullness with fullness adjustment and the number of stitches (length of

seam section) are displayed. To control the seam sequence, the current seam (left or right

seam) and the automatic changeover from left to right seam can be switched over or swit-

ched on.

Switch on the machine, select the desired program number from " ● 3" to "49", see

Chapter 4.01 Selecting the program number.

Explanation of the displays and functions

Program selection

This opens the menu for entering the program number, see Chapter 4.01 Selecting the program number.

Seam section right/left

Shows the number of seam sections in the seam program for the right/left sleeve seam.

Input mode

Exit the sewing mode and select the input mode.

Fullness

Shows the current fullness value.

Current seam section

Shows the current seam section.

23

Page 24

Sewing

Current seam

This function is used to select and display the current seam (right/left).

Automatic seam change

When this function is activated, the machine changes automatically from the right to left seam.

Needle raised

Moves the needle to its highest position

Program interruption

Interrupts the program sequence, see Chapter 5.03.01 Program interruption

Thread trimming

When the function is activated, enables thread trimming with the pedal function.

Sewing foot raised

When this function is activated, the sewing foot is raised after sewing stops.

Sewing foot lowered after thread trimming

When this function is activated, the sewing foot is not raised after thread trimming.

Sewing is carried out with the pedal functions. ●

24

Page 25

Sewing

5.03.01 Program interruption

With the "program interruption" function the programmed seam sequence is interrupted ●

(e.g. if the thread breaks).

Interrupt program sequence. ●

If necessary, tact forwards or backwards through the sections of the seam program. ●

If necessary, change the values and carry out the other functions as in manual sewing, ●

see Chapter 10.01 Manual sewing.

If necessary, call up programmed sewing again.. ●

5.04 Error messages

If an error occurs, the text "ERROR" appears on the display, together with an error code. An

error message is caused by incorrect settings, defective elements or seam programs and by

overload conditions.

For an explanation of the error codes see Chapter 7.05 Explanation of the error messages.

Eliminate the error. ●

Confi rm error elimination. ●

25

Page 26

Input

6 Input

In the input mode the functions parameter input, information, creating/adjusting a sewing

program, teach-in, program administration and service are available.

Switch on the machine. ●

Call up the input mode. ●

Explanation of the functions

Sewing mode

Quit the input mode and call up the sewing mode.

Parameter selection

Select the hundred and unit fi gures of the desired parameters, see Chapter 7.02.02 Example of a parameter input.

Altering the parameter value

Change the value of the selected parameter, see Chapter 7.02.02 Example of a parameter

input.

Software information

Calls up information about the current machine software.

Creating/adjusting a program

Opens the menu for entering or altering a seam program, see Chapter 6.01.02 Seam program input with the "Creating/adjusting a program" function.

Teach In

Opens the menu for entering seam programs after sewing a sample, see Chapter 6.01.03

Seam program input with the "Teach in" function.

26

Program administration

Opens the menu for seam program administration, see Chapter 6.03 Seam program administration.

Service

Opens the service menu, see Chapter 7.08 Service menu.

Page 27

Input

6.01 Seam program input

Seam programs can be created by entering parameters in the "Creating/adjusting a seam

program" function, or by sewing a sample with the "Teach in" function.

Irrespective of which function is being used, fi rst of all it is necessary to select the program

number and the basic settings of the seam program, which is to be sewn.

6.01.01 Basic settings for seam program input

The basic settings in the "creating/adjusting a program" and the "teach-in" functions are the

same.

Switch on the machine. ●

Call up the input mode. ●

Call up the "Creating/adjusting a seam program" or the "Teach in" function. ●

If necessary, change the selected program number and confi rm the selection. ●

If applicable, enter or change a comment. ●

27

Page 28

Input

Set the seam type (by pressing the appropriate symbol several times until the appropria- ●

te seam type is displayed).

Description of the symbols:

Sewing program with left and right seam, beginning with the right seam.

Sewing program with left seam only.

Sewing program with right seam only.

Sewing program with left and right seam, beginning with the left seam.

Conclude the input of the basic settings and change to the seam section input, see Chap- ●

ter 6.01.02 Seam program input with the "Creating/adjusting a program" function or

Chapter 6.01.03 Seam program input with the "Teach in" function.

The input can also be concluded by calling up the sewing mode. In this case

the seam program input is concluded and the machine changes to programmed

sewing.

28

Page 29

Input

6.01.02 Seam program input with the "Creating/adjusting a program" functionen"

With this function the seam program is entered by entering or changing the appropriate va-

lues on the control panel. This type of seam program input is particularly suitable for adjus-

ting existing seam programs.

Switch on the machine. ●

Call up the input mode. ●

Call up the "creating/adjusting a program" function. ●

Carry out the basic settings and conclude with the "Enter" function, see Chapter ● 6.01.01

Basic settings for seam program input.

Alter the fullness, see Chapter ● 4.02 Inputting fullness.

Alter the maximum speed for the current seam section. ●

These functions are used to scroll through the current seam program. ●

The current seam section is displayed accordingly, in addition to all the other current

values.

Enter the seam start functions, see Chapter ● 6.01.04 Entering the functions at the be-

ginning of the seam during seam programming.

Enter the functions for the end of the seam section, see Chapter ● 6

end of the seam section when programming the seam.

Select a seam type ●

It is only possible to select the right or left seam, if the seam type "right and left seam"

was selected in the basic setting, see Chapter 6.01.01 Basic settings for seam program

input.

.01.05 Entering the

29

Page 30

Input

If necessary, insert the seam section. ●

The current seam section is copied and all following seam sections are set one place

back.

If necessary, delete the current seam section. ●

If necessary, conclude the input of the current seam and store the parameter for the ●

other seam in the reverse order (mirror seam).

Set the seam end or program end. ●

If entering only one seam (only the right or only the left seam) the program end is set in

the desired seam section.

In the same way as the program end, the seam end is set when entering the right and

left seam. The seam end is set in the fi rst seam and the program end in the second

seam.

Conclude the input of the fi rst seam section and change to the next seam section. ●

Conclude the input and change to the input of the basic settings. ●

Conclude the input and change to programmed sewing. ●

30

Page 31

Input

6.01.03 Seam program input with the "Creating/adjusting a program" function

With this function the seam program is entered by sewing a sample. A new program is al-

ways created, i.e. if an existing program is selected, this will be overwritten.

Switch on the machine. ●

Call up the input mode. ●

Call up the "teach-in" function. ●

Carry out the basic settings and conclude with the "Enter" function, see Chapter ● 6.01.01

Basic settings for seam program input.

Before sewing starts the following displays and functions appear on the screen.

Enter the seam start functions, see Chapter ● 6.01.04 Entering the functions at the be-

ginning of the seam during seam programming.

Enter the fullness, see Chapter ● 4.02 Input

Enter the maximum speed for the current seam section. ●

Sew the fi rst seam section using the pedal function. ●

The number of stitches in the current seam section is counted and shown on the display.

After sewing starts, the following displays and functions are shown on the screen.

ting fullness.

31

Page 32

Input

By pressing Enter the seam section end is defi ned by stitch counting. ●

By operating the pedal in position "- ● 2", the seam section is ended by pedal operation

By operating the knee switch, the seam section is ended by knee switch operation, see ●

Chapter 2.01 Knee switch.

After the function has been called up, additional inputs can be made for the seam section ●

end or incorrect inputs can be corrected, see Chapter 6.01.05 End of seam section in-

put during seam programming.

Condensed stitches defi ned during the input of the functions for the end of the

seam section, will be carried out after the seam program input has been concluded. Up to 30 stitches will be sewn! Danger of injury in the needle area!

Set the seam end or program end. ●

If entering only one seam (only the right or only the left seam) the program end is set in

the desired seam section.

In the same way as the program end, the seam end is set when entering the right and

left seam. The seam end is set in the fi rst seam and the program end in the second

seam.

Conclude the input. ●

Conclude the input and change to the input of the basic settings. ●

Conclude the input and change to programmed sewing. ●

32

Page 33

Input

6.01.04 Entering the functions at the beginning of the seam during seam programming

After the appropriate function has been called up, the menu for entering the value of the

placement stitch appears. To begin with the condensed stitches function is not activated.

PFAFF 487, 489 PFAFF 5487

PFAFF 487 ● , 489

Switch on the single start backtack function and call up the menu for entering the values.

(1 – 9 stitches can be entered).

or

Switch on the double start backtack function and call up the menu for entering the values. ●

(1 – 9 stitches can be entered).

PFAFF 5487 ●

Switch on the condensed stitches function and call up the menu for entering the values.

(1 – 30 stitches can be entered).

In each case change the number of stitches for the condensed stitches or the number of ●

backtack stitches with the appropriate arrow keys.

Change the value for the maximum speed during the condensed stitches or backtacking ●

operation (100 – 1500 spm can be entered).

Choose whether the condensed stitches or the backtacking operation at the beginning of ●

the seam should be carried out at a fi xed speed (normal symbol) or at a pedal-controlled

speed (inverse symbol).

If necessary, sew the seam section in reverse (with activated function). ●

Conclude the input. ●

33

Page 34

Input

6.01.05 Entering the functions at the end of seam section during seam programming

After the appropriate function has been called up, the menu for entering the functions and

values for the end of the seam section without condensed stitches appears.

PFAFF 487, 489 PFAFF 5487

PFAFF 487 ● , 489

Switch on the single end backtack function and call up the menu for entering the values.

(1 – 9 stitches can be entered).

or

Switch on the double end backtack function and call up the menu for entering the values. ●

(1 – 9 stitches can be entered).

PFAFF 5487 ●

Switch on the condensed stitches function and call up the menu for entering the values.

(1 – 30 stitches can be entered).

In each case change the number of stitches for the condensed stitches or the number of ●

backtack stitches with the appropriate arrow keys.

Change the value for the maximum speed during the condensed stitches or backtacking ●

operation (100 – 1500 spm can be entered).

Switch the function for changing to the next seam section by pedal on or off. ●

Switch the function for changing to the next seam section by knee switch on or off. ●

Enter or change (with the number keys or arrow keys) the number of stitches for the ●

seam section.

34

Execute or do not execute the automatic sewing stop function at the end of the seam ●

section.

Switch the "sewing foot raised" function on or off, see Chapter ● 5.01 Manual Sewing.

Page 35

Input

Switch the "thread trimming" function on or off, see Chapter ● 5.01 Manual Sewing.

Switch the "needle raised" function on or off, see Chapter ● 5.01 Manual Sewing.

Conclude the input and change to programmed sewing. ●

It is not possible to set every combination of functions.

All the activated functions are shown as inverse symbols.

35

Page 36

Input

6.02 Examples of how to create a seam program

6

.02.01 Example of a seam program input with the "creating/adjusting a program"

function

The program to be created should

- have 3 seam sections and

- be stored under the program number "4" with the comment "PROG".

Seam area 1

Number of stitches: 40

Fullness: 0

Seam area 2

End with knee switch

Fullness: 20

Seam area 3

Without stitch count

End with pedal position "-2"

Fullness: 0

Switch on the machine. ●

Call up the input mode. ●

Call up the "creating/adjusting a seam program" function and enter program number " ● 4".

36

Set the seam type (right seam) by pressing until the appropriate symbol appears. ●

Call up the menu for comment input. ●

Enter the comment "PROG" with the keyboard and number panel. ●

Conclude the comment input. ●

Change to the input of the fi rst seam section. ●

Page 37

Input

0

Enter the value " ● 0" for the fullness.

Call up the menu for the input of the end of the seam section. ●

Switch on the stitch count function to change to the next seam section, and set value " ● 40"

for the number of stitches.

Conclude the input of the end of the seam section. ●

Change to the input of the second seam section. ●

Enter the value " ● 20" for the fullness.

Call up the menu for the input of the end of the seam section. ●

Switch on the function for changing to the next seam section with the knee switch. ●

37

Page 38

Input

Conclude the input of the end of the seam section. ●

Change to the input of the third seam section. ●

Enter the value " ● 0" for the fullness.

Call up the menu for the input of the end of the seam section. ●

Switch on the function for changing to the next seam section by pedal. ●

Switch on the "thread trimming" function. ●

Switch on the "sewing foot raised" function. ●

Conclude the input. ●

38

Page 39

Input

6.02.02 Example of a seam program input using the "teach-in" function

The program to be created should

- have 3 seam sections and

- be stored under the program number "11 " with the comment "TEACH".

Seam area 1

Learn number of stitches

Fullness: 0

Seam area 2

End with knee switch

Fullness: 30

Seam area 3

Without stitch count

End with pedal position "-2"

Fullness: 0

Switch on the machine. ●

Call up the input mode. ●

Call up the "teach-in" function and enter program number " ● 11 ".

Set the seam type (right seam) by pressing until the appropriate symbol appears. ●

Call up the menu for comment input. ●

Enter the comment "TEACH" with the keyboard and number panel. ●

Conclude the comment input. ●

Change to the input of the fi rst seam section. ●

39

Page 40

Input

Enter the value " ● 0" for the fullness.

Sew the fi rst seam section using the pedal function. ●

Change to the input of the second seam section. ●

Enter the value " ● 30" for the fullness.

Operate the knee switch ●

Conclude the input of the end of the seam section. ●

Use the pedal function to sew the second seam section. ●

Operate the knee switch ●

Change to the input of the third seam section. ●

40

Enter the value " ● 0" for the fullness.

Conclude the input. ●

Page 41

Input

6.03 Seam program administration

In the program administration the seam programs deposited in the machine memory and

the SD-Card can be deleted and copied. The left side of the display shows the programs in

machine memory. The right side of the display shows the programs on the SD-Card. Selec-

ted programs are red marked. With the MDAT-function the machine confi guration can be co-

pied or deleted. The Format-function formats the SD-Card. Further actions are shown in a

dialog window.

After SD-Card insertion it takes up to 20s until the card is detected.

Switch on the machine. ●

Call up the input mode. ●

Call up program administration. ●

Read SD-Card and machine memory again. ●

Explanation of the functions

Input mode

Calls up the basic display for the input mode.

Sewing mode

Quit input mode and call up sewing mode.

Program selection

After the program administration has been selected, at least one seam program is always

marked. Using the arrow functions, the desired seam program can be selected. With the

*-function and the arrow functions a seam program block can be marked. By pressing the

*.function again, the block function is deactivated.

Copy

Selected seam programs are copied from/to SD-Card.

Delete

Selected seam programs are deleted.

41

Page 42

Input

Dialog window

The dialog window shows questions and additional buttons for the answers.

Enter button

Enter button

Yes for one seam program.

All button

Yes for one or all marked seam programs.

Esc button

No for one or all marked seam programs.

Next button

No for one seam program.

Machine confi guration

With the MDAT-function the machine confi guration can be copied to/from SD-Card or can be

deleted on the SD-Card (fi lename: MDAT).

Format SD-Card

The Format-function formats the SD-Card.

If the SD-Card is not readable, it is new formatted. If the SD-Card is readable and the directory \P487 for the 487-machine exists then all seam programs and the machine confi guration

(MDAT) are deleted in this directory.

If the directory \P487 for the 487-machine does not exist, only the directory \P487 is created.

So all other fi les and directories on the SD-Card are not corrupted.

It is recommended to use SD-Cards with a maximum capacity of 2 GB.

42

Page 43

Adjustment

7 Adjustment differing from the basic machine

7

.01 Basic setting of the differential adjustment device

Requirement

With the fullness set at "0", the stitch length at "2.5" and the adjustment gauge 5 fi tted,

the roller 2 should be touching pressure sleeve 4.

1

Fig. 7 - 01

Switch on the machine. ●

Press key " ● 0" on keyboard 1 (LED must light up).

Switch off the machine. ●

Adjust roller ● 2 (screw 3) according to the requirement.

2

5

3

4

43

Page 44

Adjustment

7.02 Parameter settings

7

.02.01 Overview of the parameter functions

After the machine has been switched on, by pressing the appropriate function the input

mode is called up, in which the individual parameters can be called up directly. With a code it

is possible to protect all or individual parameter groups against unauthorised access.

Select parameter group

100 Operator level

200 Mechanic level

300 Sewing motor positions

400 Times

500 Counters and speeds

700 Sewing motor

800 Access rights

44

Page 45

Adjustment

7.02.02 Example of a parameter input

Switch on the machine. ●

Call up the input mode. ●

e.g. call up parameter " ● 11 3 " (switch beep tone for section change on/off)

e.g. switch beep tone on (value "ON"). ●

Conclude the input. ●

45

Page 46

Adjustment

7.03 List of parameters

Group

Parameter

1

102 Reversing

The operator has free access to the "100" parameters. Parameters "200" - "800"

can only be changed after entering a code number and may only be changed by

authorised personnel.

Description

OFF - ON OFF

Setting range

Set value

113 Beep tone for section change

114 Max. speed forwards at each pedal positio

2

201 Machine confi guration

9 = 487-918/15

10 = 5487-918/15

11 = 489-918/15

209 Fullness adjustment value (keyboard)

212 Not speed variation with change of fullness

213 program interruption with pedal-position -2

3

301 Position

"Needle point at top edge needle plate"

(P320ED)

302 Position "take-up lever t.d.c."

487, 489

5487

303 Position "needle lowered"

487, 489

5487

OFF - ON OFF

OFF - ON OFF

0 - 9 0

OFF - ON OFF

OFF - ON OFF

0 - 127 0

0 - 127

113

107

0 - 127 0

24

60

46

ev

ersing position

304

4

401 Delay time "lift foot" (s)

402 Start delay after "lower foot" (s)

403 Thread cutting time (on the 5487)

404 Time for cleaning thread monitor (s)

501 Maximum speed

5

504 Speed soft start

505 Soft start stitches

R

487, 489

5487

0 - 127 113

0,01s - 1,5s 0,02s

0,01s - 1,5s 0,15s

0,01s - 0,2s 0,15s

0,01s - 1,5s 0,25s

100 - 5500

4800

5500

100 - 5500 1500

0 - 15 0

Page 47

Adjustment

Group

Parameter

Description

701 P-quota speed controller

7

Setting range

0 - 50 16

Set value

702 I-quota speed controller

703 P-quota position controller

704 D-quota position controller

705 Time for position controller

706 P-quota position controller for rest brake

707 D-quota position controller for rest brake

708 Maximum moment for rest brake

709 Minimum machine speed

710 Maximum machine speed

487, 489

5487

Maximum motor speed

1

71

487, 489

5487

712

713 Acceleration ramp

Positioning speed

0 - 100 50

0 - 50 40

0 - 100 40

0 - 100 25

0 - 50 25

0 - 50 15

0 - 100 0

3 - 64 6

1 - 55 0

42

55

1 - 55 0

42

55

3 - 25 18

0 - 50 35

714 Brake ramp

715 Reference position

716 Time-out

717 Starting current motor

718 Anti-vibration fi lter

719 Rotation direction allocation

720 Reference position correction

721 Number of increments per revolution

(Read maximum value in Service and enter here)

- P323 MS

0 - 50 30

0 - 127 20

0 - 255 40

3 - 10 8

1 - 10 6

0 - 1 0

0 - 127 64

101 - 149 127

47

Page 48

Adjustment

Group

Parameter

Description

801 Right of access function group 100

8

Setting range

0 - 1 0

Set value

802 Right of access function group 200

803 Right of access function group 300

804 Right of access function group 400

805 Right of access function group 500

806 Right of access service

807 Right of access function group 700

808 Right of access function group 800

809 Right of access program creation

810 Enter access code

7.04 Sewing motor errors

Message Description

33

34 Brake path too short *

35

36

37

64

65

66

68

69 No increments *

70

71

73 Disturbed motor running *

74

75 Regulator blocked *

170 Invalid transmission *

171 Invalid zero point *

173

175

222

▲

P320 ED, * P323 MS

Invalid parameter value

Communication error with limit control ▲*

Switch on sequence not ready ▲*

Too many commands

Mains off during initialisation

Overcurrent directly after mains on

Short circuit ▲*

Overcurrent during operation

Motor stalling

No incremental plug ▲*

Incremental transmitter missing for speed increase/reduction

Motor blocked on fi rst stitch

Starting error

Time-out monitoring

0 - 1 1

0 - 1 1

0 - 1 1

0 - 1 1

0 - 1 1

0 - 1 1

0 - 1 1

0 - 1 1

0 - 9999 3800

▲

▲

▲

▲

*

▲

*

▲

*

▲

▲

▲

*

▲

*

48

Page 49

Adjustment

7.05 Explanation of the error messages

Message Description

E001 System error

E002 Sewing motor E002/BB/xxx

BB = 20: Time-out

02: Position forwards

03: Position in reverse

05: Position by shortest path

09: Write parameter

10: Speed

0A: Reset stitch counter

0B: Stop after xxx stitches

30: Time-out for increasing speed

31: Time-out for uncertain positioning

32: Time-out for time-out command

33: Time-out for deleting errors

34: Time-out for emergency stop

35: Time-out for writing parameters

36: Time-out for resetting stitch counter

37: Time-out for stop command after x stitches

38: Time-out for initialization

xxx = error bytes of sewing motor control unit (see list "Motor Errors")

E003 Section

E004 End of section

E005 Pedal activated when machine switched on

E006 Keyboard (CAN)

E007 End of ramp

E008 Reference for fullness adjustment not found

1: When moving towards sensor

2: When moving away from sensor

E011 Stepping motor stepping frequency too high

E012 not assigned

E014 Incorrect program number (larger than 49)

E015 Incorrect seam section number

E016 Memory full

E017 not assigned

E018 not assigned

E020 not assigned

E021 Power supply unit overloaded (24V)

E022 Mains voltage

E023 Power supply 24V too low

E024 Error at CAN interface

49

Page 50

Adjustment

7.06 Table of inputs

E1: not assigned

E2: not assignedi

E3: not assigned

E4: Start inhibitor

E5: not assigned

E6: Knee switch

E7: not assigned

E8: not assigned

E9: not assigned

E10: not assigned

E11: not assigned

E12: not assigned

E13: not assigned

E14: not assigned

E15: not assigned

E16: Reference for fullness adjustment

7.07 Table of outputs

O1: Raise sewing foot (O1.1 and O1.2)

O2: Thread trimmer (O2.1 and O2.2)

O3: not assigned

O4: not assigned

O5: Backtacking device (only 487, 489)

O6: Condensed stitches (only 5487)

O7: not assigned

O8: not assigned

O9: not assigned

O10: not assigned

O11: not assigned

O12: not assigned

O13: not assigned

O14: not assigned

O15: not assigned

O16: not assigned

50

Page 51

Adjustment

7.08 Service menu

Switch on the machine. ●

Call up the input mode. ●

Call up the service menu. ●

Explanation of the functions

Input mode

Quit the service menu and call up the input

Sewing mode

Quit the service menu and call up the sewing mode.

Set/reset outputs

Use the arrow functions to select the desired output and set "function 1" or reset

"function 2".

Cold start

See Chapter 7.09 Carry out a cold start.

Motors

After this function has been called up, the stepping motors for fullness and for the sewing

motor can be moved.

Basic position of the stepping motor

After this function has been called up, the basic position of the fullness stepping motor can

be changed.

Learning speed increase (in Motor menu)

Press this key to learn the speed increase function on machines with the control unit

P320ED. For this purpose the sewing drive sews 3 stitches at a speed of 360 min-1.

Control panel

See Chapter 4.04 Adjusting the control panel.

51

Page 52

Adjustment

7.09 Carry out a cold start

Switch on the machine. ●

Call up the input mode. ●

Call up the service menu. ●

Carry out a cold start. ●

After a cold start all programmed values are set back to their status at the time

of delivery.

All sewing programs are also deleted.

52

Page 53

Adjustment

7.10 Internet update of the machine software

The machine software can be updated with PFAFF fl ash programming. For this purpose the

PFP boot program and the appropriate control software for the machine type must be in-

stalled on a PC. To transfer the data to the machine, the PC and the machine control unit

must be connected with an appropriate null modem cable ( part no. 91-291 998-91 ).

The PFP boot program and the control software of the machine type

can be downloaded from the PFAFF-homepage using the following path:

www.pfaff-industrial.de/pfaff/de/service/downloads

To update the machine software carry out the following steps:

While the machine software is being updated, no setting up, maintenance or

adjustment work may be carried out on the machine!

Switch off the machine. ●

Connect the PC (serial interface or ap- ●

propriate USB-adapter) and the machine

control unit (RS232). To do so disconnect

the plug of the control panel.

Fig. 7 - 08

During the up-dating procedure the machine must not be switched off. ●

When the update has been completed, switch off the machine and end the PFP boot pro- ●

gram.

End the connection between the PC and the machine control unit and reconnect the con- ●

trol panel to the machine control unit.

Switch on the machine. ●

A plausibility control is carried out and, if necessary, a cold start. ●

Switch on the PC and start the PFP boot ●

program.

1

Select the machine type. ●

Press the "programming" button. ●

Hold down boot key ● 1 and switch on the

machine.

Press the "OK" button. ●

The software update is carried out, the ●

update progress is shown on the bar

display of thePFP boot program.

More information and assistance is at your disposal in the fi le "PFPHILFE.TXT",

which can be called up from the PFP boot program by pressing the "help" but-

ton.

53

Page 54

Circuit diagrams

14 Stromlaufpläne

8 Circuit diagrams

8

.01 Reference list for circuit diagrams 91-191 525-95

A1 Controller Quick P 320MS

A2 Control panel (BDF T1)

A3 Keyboard

A14 Sewing head identifi cation (OTE)

H1 Sewing lamp

M1 Sewing motor

M3 Stepping motor fullness adjustment (SM1)

Q1 Main switch

S6 Knee switch (program switching)

S17 Pedal speed control unit

S18 Sychronizer PD3

X1 Mains plug

X1A RS232 – interface 1 Control panel BDF T1

X1B VSS OTE (Sewing head identifi cation)

X3 Incremental transmitter (control unit)

XR3 Incremental transmitter (sewing motor)

XS3 Sychronizer PD3

X4B Stepping motor fullness (SM1)

X5 Inputs

X8 Sewing motor

X11A CAN interface (Keyboard)

X11B Pedal speed control unit

X13 Outputs

X21 Stepping motor fullness (SM1) )

X22 Keyboard

X36 Knee switch (program switching)

X46 Initiator reference (SM1)

X51 Y1 -910/.. Automatic presser foot lift

X52 Y2 -900/.. Thread trimmer

X55 Y5 -911/.. Backtacking unit

54

Y1 -910/.. Automatic presser foot lift

Y2 -900/.. Thread trimmer

Y5 -911/.. Backtacking unit

Page 55

91-191 525-95 Part 1 Version 20.09.07 Circuit diagrams

8.01.02 Circuit diagrams 91-191 525-95

P320 ED

P323 MS

55

Page 56

Circuit diagrams Version 20.09.07 91-191 525-95 Part 2

P320 ED

P323 MS

56

Page 57

91-191 525-95 Part 3 Version 20.09.07 Circuit diagrams

P320 ED

P323 MS

57

Page 58

Circuit diagrams Version 20.09.07 91-191 525-95 Part 4

P320 ED

P323 MS

58

Page 59

Note

Page 60

PFAFF Industriesysteme

und Maschinen AG

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Phone: +49 - 6301 3205 - 0

Fax: +49 - 6301 3205 1386

E-mail: info@pfaff-industrial.com

Hotlines:

Technical ser vice: +49 - 175/2243-101

Application consultance: +49 - 175/2243-102

Spare-parts hotline: +49 - 175/2243-103

Printed in Germany

© PFAFF Industriesysteme und Maschinen AG 2009, PFAFF is the exclusive trademark of VSM Group AB.PFAFF Industriesysteme und Maschinen AG is an authorized licensee of the PFAFF trademark.

Loading...

Loading...